Organic silicon emulsion defoaming agent of spinning pulp and preparation method of organic silicon emulsion defoaming agent

A silicone emulsion and textile size technology, applied in the direction of foam dispersion/prevention, can solve the problems of not being able to effectively wrap high-viscosity silicone compositions, affecting the efficiency of dyeing and the quality of final products, and reducing its own viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

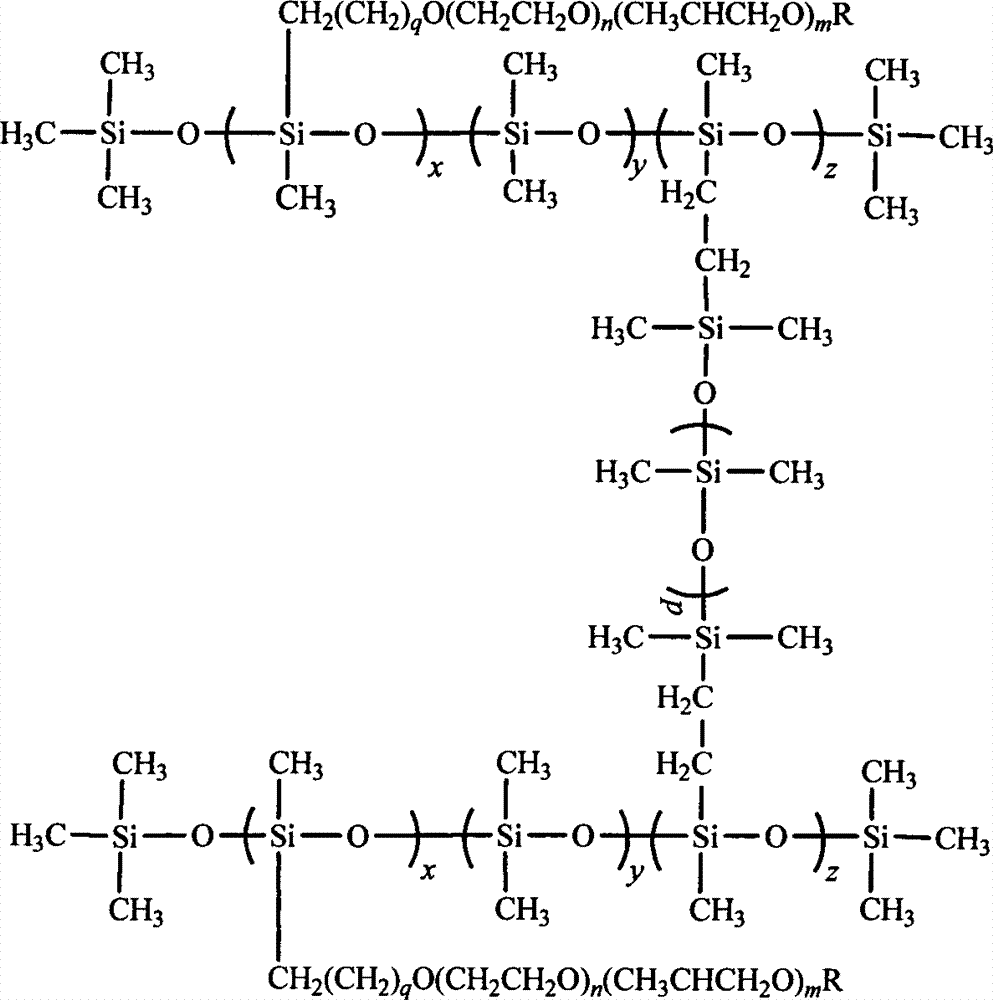

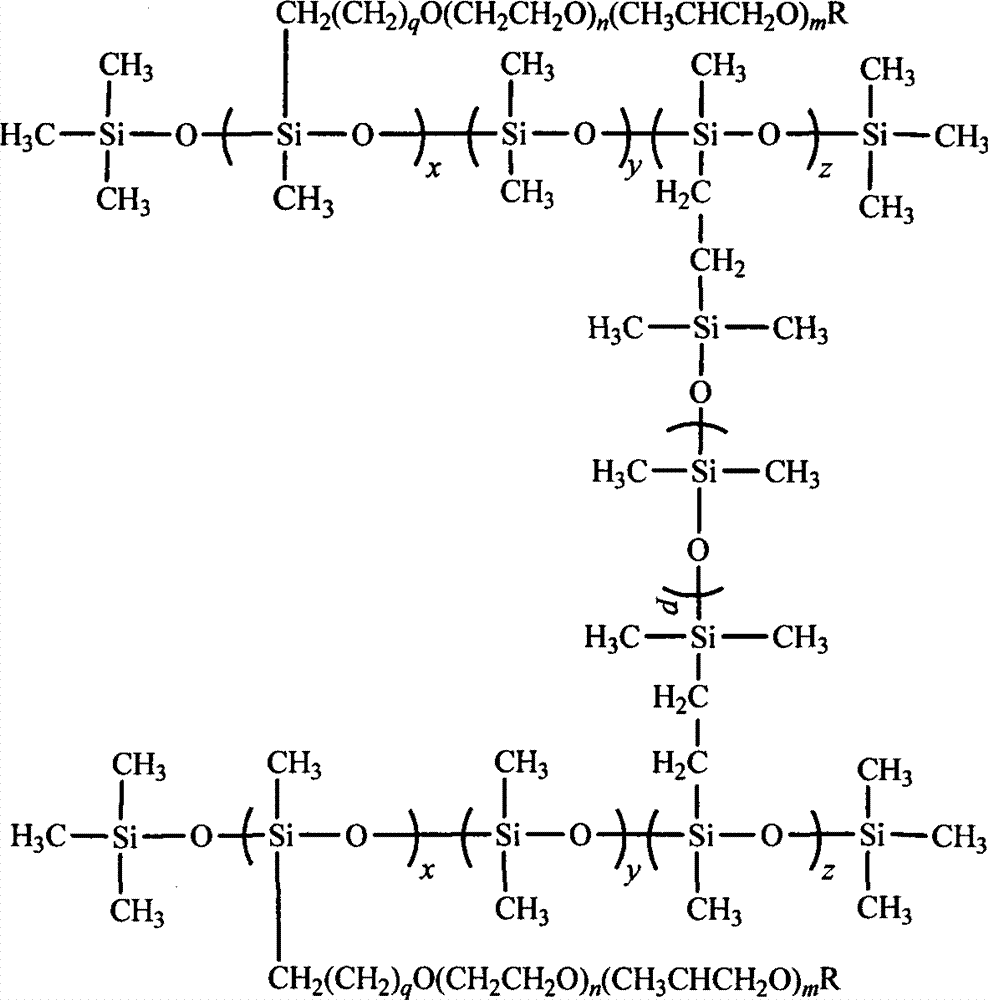

[0029] (1) Preparation of silicon polyether

[0030] The concrete value of silicon polyether described in the present invention is as follows:

[0031] Table 1 Silicon polyether

[0032] Silicon polyether

[0033] Preparation of ordinary silicon polyether: refer to the method of Example 3 in CN101298027 to prepare high-viscosity silicon polyether F1.

[0034] (2) Preparation of organosilicon composition

[0035] Refer to the preparation method of Example 1 in the patent US4639489 to prepare the following silicone compositions with different viscosities, as follows:

[0036] Table 2 High Viscosity Silicone Composition

[0037] High Viscosity Silicone Composition

[0038] Table 3 Low Viscosity Silicone Composition

[0039] Low Viscosity Silicone Composition

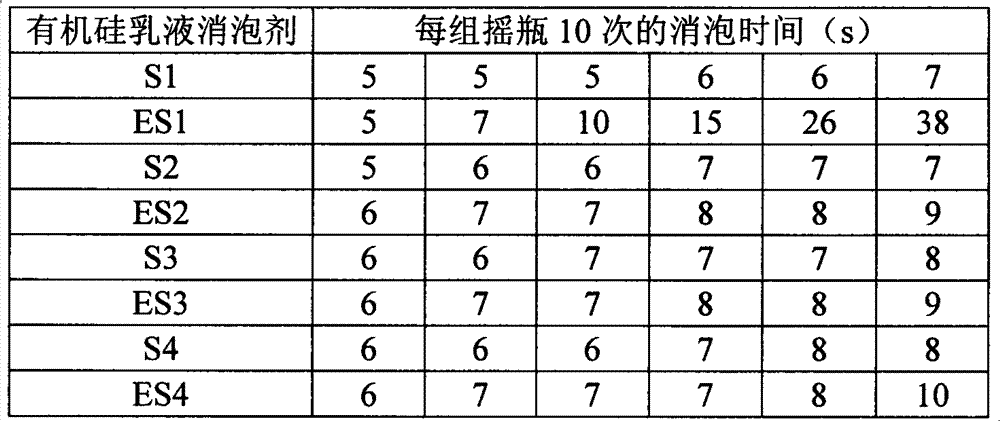

Embodiment 1

[0042] At room temperature, first mix 39g M1, 12g A1, 6g octylphenol polyoxyethylene (8) ether, and 3g water-soluble polyacrylate thickener at high speed for 0.6h; raise the temperature to 65°C, and add 40g of deionized water, the addition time of deionized water is 0.8h; after adding water, the above mixture is further emulsified by a homogenizer; add 3g of acrylic acid alkali swelling thickener and 97g of deionized water to the mixture emulsified by the homogenizer , stirred evenly, and adjusted the pH value to 7.0 to obtain the silicone emulsion defoamer S1.

Embodiment 2

[0044] At room temperature, first mix 48g of M2, 30g of A2, 9g of polyoxyethylene (12) laurate, and 3g of water-soluble polyacrylate thickener through high-speed stirring for 0.5h; raise the temperature to 70°C, and add 60g of deionized water, the addition time of deionized water is 1.5h; after the addition of water, the above mixture is further emulsified by a homogenizer; 3g of acrylic acid alkali swelling thickener and 147g of deionized water are added to the mixture emulsified by the homogenizer , stirred evenly, and adjusted the pH value to 7.0 to obtain the silicone emulsion defoamer S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com