Solid defoaming agent and preparation method

A technology of solid defoamer and carrier, which is applied in the direction of foam dispersion/prevention, and can solve the problems of easy hardening, easy attenuation, and easy attenuation during storage, etc.

Active Publication Date: 2011-03-30

JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

View PDF8 Cites 33 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The solid defoamers on the market generally have the following problems: (1) poor foam suppression performance; (2) solid defoamers with sodium tripolyphosphate as the carrier have environmental pollution problems; (3) sodium sulfate as the carrier (4) The solid defoamer with zeolite and starch as the carrier is environmentally friendly and will not become damp, but there are still products with traditional structuring agents and processing methods It is easy to harden and prone to attenuation problems during storage

From the performance of starch, it is necessary to choose a suitable structurant to endow the product with good hardness and anti-foaming performance. If the structurant and processing method are not selected properly, there are still some products that are easy to harden and attenuate during storage. The problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

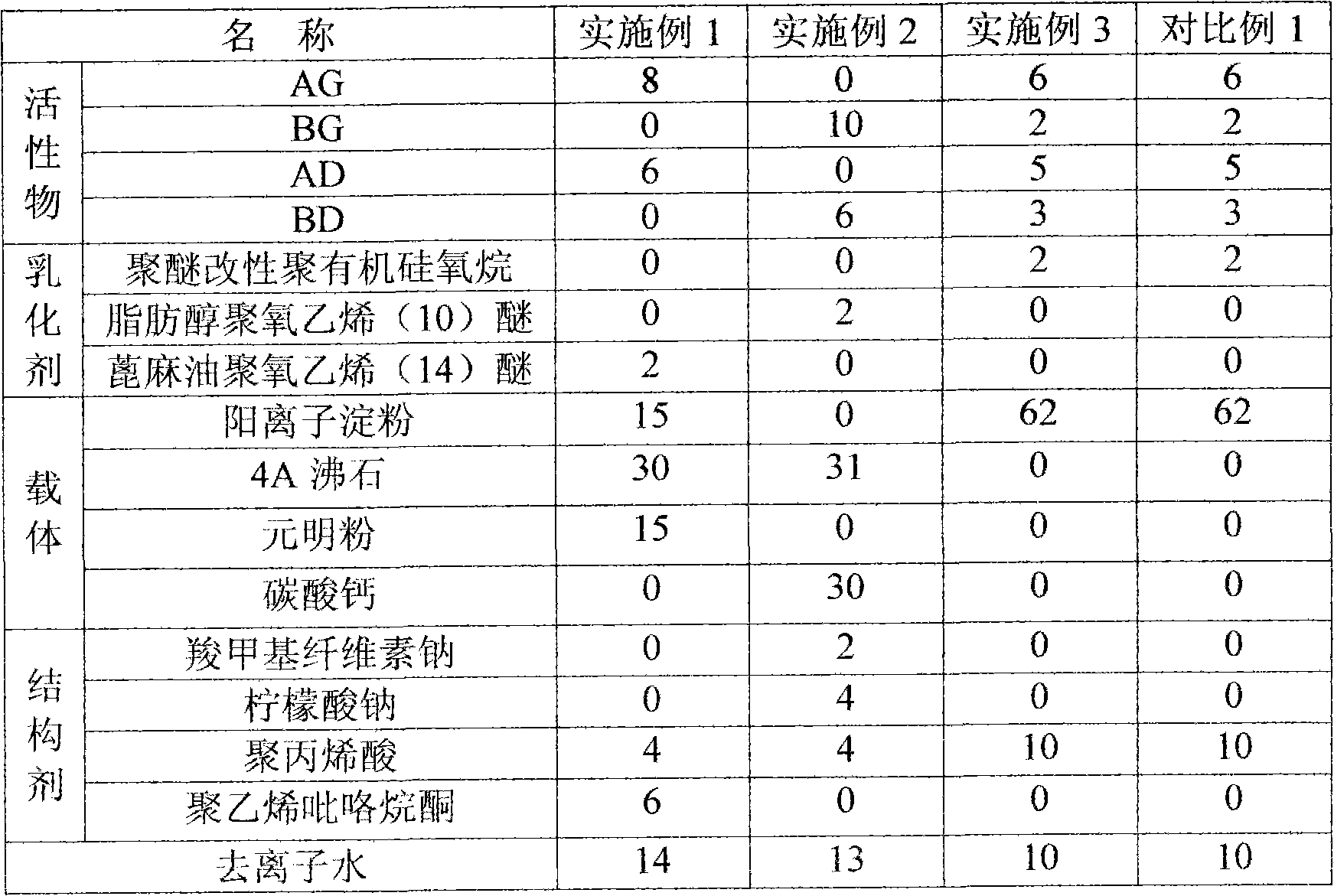

[0036] According to the preparation method of solid defoamer of the present invention and the formula in following table 1, preparation embodiment defoamer:

[0037] Table 1 The proportion (mass percentage, %) that each component of solid particle defoamer accounts for

[0038]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a solid defoaming agent. The solid defoaming agent consists of the following components in percentage by weight: 50 to 90 percent of carrier, 5 to 20 percent of defoaming active matter, 0.5 to 4 percent of emulsifier, 1 to 30 percent of structural agent and 5 to 15 percent of water. A method for preparing the solid defoaming agent comprises the following steps of: (1) adding the defoaming active matter, the emulsifier and the structural agent into a mixer and fully mixing the components so as to obtain a mixture A; (2) adding an organic carrier into the mixture A and uniformly stirring so as to obtain a mixture B; (3) adding deionized water into the mixture B and uniformly stirring so as to obtain a mixture C; and (4) pelletizing the mixture C by using a pelletizer and drying the obtained particles by using a drier so as to obtain the solid defoaming agent. The solid defoaming agent has high defoaming and foam restraining performance and anti-damping performance, and can be applied to industries such as daily use chemicals, industrial cleaning and the like.

Description

technical field [0001] The invention relates to a solid defoamer, especially a solid defoamer obtained by agglomerating polysiloxane with solid powder. This type of solid defoamer can be used in daily chemical, industrial cleaning and other industries . Solid defoamer belongs to fine chemical additives, therefore, the present invention belongs to fine chemical technology field. technical background [0002] Foam is a common phenomenon in industrial processes such as daily chemical, industrial cleaning, sewage treatment, textile printing and dyeing, and different systems have different reasons for foaming. For example, in industrial cleaning, industrial cleaning agents are usually used to remove dirt. Since the cleaning agent contains a large amount of surfactant, during the agitation process, the surfactant will be adsorbed around the air bubbles to stabilize the air bubbles, causing a large number of air bubbles to gather It is not easy to eliminate. This situation is mor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D19/04

Inventor 吴飞池跃芹曹添郭士超

Owner JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com