Low-stripping electrostatic pressure PU protective film and preparation process thereof

A preparation process and static voltage technology, which is applied in the direction of film/sheet release liner, film/sheet adhesive, adhesive type, etc., can solve the problems of easy generation of iris, high static voltage of tearing film, and bubble discharge Poor performance and other problems, to achieve the effect of obvious electrostatic phenomenon of tearing film, improvement of electrostatic phenomenon of tearing film, and less iris phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

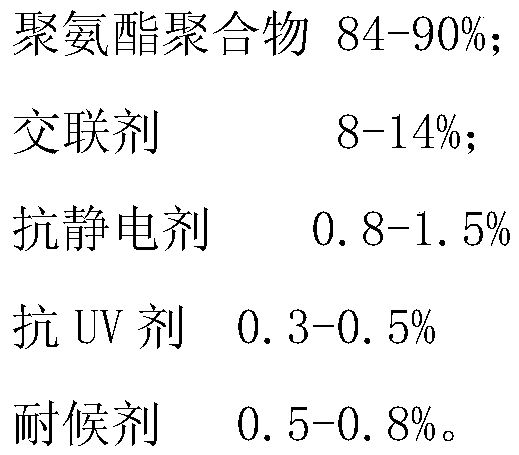

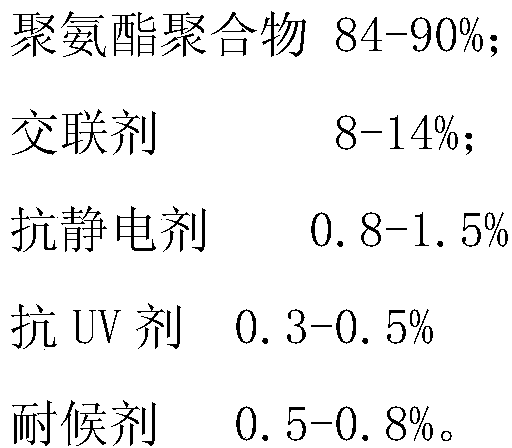

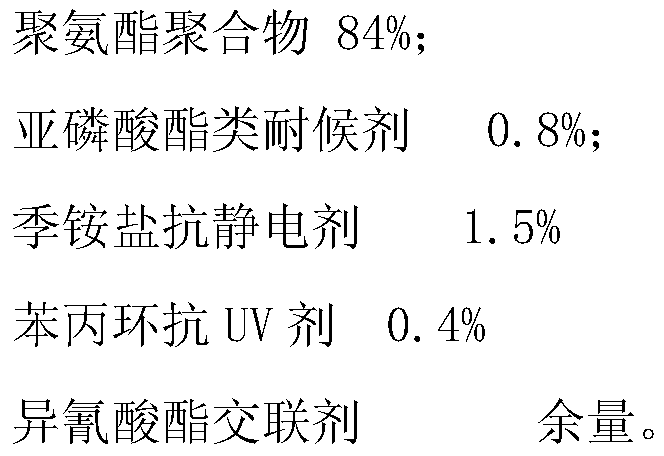

Embodiment 1

[0026] The PU protective film of this embodiment is an antistatic release layer, a polyurethane adhesive layer, a PET substrate layer, and an antistatic coating from top to bottom. 1. The antistatic release layer is usually a single-sided release surface anti-shock film, the release force is 50-100g / mm, and the impedance value is 10^8-10^10Ω. 2. As a polyurethane adhesive layer, it is required to have a strong Excellent aging resistance (high temperature aging, UV aging, etc.); good bonding performance to component materials; dry glue thickness of 8-10μm, pure polyurethane polymer. Use this formula to coat dry glue with a thickness of 8-10 μm, and test it on a PET substrate of 50 μm: 180° peel force 1-3g, 3. The PET substrate layer is 50 μm, the transmittance is greater than 90%, and the haze is less than 2 % PET substrate; 4. The antistatic coating is usually a polythiophene coating, and its impedance value is about 10^6-10^9Ω.

[0027] Production process:

[0028] Select m...

Embodiment 2

[0046] The PU protective film of this embodiment is an antistatic release layer, a polyurethane adhesive layer, a PET substrate layer, and an antistatic coating from top to bottom. 1. The antistatic release layer is usually a single-sided release surface anti-shock film, the release force is 50-100g / mm, and the impedance value is 10^8-10^10Ω. 2. As a polyurethane adhesive layer, it is required to have a strong Excellent aging resistance (high temperature aging, UV aging, etc.); good bonding performance to component materials; dry glue thickness of 8-10μm, pure polyurethane polymer. Use this formula to coat dry glue with a thickness of 8-10 μm, and test it on a PET substrate of 50 μm: 180° peel force 1-3g, 3. The PET substrate layer is 50 μm, the transmittance is greater than 90%, and the haze is less than 2 % PET substrate; 4. The antistatic coating is usually a polythiophene coating, and its impedance value is about 10^6-10^9Ω.

[0047] Production process:

[0048] Select m...

Embodiment 3

[0065] The PU protective film of this embodiment is an antistatic release layer, a polyurethane adhesive layer, a PET substrate layer, and an antistatic coating from top to bottom. 1. The antistatic release layer is usually a single-sided release surface anti-shock film, the release force is 50-100g / mm, and the impedance value is 10^8-10^10Ω. 2. As a polyurethane adhesive layer, it is required to have a strong Excellent aging resistance (high temperature aging, UV aging, etc.); good bonding performance to component materials; dry glue thickness of 8-10μm, pure polyurethane polymer. Use this formula to coat dry glue with a thickness of 8-10 μm, and test it on a PET substrate of 50 μm: 180° peel force 1-3g, 3. The PET substrate layer is 50 μm, the transmittance is greater than 90%, and the haze is less than 2 % PET substrate; 4. The antistatic coating is usually a polythiophene coating, and its impedance value is about 10^6-10^9Ω.

[0066] Production process:

[0067] Select m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com