Patents

Literature

371 results about "Dry glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry glue is an adhesion product based upon the adaptations of geckos' feet that allow them to climb sheer surfaces such as vertical glass. Synthetic equivalents use carbon nanotubes as synthetic setae on reusable adhesive patches.

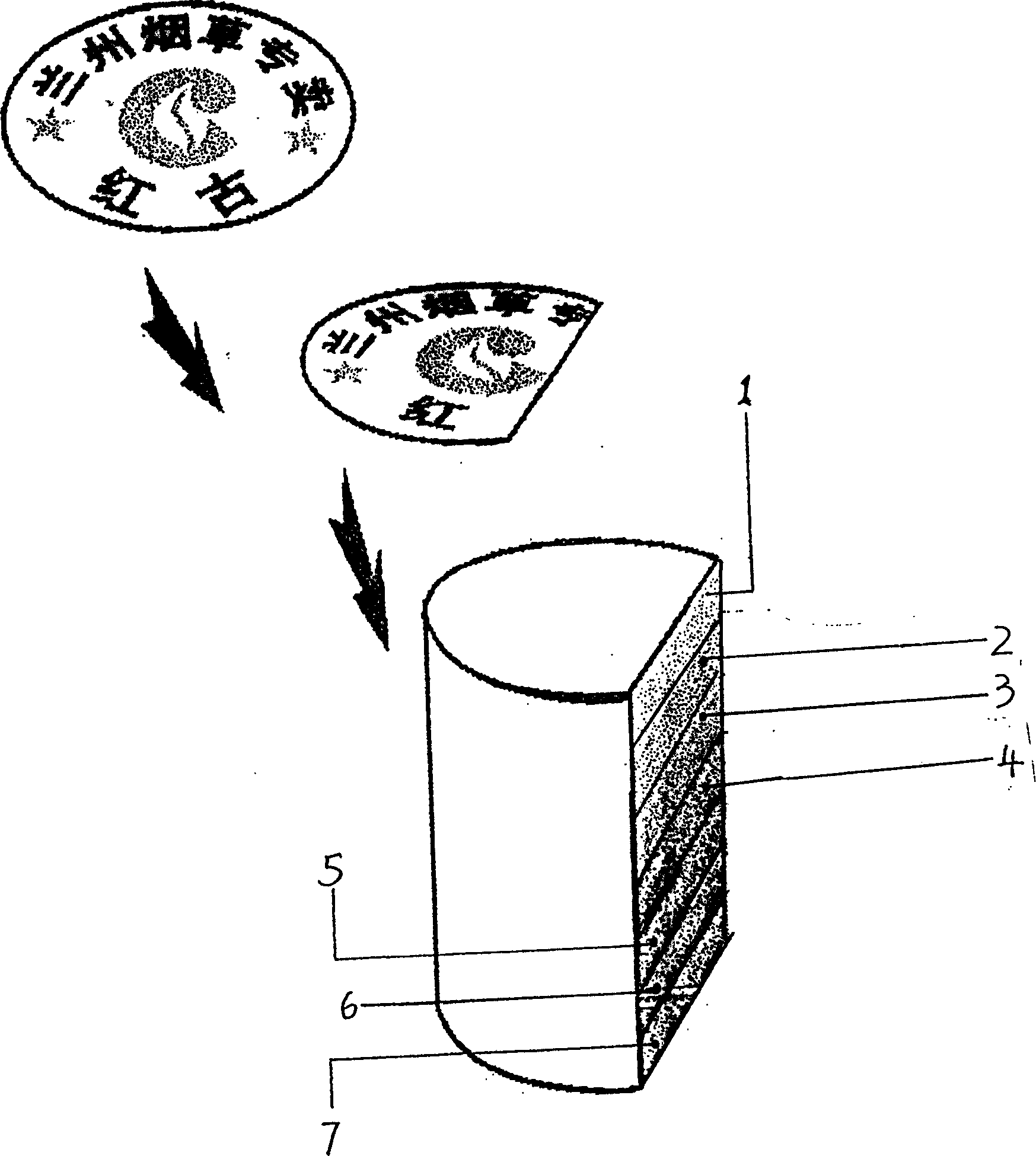

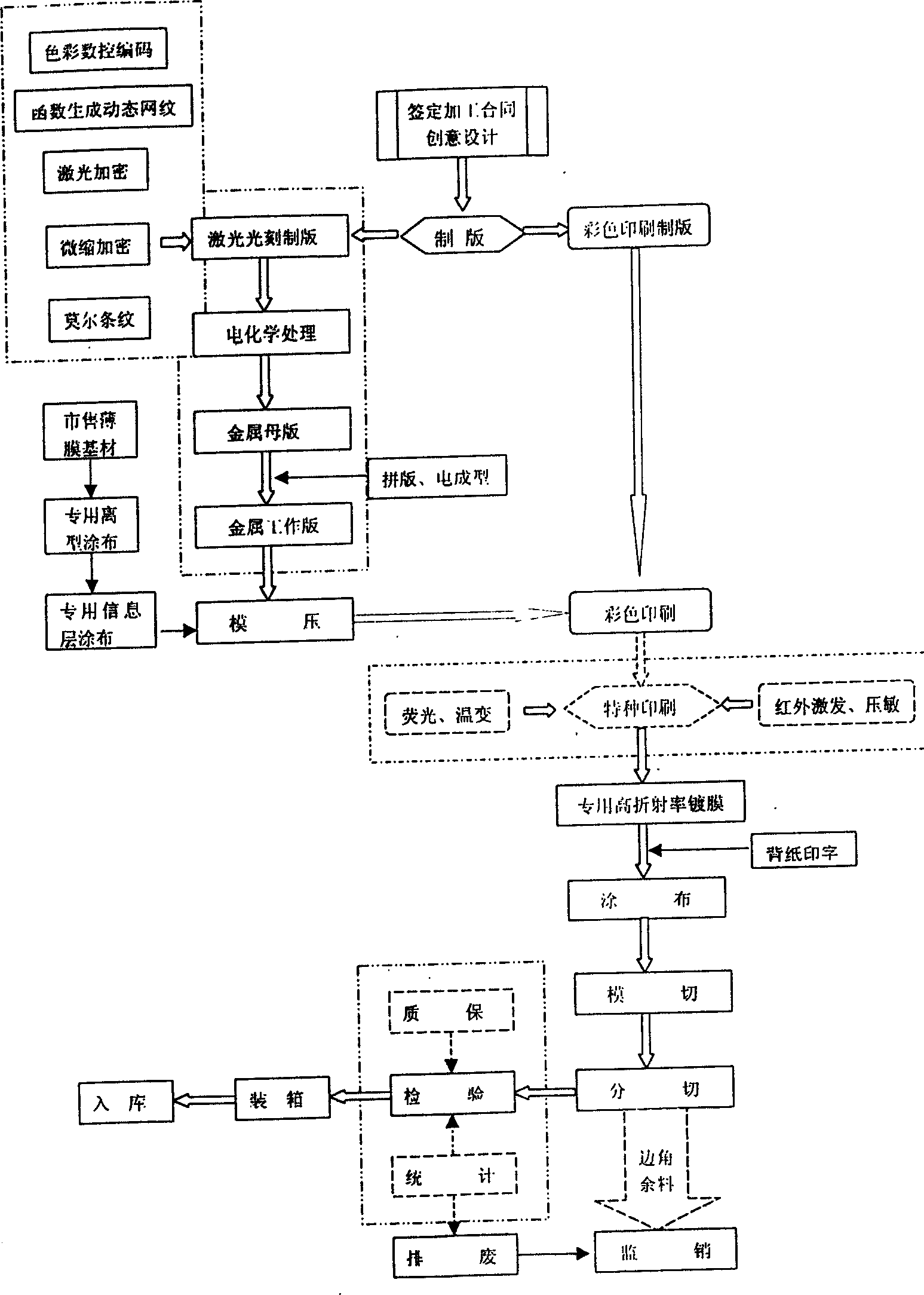

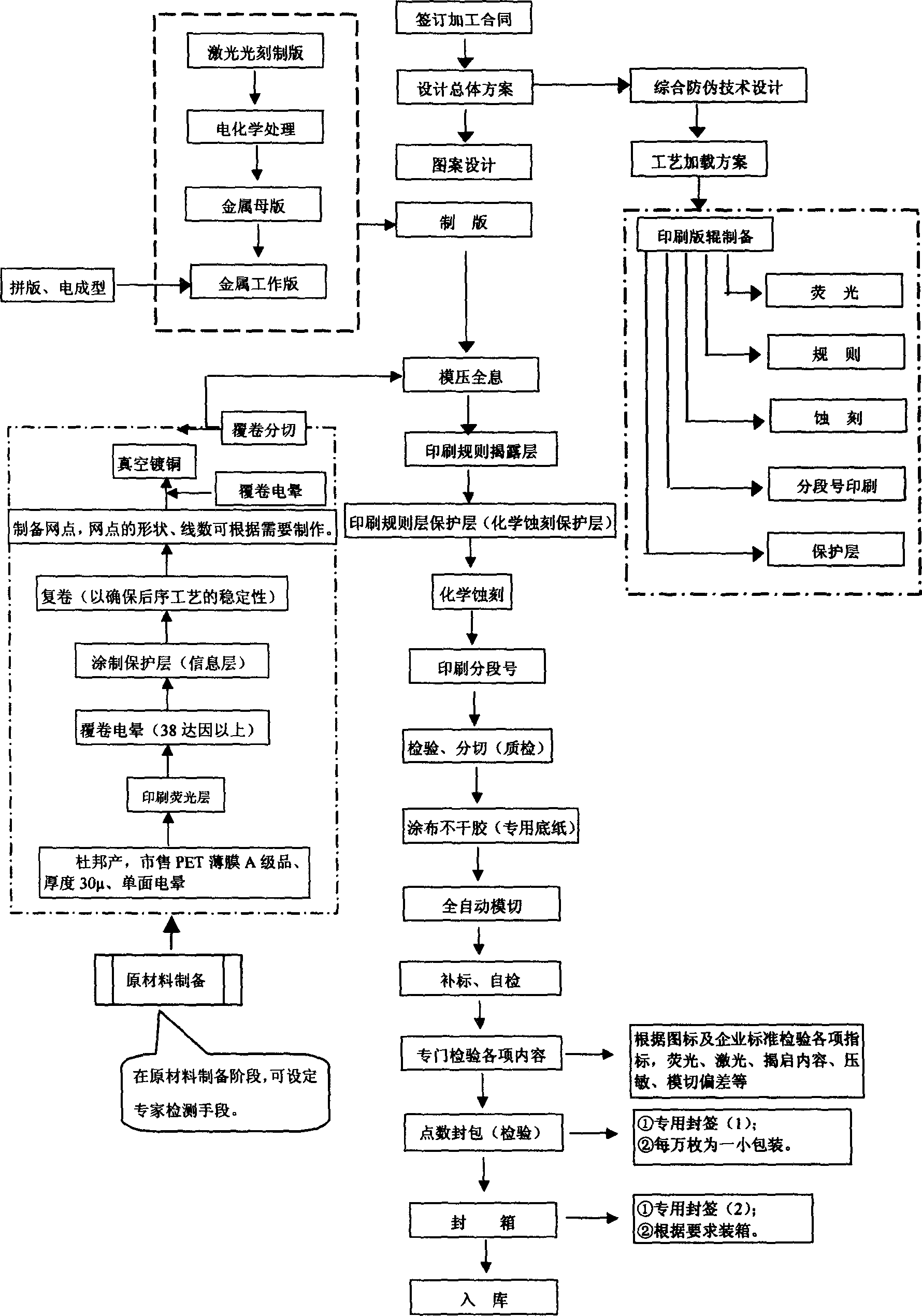

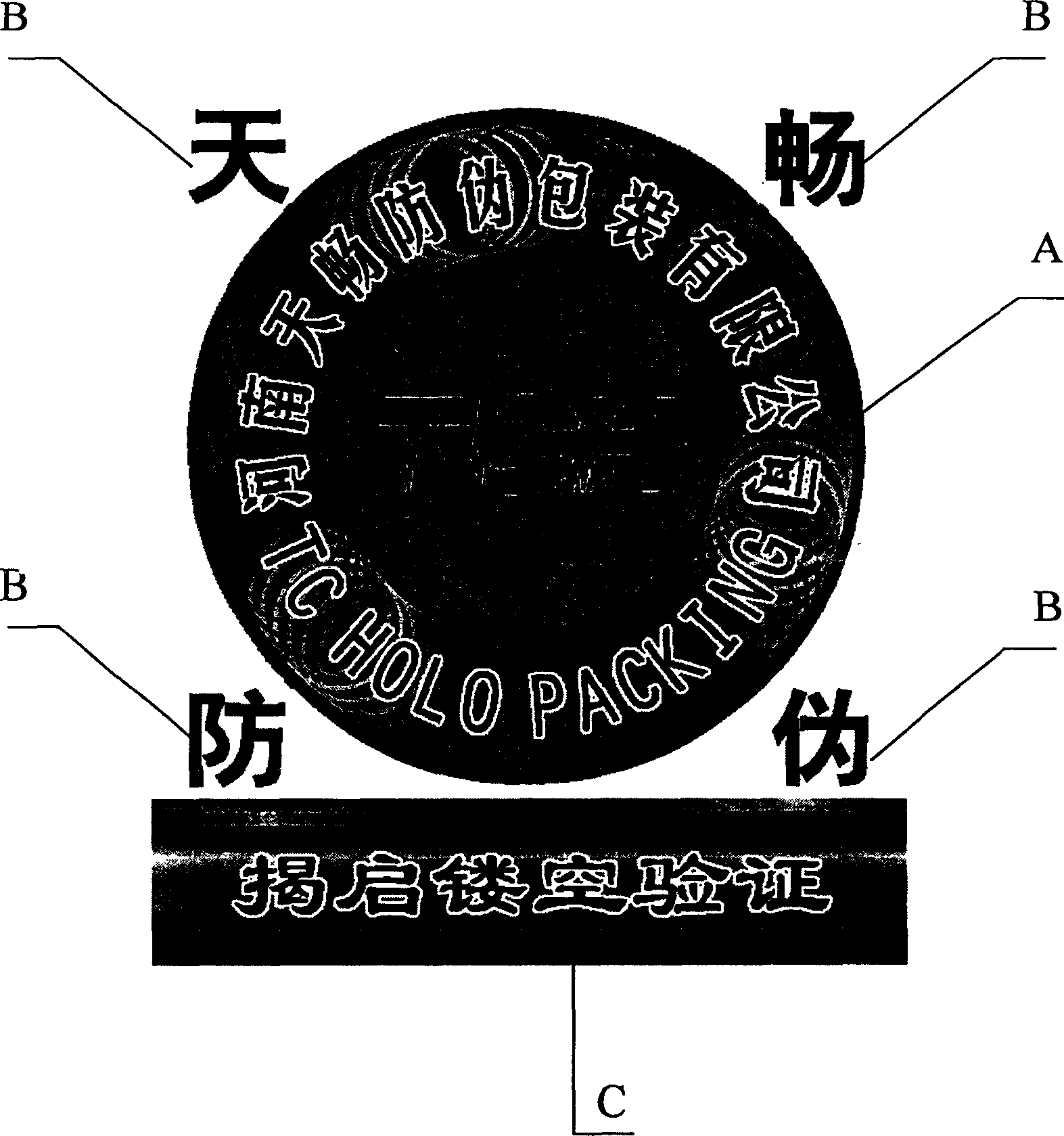

Holographic colour print antiforge mark and its production technology

InactiveCN1514423AIncrease investmentHigh anti-counterfeiting strengthStatic indicating devicesInformation layerColor printing

The invented antifalse mark is different from general color printing label and traditional holographic mark on aluminum foil. The mark includes basal lamina, information layer, isolation layer, color printing layer, special type printing layer and not dried glue layer etc. Technical flow includes following procedures: designing, plate making, raw materials preparing, die pressing, color printing, special type printing, glue spreading, die cutting, parting cut and checking up pack. The invention possesses advantages of integrating multiple antifalse techniques, easy of recognition and convenient use.

Owner:河南天畅防伪包装有限公司

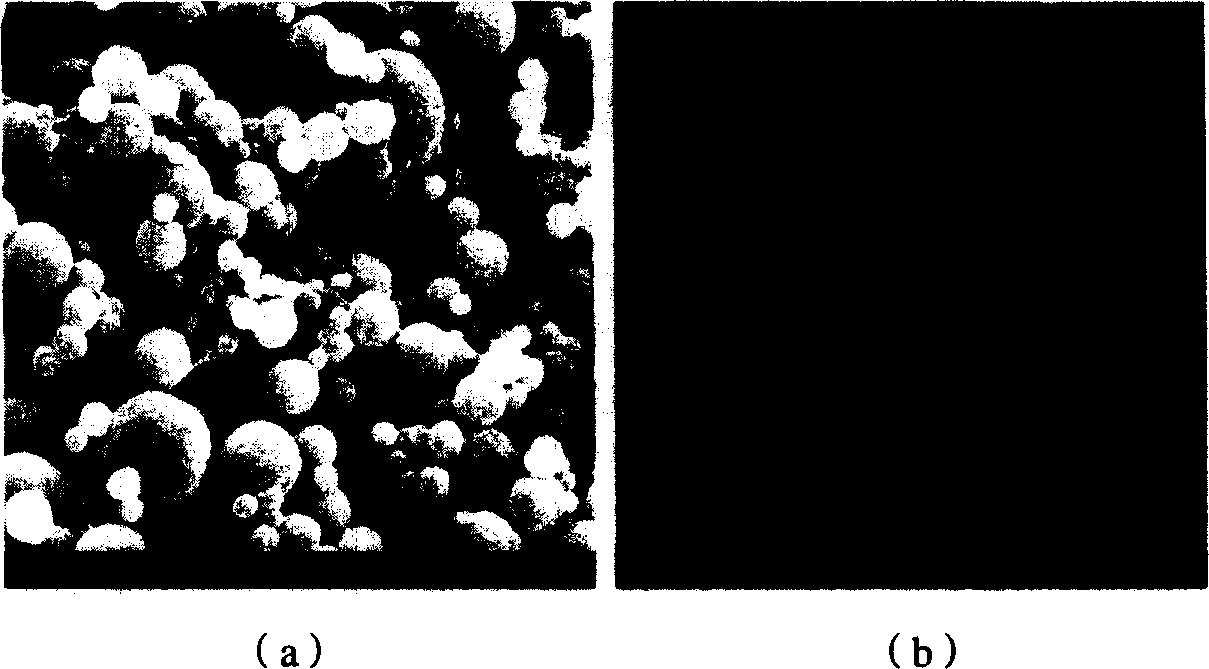

Carbon nanotube modified powder natural rubber and method for preparing same

Disclosed is a powder natural rubber modified by carbon nanostructured pipe and the preparing method, relating to the field of modifying macromolecular material with CNTs. Said powder natural rubber is characterized in that it possesses carbon nanostructured pipe which is 1%~50% of the glue of natural latex in mass.The method comprises conducting surface treatment forCNTs to make it hydrophilism: mixing it with dispersant and deionized water and getting the CNTs-water slurry; modifying the pH value to 9~12; mixing with natural latex and getting the natural rubber liquid latex added with CNTs. Then preparing modified powder natural rubber containing CNTs with the method of spray-drying, the quantity of input is 5%~30%, the temperature is 100~180DEG C. The prepared powder rubber is characterized by the adequate distribution of the CNTs in the product, the small size, and the dramatically increased mechanics property compared with the traditional powder rubber.

Owner:TSINGHUA UNIV

Composite soft heat insulating material, preparation method and applications thereof

The invention discloses a composite heat insulating material of natural rubber-plant fiber-clay, a preparation method and applications thereof. The composite heat insulating material comprises the following components by weight portions: 100 portions of natural rubber or latex (according to dry glue), 1 to 20 portions of modified plant fiber micropowder, 1 to 15 portions of clay, 0.5 to 3.3 portions of sulfur, 1.2 to 4.3 portions of accelerator, 1 to 3 portions of antioxidant and the balance of processing assistants. The preparation method comprises the following steps of: using the natural rubber as material, going through the conventional raw material compounding operation, wherein adding the modified plant fiber micropowder, the clay and other ingredients into the natural rubber, preparing into natural rubber composite heat insulating material and products containing the modified plant fiber micropowder and the clay by procedures of foaming, forming, sulfurization and the like. The obtained composite heat insulating material and the products can be applied in the preparation of soft heat insulating material boards, soft heat insulating pipes, soft heat insulating sleeves and the like, and have the characteristics of environmental improvement, high heat insulating efficiency, softness with any folding, excellent performance and the like.

Owner:JINAN UNIVERSITY

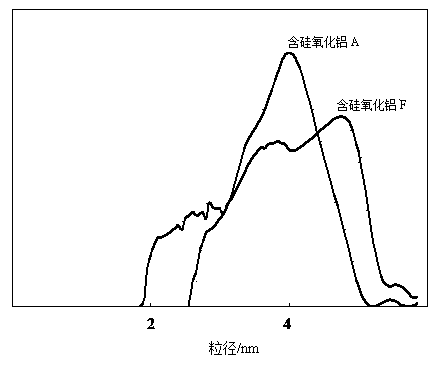

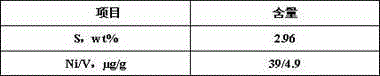

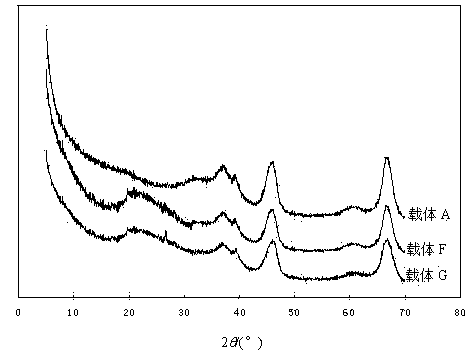

Preparation method of alumina dry glue containing silicon

ActiveCN103769232ASmall apertureUniform particle sizeCatalyst carriersHydrocarbon oils treatmentPtru catalystDry glue

The invention discloses a preparation method of an alumina dry glue containing silicon. The preparation method comprises the following steps: mixing original clay with a weak acid and a dispersant, then carrying out a hydrothermal treatment on the mixture so as to obtain modified clay; using an acidic solution containing aluminum and an alkaline solution containing aluminum to carry out a glue-forming reaction in the modified clay slurry by adopting a combined method of a pH swing method and a parallel-flow method, and after the glue-forming process, subjecting the glue-forming reaction product to processes of filtering, washing, and drying so as to obtain the alumina dry glue containing silicon. The alumina dry glue containing silicon has the advantages of uniform particle size, concentrated pore distribution, and proper acidity, and is especially suitable for being used to prepare a heavy oil or residual oil hydro-treatment catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Shell powder-natural rubber composite material and preparation method thereof

The invention relates to a shell powder-natural rubber composite material and a preparation method thereof. The composite material comprises shell powder or modified shell powder, a coupling agent, an anionic surfactant, a nonionic surfactant, milky natural rubber based on dry glue and a cross linker, and can contain fatty alcohol-polyoxyethylene ether, potassium hydroxide and paraffin-based oil or pigment. The preparation method comprises the following steps of: (1) preparing aqueous dispersion of the shell powder; (2) preparing a shell powder-natural rubber composite material in a latex state; and (3) preparing the shell powder-natural rubber composite material in a dry glue state. The tensile strength of the composite material is 20 to 28MPa, the elongation at break can reach 700 to 980 percent, 300 percent stress at definite elongation can reach 2.0 to 5.0MPa, the tearing strength is 36 to 45kN / m, and the heat generation performance is within 13 DEG C. The material has high tearing resistance, tensile resistance and slippery resistance, difficultly produces heat, has antibacterial performance, and can be applied to natural rubber products such as medical gloves, tires, rubber tubes and shoes.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

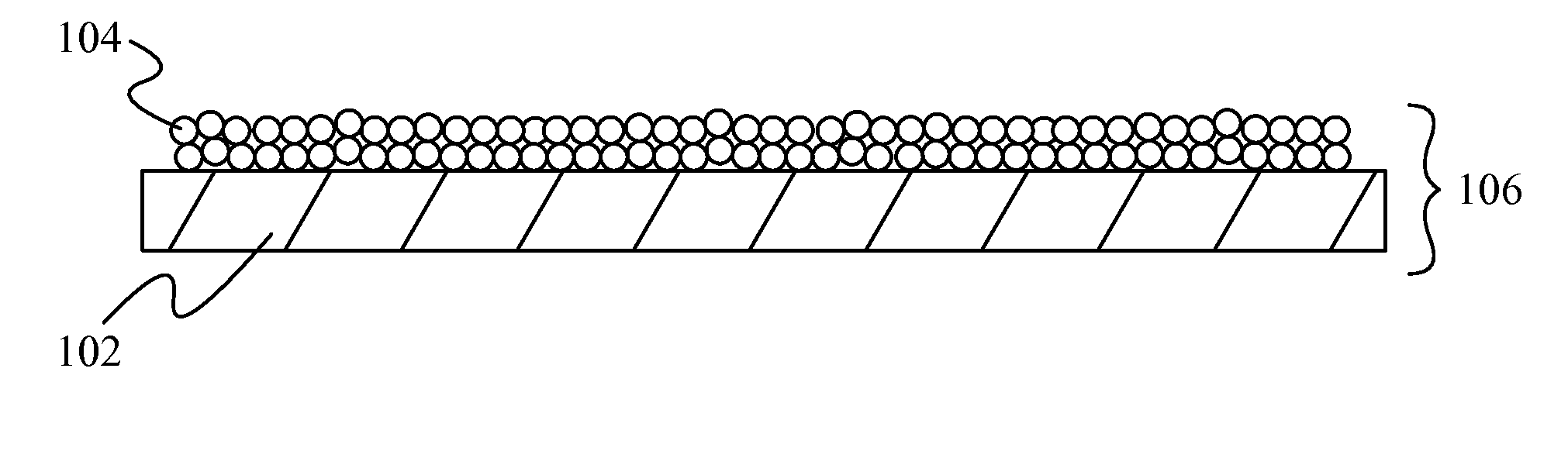

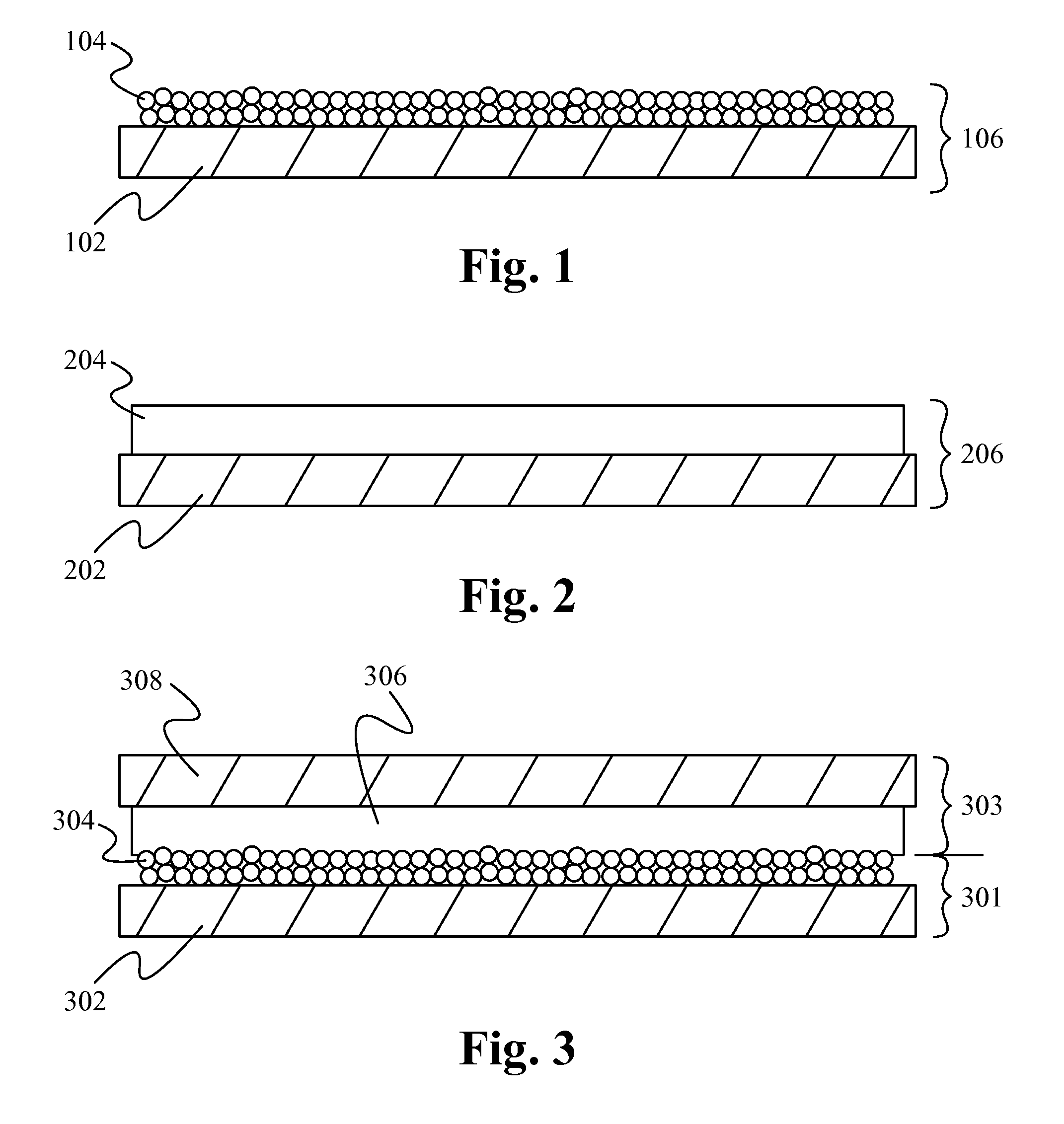

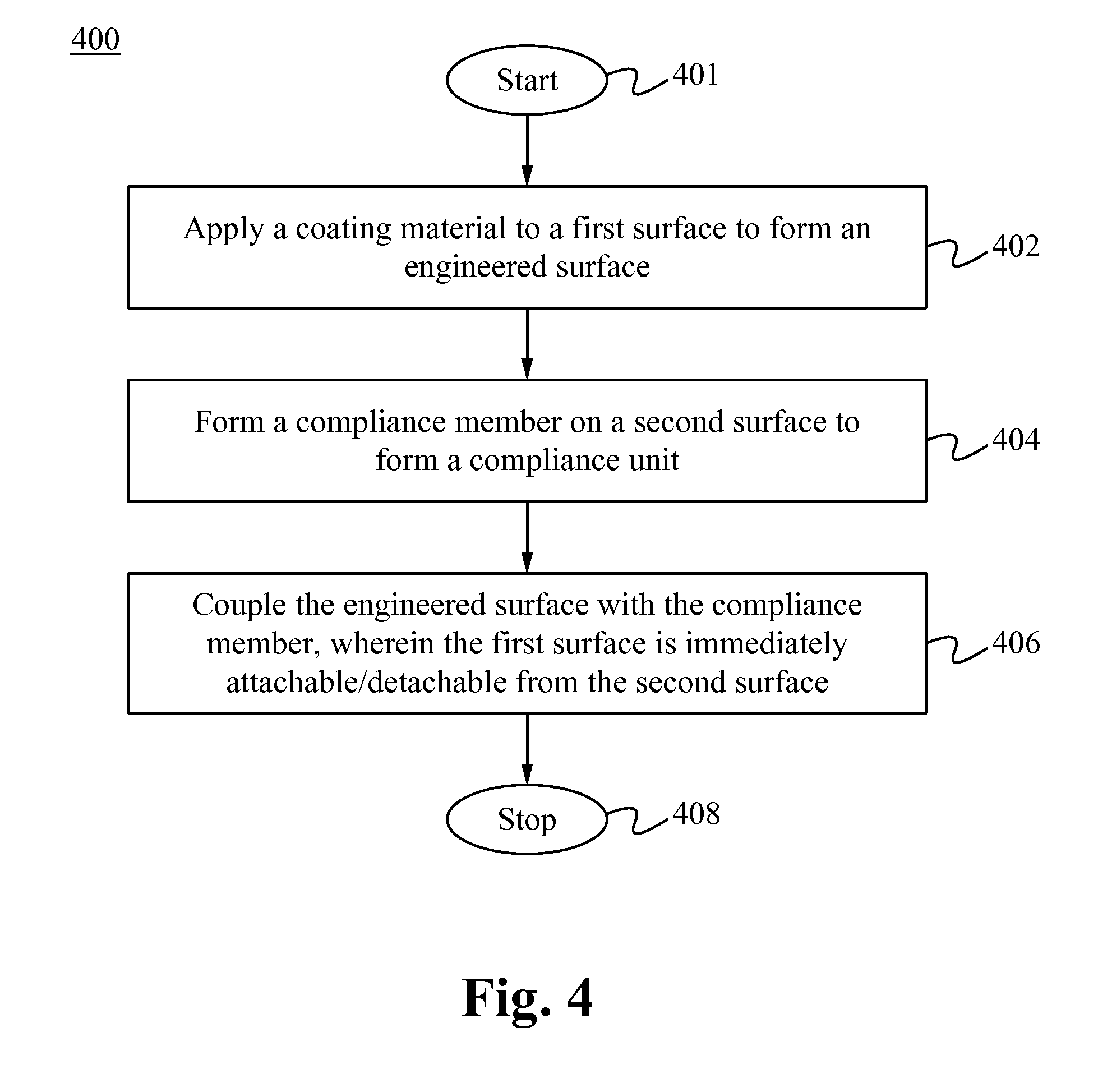

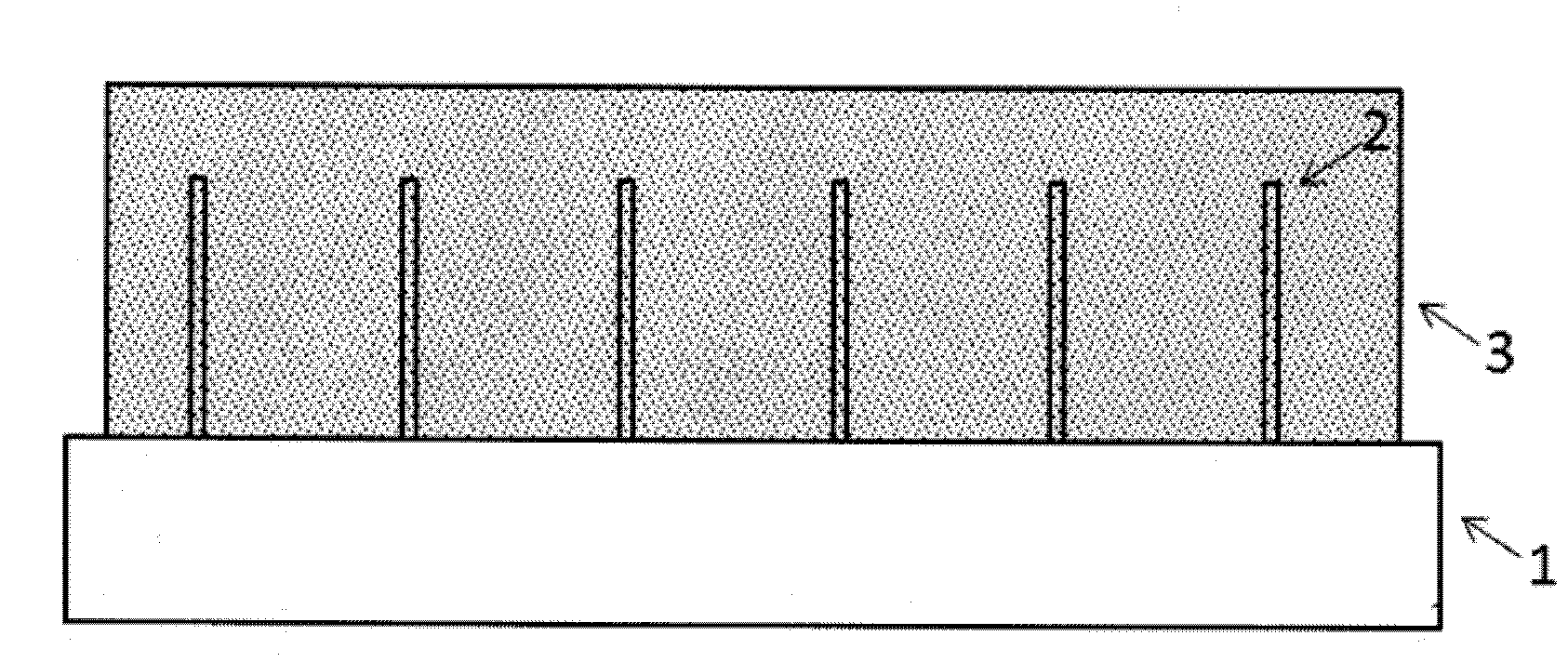

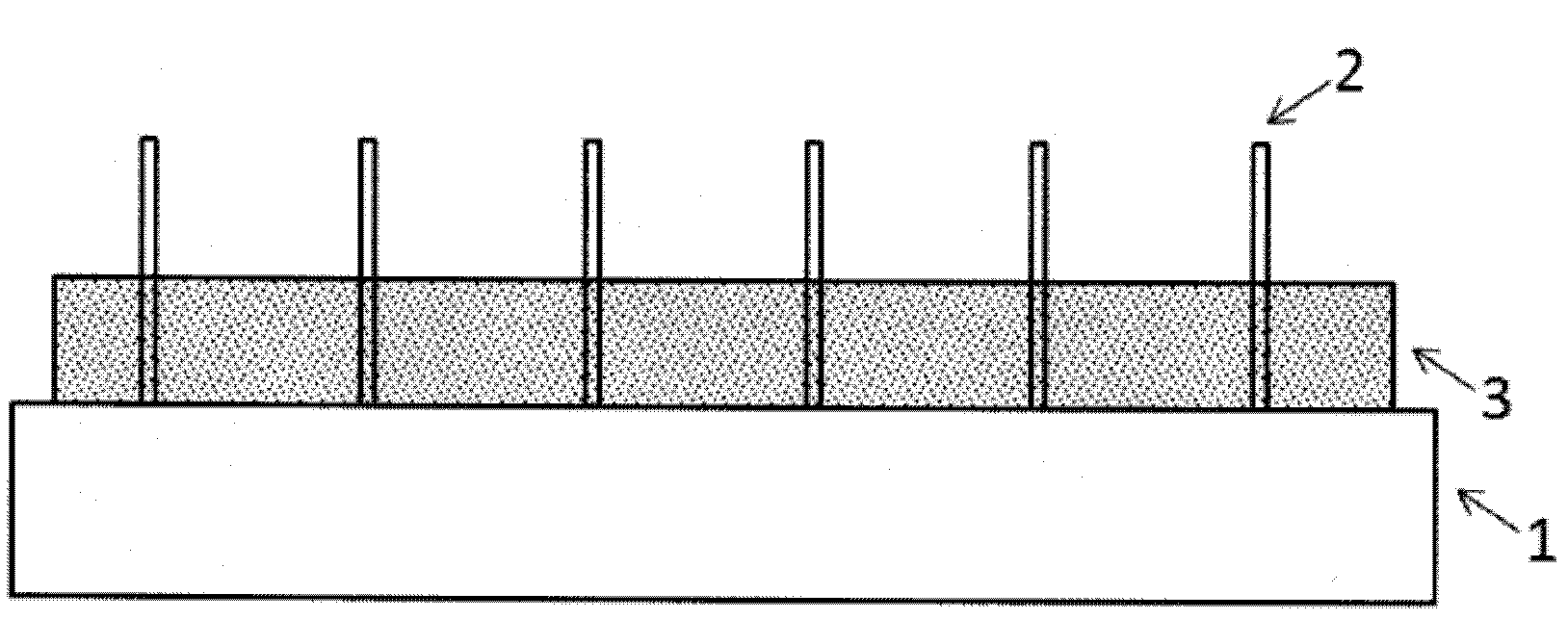

Dry adhesive

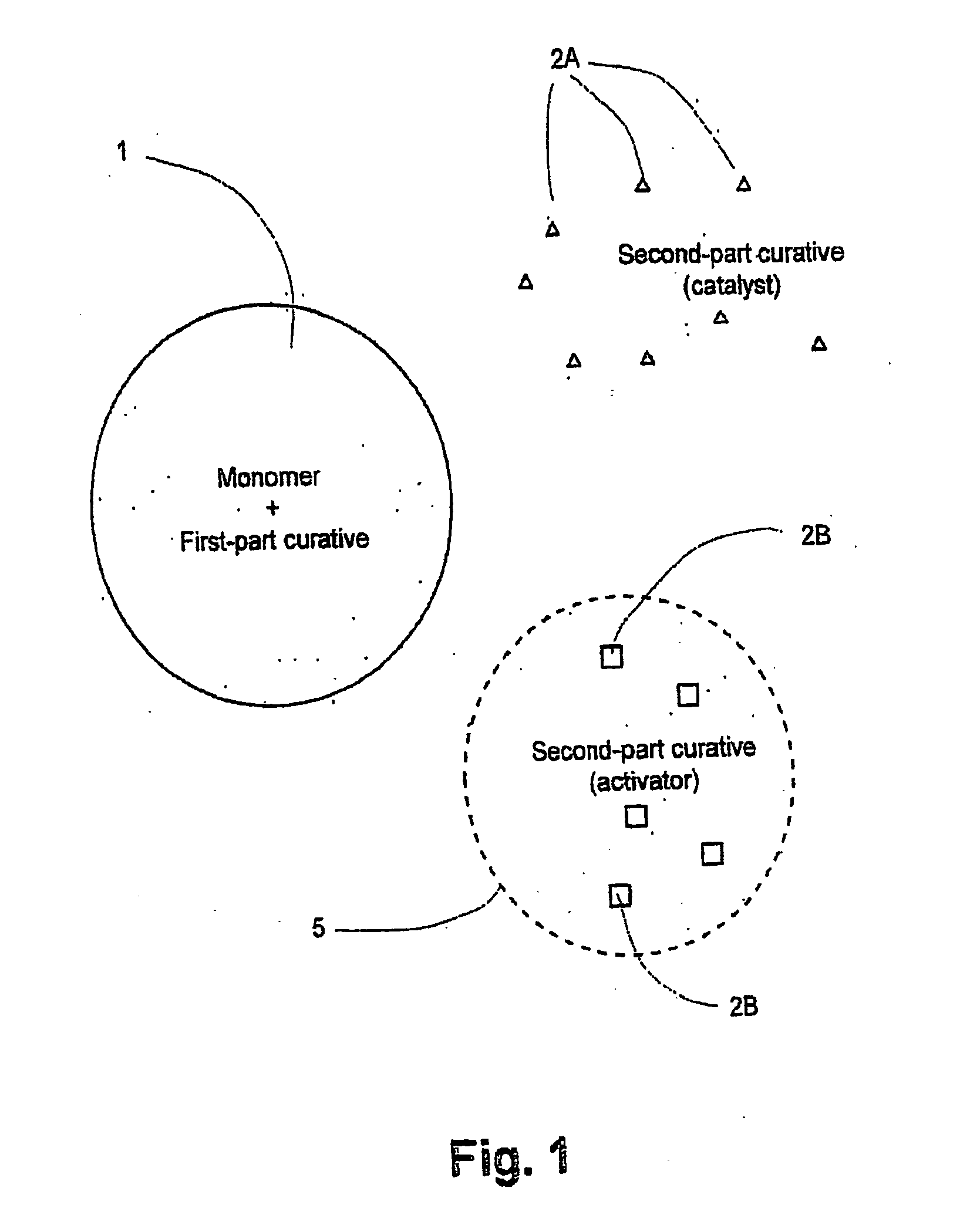

InactiveUS20120216949A1Reduce adhesionSnap fastenersAdhesive processesAdhesiveThermoplastic elastomer

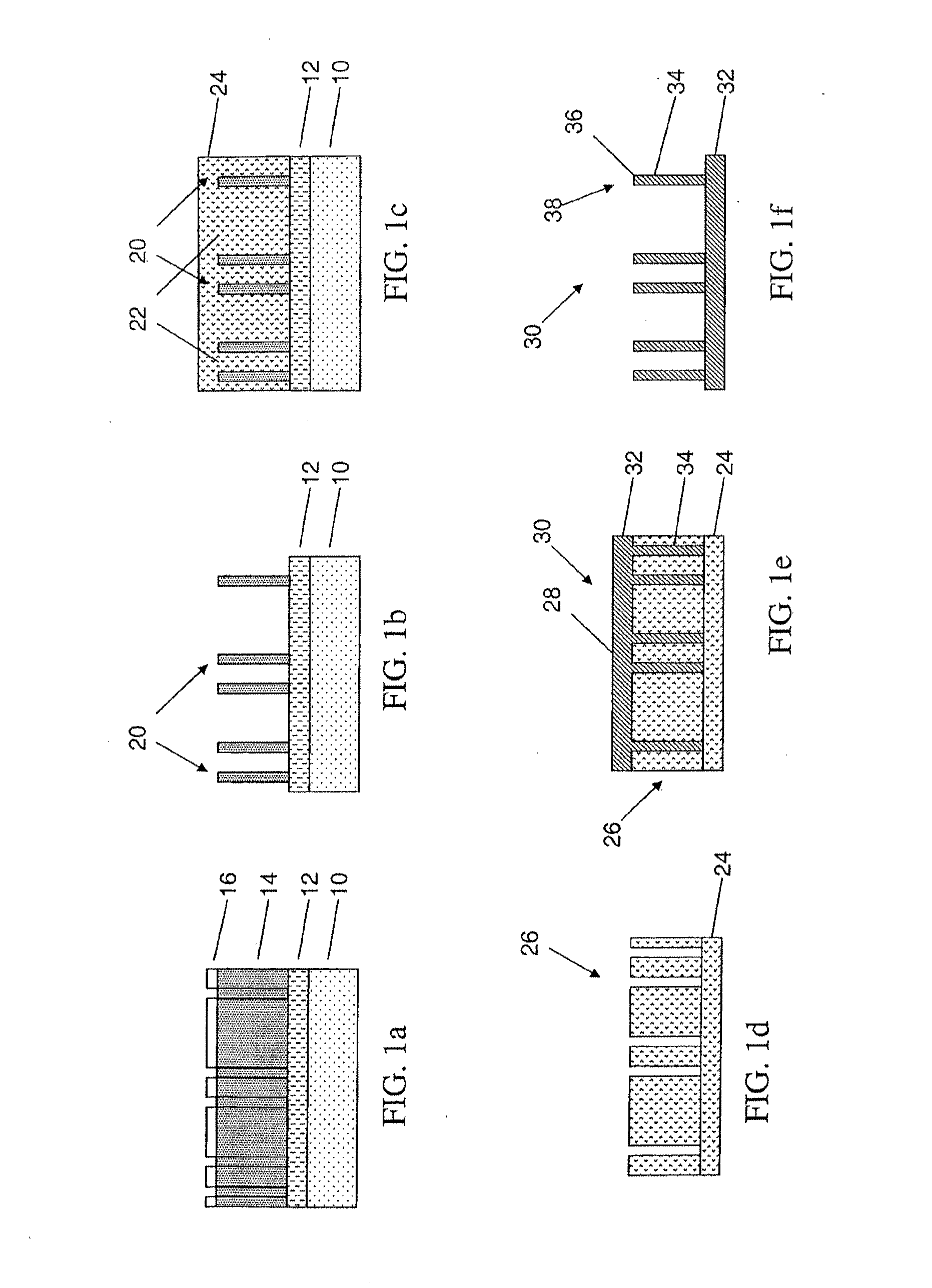

A selective adhesive mechanism comprises an engineered surface structure or substrate and a compliant member. The compliant member is able to be a dry and non-tacky substance. The compliant member is selectively adhesive to the engineered surface when the compliant member is in contact with the engineered surface. The compliant member shows adhesion to the engineered surface when the compliant member is within a pre-selected range of hardness. In some embodiments, the compliant member comprises a polymeric member, a thermoplastic elastomer, silicone, polyurethane, or a combination thereof.

Owner:CAREY & CO

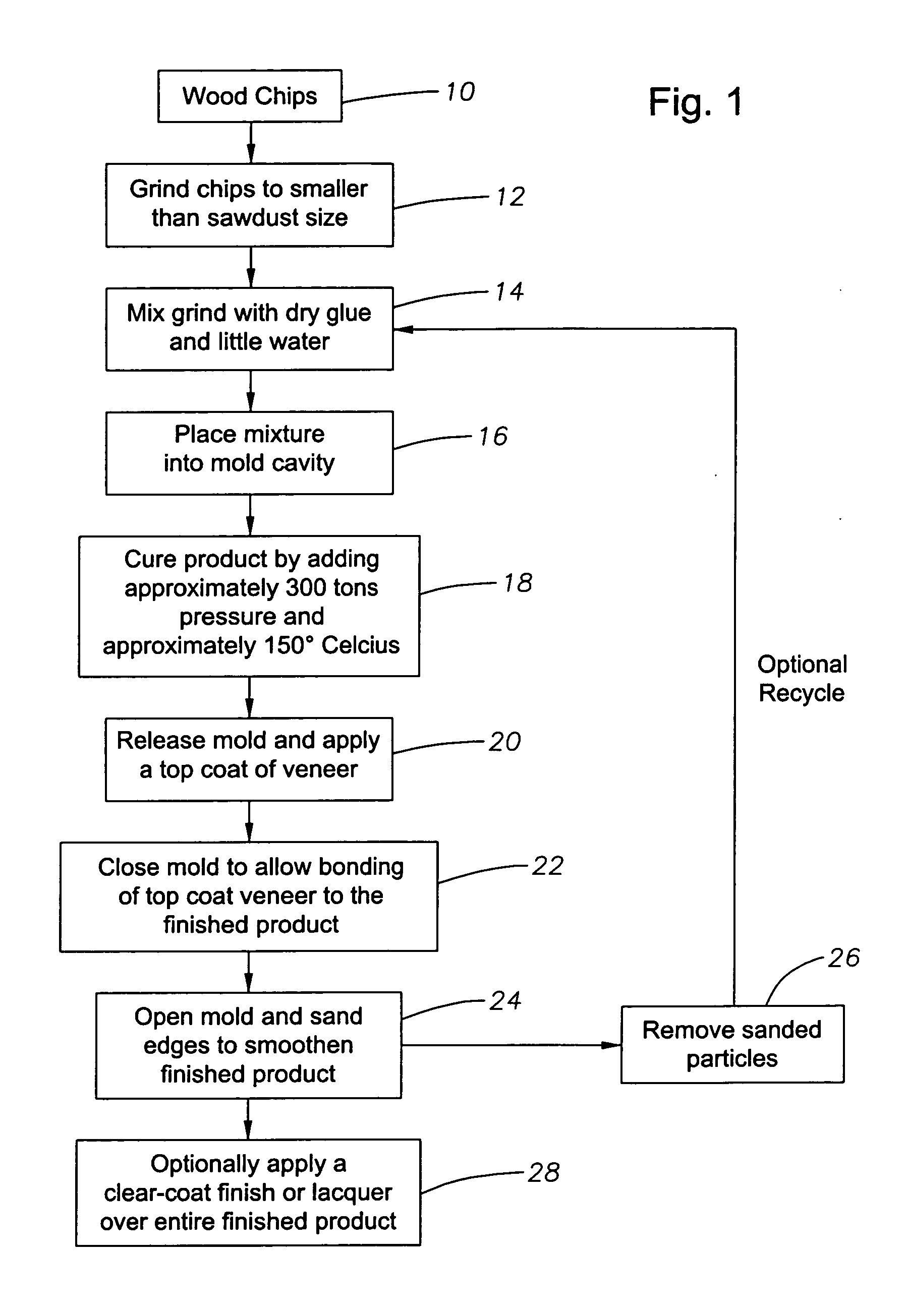

Manufacturing process for ultra light fiber board

ActiveCN102806591AEasy to prepareEasy to operateDigestersAldehyde/ketone condensation polymer adhesivesFiberAdhesive cement

The invention discloses a manufacturing process for an ultra light fiber board. The method comprises the following steps of: peeling wood, cutting to obtain sheets, screening, washing, boiling, separating fibers, mixing and applying adhesive, drying and sorting, paving and forming, prepressing, performing hot-pressing, turning the board and cooling, sanding, inspecting and classifying, and packaging and putting in storage, wherein in the boiling step, the boiling material level is 1.6 to 3m, and the boiling temperature is 165 to 175 DEG C; in the step of separating the fibers, the wood sheets enter a mill through a ribbon spiral conveyor, molten waxes are fed into the mill simultaneously, the application amount is 5.0 to 7.0kg / m<3>, and the gap of an abrasive wheel is 0 to 4mm; and in the step of mixing and applying the adhesive, melamine modified urea resin adhesive is applied, the adhesive application amount is 195 to 210kg / m<3>, the adding amount of a curing agent is 1 to 2.5 percent based on the mass of absolute drying adhesive, and the curing agent is a mixture of ammonium chloride and a (commercially available) HA101 cross-linking agent in a mass ratio of 3:1. Moreover, a method for preparing the melamine modified urea resin adhesive used by manufacturing the ultra light fiber board is correspondingly provided for matching the manufacturing process.

Owner:DAYA WOOD IND JIANGXI +1

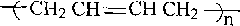

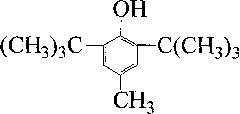

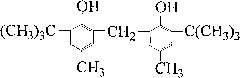

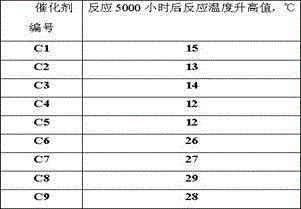

Nickel-system polybutadiene rubber composite anti-aging agent with anti-yellowing efficiency

ActiveCN101798405AOvercoming Discoloration ProblemsGood compatibilityPolymer scienceAging resistance

The invention provides a nickel-system polybutadiene rubber composite anti-aging agent with anti-yellowing efficiency, which relates to the technical field of preparing a nickel-system polybutadiene rubber composite anti-aging agent. The composite anti-aging agent comprises a bisphenol monocarboxylic acid ester antioxidant and a phosphite antioxidant and a sulfur antioxidant, the mass ratio of the bisphenol monocarboxylic acid ester antioxidant to the phosphite antioxidant to the sulfur antioxidant is 1:0.3-0.5:0.6-1.2, and anti-aging agent products are added into the nickel-system polybutadiene rubber to obtain an effective anti-aging component, wherein the mass percent of the anti-aging agent to dry glue is 0.2-0.6 percent. The composite anti-aging agent is used for synthesizing nickel-system polybutadiene rubber and has good ageing resistance and yellowing resistance.

Owner:溧阳常大技术转移中心有限公司

Preparation method for alumina carrier

ActiveCN105709711APrevent collapseStable supportCatalyst carriersRefining to eliminate hetero atomsO-Phosphoric AcidPtru catalyst

The invention discloses a preparation method for an alumina carrier. The preparation method comprises the following steps: (1) weighing a certain amount of pseudo-boehmite dry glue powder and impregnating the pseudo-boehmite dry glue powder with a proper amount of an aqueous solution containing polyol and / or carbohydrate substances; (2) subjecting a material obtained in the step (1) to hydro-thermal carbonizing treatment; and (3) subjecting a material obtained in step (2) to extrusion moulding, then subjecting the dried carrier to nonsaturated spraying and impregnation with a mixed solution of phosphoric acid and ammonium oxalate, carrying out hermetic heating treatment on the impregnated carrier and then carrying out drying and roasting so as to obtain the alumina carrier. The alumina carrier prepared by using the method has a great pore volume and great pore sizes; macro pores are nonuniformly distributed in the alumina carrier along a radial direction; and the carrier is applicable to the field of preparation of hydrogenation demetalization catalysts for heavy oil and residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

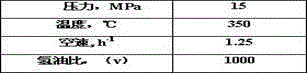

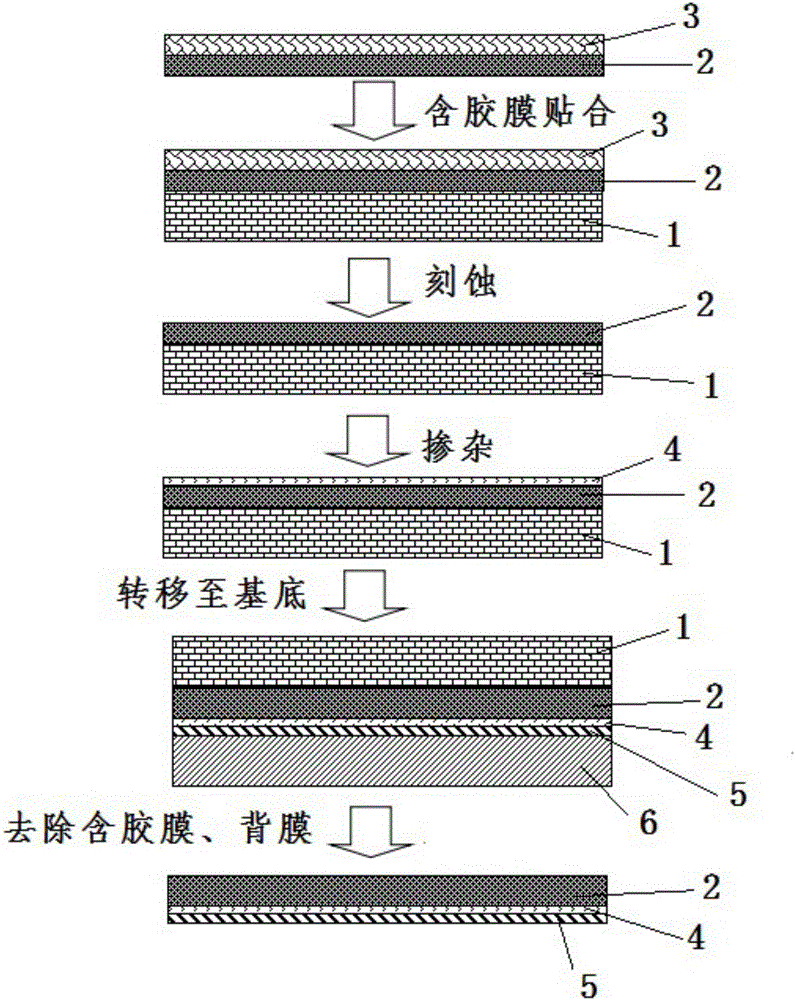

Preparation method of ultrathin and ultra-flexible graphene conductive film

ActiveCN106158144AGood lookingFunction increaseConductive layers on insulating-supportsCable/conductor manufactureMetal foilOptoelectronics

The invention discloses a preparation method of an ultrathin and ultra-flexible graphene conductive film, which comprises the following steps of: 1) attaching a graphene surface of a graphene / metal foil grown through a CVD method to a glue-containing film together, and forming a structure of glue-containing film / graphene / metal foil; 2) removing a metal foil, and forming a structure of glue-containing film / graphene; 3) drying the glue-containing film / grapheme from the step 2); 4) combining an ultrathin and ultra-flexible object substrate with a back film, performing cutting and preshrinking processes, and forming the ultrathin and ultra-flexible object substrate supported by the back film; 5) transferring the graphene of the dried glue-containing film / graphene from the step 3) to the ultrathin and ultra-flexible object substrate supported by the back film from the step 4), and forming a glue-containing film / graphene / ultrathin substrate / back film; and 6) removing the glue-containing film and the back film, and obtaining a graphene / ultrathin substrate of the invention.

Owner:WUXI GRAPHENE FILM +1

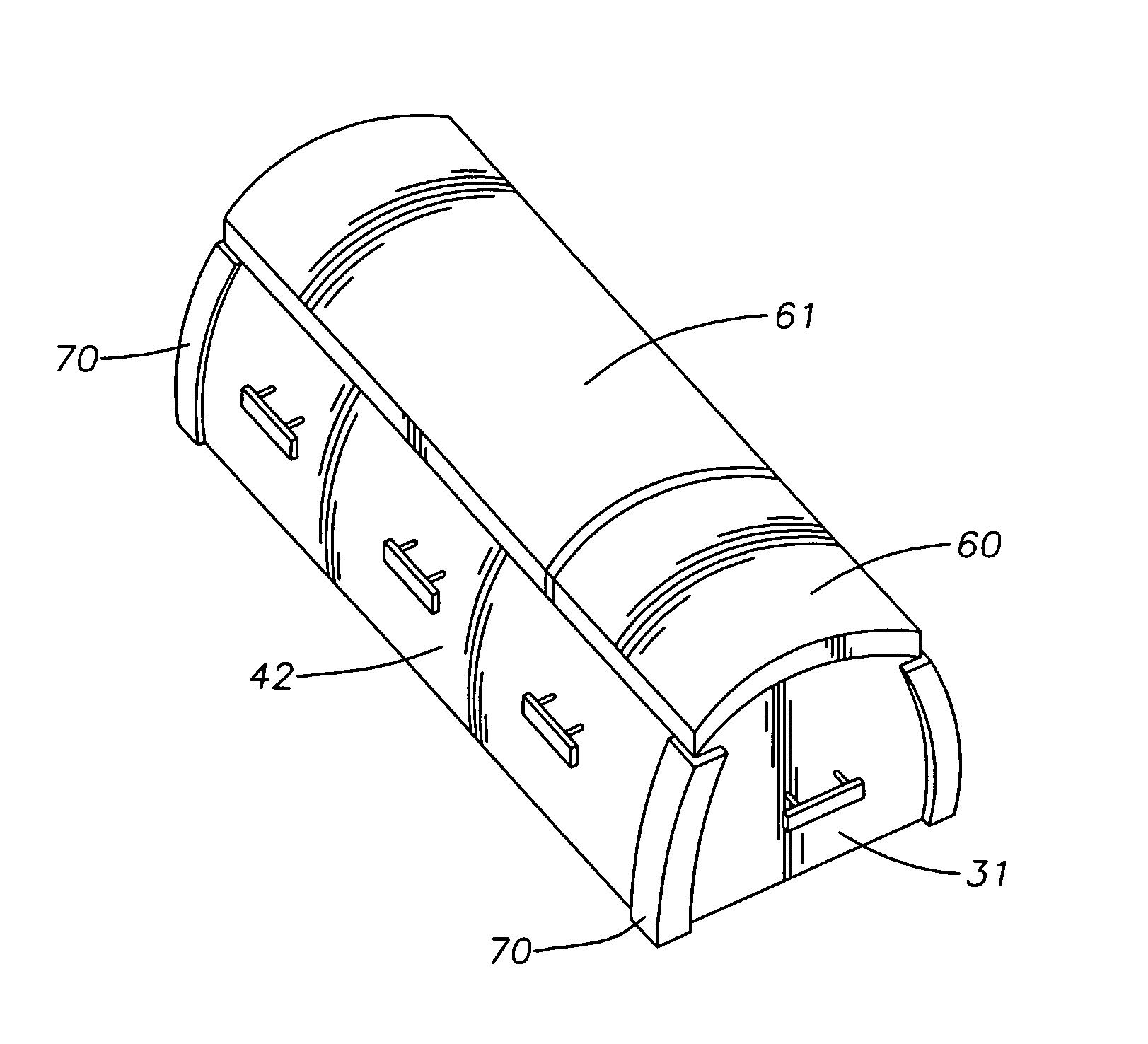

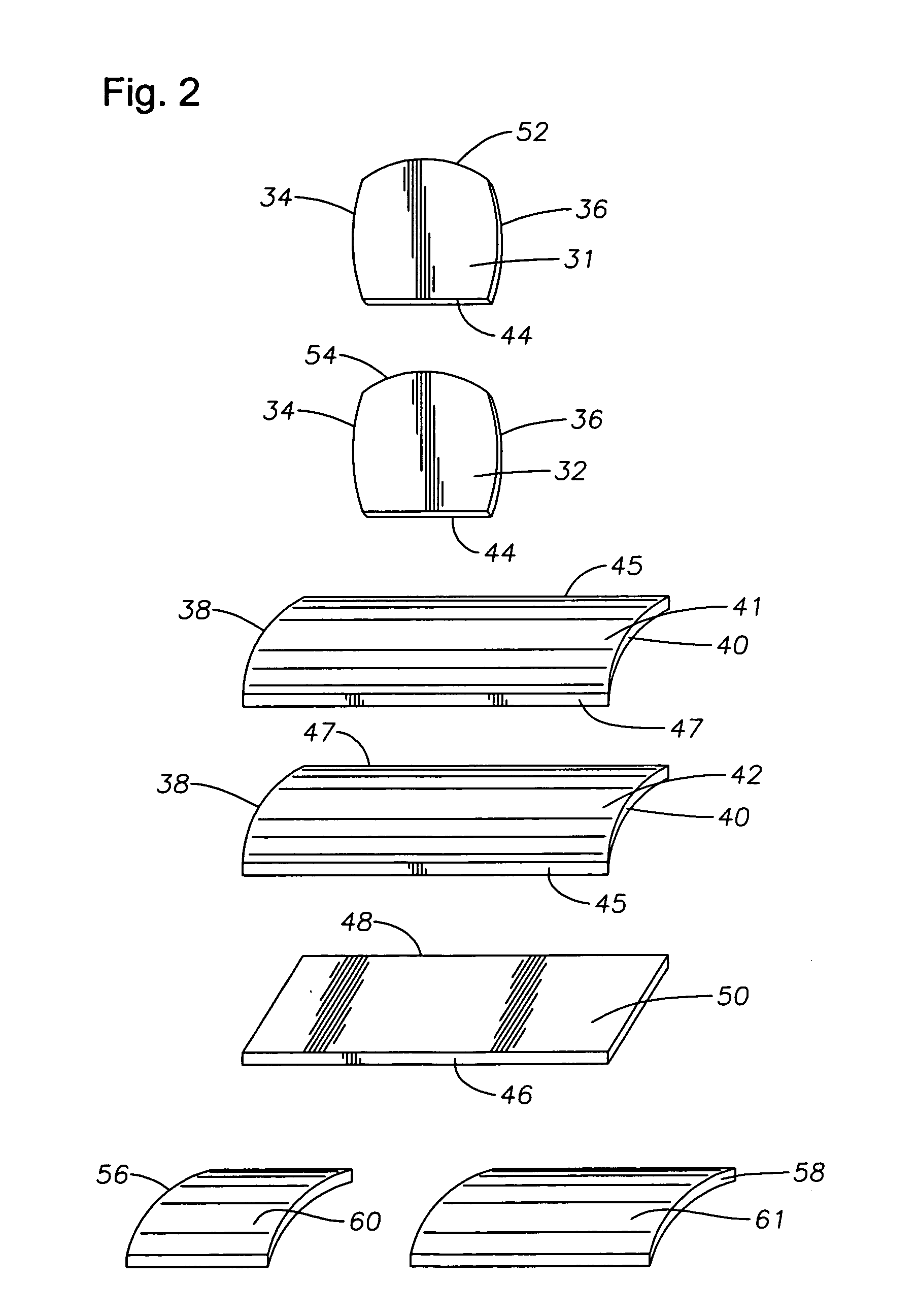

Modular casket system

Owner:LEVERETT B CALVIN

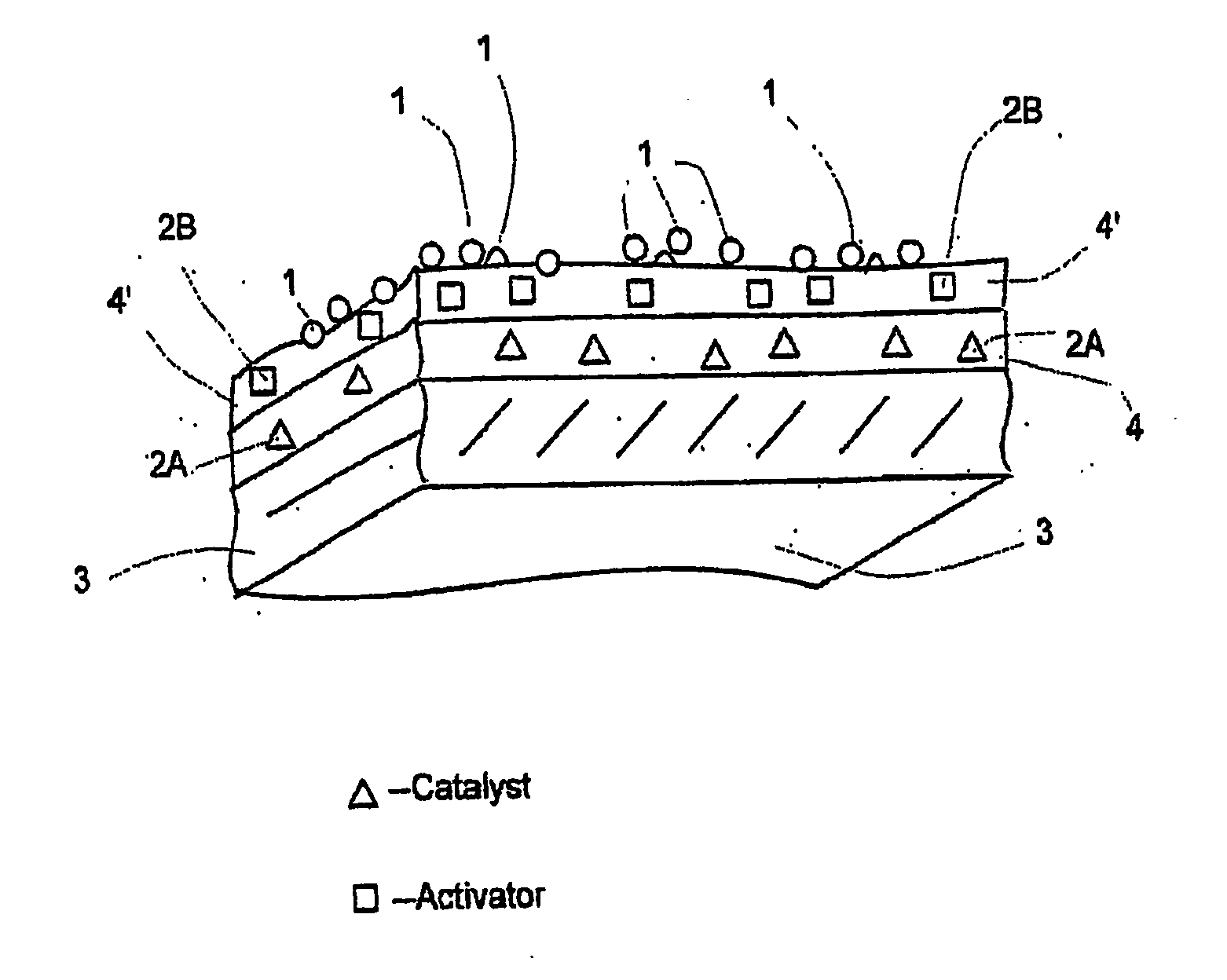

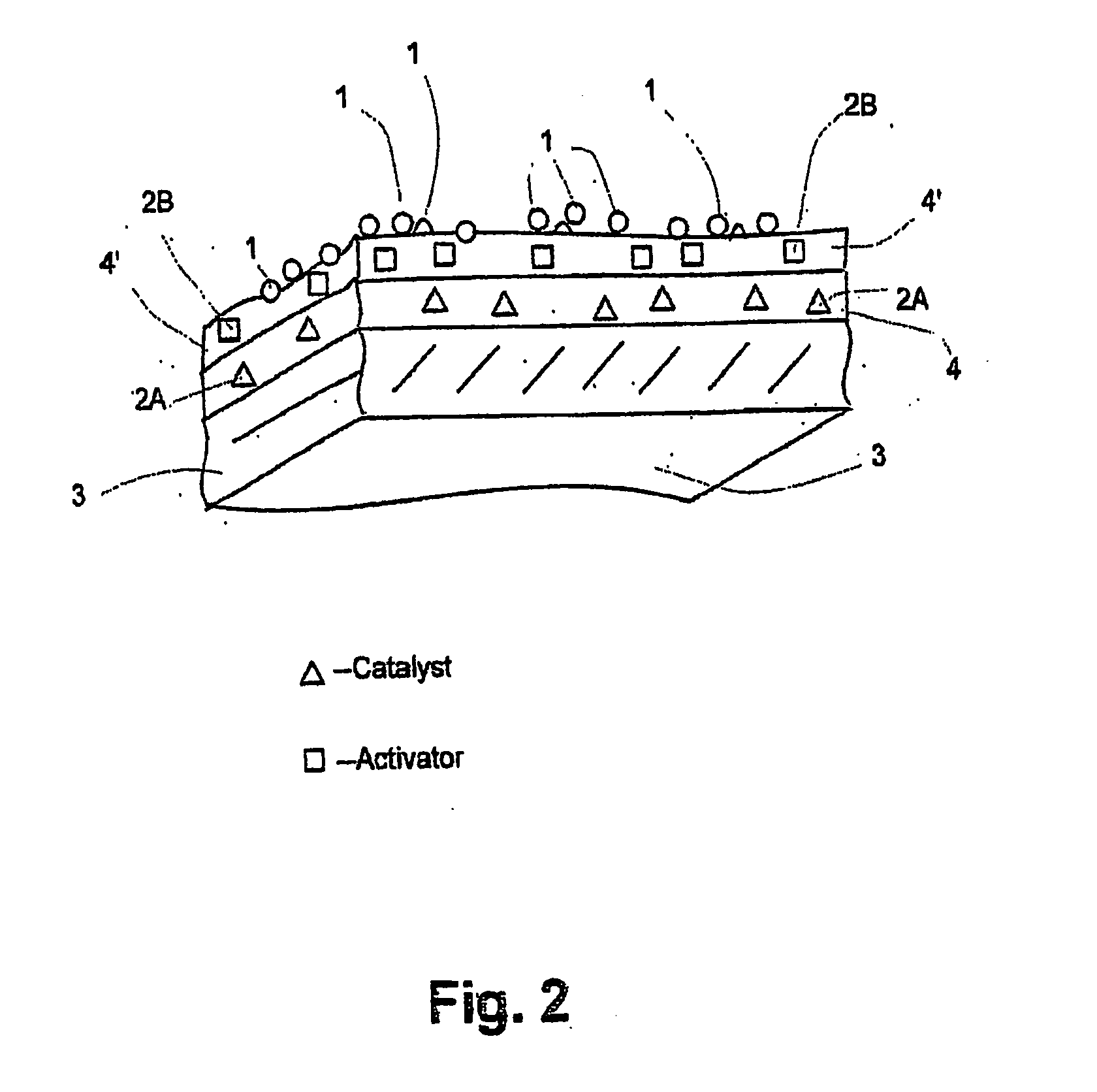

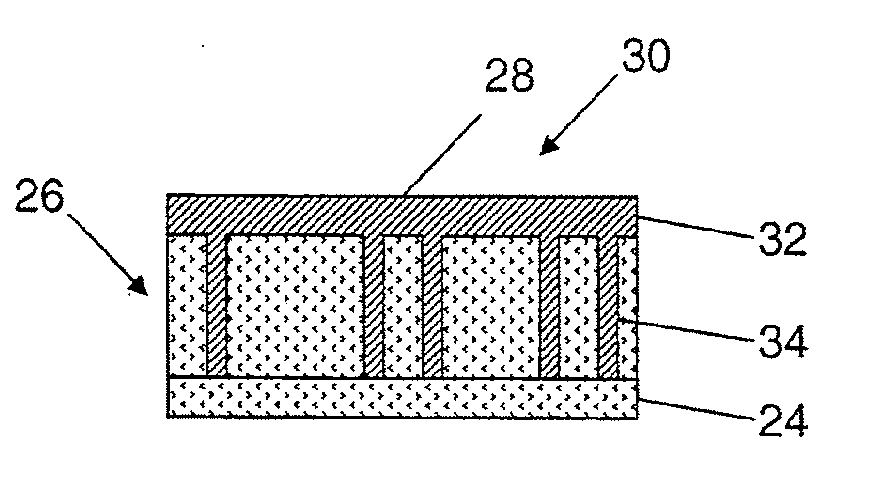

Flooring system including a dry glue

InactiveUS20100115874A1Effectiveness of adhesive can be maximizedMaximize effectivenessAdhesive processesCovering/liningsDry glueEngineering

A flooring system includes a plurality of tongue-and-groove panels, and a preglue. When activated, the preglue has a tensile strength of 7-20 kN / m when measured with a gap less than 0.1 mm and a pull rate of 2 mm / min; a storage stability of at least one year; a low initial tack value; and a set time of at least 45 minutes; as well as a creep strength of between 7 and 20 kN / m, when measured with a gap less than 0.1 mm and a pull rate of 0.02 mm / min.

Owner:PERGO

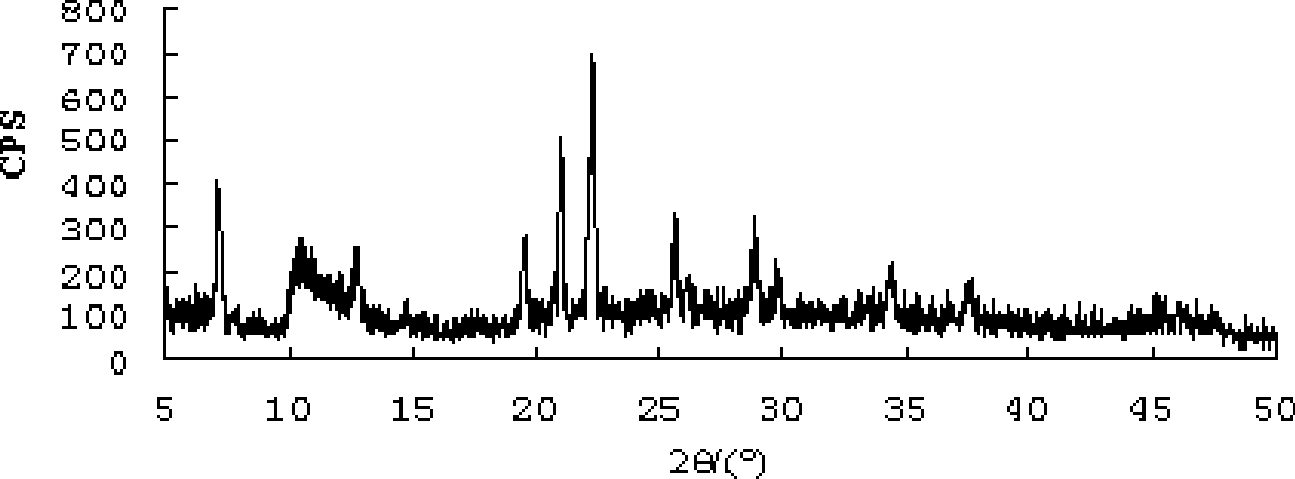

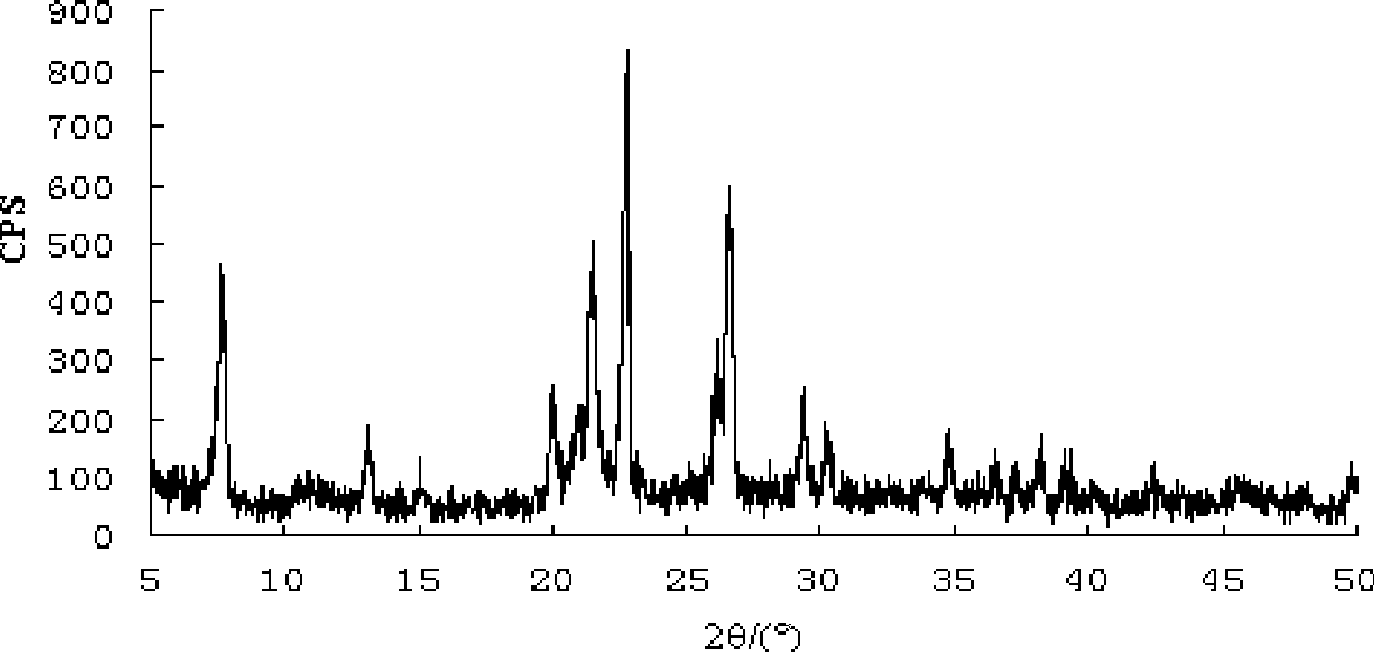

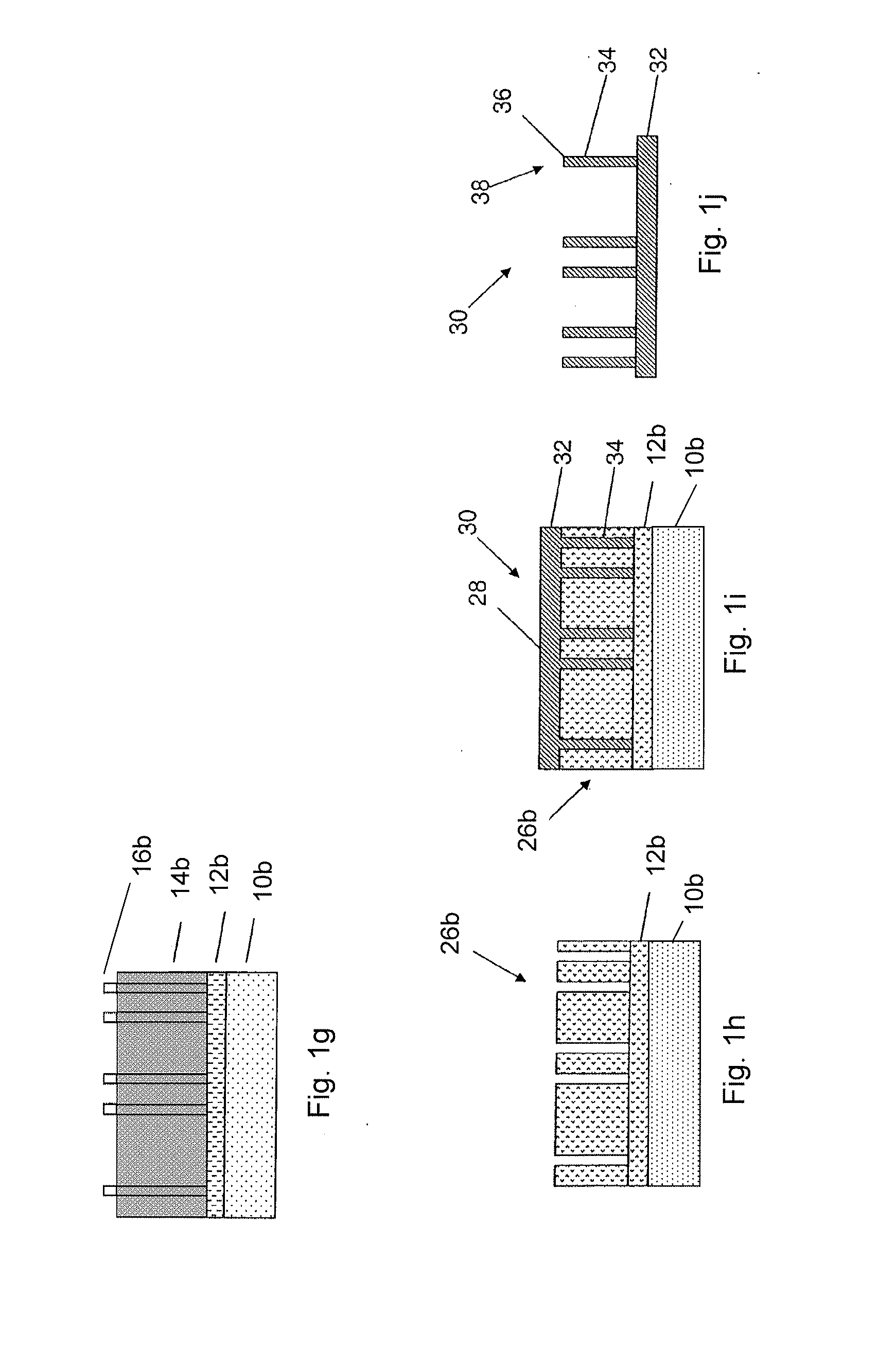

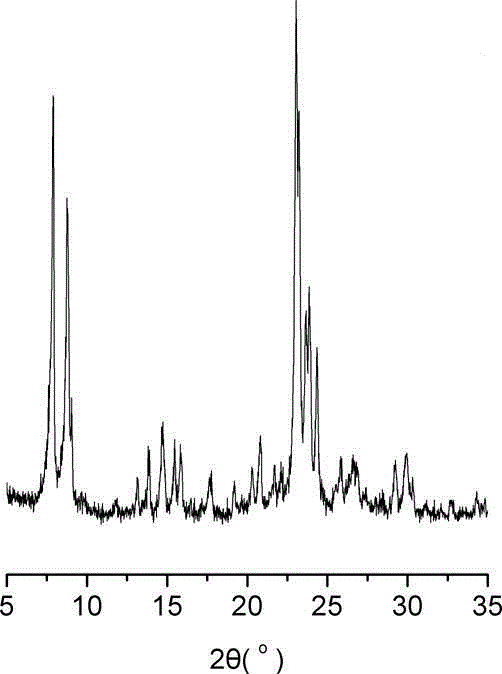

Process for producing SAPO-5 molecular sieve

InactiveCN101428819AHigh crystallinityImprove protectionMolecular-sieve and base-exchange phosphatesMolecular sieveFiltration

The invention discloses a method for preparing SAPO-5 molecular sieve, which aims to provide a method for preparing SAPO-5 molecular sieve with the advantages of simple preparation method, low requirement for equipment, good degree of crystallinity, and recoverable template agent. The invention mainly comprises technical steps as follows: precursors of silicon, aluminum and phosphorus are added into water and stirred to preparing the precursor sol of molecular sieve; the water in the sol is evaporated to dryness and dry glue is prepared; then the dry glue powder is evenly mixed with an aqueous solution of an organic amine template agent and placed into a sealed reaction kettle, reacts for 48h-120h at 120 DEG C-220DEG C, and is cooled to the room temperature in the natural state; the solid sample obtained after filtration is washed, dried, and baked for 0.5h-10h at 450 DEG C-650 DEG C; and SAPO-5 molecular sieve can be obtained.

Owner:HANERGY TECH

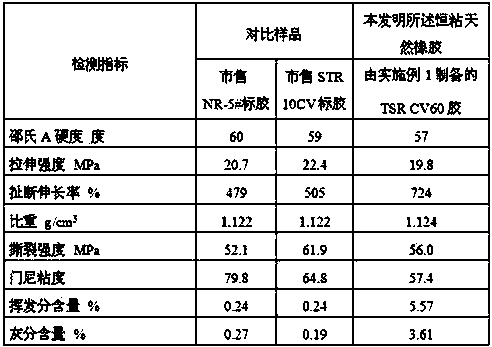

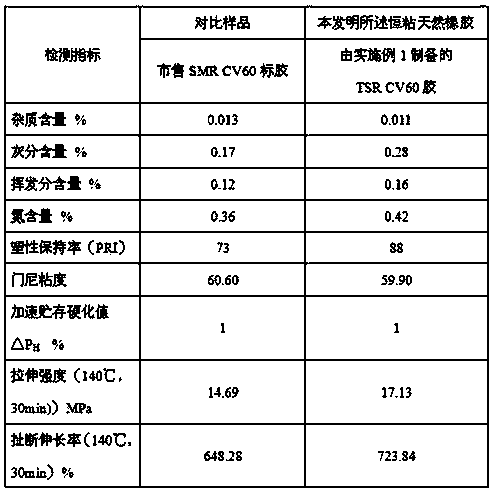

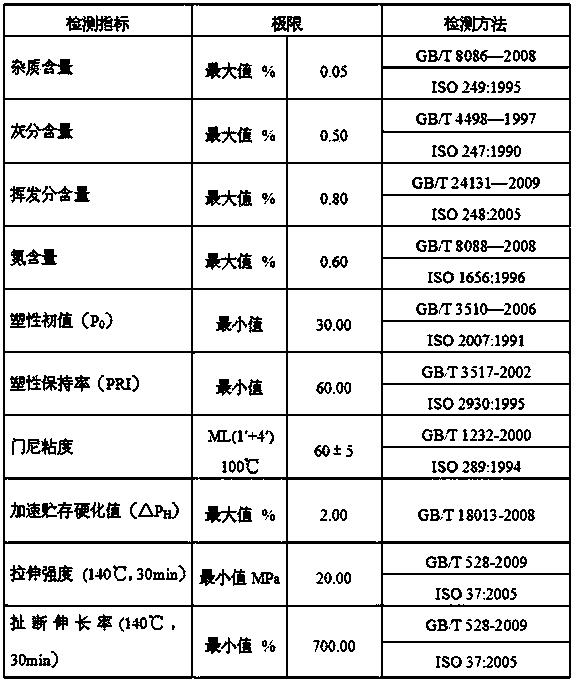

Constant viscosity natural rubber and preparation method thereof

The invention discloses constant viscosity natural rubber and a preparation method thereof, and belongs to the technical field of natural rubber processing. The rubber is 50.00-65.00 in Mooney viscosity, is more than or equal to 60% in plasticity retention percentage, higher than or equal to 14 Mpa in tensile strength, and more than or equal to 700% in elongation at break. The constant viscosity natural rubber is prepared by adding more than or equal to 2.5% of a hydroxylamine constant viscosity solution and more than or equal to 8.0% of a hydrazine hydrate solution in fresh latex. The preparation method of the constant viscosity natural rubber comprises the following processes of purification, constant viscosity treatment, solidification and curing, dehydration and impurity removal, and drying, and comprises the following steps: at first, performing the impurity removal on the fresh latex, adding more than or equal to 2.5% of the hydroxylamine constant viscosity solution and more than or equal to 8.0% of the hydrazine hydrate solution according to the dry rubber amount, and mixing for not less than 20 min; then, mixing the diluted latex with an acid at the volume ratio of (576-626):1 and enabling the mixture to flow and enter into a groove, and drying till the water content is less than or equal to 0.8% after latex coagulum is subjected to thinning, flotation, crumpling, pelleting and spraying. The constant viscosity natural rubber is stable in Mooney viscosity, high in consistency of sizing materials, excellent in performance, simple in production process, strong in interchangeability, and environment-friendly, and has a relatively high popularization value.

Owner:XISHUANGBANNA SINOCHEM RUBBER

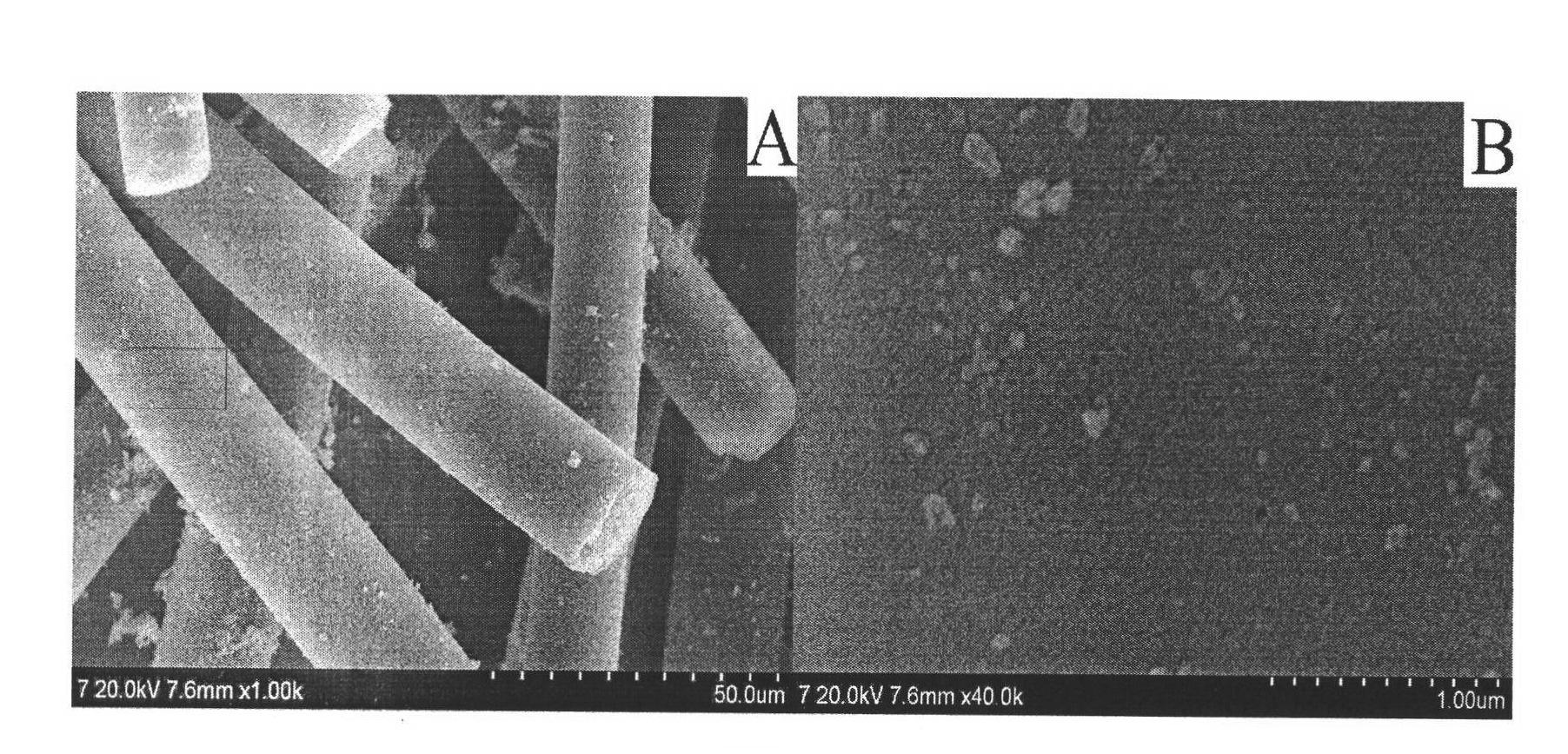

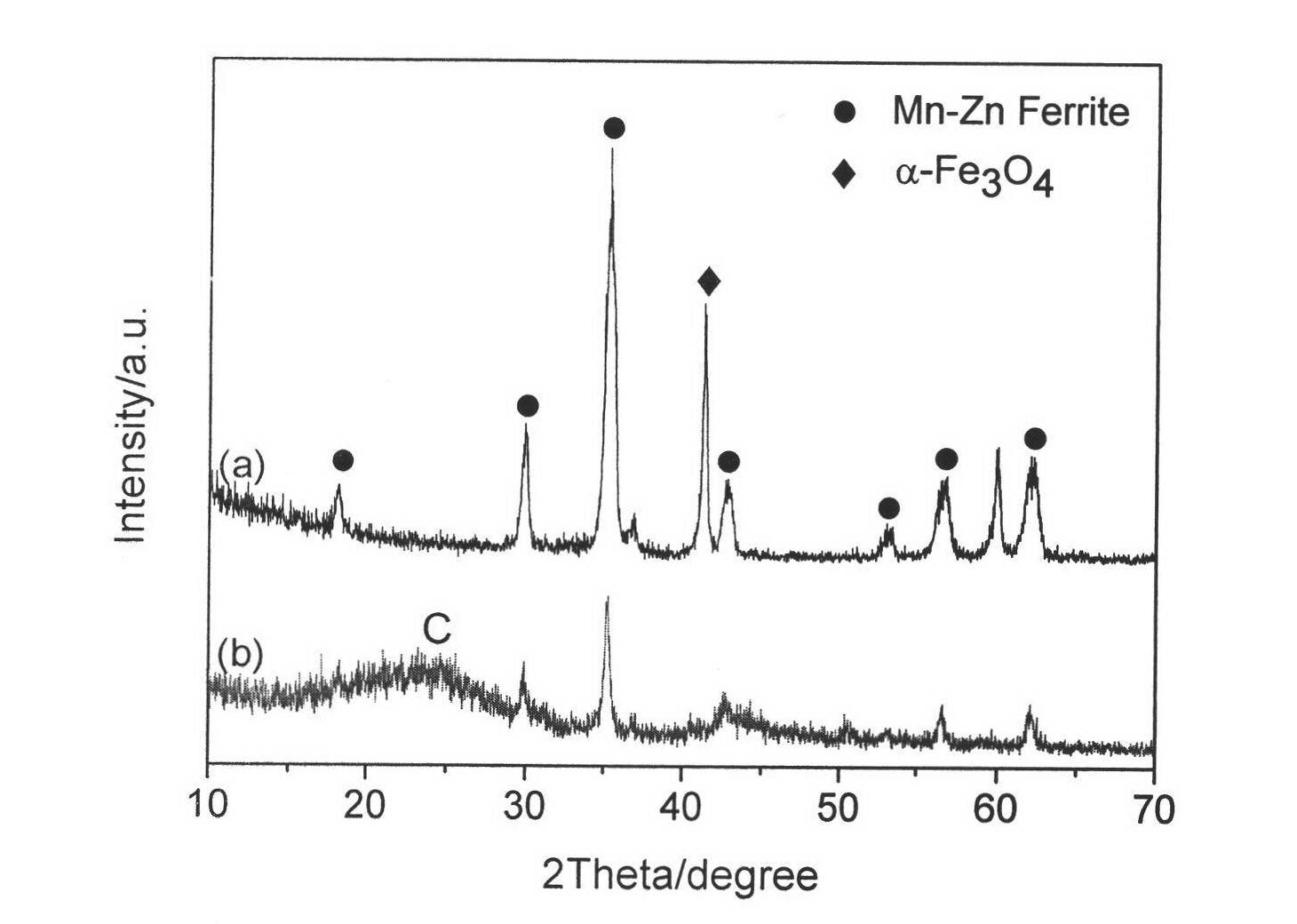

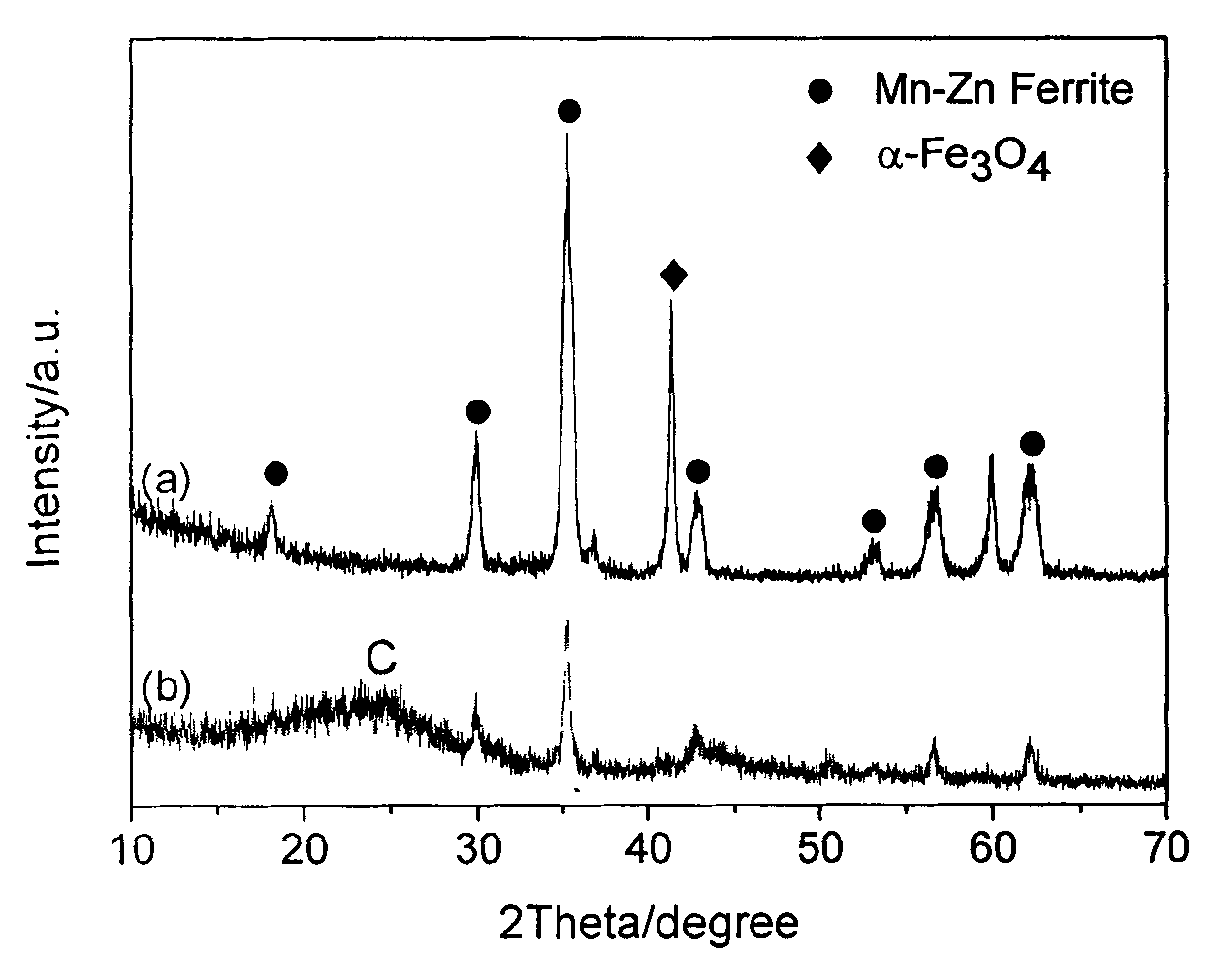

Method for preparing porous carbon born nano ferrite wave-absorbing material

The invention relates to a method for preparing a porous carbon born nano ferrite wave-absorbing material, comprising the following two main processes: firstly, preparing the mixture of porous carbon materials and dry gel; and secondly, calcining the obtained mixture of porous carbon materials and dry gel under the nitrogen atmosphere, wherein calcination comprises the following steps: placing the dried mixture of porous carbon materials and dry gel into a porcelain boat; arranging the porcelain boat at the center of a quartz tube in a horizontal reacting furnace, raising the temperature of the reacting furnace to 600-650 DEG C under the nitrogen atmosphere, and holding the temperature for one hour; reducing the temperature of a reaction tube to the room temperature through cooling under the protection of nitrogen after reaction; and obtaining the products in the porcelain boat, namely the novel porous carbon born ferrite wave-absorbing material. According to the method, the enlargement of crystallization of ferrite particles and the soft agglomeration of nano ferrite can be avoided by utilizing the special characteristics and functions of the pore structure of the porous carbon material; and the porous carbon born ferrite is firmer and hard to fall.

Owner:SHENYANG LIGONG UNIV

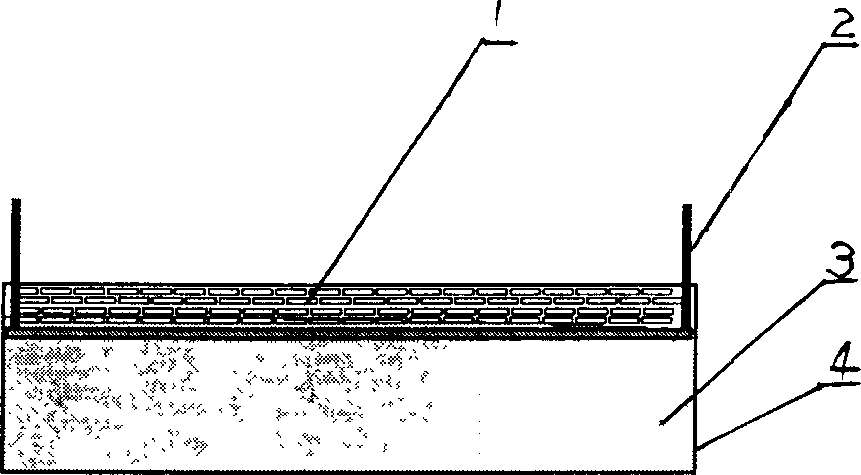

Engraved holographic antifakery labels checked by take-off and their production

Anti false identifier includes special type printing layer, basal membrane, fluorescent layer, protective layer, particularity detection layer, vacuum plating copper layer, laser hologram layer, regular engraved tearing off layer, protective coat layer of chemical etched pattern and not dried glue layer. The manufacturing procedure includes following steps: raw material, printing fluorescent layer, coating protective layer (information layer), coating particularity detection layer, vacuum plating copper, hologram molding etc. Multiple anti false techniques are integrated on the identifier, possessing advantages of easy use and easy recognition.

Owner:河南天畅图像有限公司

Method for producing float laminated blank assembly of bamboo strand lamination

InactiveCN1883904AIncrease profitImprove performanceCane mechanical workingVeneer manufactureDry glueEngineering

The invention belongs to bamboo artificial plate and composite material technique field. The steps of the invention includes: preparing bamboo strip, thin bamboo strip, bamboo thread and bamboo thread bundle of different level from bamboo, preparing uniform bamboo bundle from bamboo strip, thin bamboo strip, bamboo thread and bamboo thread bundle of quantitating, fixing grade, staggering node, reversing head and trail, constituting uniform bamboo layer unit from quantity determined uniform bamboo unit, immersing bamboo layer unit in glue solution for scheduled time and taking out, putting bamboo layer unit in float tank to constituting uniform single layer blank, glue trickling and drying glue-dipped bamboo layer unit, prepressing glue-containing bamboo layer unit for constituting blank to slice shape blank, constituting laminated blank from multi-layer slice shape prepressing material by stated direction, level and quantity, heating and compressing laminated blank in mould to preparing thin bamboo strip and bamboo thread laminated material. The excellence of the invention is simple, removing curtain weave process, capable of constituting multilayer thick blank one time, improving quality of blank assembling, reducing process steps and cost, and improving bamboo utilization ratio and bamboo performance.

Owner:国际竹藤网络中心

Preparation method of hydroxyethyl methylacrylate rubber grafted and modified clay-enhanced natural rubber composite material

The invention relates to a preparation method of a hydroxyethyl methylacrylate rubber grafted and modified clay-enhanced natural rubber composite material. The method concretely comprises the following steps: adding clay, a proper amount of coupling agent, an anionic surfactant and milky hydroxyethyl methylacrylate rubber to deionized water, stirring and ultrasonically dispersing so as to prepare clay emulsion dispersion; simultaneously, stabilizing the milky natural rubber by adopting a proper amount of nonionic surfactant and then evenly mixing the clay emulsion dispersion into milky natural rubber; dropwise adding an initiating crosslinking agent, so as to obtain the hydroxyethyl methylacrylate rubber grafted and modified clay-natural rubber composite material in a latex state; further processing the composite materials by standardized conventional processing technologies of rubber in China, such as solidifying, tabletting, washing, drying and the like to obtain the hydroxyethyl methylacrylate rubber grafted and modified clay-natural rubber composite material in a dry glue state. The clay-natural rubber composite material prepared by the method disclosed by the invention has good performances.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

Dry adhesives and methods for making dry adhesives

InactiveUS20120237730A1High yieldInexpensive to fabricateDischarging arrangementMouldsPolymer scienceAdhesive

Dry adhesives and methods for forming dry adhesives. A method of forming a dry adhesive structure on a backing material, comprises: forming a template backing layer of energy sensitive material on the backing material; forming a template layer of energy sensitive material on the template backing layer; exposing the template layer to a predetermined pattern of energy; removing a portion of the template layer related to the predetermined pattern of energy, and leaving a template structure formed from energy sensitive material and connected to the substrate via the template backing layer.

Owner:CARNEGIE MELLON UNIV

Method for preparing alumina supporter with high specific surface area

The invention discloses a method for preparing an alumina supporter with high specific surface area. The method comprises the following steps of (1) weighing a certain amount of pseudoboehmite dry glue power, a certain amount of physical pore-enlarging agent and a certain amount of extrusion assistant agent to be evenly mixed and then adding an aqueous solution containing a chemical pore-enlarging agent; (2) evenly mixing materials obtained in the step (1) and extruding a mixture into strips; and (3) drying the material obtained the step (2), and calcinating a dried material in the nitrogen atmosphere to calcinate and prepare the alumina supporter in the air atmosphere. The alumina supporter prepared by means of the preparation method is large in pore volume and specific surface area, concentrated in pore distribution and moderate in mechanical strength, can be suitable for the fields of petroleum processing, chemical engineering, environmental protection and the like, and is especially suitable for preparation of heavy oil hydrotreating catalysts and residual oil hydrotreating catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

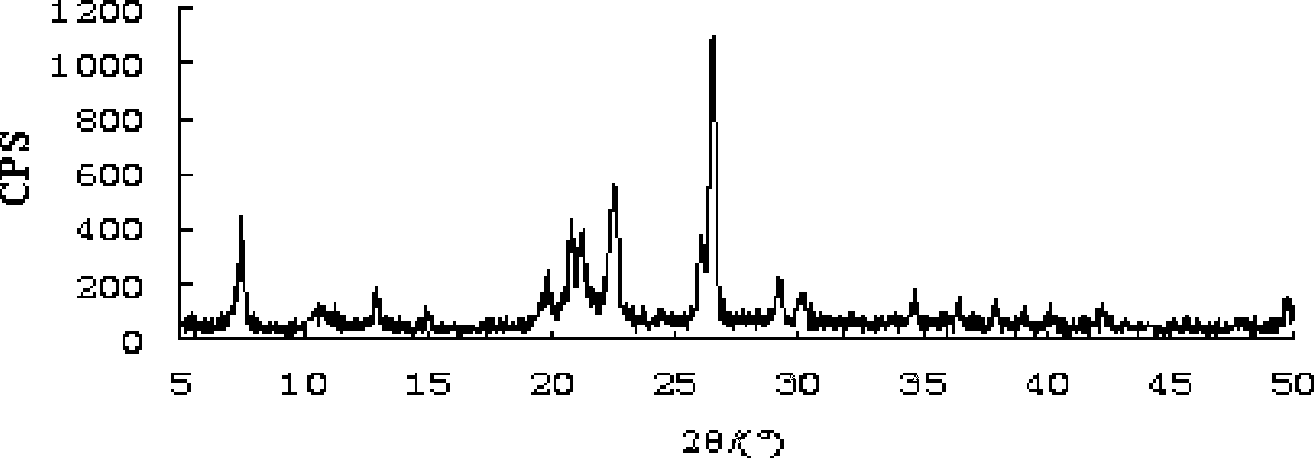

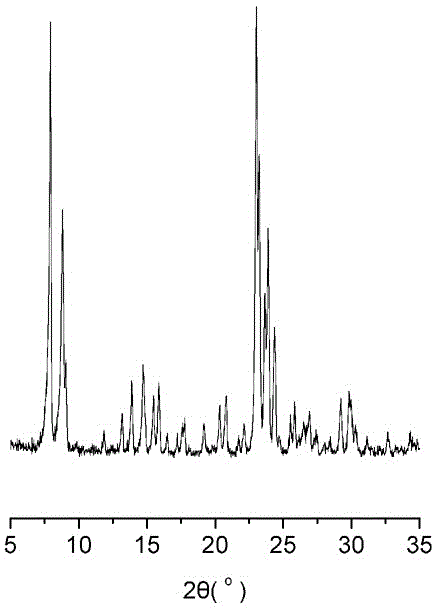

Large block porous zeolite composed of nano-crystal grains and preparation method thereof

InactiveCN105000573ASolve the problem of solid-liquid phase separationIncreased diffusion ratePentasil aluminosilicate zeolitePhysical chemistryDry glue

The invention discloses a large block porous zeolite composed of nano-crystal grains and a preparation method thereof. The preparation method includes: taking a silicon source, an aluminum source, an alkali source, a quaternary ammonium salt template agent and sodium chloride as the raw materials to prepare gel, adding a crystal growth interference agent to prepare a blocky dry glue; subjecting the blocky dry glue and a gas template agent not in direct contact to vapor phase crystallization reaction so as to obtain the large block porous zeolite that is composed of 50-500nm primary zeolite crystal grains and has a 2-50nm intergranular mesoporous system. The porous zeolite synthesized by the method provided by the invention has improved diffusion rate and acid site accessibility, and has important application value in catalytic cracking, hydrocracking, adsorption separation and other aspects of fine chemical engineering and petrochemical engineering.

Owner:TAIYUAN UNIV OF TECH

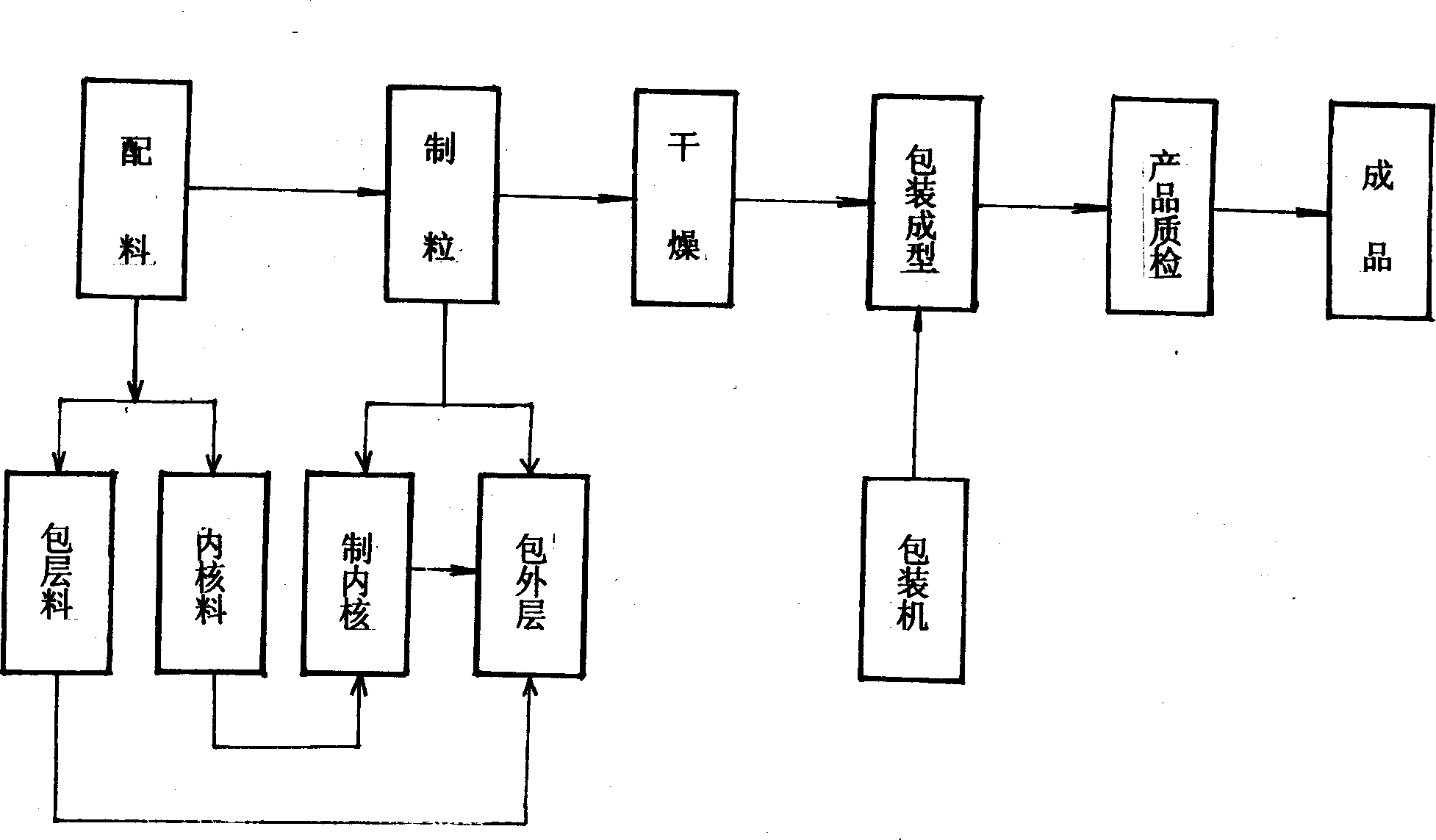

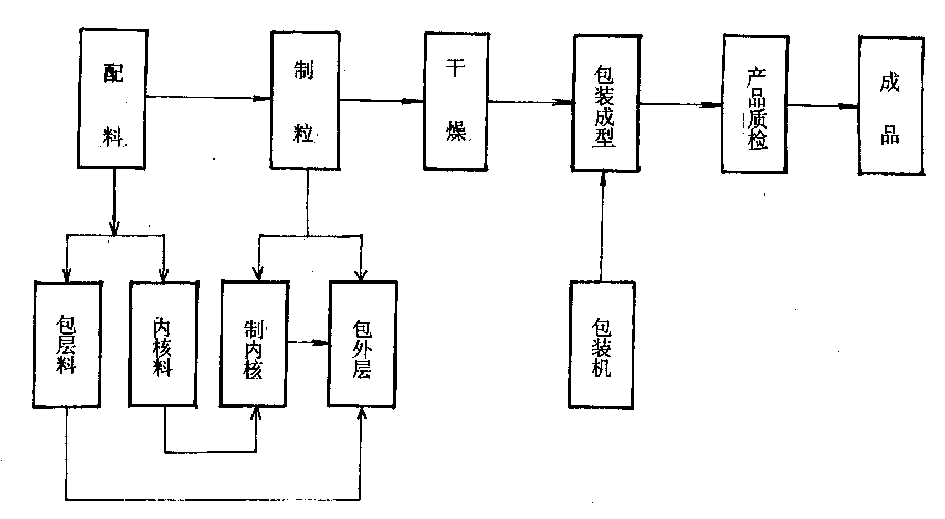

Environment protecting explosive-free safe color-light firecrackers and the production technique

The environment protecting color-liquid firecrackers consists of adhesive casing, internal safe lead and chemical grains and features that the chemical grain consists of inner kernal comprising red lead powder, copper oxide powder, Al-Mg alloy and PVA adhesive; and outer coating comprising potassium nitrate, Al-Mg alloy, charcoal. sulfur, aluminium dregs and phenolic resin. The firecrackers and produced through pelletizing in steel sieve, rolling to form inner kernel, rolling to adhere outer coating to inner kernel and other steps. It is safe in production, storage, transportation and firing and has large sound produced.

Owner:欧定锋

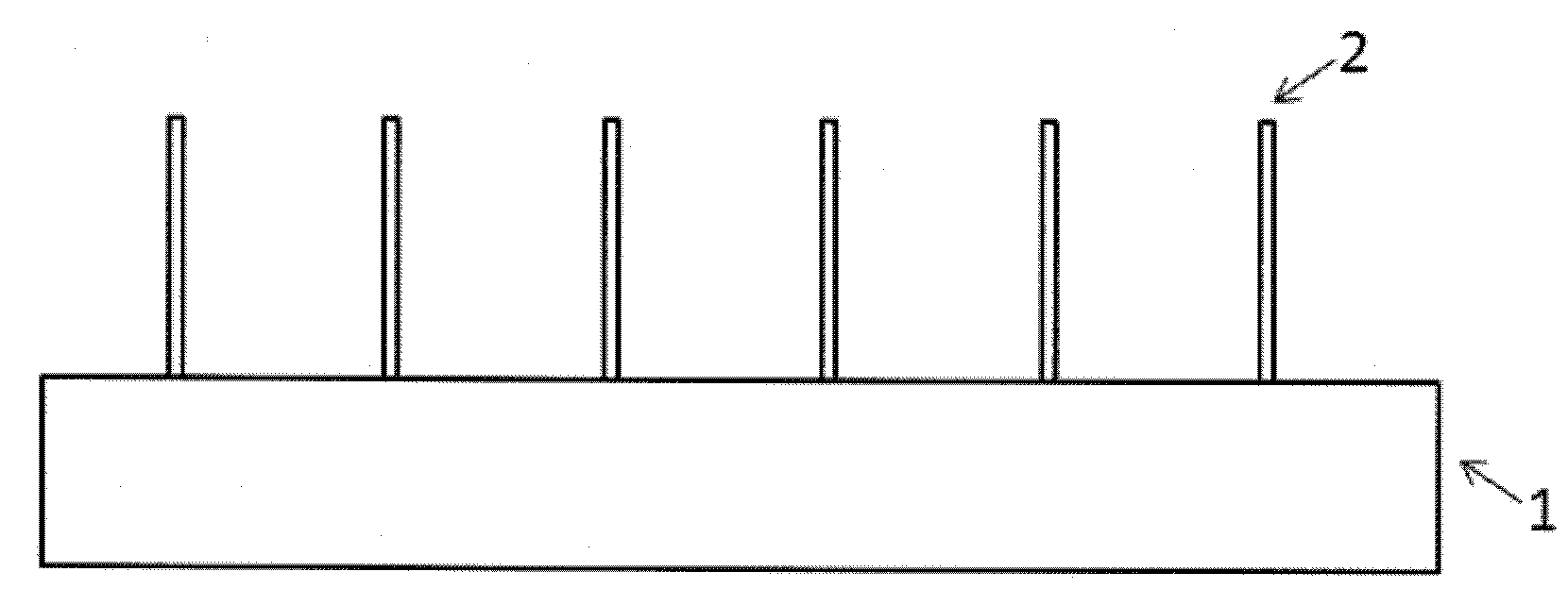

Preparation method of multifunctional integrated nano-wire array

ActiveCN102358615AImplement biomarkersAchieve surface modificationDecorative surface effectsChemical vapor deposition coatingEngineeringOrganic polymer

The invention discloses a preparation method of multifunctional integrated nano-wire array. The method comprises the following steps: firstly covering a layer of an organic polymer solution on a surface of nano-wire array, allowing the array to stand under a vacuum condition so as to allow organic polymer to uniformly penetrate into the nano-wires, then obtaining a flattened surface by a glue-evening method; treating the surface by a dry glue-removing process to expose a part of the nano-wire array, performing surface modification of the part of nano-wires; removing residual organic polymer by an organic solvent, and further modifying the exposed nano-wires. The invention can integrate multiple functions, such as luminescence, magnetism, bio-marking and the like on a surface of a single nano-wire controllably, repeatably, and consistently; the preparation process is simple; the invention has universality for various types of nano-wire array, and is applicable to new material fields of gene drug carriers, biological / chemical sensing, and composite materials.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

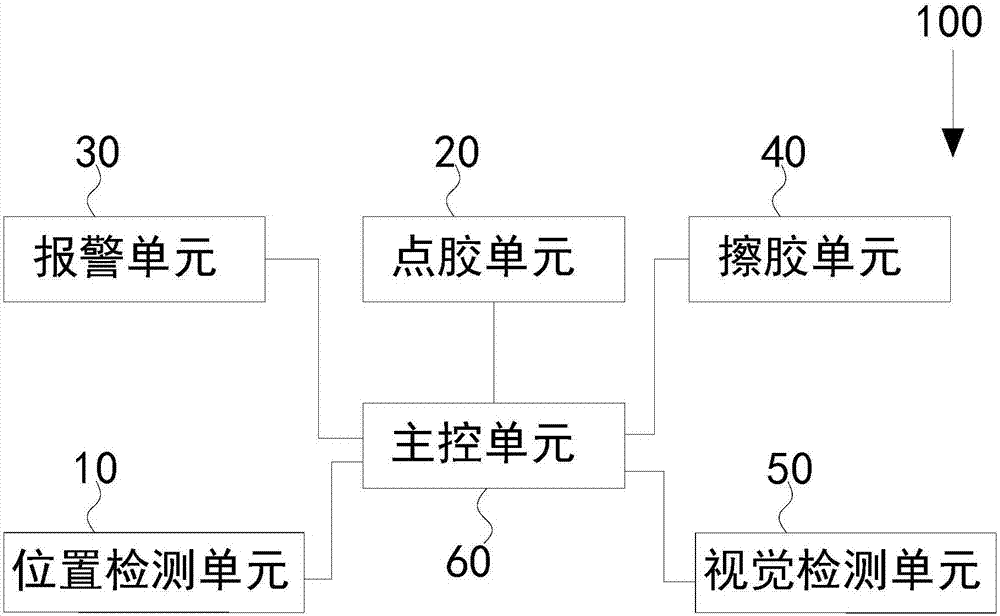

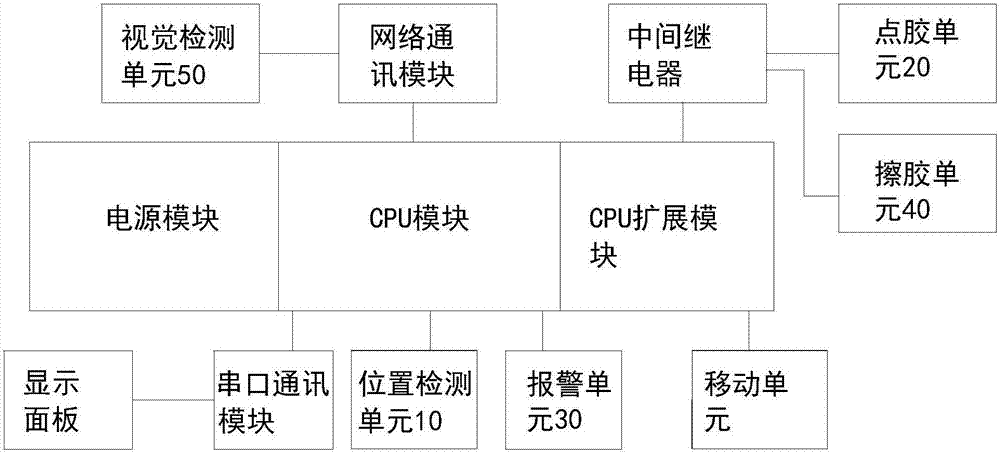

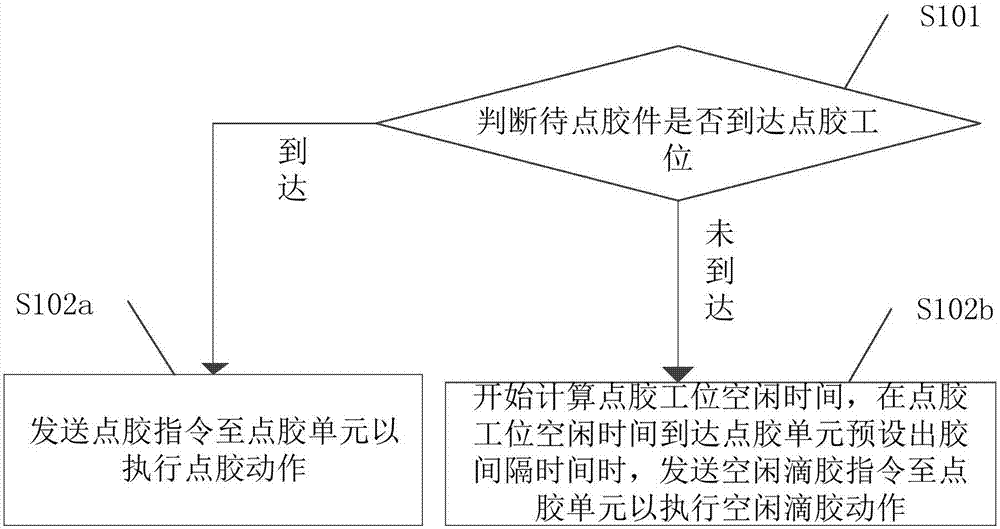

Adhesive dispensing method and system

ActiveCN107116003AAvoid the problem of dry glueRealize a high degree of automationLiquid surface applicatorsCoatingsAdhesiveEngineering

The invention discloses an adhesive dispensing method and system. The adhesive dispensing method comprises the following steps: judging whether a workpiece is placed at the dispensing working position or not; if the workpiece is placed at the dispensing working position, sending a dispensing instruction to a dispensing unit to execute the dispensing action; and if the workpiece is not placed at the dispensing working position, starting to calculate the standby time of the dispensing working position, and further sending a standby adhesive dripping instruction to the dispensing unit to execute the standby adhesive dripping action when the standby time of the dispensing working position reaches the preset adhesive exudation interval time of the dispensing unit. According to the adhesive dispensing method and system provided by the invention, the dispensing unit is controlled to carry out the standby adhesive dripping process, the problems of solidification and blockage due to that the dispensing needle does not work for a long time are solved, and the high automation degree of the overall dispensing process is realized.

Owner:GOERTEK INC

Production method of thermal-stripping acrylate pressure-sensitive adhesive tape

InactiveCN105419669AControl curl directionCurly and neatNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceMicrosphere

The invention relates to a production method of a thermal-stripping acrylate pressure-sensitive adhesive tape. The production method comprises the following steps: 1) selecting and uniformly mixing 100 parts of an acrylate polymer and 15-40 parts of expansive microspheres, adding 0.01-2 parts of an isocyanate crosslinking agent, coating a substrate with the mixture with thickness of coated dry glue being 30-60 [mu]m; 2) drying the glue coating at 60-90 DEG C to obtain a thermal-stripping pressure-sensitive adhesive tape; and 3) laminating the thermal-stripping pressure-sensitive adhesive tape onto a release film being 25-75 [mu]m to prepare the thermal-stripping acrylate pressure-sensitive adhesive tape. The pressure-sensitive adhesive tape is easy to control in winding direction when being foamed at 120 DEG C. The tape can be wound tidily and regularly.

Owner:新丰杰力电工材料有限公司

Preparation method of reinforced natural rubber composite material by grafting hydroxyethyl methacrylate rubber with modified nano calcium carbonate

The invention relates to a preparation method of a reinforced natural rubber composite material by grafting hydroxyethyl methacrylate rubber with modified nano calcium carbonate. The method comprises the following steps: adding calcium carbonate, a proper amount of coupling agent, an anionic surfactant and emulsus hydroxyethyl methacrylate rubber into deionized water so as to prepare a calcium carbonate emulsion dispersoid via ultrasonic dispersion in a stirring manner; meanwhile, stabilizing the emulsus natural rubber with a proper amount of anionic surfactant; evenly mixing the calcium carbonate emulsion dispersoid into the emulsus natural rubber; obtaining a hydroxyethyl methacrylate rubber grafted modified calcium carbonate-natural rubber composite material in a latex state by dripping a trigger crosslinking agent; further performing conventional standard China rubber processing technologies comprising solidification, tabletting, washing, drying and the like on the composite material so as to obtain the hydroxyethyl methacrylate rubber grafted modified calcium carbonate-natural rubber composite material in a dry latex state. The calcium carbonate-natural rubber composite material prepared by using the method provided by the invention has the good performance.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

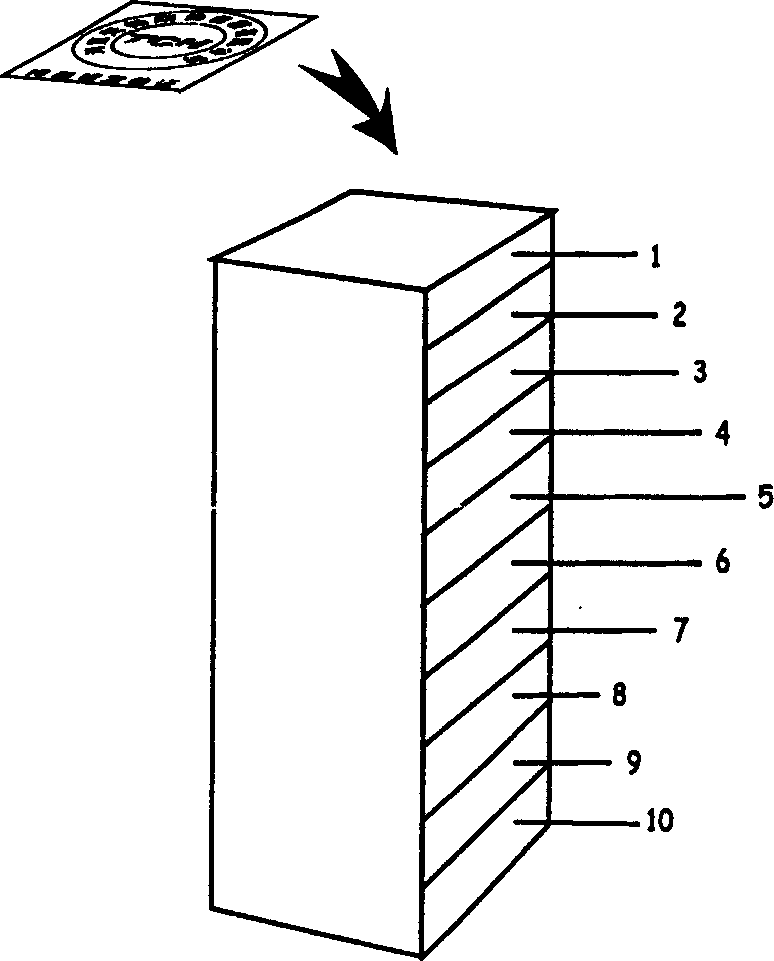

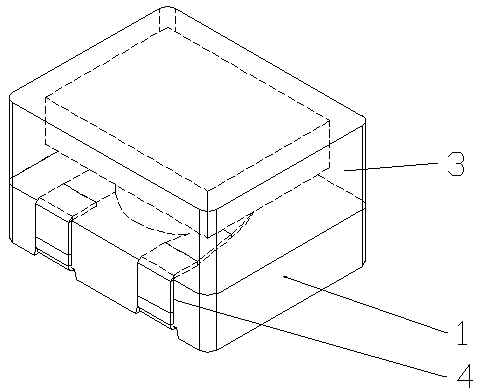

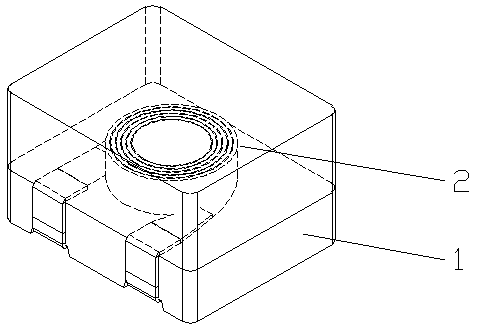

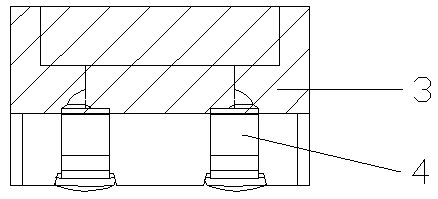

Mold pouring molding wound inductor and preparation method thereof

PendingCN109036779AHigh initial permeabilityReduce eddy current lossTransformers/inductances casingsTransformers/inductances coils/windings/connectionsNickel-zinc ferriteInductor

The invention provides a preparation method of a mold pouring molding wound inductor, It comprises the following steps, A prefabricated soft magnetic core-soft magnetic core outer coating treatment-soft magnetic core terminal electrode formation-coil wire winding, spot welding-fixture pouring magnetic glue-drying glue-lower fixture-external inspection-printing-test, That is, the soft magnetic Mn-Zn ferrite material is adopted as the winding body, the Mn-Zn ferrite material has relatively high initial magnetic permeability, the initial magnetic permeability of the Mn-Zn ferrite material is morethan 5 times of the initial magnetic permeability of the Ni-Zn ferrite material, and the eddy current loss of the Mn-Zn ferrite material is small, and the quality factor is high.

Owner:CYGE ELECTRONIC TECH (HUNAN) CO LTD

Preparation method of catalyst for hydro-treatment

ActiveCN103769121AContent adjustment is simpleHigh pore volumeCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPtru catalystDry glue

The invention discloses a preparation method of a catalyst for hydro-treatment. The preparation method comprises the following steps: mixing original clay with a weak acid and a dispersant, then carrying out a hydrothermal treatment, grinding, sieving so as to obtain modified clay with a particle size larger than 160 meshes; processing the modified clay, grinding, sieving, adding part of the modified clay into an acidic solution containing aluminum, adding part of the modified clay into a glue-forming substrate, then using the acidic solution containing aluminum and an alkaline solution containing aluminum to carry out a glue-forming treatment through a parallel flow method under proper conditions; filtering, washing, drying so as to obtain alumina dry glue containing silicon, then subjecting the alumina dry glue to the processes of forming, drying, and burning so as to obtain a catalyst carrier, and then loading a hydrogenation active metal component on the catalyst carrier through an impregnating or kneading method so as to obtain the hydro-treatment catalyst. The preparation method can organically combine clay and the generated alumina particles, and adjusts the pore structure and acidity of the catalyst. The obtained catalyst is suitable for hydrogenation demetallization, hydrogenation desulfurization, or hydrogenation conversion of heavy oil or residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

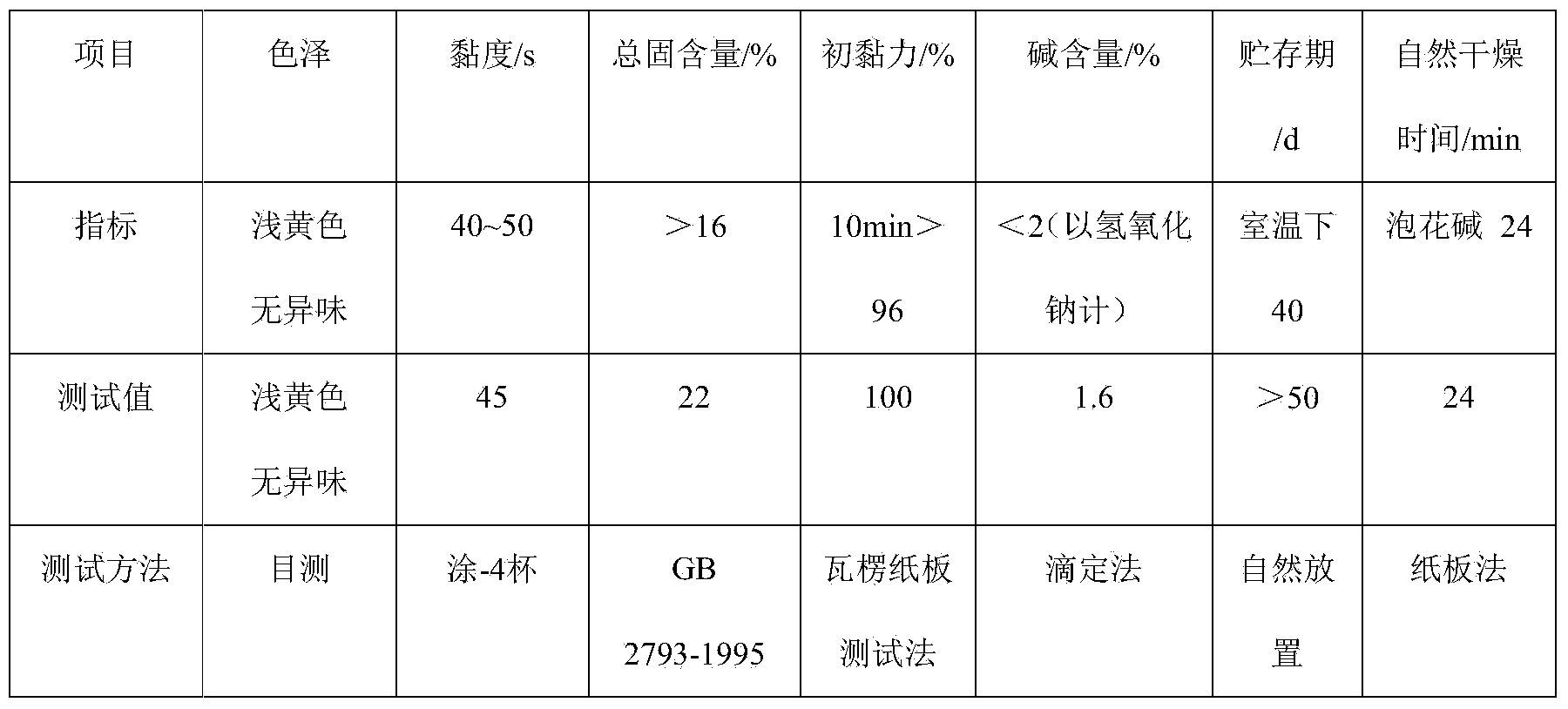

Quick dry adhesive for corrugated paper box and preparation method of quick dry adhesive

InactiveCN104231973AQuality improvementShort reaction timeNon-macromolecular adhesive additivesStarch derivtive adhesivesPtru catalystAdhesive

The invention discloses a quick dry adhesive for a corrugated paper box. The quick dry adhesive is prepared from the following components: corn starch, bentonite, sodium hypochlorite, sodium pyrosulfate, ferrous sulfate, a drier, a 3% (volume concentration) sodium hydroxide solution, borax, sodium sulfite, clean water and a defoamer. The adhesive disclosed by the invention is stable in quality, short in reaction time, fast in natural drying speed, simple in process and easy to operate. A catalyst used in the quick dry adhesive disclosed by the invention is low in cost, stable in performance and can be stored for a long time, and gelation and stratification phenomena cannot be easily caused.

Owner:JURONG GEILI PACKAGING PROD FACTORY

Preparation method of alumina carrier

ActiveCN103100426AKeep the original channel structureIncrease the diffusion coefficientCatalyst carriersAluminium oxide/hydroxide preparationPtru catalystAluminium hydroxide

The invention discloses a preparation method of an alumina carrier. The method includes: taking aluminum hydroxide dry glue powder, first wetting it by a wetting liquid containing a surface active material, conducting mixing or kneading, then adding a peptizing acid, and carrying out mixing and kneading, molding, drying and roasting, thus obtaining the alumina carrier. The method can maintain the original pore structure of dry glue powder so as to avoid the increase of small pores formed at a second time. The catalyst prepared from the carrier can increase the diffusion coefficient of reactant molecules so as to improve reaction activity. And the reduction of the small pore number also slows down the inactivation rate of the catalyst in a heavy oil hydrotreating process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com