Patents

Literature

91results about How to "Stretch resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material for rubber forming shoes and preparation method of material

The invention provides a material for rubber forming shoes and a preparation method of the material, relating to a rubber foaming material. The material for the rubber foaming shoes consists of the following raw materials in parts by mass: 100 parts of a main material, 1-5 parts of a vulcanizing agent, 1-4 parts of a vulcanizing adjuvant, 2-5 parts of a foaming agent, 8-15 parts of a plasticizer, 6-20 parts of a filler, 2-6 parts of a lubricant, 0-10 parts of an abrasion-resistant agent, 0.5-2 parts of an antioxidant, and 1.5-3 parts of pigment. The preparation method comprises the following steps of: mixing the raw materials according to the ratio into an internal mixer for mixing until a temperature of rubber is increased to 80-90 DEG C; discharging the mixed materials out the internal mixer, and pelleting through a pelleting machine; placing the pelleted material into an injection molding machine for fusing and vulcanizing; and molding through mould pressing, so as to obtain a product. The cost is low, the preparation method is simple, and the foaming rate and the rigidity are controllable; and the preparation method can be used for producing sandals, high-level beach shoes and the materials of insoles of sneakers, outsoles of leather shoes and the like. The material provided by the invention can replace the conventional shoe foaming material EVA (ethylene-vinyl acetate copolymer); and the defects of poor EVA strength, easiness of deformation, low cost performance and the like can be overcome.

Owner:泉州永悦新材料有限公司

Composite material of imitated glass reinforced plastic, its manufacture method and its application

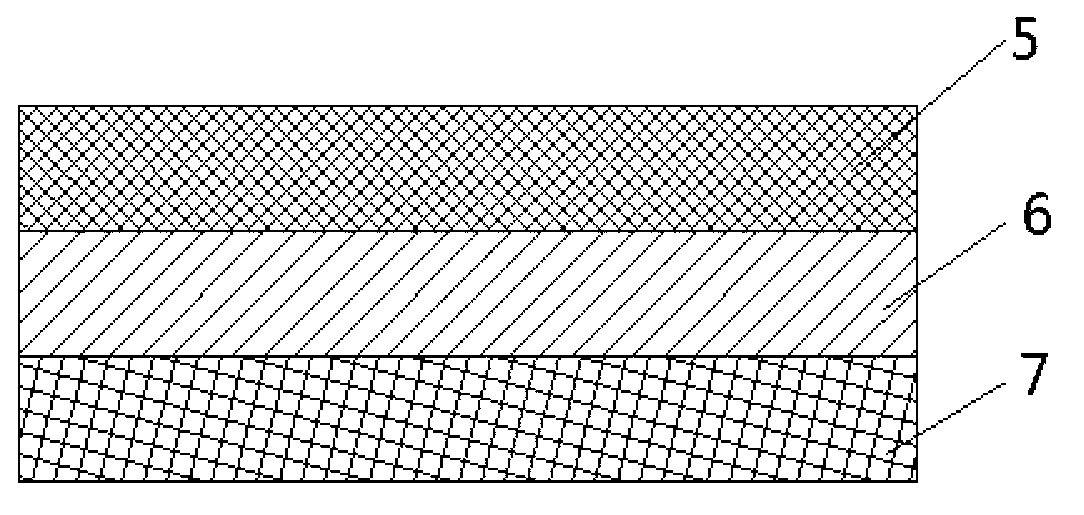

The invention discloses a composite material of an imitated glass reinforced plastic, which comprises a basic layer, the basic layer comprises the following ingredients by weight: 120-160 parts of active light calcium carbonate powder, 60-130 parts of recovered plastic, 30-60 parts of glass fiber and / or basalt fiber, 10-30 parts of coupling agent, 1-30 parts of foaming agent, 30-60 parts of processing auxiliary agent and 1-5 parts of stabilizing agent. The composite material also comprises a superficial layer and a filling layer. The composite material can replace a plurality of glass reinforced plastic products, steel products, stone products, ceramic products, wood products and plastic products. The composite material possesses the characteristics of wood, such as nailing, sawing, pasting and shaving, and enables secondary processing; and has the characteristics of B-1 grade fire protection, insect protection, no fumigation, water resistance, corrosion resistance, rust resistance, sound insulation, heat insulation, light weight, high intensity, impact resistance, strong plasticity, good physical properties, long service life, no formaldehyde containing, no radiation, acid and alkali resistance, hot and cold resistance, ultraviolet resistance, no paint requirement, easy construction, recoverable property, regeneration and utilization and the like.

Owner:黄云清

Low VOC polyurethane resin

The invention discloses a low VOC polyurethane resin. The low VOC polyurethane resin comprises an A component and a B component. The A component contains, by mass, 5 to 90 parts of a polyester and / ora polyhydroxy acrylate, 2 to 80 parts of a reactive monomer, and 0 to 0.2 part of a polymerization inhibitor; the B component comprises, by weight, 5 to 60 parts of an isocyanate, and 0 to 2.0 parts of an organic peroxide. The polyurethane composition system is composed of the reactive monomer low in viscosity and the polyhydroxy acrylate or the polyester and the diisocyanate, on one hand, the reactive monomer is capable of reducing the viscosity of the polyurethane system, and on the other hand, a crosslinked polymer is formed via reaction of the reactive monomer with polyurethane molecular chains under the action of an initiator and a promoter; and the polyurethane resin is formed via crosslinking of the polyhydroxy acrylate resin or the polyester with the diisocyanate. The above large molecular polymer obtained via two times of reaction is a solidified polymer resin.

Owner:西安天元化工有限责任公司

Method for improving orientation degree and conductivity of carbon nanotube fiber

InactiveCN111155217AGood orientationImprove compactnessCarbon fibresLiquid/gas/vapor removalFiberSpinning

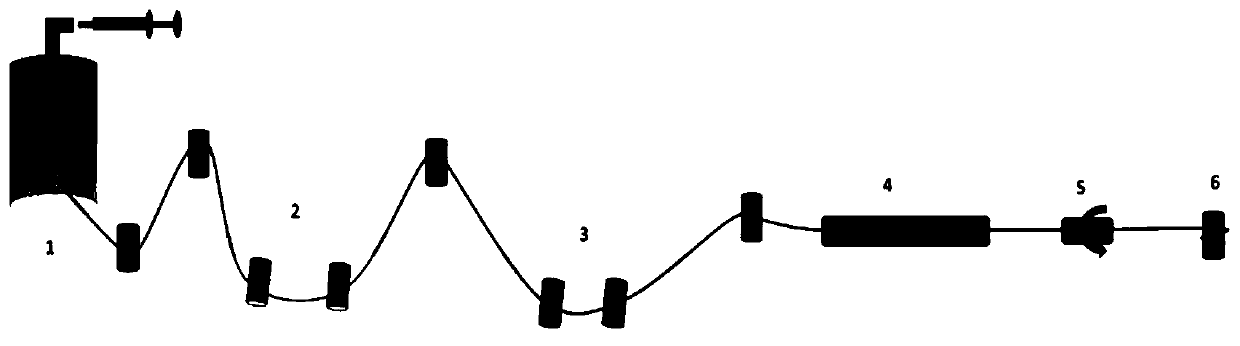

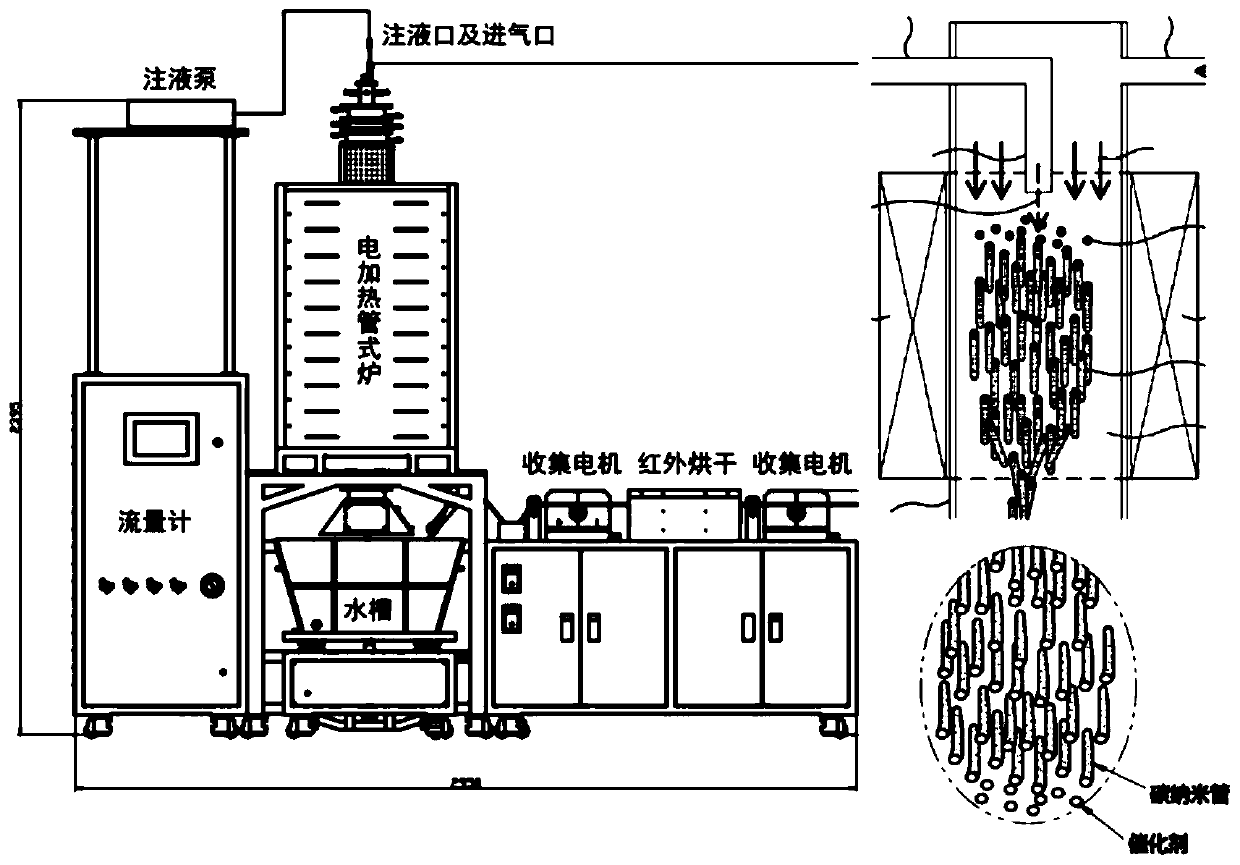

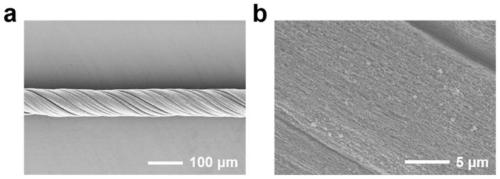

The invention discloses a method for improving the orientation degree and conductivity of a carbon nanotube fiber. The method comprises the steps of preparing a continuous carbon nanotube fiber by a floating catalytic chemical vapor deposition method; then, immersing the carbon nanotube fiber into a solvent to fully expand; performing proper stretching, so that the carbon nanotube fiber is rearranged to improve the axial orientation; next, immersing the carbon nanotube fiber into a coagulating bath; driving phase separation through solubility differences; extruding the solvent from the carbonnanotube fiber; then, performing online washing and drying to form a compact carbon nanotube fiber; and finally, twisting the carbon nanotube fiber to form a multistage spiral structure. The method has the advantages that the primary carbon nanotube fiber prepared by a direct spinning method is swelled and shrunk, and the orientation degree and compactness of the fiber are well improved, so that the electrical conductivity and the mechanical strength of the fiber are greatly improved; the preparation process is simple; the preparation conditions are mild; the cost is low; the production efficiency is high; and the method is suitable for industrial production.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

Ultrathin cast film as well as preparation method thereof and application thereof

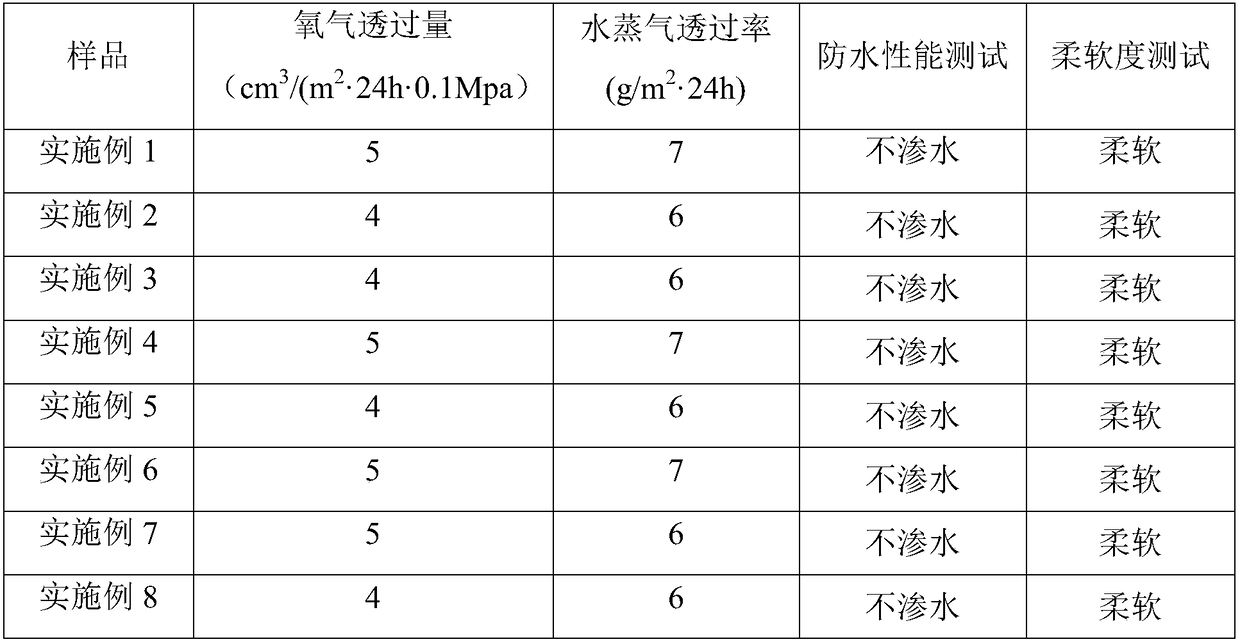

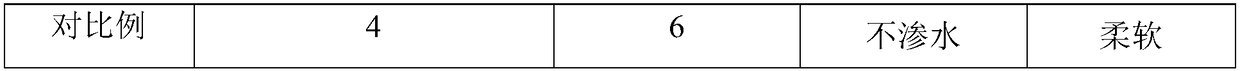

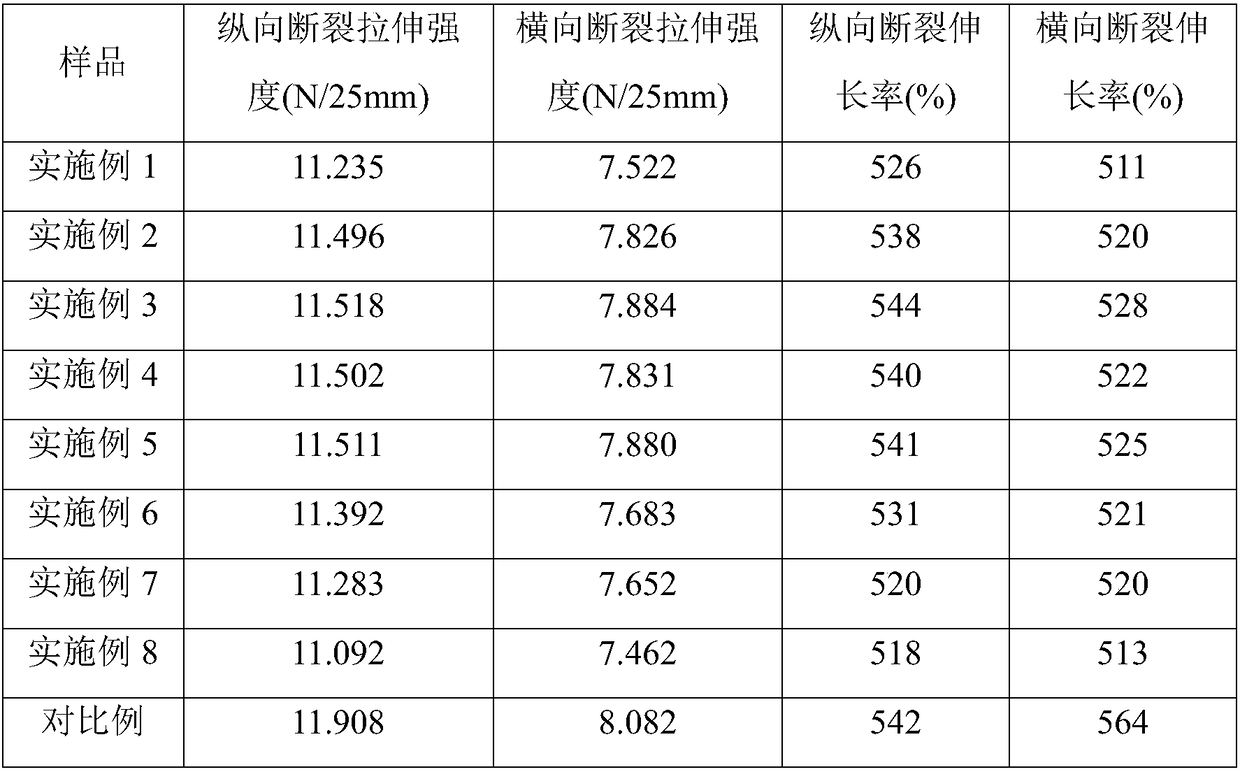

InactiveCN108129735AImprove water barrier effectEasily brokenFlexible coversWrappersCast filmsMaterials science

The invention discloses an ultrathin cast film. According to the technical scheme, the key point isThe ultrathin cast film is characterized that the ultrathin cast filmby comprises comprising the following components: 7-12 parts of LDPE, 20-25 parts of LLDPE, 30-55 parts of HDPE, 3-5 parts of MLLDPE, 1-3 parts of PP and 5-8 parts of color master batch. The invention further discloses a preparation method for the ultrathin cast film, and the preparation method comprises the following steps: adding materials; performing extrusion plastifying; , extrusion casting, calendaring, setting and cooling; performing corona treatment; and trimming and rolling, wherein during calendaring, setting and cooling, the temperature of a rubber roller is set to be 50-55 DEG C, the temperature of an embossed steel stick is set to be 60-65 DEG C and pulling speed is 60-80 m / min. On the premise of keeping barrier properties, waterproof properties, softness, tensile properties and breakage properties of the cast film, the thickness of the cast film is reduced, the unit weight yield is increased, and the cost is reduced.

Owner:天津市德利塑料制品有限公司

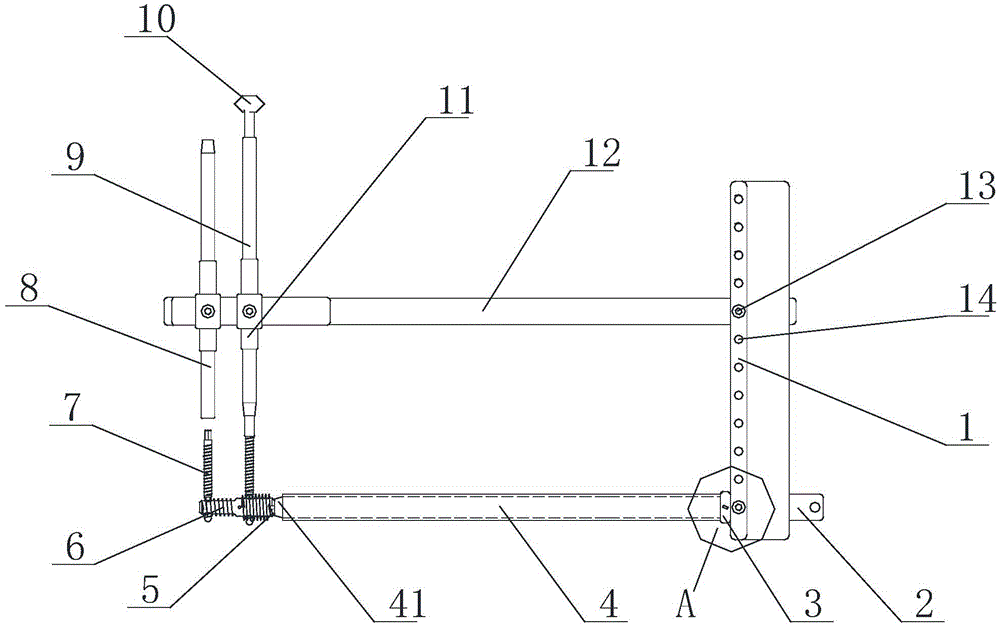

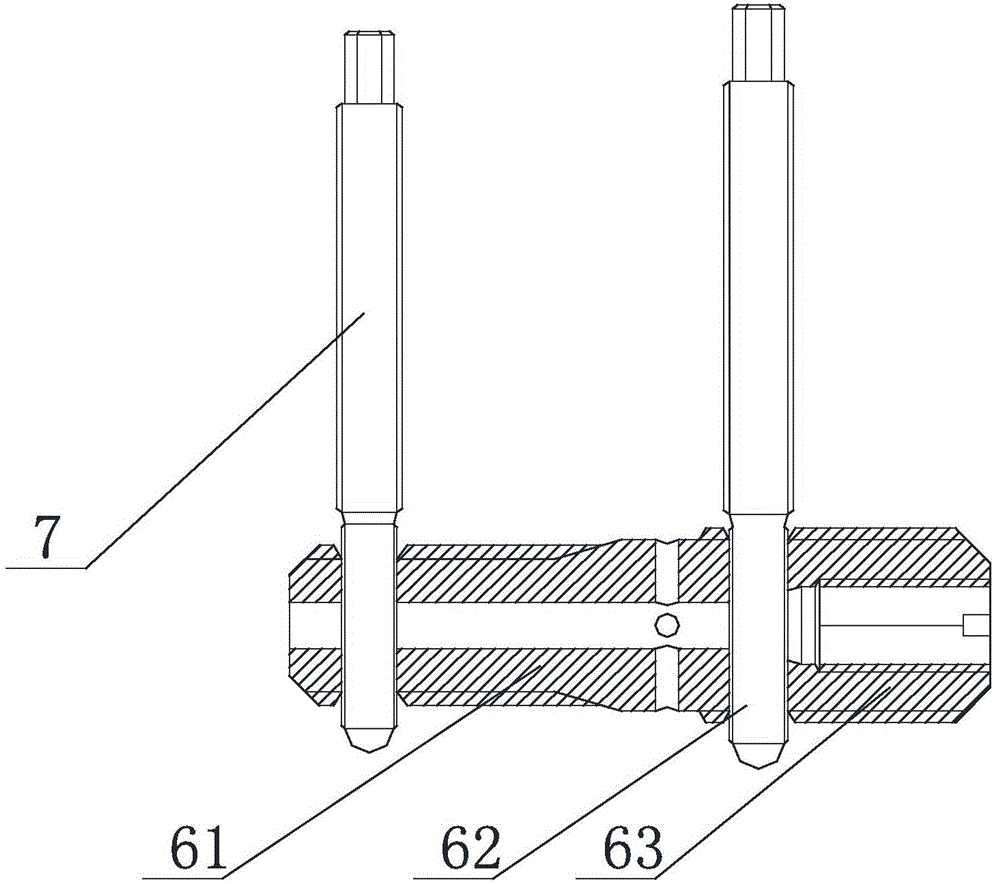

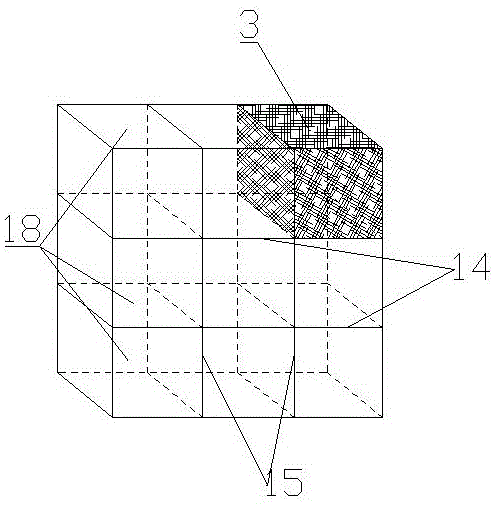

Minimally-invasive lumbosacral vertebrae axial fusion inner fixing system with lock

InactiveCN104146756ASimple structureFew adjustable partsInternal osteosythesisSpinal implantsImplanted deviceDisplacement error

The invention discloses a minimally-invasive lumbosacral vertebrae axial fusion inner fixing system with a lock. The system is characterized in that a multi-hole connecting block is included, a locating aiming device and a screw implanting device are arranged on the multi-hole connecting block respectively, a locating aiming mechanism is arranged on the locating aiming device, and a fixing device is arranged between the multi-hole connecting block and the screw implanting device. As an improvement, through holes are evenly formed in the multi-hole connecting block, and the locating arming aiming device and the screw implanting device are arranged on the through holes of the multi-hole connecting block respectively. Fastening holes corresponding to the through holes are formed in the multi-hole connecting block. The fastening holes are connected with the fastening bolts in a thread mode. The system is simple in structure, the number of adjustable parts is small during using, operation is easy and convenient, the fact that displacement errors are small can be guaranteed, and implantation accuracy is improved.

Owner:THE FIRST AFFILIATED HOSPITAL HENGYANG MEDICAL SCHOOL UNIV OF SOUTH CHINA

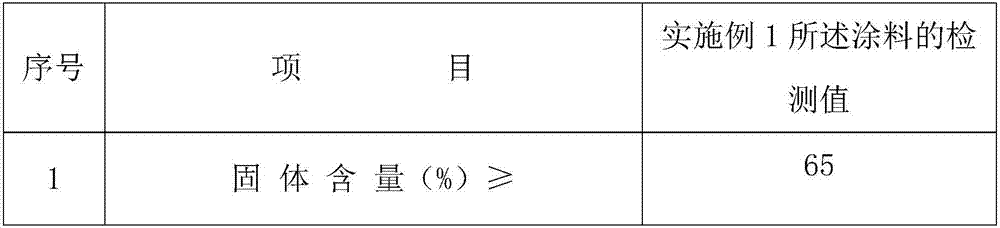

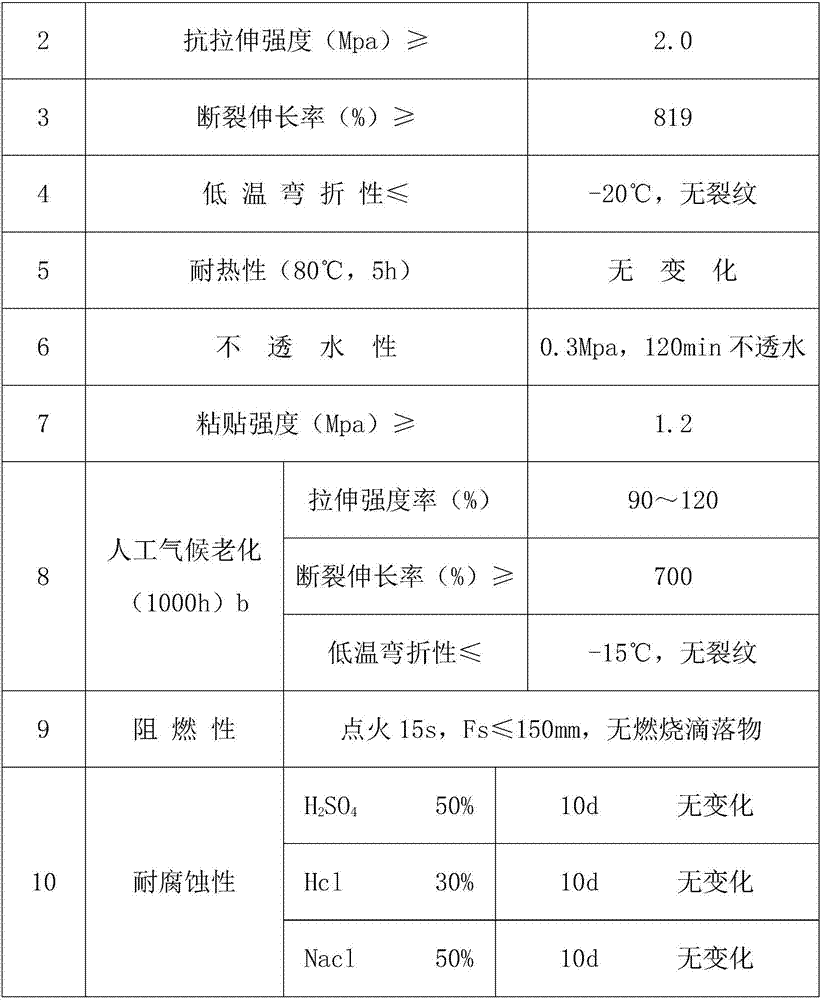

Multifunctional anticorrosion, waterproof and heat insulation paint and preparation method thereof

InactiveCN107266984AImprove wear resistanceImprove insulation performanceAnti-corrosive paintsEpoxy resin coatingsSolubilityPolyvinyl alcohol

The invention provides a multifunctional anticorrosion, waterproof and heat insulation paint and a preparation method thereof. The paint comprises, by weight, 1300-1500 parts of an ethylene-vinyl acetate copolymer, 350-450 parts of acrylic resin, 150-200 parts of DM-HX68 synthetic latex, 20-40 parts of vinyl resin, 10-20 parts of a polyvinyl alcohol emulsion; 700-900 parts of heavy calcium carbonate powder, 400-600 parts of ground silica, 120-170 parts of talcum powder, 100-150 parts of high-frequency porcelain powder, 15-30 parts of coal gangue powder, 10-20 parts of cast stone powder, 10-20 parts of hollow microsphere, 3-10 parts of titanium dioxide, 3-10 parts of nano-powder, 3-10 parts of a color paste material, and 0.5-2 parts of graphene; 70-120 parts of a plasticizer, 30-40 parts of an antifreezing agent, 15-30 parts of a defoaming agent, 15-30 parts of a binder, 10-15 parts of a PH regulator, 10-15 parts of a film-forming assistant, 7-15 parts of a dispersant, 5-10 parts of an emulsifier, 3-7 parts of a mildew-proof and algae resistant agent, 3-7 parts of a thickening agent, 3-7 parts of a polymerization inhibitor; and 1000-1200 parts of water. The paint has the advantages of good wear resistance, heat resistance and water solubility and strong waterproof properties.

Owner:吴俊

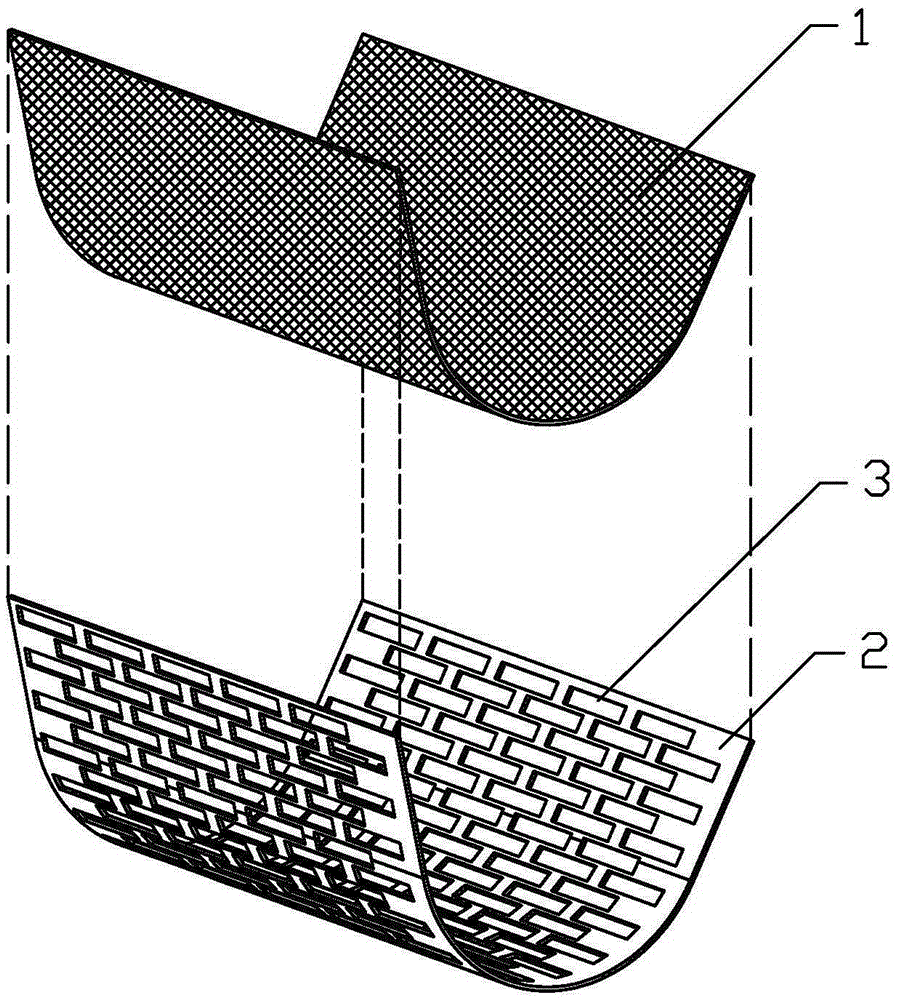

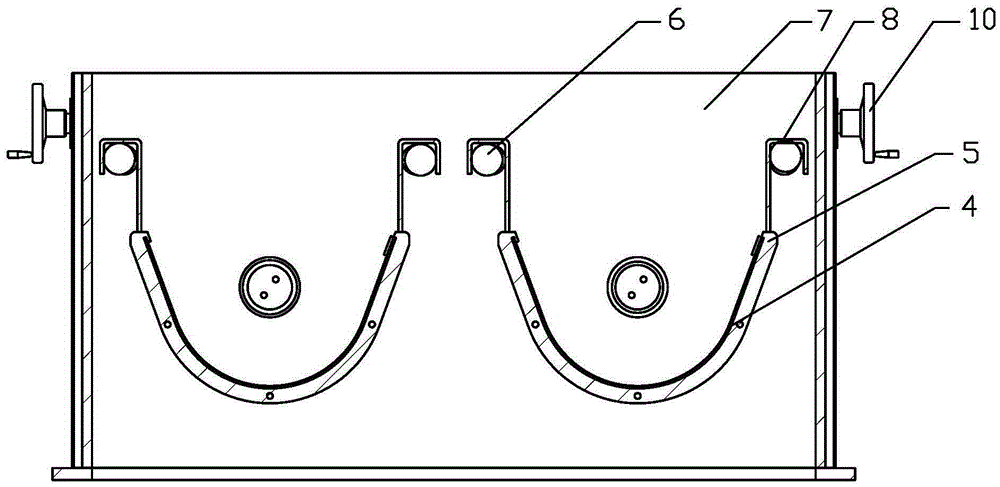

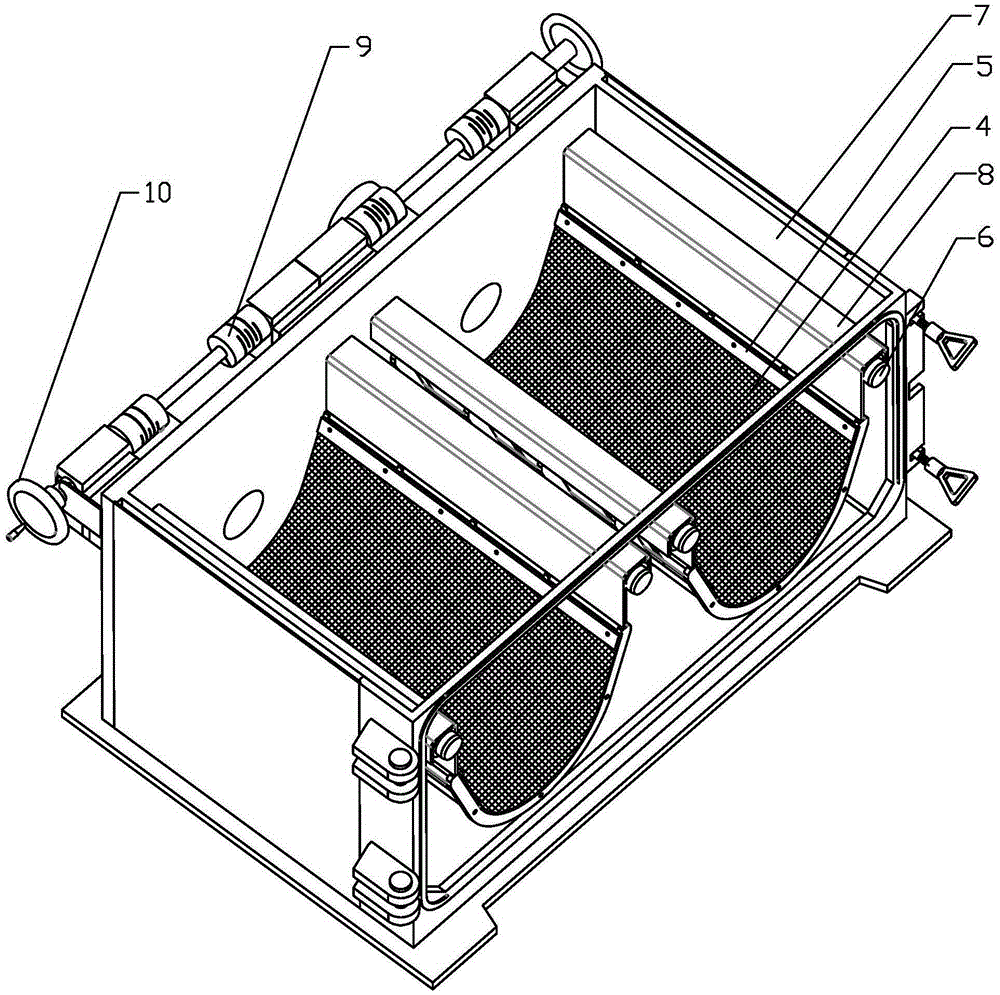

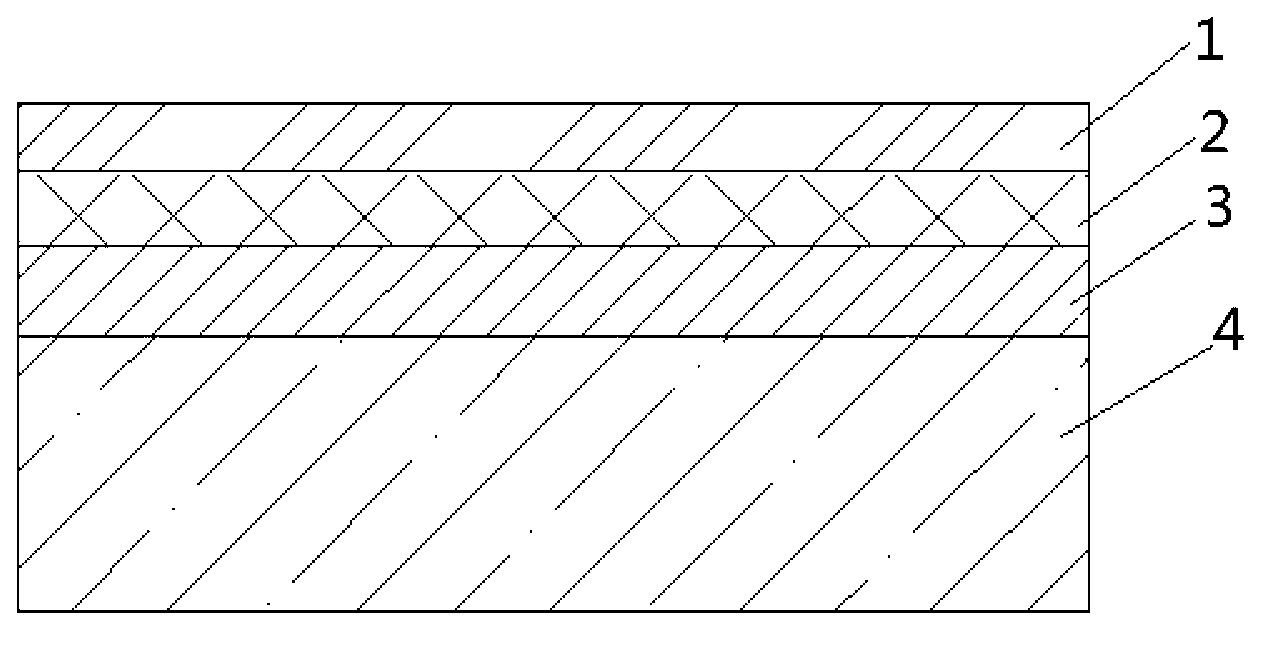

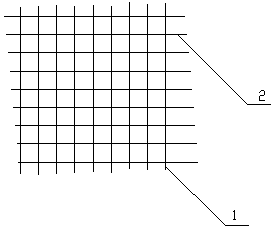

Granulate machine screen and screen mechanism of swing type granulate machine with screen

The invention relates to a screen and a screen mechanism, in particular to a granulate machine screen and a screen mechanism of a swing type granulate machine with the screen. After the screen of the conventional swing type granulate machine is broken or crushed, the crushed screen falls into medicine materials so as to pollute the medicine materials, and the replacement process of the crushed screen is tedious and time-consuming, and the working efficiency is affect and reduced virtually. The invention aims to solve the problems. A plurality of vertically-penetrated through holes are densely formed in a stainless steel plate, and a stainless steel wire net and the stainless steel plate are thermally sealed from top to bottom to form the screen. Two transmission shafts of the screen mechanism are rotationally mounted in a granulate barrel of the swing type granulate machine in parallel from the front and back, and a screen frame is U-shaped. The left end and the right end of the screen frame are detachably hooked on the two transmission shafts respectively, and the screen is detachably mounted on the inner side of the arc-shaped part of the screen frame. The granulate machine screen is used for the swing type granulate machine.

Owner:NANO PHARM TECH MACHINERY EQUIP

Waterborne thin-coating diatom mud

InactiveCN105838121AReduce humidityConvenient lifeAntifouling/underwater paintsPaints with biocidesEmulsionPreservative

The invention relates to a water-based thin coating type diatom mud, including deionized water, cellulose, antifreeze agent, defoamer, wetting agent, multifunctional auxiliary agent, dispersant, negative ion slurry, titanium dioxide, kaolin 4000 mesh , Talc powder 1250 mesh, heavy calcium 1250 mesh, multifunctional polymer powder, diatomite 800 mesh, sepiolite, inorganic composite gel, emulsion f208, film-forming aid, defoamer, preservative, antifungal agent, Thickener ase‑60 and thickener 180. The invention is a wall material integrating environmental protection and functionality. It has the functions of heat preservation and heat insulation, and can save electricity and heating costs for houses decorated with it. The energy saving standard reaches more than 80%. The coating surface not only No blistering, shedding, obvious discoloration, etc. It also has the advantages of tensile resistance, fracture resistance, noise resistance, acid and alkali resistance, water resistance, aging resistance, chalking resistance, discoloration resistance and formaldehyde purification.

Owner:赵广全

High density polyethylene modified plastic

InactiveCN103265749AHigh impact strengthResistant to aging and crackingLow-density polyethylenePolymer science

The invention discloses high density polyethylene modified plastic. The high density polyethylene modified plastic is characterized by being prepared by mixing high density polyethylene, polypropylene and additives in proportions, wherein the additives comprise a toughening agent, a reinforcing agent, an antioxidant and an ultraviolet-proof additive, the toughening agent is ethylene propylene terpolymer, the reinforcing agent is a glass fiber, the antioxidant is an antioxidant BHT (butylated hydroxytoluene), and the ultraviolet-proof additive is an ultraviolet light absorber uv-531. The high density polyethylene modified plastic provided by the invention has the characteristics of season cracking resistance, oxidation resistance, high impact strength, stretch resistance and good mechanical property and is suitable for application to plastic products used in severe conditions and open space.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

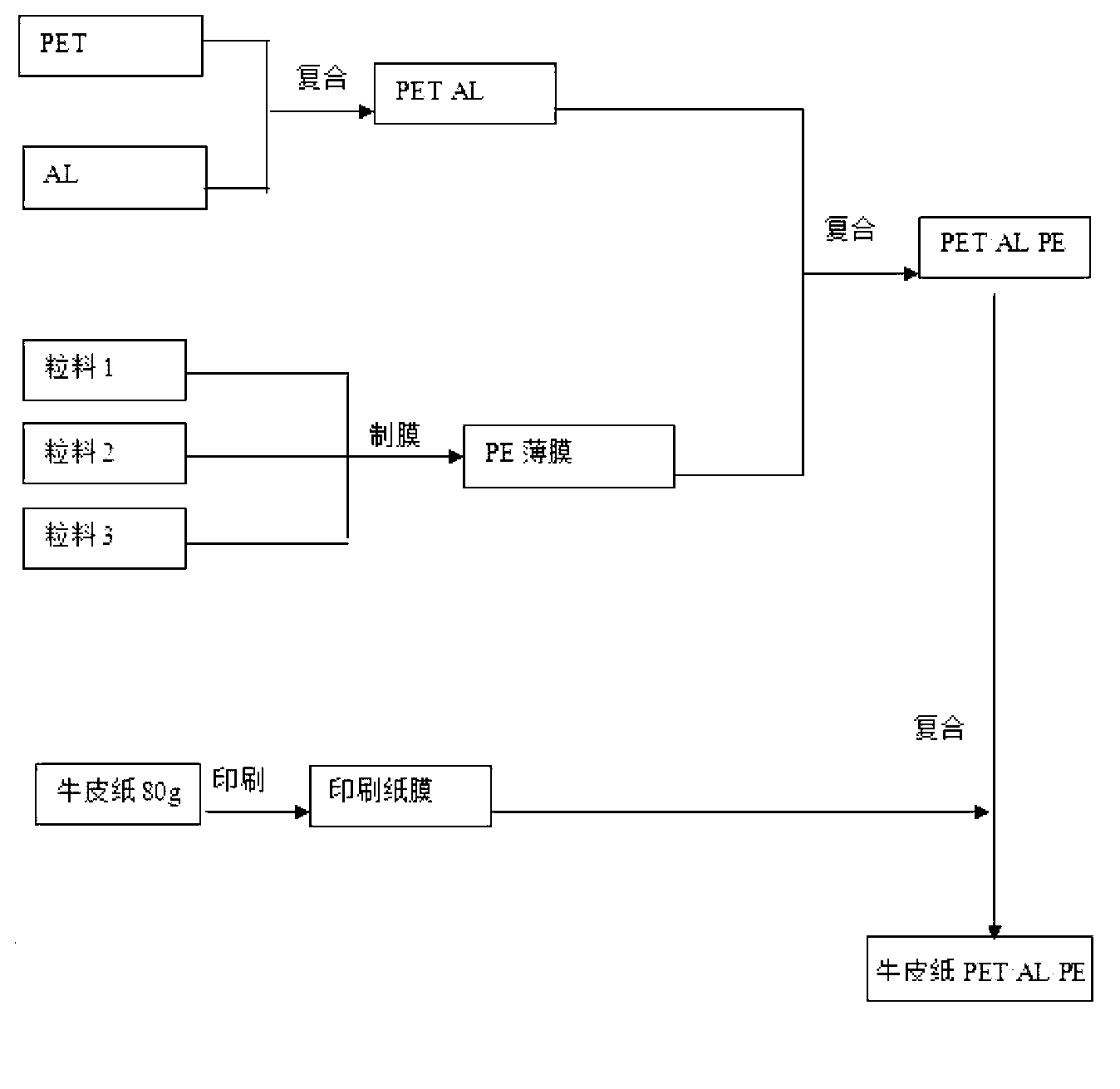

Composite heavy packaging film

Owner:HUANGSHAN NOVEL

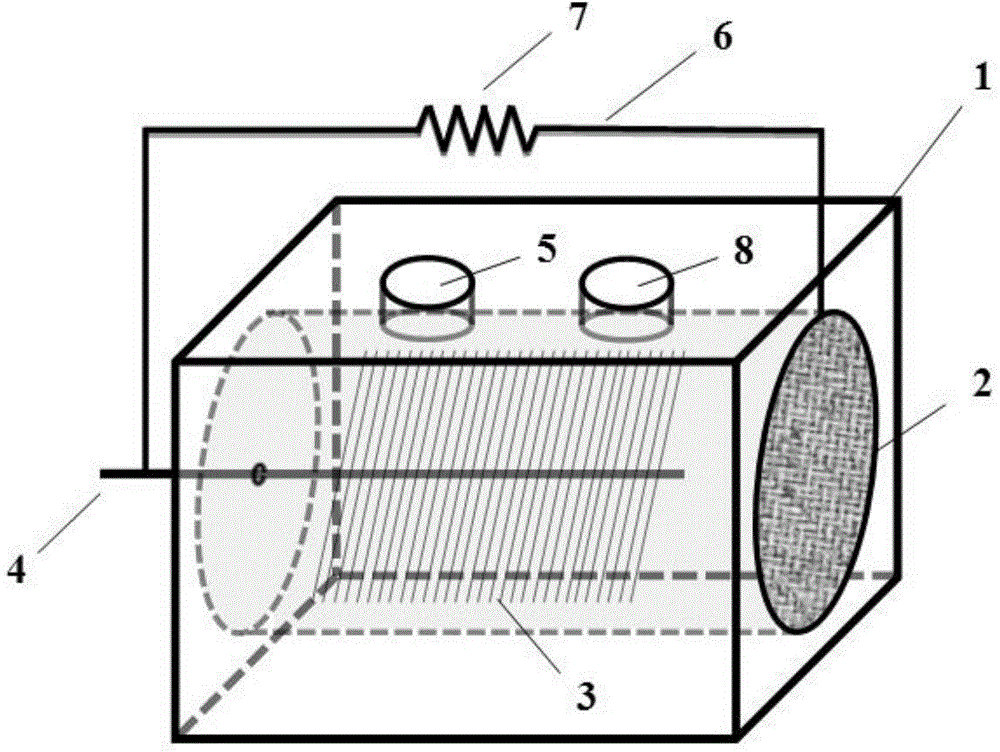

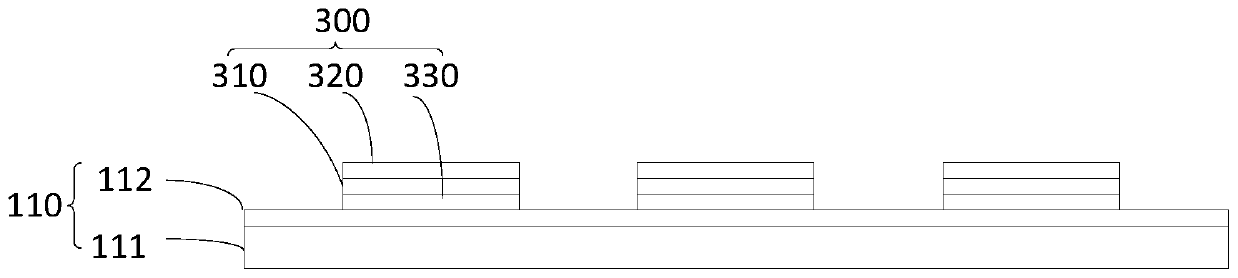

Air cathode of microbial fuel cell and preparation method of air cathode

ActiveCN104091955AStable structureLow costCell electrodesFinal product manufactureFuel cellsManufacturing technology

The invention provides an air cathode of a microbial fuel cell and a preparation method of the air cathode, relates to an air cathode of a single-chamber air cathode microbial fuel cell and a preparation method of the single-chamber air cathode microbial fuel cell, and aims at solving the problems that the air cathode in an existing microbial fuel cell is high in manufacturing cost and complicated in manufacturing technology. The air cathode comprises a liquid catalyst, a waterproof and breathable film and a stainless steel net, wherein the liquid catalyst coats the waterproof and breathable film; the stainless steel net is arranged on the side, loaded with the liquid catalyst is loaded, of the waterproof and breathable film in a stacking manner. The preparation method comprises the steps of 1, mixing a catalyst, isopropanol, Nafion and deionized water to prepare the liquid catalyst; 2, coating the waterproof and breathable film with the liquid catalyst; and 3, stacking the stainless steel net on the side, loaded with the liquid catalyst, of the waterproof and breathable film. The air cathode of the microbial fuel cell is low in manufacturing cost, simple in manufacturing technology, and short in consumed time, and the expanded production of the air cathode can be facilitated.

Owner:HARBIN INST OF TECH

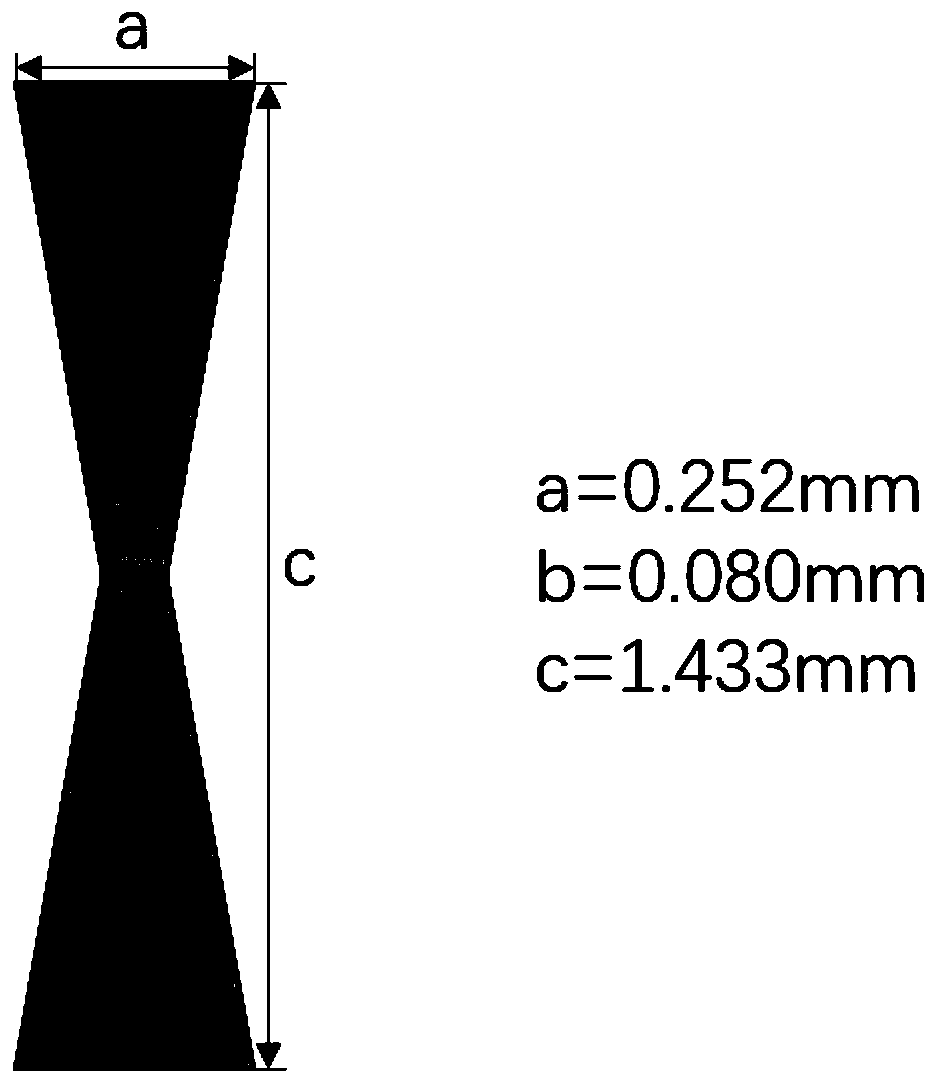

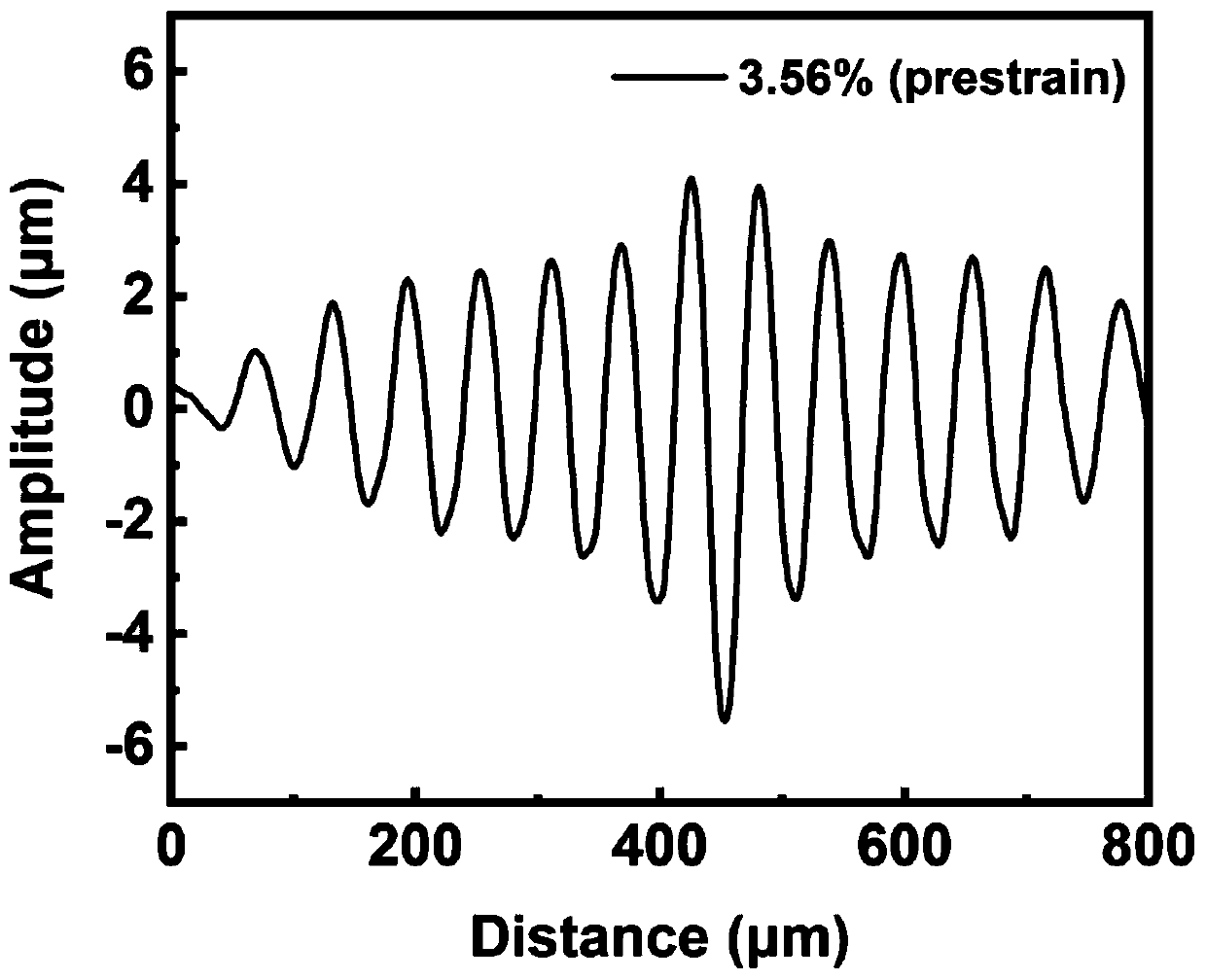

Flexible gradient strain film, preparation method and application thereof

ActiveCN110620140ASave resourcesSimple preparation processSemiconductor/solid-state device manufacturingSemiconductor devicesIsosceles trapezoidResource saving

The invention provides a preparation method of a flexible gradient strain film and application of the flexible gradient strain film and belongs to the technical field of nano film preparation. According to the preparation method of the invention, the surface of a silicon film is etched, so that symmetrical isosceles trapezoid structures with a common bottom edge is formed; the silicon film with the pattern is transferred to a preloaded PDMS substrate; and preloading is released, so that a periodic ripple structure with gradient strain can be prepared. The prepared flexible film with the ripplestructure can generate gradient strain; and strain values of different magnitudes can be obtained in the absence of stretching and repeated sample preparation. The flexible film is suitable for strain engineering research in various environments and under various conditions. The flexible film has the advantages of resource-saving performance, simple preparation process and convenient use; and gradient ripples, the same as uniform ripples, have certain tensile resistance.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation method for modified coumarone resin

The invention relates to the technical field of resin preparation, and particularly relates to a preparation method for modified coumarone resin. The preparation method for modified coumarone resin comprises the following steps of: step 1, adding 1# oil slurry in a polymerizer; step 2, adding unsaturated hydrocarbons in the polymerizer and uniformly stirring, wherein the added amount of the unsaturated hydrocarbons is 1 / 1000 to 5 / 1000 of the mass of the 1# oil slurry; and step 3, heating the materials in the polymerizer to 180-220 DEG C in 1-2 hours, controlling the pressure in the polymerizer to be minus 70-minus 95 Kpa, and performing polymerization reaction for 3-4 hours to obtain the modified coumarone resin. According to the invention, the modified coumarone resin is obtained by sequentially adding the 1# oil slurry, the unsaturated hydrocarbons and a polymerization inhibitor in the polymerizer; and the modified coumarone resin obtained by the preparation method disclosed by the invention has the characteristics of being high in viscosity, strong in adhesive force, tension-resistant and wear-resistant.

Owner:KUITUN DAYI PETROCHEM TECH

Ultrafine denier fiber ultrathin fabric

InactiveCN103306013AStretch resistantFracture resistantWoven fabricsUltimate tensile strengthFiber breakage

The invention discloses ultrafine denier fiber ultrathin fabric which is crossly knitted by ultrafine denier fiber filament warps and wefts, wherein the filament number of an ultrafine denier fiber filament is 0.5dtex; the filament density of the ultrafine denier fiber ultrathin fabric is between 100dtex and 200dtex; and the fiber breakage strength is 2.4-2.6CN / dtex. With the adoption of the mode, the ultrafine denier fiber ultrathin fabric has the advantages of stretch proofing, breakage proofing, lightness, thinness, light mass, good uniformity, high strength, neat and exquisite surface appearance, good dropping effect and the like.

Owner:SUZHOU JINKAI TEXTILE

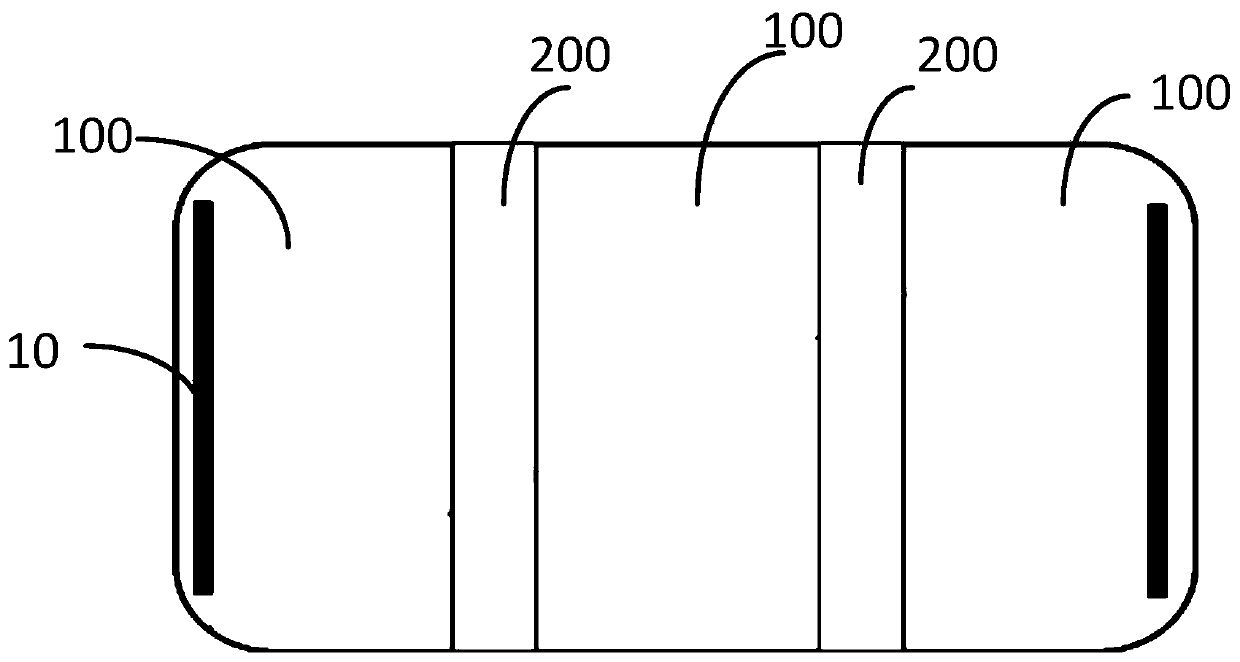

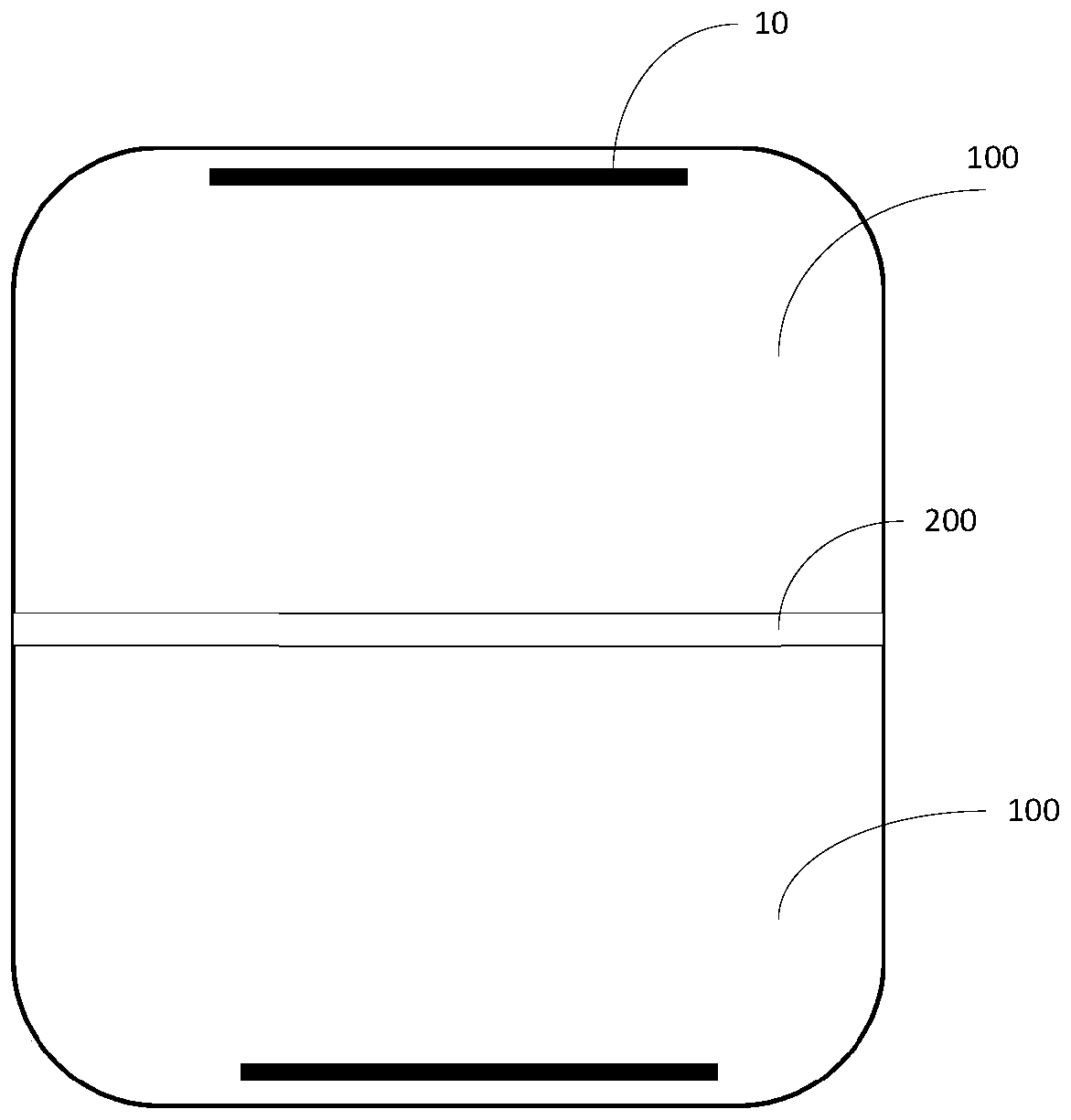

Flexible display panel, display device and display method

InactiveCN110246886AWith self-healing functionAnti-bendingSolid-state devicesIdentification meansElectricityDisplay device

The invention provides a flexible display panel, a display device and a display method. According to the invention, a display area of the flexible display panel comprises a folding area and a non-folding area, wherein the folding area comprises a flexible substrate, the flexible substrate comprises a self-healing composite electrode formed by compositing a self-healing material and a non-metal conductive layer, and the non-metal conductive layer is provided with a plurality of conductive wires; and a PMOLED display structure which is arranged on the flexible substrate and is electrically connected with the plurality of conductive wires. The invention provides a flexible display panel, a display device and a display method. According to the invention, anti-bending, anti-abrasion and anti-stretching effects are achieved.

Owner:BOE TECH GRP CO LTD

High polymer material for pipeline and preparation method of high polymer material

The invention relates to a high polymer material for a pipeline and a preparation method of the high polymer material. The high polymer material comprises 4-8 parts of urea resin, 3-10 parts of polyisocyanurate, 2-6 parts of polyisobutene, 3-8 parts of brominated butyl rubber, 3-6 parts of dicyclohexyl phthalate, 2-5 parts of glass fiber, 4-7 parts of polytetrafluoroethylene, and 3-8 parts of furan resin. The preparation method comprises the following steps: step 1, taking all of the components, feeding the components in an agitator tank, and heating the agitator tank till the components are smelted; step 2, conducting twin-screw extrusion on the uniformly stirred material in the step 1 with a twin-screw extrusion machine, extruding out the material and granulating the material to obtain the high polymer material for the pipeline. The prepared high polymer material for the pipeline has the advantages of being high in tensile strength and shock strength.

Owner:苏州凯欧曼新材料科技有限公司

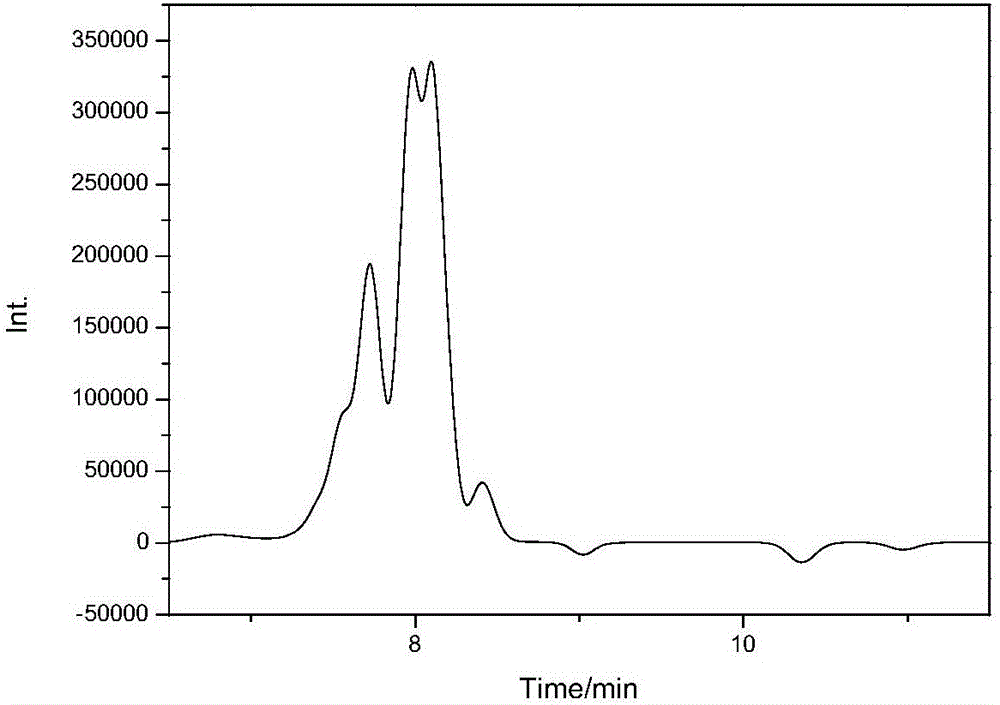

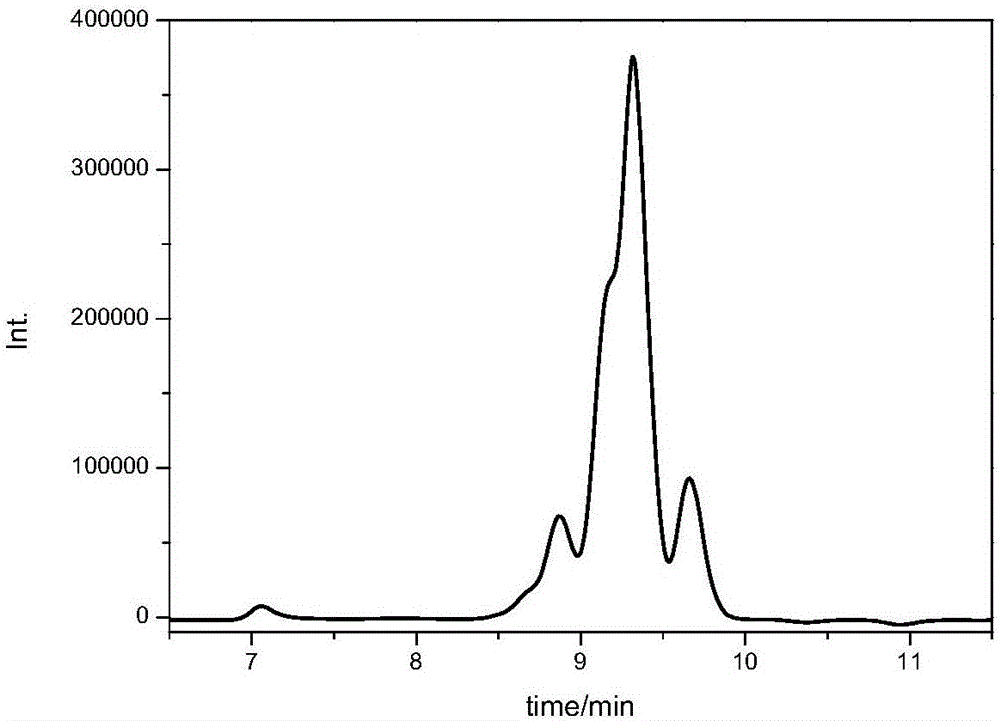

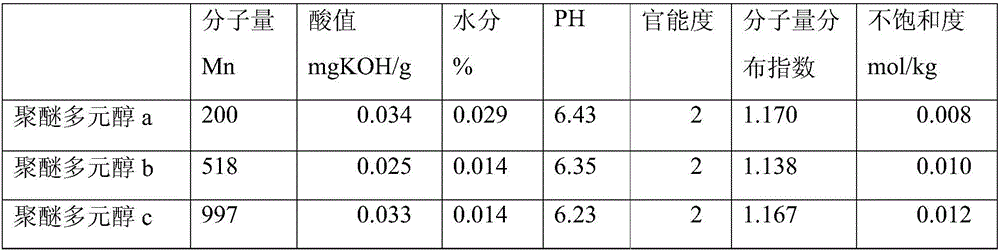

Preparation method preparation method of low-molecular-weight polyether polyol for polyetheramine

ActiveCN106242954AHigh viscosityLow melting pointEther preparation from oxiranesStructural regularityPolyol synthesis

The invention belongs to the technical field of polyether polyol synthesis and specifically relates to a preparation method of low-molecular-weight polyether polyol for polyetheramine. According to the preparation method, 2-methyl-1,3-propylene glycol, which is used as a starting agent, reacts with epoxide in the presence of an alkali metal catalyst at low temperature; and then, the reaction product is end-capped with epoxypropane at high temperature so as to obtain low-molecular-weight polyether polyol for polyetheramine. During the polymerization, 2-methyl-1,3-propylene glycol is used as the starting agent. Due to structural regularity and symmetry of 2-methyl-1,3-propylene glycol, activities at two ends are identical. During polymerization between 2-methyl-1,3-propylene glycol and the epoxide, polyether structure is more regular. During amino-capping, activities at two ends are consistent. The product has characteristics of amorphism, strong weatherability, tension resistance, strong bending resistance and the like. By the structure, polyetheramine can be endowed with characteristics of low melting point, low viscosity and good intersolubility with auxiliaries.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

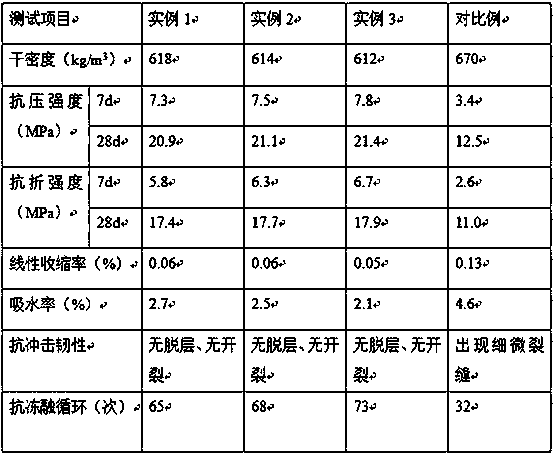

Preparation method of high-strength foam concrete

The invention belongs to the technical field of the preparation of building materials and particularly relates to a preparation method of high-strength foam concrete. The preparation method comprises:first, preparing sieved powder from raw materials diatomite and volcanic, blending the sieved powder with soybean lecithin for fermentation, preparing bamboo fibers from bamboos, and finally mixing and stirring modified organic matters, the bamboo fibers, polyvinyl alcohol fibers and modified concrete, so as to obtain the high-strength foam concrete. The sieved powder and an ethanol extract are put into a fermentation tank and are sealed for fermentation so as to obtain the modified organic matters, so that the foam concrete prepared from the modified organic matters has hydrophobicity; and by utilizing the bamboos as the raw material, the antibacterial effect of the foam concrete is improved, the service life of the foam concrete can be prolonged, the ductility of a concrete board is improved, the porosity of the prepared foam concrete is increased, and the prepared foam concrete can meet the environmental protection requirement and has wide application prospects.

Owner:俞小峰

Acorn starch blend modified pullulan-grafted pineapple fiber packaging film and preparation method thereof

The invention discloses an acorn starch blend modified pullulan-grafted pineapple fiber packaging film, comprising the following components according to parts by weight: 135-140 parts of pineapple leaf fiber, 6.5-7 parts of composite cellulase, 3.2-3.5 parts of nano magnesia particles, 4.5-5 parts of citric acid, 21-22 parts of acorn starch, 34-35 parts of pullulan, 4-5 parts of graphene oxide, 34-35 parts of corn phospholipid di-starch, 4-5 parts of hydrogenated rosin oil, 5-6 parts of water-soluble glucose, 3-4 parts of cellulose acetate butyrate, 2.5-3 parts of ferric stearate, suitable water and suitable deionized water. The graphene oxide grafted acorn starch blend modified pullulan is combined with nano pineapple leaf cellulose solution and other ingredients and is subjected to ultrasonic assisted emulsification and shearing to prepare homogeneous film solution so as to prepare the pineapple cellulose film, and the film has the advantages of good foldability and barrier performance, good tension resistance, good degradability, zero pollution and the like.

Owner:TONGLING FOUNDER PLASTICS TECH

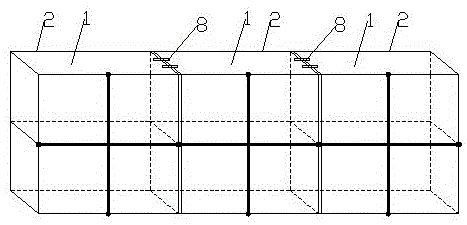

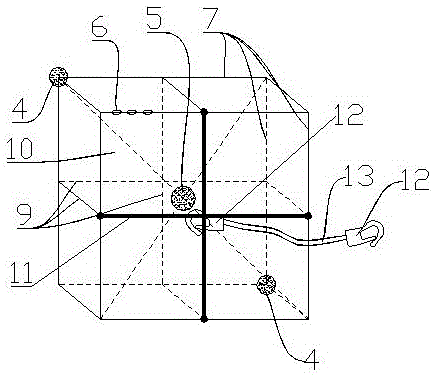

Oil absorption device for ocean oil contamination treatment

ActiveCN105113474AMeet timeliness requirementsImprove oil absorption efficiencyWater cleaningGeneral water supply conservationGraphite particleContamination

Disclosed is an oil absorption device for ocean oil contamination treatment. The oil absorption device comprises a plurality of oil absorption single bodies which are connected with one another through retaining rings. Each oil absorption single body comprises a single body outer framework and an oil absorption core bag placed in the single body outer framework. Expanded graphite particles are contained in each oil absorption core bag. Two balance weight devices are arranged at the symmetrical positions of the lowermost portion of each single body outer framework, and the specific value of the total weight of the two balance weight devices to the displacement of the corresponding oil absorption single body is 1:5 to 1:10. The oil absorption device works at the interface of water and oil all the time by adding the variable balance weight devices through buoyancy calculation; dynamic adsorption is formed by dragging a dragging rope, and the absorption speed is increased; through experimental determination, the oil absorption efficiency is improved by more than four times. The oil absorption device has the actual effects of being high in treatment speed and high in absorption cleanliness on ultrathin water surface spillage oil commonly happening to oil spillage treatment; meanwhile, the device has the advantages that stretching resistance and impact resistance are achieved and the device can be suspended.

Owner:孙勇

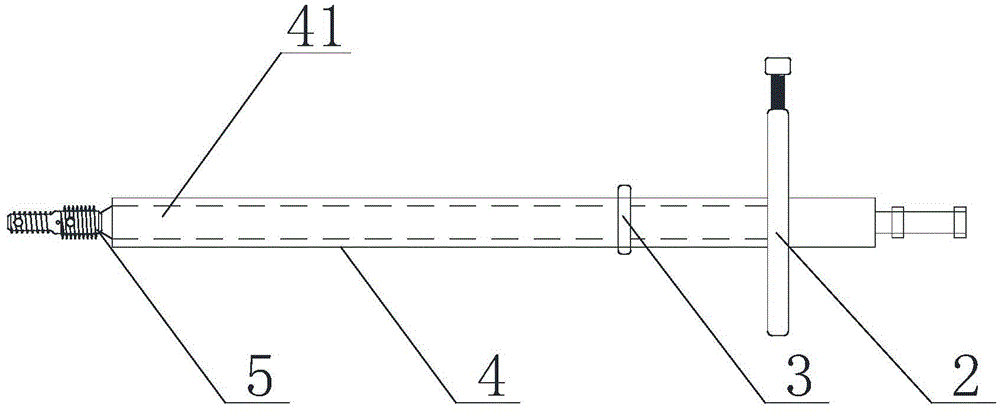

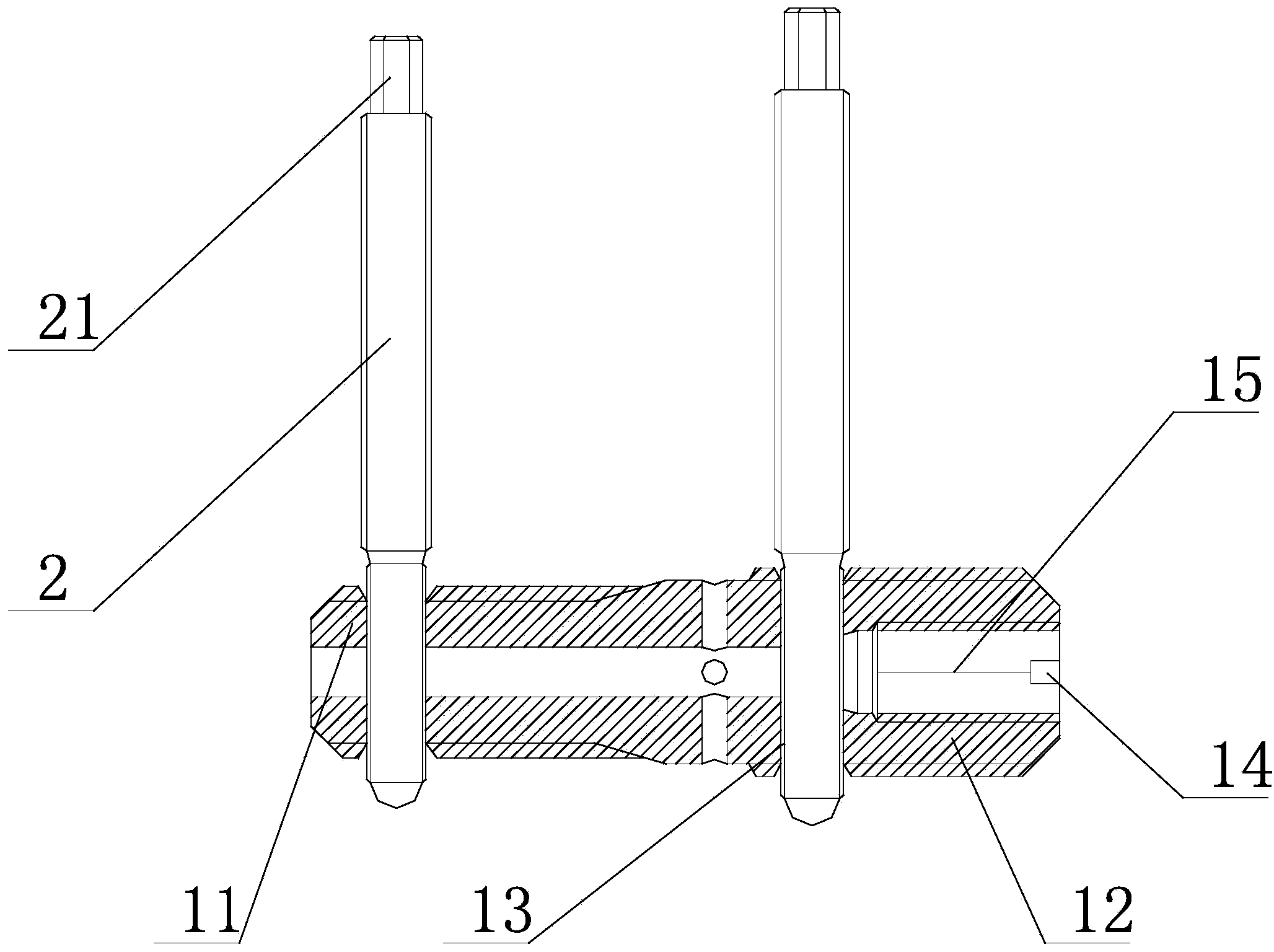

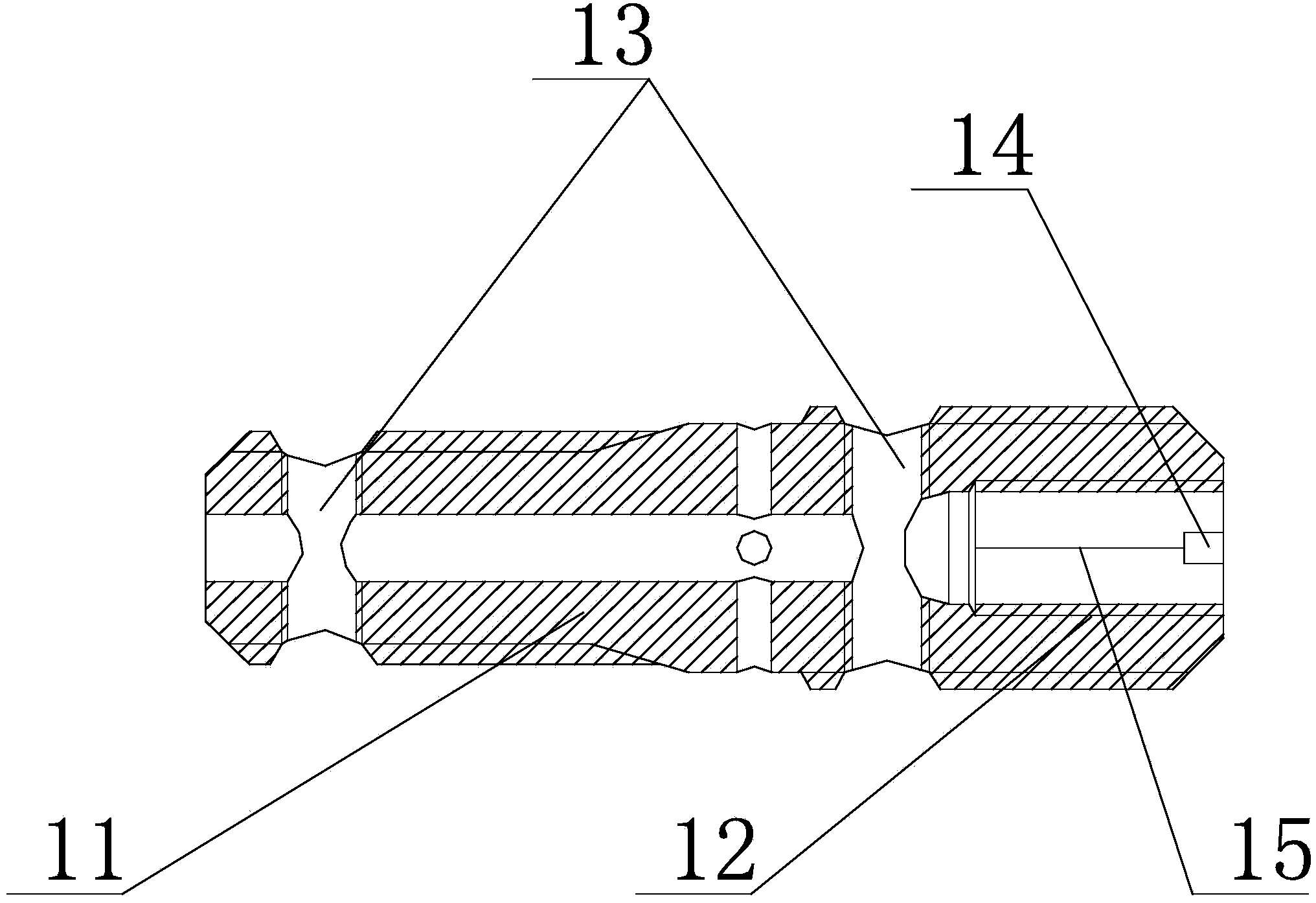

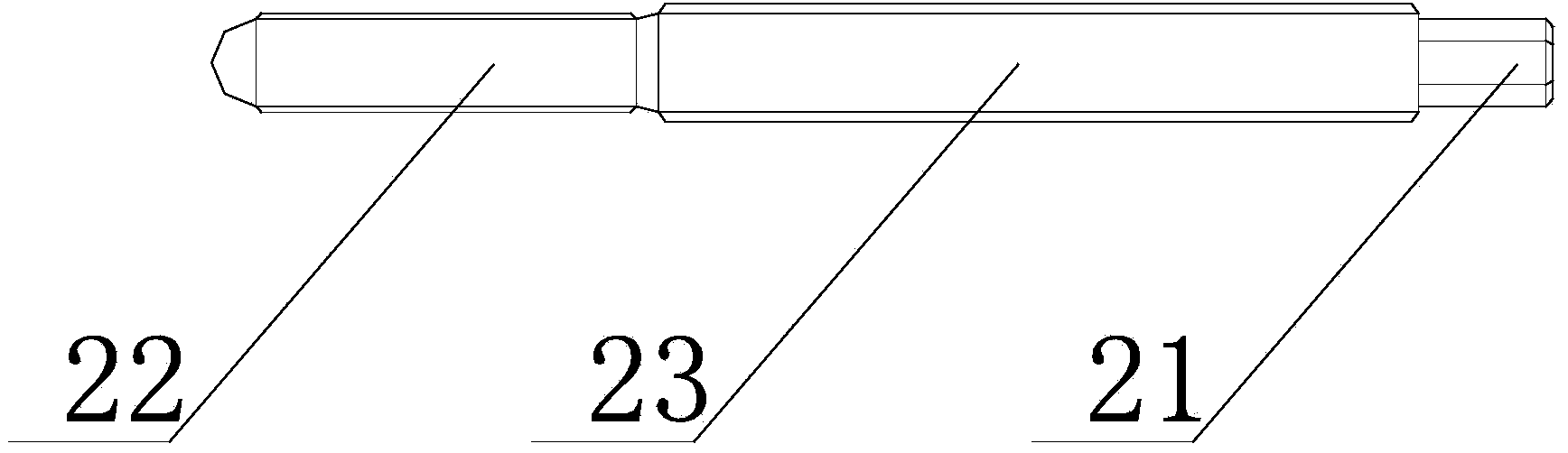

Locking screw of minimally invasive lumbosacral vertebrae locking axial fusion internal fixation system

InactiveCN104173099ASimple structureReasonable designInternal osteosythesisFastenersRotational stabilityEngineering

The invention discloses a locking screw of a minimally invasive lumbosacral vertebrae locking axial fusion internal fixation system. The locking screw comprises an axial fixing screw and an unidirectional locking screw, wherein the axial fixing screw and the unidirectional locking screw are connected with each other, a plurality of through holes are formed in the axial fixing screw, inner threads are arranged in the through holes, and one end of the unidirectional locking screw is movably connected with the inside of the through holes. The axial fixing screw comprises a screw front portion and a screw rear portion, and a through hole is formed in the screw front portion and the screw rear portion. The locking screw is simple in structure, reasonable in design, and capable of improving anti-rotation stability, a thread portion at the small end of the locking screw is rotatably locked in the through holes in the axial fixing screw for unidirectional locking so that the locking screw is not prone to exit, and the locking screw has the anti-rotation, anti-compression, anti-stretching, and anti-bending functions.

Owner:NANHUA UNIV

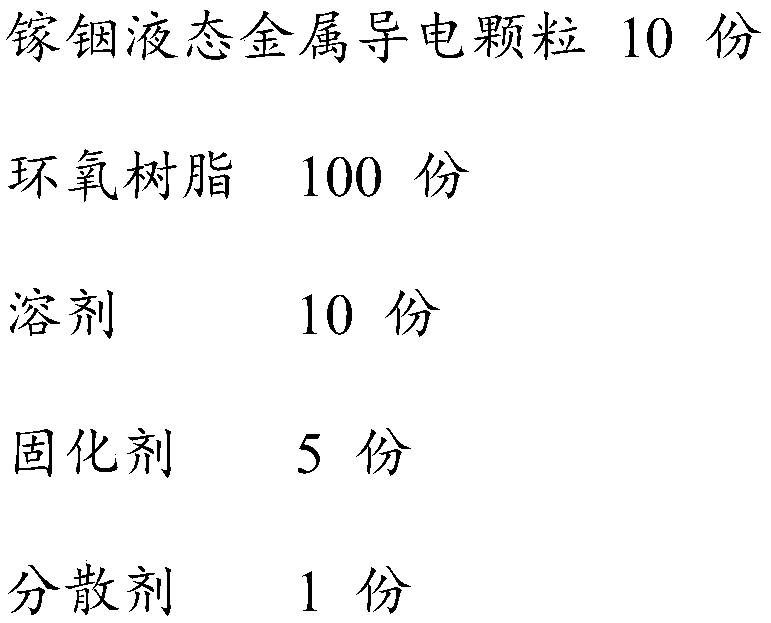

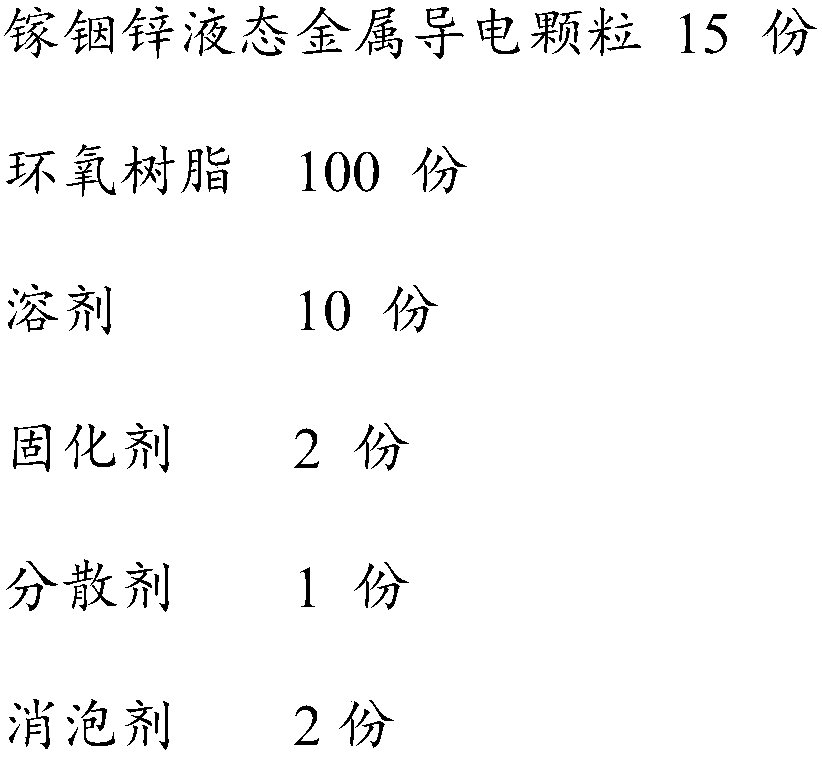

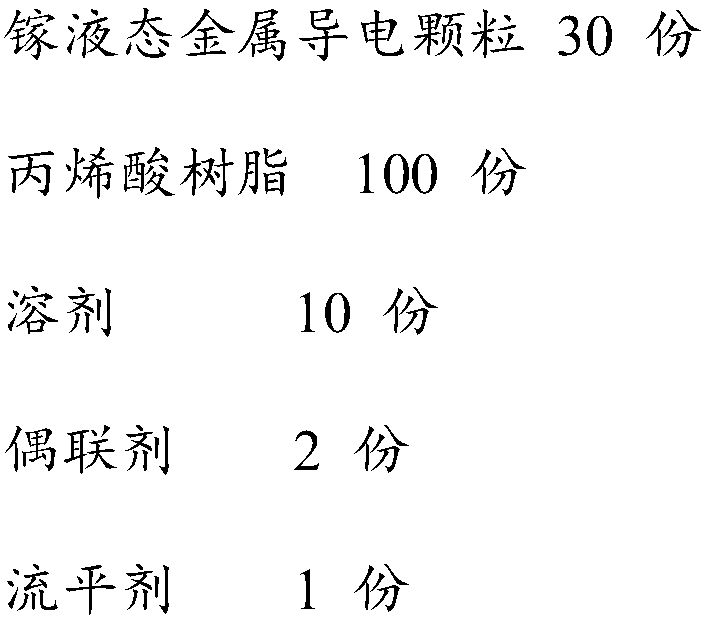

Anisotropic conductive adhesive and preparation method thereof

PendingCN110964469ALow costReduce contact resistanceAldehyde/ketone condensation polymer adhesivesOrganic non-macromolecular adhesivePolymer scienceAnisotropic conductive adhesive

The invention provides an anisotropic conductive adhesive and a preparation method thereof. According to the invention, low-melting-point metal is used as conductive particles of the anisotropic conductive adhesive, so high conductivity and low cost of the conductive adhesive can be ensured; by selecting curable resin and a curing agent, the anisotropic conductive adhesive can be quickly cured atroom temperature and can be used on various substrates with poor temperature resistance, so the application range of the anisotropic conductive adhesive is widened, and the mounting production efficiency of electronic product components can be remarkably improved; and the anisotropic conductive adhesive with the low-melting-point metal as the conductive particles has relatively low contact resistance, relatively high bonding strength and excellent damp-heat resistance stability when applied to various substrates.

Owner:BEIJING DREAM INK TECH CO LTD

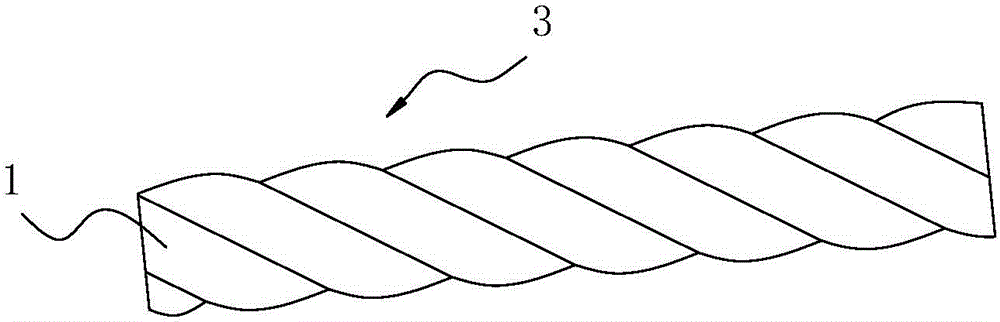

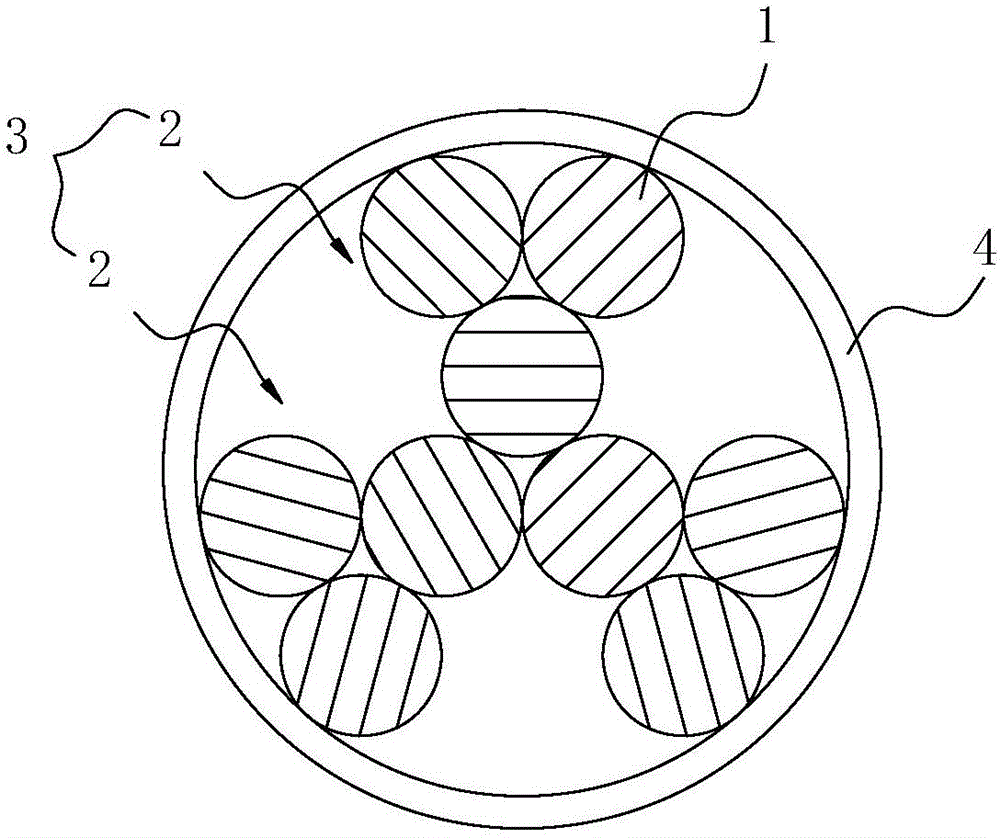

Composite type rope and production process thereof

InactiveCN104153225AStretch resistantImprove tensile propertiesTextile cablesCarbon fibersFiber bundle

The invention provides a composite type rope. The composite type rope comprises a carbon fiber rope core composed of a plurality of carbon fiber bundles, and an aramid fiber layer wrapping the carbon fiber rope core. The carbon fiber rope core is formed in a twisting mode and comprises two or more carbon fiber bundles. The aramid fiber layer is of a net structure formed by weaving a plurality of aramid fiber ropes. The rope core of the composite type rope is the carbon fiber rope core, the external wrapping layer is composed of aramid fibers, carbon fibers have the tensile property so that the tensile property of the composite type rope can be improved, and wear of the carbon fibers can be prevented due to the wear resistance of the aramid fiber layer. Meanwhile, the carbon fibers have the self-lubricating property and do not need to be lubricated independently, so that the rope is convenient to maintain. The invention further discloses a production process of the composite type rope. The production process is simple and high in operability, and can effectively prevent the carbon fibers from being broken in the processing process.

Owner:DONGGUAN TANSUO COMPOSITE MATERIAL

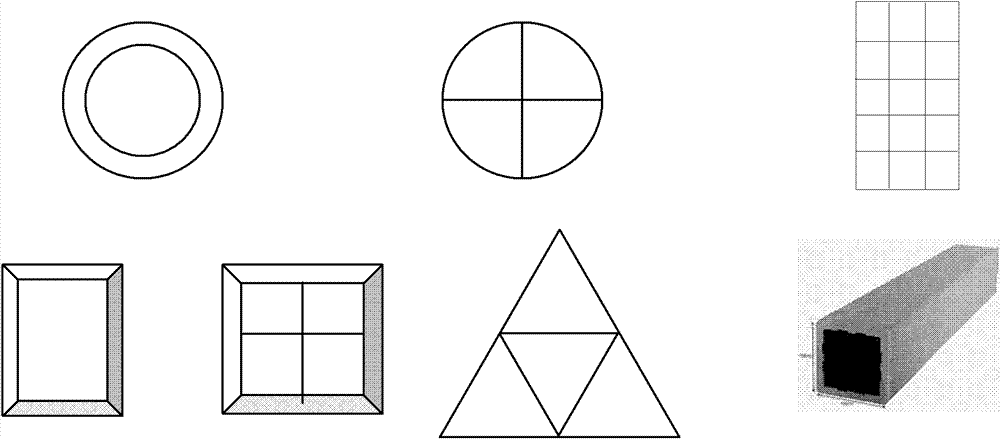

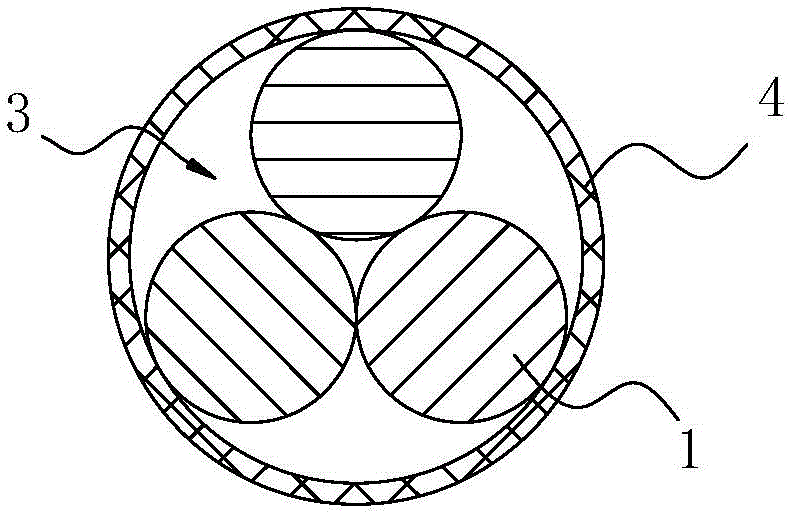

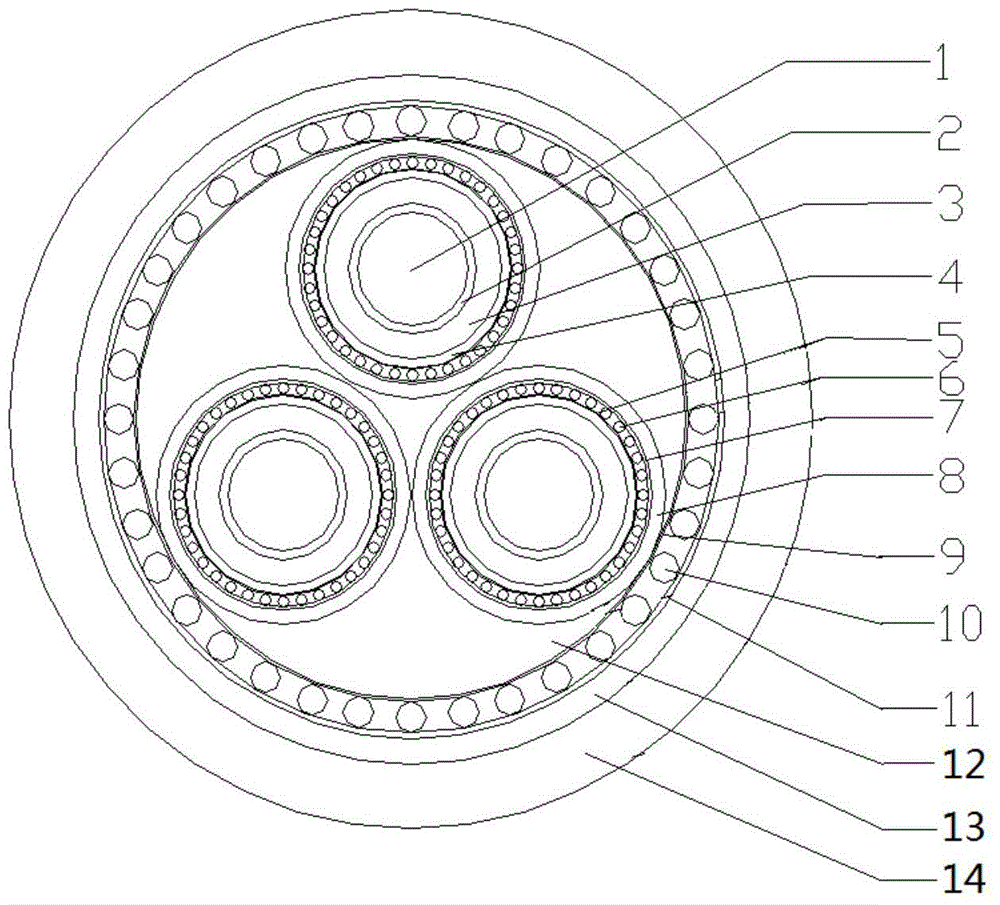

Medium voltage flame-retardant frequency-conversion power cable

InactiveCN104867604AReduce distractionsSuppress interferencePower cables with screens/conductive layersInsulated cablesPower cablePhase splitting

The invention relates to a medium voltage flame-retardant frequency-conversion power cable which comprises three cable core wires arranged in parallel and identical in structure. Each cable core wire comprises a circular conductor. A shielding layer, an insulating layer and an insulating shielding layer are arranged outside the conductor in a three-layer co-extrusion manner. The insulating shielding layer is externally covered by an inner layer plastic-aluminum composite belt, an inner copper wire sparse-winding shielding layer, an inner copper-belt wrapping shielding layer and a phase-splitting inner isolating sleeve in sequence. Gaps among the three cable core wires are filled with flame-retardant PP filling ropes and then are externally provided with a cabling layer. The cabling layer is externally covered by an outer layer plastic-aluminum composite belt, an outer copper wire sparse-winding shielding layer and an outer copper-belt wrapping shielding layer in sequence, then an outer isolating sleeve is extruded outside, and aluminum alloy linkage armour serves as the outmost layer for covering. According to the invention, the interference of pulse voltages can be reduced to the lowest level, and the frequency-conversion power cable is enabled to effectively inhibiting the interference of electromagnetic wave.

Owner:STATE GRID CORP OF CHINA +1

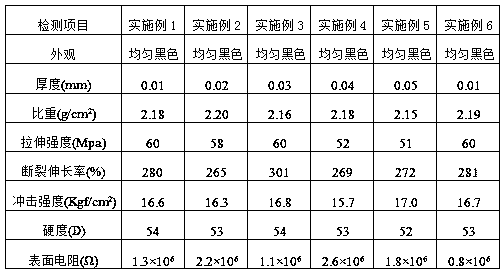

Preparation method of antistatic teflon film

InactiveCN110511518AImprove high temperature resistancePrevent piebaldCompression moldingAntistatic agent

The invention relates to the technical field of polymer materials, and in particular relates to a preparation method of an antistatic teflon film, which is prepared by the steps of raw material selection, mixing, compression molding, high-temperature sintering, turning into a film and shaping., polytetrafluoroethylene is taken as a base material, carbon black is added as an antistatic agent, raw materials with appropriate particle size, bulk density and water content are selected, the component ratio is optimized, and meanwhile, the preparation conditions of each step are strictly controlled.The prepared Teflon film product has uniform quality and good stability, has good performances of high and low temperature resistance, high strength and hardness resistance, tensile resistance and lowfriction abrasion resistance, solves the problem that the Teflon film is difficult to have both ultra-thin thickness and antistatic performance, meets the use requirements of OLED screens, and meetsthe needs of the market.

Owner:FOSHAN HUIFU POLYMER MATERIALS CO LTD

Method for producing PVC profile by taking phosphogypsum-produced hemihydrate gypsum and anhydrite as filler

The invention provides a method for producing a PVC profile by taking phosphogypsum-produced hemihydrate gypsum and anhydrite as filler. According to the invention, phosphogypsum is taken as a raw material to produce the PVC profile, so that the phosphogypsum replaces calcium powder in the traditional PVC profile production process, the source of the calcium powder for the PVC is expanded, the costs of the calcium powder for producing the PVC profile are reduced, the comprehensive utilization way of the phosphogypsum is expanded, and the comprehensive utilization rate of the phosphogypsum is improved. Furthermore, the hemihydrate gypsum and the anhydrite are respectively produced by utilizing the phosphogypsum and are taken as the filler to produce the PVC profile, so that the cooling time of the PVC profile to be produced is shortened, and furthermore, the PVC profile has a more compact structure; therefore, the hardness of the PVC profile can be improved, the produced PVC profile has compression resistance, stretching resistance and wear resistance.

Owner:GUIZHOU KAILIN GRP CO LTD

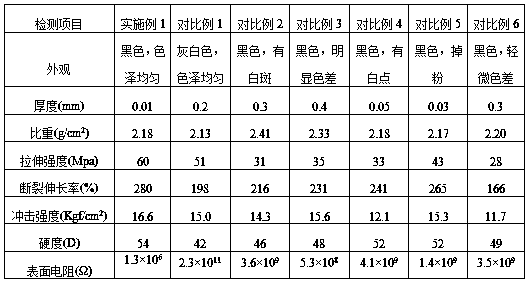

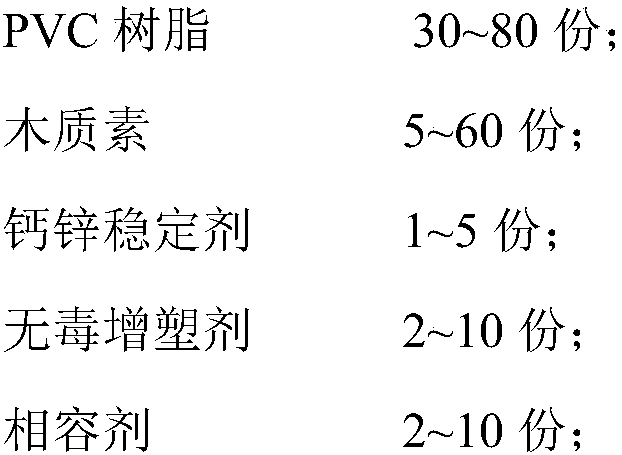

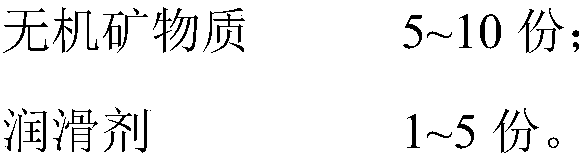

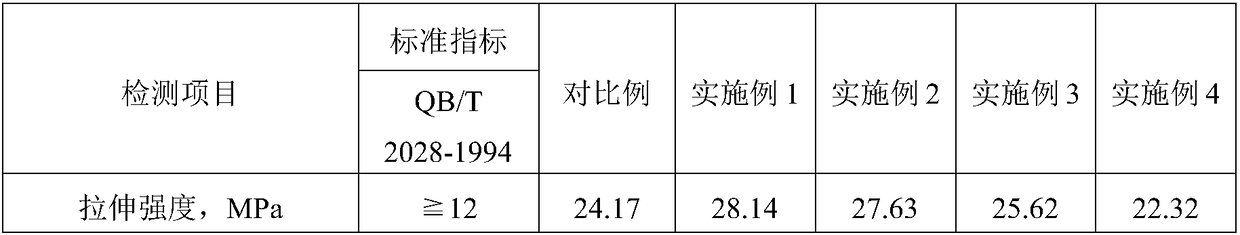

Lignin/PVC decorative film sheet and preparation method thereof

The invention discloses lignin / polyvinyl chloride (PVC) decorative film sheet. The lignin / PVC decorative film sheet comprises the following components in parts by weight: 30-80 parts of PVC resin, 5-60 parts of lignin, 1-5 parts of a calcium-zinc stabilizer, 2-10 parts of a non-toxic plasticizer, 2-10 parts of a compatilizer, 5-10 parts of inorganic minerals and 1-5 parts of lubricants. The invention also provides a preparation method of the lignin / PVC decorative film sheet. The preparation method comprises the following steps: preparing lignin; adding the raw materials into a high-speed mixeraccording to a ratio, and carrying out hot mixing and cold mixing to obtain a primary mixed material; carrying out melt extrusion on the primary mixed material through a double-screw extruder to obtain lignin / PVC decorative film sheet particles; and carrying out calendaring on the lignin / PVC decorative film sheet particles through a calender, carrying out cooling, and finally carrying out post-treatment, namely trimming, winding, checking and warehousing. The decorative film sheet provided by the invention is used for cover decoration of furniture, floors, cabinets, integrated ceilings of inner walls, and the like. The decorative film sheet prepared by the preparation method disclosed by the invention has the advantages of scratch resistance, wear resistance, tension resistance, good toughness, good thermal stability and the like.

Owner:JINING MING SHENG NEW MATERIALS CO LTD

Anti-breakage and anti-corrosion cable sheath material

InactiveCN108264699AExtended service lifeWill not be corrodedPlastic/resin/waxes insulatorsPolyolefinAntioxidant

The invention discloses an anti-breakage and anti-corrosion cable sheath material. The material is characterized by being prepared from, by weight, 50-90 parts of polyvinyl chloride resin, 40-70 partsof III type resin, 30-50 parts of EVA resin, 20-45 parts of ethylene propylene diene monomer, 15-30 parts of foamed rubber, 5-15 parts of chlorinated polyethylene, 3-10 parts of magnesium oxide, 10-25 parts of polyolefin, 15-20 parts of polypropylene, 2-5 parts of potassium pyrophosphate, 4-7 parts of antimonous oxide, 2-6 parts of titanate coupling agent, 1-4 parts of sulfanilamide, 2-7 parts ofmelamine cyanurate, 1-4 parts of stearic acid, 10-20 parts of microencapsulated red phosphorus, 4-8 parts of nanometer kaolin, 10-17 parts of talcum powder, 0.5-1 part of white carbon black, 5-15 parts of bentonite, 5-13 parts of nylon, 1-4 parts of antioxidant, 0.4-1 part of lubricant and 1-5 parts of epoxidized soybean oil. The material has the advantages of preventing breakage and corrosion, resisting stretching and being long in service life; a cable cannot be corroded even after being placed for a long time, and the structural strength of the cable is improved; the anti-breakage strengthand structural strength of the cable are enhanced.

Owner:HUAIBEI TIANXIANG CABLE

Flame-retardant anti-corrosion insulated rubber tape

InactiveCN109054668AImprove adhesionImprove compactnessNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAcrylonitrile

The invention relates to the technical field of rubber tape production, in particular to a flame-retardant anti-corrosion insulated rubber tape. The flame-retardant anti-corrosion insulated rubber tape is composed of a modified polyvinyl chloride base film and an adhesive layer, wherein the adhesive layer is prepared from the following components in parts by weight: butadiene-acrylonitrile rubber,chloride vinegar resin, chloroprene rubber, rosin resin, ethyl acetate, graphite micro powder, dimethyl dimethoxy silicane, stearic acid, diphenyl silanediol, an anti-oxidant and an inorganic filler.The rubber tape is good in adhesion force and compactness, has good tensile strength, good peel strength, chemical corrosion resistance, mildew corrosion resistance, oxidization resistance, is fireproof and flame-retardant; and the adhesive layer can achieve the wateproof effect, so that the insulation property is better.

Owner:阜南县力韦包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com