Composite heavy packaging film

A technology of heavy packaging and weight ratio, which is applied in the field of paper-aluminum-plastic composite packaging film, can solve the problems of non-compliance with food safety laws, poor barrier performance, low repacking speed, etc., and achieve good environmental adaptability, good Effect of physical and mechanical properties, good thermal tack properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

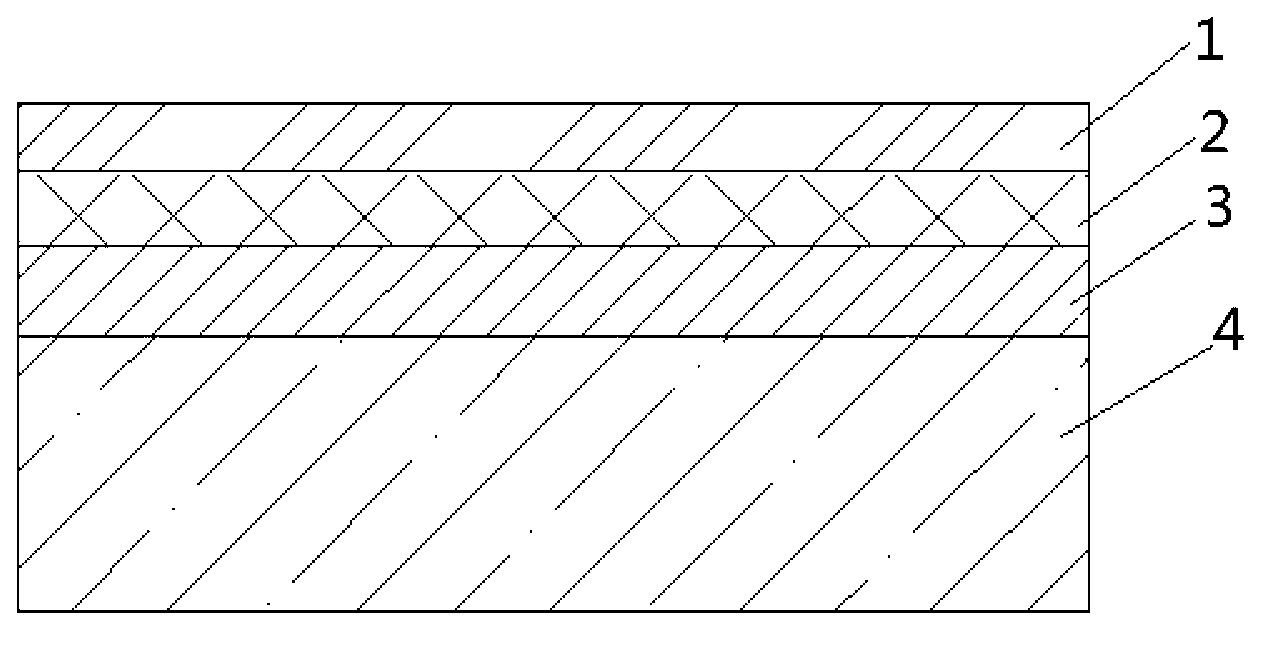

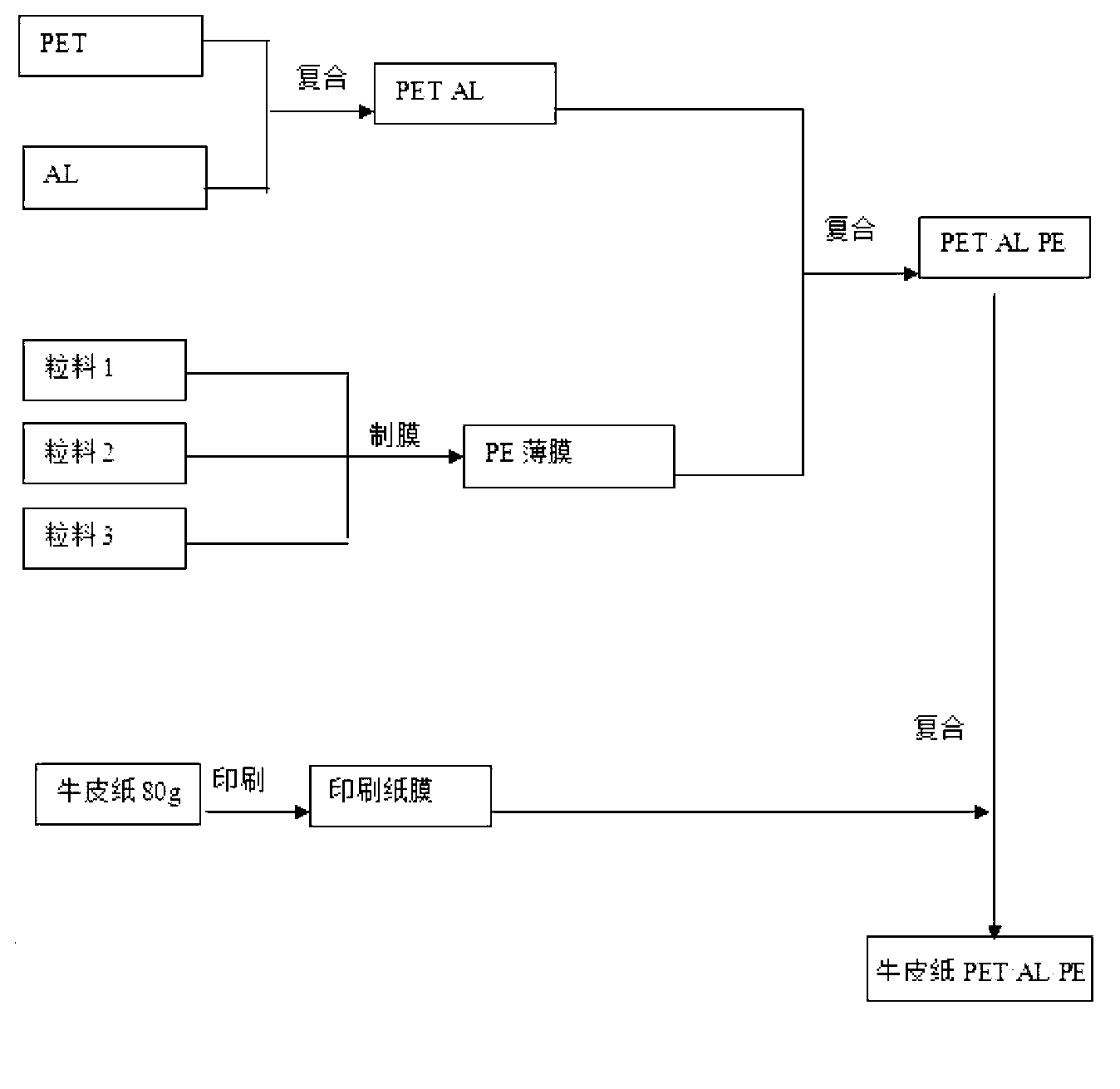

[0028] The present invention includes the following steps:

[0029] a) PET / AL composite process

[0030] b) PET / AL / PE composite process

[0031] c) Kraft paper / PET / AL / PE composite process

[0032] The b) Kraft paper / AL / PET / PE composite process includes the preparation process of PE. In the preparation process,

[0033] The outer layer is blended and extruded by high-pressure low-density polyethylene LDPE, linear low-density polyethylene LLDPE, and metallocene low-density polyethylene m-LLDPE. The weight ratio of high pressure low density polyethylene LDPE, linear low density polyethylene LLDPE and metallocene low density polyethylene m-LLDPE is 1:1:2;

[0034] The middle layer is blended and extruded by high pressure low density polyethylene LDPE, linear low density polyethylene LLDPE, and medium density polyethylene MDPE. The weight ratio of high pressure low density polyethylene LDPE, linear low density polyethylene LLDPE, and medium density polyethylene MDPE is 1:2:1

[0035] The inn...

Embodiment 2

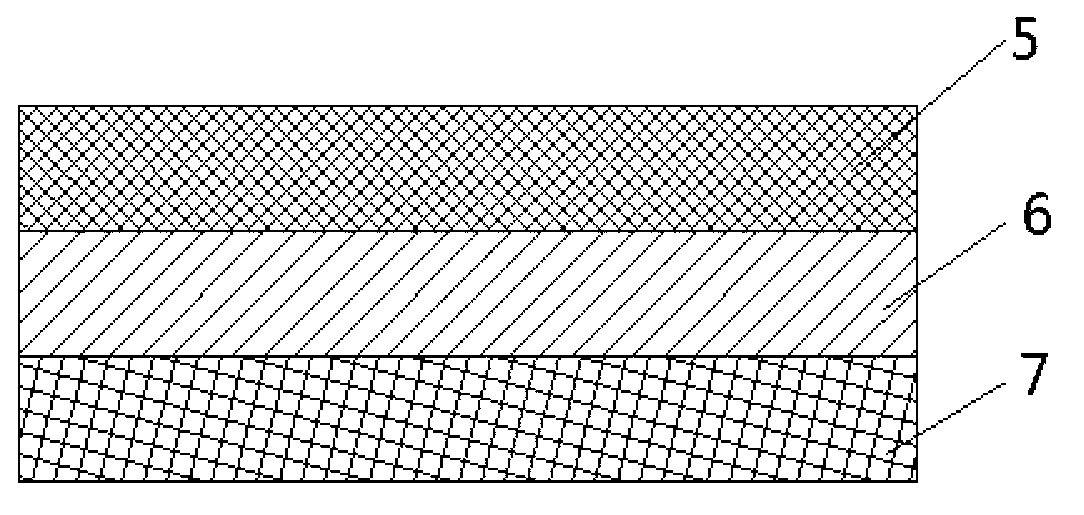

[0039] In addition to the aforementioned c) BOPA / PE composite process, including the preparation process of PE, in the preparation process,

[0040] The outer layer is blended and extruded by high-pressure low-density polyethylene LDPE, linear low-density polyethylene LLDPE, and metallocene low-density polyethylene m-LLDPE. The weight ratio of high pressure low density polyethylene LDPE, linear low density polyethylene LLDPE, metallocene low density polyethylene m-LLDPE is 1:1:1;

[0041] The middle layer is blended and extruded by high pressure low density polyethylene LDPE, linear low density polyethylene LLDPE, and medium density polyethylene MDPE. The weight ratio of high pressure low density polyethylene LDPE, linear low density polyethylene LLDPE, and medium density polyethylene MDPE is 1:1:1.

[0042] The inner layer is blended and extruded from high-pressure low-density polyethylene LDPE, metallocene linear low-density polyethylene m-LLDPE, and 3-amino-5-mercapto-1,2,4-triaz...

Embodiment 3

[0045] In addition to the above-mentioned c) BOPA / PE composite process, including the preparation process of PE, in the preparation process,

[0046] The outer layer is blended and extruded by high pressure low density polyethylene LDPE, linear low density polyethylene LLDPE, and metallocene low density polyethylene m-LLDPE. The weight ratio of high pressure low density polyethylene LDPE, linear low density polyethylene LLDPE, and metallocene low density polyethylene m-LLDPE is 1:2:1;

[0047] The middle layer is blended and extruded by high-pressure low-density polyethylene LDPE, linear low-density polyethylene LLDPE, and medium-density polyethylene MDPE. The weight ratio of high pressure low density polyethylene LDPE, linear low density polyethylene LLDPE, and medium density polyethylene MDPE is 1:1:2

[0048] The inner layer is blended and extruded by high-pressure low-density polyethylene LDPE and metallocene linear low-density polyethylene m-LLDPE. The weight ratio of high pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com