Preparation method of antistatic teflon film

A technology of Teflon and anti-static, which is applied in the field of preparation of anti-static Teflon film, can solve the problems that it is difficult to make Teflon film, the color difference of Teflon film products, and affect the normal use, so as to achieve uniform quality, Good stability, low friction and wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

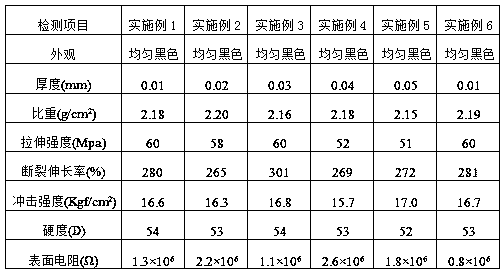

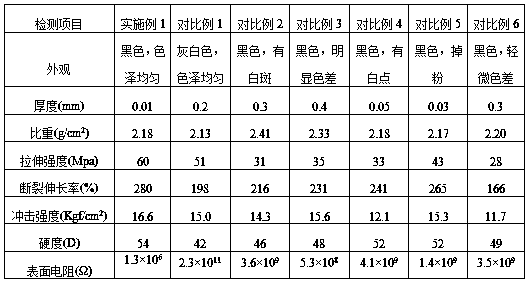

Examples

Embodiment 1

[0027] A preparation method for an antistatic Teflon film, comprising the steps of:

[0028] Step 1: raw material selection, made of 95% polytetrafluoroethylene as base material and 5% carbon black as antistatic agent;

[0029] Wherein, the polytetrafluoroethylene has an average particle size of 25 μm, a bulk density of 400 g / L, a molecular weight of 10 million, and a moisture content of ≤0.04%;

[0030] The carbon black has a surface area of 800 Å, an average particle size of 40 nm, a bulk density of 130 g / L, and a moisture content of ≤0.05%.

[0031] Step 2: Mixing materials. Put the raw materials selected in step 1 into the mixer for preliminary mixing. The speed of the mixer is 80-400 rpm. Agglomerate, and then sent to the mixer through negative pressure for continuous mixing, repeat the cycle for 2 to 4 times, so that the two raw materials are fully mixed evenly, and the Teflon mixture powder is obtained;

[0032] Step 3: Press molding to obtain a Teflon green body. I...

Embodiment 2

[0037] The step of the preparation method of the antistatic Teflon film of the present embodiment is with embodiment 1, and the difference with embodiment 1 is:

[0038] In step 1, the component content of the polytetrafluoroethylene is 94%, the average particle size is 22.5 μm, the bulk density is 300 g / L, the molecular weight is 8 million, and the moisture content is ≤0.04%;

[0039] The component content of the carbon black is 6%, the surface area is 750, the average particle size is 30nm, the bulk density is 120g / L, and the moisture content is ≤0.05%.

Embodiment 3

[0041] The step of the preparation method of the antistatic Teflon film of the present embodiment is with embodiment 1, and the difference with embodiment 1 is:

[0042] In step 1, the component content of the polytetrafluoroethylene is 95%, the average particle size is 25 μm, the bulk density is 350 g / L, the molecular weight is 15 million, and the moisture content is ≤0.04%;

[0043] Furnace carbon black is selected, its component content is 5%, the surface area is 850, the average particle size is 35nm, the bulk density is 125g / L, and the moisture content is ≤0.05%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com