Patents

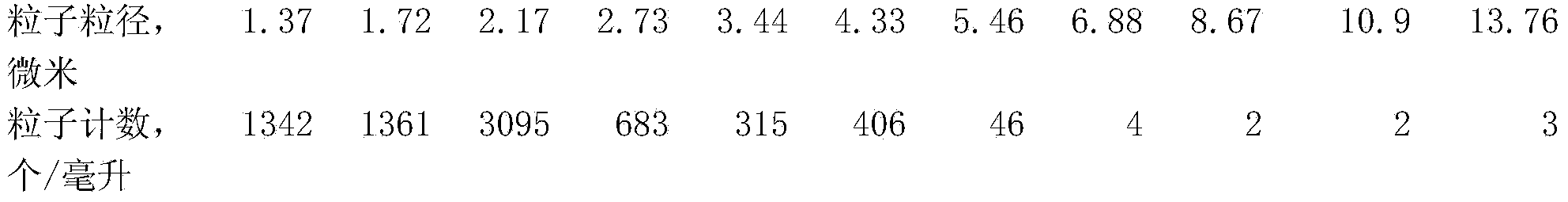

Literature

274results about How to "Solve Thickness Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

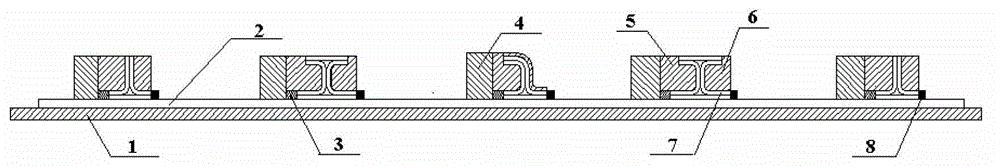

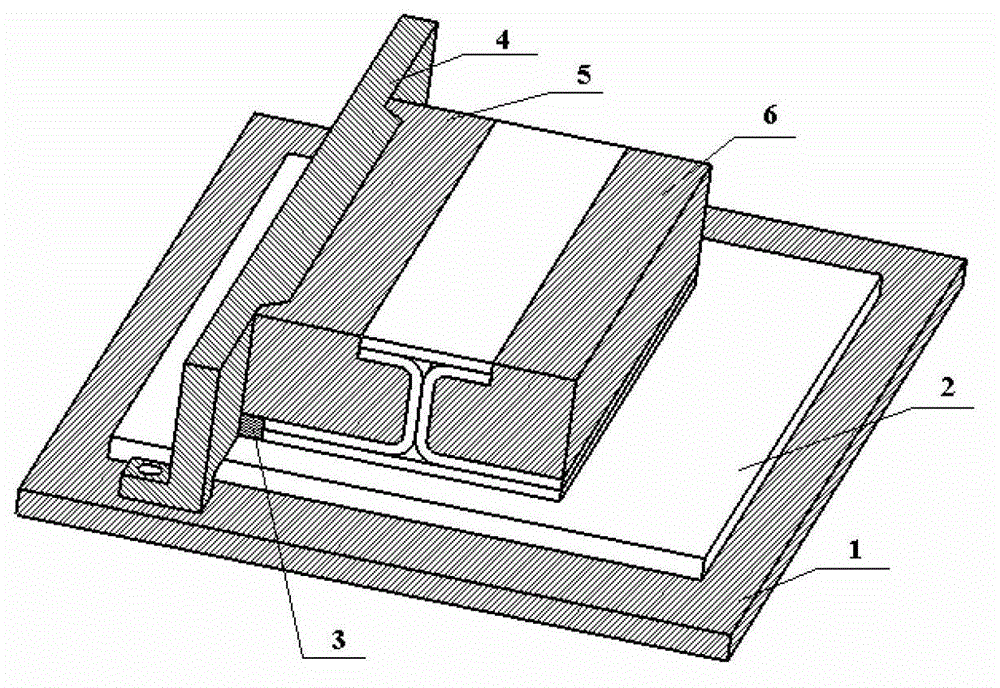

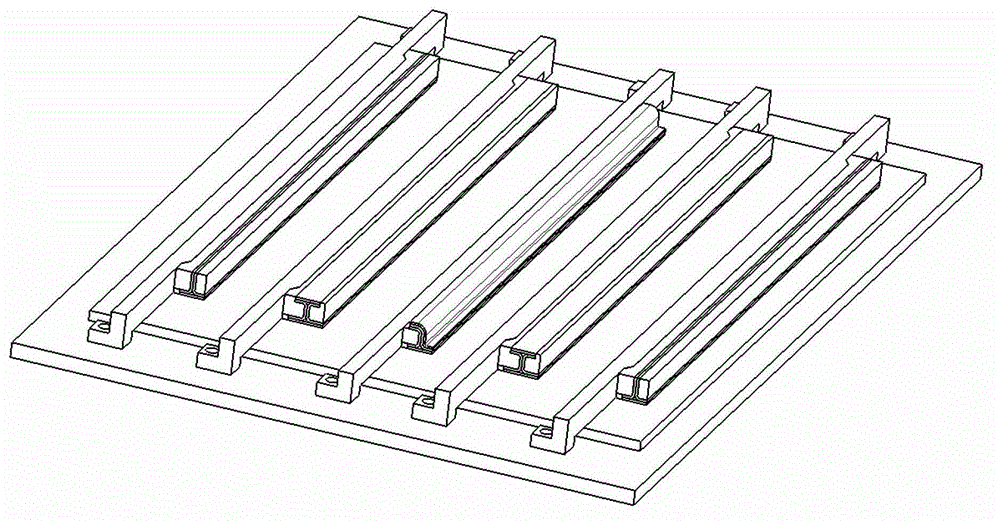

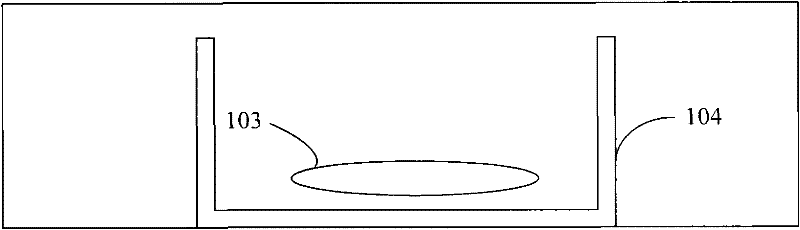

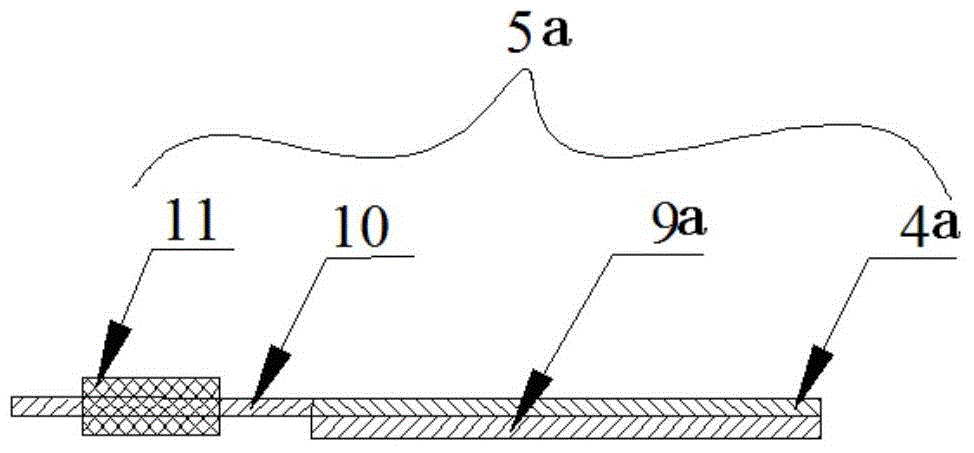

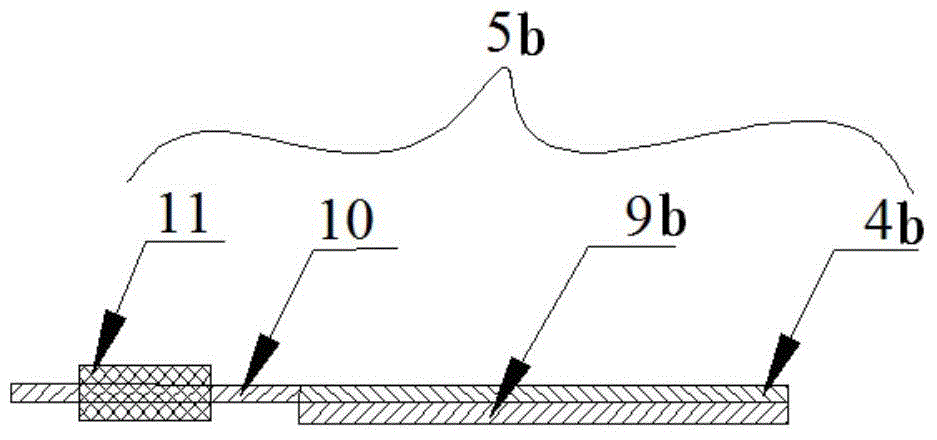

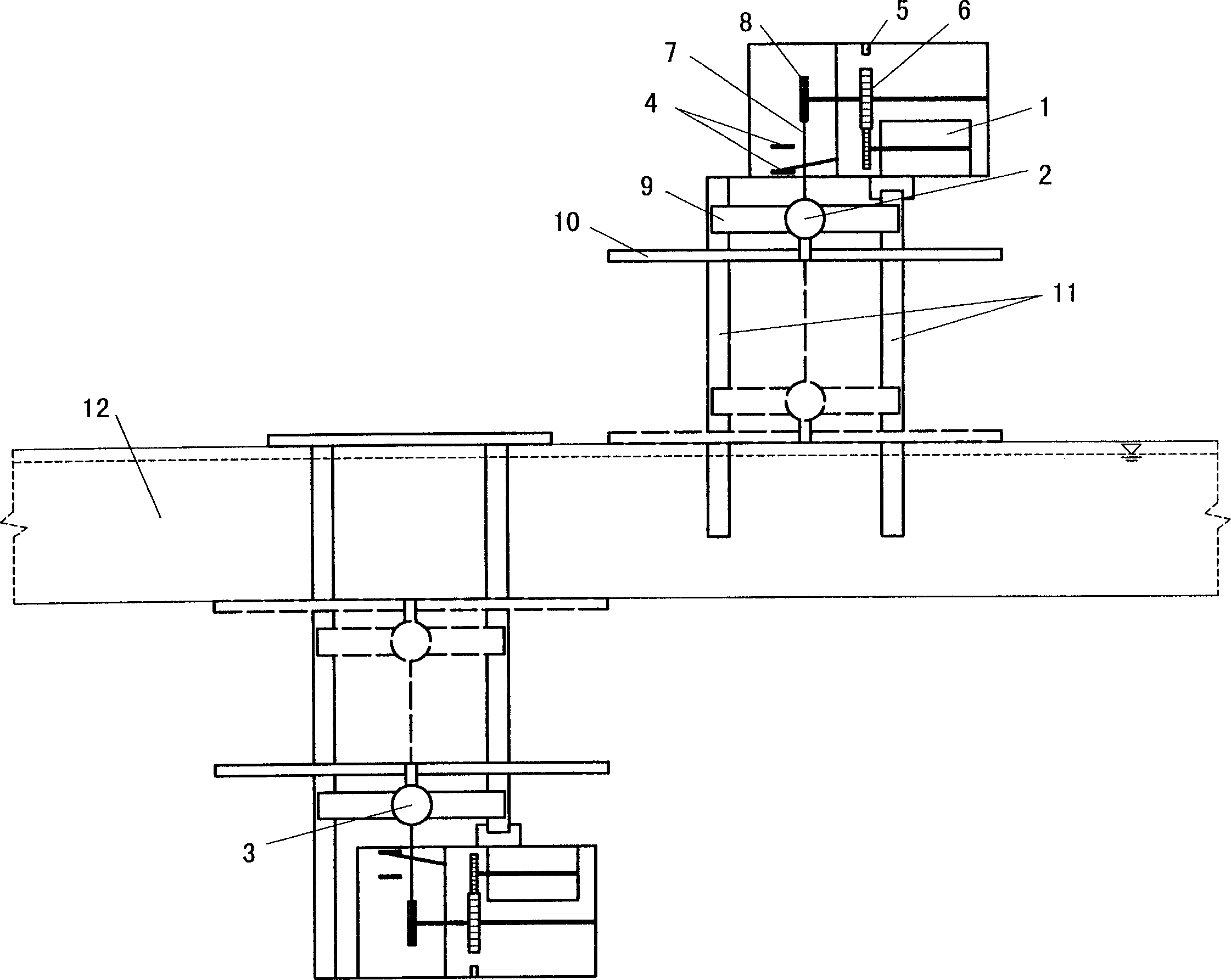

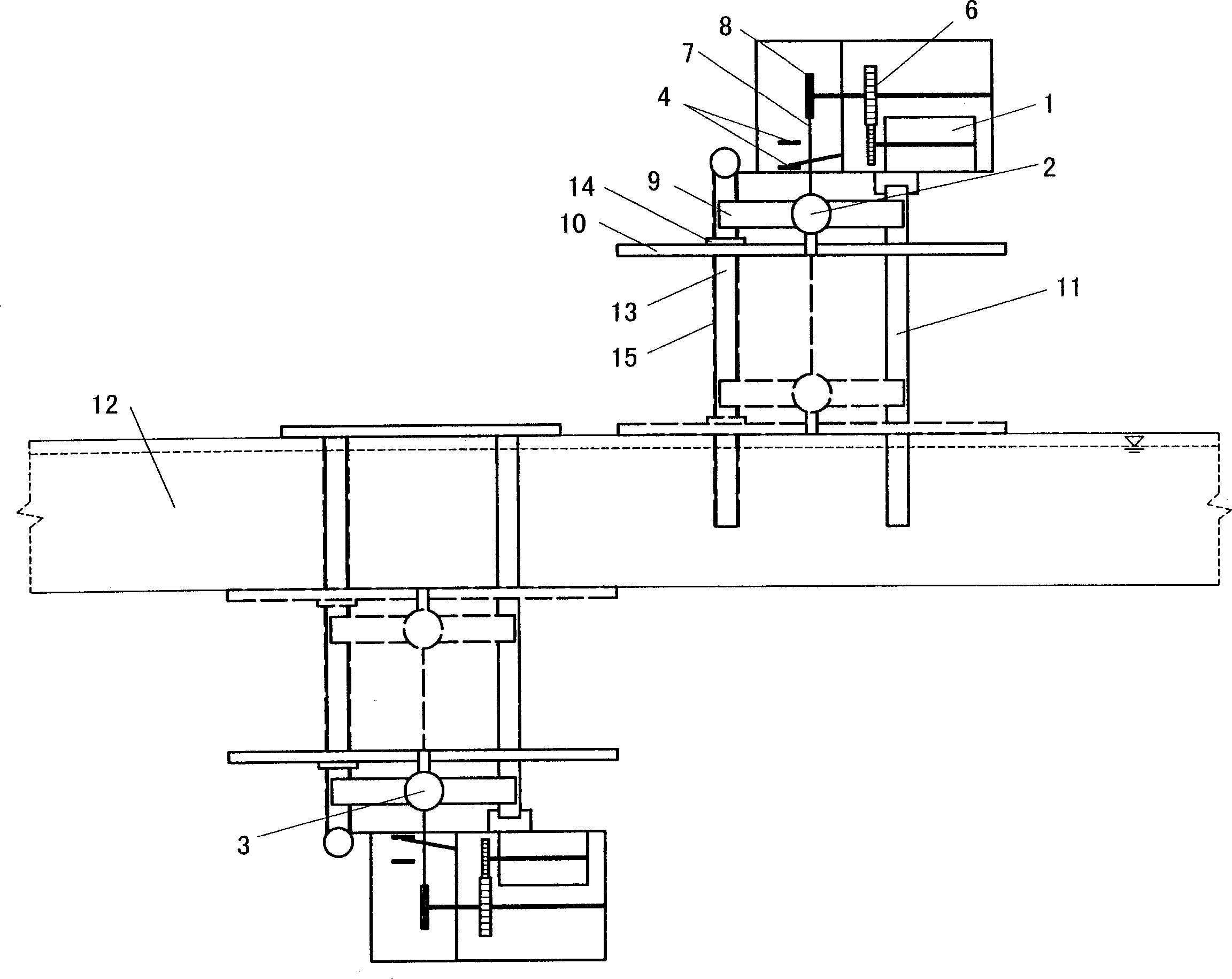

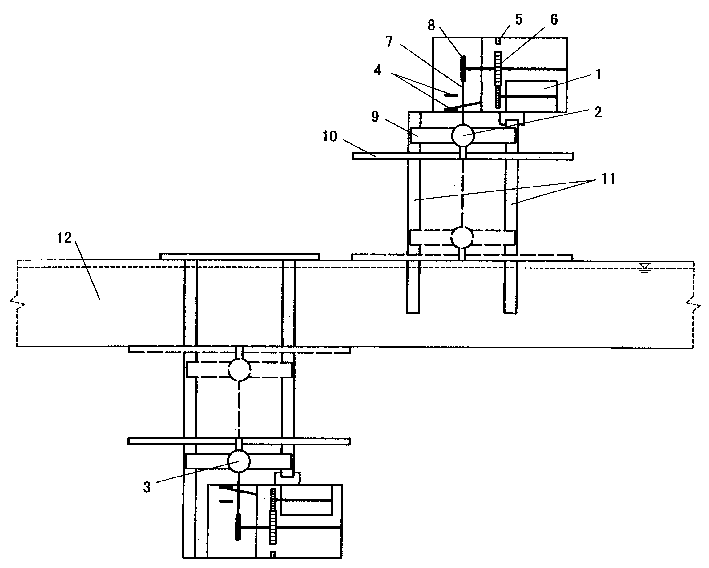

Method for forming control of long joist axial line of composite material stiffened wall panel

The invention belongs to technologies of composite material forming, and relates to a method for forming control of a long joist axial line of a composite material stiffened wall panel in an aviation aircraft. The method is a fixture method suitable for forming control of long joist axial lines of various types, such as a T shape, an I shape, a J shape and the like, of long joist composite material stiffened wall panels. A forming fixture mainly comprises a long joist forming mold A and a long joist forming mold B, a skinned curing mold, a cushion block and an axial line positioning mold. The two ends of the long joist forming mold A are designed to be dovetail-shaped and are closed matched with the axial line positioning mold to control the deviation of a long joist in the length direction of the axial line; and the axial line positioning mold is fixed on the skinned curing mold through positioning pins to control left and right deviations of the long joist axial line. By the forming fixture method, the molding surface quality and the position accuracy of a long joist product are effectively improved, and the long joist axial line is prevented from deviation.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

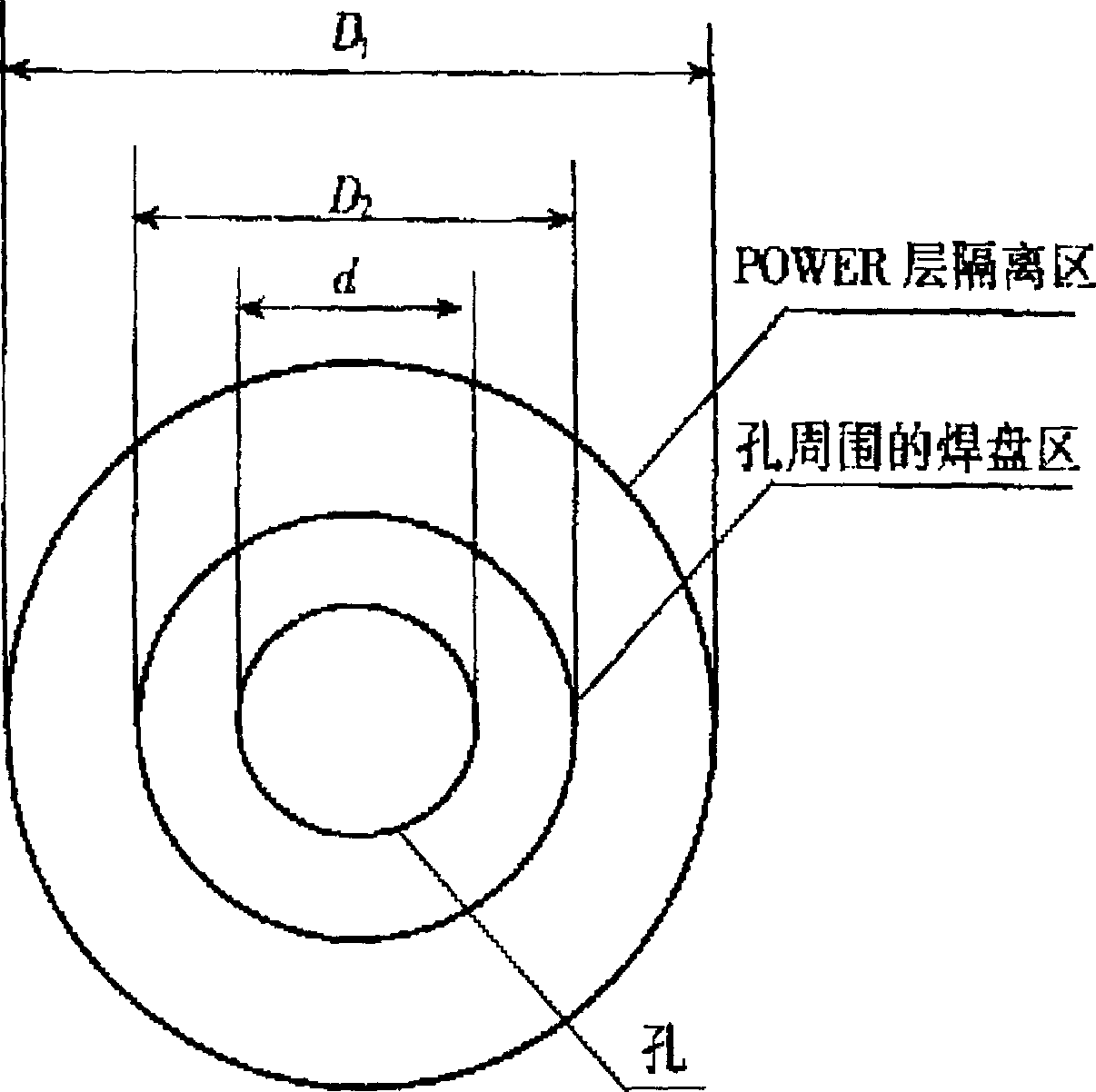

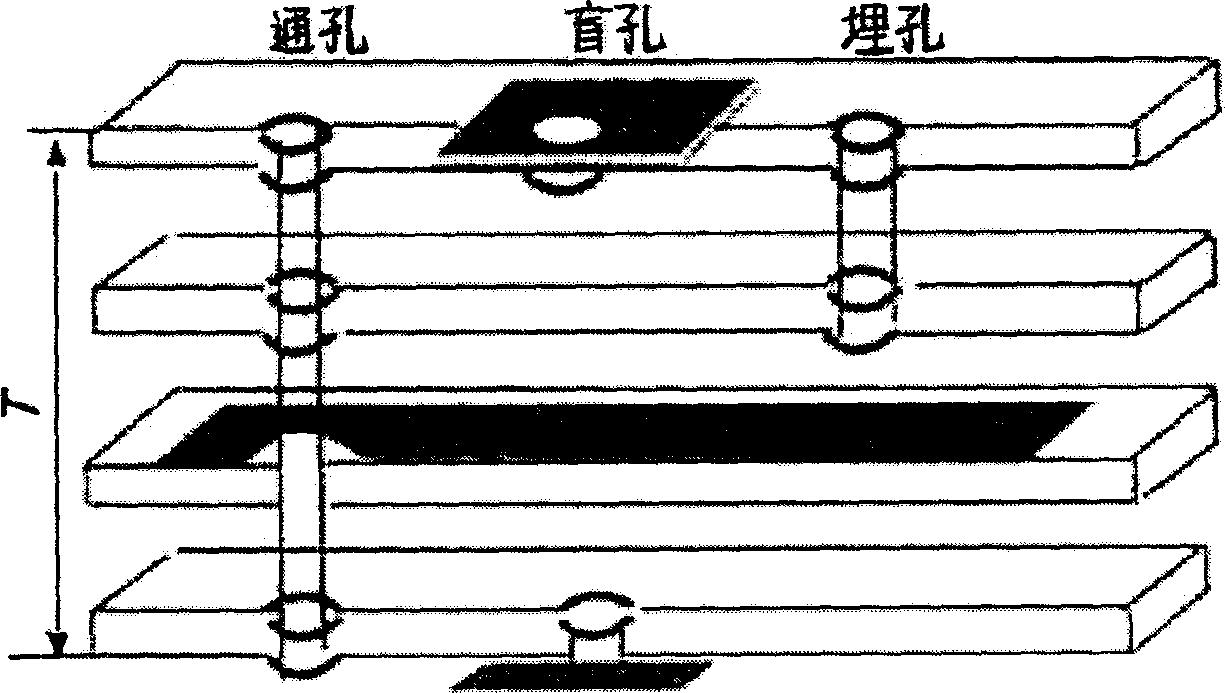

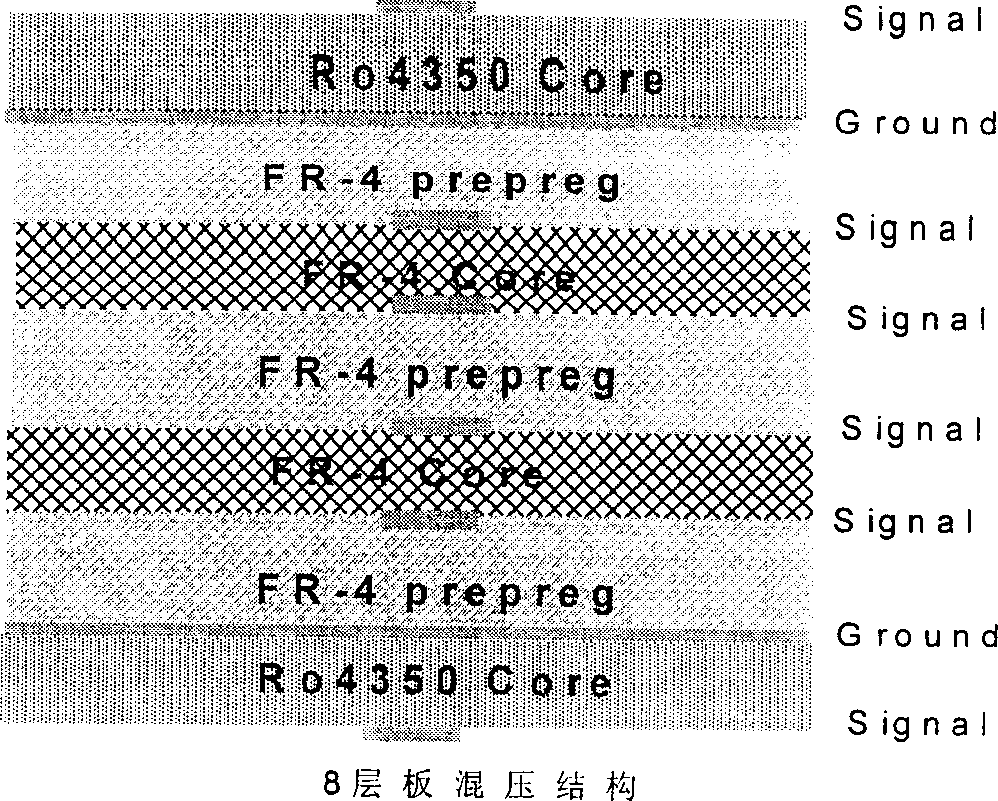

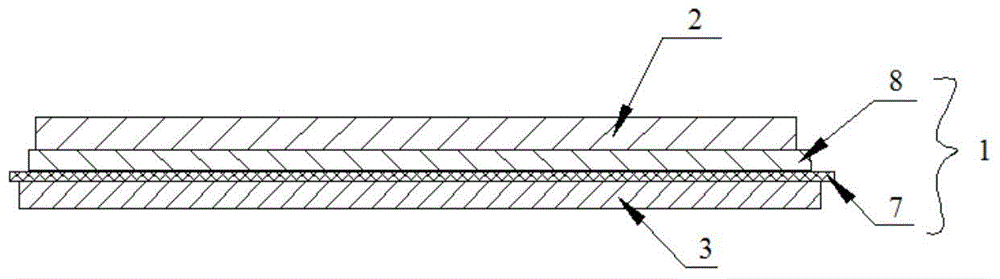

Printed circuit board capable of realizing high-speed signal transmission and making method

InactiveCN1852633ALow costOvercome limitationsCircuit susbtrate materialsMultilayer circuit manufactureCopper foilTransmission quality

The disclosed printing circuit board (PCB) is composed of two outer layers and one inner layer. The outer layer is made from plate of capable of transmitting signal in high speed; and the inner layer is made from general plate. Method for fabricating PCB includes following steps: carrying blackening / browning treatment; superimposing and pressing prepreg and outer copper foil together so as to form multilayer half finished board; drilling holes on multilayer board, plating via holes, using negative plate imaging and etching to prepare needed ducting lines in each core plate in inner layer; obtaining lines on outer layer so as to produce multilayer PCB in hybrid plates; back drilling technical holes in order to take out STUB with no connection and no attribute on end part of via holes. Features of the PCB are: high-speed signal transmission in low cost, high reliability, guaranteeing rate of good quality of PCB produced, and transmission quality of high-speed signal.

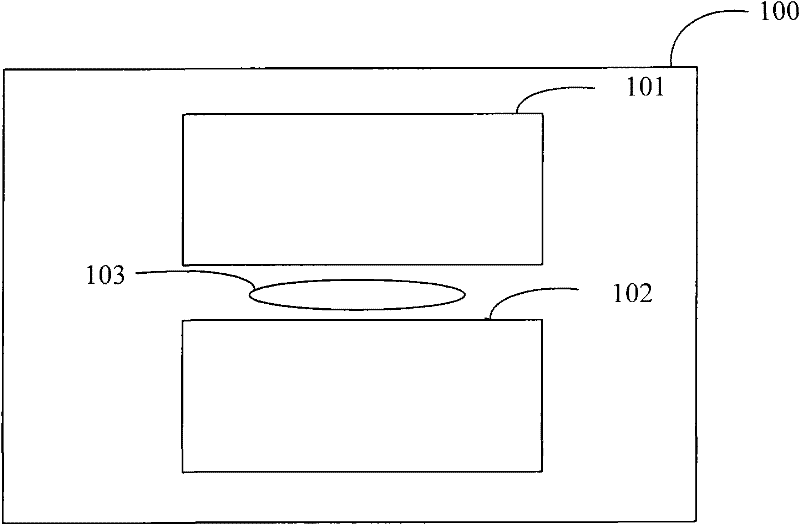

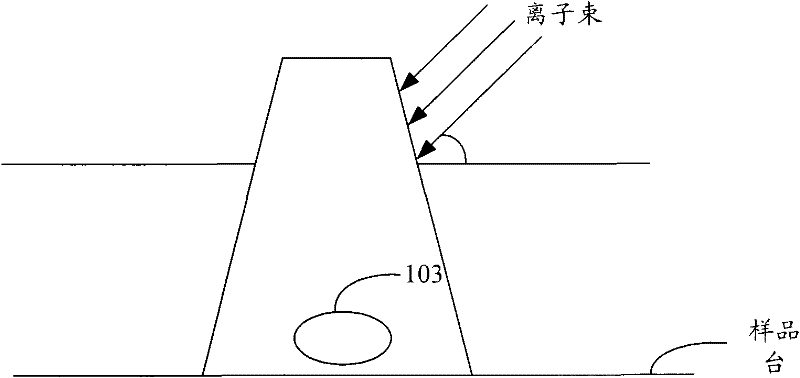

Preparation method for semiconductor sample of TEM

ActiveCN102346109ASolve Thickness ProblemsAvoid distortionPreparing sample for investigationTransmission electron microscopyMicrometer

The present invention provides a preparation method for a semiconductor sample of a transmission electron microscope (TEM). The method comprises: forming a sample containing a target structure on a wafer, and cutting the sample into the sample with a thickness of about 1 micrometer through focused ion beam (FIB), cutting the bottom of the sample to obtain a lateral opening, wherein at least the length of the lateral opening is provided for completely isolating the target structure and the wafer; retaining a protective layer above the target structure, and removing a semiconductor device on anupper layer of the wafer positioned above the target structure in the sample through the FIB; carrying out fine polishing for both side wall surfaces of the sample until the thickness of the sample containing the target structure region meets the requirement of the TEM sample. The energy of the focused ion beam is lost and the distribution of the focused ion beam is nonuniform due to the distancebetween the target structure and the sample surface, such that the thickness of the TEM sample can not meet the TEM requirement and the TEM sample is distorted and destroyed. With the TEM sample preparation method provided by the present invention, the problems are avoided; the FIB bombardment point is accurately calculated; the preparation success rate of the TEM sample of the semiconductor device positioned on the bottom layer of the wafer is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Brazing method Al2O3 ceramic and metallic material

The invention discloses a braze welding method of AI2O3 ceramics and metal material, and relates to the connection method of the AI2O3 ceramics and the metal material. The invention solves the problem of the existing method for connecting the AI2O3 ceramics and the metal material that the strength of a connector after connection is low and the air tightness of a connecting piece is low. The braze welding method of the AI2O3 ceramics and the metal material of the invention is carried out according to the following steps: 1. the cleaning of the ceramics, and the decoating of a chaff; 2. the preparation of active metalized ceramics; 3. metal cleaning; and 4. braze welding; thus obtaining a welding part of the ceramics and the metal material. Another method of the invention is carried out according to the following steps: 1. the cleaning of the ceramics, and the preparation of active metalized powder paste; 2. the preparation of the active metalized ceramics; 3. metal cleaning; and 4. braze welding; thus obtaining the welding part of the ceramics and the metal material. The connection strength of the connector of the welding part welded by the method of the invention can reach up to 50 to 100 MPa, and the leakage rate of the connector is less than 1.0 multiplied by 10<-8>Pa question mark m<3> / s.

Owner:HARBIN INST OF TECH

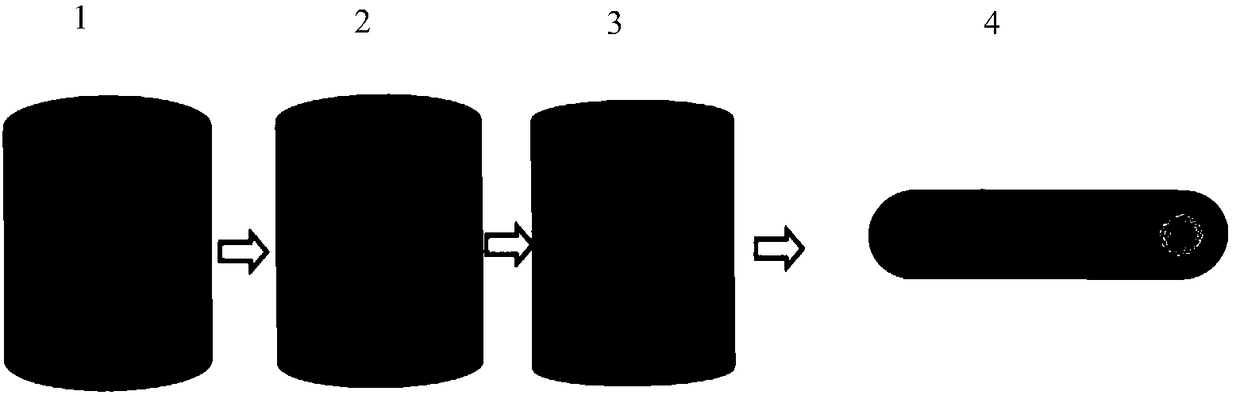

Degradable lamellar Zn-Mg composite material and preparation method thereof

ActiveCN108237214AGood biocompatibilityPromote degradationSurgeryMetallic material coating processesMg compositeMaterial Design

The invention discloses a degradable lamellar Zn-Mg composite material and a preparation method thereof. The outer layer of a lamellar medical metal composite material is made of pure zinc or zinc alloy, and the core part of the lamellar medical metal composite material is made of pure magnesium or magnesium alloy; the ratio of zinc or zinc alloy and magnesium or magnesium alloy is calculated according to volume percentage, zinc or zinc alloy accounts for 20%-50% of the total volume of the material, and the balance is magnesium or magnesium alloy. The lamellar composite material is prepared bycombining layered casting with nested extruding. The degradable lamellar Zn-Mg composite material has the advantages that: the selected magnesium alloy and the selected zinc alloy have good biocompatibility and degradability; mechanical properties and a degradation rate of the integral composite material are controlled by controlling a relative thickness of a Zn layer to a Mg layer, so that the composite material adapts to a service environment, and therefore, a condition that single metal is too quick or too slow in degradation is solved. The material design and the preparation method are simple and convenient, and the cost is low, so that industrial production is facilitated.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

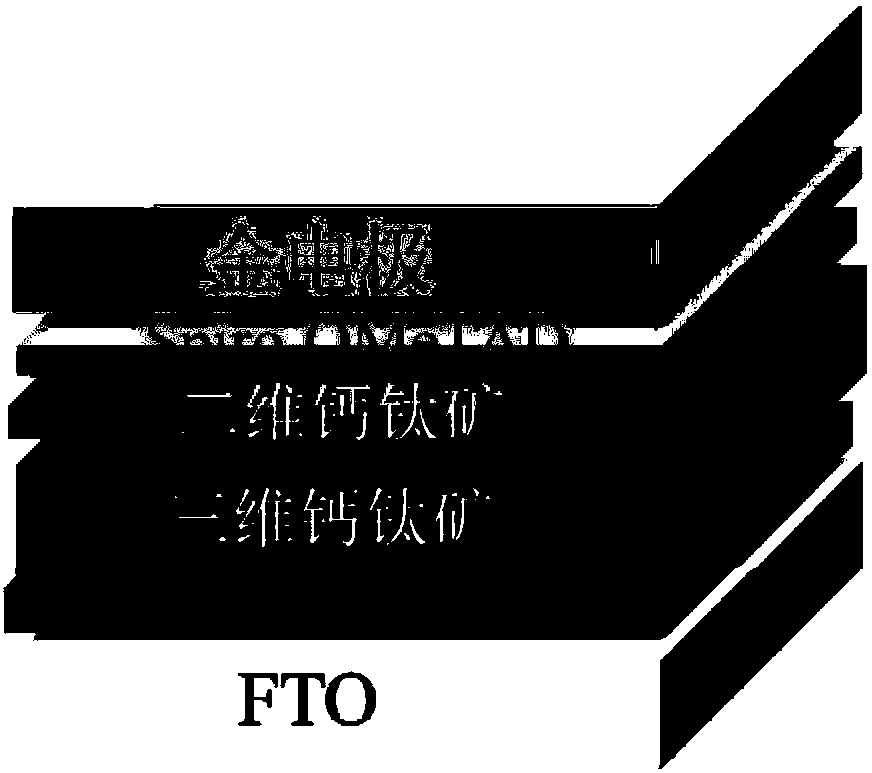

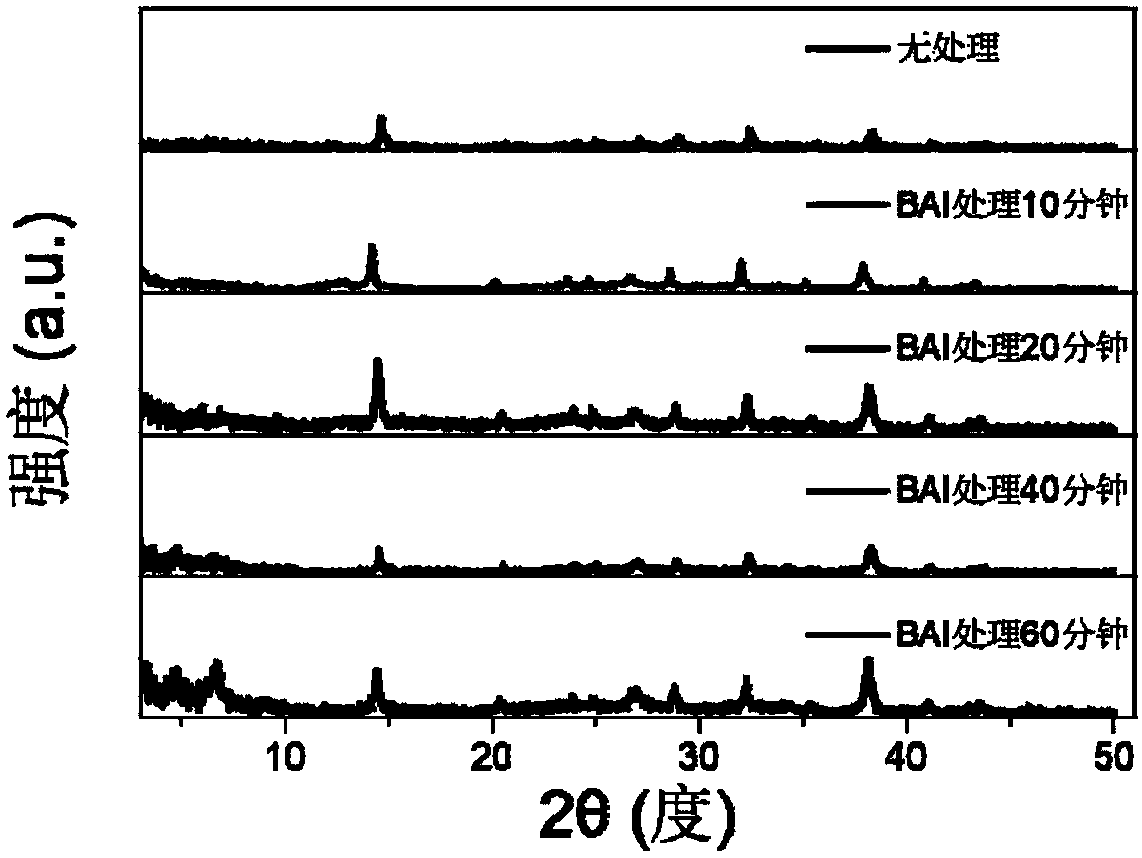

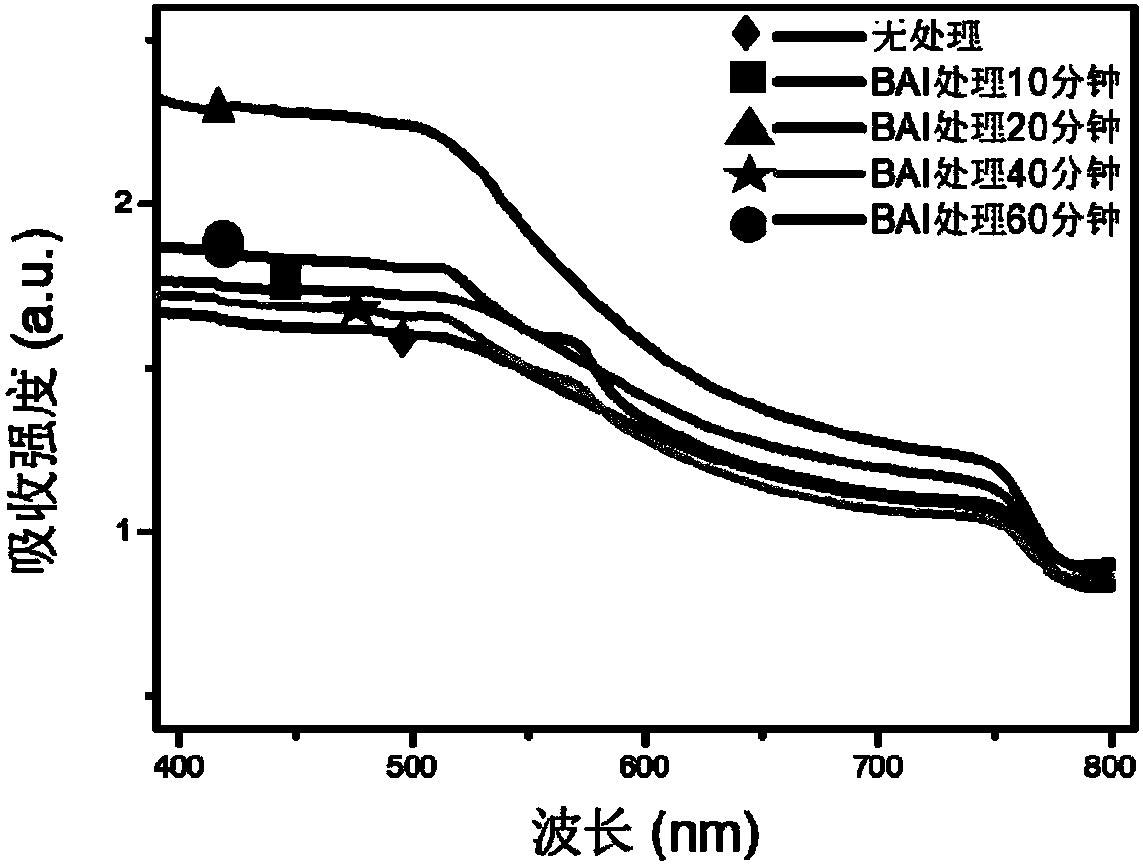

Perovskite plane heterojunction solar cell and preparation method therefor

ActiveCN108269921AAvoid introducingReduce consumption costFinal product manufactureSolid-state devicesHeterojunctionOrganic solvent

The invention relates to a perovskite plane heterojunction solar cell and a preparation method therefor. The solar cell comprises a conductive substrate FTO, an electron transmission layer, a three dimensional-two dimensional perovskite layer, a hole transmission layer, and electrodes. The three dimensional-two dimensional perovskite layer is prepared through a vapor phase method. The three dimensional-two dimensional perovskite layer serves as a light absorbing layer, thereby greatly improving the humidity and temperature stability of the solar cell, reducing the requirements for the packaging technology, and reducing the consumption of an organic solvent. Moreover, the three dimensional-two dimensional perovskite layer prepared through the vapor phase method is higher in industrial production value, and provides a new idea for the industrial production of the perovskite solar cell with the high stability.

Owner:JINAN UNIVERSITY

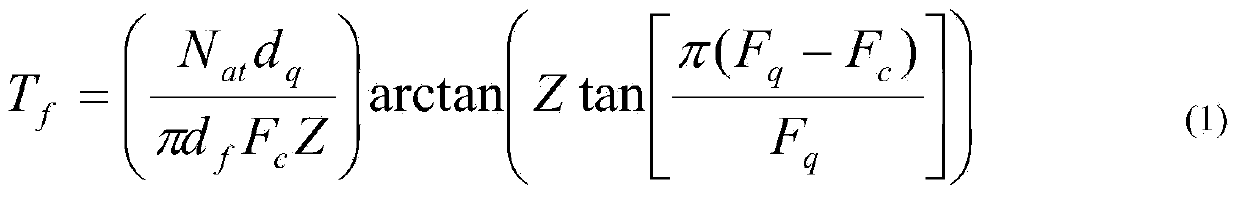

Control method of coating thickness of quartz crystal and coating device of quartz crystal

ActiveCN103469172AHigh thickness accuracySolve Thickness ProblemsVacuum evaporation coatingSputtering coatingHuman–machine interfaceControllability

The invention provides a control method of coating thickness of a quartz crystal, wherein the coating thickness is calculated according to the initial oscillation frequency of the quartz crystal before coating and the oscillation frequency of the quartz crystal after coating. The control method is characterized in that thickness measurement errors caused by rise of the oscillation frequency of the quartz crystal due to temperature increment of the quartz crystal are reduced. The coating device of the quartz crystal, provided by the invention, is convenient to operate, and the work efficiency is improved. A film thickness controller of the quartz crystal provided by the invention adopts a human-machine interface and is convenient for operators to monitor the coating process in real time and analyze the film forming data, thereby improving the controllability of the coating process. By adopting the control method and the device provided by the invention, the error on the coating thickness can be reduced to below 1 / 4 of the error in the prior art, so that the precision on the coating thickness is greatly improved.

Owner:SHANGHAI MOLIN TECH CO LTD

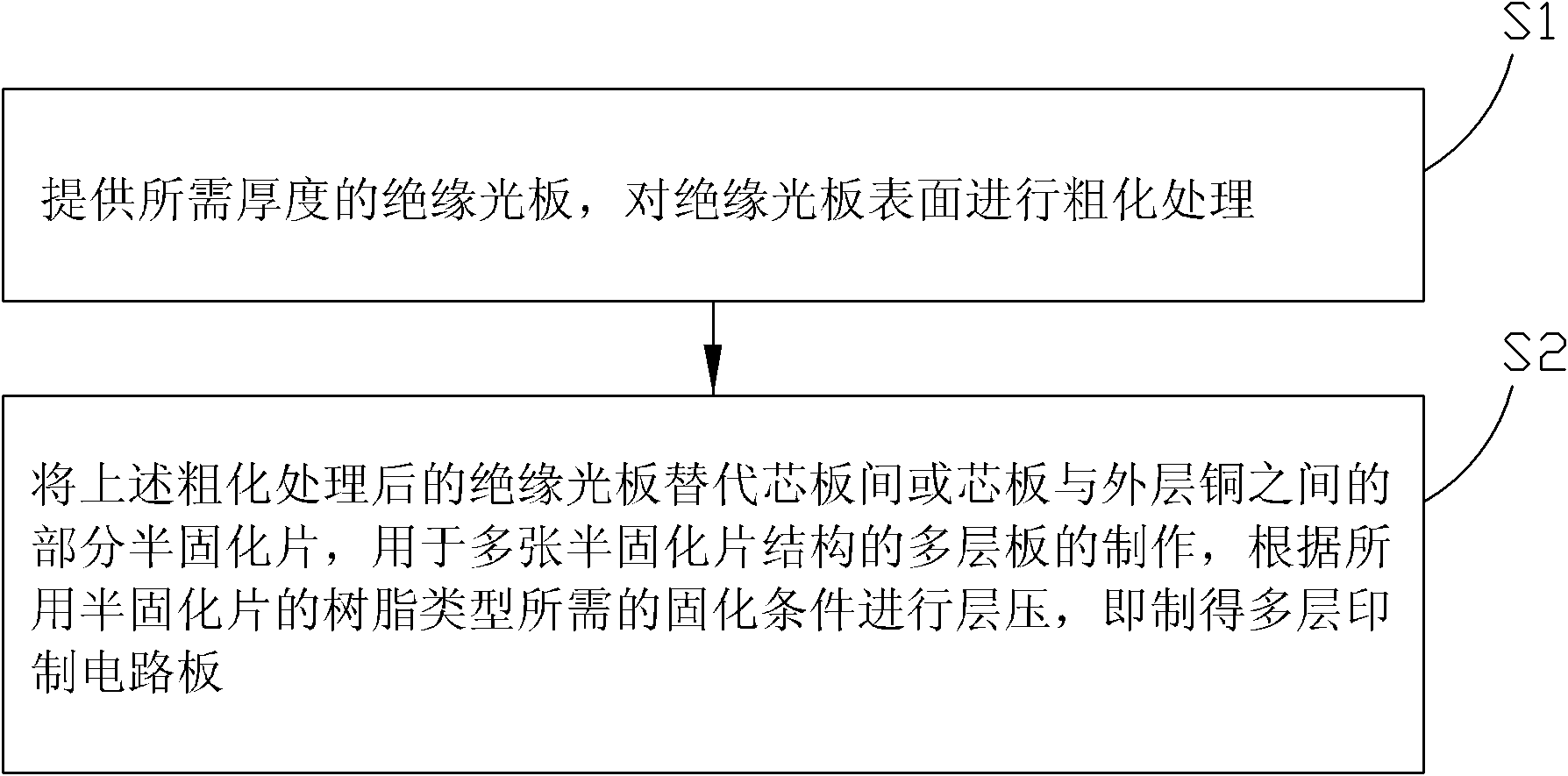

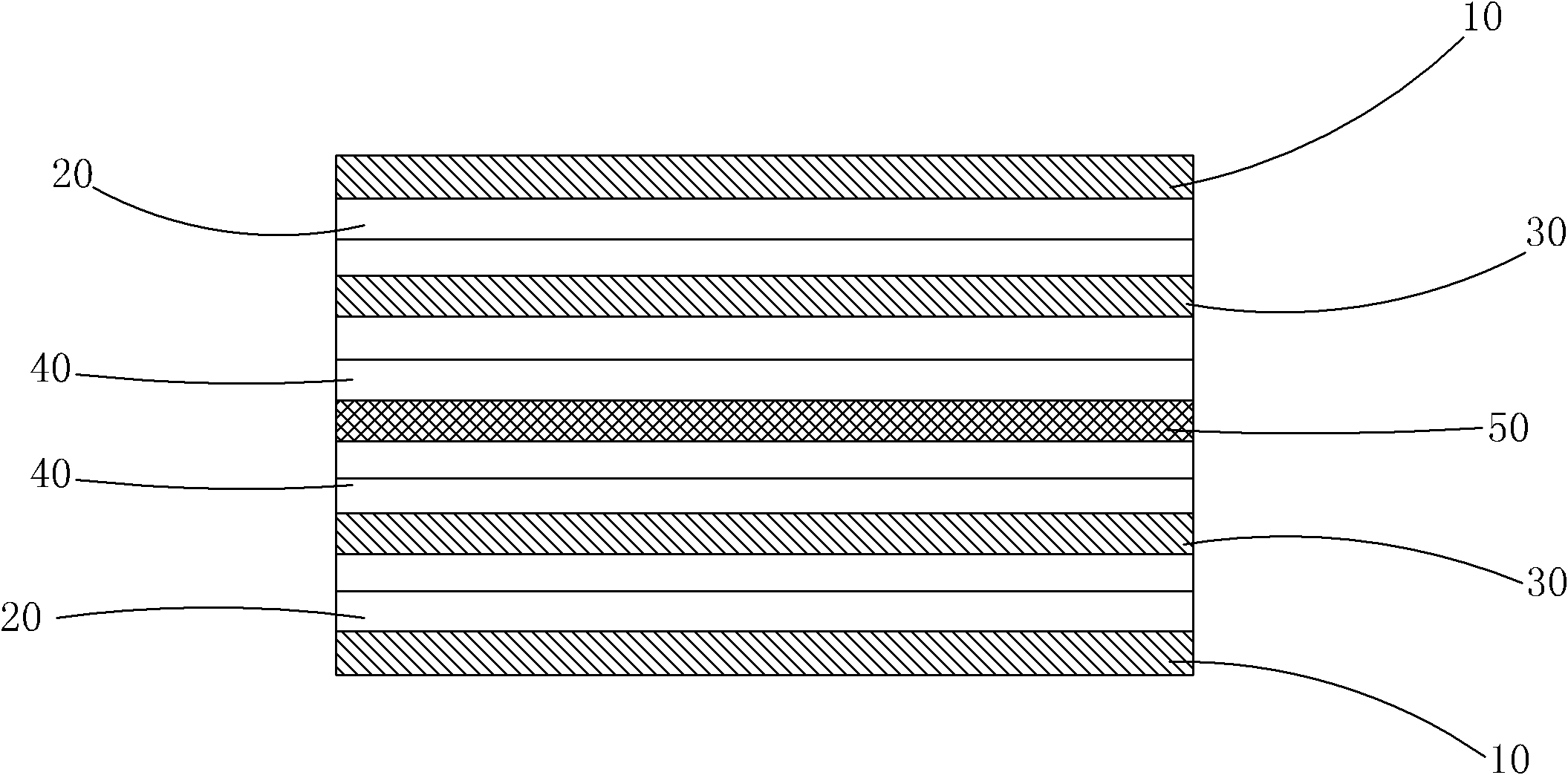

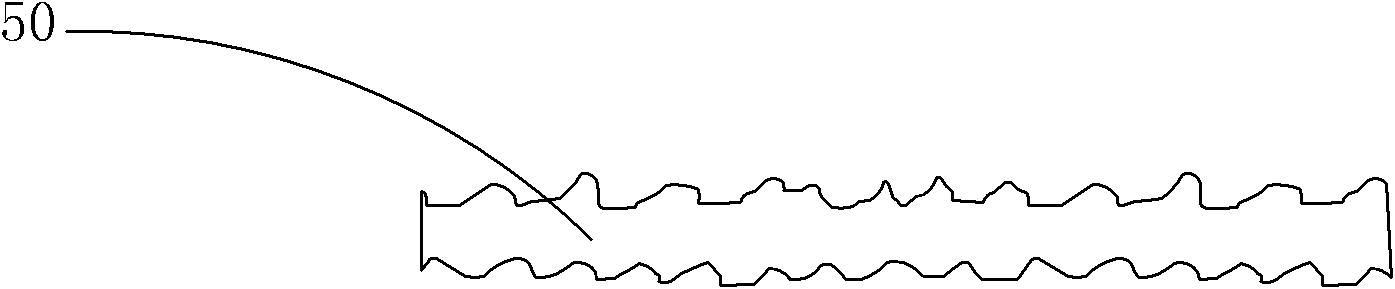

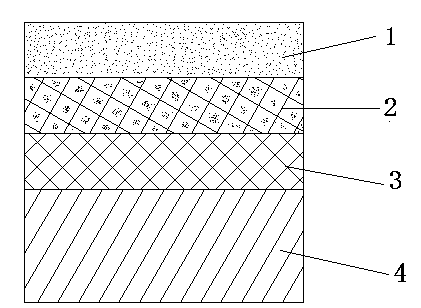

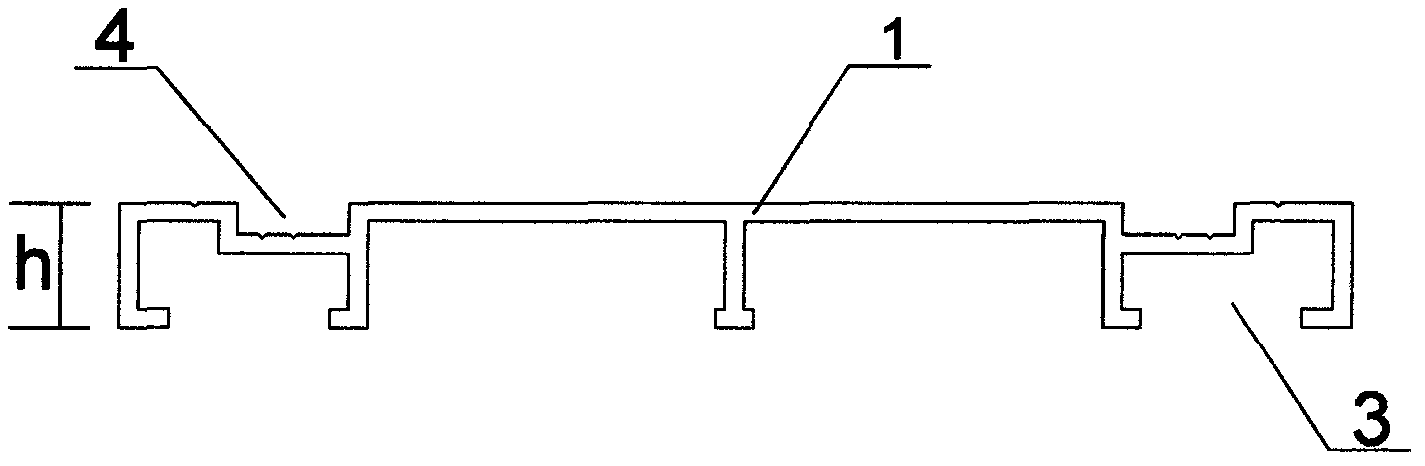

Production method of multi-layer printed circuit board and multi-layer printed circuit board

ActiveCN102014590ASolve Thickness ProblemsImprove efficiencyInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentInter layerSlide plate

The invention relates to a production method of a multi-layer printed circuit board and the multi-layer printed circuit board, and the production method of the multi-layer printed circuit board comprises the following steps: step 1) providing an insulating light board with the required thickness, and carrying out roughening treatment on the insulating light board; and step 2) using the insulating light board after the roughening treatment to replace part of semi-curing sheets in a core plate or between the core plate and an outer layer of copper so as to produce a multi-layer plate with the structure comprising a plurality of semi-curing sheets, and carrying out lamination according to curing conditions required for the resin type of the used semi-curing sheets, thus obtaining the multi-layer printed circuit board. In the production method, the insulating light board after the roughening treatment is used to replace part of the semi-curing sheets, is used for producing the multi-layer plate with the structure comprising the plurality of the semi-curing sheets, thus the problems of an inter-layer sliding plate and non-uniform thickness caused by large adhesive flow can be solved; the interface bonding force can achieve the effect of using an etched copper-clad plate; and compared with the use of the etched copper-clad plate in the prior art, the production method has the advantages of high efficiency, low cost, low pollution discharge and the like.

Owner:GUANGDONG SHENGYI SCI TECH

Penetration brazing preparation method of high-content wolfram carbide gradient wear-resisting coating

The invention provides a penetration brazing preparation method of a high-content wolfram carbide gradient wear-resisting coating, comprising the following steps: sequentially sticking a plurality of layers metal wire net flexible compound cloth containing wolfram carbide WC or wolfram carbide-cobalt WC-Co and nickel-chromium alloy powder Ni-Cr on a metal base body by using an epoxy resin binding agent; and carrying out penetration brazing in a vacuum furnace. Compared with the prior art, the Rockwell hardness of a researched coating with the WC content of 70% is HRC64-70 and the wear resistance is obviously improved.

Owner:NANCHANG INST OF TECH

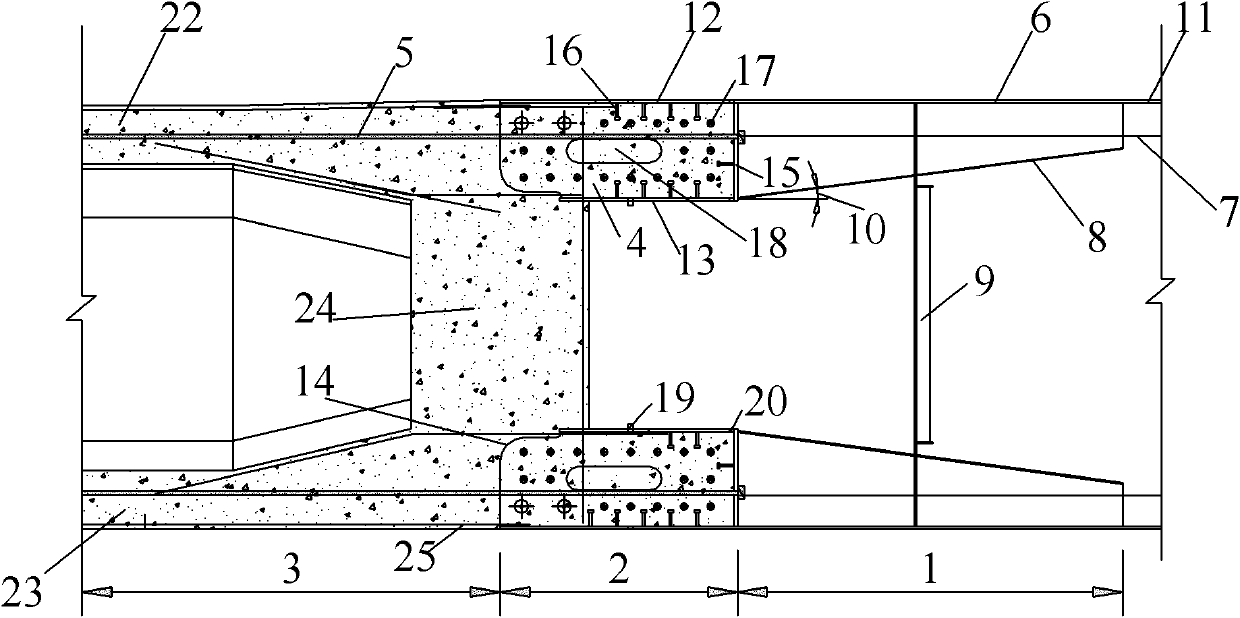

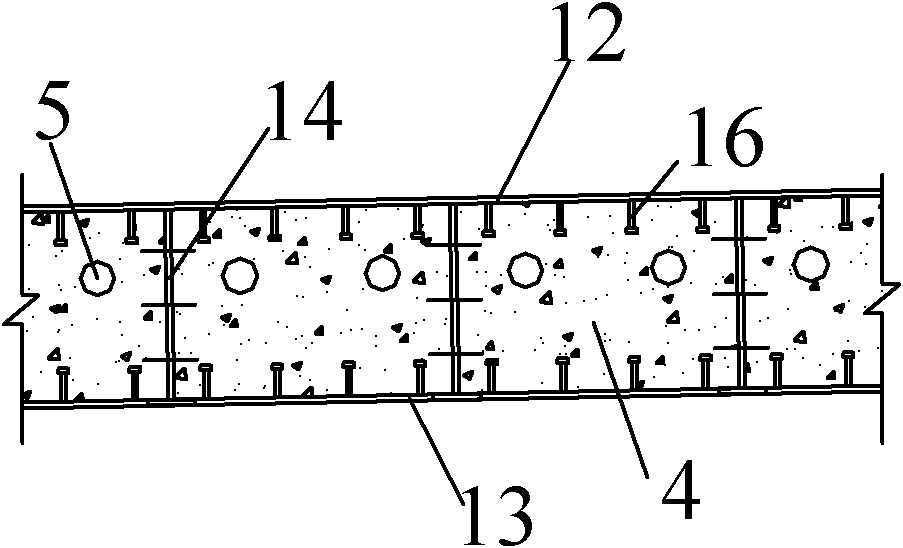

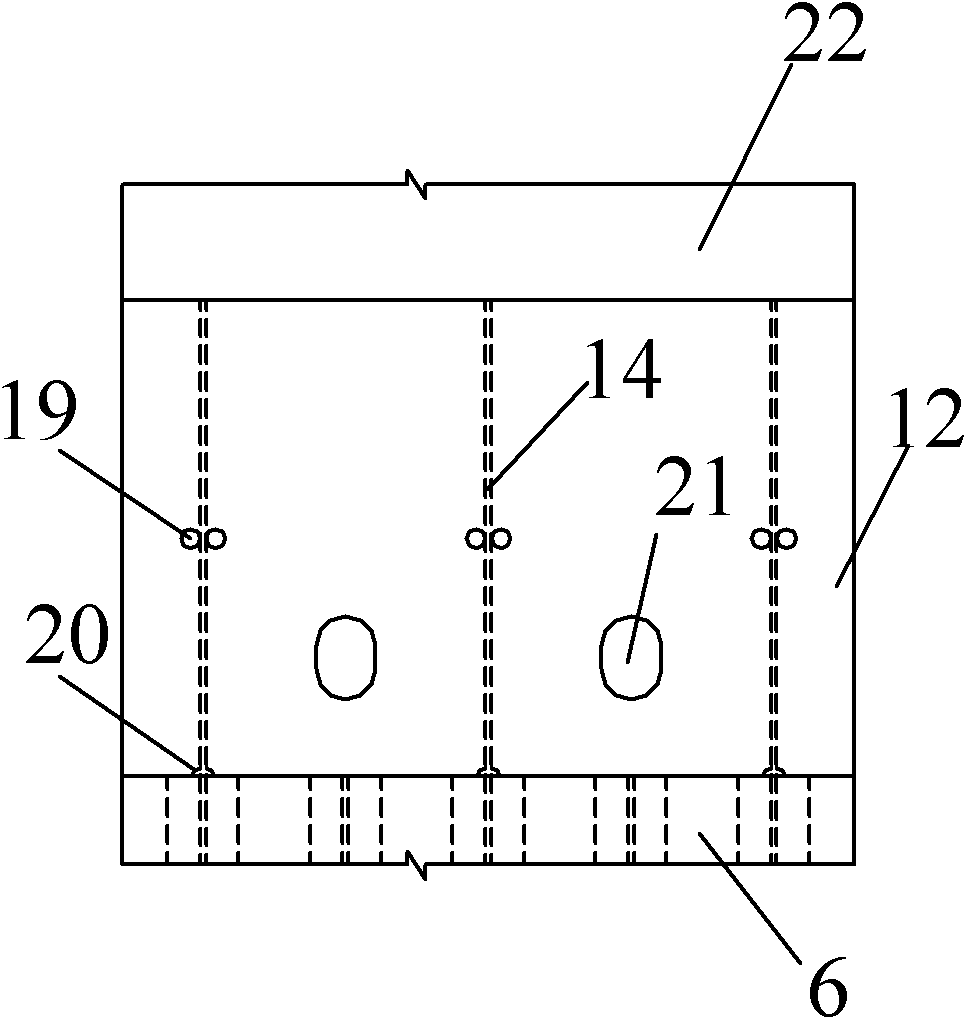

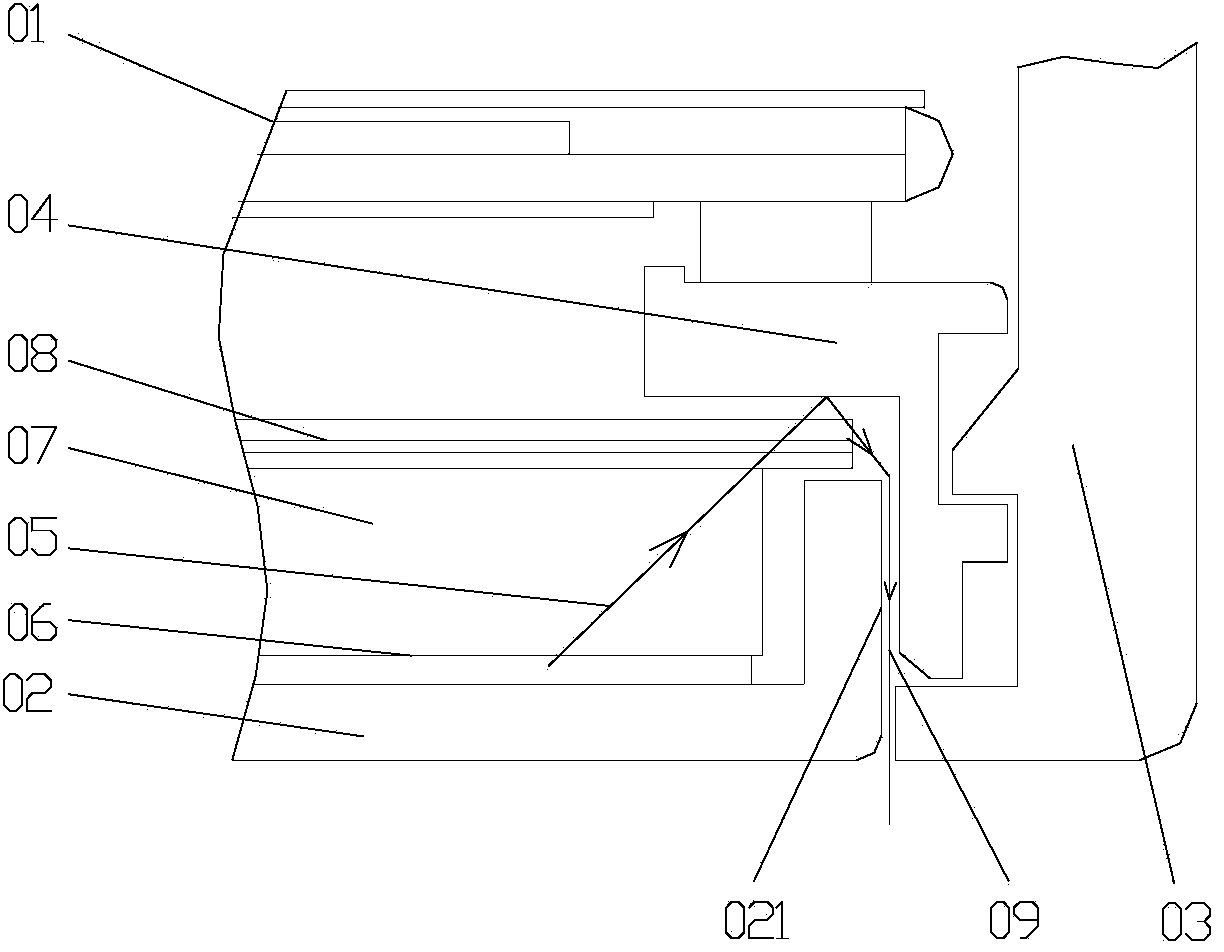

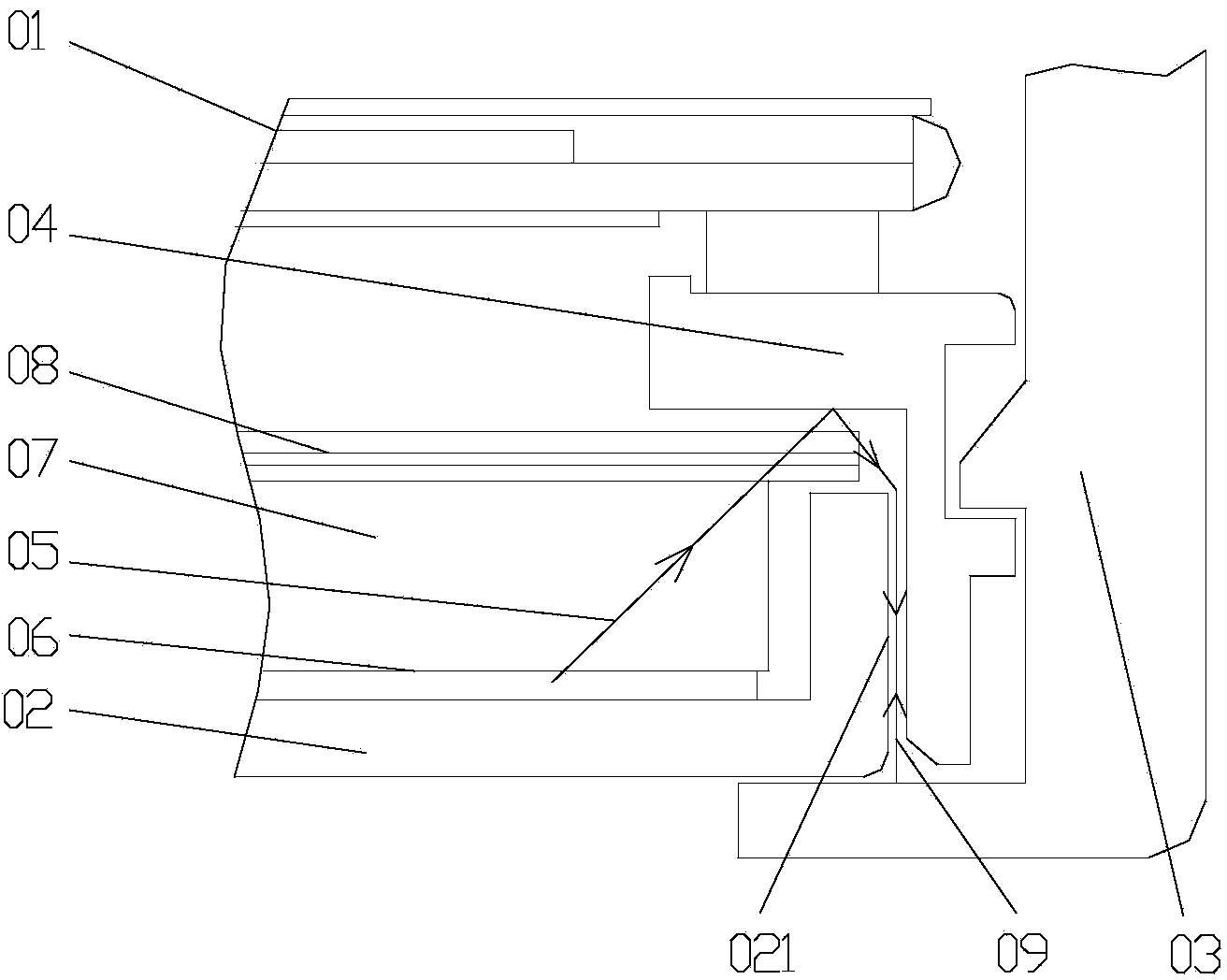

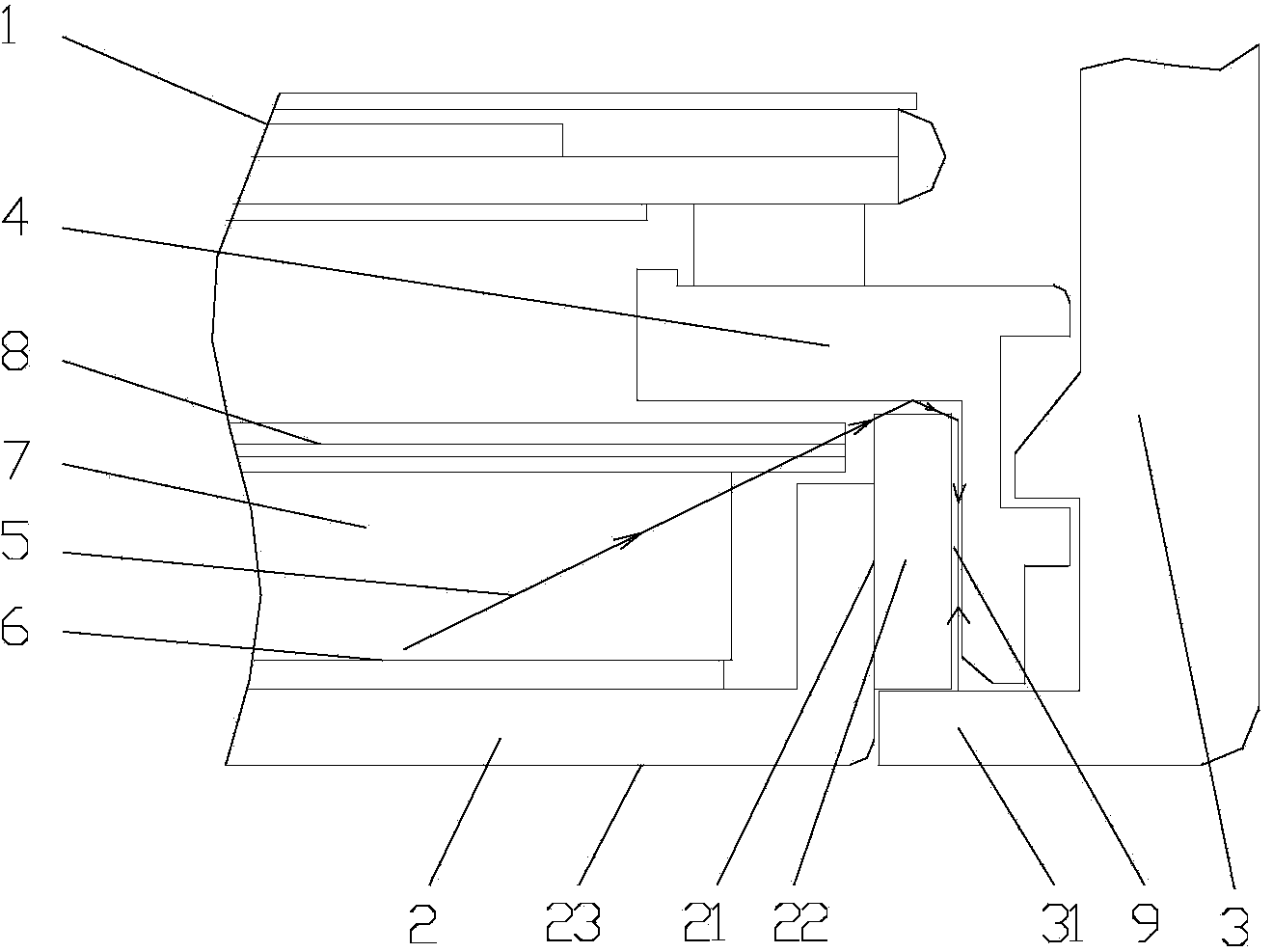

Celled hybrid beam junction with composite connectors

InactiveCN102561172AImprove clearanceImprove applicable spanCable-stayed bridgeBridge structural detailsBridge engineeringConcrete beams

The invention discloses a celled hybrid beam junction with composite connectors, which relates to the technique of bridge engineering and used for a main beam of a large-span hybrid beam cable-stayed bridge. Concrete-filled steel cell structures are disposed at the ends of a steel box girder, welding nail connectors are disposed on a top plate, a bottom plate and a bearing plate of each steel cell while the top plate, the bottom plate and the bearing plate are attached with concrete, and perforated plate connectors (PBL (perfobond leiste) connectors) are disposed on partition plates of each steel cell and integrally concreted with a concrete beam. When the celled hybrid beam junction is used, the main beam has the single-cell single-box, multi-cell and single box or single-cell and double-box cross section, and longitudinal prestress is applied to the interior of each steel cell. By means of the celled hybrid beam junction, the problem of stress of the main beam of the large-span hybrid beam cable-stayed bridge is solved effectively, structural safety is improved, welding of a great quantity of welding nail connectors in each steel cell is avoided, and the applicable span of the hybrid beam cable-stayed bridge is enlarged greatly.

Owner:CCCC HIGHWAY CONSULTANTS

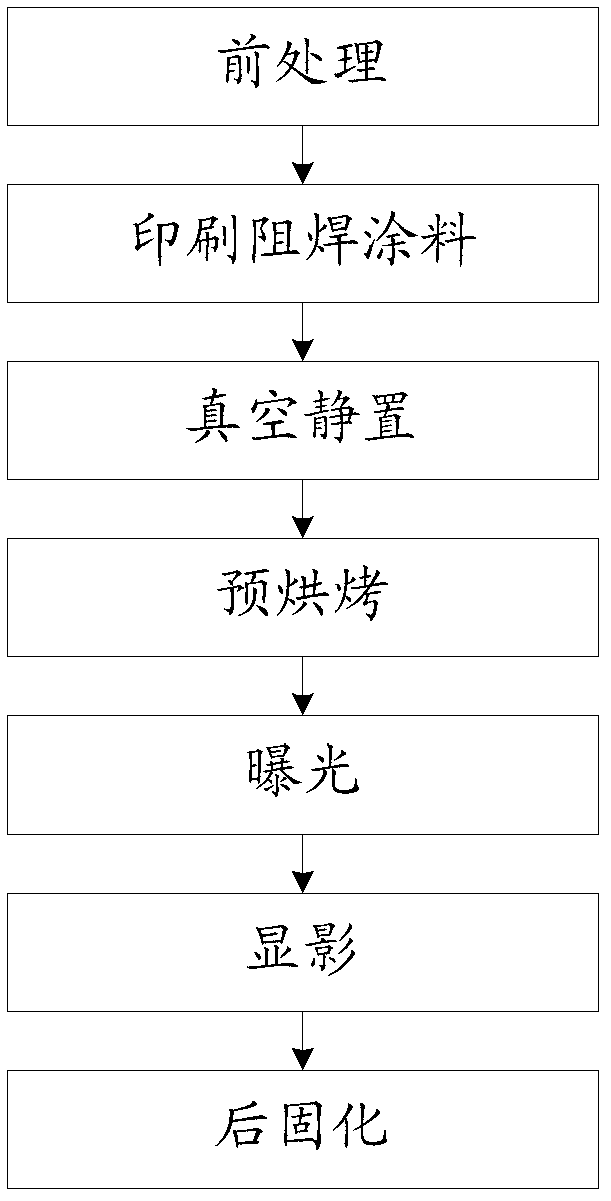

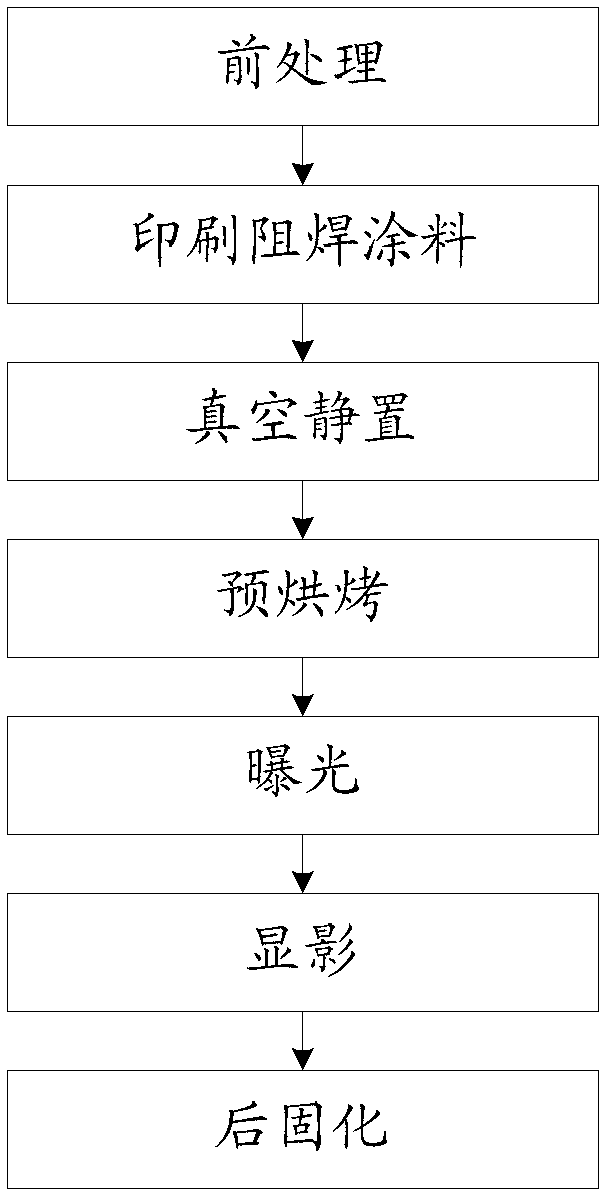

Circuit board resistance welding processing method

InactiveCN102361543AImprove exclusion effectSolve Thickness ProblemsNon-metallic protective coating applicationEngineeringCopper

The embodiment of the invention discloses a circuit board resistance welding processing method. The method comprises the steps of pretreatment, resistance welding coating printing, standing, pre-baking, exposure, development and post-curing, wherein the standing step is carried out in vacuum. The method has the following beneficial effects: the bubble elimination capability is improved by adopting vacuum standing; and the problems of insufficient resistance welding thickness and bubble generation during thick copper circuit board resistance welding processing can be solved, the process flow is shortened and the processing time is reduced.

Owner:SHENNAN CIRCUITS

Ultrathin secondary battery and preparation method thereof

ActiveCN104638213ASmall spacingControl shapeFinal product manufactureCell component detailsEngineeringSlurry

The invention relates to an ultrathin secondary battery and a preparation method thereof, and belongs to the field of electrochemistry. The thickness of the ultrathin secondary battery is 0.3-1.0mm. The ultrathin secondary battery comprises a diaphragm, a positive electrode membrane and a negative electrode membrane, wherein the positive electrode membrane and the negative electrode membrane are respectively adhered to two sides of the diaphragm and directly contact the diaphragm; the diaphragm consists of a substrate and a conductive layer; the conductive layer is positioned on one side of the substrate and directly contacts the positive electrode membrane. The preparation method comprises the following steps: firstly, respectively coating the front and back sides of the diaphragm with positive electrode slurry and negative electrode slurry according to set sizes, drying and rolling, thereby obtaining the diaphragm with the positive electrode membrane and the negative electrode membrane; secondly, pressing, thereby enabling a positive electrode current collector and a negative electrode current collector to respectively tightly contact the positive electrode membrane and the negative electrode membrane; finally, packaging by using a package membrane according to design size, performing vacuum dewatering and electrolyte injection in sequence, subsequently sealing, activating, forming, packaging for the second time, and performing volume division, thereby obtaining the ultrathin secondary battery.

Owner:HUNAN GAOYUAN BATTERY

High-permeability super black decorated base paper and preparation method thereof

ActiveCN103614949AImprove permeabilityImprove breathabilitySpecial paperPaper/cardboardTitaniumWet strength

The invention relates to high-permeability super black decorated base paper and a preparation method of the high-permeability super black decorated base paper, and belongs to the technical field of decoration base paper. The preparation method is characterized by comprising the following steps: taking pulp mixed from bleached softwood pulp and bleached hardwood pulp according to the mass ratio of 1:(3.6-4.4) as a main raw material; reducing the beating degree of bleached wood pulp to 32 SR, enabling the mass concentration to reach 4%, and then pumping into a repulping pond for later use; directly adding a black pigment to the repulping pond, wholly substituting kaoline for titanium dioxide to prepare the decorated base paper with a black and shiny color, the fluorescent whiteness of 6%-8%, the basis weight of 70-90g / m<2>, the ash content of 10%-15%, the wet strength of 6.5-9N, the dry strength of 35-50N, the water absorption of 20-35mm / 10 minutes and the air permeability of 15-20s / 100ml. The high-permeability super black decorated base paper disclosed by the invention has the advantages of uniformity in coloring, good covering power, high air permeability, low basis weight and high paper output ratio; a processed decorating plate is high in stereoscopic impression, pure and bright in color and luster, green and environmental-friendly without white patterns.

Owner:ZIBO OU MU SPECIAL PAPER

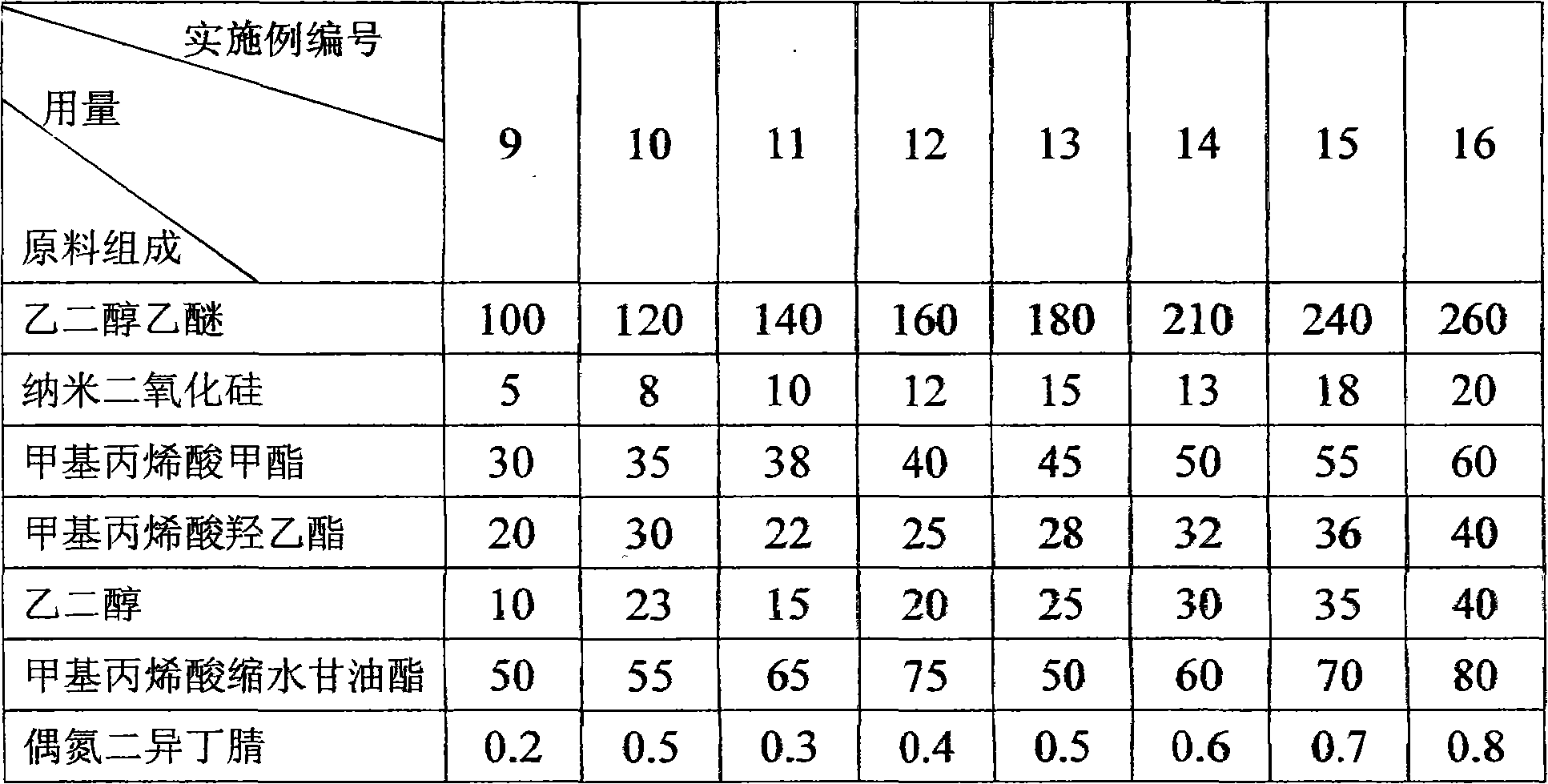

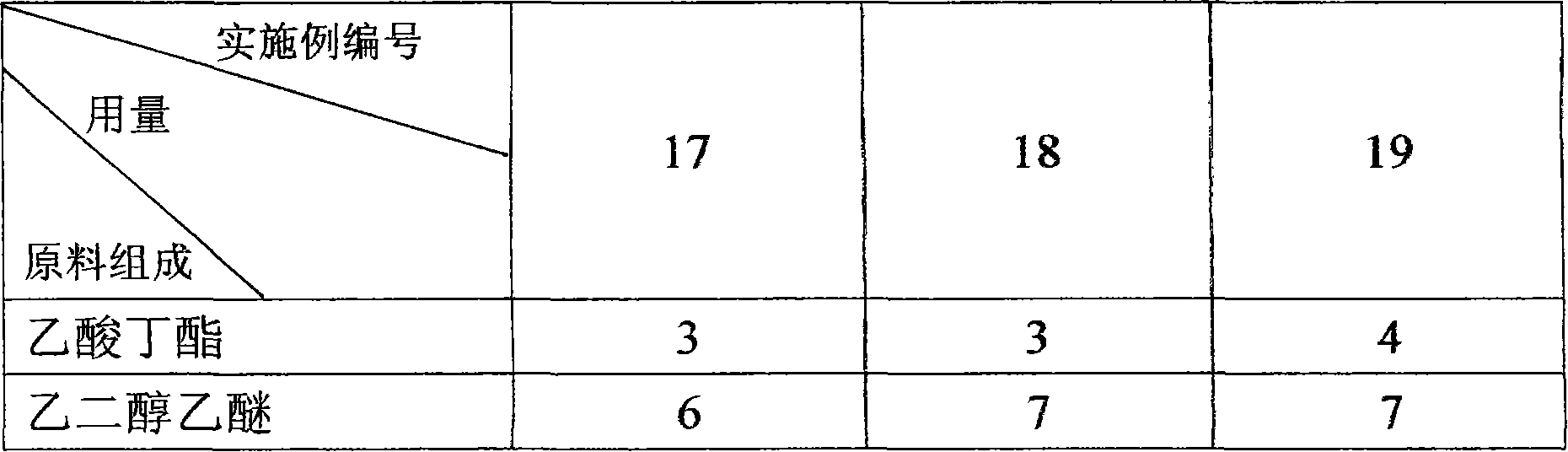

Production method for transparent suboptical polyester film

A preparation method of a transparent matting polyester film is characterized in that 100-260 parts by weight of ethylene glycol ethyl ether is added into a reactor and heated up to 80-100 DEG C for stirring up; 5-20 parts of nano silicone oxide is added and heated up to 125-135 DEG C; then 30-60 parts of methyl metharcrylate, 10-40 parts of ethanediol, 20-40 parts of 2 - hydroxyethyl methacrylate and 50-80 parts of glycidyl methacrylate are added in sequence for uniformly stirring up and introduced with nitrogen, then 0.2-0.8 part of azobisisobutyronitrile is added; the reaction is carried out for 6-8 hours under 80-115 DEG C, so as to obtain a transparent matting acrylic resin; the transparent matting acrylic resin is mixed with solution to obtain acrylic acid transparent matting resin solution; finally, the obtained acrylic acid transparent matting resin solution is coated on polyester film via coating process, thus obtaining the transparent matting polyester film. The film is applicable in heat transfer field, optics, advertisement cartography field, etc.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Contact type automatic ice and snow depth measuring method

InactiveCN1448689AReliable dataEasy to carry on siteMechanical thickness measurementsElectrical/magnetic thickness measurementsPhysical hard workResting time

The automatic ice and snow thickness contact measuring method belongs to ice and snow thickness variance monitoring technology. Two detecting boards are made to face-to-face move automatically and vertically, and the distance between the reference point and the surface of ice or snow is detected to determine the thickness variance of ice or snow. The sensor for measuring the moving distance ofdetecting boards is either rotation speed sensor or magnetostricctive displacement sensor. The stay time for the detecting boards on ice or snow on the ice or snow interface is at most 10 sec to avoid no freezing with the detecting boards staying in reference position in rest time. The interval between two times of automatic measurement is optional in 0-60 min. The present invention can perform automatic in-situ measurement.

Owner:DALIAN UNIV OF TECH

Light leaking prevention liquid crystal display

ActiveCN104391399AChange reflection angleReduce thicknessNon-linear opticsLiquid-crystal displayLight guide

The invention relates to the field of liquid crystal display, in particular to a light leaking prevention liquid crystal display which comprises a liquid crystal panel, a back plate, a middle frame and a rubber frame, wherein the back plate is concave; a reflection piece, a light guide plate and an optical membrane piece are sequentially arranged from bottom to top inside the back plate; the liquid crystal panel is arranged above the optical membrane piece; the middle frame is arranged outside the side surface of the back plate; the rubber frame is T-shaped and is arranged among the liquid crystal panel, the optical membrane piece, the side surface of the back plate and the middle frame; a bent part is arranged outside the side surface of the back plate; an extension part is arranged at the bottom of the middle frame; the vertical distance between one end corresponding to the bottom side of the back plate, of the bent part, and the bottom side of the back plate is equal to the thickness of the extension part; the bent part and the rubber frame are both positioned in an accommodation cavity formed among the back plate, the middle frame and the extension part of middle frame; the bent part and the back plate are integrally formed in a punched manner; the other end of the bent part is higher than the side surface of the back plate; the sum of the thicknesses of the rubber frame and the bent part is equal to the length of the extension part.

Owner:L&T DISPLAY TECH FUJIAN

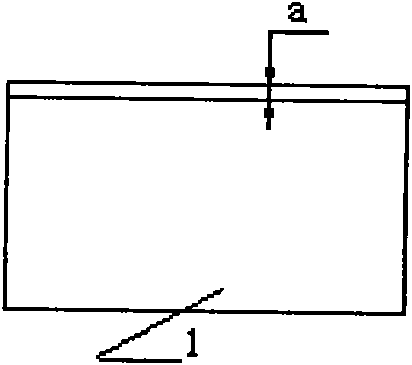

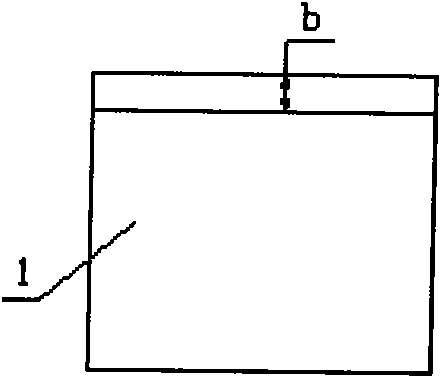

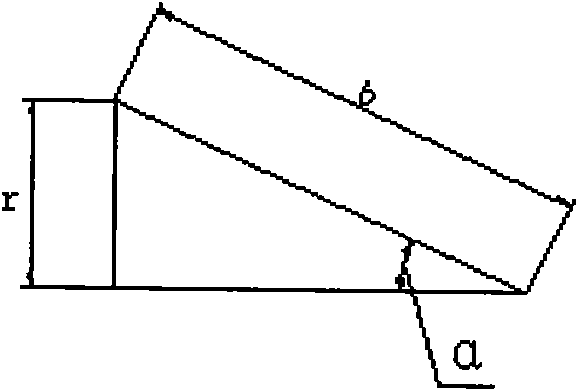

Measuring method for thickness of extremely thin covering layer

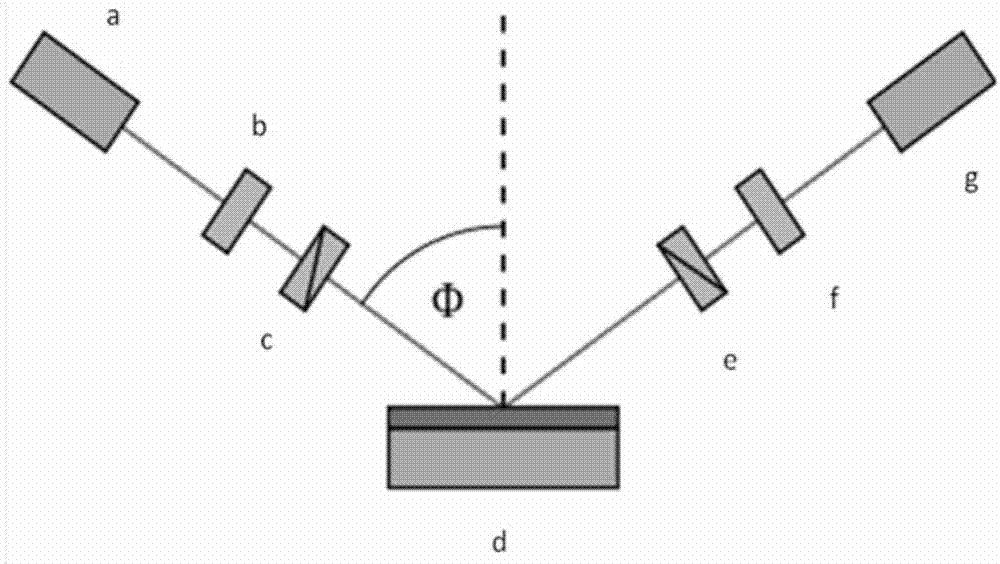

InactiveCN102564326ASufficient measurement accuracyEfficient measurementUsing optical meansOxide coatingAngle alpha

The invention discloses a measuring method for the thickness of an extremely-thin covering layer, comprising the following steps of: sampling in a way of being obliquely crossed with a covering layer on a metallographic specimen, and measuring the thickness value of the specimen through a microspore according to Measuring Methods for Thickness of Metal and Oxide Coating by Microscopical Examination specified in the GB6462-86 standard, wherein a manufacturing method of a specimen matrix comprises the following steps of: intercepting a specimen along an intercepting surface vertical to the covering layer to obtain a section as a detected surface, and measuring the thickness value a of the detected surface; and intercepting a detection amplifying surface on a surface obliquely crossed with the surface of the covering layer to form an included angle alpha, and measuring the thickness value b of the detection amplifying surface; and finally, obtaining a measured value delta=bsinalpha.

Owner:AVIC STANDARD PARTS MFG

Composite nuclear track membrane and preparation method thereof

ActiveCN104001429AImprove surface hydrophilicityHigh mechanical strengthSemi-permeable membranesPolyesterVolumetric Mass Density

The invention discloses a composite nuclear track membrane and a preparation method thereof. The composite nuclear track membrane comprises a polyester nuclear track membrane or a polycarbonate nuclear track membrane, wherein a porous cellulose acetate membrane is composited on one surface of the polyester nuclear track membrane or the polycarbonate nuclear track membrane so as to form the composite nuclear track membrane of which the thickness is 67-160 microns, the aperture of the polyester nuclear track membrane or the polycarbonate nuclear track membrane is 1-10 microns, the pore density of the polyester nuclear track membrane or the polycarbonate nuclear track membrane is 2*10<5> / cm<2>-2*10<7> / cm<2>, and the thickness of the polyester nuclear track membrane or the polycarbonate nuclear track membrane is 7-25 microns. The composite nuclear track membrane has the advantage that the surface hydrophilicity is good, the mechanical strength is high, the membrane thickness is moderate, the automatic operation can be realized easily, the flux of the filtering liquid is high, and the assimilative capacity is strong; the composite membrane is an integer, is not layered and is suitable for fabricating roll type filter cores; the porous cellulose acetate membrane composited on the nuclear track membrane is taken as a pre-filtering layer or a support layer of the nuclear track membrane, so that the problems about mechanical strength and thickness of the membrane are solved, and meanwhile, the a pre-filtering problem of the membrane is solved.

Owner:天津理源科技有限公司

Method for preparing nanometer flake silver powder through chemical deposition

The invention discloses a method for preparing nanometer flake silver powder through chemical deposition, which comprises the following steps that firstly, soluble resin is applied to a substrate, then a nanometer silver film is deposited on the substrate through the chemical deposition, an organic solvent is adopted to dissolve the resin layer, the silver film is changed into coarse flake silver powder which is pulverized by a high-energy ultrasonic instrument, and then the nanometer thin flake silver powder is obtained. The obtained nanometer flake silver powder has the characteristics of smooth surface, uniform thickness, controllable granularity and the like. According to the method, the nanometer flake silver powder is prepared on the basis of the chemical deposition, the defects of rough surface, nonuniform thickness and the like of the flake silver powder prepared by using a mechanical ball milling method are overcome, and the method disclosed by the invention can be applied to the industry of electronic paste.

Owner:SUN YAT SEN UNIV

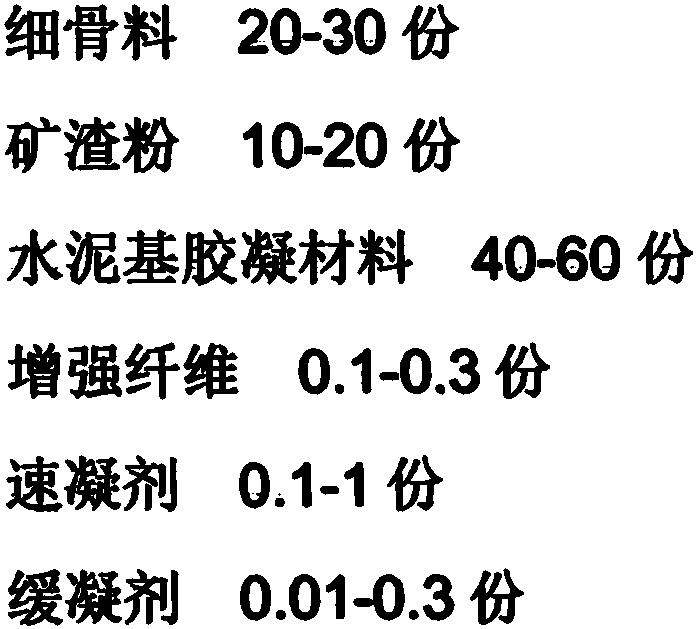

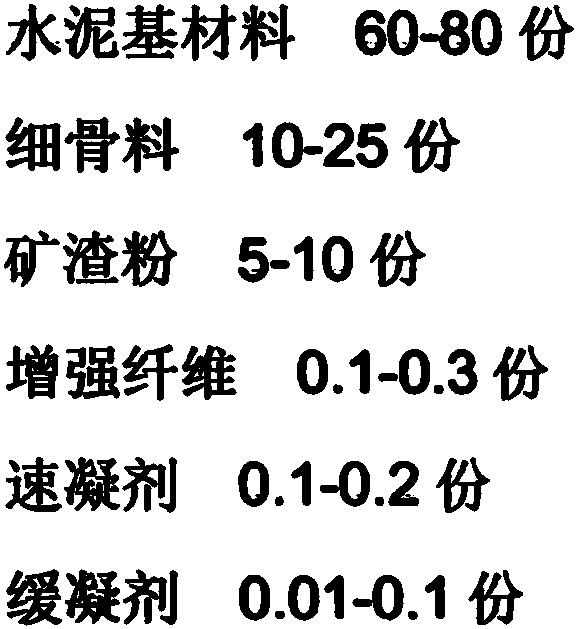

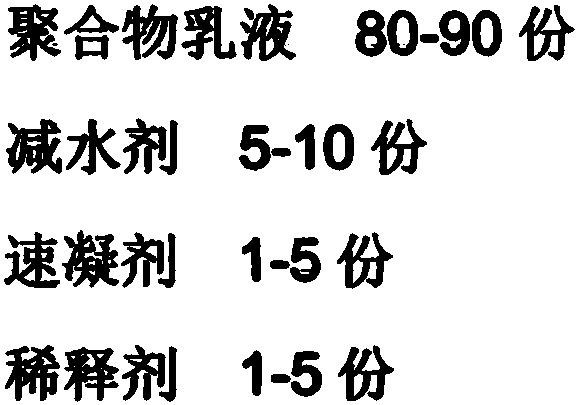

Flexible spraying material for mine laneway supporting and preparation method and application of flexible spraying material

ActiveCN111533518ANon-volatileEfficient use ofUnderground chambersTunnel liningSlagHazardous substance

The invention relates to a flexible spraying material for mine roadway support and a preparation method and application of the flexible spraying material, and belongs to the technical field of mine roadway supporting. The slag-based anchoring and shotcreting support guniting material prepared by the method is an organic-inorganic hybrid material and does not volatilize harmful substances and is safe and environment-friendly; a slag doped guniting material is adopted so that effective utilization of slag is developed, secondary pollution is relieved, and the cost is reduced; vertical face and top face spraying construction does not flow, the construction environment is friendly, and any springback and dust pollution problems are avoided; the curing temperature is low, and the flame-retardant property is realized.

Owner:赣州创可通科技有限公司

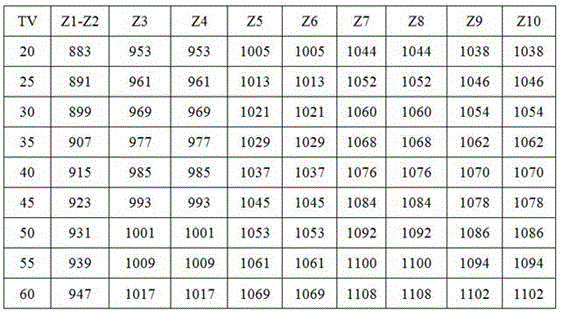

Duplex stainless steel cold rolling annealing and pickling process

ActiveCN105586600AHigh glossSolve the problem of black bandsFurnace typesHeat treatment furnacesElectrolysisSS - Stainless steel

The invention discloses a duplex stainless steel cold rolling annealing and pickling process and belongs to the technical field of duplex stainless steel smelting. The process comprises the following steps: respectively connecting stainless steel rolls with annealing temperature approximating to the annealing temperature of duplex stainless steel to the front end and the rear end of the duplex stainless steel; setting process speed, calculating TV value according to the thickness and the process speed of the steel rolls, setting the hearth temperature of each region according to the TV value and carrying out annealing on the steel rolls; and then carrying out Na2SO4 electrolysis, HNO3 electrolysis, scrubbing, pickling with mixed acid and washing with desalted water on the stainless steel rolls after annealing, and finally cutting off the stainless steel rolls at the front end and the rear end of the duplex stainless steel roll, thus obtaining the duplex stainless steel roll finished products. According to the invention, by using proper annealing and pickling processes, the problems that black strips appear on the rear surface of the duplex stainless steel after pickling and width shrinking and thickness reduction are easy to cause are solved, an oxidation film on the surface of the duplex stainless steel is completely removed, the surface glossiness of the steel rolls is high, and the quality requirements of products can be met.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Flexible spraying material for tunnel roadway support and preparation method and application thereof

The invention relates to a flexible spraying material for tunnel roadway support and a preparation method and application thereof, and belongs to the technical field of tunnel roadway support. Vertical face and top face spraying construction does not flow, the construction speed is high, the construction environment is friendly, and any springback and environmental pollution problems are avoided;a spraying material can be subjected to long-distance spraying construction through conventional spraying equipment, the safety distance of manual operation is long, the time is short, and the construction process is safer and more reliable; and the material curing speed is high, the tensile strength and the bonding strength are increased rapidly, the problems that a guniting layer is large in thickness, prone to falling off and cracking and needing to be maintained repeatedly are solved, and the technology is particularly suitable for supporting and reinforcing, air leakage preventing and water leakage preventing treatment of key positions of tunnels or positions where surrounding rock is seriously broken.

Owner:赣州创可通科技有限公司

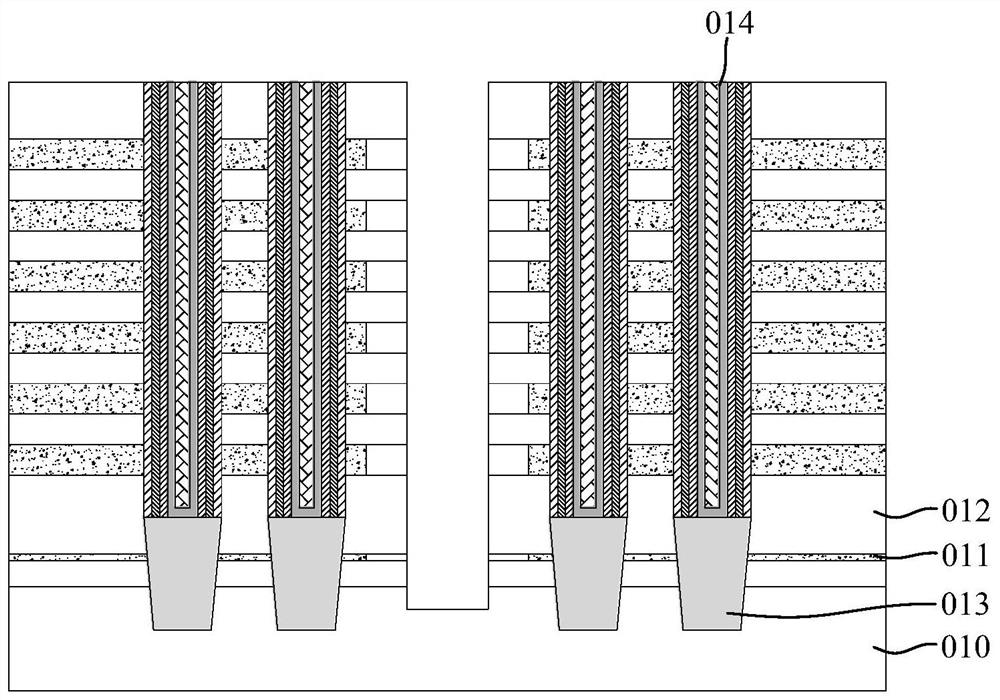

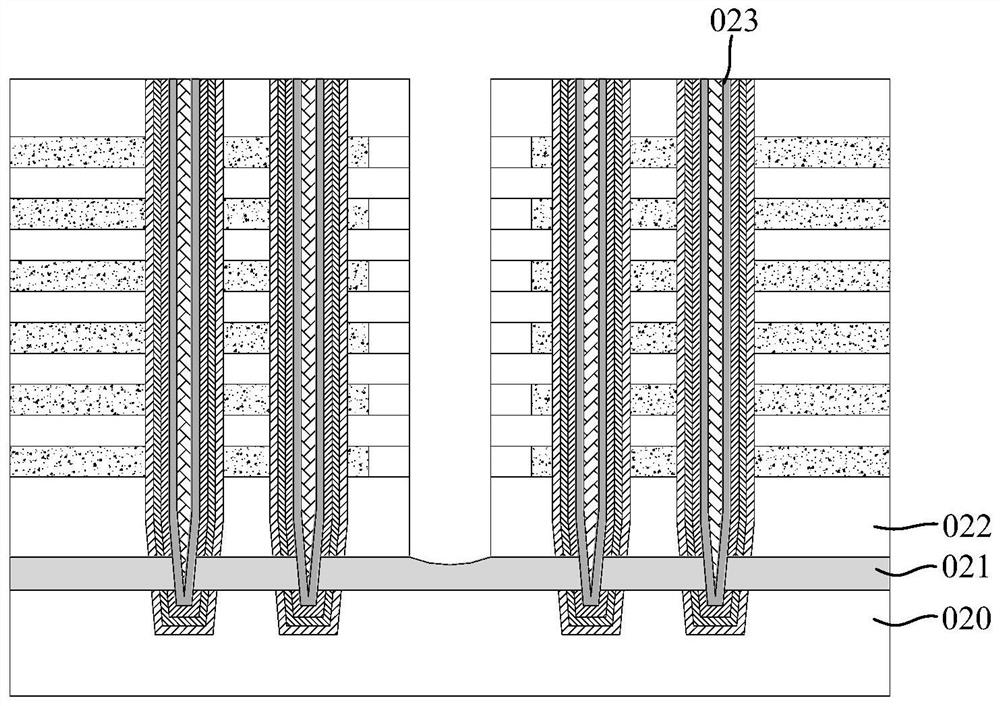

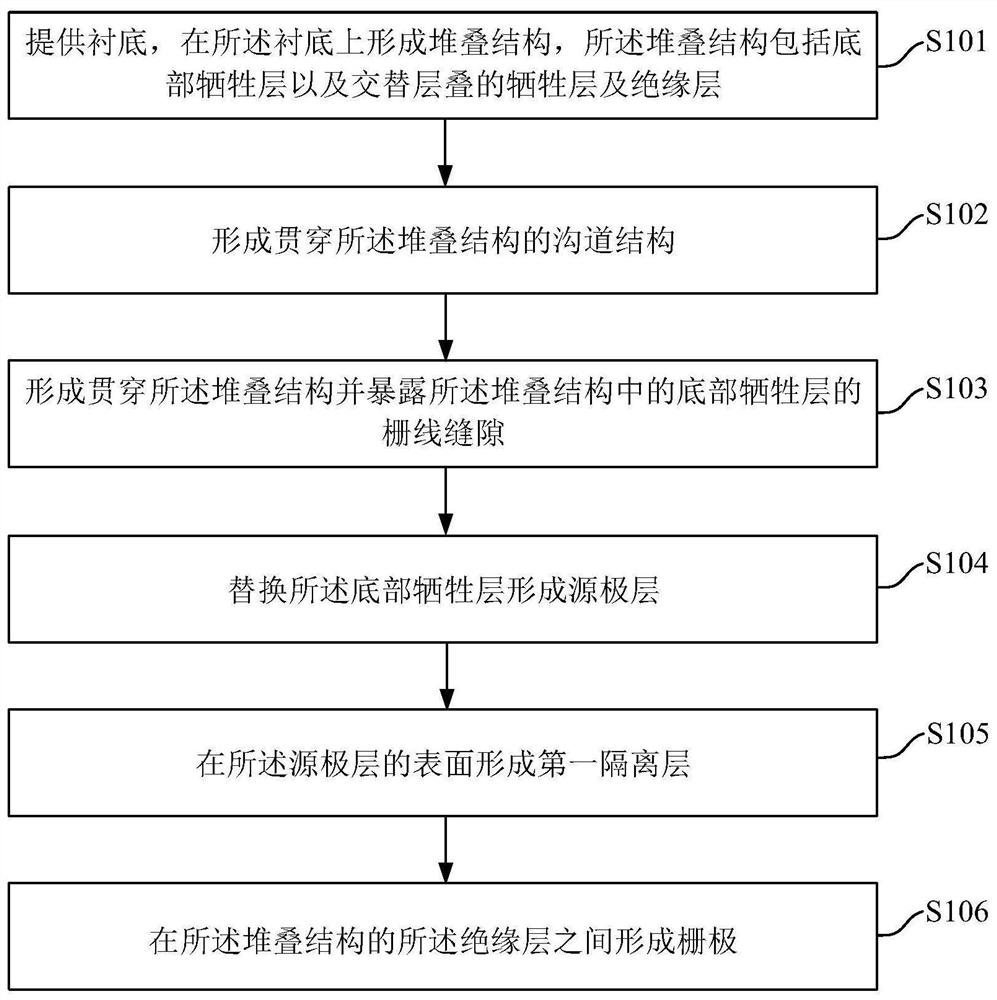

3D NAND memory and manufacturing method thereof

ActiveCN111627918AImprove uniformityUniform inversionSolid-state devicesSemiconductor devicesPhysicsComposite material

The invention provides a 3D NAND memory and a manufacturing method thereof. According to the method, a stacked structure comprising a bottom sacrificial layer, sacrificial layers and insulating layersis formed on a substrate, the sacrificial layers and the insulating layers are alternately stacked on the bottom sacrificial layer, the bottom sacrificial layer is replaced with a source electrode layer, oxidation treatment is conducted on the source electrode layer, a first isolation layer is formed on the surface of the source electrode layer, and the function of selecting gate oxide on the back is achieved. The method facilitates control over thickness of the first isolation layer and improves the uniformity of the first isolation layer, so that uniform inversion of the source electrode layer is facilitated, and an electronic channel is ensured in read-write operation of the memory. The problems in the thickness and uniformity of the source electrode layer caused by the thickness problem of the back selection gate oxide layer are solved, and the continuity of a P-type trap and supply of holes in the erasing process can be realized. The source electrode layer is formed in the channel structure in the stacking direction at the same time, the contact area of the source electrode layer and the channel layer is increased, and electrical connection between the source electrode layerand the channel layer is enhanced.

Owner:YANGTZE MEMORY TECH CO LTD

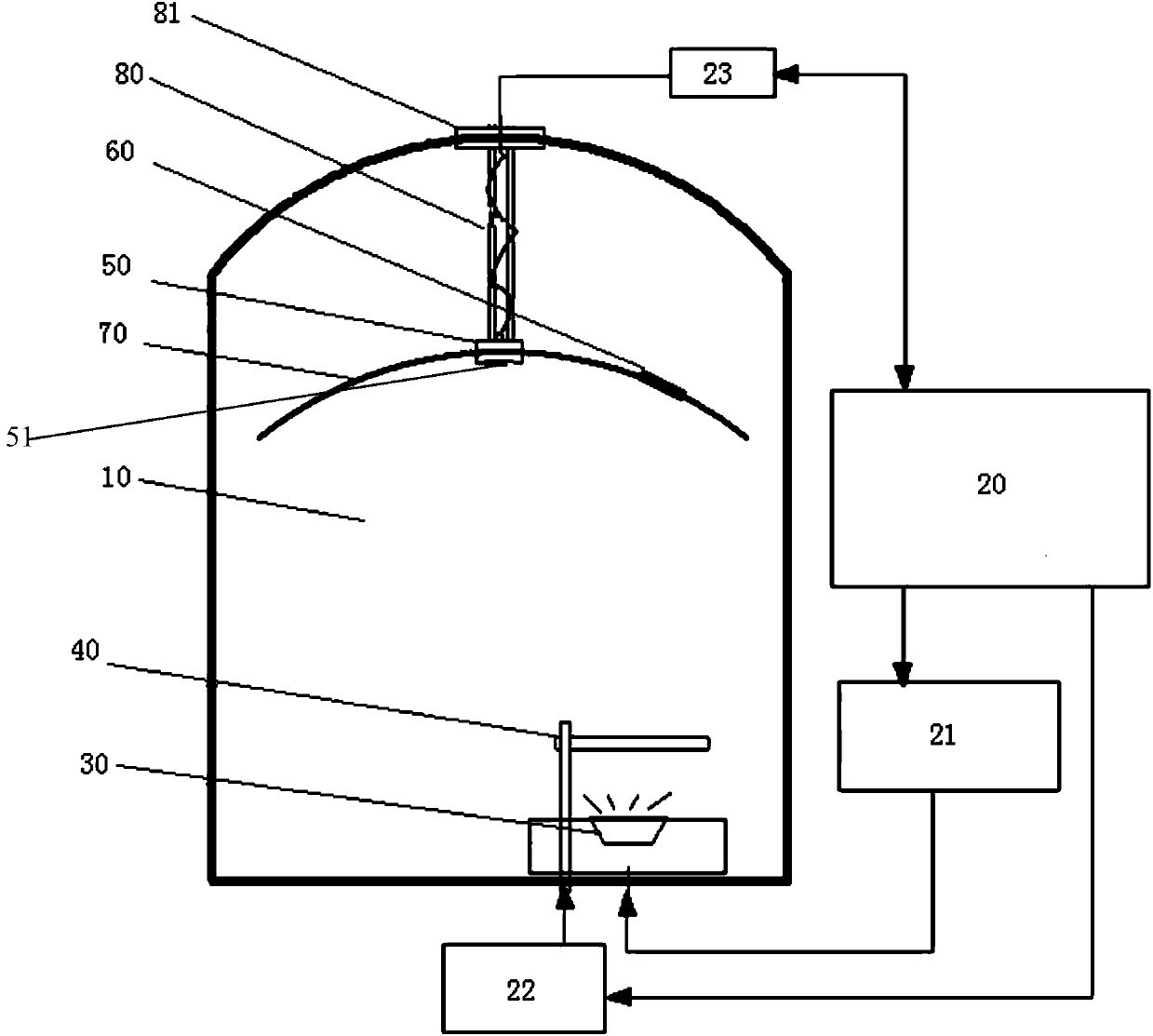

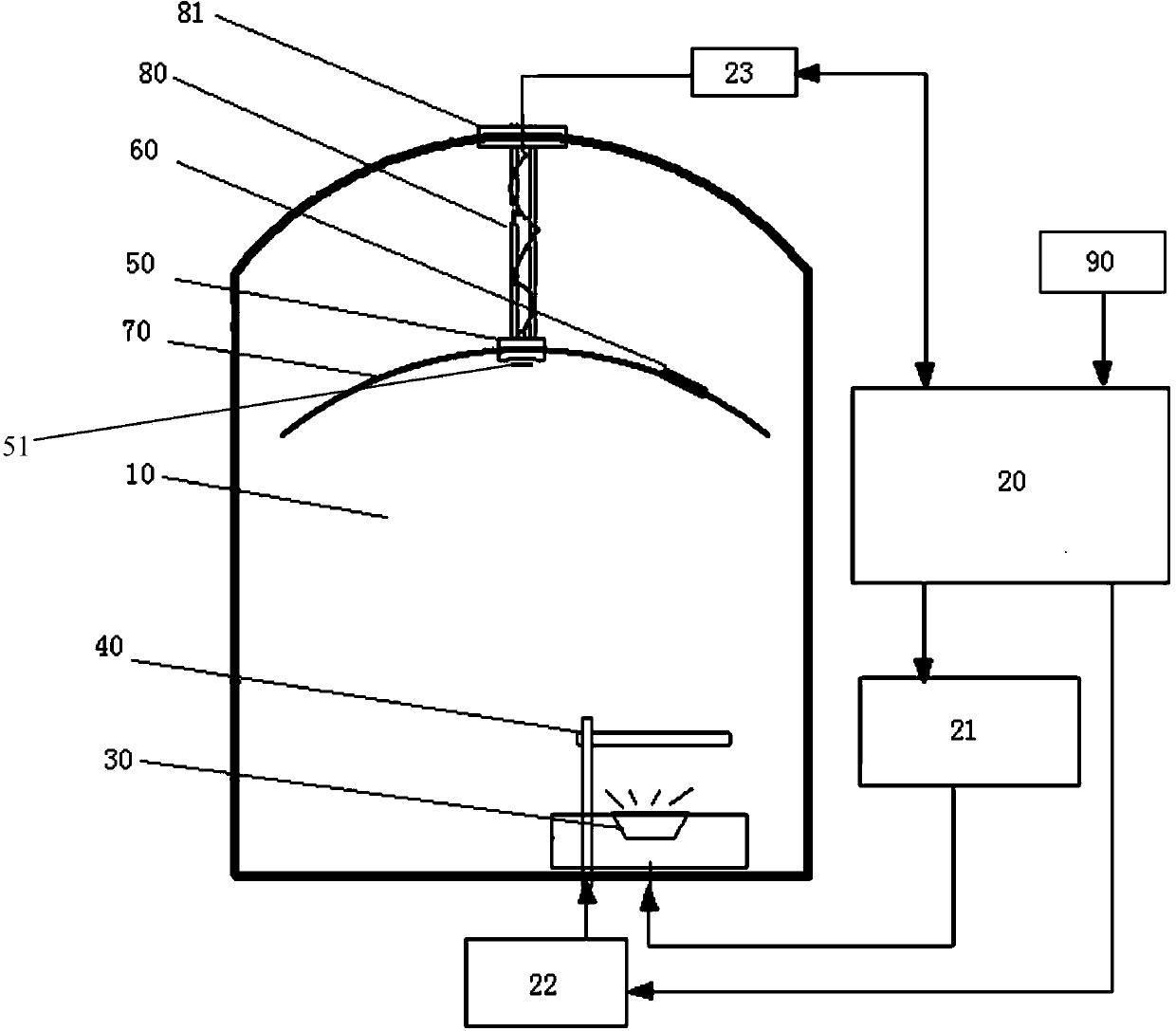

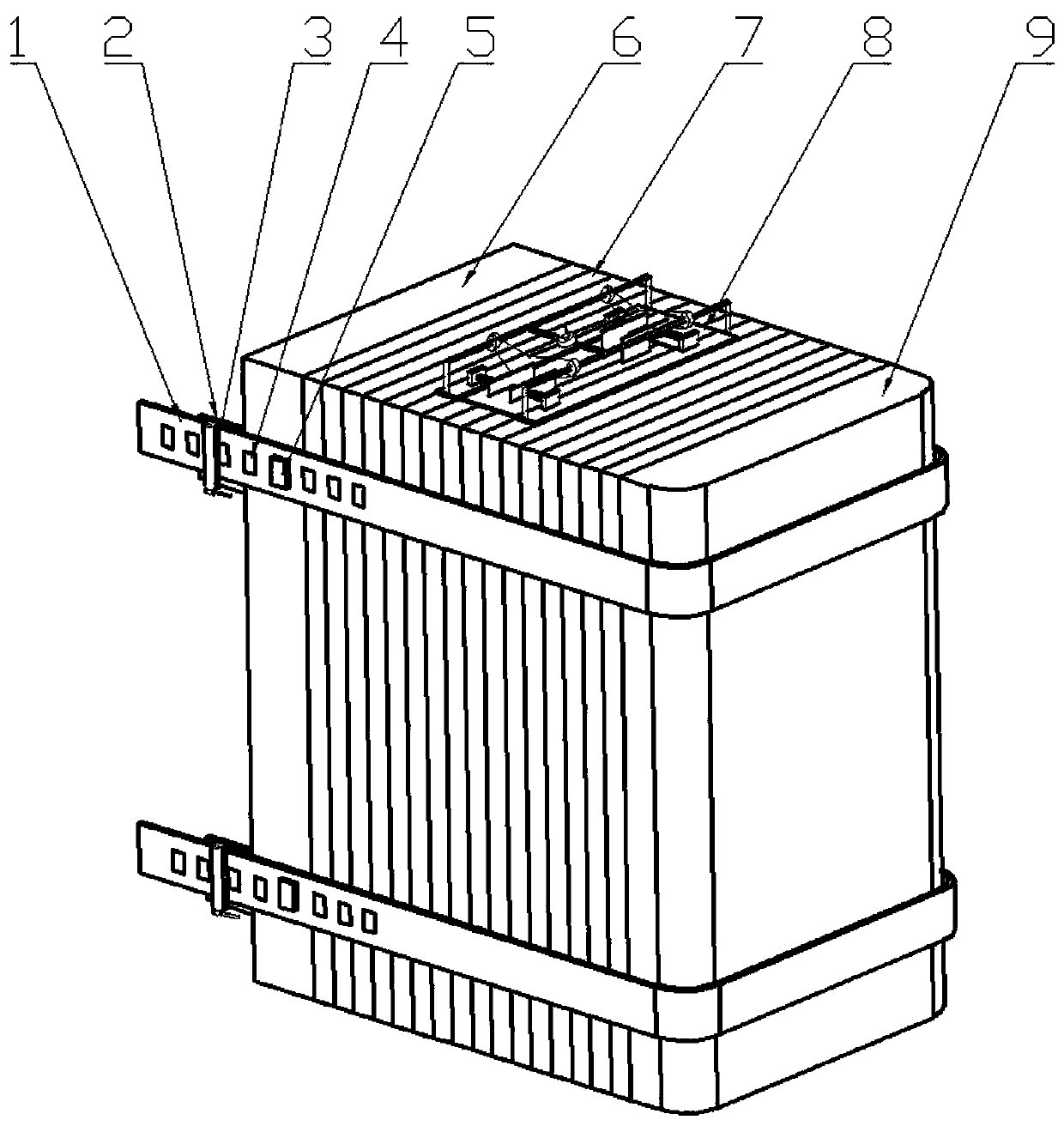

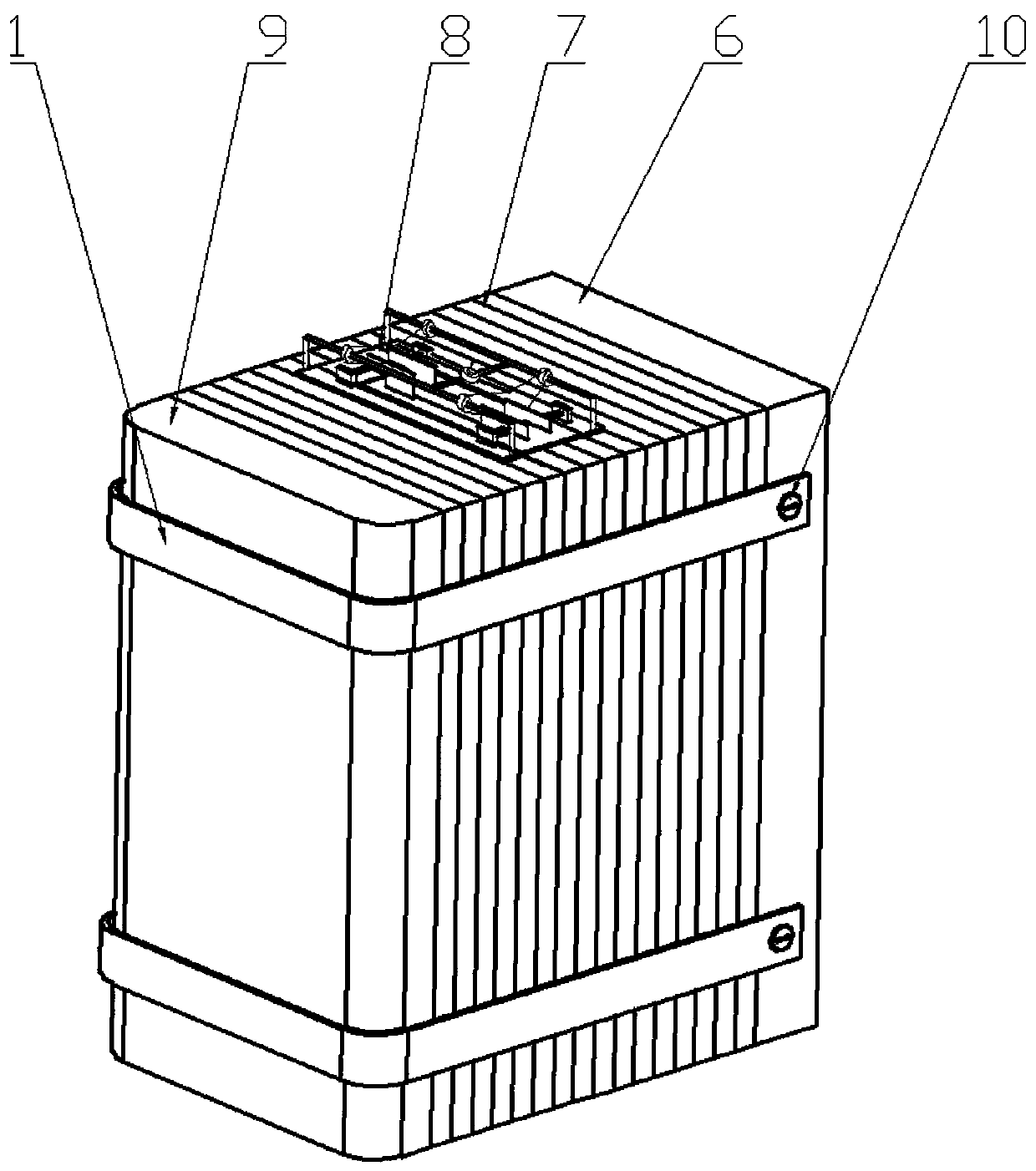

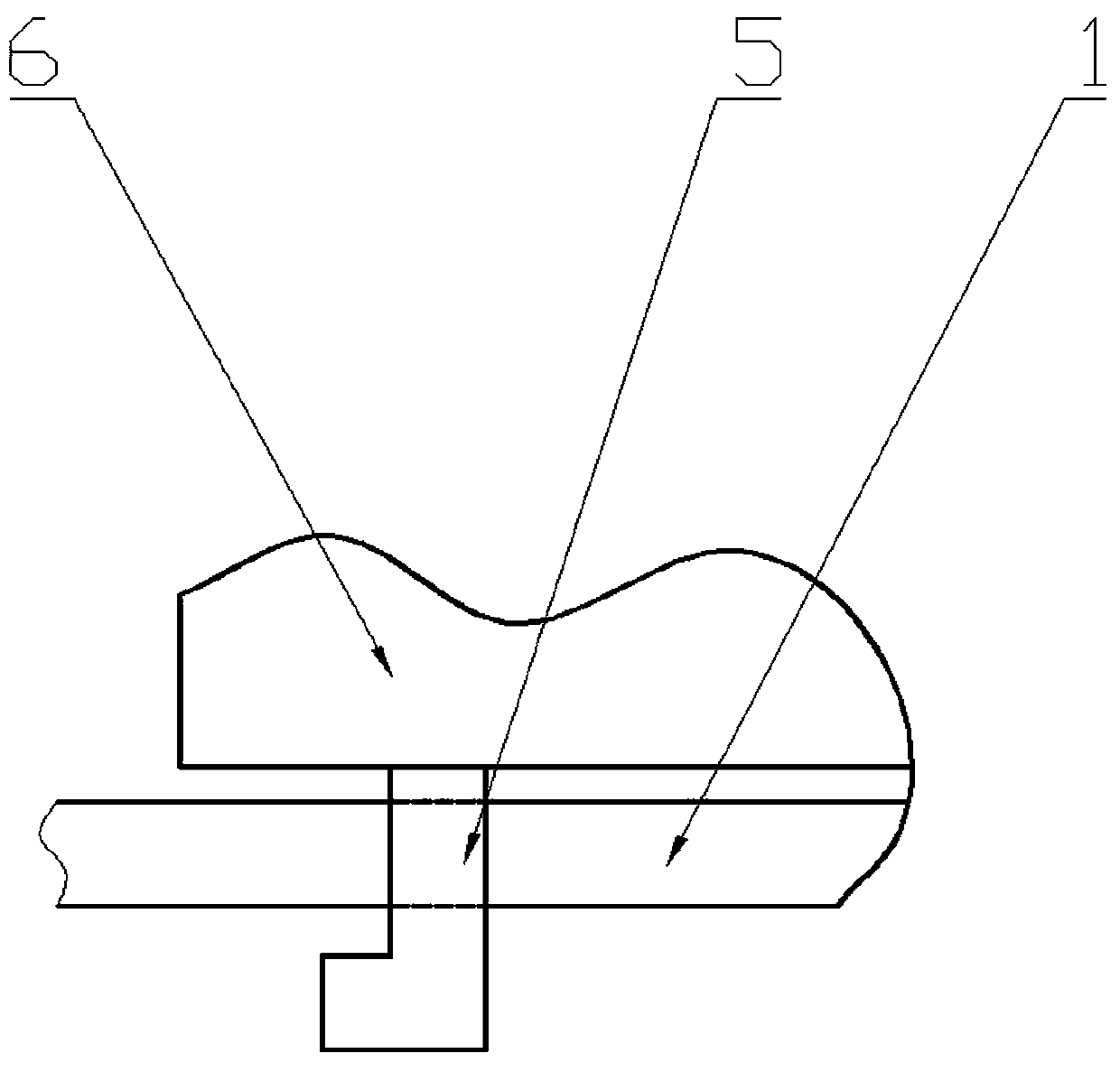

Fuel cell stack bandage type pressing assembly structure and design method thereof

PendingCN110190313AImprove uniformityWith compressed supplementFinal product manufactureFuel cellsFuel cellsCurrent distribution

The invention relates to a fuel cell stack bandage type pressing assembly structure and a design method thereof and belongs to the technical field of fuel cells. The structure comprises multiple fuelcells. A main end plate is arranged at one end of the fuel cells and an auxiliary end plate is arranged at the other end of the fuel cells. A plurality of compression belts are arranged between the outer wall of the main end plate and the outer wall of the auxiliary end plate. A fixing screw in threaded connection and fixation with the main end plate is arranged between one end of each compressionbelt and the outer wall of the main end plate. A hook pin fixedly connected with the main end plate in a clamped and embedded mode is arranged between the other end of each compression belt and the outer wall of the main end plate. A plurality of belt holes are formed in the compression belts. A plurality of gap adjusting springs are arranged between the auxiliary end plate and the fuel cells, and spring gaskets are arranged between the gap adjusting springs and the auxiliary end plate. The assembly structure has the advantages of compact structure, compression supplement, high sealing performance, uniform current distribution, easiness in assembly and maintenance and long service life. The repeatability of the assembly structure is improved, and the structural pressure uniformity is improved. The influence of manufacturing tolerance and change of raw material size on the structural size precision is avoided.

Owner:众泰新能源汽车有限公司

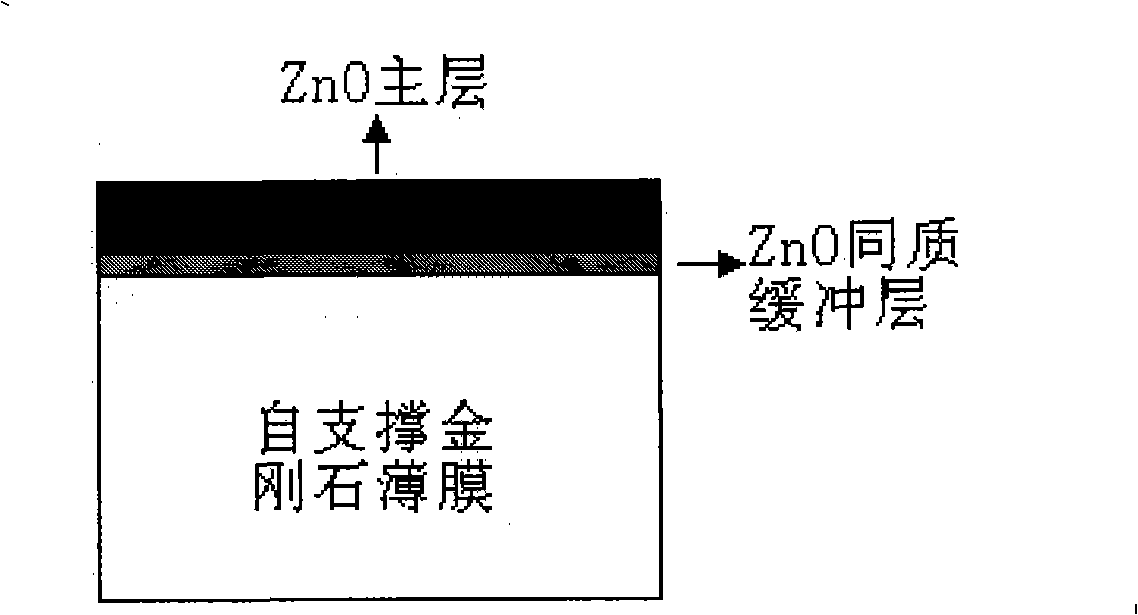

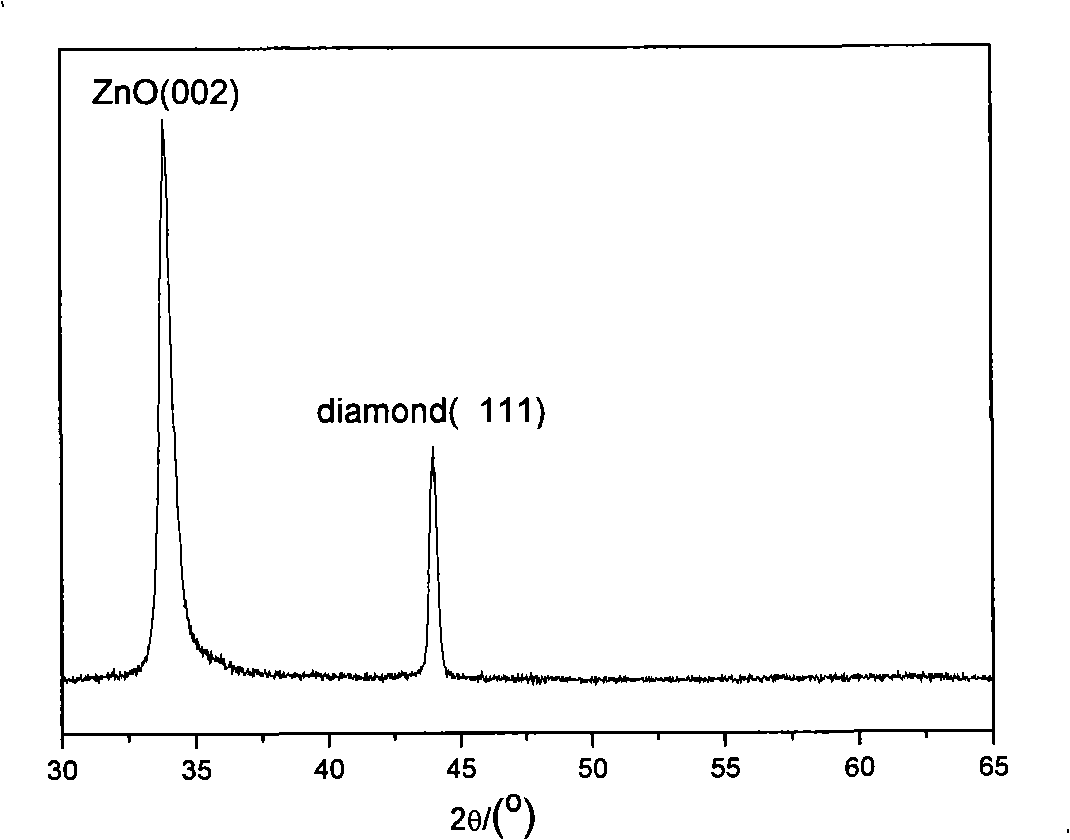

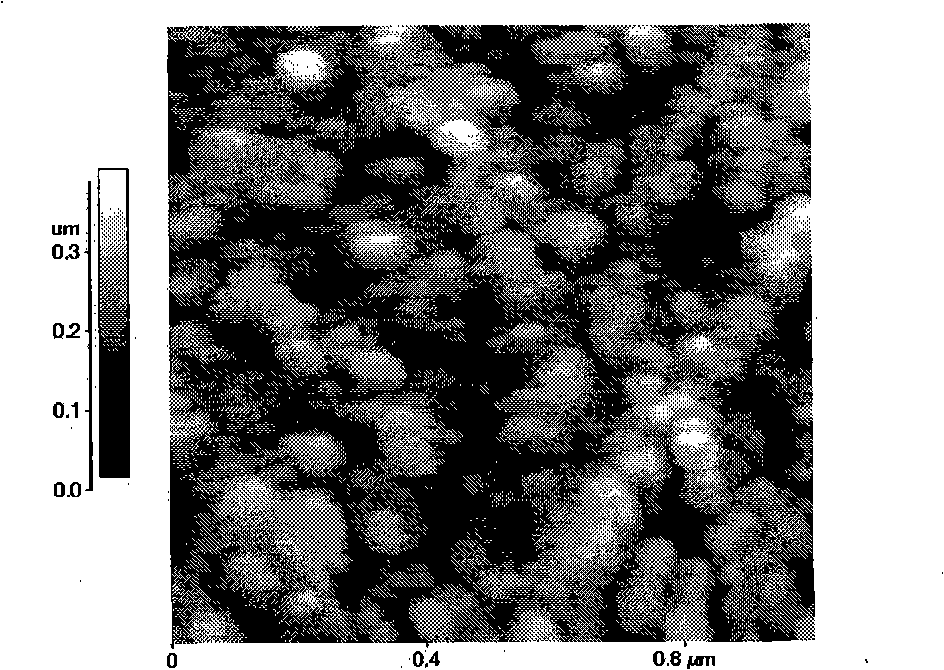

Method for preparing high quality ZnO film using cushioning layer

InactiveCN101323971ASolve Thickness ProblemsHigh crystallinityPolycrystalline material growthFrom chemically reactive gasesGas phaseDirect current magnetron sputtering

The invention relates to a method that prepares a high-quality ZnO film by utilizing a buffer layer, which comprises following main steps: a silicon substrate is preprocessed and placed into a reaction chamber of a hot filament chemical vapor depositing device as a deposited substrate; nucleation and growth of a diamond film are implemented in mixed reaction gases of hydrogen and acetone, and the silicon substrate is soaked and rusted in a mixed solution of HNO3 and HF, thus forming the self-supporting diamond film; the ZnO film is prepared on the self-supporting diamond film by the direct current magnetron sputtering method, the ZnO buffer layer is firstly sputtered and deposited in Ar and O2, and then a ZnO main layer is deposited. The method that prepares the high-quality ZnO film has simplified techniques and low cost and is favor for promoting large-scale application of high-quality ZnO film devices. The produced ZnO film has small crystal grain size, high crystal quality and low surface roughness.

Owner:SHANGHAI UNIV

Process for producing conductive cloth

InactiveCN1408897AProcess system is stableNo dustingVacuum evaporation coatingSputtering coatingFiberMetallurgy

The conductive cloth producing process is one physical vapor deposition process. Continuous fiber fabric is made to pass through a serial technological process inside a vacuum equipment so that single or multiple sputtered metal film is formed on th fabric. The said process can producing conductive cloth with metal layer bonding to fiber fabric firmly continuously and in large scale.

Owner:长沙鑫邦工程新材料技术有限公司

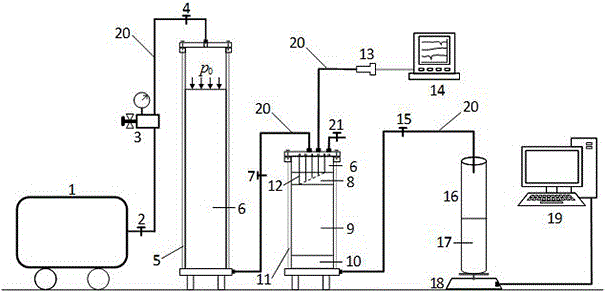

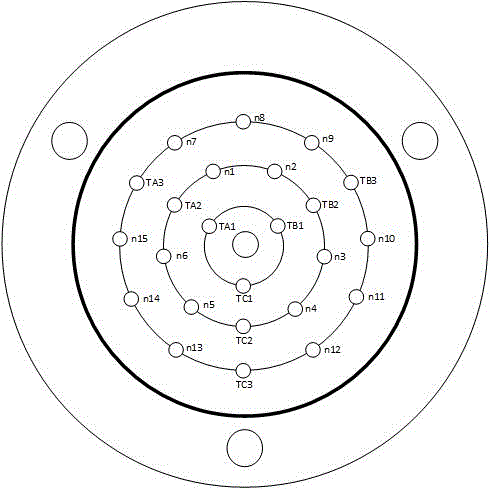

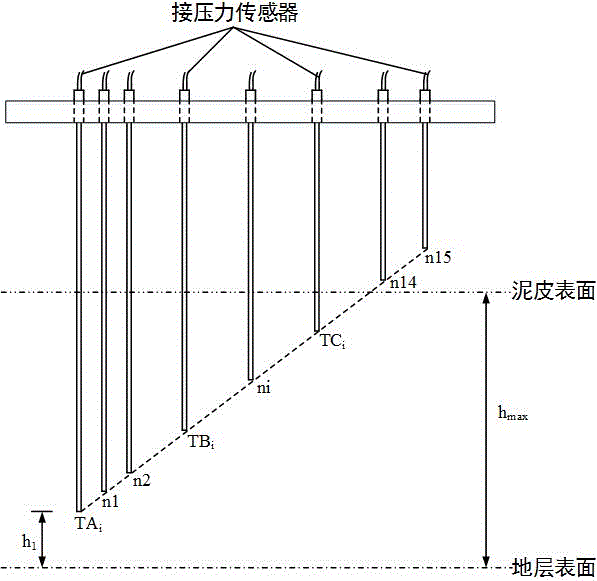

Slurry shield model test mud cake thickness real-time measurement device and measurement method

ActiveCN106153862ASolve Thickness ProblemsSolve real-timePreparing sample for investigationEarth material testingMeasurement deviceGraduated cylinder

The invention provides a slurry shield model test mud cake thickness real-time measurement device which structurally comprises an air compressor, a valve A, a pressure regulating valve, a valve B, a sludge barrel, sludge, a valve C, a glass barrel, a valve D, a measuring cylinder, filtrate, an electronic balance, a computer, hoses and a valve E, wherein the air compressor is connected with the sludge barrel through the hoses, the valve A, the pressure regulating valve and the valve B, the sludge barrel is connected with the glass barrel through the hoses and the valve C, the glass barrel is connected with the measuring cylinder containing the filtrate through the hoses and the valve D, the measuring cylinder is placed on the electronic balance, the electronic balance is connected with the computer through a serial data cable, the valve E is connected with the glass barrel, and the sludge is placed in the sludge barrel. A real-time measurement method includes the steps: (1) preparing the sludge, a stratum layer and a filter layer; (2) measuring the thickness of a mud cake in real time. The device has the advantage that the thickness of the mud cake can be measured by probe pressure in real time conveniently and accurately.

Owner:NANJING FORESTRY UNIV

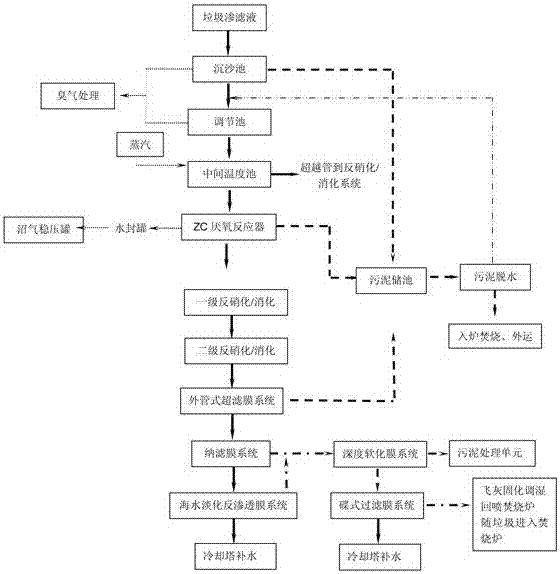

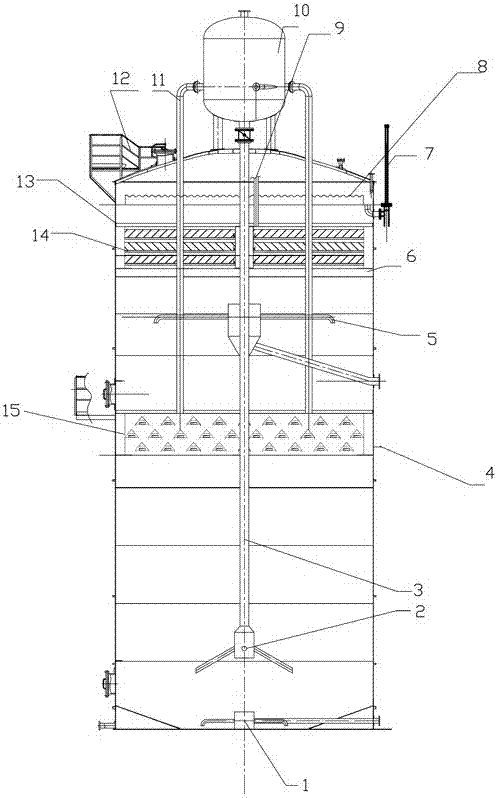

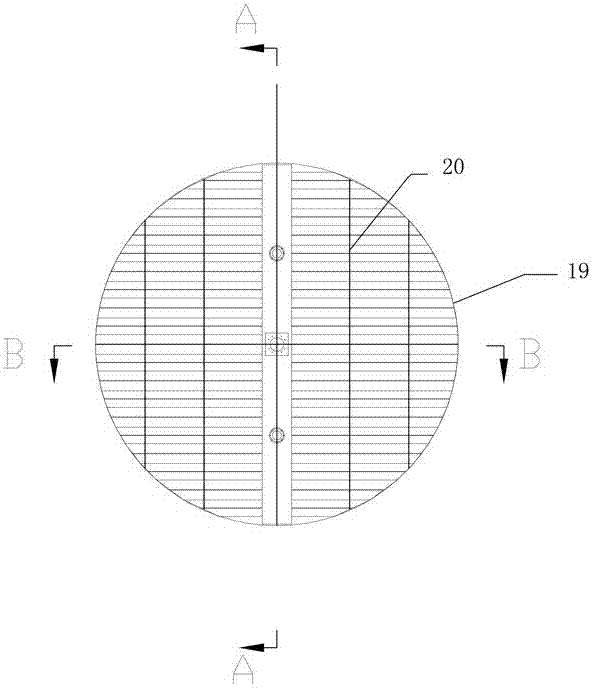

Leachate treatment method of waste incineration power station

InactiveCN107200440AIncrease water production rateGuaranteed normal consumptionWater treatment parameter controlGeneral water supply conservationAnaerobic decompositionAnaerobic reactor

The invention discloses a leachate treatment method of a waste incineration power station. The leachate treatment method comprises the following steps: 1) introducing the waste incineration leachate into a sand settling pond, and preprocessing the waste incineration leachate to remove a great amount of settled sand in sewage; 2) introducing the leachate into a regulating pond, tempering the leachate, so that the PH of the inlet water of the sewage is kept at 5 to 6 in 2 days; 3) enabling the leachate to enter an intermediate temperature pond, introducing steam to adjust the temperature to be between 35 DEG C and 39 DEG C, and homogenizing the sewage temperature by virtue of a stirrer in the intermediate temperature pond; 4) introducing the incineration waste leachate after being processed in the intermediate temperature pond to have anaerobic decomposition, decomposing and converting various complex organic matters into marsh gas, so that the incineration waste leachate is primarily purified; 5) carrying out the denitrification / nitrification treatment; and 6) filtering. By adopting the leachate treatment method, the water yield of a leachate treatment system in the waste incineration power station, the residual concentrated liquid can be ensured to be completely consumed in the waste incineration power station, and the emission of the concentrated liquid can be prevented from severely polluting the environment.

Owner:佛山市银禾工业设计有限公司

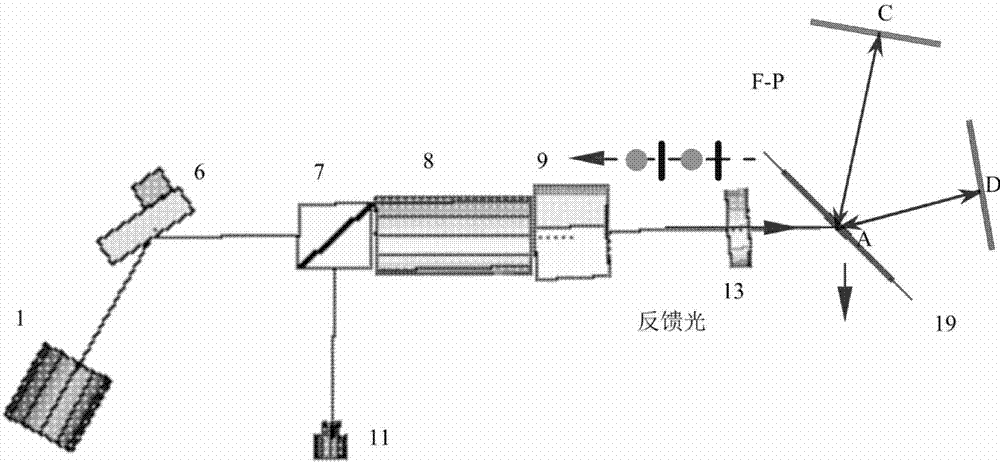

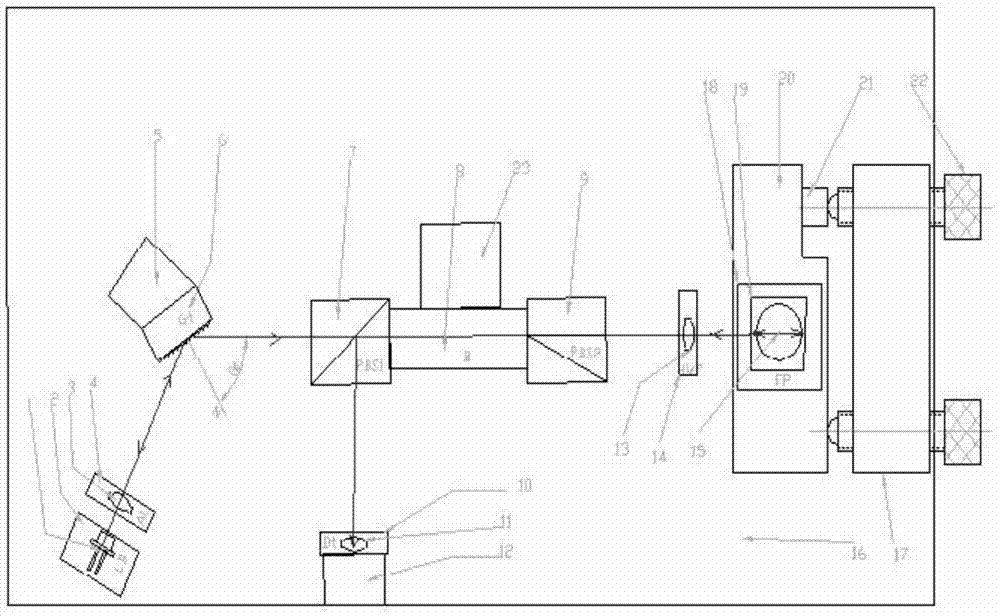

Apparatus for measuring film thickness and refractive index in medium

InactiveCN103759661ASolve Thickness ProblemsSolve the measurement problem of refractive indexPolarisation-affecting propertiesUsing optical meansRefractive indexOptical measurements

The invention, which belongs to the technical field of optical measurement, relates to an apparatus for measuring a film thickness and a refractive index in a medium. After being emitted by a semiconductor diode is collimated by a non-aspheric surface collimating lens, light enters a diffraction grating by an incident way at a certain angle and is diffracted by the diffraction grating; the first-stage diffraction light is reflected back by the same route; the zero-stage diffraction light passes through a detachable optoisolator and a half wave plate and then enters an F-P cavity by an incident way to form optical feedbacking; the feedback light successively passes through a second PBS and a first PBS and then is detected by a PD detector; and the detected light is displayed by an oscilloscope to realize detection of the feedback light intensity and the spectral characteristic. According to the invention, a problem of measurement of the film thickness and refractive index in medium can be solved; and the measurement precision is substantially improved. Moreover, the apparatus can be operated simply and stably.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

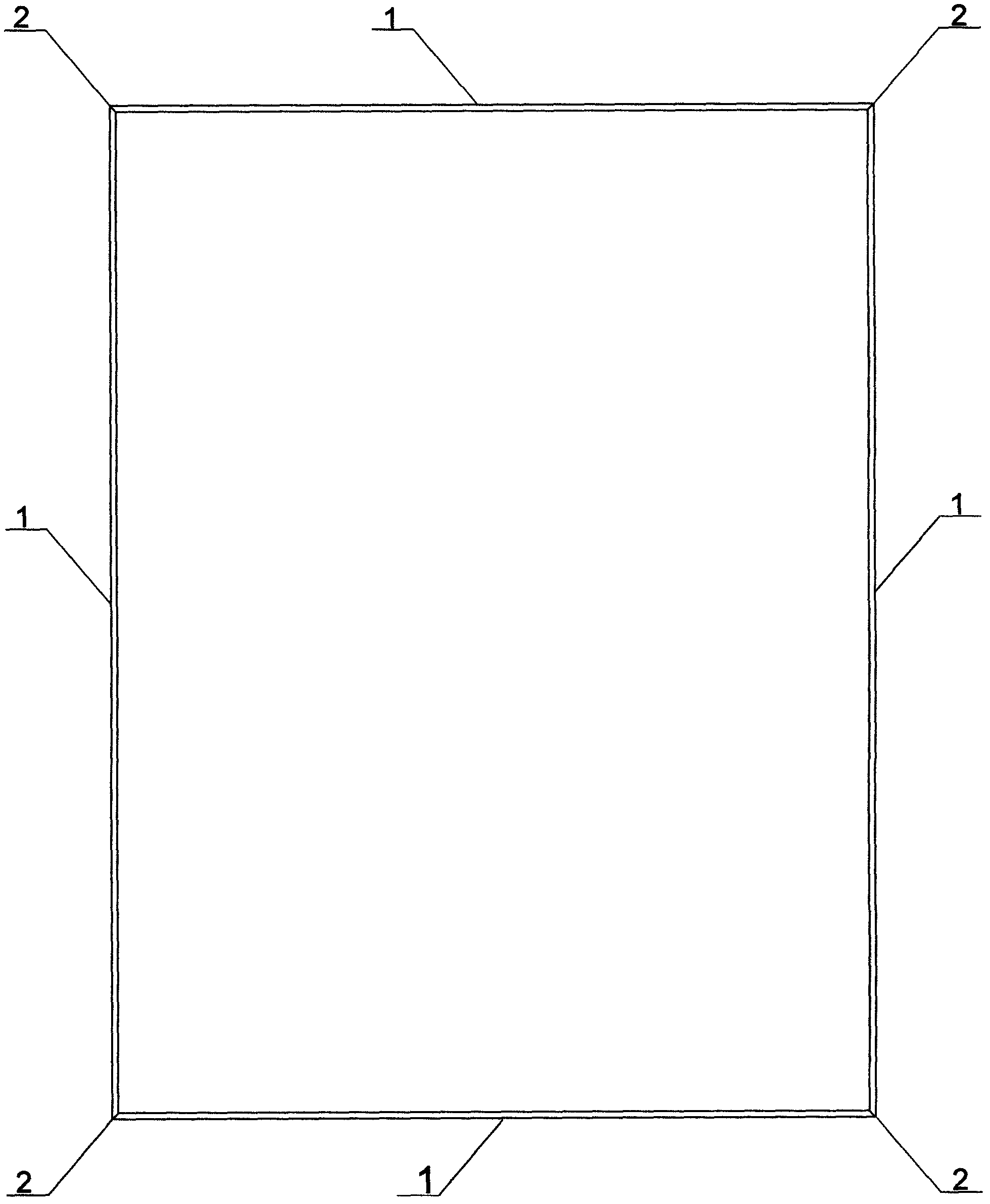

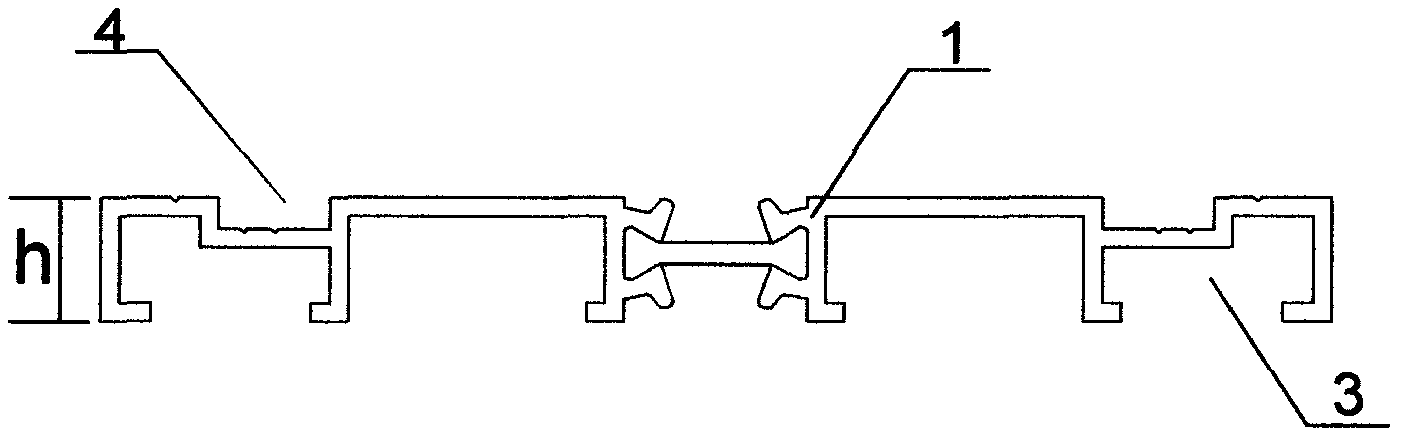

Thin combined installation door and window auxiliary frame

ActiveCN103573111ASolve the strength problemSolve Thickness ProblemsWindow/door framesPush pullAlloy

The invention discloses a thin combined installation door and window auxiliary frame which is made of metal or plastic profiles and has a bridge-breaking heat insulation type and an ordinary type, wherein each type has a push-pull mode and a sliding mode. The auxiliary frame is in a shape of double Es, the thickness of the auxiliary frame is larger than 4mm and smaller than 15mm, wall fixing screws and angle steel fixing screw grooves are arranged on the surface of the auxiliary frame, and an angle steel groove and angle steel are arranged on the back surface of the auxiliary frame. The auxiliary frame is provided with a standard seat frame for supporting the installation of the auxiliary frame, wherein the seat frame is made of aluminum alloy or metal profiles and has an adjustable mode and a fixed mode. Clamping rods, clamping hooks, horizontal correction devices, vertical correction devices, sill concentric correction devices and rulers are arranged on the seat frame. In installation, the auxiliary frame is fixed on the seat frame through the screws, the seat frame is installed in a door and window hole to be clamped tightly, correction is performed through a correction device, a wall horizontal inked line and a wall vertical inked line, hard plastic gaskets are wedged the back surface of the auxiliary frame tightly, the auxiliary frame is fixed on the wall through two lines of screws, the seat frame is dismantled, cement mortar is filled in slits between the frame and the wall, and a firm standard door and window auxiliary frame is formed after the cement mortar is coagulated.

Owner:HUIZHOU BAINIAN FANGZHENG ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com