Duplex stainless steel cold rolling annealing and pickling process

A technology for cold rolling, annealing, pickling, and duplex stainless steel. It is used in manufacturing tools, furnace types, and furnaces. , stabilize the annealing temperature, and improve the effect of pickling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A cold-rolled hard state 2205 duplex stainless steel annealing and pickling process with a thickness of 1.0mm comprises the following steps:

[0026] a. Connect 304 austenitic stainless steel coils to the front and rear ends of the duplex stainless steel coils;

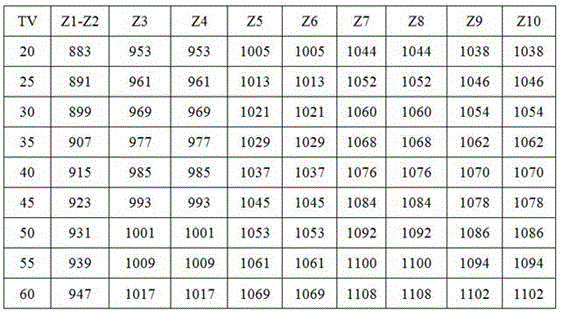

[0027] b. Set the process speed as 30m / min, get the TV value as 30, set the temperature of each annealing furnace zone according to the TV value according to the annealing curve as shown in Table 2 below:

[0028] Table 2 Furnace temperature in each zone during annealing of duplex stainless steel with TV value of 30 (°C)

[0029]

[0030] c. The annealed stainless steel coil is subjected to Na 2 SO 4 Electrolysis, Na 2 SO 4 Solution specific gravity 1.15g / cm 3 , temperature 70°C, pH value 5, electrolysis current 100A / cm 2 , electrolysis speed 20m / min;

[0031] d. Continue to HNO the duplex stainless steel coil in c 3 Electrolysis, HNO 3 The concentration is 130g / L, the temperature is 60°C, and the...

Embodiment 2

[0037] A cold-rolled hard state 2205 duplex stainless steel annealing and pickling process with a thickness of 0.5mm comprises the following steps:

[0038] a. Connect 309S austenitic stainless steel coils to the front and rear ends of the duplex stainless steel coils;

[0039] b. Set the process speed as 40m / min, get the TV value as 20, and set the temperature of each zone according to the TV value as shown in Table 3 below:

[0040] Table 3 Furnace temperature in each zone during annealing of duplex stainless steel with TV value of 20 (°C)

[0041]

[0042] c. The annealed stainless steel coil is subjected to Na 2 SO 4 Electrolysis, Na 2 SO 4 Solution specific gravity 1.15g / cm 3 , temperature 65°C, pH value 3, electrolysis current 120A / cm 2 , electrolysis speed 10m / min;

[0043] d. Continue to HNO the duplex stainless steel coil in c 3 Electrolysis, HNO 3 The solution concentration is 110g / L, the temperature is 55°C, and the electrolysis current is 120A / cm 2 ,...

Embodiment 3

[0049] The annealing and pickling of this embodiment is that the cold-rolled hard state 2205 duplex stainless steel coil with a thickness of 1.5mm comprises the following steps:

[0050] a. Connect 310S austenitic stainless steel coils to the front and rear ends of the duplex stainless steel coils;

[0051] b. Set the process speed as 40m / min, get the TV value as 60, and set the temperature of each zone according to the TV value as shown in Table 4 below:

[0052] Table 4 Furnace temperature in each zone during annealing of duplex stainless steel with TV value of 60 (°C)

[0053]

[0054] c. The annealed stainless steel coil is subjected to Na 2 SO 4 Electrolysis, Na 2 SO 4 Solution specific gravity 1.15g / cm 3 , temperature 75°C, pH value 4, electrolysis current 200A / cm 2 , electrolysis speed 30m / min;

[0055] d. Continue to HNO the duplex stainless steel coil in c 3 Electrolysis, HNO 3 The solution concentration is 150g / L, the temperature is 60°C, and the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com