Patents

Literature

265results about How to "Increase water production rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

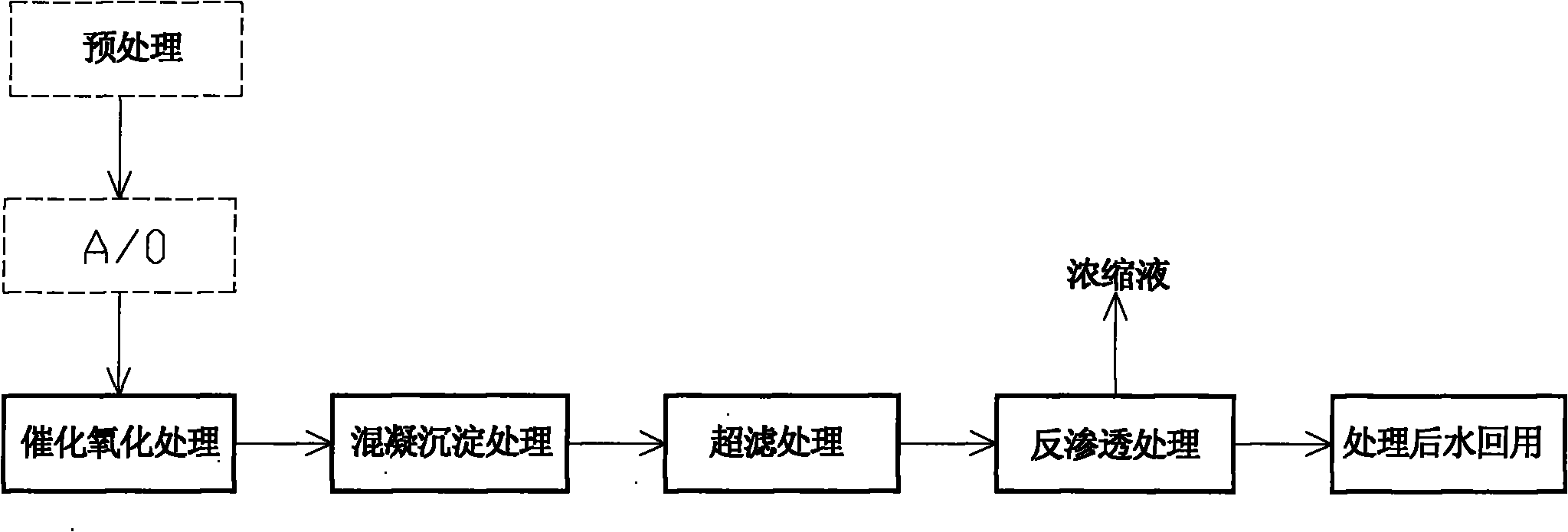

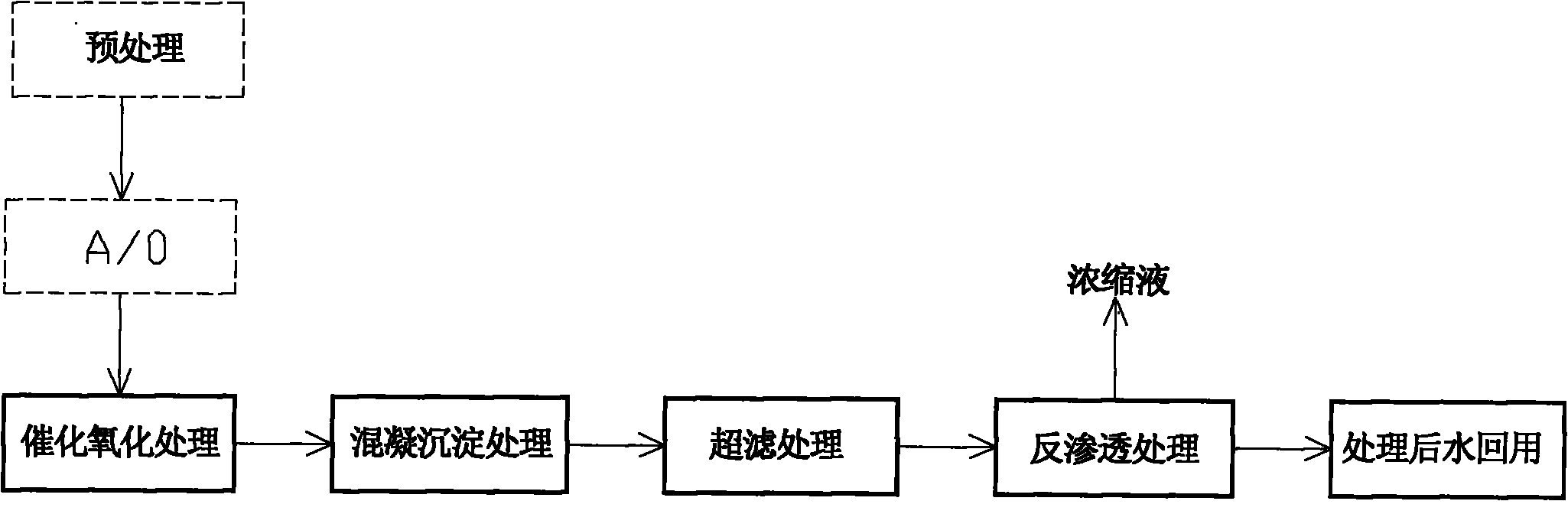

Technology for deeply processing coking wastewater through combining catalytic oxidation method and membrane separation technique

ActiveCN101781039AAchieve reuseAchieving zero emissionsWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSeparation technologySlag

The invention relates to a technology for deeply processing coking wastewater through combining catalytic oxidation method and membrane separation technique. Preprocessed coking wastewater is processed through pretreatment, A / O biochemical treatment, catalytic oxidation, coagulating sedimentation, ultrafiltration and reverse osmosis treatment. The invention has the advantages that the technology can greatly reduce the amount of COD, suspended substance and pollutant and the like, and has the advantages of low investment once, stable treatment effect and high water yield. Water from catalytic oxidation is separated through a coagulative precipitation tank, and clean water can be used for production, daily use or slag washing in iron works. Water from reverse osmosis can be directly reused as make-up water in water circulating systems, thereby realizing reutilization of water sources and zero discharge of coking wastewater. The technology has remarkable social benefits.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

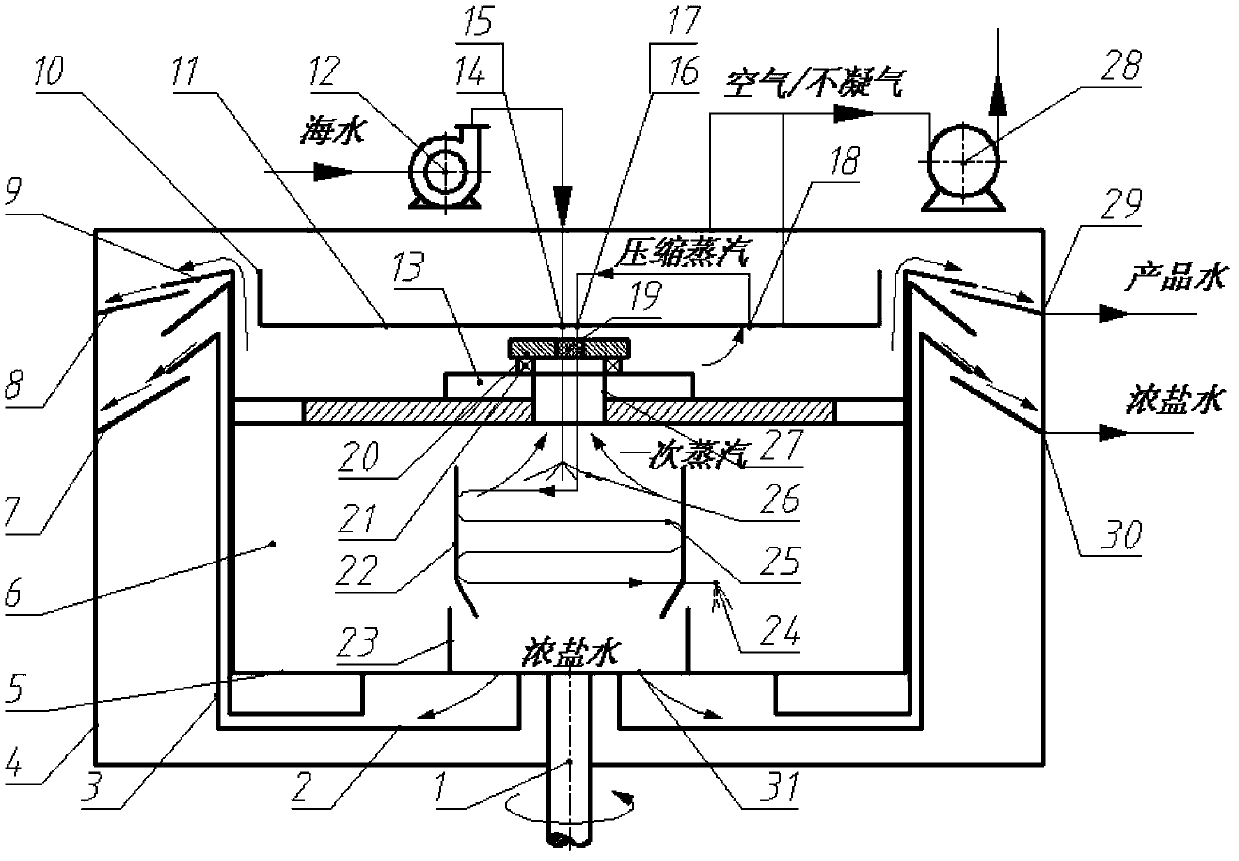

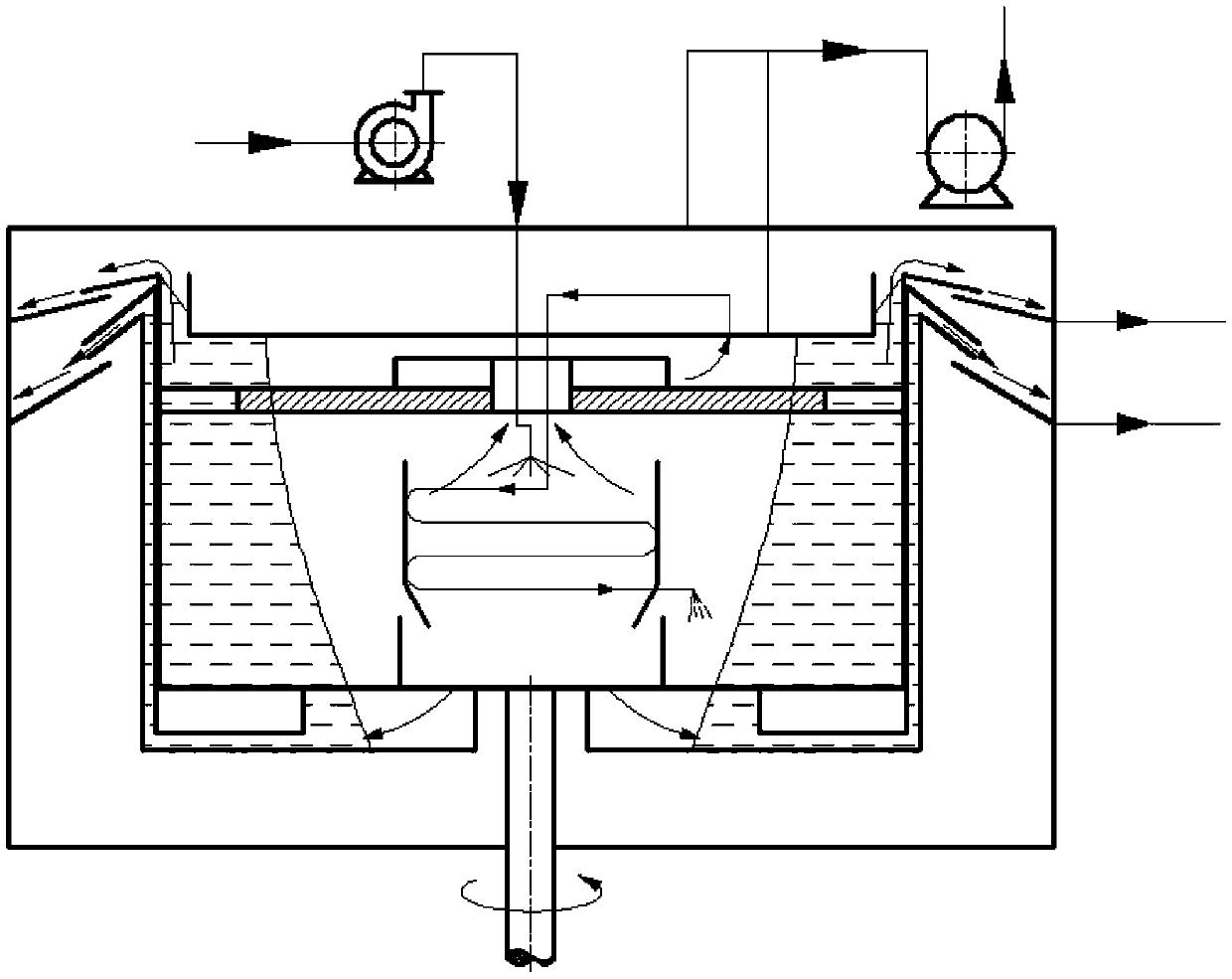

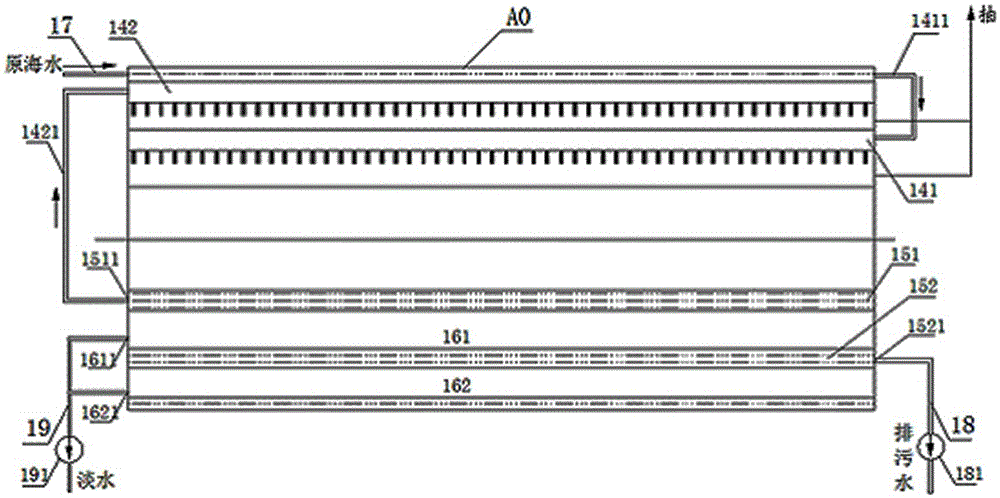

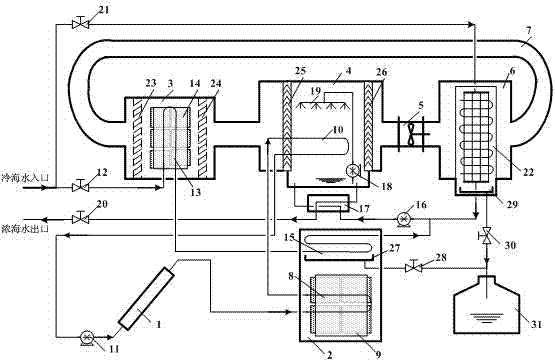

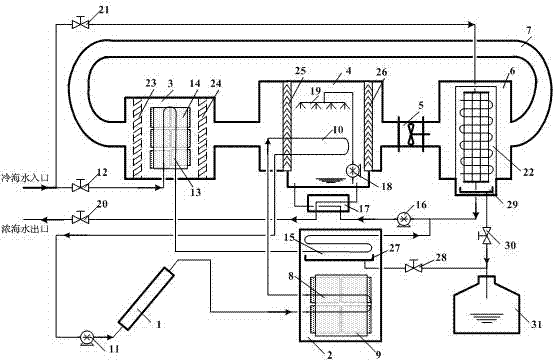

A vacuum vapor compression distillation sea water desalination device

InactiveCN103387270AIncrease water production rateIncrease heat and mass transfer rateGeneral water supply conservationSeawater treatmentWater desalinationSteam condensation

The present invention relates to a vacuum vapor compression distillation sea water desalination device comprising: a sea water pump, a seal chamber, a vacuum evaporation chamber and a vacuum pump and other components. In operation, a drive shaft drives the vacuum evaporation chamber filled with fresh water to rotate, after the formation of a vacuum area without water, sea water is fed in, and at the same time working vapor is fed in a vapor pipe coil, heat transfer between the vapor in the vapor pipe coil and the outside sea water enable the condensation of the vapor to obtain fresh water, while the sea water volatilizes to form primary vapor; and after temperature and pressure rise via a impeller, the primary vapor is fed in the vapor pipe coil as the working vapor for continuous vapor compression distillation to achieve sea water desalination. According to the device of the invention, centrifugal force is employed to replace the gravity to obtain a vacuum environment, operations are all in room temperature, no external heat source is required, and circular energy supply is achieved by the utilization of latent heat of the vapor; the water production rate and the energy utilization rate of the system are high; and the device has advantages of a simple process, a compact structure, little corrosion and scaling, etc.

Owner:HAINAN UNIVERSITY +1

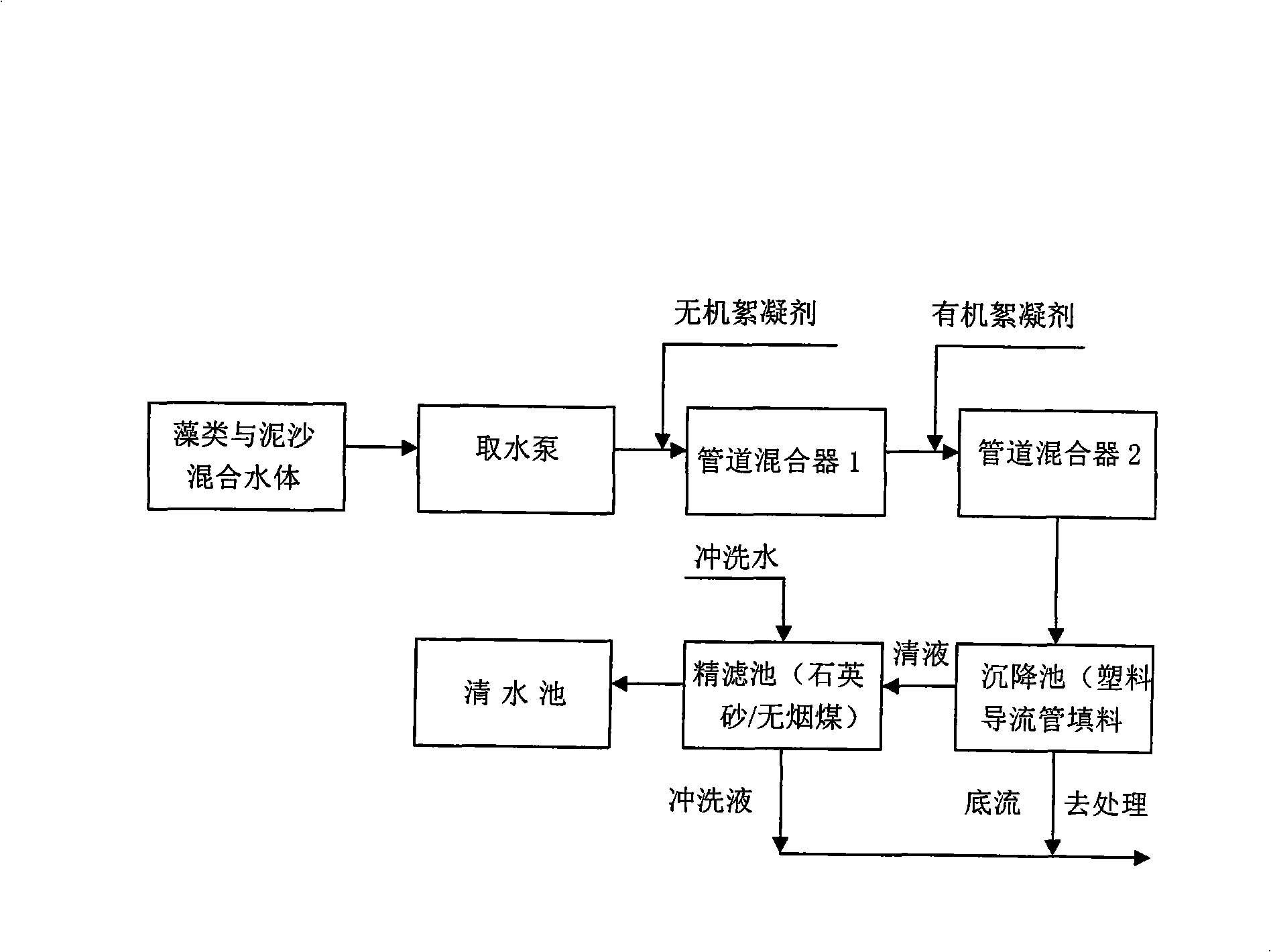

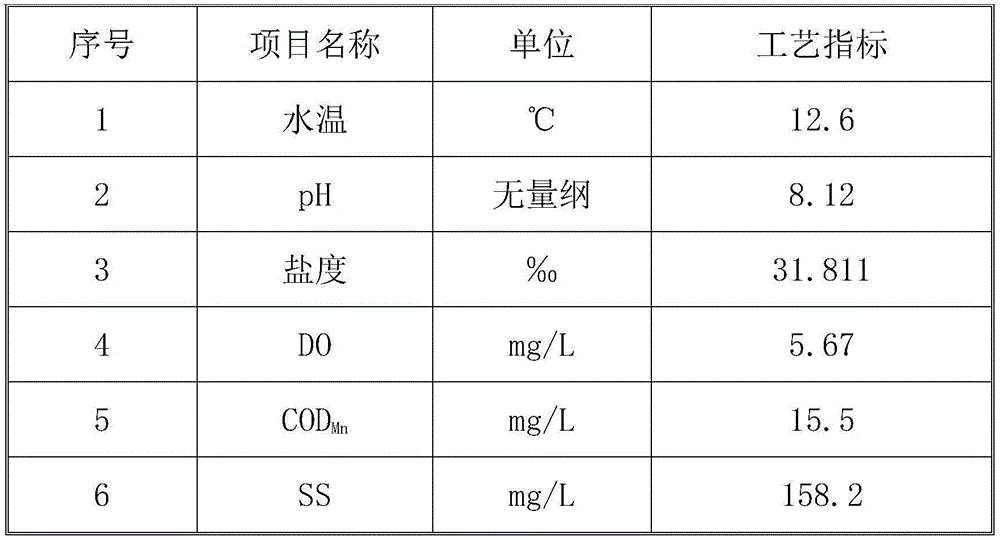

Purification method of mixed water body with algae and silt

ActiveCN101306884AReduce processing stepsSimple processMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationPurification methods

The invention discloses a method for clarifying a mixed water body containing algae and sand. Firstly, inorganic flocculating agent is added into the mixed water body containing the algae and the sand, and is evenly mixed through a pipeline mixer to generate flocculation, then organic flocculating agent is added after a plurality of small flocculating conglomerations are produced, and is evenly mixed through the pipeline mixer to form a coagulated water body containing large flocculating conglomerations, wherein, the adding amount of the inorganic flocculating agent is 0.0005 to 0.0100 percent of the weight of the water body, and the adding amount of the organic flocculating agent is 0.0001 to 0.0030 percent of the weight of the water body. Then the coagulated water body is drawn into a single-segment sedimentation pond for sedimentation treatment, and water overflows from the upper layer of the sedimentation pond, enters a fine filter chamber, and passes through a quartz sand and anthracite filtering layer for fine filtration treatment, thereby obtaining clear water with SS less than or equal to 5mg / L and a turbidity less than or equal to 1.

Owner:YUNNAN THREE CIRCLES SINOCHEM FERTILIZERS CO LTD

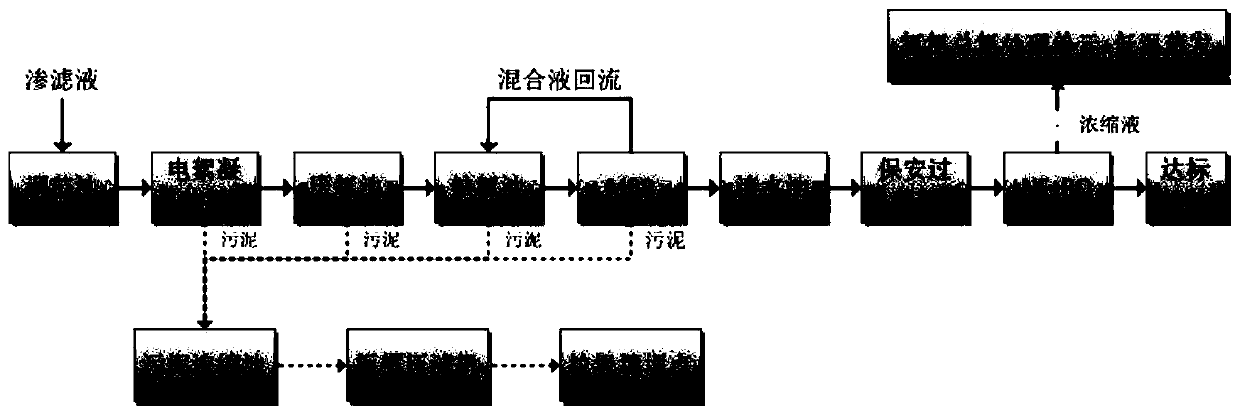

Zero discharge recycle treatment method for garbage leachate

InactiveCN101508514AReduce the concentration of ammonia nitrogenReduce processing costsTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFiltrationReverse osmosis

The invention discloses a refuse percolate zero discharge reclamation treatment method, and relates to the wastewater treatment technology. The invention provides a refuse percolate zero discharge reclamation treatment method. The method comprises the following steps: sending the raw liquor of the refuse percolate into a raw water regulation pond, removing the suspended solids and impurities in the outputted water through a membrane coagulation reactor, returning the outputted water to the raw water regulation tank through the back flushing of the membrane coagulation reactor, and sending the discharged wastewater into a membrane contact reactor to form a by product of an ammonium sulphate solution; sending the outputted water of the membrane contact reactor into an upwash type anaerobic bioreactor for the anaerobic biochemical treatment, and sending the outputted water of the upwash type anaerobic bioreactor into a membrane bioreactor for the aerobic biochemical treatment; sending the outputted water of the membrane bioreactor into a continuous membrane filtering system for filtration, and returning the concentrated liquor and back flushing water of the continuous membrane filtering system to the raw water regulation tank; and sending the outputted water of the continuous membrane filtering system into a reverse osmosis system, removing the concentrated liquor of the reverse osmosis system through boiler oxidation and torch firing, and obtaining the reclaimable pure water which is the outputted water of the reverse osmosis system.

Owner:厦门凯瑞尔数字环保科技有限公司

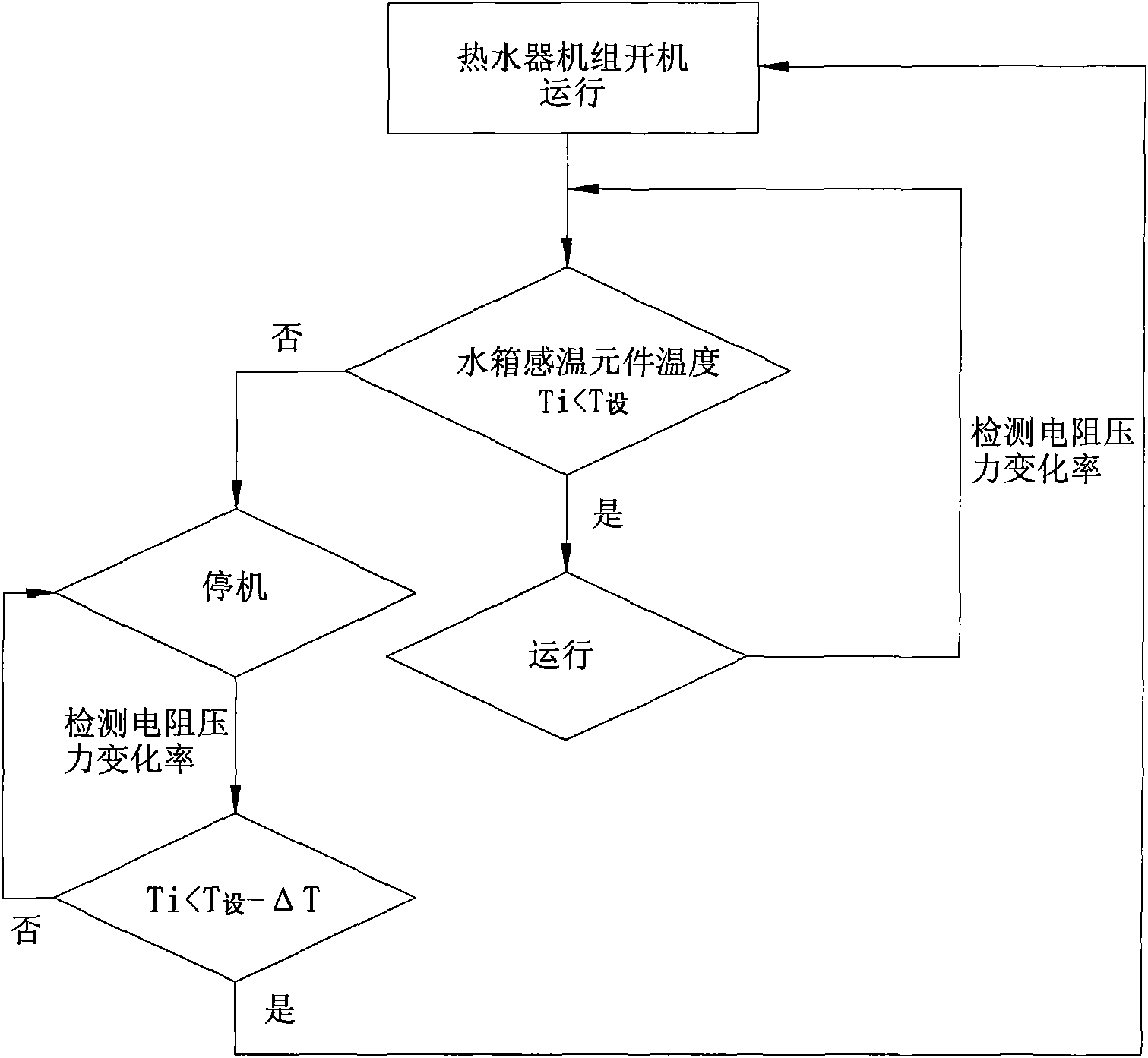

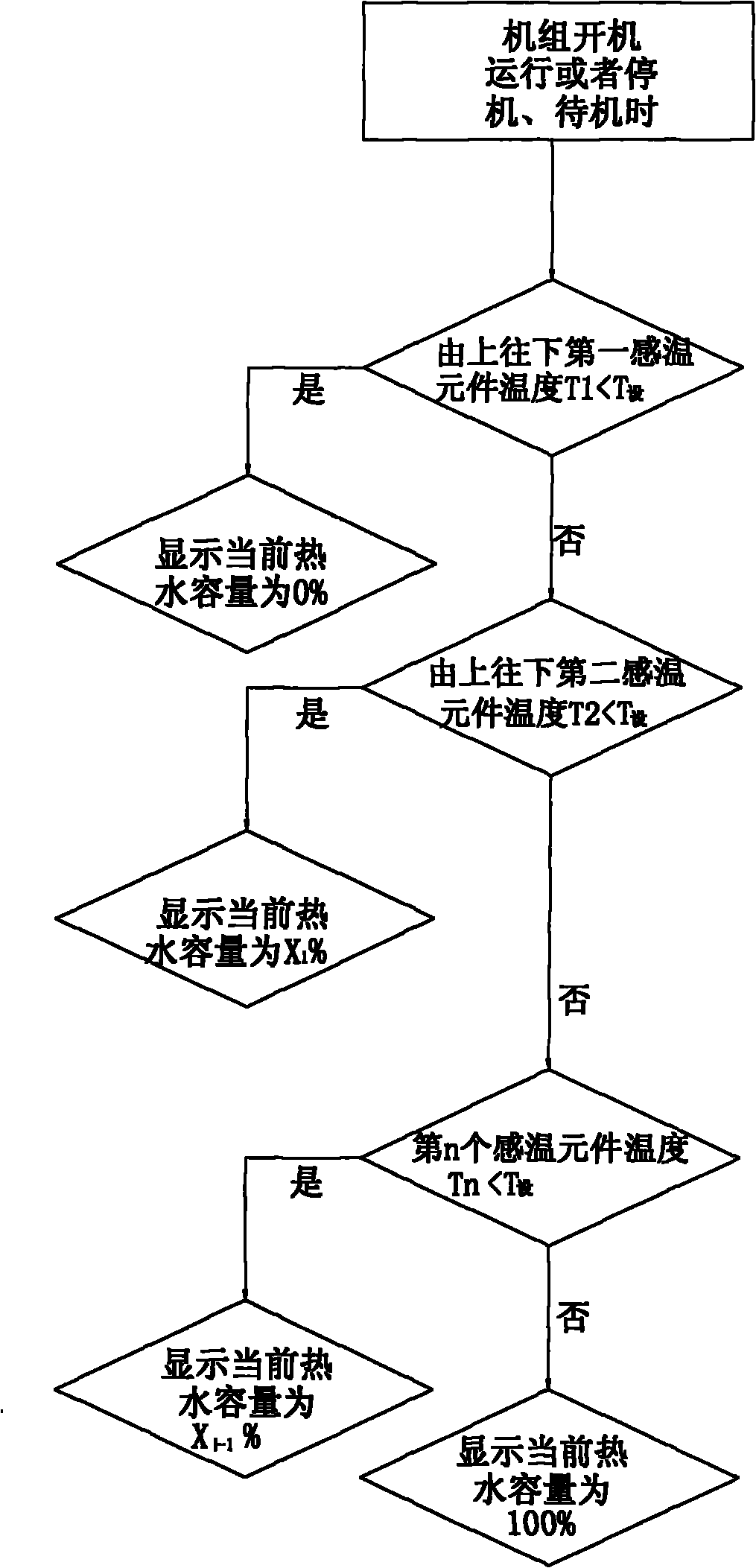

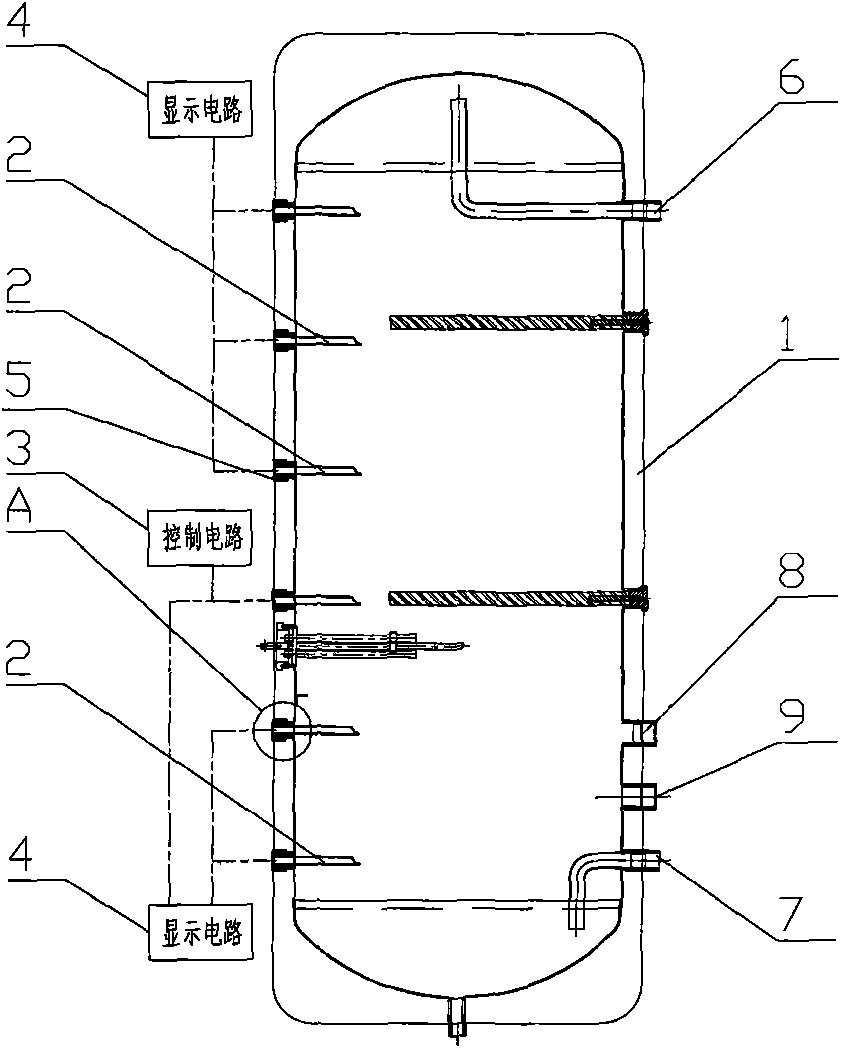

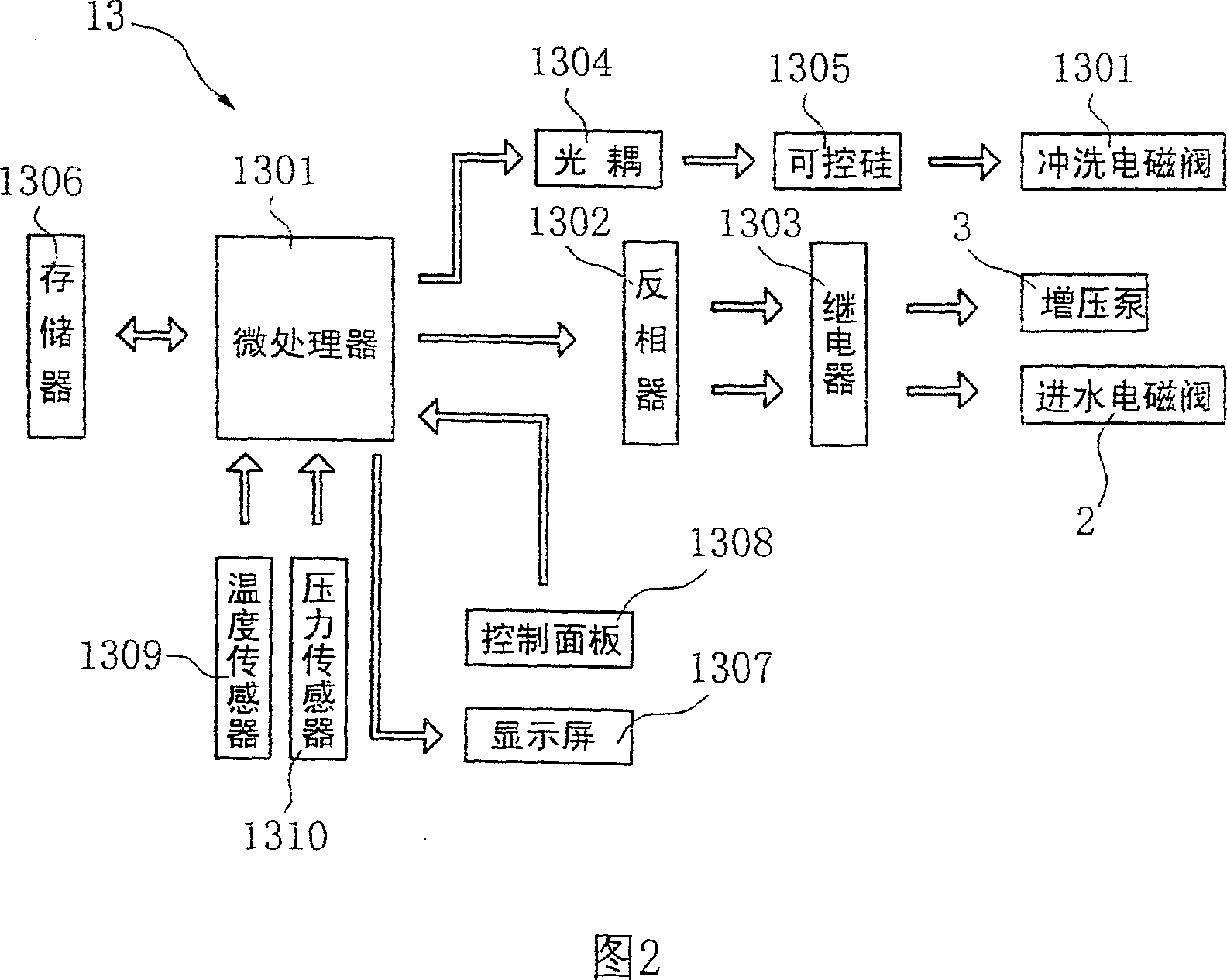

Water heater and control method thereof

ActiveCN101957053AReal-time analysis and judgment capacityIncrease the number ofTemperatue controlEnergy efficient heating/coolingMicrocontrollerComputer module

The invention provides a water heater and a control method thereof. Water temperature and available hot water yield in a box can be exactly measured such that a user can exactly know the temperature of the hot water and the available hot water yield in the water heater. The invention is realized by the following technical scheme: the water heater comprises a pressure-bearing water box, a manual operator and a detection controller, wherein the pressure-bearing water box comprises a box and temperature-sensing elements arranged on the box; the upper part of the box is provided with a hot water outlet; the lower part of the box is provided with a water supplement inlet; the box is provided with n-numbered temperature-sensing elements, and n is an integer which is more than or equal to 2; altitude difference exists between the mounting positions of the two adjacent temperature-sensing elements; the detection controller is provided with a single chip and comprises a control circuit and a display circuit; and the control circuit comprises a detection module, a judgment module and a control module for the start and stop of a unit.

Owner:GREE ELECTRIC APPLIANCES INC

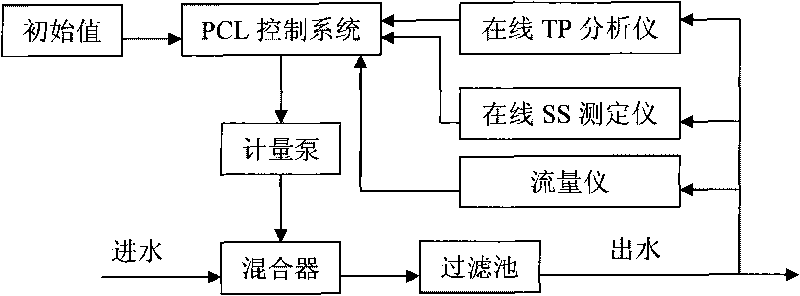

Method for controlling automatic flocculant addition

InactiveCN101717143ALow costGuaranteed stabilityWater/sewage treatment by flocculation/precipitationProgramme control in sequence/logic controllersSewageStreamflow

The invention discloses a method for controlling automatic flocculant addition, which belongs to the field of sewage treatment. A feedback control system determines the flow of sewage and the concentration of TP and SS after sewage treatment and feeds back determination results to a PLC control system; and the PLC control system performs calculation by using undetermined parameters through a formula as follows: delta X dosage=k*Q*L*(P-1.1A)a*(S-1.05B)b / (lambda*N)according to the feedback of the feedback control system of the flow, the TP and the SS to indirectly determine the dosage of flocculant. The invention can regulate the dosage of the flocculant in time according to the coagulation effect of the sewage treatment and ensure the optimal dosage of the flocculant and the effect of the sewage treatment.

Owner:HOHAI UNIV

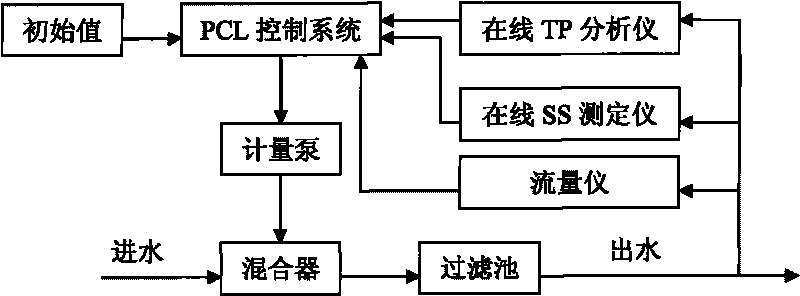

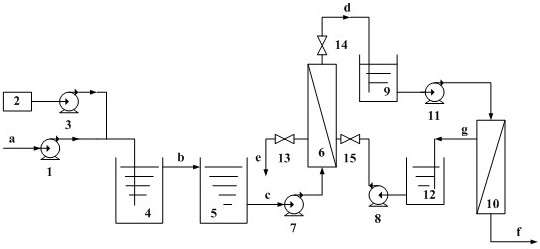

A wastewater desalination process with a high water yielding rate and a device thereof

ActiveCN103288252AExtend your lifeIncrease water production rateGeneral water supply conservationMultistage water/sewage treatmentHigh concentrationDesalination

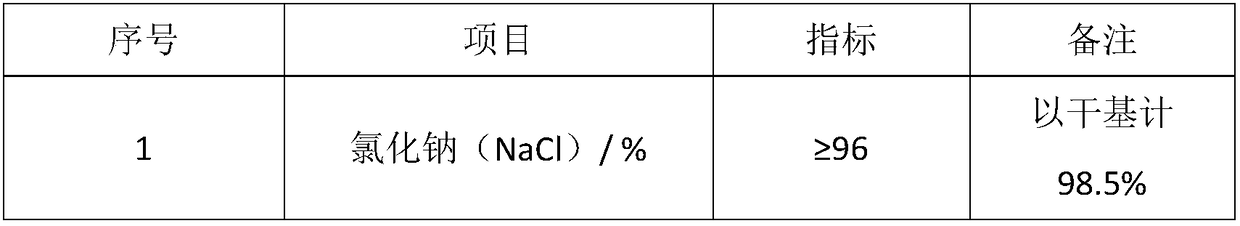

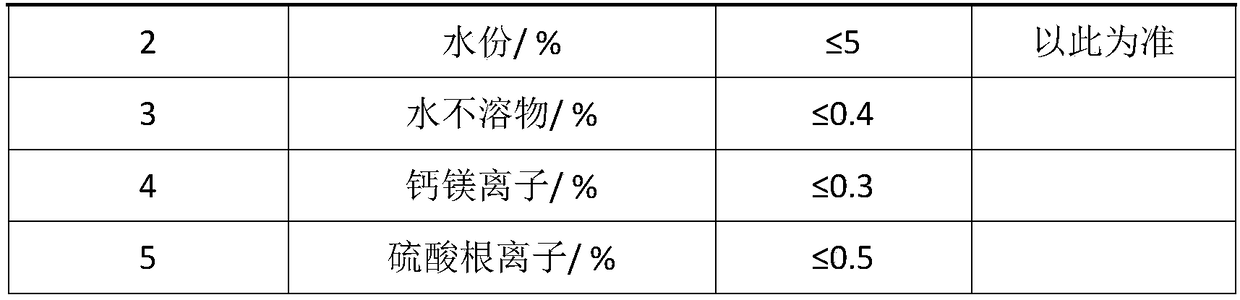

The present invention relates to a wastewater desalination process with a high water yielding rate and a device thereof, belonging to the field of wastewater advanced treatment. In the process, by using a sodium chloride solution as a drawing solution, though the combination of forward osmosis and electrodialysis and the use of an osmotic pressure generated by a sodium chloride solution of a high concentration, water molecules naturally osmose and are drawn from wastewater with a high water yielding rate; pure water is obtained after the electrodialysis treatment of the diluted sodium chloride solution; and a concentrated sodium chloride solution is returned to a forward osmosis unit as the drawing solution. The device comprises the forward osmosis unit and an electrodialysis unit which are connected with each other; and the outlet of the electrodialysis unit is connected with the forward osmosis unit. According to the present invention, an electrodialysis membrane has no membrane fouling problem, membrane fouling of the forward osmosis membrane can be easily subjected to backwash to restore flux, and a very high water yielding rate can be achieved.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

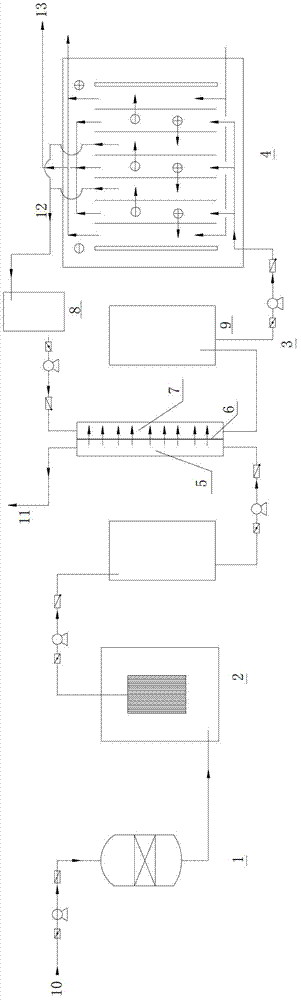

Zero discharge process for high-salt wastewater discharged from titanium dioxide production

ActiveCN108529802AAvoidance of foulingAvoid foulingGeneral water supply conservationWater softeningUltrafiltrationCatalytic oxidation

The invention relates to a zero discharge process for high-salt wastewater discharged from titanium dioxide production, and the steps are as follows: high-salt wastewater, removal of silicon by a magnesium agent, medicinal agent softening, high-density precipitation, immersion-type ultrafiltration, brackish water reverse osmosis membrane concentration, seawater desalination reverse osmosis membrane concentration, reduction of COD by catalytic oxidation, ion exchange softening, multi-stage nanofiltration salt separation, high pressure reverse osmosis membrane concentration, DTRO / ED electrodialysis concentration, and evaporation crystallization / freezing crystallization. The zero discharge process adopts corresponding treatment processes separately, realizes for the first time the zero discharge of the high-salt wastewater of titanium dioxide by a detailed control technology of each specific process in the system, ensures the normal and smooth operation of the system, and recovers a largeamount of fresh water resources and industrial salts. The purpose of resource recycling of the titanium dioxide production wastewater is realized, and on the basis of creating of certain economic benefits, significant environmental and social benefits are reflected.

Owner:SHANDONG YUXIN ENVIRONMENTAL SCI & TECH

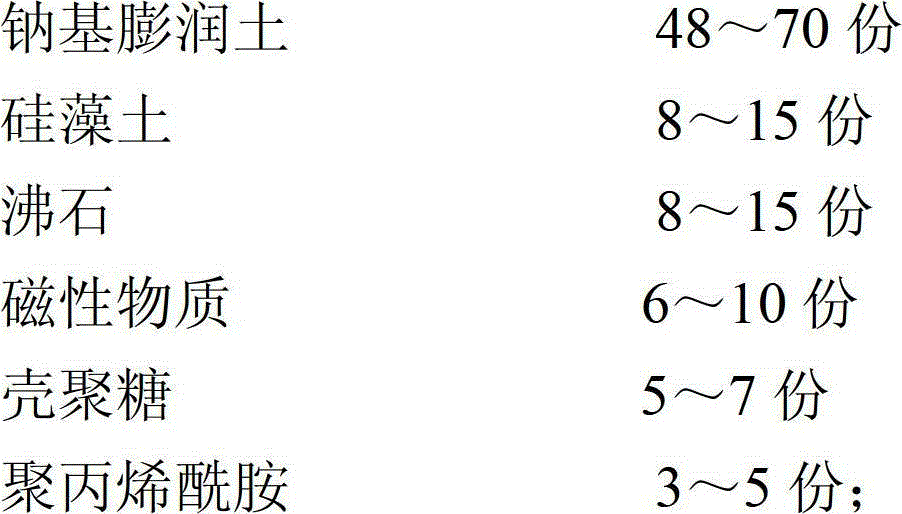

Compound water treatment agent and preparation method and application of water treatment agent

ActiveCN102908997AEnhanced physical adsorptionAccelerate the speed of adsorption equilibriumOther chemical processesWater/sewage treatment by magnetic/electric fieldsIonChemistry

The invention provides a compound water treatment agent and a preparation method and an application of the water treatment agent. The compound water treatment agent comprises the following components in parts by weight: 48-70 parts of sodium bentonite, 8-15 parts of kieselguhr, 8-15 parts of zeolite, 6-10 parts of magnetic substance, 5-7 parts of chitosan and 3-5 parts of polyacrylamide. The preparation method of the compound water treatment agent is simple, and a material source is wide. With the adoption of the compound water treatment agent, heavy metal ions and organic contaminants in water can be removed while electrolyte concentration in the water can be lowered, and solid-liquid separation can be conducted quickly by virtue of a magnetic filter method. The compound water treatment agent can be applied to a pre-treatment process of a reverse osmosis system, facilitates increasing the water production rate of the reverse osmosis system, reduces operating pressure of the reverse osmosis system, and is significant in practical value and broad in market prospect.

Owner:JINAN UNIVERSITY

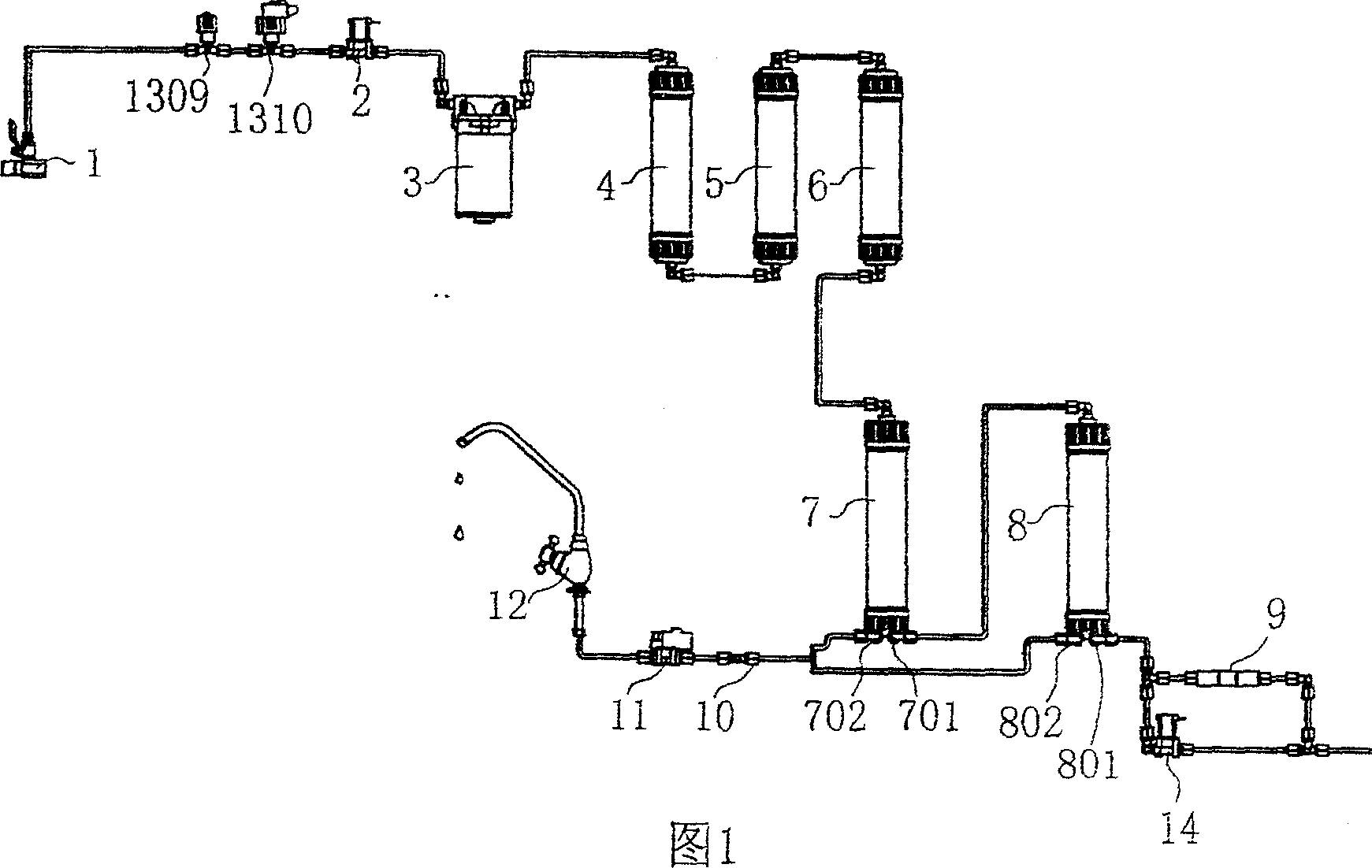

Reverse osmosis type water conditioner able to improve pressure automatically

InactiveCN101032679AReady-to-drinkIncrease water production rateReverse osmosisWater/sewage treatment bu osmosis/dialysisReverse osmosisContamination

The present invention discloses one kind of automatically pressurized reverse osmosis membrane water purifier, which has a computer in a box to control the booster pump based on the raw water pressure and temperature, a temperature sensor and a pressure sensor set inside the raw water pipeline. Owing to the booster pump operating based on the raw water pressure and temperature, the reverse osmosis membrane always has high water yield and the water purifier has no need of water storing tank and no corresponding secondary contamination on water. The reverse osmosis membrane water purifier has saving in energy, saving in water and capacity of providing boiled water timely.

Owner:佳尼特(上海)纯水设备有限公司

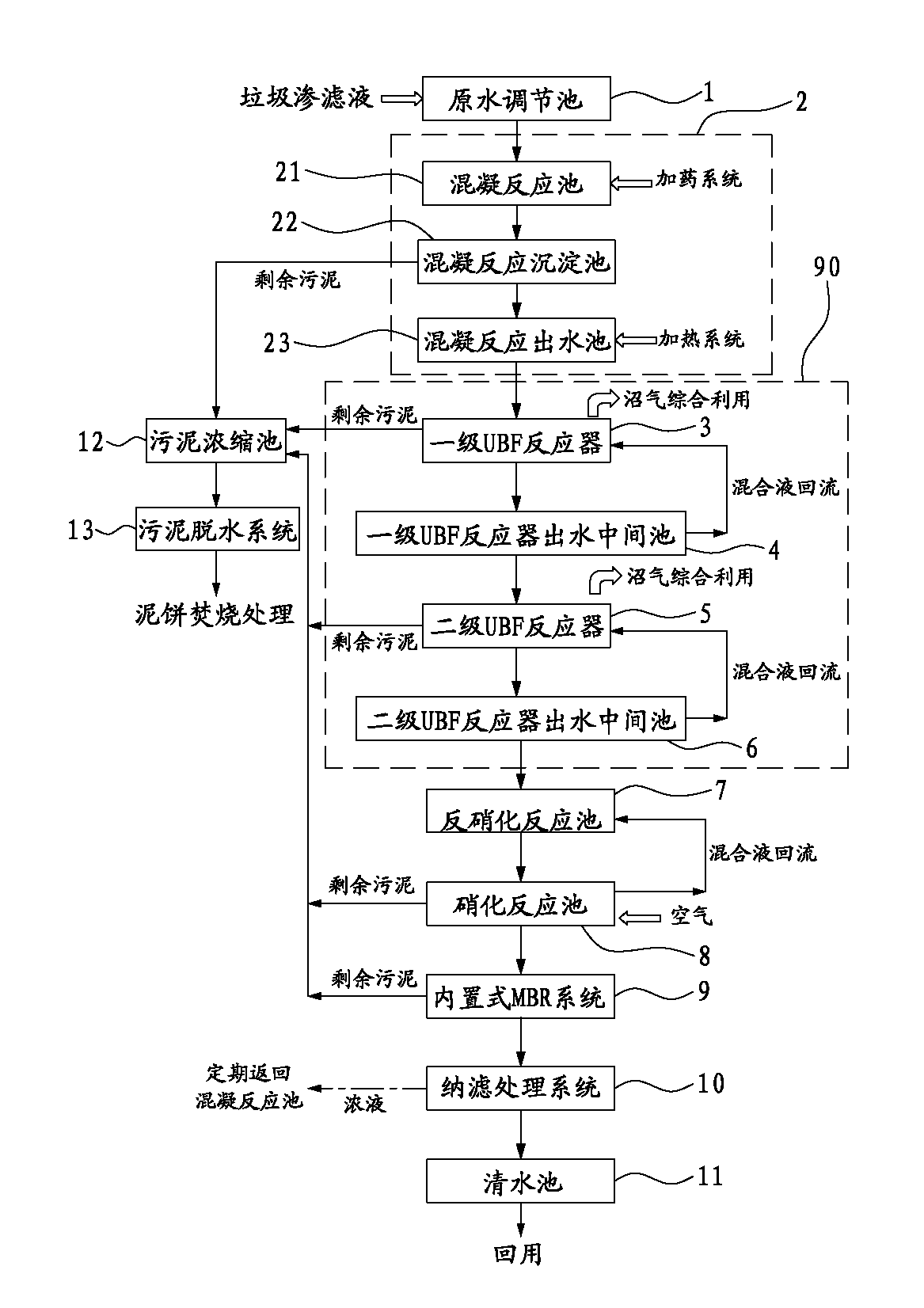

Treatment method for waste incineration power plant leachate and device thereof

ActiveCN102795746AGuaranteed concentrationGuaranteed processing efficiencyTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesSludgeFiltration

The invention discloses a treatment method for waste incineration power plant leachate and a device thereof. The waste leachate is put into a raw water regulation pool, a coagulation reaction system, a first-stage UBF reactor, a first-stage UBF reactor effluent middle pool, a second-stage UBF reactor, a second-stage UBF reactor effluent middle pool, a denitrification pool, a nitration pool, a built-in MBR system, and a nanofiltration system for processing. According to the invention, the UBF reactor effluent middle pools are arranged behind the UBF reactors for mud-water separation and backflow after the UBF reactor effluent, guaranteeing the mud concentration in the UBF reactors and treatment effeciency. Using a built-in MBR membrane module placed in a biochemical pool helps to reduce floor space and lower energy consumption. The use of physical and chemical, biochemical, and membrane filtration technology association for the direct treatment of waste leachate can reach recycling with zero emission.

Owner:NEWSKY CHINA ENVIRONMENT & TECH

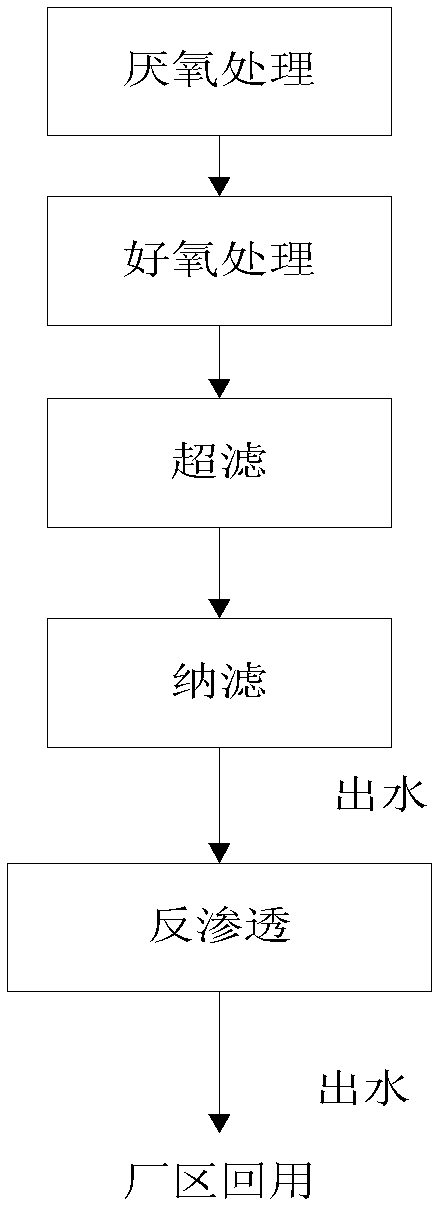

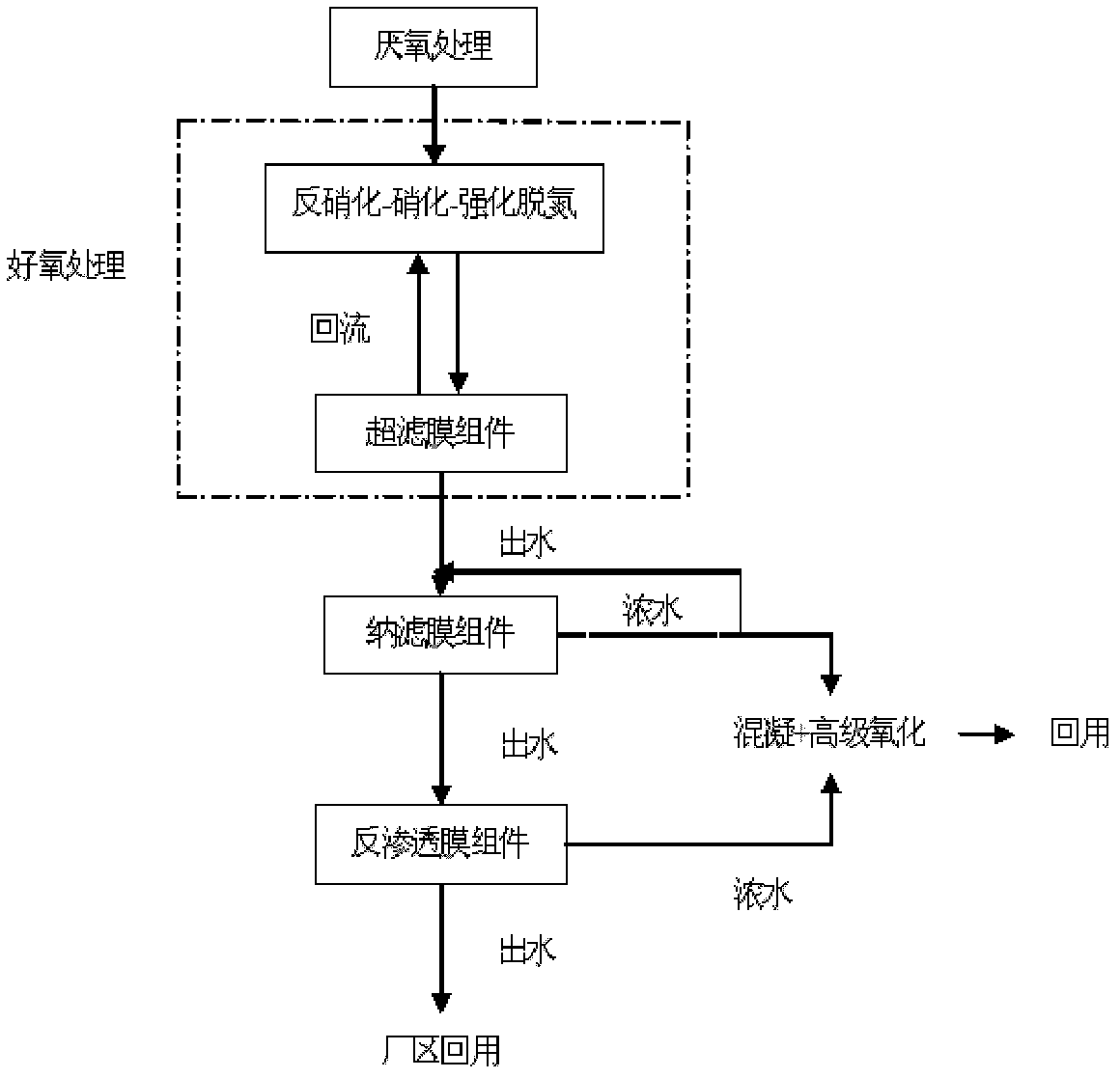

Method for advanced treatment and recycling of landfill leachate

InactiveCN102603128AGuaranteed uptimeLow running costMultistage water/sewage treatmentUltrafiltrationReverse osmosis

The invention relates to a method for advanced treatment and recycling of landfill leachate. The method comprises the following steps: (1) conducting anaerobic treatment on landfill leachate; (2) conducting aerobic treatment on effluent obtained by the anaerobic treatment in the step (1), and conducting ultrafiltration on the effluent which is subjected to aerobic treatment; (3) conducting nanofiltration on the effluent obtained by ultrafiltration in the steps (2); and (4) conducting reverse osmosis treatment on the effluent obtained by nanofiltration in the step (3) so as to obtain recycling effluent. The method has the advantages that (1) the removing rate of organic pollutants is more than 98%, and the stable running of a subsequent system can be ensured; (2) the denitrification rate is more than 98%, the stoste of the landfill leachate is taken as supplementary carbon source, and the running cost is saved; and (3) the processed sewage meets the recycling standard, so that the secondary pollution is avoided.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +1

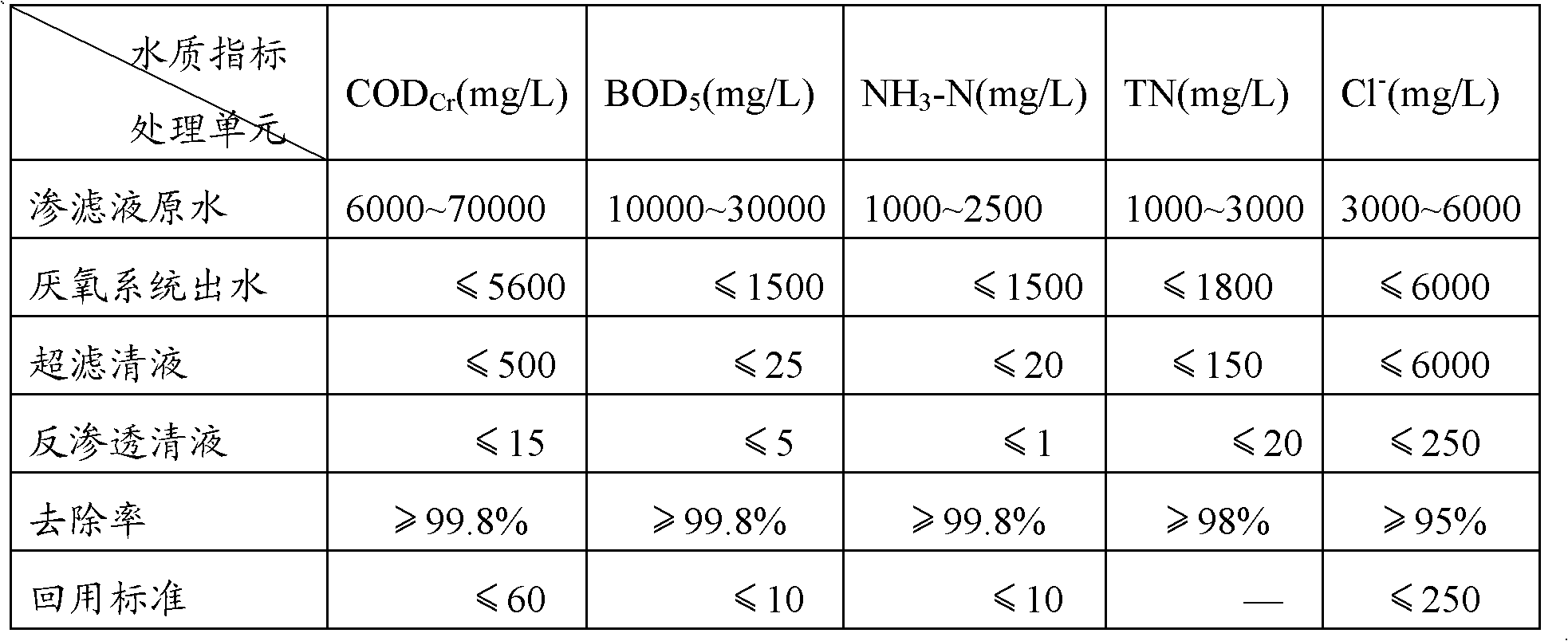

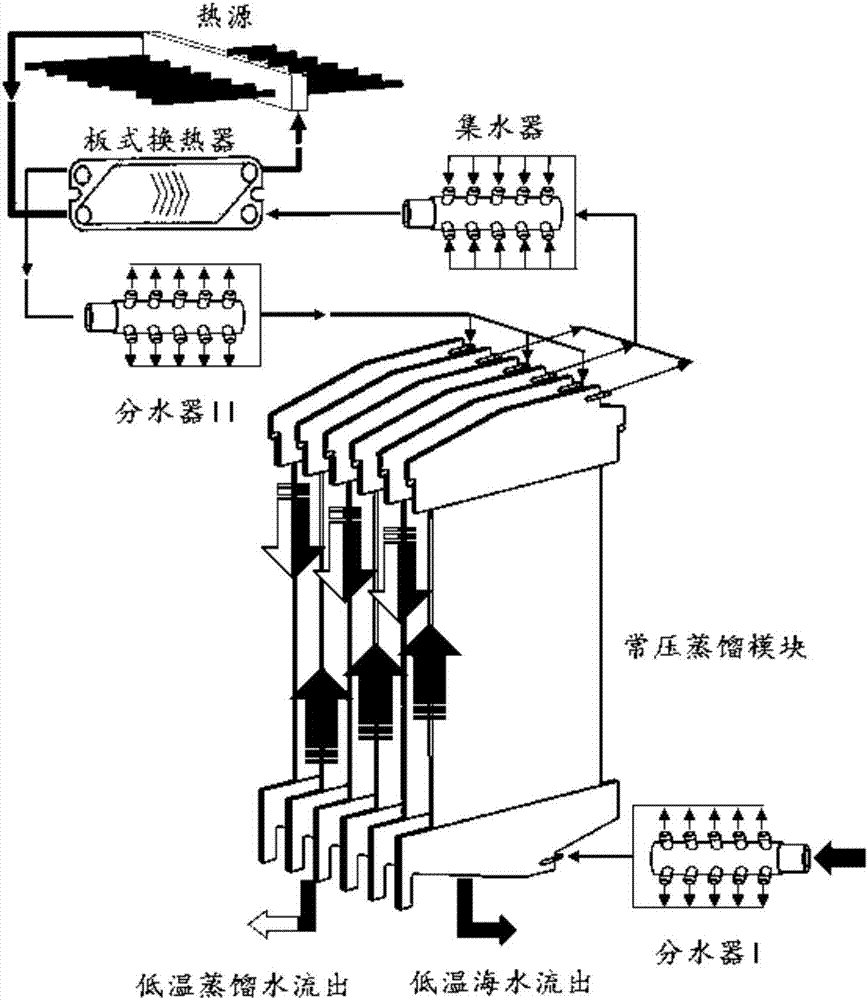

Low-temperature multiefffect distilled seawater desalination system

InactiveCN106115825ALower water costsReduce power consumptionGeneral water supply conservationSeawater treatmentCounter flowWater production

The invention relates to a low-temperature multiefffect distilled seawater desalination system, which comprises a zero-effect vapor generator, n-effect evaporators, a vapor condenser and a vacuumizing system, wherein high-temperature hot water flows in the zero-effect vapor generator through a high-temperature hot water pipe, the zero-effect vapor generator generates starting vapor, the vapor flows in the first-effect evaporator through a pipeline, vapor generated in the first-effect evaporator flows in the next-effect evaporator through a pipeline, until flows in the nth-effect evaporator, and vapor generated in the nth-effect evaporator flows in the vapor condenser to form finished water. By directly utilizing low-temperature residual heat unutilized by industrial mining enterprises, the water production cost of seawater desalination can be greatly lowered, the low-temperature multiefffect distilled seawater desalination system is an important action of offshore industrial and mining enterprises to realize energy saving and emission reduction, electricity consumption is reduced by adopting a hot water direct driven optimized scheme, and the water productivity and energy utilization rate of the whole system can be improved by adopting width counter flowing feeding mode through reasonable design optimization.

Owner:BEIJING JINDAYU ENVIRONMENT TECH CO LTD

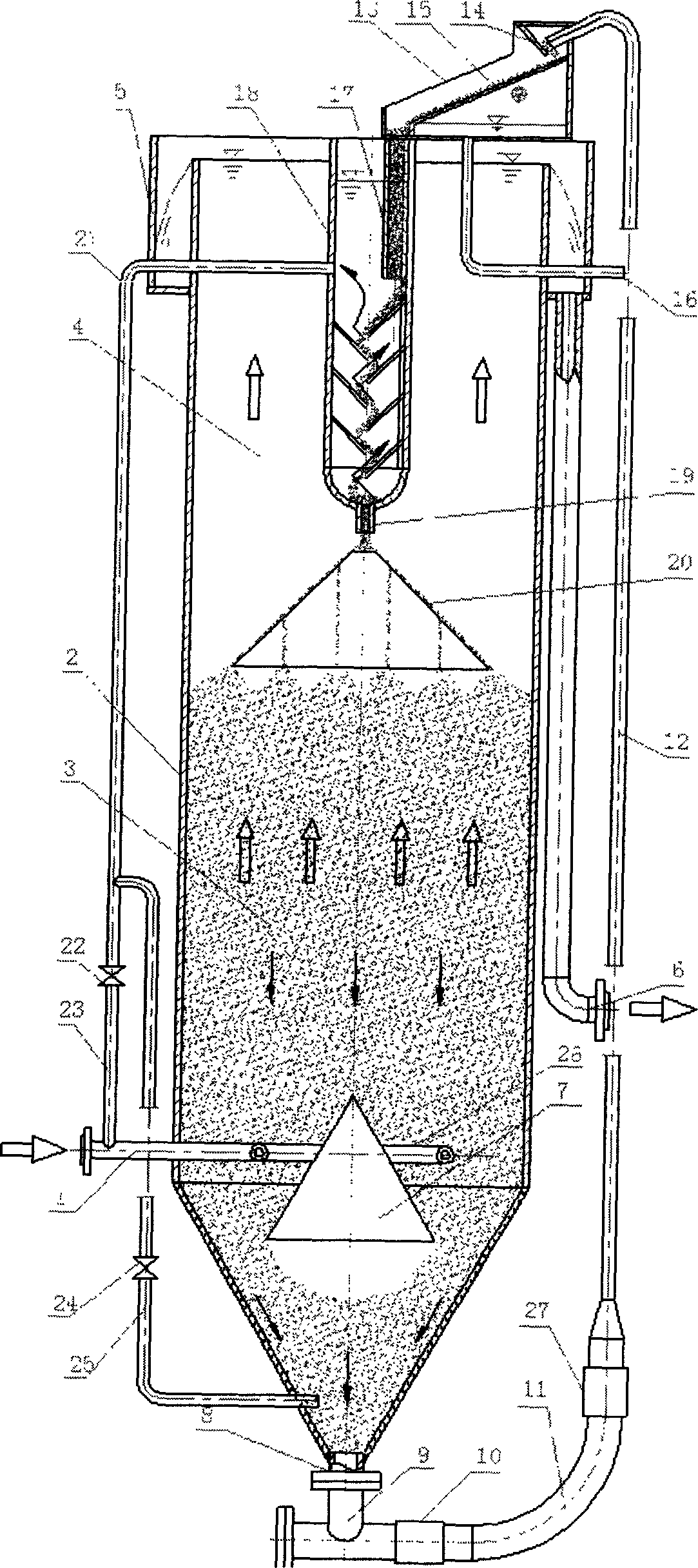

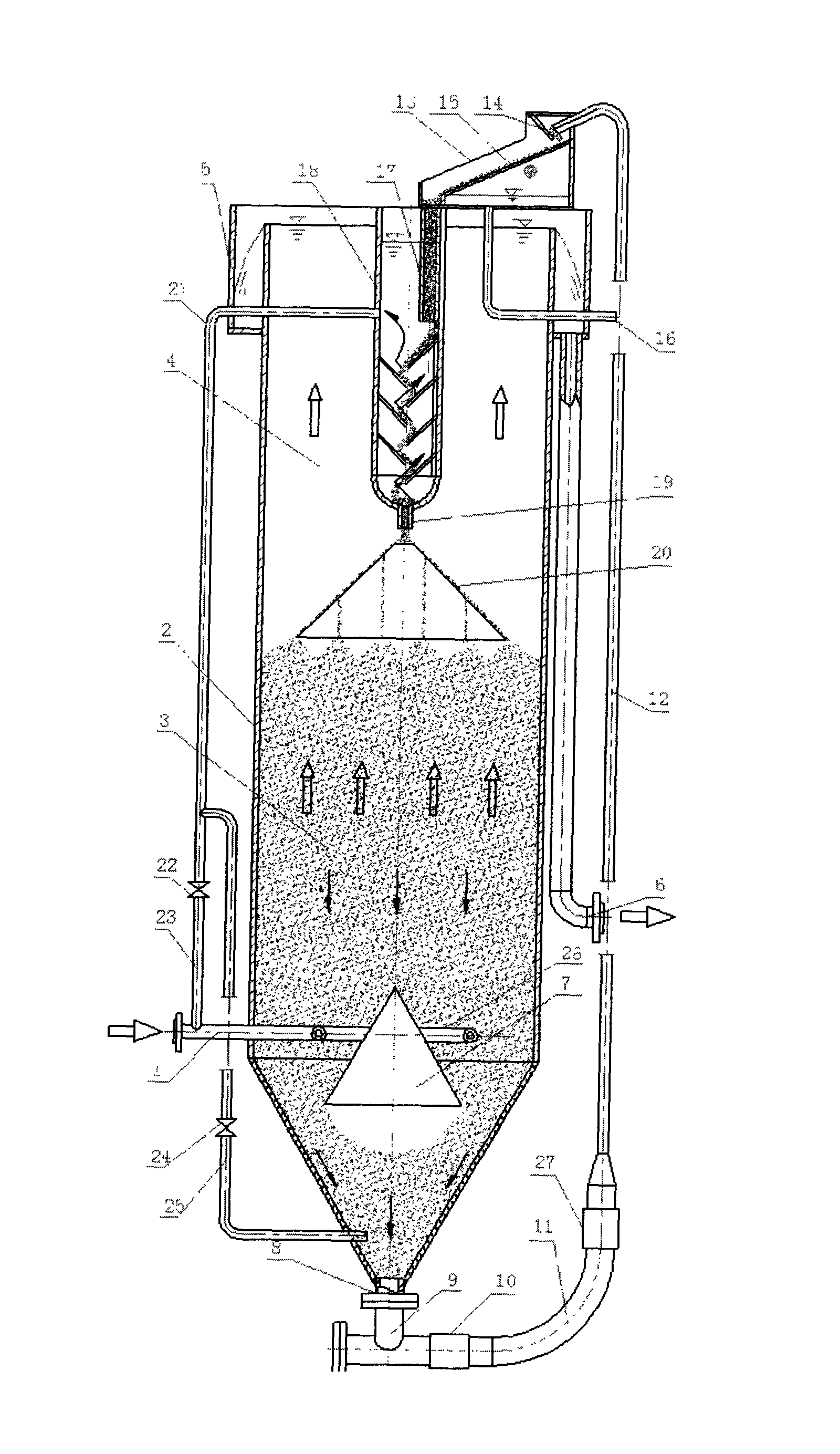

Device for removing suspended matter in water

InactiveCN1597041AReduce the amount of waterIncrease the concentration factorLoose filtering material filtersGravity filtersWater qualitySewage

An apparatus for removing the suspended substance from water is a filter unit which is composed of cylindrical tank, overflow dam, water outlet tube, water inlet tube, water distributor, filtering material washer, fairing unit, filtering material distributor, cyclic filtering material lifting tube and air distributor. It features its additional suspended substance separator, between the outlet of said lifting tube and filtering material washer.

Owner:CHINA PETROLEUM & CHEM CORP +1

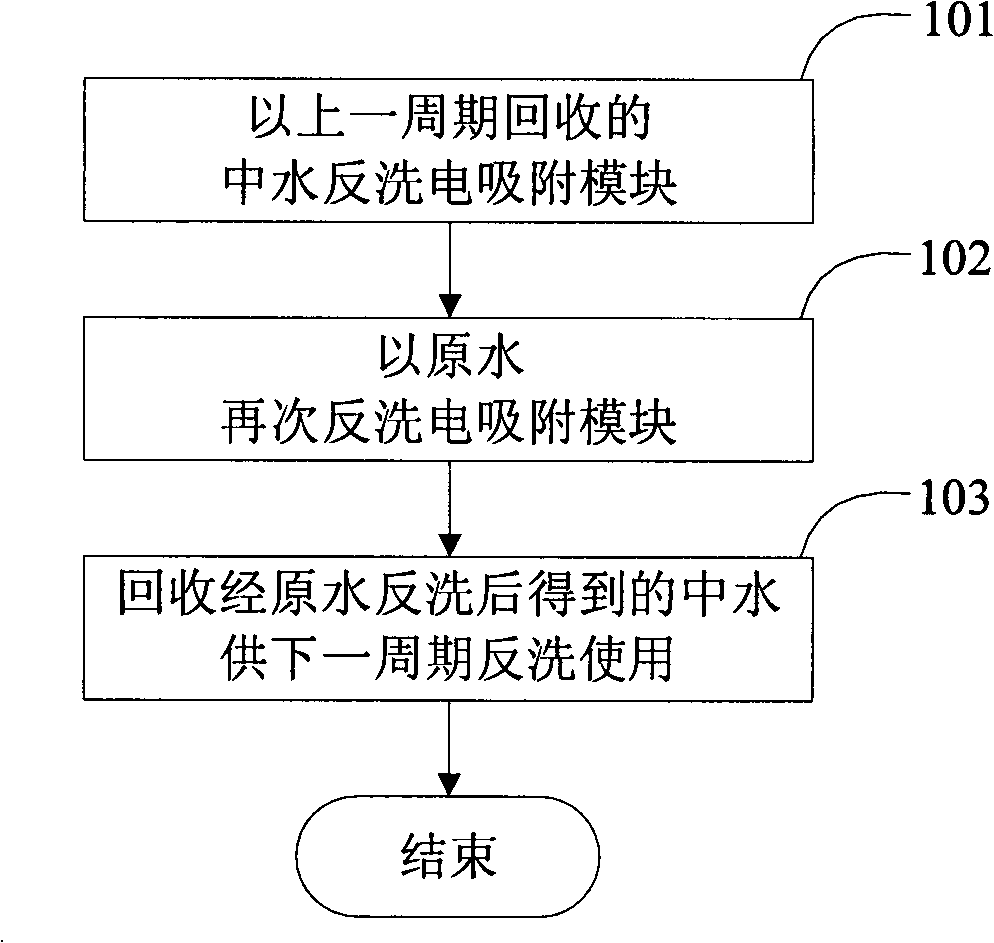

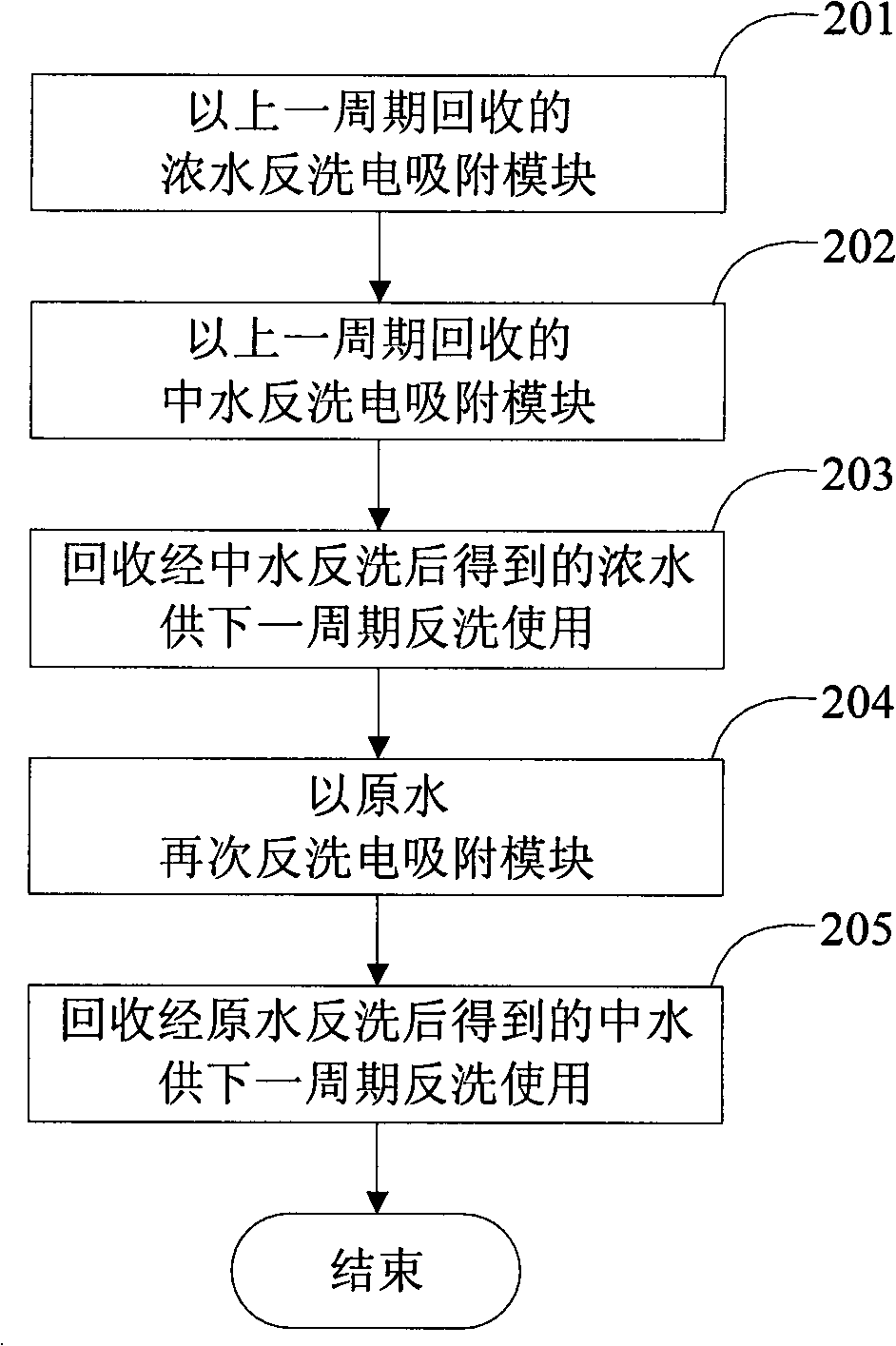

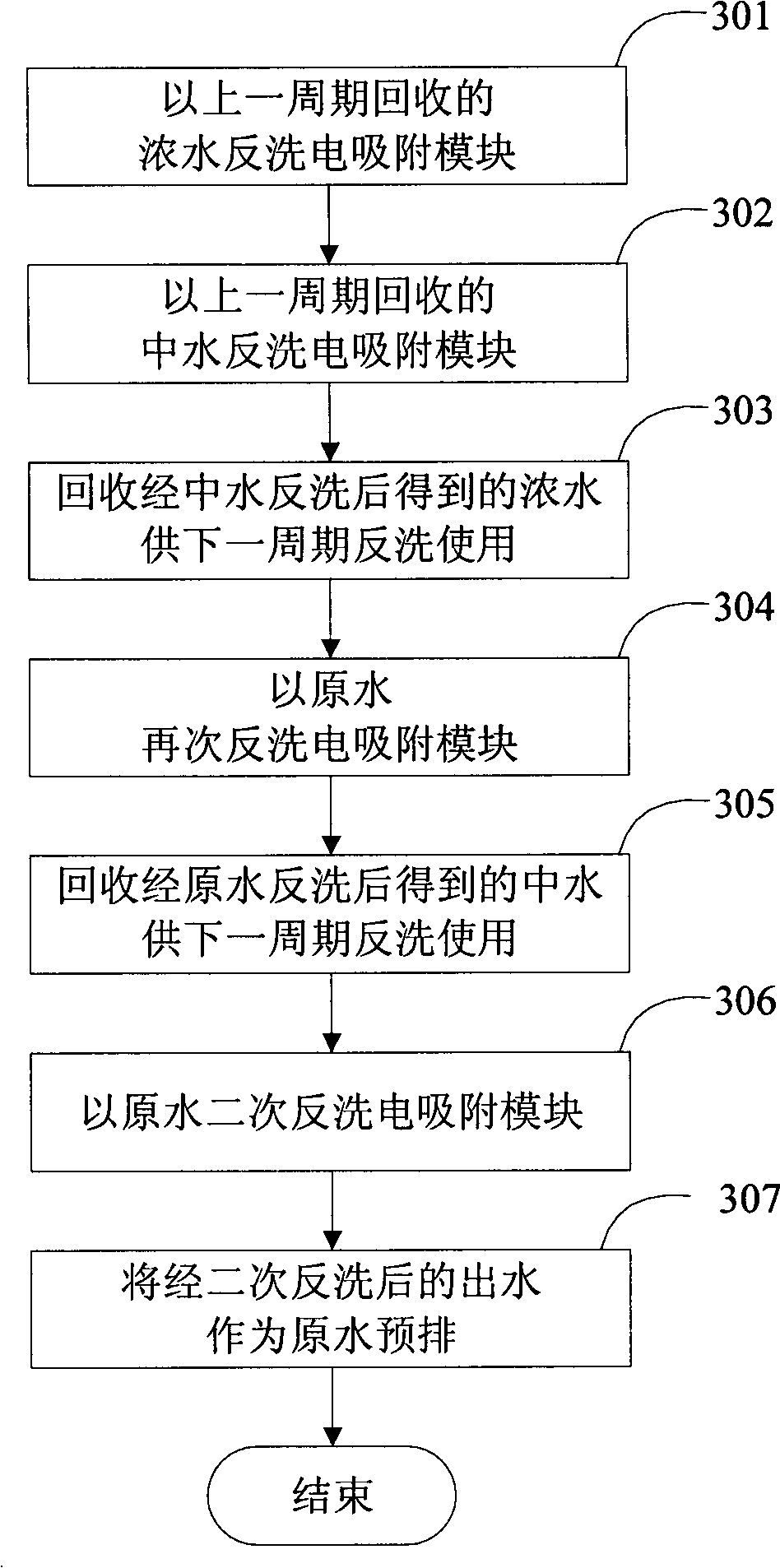

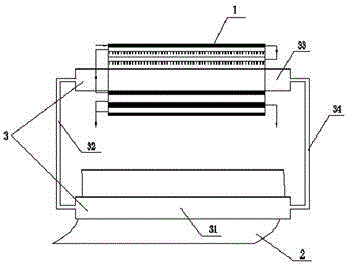

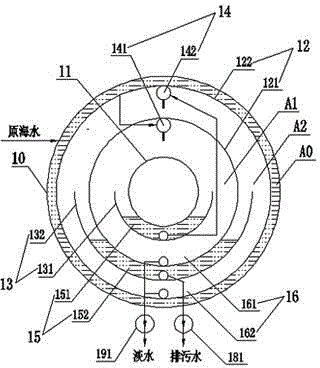

Method and system for desalting and backwashing through electric absorption

ActiveCN102010039ASave raw water consumptionIncrease water production rateDispersed particle separationRaw waterElectricity

The invention discloses a method and a system for desalting and backwashing through electric absorption, belonging to the field of water treatment. The invention aims at solving the problem that the prior art can not ensure both the regeneration effect of an electric absorbing module and higher water yield. The method comprises the following steps of: backwashing the electric absorbing module by water recycled in the previous period, re-backwashing the electric absorbing module by raw water, and recycling water obtained by backwashing through the raw water for backwashing in the next period. The system comprises an electric absorbing module to be regenerated, a recycled water tank, a recycled water backwashing unit, a raw water tank, a raw water backwashing unit and a recycling water unit. By increasing the steps and units on the basis of the prior art, the invention realizes both the regeneration effect of the electric absorbing module and the higher water yield.

Owner:EST WATER & TECH

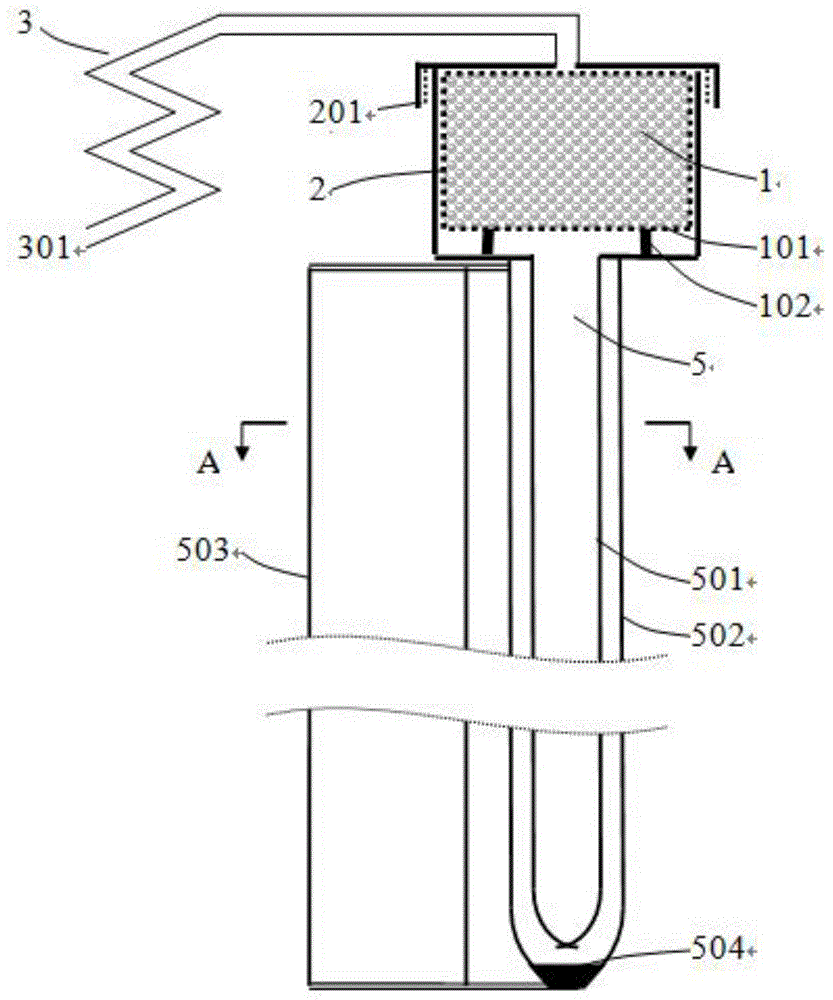

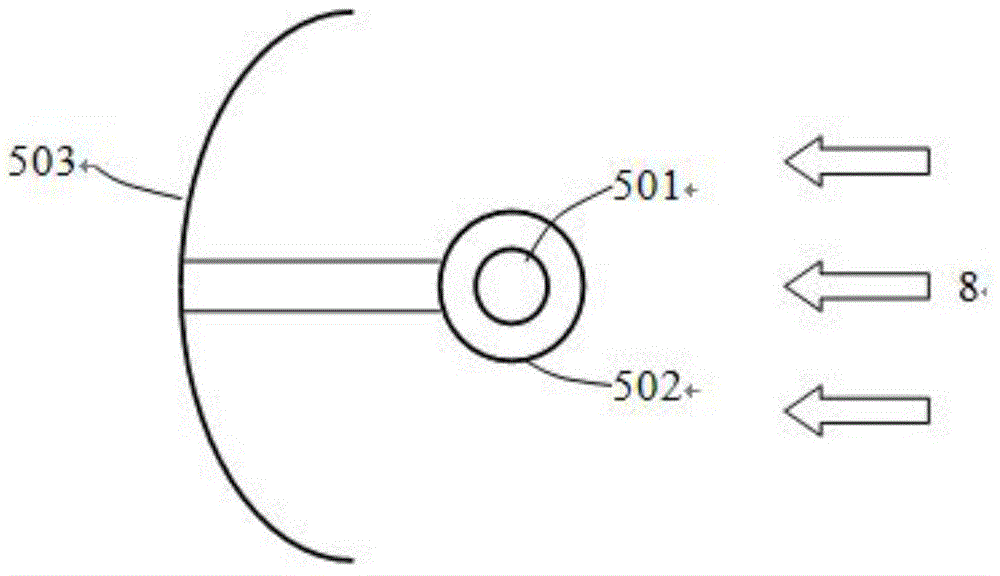

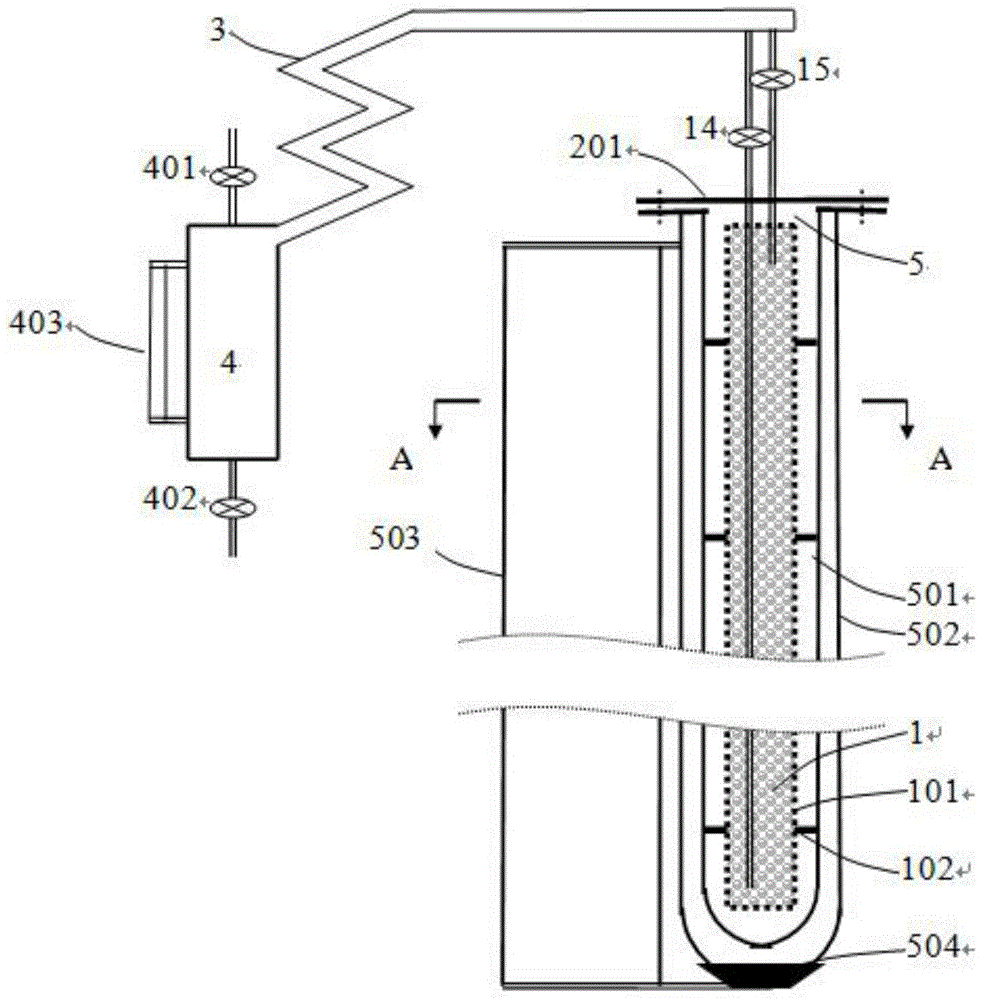

Loop heat pipe-type cylindrical solar seawater desalination device

ActiveCN104591327AIncrease heat transfer distanceHigh heat transferGeneral water supply conservationSeawater treatmentDistillationConcentration ratio

The invention discloses a loop heat pipe-type cylindrical solar seawater desalination device. The device comprises a cylindrical multiple-effect distiller, a light collection groove and a loop heat pipe. An evaporating pipe of the loop heat pipe is used as a solar heat collecting pipe and a condenser pipe of the loop heat pipe is used as a distiller heating pipe so that characteristics of good heat transfer performance and high integral efficiency are obtained. A heating pipe, a heat-transfer pipe, a semi-circular groove and a nozzle unit are tightly arranged in a heat-insulation cylinder inner-cavity so that a pre-heating chamber, a distillation chamber, a seawater tank and a fresh water tank are formed and thus the distiller structure is very compact, can be processed easily and is suitable for standard production. The distiller has the characteristics of repeated use of vaporization latent heat, reinforcement of inner heat and mass transfer processes and improvement of an operation temperature. The heat transfer areas of the distillation chamber are increased from inside to outside so that a small heat transfer temperature difference is kept, the whole distiller effective number is improved and a concentration ratio and a water yield are further improved. The loop heat pipe-type cylindrical solar seawater desalination device is suitable for low-cost modularization production and can be widely used in the field of solar energy seawater desalination.

Owner:JIMEI UNIV

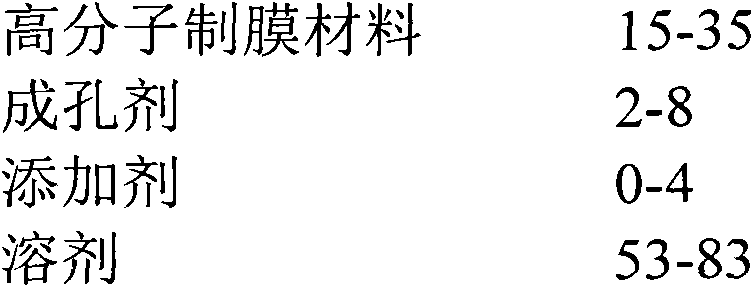

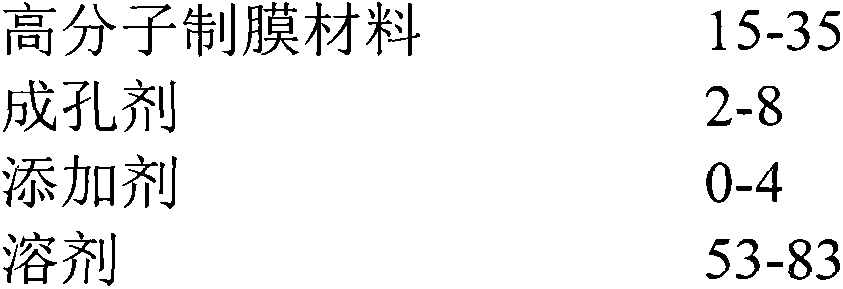

Internal pressure type fiber-reinforced filter membrane and preparation method thereof

ActiveCN103949166ASimple designEasy to operateSemi-permeable membranesInternal pressureWater production

The invention relates to an internal pressure type fiber-reinforced filter membrane and a preparation method thereof. The internal pressure type fiber-reinforced filter membrane is formed by coating the inner surface of a hollow braided tube with a layer of high-polymer membrane casting liquid and carrying out solidification and water washing under the action of internal and external coagulating bath solutions. By preparing the membrane by virtue of the hollow braided tube, the membrane casting liquid and a spinneret plate coextruded by internal coagulating core liquid, a continuous membrane preparation process is realized; the high-polymer membrane casting liquid contains a hydrophilic agent, and thus the prepared fiber-reinforced filter membrane is high in flux and strong in anti-pollution capacity. The internal pressure type fiber-reinforced filter membrane has the beneficial effects that the filter precision is high, a pore structure of the membrane can be controlled by virtue of process parameters of a membrane casting liquid preparation process and a membrane preparation process, the cross flow of inlet water is realized, the reflux ratio is low, and the water production rate is high; compared with an internal pressure type filter membrane, the internal pressure type fiber-reinforced filter membrane has the advantages that a runner is wide and is unlikely to be blocked, feed liquid with high content of suspended solids can be directly processed, and the pretreatment cost is lowered.

Owner:盐城海普润科技股份有限公司

Preparation method of gourmet powder industrial waste water treatment membrane cleaning agent

InactiveCN102029113AGuaranteed uptimeRestore fluxSemi-permeable membranesCleansing AgentsFatty alcohol

The invention relates to a preparation method of a gourmet powder industrial waste water treatment membrane cleaning agent. The preparation method comprises the following steps of: mixing inorganic salt, a coupling agent, a function monomer with surface activity, a stabilizer, an addition agent, an organic solvent and deionized water, placing the materials in a reactor, and stirring at normal temperature and normal pressure to prepare the gourmet powder industrial waste water treatment membrane cleaning agent. The gourmet powder industrial waste water treatment membrane cleaning agent is prepared by using ethanol water as the medium and comprises the following components in percent by weight: 20-33% of sodium hydroxide, 0.5-5% of sodium triphosphate, 2.5-5% of sodium alkyl benzene sulfonate, 0.1-0.5% of alkyl polyglucoside, 1-5% of kieselguhr, 1-5% of sodium hypochlorite, 1-6% of sodium silicate, 0.3-0.8% of fatty alcohol polyoxyethylene ether sulfate, 0.1-0.5% of zirconium aluminum acid ester coupling agent, 0-5% of sodium sulfate, 0-8% of sodium carbonate, 0-7% of edetic acid disodium slat, 5-10% of ethanol and 35-45% of water. The gourmet powder industrial waste water treatment membrane cleaning agent is prepared by the step of stirring the components for 4-8h at room temperature and normal pressure in a reactor.

Owner:CHINA NAT OFFSHORE OIL CORP +1

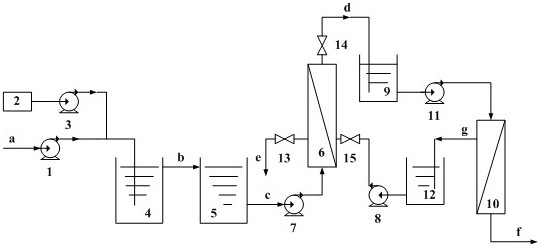

Device and method for performing advanced treatment on citric acid waste water through dual membrane process

ActiveCN102690003AIncreased loading areaCompact structureWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSilt Density IndexUltrafiltration

The invention relates to a device and a method for performing advanced treatment on citric acid waste water through dual membrane process. The device comprises an inflow system, a flocculating settling system, a ceramic membrane ultrafiltration system and a reverse osmosis system which are connected in sequence. The method is characterized in that citric acid waste water processed after (Anoxic / Oxic) A / O process is further flocculated and settled and then enters into the ceramic membrane ultrafiltration system. Effluent of the ceramic membrane ultrafiltration system meets requirements that Silting Density Index (SDI) is equal to or less than 2 and is then processed by the reverse osmosis system. Reverse osmosis (RO) effluent can be directly used as process water (workshop section including size mixing, fermentation, extraction, lime milk configuration and the like) for producing citric acid and softening water (circulating cooling water and make-up water). By means of the dual membrane process, the device and the method realize treatment and reuse of citric acid waste water, the equipment is compact, the automation degree is high, the operation is simple and convenient, effluent quality is good and stable and the device and method have remarkable environmental benefit and economic benefit.

Owner:JIANGSU JIUWU HITECH

Solar seawater desalination plant and operation method thereof

InactiveCN102328965ARealize cascade utilizationIncrease water production rateGeneral water supply conservationSeawater treatmentDistillationDesorption

The invention discloses a solar seawater desalination plant and an operation method thereof, belonging to the technical field of seawater desalination. The plant mainly consists of an air circulation system, a seawater treatment system, a solar heating system, a fresh water collecting system and the like. According to the invention, saturated air generates fresh water in a large temperature difference range through humidifying air with hot seawater and then dehumidifying the air with cold seawater by virtue of an adsorption type air water taking device and a saturated air humidifying and dehumidifying type solar distillation device, and simultaneously, cold air generates fresh water in a small temperature difference range through adsorption and desorption processes, thereby utilizing the moisture content of the air to the greatest extent, realizing the generation of fresh water by using air in the full temperature difference range and a full humidity range, effectively improving the fresh water yield of air flow per unit and improving the property index of the whole system.

Owner:苏州南师大智慧创意产业有限公司

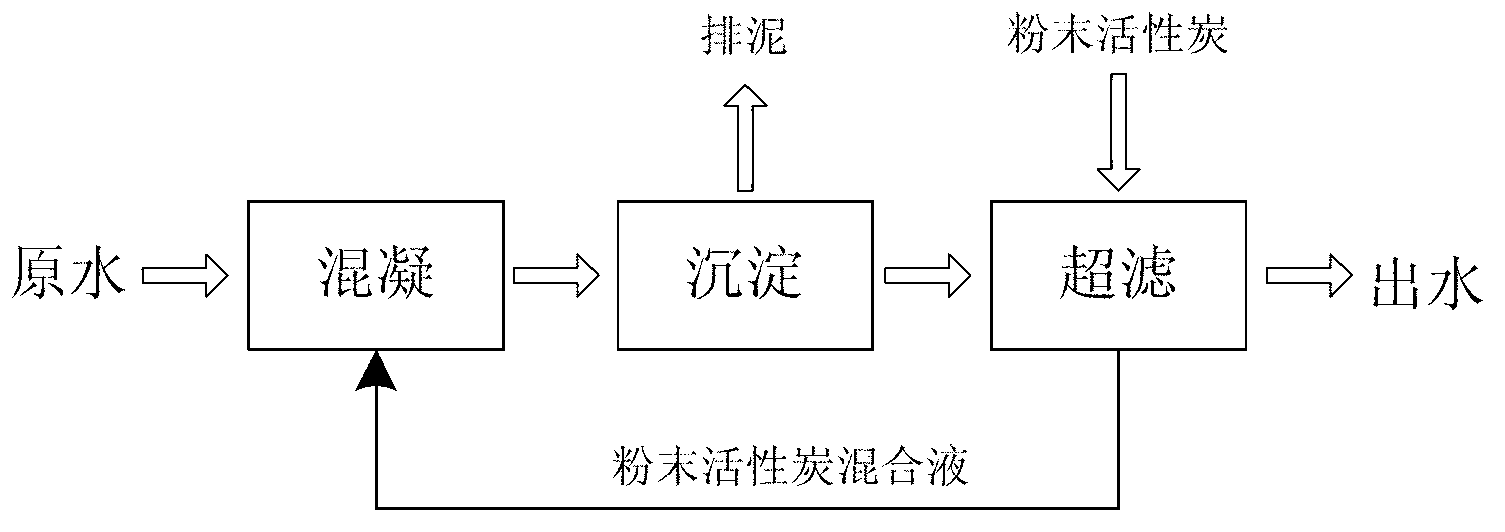

Powdered activated carbon reflux/ultrafiltration combined technology for water treatment plant

InactiveCN103214117AReduce pollution pressureReduce operational complexityMultistage water/sewage treatmentActivated carbonFlocculation

The invention relates to a powdered activated carbon reflux / ultrafiltration combined technology for a water treatment plant. The technology is characterized in that powdered activated carbon are fed into an ultrafiltration membrane tank, and the powdered activated carbon which are kept in the ultrafiltration membrane tank for a proper time are refluxed to a pre-treatment coagulation period at a proper reflux ratio through utilizing a reflux pump, wherein the addition amount of the powdered activated carbon is 5-20mg / L, the reflux ratio is 1%-5% of a system flow, and the retention time of the powdered activated carbon is 2-24 hours. The organic pollutant content of raw water is reduced through fully utilizing the adsorptive capability of the powdered activated carbon in a mixed liquid of the technology, powdered activated carbon particles serve as flocculation cores so as to enhance coagulation, and a treatment effect of a coagulation period is improved; and moreover, the operation stability of a system is improved, and the water production rate is increased. The technology can be widely applied to an ultrafiltration combined technology for the water treatment plant.

Owner:BEIJING UNIV OF TECH

Equipment for collecting water from ambient air

InactiveCN104452885AThere will be no local overheating damageHeating up fastDrinking water installationLiquid waterWater vapor

The present invention relates to the technical field of extracting water from air, in particular to equipment for collecting water from ambient air by using a solid absorbent. The equipment mainly comprises a moisture absorption unit, a heater and a condenser, wherein the moisture absorption unit is respectively communicated with the heater and the condenser, heat generated by the heater promotes air to circularly flow between the moisture absorption unit and the heating surface of the heater, circular airflow transmits the heat provided by the heater to the moisture absorption unit, the moisture absorption unit desorbs to produce water vapor, and then the water vapor is condensed in the condenser into liquid water. The equipment for collecting water from ambient air provided by the invention has a simple structure and can achieve a higher water yield.

Owner:GUANGDONG UNIV OF TECH

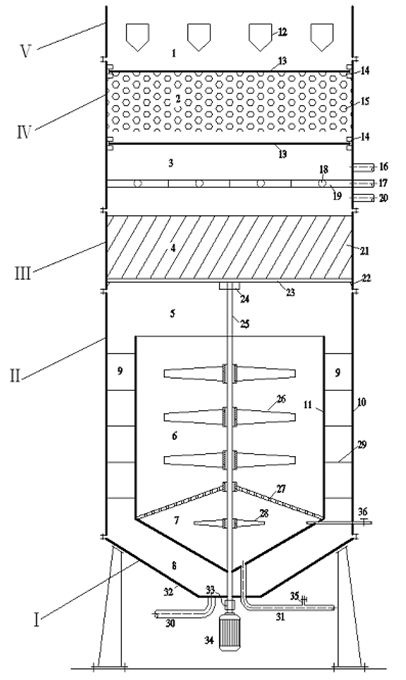

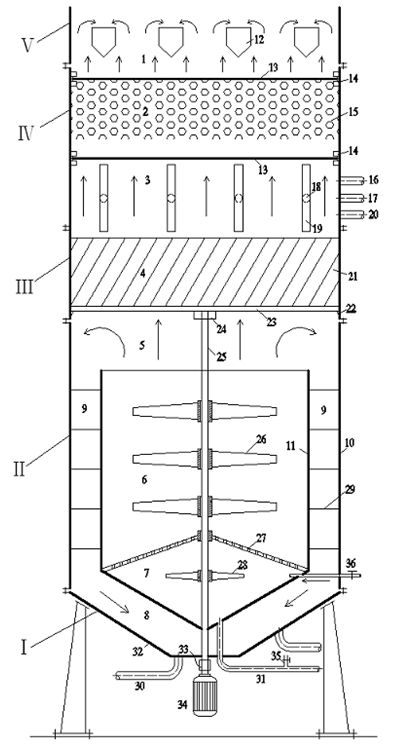

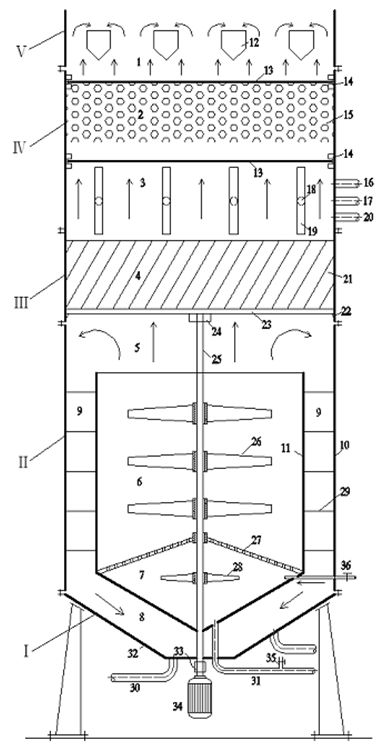

Intensive integrated water purification equipment

InactiveCN102120655ASmall footprintImprove land utilizationMultistage water/sewage treatmentFlocculationSludge

The invention discloses intensive integrated water purification equipment. The equipment is separated into five sections according to difference of water purification units, and the five sections are connected through flanges; and the equipment is provided with a mud collecting area, a primary flocculation area, an inner-cylinder clustering flocculation area / and an outer-cylinder sludge concentration area, a sludge separation area, an inclined tube sedimentation area, a backwashing gas distribution area, a filtration area, and a clear water area from bottom to top. The equipment is provided with devices such as an agitator blade used for particles to form agglomerated floc, a rotary gas distribution plate used for gas-water backwashing of a filter material, small-space spiral sloping panels used for concentrating sludge and the like; and the whole equipment is simple in structure, water purification functional units are compactly connected, the flat plane utilization rate is high, and the equipment is convenient to operate, can maximize the water purification function, and has important practical significance for medium and small water supply systems.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Zero-emission reuse treatment method for electroplating cyanide-containing wastewater

ActiveCN102718350ASimple process conditionsReduce processing costsWater contaminantsWaste water treatment from metallurgical processFiltrationReverse osmosis

The invention discloses a zero-emission reuse treatment method for electroplating cyanide-containing wastewater and relates to a wastewater treatment technology. The wastewater is sent to a raw water regulation pool and then passes through a photocatalytic oxidation reactor and a membrane coagulation gas flotation reactor successively; back flushing outflow water of the membrane coagulation gas flotation reactor flows back to the raw water regulation pool; the outflow water of the membrane coagulation gas flotation reactor is sent to a continuous membrane filtration system for filtering, concentrated liquor of the continuous membrane filtration system and back-flushed water flow back to the raw water regulation pool; outflow water of the continuous membrane filtration system passes through a reverse osmosis system, an anion exchange column, an electro-adsorption reactor and a cation exchange column successively, and outflow water of the cation exchange column is recyclable purified water; eluted concentrated water of the electro-adsorption reactor and concentrated water of the reverse osmosis system are sent to a reverse osmosis concentrated water collecting pool, and outflow water enters a membrane contact reactor for cyanogen recovery; outflow water of the membrane contact reactor is sent to the electro-adsorption reactor, and metal electroplating liquid is obtained through evaporation, crystallization and concentration of eluted concentrated water; and outflow water of the electro-adsorption reactor is sent to the cation exchange column, and the outflow water is recyclable purified water.

Owner:厦门溢盛环保科技有限公司

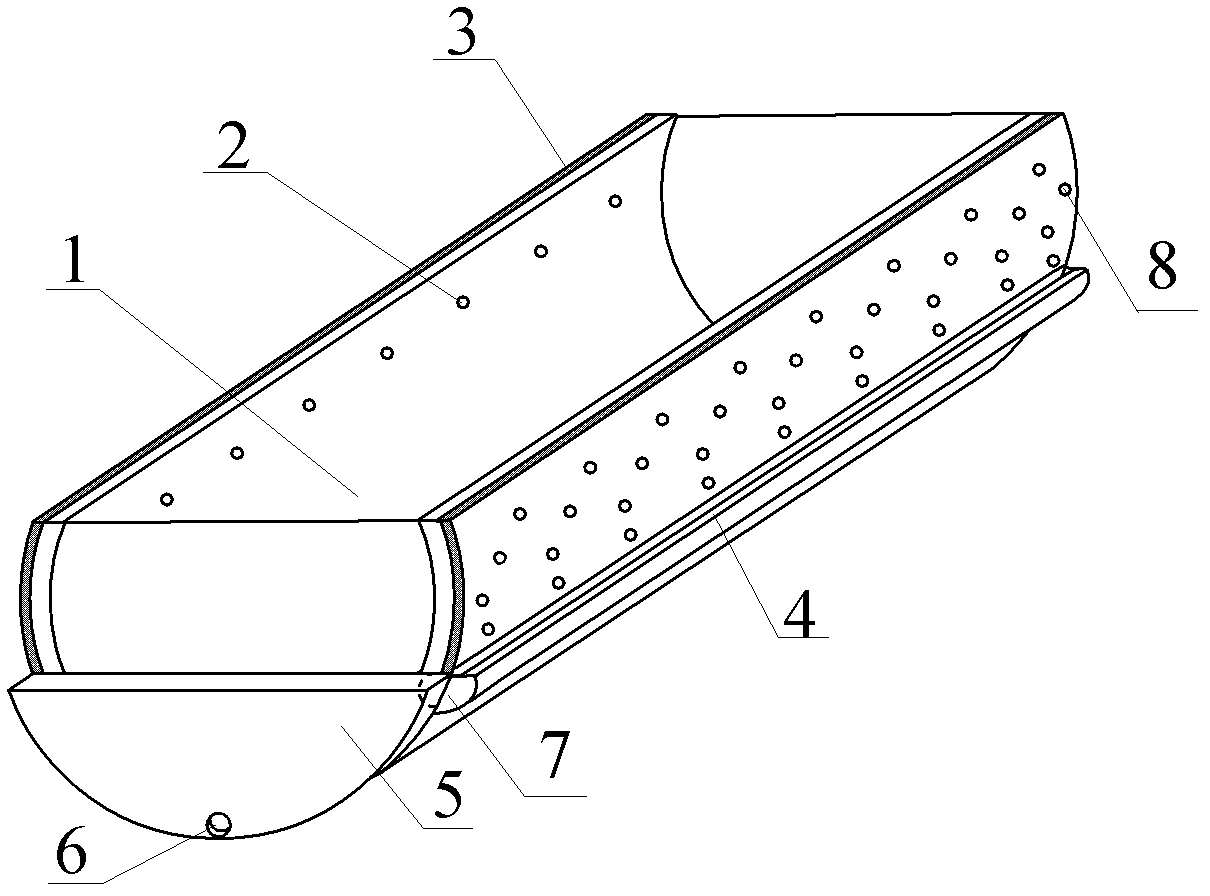

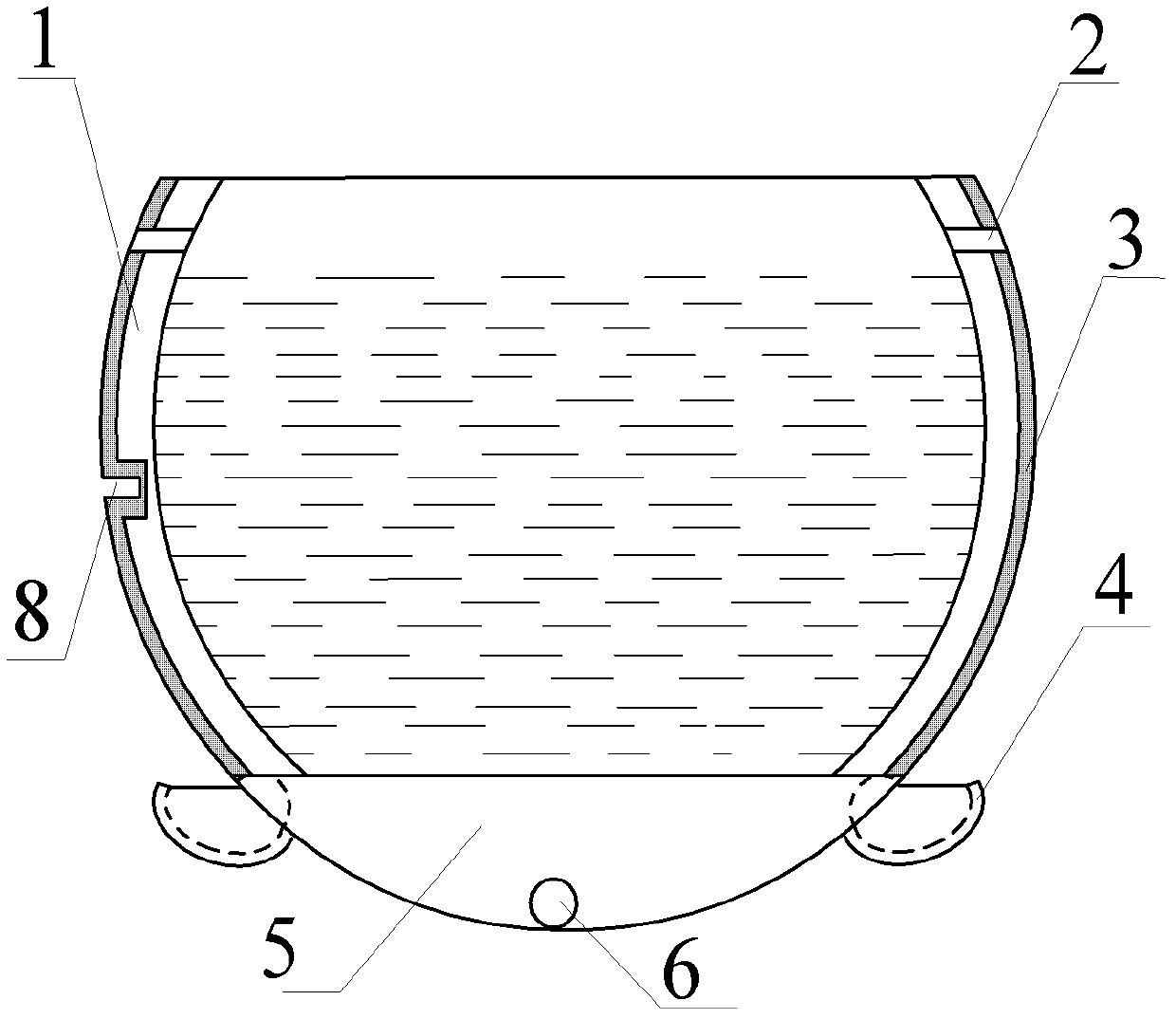

Hydrophilic evaporation tank for tubular solar desalination device

InactiveCN102603022AImprove efficiencyIncrease water production rateGeneral water supply conservationSeawater treatmentSeawaterHoneycomb

The invention provides a hydrophilic evaporation tank for a tubular solar desalination device, which belongs to the technical field of sea water desalinization and water treatment. The hydrophilic evaporation tank comprises a water tank, a hydrophilic ceramic membrane, catchment wings and a catchment device, wherein a cylindrical shell serves as the water tank, and an opening is axially formed onthe upper edge of the shell; through holes are uniformly and axially distributed on the outer edges on two sides at the top of the water tank; honeycomb holes are uniformly distributed on the outer surface of the water tank, and the hydrophilic ceramic membrane is uniformly adhered on the outer surface of the water tank; grooves are symmetrically arranged below the outer surface sides of the water tank, and the arc catchment wings equilong with the water tank are welded on the outer edges of the grooves; one ends of the catchment wings are semi-closed, and the other ends of the catchment wings are closed; the catchment device is arranged at one end of the water tank, and a drain hole is formed on the catchment device; and holes on the catchment wings are communicated with an inner cavity of the catchment device. The hydrophilic evaporation tank utilizes the hydrophilic performance of the hydrophilic ceramic membrane and the honeycomb hole structure to enhance the heat energy utilization efficiency of the tubular solar desalination device, thus enhancing water production rate and shortening system water outlet time.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

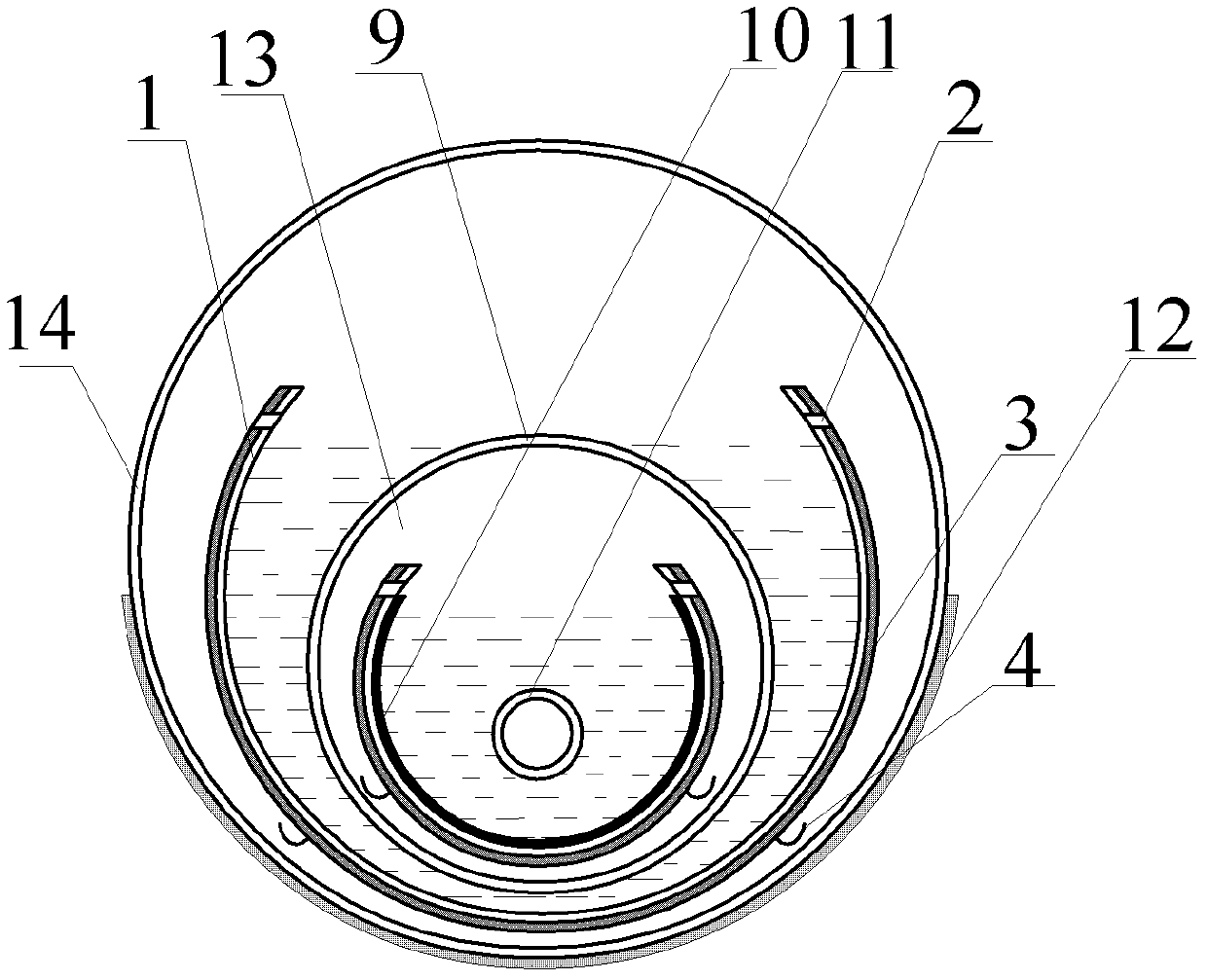

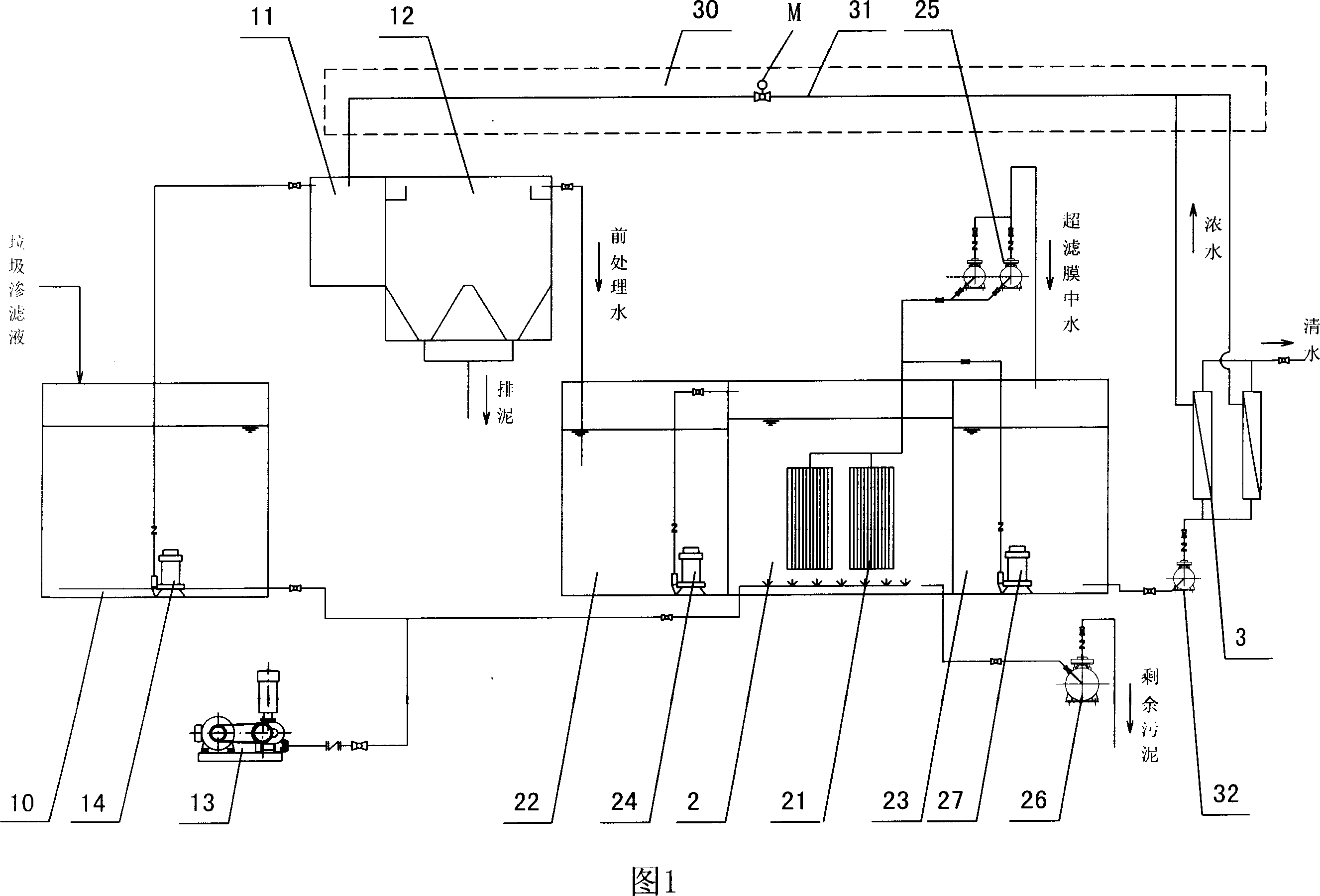

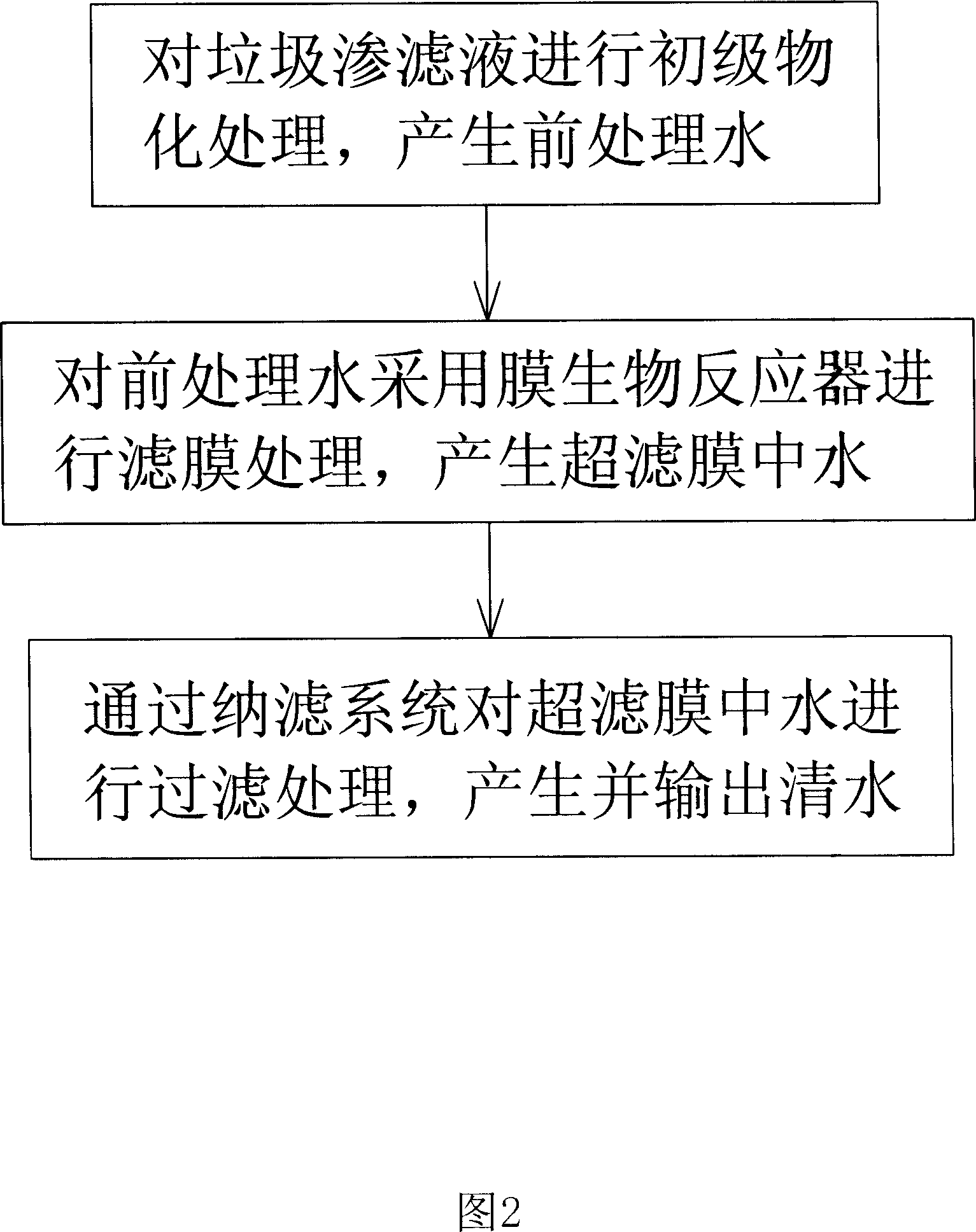

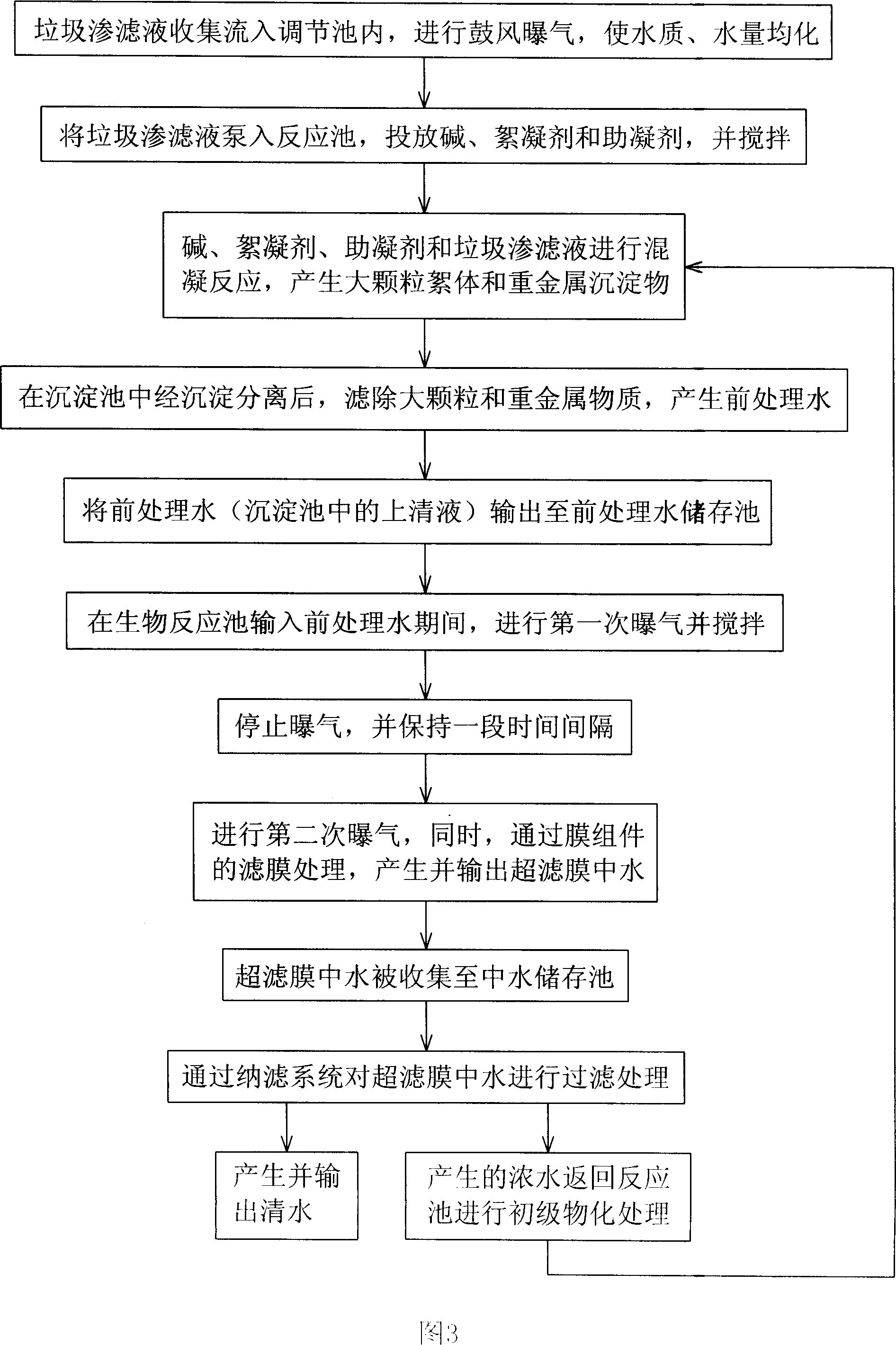

Garbage leachate processing process and system based on membrane bioreactor-nano filtering membrane technology

ActiveCN1970474AGuarantee water qualityHigh quality and stable water qualityWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesMembrane technologyFilter system

The invention discloses a rubbish percolation liquid disposing technique and system based on film biological reactor-nanometer filter film technique, which comprises the following steps: A. proceeding primary physicochemical disposal for rubbish percolation liquid; removing large particle and heavy metal material in the rubbish percolation liquid; forming front disposal water; B. adopting film biological reactor to do filter film disposal; generating hyperfiltration membrane water; C. filtering hyperfiltration membrane water through nanometer filter system; generating and outputting clean water. The system contains at least reacting pond, sediment pond and relative pump equipment to dispose primary physicochemical disposal, which also concludes nanometer filter system to do filtering disposal for water in the hyperfiltration membrane to output clean water.

Owner:JIANGXI JDL ENVIRONMENTAL PROTECTION CO LTD

Landfill leachate treatment method

InactiveCN110713314AReduce conductivityImprove biodegradabilityWater contaminantsTreatment involving filtrationAmmoniacal nitrogenWater production

The invention relates to the technical field of landfill leachate treatment, in particular to a landfill leachate treatment method. The landfill leachate treatment method comprises the following steps: step 1, treatment in an adjusting tank; step 2, electric flocculation treatment; step 3, anaerobic tank treatment; step 4, treatment in an anoxic tank; 5, aerobic treatment on the MBR membrane reactor; step 6, filter treatment; step 7, NF membrane and RO membrane treatment; and step 8, treatment on the landfill leachate concentrated solution. The landfill leachate treatment method can effectively reduce the conductivity and part of COD, ammonia nitrogen and other pollutants in the leachate; the biodegradability and stability of the landfill leachate are improved, the occupied area of a biochemical treatment system is reduced under the same condition, the service life of a membrane system is prolonged, the water production rate of the membrane system is improved, and meanwhile, the problems encountered in recharging and evaporation of a concentrated solution are effectively solved.

Owner:GUANGREEN ENVIRONMENTAL PROTECTION ENG

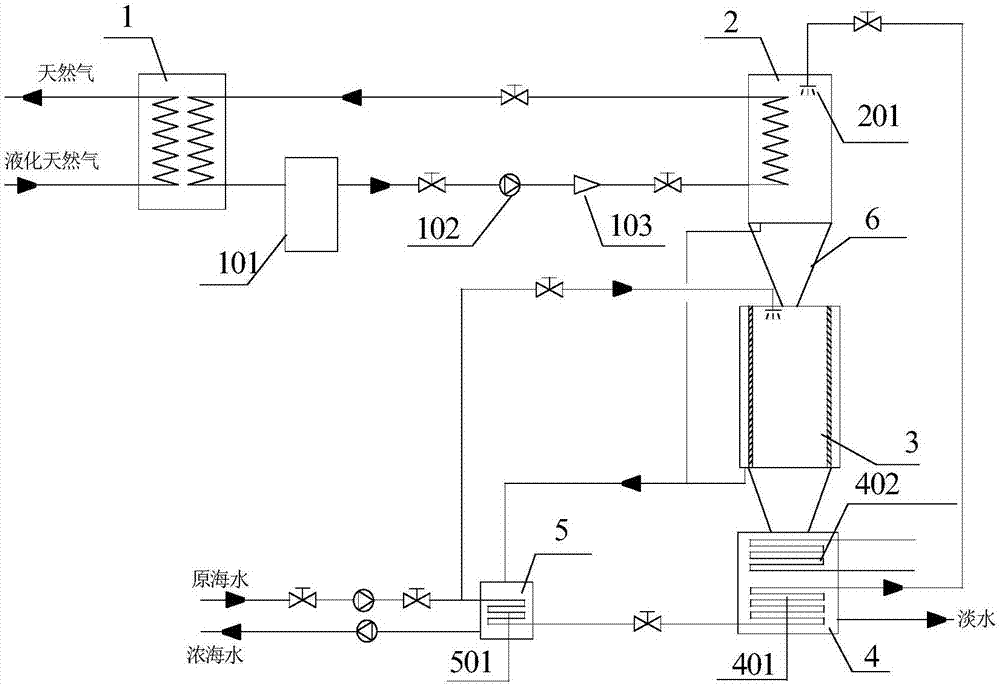

Composite sea water desalination method and system based on cold energy of liquefied natural gas

ActiveCN107140772AHigh purityHelp to separateGeneral water supply conservationSeawater treatmentWater desalinationIce water

The invention provides a freezing-water adding-centrifugation composite sea water desalination method and system based on cold energy of liquefied natural gas. The method comprises the following steps: (1) exchanging heat between LNG (Liquefied Natural Gas) and a second refrigerant, and freezing sea water into sheet ice and concentrated sea water through the second refrigerant via a sheet ice maker; (2) conveying the obtained sheet ice into a filtering type centrifugal desalination device, and adding raw sea water; (3) centrifugating an obtained ice-water mixture; (4) melting separated ice. The invention further provides a sea water desalination system based on the cold energy of the LNG. According to the method and the system, the low-cost cold energy of the LNG is used as a cold source for the process; by the adding of the raw sea water, the melting of part of the ice is accelerated, and the brine viscosity on the ice surface is reduced, so that salt cells can be separated under the mechanically centrifugal action; by optimization of parameters of all stages of desalination operations, high desalinization rate and high water yield are realized; furthermore, the engineering cost is reduced, the time and the energy consumption are reduced, and balancing of factors such as an implementation factor is facilitated; the method and the system have extremely high industrial popularization value.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

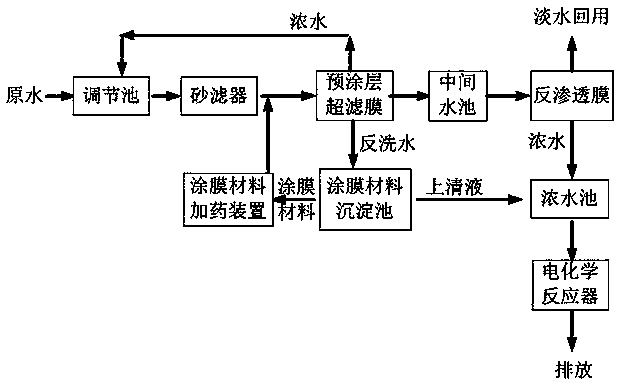

Advanced treatment and reuse method of pre-coated membrane of tail water of sewage plant

ActiveCN103964619AReduce direct contactRealize resource utilizationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentUltrafiltrationElectrochemical response

The invention discloses an advanced treatment and reuse method of a pre-coated membrane of tail water of a sewage plant. The method comprises the following steps: firstly, feeding tail water into an adjusting pool so as to be homogenized, and then passing through a sand filter; passing through an ultrafiltration membrane by a solution containing a pre-coated membrane material and sand filtered effluent and effectively forming a dynamic membrane on the surface of the ultrafiltration membrane, wherein concentrated water of the ultrafiltration membrane returns to the adjusting pool while the effluent enters into a middle water tank; backwashing the ultrafiltration membrane through a pump by part of water in the middle water tank periodically, wherein the pre-coated membrane automatically falls and the sediment of the coating material is recycled to a pre-coated membrane material dosing device repeatedly, so that the operating cost is lowered; entering into reverse osmosis membrane treatment by water in the middle water tank, fresh reverse osmosis membrane is used as industrial water in the park to be returned, and the concentrated water is treated by an electrochemical reactor, and the effluent reaches the standard to be discharged. By adopting the pre-coated membrane method, the ultrafiltration backwashing frequency is low, and the water yield of the ultrafiltration membrane is improved. Loose filter cake layers with great holes can be formed to effectively relieve the rate of descent of membrane flux, improve the anti-pollution capacity of the membrane and improve the removal effect of the membrane on the water quality index at the same time.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

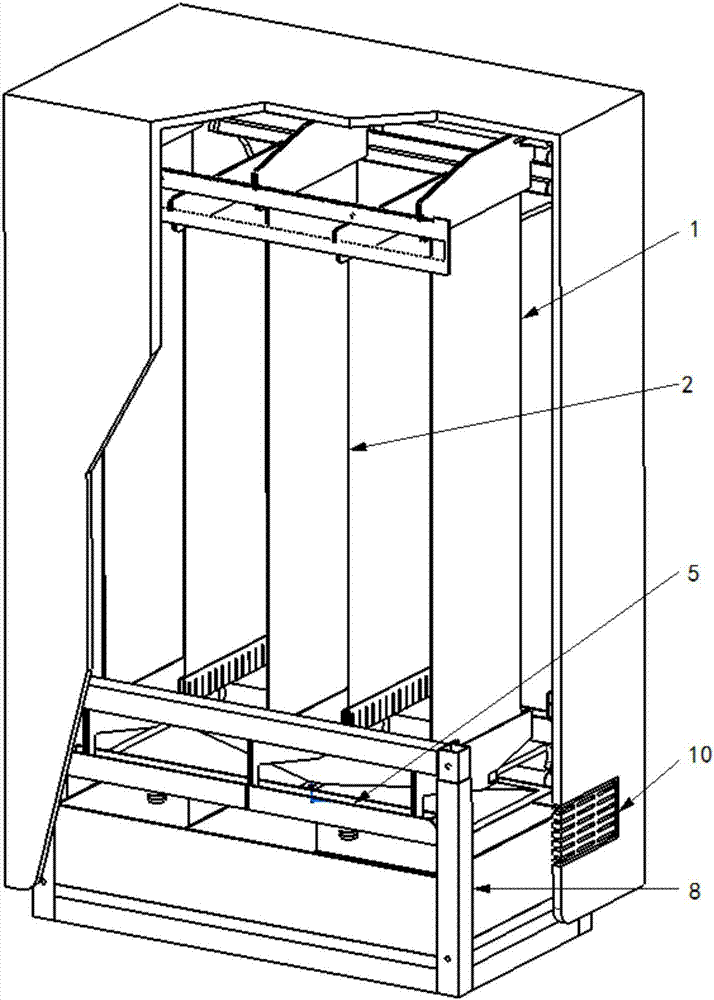

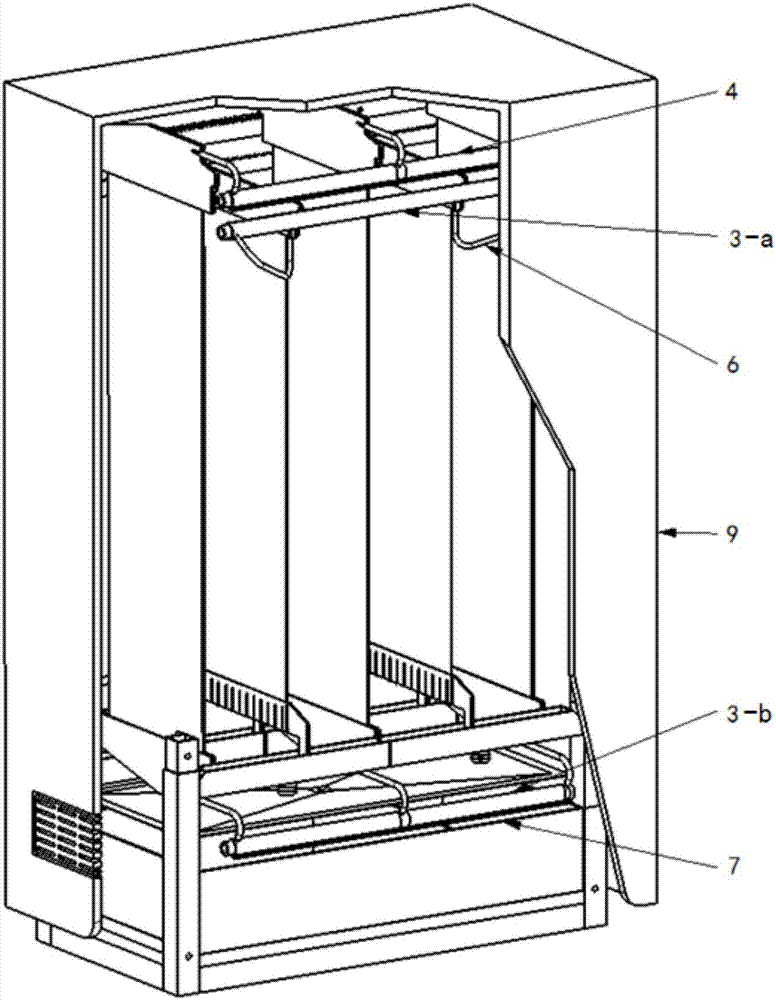

Distillation method and device for seawater desalination at atmospheric pressure

PendingCN107096246ALow energy consumptionIncrease water production rateGeneral water supply conservationSeawater treatmentSeawaterWater collection

The invention discloses a distillation method and device for seawater desalination at atmospheric pressure. The distillation device comprises an atmospheric pressure distillation module, wherein the atmospheric pressure distillation module comprises an atmospheric pressure box structure, a plurality of hollow water collection plate assemblies and a plurality of liquid-absorbing core board assemblies, wherein the hollow water collection plate assemblies and the liquid-absorbing core board assemblies are arranged in an inner cavity of the atmospheric pressure box structure in an interphase manner, and one liquid-absorbing core board assembly is arranged between two adjacent hollow water collection plate assemblies; catch basin assemblies for collecting condensed distilled water are arranged at the lower ends of the outer walls of the hollow water collection plate assemblies; the flow direction of a fluid in each hollow water collection plate assembly is opposite to that in each liquid-absorbing core board assembly; the temperature of the fluid which flows through the inner cavity of a hollow core board of each hollow water collection plate assembly is lower than that which flows through two sides of the panel of a liquid-absorbing core board of each liquid-absorbing core board assembly; and the operating temperature of the fluid which flows through two sides of the panel of each liquid-absorbing core board is 55-98 DEG C. Therefore, the water production performance and the efficiency of a system can be effectively improved, and the operation cost of the system is reduced.

Owner:南京艾普能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com