Device and method for performing advanced treatment on citric acid waste water through dual membrane process

A technology for citric acid wastewater and advanced treatment, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of improving the overall water production rate, low operating energy consumption, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

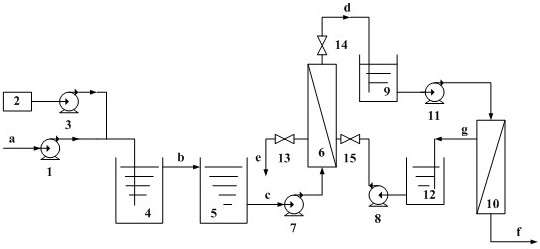

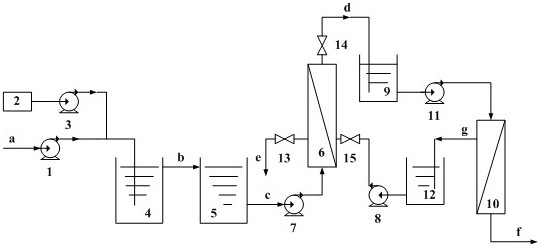

[0056] Such as figure 1 As shown, a device for advanced treatment of citric acid wastewater according to the present invention includes a water inlet system, a flocculation sedimentation system, a ceramic membrane ultrafiltration system and a reverse osmosis system connected in sequence. The water inlet system includes an inlet pump 1; the flocculation and sedimentation system includes a flocculant storage tank 2, a flocculant metering pump 3, an inclined tube settling tank 4 and a clear liquid tank 5; the ceramic membrane ultrafiltration system includes a ceramic membrane ultrafiltration module 6 and ceramic Membrane feed pump 7; reverse osmosis system includes reverse osmosis component 10, feed pump 11 and reverse osmosis concentrated water tank 12; citric acid wastewater enters inclined tube settling tank 4 through inlet pump 1, and is discharged to The clear liquid pool 5 is pumped by the ceramic membrane feed pump 7 to the ceramic membrane ultrafiltration module 6 for ult...

Embodiment 2

[0058] Compared with Embodiment 1, the only difference is that ceramic membrane recoil pump 8 is provided in ceramic membrane ultrafiltration assembly 6 in this embodiment, and the connection sequence of each part is as follows: inlet pump 1 is connected to inclined tube settling tank 4, and in the A flocculant storage tank 2 and a flocculant metering pump 3 are arranged between the water inlet pump 1 and the inclined tube settling tank 4, wherein the inclined tube settling tank 4, the clear liquid tank 5, the ceramic membrane ultrafiltration module 6, and the ceramic membrane feeding pump 7 , a ceramic membrane recoil pump 8, an intermediate pool 9, a reverse osmosis component 10, a reverse osmosis feed pump 11 and a reverse osmosis concentrated water pool 12 are connected in sequence.

[0059] In this embodiment, the inclined tube settling tank 4 adopts Ф60 honeycomb packing.

[0060] In this embodiment, the material of the ceramic ultrafiltration membrane is alumina, and th...

Embodiment 3

[0063] Compared with Example 2, the difference is only that: the ceramic membrane ultrafiltration assembly in this embodiment includes a ceramic ultrafiltration membrane and a ceramic membrane recoil pump; the material of the ceramic ultrafiltration membrane is zirconia, and the ceramic ultrafiltration membrane The average pore size ranges from 0.02-0.1 μm. The reverse osmosis component is a roll type reverse osmosis membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com