Self-supporting composite material as well as preparation method and application thereof

A composite material, self-supporting technology, applied in the field of electrocatalysis, can solve the problems of poor stability for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

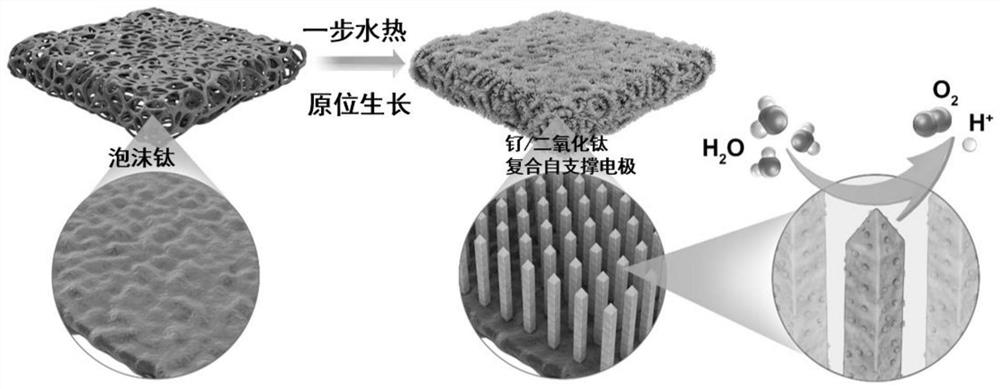

[0032] The invention provides a kind of preparation method of self-supporting composite material, comprises the following steps:

[0033] Etching the foamed titanium with acid to obtain etched foamed titanium;

[0034] The self-supporting composite material is obtained by mixing the etched foam titanium, the soluble ruthenium source and the acid solution, and performing a solvothermal reaction.

[0035] In the invention, the foamed titanium is acid-etched to obtain etched foamed titanium. In the present invention, the thickness of the titanium foam is preferably 0.5-0.7 mm, more preferably 0.6 mm; the pore diameter is preferably 0.04-0.06 mm, more preferably 0.05 mm. In the present invention, there is no special limitation on the size of the foamed titanium, which can be set as required. In the present invention, before the acid etching, it is preferable to further include: washing the foamed titanium with water, acetone and absolute ethanol in sequence. In the present inve...

Embodiment 1

[0066] Cut the titanium foam with a thickness of 0.6mm into a rectangle of 60mm×10mm, and then ultrasonically wash it with ultrapure water, acetone and absolute ethanol for 15 minutes respectively;

[0067] Soak the washed titanium foam in 30mL of 18% hydrochloric acid aqueous solution, acid etch at 90°C for 15min; use 80mL of ultrapure water to ultrasonically wash the acid-etched titanium foam for 4min at a power of 1000W to medium properties, to get etched foam titanium;

[0068] Ruthenium trichloride and 3% hydrochloric acid aqueous solution were mixed to obtain 15 mmol / L ruthenium trichloride solution, and the pH value of the ruthenium trichloride solution was 3.60;

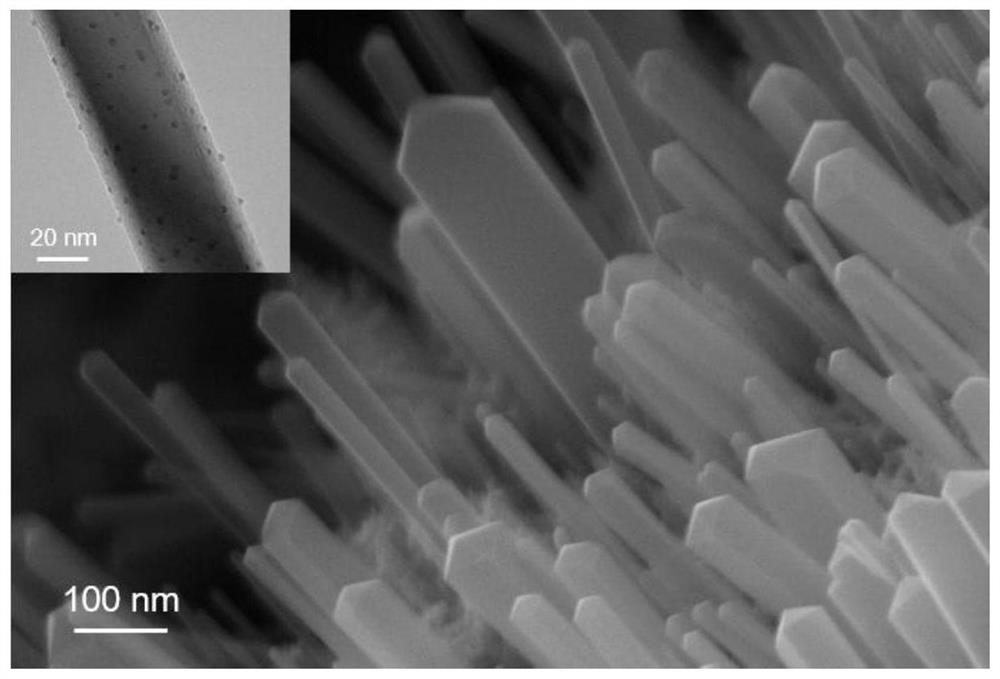

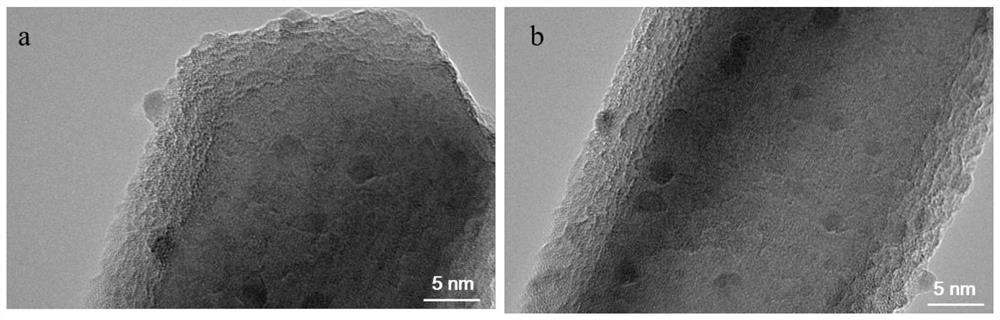

[0069] Put the etched foamed titanium in 10 mL of ruthenium trichloride solution, perform solvothermal reaction at 200 ° C for 20 h, cool down to 25 ° C for solid-liquid separation, and wash the solid obtained by the solid-liquid separation with ultrapure water for 3 and anhydrous ethanol for 3 times, and th...

Embodiment 2

[0071] The self-supporting composite material was prepared according to the method of Example 1, except that the temperature of the solvothermal reaction was 160°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com