Patents

Literature

297 results about "Ruthenium trichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

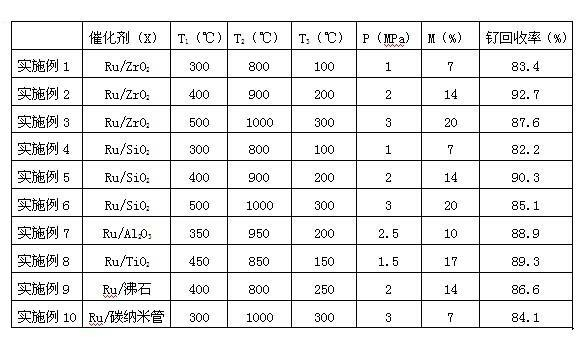

Method for recycling ruthenium in supported type ruthenium catalyst

ActiveCN102108444AReduce recycling stepsEasy to recycleProcess efficiency improvementEconomic benefitsNitrogen

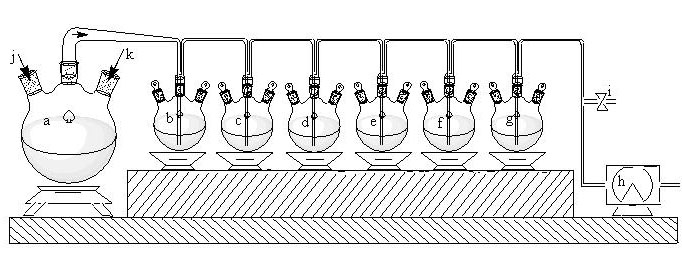

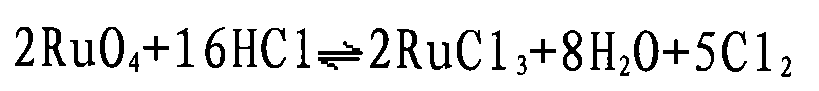

The invention discloses a method for recycling ruthenium in a supported type ruthenium or ruthenium oxide catalyst. The method comprises the following technological steps: (1) placing a supported type ruthenium catalyst or a supported type ruthenium oxide catalyst in an airtight container, heating to 300-500 DEG C, and roasting for 1-2 hours; and feeding nitrogen for protection during roasting process; (2) stopping the feeding of nitrogen stream in the step (1), continuing to heat to 800-1000 DEG C, and roasting for 2-10 hours; and obtaining black solids after cooling; (3) grinding black solids into powder, placing in the airtight container, and heating to 100-300 DEG C; and feeding oxygen / ozone to oxidize solid powder and generate ruthenium tetroxide gas; and (4) feeding the ruthenium tetroxide gas into diluted hydrochloric acid, and restoring the acid combined with the gas into a red and brown ruthenium trichloride solution. According to the device, the step of recycling the catalyst is reduced; not only is the cost reduced during the recycling process of ruthenium catalyst, but also the recycling process is simplified; and economic benefit and the environment benefit are greatly improved.

Owner:KAILUAN ENERGY CHEM

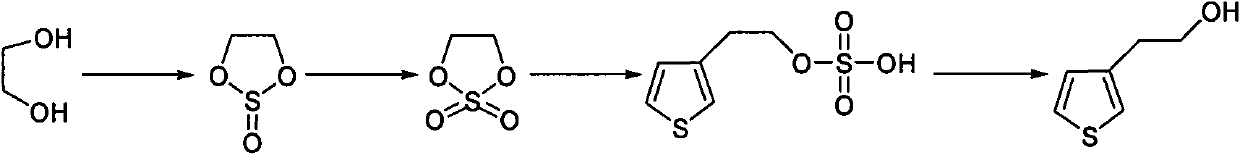

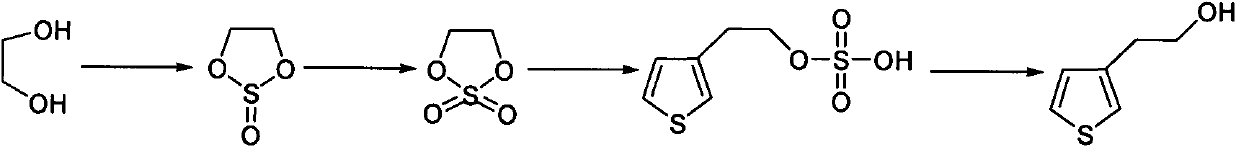

Synthetic method of thiophene-3-ethanol

The invention discloses a synthetic method of thiophene-3-ethanol. The method comprises the following steps of: adding a halogenated hydrocarbon solvent and ethylene glycol into a reaction kettle, dropwise adding thionyl chloride and preserving heat for reacting; separating liquid and extracting to obtain an organic phase containing a substance shown in the specifications; adding a ruthenium trichloride aqueous solution and a sodium bicarbonate aqueous solution in the presence of the halogenated hydrocarbon solvent and dropwise adding a sodium hypochlorite aqueous solution; after detecting that a system does not have oxidizing property, performing liquid separation, concentration, devitrification and drying to obtain a substance shown in the specifications, adding an ester solvent and butyl lithium into a reaction kettle, adding a prepared ester solution of tribromothiofuran and a prepared ester solution of the substance, separating the liquid and extracting to obtain a system containing a substance shown in the specifications; and adding a dilute sulfuric acid into the system containing the substance shown in the specifications, concentrating, neutralizing, extracting and concentrating to obtain an end product. The method has the advantages of high reaction purity and yield, stable process condition, easiness for operation and mass production capability; and the thiophene-3-ethanol is prepared from tribromothiofuran by performing low-temperature lithiation, so that the use of epoxy ethane serving as an explosive hazard is avoided, and mass production becomes possible.

Owner:ASYMCHEM LAB TIANJIN +4

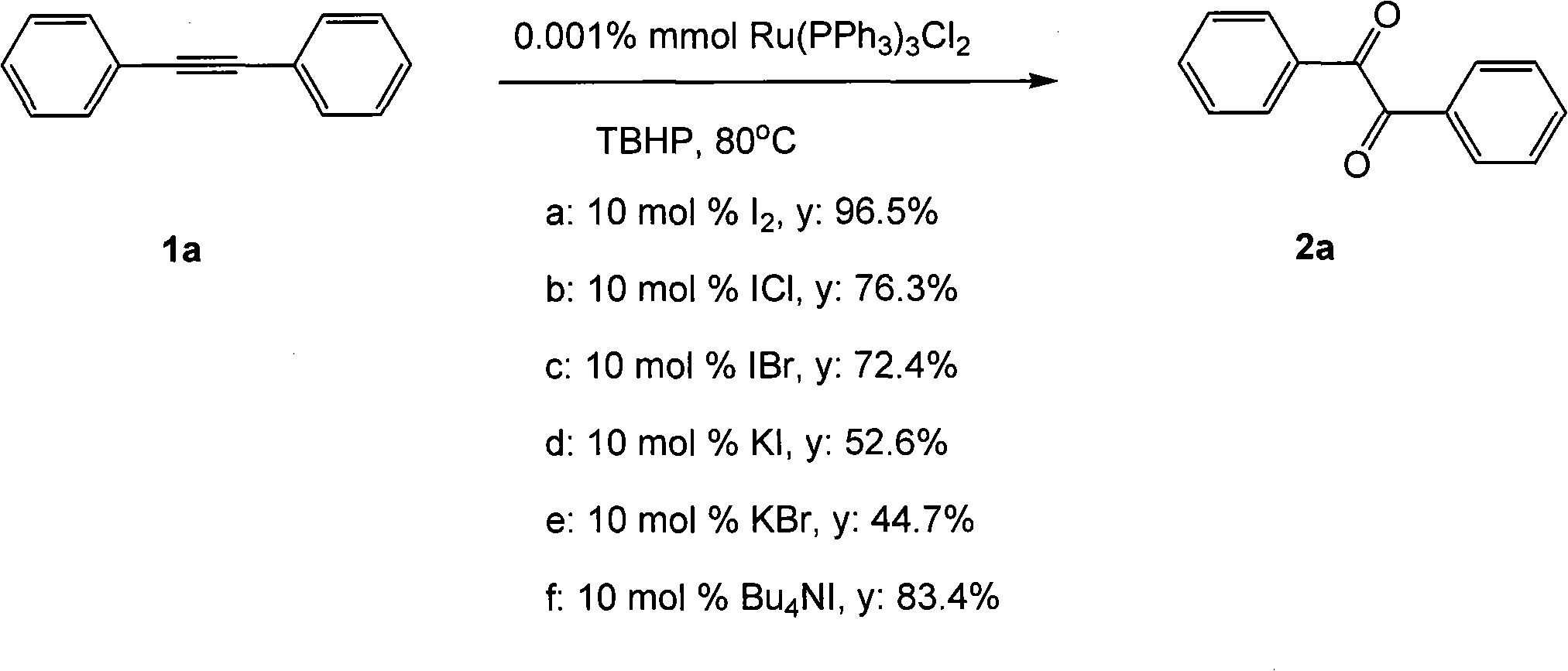

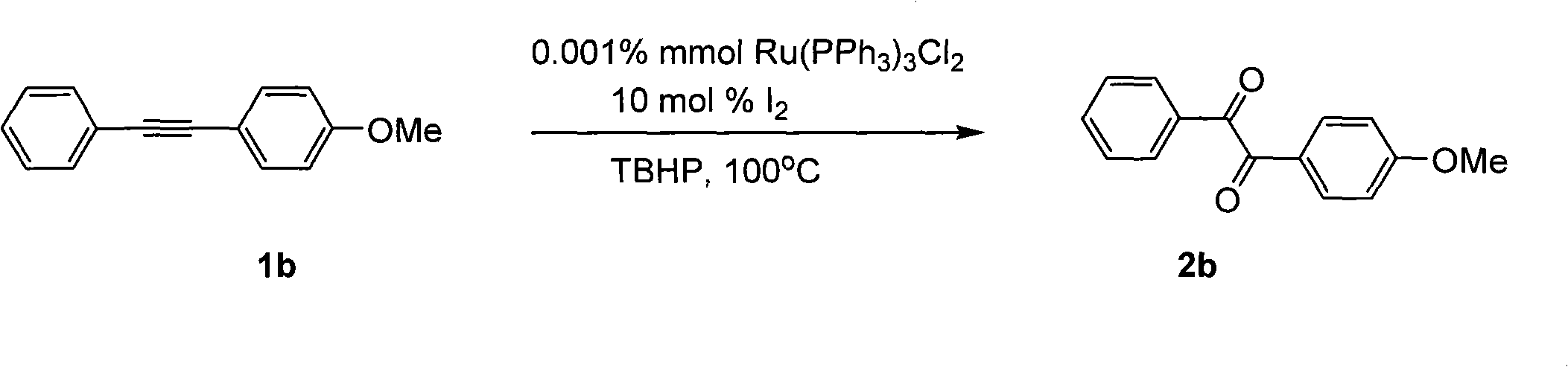

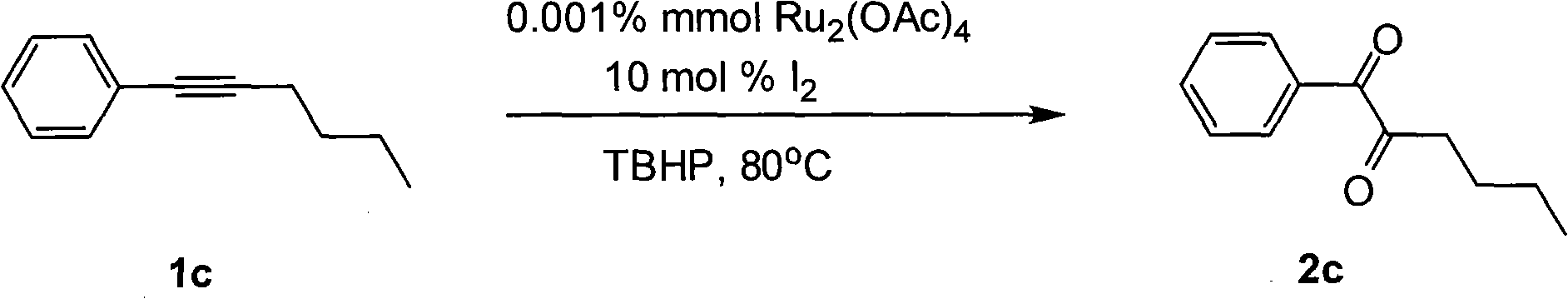

Method for preparing 1, 2-diketone by catalyzing and oxidizing alkynes

InactiveCN101624322AMild reaction conditionsMeet the requirementsCarboxylic acid nitrile preparationOrganic compound preparationCatalytic oxidationKetone

The invention belongs to the field of catalysis and oxidization, and particularly discloses a method for preparing 1, 2-diketone by catalyzing and oxidizing alkynes. The method comprises the following steps: taking alkynes R1-C-C-R2 (acetylenic link exists between C and C) as a reaction substrate, taking one of TBHP, m-chloroperoxybenzoic acid and p-benzoquinone as a oxidant, taking one of dichloro (p-cymene) ruthenium (II) dimer, tri (triphenylphosphine) ruthenous chloride, ruthenium acetate, ruthenium dichlorophenyl (II) dimer, ruthenium trichloride, BINAP ruthenous chloride, dodecacarbonyltriruthenium and tricarbonyldichlororuthenium (II) dimer as a catalyst, taking one of iodine, iodine chloride, iodine bromide, potassium iodide, tetrabutyl ammonium iodide and potassium bromide as a cocatalyst, and taking 1, 4-dioxane as a solvent to react under 40 DEG C to 100 DEG C for 4 to 24 h to prepare the 1, 2-diketone. The method is economic, environmental-friendly and mild.

Owner:SUZHOU UNIV

Titanium electrode for chlorine generator and preparation method thereof

The invention provides a titanium electrode for a chlorine generator and a preparation method thereof, relating to a chlorine generator. The invention provides a titanium electrode with higher chlorine yield efficiency and longer service life for a chlorine generator and a preparation method thereof. The titanium electrode for the chlorine generator is provided with a titanium substrate on which a surface coating is arranged, wherein the surface coating is an oxide layer prepared from the following metals in percentage by mass: 0-70 percent of platinum, 10-80 percent of iridium and 20-90 percent of ruthenium. The preparation method comprises the following steps of: soaking the titanium substrate after surface treatment in water for later use; dissolving chloroplatinic acid, chloro-iridic acid and ruthenium trichloride in a mixed solution of isopropyl alcohol and hydrochloric acid to obtain a coating solution; and cooling, stirring and recoating the coating solution on the titanium substrate, drying, baking, recoating and baking to obtain the finished product.

Owner:INTEX IND (XIAMEN) CO LTD

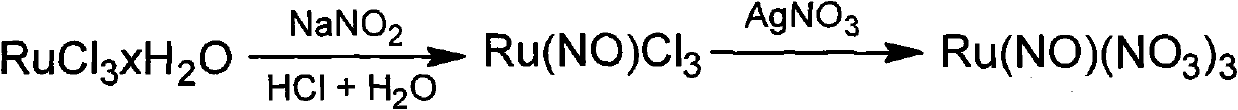

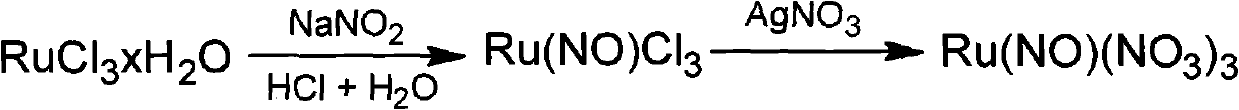

New method for preparing ruthenium nitrosylnitrate solid

ActiveCN102167405AReduce usageHigh purityRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsDiethyl etherSodium nitrite

Owner:KUNMING INST OF PRECIOUS METALS

Method for preparing carbon nano-tube loading ruthenium oxide hydration composite material

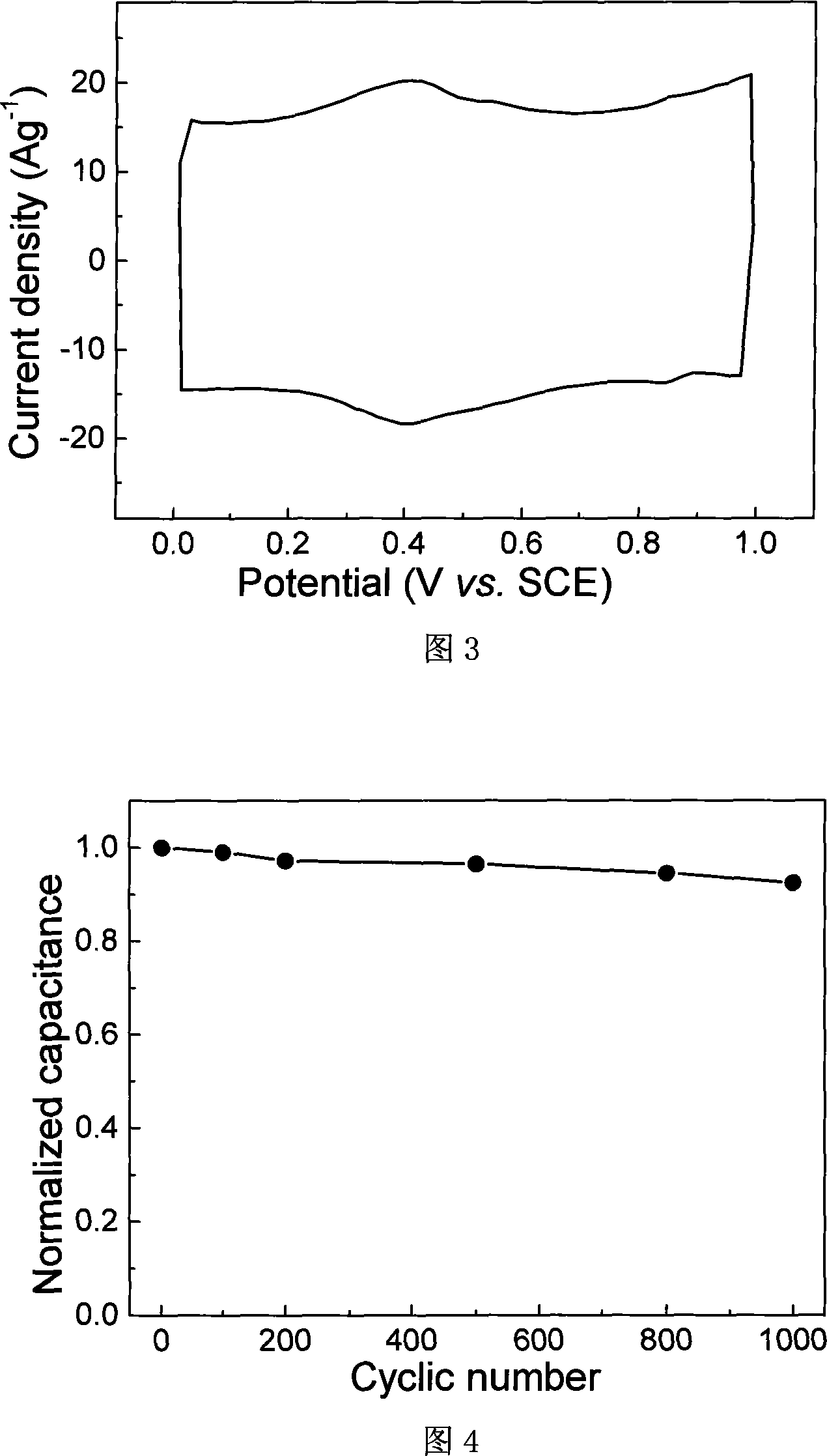

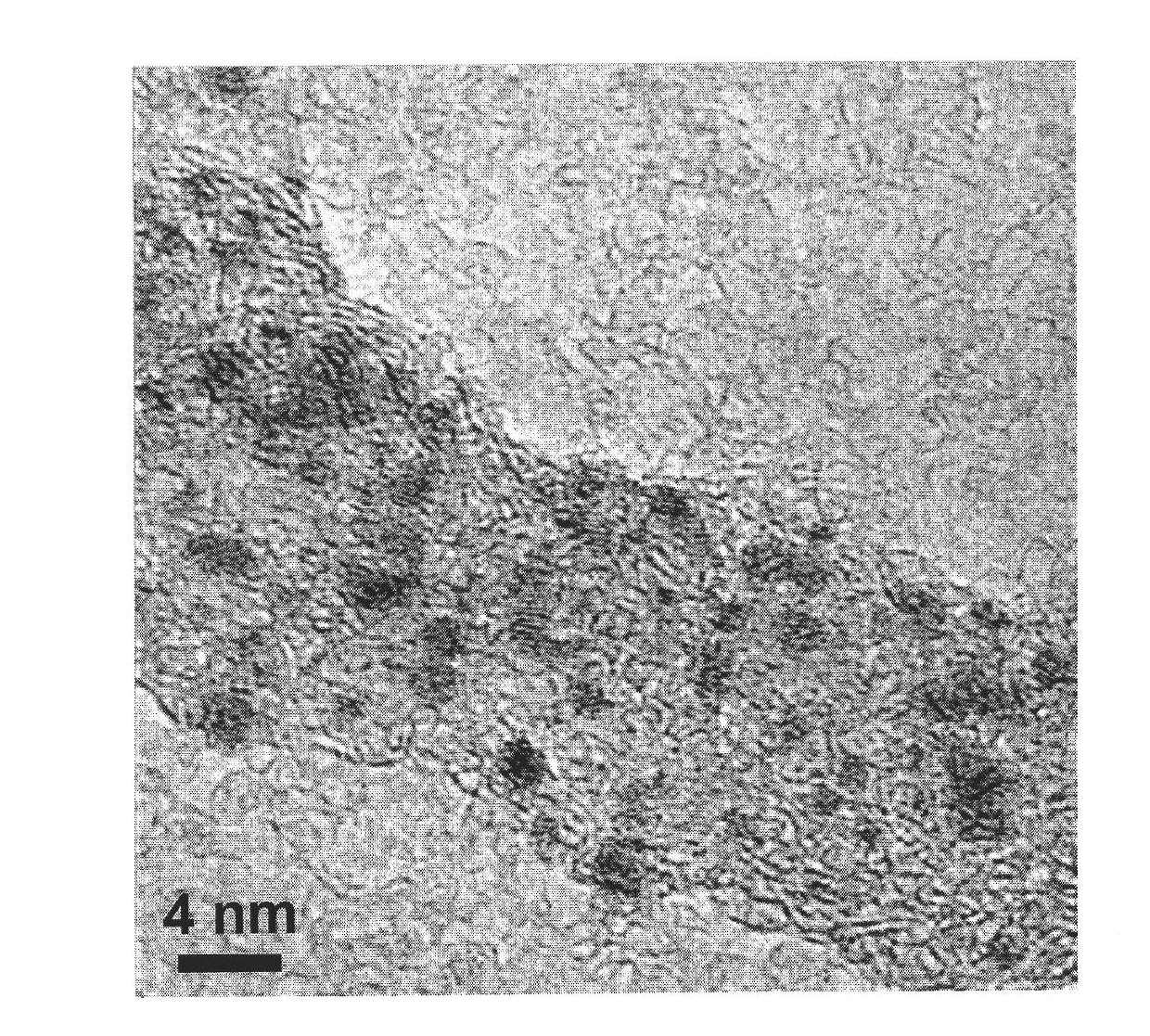

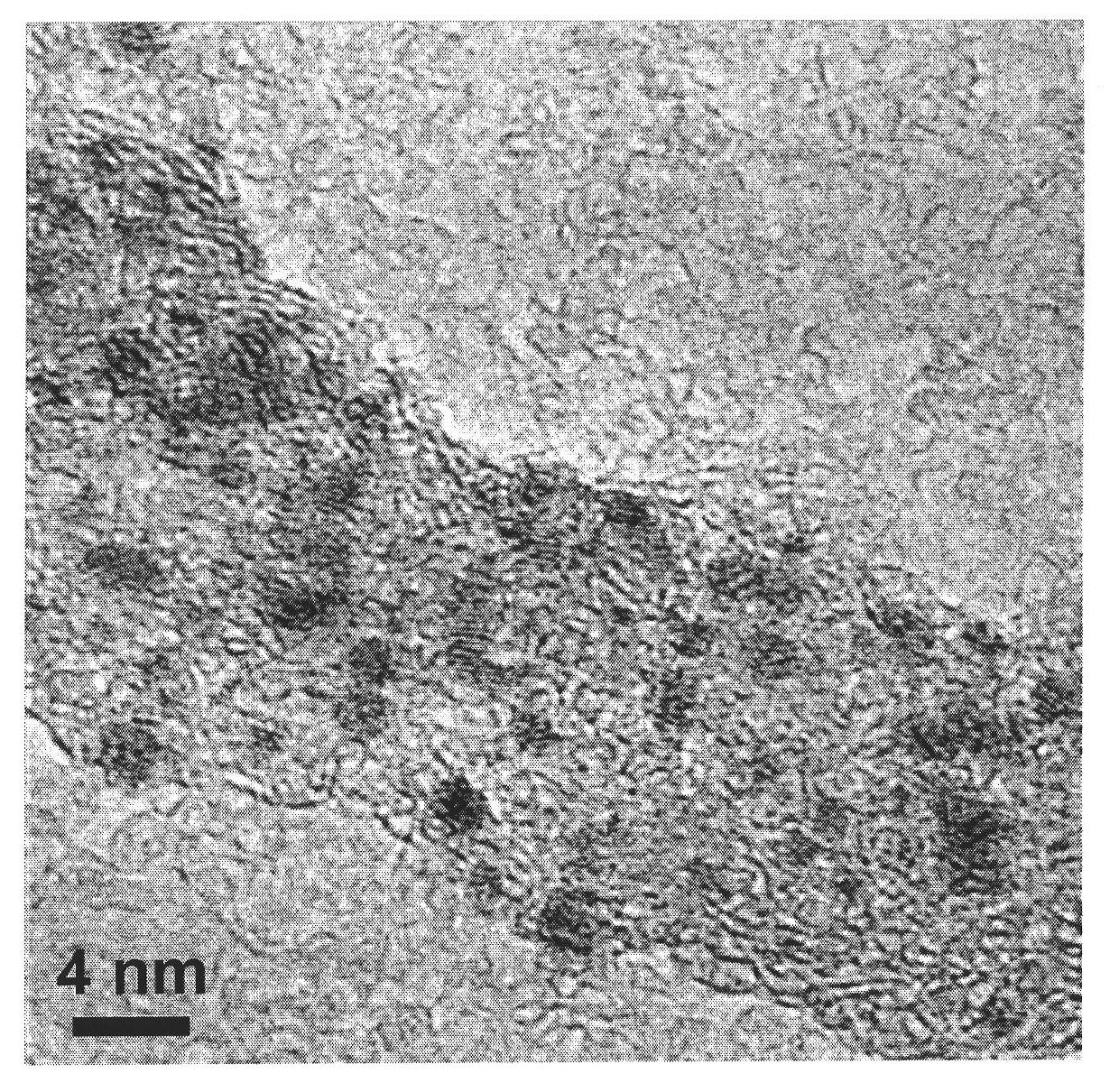

InactiveCN101122040AIncrease loadIncrease profitFixed capacitor electrodesElectrolytic organic material coatingHigh volume manufacturingCarbon nanotube

The invention provides a method of preparing a carbon nano pipe load hydrous ruthenium oxide composite material. First, an electric deposition solution is prepared, and then the carbon nano pipes are spread in the main solution; the ruthenium hydroxide is deposited and loaded on the carbon nano pipes through the electric deposition method, to form the precursor of the carbon nano pipe load hydrous ruthenium oxide composite material; the carbon nano pipes / ruthenium hydroxide settling after the electric deposition are put into a drying box to receive heat treatment, and after natural cooling, the carbon nano pipe load hydrous ruthenium oxide nano powder composite material is obtained. The invention has simple preparing conditions, easy to realize, does not include the complicated technology of re-oxidation treatment after traditional deposition of ruthenium trichloride and alkalinesubstance, so as to prevent introduction of impurity ion, make sure of high purity of products, prevent deficiencies of low output and difficulty in realizng industrialization, can prepare a large amount of carbon nano pipe / hydrous ruthenium oxide compound powder, and helps in industrial large-scale production.

Owner:HARBIN ENG UNIV

Catalyst for ternary polymerization of norbornene, derivative of norbornene, tetrafluoroethylene and cyclohexene and method of ternary polymerization

The invention relates to a catalyst for ternary polymerization of norbornene, a derivative of the norbornene, tetrafluoroethylene and cyclohexene and a method of the ternary polymerization. The preparation method of the catalyst comprises steps of dissolving ruthenium trichloride, ligand and an alkyl metal compound to a first solvent in a dry single-opening glass bottle in which inert gas is filled, sealing the bottle opening by using an emulsion tube, keeping the bottle at the constant temperature for 20-30 minutes in the water bath of 50 DEC C, cooling and obtaining a ruthenium complex catalyst. Compared with the prior art, the catalyst is the novel ruthenium complex catalyst, the catalyst can produce catalytic activity under certain pressure, at the temperature from 20 DEG C to 120 DEG C and in the nitrogen protection system, the norbornene, the tetrafluoroethylene and the cyclohexene are catalyzed and are subjected to the ternary polymerization, and products are easy to wash and separate after being soaked by methanol. The yield of copolymer is high, the reaction temperature is low, the catalyst is easy to obtain and the catalyst efficiency is high.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Fuel cell anode catalyst using heteropolyacid as promoter and preparation method thereof

InactiveCN1624963AHigh activityEnhanced anti-toxicityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsFuel cellsHeteropoly acid

This invention relates to a preparing method of positive pole catalyst of fuel battery using heteropolyacid as improver, including: (1) add the carbon carrier into the mixture solution of nitric acid and vitriol to react to get pre-process carbon carrier; (2) impregnate the carbon carrier in the heteropolyacid solution, heat process and obtain the electric conducting carbon carrier containing heteropolyacid; (3) suspend the conducting carbon carrier of (2) in the secondary distilled water, stir and make the carrier disperse and get carbon dispersing liquid; (4) fully dissolve chloroplatinic acid or platinous chloride and ruthenium trichloride in deionized water, and drop it to the dispersing solution of (3); (5) dry to get the catalyst containing heteropolyacid.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of graphene supported ruthenium oxide electrode materials

ActiveCN102005307AOvercoming the current situation of low specific capacitanceLower specific capacitanceElectrolytic capacitorsCalcinationSodium hydroxide

The invention provides a preparation method of graphene supported ruthenium oxide electrode materials, which comprises the following steps of: adding sodium hydroxide into graphite oxide colloid subjected to ultrasonic stripping to regulate the pH value; dripping the regulated graphite oxide colloid into a water-containing ruthenium trichloride solution; then, adding sodium hydroxide into the mixed solution to regulate the pH value to 7; filtering materials after hydro-thermal treatment; drying the materials after water washing; and obtaining the graphene supported ruthenium oxide super capacitor electrode materials after low-temperature calcinations.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

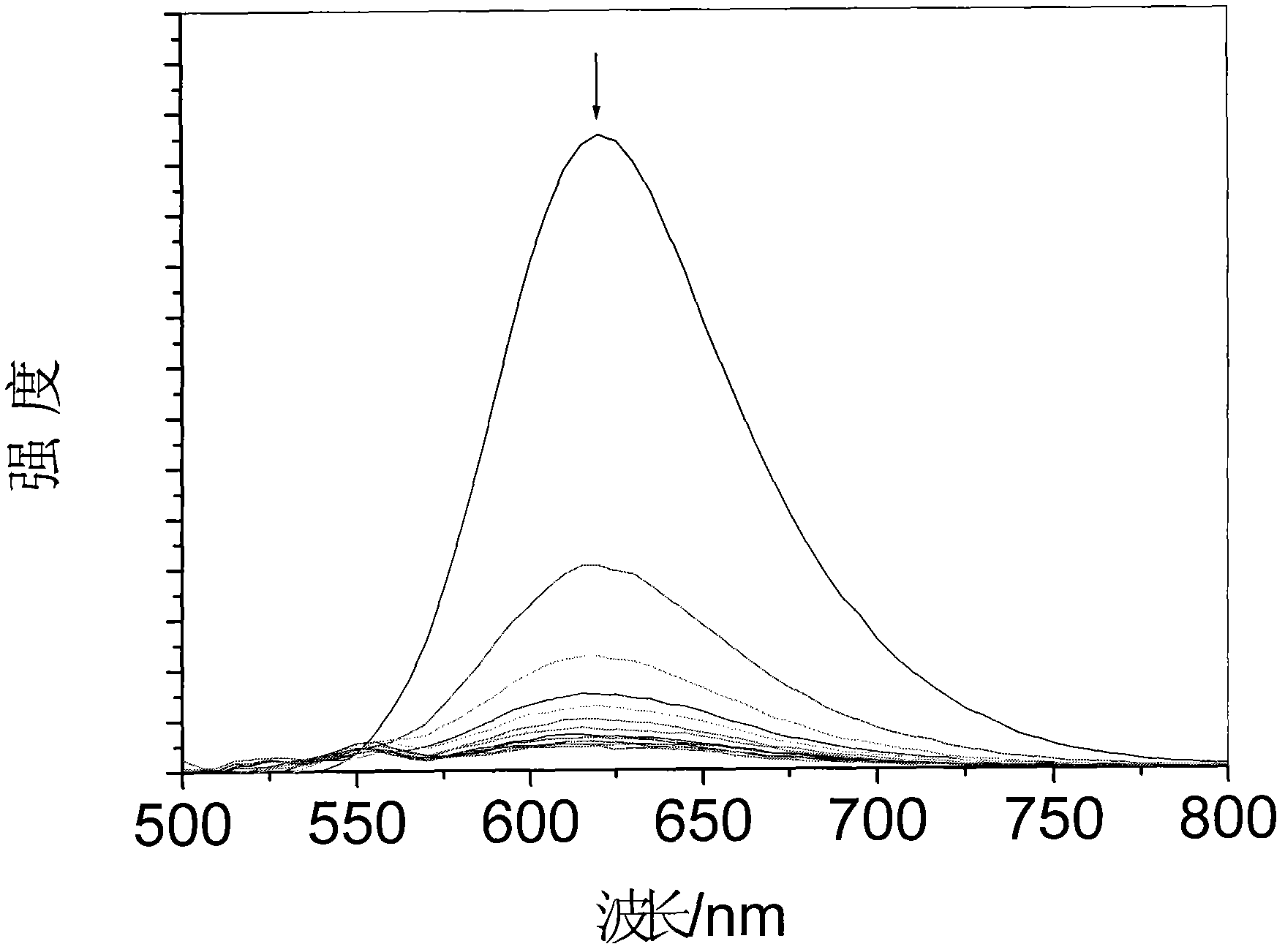

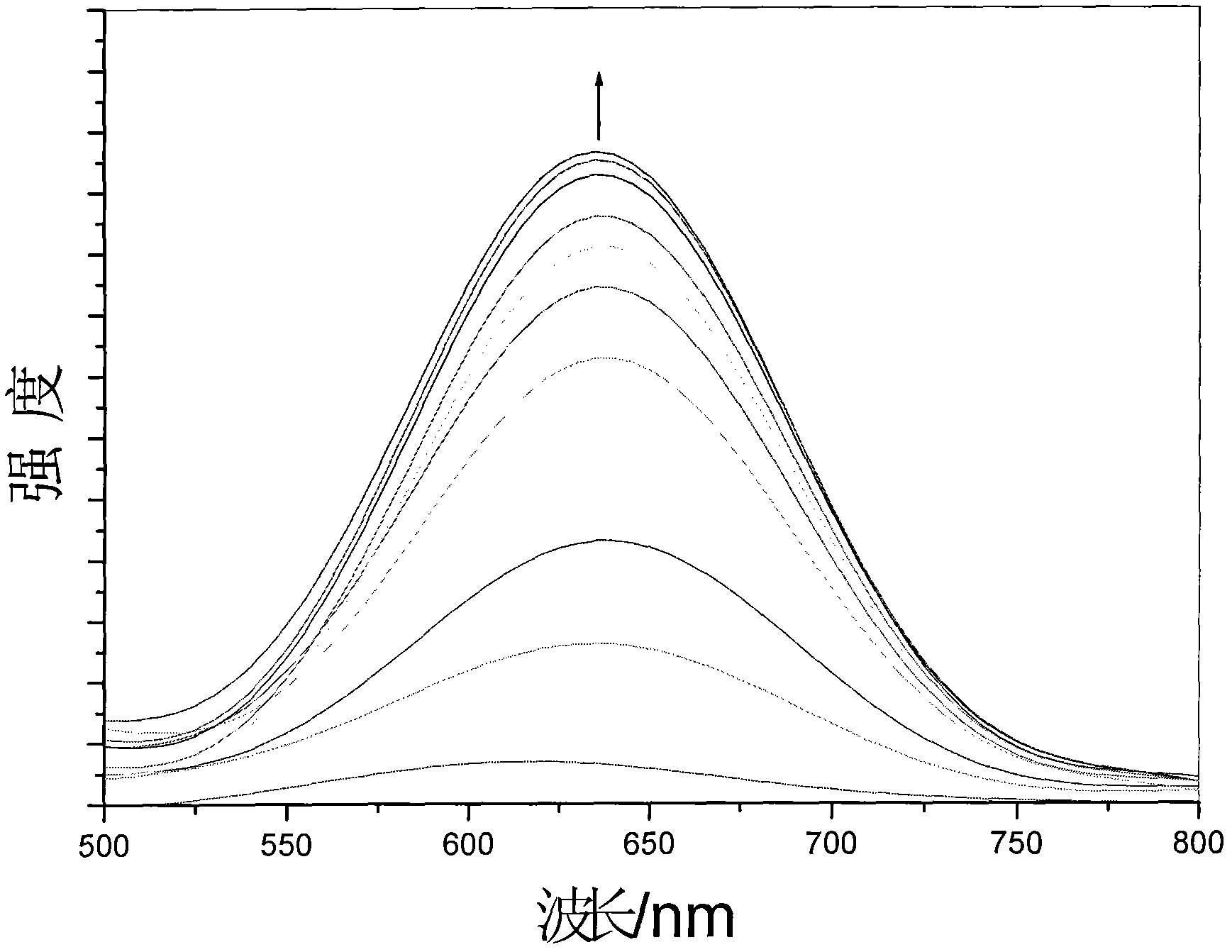

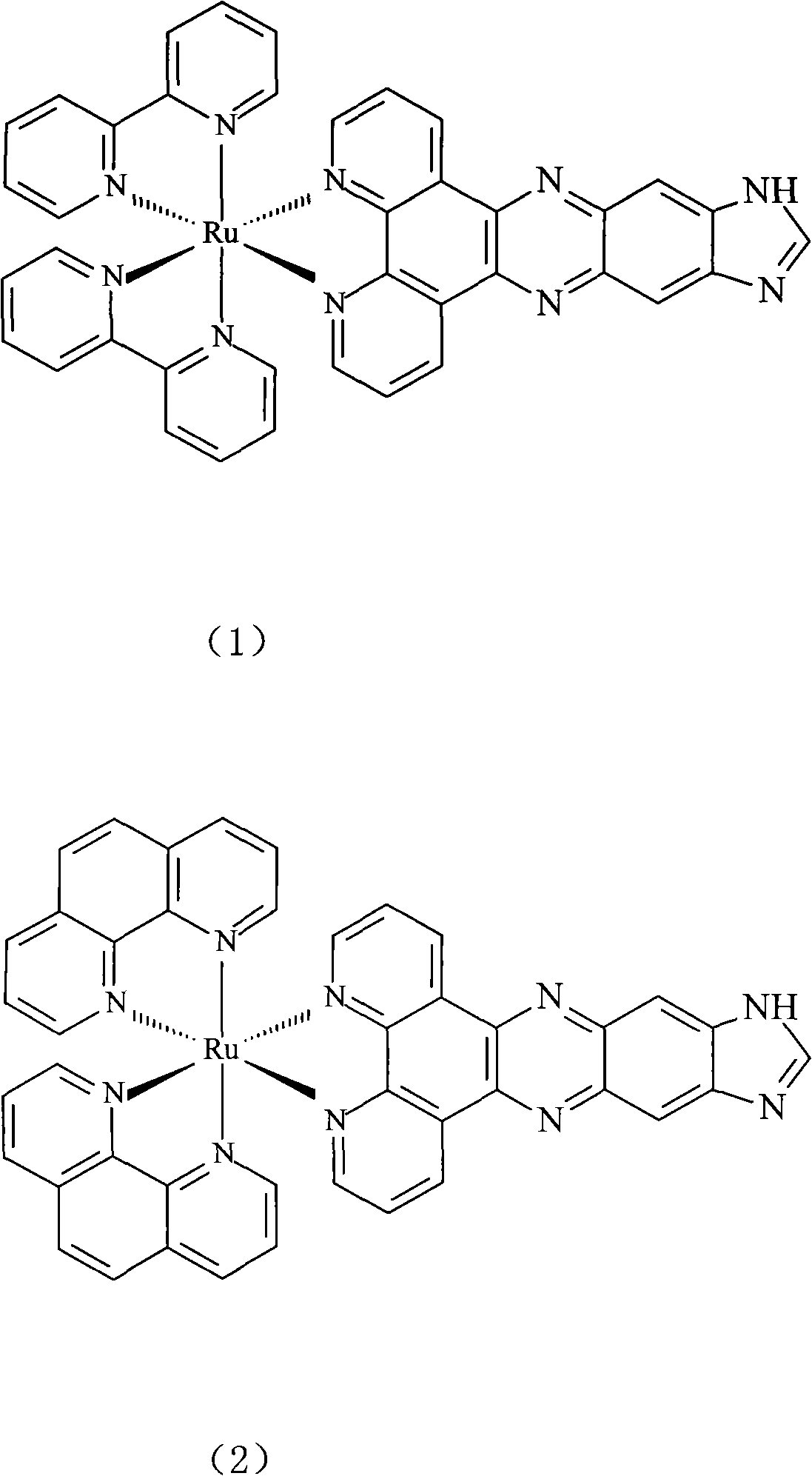

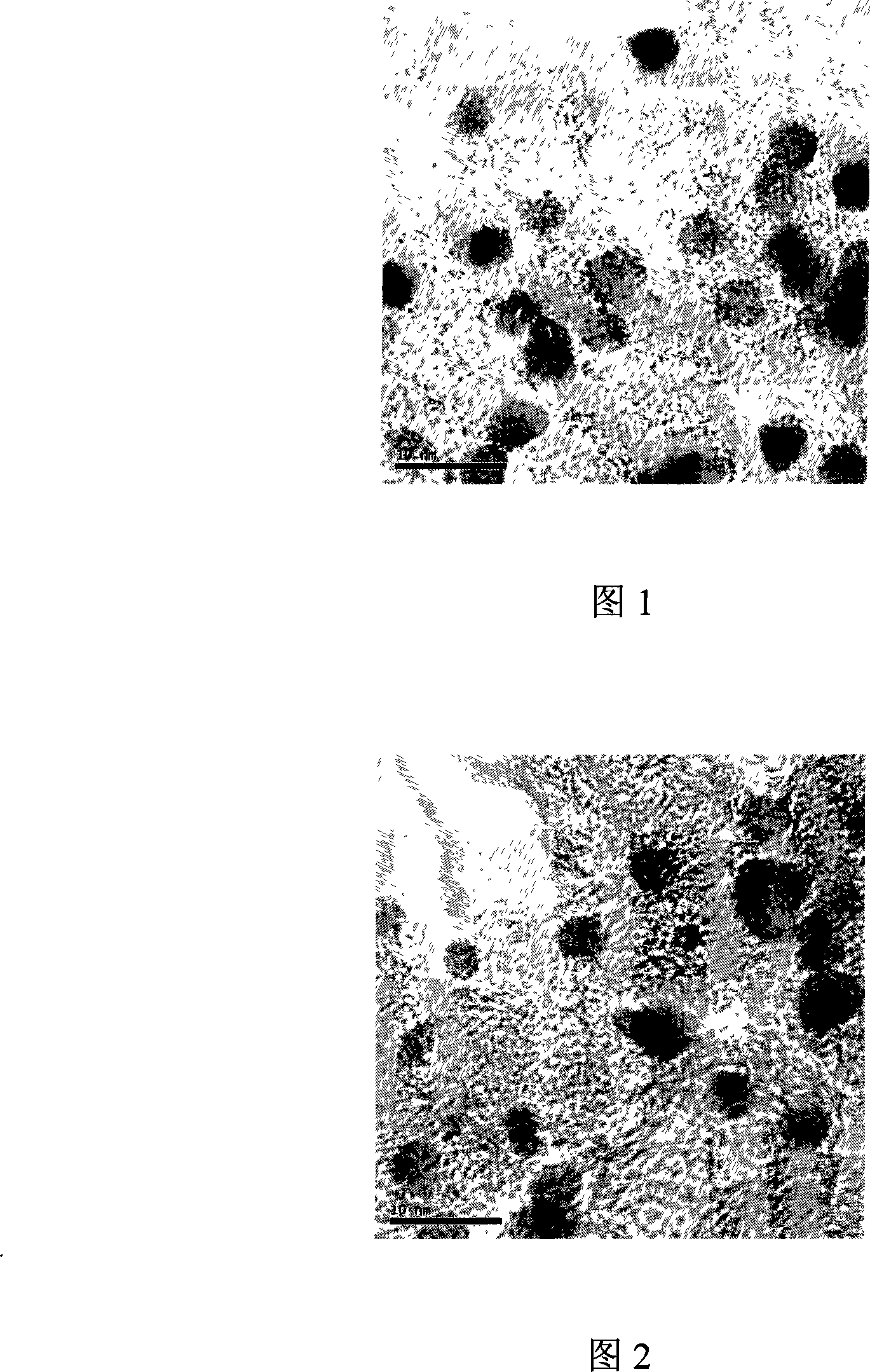

Ruthenium (II)-polypyridine complex, and preparation method and application thereof

InactiveCN102464676AG-quadruplex DNA molecular optical switch with good performanceMicrobiological testing/measurementGroup 8/9/10/18 element organic compoundsLithium chlorideFiltration

The invention provides a ruthenium (II)-polypyridine complex. For the ruthenium (II)-polypyridine complex, bipyridyl (bpy) or phenanthroline hydrate (phen) is used as an ancillary ligand, and dipyridine[3,2-a:2',3'-c]phenazine-11,12-imidazole (dppzi) is used as a main ligand. The preparation method comprises the following steps: preparing 5,6-dinitrobenzimidazole from 5,6-nitrobenzimidazole; reducing 5,6-dinitrobenzimidazole into 5,6-diaminobenzimidazole by using hydrazine hydrate and palladium / carbon; preparing dppzi from phenanthroline hydrate-5,6-dione and 5,6-diaminobenzimidazole and preparing cis-[Ru(bpy)2Cl2].2H2O from ruthenium trichloride, bpy and lithium chloride; preparing cis-[Ru(phen)2Cl2].3H2O from ruthenium trichloride, phen and lithium chloride; carrying out a heating reflux reaction on dppzi and cis-[Ru(bpy)2Cl2].2H2O or cis-[Ru(phen)2Cl2].3H2O under the protection of argon, carrying out cooling, adding ammonium hexafluorophosphate, allowing precipitate to deposit and carrying out filtration and column chromatography so as to obtain a target product. The ruthenium (II)-polypyridine complex provided in the invention can be used as an optical switch for G-quadruplex DNA molecules.

Owner:TONGJI UNIV

Reverse micelle method for preparing platinum ruthenium/carbon catalyst

The invention discloses a reverse micelles method of preparing platinum ruthenium / carbon catalyst, which includes the following steps: 0.02 to 0.10mol / L chloroplatinic acid aqueous solution and 0.04 to 0.20 mol / L ruthenium trichloride aqueous solution are prepared to form water phase; hexamethylene is prepared into oil phase, sodium laurylsulfate is taken as surfactant and n-octyl alcohol is taken as cosurfactant; the mass ratio of sodium laurylsulfate, hexamethylene and n-octyl alcohol is 1:0.07 to 0.15:0.5 to 1.2; the product is mixed and added in carbon black, and the receives ultrasonic vibration and mechanical mixing for 20 to 60 min, so that a reverse micelle is loaded on the carbon black; a reducing agent, demulsifier acetone and solution are added for filtration and drying. The reverse micelle of the invention provides a micro environment, and can become an ideal place of nano particle synthetization. Because of the method of preparing nano particles, only simple equipments are needed, the operation is under room temperature, the metal particles have grain size which is easy to be controlled and spread quite evenly.

Owner:TIANJIN UNIV

Method of preparing anode catalyst for direct methyl alcohol fuel cell

InactiveCN1601788AGood dispersionEvenly dispersedCell electrodesMetal/metal-oxides/metal-hydroxide catalystsAlcohol fuelPt element

Method of spraying pyrolysis and carrier gas deoxidation is adopted to make particles of platinum and ruthenium deoxidized from chloro-platinic acid and ruthenium trichloride distribute in pores of active carbon and surface evenly. Moreover, particle diameter of platinum is in 3+ / - 0.5 Nano evenly. Features of the method are simple operation, producing Nano platinum and ruthenium / carbon electrocatalyst continuously without need of procedures of filtering, washing and drying. Performance of the electrocatalyst for oxidation catalysis of methanol is better than relevant product of platinum and ruthenium / carbon electrocatalyst produced from E-TEK Company.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

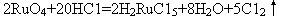

Method for preparing ruthenium trichloride from coarse ruthenium powder

InactiveCN101891261ASimple processReduce energy consumptionRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsDistillationReaction temperature

Owner:CHENZHOU GAOXIN PLATINUM

Preparation of ruthenium trichloride

InactiveCN101462778AEfficient manufacturingSimple preparation processRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsSodium hypochloriteCrystallization

The invention discloses a method for preparing ruthenium trichloride. The method comprises the following steps that: a, ruthenium powder and sodium hypochlorite react, and a solution is brownish-black; b, the solution generated in the step a is added with sulphuric acid for reaction to generate golden yellow RuO4 gas; c, the RuO4 gas generated in the step b is introduced to a hydrochloric acid solution for reaction to generate ruthenium trichloride, and the step a and the step b are repeated till the solution is colorless and transparent; and finally, the obtained ruthenium trichloride solution is evaporated and crystallized. The preparation method has a simple process, can effectively prepare ruthenium trichloride and has high yield of a finished product; and the yield can reach 95 percent above.

Owner:CHINA NAT BLUESTAR GRP CO LTD +1

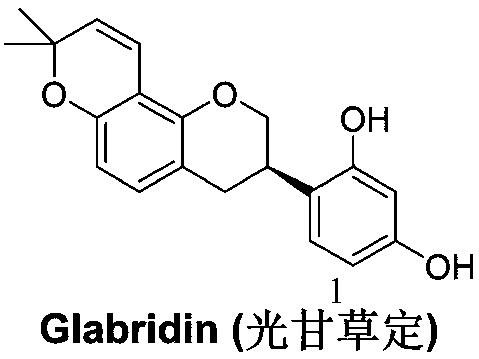

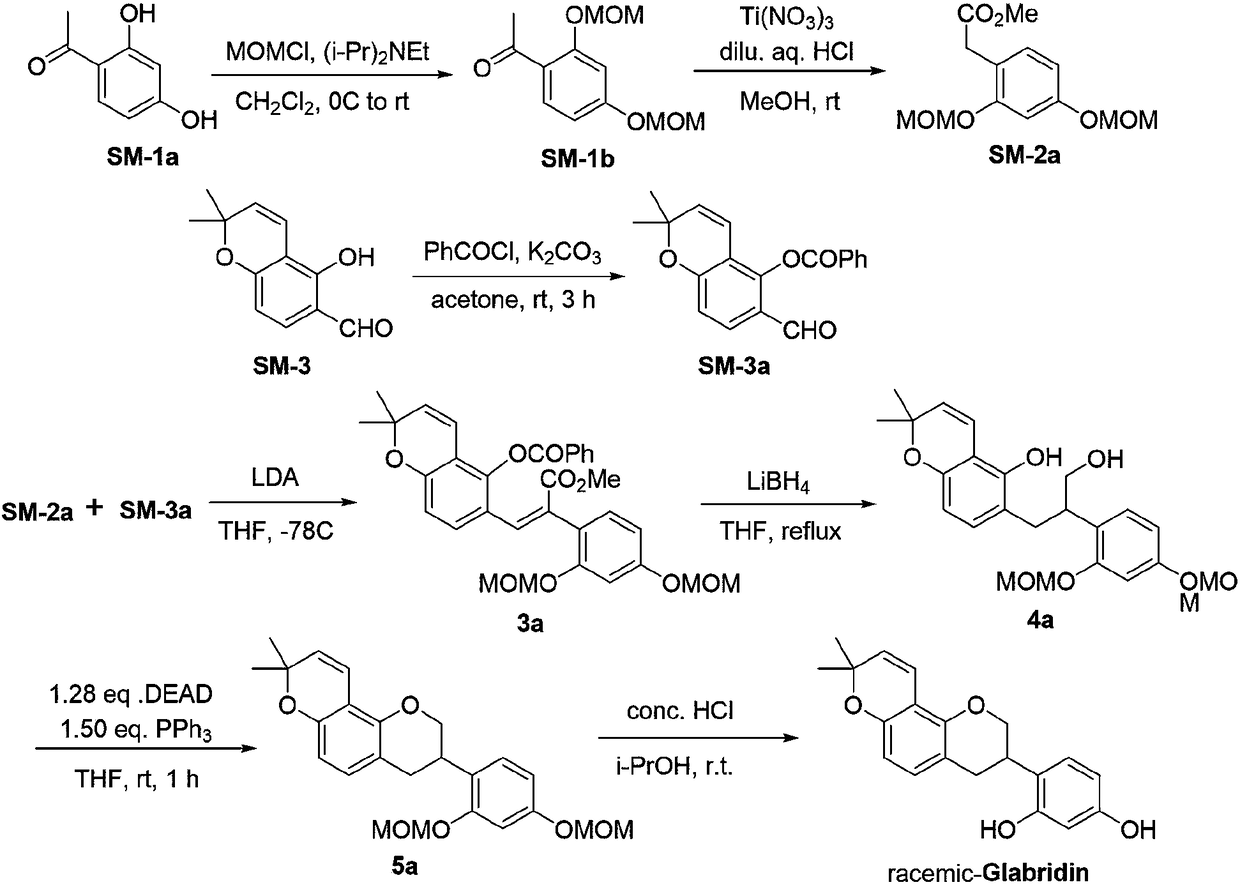

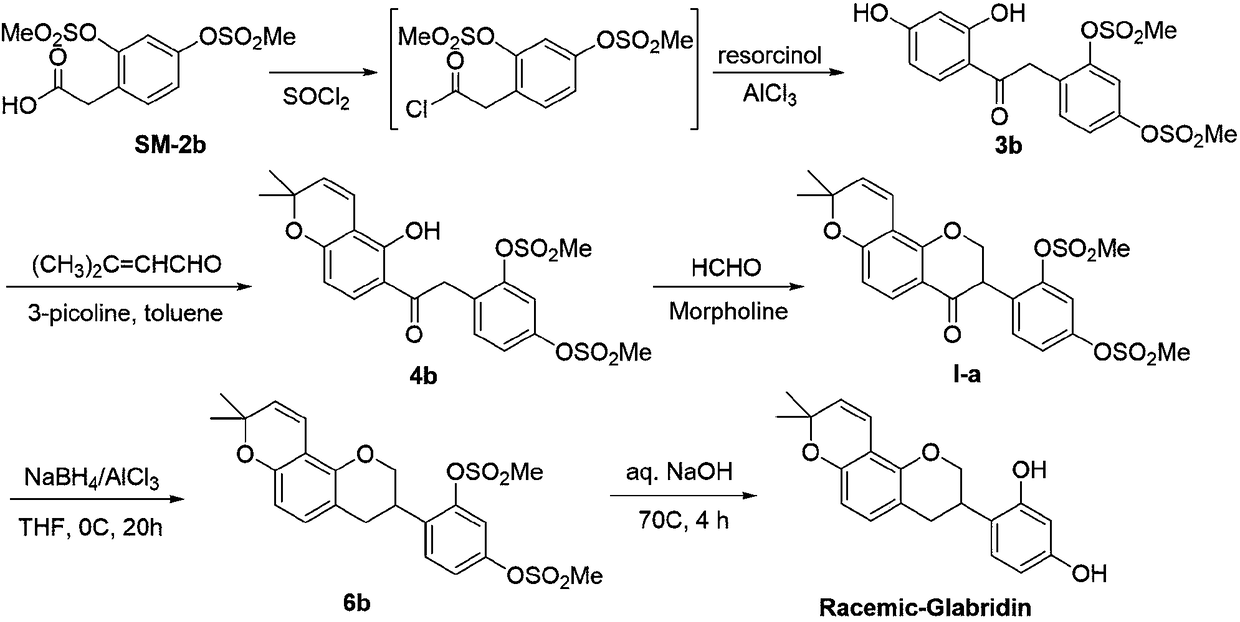

Method for asymmetrically synthesizing glabridin with optical purity under catalysis of ruthenium compound

ActiveCN108440553AHigh yieldHigh stereoselectivityOrganic chemistry methodsBulk chemical productionAbsolute configurationTrifluoroacetic acid

The invention relates to a method for asymmetrically synthesizing glabridin with optical purity under catalysis of a ruthenium compound. The method comprises the following steps: 1) taking isoflavoneprotected by a protection group as a raw material and carrying out dynamic kinetic asymmetric hydrogen transfer reaction under the catalysis effect of a ruthenium trichloride compound and the action of an acid-alkali buffering system to obtain chiral isoflavol with an absolute configuration being (3R, 4R); 2) removing hydroxyl of the chiral isoflavol under the action of triethylsilane and trifluoroacetic acid to obtain a product with an absolute configuration being (R); 3) removing a protection group of the product with the configuration being (R) in step 2) under an acidic or alkaline condition to obtain the glabridin with the configuration (R) and the optical purity. The method provided by the invention can be used for synthesizing the glabridin with the optical purity in a high-yield and high-stereoselectivity manner; the obtained product is completely the same as that of the glabridin extracted from glycyrrhiza glabra and can be used for replacing the glabridin derived from naturalplants to be industrially applied.

Owner:烟台六谛医药科技有限公司 +2

Method for preparing fine Mo-Ru solder powder

The invention discloses a method for preparing Mo-Ru solder powder by using a chemical coprecipitation method. The method comprises the following steps of: preparing solution of ruthenium trichloride and solution of ammonium molybdate respectively; mixing the solution of ruthenium trichloride and the solution of ammonium molybdate and drying the mixed solution at a low temperature; heating the obtained product to remove ammonium chloride; reducing the product with hydrogen; and grinding and sieving the product to prepare the required ingredient, namely Mo-Ru solder powder, wherein the particle size of 90 percent of the solder powder is less than or equal to 6 microns, and the maximum particle size is less than or equal to 10 microns. The Mo-Ru solder powder prepared by the method has the characteristics of fine solder powder (the particle size of 90 percent of the particles is less than or equal to 6 microns) and uniform ingredients, so that the method can solve the problems of non-uniform ingredients, poor manufacturability and the like existing in the use of the Mo-Ru solder in the prior art.

Owner:SINO PLATINUM METALS CO LTD

Method for synthesizing ethylene sulfate

The invention relates to a method for synthesizing ethylene sulfate, and belongs to the technical field of chemical power supplies. The method comprises the following steps: A, carrying out a contactreaction on sulfur dioxide with ethylene oxide in the presence of a composite catalyst, controlling the reaction temperature to be 120-160 DEG C, introducing sulfur dioxide gas to keep the pressure ofthe reaction system at 5-12 MPa, and controlling the reaction time at 1-2.5 hours to obtain ethylene sulfite for standby use; B, adding an aqueous solution of sodium hydrogen carbonate into the ethylene sulfite obtained in the step A, carrying out cooling to a temperature ranging from -5 DEG C to 5 DEG C, dropwise adding a mixed solution of sodium periodate and ruthenium trichloride under a condition with a temperature ranging from -5 DEG C to 5 DEG C, keeping the temperature for 1-1.5 hours after the adding is completed so as to obtain a reaction solution with co-existed water phase and organic phase, carrying out standing for layering, and separating out the water phase to obtain the organic phase, namely a crude product of the ethylene sulfate; and C, carrying out molecular distillation on the crude product of the ethylene sulfate obtained in the step B under the condition with a temperature of 70-80 DEG C to obtain the ethylene sulfate. The ethylene sulfate prepared by the methodhas high purity and high yield, and when the ethylene sulfate is added into a battery, the performance of the battery is better.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

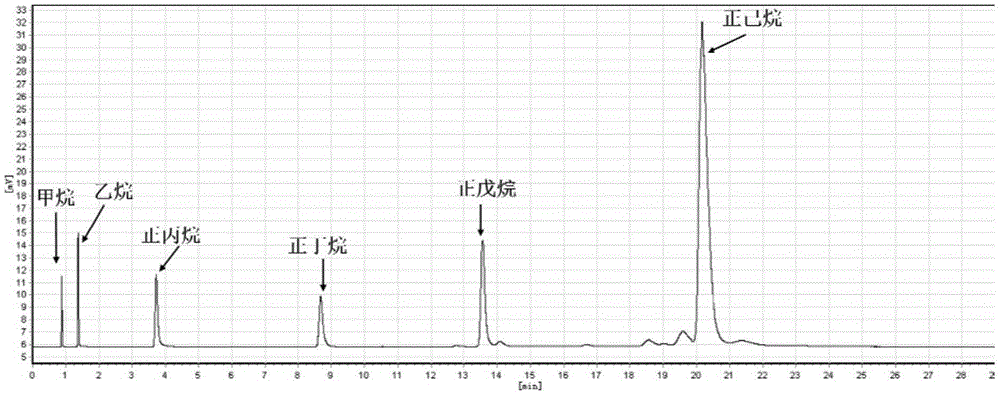

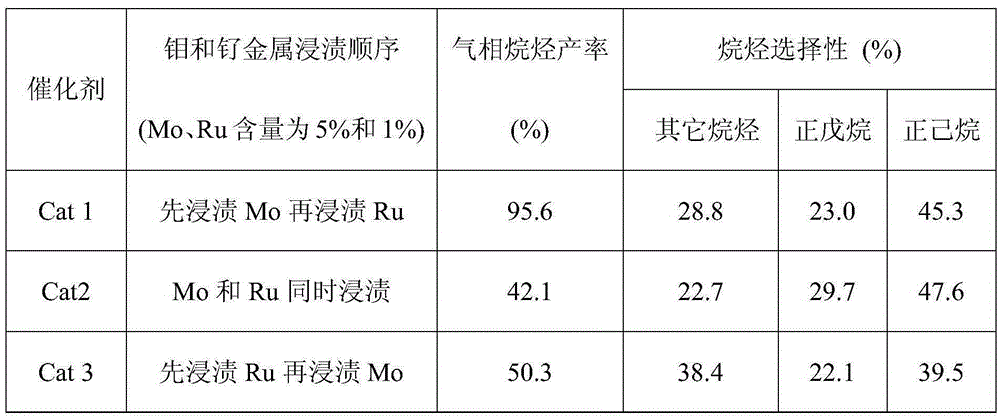

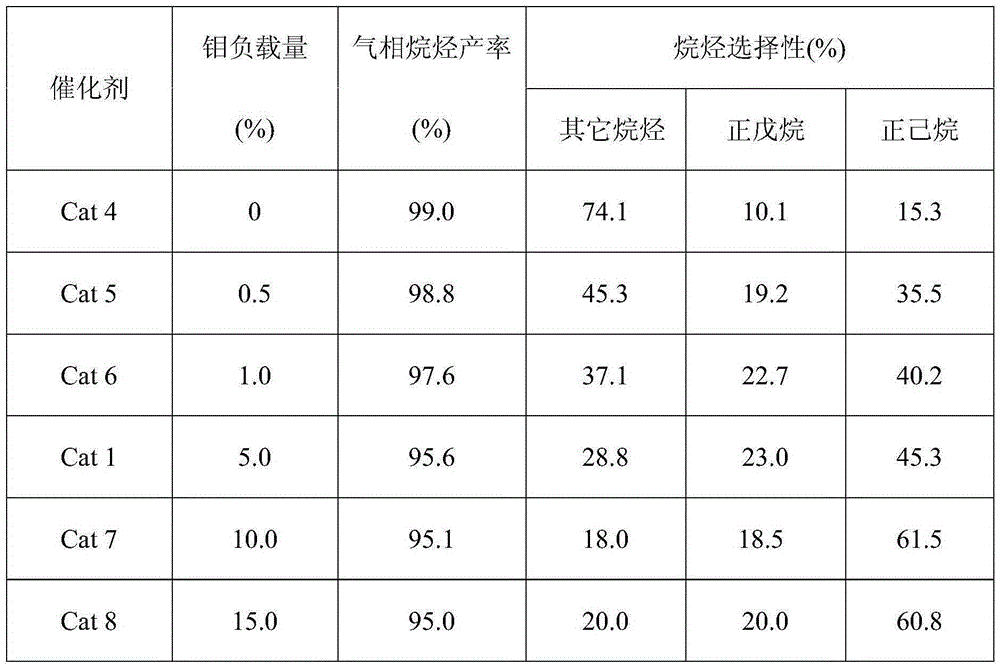

Linear-chain C5/C6 alkane catalyst prepared by sorbitol aqueous phase hydrogenation and preparation method thereof

ActiveCN105289601AHigh selectivityHigh activityHydrocarbon from oxygen organic compoundsMetal/metal-oxides/metal-hydroxide catalystsAlkaneCarbon–oxygen bond

The invention relates to a preparation method of a linear-chain C5 / C6 alkane catalyst prepared by sorbitol aqueous phase hydrogenation. The method comprises the following steps: (1) selecting activated carbon as a catalyst carrier, and drying at the temperature of 100-200 DEG C; (2) adding the dried activated carbon into an ammonium paramolybdate aqueous solution, and drying to obtain a catalyst carrier precursor containing molybdenum; (3) calcining the catalyst carrier precursor containing molybdenum in a muffle furnace to obtain a catalyst carrier containing molybdenum; (4) adding a ruthenium trichloride solution into the catalyst carrier for soaking, and drying to obtain a catalyst carrier precursor containing ruthenium and molybdenum; (5) calcining the catalyst carrier precursor containing ruthenium and molybdenum to obtain an initial catalyst; and (6) performing hydrogen gas reduction on the initial catalyst at the temperature of 250-400 DEG C for 4-8h to obtain the sorbitol aqueous phase hydrogenation catalyst. According to the method, a step soaking method is adopted to inhibit carbon-carbon bond breakage and selectively break carbon-oxygen bonds, so that the selectivity and the excitation capacity of sorbitol hydrodeoxygenation reaction can be improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Method for producing surface-activated superfine nickel powder

InactiveCN101797650AGuaranteed purityEasy for industrial implementationActive agentNickel sulfate hydrate

The invention discloses a method for producing surface-activated superfine nickel powder. The process comprises the following steps of: dissolving nickel sulfate hexahydrate in water; reacting the obtained solution with prepared alkaline liquor to produce nickel hydroxide precipitate; adding a certain amount of noble metal ruthenium trichloride into the precipitate so as to activate the surface of a precursor; directly adding nickel hydroxide paste into a pressure container for liquid-phase hydrogen reduction without being filtered and washed, wherein the temperature and pressure for the liquid-phase hydrogen reduction are controlled to be fixed values; performing liquid-solid separation and washing the solid after the reaction is performed for a fixed time; and drying the solid in a baking box and transferring the dried solid into a hydrogen reducing furnace for reduction at the temperature of between 300 and 500 DEG C for a certain time so as to obtain the superfine nickel powder. The method has the advantages that: the conventional high-temperature and high-pressure hydrogen reduction conditions are weakened by adopting a liquid-solid combined reduction method so as to make large-scale industrial production easy; and simultaneously, the noble metal consumption cost is reduced and the average particle diameter of the prepared superfine nickel powder is less than 2 microns because the noble metal ruthenium trichloride is used as an active agent in place of palladium chloride.

Owner:KUNMING INST OF PRECIOUS METALS

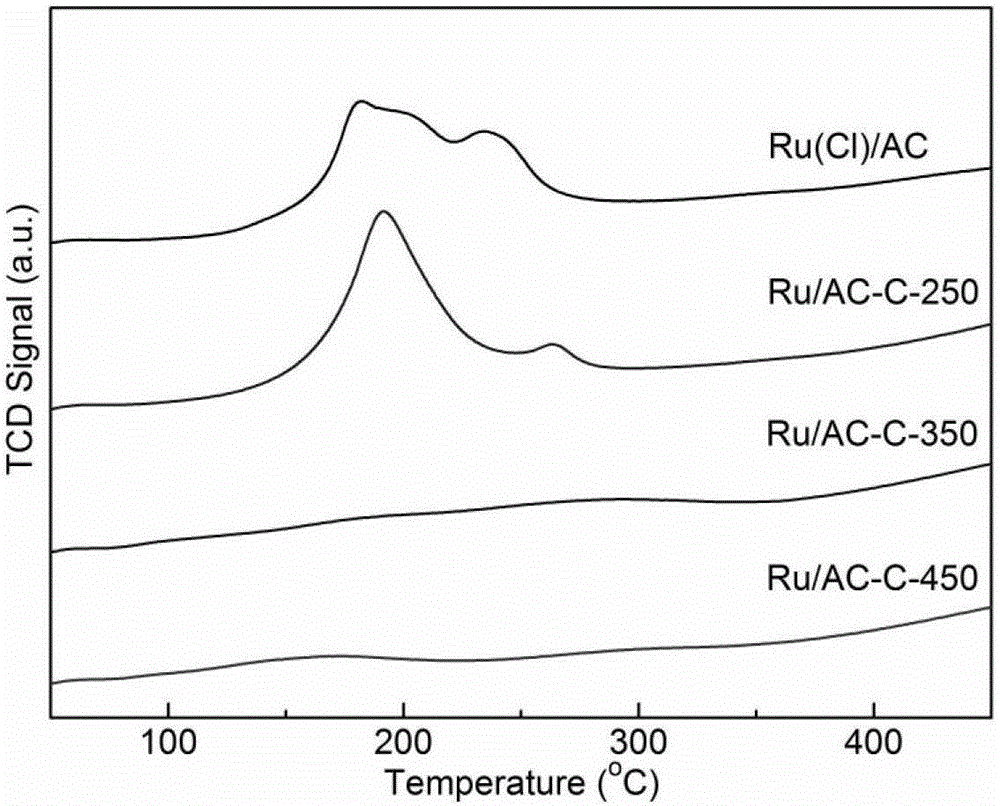

Preparation method of carbon-loaded Ru base catalyst by carbon thermal reduction

InactiveCN106622218ALow costEasy to useCarboxylic preparation by ozone oxidationMetal/metal-oxides/metal-hydroxide catalystsMetallurgyHigh activity

The invention discloses a preparation method of a carbon-loaded Ru base catalyst with uniform distribution, small grain diameter and high activity by carbon thermal reduction. The preparation method includes steps of taking ruthenium trichloride hydrate as a metal precursor, and taking active carbon, mesoporous carbon, coking carbon, foam carbon and other carbon-containing materials as a carrier; preparing by an equivalent-volume impregnation method; performing carbon thermal reduction in inert gases such as He, Ar, N2 and other atmosphere at 350-600 DEG C; acquiring uniformly distributed and small metal grains, and preparing the high-activity and high-stability carbon-loaded Ru base catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method and application of graphene loaded Ru catalyst

ActiveCN104815650AEasy to useImprove thermal stabilityHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNano catalystPtru catalyst

The invention relates to a preparation method and an application of a graphene loaded Ru catalyst. The method includes the following steps that (1) a nanometer Ru catalyst is prepared, and specifically, according to a weight ratio (1-10): 1 between polyvinyl pyrrolidone (PVP) and ruthenium trichloride, dissolving, potential of hydrogen (pH) adjusting, stirring and temperature rising and washing are performed to obtain a product that is the nanometer Ru catalyst; (2) a graphene dispersion liquid is prepared; (3) the graphene loaded nanometer Ru catalyst is prepared, and specifically, according to a weight ratio (1-10): 1 between PVP and the ruthenium trichloride, mixing, stirring, adsorption, centrifugal separation and vacuum drying are performed to obtain the graphene loaded nanometer Ru catalyst. By means of the preparation method and the application of the graphene loaded Ru catalyst, the prepared graphene stabilized nanometer Ru catalyst can efficiently catalyze benzene hydrogenation to generate cyclohexane at low temperature, and the catalyst is excellent in reusable property and good in heat stability and industrial application prospect.

Owner:ZHENGZHOU UNIV +2

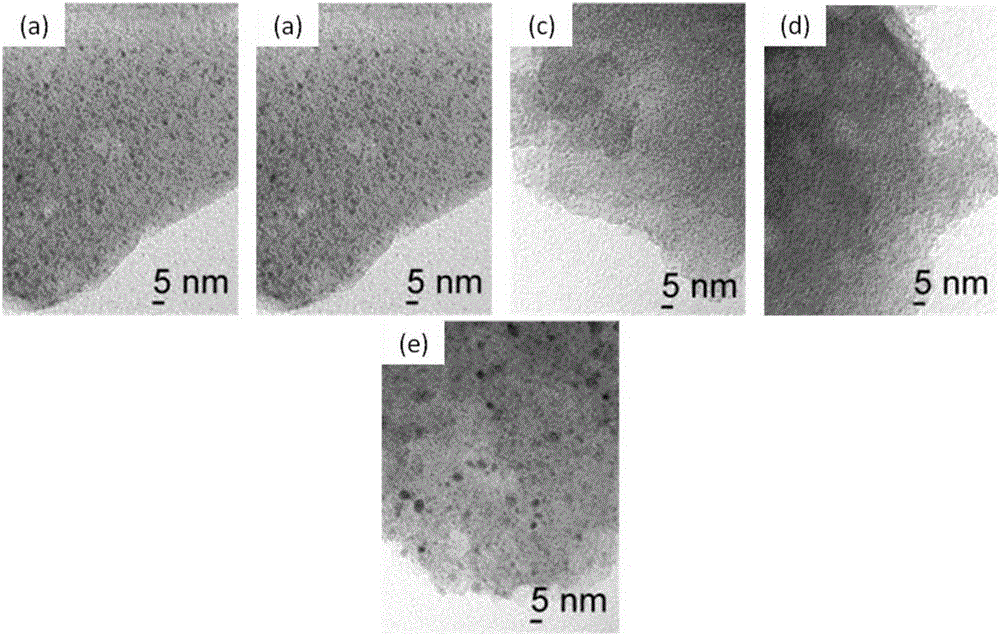

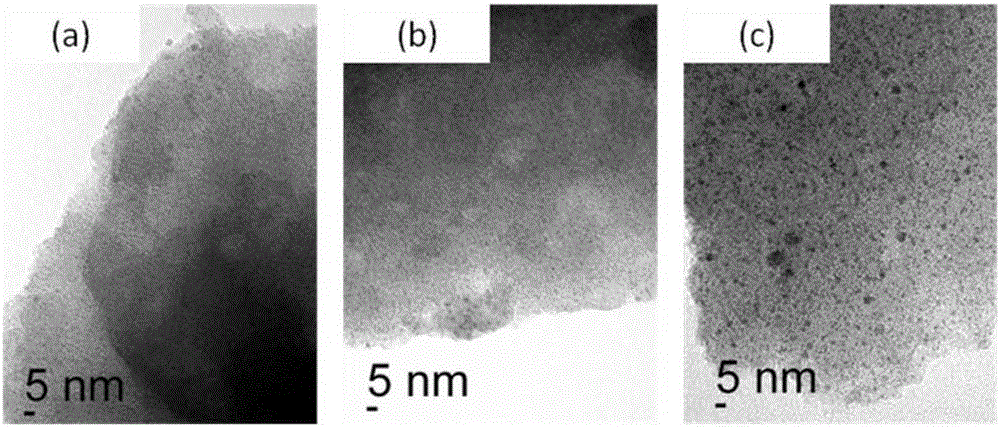

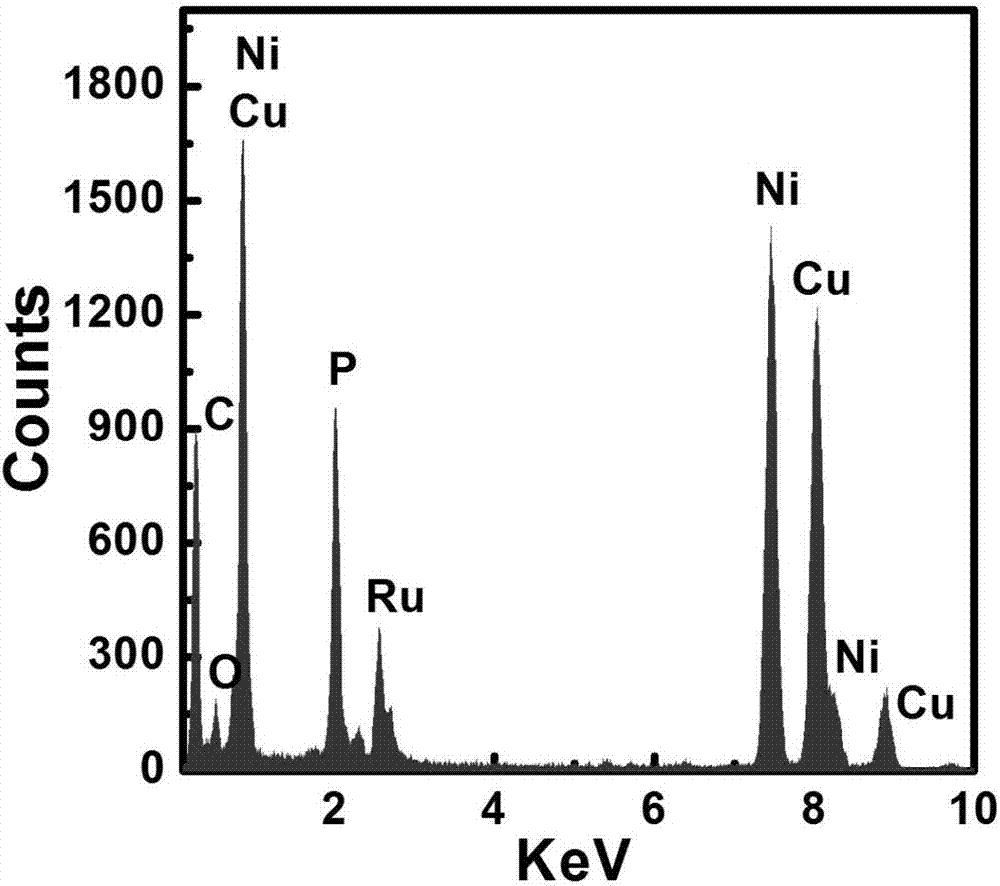

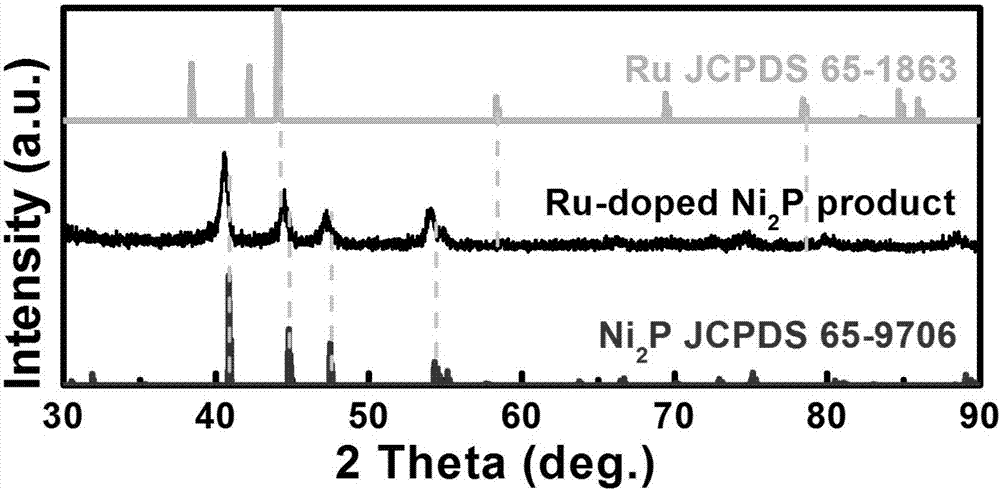

Two-dimensional Ru doped Ni2P disc-shaped nanosheet and preparation method and application thereof

ActiveCN107088432AImprove electrocatalytic performanceLarge specific surface areaPhysical/chemical process catalystsEnergy inputOxygen evolutionOleic Acid Triglyceride

The invention discloses a Ru doped Ni2P disc-shaped nanosheet and a preparation method thereof and application of the nanosheet serving as a difunctional electrocatalyst in a hydrogen evolution reaction (HER) and a oxygen evolution reaction (OER). The preparation method comprises the steps that nickel formate / nickel acetylacetonate, ruthenium trichloride / ruthenium acetylacetonate, tri-n-octylphosphine, dodecylamine and oleic acid are subjected to ultrasonic mixing, programmable heating is conducted to reach 280-300 DEG C for reacting, after heat preservation is conducted for 60-120 min, natural cooling is conducted to reach the room temperature, centrifugal separation and washing drying are conducted, and the Ru doped Ni2P disc-shaped nanosheet is obtained. According to the preparation method, under normal pressure, the Ru doped Ni2P disc-shaped nanosheet is synthesized through a one-pot method, the technology is simple, and the repeatability is high. The two-dimensional Ru doped Ni2P disc-shaped nanosheet shows the excellent electrocatalysis property, the nanosheet serving as the difunctional electrocatalyst can be applied to the HER and the OER simultaneously, and a broad application prospect is achieved in the field of renewable energy sources such as electrolytic water.

Owner:江苏仕航电气有限公司

Catalyst for electrocatalytic reduction of nitrate as well as preparation method and application thereof

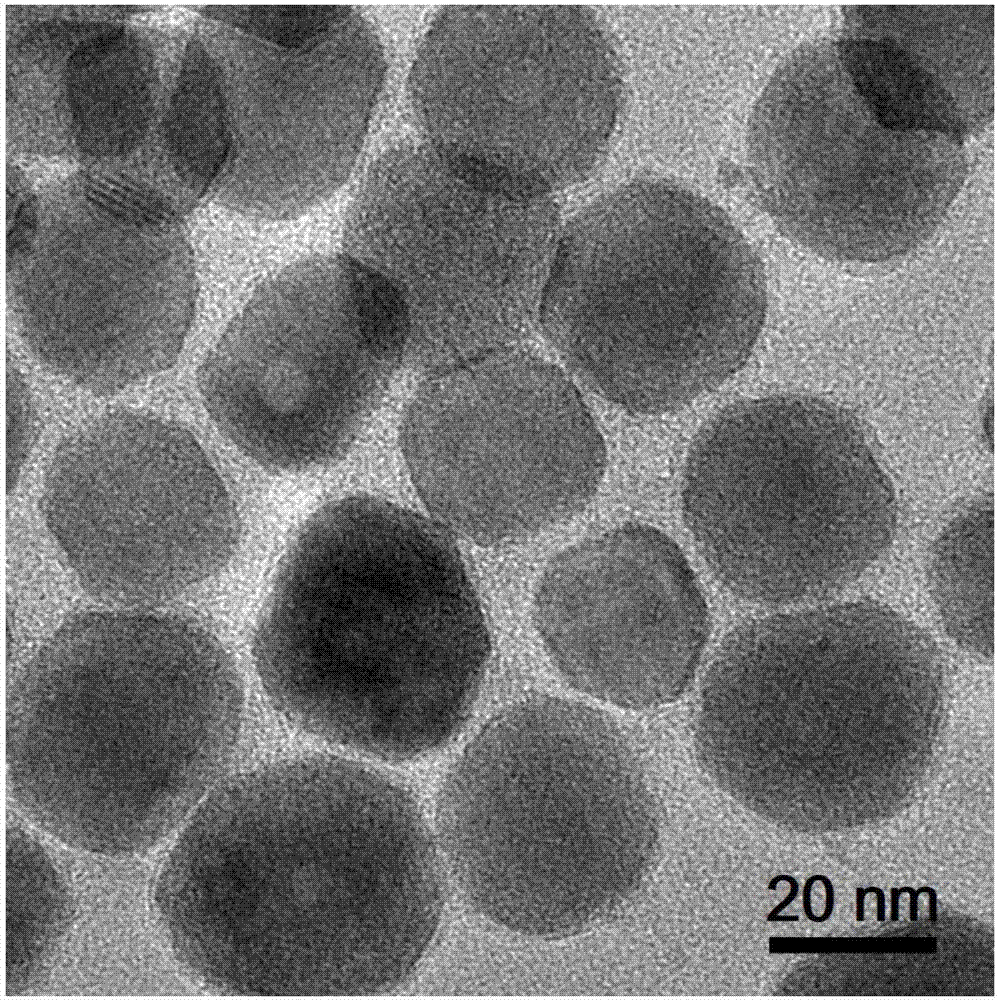

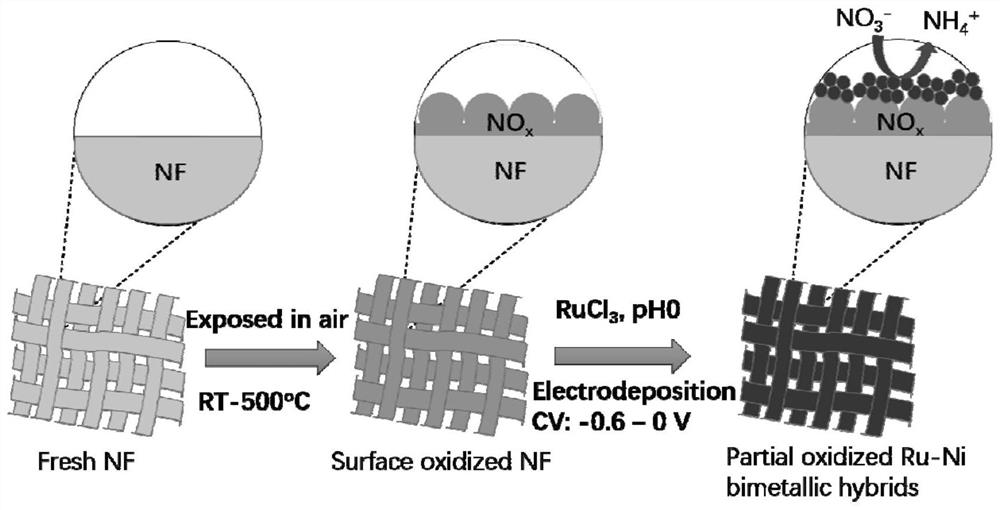

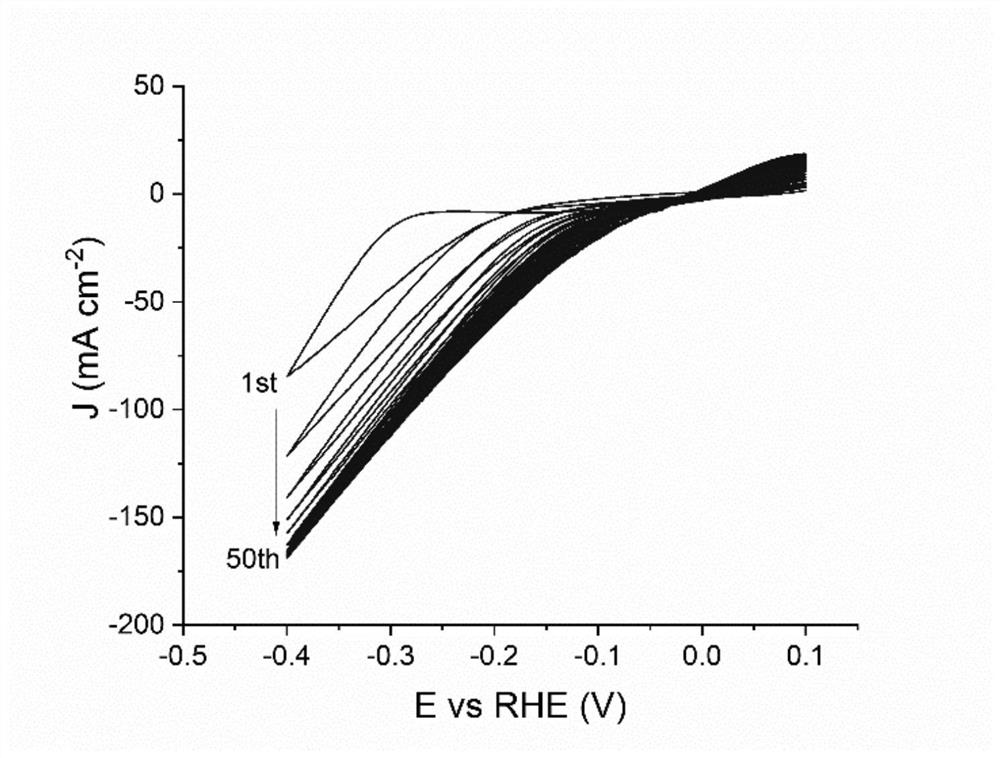

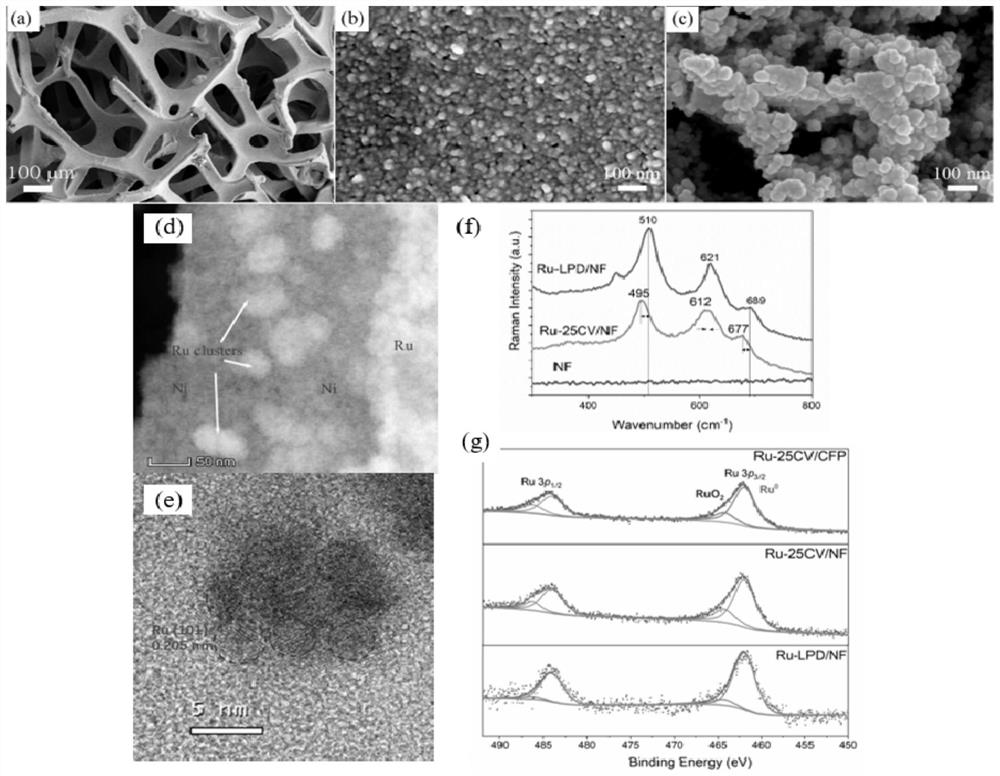

PendingCN112237927AEnhanced catalytic performance for reductionLow load RuWater contaminantsCatalyst activation/preparationPtru catalystNitrate

The invention relates to the technical field of catalyst preparation, in particular to a preparation method of a catalyst for electrocatalytic reduction of nitrate. The method comprises the followingsteps: by using foamed nickel as a substrate, forming a nickel oxide layer on the surface of the foamed nickel to obtain a compound; and depositing ruthenium nanoparticles on the compound by adoptinga ruthenium trichloride solution and adopting an electrochemical cyclic voltammetry to obtain the NiRu composite catalyst. According to the preparation method of the catalyst for electrocatalytic reduction of nitrate, the preparation method is simple in process, the catalyst load Ru amount is low, and the catalyst cost is low; the invention also provides an application of the catalyst for electrocatalytic reduction of nitrate. The catalyst has higher current density, higher current Faraday efficiency and higher nitrate elimination rate of synthetic ammonia in a wide voltage range.

Owner:DONGGUAN UNIV OF TECH

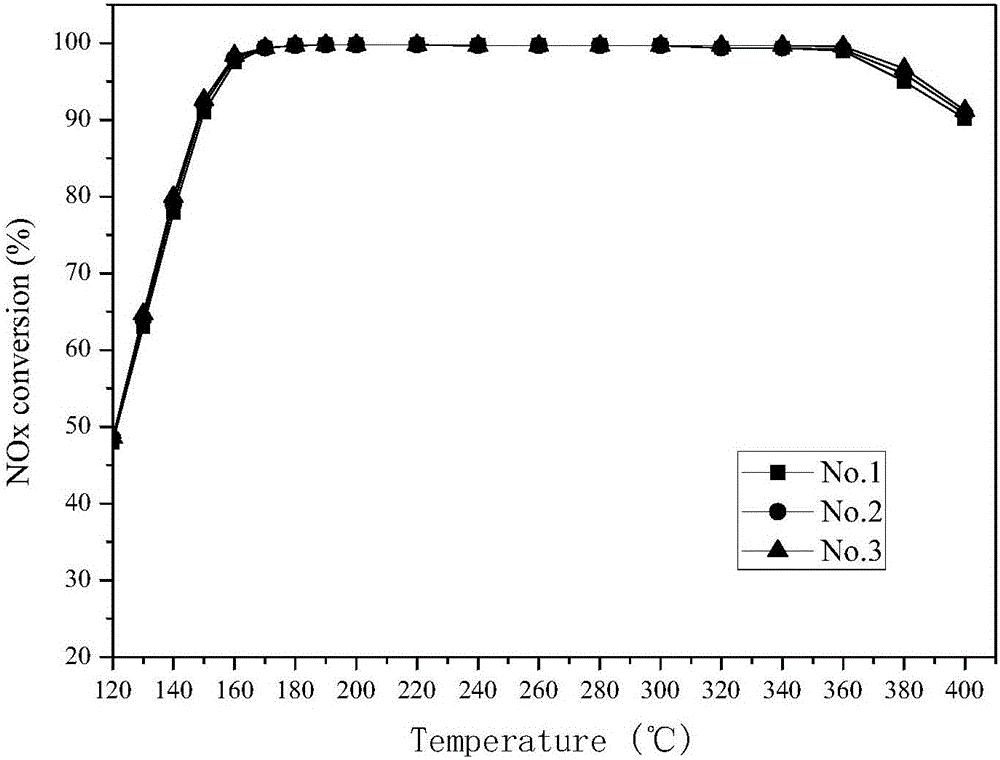

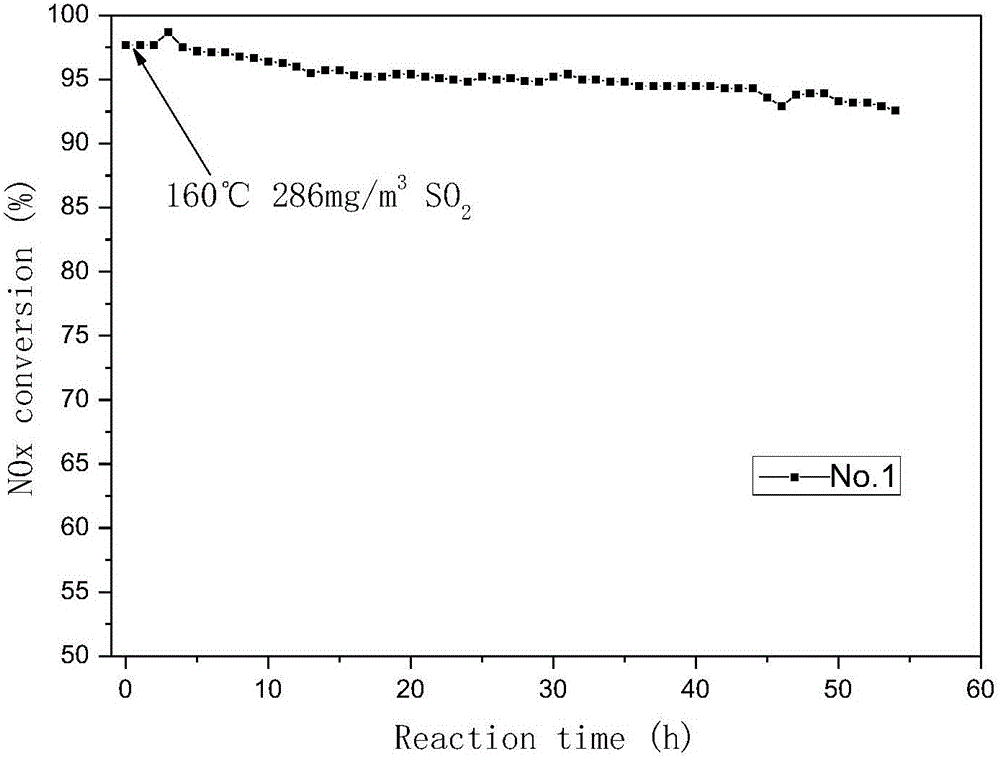

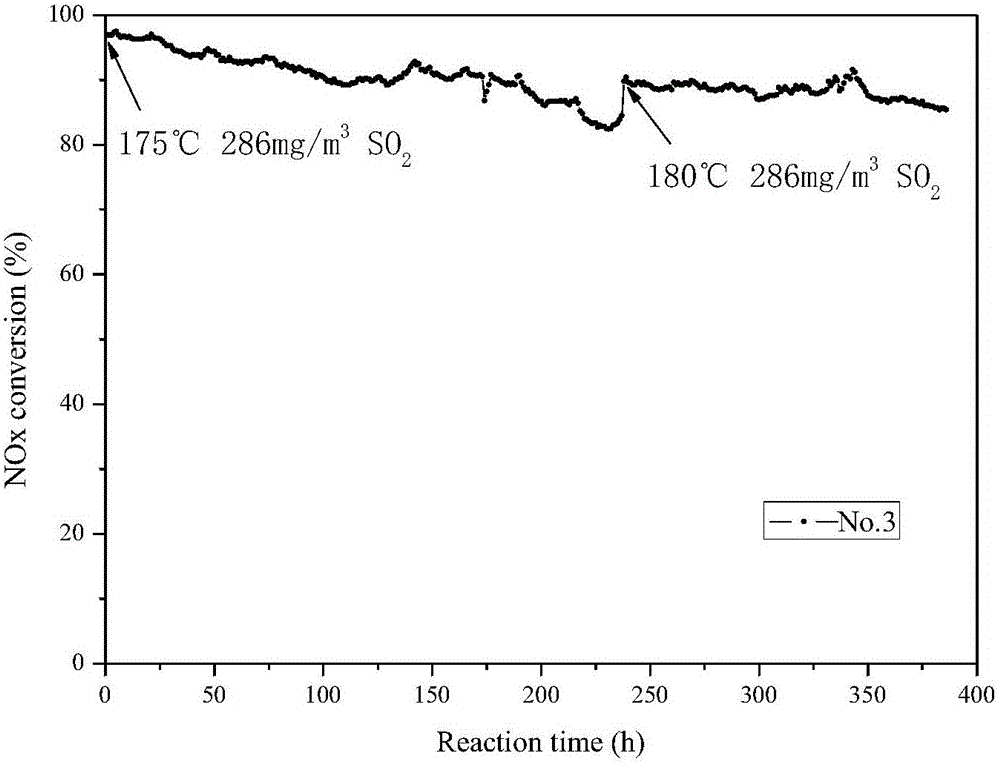

Low-temperature sulfur-resistant vanadium-titanium denitration catalyst and preparing method

InactiveCN106111135ALower catalytic temperatureExcellent low temperature sulfur resistanceCatalyst carriersGas treatmentTungstateAmmonium metavanadate

A low-temperature sulfur-resistant vanadium-titanium denitration catalyst and a preparing method are disclosed and belong to the field of denitration catalysts. The low-temperature sulfur-resistant vanadium-titanium denitration catalyst is prepared with a steeping method, anatase type titanium dioxide serves as a carrier, and vanadium pentoxide, tungsten trioxide and ruthenium are loaded on the surface of the carrier, wherein TiO2 accounts for 70-95 wt%, V2O5 accounts for 0-10 wt%, WO3 accounts for 0-20 wt%, and Ru accounts for 0.1-0.8 wt%. The chemical composition precursors of V2O5, WO3 and Ru are ammonium metavanadate, ammonium tungstate and ruthenium trichloride respectively. By loading trace precious metal elements, the denitration catalyst can maintain the efficiency of 90% or above at 150-400 DEG C, and the toxic action of sulfates formed by Sox in the sulfur-containing smoke atmosphere on the catalyst can be relieved. The service life of the catalyst can be prolonged, the preparing method is easy and convenient to implement, and the production efficiency is high.

Owner:BEIJING UNIV OF TECH

Preparation method for ruthenium-oxide-based electrode material

InactiveCN103887078AHigh specific capacityLower equivalent series resistanceHybrid capacitor electrodesCarbon nanotubeImpurity

The invention discloses a preparation method for a ruthenium-oxide-based electrode material. The preparation method comprises the following steps of dissolving 2-5 g of hydration ruthenium trichloride and 1-3 g of carbon material into 100-200 ml of alcohol-water solution, and evenly mixing the mixture to obtain mixed solution; adding 10-150 ml of NH4HCO3 solution with the concentration of 1.0-2.0 mol / L into the mixed solution, and adjusting a PH value into 7-9 to obtain Ru(OH)4; after aging is conducted and foreign ions are removed in a centrifugal mode, conducting dehydration processing to obtain a composite electrode material of amorphous ruthenium dioxide and the carbon material; adding a conductive agent of carbon nano-tubes or KS6 conductive graphite counting for 10-20% of the total weight into the prepared composite electrode material, and fully mixing and grinding the mixture to obtain the ruthenium-oxide-based electrode material. Precursors adopted in the preparation method for the ruthenium-oxide-based electrode material are the hydration ruthenium trichloride, the carbon material and ammonium bicarbonate, mixing is more even, the carbon nano-tubes or KS6 conductive graphite is selected to serve as the conductive agent, the composite electrode material has the advantages of being high in specific capacity, low in equivalent series resistance, long in service life, low in cost and the like.

Owner:CHENGDU DAAISI TECH

Method for extracting noble metal ruthenium from mixed oxide containing ruthenium, iridium, titanium, tin, zirconium and palladium

The method discloses a method for extracting noble metal ruthenium from a mixed oxide containing ruthenium, iridium, titanium, tin, zirconium and palladium. The method comprises the following steps: firstly, placing a mixed metal oxide containing noble metal ruthenium in a KOH and KNO3 mixed molten salt for dissolving; secondly, cooling the molten salt, immersing and dissolving the molten salt in water, and filtering and separating the solution; thirdly, adding the filtrate into a reaction bottle, adding sodium hypochlorite and sulfuric acid in the reaction bottle, and generating ruthenium tetroxide gas from the reaction; and fourthly, leading the ruthenium tetroxide gas into an absorption device, adding hydrochloric acid in the absorption device, and generating ruthenium trichloride from the reaction. The method can separate and extract the noble metal ruthenium from a waste electrode coating and a waste electrode cladding and achieving the aim of conserving and reutilizing energy; and the method is also applicable to ruthenium extraction in ruthenium catalyst in the pharmaceutical industry.

Owner:CHINA NAT BLUESTAR GRP CO LTD +1

Catalyst used for one-step preparation of vinyl chloride from dichloroethane and acetylene, and preparation method and application thereof

ActiveCN106391078ALow reaction temperatureExtend your lifePhysical/chemical process catalystsPreparation by hydrogen halide split-offWater bathsReaction temperature

The invention discloses a catalyst used for one-step preparation of vinyl chloride from dichloroethane and acetylene, and a preparation method and application thereof. The preparation method for the catalyst comprises the following steps: (1) subjecting a nitrogen-containing precursor, active carbon and a solvent to stirring and impregnation at 30 to 100 DEG C for 1 to 12 h and then evaporating the solvent to dryness; (2) putting a product obtained in the step (1) into a heating furnace, carrying out heating to 300 to 1, 000 DEG C in an inert gas atmosphere at a heating rate of 1 to 10 DEG C / min, maintaining the product at the temperature for 0.5 to 6 h and then cooling the product to room temperature so as to obtain a nitrogen-doped active carbon carrier N-AC; and (3) impregnating N-AC with an aqueous solution of ruthenium trichloride by using an equivalent-volume impregnation, carrying out water-bath drying and then carrying out stoving so as to obtain the catalyst used for one-step preparation of vinyl chloride from dichloroethane and acetylene. The catalyst is used for catalyzing a one-step reaction of dichloroethane with acetylene for preparation of vinyl chloride, so activity is improved, reaction temperature and energy consumption are lowed, coking and carbon formation of a reactor are reduced, and the service life of the catalyst is prolonged.

Owner:TIANJIN UNIV

Method for preparing ethylene sulfate by using microchannel reactor

ActiveCN107973774AImprove uniformityFully contactedOrganic chemistrySulfateSodium hypochlorite solution

The invention discloses a method for preparing ethylene sulfate by using a microchannel reactor, wherein the method has a high yield and high product purity and is convenient for industrial application. Production equipment includes the microchannel reactor, the microchannel reactor is internally provided with a premixer and a microchannel module, the premixer communicates with three micro-pumps,an oxidant micropump communicates with a conveying pipe between the premixer and the microchannel module, and a material discharge pipe is arranged at the material discharge end of the microchannel module. The temperature of the microchannel reactor is controlled at -30 to 30 DEG C, a dichloromethane solution of glycol sulfite, a sodium bicarbonate solution and a ruthenium trichloride solution areseparately pumped by the three micropumps to the premixer to form a mixed solution, a sodium hypochlorite solution is pumped by the oxidant micropump, the sodium hypochlorite solution and the mixed solution are pumped synchronously to a microchannel in the microchannel module for an oxidation reaction, a reaction solution generated after complete reaction in the microchannel module is delivered outwards from the material discharge pipe, and the reaction solution is sequentially subjected to layering, drying and concentration, so that the target product ethylene sulfate is obtained.

Owner:ZHANGJIAGANG HICOMER CHEM CO LTD

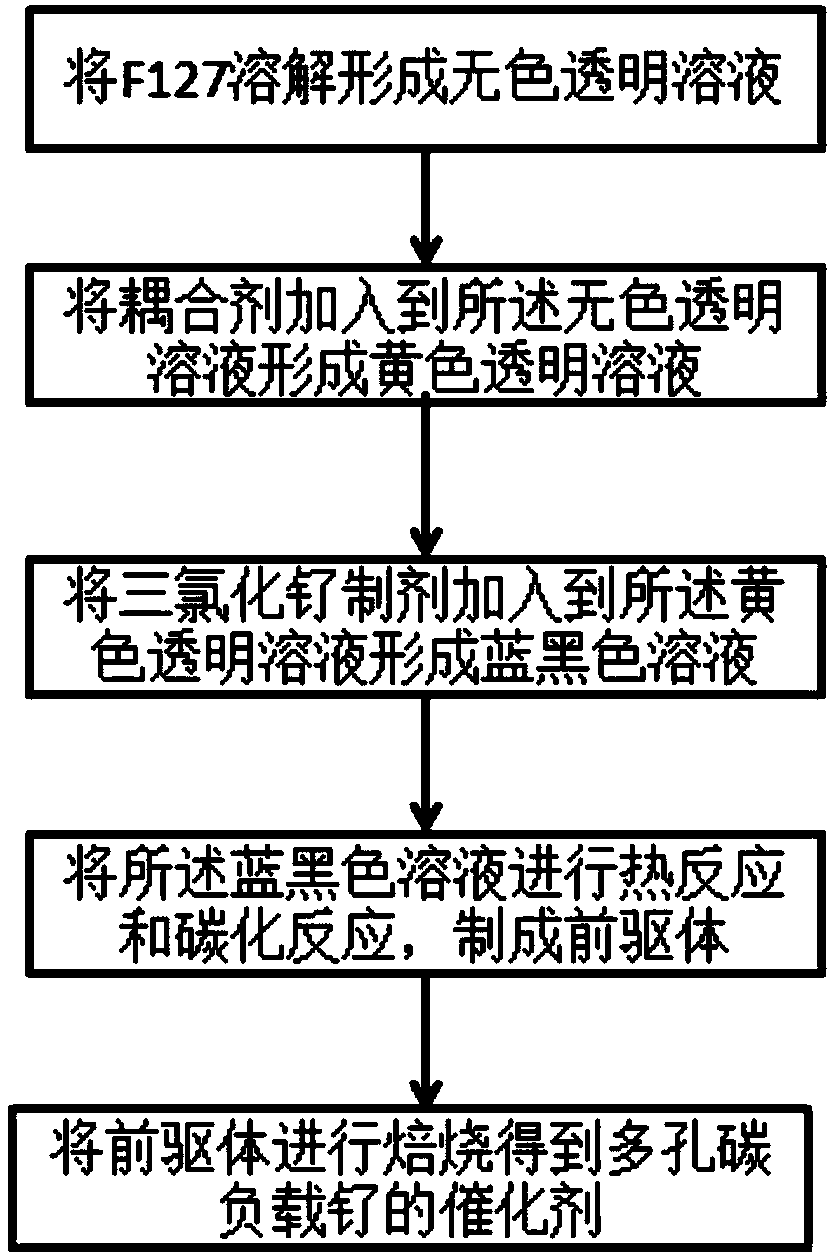

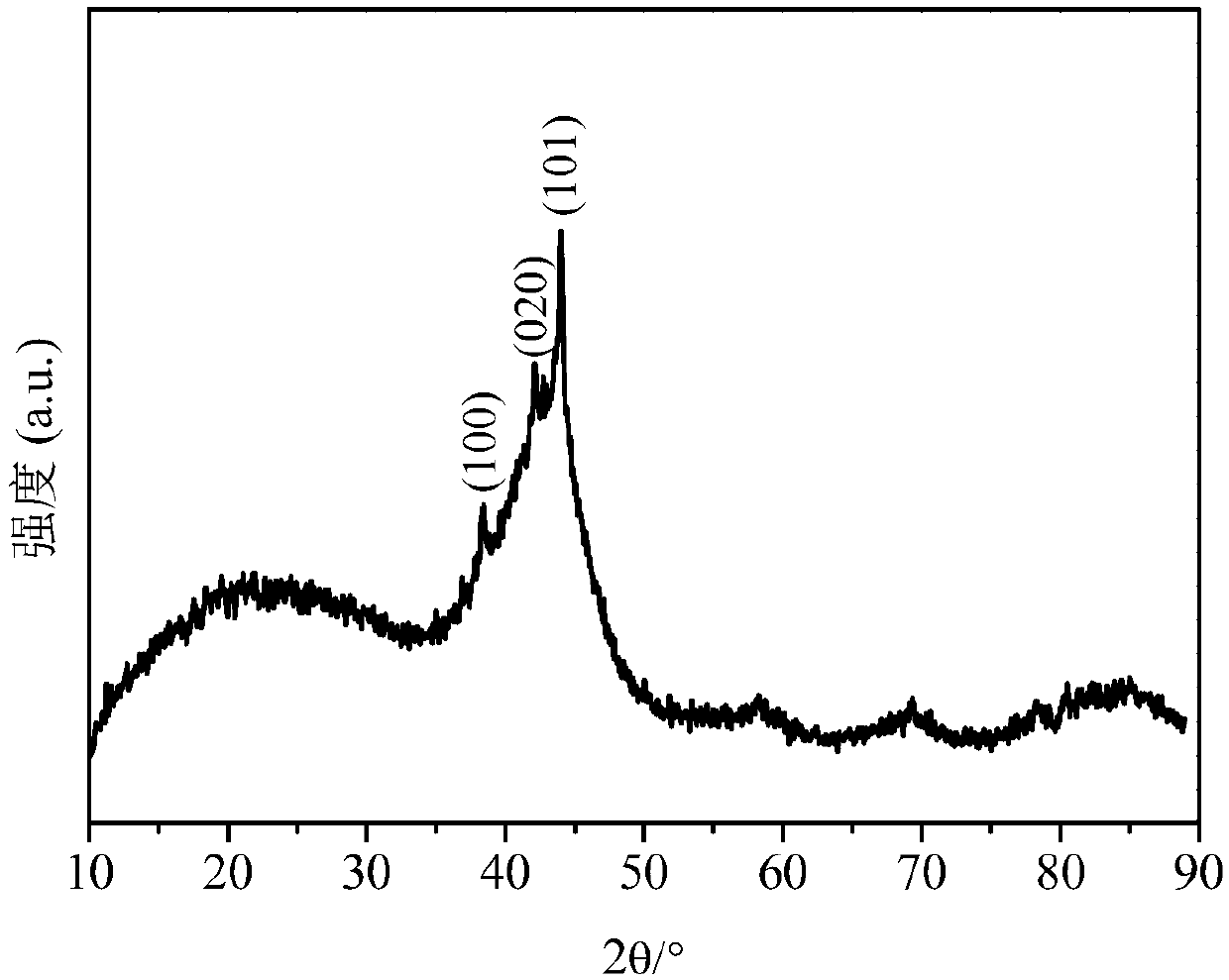

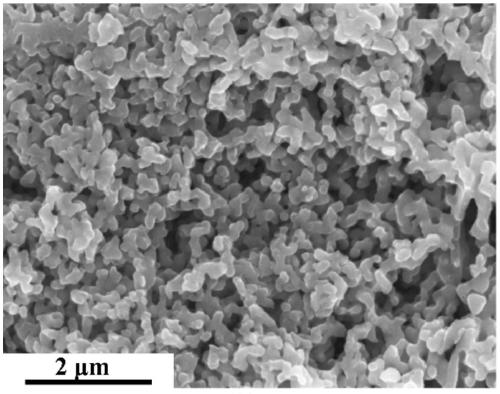

Method for preparing ruthenium catalyst supported on porous carbon

The invention discloses a method for preparing a ruthenium catalyst supported on porous carbon and relates to the technical fields of carbon materials and hydrogen evolution catalysts of electrolyticwater. The method comprises the following steps: 1, dissolving F127 in a solvent and stirring until the F127 is completely dissolved in the solvent to obtain a colorless transparent solution; 2, adding a coupling agent to the colorless transparent solution and continuously stirring until the coupling agent is completely dissolved to obtain a yellow transparent solution; 3, adding a mixed solutionof ruthenium trichloride and ethanol to the yellow transparent solution and continuously stirring to obtain a blue black solution; 4, manufacturing a precursor through thermal reaction and carbonization reaction; and 5, placing the precursor in a tube furnace and roasting the precursor in the tube furnace to obtain the ruthenium catalyst supported on porous carbon. The method for preparing the ruthenium catalyst supported on porous carbon, which is provided by the invention, has the advantages that the process is simple; the cost is low; and the performance of the prepared catalyst is good.

Owner:SHANGHAI UNIV

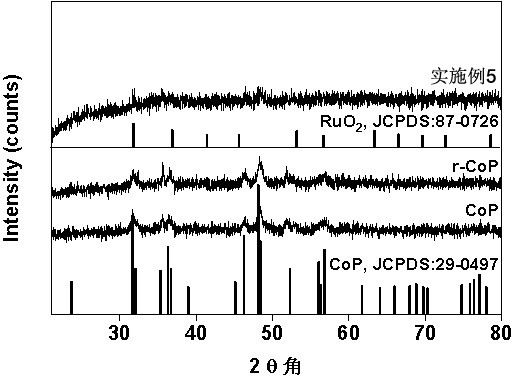

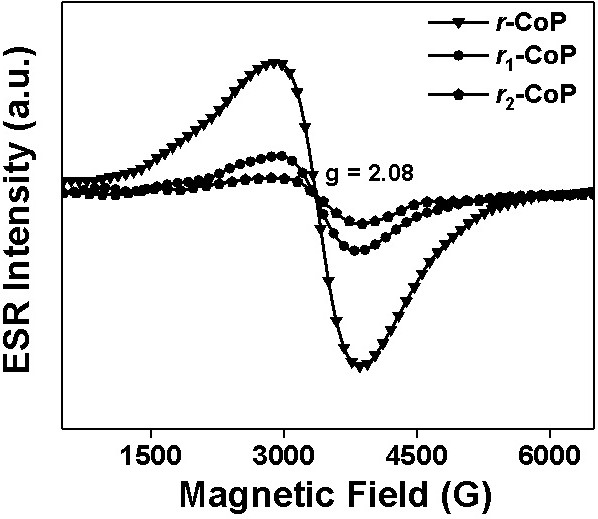

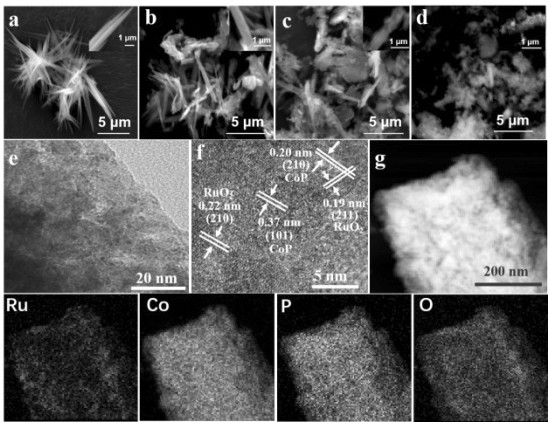

Preparation method of catalyst for hydrogen production based on Ru/r-CoP composite material hydrolysis

ActiveCN111905782AGood dispersionImprove conductivityPhysical/chemical process catalystsHydrogen productionHydration reactionPtru catalyst

The invention belongs to the field of chemical hydrogen evolution energy, and particularly relates to a preparation method of a catalyst for hydrogen production based on Ru / rCoP composite material hydrolysis, which comprises the following steps: preparing a cobalt-based precursor, a cobalt phosphide (CoP) precursor and a phosphorus hole precursor (r-CoP); dispersing the phosphorus hole precursor (r-CoP) in water, adding a proper amount of ruthenium trichloride hydrate, and adding a sodium borohydride solution for reduction; performing centrifuging, washing and drying to obtain a phosphorus hole precursor loaded ruthenium composite material (Ru / r-CoP); by enriching the phosphorus hole loaded ruthenium nano composite material, the dispersity and conductivity of ruthenium loaded on a precursor are improved, so that the intrinsic catalytic activity is improved, and the Ru / r-CoP composite material shows efficient hydrogen evolution performance in an alkaline sodium borohydride aqueous solution; and an effective synthetic route is provided for preparing an efficient sodium borohydride hydrolysis hydrogen evolution catalyst.

Owner:GUANGXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com