Patents

Literature

472results about How to "Enhanced anti-toxicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst and preparation method

ActiveCN102114424ARich pore structureLarge specific surface areaDispersed particle separationCatalyst activation/preparationSilicon-controlled rectifierManganese oxide

The invention relates to a low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst, which comprises a carrier, a manganese oxide, and composite oxide of one or more of Ce, Zr, Ti, Co, Fe and Cu, the mass content of manganese is 0.1-66 percent, and the total mass content of the Ce, Zr, Ti, Co, Fe or / and Cu is 0-50 percent; and glass fiber and / or kieselguhr is used as the carrier, wherein the glass fiber of the carrier is calcined for 2-4 hours at temperature of 400-600 DEG C, then placed in a nitric acid, sulfuric acid or hydrochloric acid solution with mass concentration of 5-40 percent for acidizing for 1-8 hours, washed by distilled water to be neutered, dried at temperature of 80-120 DEG C, and crushed to have the fineness of 20-325 meshes. The catalyst uses the glass fiber and the kieselguhr as the carriers, so that the dispersion effect of nanoparticles and specific surface area of the catalyst are increased, the high adsorptive capacity and strong heat resistance and corrosion resistance capacity are achieved, stronger toxic resistance capacity to sulfur dioxide and stream contained in the smoke is realized, the invention can be used for 10-200 DEG C of low temperature smoke denitration, and has strong water resisting and sulphur toxic resisting capacities.

Owner:GUODIAN SCI & TECH RES INST +1

SCR denitration catalyst and preparation method thereof

ActiveCN101185886AImprove structural stabilityImprove mechanical stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSilanesAmmonium paratungstate

The invention relates to a preparation method of an SCR denitration catalyst, which comprises the following steps: (1) Al2O3 sol is prepared, which comprises the steps that hot ammonia, the Al2O3 is added in drops into the ammonia and then HCI is added and the mixture is stirred; (2) Al2O3-SiO2-TiO2 composite sol is prepared, which comprises the steps that tetratethoxy-silane, butyl titanate, deionized water are sequentially put into ethanol to be aging and then the sol prepared by step (1) is adding to be stirred and aging; (3) vector is coated, which comprises the steps that cordierite honeycomb immersed into the sol of step (2) and the raffinate in a channel is cleaned, dried and roasted after being taken out; (4) active component impregnating solution is prepared, which comprises the steps that lanthanum nitrate, ammonium metavanadate and ammonium paratungstate are dissolved into the deionized water after being mixed together and oxalate acid is added to be aging; (5) the active component is loaded, which comprises the steps that the vector of the step (3) is immersed into the impregnating solution of the step (4) and then the raffinate in the channel is cleaned to be dried and roasted. The invention also relates to the denitration catalyst which is prepared by the method.

Owner:山西蒲洲博奇环保科技有限公司

Method for preparing low-temperature SCR (selective catalytic reduction) denitration catalyst

InactiveCN102716752AGood activity at low temperatureHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideAmmonium metavanadate

The invention relates to a method for preparing a low-temperature SCR (selective catalytic reduction) denitration catalyst, and belongs to the technical field of catalysis. The denitration catalyst has a good nitric oxide removal rate, water resistance and sulfur resistance when the temperature of flue gas ranges from 150 DEG C to 250 DEG C. The method includes dissolving ammonium metavanadate, transition metal salts and titanium and tungsten powder in water; and drying and calcining the mixed liquor to prepare the low-temperature SCR denitration catalyst. The prepared catalyst is good in low-temperature activity, and can keep the good nitric oxide removal rate, the water resistance and the sulfur resistance at the temperature ranging from 150 DEG C to 250 DEG C. In addition, owing to the high activity and poison resistance at the temperature ranging from 150 DEG C to 250 DEG C, the catalyst can be applied to the field of flue gas after the flue gas flows via dust catchers of thermal power plants and flue gas, with the temperature ranging from 150 DEG C to 250 DEG C, of industrial furnaces and the like, and denitration catalyst technology and application breakthrough is realized.

Owner:JIANGSU LONGYUAN CATALYST CO LTD

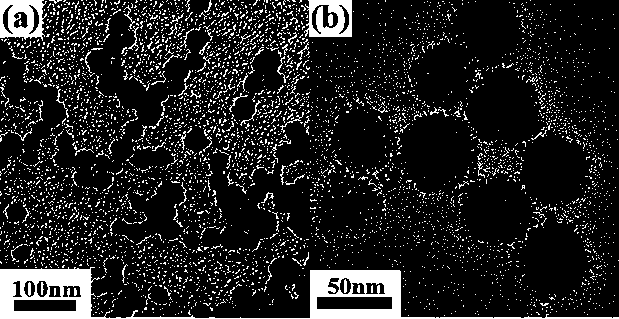

Carbon supported noble metal catalyst and method for preparing same

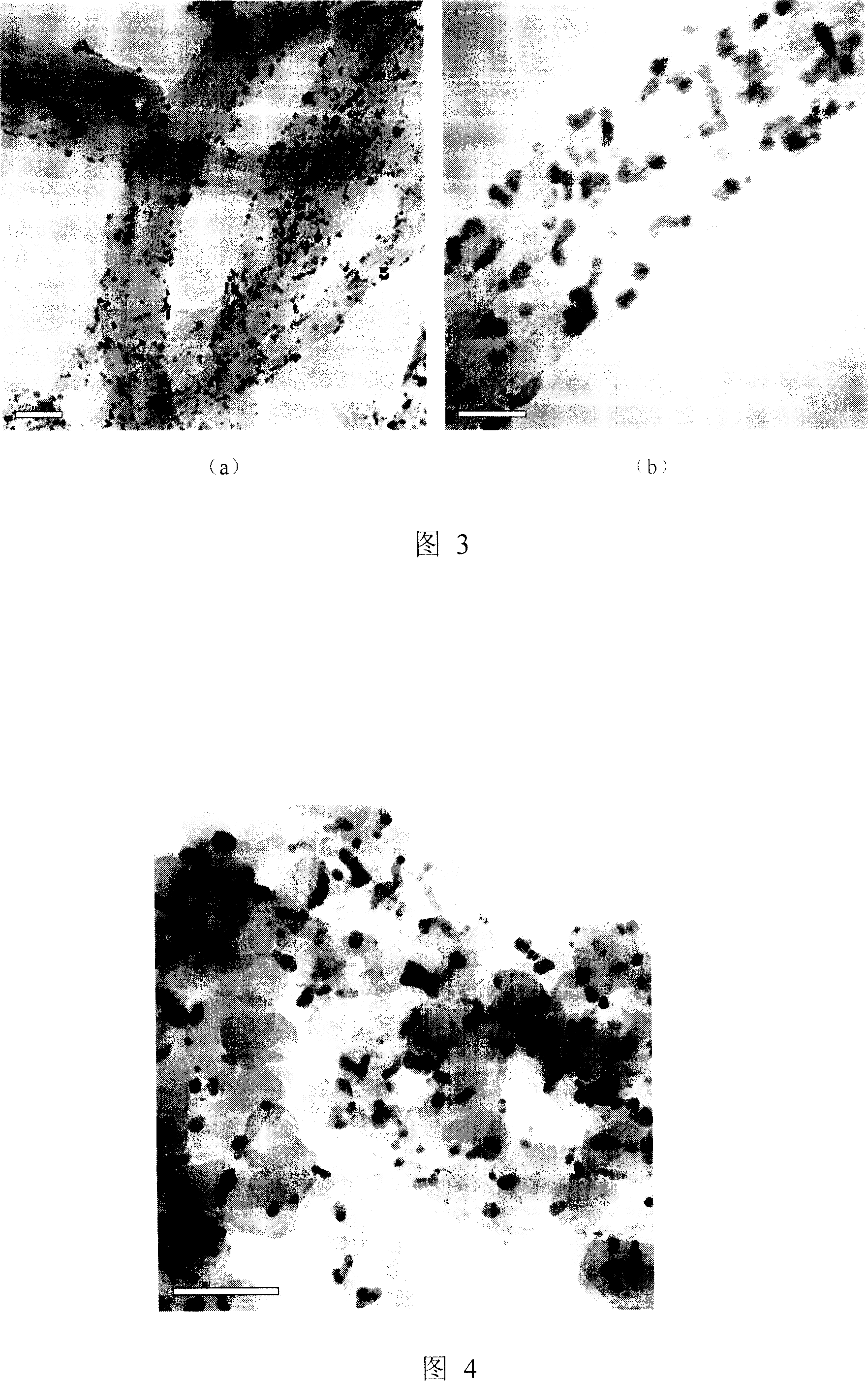

InactiveCN1994563AReduce surface tensionGood dispersionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsSolventHigh pressure

The invention relates to a carbon-carrier metal catalyst, wherein the active component is 5-80%; the mol ration of metal atoms is 3:1-1:3; the metal diameter of catalyst is 1-4nm. And the production comprises that: adding active component, complex agent, alcohol reducer and carrier into solvent; functioning ultrasonic wave at room temperature, adding alkali material, adjusting the pH, adding nitrogen gas to protect reflux at normal pressure, or reacting at high-pressure kettle; cooling to room temperature, adding acid, breaking gel via ultrasonic wave; filtering, washing with water until there is no CI-ion detected; vacuum drying; thermally treating at inertia gas; cooling in nitrogen gas to obtain the carbon-carrier metal catalyst. The invention has simple process; the catalyst active component is two-dimension at the surface of carrier; it has small particles, low crystallization degree, high metal utilization, and high catalysis activity.

Owner:SOUTH CHINA UNIV OF TECH

Carbon-carried platinum-based catalyst for fuel cell and its preparation method

InactiveCN1803292AIncrease profitHigh recovery rateCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNitrogen gasFilter cake

The invention discloses a making method of platinum-on-carbon based catalyst in the fuel battery, which comprises the following steps: adding the metal salt pioneer body, complexing agent and alcohol reducer in the organic solvent; stirring at atmospheric temperature; adding alkaline material; adjusting the pH value; protecting heat reflux through nitrogen or in the autoclave; adding the carbon carrier to stir at atmospheric temperature; diffusing the metal sol particle evenly on the carbon carrier; adding acid material to adjust the pH value; adding second distilled water to break sol through ultrasonic shock; filtering the filter cake until the Cl- is not detected; drying the vacuum; cooling; grinding to produce the platinum-on-carbon based catalyst within Pt / C, Pt-Ru / C, Pt-Ru-Ir / C, Pt / CNT, Pt-Ru / CNT and Pt-Ru-Ir / CNT.

Owner:SOUTH CHINA UNIV OF TECH

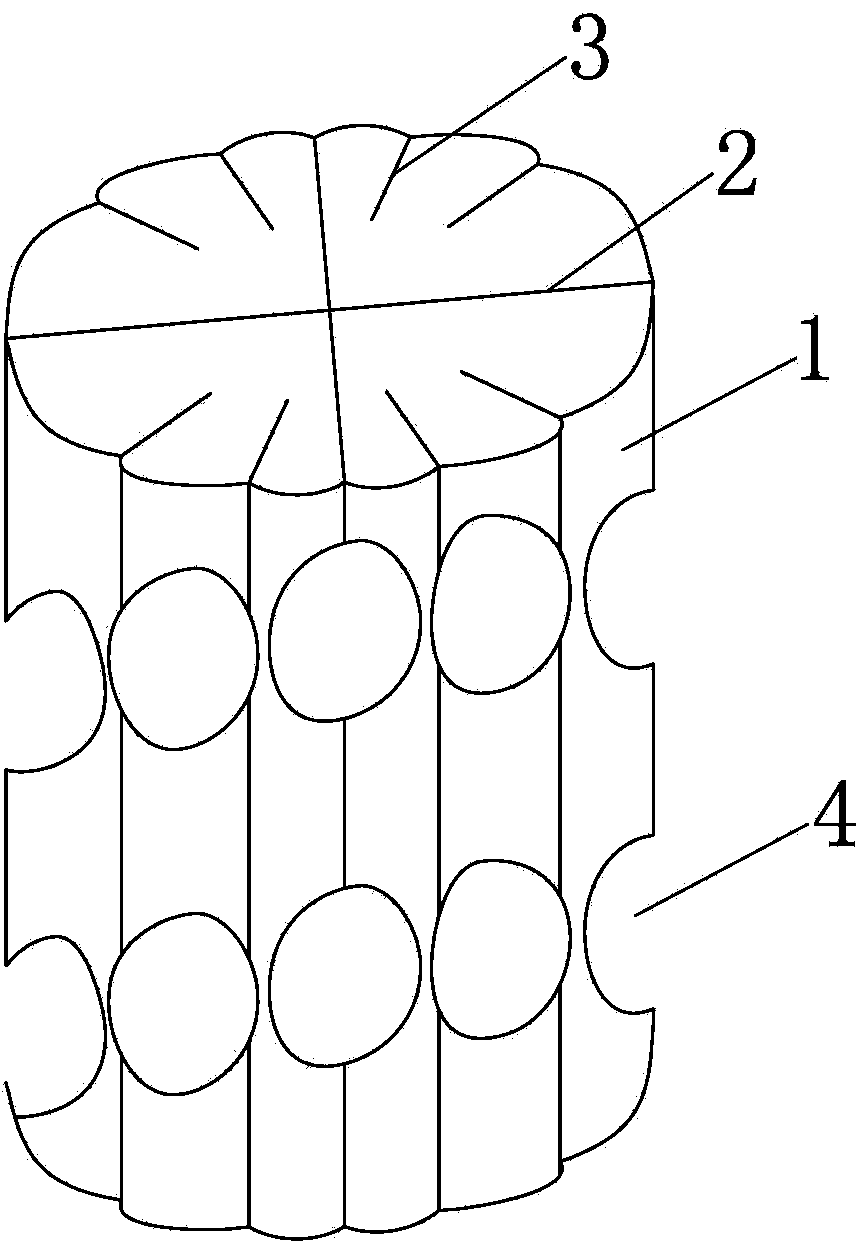

Fluidized bed biofilm filler, and preparation method and filler structure thereof

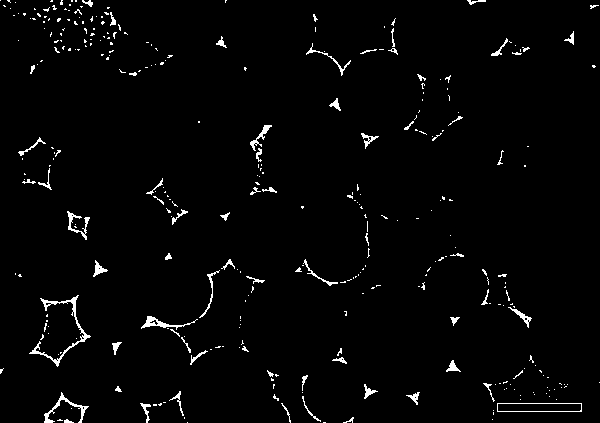

ActiveCN103708619ALarge specific surface areaEnhanced anti-toxicityTreatment with aerobic and anaerobic processesSustainable biological treatmentChemistryPolypropylene

The invention discloses fluidized bed biofilm filler. The fluidized bed biofilm filler is characterized by being prepared from the following components in weight percentage: 80-90% of high-density polyethylene or polypropylene, 1-3% of a coupling reagent, 3-10% of inorganic carbon material, 1-3% of an antioxidant, 2-6% of a nutritional agent, and 3-8% of a hydrophilic agent. The invention also comprises a preparation method of the fluidized bed biofilm filler and a filler structure of the fluidized bed biofilm filler prepared from the method. The fluidized bed biofilm filler, and the preparation method and the filler structure thereof have the characteristics of large specific surface area, good hydrophilcity, strong toxicity resistance, easiness in biofilm formation and fluidization and the like.

Owner:VISBE XIAMEN ENVIRONMENT TECH CO LTD

Catalyst for removing NOx in incineration gas and preparation method thereof

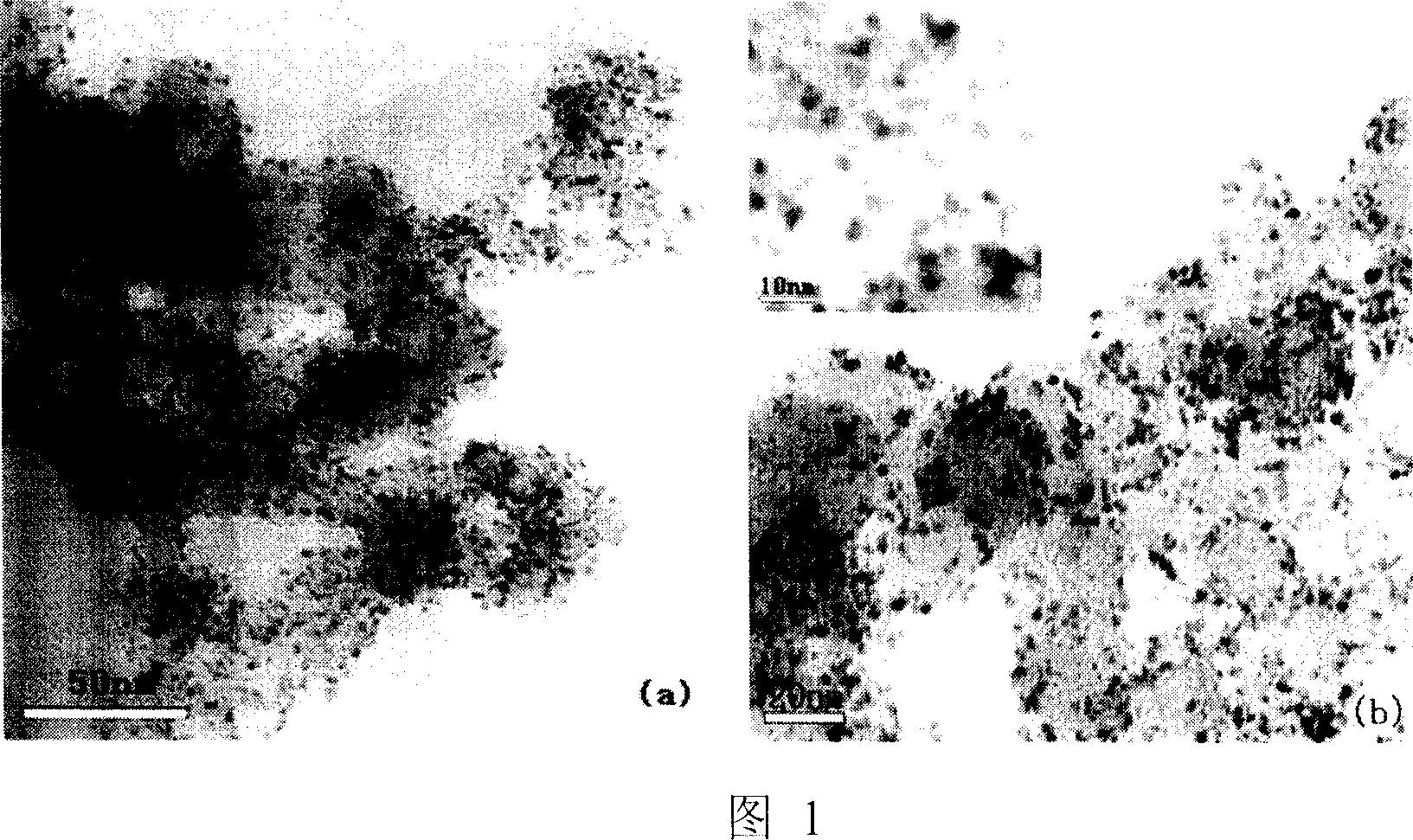

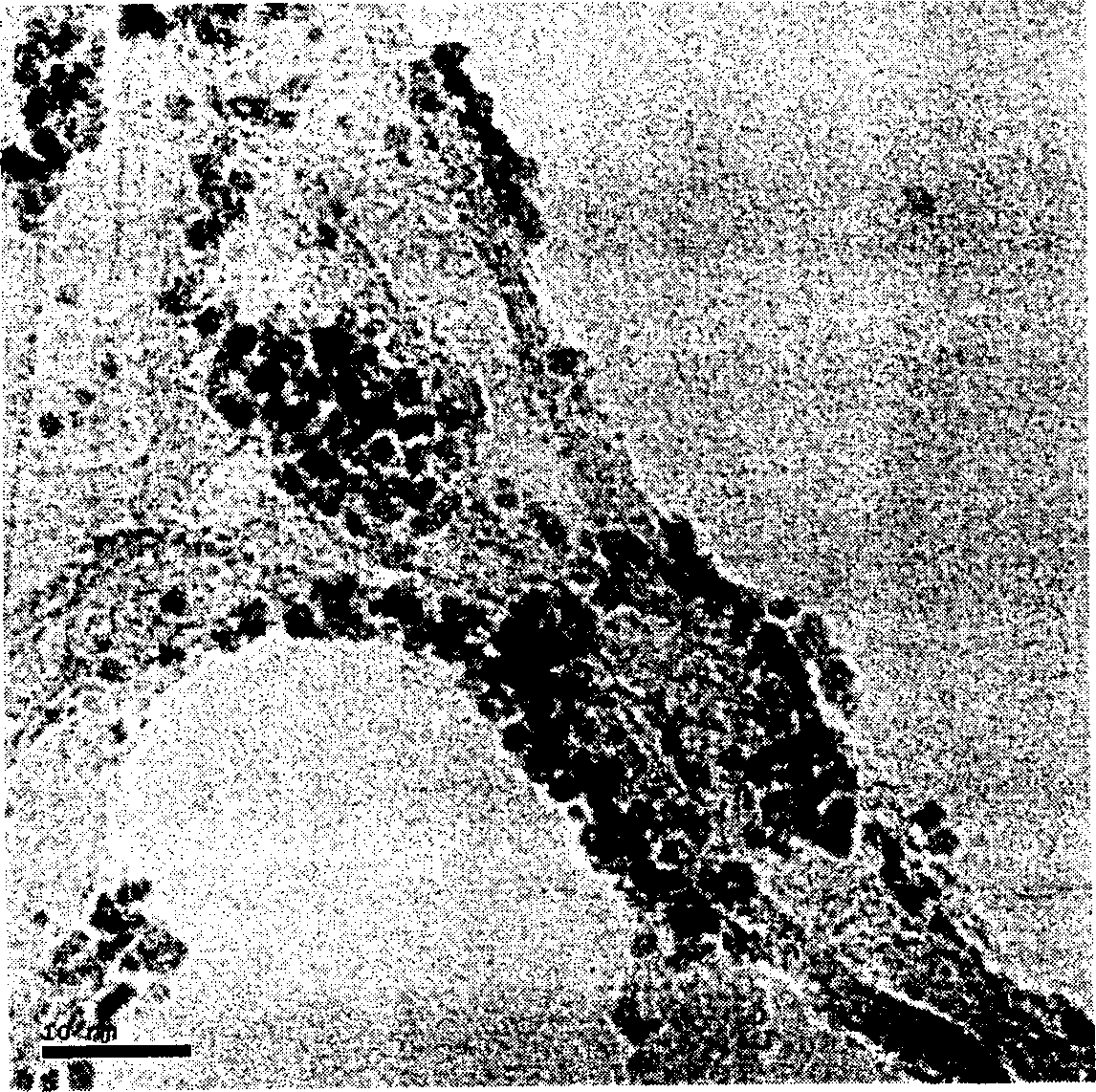

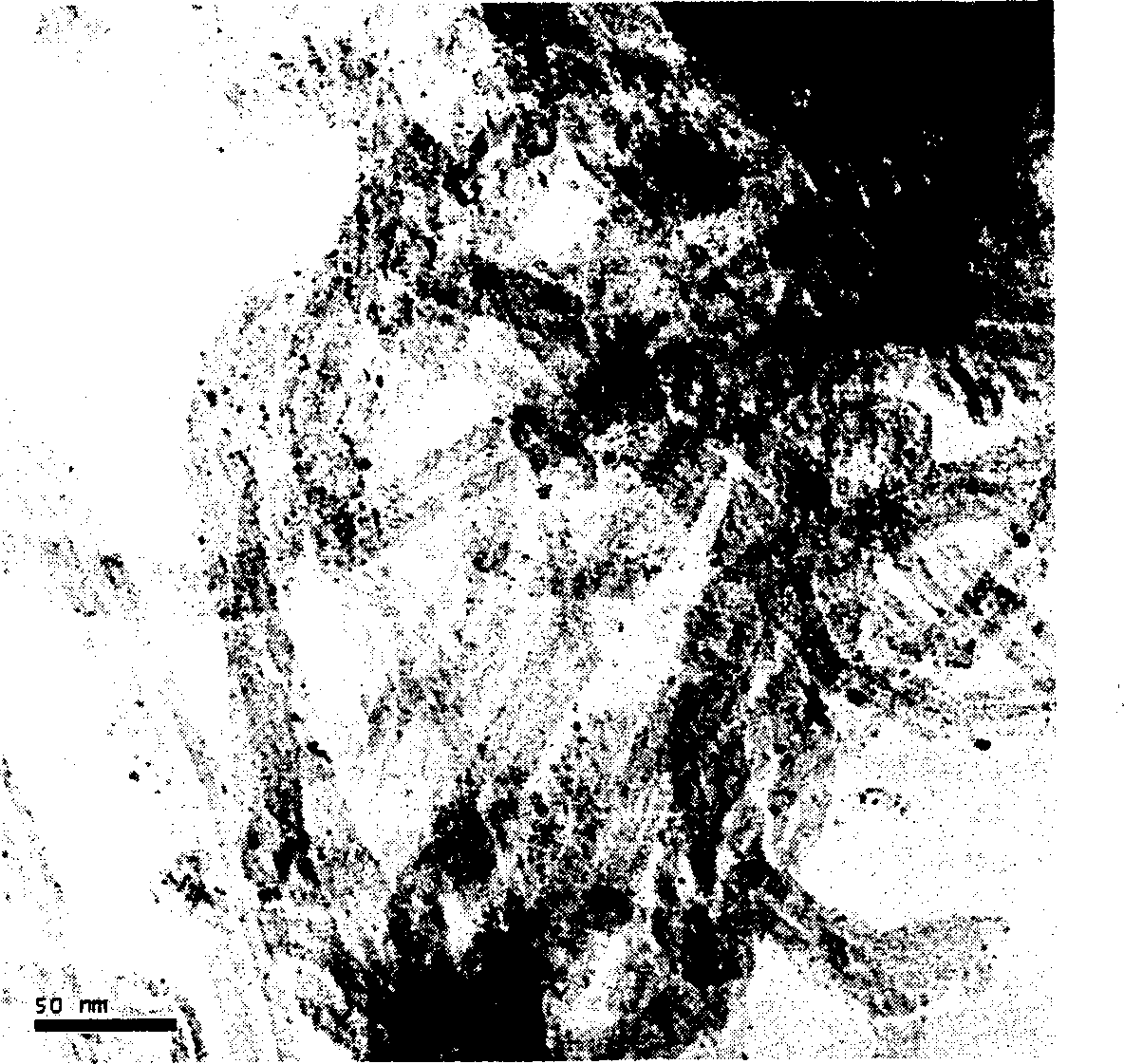

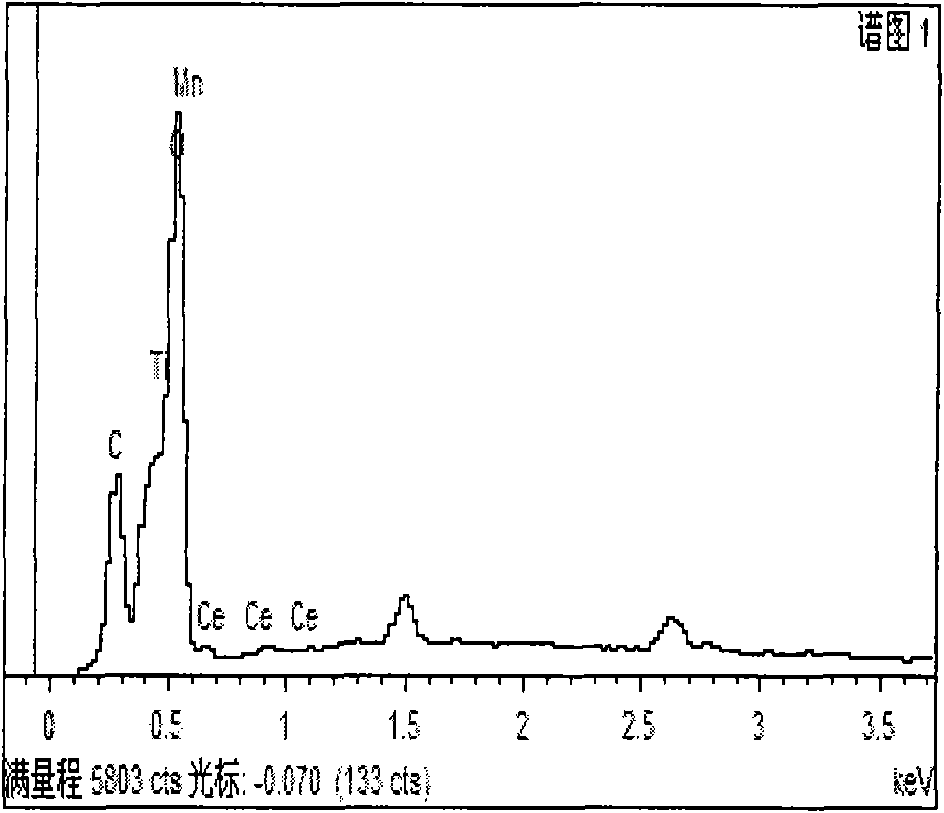

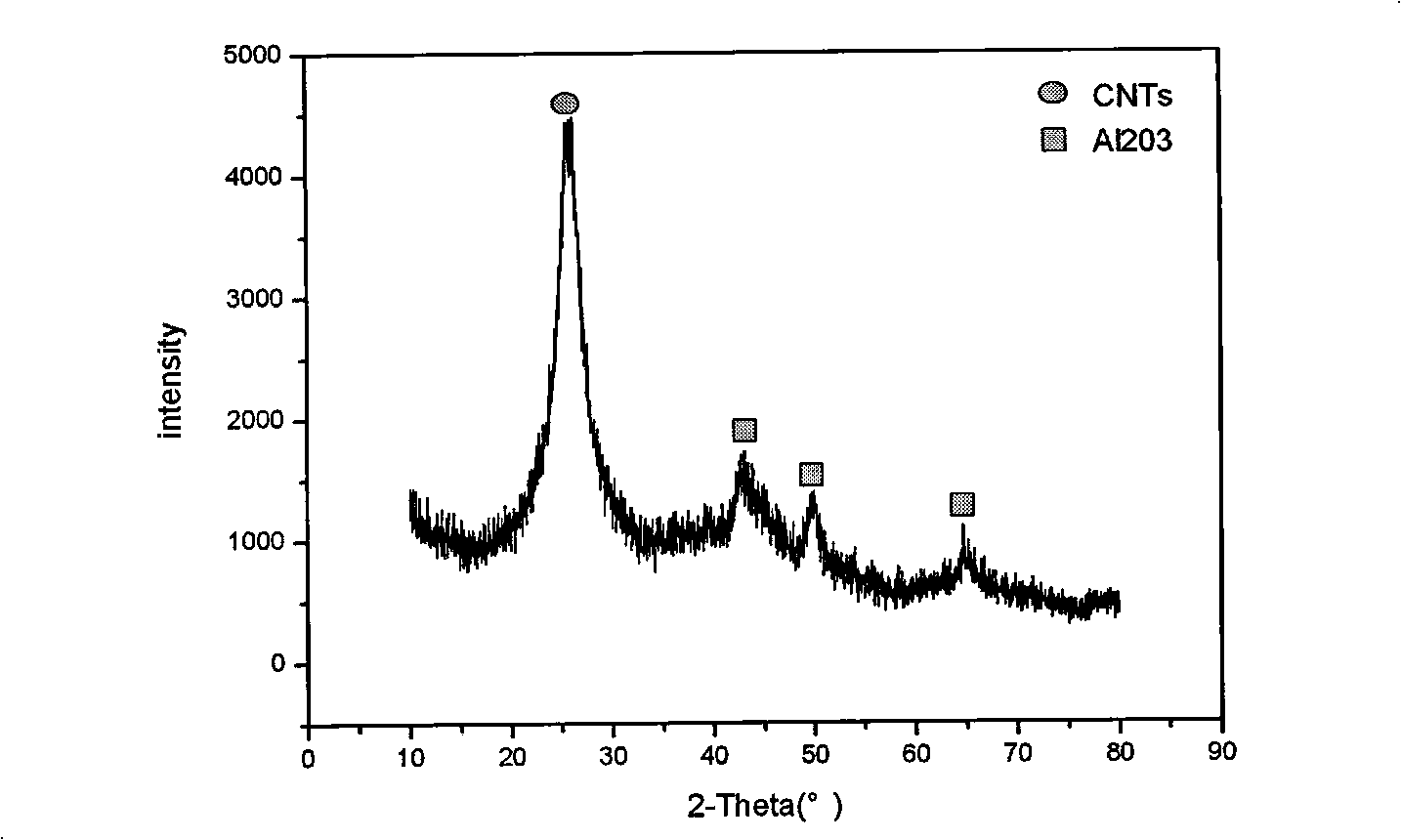

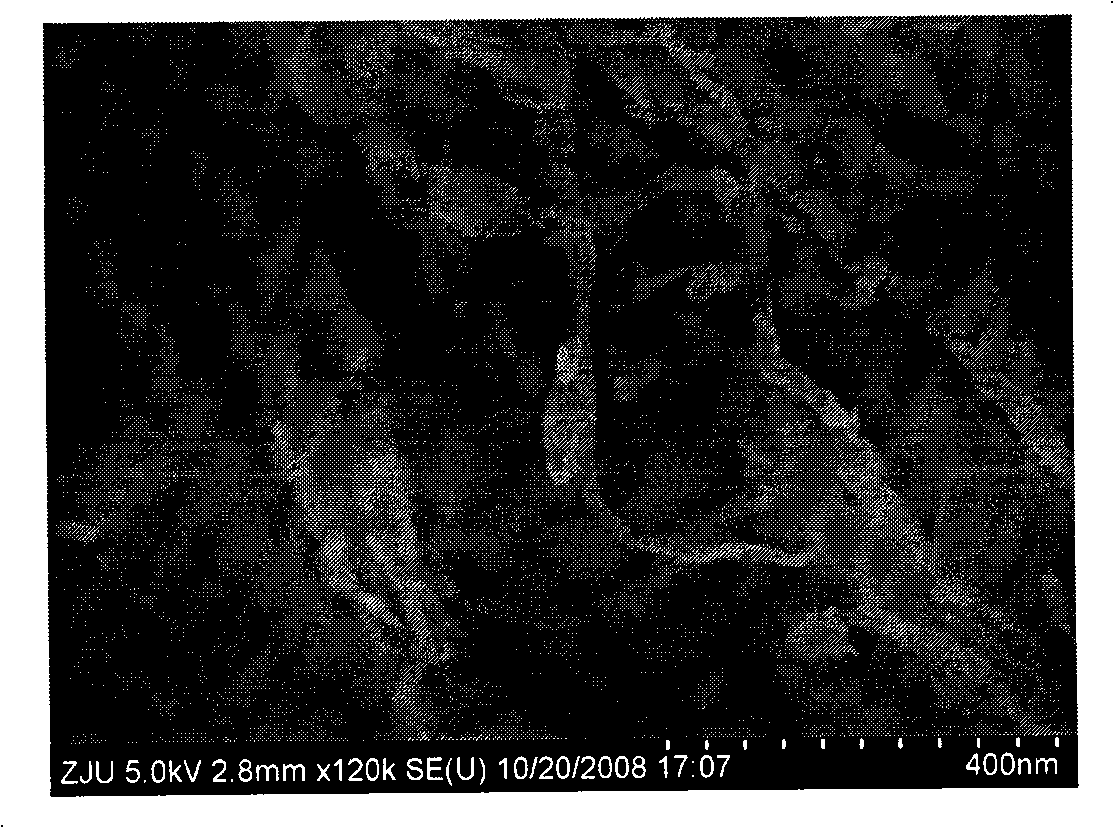

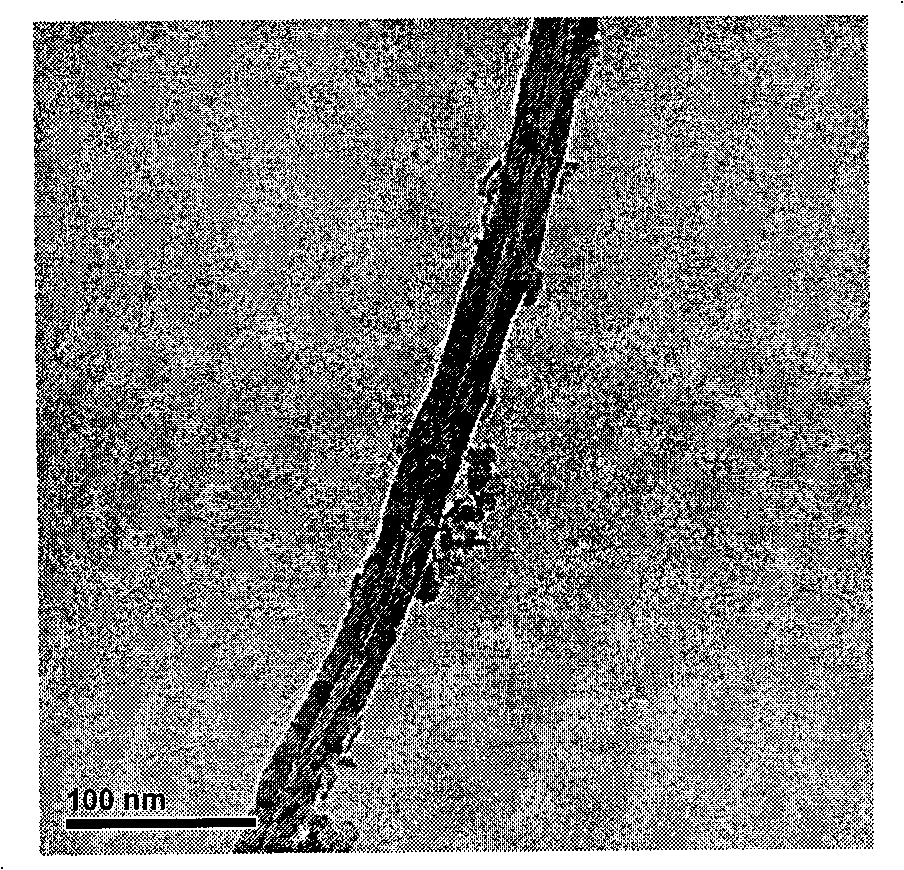

ActiveCN101773824ALarge specific surface areaStrong resistance to poisonDispersed particle separationCatalyst activation/preparationCarbon nanotubeSol-gel

The invention discloses catalyst for removing NOx in incineration gas. The catalyst takes carbon nano tubes and titanium dioxide as carriers and takes manganese oxide and cerium oxide as binary active ingredients. The preparation method can be a sol gel method, a solvothermal method or a coprecipitation method. The catalyst of the invention takes both the carbon nano tubes and the TiO2 as the carriers, the excellent adsorption property of CNTs and the large specific surface area are utilized, the advantages of the TiO2 as traditional carriers are combined and the nontoxic and pollution-free MnOx and CeOx as the binary active ingredients, so the absorption function of the CNTs and the catalytic action of the MnOx and CeOx cooperate with each other, the operating temperature of the selective catalytic reaction is reduced and the NOx removal rate can reach 99.5 percent under 125 DEG C. The catalyst can be used to remove NOx atmospheric pollutants emitted in the high-temperature processes of the coal-fired power plants, the metallurgical industry, the waste incineration and the like.

Owner:ZHEJIANG UNIV

Catalyst for removing nitrogen oxide and organic pollutant discharged in burning and method for preparing same

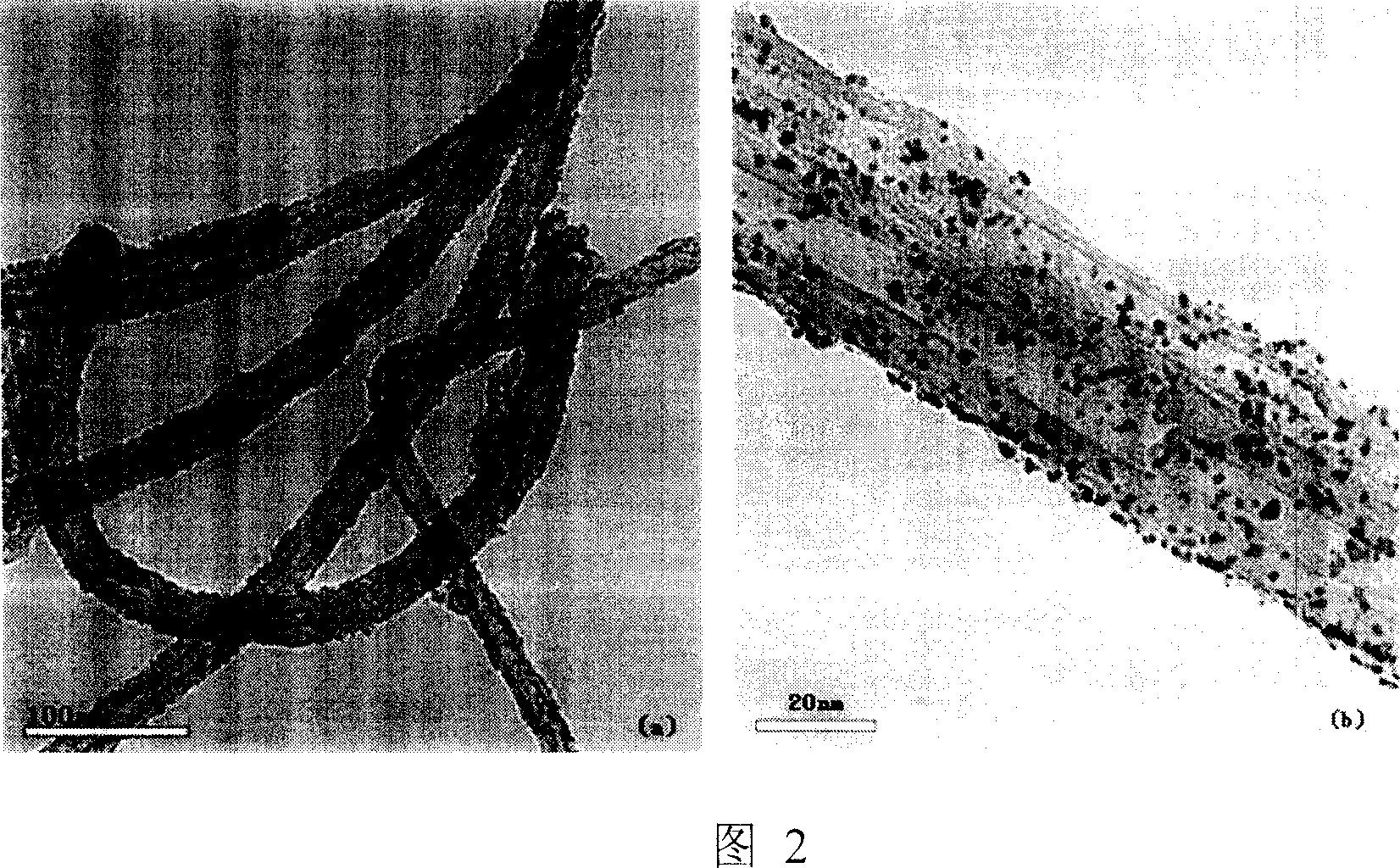

InactiveCN101513612AGuarantee structureExcellent low temperature SCR characteristicsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChlorobenzeneCarbon nanotube

The invention discloses a catalyst for removing nitrogen oxide and organic pollutant discharged in burning, comprising carbon nanotube and alumina as the carrier and manganese oxide as the active ingredient, the active ingredient in the catalyst accounts for 1 to 10% of the total catalyst mass. The catalyst is prepared by a solvent-thermal method. In the inventive catalyst, CNTs and Al2O3 are simultaneously used as the carrier for the first time, thus the catalyst has big specific surface area and high mechanical strength, at the same tine the temperature of the selective catalytic reaction is reduced, 94.2% of chlorobenzene removing ratio can be obtained at the temperature of 150 DEG C, 88.8% of NOx removing ratio is obtained at the temperature of 200 DEG C. The catalyst can be used for removing the nitrogen oxide (NOx)and dioxin organic pollutant discharged in the high-temperature process in the fire coal power plant, metallurgy industry, garbage burning and the like.

Owner:ZHEJIANG UNIV

Preparation method of mesoporous titanium dioxide ball supported Mn-Ce-W compound oxide denitration catalyst

ActiveCN104014331AHigh catalytic activityImprove catalytic stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAdditive ingredientCerium

The invention relates to a preparation method of a denitration catalyst and relates to the technique field of preparation of supported denitration catalysts and the field of environment protection. The denitration catalyst takes a mesoporous titanium dioxide ball as a carrier and cerium tungsten manganese oxides as active ingredients. According to the key points of the preparation method, the mesoporous titanium dioxide ball is used as the carrier; three ingredients, namely cerium, tungsten and manganese, are supported on the surface of the mesoporous titanium dioxide ball by using an impregnation method so as to realize uniform dispersion and strong interactions of cerium, tungsten and manganese, and finally the efficient denitration catalyst is obtained through calcining. The catalyst has a mesoporous structure, so that the specific surface area of the catalyst is remarkably enlarged; by using multiple-ingredient cooperation effect, the catalytic activity of the catalyst is effectively improved; the temperature window is widened; the preparation method has the advantage of being environmentally friendly, simple in production technique and suitable for large scale industrial production, and can be used for removing nitric oxide emitted from a fixed source and a mobile source.

Owner:SHANGHAI UNIV +1

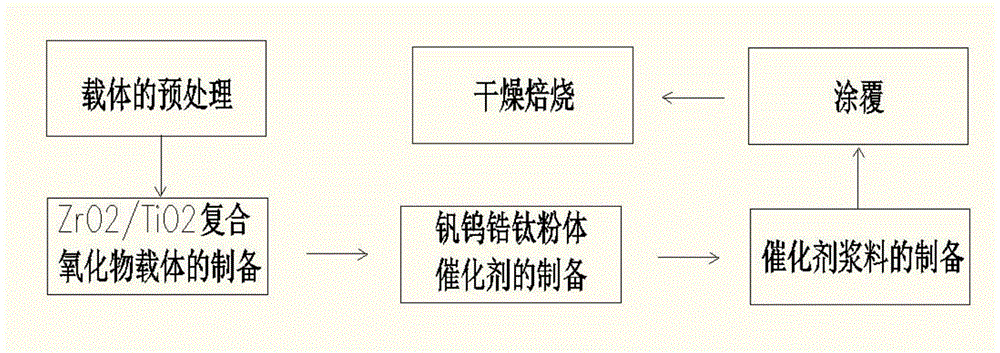

Monolithic SCR (Selective Catalytic Reduction) honeycomb catalyst for processing diesel exhaust and preparation method of catalyst

ActiveCN103908970AEvenly dispersedLarge specific surface areaCatalyst carriersDispersed particle separationRare earthSlurry

The invention discloses a monolithic SCR (Selective Catalytic Reduction) honeycomb catalyst for processing diesel exhaust and a preparation method of the catalyst. The catalyst comprises a honeycomb ceramic carrier and a coating; the coating coats a honeycomb hole, and the coating consists of a ZrO2 / TiO2 composite oxide carrier and catalyst active components. The ZrO2 / TiO2 composite oxide carrier comprises the following components in percentage by weight: 5wt%-20wt% of ZrO2 and 50wt%-85wt% of TiO2. The catalyst active components comprise the following components in percentage by weight: 1wt%-5wt% of V2O5, 1wt%-10wt% of WO, 1wt%-5wt% of Fe2O3, 1wt%-5wt% of CuO, 1wt%-10wt% of rare earth metal oxide and the balance of an adhesion agent. The preparation method of the catalyst comprises the following steps: firstly preparing the ZrO2 / TiO2 composite oxide carrier, subsequently preparing a vanadium-tungsten-zirconium-titanium powder catalyst, then dispersing the vanadium-tungsten-zirconium-titanium powder catalyst in other components to prepare a catalyst slurry; and then coating the honeycomb ceramic carrier with the catalyst slurry, drying and roasting, and then preparing the monolithic SCR honeycomb catalyst. The monolithic SCR honeycomb catalyst is suitable for purifying diesel exhaust NOx and has the characteristics of wide active temperature window at 160-550 DEG C, high NOx removal rate, strong antitoxic performance, long service life and simplicity in preparation.

Owner:浙江欧信环保科技有限公司

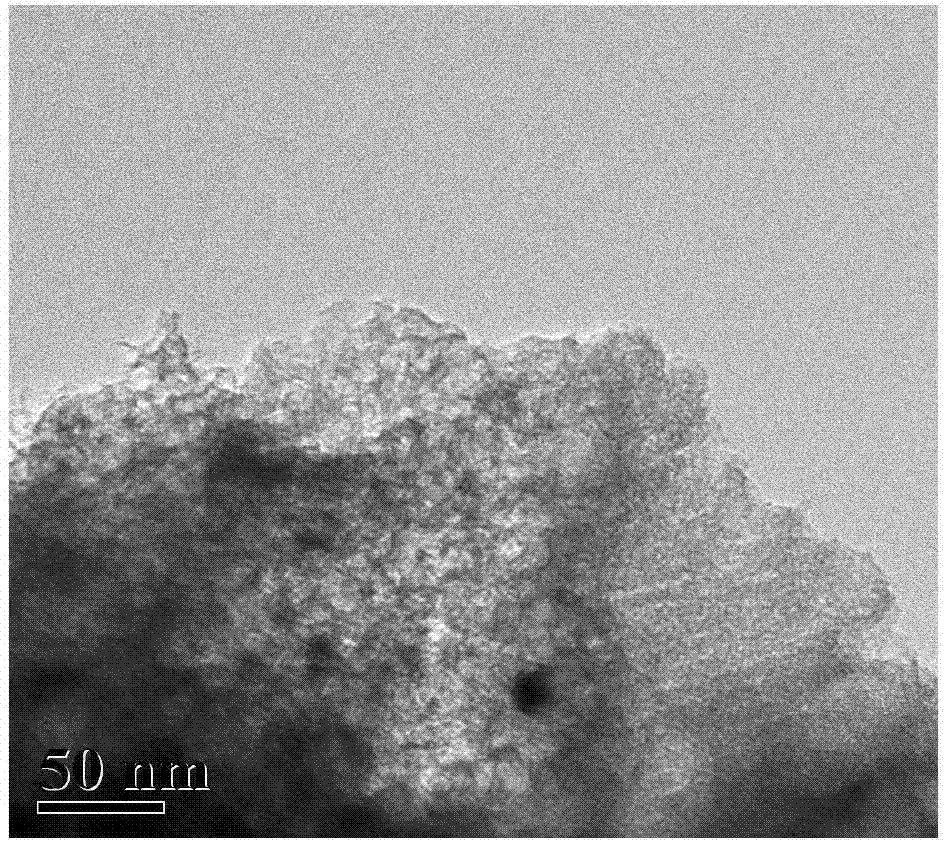

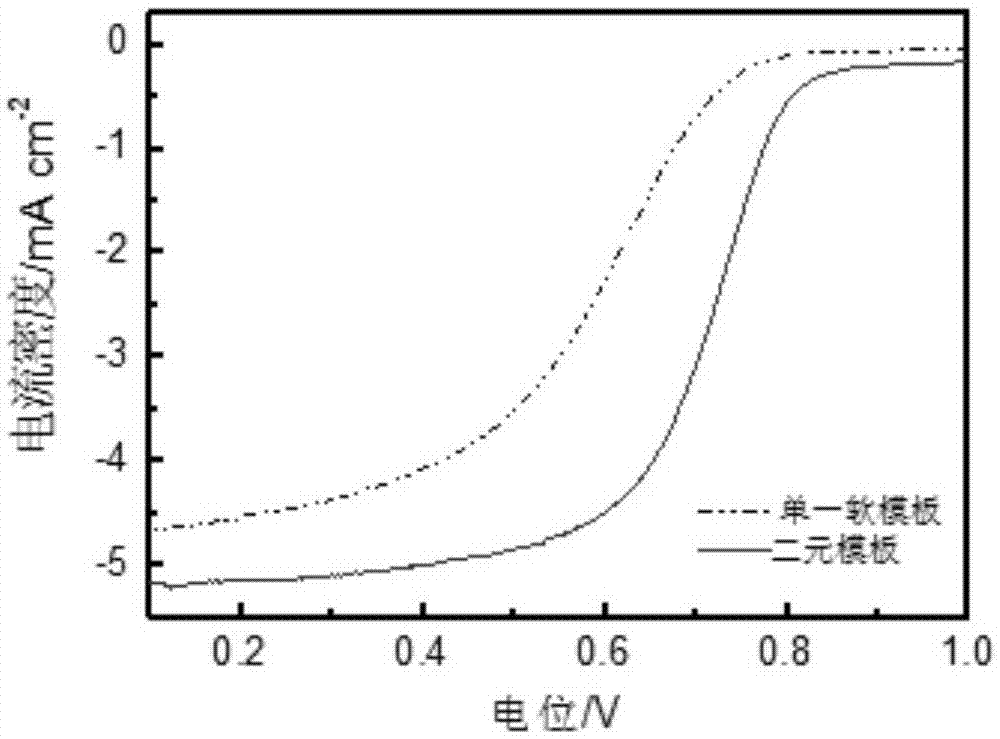

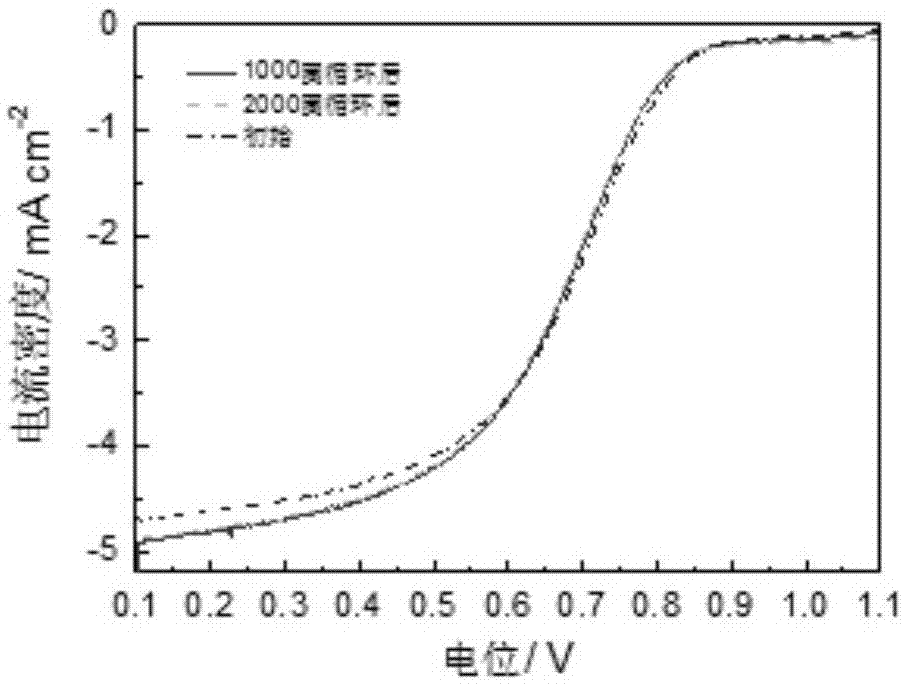

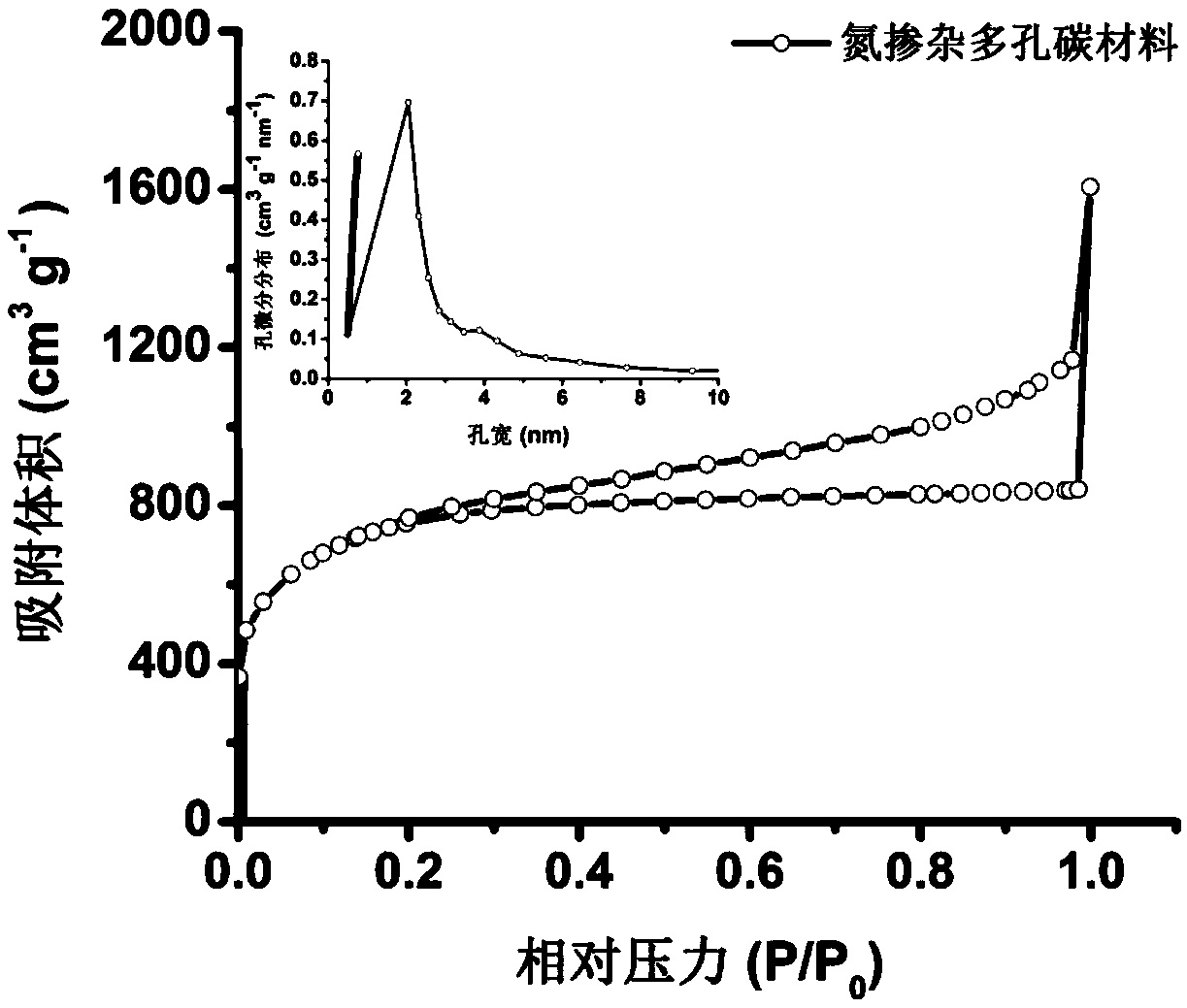

Preparation of nitrogen-doped orderly-graded mesoporous carbon catalyst as well as carbon catalyst and application of carbon catalyst

ActiveCN106861740AHigh active specific surfaceEnhanced mass transferPhysical/chemical process catalystsCell electrodesEtchingOxygen

The invention discloses a preparation method of a nitrogen-doped orderly-graded mesoporous carbon catalyst and application of the nitrogen-doped orderly-graded mesoporous carbon catalyst to proton exchange membrane fuel cells. The catalyst is prepared though a binary mixing template method; a triblock copolymer is used as a soft template agent and one or more of a Y-type molecular sieve, an MCM-41 molecular sieve and a ZSM-5 molecular sieve are used as a hard template agent; soluble resin is used as a carbon source; in a preparation process, a transition metal salt is added and a transition metal element is introduced in situ; meanwhile, a nitrogen element is introduced through roasting in an ammonia atmosphere. The nitrogen-doped orderly-graded mesoporous carbon material provided by the invention has an ordered mesoporous structure (with the size of 3nm to 5nm) generated by soft template induction and a three-dimensional through mesoporous structure (with the size of 10nm to 50nm) generated by hard template etching, has a high-activity specific surface and good mass-transferring performance and has excellent oxygen reduction catalysis performance and good electrochemical stability. By adopting the carbon material provided by the invention, application of the binary mixing template method to preparation of an oxygen reduction carbon-based catalyst is realized for the first time; meanwhile, the carbon material has the advantages of good process repeatability, low cost, good environmental friendliness and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ceramic catalyst body

InactiveUS20020039966A1Enhanced anti-toxicityPreventing catalyst poisoningCatalyst protectionOther chemical processesExhaust gasCordierite

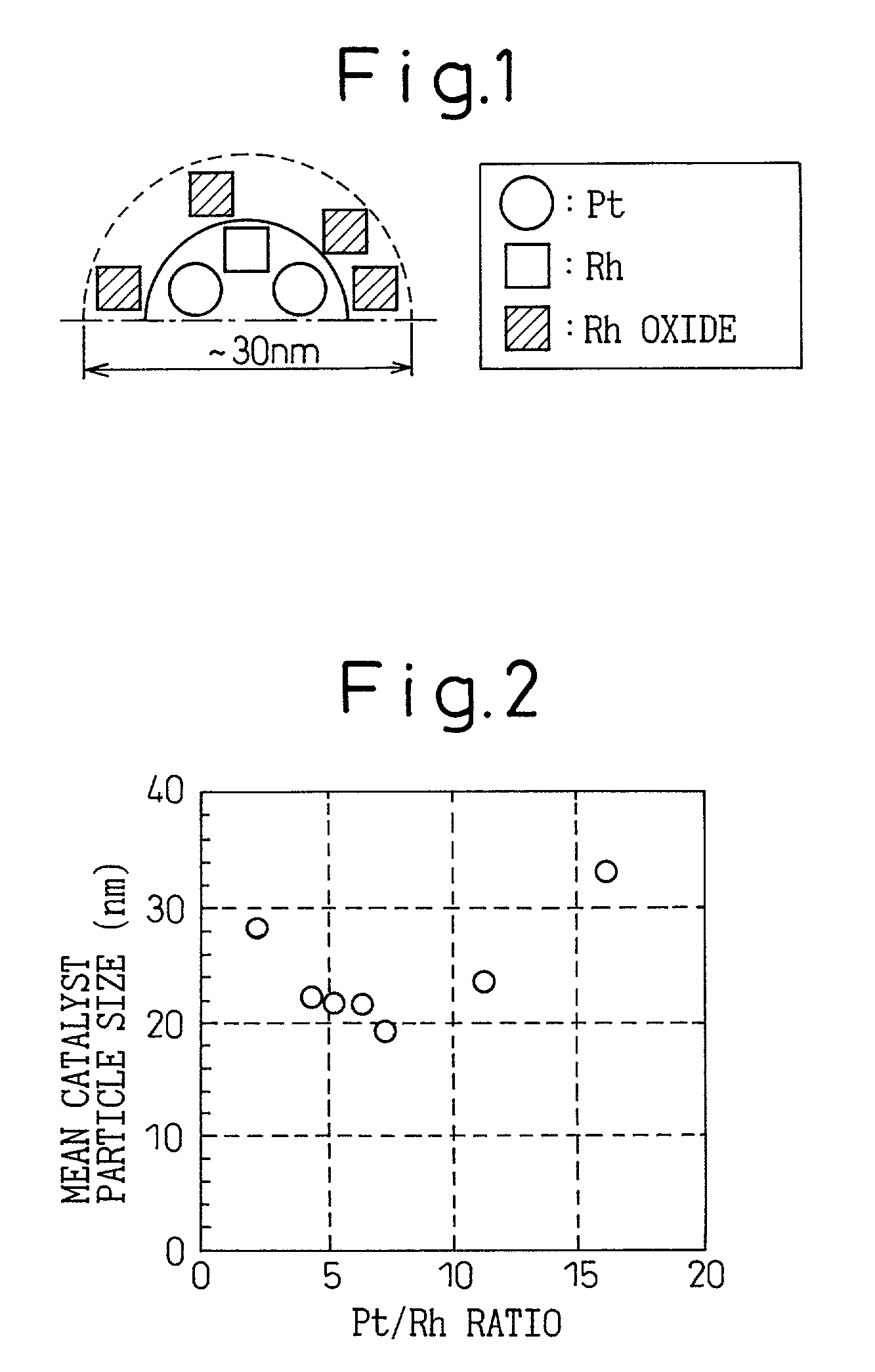

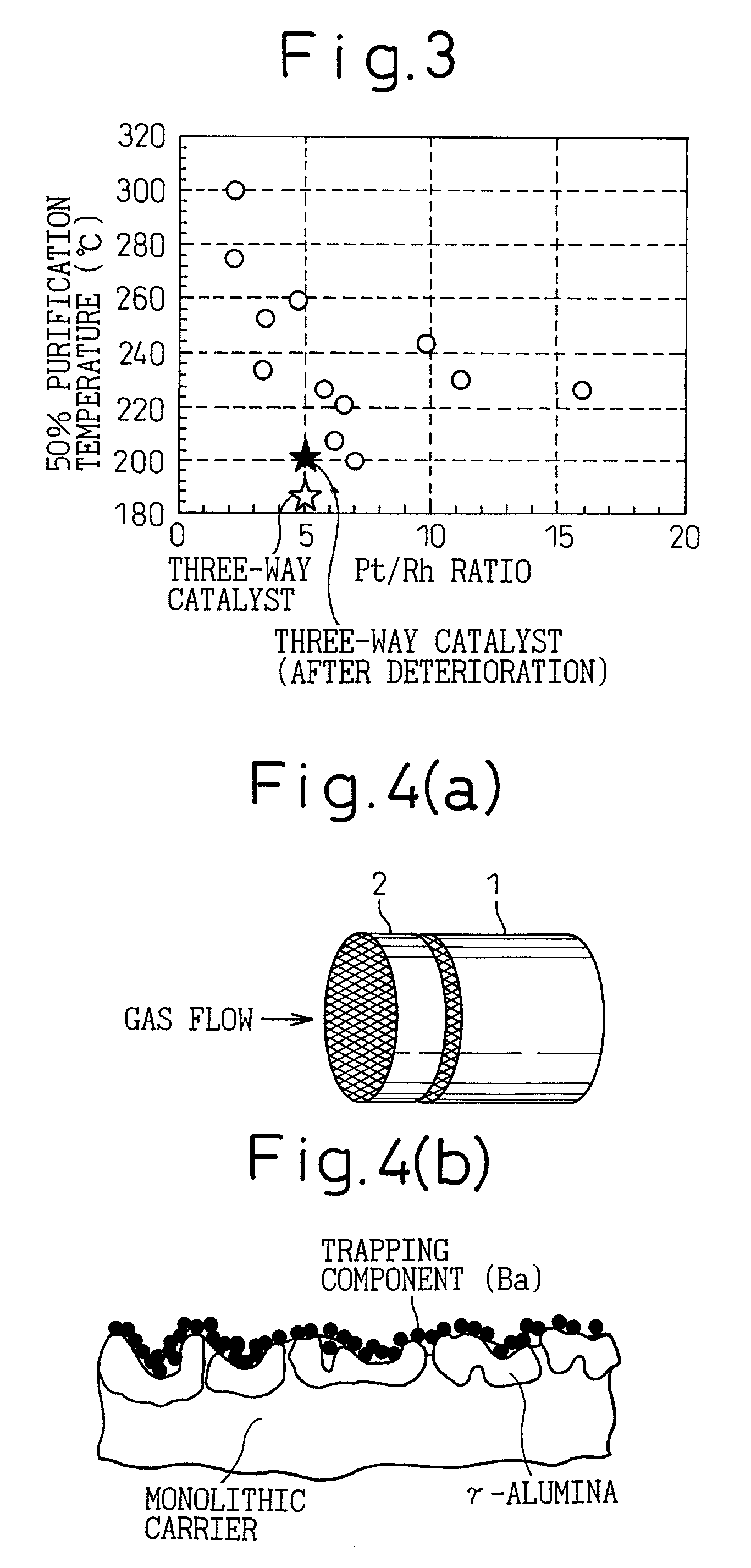

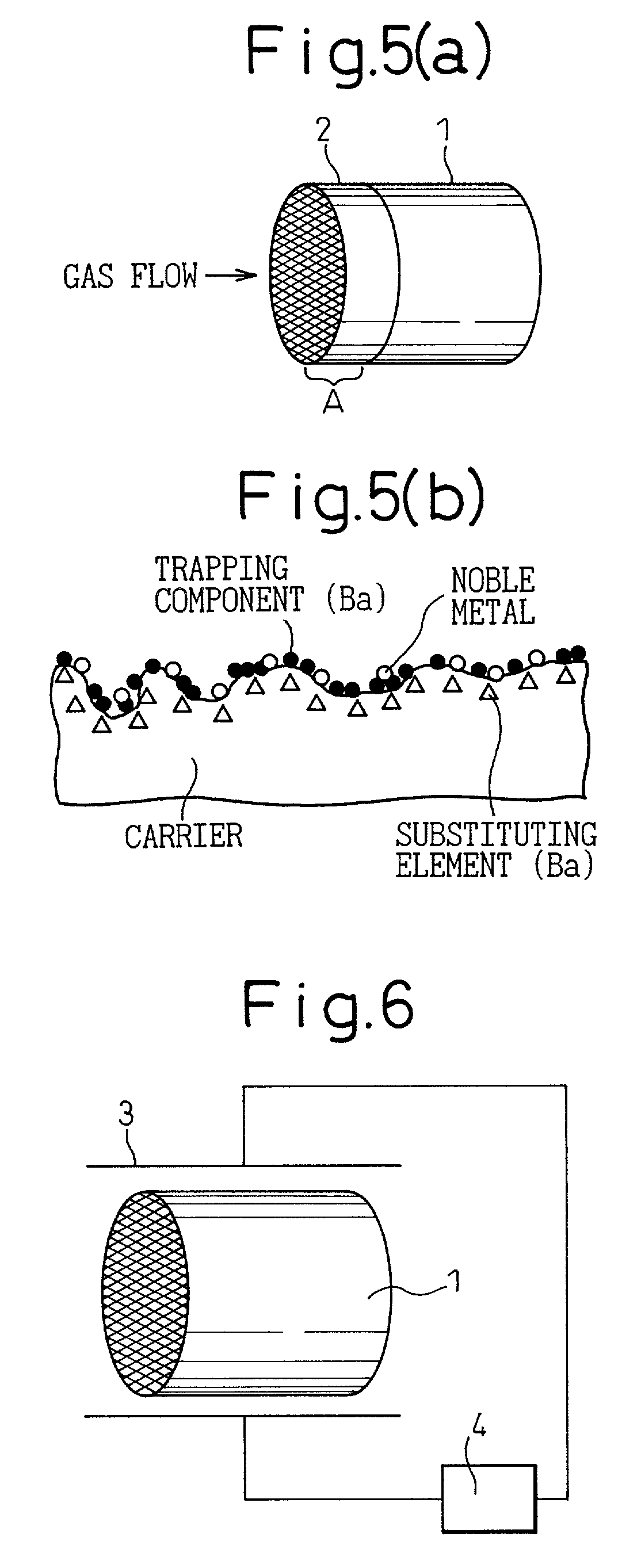

(i) In a ceramic catalyst body which comprises a ceramic carrier which has a multitude of pores capable of supporting a catalyst directly on the surface of a substrate ceramic and a catalyst supported on the ceramic carrier, a layer containing an anti-evaporation metal such as Rh is formed on the outer surface of catalyst metal particles such as Pt or Rh. The layer containing the anti-evaporation metal protects the catalyst metal and prevents evaporation thereof, thereby suppressing the deterioration; and / or (ii) A ceramic catalyst body is made by having a main catalyst component and a promoter component directly on a ceramic carrier which can directly support the catalyst by substituting a part of the constituent elements of cordierite, and a trap layer is provided in the upstream thereof for trapping sulfur which is a catalyst poisoning component included in the exhaust gas. Since sulfur included in the exhaust gas can be collected by the trap layer, the catalyst poisoning component can be removed from the gas which enters the catalyst, thus preventing catalyst poisoning.

Owner:DENSO CORP +1

Preparation method of metal organic framework material and application of metal organic framework material in cyclohexyl hydroperoxide decomposition reaction

ActiveCN105712867AEasy to makeShort synthesis cycleOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSodium acetateAlkali free

The invention discloses a preparation method of a metal organic framework material and application of the metal organic framework material in a cyclohexyl hydroperoxide decomposition reaction. Transition metal salt and terephthalic acid or a derivative thereof are subjected to a hydrothermal synthesis reaction in a sodium acetate solution to obtain the metal organic framework material, then the metal organic framework material serving as a catalyst is added into industrial cyclohexane uncatalysed oxidation liquid, the temperature is controlled to be 50-150 DEG C, the time is controlled to be 0.1-5 h, cyclohexyl hydroperoxide decomposition is carried out to obtain hexamethylene and cyclohexanone, the conversion rate of cyclohexyl hydroperoxide is larger than 95%, and the selectivity of alcohol ketone reaches up to 100%; the activity of the repeatedly-recycled catalyst is kept unchanged basically. Compared with other catalysts containing metal active components, the catalyst is high in catalytic efficiency, recyclable and stable in reusability; when the catalyst is applied to the cyclohexyl hydroperoxide decomposition reaction, the decomposition process is conducted under the alkali-free condition, the catalytic efficiency is very high, and pollution caused by waste alkali liquor to the environment is avoided.

Owner:XIANGTAN UNIV

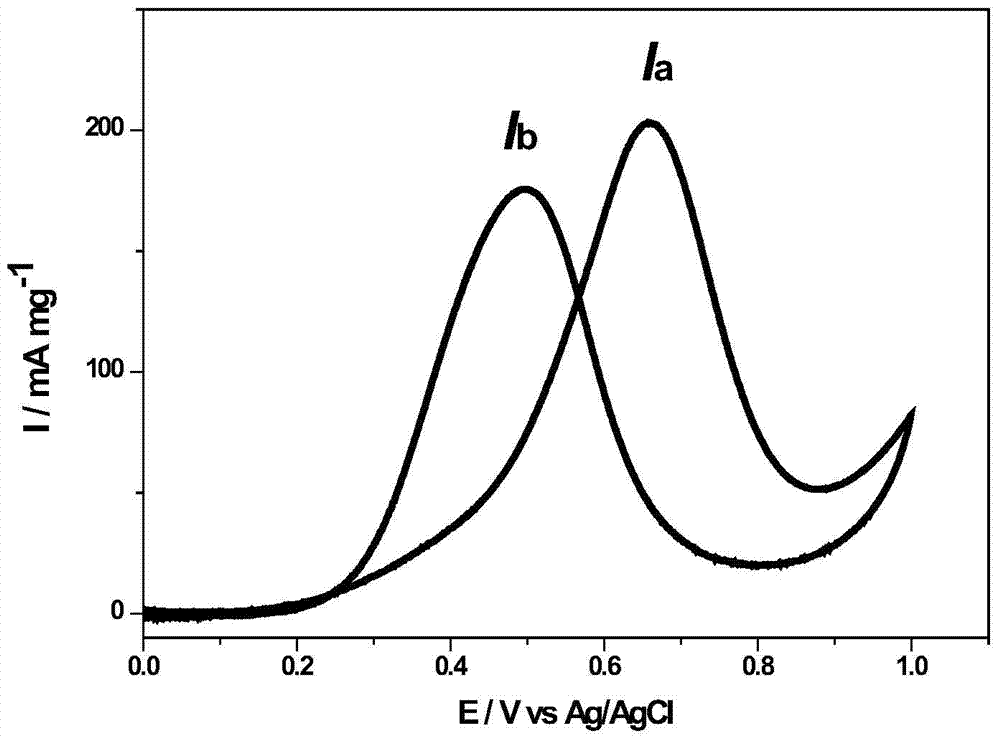

Fuel cell anode catalyst using heteropolyacid as promoter and preparation method thereof

InactiveCN1624963AHigh activityEnhanced anti-toxicityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsFuel cellsHeteropoly acid

This invention relates to a preparing method of positive pole catalyst of fuel battery using heteropolyacid as improver, including: (1) add the carbon carrier into the mixture solution of nitric acid and vitriol to react to get pre-process carbon carrier; (2) impregnate the carbon carrier in the heteropolyacid solution, heat process and obtain the electric conducting carbon carrier containing heteropolyacid; (3) suspend the conducting carbon carrier of (2) in the secondary distilled water, stir and make the carrier disperse and get carbon dispersing liquid; (4) fully dissolve chloroplatinic acid or platinous chloride and ruthenium trichloride in deionized water, and drop it to the dispersing solution of (3); (5) dry to get the catalyst containing heteropolyacid.

Owner:SOUTH CHINA UNIV OF TECH

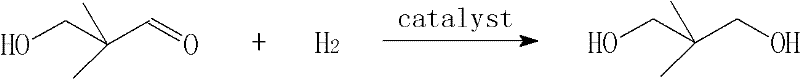

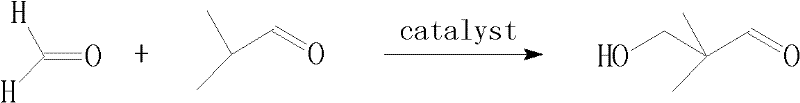

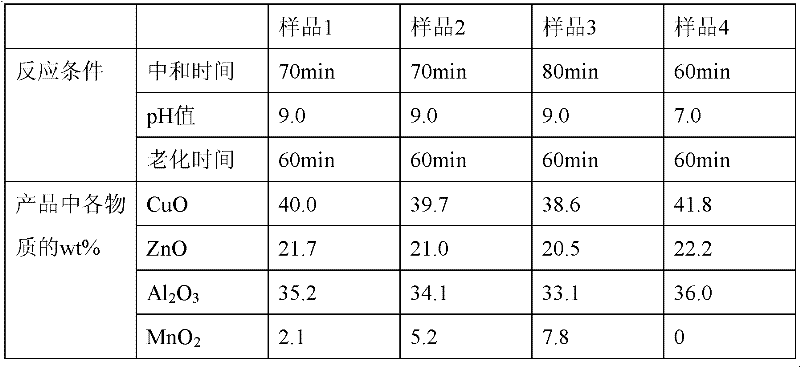

Catalyst for preparing neopentyl glycol by hydrogenation of hydroxypivalaldehyde and preparation method thereof

InactiveCN102302937ALow priceAvoid pollutionOrganic compound preparationHydroxy compound preparationCopper oxideManganese oxide

The invention provides Cu-Zn-Al-Mn catalyst for preparing neopentyle glycol by hydrogenation of hydroxypivalaldehyde and a preparation method thereof, and belongs to the technical field of a catalyst. Based on the weight percentage of the catalyst, the catalyst comprises the following substances in percentage by weight: 20 to 50 percent of copper oxide, 20 to 40 percent of zinc oxide, 20 to 40 percent of alumina, and 1 to 10 percent of manganese oxide. The catalyst is prepared by a one-step precipitation method, has the advantages of high activity, good stability and the like, and has better hydrogenation capability to hydroxypivalaldehyde hydroxypivalic ester.

Owner:SHANGHAI HUAYI ENERGY CHEM

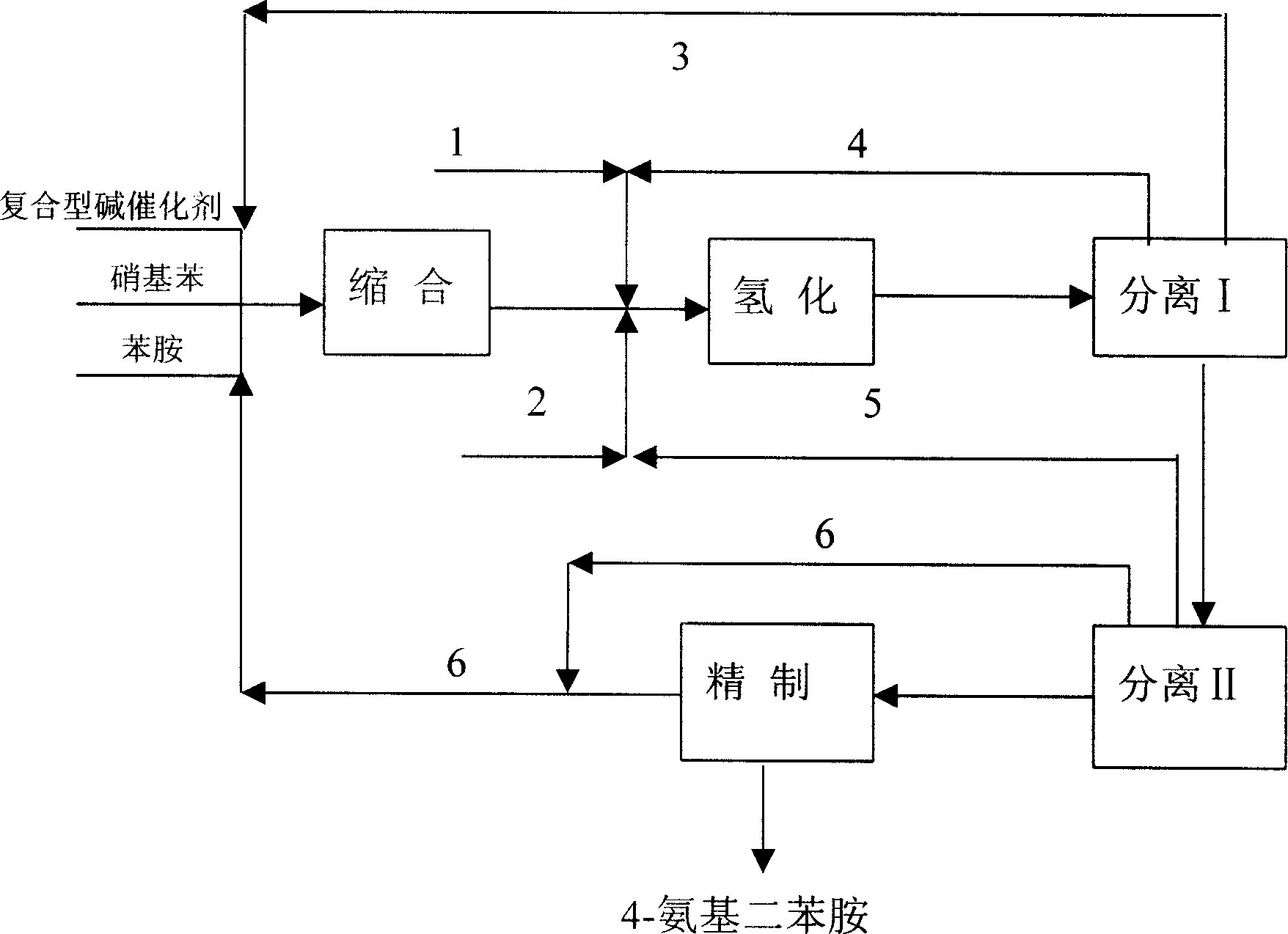

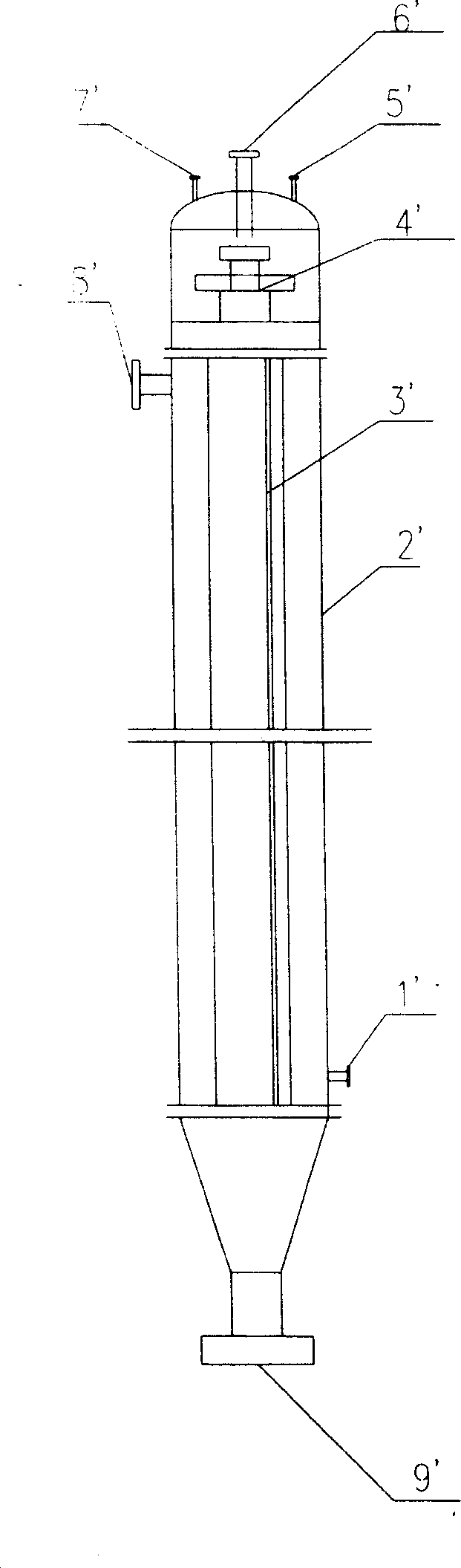

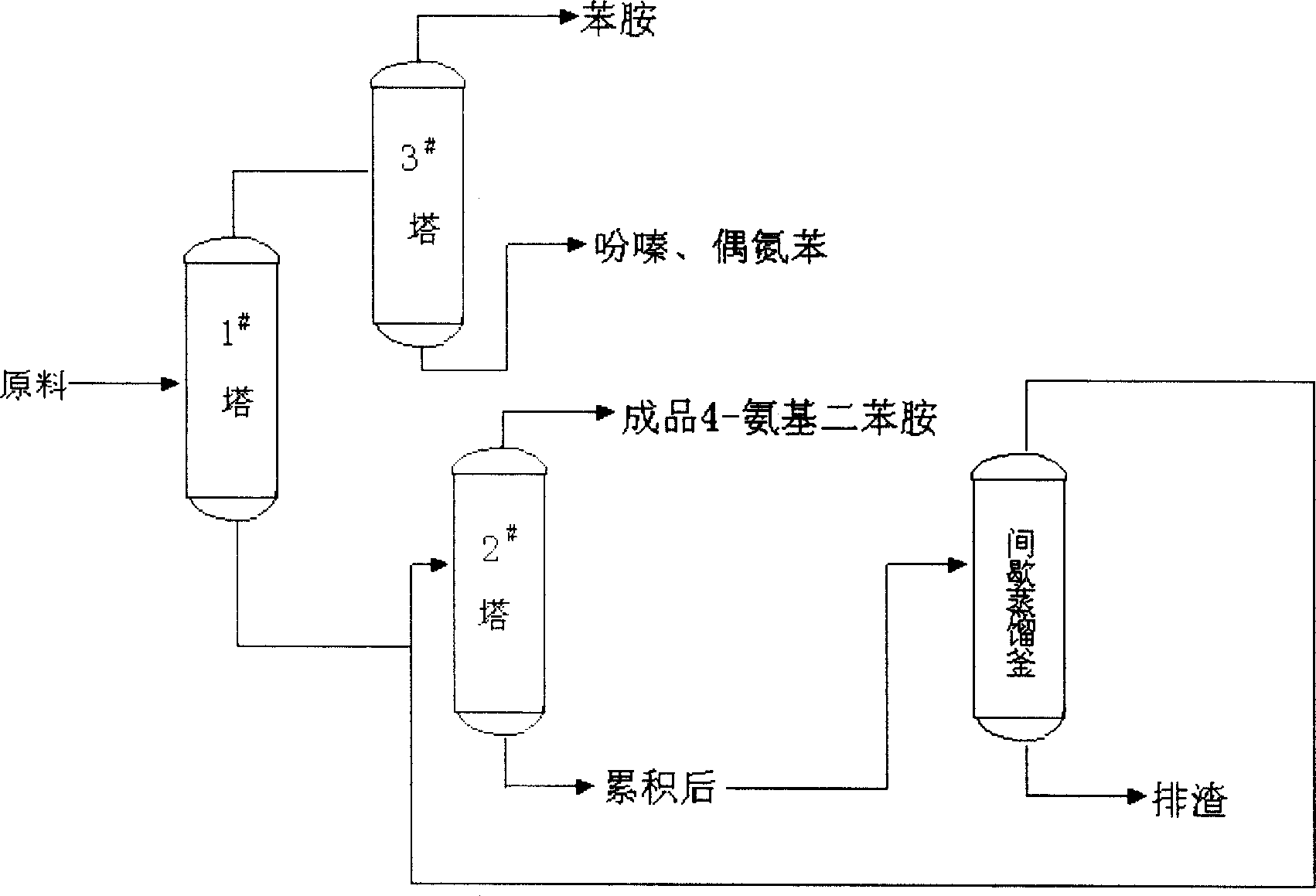

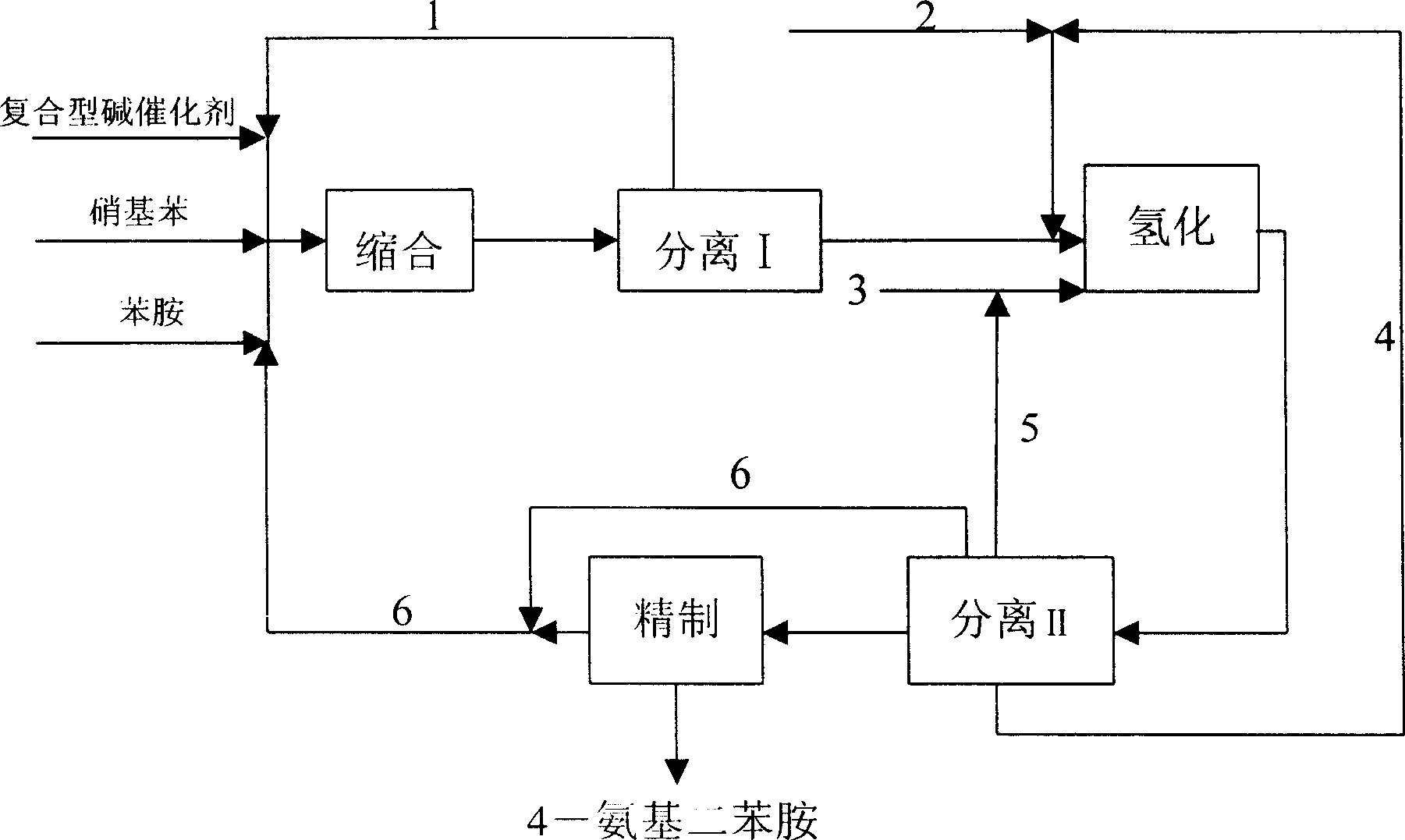

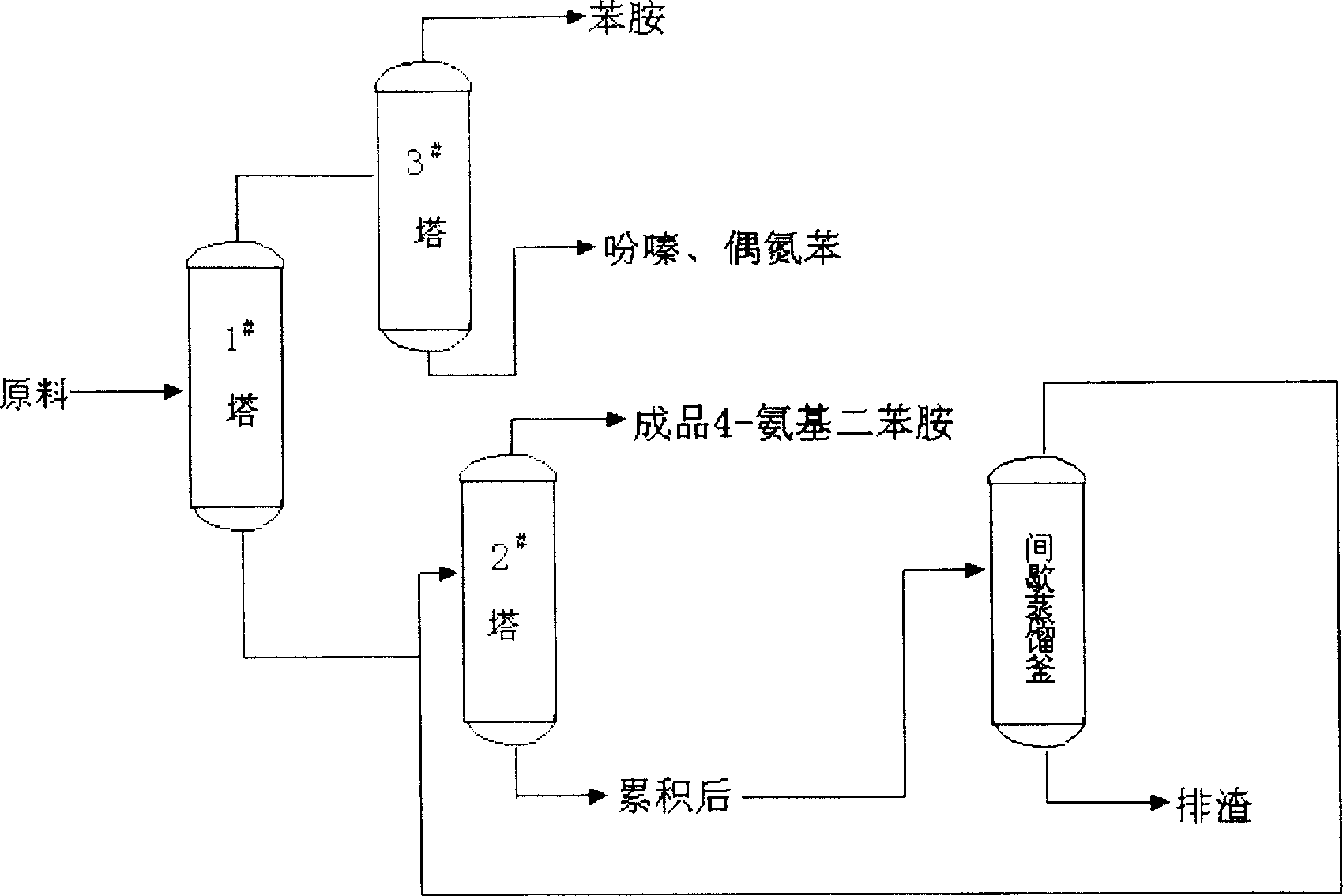

Process for preparing 4-amino diphenylamine

ActiveCN1721391AAvoid smallRaise the ratioAmino preparation from aminesChemical recyclingNitrobenzeneSolvent

The present invention discloses production process of 4-amino diphenylamine with nitrobenzene and phenylamine as materials. The production process includes five steps of condensation; hydrogenation; separating, recovering and reusing composite alkali catalyst, and separating, recovering and reusing at least partial regenerated composite powdered catalyst; separating, recovering and reusing phenylamine and hydrogenation solvent; and refining. For the condensation and hydrogenation, composite alkali catalyst and composite powdered catalyst are adopted separately. The production process has mild reaction condition and less side products, may be completed continuously, and is suitable for industrial production. The production process has 4-amino diphenylamine yield industrial scale over 95 % and 4-amino diphenylamine purity over 99 wt%.

Owner:JIANGSU SINORGCHEM TECH CO LTD

Aluminum oxide-loaded cerium oxide catalyst and preparation method and application thereof

InactiveCN102861565ALarge specific surface areaHigh chemical activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFlue gas

The invention discloses an aluminum oxide-loaded cerium oxide catalyst and a preparation method and application thereof. Calculated by mass ratio, the mass ratio of aluminum oxide to cerium oxide in the aluminum oxide-loaded cerium oxide catalyst is 85:15. The preparation method for the aluminum oxide-loaded cerium oxide catalyst is characterized in that by adopting an equivalent-volume impregnation method, a coprecipitation method or a sol-gel method, the finally obtained aluminum oxide-loaded cerium oxide catalyst is higher in denitration activity at the lower reaction temperature of 200 DEG C when being used in a selective catalytic reduction flue gas denitration process, and the denitration efficiency can reach at least 90 percent, and thereby, the abuse that the reaction temperature of a traditional catalyst is high is overcome.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Non-noble metal catalyst used for catalytic combustion of PTA exhaust gas and preparation method thereof

ActiveCN103252242BSimple preparation processLow priceCatalyst activation/preparationIncinerator apparatusOxide compositeManganese

The invention relates to a non-noble metal catalyst used for catalytic combustion of a PTA exhaust gas. The catalyst is prepared by mixing CuO, MnO2 and CeO2 oxide composite particles, uniformly dispersing, and loading on honeycomb ceramic, wherein CuO, MnO2 and CeO2 are in such weight parts that a ratio of amount of substance of copper and manganese is 1 : 1 to 1 : 7, and a ratio of a total mass of the CuO and the MnO2 and a mass of the CeO2 is 1 : 3 to 1 : 19. The catalyst uses honeycomb ceramic as base, an oxygen storage material CeO2 as a coating, and non-noble metals Cu and Mn as active components. The catalyst prepared by the invention has characteristics of low raw material cost, simple preparation technology, high catalytic activity and good toxin immunity, and can realize high-efficient catalytic combustion removal for PTA exhaust gas and other industrial exhaust gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

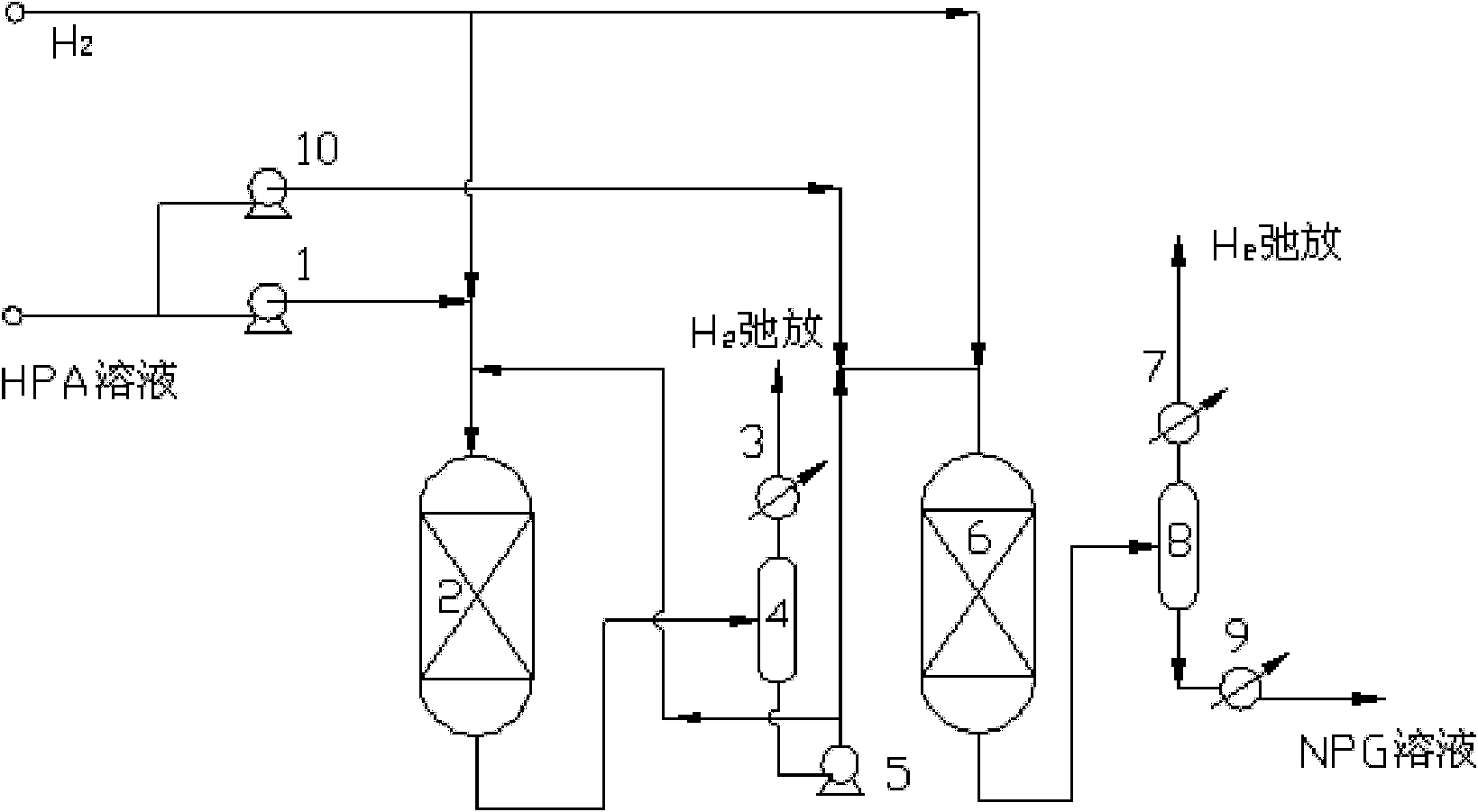

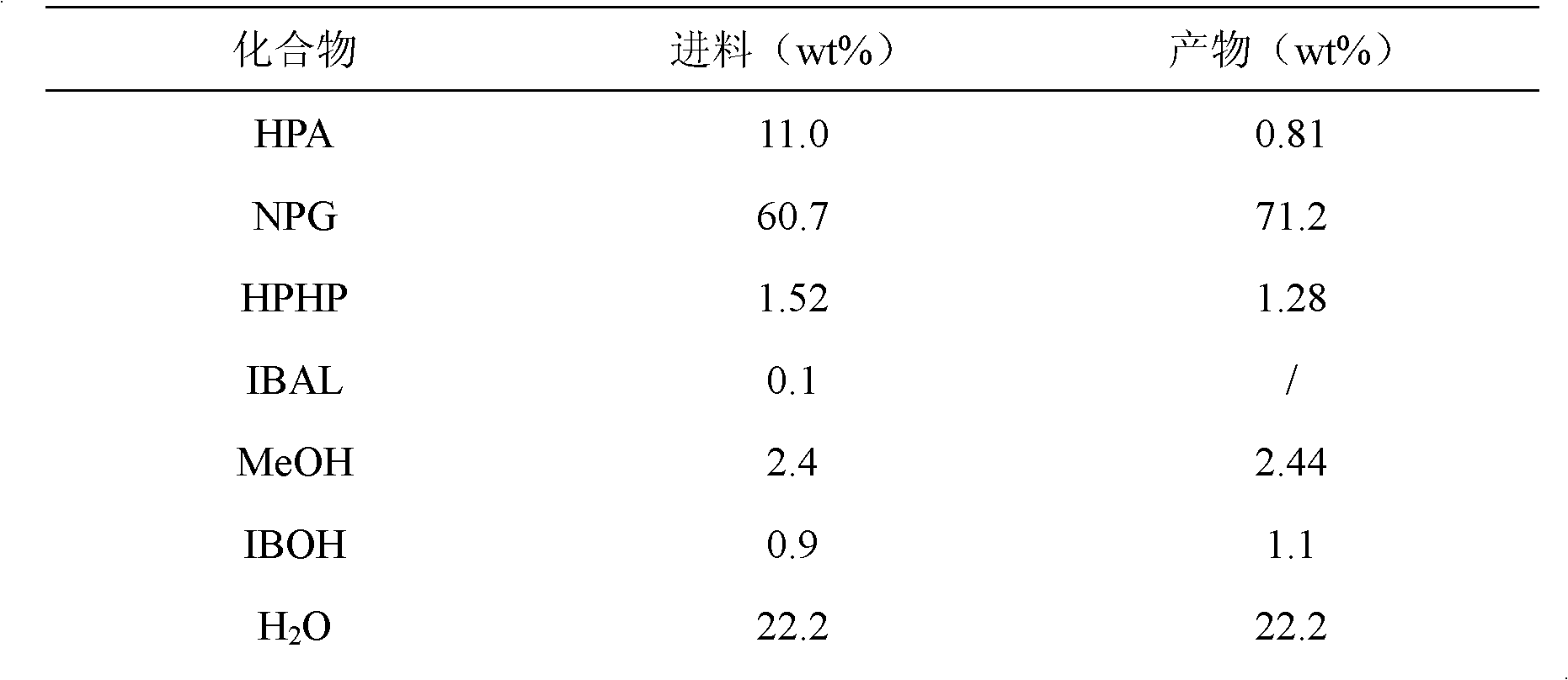

Two-step-method hydrogenation process for preparing neopentyl glycol

ActiveCN102249854ALow priceAvoid pollutionOrganic compound preparationHydroxy compound preparationAluminiumHigh selectivity

The invention provides a two-step-method hydrogenation process for preparing neopentyl glycol. The two-step-method hydrogenation process for preparing the neopentyl glycol comprises the following steps of: inputting a solution containing hydroxyl pivalaledhyde (HPA) into a hydrogenation procedure and carrying out a hydrogenation reaction on the solution containing the HPA and hydrogen gas under the effect of a hydrogenation catalyst to obtain a solution containing a neopentyl glycol product, wherein the hydrogenation procedure comprises a first hydrogenation reactor and a second hydrogenation reactor which are connected in series, the catalyst which is filled into the first hydrogenation reactor comprises three metal elements, such as copper, zinc and aluminum, and the catalyst which is filled into the second hydrogenation reactor comprises four metal elements, such as copper, zinc, aluminum and manganese. According to the process provided by the invention, the HPA of the HPA solution obtained condensation can be almost completely transformed in the hydrogenation procedure by utilizing a second-grade hydrogenation process with serial connection of copper-zinc-aluminum and copper-zinc-aluminum-manganese; and the HPA has a higher selectivity of NPG (Neopentyl Glycol) and the selectivity can be not less than 97%.

Owner:SHANGHAI HUAYI ENERGY CHEM

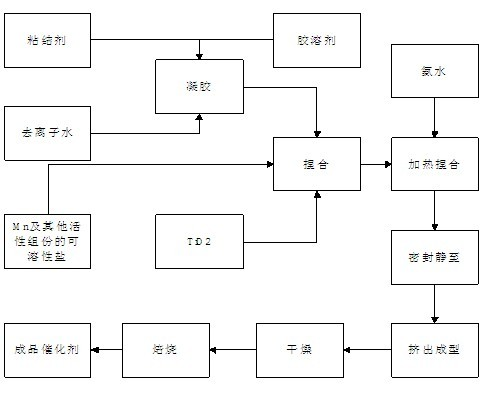

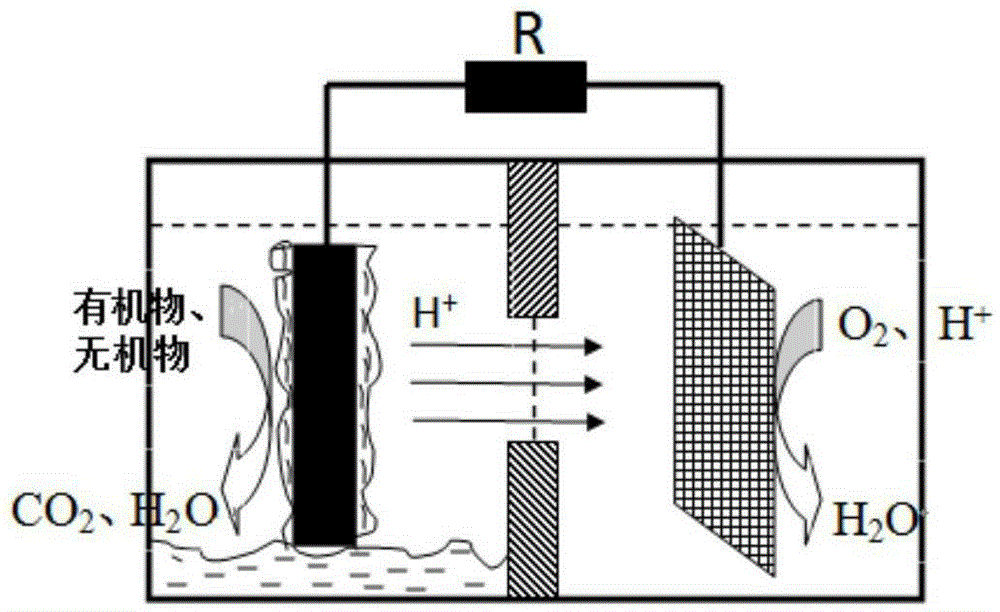

Low-temperature SCR catalyst prepared by extrusion molding, and preparation method thereof

ActiveCN102489294AHigh activityLarge specific surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMetallurgy

The invention relates to a low-temperature SCR catalyst prepared by extrusion molding, and a preparation method thereof. The invention belongs to the field of atmosphere pollution controlling. According to the invention, an extrusion molding method is adopted for preparing the catalyst, and the technology is skillfully designed. The activity, sulfur dioxide resistance and water intoxication resistance of the prepared catalyst satisfy application requirements. The activity, the sulfur dioxide resistance and the water intoxication resistance of the catalyst are maintained, and a certain mechanical strength is ensured in the catalyst particles.

Owner:GUODIAN SCI & TECH RES INST

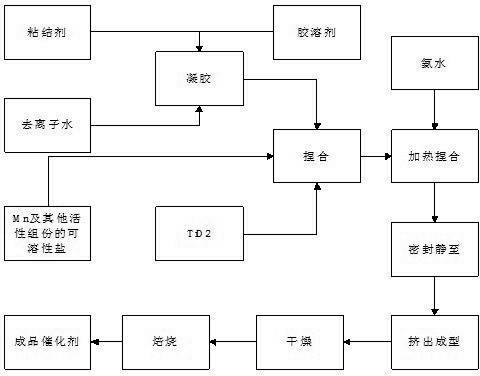

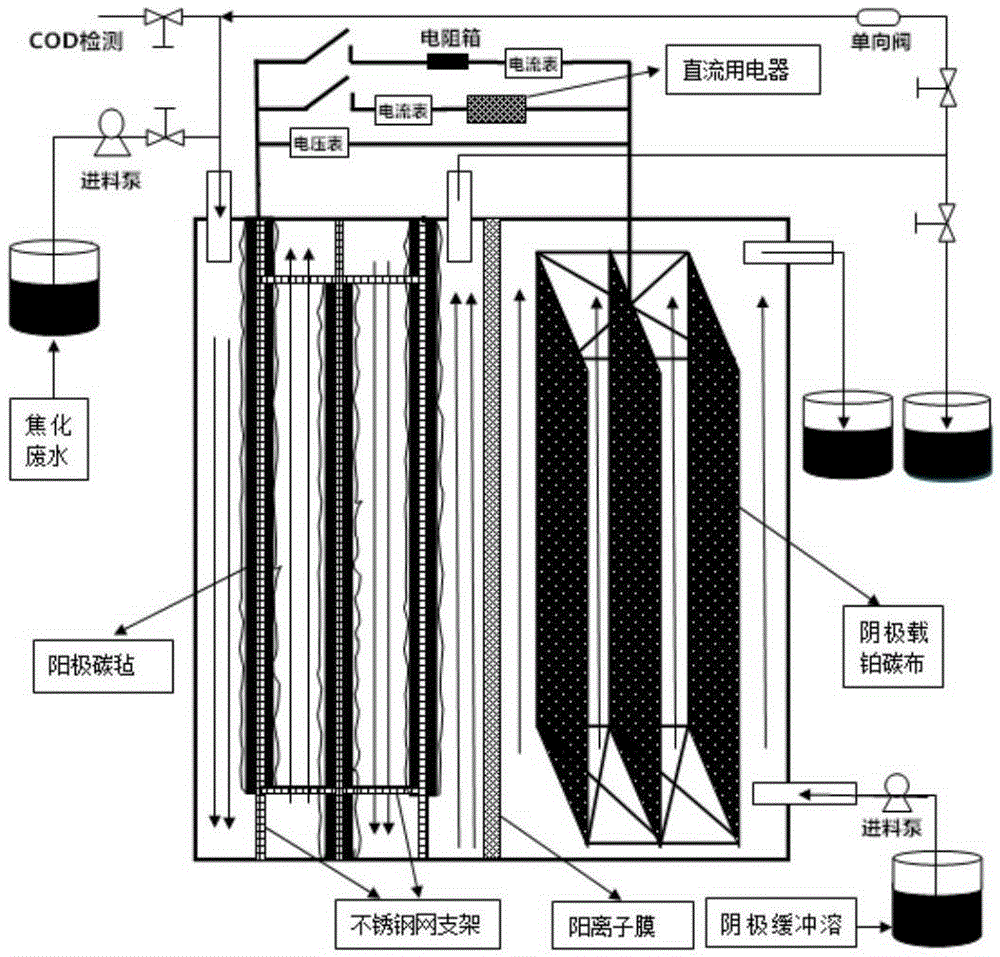

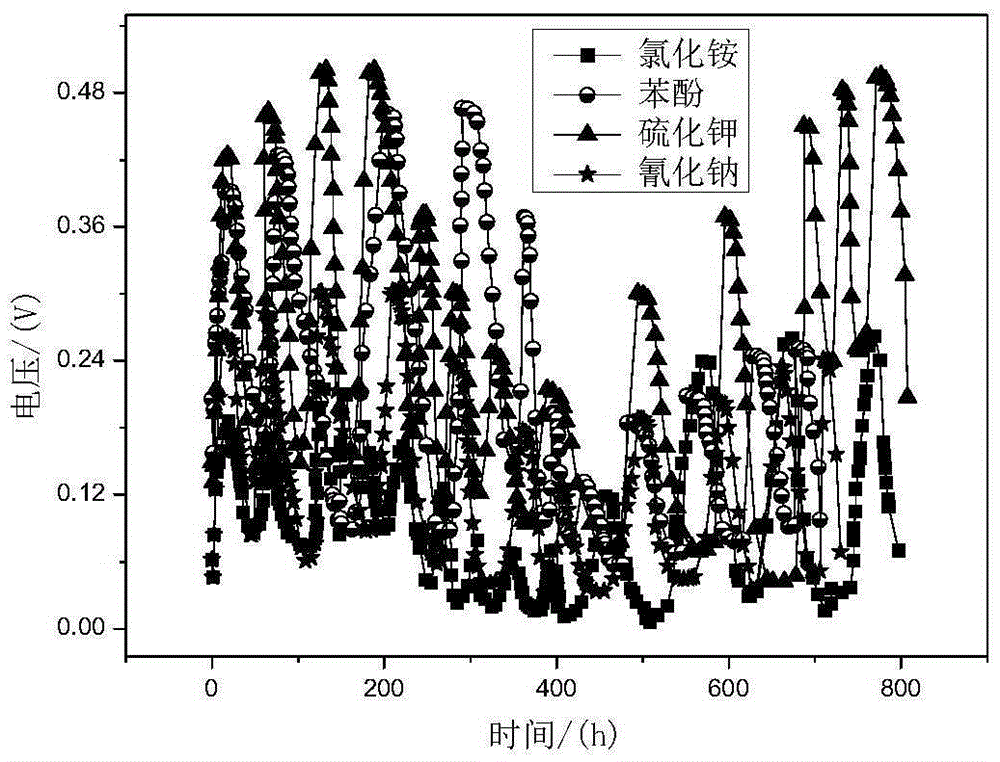

Method for coking wastewater degradation and synchronous power generation by taking coking active bacterium as biocatalyst

The invention relates to a method for coking wastewater degradation and synchronous power generation by taking coking active bacterium as a biocatalyst. The method is carried out according to the following steps of partitioning a carbon-based active coking microbial film positive electrode and a platinum-loaded carbon fabric negative electrode at two chambers by using a cation membrane or a proton membrane; degrading organic matters and inorganic matters which are high in toxicity and are difficult to be degraded in coking wastewater in an anode anaerobic environment by using the coking active bacterium; allowing oxidation reaction; transferring electrons released through reaction to a positive carbon felt by a medium or a pigment secreted from the bacterium; sequentially transmitting the electrons to a negative electrode through an external wire; and allowing an electron acceptor of the negative electrode to generate reduction reaction. By the process, the treatment of high-toxicity and degradation-resistant coking wastewater is achieved, chemical energy reserved in the process is also converted to electrical energy, a new method is provided for coking wastewater treatment, and meanwhile, a wide prospect is provided for green treatment of the coking wastewater in future.

Owner:TAIYUAN UNIV OF TECH

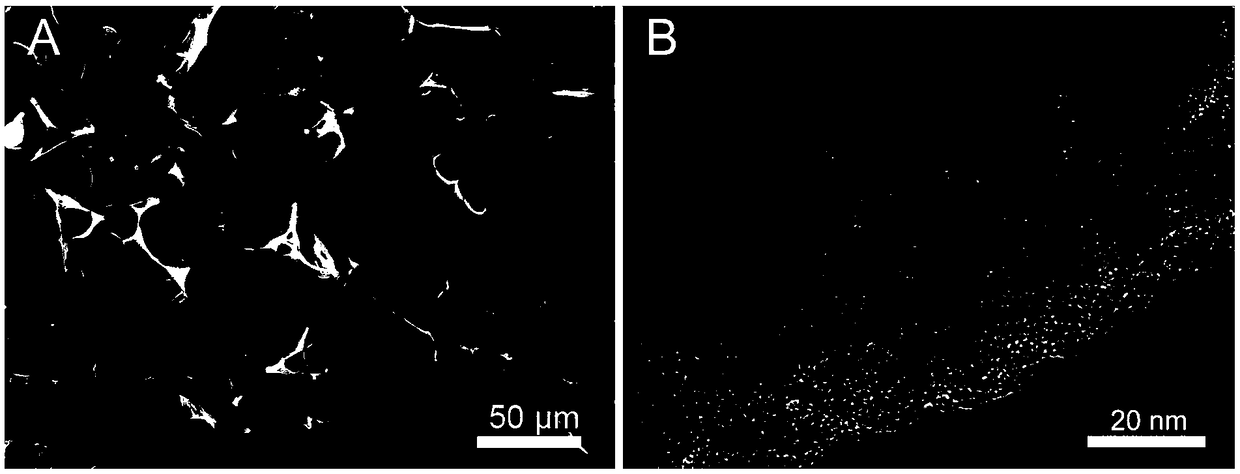

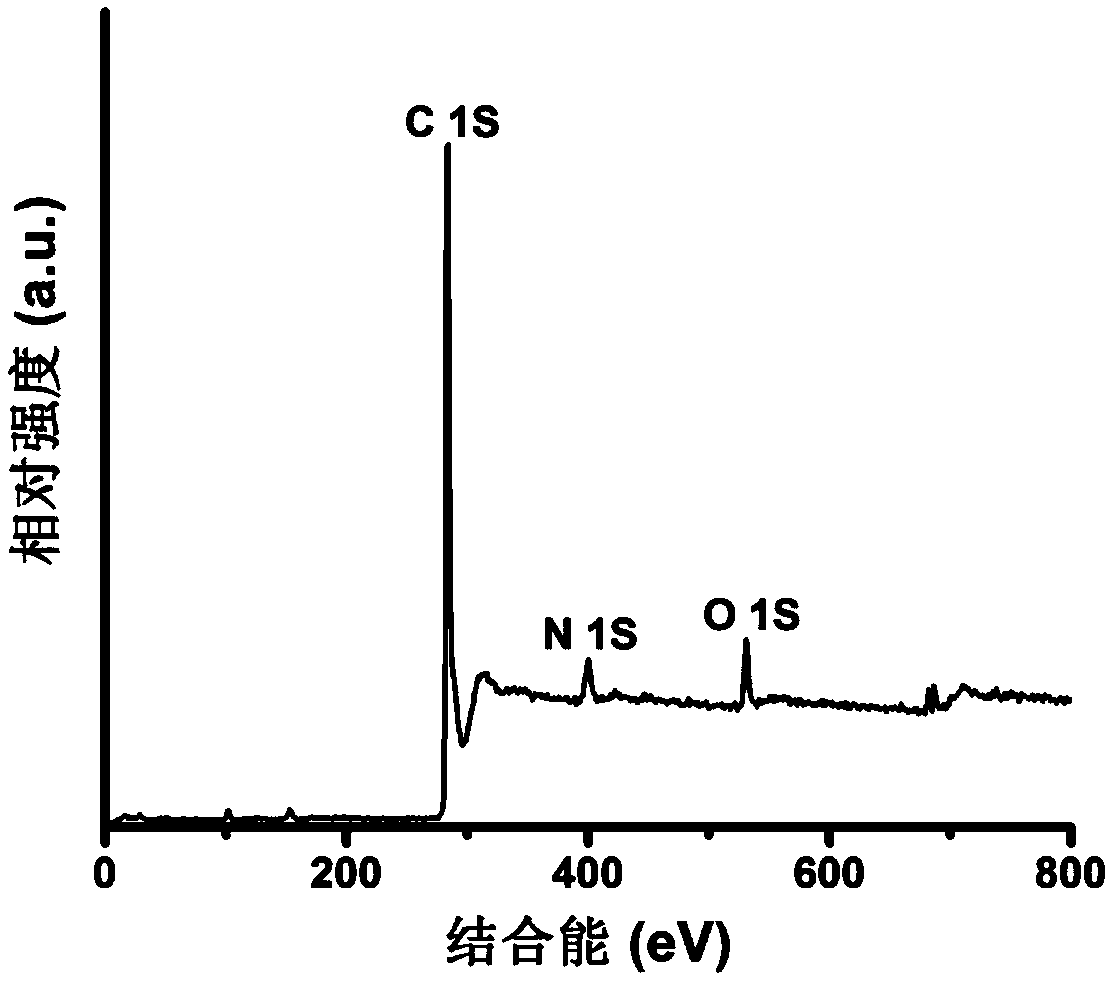

A method for preparing a high-performance nitrogen-doped porous carbon-supported PtNi alloy particle methanol fuel cell catalyst

ActiveCN109103474ADifferent structureLow costMaterial nanotechnologyCell electrodesPtru catalystFuel cells

The invention relates to a method for preparing a high-performance nitrogen-doped porous carbon supported PtNi alloy particle methanol fuel cell catalyst. The method uses waste cigarette end filter core as carbon source and nitrogen source to generate nitrogen-doped porous carbon material in one step; Non-noble metal Ni and noble metal Pt alloy particles are supported on nitrogen-doped porous carbon materials to form catalysts. The invention provides a simple preparation method of nitrogen-doped porous carbon-supported PtNi binary alloy (PtNi / N-HPC) catalyst, which improves the CO poisoning disadvantage of a single Pt-based catalyst.

Owner:HEBEI UNIV OF TECH

Nano grade transition metal oxidation catalyst and its preparing method and use

InactiveCN1714936AHigh activityEnhanced anti-toxicityCatalyst carriersCatalyst activation/preparationMischmetalGranularity

The present invention is efficient oxidizing catalyst for organic waste water treating and its preparation process and application. The carrier prepared with composite powder of Ti, Si, Al and RE oxide and in the average granularity smaller than 100 nm is loaded with at least two kinds of transition metal to prepare the catalyst. The catalyst contains TiO2-SiO2-Al2O3 65-85 wt%, RE oxide 5-15 wt%, and transition oxide 5-30 wt%. The preparation process of the catalyst includes preparing carrier powder with the carrier components and through precipitation, homogenization, ageing, filtering, washing, pulping, dispersing, fluidizing at supercritical condition to eliminate water and activating; forming the carrier, soaking, fluidizing and drying, and activating to obtain the catalyst. The catalyst is used in acid organic waste water treatment and has COD degrading rate higher than 95 %, ammonia nitrogen oxidizing conversion rate higher than 99 % and chroma eliminating rate higher than 95 %.

Owner:CNPC JILIN CHEM GROUP CORP

Process for preparing 4-amino diphenylamine

ActiveCN1721390AAvoid smallRaise the ratioAmino preparation from aminesAmino compound preparation by condensation/addition reactionsDecompositionNitrobenzene

The present invention discloses production process of 4-amino diphenylamine with nitrobenzene and phenylamine as materials. For the condensation and hydrogenation, corresponding composite alkali catalyst and composite powdered catalyst are adopted separately. The production process includes the successive steps of condensation, separation I, hydrogenation, separation II and refining, and may be completed continuously. The composite alkali catalyst is separated and reused before the hydrogenation step, and this avoids the heat decomposition of the composite alkali catalyst and increases the catalyst selecting range. The production process has 4-amino diphenylamine yield industrial scale over 95 % and 4-amino diphenylamine purity over 99 wt%.

Owner:JIANGSU SINORGCHEM TECH CO LTD

MnOx/ZrO2-TiO2 low temperature selective catalytic reduction NOx catalyst possessing anti SO2 performance and its preparation technology

ActiveCN100998939AReduce depositionEnhanced anti-toxicityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSolventTitanium

A catalyst MnOx / ZrO2-TiO2 with thd SiO2-resistant performance for selectively catalytic reduction to NOx at low temp is proportionally prepared from titanium alkoxide, alcohol-type solvent, water, protonic acid, the soluble salt of Mn, and the soluble salt of Ar through proortional mixing, stirring until the sol becomes gel, drying, grinding and high-temp calcining. Its NO removing rate at 150 deg.C is more than 90%.

Owner:ZHEJIANG UNIV

Method for preparing nano-dendritic platinum catalyst

InactiveCN103464783AImprove electrocatalytic activityGood anti-CO poisoning performanceNanotechnologyMetal/metal-oxides/metal-hydroxide catalystsCentrifugationMethanol fuel

The invention relates to a method for preparing a nano-dendritic platinum catalyst. The method comprises the steps: mixing H2PtCl6.6H2O with PVP (Polyvinylpyrrolidone), and adding isopropanol after uniformly mixing; irradiating under the irradiating dosage of 140KGy, transferring an obtained product into a centrifuge tube, and then, carrying out high-speed centrifugation so as to obtain a precipitate; discarding supernatant, repeatedly washing the precipitate by using ethanol and water, and carrying out centrifugation repeatedly until no suspended matters appear in an upper layer; drying the precipitate for a period of time in a vacuum drying oven at certain temperature, thereby finally obtaining the nano-dendritic platinum catalyst. According to the nano-dendritic platinum catalyst obtained by the method, the effective electrochemical surface area is 39.5m<2> / g, the If / Ib is 1.57, the electrocatalysis activity and poisoning resistance are high, the problems during the anodic electrooxidation of methanol that the rate is slow, the phenomenon of polarization is serious, the catalysis efficiency is low, and the like can be solved, and the nano-dendritic platinum catalyst can directly serve as an anode catalyst of a methanol fuel cell.

Owner:SHANGHAI UNIV

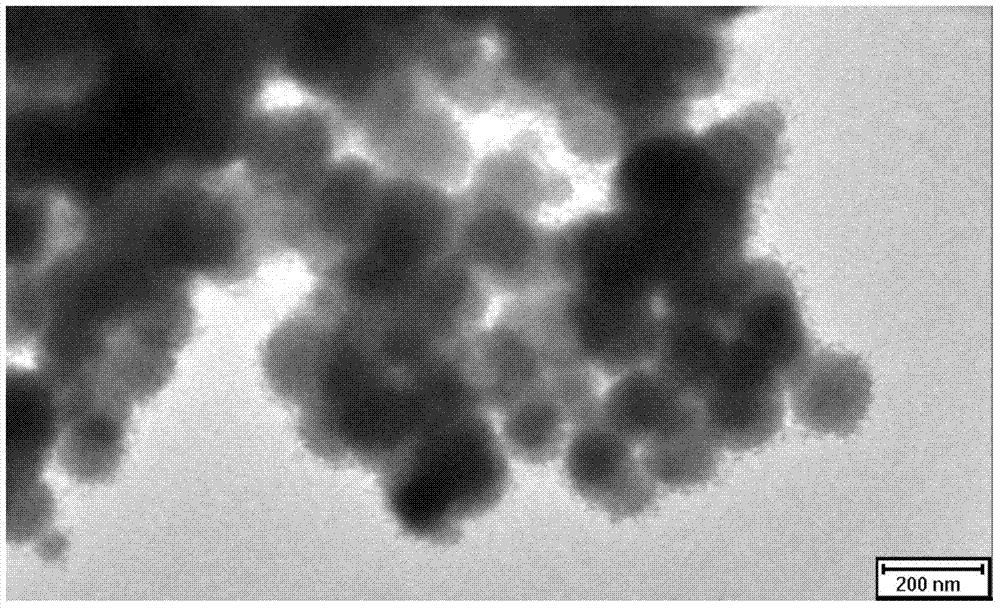

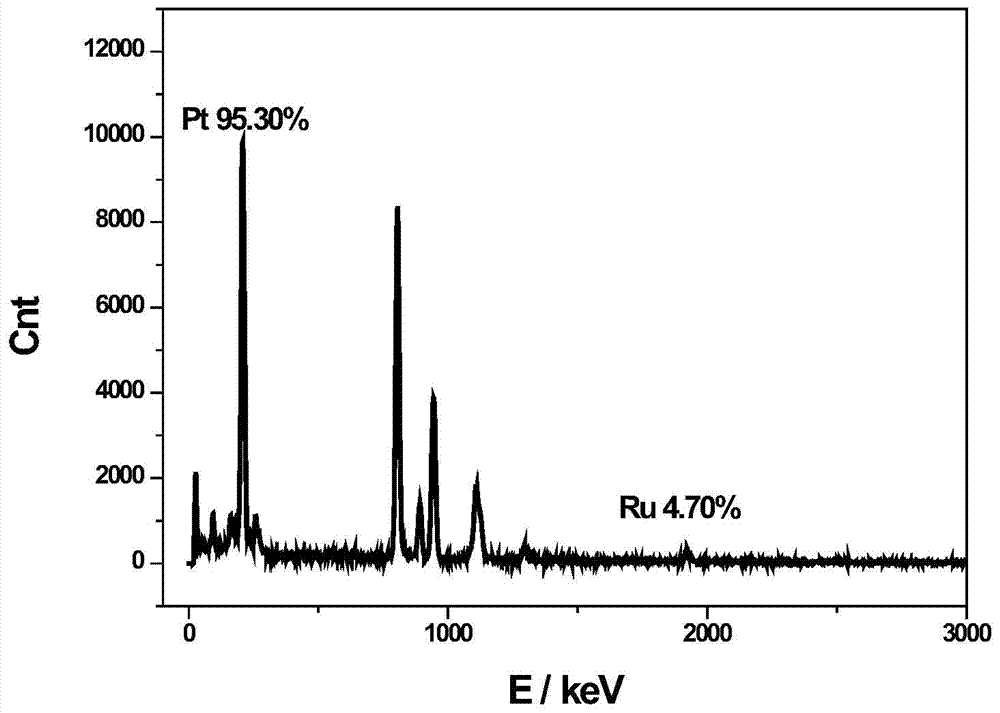

Preparation method of Pt-Ru alloy catalyst with high catalytic activity

InactiveCN103933975AEnhanced anti-toxicityHigh electrocatalytic activityMetal/metal-oxides/metal-hydroxide catalystsWater bathsAlloy

The invention provides a preparation method of a Pt-Ru alloy catalyst with high catalytic activity. According to the preparation method, Pt and Ru of the alloy catalyst come from chloroplatinic acid and rutheniumchloride hydrate respectively; lyotropic liquid crystals are formed from Pt and Ru with amphipathic segmented copolymer P123, water, and ethanol; ascorbic acid is taken as a reducing agent for reduction via ultrasonic water bath; and the Pt-Ru alloy catalyst with high catalytic activity is obtained via washing, centrifugation, and roasting. Catalytic activity and poison resistance of the Pt-Ru alloy catalyst with high catalytic activity obtained via the preparation method are higher than that of commercial Pt black catalyst.

Owner:BEIJING UNIV OF CHEM TECH

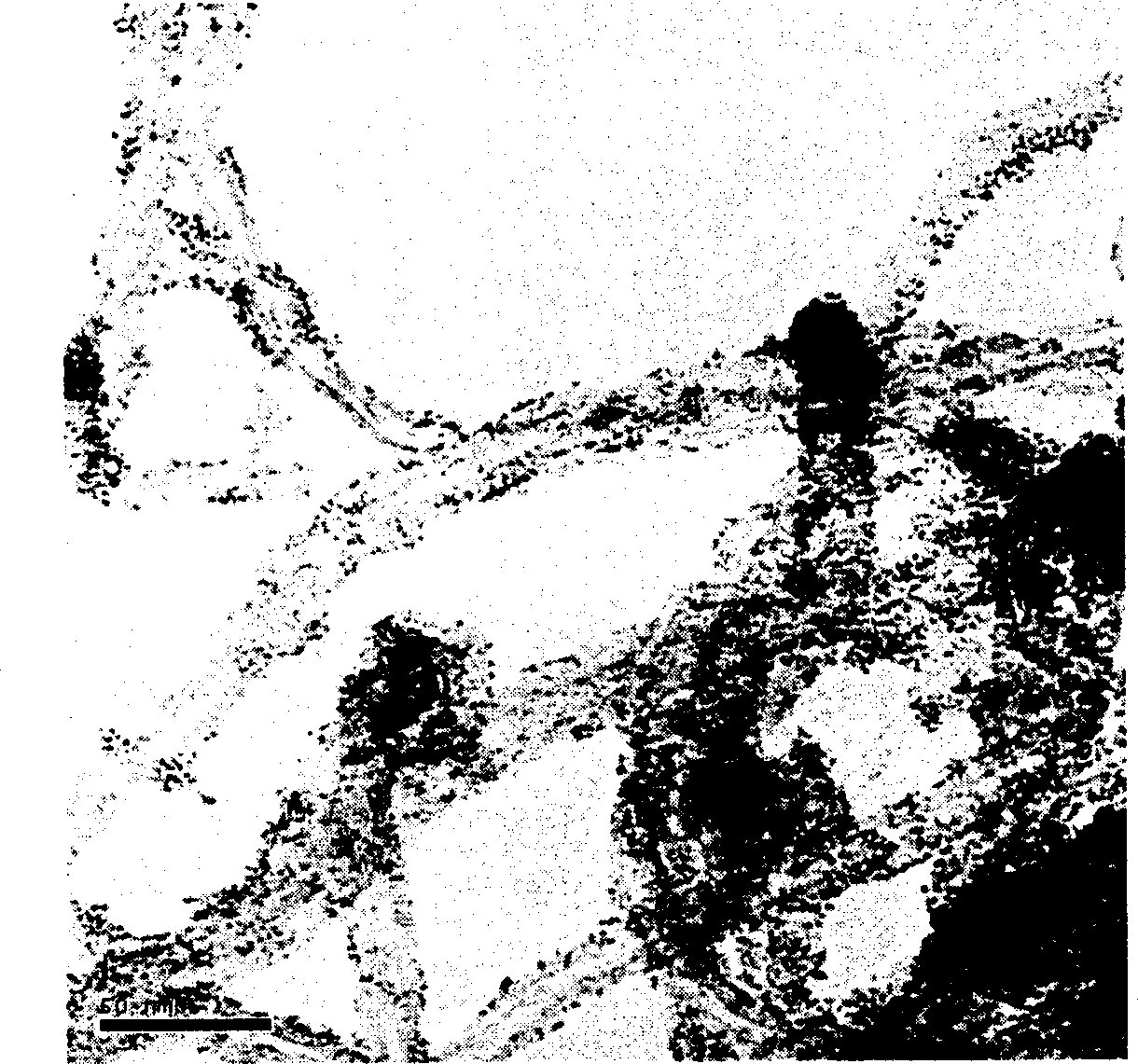

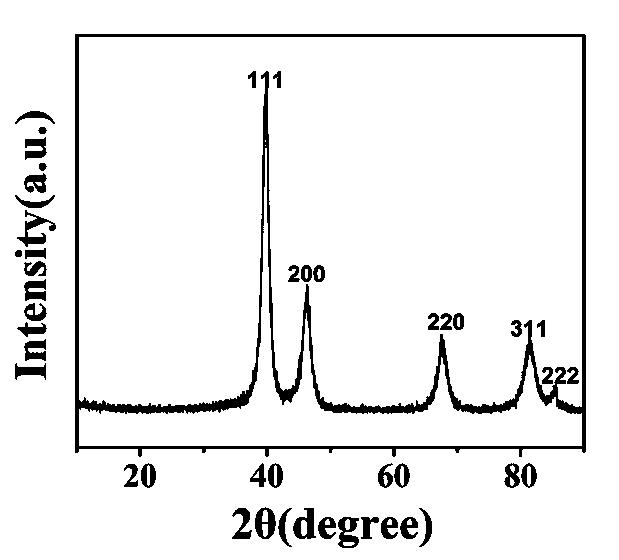

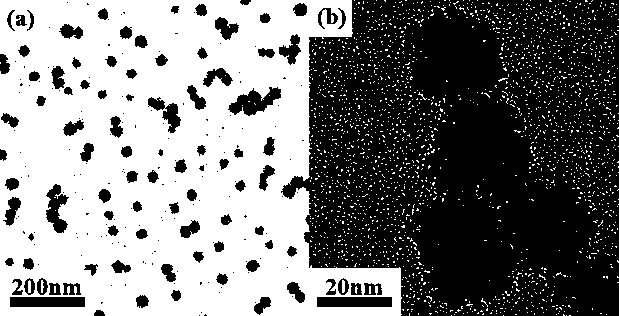

Pain relief composition comprising paramagnetic silver nanoparticles

InactiveUS20080193559A1Fast absorptionEnhanced anti-toxicityMaterial nanotechnologyBiocideArthroscopic procedureSurgical treatment

The present invention relates to a pain relief composition comprising paramagnetic silver nanoparticles. More specifically, the composition is characterized in that it comprises from 0.03 to 0.05% by weight of paramagnetic silver nanoparticles having specific properties that were not revealed by conventional diamagnetic silver nanoparticles. The pain relief composition according to the present invention shows excellent effect of relieving pain of arthritis due to antibiotic property and anti-toxicity of paramagnetic silver nanoparticles. By using the paramagnetic silver nanoparticles having small particle size, the composition is rapidly absorbed into cells upon being applied to skin. In addition, by virtue of using silver (Ag), no complication such as skin coloration or edema was observed. According to the present invention, pain is relieved by simple application, so that the usage is easy as compared to surgical treatment such as arthroscopic operation to provide high satisfaction to a patient.

Owner:NPC CO LTD

Preparation method of poisoning-resistant catalyst for unsaturated oil hydrogenation

ActiveCN102513114AHigh strengthStable physical parametersFatty acid hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickel saltHydrogen

The invention discloses a preparation method of a poisoning-resistant catalyst for unsaturated oil hydrogenation. The preparation method is characterized by comprising the following steps of 1, putting an alkaline precipitator solution into a reactor, and heating to a temperature of 60 to 70 DEG C, 2, adding a mixed solution of a soluble nickel salt, a ferric salt and a rare earth salt into the heated alkaline precipitator solution with stirring in a period of 1 to 2 hours, 3, then fast adding alumina carriers into the mixed solution obtained by the steps 2, stirring for 0.5 to 1 hour, filtering, and washing by deionized water until acid radical ions are removed completely, and 4, drying at a temperature of 110 to 120 DEG C for 4 to 5 hours, crushing, and carrying out hydrogen feeding at a temperature of 400 to 500 DEG C for 2 to 3 hours to obtain the poisoning-resistant catalyst for unsaturated oil hydrogenation, wherein an Ni / Fe atomic ratio of the soluble nickel salt to the ferric salt is in a range of 5 to 25 and the poisoning-resistant catalyst for unsaturated oil hydrogenation contains 30 to 50 wt% of nickel, 2 to 5 wt% of iron, 0.5 to 1.0 wt% of a rare earth salt of cerium and 0.5 to 1.0 wt% of a rare earth salt of lanthanum.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Non-noble metal catalyst used for catalytic combustion of PTA exhaust gas and preparation method thereof

ActiveCN103252242ASimple preparation processLow priceCatalyst activation/preparationIncinerator apparatusOxide compositeManganese

The invention relates to a non-noble metal catalyst used for catalytic combustion of a PTA exhaust gas. The catalyst is prepared by mixing CuO, MnO2 and CeO2 oxide composite particles, uniformly dispersing, and loading on honeycomb ceramic, wherein CuO, MnO2 and CeO2 are in such weight parts that a ratio of amount of substance of copper and manganese is 1 : 1 to 1 : 7, and a ratio of a total mass of the CuO and the MnO2 and a mass of the CeO2 is 1 : 3 to 1 : 19. The catalyst uses honeycomb ceramic as base, an oxygen storage material CeO2 as a coating, and non-noble metals Cu and Mn as active components. The catalyst prepared by the invention has characteristics of low raw material cost, simple preparation technology, high catalytic activity and good toxin immunity, and can realize high-efficient catalytic combustion removal for PTA exhaust gas and other industrial exhaust gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com