Process for preparing 4-amino diphenylamine

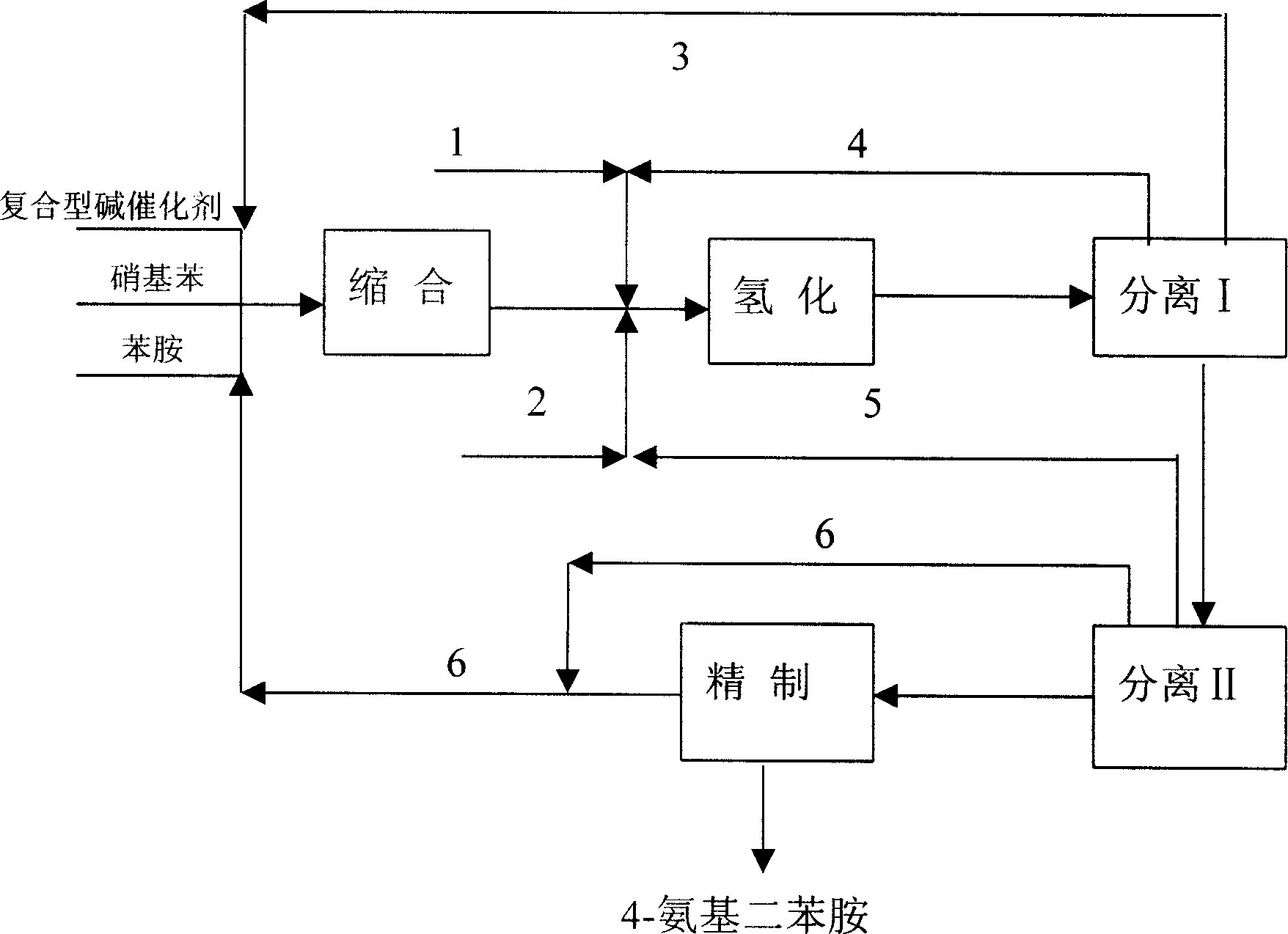

A technology of aminodiphenylamine and aniline, which is applied to the preparation of amino compounds from amines, the preparation of amino compounds through condensation/addition reactions, and chemical recovery. It can solve the problems of difficult operation, prolonged reaction time, and increased production costs. Reduce the difficulty of manipulation, reduce the amount of aniline, and avoid the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

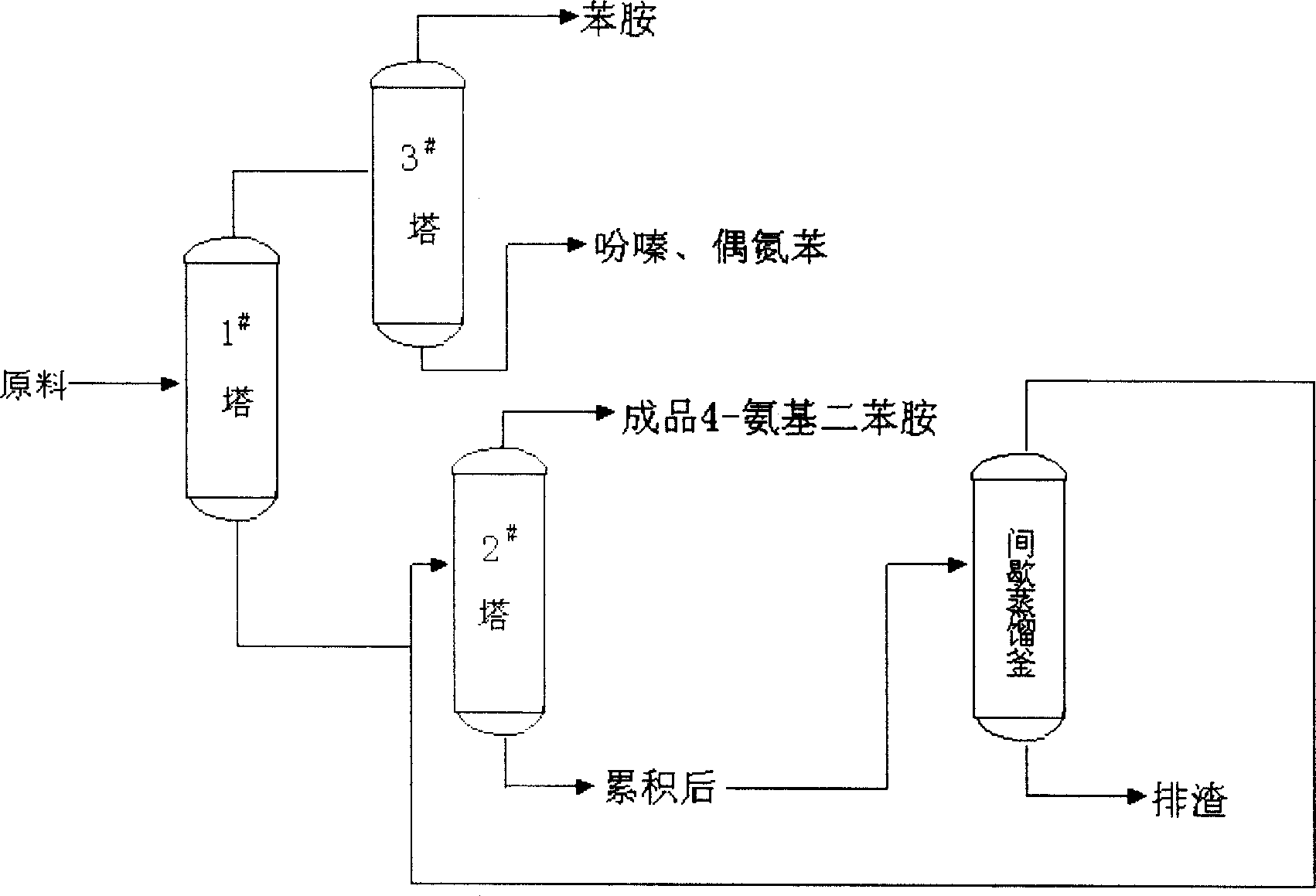

Method used

Image

Examples

Embodiment 1

[0075] Preparation of composite base catalyst:

[0076] In a 1000 ml three-necked flask equipped with a condenser and a stirrer, add 227.5 grams of 20% (by weight) tetramethylammonium hydroxide aqueous solution (0.50 moles), 10 grams of sodium hydroxide (0.25 moles), 346 grams of 30% tetramethylammonium carbonate aqueous solution (0.5 mol), stirred evenly at 72-77 ℃, promptly made composite base catalyst, concentration 27.3% (weight).

Embodiment 2

[0078] Preparation of composite powder catalyst:

[0079]Take 46 grams of nickel powder, 51 grams of aluminum powder, and 3 grams of iron powder, mix them evenly, and melt them into an alloy in an induction furnace. The molten alloy is sprayed on the high-speed rotating copper drum through the nozzle by the pressure of the gas, and it is rapidly quenched. (The cooling rate can reach 10 5 -10 6 K / S). The cooled alloy is rolled into powder by a ball mill, and sieved to obtain 99.7 grams of 40-300 mesh powder. In a three-necked flask equipped with a thermometer and a stirrer with a capacity of 500 milliliters, 375 grams of a concentration of 20% (weight) of NaOH aqueous solution was added slowly, and the powder prepared above was slowly added, stirred at 60° C. for 4 hours, and then The solid was washed with deionized water until neutral to obtain a composite powder catalyst.

Embodiment 3

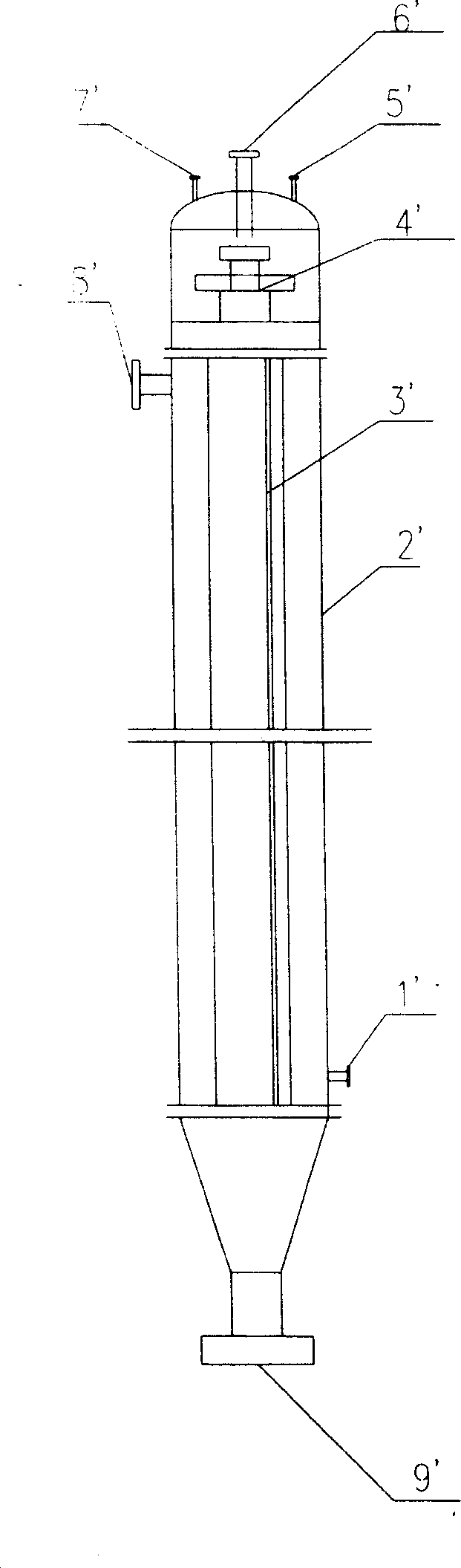

[0081] Open the composite base catalyst, aniline and nitrobenzene transfer pump simultaneously under vacuum, adjust the flow rate to 150 kg / hour of aniline, 30 kg / hour of nitrobenzene, and 200 kg / hour of composite base catalyst, the above components Nitrobenzene, aniline and composite base catalysts are continuously fed into the falling film reactor for heating to carry out condensation reaction; the condensation liquid in the falling film reactor is discharged from the lower part into the primary reactor to continue the condensation reaction; part one The condensate at the bottom of the first-stage reactor is returned to the falling film reactor through the circulation pump to form a partial circulation system. The heat medium of the falling film reactor is alcohol vapor at 78-90°C. Control the reaction temperature to 75°C, the pressure to 0.008MPa (absolute pressure), and the flow rate of the circulating fluid to be 1 meter 3 / Hour. The material from the primary reactor ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com