Patents

Literature

1025 results about "Lead electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

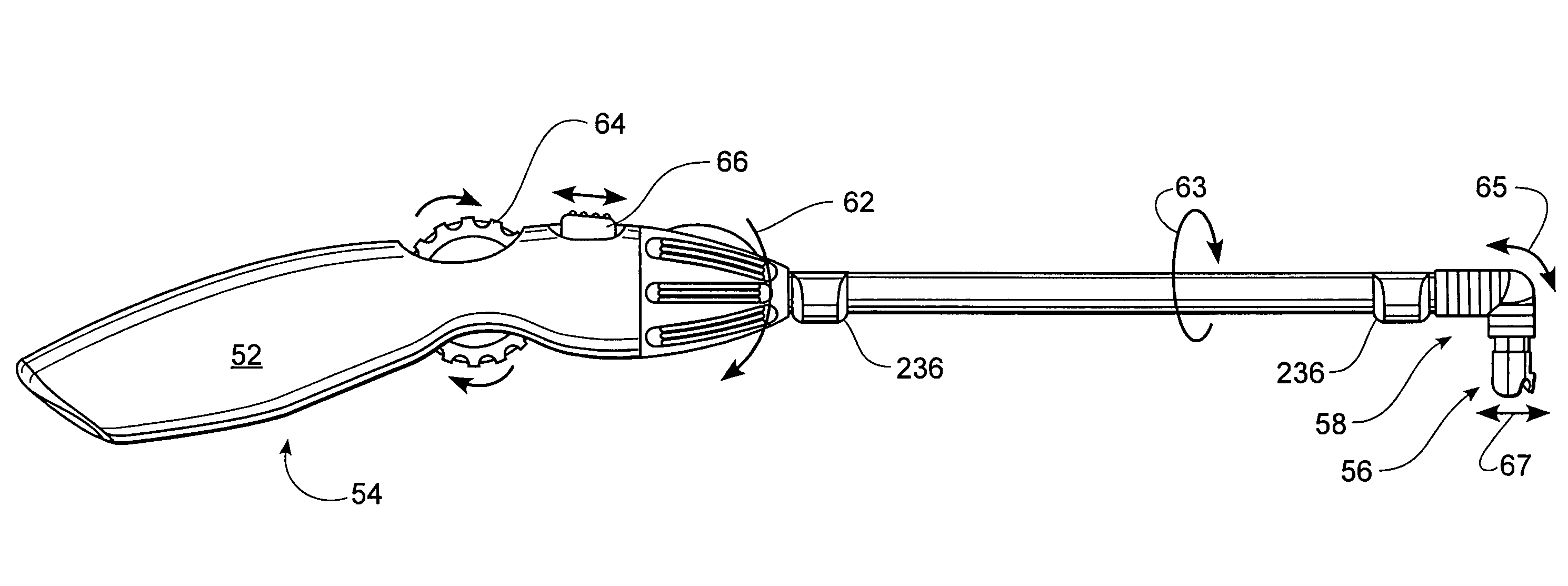

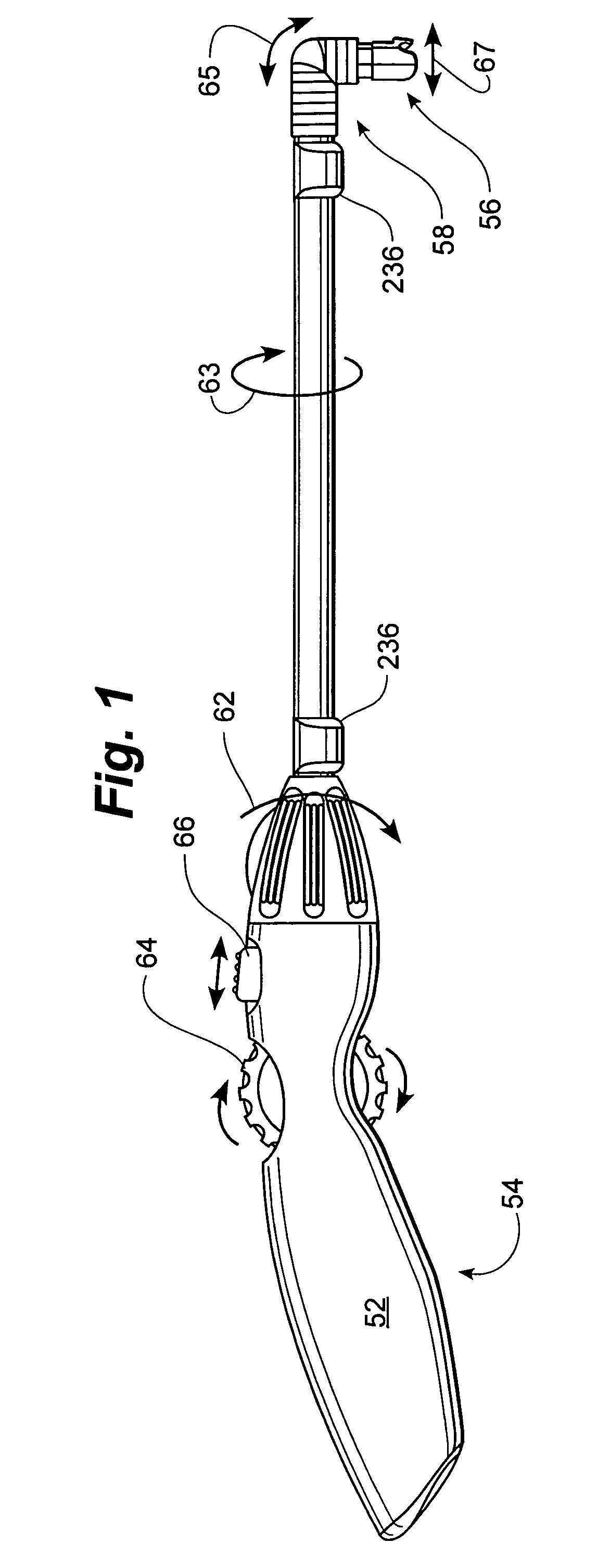

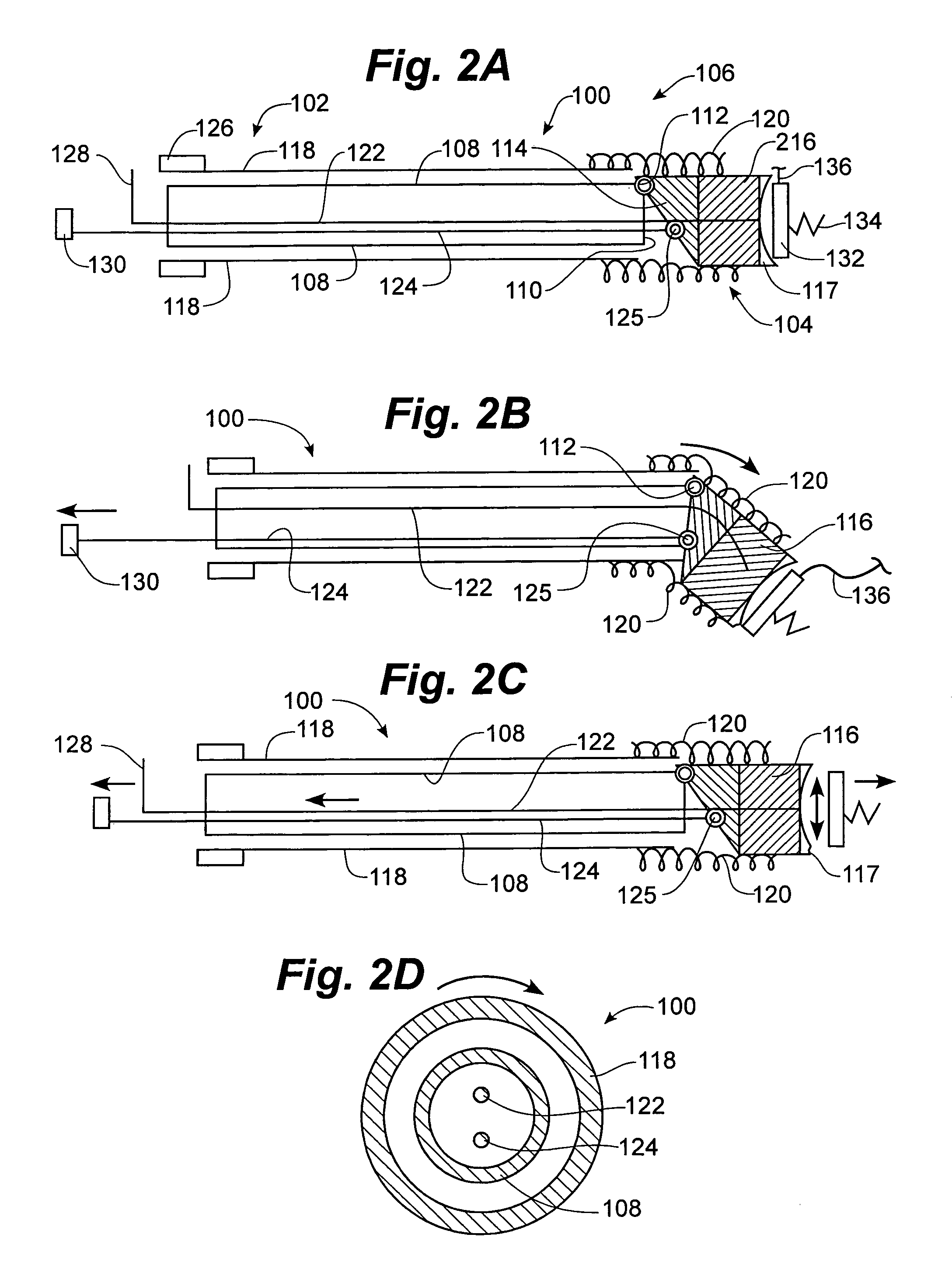

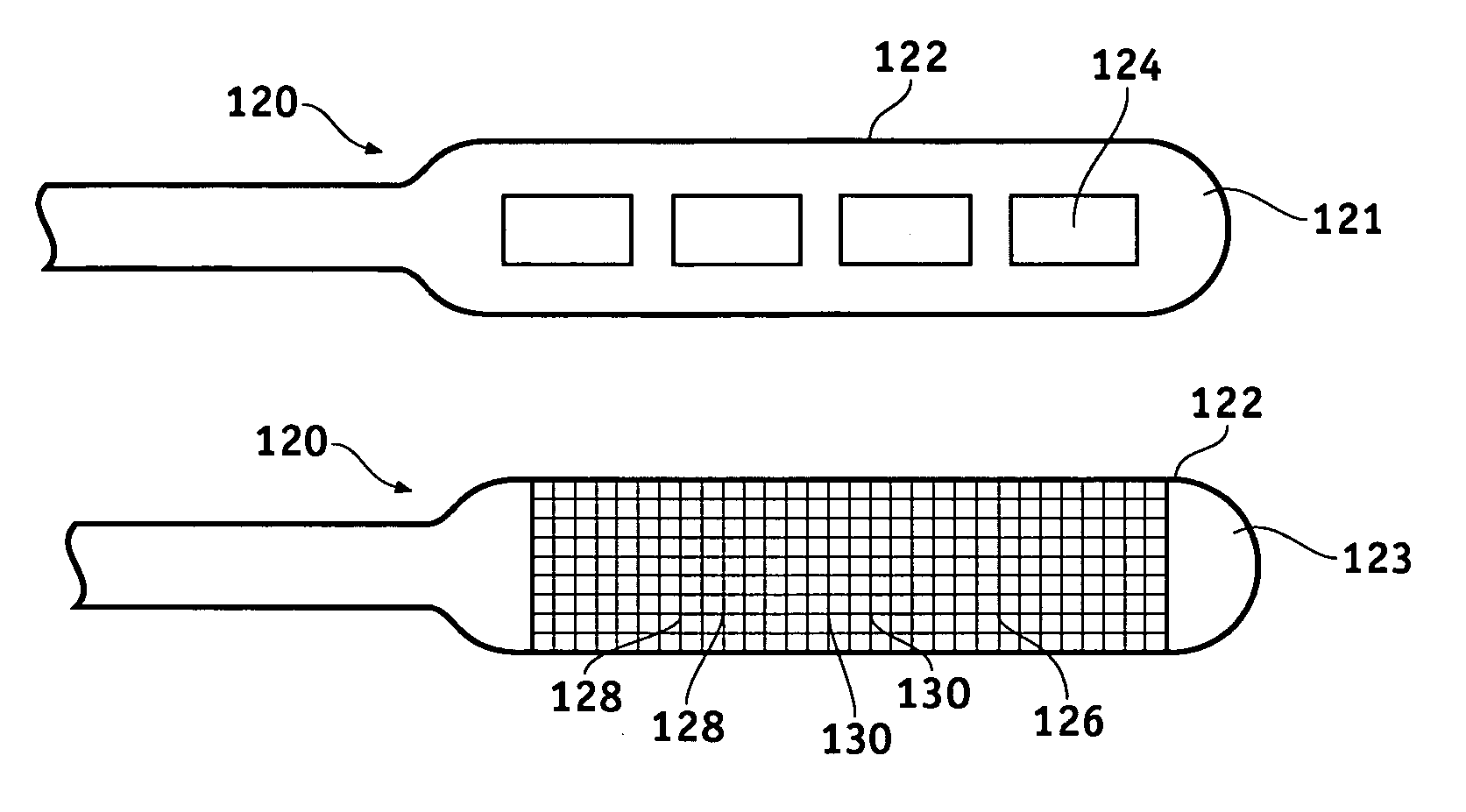

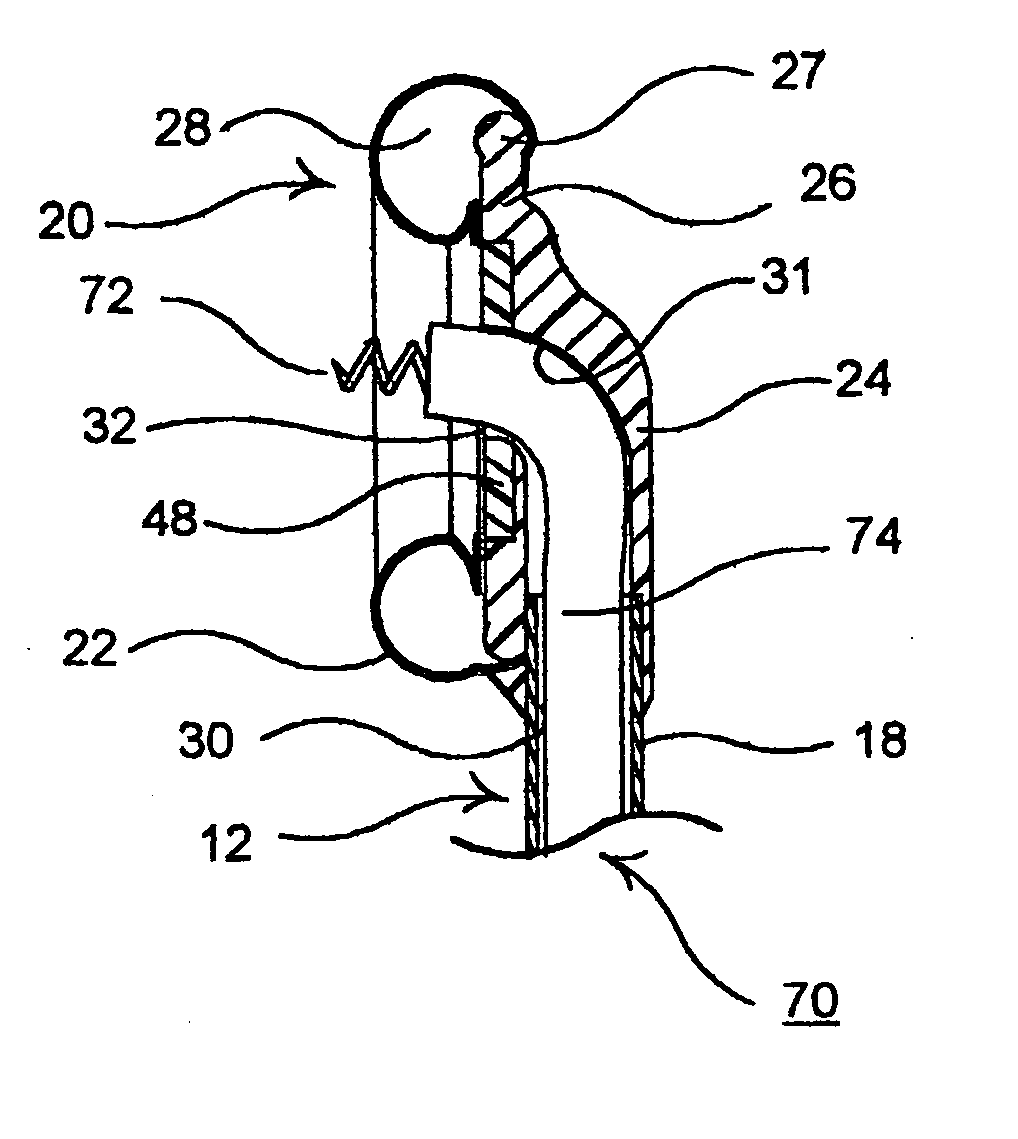

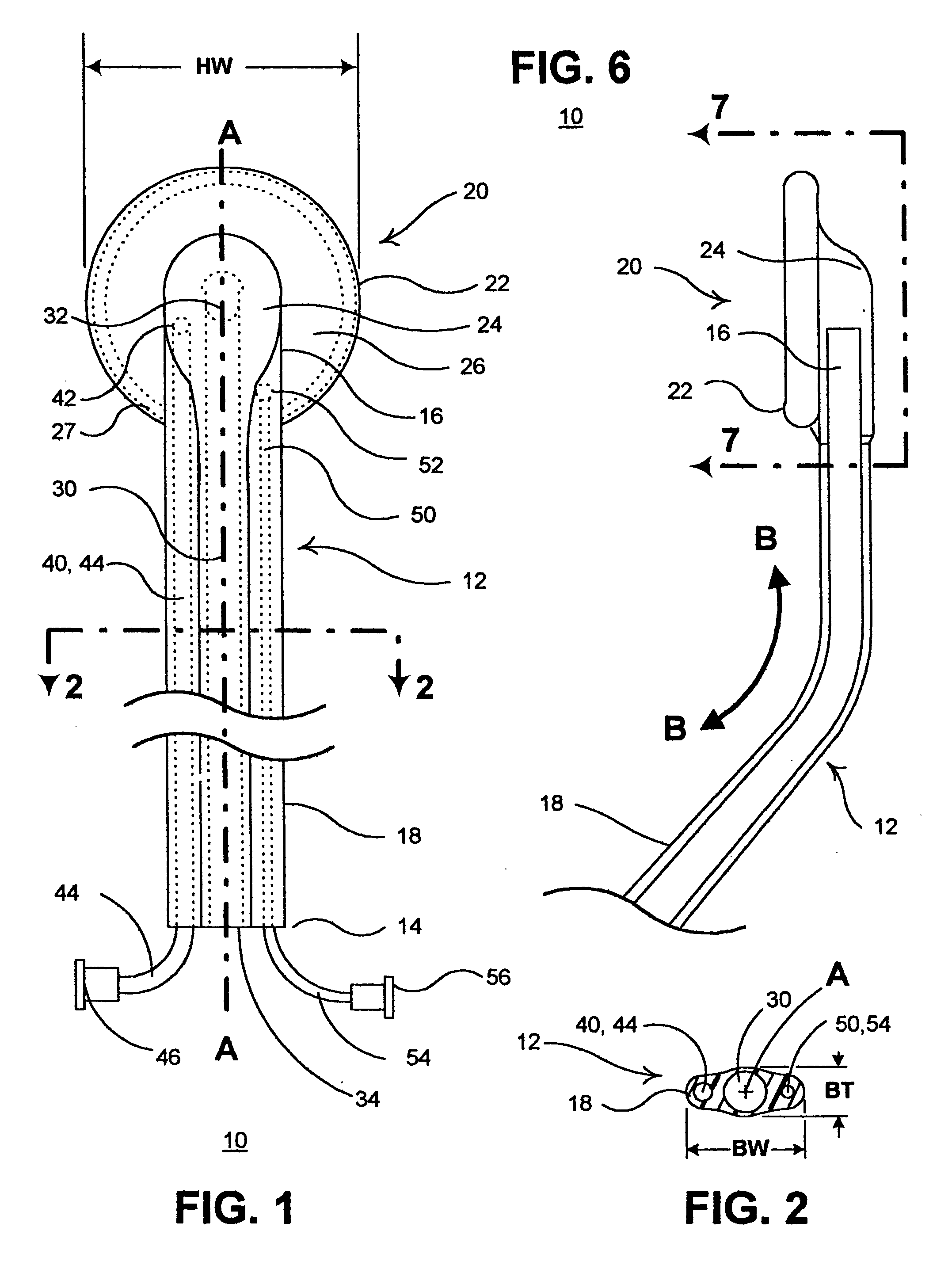

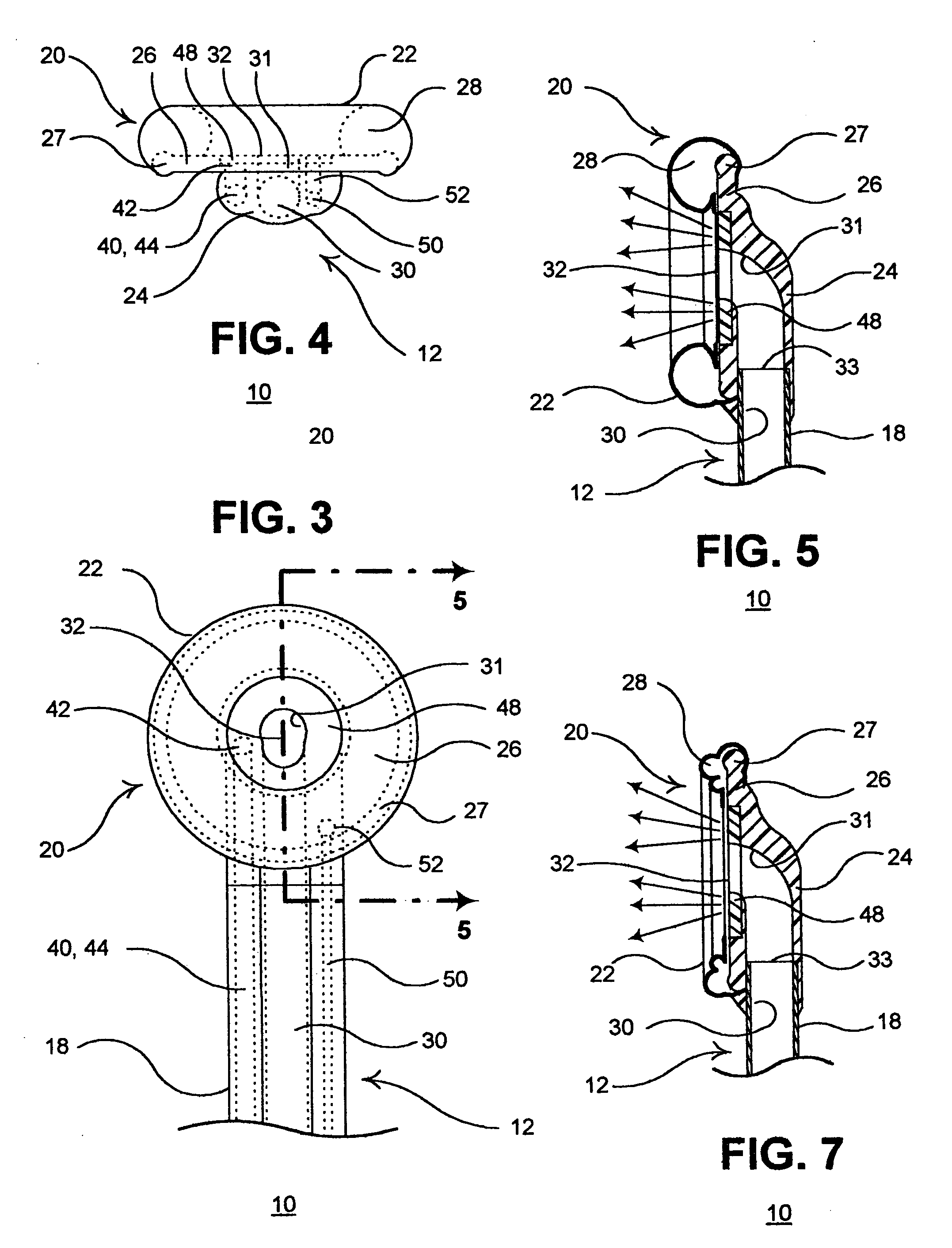

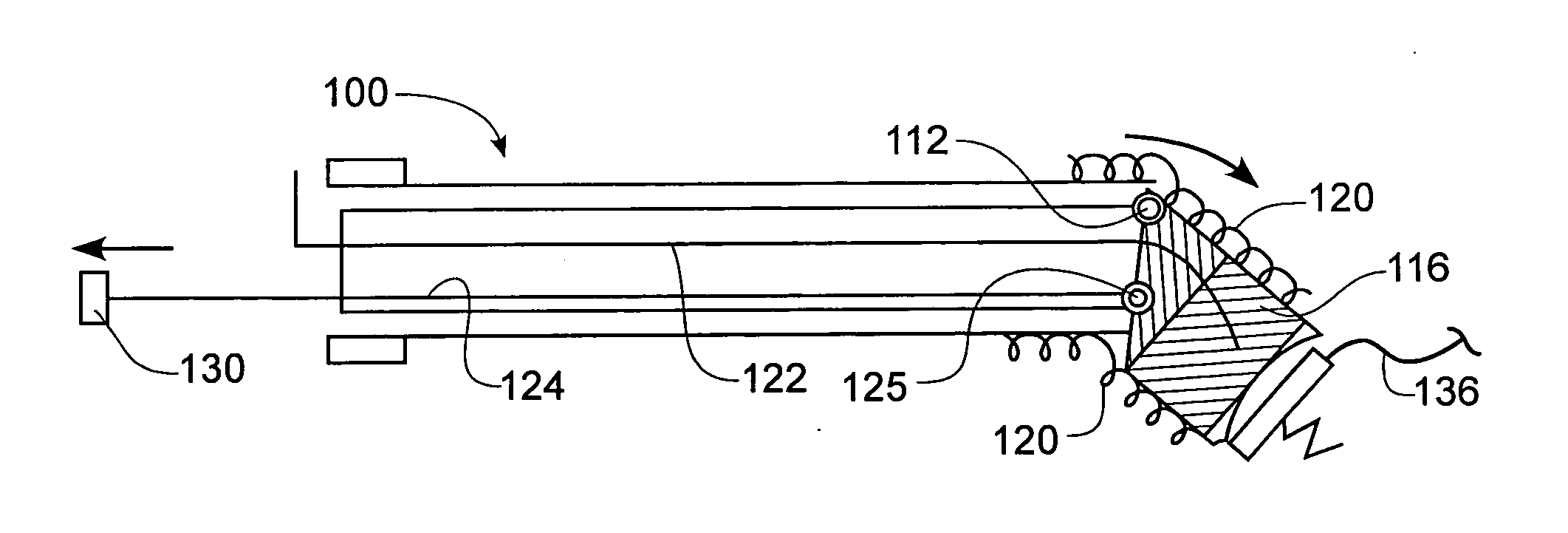

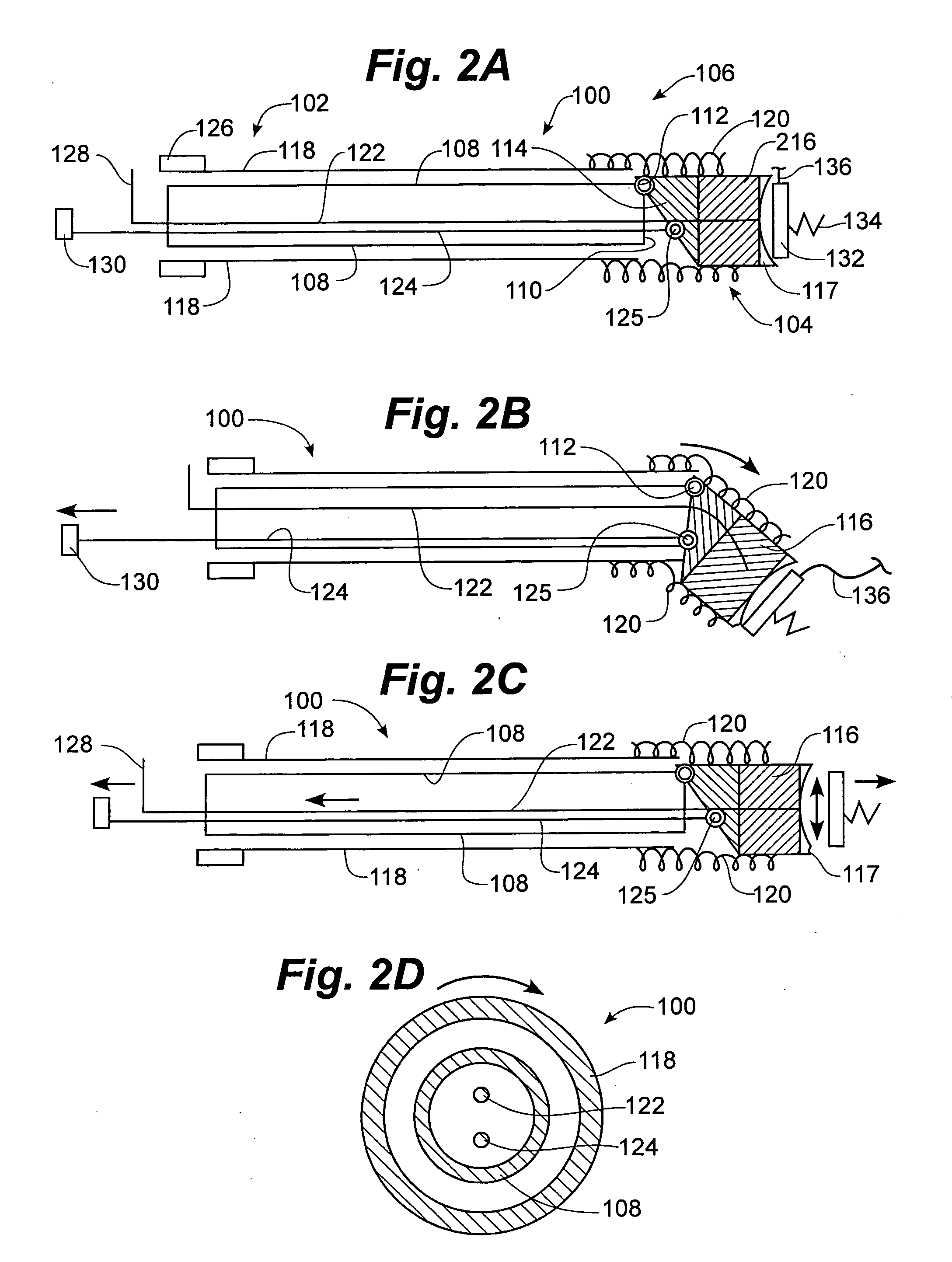

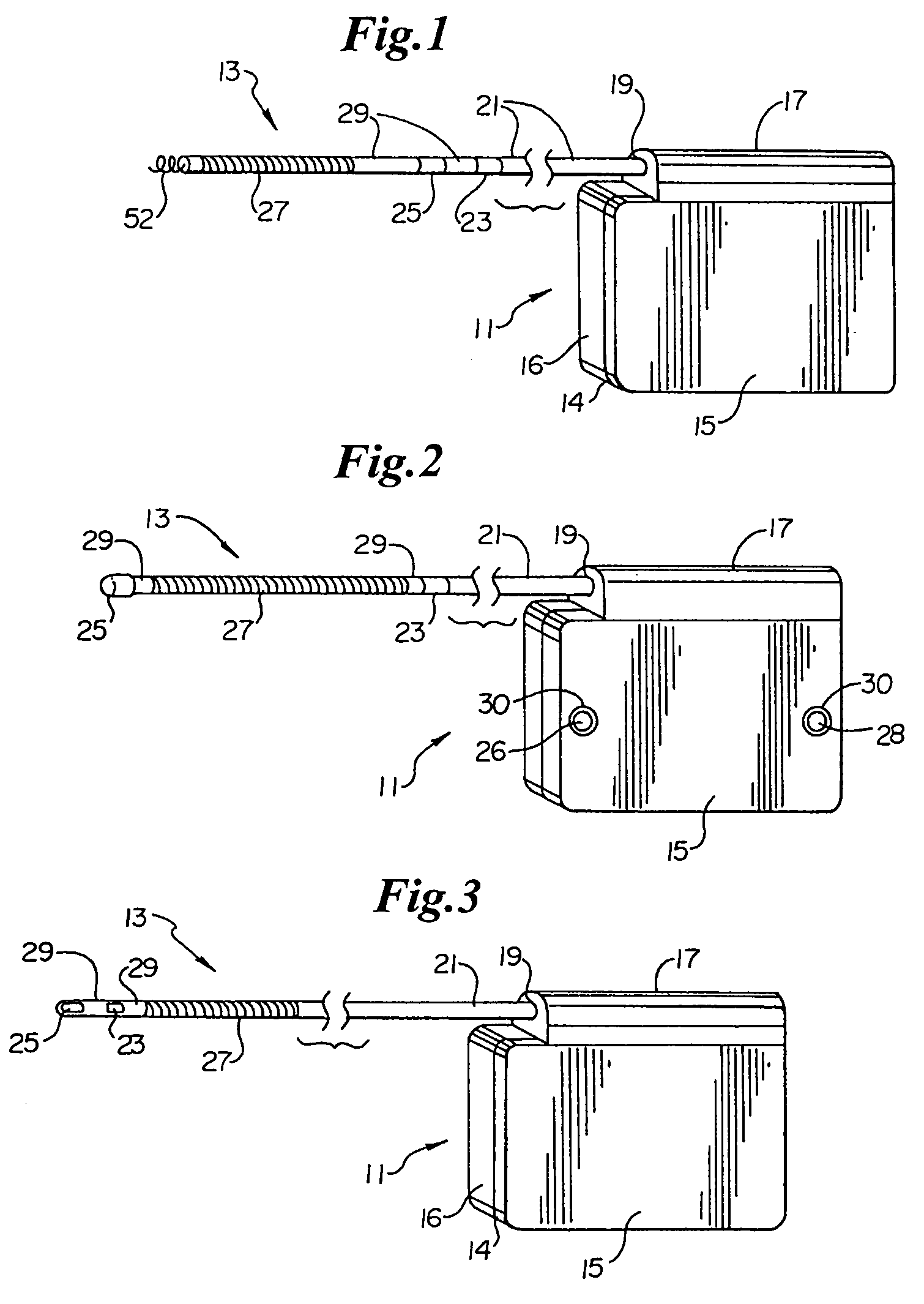

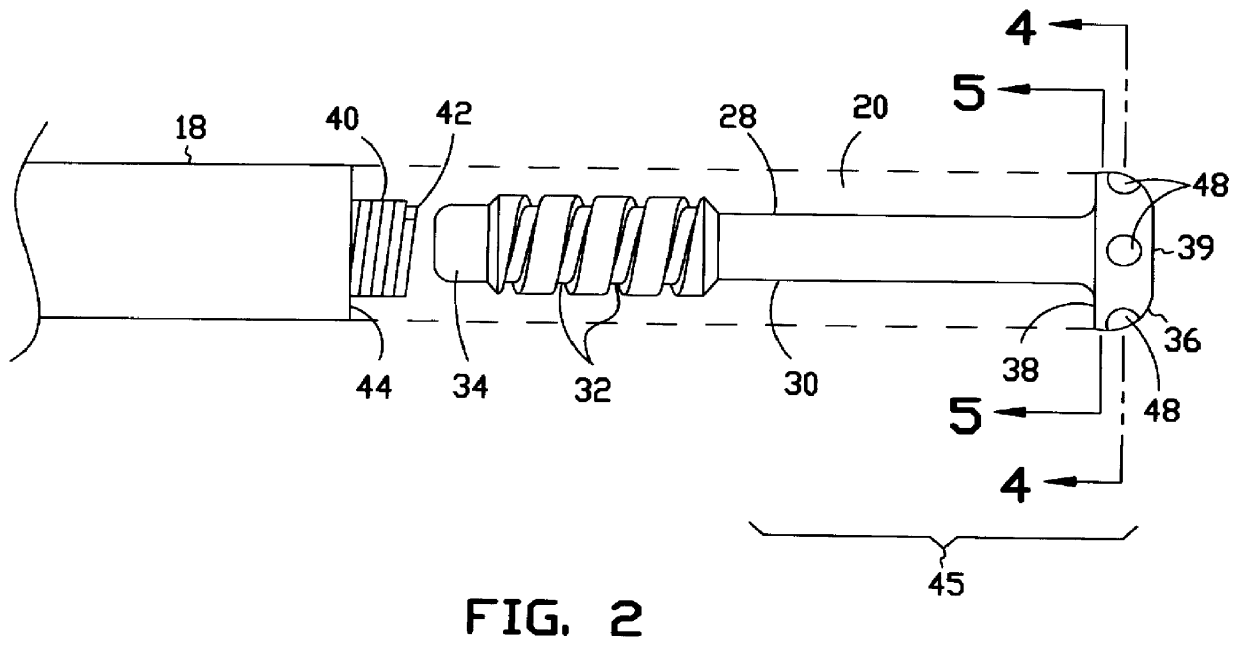

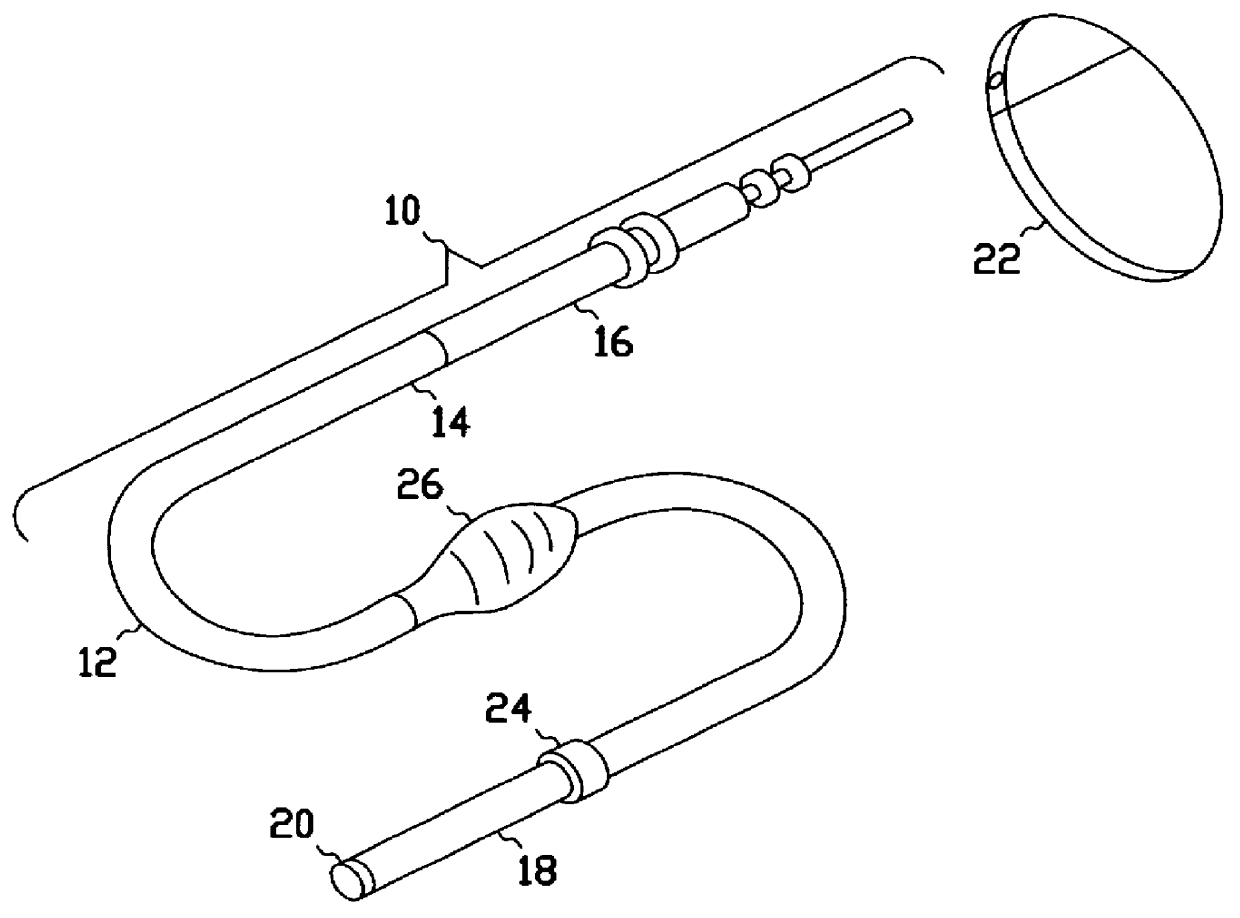

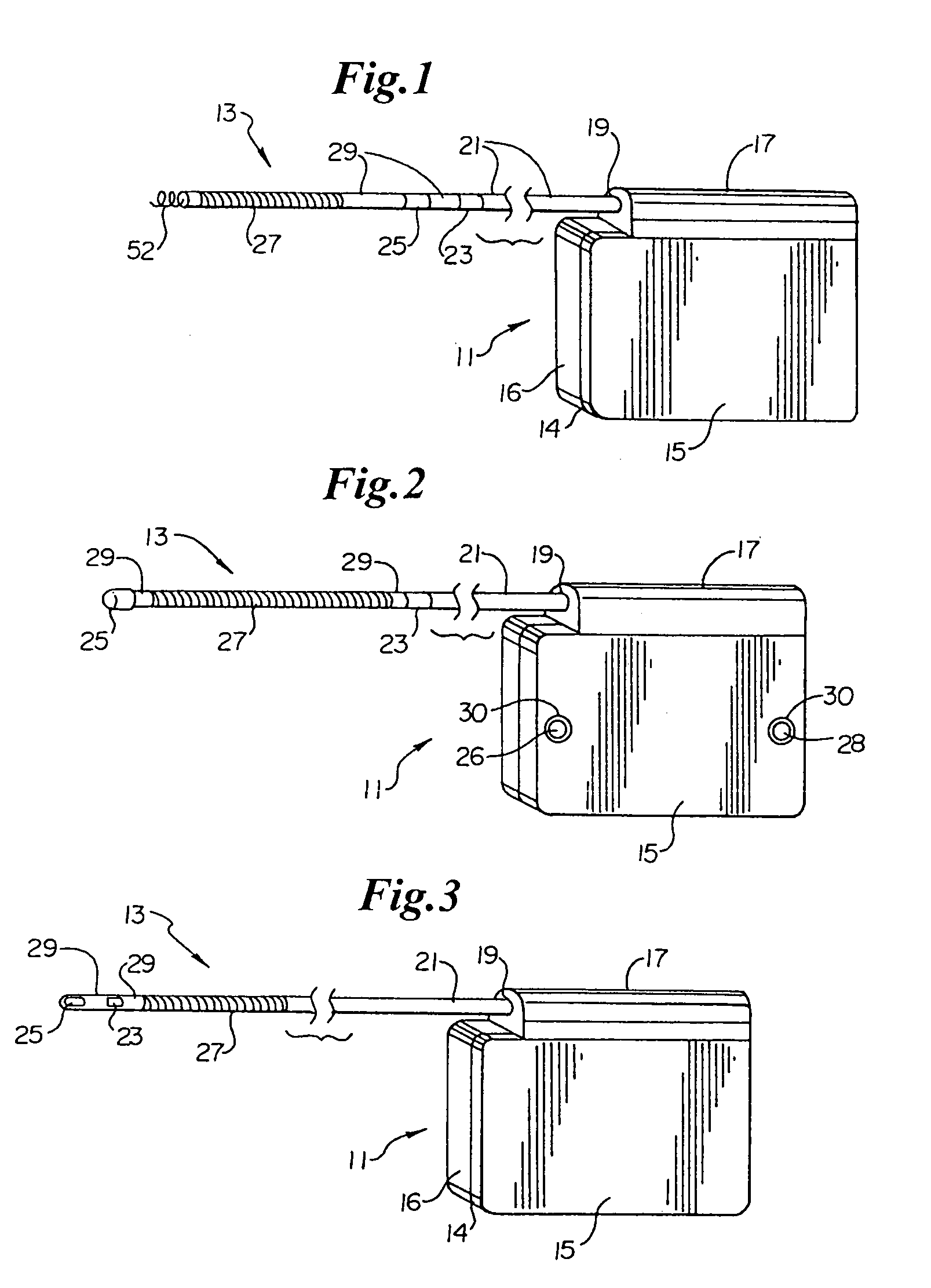

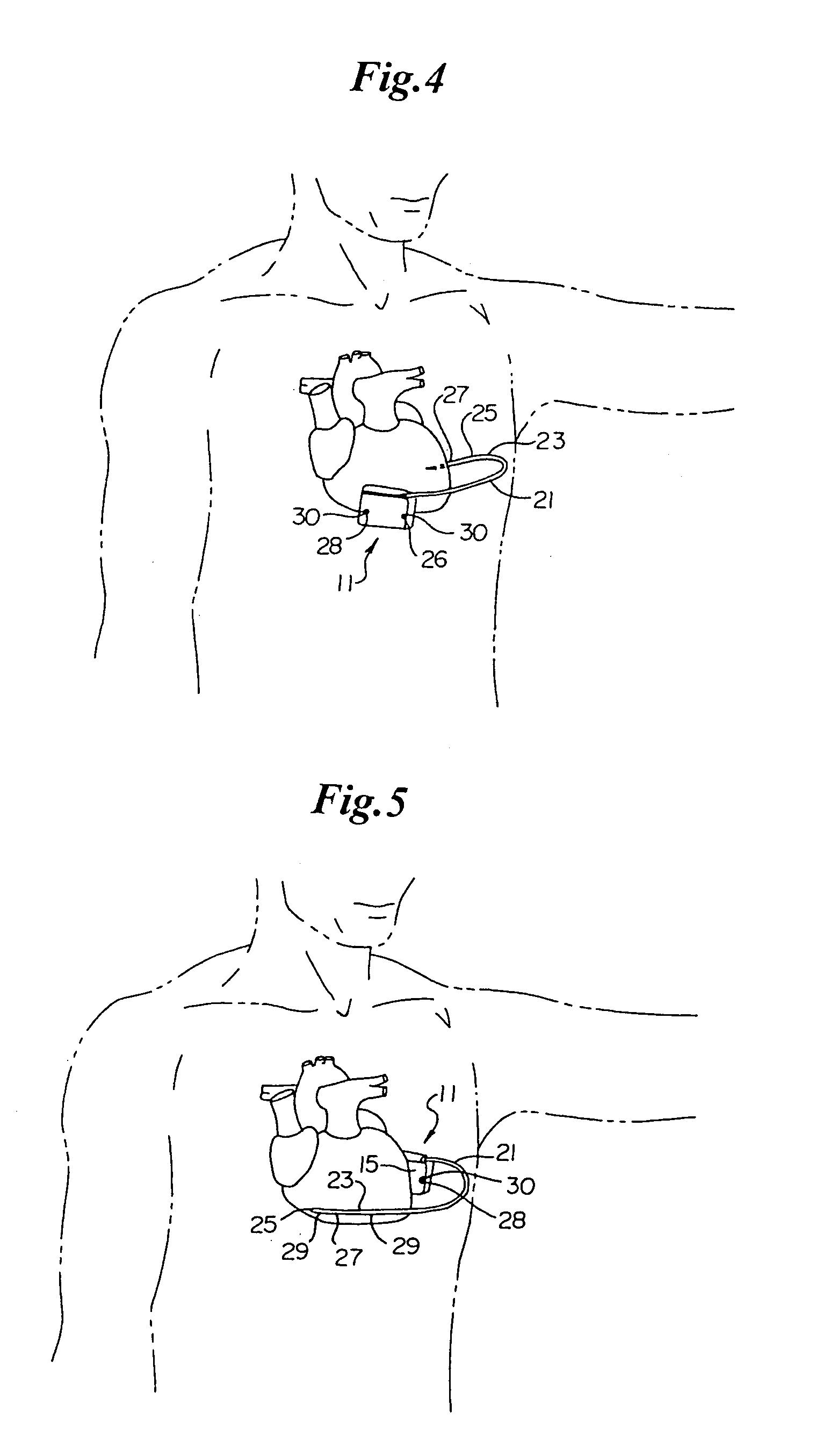

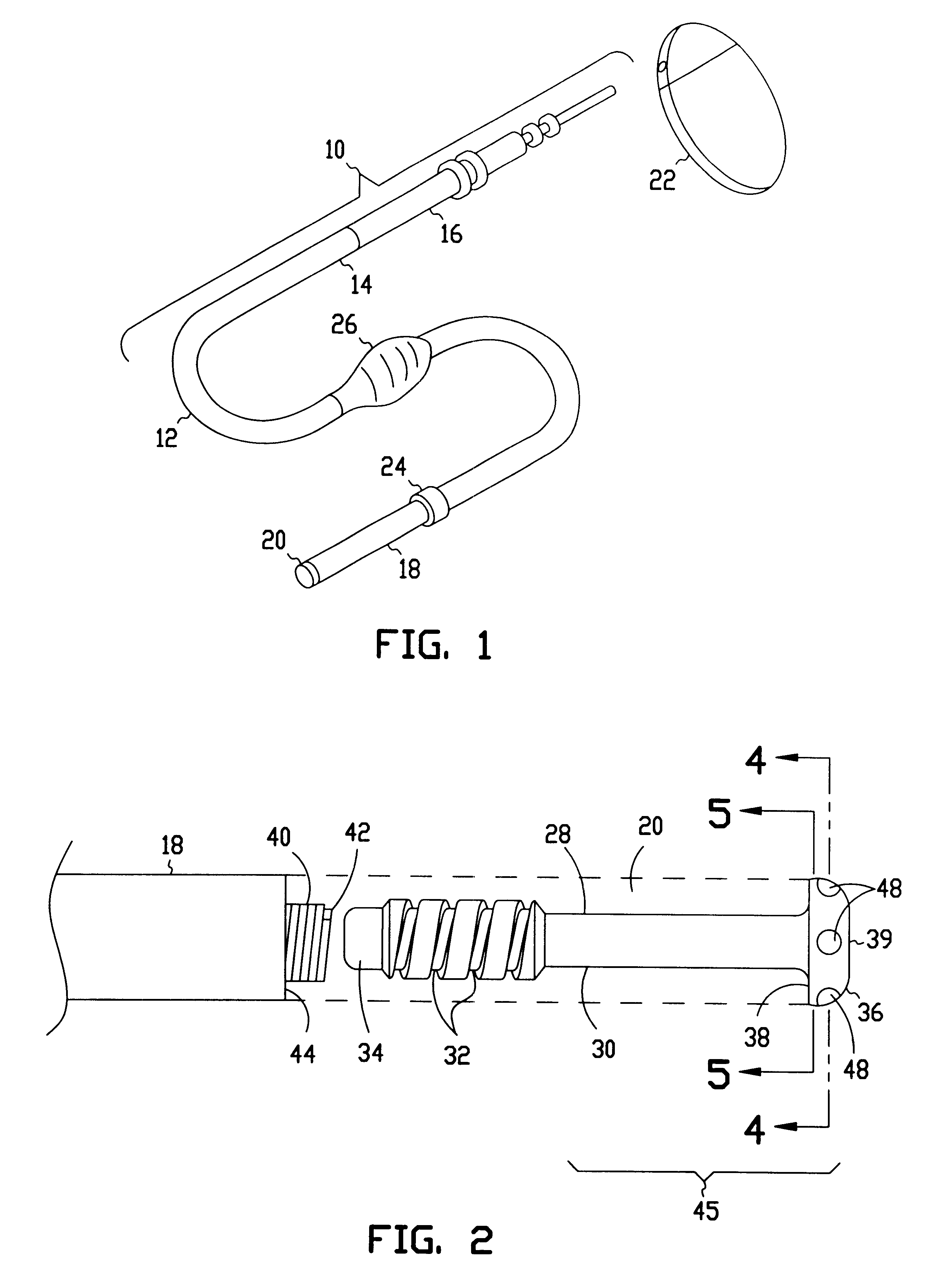

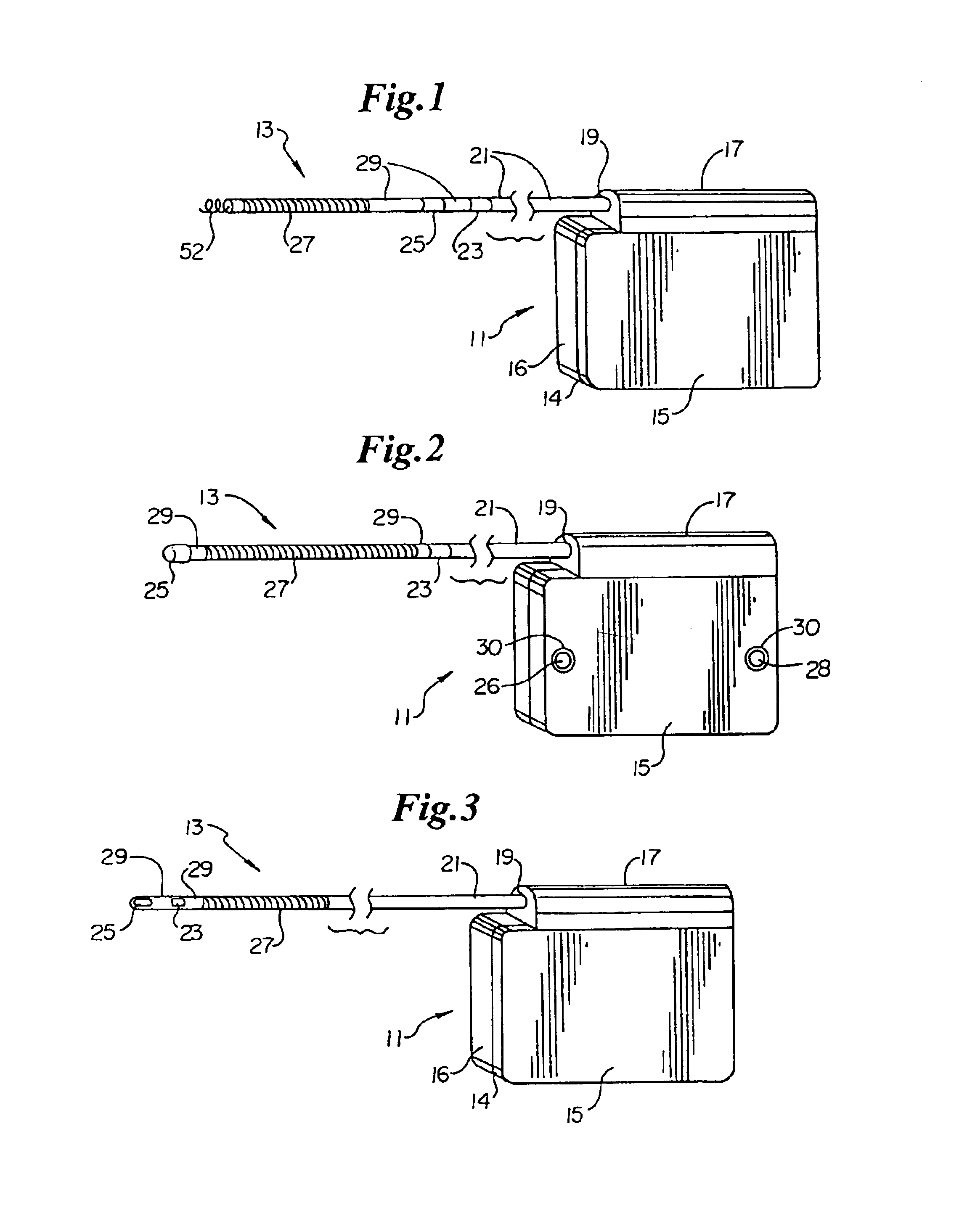

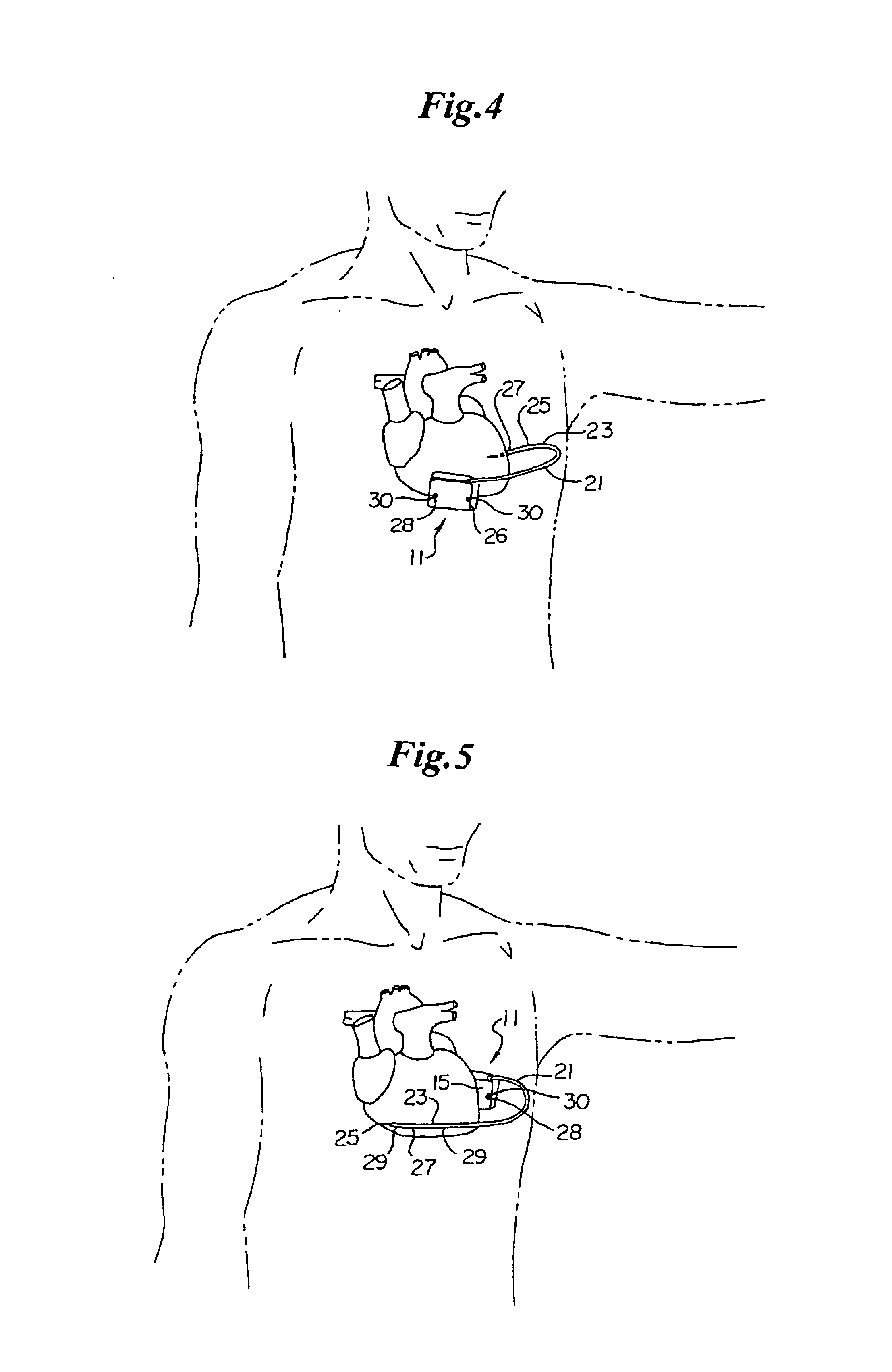

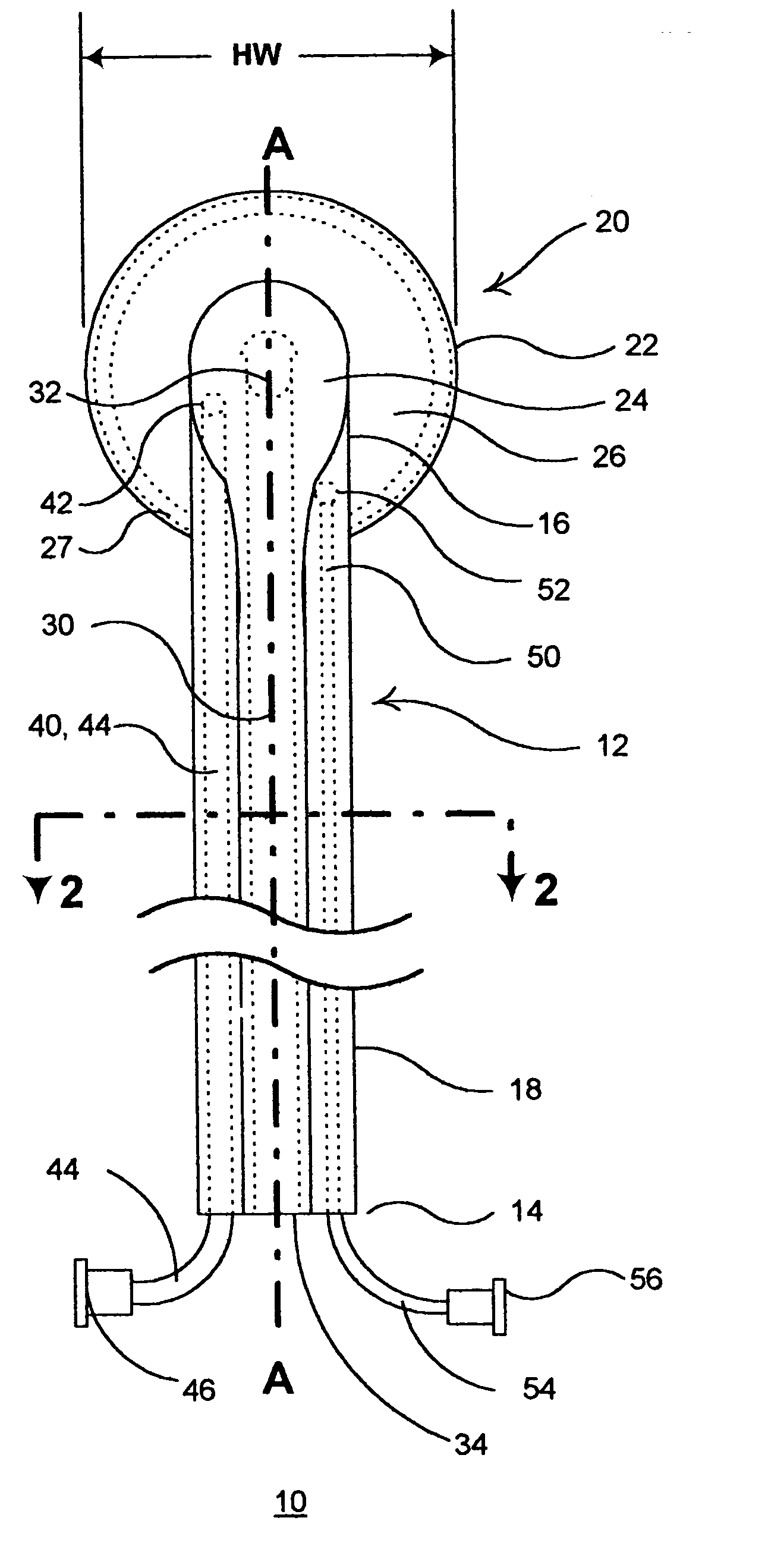

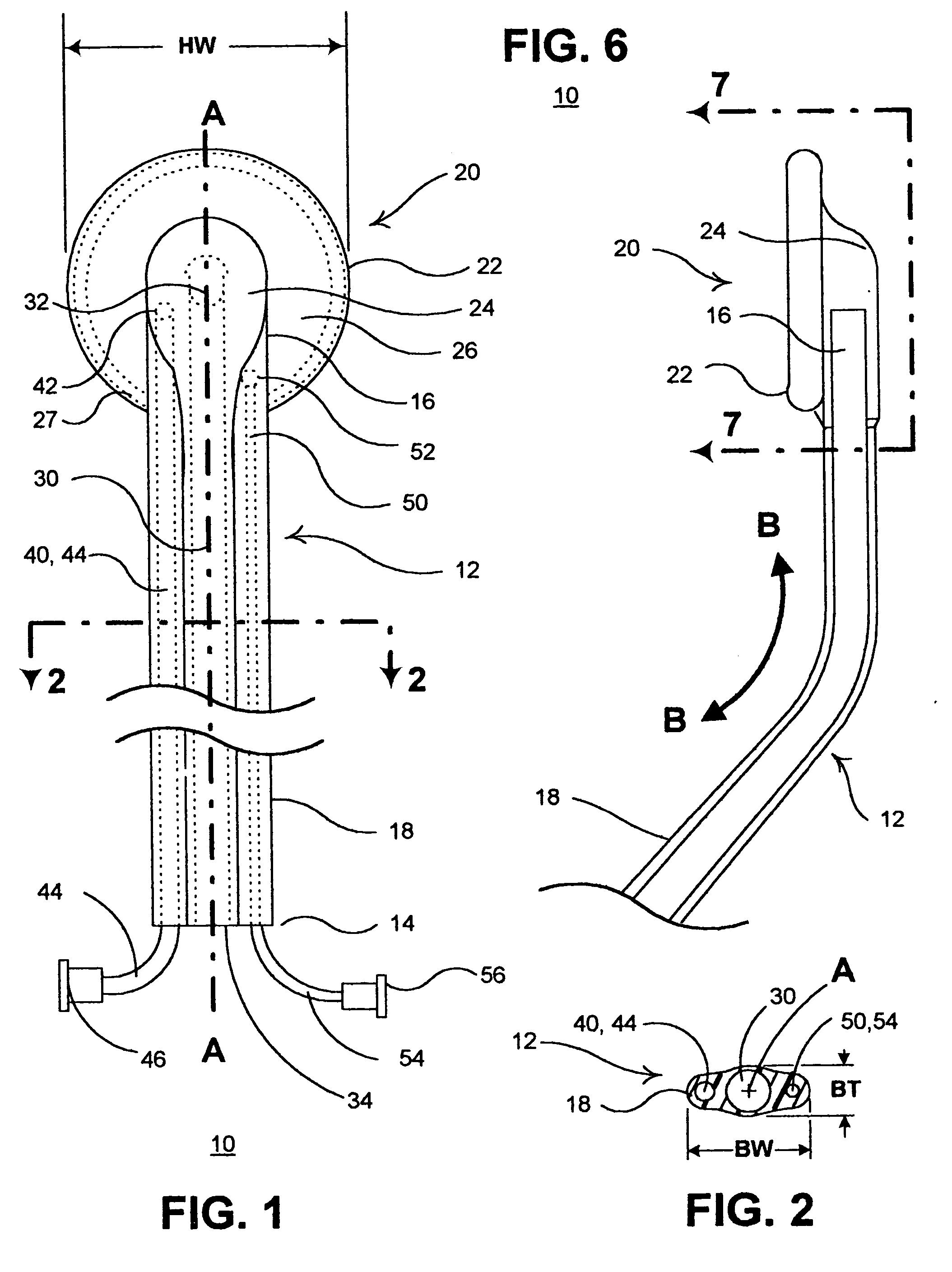

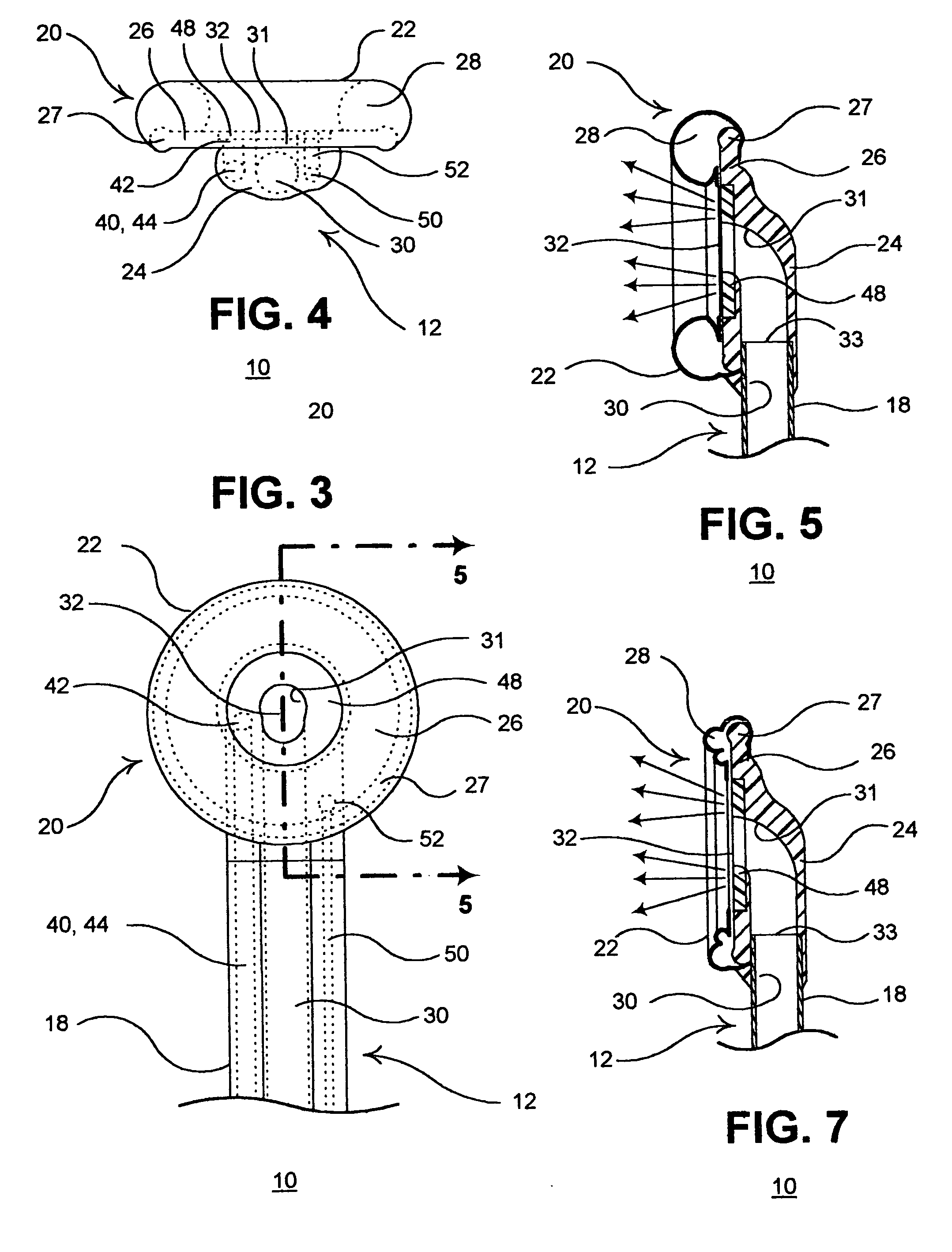

Rotatable lead introducer

Minimally invasive introducers and methods that can be used for rotationally securing devices within the human body. Introducers can include a distal element for releasably engaging a lead head controllable from a proximal control located outside of the body. An inner stem can extend between a proximal portion and a distal portion, and be pivotally and rotatably coupled to the distal lead engagement mechanism. An outer tube can be rotatably disposed over the inner stem and be flexibly coupled over the pivot to rotationally drive the distal element. A helical epicardial-myocardial lead electrode can be secured and oriented straight ahead and introduced through a port or small incision with the introducer in a straight configuration. The introducer can then be bent and rotated to screw the helical electrode into the heart.

Owner:WILSON GREATBATCH LTD

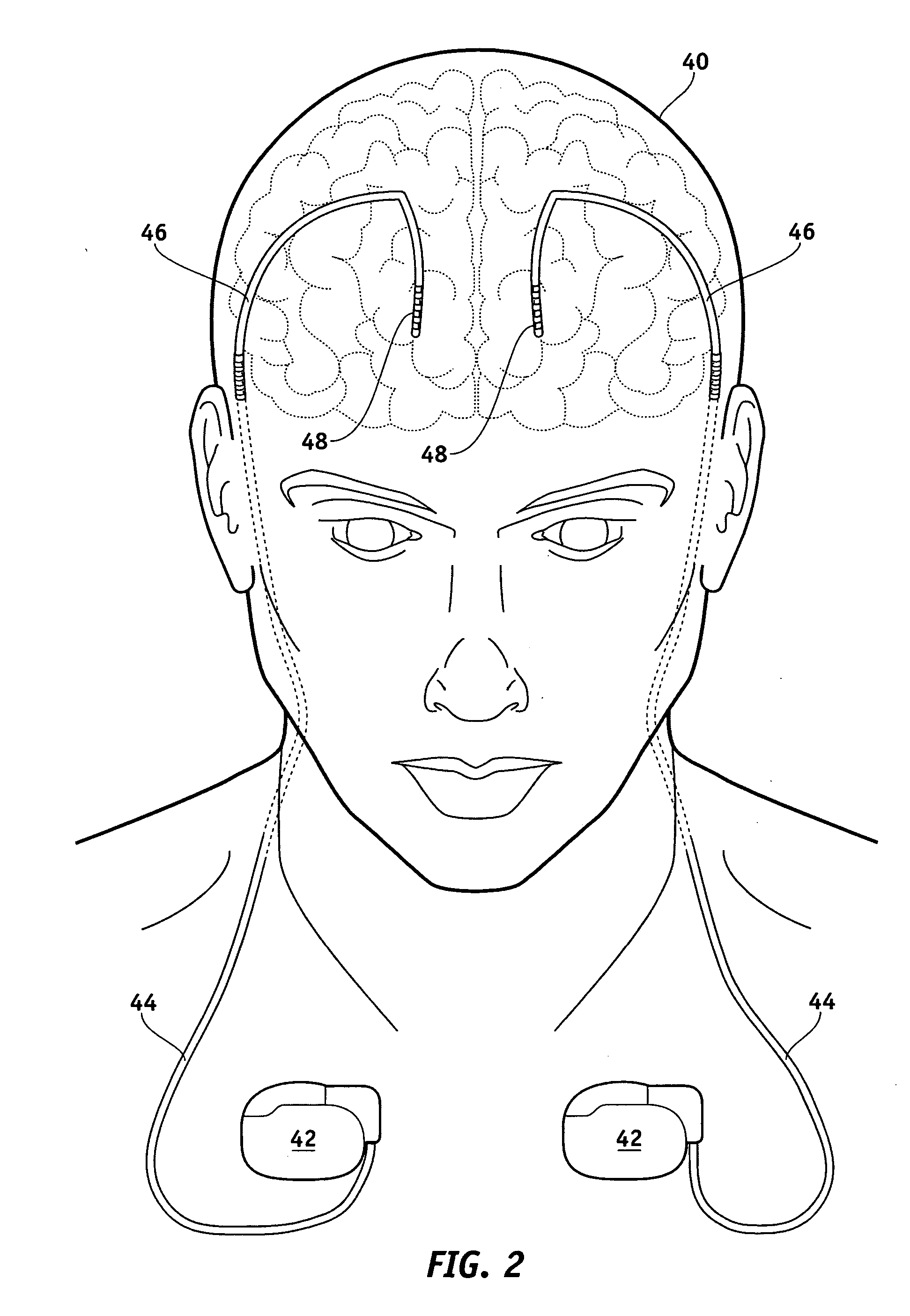

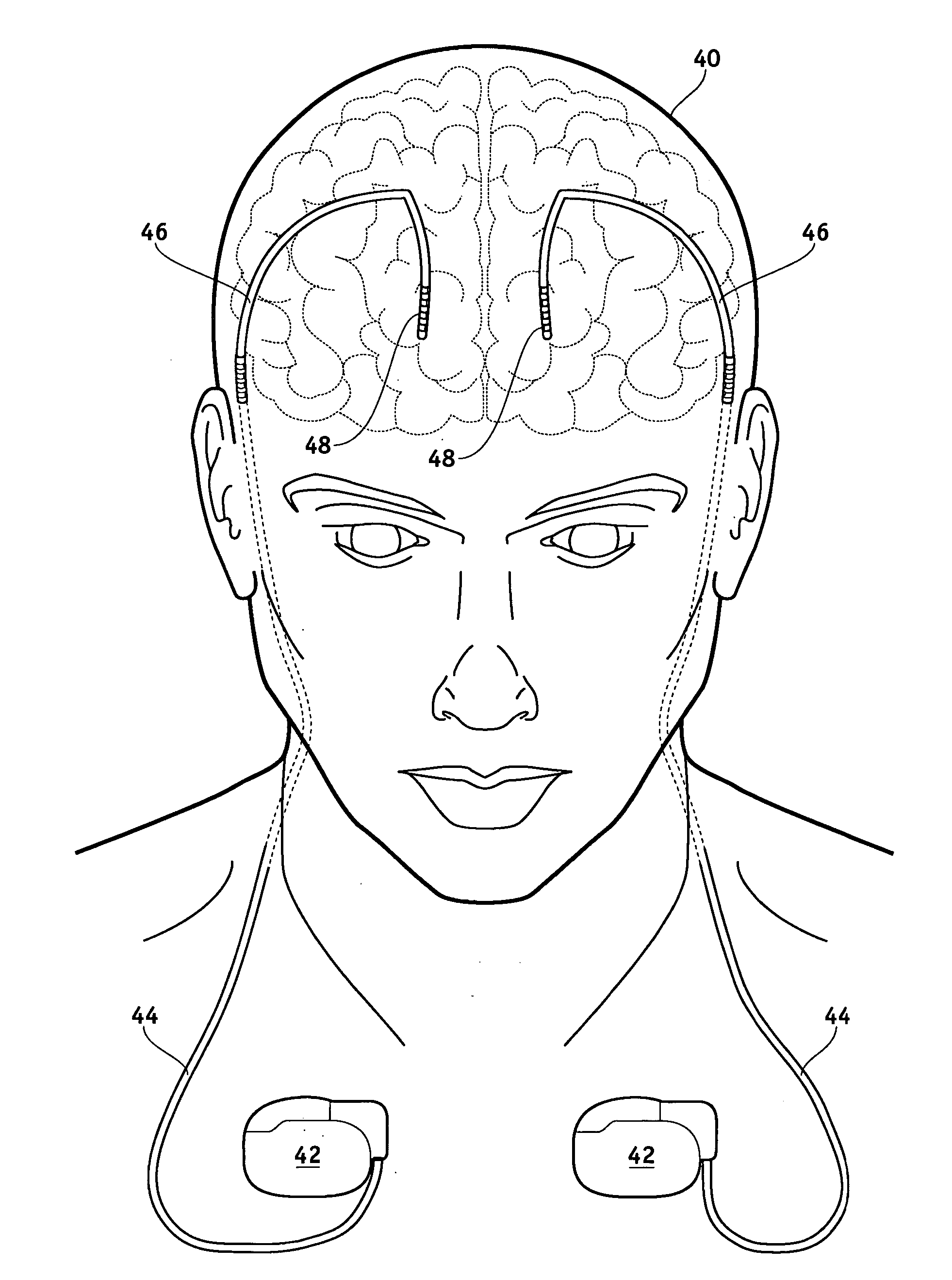

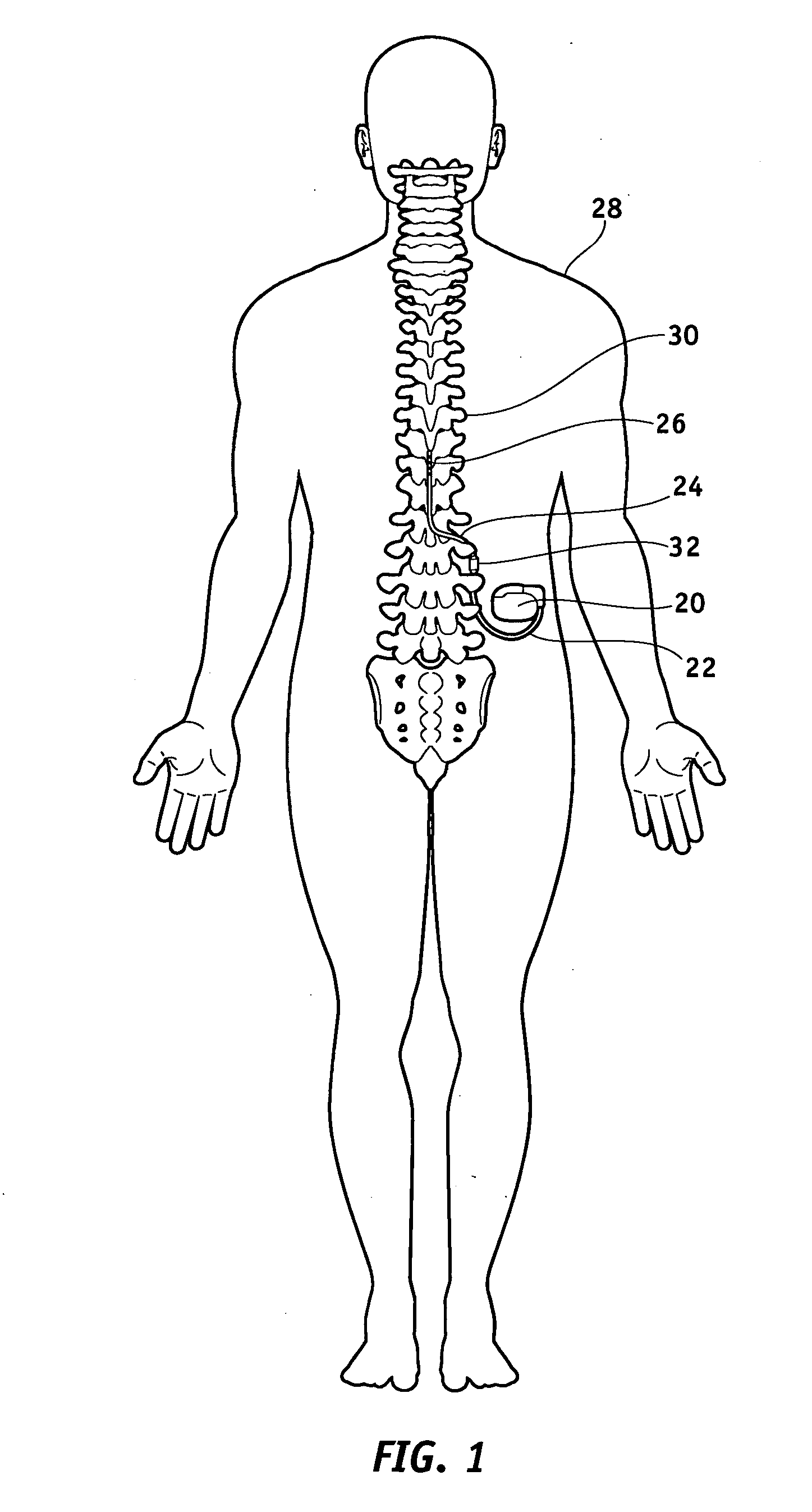

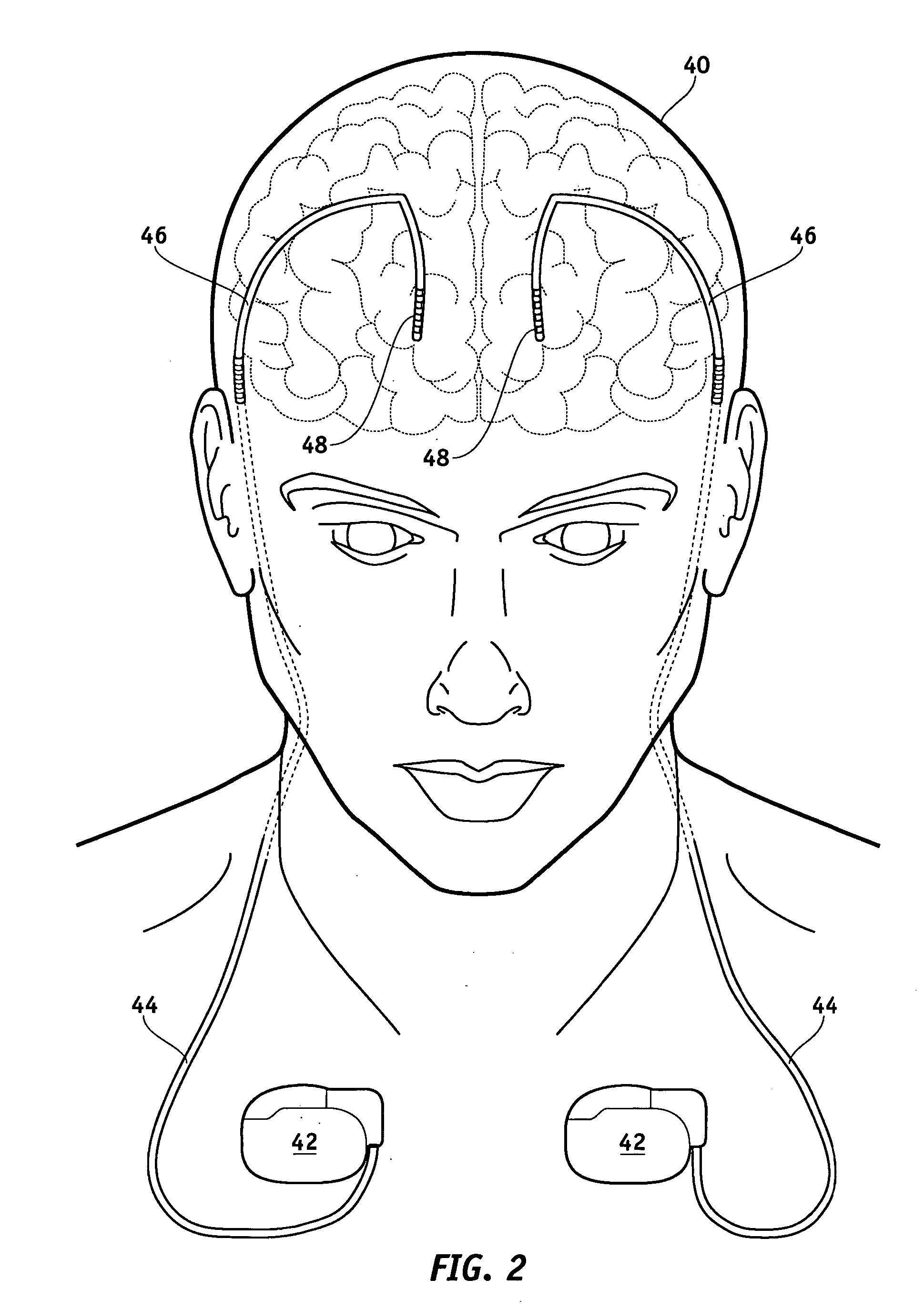

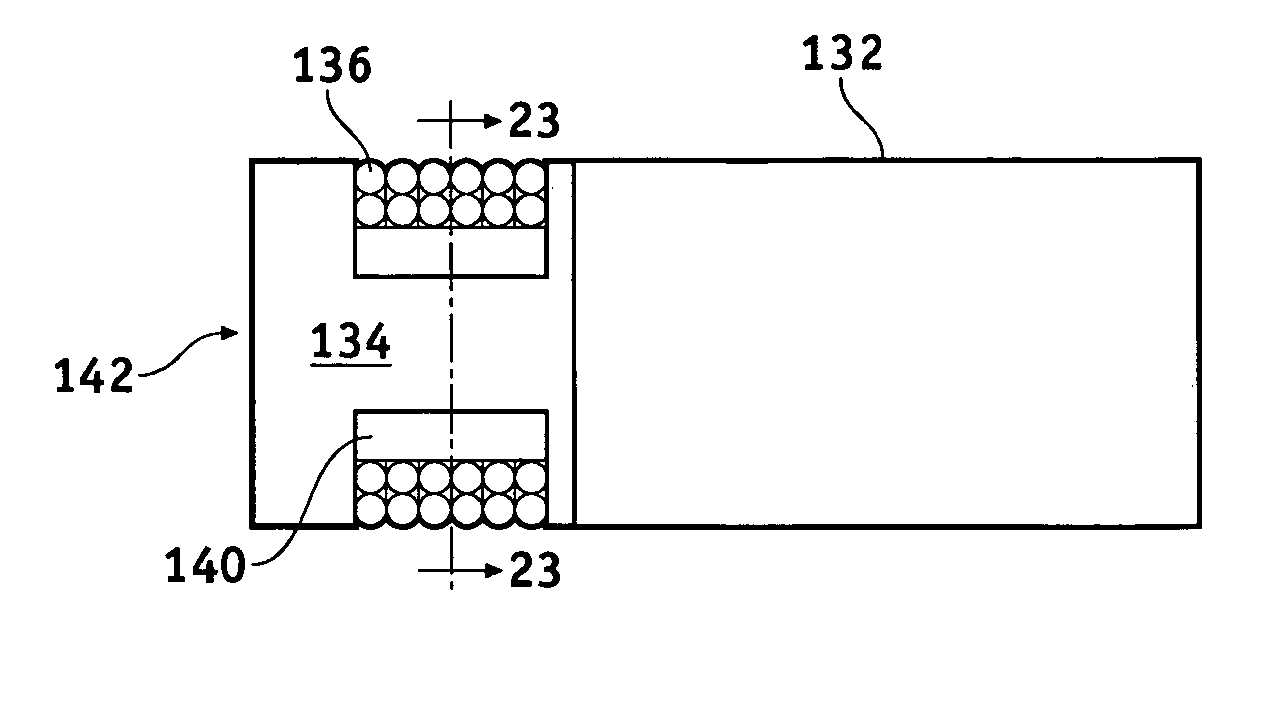

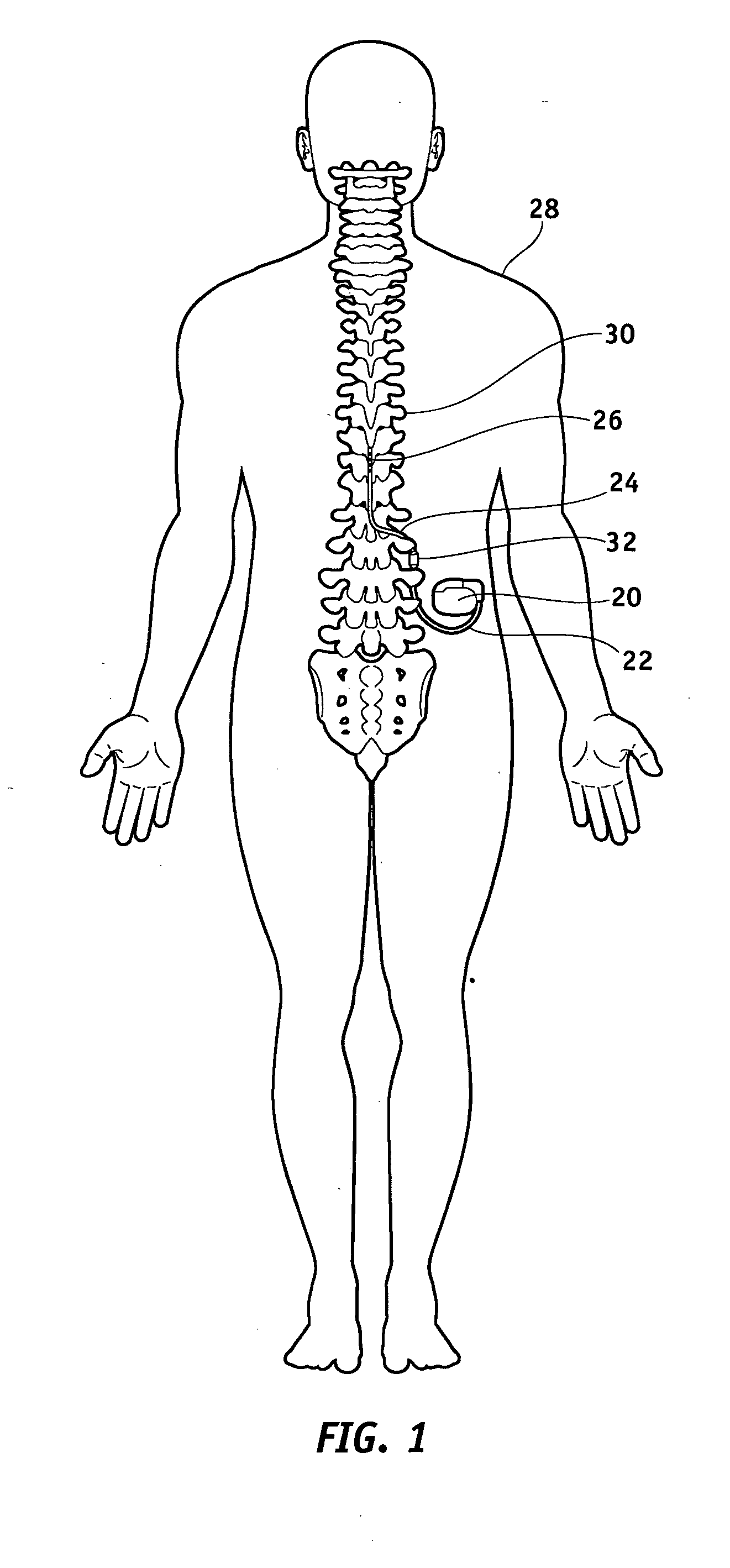

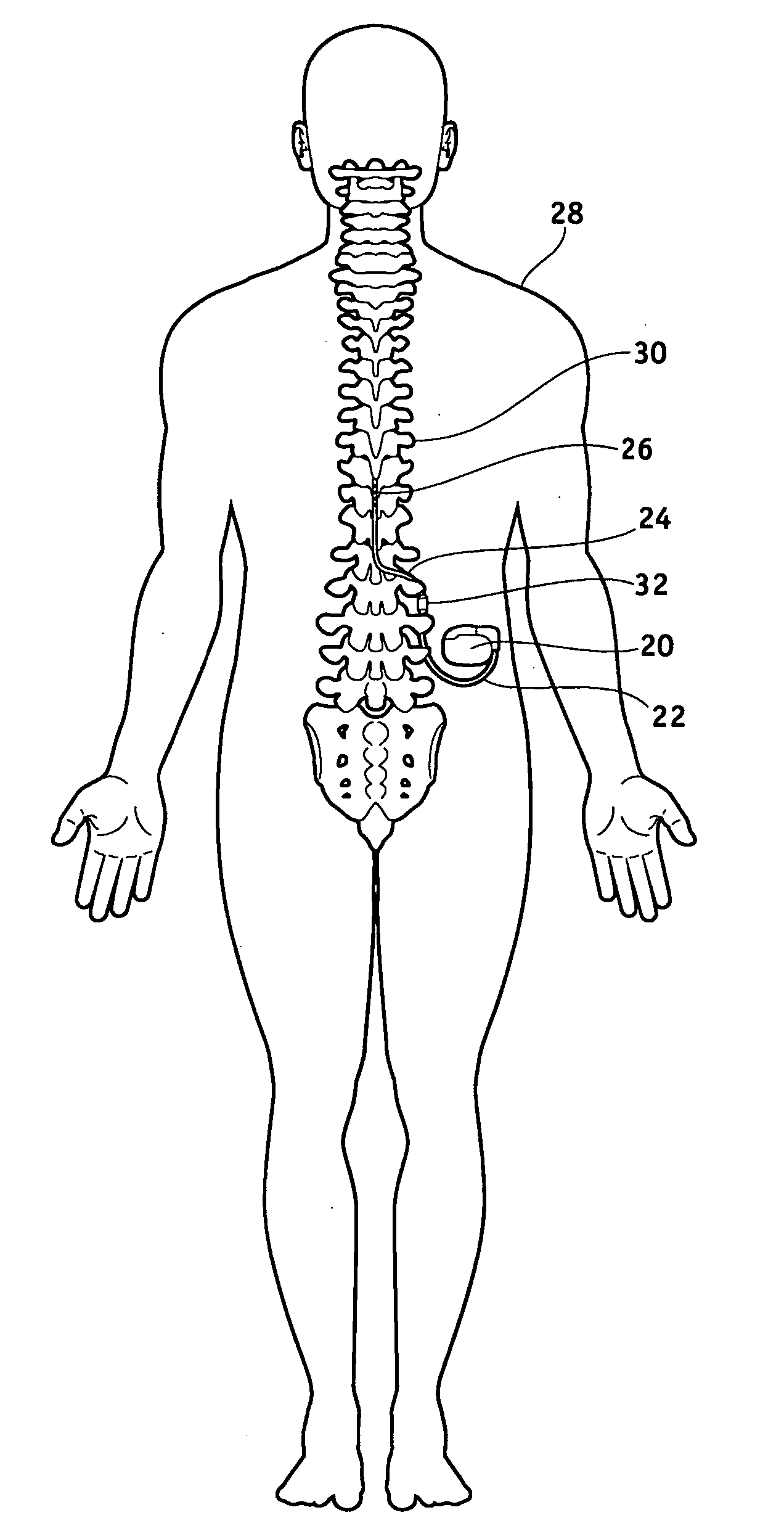

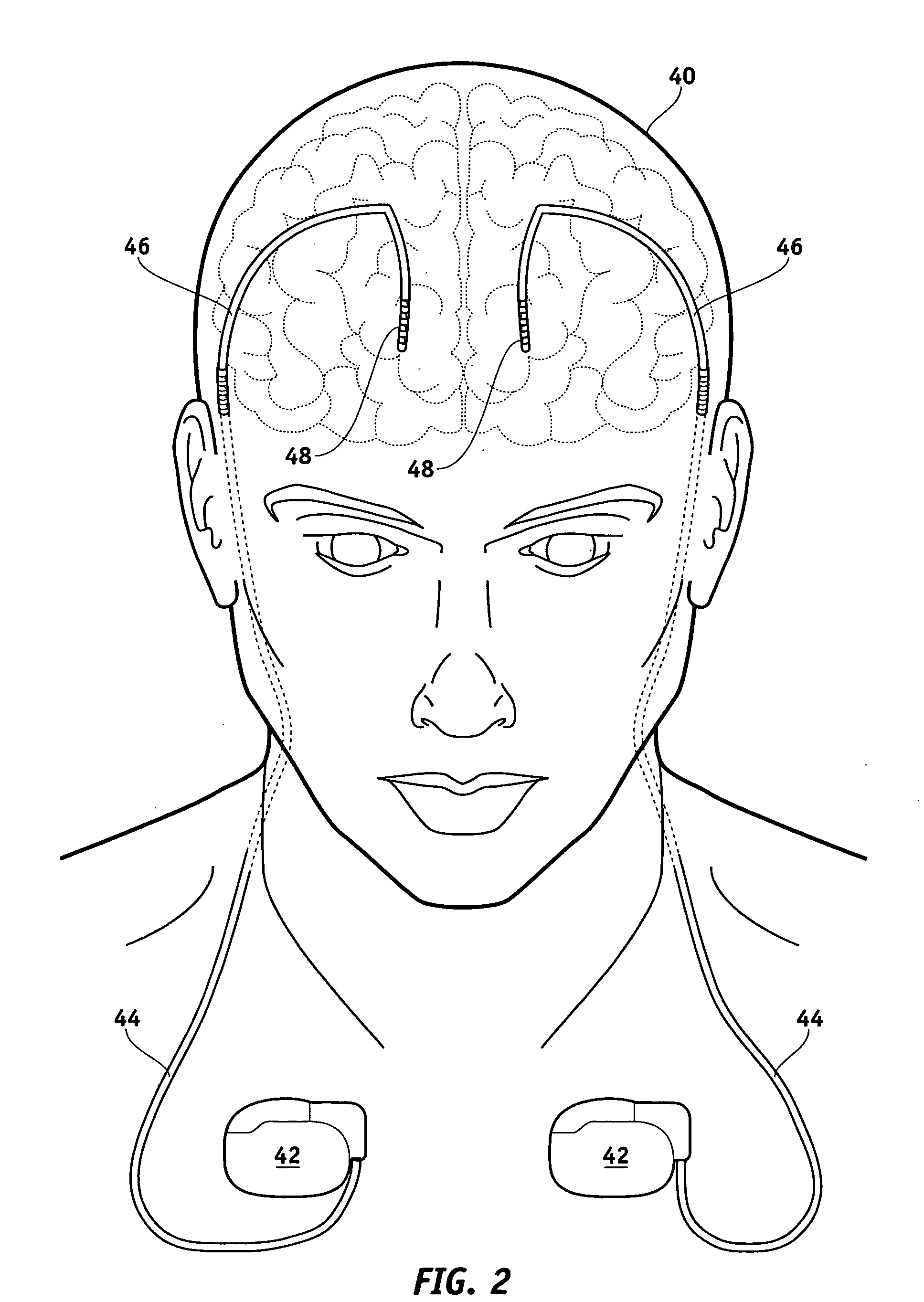

Lead electrode for use in an MRI-safe implantable medical device

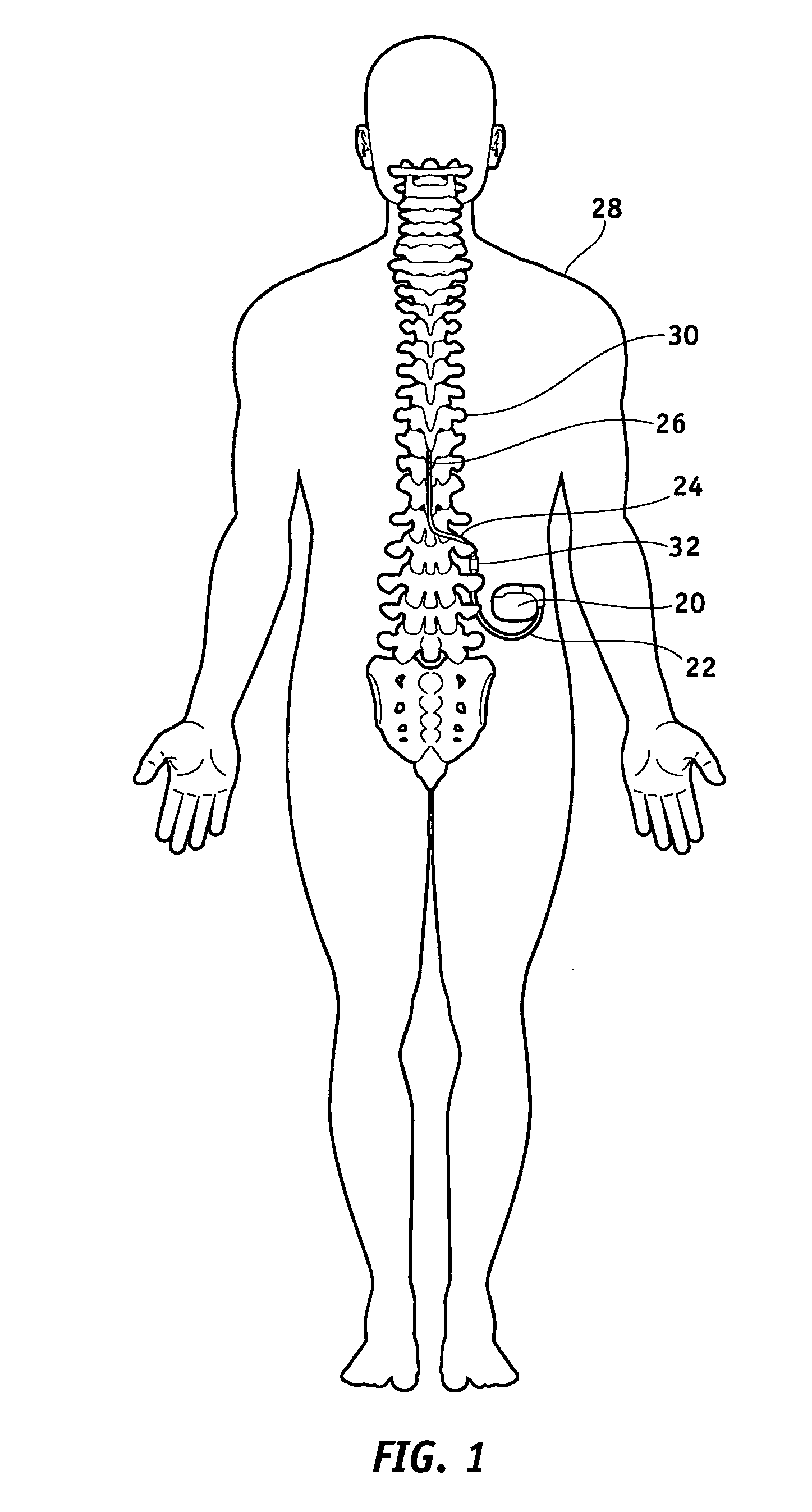

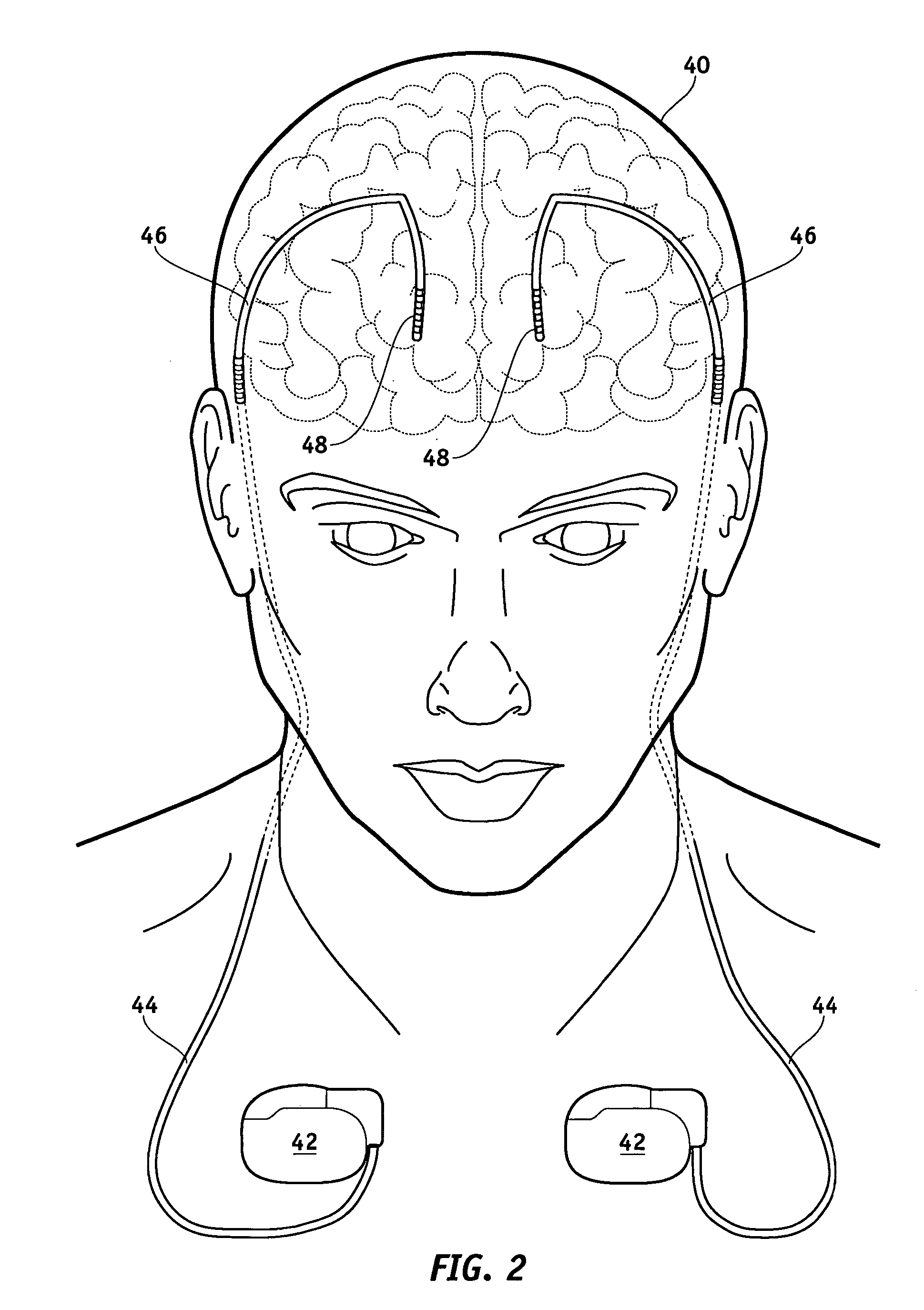

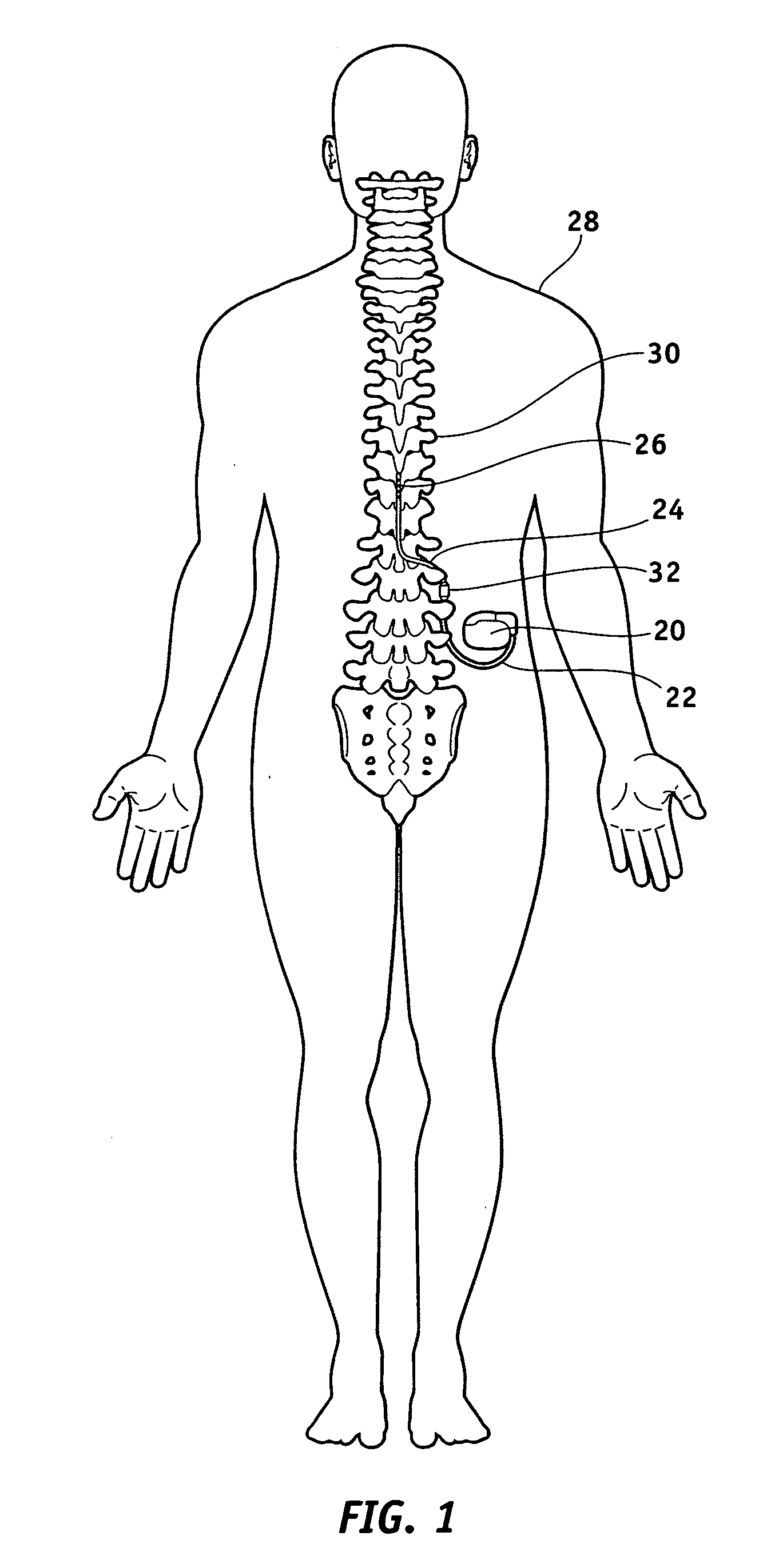

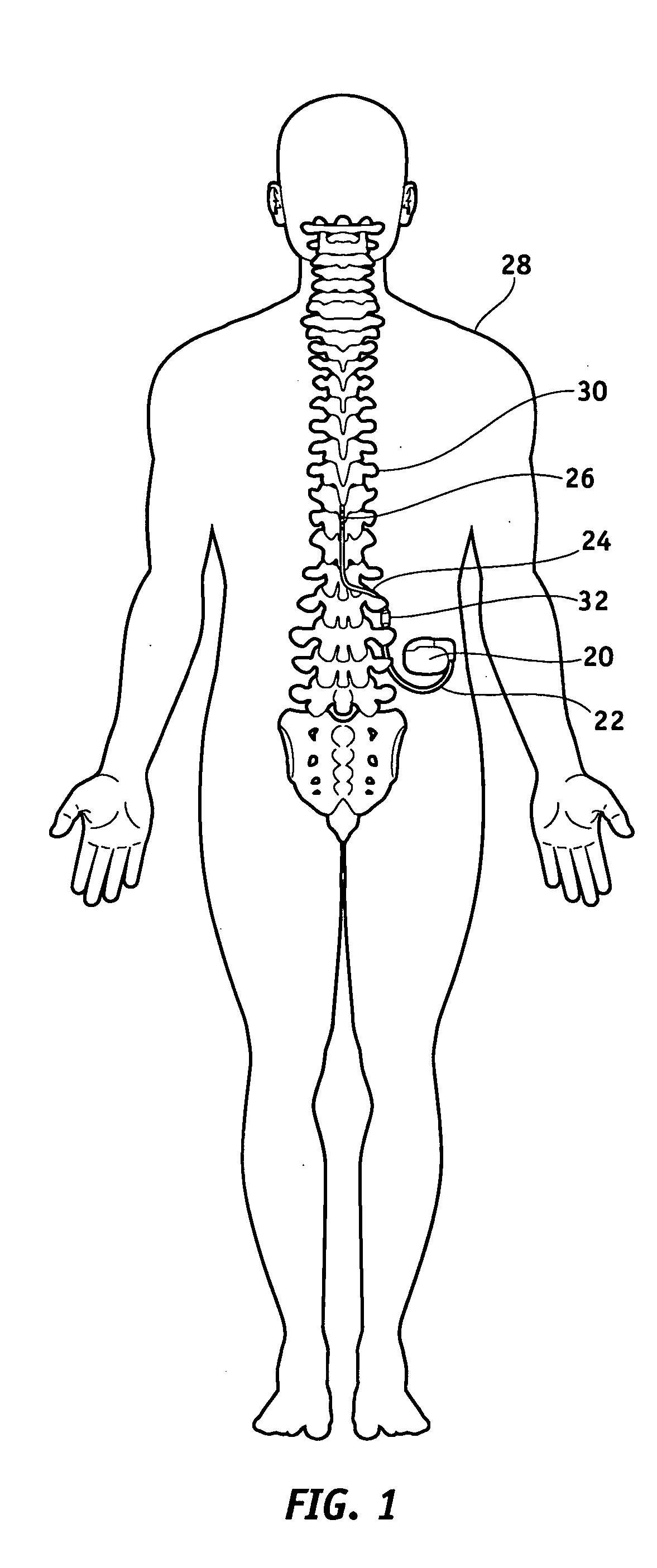

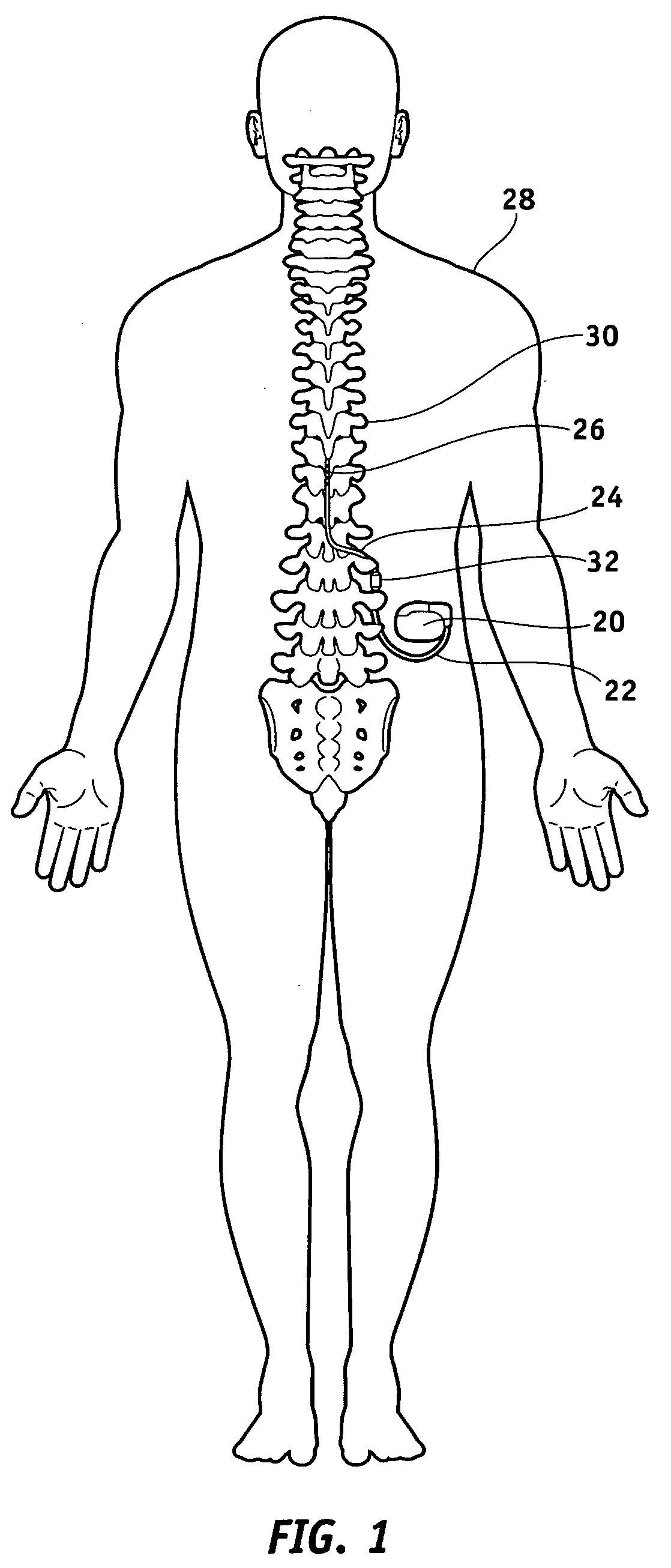

A pulse stimulation system configured for implantation into a patient's body comprises a pulse stimulator, a conductive stimulation lead having a proximal end electrically coupled to the pulse simulator and having a distal end, and an electrode assembly coupled to the distal end of the stimulation lead. The electrode assembly comprises an electrode body having a therapy electrode thereon that is electrically coupled to the stimulation lead for delivering therapy to the patient. A floating electrode is configured to contact the patient's body tissue and has a surface area substantially larger than that of the therapy electrode. A filter is coupled between the therapy electrode and the floating electrode for diverting RF energy toward the floating electrode and away from the therapy electrode.

Owner:MEDTRONIC INC

Lead electrode for use in an MRI-safe implantable medical device

ActiveUS20050222658A1Reduce electromagnetic couplingSpinal electrodesHead electrodesElectromagnetic couplingMedicine

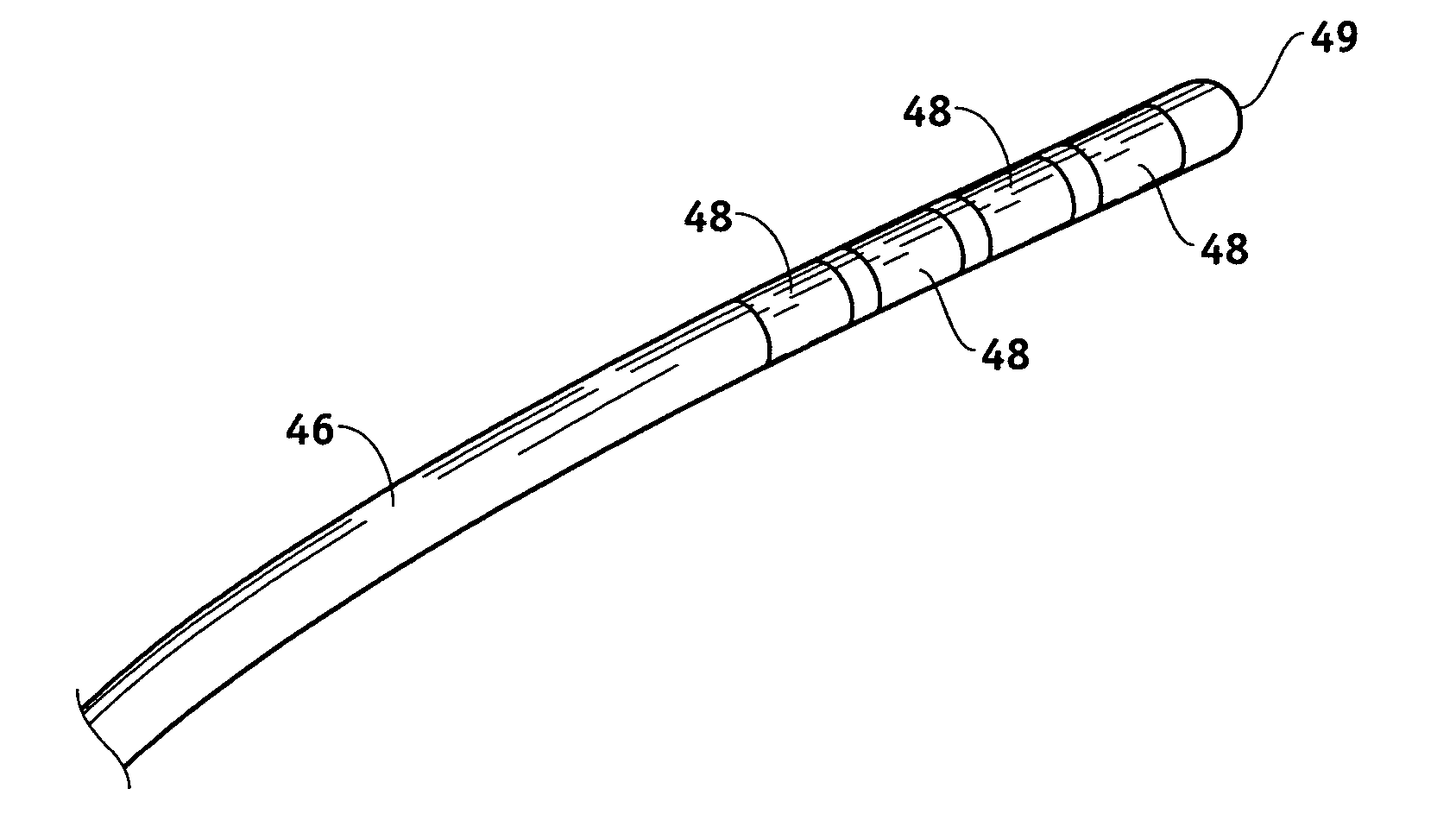

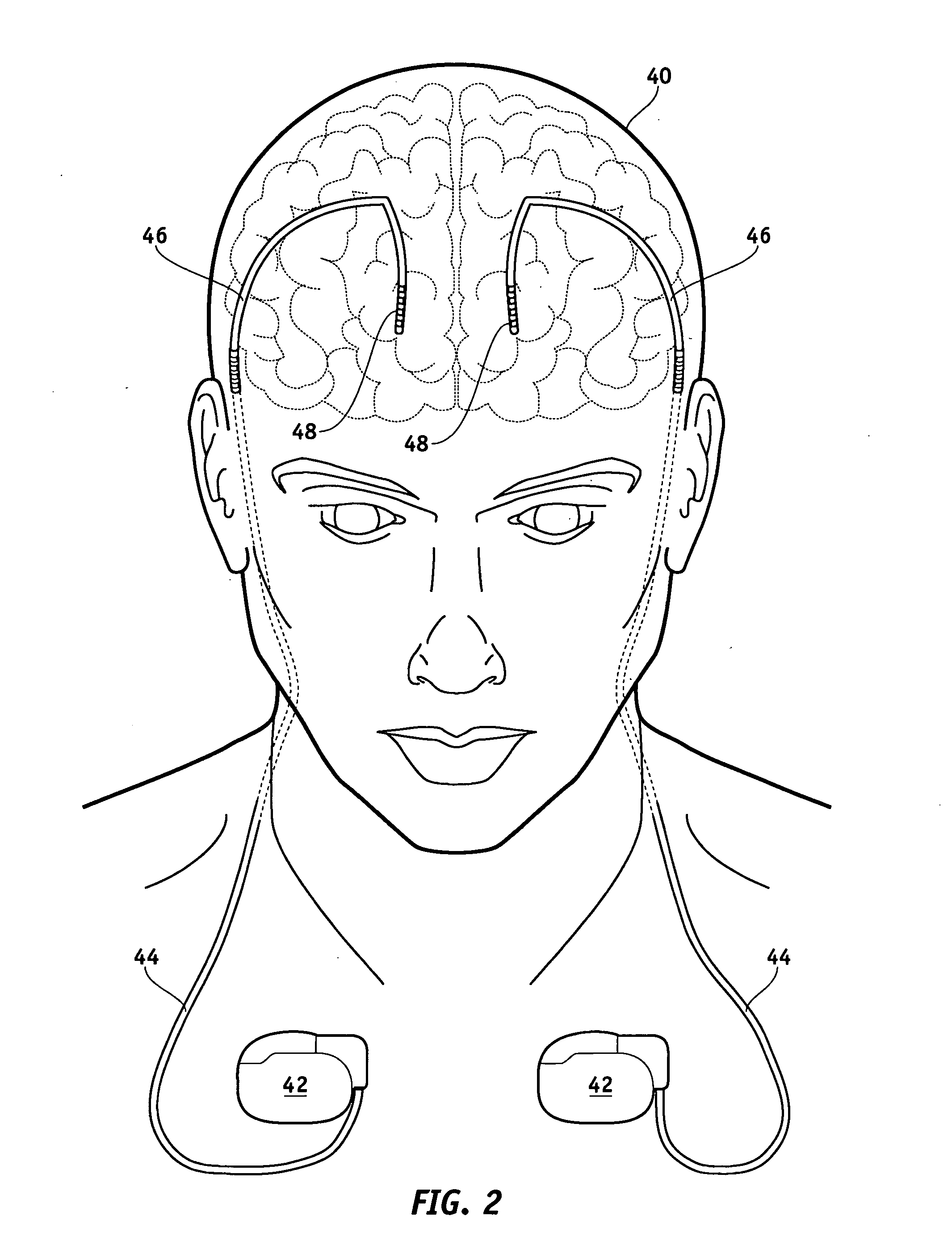

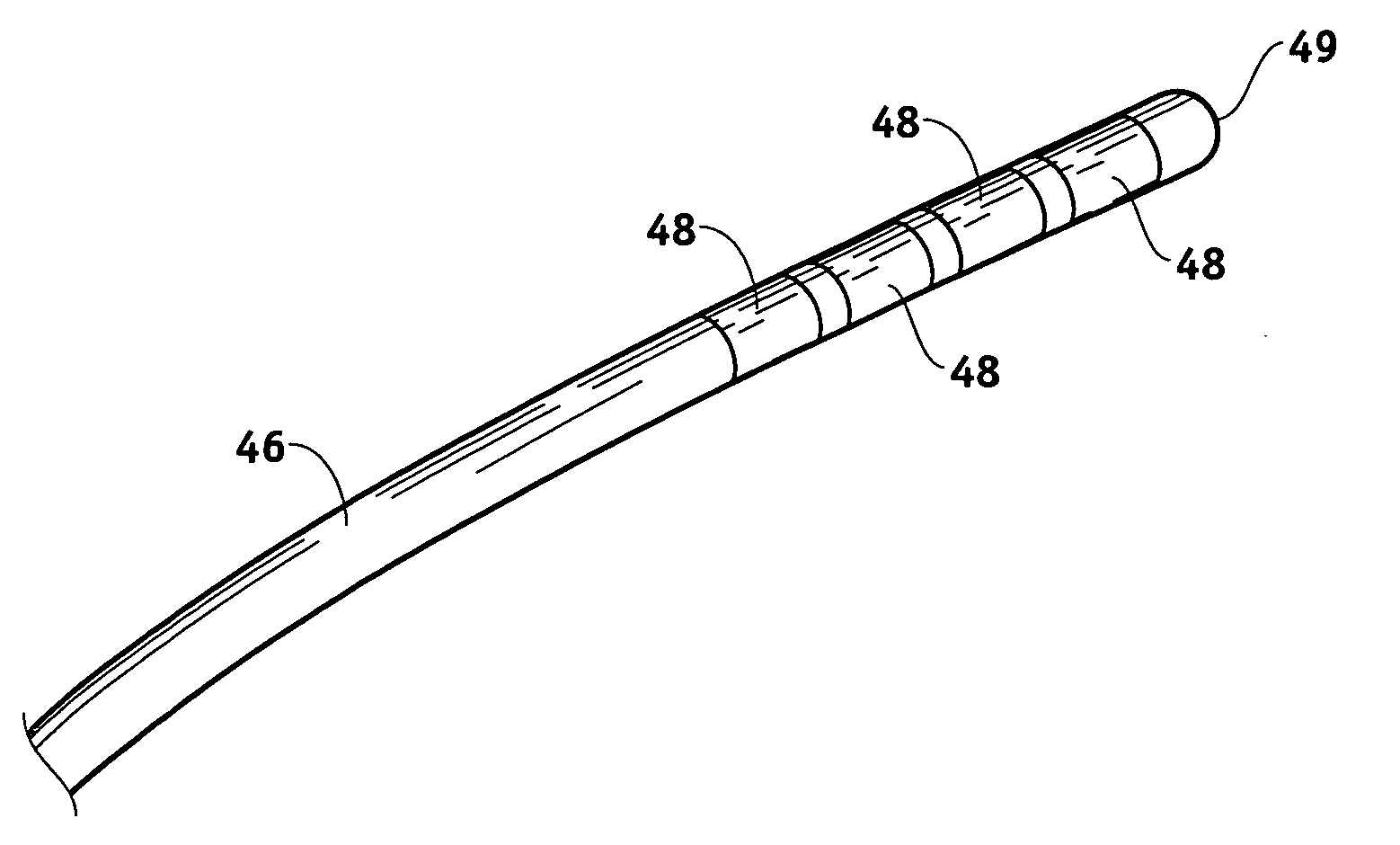

A neurostimulation lead is configured to be implanted into a patient's body and has at least one distal electrode. The lead comprises at least one conductive filer electrically coupled to the distal electrode, a jacket for housing the conductive filer and a shield surrounding at least a portion of the filer for reducing electromagnetic coupling to the filer.

Owner:MEDTRONIC INC

Lead electrode for use in an MRI-safe implantable medical device

A pulse stimulation system configured for implantation into a patient's body comprises a pulse stimulator, a conductive stimulation lead having a proximal end electrically coupled to the pulse simulator and having a distal end, and an electrode assembly coupled to the distal end of the stimulation lead. The electrode assembly comprises an electrode body having a therapy electrode thereon that is electrically coupled to the stimulation lead for delivering therapy to the patient. A floating electrode is configured to contact the patient's body tissue and has a surface area substantially larger than that of the therapy electrode. A filter is coupled between the therapy electrode and the floating electrode for diverting RF energy toward the floating electrode and away from the therapy electrode.

Owner:MEDTRONIC INC

Lead electrode for use in an MRI-safe implantable medical device

A lead configured to be implanted into a patient's body comprises a lead body and a conductive filer positioned within the lead body and having a distal portion. An electrode is electrically coupled to the lead body and comprises a stimulation portion, a bobbin, and at least one coil of wire wound on the bobbin and electrically coupled between the stimulation portion and the distal end region to form an inductor between the distal end region and the stimulation portion.

Owner:MEDTRONIC INC

Lead electrode for use in an MRI-safe implantable medical device

An implantable stimulation system comprises a stimulator for generating electrical stimulation and a conductive stimulation lead having a proximal end electrically coupled to the stimulator, wherein at least a first component of the impedance looking into the stimulator is substantially matched to the impedance of the stimulation lead. At least one distal stimulation electrode is positioned proximate the distal end of the stimulation lead.

Owner:MEDTRONIC INC

Lead electrode for use in an MRI-safe implantable medical device

A medical lead is configured to be implanted into a patient's body and comprises a lead body, and an electrode coupled to the lead body. The electrode comprises a first section configured to contact the patient's body, and a second section electrically coupled to the first section and configured to be capacitively coupled to the patient's body.

Owner:MEDTRONIC INC

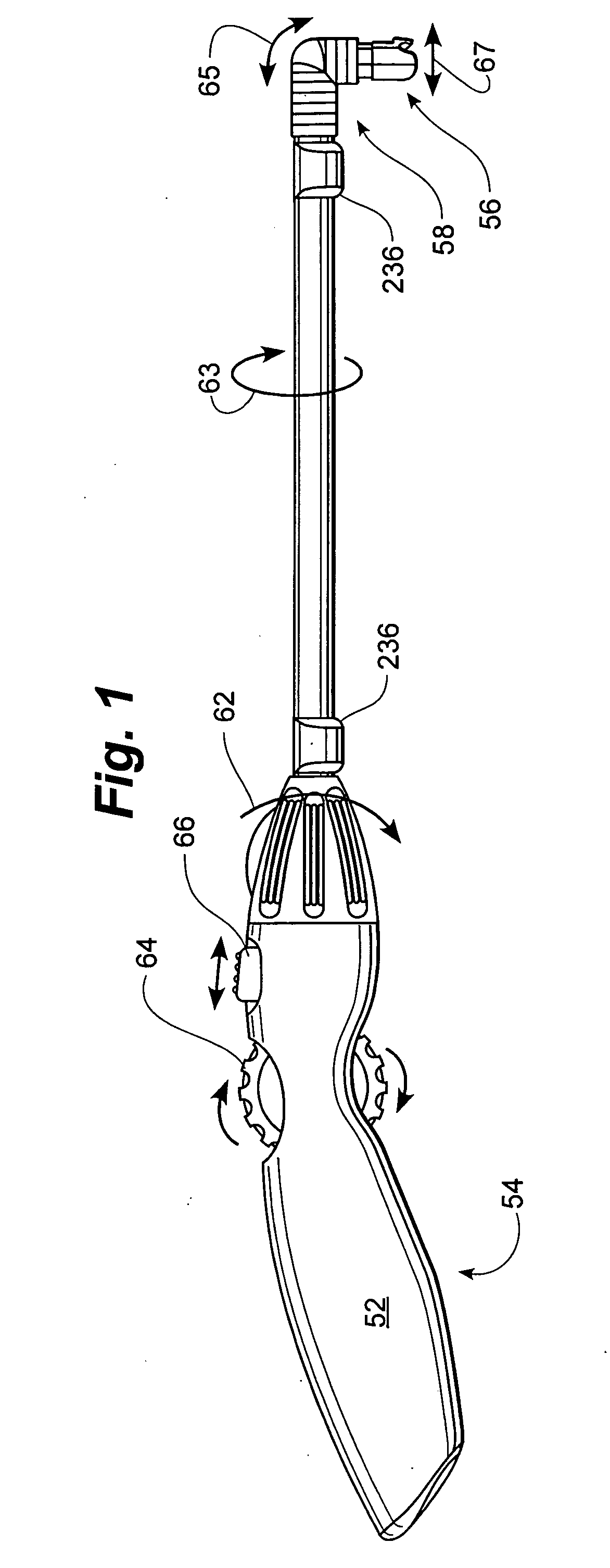

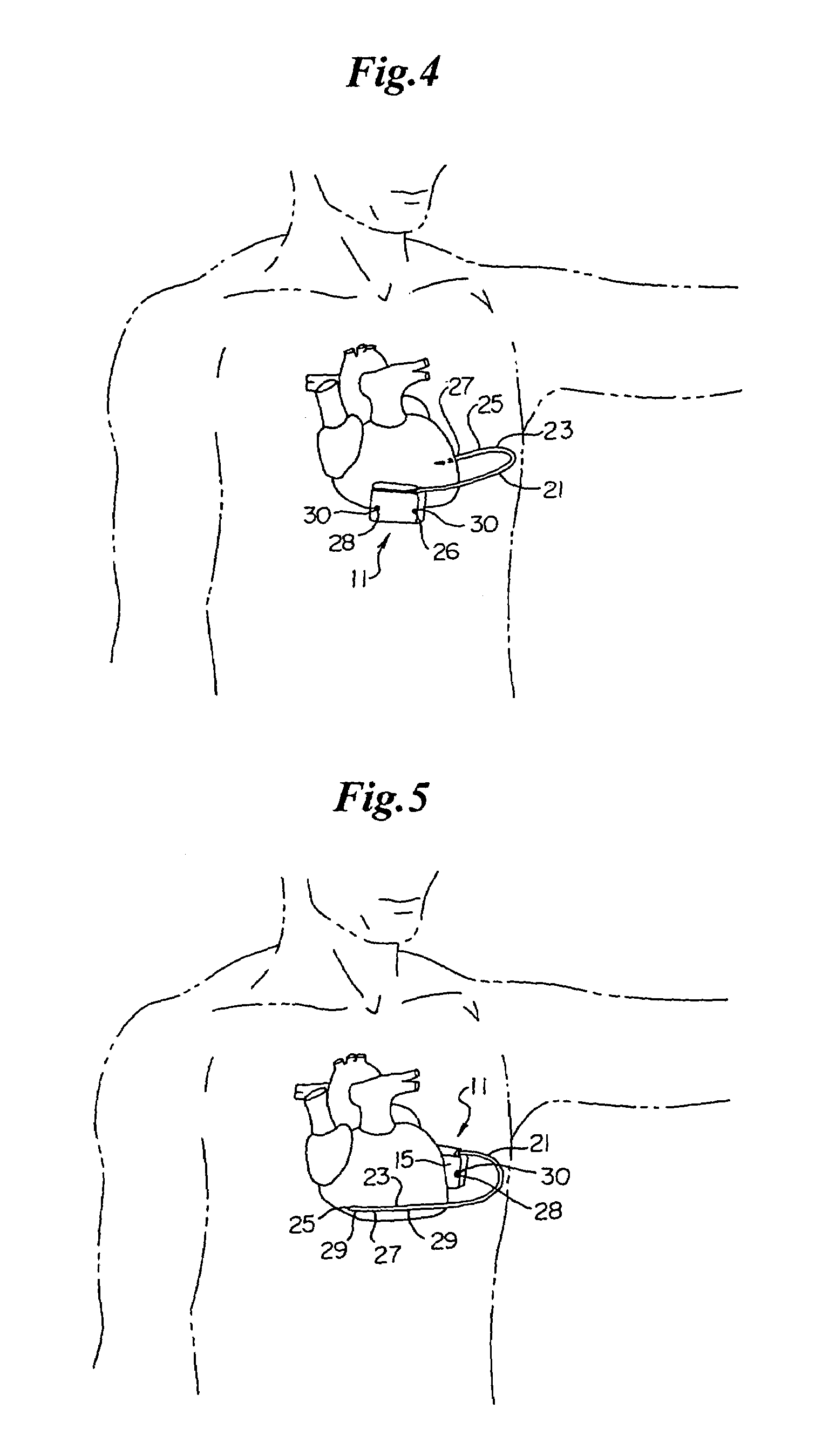

Instruments and methods for accessing an anatomic space

InactiveUS20050182465A1Convenient introductionRigid enoughStentsCannulasPericardial spaceAnatomic Site

An anatomic space of the body, particularly the pericardial space, is accessed in a minimally invasive manner from a skin incision by an access instrument to facilitate visualization and introduction of devices or drugs or other materials, performance of medical and surgical procedures, and introducing and fixating a cardiac lead electrode to the heart. An elongated access instrument body preferentially bends in one direction and resists bending in a transverse direction, whereby the access instrument body distal end can be directed through a path around body structures to the anatomic site by manipulation of the access instrument body proximal end portion. A distal header formed at the access instrument body distal end extends outward of the access instrument body in the transverse direction and supports an inflatable balloon surrounding a working lumen exit port that is directed toward an anatomic surface when the balloon is inflated by inflation media introduced through an inflation lumen.

Owner:MEDTRONIC INC

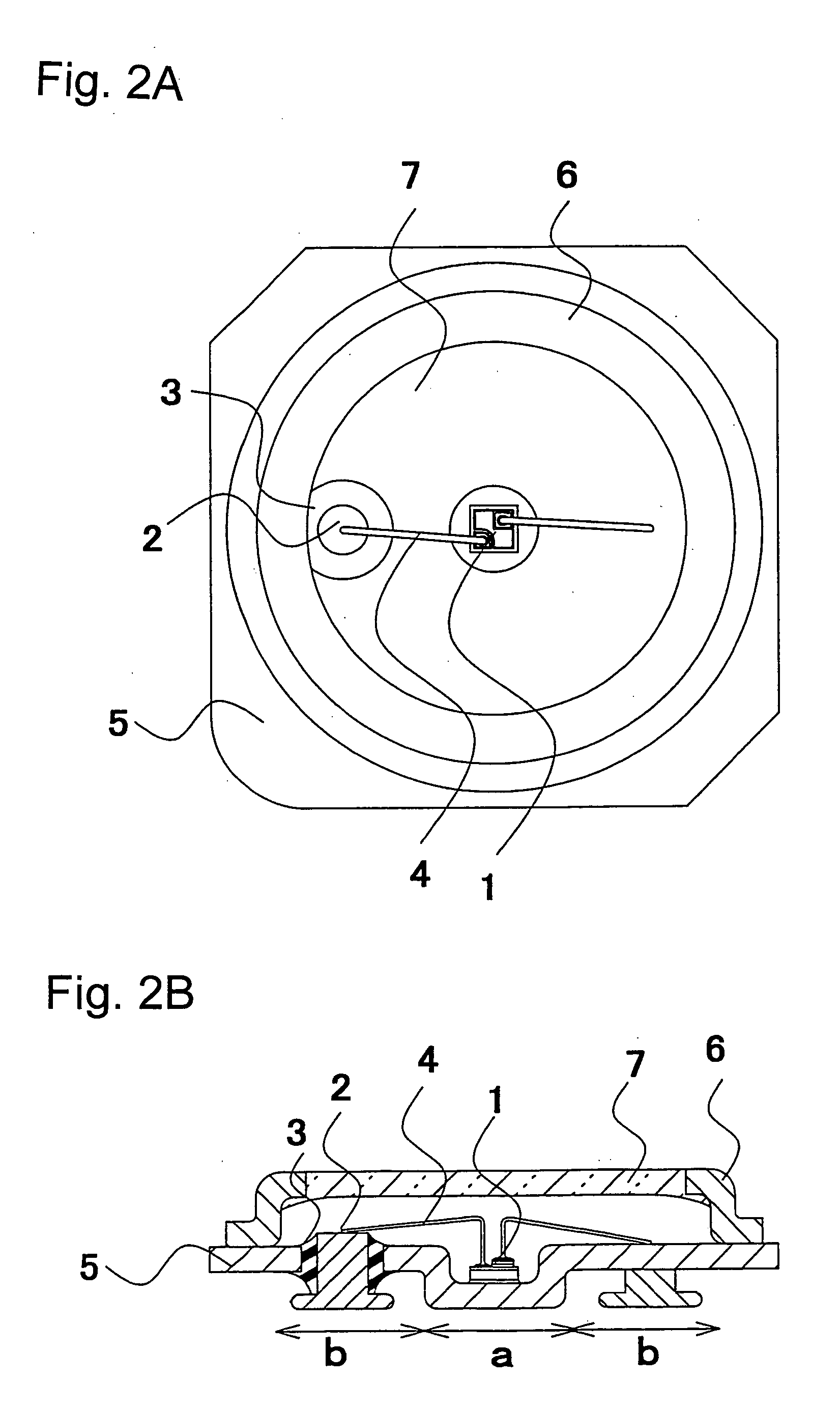

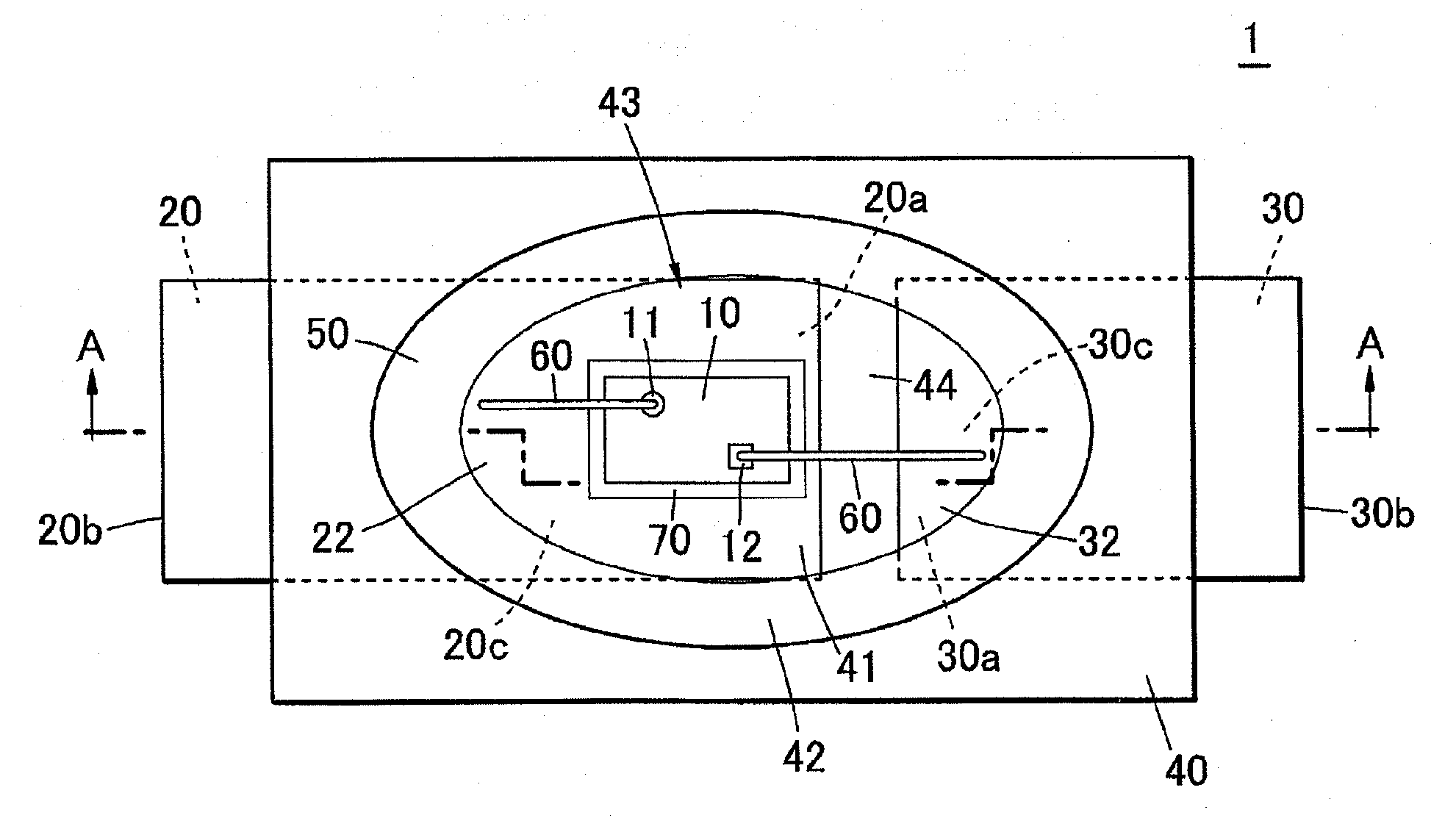

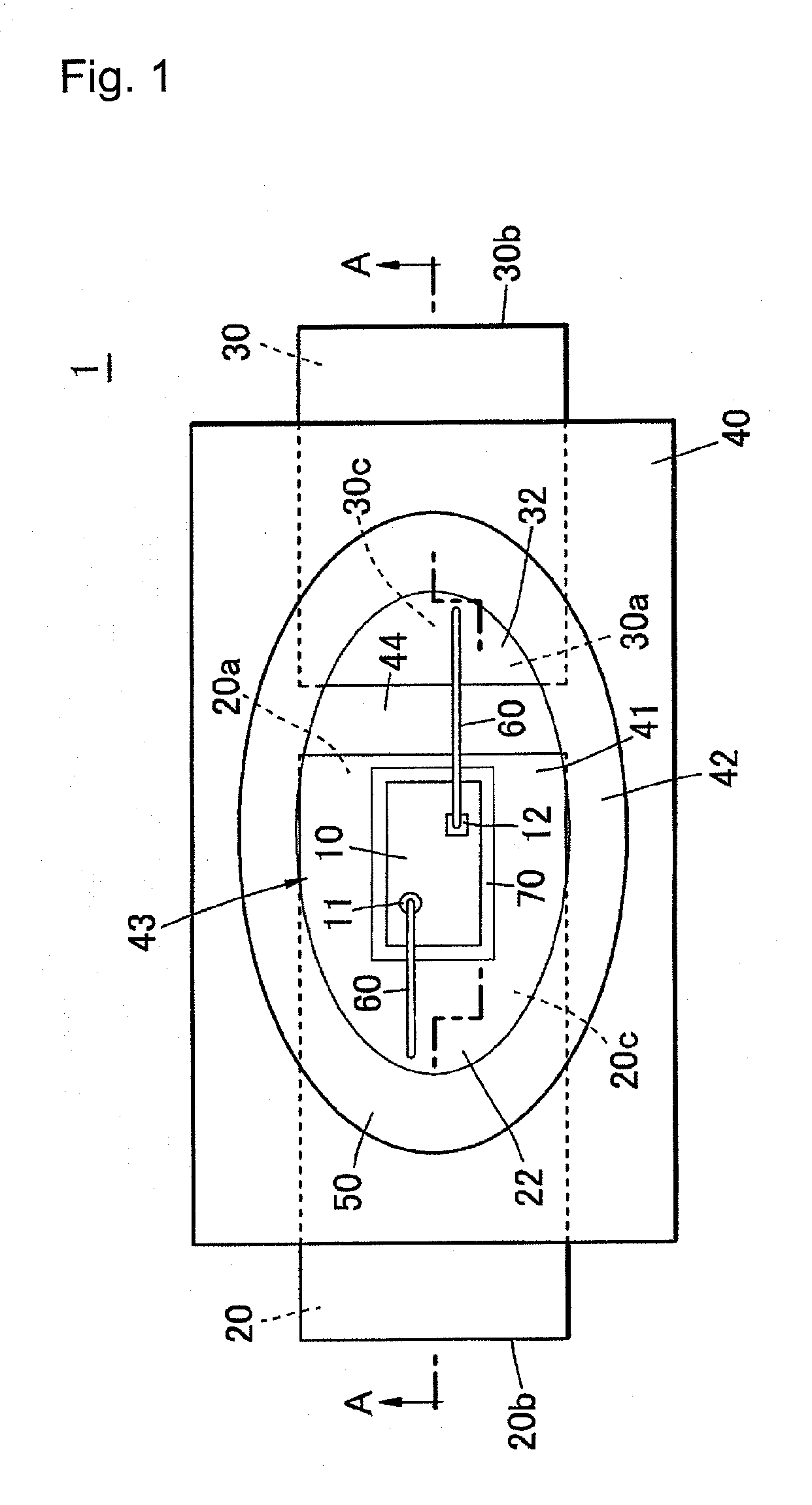

Integrated antenna type circuit apparatus

InactiveUS20060049995A1Reduce areaImprove emission efficiencyAntenna supports/mountingsPrinted electric component incorporationElectrical conductorIntegrated antenna

An integrated antenna type circuit apparatus which provides excellent circuit characteristics while suppressing an increase in packaging area. The integrated antenna type circuit apparatus includes an insulating base, a semiconductor circuit device, chip parts, a molding resin, an antenna conductor, a ground conductor, and external lead electrodes. The plurality of chip parts are mounted on the insulating base, and are soldered to electrodes of wiring conductors on the top of the insulating base for electric and physical connection. The insulating base has a multilayer structure, being formed by laminating a plurality of insulator layers. The antenna conductor is formed on the bottom of the insulating base. A wiring conductor adjacent to the antenna conductor is provided with the ground conductor so that it overlaps with the antenna conductor.

Owner:SANYO ELECTRIC CO LTD

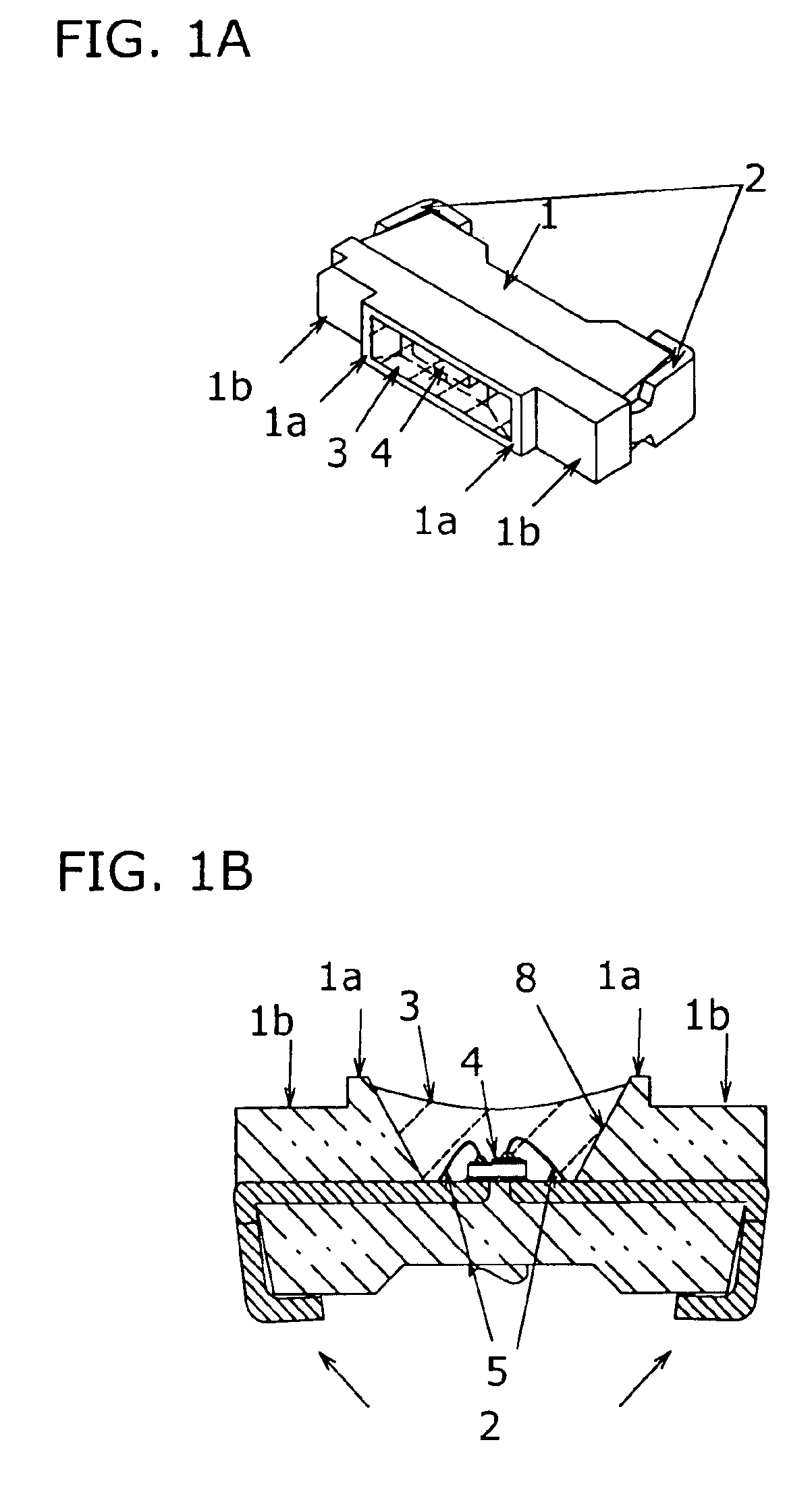

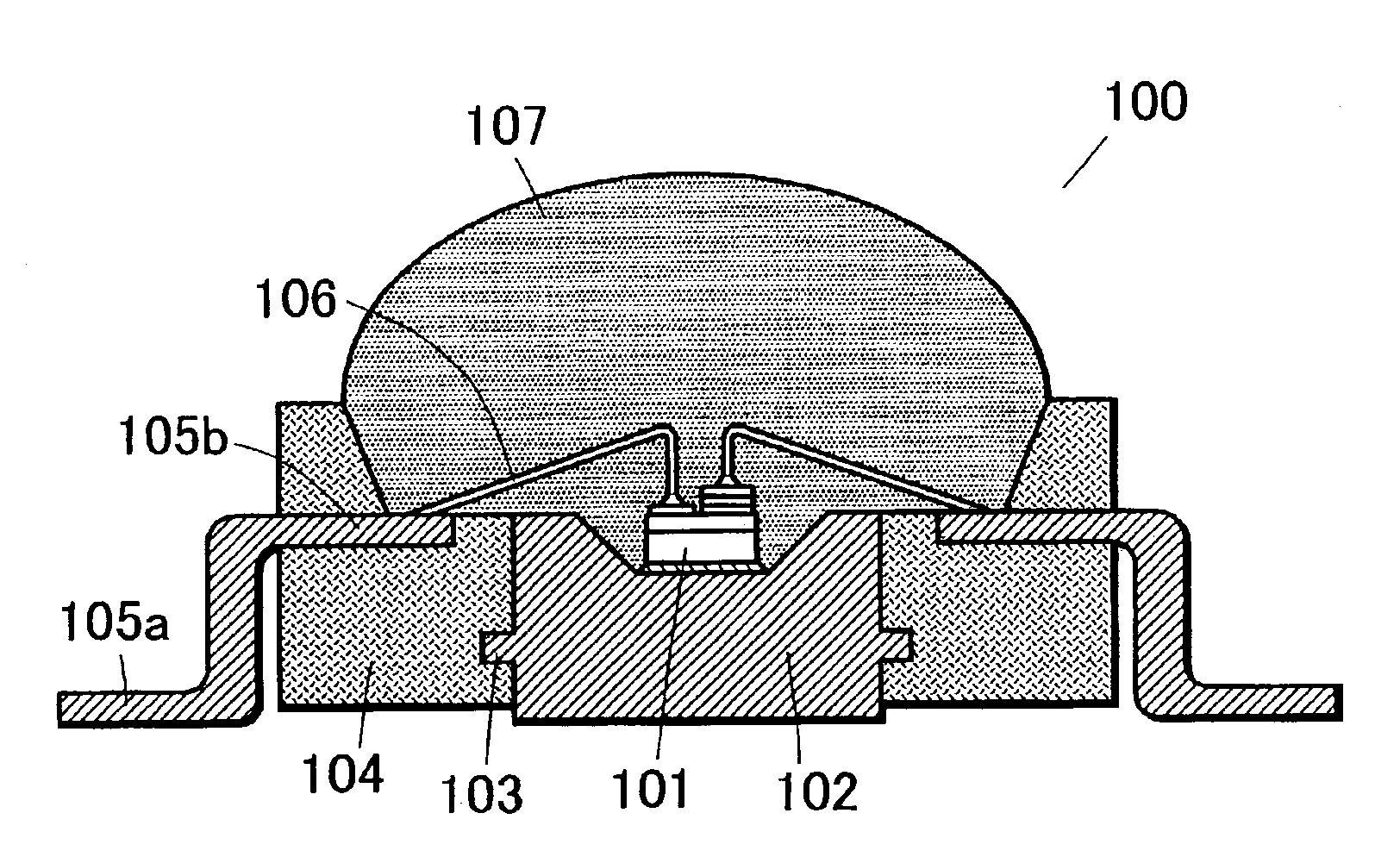

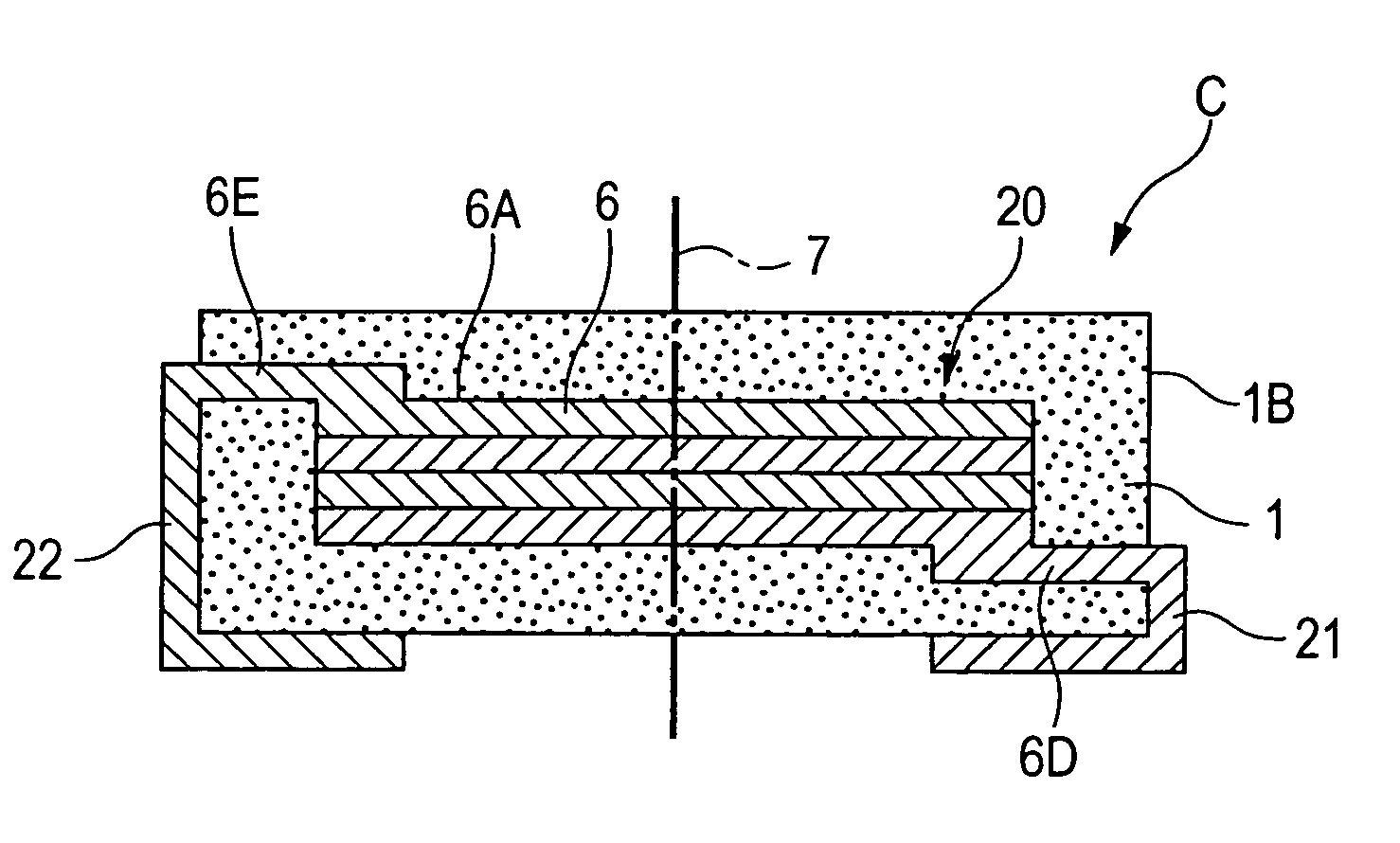

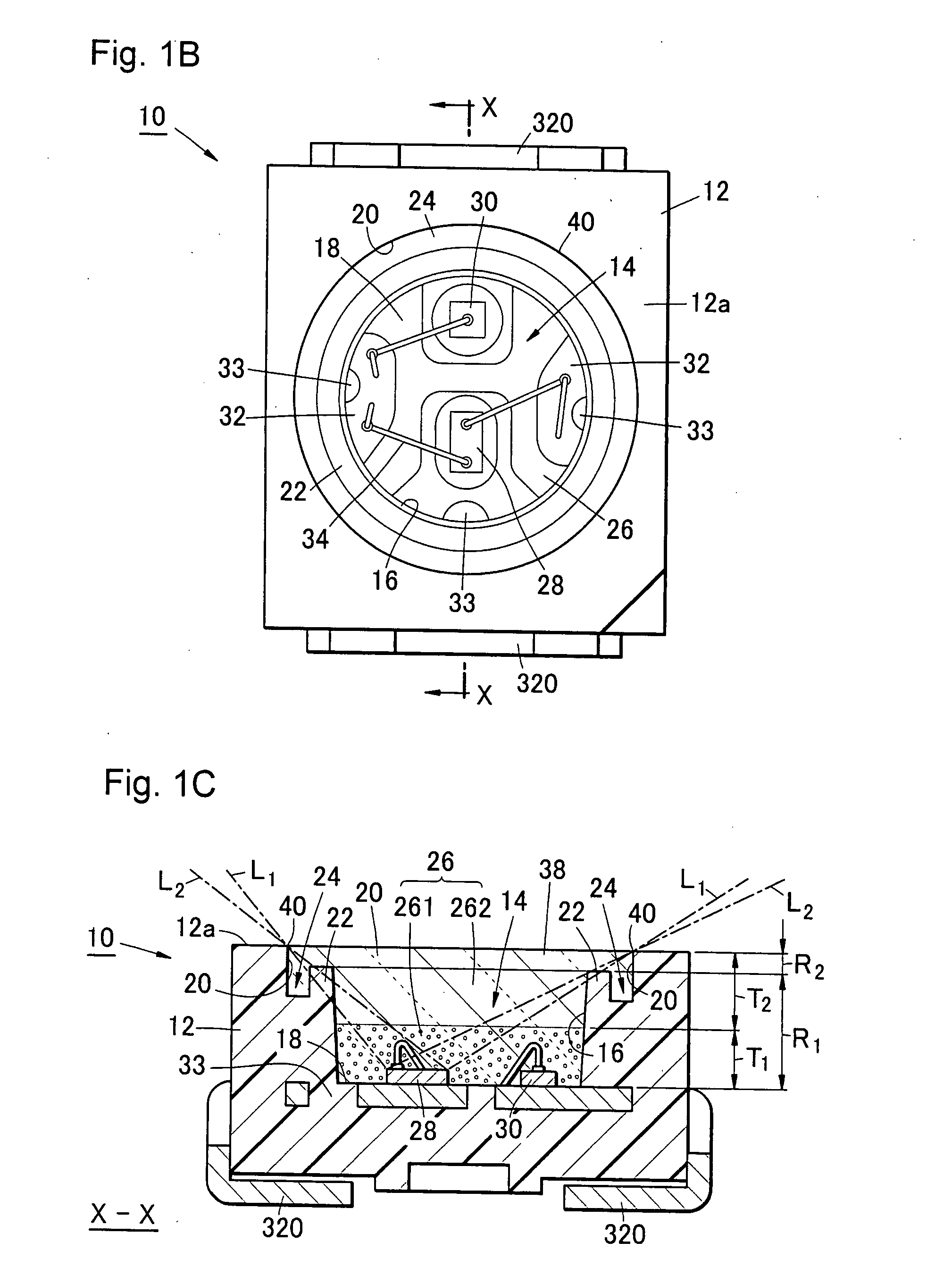

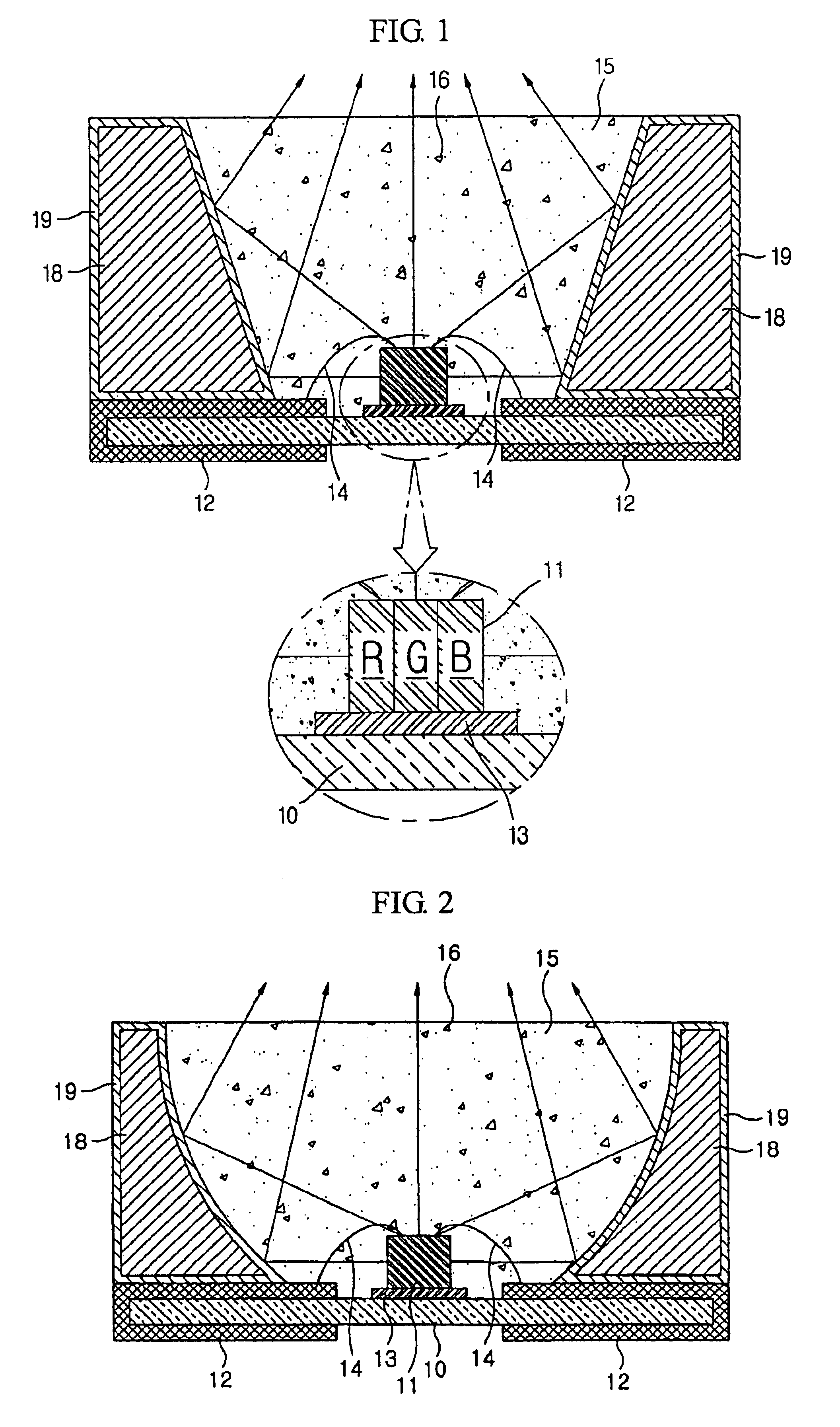

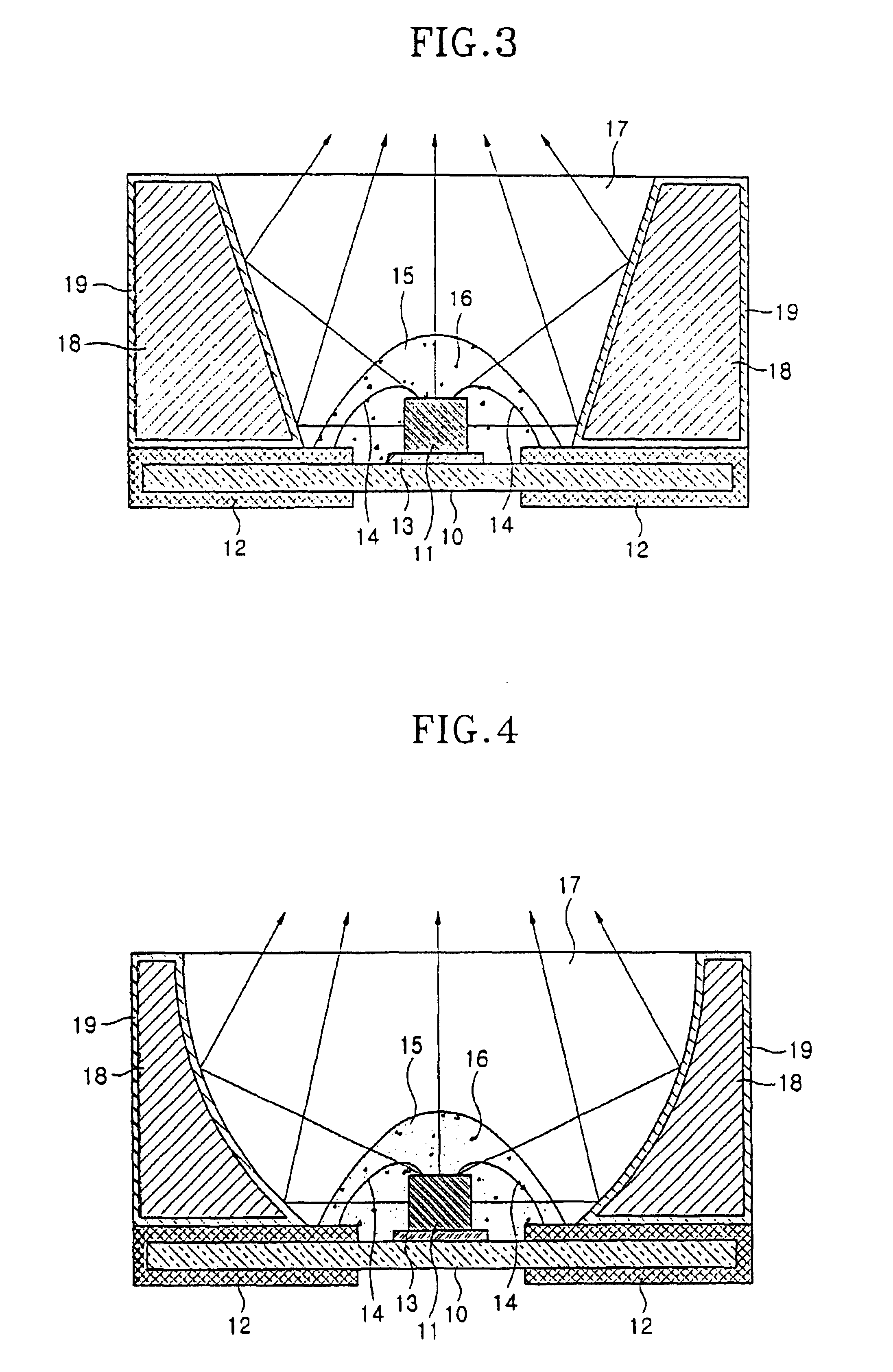

Semiconductor device and an optical device using the semiconductor device

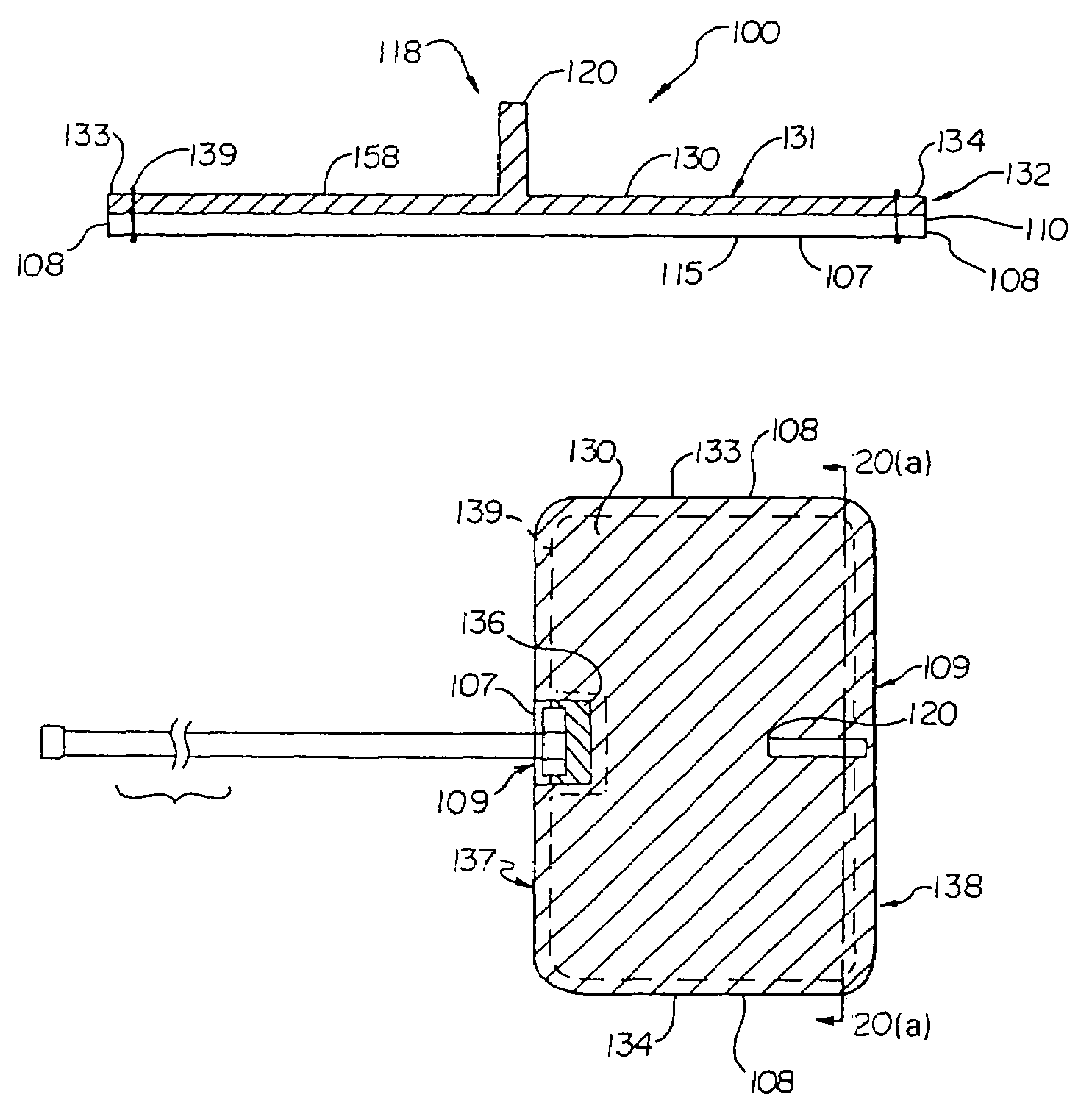

InactiveUS6953952B2Increase the rate of heatingHeat release rate downDischarge tube luminescnet screensSemiconductor/solid-state device detailsEngineeringLead electrode

A semiconductor device comprising a semiconductor element and a support member having a recess for housing the semiconductor element is disclosed. The support member includes lead electrodes and a support part holding the lead electrodes so that a surface of tip portions of the lead electrodes are exposed in a bottom of the recess. A main surface of the support member has at least a first main surface disposed adjacent to the recess and a second main surface disposed adjacent to the first main surface. The second main surface preferably has a protrusion and a further recess. The protrusion preferably forms an outer wall around a depression. The semiconductor device having this configuration has excellent and accurate positioning and can be strongly bonded with other members. The semiconductor device can also be obtained with a high process yield.

Owner:NICHIA CORP

Rotatable lead introducer

Minimally invasive introducers and methods that can be used for rotationally securing devices within the human body. Introducers can include a distal element for releasably engaging a lead head controllable from a proximal control located outside of the body. An inner stem can extend between a proximal portion and a distal portion, and be pivotally and rotatably coupled to the distal lead engagement mechanism. An outer tube can be rotatably disposed over the inner stem and be flexibly coupled over the pivot to rotationally drive the distal element. A helical epicardial-myocardial lead electrode can be secured and oriented straight ahead and introduced through a port or small incision with the introducer in a straight configuration. The introducer can then be bent and rotated to screw the helical electrode into the heart.

Owner:WILSON GREATBATCH LTD

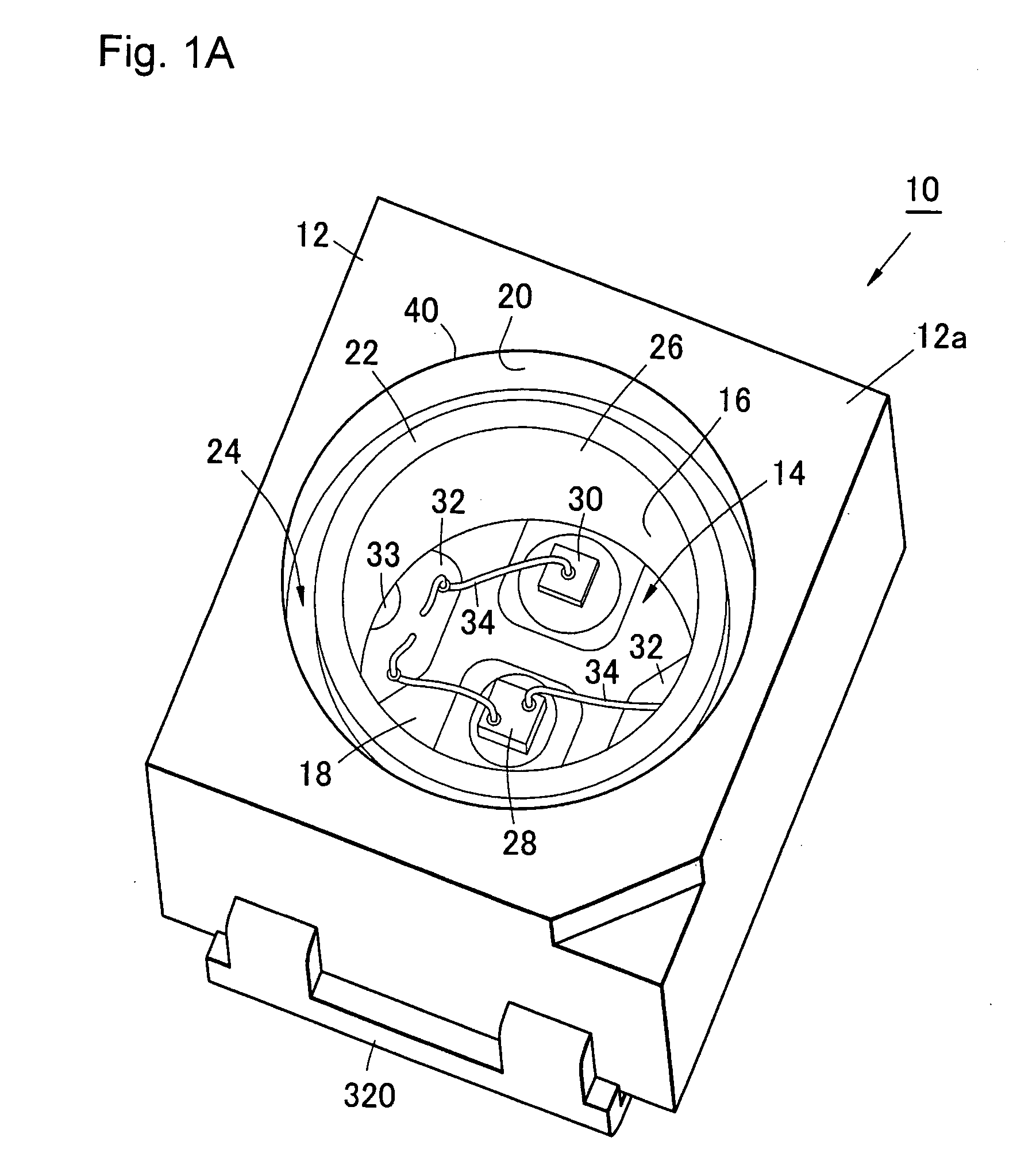

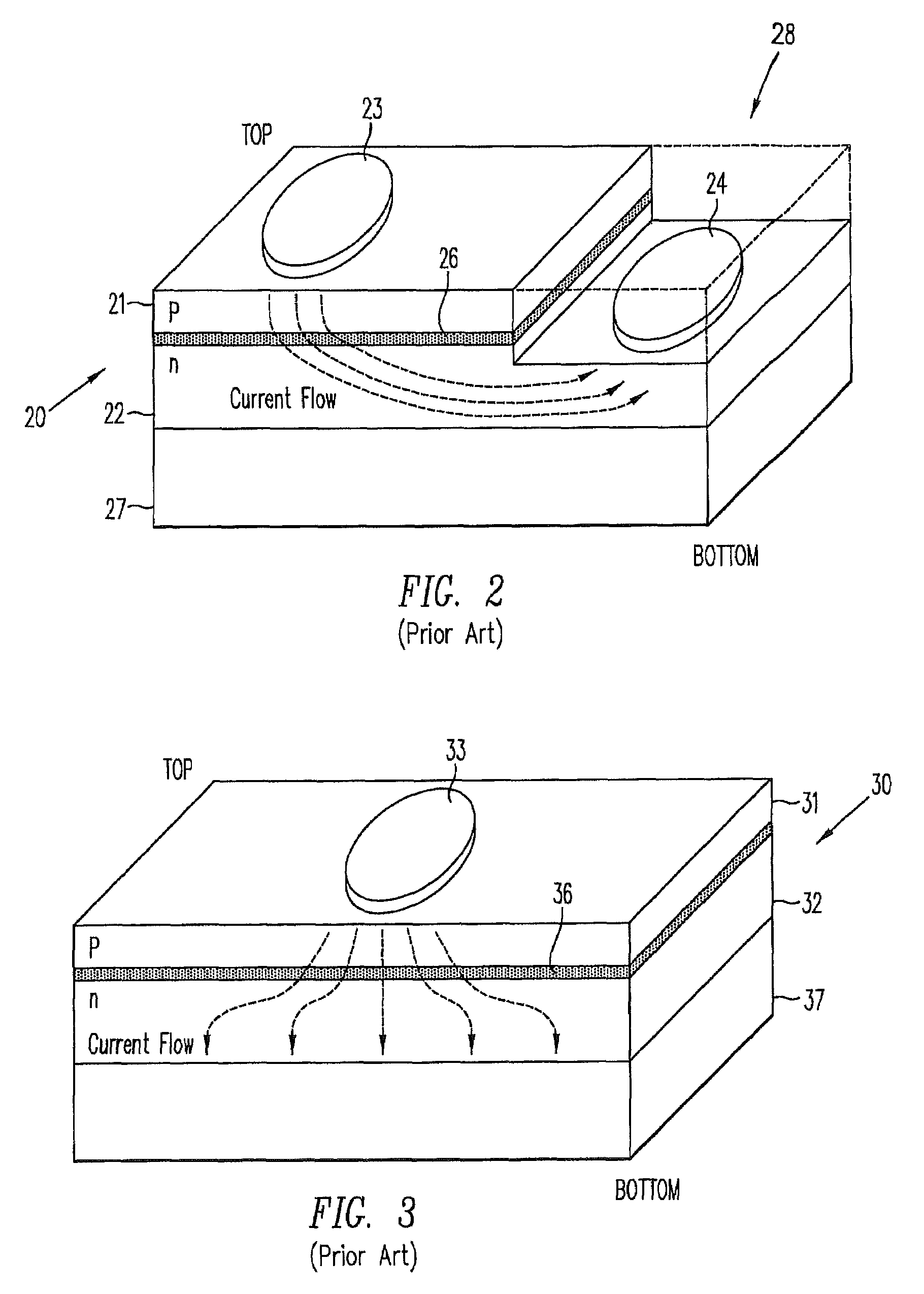

Semiconductor device and manufacturing method for same

InactiveUS6943433B2Well formedPrevent leakageSemiconductor/solid-state device detailsSolid-state devicesEngineeringLight emitting device

To provide a light emitting device having a high reliability wherein no resin burrs occur, The semiconductor device comprises a semiconductor element, a package having a recess for housing the semiconductor element and a mold member for sealing the semiconductor element in the recess and the package comprises lead electrodes and a package support part supporting the lead electrodes so that main surfaces of the tip portions of the lead electrodes are exposed from the bottom surface of the recess.

Owner:NICHIA CORP

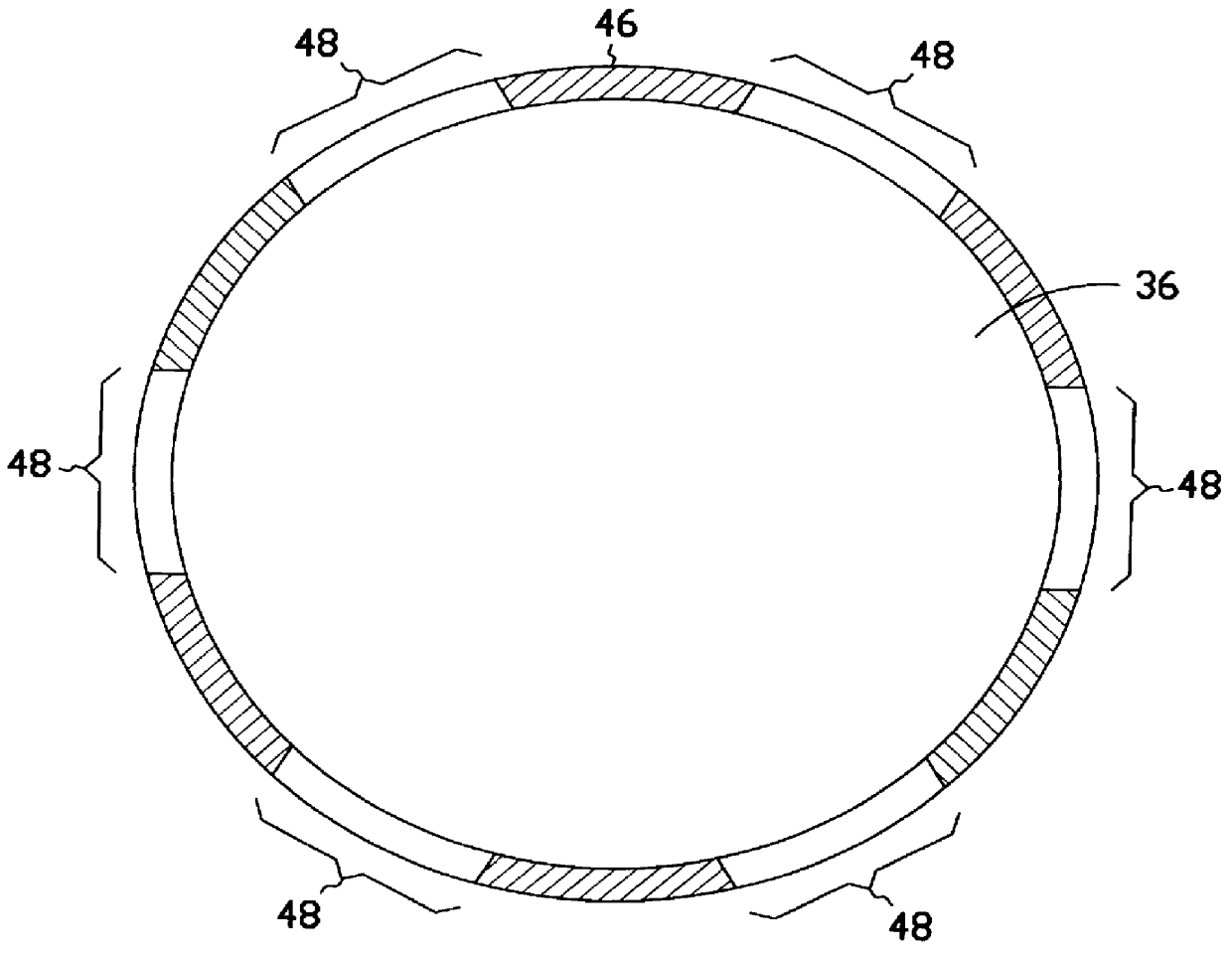

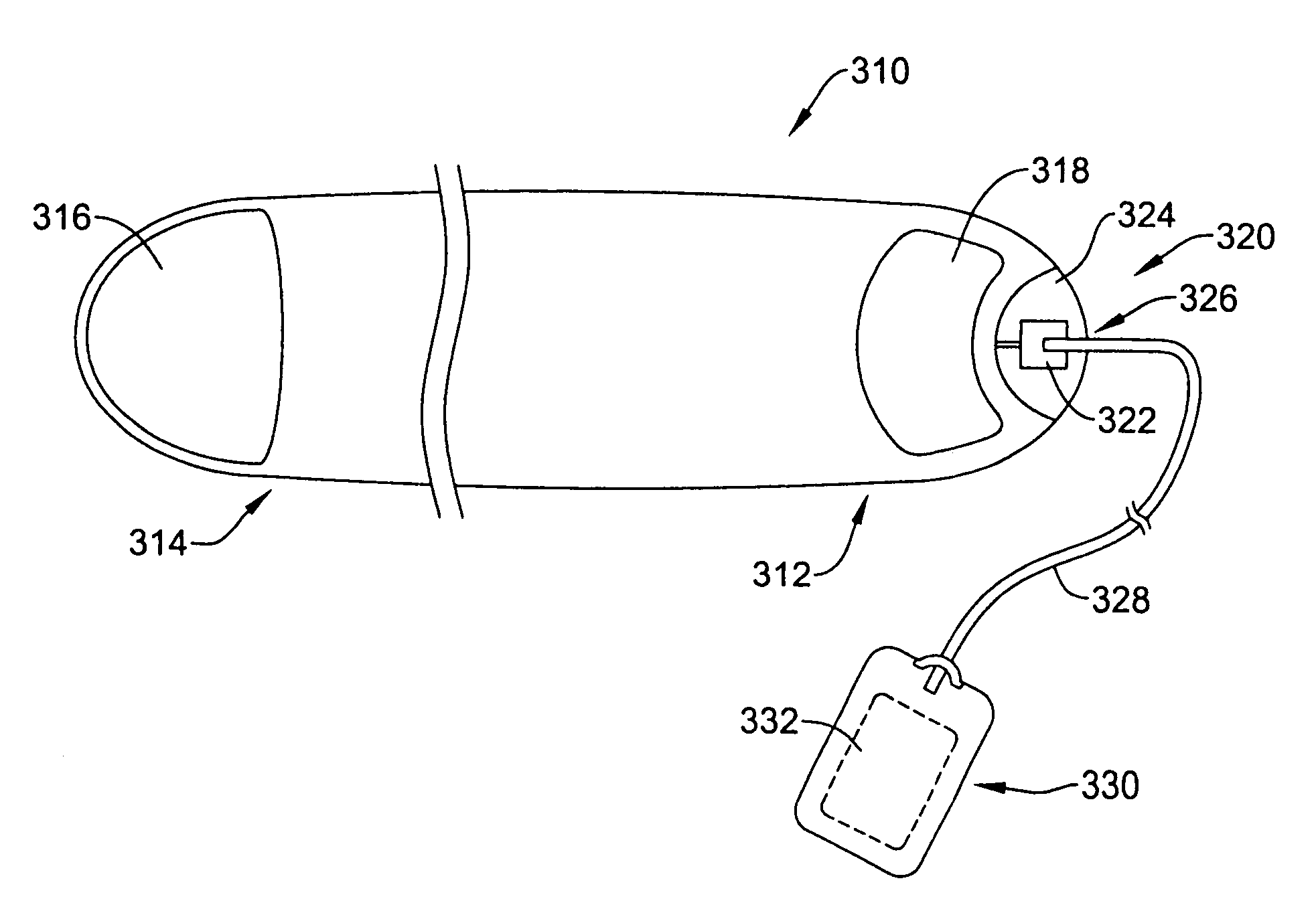

Subcutaneous electrode with improved contact shape for transthorasic conduction

One embodiment of the present invention provides a lead electrode assembly for use with an implantable cardioverter-defibrillator subcutaneously implanted outside the ribcage between the third and twelfth ribs comprising the electrode.

Owner:CAMERON HEALTH

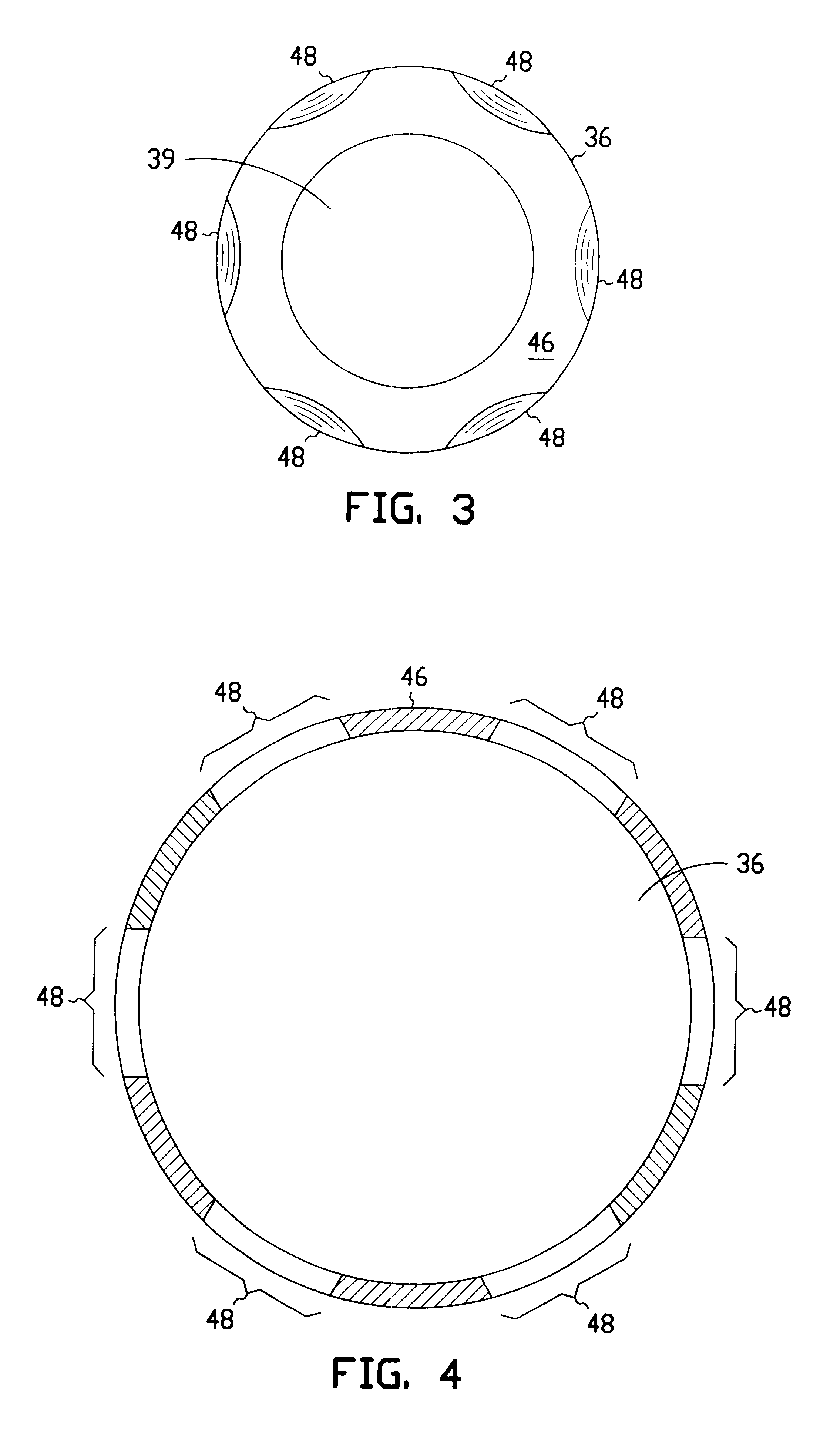

Method for making cardiac leads with zone insulated electrodes

An electrode for a cardiac lead and method of making the same are provided. The electrode includes an electrode member and a coating applied to the electrode member. A method of fabricating a high impedance cardiac lead electrode is provided. The method includes the steps of providing an electrode member and coating a first portion of the electrode member with an electrically insulating material and placing a tubular mask or shield over the electrode. Portions of the insulating material are removed to expose selected areas of the electrode. The second or exposed portion enhances the impedance of the electrode, resulting in power savings and extended life spans for implantable stimulation and sensing devices. Exemplary materials for the coating includes diamond-like carbon and sapphire.

Owner:INTERMEDICS

Light-emitting apparatus

InactiveUS20040120155A1Improve reliabilityImprove productivityMeasurement apparatus componentsVehicle interior lightingEngineeringLight emitting device

A light emitting device comprises a light emitting element, a metal package having a recess part for housing the light emitting element and a base part which has one or more through holes, one or more lead electrode pins which penetrate the through holes and are separated from the through holes by a insulating member respectively, wherein the bottom faces of the lead electrode pins project out from the bottom face of the base part and positioned on a same plane including a outer bottom face of the recess part. With this configuration, the light emitting device which has a good heat radiating characteristic and high mechanical strength.

Owner:NICHIA CORP

Implantable cardioverter-defibrillator having two spaced apart shocking electrodes on housing

InactiveUS6988003B2Heart defibrillatorsHeart stimulatorsThoracic cavityImplantable cardioverter-defibrillator

One embodiment of the present invention provides an implantable cardioverter-defibrillator for subcutaneous positioning over a patient's ribcage, the implantable cardioverter-defibrillator includes a housing having a first end and a second end; a first electrode disposed upon the first end of the housing; a second electrode disposed upon the second end of the housing; an electrical circuit located within the housing, wherein the electrical circuit is electrically coupled to the first electrode and the second electrode; and a lead electrode electrically coupled to the electrical circuit located within the housing.

Owner:CAMERON HEALTH

Method for making cardiac leads with zone insulated electrodes

InactiveUS6526321B1Internal electrodesDiagnostic recording/measuringDiamond-like carbonBiomedical engineering

An electrode for a cardiac lead and method of making the same are provided. The electrode includes an electrode member and a coating applied to the electrode member. A method of fabricating a high impedance cardiac lead electrode is provided. The method includes the steps of providing an electrode member and coating a first portion of the electrode member with an electrically insulating material and placing a tubular mask or shield over the electrode. Portions of the insulating material are removed to expose selected areas of the electrode. The second or exposed portion enhances the impedance of the electrode, resulting in power savings and extended life spans for implantable stimulation and sensing devices. Exemplary materials for the coating includes diamond-like carbon and sapphire.

Owner:INTERMEDICS

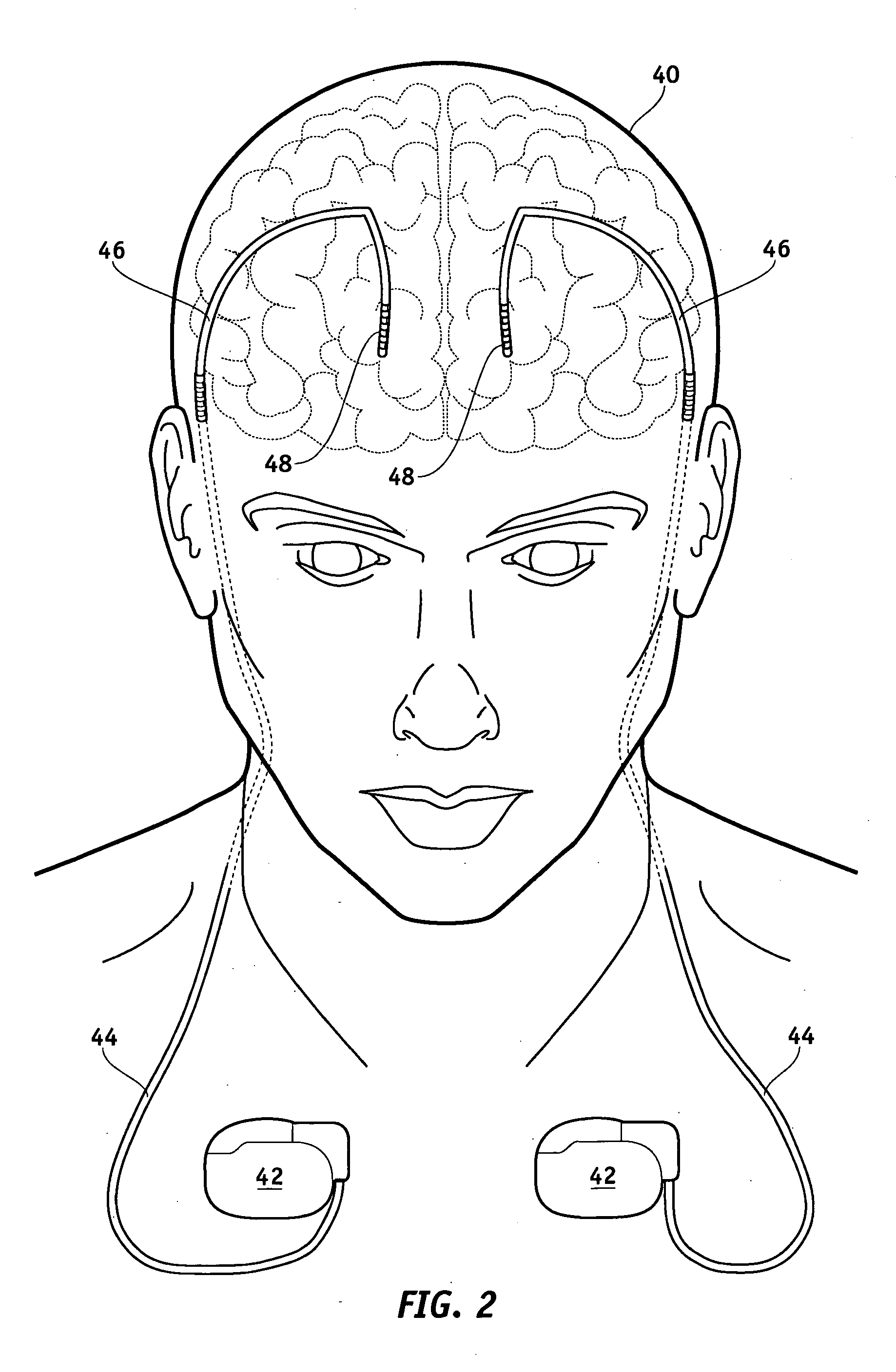

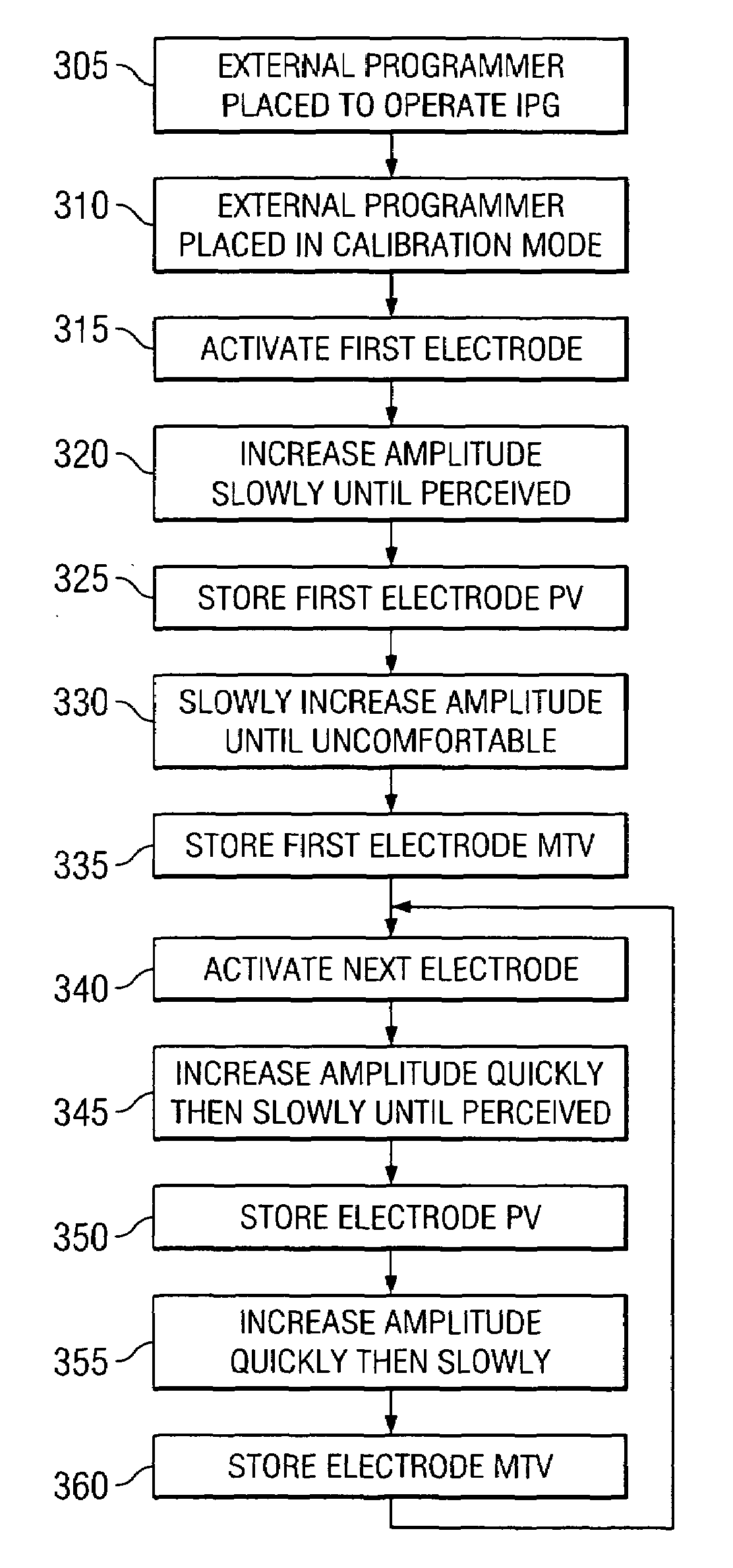

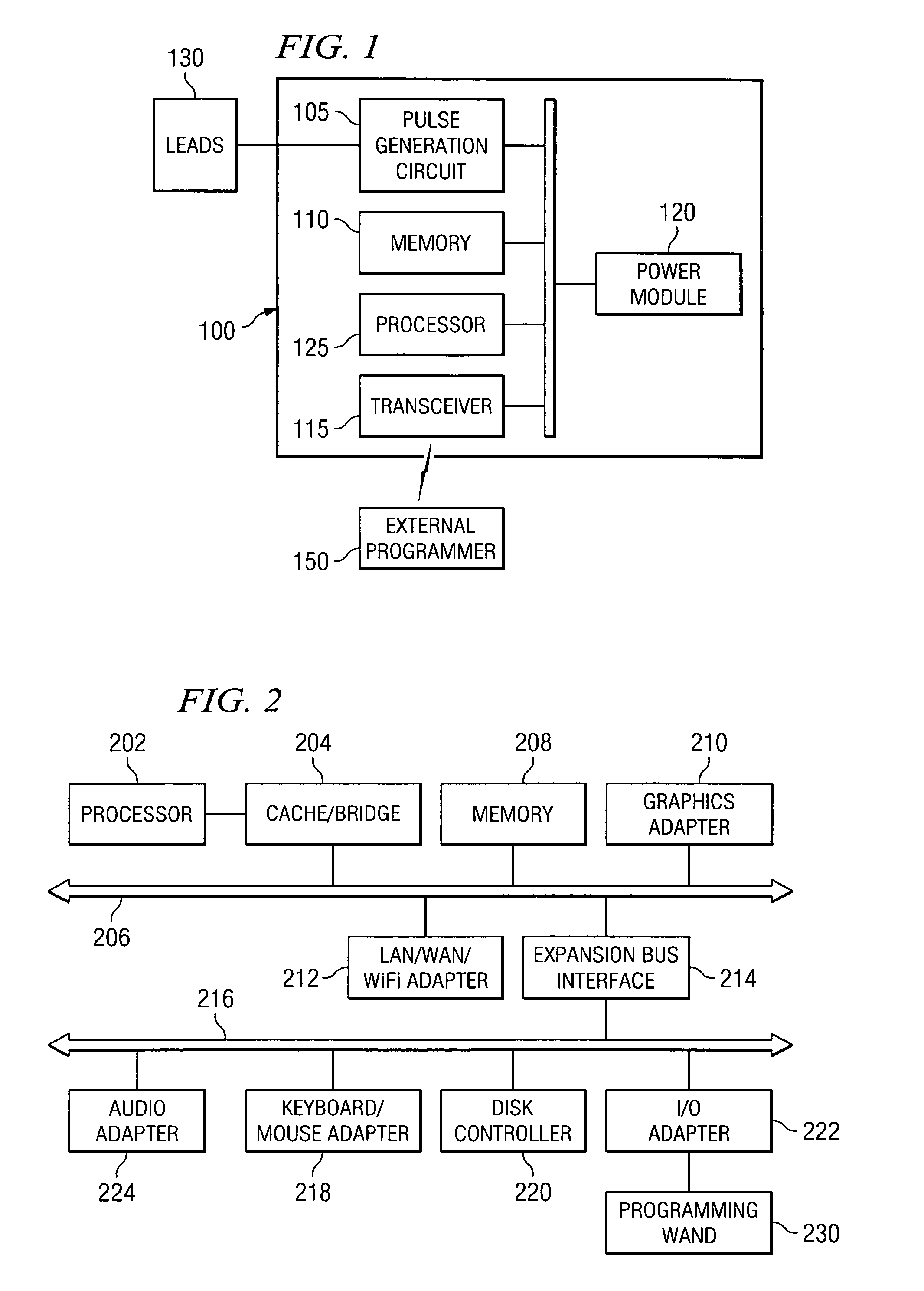

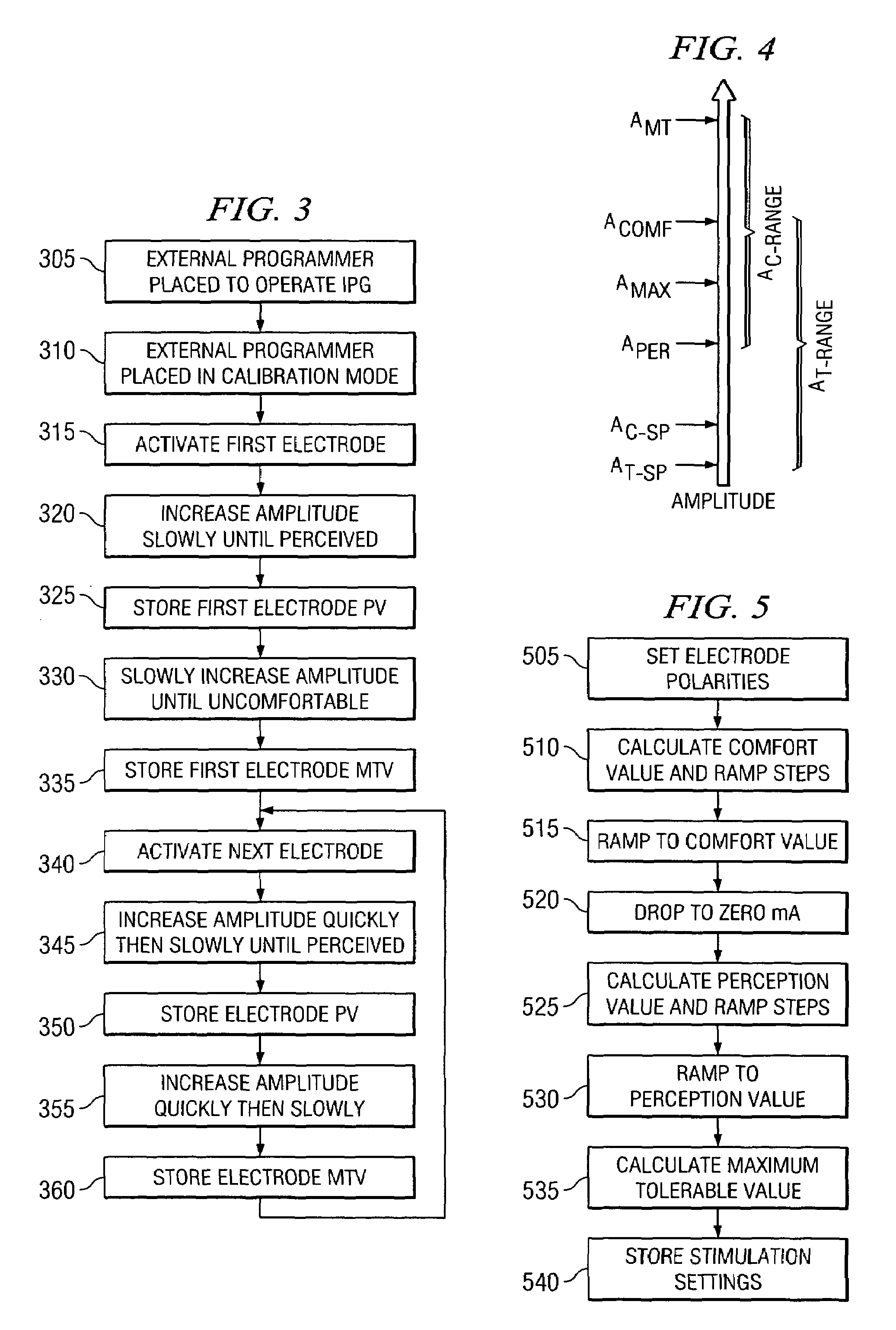

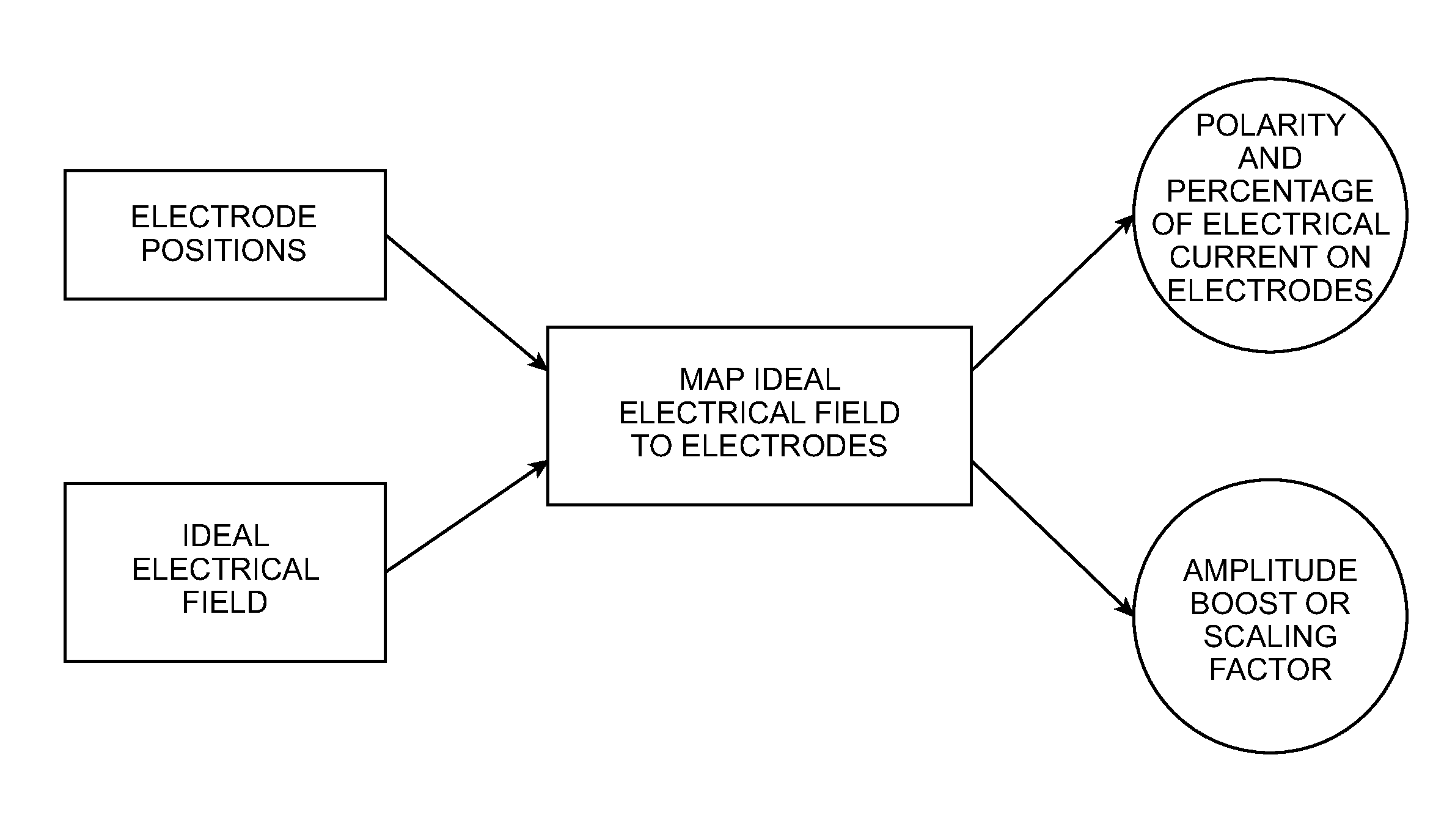

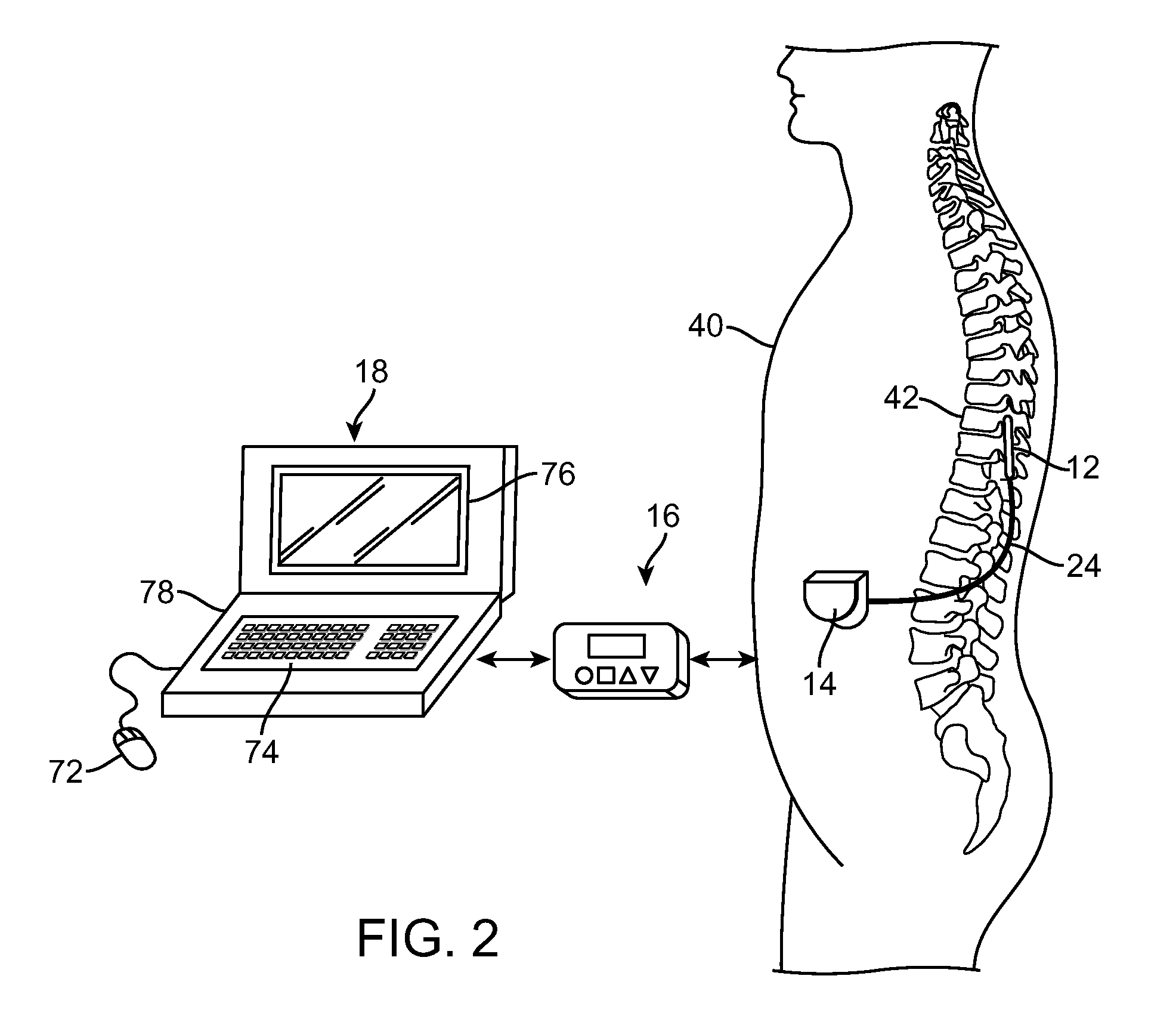

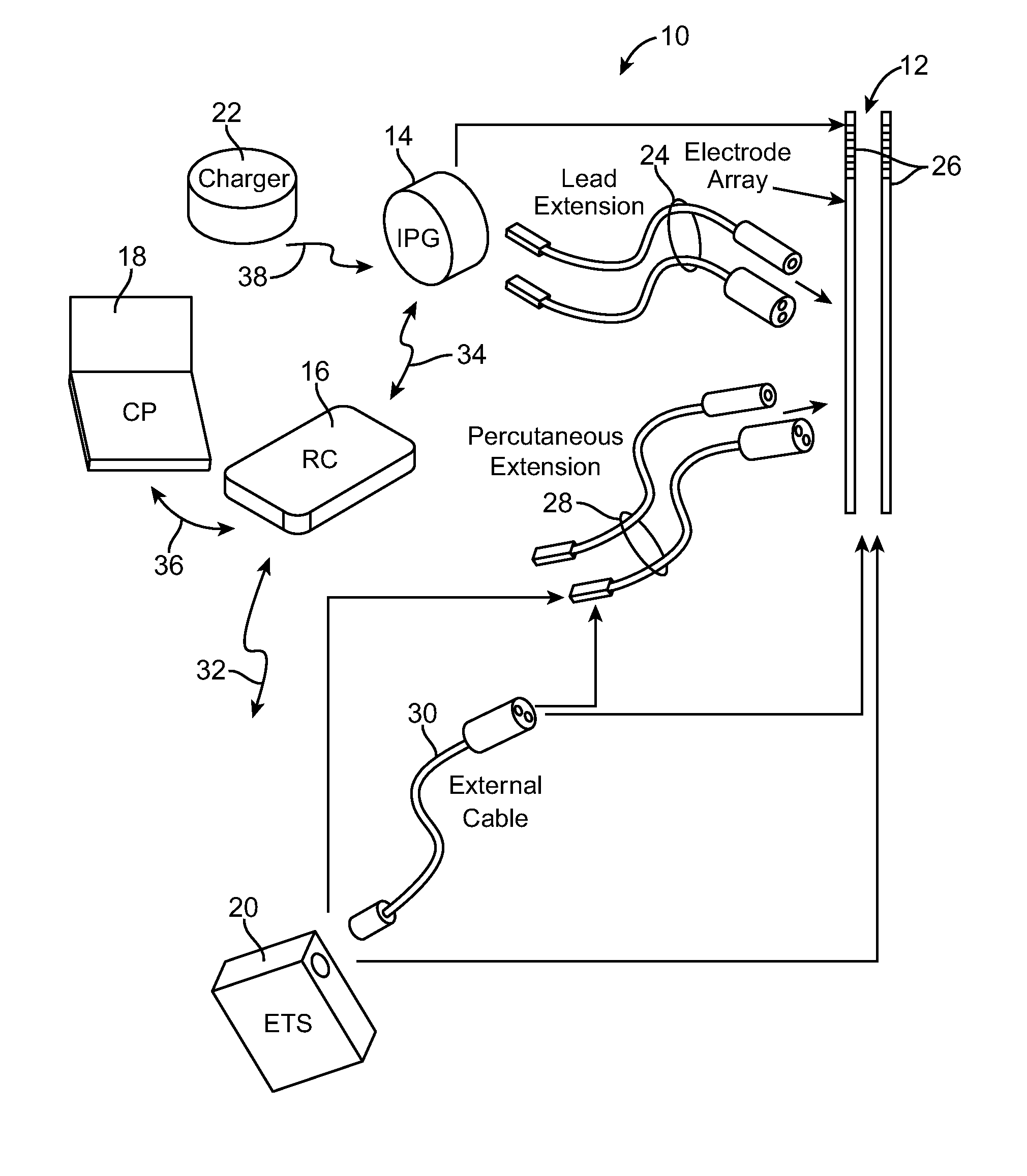

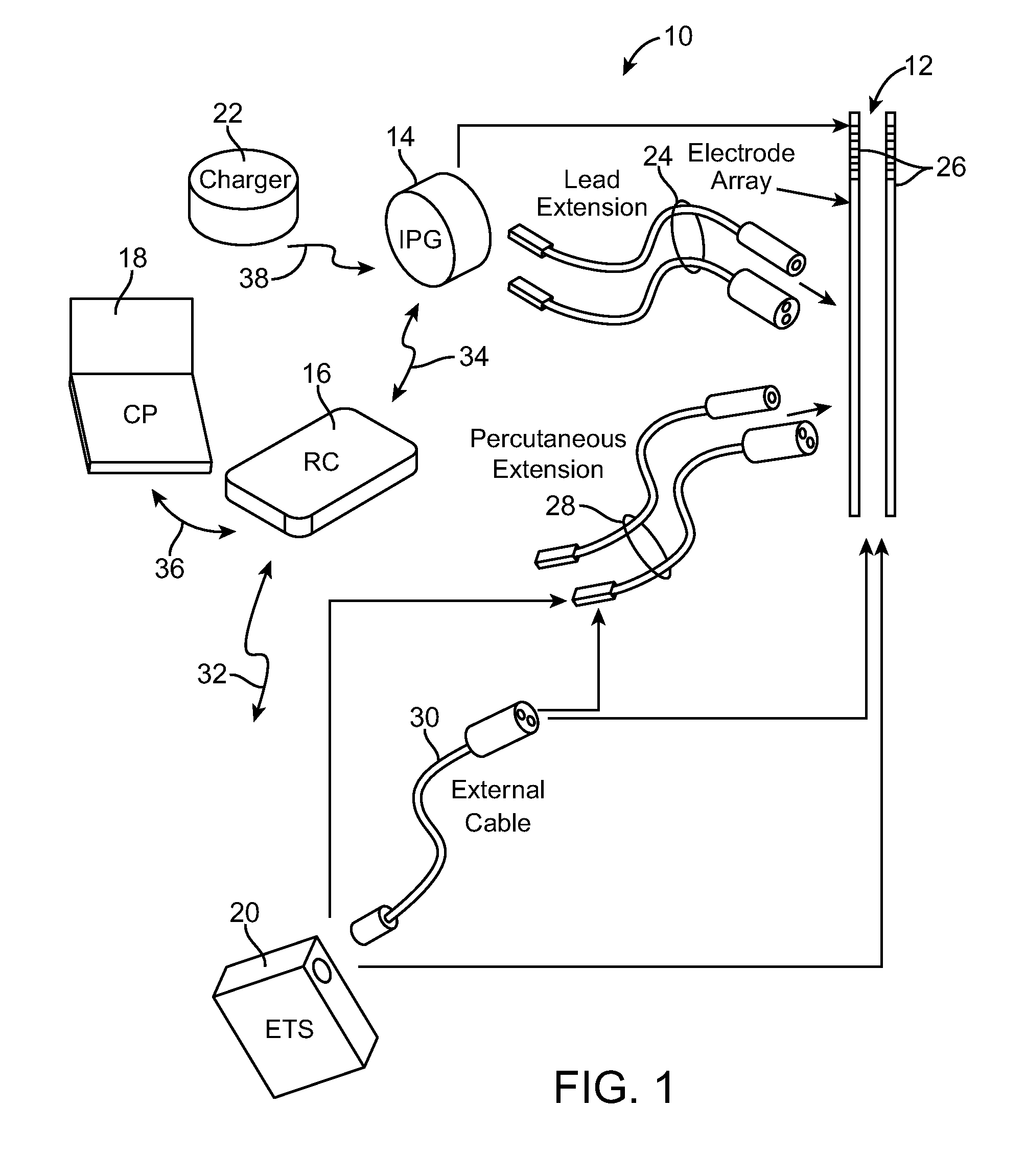

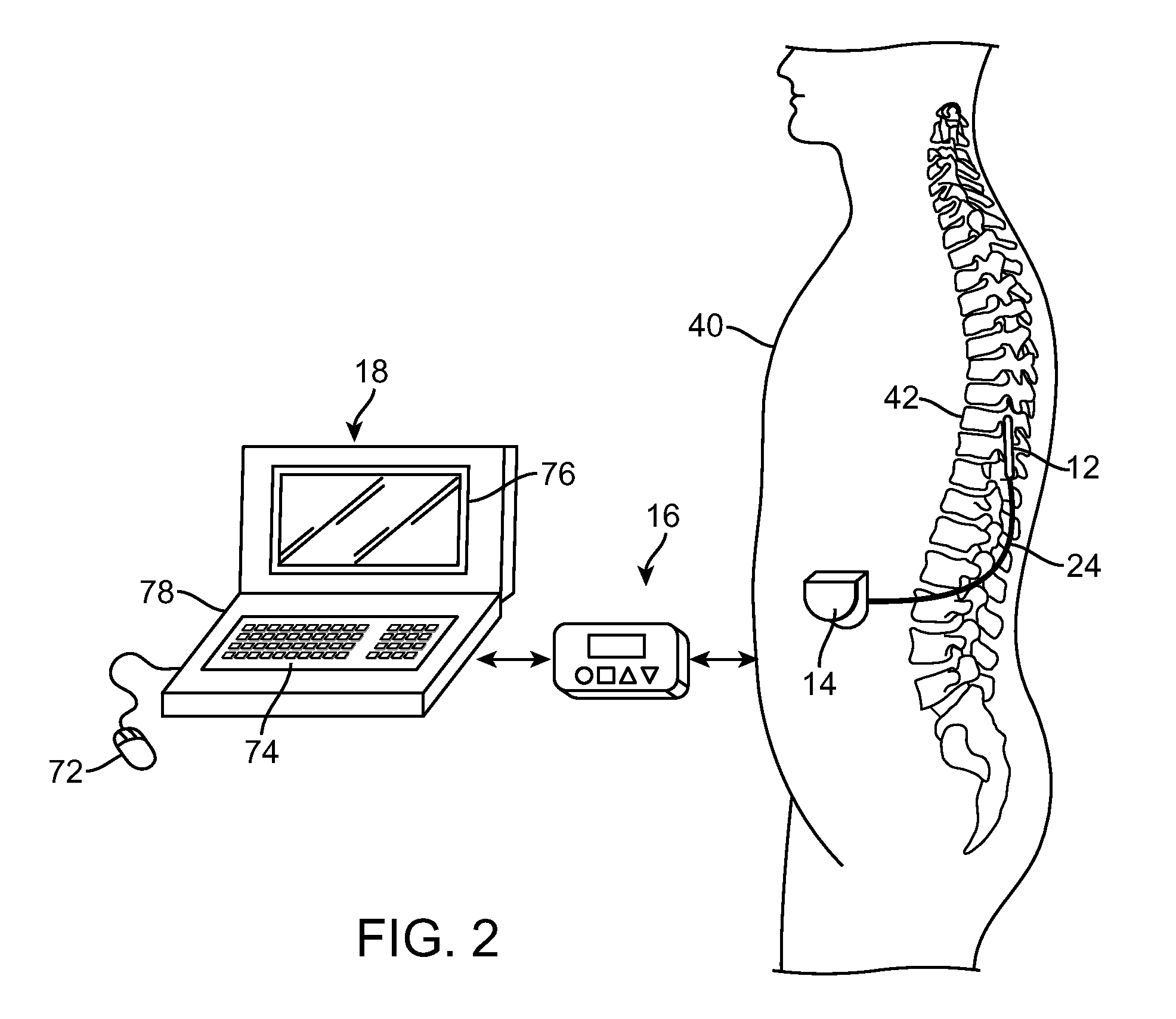

System and method for stimulus calibration for an implantable pulse generator

A system, method, and computer program product for calibrating a stimulation device such as an implantable pulse generator (IPG). An IPG, whether it is a self-contained implantable pulse generator (SCIPG) or externally-powered implantable pulse generator (EPIPG), communicates with an external programmer to determine the characteristics of the stimuli delivered to the lead electrodes. An external programmer is used with patient feedback to determine initial threshold levels, and using the initial threshold levels, to determine threshold levels for combined electrode arrays.

Owner:ADVANCED NEUROMODULATION SYST INC

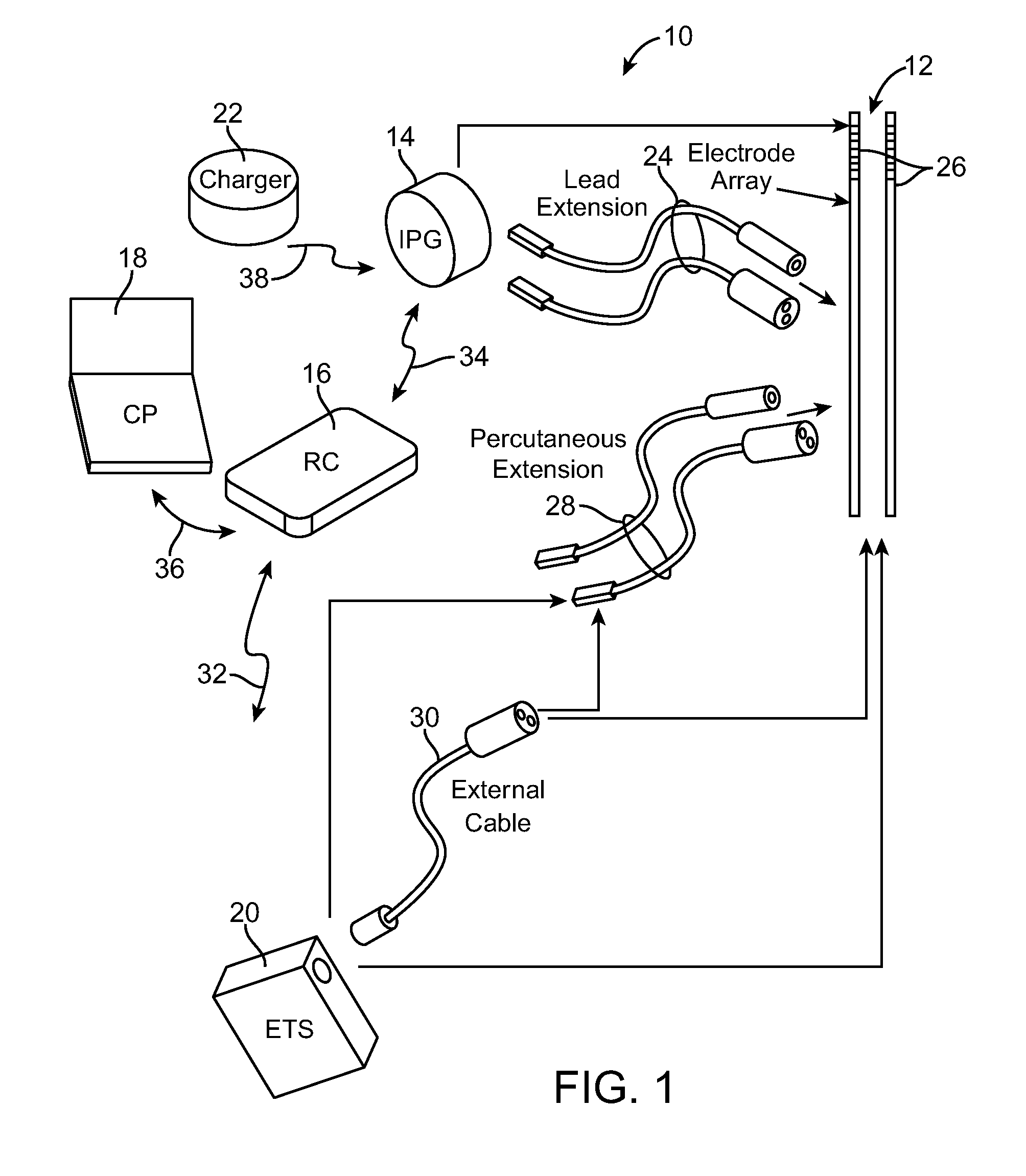

System and method for mapping arbitrary electric fields to pre-existing lead electrodes

A method and system for stimulating tissue using a plurality of electrodes is provided. Desired electrical parameter (e.g., field potential) values are determined at a plurality of spatial points. A plurality of constituent current sources is selected at the locations of the electrodes. The relative strengths of the constituent current sources that, when combined, result in estimated electrical parameter (e.g., field potential)|values at the spatial points that best matches the desired electrical parameter values at the spatial points are determined. The polarity and percentage of electrical current to be associated with each of the electrodes is selected based on the determined strengths of the constituent current sources. Electrical current is conveyed through the plurality of electrodes in accordance with the selected electrical current magnitudes to stimulate the tissue.

Owner:BOSTON SCI NEUROMODULATION CORP

System and method for mapping arbitrary electric fields to pre-existing lead electrodes

ActiveUS20110106215A1Medical simulationPhysical therapies and activitiesElectricityElectrical polarity

A method and system for stimulating tissue using a plurality of electrodes is provided. Desired electrical parameter (e.g., field potential) values are determined at a plurality of spatial points. A plurality of constituent current sources is selected at the locations of the electrodes. The relative strengths of the constituent current sources that, when combined, result in estimated electrical parameter (e.g., field potential)|values at the spatial points that best matches the desired electrical parameter values at the spatial points are determined. The polarity and percentage of electrical current to be associated with each of the electrodes is selected based on the determined strengths of the constituent current sources. Electrical current is conveyed through the plurality of electrodes in accordance with the selected electrical current magnitudes to stimulate the tissue.

Owner:BOSTON SCI NEUROMODULATION CORP

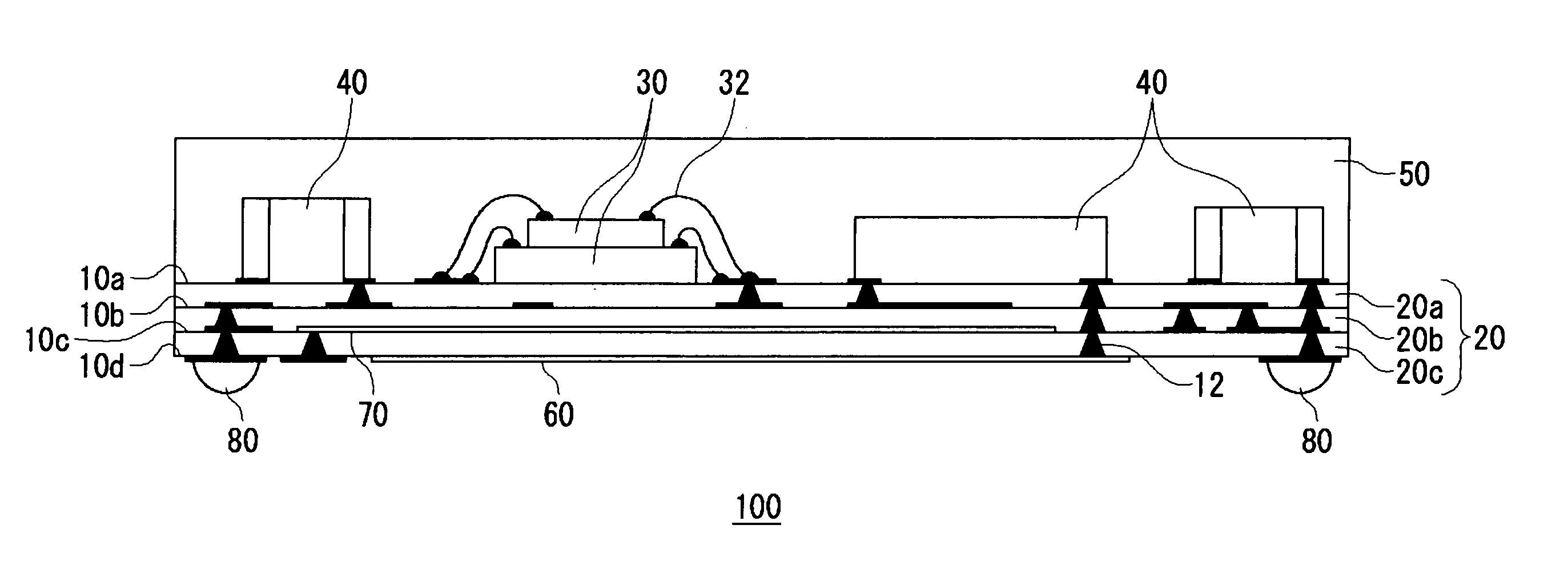

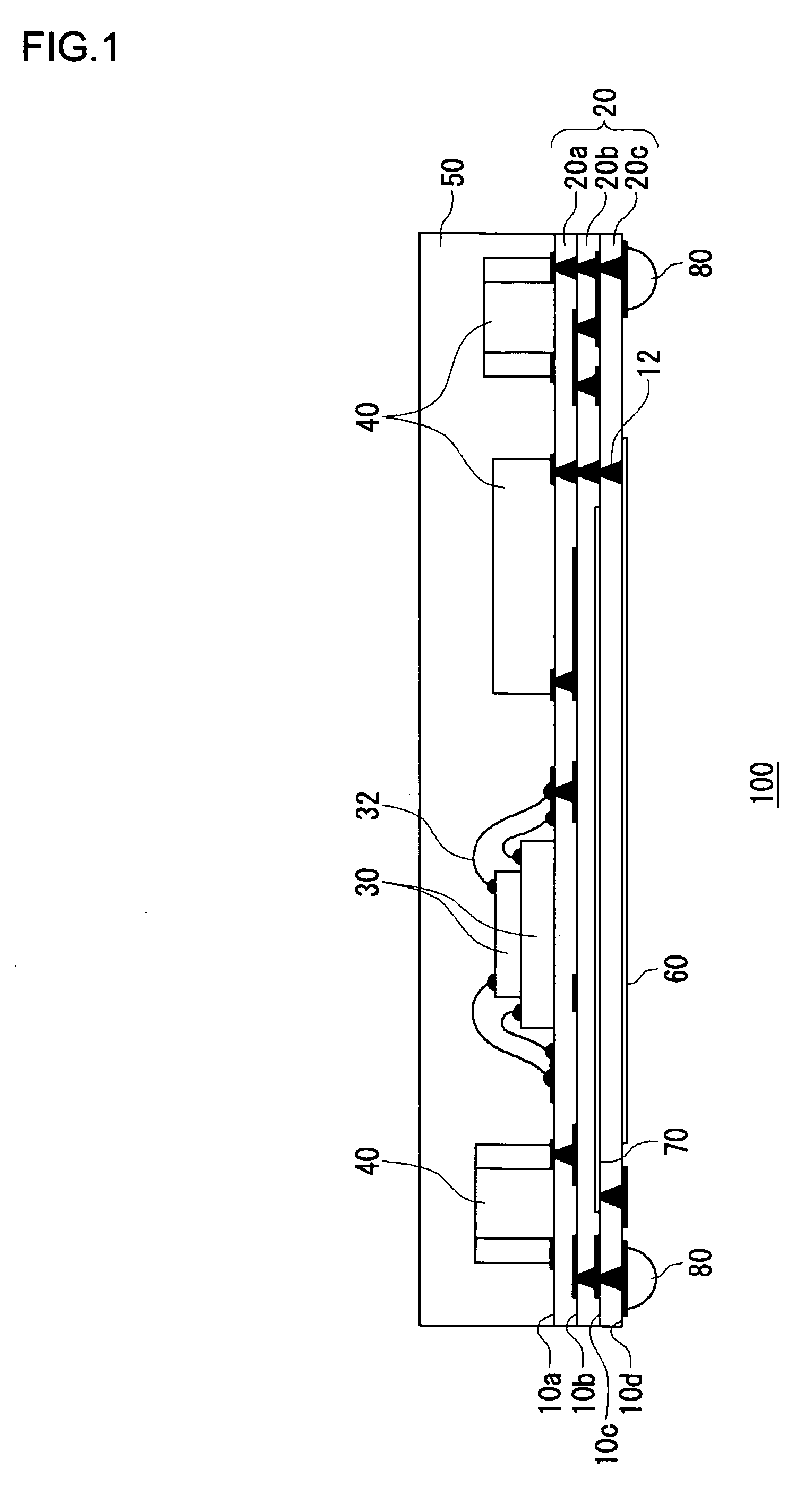

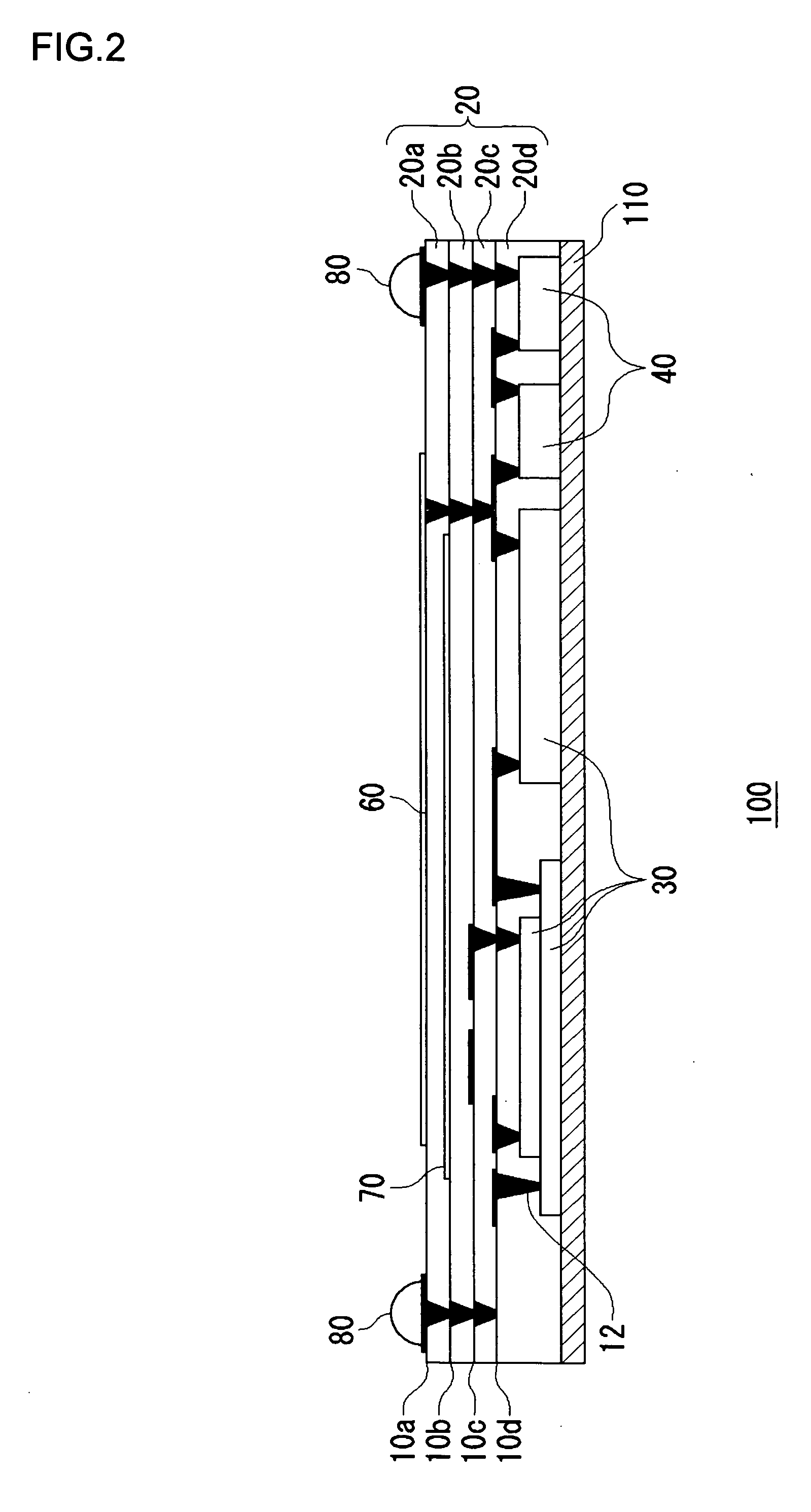

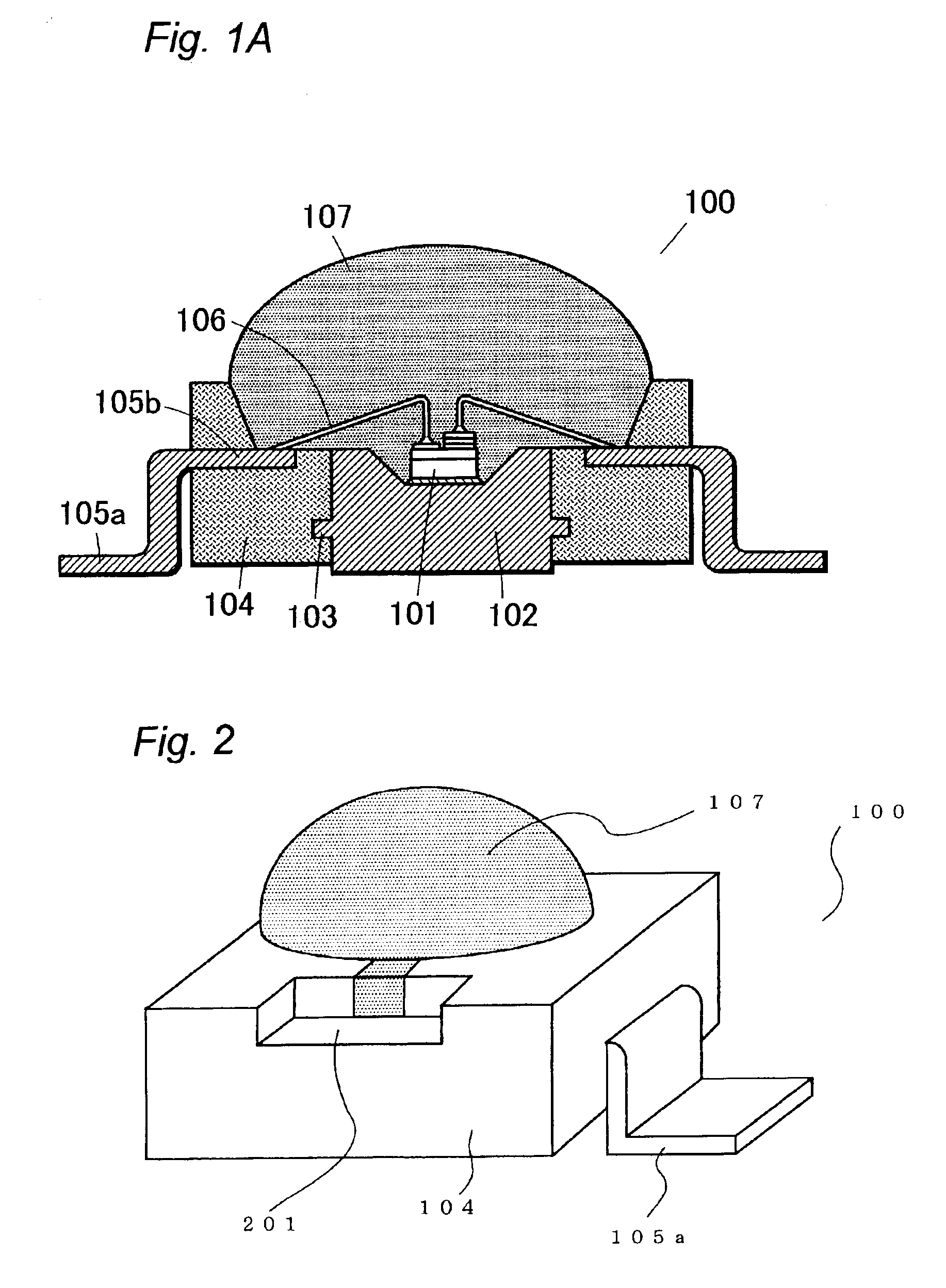

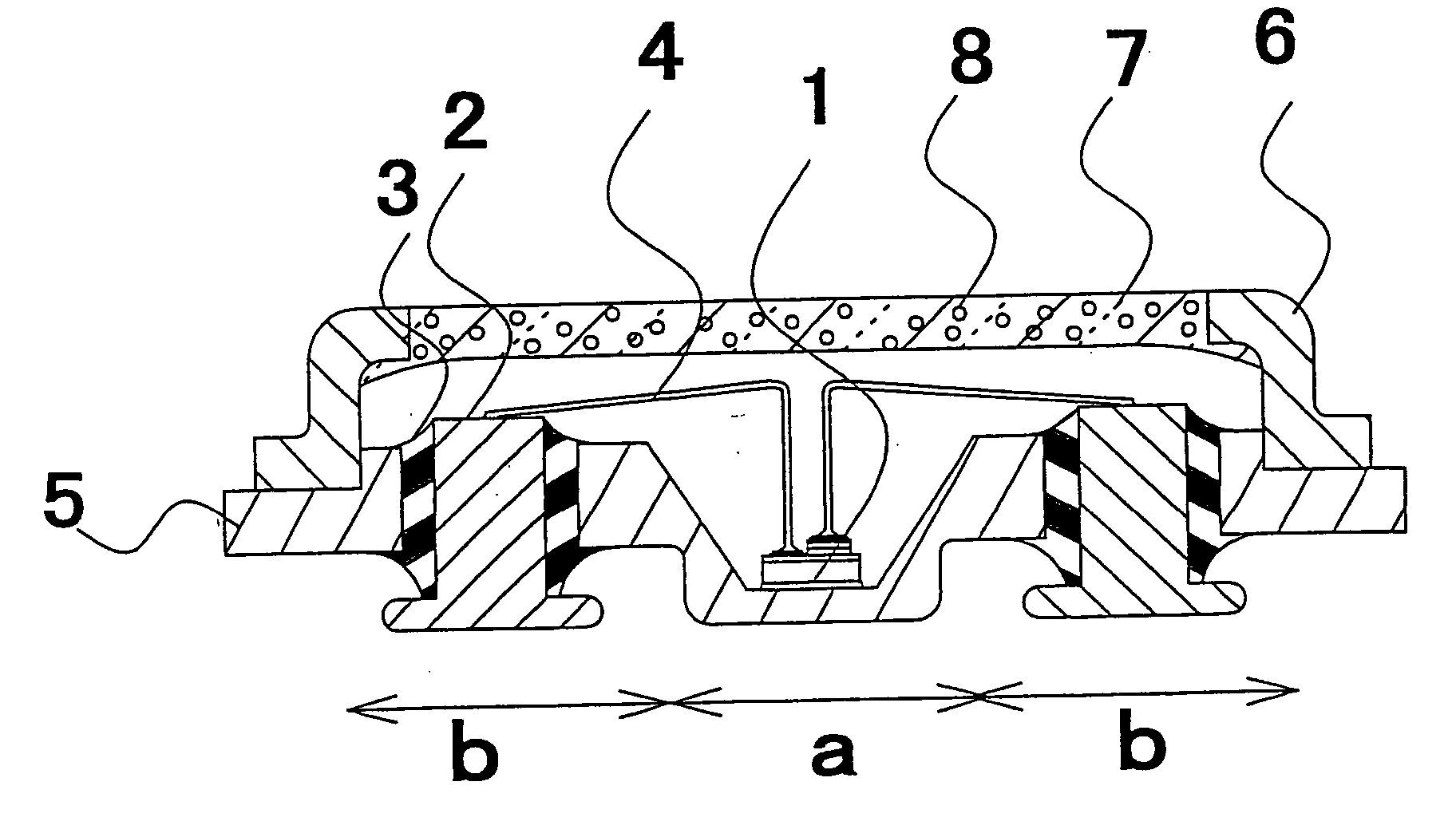

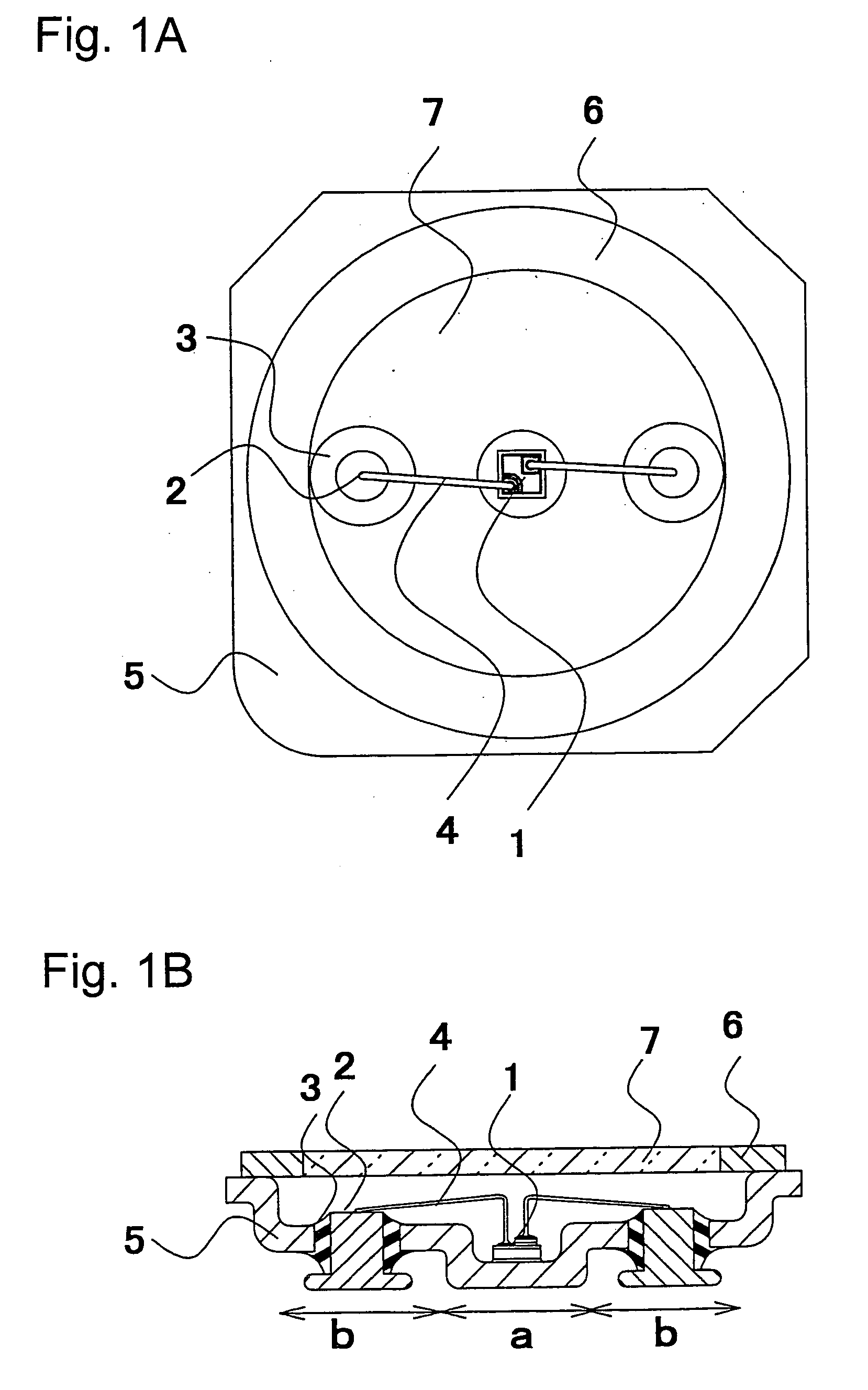

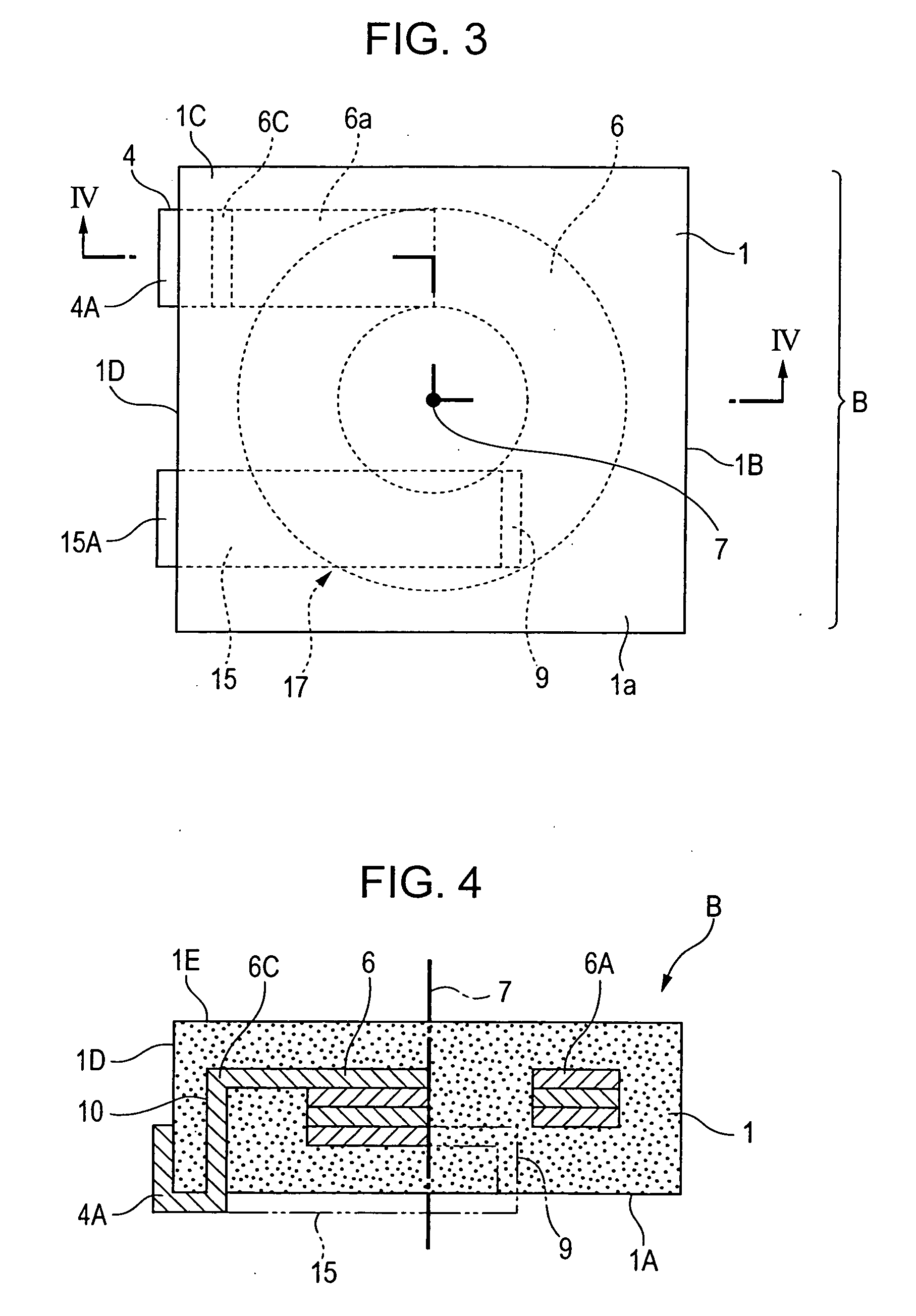

High output power light emitting device and packaged used therefor

ActiveUS20090261374A1Increase output powerEasy to useSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight emitting device

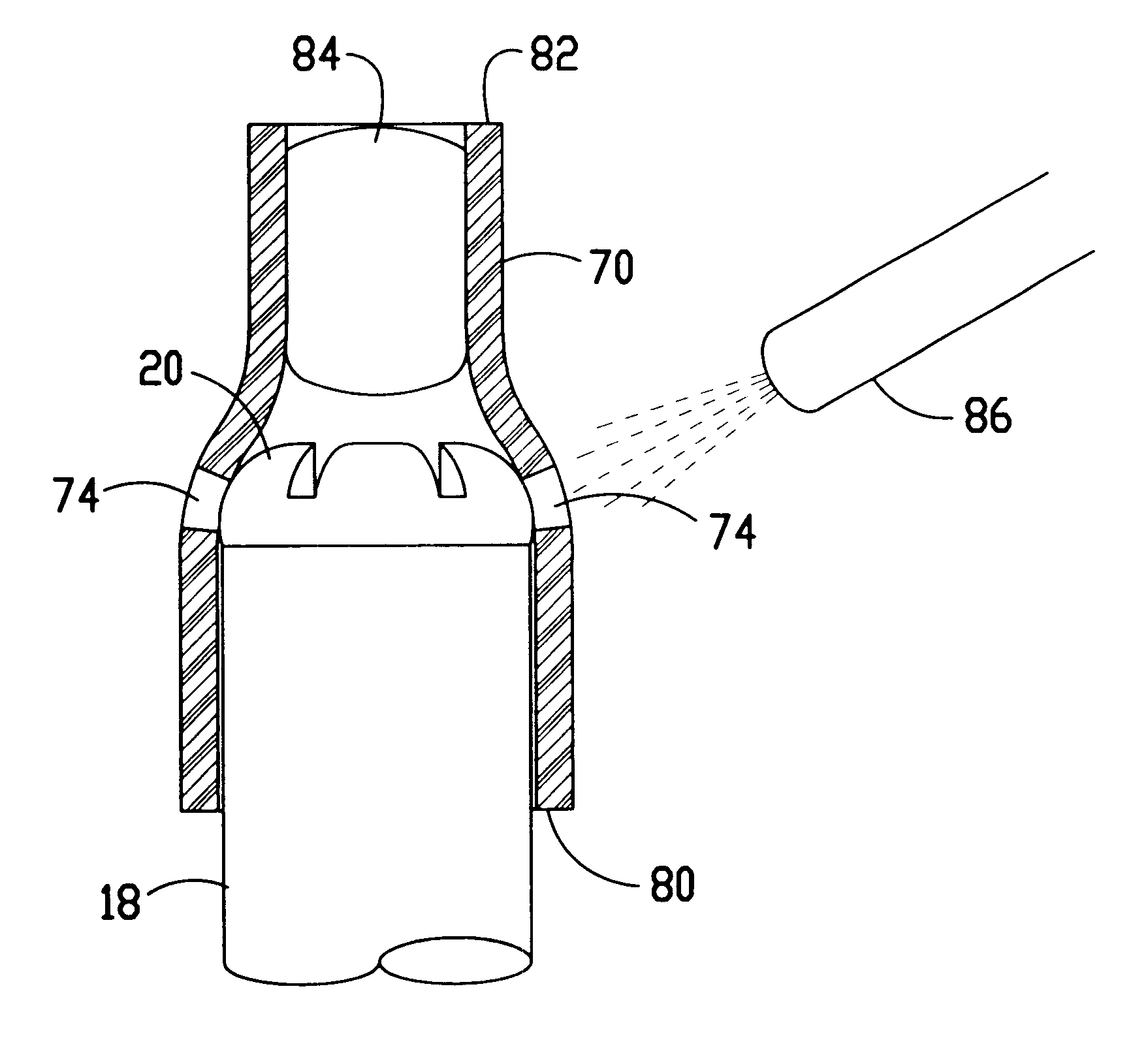

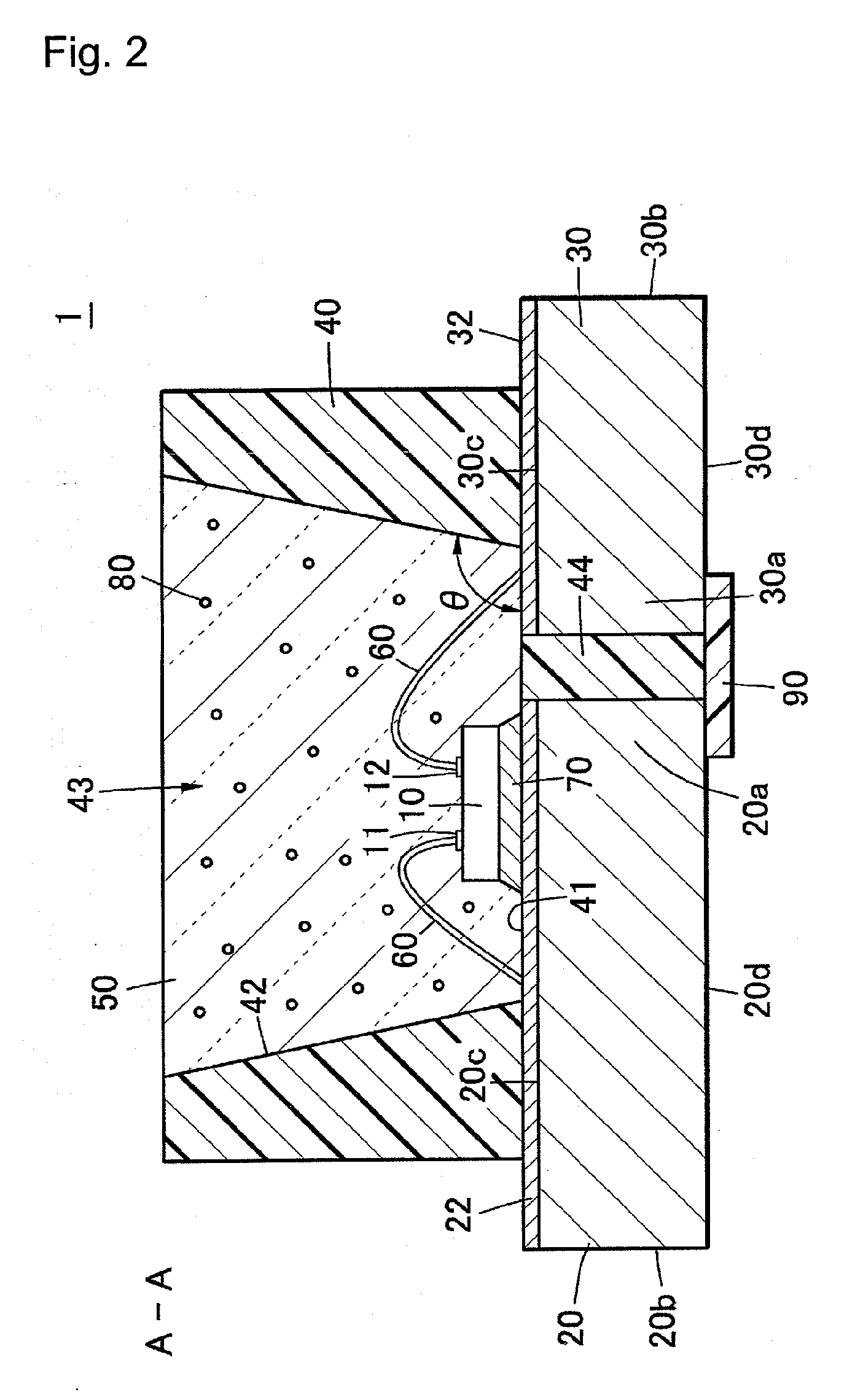

An object of the present invention is to provide a light emitting device that has high output power and long service life where a package is suppressed from discoloring due to heat generation. The light emitting device 1 of the present invention contains a light emitting element 10, a package 40 formed of a thermosetting resin, the package having a recess 43 wherein the light emitting element 10 is mounted, a first lead electrode 20 which is exposed at the bottom of the recess 43 of the package 40 and whereon the light emitting element 10 is mounted, and a second lead electrode 30 which is exposed at the bottom of the recess 43 of the package 40 and is electrically connected to the light emitting element 10. The light emitting element 10 is bonded to the first lead electrode 20 through a eutectic layer 70, and at least a surface of the first electrode 20 is coated with an Ag film 22, a thickness of the Ag film 22 being in the range from 0.5 μm to 20 μm.

Owner:NICHIA CORP

Subcutaneous electrode for transthoracic conduction with low-profile installation appendage and method of doing same

One embodiment of the present invention provides a lead electrode assembly for subcutaneous implantation including an electrode; a riser coupled to the electrode; and a head coupled to the riser.

Owner:CAMERON HEALTH

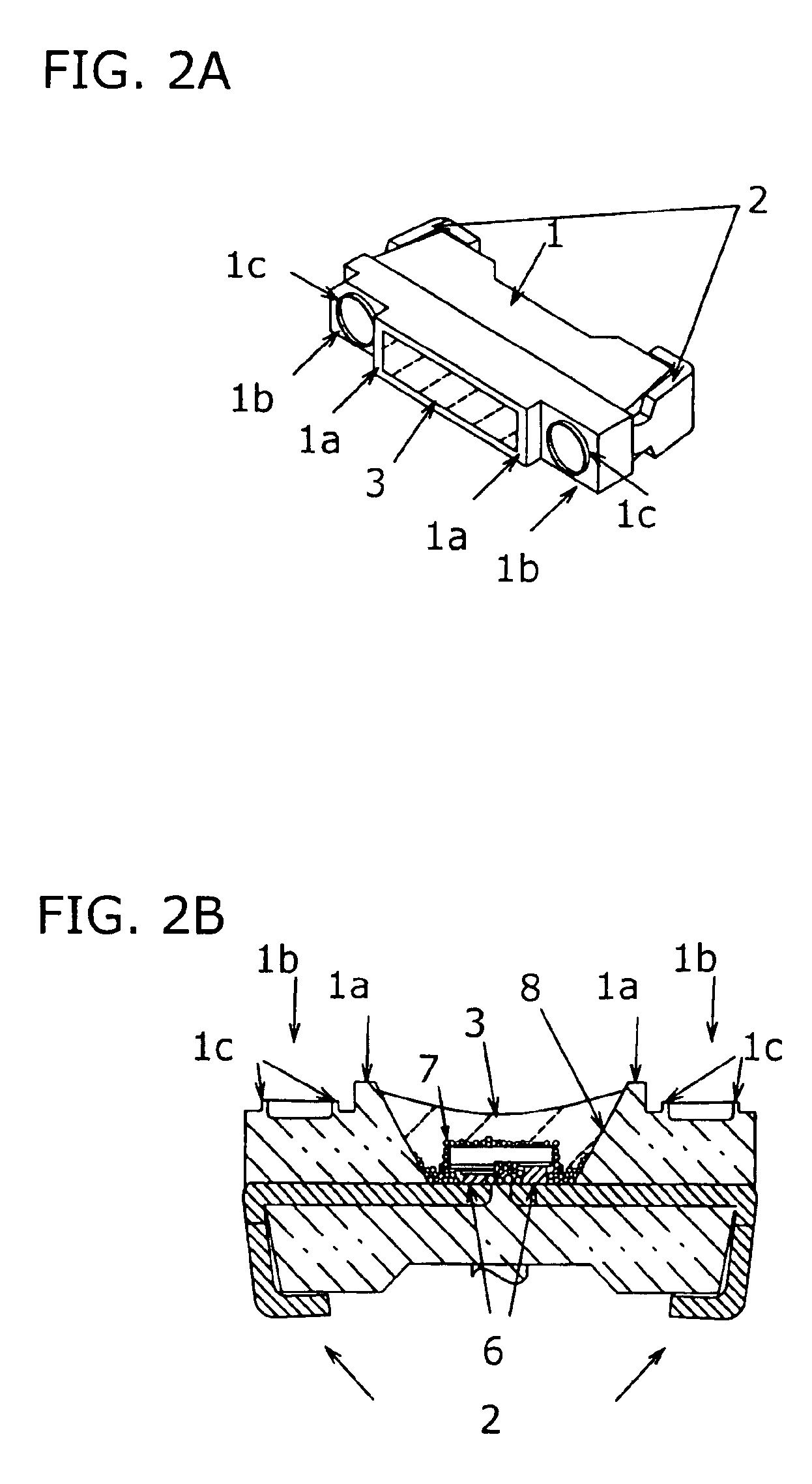

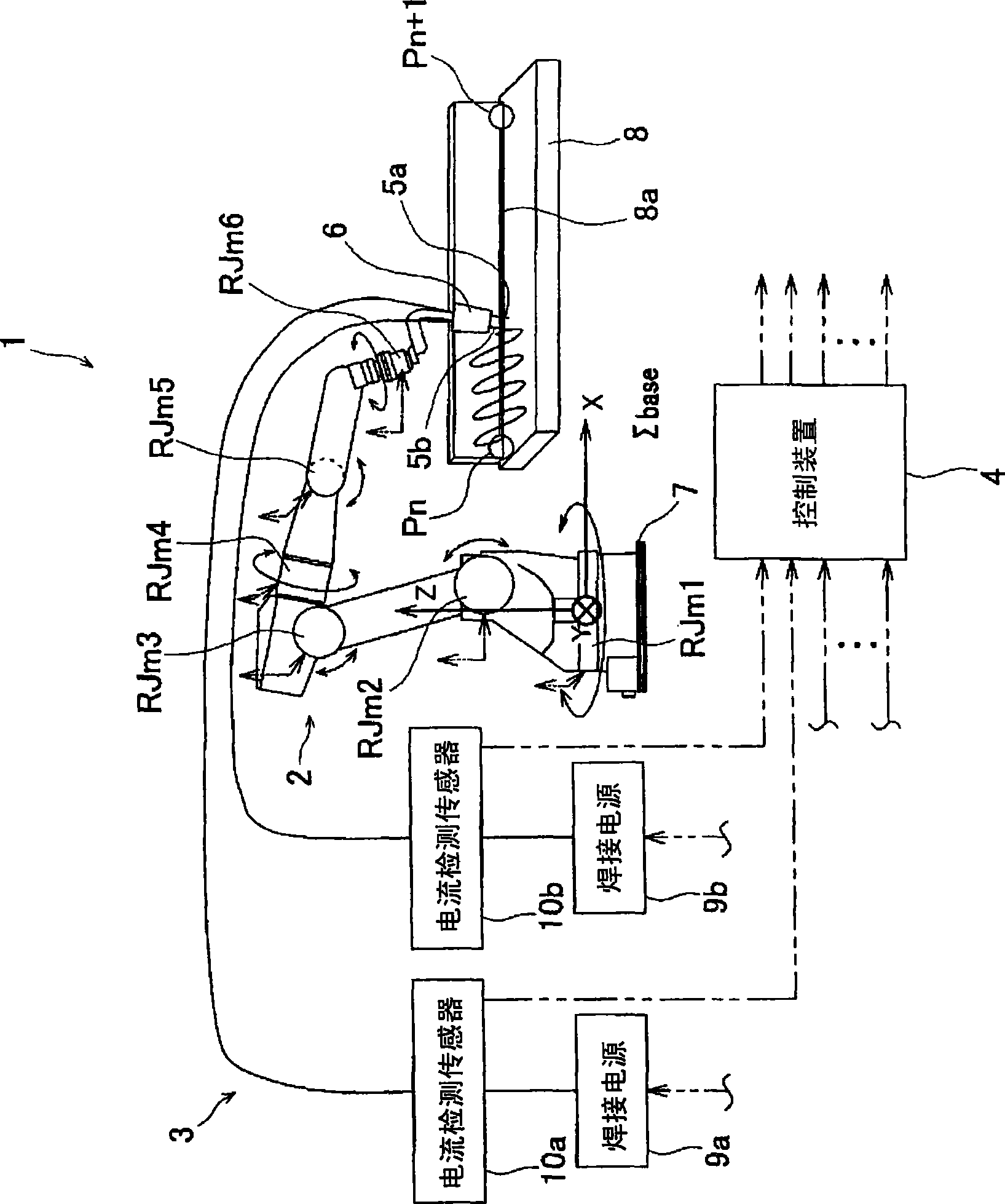

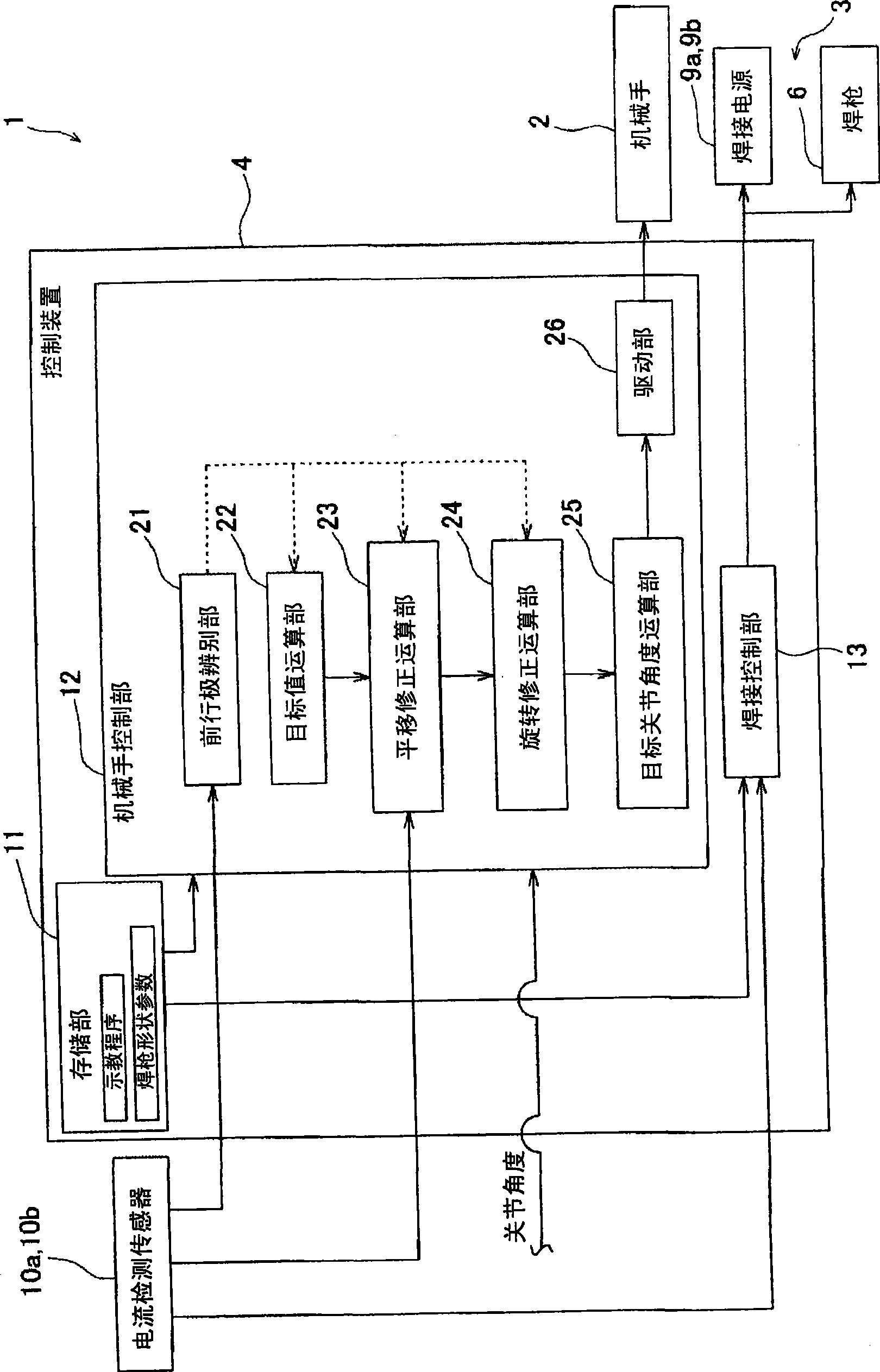

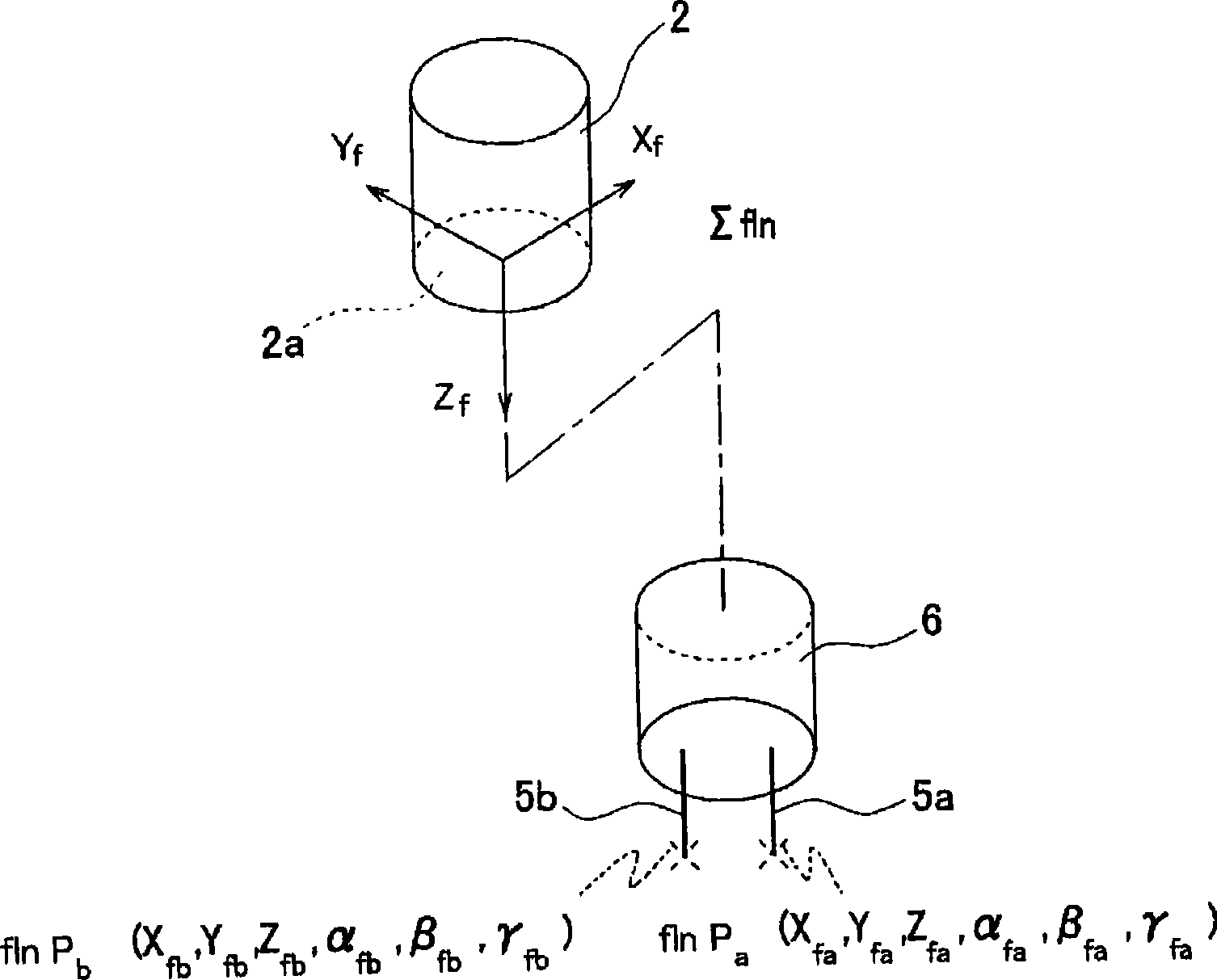

Welding robot

ActiveCN101486123AQuality improvementEfficient Tracking and TracingProgramme-controlled manipulatorArc welding apparatusEngineeringTorch

The invention provides a welding robot which makes it possible to, in a seam tracking operation during tandem welding, realize a high tracking ability, not only for a leading electrode, but also for a trailed electrode. A translational correction calculating unit (23) corrects a target value Plead(t) of the leading electrode (5a) using a translational correction amount Delta P(t) in a base coordinate system Sigmabase for a next time position of the leading electrode (5a), to obtain a primary correction target value Plead(t)'. A rotational correction calculating unit (24) calculates a rotation correction amount Delta theta(t) for correcting displacement of an orientation of a torch (6) around the leading electrode (5a) with respect to a actual weld line Lre generated because of the translational correction amount Delta P(t), and calculates a secondary correction target value Plead(t)'' resulting from correcting the primary correction target value Plead(t)' so that the torch (6) rotates around the leading electrode (5a) by the rotation correction amount Delta theta(t). A manipulator (2) is driven on the basis of the secondary correction target value Plead(t)''.

Owner:KOBE STEEL LTD

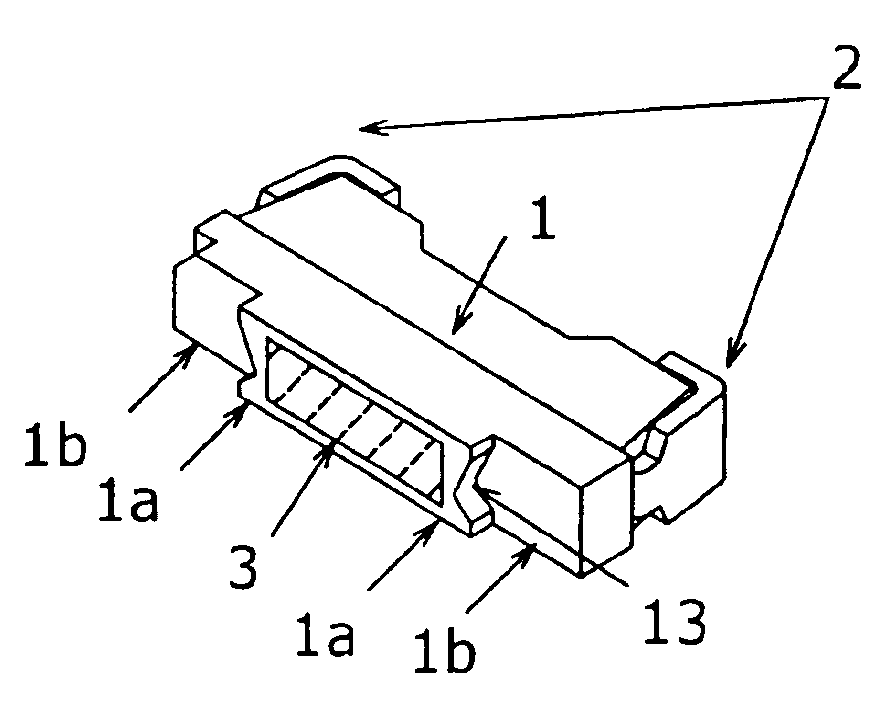

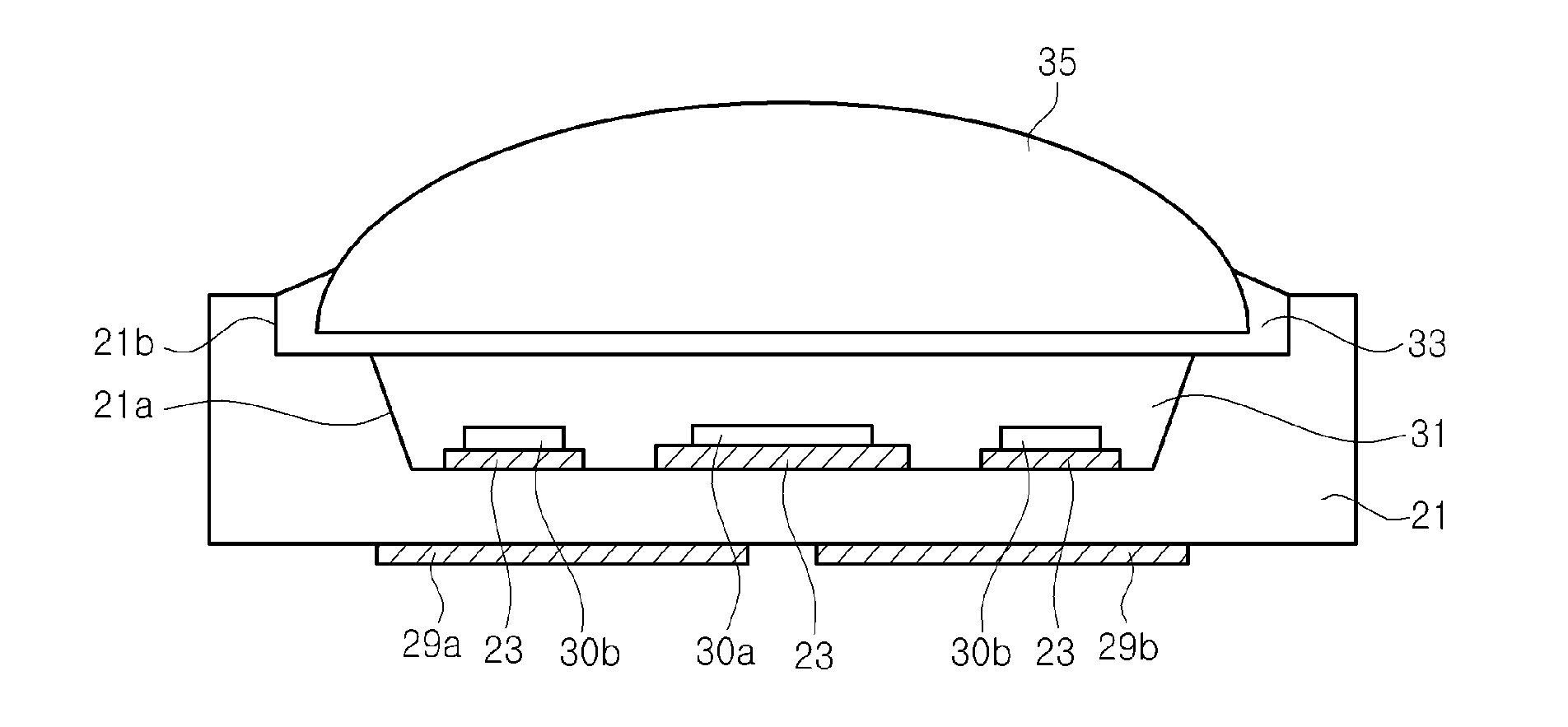

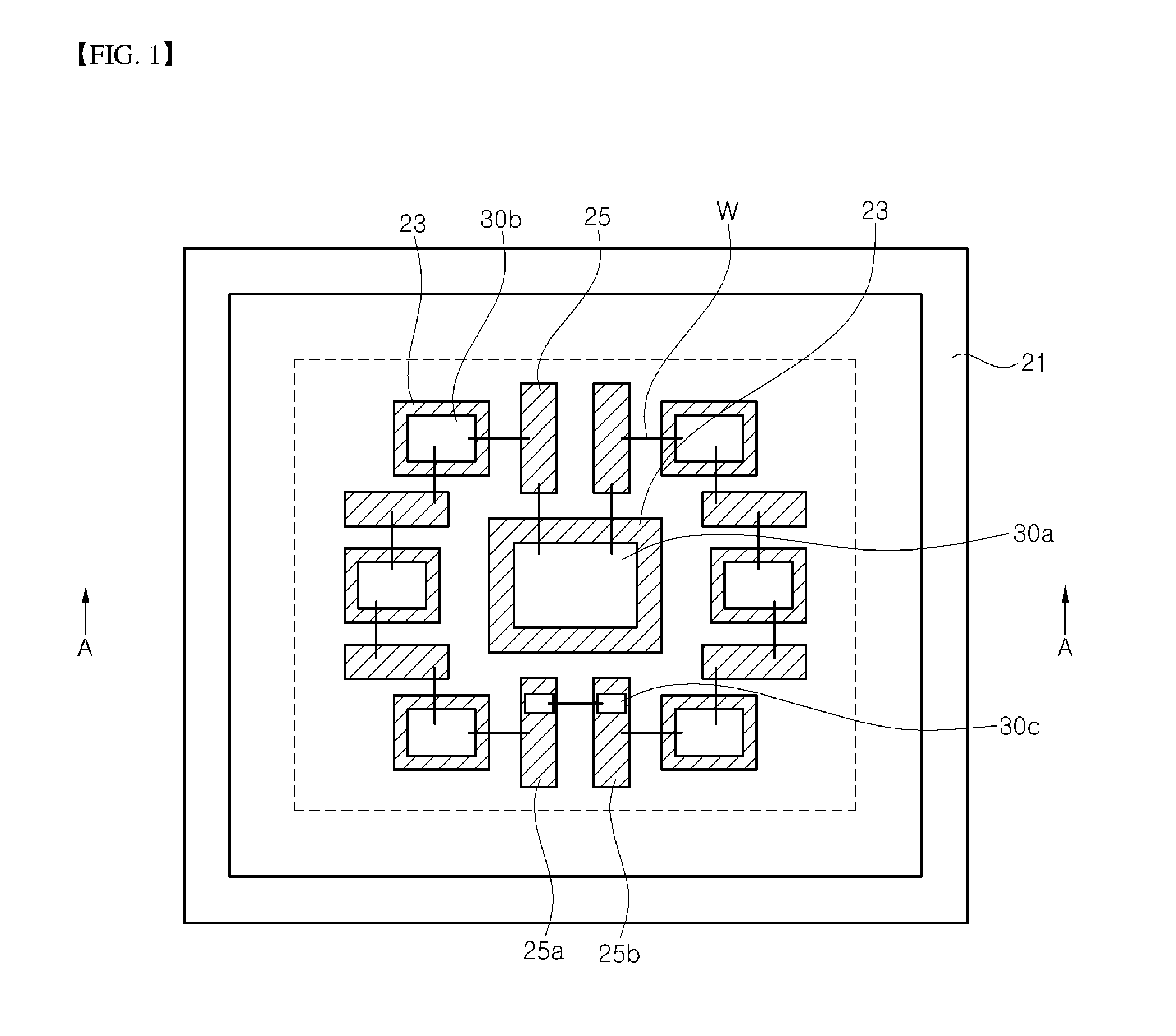

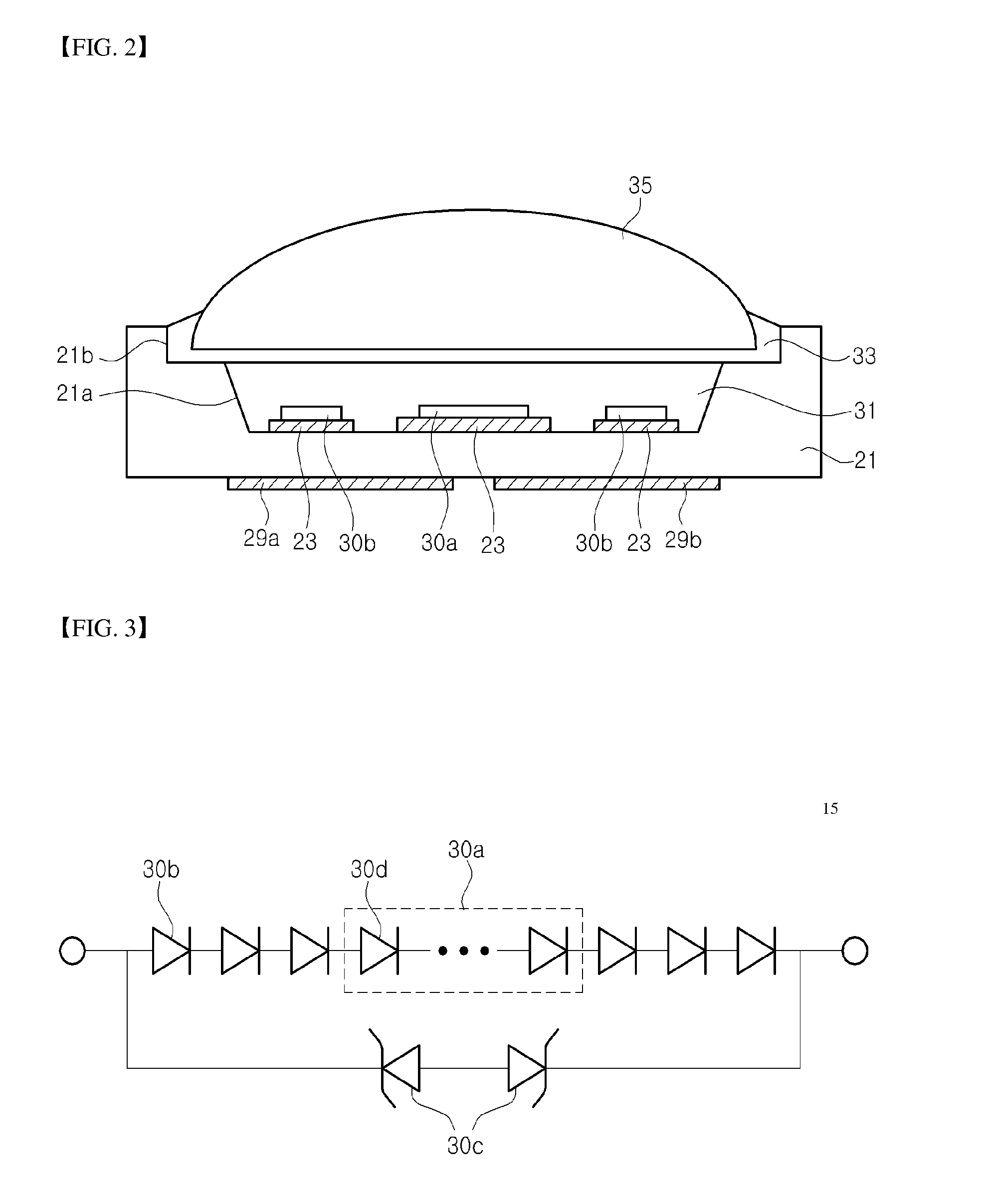

Light emitting diode package

ActiveUS20120056217A1Reduce package sizePrevent leakageSolid-state devicesSemiconductor devicesPhosphorLight-emitting diode

Disclosed herein is a light emitting diode package including a package body having a cavity, a light emitting diode chip having a plurality of light emitting cells connected in series to one another, a phosphor converting a frequency of light emitted from the light emitting diode chip, and a pair of lead electrodes. The light emitting cells are connected in series between the pair of lead electrodes.

Owner:SEOUL SEMICONDUCTOR

Instruments and methods for accessing an anatomic space

InactiveUS20070010708A1Rigid enoughConvenient introductionStentsCannulasPericardial spaceAnatomic Site

An anatomic space of the body, particularly the pericardial space, is accessed in a minimally invasive manner from a skin incision by an access instrument to facilitate visualization and introduction of devices or drugs or other materials, performance of medical and surgical procedures, and introducing and fixating a cardiac lead electrode to the heart. An elongated access instrument body preferentially bends in one direction and resists bending in a transverse direction, whereby the access instrument body distal end can be directed through a path around body structures to the anatomic site by manipulation of the access instrument body proximal end portion. A distal header formed at the access instrument body distal end extends outward of the access instrument body in the transverse direction and supports an inflatable balloon surrounding a working lumen exit port that is directed toward an anatomic surface when the balloon is inflated by inflation media introduced through an inflation lumen.

Owner:MEDTRONIC INC

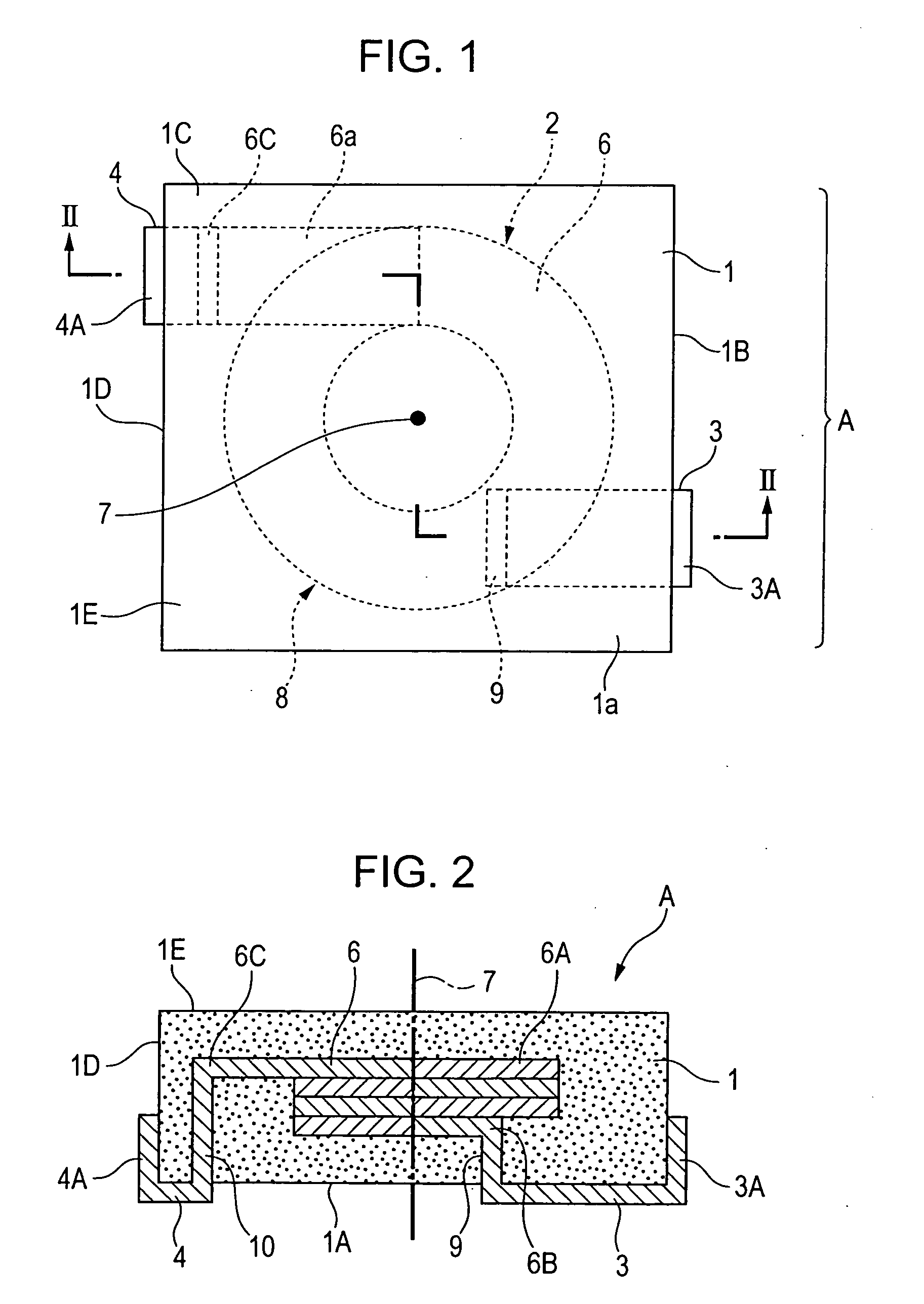

Coil-embedded dust core

InactiveUS20060038651A1No unevenness in compactionUniform compactionTransformers/inductances casingsTransformers/inductances coils/windings/connectionsEngineeringMechanical engineering

A coil-embedded dust core of the present invention is provided with a molded coil component including a coil main body having a structure in which a flat type conductor wire is wound edgewise, one end side terminal portion disposed by being lead in the thickness direction of the coil main body, the other end side terminal portion, one end side leading electrode portion disposed by extending the one end side terminal portion, and the other end side leading electrode portion disposed by extending the other end side terminal portion; and a dust core composed of a soft magnetic alloy powder disposed covering the coil main body, the one end side terminal portion, and the other end side terminal portion of the molded coil component.

Owner:ALPS ALPINE CO LTD

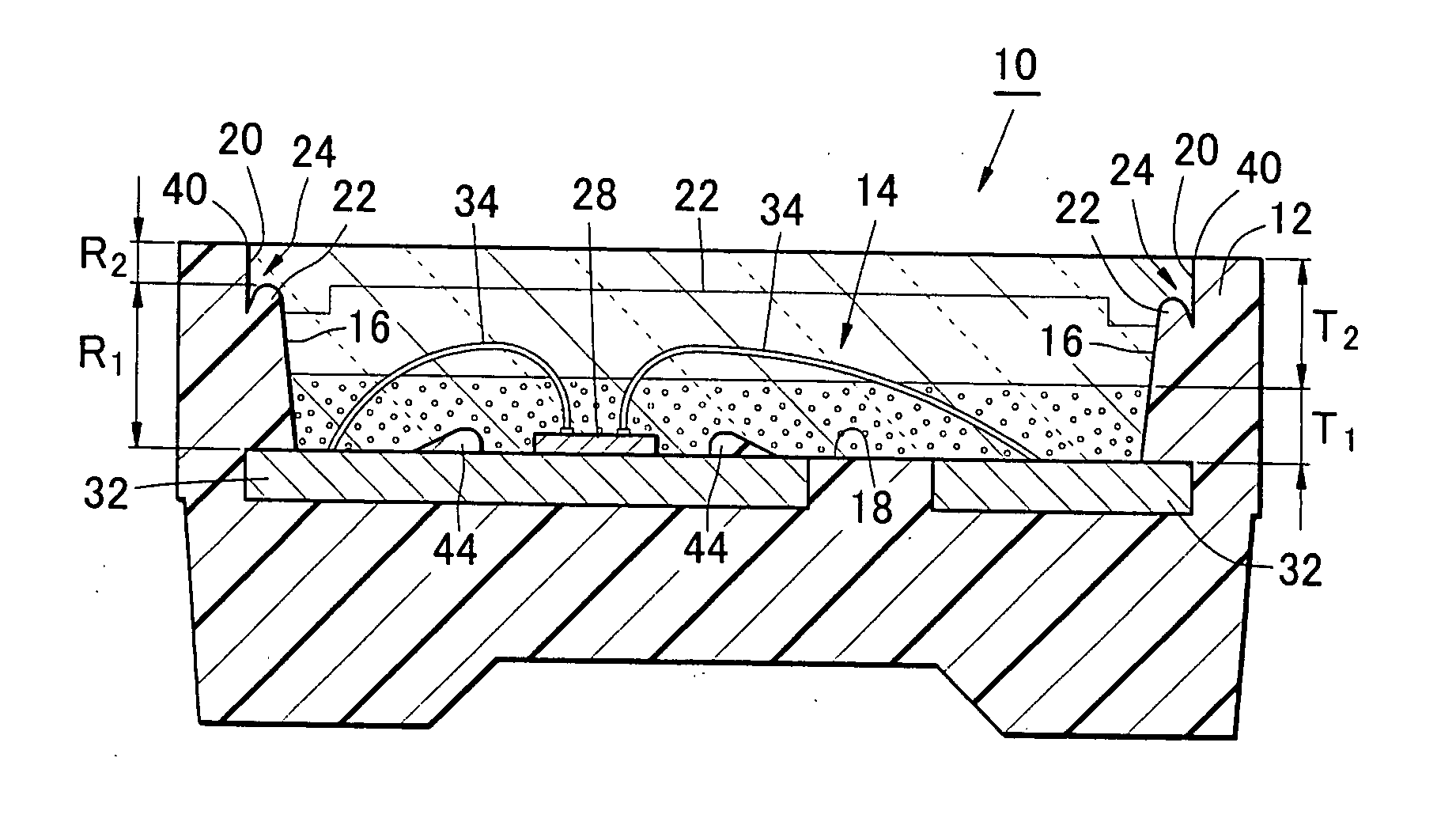

Light emitting device

ActiveUS20080037252A1Improve reliabilityEasy to useLighting heating/cooling arrangementsSolid-state devicesEngineeringLight emitting device

The present invention provides a light emitting device which has high reliability and long service life by suppressing the sealing resin from peeling off the inner edge of the opening of the recess of the housing. The light emitting device of the present invention comprises a light emitting element having a pair of electrodes, a housing having a recess for accommodating the light emitting element, a first lead electrode and a second lead electrode which are exposed on the bottom of the recess, electrically conductive members for electrically connecting the pair of electrodes of the light emitting element to the first lead electrode and to the second lead electrode respectively, a transparent sealing material which fills in the recess and granular additives contained in the sealing material, wherein the inner wall surface of the recess has a light blocking section that blocks light emitted by the light emitting device toward the inner edge of the opening of the recess, the quantity of the granular additives contained in the sealing material is controlled to such a level that enhances scattering of light in a first region located below the light blocking section and to such a level that suppresses scattering of light in a second region located above the light blocking section.

Owner:NICHIA CORP

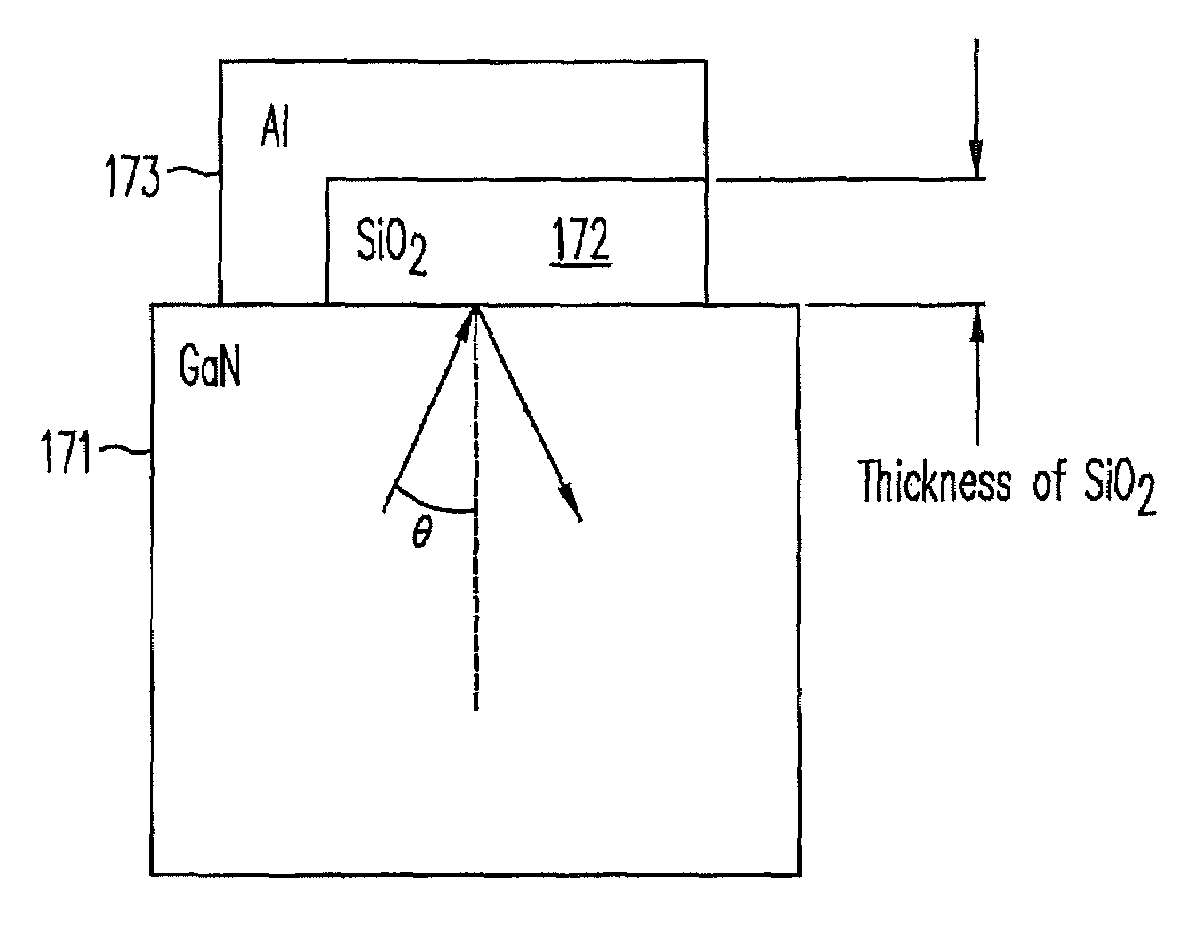

LED electrode

ActiveUS7573074B2Increase reflectionIncrease brightnessLaser detailsSolid-state devicesDielectricSemiconductor materials

An electrode structure is disclosed for enhancing the brightness and / or efficiency of an LED. The electrode structure can have a metal electrode and an optically transmissive thick dielectric material formed intermediate the electrode and a light emitting semiconductor material. The electrode and the thick dielectric cooperate to reflect light from the semiconductor material back into the semiconductor so as to enhance the likelihood of the light ultimately being transmitted from the semiconductor material. Such LED can have enhanced utility and can be suitable for uses such as general illumination.

Owner:BRIDGELUX INC

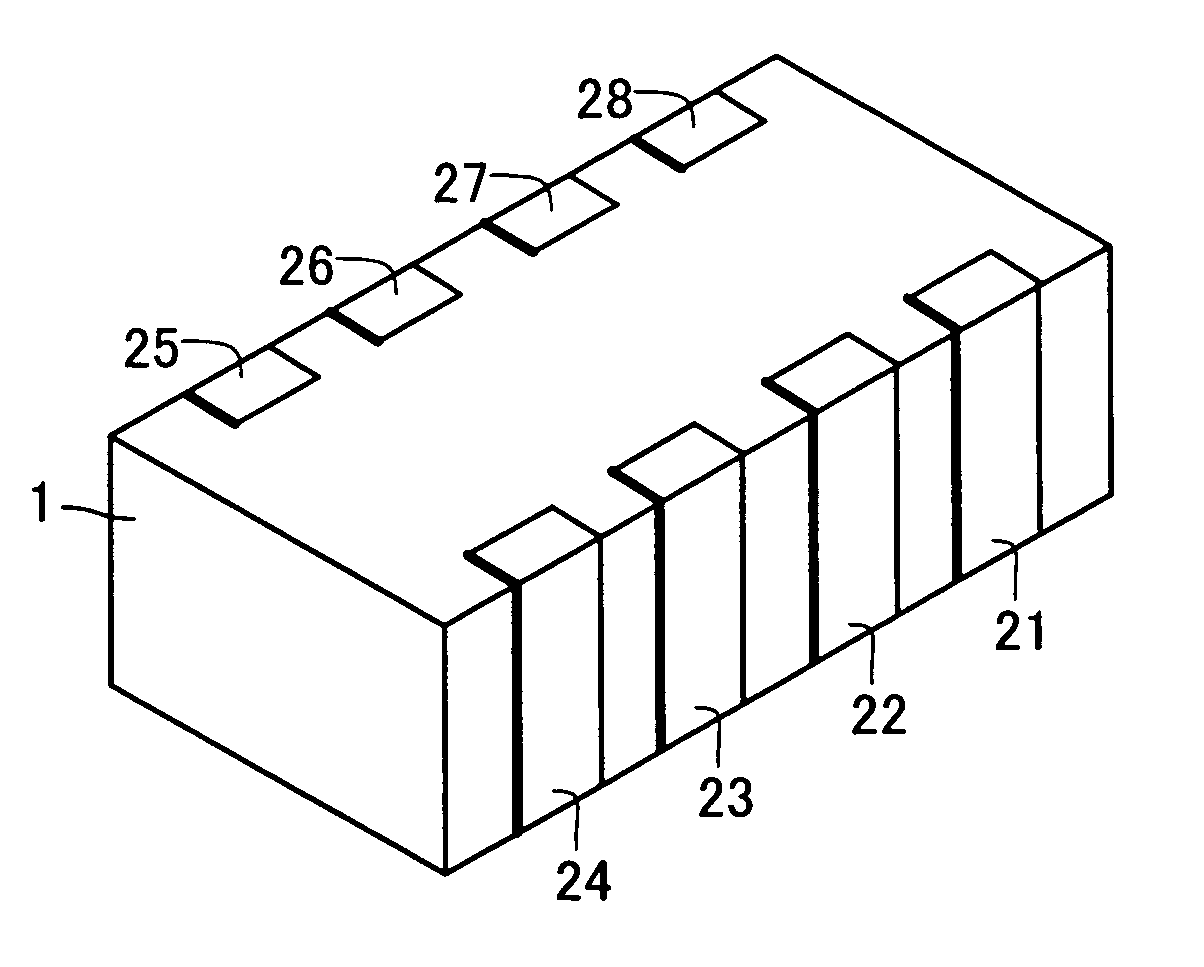

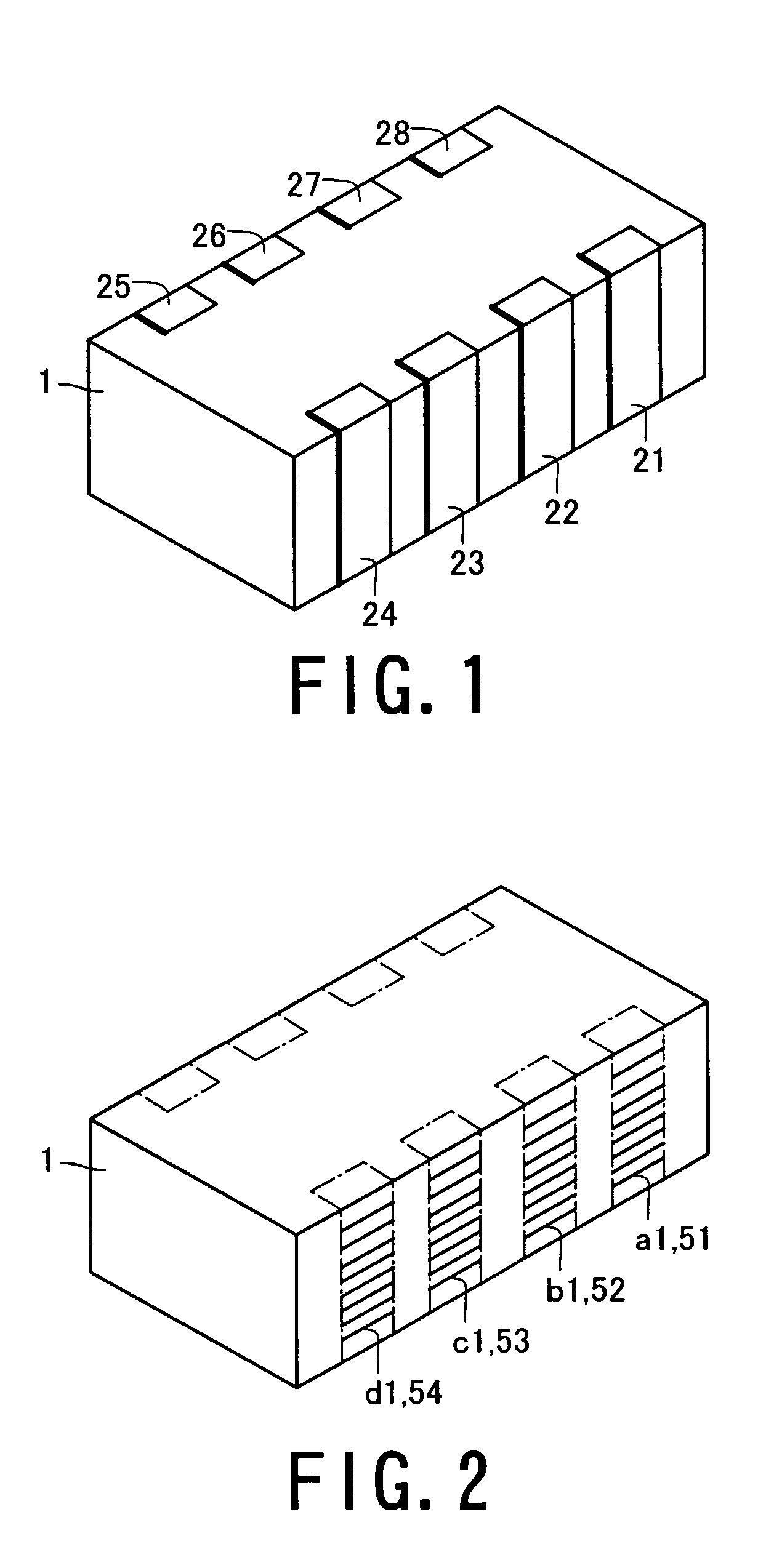

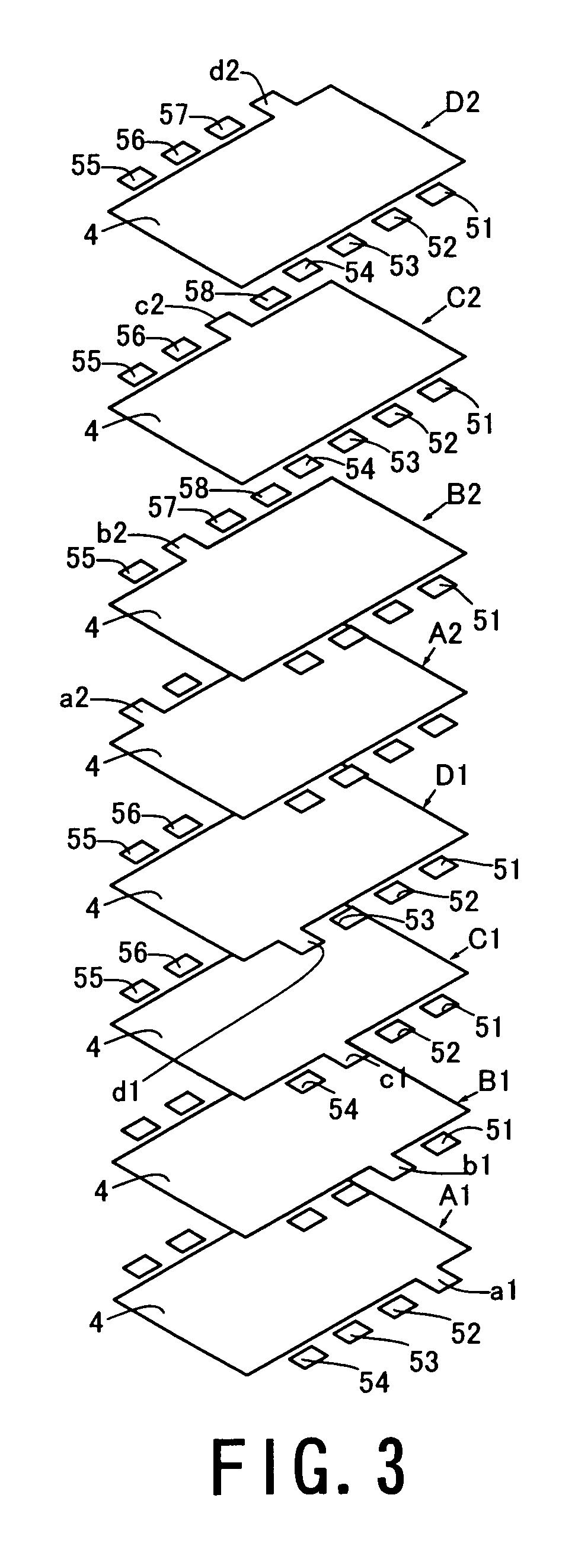

Laminated ceramic capacitor

ActiveUS7050288B2Reduce connectionsReducing occurrence of delaminationMultiple fixed capacitorsFixed capacitor electrodesCeramic capacitorEngineering

Internal electrodes A1 to D1 and A2 to D2 are laid in layers at spaces in the direction of thickness of a ceramic body 1. Lead electrodes a1 to d1 and a2 to d2 are led out to a side face to form lead portions. Dummy electrodes 51 to 58 have one-side ends led out to a side face to form lead portions in layers provided with the internal electrodes A1 to D1 and A2 to D2. The lead portion of a lead electrode a1 to d1 or a2 to d2 of each layer is superposed over the lead portion of a dummy electrode 51 to 58 belonging to another layer in the direction of thickness.

Owner:TDK CORPARATION

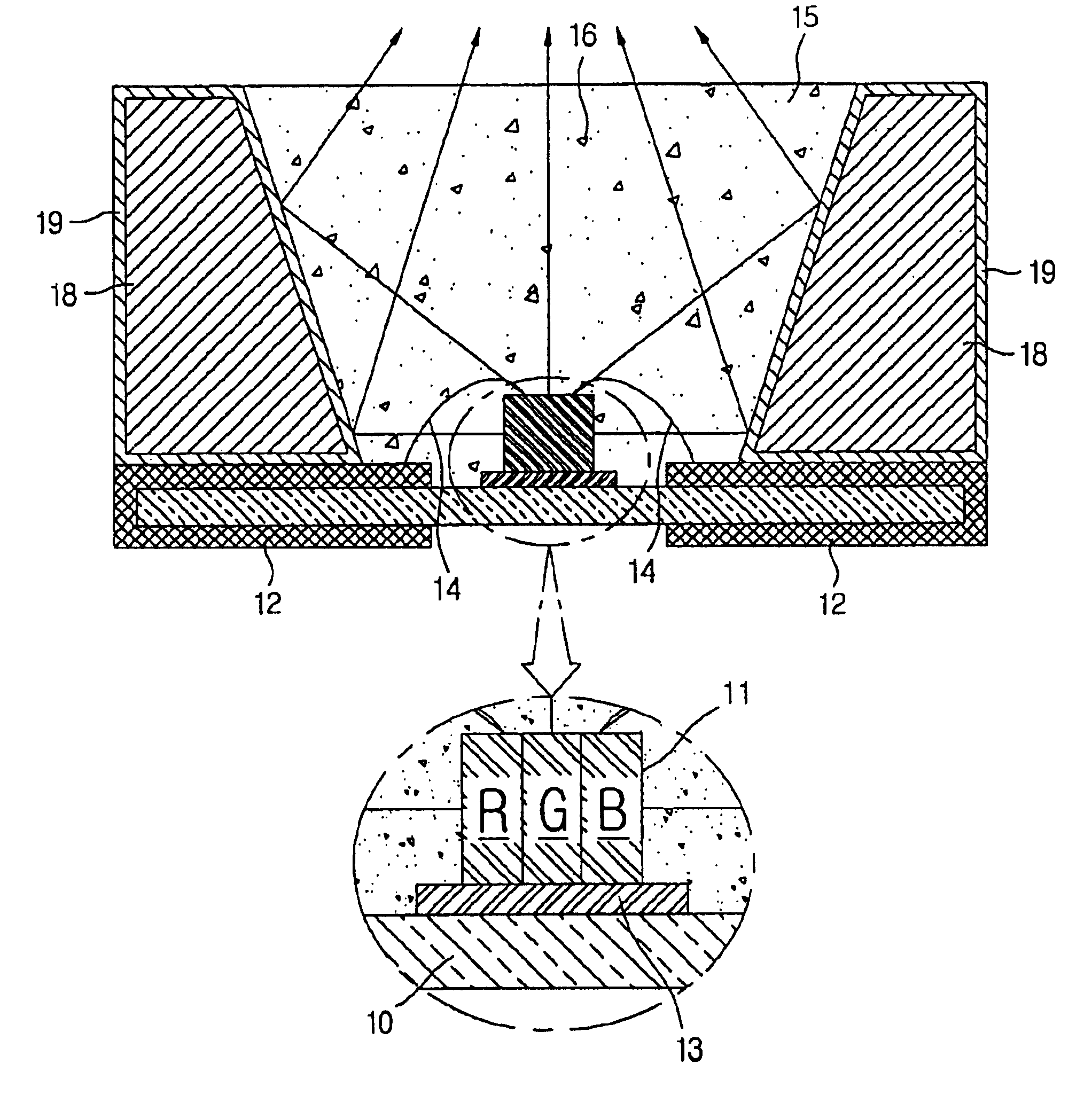

Semiconductor light emitting device with reflectors having cooling function

InactiveUS6909123B2Improve thermal conductivityImprove reflectivitySolid-state devicesSemiconductor/solid-state device manufacturingLength waveLight emitting device

A semiconductor light emitting device includes a base substrate, lead electrodes provided on the base substrate, at least one semiconductor light emitting element loaded on the base substrate so as to be spaced apart from the lead electrodes and radiating blue light, a connection member for electrically interconnecting the electrodes and the semiconductor light emitting element, a reflector extended from a bottom of the base substrate to a predetermined height for surrounding the semiconductor light emitting element, and a translucent cover layer formed in the receiving space for housing the light emitting element, the translucent cover layer containing a color-shifting substance for absorbing at least a part of blue light radiated from the light emitting element to radiate a light having a different wavelength. The reflector is made of a material having high translucency and high thermal conductivity on a surface thereof so as to reflect the light radiated from the light emitting element and form a uniform planar light, and the reflector radiates the heat radiated from the light emitting element to outside so as to cool an inside of a receiving space for receiving the light emitting element. Thus, the device emits white light outside by combination of the blue light radiated from the light emitting element and the light having a different wavelength.

Owner:HIGH POWER LIGHTING CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com