Patents

Literature

185results about How to "Increase the rate of heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

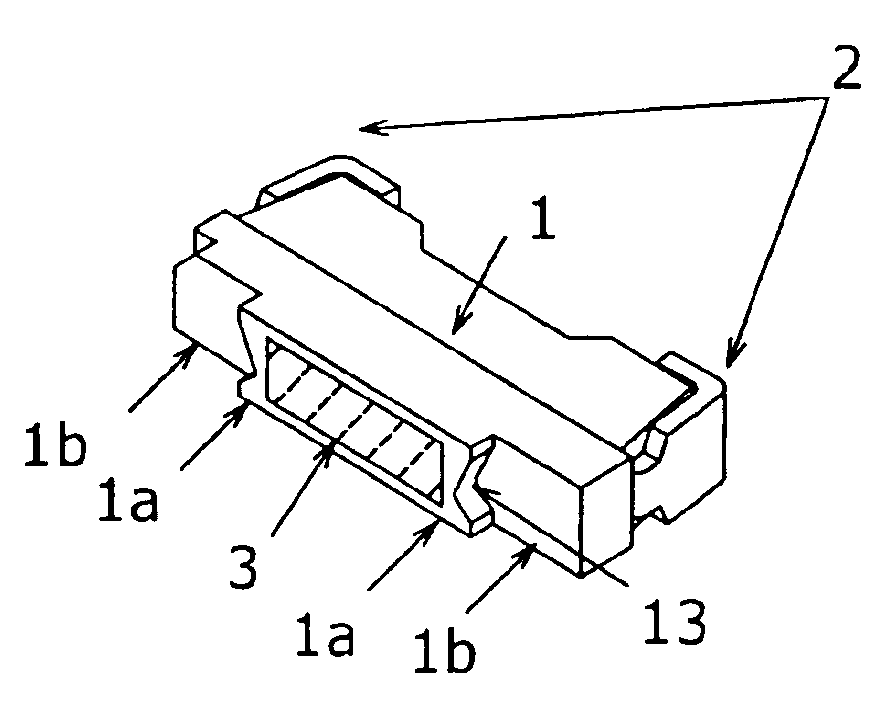

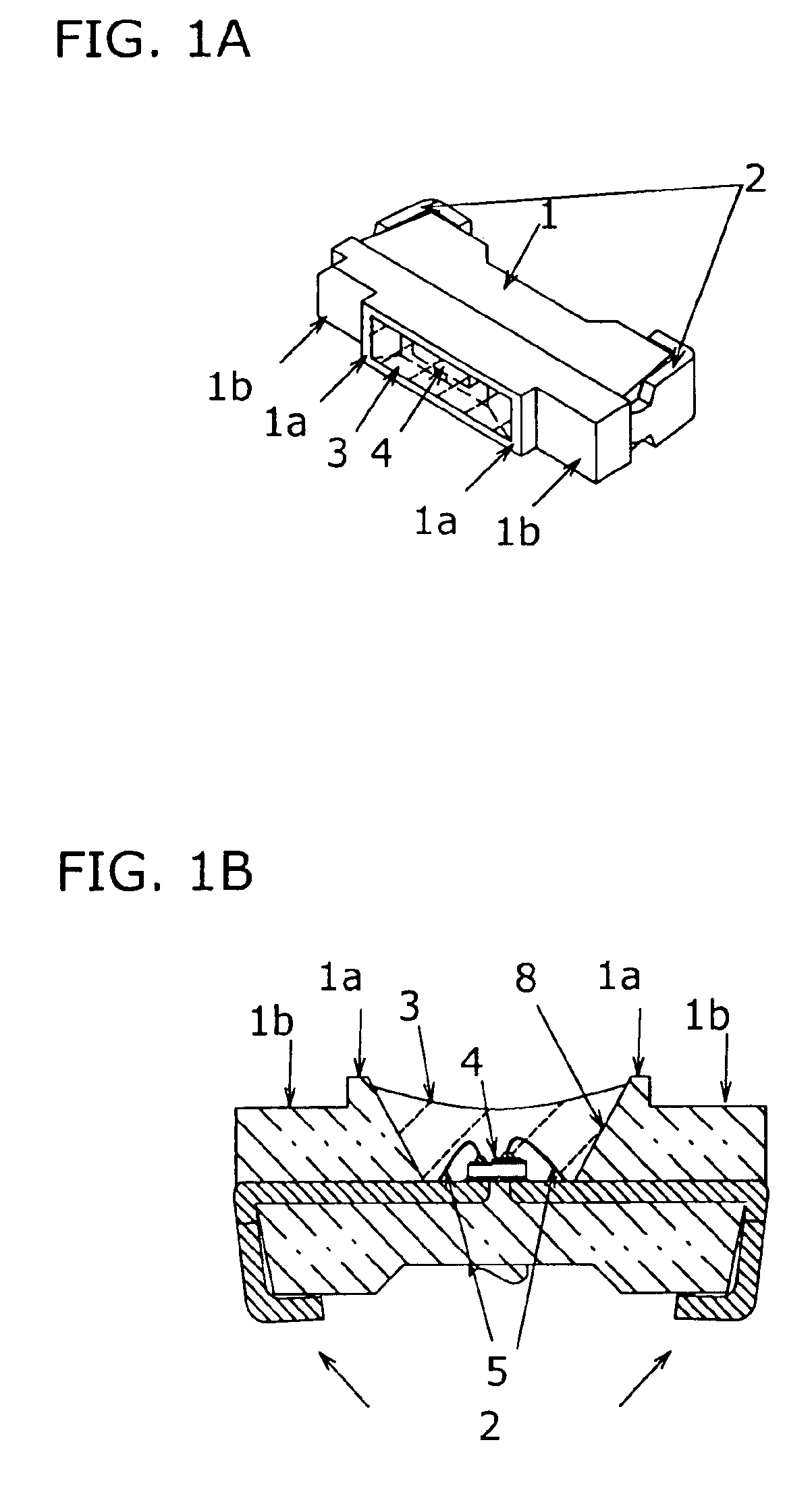

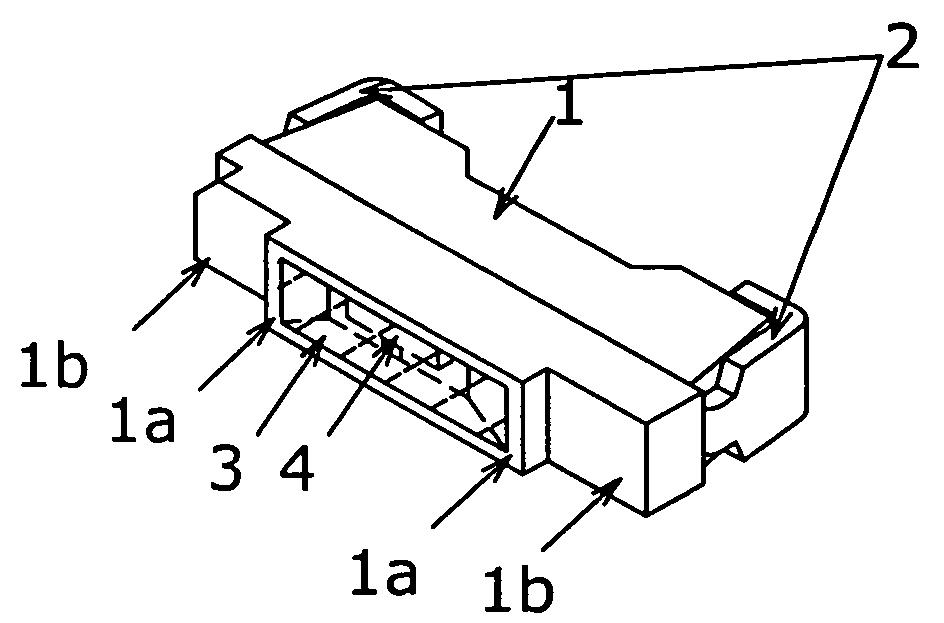

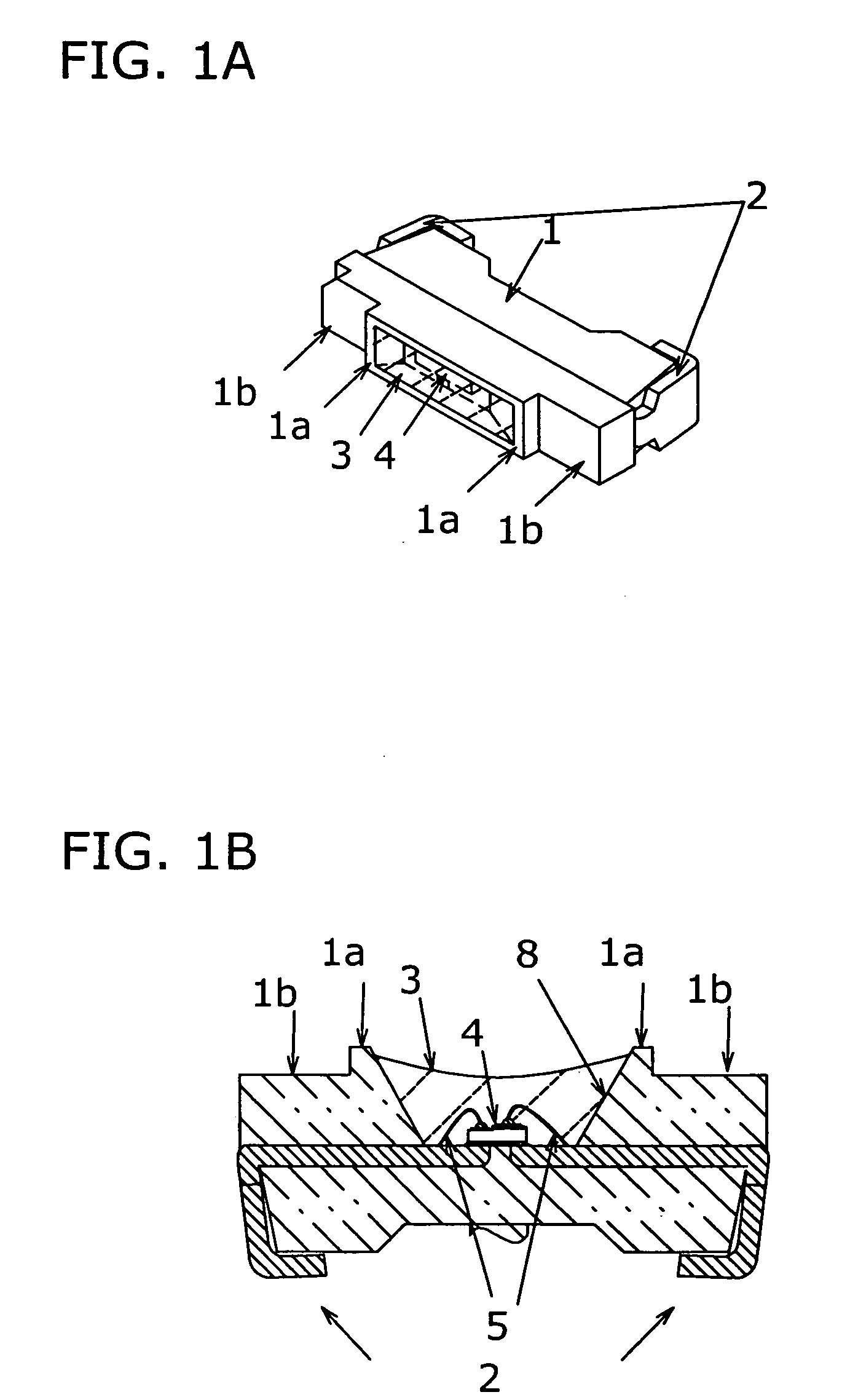

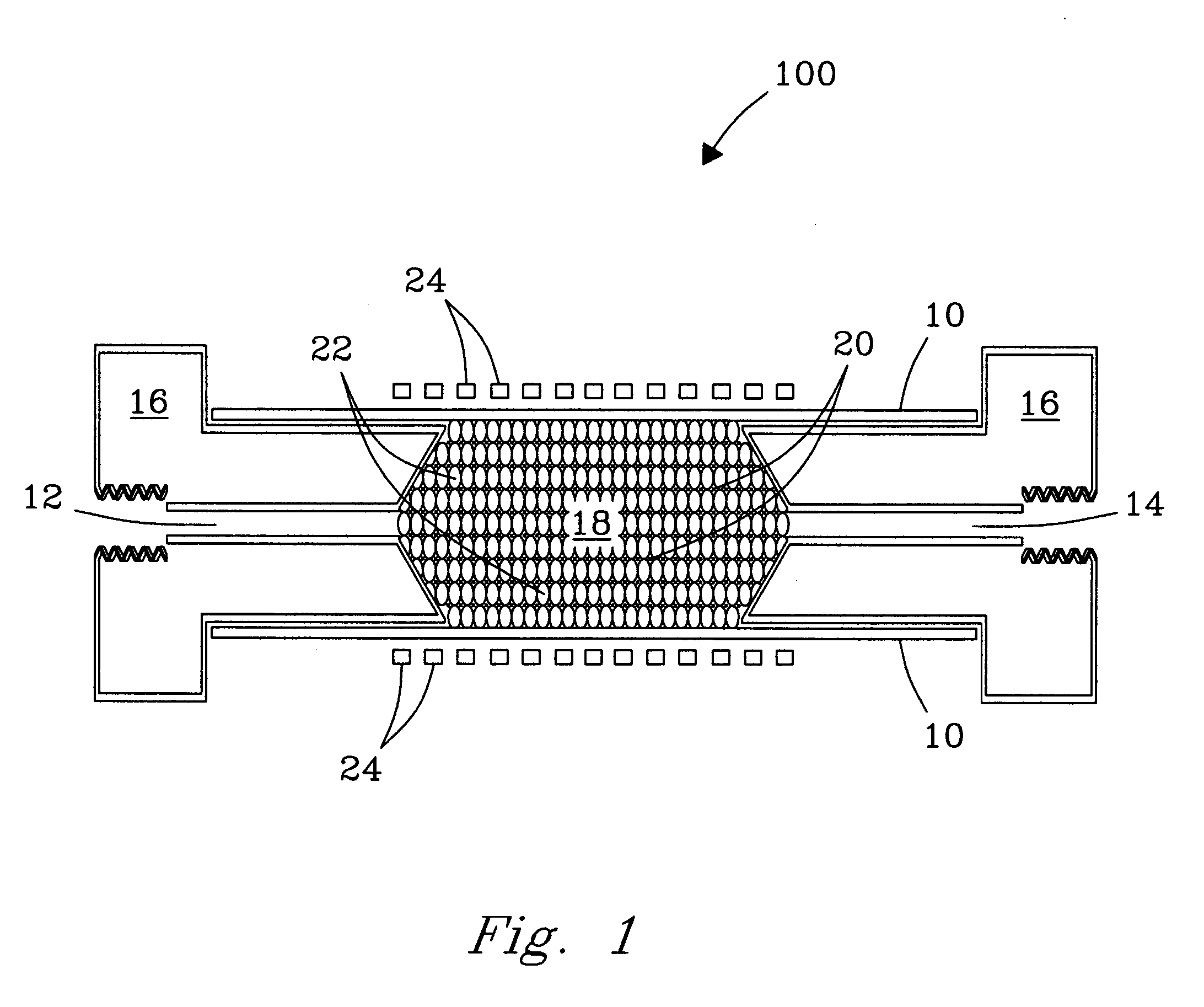

Semiconductor device and an optical device using the semiconductor device

InactiveUS6953952B2Increase the rate of heatingHeat release rate downDischarge tube luminescnet screensSemiconductor/solid-state device detailsEngineeringLead electrode

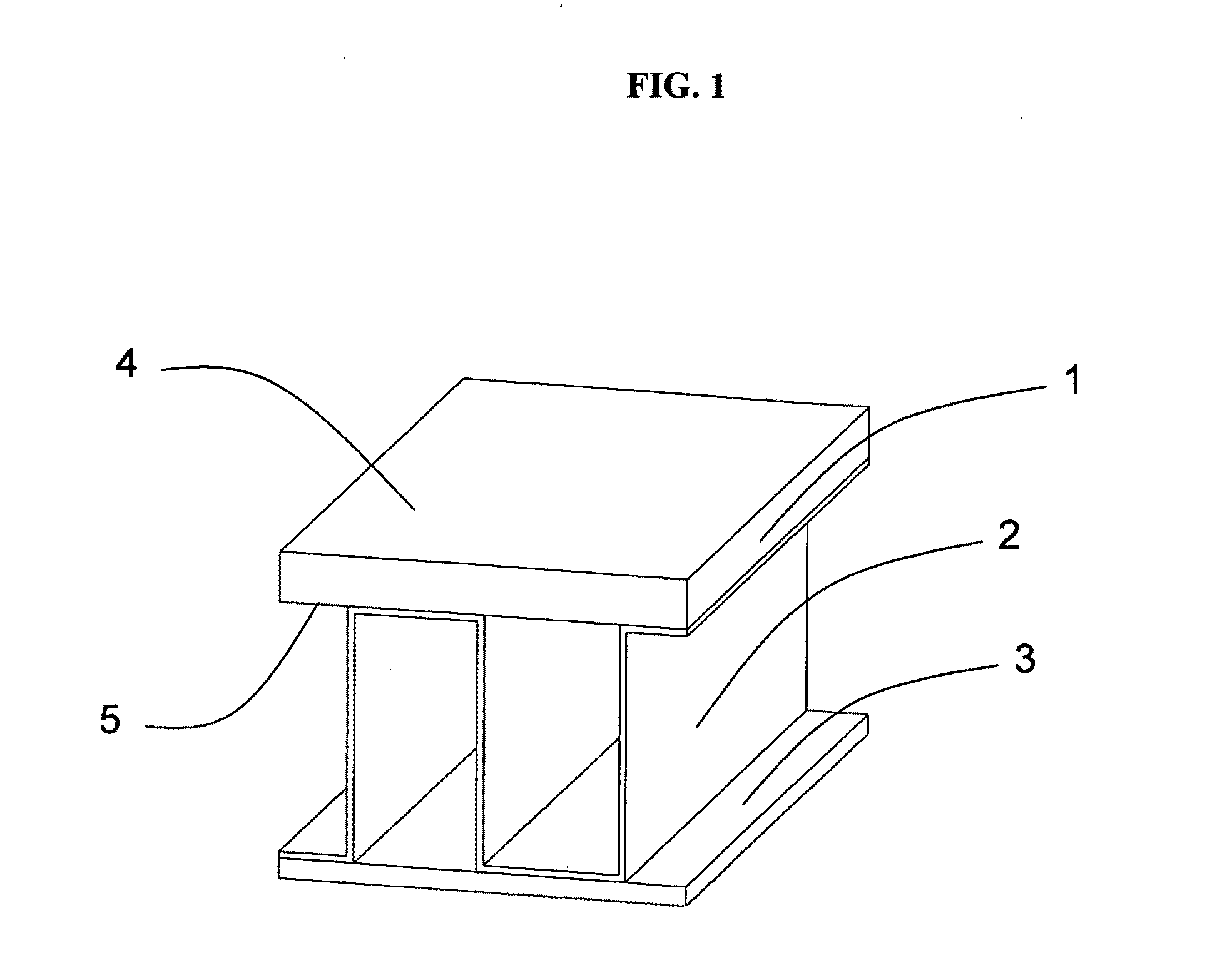

A semiconductor device comprising a semiconductor element and a support member having a recess for housing the semiconductor element is disclosed. The support member includes lead electrodes and a support part holding the lead electrodes so that a surface of tip portions of the lead electrodes are exposed in a bottom of the recess. A main surface of the support member has at least a first main surface disposed adjacent to the recess and a second main surface disposed adjacent to the first main surface. The second main surface preferably has a protrusion and a further recess. The protrusion preferably forms an outer wall around a depression. The semiconductor device having this configuration has excellent and accurate positioning and can be strongly bonded with other members. The semiconductor device can also be obtained with a high process yield.

Owner:NICHIA CORP

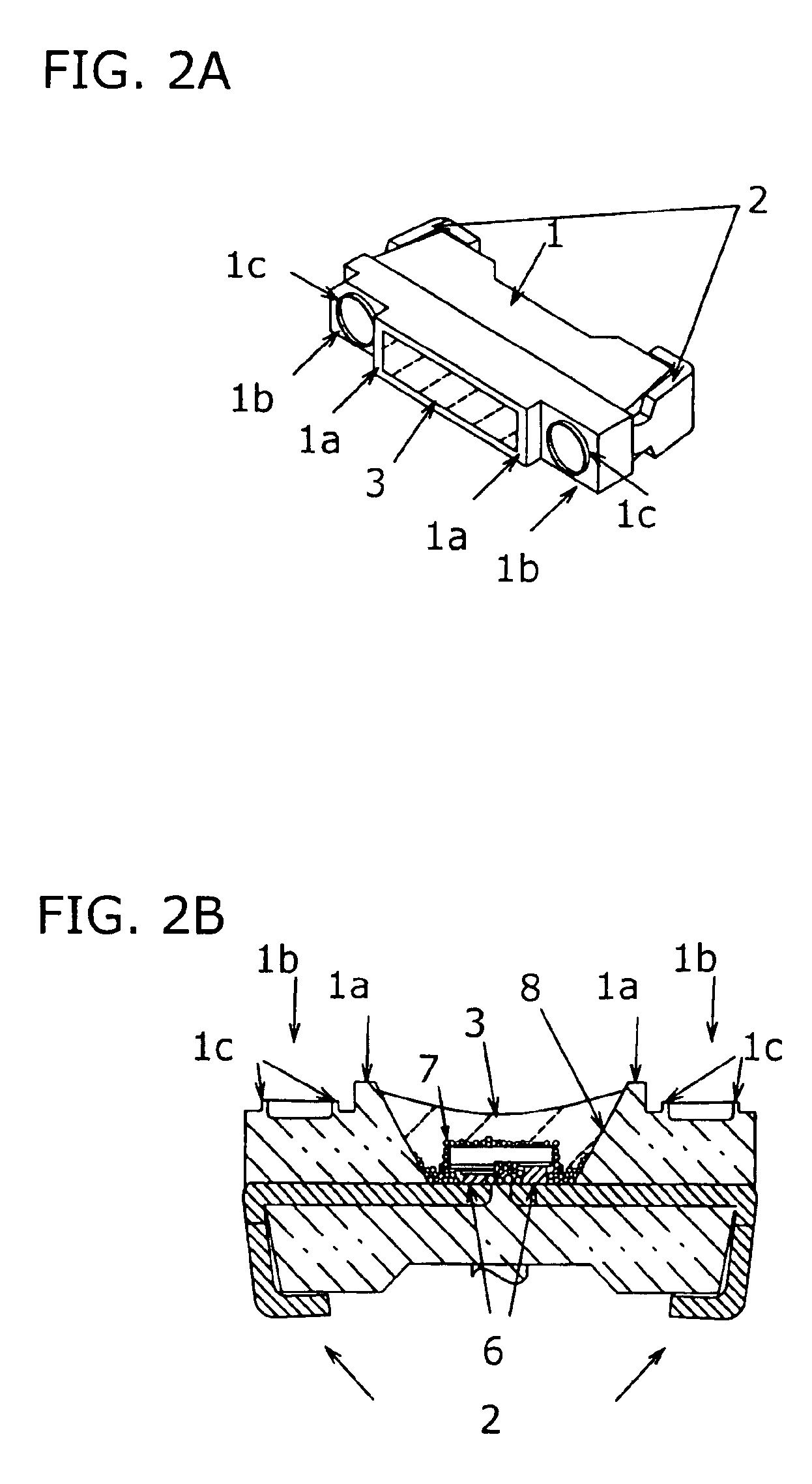

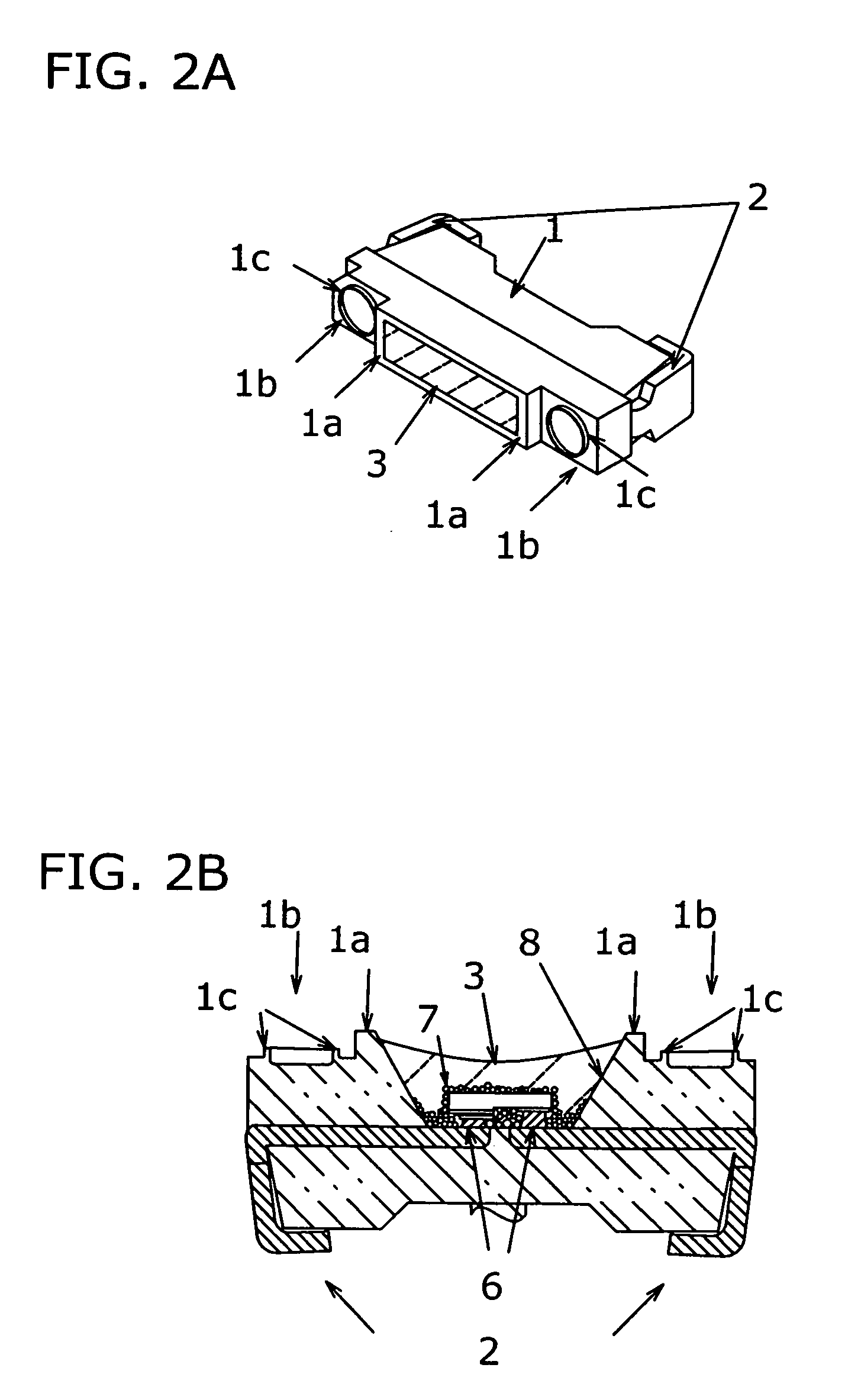

Method for making a semiconductor device

ActiveUS20050277216A1Increase the rate of heatingHeat release rate downSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialLead electrode

A method of making a semiconductor device comprising a semiconductor element and a support member having a recess for housing the semiconductor element is disclosed. The method includes placing at least two lead electrode portions in the molding die; supplying a molding member to the molding die so that the molding member contacts the portion of at least two lead electrode portions; heating the molding member in the molding die so as to cure the molding member into a package with the portion of at least two lead electrode portions; and removing the package from the molding die by a pushing member such that at least one of a protrusion and a recess are formed in a surface of the package. Using this process, a semiconductor device can be obtained with a high process yield.

Owner:NICHIA CORP

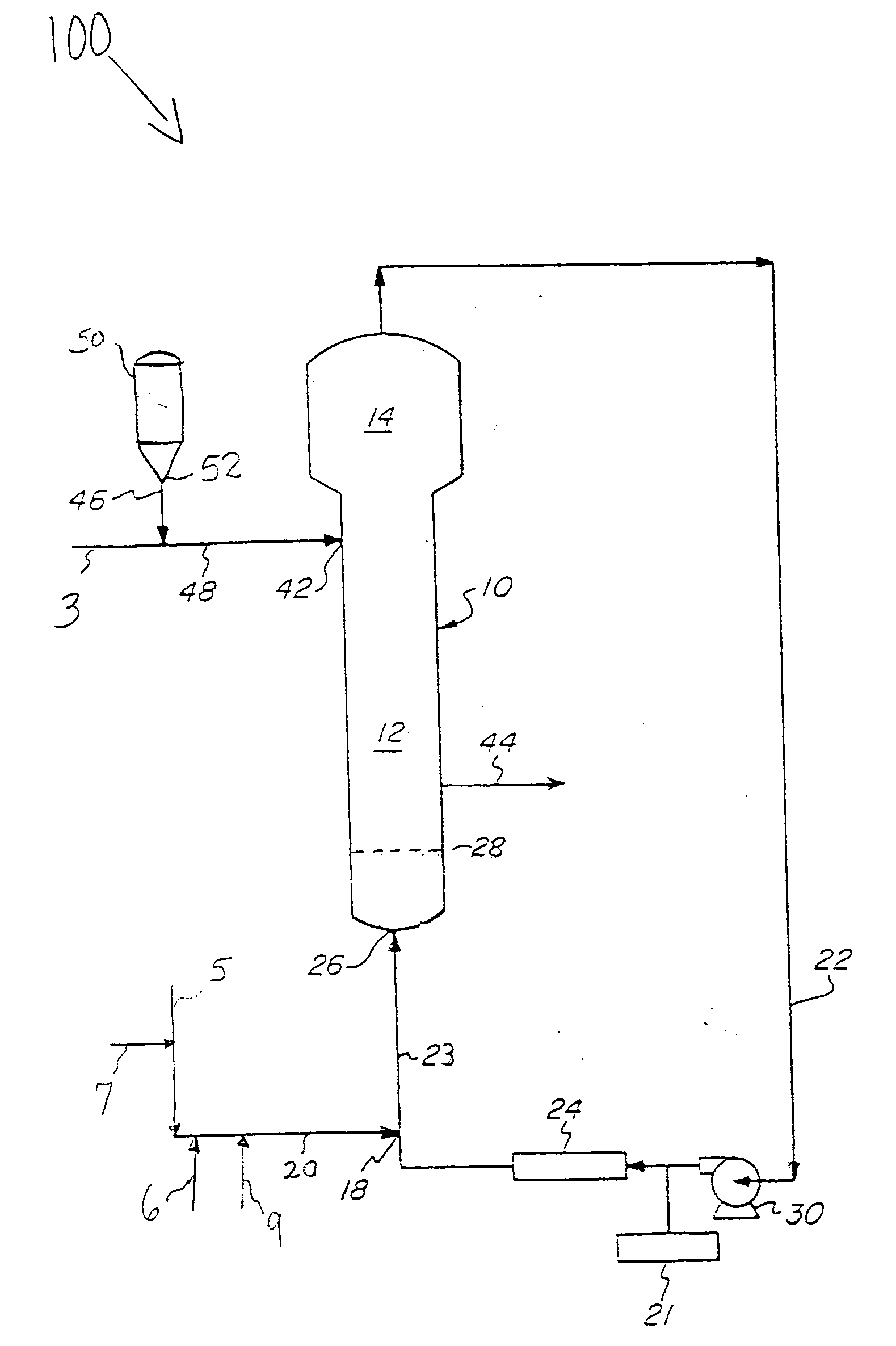

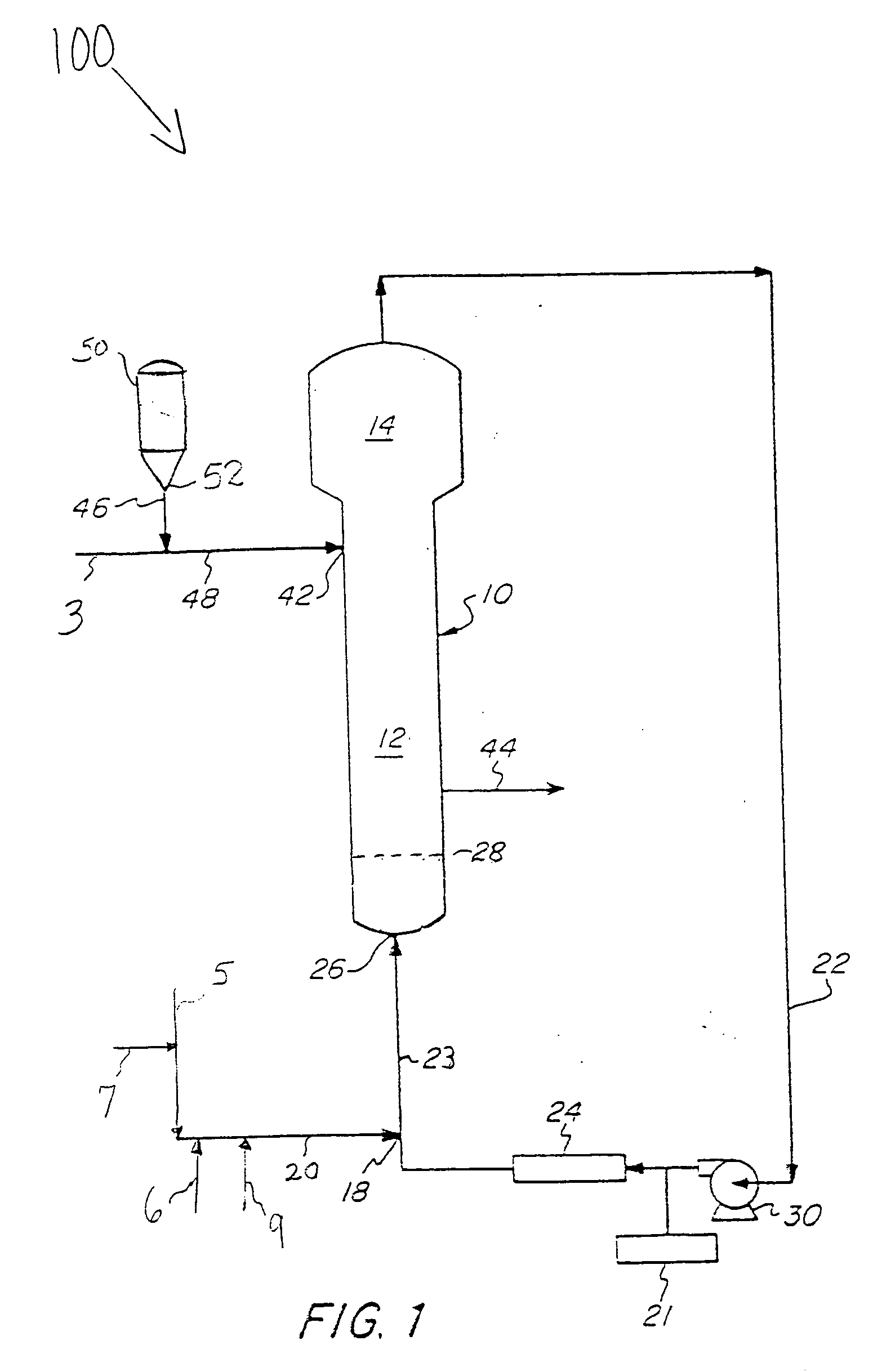

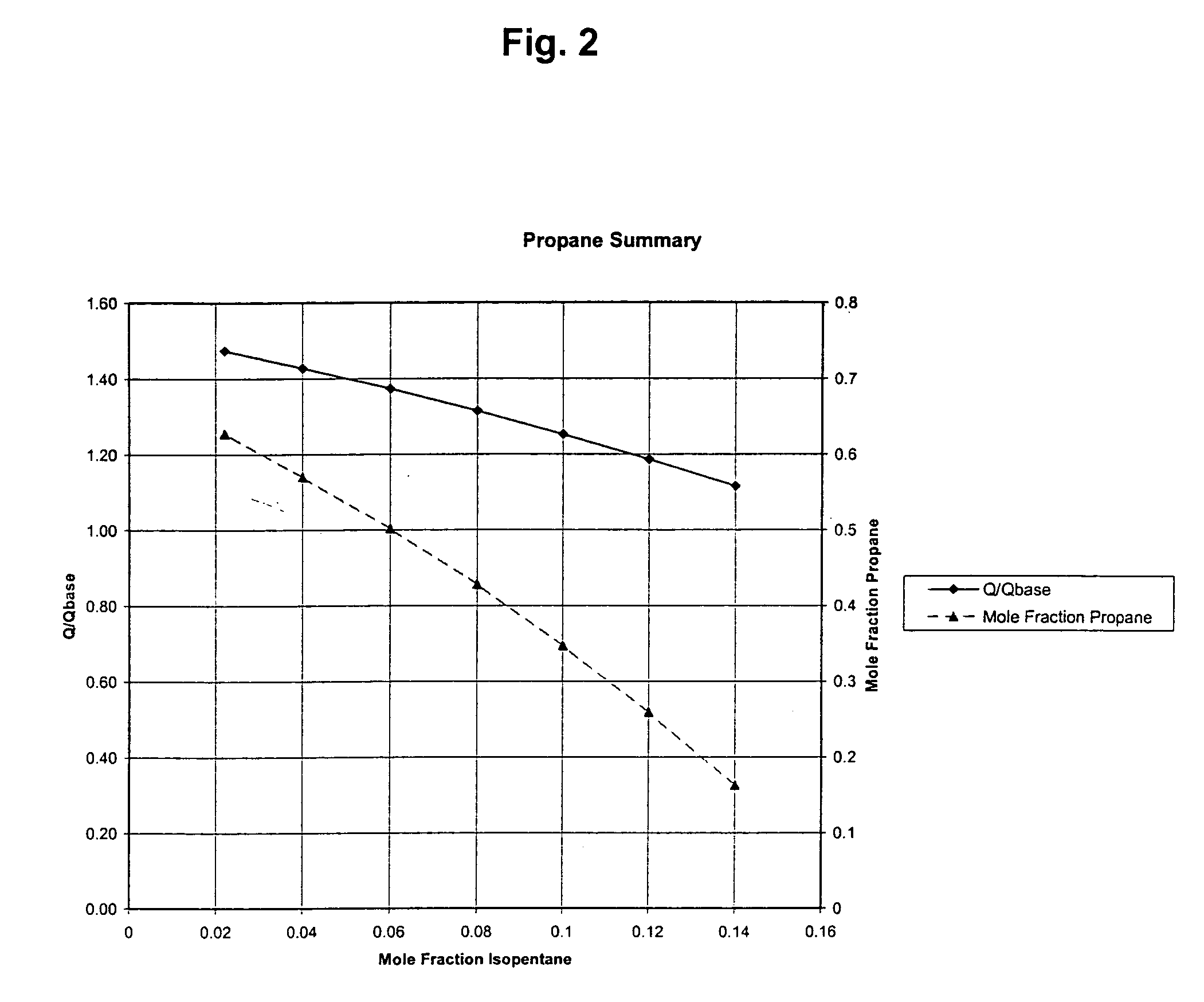

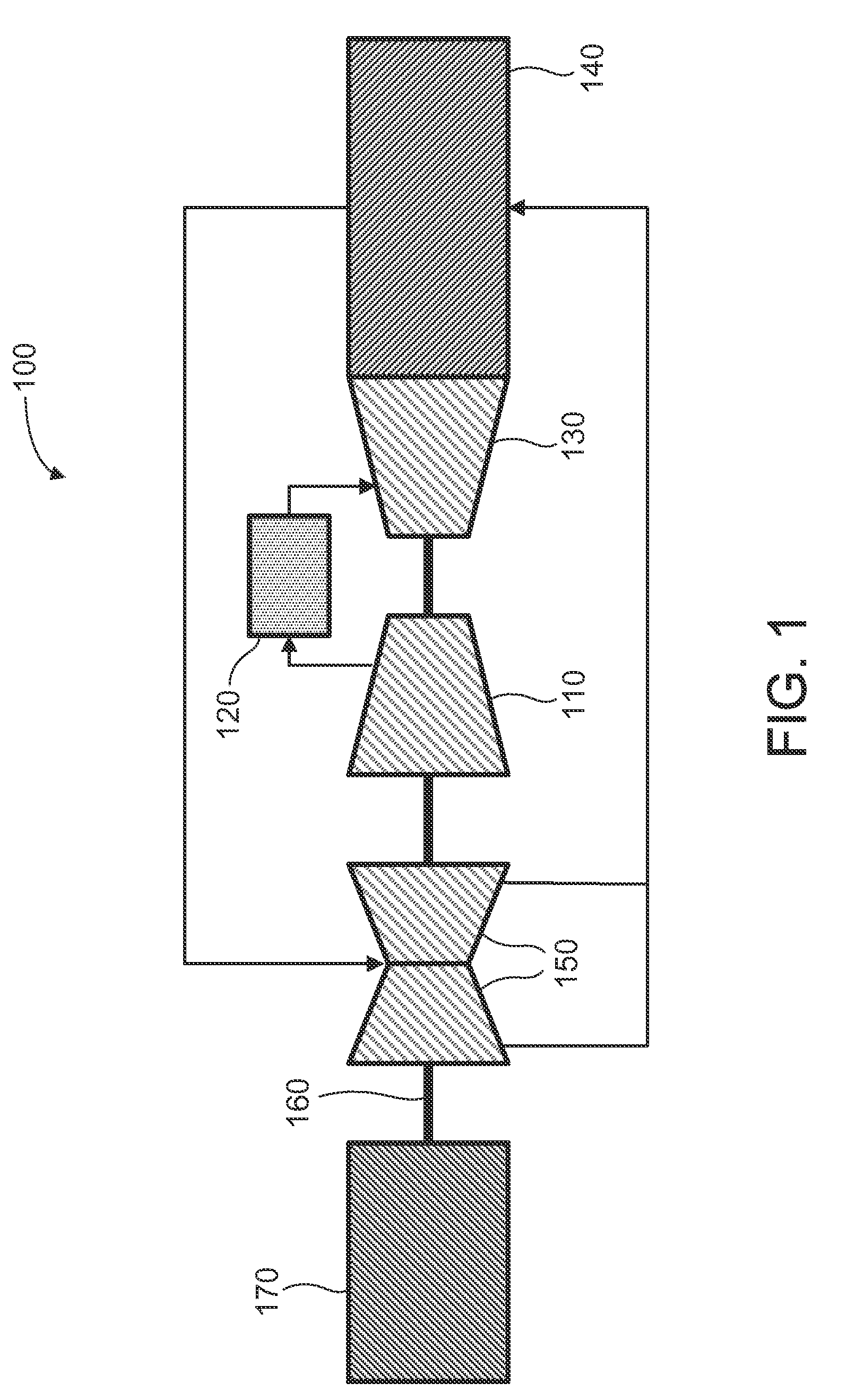

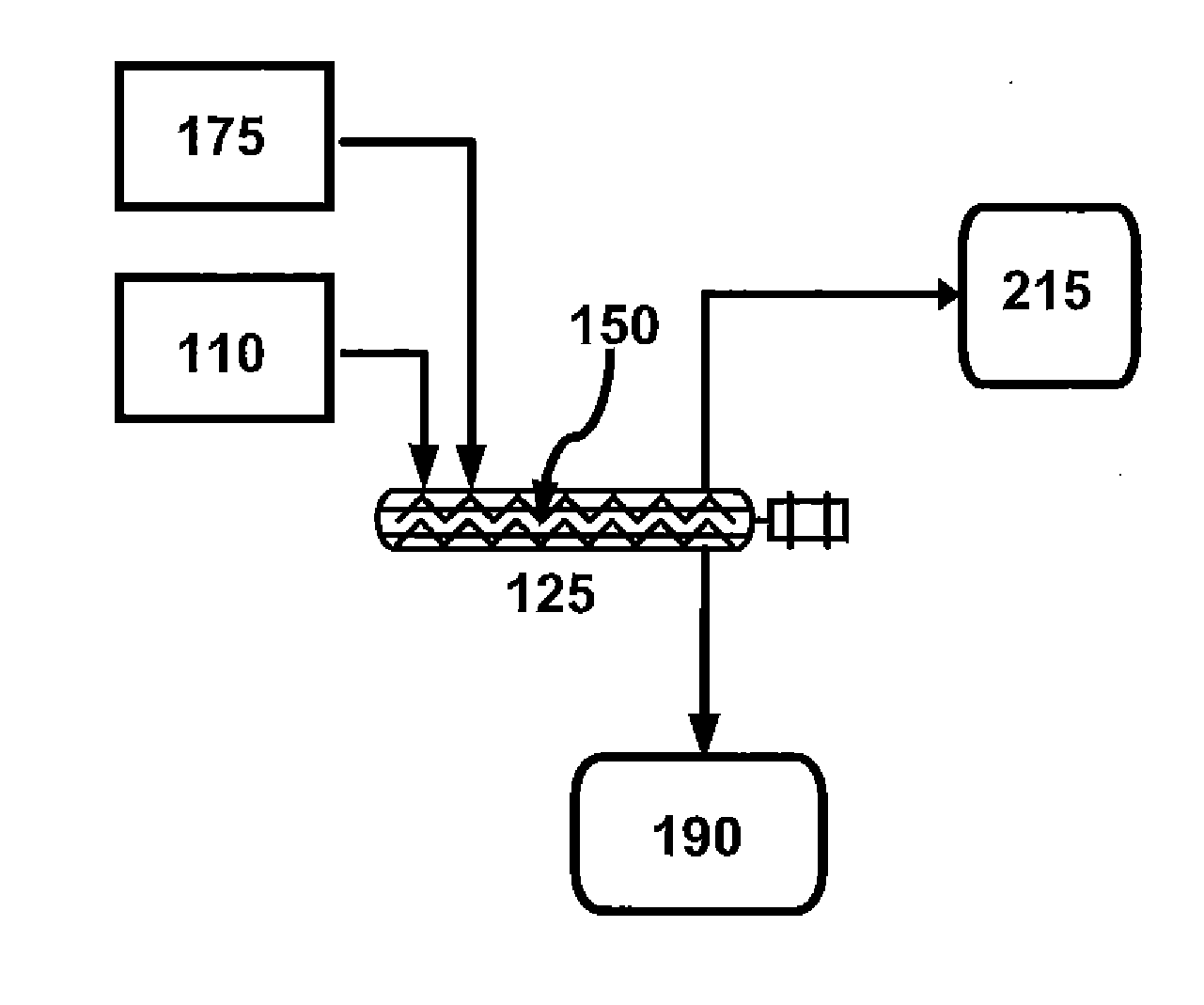

Method for operating a gas phase polymerization reactor

Disclosed herein is a method of operating a polymerization reactor for a polymerization reaction comprising modifying a recycle gas composition to increase the heat capacity of the recycle gas wherein the recycle gas composition is modified by reducing or eliminating the nitrogen concentration in the recycle gas. In an embodiment, the nitrogen concentration is reduced or eliminated by reducing or eliminating one or more nitrogen input sources to the polymerization reactor and replacing the nitrogen with an alternate inert fluid (a gas or liquid that is inert to the catalyst and reactants). The alternate inert fluid has a higher heat capacity and a higher molecular weight than nitrogen. In an embodiment, the nitrogen utilized to convey a catalyst into the polymerization reactor is replaced with an alternate inert fluid. In an embodiment, the alternate inert fluid is ethane, propane, isobutane, or combinations thereof.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

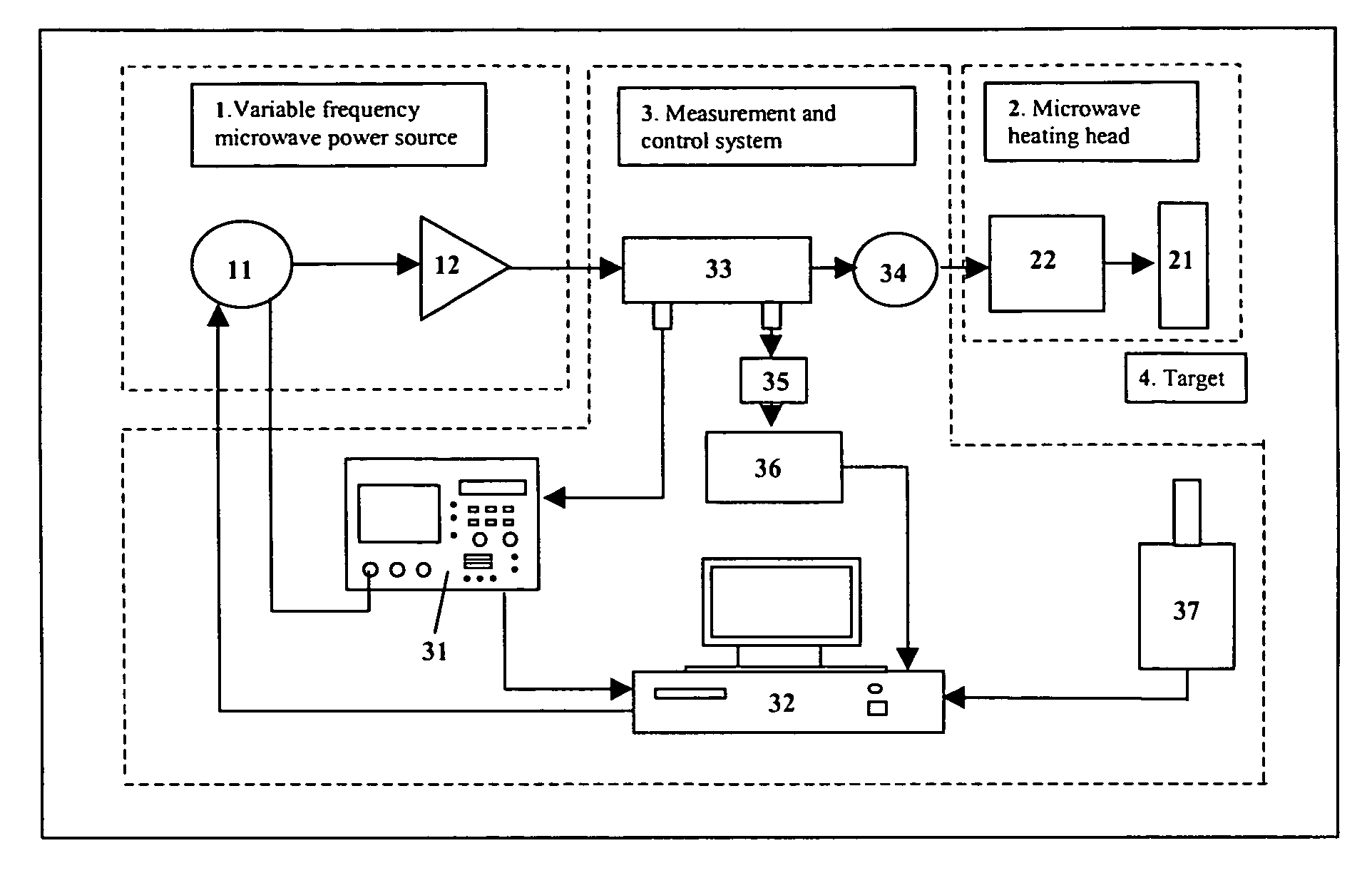

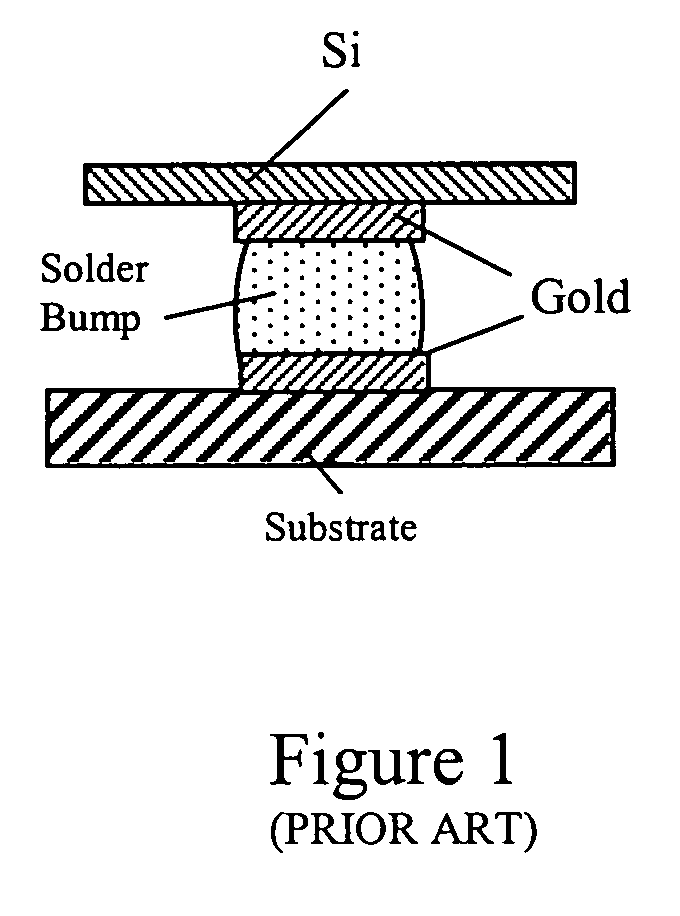

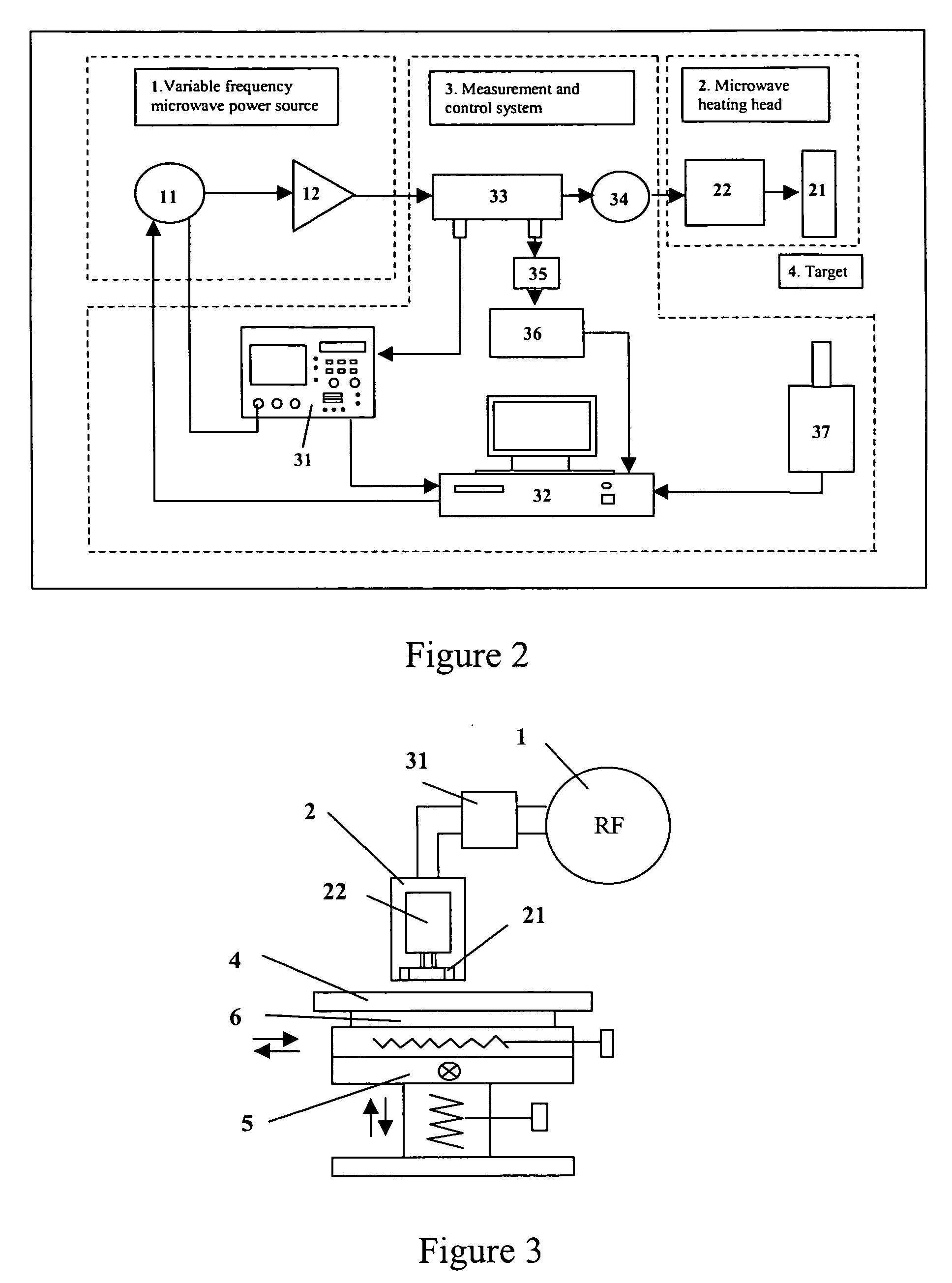

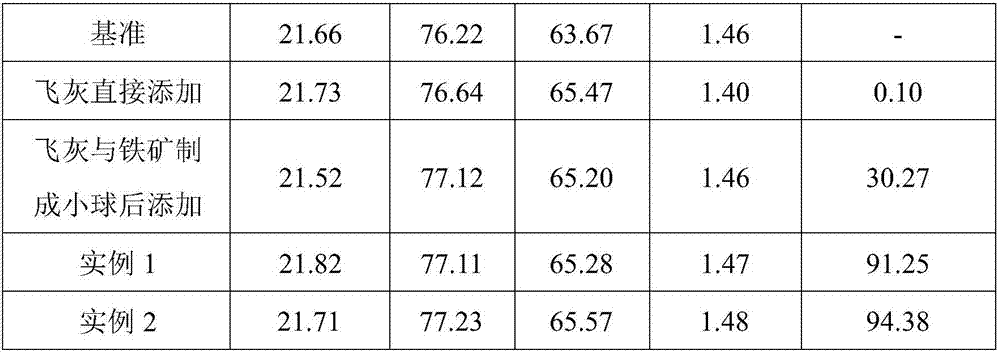

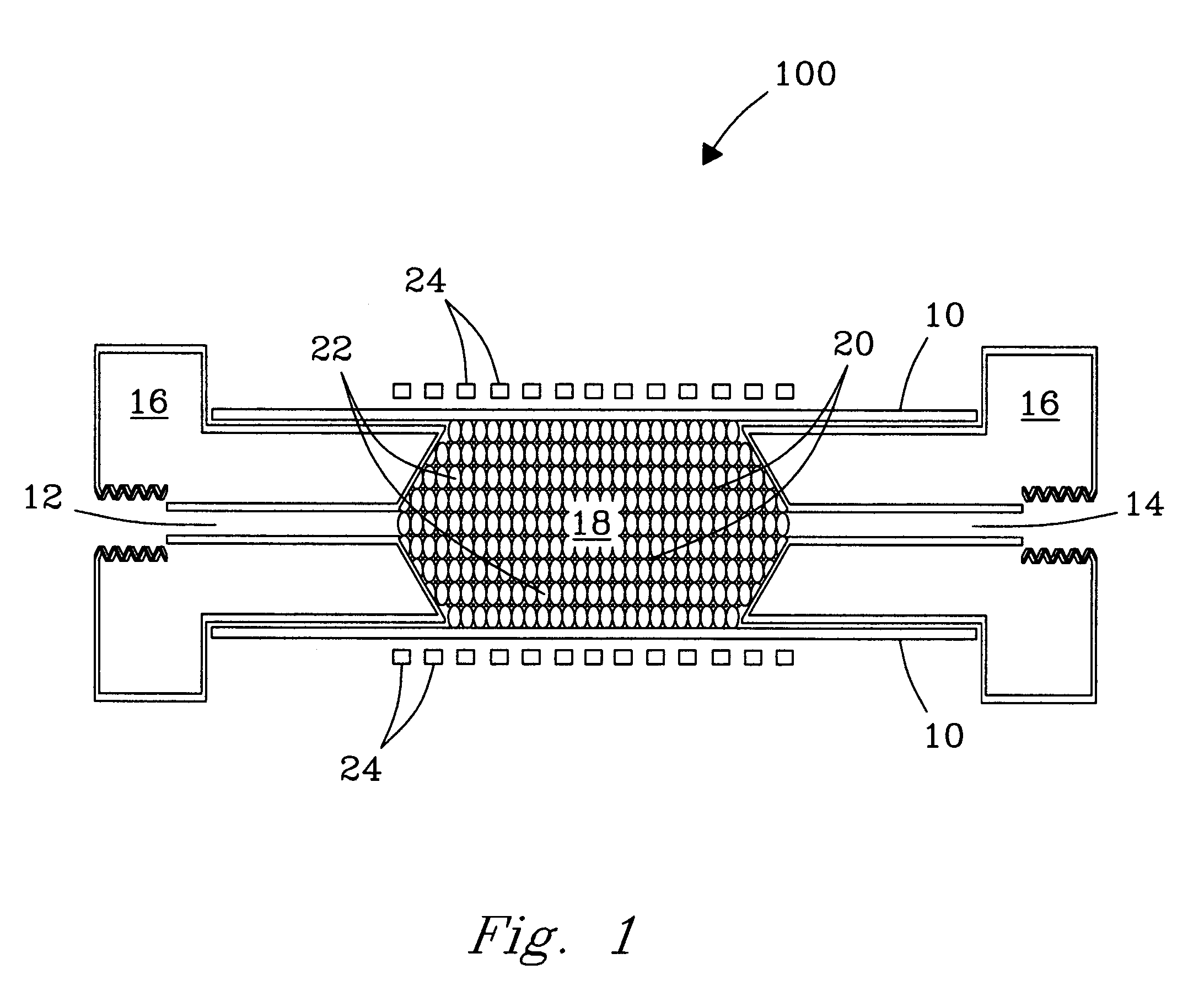

Method and apparatus for rapid thermal processing and bonding of materials using RF and microwaves

ActiveUS20070108195A1Heating fastMicrowave heating is fastSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceInterconnection density

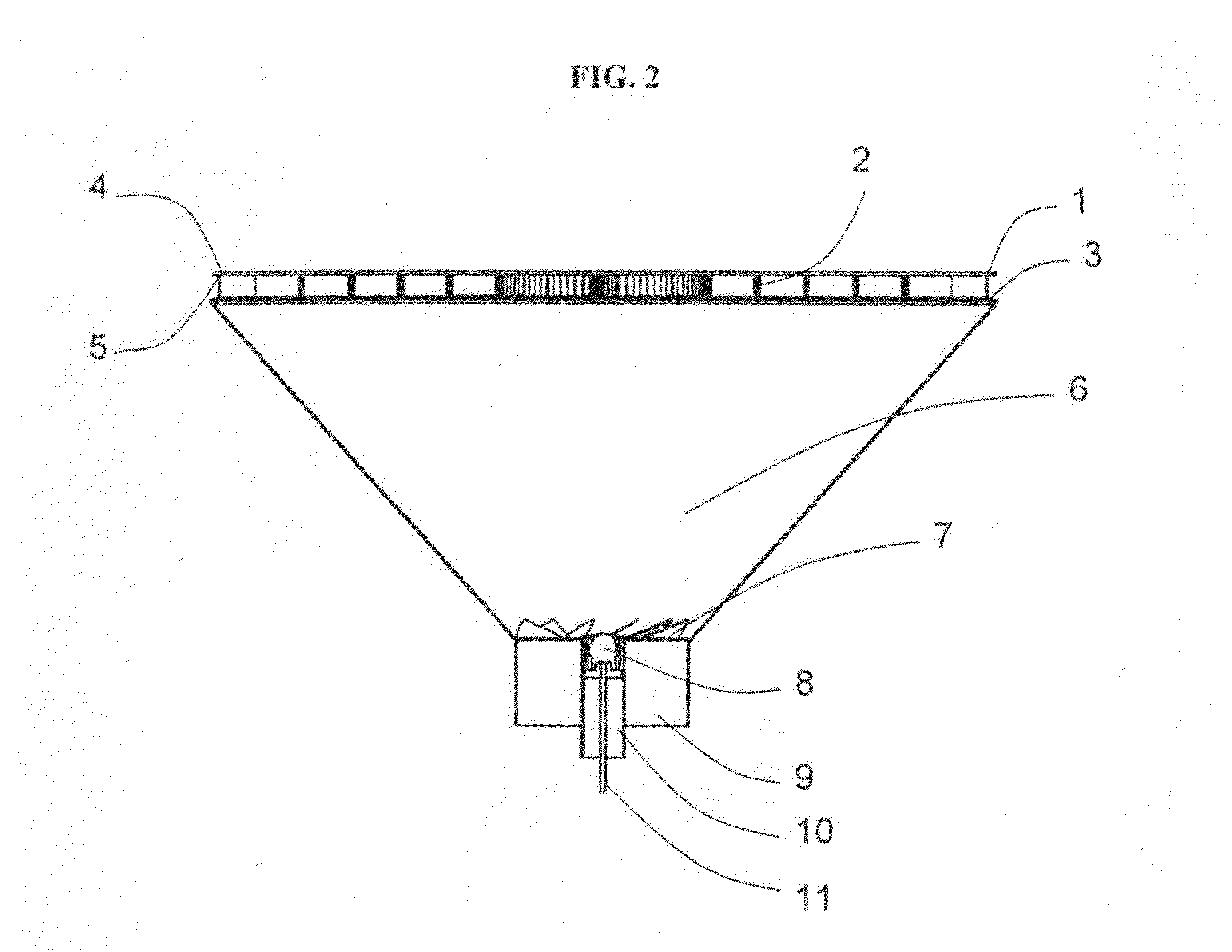

A method and apparatus for rapid and selective heating of materials using variable frequency RF and microwaves. The apparatus uses variable frequency solid state electronics as a microwave power source, a novel microwave heating head to couple microwave energy to the target materials and a match-up network to tune the frequency and impedance match between the microwave source and the load. An electronic and computer measurement and control system is employed to monitor and control the microwave heating process. The method teaches the use of inductive microwave coupling for thin conductive materials such as metal film and impurity doped silicon wafers. The method also teaches the use of capacitive microwave coupling for dielectric material such as glass and ceramics. The method further teaches the use of rapid and selective heating of heterostructure for bonding and sealing of mems and integrated circuits. The method and apparatus can provide ultra-high heating speed along with ultra-high heating temperatures for rapid thermal processing of semiconductors and other materials. It also allows the use of bonding materials with high melting temperature for strong bonding and sealing of mems and IC devices. The apparatus further provides for high interconnection density of integrated circuits as connections are made without the use of solder bumps.

Owner:TIAN YONGLAI +1

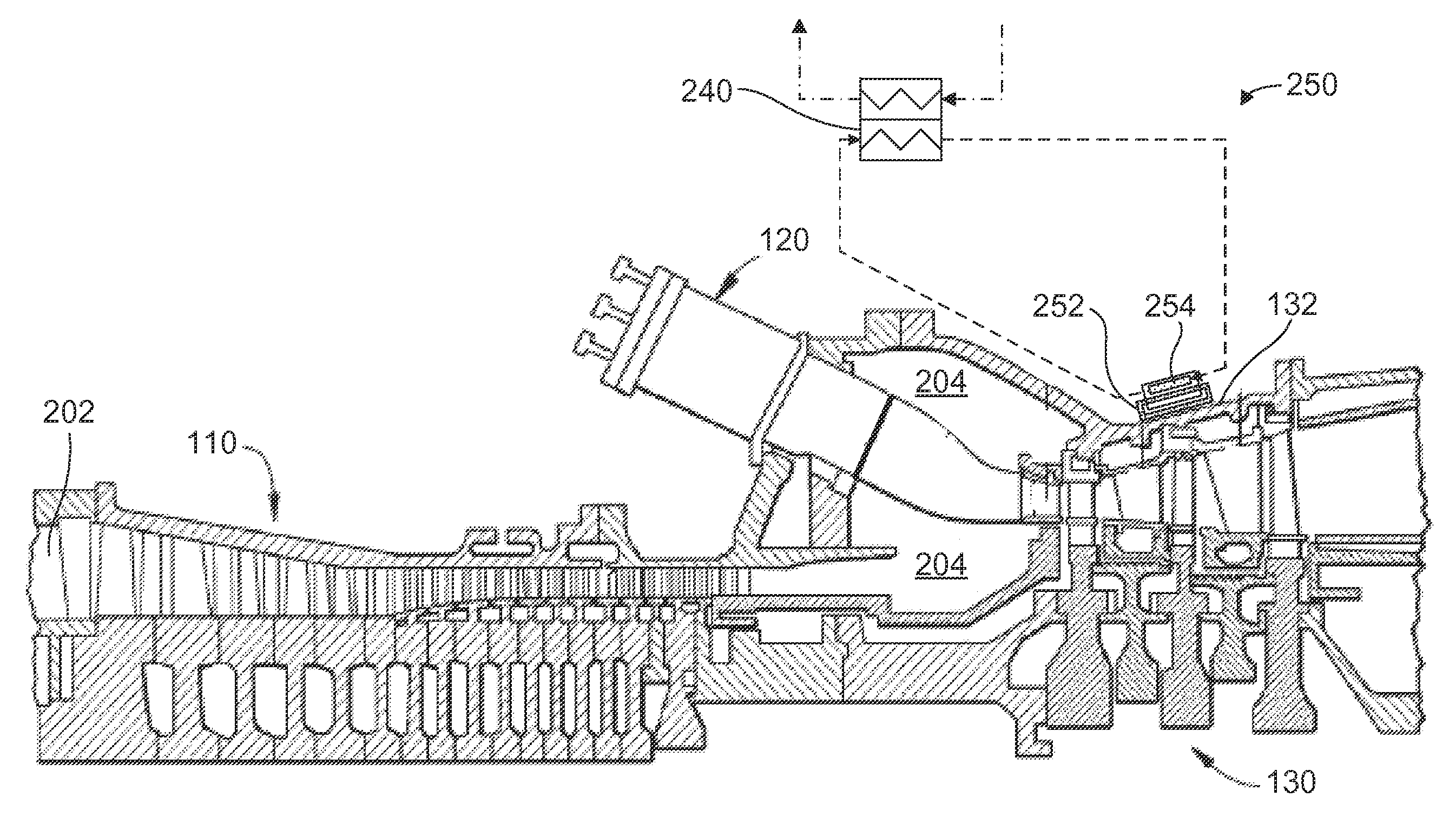

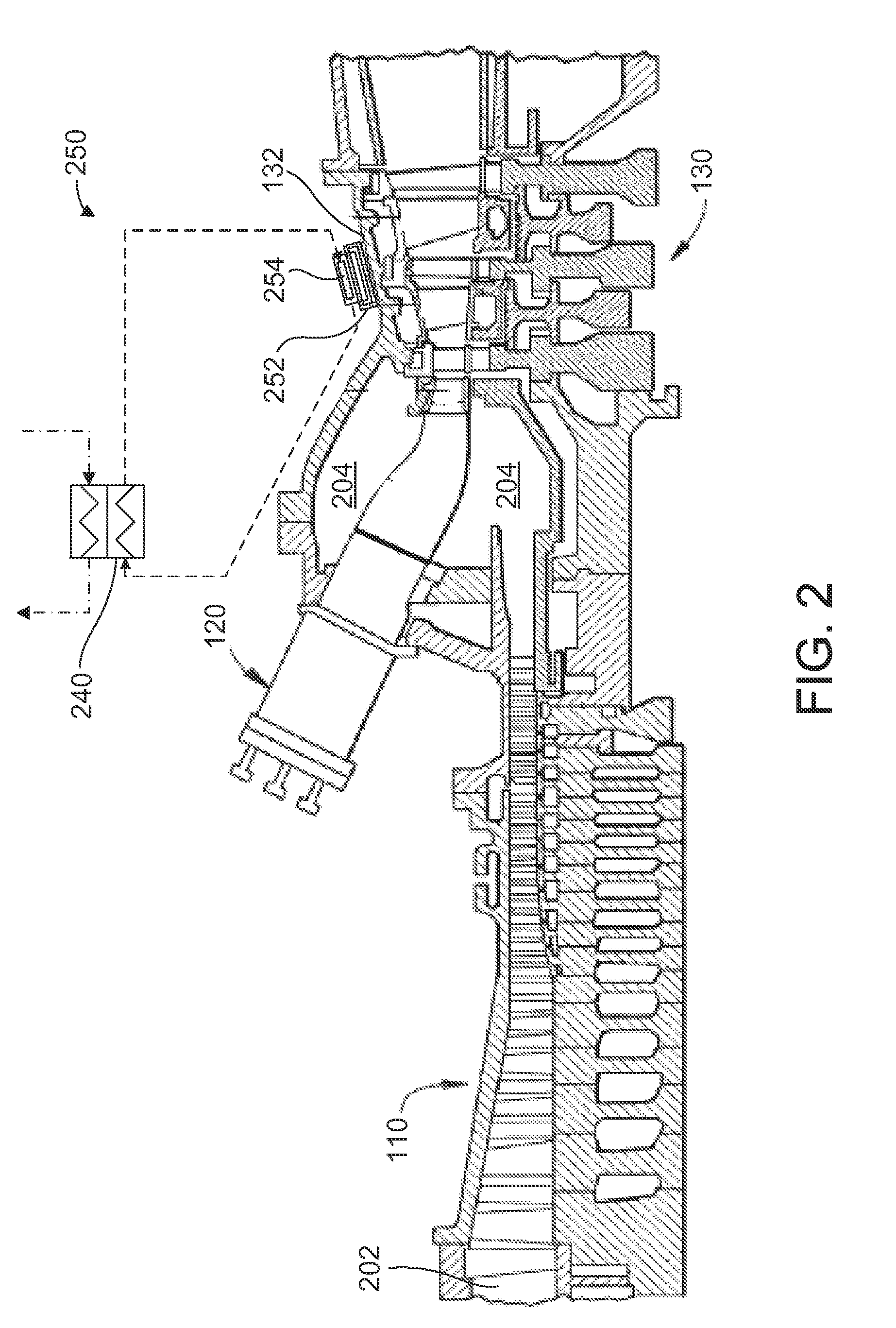

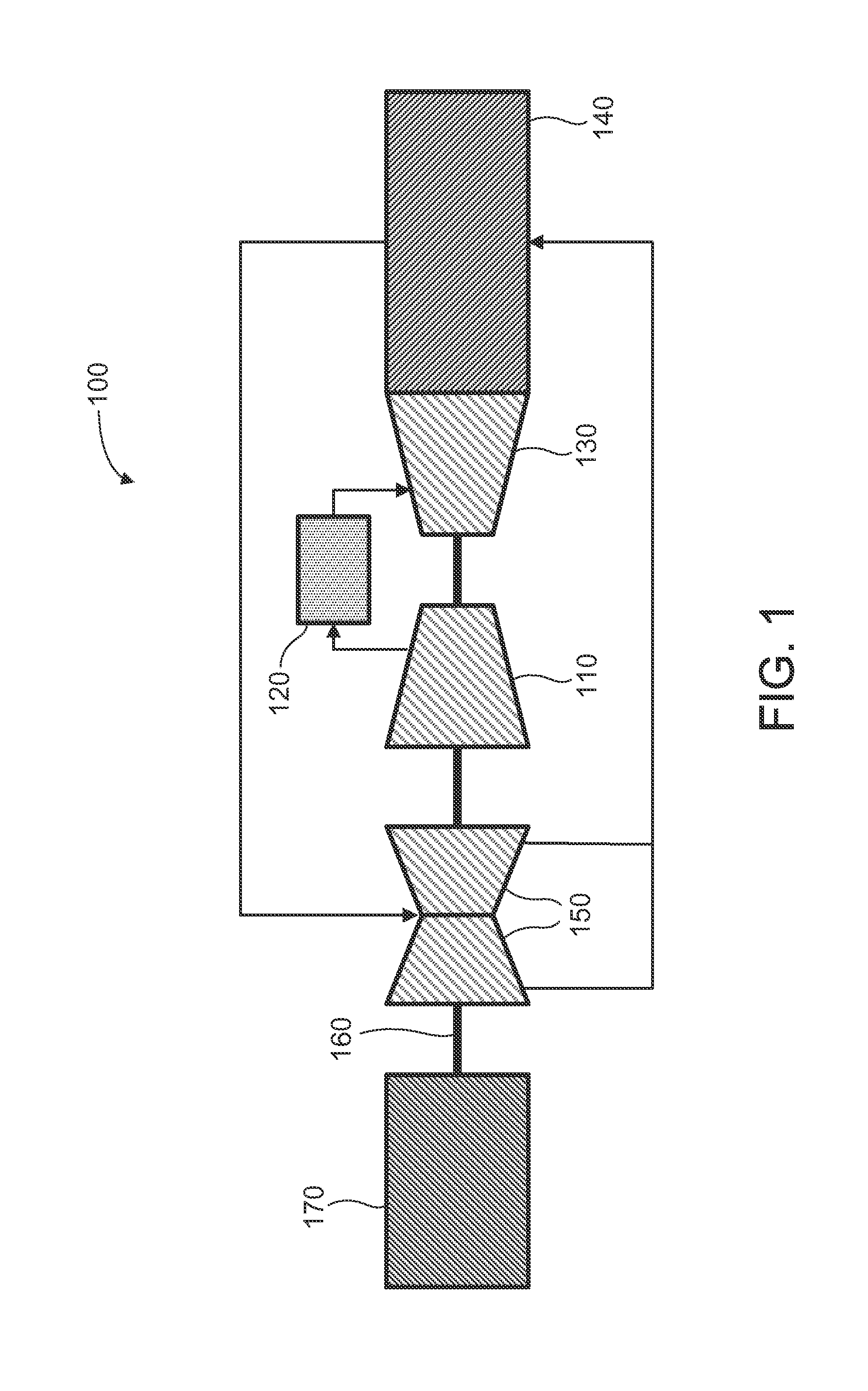

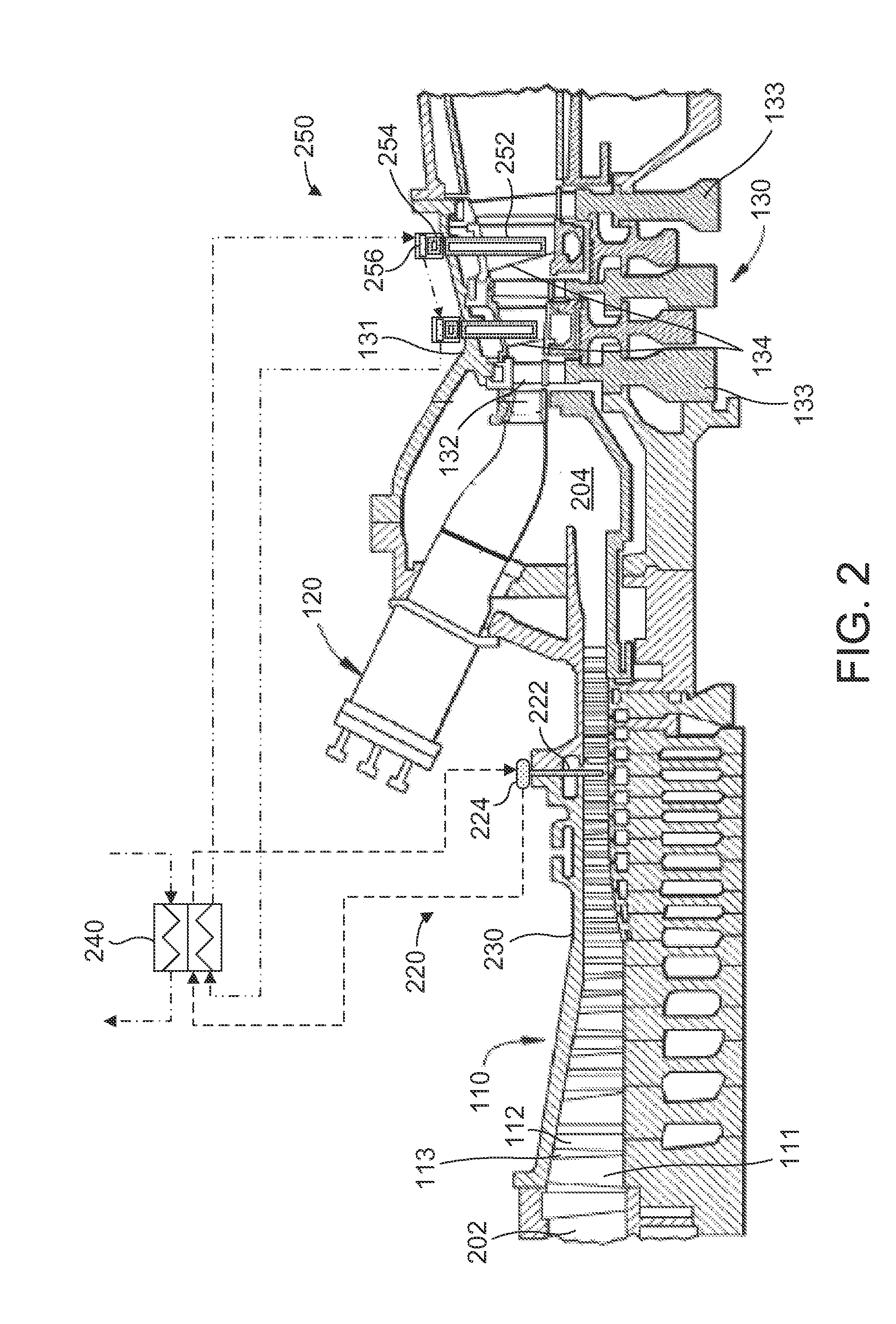

Heat pipe cooled turbine casing system for clearance management

InactiveUS20160290214A1Extend your lifeImprove efficiencyInternal combustion piston enginesEngine fuctionsCombustorTurbine

A turbomachine includes a compressor configured to compress air received at an intake portion to form a compressed airflow that exits into an outlet portion. A combustor is operably connected with the compressor, and the combustor receives the compressed airflow. A turbine is operably connected with the combustor, and the turbine receives combustion gas flow from the combustor. The turbine has a turbine casing. A cooling system is operatively connected to the turbine casing. The cooling system includes a plurality of heat pipes attached to and in thermal communication with the turbine casing. The plurality of heat pipes are operatively connected to one or more manifolds. The plurality of heat pipes and the one or more manifolds are configured to transfer heat from the turbine casing to a plurality of heat exchangers.

Owner:GENERAL ELECTRIC CO

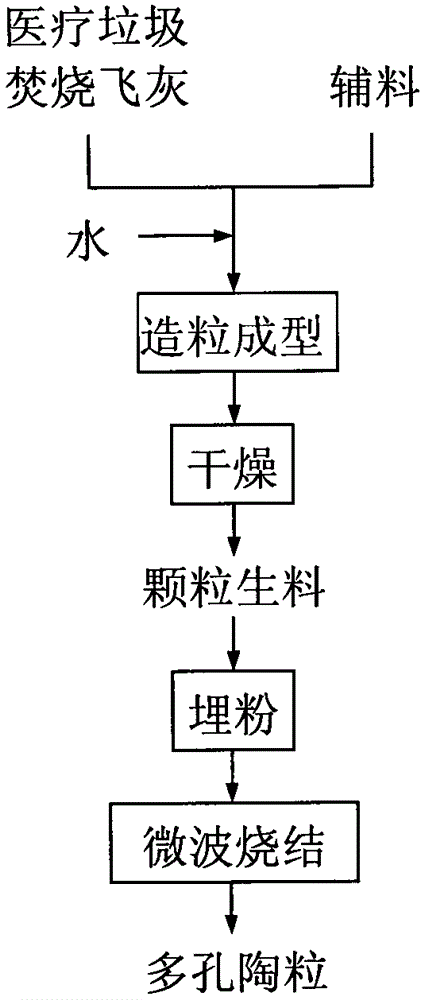

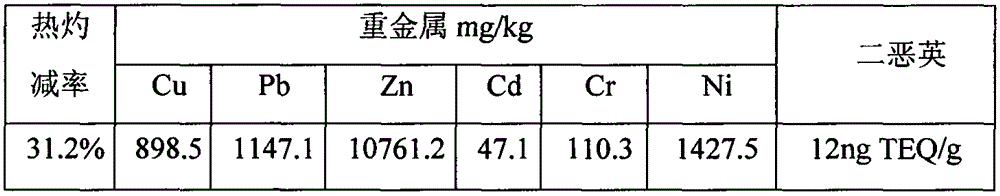

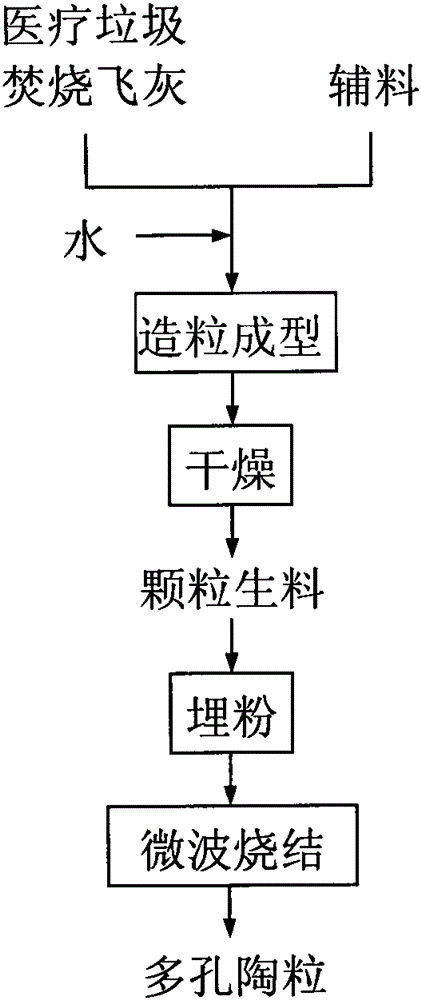

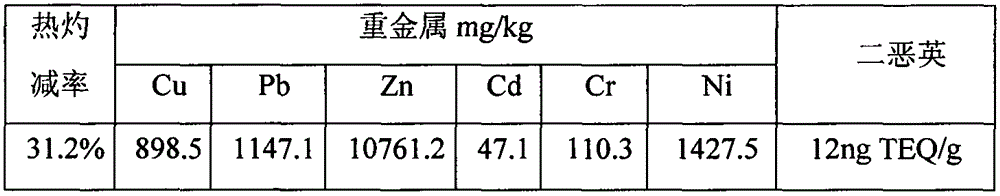

Method for microwave firing of porous ceramsites by adopting medical waste incineration fly ash

The invention discloses a method for microwave sintering of porous ceramsites by adopting medical waste incineration fly ash. The method comprises the following steps: (1) fully mixing the medical waste incineration fly ash with an auxiliary material, adding a small amount of water into the mixture, and carrying out granulation molding by a molding machine; (2) carrying out granulation molding, drying to obtain a particle raw material, filling the periphery of the particle raw material with a microwave coupling agent powder; and (3) carrying out microwave sintering of the particle raw material filled with the powder, and after sintering, cooling to the room temperature to obtain the porous ceramsites. The method can utilize a 'hot spot' effect of fly ash high-content active carbon in a microwave field to instantly completely decompose dioxins in the fly ash, at the same time, allows most heavy metals to be wrapped and cured in grids of the sintered product, and rapidly sinters the fly ash into the porous ceramsites; and the ceramsites can be used for building aggregates or wastewater filter materials, achieves further resource utilization while achieving harmlessness treatment of the medical waste incineration fly ash, and achieves many things at one stroke.

Owner:TIANJIN CHENGJIAN UNIV

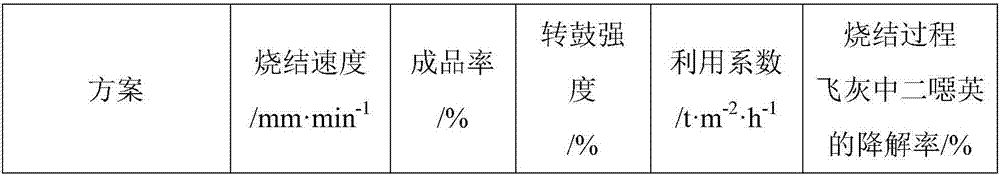

Dioxin control method for iron ore sintering garbage fly ash coprocessing process

ActiveCN107159678ARealize normal sinteringEffectively fixedTransportation and packagingSolid waste disposalSludgeLitter

The invention discloses a dioxin control method for the iron ore sintering garbage fly ash coprocessing process. According to the method, garbage fly ash, lime milk, flammable solid fuel and sludge are subject to mixed granulation and drying, and small balls containing garbage fly ash are obtained; iron core sintering raw materials are granulated and then are mixed with the small balls of the garbage fly ash, and after distribution, ignition and sintering are carried out. According to the method, on the premise that the iron ore sintering is not affected, efficient decomposing of dioxin contained in the fly ash can be achieved, dioxin secondarily formed in the garbage fly ash sintering process is prevented, according to the method, the decomposing rate of the garbage fly ash dioxin reaches 90% or above, meanwhile, effective solidifying of the garbage fly ash can be ensured, and in the sintering process, the aim of cleaning the garbage fly ash is achieved.

Owner:CENT SOUTH UNIV +1

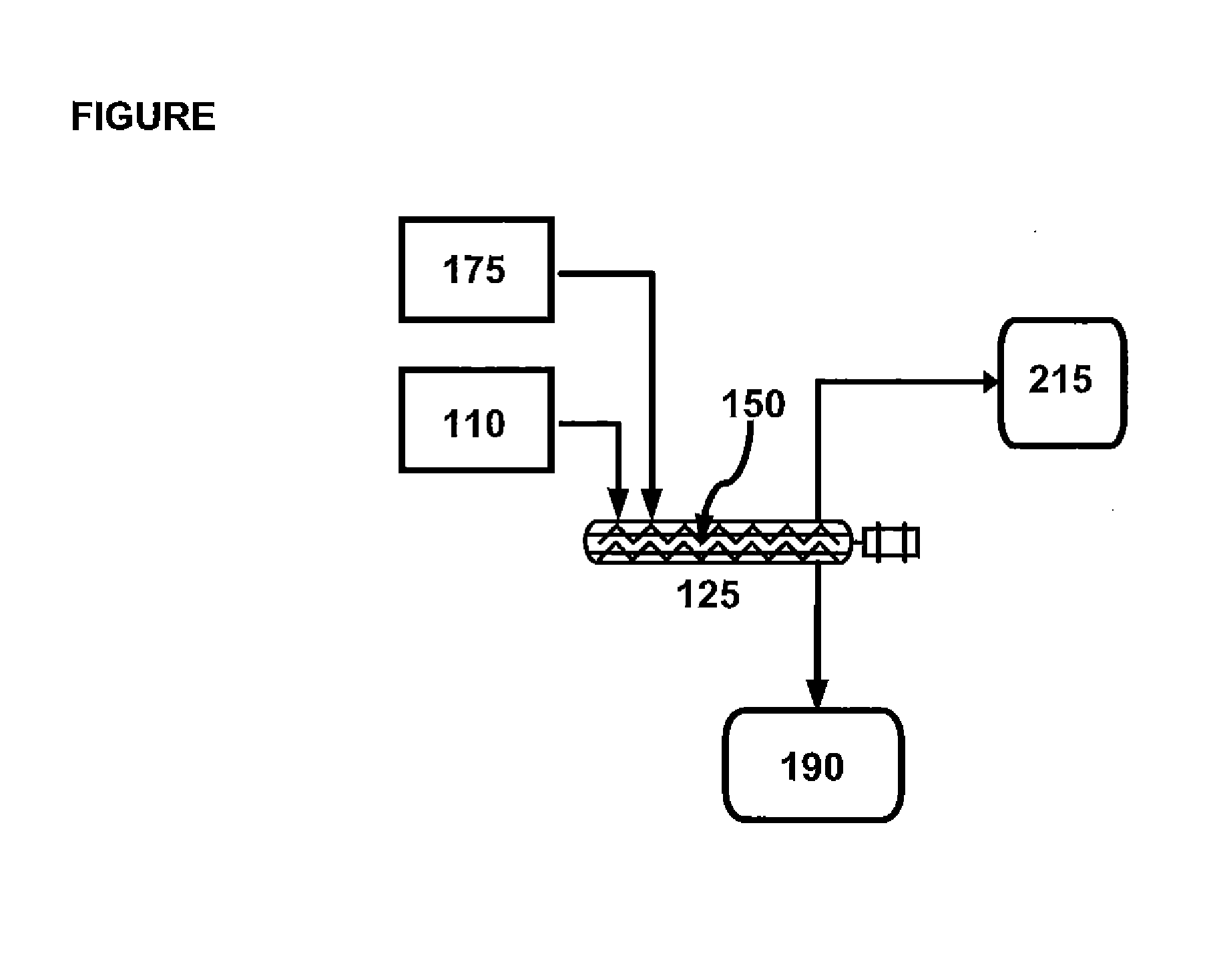

Method and apparatus for concentrating vapors for analysis

ActiveUS20070180933A1Increase the rate of heatingImprove thermal conductivityComponent separationWithdrawing sample devicesImage resolutionDetection limit

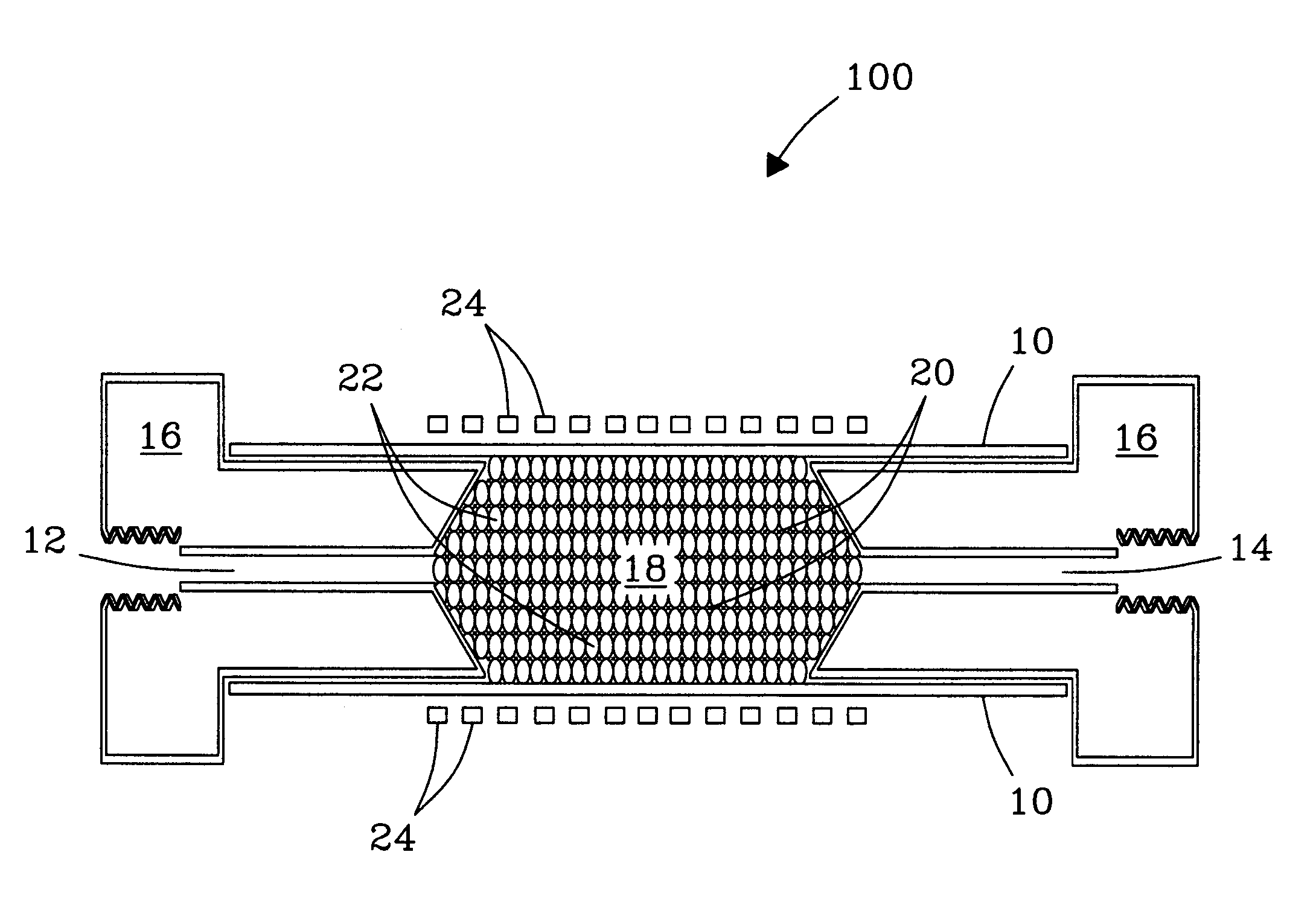

An apparatus and method are disclosed for pre-concentrating gaseous vapors for analysis. The invention finds application in conjunction with, e.g., analytical instruments where low detection limits for gaseous vapors are desirable. Vapors sorbed and concentrated within the bed of the apparatus can be thermally desorbed achieving at least partial separation of vapor mixtures. The apparatus is suitable, e.g., for preconcentration and sample injection, and provides greater resolution of peaks for vapors within vapor mixtures, yielding detection levels that are 10-10,000 times better than for direct sampling and analysis systems. Features are particularly useful for continuous unattended monitoring applications.

Owner:BATTELLE MEMORIAL INST

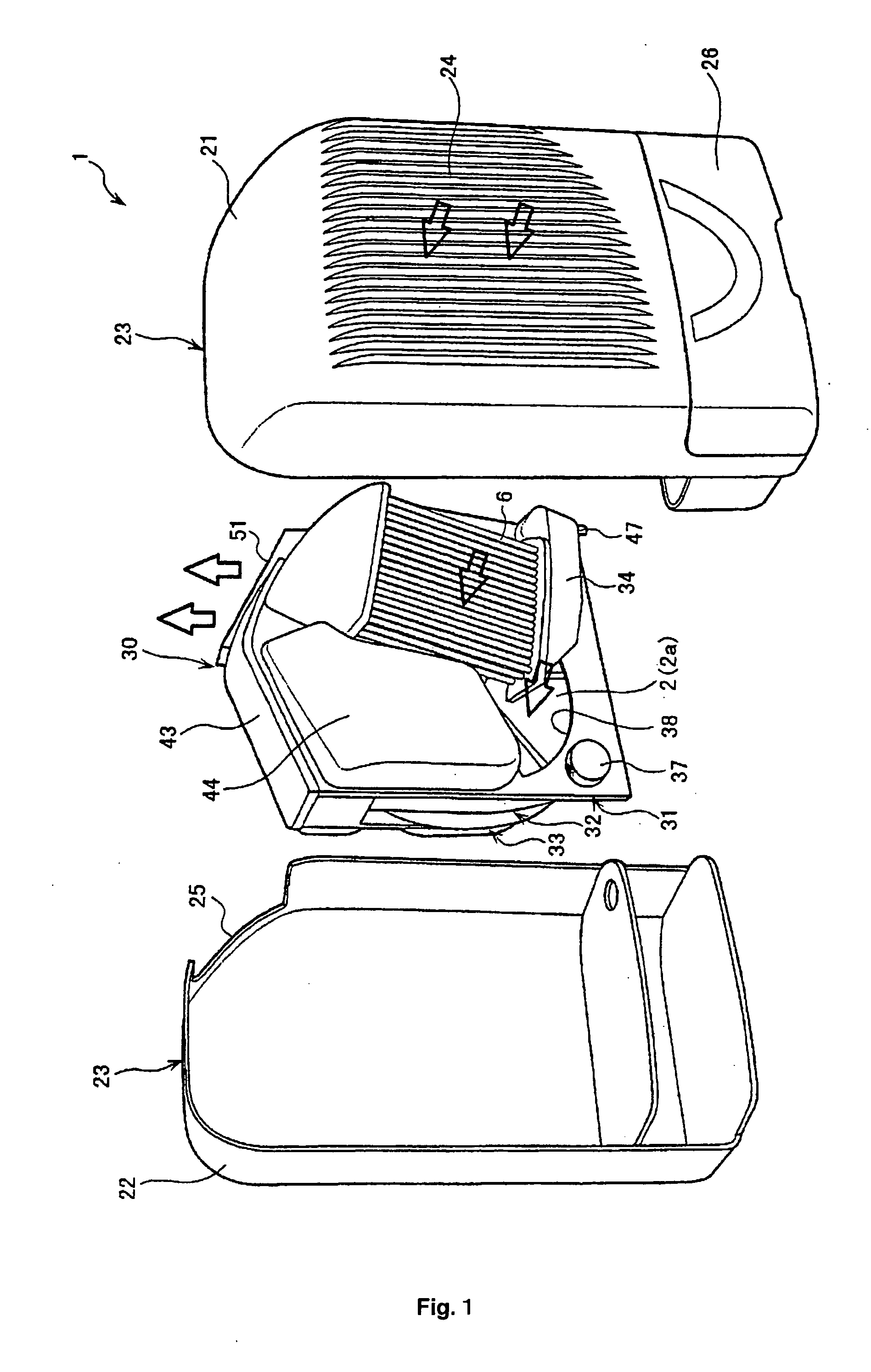

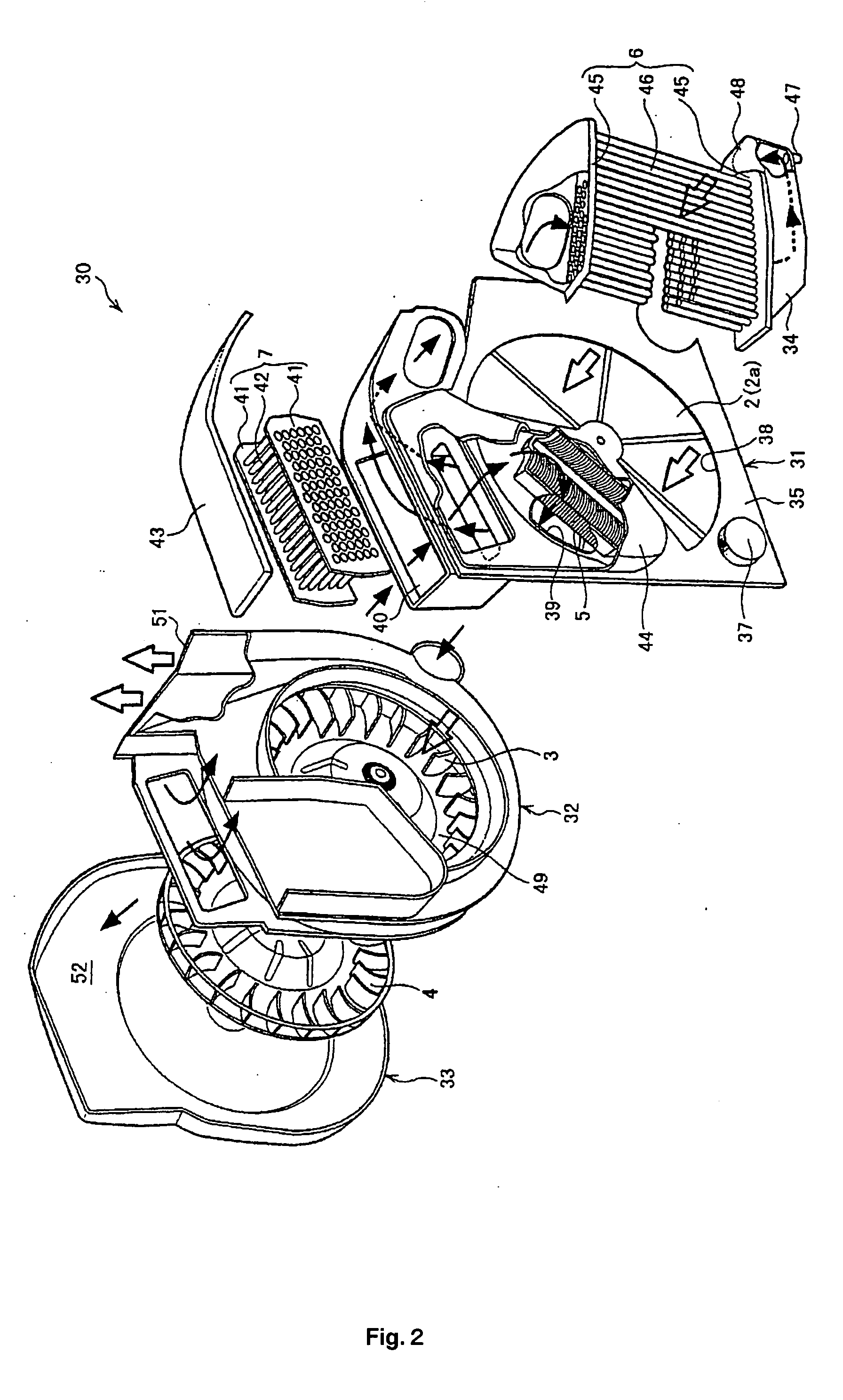

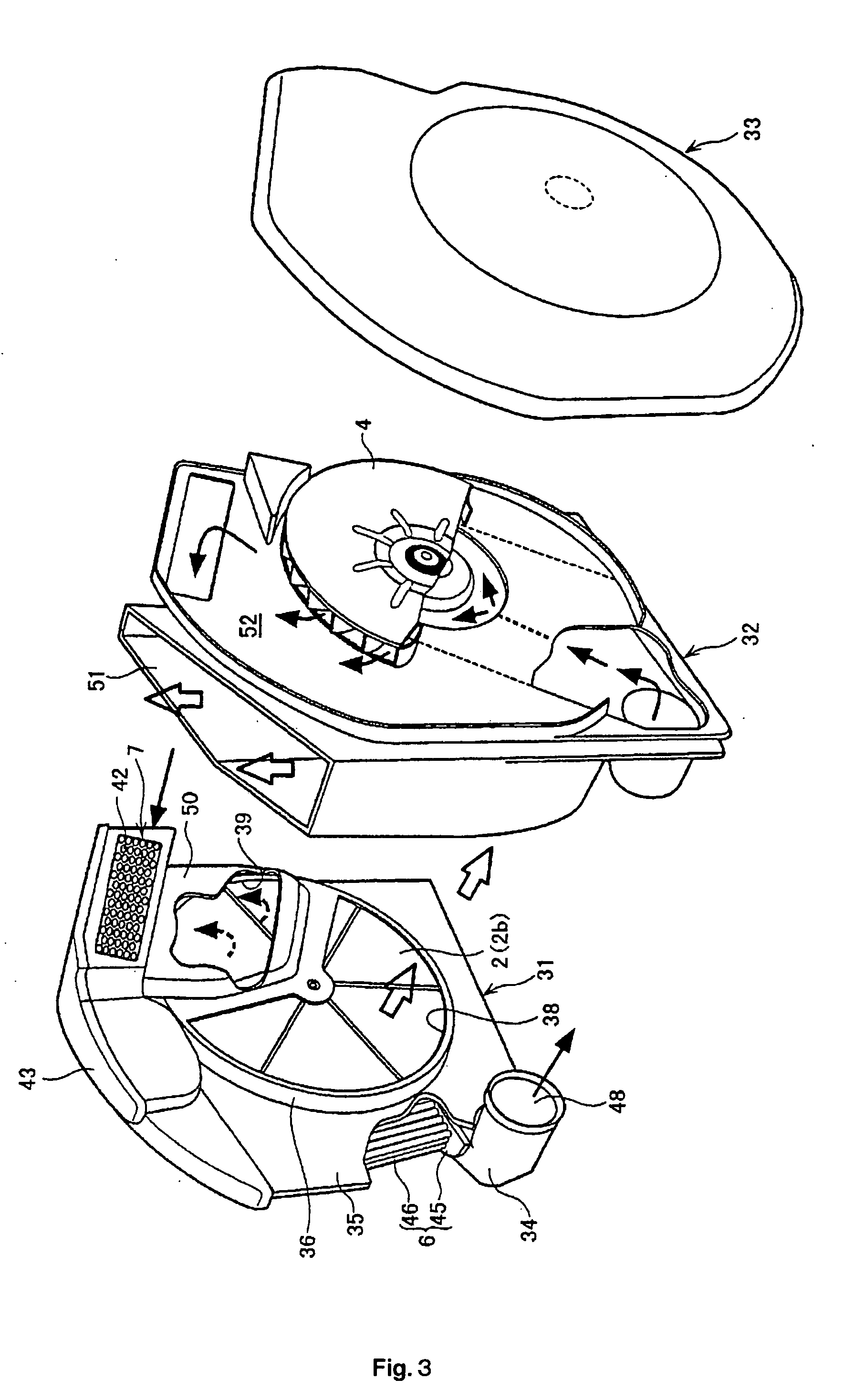

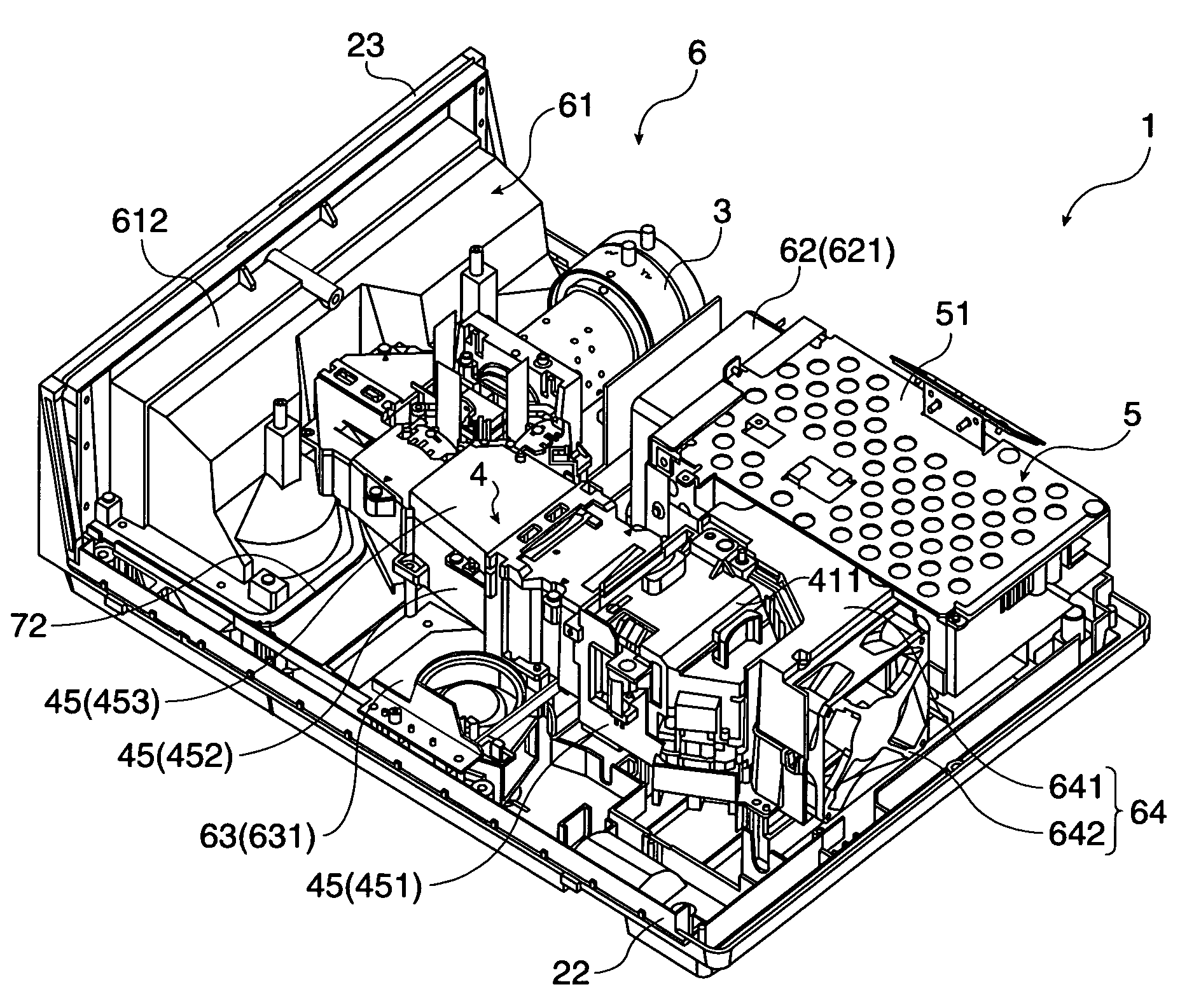

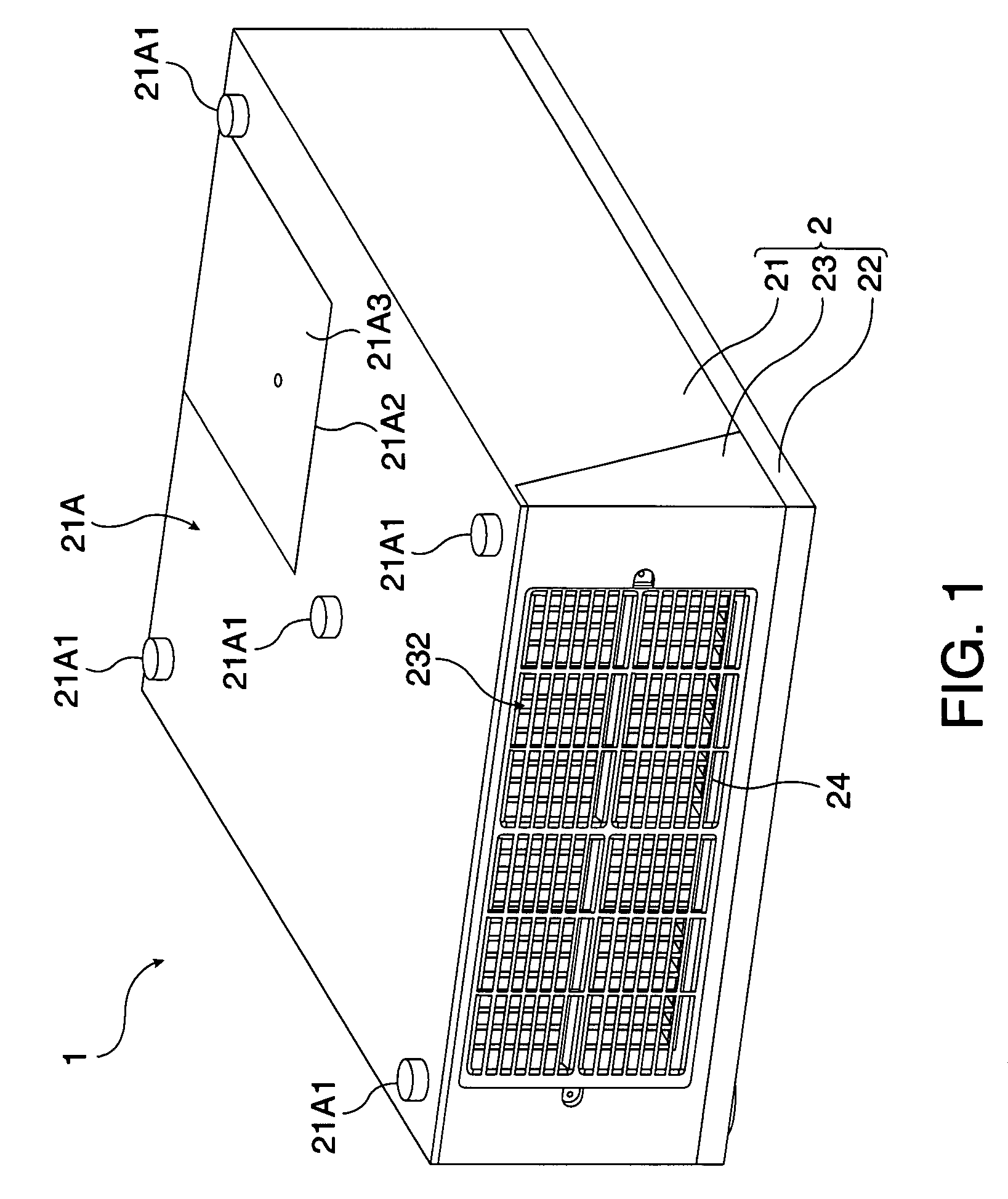

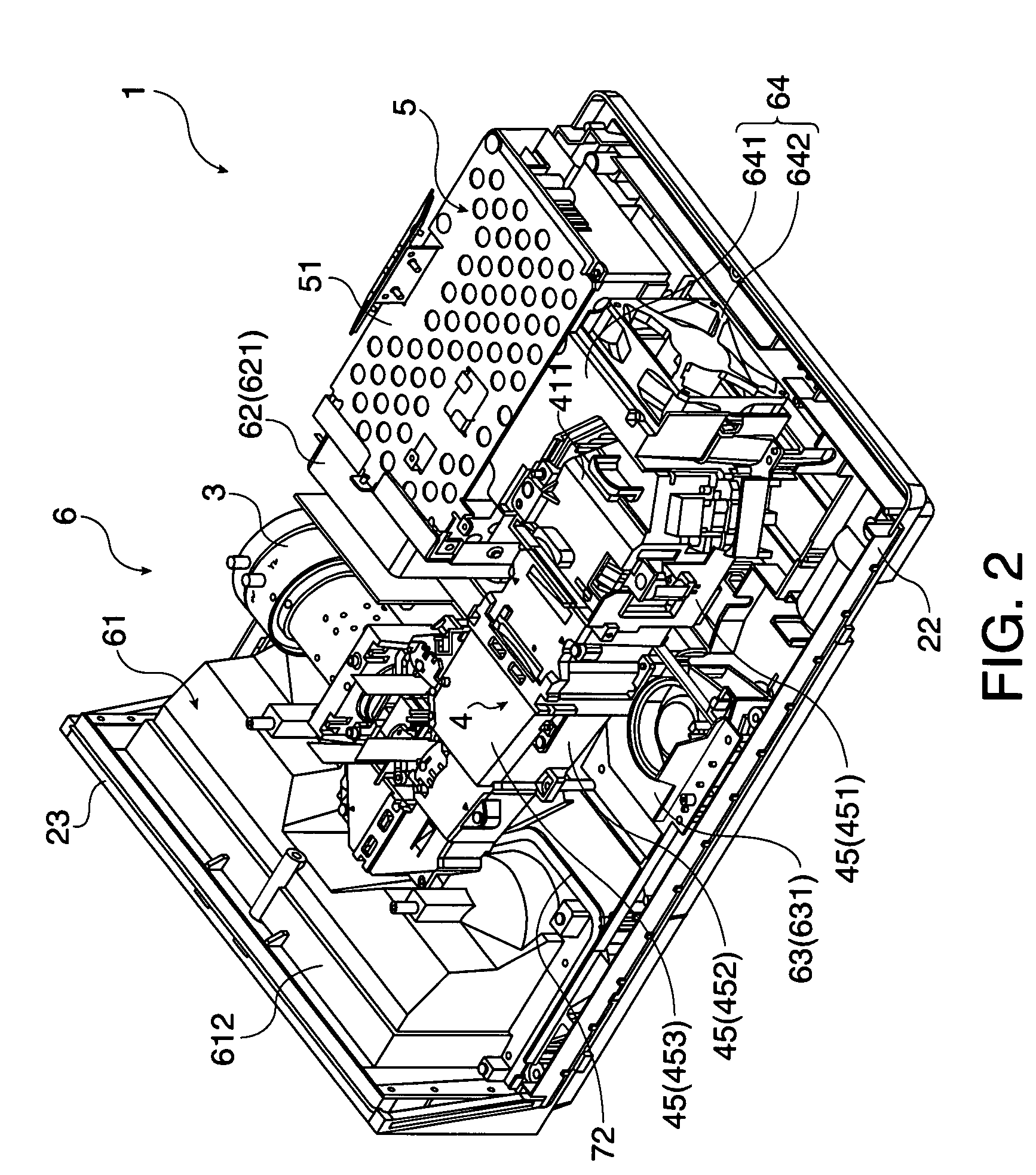

Dehumidifier

InactiveUS20060015974A1Reduce power consumptionAmount of dehumidification per a power consumption can be promotedAir treatment detailsNuclear energy generationEngineeringMechanical engineering

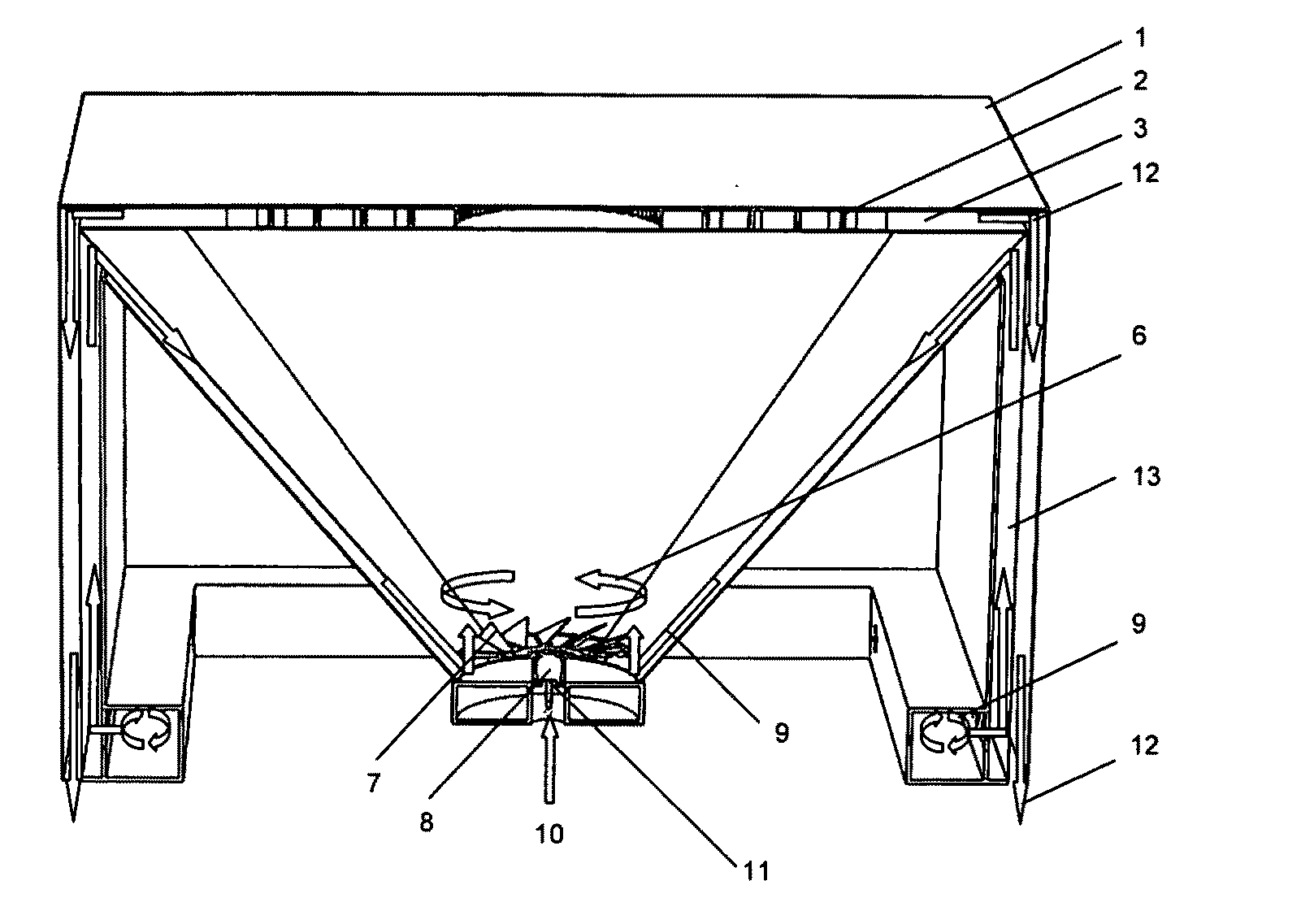

A dehumidifier by which the rate of heat recovery by the heat exchanger for recovering heat can be increased, the power consumption of the heater can be decreased, and by which the amount of dehumidification per a power consumption can be promoted, is disclosed. The dehumidifier 1 comprises a rotor case 31 harboring a dehumidification rotor 2 rotatably and drivably mounted therein, having an opening for dehumidification 38 through which air to be dehumidified passes, and having an opening for regeneration 39 through which air for regeneration passes; a heater 5 for heating the air for regeneration before passing through the opening for regeneration; a heat exchanger for recovering heat 7 which transfers heat of the air for regeneration passing through the second passage section to the air for regeneration passing through the first passage section; a dehumidification passage X harboring a dehumidification fan 3; and a regeneration passage Y harboring a regeneration fan 4. The direction of rotation of the dehumidification rotor 2 is set such that the air for regeneration which passed through posterior area C of the dehumidification rotor flows into downstream portion in the second passage section, and that the air for regeneration which passed through anterior area H of the dehumidification rotor flows into upstream portion in the second passage section.

Owner:AMBIENT CORPORATION

Amendment and uses of the same in sludge composting

InactiveCN101367678AReduce loss rateLow running costBio-organic fraction processingClimate change adaptationSludge compostMass transfer

The invention relates to a conditioner and the application in sludge composting thereof, relating to a conditioner and the application thereof. The invention solves the problems that the existing conditioner is large in dosing quantity, easy to be decomposed, low in mass transfer efficiency, difficult to be recycled and easy to have anaerobic acidification. The conditioner is pumice with the grain diameter of 0.2 cm to 10 cm. The conditioner has the following applications: firstly, the conditioner is mixed with sludge so as to obtain a mixing material; secondly, the mixing material is put in a fermentation apparatus to carry out fermentation; thirdly, material is discharged after fermentation, then the conditioners is sieved out, namely, the application of the conditioner in sludge composting is finished. The dosing quantity of the conditioner is decreased by 30 percent, and the space structure thereof is stable, and the conditioner is not easy to be decomposed, high in mass transfer efficiency, able to be recycled and not easy to have anaerobic acidification.

Owner:HARBIN INST OF TECH

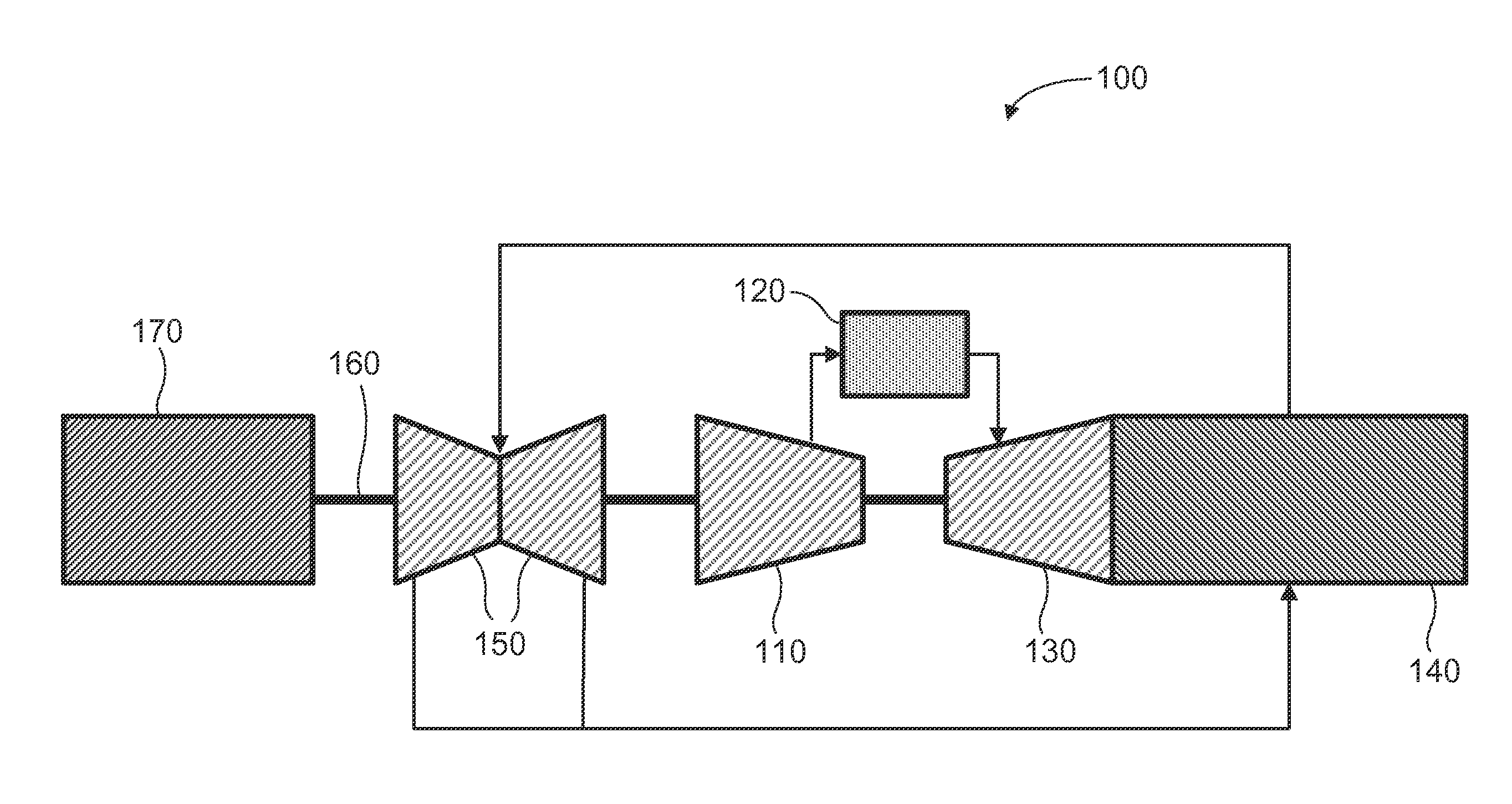

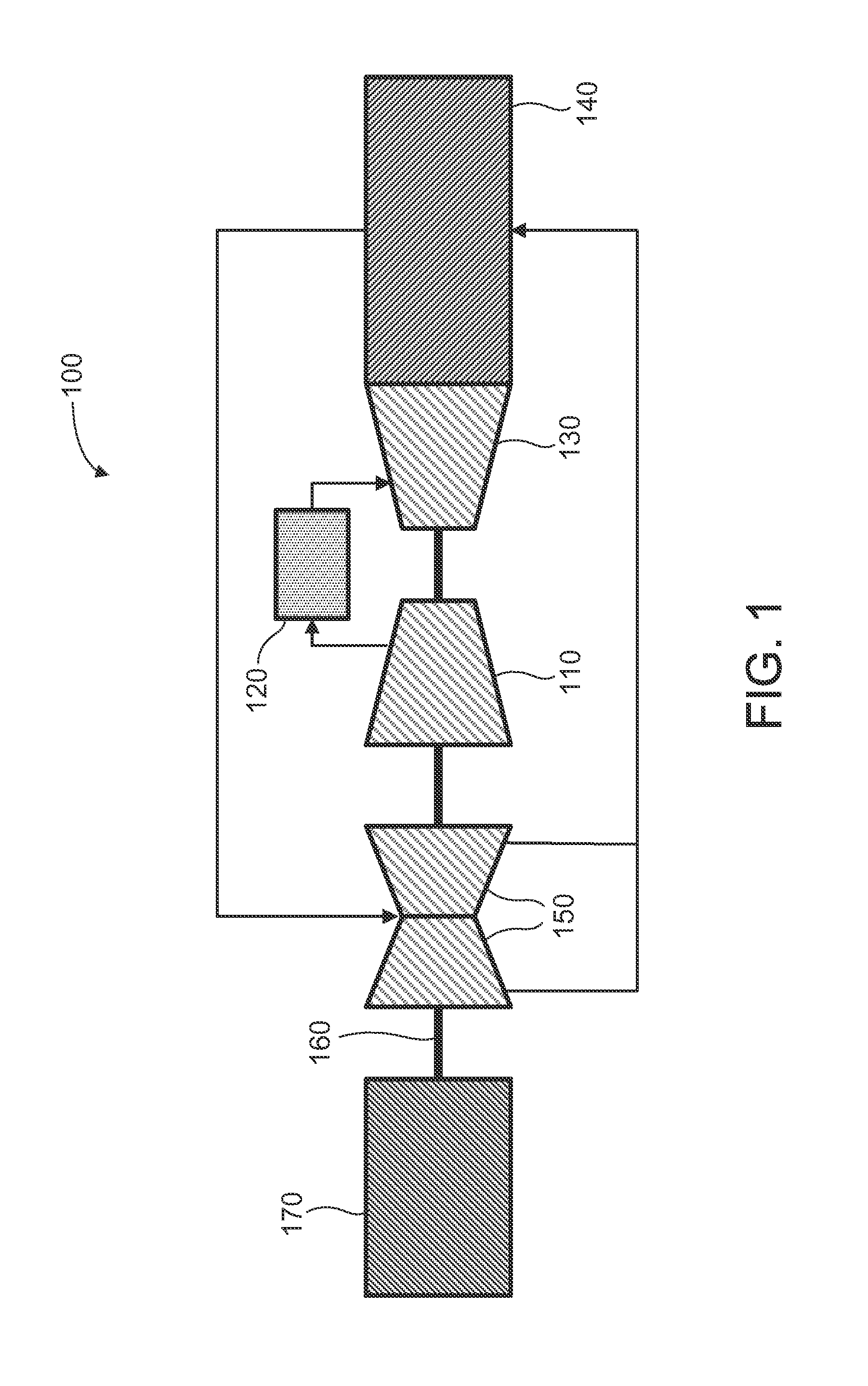

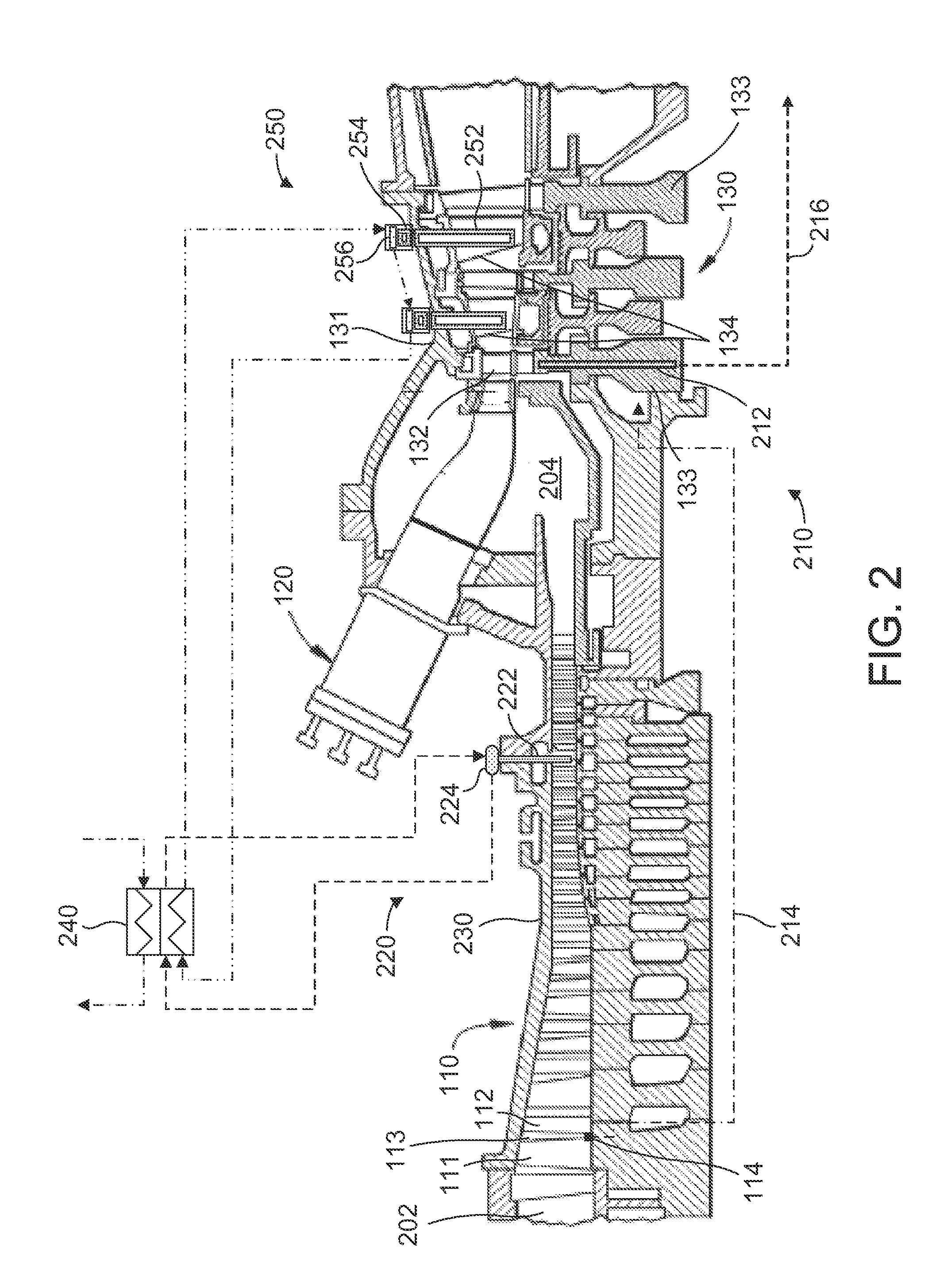

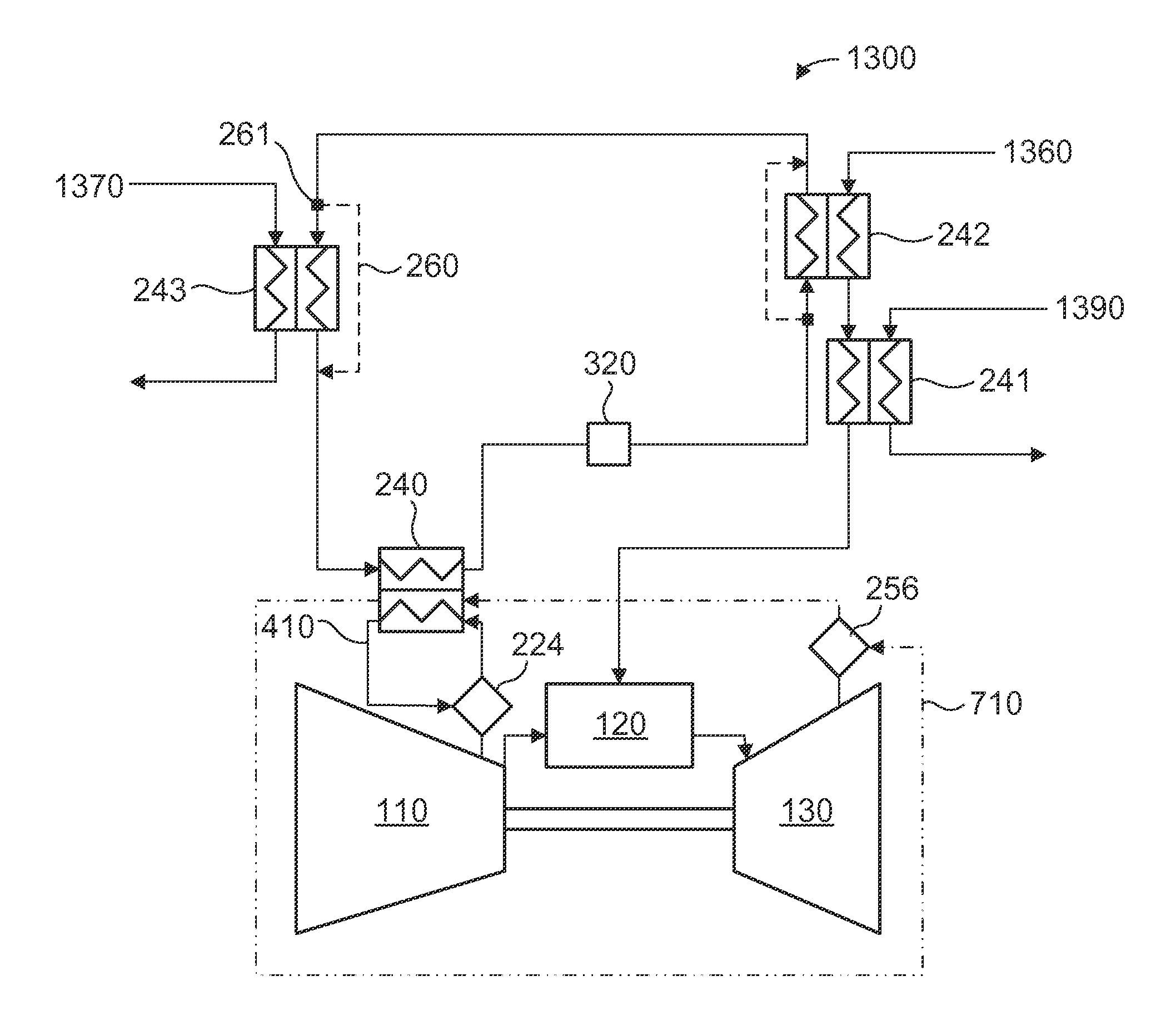

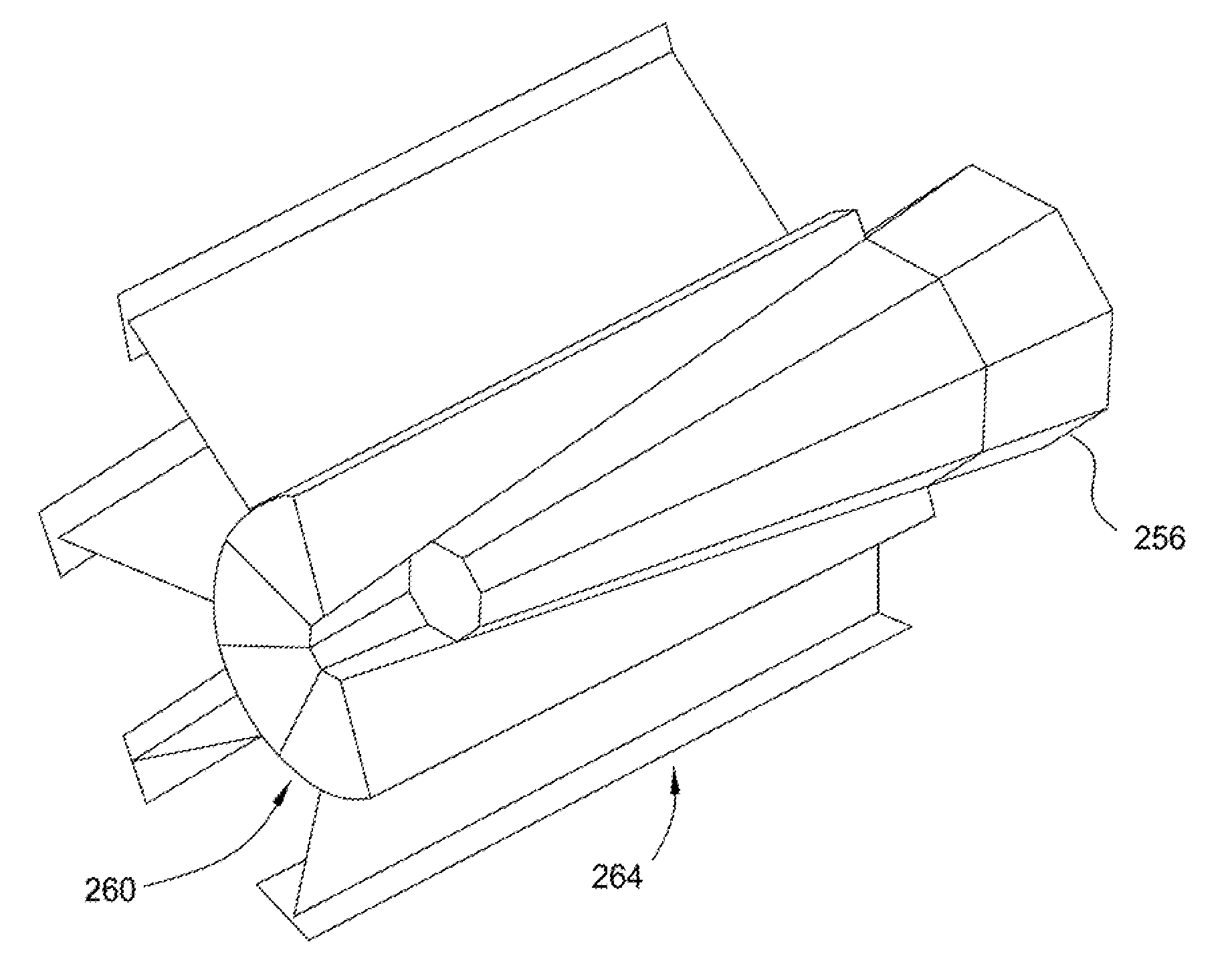

Heat pipe temperature management system for a turbomachine

InactiveUS20160290235A1Extend your lifeImprove efficiencyTurbine/propulsion engine coolingEngine fuctionsIntercoolerChiller

A turbomachine includes a compressor, combustor and a turbine. An intercooler is operatively connected to the compressor. The intercooler includes a first plurality of heat pipes that extend into the inter-stage gap of the compressor, and the heat pipes are operatively connected to a first manifold. The heat pipes and the manifold are configured to transfer heat from the compressed airflow to one or more heat exchangers. A first cooling system is operatively connected to the turbine. The first cooling system includes a second plurality of heat pipes attached to or embedded within at least one of the plurality of wheels. The compressor bleed off air is configured to impinge onto at least one of the plurality of wheels or the second plurality of heat pipes. The second plurality of heat pipes and the compressor bleed off air are configured to cool at least one of the plurality of wheels.

Owner:GENERAL ELECTRIC CO

A method of microwave firing porous ceramsite from medical waste incineration fly ash

ActiveCN103601526BPromote formationGood consolidationSolid waste disposalCeramicwarePrillResource utilization

The invention discloses a method for microwave sintering of porous ceramsites by adopting medical waste incineration fly ash. The method comprises the following steps: (1) fully mixing the medical waste incineration fly ash with an auxiliary material, adding a small amount of water into the mixture, and carrying out granulation molding by a molding machine; (2) carrying out granulation molding, drying to obtain a particle raw material, filling the periphery of the particle raw material with a microwave coupling agent powder; and (3) carrying out microwave sintering of the particle raw material filled with the powder, and after sintering, cooling to the room temperature to obtain the porous ceramsites. The method can utilize a 'hot spot' effect of fly ash high-content active carbon in a microwave field to instantly completely decompose dioxins in the fly ash, at the same time, allows most heavy metals to be wrapped and cured in grids of the sintered product, and rapidly sinters the fly ash into the porous ceramsites; and the ceramsites can be used for building aggregates or wastewater filter materials, achieves further resource utilization while achieving harmlessness treatment of the medical waste incineration fly ash, and achieves many things at one stroke.

Owner:TIANJIN CHENGJIAN UNIV

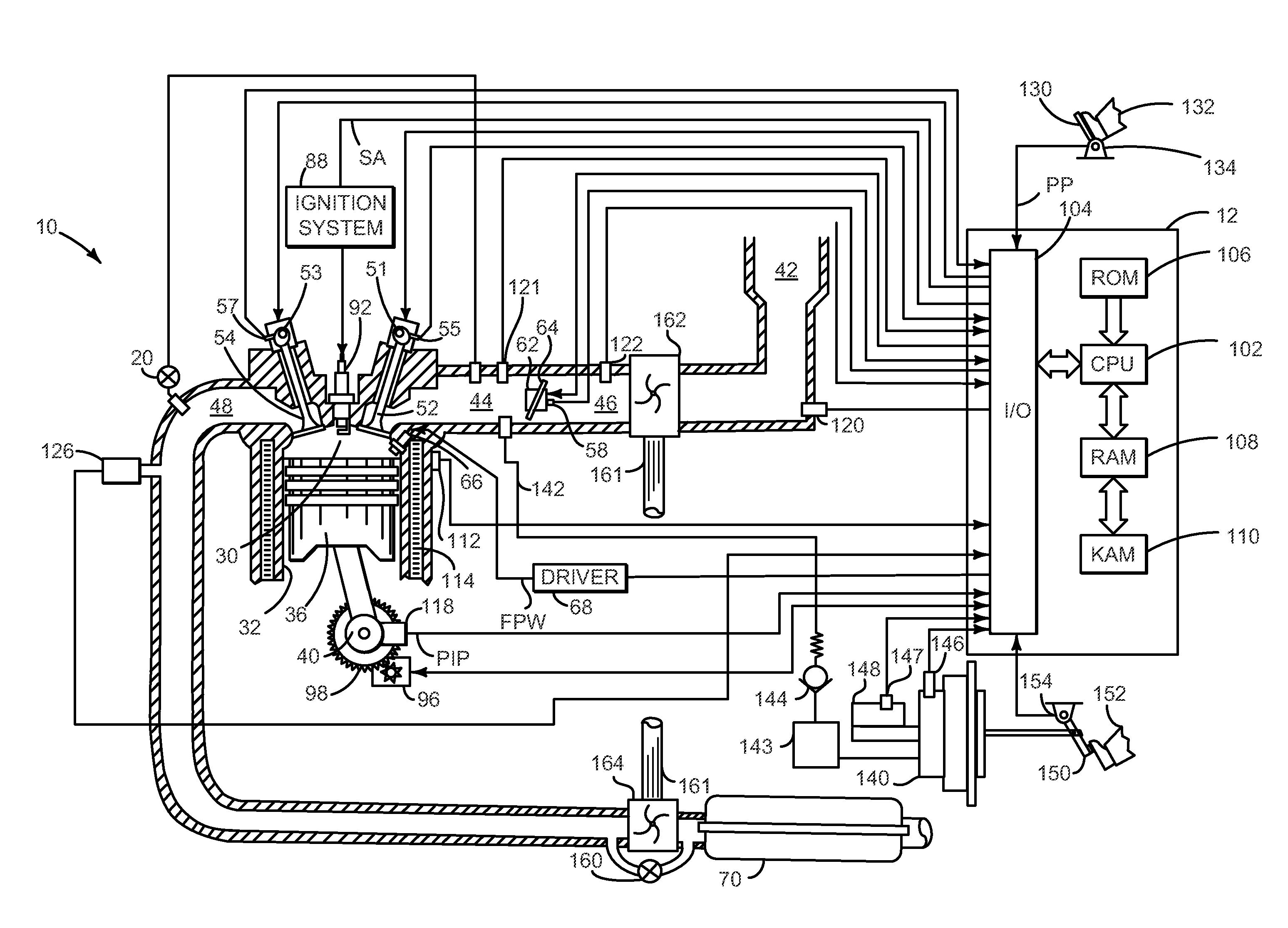

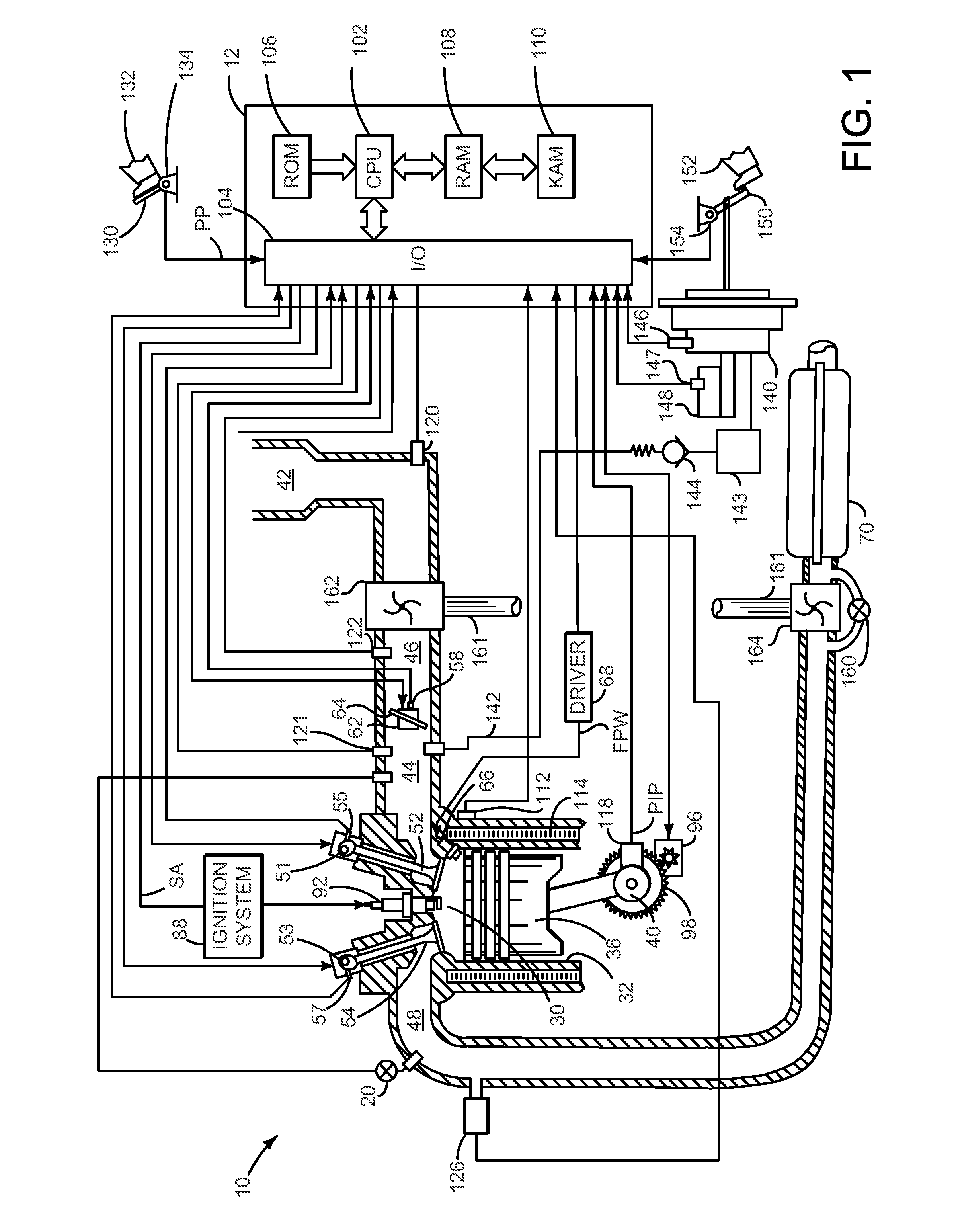

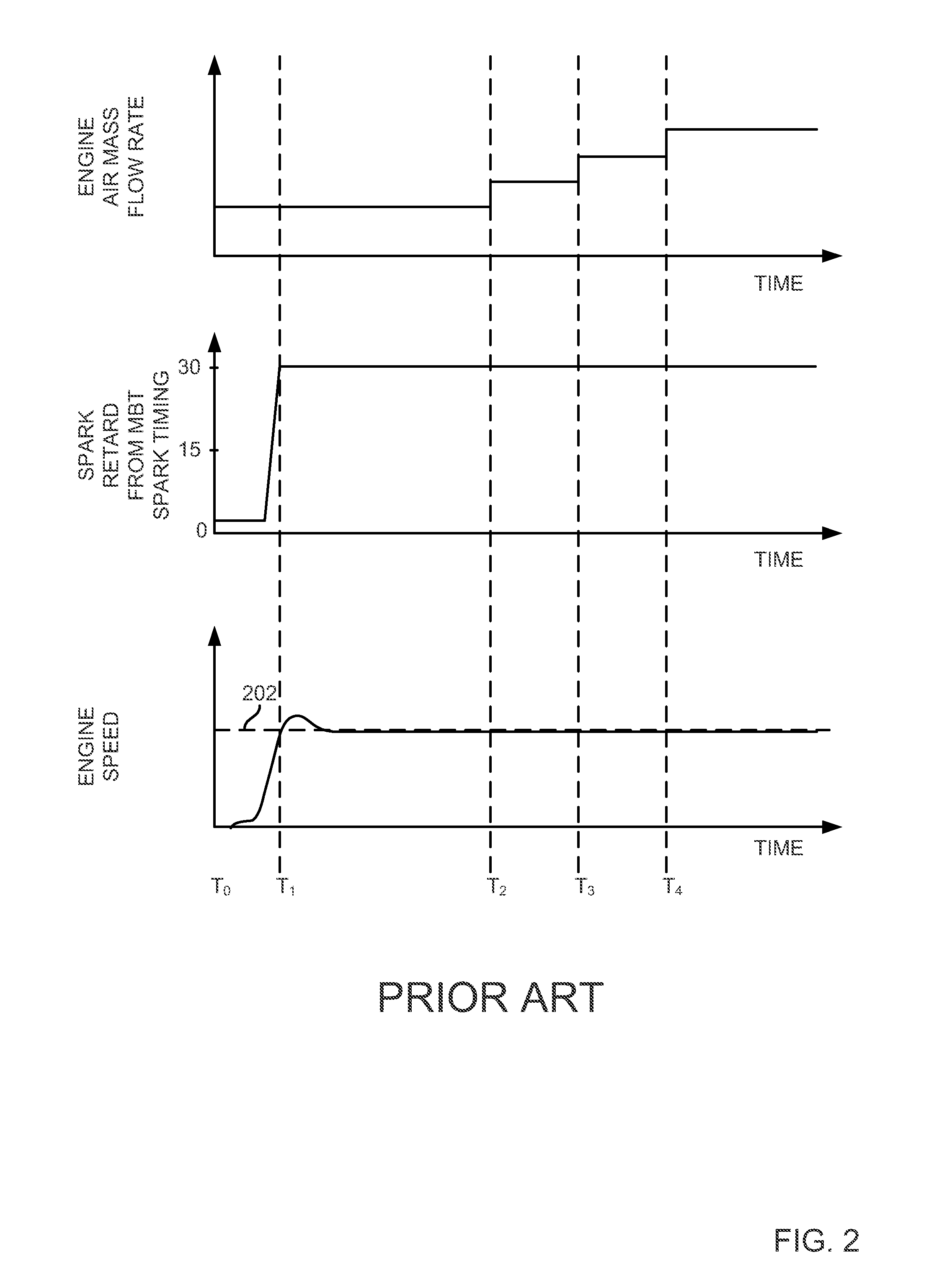

Method for improving engine starting

ActiveUS20130146024A1Reduce exhaust emissionsLow efficiencyAnalogue computers for vehiclesElectrical controlAfter treatmentHeat flux

A method for improving exhaust after treatment initial warm up during engine starting is presented. In one example, the method adjusts an engine air flow amount to a level where a desired substantially constant heat flux is provided by the engine to an exhaust after treatment device. The method may reduce fuel consumption and a need for a vacuum pump to provide vacuum to vacuum consumers of a vehicle during exhaust after treatment heating.

Owner:FORD GLOBAL TECH LLC

Heat pipe temperature management system for a turbomachine

ActiveUS20160290233A1Extend your lifeImprove efficiencyTurbine/propulsion engine coolingEngine fuctionsCombustorEngineering

A turbomachine includes a compressor having an inter-stage gap between adjacent rows of rotor blades and stator vanes. A combustor is connected to the compressor, and a turbine is connected to the combustor. An intercooler is operatively connected to the compressor, and includes a first plurality of heat pipes that extend into the inter-stage gap. The first plurality of heat pipes are operatively connected to a first manifold, and the heat pipes and the first manifold are configured to transfer heat from the compressed airflow from the compressor to heat exchangers. A cooling system is operatively connected to the turbine, and includes a second plurality of heat pipes located in the turbine nozzles. The second plurality of heat pipes are operatively connected to a second manifold, and the heat pipes and the second manifold are configured to transfer heat from the turbine nozzles to the heat exchangers.

Owner:GENERAL ELECTRIC CO

Flameless cooking appliance

ActiveUS20110165300A1High surface areaImprove heating efficiencyDomestic stoves or rangesCatalytic ignitersJP-8Cooker

A flameless cooking apparatus for use with liquid fuels and for indoor or outdoor use under field operations. The burner exhibits low CO and hydrocarbon emissions and meets standards for burner thermal efficiency when used with JP-8 fuel. The apparatus employs a catalytic burner having among its parts (i) a combustion catalyst; (ii) a conductive surface, e.g., cooking surface; and (iii) in between the catalyst and the conductive surface and in direct physical contact with both surfaces, a heat spreader for conductively transferring heat of combustion from the catalyst to the conductive surface. Also claimed are a method of heat flux and a method of cooking.

Owner:PRECISION COMBUSTION

Method and apparatus for concentrating vapors for analysis

ActiveUS7430928B2Increase the rate of heatingImprove thermal conductivityComponent separationWithdrawing sample devicesDetection limit

Owner:BATTELLE MEMORIAL INST

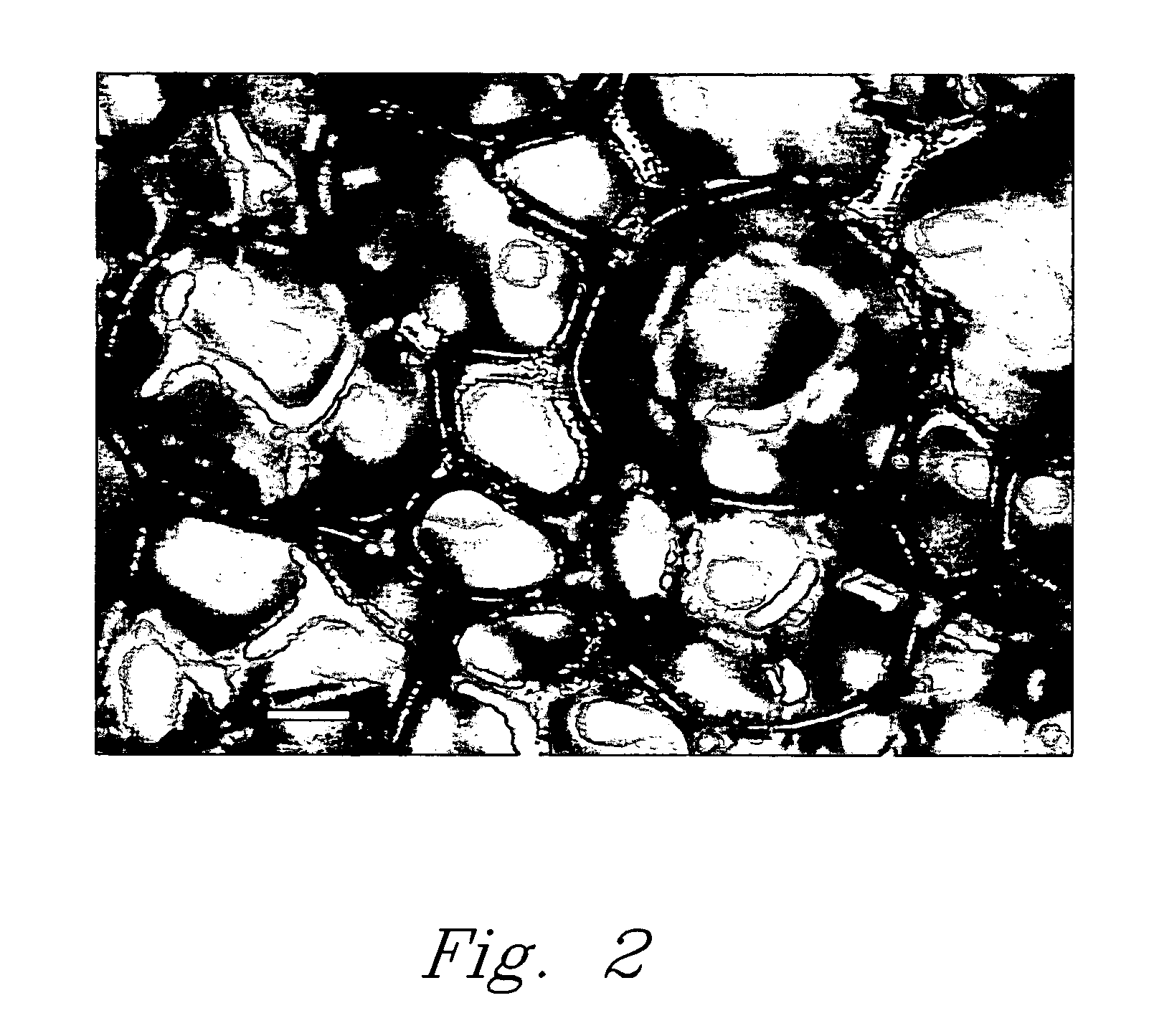

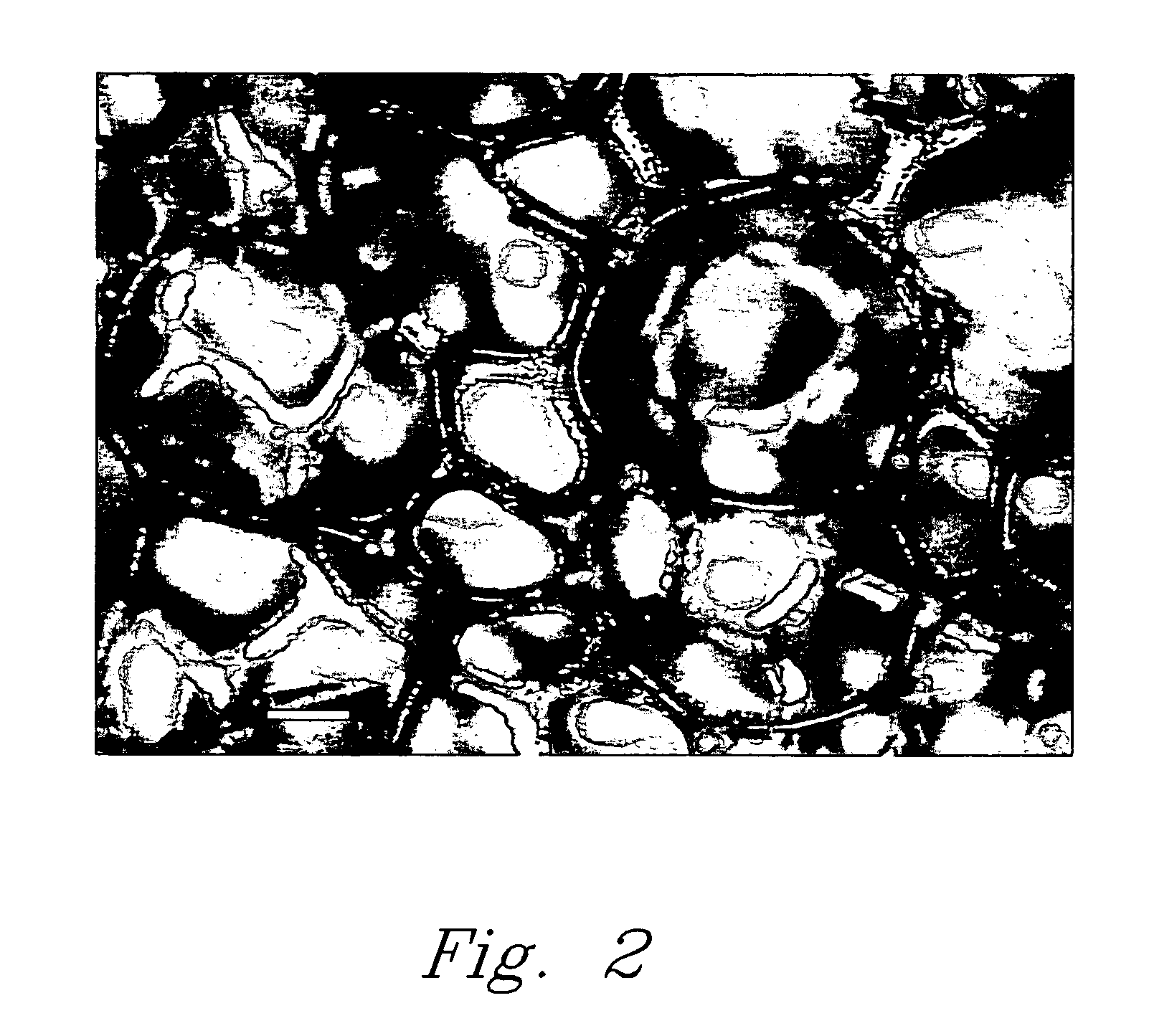

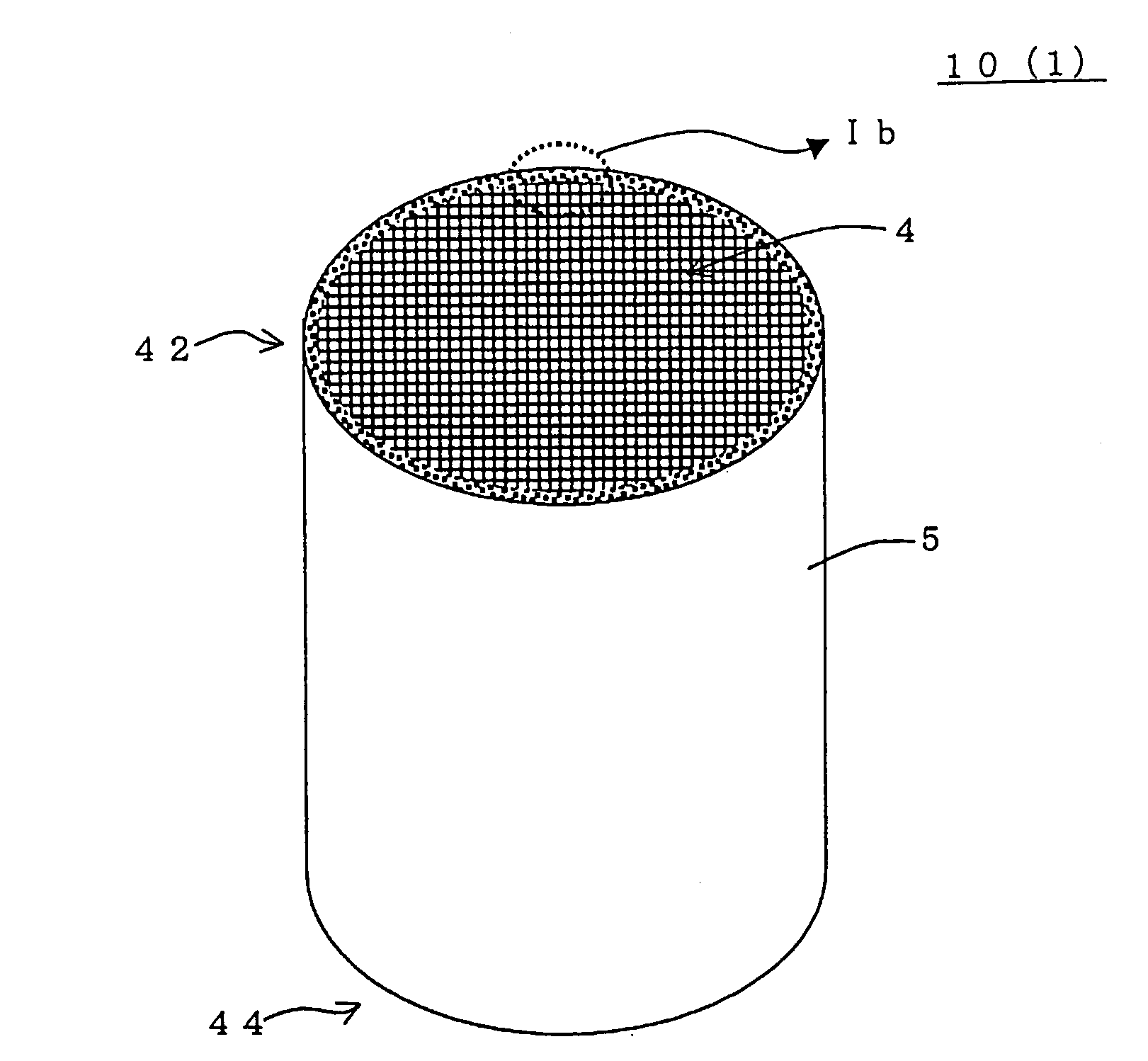

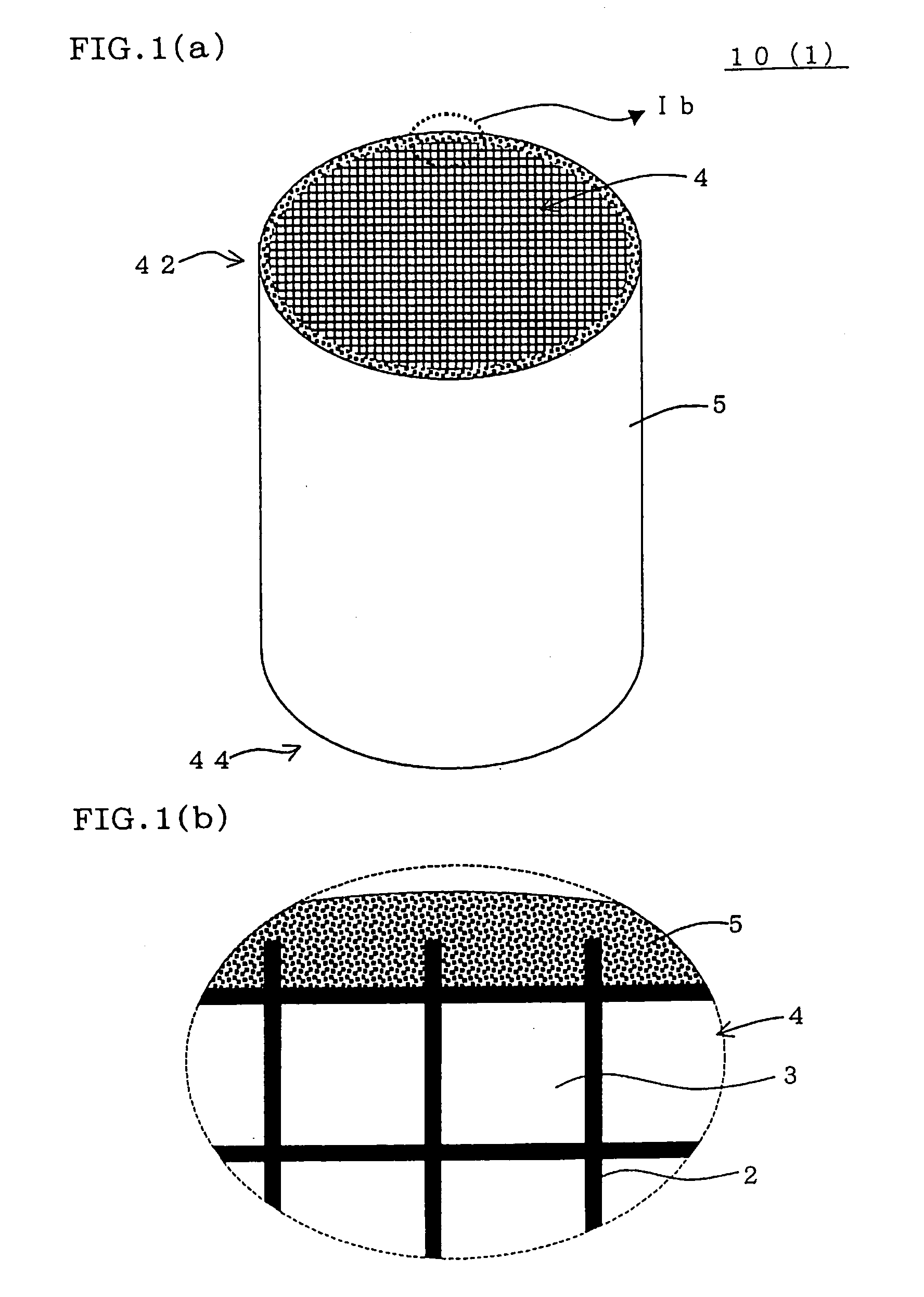

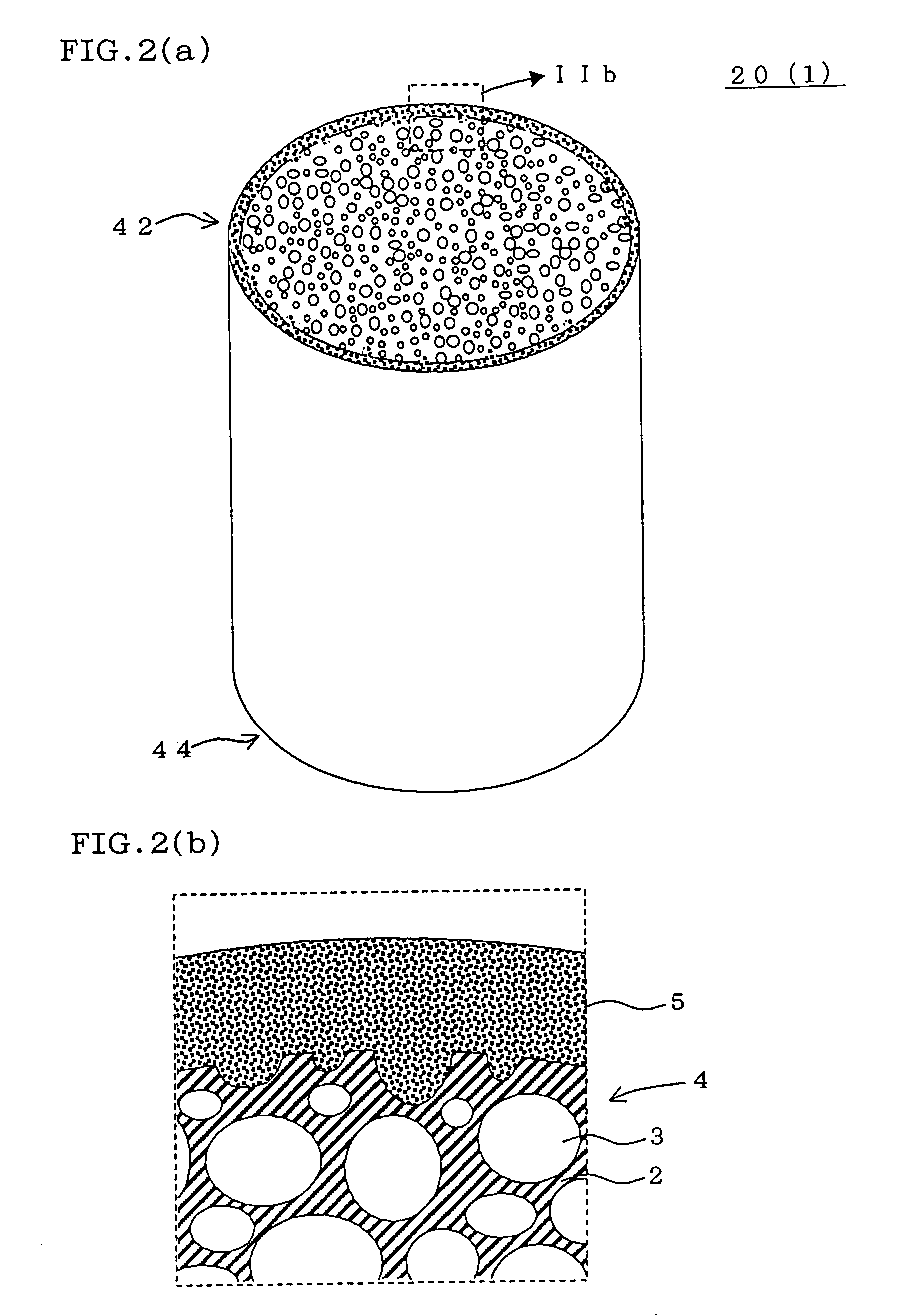

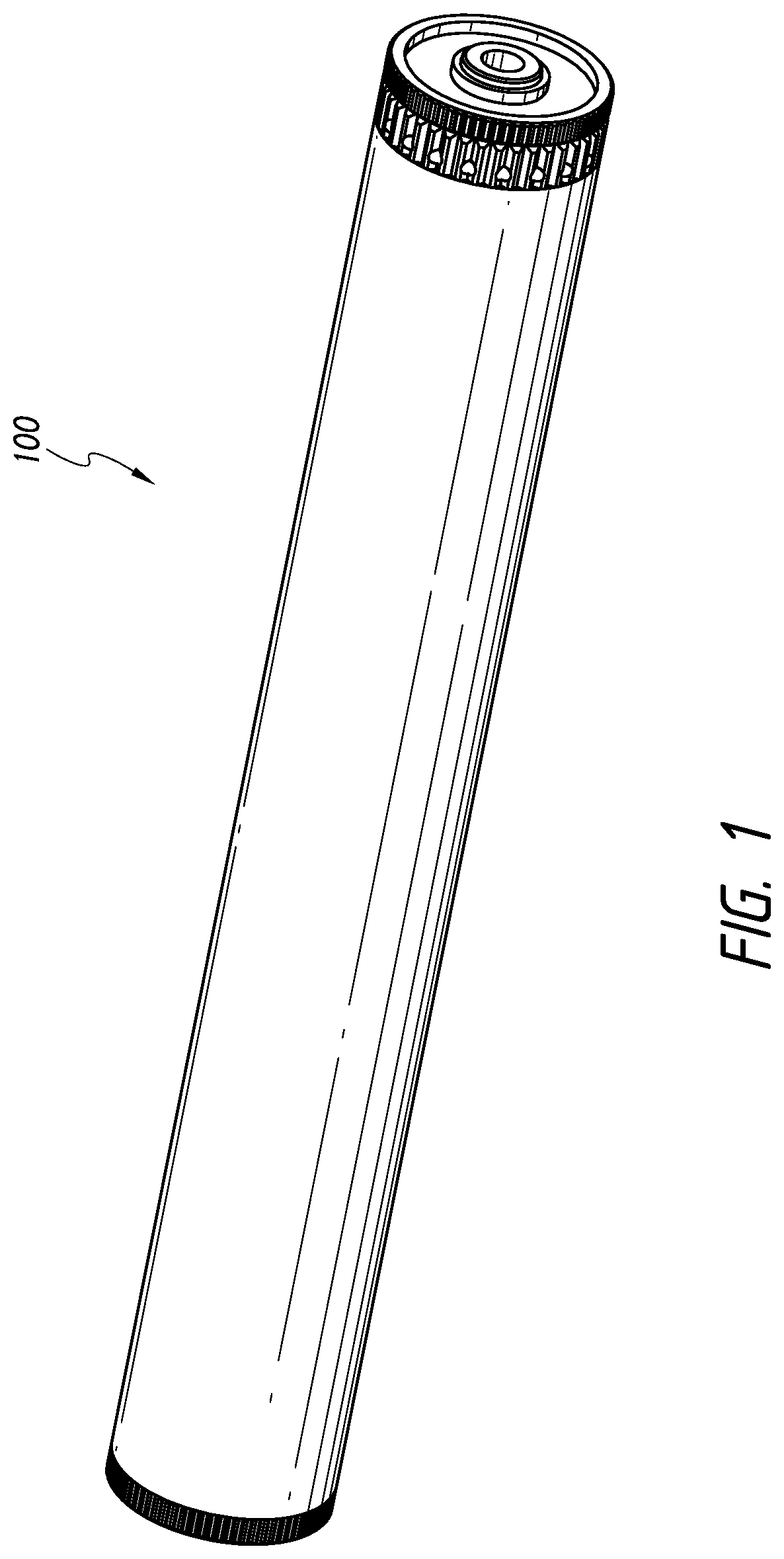

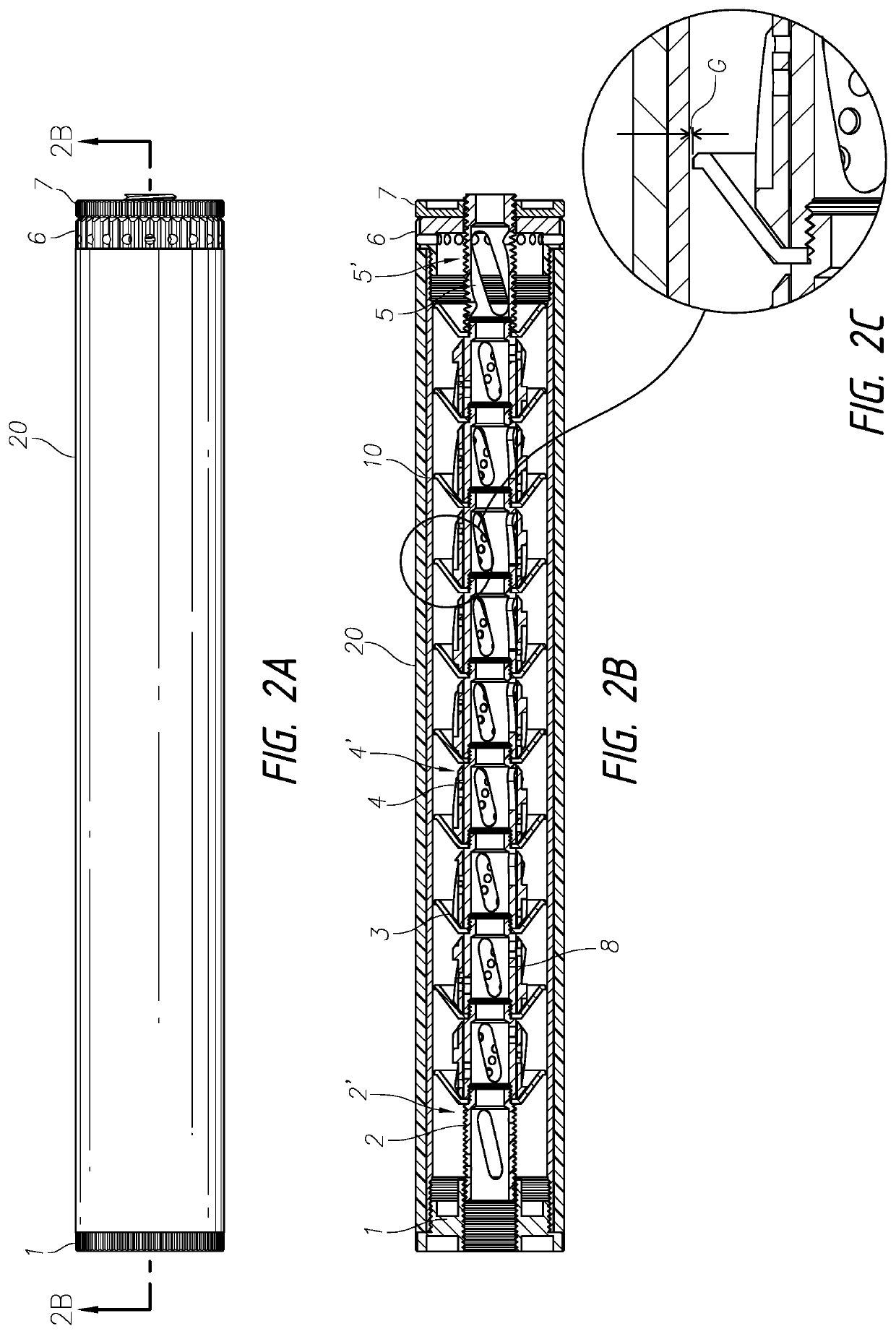

Cell Structure And Method Of Manufacturing The Same

ActiveUS20080220203A1Reduce temperature rise rateHigh mechanical strengthDispersed particle filtrationSolid waste managementPorous layerBiomedical engineering

There is provided a cell structure, where the outer wall portion has high heat-insulating ability, the cell structural portion has a high temperature rise rate, and a temperature distribution is more uniform, and a method for manufacturing the cell structure. The cell structure 1 includes: a cell structural portion 4 having partition walls forming a plurality of cells extending from one end face to the other end face, and an outer wall portion 5 disposed on an outer peripheral surface of the cell structural portion 4. The outer wall portion 5 has at least a porous layer having a porosity of 40% or more or a porous layer having a hollow body. The manufacturing method can easily manufacture the cell structure.

Owner:NGK INSULATORS LTD

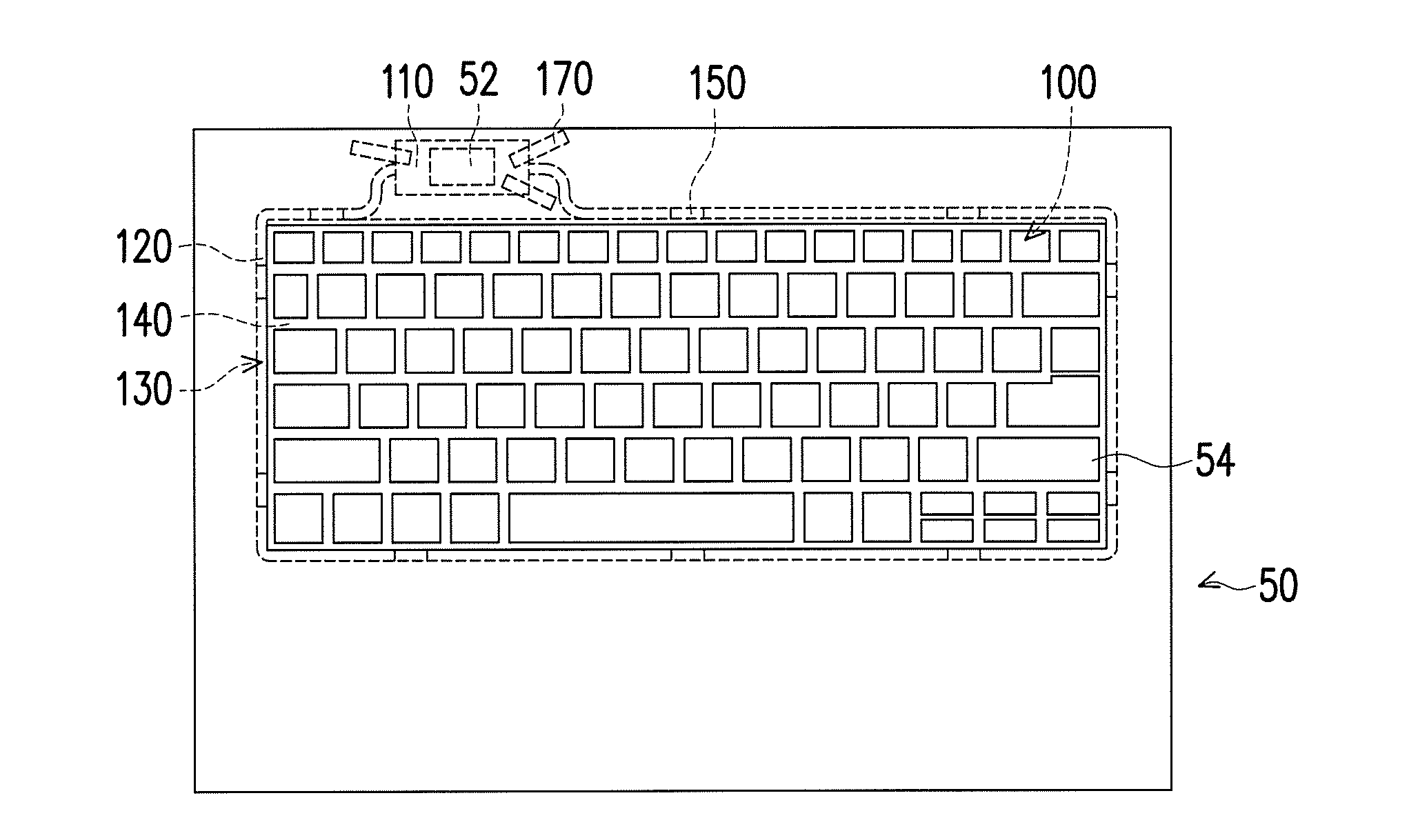

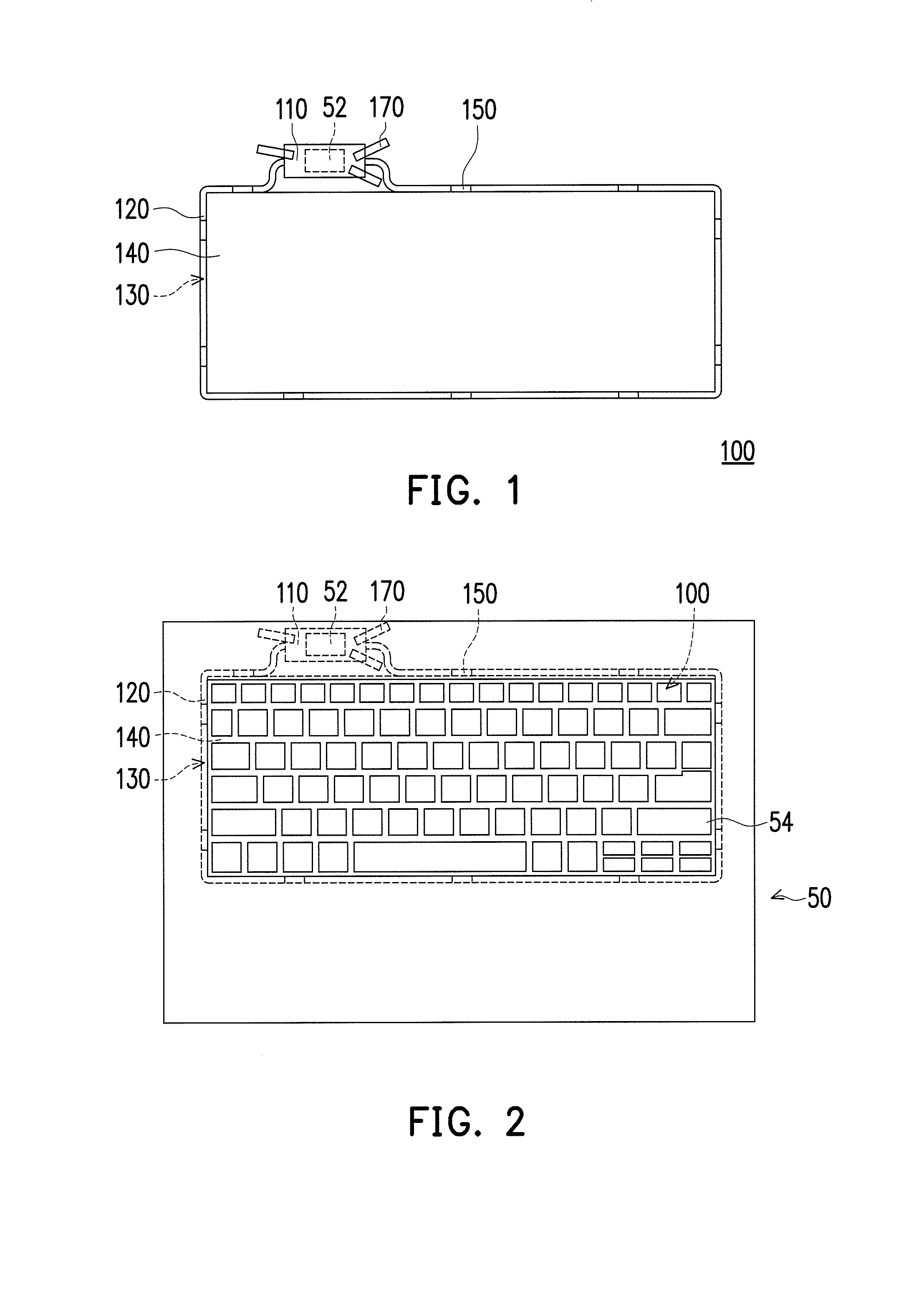

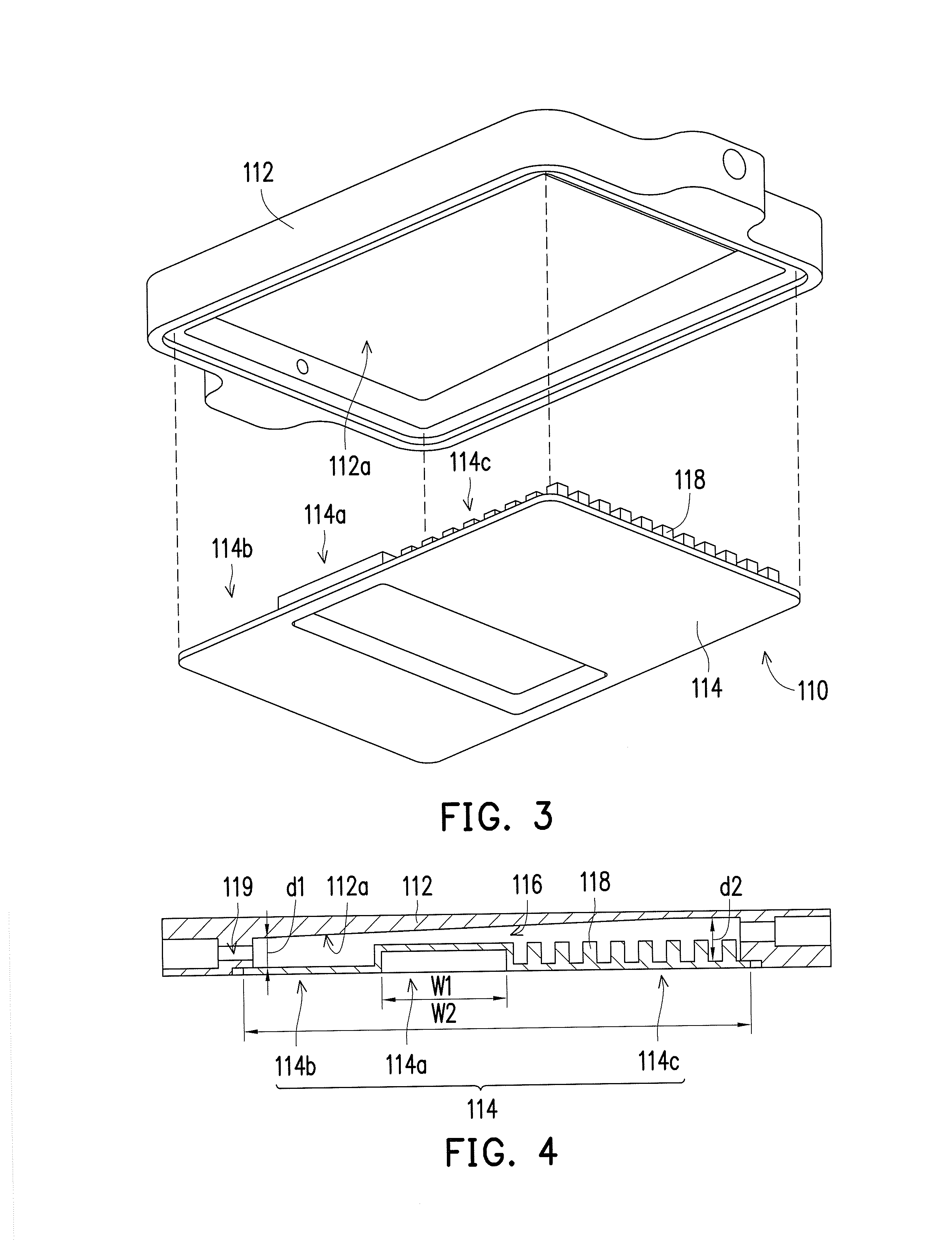

Wind velocity measuring device and electronic apparatus

Owner:SEIKO EPSON CORP

Catalytic pyrolysis of biomass in an auger reactor

InactiveUS20130327626A1Low costImprove throughputCoke ovensLiquid hydrocarbon mixture productionCatalytic pyrolysisHydrocarbon

The present invention relates generally to the thermal conversion of biomass. Processes are disclosed for converting algal biomass to condensable vapor intermediates such as pyrolysis oil by means of pyrolysis in a reactor comprising at least one auger. The intermediates may be further processed for production of renewable hydrocarbon fuels. The disclosed processes assist in preventing premature devolatization of algal biomass during pyrolysis, thereby increasing efficiency and commercial feasibility.

Owner:PHILLIPS 66 CO

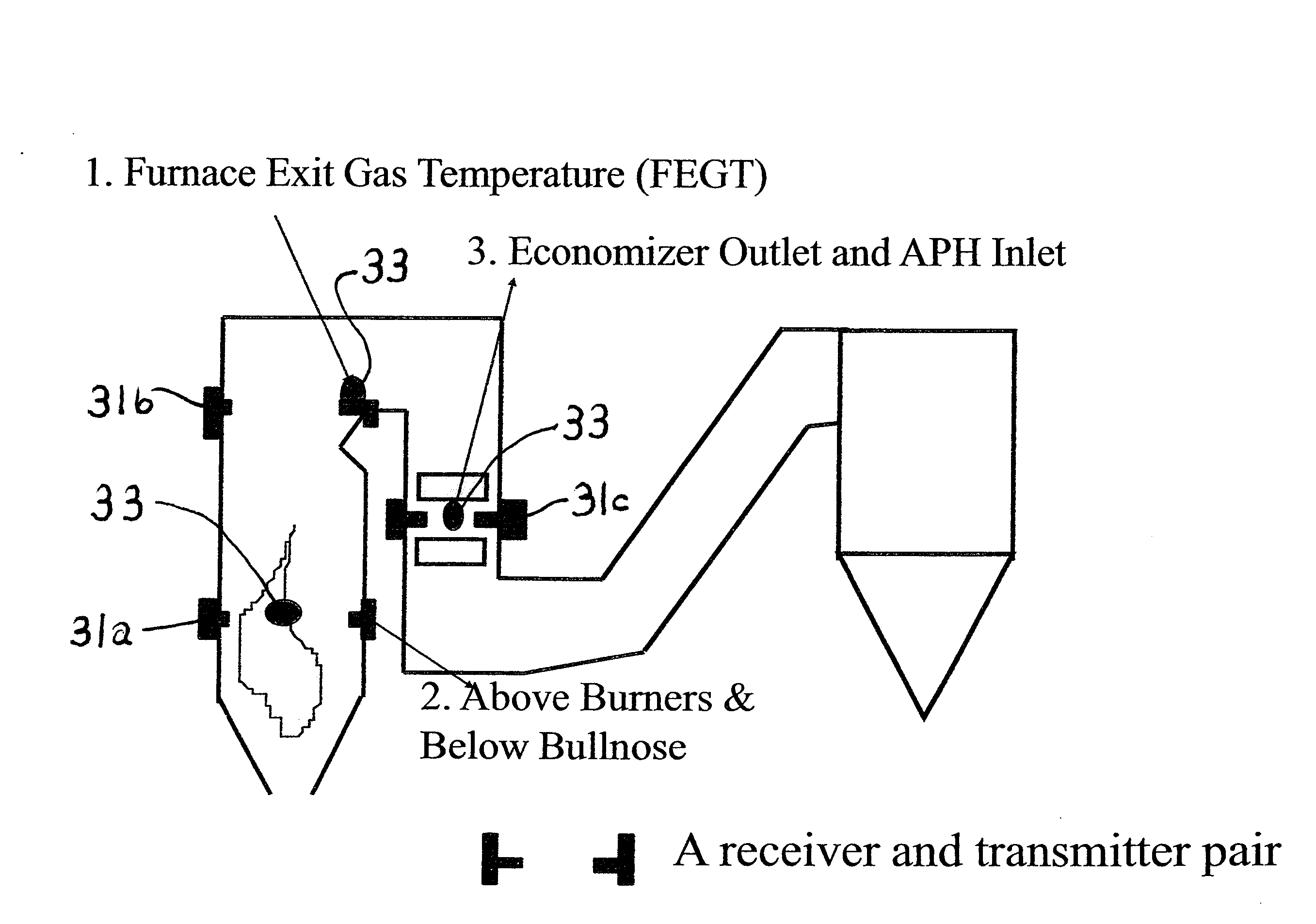

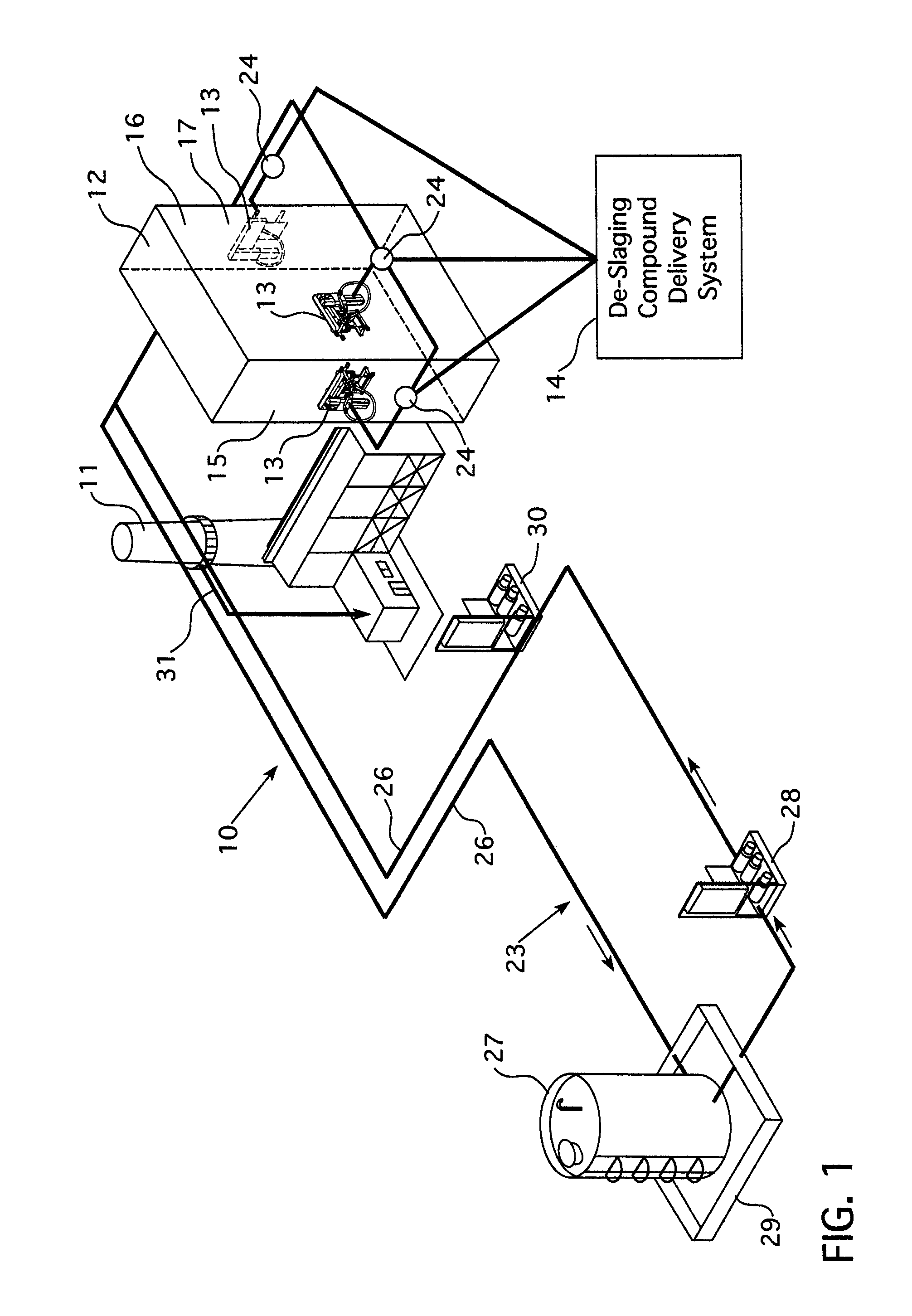

METHOD AND APPARATUS FOR REDUCING NOx EMMISIONS AND SLAG FORMATION IN SOLID FUEL FURNACES

Selective non-catalytic reduction (SNCR) of pollutant emissions is accomplished in a solid fuel combustion furnace by injecting and directing jet streams of liquid NOx reducing agent, with or without dilution water mixing, into combustion zones and radiant section and convective paths of the furnace with water cannons as controlled by intelligent knowledge-based control algorithms. The control algorithms are based upon continuously monitored online-measured flue gas temperature, O2, CO and NOx mapping data profiles for the furnace.

Owner:POWER & INDAL SERVICES

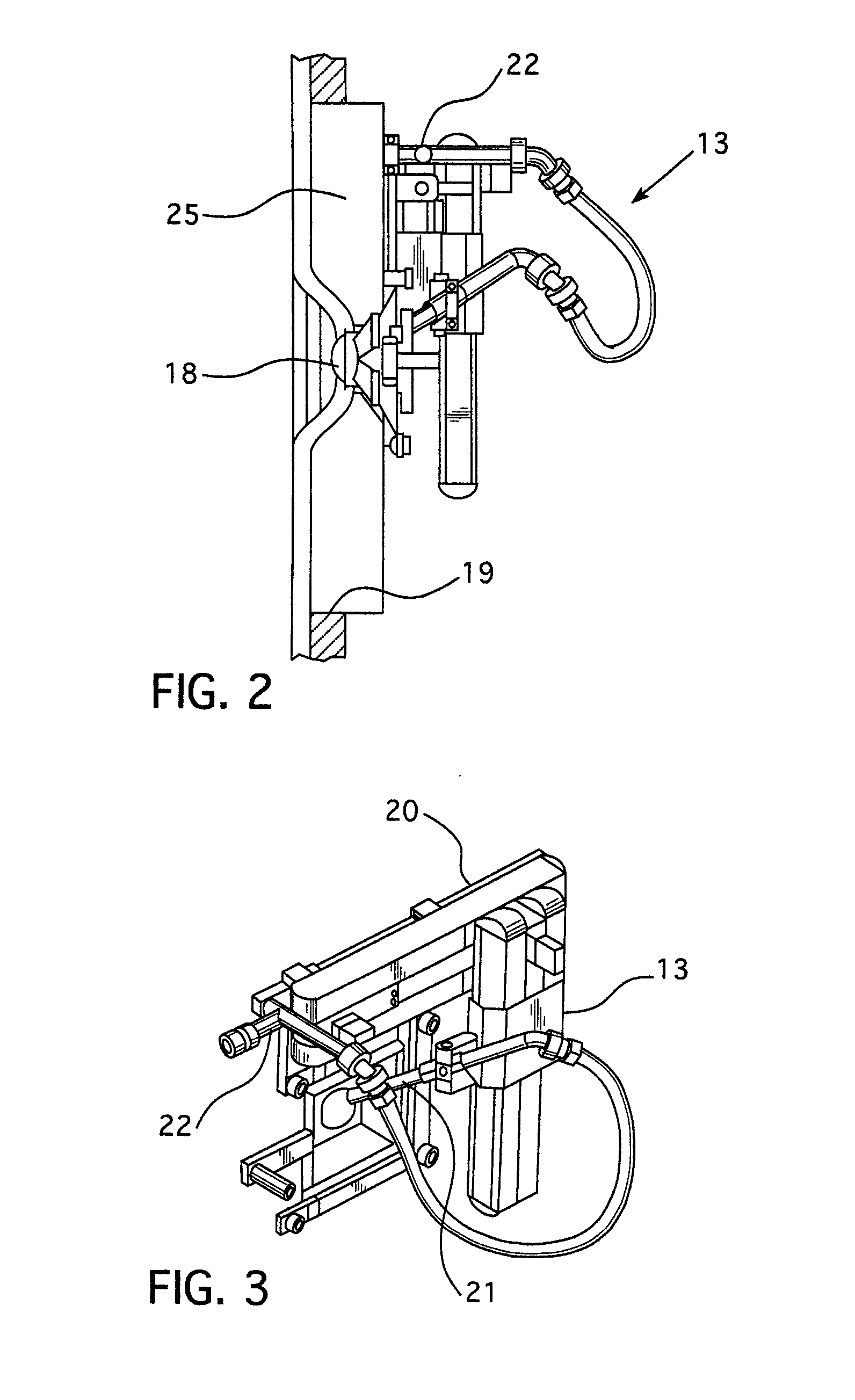

Modular gun silencer with heat dissipator

InactiveUS20200173751A1Dissipate heat generatedPreventing muzzle flashHeat exhanger finsWeapon componentsEngineeringMechanical engineering

Owner:MAD MINUTE IP HOLDCO INC

Preparation method for microbial organic soil bactericidal and insecticidal warming conditioning agent

InactiveCN105347926AImprove compactionAdjust the aggregate structureBioloigcal waste fertilisersOrganic fertiliser preparationDiseaseGround temperature

The invention relates to a preparation method for a microbial organic soil bactericidal and insecticidal warming conditioning agent. Fermentation raw materials are domestic fungus cultivation residue substances, the fermentation raw materials are crushed and added with water, and thus the water content mass percent of the fermentation raw materials is 25-35%; decomposing inoculants are added at a mass ratio of1:1000, the mixture is mixed uniformly, the fermentation raw materials mixed with strains are added with tourmaline powder with a mass percent of 5%, rare earth negative ion powder with a mass percent of 2%, composite biological insecticides accounting for 1% of the finished product total mass and composite biological bactericides accounting for 1% of the finished product total mass, the mixture is mixed uniformly, then loose packing or granulation is carried out, drying is carried out and the water content is 10%; packaging is carried out, and a microbial organic soil bactericidal and insecticidal warming conditioning agent is prepared. The produced conditioning agent is advantageous in that the organic matter content is high, the ground temperature is raised, absorption of phosphor and potassium for crops can be raised, the conditioning agent has functions of preventing soil borne diseases, releasing phosphorus and potassium, fixing nitrogen and killing nematodes and green environmental protection is achieved.

Owner:SUIHUA KAIHUA AGRI TECH CO LTD

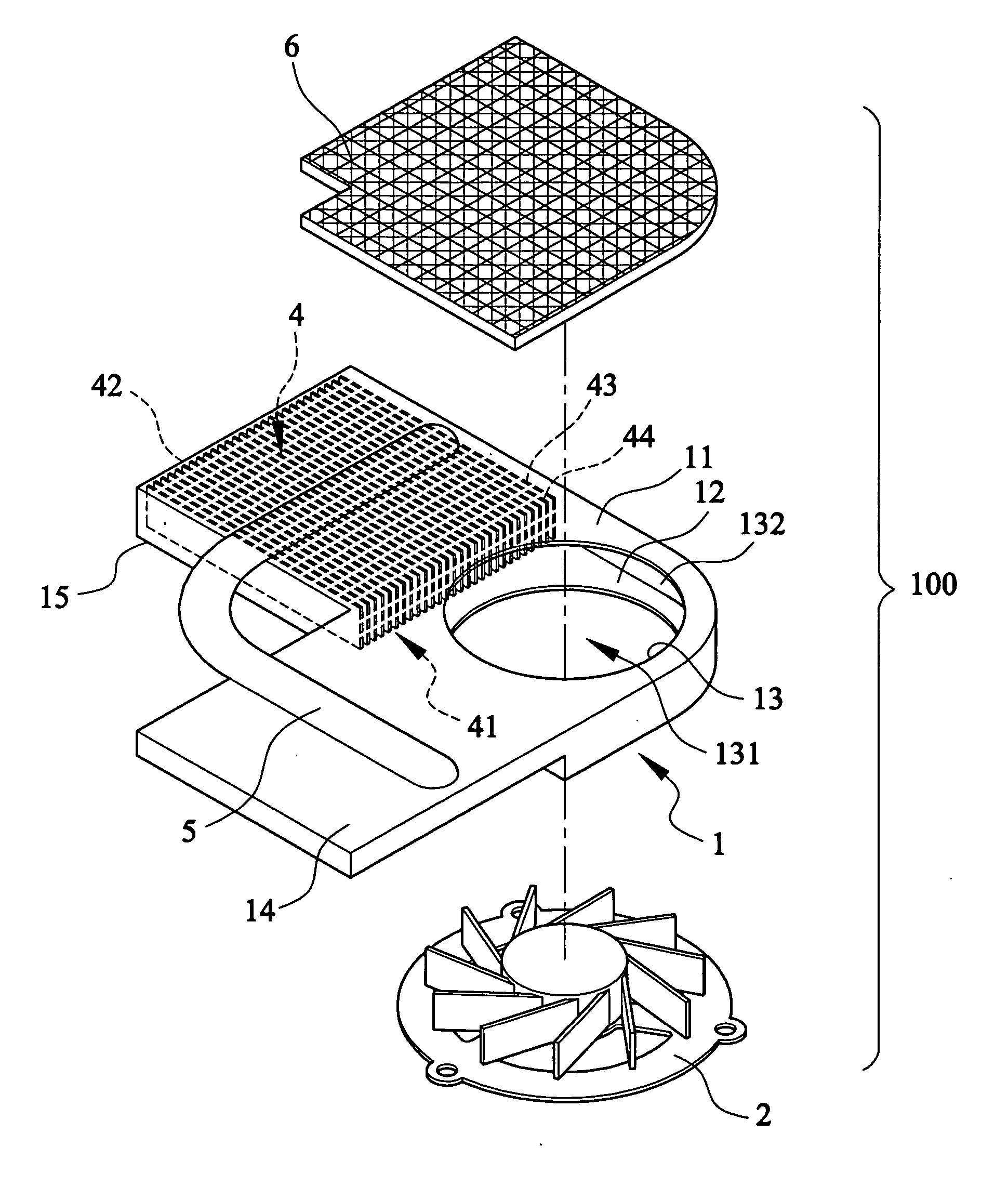

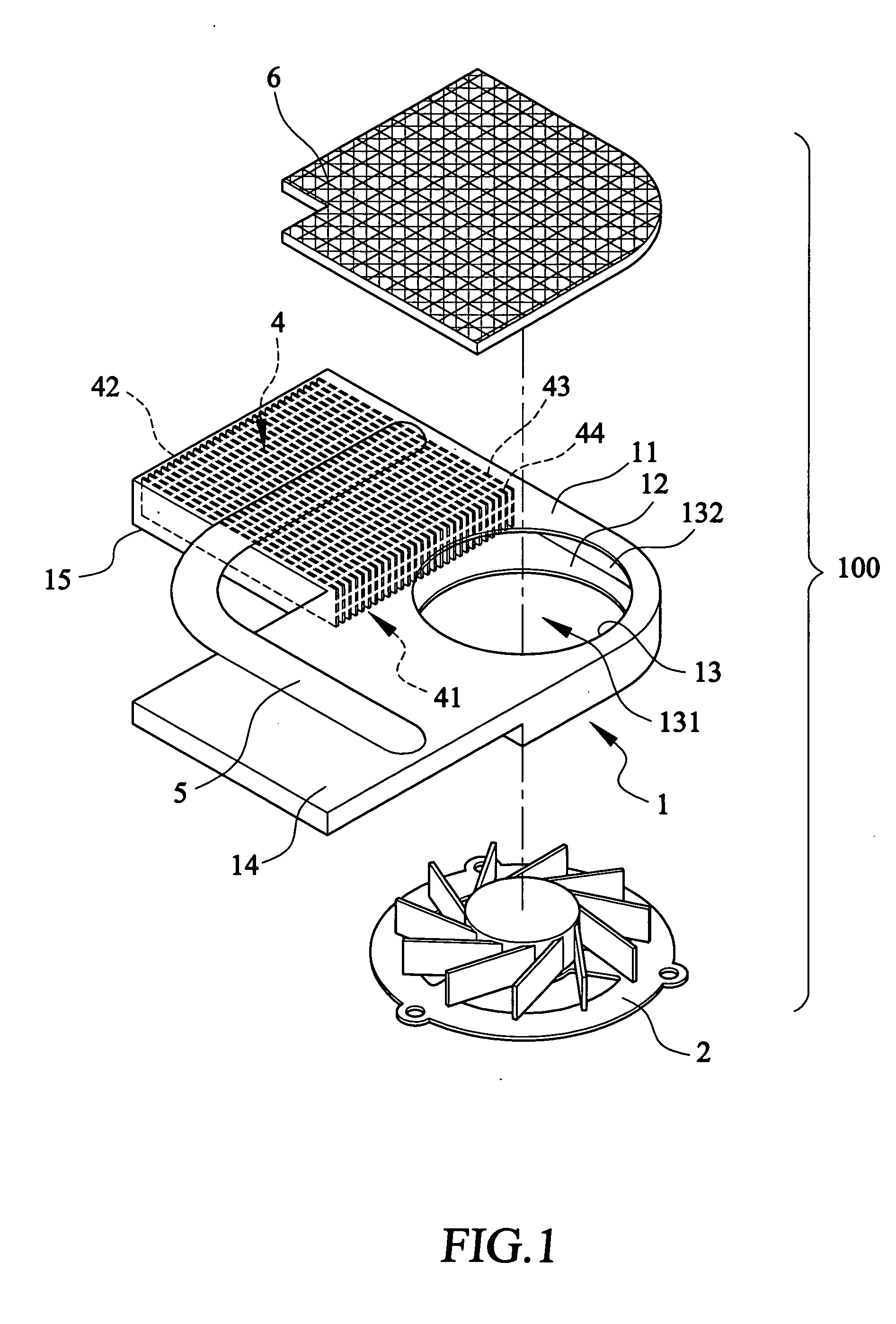

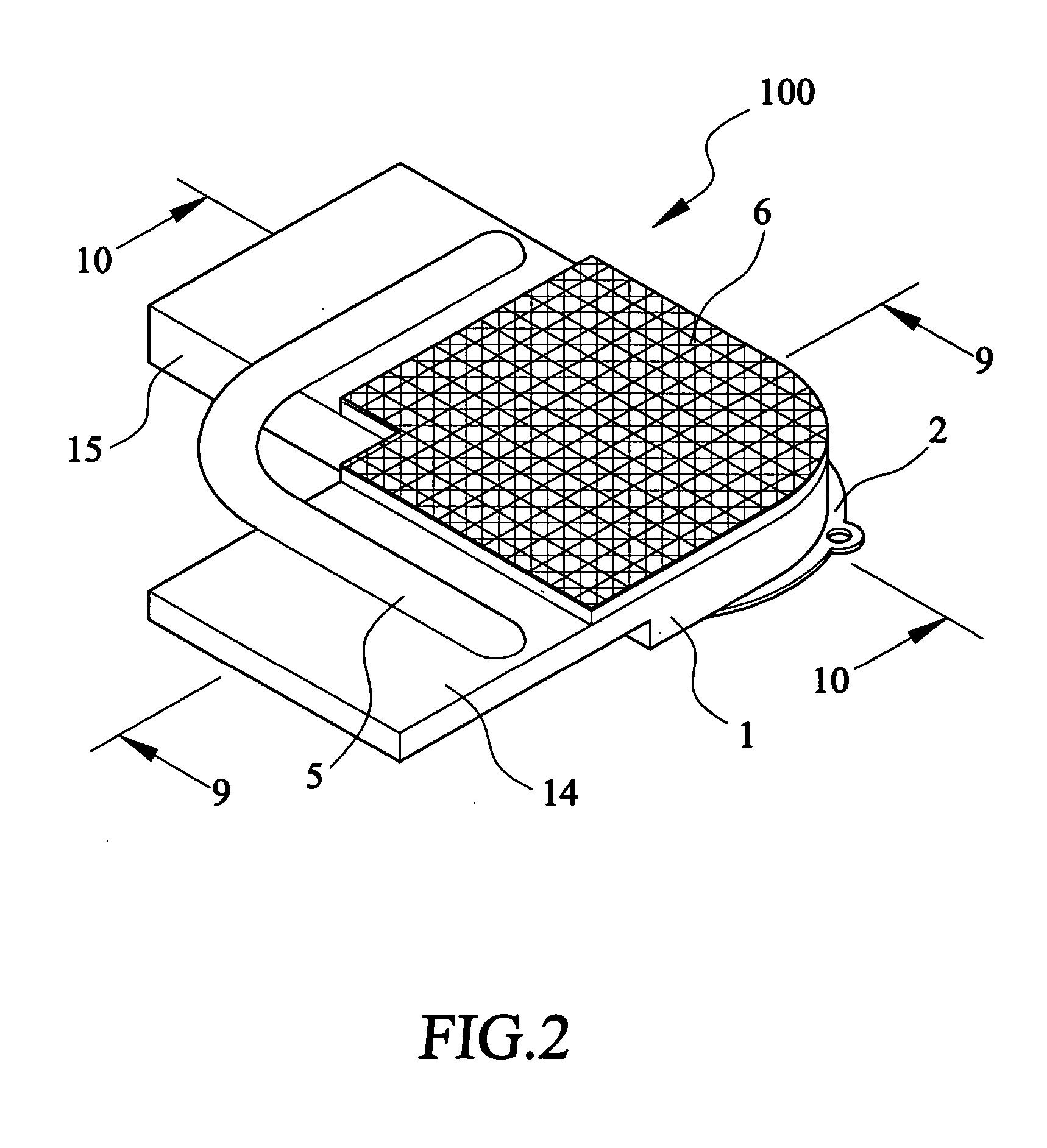

Heat dissipation device having thermally conductive cover board

InactiveUS20050252641A1Improve heat transfer performanceIncrease heat removal rateSemiconductor/solid-state device detailsSolid-state devicesEngineeringSurface cover

A heat dissipation device includes a casing forming a receptacle for receiving and retaining a fan module and a finned structure that includes spaced fins to define channels through air flows for primary exchange of heat with the heat dissipation device. The heat dissipation device further includes a thermally conductive surface cover board that is mounted to the casing to at least partly cover an air entrance that is defined in the casing to allow air to be drawn into the casing by the fan module. The surface cover board defines air passages through which air is conducted into the casing. Heat is exchanged with the air when the airflow passes through the surface cover board. Thus, the heat dissipation device features twice heat exchange with airflow and thus enhanced heat removal rate by simply adding the surface cover board to the casing and without significant modification of the existing heat dissipation device.

Owner:MITAC TECH CORP

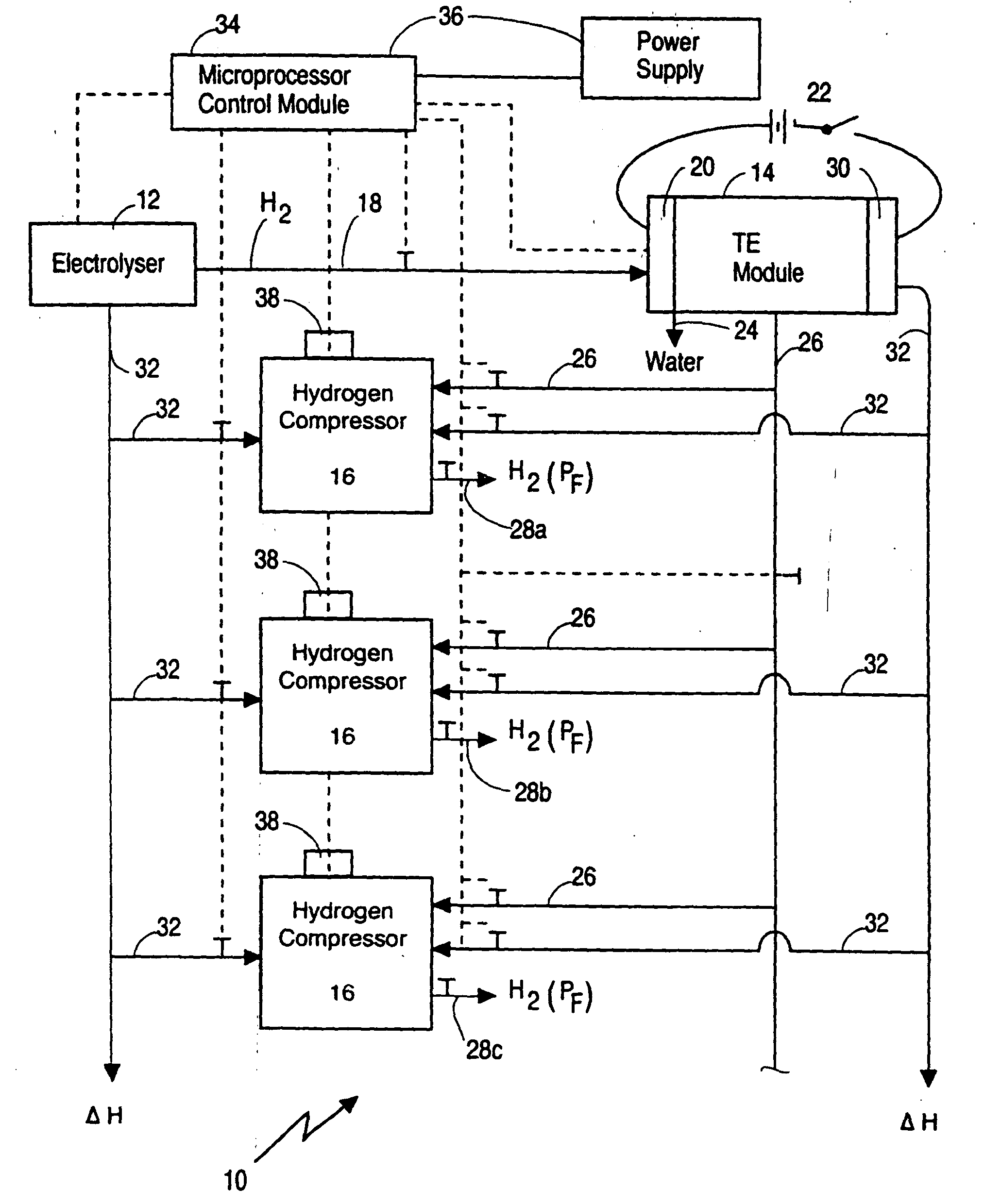

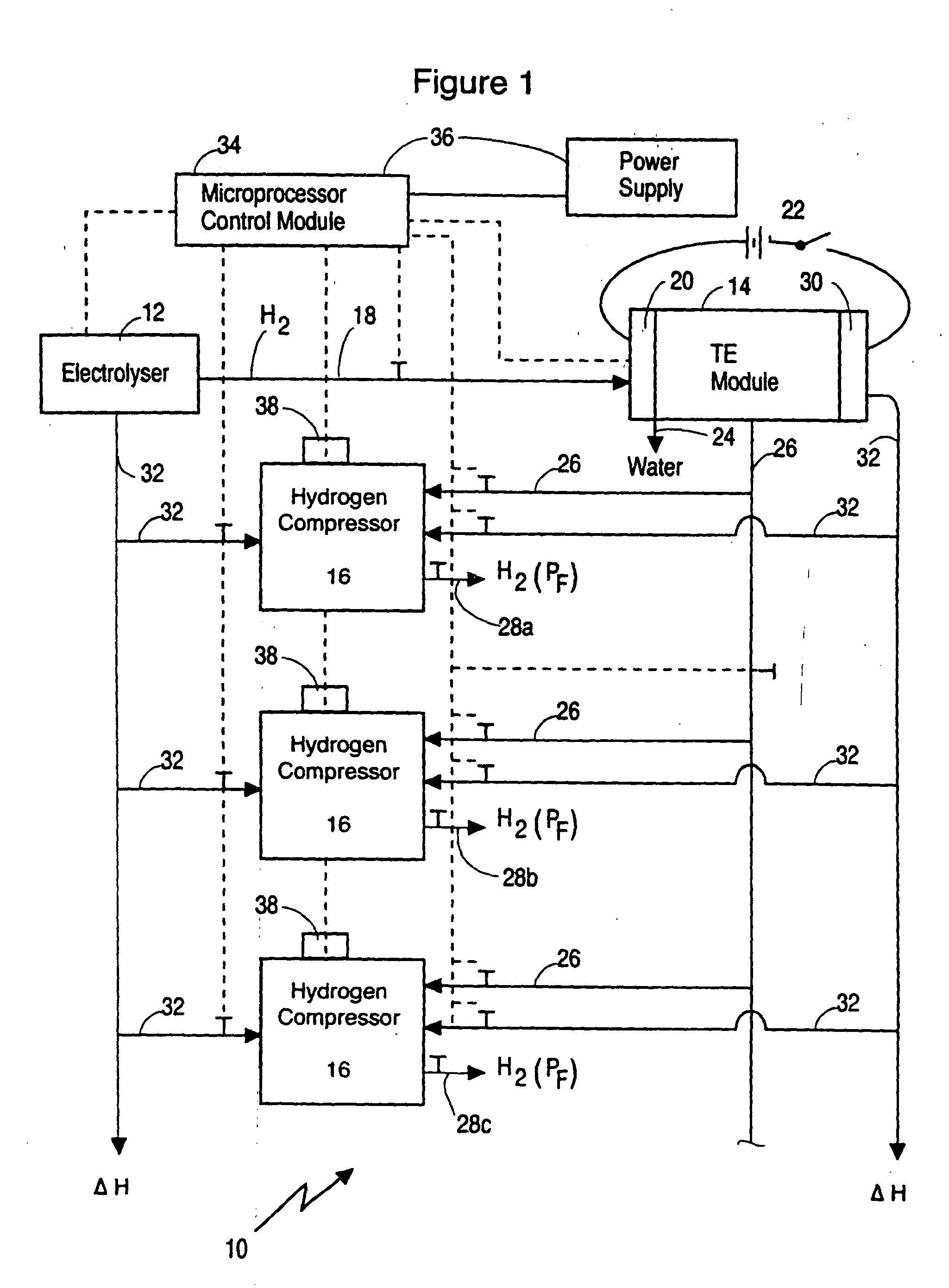

Method and apparatus for providing pressurized hydrogen gas

InactiveUS20040042957A1Speed up coolingIncrease the rate of heatingReversible hydrogen uptakeMultiple metal hydridesChemistryHydride

Apparatus and process for producing hydrogen gas at a desired pressure comprising feeding a hydrogen gas at a first temperature and first pressure from a hydrogen source to heat transfer means comprising cooling means and heating means; cooling the hydrogen gas with the cooling means to provide cooled hydrogen gas; feeding the cooled hydrogen gas to a metal hydride generator containing the metal; forming the metal hydride within the generator; heating the formed metal hydride to a temperature Tp and desired pressure; and releasing the pressurized hydrogen gas at the desired pressure from the generator and producing regenerated metal. Preferably, the apparatus comprises a plurality of generators linked to the heat transfer means to allow for continuous usage of both cooled hydrogen gas and generated heat from the heat transfer means to collectively provide a continuous pressurized hydrogen gas product

Owner:MARTIN DAVID

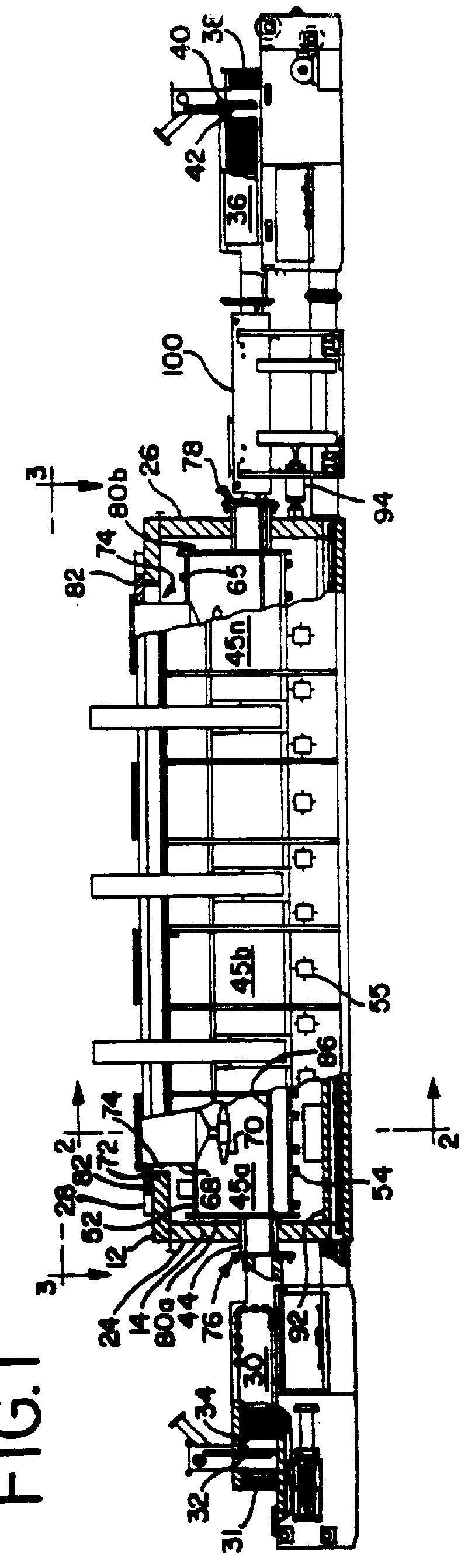

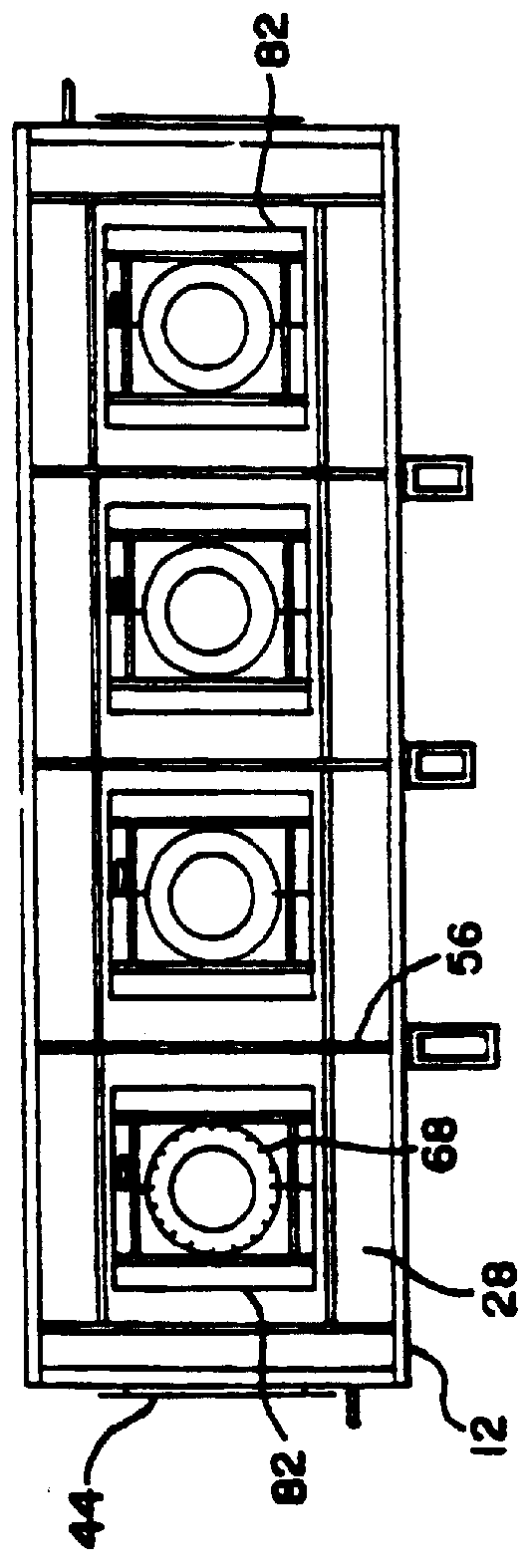

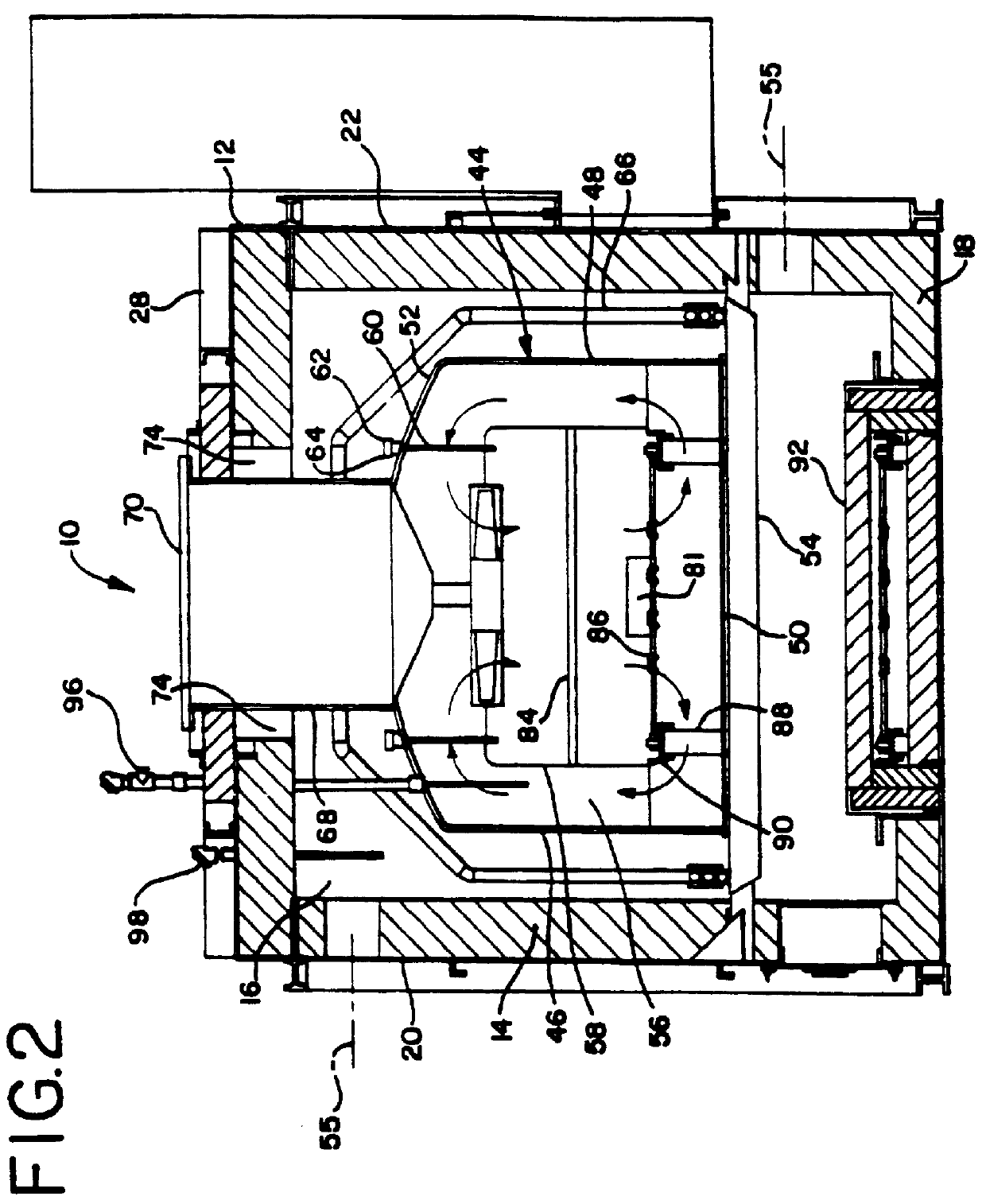

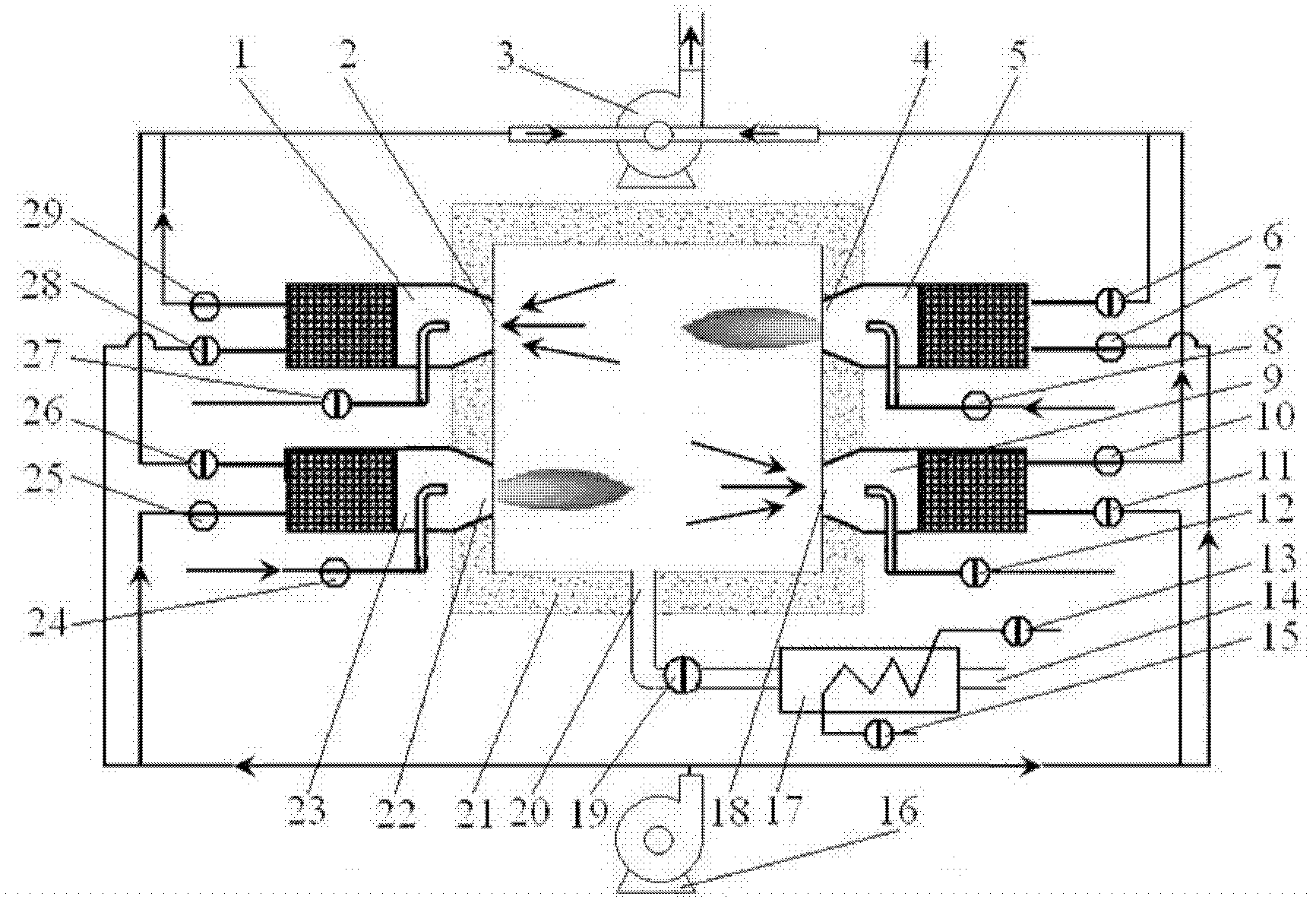

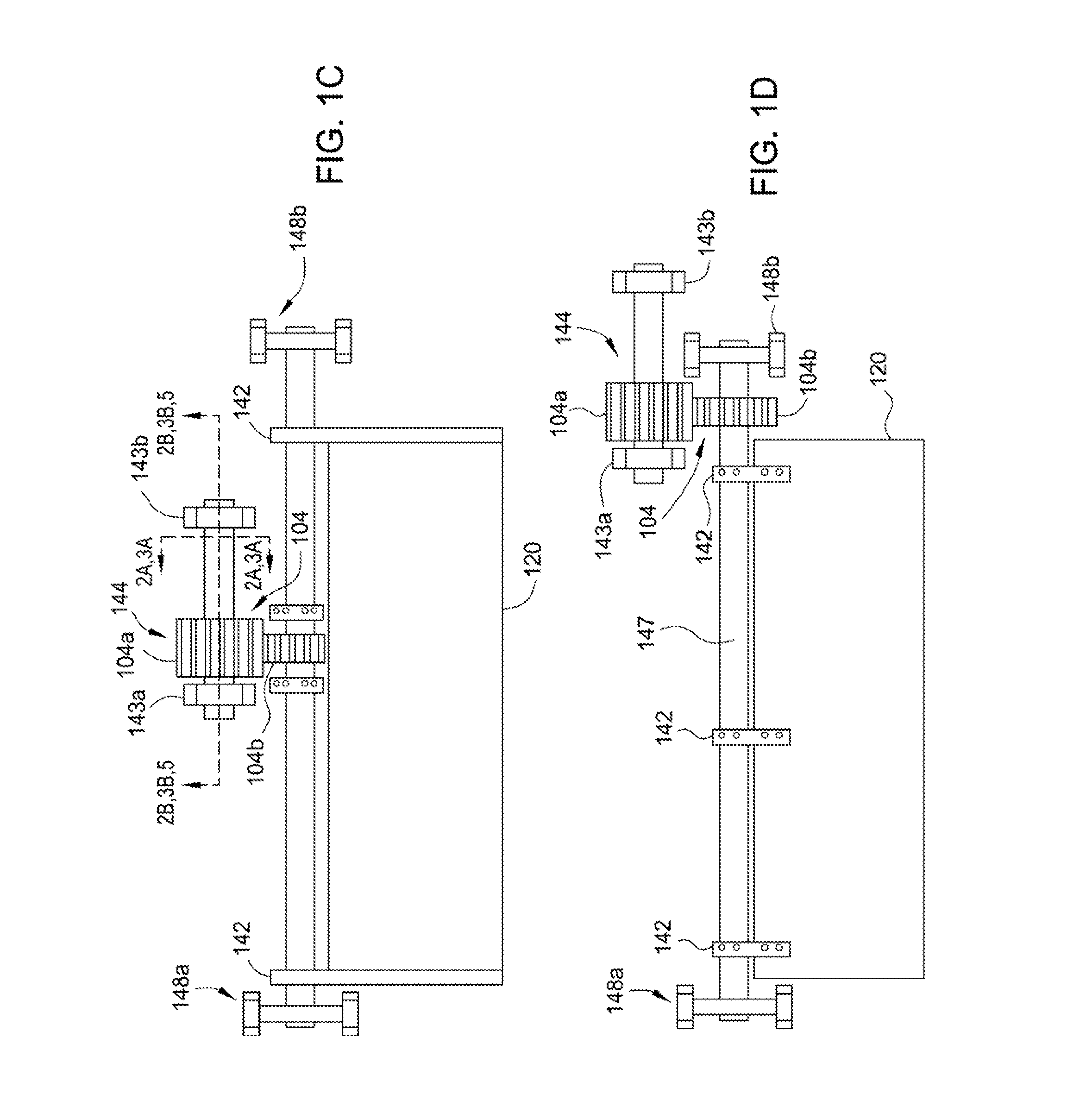

Muffle convection brazing/annealing system

InactiveUSRE36960E1Increase in temperatureIncrease in heat rateSoldering apparatusMaintainance of heating chambersMuffle furnaceForced convection

A convection muffle furnace for brazing and / or annealing a workpiece includes a muffle having towers formed integrally therewith and being mounted movable relative to a top wall of a furnace. Circulation fans are mounted in the towers so as to move along with the muffle during its expansion and contraction for producing forced convection heat transfer.

Owner:SECOWARWICK

Heat dissipation module

InactiveUS20160258691A1Improve cooling effectIncrease flow rateDigital data processing detailsIndirect heat exchangersEngineeringElectronic component

A heat dissipation module including an evaporator, a copper tube communicated with the evaporator to construct a loop, and a heat-transmitting medium flowing in the loop is provided. The evaporator includes an upper cover and a lower cover connected with each other and constructing a cavity. The lower cover has a heat-isolating wall protruded toward the cavity, so as to separate a heat-isolating region and a heating region at the lower cover. The upper cover has a slope inclining toward the cavity. A heat of an electronic element is transmitted to the heat-transmitting medium through the heating region, so that the heat-transmitting medium flows out of the evaporator towards a single direction along the slope after absorbing the heat, flows in the copper tube to transmit the heat outward through the copper tube, and then flows back to the evaporator through the copper tube after dissipating the heat.

Owner:ACER INC

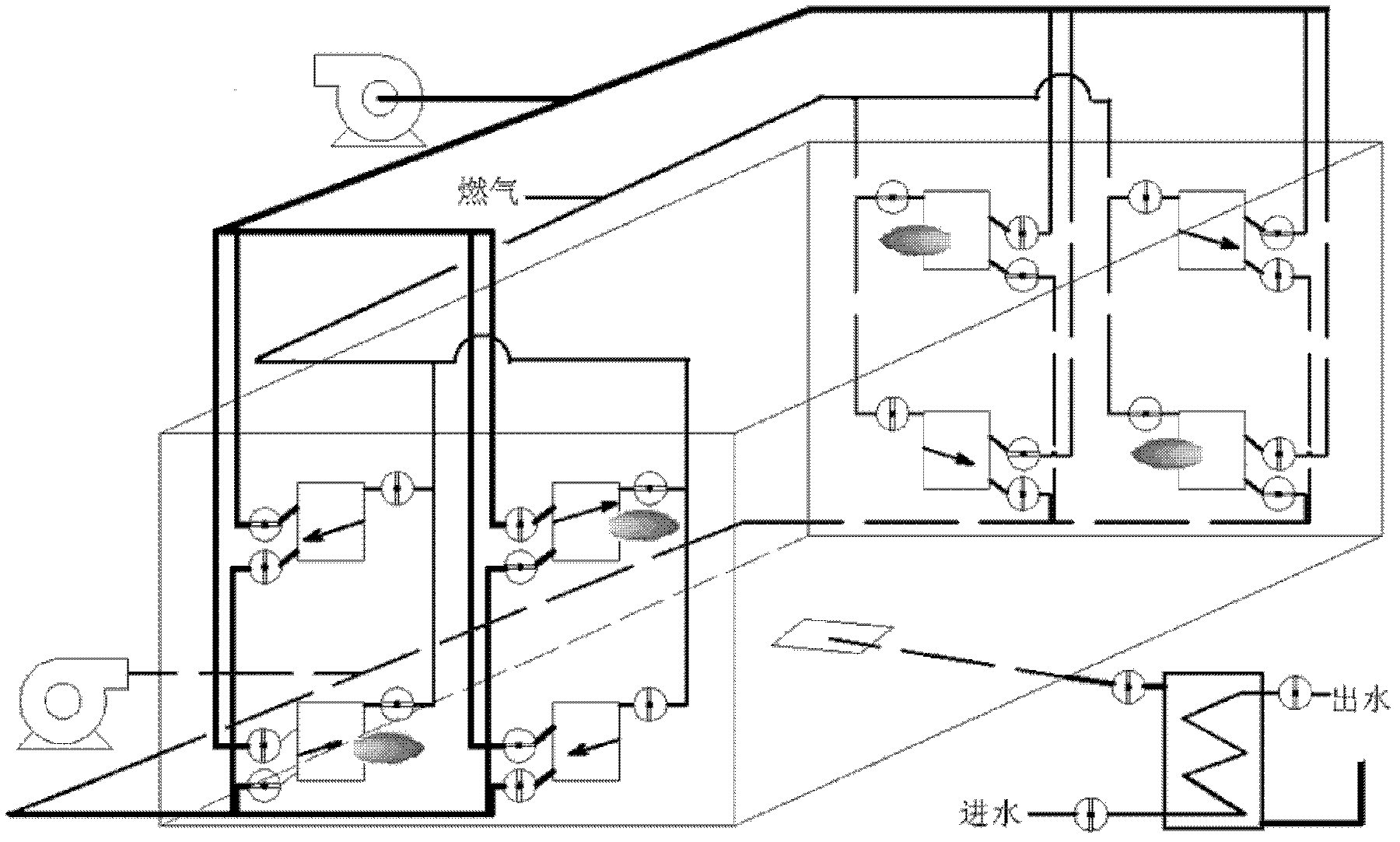

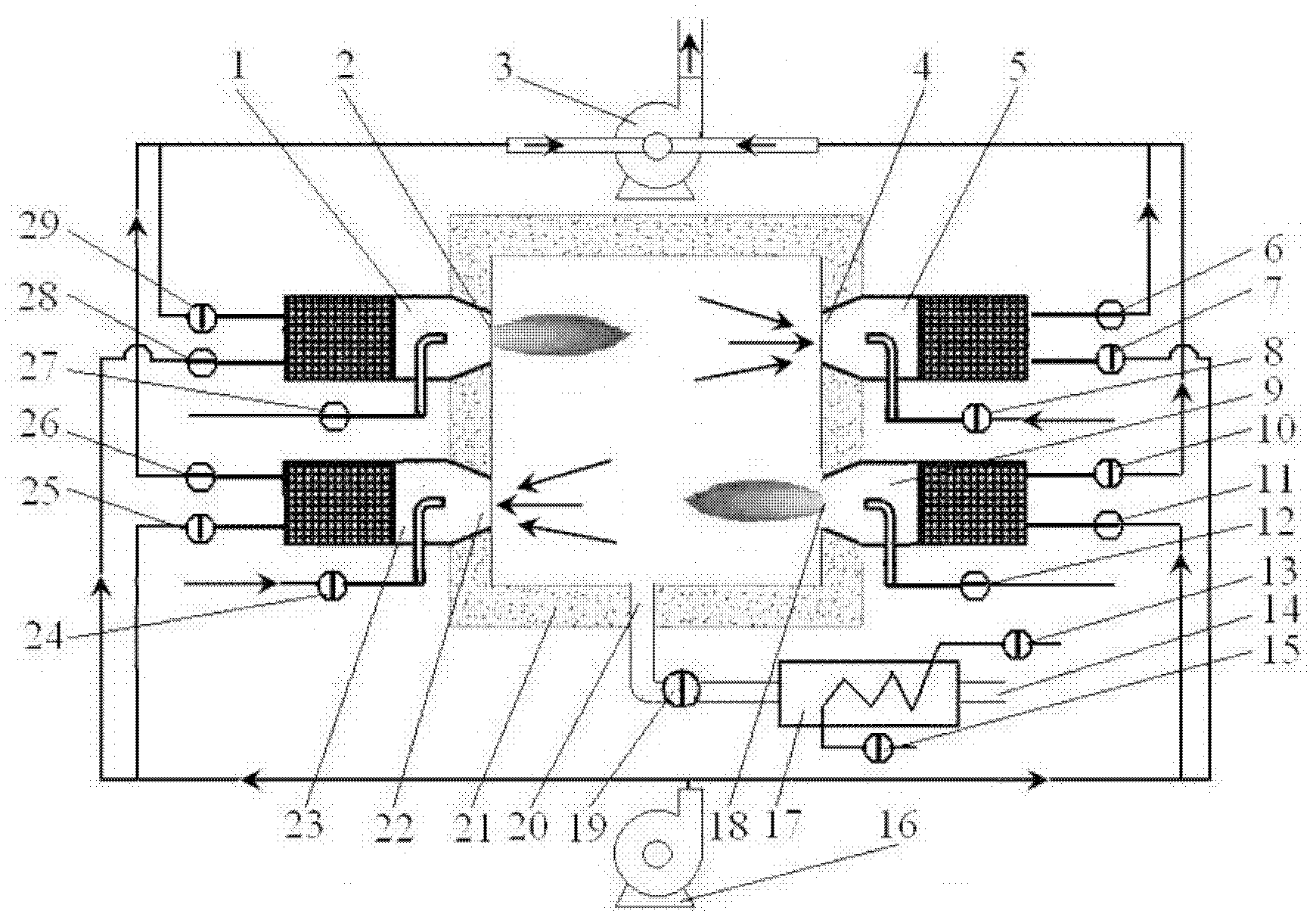

Energy-saving type shuttle type kiln

InactiveCN102564127AIncrease disturbanceUniform pressure distributionFurnace typesIncreasing energy efficiencyCombustorEngineering

The invention discloses an energy-saving type shuttle type kiln. The energy-saving type shuttle type kiln comprises a furnace body, at least one pair of heat-accumulating type combustors, a heat exchanger, corresponding valves, pipelines and a fan, wherein the combustors are arranged on the furnace body and are connected with the fan and a gas pipeline by the pipelines and the valves. When one of the combustors is in a combusting state, the other one is in a smoke-exhausting state, and the smoke stores heat in a heat-accumulating material in the combustors, and then is exhausted out of the system. When the preset time is up, the valves of the two combustors are switched, the combustor in the smoke-exhausting state is changed to be in the combusting state, and air absorbs the heat stored in the heat-accumulating material when passing through the combustor and carries the heat into a furnace so as to realize heat recovery. When a plurality of pairs of combustors are arranged, the working state of each combustor is opposite to that of the peripheral combustors so as to realize cross combustion. In the cooling process, heating and water supply are performed on the hot air by the heat exchanger on a spare flue, and the heat is absorbed by water so as to be utilized. The energy-saving type shuttle type kiln has the advantages that not only is the energy-saving effect obvious, but also the temperature distribution in the hearth is uniform, the temperature rising speed is high and the combustion temperature is high.

Owner:WUHAN ANHE ENERGY SAVING TECH

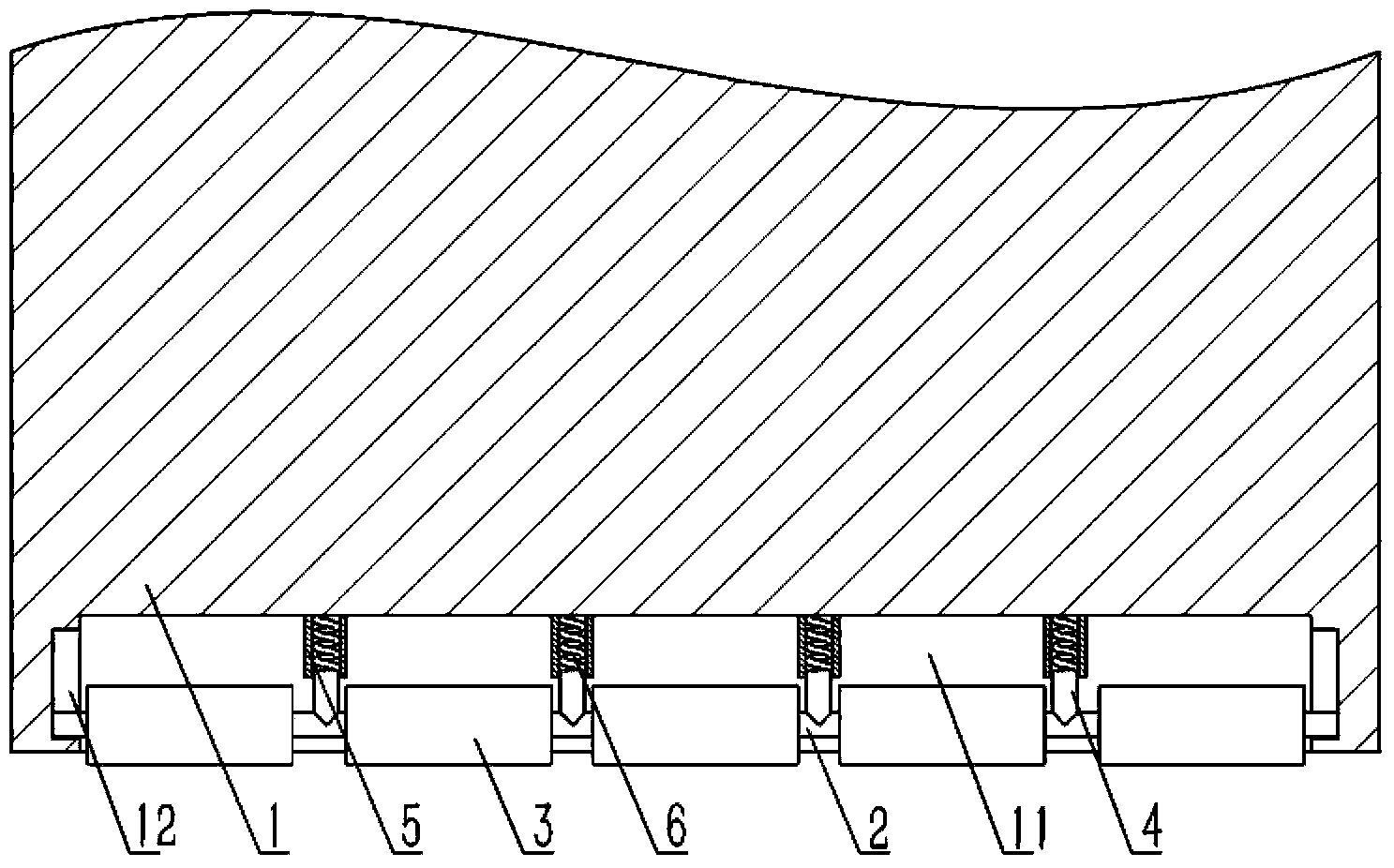

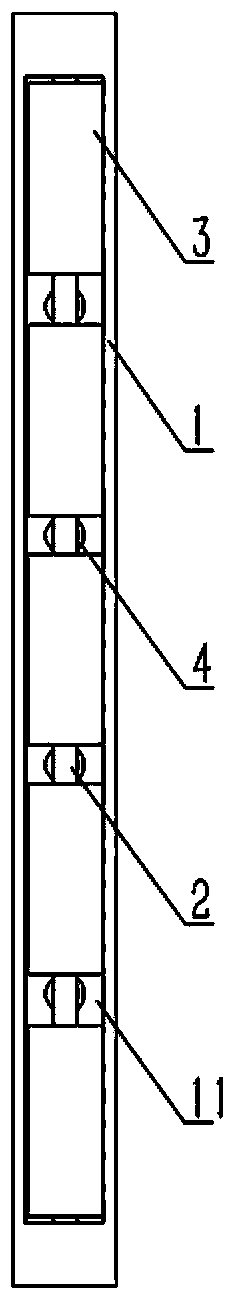

Wooden door with seal rollers

ActiveCN103452441AImprove cooling speedIncrease the rate of heatingSealing arrangementsDoor leavesEngineeringMechanical engineering

The invention discloses a wooden door with seal rollers, comprising a main body (1) of the wood door, wherein a rectangular groove (11) is moulded on the bottom end plane of the main body (1); vertical sliding chutes (12) are moulded on the left and right side edges of the rectangular groove (11); horizontal main shafts (2) are arranged in the sliding chutes (12); a plurality of vertical fulcrum shafts (4) are fixed on the main shafts (2); the fulcrum shafts (4) are sleeved in shaft sleeves (5) in an inserting way; the shaft sleeves (5) are fixed on the upper end plane of the rectangular groove (11); compressed springs (6) are arranged in the shaft sleeves (5); the lower ends of the compressed springs (6) lean against the top end planes of the fulcrum shafts (4); a plurality of rollers (3) are hinged to the main shafts (2). The gap of the door bottom is sealed by using the rollers with adjustable height, so that a larger gap can be reserved on the bottom of the door when the wooden door is manufactured so as to cope with the deformation, affected with damp, of the wooden door, the problem that the door cannot be closed due to the deformation can be effectively solved, and the speeds for rising and reducing the temperature of an indoor air conditioner can be increased in a seal way.

Owner:江苏金泰祥内外门业有限公司

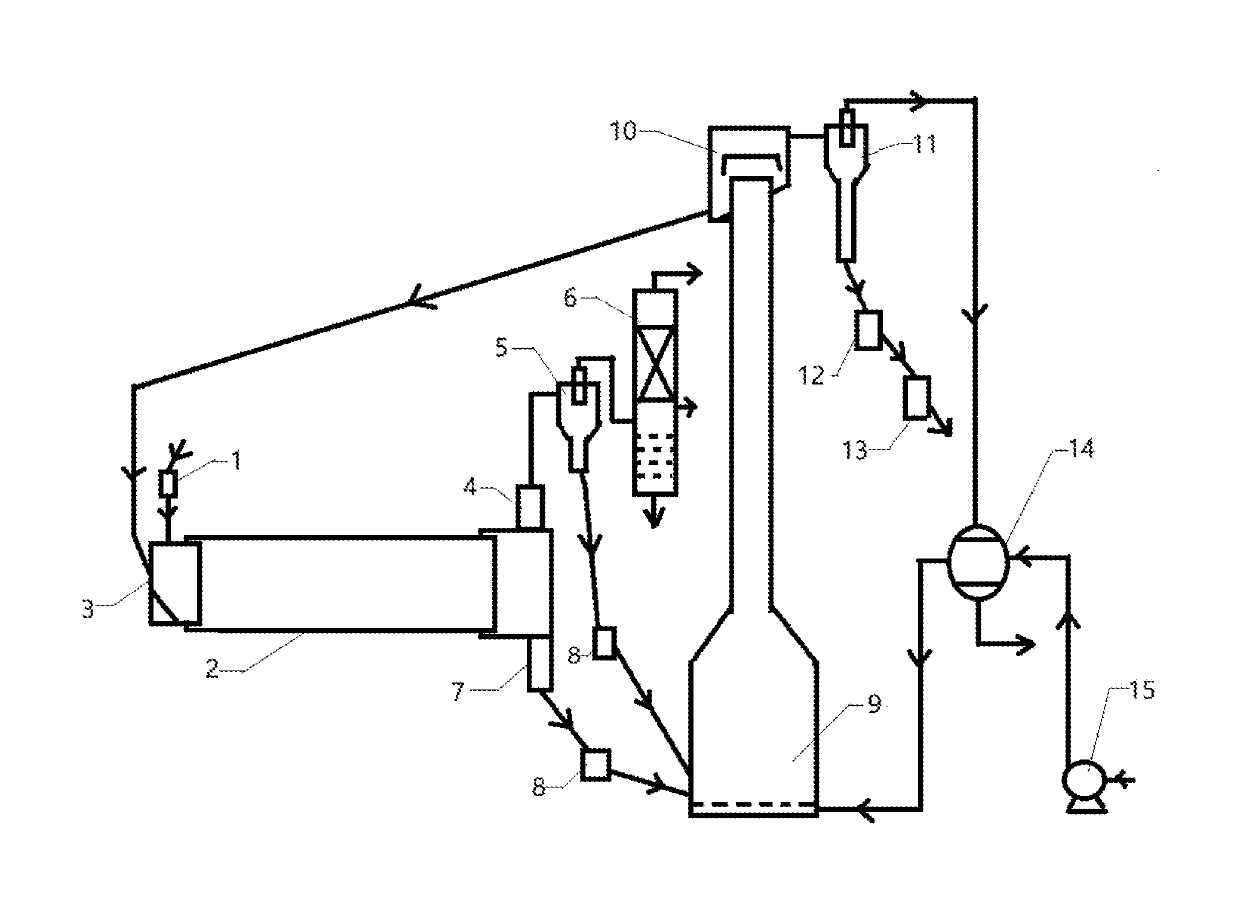

Method for pyrolysis treatment of oily sludge and environment-friendly renovation of the residue thereof with humic acid substance

ActiveUS10487265B1Improve liquid yieldReduce in quantitySolid waste disposalDirect heating destructive distillationHeat carrierSludge

Providing a method for pyrolysis treatment of oily sludge and environment-friendly renovation of the residue thereof with humic acid substance. The method relates to inside-mixing solid heat carrier with oily sludge to improve the liquid yield, and completely removing the petroleum hydrocarbons from pyrolyzing residue by calcinating it in a fluidized bed, and using the fractionated large and medium particles as the circulating heat carrier, and discharging the fine particles, and performing environment-friendly renovation with the biological humic acid substance to achieve combinations of the harmless technical measures, thereby achieve harmlessness, reduced quantity and resourceful treatment of the oily sludge.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

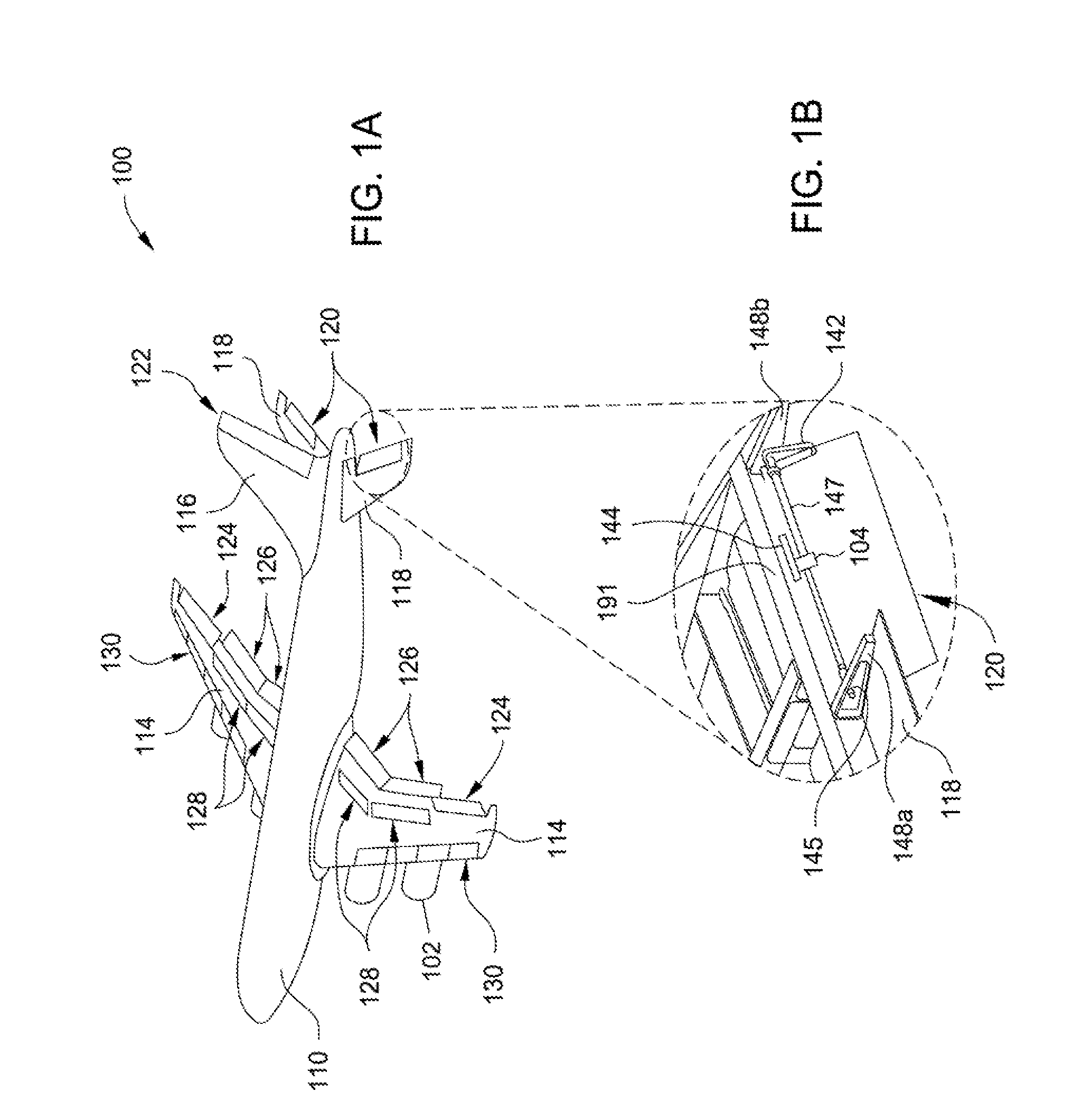

Integrated high thermal conductive fiber as cooling fin for sma actuator with expandable sleeve

ActiveUS20160201654A1Facilitates radial expansionSpeed up coolingAircraft stabilisationWithout power ampliicationFiberControl theory

Aspects of the present disclosure generally relate to an SMA actuator that includes a cooling device disposed within a torque tube. In one aspect, the cooling device includes a sliding sleeve, an expandable sleeve, and plurality of cooling fins coupled to the expandable sleeve. Axial movement of the sliding sleeve relative to the expandable sleeve facilitates radial expansion of the expandable sleeve and urges the cooling fins into contact with the torque tube. The cooling fins function as heat sinks when in contact with the torque tube to facilitate the removal of heat from the torque tube to increase the cooling rate of the torque tube. During heating of the torque tube, the cooling fins may be spaced apart from the torque tube to reduce the thermal mass that is heated, thus increasing the heating rate of the torque tube.

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com