A method of microwave firing porous ceramsite from medical waste incineration fly ash

A technology for incinerating fly ash and medical waste, applied in the field of environmental pollution control, to achieve the effect of solving temperature gradient, increasing heating speed, and improving heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

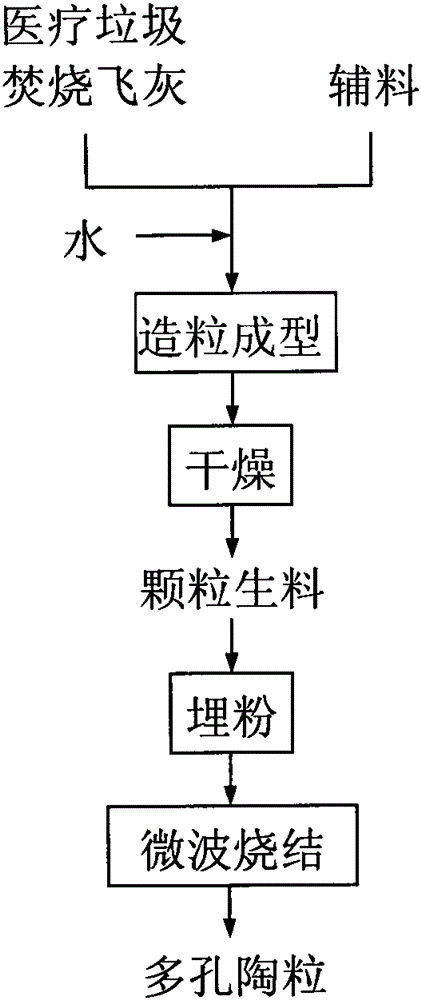

Method used

Image

Examples

Embodiment 1

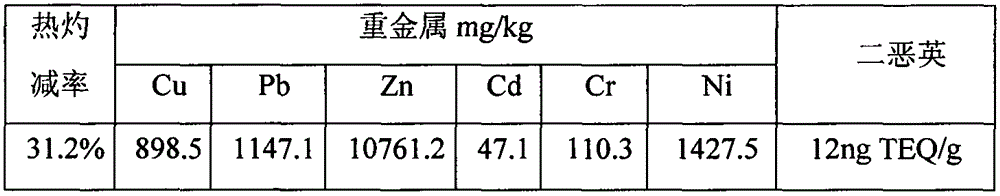

[0018] The chemical composition of a certain medical waste incineration is shown in Table 1, and the thermal ignition reduction rate, heavy metal, dioxin and chlorine content of fly ash are shown in Table 2. Put the medical waste incineration fly ash and quartz sand into the mixer according to the mass ratio of 5:1 and mix them thoroughly, then add deionized water (the total moisture content is controlled at 5%) and stir evenly, and send the mixture into the flat die molding machine Extruded into strip-shaped particles with a diameter of 0.8mm, put the strip-shaped particles in a drying oven to dry for 24 hours to remove the moisture in them, and after drying, the raw materials of the particles are placed in an industrial microwave sintering furnace, and silicon carbide powder is used for buried powder sintering and microwave sintering The working frequency of the furnace is 2.45GHz, and the power of the microwave oven is adjusted to 3.6kW. When the microwave sintering temperat...

Embodiment 2

[0026] The medical waste incineration fly ash sample that adopts is identical with embodiment 1, and the mass ratio of medical waste incineration fly ash and waste glass powder is put into the mixer by 2:1 and fully mixed, then deionized water (total water content control 10 %) Stir evenly, send the mixture into a flat die forming machine and extrude into strip-shaped granules with a diameter of 0.8mm, put the strip-shaped granules in a drying oven for 24 hours to remove moisture, and place the dried granule raw materials in an industrial microwave In the sintering furnace, the mixed powder of activated carbon and silicon carbide (the mass ratio of the two is 3:1) is used for buried powder sintering. The operating frequency of the microwave sintering furnace is 2.45GHz, and the power of the microwave oven is adjusted to 7.2kW. When the microwave sintering temperature Reach 1000°C, keep warm for 25 minutes, take out the furnace after sintering and cool to room temperature to obt...

Embodiment 3

[0030] The medical waste incineration fly ash sample that is adopted is the same as in Example 1, and the medical waste incineration fly ash and waste glass powder are put into a mixer and fully mixed in a mass ratio of 1:1, and then deionized water is added (total moisture content control 15%) and stir evenly, send the mixture into a flat die forming machine and extrude into strip-shaped particles with a diameter of 0.8mm, put the strip-shaped particles in a drying oven for 24 hours to remove moisture, and place the dried granular raw materials in the industrial In the microwave sintering furnace, ferric iron tetroxide powder is used for buried powder sintering. The operating frequency of the microwave sintering furnace is 2.45GHz, and the power of the microwave oven is adjusted to 7.2kW. When the microwave sintering temperature reaches 1100°C, keep it warm for 5 minutes. Take it out of the furnace and cool to normal temperature to obtain porous ceramsite. The technical index...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com