Patents

Literature

40 results about "Thermal ignition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

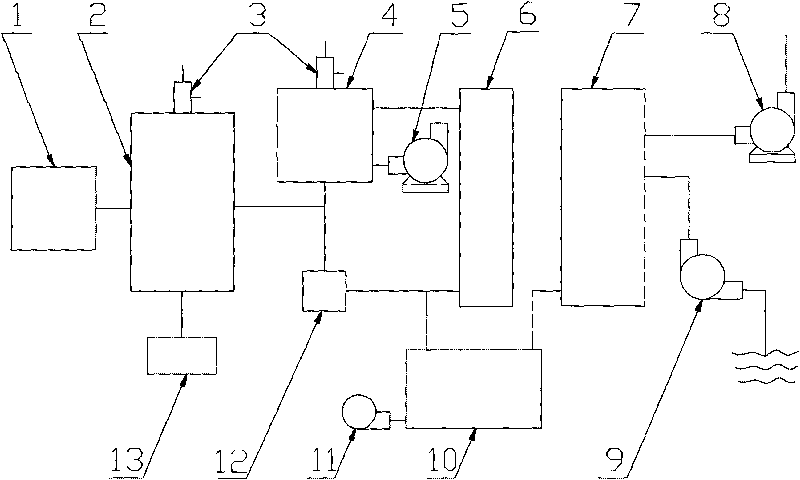

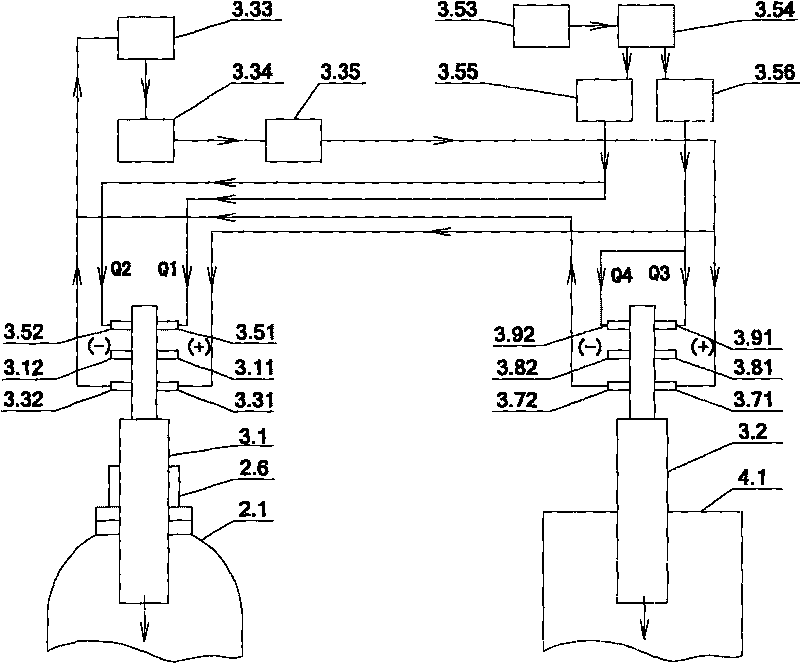

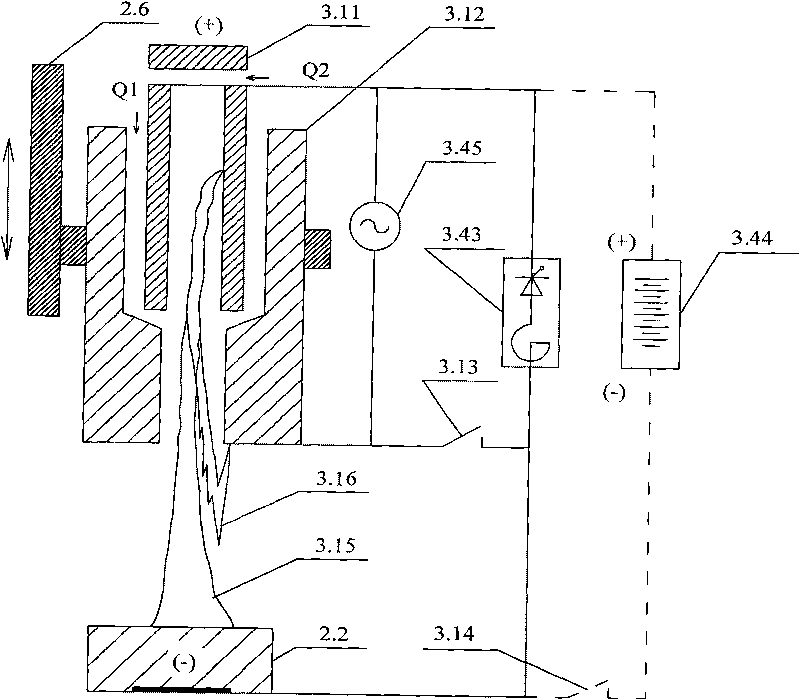

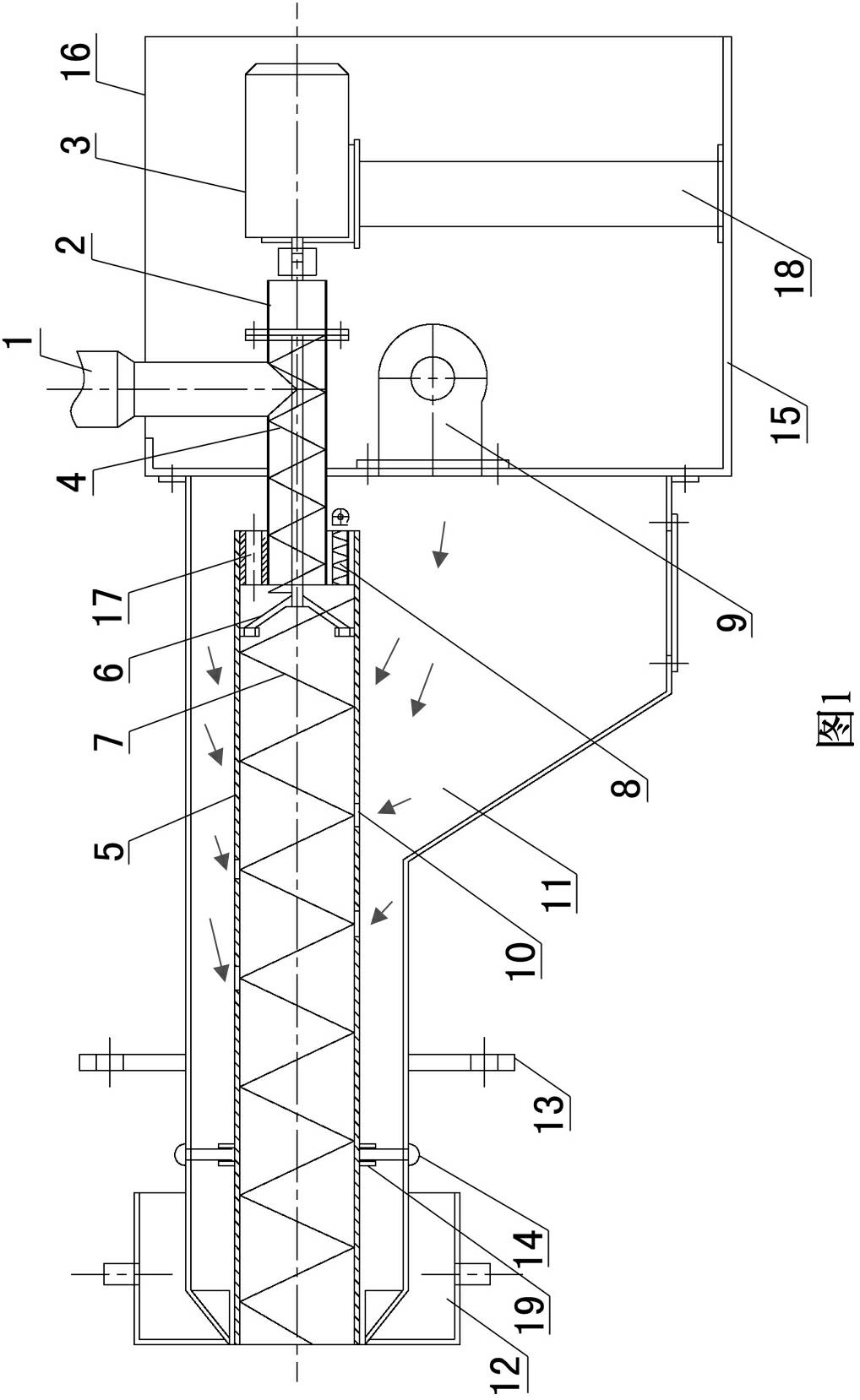

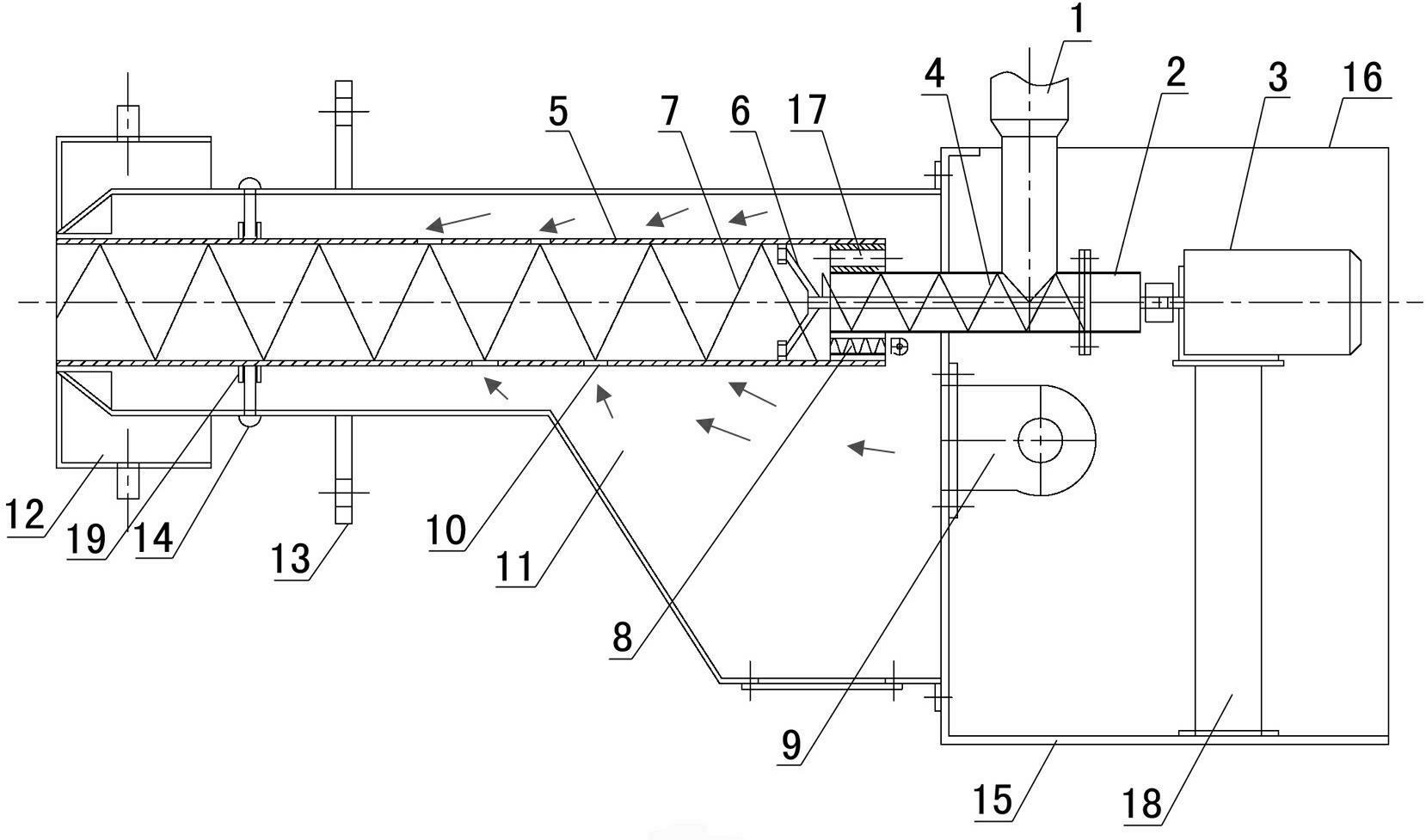

Thermal plasma device for incinerating marine garbage

ActiveCN101737785AGood heat transfer performanceImprove incineration efficiencyCombustion technology mitigationIncinerator apparatusLoss rateMelting tank

The invention relates to a thermal plasma device for incinerating marine garbage, which comprises a feed system, an incinerator, a plasma system, a secondary combustion chamber, a blast blower, a heat exchanger, a desulfurization and dust removal tower, a draught fan, a first water pump, a quench cooler, a second water pump, a tapping device and an automatic control system. The invention adopts a transferred-arc and non-transferred arc dual-purpose direct-current plasma generator as an incineration heat source, which not only can make full use of a shipborne dynamic power supply (or an accumulator battery) but also can use a non-transferred arc in the initial stage of incineration and adopt the working mode of a transferred arc after a molten pool is molten. Compared with a single non-transferred arc operation mode, the heat transmission property is better, the incineration efficiency is higher, and more energy is saved; in the invention, the secondary combustion chamber adopts plasma heating in a similar way, and the condition that new pollution is generated in the treatment process of secondary combustion is avoided; and by high temperature generated by the plasma generator adopted by the invention, the temperature of the molten pool exceeds 1500 DEG C and is sufficient to enable inorganic substances, slag and heavy metal to be fused together, the inorganic substances, the slag and the heavy metal are solidified in a neutral vitreous body and are not easy to precipitate, the treatment of the garbage is finished by one step, and the thermal ignition loss rate is less than 3%.

Owner:AEROSPACE ENVIRONMENTAL ENG

Oil reservoir fire-flooding thermal-ignition method

InactiveCN1995697AAutoignition point reachedRealize the purpose of burning oil layer to drive oilFluid removalThermal energyWater vapor

The invention relates to a thermal igniting method in fire-flooding oil recovery reservoir for ignition in fire-flooding oil recovery reservoir in oilfield and oil well. An active prying gas-steam generator system is used to burn diesel oil to generate mixed air with nitrogen air, carbon dioxide and water steam so on and a mass of heat energy by high-temperature high-pressure burning technology. When the burning temperature in gas-steam generator achieves 1800DEG C, temperature is fallen to 300-400DEG C by mixing water and the pressure is less than 25MPa. The mixed air injects into reservoir by wellhead equipment of oil well and injection tube. The mixed air with the temperature of 300-400DEG C and the cubage of 3-10*104Nm3 is injected to preheat the reservoir and air is injected in the well continuously. In reservoir, the crude oil and the air generate oxygenation to discharge heat. The self-burning point is achieved and burning happens so that the purpose of flooding by combustion. The method solves following problems that the heater is destroyed easily because of over high heating temperature in prior technology and the successful ignition by chemical method is low. The invention can be widely applied in ignition in fire-flooding oil recovery reservoir in oilfield and oil well.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

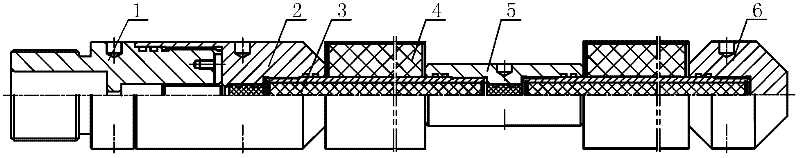

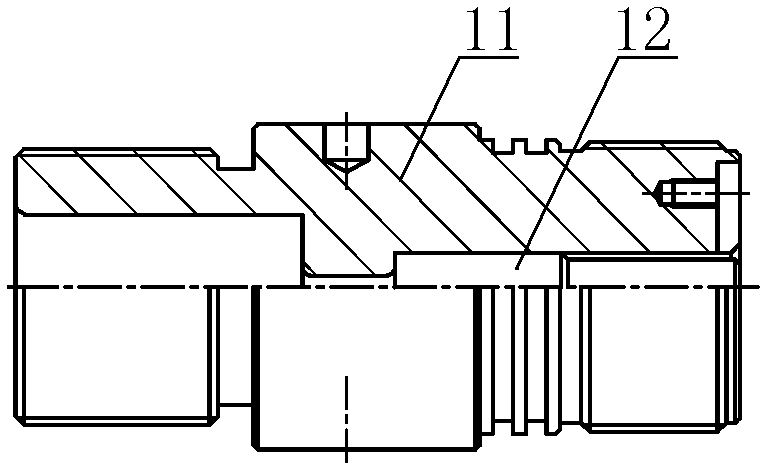

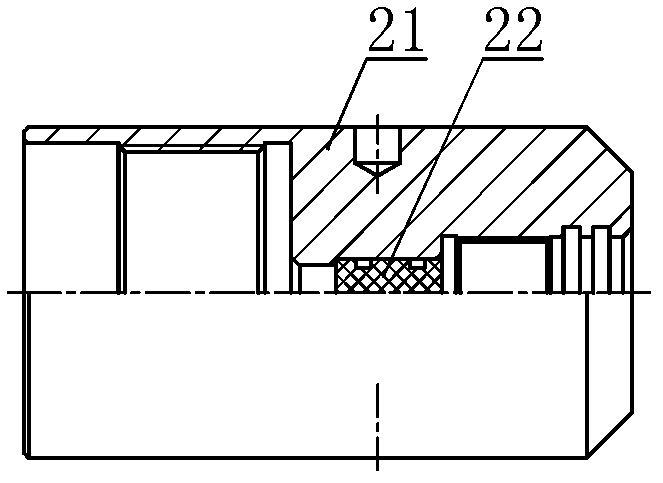

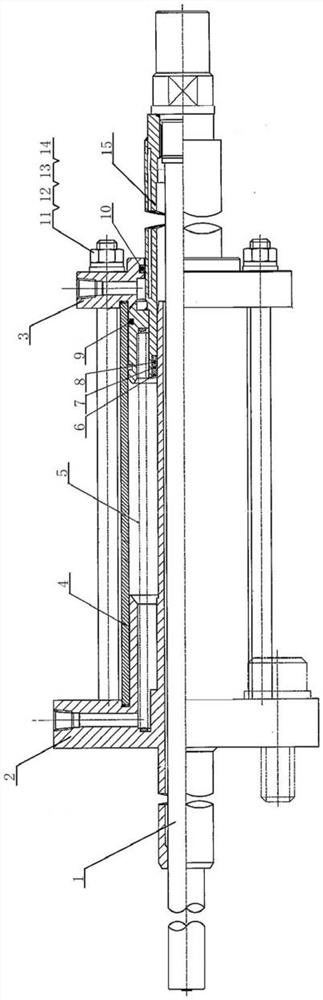

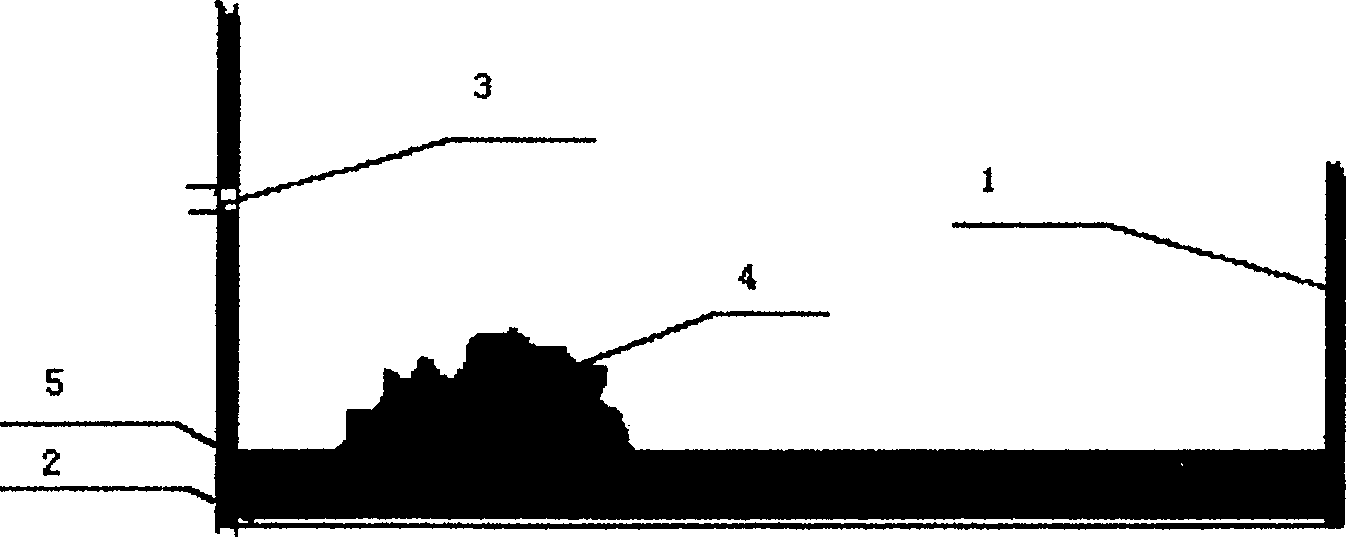

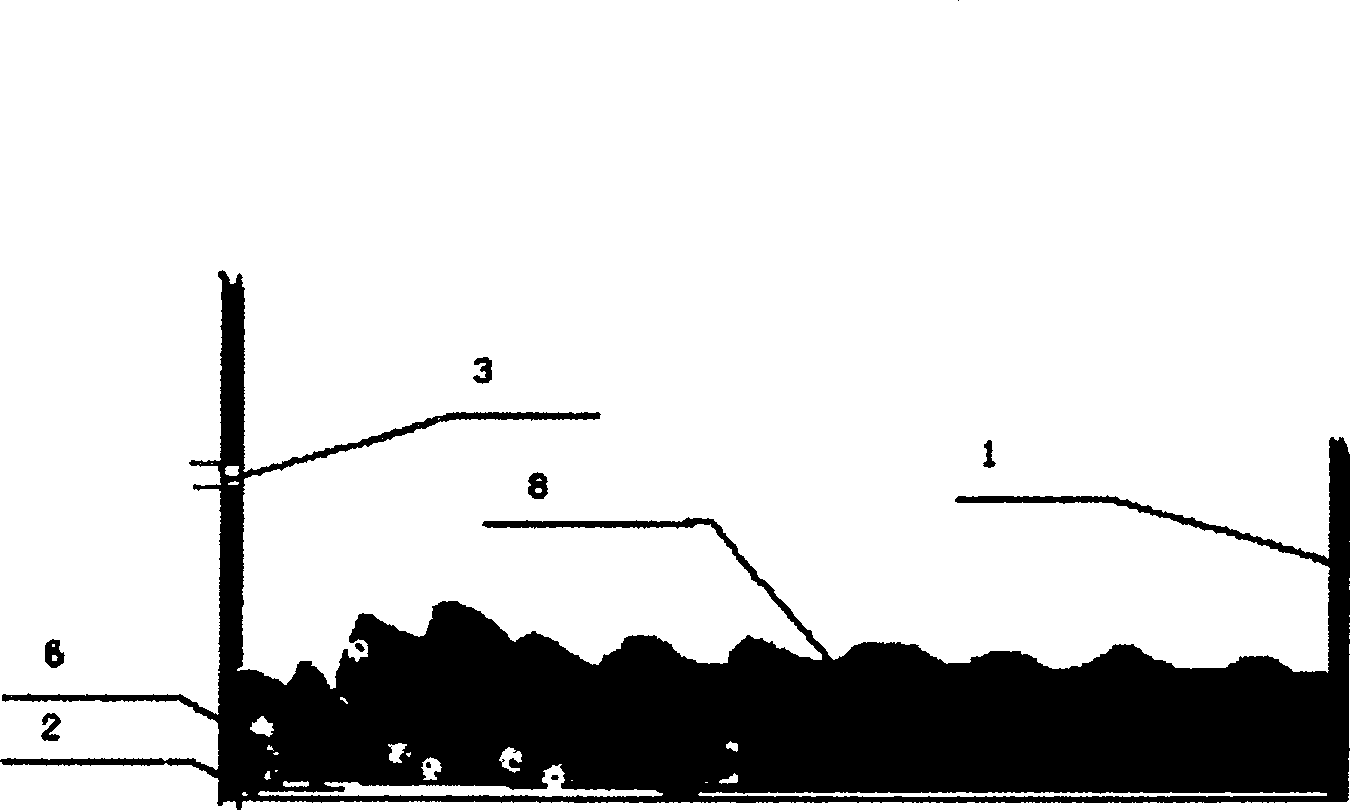

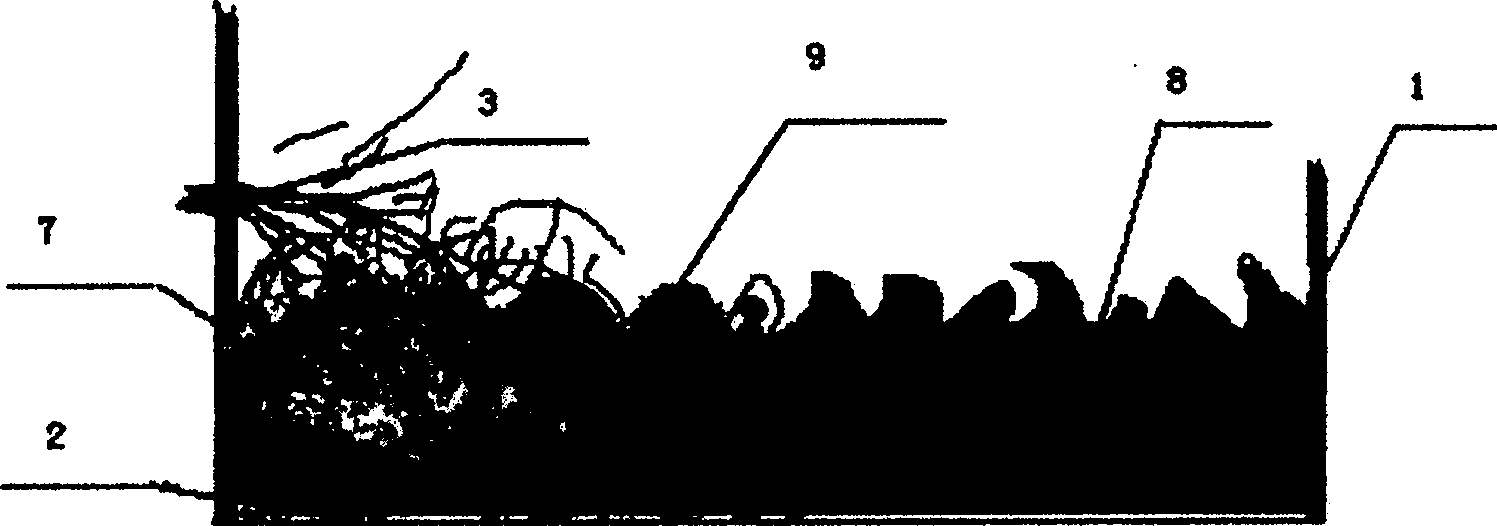

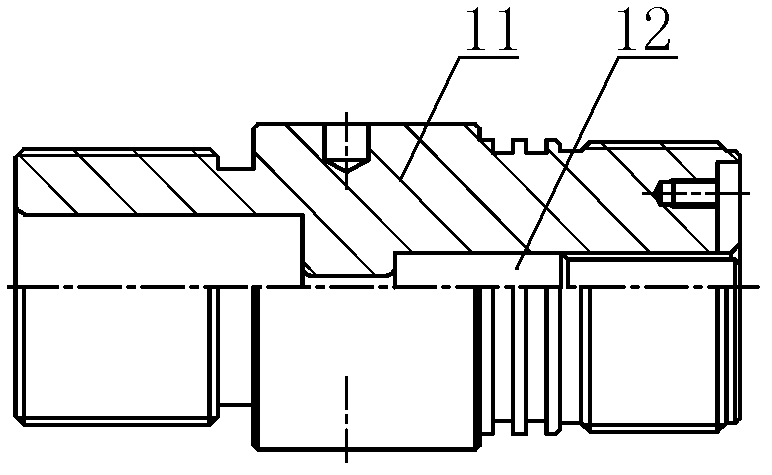

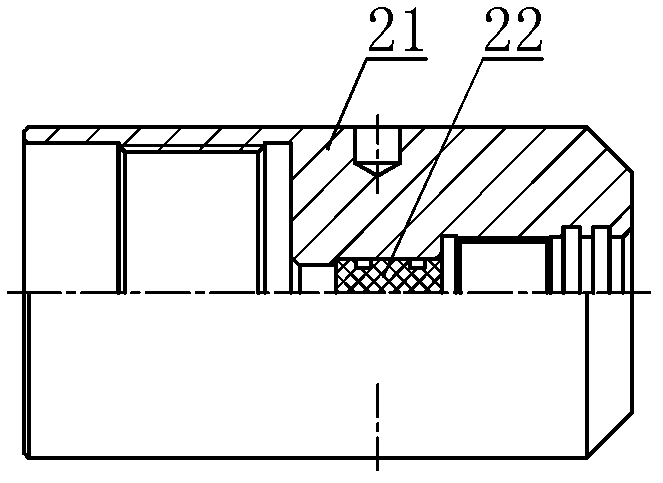

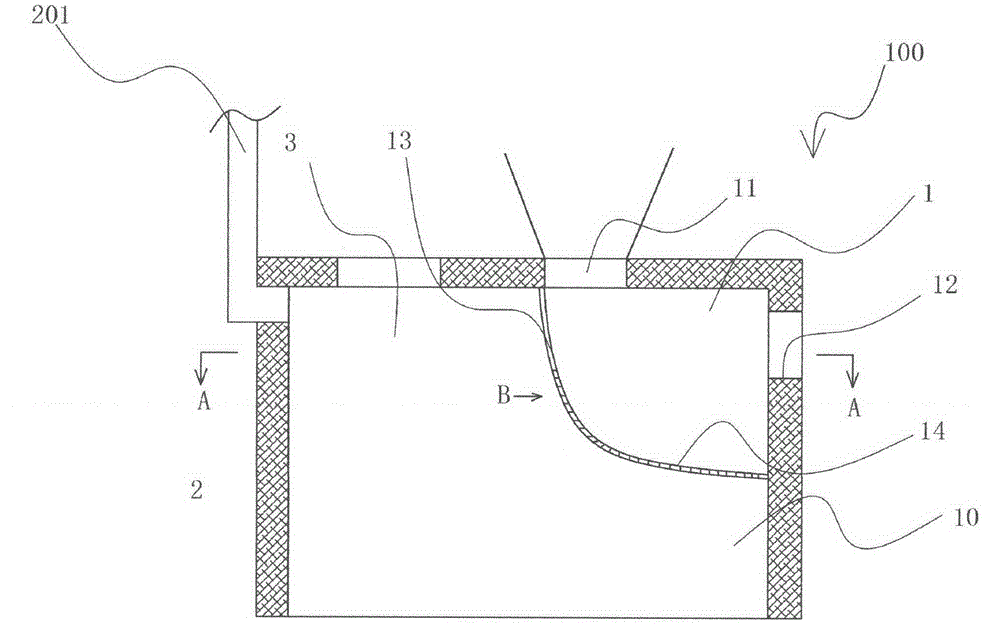

Thermal-ignition high-energy gas pulse fracturing device

The invention discloses a thermal-ignition high-energy gas pulse fracturing device. The thermal-ignition high-energy gas pulse fracturing device is formed by connecting an oil transmission or cable ignition joint component, a fire transmission joint component, one or more airtight thermal ignition device components, one or more fracturing main charge components, one or more series-connected joint components and a gun breech in series, wherein the airtight thermal ignition device components are ignited by using ignition tubes; the ignition tubes ignite high-heat micro-air gunpowder or airless high-heat explosives in the airtight thermal ignition devices; the airtight thermal ignition devices are sealed systems and keep a complete structure before and after ignition; main charges are ignited by heat transmitted from the airtight thermal ignition devices; and the main charges combust and quickly generate a great amount of fuel gas. A plurality of devices are connected in series by using ignition joints, the number of the devices connected in series is not limited, and the instant or delayed ignition tubes are filled in the ignition joints, so that the combustion transmission of multi-level devices is realized. The thermal-ignition high-energy gas pulse fracturing device solves the problems that a deflagration state is difficult to control, pressure in mineshafts is superposed and sleeves are damaged, and a great amount of debris pollutant and blockage exist after deflagration in the prior art.

Owner:NORTH SCHLUMBERGER OILFIELD TECH XIAN

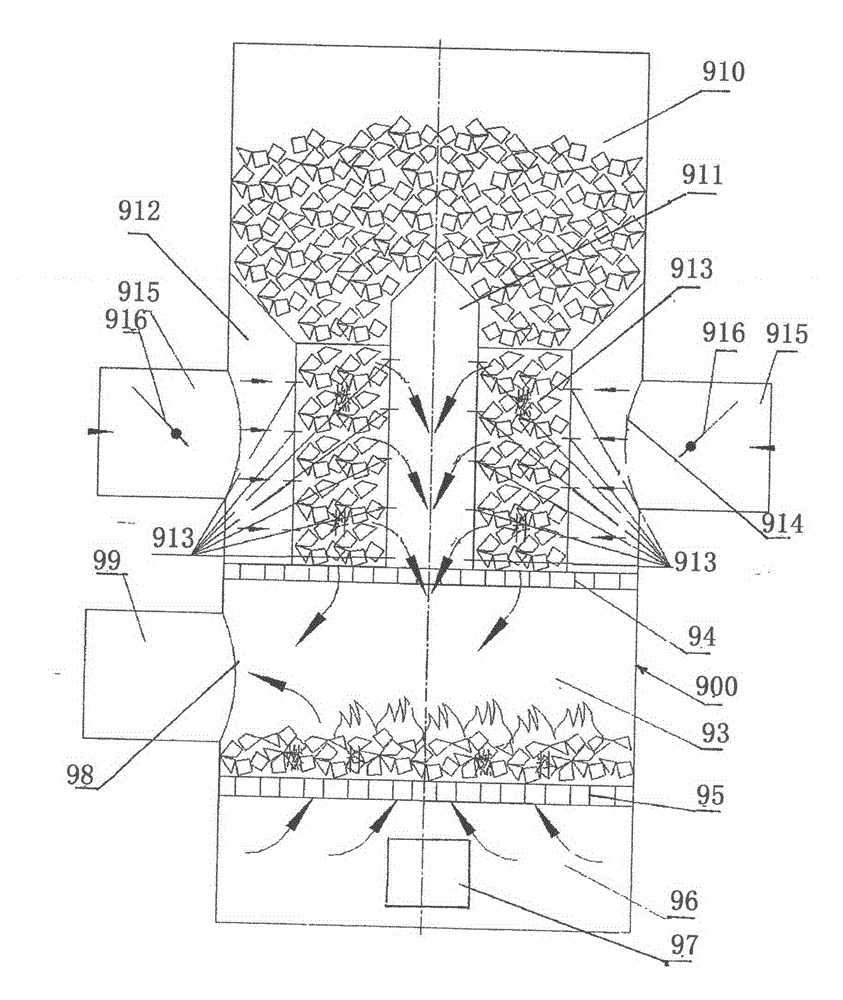

Fluidized bed boiler hot material firing mode

InactiveCN1632380ALow costSimple and fast operationFluidized bed combustionIncandescent ignitionThermal ignitionFluidized bed

The invention relates to a boiler ignition mode, in particular to a coal-fired fluidized bed boiler heating material ignition mode. The fluidized bed heating material ignition mode of the present invention is realized through the following technical scheme. The hot material ignition of the present invention is to take out the inert hot bed material that is nearly burned out in the running boiler, put it into the pre-start fluidized bed boiler, and use it as an ignition source to make it fluidized after air distribution and coal supply. State combustion, the combustion proceeds from point to surface until the whole bed is stably combusted. The process of the heating material ignition method of the circulating fluidized boiler of the present invention is as follows: laying the bottom material → taking and sending the heating material → air distribution, coal feeding → fluidized combustion → air distribution, coal feeding → extended combustion → stable combustion of the whole bed. The advantages of the invention are: the ignition cost of the invention is greatly reduced; the ignition and combustion process is from point to surface, and the ignition is easy and stable; the operation is simple, convenient and intuitive; the controllability is strong; the safety and reliability are high, and the ignition success rate is high; Transformation promotion. The invention is applicable to various coal-fired fluidized bed boilers.

Owner:王天伟

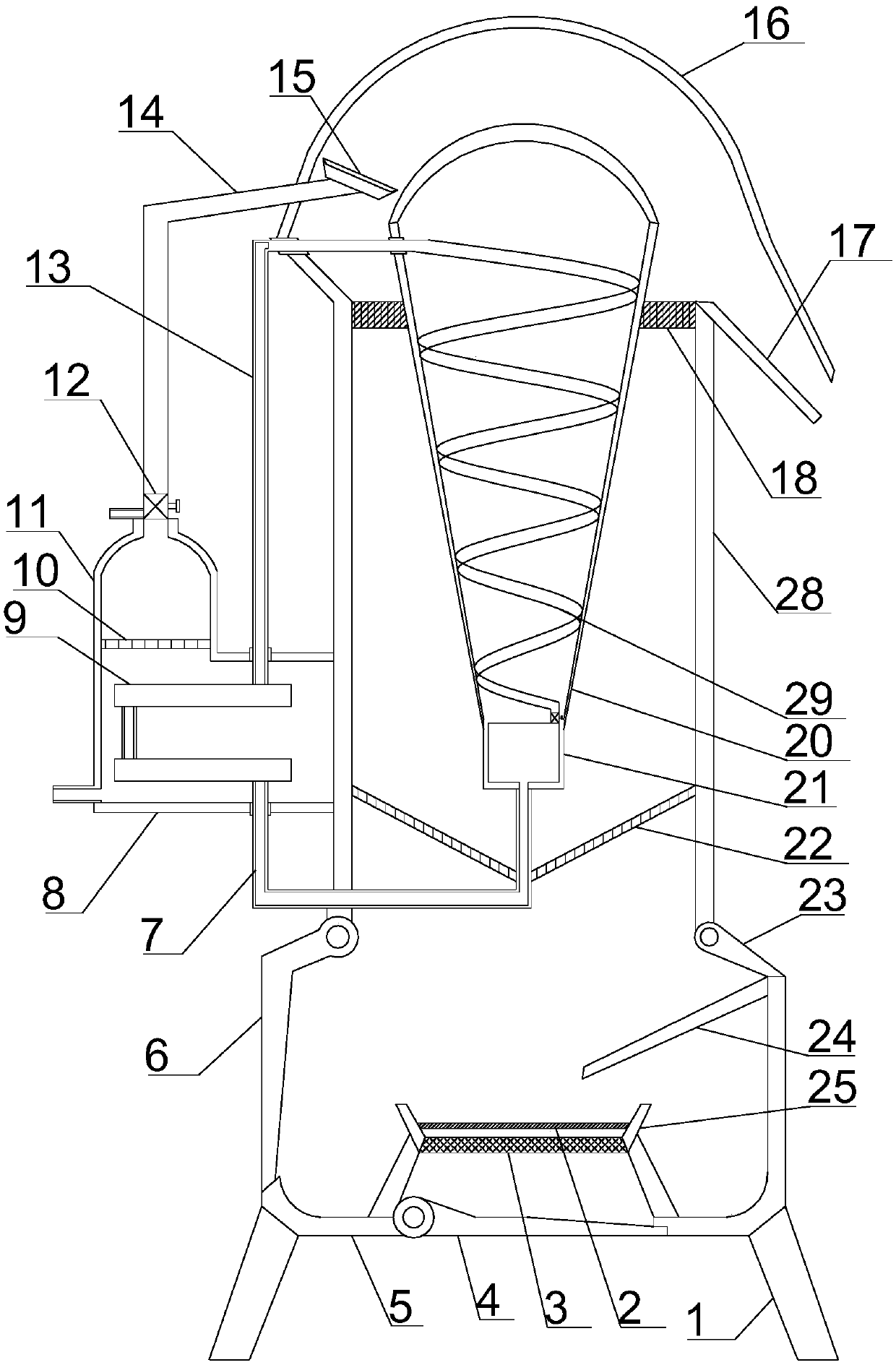

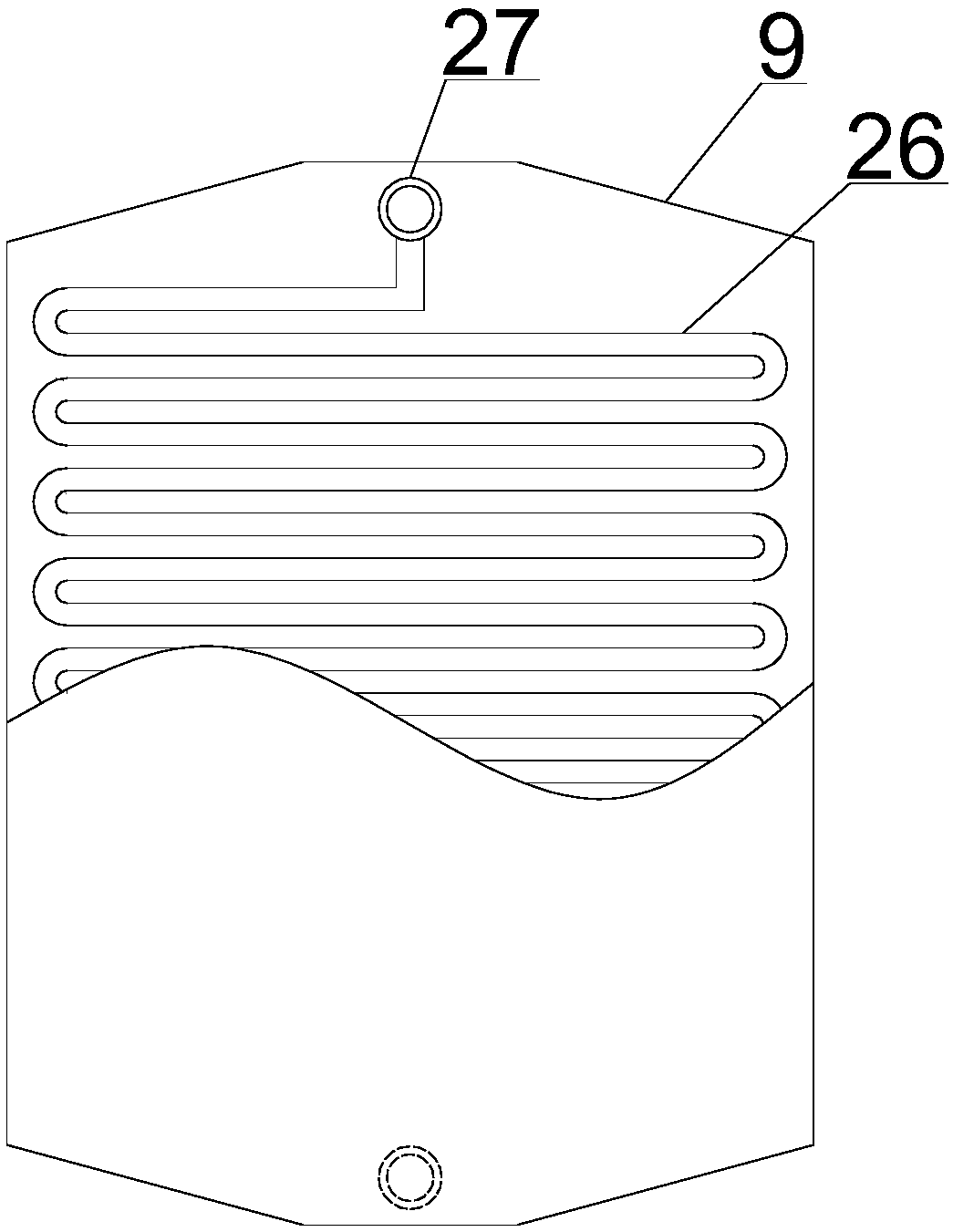

Rotary water-cooled spray-burning type biomass particle burner

ActiveCN102537939AEject evenlyPrevent backflowSolid fuel combustionBlast-producing apparatusThermal ignitionCombustor

The invention discloses a rotary water-cooled spray-burning type biomass particle burner, comprising a burning cylinder arranged horizontally and an air chamber which surrounds the periphery of the burning cylinder and is used for covering the air outlet of a blower; the external wall of the air chamber is provided with a flange for connecting a hearth; the internal side wall of the burning cylinder is fixedly provided with a spiral fin; the side wall of the burning cylinder is provided with an air hole for communicating the inside of the burning cylinder with the air chamber; the feeding inlet of the burning cylinder is provided with an electro-thermal ignition device and a axial directional air inlet for communicating the inside of the burning cylinder with the air chamber; one end of the feeding inlet of the burning cylinder is concentrically and fixedly sleeved with the discharging end of a material pipe; an auger in the material pipe is fixedly connected with the burning cylinder through a connecting piece; a concentric locating piece is connected between the air chamber and the burning cylinder; and a speed regulating motor is used for driving the auger and the burning cylinder to rotate. The burner is applicable to burning straw pellets; bonding slag obtained after burning can be automatically cleaned out of the burning cylinder; and the spray-burning port of the burning cylinder is provided with a water jacket, so that the slag-bonding can be prevented or lightened.

Owner:北京恩派苏阳清洁燃烧技术有限公司 +1

Ignition control device

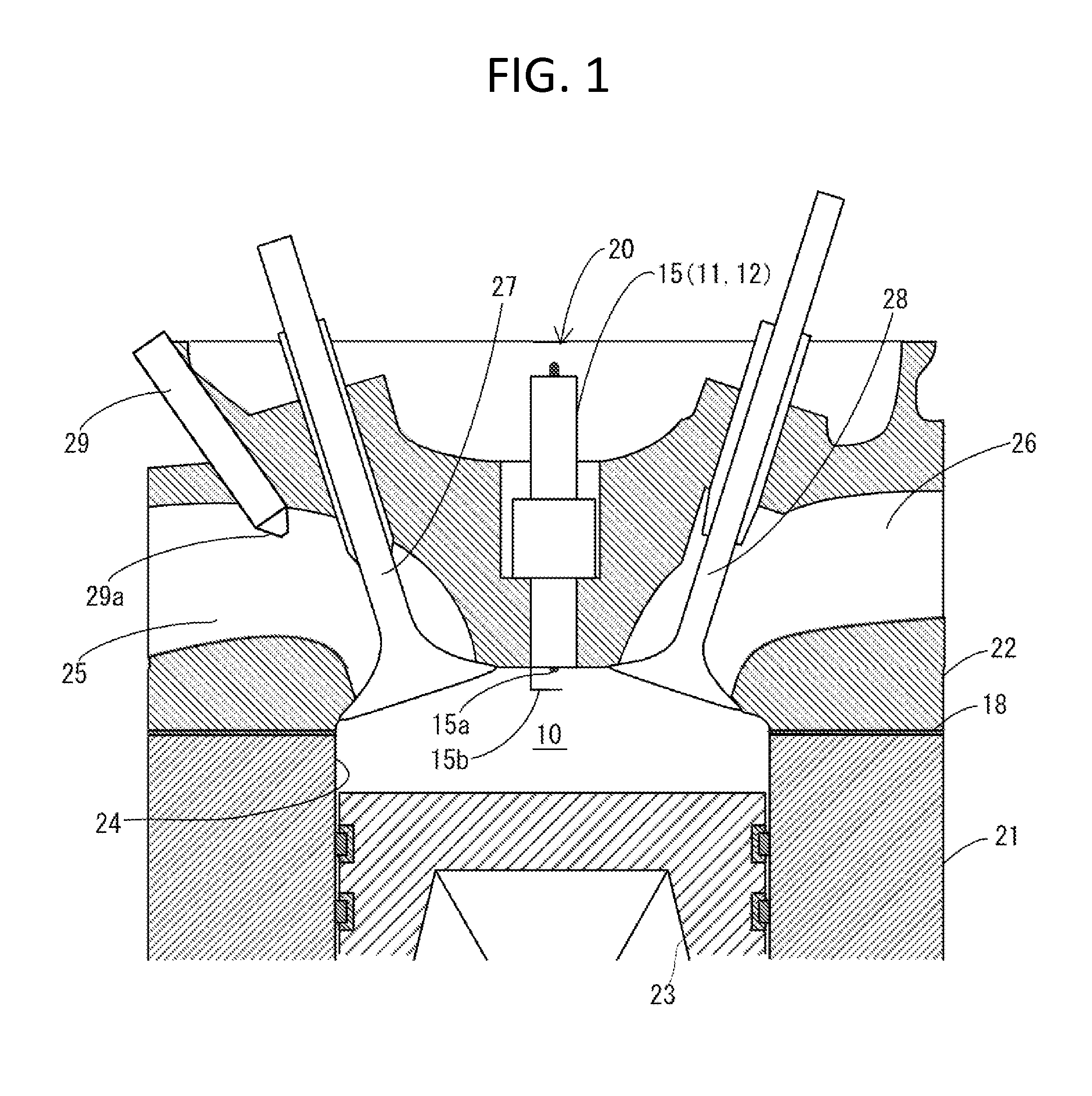

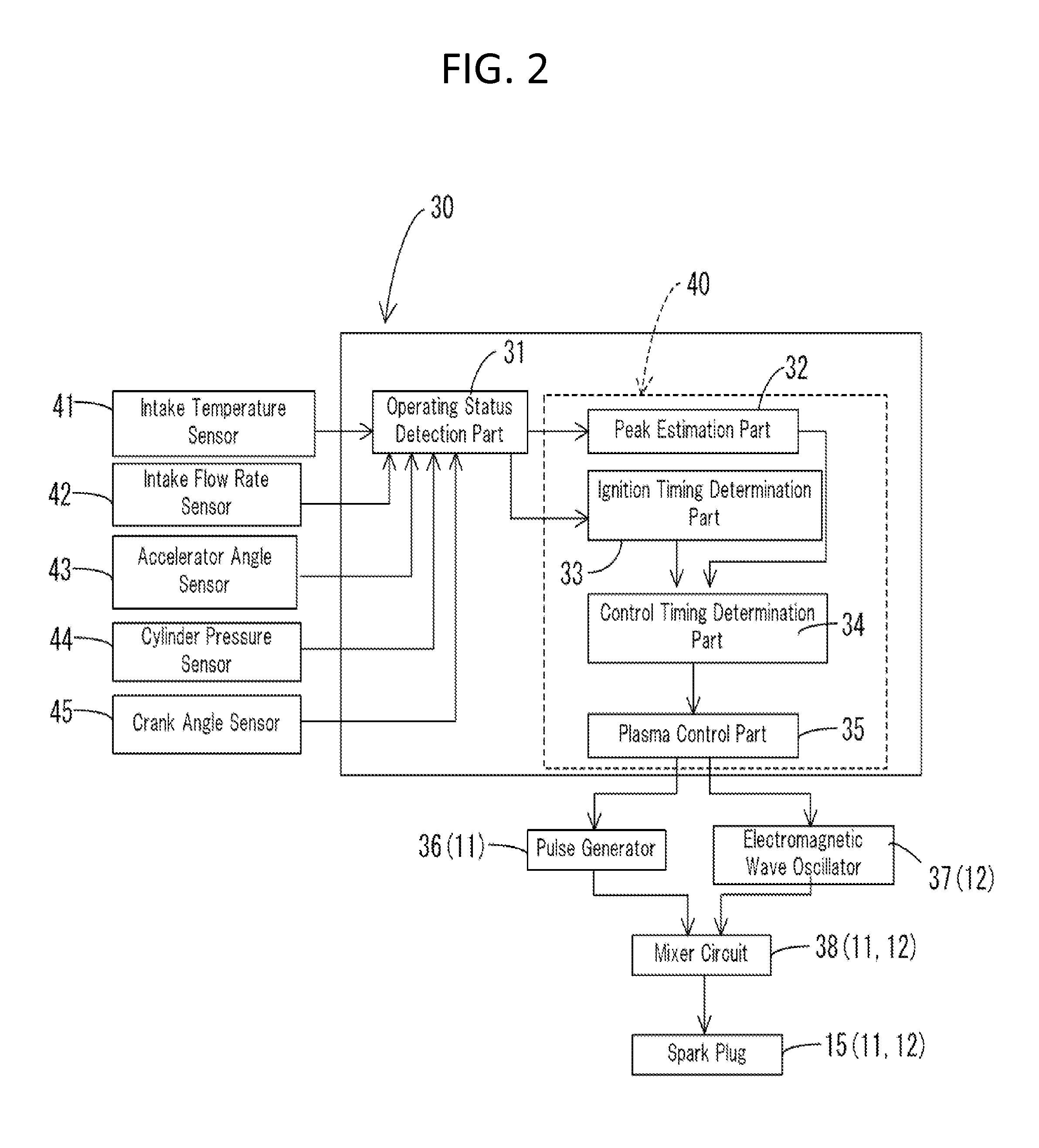

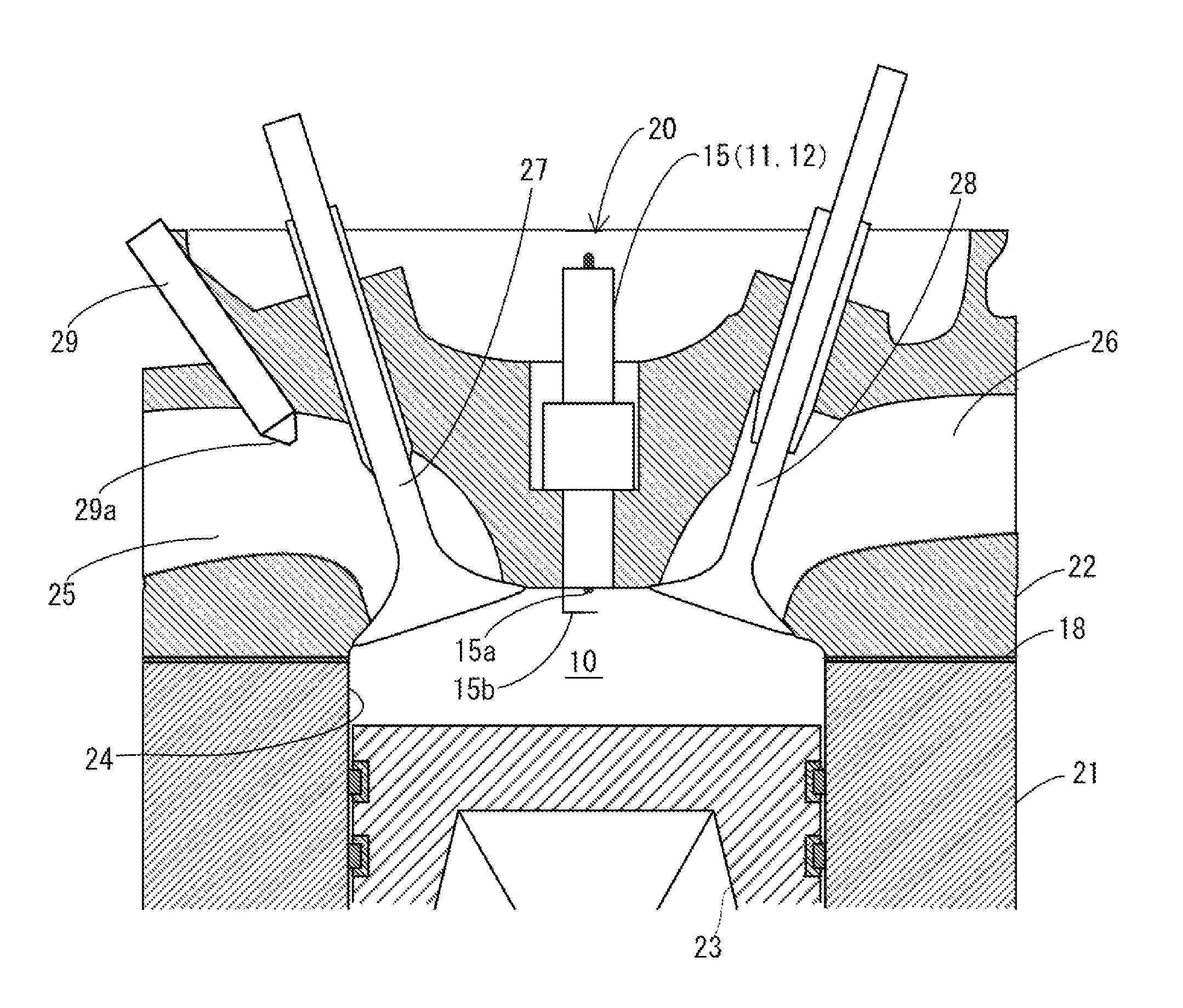

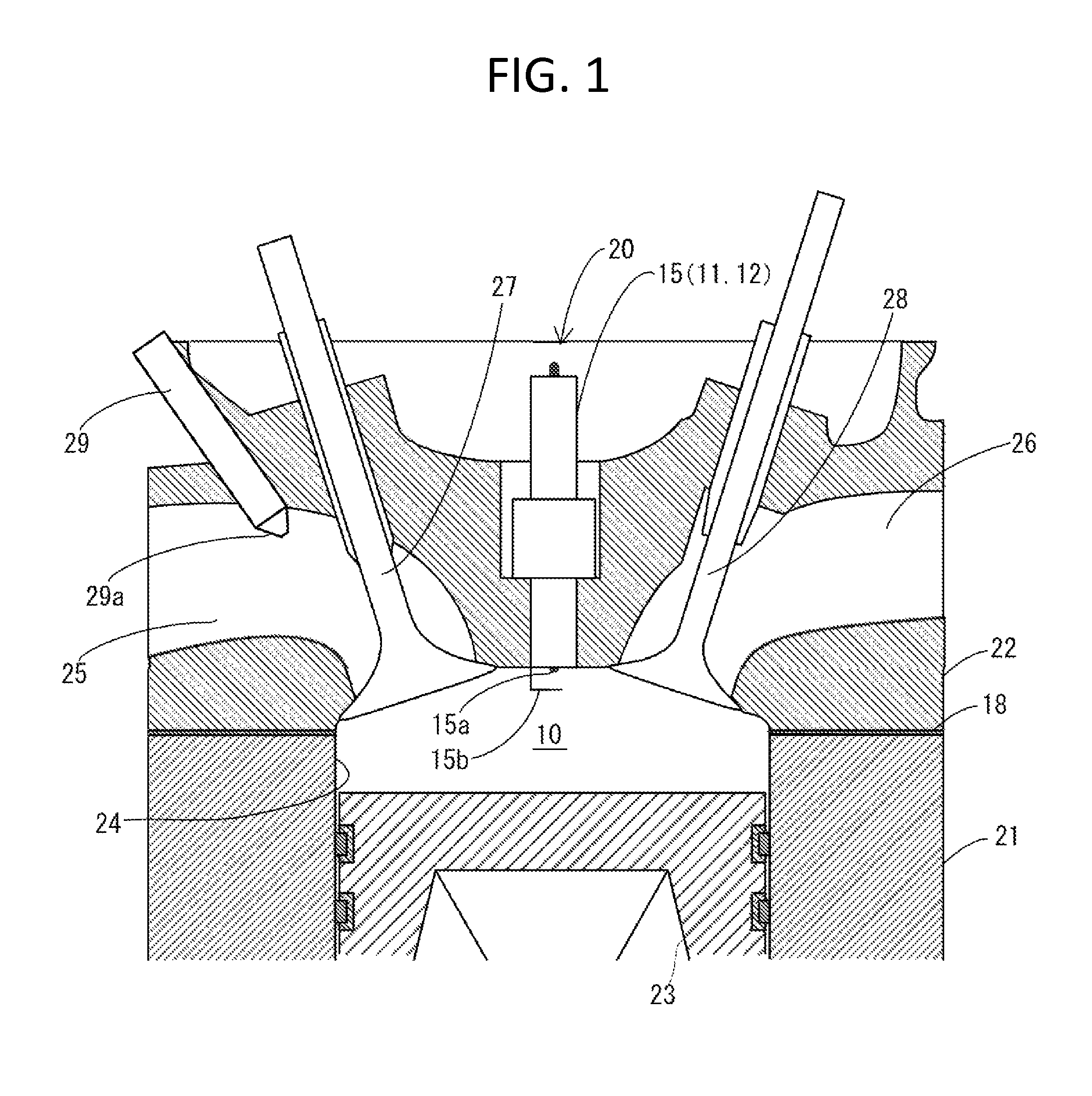

InactiveUS20130019841A1Less energyEffective controlAnalogue computers for vehiclesElectrical controlThermal ignitionEngineering

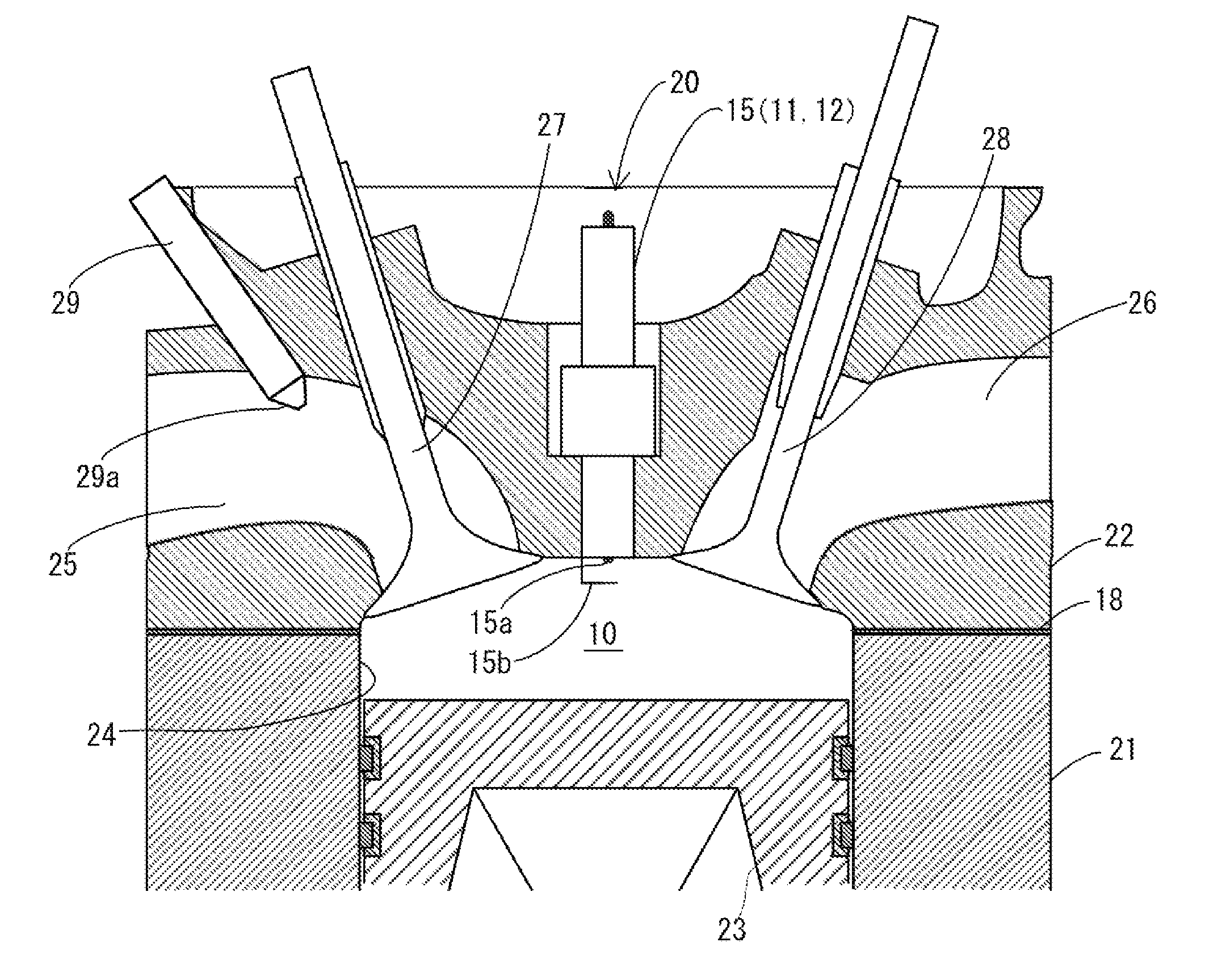

In order to provide an ignition control device 30 which can efficiently control timing of thermal ignition of gaseous mixture in a combustion region 10, the peak estimation part 32, the ignition timing determination part 33, the control timing determination part 34, and the plasma control part 35 control timing of thermal ignition of the gaseous mixture in the combustion region 10 by controlling the pulse generator 36, the electromagnetic wave oscillator 37, the mixer circuit 38, and the spark plug 15 so as to increase the amount of OH radicals in the combustion region 10 during a low-temperature oxidation preparation period that occurs prior to a peak of a heat release rate before the thermal ignition of the gaseous mixture.

Owner:MAGINEERING INC

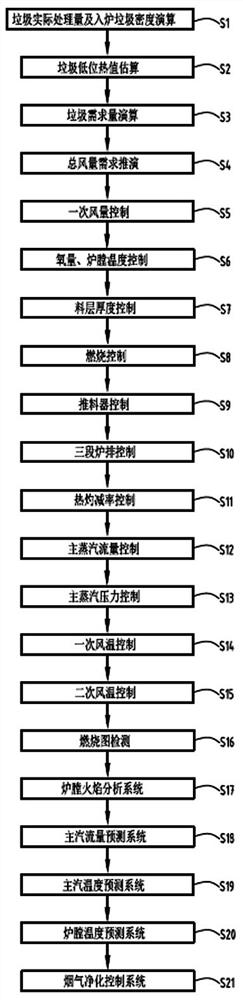

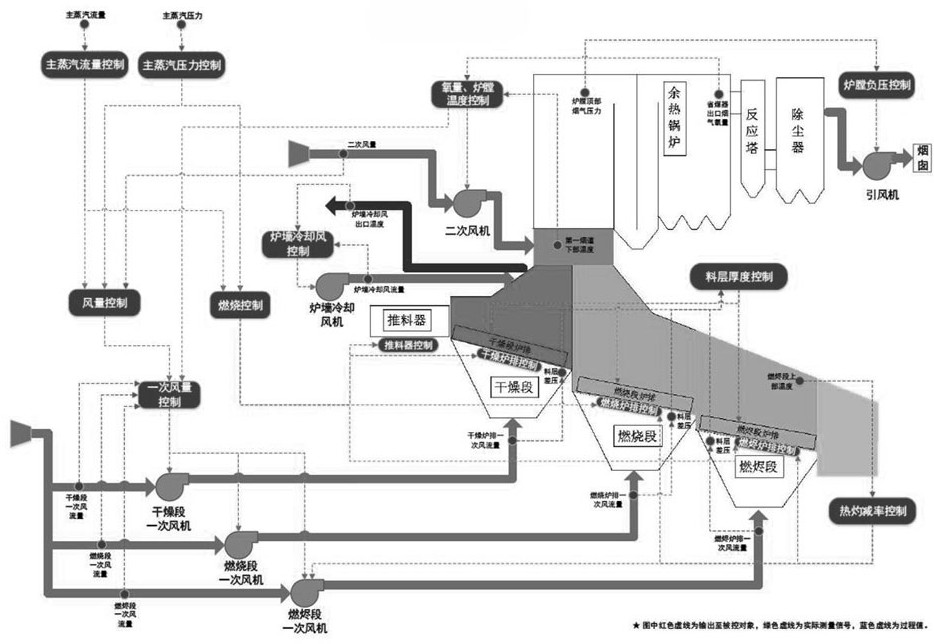

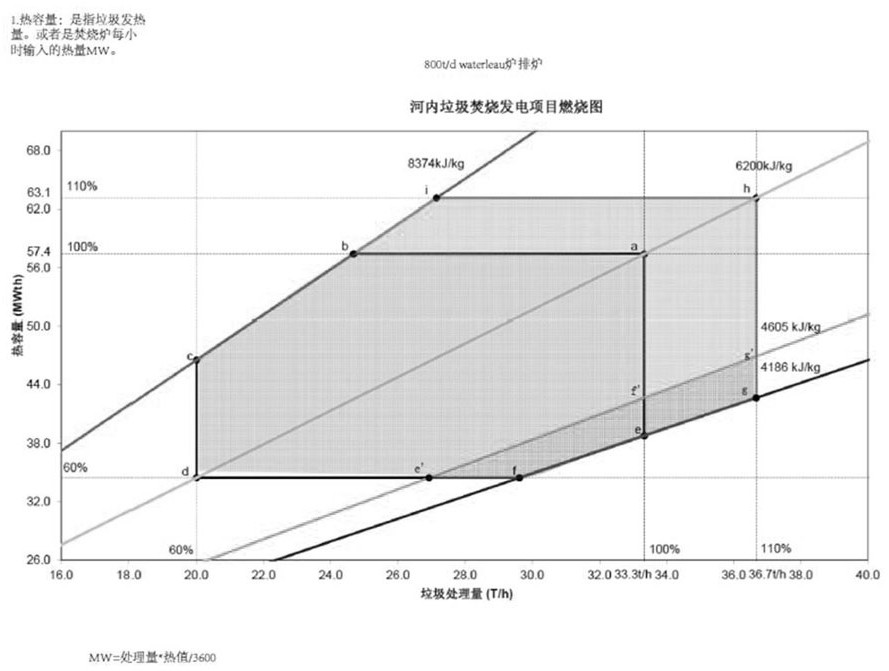

ACC automatic combustion control method for waste incineration plant

ActiveCN113701160AAchieve estimatesRealize the calculation of actual processing volumeIncinerator apparatusCombined combustion mitigationSteam pressureAir volume

The invention discloses an ACC automatic combustion control method for a waste incineration plant. The ACC automatic combustion control method for the waste incineration plant comprises the following steps of calculating the actual garbage treatment capacity and the density of garbage entering a furnace, estimating a garbage lower calorific value, calculating the garbage demand quantity, deducing the total air quantity demand, controlling the primary air quantity, controlling the oxygen quantity and the hearth temperature, controlling the material layer thickness, controlling combustion, controlling a material pusher, controlling a three-section fire grate, controlling the thermal ignition loss, controlling the main steam flow, controlling the main steam pressure, controlling the primary air temperature, controlling the secondary air temperature, detecting a combustion diagram, and operating a hearth flame analysis system, a main steam flow prediction system, a main steam temperature prediction system, a hearth temperature prediction system and a flue gas purification control system. According to the ACC automatic combustion control method for the waste incineration plant provided by the invention, estimation of the garbage lower calorific value of a garbage incineration plant and calculation of the actual garbage treatment capacity are achieved, and the thickness of a material layer of a fire grate is accurately controlled, so that garbage is fully combusted, the heat efficiency is improved, the automatic input rate is fully improved, and meanwhile, the manual operation intensity is reduced.

Owner:CHINA TIANYING +1

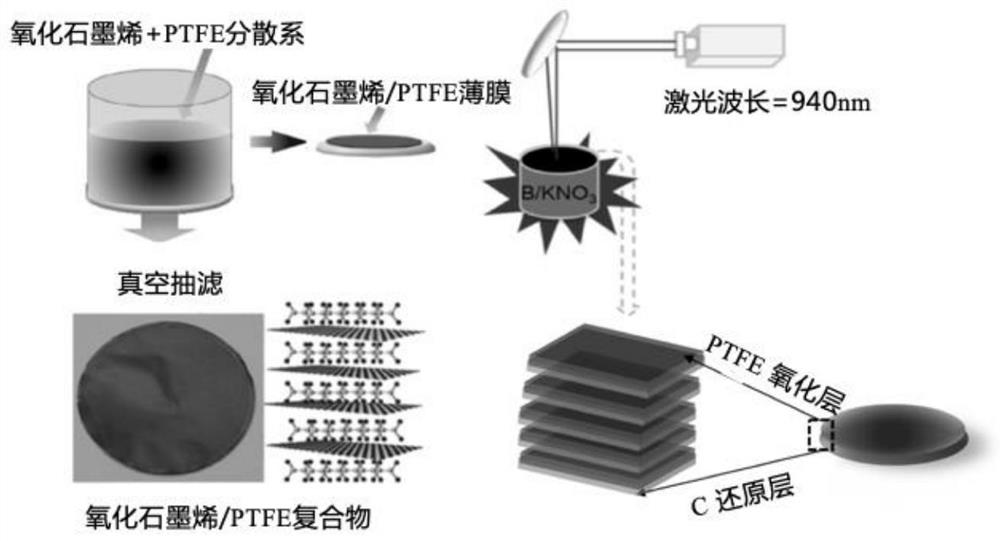

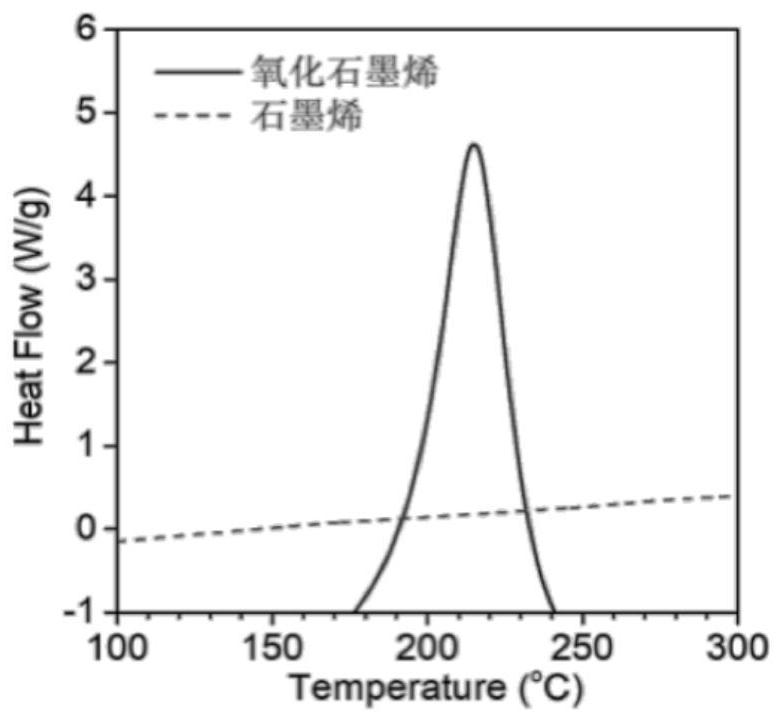

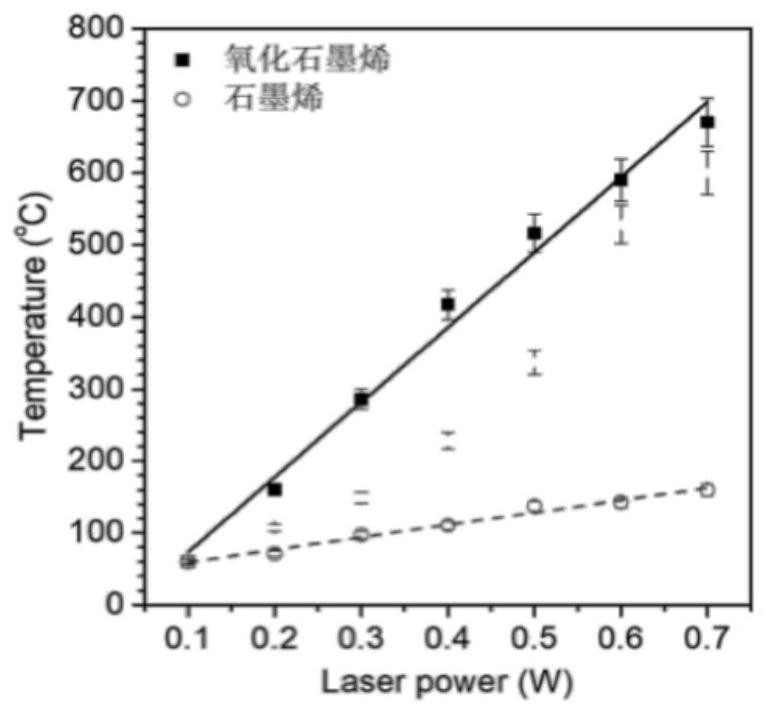

Method of reducing laser ignition energy

InactiveCN112707774ADoes not affect the natureEasy to operateBlasting cartridgesExplosivesThermal ignitionM-aminophenol

The invention discloses a method for reducing laser ignition energy of an energetic material, which comprises the following steps: preparing a self-supporting film from a photothermal conversion material with a two-dimensional lamellar nanostructure, and directly attaching the self-supporting film to an energetic grain; the photothermal conversion material comprises graphene oxide, a graphene oxide 3-aminophenol formaldehyde compound, a graphene oxide polytetrafluoroethylene compound and an MXene polytetrafluoroethylene compound. According to the method, the photo-thermal conversion efficiency of a laser ignition device can be enhanced, so that the triggering energy of laser photo-thermal ignition is reduced.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

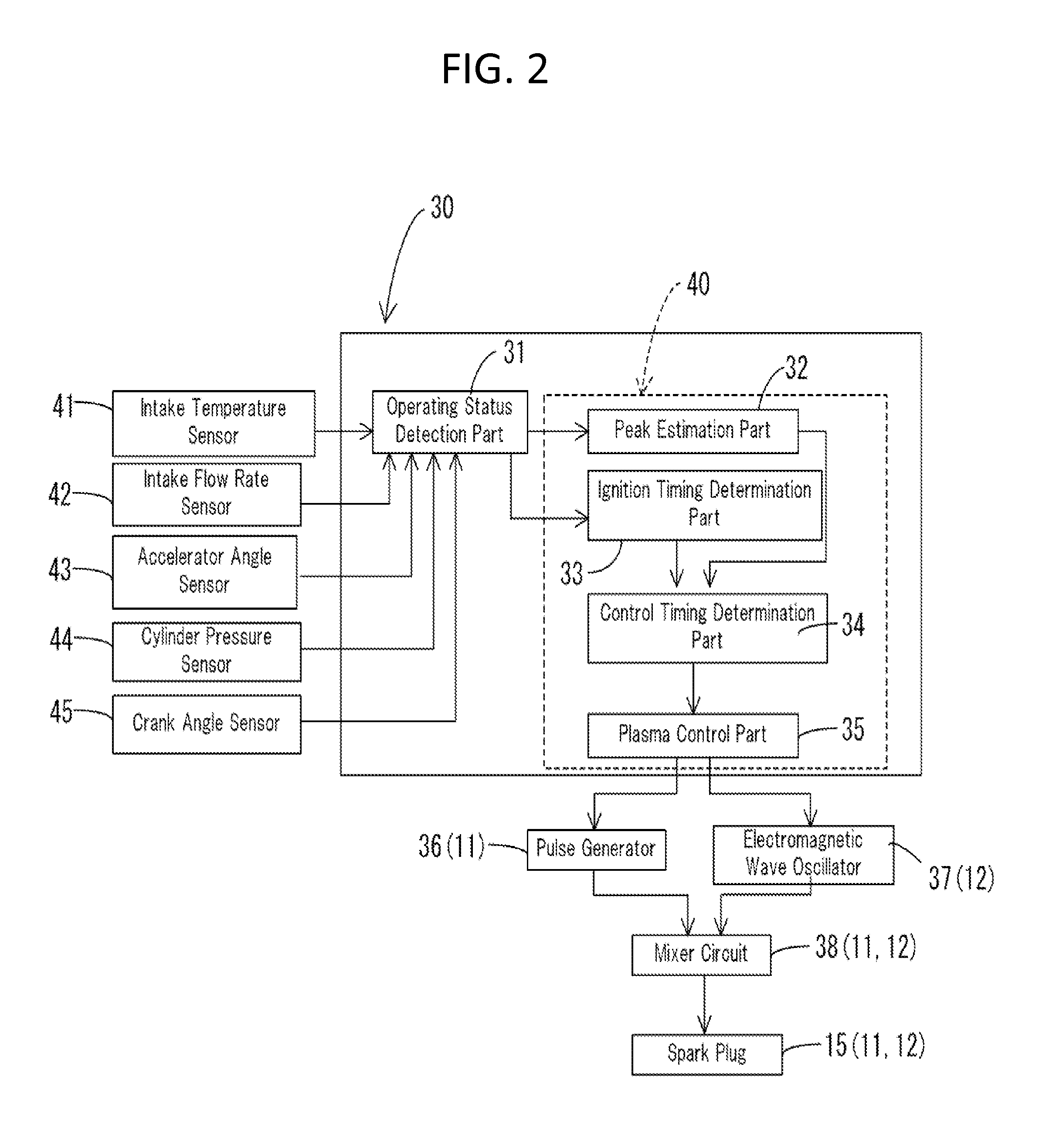

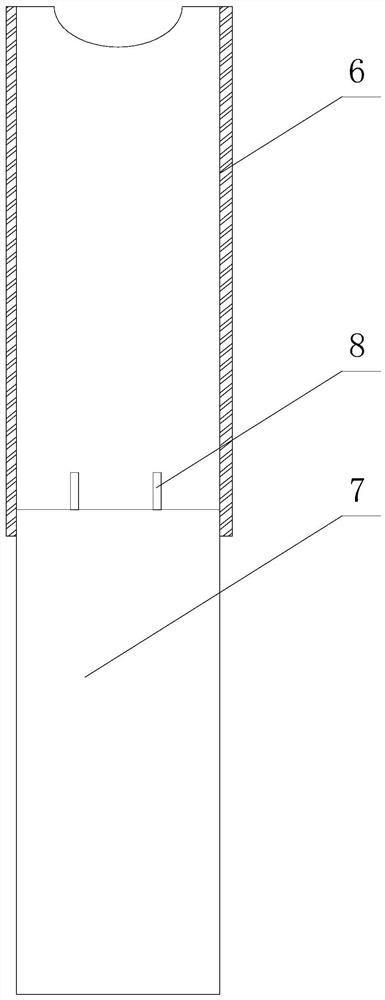

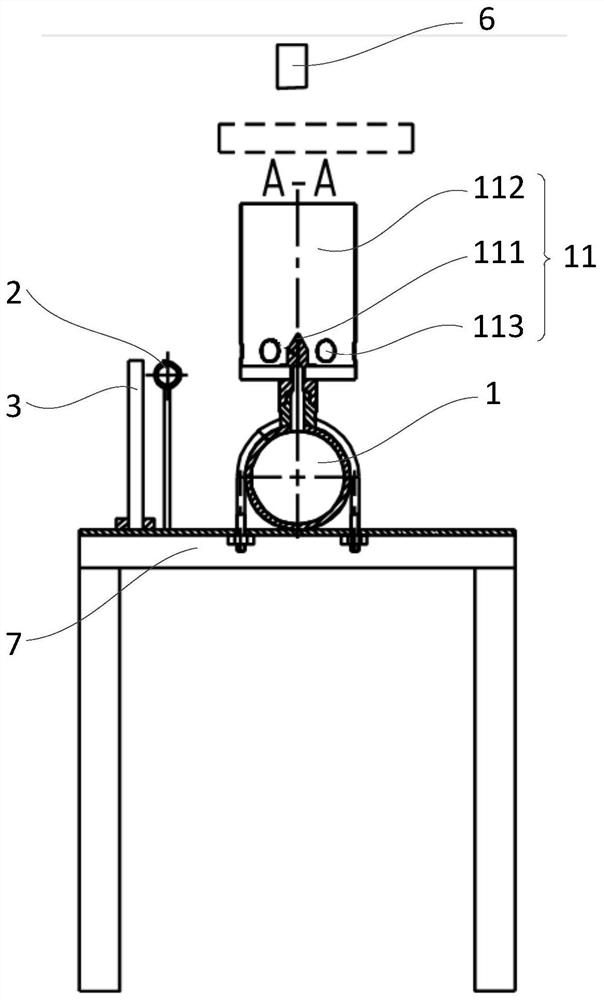

Ignition loss rate tester and testing method

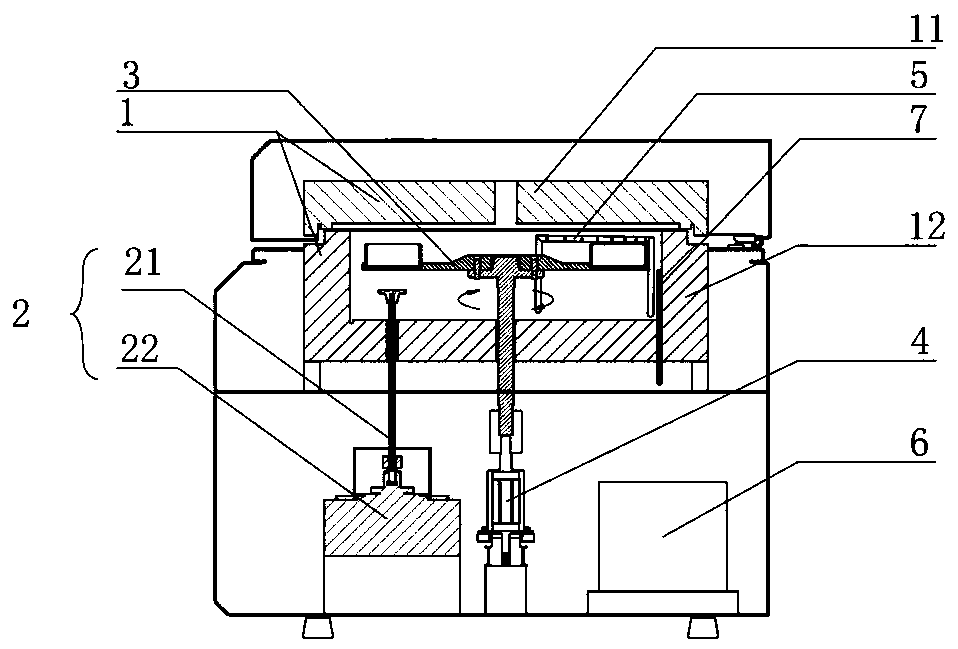

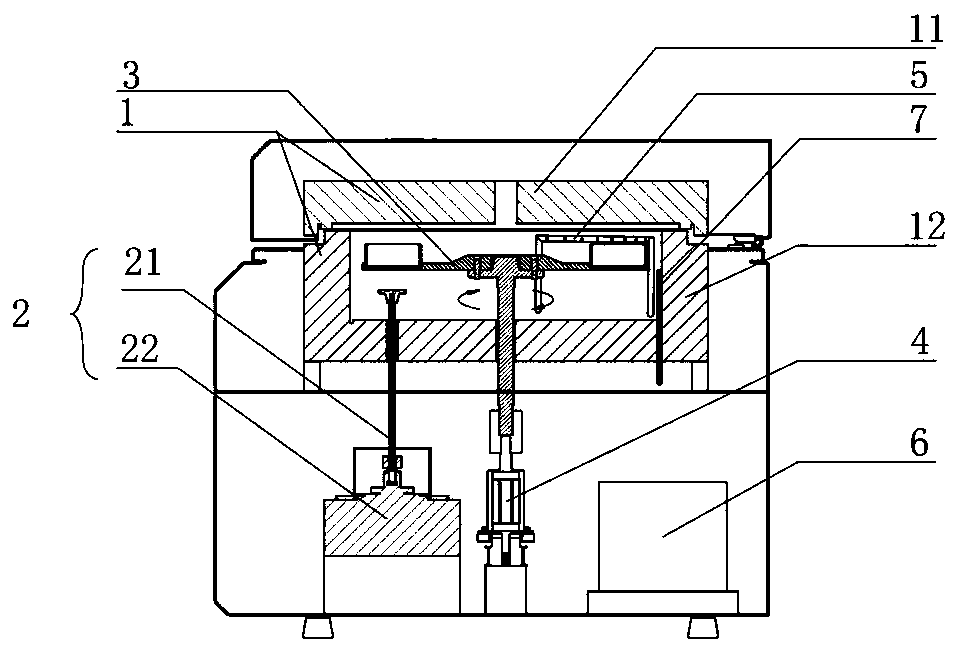

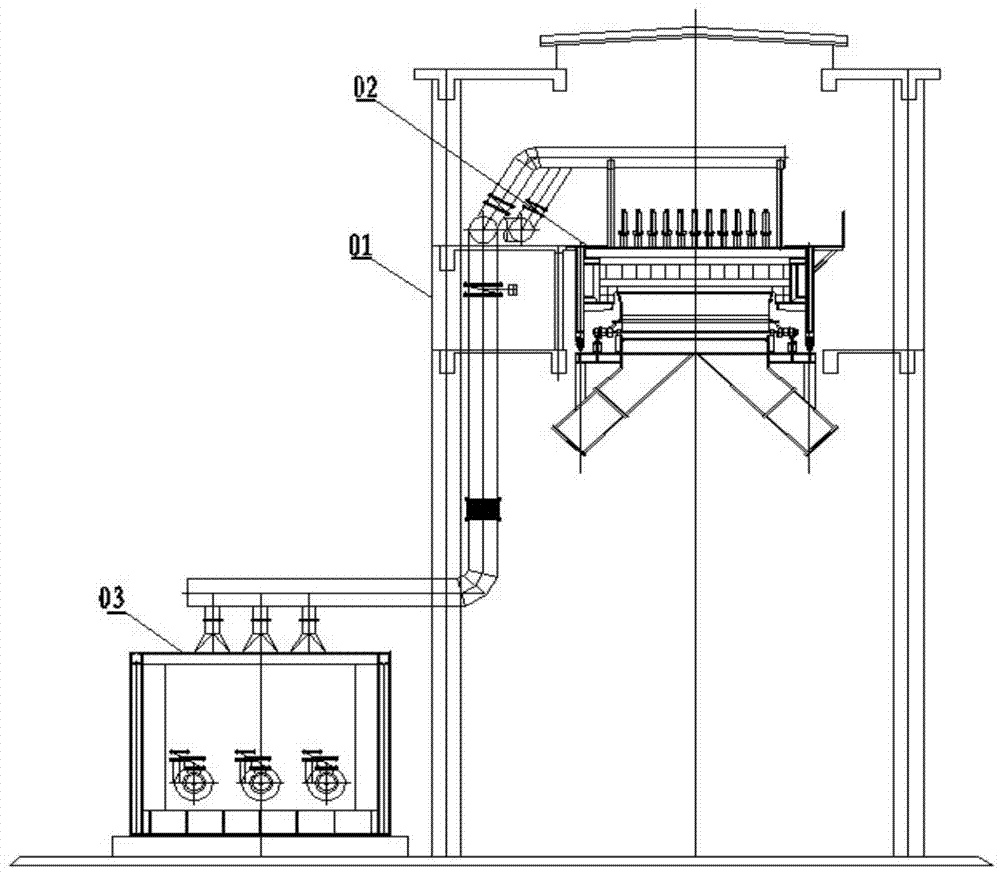

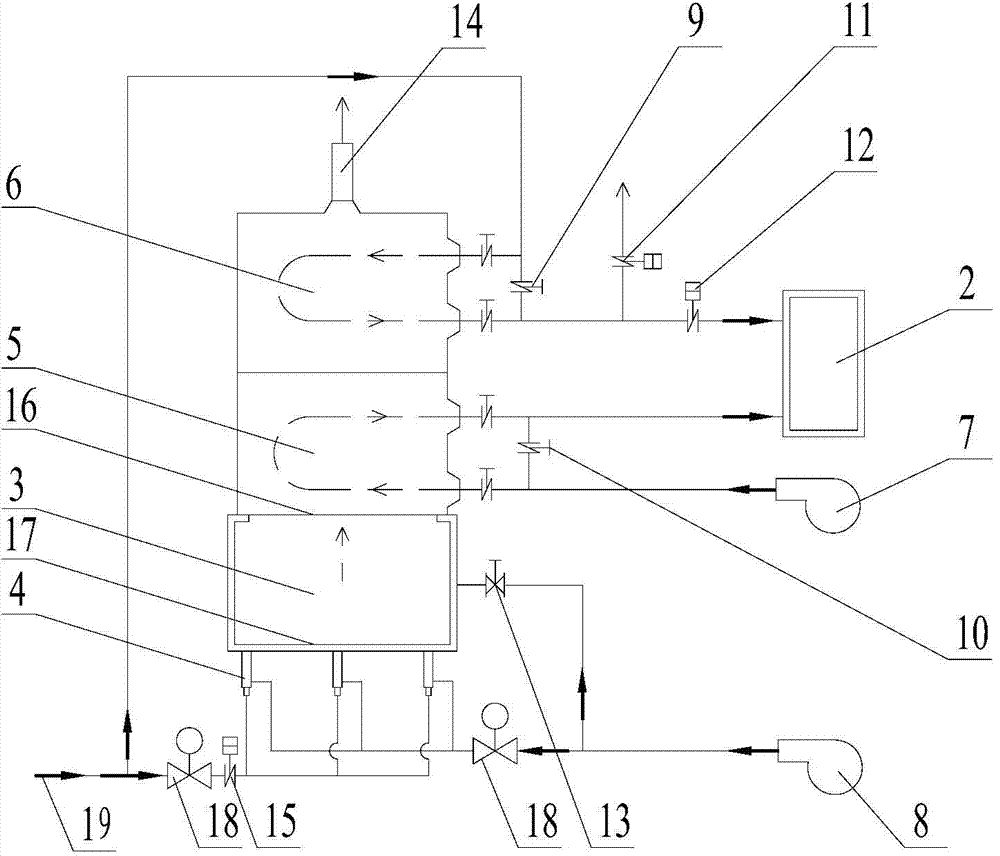

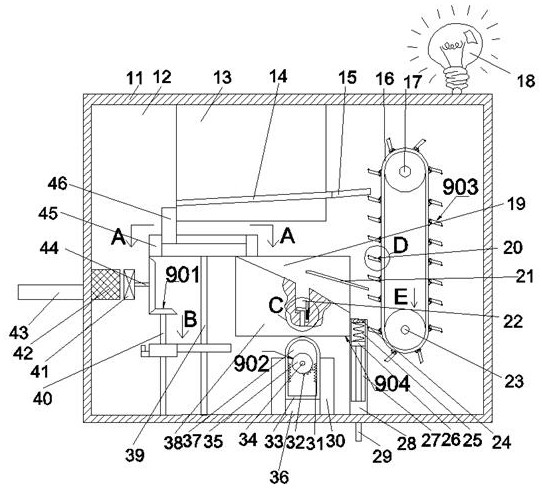

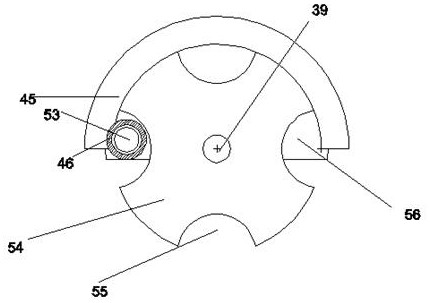

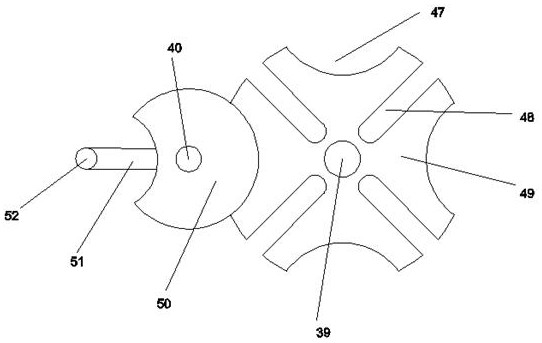

PendingCN110006775ALess contact with samplesReduce the risk of inhaling toxic and harmful gasesWeighing by removing componentStructural/machines measurementThermal ignitionCrucible

The invention discloses an ignition loss rate tester which comprises a shell, and a heating and heat preservation device, a weighing mechanism, a sample placing disc, a lifting and rotating mechanism,a ventilation device and a controller are arranged in the shell; wherein the sample placing disc is arranged in the heating and heat preservation device, the lifting and rotating mechanism is connected with the sample placing disc, the weighing mechanism is arranged below the sample placing disc, the ventilation device is arranged in the heating and heat preservation device, and the controller isconnected with the lifting and rotating mechanism and the weighing mechanism and used for controlling the lifting and rotating mechanism to move and storing and processing weighing data. The invention also discloses a test method based on the thermal ignition loss rate tester, which comprises the following steps: S1, weighing the weight of the empty crucible, putting a sample, drying the sample and weighing; S2, setting the temperature and the constant temperature time required by sample ignition, and cooling to room temperature after ignition is completed; and S3, weighing the mass of the fired crucible, and calculating the ignition loss rate through mass loss. According to the invention, full-automatic testing of the ignition loss rate is realized.

Owner:湖南三德盈泰环保科技有限公司

Series preheating method and series preheating system for coal gas of sintering ignition furnace

ActiveCN103667685AImprove ignition performanceGuarantee the quality of sinterFurnace typesCombustionFlue gas

The invention belongs to the field of combustion equipment and provides a series preheating method for combustion air and coal gas for a sintering ignition furnace. The series preheating method comprises the following steps: connecting a combustion air heat exchanger with a coal gas heat exchanger in series and combusting coal gas as a fuel in a hearth of a preheating furnace to generate flue gas; firstly, preheating the combustion air for the ignition furnace by using high-temperature flue gas, then preheating the coal gas for the ignition furnace by using low-temperature flue gas to ensure that the combustion air for the ignition furnace is preheated to 200-350 DEG C, and the coal gas for the ignition furnace is preheated to 150-300 DEG C, and then feeding into the sintering ignition furnace, performing heat convection on the combustion air for the ignition furnace and the high-temperature flue gas; performing heat convection on the coal gas for the ignition furnace and the low-temperature flue gas. The series preheating method disclosed by the invention can be applicable to the sintering ignition furnace which takes low-heating-value coal gas as a fuel, an ignition effect is improved, and the sintering ore quality is ensured. As the low-heating-value coal gas is used as the fuel, the energy consumption is reduced. Double-stroke tubular heat exchangers are used for heat exchange, so that the heat exchangers and the heat exchange areas are reasonably configured, the heat exchange effect is good, the heat exchange coefficient can be up to 20kcal / m2.h.DEG C, and the service life of the heat exchanger is prolonged.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

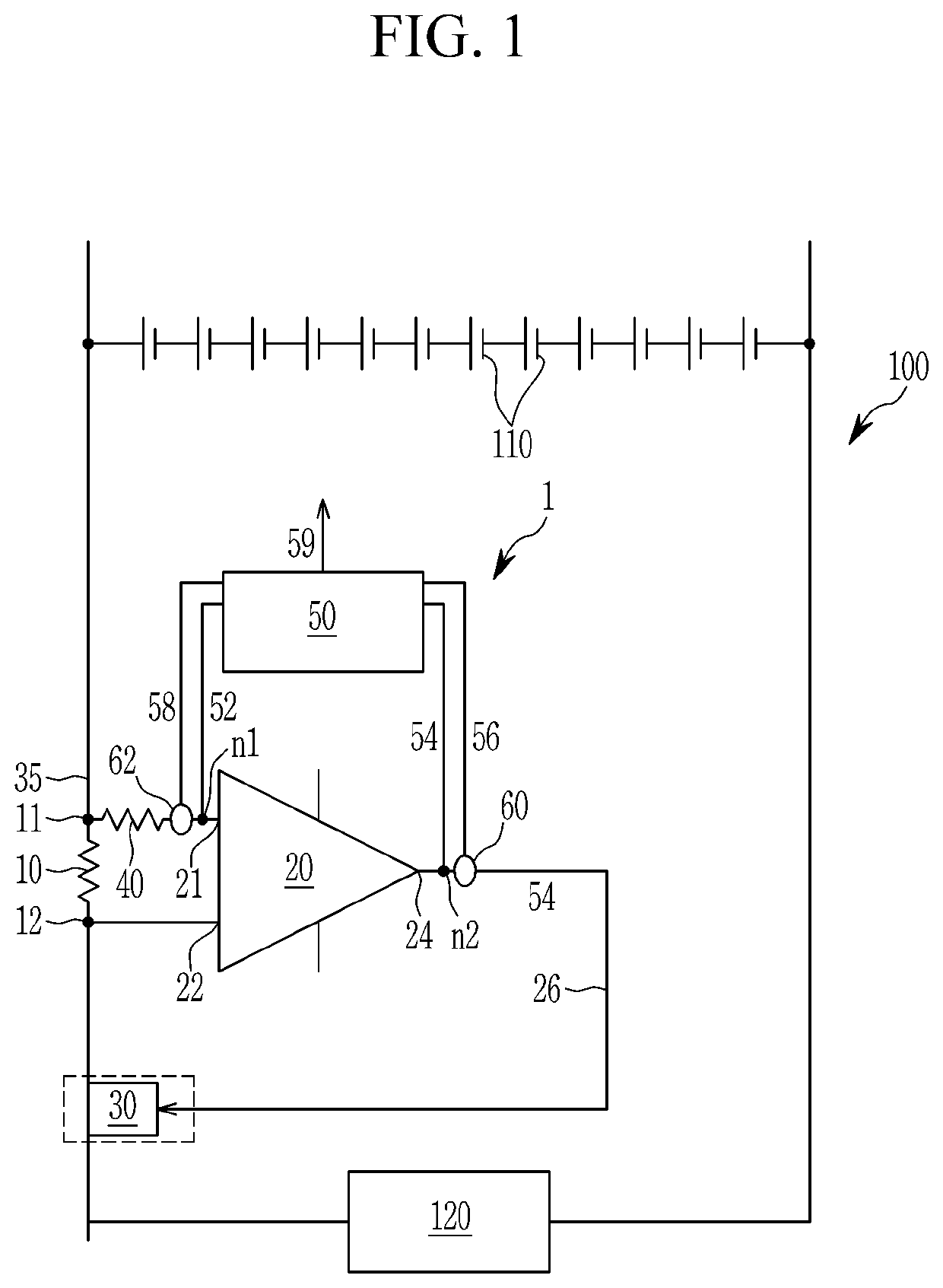

Ignition control device

InactiveUS8442746B2Less energyEffective controlAnalogue computers for vehiclesElectrical controlThermal ignitionIgnition timing

In order to provide an ignition control device 30 which can efficiently control timing of thermal ignition of gaseous mixture in a combustion region 10, the peak estimation part 32, the ignition timing determination part 33, the control timing determination part 34, and the plasma control part 35 control timing of thermal ignition of the gaseous mixture in the combustion region 10 by controlling the pulse generator 36, the electromagnetic wave oscillator 37, the mixer circuit 38, and the spark plug 15 so as to increase the amount of OH radicals in the combustion region 10 during a low-temperature oxidation preparation period that occurs prior to a peak of a heat release rate before the thermal ignition of the gaseous mixture.

Owner:MAGINEERING INC

Bird repelling bomb and bird repelling device

PendingCN113432491AEasy to carryRespond in a timely mannerAmmunition projectilesAnimal repellantsThermal ignitionIron powder

The invention discloses a bird repelling bomb and a bird repelling device. The bird repelling bomb comprises a lift-off part and a protection part, wherein the added protection part provides lift-off power and protection for the lift-off part, withstands gunpowder combustion residues jetted by the lift-off part and keeps an inner cavity of a launching device clean; the bird repelling device comprises the bird repelling bomb and the launching device; the bird repelling bomb is installed in the launching device; the launching device is further divided into a bomb loading part and a handheld part; and the bomb loading part and the handheld part are in threaded connection. In addition, the ignition mode is improved, the mode of explosive and resistance heating ignition is not adopted for ignition any more, electric arc ignition is adopted, more convenience and safety are achieved, and the cost is lower. According to the ignition fuse, combustion-supporting powder, iron powder and an adhesive are added on the basis of an existing common fuse, so that the problem that the fuse is difficult to ignite through electric arc ignition is solved. The launching device can be held in one hand and is convenient to carry. The bird repelling bomb can be launched after being loaded, and can be rapidly and continuously launched to timely deal with bird activities only by cleaning once after being used for one day.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

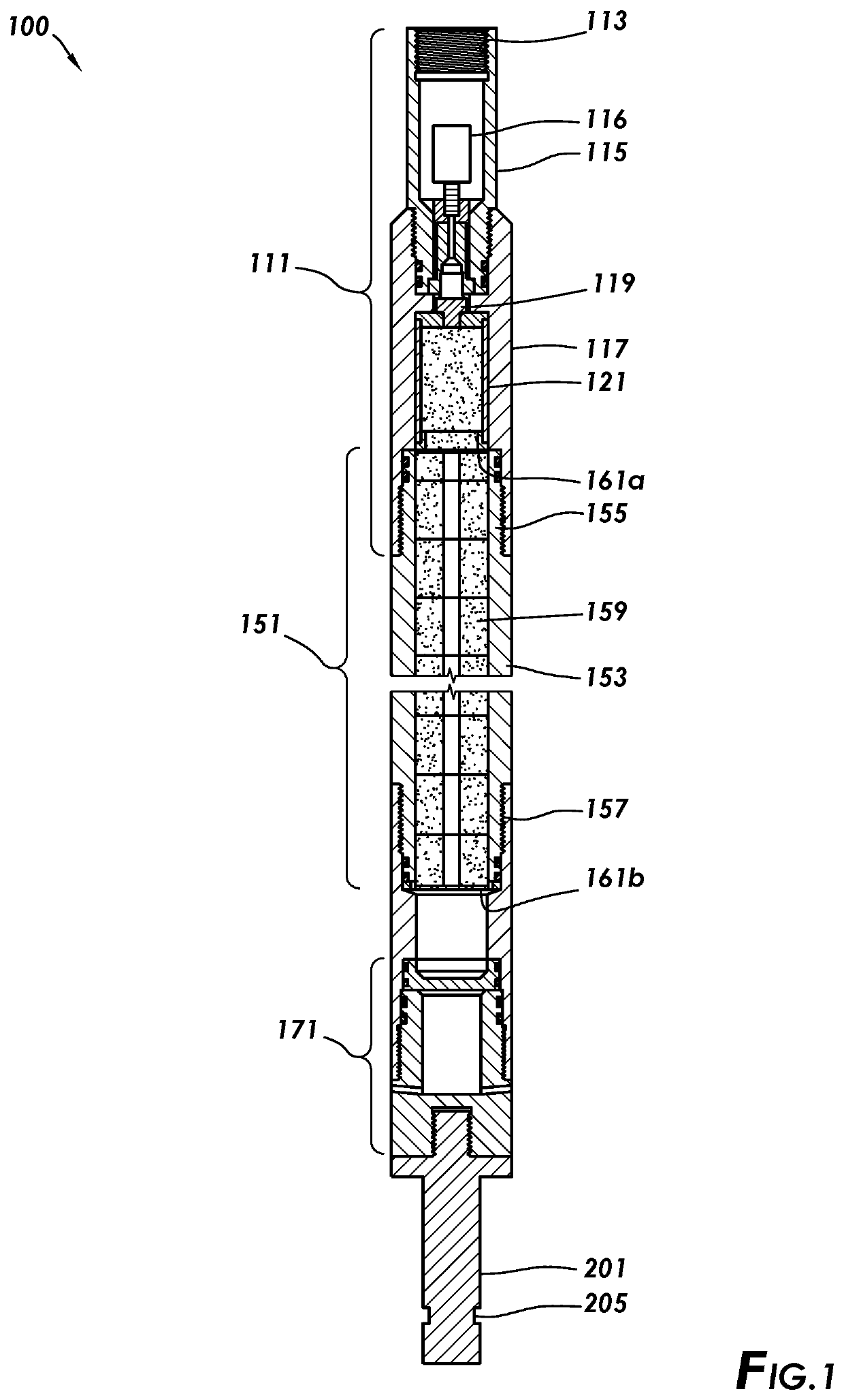

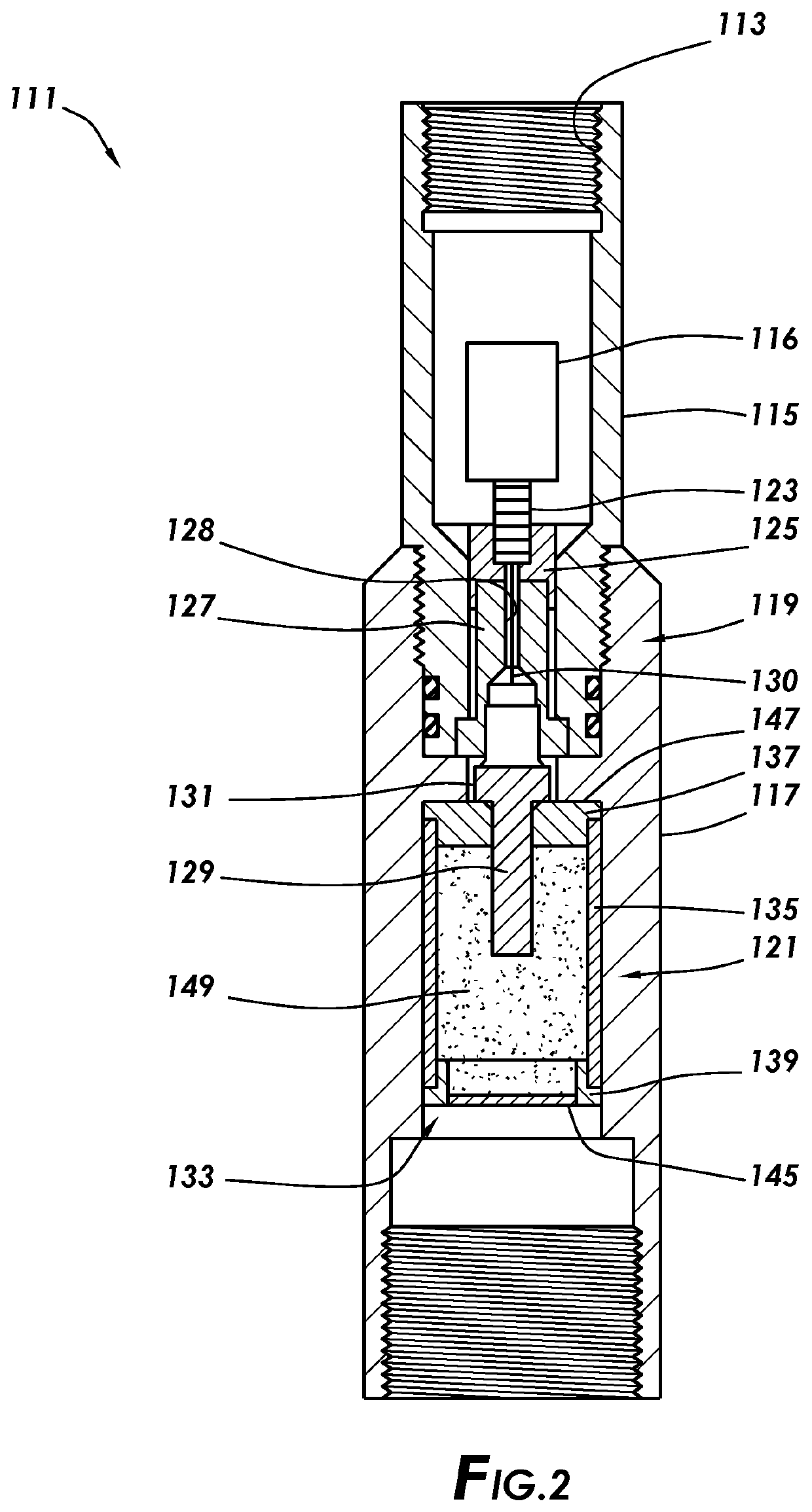

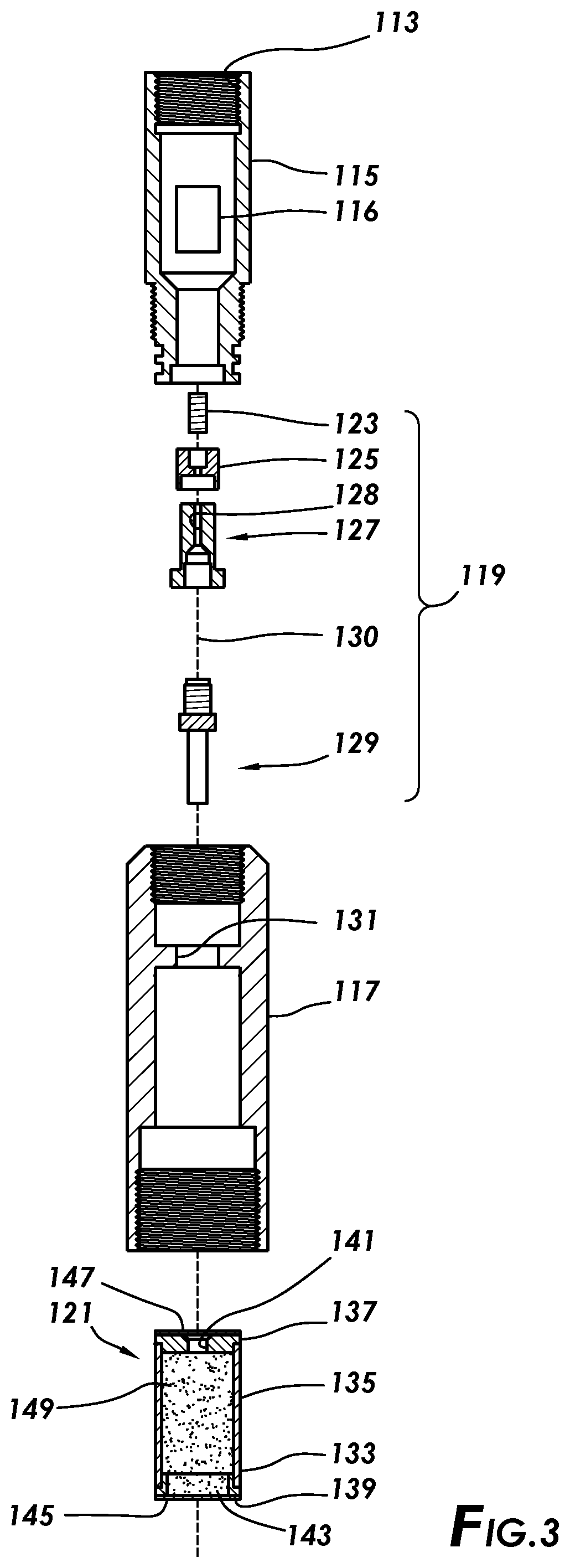

Non-mechanical ported perforating torch

A perforating torch includes a thermal igniter assembly, a compressed grain magazine, and a perforating head assembly. The compressed grain magazine is coupled to the thermal igniter. The perforating head assembly includes a port. A port plug may be positioned in the port. A rupture disc may be positioned between the compressed grain magazine and the perforating head.

Owner:CHAMMAS PLASMA CUTTERS LLC

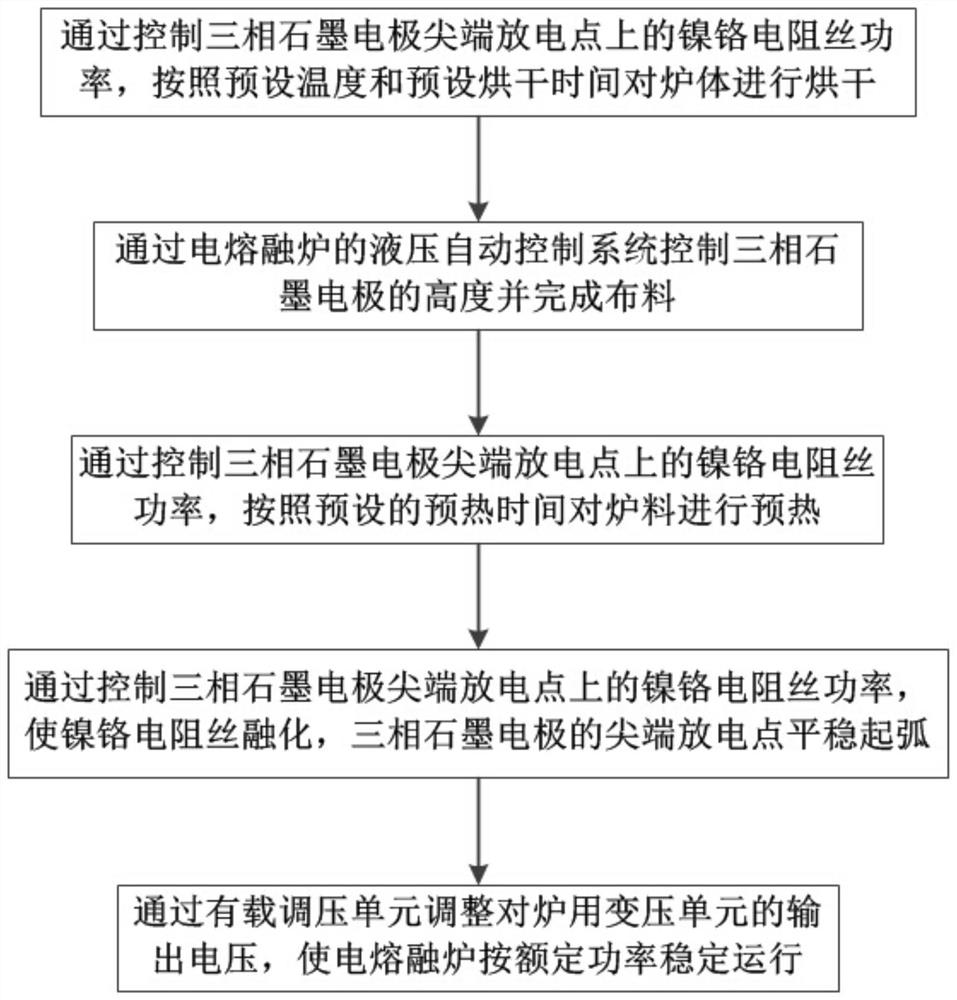

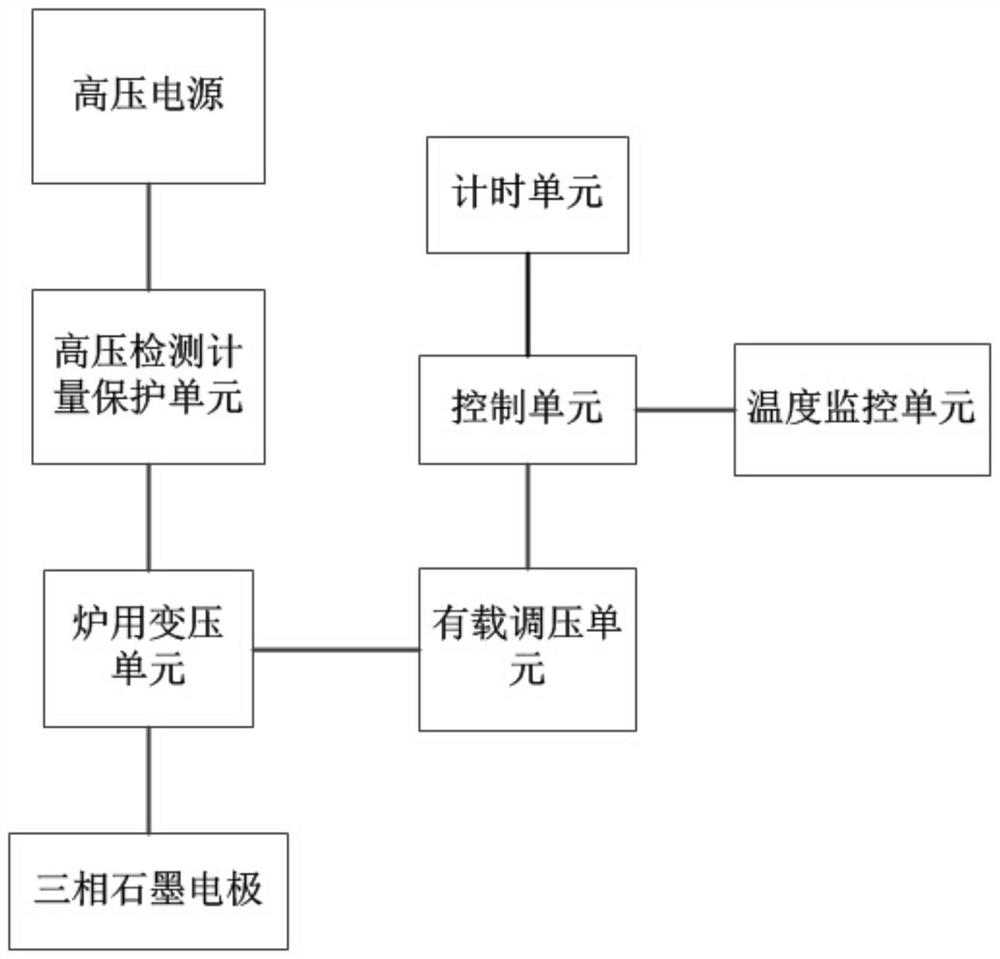

A kind of preheating ignition method and device for electric melting furnace

The invention provides a preheating ignition method and device for an electric melting furnace. The preheating ignition method and device are used for producing rock wool by using red mud. A large-power nickel-chromium resistance wire is additionally introduced to a point discharge point of a three-phase graphite electrode for preheating and serving as an ignition device to dry the interior of a novel electric melting furnace, preheat furnace materials and realize stable transition after electric arc ignition through the three-phase electrode. The electric melting furnace is high in electric arc ignition speed, steady one-time arc ignition can be achieved, the three-phase current is balanced, and automatic or manual control can be realized. The voltage and the current do not fluctuate severely. Unstable electric arc burning does not exist. Short circuit and arc breaking are avoided. The preheating ignition method and device have no impact on a power grid and are free of harmonic pollution in the implementation process.

Owner:北京金亚润环保科技有限公司

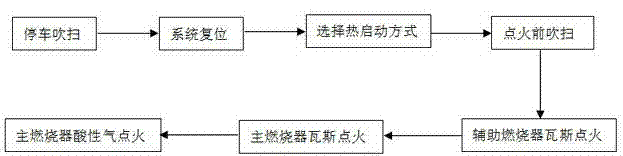

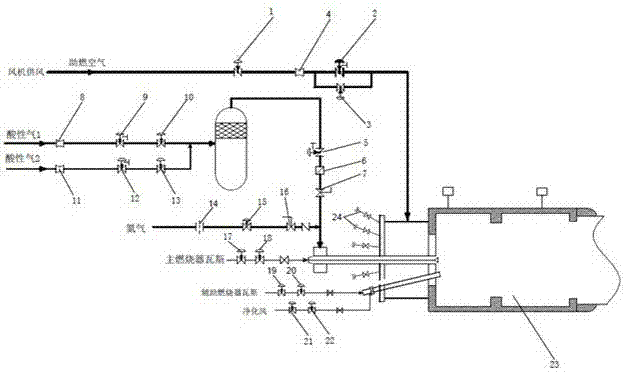

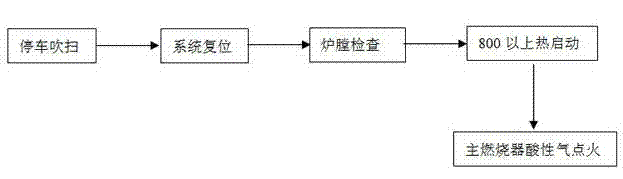

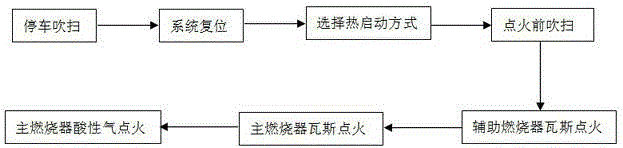

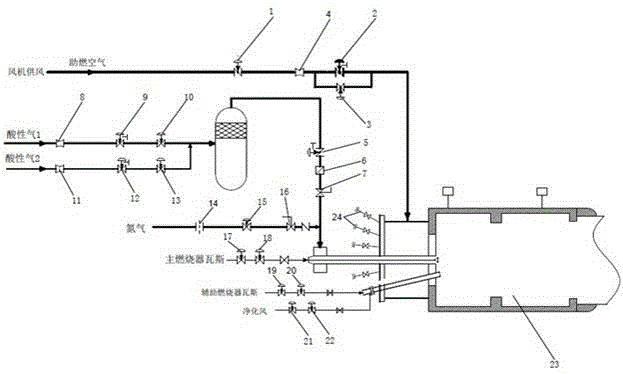

Improved thermal ignition method of combustion furnace of sulfur recovery device

ActiveCN102954489ASimplified ignition procedureReduce flareSulfur preparation/purificationCombustion ignitionThermal ignitionProcess engineering

The invention discloses an improved thermal ignition method of a combustion surface of a sulfur recovery device. The improved thermal ignition method comprises the following steps of: (1) stopping to blow; (2) replacing the system; (3) inspecting a hearth: inspecting whether the temperature in the hearth is above 800 DEG C after the system is replaced, if so, carrying out the following step, and if not, igniting according to the original ignition process; (4) carrying out hot start at temperature more than 800 DEG C: switching on a combustion air interlocking valve, and allowing to switch on an acidic gas interlocking valve; and (5) igniting main combustion acidic gas: switching on the combustion air interlocking valve, feeding combustion air into the combustion furnace, then switching on the acidic gas interlocking valve, an acidic gas control valve and an acidic gas furnace feeding ball valve, and feeding the acidic gas into the furnace, igniting, and finally canceling the hot start procedure under temperature more than 800 DEG C. By adopting the improved heating ignition method, the ignition efficiency can be improved, the torching of the acidic gas can be reduced, and the environmental pollution can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP

Fire-flooding thermal-ignition method for oil layer

InactiveCN100560935CTo achieve the purpose of oil displacementAutoignition point reachedFluid removalThermal energyHigh pressure

A thermal ignition method for fire-flooded oil-flooded oil-flooded oil wells in an oil field, using a movable skid-mounted gas-steam generator set, and using high-temperature, high-pressure combustion technology to burn diesel to produce nitrogen, carbon dioxide, and water Steam mixed gas and a large amount of heat energy; when the combustion temperature in the gas-steam generator reaches 1800°C, the mixed gas is mixed with water to cool down to 300-400°C, the pressure is less than 25MPa, and injected into the oil layer through the wellhead device and injection pipe string of the oil well; Inject 3-10×104Nm3, 300-400°C mixed gas to preheat the oil layer, and then continuously inject air into the well to oxidize crude oil and air in the oil layer, release heat, reach the spontaneous ignition point, and carry out combustion to realize fire oil layer The purpose of oil displacement. The method solves the problems in the prior art that the heating temperature is too high and the heater is easily burnt out; the chemical method has a low ignition success rate. The invention can be widely used for ignition of oil wells in fire flooding and recovery oil layers in oil fields.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Environment-friendly waste incineration device

InactiveCN107702106AIncrease profitSolve problems such as wasteIncinerator apparatusThermal ignitionHigh energy

The invention discloses an environmentally friendly garbage incineration device, which includes a feed incineration module and a heat exchange steam waste gas treatment module. The feed incineration module includes a feed incineration bin, and the lower end of the feed incineration bin is symmetrically arranged with supporting columns. An incineration installation frame is installed in the middle of the lower end of the feed incineration bin, and an incineration tray is installed on the upper end of the incineration installation frame. The left end of the feed incineration bin at the lower end of the incineration installation frame is equipped with a blanking gate through an electric control shaft. The lower end of the incineration tray With the horizontal penetration of the blanking gate, a limited-diameter blanking sieve plate is installed. An electric auxiliary hot wire is installed horizontally in the incineration tray above the limited-diameter blanking sieve plate. The feed gate has the advantages of compact structure, novel design, controllable incineration process, high energy utilization rate, good safety, economy and environmental protection.

Owner:曹茂娟

A retractable ignition nozzle

ActiveCN109339953BAchieving a sliding sealGuaranteed sliding tightnessGas turbine plantsJet propulsion plantsThermal ignitionCombustion chamber

The invention belongs to the field of gas turbine ignition systems, and specifically designs a retractable ignition nozzle. Including nozzle assembly, front flange, rear flange, cylinder, spring, limit washer, step seal, sealing ring and sealing sleeve. The retractable ignition electric nozzle of the present invention can provide ignition when the gas turbine is unloaded, and can be supplied with pressure by an air pump under high pressure and high temperature conditions, and the electric nozzle parts can be inserted into the combustion chamber to ignite again. It can fundamentally solve the problem that the electric nozzle parts are in a high-voltage and high-temperature working environment for a long time, thereby improving the reliability of the ignition electric nozzle.

Owner:天津航空机电有限公司

Fluidized bed boiler hot material firing mode

InactiveCN100526719CLow costSimple and fast operationFluidized bed combustionIncandescent ignitionThermal ignitionFluidized bed

Owner:王天伟

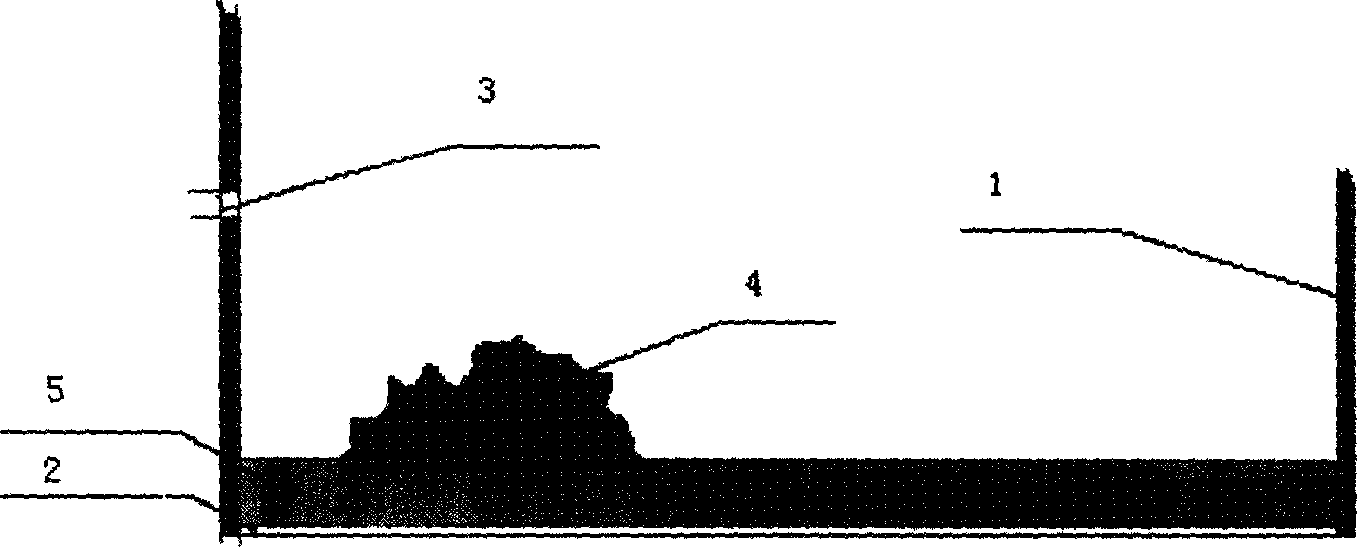

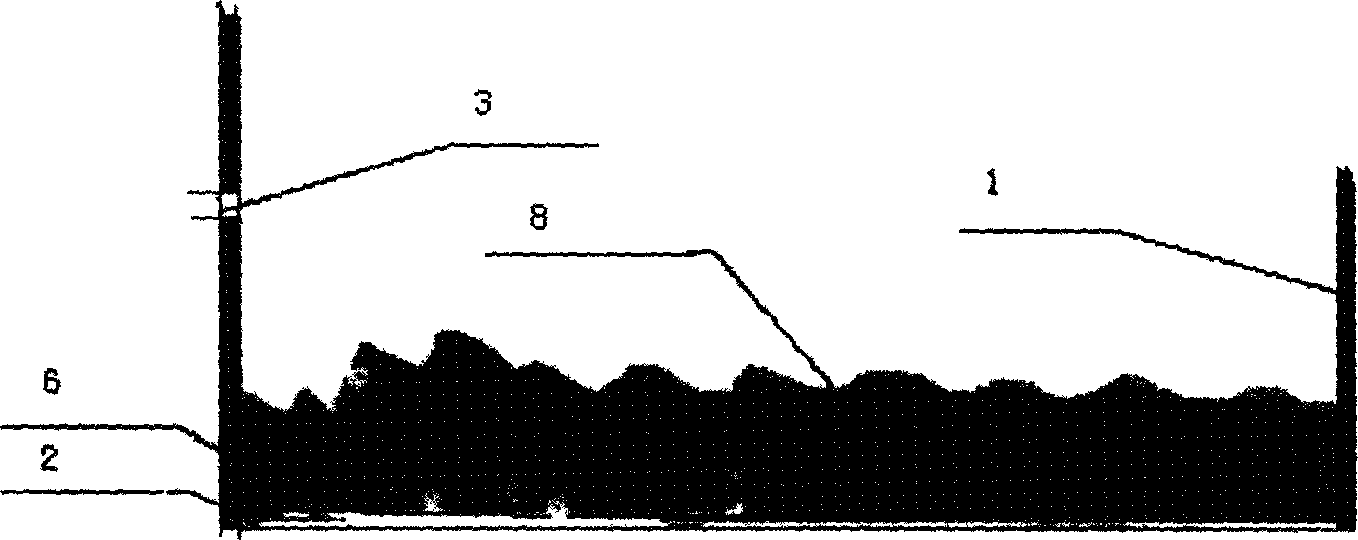

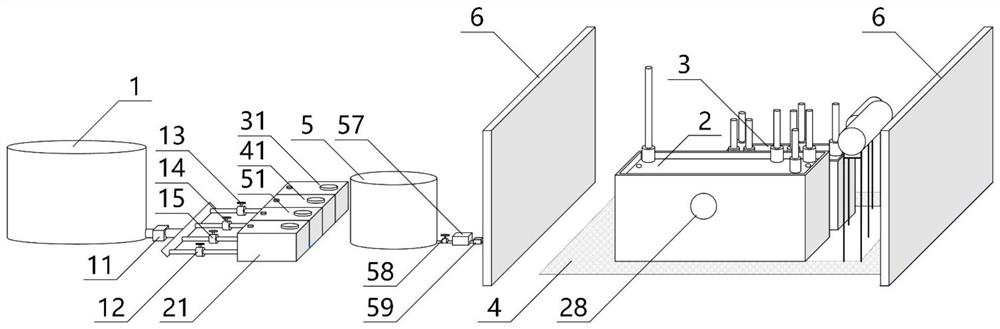

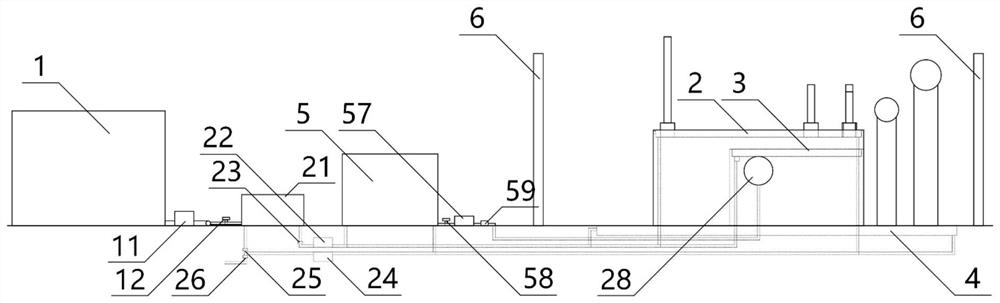

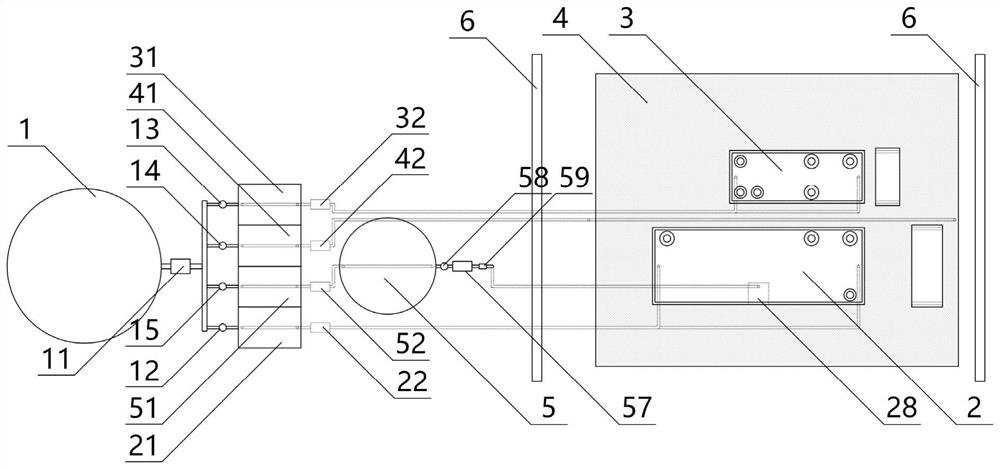

Oil control device and method for solid fire test of extra-high voltage alternating-current transformer

The invention discloses an oil control device and method for an extra-high-voltage alternating-current transformer entity fire test. The oil control device comprises a data acquisition and central control system, an oil module for an oil storage tank test, an oil module for a body transformer test, an oil module for an adjustment and compensation transformer test, an oil module for an oil collection pit test and an oil module for an overflow oil storage tank test. The oil storage tank test oil module comprises an oil storage tank and an oil transportation mechanism. The oil outlet end of the oil transportation mechanism is provided with a body variable oil transportation end, an adjusting and supplementing variable oil transportation end, an oil collection pit oil transportation end and an overflow oil storage tank oil transportation end. The method comprises the steps of self-inspection, oil injection, cyclic heating, ignition, overflow fire formation, fire extinguishment, oil discharge and test termination. The device has the advantages that oil for testing can be managed and controlled in the whole process, the functions of oil injection and heating before testing, overflow in testing, oil discharge after testing and the like are achieved, and effective development of an extra-high-voltage alternating-current transformer entity fire test is guaranteed.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +2

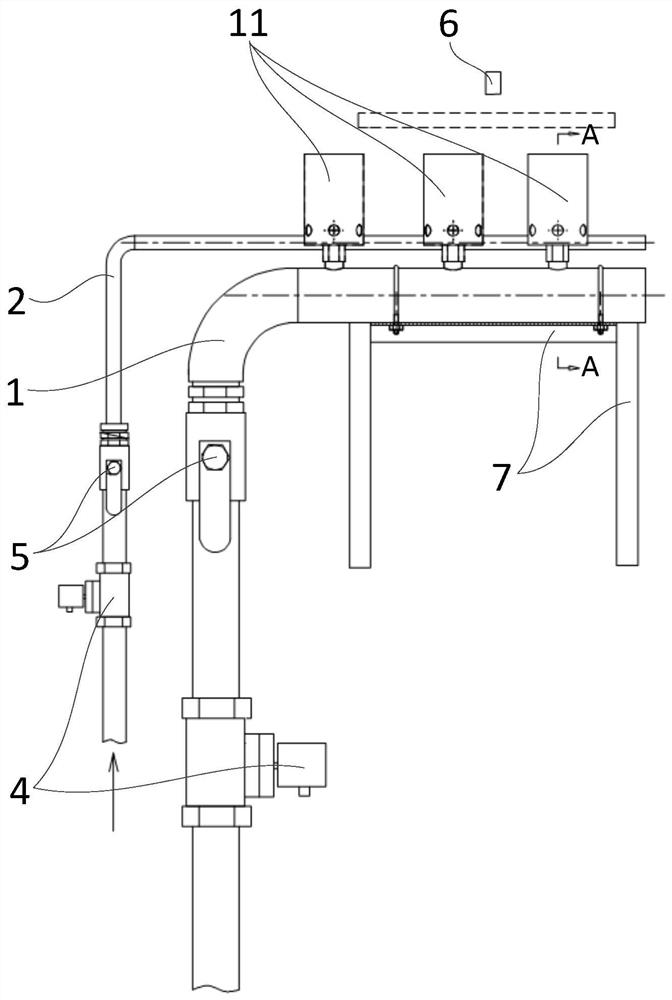

An indirect ignition preheating system

ActiveCN111664471BImprove ignition efficiencyElectric spark ignitersGaseous fuel burnerThermal ignitionCombustible gas

The invention discloses an indirect ignition preheating system. The interior of the gas supply main pipe is used to transport combustible gas, and the flame injectors for spraying gas are arranged at intervals on the gas supply main pipe. After the flame injector is ignited, the flame sprayed is used to The corresponding structure is preheated; the ignition auxiliary pipe is made of a conductive pipe with a diameter smaller than the main gas supply pipe, which can transmit electric sparks and is used to transport combustible gas inside; the ignition section of the ignition auxiliary pipe is arranged side by side with the flame injector, and The corresponding flame injector on the combustion section is provided with an ignition injection hole for injecting gas outward; the igniter is close to the secondary ignition pipe and can generate an electric spark, and the gas ejected from the secondary ignition pipe is ignited by the electric spark, and passed through an igniter All the injection holes on all the ignition sub-pipes are ignited, and the flame ejected from the injection holes further ignites the flamethrower, thereby indirectly igniting the flamethrower, so that multiple flamethrowers are ignited synchronously, and the ignition efficiency is improved.

Owner:YANKUANG GRP CO LTD +1

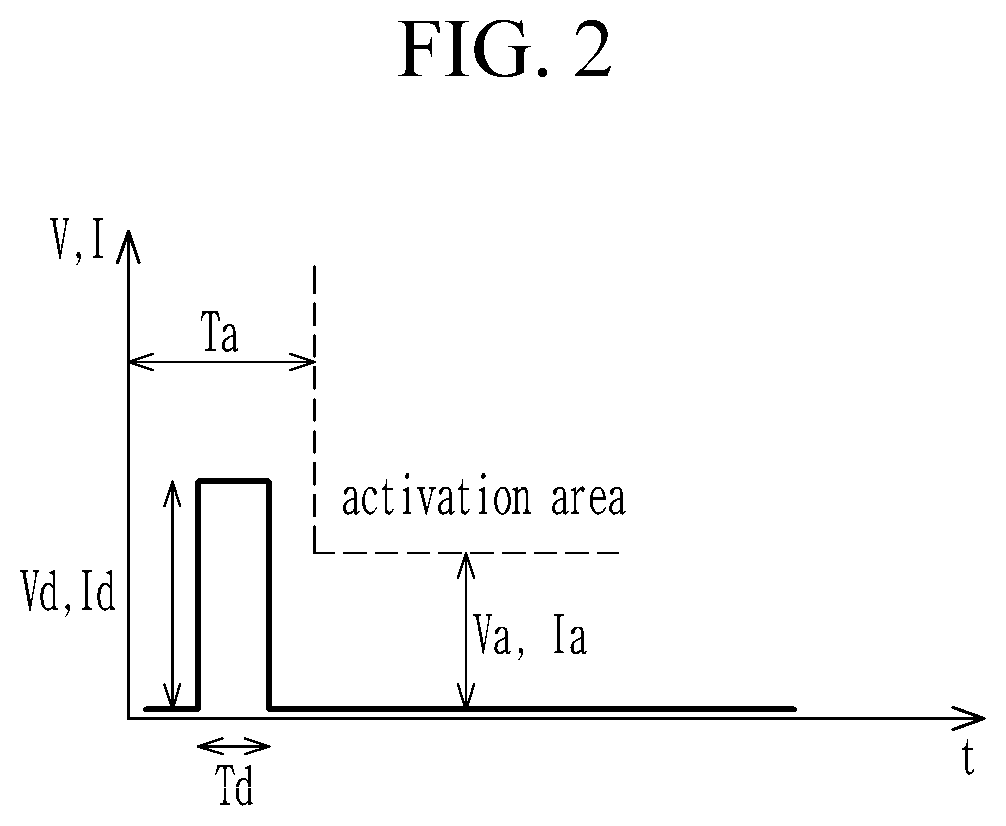

Pyro igniter circuit and testing method

ActiveUS20210296884A1Easy to controlQuick testCircuit monitoring/indicationElectric devicesThermal ignitionControl theory

A pyro igniter circuit and a method for testing the same is provided. The pyro igniter circuit includes a supervisory circuit configured to: transmit a test signal having a pulse duration time below an igniter activation pulse time of a pyro igniter disconnect element and / or an ignition control signal, in response to the transmitted test signal, has an amplitude below an igniter activation amplitude of the pyro igniter disconnect element; and receive a diagnostic response signal in response to the transmitted test signal.

Owner:SAMSUNG SDI CO LTD

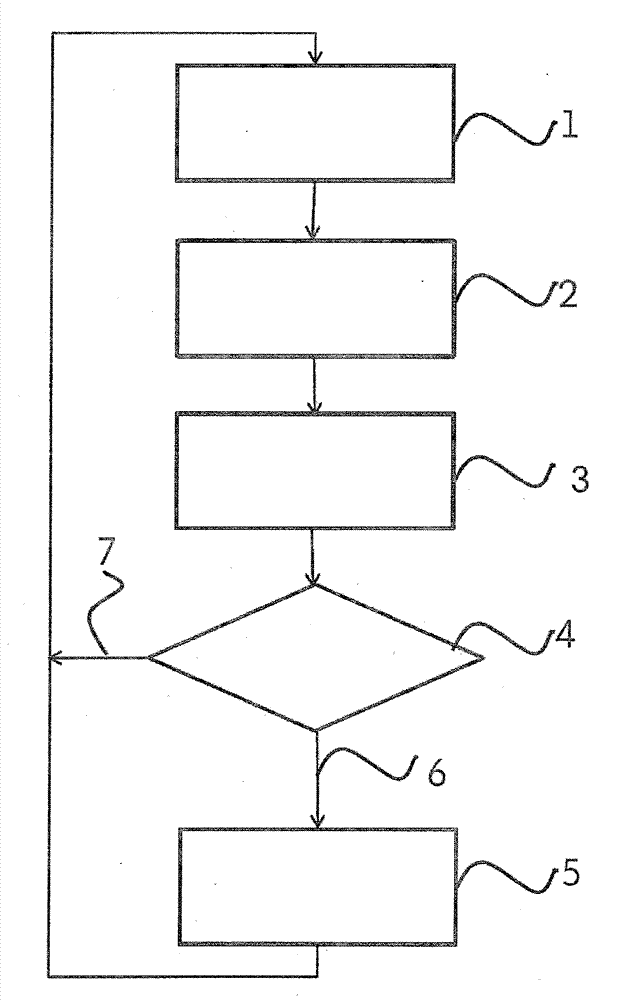

Method and device for detecting glow ignition of an internal combustion engine in a motor vehicle

ActiveCN104755730AEffective protectionAvoid damageInternal-combustion engine testingElectrical controlThermal ignitionCombustion chamber

The invention relates to a method for detecting glow ignition of a fuel-air mixture in a combustion chamber of an internal combustion engine (12) having at least a first and a further cylinder, which are connected by a crankshaft, according to which method partial segment times of the first cylinder are measured. The method is characterized in that partial segment times of the at least one further cylinder are measured and a reference characteristic for the glow ignition is formed by a comparison of partial segment times of the first cylinder with partial segment times of the at least one further cylinder and subsequently a signal is generated for the detection of the glow ignition on the basis of the comparison.

Owner:VOLKSWAGEN AG

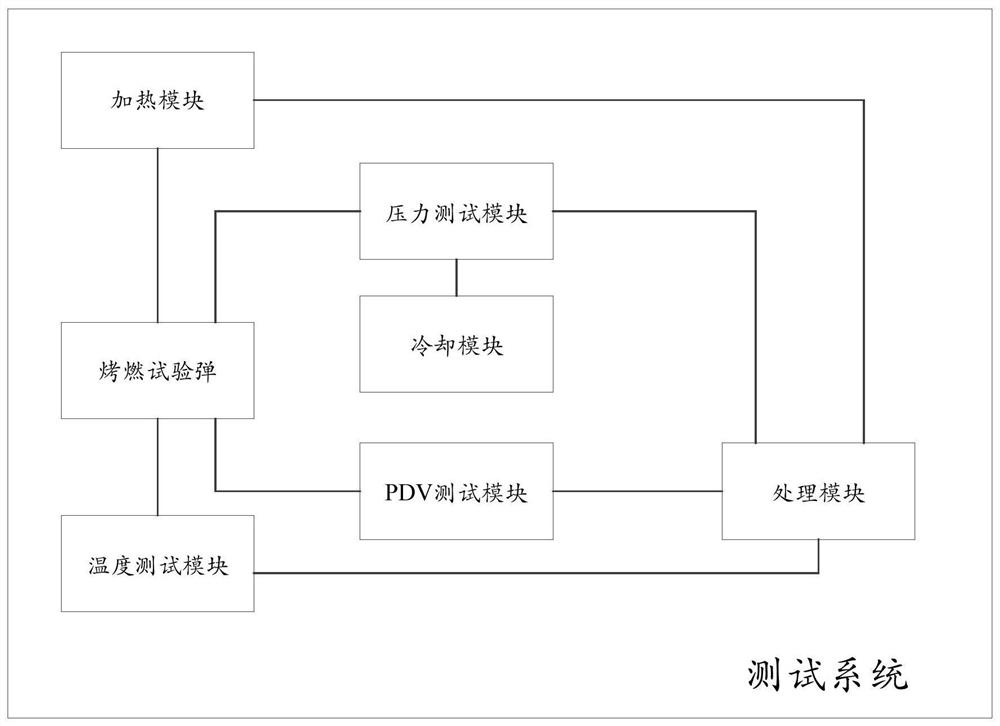

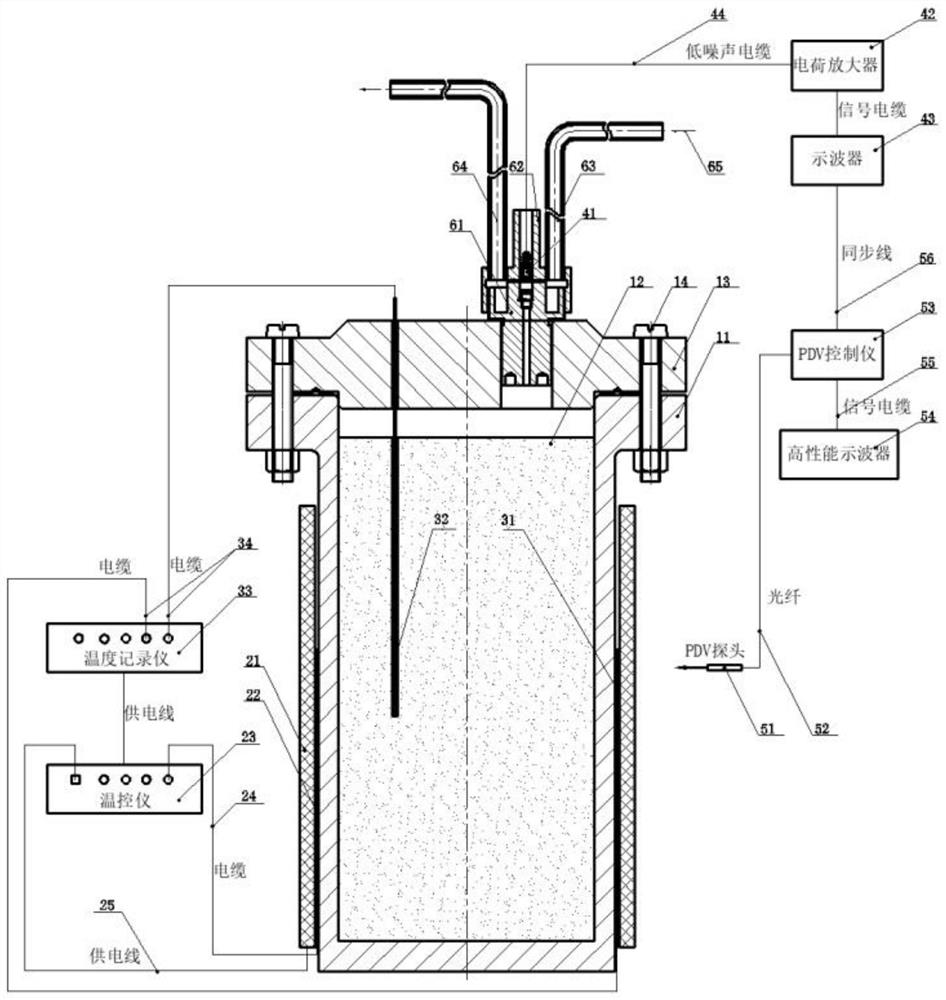

A test system for the whole process of heat-stimulated ammunition charge ignition and its reaction growth

ActiveCN111912303BPromote progressHigh measurement accuracyAmmunition testingThermal ignitionThermodynamics

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Spark plug over-limit temperature overlong alarm device

InactiveCN112067148AAffect jump overExtended service lifeThermometer detailsThermal ignitionEngineering

The invention discloses a spark plug over-limit temperature overlong alarm device which comprises a shell. An inner cavity is formed in the shell, a temperature sensing block is arranged on the left side wall of the shell in a penetrating mode, an indicator lamp is fixedly arranged on the outer end face of the upper side wall of the shell, a shaft wheel device is arranged in the inner cavity, andthe shaft wheel device comprises a magnetic sensor fixedly connected with the right end face of the temperature sensing block. According to the spark plug, when the spark plug works exceeding the limited temperature for a long time, what is indicated is that components of the spark plug go wrong, an alarm is given out at the moment, the phenomena that carbon deposition formed on the insulator skirt causes electric leakage between electrodes, spark plug flashover is affected, and blazing fire happens to the mixed gas can be prevented, the service life of the engine is prolonged, and the safetyof a driver is improved.

Owner:磐安字根电子科技有限公司

Improved thermal ignition method of combustion furnace of sulfur recovery device

ActiveCN102954489BSimplified ignition procedureReduce flareSulfur preparation/purificationCombustion ignitionThermal ignitionProcess engineering

Owner:CHINA PETROLEUM & CHEM CORP

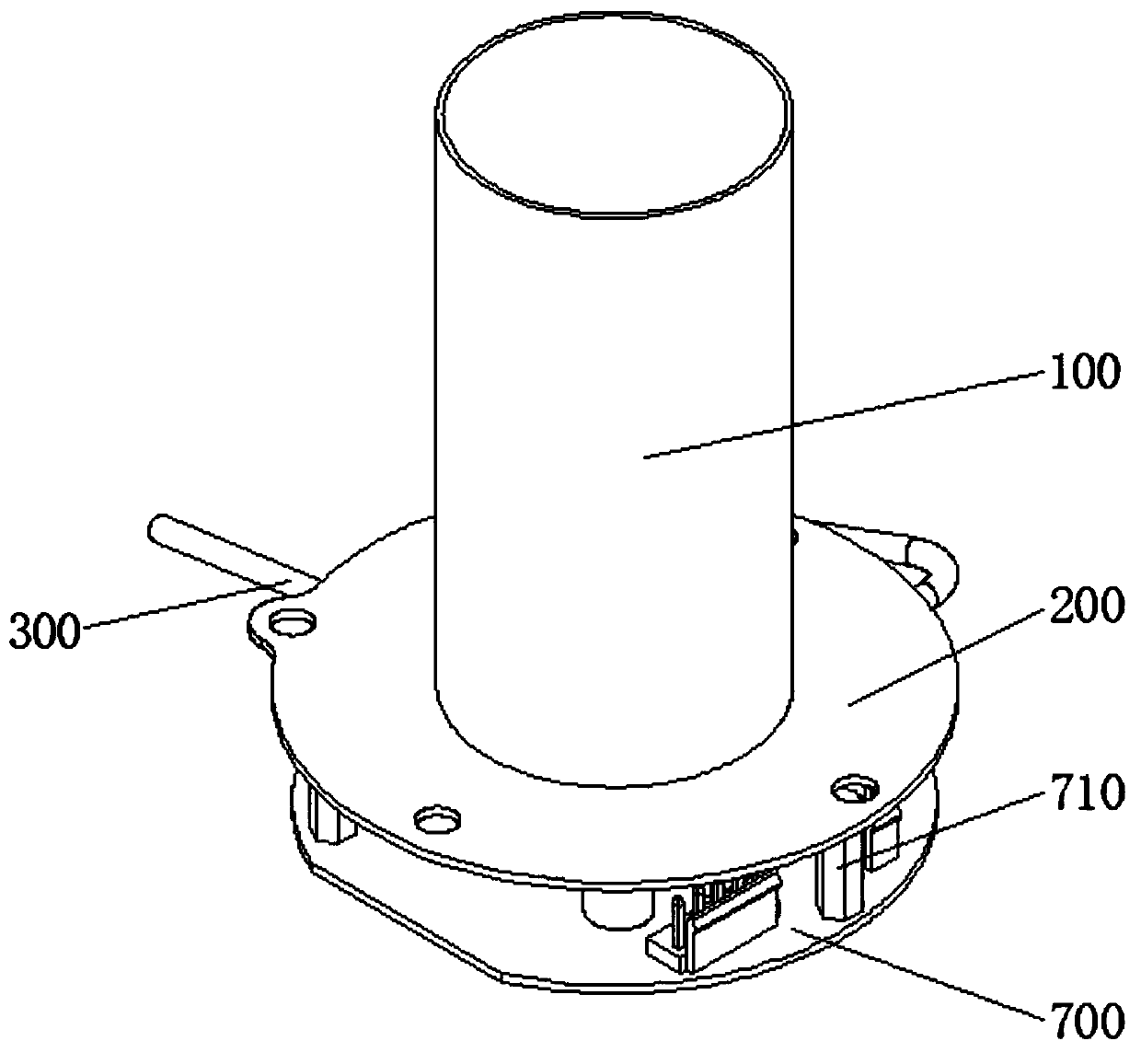

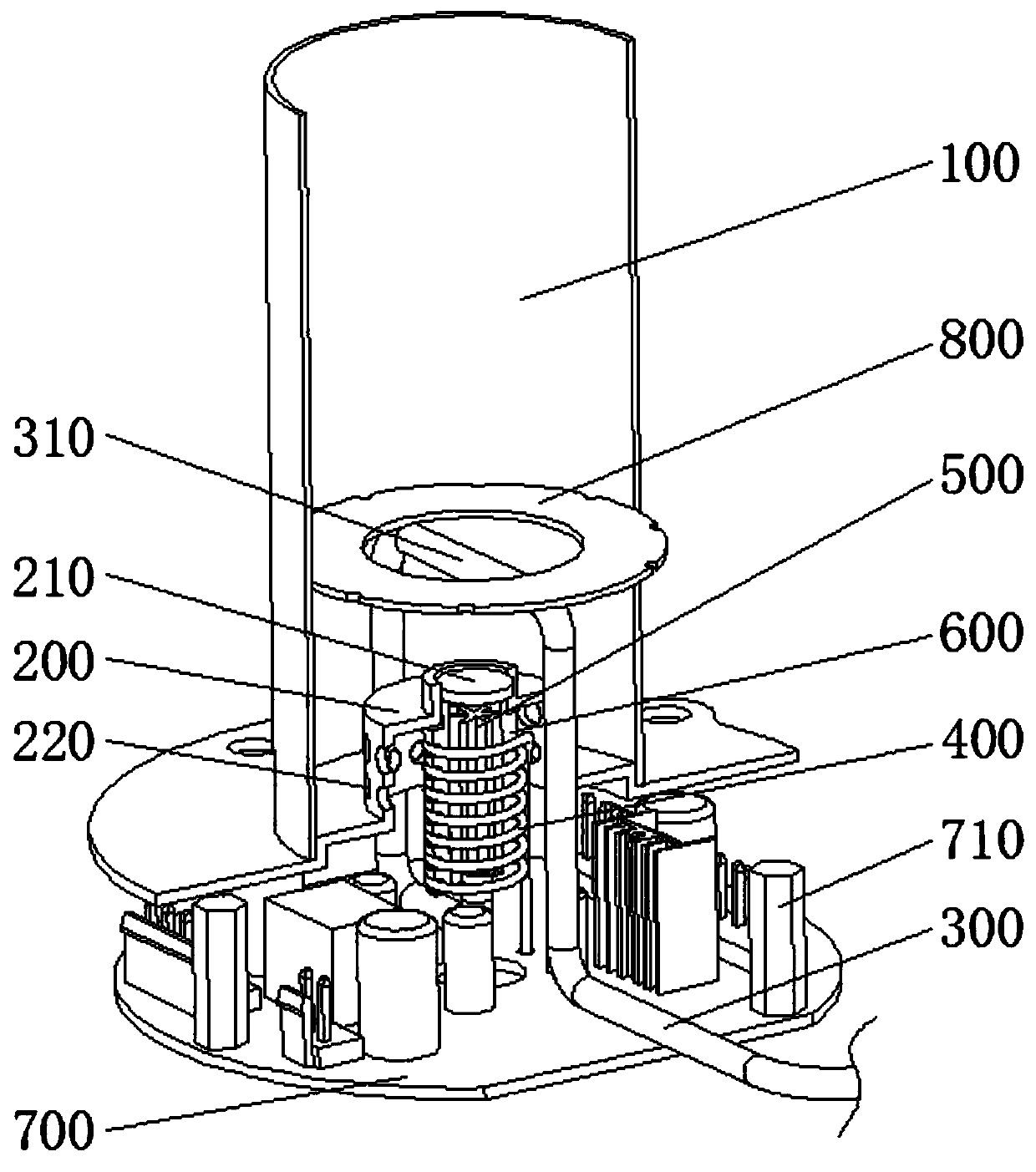

High-frequency coil preheating ignition structure of parking air heating heater

PendingCN111347839AImproved vaporizationBlock high temperature conductionAir-treating devicesVehicle heating/cooling devicesThermal ignitionCombustion chamber

The invention provides a high-frequency coil preheating ignition structure of a parking air heating heater. The high-frequency coil preheating ignition structure includes a combustion chamber for combusting fuel oil; a combustion seat arranged at the lower end of the combustion chamber and used for fixing the combustion chamber; an oil pipe used for conveying fuel oil; a high-frequency coil, wherein the high-frequency coil is arranged in the combustion seat, the fuel oil vaporization metal piece is arranged in the combustion seat, a heat-insulating flame-retardant pipe is arranged between thefuel vaporization metal piece and the high-frequency coil, the heat-insulating flame-retardant pipe is communicated with the oil outlet of the oil pipe to form a channel for fuel oil to circulate, theoil outlet end of the oil pipe is communicated with the heat-insulating flame-retardant pipe. Through the principle that the high-frequency coil can quickly heat red metal, fuel oil can be quickly vaporized and ignited after flowing out of the oil pipe, the heat insulation flame-retardant pipe effectively prevents high temperature of the fuel oil vaporization metal piece from being conducted to the circuit board, normal use of the circuit board is guaranteed, the upper end of the oil pipe is bent to pass through the position over the combustion seat, when fuel oil burns, high temperature of flame can preheat the oil pipe, and the vaporization effect of the fuel oil is improved.

Owner:温州星火科技有限公司

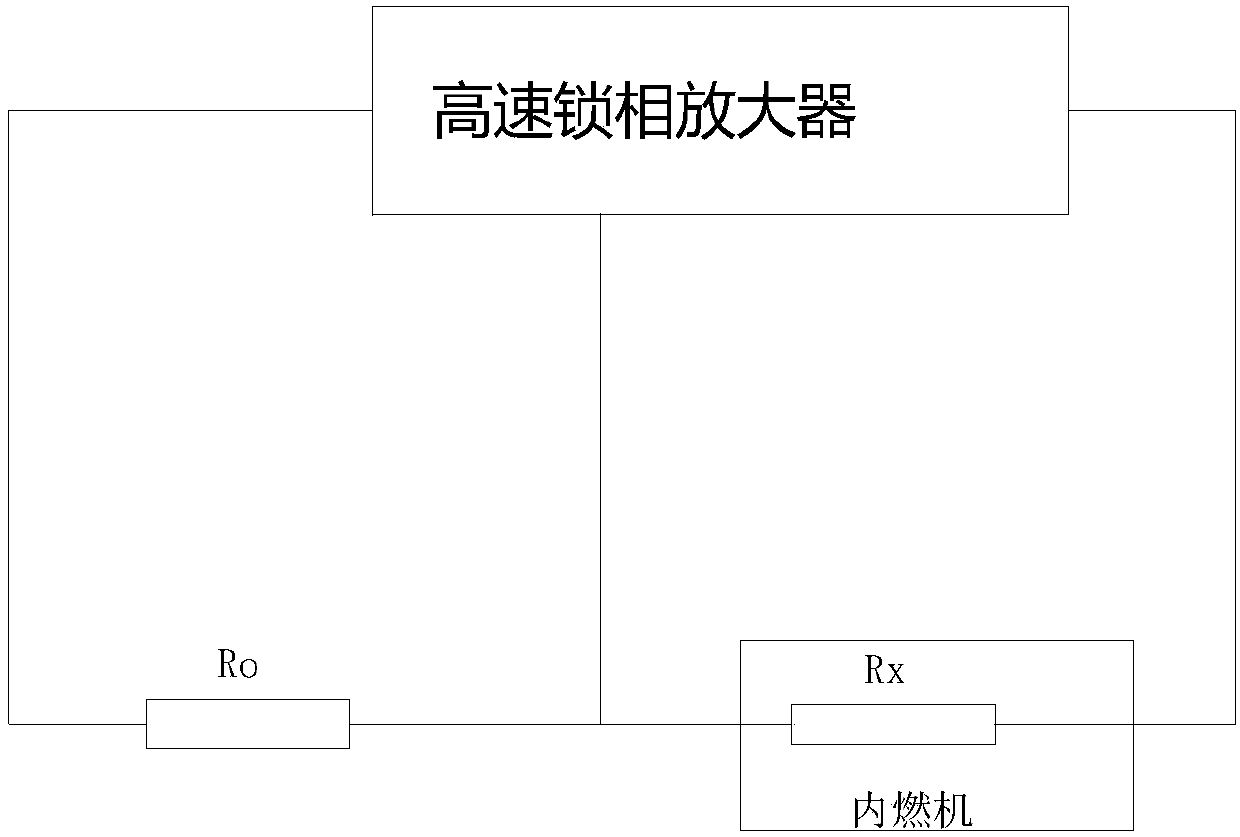

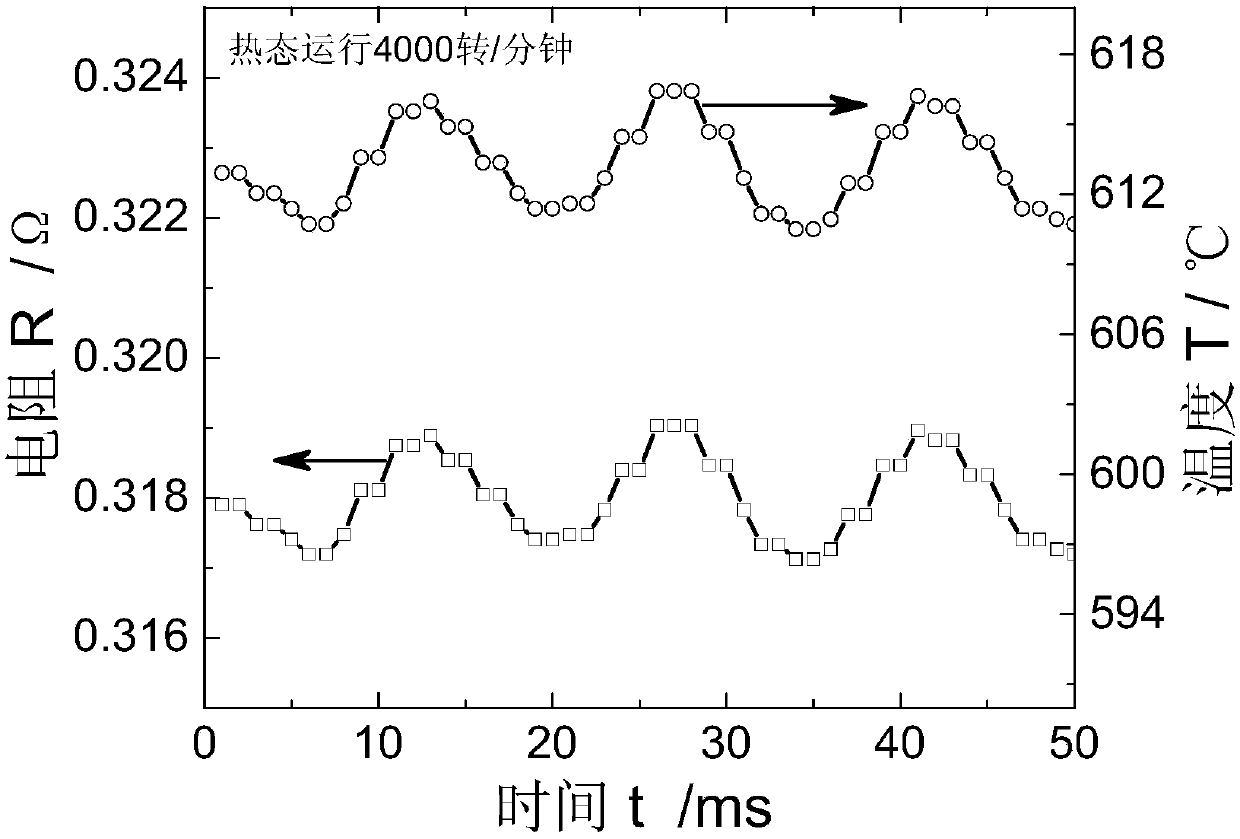

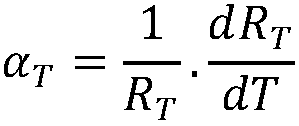

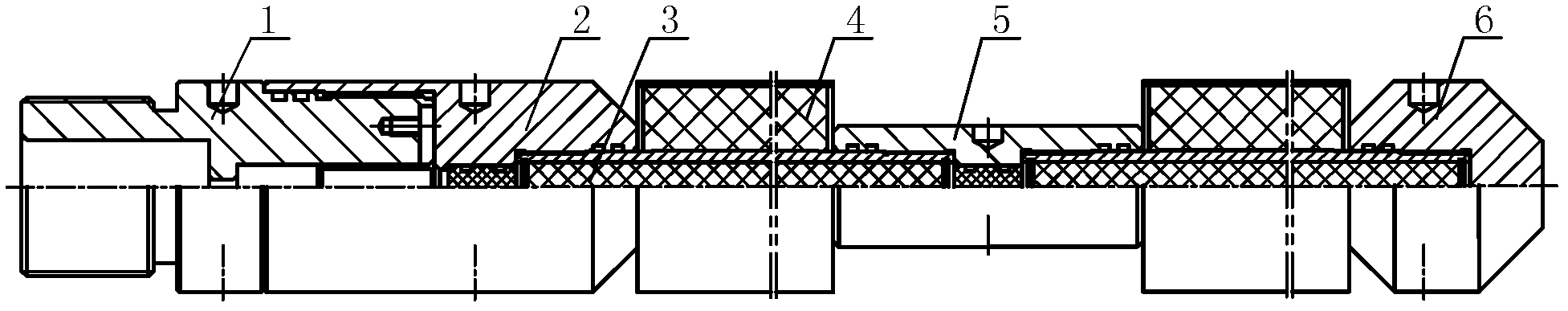

Micro internal combustion engine self-heat-storage ignition temperature measuring method and device

InactiveCN107806938AThermometers using electric/magnetic elementsUsing electrical meansElectrical resistance and conductanceAlloy

The invention provides a micro internal combustion engine self-heat-storage ignition temperature measuring device, which comprises an internal combustion engine, a high-speed phase-locked amplifier and a voltage divider resistor Ro. A heating filament of a heat-storage igniter in the internal combustion engine is a resistor Rx to be measured; the voltage divider resistor Ro is connected in serieswith the resistor Rx to be measured; and the high-speed phase-locked amplifier is connected in parallel with the voltage divider resistor Ro and the resistor Rx to be measured. The heat-storage igniter heating filament is made of platinum or platinum-rhodium alloy. The voltage divider resistor Ro is a variable resistor, resistance range being 10-50 ohm. The advantages are that method and device can realize measurement by directly obtaining the voltages signals at the two ends of the heat-storage igniter in a test circuit, and can obtain resistance of the heating filament through conversion, and thus ignition temperature and dynamic change data can be obtained.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

A hot-fire high-energy gas pulse fracturing device

ActiveCN102337878BComplete structureThe combustion state is stable and controllableFluid removalHigh energyIgnition coil

The invention discloses a thermal-ignition high-energy gas pulse fracturing device. The thermal-ignition high-energy gas pulse fracturing device is formed by connecting an oil transmission or cable ignition joint component, a fire transmission joint component, one or more airtight thermal ignition device components, one or more fracturing main charge components, one or more series-connected joint components and a gun breech in series, wherein the airtight thermal ignition device components are ignited by using ignition tubes; the ignition tubes ignite high-heat micro-air gunpowder or airless high-heat explosives in the airtight thermal ignition devices; the airtight thermal ignition devices are sealed systems and keep a complete structure before and after ignition; main charges are ignited by heat transmitted from the airtight thermal ignition devices; and the main charges combust and quickly generate a great amount of fuel gas. A plurality of devices are connected in series by using ignition joints, the number of the devices connected in series is not limited, and the instant or delayed ignition tubes are filled in the ignition joints, so that the combustion transmission of multi-level devices is realized. The thermal-ignition high-energy gas pulse fracturing device solves the problems that a deflagration state is difficult to control, pressure in mineshafts is superposed and sleeves are damaged, and a great amount of debris pollutant and blockage exist after deflagration in the prior art.

Owner:NORTH SCHLUMBERGER OILFIELD TECH XIAN

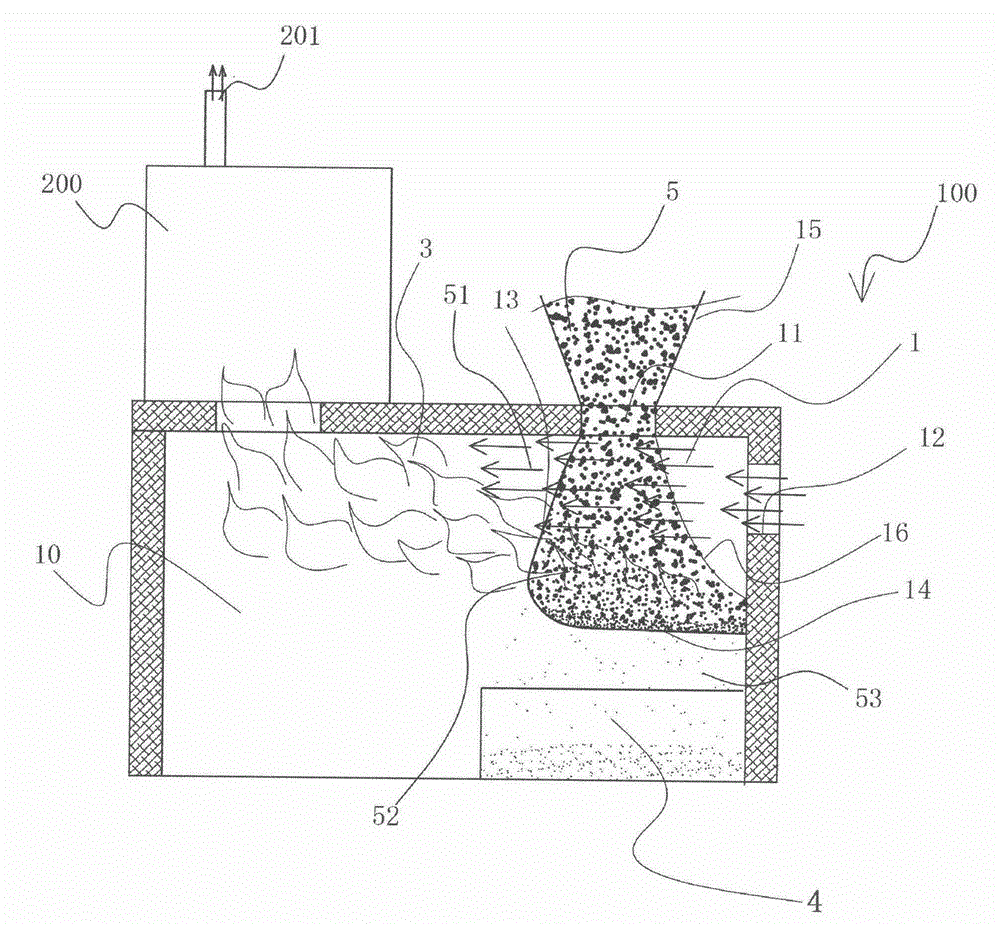

Burning method and burning device of solid fuel

InactiveCN104819456ASolve potential safety hazardsBurn speed matchSolid fuel combustionCombustion apparatusThermal ignitionSolid fuel

The invention provides a burning method and a burning device of a solid fuel. The burning method is to define a stacking area in a hearth; a burning cavity is formed in one side of the stacking area; in burning, the solid fuel enters the stacking area from the top of the stacking area; wind enters from the other side of the stacking area opposite to the burning cavity; the lower layer of the fuel is burnt to generate burning flame; the upper layer of the fuel is heated to separate out a volatile matter; the wind transversely penetrates through the upper layer of the fuel, and carries the separated volatile matter to flow towards the burning cavity; and thermal ignition generated by the volatile matter burning flame is burnt in the burning cavity. The burning method not only can enable the volatile matter to be fully burnt, but also can realize natural matching between the automatic ordered feeding and the burning speed, solves the ash melting problem, and guarantees the stable lasting burning.

Owner:车战斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com