Series preheating method and series preheating system for coal gas of sintering ignition furnace

A technology of ignition furnace and sintering point, which is applied in the direction of furnace, furnace type, lighting and heating equipment, etc. It can solve the problems of not being suitable for large sintering machines, poor ignition effect, and low ignition temperature, so as to improve ignition effect and prolong life , Guarantee the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

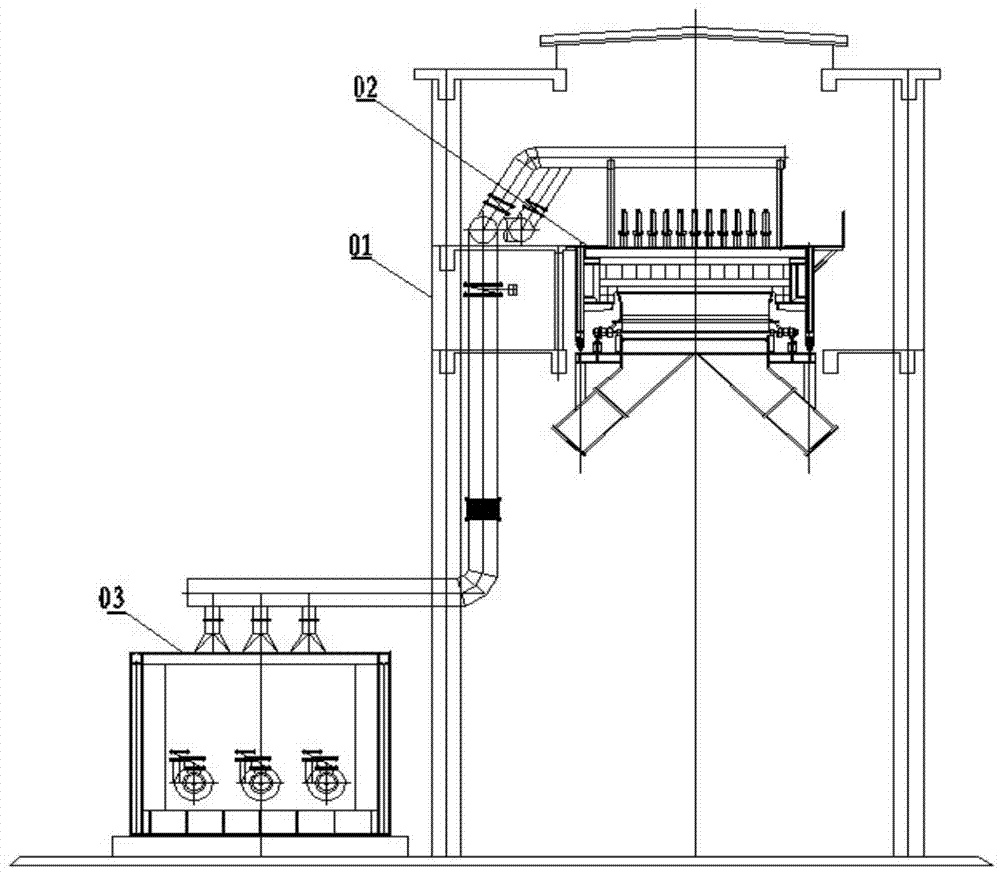

[0027] This embodiment uses a series preheating system of combustion air heat exchanger and gas heat exchanger for sintering ignition furnace, which is arranged under the sintering machine ( figure 1 ), outside the sintering machine workshop 1, the sintering machine is 180m 2 Sintering Machine.

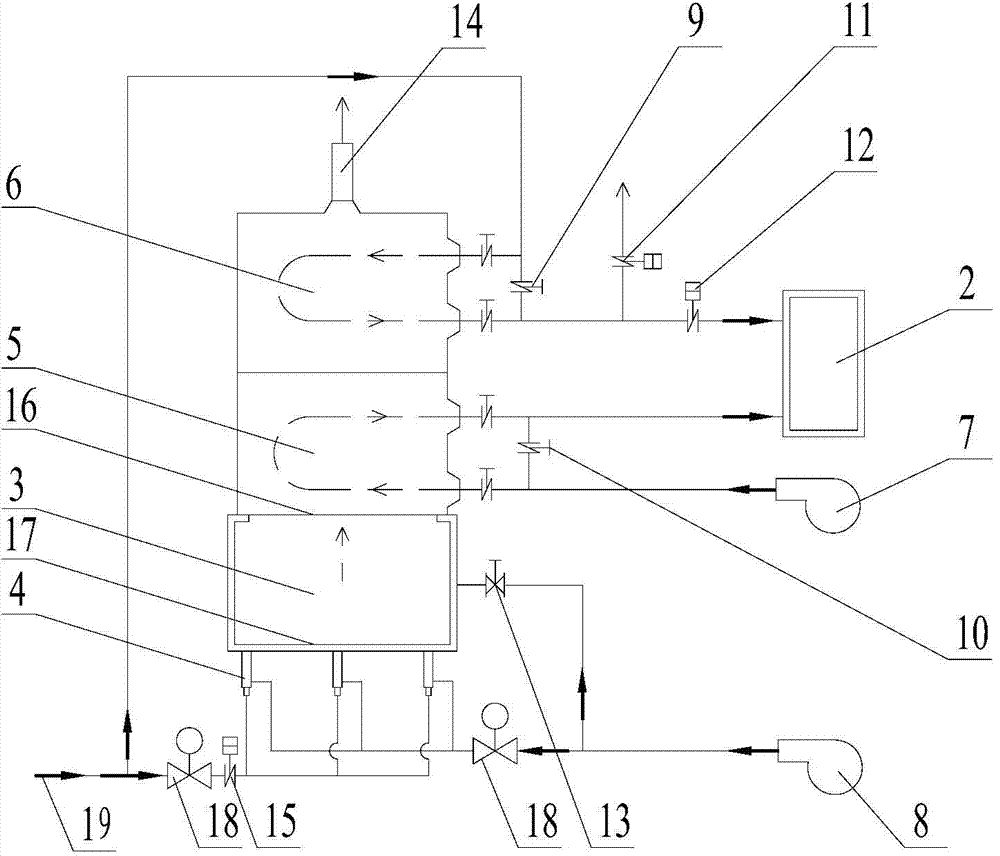

[0028] The sintering ignition furnace uses a combustion air heat exchanger and a gas heat exchanger to preheat the system structure in series ( figure 2 ) Including preheating furnace 3, combustion air heat exchanger 5 for ignition furnace and gas heat exchanger 6 for ignition furnace; preheat furnace 3, combustion air heat exchanger 5 for ignition furnace and gas heat exchanger 6 for ignition furnace The flow direction of the preheating furnace flue gas is arranged in series, the area of the combustion air heat exchanger 5 for the ignition furnace and the gas heat exchanger 6 for the ignition furnace are respectively 110m 2 And 130m 2 . The combustion-supporting air heat exchanger 5 ...

Embodiment 2

[0034] Sintering machine is 300m 2 Sintering Machine. The sintering ignition furnace uses a system for preheating in series with a combustion air heat exchanger and a gas heat exchanger. The heat exchange area of the combustion air heat exchanger 5 and the gas heat exchanger 6 are 180m respectively 2 And 210m 2 . Three burners are arranged on the furnace end wall of preheating furnace 3, and the heating capacity of the burners is 5×10 9 J / h·Taiwan.

[0035] The other settings of the system are the same as in Example 1.

[0036] The preheating furnace uses blast furnace gas (heat value 780kCal / m 3 ) Is the fuel. The combustion-supporting air for the ignition furnace is provided by the combustion-supporting fan 7 for the ignition furnace. When it passes through the combustion-supporting air preheater 5 for the ignition furnace, it undergoes cross-flow convection heat exchange with high-temperature flue gas, and the temperature reaches 330°C; When the coal gas passes through the ga...

Embodiment 3

[0039] Sintering machine is 400m 2 Sintering Machine. The sintering ignition furnace is a series preheating system of combustion air heat exchanger and gas heat exchanger. The heat exchange area of the combustion air heat exchanger and the gas heat exchanger are 220m respectively. 2 And 260m 2 . Three burners are arranged on the furnace end wall of preheating furnace 3, and the heating capacity of the burners is 6.7×10 9 J / h·Taiwan.

[0040] The other settings of the system are the same as in Example 1.

[0041] The preheating furnace uses blast furnace gas (heat value 780kcal / m 3 ) Is the fuel. The combustion air for the ignition furnace is provided by the combustion air fan 7 for the ignition furnace. When it passes through the combustion air preheater 5 for the ignition furnace, it undergoes cross-flow convection heat exchange with the high-temperature flue gas, and the temperature reaches 320℃; When the coal gas passes through the gas preheater 6 for the ignition furnace, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com