Patents

Literature

166results about How to "High-temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

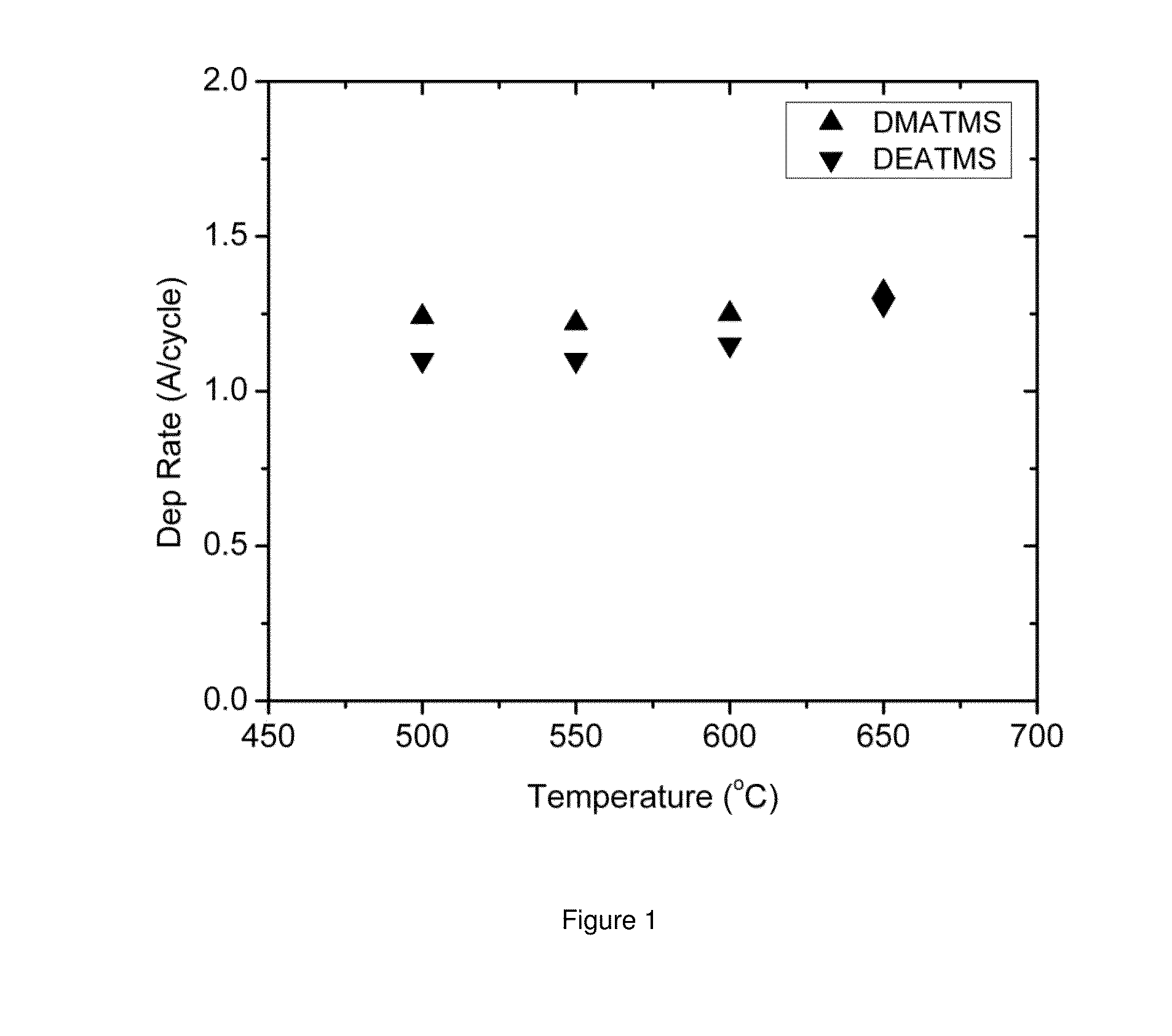

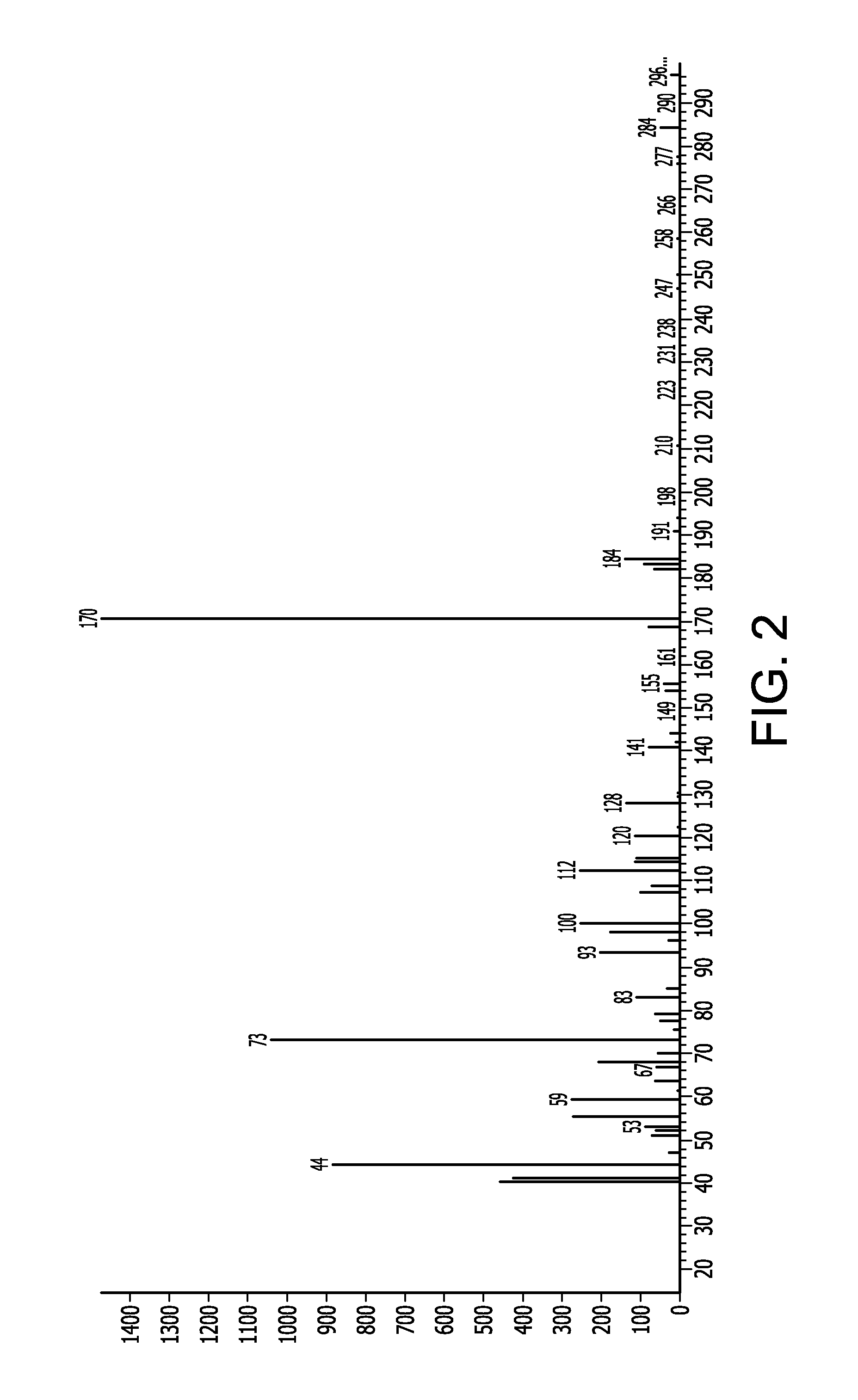

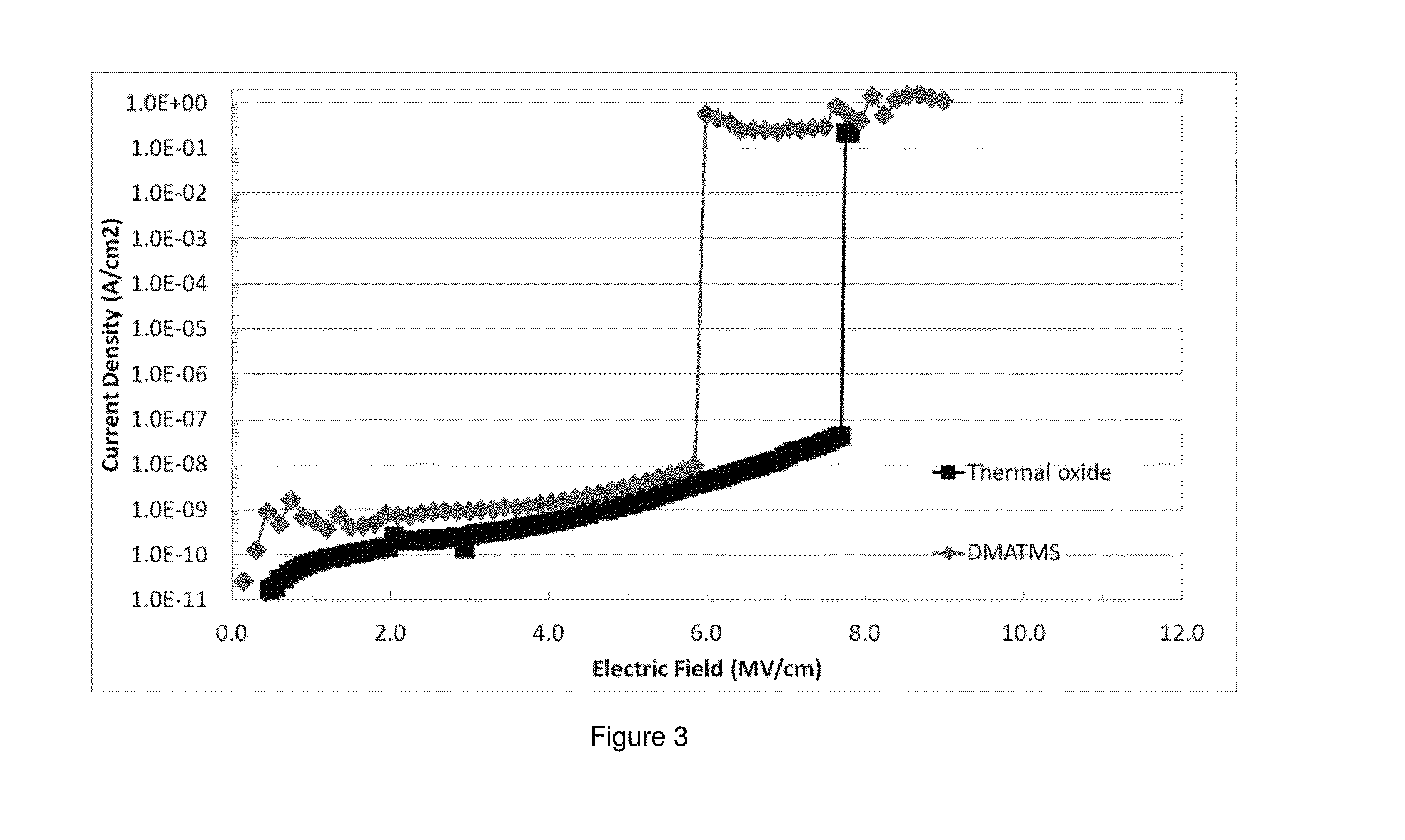

High temperature atomic layer deposition of silicon oxide thin films

ActiveUS20130295779A1High temperatureSilicon organic compoundsSemiconductor/solid-state device manufacturingSilicon oxideDeposition temperature

Composition(s) and atomic layer deposition (ALD) process(es) for the formation of a silicon oxide containing film at one or more deposition temperature of about 500° C. is disclosed. In one aspect, the composition and process use one or more silicon precursors selected from compounds having the following formulae I, II, described and combinations thereofR1R2mSi(NR3R4)nXp; and I.R1R2mSi(OR3)n(OR4)qXp. II

Owner:VERSUM MATERIALS US LLC

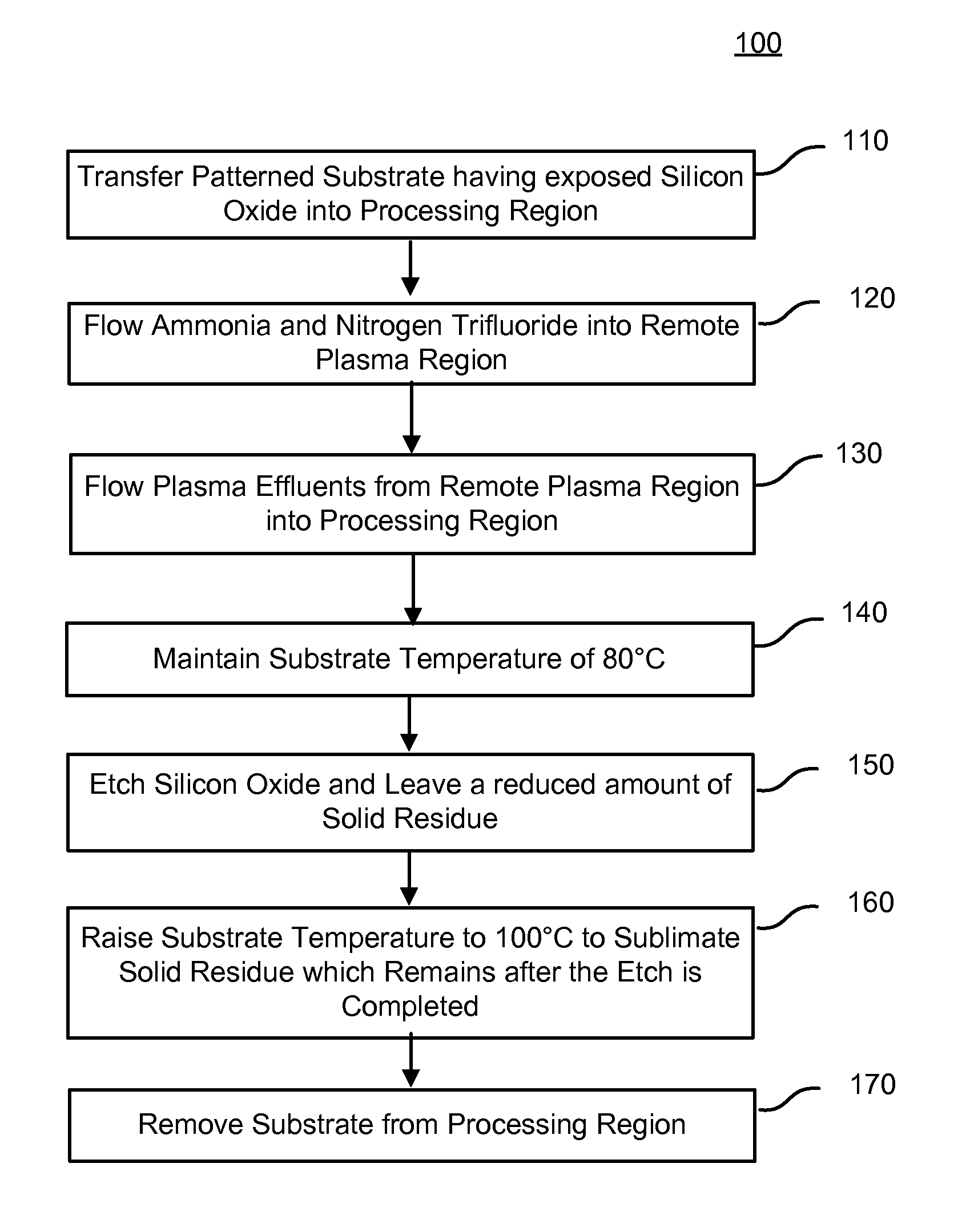

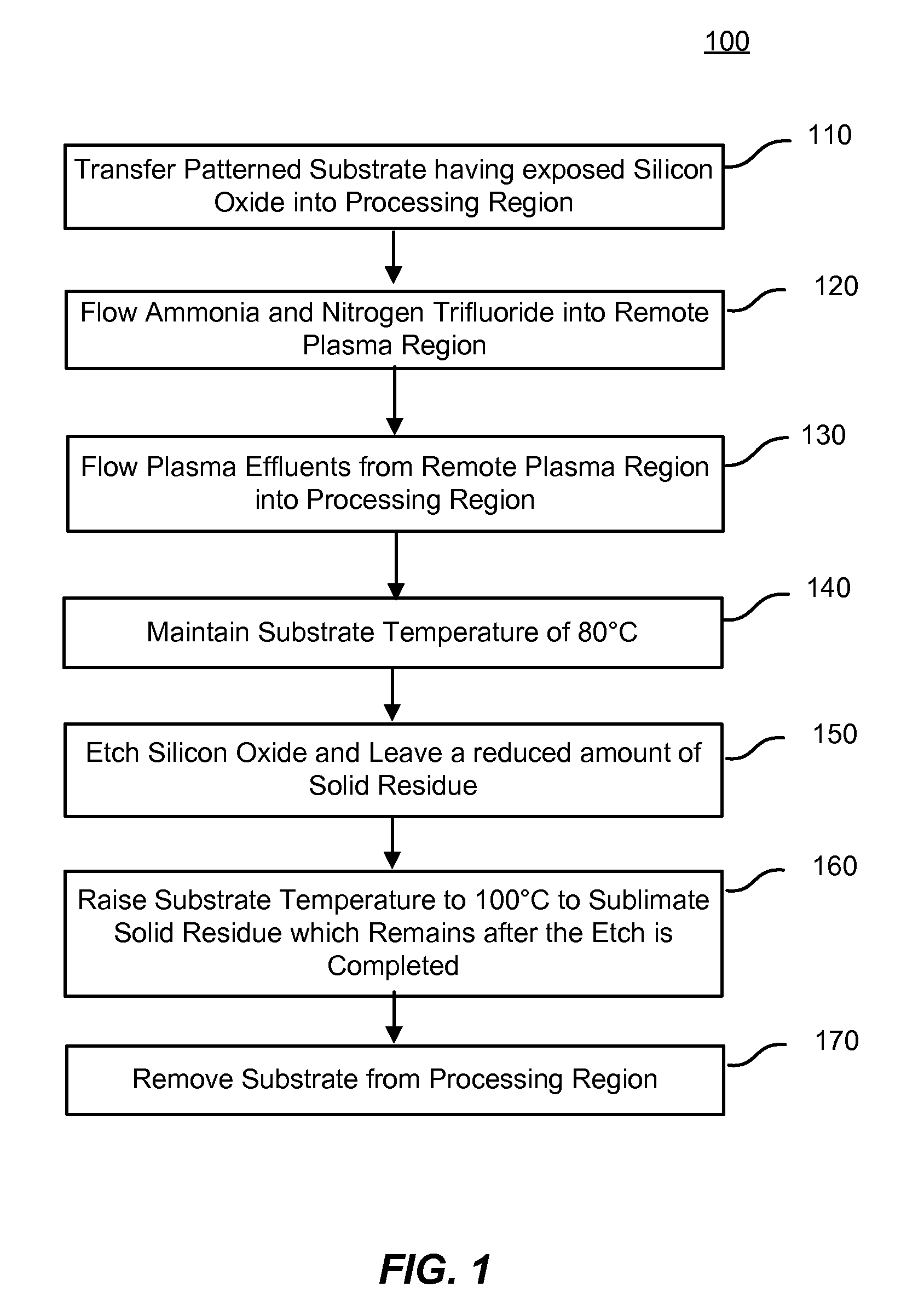

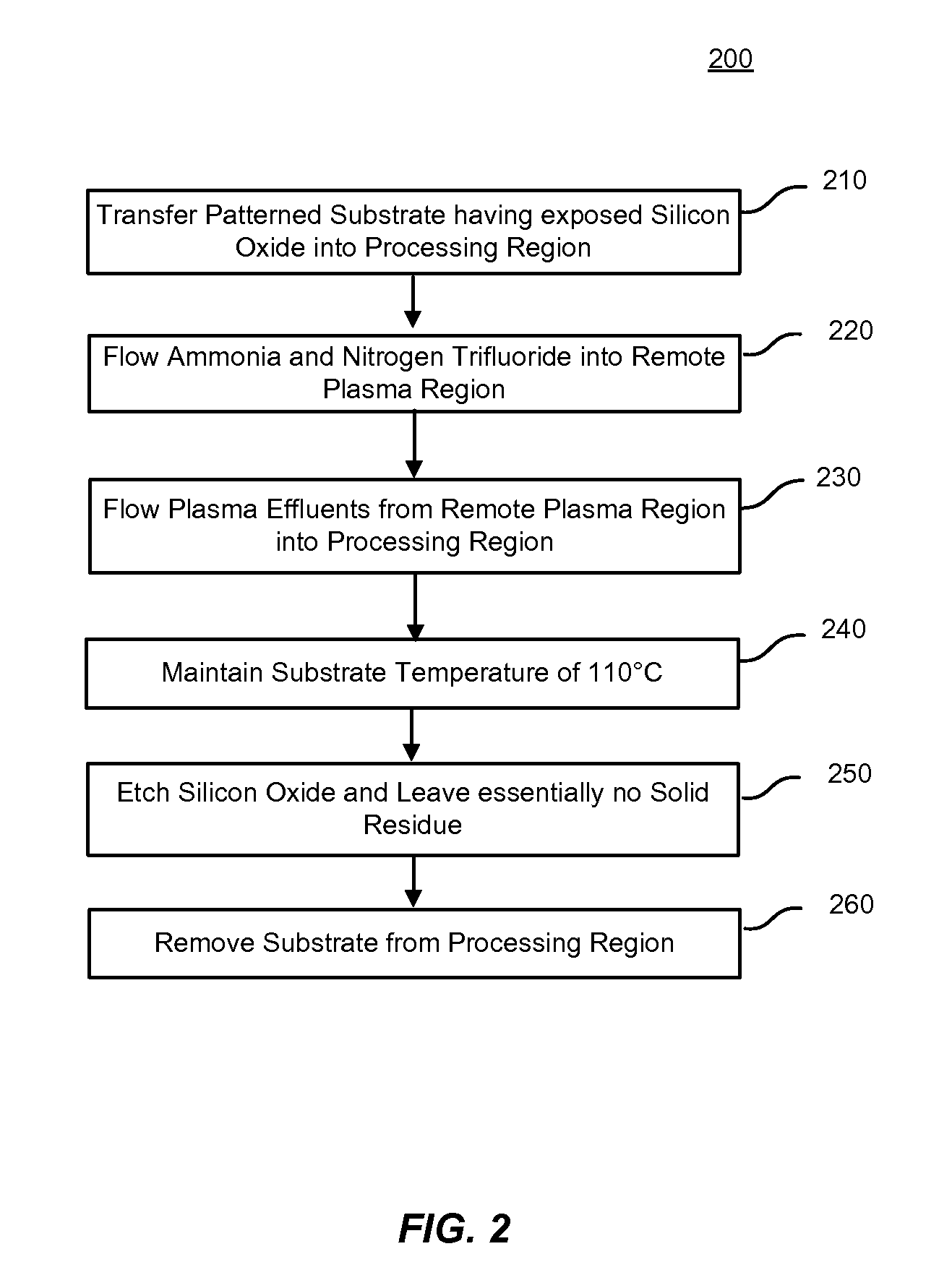

High-temperature selective dry etch having reduced post-etch solid residue

ActiveUS20110266252A1Reduce surfaceHigh temperatureElectric discharge tubesDecorative surface effectsChemistryEtching rate

Methods of dry etching silicon-containing dielectric films are described. The methods include maintaining a relatively high temperature of the dielectric films while etching in order to achieve reduced solid residue on the etched surface. Partially or completely avoiding the accumulation of solid residue increases the etch rate.

Owner:APPLIED MATERIALS INC

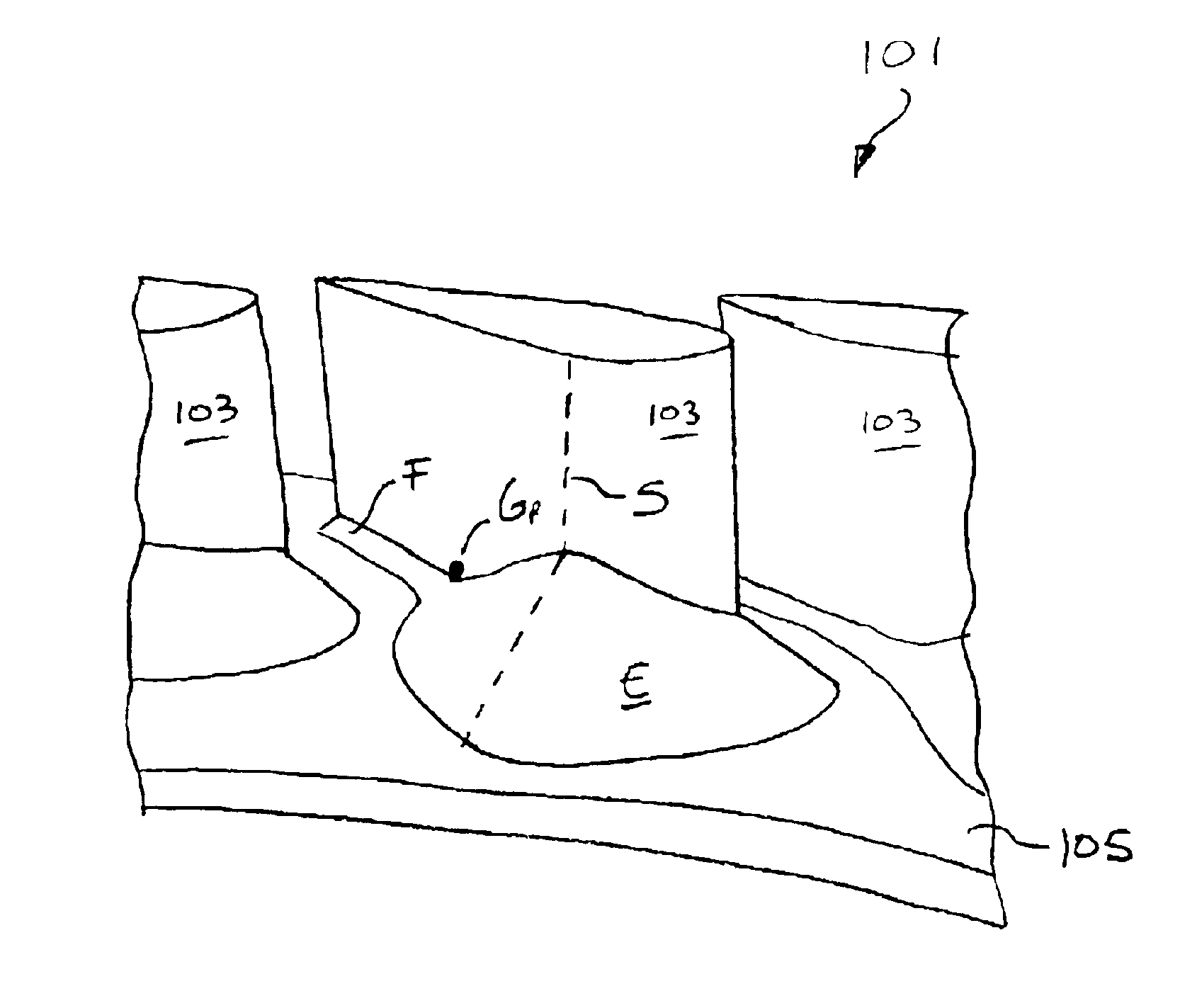

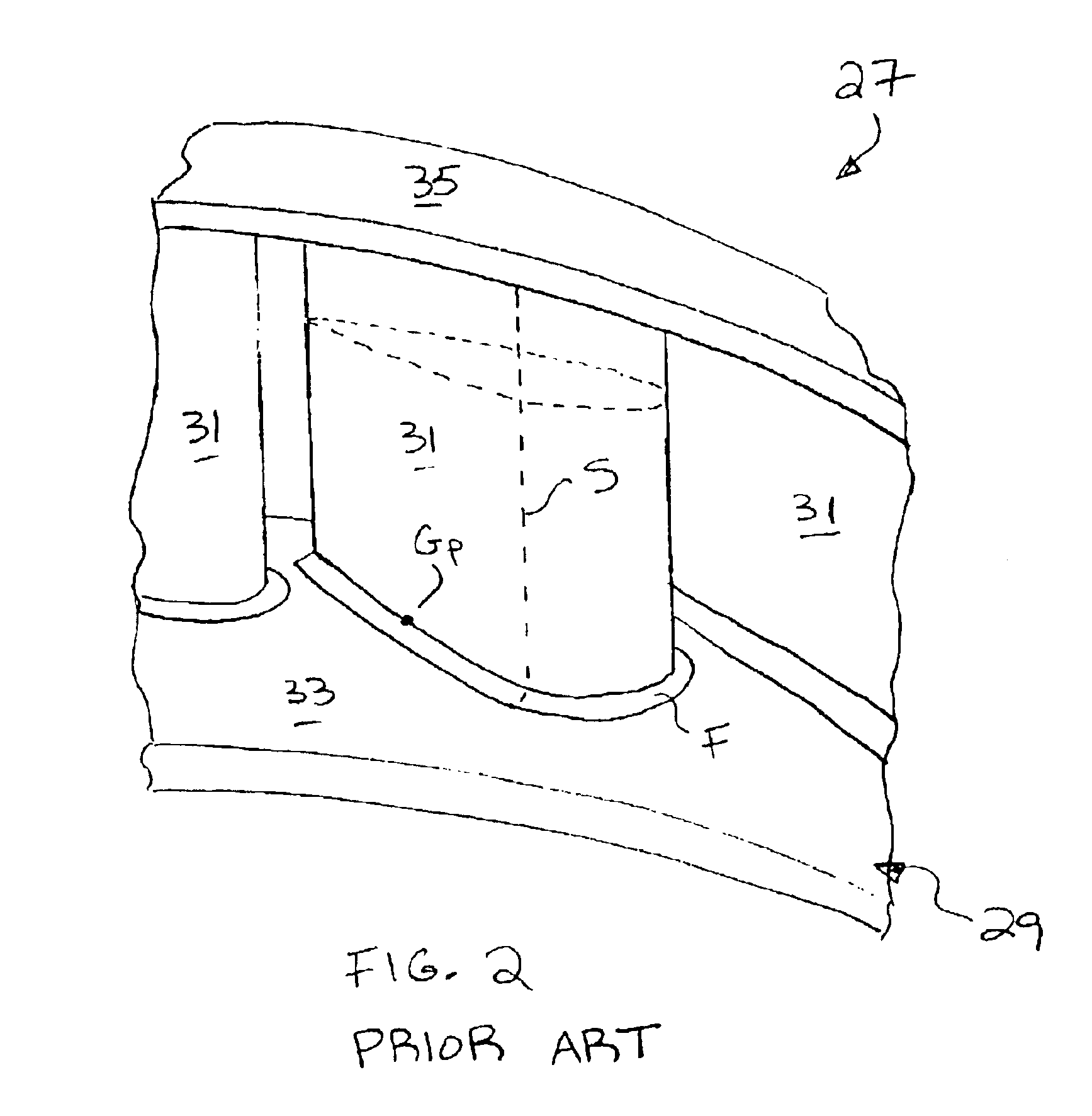

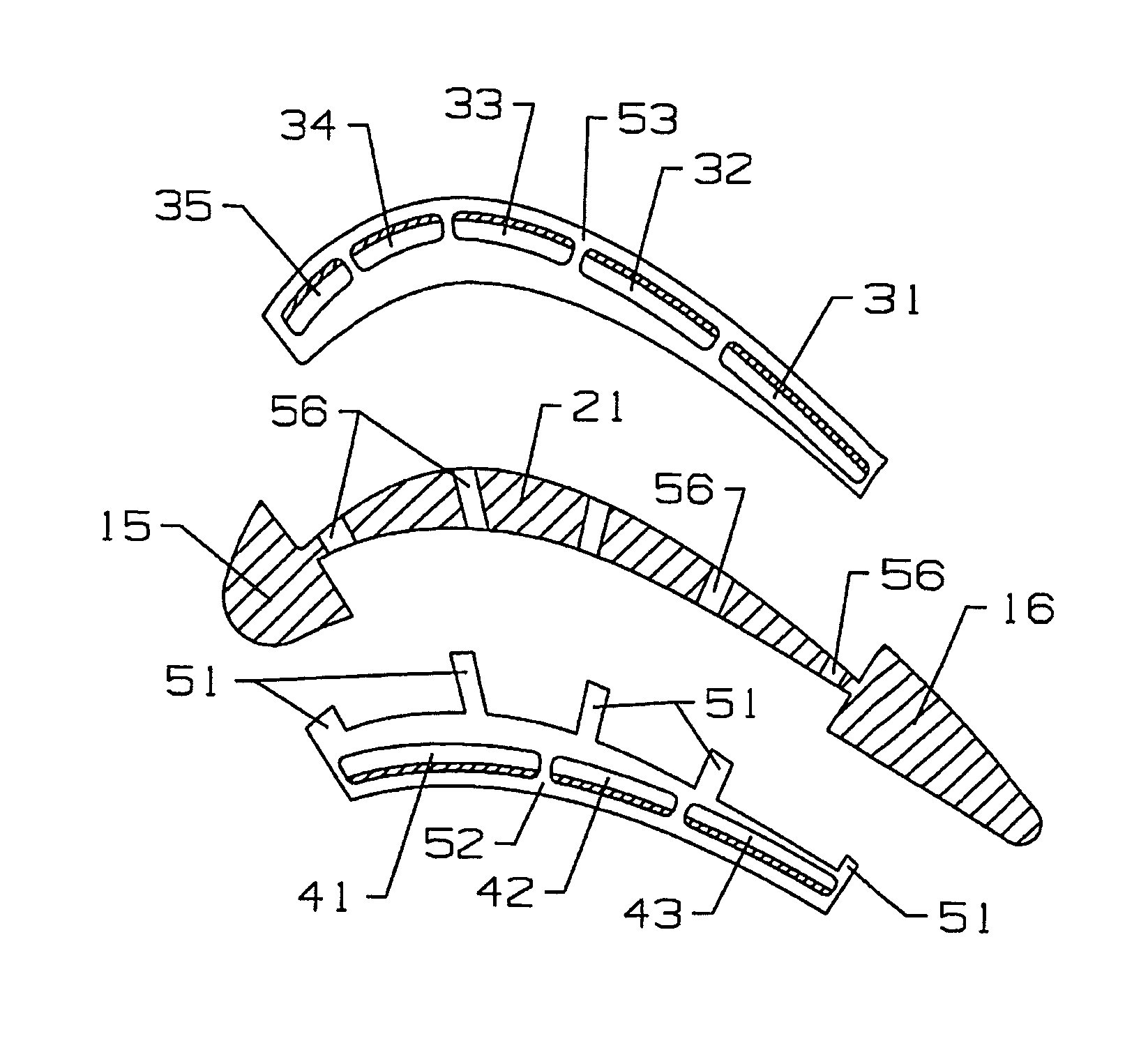

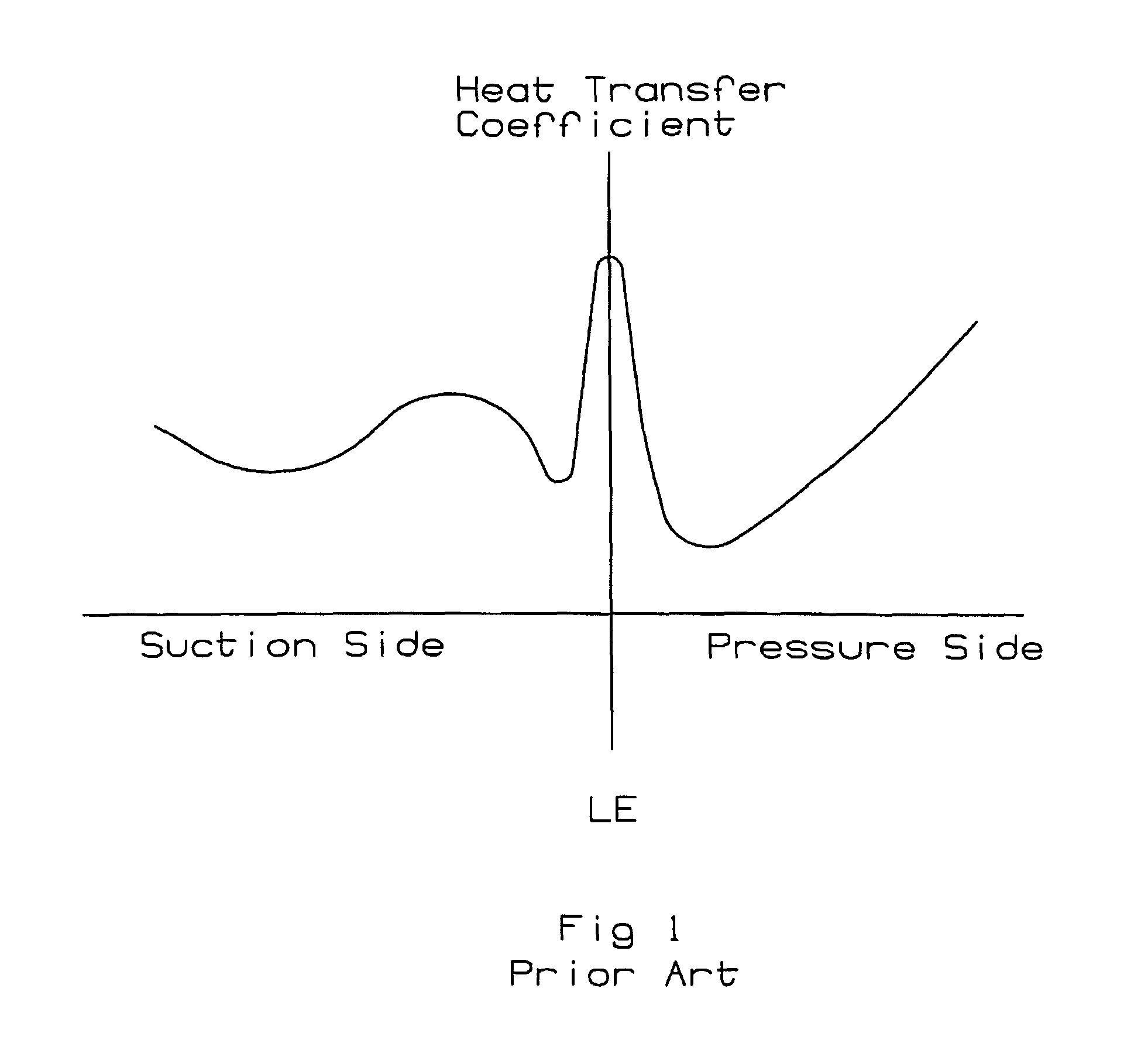

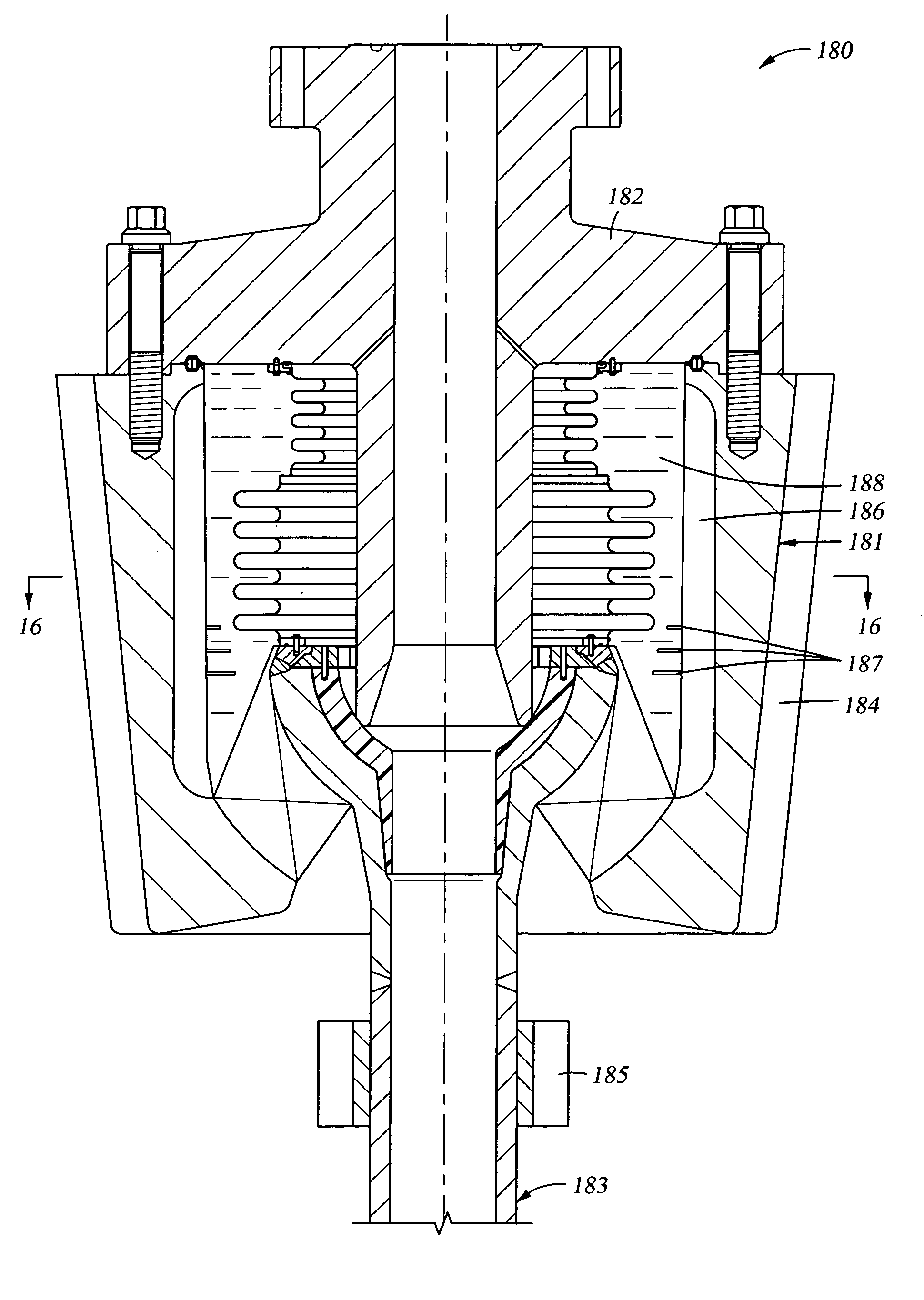

Flow directing device

InactiveUS6969232B2Reduce heat loadHigh temperaturePropellersGas turbine plantsTrailing edgeLeading-edge slats

A flow directing device of a gas turbine engine, comprising: an airfoil having a leading edge, trailing edge, suction side and pressure side; a wall abutting the airfoil; and a fillet between the airfoil and wall. The fillet has an enlarged section at the leading edge, along the suction and pressure sides, and towards the trailing edge. The device could be part of a vane segment. In addition to eliminating a horseshoe vortex, the device also reduces heat load on the airfoil by directing the cooler gas from the proximal end of the airfoil to the hotter gas at the medial section of the airfoil.

Owner:RAYTHEON TECH CORP

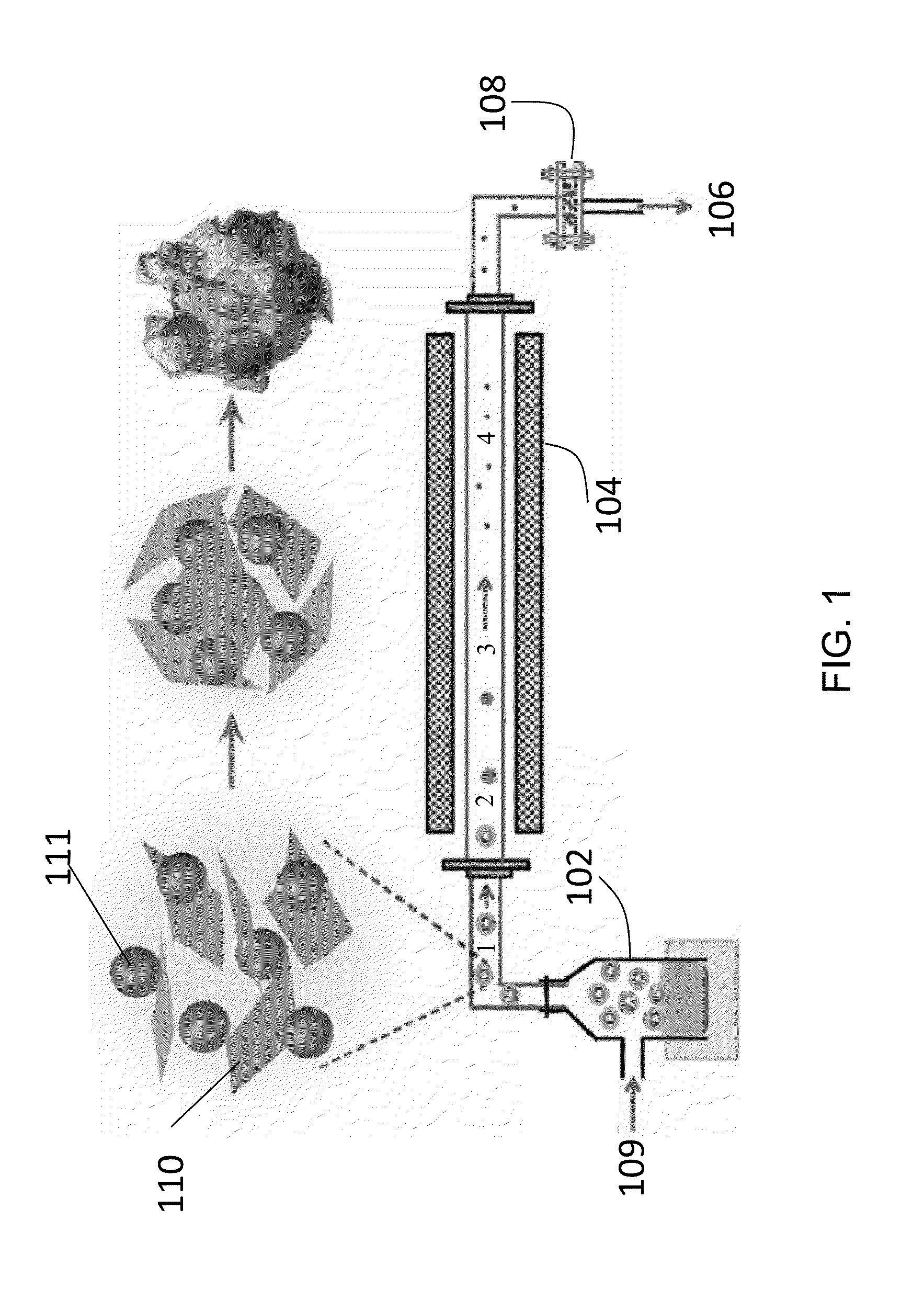

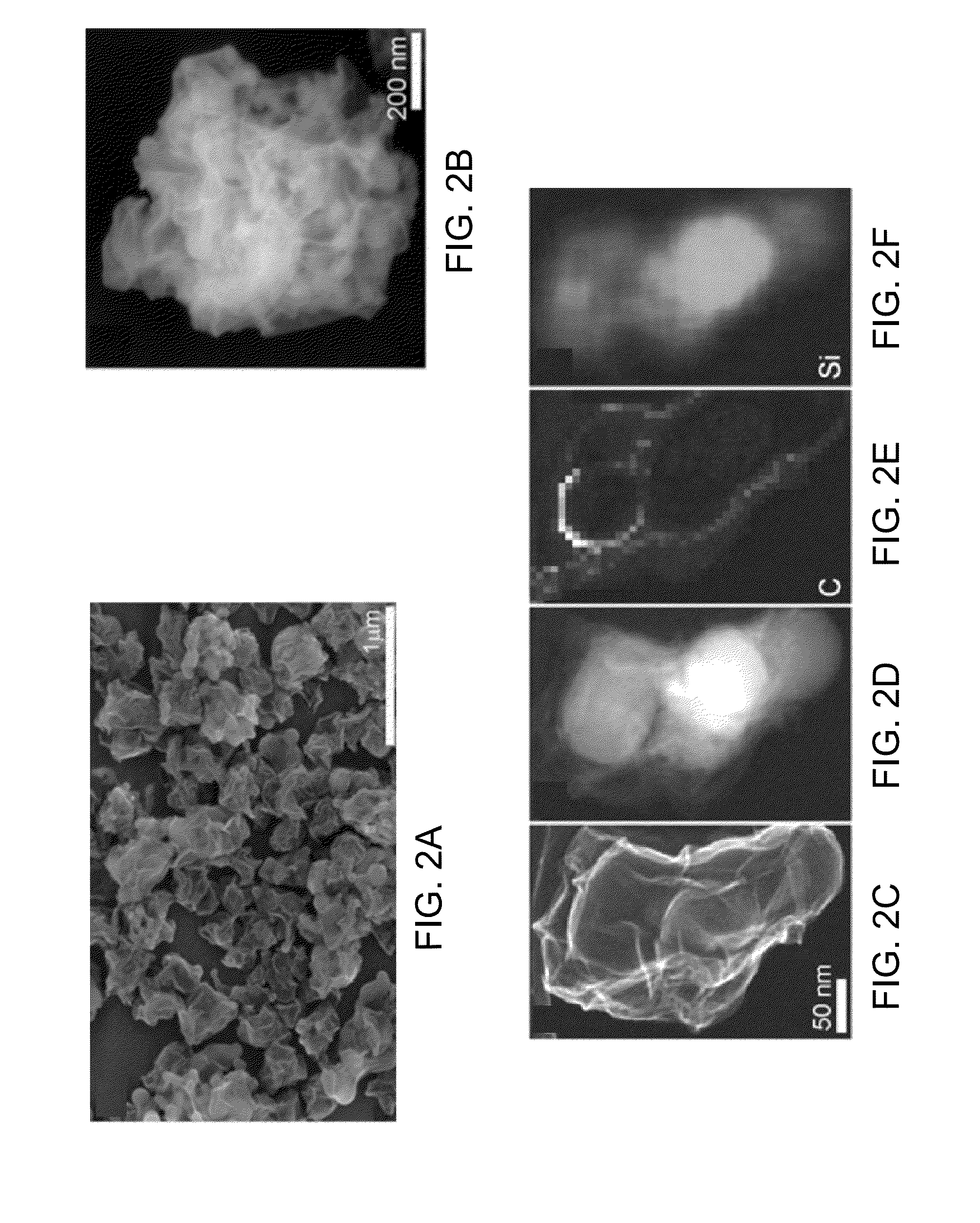

Crumpled graphene-encapsulated nanostructures and lithium ion battery anodes made therefrom

ActiveUS20130344392A1High temperaturePigmenting treatmentMaterial nanotechnologyNanometreElectrochemistry

Capsules comprising crumpled graphene sheets that form a crumpled graphene shell encapsulating an internal cargo comprising nanostructures of a second component are provided. Also provided are anode materials for lithium ion batteries comprising the capsules, wherein the nanostructures are composed of an electrochemically active material, such as silicon.

Owner:NORTHWESTERN UNIV +1

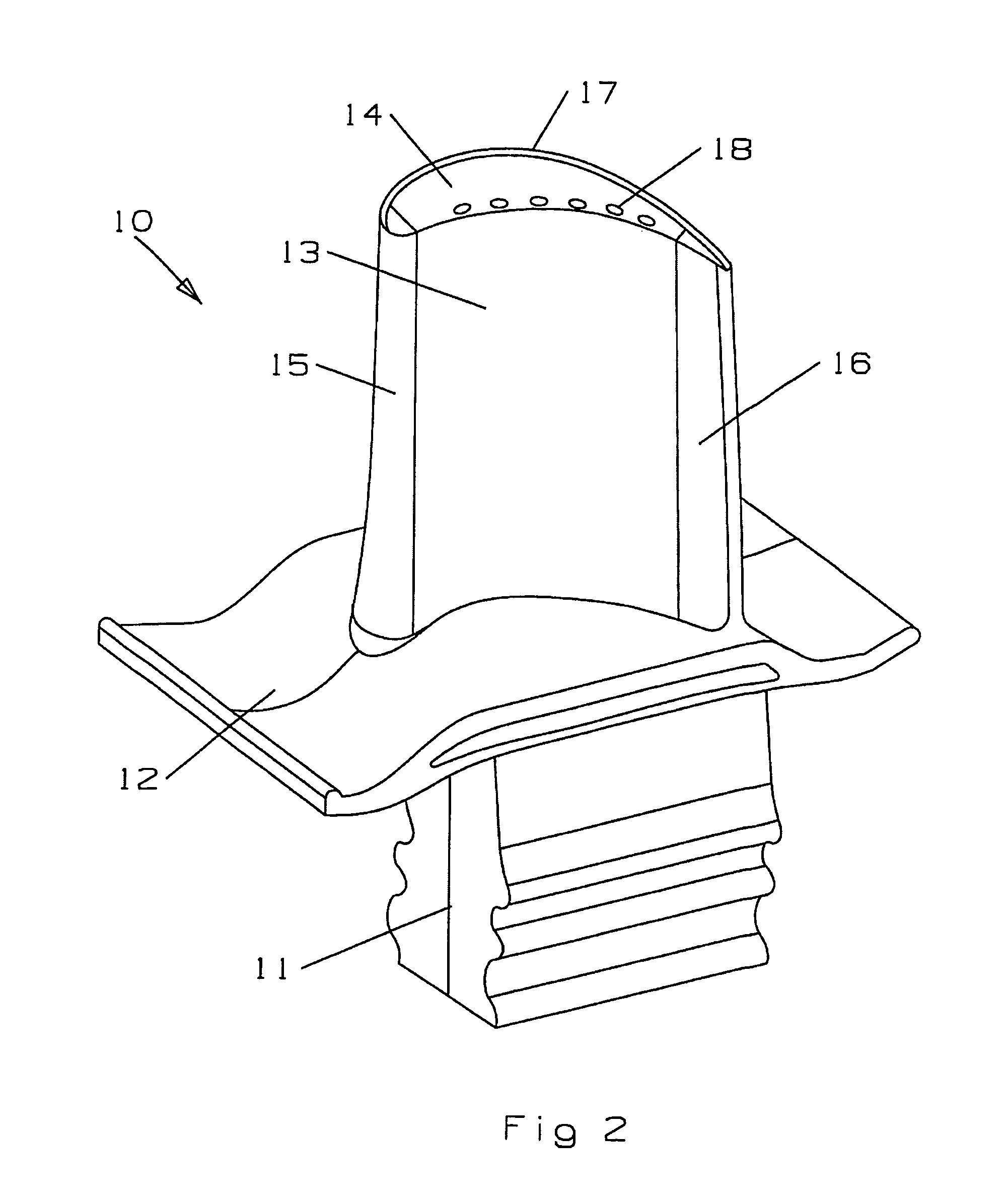

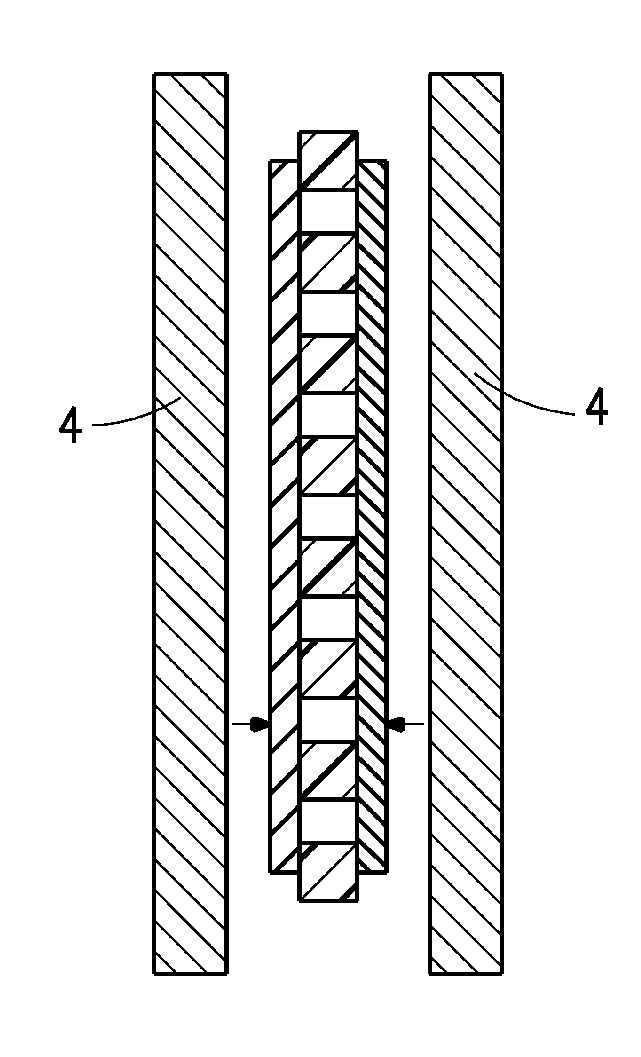

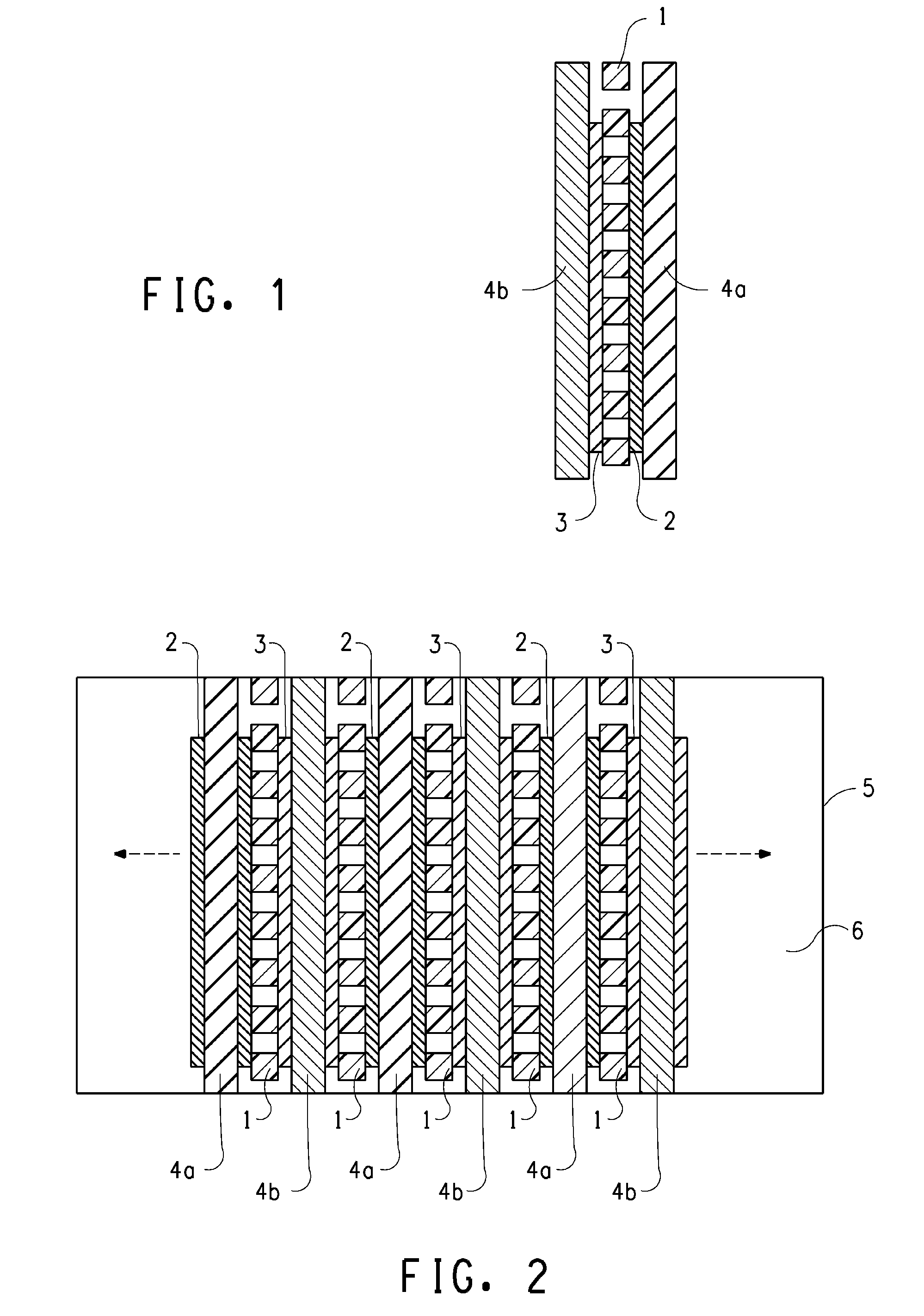

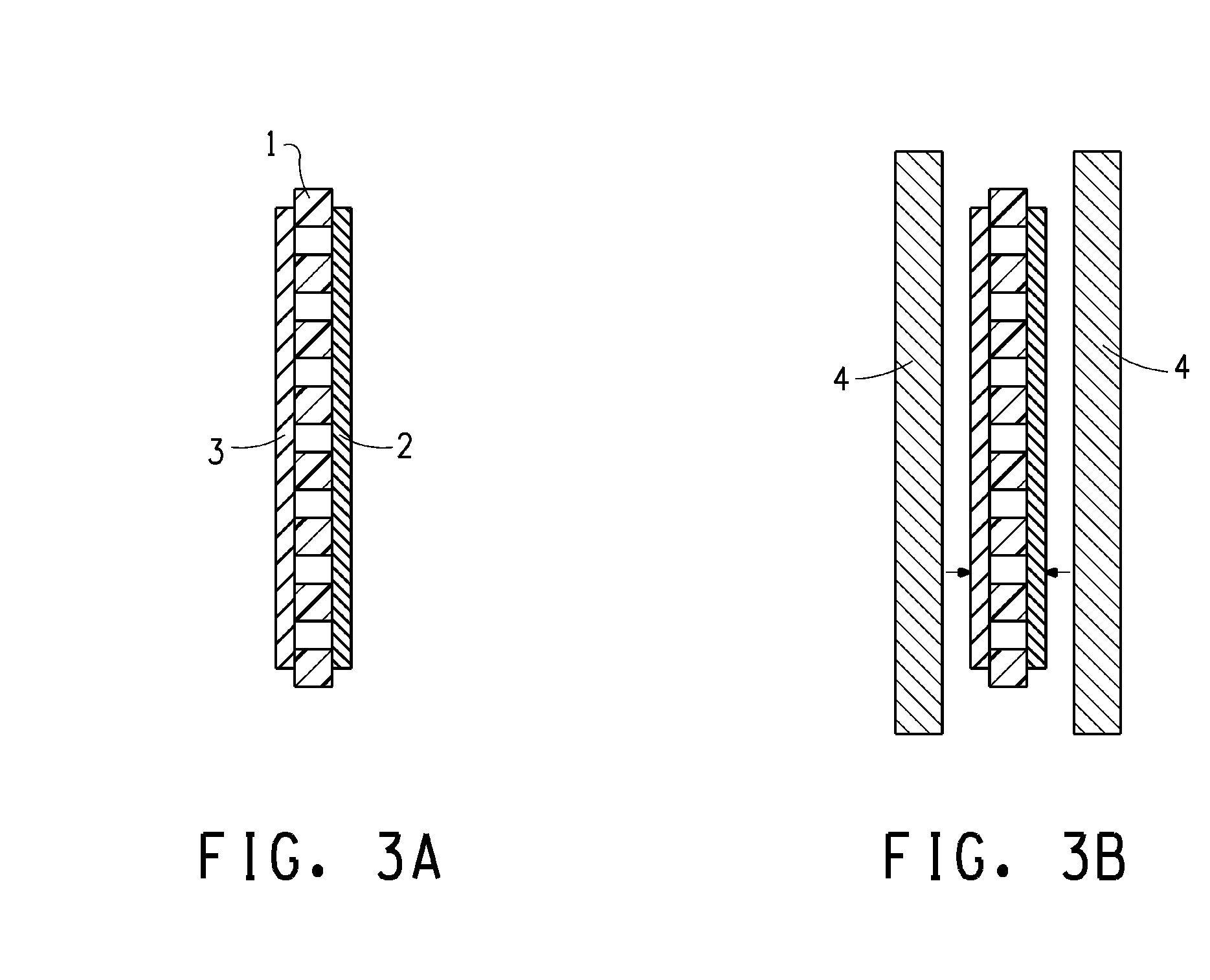

Composite air cooled turbine rotor blade

InactiveUS8366392B1Flow requirement be lowHigh temperaturePropellersEngine manufactureTrailing edgeCross over

A composite turbine rotor blade that uses the high heat resistance capability of a ceramic material along with the high strength capability of a high strength metallic material. A main body or insert piece with a leading edge, a trailing edge and a blade tip is made from a single piece of CMC, Carbon / Carbon or high temperature resistant metallic material such as Columbium or Molybdenum. A pressure side wall piece and a suction side wall piece both made of the metallic material that is bonded together to sandwich in-between the insert piece. The insert piece includes a number of cross-over holes in which locking pins pass through from one of the two metallic pieces and form bond surfaces to bond the two metallic pieces together with the insert piece sandwiched in-between. The two metallic pieces each include a serpentine flow cooling circuit to provide cooling air flow form the metallic pieces.

Owner:FLORIDA TURBINE TECH

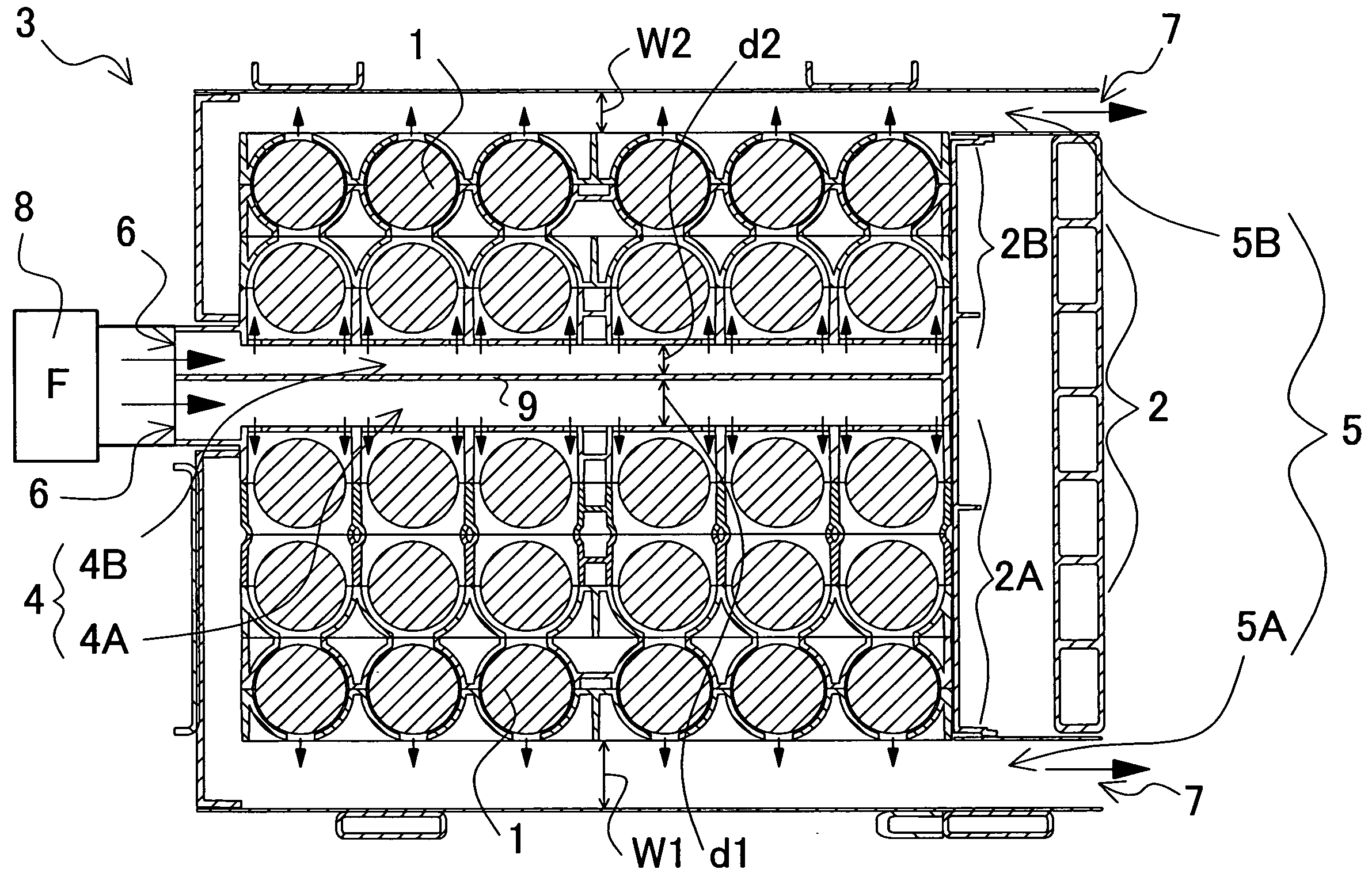

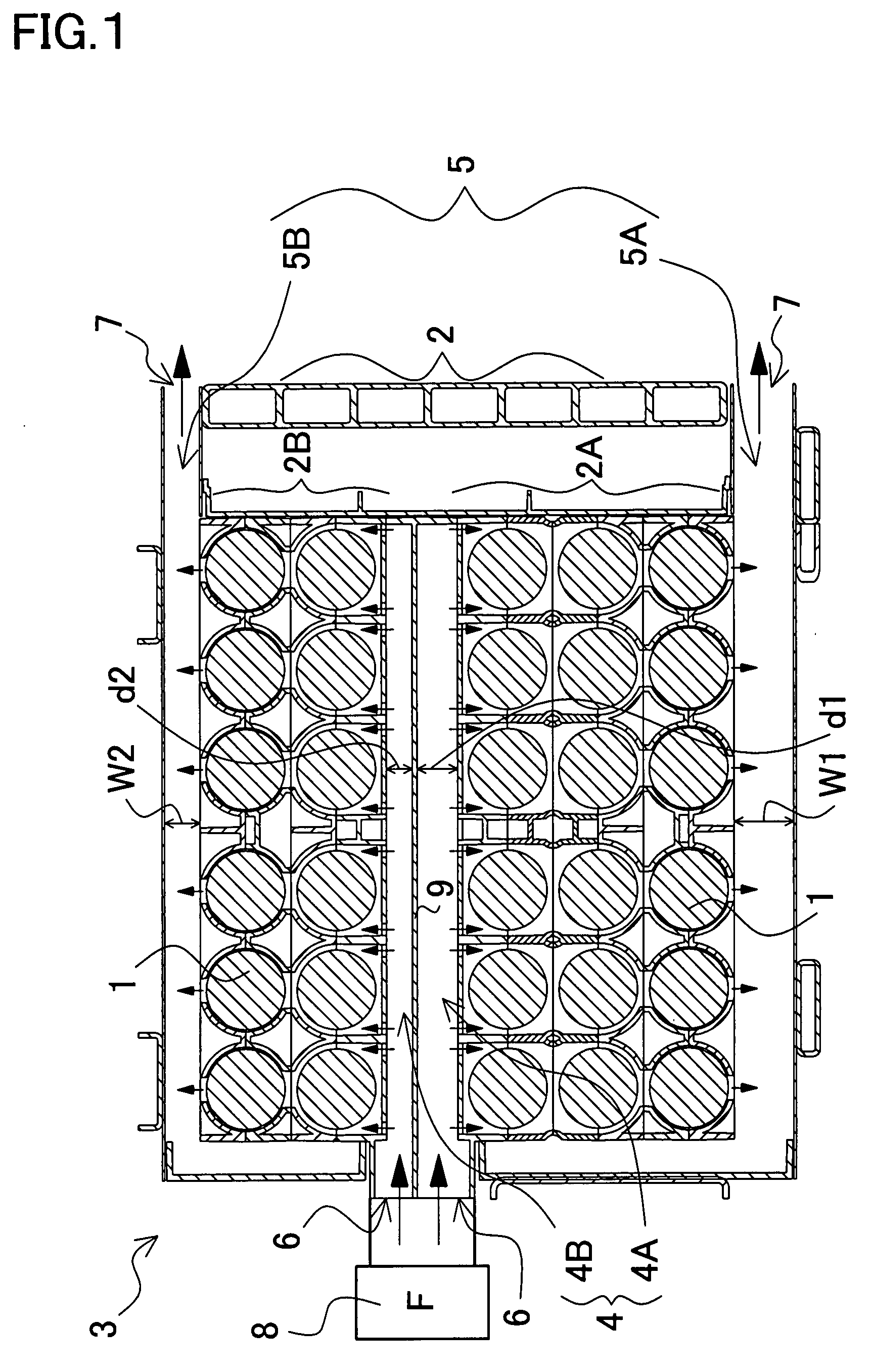

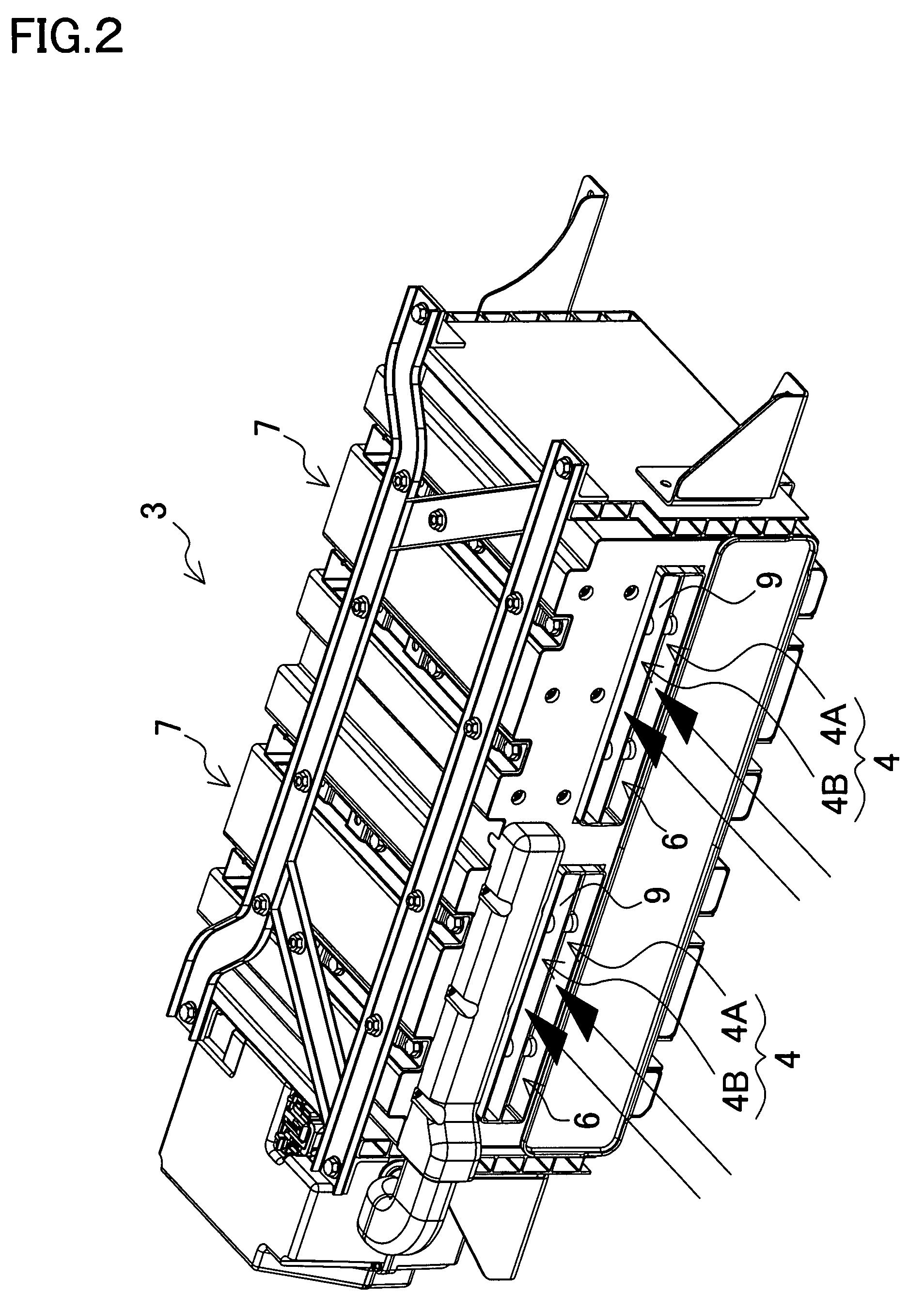

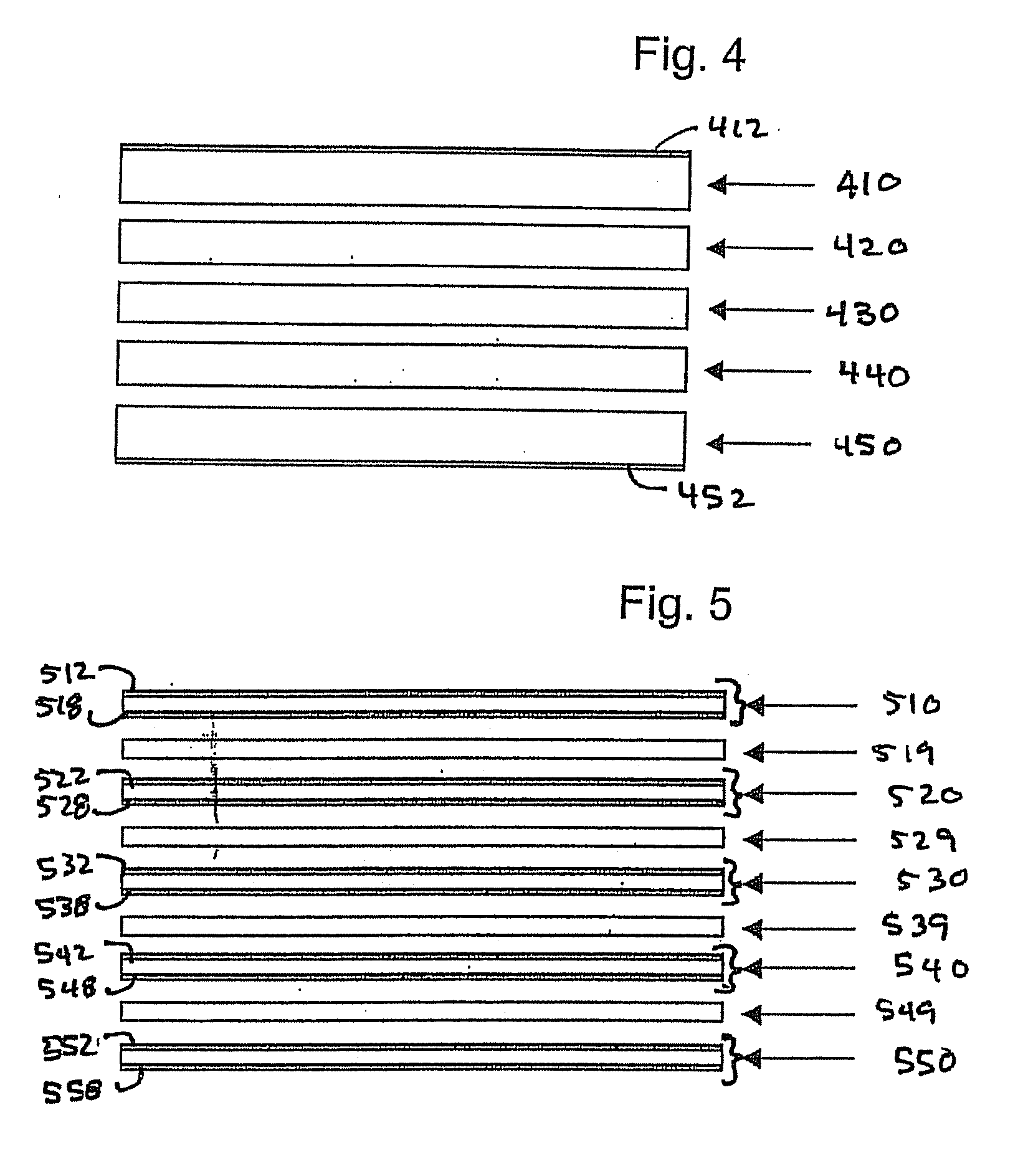

Electric power source

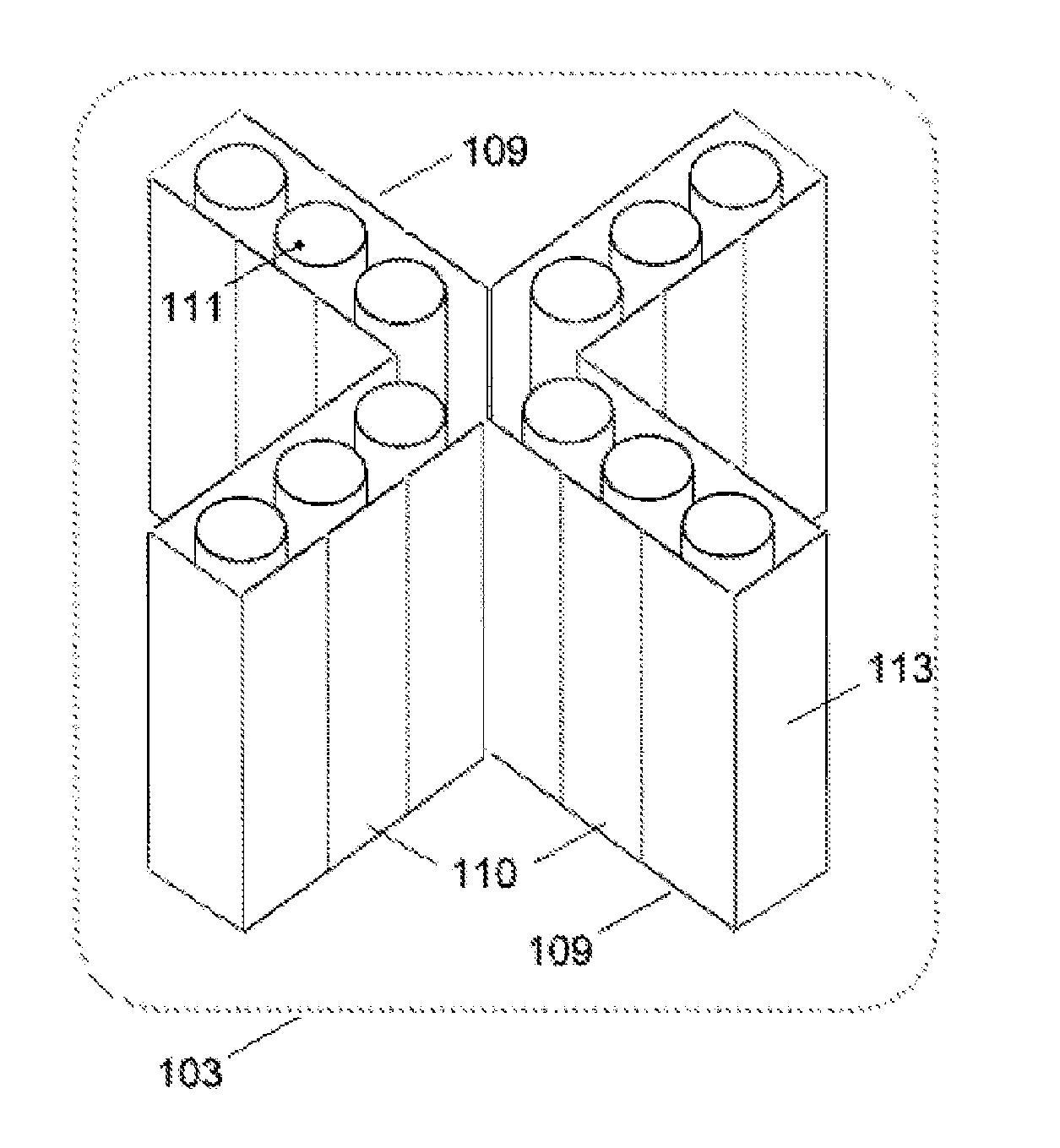

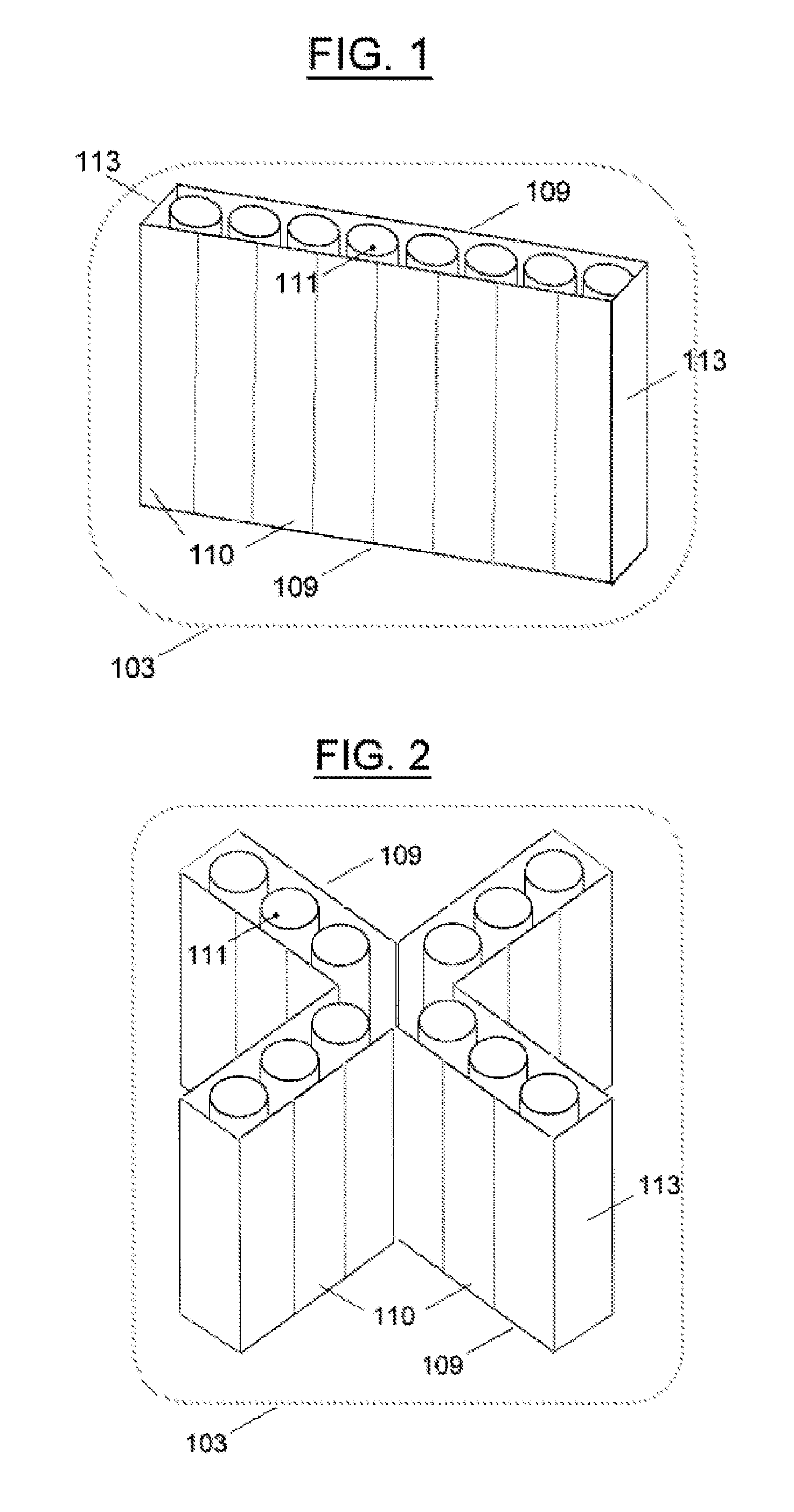

InactiveUS20080026284A1Cool performance less efficientHigh temperatureCell temperature controlCells cooling/heatingEngineeringElectric power system

The electric power source contains a plurality of batteries stacked in two or more tiers in a battery case which is provided with an intermediary duct placed between the first sub holder case and second sub holder case. A first outer duct is outside the first sub holder case and a second outer duct is outside the second sub holder case. The power source is so designed that cooling air is blown to the intermediary duct, the holder case and the outer duct, thus cooling the batteries in the holder case. Further, the power source has a partition disposed inside the intermediary duct, with the first intermediary sub duct being connected to the first sub holder case and the second intermediary duct being connected to the second sub holder case.

Owner:SANYO ELECTRIC CO LTD

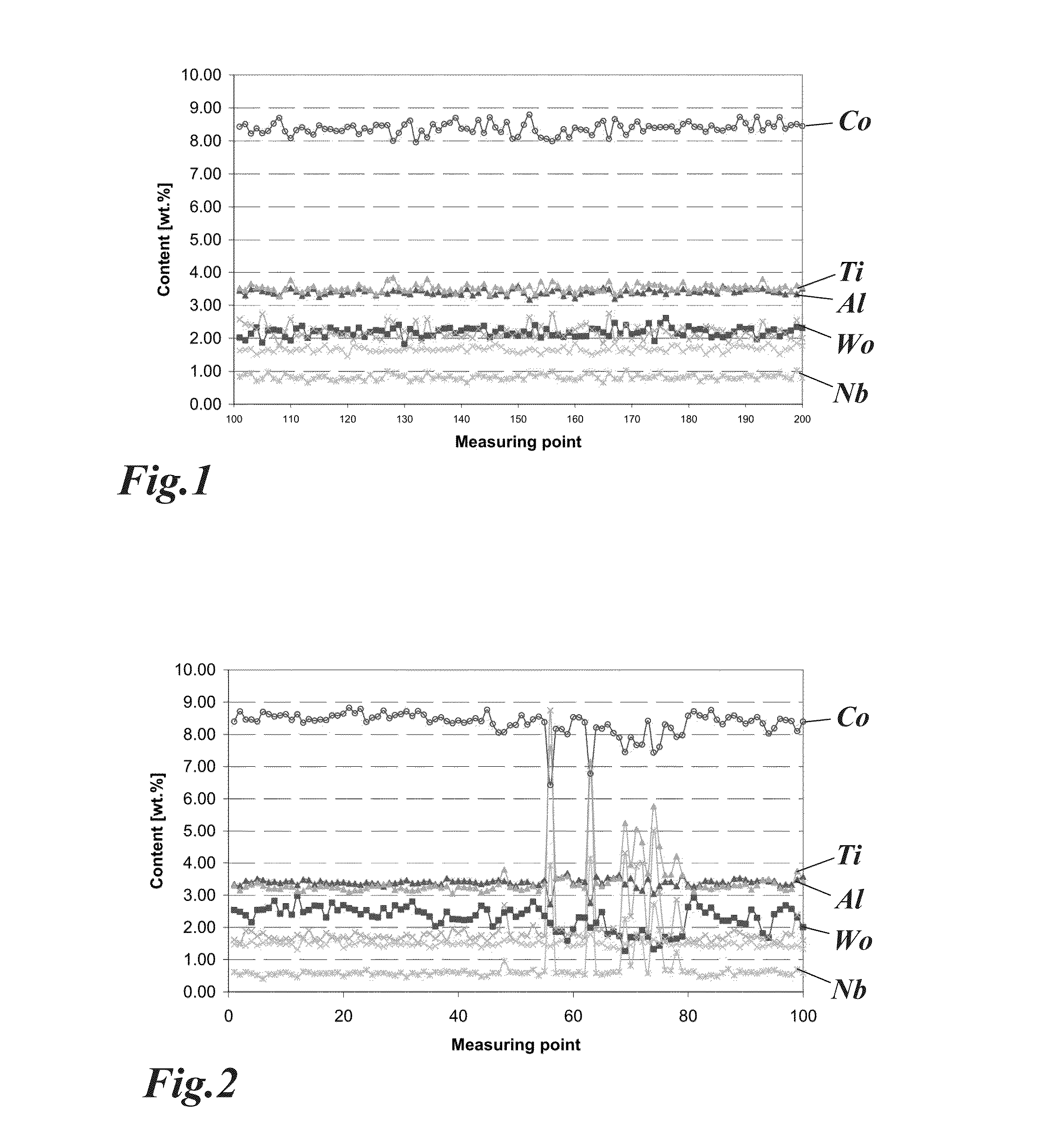

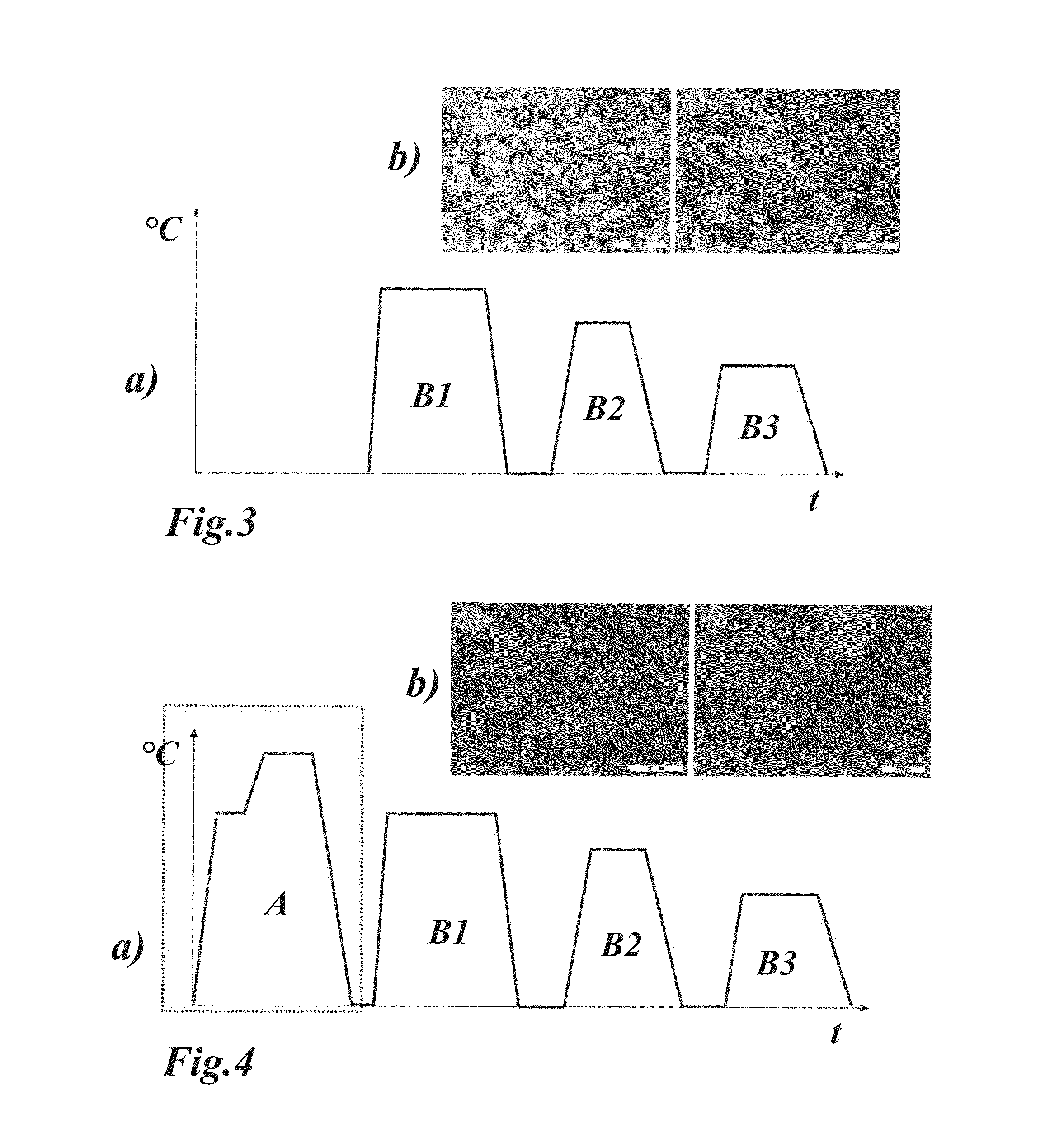

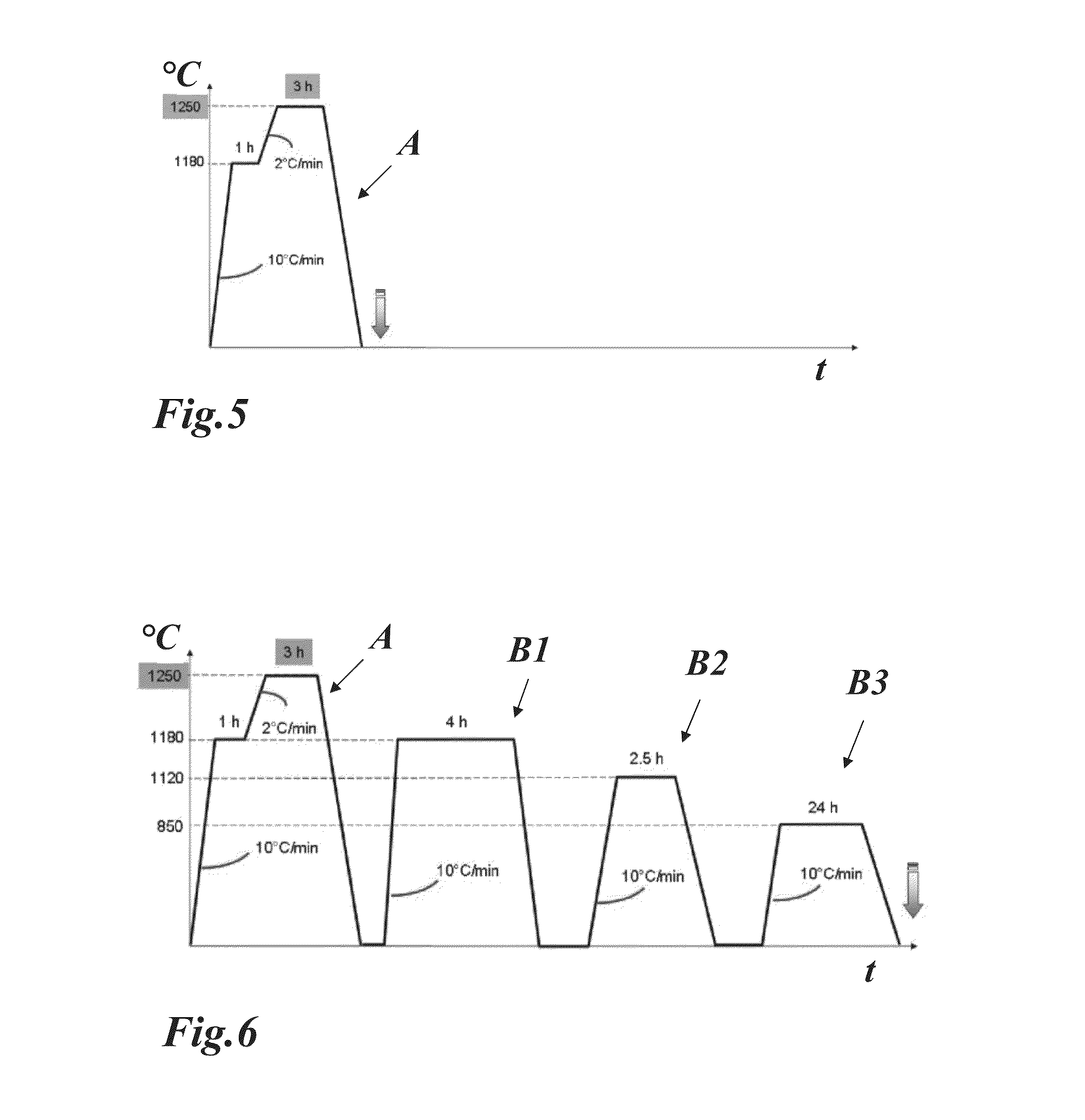

Method for manufacturing components or coupons made of a high temperature superalloy

InactiveUS20130263977A1Material property be optimizeHigh temperatureTurbinesAdditive manufacturing apparatusHeat treatedSuperalloy

A method for manufacturing a component or coupon made of a high temperature superalloy based on Ni, Co, Fe or combinations thereof includes forming the component or coupon using a powder-based additive manufacturing process. The manufacturing process includes completely melting the powder followed by solidifying the powder. The formed component or coupon is subjected to a heat treatment so as to optimize specific material properties. The heat treatment takes place at higher temperatures compared to cast components or coupons.

Owner:ANSALDO ENERGIA IP UK LTD

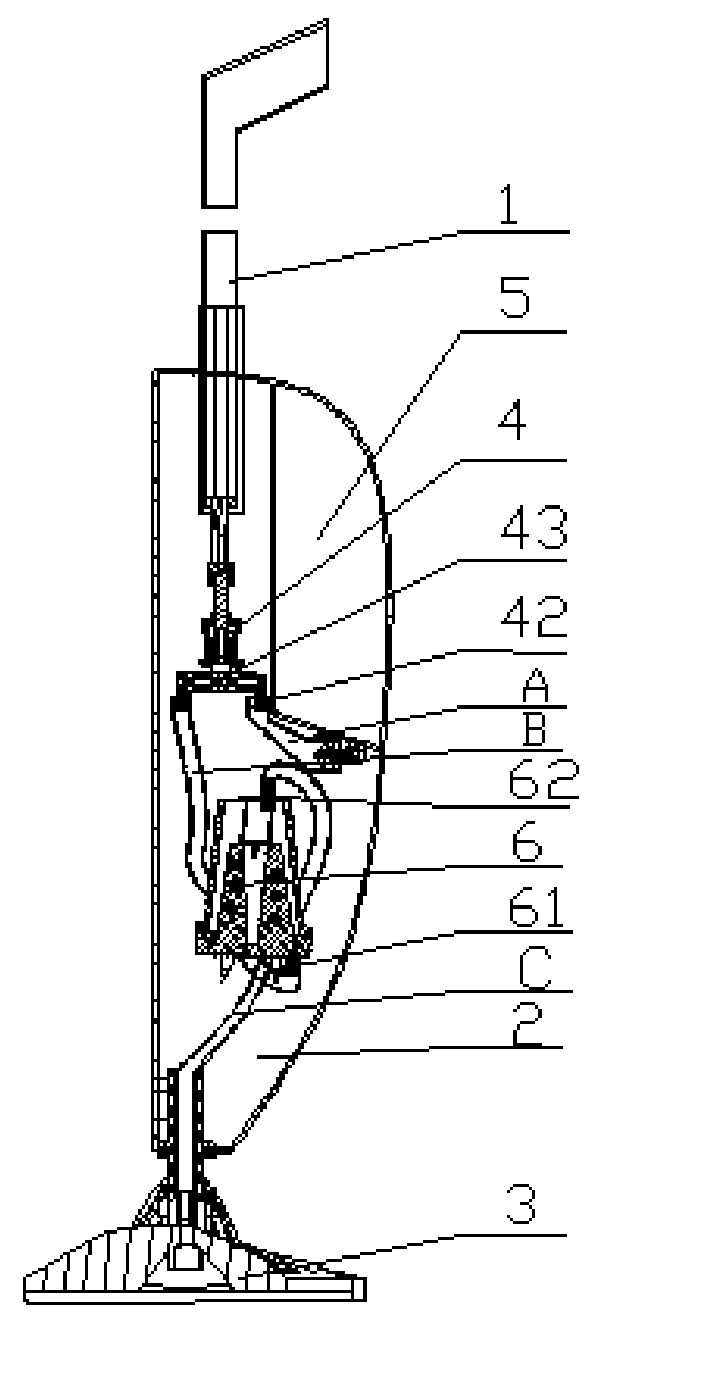

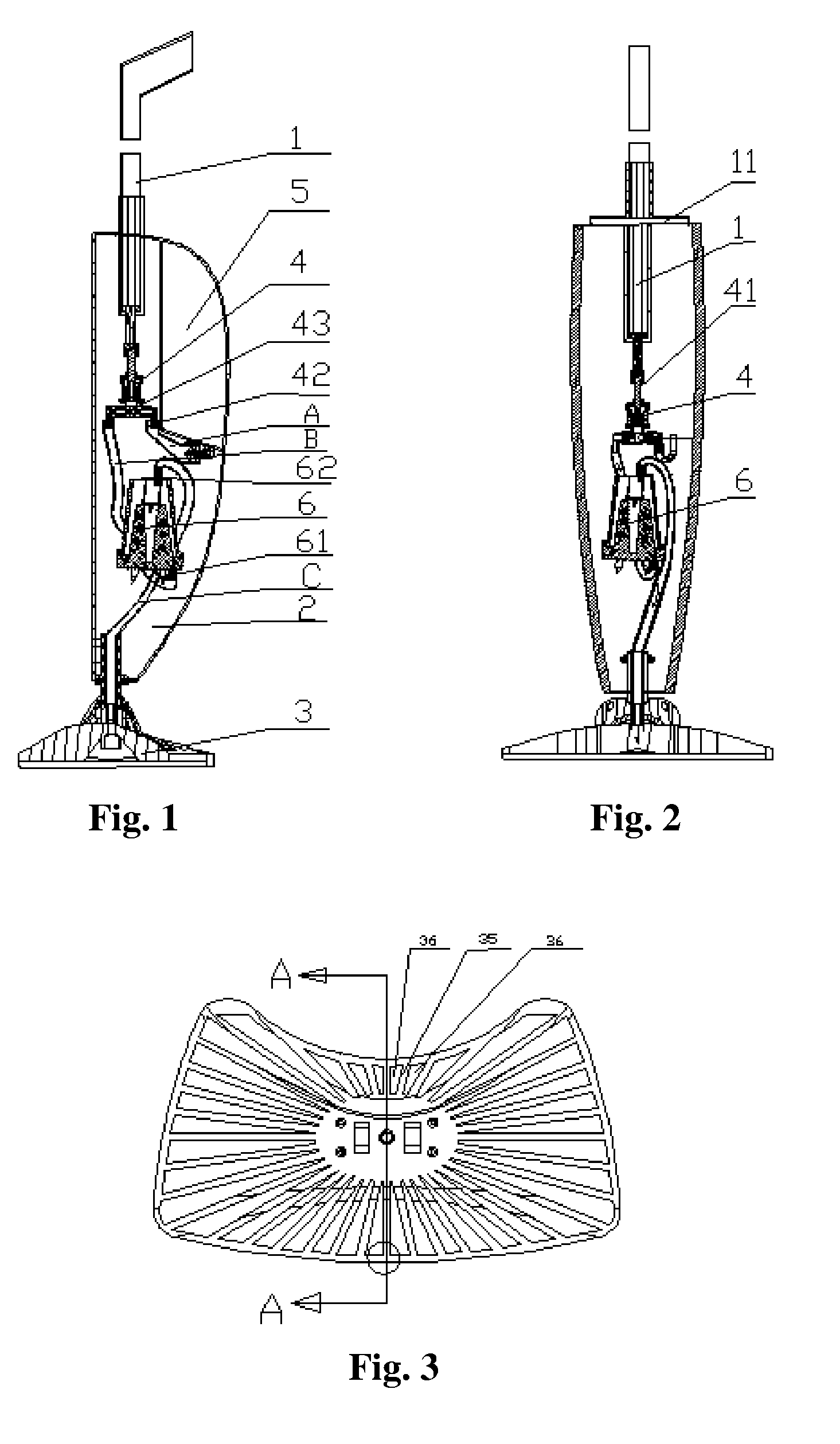

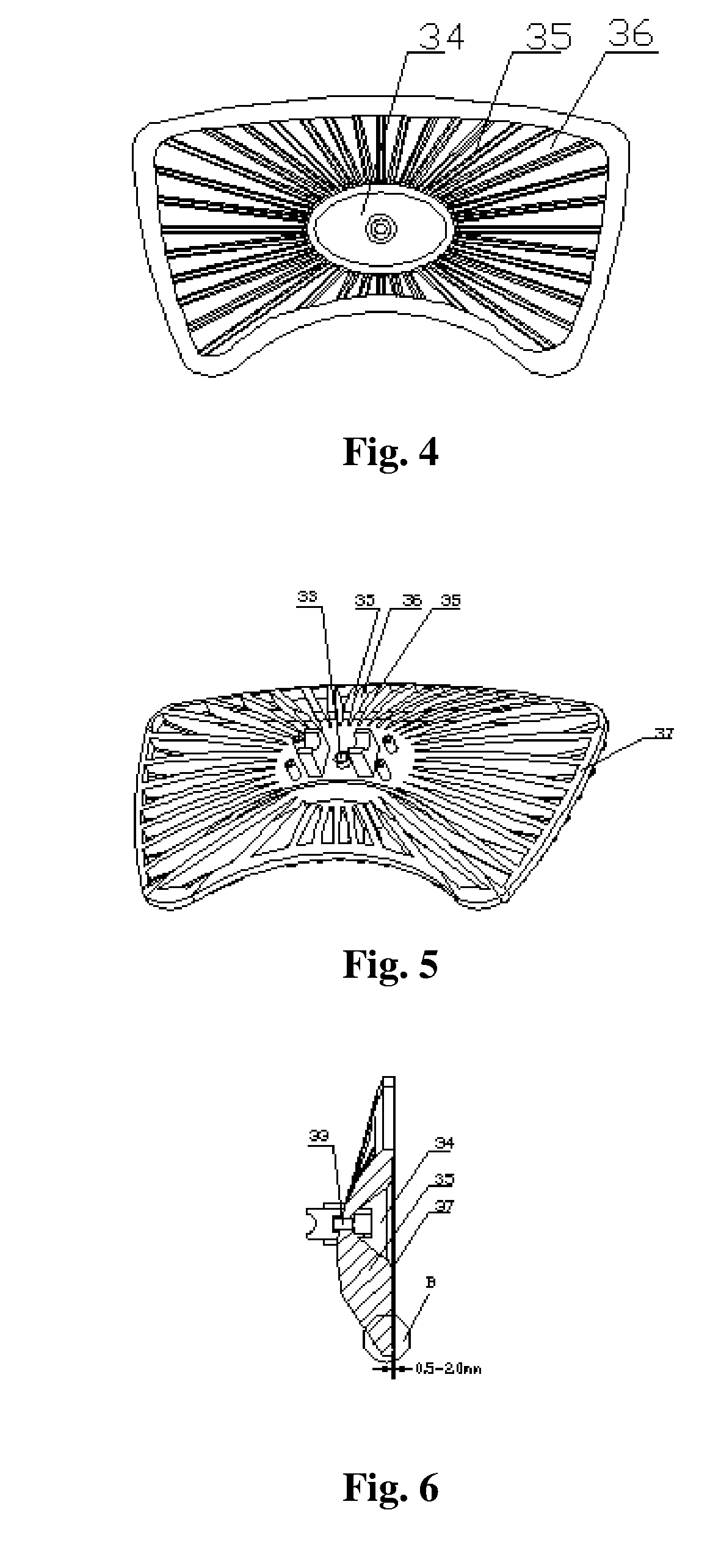

Steam floor mop

ActiveUS20070130719A1Easy to cleanHigh temperatureSteam generation heating methodsCarpet cleanersEngineeringSteam mop

The present invention discloses a steam floor mop, comprising a handle; a central body inside which a manual water pump, a water tank, and a steam generator are housed; and a floor brush connected flexibly to the central body, wherein the manual water pump, the water tank, and the steam generator are connected to the floor brush by means of pipes; said handle is connected directly to the piston rod of the manual water pump and serves to manipulate the operation of the manual water pump; said floor brush is covered by a cleaning cloth. In accordance with the steam floor mop of the present invention, by only pushing the handle of the steam floor mop, the steam can be generated and distributed to the floor brush so that the cleaning work having an effect of high temperature disinfecting and sterilization can be realized. It is not needed to power on the water pump additionally so as to supply water to the steam generator to generate the steam. Besides, a plurality of rib stripes are set on the floor brush, and a plurality of steam distributing grooves are formed between the rib stripes, so that the steam can be distributed uniformly to the whole cleaning surface of the floor brush. In addition, the floor brush is covered tightly by a cleaning cloth having a plurality of #-shaped checks formed thereon, so that the stains adhered to the floor can be cleaned easily. Therefore, by utilizing the steam floor mop of the present invention, the cleaning work can be performed conveniently and is time and labor saving, the effect of high temperature disinfecting and sterilization can be realized thoroughly.

Owner:SHARKNINJA OPERATING LLC

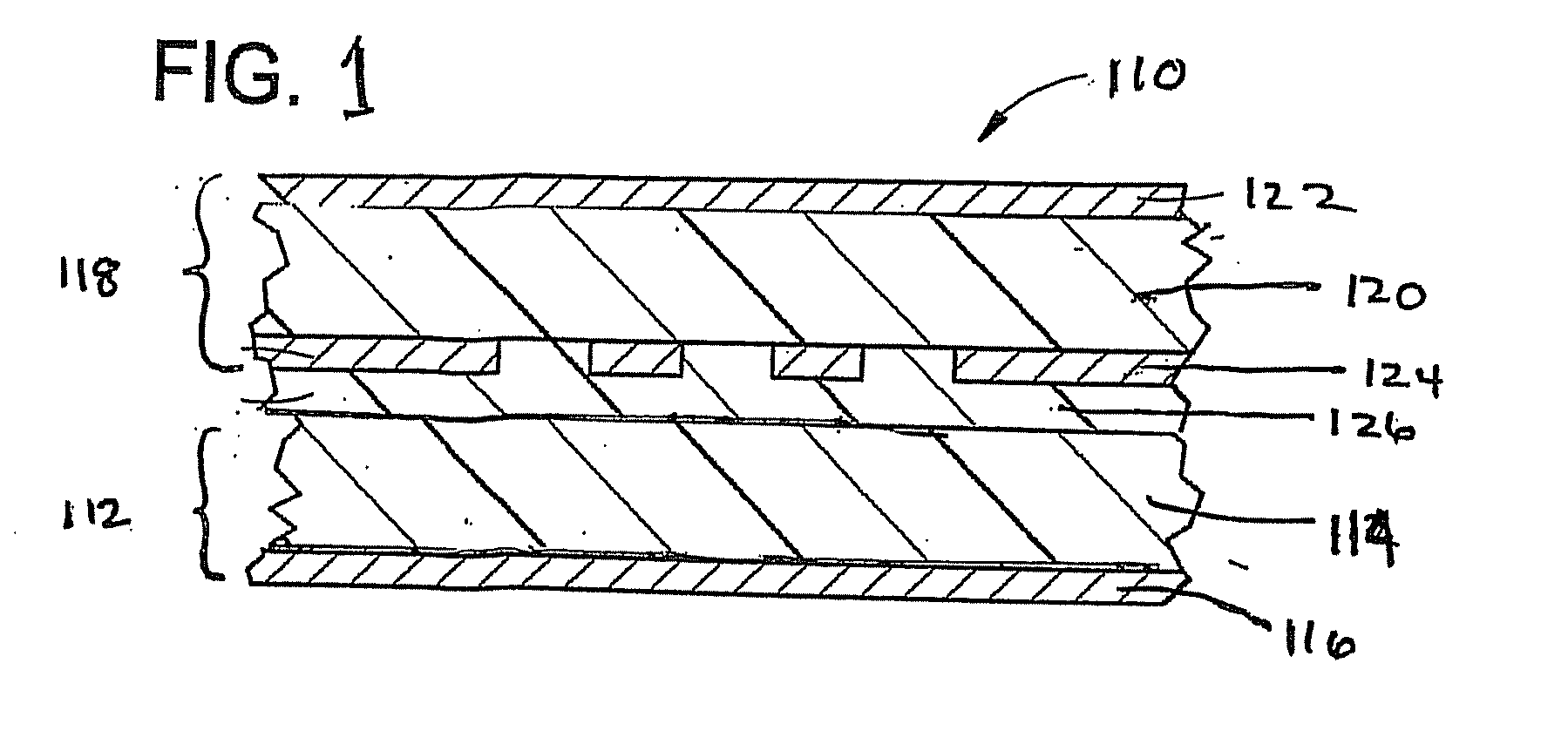

Multi-layer article comprising polyimide nanoweb

ActiveUS20110143207A1High temperatureHybrid capacitor separatorsFinal product manufacturePolyimideElectrochemical cell

This invention provides a multi-layer article comprising a first electrode material, a second electrode material, and a porous separator disposed between and in contact with the first and the second electrode materials, wherein the porous separator comprises a nanoweb consisting essentially of a plurality of nanofibers of a fully aromatic polyimide. Also provided is a method for preparing the multi-layer article, and an electrochemical cell employing the same. A multi-layer article comprising a polyimide nanoweb with enhanced properties is also provided.

Owner:DUPONT SAFETY & CONSTR INC

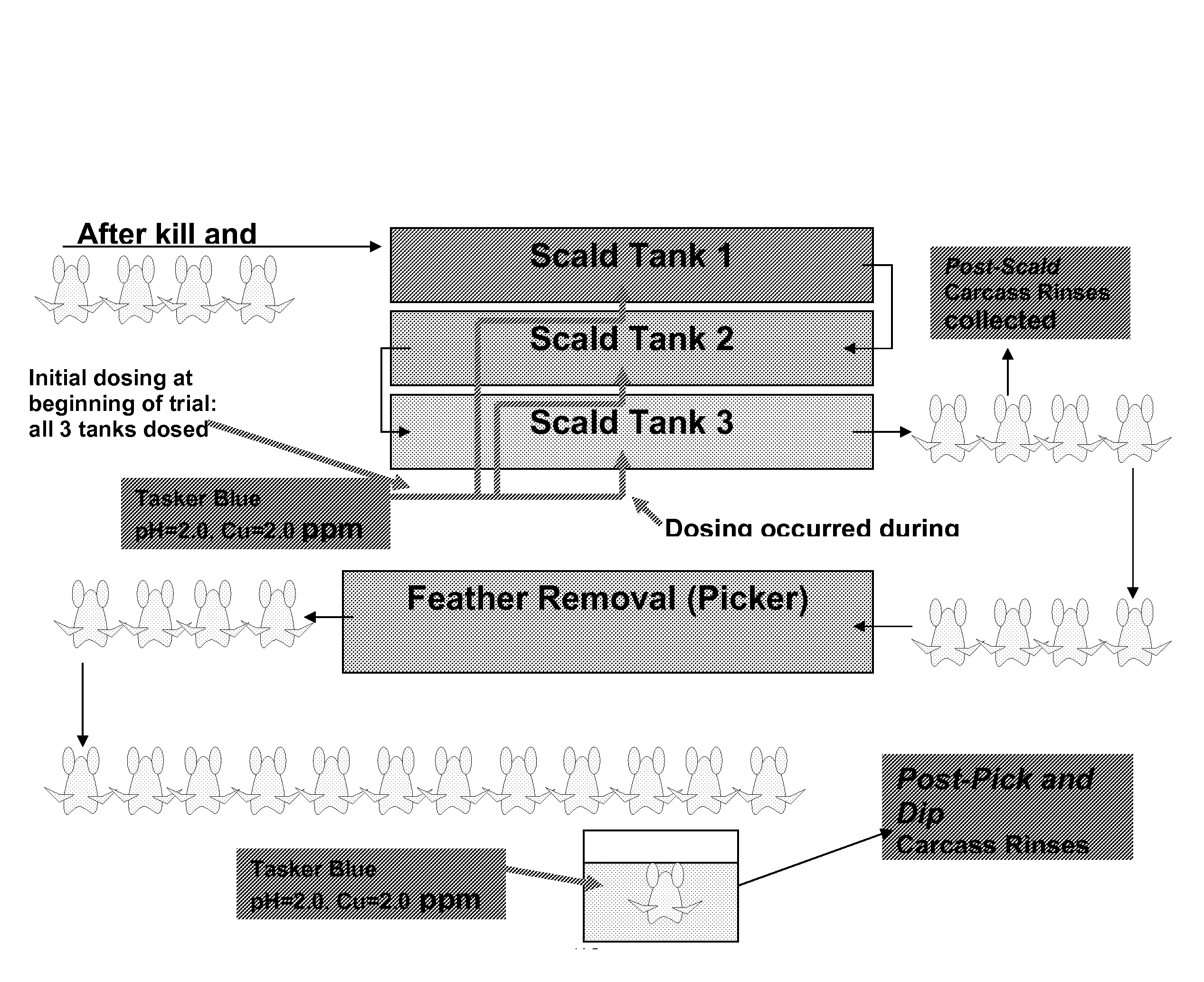

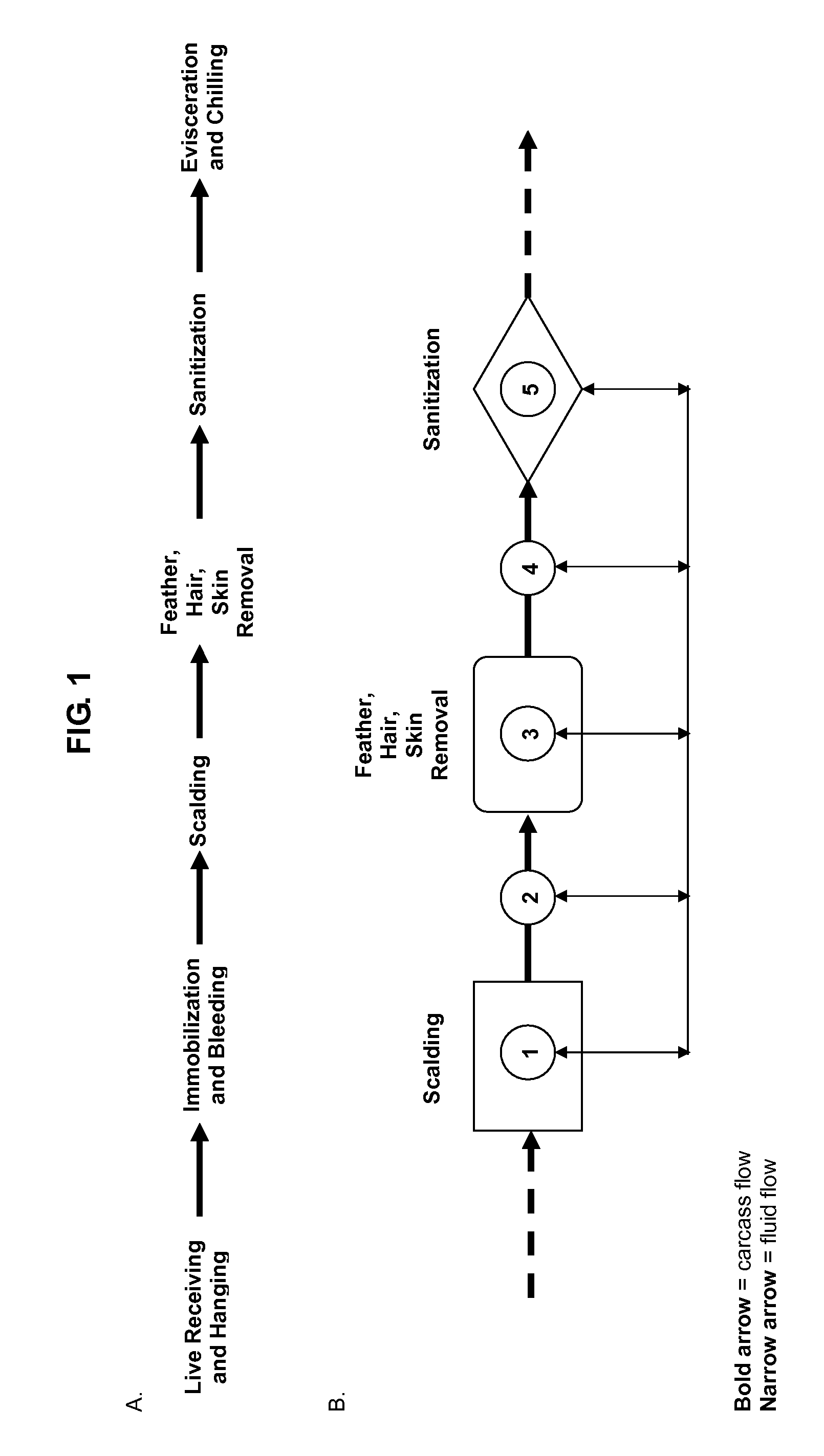

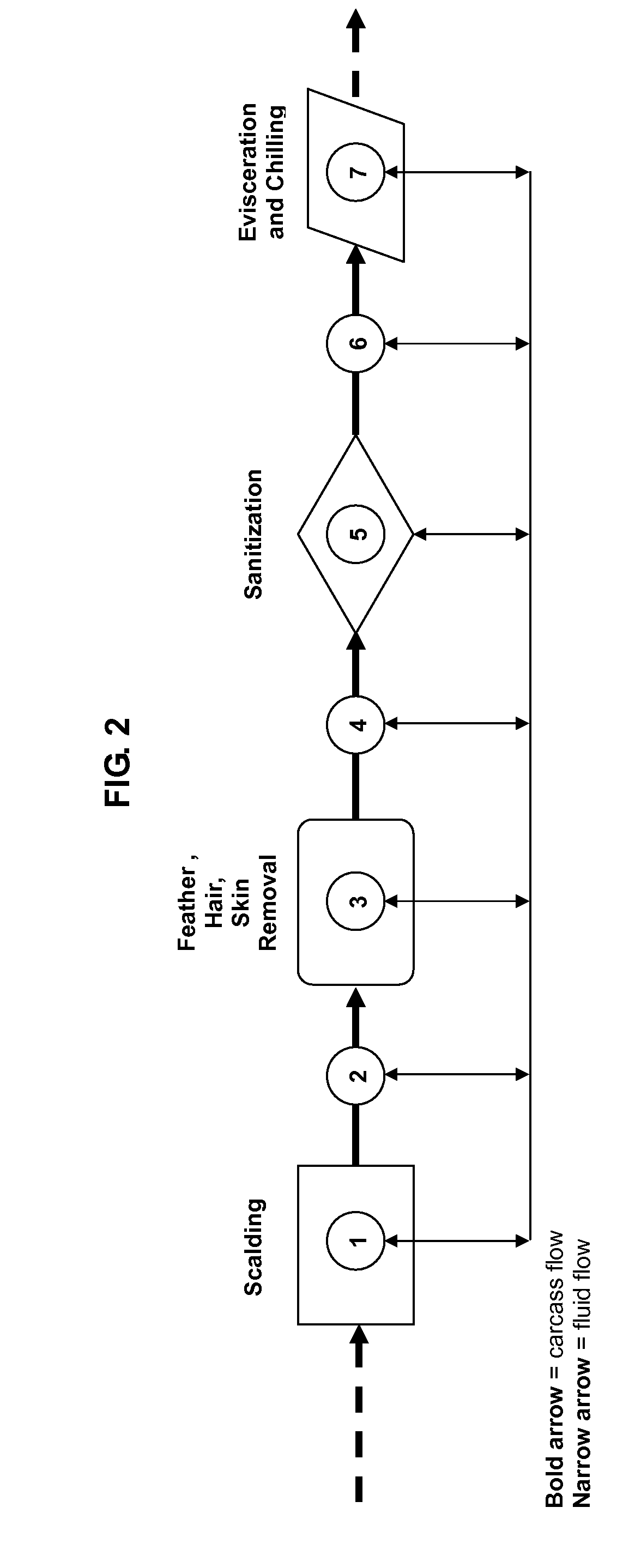

Compositions and methods for reducing microbial contamination in meat processing

InactiveUS20070269563A1Reduce contaminationHigh temperatureBiocideMilk preservationMicrobial contaminationScalding

The present invention is directed to compositions, methods, and systems for reducing microbial contamination in meat processing. In accordance with one aspect of the invention, disinfection composition and / or recycled disinfection composition comprising an acid, a buffer, and optionally an antimicrobial metal is applying to a carcass during at least one processing step of sacrificing, scalding, feather / hair / hide removal, eviscerating, and washing. Other aspects of the invention provide a carcass processing system comprising processing stations intermittently fluidly connected via a buffered acidic disinfection composition.

Owner:TASKER CAPITAL

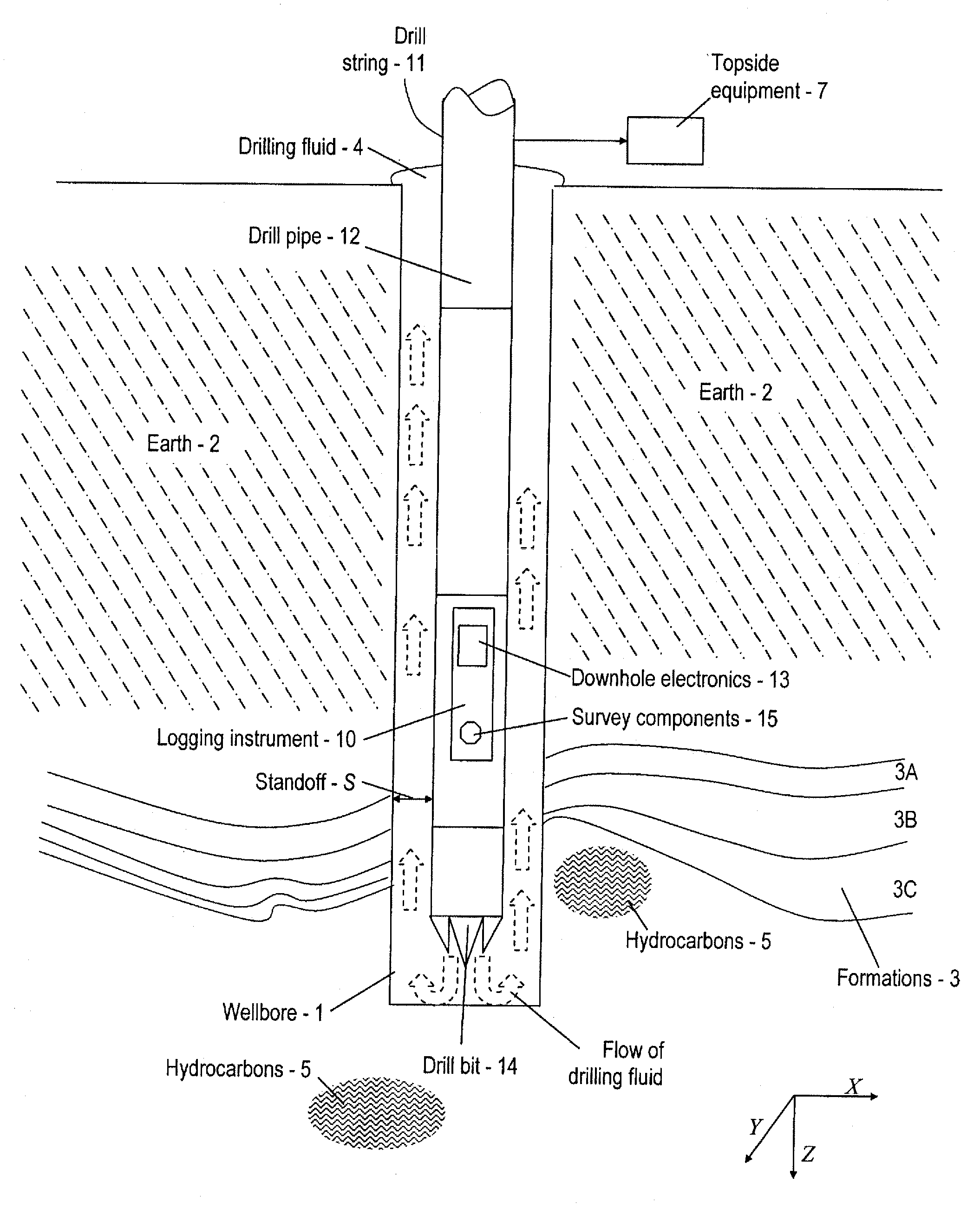

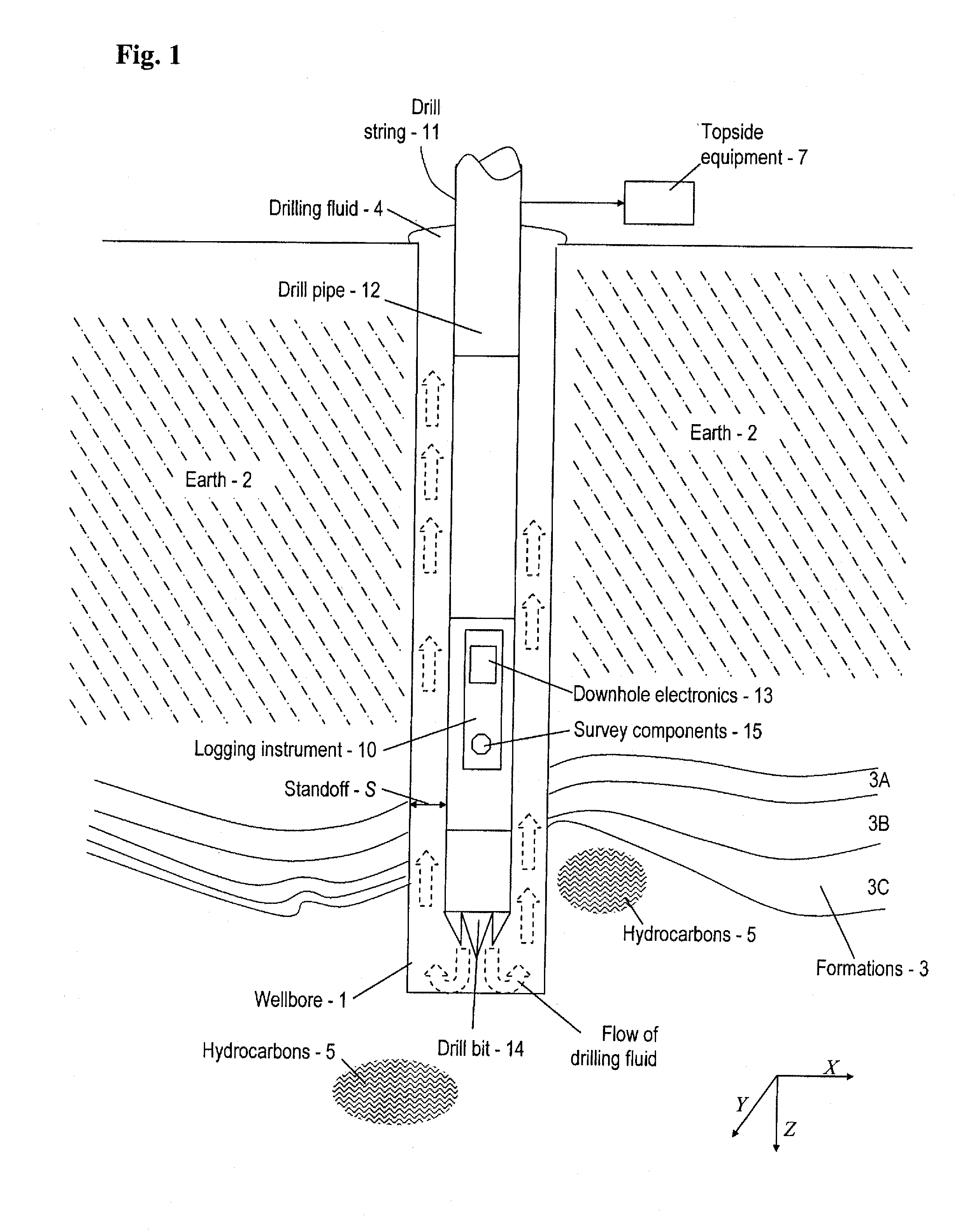

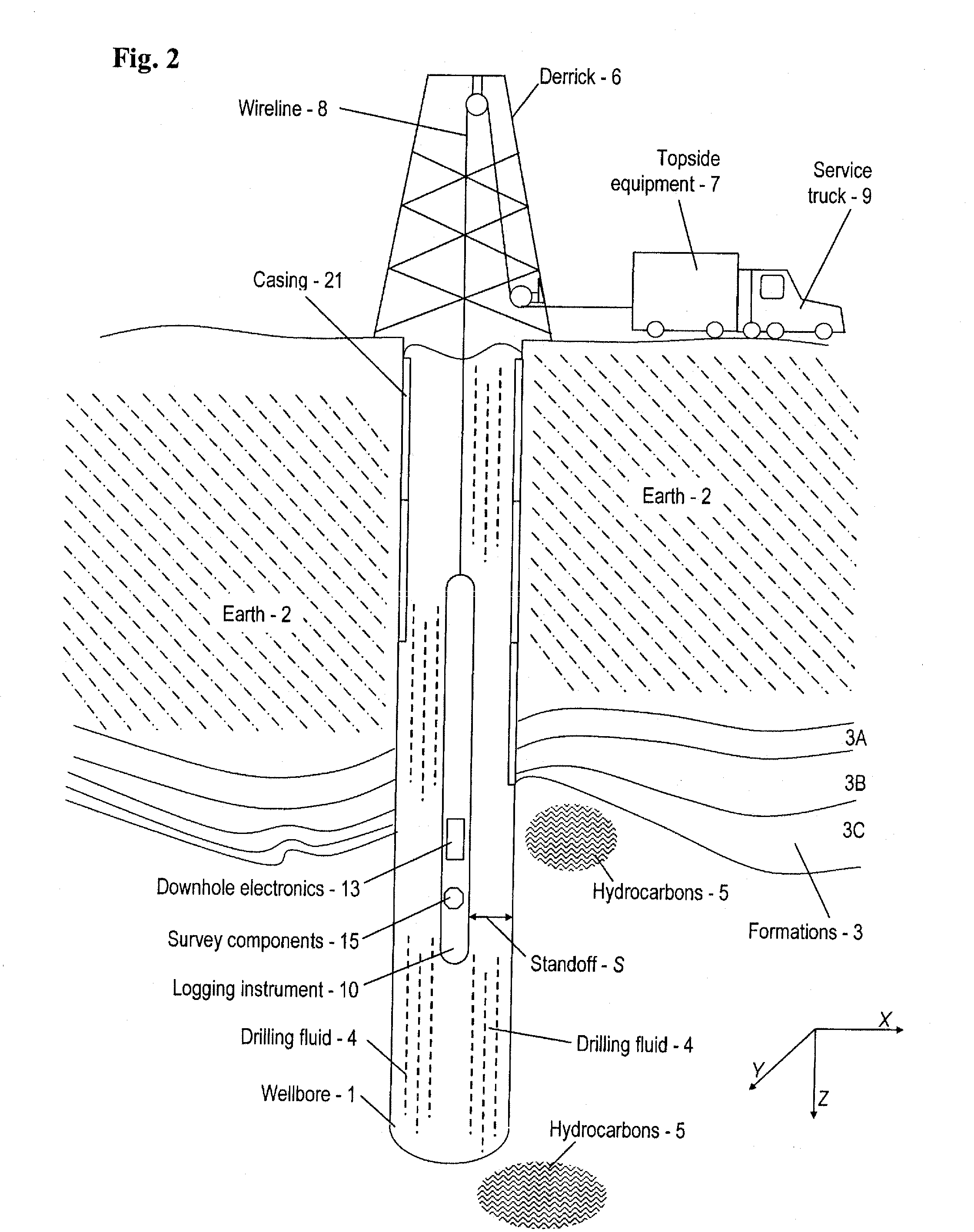

Production logging instrument

ActiveUS20130271066A1High temperatureHigh energy storageBatteries circuit arrangementsDrilling rodsAutomotive engineeringElectronics

A logging system and method for operating a logging system are typically used in a wellbore. The logging system may include a logging instrument including a rechargeable energy storage and logging electronics, and a cable configured to trickle charge the rechargeable energy storage. The rechargeable energy storage may include an ultracapacitor. The rechargeable energy storage may be trickle charged through the cable from a remote power source.

Owner:FASTCAP SYST

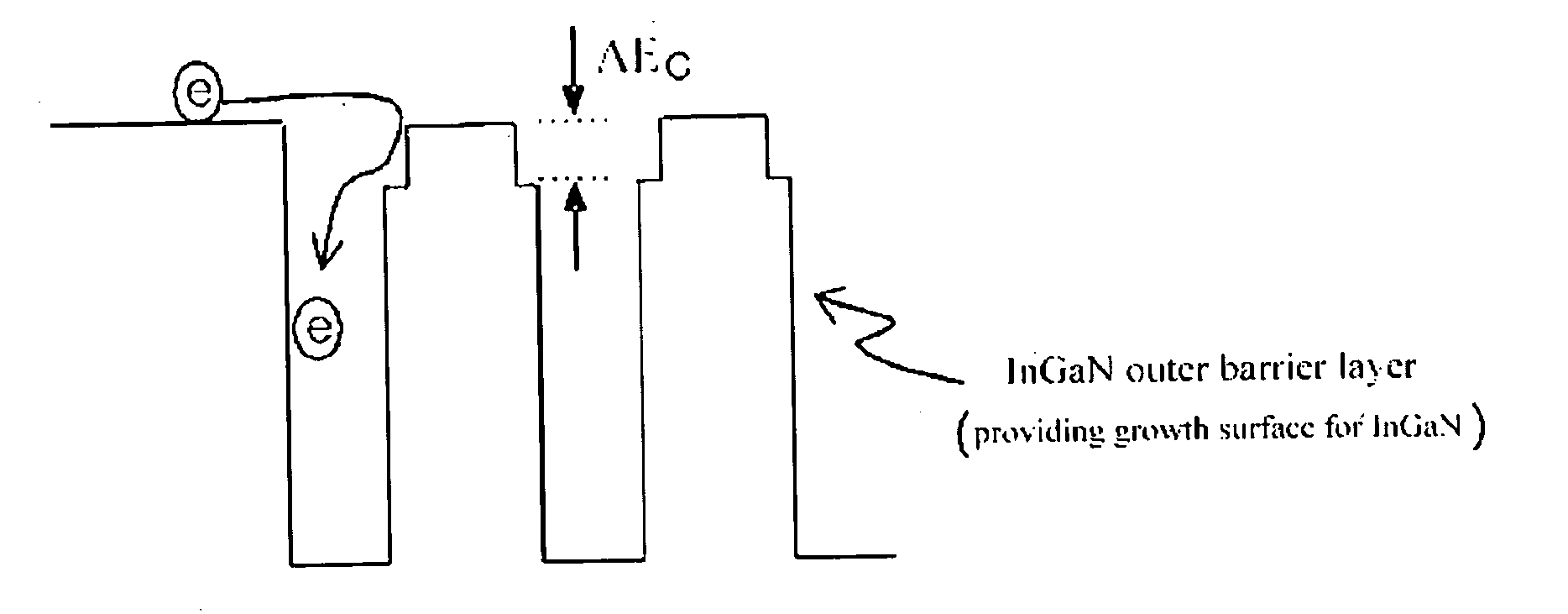

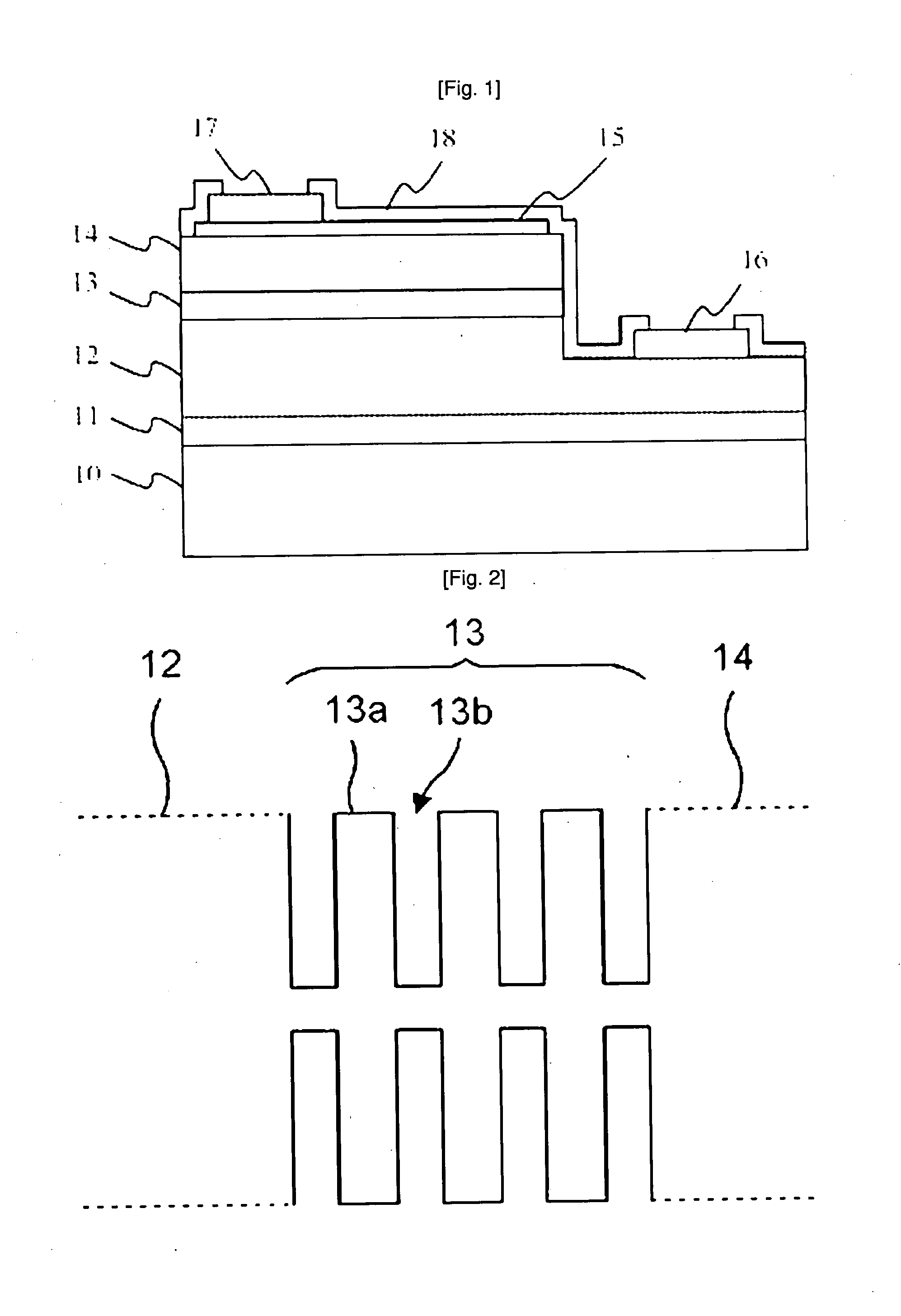

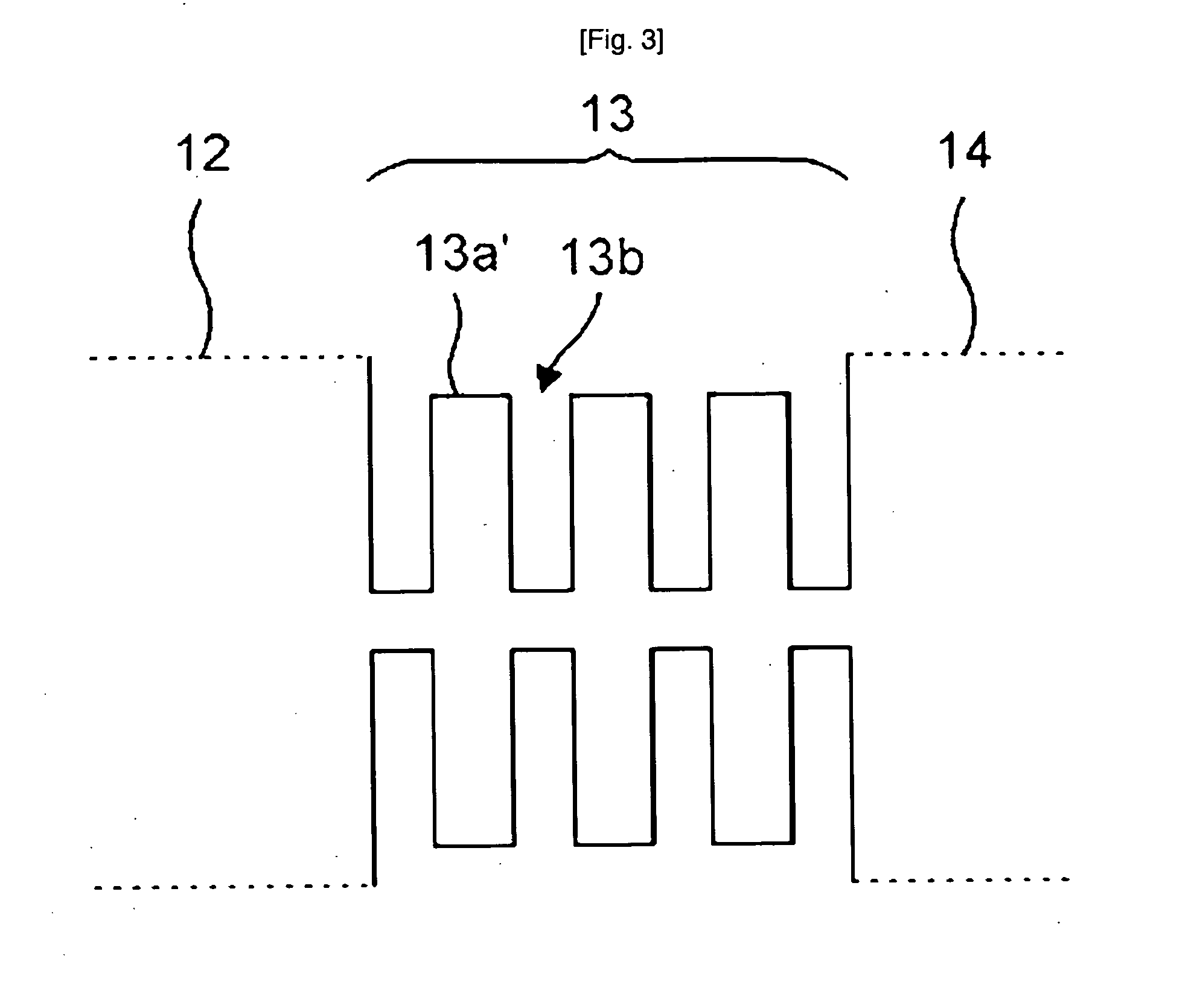

Iii-Nitride Compound Semiconductor Light Emitting Device

InactiveUS20080149917A1High-temperatureEasily achieve a high-efficiency green light emissionLaser detailsIndoor gamesQuantum wellGreen-light

The present invention relates to a III-nitride compound semiconductor light emitting device comprising an active layer with the multi-quantum wells interposed between an n-InxAlyGazN(x+y+z=1, 0<x<1, 0<y<1, 0<z≦1) layer and a p-InxAlyGazN(x+y+z=1, 0<x<1, 0<y<1, 0<z<1) layer, wherein the active layer comprises an alternate stacking of a quantum-well layer made of InxGa1-xN(0.05<x<1) and a sandwich barrier layer, the sandwich barrier layer comprising a first outer barrier layer of InaGa1-aN(0<a<0.05), a middle barrier layer of AlyGa1-yN(0<y<1) formed on the first outer barrier layer and a second outer barrier layer of InbGa1-bN(0<b<0.05) formed on the middle barrier layer, thereby a high-efficiency / high-output light emitting device with high-current and high-temperature properties can be obtained, and it is possible to easily achieve a high-efficiency green light emission at a wavelength equal to or over 500 nm, and high-efficiency near UV light emission.

Owner:EPIVALLEY

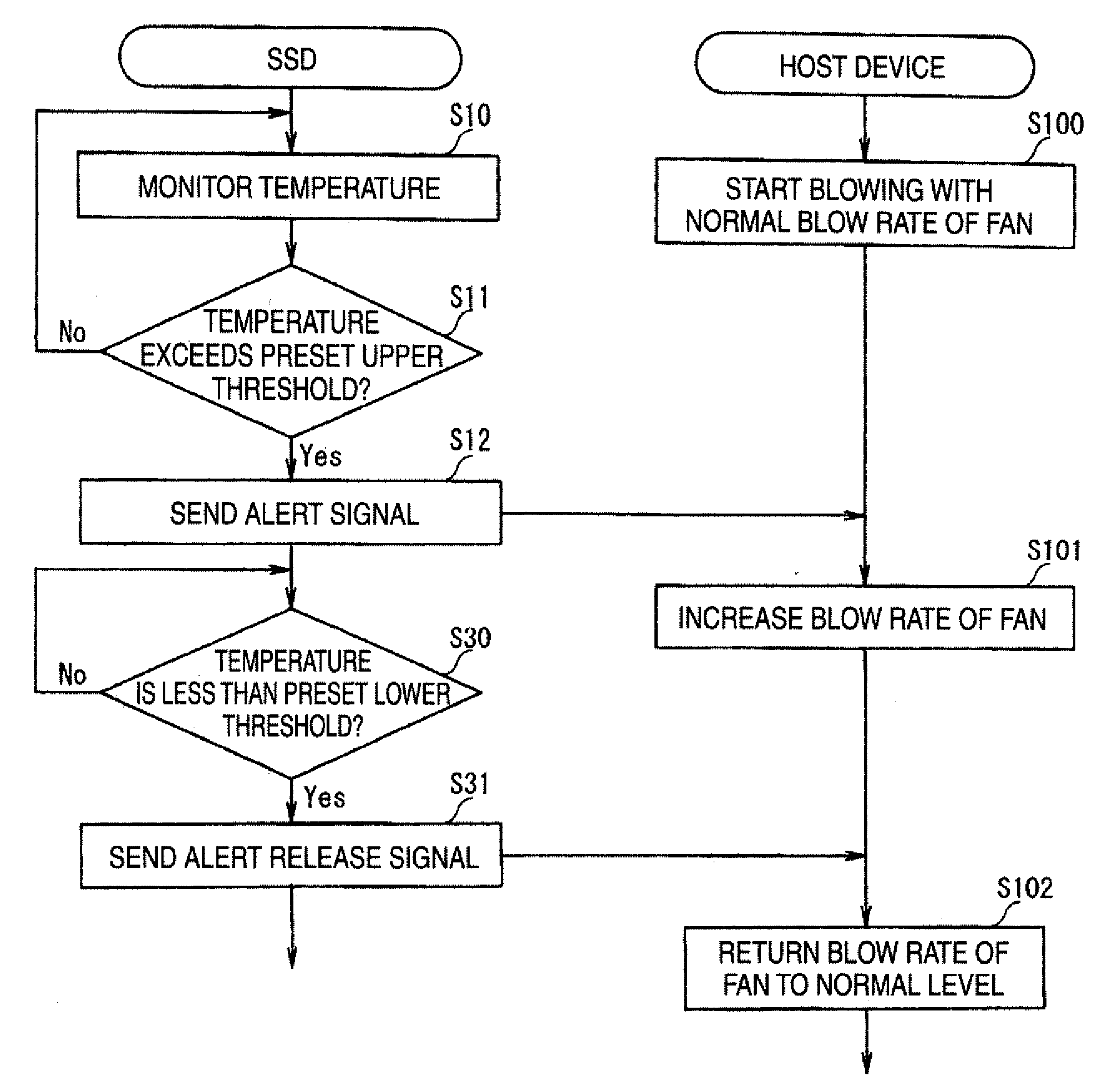

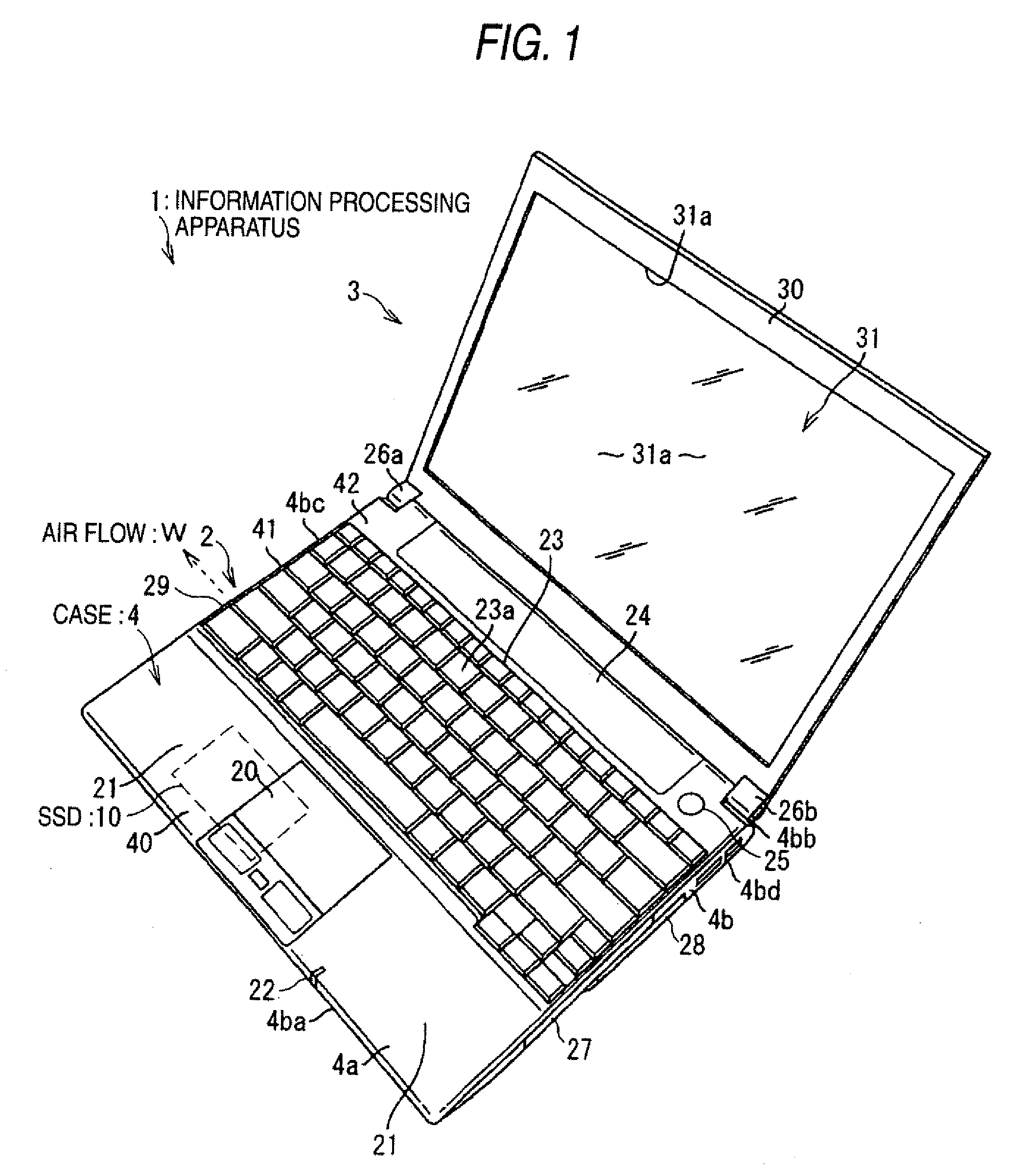

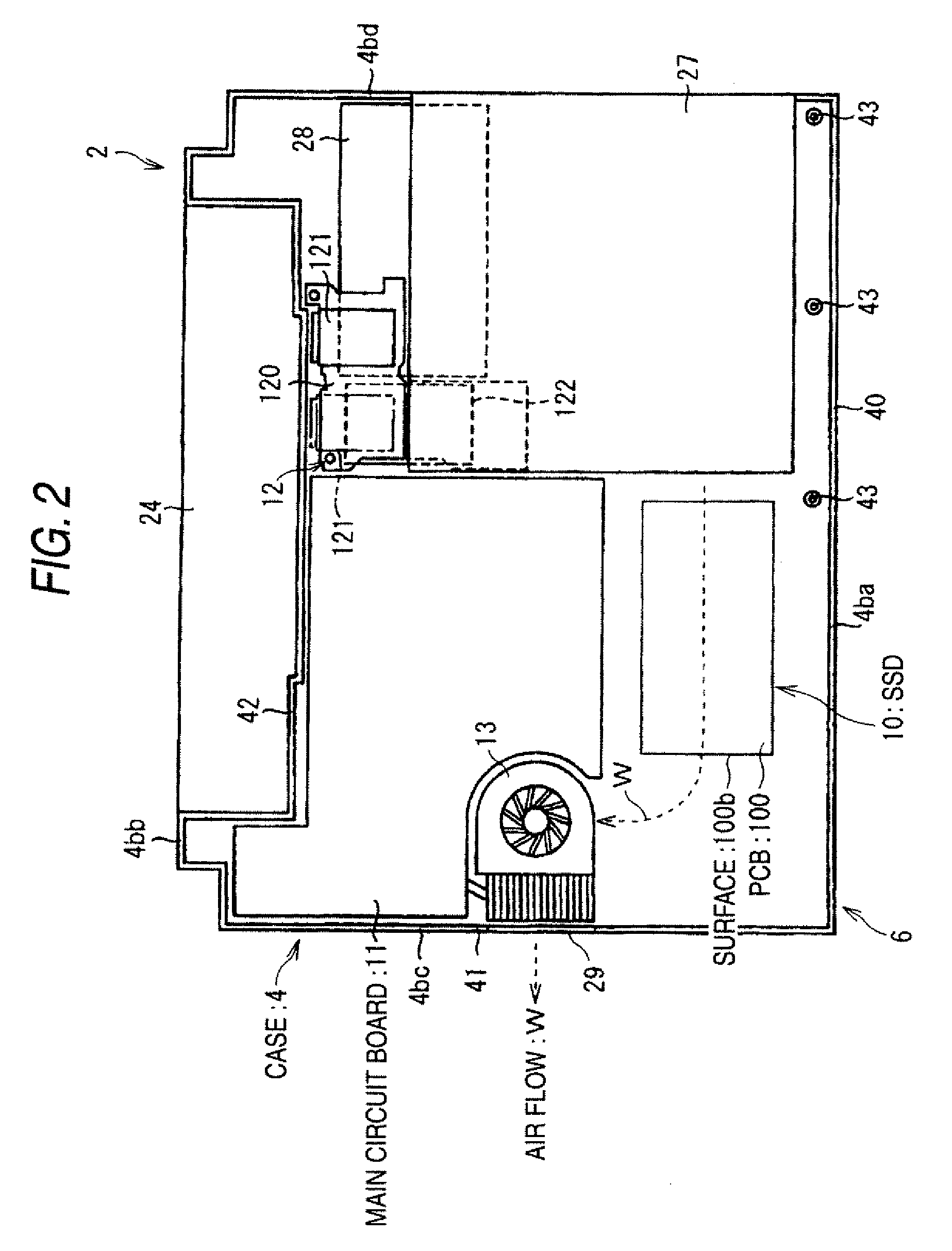

Information Processing Apparatus and Semiconductor Storage Drive

InactiveUS20090171513A1High temperatureTemperatue controlDigital data processing detailsMemory controllerPrinted circuit board

An information processing apparatus includes: a nonvolatile semiconductor storage device that is used as an external storage device, the device including: a printed circuit board; a nonvolatile semiconductor memory that is mounted on the printed circuit board; a memory controller that is mounted on the printed circuit board and controls the nonvolatile semiconductor memory; and a temperature sensor that is mounted on the printed circuit board and detects temperature within the nonvolatile semiconductor storage device; and a main controller that performs a process to lower the temperature of the nonvolatile semiconductor storage device based on the temperature detected by the temperature sensor provided in the nonvolatile semiconductor storage device.

Owner:KK TOSHIBA

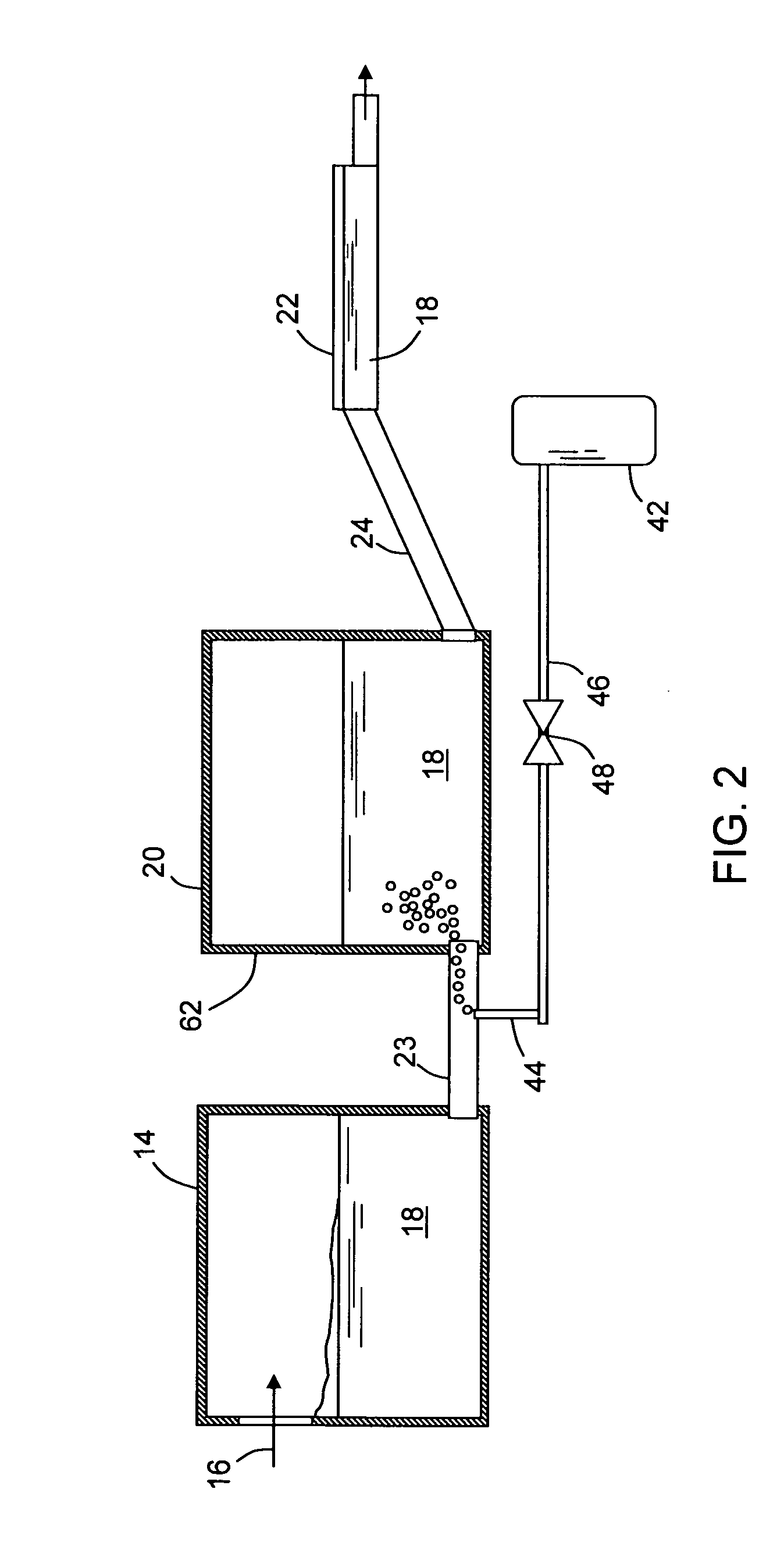

Method of bubbling a gas into a glass melt

InactiveUS20090320525A1High temperatureHigh diffusivityGlass furnace apparatusMetalRefractory metals

Feed materials are melted in a furnace to form a glass melt in a first vessel, transferred through a first refractory metal connecting tube to a second vessel for conditioning, then transferred through a second refractory metal connecting tube to a third vessel where the glass melt is fined. A gas is bubbled into the glass melt through an injection tube disposed in the first connecting tube, optionally in the second connecting tube, and optionally in both connecting tubes. The gas may be used to mix the melt and / or recharge a fining agent with oxygen.

Owner:CORNING INC

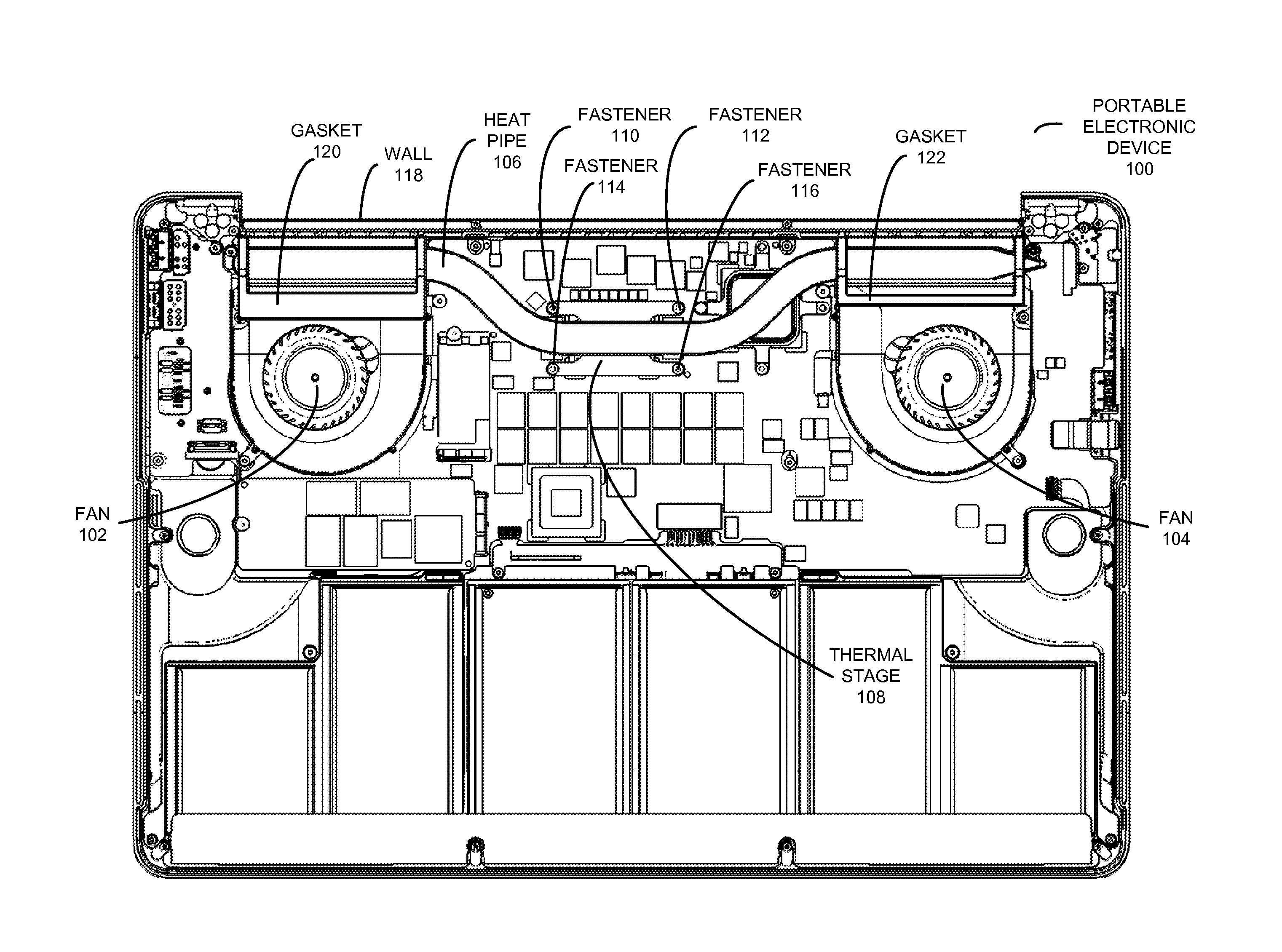

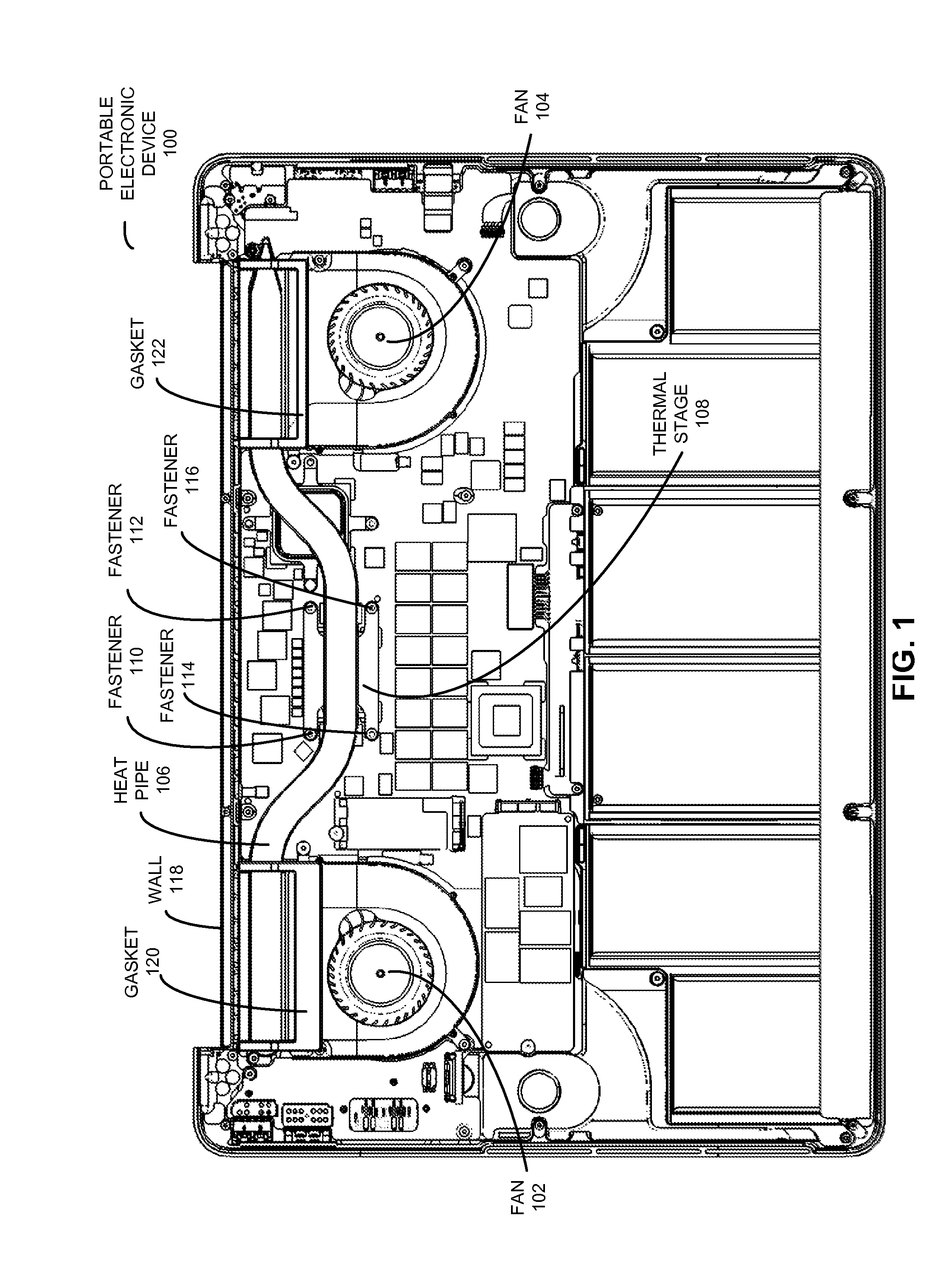

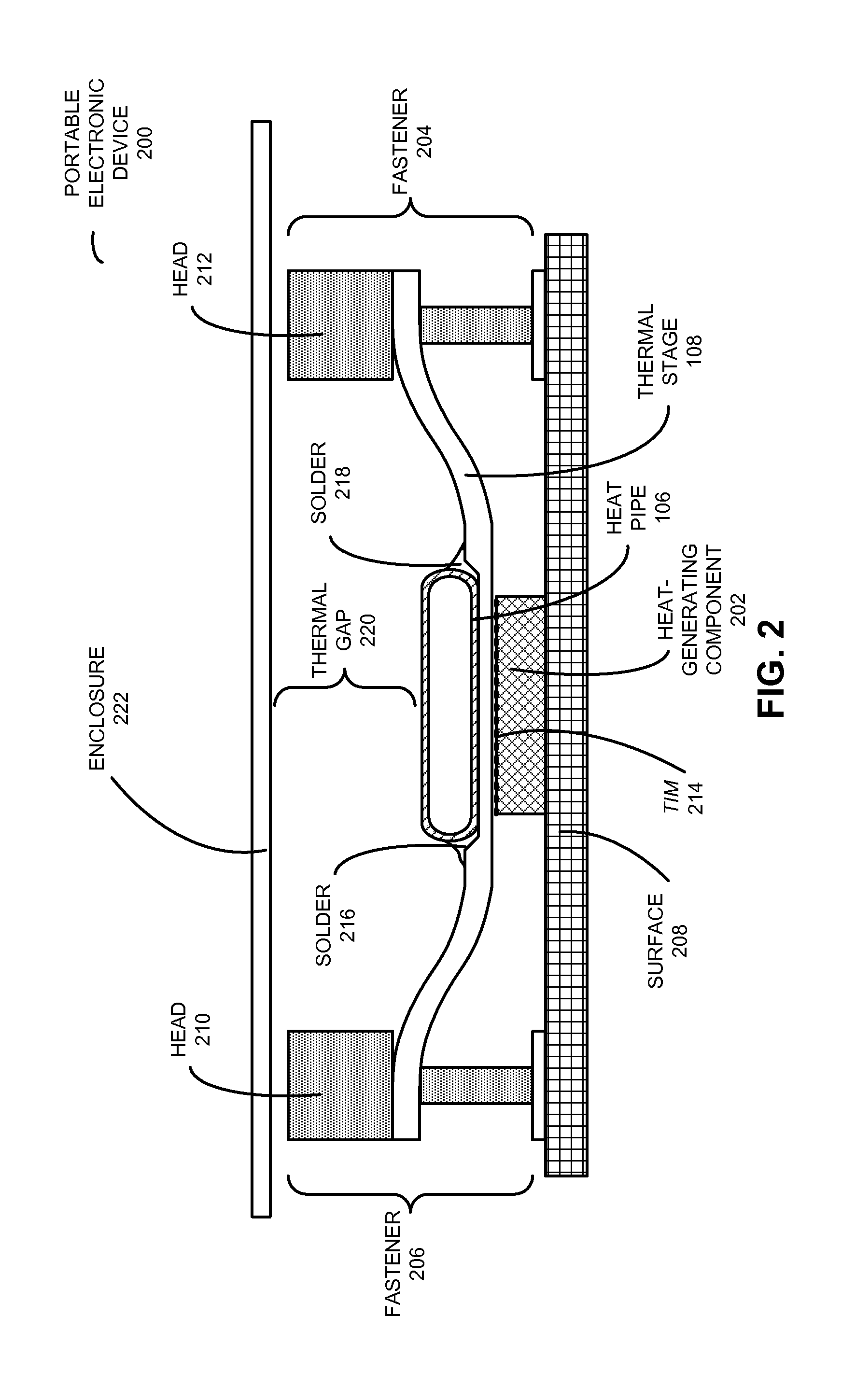

Optimized vent walls in electronic devices

ActiveUS20130327507A1High temperatureReduce flow impedanceWave amplification devicesDigital data processing detailsEngineeringElectronic equipment

Owner:APPLE INC

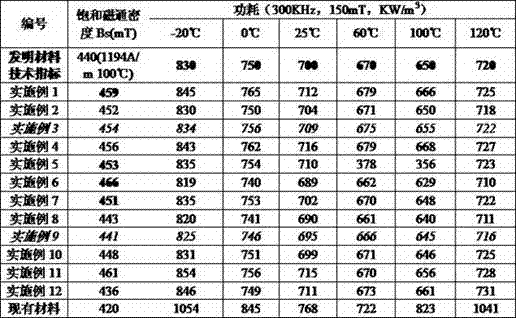

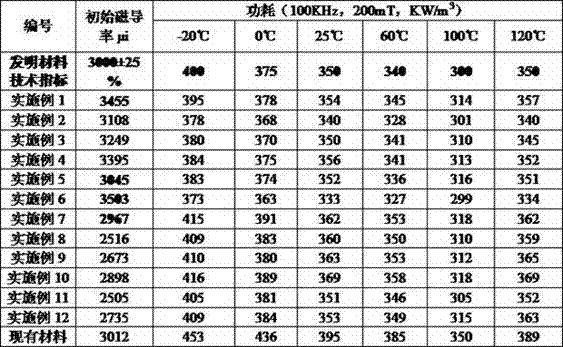

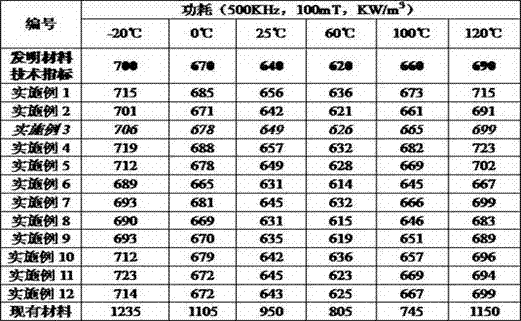

Broadband wide temperature range high-power density low-loss manganese-zinc soft magnetic ferrite material and preparation method thereof

ActiveCN107473727AImprove workabilityLow high frequency lossInorganic material magnetismSpray GranulationManganese

The invention discloses a broadband wide temperature range high-power density low-loss manganese-zinc soft magnetic ferrite material. The material comprises main ingredients, an auxiliary ingredient A and an auxiliary ingredient B, wherein the main ingredients comprise the following components in percentage by weight: Fe2O3, MnO and ZnO; based on the weight of the main ingredients, the auxiliary ingredient A comprises at least three of CaCO3, Nb2O5, NiO, SnO2 and Co3O4; and the auxiliary ingredient B comprises at least three of SiO2, Y2O3, K2CO3, Al2O3, CuO, MoO and Bi2O3. The preparation method of the material sequentially comprises the following steps: primary batching, primary sanding, pre-sintering, secondary batching, secondary sanding, performing component analysis, performing spray granulation, molding and sintering. The material disclosed by the invention has low loss in a temperature range from 20 DEG C below zero to 120 DEG C under the conditions of 100-500KHz and 100-200mT, and has high magnetic conductivity and high high-temperature saturation flux density. Compared with the conventional material, the material disclosed by the invention is energy-saving and can enable a switching power module to be miniature and efficient.

Owner:郴州市久隆旺高科电子有限公司

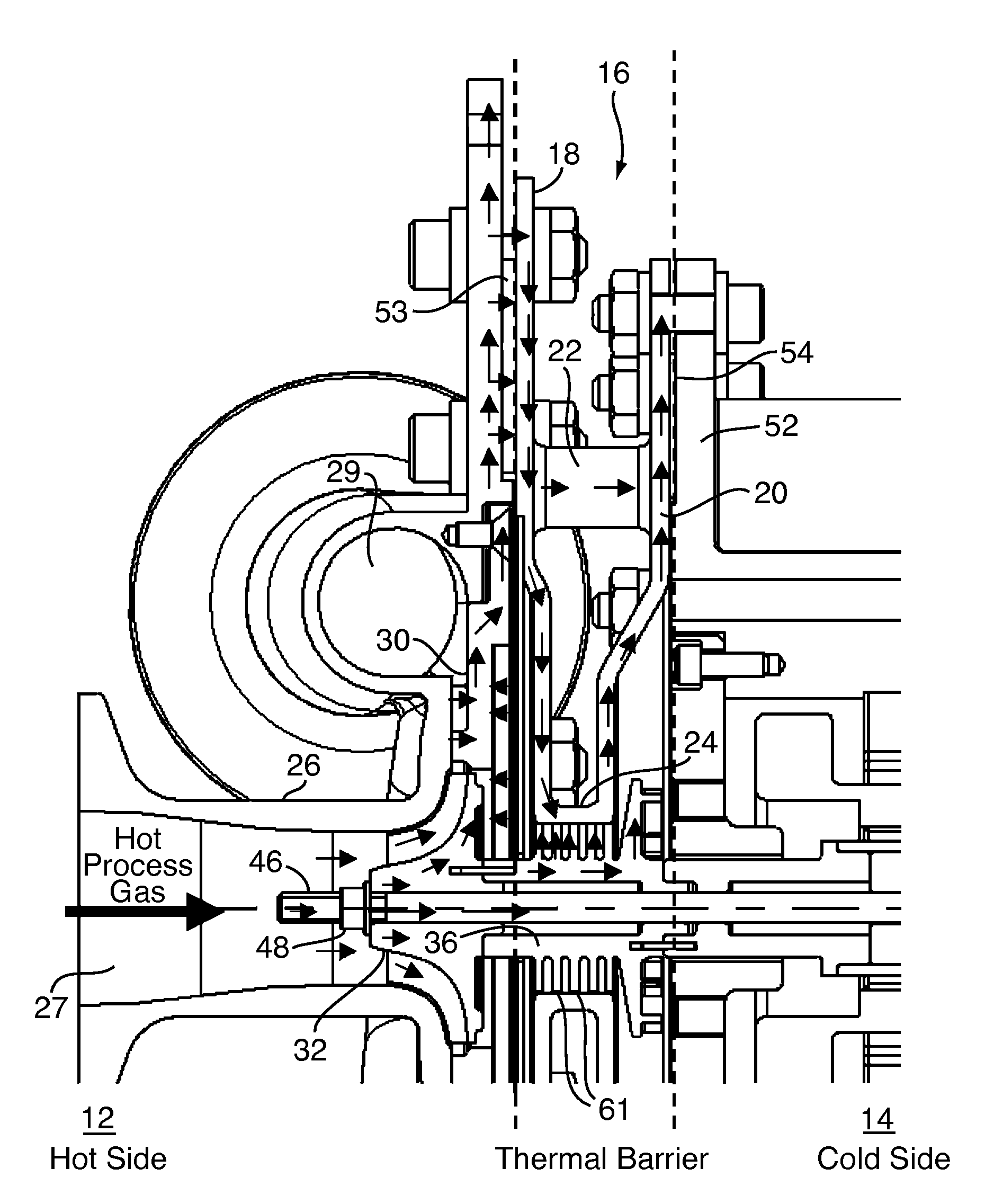

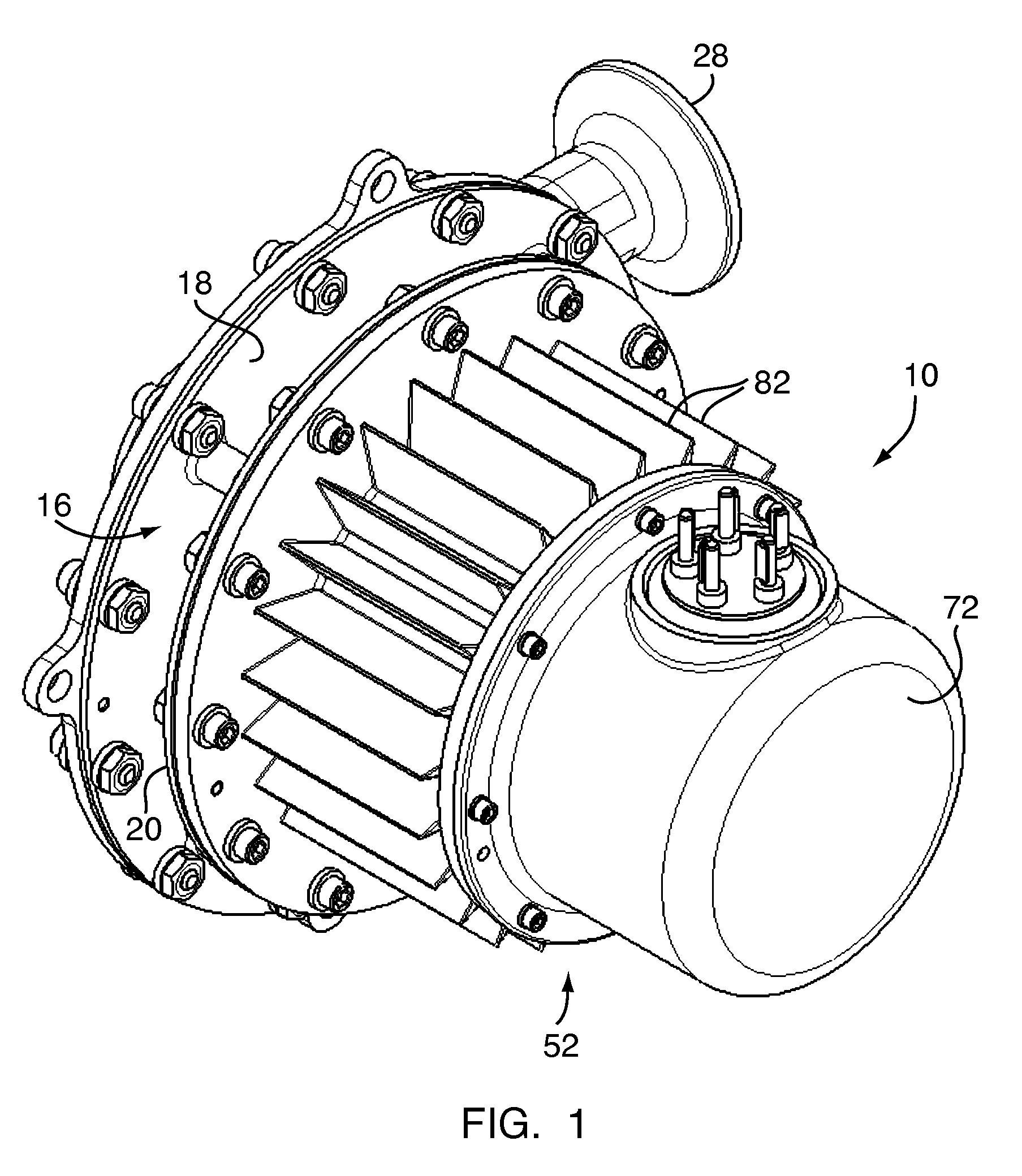

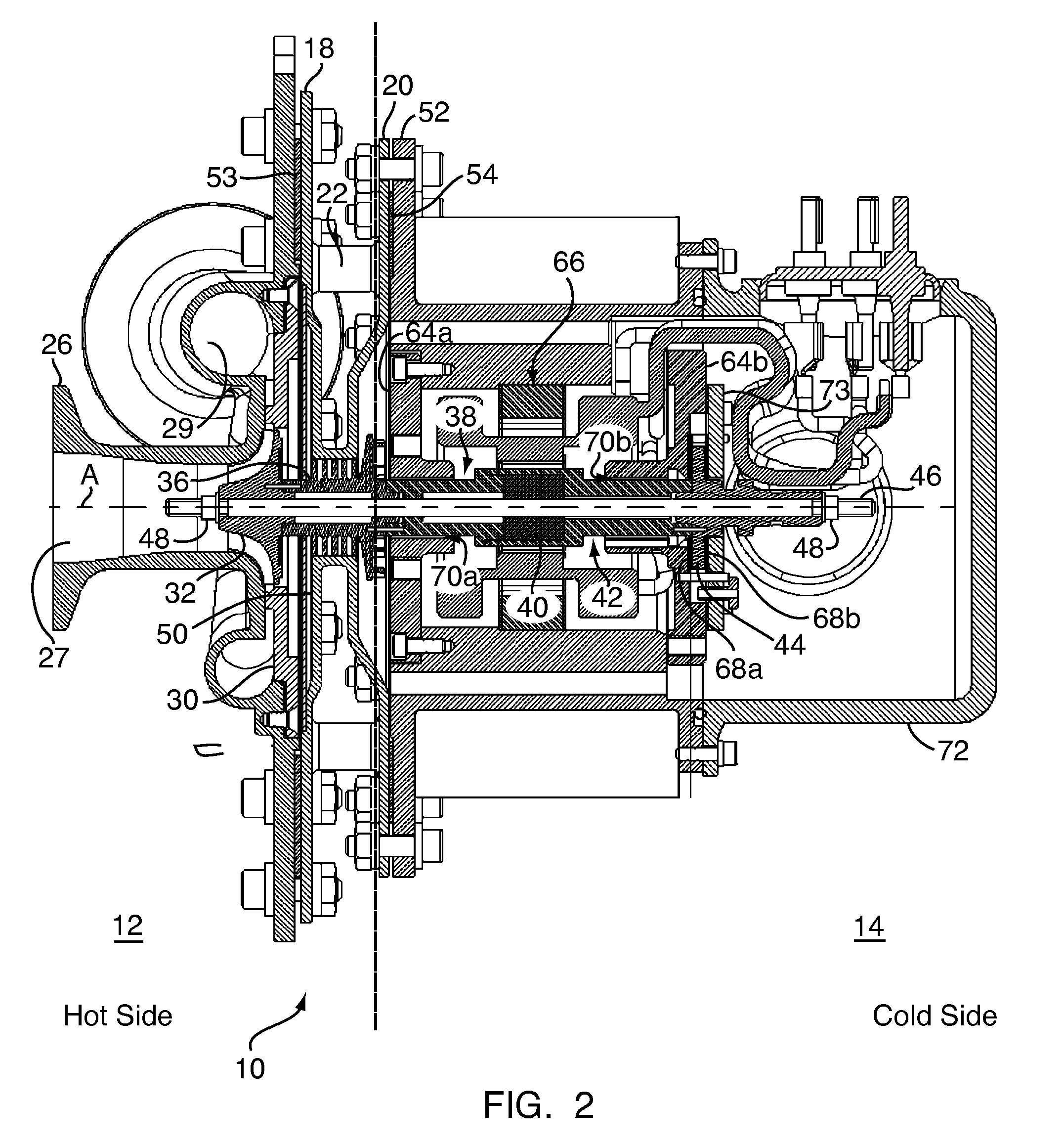

Foil gas bearing supported high temperature centrifugal blower and method for cooling thereof

InactiveUS20090087299A1Reduce heat transferHigh temperatureReaction enginesNon-positive displacement enginesImpellerEngineering

This invention provides a blower design capable of high temperature operation due to use of a self-sustaining cooling scheme through a sealed motor housing in which a cooling circuit can be created, and the use of a thermal barrier across which a temperature gradient may be formed. The thermal barrier may be formed by a thermal choke plate assembly positioned between a hot side and a cold side of the blower to dissipate heat conducted from the hot side. Alternatively, the thermal barrier may be formed by an internal fan ring provided with the blower's rotating assembly to dissipate heat conducted from the blower's impeller. The thermal choke plate assembly and the fan ring may further be used in combination to block heat transfer by all modes between a hot side and a cold side of the blower.

Owner:R & D DYNAMICS

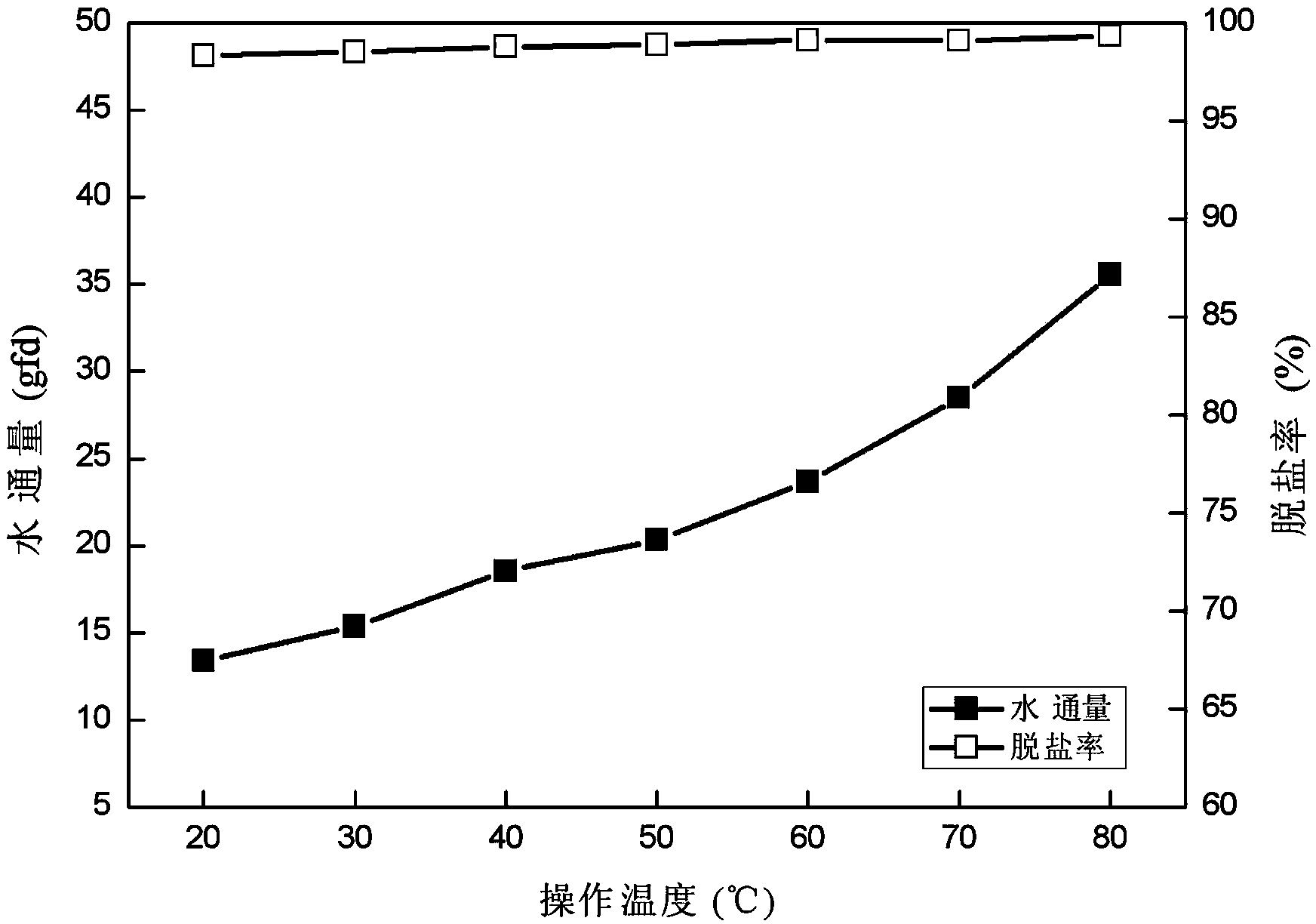

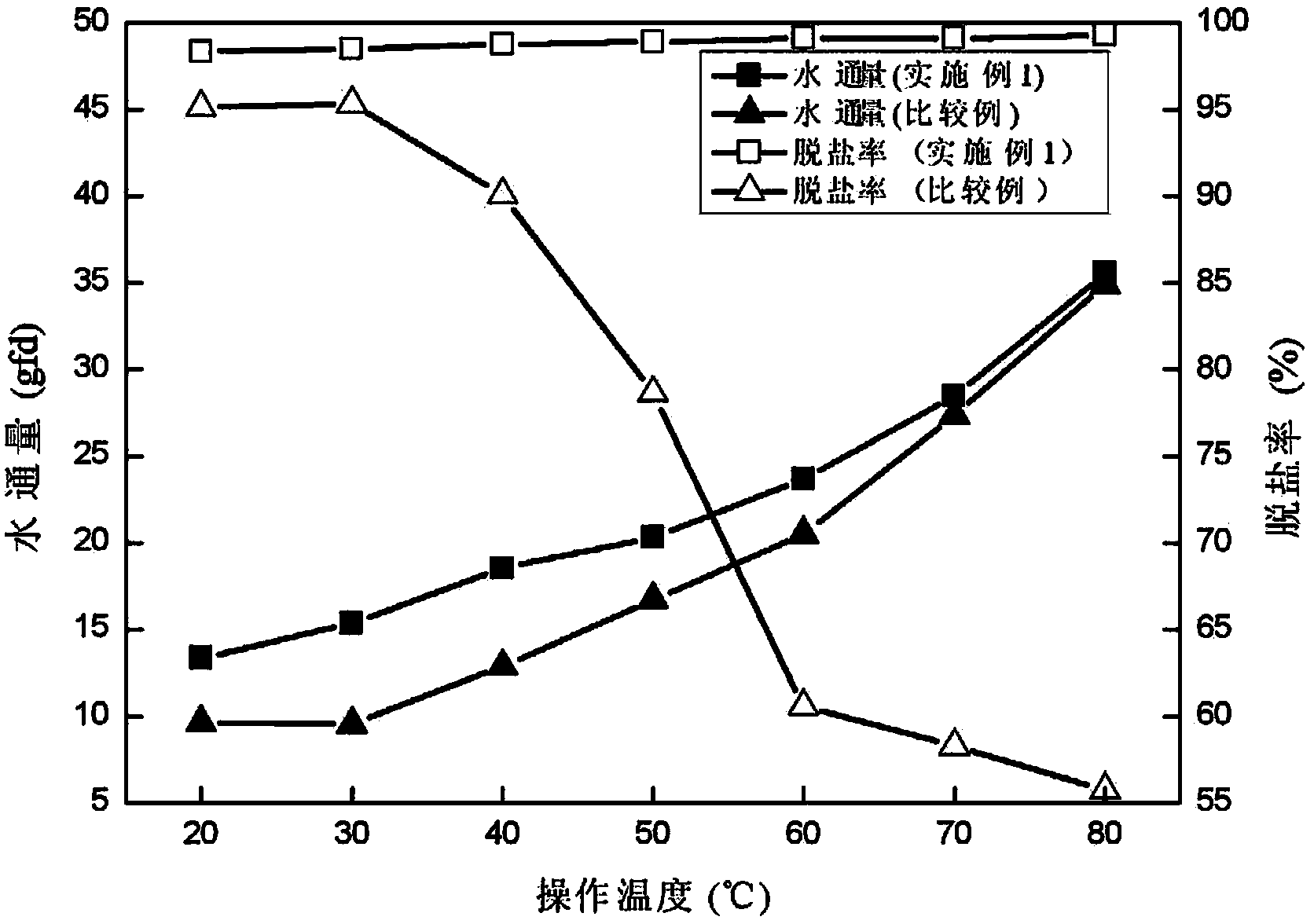

High-temperature resistance double-layer forward osmosis composite film and preparation method thereof

ActiveCN103432913AHigh temperatureReduce concentration polarizationSemi-permeable membranesPolyamideFilm material

The invention discloses a high-temperature resistance double-layer forward osmosis composite film and a preparation method thereof. The forward osmosis composite film comprises a non-woven fabric layer; each of the two surfaces of the non-woven fabric layer is provided with a high-temperature resistance porous supporting film layer; each of the high-temperature resistance porous supporting film layers is provided with a polyamide separation layer; the high-temperature resistance porous supporting film layer is mainly formed by high-temperature resistance polymer. The preparation method comprises the following steps: carrying out blade coating of a casting solution prepared from the high-temperature resistance polymer, a solvent and an additive on both surfaces of the non-woven fabric layer and by phase inversion and heat treatment, and obtaining a supporting film material comprising the non-woven fabric layer and the high-temperature resistance porous supporting film layers; firstly soaking the supporting film material in a water-phase solution and then soaking the supporting film material into an organic-phase solution and forming the polyamide separation layers by reaction so as to obtain the high-temperature resistance double-layer forward osmosis composite film. The forward osmosis composite film disclosed by the invention has high salt rejection, large water flux and high processing efficiency; the preparation method is simple; the process is relatively mature; the forward osmosis composite film is easy for scale production.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

High temperature resistant titanium and aluminum based alloy and manufacturing method thereof

The invention provides a high temperature resistant titanium-aluminium base alloy and a method for preparing the same, wherein, the alloy which belongs to gamma-TiAl alloy has components of Al of 44.0-48.0at%, Nb of 3.0-5.0at%, Cr of 0.2-2.0at%, Ni of 0.1-0.8at%, Si of 0-0.8at% and the rest are Ti and ineluctable impurity elements; the method comprises steps of using titanium sponge, AlNb alloy, AlCr alloy, Ni, Al and Si as the raw material, smelting, casting and shaping the raw material in a vacuum consumable electrode electrical arc skull crucible or a vacuum induction furnace, and when the casting process is performed, Ti-Al alloy casting ingot can be casted after vacuum melting or be casted after argon-filling smelting.The alloy of the invention has characteristics of favorable room-temperature plasticity, creep-resistance capability and anti-oxygenic property, can be used under a temperature of 800-900 DEG C, is suitable for the casting of parts with thin walls, can improve the use characteristics of aircraft engines and car engines, and has a wide market outlook.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Solar receiver

InactiveUS20100252025A1High temperatureSolar heating energySolar heat collector controllersHeat transfer fluidEngineering

A solar energy conversion system may include a receiver with a first heat transfer fluid channel having at least two opposite sides. Each side may present an external surface facing in a direction opposite to that of the external surface of the other opposite side. Each side may be configured to contact a heat transfer fluid carried in the first heat transfer fluid channel. A heliostat field may be configured to direct solar energy to each of the at least two opposite sides during the course of a day such that a thermal stress tending to bend the channel remains below a specified level.

Owner:BRIGHTSOURCE INDS ISRAEL

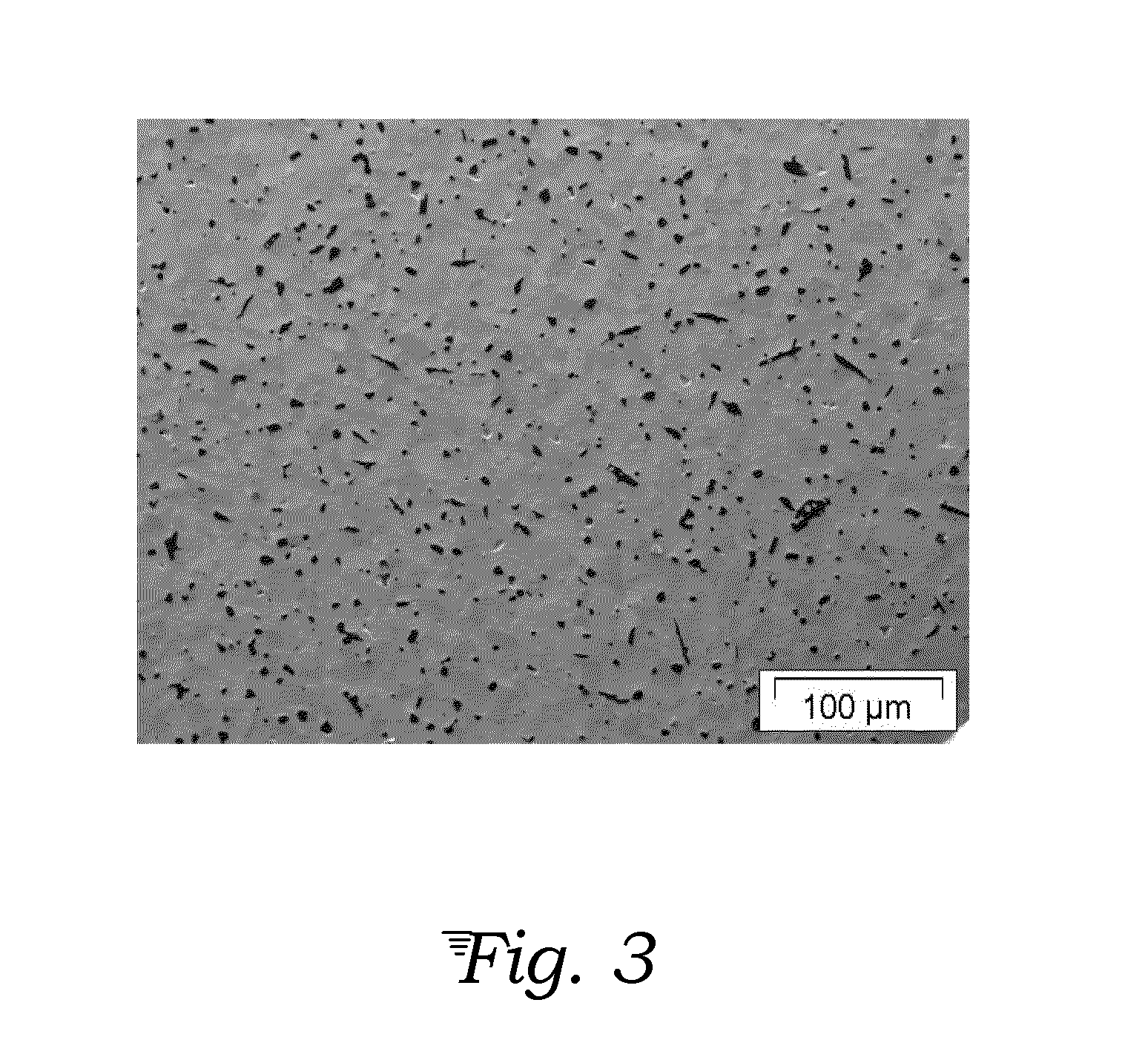

In-situ formation of reinforcement phases in ultra high temperature ceramic composites

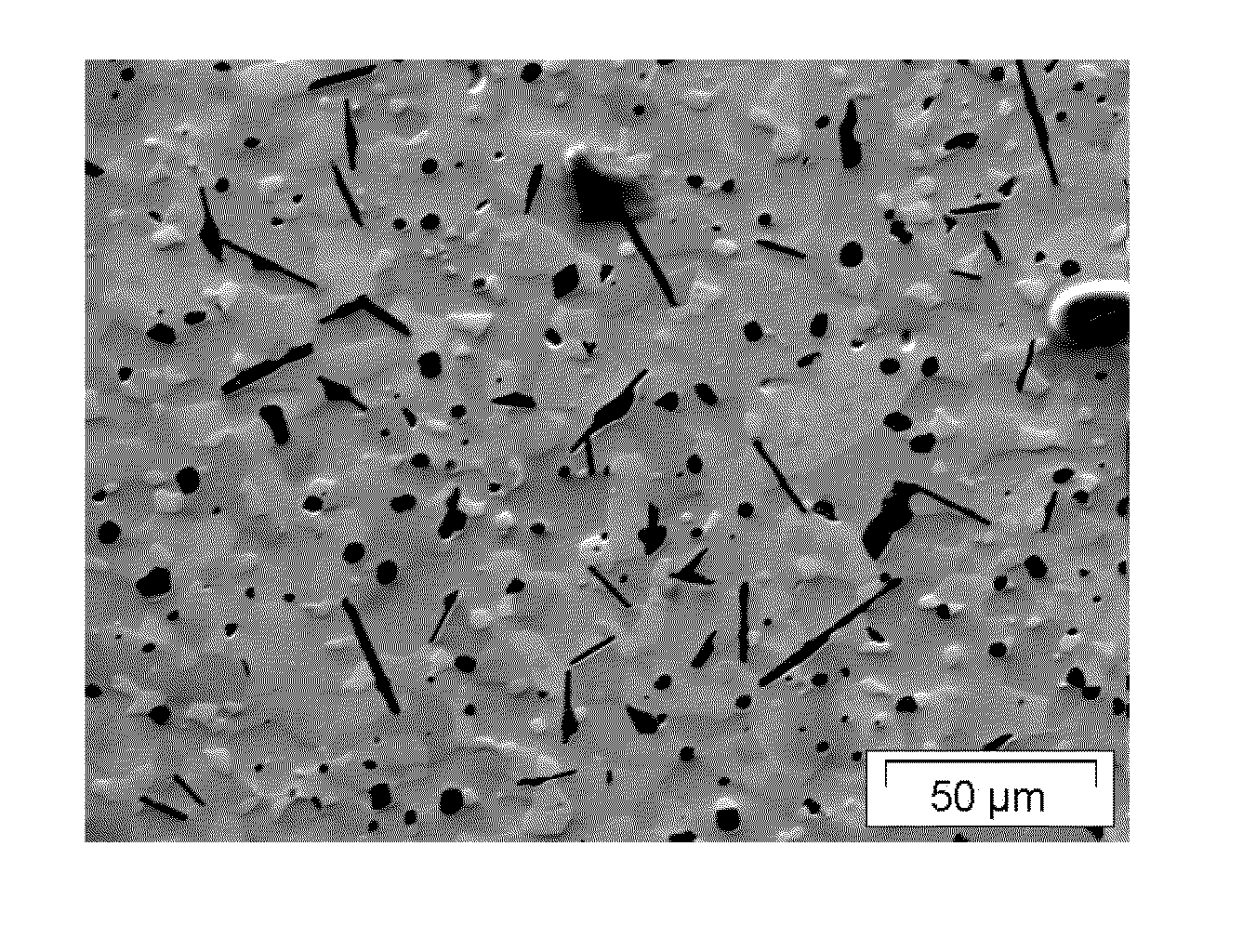

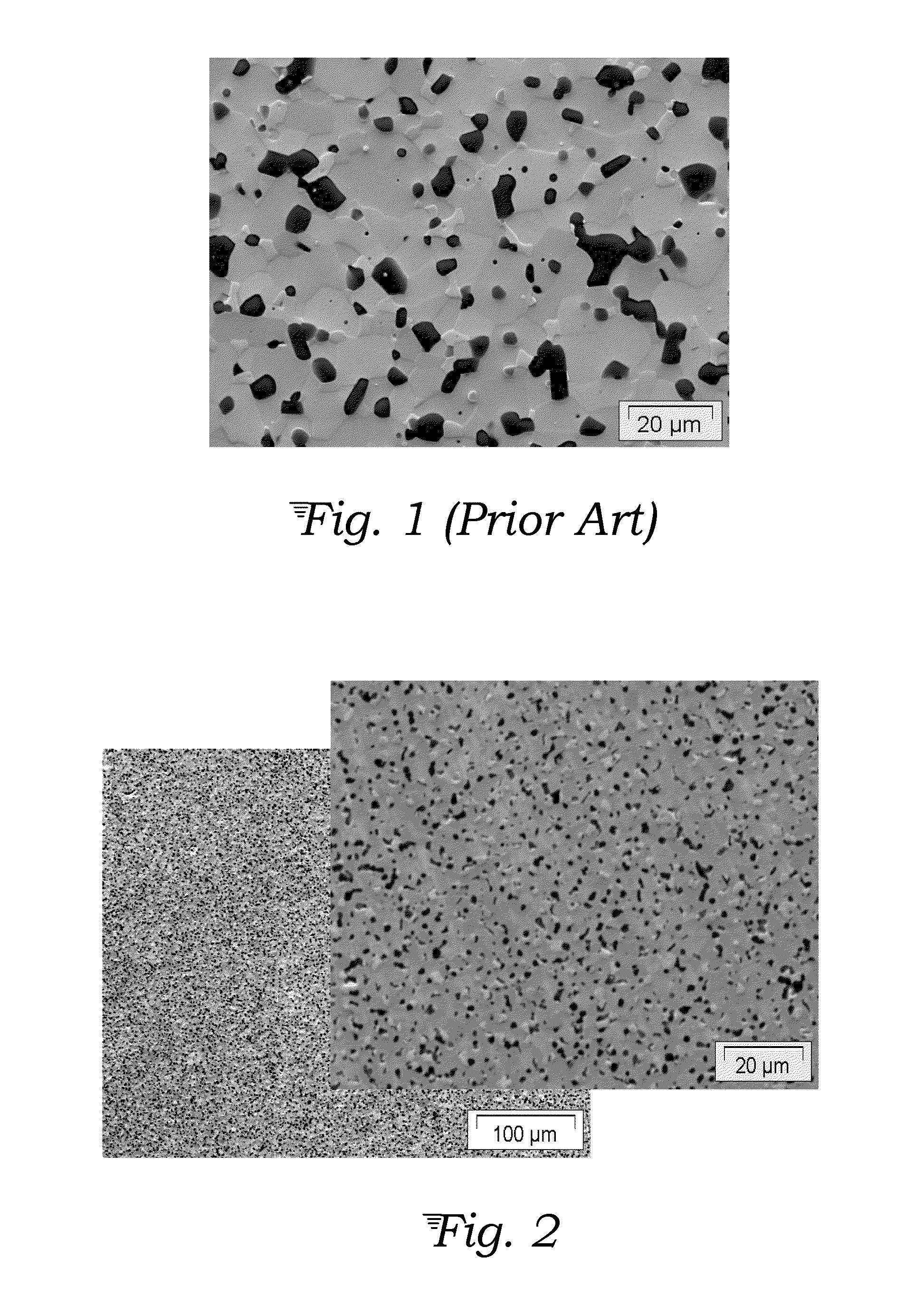

InactiveUS8409491B1Improve thermal shock resistanceHigh-temperatureCeramic shaping apparatusNatural mineral layered productsUltra-high-temperature ceramicsCarbide

A tough ultra-high temperature ceramic (UHTC) composite comprises grains of UHTC matrix material, such as HfB2, ZrB2 or other metal boride, carbide, nitride, etc., surrounded by a uniform distribution of acicular high aspect ratio reinforcement ceramic rods or whiskers, such as of SiC, is formed from uniformly mixing a powder of the UHTC material and a pre-ceramic polymer selected to form the desired reinforcement species, then thermally consolidating the mixture by hot pressing. The acicular reinforcement rods may make up from 5 to 30 vol % of the resulting microstructure.

Owner:NASA

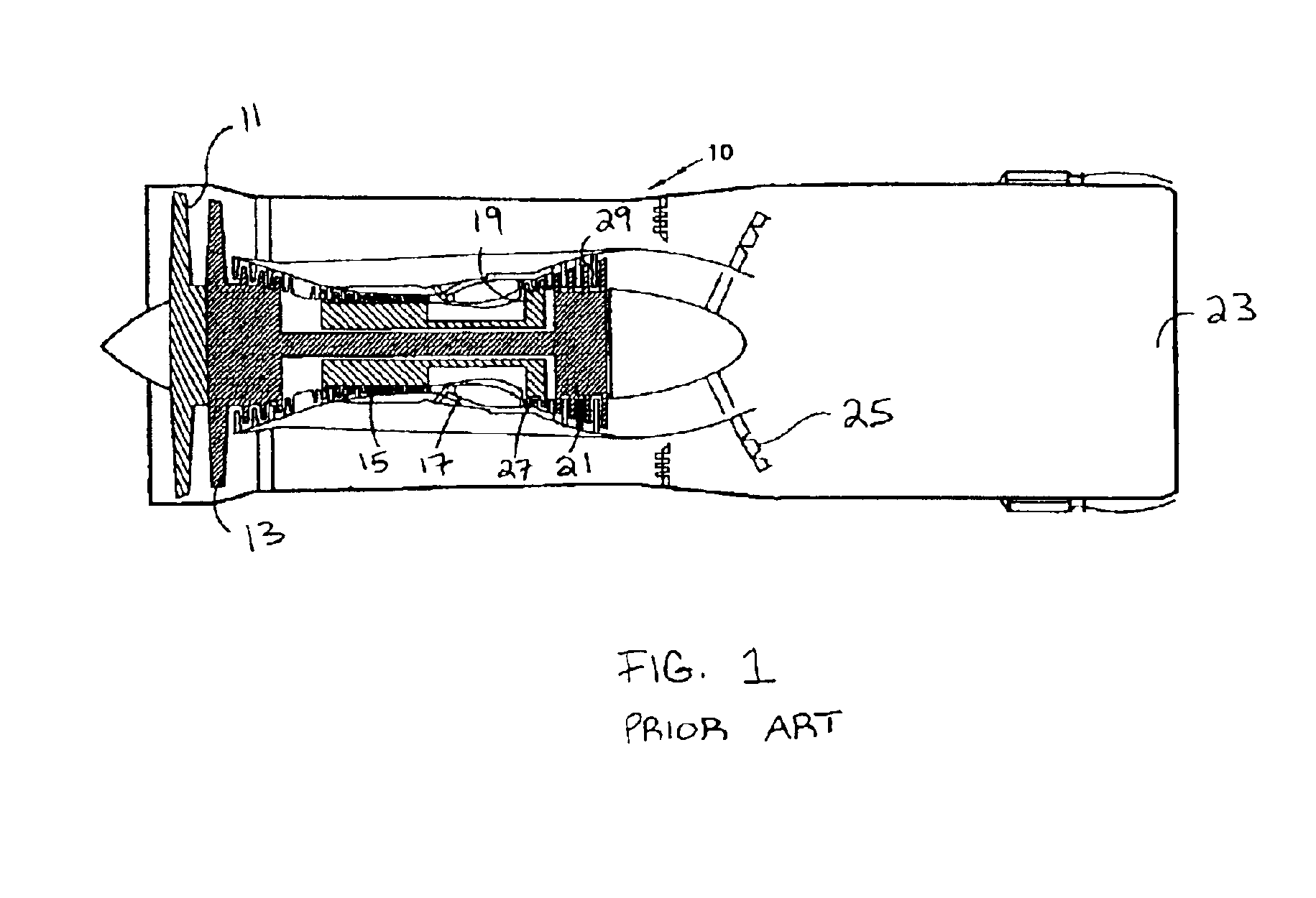

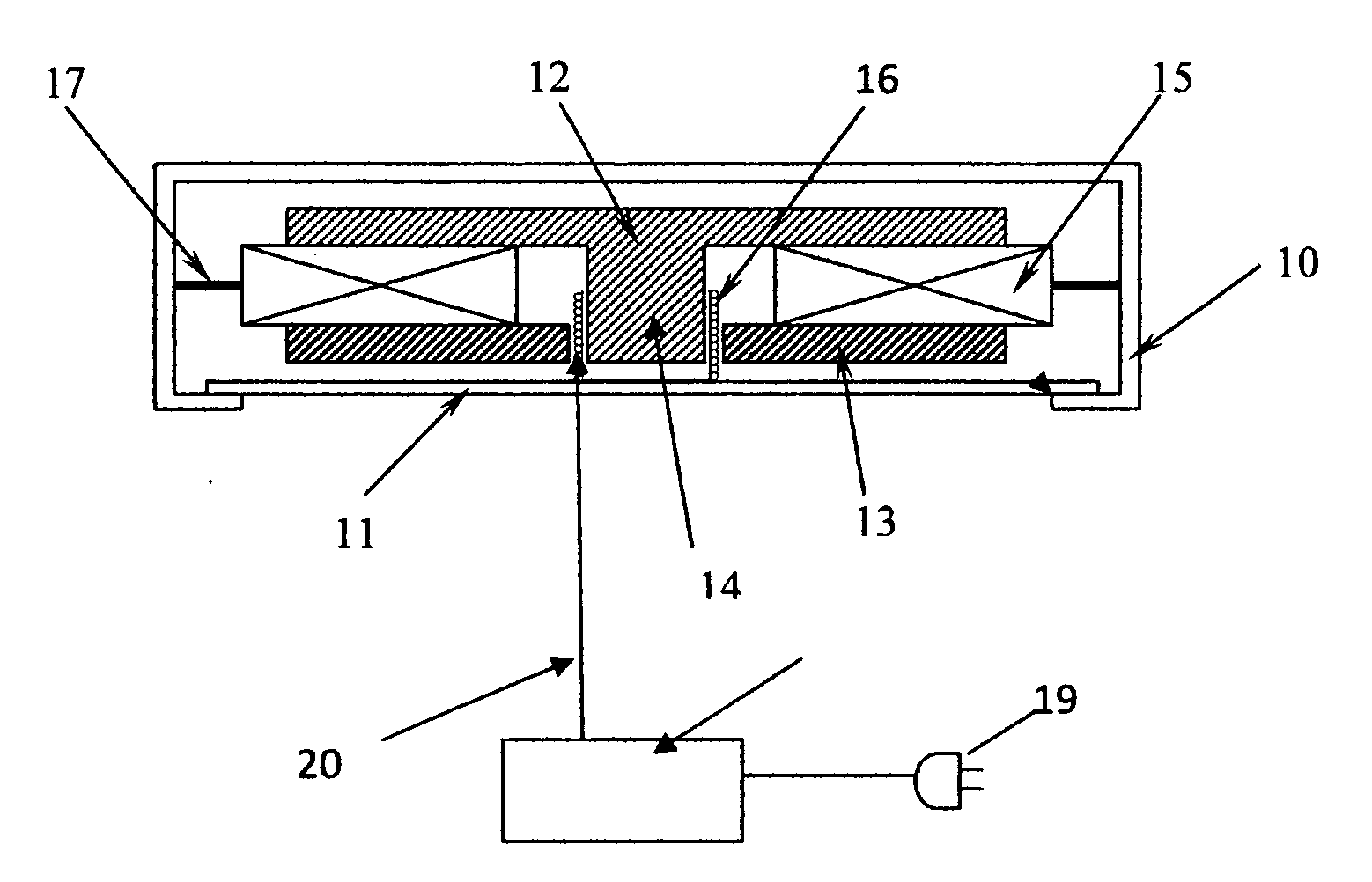

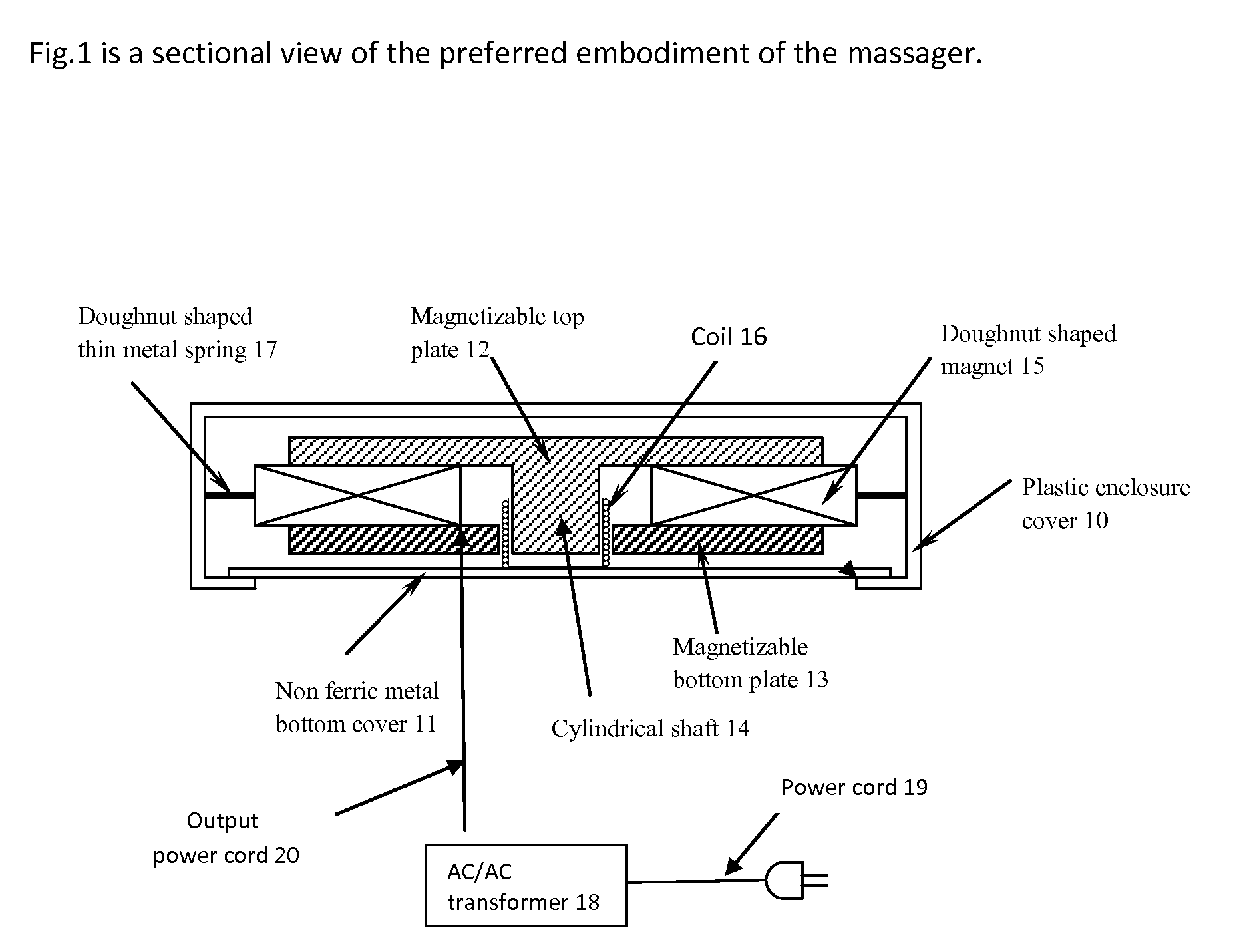

Compact and light weight portable transducer massager

InactiveUS20110166486A1Low costHigh temperatureChiropractic devicesVibration massageAc frequencyLoudspeaker

An electric massager comprising an enclosure box that contains a reverse structure of audio speaker less a speaker diaphragm, the said reverse structure in the box comprising two metal plates sandwiching a permanent magnets, a coil-cone and a thin metal leaf spring connecting to the said magnet and to the enclosure box. The said massager as a kit includes a separate AC / AC transformer, and as an optional item, a DC / AC inverter for an automobile use. When the said coil is energized by the AC / AC transformer or the DC / AC inverter, the said sandwiched magnet vibrates at a given AC frequency. The vibration is transferred to the enclosing box via the said leaf spring so that the enclosure box vibrates and the heat generated by the coil is trapped within the enclosure box and warms the box, the massager.

Owner:KUMANOMIDO NORIO

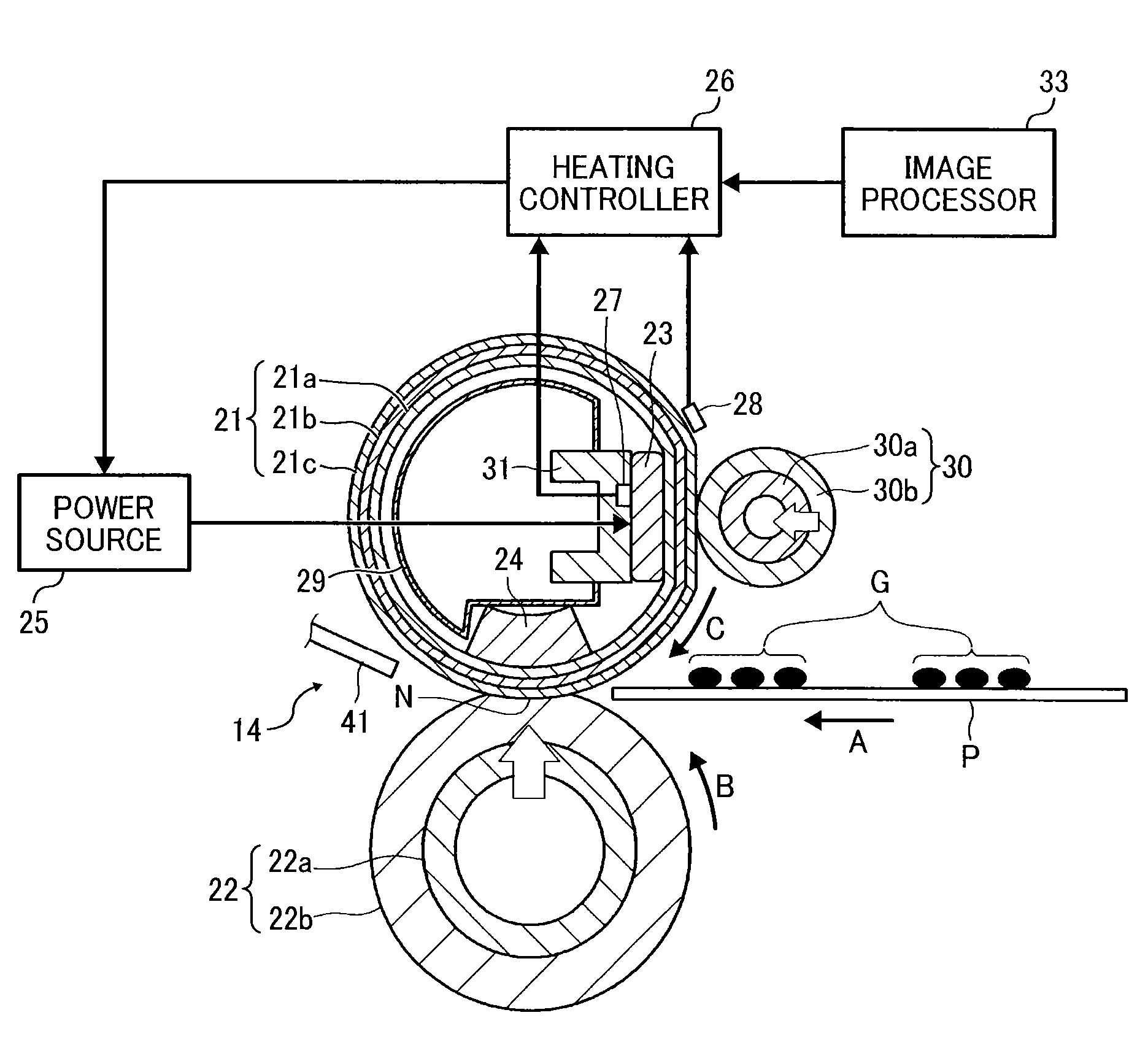

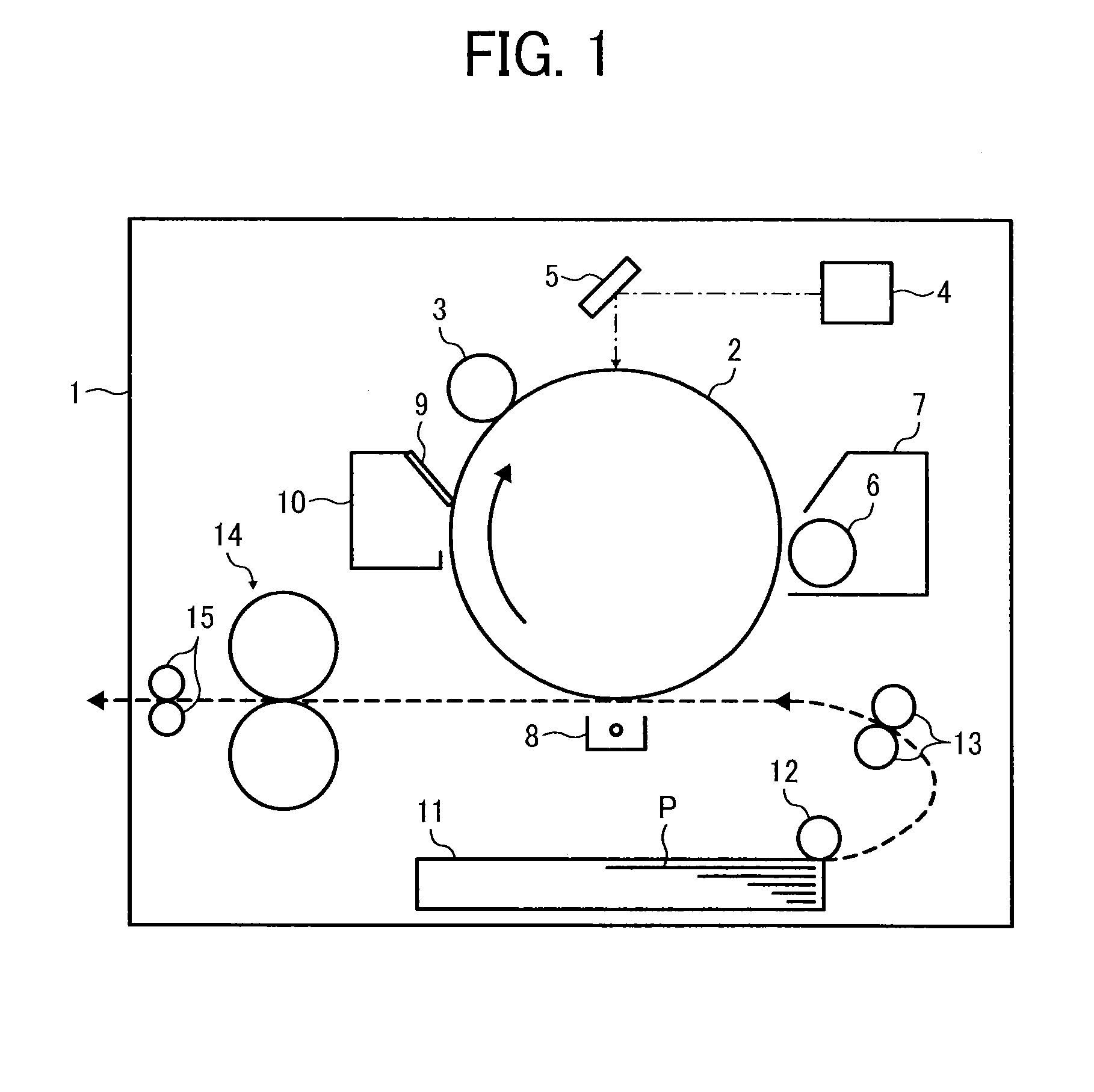

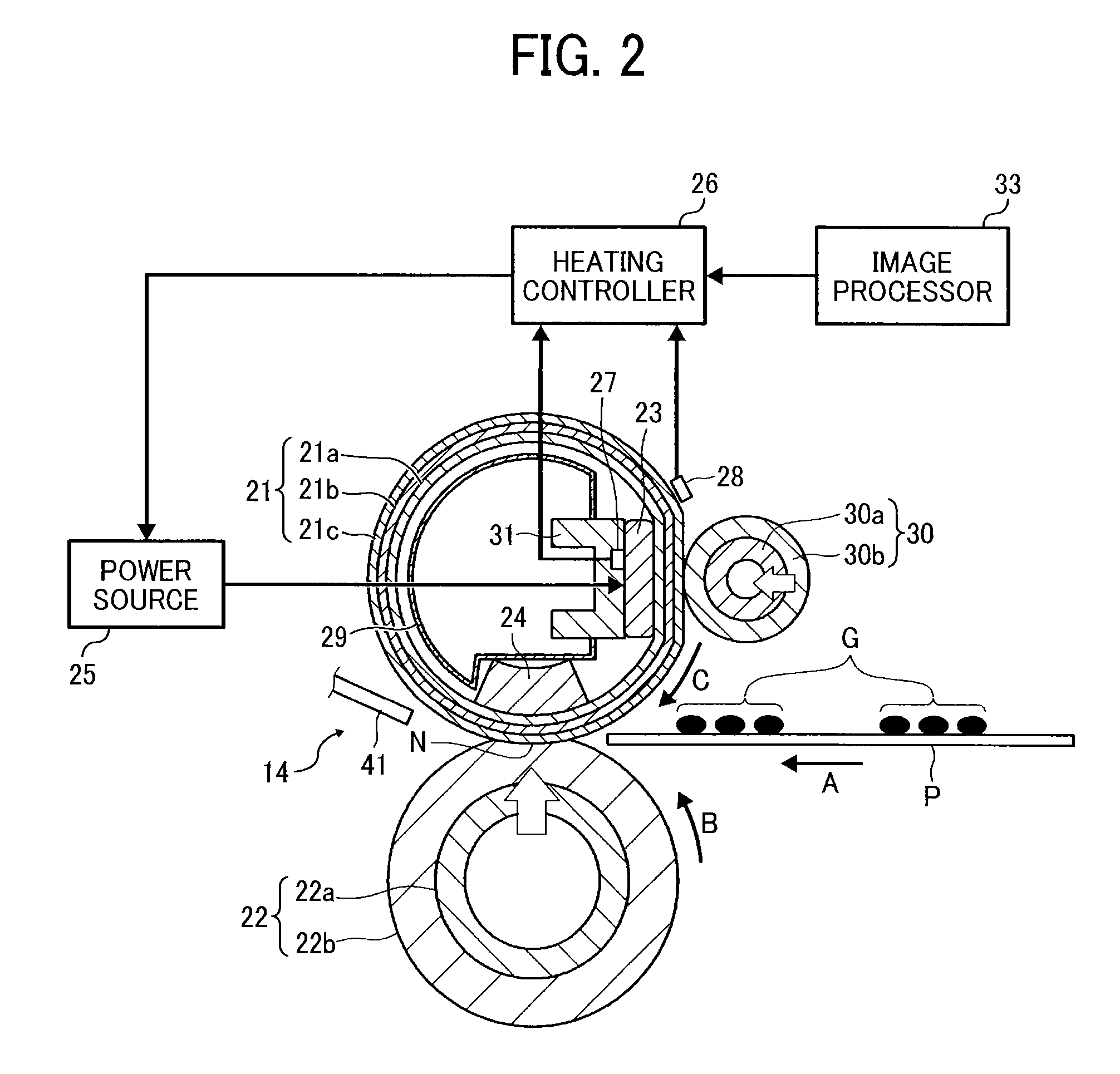

Fixing device and image forming apparatus including same

ActiveUS20140219672A1High temperatureElectrographic process apparatusEngineeringElectrical and Electronics engineering

A fixing device includes a fixing rotary body, an opposed member, a heater, and a heating controller. The opposed member opposes the fixing rotary body to form a nipping portion therebetween. The heater includes heat generators arranged in a width direction of a recording medium. When the recording medium fed to the nipping portion has an image area and a non-image area, the heating controller controls the outputs of the heat generators based on image information so that a first heat generator of the heat generators corresponding to the image area is higher in temperature and a second heat generator of the heat generators corresponding to the non-image area is lower in temperature. Based on information other than the image information, the heating controller temporarily shifts an area of the fixing rotary body corresponding to the non-image area to a temperature differing from a normal temperature.

Owner:RICOH KK

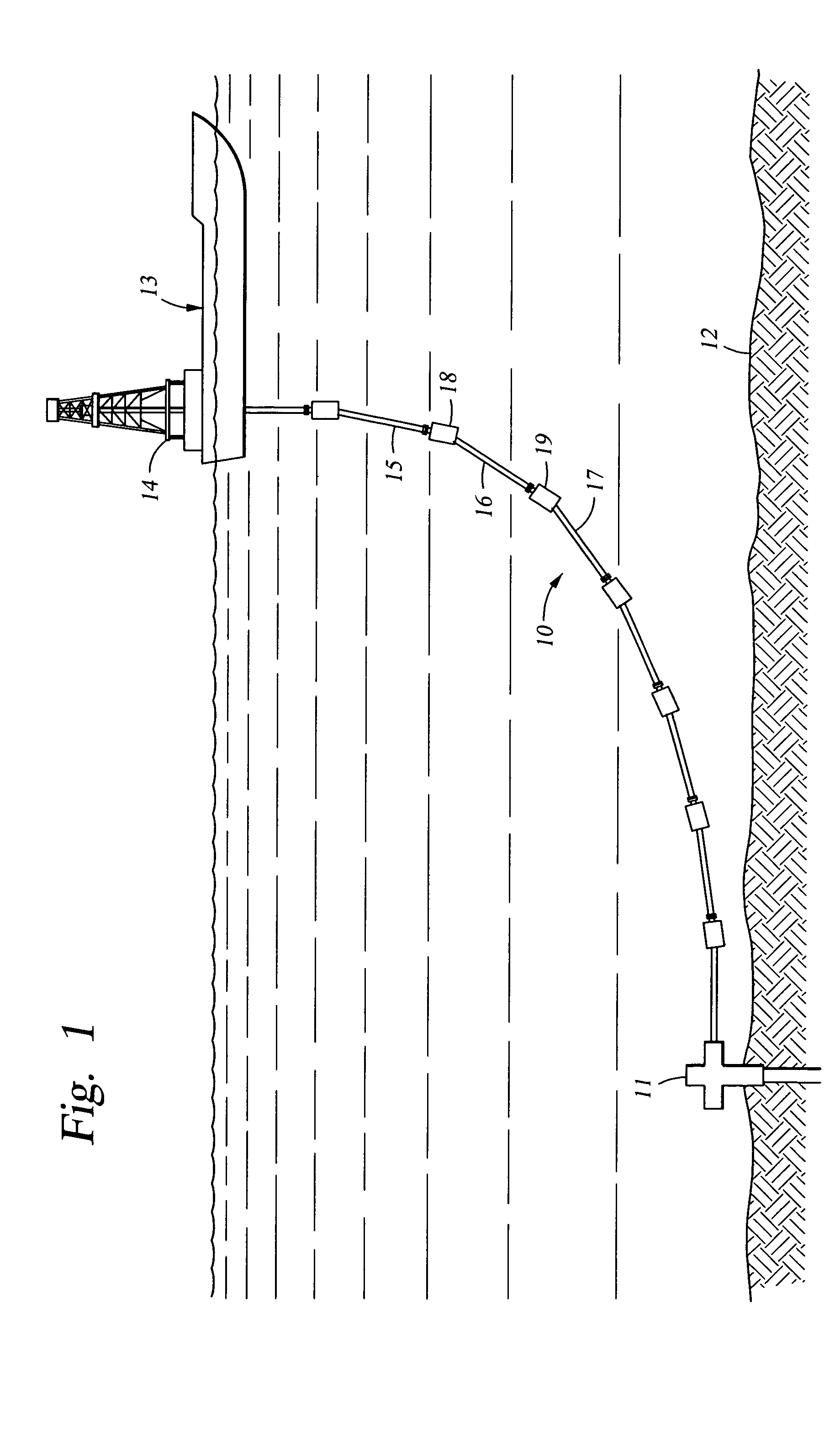

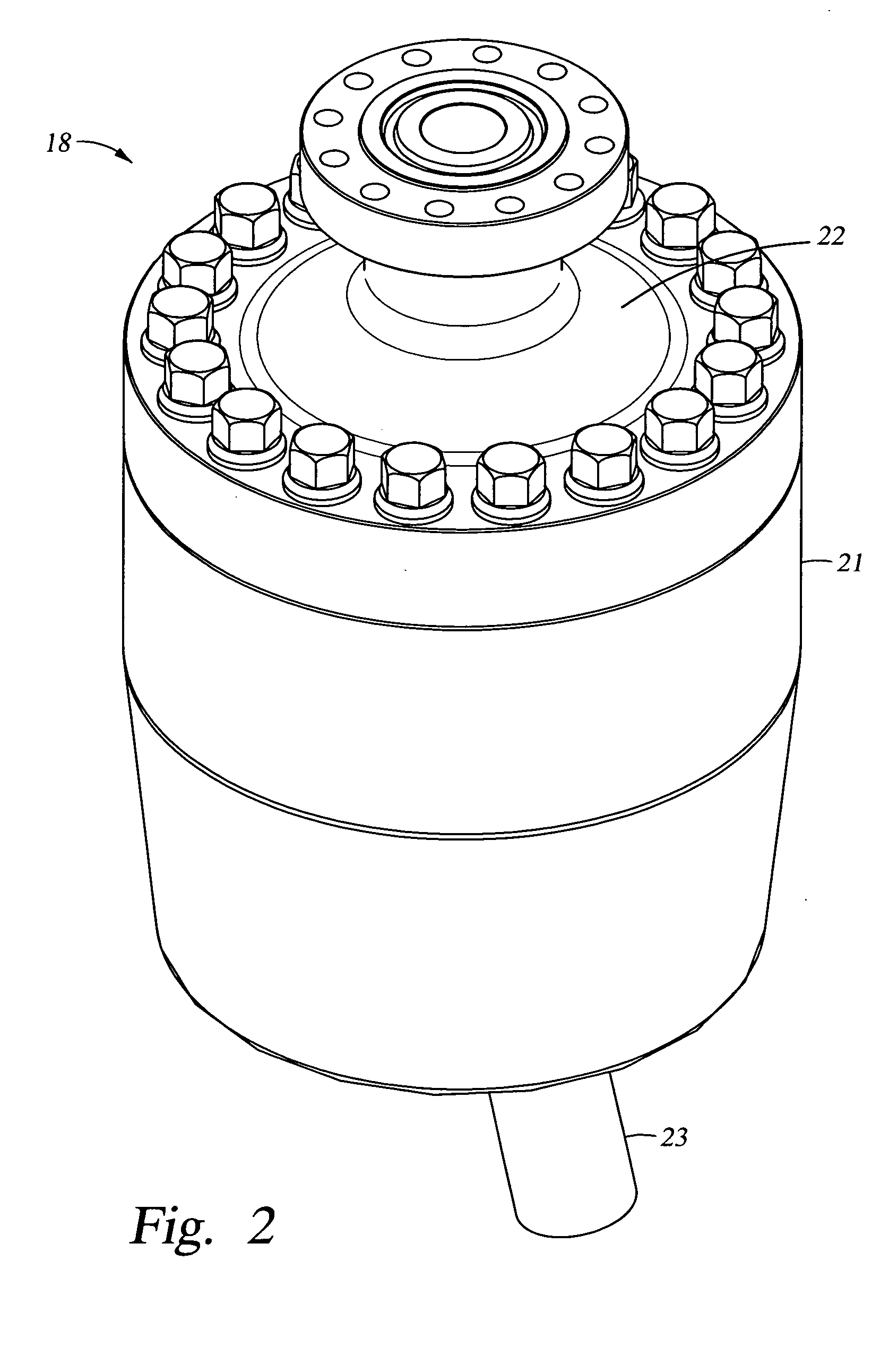

High temperature flexible pipe joint

ActiveUS20050167978A1High-temperatureContinuous operationDrilling rodsAdjustable jointsElastomerMetal alloy

For continuous high temperature operation over a service life in excess of twenty years, a flexible pipe joint includes various features that tend to reduce the temperature of the load-bearing flex element or reduce strain in the warmer elastomeric layers of the flex element. These features include a heat shield of low heat conductivity material integrated into the inner profile of the pipe extension and interposed between the central bore of the pipe joint and the flex element, low heat conductivity metal alloy components between the hot production fluid and the flex element, high temperature resistant elastomer at least in the warmest inner elastomer layer of the flex element, and a flex element constructed to shift strain from the warmer inner elastomer layers to the colder outer elastomer layers by providing greater shear area, different layer thickness, and / or higher elastic modulus elastomer for the warmer inner elastomer layers.

Owner:WELLS FARGO BANK NAT ASSOC +1

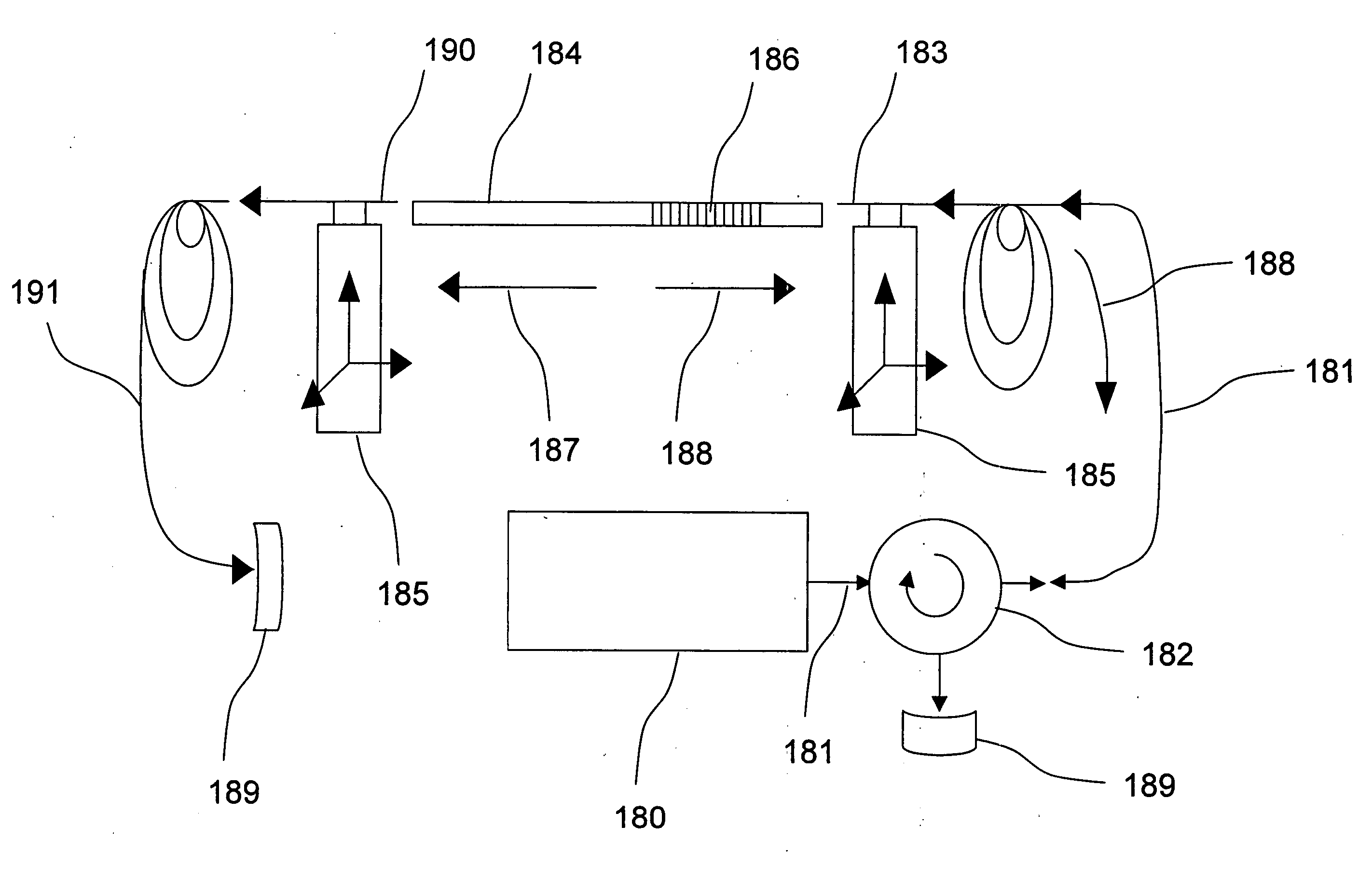

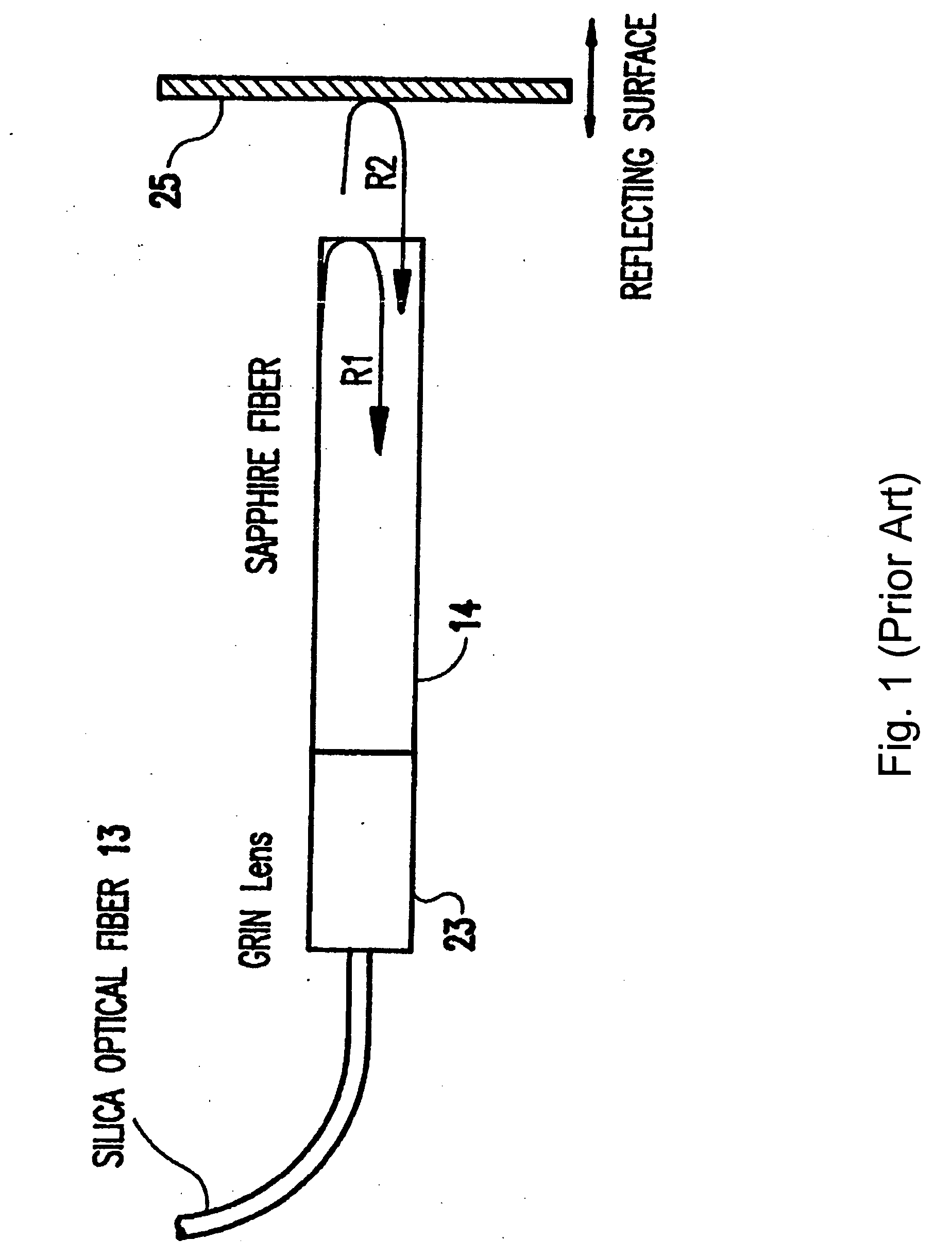

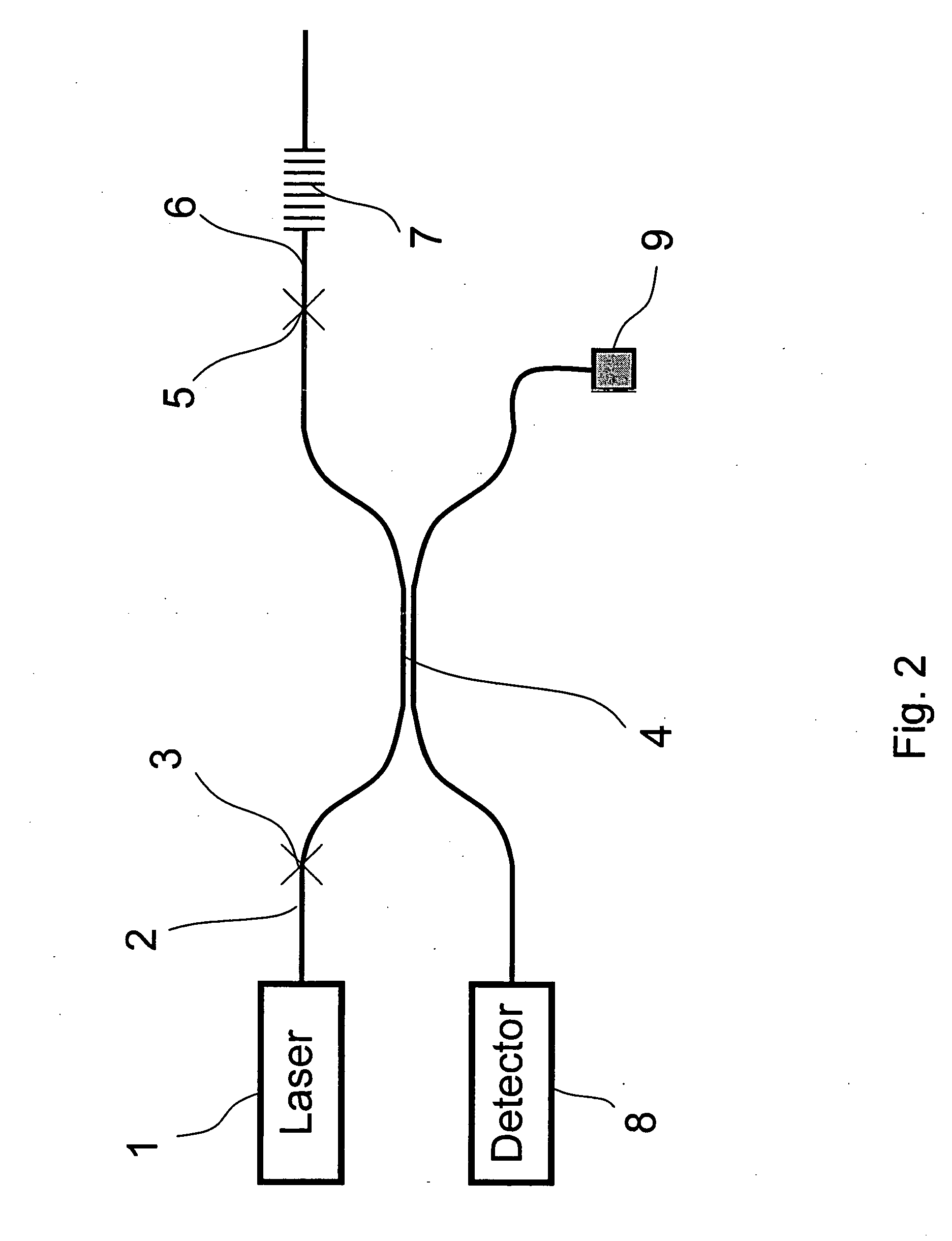

Optical fiber sensor based on retro-reflective fiber bragg gratings

InactiveUS20050232541A1High temperatureCoupling light guidesOptical waveguide light guideFiber optic sensorPulse duration

A retro-reflective sensor for sensing mechanical, chemical or temperature related information, is disclosed. The sensor is formed of an optical waveguide suitable for use in-situ in a high temperature environment having a Bragg grating written into a core region thereof with short-pulsed electromagnetic radiation, said optical waveguide having a glass transition temperature substantially higher than that of silica. Preferably the sensor is written into a length of sapphire fiber or within a zirconium waveguide. Preferably the pulse duration of the short pulsed electromagnetic radiation is less than 500 picoseconds.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF IND THROUGH THE COMM RES CENT

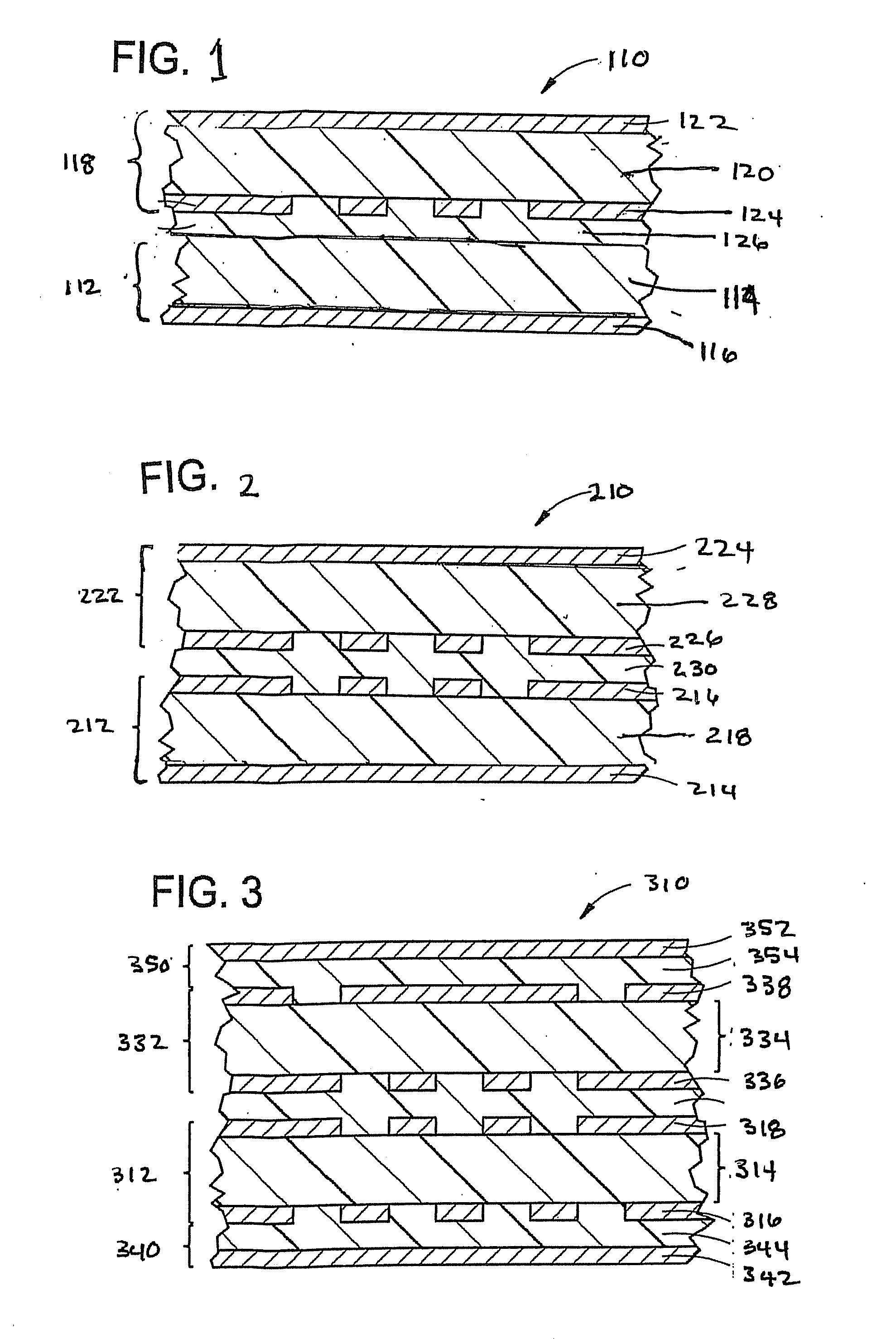

Circuit materials, multilayer circuits, and methods of manufacture thereof

ActiveUS20080254313A1High temperatureExcellent electrical and physical propertyDielectric materialsPrinted circuit detailsKetoneDecomposition

A circuit assembly comprises two or more circuit laminates, each comprising a conductive metal layer disposed on a poly(arylene ether ketone) substrate layer, wherein at least one of the conductive metal layers has been patterned to form a circuit, and a bond ply layer comprising a thermoplastic or thermosetting material. The thermoplastic bond ply has a melting point between 250° C. and 370° C., a decomposition temperature greater than about 290° C. and a dissipation factor of less than 0.01 at 10 GHz. The thermoset bond ply has a dissipation factor less than 0.01 at 10 GHz and a decomposition temperature greater than about 290° C. after lamination. Methods of forming the above circuit assemblies are also disclosed.

Owner:WORLD PROPERTIES

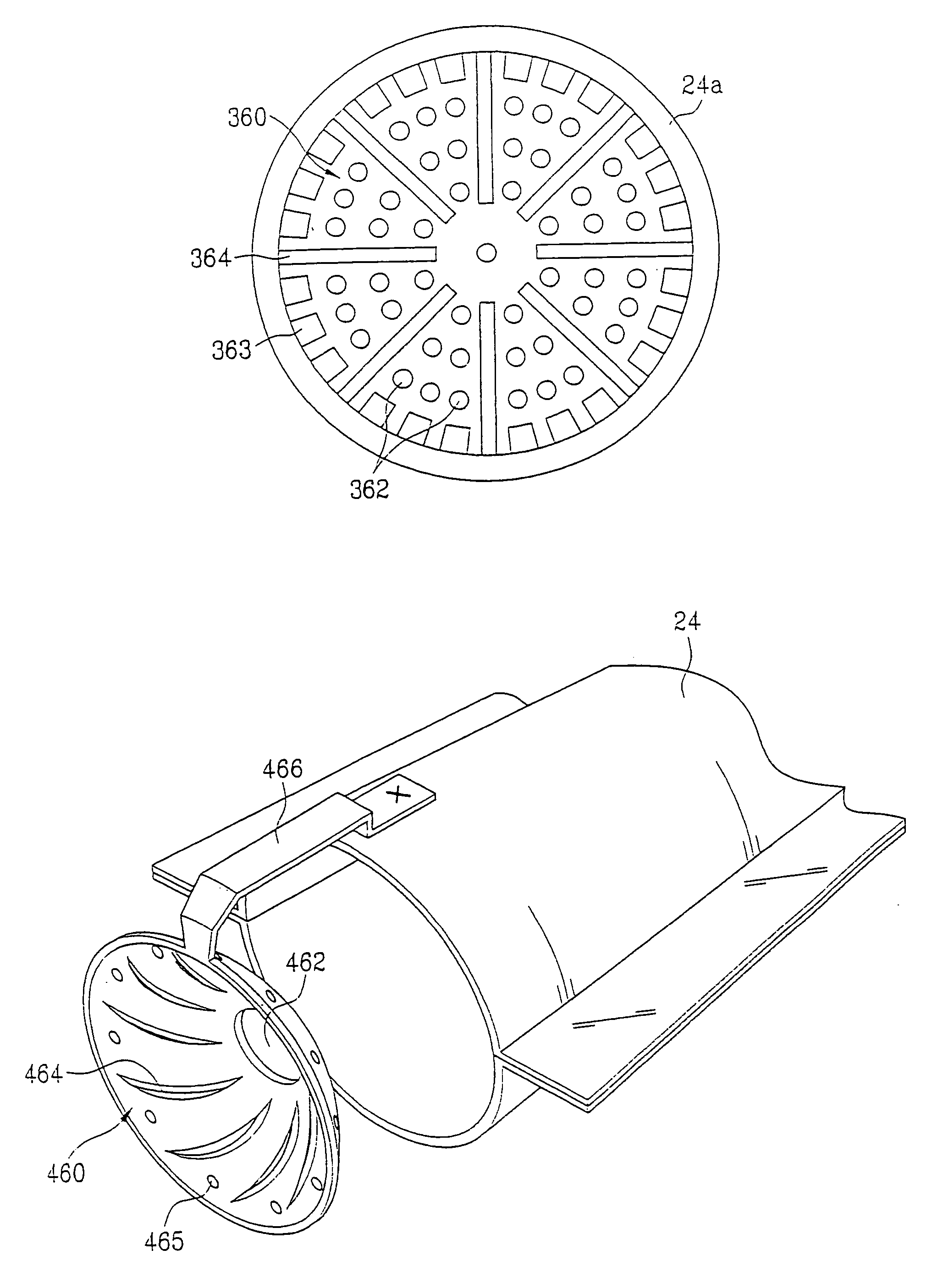

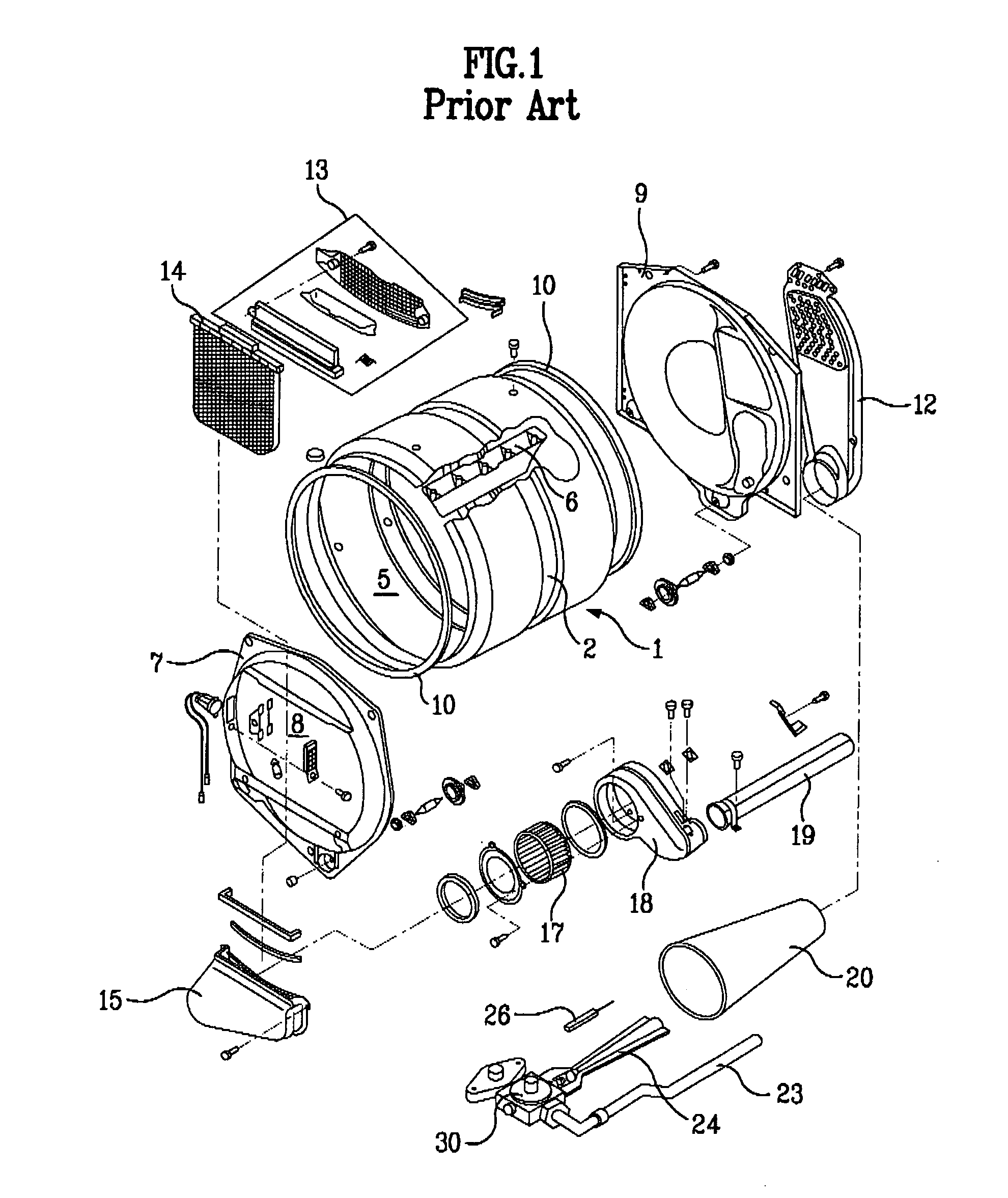

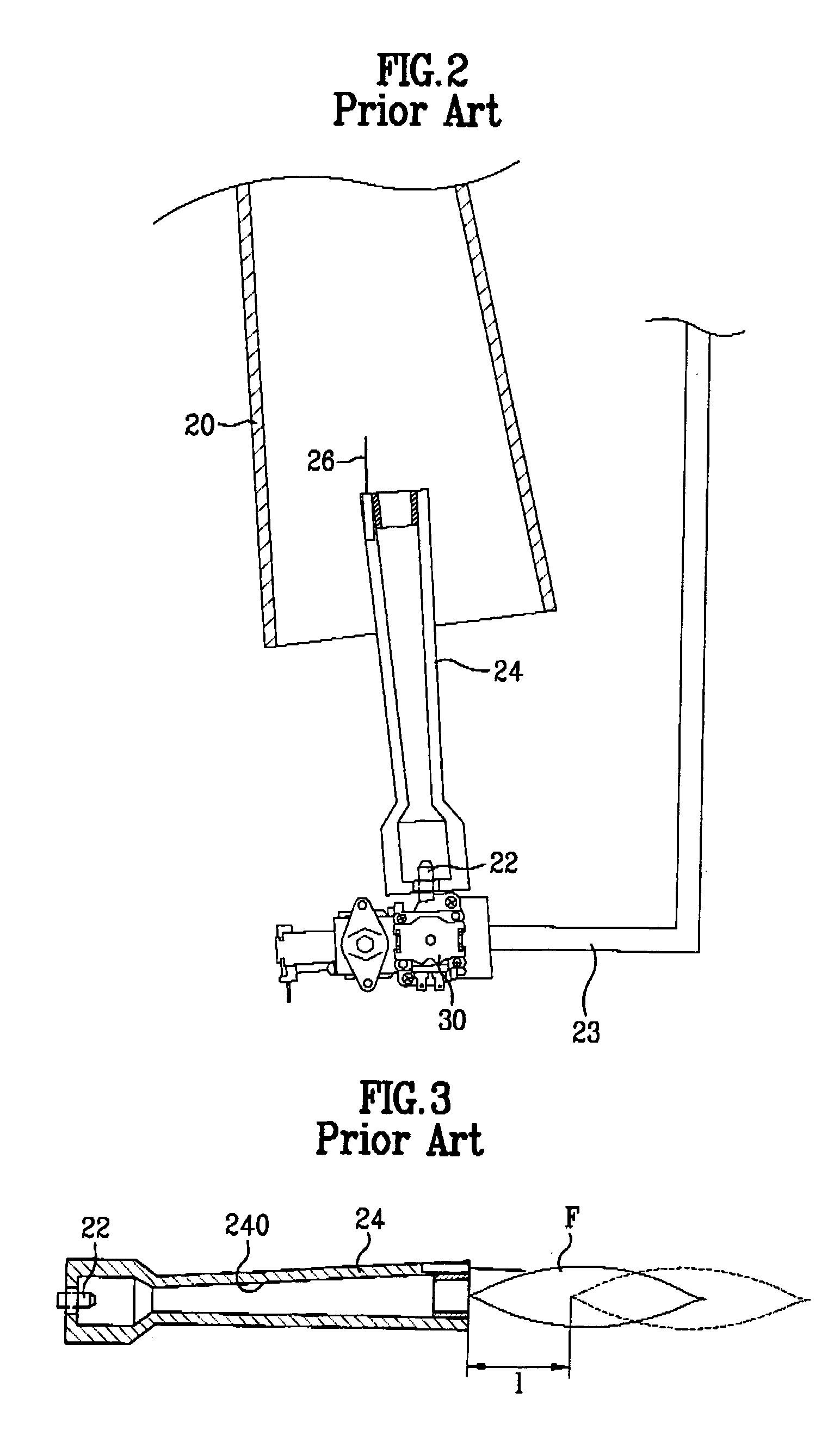

Gas burner for dryer

InactiveUS7204688B2Improves initial ignition performanceHigh temperatureDrying solid materials with heatElectric spark ignitersProcess engineeringGas burner

Gas burner for a dryer including a gas nozzle for receiving, and injecting gas, a mixing tube for mixing the gas injected from the gas nozzle and primary air, igniter fitted to an outlet of the mixing tube for igniting the gas mixed with the primary air coming out of the outlet of the mixing tube, and a flame holder fitted to the outlet of the mixing tube having flame holes for splitting, and ejecting the gas mixed with the primary air in burning the gas, thereby forming shorter flame lengths, and securing stability of the flame by enhancing an initial igniting capability, and splitting the flame into many parts to increase introduction of secondary air into the flame.

Owner:LG ELECTRONICS INC

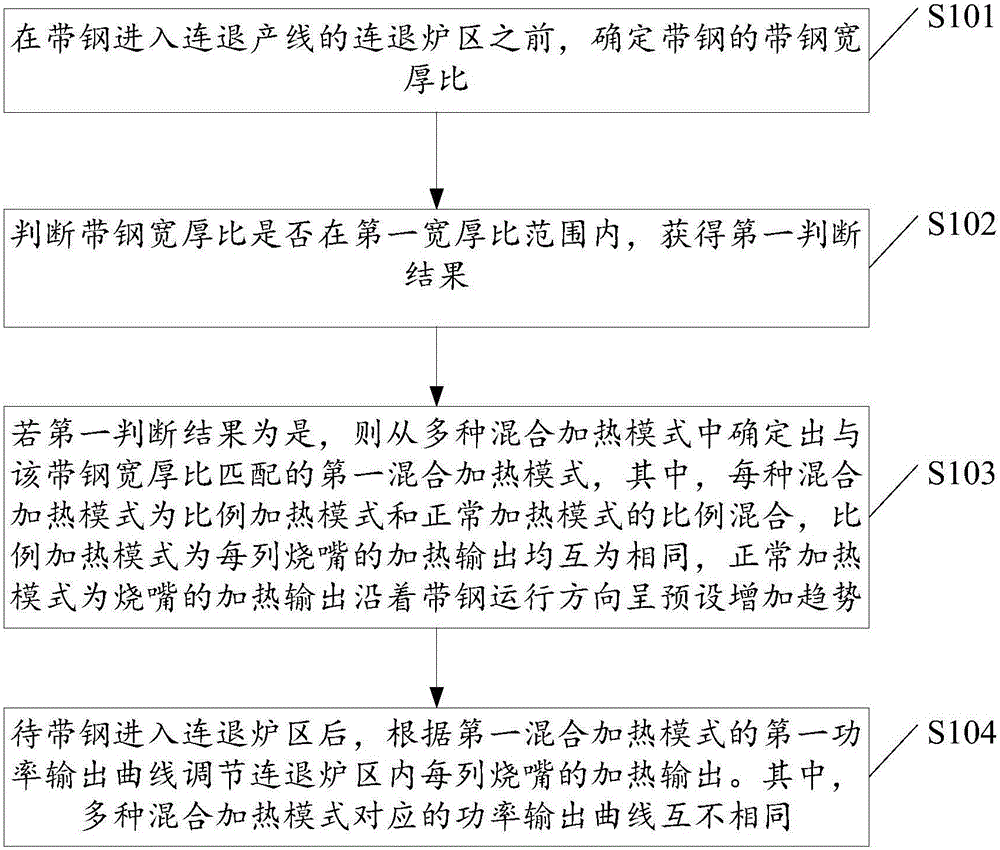

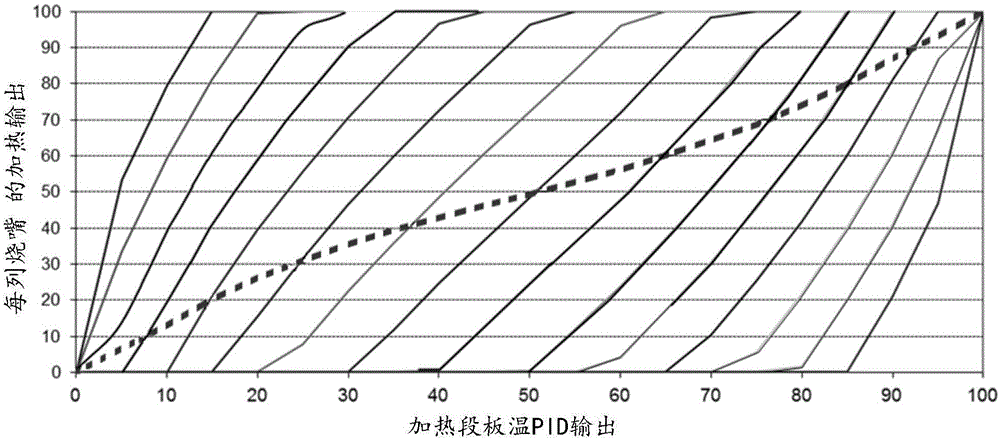

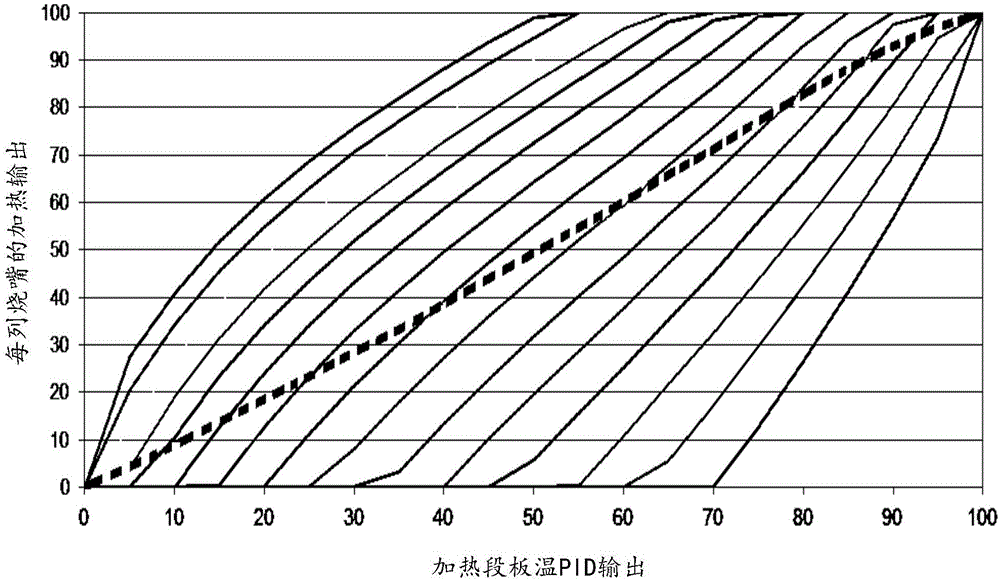

Control method for heating output of continuous annealing production line

ActiveCN105112643AHigh temperatureLarge plate temperature differenceFurnace typesHeat treatment process controlHeat outputControl system

The invention discloses a control method for heating output of a continuous annealing production line. The control method is applied to a control system of the continuous annealing production line, and the technical problem that in the prior art, thin gauge strip steel in a continuous annealing machine furnace is prone to heating buckling is solved. The control method for the heating output of the continuous annealing production line comprises the steps that the strip steel width-to-thickness ratio of strip steel is determined before the strip steel enters a continuous annealing furnace area of the continuous annealing production line; whether the strip steel width-to-thickness ratio is within the range of a first width-to-thickness ratio is judged, and a first judged result is obtained; and if the first judged result is yes, then a first mix heating mode matched with the strip steel width-to-thickness ratio is determined from various mix heating modes, wherein each mix heating mode is a proportional mix of a proportional heating mode and a normal heating mode, and after the strip steel enters the continuous annealing furnace area, the heating output of each line of burners in the continuous annealing furnace area is adjusted according to a first power output curve of the first mix heating mode, and the product quality of the thin gauge strip steel is further improved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

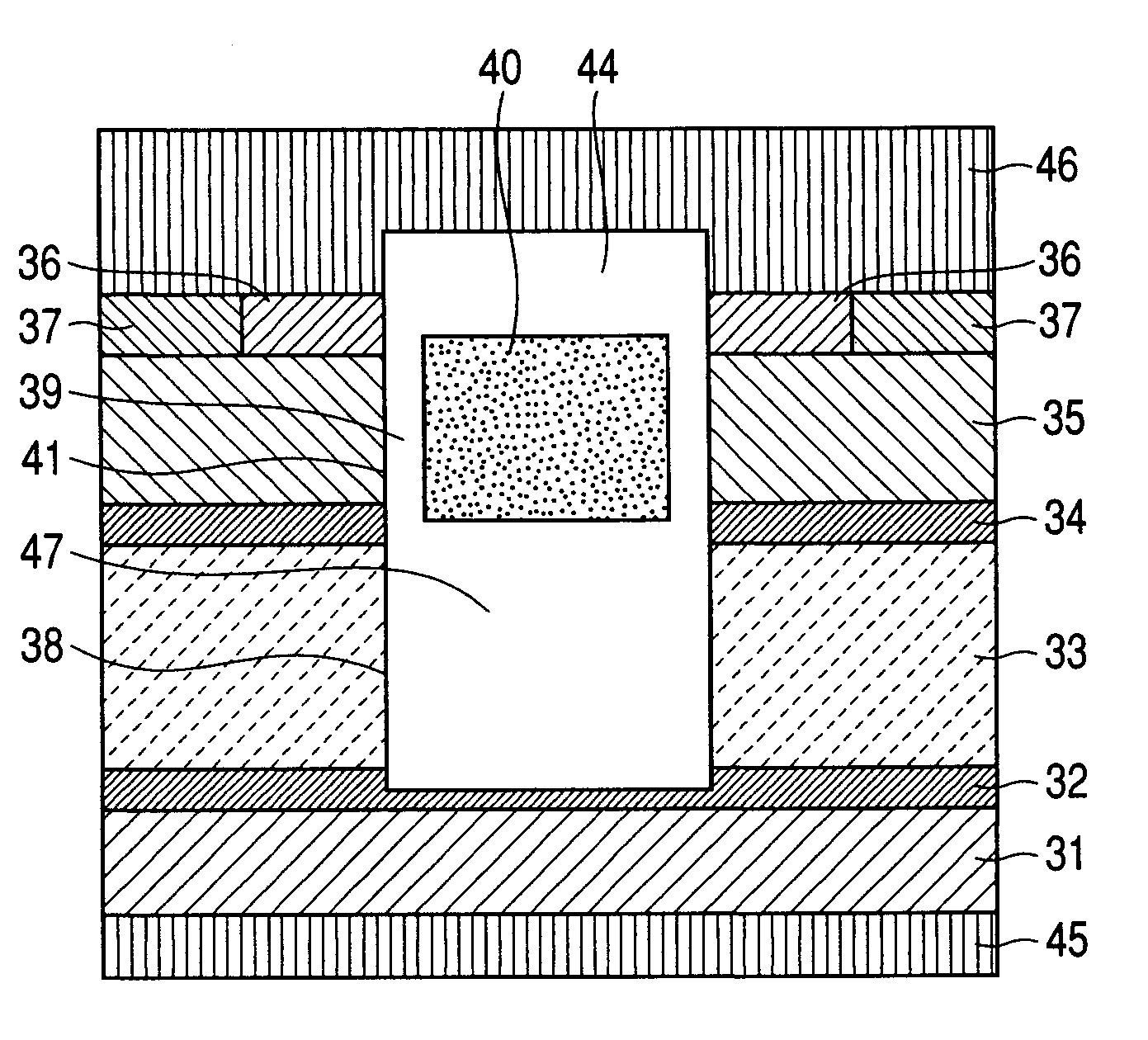

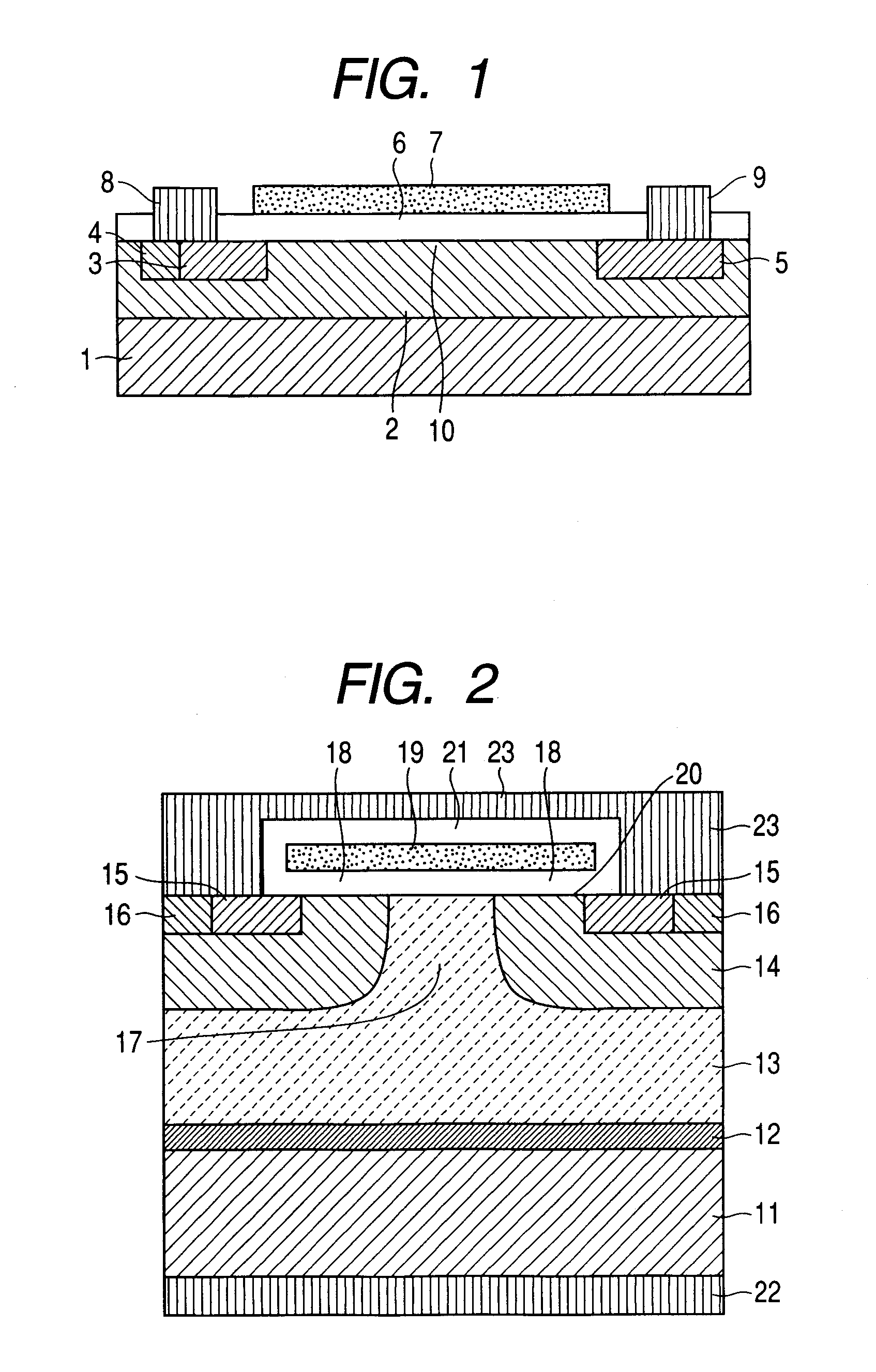

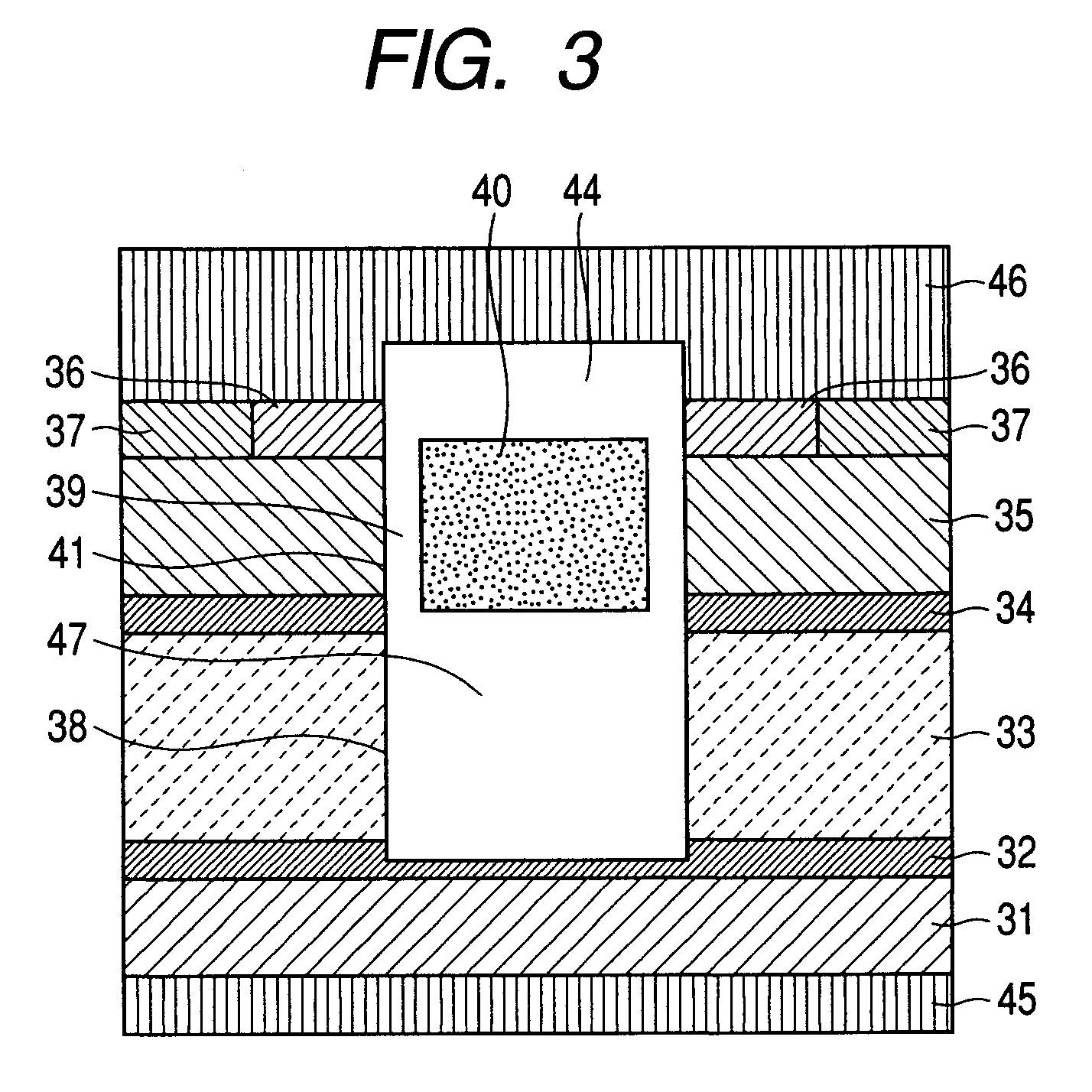

Silicon carbide semiconductor device and manufacturing method thereof

InactiveUS20070243722A1Simplify production processHigh temperatureSemiconductor/solid-state device manufacturingSemiconductor devicesState densityOxide

A method of manufacturing a device on a silicon carbide substrate is disclosed. The device includes an oxide layer which has silicon oxide as a main component on the silicon carbide semiconductor substrate. The method includes depositing and oxide layer on a surface of the silicon carbide semiconductor substrate; raising a temperature of the oxide layer in a non-oxidizing atmosphere to a temperature bringing the oxide layer into a liquefied state; and then rapidly cooling the oxide layer down to a temperature equal to or less than 1140° C. to form the oxide layer including silicon oxide as a main component. The silicon carbide semiconductor device has improved channel mobility to lower on-resistance by decreasing an interface state density at an interface between the oxide insulator film that has silicon oxide as its main component and the silicon carbide semiconductor substrate.

Owner:FUJI ELECTRIC HLDG CO LTD

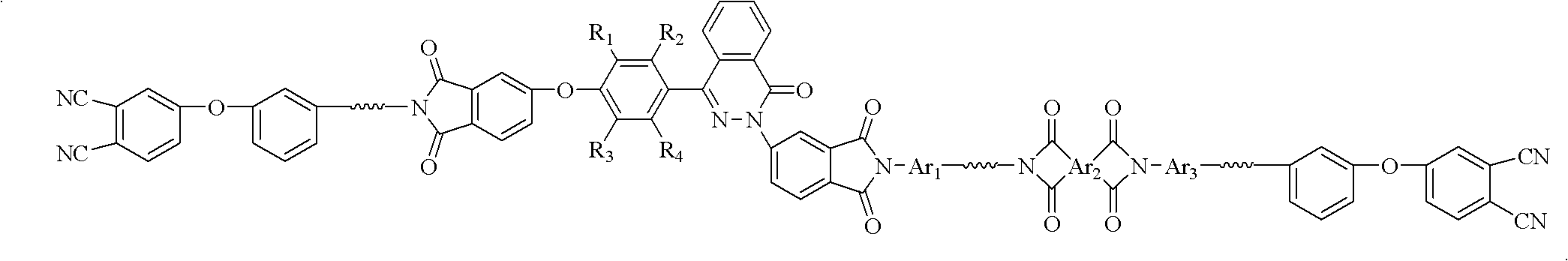

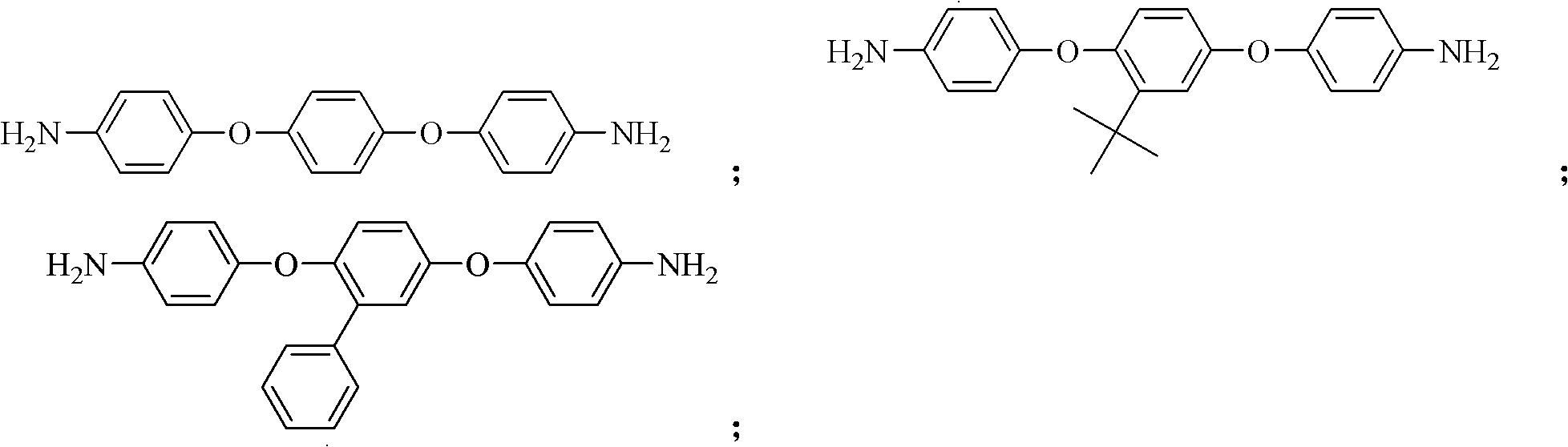

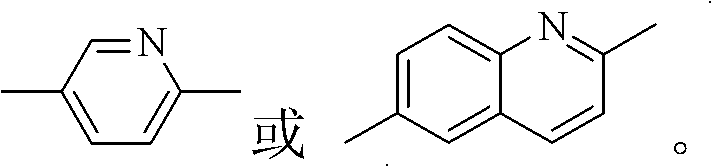

Phthalonitrile-terminated polyimide resin containing phthalazinone structure, cured product and preparation method thereof

The invention belongs to the field of synthesis of polymer materials and specifically relates to phthalonitrile-terminated polyimide resin containing a phthalazinone structure, a cured product and a preparation method thereof. The phthalonitrile-terminated polyimide resin containing the phthalazinone structure is prepared by taking 4-(3-aminophenoxy) phthalonitrile as a terminating agent and carrying out solution nucleophilic substitution reaction. The method has simple steps and is convenient and feasible. The polyimide resin shows great solubility in commonly used polar solvents, can be processed and molded by a variety of ways, and simultaneously has great curing reaction activity. The cured product of the polyimide resin containing the phthalazinone structure with dimension stability and high thermal stability can be obtained by carrying out pre-curing on the resin at the temperature of 150-300 DEG C and carrying out thermal treatment at the temperature of 350-400 DEG C in the presence of aromatic diamine. The phthalonitrile-terminated polyimide resin containing the phthalazinone structure can be used for preparing coatings, insulating paint, sizing agents, thin films, high-performance composite materials and the like and has wide application prospects.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com