Patents

Literature

155 results about "Ultra-high-temperature ceramics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultra-high-temperature ceramics (UHTCs) are a class of refractory ceramics that offer excellent stability at temperatures exceeding 2000 °C being investigated as possible thermal protection system (TPS) materials, coatings for materials subjected to high temperatures, and bulk materials for heating elements. Broadly speaking, UHTCs are borides, carbides, nitrides, and oxides of early transition metals. Current efforts have focused on heavy, early transition metal borides such as hafnium diboride (HfB₂) and zirconium diboride (ZrB₂); additional UHTCs under investigation for TPS applications include hafnium nitride (HfN), zirconium nitride (ZrN), titanium carbide (TiC), titanium nitride (TiN), thorium dioxide (ThO₂), tantalum carbide (TaC) and their associated composites.

High-entropy carbide ultrahigh temperature ceramic powder and preparation method thereof

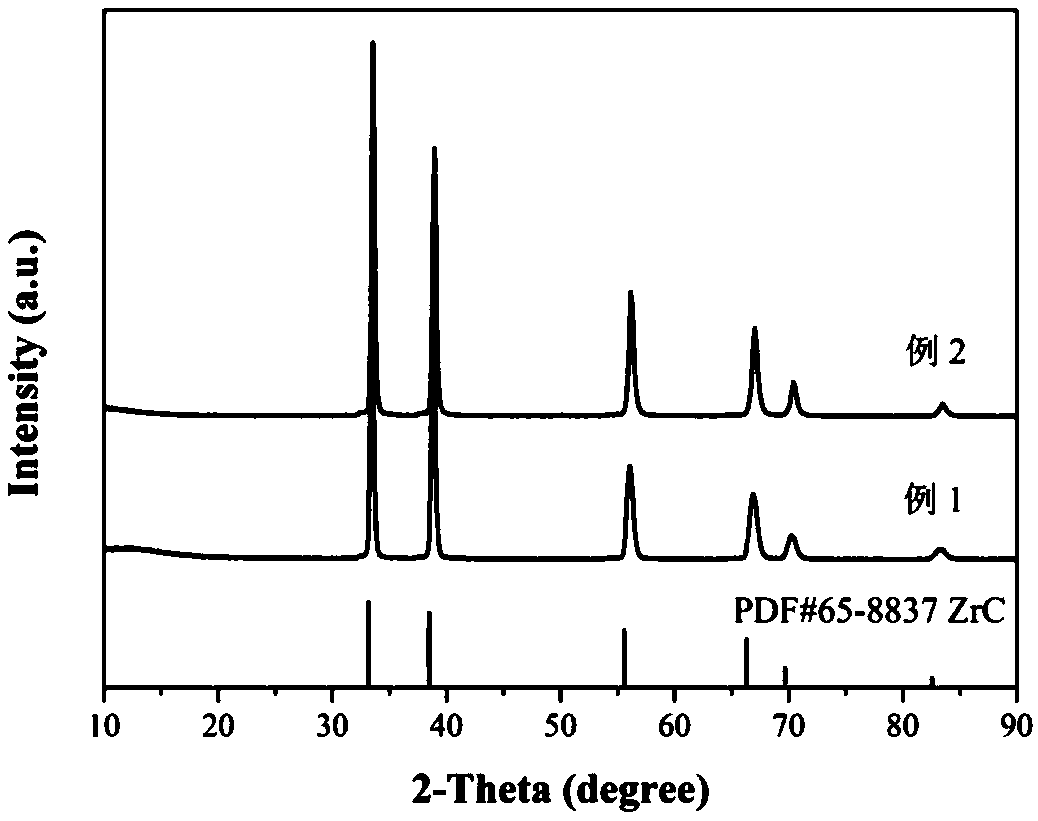

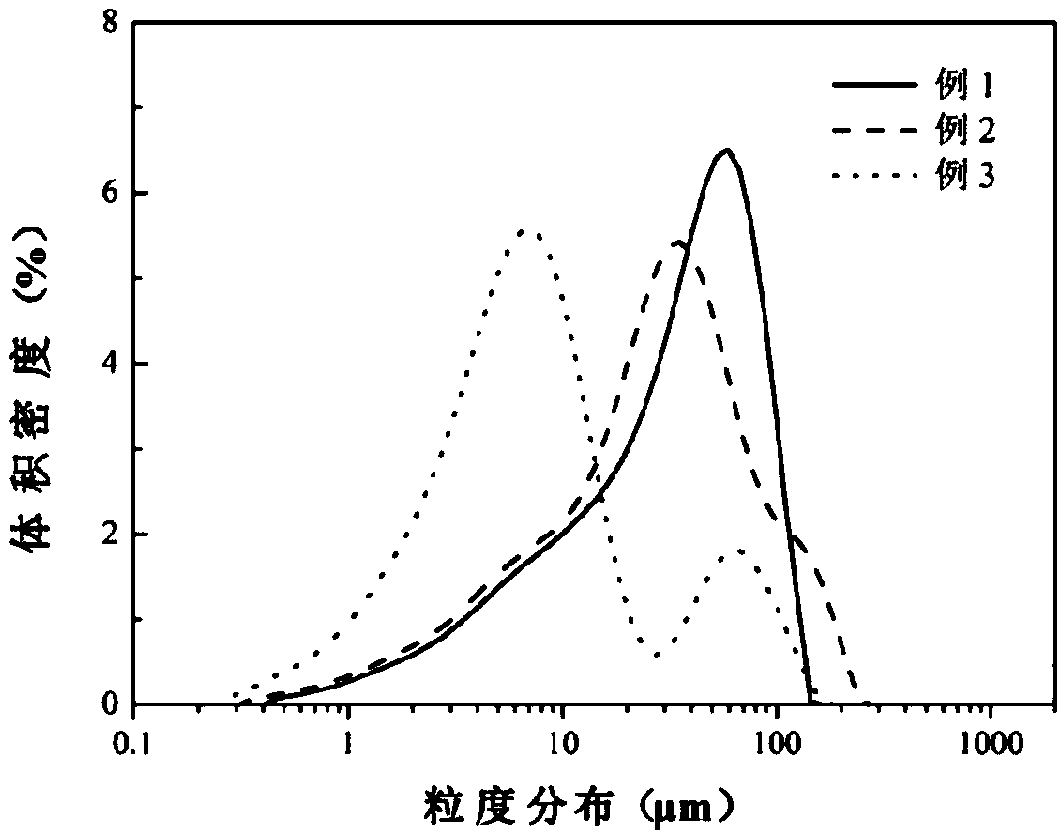

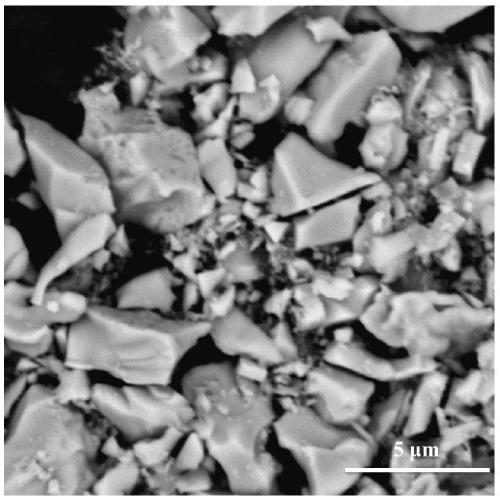

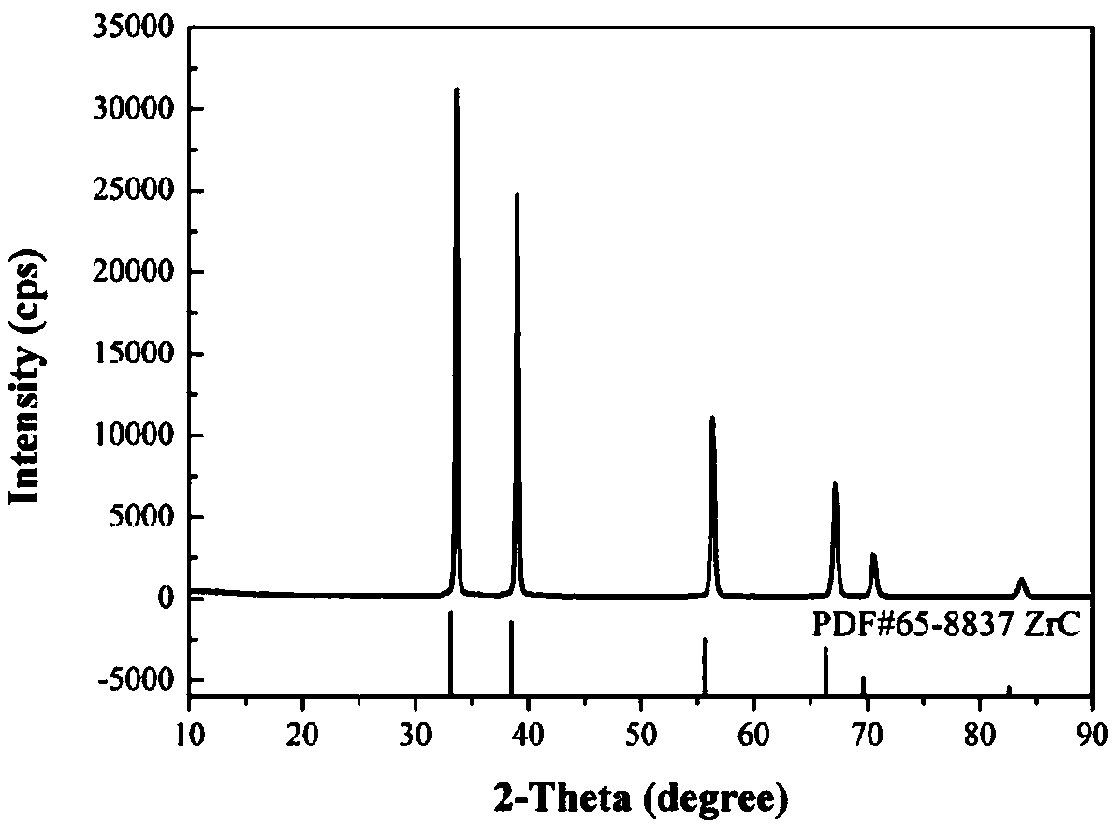

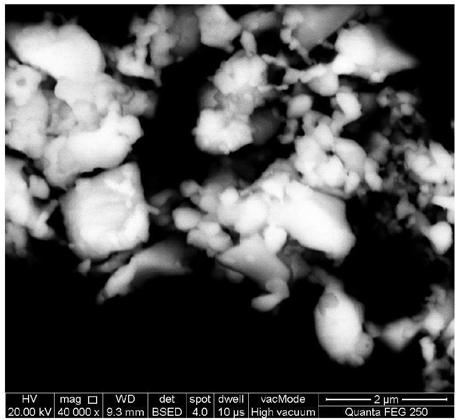

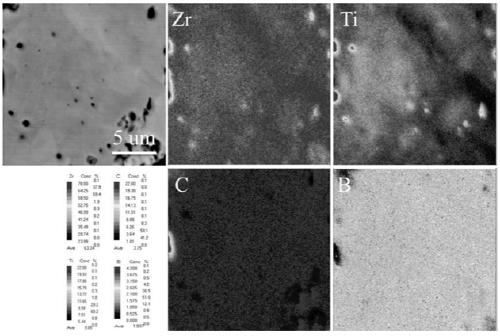

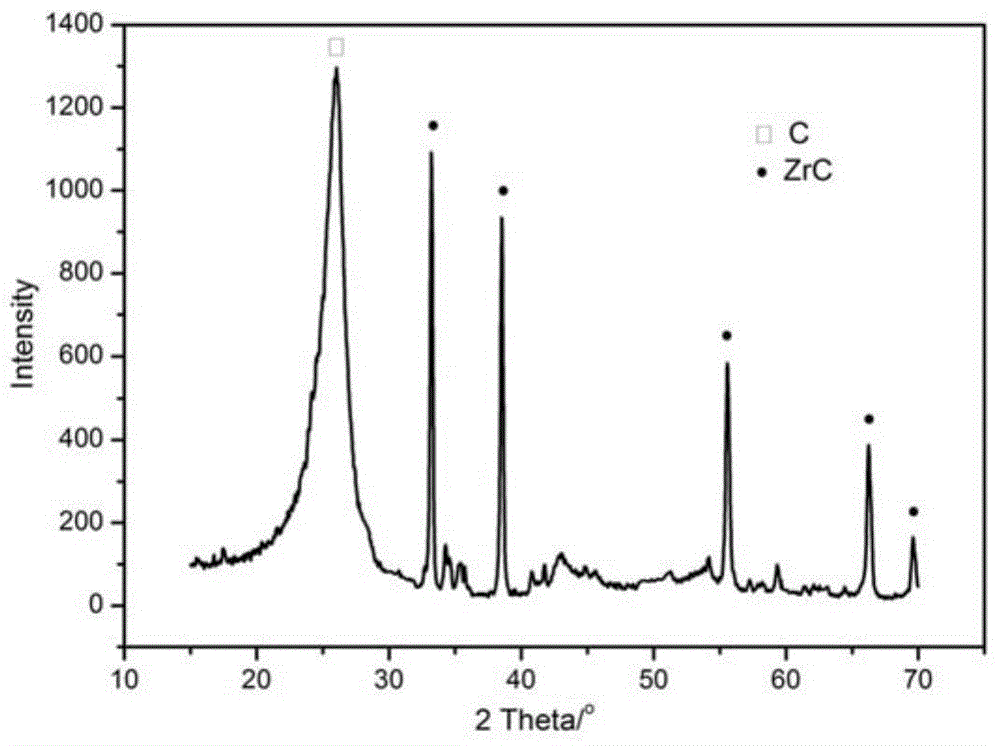

The invention belongs to the technical field of carbide ceramics, and concretely relates to a high-entropy carbide ultrahigh temperature ceramic powder and a preparation method thereof. The molecularformula of the ceramic powder is XCy, wherein X is at least two of Zr, Ti, Hf, V, Nb, Ta, Cr, Mo and W, and y is equal to or more than 0.6 and less 1.0. The ceramic powder has a single phase face-centered cubic structure, and has a free carbon content of 0.035 wt% or below. The ceramic powder is prepared through the steps of ball-milling mixing of at least two metal powders and C powder, and pressureless plasma sintering. The high-entropy carbide ultrahigh temperature ceramic powder is a single-phase solid solution, has the single phase face-centered cubic structure, and also has the advantages of low free carbon content, high purity, loose structure, fragility, and facilitation of post-processing applications.

Owner:CENT SOUTH UNIV

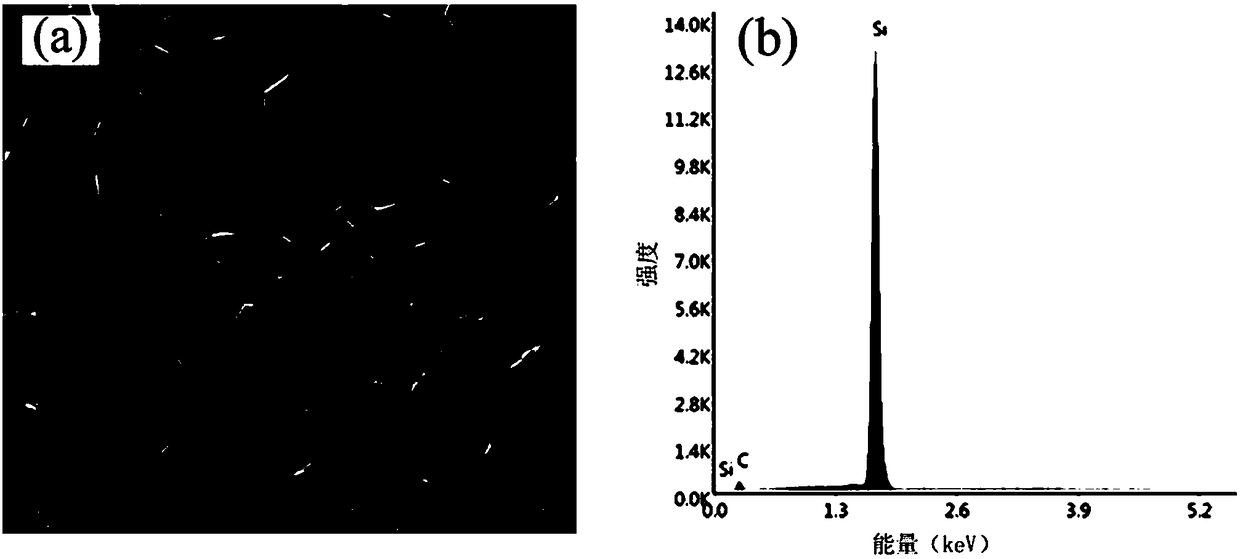

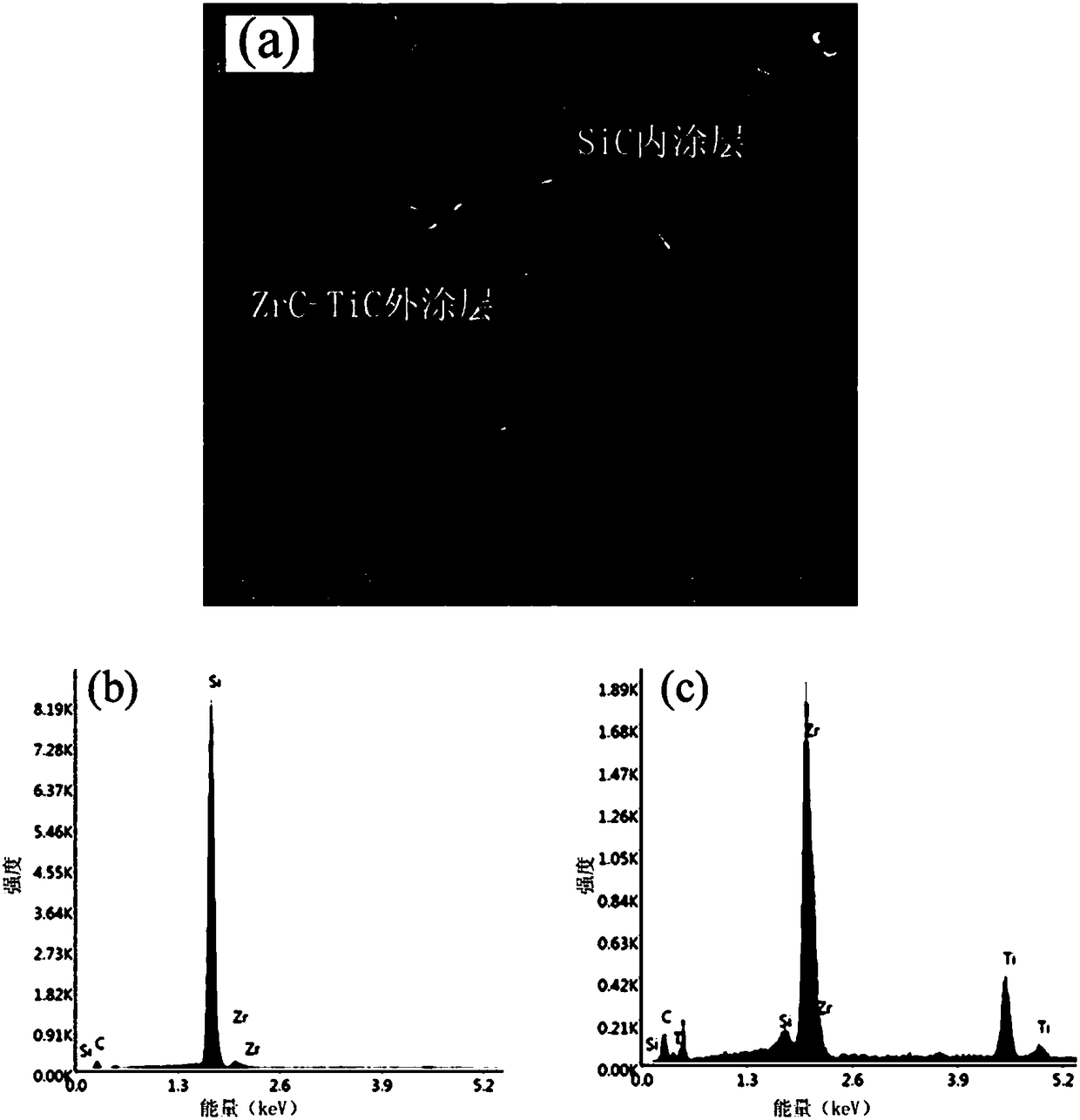

C/C composite material superhigh temperature ceramic coating, and preparation method thereof

InactiveCN108530110AExtended service lifeReduce Mismatch ProblemsUltra-high-temperature ceramicsCeramic coating

The invention discloses a C / C composite material superhigh temperature ceramic coating, and a preparation method thereof. The C / C composite material superhigh temperature ceramic coating is composed of an anti-oxidation SiC transition internal layer and a superhigh temperature ablation-resistant ceramic external layer; the superhigh temperature ablation-resistant ceramic external layer is composedof more than one ingredients selected from SiC, ZrC, HfC, TaC, TiC, ZrB2, HfB2, TaB2, and TiB2. The preparation method is suitable for industrialized production, is simple in equipment, is convenientin operation, is capable of controlling coating thickness, satisfying preparation requirements of large size C / C composite material superhigh temperature ceramic coating with complex shapes, and is asuperhigh temperature ceramic coating preparation method with excellent development potential.

Owner:CENT SOUTH UNIV

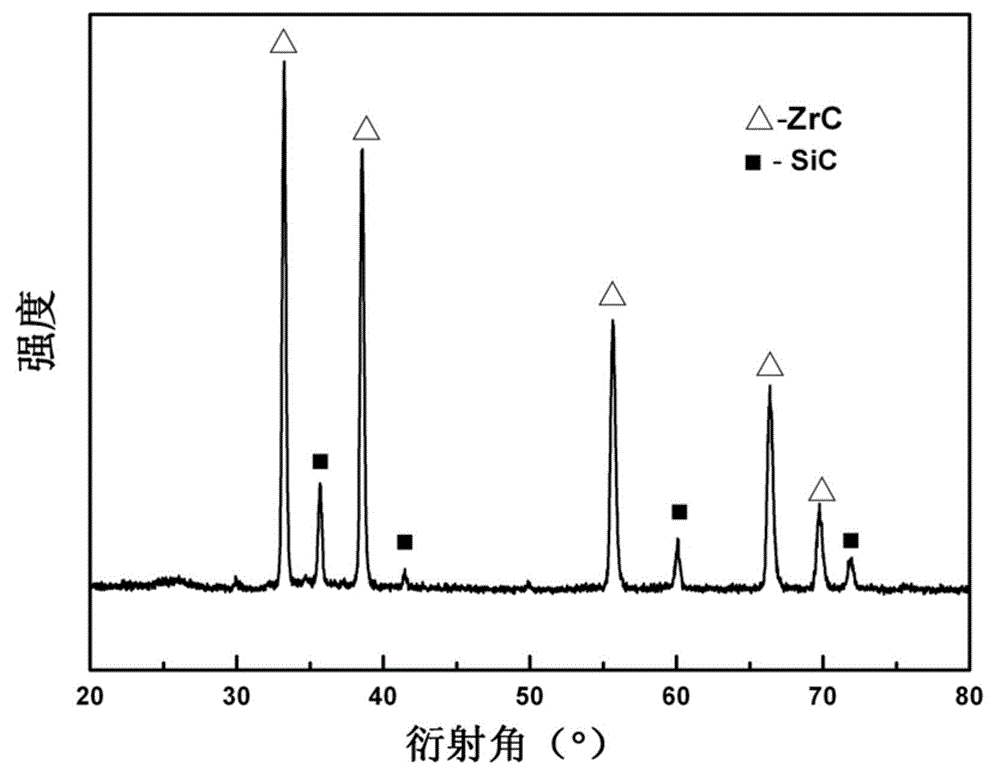

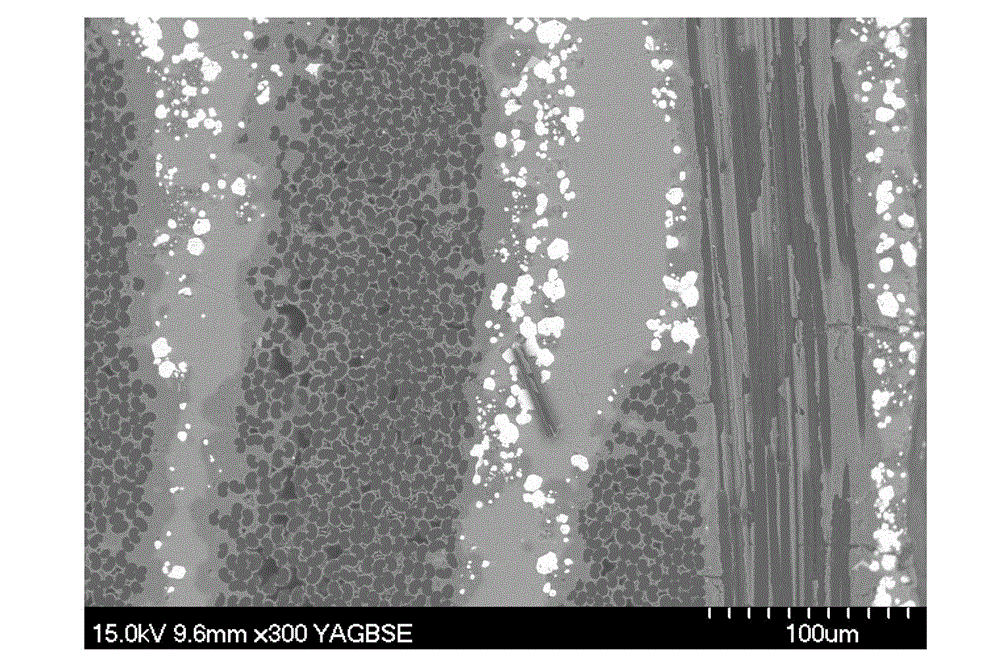

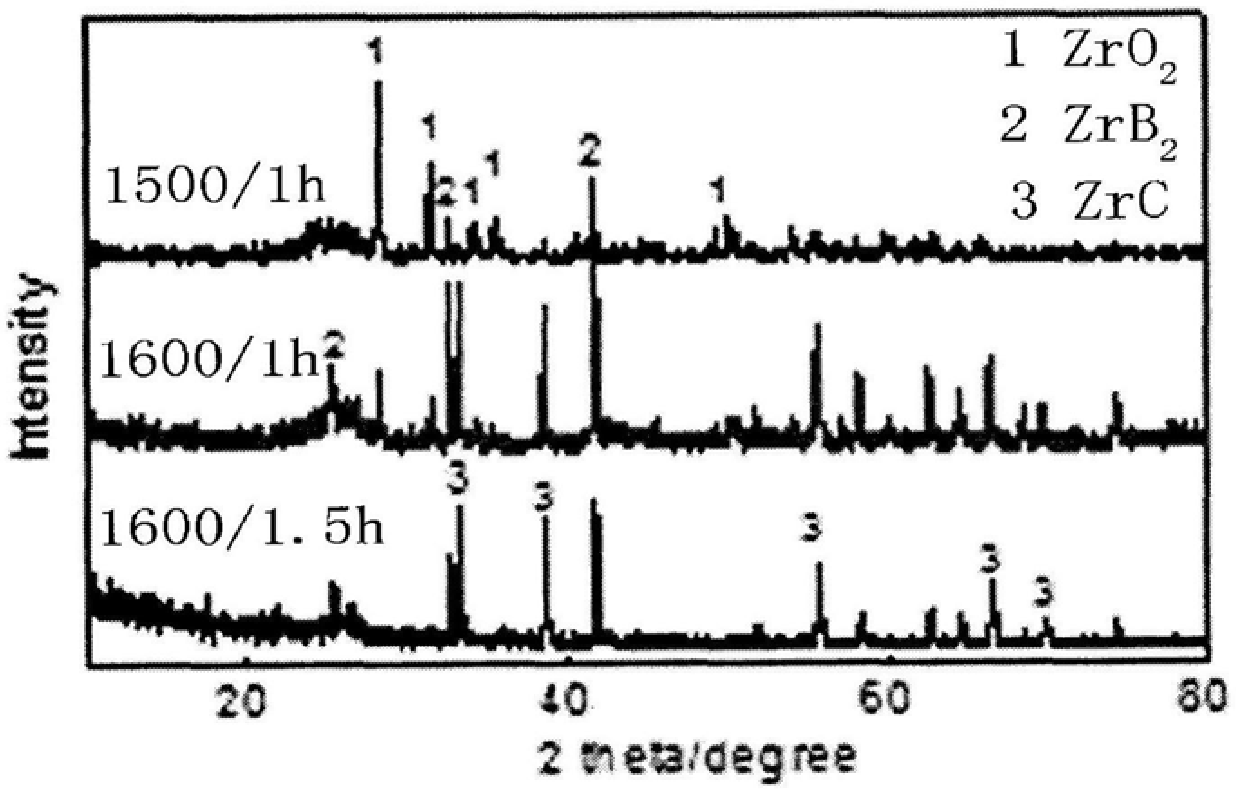

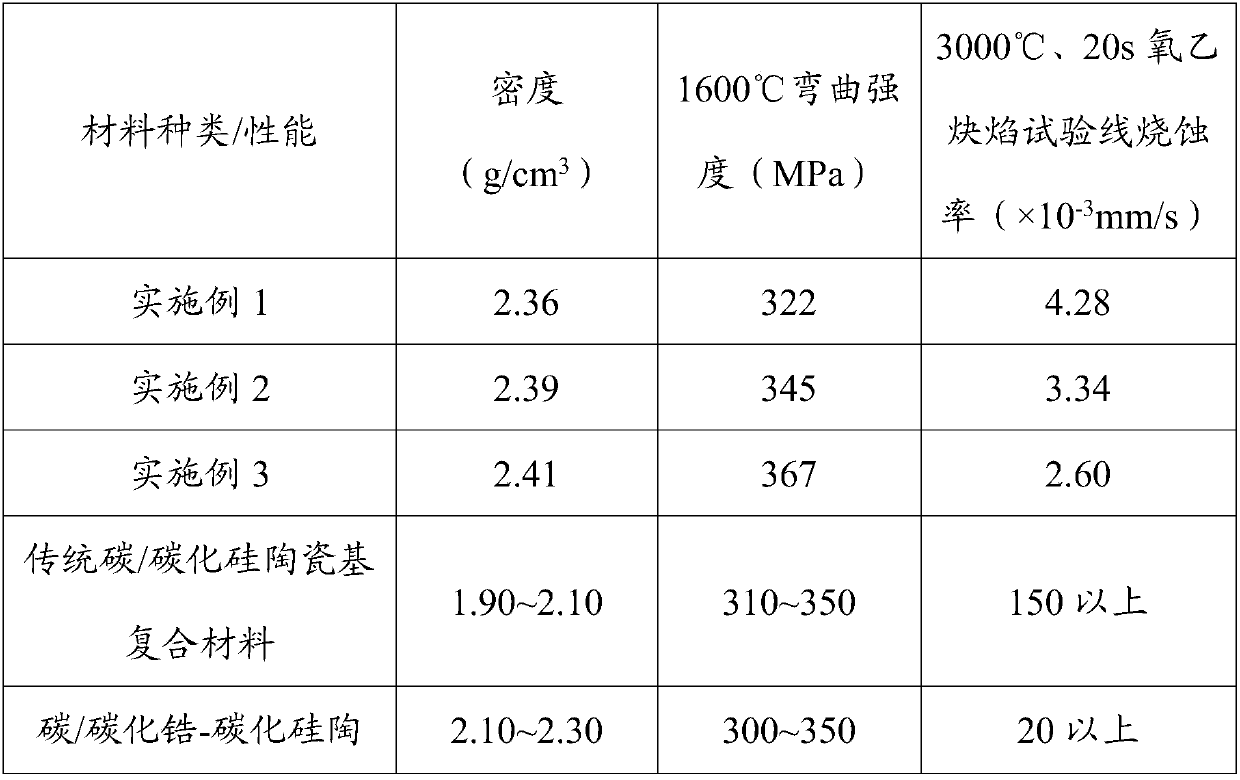

Method for preparing Cf/ZrC-SiC superhigh-temperature ceramic composite material through hot-pressing sintering/precursor cracking process

ActiveCN104311090AImprove high temperature resistanceMeet the practical applicationFiberCarbon fibers

The invention relates to a method for preparing a Cf / ZrC-SiC superhigh-temperature ceramic composite material through a hot-pressing sintering / precursor cracking process, and concretely relates to an in-situ preparation method for the Cf / ZrC-SiC superhigh-temperature ceramic composite material by combining a precursor cracking process and a hot-pressing sintering process. The method comprises: introducing ZrSi2 powder into carbon fiber fabric, employing the hot-pressing sintering process for in-situ generation of ZrC and SiC ceramic base bodies, and employing the precursor cracking process to perform final densification processing, so as to obtain the compact Cf / ZrC-Si superhigh-temperature ceramic composite material. The superhigh-temperature ceramic composite material prepared by employing the preparation method has excellent superhigh temperature usage performance, and the method is simple in process and short in time consumption. The obtained Cf / ZrC-SiC superhigh-temperature ceramic composite material can basically satisfy practical application of some heatproof structural members, and has wide application prospect in extreme environments such as super hypersonic speed flight, aerosphere reentry, trans-atmospheric flight, rocket propulsion system and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

High-entropy boron-containing carbide ultrahigh temperature ceramic powder and preparation method thereof

The invention belongs to the technical field of carbide ceramics, and concretely relates to a high-entropy boron-containing carbide ultrahigh temperature ceramic powder and a preparation method thereof. The molecular formula of the ceramic powder is XCyBz, wherein X is at least two of Zr, Ti, Hf, V, Nb, Ta, Cr, Mo and W, y is equal to or more than 0.6 and less 1.0, z is more than 0 and equal to orless than 0.4, and y + z = 1. The ceramic powder has a single phase face-centered cubic structure. The preparation method comprises the following steps: carrying out ball-milling mixing on at least two metal powders and C powder, carrying out pressureless plasma sintering and crushing to obtain carbide powder, mixing the carbide powder with B2O3 powder and a carbon source, and then performing high temperature sintering and crushing to obtain the ceramic powder. The ceramic powder is a single-phase solid solution, has the face-centered cubic structure, and contains the boron element, so the ceramic powder integrates the high temperature resistance of carbides and the oxidation resistance of borides, and can be used to prepare an ablation and oxidation resistant high-entropy boron-containing carbide ultrahigh temperature ceramic block or composite material.

Owner:CENT SOUTH UNIV

Method for preparing UHTC (Ultra-High Temperature Ceramic) matrix composite material through modification of UHTC powder basal body

InactiveCN103058711AImprove mechanical propertiesGuaranteed mechanical propertiesFiberVacuum pressure

The invention discloses a method for preparing an UHTC (Ultra-High Temperature Ceramic) matrix composite material through modification of a UHTC powder basal body. The method comprises the steps of: introducing UHTC powder and a carbon organic precursor into C / SiC with a gas hole ratio of 30 vol% to 40 vol% by adopting a vacuum pressure impregnation way; and performing in-situ reaction on melting silicon and splitting carbon in the basal body, and compacting the material through the combination of RMI (Reactive Melt Infiltration) so as to prepare a C / SiC-UHTC composite material. For one aspect, the SiC basal body protects fibers from being eroded by the melting silicon so as to improve mechanical properties of the material as the C / SiC with the gas hole ratio of 30 vol% to 40 vol% is adopted as a prefabricated body; and for the other aspect, a certain amount of the UHTC powder is introduced into the prefabricated body to improve anti-ablation performances.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing fiber reinforced multiphase ceramic matrix composite material

InactiveCN108395266AImprove ultra-high temperature resistanceThe introduction method is simpleCarbon fibersUltra-high-temperature ceramics

The invention relates to a method for preparing a fiber reinforced multiphase ceramic matrix composite material. The method comprises the following steps: using a carbon fiber or silicon carbide fiberas a reinforcement, and combining a slurry method to prepare a fiber prepreg, and then preparing the fiber reinforced multiphase ceramic matrix composite material by hot press forming, carbonizationand infiltration. The powder body such as ZrB2, ZrC, HfB2, and HfC are directly added into a slurry, thereby introducing an ultra-high temperature component, and improving the ultra-high temperature resistance of the composite material. The method overcomes the defects of long preparation period and high cost of the traditional fiber reinforced ultra-high temperature ceramic matrix composite material, and can prepare the ultra-high temperature ceramic matrix composite material with excellent performances in a short cycle and low cost.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

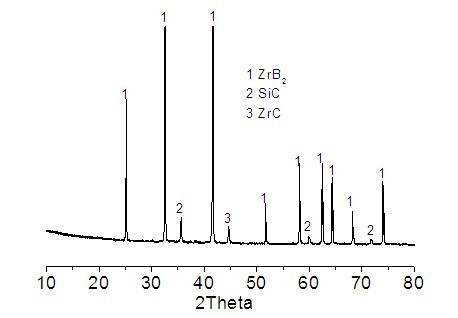

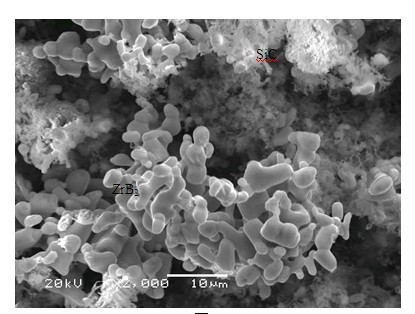

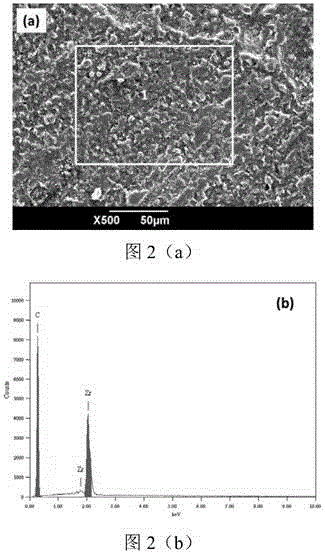

ZrB2-SiC composite powder and preparation method thereof

InactiveCN102320850AFix issues with restricted usageSynthesis temperature is lowUltra-high-temperature ceramicsRefractory

The invention discloses ZrB2-SiC composite powder and a preparation method thereof. According to the invention, zircon sand, a boron raw material and a carbon raw material are adopted as main materials. The main materials are mixed, grinded, and are heated under a temperature of 1350 to 1480 DEG C, such that the powder is obtained. The powder comprises components of, by weight: 37 to 63% of ZrSiO4, 16 to 32% of B2O3, and 20 to 28% of C, wherein the boron raw material is calculated according to the amount of B2O3, and the carbon raw material is calculated according to the amount of C element. According to the invention, natural zircon sand with a relatively low price is used as a raw material for producing high-grade ZrB2-SiC. The advantages of ZrB2 and SiC are combined. Mutual complement of advantages can be realized when ZrB2 and SiC are used in the field of high-temperature materials. ZrB2-SiC provides relatively high thermal conductivity, excellent thermal shock resistance and corrosion resistance. When ZrB2-SiC is introduced into the composite powder, high-temperature mechanical properties, oxidative stabilities and corrosion resistances of ultra-high temperature ceramics and refractory materials can be improved.

Owner:ZHENGZHOU UNIV

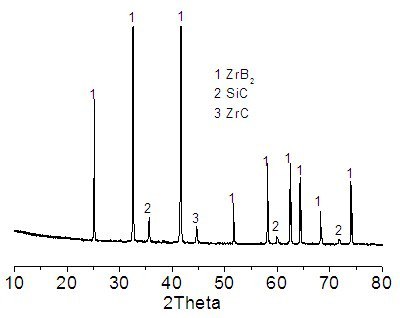

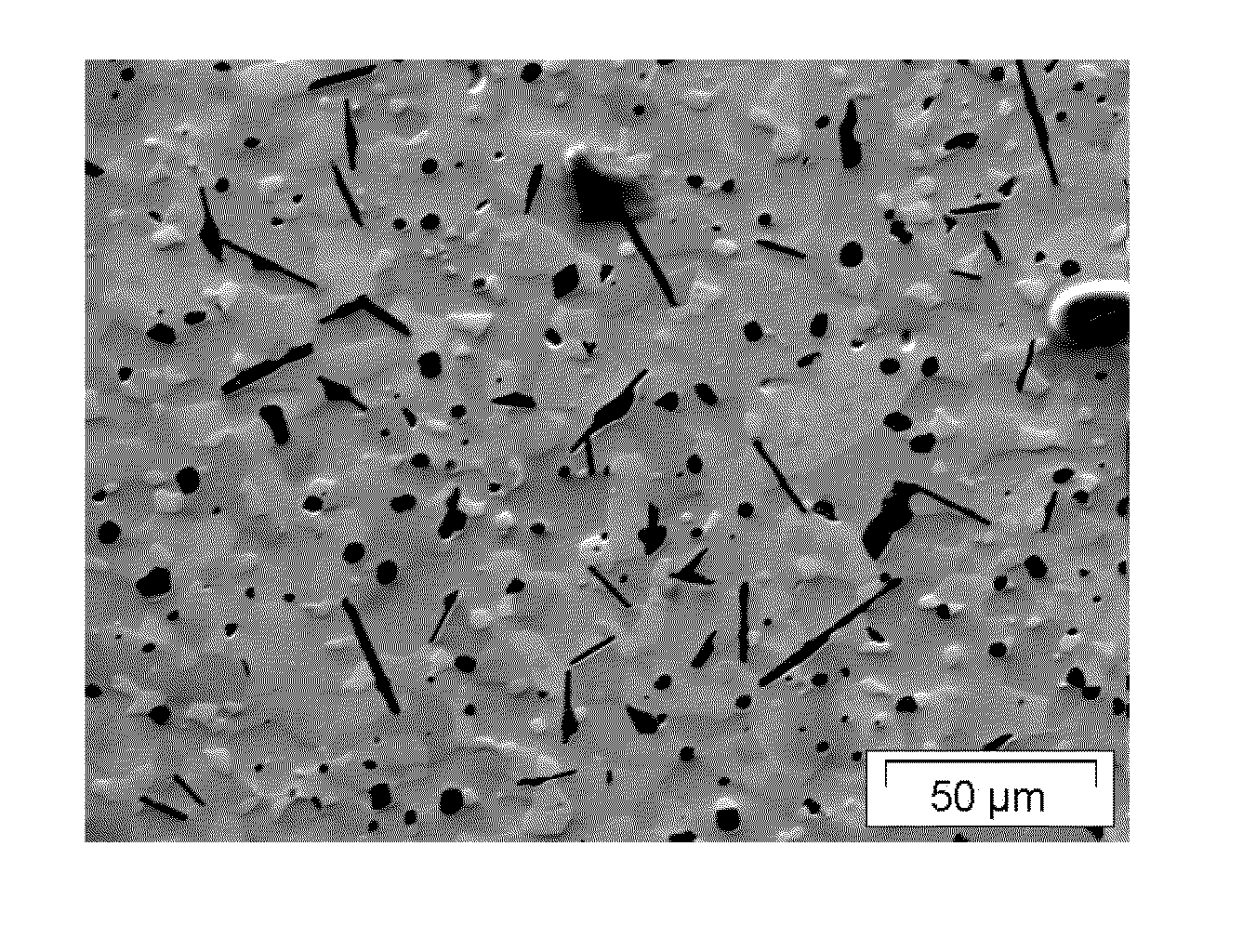

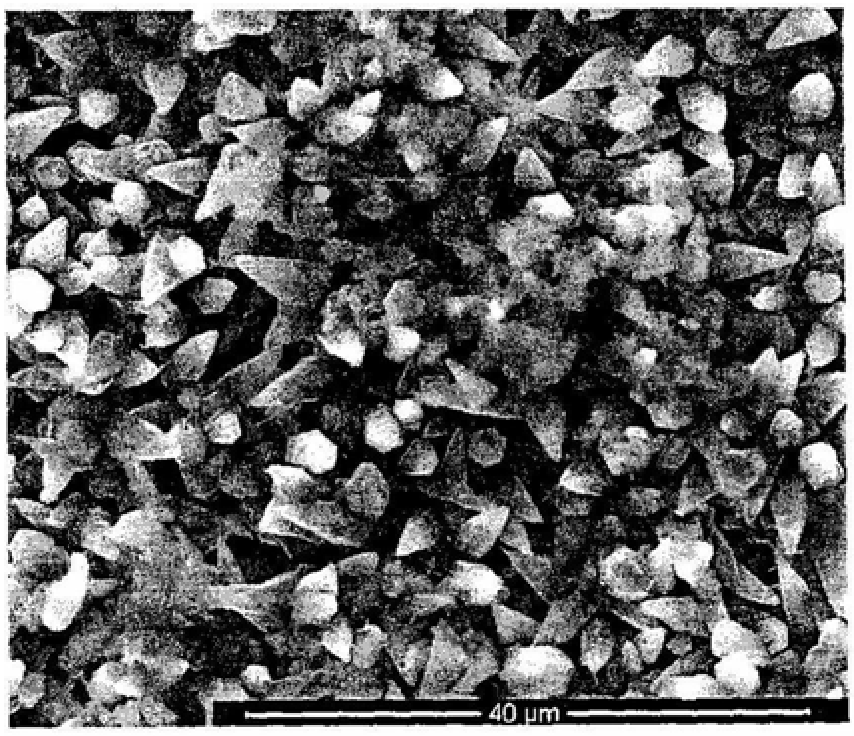

In-situ formation of reinforcement phases in ultra high temperature ceramic composites

InactiveUS8409491B1Improve thermal shock resistanceHigh-temperatureCeramic shaping apparatusNatural mineral layered productsUltra-high-temperature ceramicsCarbide

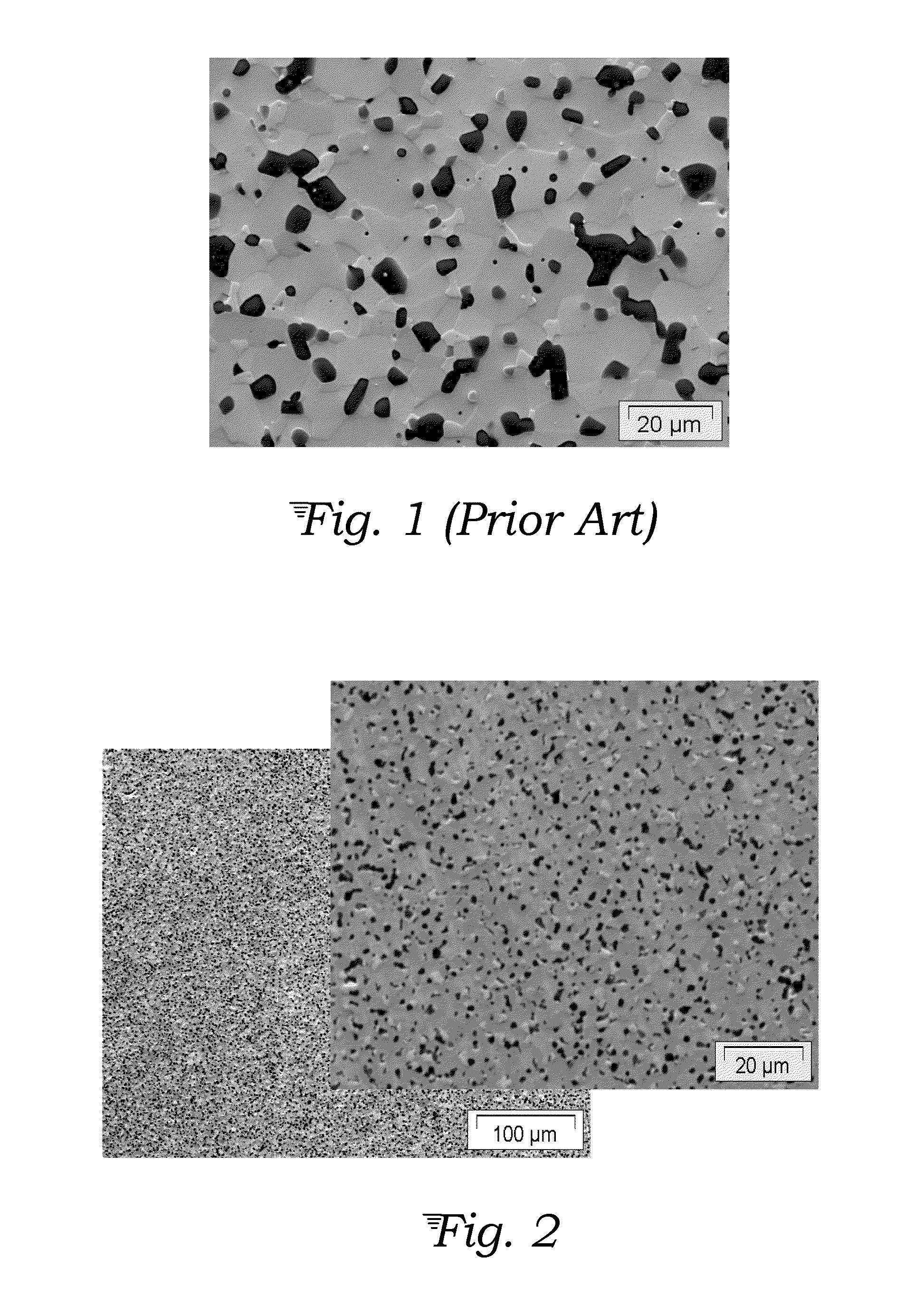

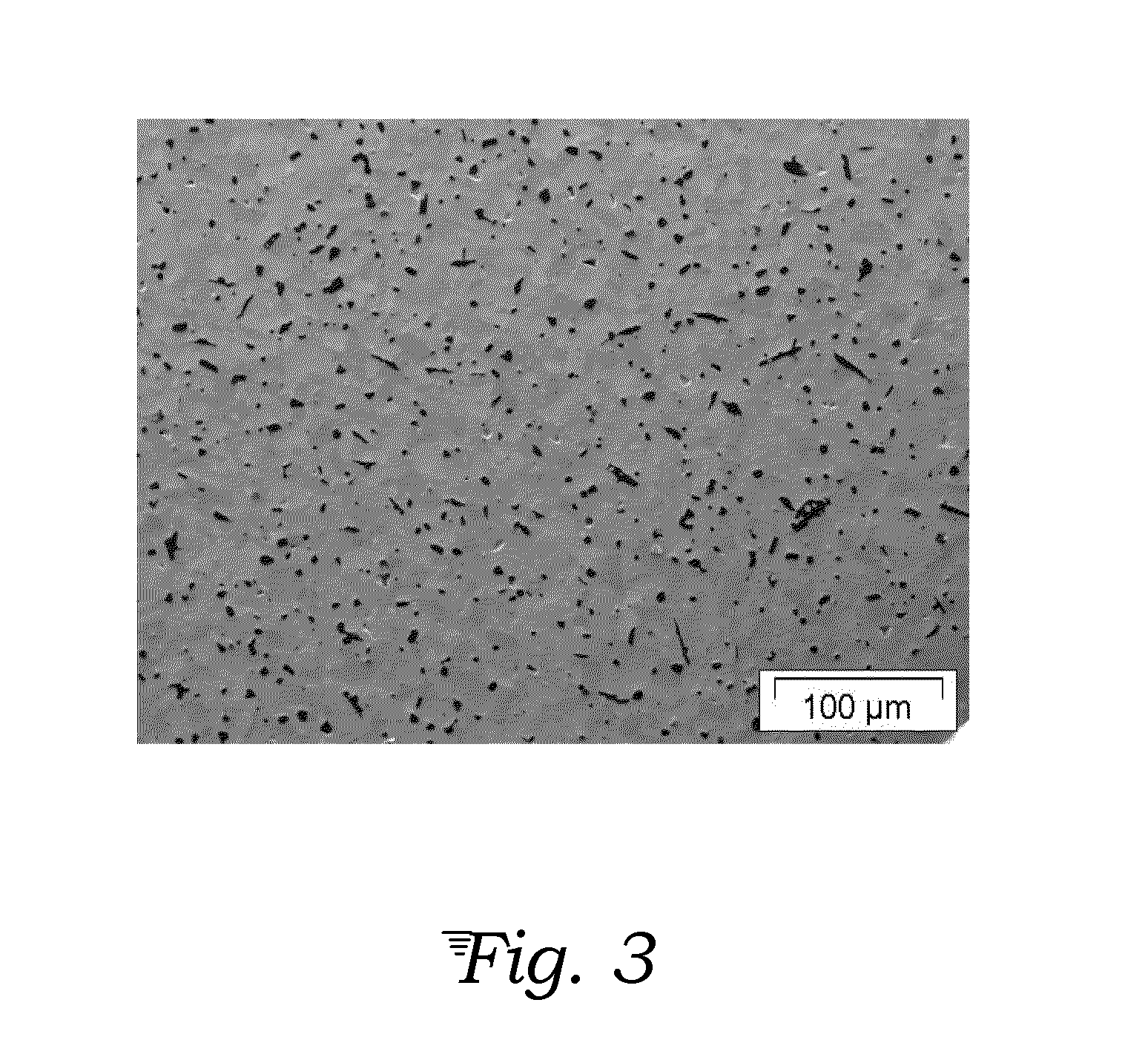

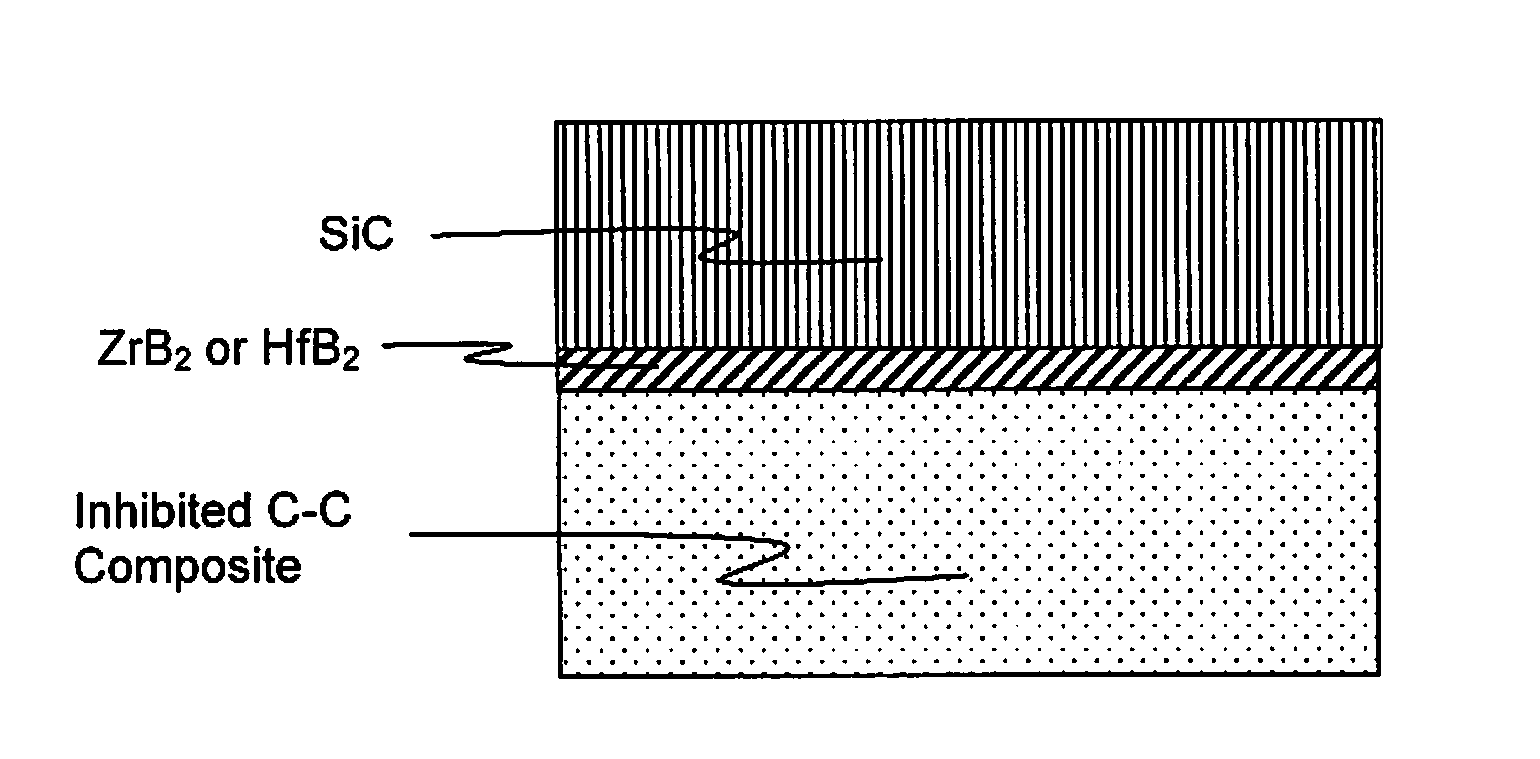

A tough ultra-high temperature ceramic (UHTC) composite comprises grains of UHTC matrix material, such as HfB2, ZrB2 or other metal boride, carbide, nitride, etc., surrounded by a uniform distribution of acicular high aspect ratio reinforcement ceramic rods or whiskers, such as of SiC, is formed from uniformly mixing a powder of the UHTC material and a pre-ceramic polymer selected to form the desired reinforcement species, then thermally consolidating the mixture by hot pressing. The acicular reinforcement rods may make up from 5 to 30 vol % of the resulting microstructure.

Owner:NASA

Multilayer ultra-high-temperature ceramic coatings

ActiveUS8137802B1Record information storageCeramic layered productsCarbon compositesUltra-high-temperature ceramics

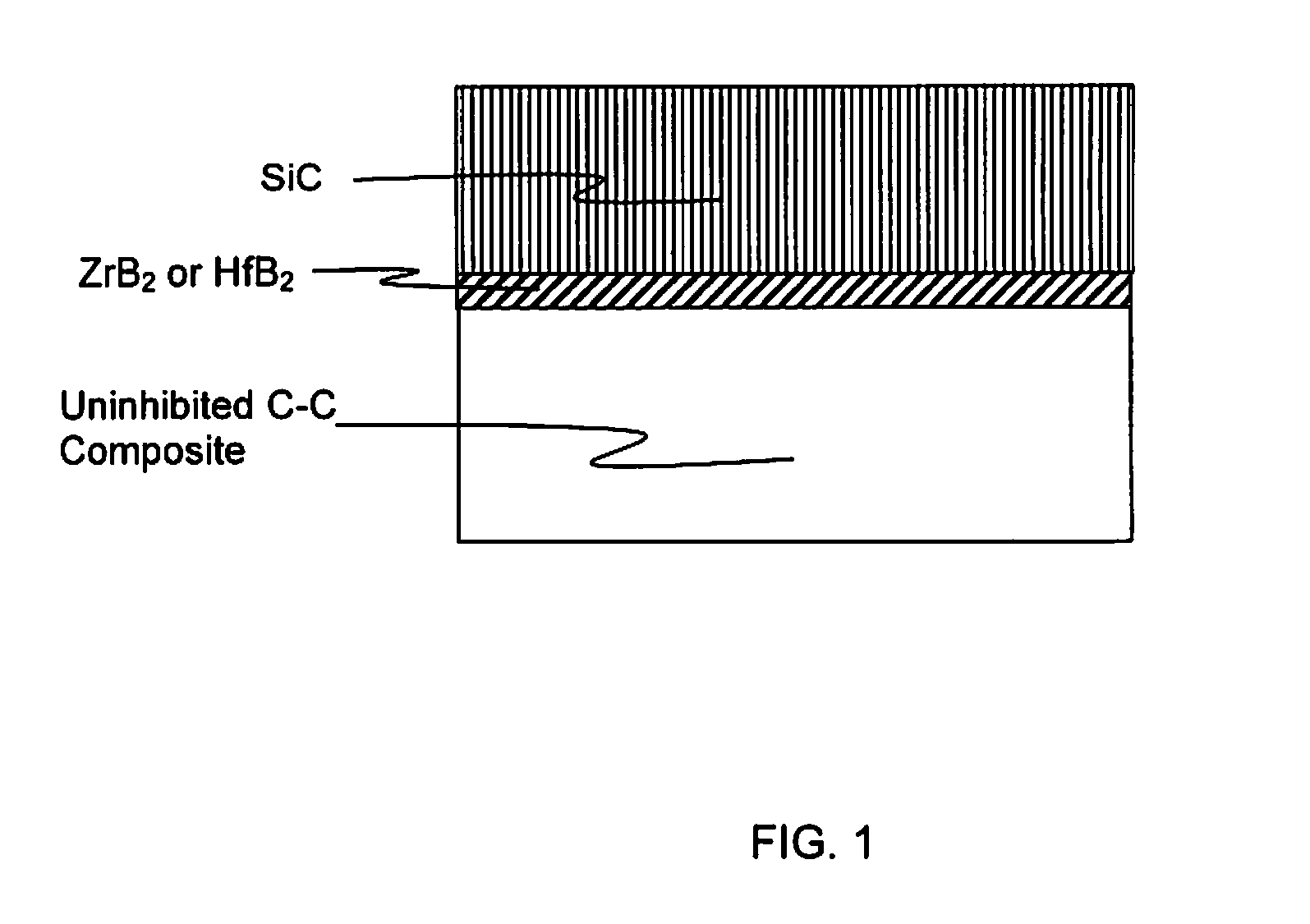

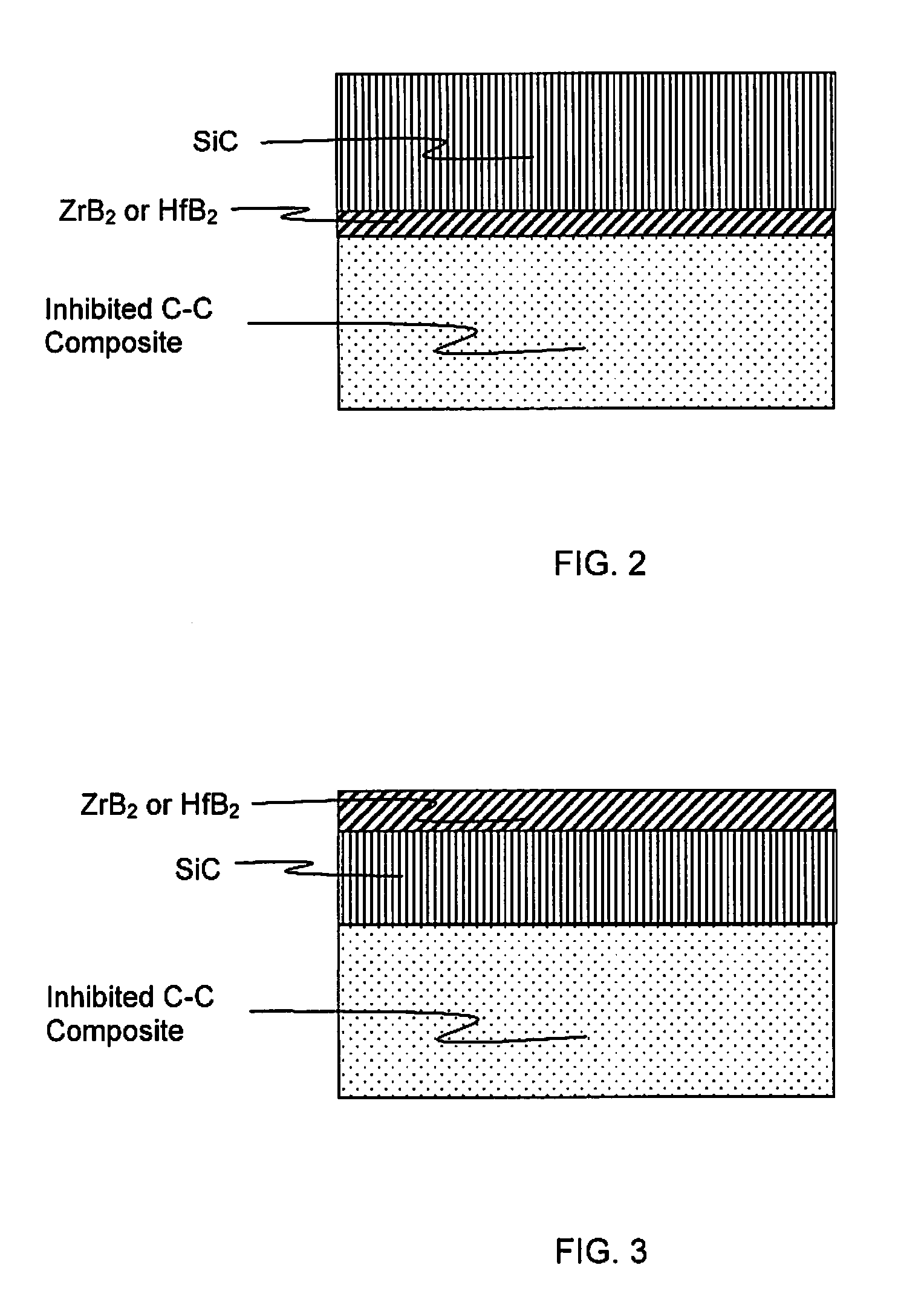

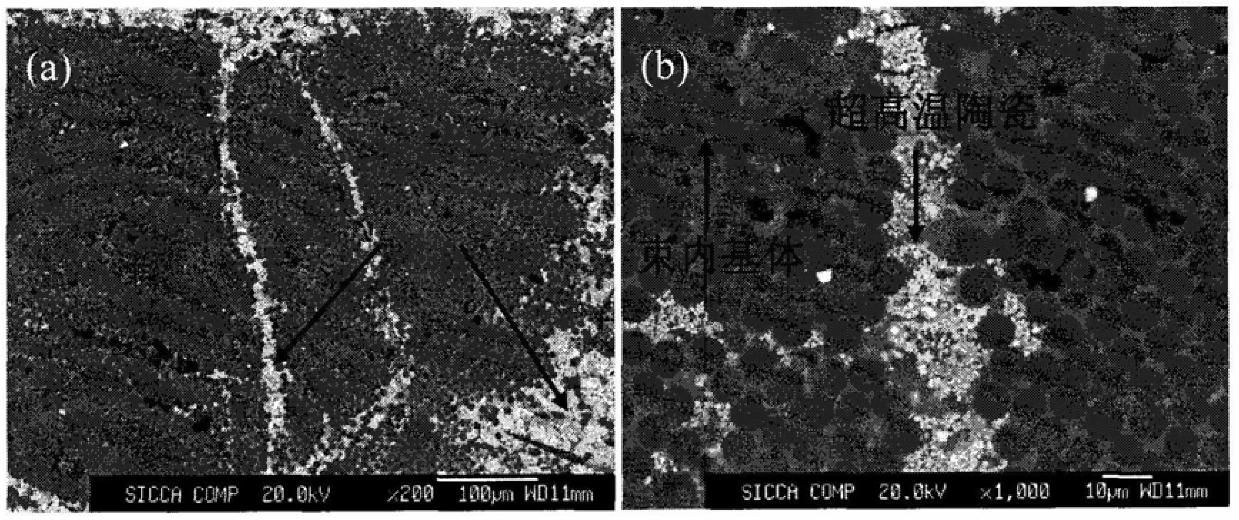

A coated carbon-carbon composite material with multiple ceramic layers to provide oxidation protection from ultra-high-temperatures, where if the carbon-carbon composite material is uninhibited with B4C particles, then the first layer on the composite material is selected from ZrB2 and HfB2, onto which is coated a layer of SiC coated and if the carbon-carbon composite material is inhibited with B4C particles, then protection can be achieved with a layer of SiC and a layer of either ZrB2 and HfB2 in any order.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Preparation method of carbon fiber reinforced ultra-high temperature ceramic matrix composite material

ActiveCN106342033BIncrease contentImprove ultra-high temperature oxidation resistanceCeramic matrix compositeUltra-high-temperature ceramics

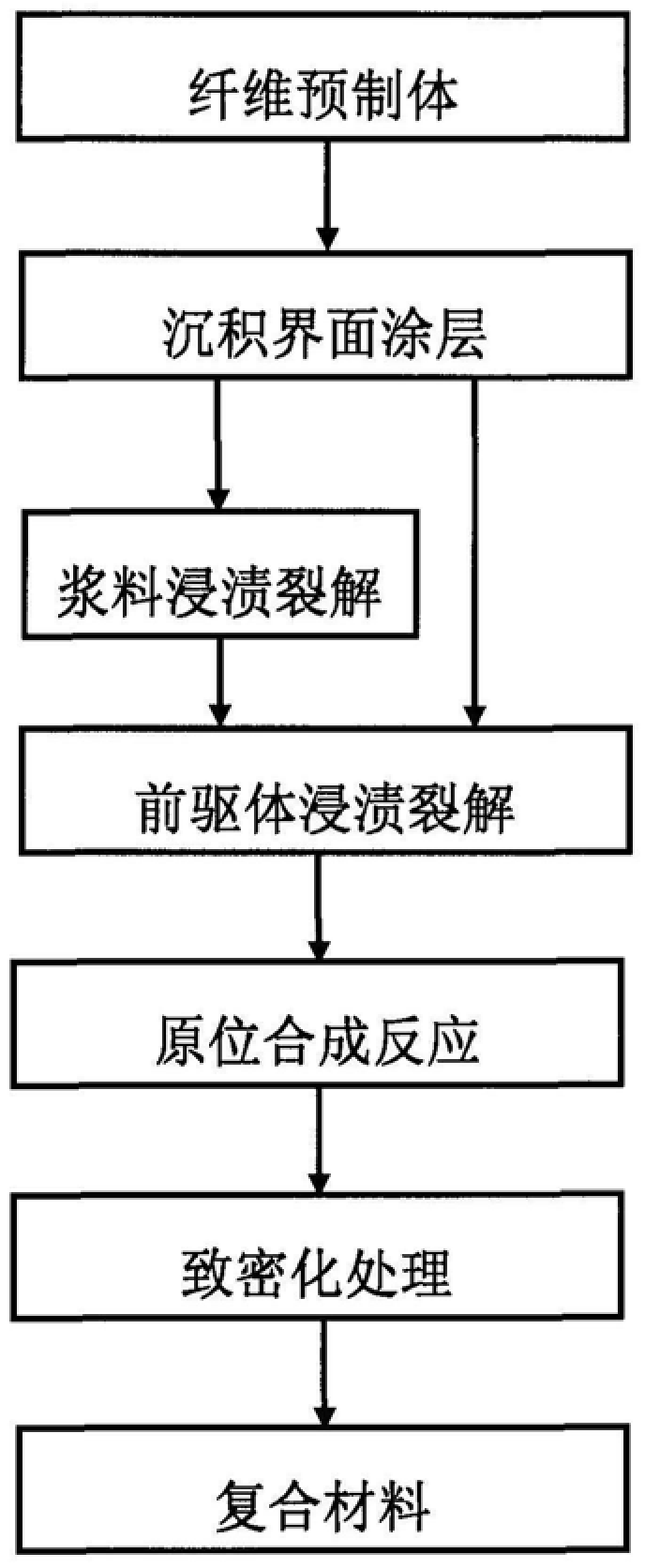

The invention relates to a preparation method of carbon fiber reinforced ultra-high temperature ceramic matrix composite material, belonging to the field of ceramic matrix composite material. The present invention firstly impregnates the soluble precursor containing ultra-high temperature ceramic constituent elements into the composite material, and then synthesizes the ultra-high temperature ceramic phase in situ through the reaction between various substances at high temperature, so as to increase the content of the ultra-high temperature ceramic phase in the matrix of the composite material and the purpose of distribution uniformity. A fiber-reinforced ultra-high temperature ceramic matrix composite material with high content of ultra-high temperature ceramics and uniform distribution is obtained by further densifying the composite material. The method has the advantages of simple process, strong repeatability and simple operation.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

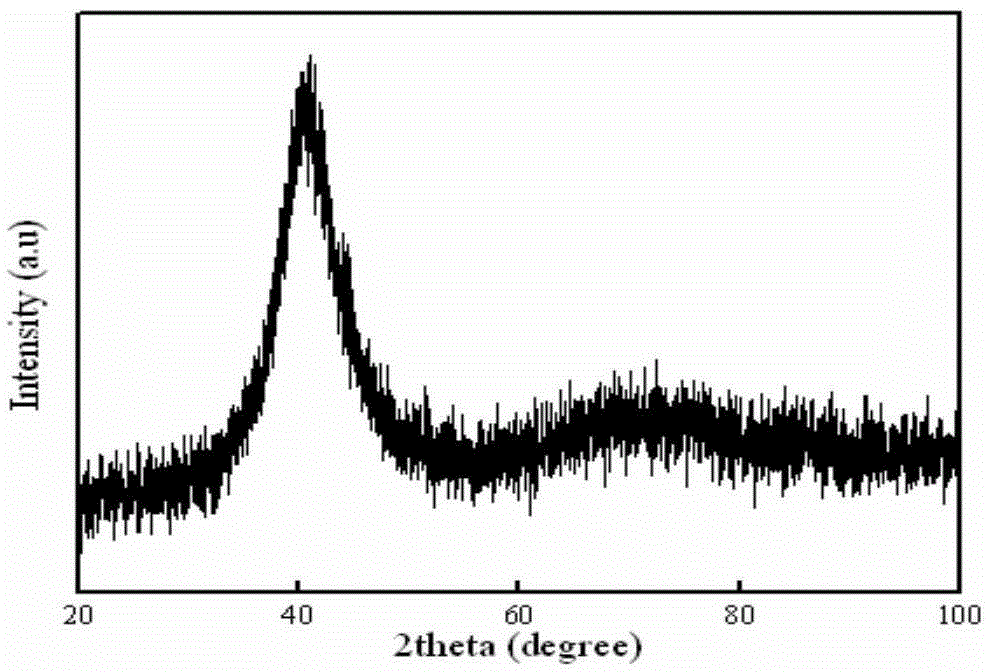

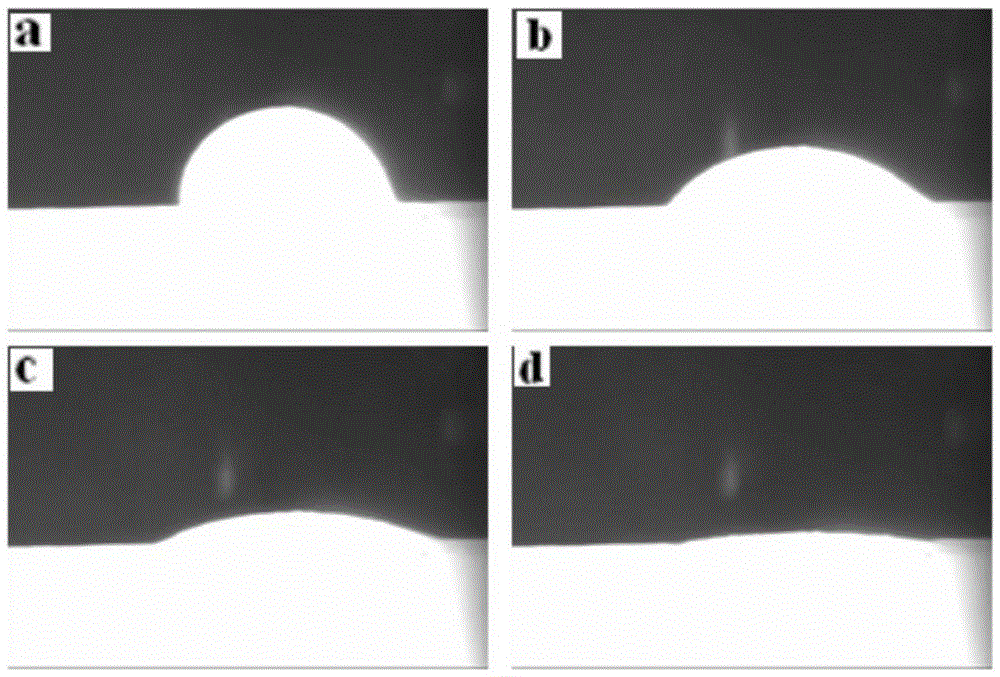

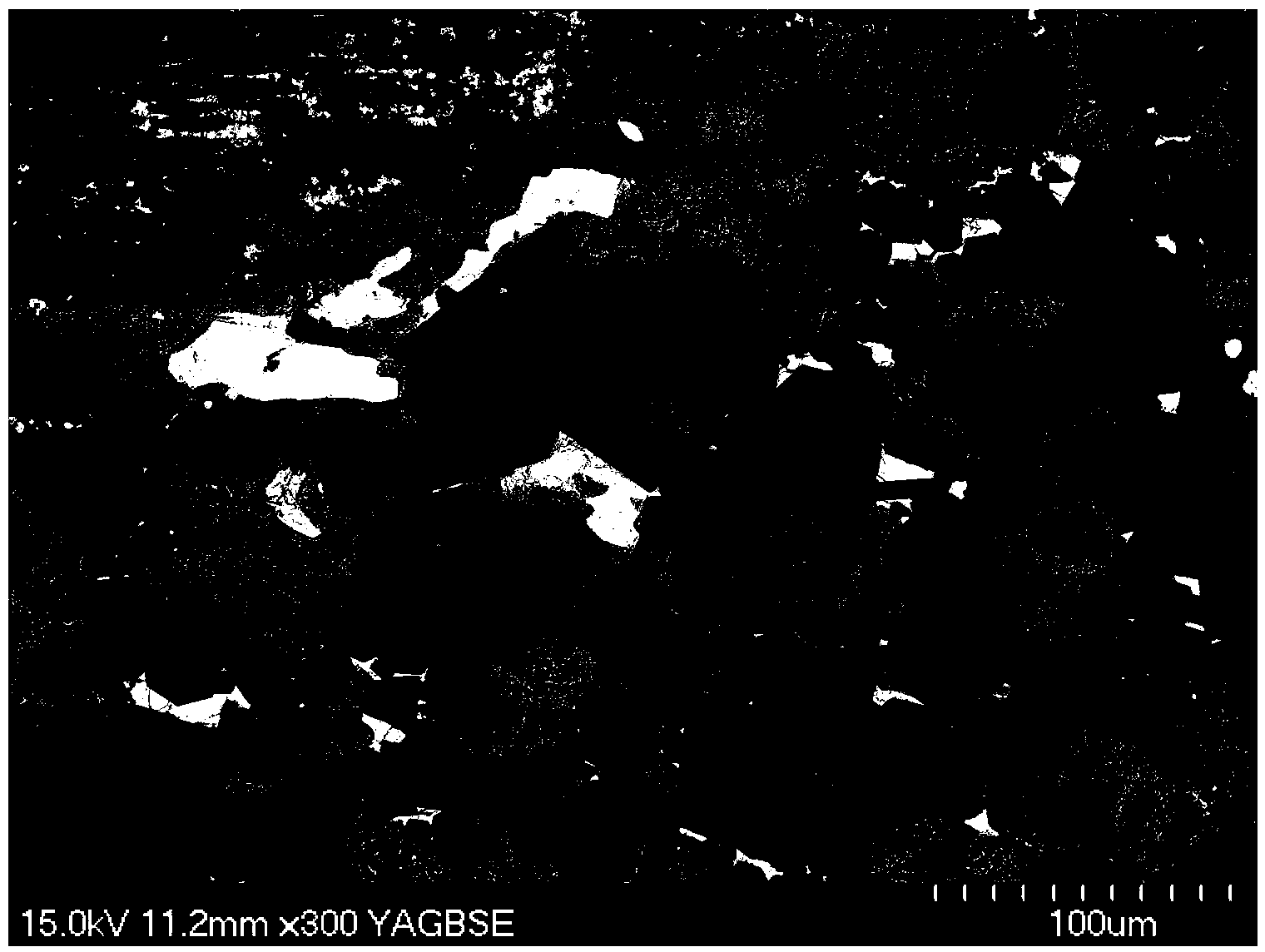

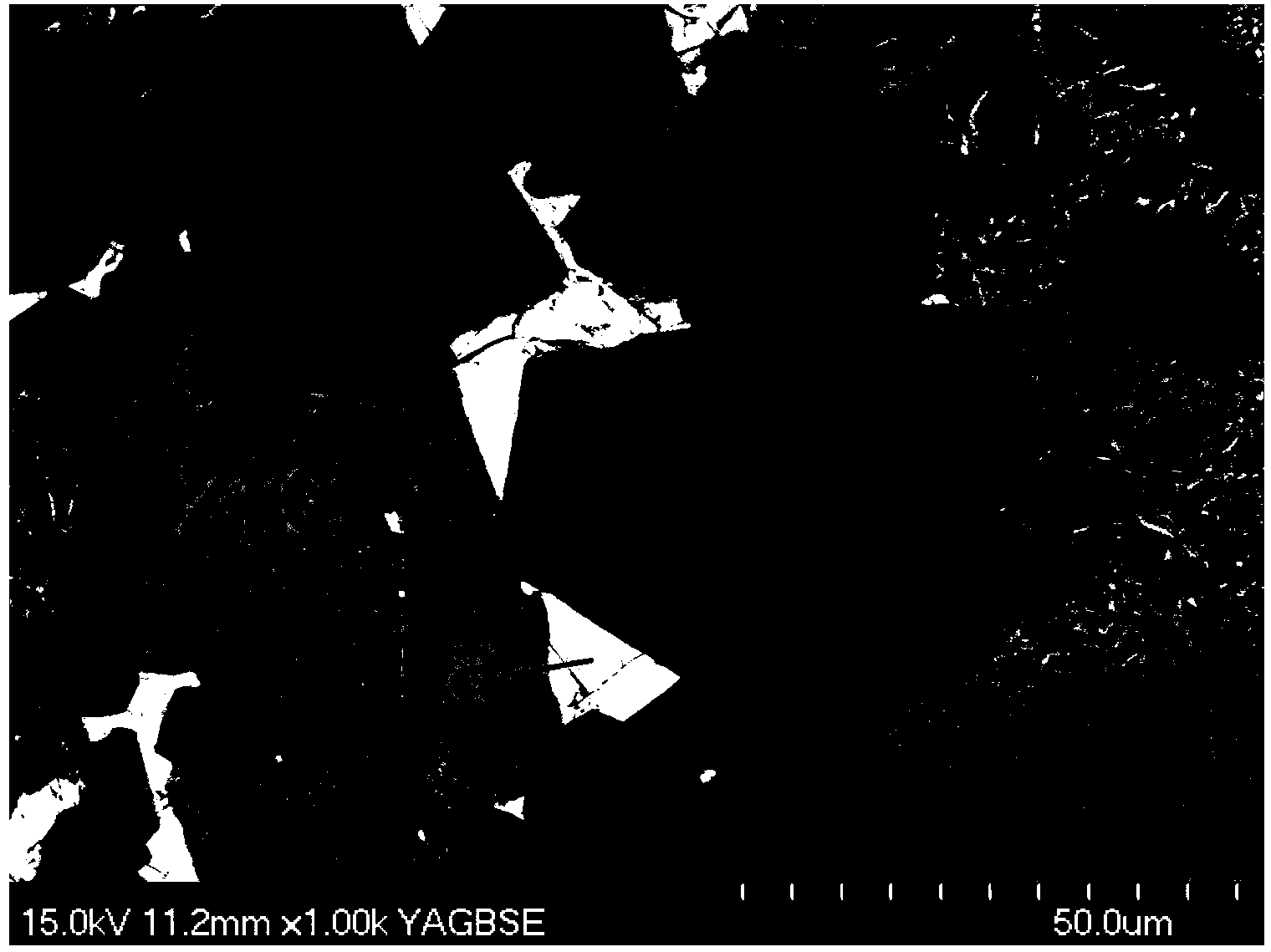

Active amorphous brazing filler metal for brazing ZrB2-SiC ceramic materials, preparation method for active amorphous brazing filler metal and brazing process

InactiveCN105252169AImprove wettabilityImprove toughnessWelding/cutting media/materialsSoldering mediaUltra-high-temperature ceramicsRoom temperature

The invention discloses active amorphous brazing filler metal for brazing ZrB2-SiC ceramic materials, a preparation method for the active amorphous brazing filler metal and a brazing process, particularly relates to Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal for brazing ZrB2-SiC ultra-high-temperature ceramic materials, a preparation method for the Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal and a brazing process, and belongs to brazing filler metal in the amorphous and metallurgy fields. The components of the brazing filler metal comprise, by atomic percentage, 36.0-42.0% of Cu, 30.0-35.0% of Ti, 16.0-23.0% of Zr and the balance Ni. The melting temperature of the active amorphous brazing filler metal is 1110-1150 K, and the brazing temperature is 1183-1273 K. The Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal obtained through the rapid condensation technology has good wettability. The room temperature shearing strength of the ZrB2-SiC ultra-high-temperature ceramic materials brazed through the amorphous brazing filler metal in a vacuum brazing mode can be as high as 160 MPa and much higher than that of Cu-based and Ag-based brazing filler metal.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Preparation method of carbon fiber-reinforced ultra high-temperature ceramic-base composite material capable of being repeatedly ablated for use

The invention relates to a preparation method of a carbon fiber-reinforced ultra high-temperature ceramic-base composite material capable of being repeatedly ablated for use. Vacuum pressure is adopted to soak and combine reaction melt, the reaction melt is permeated in the conventional carbon fiber-reinforced ultra high-temperature ceramic-base composite material, and rear-earth metal elements such as La, Y, Yb, Sc, and the like are added to achieve effects of reducing volatilization of SiO2 at a high temperature, stabilizing a ZrO2 / HfO2 crystal form and generating rare-earth zirconate or rear-earth hafnate. After ablation, glass-state SiO2 is formed on the material surface and filled between ZrO2 and HfO2; and a compaction layer of the rare-earth zirconate / the rear-earth hafnate is mixed to protect the material very well, so that repeatable ablation of the ultra high-temperature ceramic-base composite material is possible.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Ceramic matrix composite and preparation method and application thereof

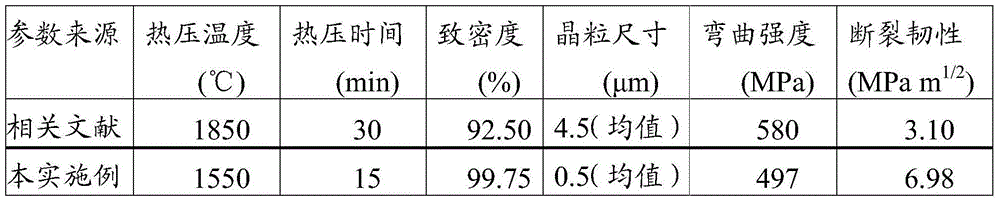

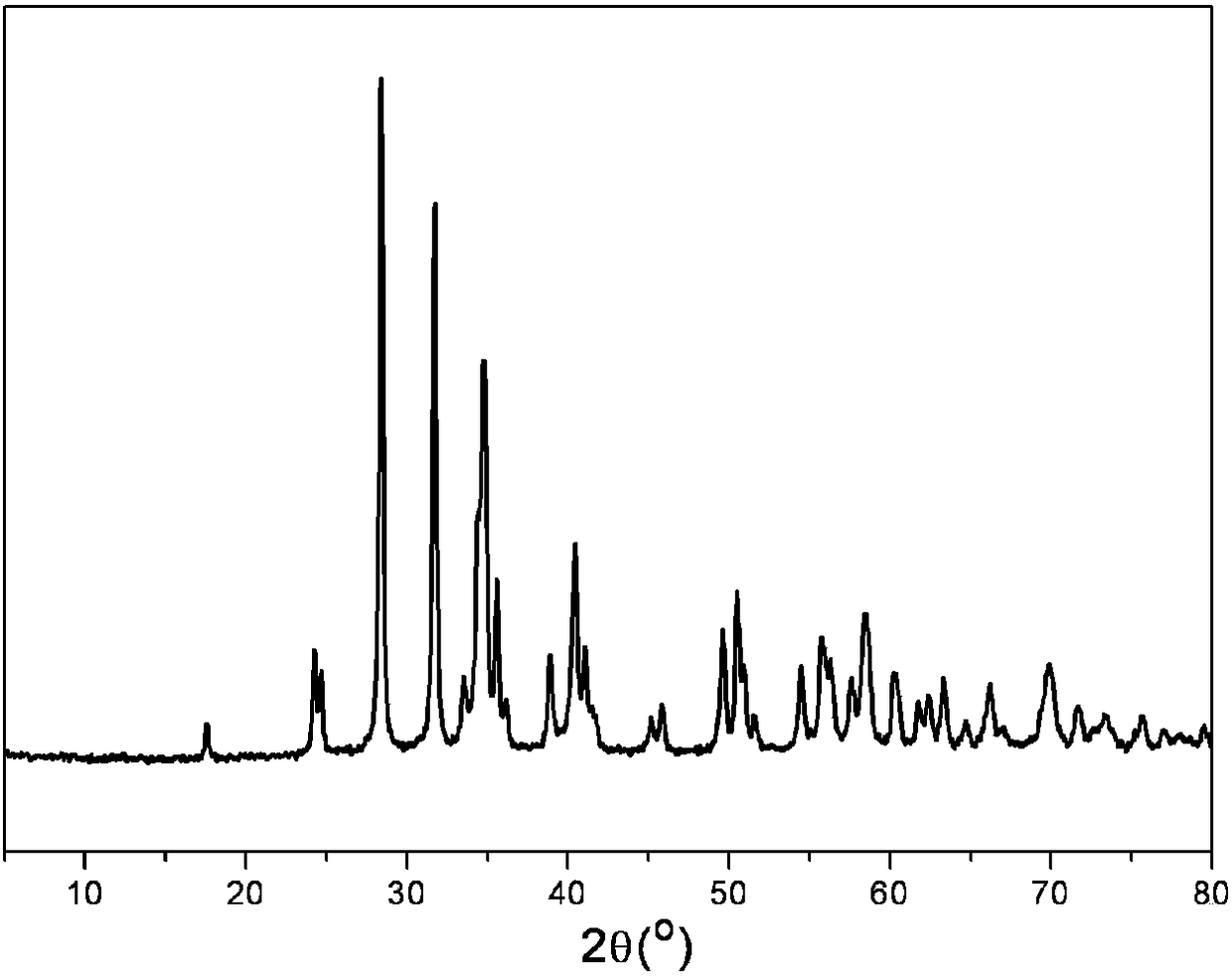

The invention discloses a ceramic matrix composite and a preparation method and application thereof, belongs to the technical field of ultra-high temperature ceramic matrix composites, and relates to a preparation method of a high-strength, high-toughness, high-density and fine-grain organization material. Zirconium diboride powder is used as a matrix phase, and zirconium disilicide powder is used as a sintering aid, so that the optimum sintering temperature, sintering pressure and sintering time of the ceramic matrix composite are lower than the requirements of the hot pressing sintering technology in the prior art; a multi-wall carbon nanotube is used as an additive for improving the internal organization structure of the ceramic matrix composite, obviously reduces the crystal grain size of the ceramic matrix composite, and improves the breaking tenacity of the ceramic matrix composite to 6.98 MPa.m<1 / 2>. The preparation method uses a two-step hot pressing sintering technology with fast and low-temperature characteristics to prepare the zirconium diboride ceramic matrix composite with high density and mechanical properties, and facilitates the subsequent large-scale production preparation and fiber toughening technology.

Owner:DALIAN UNIV OF TECH

Cf/HfC-TaC-C composite material and preparation method thereof

The invention provides a Cf / HfC-TaC-C composite material and a preparation method thereof, wherein a carbon fiber preform as a skeleton is immersed in a precursor solution containing a hafnium-tantalum precursor copolymer, and curing and cracking are performed to obtain the Cf / HfC-TaC-C composite material. According to the present invention, the process is simple, and the preparation period is short; and the prepared ultra-high temperature ceramic matrix composite material has advantages of excellent high-temperature resistance, excellent oxidation resistance and excellent ablation resistance,can be used as the high temperature thermal structure material of highly-hypersonic aircrafts and rocket propulsion systems, and has wide application prospect.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

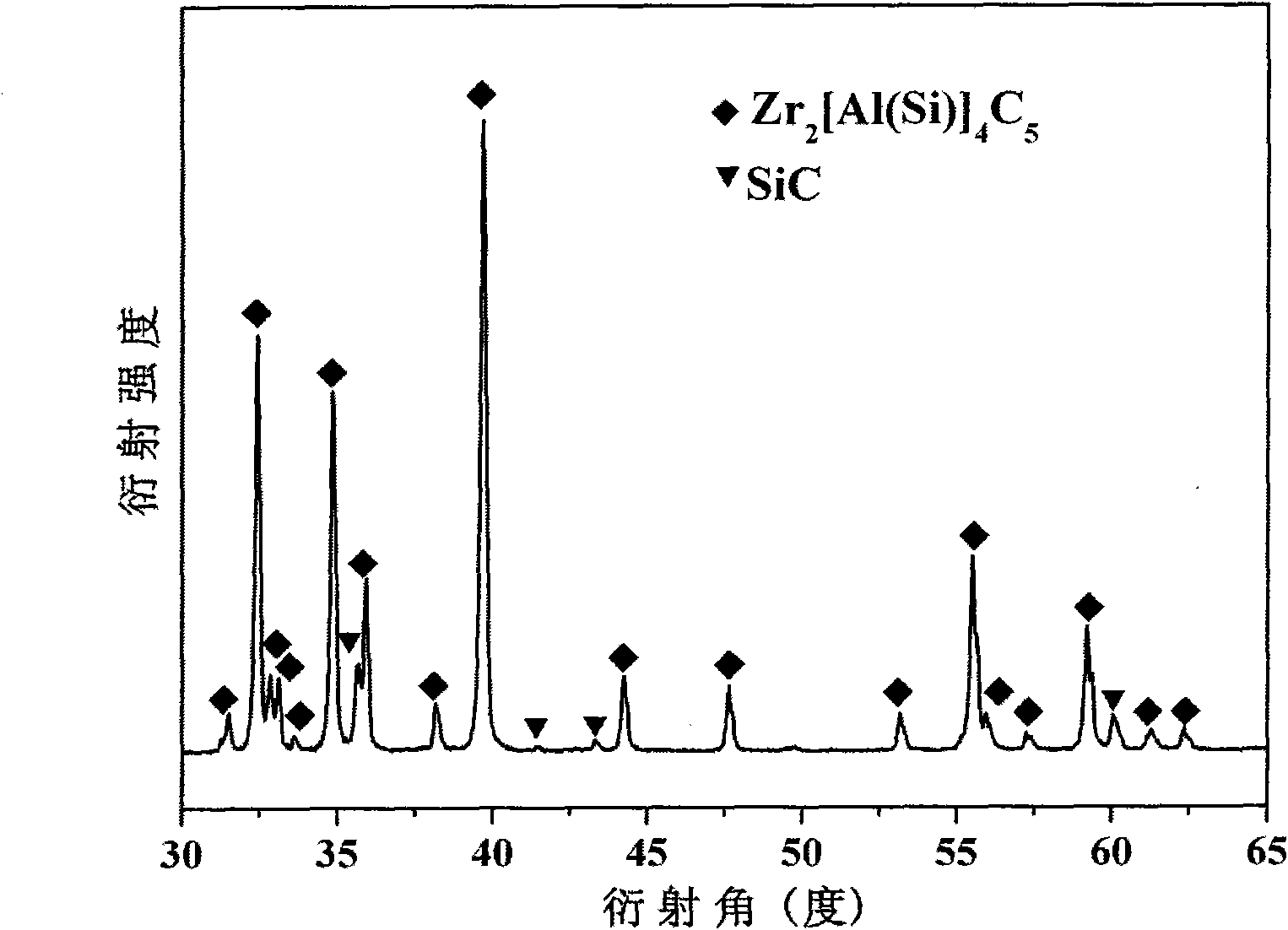

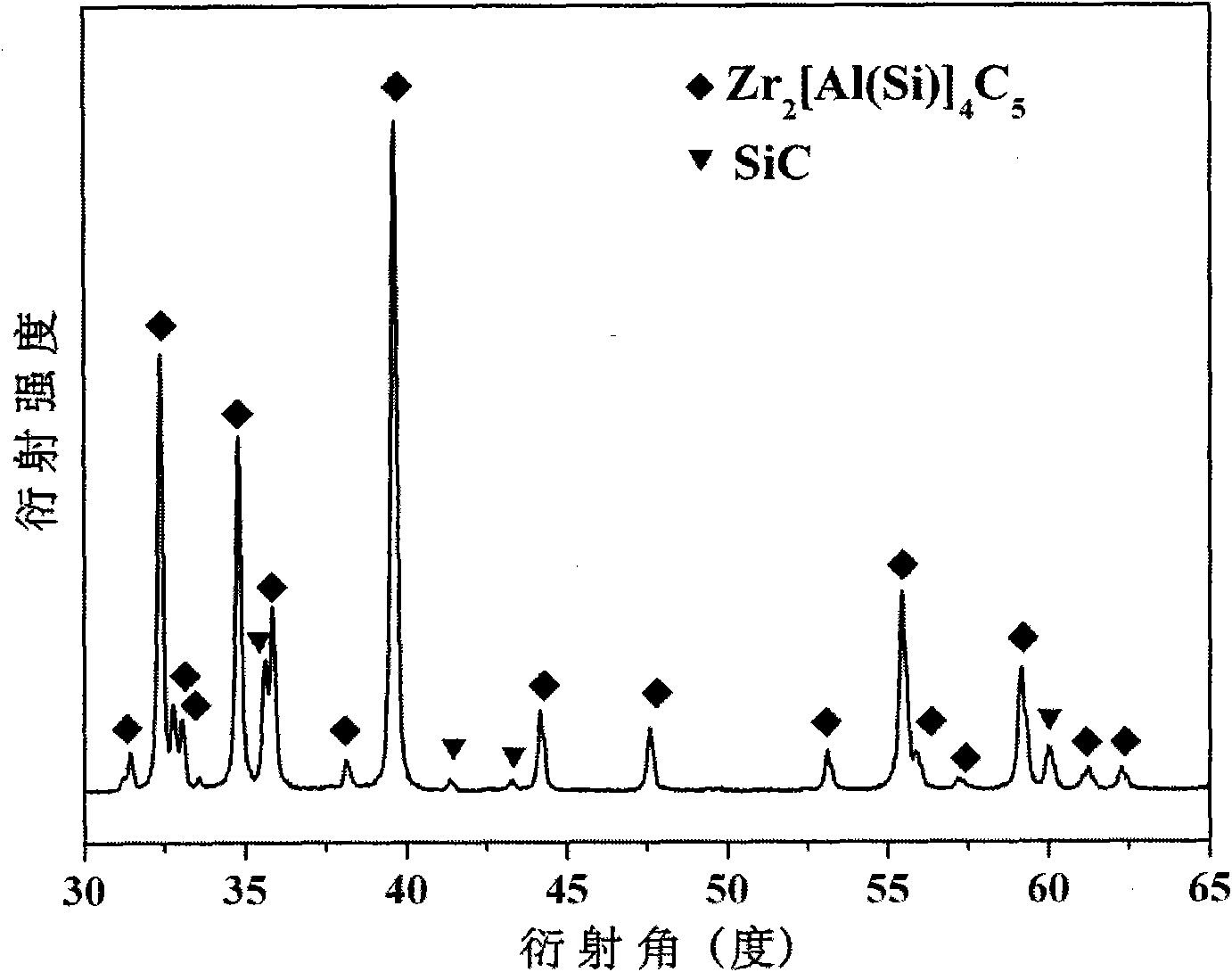

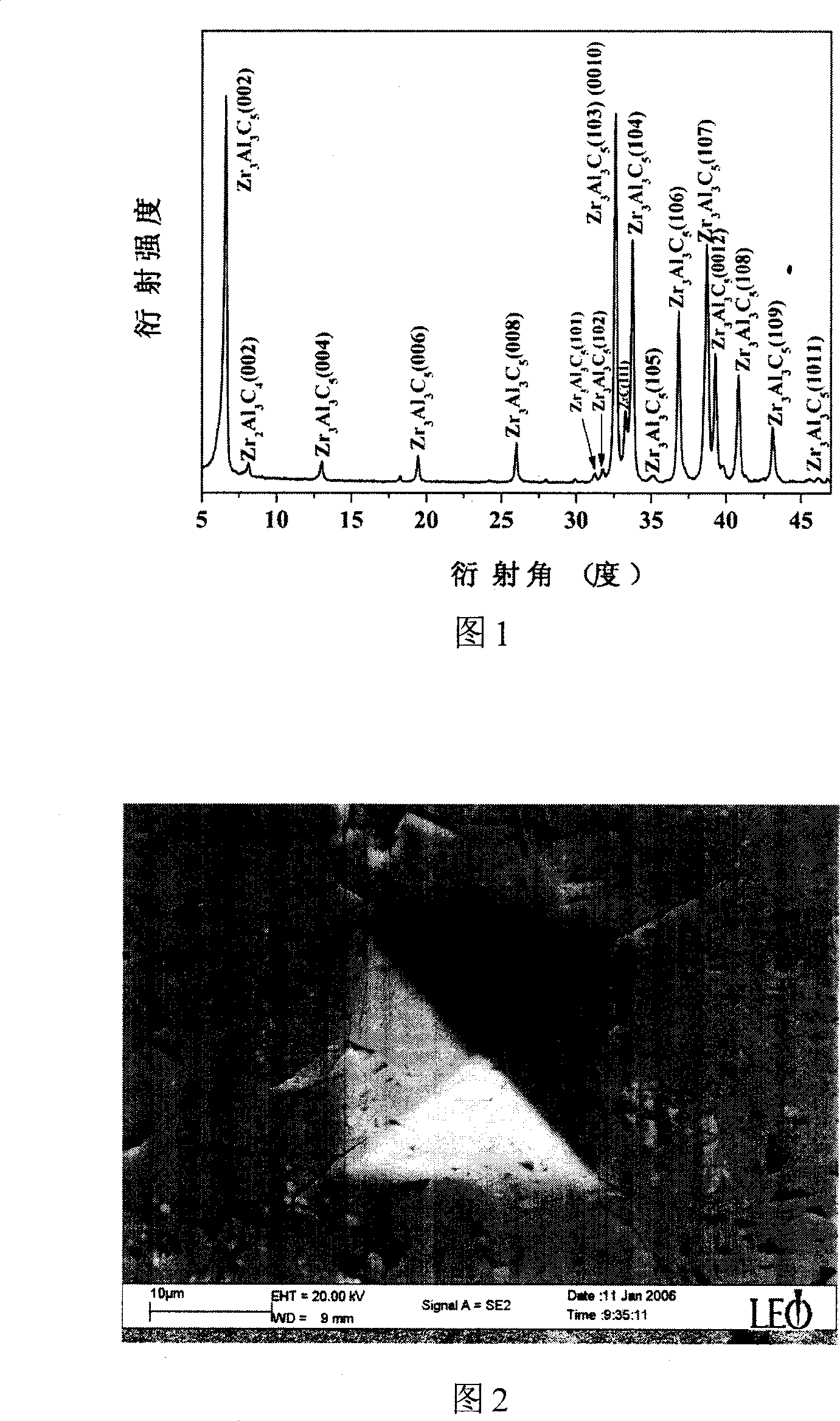

Zirconium-aluminum-silicon-carbon-silicon carbide composite material and preparation method thereof

The invention relates to ultrahigh temperature resistant ceramic and preparation technology thereof, in particular provides a zirconium-aluminum-silicon-carbon-silicon carbide composite material and a method for preparing the zirconium-aluminum-silicon-carbon-silicon carbide composite material by in-situ reactive hot pressing. Zr powder, Al powder, Si powder and C powder in a certain stoichiometric ratio are used as raw materials; the raw materials are mixed for 5 to 50 hours by using a physical and mechanical method and are cold-pressed into cakes under the pressure of 5 to 20MPa; and the cakes are filled into a graphite mold and are heated to 1,600 to 2,400 DEG C in a hot pressing furnace into which inert gas serving as protective gas is introduced (or in vacuum) for in-situ hot pressing reaction for 0.1 to 4 hours under the hot pressing pressure of 20 to 40MPa. In the invention, the zirconium-aluminum-silicon-carbon-silicon carbide composite material with high hardness, high strength, high toughness, high ultrahigh-temperature resistance and the like can be synthesized at a relatively low temperature in a short time; and the material obtained by the method can be used at the ultrahigh temperature of above 1,600 DEG C.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

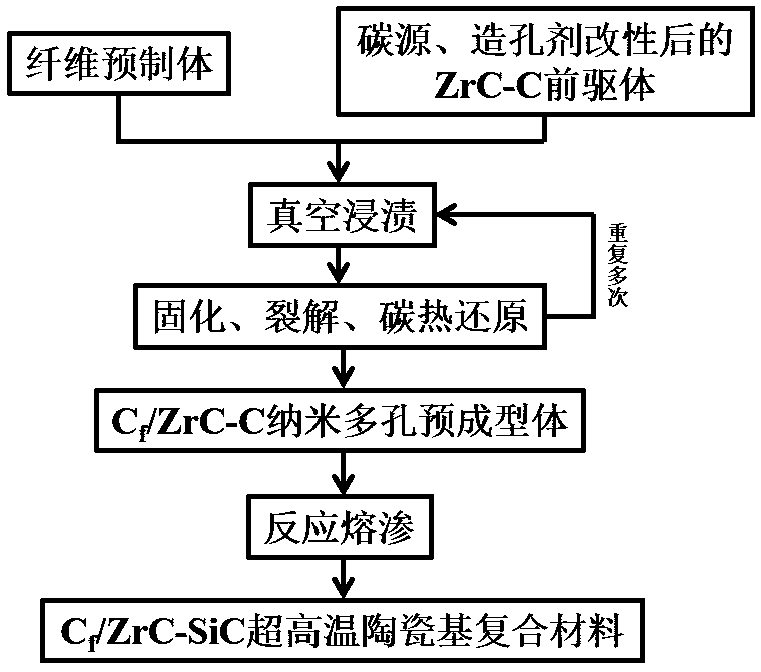

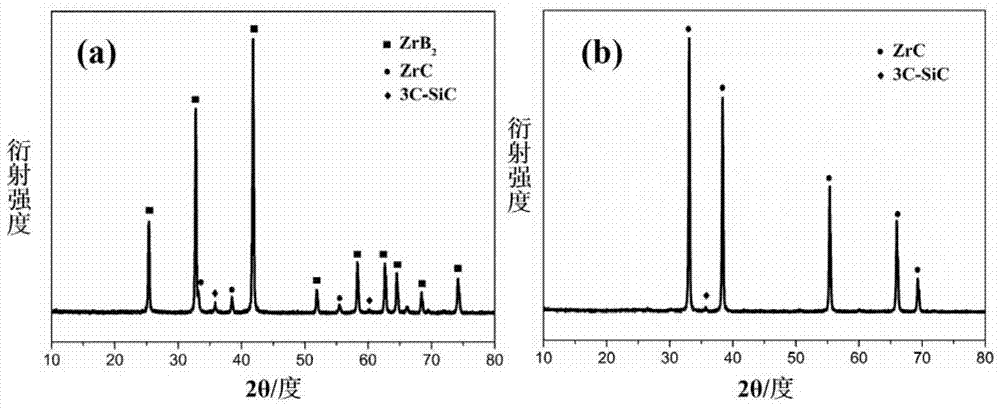

Cf/ZrC-SiC ultra-high temperature ceramic-based composite material and preparation method thereof

The invention provides a Cf / ZrC-SiC ultra-high temperature ceramic-based composite material and a preparation method thereof. The preparation method comprises the steps of: (1) mixing a pore-forming agent, a carbon source and a ZrC ceramic precursor so as to obtain a modified ZrC-C ceramic precursor; (2) introducing the modified ZrC-C ceramic precursor into a carbon fiber prefab, and then performing curing, cracking and carbothermic reduction to obtain a nanoporous Cf / ZrC-C prefab; and (3) infiltrating molten silicon or molten silicon-zirconium alloy into the porous Cf / ZrC-C prefab, and carrying out an infiltration reaction to obtain the Cf / ZrC-SiC ultra-high temperature ceramic-based composite material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

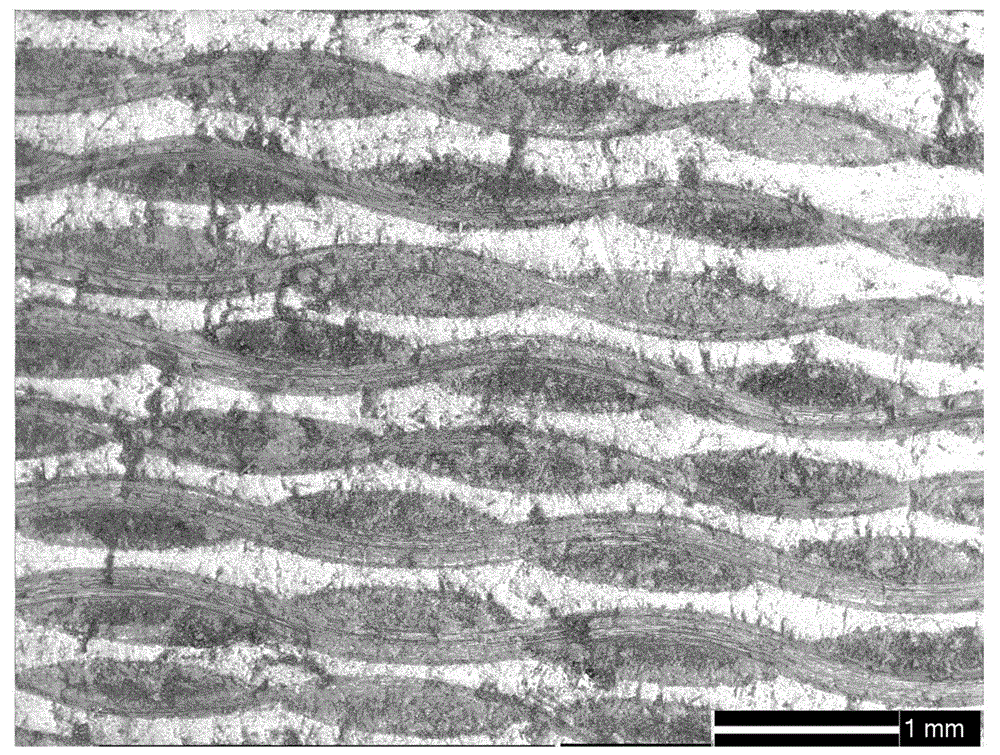

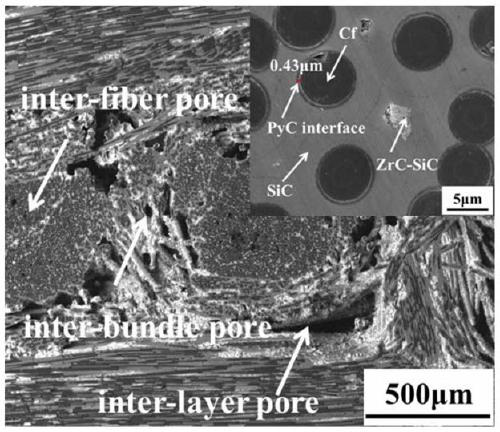

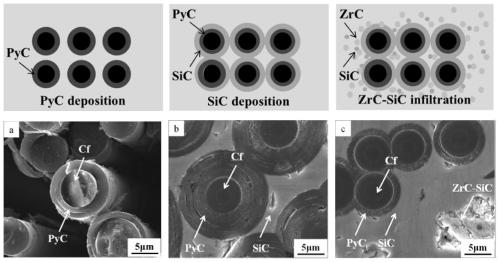

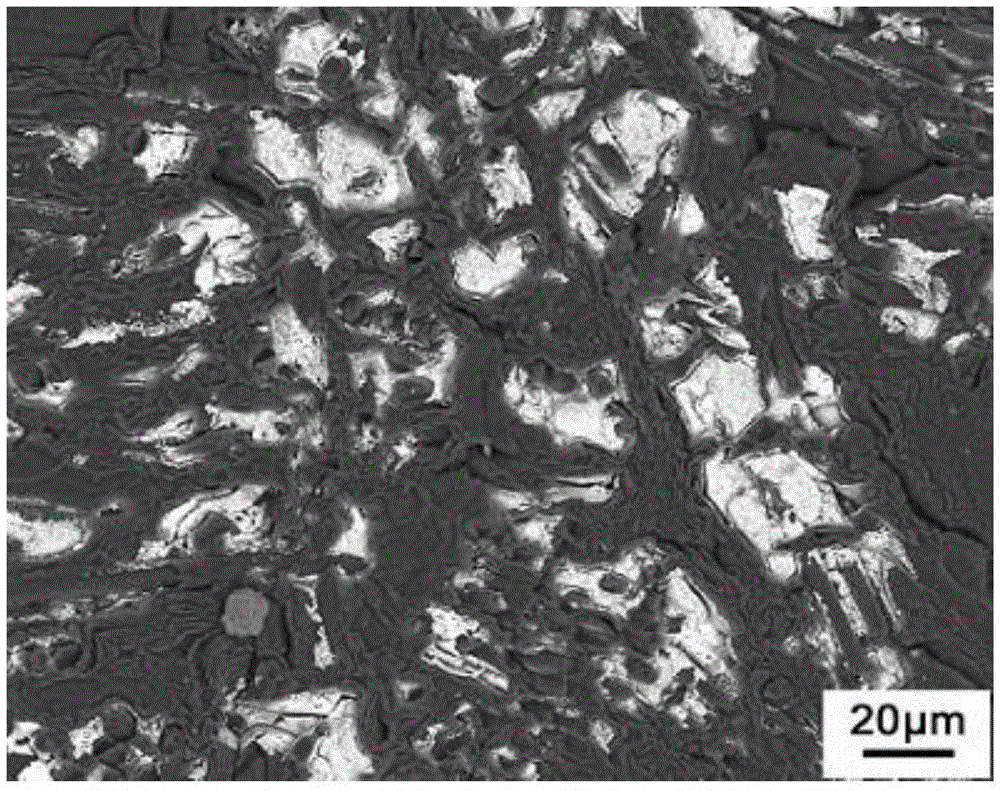

Carbon fiber-reinforced (carbon-) silicon carbide base-ultra-high temperature ceramic base compound material and production method thereof

The invention discloses a carbon fiber-reinforced (carbon-) silicon carbide base-ultra-high temperature ceramic base compound material and a production method thereof, and belongs to the technical field of ultra-high temperature ceramic base compound materials. According to the compound material, on the basis of the characters of components of carbon fibers, pyrolytic carbon (PyC), silicon carbide(SiC) and ultra-high temperature ceramics (UHTC), the components are combined to form four functional areas, namely a carbon fiber load-carrying skeleton area, a PyC interface layer area, a PyC-SiC load-bearing and anti-oxidation area and an ultra-high temperature anti-oxidation ablation-resistant area, and a CVI-PIP-CVD compound technology is adopted for producing the compound material with excellent mechanical performance and high-temperature-resistant and anti-oxidation performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

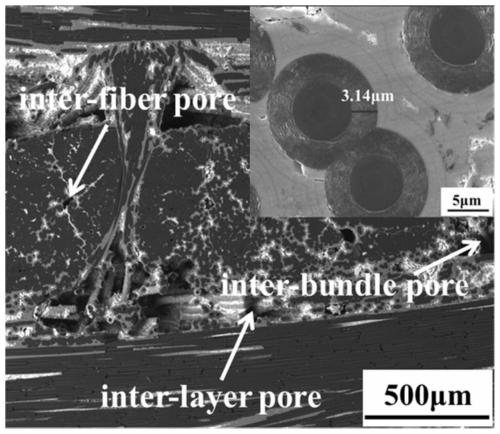

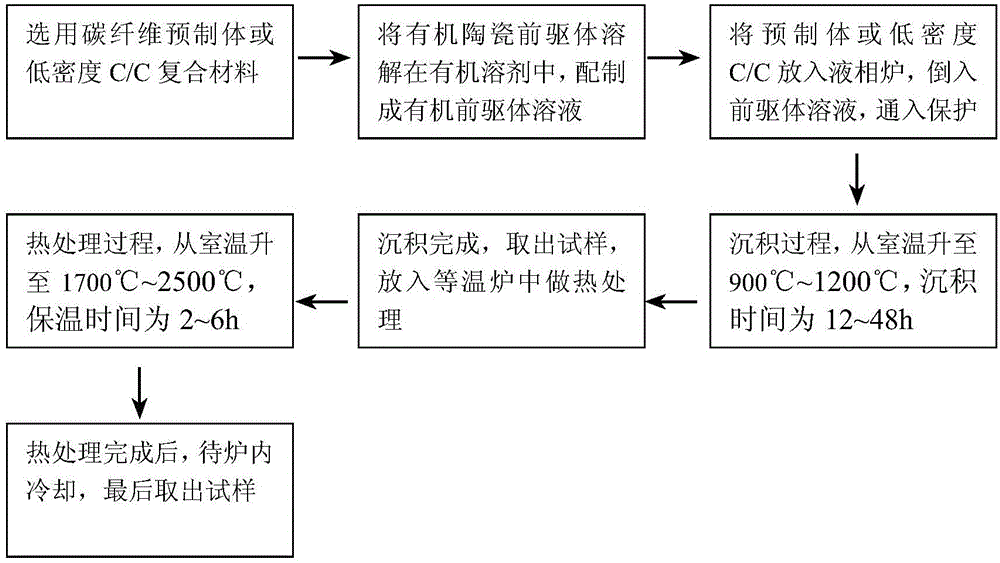

Preparation method for ultra-high-temperature ceramic modified C/C composite material

The invention relates to a preparation method for an ultra-high-temperature ceramic modified C / C composite material. The preparation method comprises: carrying out a reaction on an ultra-high-temperature ceramic precursor solution at a high temperature by adopting a chemical liquid phase vaporized deposition process technology to generate a ceramic and pyrolytic carbon; depositing the ceramic and pyrolytic carbon; in a carbon fiber preform; and finally carrying out thermal treatment to obtain the ultra-high-temperature ceramic modified C / C composite material. The innovation of the preparation method provided by the invention is that the ultra-high-temperature ceramic modified C / C composite material is prepared by adopting the chemical liquid phase vaporized deposition process, so that the problems that a conventional process method is long in production period, has a certain damage to fiber and the like are overcome, and the ultra-high-temperature ceramic modified C / C composite material which is uniformly distributed is prepared within a short time. In the method, the component proportion, the chemical liquid phase vaporized deposition process parameters and the thermal treatment process have a great influence on the experimental result. By adjusting the experimental parameters, the ultra-high-temperature ceramic which is uniformly distributed can be obtained in the C / C composite material, so that the anti-oxidizing and ablation-resisting performances of the C / C composite material are favorably enhanced.

Owner:无锡博智复合材料有限公司

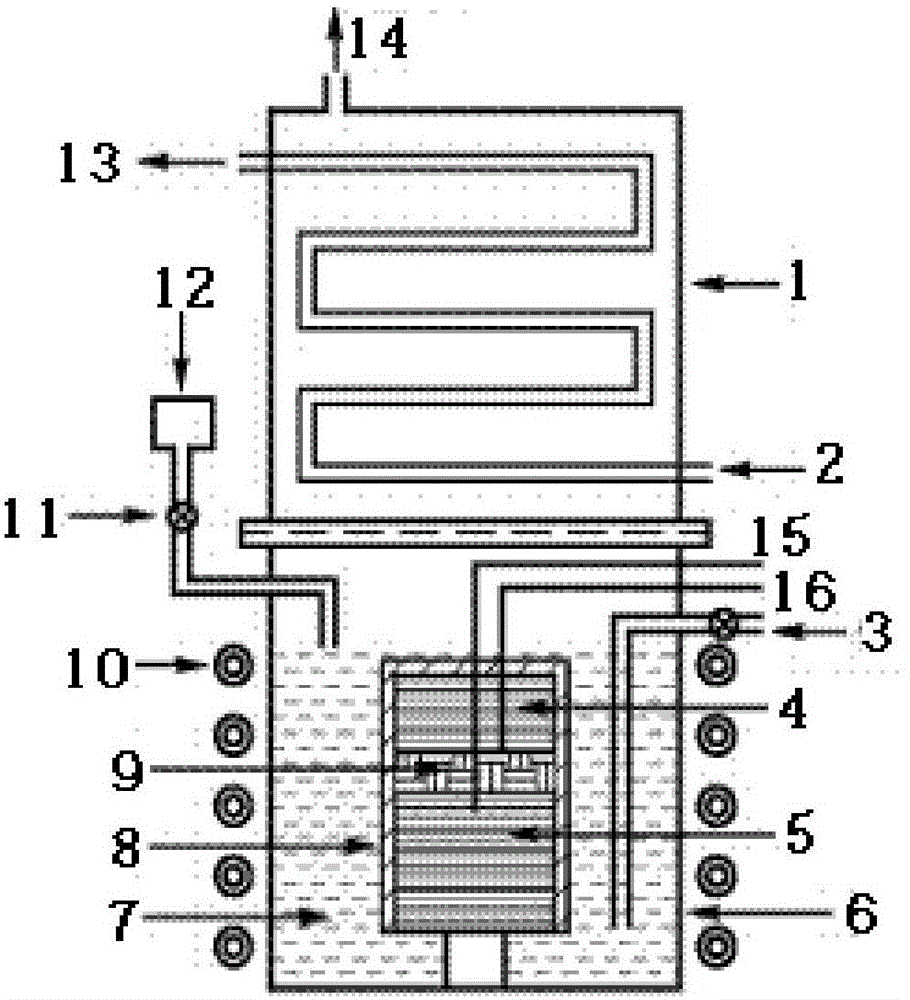

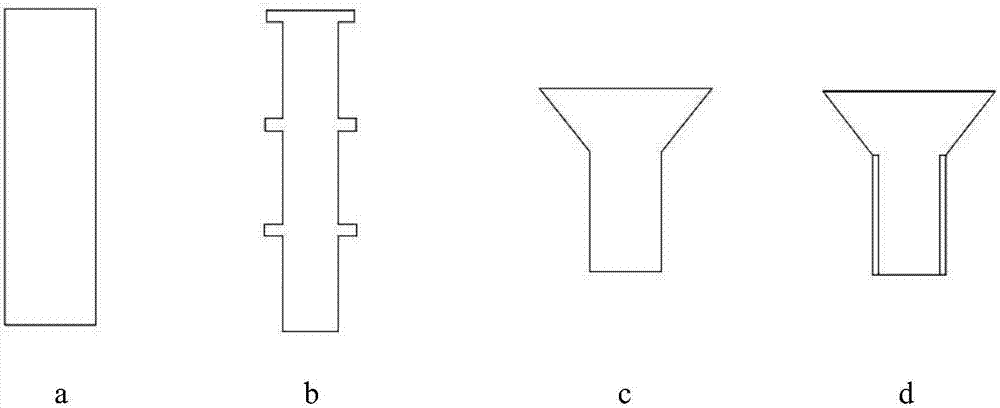

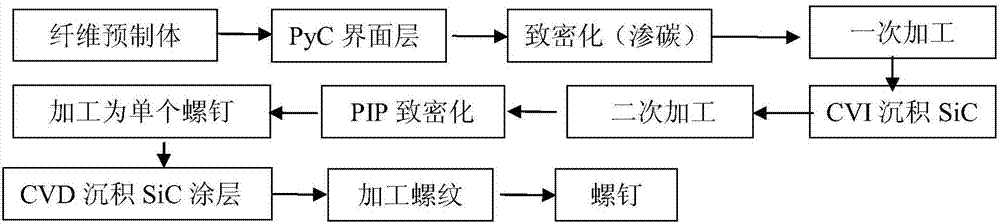

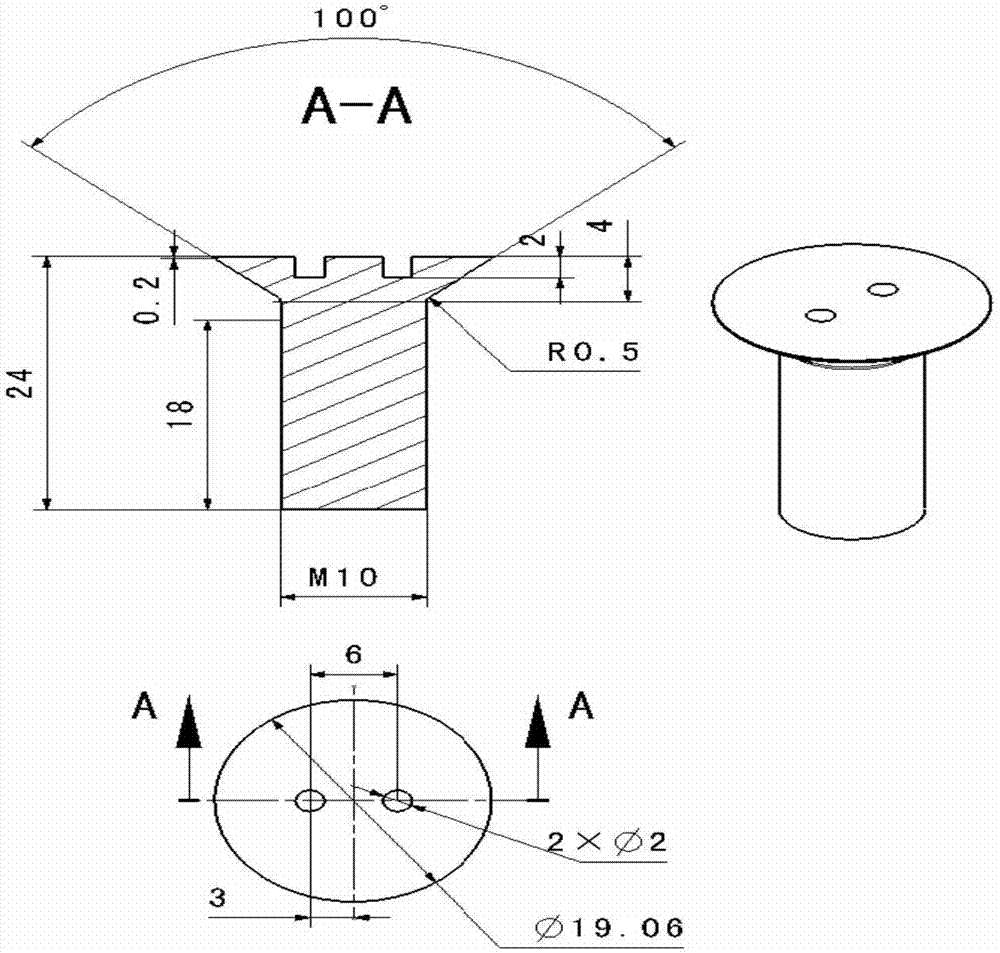

Preparation method of high temperature resistant ceramic matrix composite screw

ActiveCN107021770AImprove temperature resistanceImprove mechanical propertiesUltra-high-temperature ceramicsOxidation resistant

The invention relates to a preparation method of a screw, in particular to a preparation method of a high temperature resistant ceramic matrix composite screw. The preparation method of the high temperature resistant ceramic matrix composite screw comprises the following steps: (1) preparing a fiber perform; (2) depositing pyrolytic carbon in the fiber perform; (3) carrying out primary processing according to the size of the screw, after leaving a processing allowance, processing the fiber perform into a continuous screw rod; (4) depositing an SiC matrix in the screw rod; (5) carrying out secondary processing according to the size of the screw, and finishing in place; (6) by taking an ultra-high temperature ceramic precursor as a raw material, introducing an ultra-high temperature ceramic matrix; (7) processing the continuous screw rod into single screws, and preparing SiC coatings on the surfaces respectively; and (8) carrying out thread processing according to the requirements of the screw to obtain a screw product. According to the preparation method, by organically combining preparation and processing of a screw material, the prepared screw resists high temperature, is intact in screw tooth size and high in accuracy and has higher mechanical performance and oxidation resistance performance.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

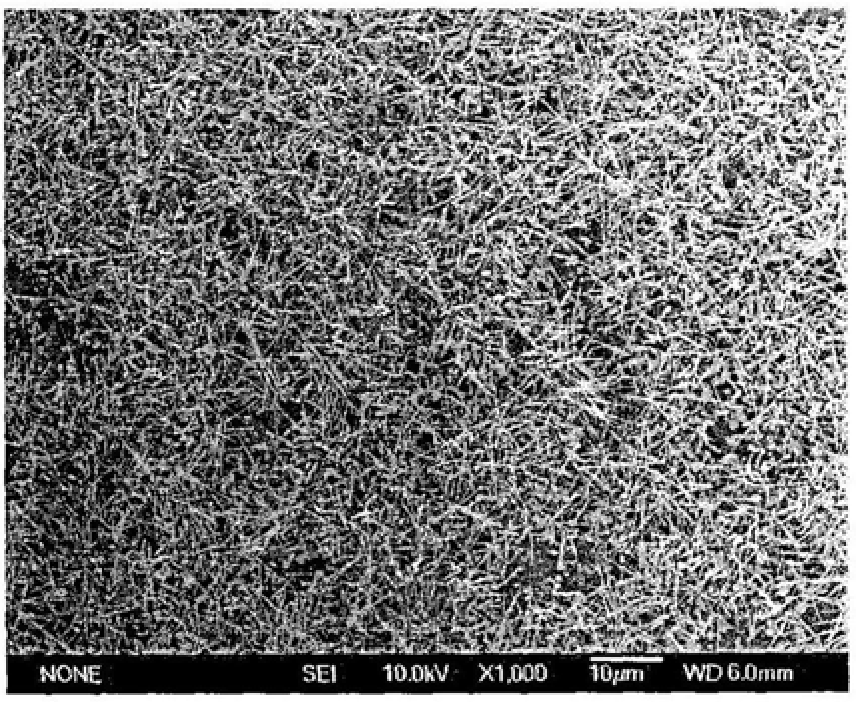

Fiber-reinforced ceramic matrix composite material with ablation resistance, thermal shock resistance, high temperature and oxidation resistance coating and preparation method thereof

ActiveCN106342035BHigh bonding strengthImprove pinning effectCeramic layered productsChemical vapor deposition coatingNanowireUltra-high-temperature ceramics

The invention proposes a high-temperature anti-oxidation coating on ablation-resistant and thermal-shock-resistant fiber-reinforced ceramic matrix composites, which is characterized in that the coating is formed by CVI- SiC coating formed by CVD process after SiC reinforcement layer; or using CVD process to alternately deposit one or two ultra-high temperature ceramic layers and SiC layers in MC or MB2 on the basis of using the aforementioned SiC coating as a transition layer The formed (MC / SiC)n or (MB2 / SiC)n or (MC / MB2 / SiC)n multilayer ultra-high temperature oxidation resistant coating, 1≤n≤100, the SiC layer in the multilayer ultra-high temperature oxidation resistant coating SiC nanowires and / or SiC whiskers are formed on the surface by in-situ growth through CVD process. In addition, the invention also proposes a preparation method of the high-temperature anti-oxidation coating. The invention can be widely used in the preparation of ablation-resistant, thermal shock-resistant, high-temperature and oxidation-resistant coatings on the surface of thermal structural parts.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Ceramic matrix composite material and preparation method thereof

ActiveCN110028330AStrong chemical bondGive full play to the synergistic antioxidant effectCarbon fibersHafnium

The invention provides a ceramic matrix composite material and a preparation method thereof, wherein a carbon fiber preform is used as a skeleton, and is immersed in a hafnium-tantalum-silicon ternarycomposite phose ceramic precursor solution, and curing and cracking are performed to prepare the composite material. According to the preparation method, a pyrolytic carbon interface layer is prepared on a carbon fiber preform by using a chemical vapor infiltration method, matrix densification treatment is performed by using a hafnium-tantalum-silicon ternary composite phose ceramic precursor impregnation cracking method, and finally pore sealing treatment is performed by using a chemical vapor infiltration method. According to the present invention, the method has characteristics of simple process and short development period; and the prepared ultra-high temperature ceramic matrix composite material has the uniform distribution of various components of the matrix, has characteristics ofultra-high-temperature resistance, oxidation resistance and ablation resistance, can be used as the high temperature thermal structure material for hypersonic vehicles and rocket propulsion systems, and has broad application prospects.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

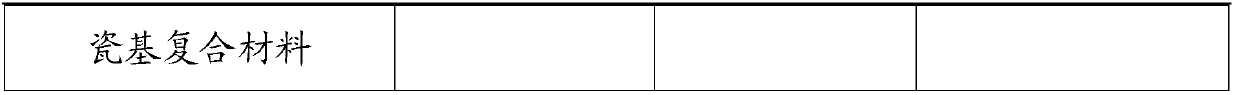

Method for preparing zirconium-aluminium-carbon ceramic cube material by in-situ reaction heat-pressing

The invention relates to a manufacturing technology for super high temperature endurable ceramic. The feature is that it uses Zr powder, Al powder and C powder as raw material, taking ball milling for 10-30 hours, pressing to cake shape under 10-20MPa, encasing into graphite mold, heating to 1600-1900 degree centigrade in hot-pressing furnace at 2-50 degree centigrade per minutes under protection of noble gas, taking home position hot pressing / solid-liquid phase reacting for 0.5-4 hours, and the hot pressing pressure is 30-40MPa. The invention could compound high purity, high intension, and corrosion proof zirconium aluminum carbon block material at low temperature and in short tie. The material could be used in the environment temperature over 1600 degree centigrade.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

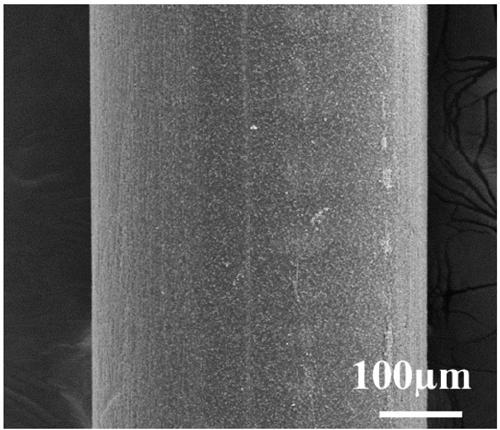

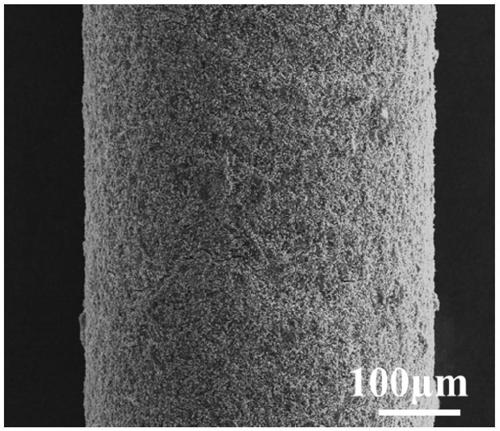

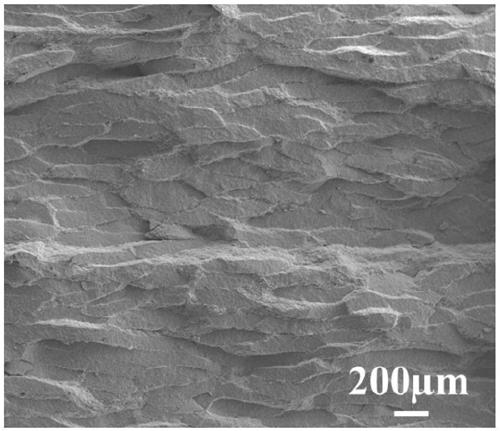

Preparation method of in-plane isotropic zirconium boride-based ultra-high temperature monolithic structure ceramic with high damage tolerance

ActiveCN109293384ASolve the problem of in-plane anisotropyImprove fracture toughnessInorganic material artificial filamentsBorideFiber

The invention relates to a preparation method of a zirconium boride-based ultra-high temperature monolithic material, in particular to a preparation method of an in-plane isotropic zirconium boride-based ultra-high temperature monolithic structure ceramic with high damage tolerance, and aims to solve the problems that ZrB2-based ultra-high temperature ceramic has poor damage tolerance and seriousin-plane anisotropy exists in ZrB2-based fiber monolithic ceramic. The preparation method includes: dissolving polyether sulfone in N-methylpyrrolidone, and conducting ball milling mixing with ZrB2 powder and SiC powder to obtain a ZrB2-SiC slurry, and subjecting the ZrB2-SiC slurry to extrusion curing to obtain continuous ZrB2-SiC ceramic fiber; dispersing ZrB2 powder, SiC powder and Graphene indeionized water to obtain a ZrB2-SiC-Graphene slurry; coating the continuous ZrB2-SiC ceramic fiber with the ZrB2-SiC-Graphene slurry, performing drying, and conducting prepressing, high temperature glue discharge and hot pressing sintering. The method provided by the invention solves the in-plane anisotropy problem of uniaxially arranged ZrB2-based fiber monolithic ceramic, and improves the damage tolerance. The method provided by the invention is suitable for preparation of zirconium boride-based ultra-high temperature monolithic structure ceramic.

Owner:HARBIN INST OF TECH

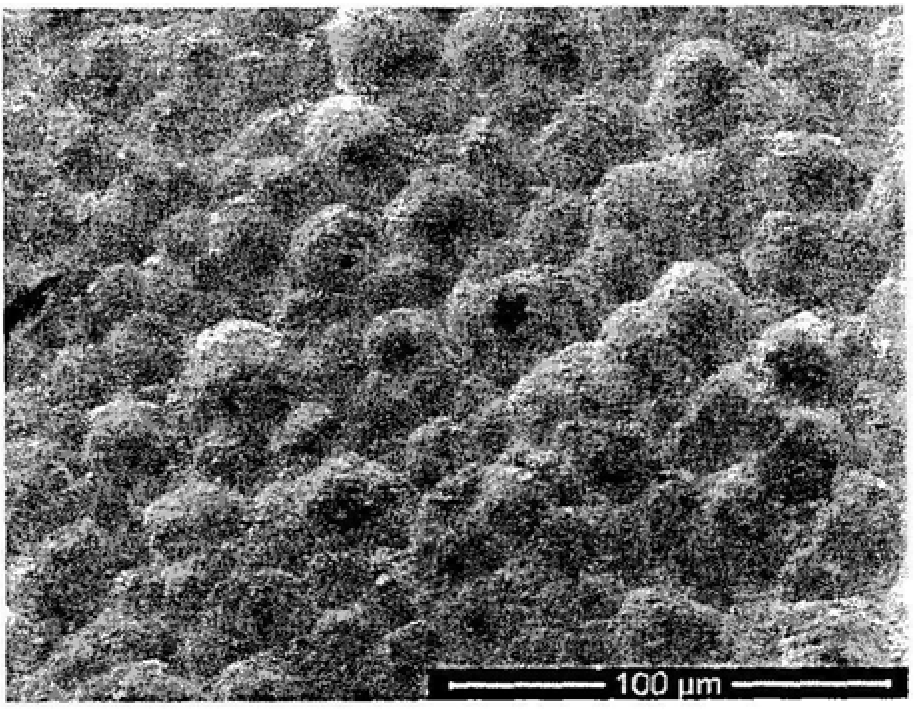

Boride-silicon carbide-boron carbide ternary ceramic-base composite material and preparation method thereof

InactiveCN101265108AGrowth inhibitionGood for fine grain strengthening mechanismBorideUltra-high-temperature ceramics

The invention relates to a boride-silicon carbide-boron carbide ternary ceramic matrix composite material and a production method thereof. The invention relates to a ternary ceramic matrix composite material and a production method thereof, and solves the problem of poor toughness of the existing ultrahigh temperature ceramic materials. The inventive boride-silicon carbide-boron carbide ternary ceramic matrix composite material is made from, by volume percentages, 50%-80% of borides, 10%-30% of silicon carbide and 5%-30% of boron carbide. The production method comprises the following steps: (1) wet mixing and sieving; and (2) hot-press sintering. The maximal bending strength of the boride-silicon carbide-boron carbide ternary ceramic matrix composite material reaches 890 MPa, and the maximal fracture toughness thereof reaches 7.1 MPa / m<2>.

Owner:HARBIN INST OF TECH

ZrB2-SiC-SiB6 superhigh-temperature ceramic material and preparing method thereof

InactiveCN106007734AImprove sintering performanceDoes not affect high temperature performanceUltra-high-temperature ceramicsOxidation resistant

The invention relates to a ZrB2-SiC-SiB6 superhigh-temperature ceramic material and a preparing method thereof, in particular to a method for preparing an SiB6 particle and SiC particle dual-phase reinforced ZrB2 superhigh-temperature ceramic material through a hot pressed sintering method. The material has excellent high-temperature oxidation resistance, is simple in preparing process and short in period and belongs to the technical field of high-temperature thermal-protecting materials. According to a scattering method of powder of the ZrB2-SiC-SiB6 superhigh-temperature ceramic material, three kinds of powder of ZrB2, SiC and SiB6 are evenly scattered and mixed through a high-speed ball milling method, and then mixed powder can be obtained through a drying and grinding method. According to the preparing method of the ZrB2-SiC-SiB6 superhigh-temperature ceramic material, a high-temperature hot pressed sintering method is chosen, effects of different sintering techniques on the material are systematically analyzed, and a relative-compact block material can be obtained in a reasonable sintering technique condition.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

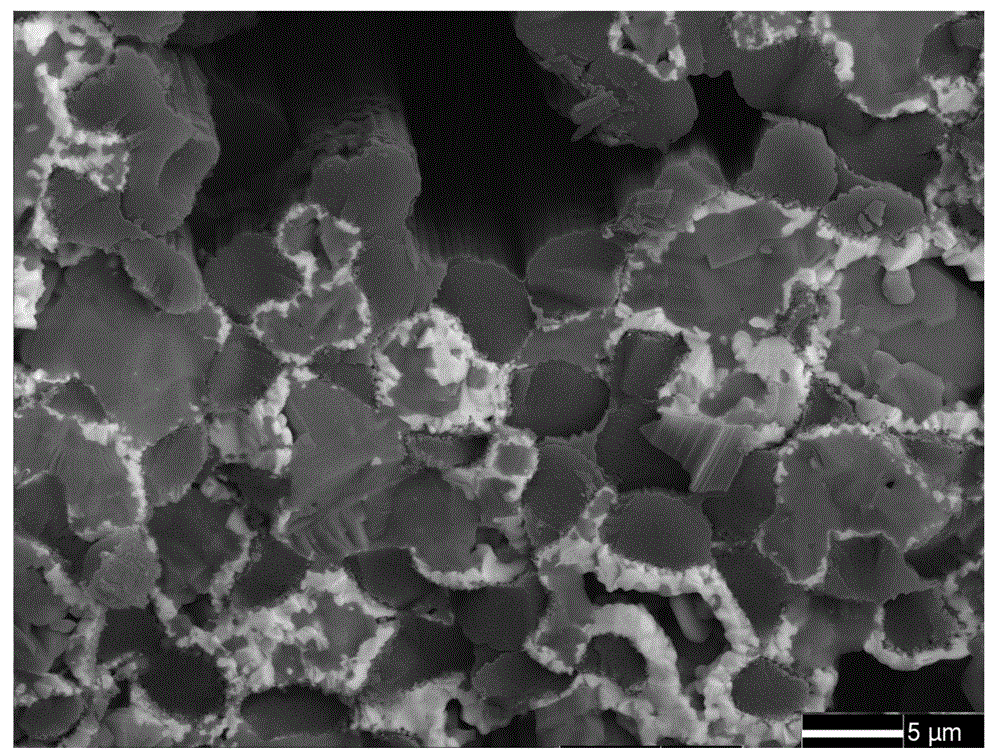

Cf/C-MC ultra-high-temperature ceramic matrix composite and preparation method thereof

The invention provides a Cf / C-MC ultra-high-temperature ceramic matrix composite and a preparation method of the Cf / C-MC ultra-high-temperature ceramic matrix composite. The method includes the steps of selecting a carbon fiber prefabricated body as a reinforcement body, taking biomass carbon as a carbon source, conducting carbon microsphere sedimentation in the fiber prefabricated body through a homogeneous phase hydrothermal method, depositing oxides in the carbon fiber prefabricated body through the microwave hydrothermal method, repeatedly executing the carbon microsphere and oxide depositing step, and conducting calcination in the argon atmosphere to obtain the Cf / C-MC ultra-high-temperature ceramic matrix composite. According to the Cf / C-MC ultra-high-temperature ceramic matrix composite prepared through the method, the density ranges from 1.20 g / cm<3> to 2.05 g / cm<3>, and the porosity ranges from 6% to 13%. The method is easy to operate, short in preparation cycle and low in cost. No damage is caused to carbon fiber in the preparation process, and the method is environmentally friendly.

Owner:SHAANXI UNIV OF SCI & TECH

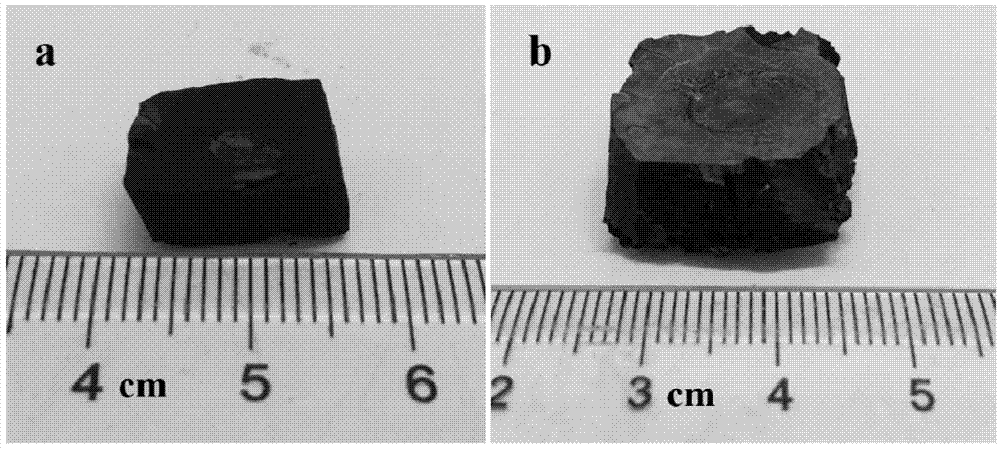

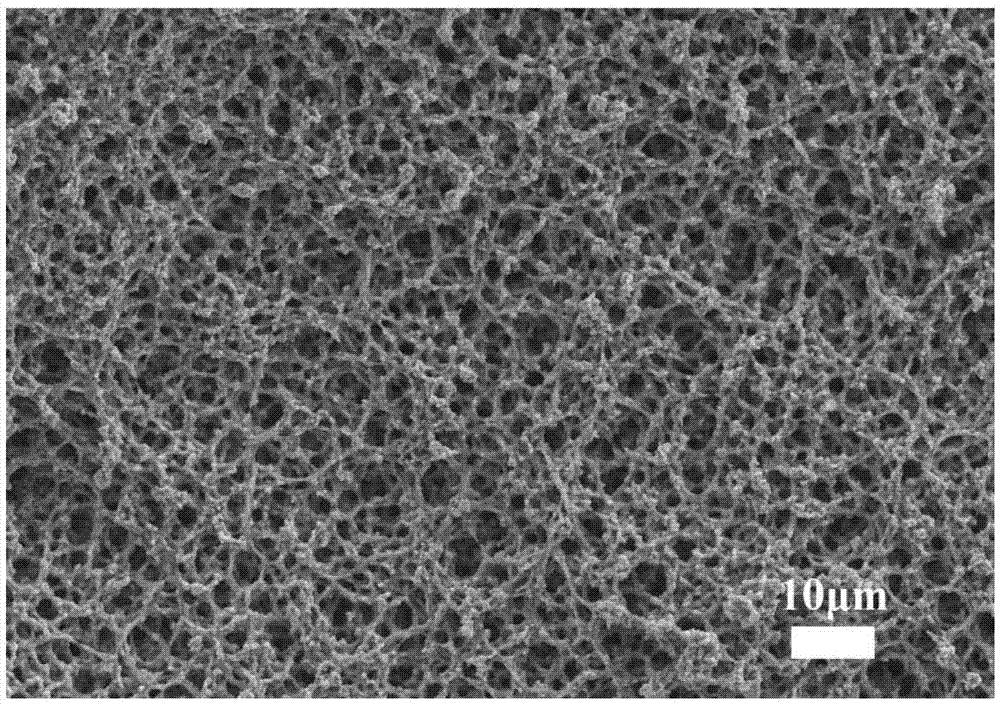

Ultra high temperature ceramic based aerogel material and preparation method thereof

The invention relates to an ultra high temperature ceramic based aerogel material and a preparation method thereof. The preparation method comprises the following steps: a soluble transition metal precursor, organosilicon and soluble carbon and boron sources are dissolved in a solvent to obtain a mixed solution for reaction at 30 to 80 DEG C to obtain a precursor sol, or the soluble transition metal precursor, the organosilicon and the soluble carbon source are dissolved in a solvent to obtain a mixed solution for reaction at 30 to 80 DEG C to obtain a precursor sol; the obtained composite precursor is cured to obtain an aerogel preform; and the ultra high temperature ceramic based aerogel material is obtained by ceramic conversion of the obtained aerogel preform under protection of atmosphere at 1000 to 1800 DEG C.

Owner:江苏先进无机材料研究院

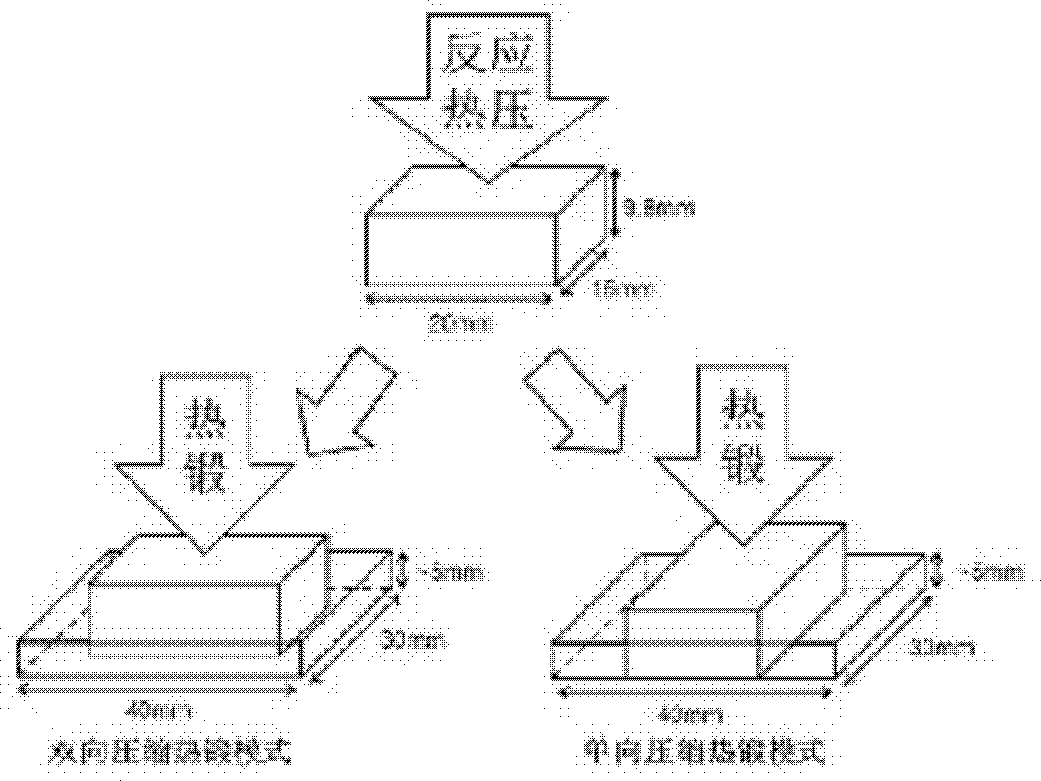

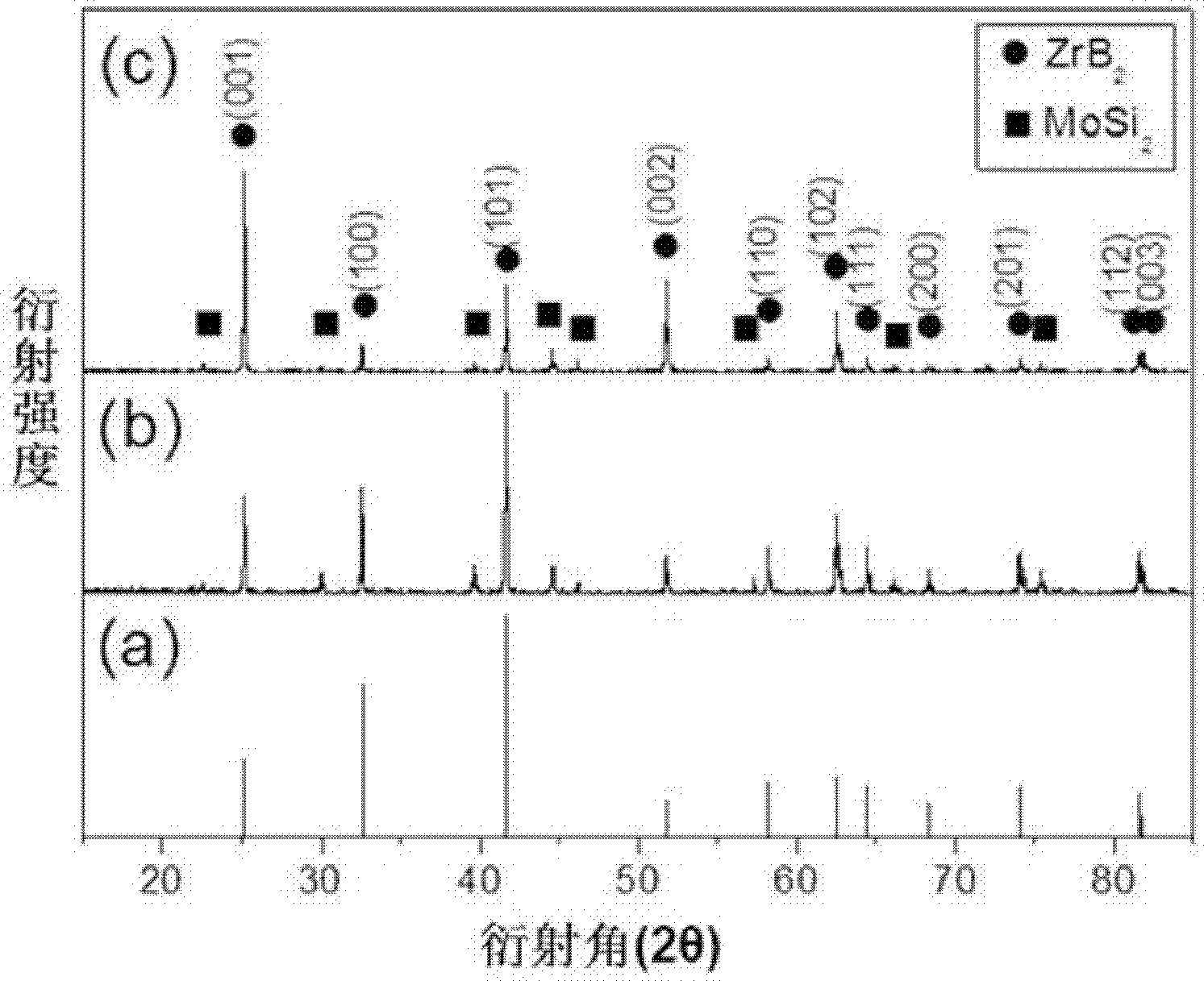

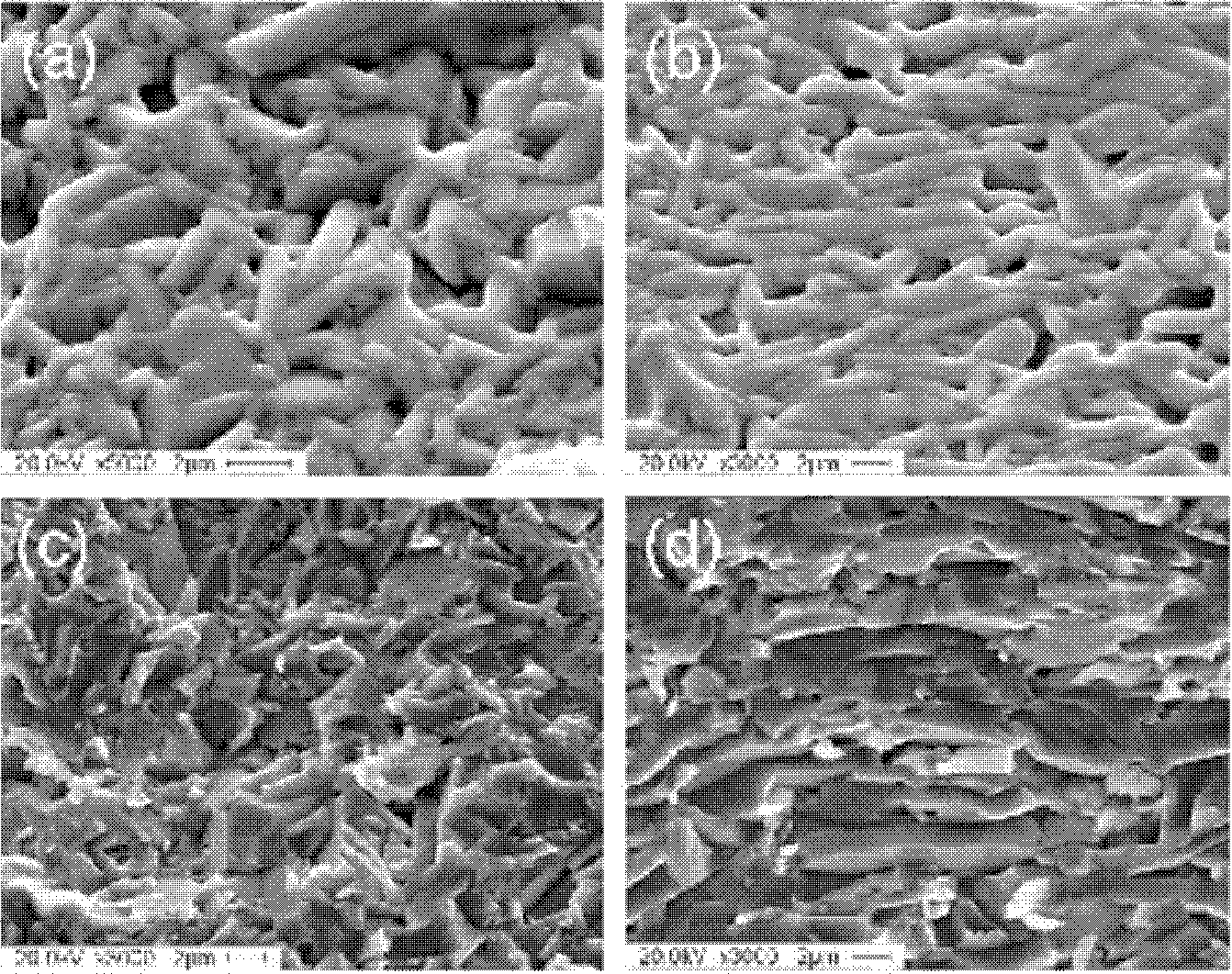

Textured boride base ultra-high temperature ceramic material and its preparation method

The invention discloses a textured boride base ultra-high temperature ceramic material and its preparation method. The ceramic material is a boride-silicide base composite material and is prepared from raw materials of group IVB metal, boron, silicon and transition metal. In addition, the microstructure of the composite material contains boride crystal grains of anisotropic grain growth and directional arrangement. The ceramic material is prepared by the following steps of: firstly performing reactive hot-pressing sintering to prepare densified boride base ceramic with the anisotropy crystal grain microstructure, and carrying out microstructure modulation on the ceramic which has undergone reactive hot-pressing sintering by a hot forging method to realize directional arrangement of the crystal grains of anisotropic grain growth. Therefore, the textured boride base ultra-high temperature ceramic material with the anisotropic grain growth crystal grain microstructure is obtained. According to the invention, relative density of the obtained ceramic material is greater than 98%; Lotgering orientation factor f (001) can reach up to 0.91; and its oxidation resistance, thermal conductivity and other properties all show obvious anisotropy.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

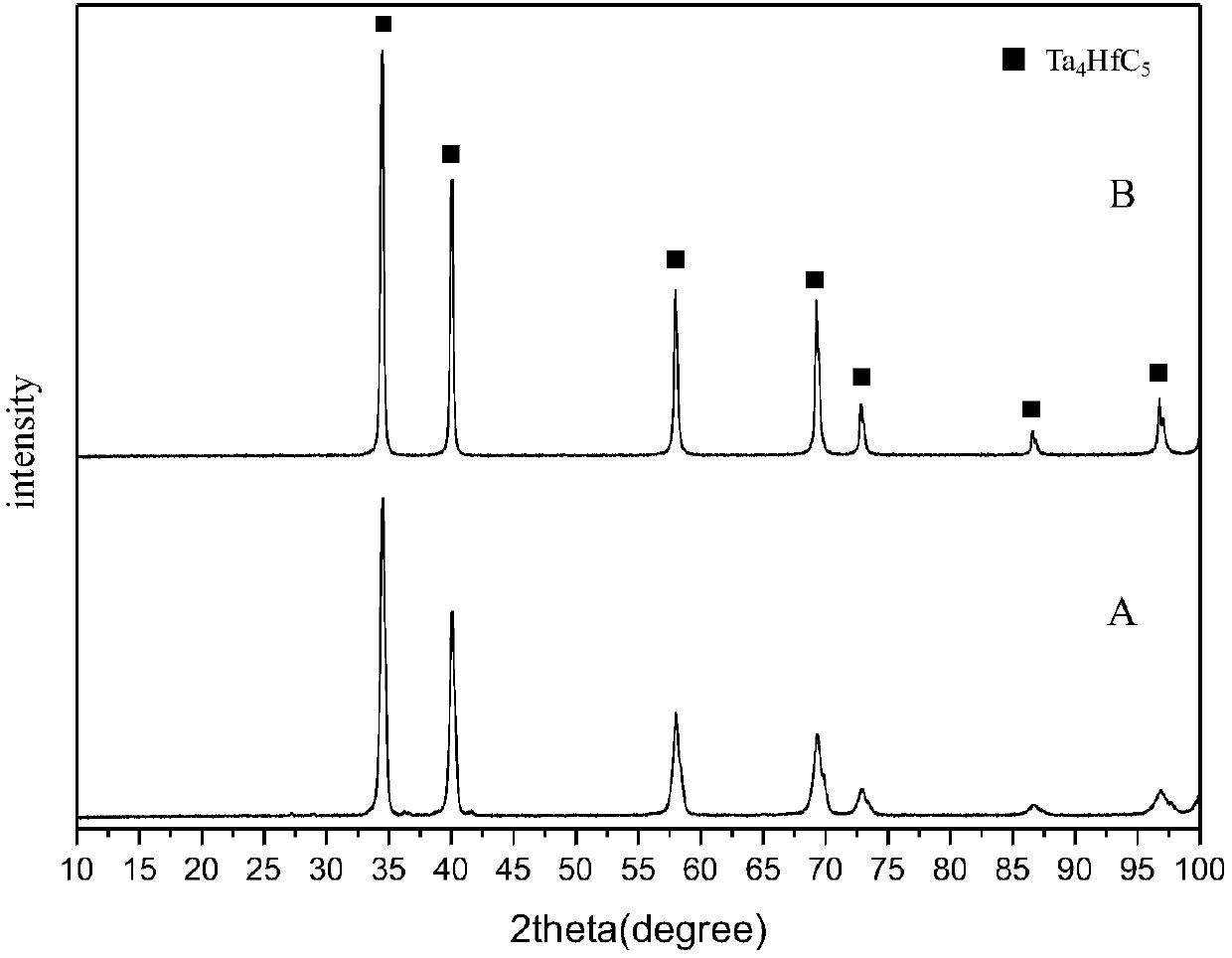

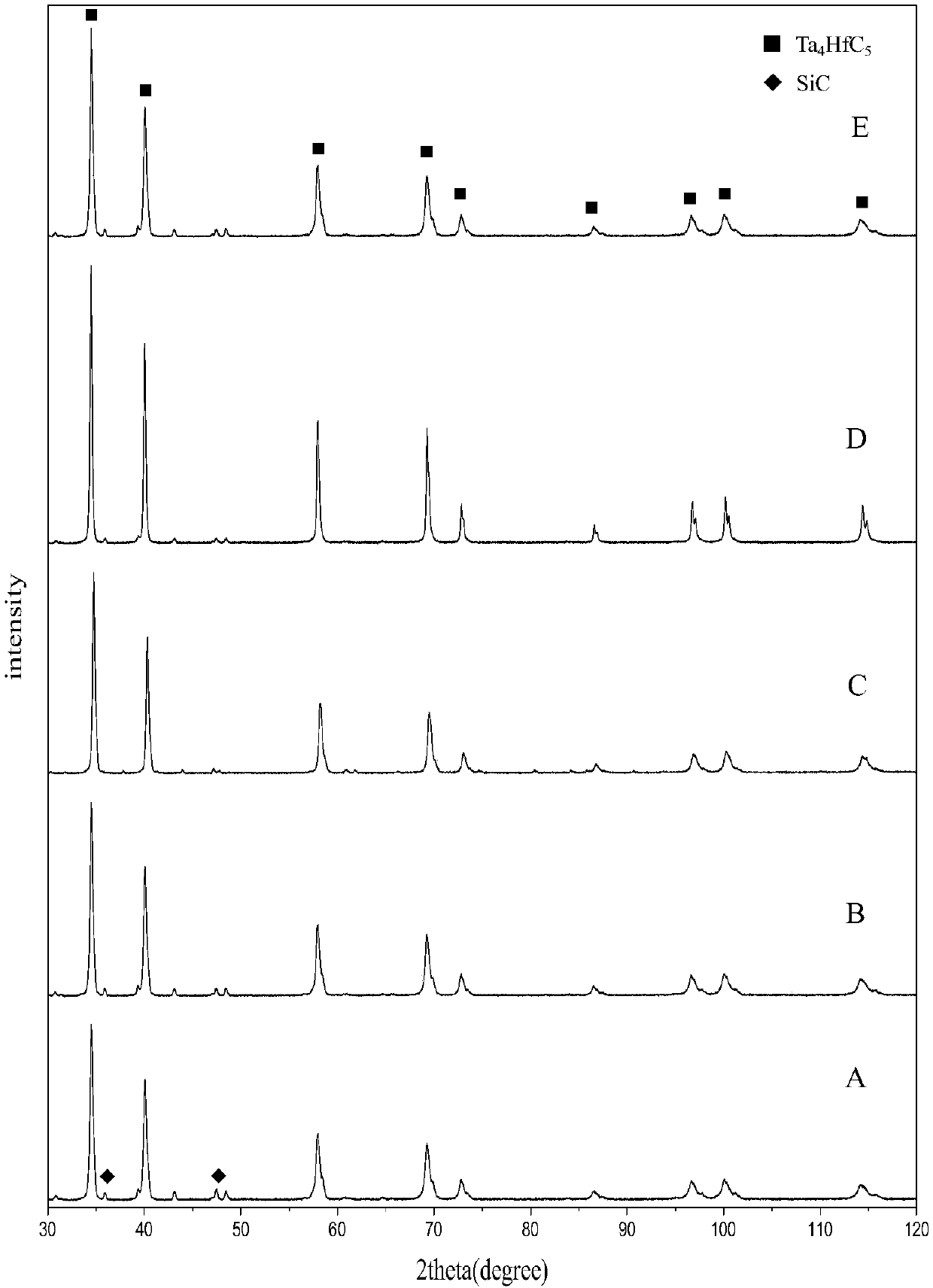

Preparation method of high-density ultra-high-temperature Ta4HfC5 ceramic block material

The invention discloses a preparation method for a high-density ultra-high-temperature Ta4HfC5 ceramic block material and belongs to the technical field of ultra-high-temperature ceramics. In the preparation method, a Ta4HfC5 solid solution powder and a sintering flux are mixed according to a volume ratio, and after high-energy ball milling, the high-density ultra-high-temperature Ta4HfC5 ceramicblock material is prepared by SPS. Compared with the prior art, the raw material used in the preparation method is the powder form of the solid solution Ta4HfC5 ceramic material instead of a mixed powder of TaC and HfC, thereby avoiding a complicated procedure of mixing the two powders, and avoiding influence on sintering caused by uneven particle size distribution and uneven mixing of the two powders. The high-density ultra-high-temperature Ta4HfC5 ceramic prepared by the preparation method has a high density, excellent physical properties such as hardness, elastic modulus and fracture toughness. After testing, the Vickers hardness is 1000 HV to 2100 HV, the elastic modulus is 300 GPa to 490 GPa, and the fracture toughness reaches 2.0 MPa*m<1 / 2> to 3.5 MPa*m<1 / 2>.

Owner:BEIHANG UNIV

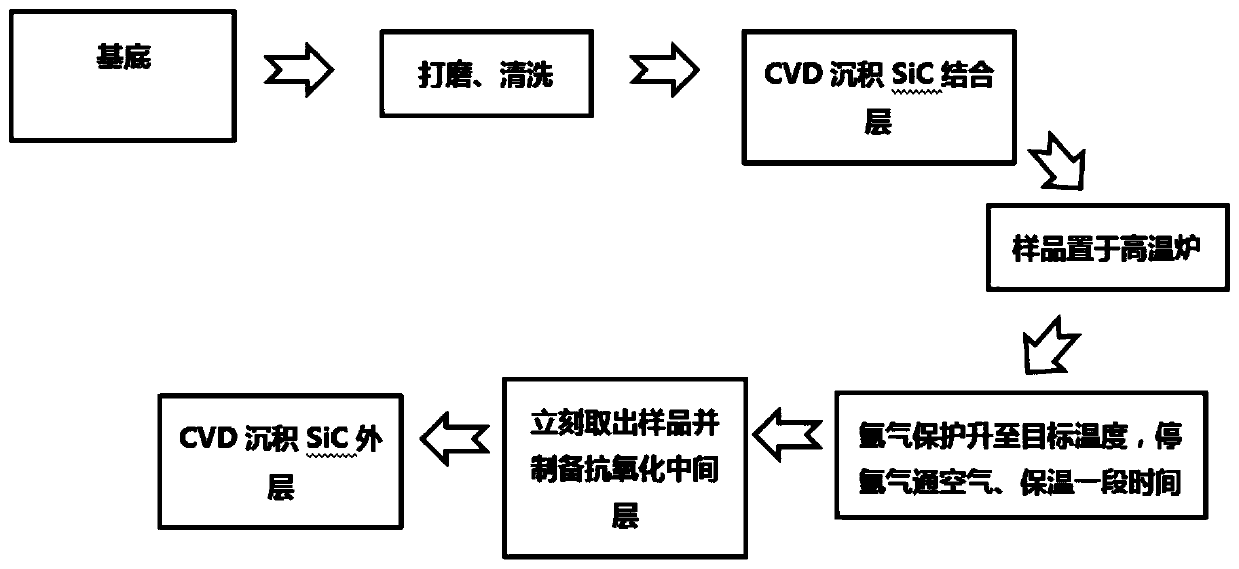

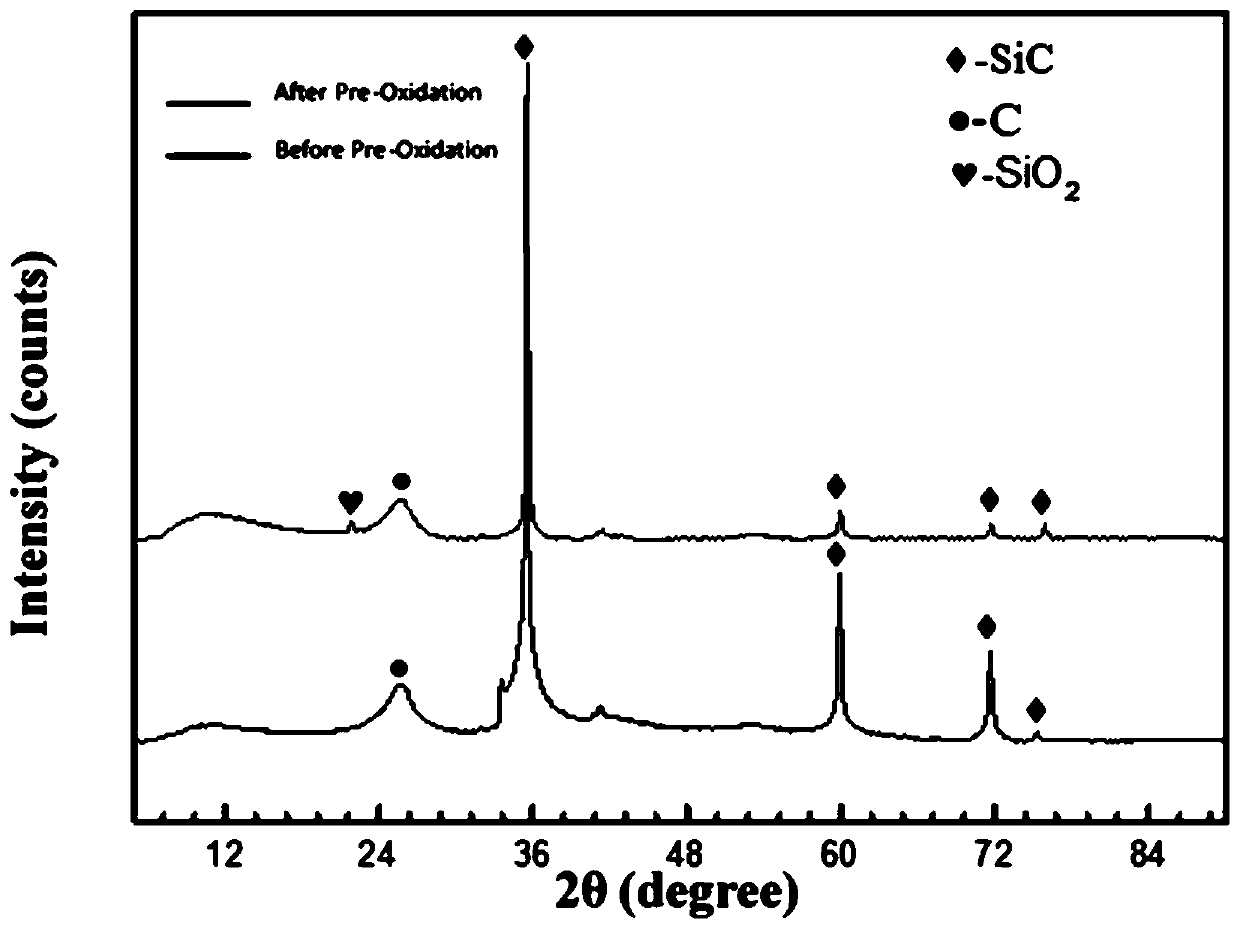

Method for improving bonding strength of anti-oxidation coating on surface of carbon-based or ceramic-based composite material

The invention discloses a method for improving the bonding strength of an anti-oxidation coating on the surface of a carbon-based or ceramic-based composite material, and belongs to the technical field of anti-oxidation of carbon-based and ceramic-based composite materials. The method comprises: preparing a SiC bottom layer on the surface of a substrate material by using a CVD process; carrying out pre-oxidation treatment on the substrate material deposited with SiC to form silicon oxide on the surface; preparing a super-high temperature ceramic anti-oxidation middle layer on the surface of the pre-oxidized sample by using a slurry brushing-sintering process; and depositing a SiC outer layer on the surface of the sample. According to the present invention, with the pre-oxidation process, the bonding strength between the brushing middle layer and the SiC bottom layer can be effectively improved so as to obtain the high-bonding strength SiC / ZrB2-SiC / SiC three-layer composite anti-oxidation coating.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com