Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152results about How to "Strong chemical bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

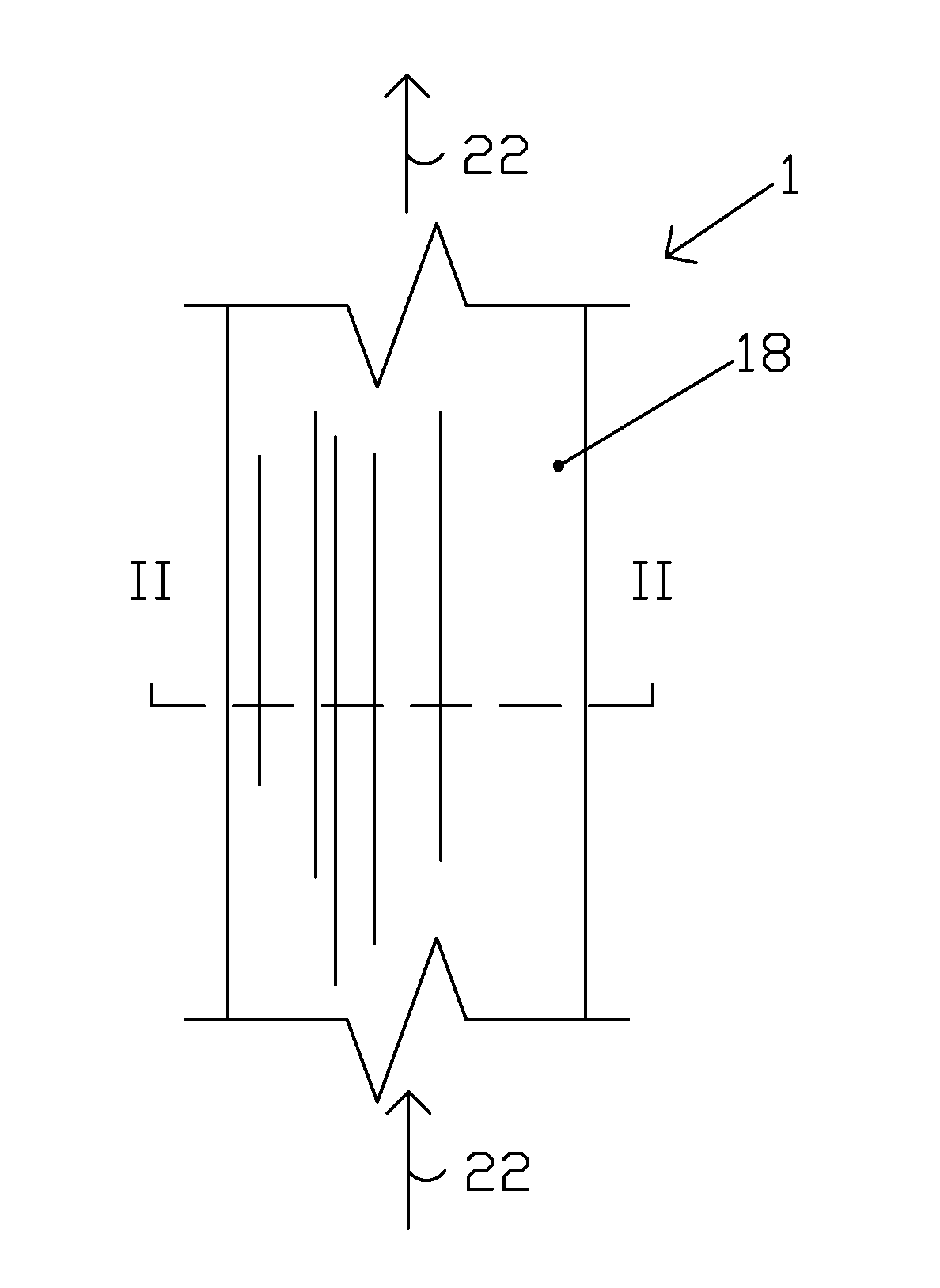

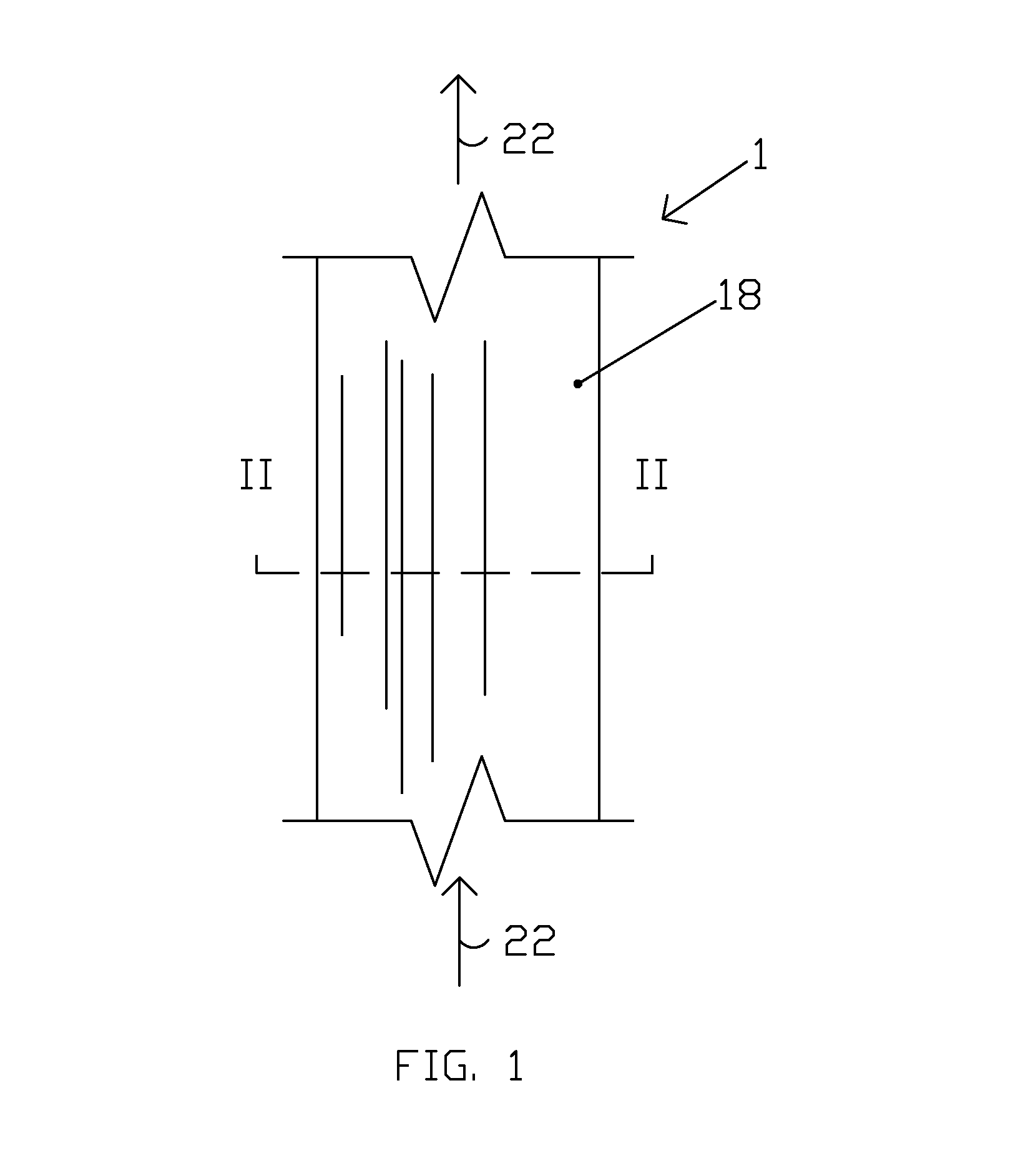

Method to remove agent from liquid phase

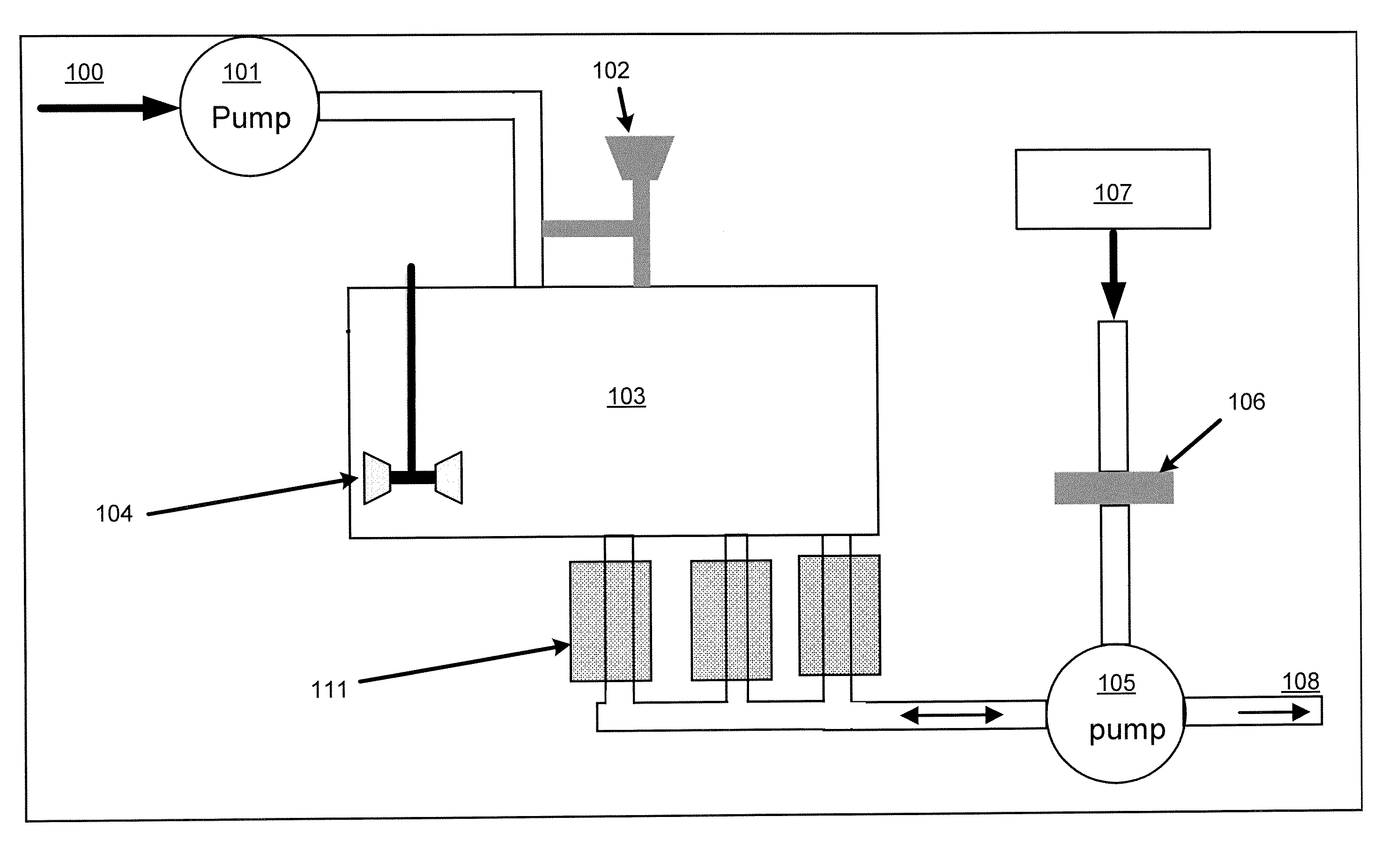

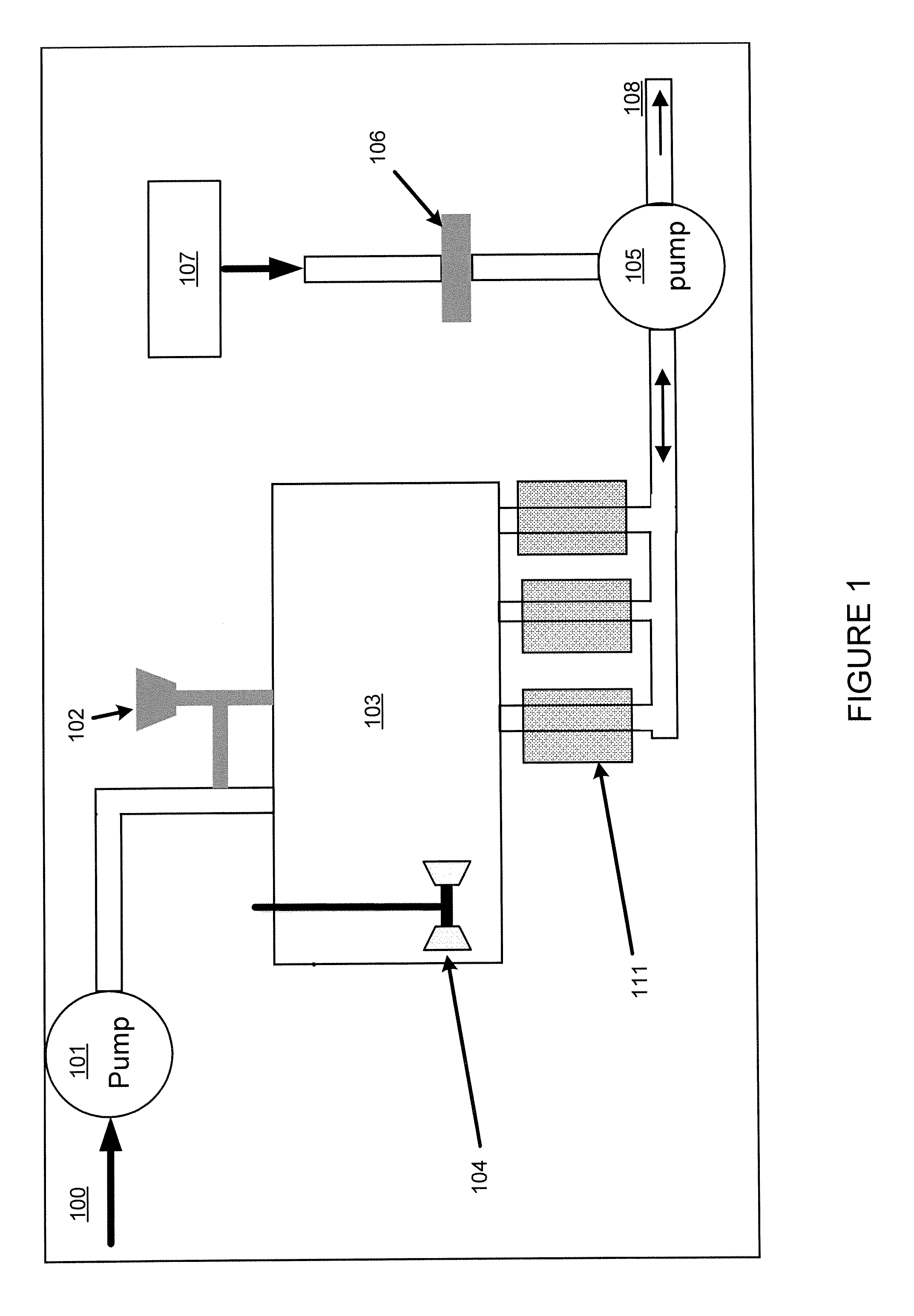

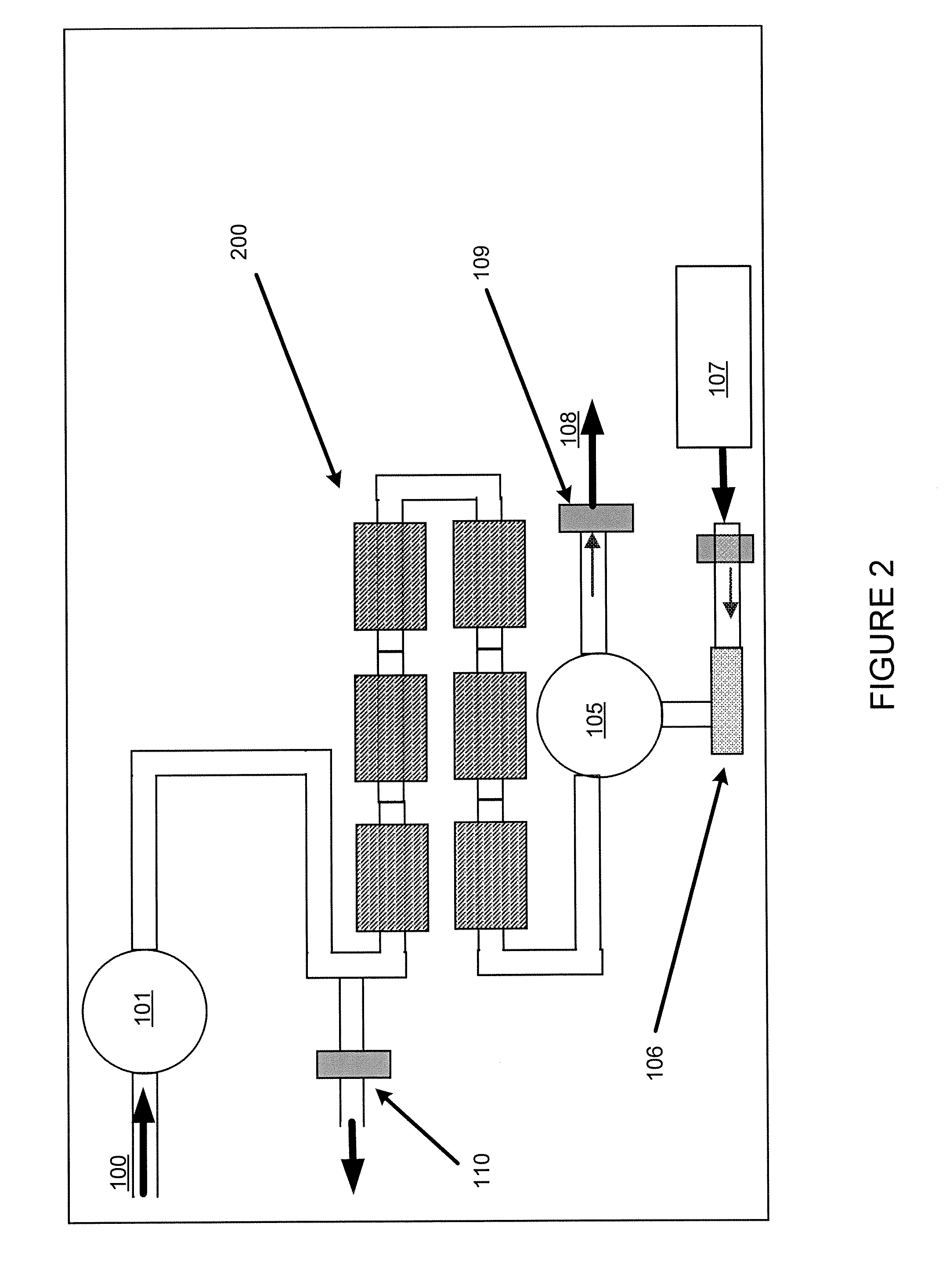

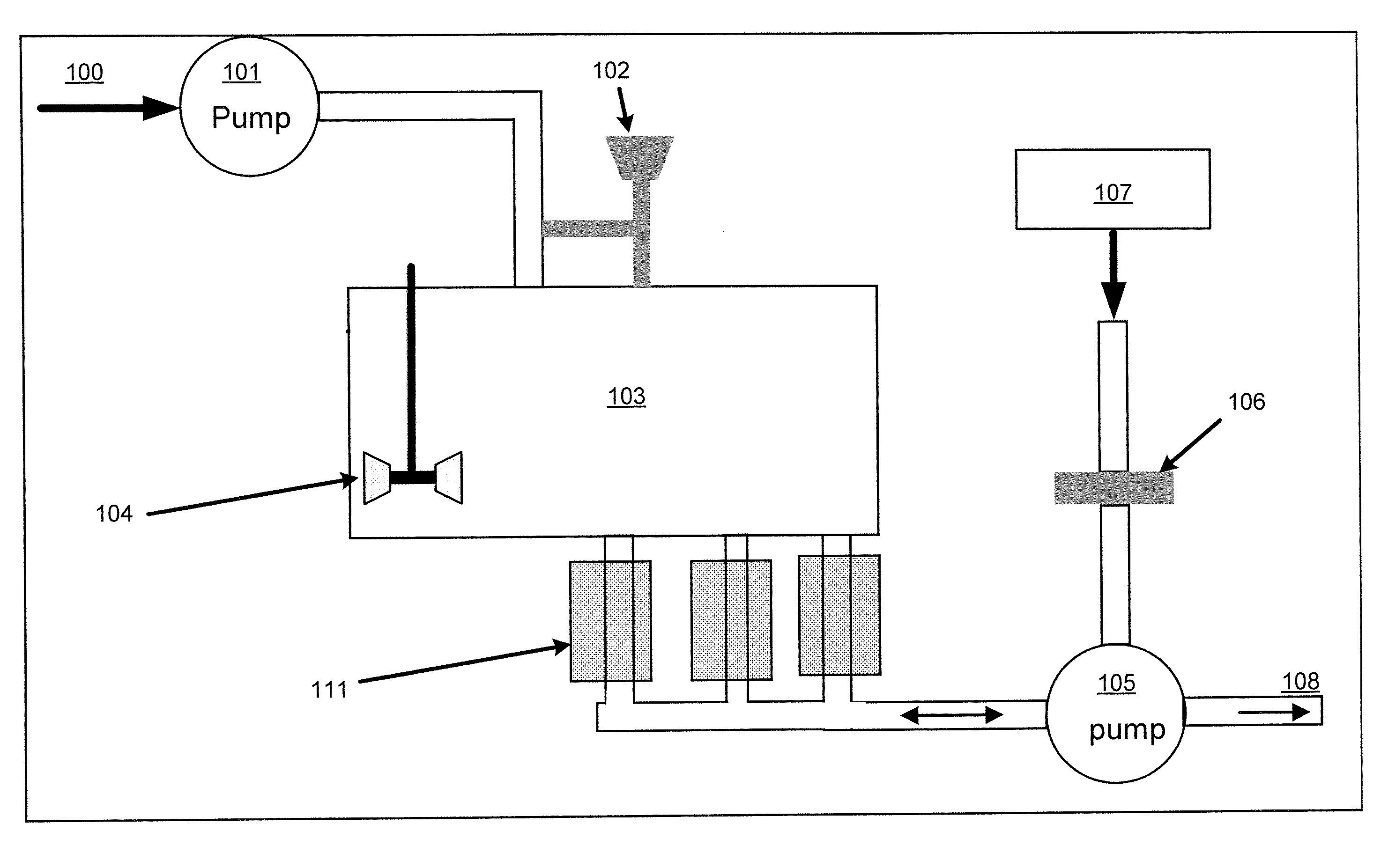

InactiveUS7520994B2Easy to useStrong chemical bondIon-exchanger regenerationWater/sewage treatment by magnetic/electric fieldsProcess systemsSorbent

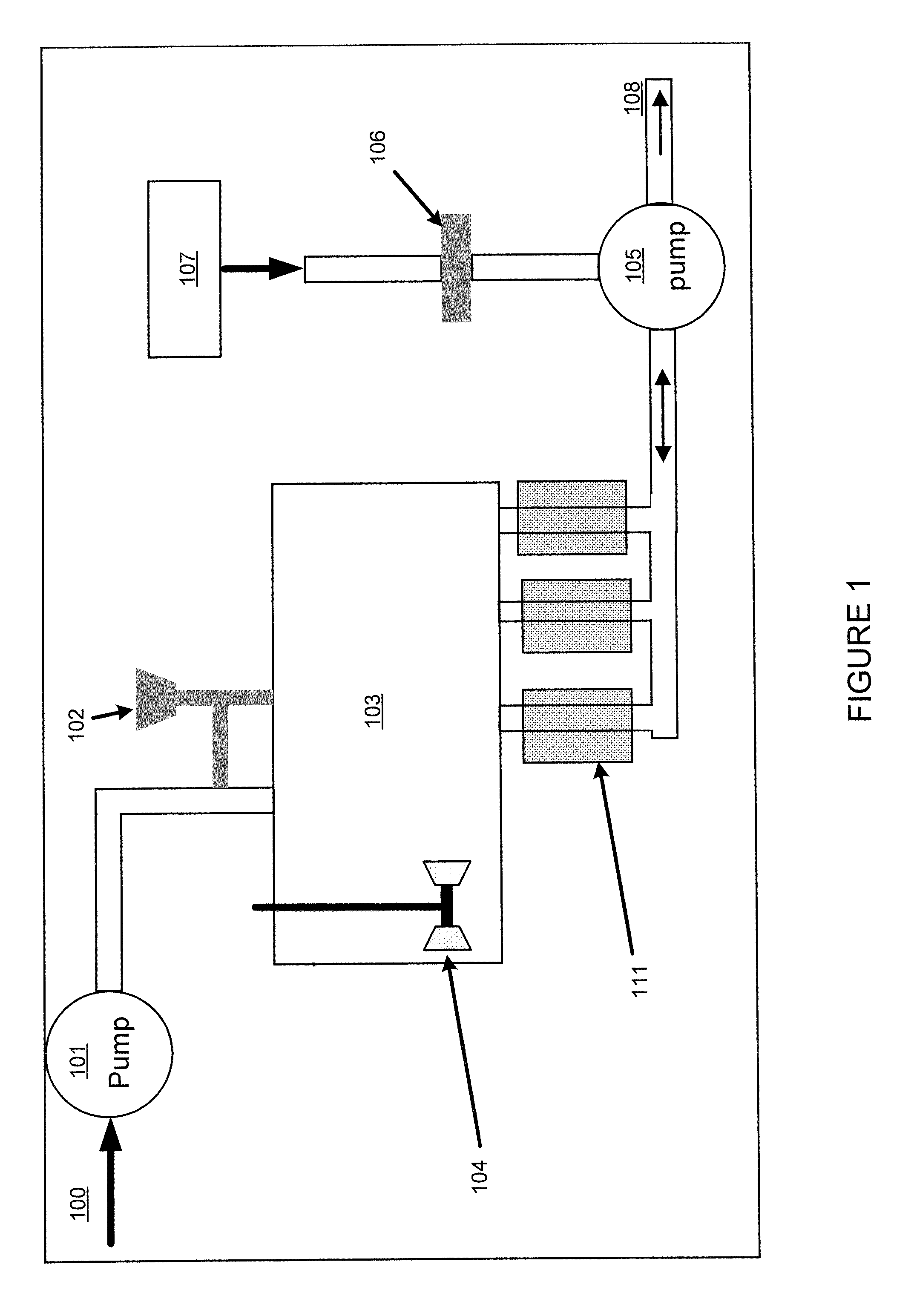

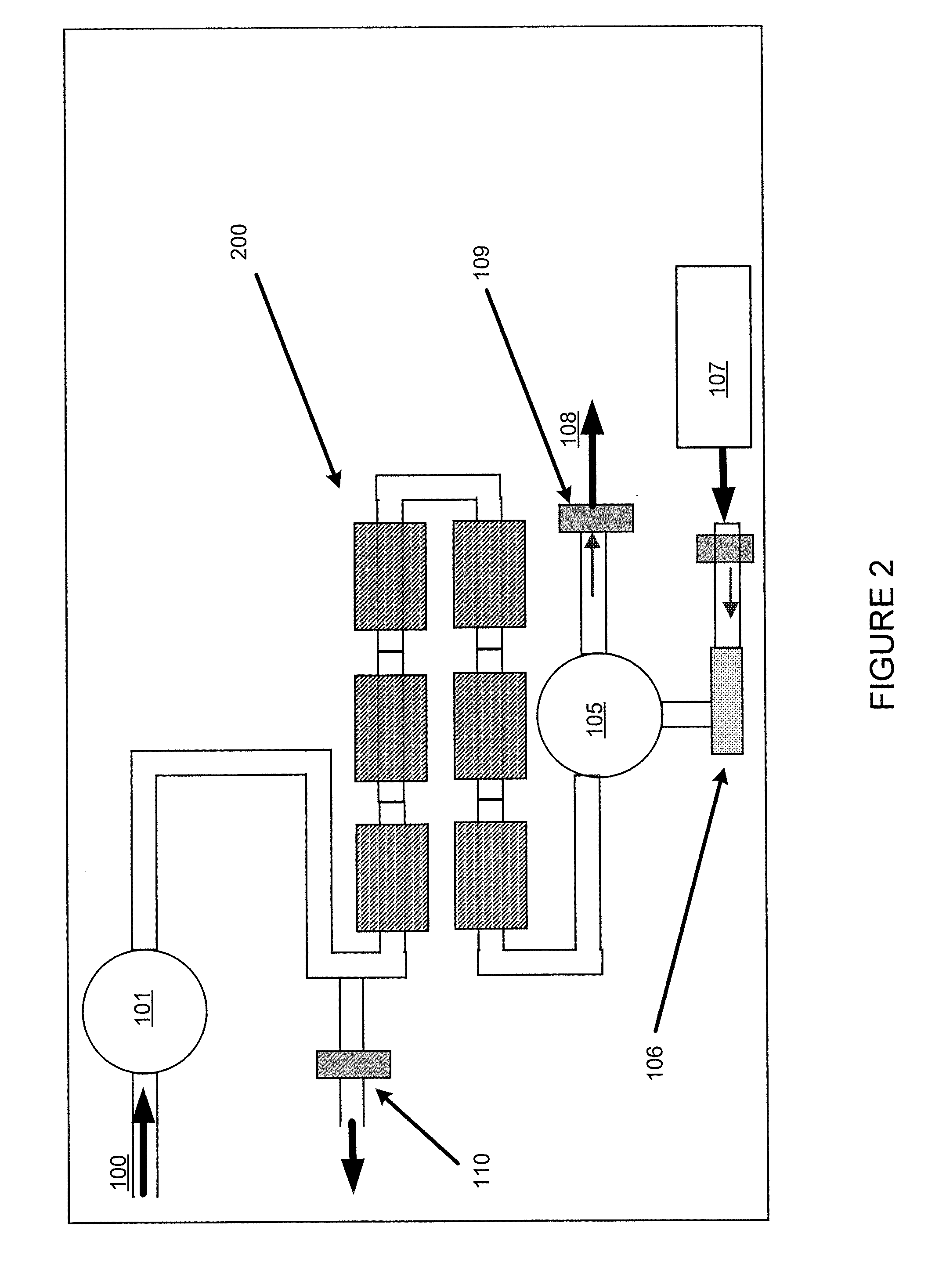

A system and method to remove a polluting agent or contaminant, including but not limited to mercury, from the liquid phase of a process system using an adsorbent. In one exemplary embodiment, a magnetic or non-magnetic support with a chemisorbing or physisorbing sorbent is suspended in the liquid phase of a process system, under conditions in which the polluting agent binds to the adsorbent. The pollutant-bearing adsorbent may then be separated from the process system by either physical or magnetic means. The polluting agent may then disassociated from the adsorbent so the adsorbent is regenerated and capable of repeated use.

Owner:DONG XING +1

Method and system to remove agent from liquid phase

InactiveUS20080011683A1Enhance capture capabilityExtend filter lifeIon-exchanger regenerationLoose filtering material filtersProcess systemsSorbent

A system and method to remove a polluting agent or contaminant, including but not limited to mercury, from the liquid phase of a process system using an adsorbent. In one exemplary embodiment, a magnetic or non-magnetic support with a chemisorbing or physisorbing sorbent is suspended in the liquid phase of a process system, under conditions in which the polluting agent binds to the adsorbent. The pollutant-bearing adsorbent may then be separated from the process system by either physical or magnetic means. The polluting agent may then disassociated from the adsorbent so the adsorbent is regenerated and capable of repeated use.

Owner:DONG XING +1

Composition and process for coloring and preserving wood

InactiveUS20050152994A1Uniform colorHigh affinityBiocideInorganic boron active ingredientsNuclear chemistryMetal

Owner:OSMOSE +1

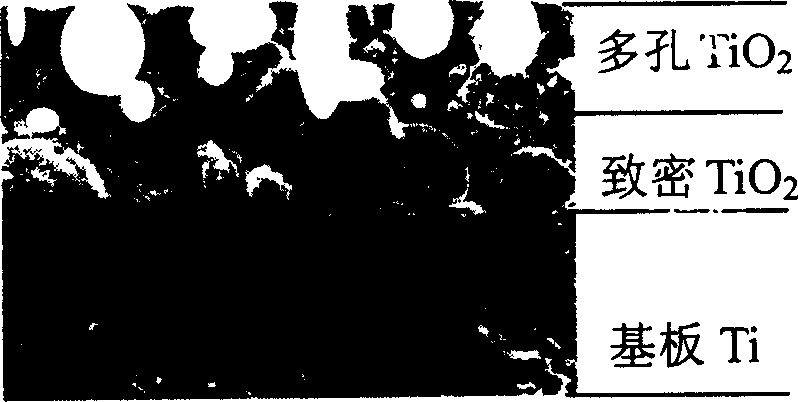

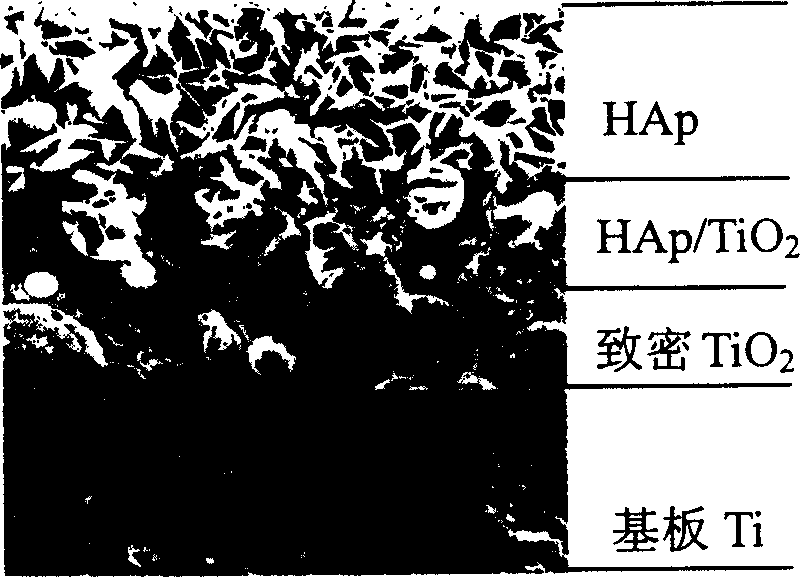

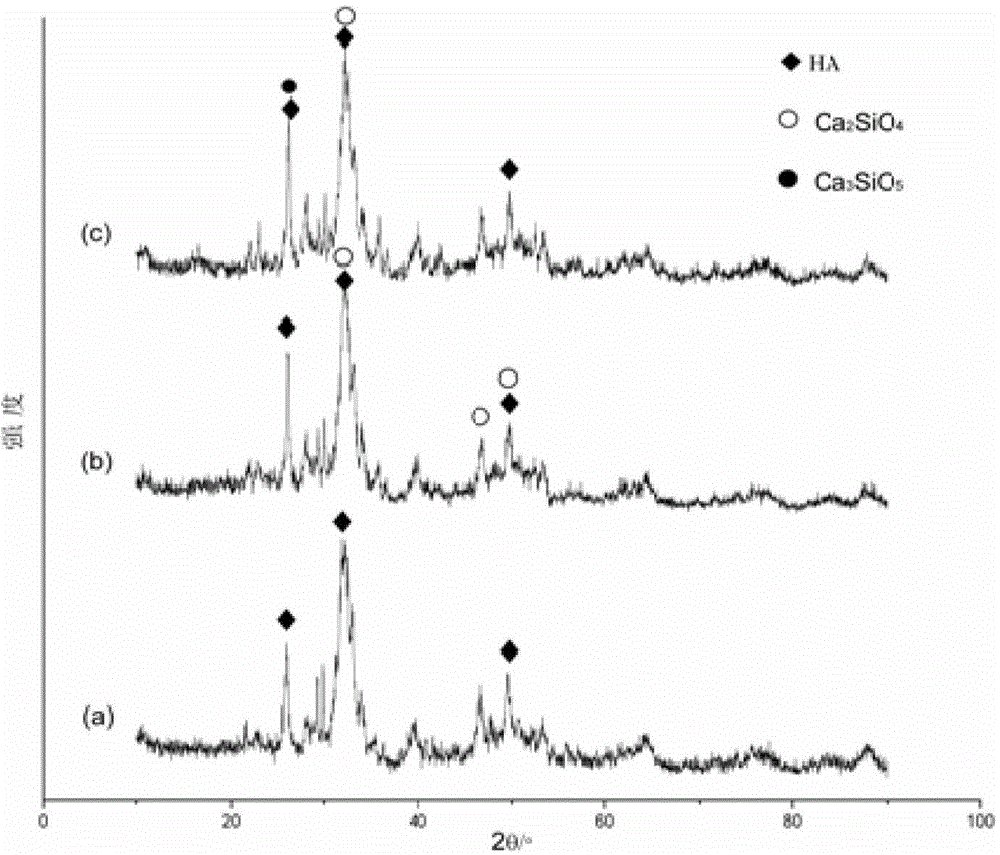

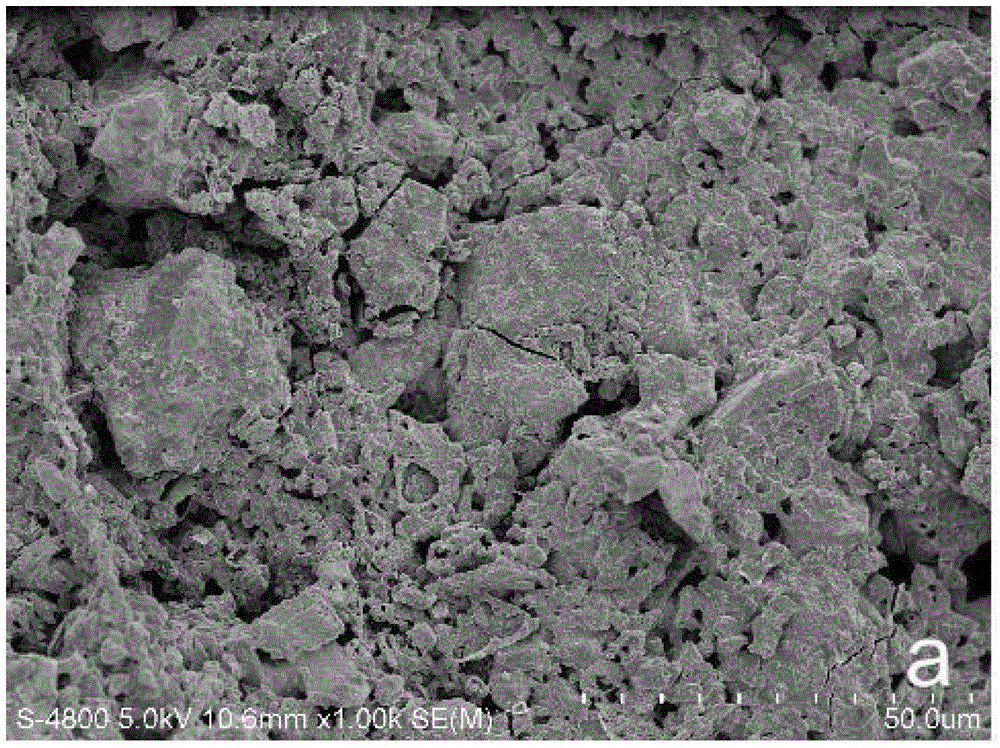

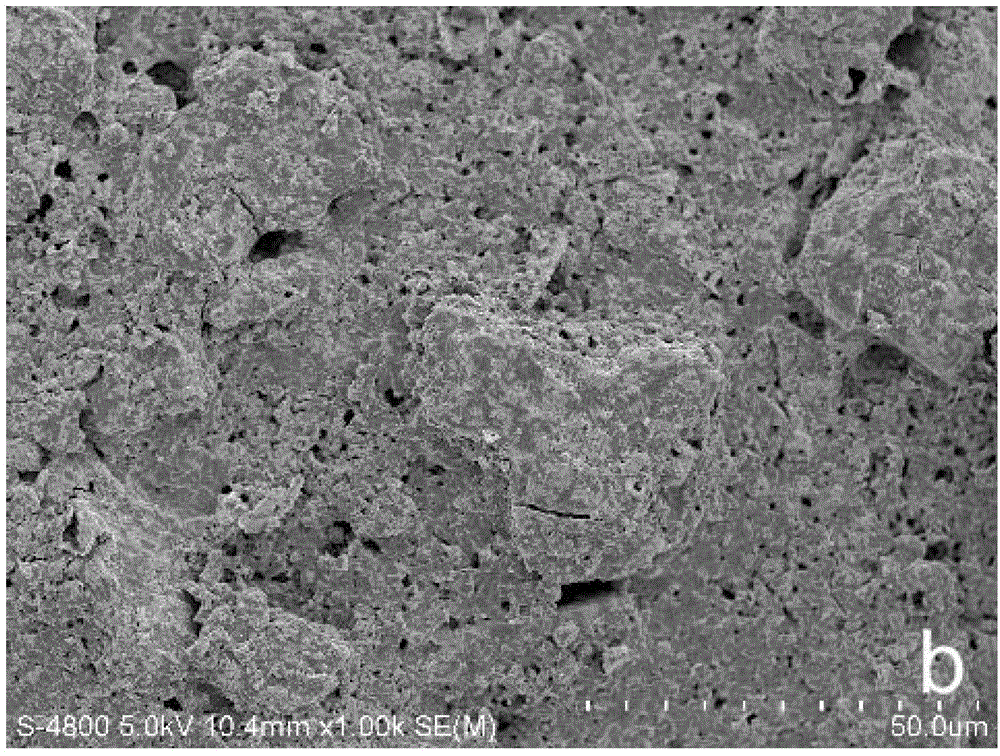

Process for preparing hydroxy apatite / titanium oxide gradient coating

InactiveCN1629364AImprove biological activityHigh bonding strengthElectrolytic inorganic material coatingPlasma electrolytic oxidationMicro arc oxidation

Disclosed is a process for making hydroxy apatite / TiO2 biological ceramic coating on titanium based medical metallic material surface, which comprises, using titanium or titanium alloy as anode, stainless steel or titanium as cathode, oxidizing titanium or titanium alloy by using DC source or DC impulse source, then using the obtained titanium or titanium alloy with deposited oxidation film as cathode, using platinum wire or platinum sheets as anode, depositing ceramic film in Hap deposition solution.

Owner:CENT SOUTH UNIV

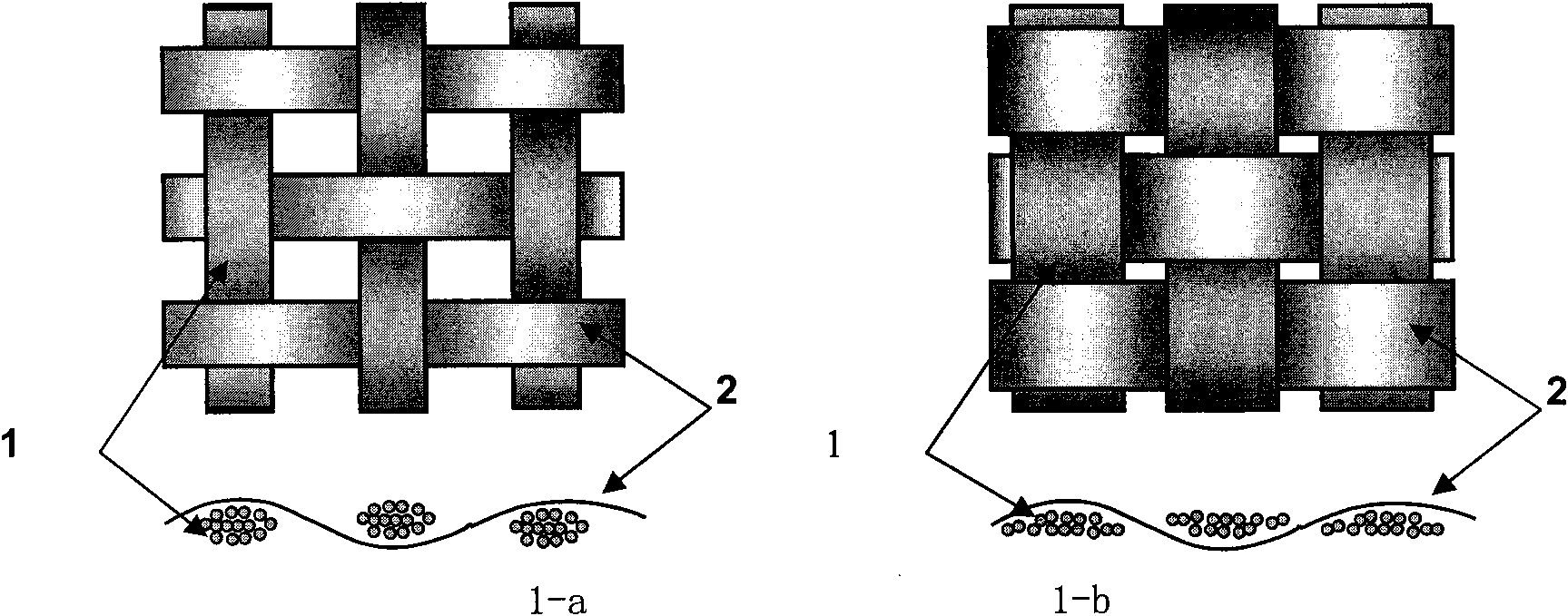

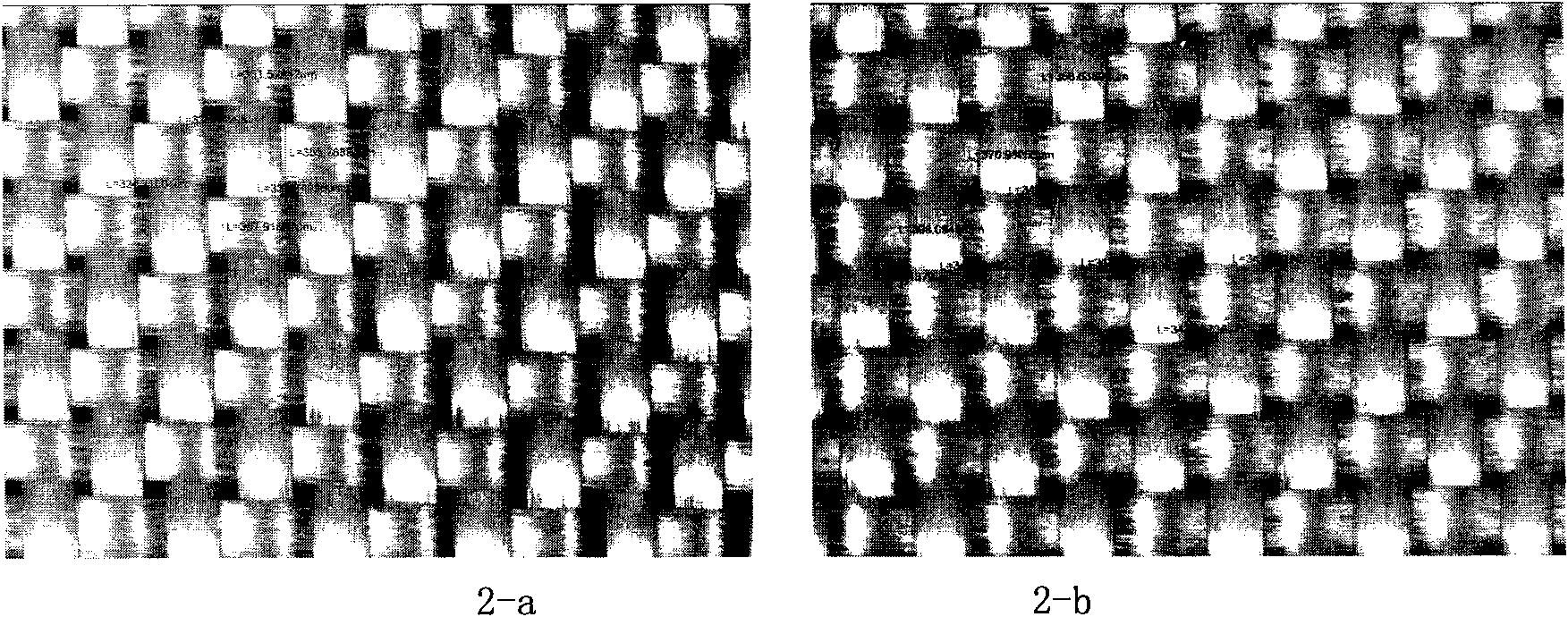

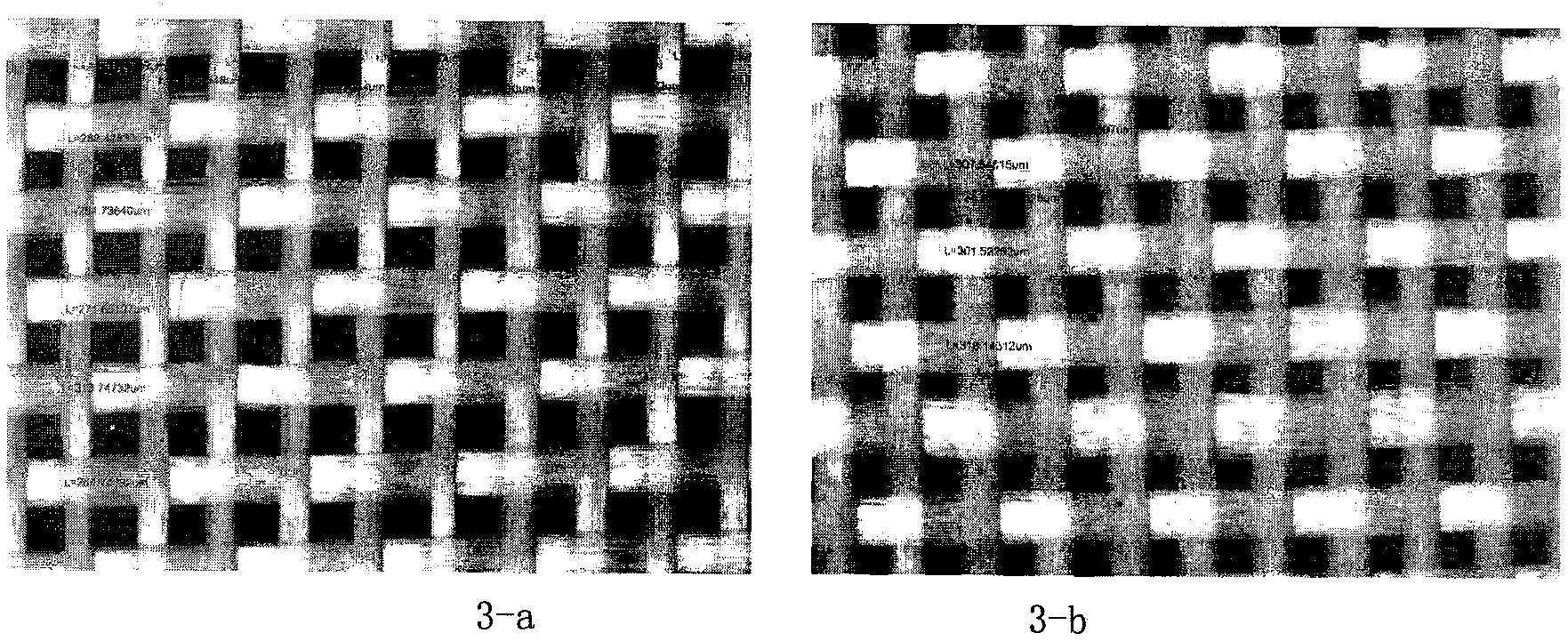

Fiber opening process of electronic grade glass fiber cloth and size used in same

The invention relates to a fiber opening process of electronic grade glass fiber cloth and size used in the same. The fiber opening process is applied to the technical field of electronic grade glass fibers and is characterized by preparing and boiling the size: in particular, firstly weighing a certain amount of main size PVA and then pouring the PVA into a size boiling barrel, adding a certain amount of deionized water, stirring the mixture and raising the temperature to dissolve the PVA, then adding the weighed leavening agent after the PVA is completely dissolved and becomes transparent and clear solution, and preserving heat for half an hour after stirring the mixture until the PVA is completely dissolved, thus the size can be used. The size comprises the following components in percentage by mass: 5-10% of main size PVA, 0.5-1% of added leavening agent and the balance water. The invention provides the fiber opening technology of the electronic grade glass fiber cloth suitable for printed-circuit boards with high precision, high uniformity and high performance. The electronic grade glass fiber cloth prepared by the fiber opening technology is thin and uniform, has faster resin impregnation, is suitable for the insulation enhanced materials of the printed-circuit boards and is extensively applied to the high-end products such as mobile phone boards, notebook computers, automotive sheets, digital cameras, digital players, navigation equipment and the like.

Owner:SHANGHAI GRACE FABRIC

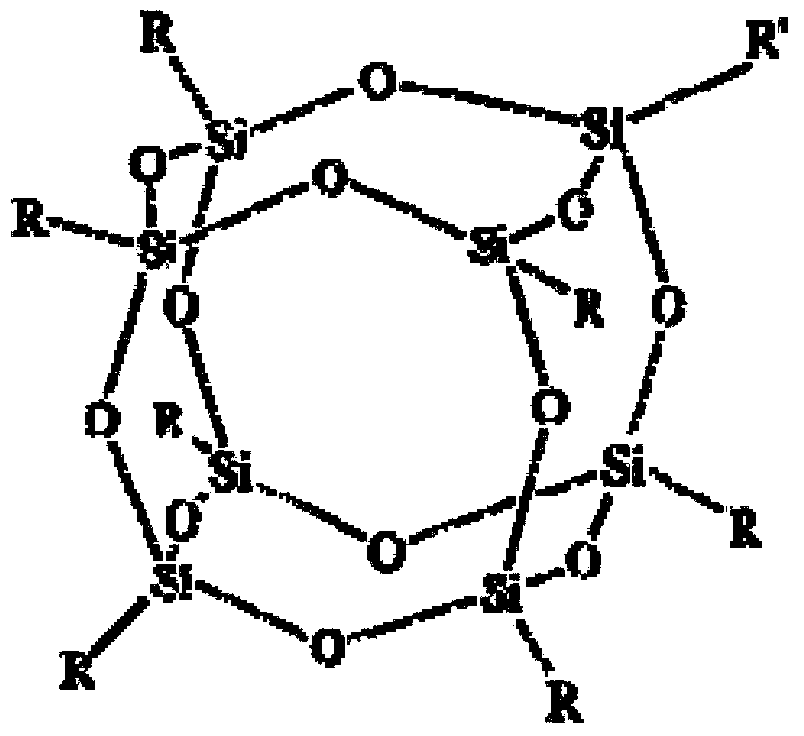

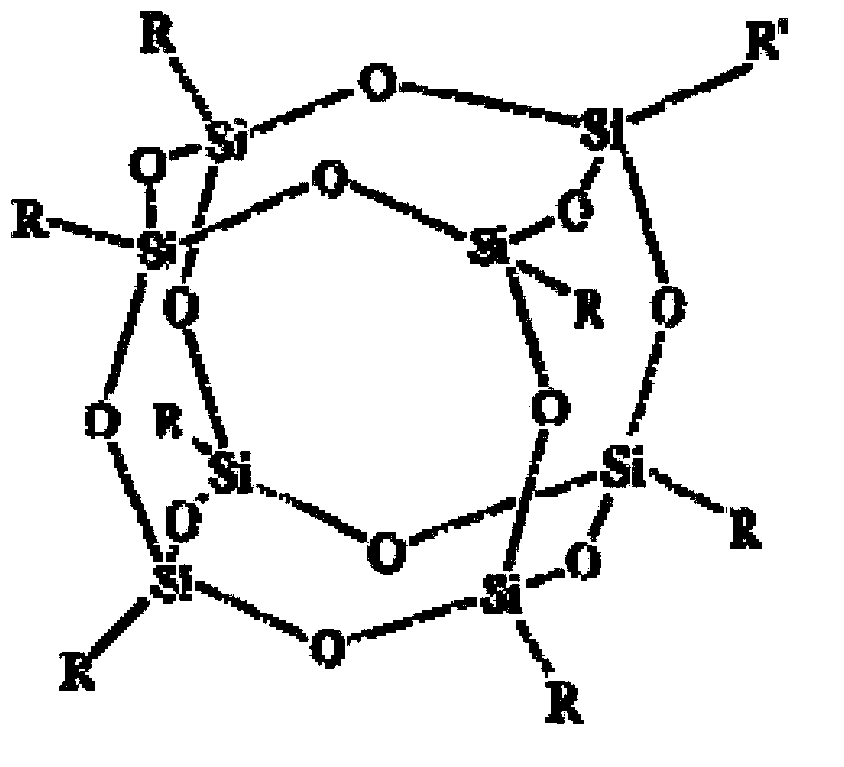

POSS (Polyhedral Oligomeric Silsesquioxane) based hybridized fluorinated acrylate resin, and preparation method and application thereof

InactiveCN103435741AEfficient separation characteristicsSignificance of great practical applicationPolyurea/polyurethane coatingsCross-linkScale structure

The invention discloses a POSS (Polyhedral Oligomeric Silsesquioxane) based hybridized fluorinated acrylate resin, and a preparation method and an application thereof. The formula of the resin comprises the following components by weight percent: 0.9-14% of POSS based monomer, 1.5-10% of hard monomer, 2.5-14% of soft monomer, 4-10.5% of acrylic higher ester monomer, 1.8-6% of fluoridized acrylate monomer, 1.8-9% of cross-linked monomer, 0.4-1.5% of initiator and 50-80% of solvent. According to the invention, the acrylic higher ester monomer is introduced as an oleophilic monomer into a fluorinated acrylate copolymer and then a hydrophobic and oleophilic compound multi-scale structure is established on filter paper or a metal filter screen by virtue of aggregating self-assembly of the POSS base in the copolymer; therefore, a hydrophobic and oleophilic coating is prepared. The resin coating prepared from the resin provided by the invention is applicable to the oil-water separation field and capable of removing trace moisture in the fuel oil, and has great practical application significance.

Owner:SOUTH CHINA UNIV OF TECH

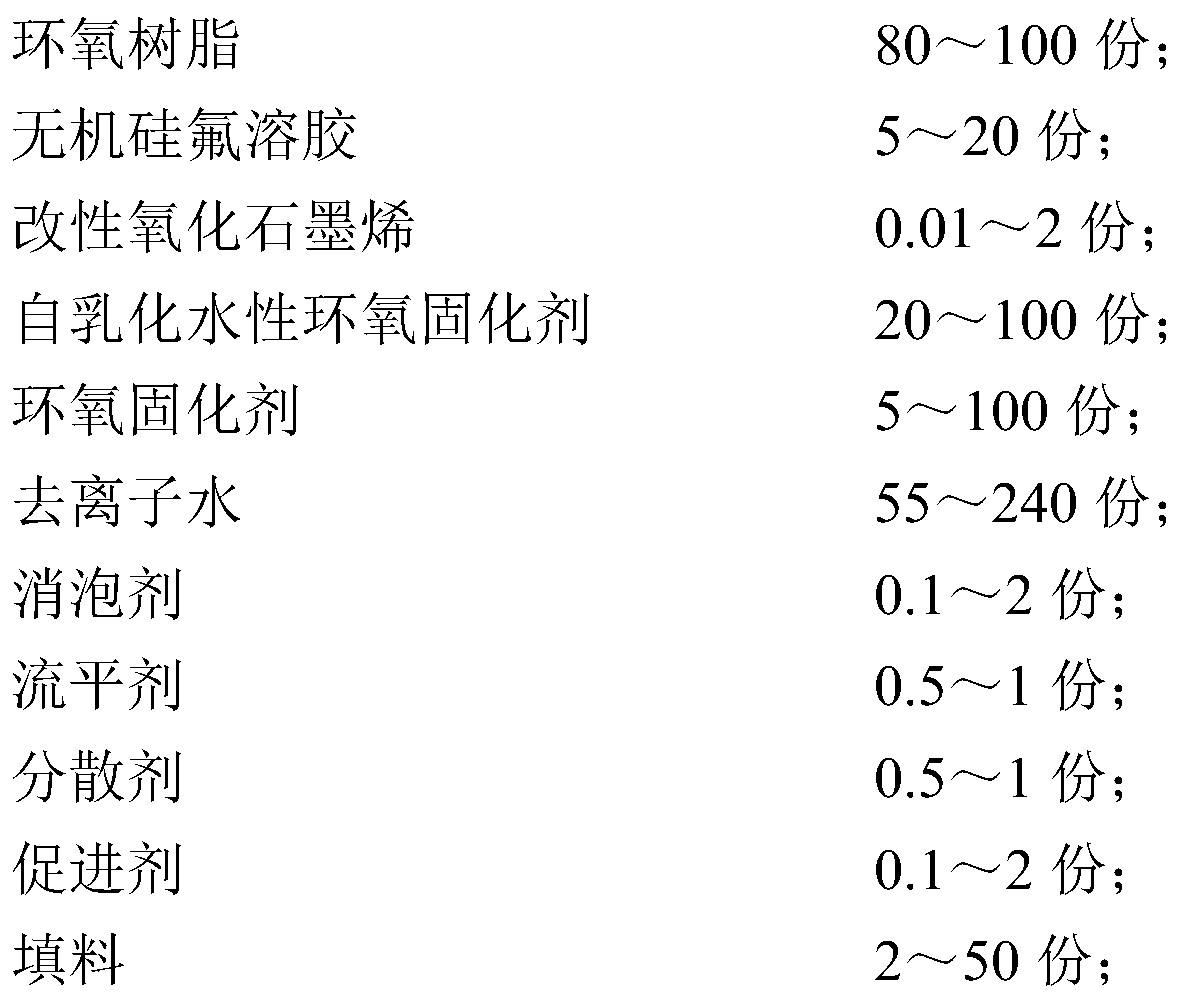

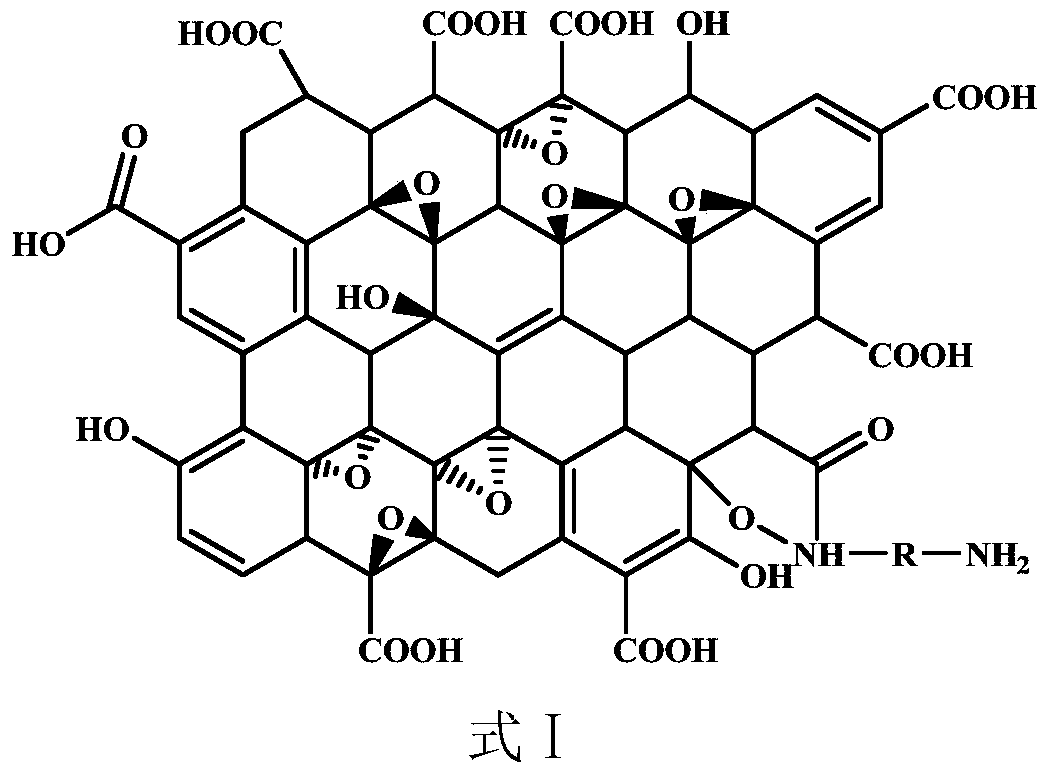

Low-surface-energy water-based epoxy anticorrosive coating and preparation and application thereof

ActiveCN110330862AWear-resistantLower surface energyAntifouling/underwater paintsPaints with biocidesPolymer scienceFluorographene

The invention discloses a low-surface-energy water-based epoxy anticorrosive coating and preparation and application thereof. The molecular structure of the coating contains structures such as epoxy groups, polyether, silicon fluoride and graphene; in the stage of emulsifying epoxy resin of the coating, the coating has excellent aqueous property and high emulsifying capability owing to a self-emulsifying aqueous epoxy curing agent, the coating has good compatibility with the epoxy resin, and the stability of emulsion is improved. In a curing stage of modification of a graphene oxide modified coating, it is ensured that the self-emulsifying water-based epoxy curing agent does not separate out from a coating layer to form a stable coating layer; a flexible micro-region is formed by flexiblelong-chain polyether in the coating layer, so that the mechanical property of a coating film is improved; by silicon-fluorine sol, the surface energy of the coating film is reduced; graphene is grafted into the molecular structure through chemical bonds, after the dispersion performance is improved, the graphene can cover a metal surface efficiently, and the corrosion resistance of the coating layer is improved. Therefore, the coating provided by the invention has excellent properties of adhesion, hardness, acid and alkali resistance, water resistance and the like after film formation, variouscomponents are compatible well, and the coating can be used for metal parts and the like.

Owner:中科广化(重庆)新材料研究院有限公司 +2

Composite biological material capable of injecting bioglass-calcium phosphate bone cement and preparation

InactiveCN103143063AImprove mechanical propertiesGood application prospectSurgeryProsthesisSolid phasesBiological materials

The invention discloses a composite biological material capable of injecting bioglass-calcium phosphate bone cement and a preparation method thereof. The prepared composite biological material capable of injecting bioglass-calcium phosphate bone cement is composed of solid phase powder and liquid phase, wherein, the liquid phase is monopotassium phosphate and dipotassium phosphate water solution which the concentration is 1M, and the ratio between the solid phase powder and the liquid phase is 2.0 g / ml-3.0 g / ml; the solid phase powder is composed of calcium phosphate bone cement and 45S4 bioglass in a mixed mode based on a weight ratio, wherein the addition of the 45S5 bioglass accounts for 5%-40% of the gross of the solid phase powder; and the calcium phosphate bone cement is composed of tetra calcium phosphate and anhydrous calcium phosphate dibasic in a mixed mode with a 1:1 molar ratio. The composite biological material capable of injecting bioglass-calcium phosphate bone cement and the preparation have the advantages of being capable of having good liquidity, higher mechanics performance, degradation rate and biological activity, offsetting the defects of single calcium phosphate cement (CPC) or the bioglass, and being used for bone defect recovery of an oral cavity, a skull facial portion and orthopedics.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Method for preparing surface material with anti-marine biological pollution function

ActiveCN104073114AGood antifoulingBroad application prospectsAntifouling/underwater paintsPaints with biocidesToxicityMarine life

The invention discloses a method for preparing a surface material with an anti-marine biological pollution function. The surface material with the anti-marine biological pollution function is prepared by soaking and self-assembling anti-pollution copolymer of a dopamine structure onto materials such as titanium, silicon, aluminum, iron and ceramic. The copolymer is applicable to various substances, is environmental friendly and good in anti-pollution property, and is in solid chemical bonding with a substance surface. The process is simple, and the surface material with the anti-marine biological pollution function can be prepared by only directly soaking and drying. The surface material is not only good in marine pollution resistance, but also free of toxicity or pollution, and does not influence the marine environment.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

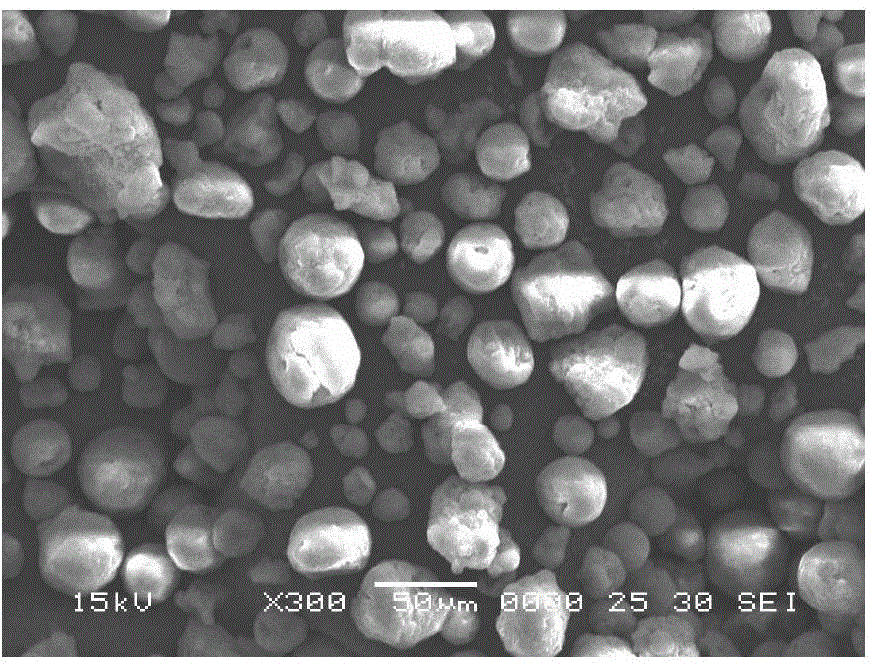

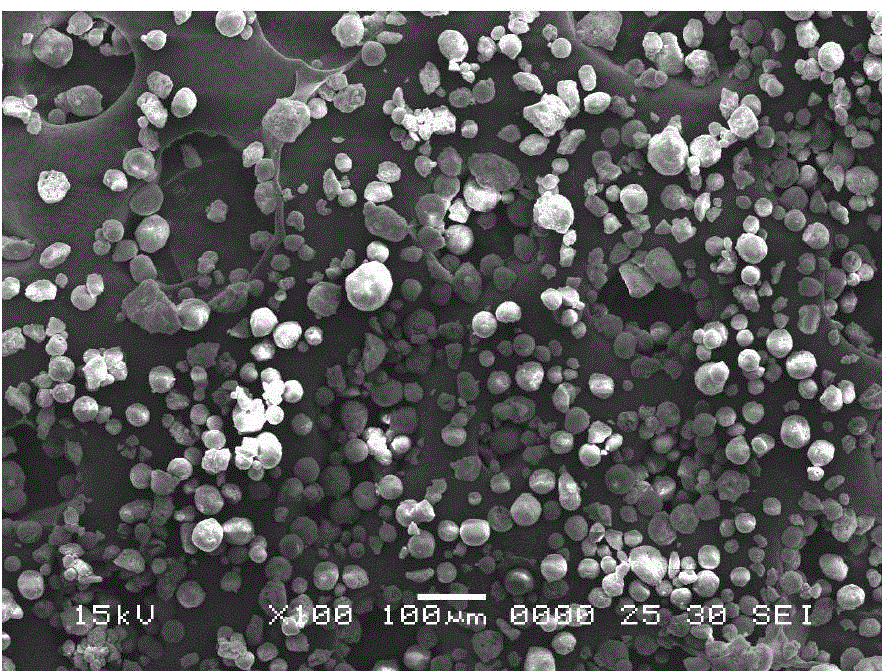

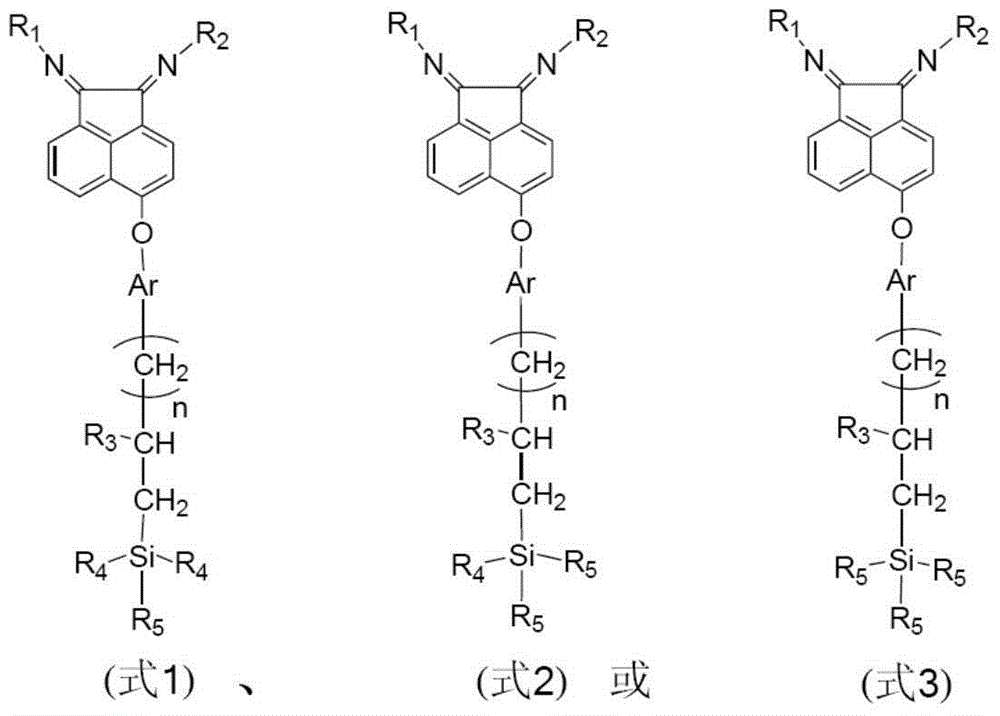

Supported alpha-diimine compound and application of supported alpha-diimine compound in olefin polymerization

InactiveCN104804030AStrong chemical bondPrevent falling offSilicon organic compoundsNickel organic compoundsOlefin polymerizationCoordination complex

The invention relates to a supported alpha-diimine compound and an application of the supported alpha-diimine compound in olefin polymerization. The compound has the following structural formula as shown in the specification, wherein R1 and R2 are identical or different C6-C60 aromatic alkyl; R3 is H or C1-C20 alkyl; R4 is C1-C20 alkyl; R5 is C1-C20 alkoxyl or a chlorine atom; n is 1, 2, 3, 4, 5, 6 or 7; an alpha-diimine compound reacts with a carrier to be supported on the carrier in a covalent bonding manner to form the supported alpha-diimine compound; the supported alpha-diimine compound is matched with a metal compound of nickel (II) and palladium (II) to form a supported alpha-diimine metal complex; and the supported alpha-diimine compound is applied to the olefin polymerization as a main catalyst and can regulate polymerization activity, as well as a molecular chain structure, molecular weight and distribution of a polymer.

Owner:TIANJIN POLYTECHNIC UNIV

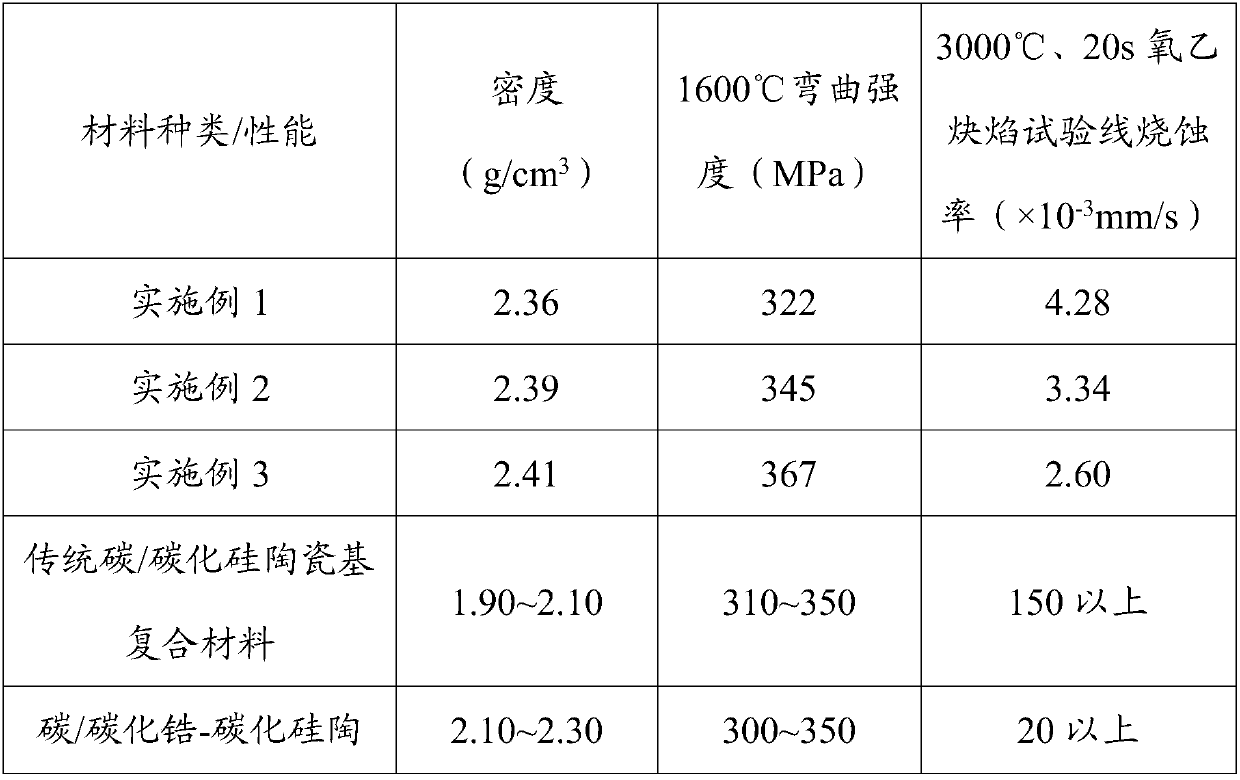

Ceramic matrix composite material and preparation method thereof

ActiveCN110028330AStrong chemical bondGive full play to the synergistic antioxidant effectCarbon fibersHafnium

The invention provides a ceramic matrix composite material and a preparation method thereof, wherein a carbon fiber preform is used as a skeleton, and is immersed in a hafnium-tantalum-silicon ternarycomposite phose ceramic precursor solution, and curing and cracking are performed to prepare the composite material. According to the preparation method, a pyrolytic carbon interface layer is prepared on a carbon fiber preform by using a chemical vapor infiltration method, matrix densification treatment is performed by using a hafnium-tantalum-silicon ternary composite phose ceramic precursor impregnation cracking method, and finally pore sealing treatment is performed by using a chemical vapor infiltration method. According to the present invention, the method has characteristics of simple process and short development period; and the prepared ultra-high temperature ceramic matrix composite material has the uniform distribution of various components of the matrix, has characteristics ofultra-high-temperature resistance, oxidation resistance and ablation resistance, can be used as the high temperature thermal structure material for hypersonic vehicles and rocket propulsion systems, and has broad application prospects.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

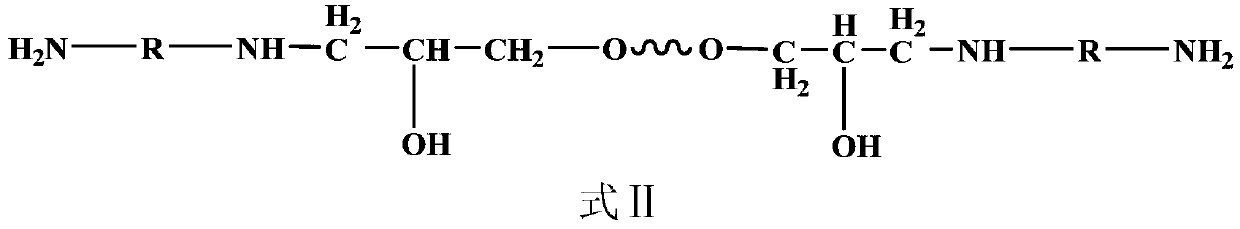

Method for preparing imitative mussel functionalized fracture adhesive

The invention discloses a method for preparing an imitative mussel functionalized fracture adhesive. The method adopts a catechol-containing structural polymer, hydroxyapatite and chitosan as raw materials, the catechol-containing structural polymer is prepared from polyethylene glycol, chloroacrylic acid and a catechol-containing structural compound, and the catechol-containing structural compound is dopamine hydrochloride. The method comprises the following steps: carrying out a condensation reaction on the polyethylene glycol and the chloroacrylic acid; dissolving the obtained condensationproduct, and reacting the condensation product with the dopamine hydrochloride to generate the catechol-containing structural polymer; weighing the chitosan, and adding the chitosan into an acetic acid solution to form an acetic acid solution of chitosan; weighing the hydroxyapatite, and adding the hydroxyapatite into the acetic acid solution of chitosan to obtain a mixed solution; and weighing the catechol-containing structural polymer and the mixed solution, and stirring and mixing the catechol-containing structural polymer and the mixed solution to obtain the adhesive. The adhesive has extremely strong adhesive property, plays a full role in bone adhesion under the wet conditions in the physiological environment, and also has very good adhesive property, high bio-safety, and good bone defect filling performance.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Method for preparing novel polyethylene wood-plastic composite material

The invention discloses a method for preparing a novel polyethylene wood-plastic composite material. The method comprises the following steps: (1) smashing a rape stalk, a cotton stalk and a cotton straw, baking to obtain wood powder, immersing the wood powder in a NaOH solution to perform ultrasonic treatment, taking out, rinsing by deionized water, drying and screening to obtain the alkalified wood powder; (2) mixing polyethylene, maleic anhydride, rare earth oxide and DCP to obtain a rare earth compatilizer; (3) adding phenolic resin and rare earth chloride into a reaction kettle, heating and stirring, heating the reaction solution till boiling, performing reflux reaction, continuously heating, keeping the temperature, stopping heating and reacting to obtain the rare earth phenolic resin; (4) mixing polyethylene, the alkalified wood powder, the compatilizer and the rare earth phenolic resin, moving to an oven, and drying to achieve constant weight to obtain the mixed materials; (5) adding the mixed materials into a conical twin-screw extruder, extruding and granulating to obtain the granules, and baking to obtain the polyethylene wood-plastic composite material.

Owner:江西欧居工程有限公司

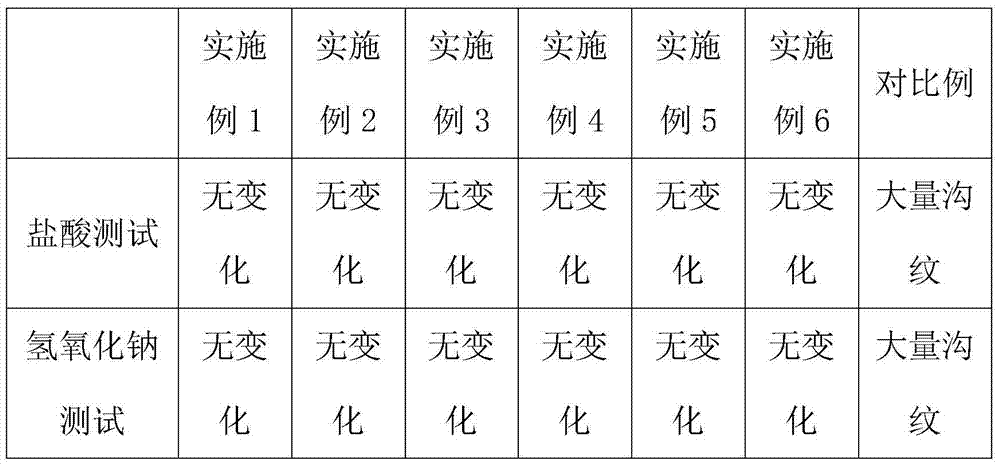

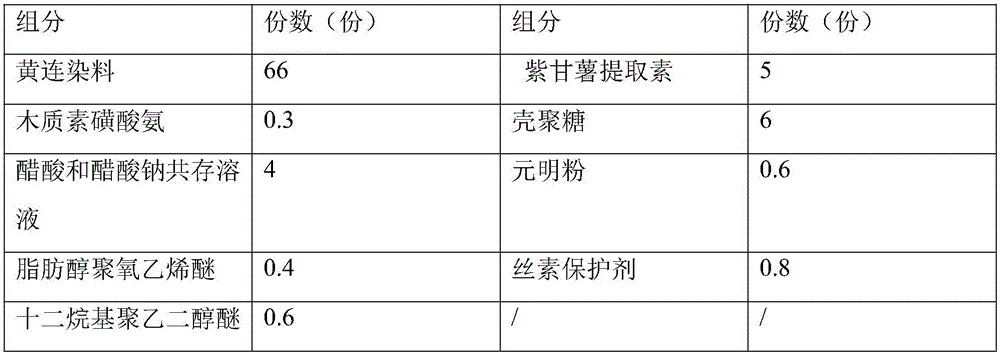

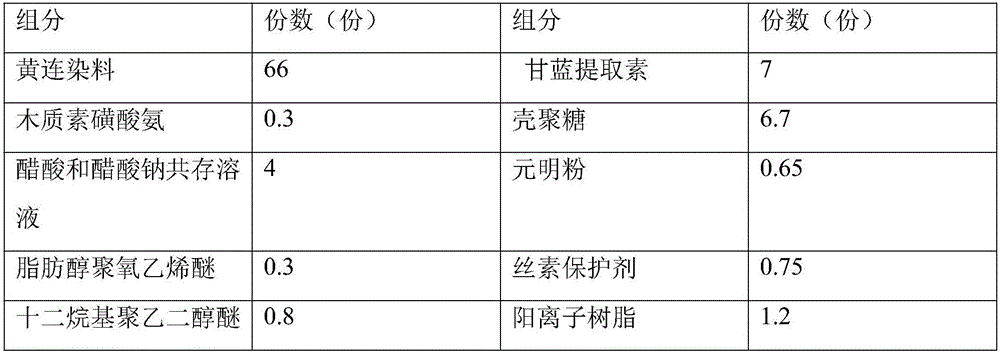

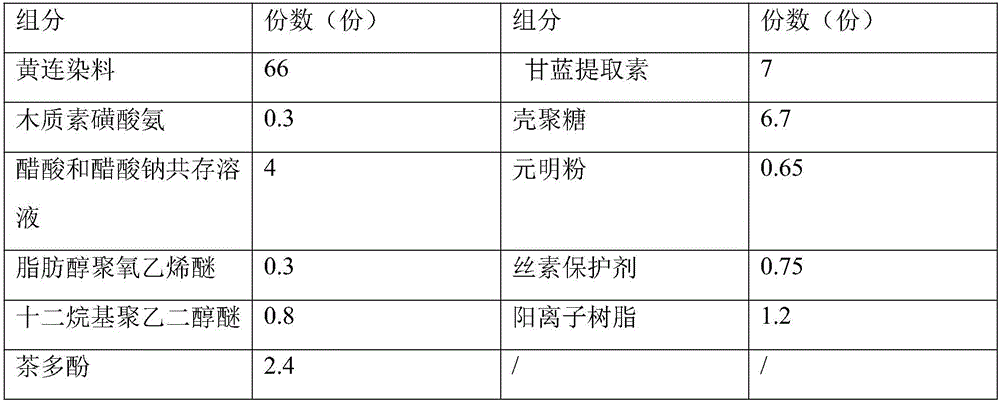

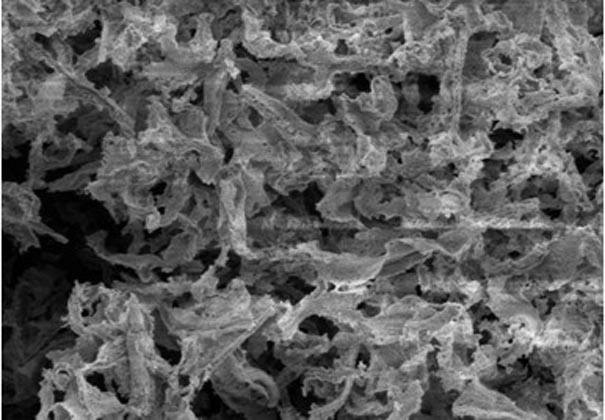

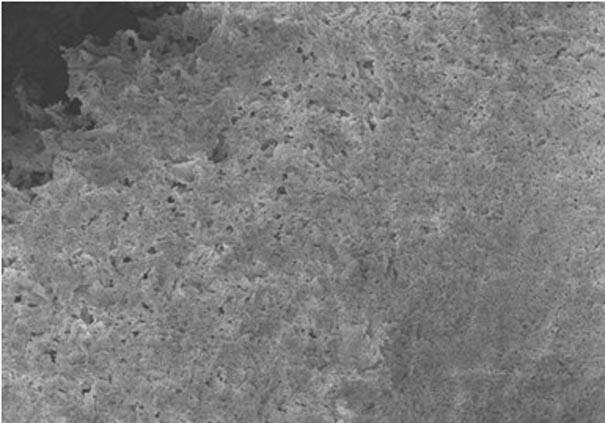

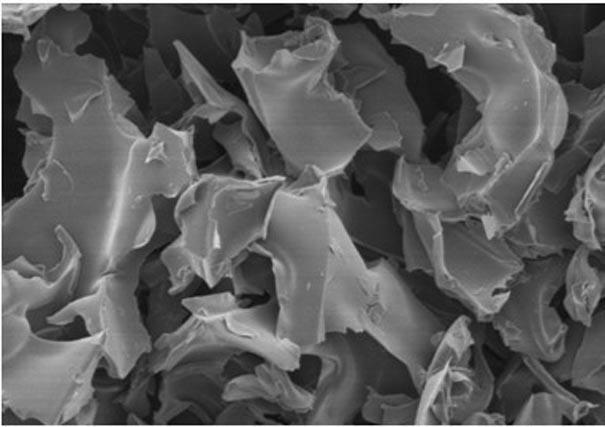

Dyeing agent and process for dyeing real silk by aid of dyeing agent

InactiveCN105970682AIncrease the amount of cationsFirmly attachedLight resistant fibresDyeing processFiberMordant

The invention discloses a dyeing agent and a process for dyeing real silk by the aid of the dyeing agent. According to the technical scheme, the dyeing agent and the process have the advantages that the problem that existing fiber fabrics contain heavy metal ions after being dyed can be solved; purple sweet potato extract elements, cabbage extract elements and purple perilla extract elements in the dyeing agent do not contain heavy metal ions, effects which are identical to effects of a mordant can be realized by the purple sweet potato extract elements, the cabbage extract elements and the purple perilla extract elements, accordingly, post-dye-uptake fiber fabrics are colorful and attractive on the premise that the dyeing agent and the process are favorable for improving the dye-uptake efficiency of the fiber fabrics, and environmental pollution can be prevented.

Owner:杭州余杭兴隆绸厂

Method for preparing inflaming-retarding wool fabric and inflaming-retarding working solution

InactiveCN102660869AStrong chemical bondOvercome the lack of washing resistanceFibre treatmentLiquid/gas/vapor textile treatmentNitrogenAmmonia

The invention discloses a method for preparing inflaming-retarding wool fabric and an inflaming-retarding working solution. The working solution contains the following components by weight: 15-30% of phosphorus-nitrogen components, 0.1-0.5% of ammonia water, 0.1-0.3% of initiator and the balance water, wherein the phosphorus-nitrogen components are formed by phosphorus-containing components and nitrogen-containing components, and the weight ratio of the phosphorus-containing components to the nitrogen-containing components is 1:(0.5-1). The wool fabric to be processed is processed in the inflaming-retarding working solution in a twice-soaking twice-rolling method, the dipping time is 1-3 minutes, mangle expression is more than 90%, and the inflaming-retarding wool fabric can be obtained through steaming, washing and drying. The method can remarkably reduce using amount of the phosphorus-containing components, can improve inflaming-retarding efficiency and is favorable for industrial production.

Owner:SUZHOU UNIV

PA6-56 copolymerized material and preparation method thereof

The invention relates to the field of polymer materials, and discloses a PA6-56 copolymerized material and a preparation method thereof. The PA6-56 copolymerized material is prepared through blend polymerization of liquid caprolactam and a water solution of pentamethylene diamine adipate, wherein the molar ratio of the liquid caprolactam to the pentamethylene diamine adipate is 7:3-9:1. The methodcomprises the following steps: mixing the liquid caprolactam, the water solution of the pentamethylene diamine adipate and other reaction raw materials according to a certain proportion, carrying outstirring in a reactor under the protection condition of inert gas, and carrying out a polycondensation reaction at a temperature of 150-300 DEG C, so as to obtain the PA6-56 copolymer material. According to the invention, PA6 monomer caprolactam is mainly copolymerized with PA56 monomer pentamethylene diamine adipate to prepare the PA6-56 copolymer material, and the material not only has the advantages of high strength, wear resistance, acid and alkali resistance of PA6, but also has better hygroscopicity and dyeability, so that better wearing comfort and more abundant color are provided to the textiles.

Owner:浙江恒逸锦纶有限公司

Method To Synthesize Highly Luminescent Doped Metal Nitride Powders

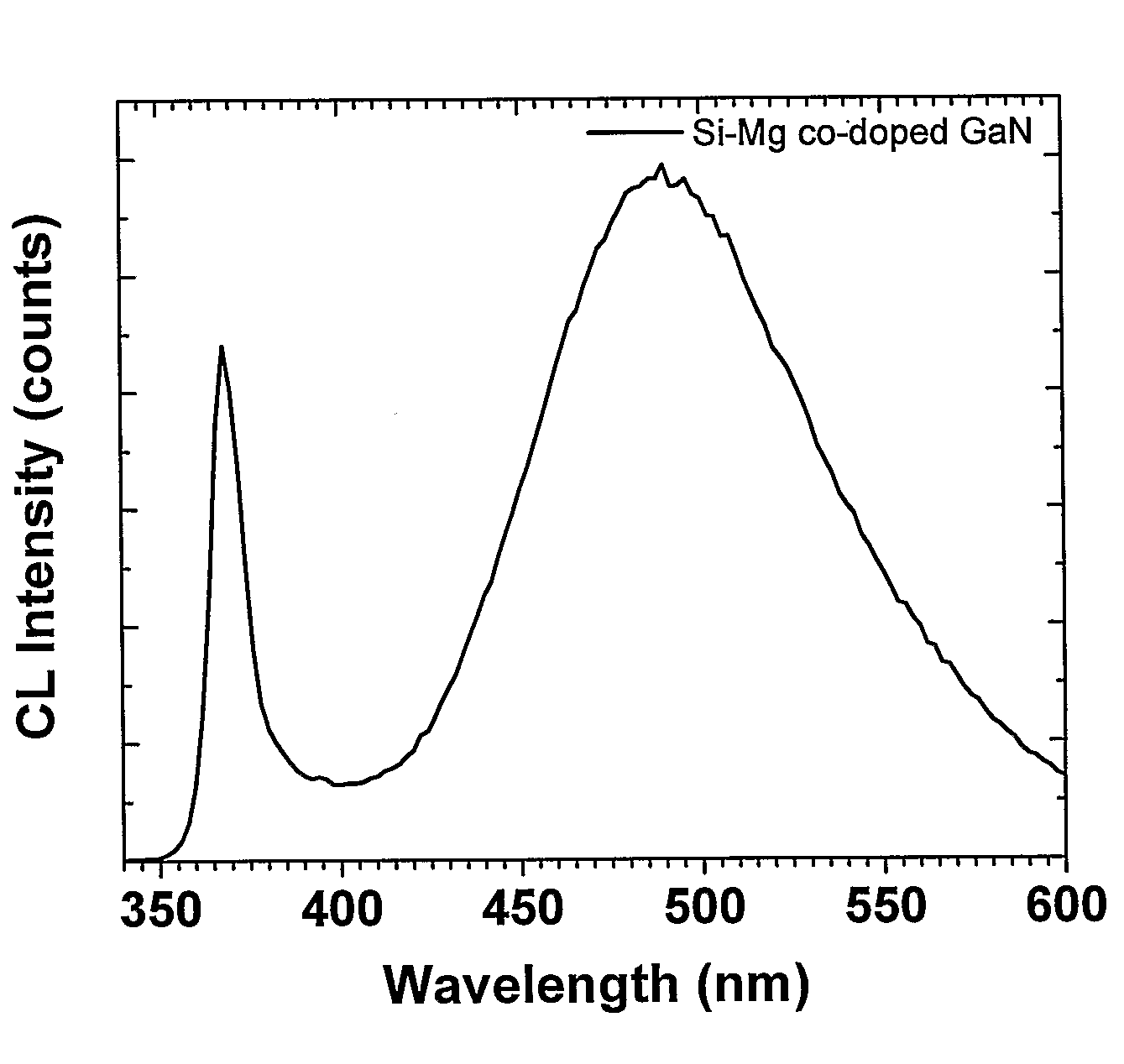

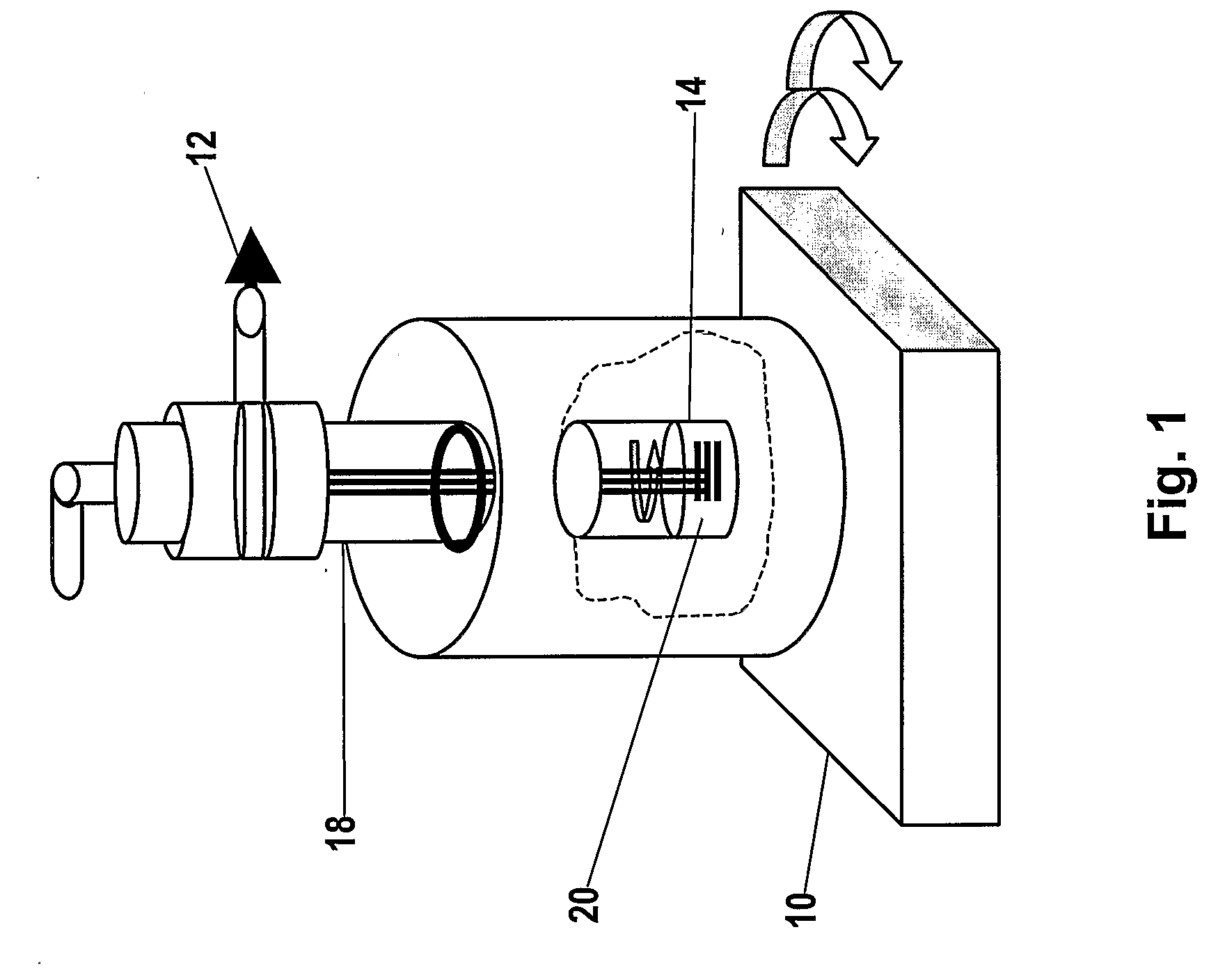

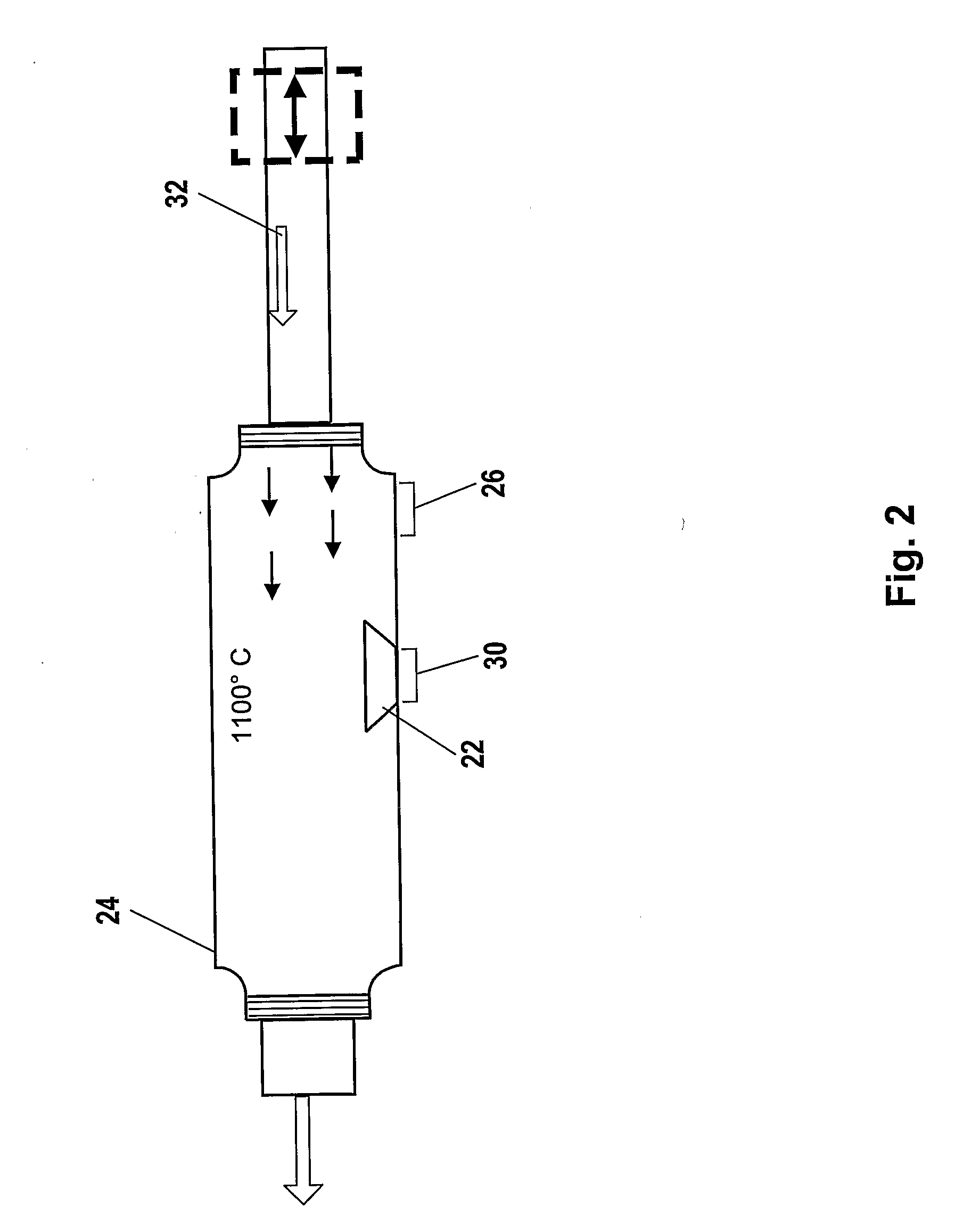

InactiveUS20080025902A1Improve luminous performanceSimple and inexpensive processNitrogen-metal/silicon/boron binary compoundsLuminescent compositionsDopantAlloy

A simple, inexpensive method of producing in bulk a doped metal nitride powder that exhibits a high luminescent efficiency, by first forming a metal-dopant alloy and then reacting the alloy with high purity ammonia under controlled conditions in a reactor. The resulting doped metal nitride powders will exhibit a luminescent efficiency that greatly exceeds that seen in pure undoped GaN powders, doped GaN thin films, and ZnS powders.

Owner:WORLD PROPERTIES +1

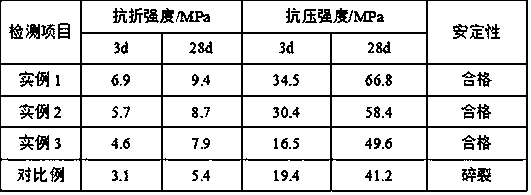

Modified steel slag cement

The invention discloses modified steel slag cement, and belongs to the technical field of building materials. A preparation method of the modified steel slag cement comprises the following steps: pulverizing and sieving steel slag to obtain steel slag powder; stirring the steel slag powder and sulfuric acid for reacting, performing cyclic freezing and unfreezing, and performing filtering and drying to obtain pretreated steel slag powder; performing ball milling, stirring and mixing on potassium permanganate and the pretreated steel slag powder, and performing high-temperature calcination to obtain calcined steel slag powder; performing ball milling, stirring and mixing on calcium carbonate, aluminum powder and the calcined steel slag powder, and performing combustion reaction to obtain modified steel slag powder; and adding cement, the modified steel slag powder, modified bagasse, a silane coupling agent and water to a mixer, and performing stirring and mixing to obtain the modified steel slag cement. The modified steel slag cement provided by the invention has excellent early strength, mechanical strength and stability.

Owner:湖州昂狮环保有限公司

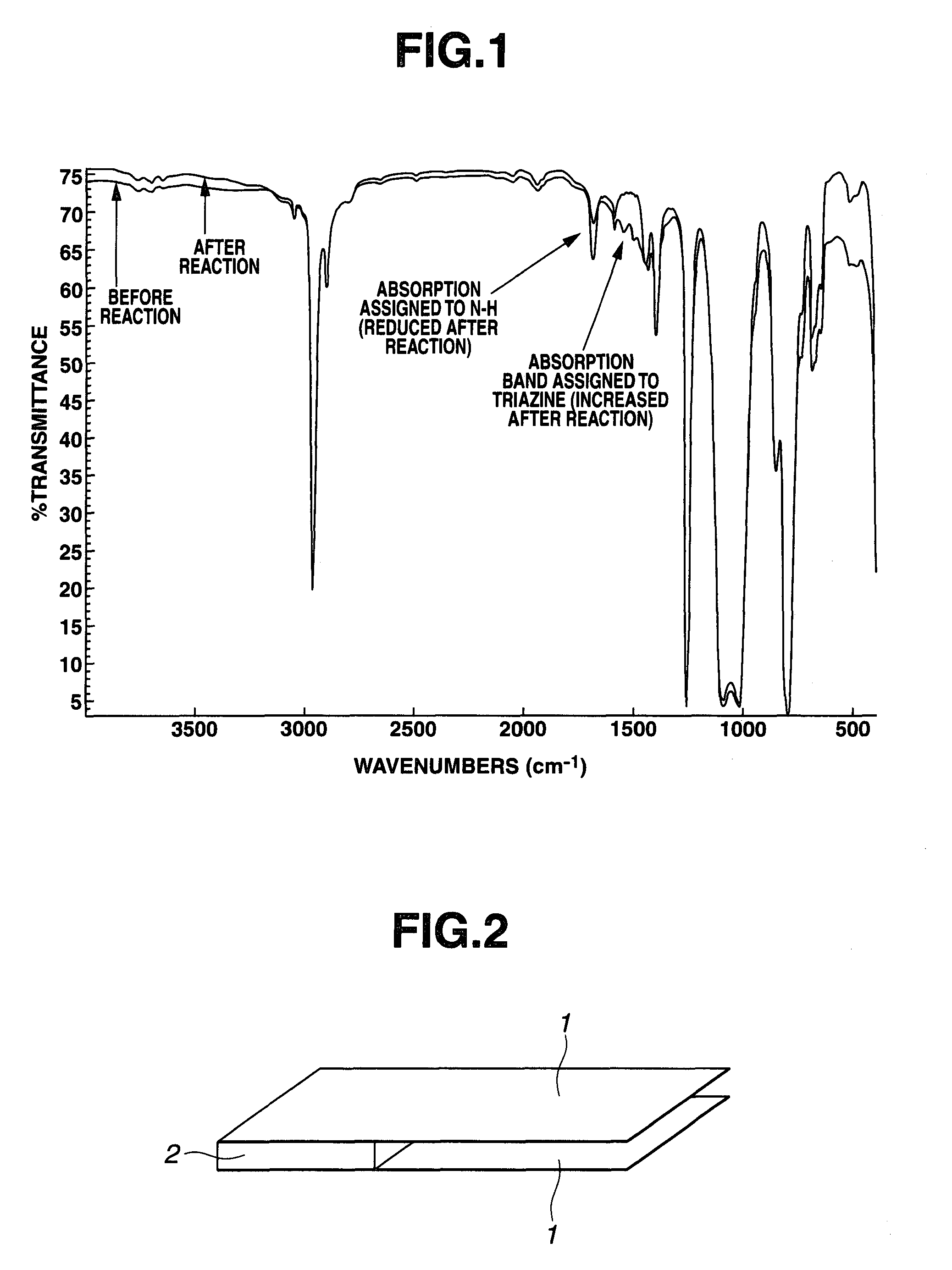

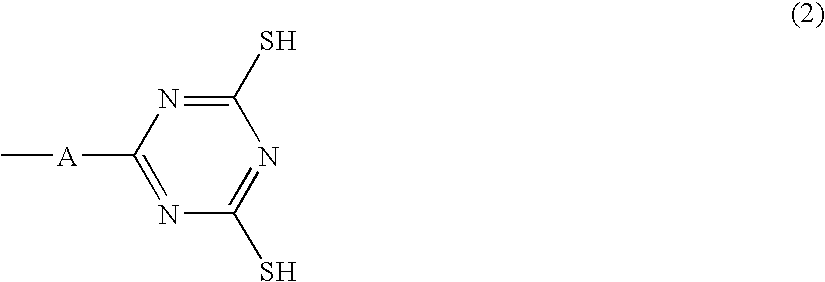

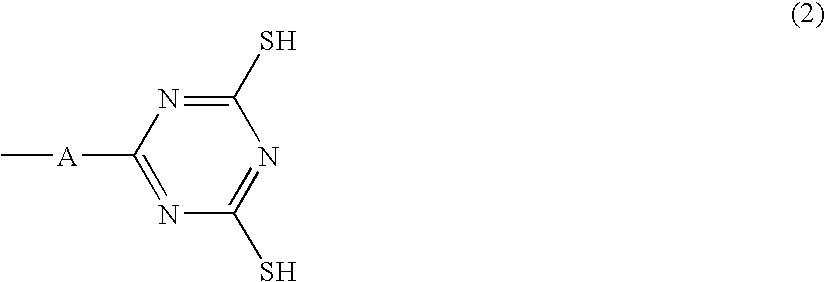

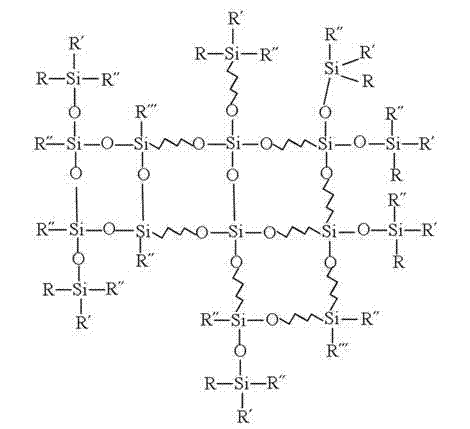

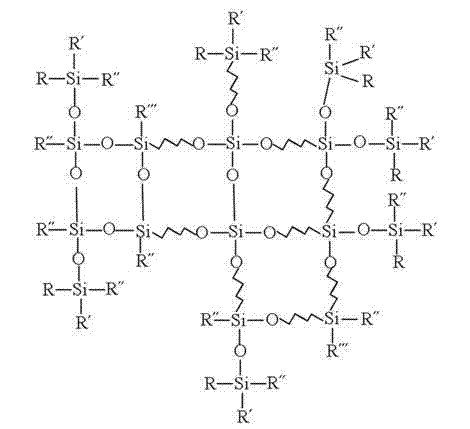

Triazinethiol and alkenyl-containing organopolysiloxane, making method, and primer composition comprising same

ActiveUS20090209691A1Improve adhesionEffective combinationConductive materialOrganic conductorsOrganosiliconMoiety

An organopolysiloxane having triazinethiol and alkenyl radicals in a molecule and a primer composition comprising the same are provided. The primer composition assists in establishing a high bond strength between metal and silicone rubber by the mechanism that the triazinethiol moieties form strong chemical bonds with a difficult-to-bond metal such as gold, silver or copper, and the alkenyl moieties are involved in silicone rubber vulcanization.

Owner:SHIN ETSU CHEM IND CO LTD

Anticorrosive and environmentally-friendly water-based coating and preparation method thereof

InactiveCN109021788AAvoid pollutionAvoid wastingFireproof paintsAntifouling/underwater paintsWater basedEpoxy

The invention discloses an anticorrosive and environmentally-friendly water-based coating. The coating is mainly prepared from, by weight, 40-50 parts of waterborne epoxy resin, 30-50 parts of a basematerial, 5-10 parts of a filler, 4-6 parts of modified graphene oxide, 1-2 parts of a photocatalyst, 1-3 parts of an emulsifier, 2-3 parts of a silicone acrylate leveling agent, 3-5 parts of sodium diisooctyl sulfosuccinate, 2-5 parts of an NXZ defoamer, 2-3 parts of hydroxyethyl cellulose, 20-30 parts of deionized water and 0.5-1 part of 2-amino-2-methyl-1-propanol. The invention also disclosesa preparation method of the coating. The preparation method comprises the following steps: emulsification of the waterborne epoxy resin, preparation of a filler mixture, preparation of a base materialmixture, and uniform grinding and stirring. Potassium silicate, sodium silicate and silica sol are compounded as a base material, the waterborne epoxy resin is used as an emulsion, and water as a dispersion medium, so environmental pollution and resource waste caused by using of an organic solvent are avoided, and the coating has no pollution in the production or use process, and has excellent environmental protection performance and mechanical performances.

Owner:SHENZHEN NANSHUO MINGTAI TECH CO LTD

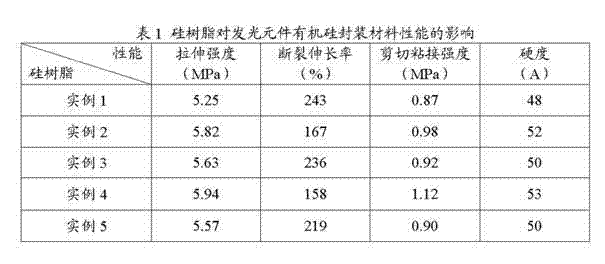

Silicone resin containing alkenyl and preparation method thereof

The invention relates to a field of silica gel materials, and discloses silicone resin and a preparation method thereof. The silicone resin is the silicone resin containing an alkenyl active group and having a three-dimensional mesh-like structure. The method comprises co-hydrolyzing an end-capping reagent and the silane agent containing the alkenyl functional group in the presence of an acid catalyst, adding tetrafunctional organic silicon monomer in drops, performing a hydrolysis-condensation reaction, extracting, cleaning, and distilling to obtain the silicone resin solution containing the alkenyl. The silicone resin provided by the invention not only improves adhesion, reinforcement and other aspects of performance with metal materials and inorganic materials, but also has good compatibility and dispersibility. The method for preparing the silicone resin provided by the invention uses a nontoxic and harmless extractant to substitute toluene used in prior art, and thus does not cause harm to human and pollute the environment; and the silicone resin is not easy to gel, and wide in application.

Owner:汕头海洋第一聚酯薄膜有限公司

Special compacting agent for anti-permeability and anti-cracking concrete

The invention discloses a special compacting agent for anti-permeability and anti-cracking concrete, and belongs to the technical field of building materials. According to the compacting agent, calcium nitrate solution, chitosan liquid, a modifying addition agent, urea and bacillus pasteurii liquid are stirred and mixed, sodium sulfate solution is added, then stirred and mixed, cooling is conducted, glutaraldehyde solution is dropwisely added, then stirred and mixed, pH is adjusted, and filtering and drying are conducted to obtain modified microcapsules; 20-30 parts of modified sodium alginatesolution, 20-30 parts of calcium bicarbonate solution, 30-40 parts of basic phenolic resin, 20-30 parts of the modified microcapsules, 20-30 parts of gelatin solution, 8-10 parts of phospholipid and8-10 parts of plant essential oil, by weight, are placed in a mixing machine, and stirred and mixed at a speed of 300-500 r / min for 40-60 min to obtain the special compacting agent for the anti-permeability and anti-cracking concrete. The special compacting agent prepared by the above technical scheme has the advantages that the crack resistance, mechanical properties and anti-permeability performance of the concrete are significantly improved.

Owner:NOTTING CHANGZHOU PRECISION MACHINERY

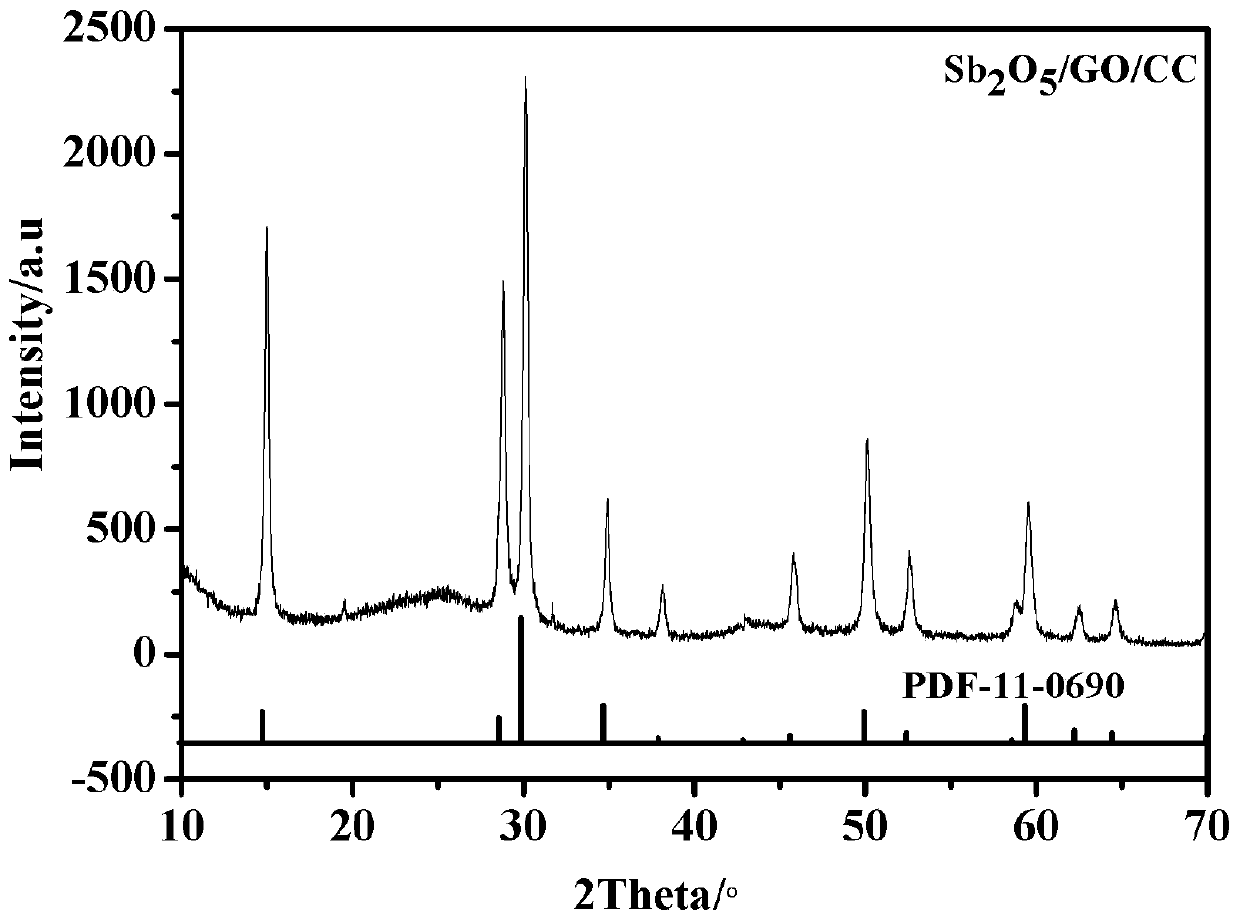

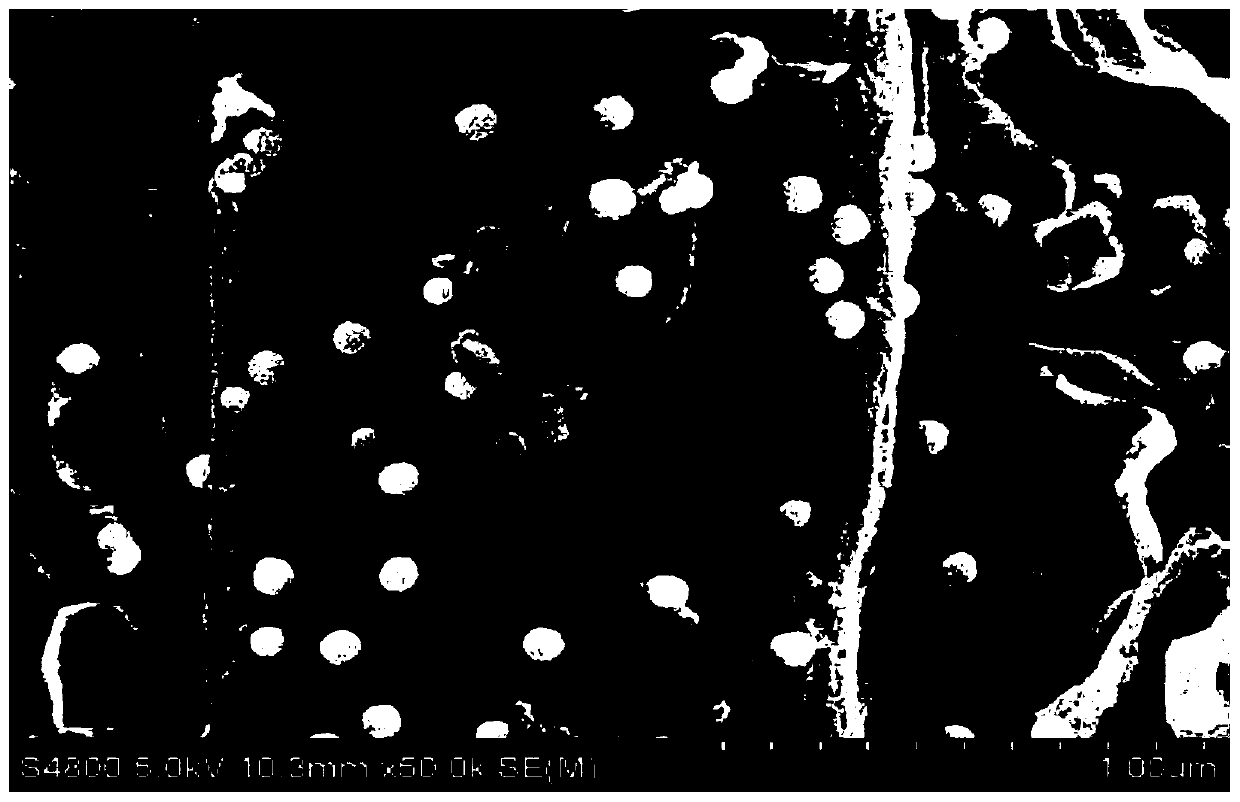

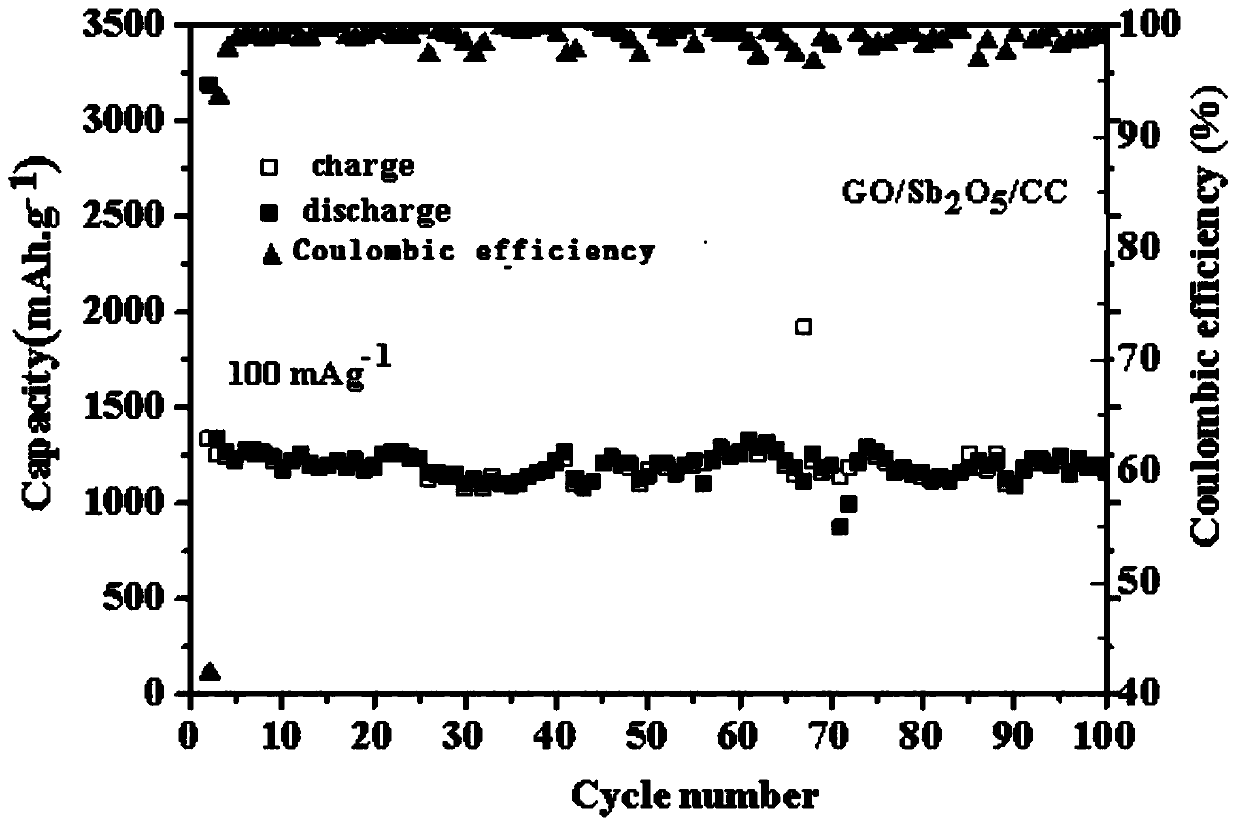

Preparation method of Sb2O5/GO/carbon cloth electrode material for negative electrode of carbon cloth-based flexible sodium ion battery

ActiveCN110212165AGood dispersionImprove electrochemical performanceNegative electrodesSecondary cellsSodium-ion batteryAntimony trichloride

The invention provides a preparation method of a Sb2O5 / GO / carbon cloth electrode material for the negative electrode of a carbon cloth-based flexible sodium ion battery; the preparation method comprises the following steps of step 1, soaking carbon cloth in acetone for impurity removal, and then carrying out washing, positive electrode oxidation treatment, washing and drying; step 2, adding graphene oxide and antimony trichloride into absolute ethyl alcohol to obtain an antimony solution, then adding a sodium hydroxide aqueous solution into the antimony solution, and adjusting the pH value to8-12 to obtain a mixed solution, and soaking the carbon cloth pretreated in the step 1 in the mixed solution; and step 3, transferring the mixed solution obtained in the step 2 and the carbon cloth into a reaction container, and carrying out hydrothermal reaction at 150-180 DEG C, cooling to room temperature after the reaction is ended, taking out the carbon cloth, carrying out cleaning and dryingto obtain the Sb2O5 / GO / carbon cloth electrode material for the negative electrode of the sodium ion battery. The Sb2O5 / GO / carbon cloth sodium ion battery negative material prepared by the method of the invention shows excellent electrochemical cycling performance; and meanwhile, the preparation method is simple and novel, short in preparation period, high in repeatability and suitable for large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

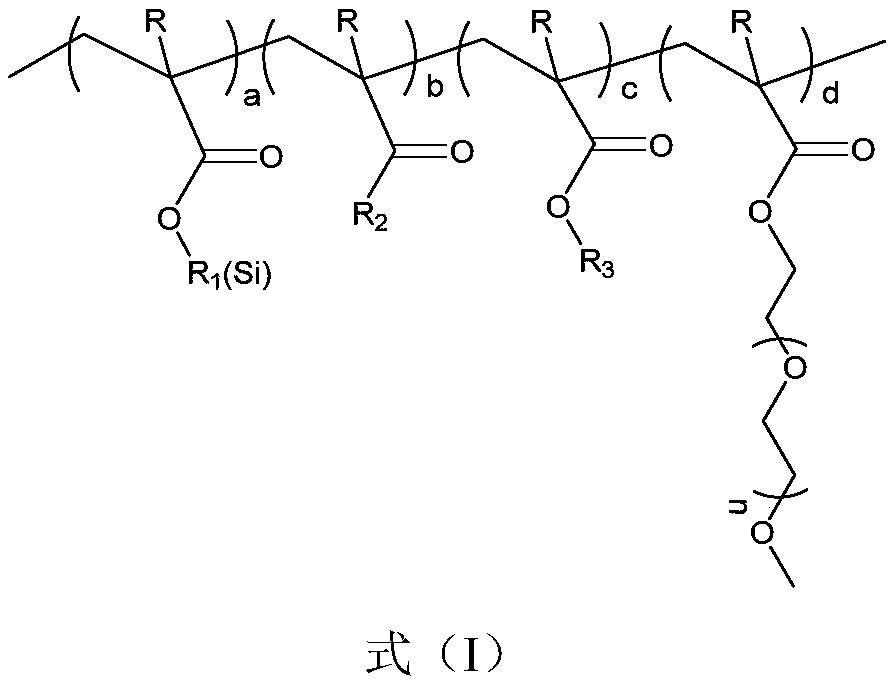

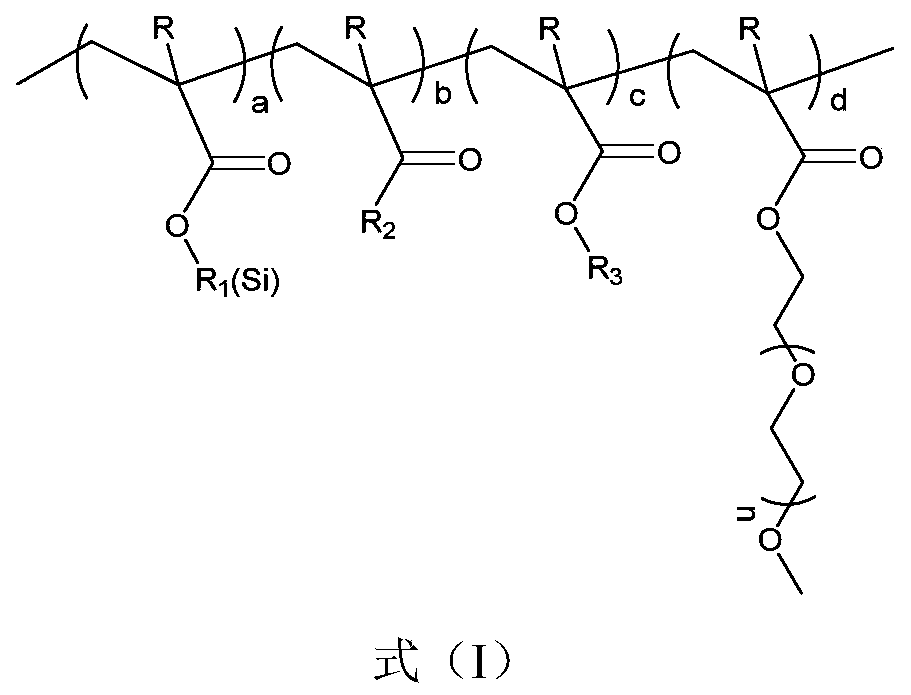

Silicon-containing polymer binder, preparation method and application in silicon-based electrode lithium ion battery thereof

ActiveCN109904454AGood compatibilityImprove conduction rateCell electrodesSecondary cellsPolyethylene glycolLithium-ion battery

The invention discloses a silicon-containing polymer binder, a preparation method and an application in a silicon-based electrode lithium ion battery thereof. The silicon-containing polymer binder isformed by free radical polymerization or anionic polymerization of silica-containing acrylate monomers, acrylic monomers, acrylate monomers, and polyethylene glycol acrylate monomers; and after the prepared binder is mixed with active materials and conductive agents to form electrode paste, coating is conducted to form an electrode, and the electrode can be applied to the silicon-based electrode lithium ion battery. According to the silicon-containing polymer binder, the preparation method and application in the silicon-based electrode lithium ion battery thereof, cycle performance of the silicon-based anode lithium ion battery is improved through addition of the binder, the prepared battery has high discharge specific capacity, and has the great application prospect in the development field of the novel silicon-based anode lithium ion battery.

Owner:ZHEJIANG UNIV

Pavement skid-resistant coating with photoluminescence function

InactiveCN108753050ALarge specific surface areaHigh surface energyLuminescent paintsPolyurea/polyurethane coatingsVisibilityPhotoluminescence

The invention discloses pavement skid-resistant coating with a photoluminescence function. The pavement skid-resistant coating comprises, by weight, 25-35% of resin, 25-45% of pigments and fillers, 20-40% of skid-resistant aggregate, 1-10% of photoluminescence nanometer materials, 0.5-2.5% of curing agents and 0.1-2.5% of auxiliaries. The sum of the mass percents of various raw materials for the pavement skid-resistant coating is 100%. The pavement skid-resistant coating has the advantages that energy can be acquired when external light sources irradiate on the pavement skid-resistant coating,the photoluminescence nanometer materials can be excited to emit light, good light emission effects can be realized by the pavement skid-resistant coating, and the pavement skid-resistant coating islong in service life; the identification degrees of pavement safety marks can be effectively upgraded under low-visibility and night conditions and the like by photoluminescence effects realized by the aid of the external light sources such as automobile lamps and street lamps, accordingly, the pavement traffic safety can be guaranteed, and the like.

Owner:FUZHOU UNIV

Special paper tube adhesive for paper

InactiveCN107556946ARich porosityEasy to embedMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolyvinyl alcoholAdhesive

The invention discloses a special paper tube adhesive for paper and belongs to the technical field of binding agents. The special paper tube adhesive for the paper is prepared by the following steps:stirring and mixing nano silicon dioxide, a silane coupling agent and an ethanol solution and reacting; then filtering, washing and drying to obtain modified nano silicon dioxide; then carrying out ultrasonic dispersion on the modified nano silicon dioxide and absolute ethyl alcohol to obtain a modified nano silicon dioxide dispersed solution; mixing glass fibers and the modified nano silicon dioxide dispersed solution and immersing; then drying the immersed glass fibers until the weight is constant; mixing the immersed glass fibers and a dopamine solution and immersing; then drying the immersed glass fibers until the weight is constant, so as to obtain modified glass fibers; stirring and mixing polyvinyl alcohol, a cyclodextrin derivative and water; then adding polyvinyl acetate emulsion,cellulase, the glass fibers and polystyrene emulsion, and stirring and mixing to obtain the special paper tube adhesive for the paper. The special paper tube adhesive for the paper, which is preparedby the technical scheme, has the characteristics of excellent bonding performance and has a wider application and development field.

Owner:常州市绿意管道有限公司

High-temperature molding method for nutritive block

InactiveCN103385363AImprove bindingHigh mechanical strengthAnimal feeding stuffCompression moldingAdhesive

The invention relates to the field of forages, and specifically relates to a high-temperature molding method for a nutritive block. The molding method comprises: respectively crushing the raw materials comprising corn, wheat bran and rapeseed meal, uniformly mixing to form a solid mixture according to a ratio; also heating molasses, adding urea, heating and thawing to form a molasses-urea liquid mixture; and mixing the solid mixture and the molasses-urea liquid mixture, heating, performing compression molding in a mold and drying. By employing a high-temperature molding technology, the starch in wheat bran and corn flour are gelatinized at a high temperature to form a high-viscosity starch adhesive, the adhesive and the molasses are adsorbed to the surface of solid particles together, and thus strong chemical bonds are formed. The improvement of the binding force between the particles is beneficial to improving mechanical strength of the block; because the starch adhesive is hard after cooling, the hardness of the block is enhanced, and the enhancement of the hardness is beneficial to controlling intake; and also the alleviation of the water penetration speed helps to improve water proofness of the block.

Owner:SICHUAN AGRI UNIV

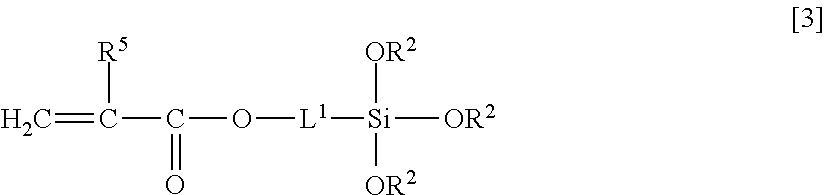

Curable composition including siloxane oligomer and inorganic fine particles

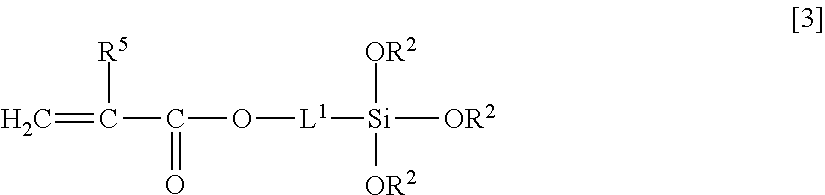

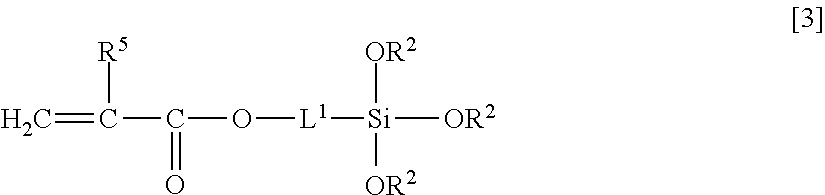

ActiveUS20160108250A1High transparencyLow refractive indexSynthetic resin layered productsElectrical equipmentOligomerRefractive index

There is provided a material having a low refractive index that exhibits a sufficiently low refractive index without deteriorating the strength of the cured film produced therefrom, and that can be cured by an active energy ray that is applicable for a resin base material that is not desired to be exposed to heat. A curable composition comprising: a siloxane oligomer (a) containing a radically polymerizable double bond obtained through hydrolysis and condensation of alkoxysilanes containing at least an alkoxysilane A of Formula [1] and an alkoxysilane B of Formula [2] in an amount of 100 parts by mass; inorganic fine particles (b) in an amount of 10 parts by mass to 1,000 parts by mass; and a polymerization initiator (c) generating a radical upon active energy ray irradiation in an amount of 0.1 parts by mass to 25 parts by masR1aSi(OR2)4-a [1]R3bSi(OR4)4-b [2]a cured film produced from the composition, and a laminate comprising a low refractive index layer produced from the composition.

Owner:NISSAN CHEM IND LTD

Ceramic coating and process for applying the same

InactiveUS20160305651A1Reduce corrosionReduce erosionLiquid surface applicatorsBoiler flue tubes/fire tubesCeramic coatingComposite ceramic

A dual color sprayed on composite ceramic coating configured and formulated to protect fireside boiler tubing while also acting as a visual inspection aid. The coating is an environmentally safe, non-reactive, water soluble composite ceramic that will withstand operating temperatures up to 2000° F. (1093° C.). This coating is ideal for fluidized bed boilers and coal fired utility boilers experiencing tube erosion, corrosion and slagging. This sprayed-on ceramic coating system allows for fast application rates reducing equipment down time. The composite ceramic coating is a high solids system that will withstand severe thermal cycling from −300° F. (−185° C.) to 1600° F. (871° C.). This composite system is applied in two distinct colors to enable easy visual inspection of coating thickness.

Owner:FIRESIDE COATINGS INC

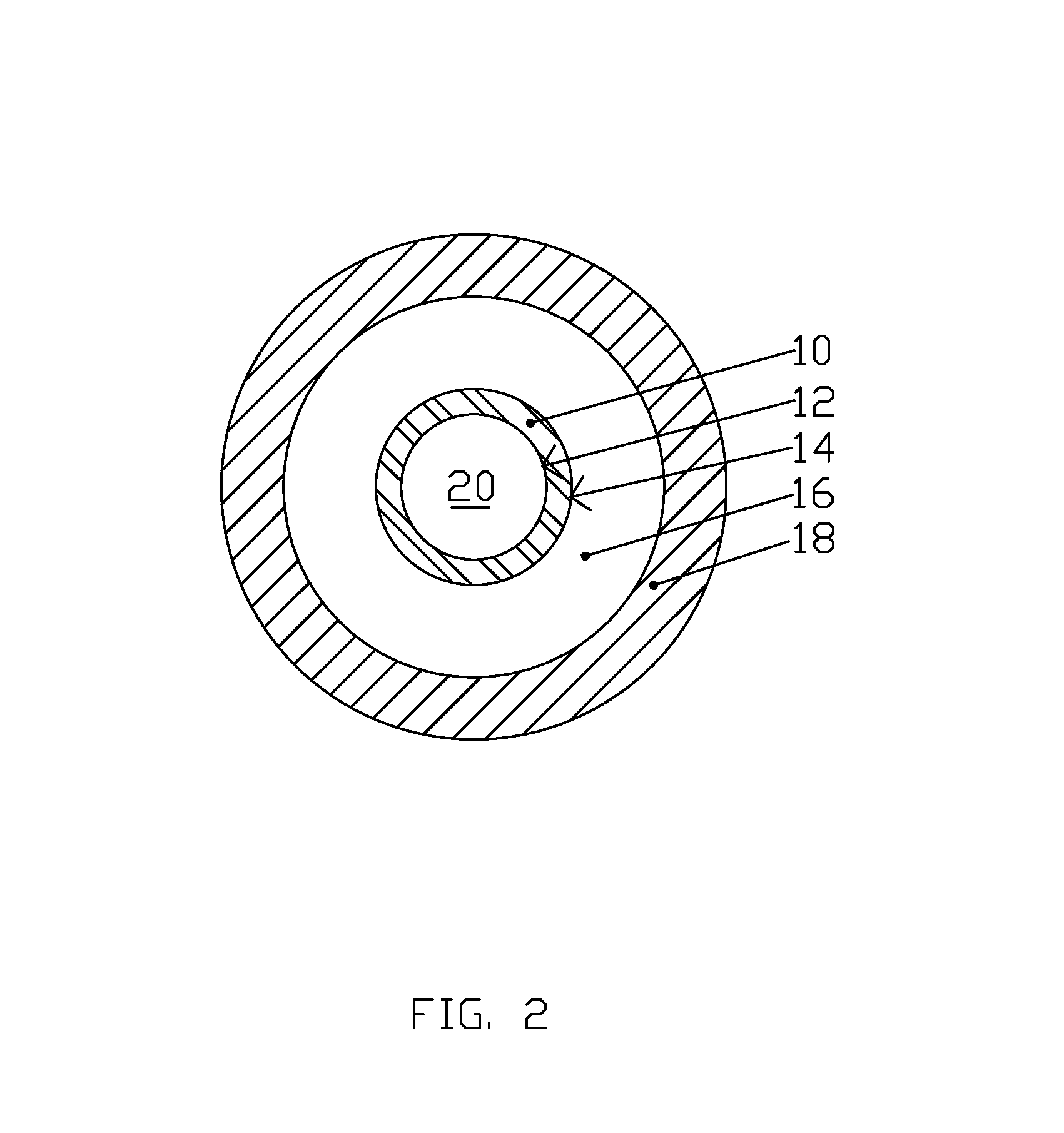

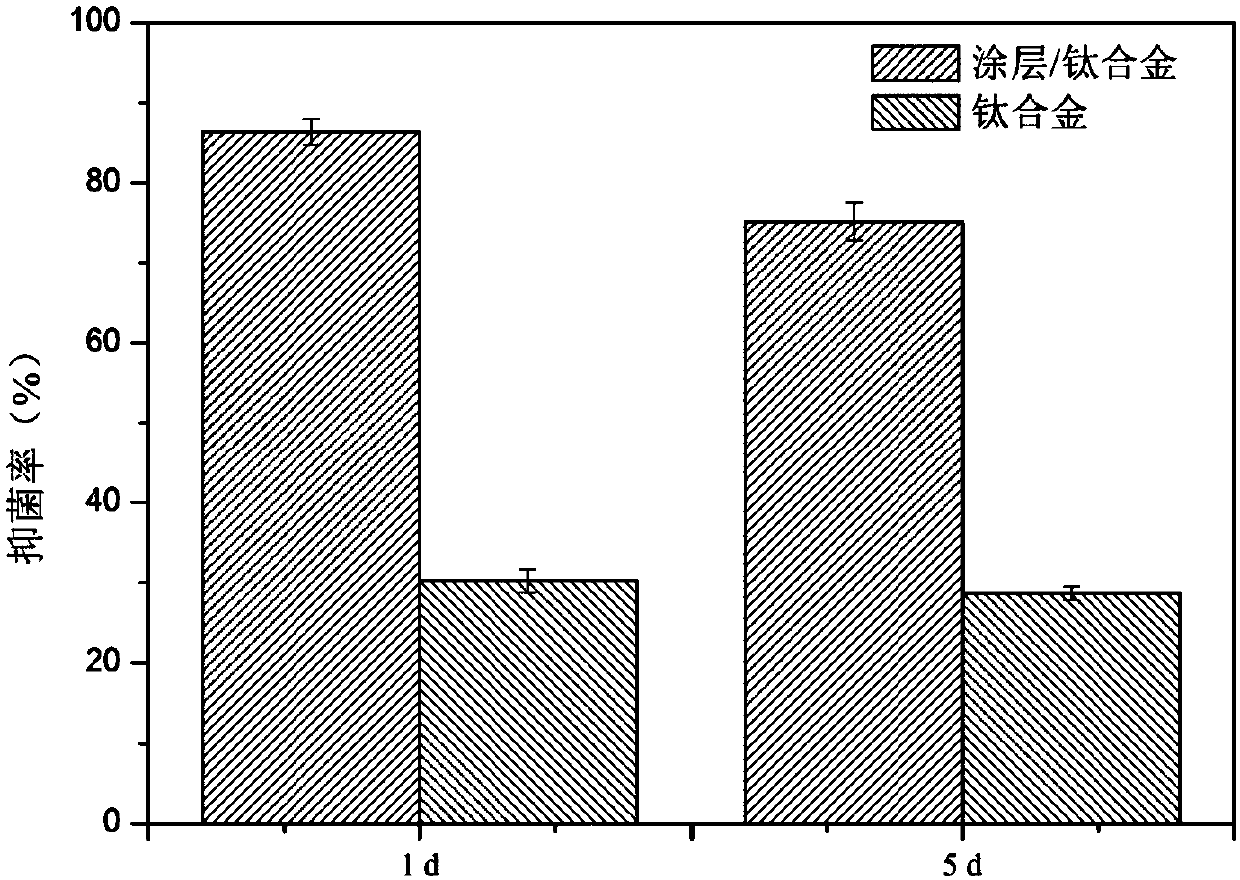

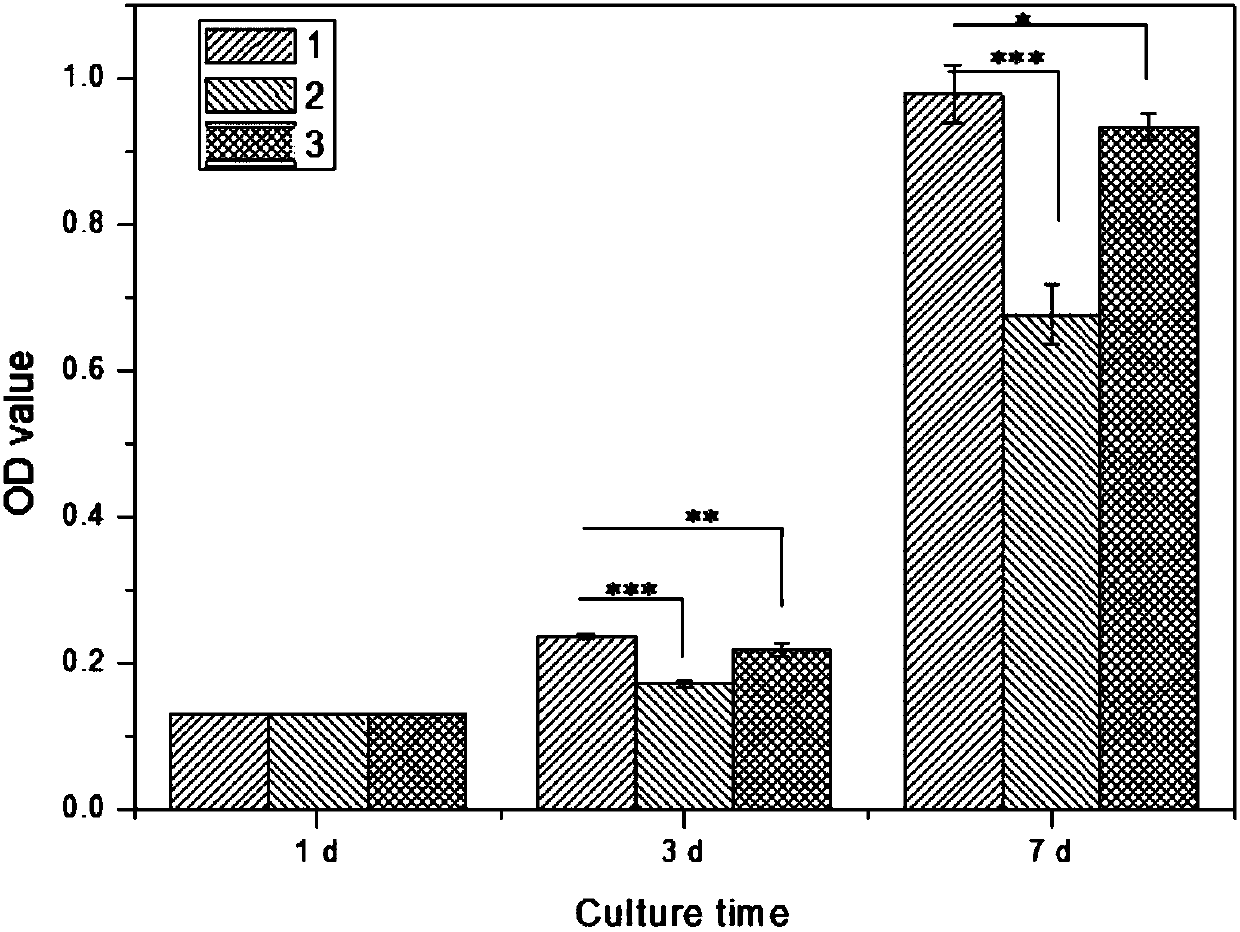

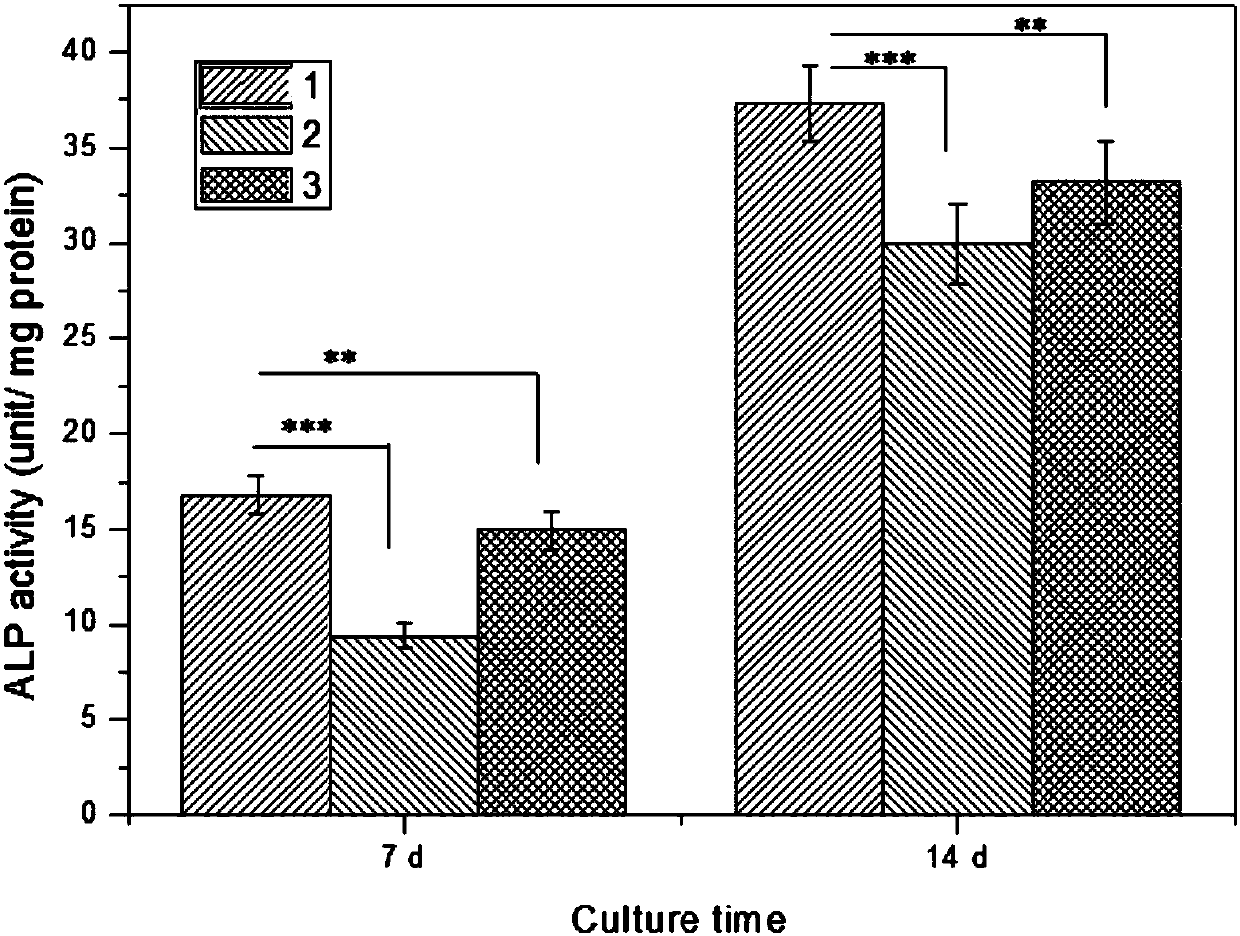

Titanium alloy surface collagen coating loaded with antibacterial polypeptides and preparation method of coating

ActiveCN110292654AImprove bindingPromote ingrowthLiquid surface applicatorsPharmaceutical delivery mechanismMicro arc oxidationInfection risk

The invention discloses a titanium alloy surface collagen coating loaded with antibacterial polypeptides and a preparation method of the coating. An electrostatic spraying technology is also used, thecollagen coating loaded with the antibacterial polypeptides is simultaneously constructed on the surface of porous titanium alloy, the process is simple and convenient, and the spraying efficiency ishigh. Dopamine is oxidized to form polydopamine which has good adhesion, combination of the coating and a titanium alloy matrix can be enhanced, the coating is not likely to fall off, and the coatingcan coexist with a micro-arc oxidation structure on the surface of the porous titanium alloy; meanwhile, the antibacterial polypeptides are loaded on the surface of the titanium alloy; the collagen coating loaded with the antibacterial polypeptides can induce generation of bones and cartilage, more stable chemical bonding and higher biological activity are provided for the titanium alloy implants, the collagen coating is more beneficial for ingrowth of new bone issue, a good antibacterial property is achieved, the infection risk caused by implantation of the titanium alloy can be effectivelyreduced, and the implantation effect is improved.

Owner:GUANGZHOU TRAUER BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com