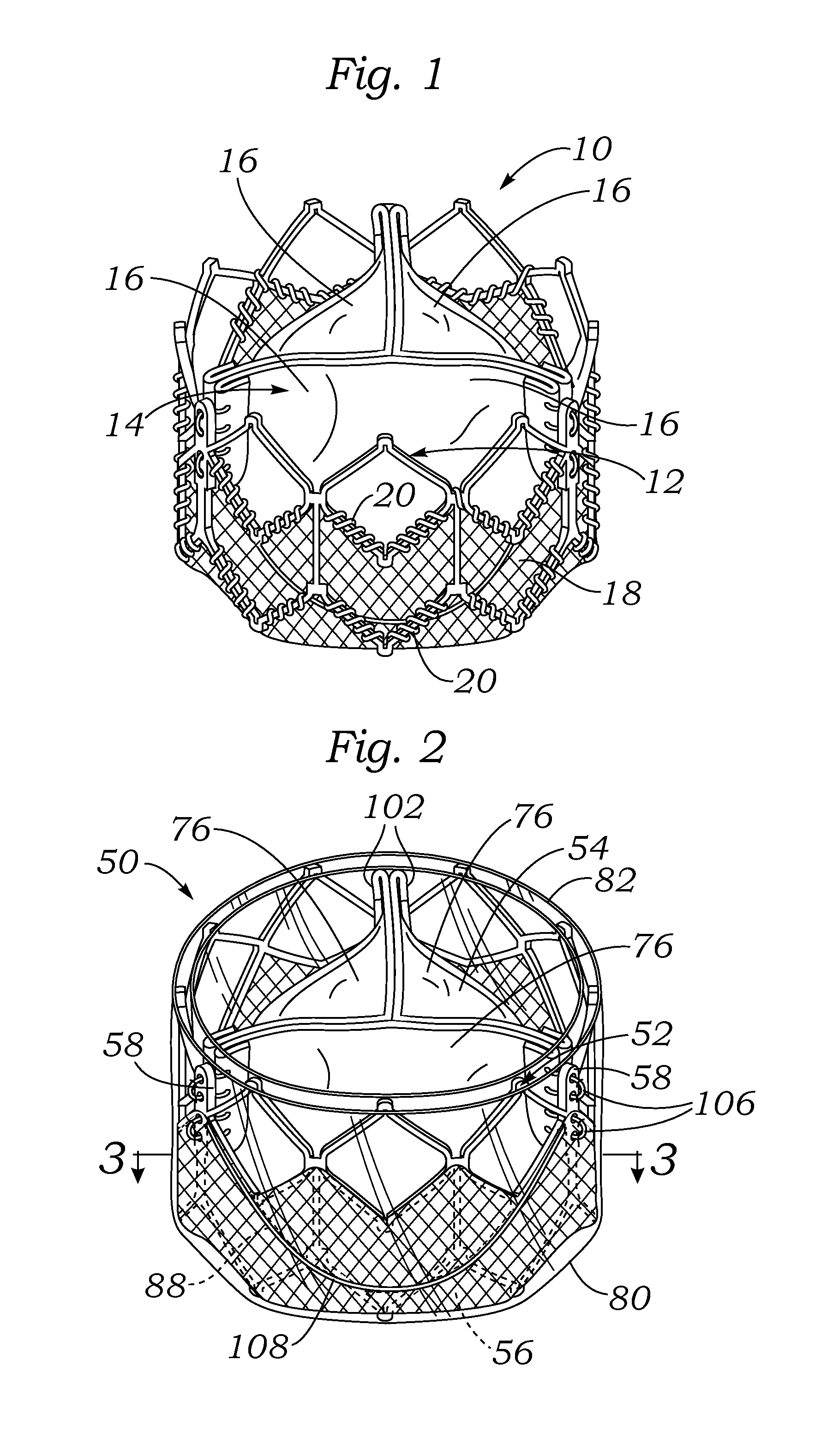

Patents

Literature

683results about How to "Promote ingrowth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

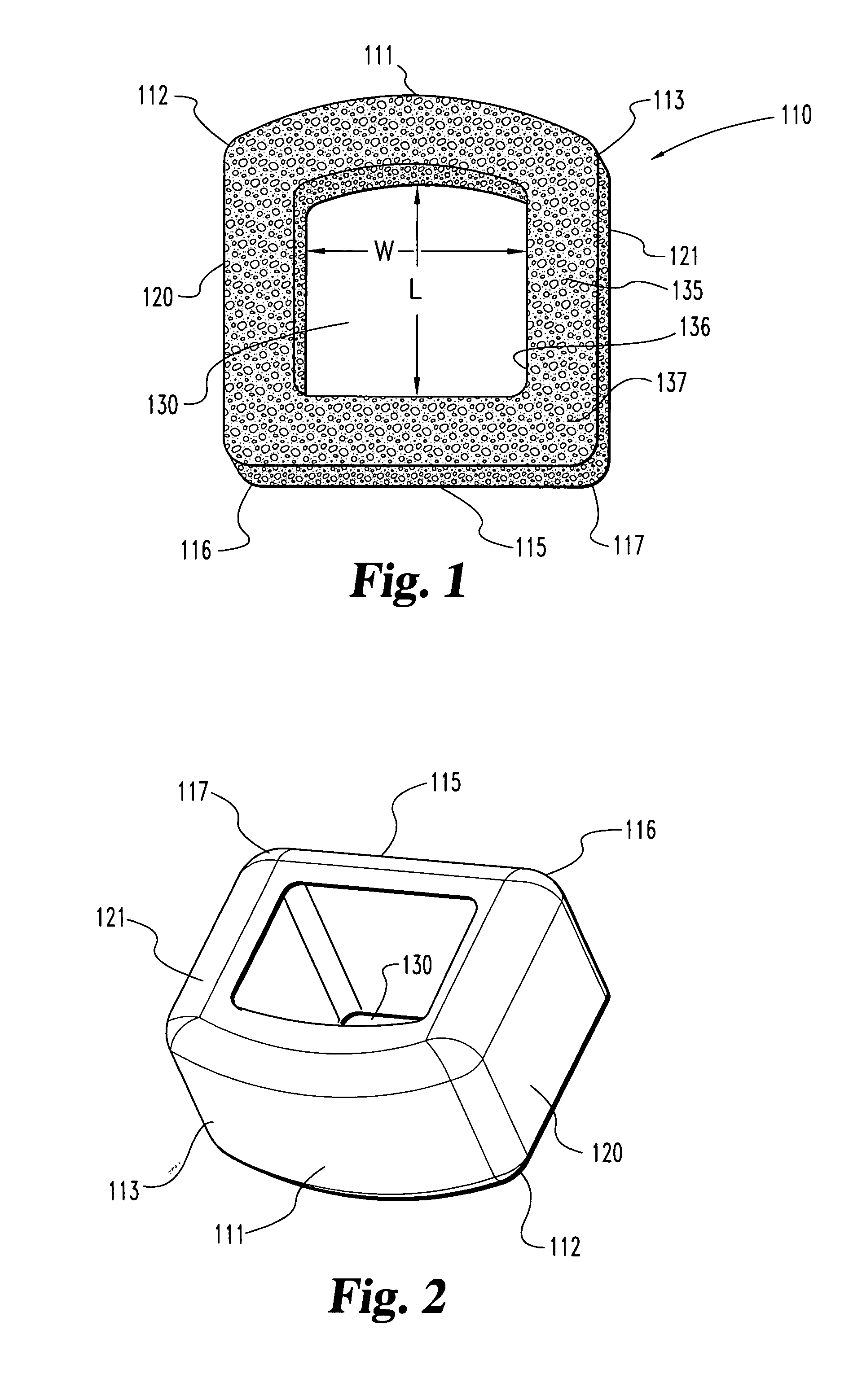

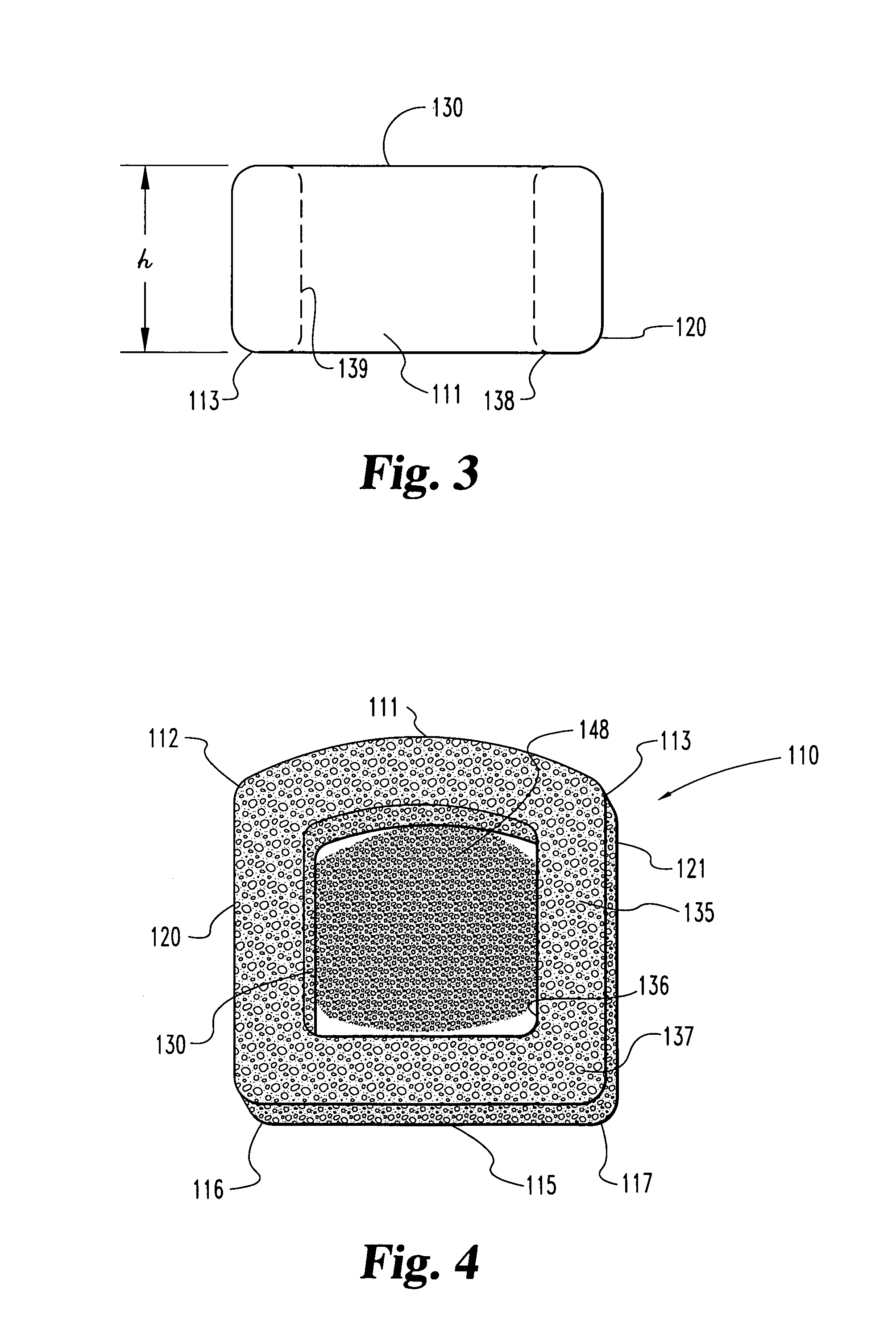

Vertebral implant for promoting arthrodesis of the spine

This invention provides a vertebral implant for impaction in a disc space to restore and / or maintain desired disc space height and spinal orientation. The implant has an elongated basis body having a generally lens-shape provided by convex upper and lower surfaces. Bearing surfaces are provided on the cross-edge surfaces of the endwalls. Grooves are provided in the upper and lower surfaces positioned between the bearing surfaces. The implant can be prepared from a wide variety of materials including metallic materials, synthetic materials, polymeric materials, ceramic materials, and composite materials including reinforced materials i.e. glass, fiber, and / or carbon fiber reinforced materials (CFRP). These preferred materials for fabricating implants in the present invention reduce costs, increase service life and provide excellent physiological compatibility. The non-metallic material can be selected to be either a substantially permanent material, a biodegradable material or a bioerodable material. Further, the implant material can be provided to be radio opaque to facilitate monitoring of bone ingrowth both into the implant and between the opposing endplates of the adjacent vertebrae.

Owner:WARSAW ORTHOPEDIC INC

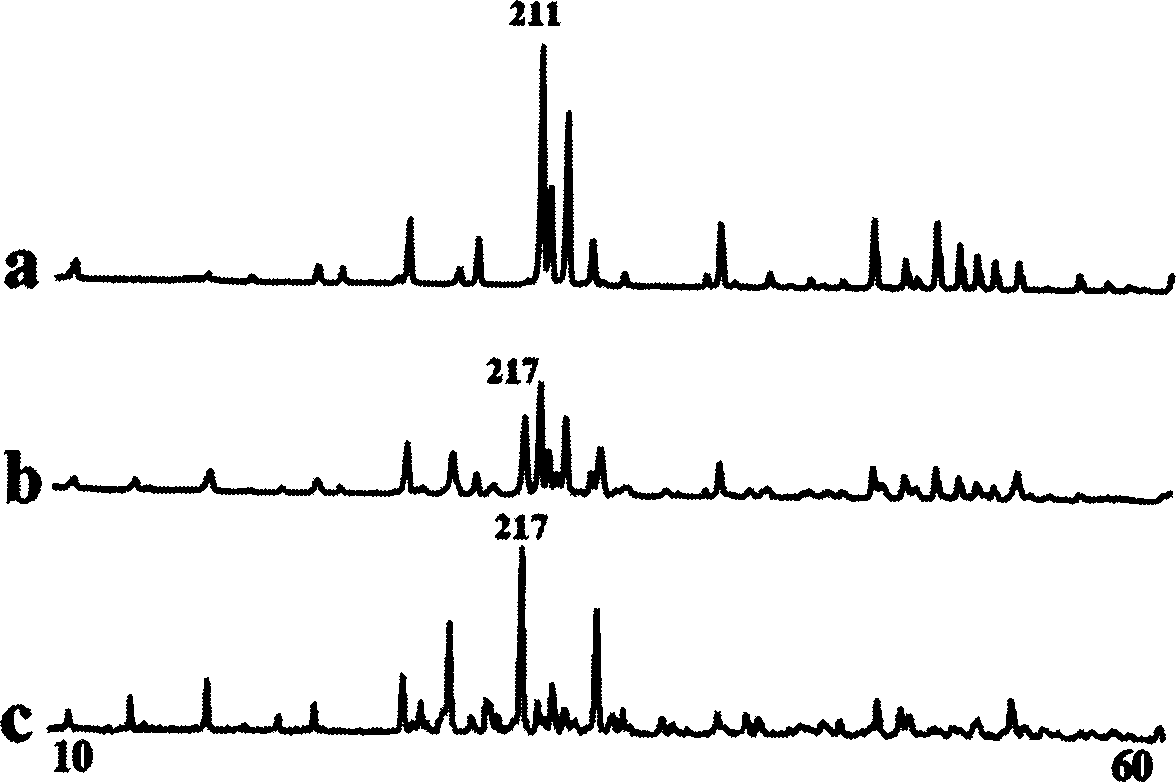

Polymer-bioceramic composite for orthopaedic applications and method of manufacture thereof

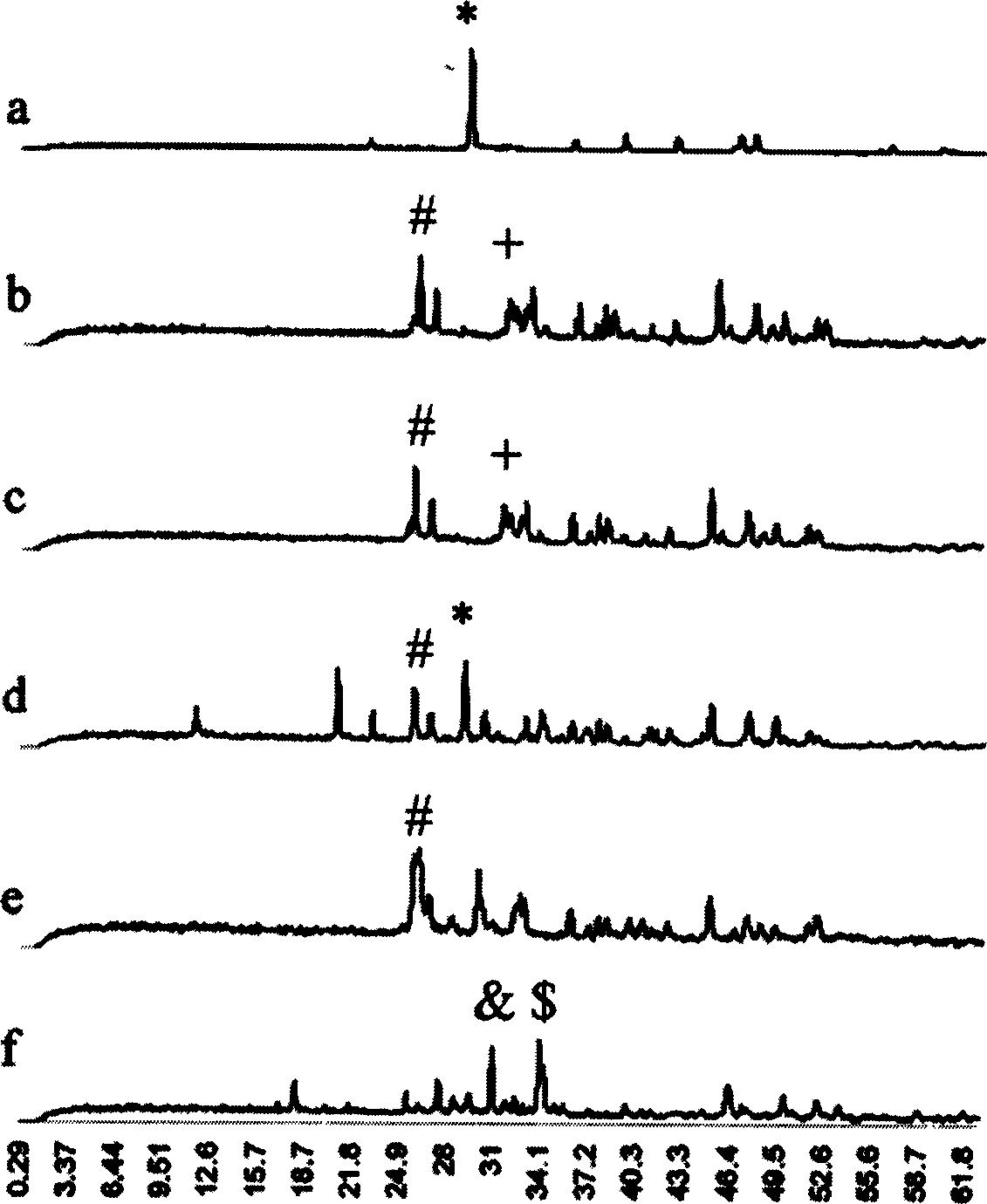

InactiveUS20040002770A1Promote ingrowthImprove toughnessBone implantJoint implantsCompression moldingPolymer science

Polymer-bioceramic structures are described for use in the repair of bone defects. The composites of the present disclosure are characterized by a polymer disposed in a porous bioceramic matrix. Processes for preparing the composites of the present invention by compression molding are described, including compression molding to induce orientation of the polymer is multiple directions. The composites of the present invention are also useful as drug delivery vehicles to facilitate the repair of bone defects.

Owner:DEPUY SYNTHES PROD INC

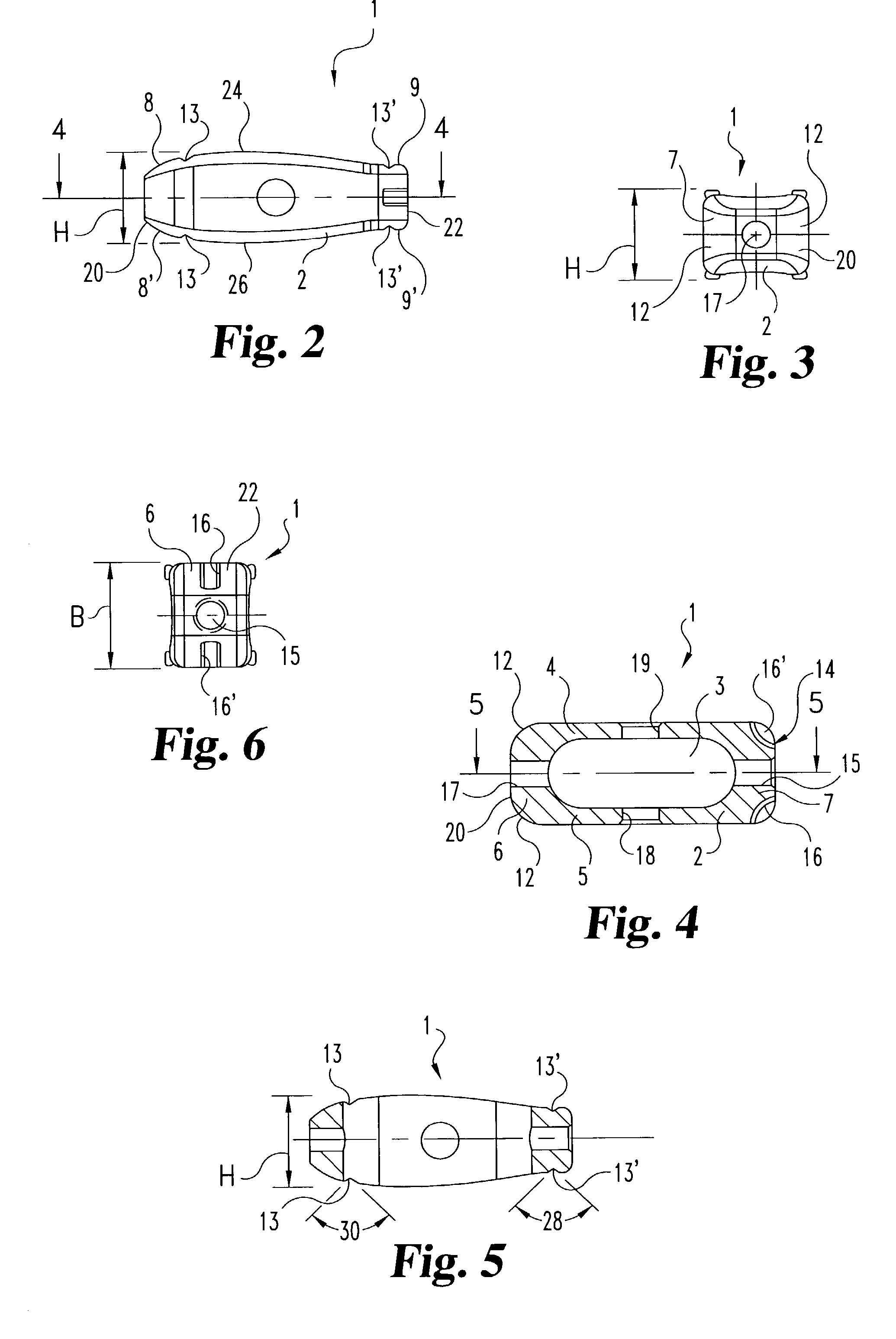

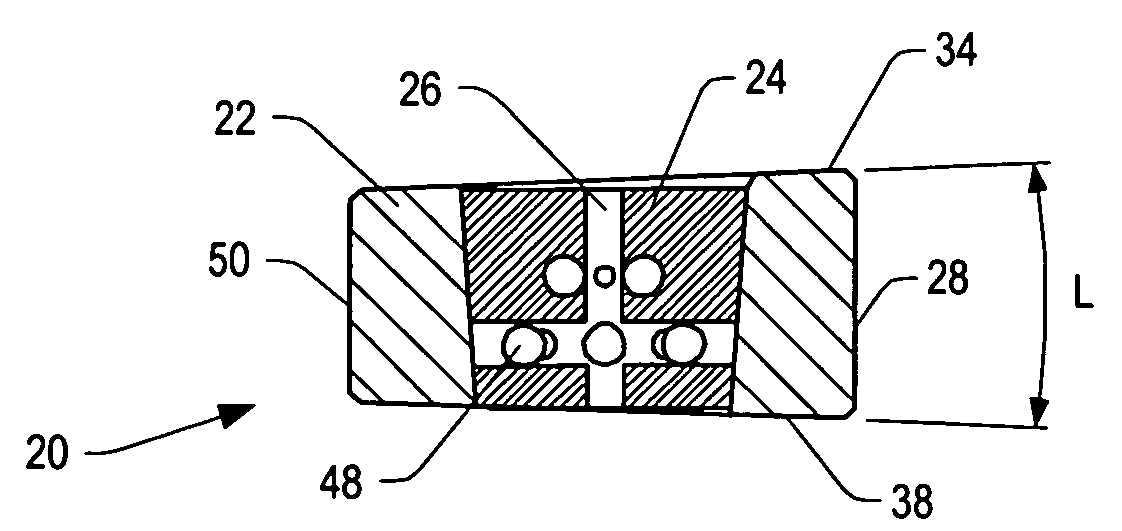

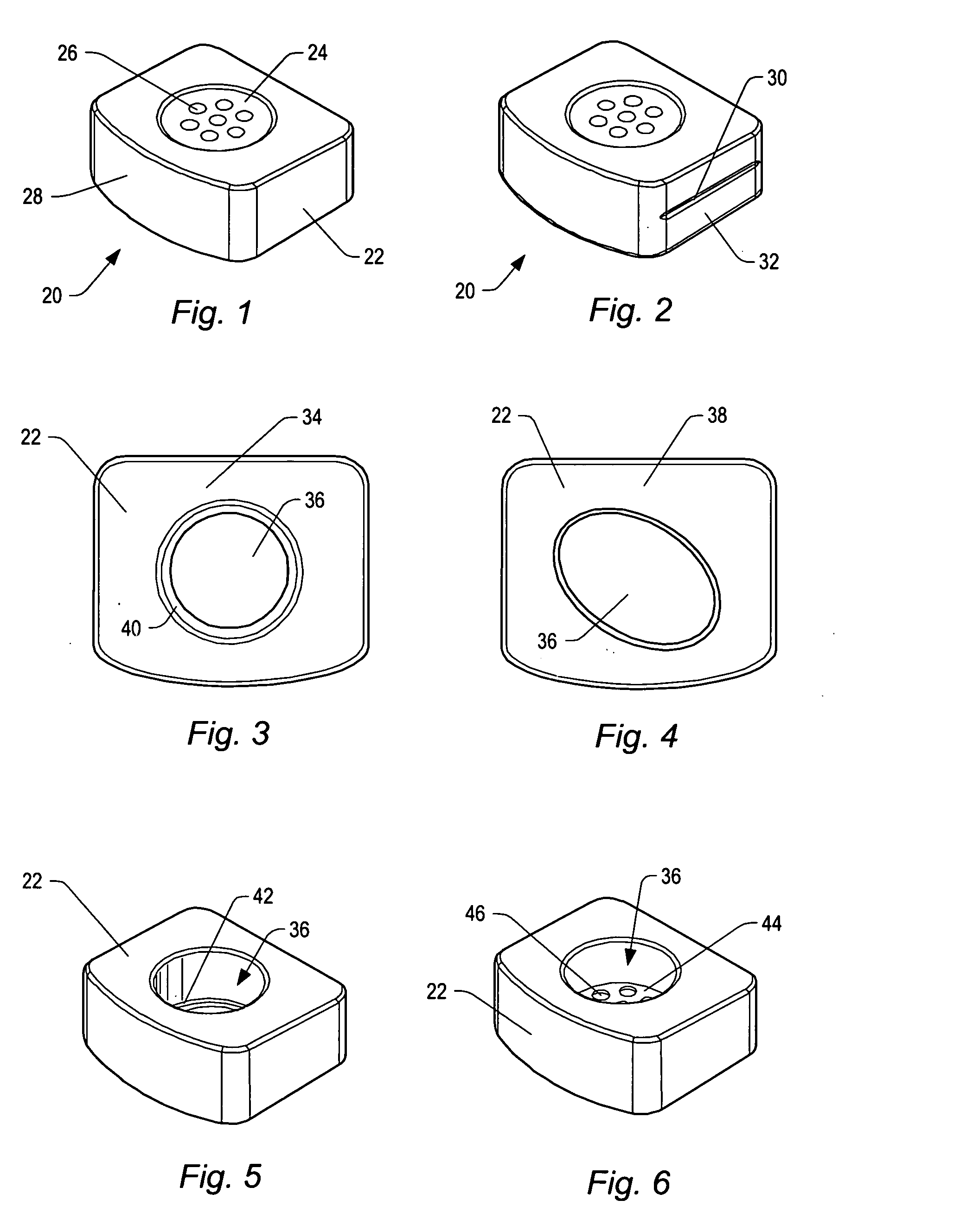

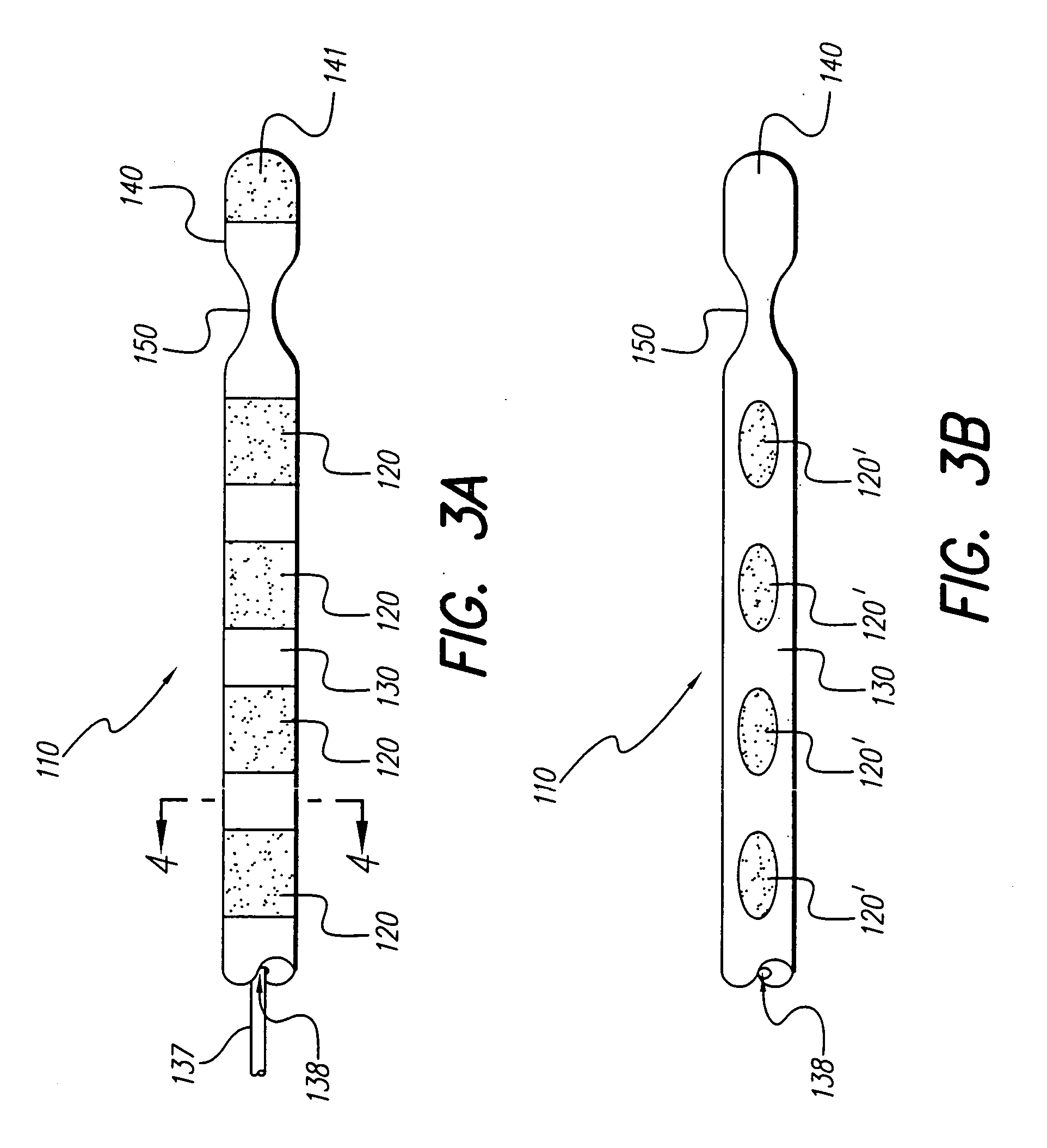

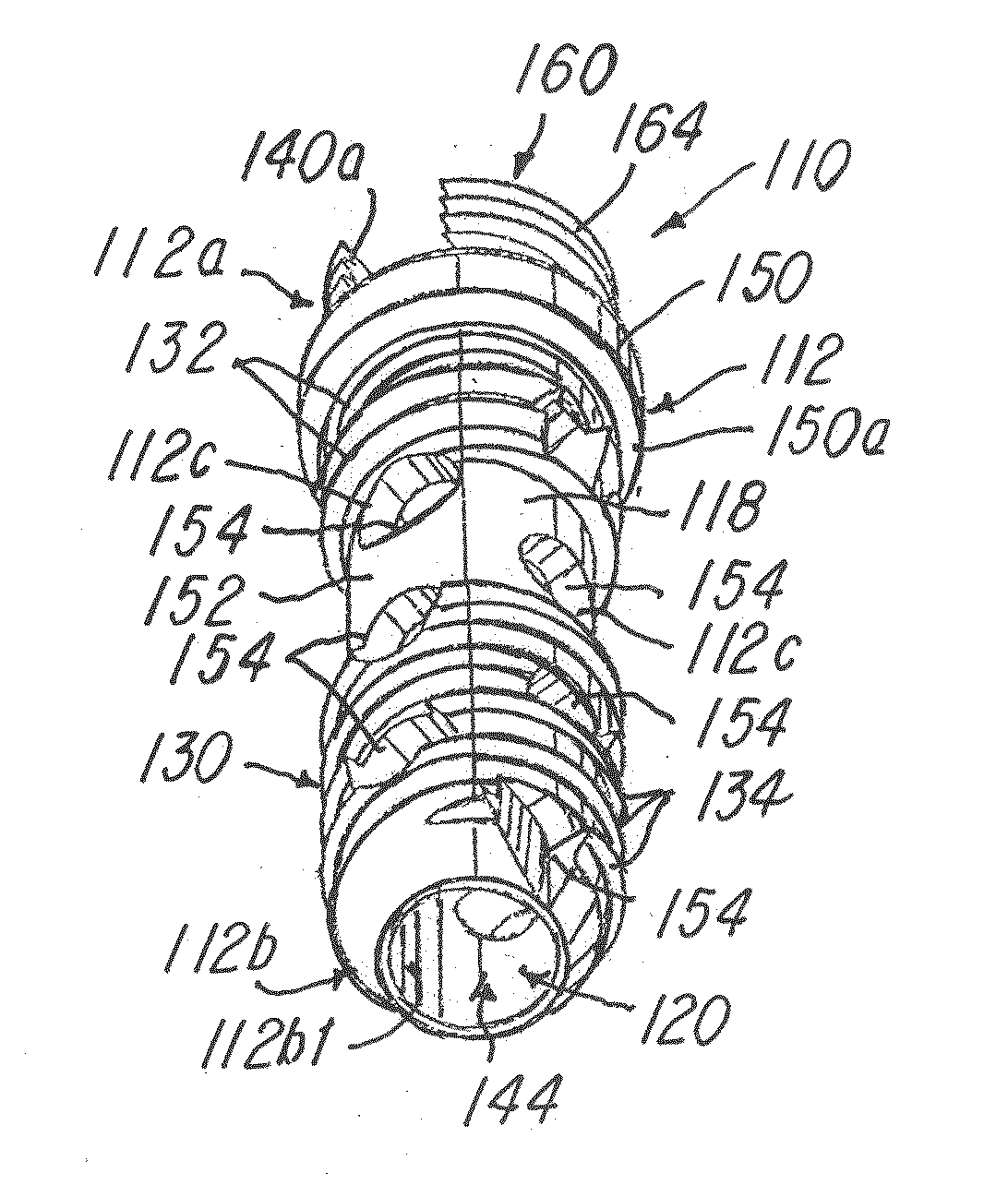

Spinal implants with body and insert

ActiveUS20050251257A1Easy to integrateAvoid passingBone implantJoint implantsBone growthSpinal implant

A spinal implant is provided which maintains intervertebral spacing and stability within the spine. The spinal implant may include a body and an insert. The body of the spinal implant may be formed of a ceramic material. In some embodiments, the body may be formed of beta tricalcium phosphate. The body may include an opening that is complementary to the insert. The insert may fit within the opening. The insert may include a number of passageways. Some of the passageways may intersect to form a scaffold for bone growth. Bone growth promoting material may be introduced into the insert before the insert is positioned in a body and inserted in a patient between two vertebrae.

Owner:ZIMMER BIOMET SPINE INC

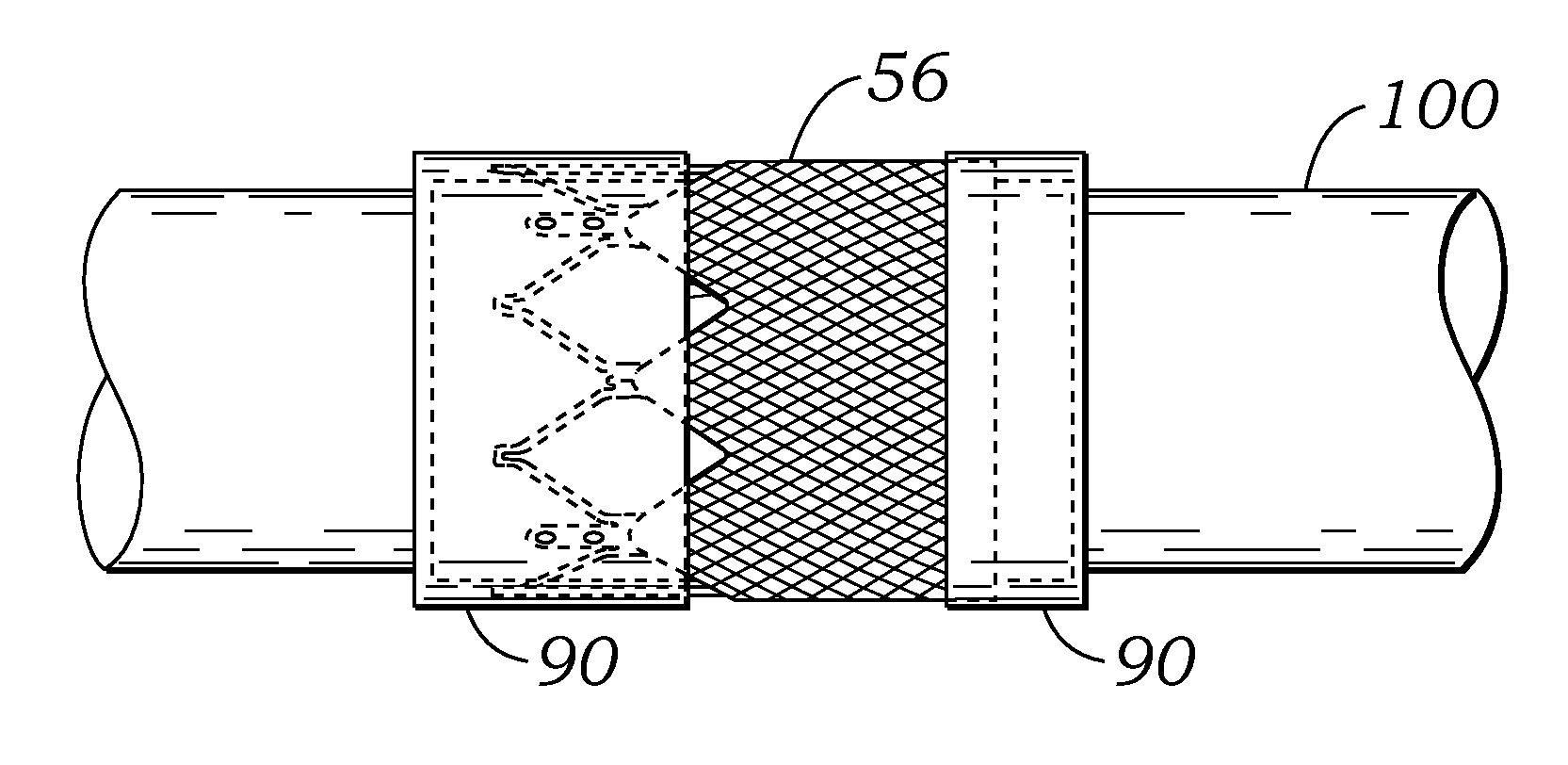

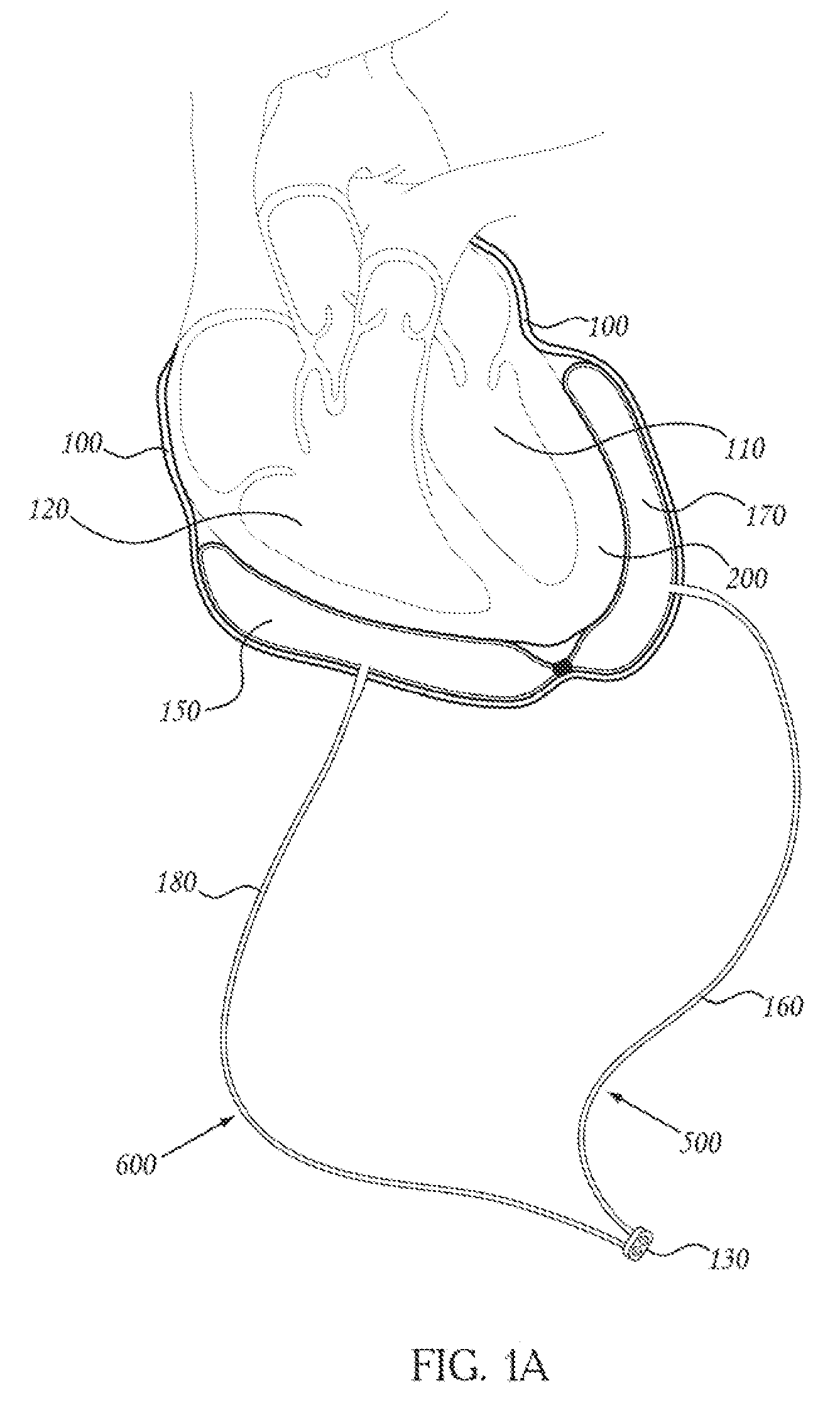

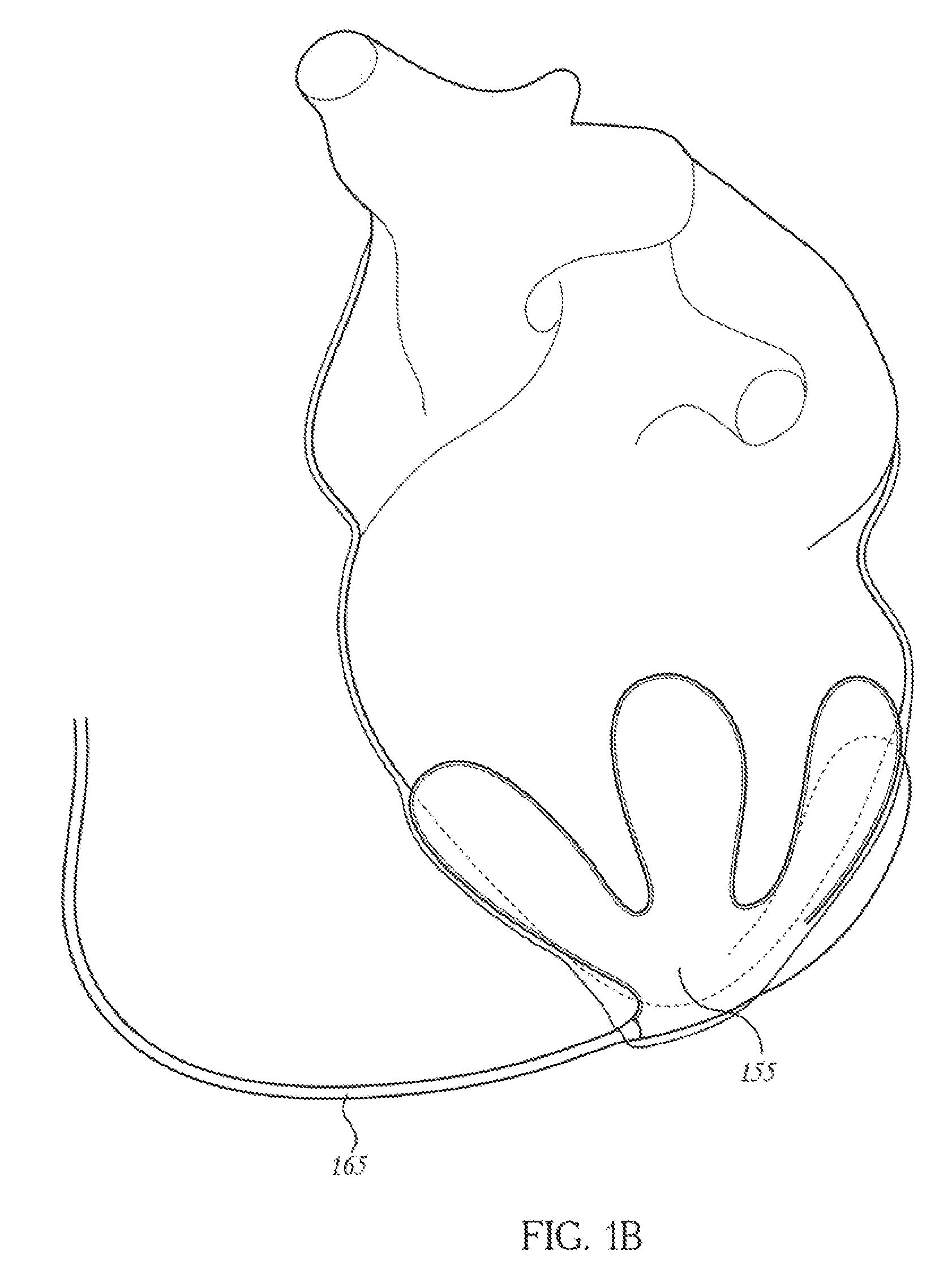

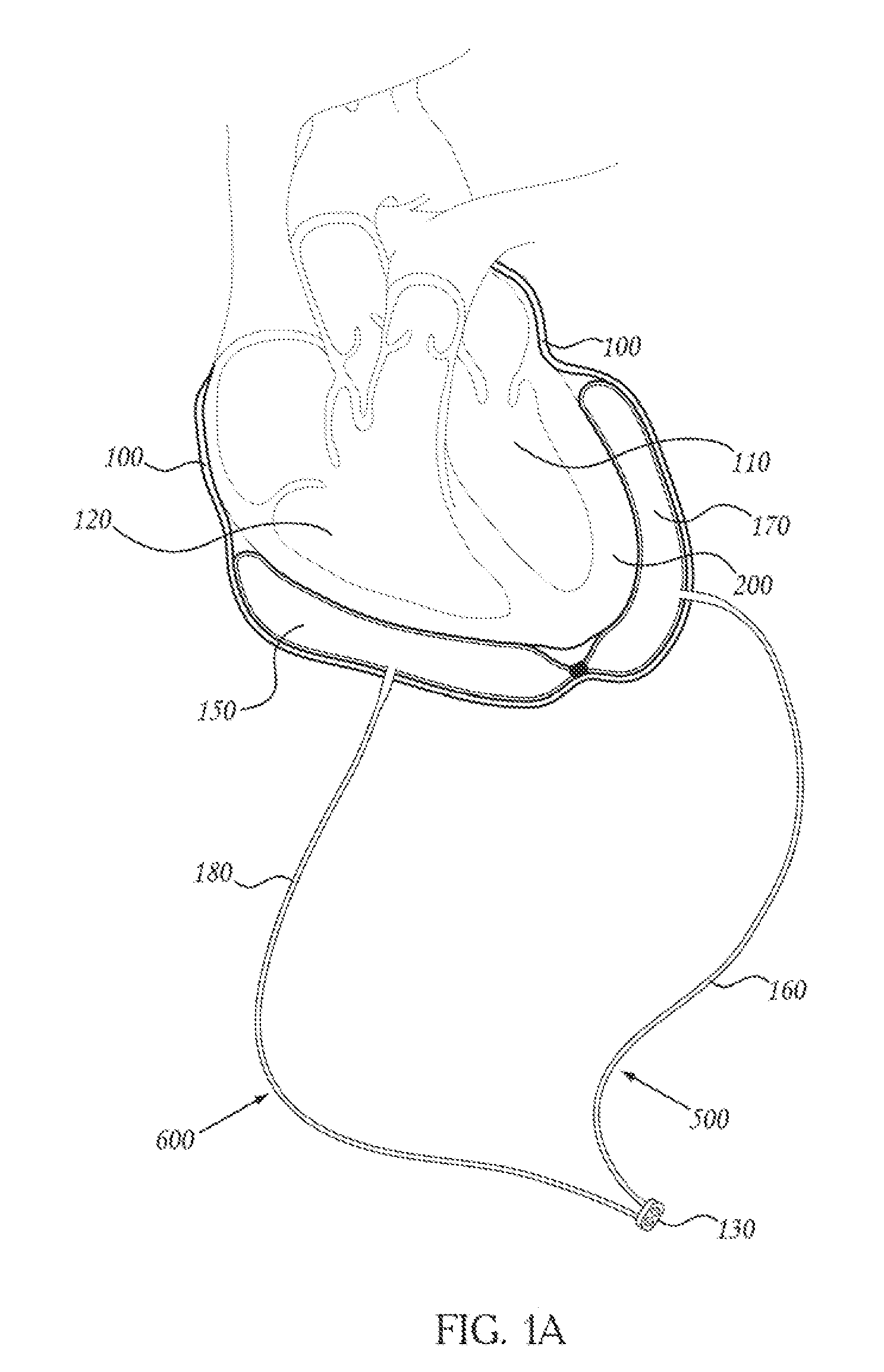

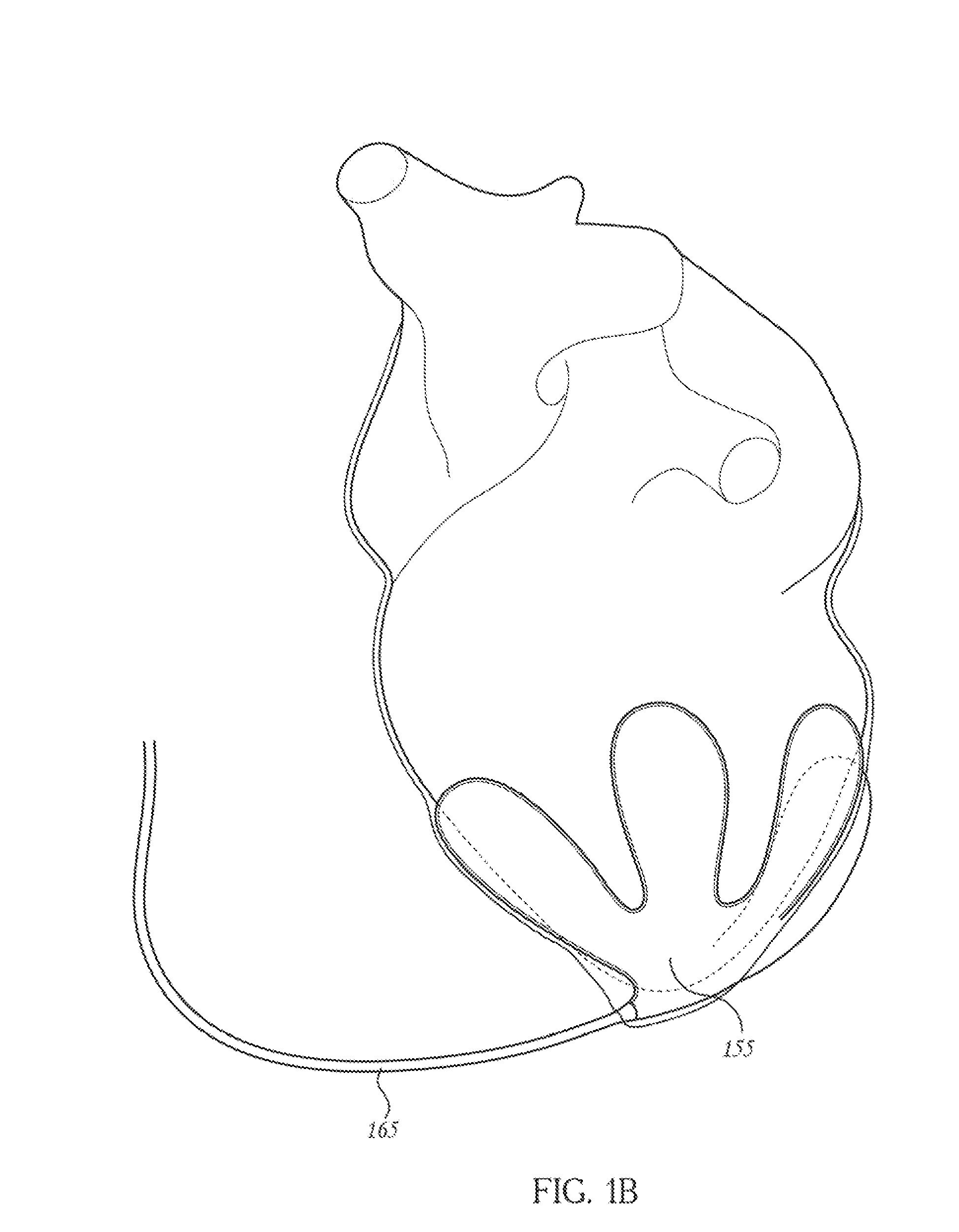

Methods of making encapsulated heart valves

ActiveUS20140209238A1Minimize the numberReplacement is neededHeart valvesLaminationProsthetic valveProsthesis

The present disclosure concerns embodiments of implantable prosthetic devices, and in particular, implantable prosthetic valves, and methods for making such devices. In one aspect, a prosthetic device includes encapsulating layers that extend over a fabric layer and secure the fabric layer to another component of the device. In particular embodiments, the prosthetic device comprises a prosthetic heart valve, and can be configured to be implanted in any of the native heart valves. In addition, the prosthetic heart valve can be, for example, a transcatheter heart valve, a surgical heart valve, or a minimally-invasive heart valve.

Owner:EDWARDS LIFESCIENCES CORP

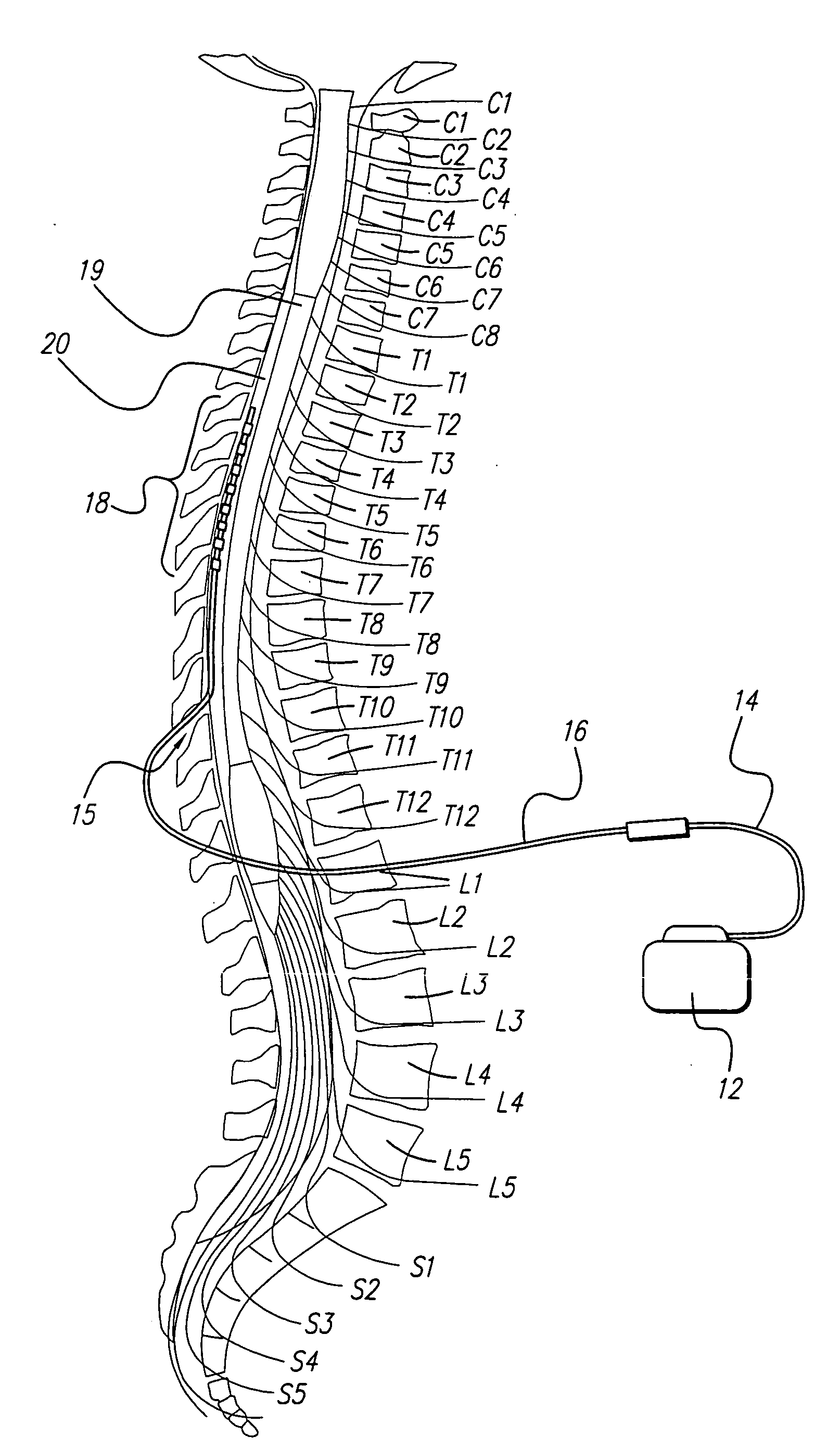

Implantable medical lead

InactiveUS20070213795A1Increase flexibilityFacilitates post-implant anchoringSpinal electrodesExternal electrodesDistal portionSurgery

An improved percutaneous lead is provided. The lead has a circumferential, concave neck located on the distal portion of the lead and a stylet lumen traversing through the lead including through the concave neck. The concave neck has a narrower circumference than the remainder of the lead. The concave neck is designed to bend up to 45 degrees with a pre-curved stylet inserted into the stylet lumen. The presence of a concave neck permits the ingrowth of tissue into and around the concave neck, thereby helping to anchor the lead post-implant. The concavity in the neck presents no sharp edges to disrupt the isodiametric lead profile.

Owner:BOSTON SCI NEUROMODULATION CORP

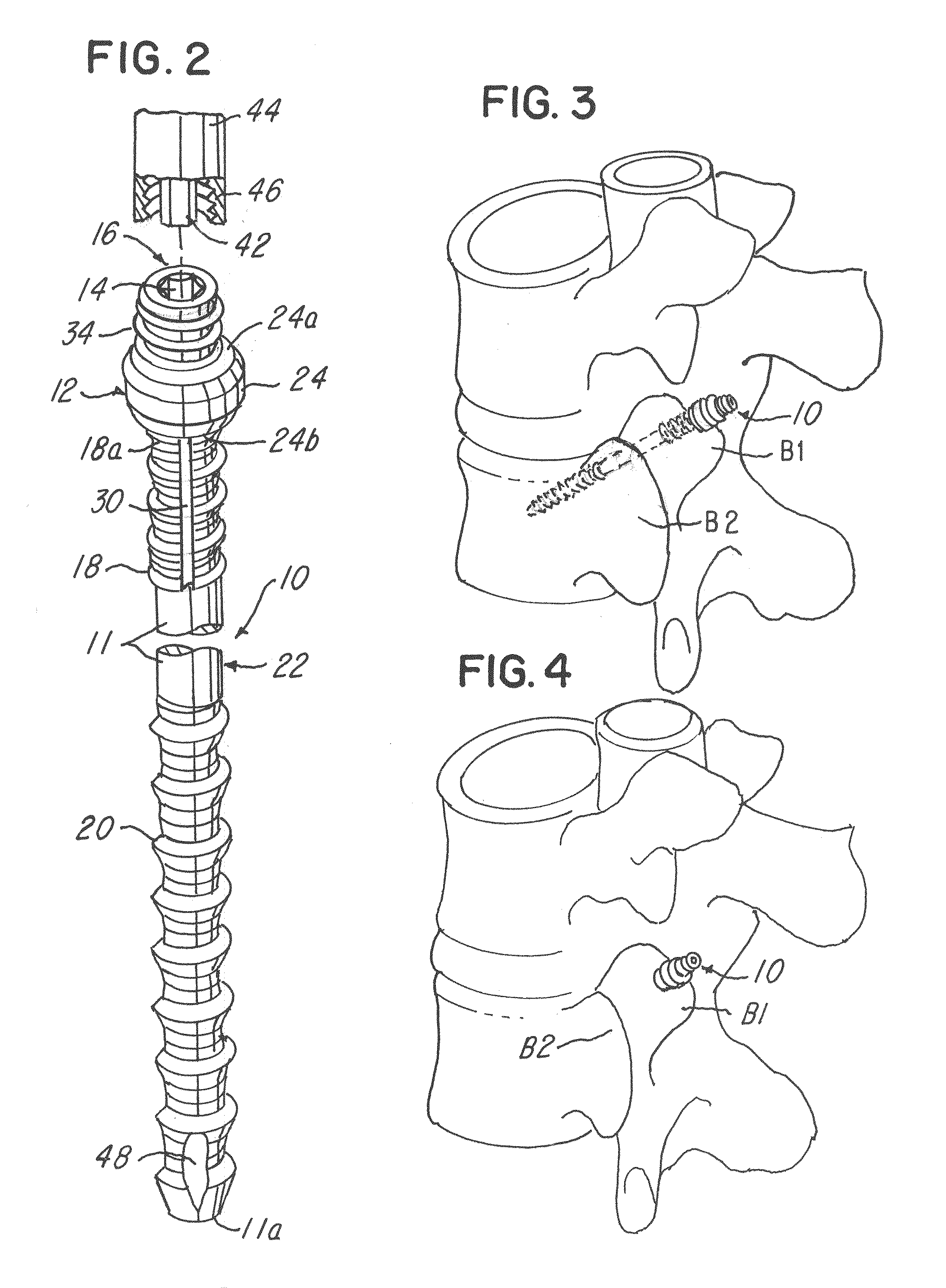

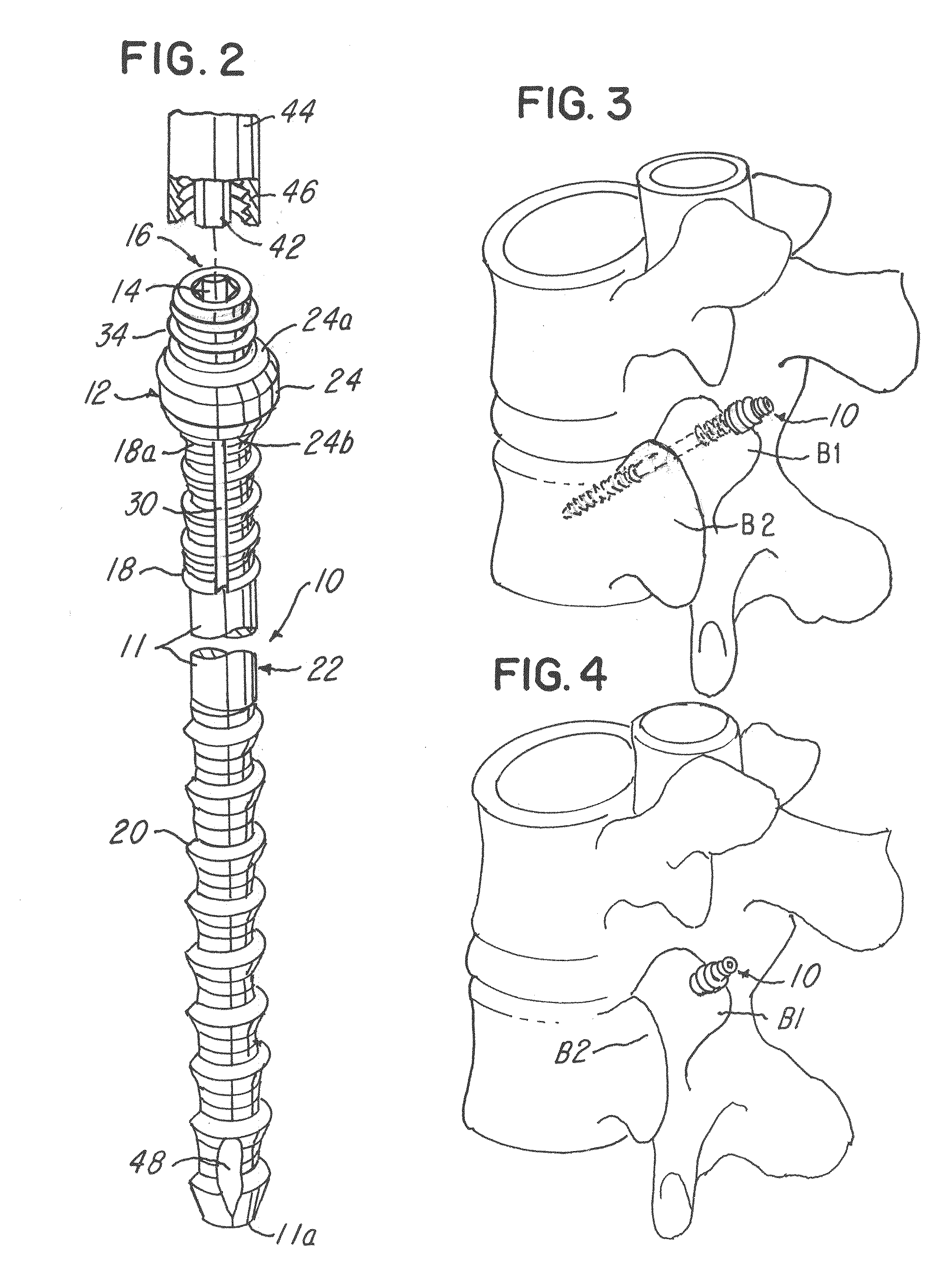

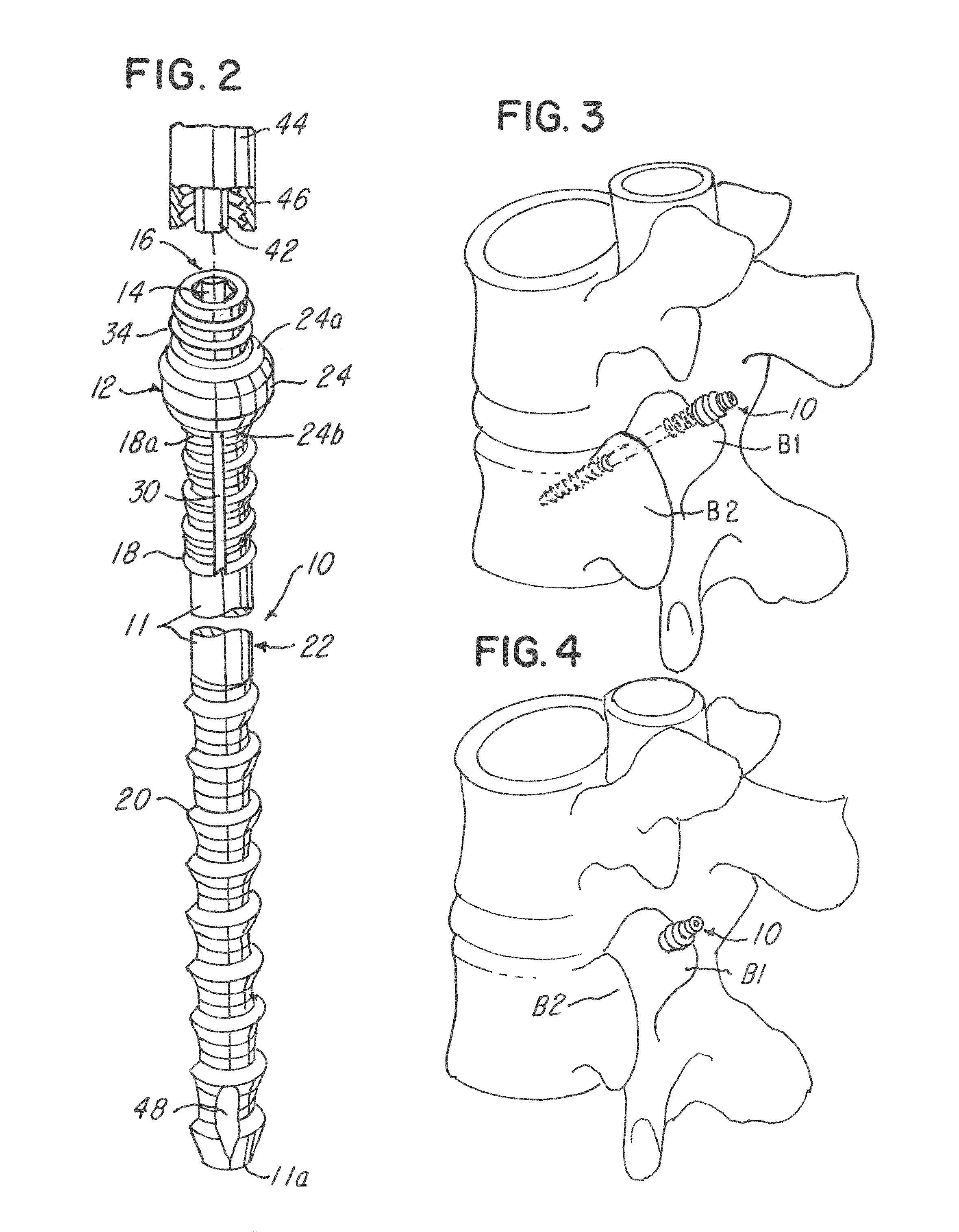

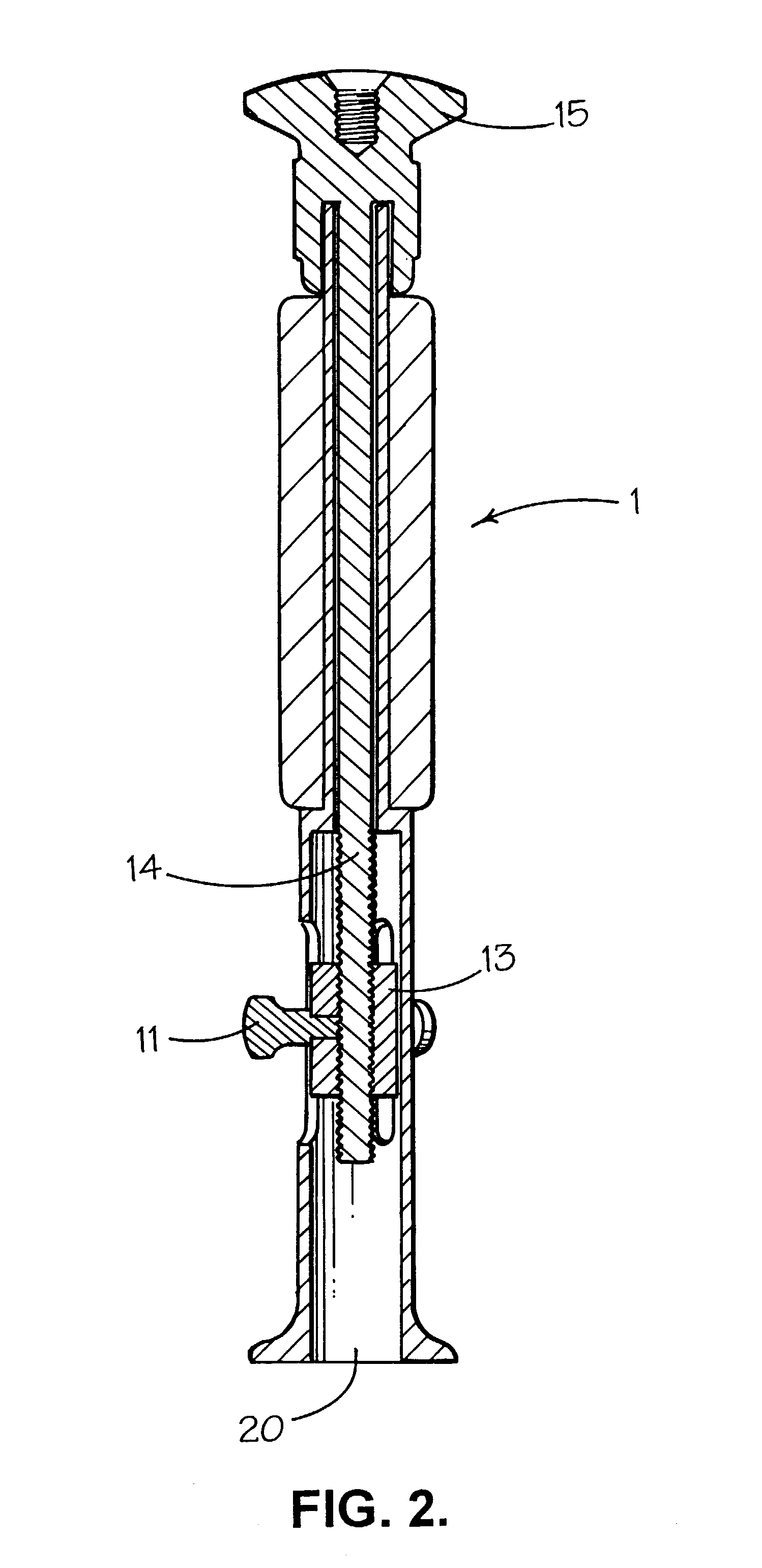

Minimally invasive spinal facet compression screw and system for bone joint fusion and fixation

ActiveUS20120197311A1Prevent the screw from looseningPrevent disengagementSuture equipmentsInternal osteosythesisSpinal columnBones joints

A system comprising a screw element having a generally cylindrical body having a bore or lumen therethrough and a plurality of fenestrations or windows through which biological material may be provided. The system comprises a tool for inserting the biological material into the screw element so that the biological material may extrude through the plurality of fenestrations or windows and through an aperture in the tip of the screw element thereby enabling providing a fusion mass across two adjacent facet bones or a facet joint wherein the screw itself provides both a fixation component and a screw component.

Owner:X SPINE SYST

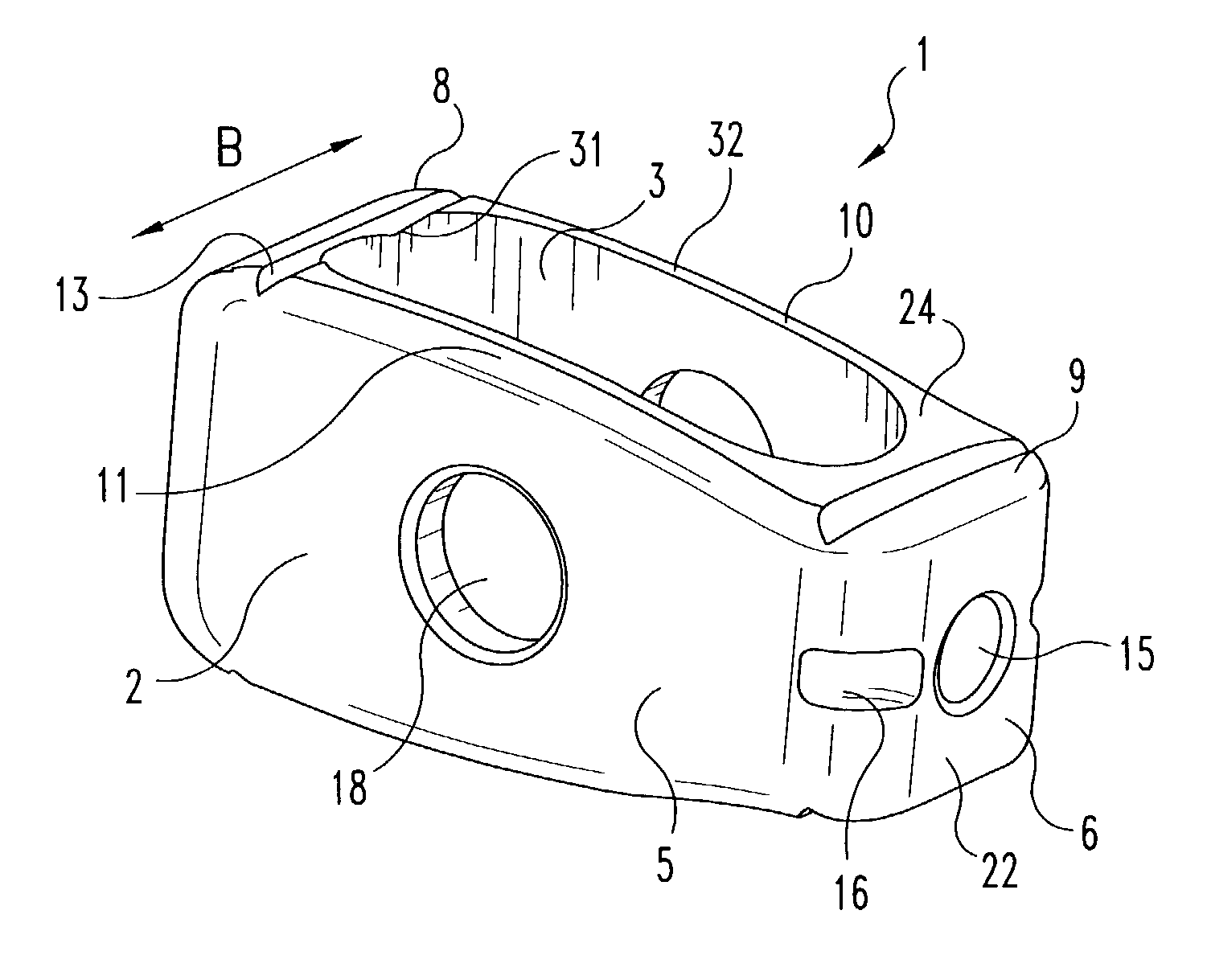

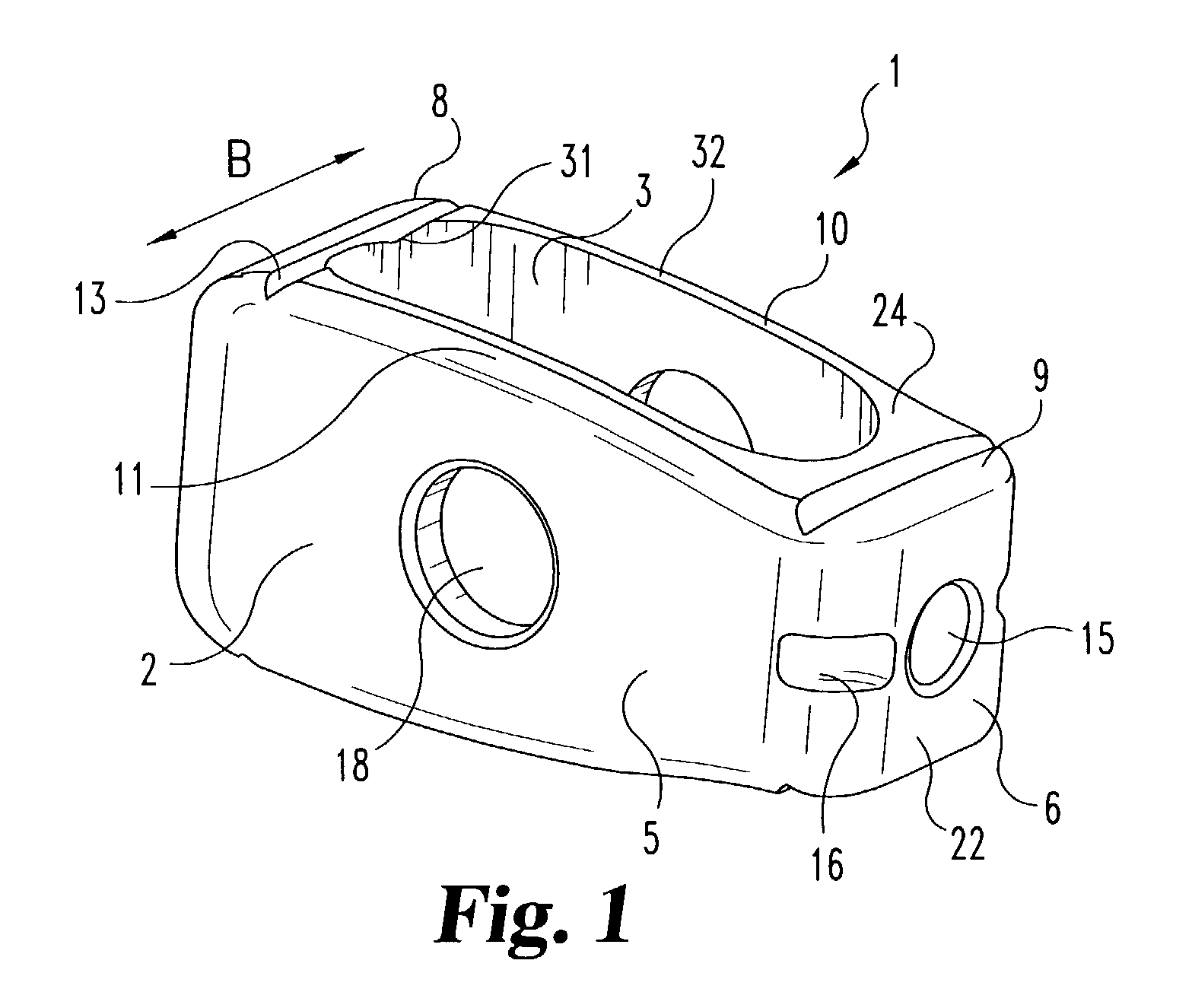

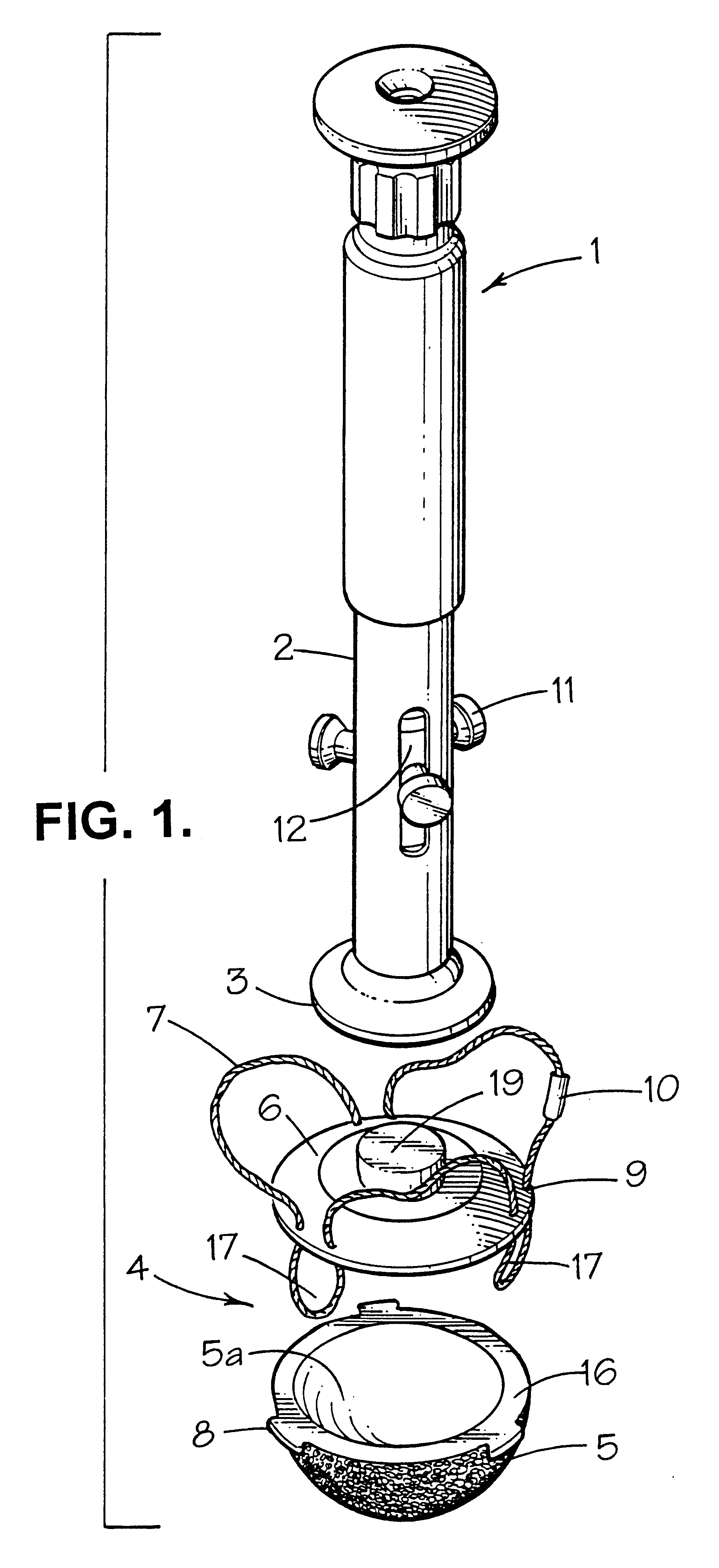

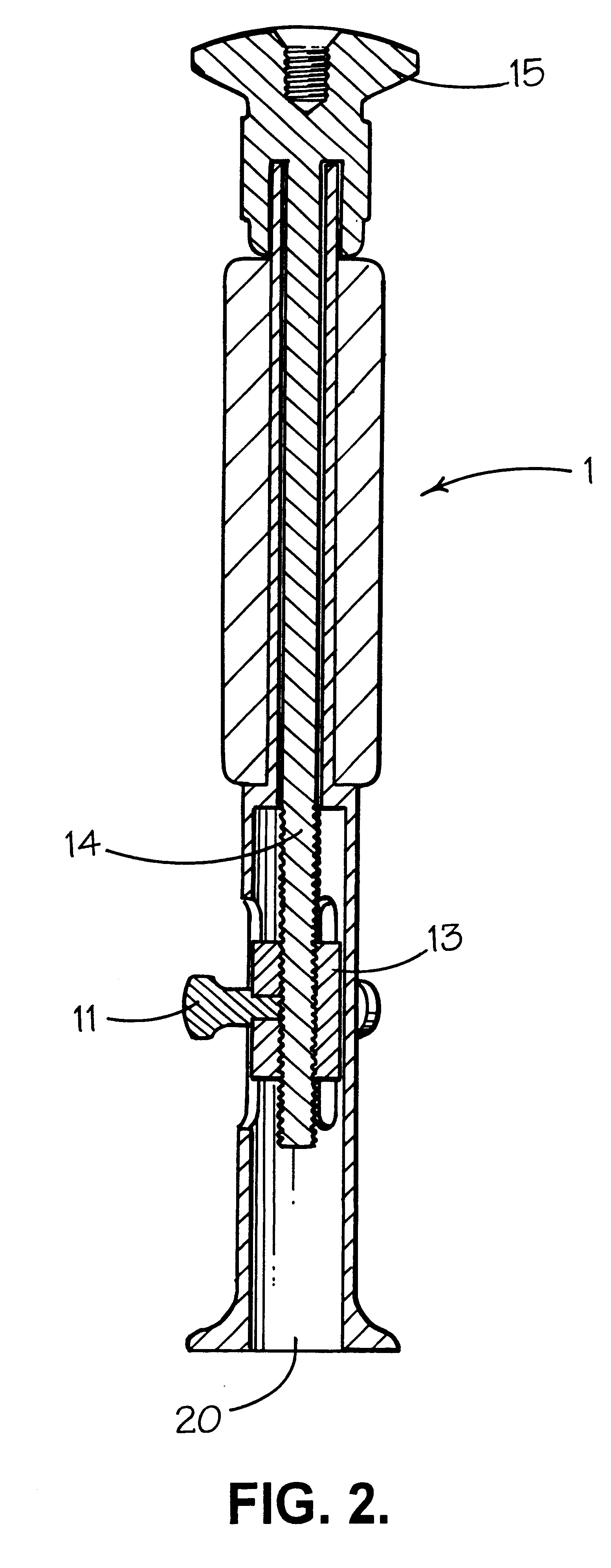

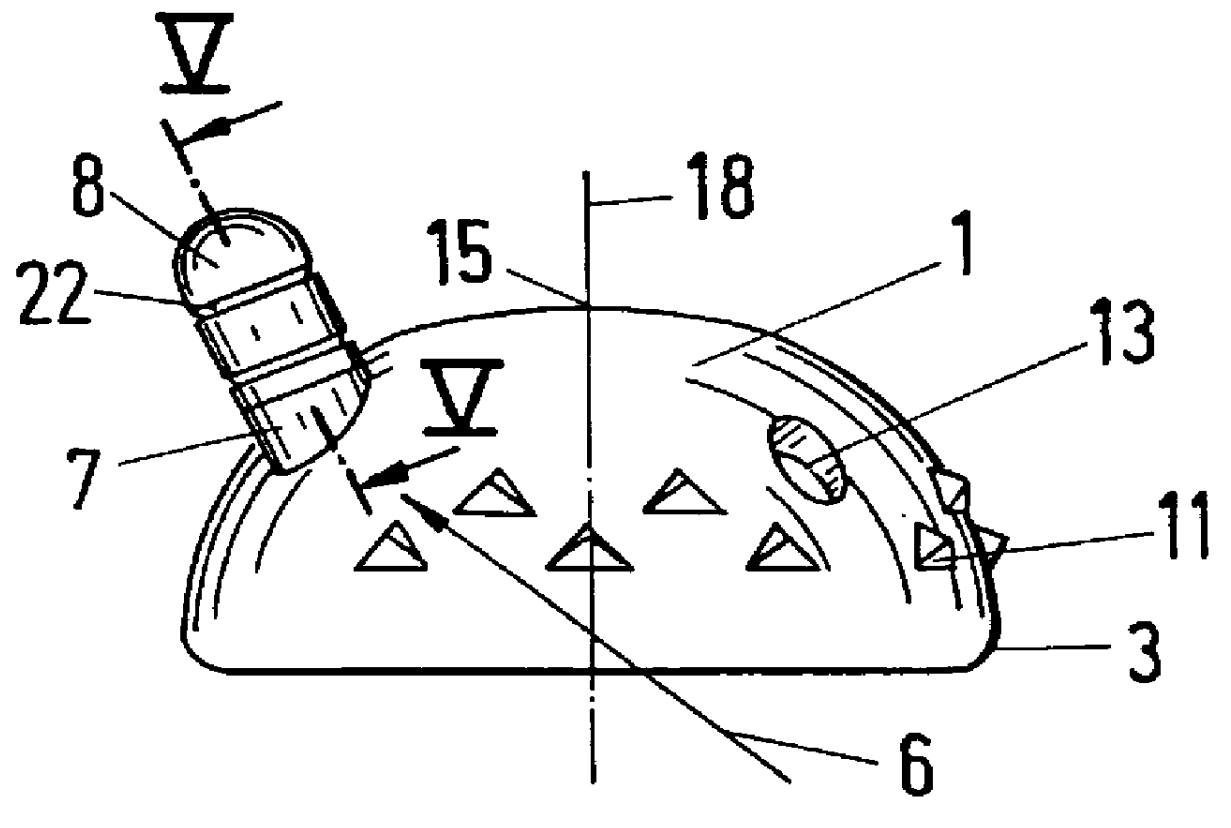

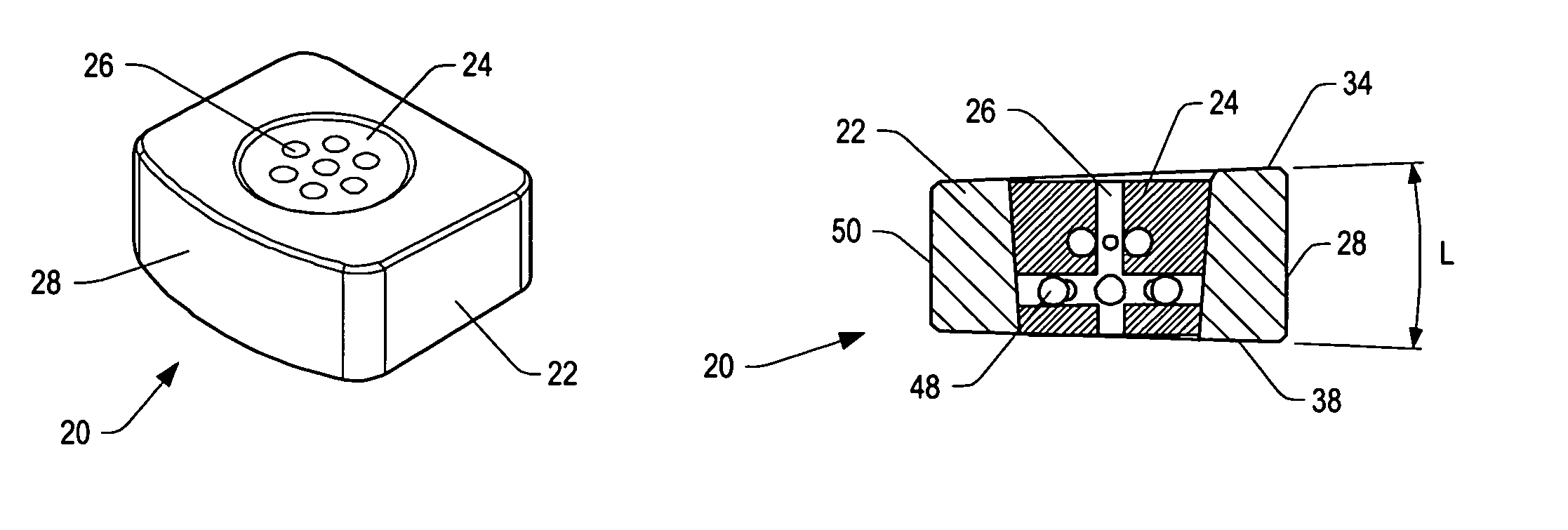

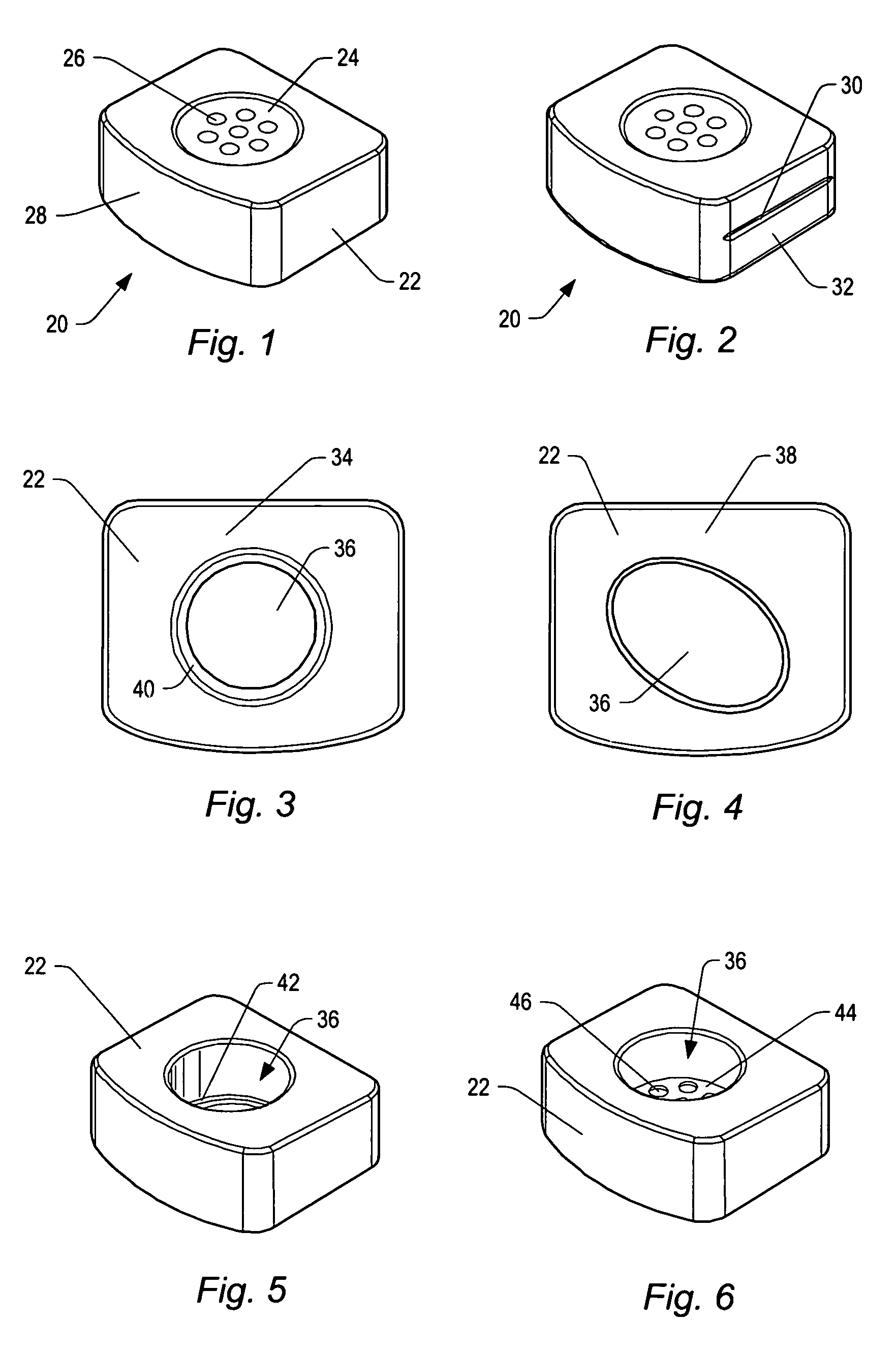

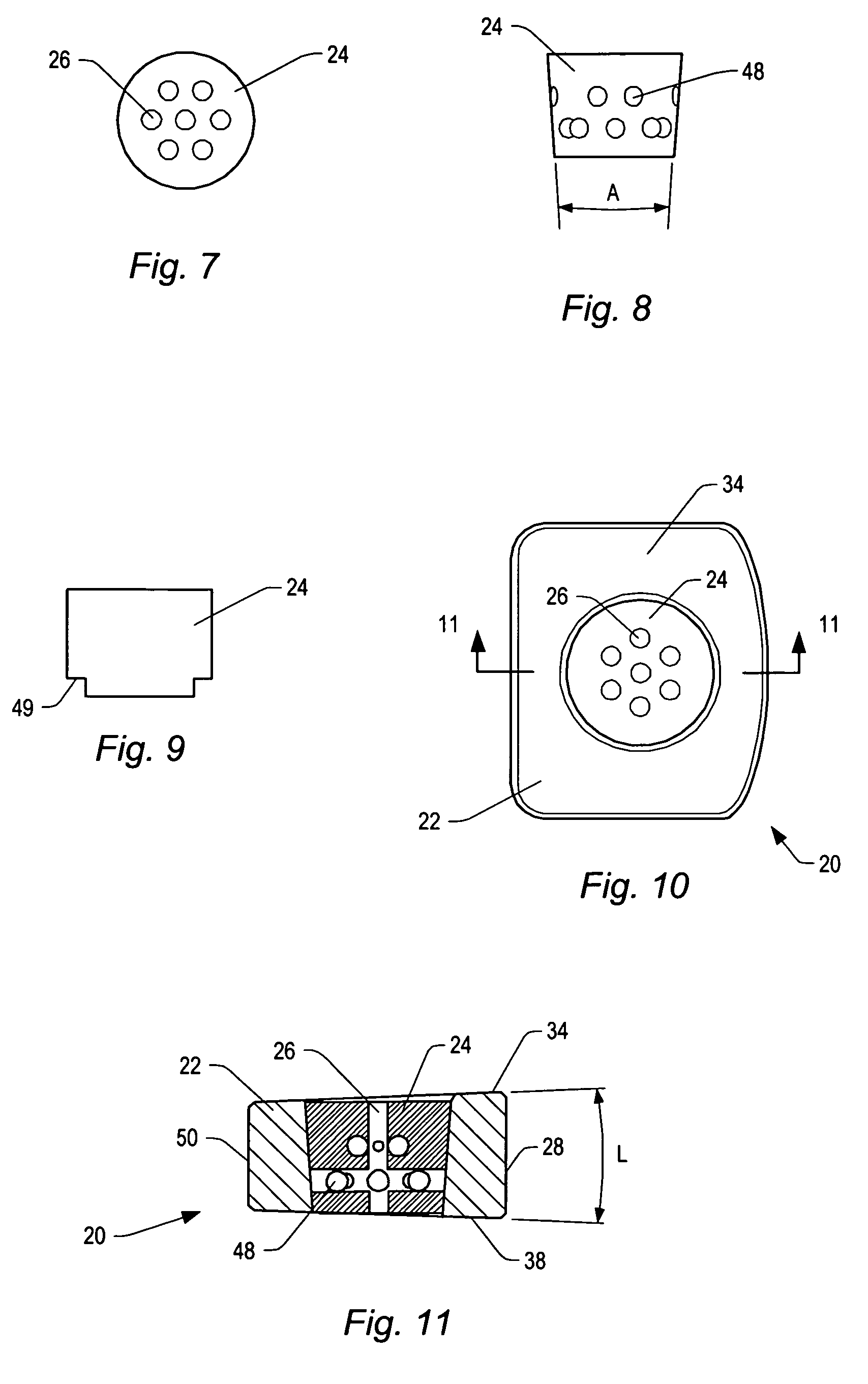

Prosthetic implant and surgical tool

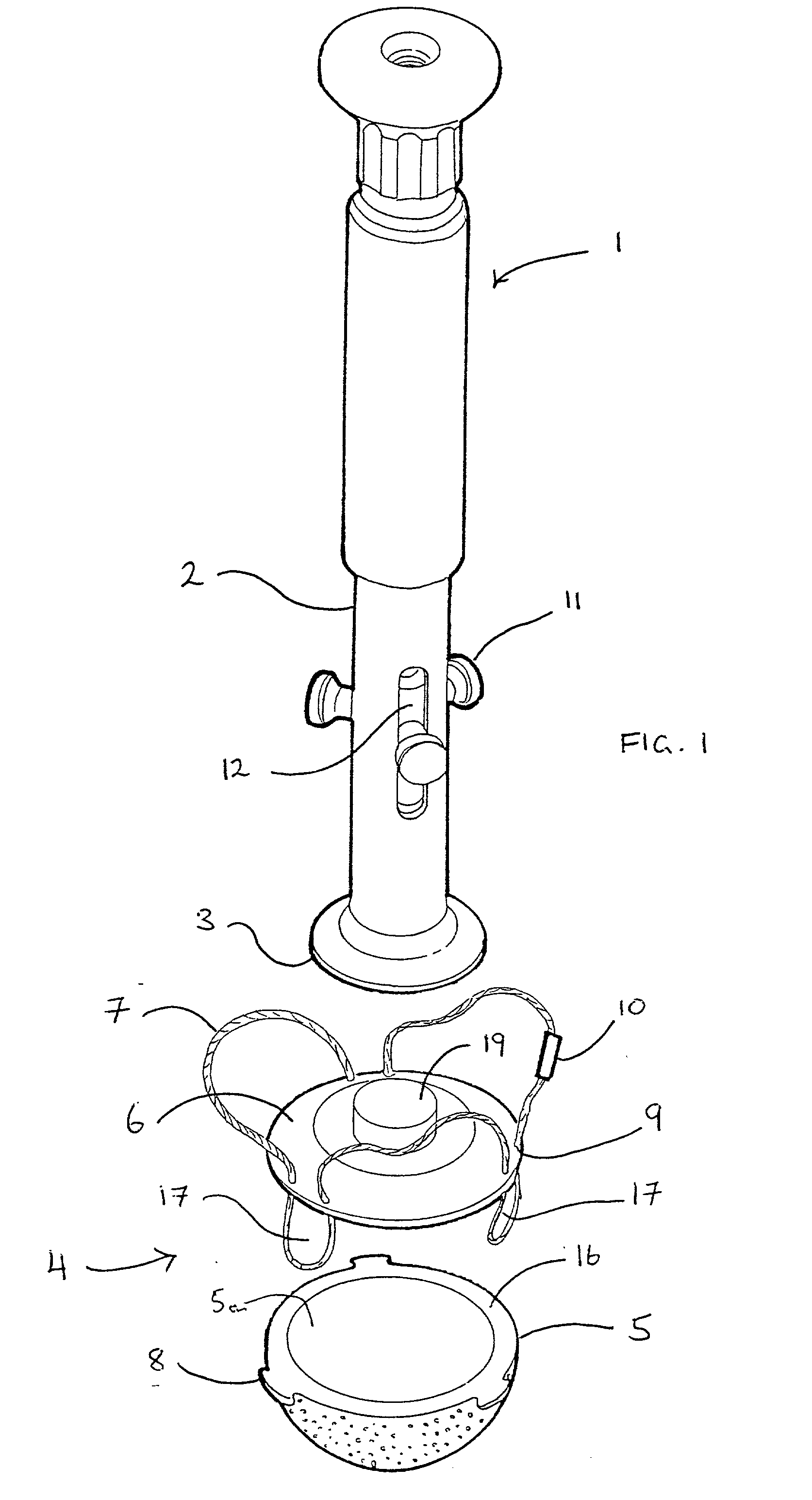

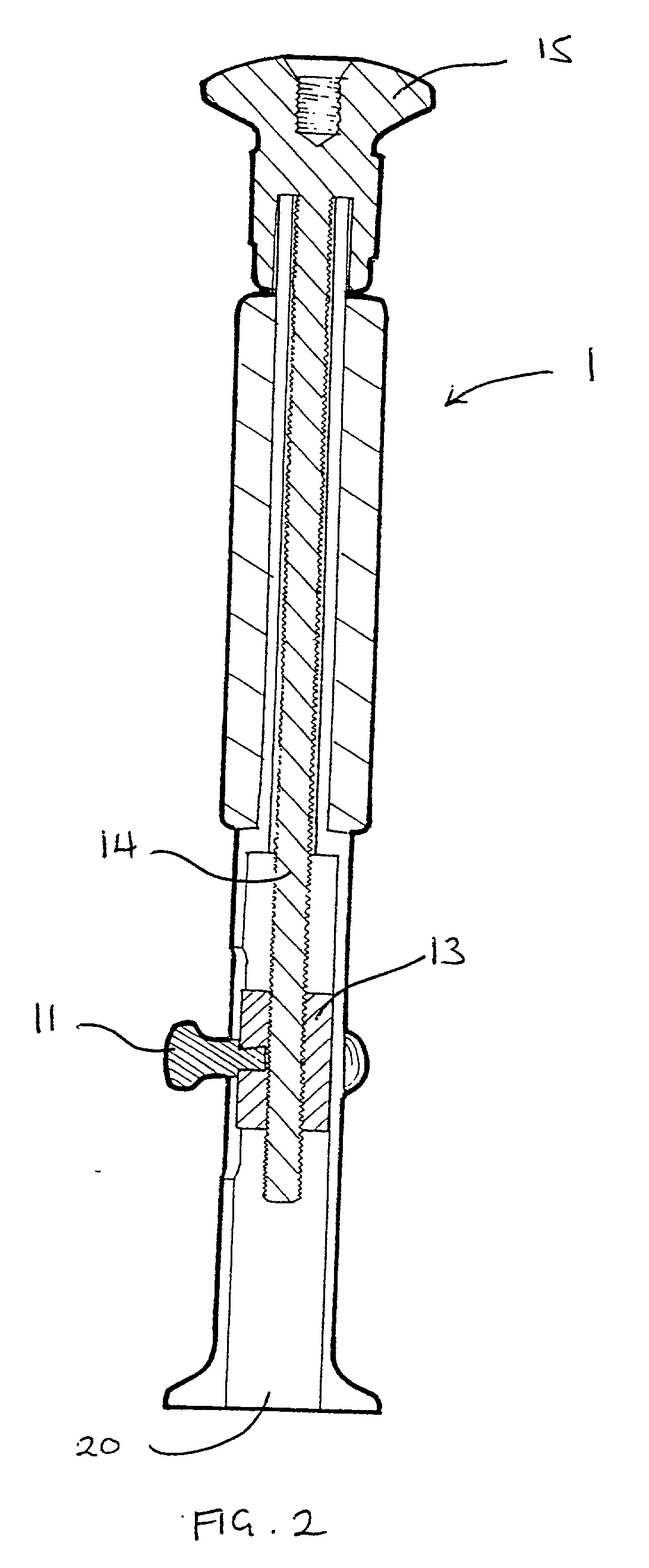

InactiveUS6746452B2Promote ingrowthCompromise integrityJoint implantsCoatingsProsthesisSurgical department

Owner:T J SMITH & NEPHEW

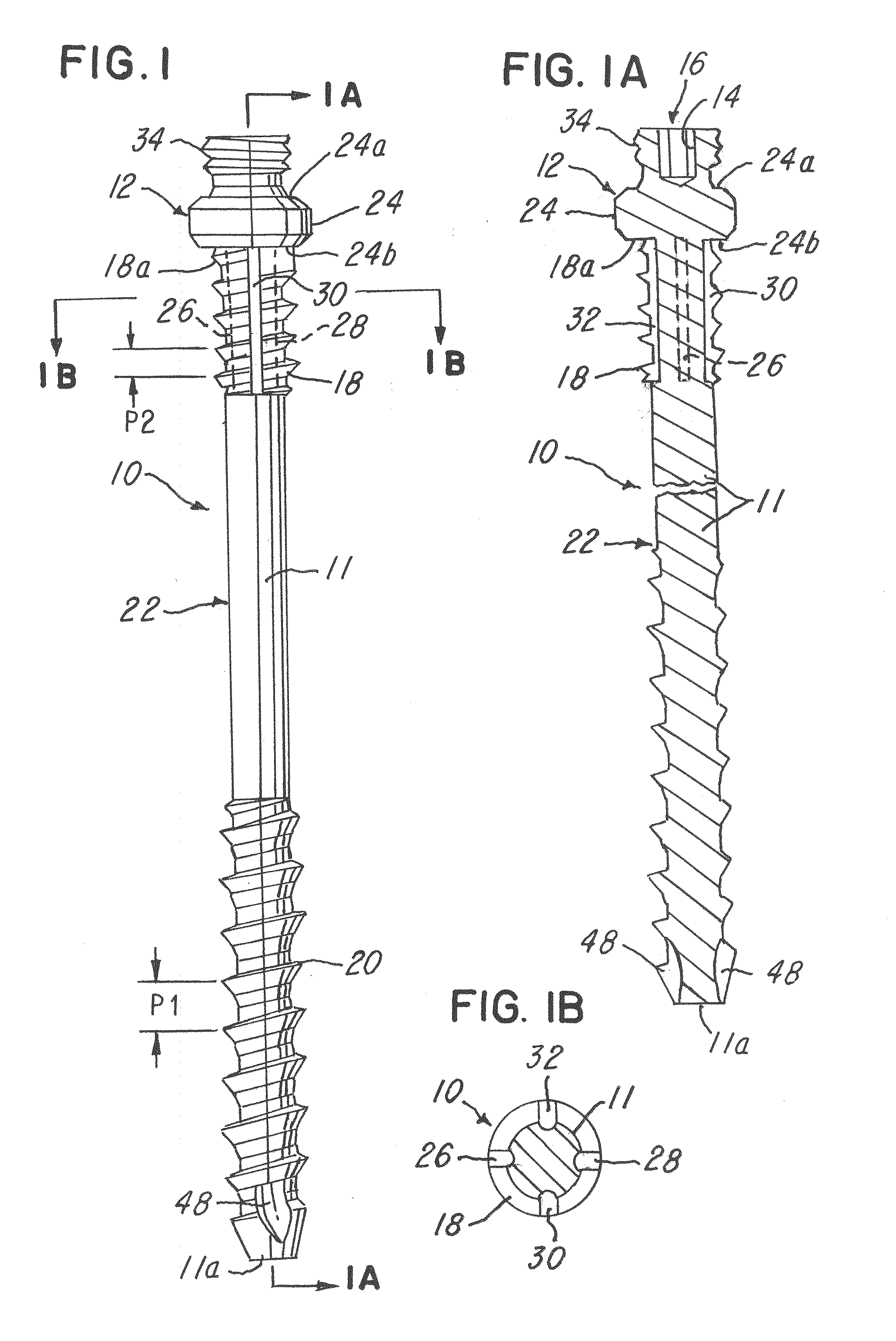

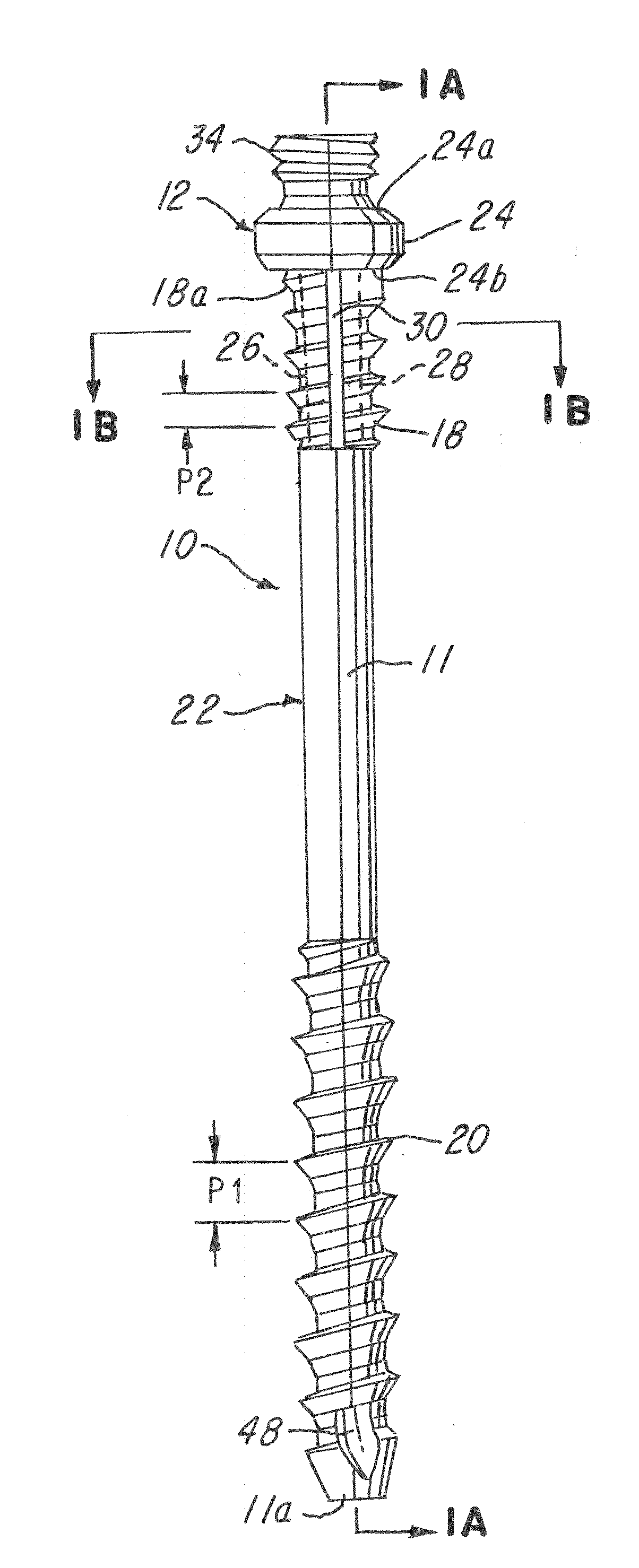

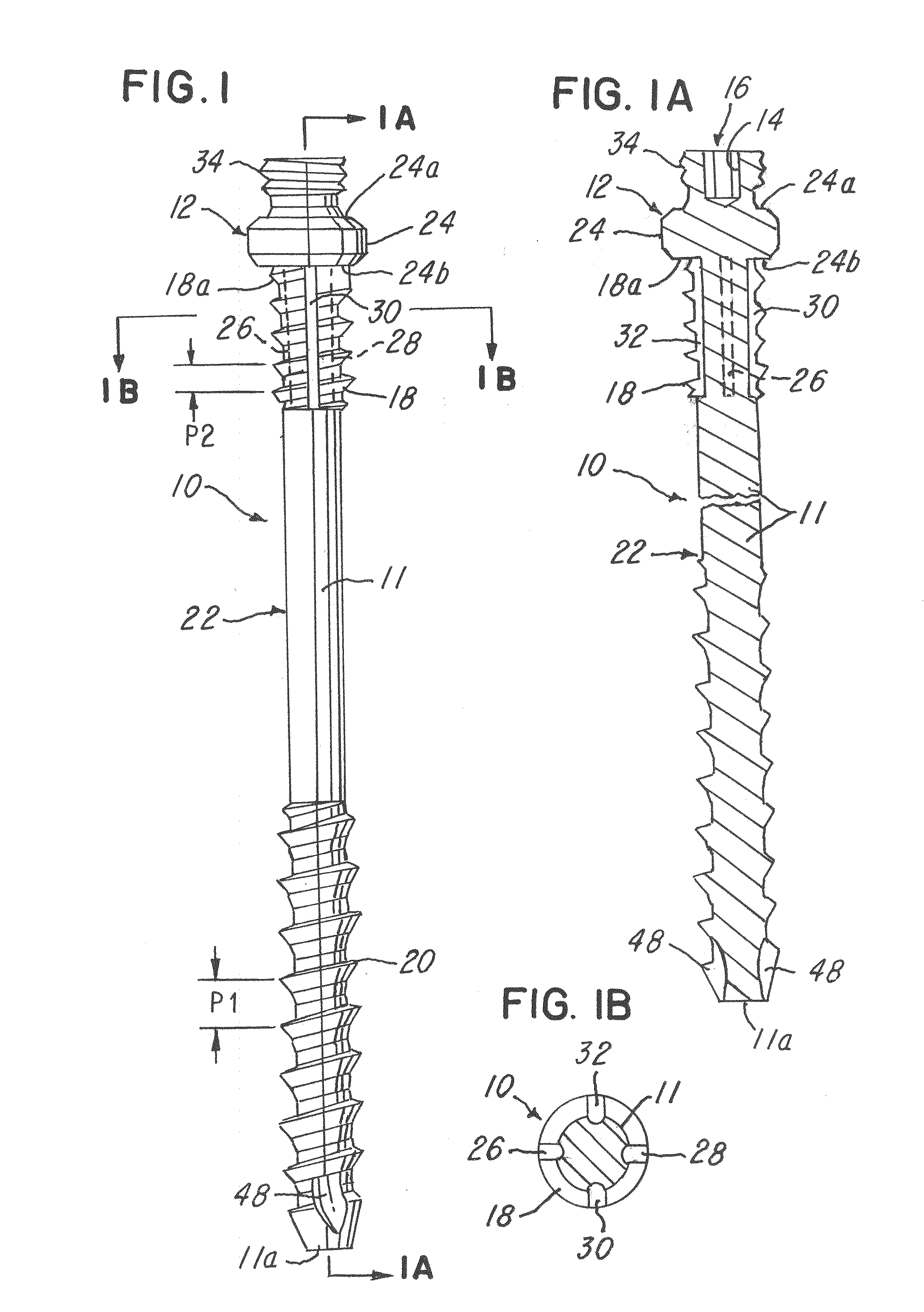

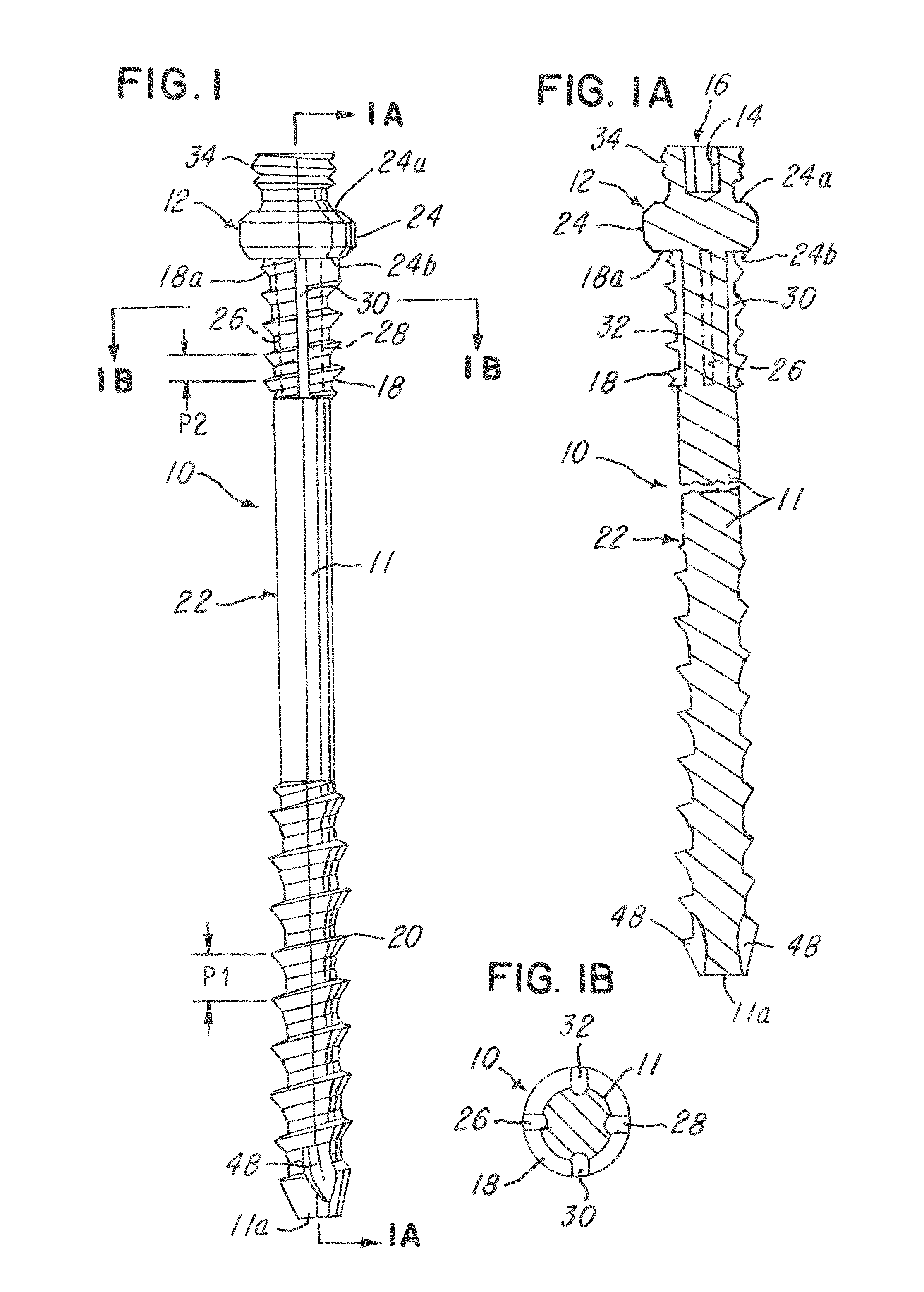

Spinal facet compression screw with variable pitch thread zones and buttress head

ActiveUS20120022603A1Prevent the screw from looseningPrevent disengagementSuture equipmentsInternal osteosythesisIliac screwScrew thread

A surgical implant comprising a screw element having a screw head, a first thread having a first thread pitch, a second thread having a second thread pitch and an intermediate portion coupling the first and second thread pitches with the first and second thread pitches being different. The implant has a buttressing head associated with the first thread, and it is dimensioned to be larger than a diameter of the first threads to provide external buttressing as the first and second threads compress a first bone and a second bone together.

Owner:X SPINE SYST

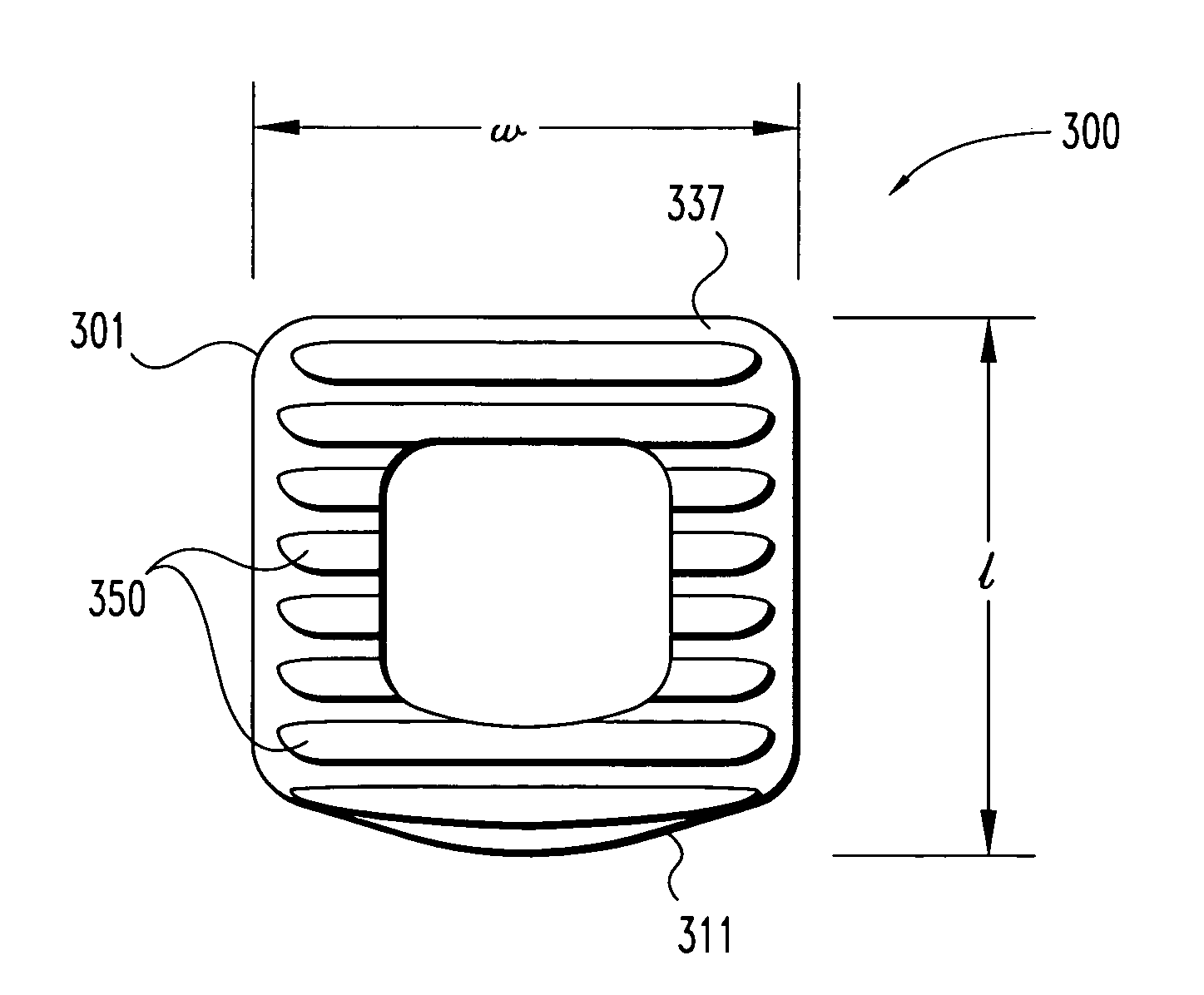

Bone grafts

InactiveUS7276081B1Avoids stress shieldPromote ingrowthInternal osteosythesisBone implantEnthesisBiomedical engineering

A spinal spacer 300 for engagement between vertebrae is provided which includes a body 301 formed of a bone composition. The body 301 includes a first end 311, an opposite second 315 end, a superior face 335 defining a superior vertebral engaging surface 337 and an inferior face 338 defining an inferior vertebral engaging surface 340. At least one of the vertebral engaging surfaces defines a set of migration resistance grooves 350. Each of the grooves 350 includes a first face 355 defining an angle of no more than about 90 degrees relative to the engaging surface 340 and a second opposing sloped face 360. The first and second faces 355, 360 define an arcuate pocket 370 therebetween for trapping vertebral bone to resist migration of the spacer 300. In one embodiment, the grooves 350 are arranged in series in that all of the second faces 360 slope in the same direction.

Owner:WARSAW ORTHOPEDIC INC

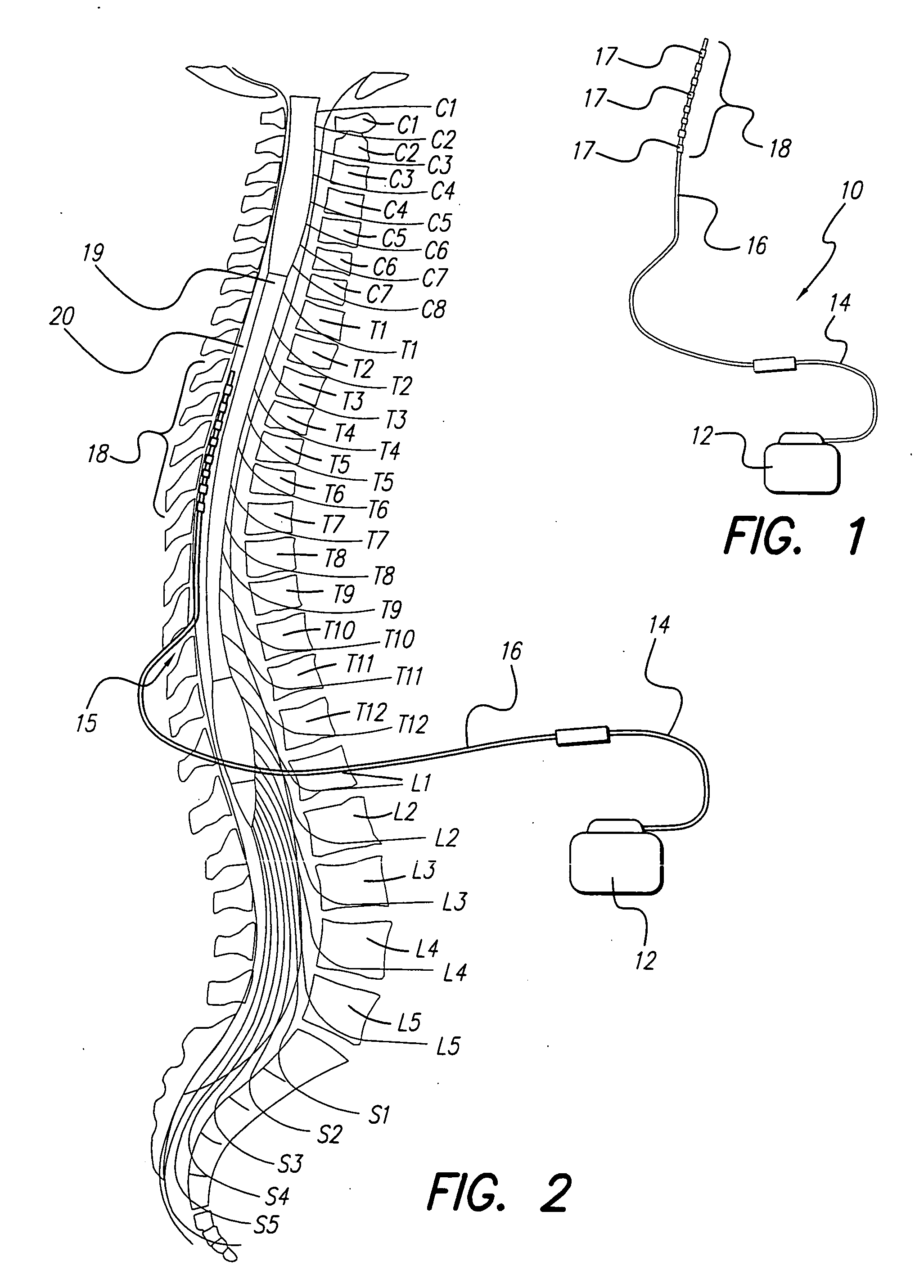

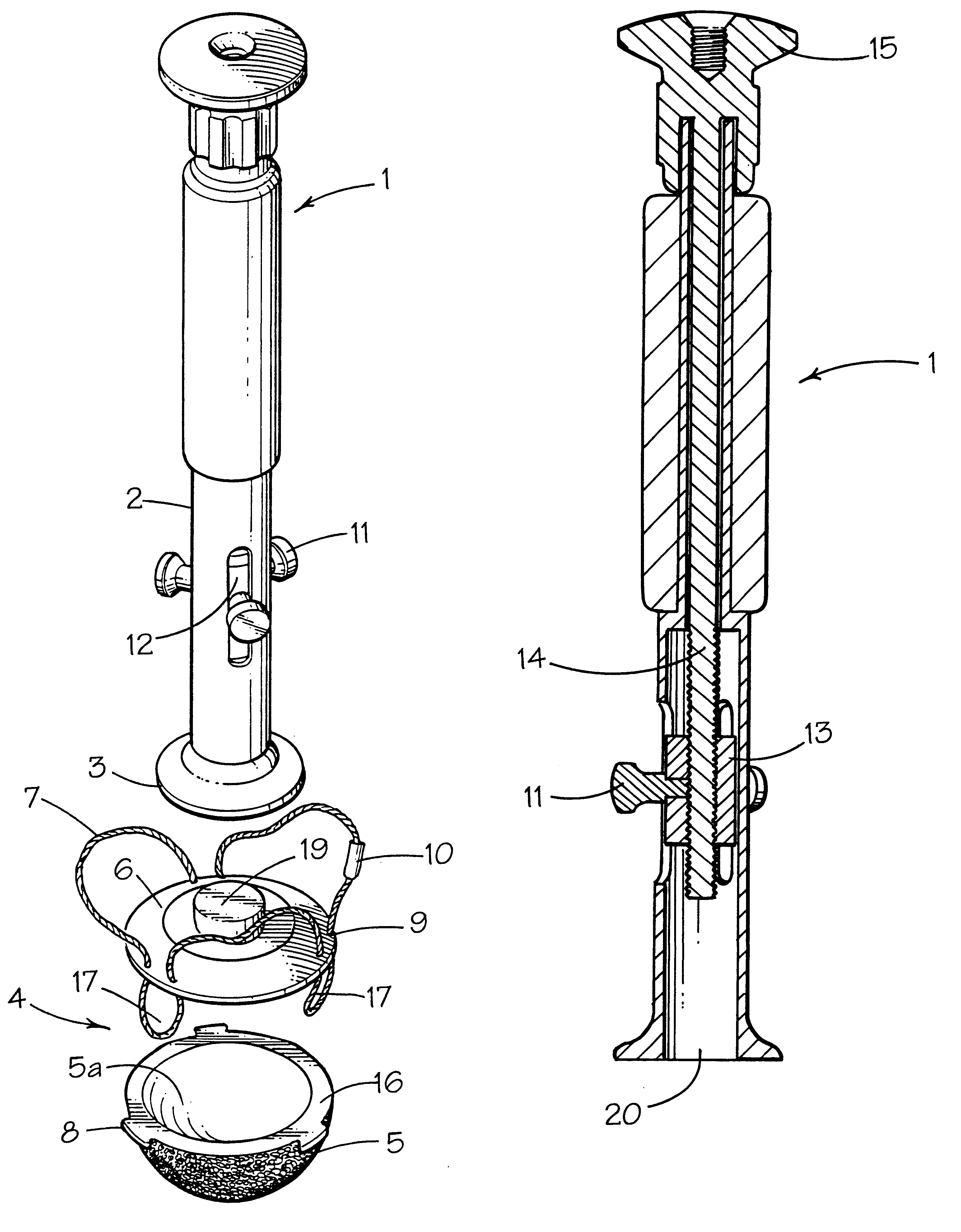

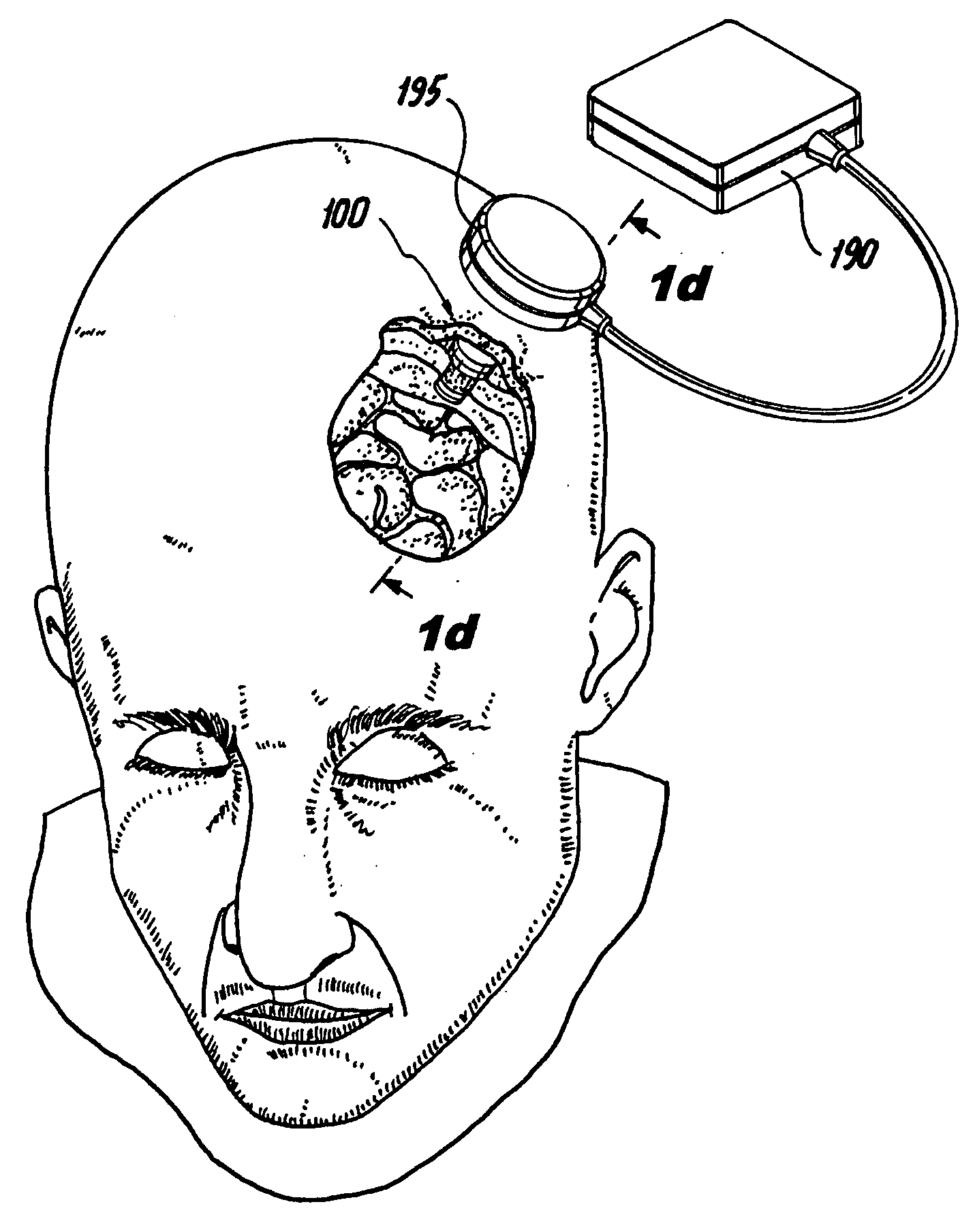

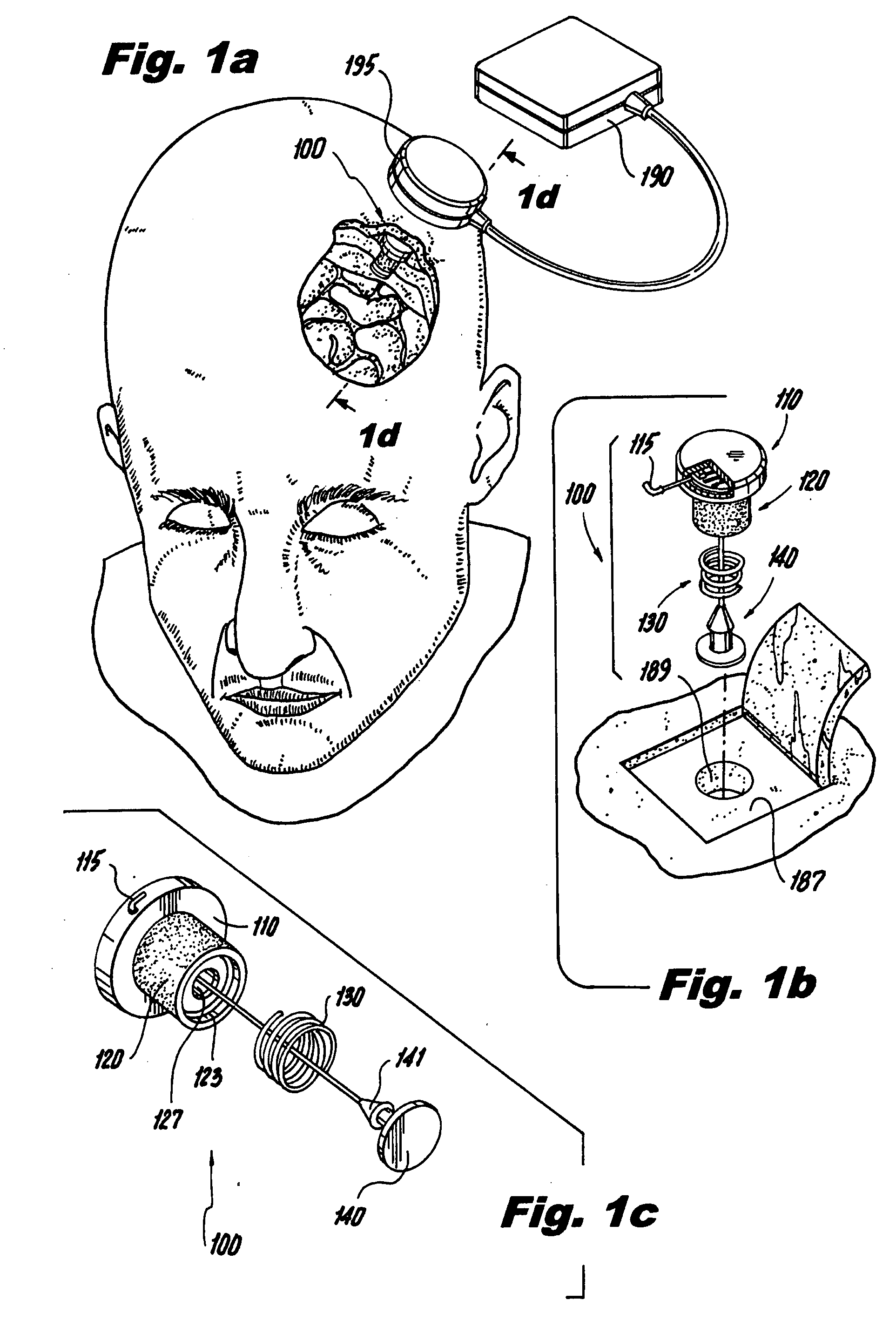

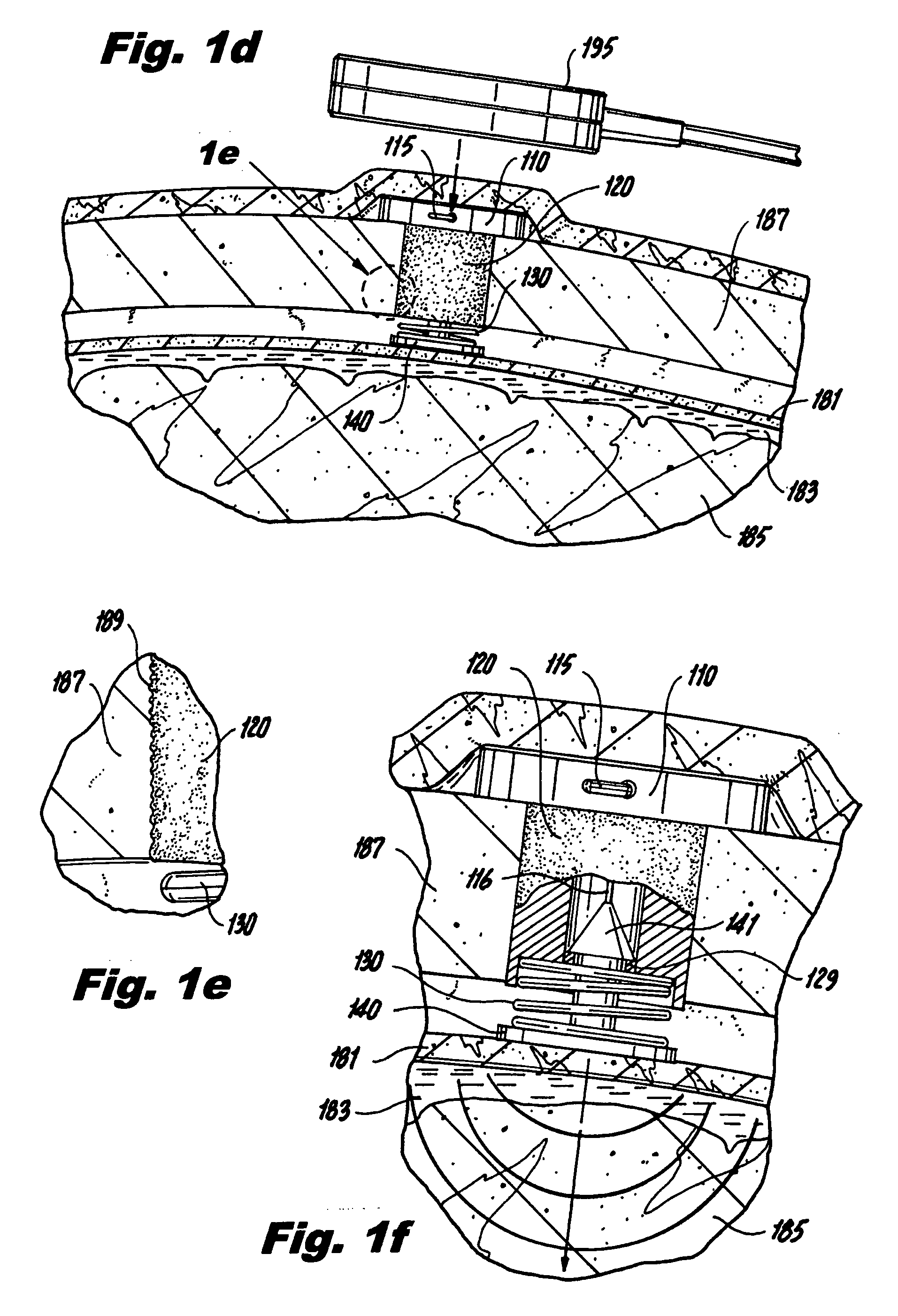

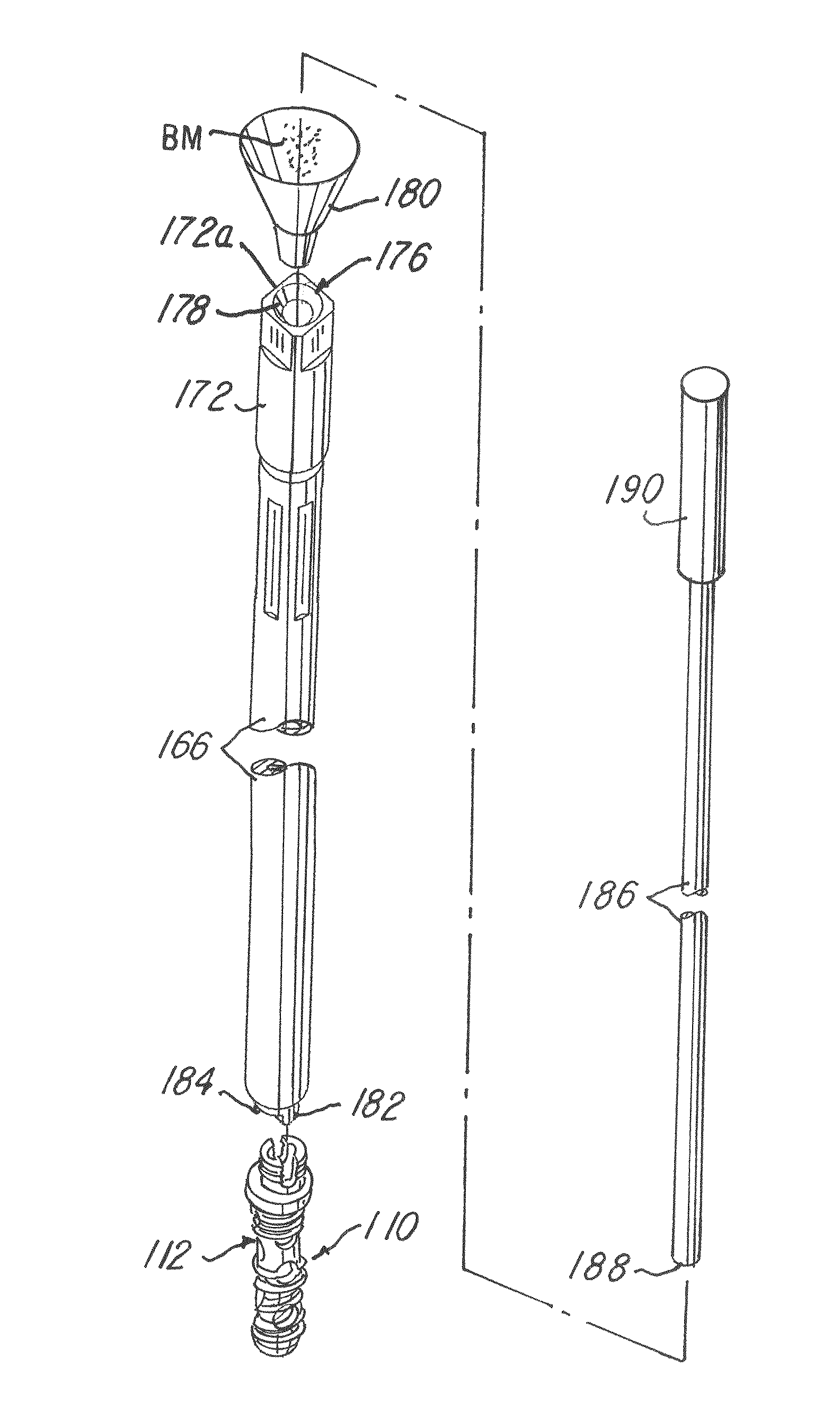

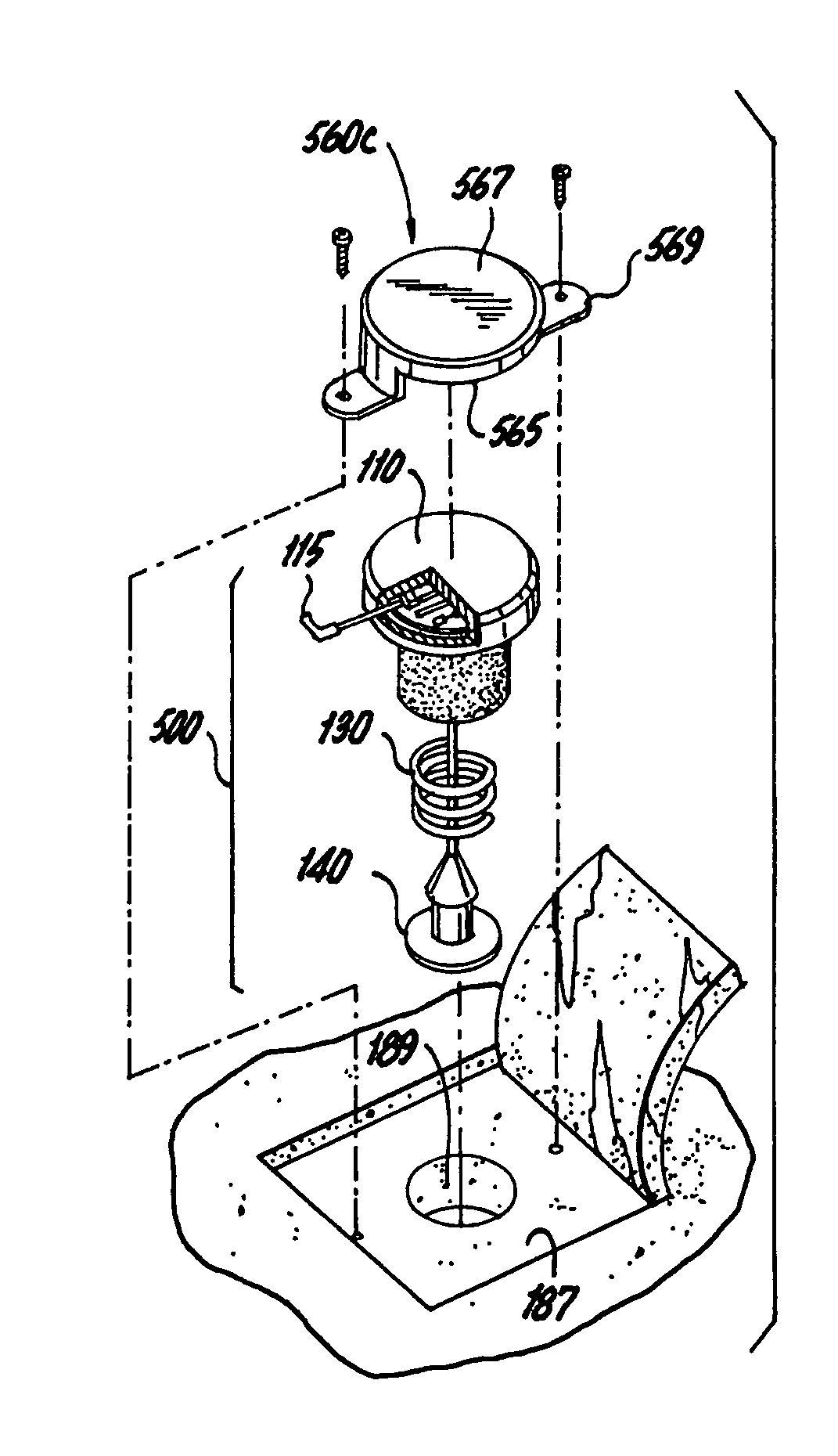

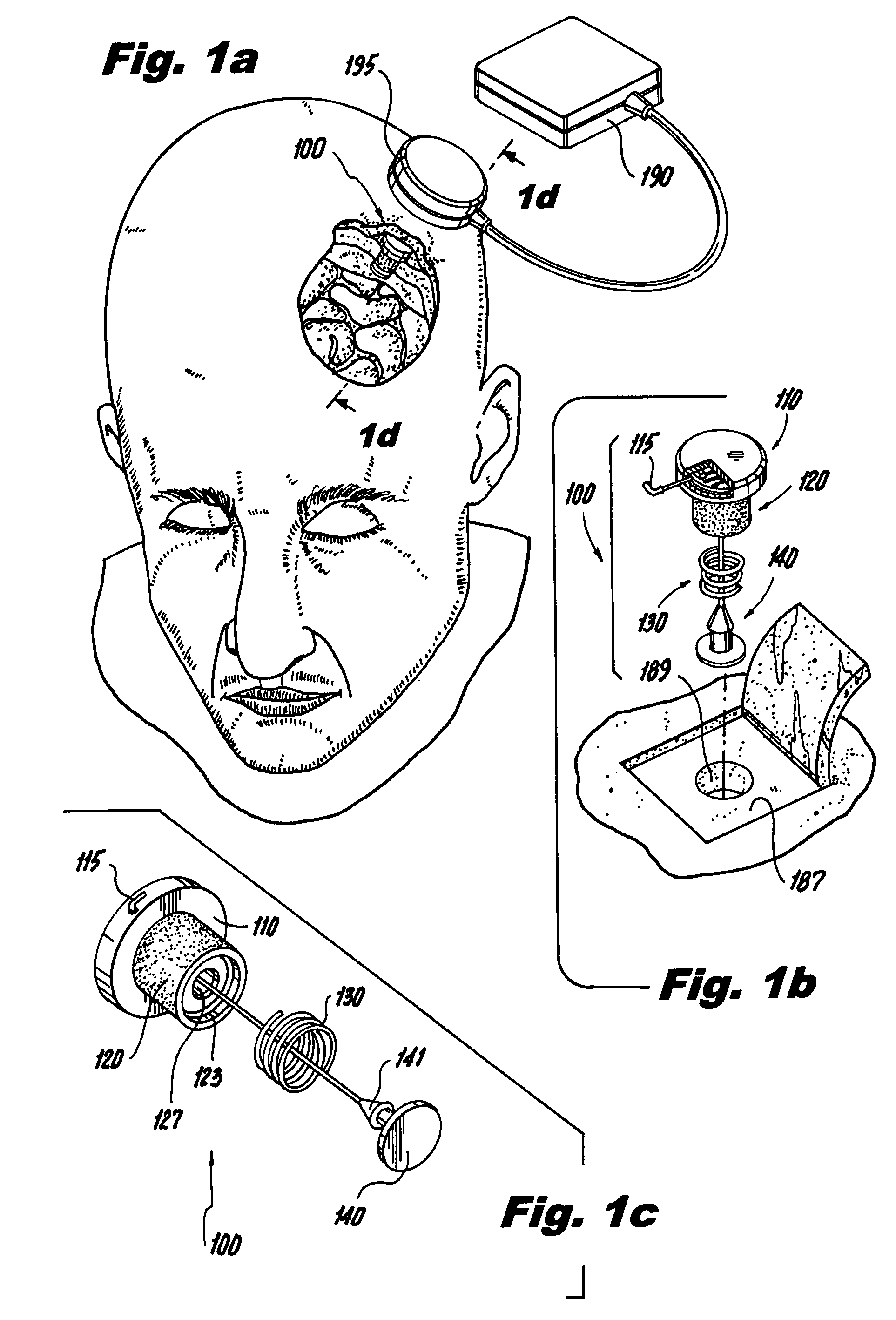

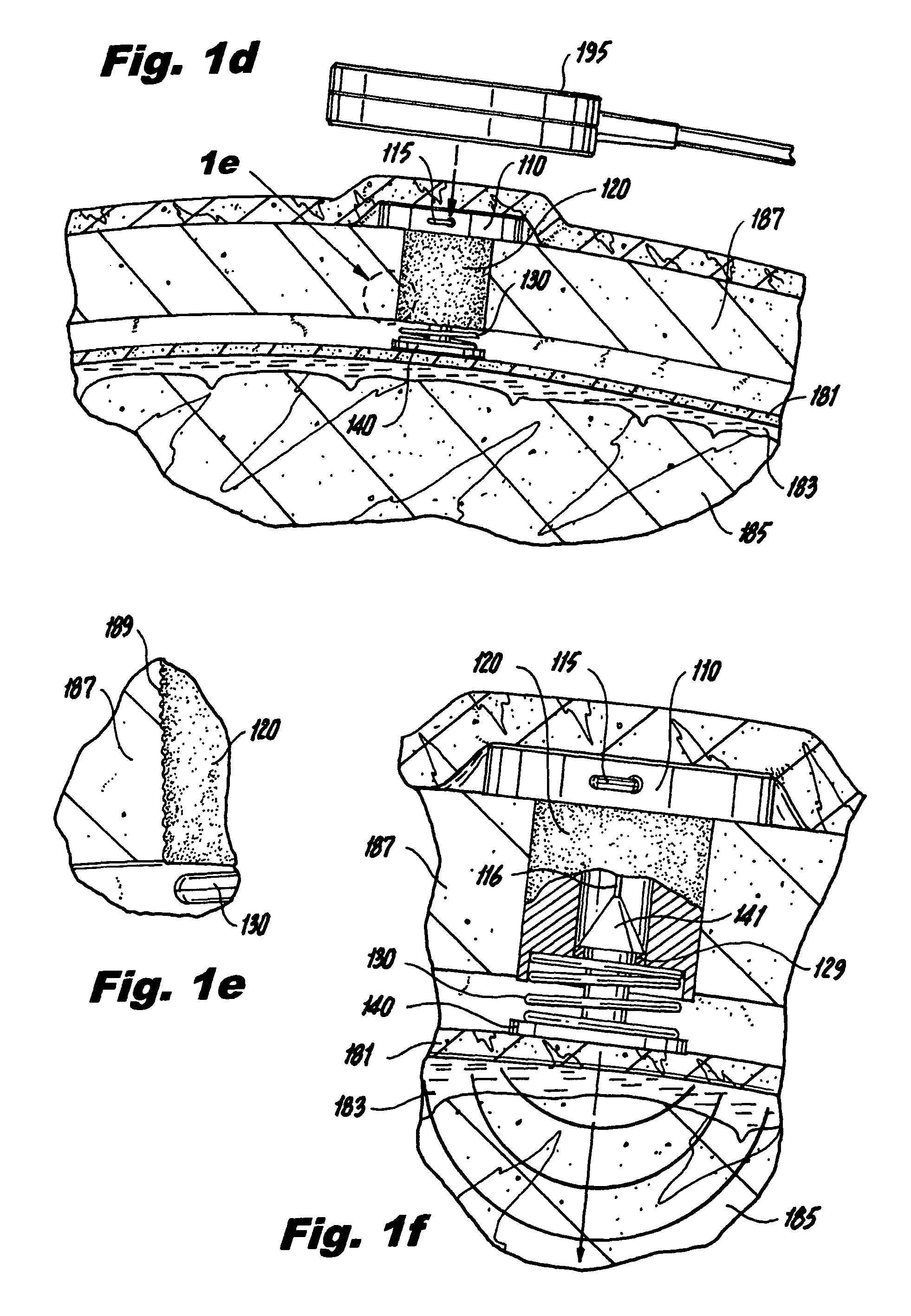

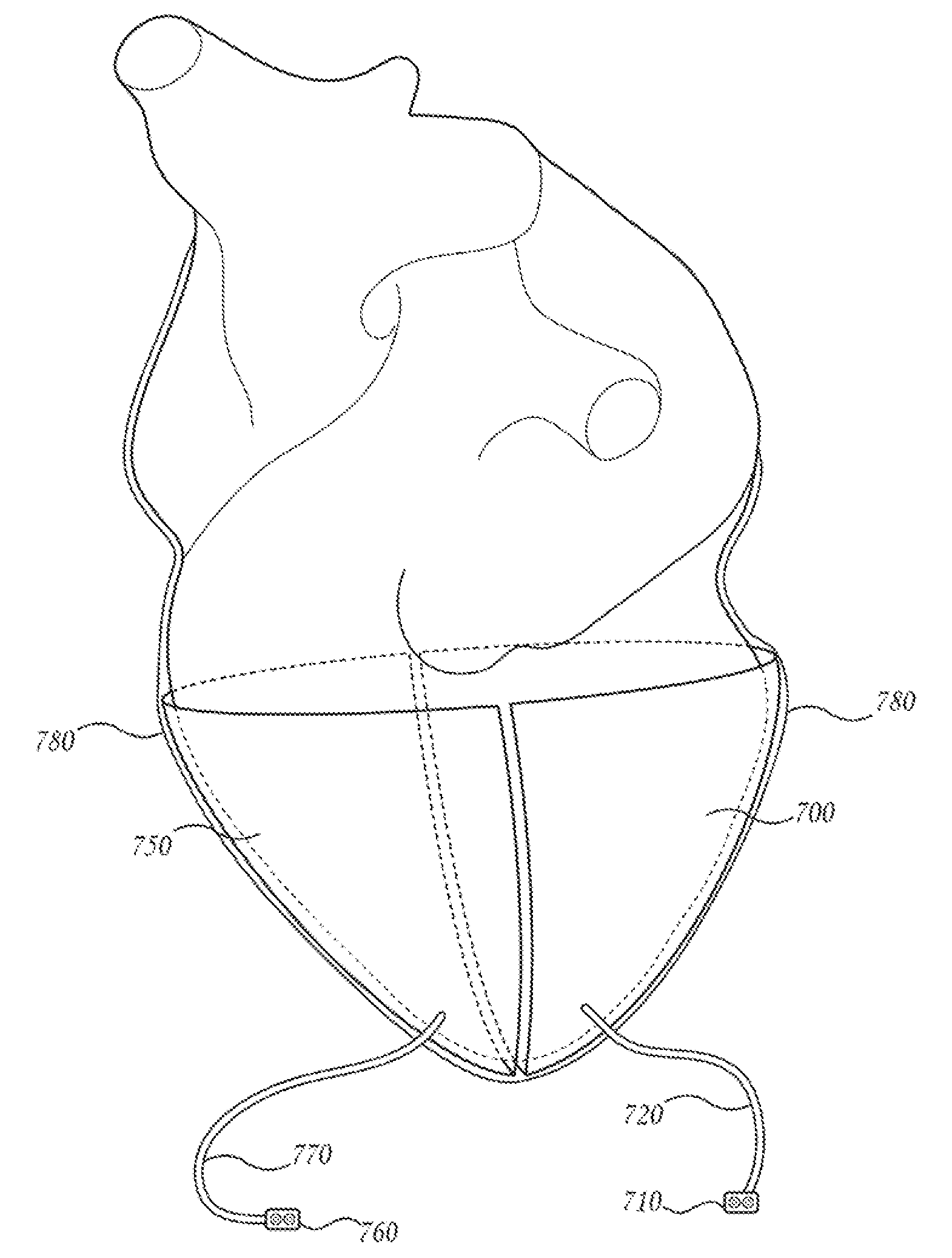

Implantable neurostimulation systems

ActiveUS20080004676A1Reduce excitabilityHigh-frequency ACHead electrodesExternal electrodesInjury brainMotor evoked potentials monitoring

The subject invention is directed to new and useful neurostimulation systems that include an implantable pulse generator dimensioned and configured for implantation in the skull of a patient. The implantable pulse generator has an electrode operatively associated with a distal end portion thereof and can be provided with adjustment means, such as an adjustable biasing member or spring arranged between the electrode to the distal end portion of the pulse generator. The subject invention is also directed to systems involving networked neurostimulators that are configured and adapted to work jointly in accordance with prescribed treatment protocol to effect a desired recovery from brain injury. Such networked neurostimulation systems are particularly advantageous for effecting relatively large and / or relatively distant regions of the brain. The subject invention is further directed to systems and methods for motor-evoked potential (MEP)-based neuromodulation. Further, AC and / or DC stimulation can be utilized, depending on the precise implementation.

Owner:NEUROPOINT MEDICAL

Minimally invasive spinal facet compression screw and system for bone joint fusion and fixation

ActiveUS8945193B2Prevent the screw from looseningPrevent disengagementSuture equipmentsInternal osteosythesisSpinal columnBones joints

A system comprising a screw element having a generally cylindrical body having a bore or lumen therethrough and a plurality of fenestrations or windows through which biological material may be provided. The system comprises a tool for inserting the biological material into the screw element so that the biological material may extrude through the plurality of fenestrations or windows and through an aperture in the tip of the screw element thereby enabling providing a fusion mass across two adjacent facet bones or a facet joint wherein the screw itself provides both a fixation component and a screw component.

Owner:X SPINE SYST

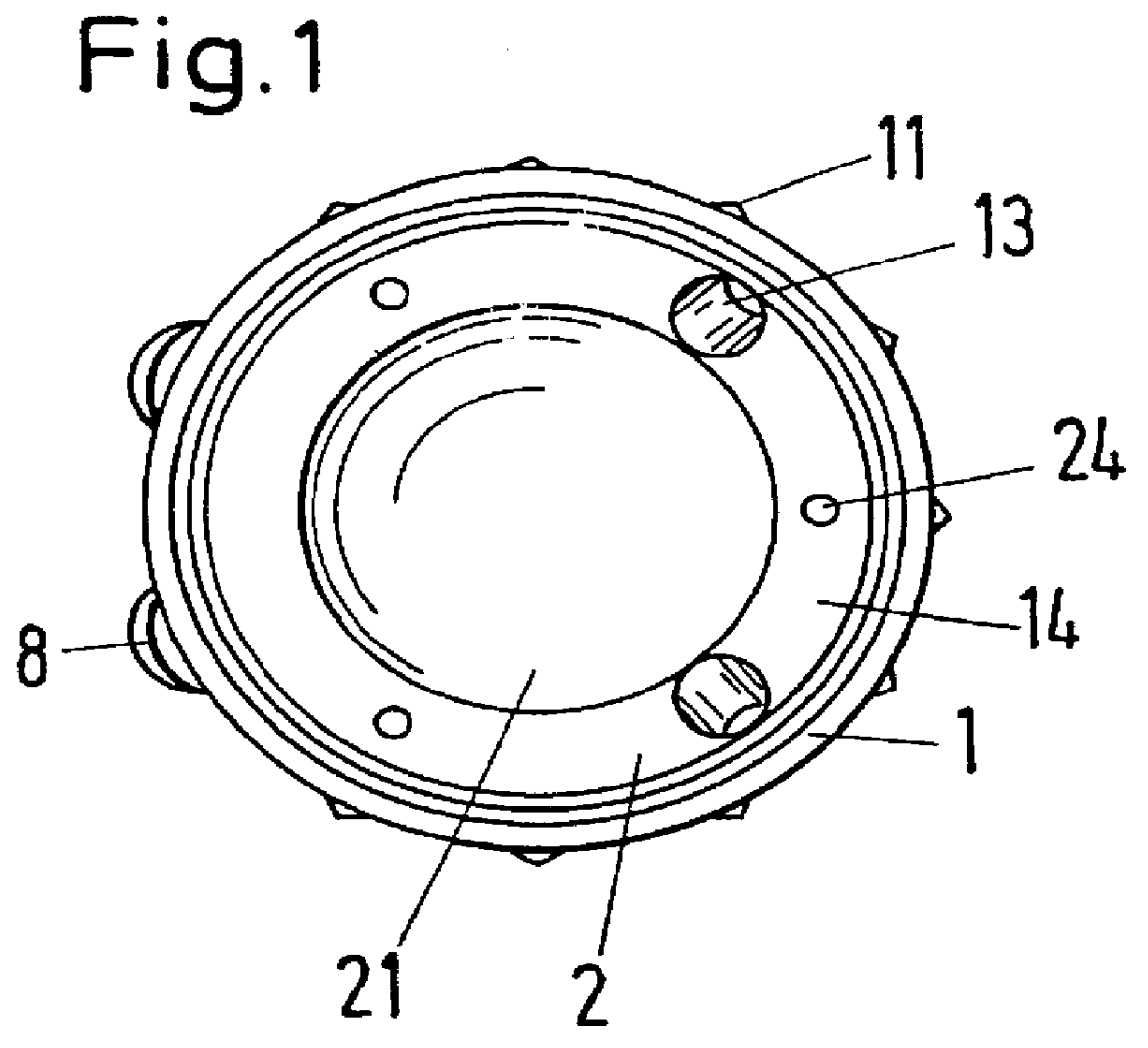

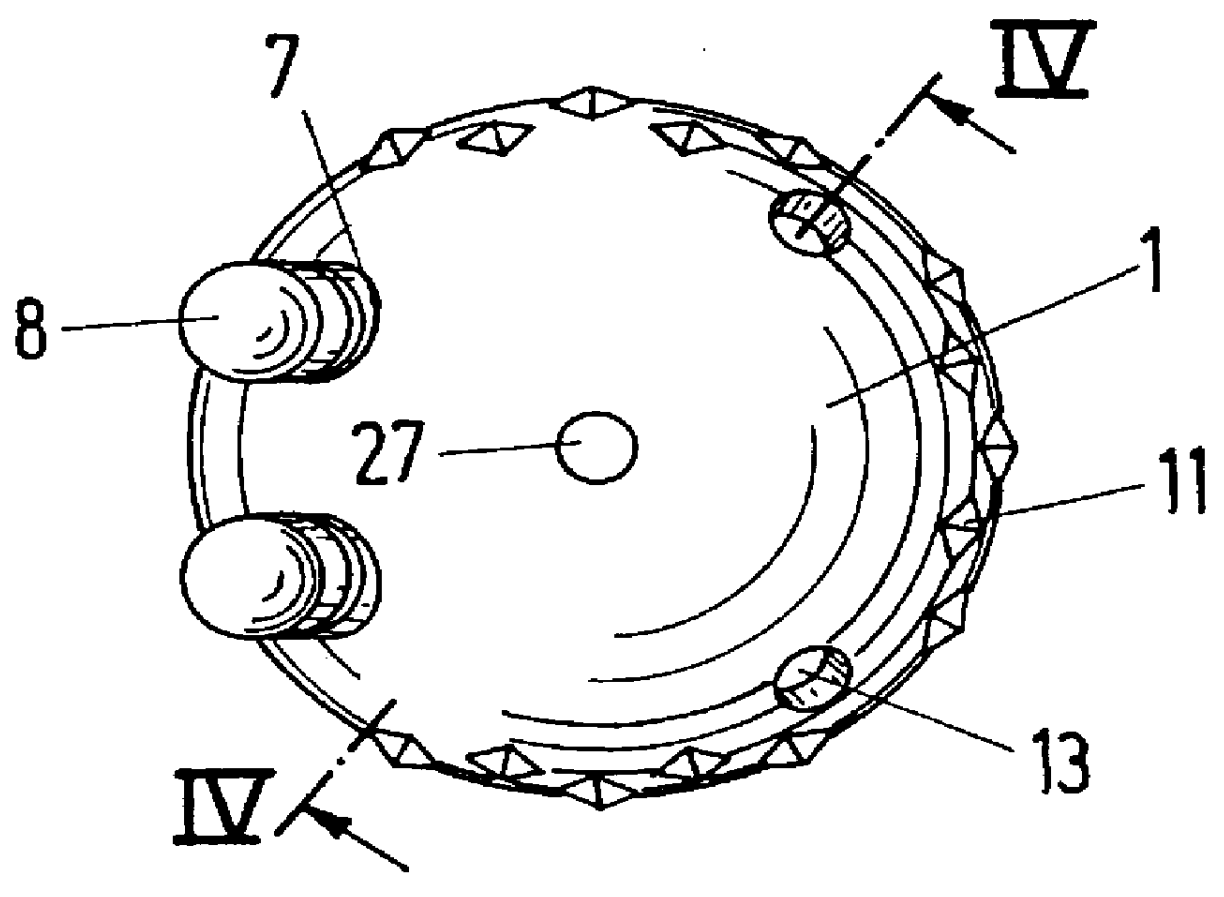

Twin-shelled artificial hip joint and its manufacture

InactiveUS6045583AHigh degree of polymerizationReduce wear rateJoint implantsCoatingsArtificial hip jointsCoxal joint

The invention shows a hip joint socket and its manufacture, with the hip joint socket including a thin walled metallic outer shell with anchoring pins which is firmly connected to an inner shell of plastic. Since the bearing surface of the inner shell is not produced until after the assembly, a high accuracy of shape of the bearing surface results together with a relatively elastic outer shell and with good anchoring aids for a primary anchoring.

Owner:SULZER ORTHOPAEDIC

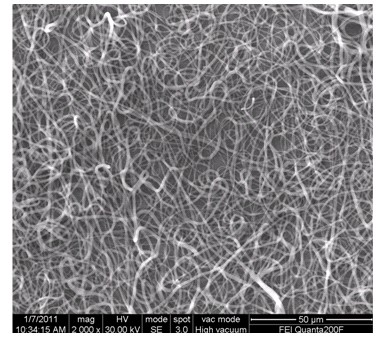

Preparation method and application of polycaprolactone/natural polymer composite porous scaffold

InactiveCN102277737AImprove hydrophilicityEasy to spreadLayered productsFibre typesFiberPolymer science

Preparation method and application of polycaprolactone / natural polymer composite porous scaffold, method: including preparation of polycaprolactone electrospun nanofiber membrane; (1) placing polycaprolactone electrospun nanofiber membrane in alkaline solution reaction, soaking and rinsing in deionized water; (2) putting the fiber membrane obtained in (1) into DMTMM or natural polymer solution of DTMMM to react, immersing and rinsing in deionized water, and then immersing in natural polymer for room temperature reaction, to remove Ionized water soaking and rinsing; (3) Evenly coating and casting the mixed solution of natural polymer materials on the fiber membrane obtained in (2), freeze-drying, and extracting the solvent; (4) Applying the double-layer scaffold obtained in (3) After soaking in the cross-linking room temperature reaction, soaking in deionized water, rinsing, and freeze-drying. The porous scaffold prepared by the invention is stable, has suitable pore diameter, good biocompatibility and fast degradation rate, and can be used for skin and clinical tissue and organ defect repair, reconstruction or wound dressing.

Owner:NANCHANG UNIV

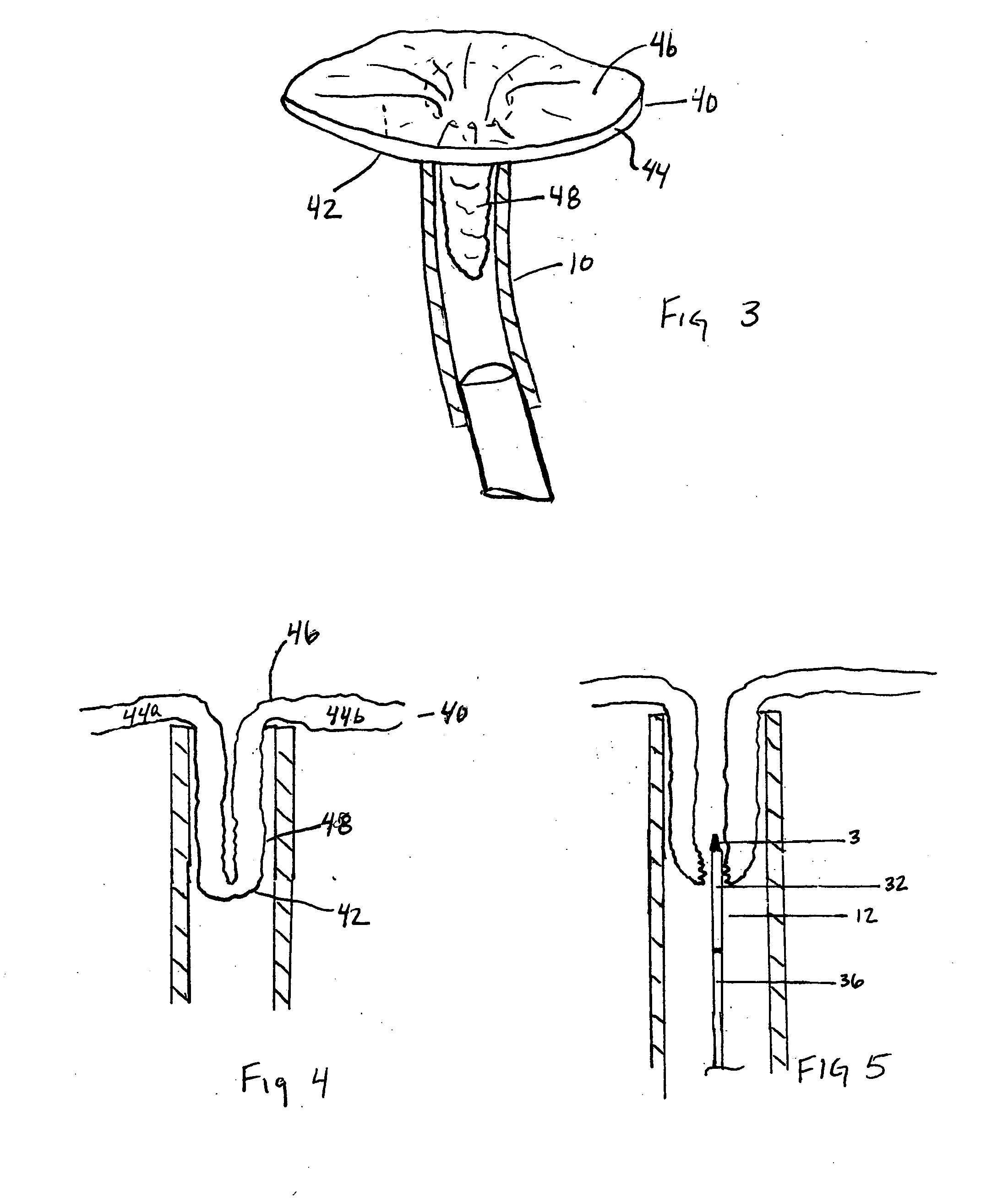

Methods and apparatus for securing an anchor to soft tissue

InactiveUS20070021760A1Improve the immunityPromote ingrowthSuture equipmentsSurgical pincettesAnchor pointBiomedical engineering

The preferred methods and devices described herein create more secure anchors in one or more segments of soft tissue that can be used as anchor points for other procedures. The device draws tissue into a fold, cuts an opening through the tissue fold and inserts an element alongside the outer walls of the tissue. In one aspect the element includes an anchor coupled to the element. The device then fastens the tissue walls and element together so that the element is sandwiched between the outer walls of the tissue and the anchor resides along the inner walls of the tissue.

Owner:KELLEHER BRIAN

Implantable neurostimulation systems

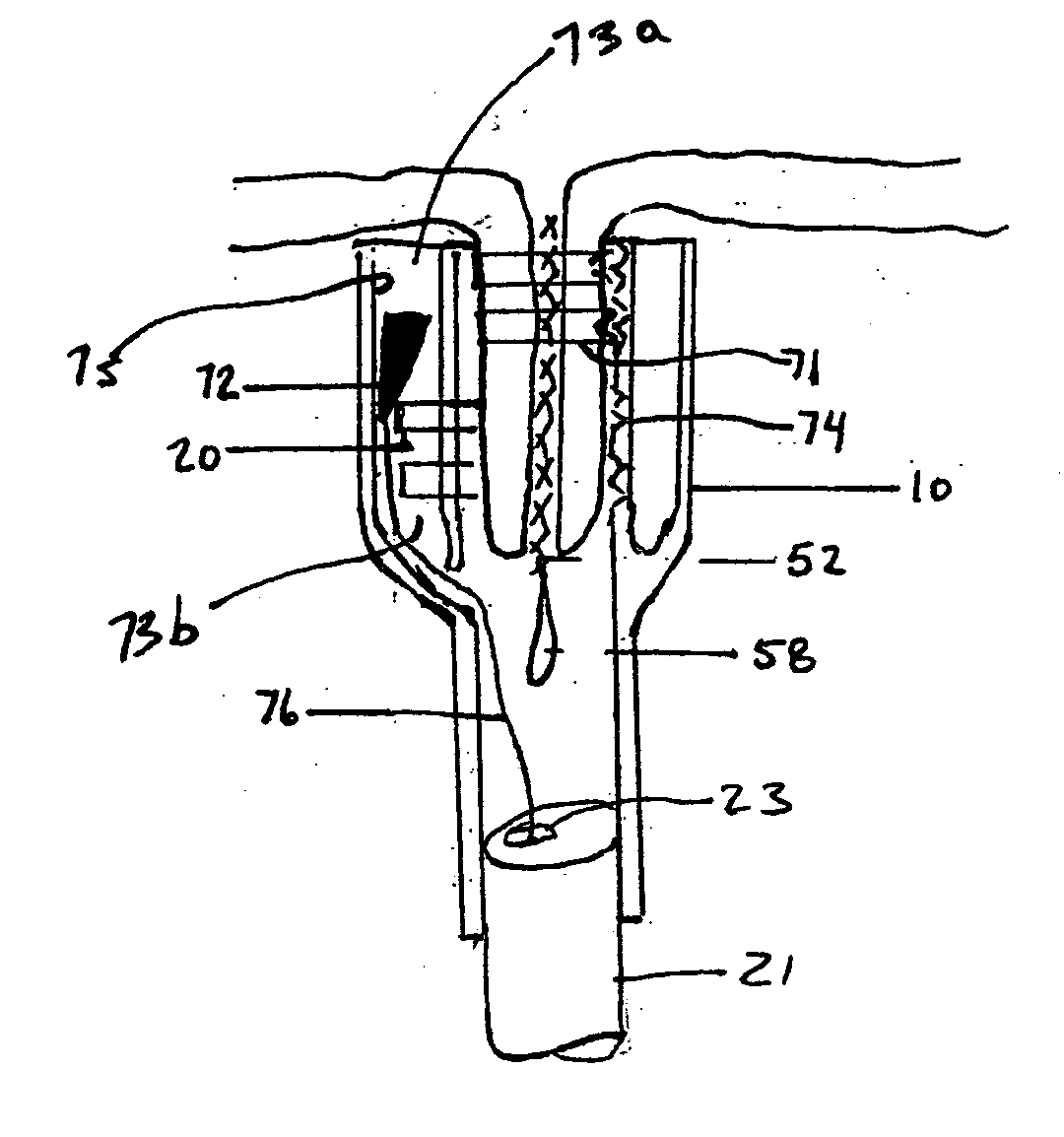

ActiveUS8116875B2Promote ingrowthPrevent unintentional relative translationHead electrodesExternal electrodesMotor evoked potentials monitoringBiomedical engineering

New and useful neurostimulation systems are provided that include an implantable pulse generator dimensioned and configured for implantation in the skull of a patient. The implantable pulse generator has an electrode operatively associated with a distal end portion thereof and can be provided with adjustment means, such as an adjustable biasing member or spring arranged between the electrode to the distal end portion of the pulse generator. Also provided are systems involving networked neurostimulators that are configured and adapted to work jointly in accordance with prescribed treatment protocol to effect a desired recovery from brain injury. Such networked neurostimulation systems are particularly advantageous for effecting relatively large and / or relatively distant regions of the brain. Additionally, systems and methods for motor-evoked potential (MEP)-based neuromodulation are provided. Further, AC and / or DC stimulation can be utilized, depending on the precise implementation.

Owner:NEUROPOINT MEDICAL

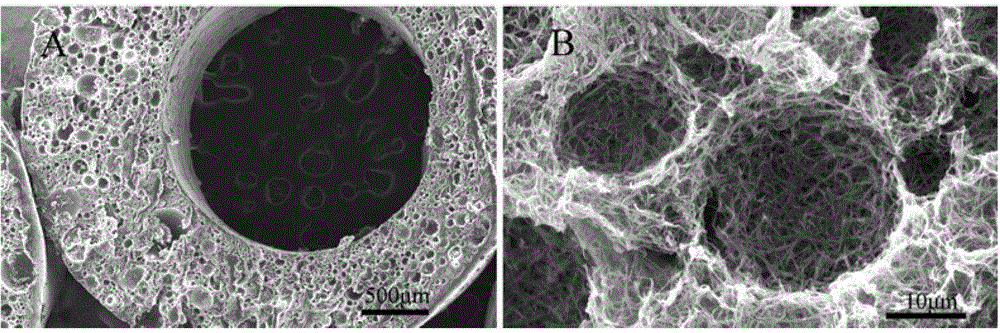

Bone repair porous bracket and rapid forming method

The invention relates to a bone repair porous bracket, which comprises a substrate with a bionic porous structure and growth factor controlled-release microspheres, wherein the growth factor controlled-release microspheres are adsorbed into gaps of the bionic porous structure on the substrate or are dispersed into the substrate by being uniformly mixed with substrate raw material in a substrate forming process. The invention further provides a rapid forming method for the bone repair porous bracket. The method comprises the following steps of: preparing growth factor controlled-release microspheres; forming a substrate; and adsorbing. The invention further provides another rapid forming method for the bone repairing porous bracket. The method comprises a step for preparing growth factor controlled-release microspheres and a step for forming a substrate. The growth factor controlled-release microspheres are introduced into the bracket, bone growth can be induced under the action of the controlled release of growth factors, and inward bone tissue growth is facilitated through a porous structure formed by degradation of the controlled-release microspheres, so that bone tissue regeneration repair is achieved, and bone healing is facilitated effectively. Three-dimensional printing is performed by adding controlled-release microspheres and adopting a rapid forming technology, and a forming process is simple and rapid.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

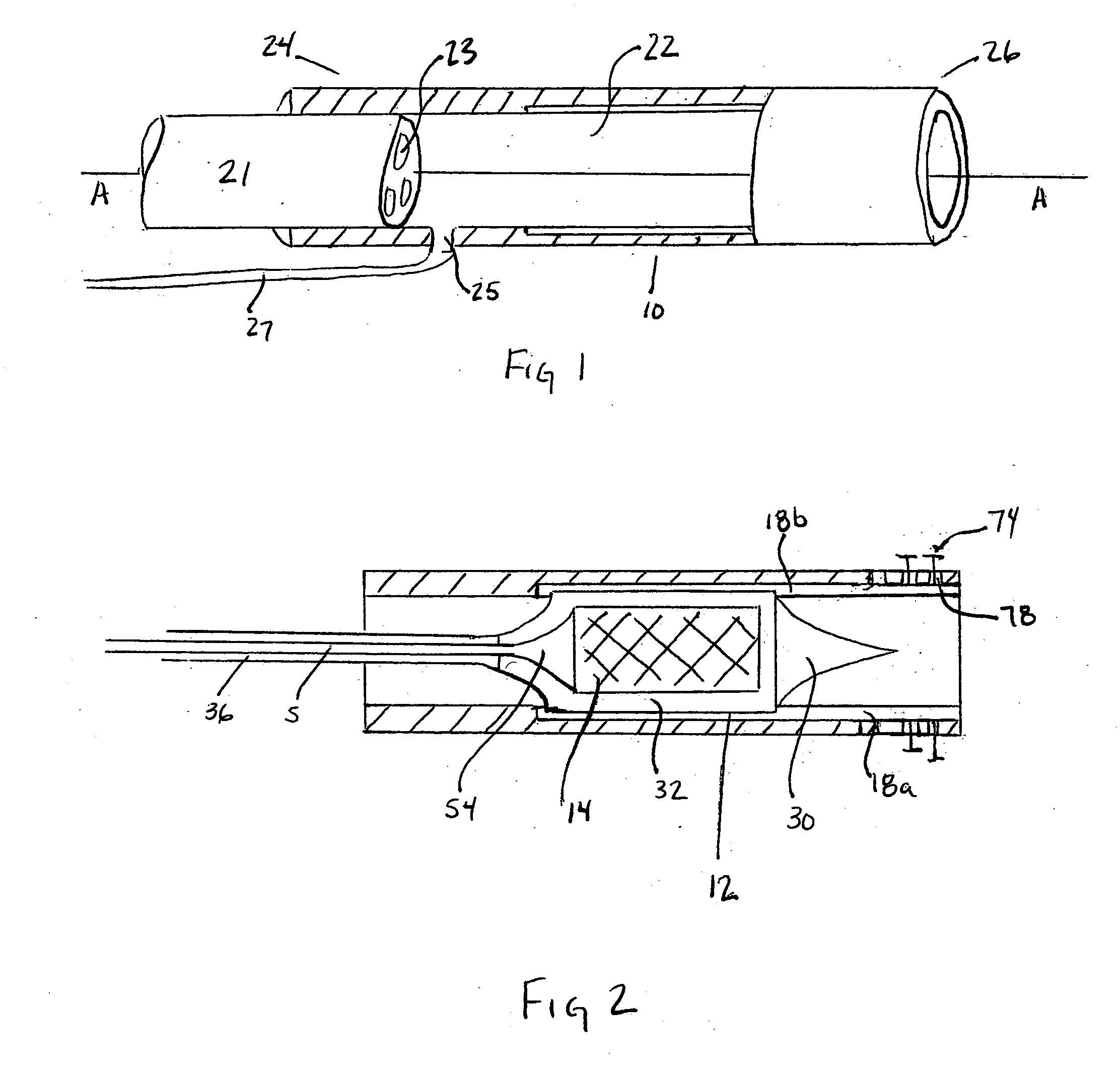

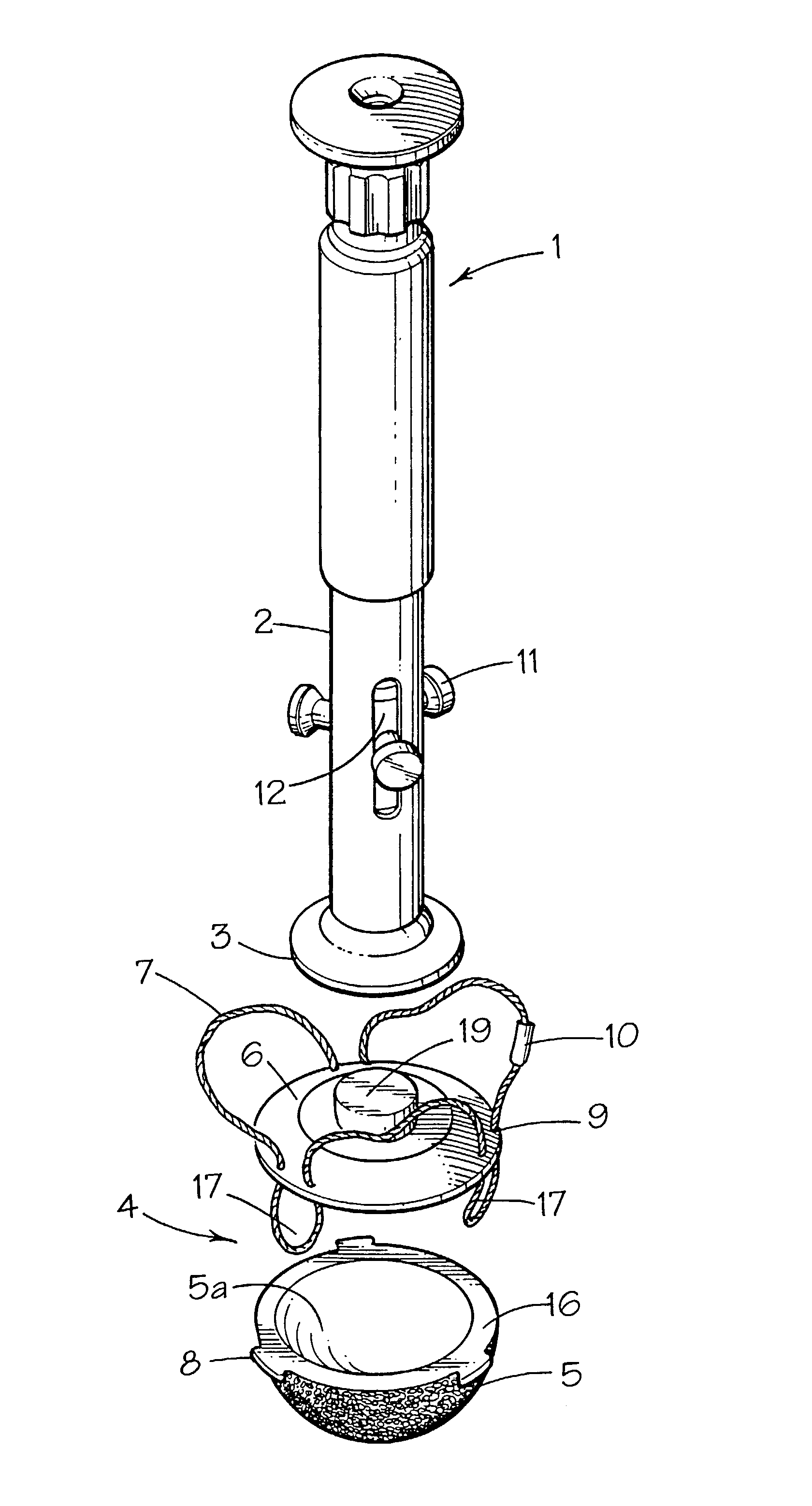

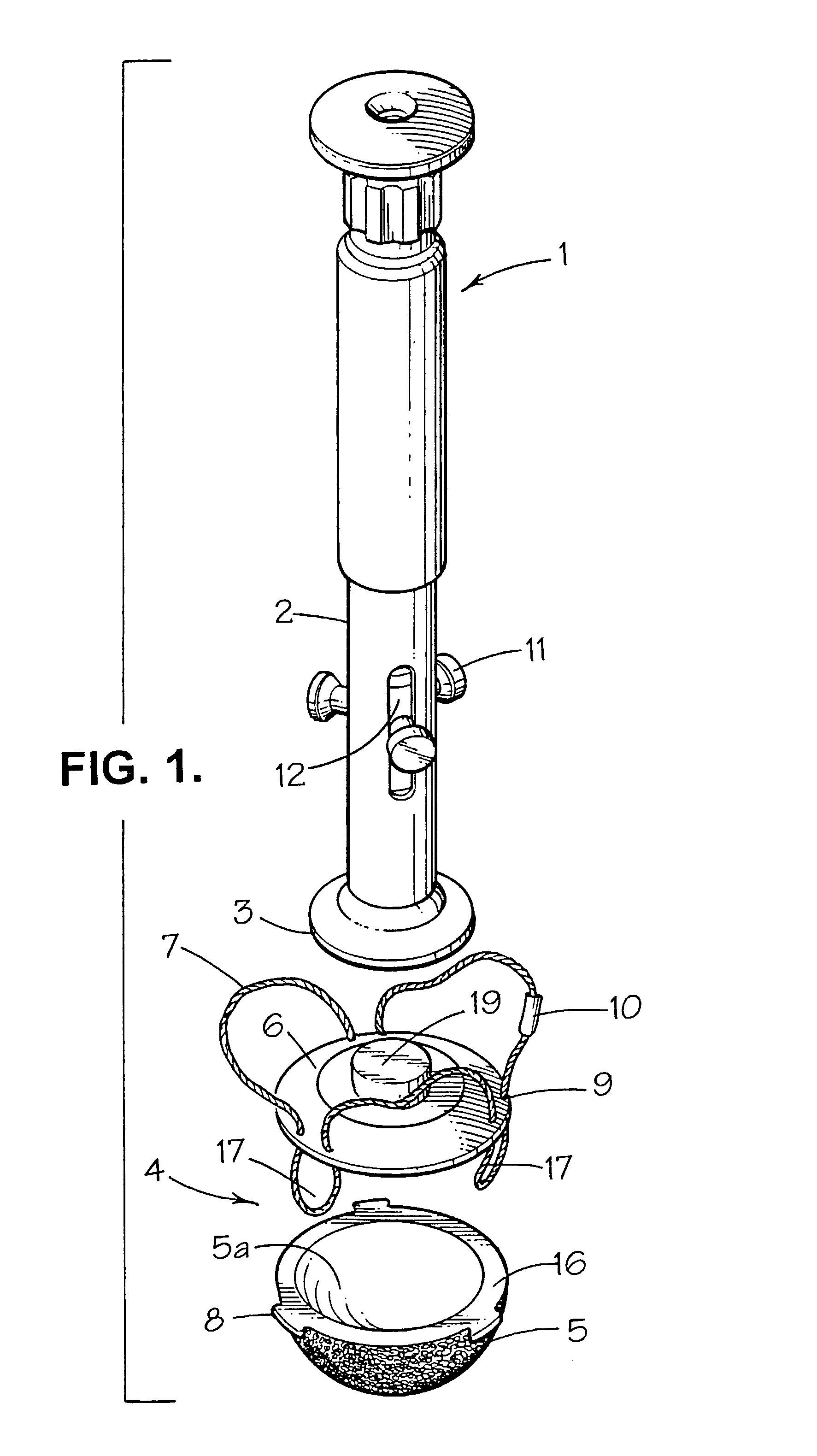

Prosthetic implant and surgical tool

InactiveUS20020177854A1Promote ingrowthCompromise integrityJoint implantsCoatingsBone chamberSacroiliac joint

The invention relates to a prosthetic implant comprising a main body portion having a first surface for presentation to a receptive bone surface or into a bone cavity and a second surface for receipt of an articulating joint, and means on the implant adapted for attachment of a filamentary member, such as a cable. The invention also relates to a surgical tool for gripping the implant, comprising an elongate body having a first end surface for bearing on the prosthetic implant and means for attachment of the tool to the implant, directly or indirectly by means of the cable.

Owner:T J SMITH & NEPHEW

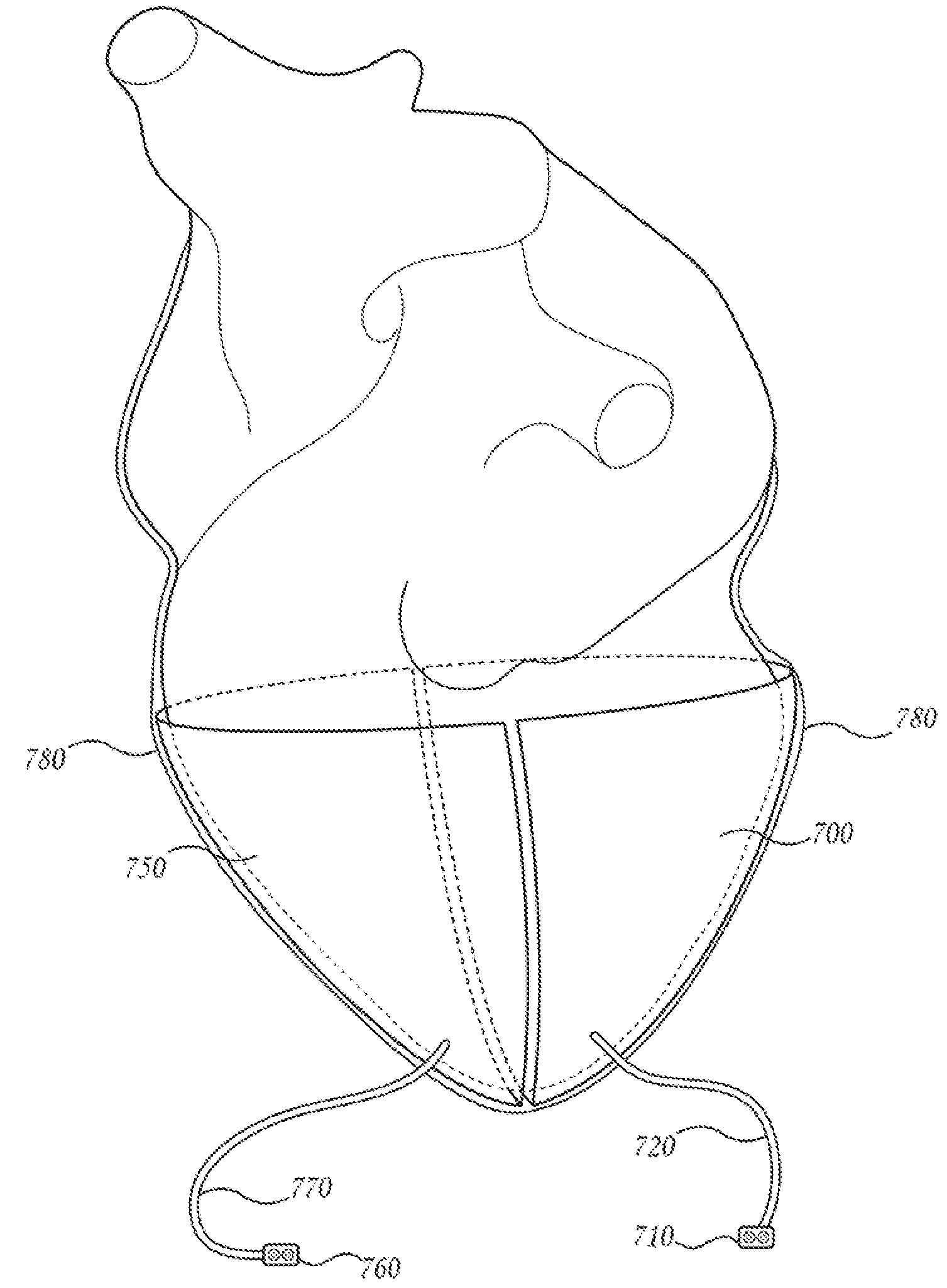

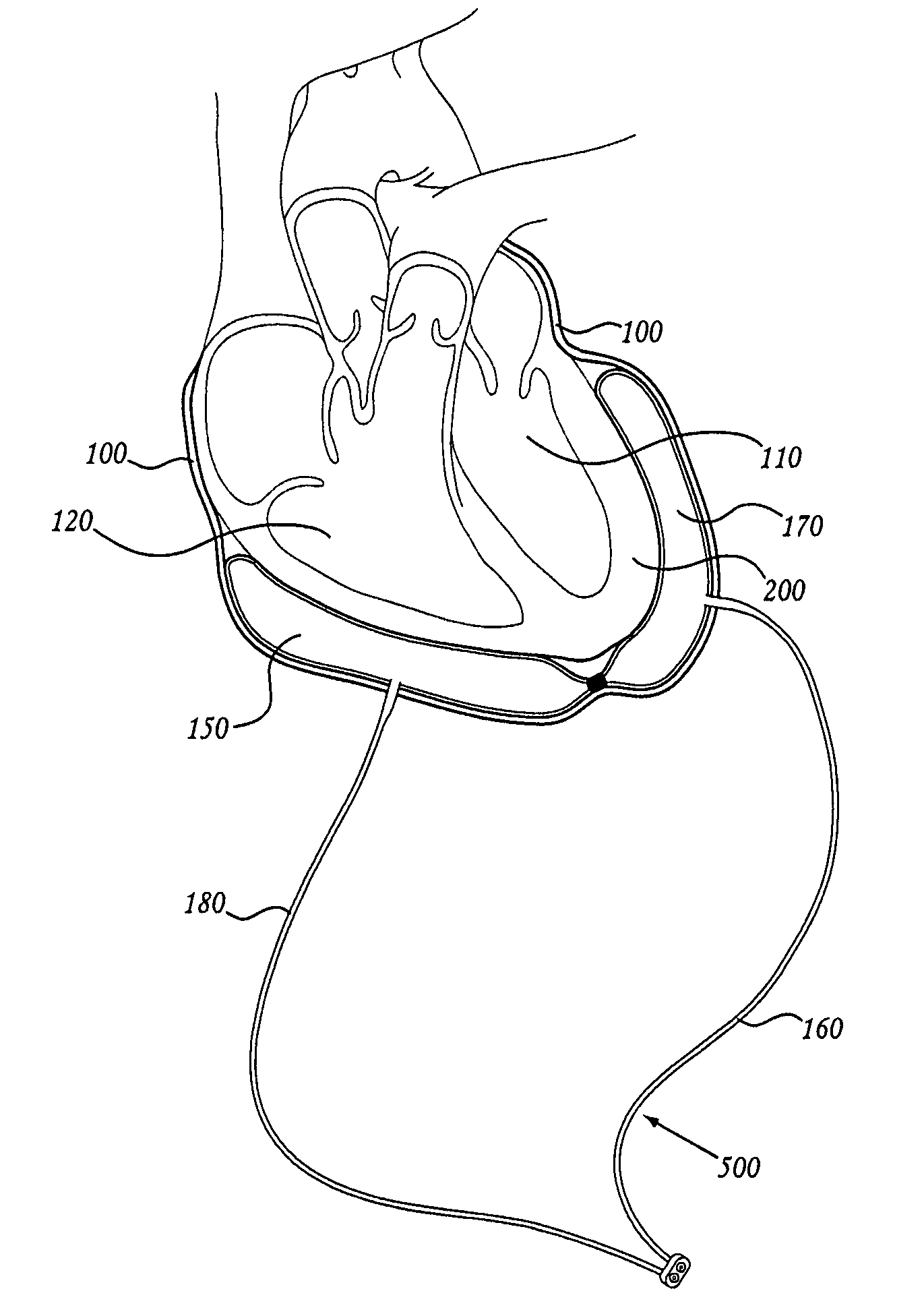

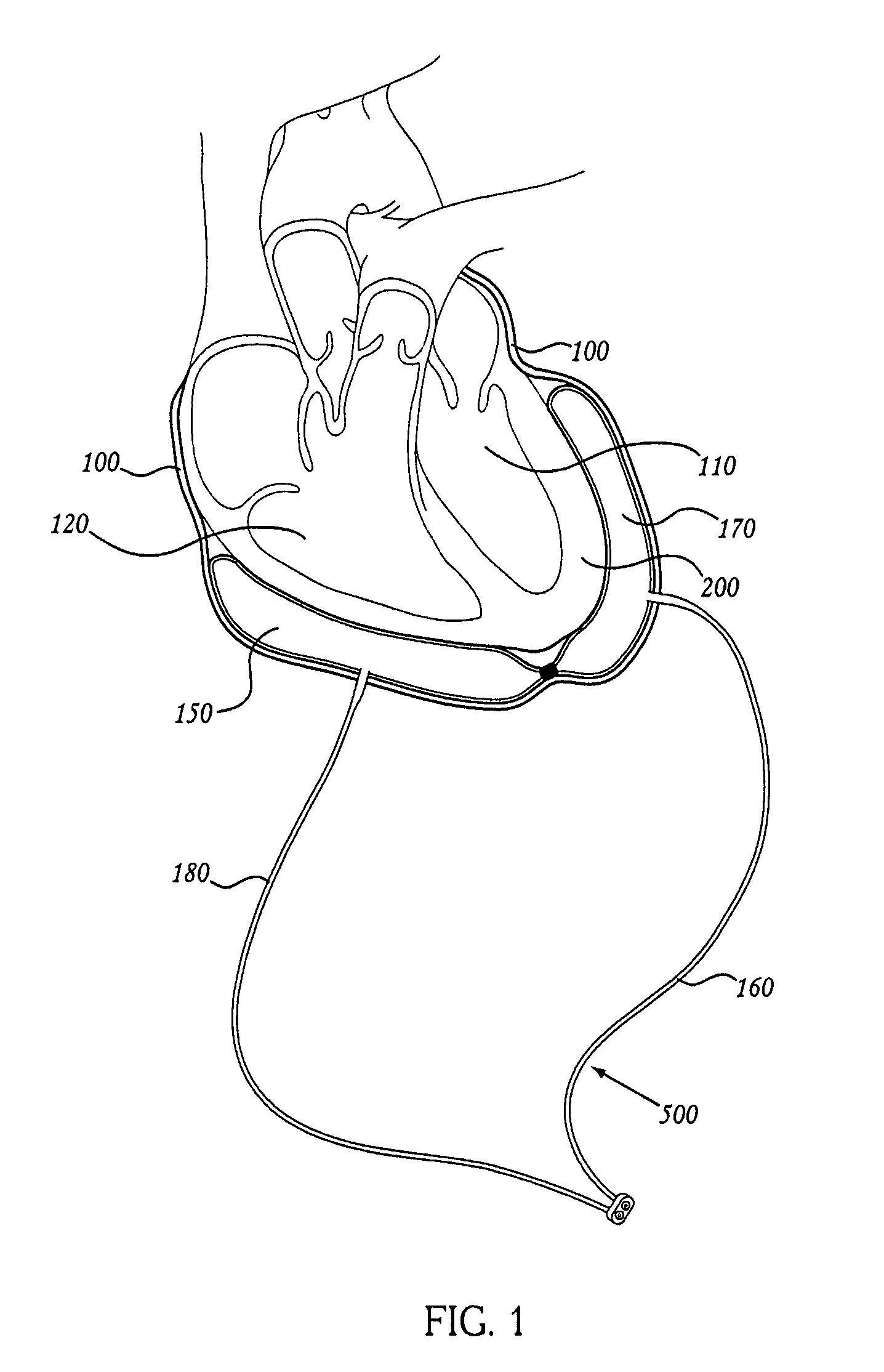

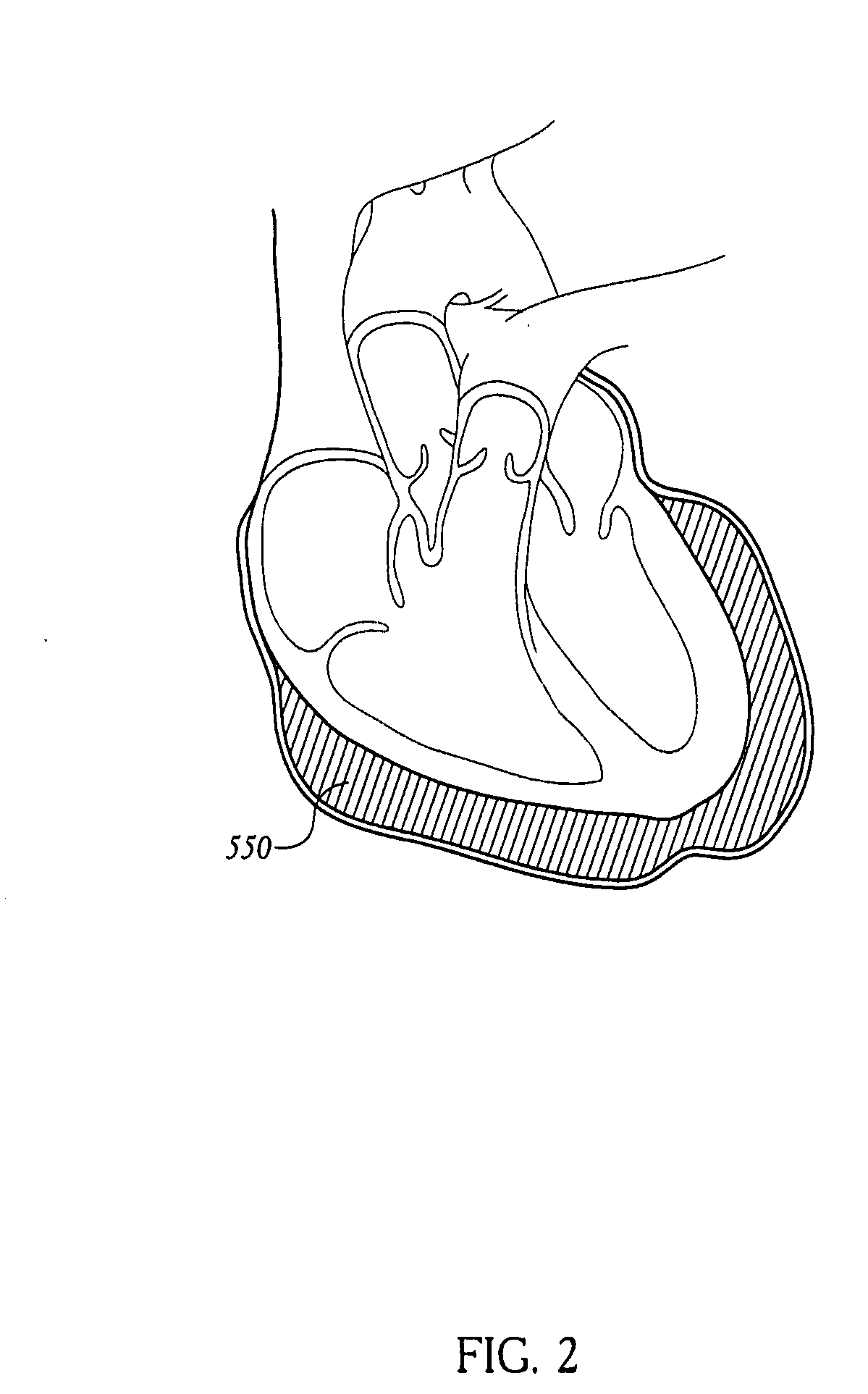

Methods of using pericardial inserts

InactiveUS20080275295A1Expansion is limitedGood biocompatibilityEpicardial electrodesHeart valvesPericardium

Devices, systems and methods are provided which are capable of applying pressure and constraint to the heart and use the pericardium to assist in the application of the pressure and force to the heart.

Owner:GERTNER MICHAEL

Spinal implants with body and insert

A spinal implant is provided which maintains intervertebral spacing and stability within the spine. The spinal implant may include a body and an insert. The body of the spinal implant may be formed of a ceramic material. In some embodiments, the body may be formed of beta tricalcium phosphate. The body may include an opening that is complementary to the insert. The insert may fit within the opening. The insert may include a number of passageways. Some of the passageways may intersect to form a scaffold for bone growth. Bone growth promoting material may be introduced into the insert before the insert is positioned in a body and inserted in a patient between two vertebrae.

Owner:ZIMMER BIOMET SPINE INC

Composite material for porous material and gel use thereof

InactiveCN1644221AImprove stabilityGood adhesionProsthesisCalcium biphosphateAlpha-tricalcium phosphate

A composition of porous material and gel for preparing artificial bone is prepared from collagen and porous material chosen from alpha-tricalcium phosphate / hydroxy apatite, beta-tricalcium phosphate / hydroxy apatite-coral, calcium phosphate / hydroxy apatite, calcium carbonatel tricalcium phosphate, etc.

Owner:徐小良

Prosthetic implant and surgical tool

InactiveUS20010051830A1Improve visibilityReduce risk of damageJoint implantsCoatingsBone chamberSacroiliac joint

The invention relates to a prosthetic implant comprising a main body portion having a first surface for presentation to a receptive bone surface or into a bone cavity and a second surface for receipt of an articulating joint, and means on the implant adapted for attachment of a filamentary member, such as a cable. The invention also relates to a surgical tool for gripping the implant, comprising an elongate body having a first end surface for bearing on the prosthetic implant and means for attachment of the tool to the implant, directly or indirectly by means of the cable.

Owner:T J SMITH & NEPHEW

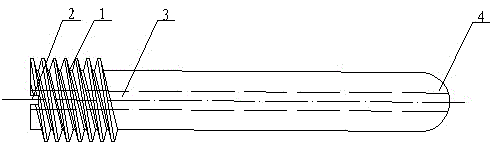

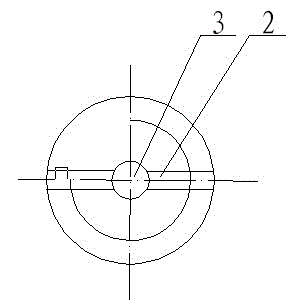

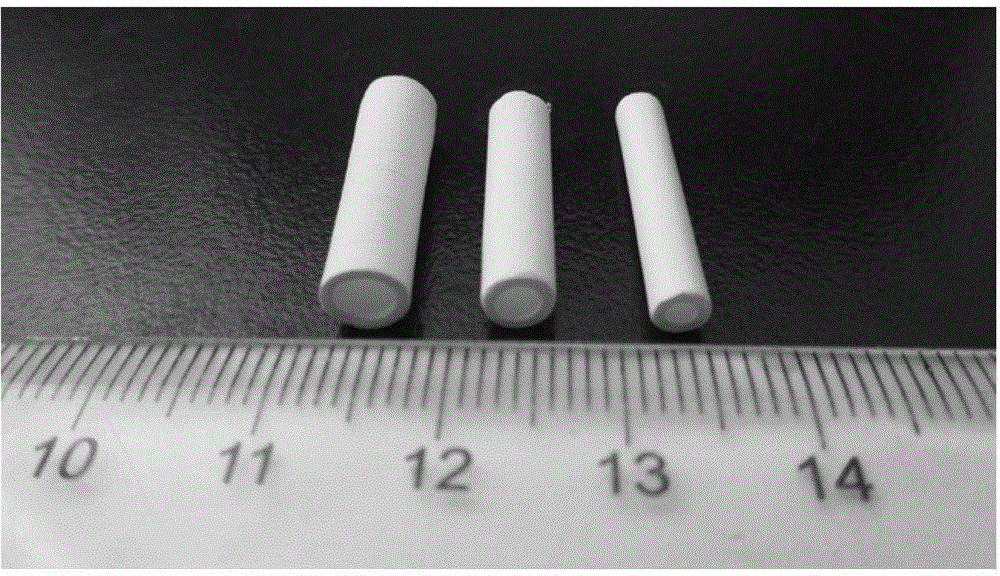

Porous tantalum rod

ActiveCN102743218AEasy to fixIncrease success rateInternal osteosythesisFastenersNeck structureRight femoral head

The invention relates to a medical implant part for femoral head joint surface depression or I-stage or II-stage femoral head necrosis, namely a porous tantalum rod. One end of the implant part is provided with a connection fastening structure connected with a bone tissue, and a through hole is formed in the center of the tantalum rod; the porous tantalum rod is made of a porous tantalum material with a foam structure of pore three-dimensional communicated distribution, and is sintered by adopting a foam impregnation method; and tantalum powder particles have a sinter neck structure on a foam frame formed by accumulating the sintered pure tantalum powder. The through hole in the porous tantalum rod facilitates accurate positioning in an operation; and a related object can be picked out and injected conveniently through the through hole, so that the effect of constant pressure reduction can be achieved.

Owner:CHONGQING RUNZE PHARM CO LTD

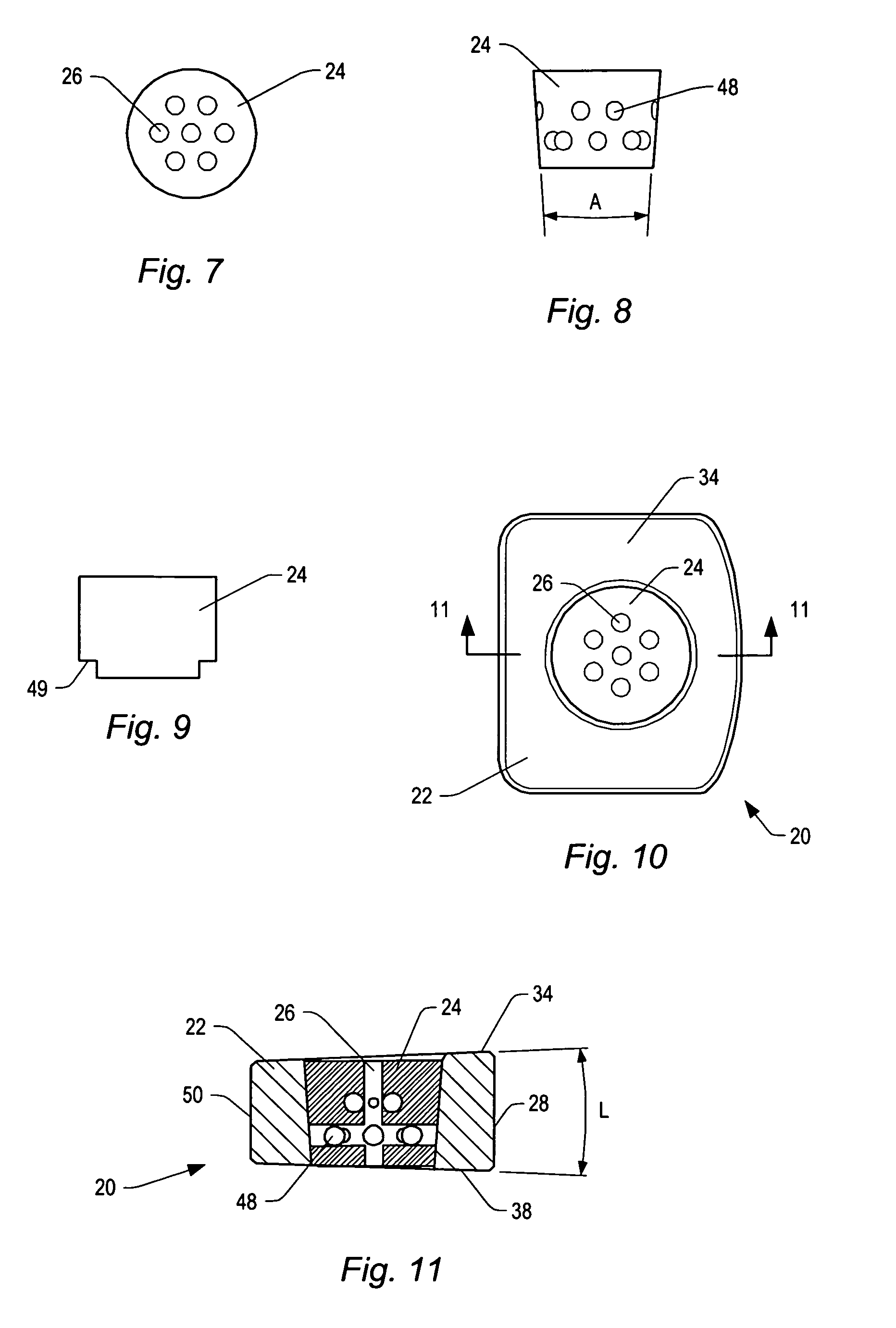

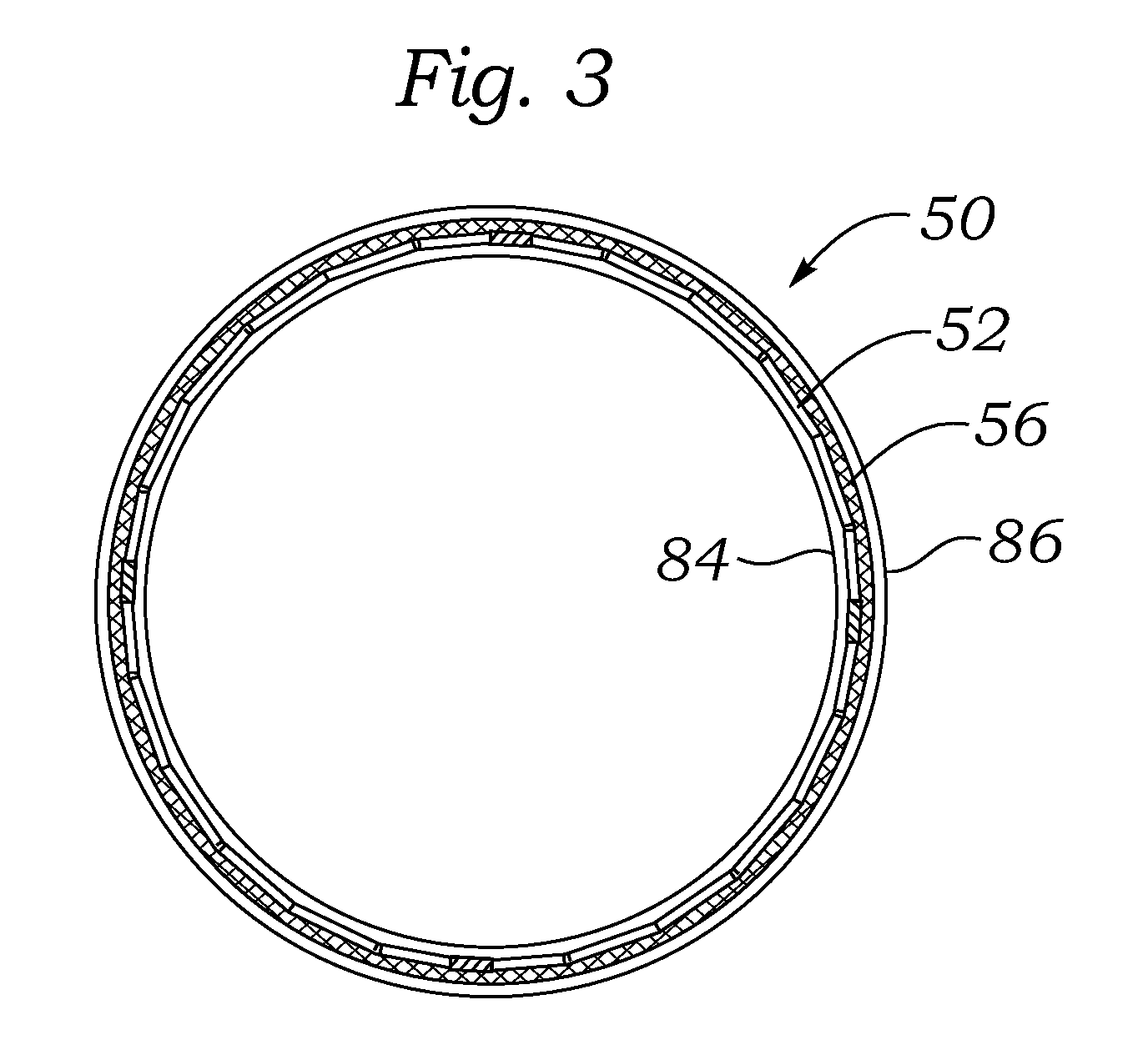

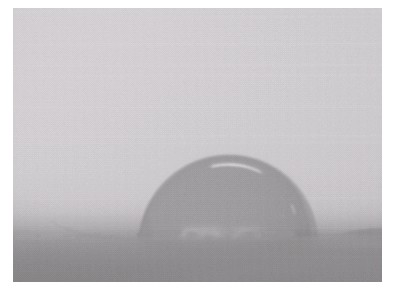

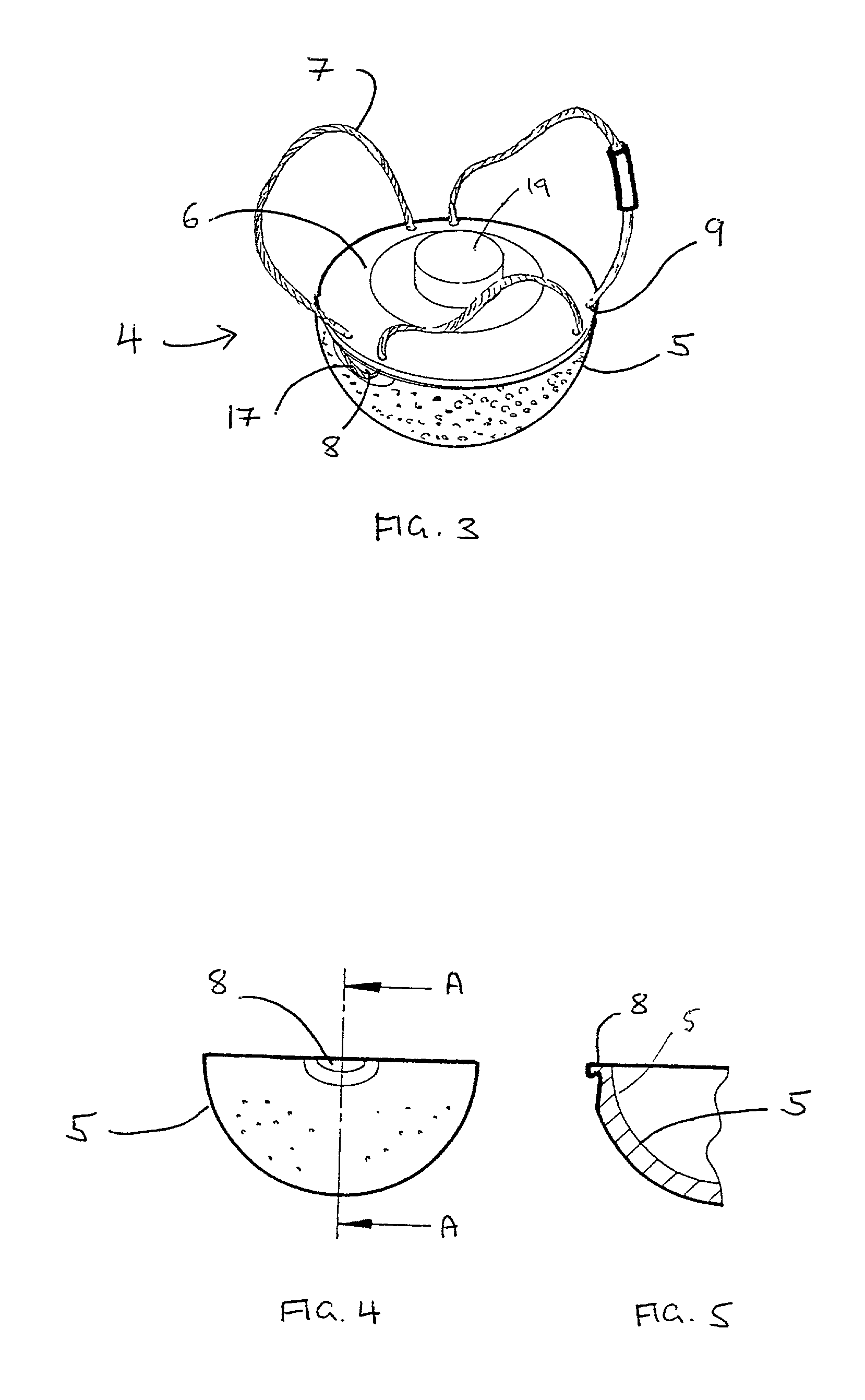

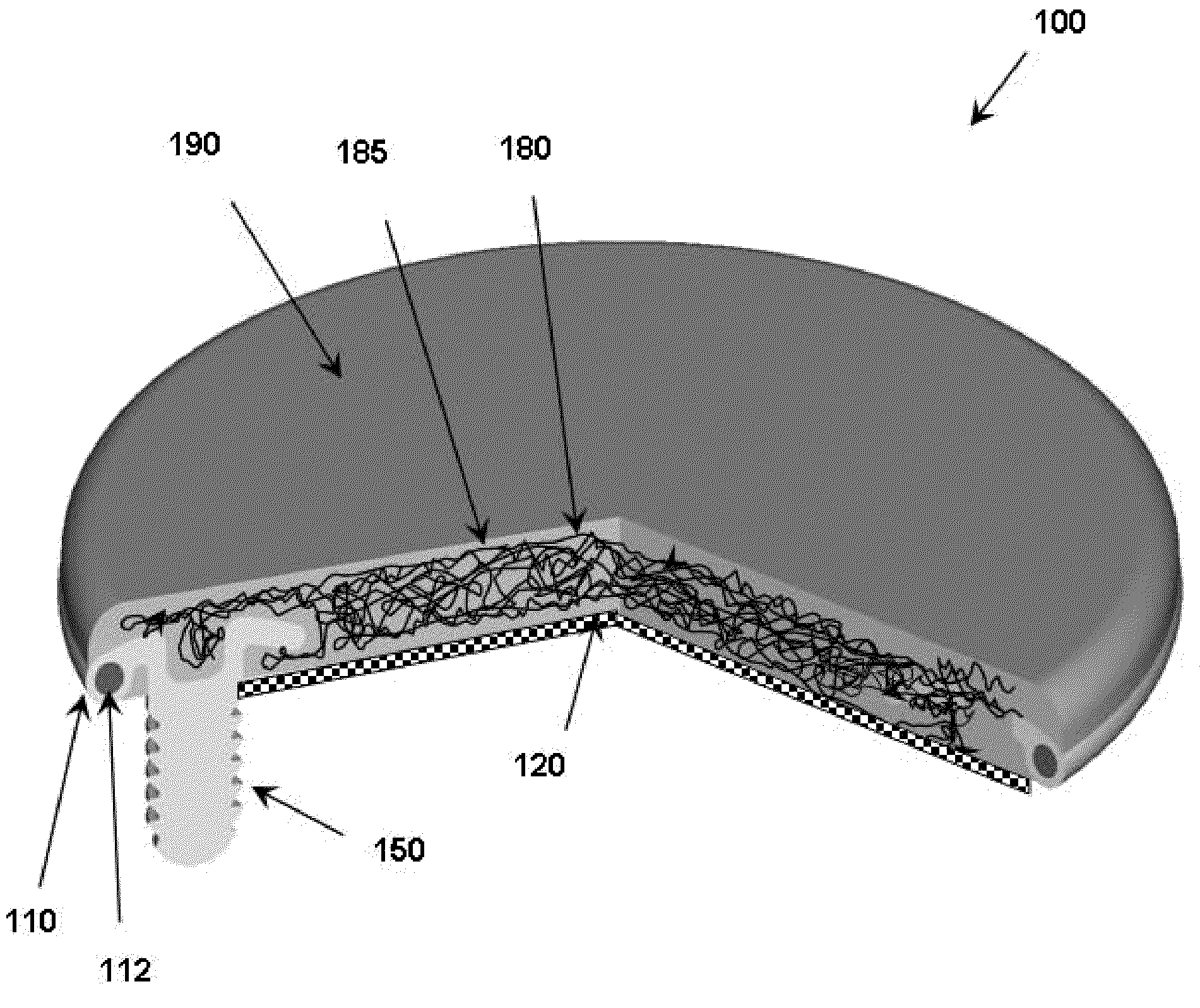

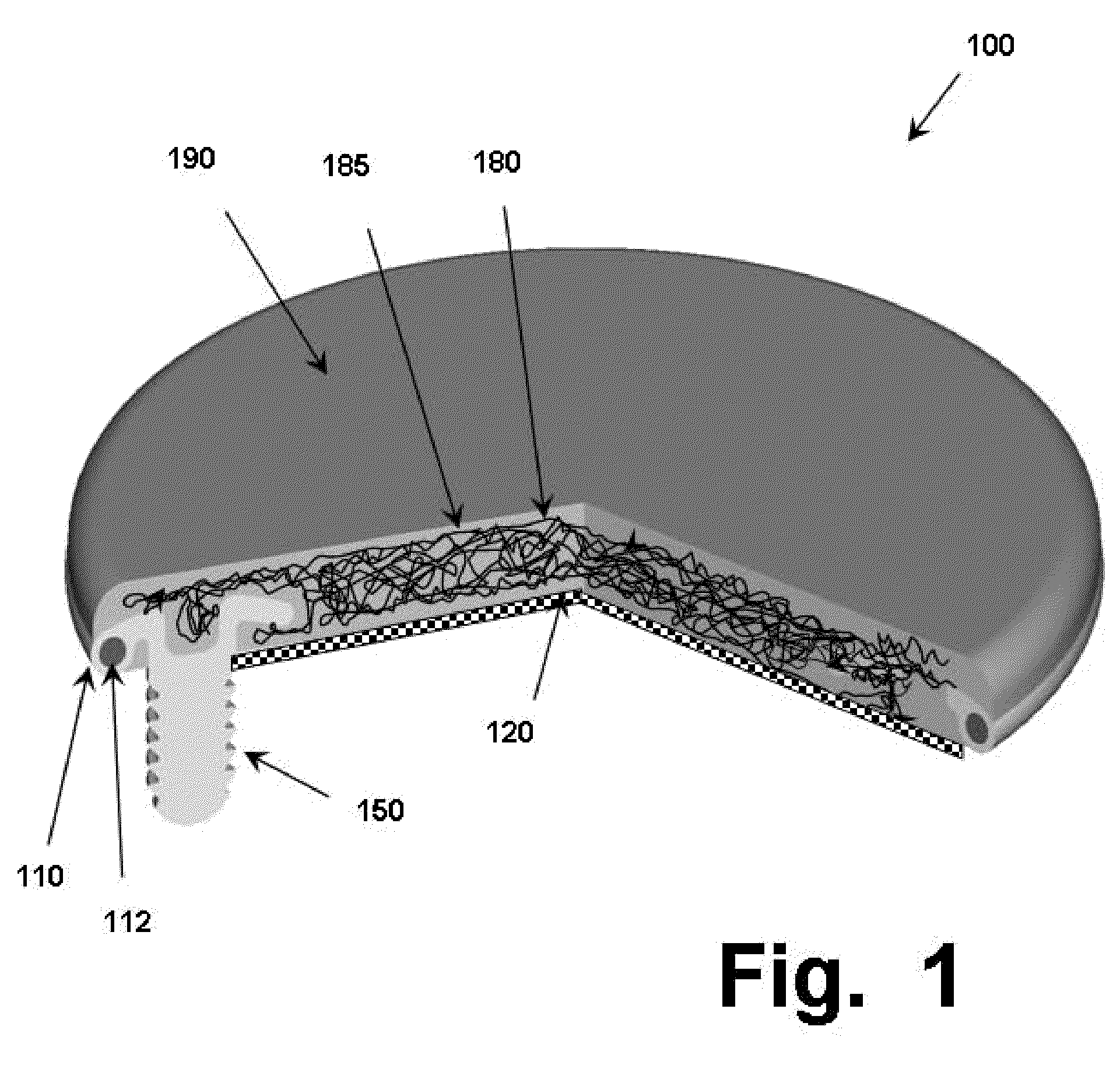

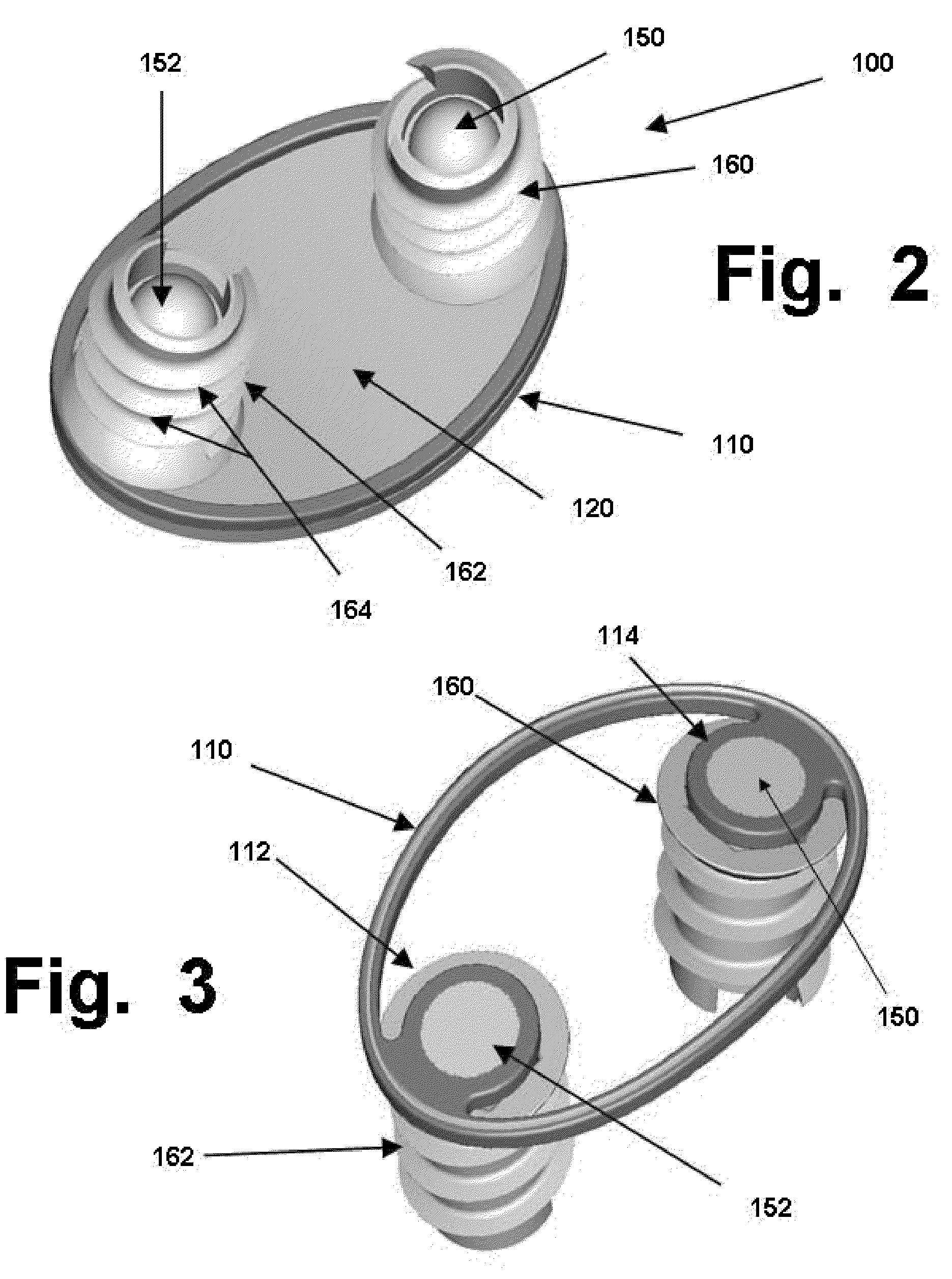

Anchoring systems and interfaces for flexible surgical implants for replacing cartilage

Surgical implants for replacing cartilage are provided with hydrogel polymers affixed to anchors made of “shape-memory” materials, such as nitinol alloys. These implants can be flexed, allowing them to be inserted into joints arthroscopically. After insertion, an implant will return to its manufactured size and shape, and can be anchored to bone or other tissue. The anchoring components can grip and hold hydrogels or other soft polymers by means of an interface of porous fabric. The fabric can support a reinforcing mesh embedded within the soft polymer, and its bottom surface can promote tissue ingrowth, leading to stronger anchoring. Two or more porous layers can enclose a soft polymer, for purposes such as sustained drug release or holding transplanted cells.

Owner:FORMAE

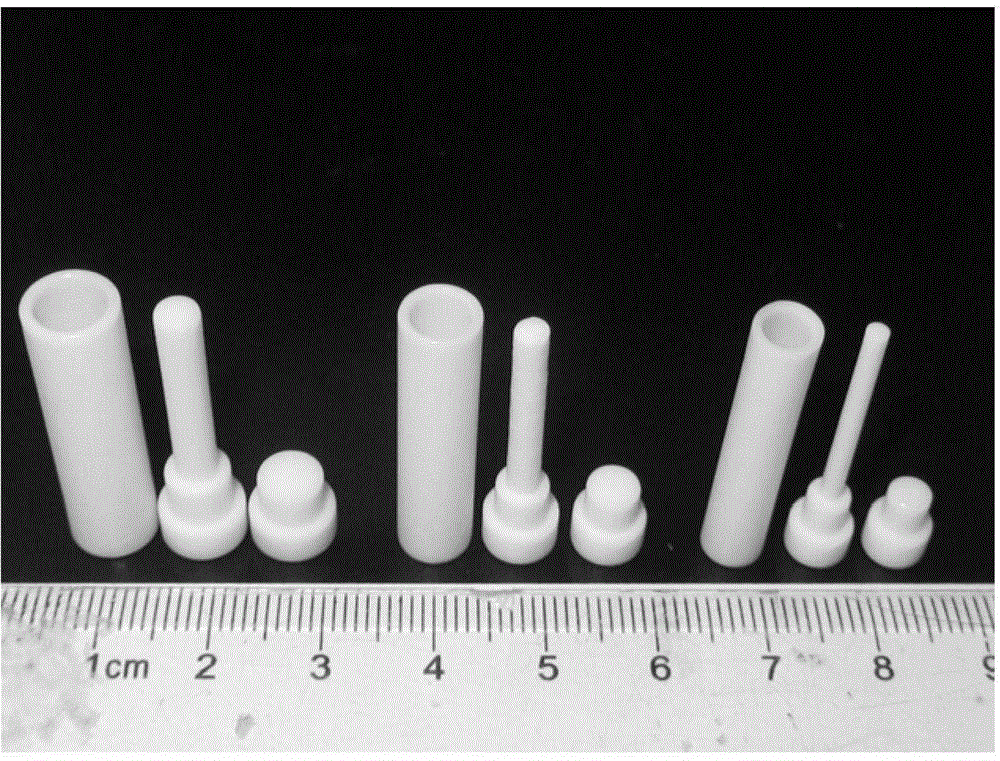

Medicinal porous titanium implant and method for preparing same

InactiveCN101518467AAchieve long-term stabilityIncrease initiativeDental implantsImpression capsStress concentrationMicrosphere

The invention discloses a medicinal porous titanium implant and a method for preparing the same. The porous titanium implant is prepared by a powder coinjection molding method; and a nano HA and TGF loaded sustained-release gelatin microsphere compound coating is deposited on the porous outer layer of the product. The outer layer of the implant has a communicated porous structure, the thickness of the porous layer is 0.4 to 1.1 millimeters, the porosity of the porous layer is 50 to 70 percent, and the aperture of the porous layer is 50 to 400 mum; the surface of the porous layer is deposited; and the binding strength of the outer layer and an inner core is 150 to 300MPa. Compared with the prior medicinal titanium implant material, the material of the medicinal porous titanium implant has higher mechanical strength, is in accordance with the mechanical performance of osseous tissue, avoids stress concentration and stress shielding, promotes stress transmission and growth of new bones, reduces time for osseointegration, and ensures the long-term stability of the implant. The method adopts once-for-all molding without post machining, thereby considerably reducing the cost.

Owner:CENT SOUTH UNIV

Pericardial inserts

InactiveUS20080275294A1Expansion is limitedGood biocompatibilityEpicardial electrodesHeart valvesPericardium tissueCardiology

Devices, systems and methods are provided which are capable of applying pressure and constraint to the heart and use the pericardium to assist in the application of the pressure and force to the heart.

Owner:GERTNER MICHAEL

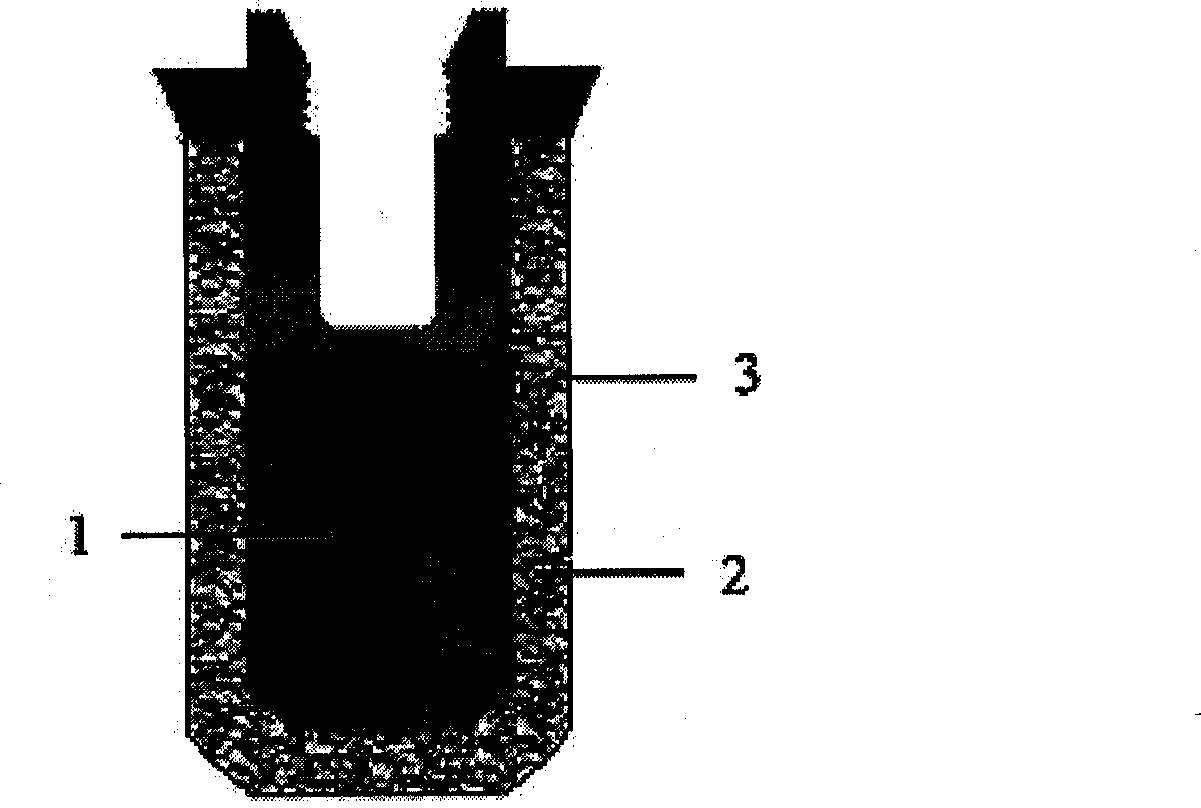

Degradable open porous magnesium and magnesium alloy biomaterial and preparation method thereof

The invention discloses a degradable open porous magnesium and magnesium alloy biomaterial and a preparation method thereof. The magnesium and magnesium alloy biomaterial is in a completely open structure, the hole shape and size are controllable, holes are communicated by virtue of communicating holes, and the number and size of the communicating holes in hole walls are controllable; the holes are uniformly distributed and the porosity is adjustable. The preparation method comprises the following steps: sintering sodium chloride crystal particles to obtain an open porous sodium chloride prefabricated structure; pouring molten magnesium or magnesium alloy into a mould cavity with a sodium chloride prefabricated body, and performing seepage pressure casting; and removing magnesium or magnesium alloy block outer skin with the sodium chloride prefabricated body, washing with alkali, and filtering to remove sodium chloride to obtain the degradable open porous magnesium and magnesium alloy biomaterial. The preparation process is simple, convenient to perform and pollution-free; the prepared open porous structure is provided with the communicated and uniformly distributed holes, is controllable in hole shape and size, relatively high in porosity and strength, free of pore former residues and pore closing phenomenon and adjustable in degradation rate, and can serve as a new-generation degradable bone tissue engineering scaffold.

Owner:SHANGHAI INNOVATON MEDICAL TECH CO LTD

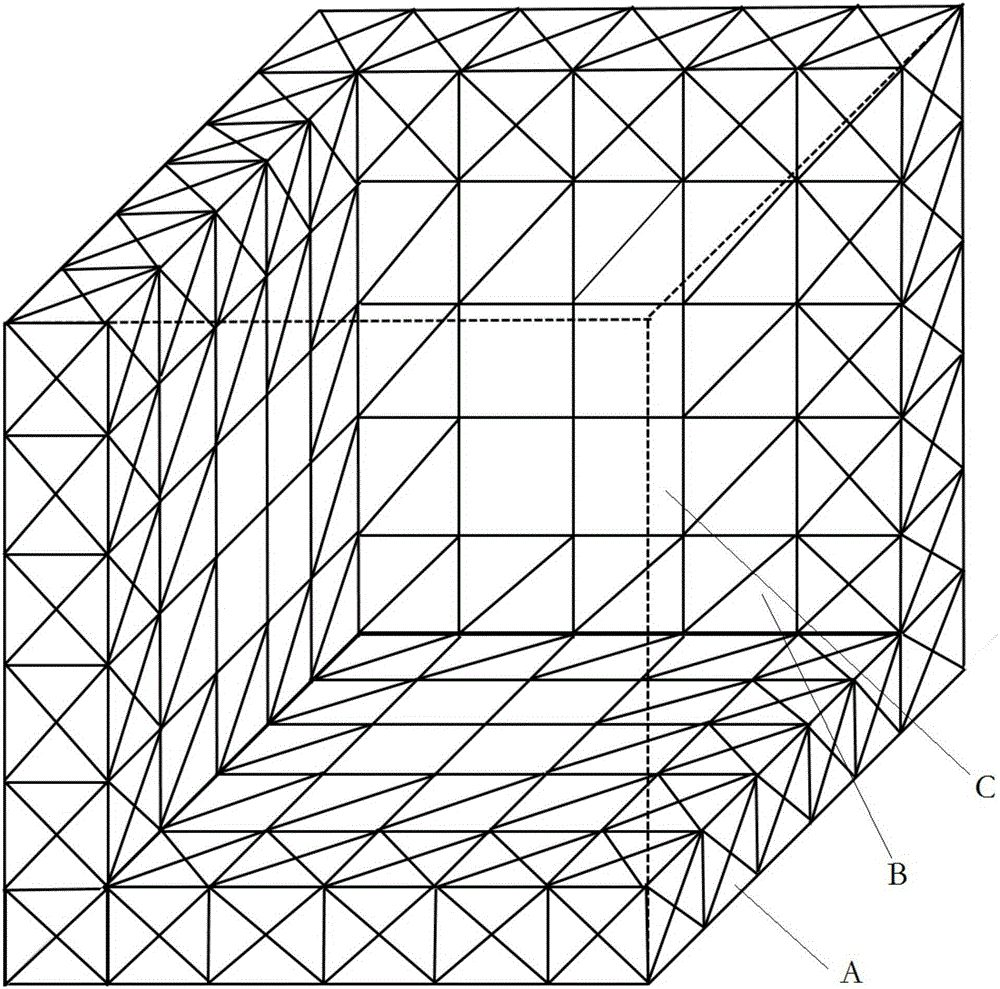

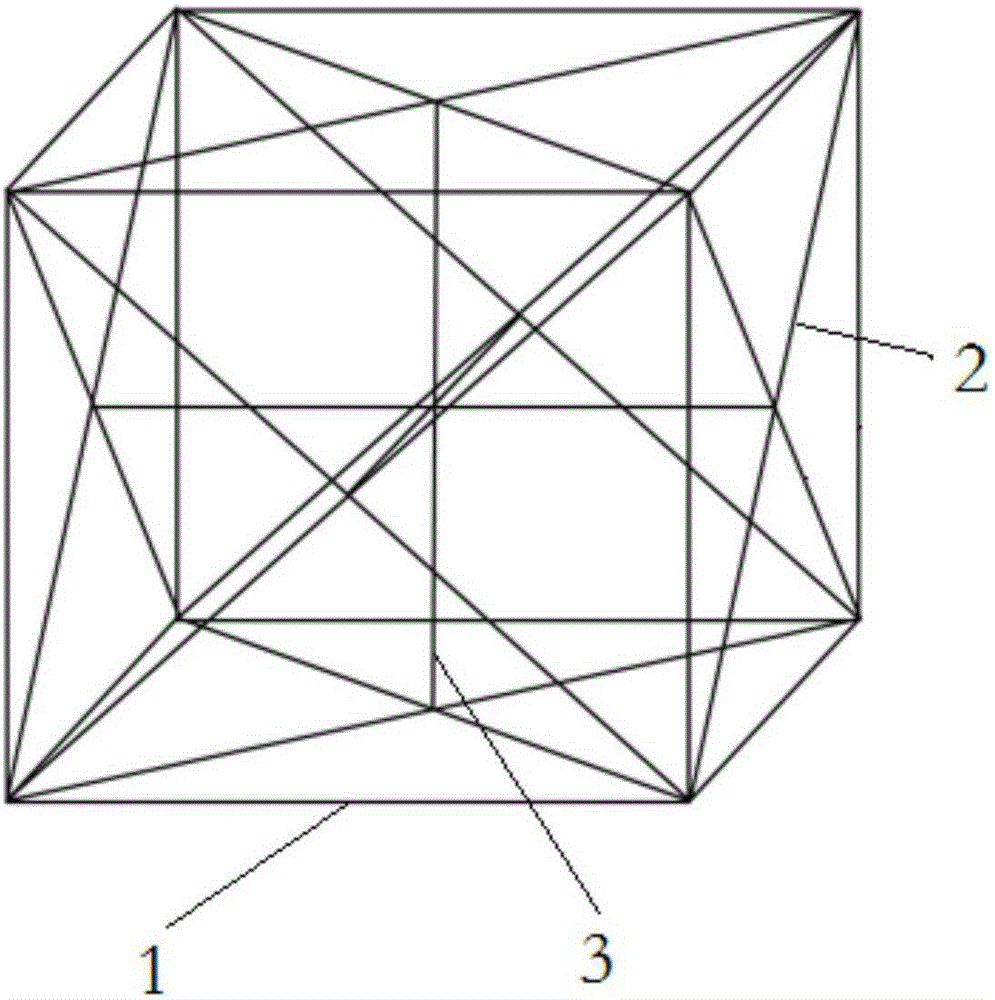

3D-printed gradient-diameter medical porous metal bone tissue scaffold

The invention discloses a 3D-printed gradient-diameter medical porous metal bone tissue scaffold and aims to solve the problems that a single repeated microporous structure in the prior art is adverse to bone tissue ingrowth and a bone tissue implant has difficulty in bony healing with self-bones. The scaffold is in a hexahedron structure as a whole, and comprises components A, components B and components C in tight arrangement, wherein the components A are arrayed on an outermost layer of the hexahedron structure; the components B are arrayed on a secondary outer layer; and the components C are arrayed on the innermost layer; all the components A, B and C are in a hexahedron frame structure; the pore diameter of the components A is greater than that of the components B; and the pore diameter of the components B is greater than that of the components C. Through the reinforcing structural design, the gradient-pore tissue engineering bone scaffold is produced; through regulating the ingrowth of bone tissues, fibroblasts and the like by gradient-change pores, the optimal bone healing can be achieved finally.

Owner:JILIN UNIV

Methods of using pericardial inserts

InactiveUS20080027269A1Expansion is limitedGood biocompatibilityEpicardial electrodesHeart valvesPericardium tissue

Devices, systems and methods are provided which are capable of applying pressure and constraint to the heart and use the pericardium to assist in the application of the pressure and force to the heart.

Owner:GERTNER MICHAEL

Bio-medical porous titanium products and preparation method thereof

InactiveCN101418392AReduce stress concentration effectsGood obedienceSurgeryProsthesisPowder metallurgyArtificial joints

The invention relates to a biological medical porous titanium material and a preparation method thereof. The preparation method, namely a method adopting powder metallurgy, is to add spherical particles of novel polymethyl methacrylate pore-forming agent to prepare a structure provided with a rough surface and three-dimensionally communicated open pores, wherein the number, the shape and the size of the pores can be controlled, namely, the porosity degree is less than 70vol. percent, the open porosity factor is more than 60 percent, the average pore diameter is less than 500 mums, the Young's modulus in compression is more than 0.3 GPa, the compressive strength is more than 40MPa, and the bending strength is more than 50MPa. The biological medical porous titanium material can be widely applied in the field of biological medical implants such as dental implants, artificial joints, spinal orthopaedic internal fixed systems, medullary internal nails and orthopaedic armor plates.

Owner:DALIAN JIAOTONG UNIVERSITY

Preparation method of porous nano-fiber tubular scaffold

InactiveCN102908208AImprove toughnessIncrease elasticityTubular organ implantsPorosityPolymer dissolution

The invention relates to a preparation method of a porous nano-fiber tubular scaffold, which comprises the steps that (1) PLLA (Poly L Lactic Acid) and other polymers are dissolved in a solvent to get a polymer solution; (2) the polymer solution is injected into a tubular mold and rapidly placed at a low temperature for phase separation, then the polymer solution is taken out, a tubular mold housing is removed, polymer gel after the phase separation and a core mold are immersed in ice water together, then the core mold is taken out, the polymer gel is immersed in deionized ice water to exchange the solvent, and the tubular scaffold is obtained; and (3) finally, the tubular scaffold obtained is frozen and dried for 48-120 hours, and then the porous nano-fiber tubular scaffold is obtained. The preparation method is simple to operate, and requires no additional hole-foaming agent, is suitable for volume production, and is lower in preparation cost; the prepared tubular scaffold has a nano-fiber structure similar to an extracellular matrix of a human tissue, and a porous structure with the diameter and porosity capable of being adjusted, and facilitates growth of cells and reconstruction of a cambium.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com