Patents

Literature

30 results about "Alpha-tricalcium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite material for porous material and gel use thereof

InactiveCN1644221AImprove stabilityGood adhesionProsthesisCalcium biphosphateAlpha-tricalcium phosphate

A composition of porous material and gel for preparing artificial bone is prepared from collagen and porous material chosen from alpha-tricalcium phosphate / hydroxy apatite, beta-tricalcium phosphate / hydroxy apatite-coral, calcium phosphate / hydroxy apatite, calcium carbonatel tricalcium phosphate, etc.

Owner:徐小良

Composite organism ceramic material composed of apatite-wollastonite/beta-tricalcium phosphate

InactiveCN1923752AImprove biological activityFast adhesionCeramicwarePorosityAlpha-tricalcium phosphate

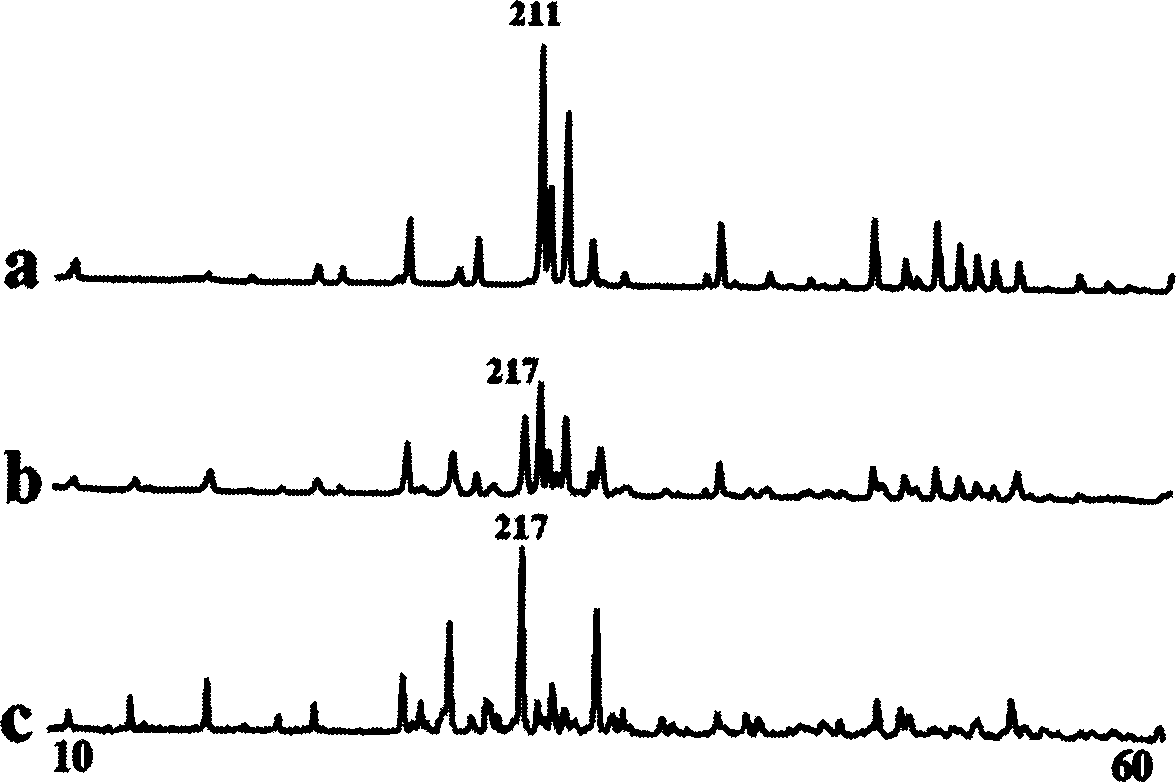

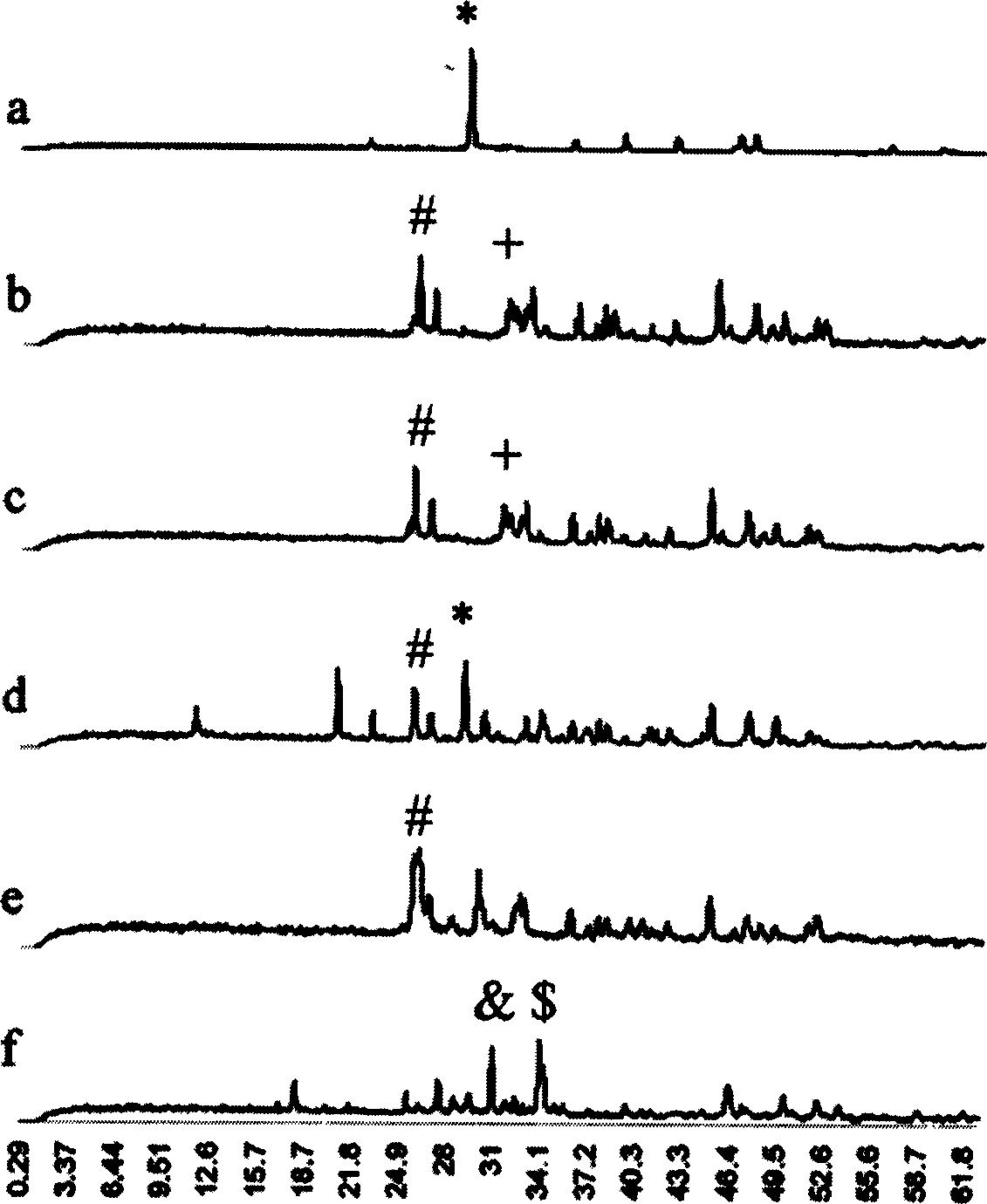

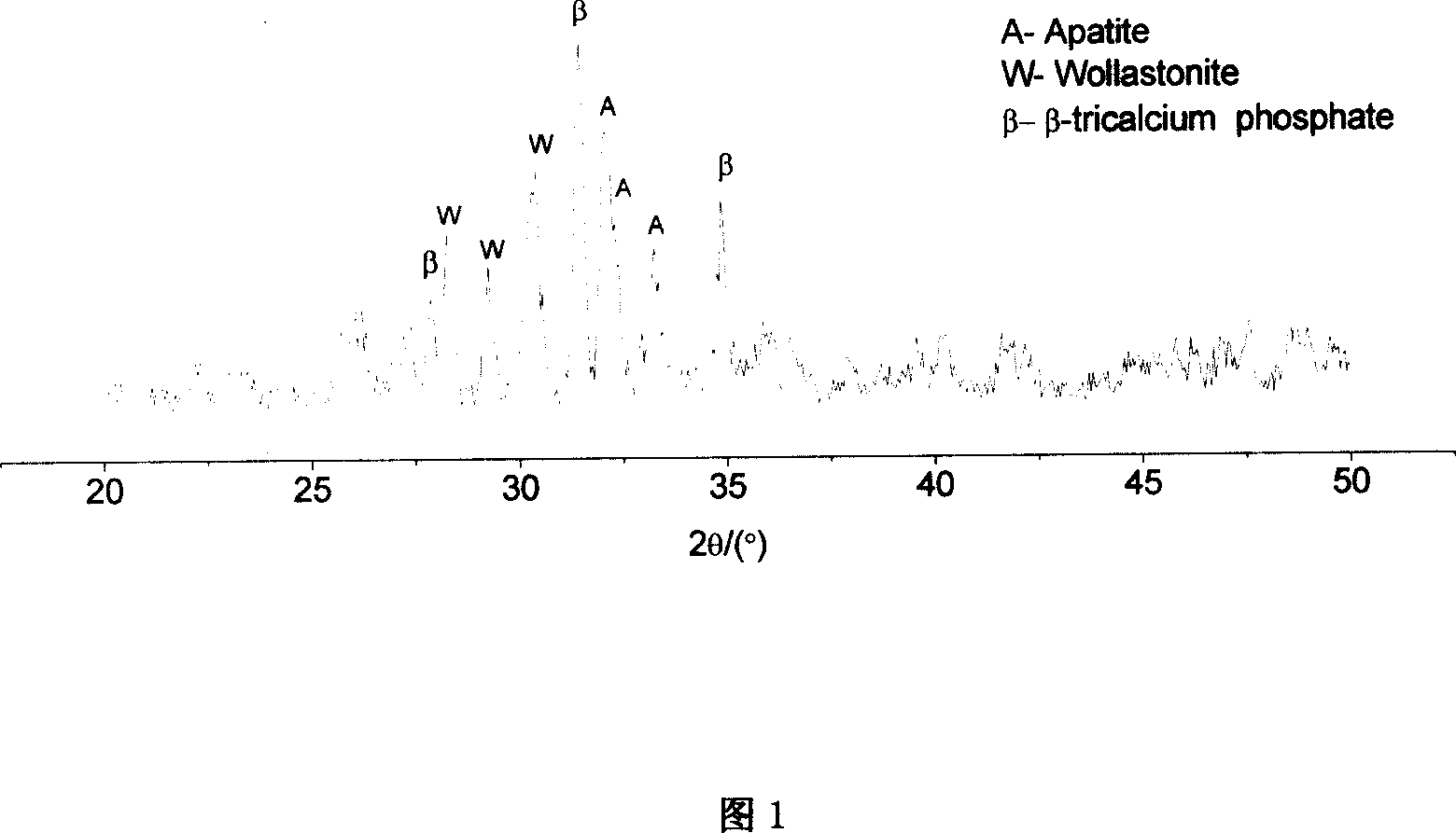

The invention discloses a composite biological active ceramic material of Apatite-Wollastonite / beta-tricalcium phosphate (AW / beta-TCP), which comprises the following steps: adopting sol-gel process to prepare AW former powder; preparing TCP former powder through chemical sediment method; sieving TCP former powder through 60-order standard sieve; putting AW former powder and TCP former particle in the material mixing machine according to different proportion; adding certain rate corresponding to powder weight geoceric acid or naphthalene particle with grain size at 20-30 order; making 5wt% polyvinyl alcohol solution as adhesive; blending completely; moulding; drying; sintering to obtain porous product.

Owner:SICHUAN UNIV

Process for manufacturing alpha-tricalcium phosphate-alpha-calcium sulfate hemihydrates bone cement porous bracket through squashing method

InactiveCN106390190APromote healingDegradation rate matchingTissue regenerationProsthesisWater bathsAlpha-tricalcium phosphate

The invention relates to a process for manufacturing an alpha-tricalcium phosphate-alpha-calcium sulfate hemihydrates bone cement porous bracket through a squashing method. The process comprises the following steps: mixing raw materials calcium hydrophosphate and calcium carbonate in molar ratio through a solid-solid reaction process, roasting the raw materials at a temperature ranging from 1250 DEG C to 1400 DEG C, and quickly cooling the raw materials to the room temperature, preparing alpha-TCP powder; putting calcium sulphate dehydrate into distilled water, adding sodium citrate and magnesium sulfate, heating reactants in certain proportion in a sealed container to 130 DEG C, reacting for 6 hours, filtering and drying to prepare alpha-CSH powder; and mixing alpha-TCP and alpha-CSH powder in a mass ratio from (9 to 1) to (5 to 5), taking soluble salt particles or sugar particles with particle diameter being 100 to 300mu m as a pore-foaming agent, sufficiently mixing powder, pressing and forming by use of a tablet press through a proper mould, soaking in 37DEG C water bath, removing the pore-foaming agent during curing, thereby preparing the bone cement porous bracket. According to the process, adopted raw materials are simple and the preparation process is easy, so that the process is suitable for large-scale production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

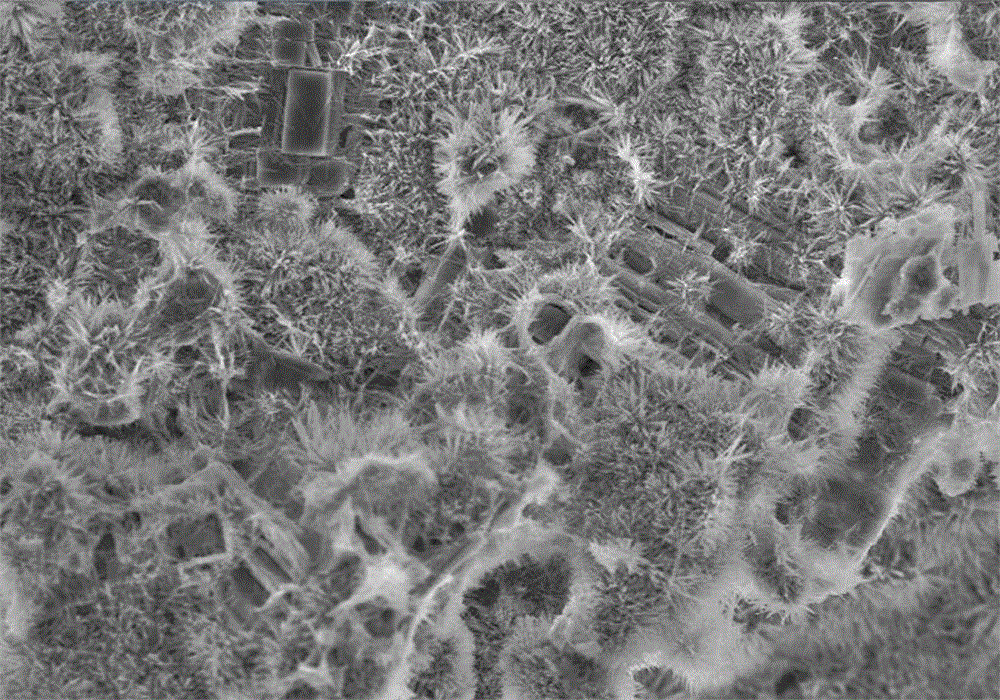

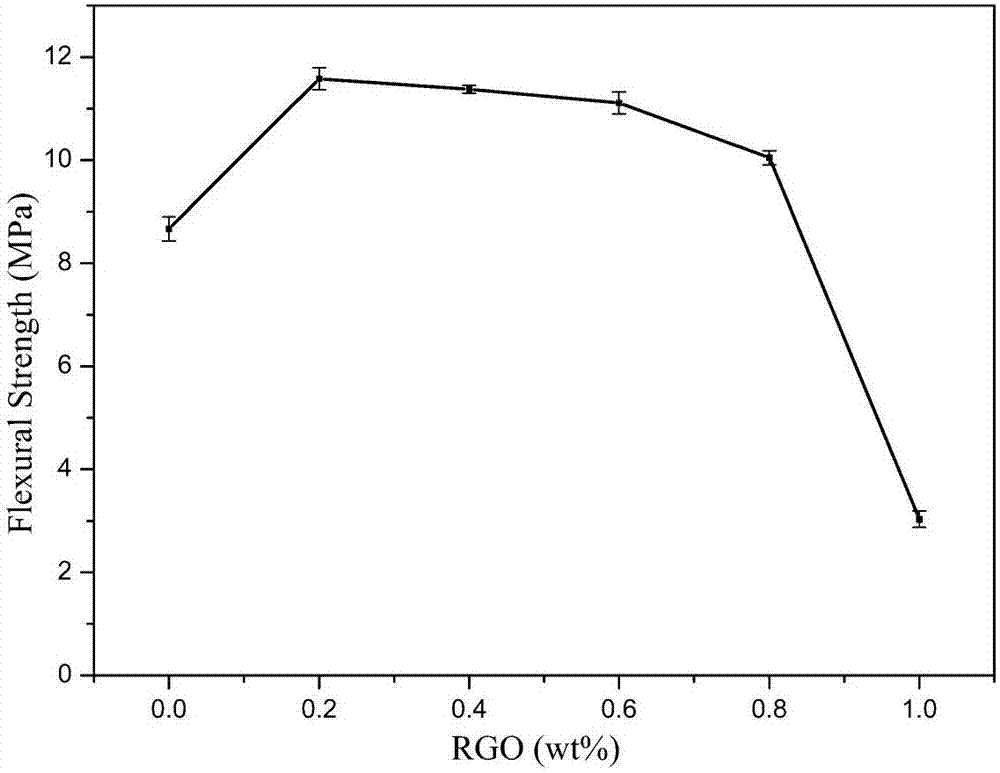

Calcium phosphate biological bone cement composite material reinforced by carbon nanotube and graphene

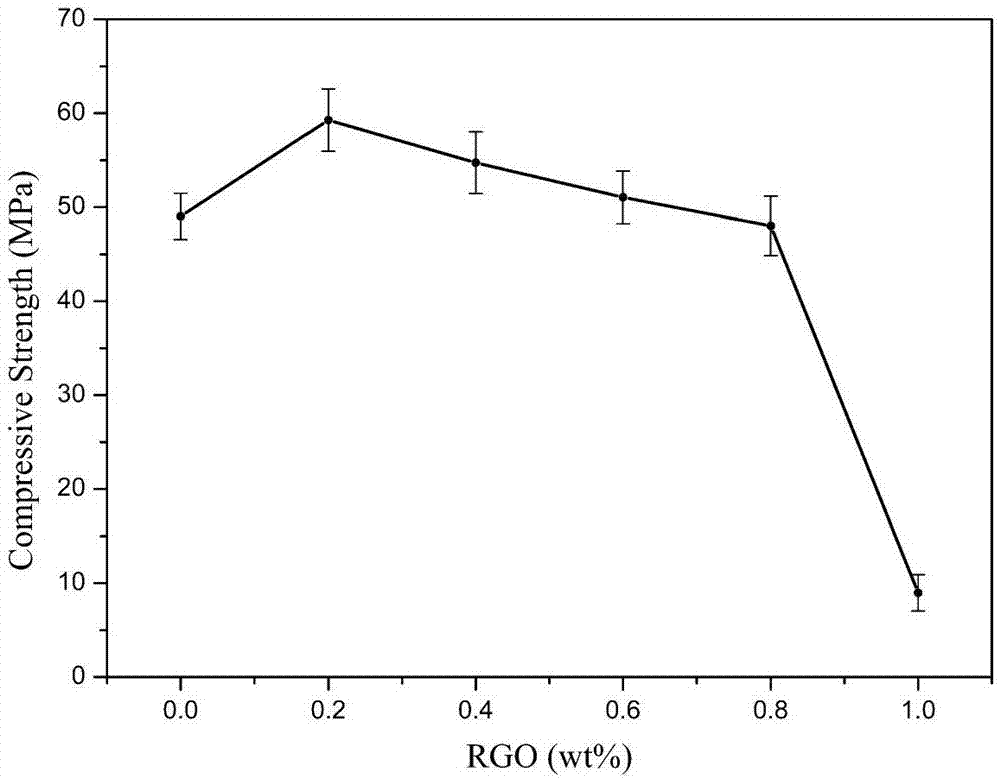

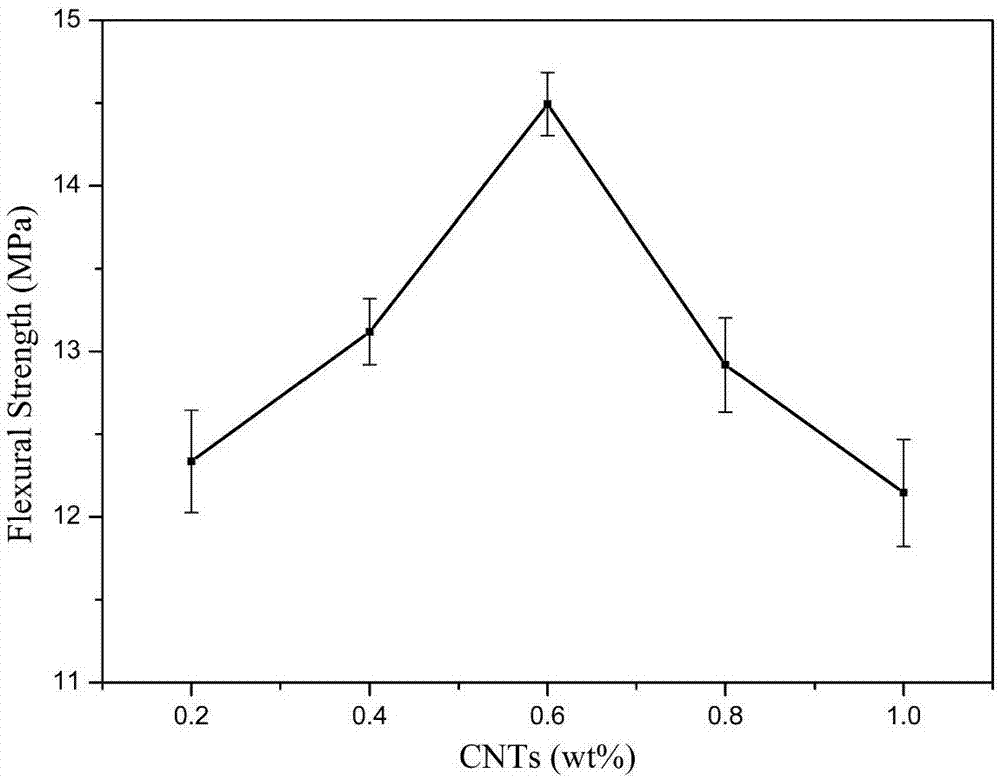

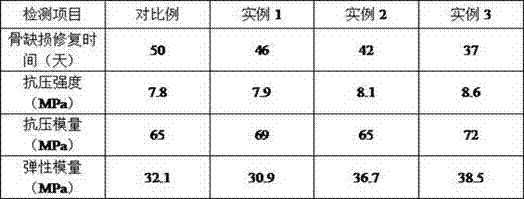

ActiveCN107362389AHigh strengthGood biocompatibilityTissue regenerationProsthesisAlpha-tricalcium phosphateCarbon nanotube

The invention discloses a calcium phosphate biological bone cement composite material reinforced by carbon nanotube and graphene. The calcium phosphate biological bone cement composite material is composed of the following components in parts by weight: 94.2-95 parts of alpha-tricalcium phosphate, 4.8-5.2 parts of hydroxyapatite, 0.2-1 part of graphene, and 0.2-1 part of carbon nanotube. According to the calcium phosphate biological bone cement composite material, graphene and the carbon nanotube are adopted as the reinforcing bodies of alpha-tricalcium phosphate bone cement, so that the prepared calcium phosphate biological bone cement composite material has good strength and good biocompatibility, meanwhile, after microwave treatment, the coagulation time of the calcium phosphate biological bone cement composite material can be greatly shortened, and the strength of the calcium phosphate biological bone cement composite material is further improved. The calcium phosphate biological bone cement composite material can be used for repairing and replacing human bones and treating other orthopedic diseases. The problems of low strength and poor toughness existing in the calcium phosphate biological bone cement composite material in the prior art are solved.

Owner:SHANDONG UNIV

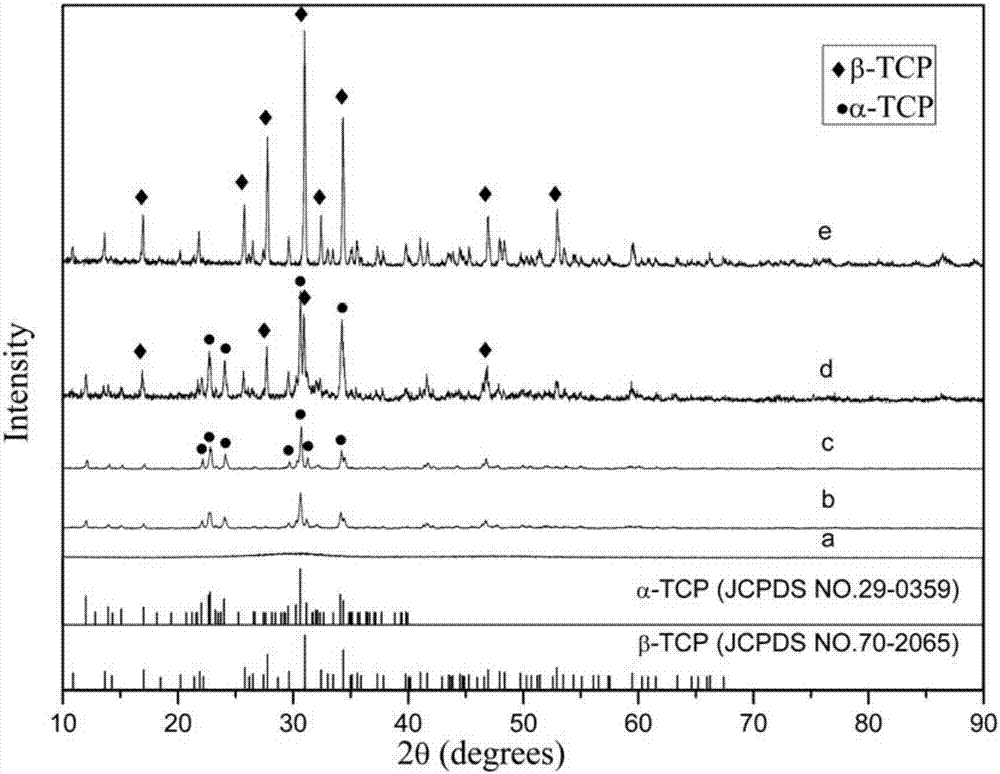

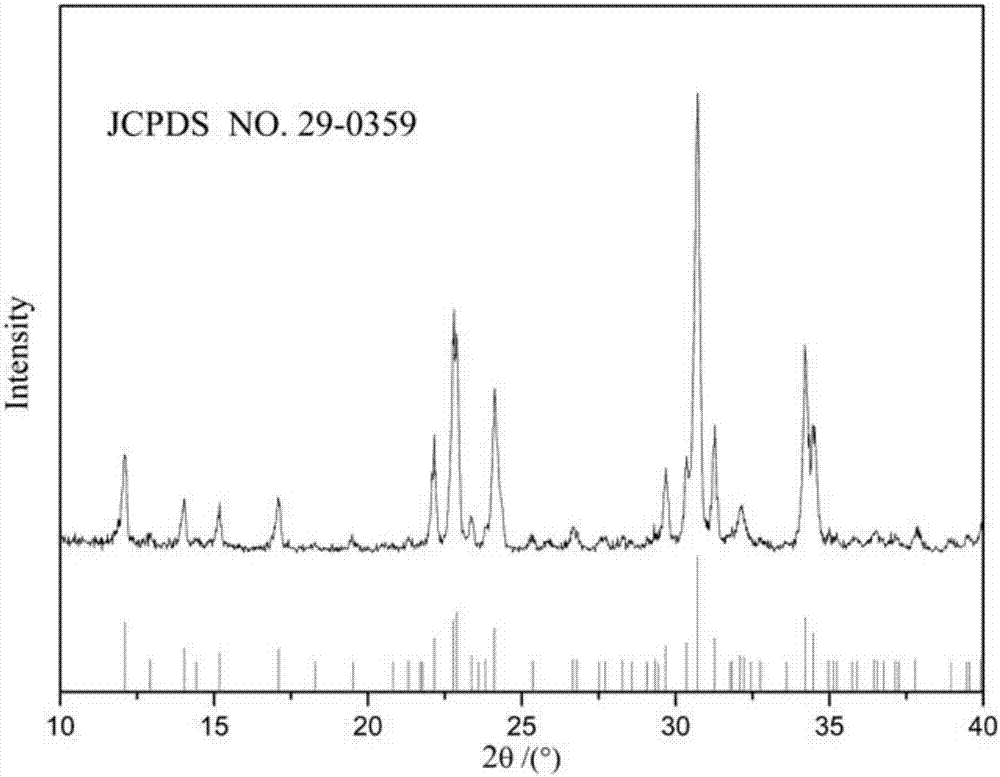

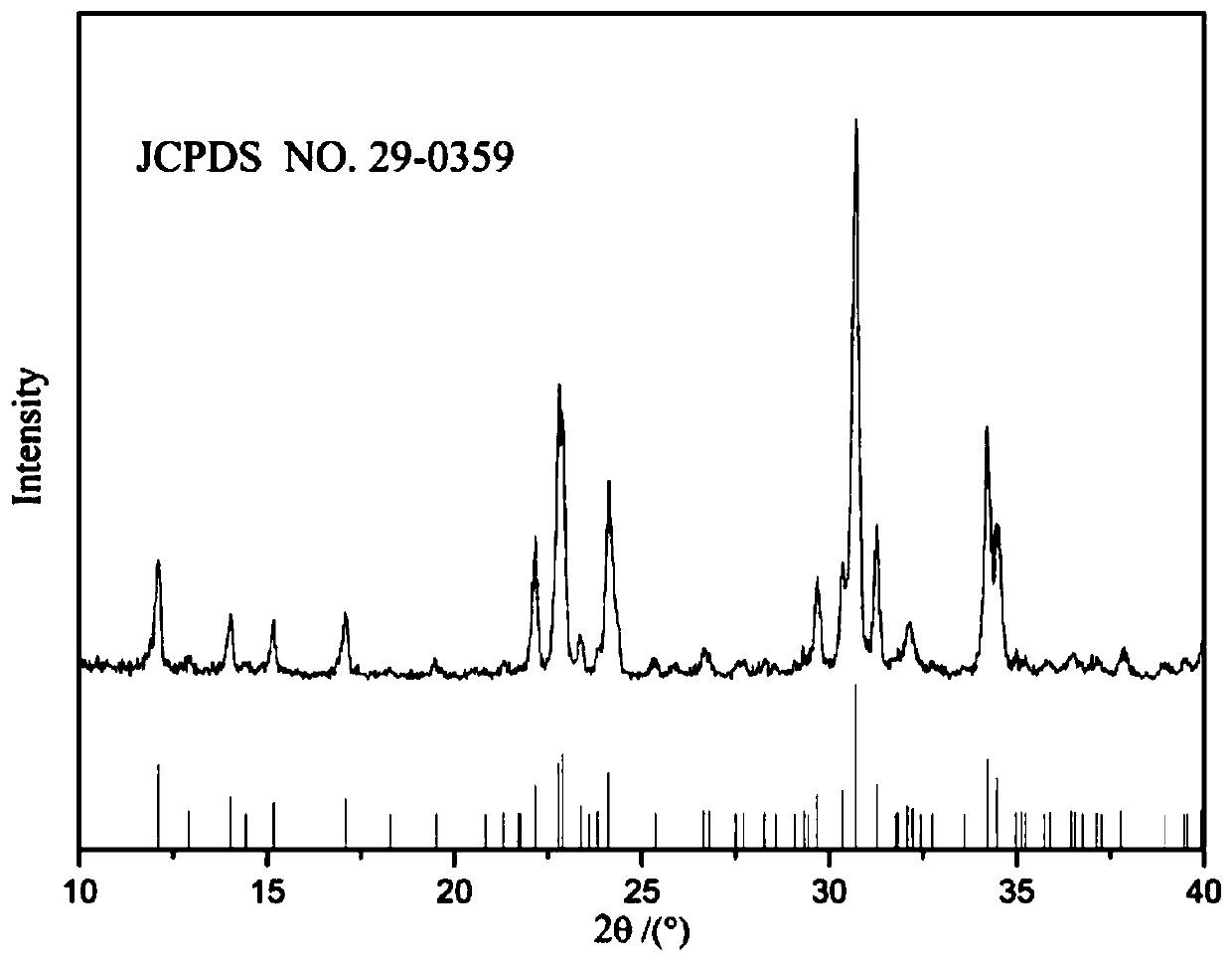

Method of preparing alpha-tricalcium phosphate through low temperature calcining

ActiveCN107188148AImprove performanceSimple processMaterial nanotechnologyPhosphorus compoundsSal ammoniacAlpha-tricalcium phosphate

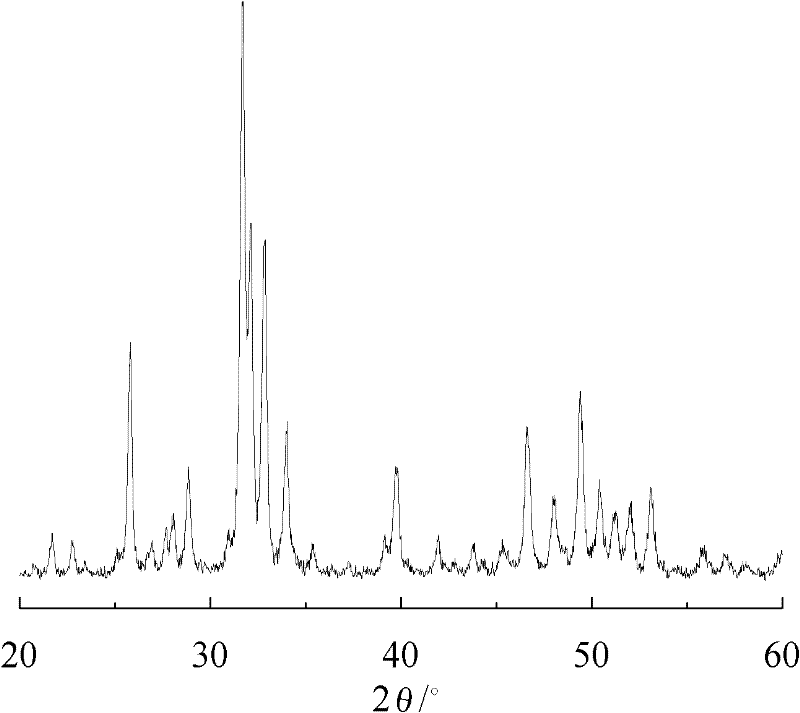

The invention discloses a method of preparing alpha-tricalcium phosphate through low temperature calcining. According to the method, alpha-cyclodextrin is taken as the template, Ca(NO3)2.4H2O, and (NH4)2HPO4 are taken as the raw materials, the standing time of the solution is controlled, the pH is adjusted by ammonia liquor, a chemical precipitation method is adopted to obtain an amorphous tricalcium phosphate precursor, the amorphous tricalcium phosphate precursor is dried by a special mode, then the precursor is calcined for 2 to 4 hours at a constant temperature of 600 to 650 DEG C, and finally the precursor is cooled in the furnace to obtain the alpha-tricalcium phosphate. The technology is simple, the energy consumption is little, and the cost is low. The detection on the curing performance of alpha-tricalcium phosphate and mechanical properties after curing shows that the performance of prepared alpha-tricalcium phosphate is better than that of alpha-tricalcium phosphate prepared by a conventional technology.

Owner:SHANDONG UNIV

Preparation method of silicon-doped alpha-tricalcium phosphate ceramic

ActiveCN104557015AEasy to synthesizeOvercome the gross disadvantageNano siliconAlpha-tricalcium phosphate

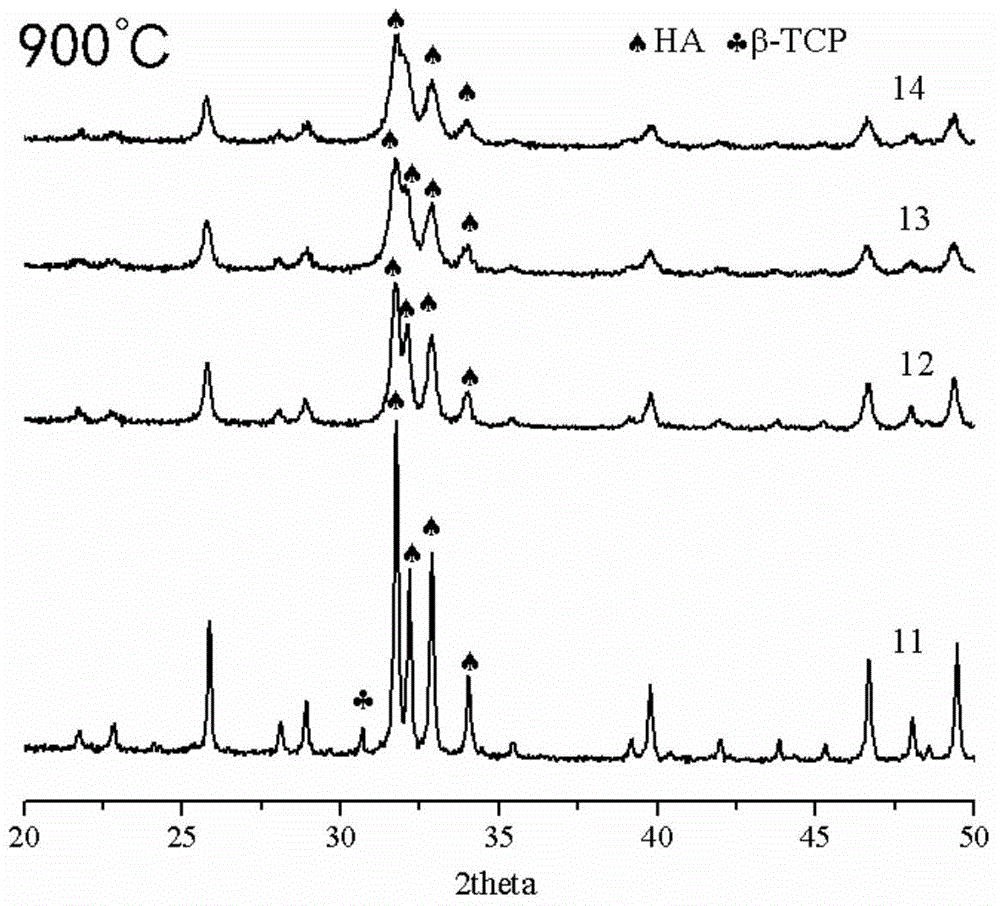

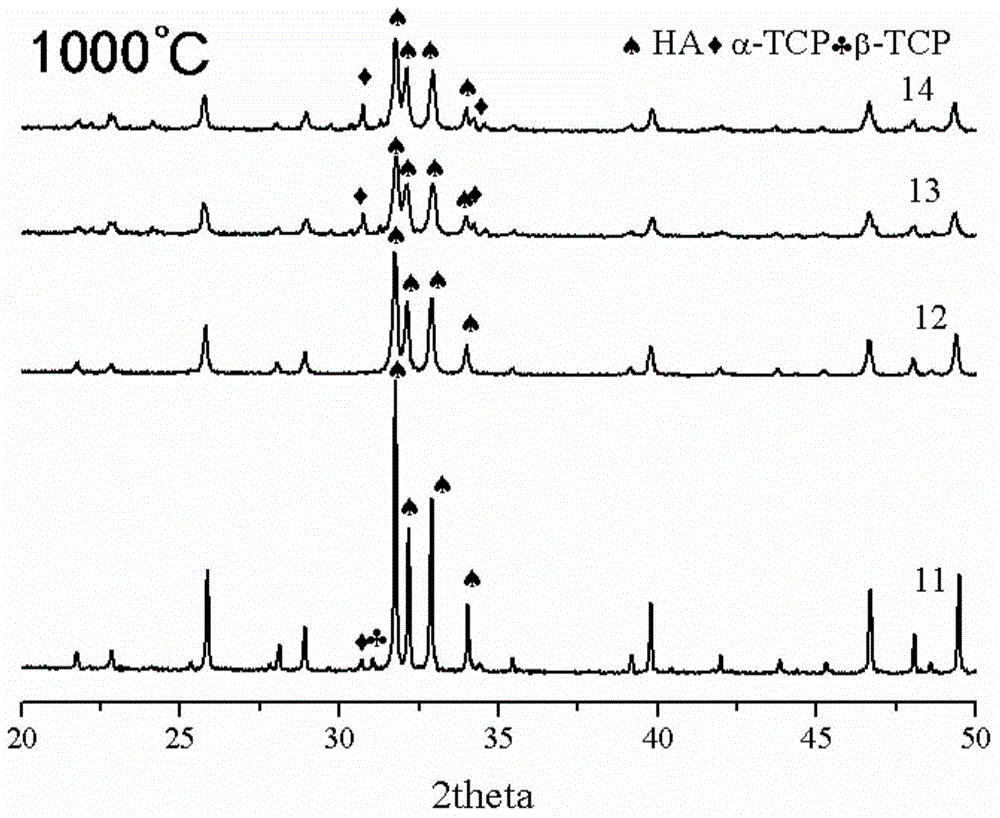

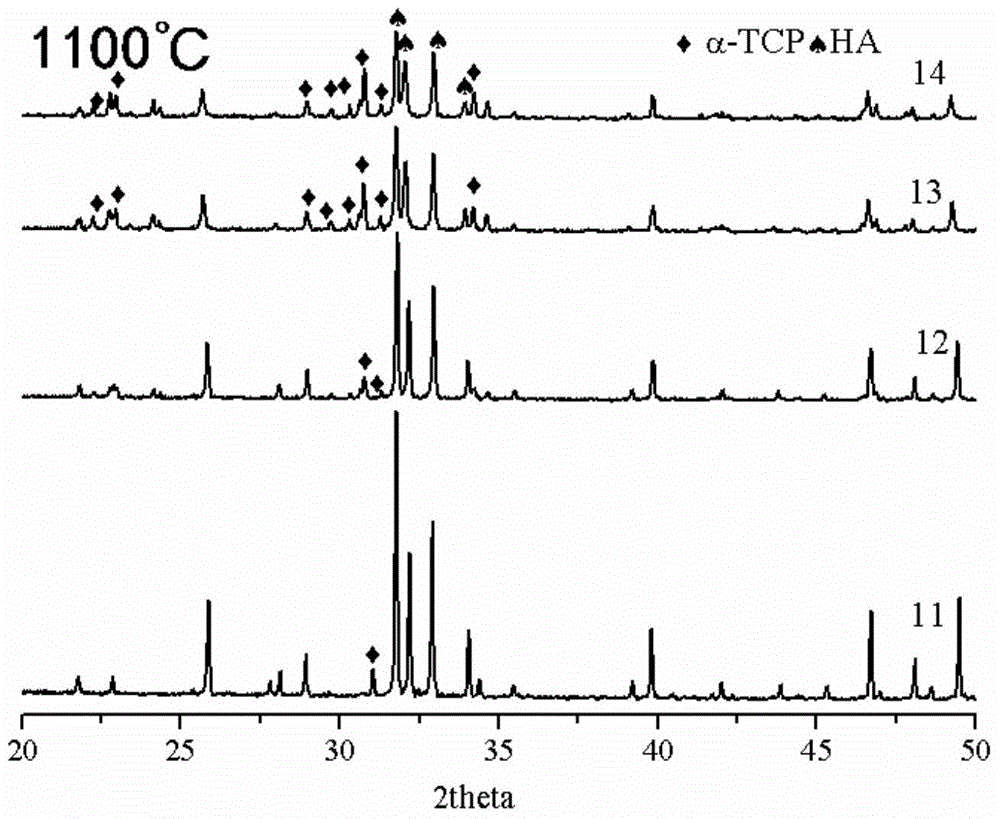

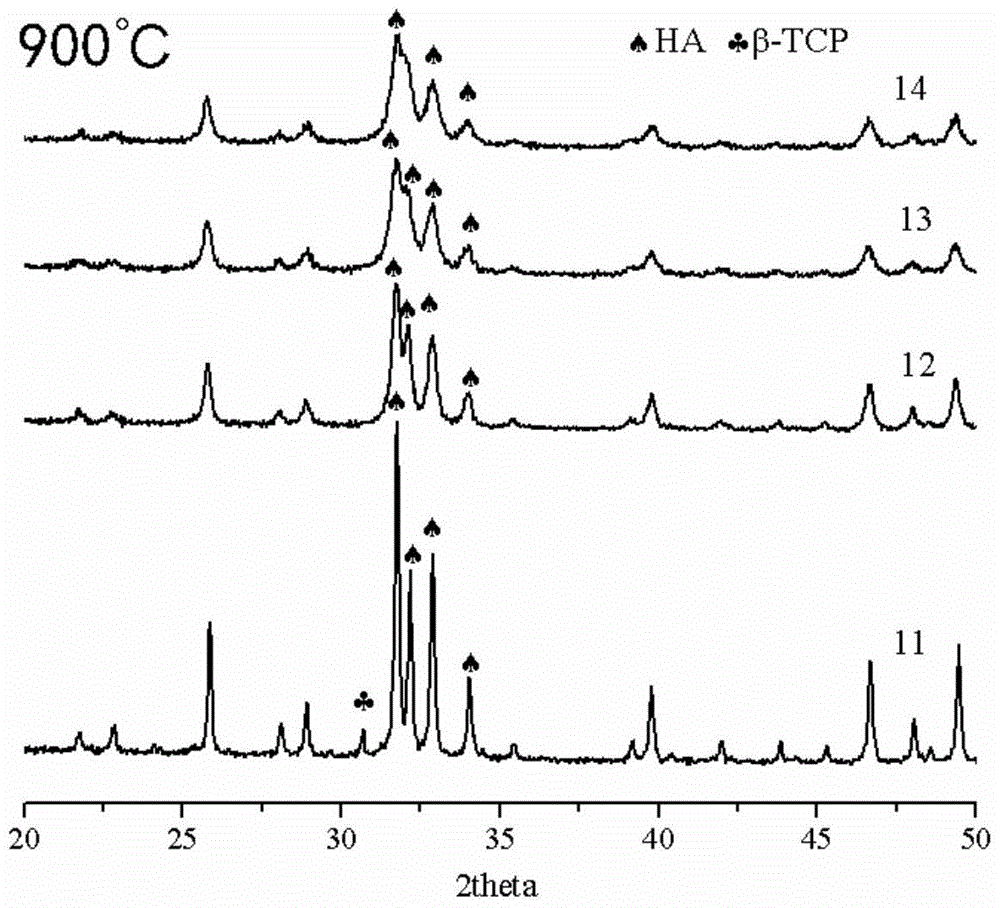

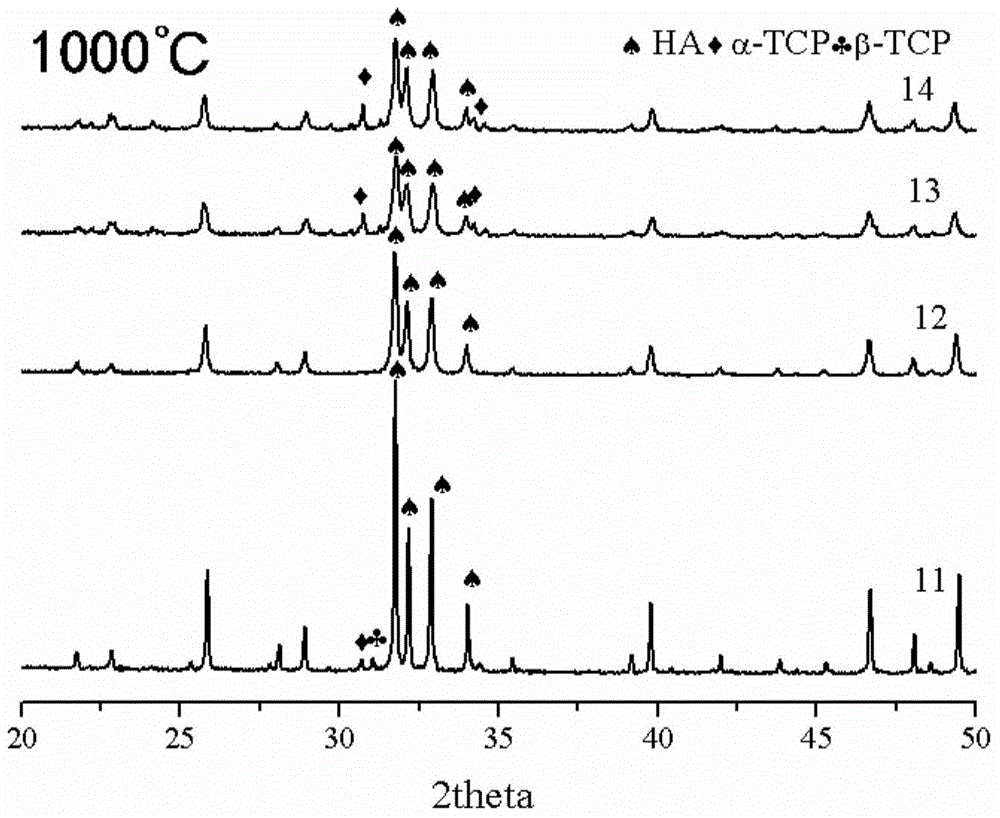

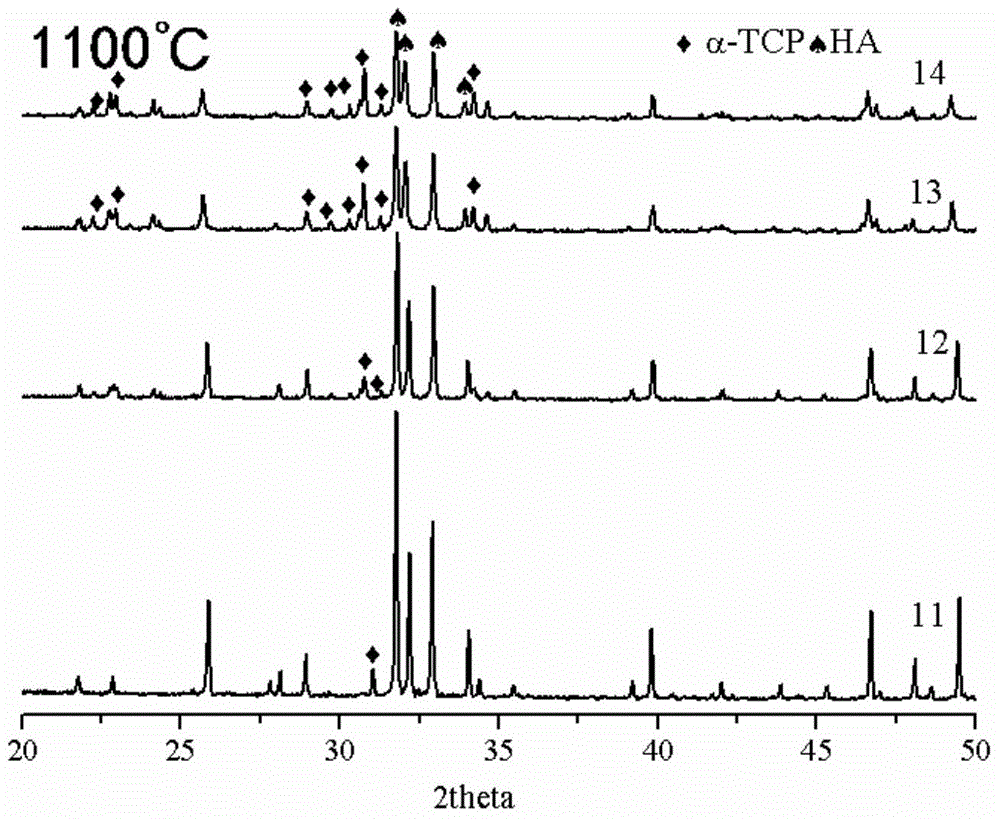

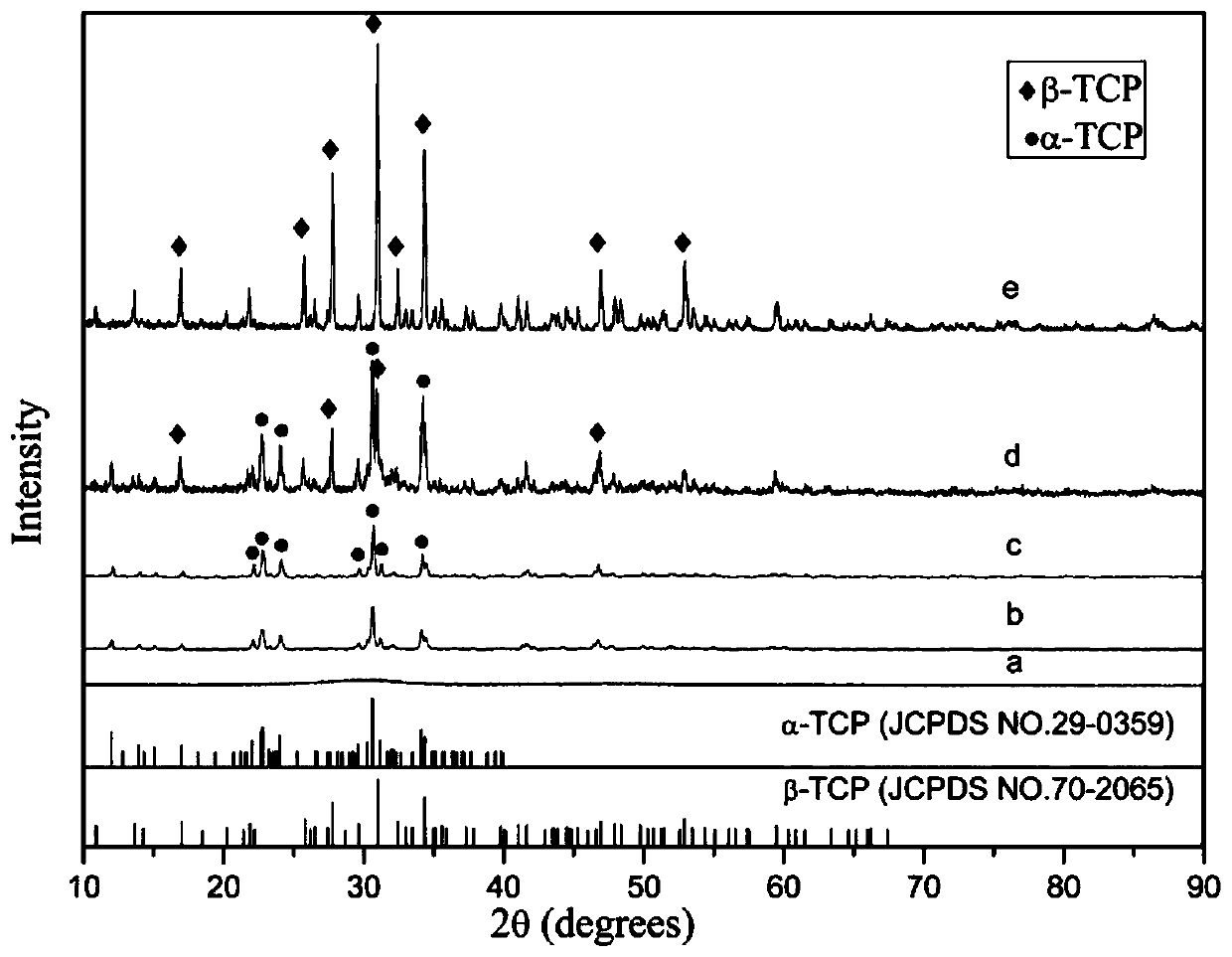

The invention discloses a preparation method of silicon-doped alpha-tricalcium phosphate ceramic. The preparation method comprises the following steps: (1) mixing Ca(NO3)2.4H2O, (NH4)3PO4.3H2O and Si(OCH2CH3)4 of different amounts at a certain temperature according to a molar ratio Ca / (P+Si)=1.67 to obtain precursor nano silicon-doped hydroxyapatite powder; and (2) sintering the precursor nano silicon-doped hydroxyapatite powder in a muffle at 900-1,200 DEG C according to a heating rate of 5-10 DEG C / min, preserving heat for 3-10h, and cooling to normal temperature at a cooling rate of 5-10 DEG C / min to obtain ceramic powder. Compared with the prior art, the method disclosed by the invention can be used for preparing Si-alpha-TCP ceramic powder without beta-TCP at a relatively low temperature, and the content of Si-alpha-TCP can be controlled by controlling the silicon doping amount and the precursor synthesis temperature.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing pyrogene-free calcium phosphate

InactiveUS20100055018A1Accelerate transformationAvoid problemsPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAlpha-tricalcium phosphateGas phase

The method relates to the production of essentially pyrogene-free calcium phosphate starting from one or more calcium phosphate educts having a Ca / P molar ratio in the range of 1.00 to 2.00 and being formed in a pre-determined shape which remains essentially the same during the following procedural steps: A) transforming said educt(s) at least partly to beta-tricalcium phosphate (α-TCP), alpha-tricalcium phosphate (α-TCP), tetracalciumphosphate.(TetCP) or a mixture thereof at a temperature above 600° C.; B) cooling down the material obtained in step A with said β-TCP, α-TCP, TetCP or a mixture thereof to below 600° C.; C) reacting the material obtained in step B with said β-TCP, α-TCP, TetCP or a mixture thereof with water in gas or liquid phase or in an aqueous Solution at a temperature above room temperature to obtain an end-product which is essentially pyrogene-free. The pyrogene-free calcium phosphate obtained as an end-product by the method according to the invention can be advantageously used as a bone fixation or bone replacement implant or as a surface layer for a bone fixation or bone replacement implant.

Owner:DR H C ROBERT MATHYS STIFTUNG

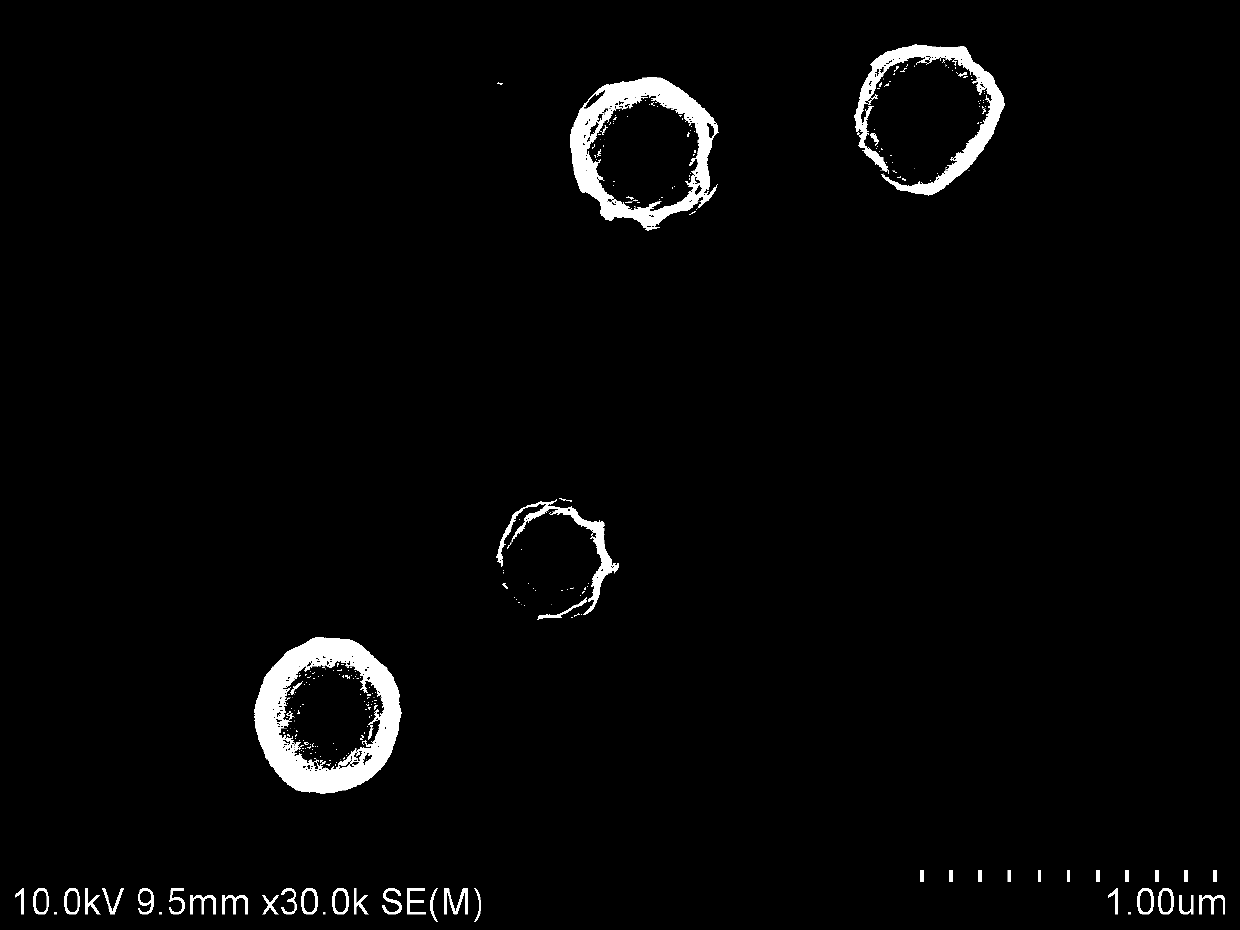

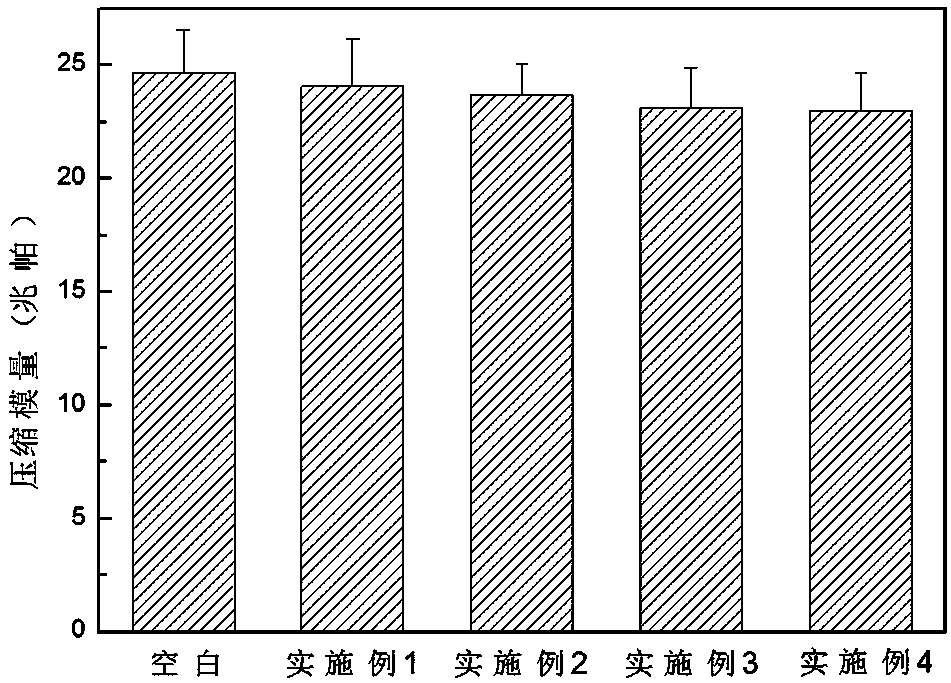

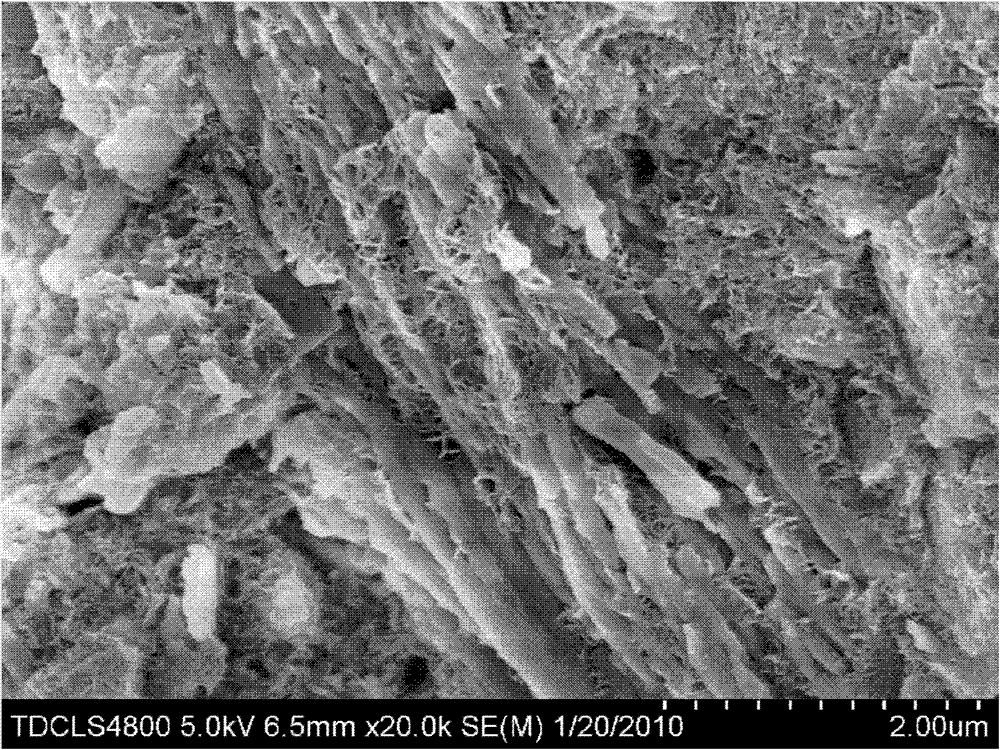

Biological porous bone cement prepared by compositing Sr-doped calcium-phosphorus bioglass and alpha-tricalcium phosphate and preparation method thereof

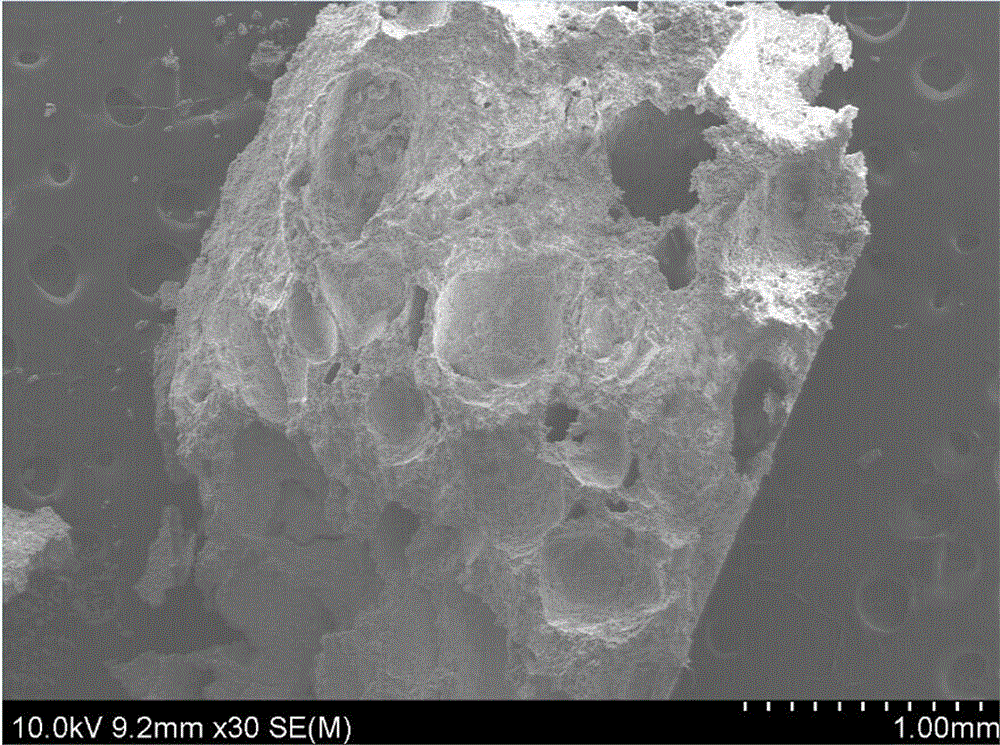

InactiveCN102249728AHigh compressive strengthPromote degradationCeramicwarePorosityAlpha-tricalcium phosphate

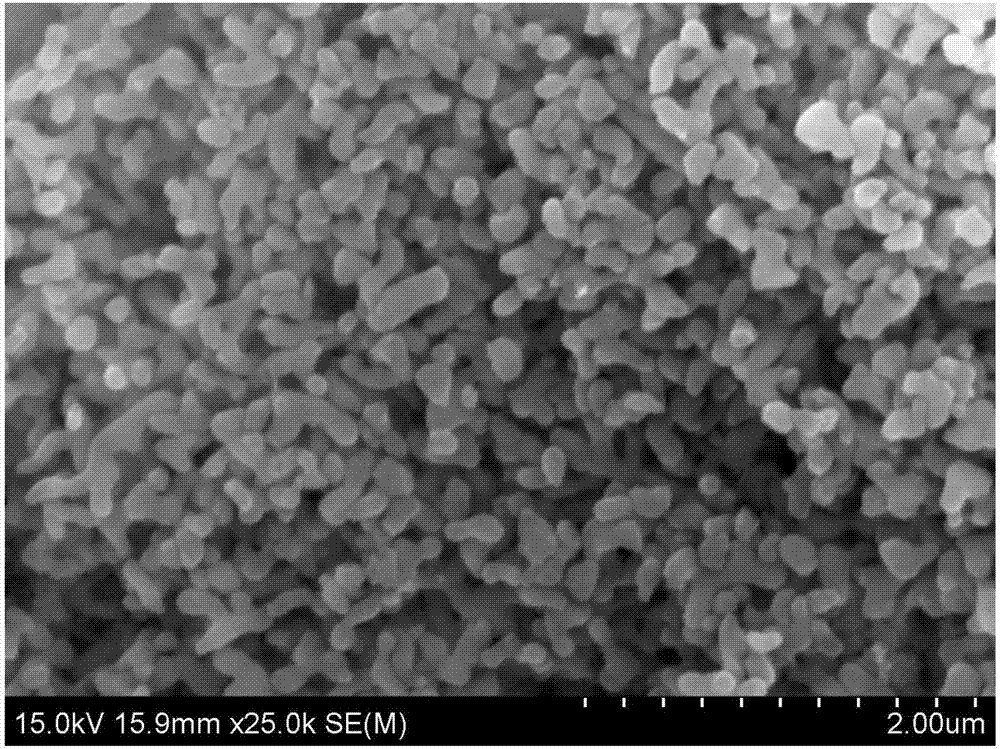

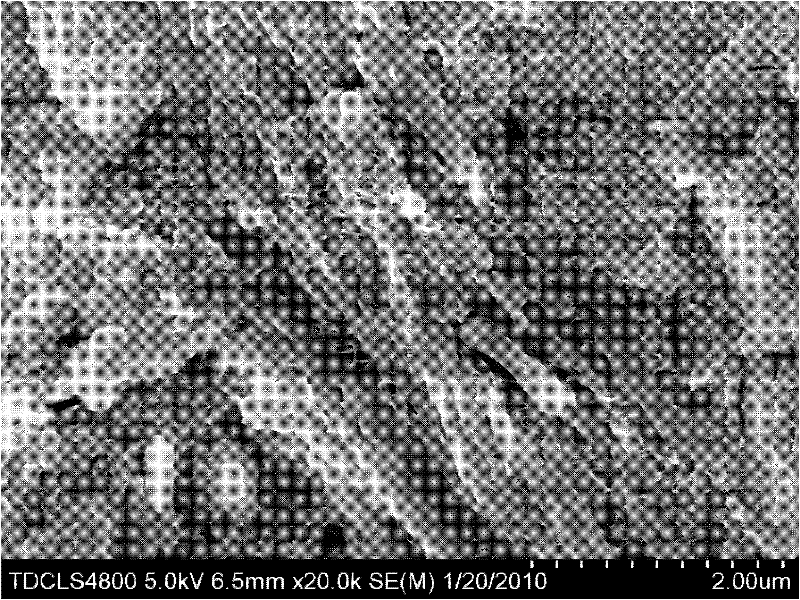

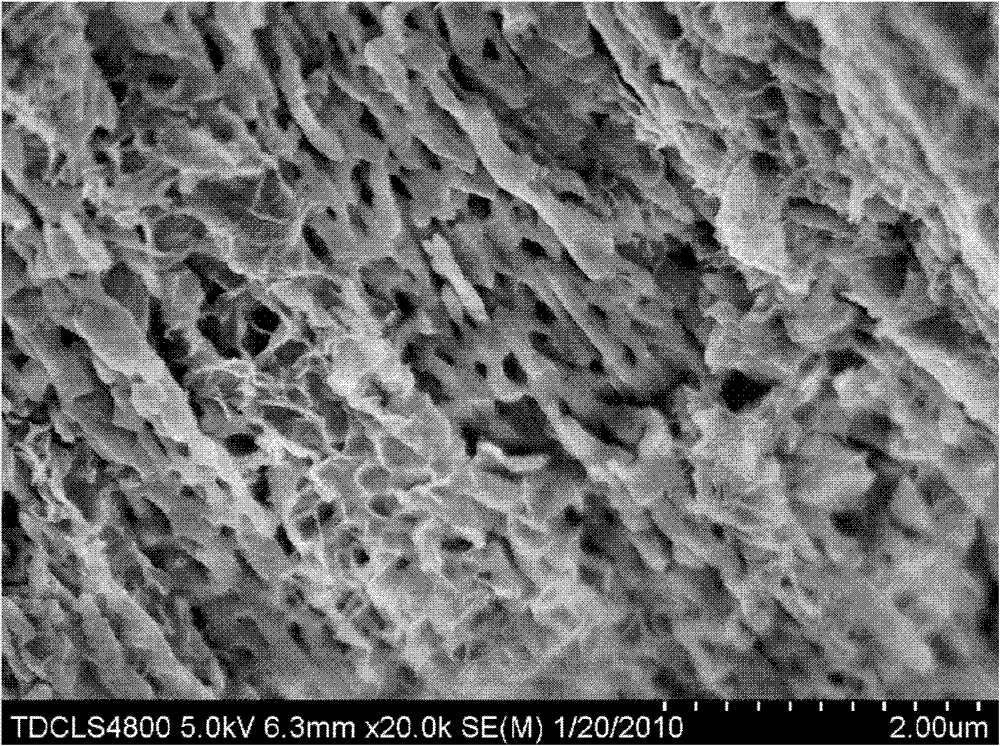

The invention relates to a biological porous bone cement prepared by compositing Sr-doped calcium-phosphorus bioglass and alpha-tricalcium phosphate and a preparation method thereof. The bone cement provided by the invention is characterized in that the porousness of the bone cement is 39-57%, and the size of a micropore is between 0.5 um and 4 um; and the compression strength is 23.6-38.5 Mpa. In the invention, through compositing the Sr-doped calcium-phosphorus bioglass and alpha-tricalcium phosphate, the porous-structured bone cement is formed. In the invention, the solidification time and microstructure of the bone cement can be adjusted through the rapid dissolving of the Sr-doped calcium-phosphorus glass so as to form a porous structure with a high porousness, and the degradation property of a hydrated product (hydroxyapatite) can be improved; and in addition, by virtue of Sr ions introduced by biodegradable calcium-phosphorus glass, the compression strength of the bone cement is improved, thereby achieving the properties such as high strength and good degradability of the bone cement better.

Owner:TIANJIN UNIV

Preparation method for natural bone repairing material capable of accelerating osteanagenesis

InactiveCN106943623AGood osteoinductivityPromote regenerationTissue regenerationProsthesisAlpha-tricalcium phosphateBiocompatibility Testing

The invention discloses a preparation method for a natural bone repairing material capable of accelerating osteanagenesis, and belongs to the technical field of medical materials. The preparation method comprises the following steps: calcining by taking ox bones as raw materials, generating a high-intensity alpha-tricalcium phosphate crystal form and a high-degradability high-bioactivity excellent-osteoinductivity beta-tricalcium phosphate crystal form; then, compounding with carboxymethylcellulose to prepare composite powder; mixing with deionized water for carrying out compression moulding, and drying to obtain a bracket material; subsequently, mixing bone morphogenetic protein, platelet-derived growth factors and phosphate buffer to prepare phosphate nutrient solution; then, dipping the bracket material in the phosphate nutrient solution for culture growth; finally, taking out, drying and sterilizing the bracket material to obtain the natural bone repairing material capable of accelerating osteanagenesis. The bone repairing material prepared with the preparation method has the advantages of high mechanical strength, good biocompatibility with the human body, good osteoinductive activity, good biodegradability and a wide application prospect, and bone defect repair can be quickly finished.

Owner:常州力纯数码科技有限公司

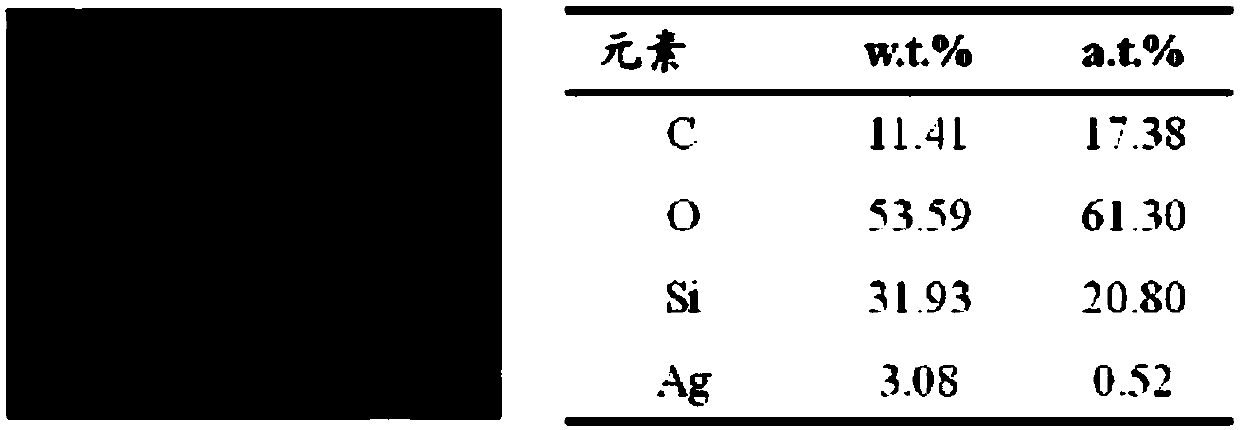

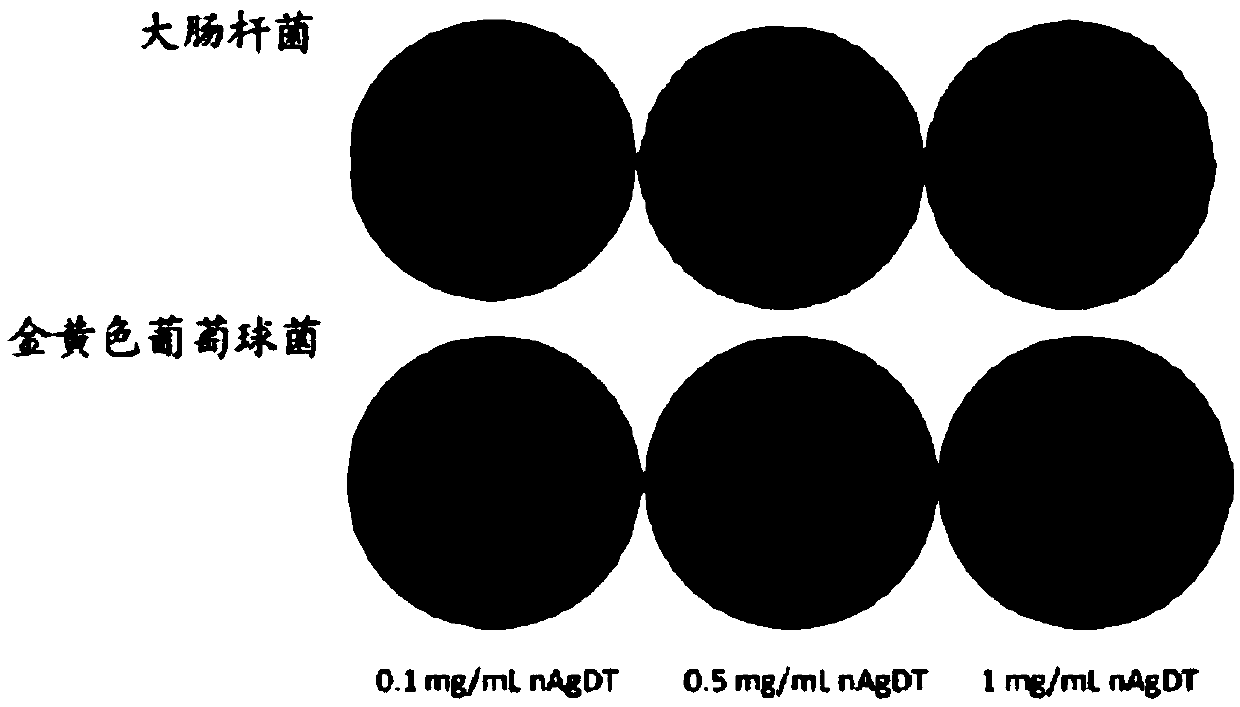

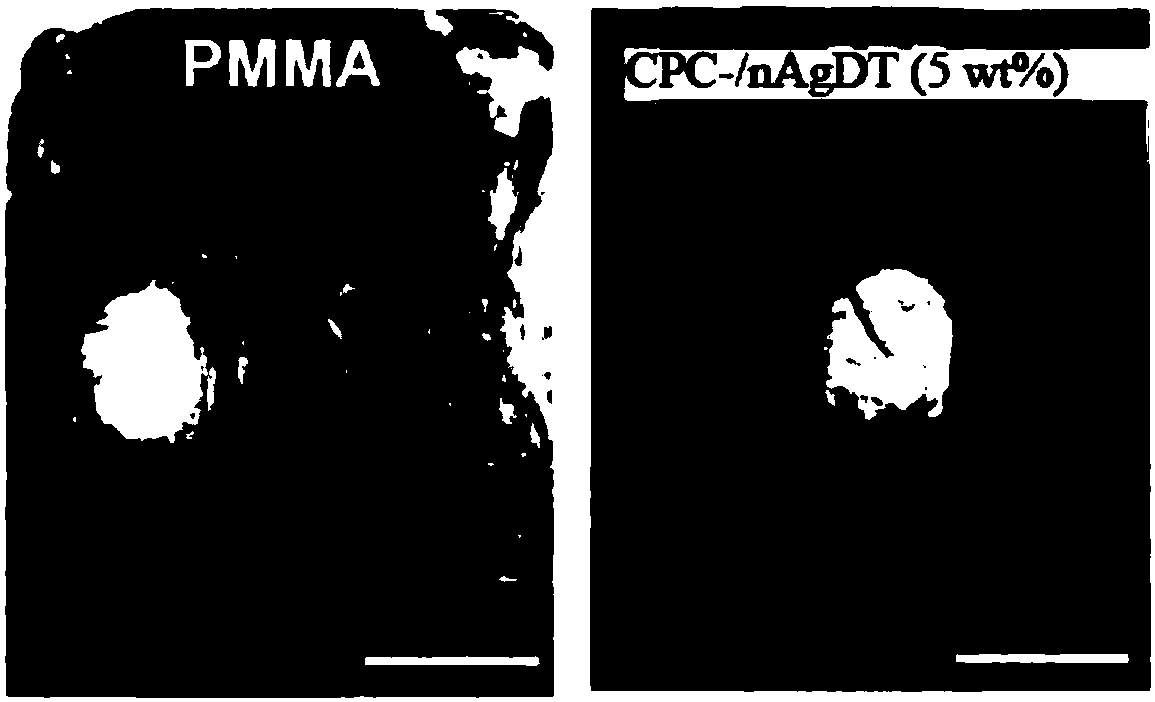

Bone cement as well as preparation method and application thereof

ActiveCN107899073APharmaceutical delivery mechanismProsthesisAlpha-tricalcium phosphateGlucocorticoid

The invention relates to bone cement as well as a preparation method and application thereof. The bone cement is prepared from 50 to 92 weight percent of alpha-tricalcium phosphate, 3 to 10 weight percent of dicalcium phosphate dihydrate, 2 to 30 weight percent of starch and 0.5 to 15 weight percent of nano-silver loaded diatomite. The bone cement disclosed by the invention has the advantages of injection, antibacterial property and degradability, and can be used for treating vertebral compression fracture caused by osteoporosis induced by glucocorticoid.

Owner:PEKING UNIV FIRST HOSPITAL

Calcining defluorination method in feed-grade tricalcium phosphate production

InactiveCN106698375ACalcination temperature is lowThe mass fraction of fluorine is smallPhosphorus compoundsAlpha-tricalcium phosphateCombustion

The invention discloses a calcining defluorination method in feed-grade tricalcium phosphate production. According to the method, phosphoric acid is added to dry rock phosphate and sodium salt and the materials undergo granulation in a disk granulating machine; the granulated materials enter a rotary calcining kiln from the tail part; primary air and secondary air are introduced into the kiln head of the rotary calcining kiln so as to support combustion of fuel in the combustion section, and the materials undergo countercurrent calcining in the combustion section of the rotary calcining kiln; a steam pipeline extends into the kiln, steam which accounts for 10-60% of content of the total materials is added according to content of the materials and content of fluorine in the raw materials during calcining, and letting the steam fully react with the materials to take away the fluorine in the form of HF from the materials by tail gas. After the calcining, mass fraction of the fluorine in the materials is less than 0.18%. The method is simple, convenient and stable to operate, and no defluorination agent is added. Cost is low, and content of fluorine in the product can be effectively reduced. In the production, steam can be adjusted according to the content of fluorine in the materials. The method is easy to control, and the content of fluorine in the product is stable. The method is an ideal defluorination technology for the feed-grade tricalcium phosphate production.

Owner:WENGFU (GRP) CO LTD

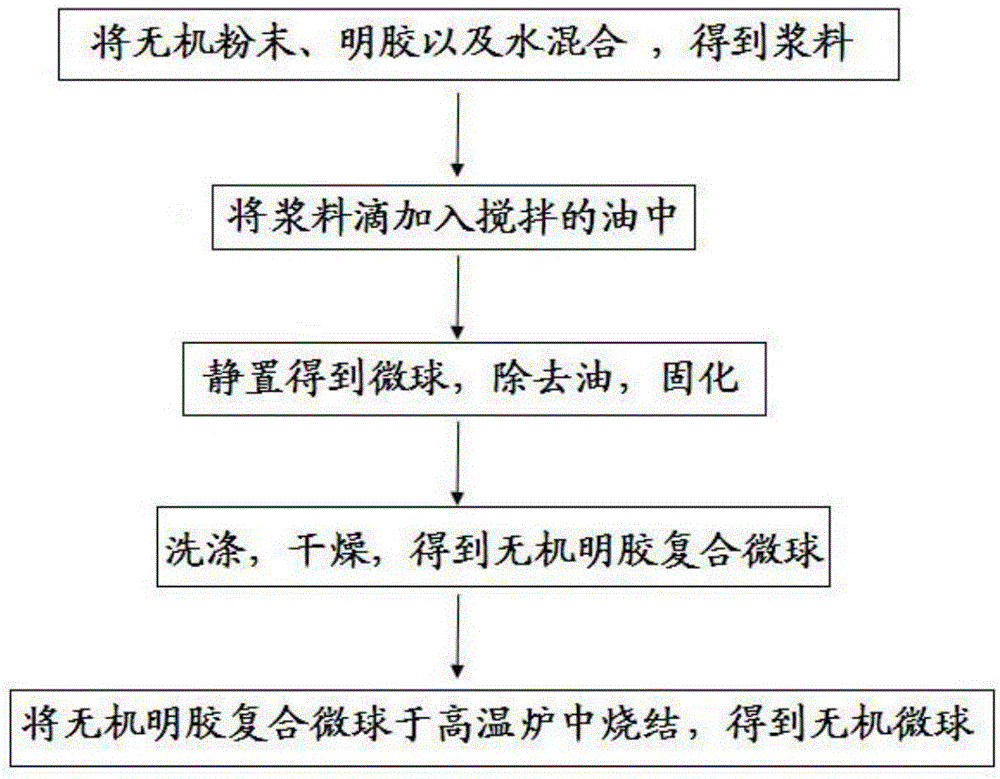

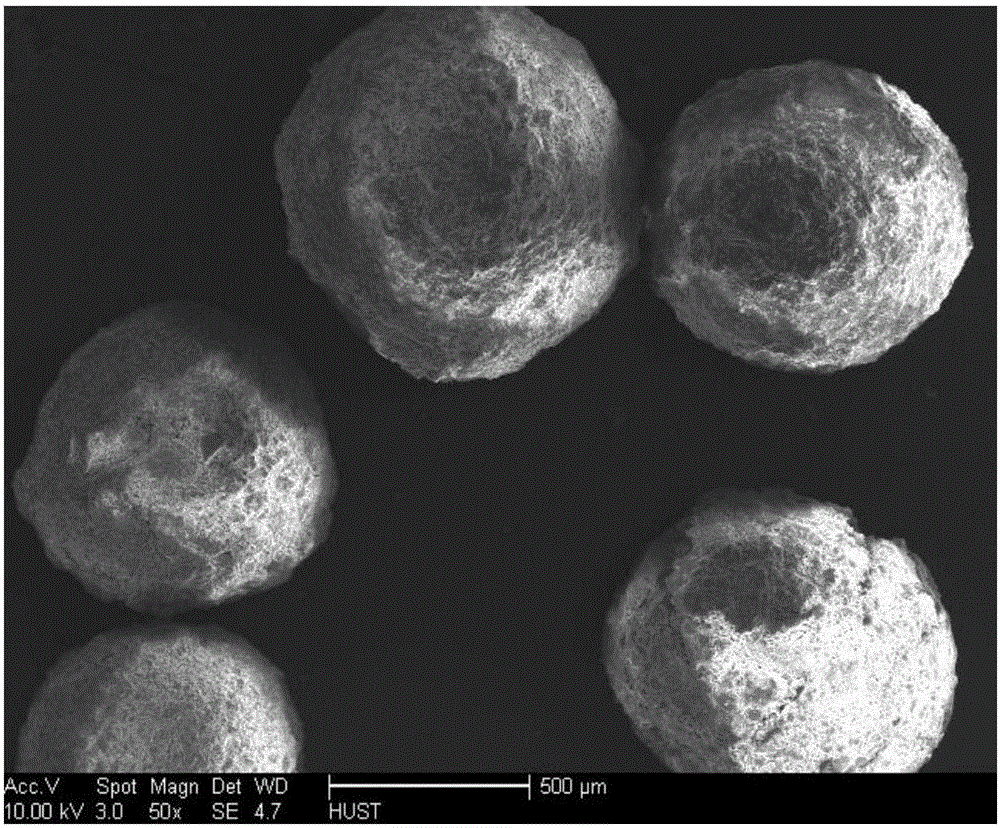

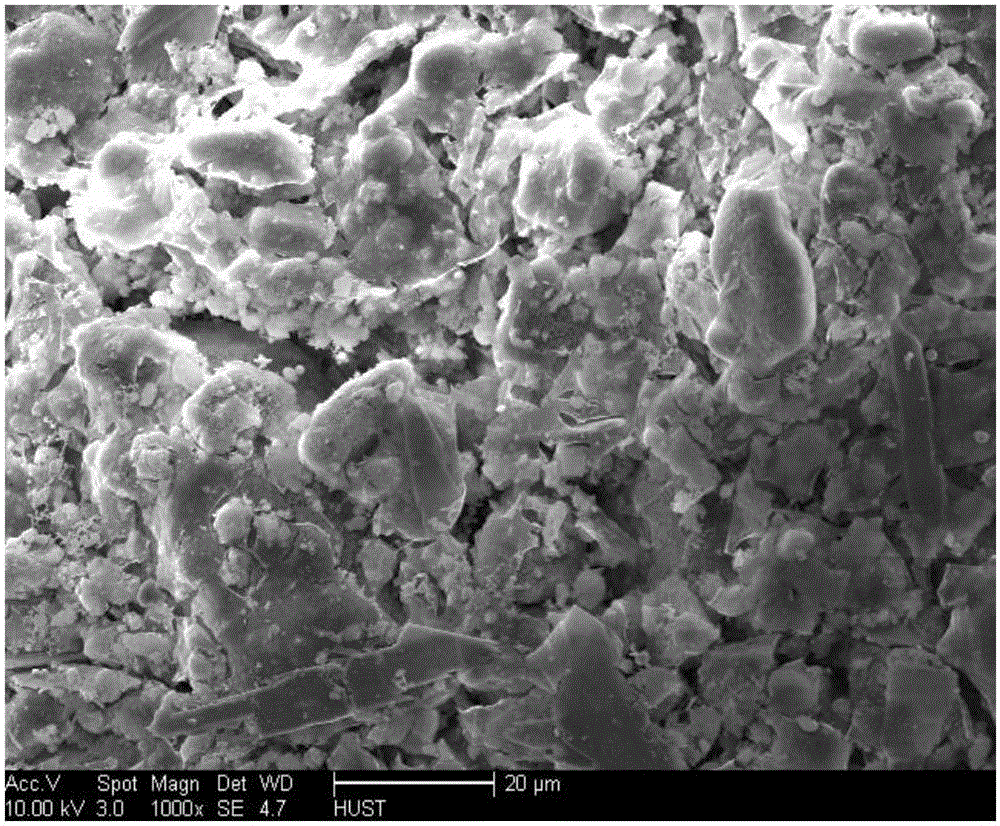

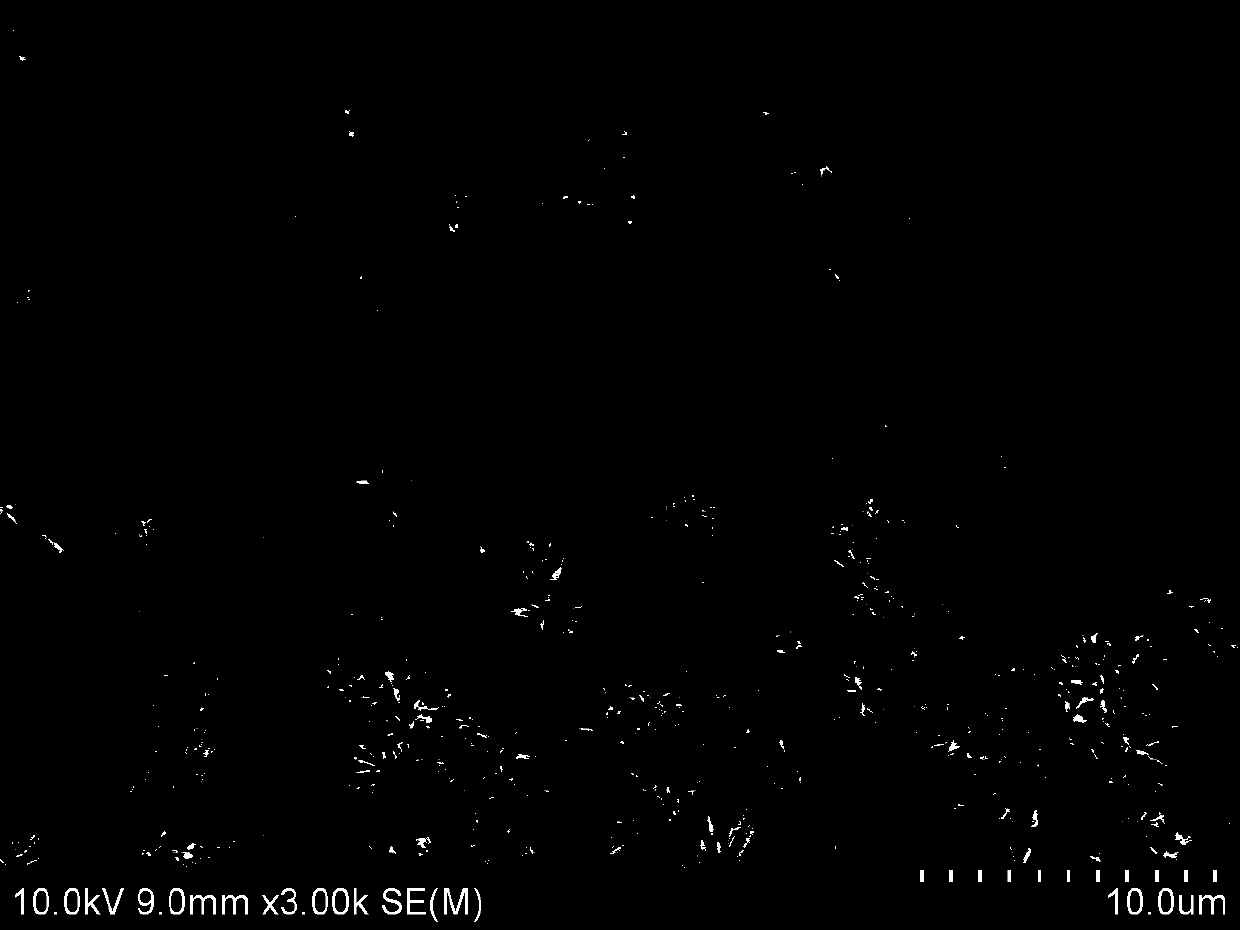

Preparation method for inorganic microspheres, inorganic microspheres prepared thereby, and application of inorganic microspheres

ActiveCN105858629ASmall particle sizeLarge specific surface areaPhosphorus compoundsMagnesiaAlpha-tricalcium phosphateInjectable bone

The invention relates to a preparation method for inorganic microspheres, the inorganic microspheres prepared by the preparation method, and an application of the inorganic microspheres. The preparation method for the inorganic microspheres comprises the following steps: with gelatin as a microsphere template, controlling a sphere-shaping temperature and a sphere diameter, preparing inorganic powder into inorganic / gelatin composite microspheres, then carrying out sintering, and removing the gelatin so as to obtain the inorganic microspheres. The preparation method provided by the invention has simple preparation process and good reproducibility, and can obtain the inorganic microspheres with a variety of diameter ranges; the method directly prepares the microspheres through sintering, can prevent the powder sensitive to water from deterioration during formation of the microspheres, and is especially applicable to preparation of the inorganic microspheres sensitive to water (like alpha-tricalcium phosphate and magnesium oxide); meanwhile, the prepared inorganic microspheres have potential application values in the field of injectable bone cement.

Owner:ASIA BIOMATERIALS WUHAN CO LTD

Manufacturing method of tissue engineered cartilage

InactiveCN1565647AEasy to obtainGood biocompatibilitySkeletal/connective tissue cellsProsthesisCartilage cellsAlpha-tricalcium phosphate

The invention belongs to tissue engineering field, and discloses a manufacturing method of tissue engineered cartilage comprising needed degradable porous biological ceramic materials. The invention composite generates cartilage tissue by inorganic biological bracket materials(alpha tricalcium phosphate porous ceramic materials) and tissue cell(cartilage cell) to restore articular cartilage injury. The invention can realize functional restoration of cartilage injury and has a considerate clinical practice prospect.

Owner:INST OF BASIC MEDICAL SCI ACAD OF MILITARY MEDICAL SCI OF PLA

Preparation method of superfine tricalcium phosphate

InactiveCN103071572APromote absorptionThe method is reasonableGrain treatmentsAlpha-tricalcium phosphatePhosphate product

The invention discloses a preparation method of superfine tricalcium phosphate, which comprises the steps that raw materials (phosphoric acid and calcium carbonate) are used for neutralization reaction; a neutralization solution is dried by a spraying dryer at 370-400 DEG C; a crude tricalcium phosphate product is prepared by drying; the crude tricalcium phosphate product is put into a cyclonic high-pressure airflow crusher for crushing and classification; the pressure of air is 0.7-0.8 MPa when the airflow crushing is conducted; the air is sprayed towards a crushing chamber through a supersonic nozzle of the cyclonic high-pressure airflow crusher; crushed materials enter a classifier with upward airflows; the classification is conducted at classification frequency of 55-65Hz; superfine tricalcium phosphate with a particle size of 2-3 micrometers is obtained by the classification; superfine tricalcium phosphate is allowed to pass through a 10-40-mesh sieve; and finished superfine tricalcium phosphate is obtained after magnetic separation. According to the method, a technology is more reasonable; the particle size and the production cost of superfine tricalcium phosphate can be controlled effectively; and prepared superfine tricalcium phosphate has good fluency and is absorbed by a human body easily.

Owner:LIANYUNGANG DEBANG FINE CHEM

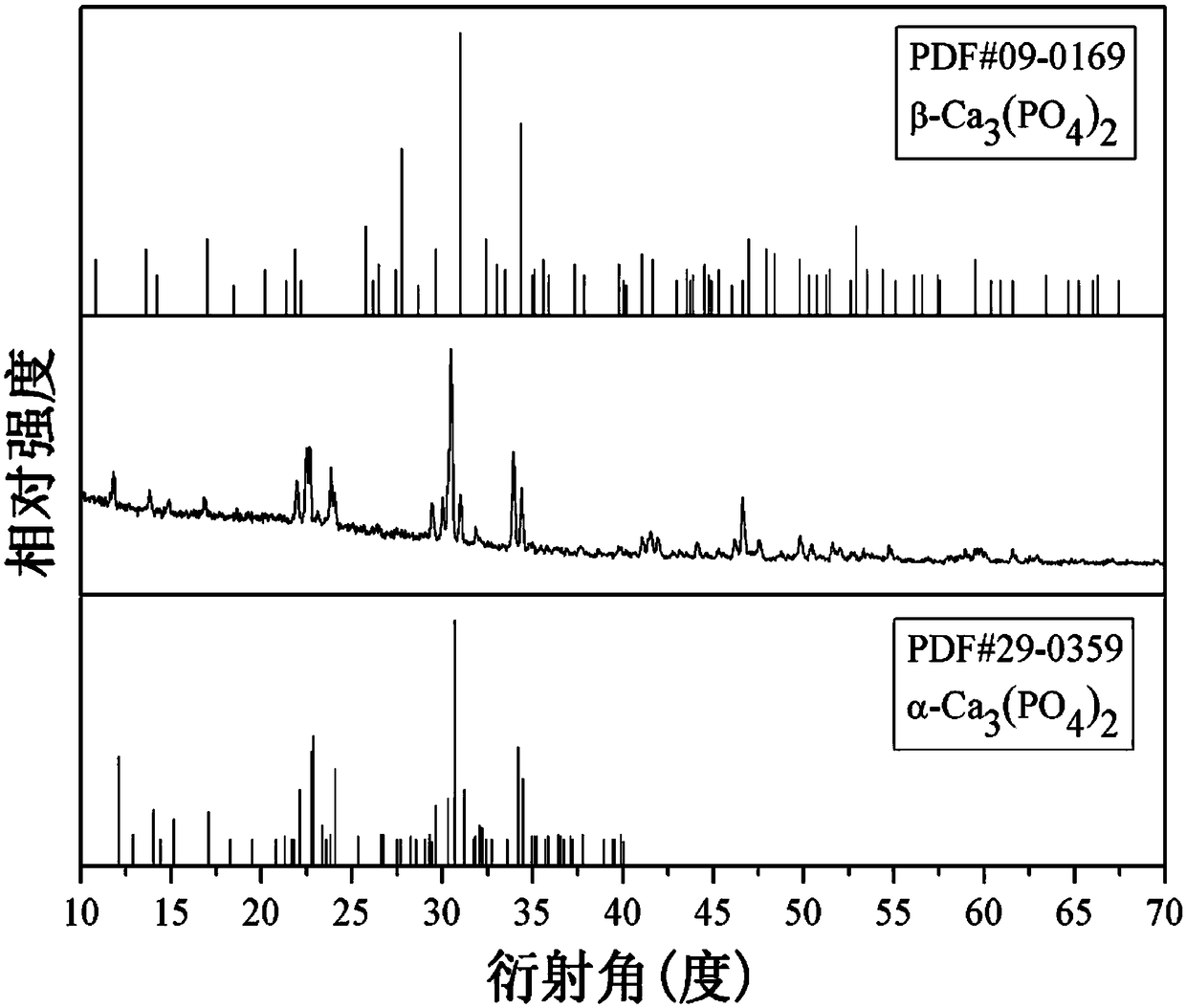

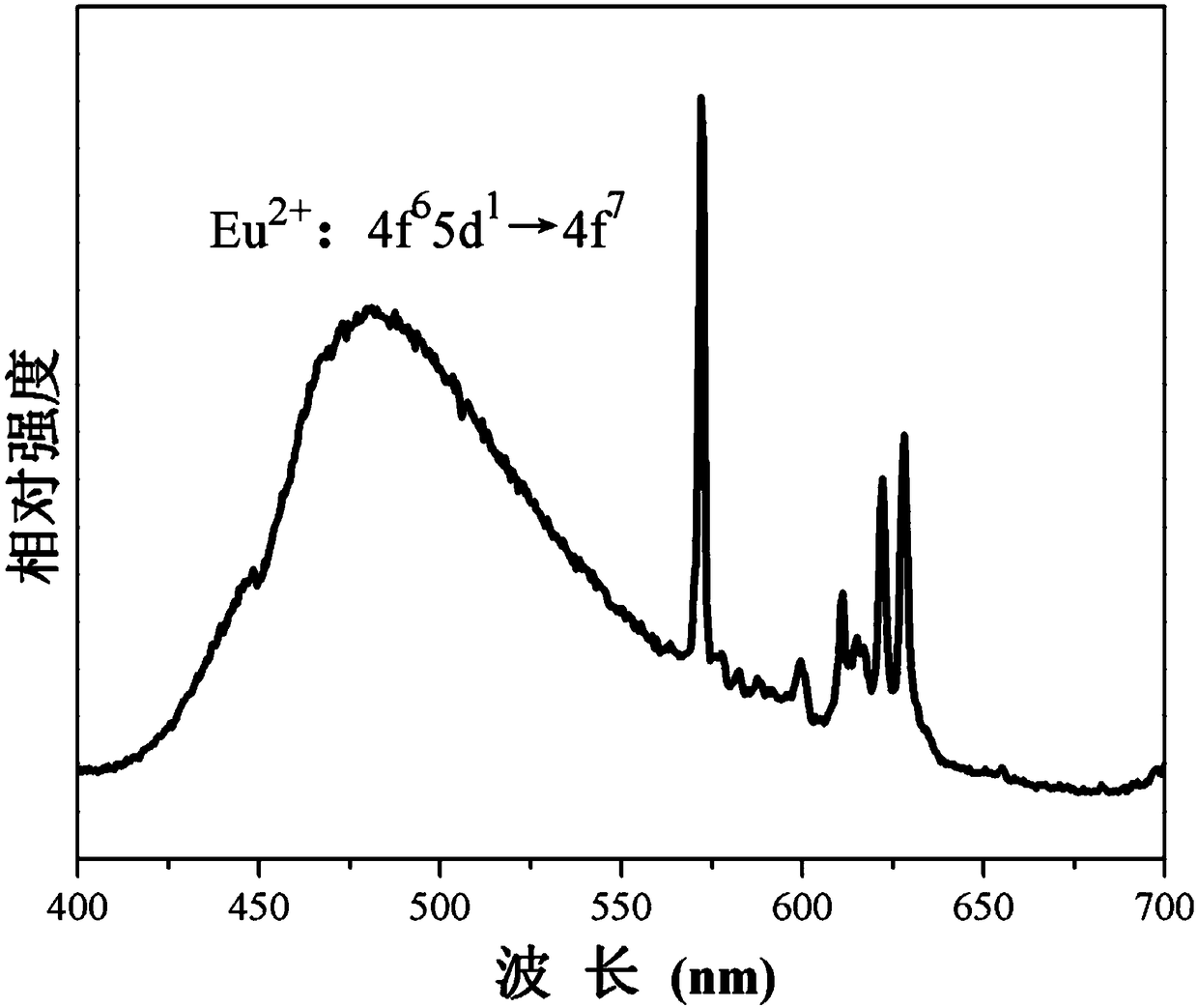

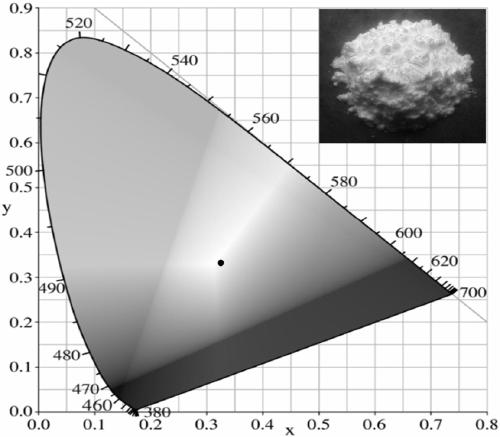

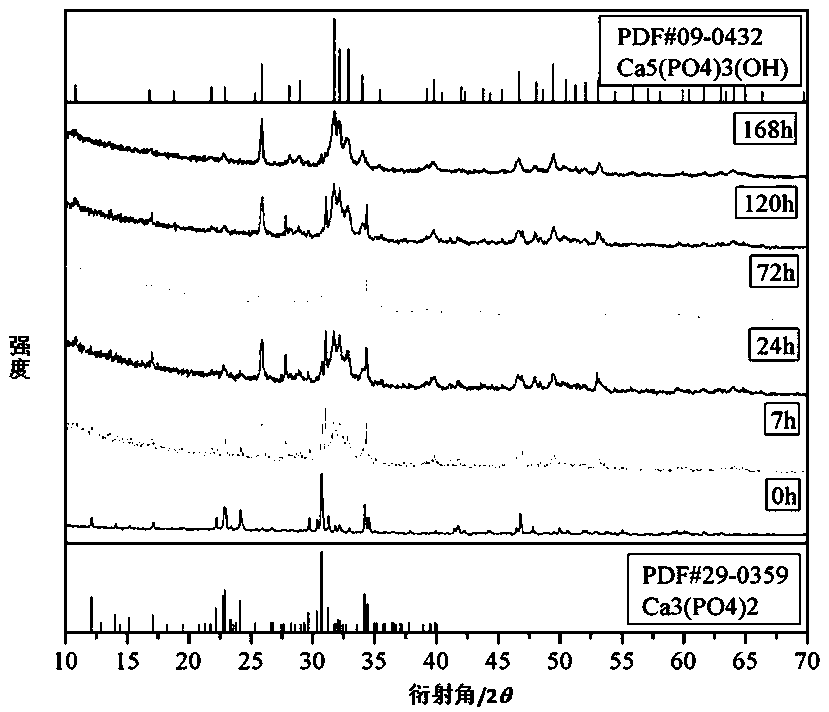

Biphase tricalcium phosphate white phosphor as well as in-situ synthesis method and application thereof

InactiveCN109054836AEasy to replaceProcess stabilityEnergy efficient lightingLuminescent compositionsAlpha-tricalcium phosphateSynthesis methods

The invention relates to the technical field of near UV excited inorganic light emitting materials, in particular to Eu<2+> and Eu<3+> co-activated biphase tricalcium phosphate white phosphor as wellas an in-situ synthesis method and an application thereof. A matrix of the white phosphor is formed through biphase in-situ composition of alpha-tricalcium phosphate and beta-tricalcium phosphate andhas the chemical formula of Ca(3-x)Eux(PO4)2, wherein x is larger than or equal to 0.001 and smaller than or equal to 0.3, and the mole ratio of (Ca+Eu) / P atoms is 1.45-1.55. The white phosphor has the characteristics of single chemical composition, high color purity and color saturation and the like, the color temperature of the while phosphor can be flexibly and conveniently regulated through process control, the light emitting quality is high and the performance is stable. The white phosphor can be used as near UV excited LED white phosphor, has good biocompatibility and high light emittingintensity and can be used as a biofluorescence marker. The provided in-situ synthesis method has the characteristics of being low in equipment input, simple in process, energy-saving, environmentallyfriendly, pollution-free in the process and the like.

Owner:SUZHOU DINGAN ELECTRONICS TECH

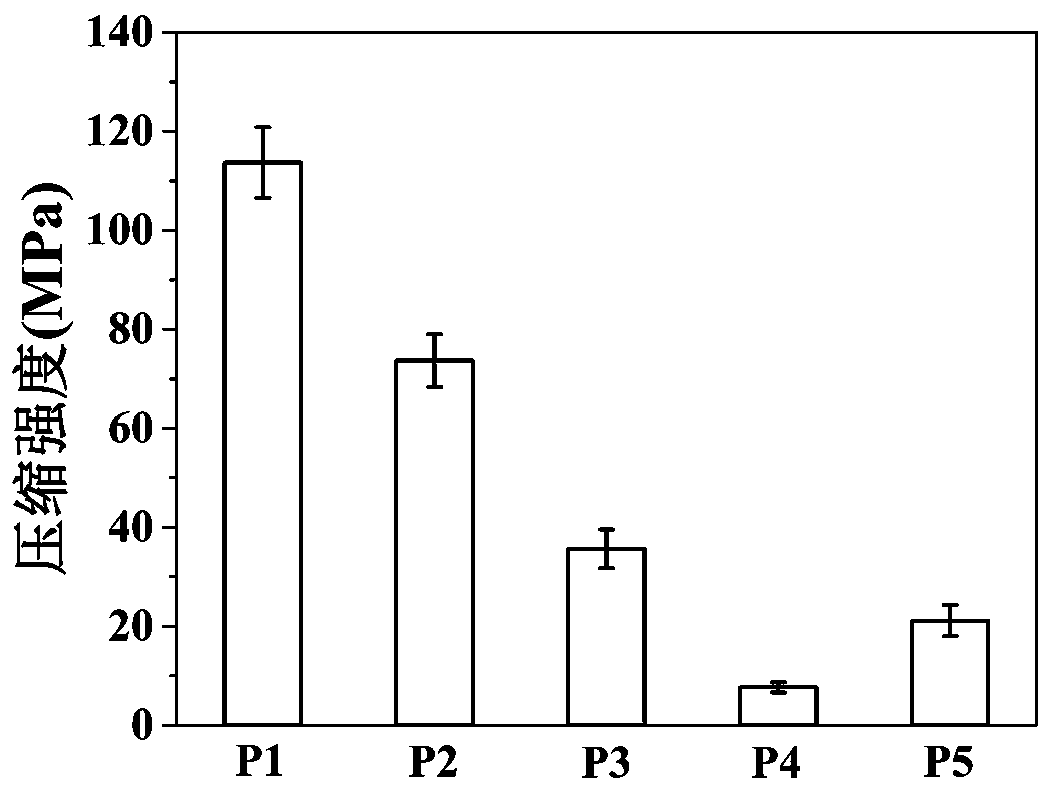

Preparation method of high-strength injectable polyphase calcium phosphate based bone cement

ActiveCN110498664ASoluble in waterBiodegradablePharmaceutical delivery mechanismTissue regenerationAlpha-tricalcium phosphateFiller Excipient

The invention belongs to the field of bone restoration medical material, and discloses a preparation method of a high-strength injectable polyphase calcium phosphate based bone cement. The high-strength injectable polyphase calcium phosphate based bone cement is prepared through uniform blending and solidification of a bone cement power with a solidification liquid containing meglumine, wherein the bone cement powder is prepared through uniform mixing of alpha-tricalcium phosphate powder, calcium sulfate hemihydrate powder, biologically active glass, and polyglutamic acid at a certain ratio. The obtained bone cement material possesses excellent injectable performance, and collapse resistance; after 7 days of solidification at 37 DEG C, the mechanical compression strength reaches 113.68+ / 7.11Mpa; in decomposition process, Ca<2+> and PO4<3-> are released, and Si ions capable of promoting bone induction are released at the same time, so that the high-strength injectable polyphase calciumphosphate based bone cement is suitable to be taken as a centrum filter in PVP / PKP minimally invasive surgery. The preparation method is simple in technology; product comprehensive performance is excellent; and large scale production application can be realized.

Owner:YANGZHOU UNIV

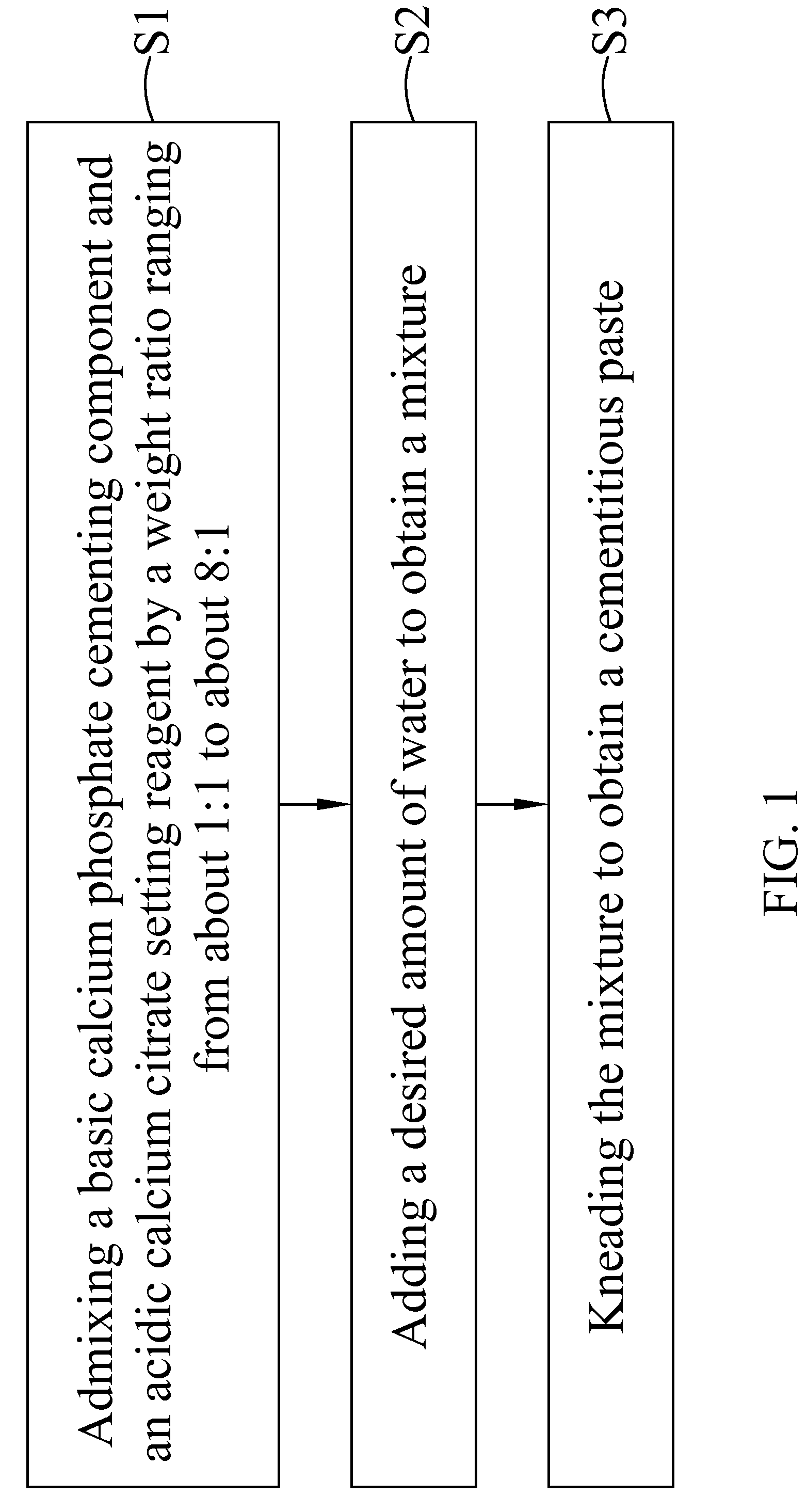

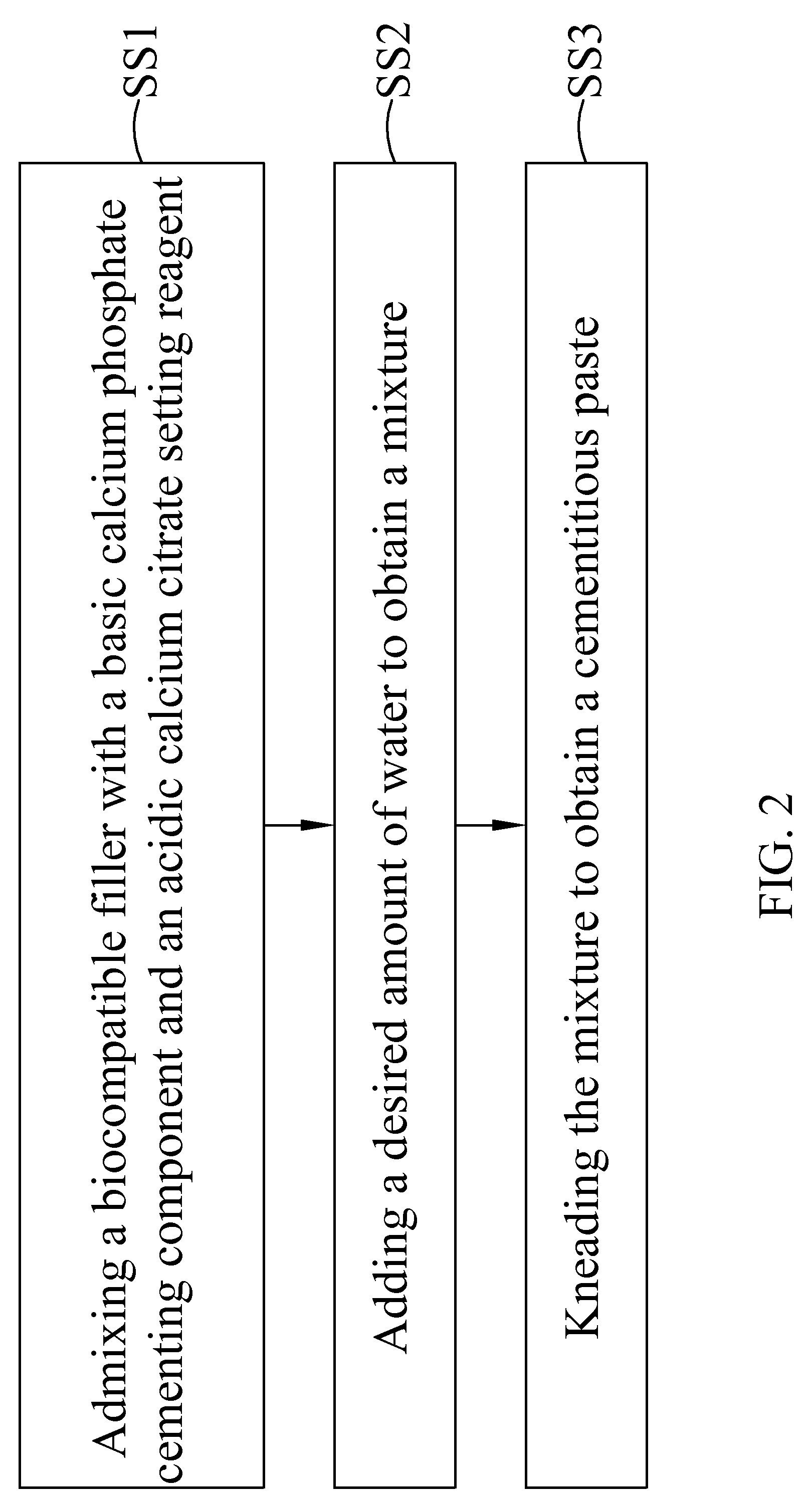

Surgical calcium phosphate citrate-containing cement and method of manufacturing the same

The present invention discloses a surgical cement and a manufacturing method thereof. The surgical cement comprises a cementing component selected form the group of a basic calcium phosphate consisting of tetracalcium phosphate, alpha-tricalcium phosphate, decomposed hydroxyapatite, or a combination thereof; a setting reagent selected form the group of an acidic calcium citrate consisting of monocalcium citrate, dicalcium citrate, or a combination thereof; and water; wherein a weight ratio of the cementing component and the setting reagent ranges from about 1:1 to about 8:1. The surgical cement is bioresorbable and bioactive and is useful in orthopedic, maxillofacial and dental applications. In addition, the surgical cement of this invention has a good flow character and a relatively short setting time.

Owner:MAXIGEN BIOTECH

Alpha-tricalcium phosphate and preparation method thereof

ActiveCN110562945ANo reunionEasy to preparePhosphorus compoundsAlpha-tricalcium phosphateRepair material

The invention relates to the technical field of bone repair materials, and discloses a preparation method of alpha-tricalcium phosphate. The problem in alpha-tricalcium phosphate sintering process that agglomeration is easily caused is solved. The preparation method comprises the following steps: (1) mixing calcium hydrophosphate and calcium carbonate by adopting a solid-phase reaction method, grinding for 20-40 minutes, heating to 850-920 DEG C for calcining, cooling, and sieving using a 10-200 micron sieve so as to obtain a powder A; (2) adding the powder A obtained in step (1) into zirconium dioxide powder, increasing the temperature to 1125-1500 DEG C after uniform mixing, carrying out heat preservation for 2-5 h, and then taking an obtained product out, and cooling, wherein the particle size of the zirconium dioxide powder is larger than that of the powder A; 3) sieving to obtain alpha-tricalcium phosphate powder. The above preparation method is capable of reducing agglomeration of alpha-tricalcium phosphate, and maintaining the original size structure of the powder; the grinding step of alpha-tricalcium phosphate after sintering is avoided; the preparation process is simple,and zirconium dioxide can be repeatedly used.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

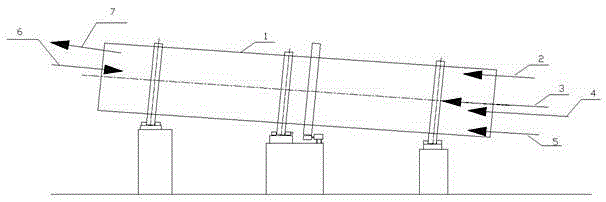

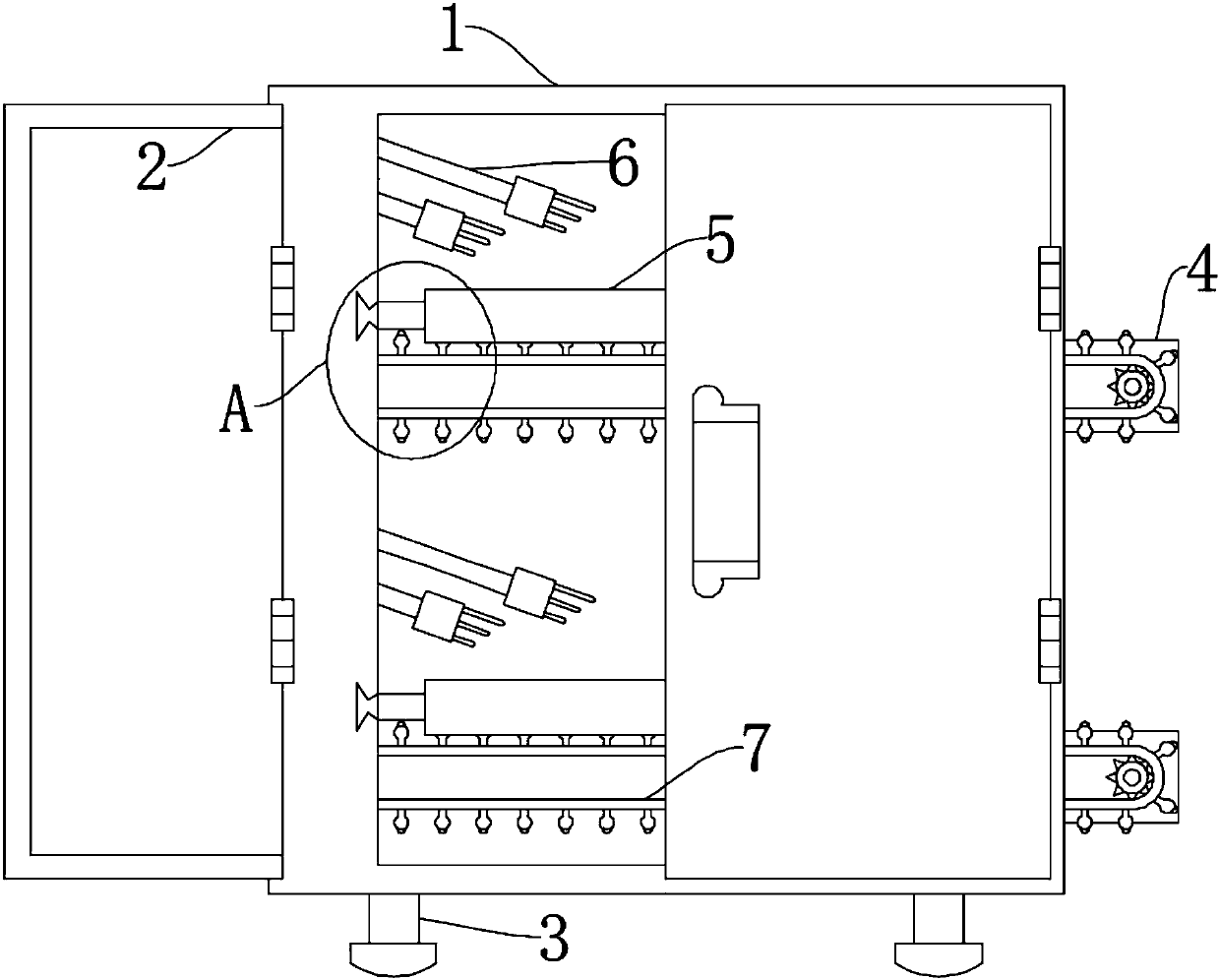

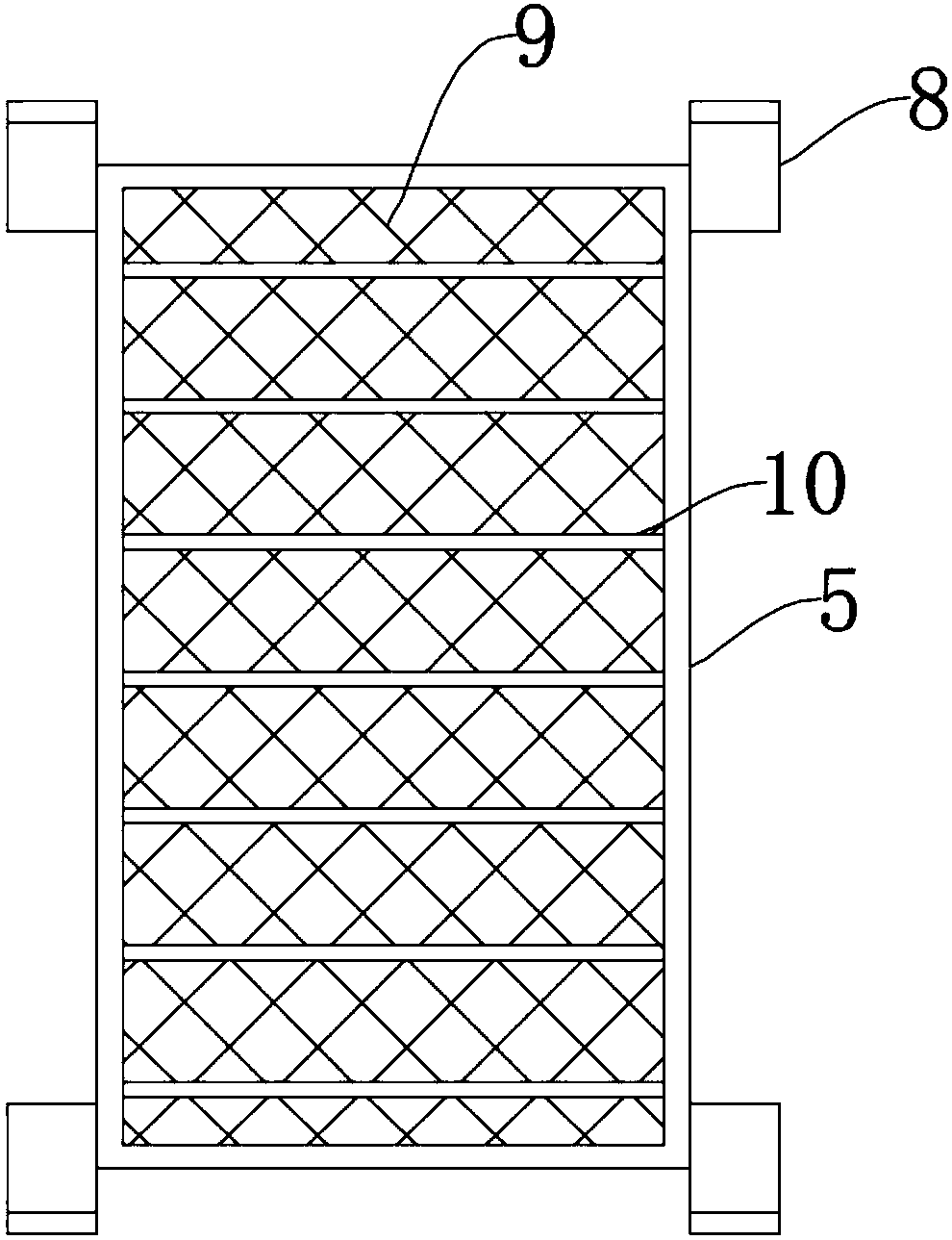

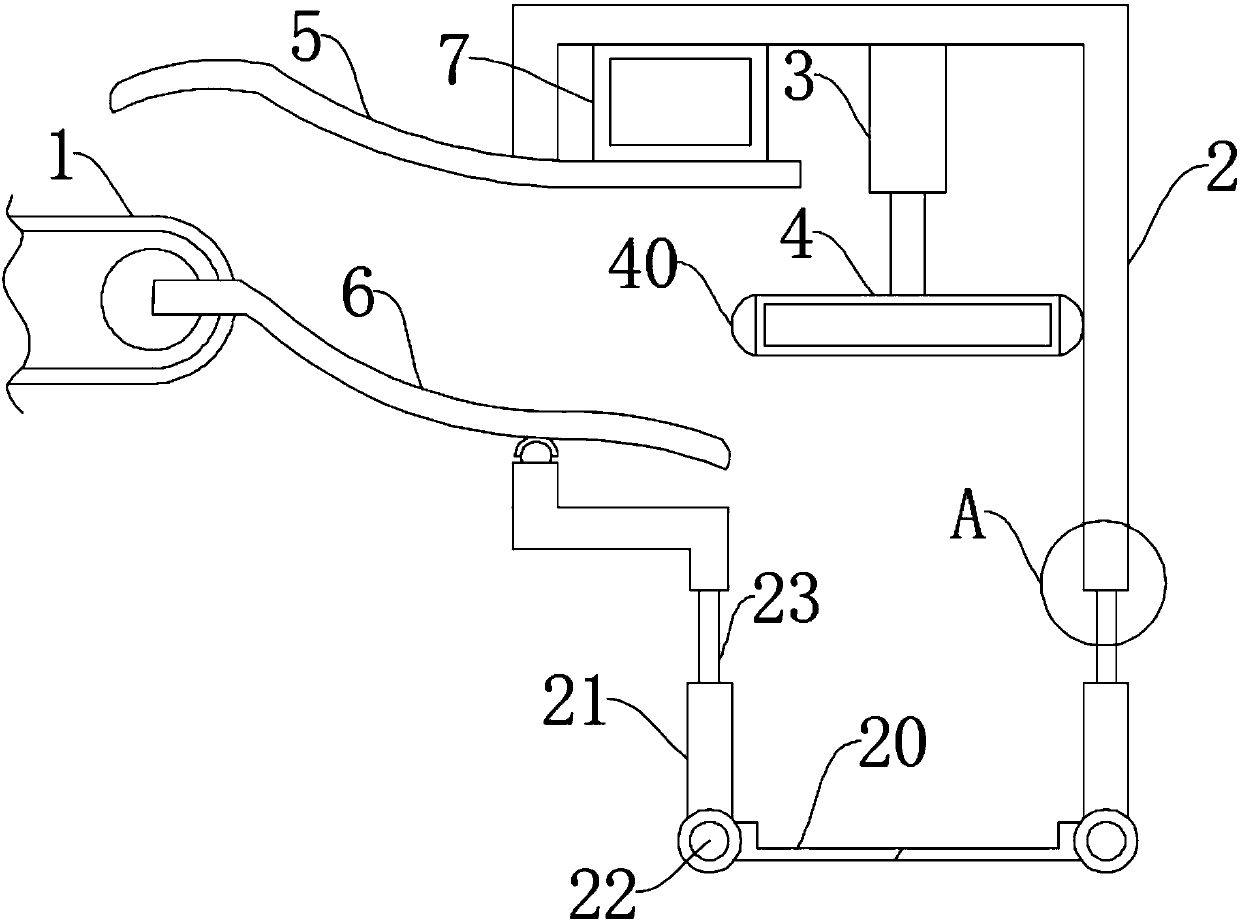

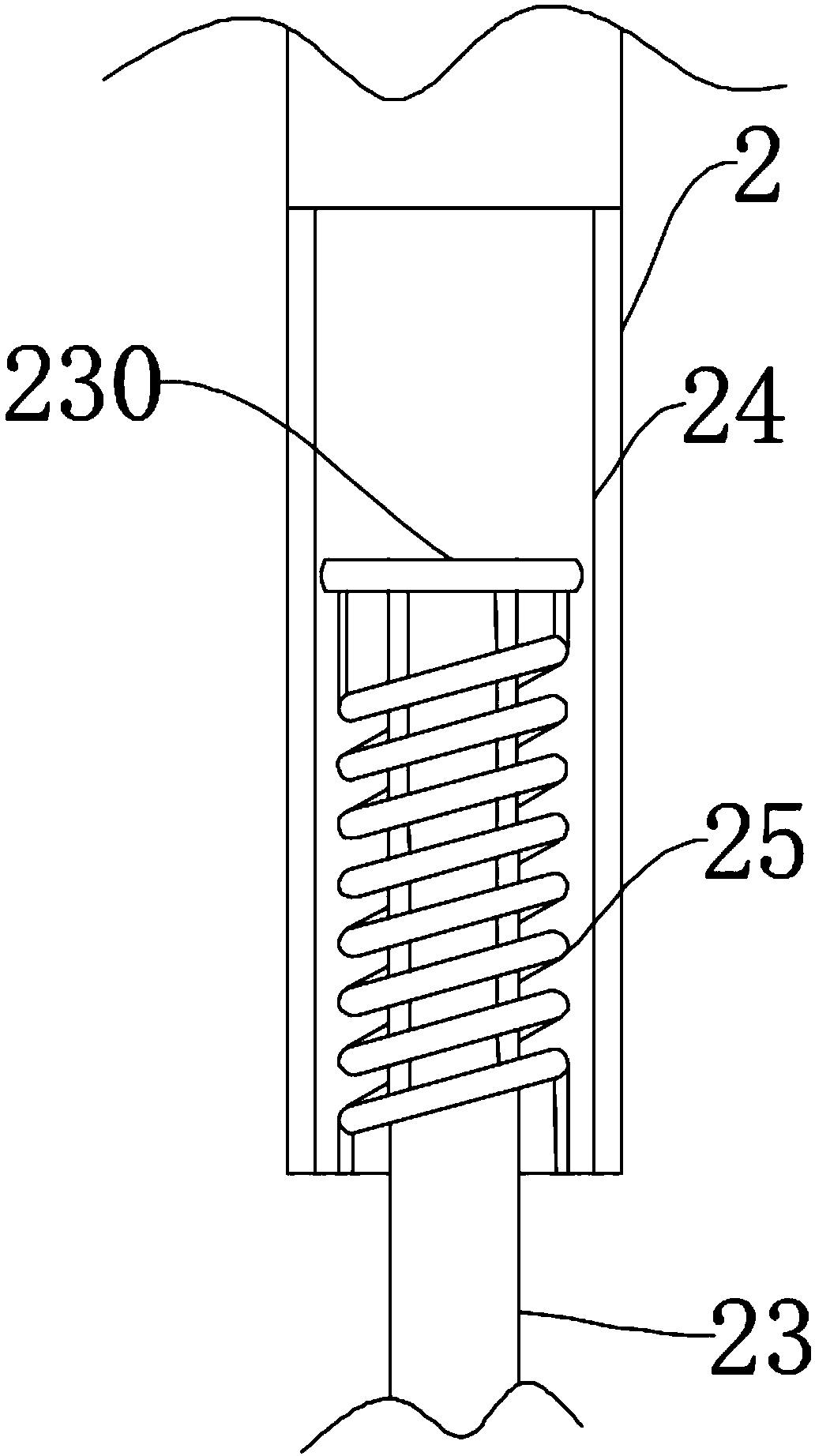

High-temperature calcining apparatus for preparing food-grade tricalcium phosphate

InactiveCN110540181ACalcined evenlySimple structurePhosphorus compoundsAlpha-tricalcium phosphateEngineering

The invention discloses a high-temperature calcining apparatus for preparing food-grade tricalcium phosphate. The high-temperature calcining apparatus comprises a calcining work chamber, calcining pipes and a shelving device. According to the invention, one ends of the calcining pipes are fixed to the inner wall of the calcining work chamber, the other ends of the calcining pipes are inclined towards movable plates, and altogether four calcining pipes are symmetrically arranged relative to the movable plates, so the calcining pipes in the structure of the apparatus can realize more uniform calcining of the movable plates; two shelving frames are arranged along the longitudinal direction of the calcining work chamber, the calcining work chamber is provided with sliding chutes correspondingto fixed sliding blocks, and the fixed sliding blocks are slidably connected with the sliding chutes, so the structure is simple and clear, and has high practicability; and the movable plates and movable rods are movably connected with the shelving frames, the movable rods are fixed to the lower end faces of the movable plates, and fixed protruding blocks are elastically connected with conveying belts through torsional springs and are movably connected with the movable rods, so the movable plates in the novel structure can be jacked up rhythmically, and better calcining effect is obtained.

Owner:SUQIAN MODERN CHEM

Plastic DBM (decalcified bone matrix) bone induced self-curing bone grafting material and preparation method thereof

InactiveCN109985275AExpand sourceGood biocompatibilityPharmaceutical delivery mechanismTissue regenerationAlpha-tricalcium phosphateIn vivo

The invention belongs to the field of biomedical materials and particularly relates to a plastic DMB (decalcified bone matrix) bone induced self-curing bone grafting material and a preparation methodthereof. The bone grafting material is composed of a powder and a curing solution in the proportion of 1:0.8-1.5, and the powder is prepared from, by weight, 20%-40% of calcium sulfate, 5%-40% of calcium phosphate, 2%-15% of an organic addition agent and 20%-60% of DBM bone powder; the calcium sulfate is calcium sulfate semi-hydrate and calcium sulphate dihydrate; the calcium phosphate is alpha-tricalcium phosphate, beta-tricalcium phosphate or hydroxyapatite. The bone grafting material has excellent bone induction and bone conductivity and anti-collapse performance, can solidify in vivo, fixDBM in bone defect area, slow degradation of DBM and continuously release growth factor; different dosage forms can be prepared by controlling the liquid-solid ratio, which can meet the needs of patients.

Owner:湖北联结生物材料有限公司

A kind of preparation method of silicon-doped α-tricalcium phosphate ceramics

ActiveCN104557015BEasy to synthesizeOvercome the gross disadvantageNano siliconAlpha-tricalcium phosphate

Owner:SOUTH CHINA UNIV OF TECH

A method for preparing α-tricalcium phosphate by low-temperature calcination

ActiveCN107188148BImprove performanceSimple processMaterial nanotechnologyPhosphorus compoundsSal ammoniacAlpha-tricalcium phosphate

The invention discloses a method of preparing alpha-tricalcium phosphate through low temperature calcining. According to the method, alpha-cyclodextrin is taken as the template, Ca(NO3)2.4H2O, and (NH4)2HPO4 are taken as the raw materials, the standing time of the solution is controlled, the pH is adjusted by ammonia liquor, a chemical precipitation method is adopted to obtain an amorphous tricalcium phosphate precursor, the amorphous tricalcium phosphate precursor is dried by a special mode, then the precursor is calcined for 2 to 4 hours at a constant temperature of 600 to 650 DEG C, and finally the precursor is cooled in the furnace to obtain the alpha-tricalcium phosphate. The technology is simple, the energy consumption is little, and the cost is low. The detection on the curing performance of alpha-tricalcium phosphate and mechanical properties after curing shows that the performance of prepared alpha-tricalcium phosphate is better than that of alpha-tricalcium phosphate prepared by a conventional technology.

Owner:SHANDONG UNIV

Degradable nanometer composite material for biological and medical use and method of preparation the same

InactiveCN1270783CPromote degradationFully functionProsthesisCalcium biphosphateAlpha-tricalcium phosphate

A nanometer-grade medical decomposable composite material and its preparation method. By different Ca / P, different crystallizing states in the inorganic phase, the composite material adjusts decomposing rate, recombines with decomposable polymer, thus the biological decomoposing rate of the whole composite material is adjustable. The inorganic phase is selected from one or two of amorphous calcium phosphate, alpha-tricalcium phosphate, beta-tricalcium phosphate, phosphorite and calcium phosphate dibasic. The preparation method comprises selecting organic solvents for uniformly dispersing calcium phosphate powder in a decomposable polymer matrix, then obtaining nanometer-grade composite material.

Owner:ZHEJIANG UNIV

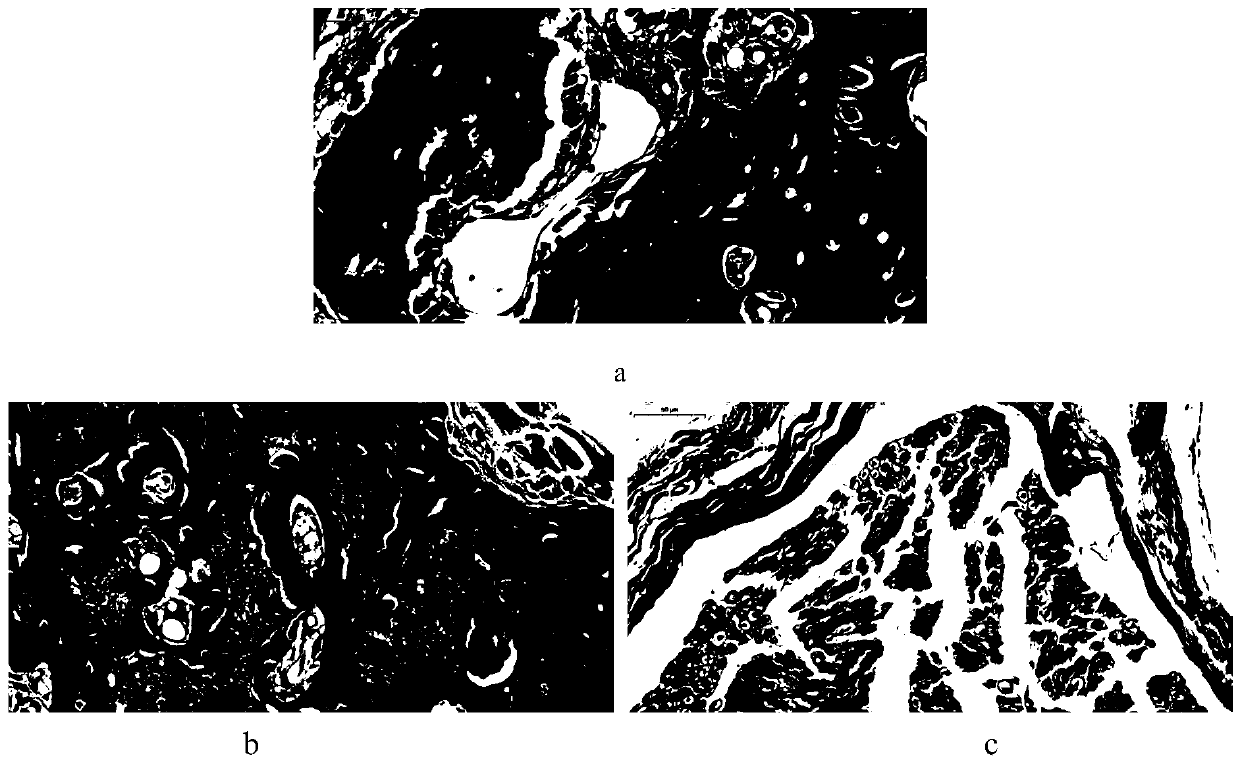

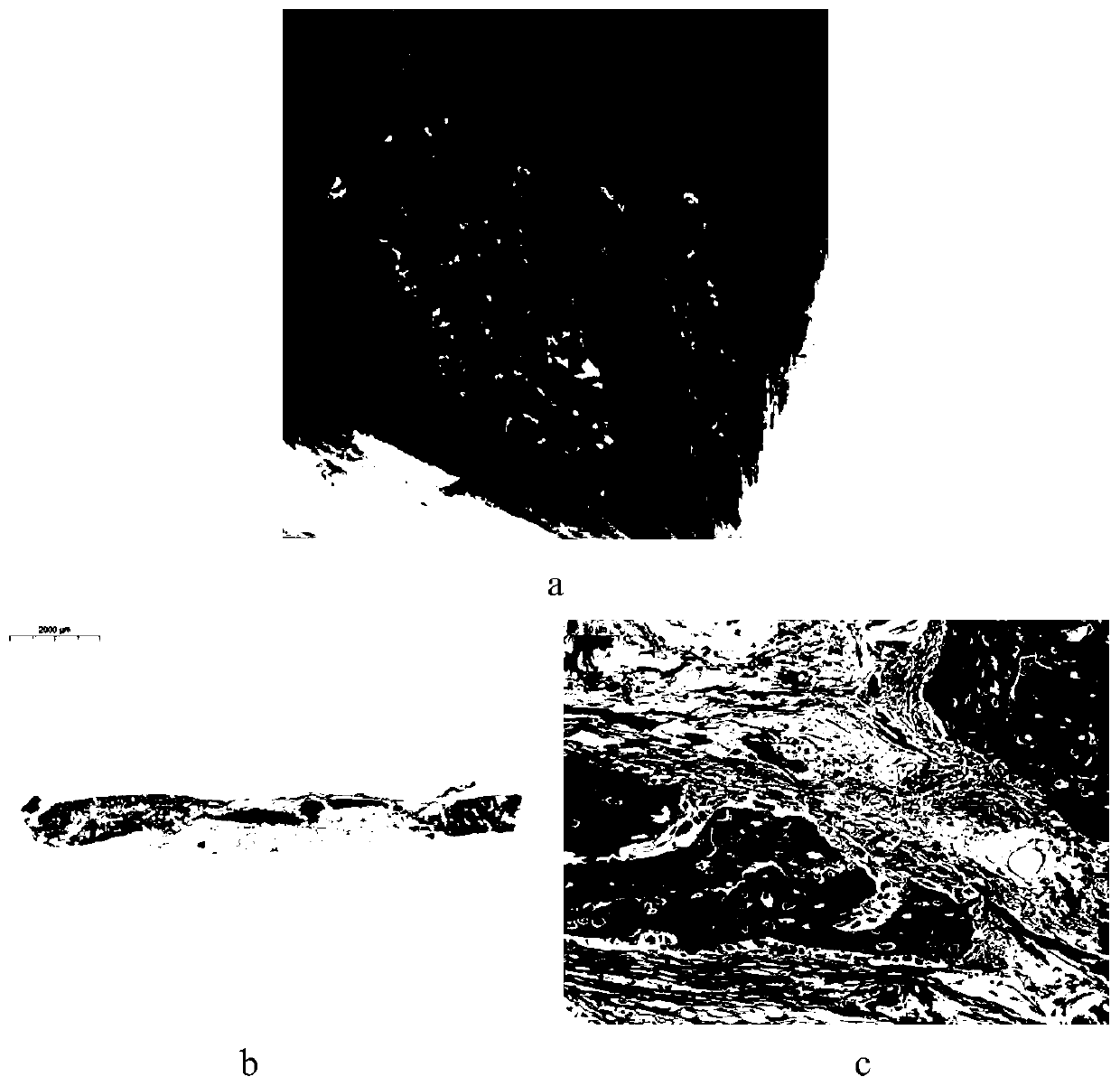

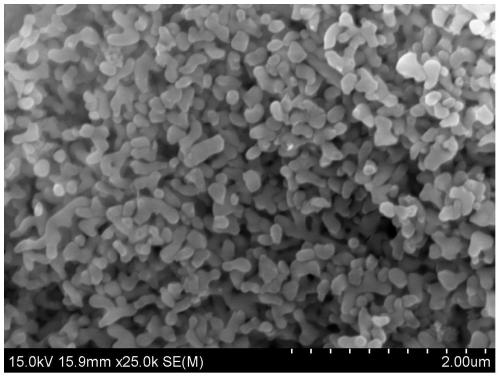

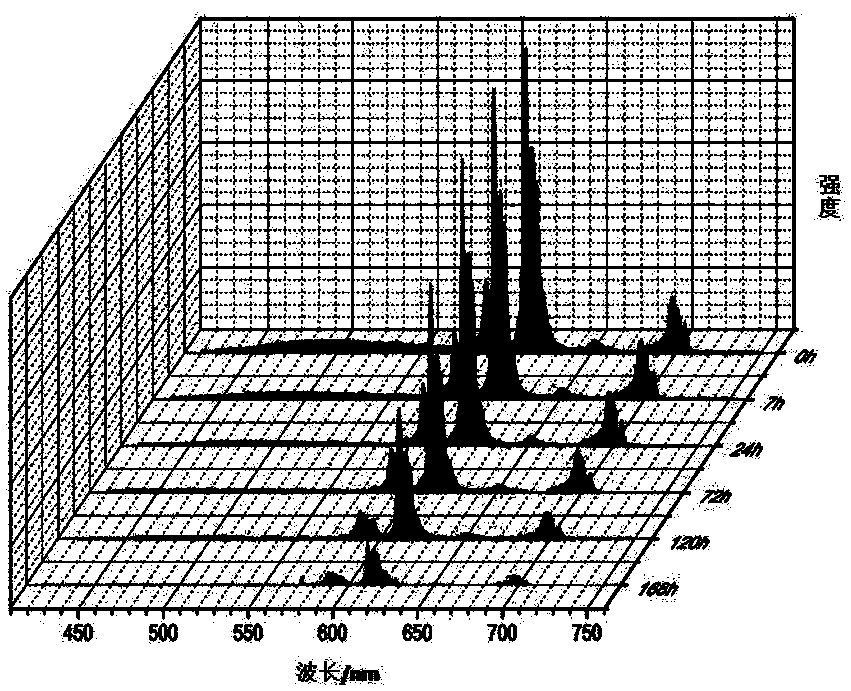

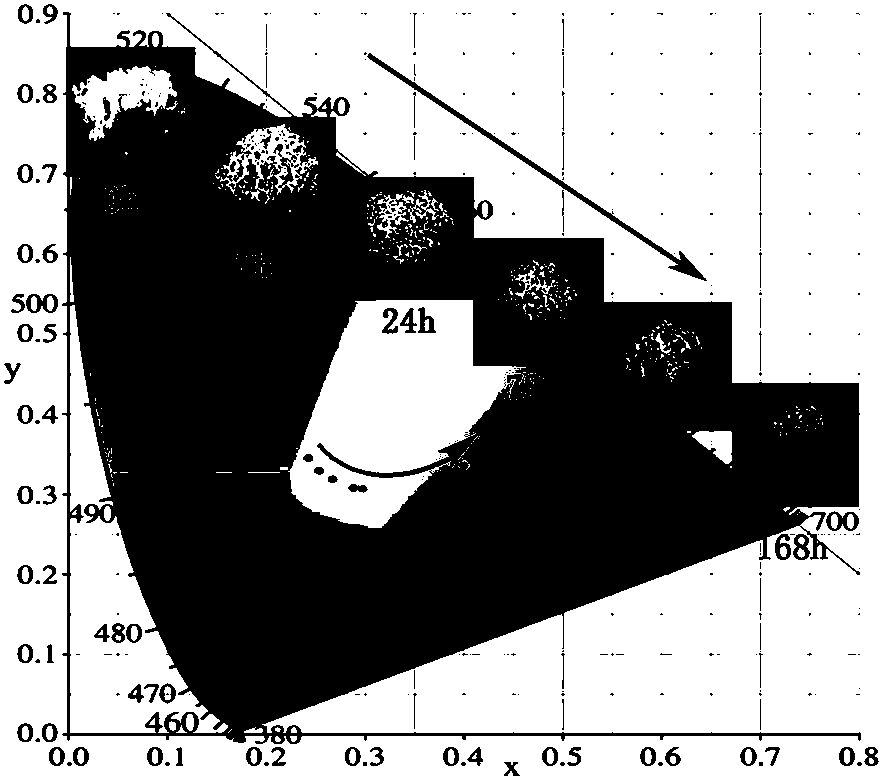

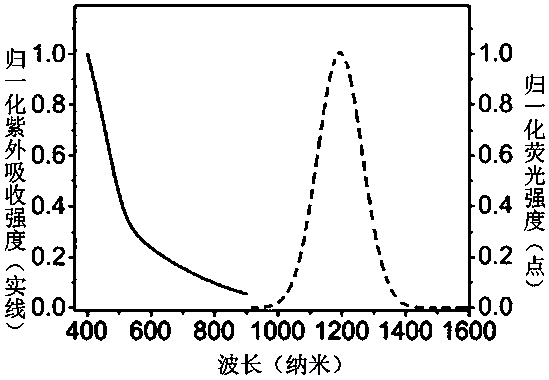

Fluorescent tracing method of Alpha-tricalcium phosphate hydration process

ActiveCN110132928APromote regenerationHigh luminous intensityFluorescence/phosphorescenceAlpha-tricalcium phosphateLuminous intensity

The invention relates to a fluorescent tracing method of Alpha-tricalcium phosphate hydration process. Eu<2+> / Eu<3+> co-doped Alpha-tricalcium phosphate [Alpha-Ca<3(1-x)>Eu<3x>(PO4)2, 0.001<=x<=0.1] is gradually hydrated to form bone-like hydroxyapatite in a phosphate buffer solution, a simulation body liquid or implantation animal or an environment in a human body, the ultraviolet excitation spectrum intensity corresponding to Eu<2+> and Eu<3+> are respectively attenuated with different degrees, and CIE chromatic coordinate or fluorescent color is gradually changed to achieve in-situ real-time fluorescent tracing of the Alpha-tricalcium phosphate hydration process. The Alpha-Ca<3(1-x)>Eu<3x>(PO4)2 has the advantages of good biological compatibility, no biological toxicity, long fluorescent lifetime, high light-emitting intensity and continuous and stable light-emitting performance, and thus, the Alpha-Ca<3(1-x)>Eu<3x>(PO4)2 can be used as a biological fluorescent marker used in clinical research.

Owner:SUZHOU DINGAN ELECTRONICS TECH

A kind of calcium phosphate bone cement embedding drug-loaded siliceous body and its preparation method and application

ActiveCN107158473BEasy to prepareSimple ingredientsPharmaceutical delivery mechanismTissue regenerationAlpha-tricalcium phosphateSodium phosphates

The invention relates to medicine-loaded siliceous body embedded calcium phosphate bone cement and a preparation method and application thereof. The preparation method comprises the following steps: mixing a self-curing component and a heating nanomaterial to obtain modified bone cement solid powder, wherein an alpha-tricalcium phosphate material plays embedding and carrying roles and a paclitaxel@siliceous body plays an anti-cancer role; with sodium phosphate as a main body and phosphorylated chitosan, hydroxypropyl methyl cellulose and gelatin as modifiers, preparing a neutral bone cement curing solution which improves injectability of a formula; mixing the bone cement solid powder and the curing solution, wherein a main component hydroxyapatite of a cured product is added and the paclitaxel@siliceous body has very good degradability in a living body. The preparation method is simple and convenient, used raw materials are simple, and the preparation method is suitable for mass production; the develop medicine-loaded novel formula improves the biocompatibility of the original bone cement; through addition of the paclitaxel@siliceous body with a thermotherapeutic effect, the injectability of the medicine-loaded siliceous body embedded calcium phosphate bone cement is improved.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

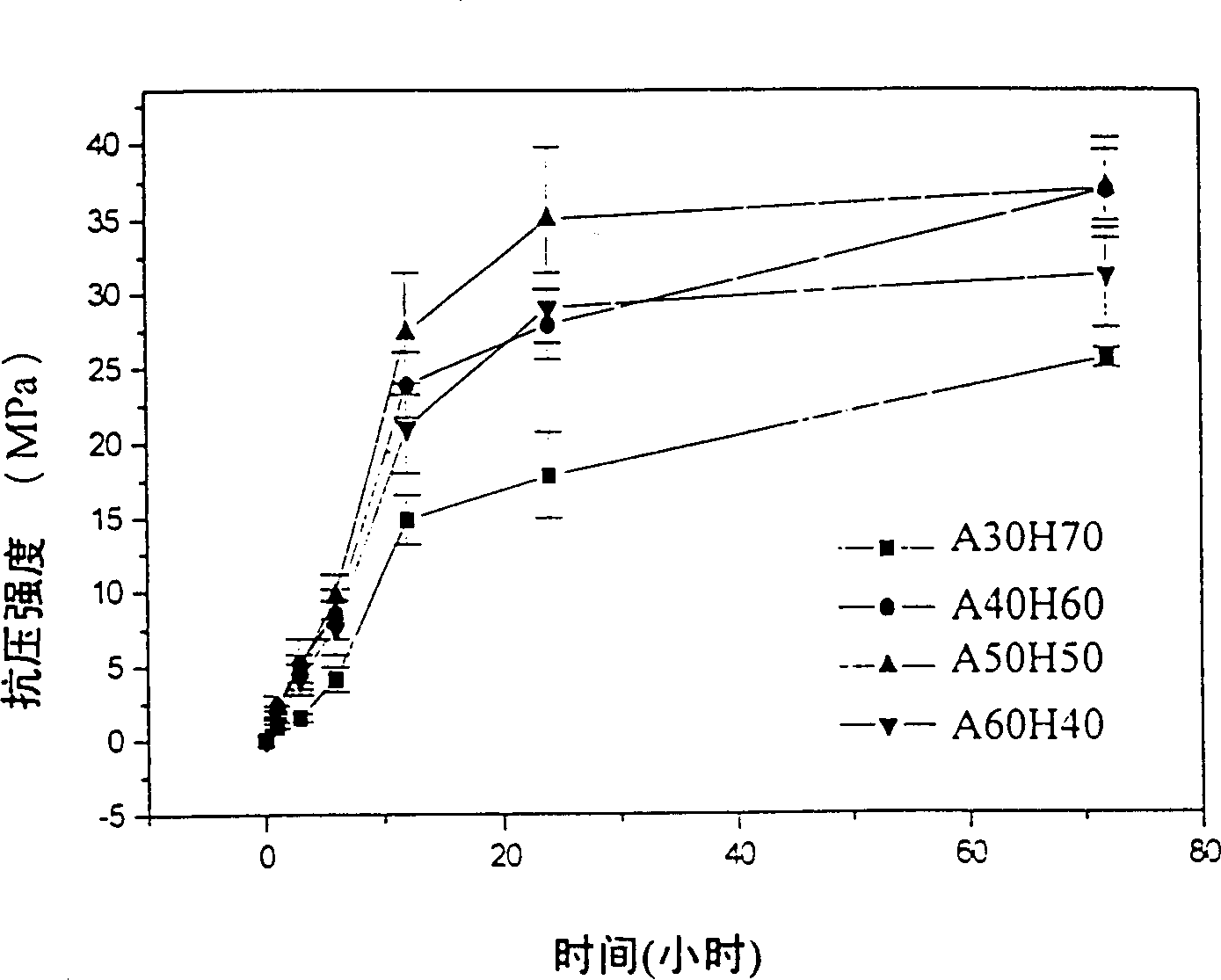

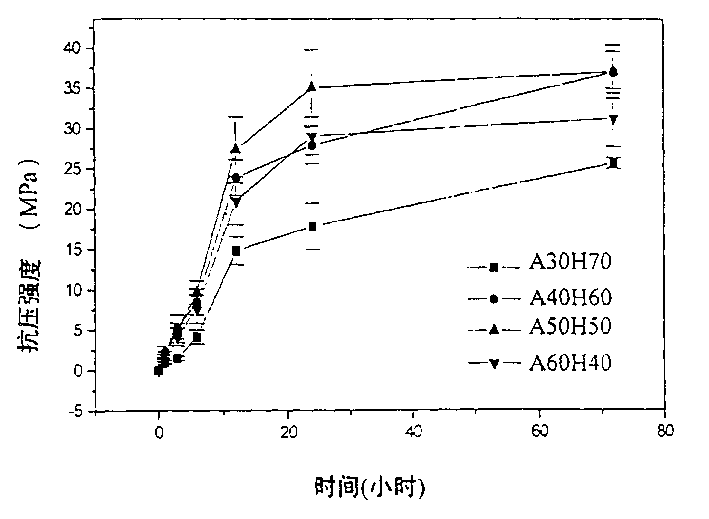

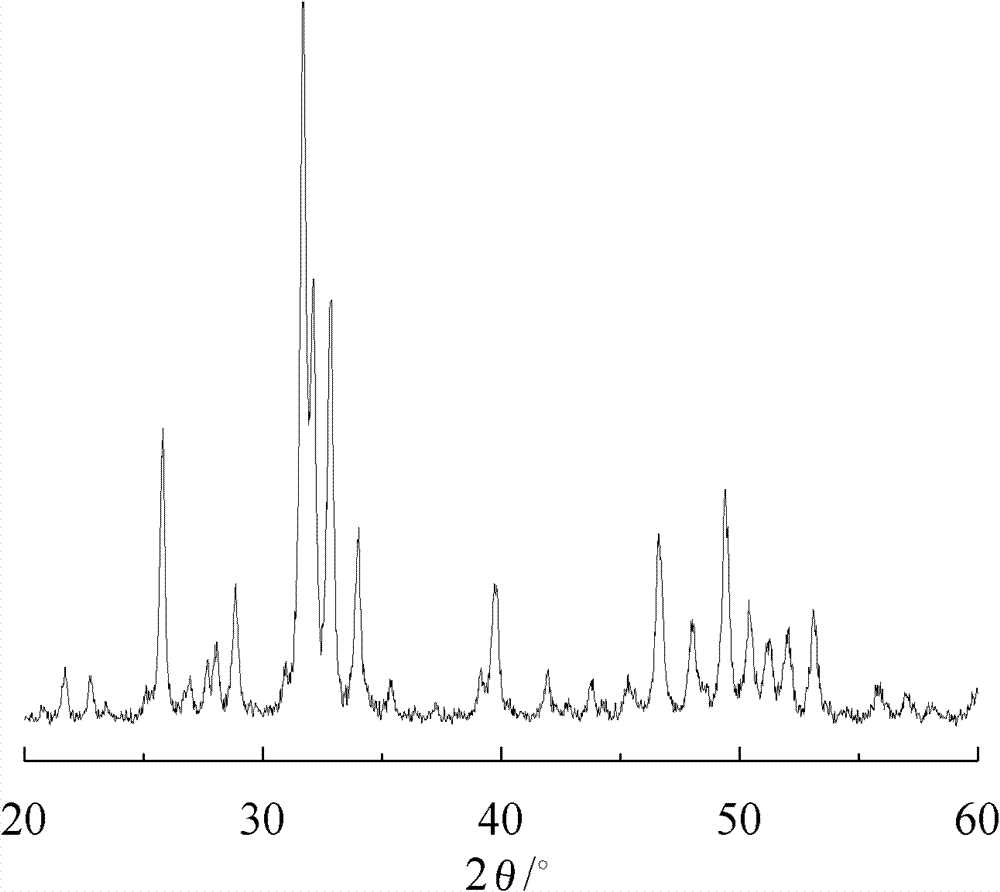

Two-phase alpha-tricalcium phosphate/oxyhydrogen-base apatite bone cement and its preparing process

A two-phase alpha-TCP / HAP bone cement contains alpha-tricalcium phasphate (30-60 wt.%) and hydroxide apatite (40-70 wt.%) and features that it can be quickly settled when it is immersed in aqueous solution, so it is an excellent bone cement. Its preparing process is also disclosed, which features that the ratio of both components in it can be controlled.

Owner:PURZER PHARMA

Biological porous bone cement prepared by compositing Sr-doped calcium-phosphorus bioglass and alpha-tricalcium phosphate and preparation method thereof

InactiveCN102249728BHigh compressive strengthPromote degradationCeramicwarePorosityAlpha-tricalcium phosphate

The invention relates to a biological porous bone cement prepared by compositing Sr-doped calcium-phosphorus bioglass and alpha-tricalcium phosphate and a preparation method thereof. The bone cement provided by the invention is characterized in that the porousness of the bone cement is 39-57%, and the size of a micropore is between 0.5 um and 4 um; and the compression strength is 23.6-38.5 Mpa. In the invention, through compositing the Sr-doped calcium-phosphorus bioglass and alpha-tricalcium phosphate, the porous-structured bone cement is formed. In the invention, the solidification time andmicrostructure of the bone cement can be adjusted through the rapid dissolving of the Sr-doped calcium-phosphorus glass so as to form a porous structure with a high porousness, and the degradation property of a hydrated product (hydroxyapatite) can be improved; and in addition, by virtue of Sr ions introduced by biodegradable calcium-phosphorus glass, the compression strength of the bone cement is improved, thereby achieving the properties such as high strength and good degradability of the bone cement better.

Owner:TIANJIN UNIV

Preparation method of composite bone reconstruction scaffold with bone tumor resistance

InactiveCN107551319APromote growth recoveryEasy to integrateProsthesisAlpha-tricalcium phosphatePolyamide

The invention discloses a preparation method of a composite bone reconstruction scaffold with bone tumor resistance. The preparation method is prepared from raw materials in parts by mass as follows:20-30 parts of polyamide, 20-25 parts of a strontium compound, 15-20 parts of hydroxyapatite, 50-60 parts of calcium phosphate, 5-10 parts of alkaline phosphatase, 50-60 parts of alpha-tricalcium phosphate, 50-60 parts of calcium hydrogen phosphate, 20-30 parts of disodium hydrogen phosphate, 20-30 parts of calcium sulfate powder, 5-10 parts of hydrochloride, 10-20 parts of a calcium hydrogen carbonate suspension, 10-20 parts of phosphoric acid and 10-20 parts of a collagen solution. The composite bone reconstruction scaffold has good integration and can fix injured bone after being contactedwith human bone to prevent secondary injury on one hand and supplement calcium ions to the injured bone to promote growth and recovery of the bone on the other hand.

Owner:JILIN UNIV

Preparation method capable of monitoring degraded bone cement with NIRII region fluorescent light, degraded bone cement product and application of degraded bone cement product

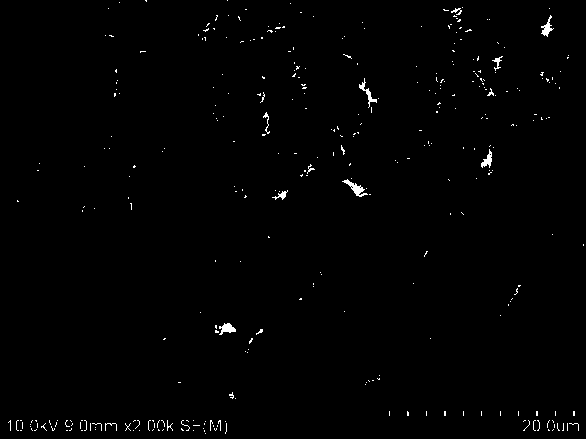

InactiveCN109602945AImprove performanceMetabolic safetyPharmaceutical delivery mechanismTissue regenerationAlpha-tricalcium phosphatePhosphorylation

The invention relates to a preparation method capable of monitoring degraded bone cement with NIRII region fluorescent light, a degraded bone cement product and an application of the degraded bone cement product. For solid parts, alpha-tricalcium phosphate of which the particle diameter is 15-100nm and calcium sulphate of which the particle diameter is 20-100um are used as main sclerotin repair components, biocompatibility macromolecule components of hyaluronic acid, phosphorylation chitosan, gelatin and the like are added so as to improve the fluidity of inorganic granules, and the biocompatibility macromolecule components are used as repair function parts capable of injecting bone cement; and the other part is Ag2S quantum dots of which the components are modified so as to give a near-infrared developed function for a repair material system. The solution part is a monosodium phosphate solution so as to promote cross-linking of alpha-calcium phosphate granules and near-infrared calcium sulphate granules so as to construct a bearing structure. An appropriate quantity of Ag2S quantum dot components are added to the bone cement, the bone cement can develop so as to monitor the degradation rate under NIRII region fluorescent light, and the preparation method can be used for tracking internalization absorption of bone materials.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Pressing device for tricalcium phosphate powder

InactiveCN110540183AStable deliveryPrevent leakageFood shapingPhosphorus compoundsAlpha-tricalcium phosphateEngineering

The invention discloses a pressing device for tricalcium phosphate powder. The device comprises a powder conveyor belt and a powder collecting box. According to the invention, a first limiting plate is arranged at the upper ends of a second limiting plate and the powder conveying belt, and the second limiting plate and the powder conveying belt are located on the same plane all the time, so when the structure of the device works, connection between the powder conveying belt and the powder collecting box is smoother and powder conveying is smoother; a negative-pressure air duct is arranged on the side face, facing the powder conveying belt, of the first limiting plate and communicates with a fixed fan, so the pressing device can adsorb powder and prevent the powder from leaking out; and embedded rods are elastically connected with the powder collecting box, two first movable plates are symmetrically arranged relative to a fixed pressing disc, and U-shaped grooves are formed in the sidefaces, facing the fixed pressing disc, of the two first movable plates, so the novel structure is good in overall buffering performance, more thorough in compression and capable of meeting actual requirements.

Owner:SUQIAN MODERN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com