Patents

Literature

176 results about "Bone replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

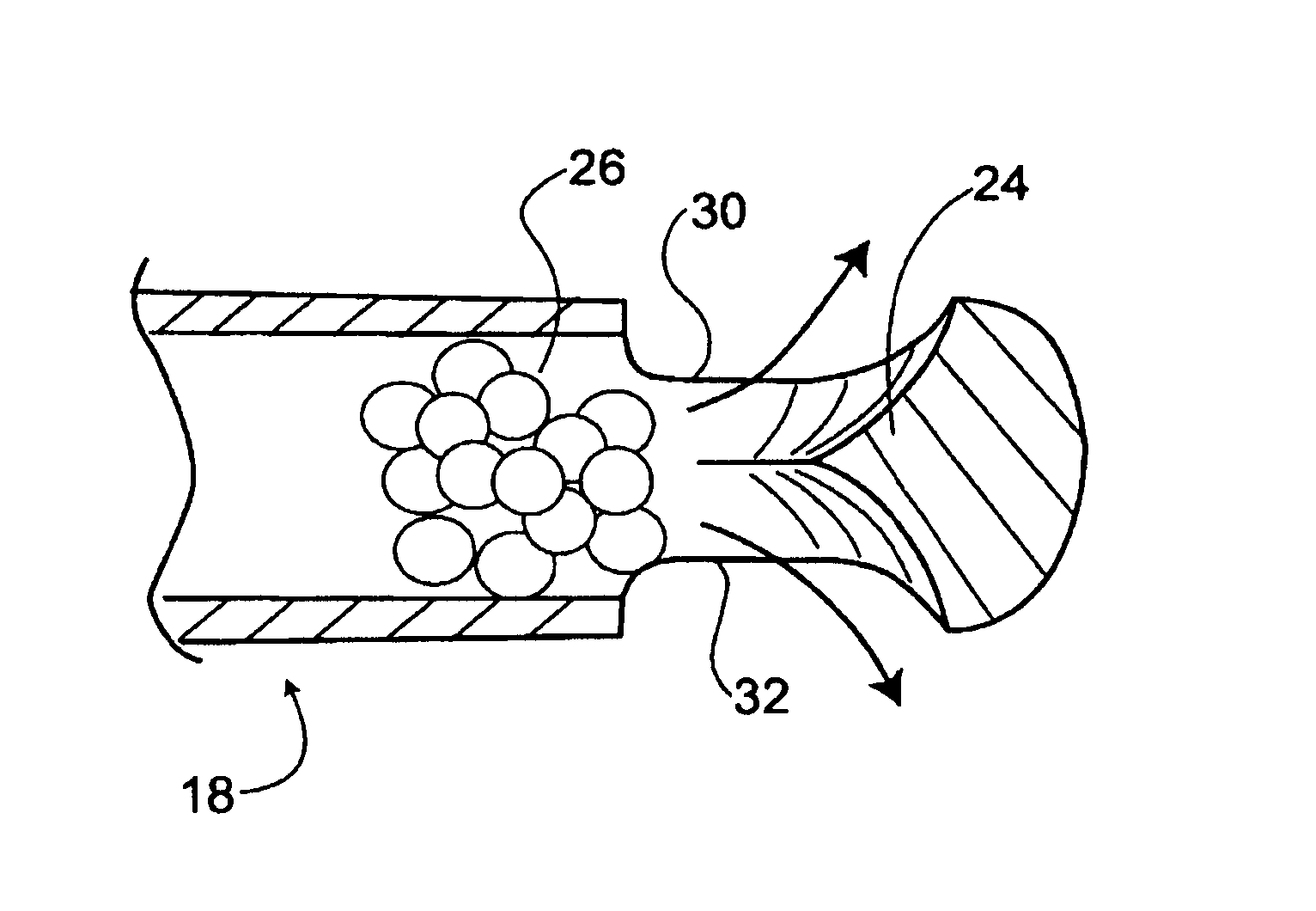

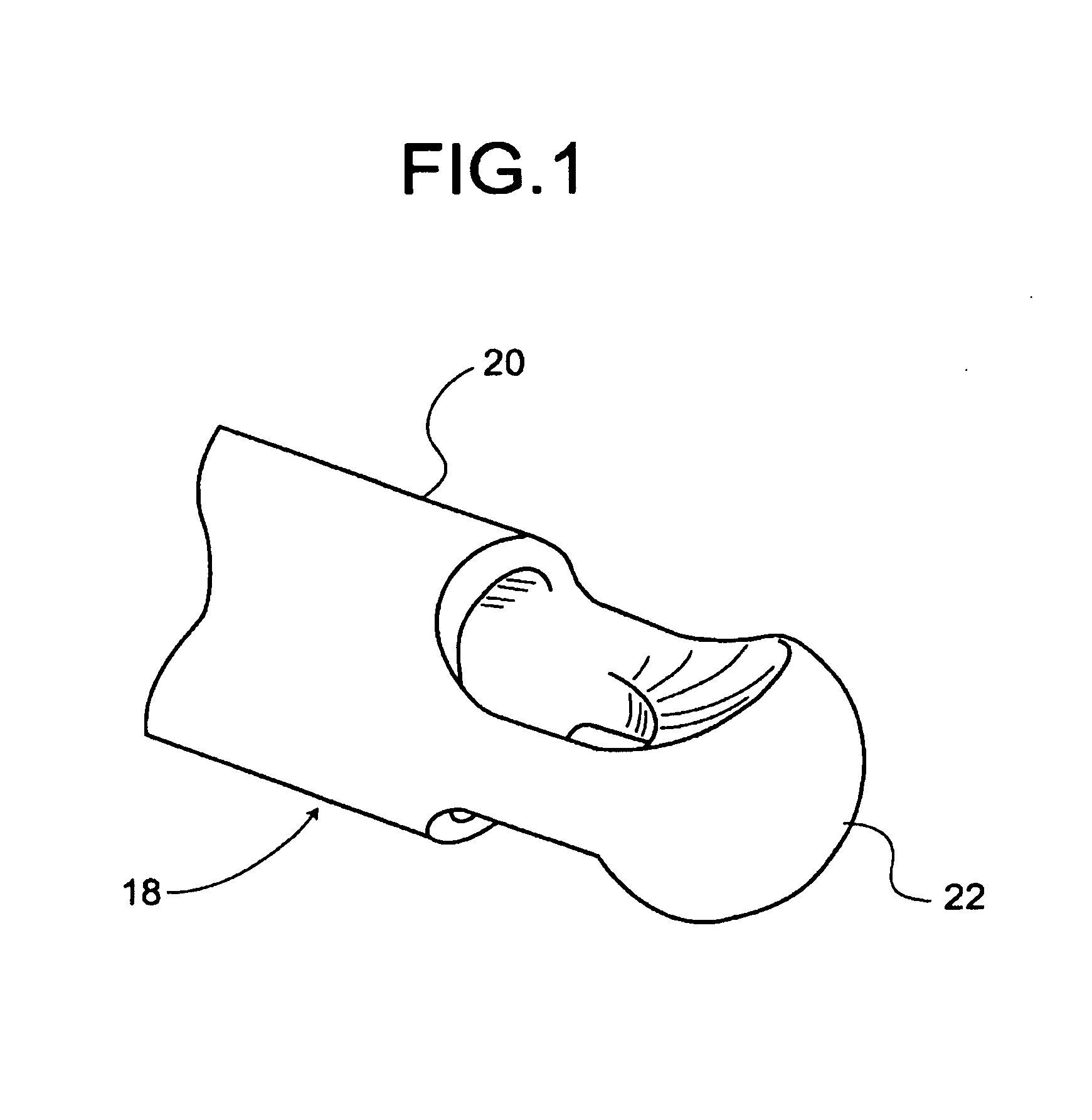

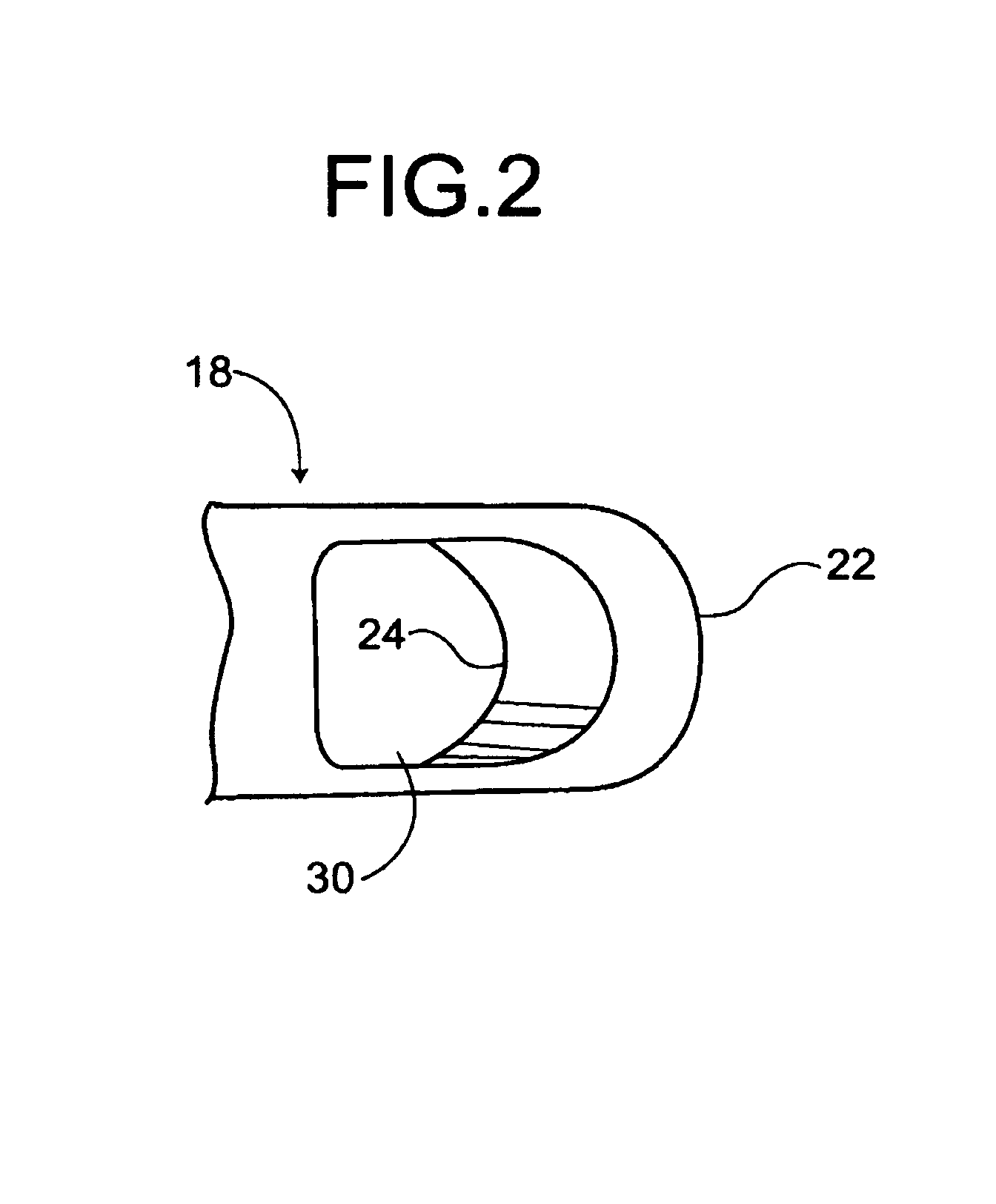

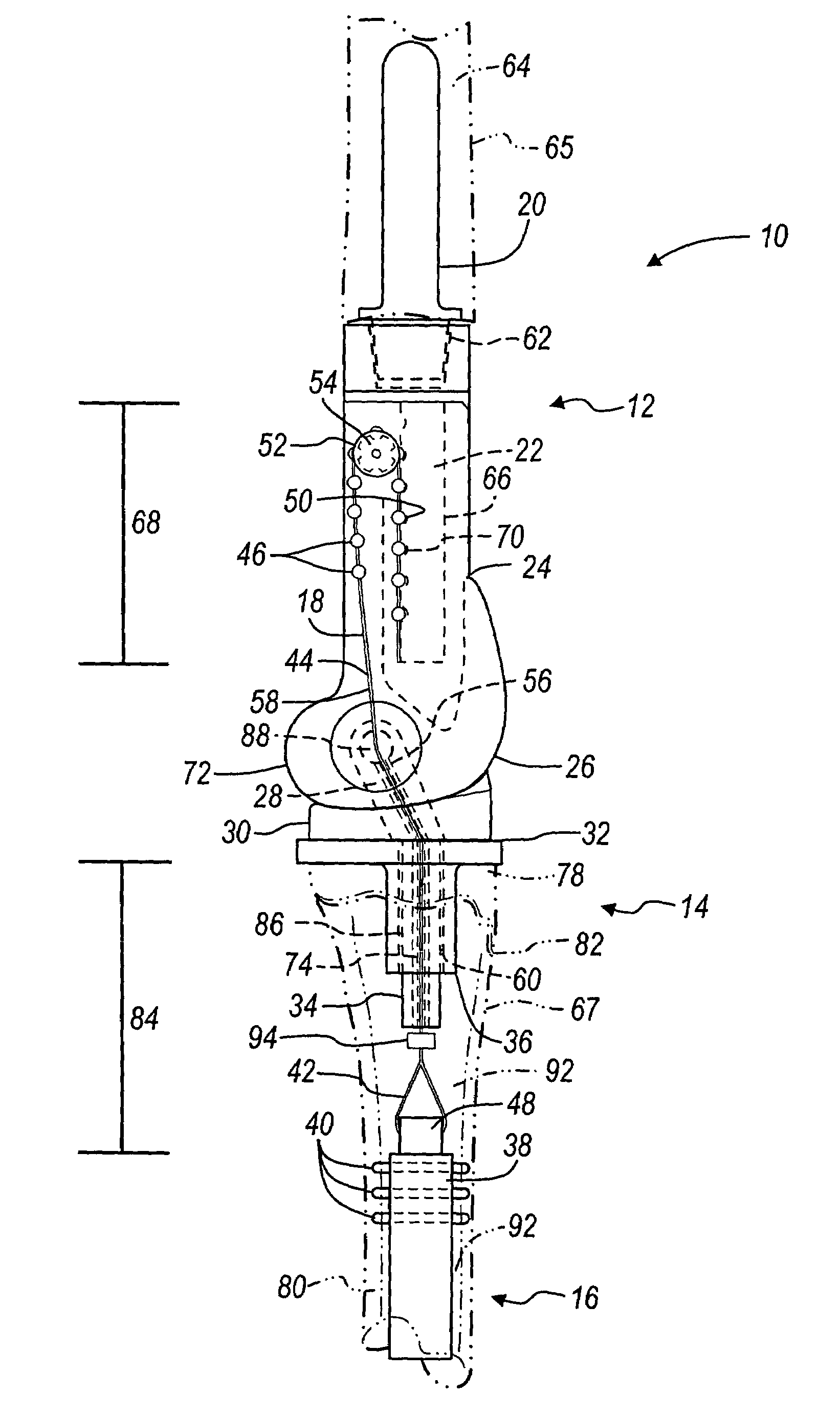

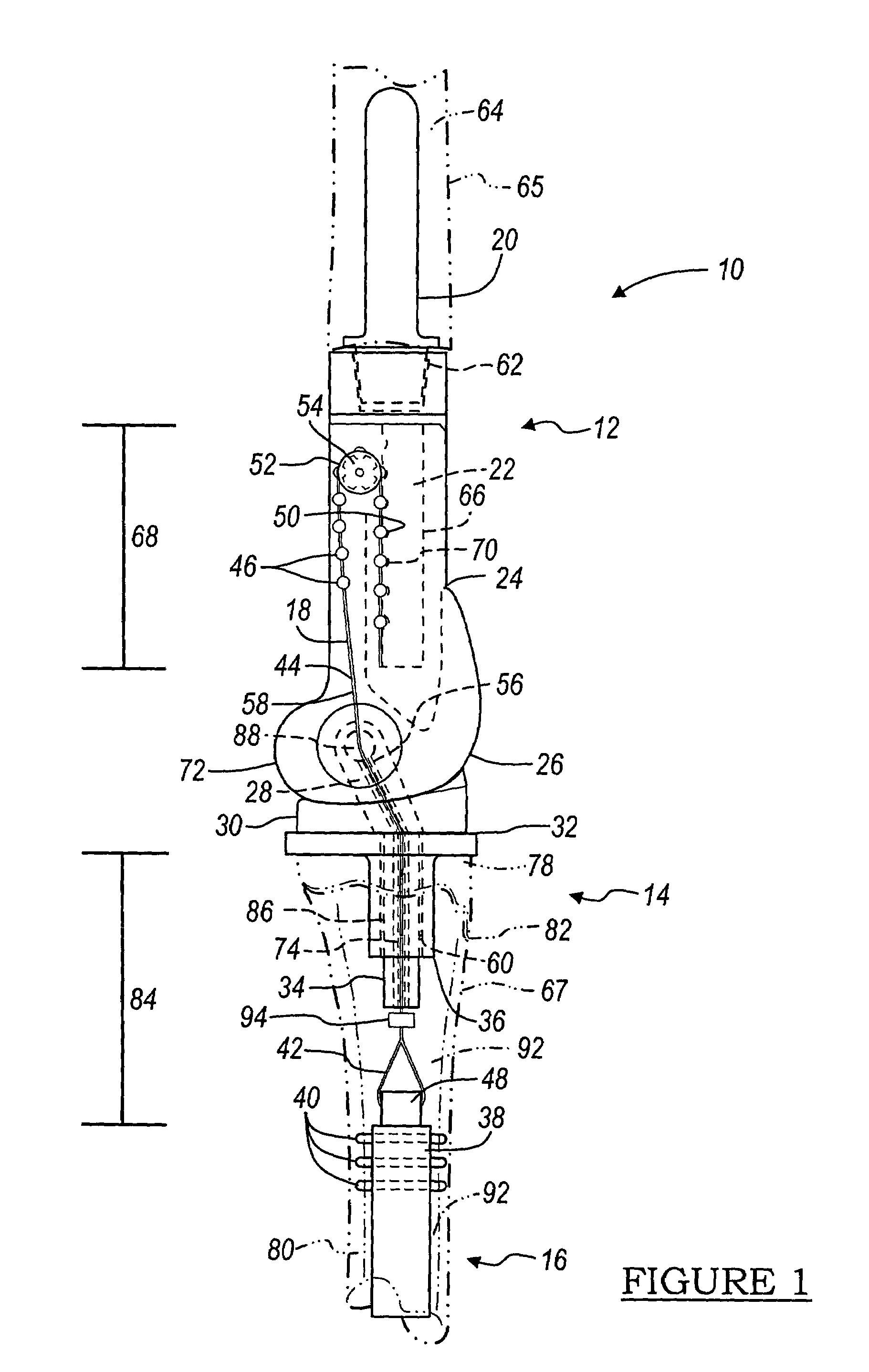

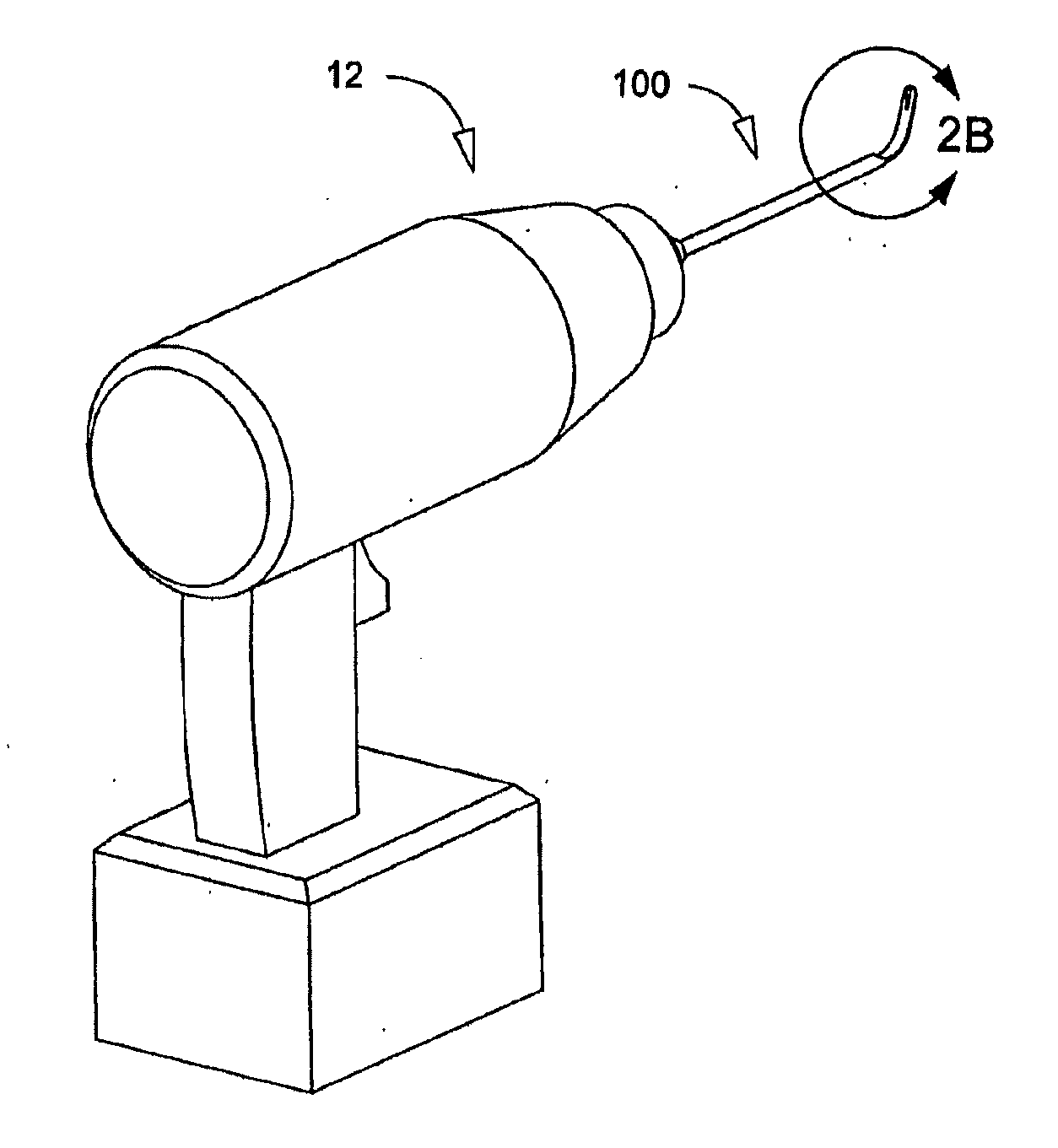

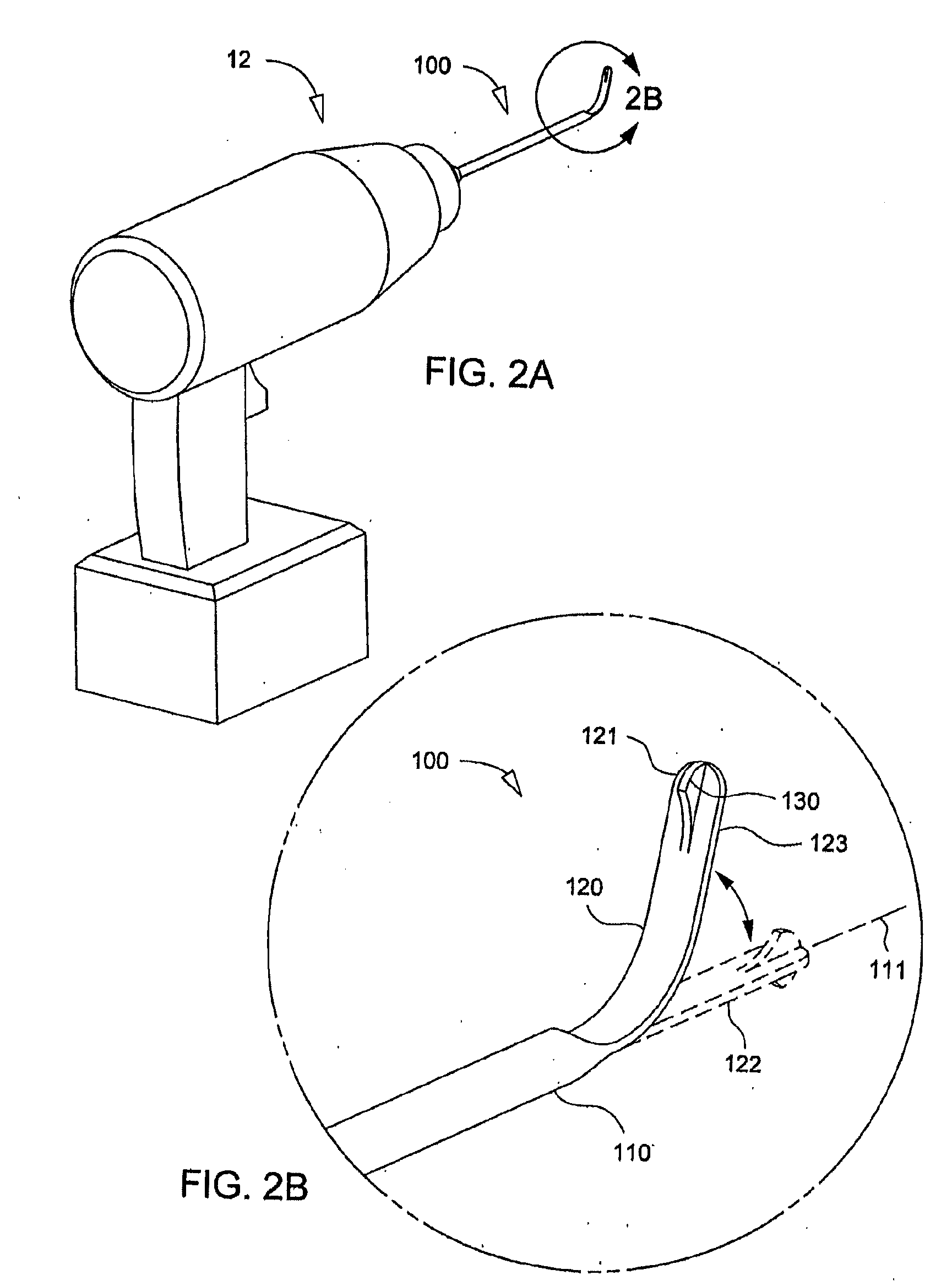

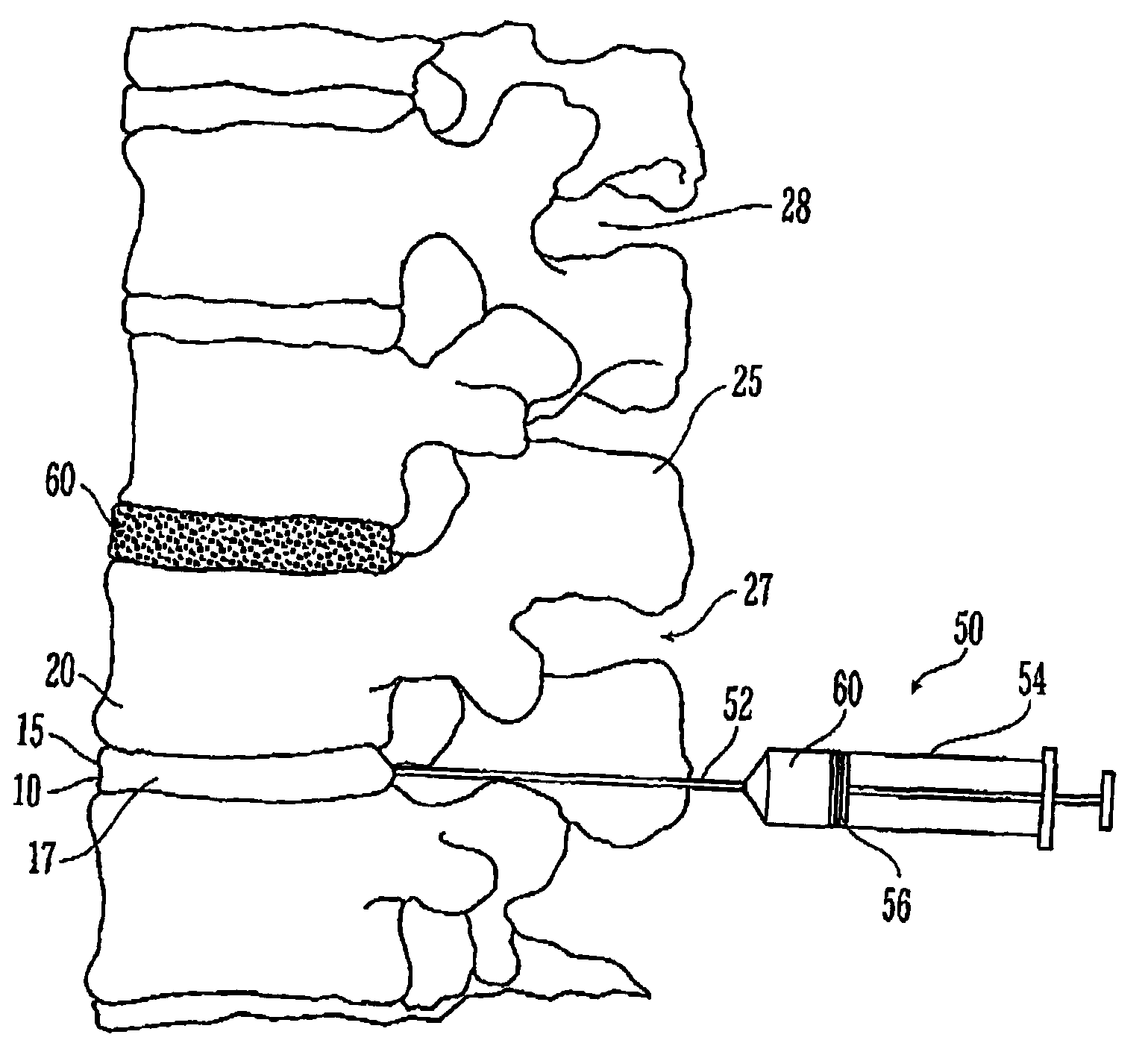

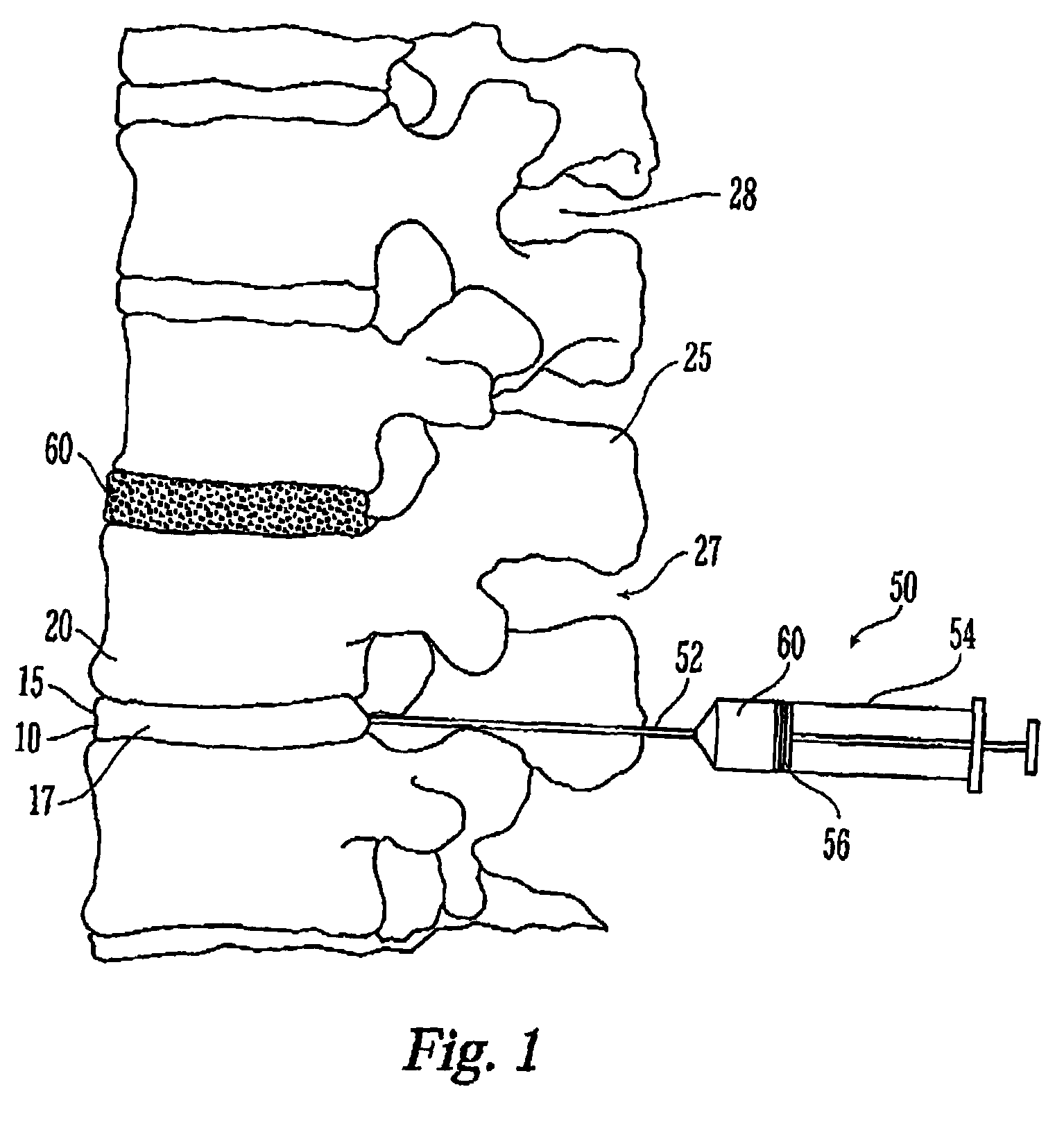

Tool to direct bone replacement material

InactiveUS7025771B2Great tractionIncrease the separation distanceInternal osteosythesisBone implantBone replacementSurgery

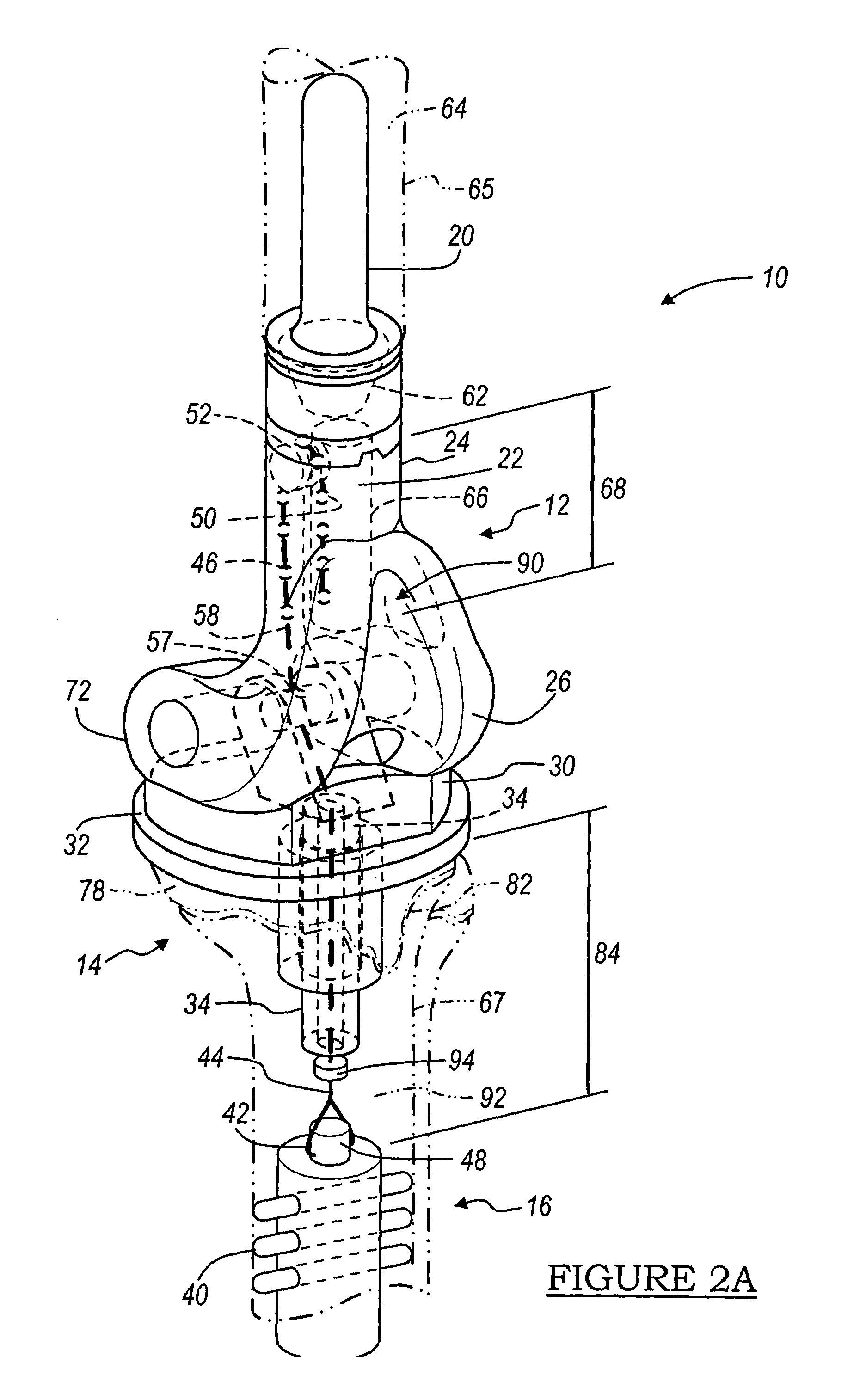

A fill tool for directing bone replacement material into an expandable bag within a reamed out disc includes a deflector at its distal end which deflects the flow of such material to a one or more side openings at the distal end of the fill tool. This allows the tool to be used without being ejected when filling the bag under pressure and greatly increases the distraction forces possible when filling the bag.

Owner:SPINEOLOGY

Device

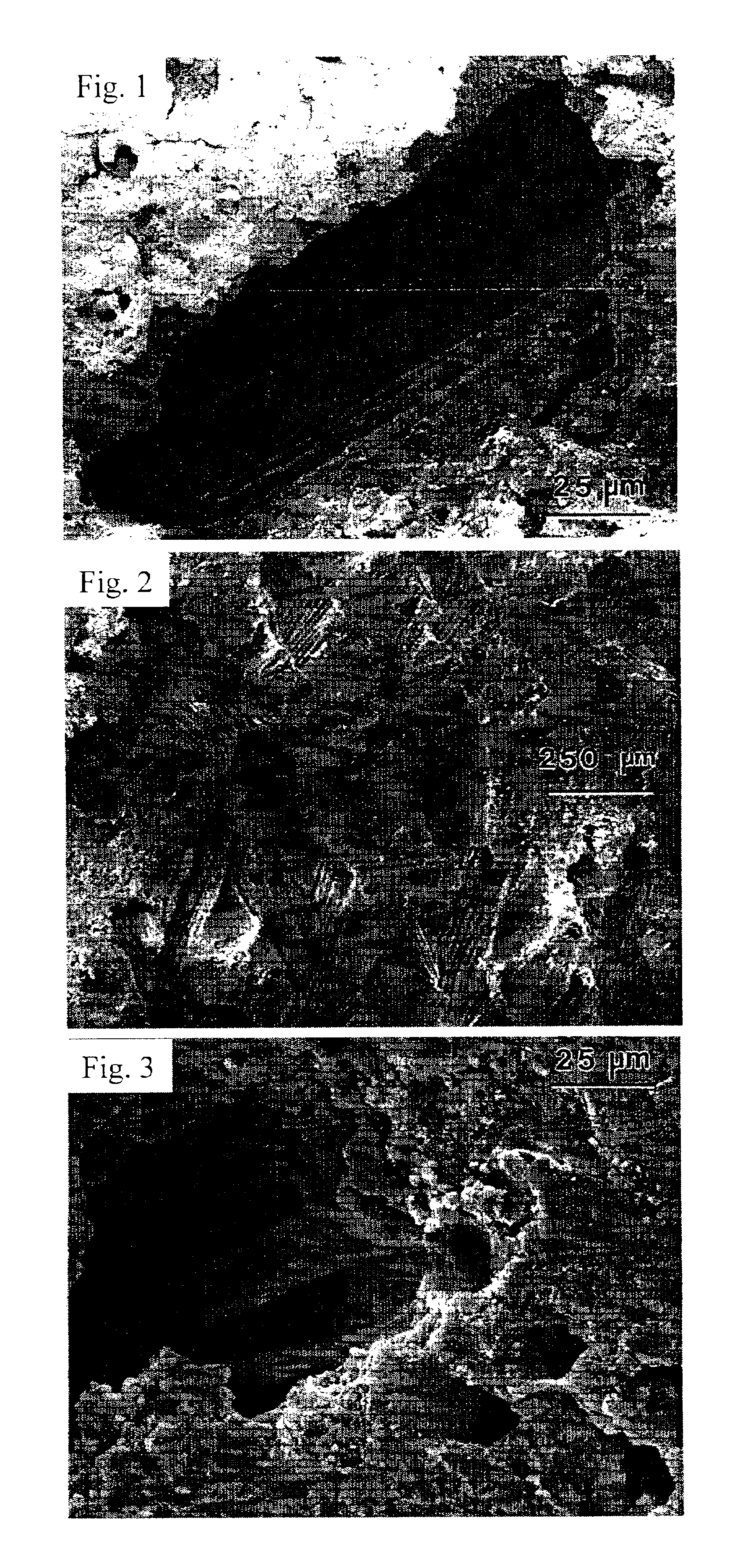

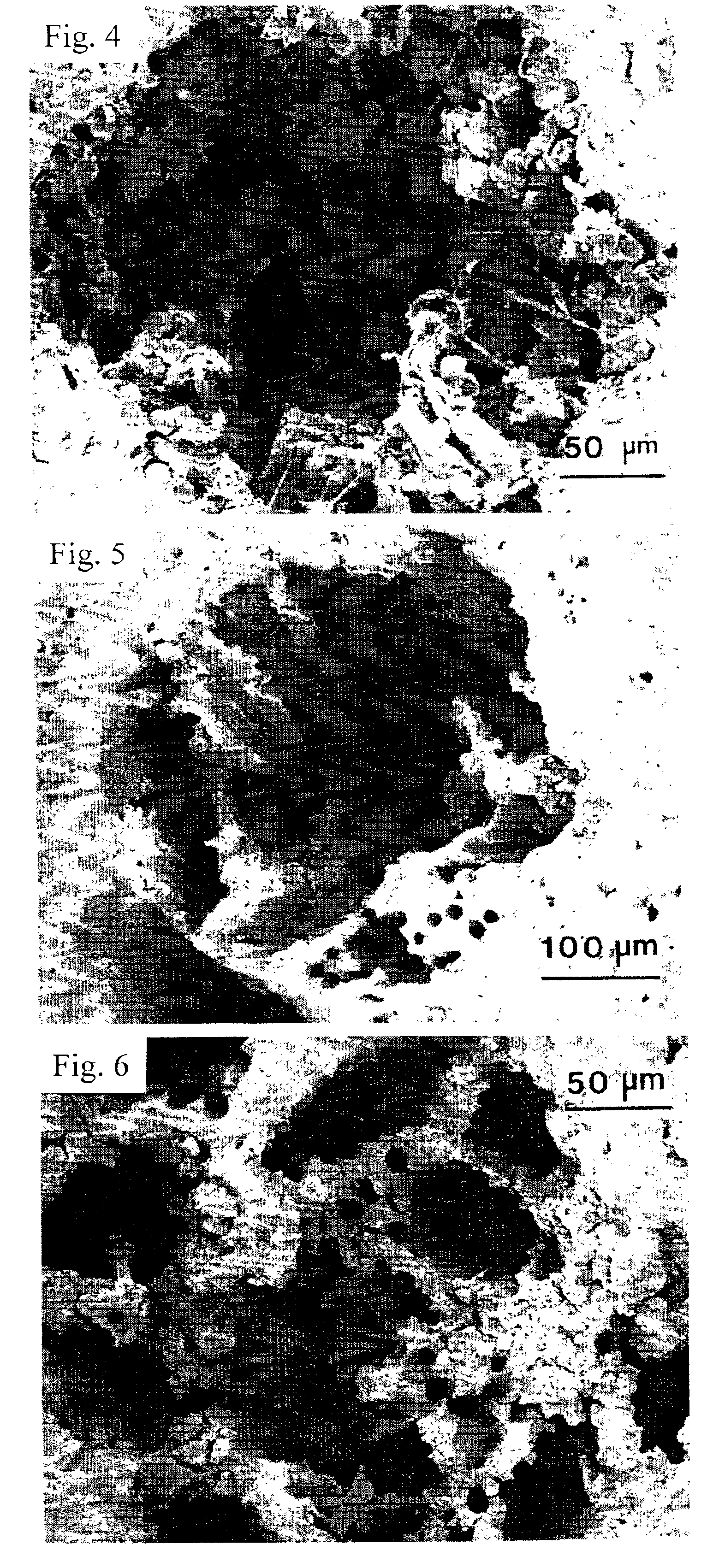

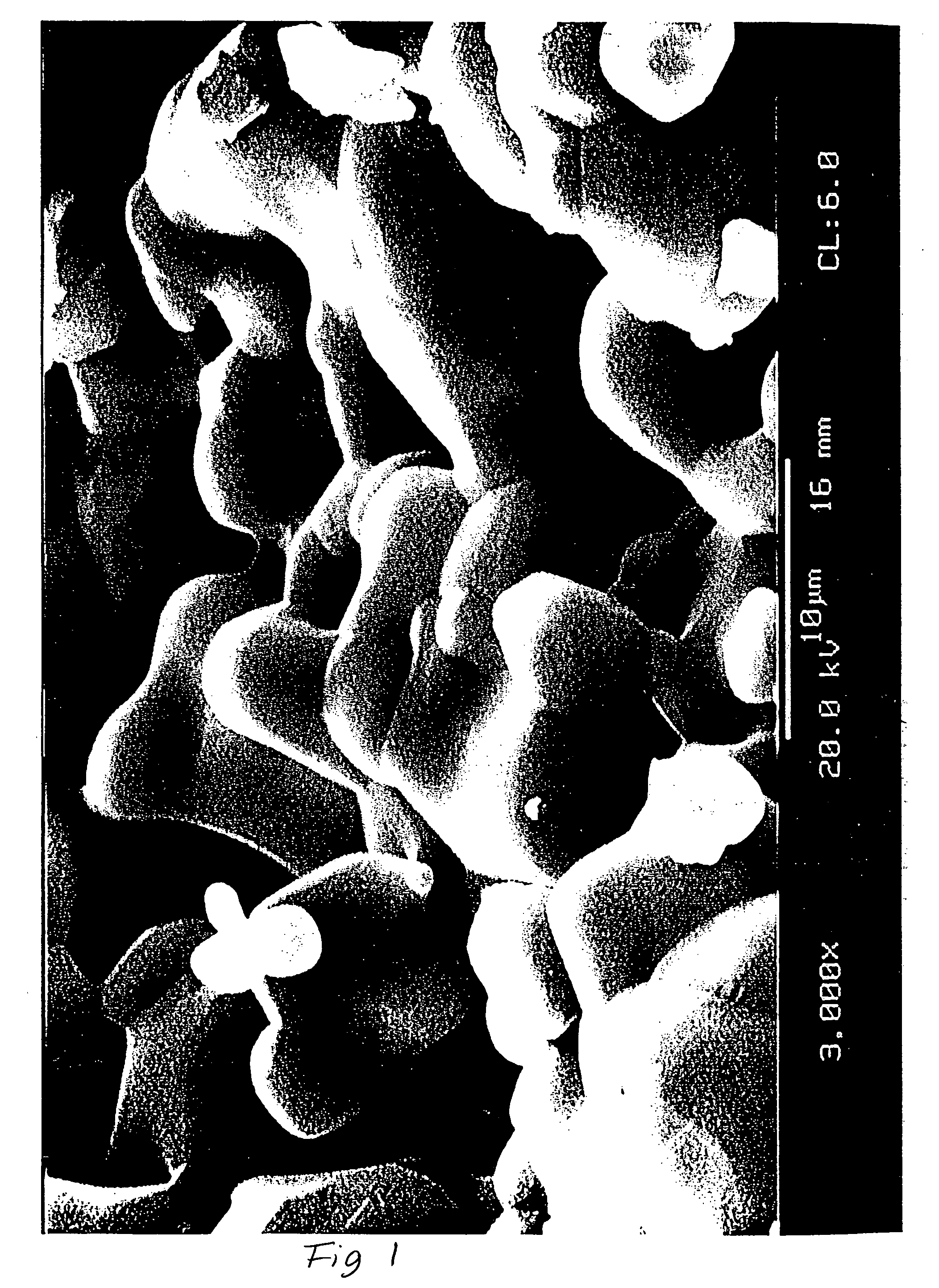

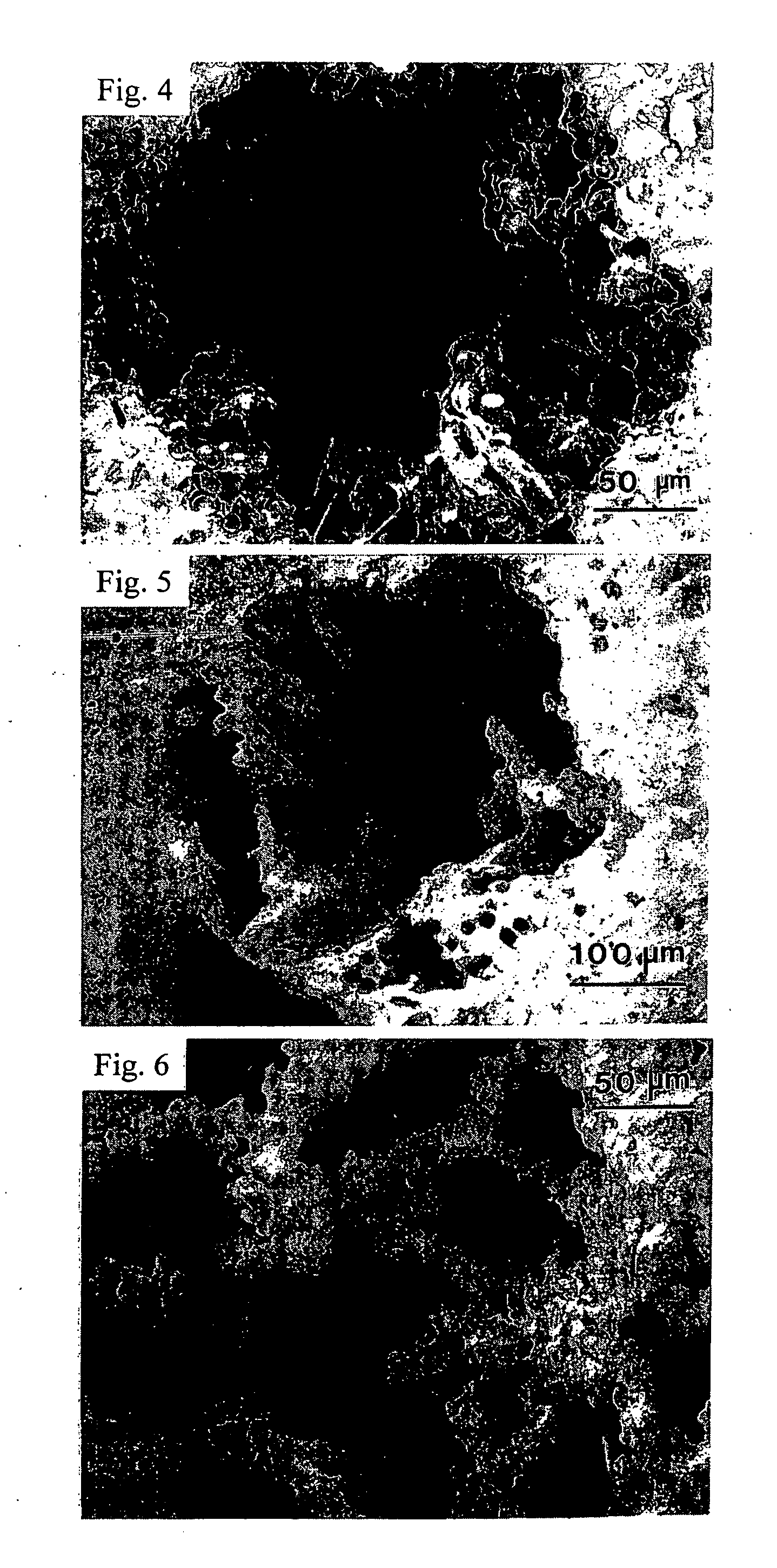

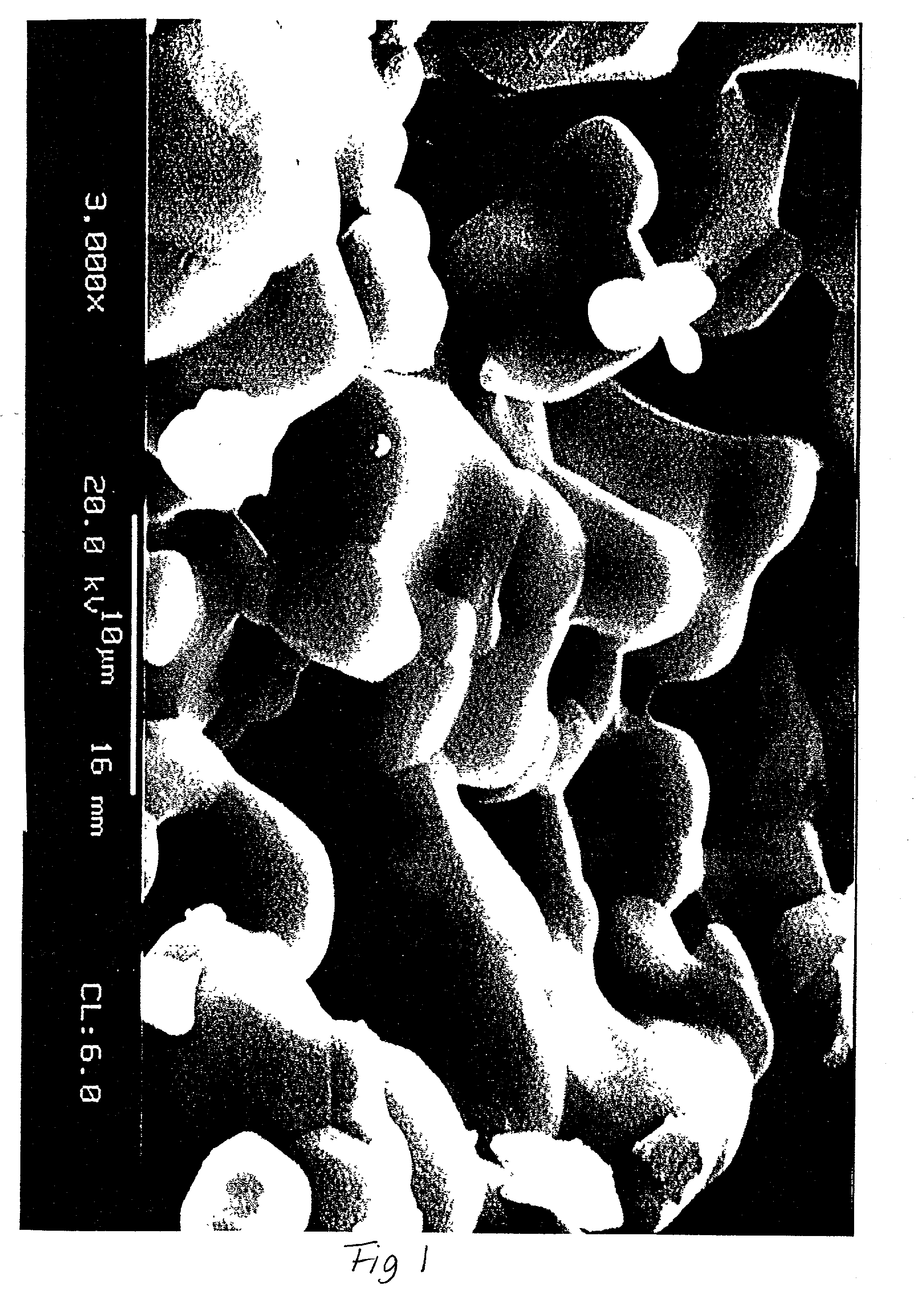

InactiveUS20100094430A1High porositySusceptible to corrosive attackBone implantPretreated surfacesBone replacementMaterials science

An implant for bone replacement and attachment in an animal's body including, a structural portion having an outer porous surface, a ceramic material applied to the porous surface of the structural portion, characterised in that the thickness of the ceramic material as applied utilizing pulsed pressure MOCVD is such that at least some of the pores of the porous surface are not completely closed.

Owner:CANTERPRISE LTD

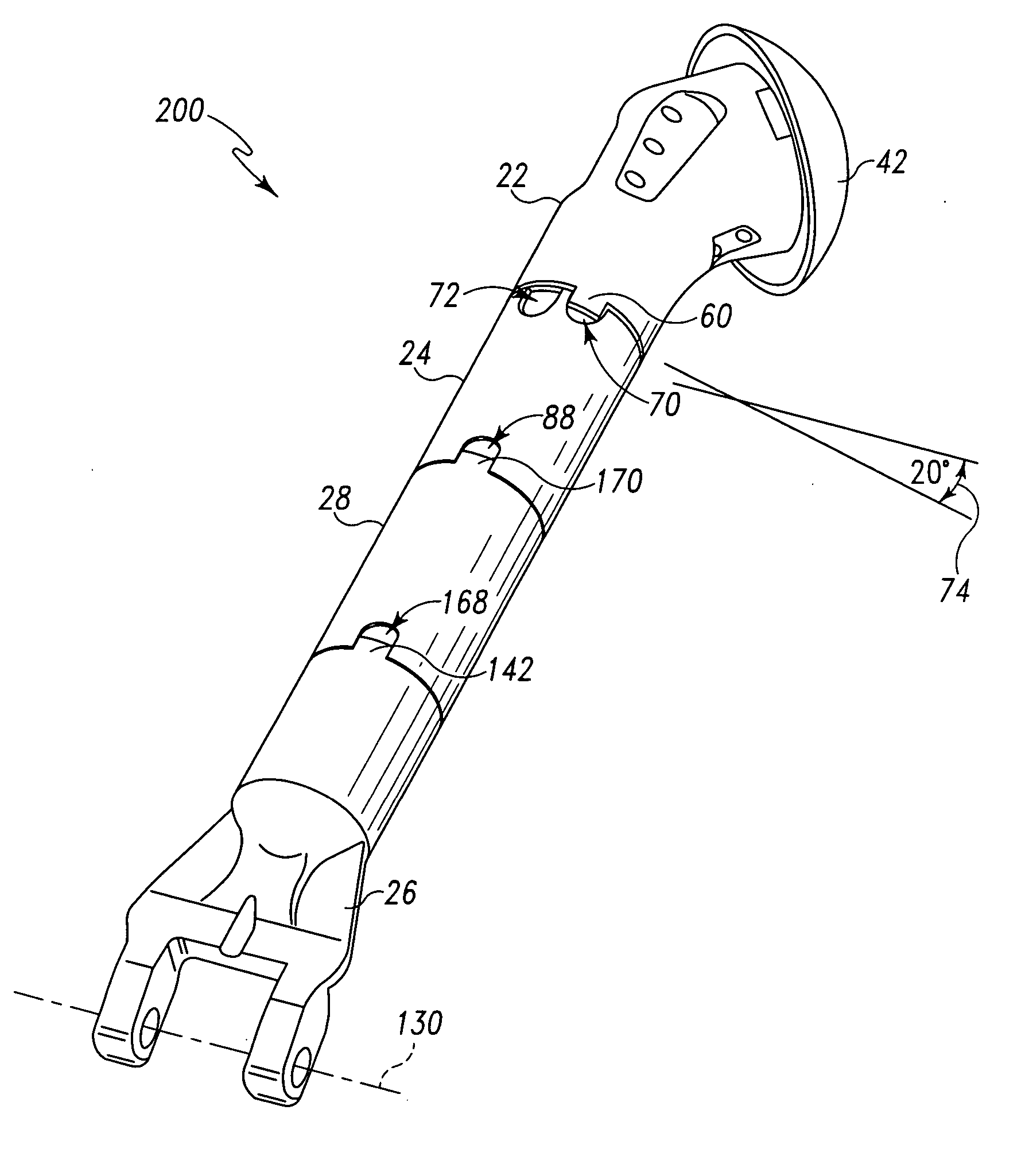

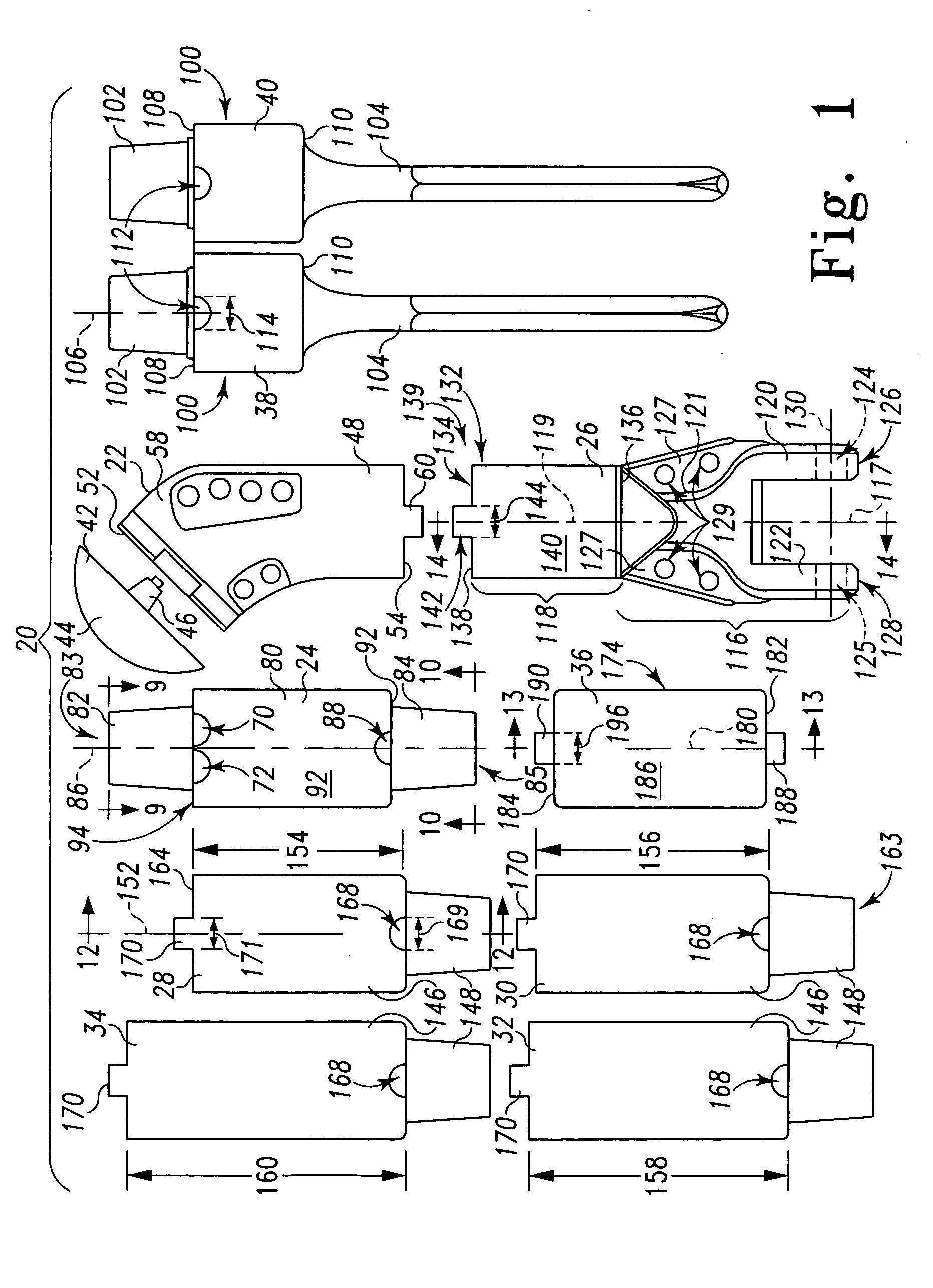

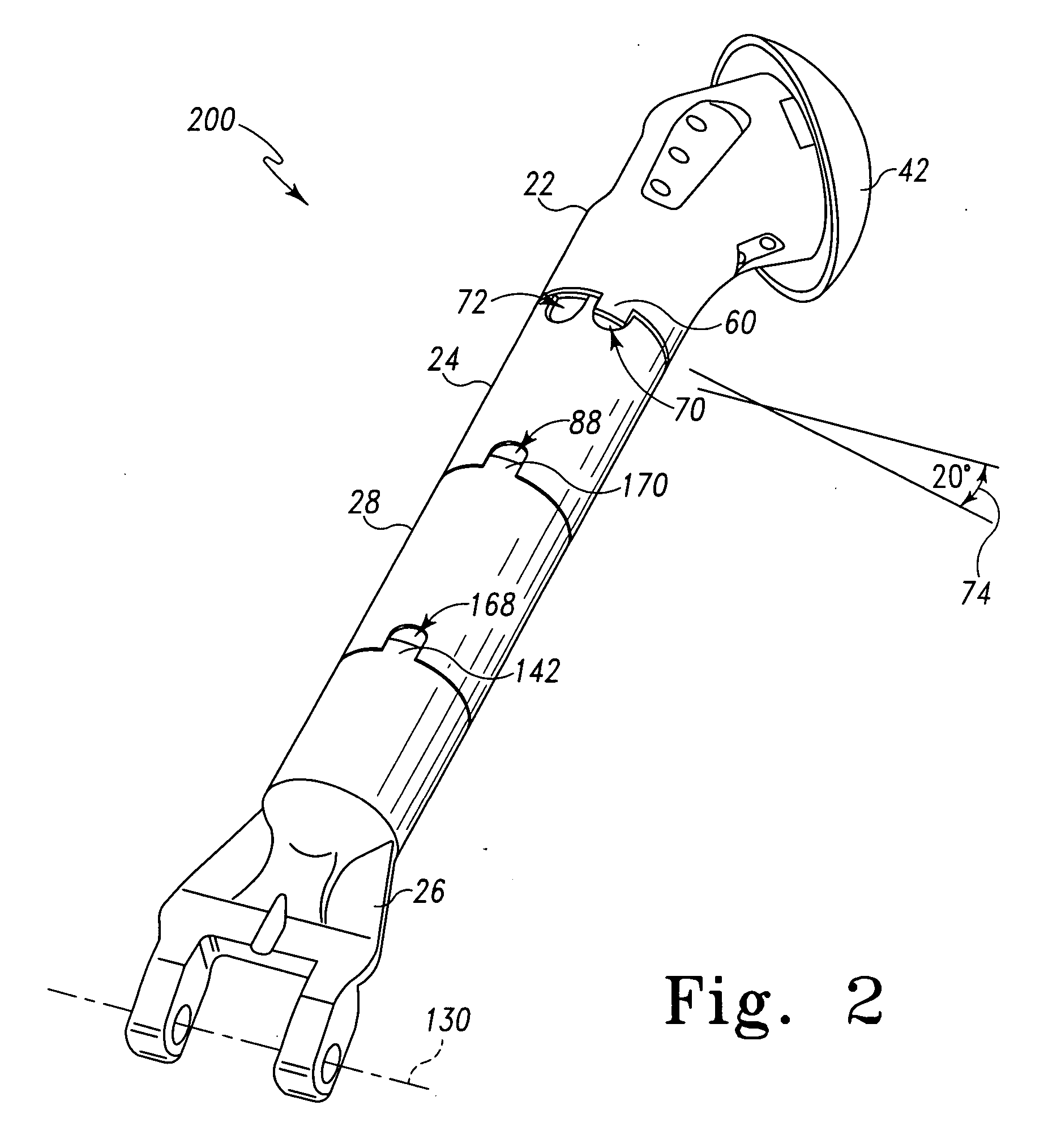

Method and apparatus for use of a non-invasive expandable implant

The present invention relates to a non-invasive expandable implant utilizing energy from an epiphyseal growth plate of a human long bone to expand the implant. A bone replacement section includes a housing, an expansion shaft, a connection system, and an implant member. An anchoring member is secured to the second bone portion and spaced from the implant member. The expansion shaft is configured to translate a first distance between the housing and the first bone member. Growth of the bone causes an increase of a second distance between an implant portion and the anchoring member. The increase of the second distance causes the anchoring member to exert a force on a connection system causing an increase of the first distance, thus expanding the implant.

Owner:BIOMET MFG CORP

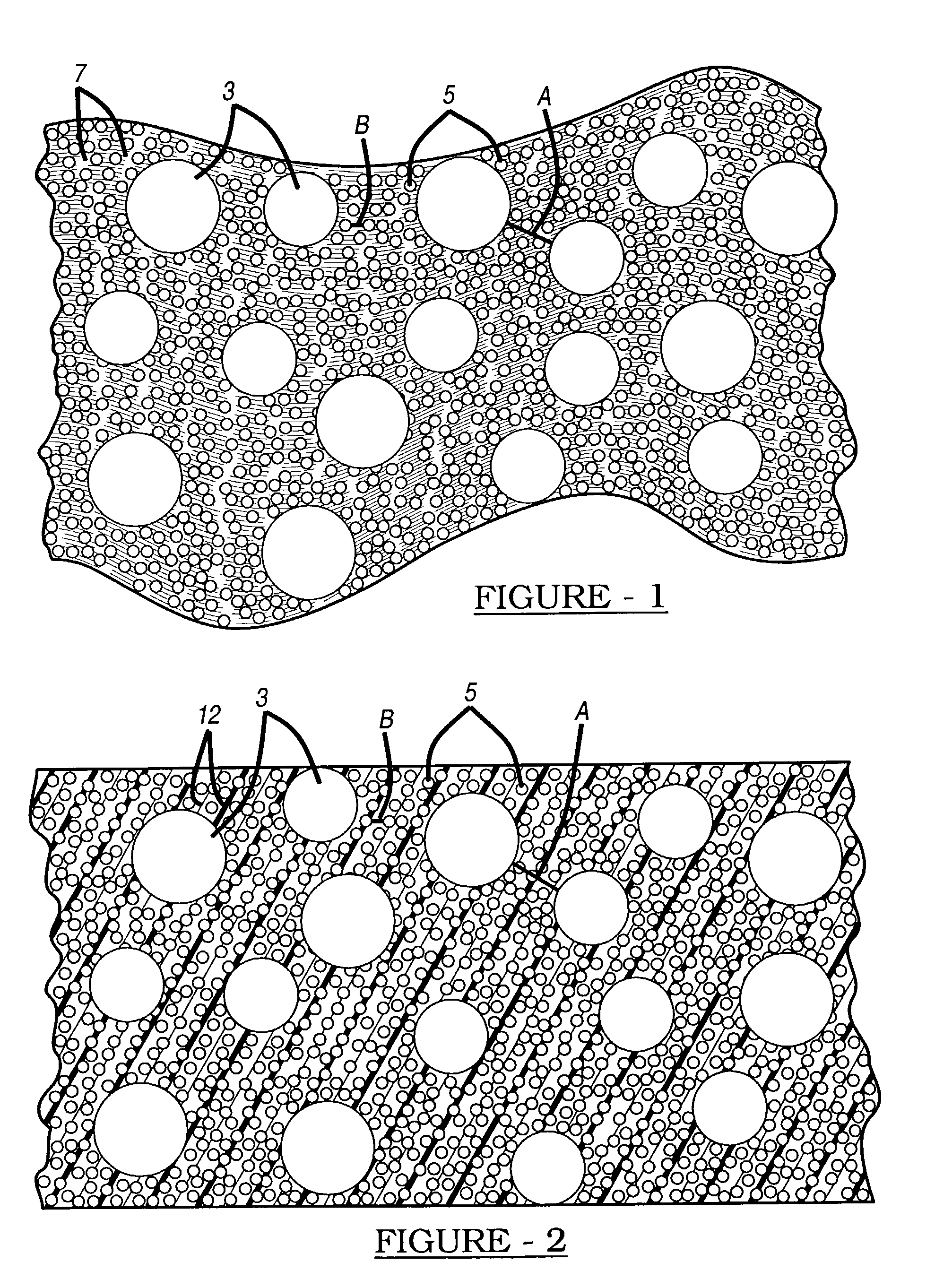

Bone replacement materials

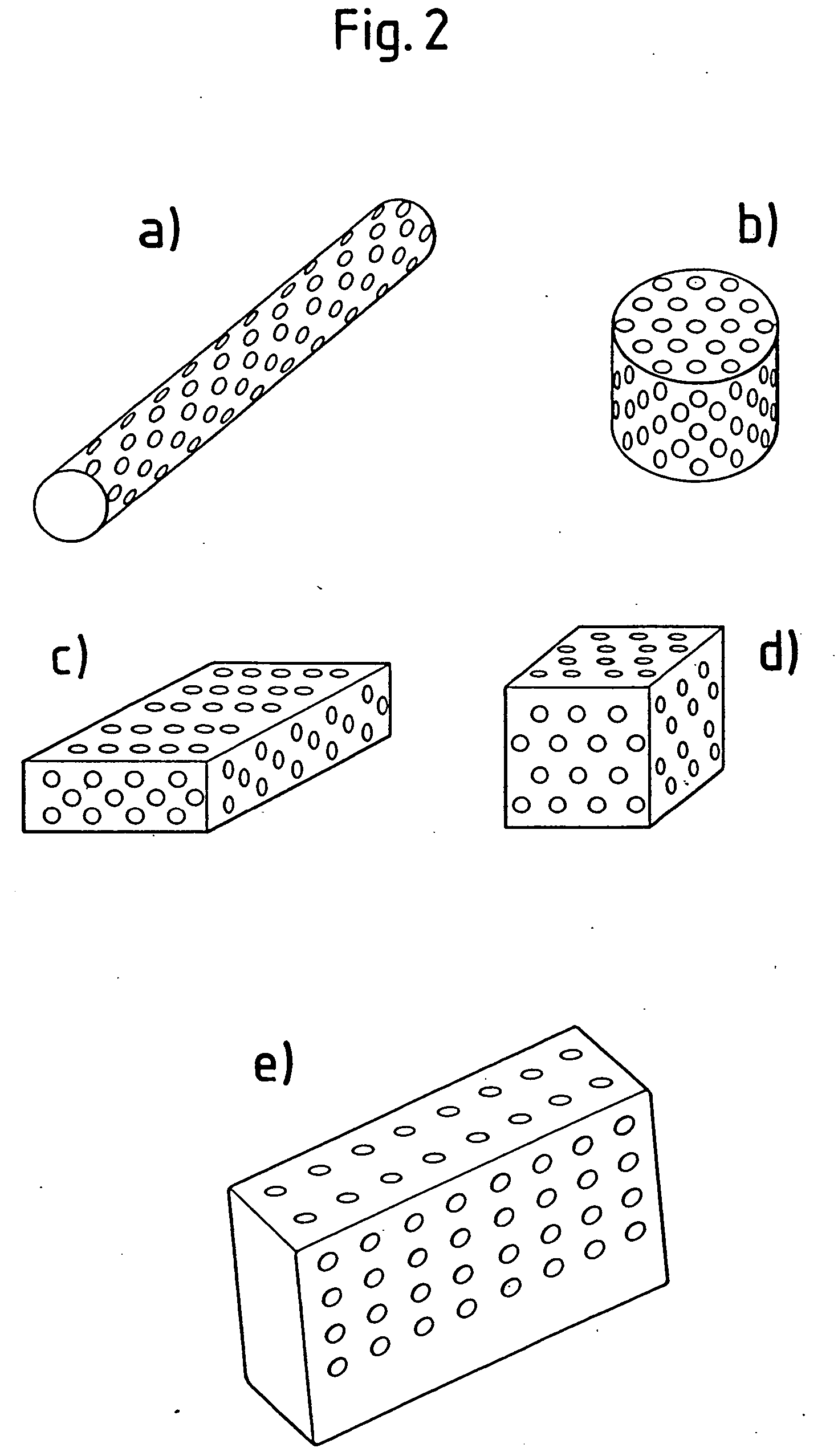

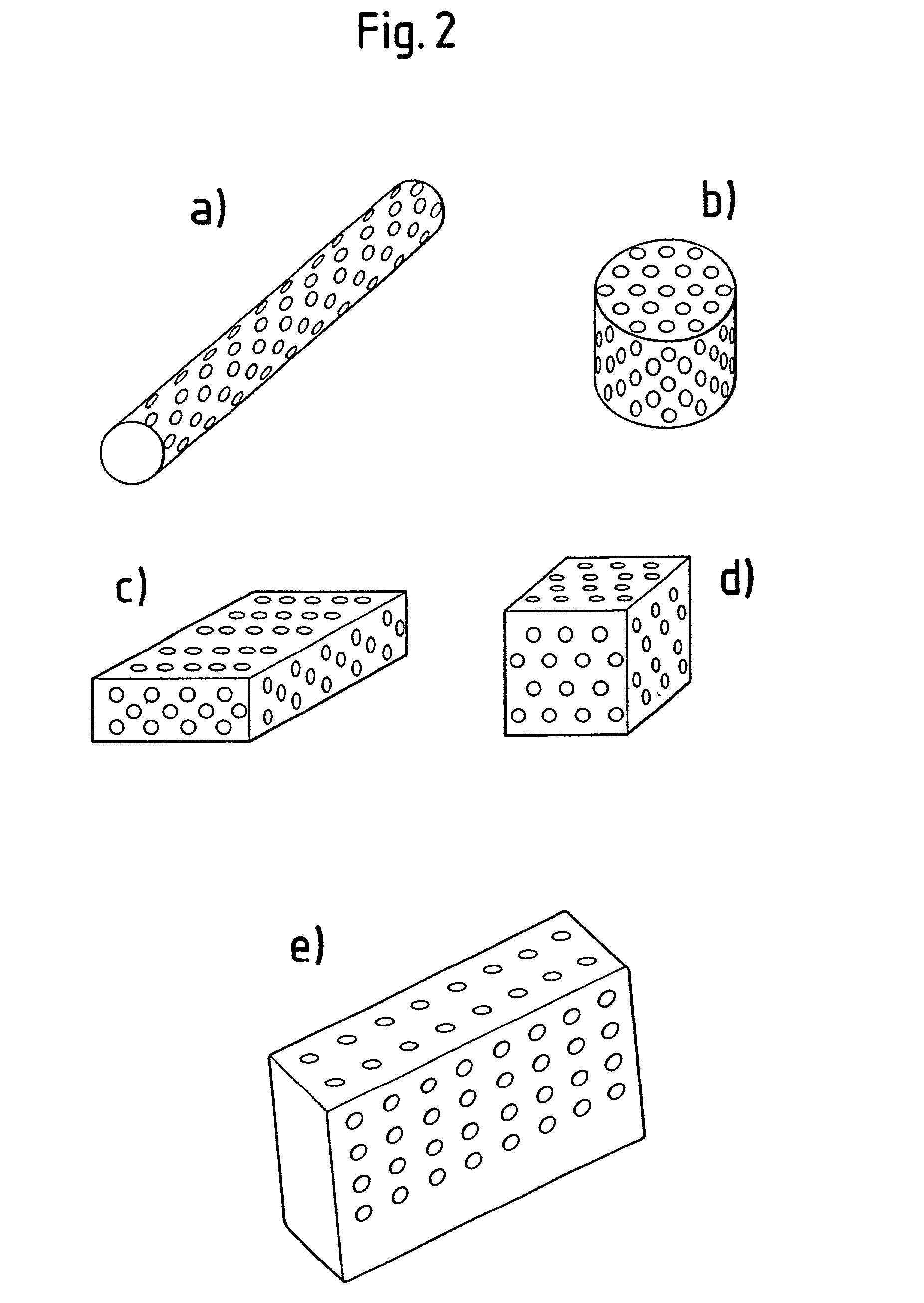

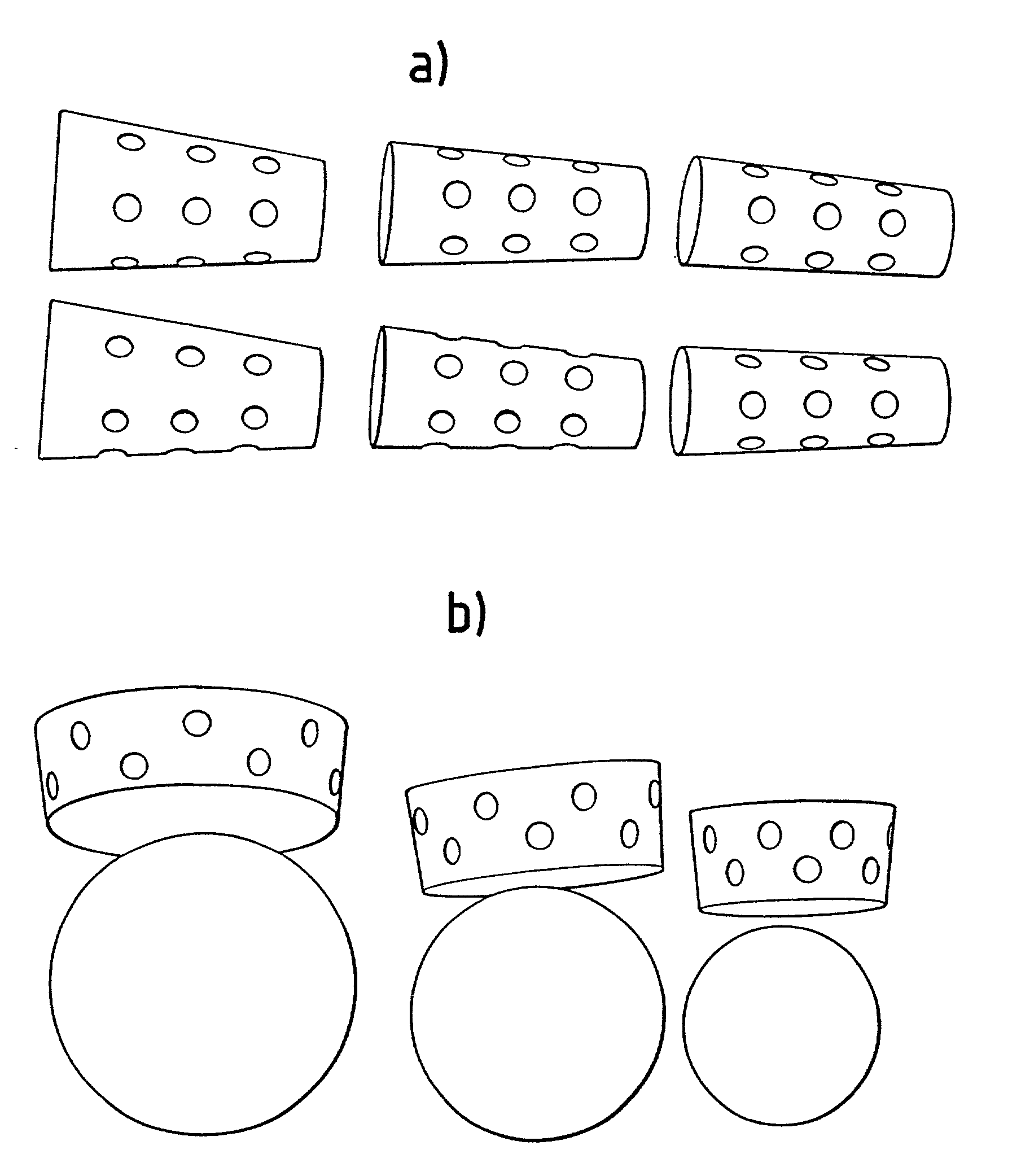

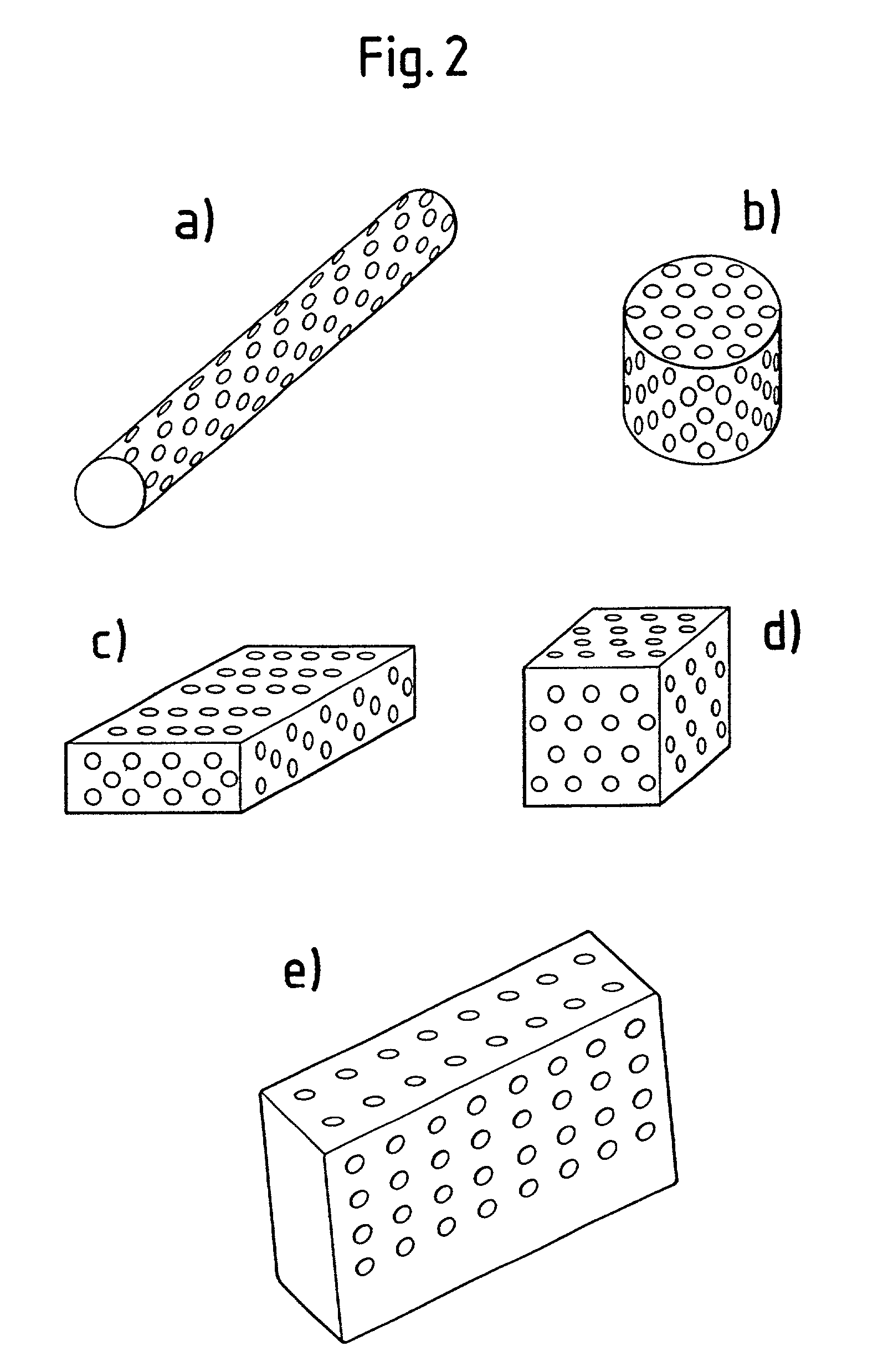

ActiveUS20070203584A1Easy adhesionFacilitate cell growthAdditive manufacturing apparatusBone implantBone tissueBone tissue engineering

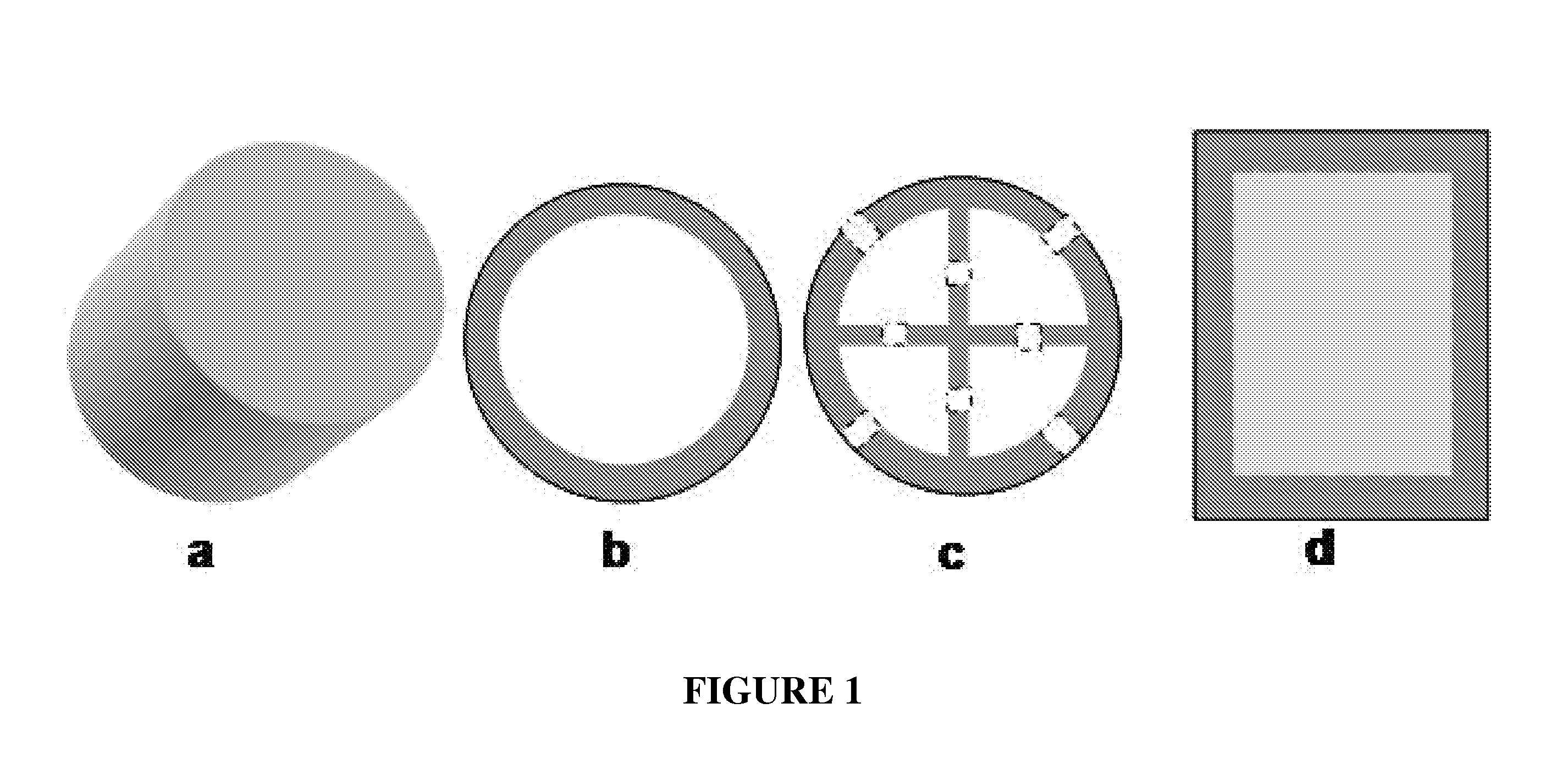

Particular aspects provide novel devices for bone tissue engineering, comprising a metal or metal-based composite member / material comprising an interior macroporous structure in which porosity may vary from 0-90% (v), the member comprising a surface region having a surface pore size, porosity, and composition designed to encourage cell growth and adhesion thereon, to provide a device suitable for bone tissue engineering in a recipient subject. In certain aspects, the device further comprises a gradient of pore size, porosity, and material composition extending from the surface region throughout the interior of the device, wherein the gradient transition is continuous, discontinuous or seamless and the growth of cells extending from the surface region inward is promoted. Additional aspects provide a device for bone tissue engineering, comprising a metal or metal-based composite member / material comprising an interior porous structure, wherein the pore size, porosity and material composition is selected to provide a device having an optimal density and / or elastic modulus and / or compression strength for a specific recipient. Novel methods for fabricating the devices are also provided.

Owner:WASHINGTON STATE UNIVERSITY

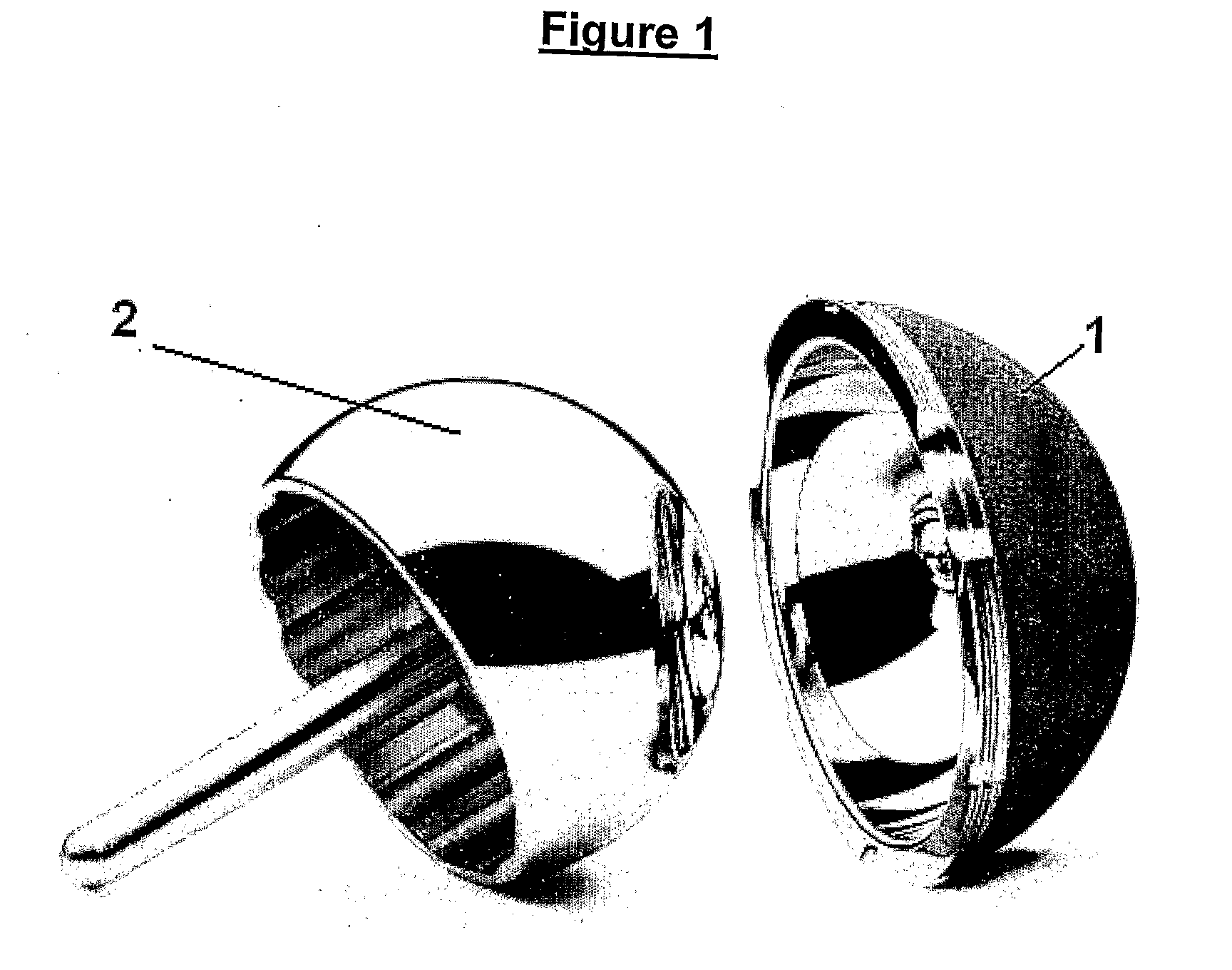

Modular long bone prosthesis for partial or total bone replacement

ActiveUS20050071014A1Facilitate rotational alignmentEasy alignmentBone implantJoint implantsProsthesisBone replacement

A modular long bone prosthesis is provided having a proximal component and a retroversion component. The proximal component is configured at a proximal end to receive a head forming a portion of a joint and is formed at a distal end to mate with additional prosthesis components. The proximal component is formed to simulate an angle inherent in the proximal end of the bone to be replaced and includes an indicator adjacent the distal end to facilitate rotational alignment of the proximal component and additional prosthesis components. The retroversion component includes a proximal end configured to mate with the distal end of the proximal component. The proximal end includes alignment indicia for positioning relative to the indicator on the proximal component. When the indicator is in a first position relative to the alignment indicia the proximal component and the retroversion component establish a first alignment orientation forming an angle simulating the angle inherent in the proximal end of the right long bone of the long bone to be replaced. When the indicator is in a second position relative to the alignment indicia the proximal component and the retroversion component establish a second alignment orientation forming an angle simulating the angle inherent in the proximal end of the left long bone of the long bone to be replaced.

Owner:DEPUY PROD INC

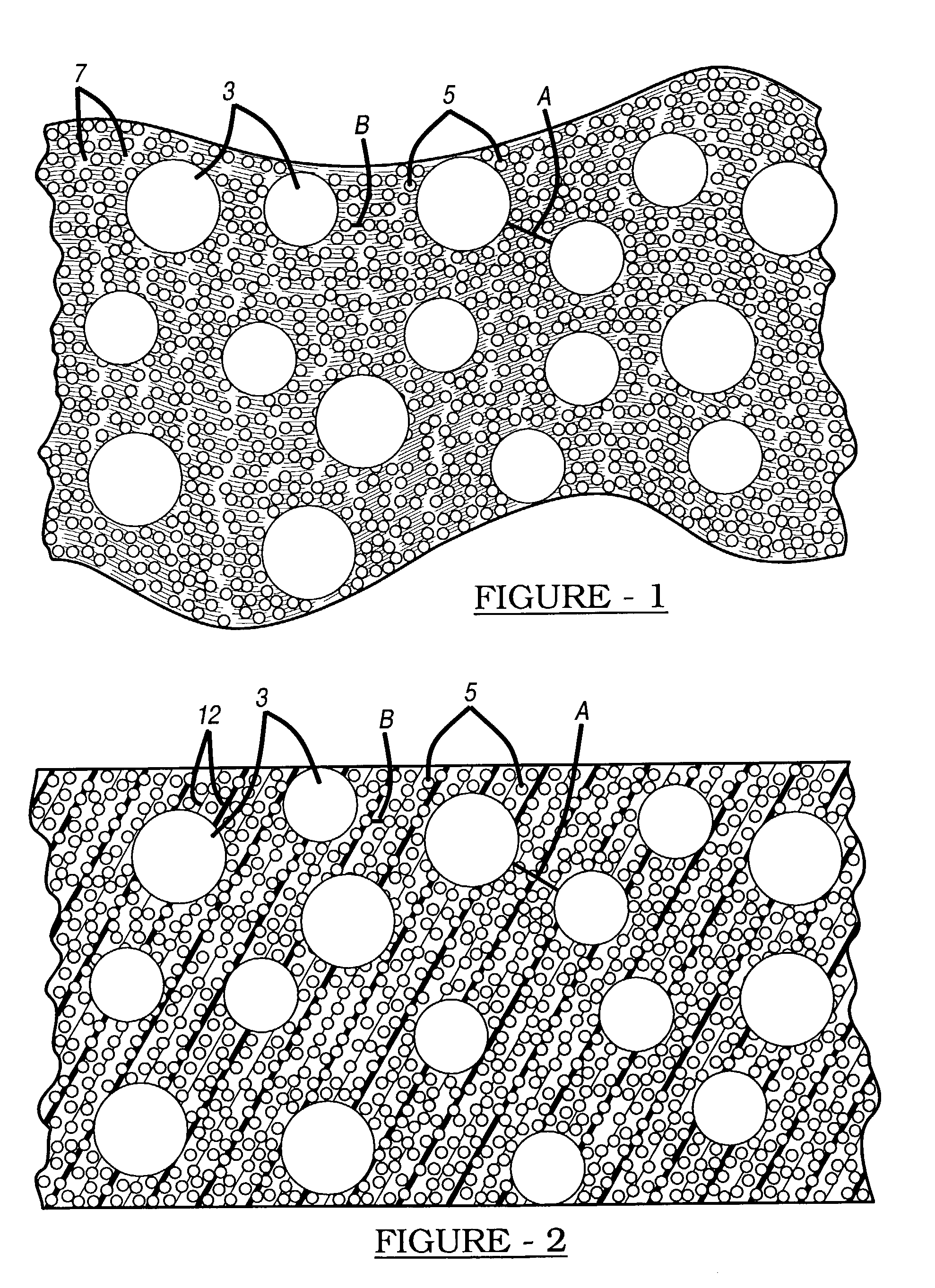

Self-hardening calcium phosphate materials with high resistance to fracture, controlled strength histories and tailored macropore formation rates

InactiveUS6955716B2Strong and tough self-hardeningHigh strengthPhosphatesOther chemical processesFiberHigh resistance

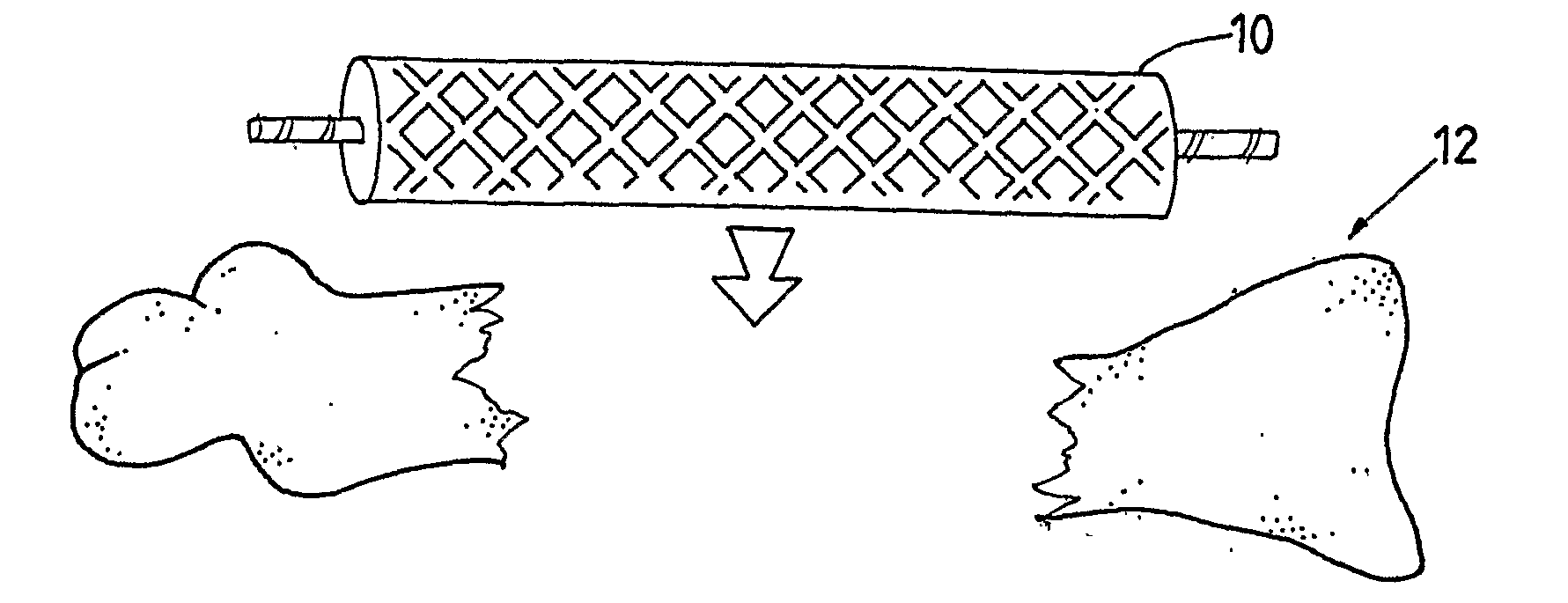

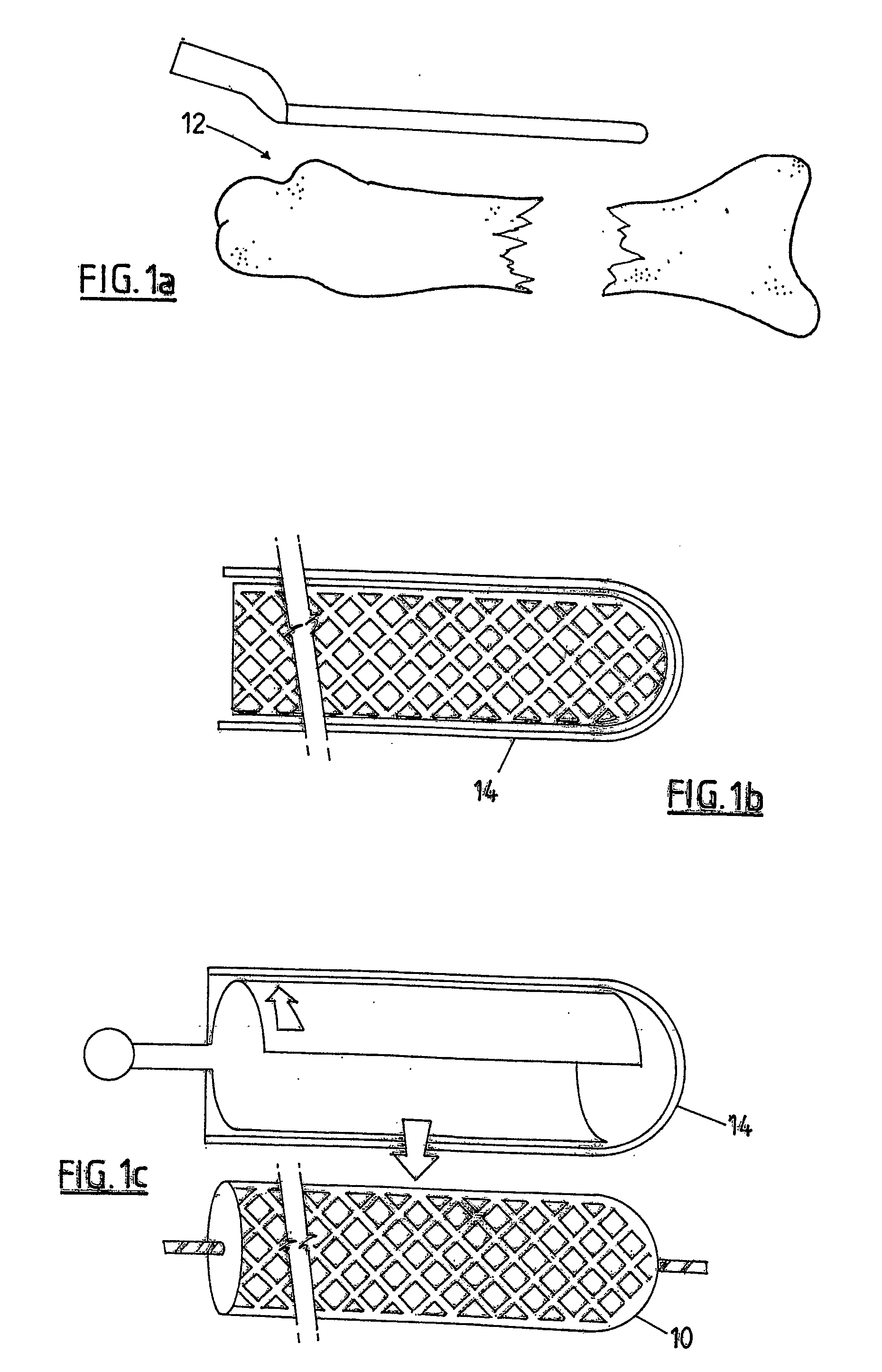

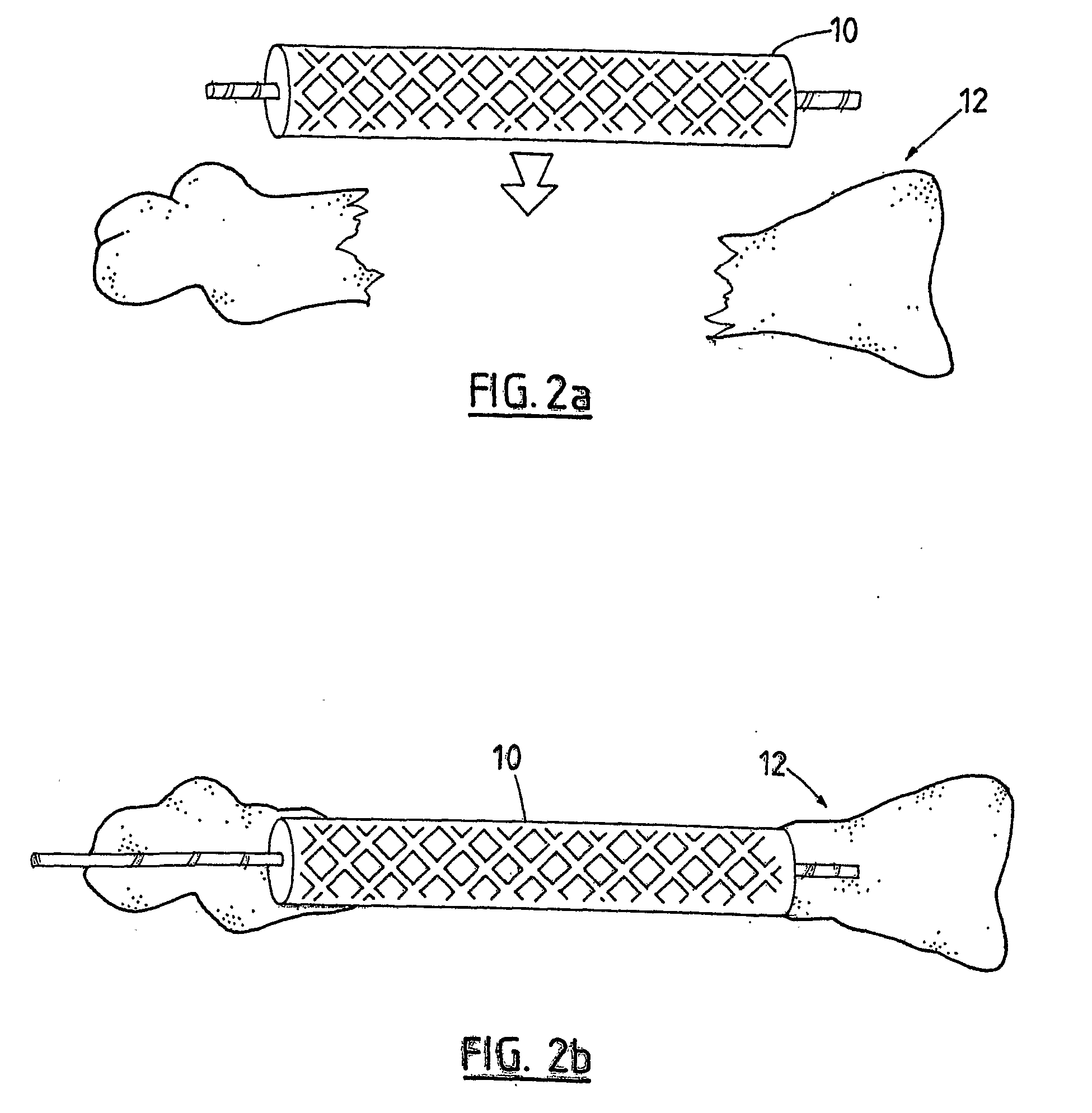

A bone replacement material and therapy comprises the combination of calcium phosphate compounds and two or more soluble fillers in the form of fibers, mesh or other materials which have the dual functions of reinforcing an in vivo implant while dissolving at a programmed rate to form macropores capable of receiving natural bone ingrowth.

Owner:ADA FOUND

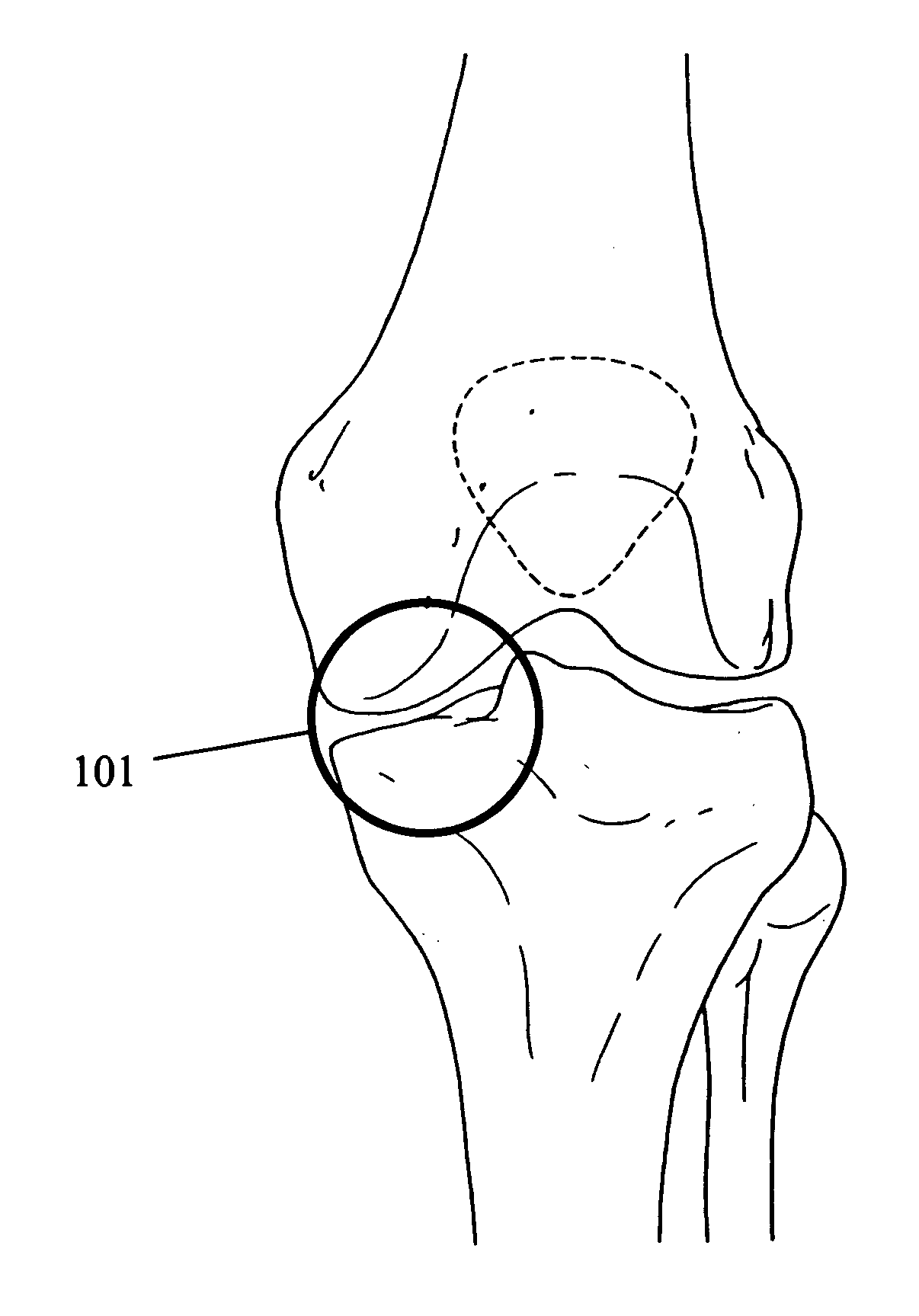

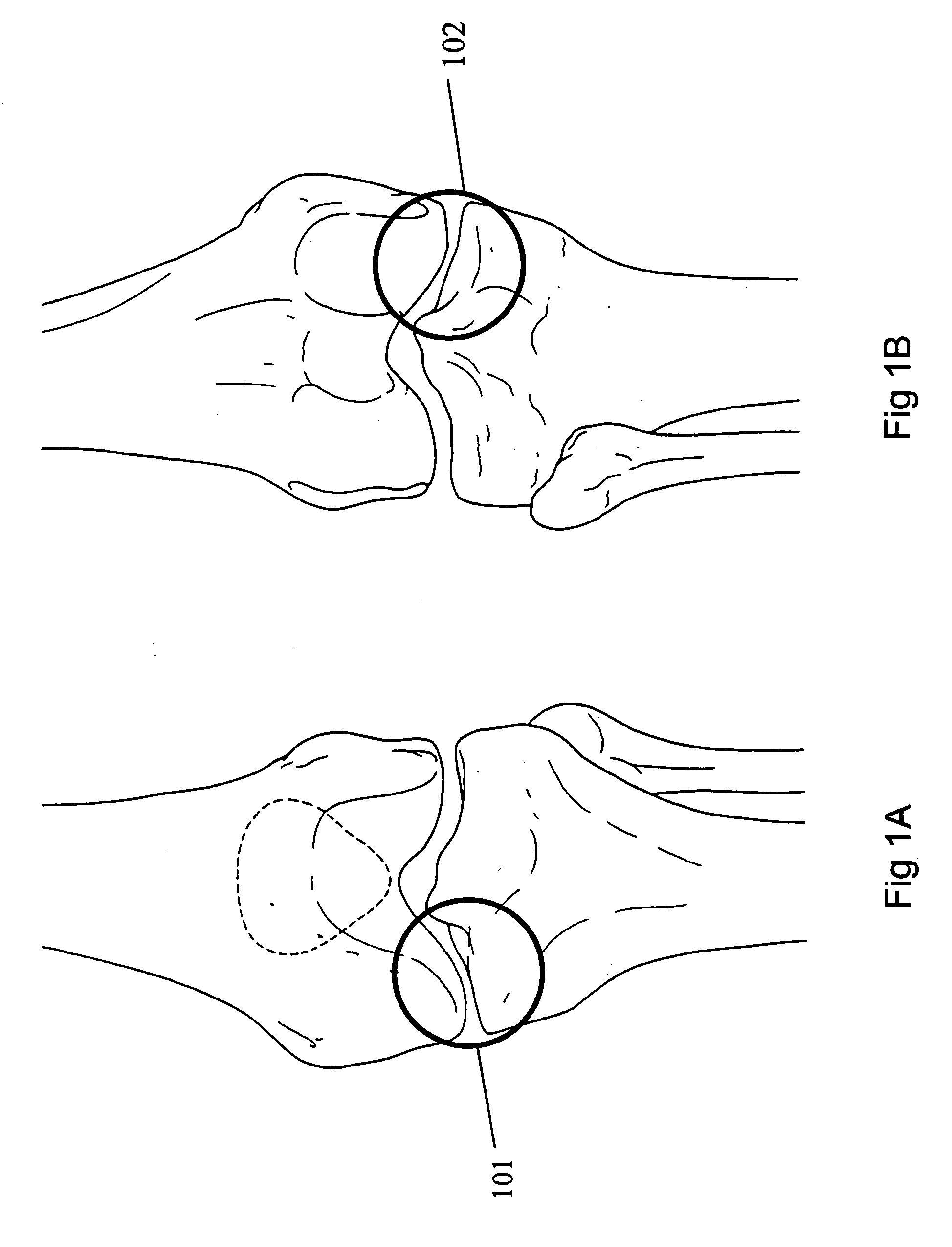

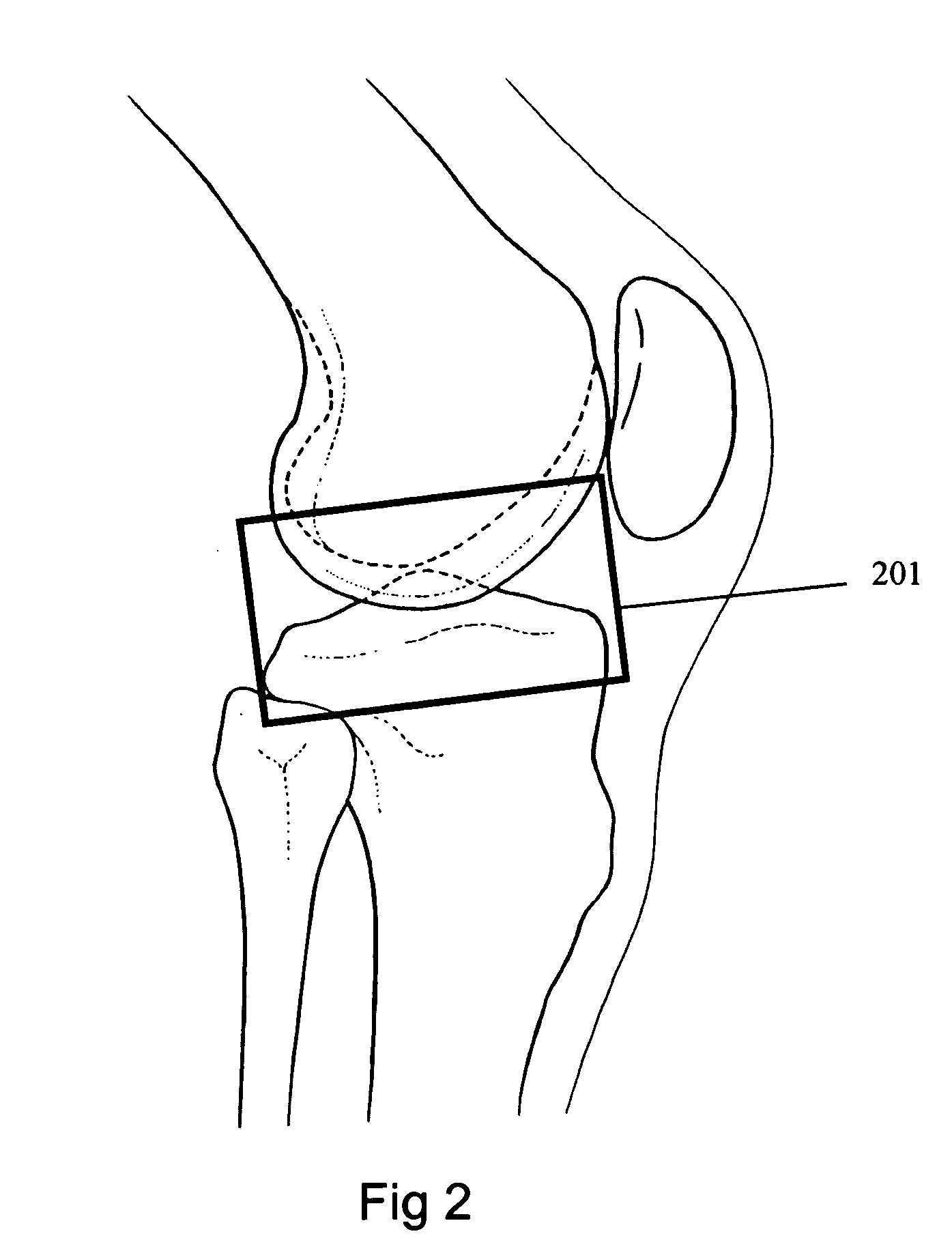

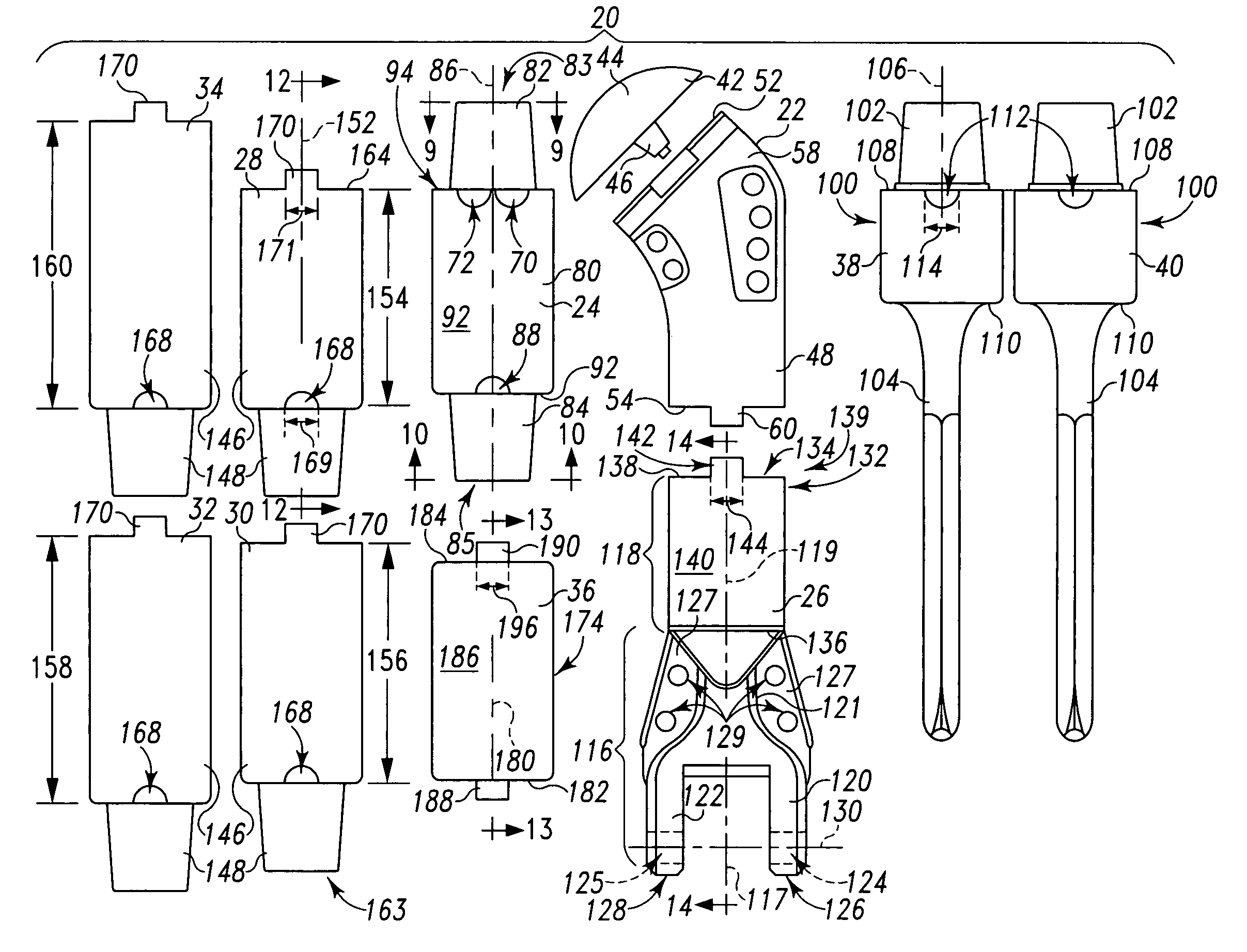

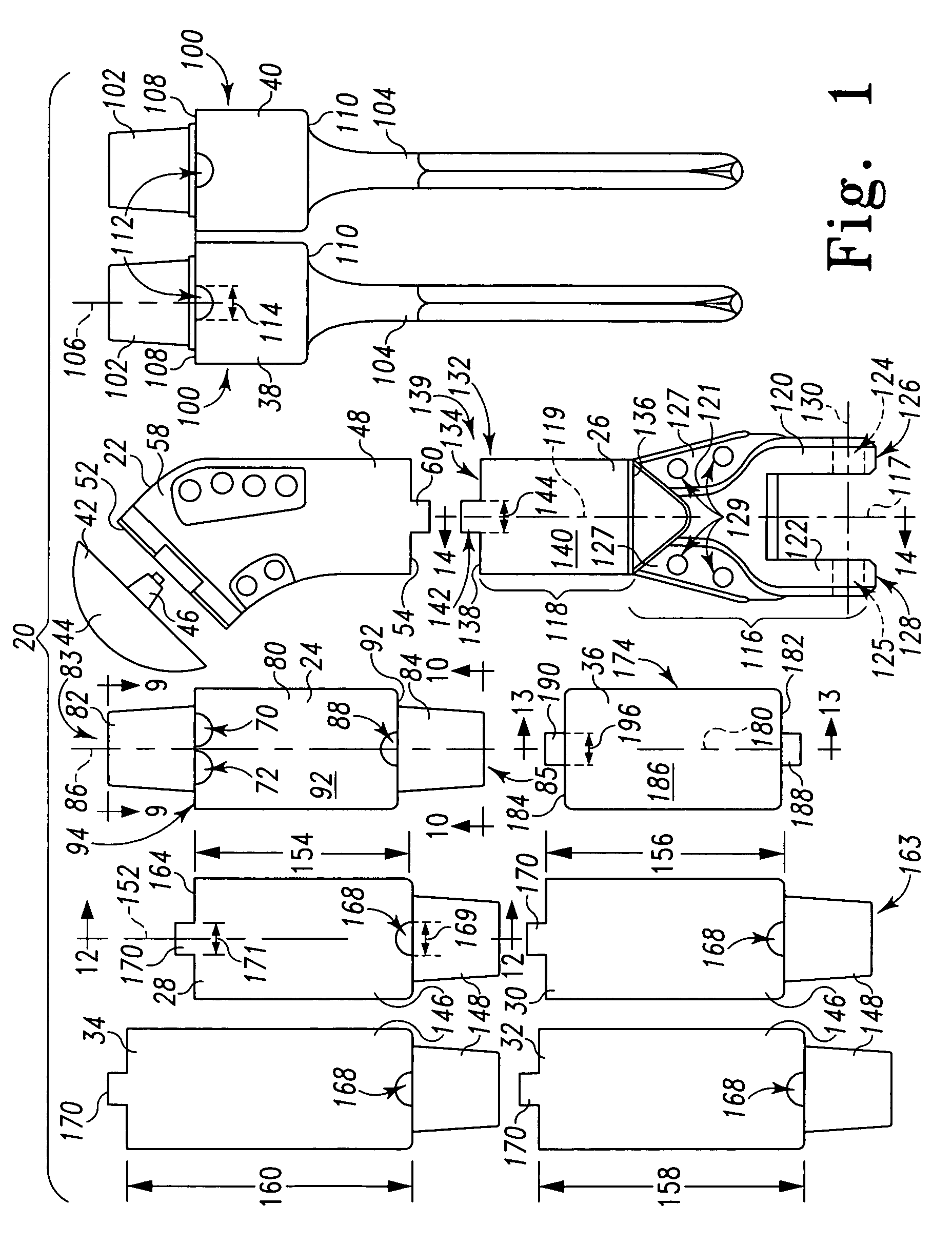

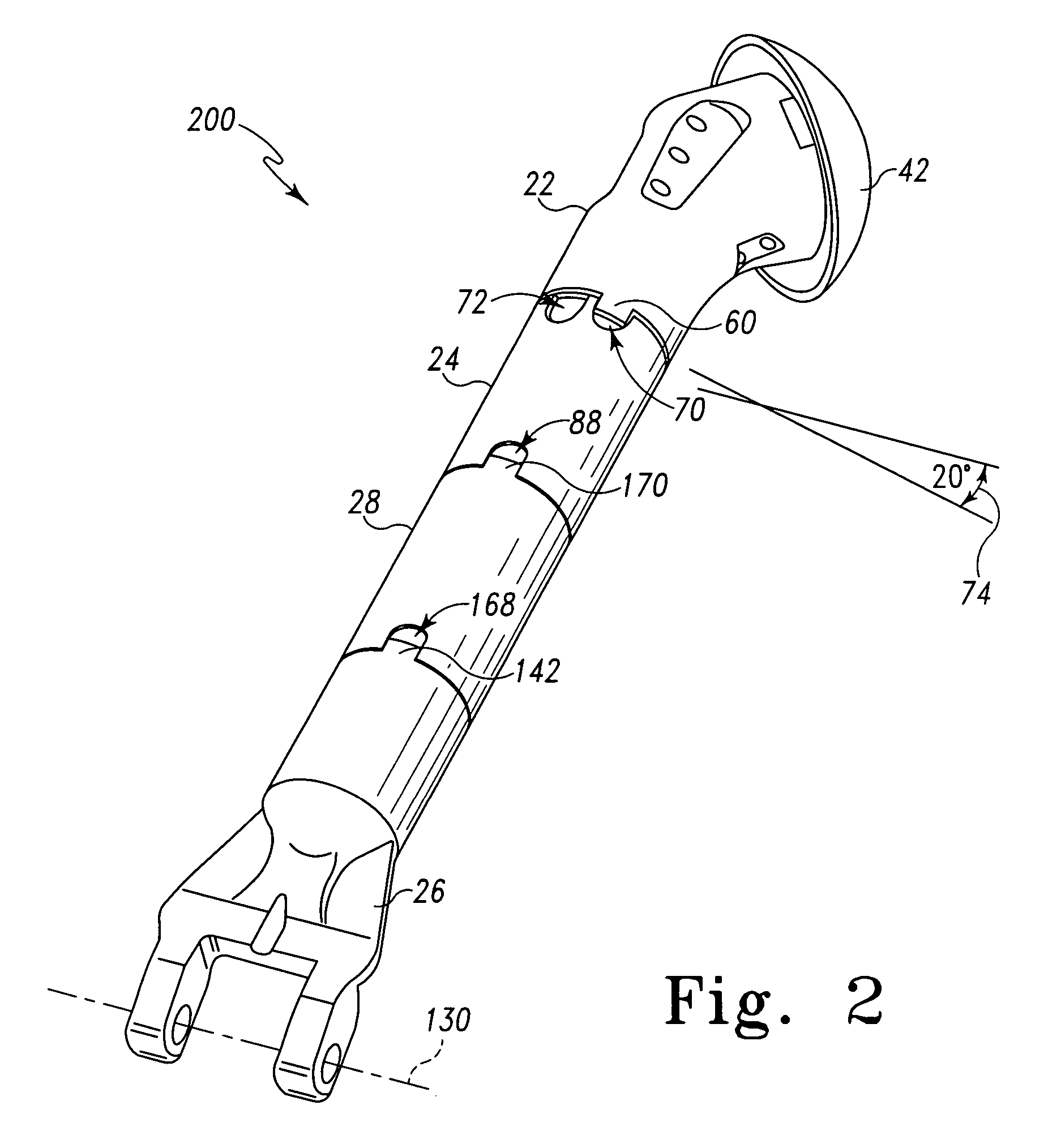

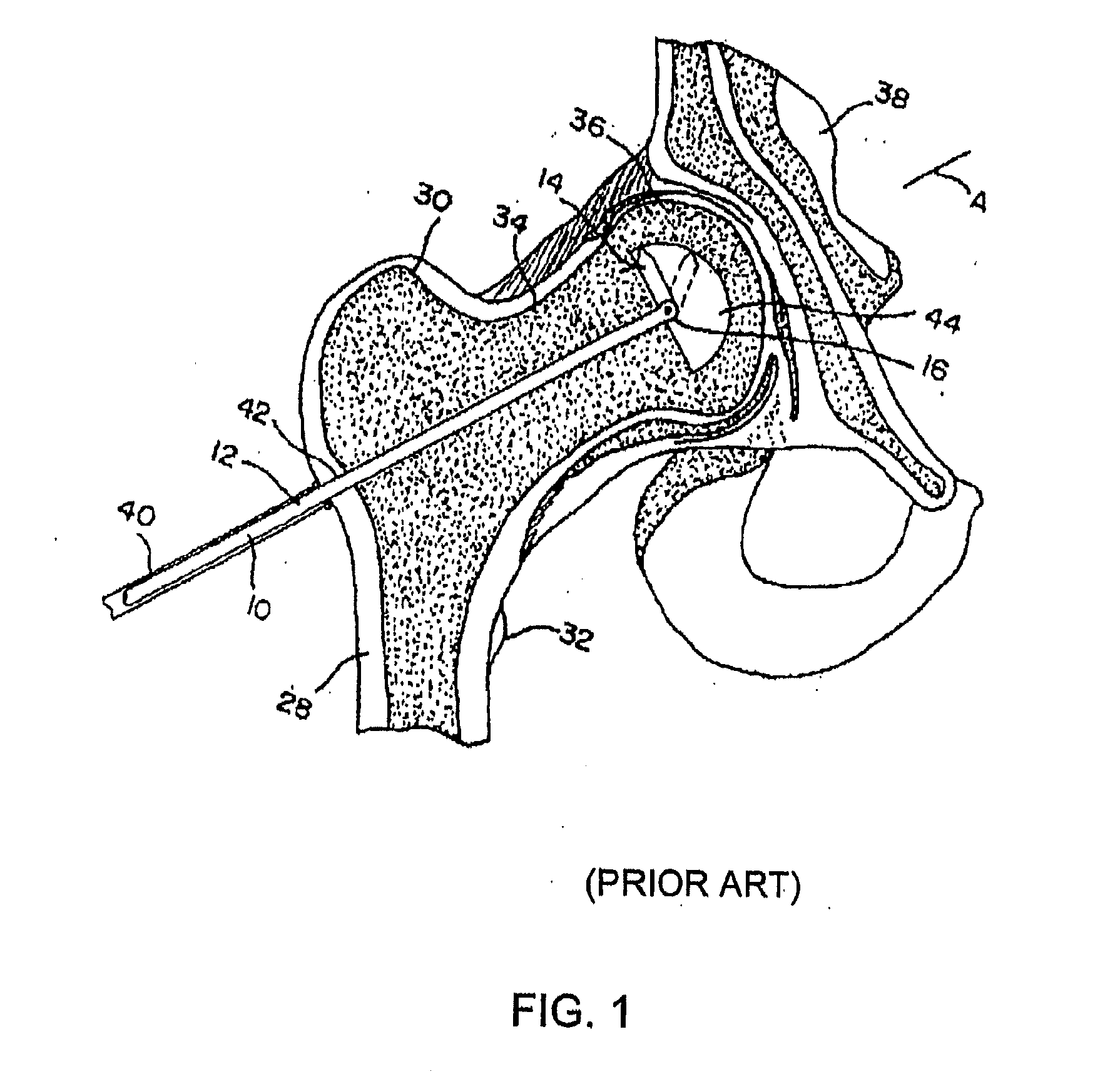

Bone treatment method with implants and instrumentation

A method, instrumentation and implants for a minimally invasive bone and joint treatments allow cuts in bones to be made simultaneously. This method produces a simple precise alignment of cuts on opposite sides of a joint or bone part. It eliminates many steps need to align the numerous cuts used in current joint replacement and bone treatments. In some cases only one cut will be needed. The cuts can also easily be adapted to different anatomical variation and allows implants to be implanted in a fashion where the implants oriented individually in several different planes. The method and instruments allows for other joint and bone treatments besides joint replacement.

Owner:HYDE EDWARD ROBERT JR

Customized implants for bone replacement

InactiveUS20110144752A1Reduce the chance of solidificationLow process temperatureImpression capsAdditive manufacturing apparatusNatural boneCustom made implant

The present invention relates to customized implants for bone replacement that are prepared from poly(ether ketone ketone) or PEKK, and to a computer-based imaging and rapid prototyping (RP)-based manufacturing method for the design and manufacture of these customized implants. The PEKK customized implants made using rapid prototyping demonstrate biomechanical properties similar (if not identical) to that of natural bone even when prepared without the use of processing aids such as carbon black and aluminum powder.

Owner:OXFORD PERFORMANCE MATERIALS

Modular long bone prosthesis for partial or total bone replacement

A modular long bone prosthesis is provided having a proximal component and a retroversion component. The proximal component is configured at a proximal end to receive a head forming a portion of a joint and is formed at a distal end to mate with additional prosthesis components. The proximal component is formed to simulate an angle inherent in the proximal end of the bone to be replaced and includes an indicator adjacent the distal end to facilitate rotational alignment of the proximal component and additional prosthesis components. The retroversion component includes a proximal end configured to mate with the distal end of the proximal component. The proximal end includes alignment indicia for positioning relative to the indicator on the proximal component. When the indicator is in a first position relative to the alignment indicia the proximal component and the retroversion component establish a first alignment orientation forming an angle simulating the angle inherent in the proximal end of the right long bone of the long bone to be replaced. When the indicator is in a second position relative to the alignment indicia the proximal component and the retroversion component establish a second alignment orientation forming an angle simulating the angle inherent in the proximal end of the left long bone of the long bone to be replaced.

Owner:DEPUY PROD INC

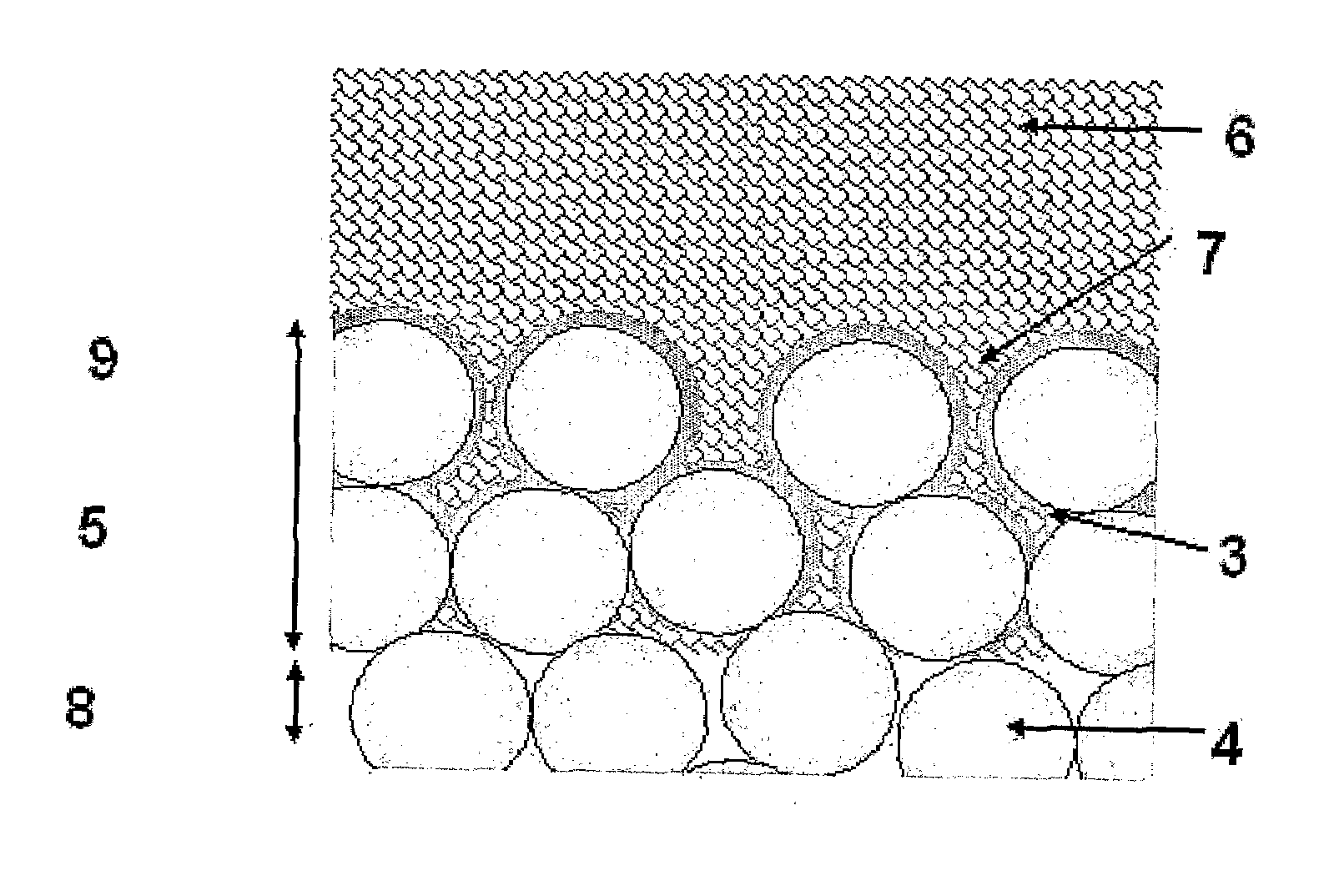

Reduced exothermic bone replacement cement

InactiveUS7138442B2High and substantially necrotic temperatureReduce amountImpression capsSurgical adhesivesBone replacementBone cement

A bone cement having a dry component including a large constituent and a small constituent. The small constituent fills a substantial volume of the interstitial spaces between the particles of the large constituent. Therefore, only a second or minor interstitial space is left remaining between the individual particles of the small constituent and the particles of the small constituent and the particles of the large constituent. Therefore, a reduced amount of a polymerizable component need be added to the dry component to form a bone cement. Such a bone cement formulation decreases the exothermic temperature of the bone cement and decreases the possibility of tissue necrosis in the implantation area.

Owner:BIOMET MFG CORP

Tissue Cavitation Device and Method

InactiveUS20100241123A1Small entrancePromote healing of a bony deficitProsthesisOsteosynthesis devicesCavitationMinimally invasive procedures

A percutaneous surgical device and method for creating a cavity within tissue during a minimally invasive procedure. A cavitation device includes a shaft interconnected to a flexible cutting element. A flexible cutting element has a first shape suitable for minimally invasive passage into tissue. The flexible cutting element has a means to move toward a second shape suitable for forming a cavity in tissue. When used in bone, the resulting cavity is usually filled with bone cement or suitable bone replacement material that is injectable and hardens in situ. The disclosed cavitation device and methods can be used for the following applications: (1) treatment or prevention of bone fracture, (2) joint fusion, (3) implant fixation, (4) tissue harvesting (especially bone), (5) removal of diseased tissue (hard or soft tissue), and (6) general tissue removal (hard or soft tissue).

Owner:MIDDLETON LANCE +1

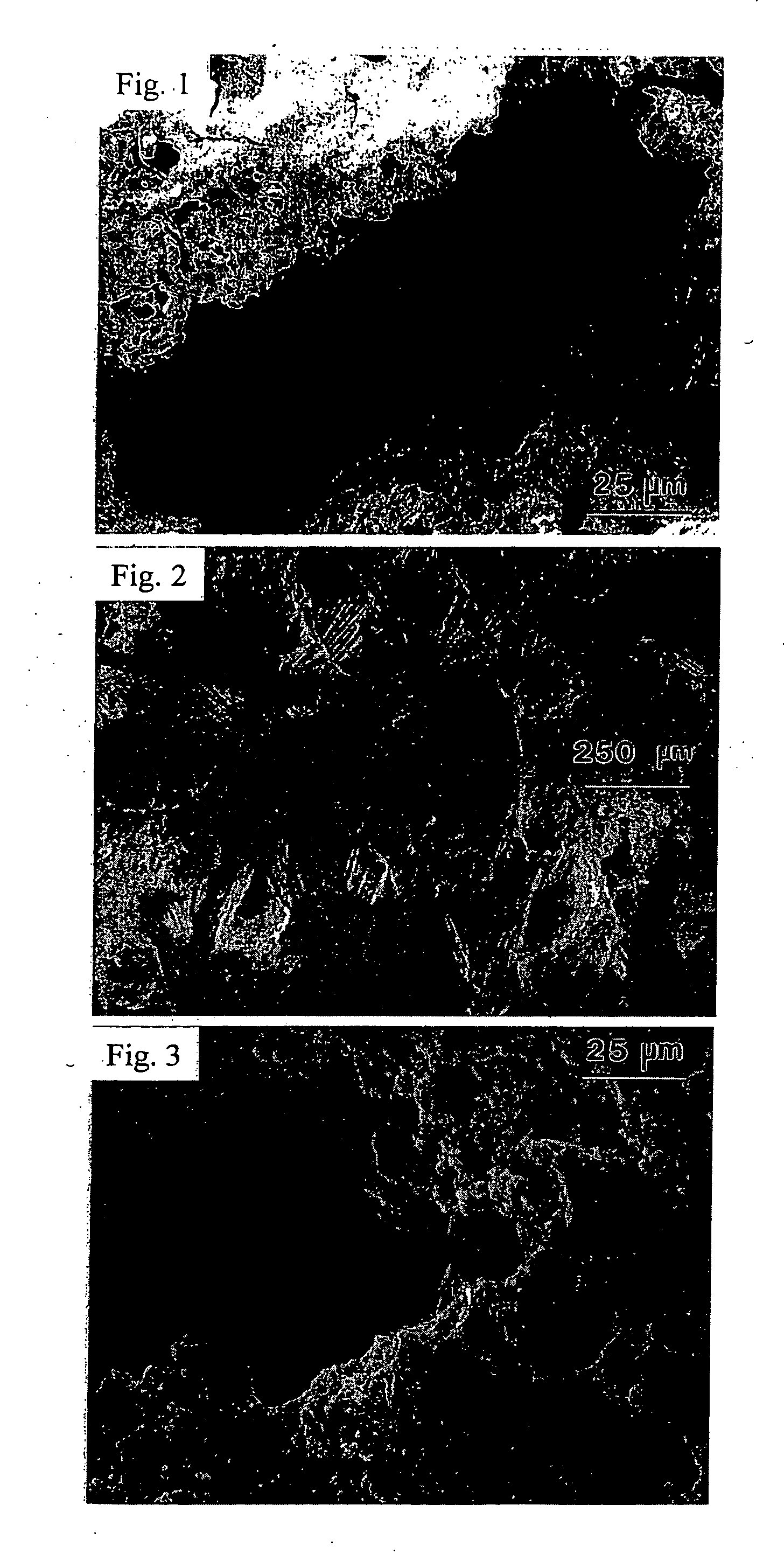

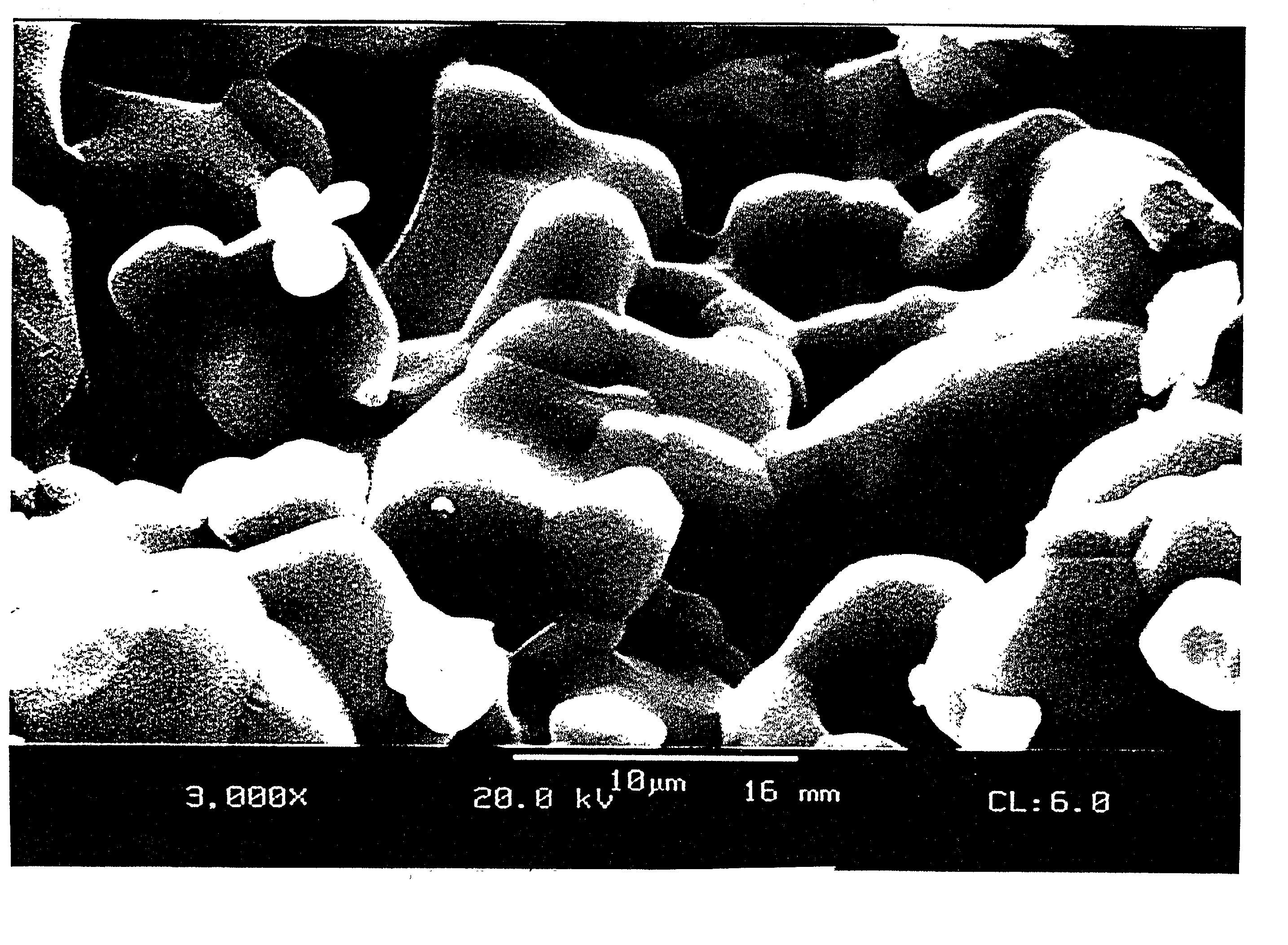

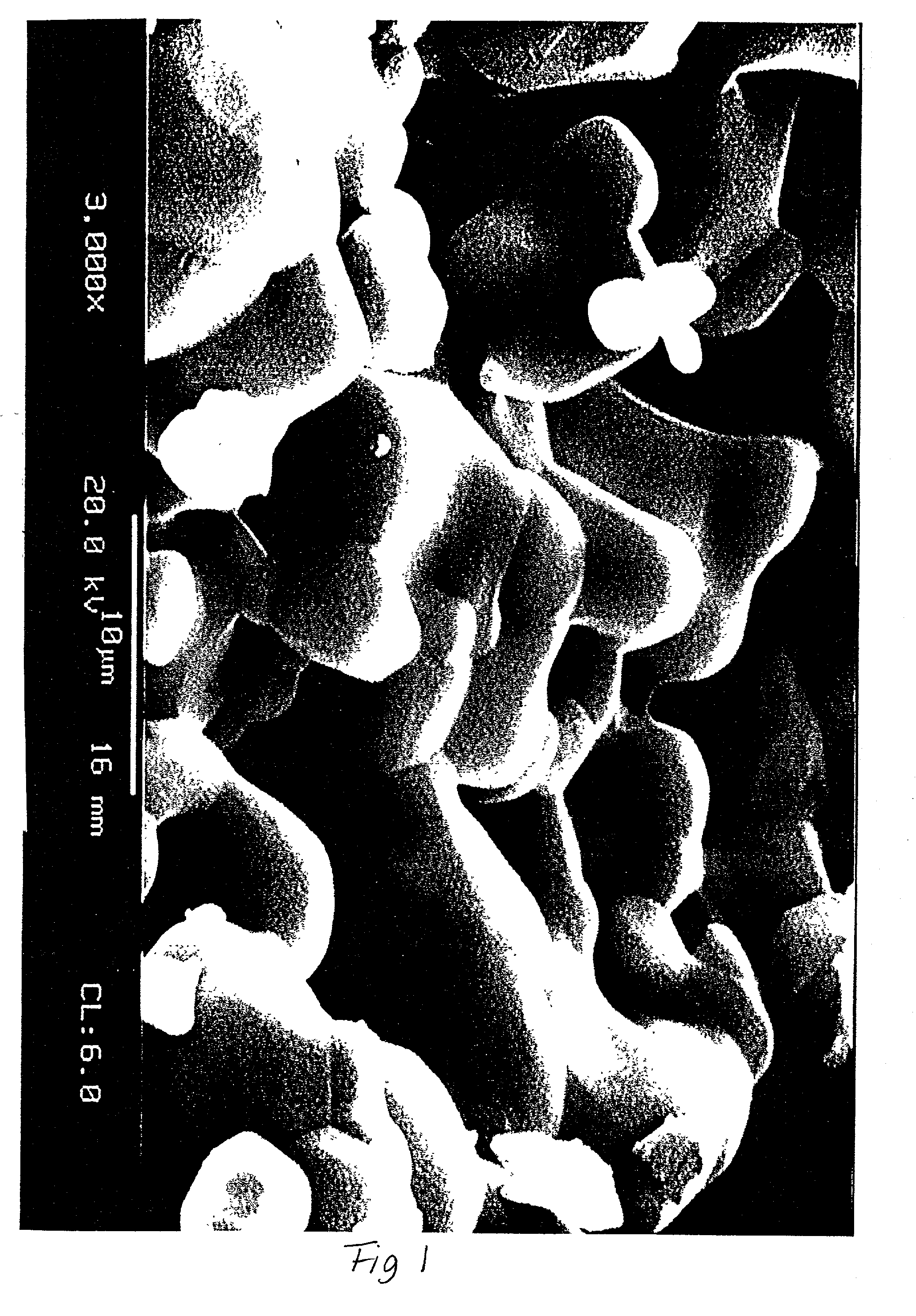

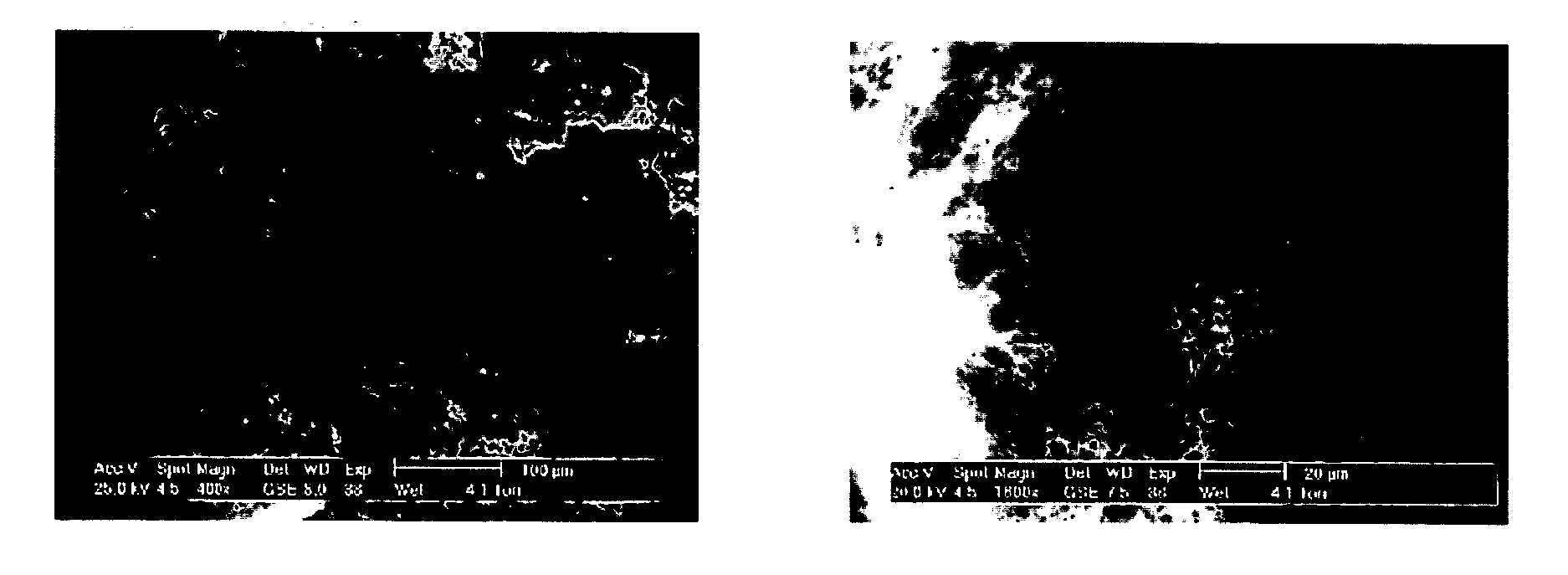

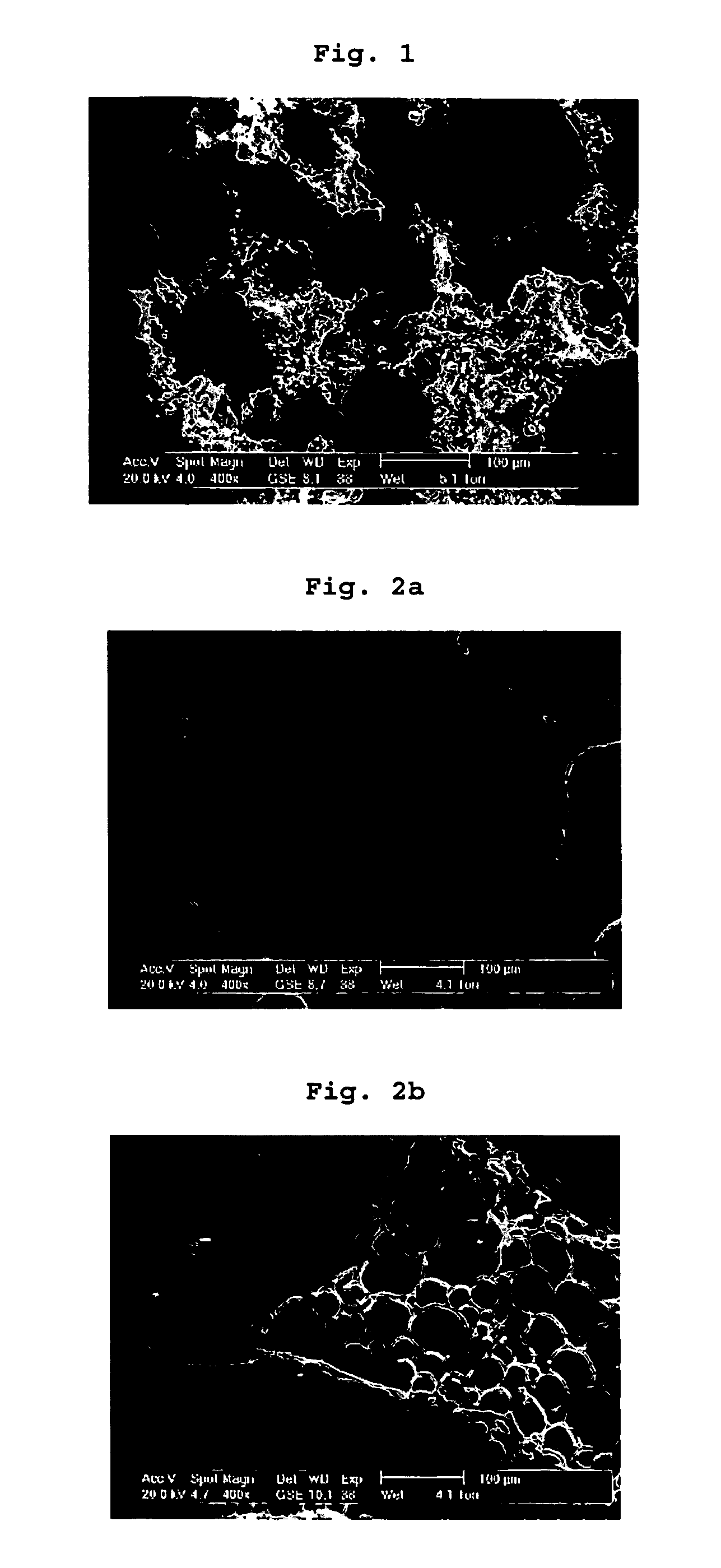

Resorbable bone replacement and bone formation material

The invention relates to a resorbable bone replacement and bone formation material (augmentation material) based on porous β-tricalcium phosphate (β-TCP).

Owner:CURASAN

Self-hardening calcium phosphate materials with high resistance to fracture, controlled strength histories and tailored macropore formation rates

InactiveUS20050081750A1Encourage bone ingrowthHighly integratedImpression capsPhosphatesHigh resistanceFiber

A bone replacement material and therapy comprises the combination of calcium phosphate compounds and two or more soluble fillers in the form of fibers, mesh or other materials which have the dual functions of reinforcing an in vivo implant while dissolving at a programmed rate to form macropores capable of receiving natural bone ingrowth.

Owner:ADA FOUND

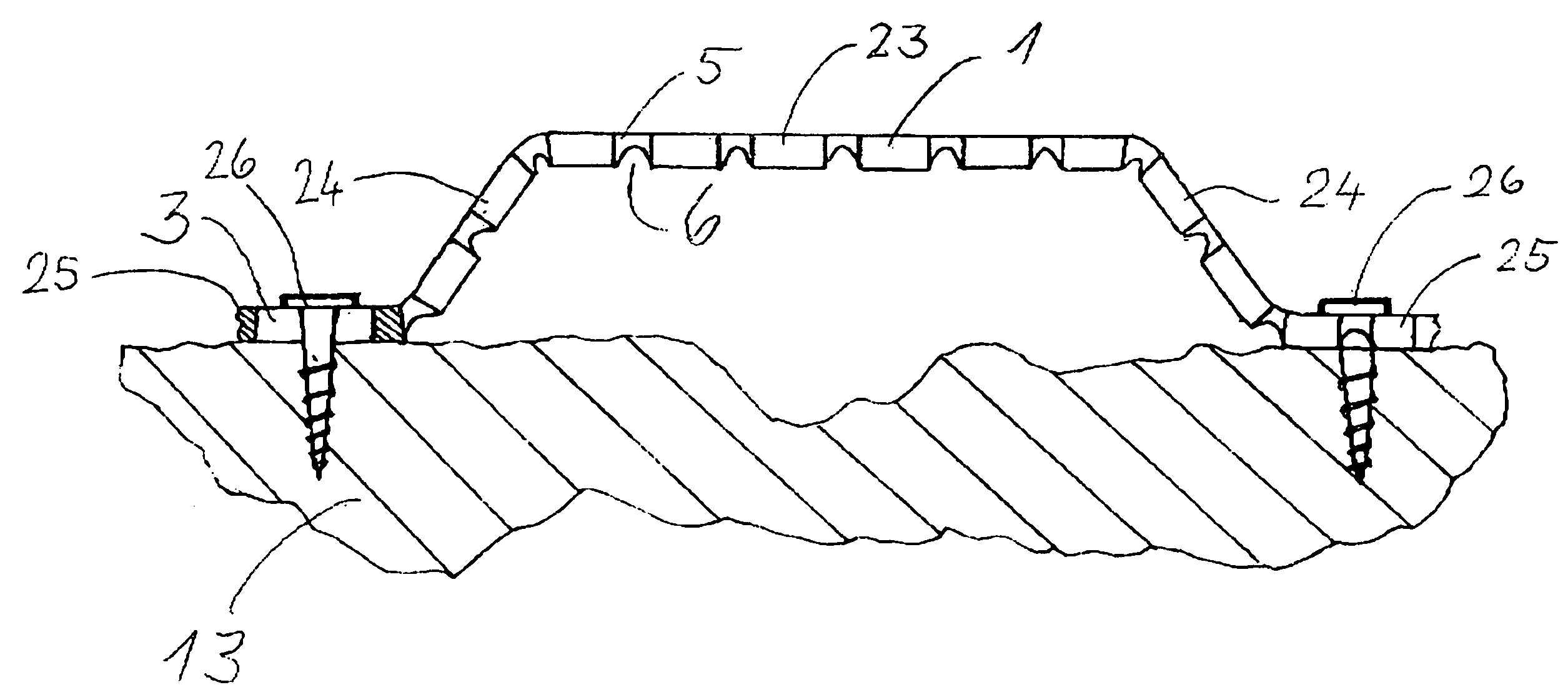

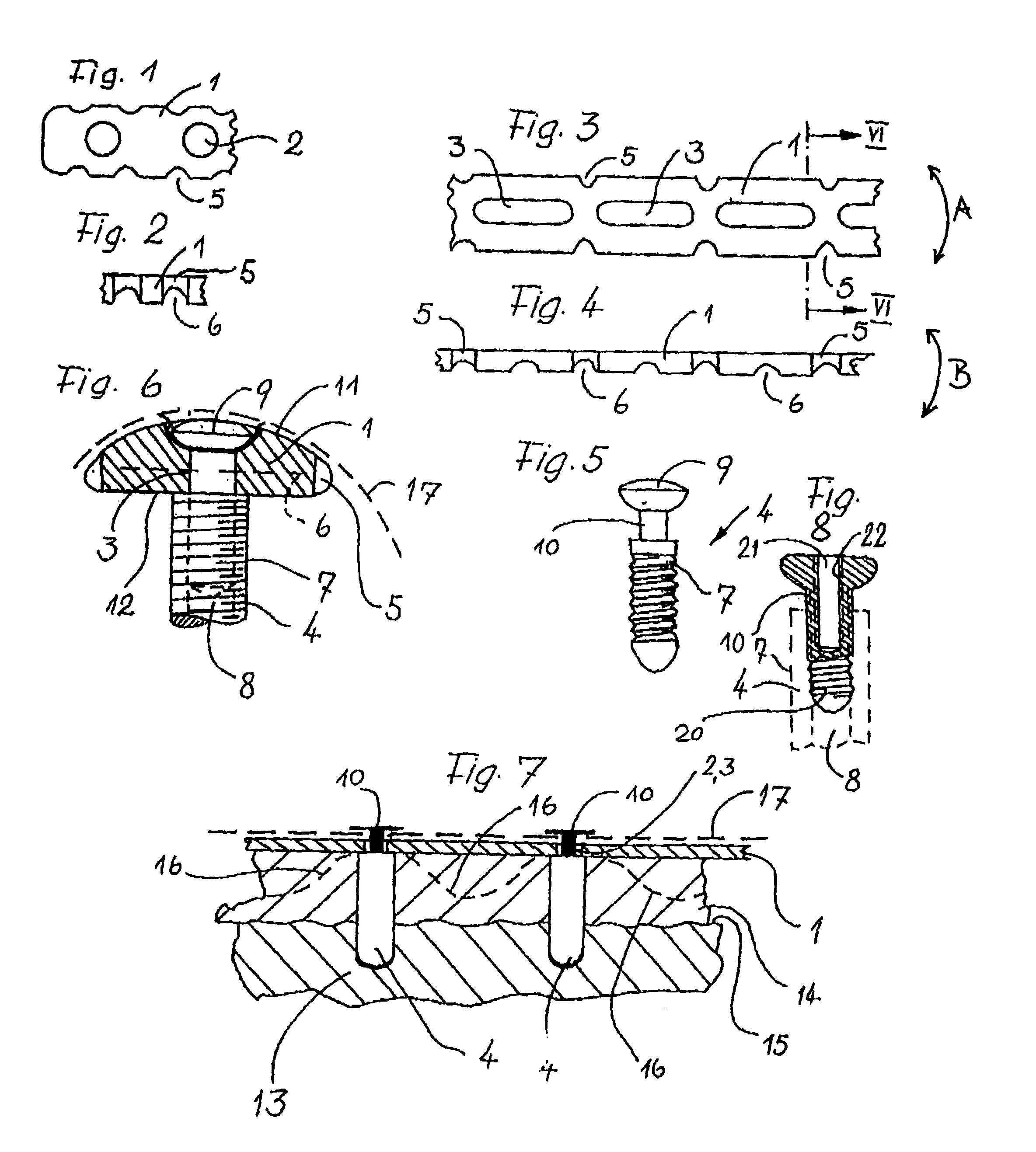

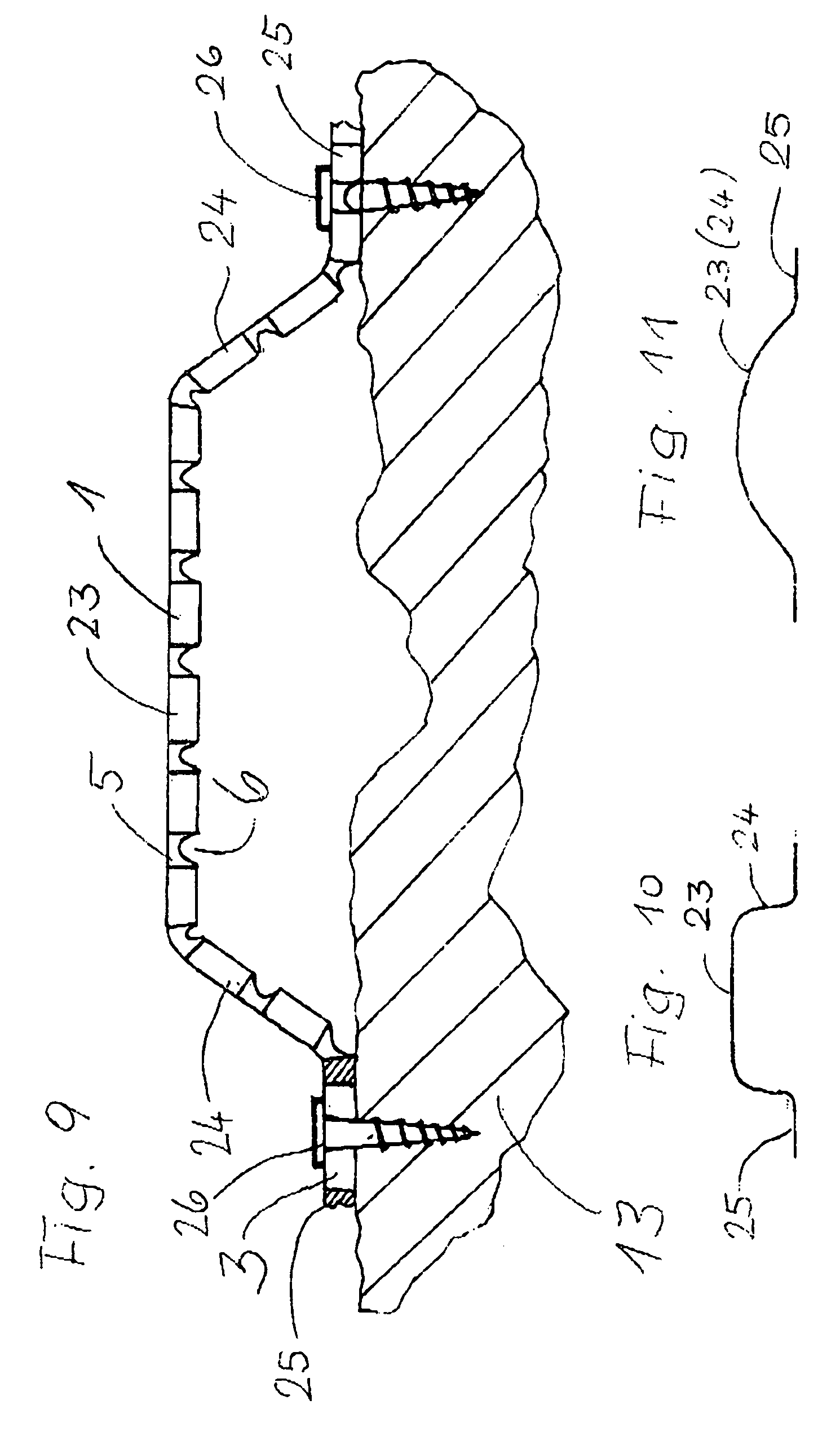

Device for regenerating, repairing, and modeling human and animal bone, especially the jaw area for dental applications

InactiveUS7172422B1Reduce stress loadStabilization and protectionDental implantsInternal osteosythesisTransverse grooveBone replacement

A device for reshaping human or animal bone with bone replacement material includes at least two spaced apart implants and a bar connected to the at least two spaced apart implants and bridging at least one reshaping location. The bar has notches at the longitudinal sides and transverse grooves at the underside. The bar has slotted holes extending in the longitudinal direction of the bar for receiving the implants, respectively, fasteners of the implants.

Owner:ESSIGER HOLGER K

Resorbable bone replacement and bone formation material

The invention relates to a resorbable bone replacement and bone formation material (augmentation material) based on porous beta-tricalcium phosphate (beta-TCP).

Owner:CURASAN

Resorbable bone replacement and bone formation material

The invention relates to a resorbable bone replacement and bone formation material (augmentation material) based on porous β-tricalcium phosphate (β-TCP).

Owner:CURASAN

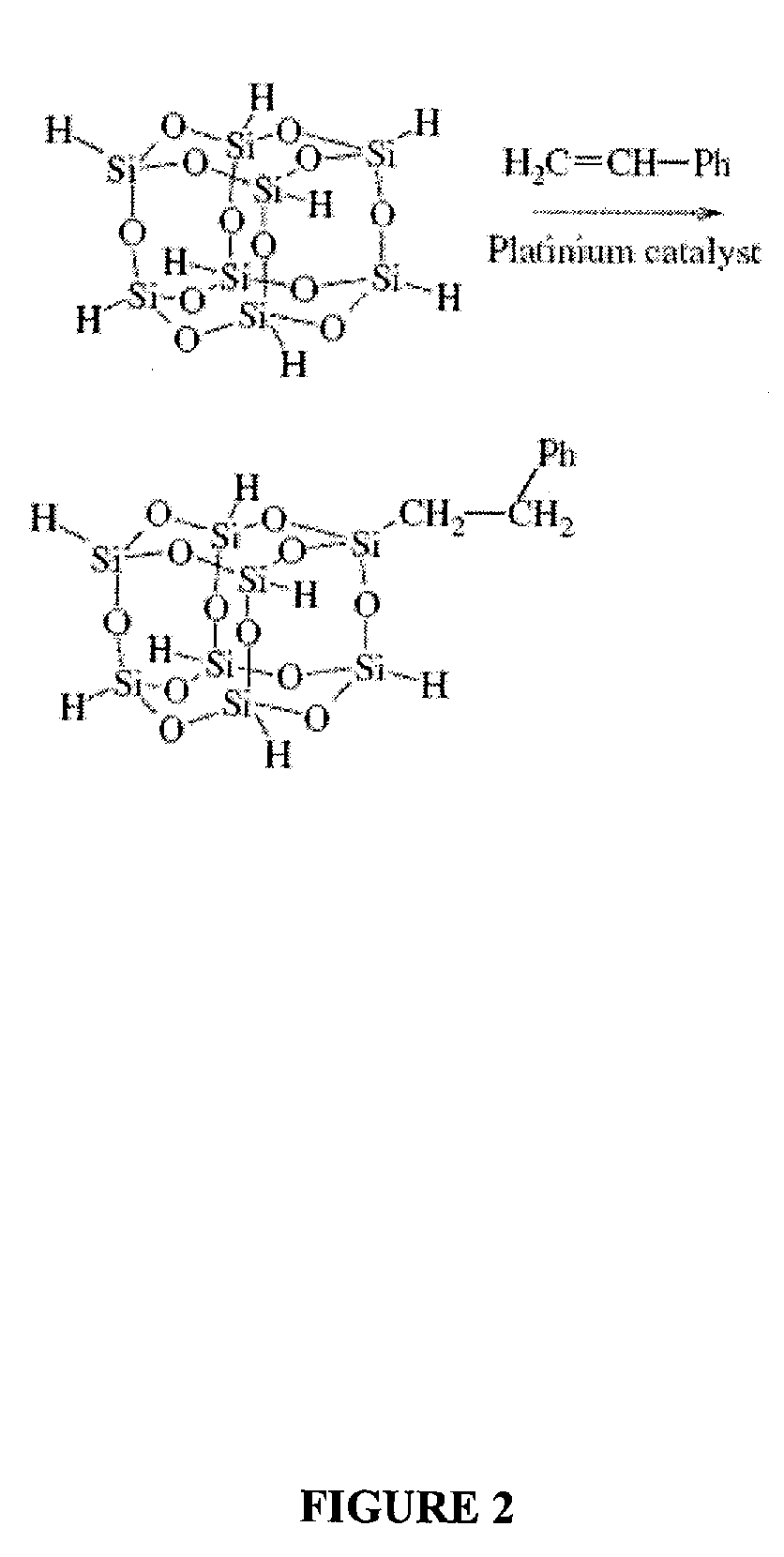

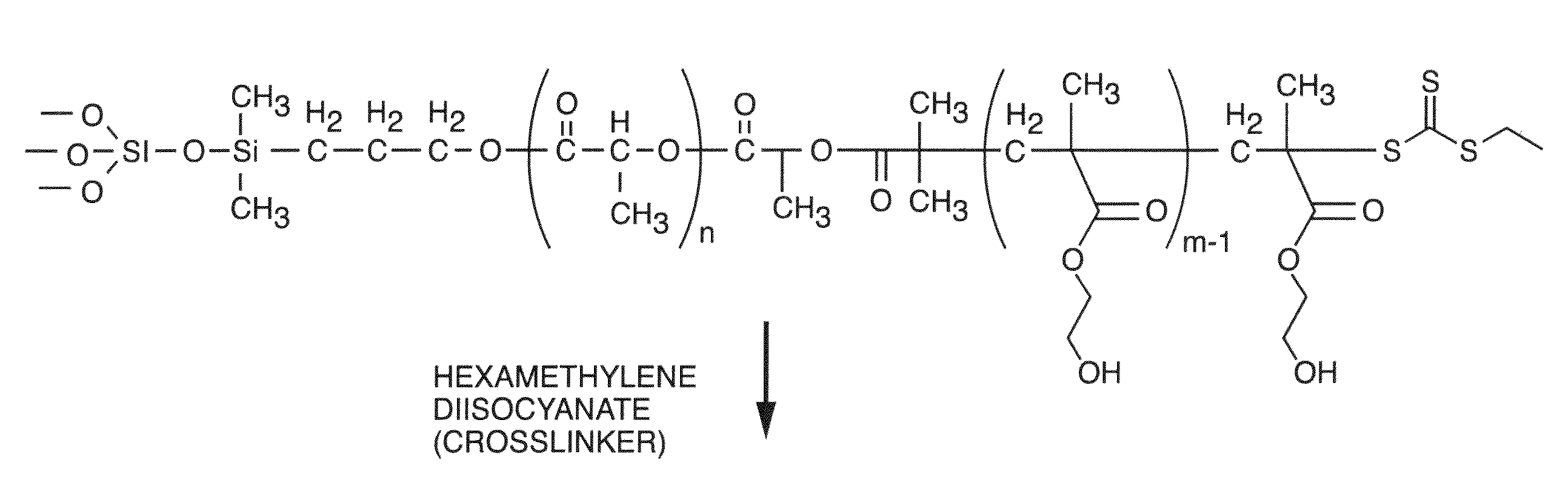

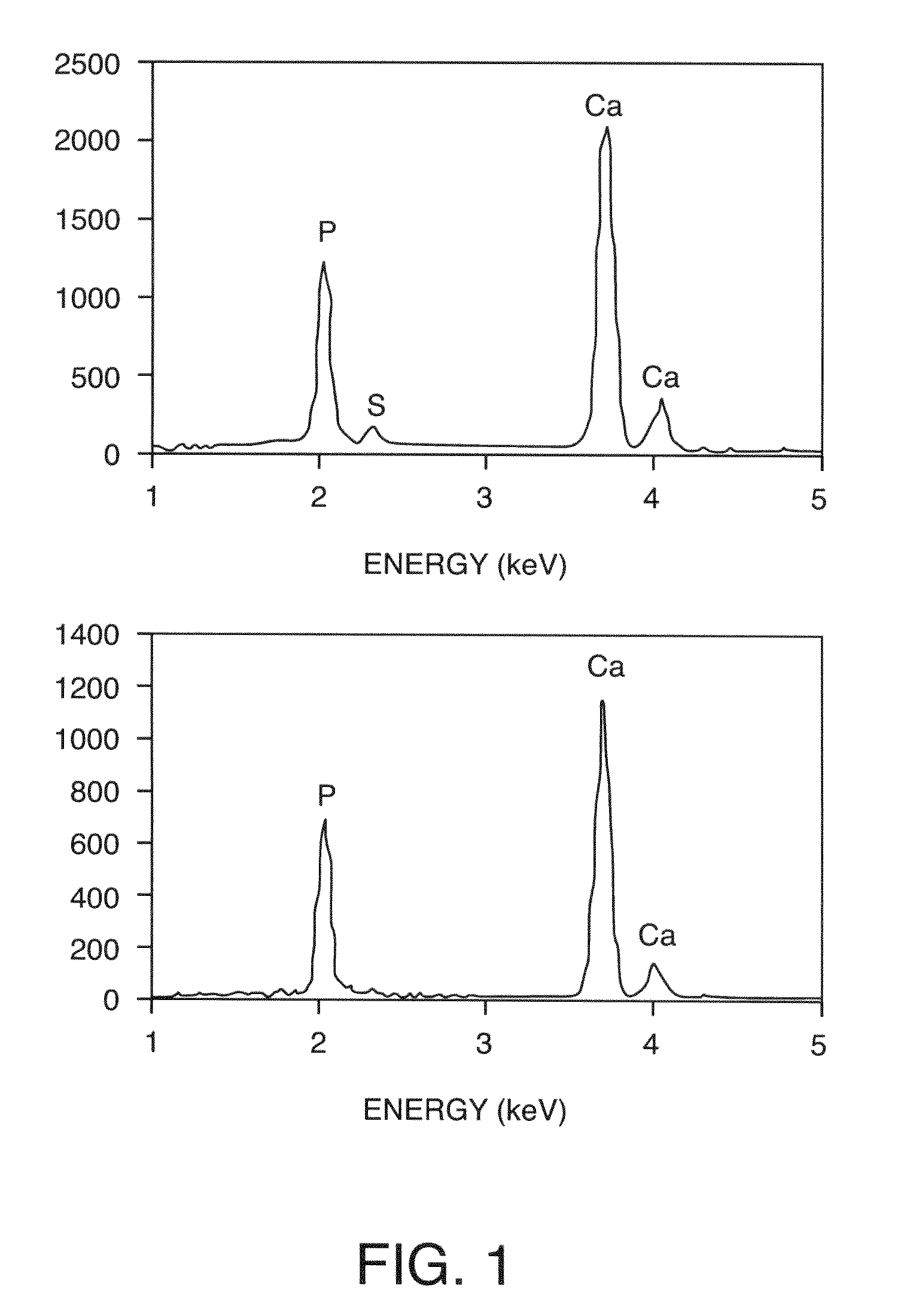

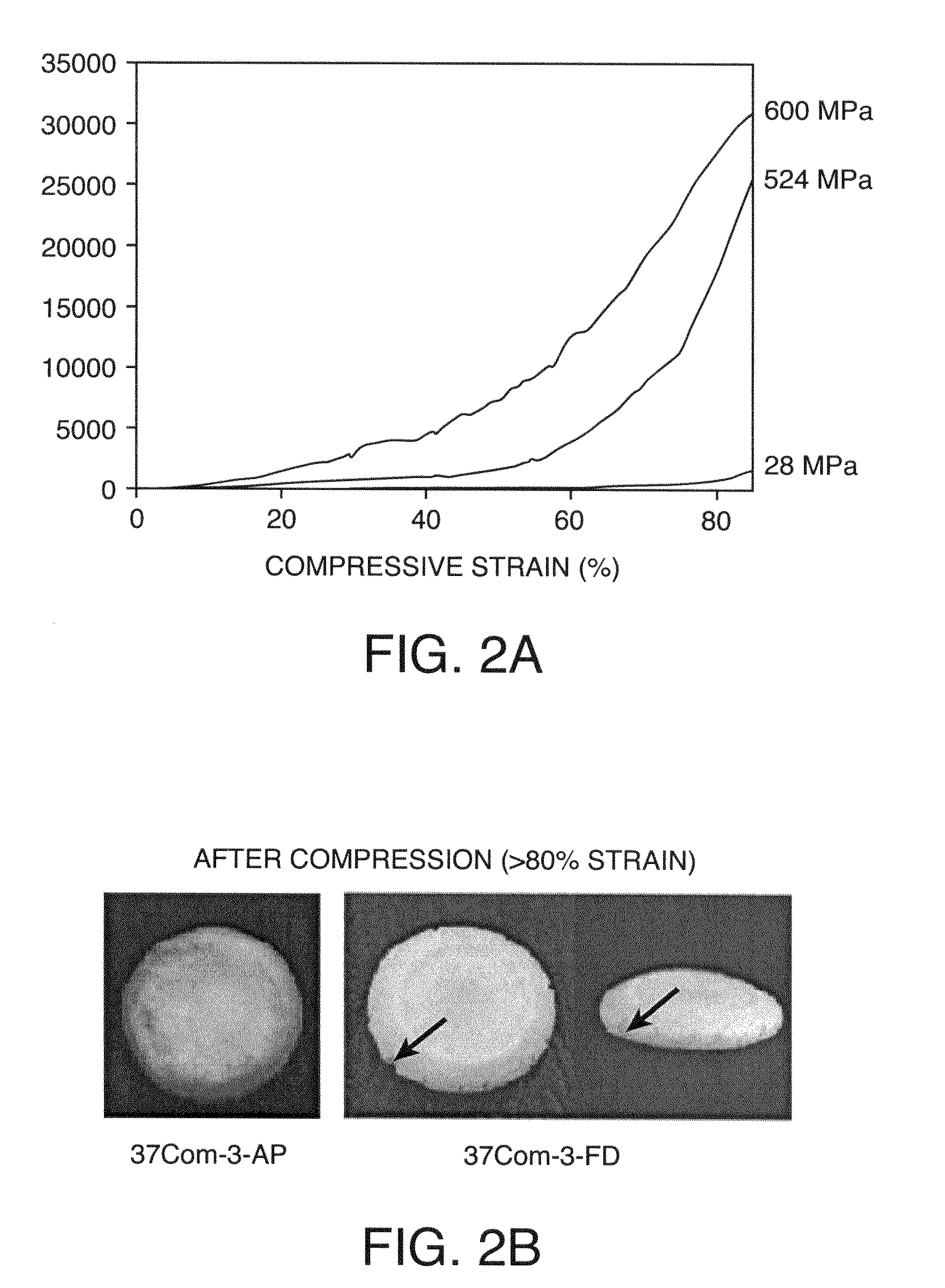

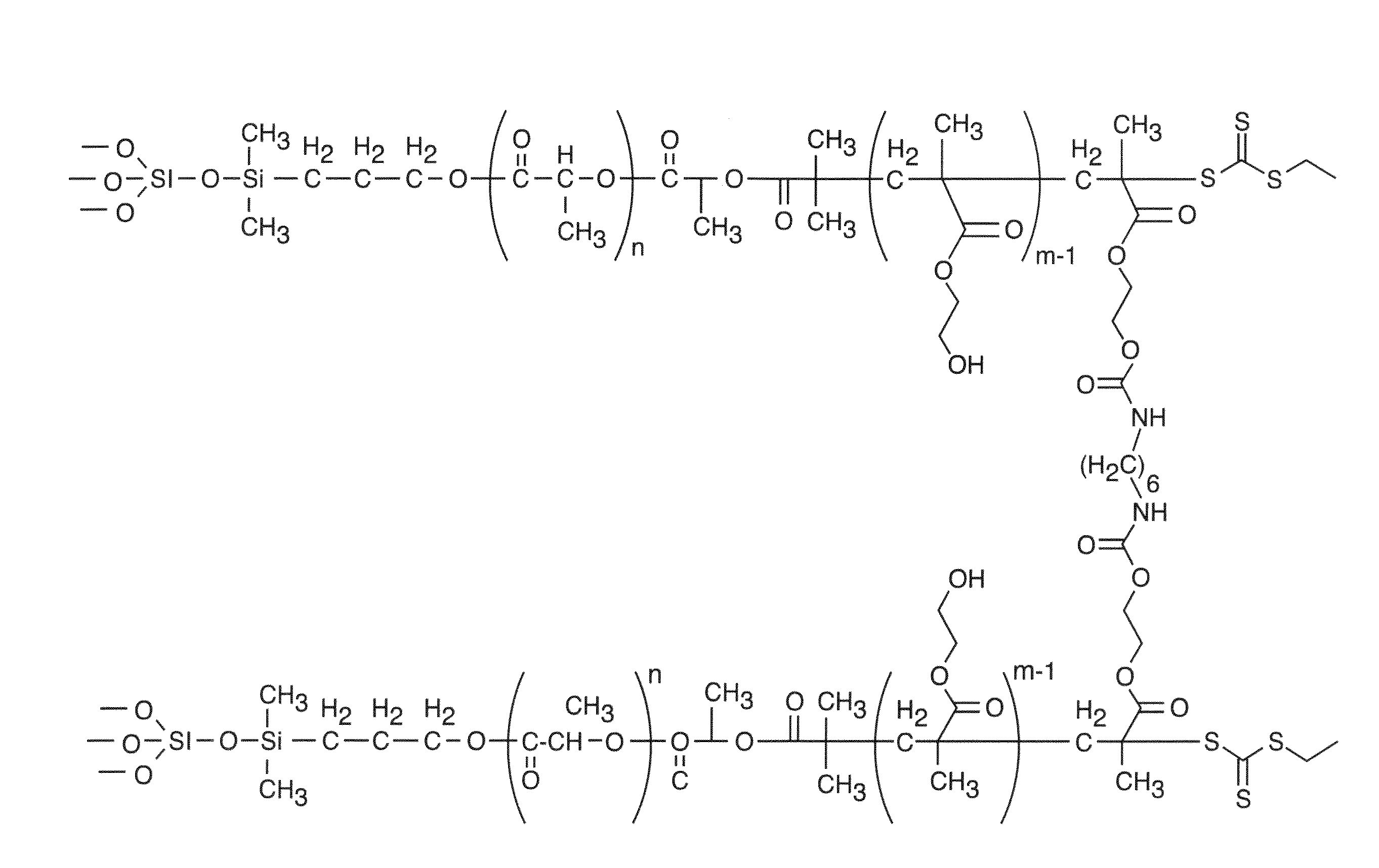

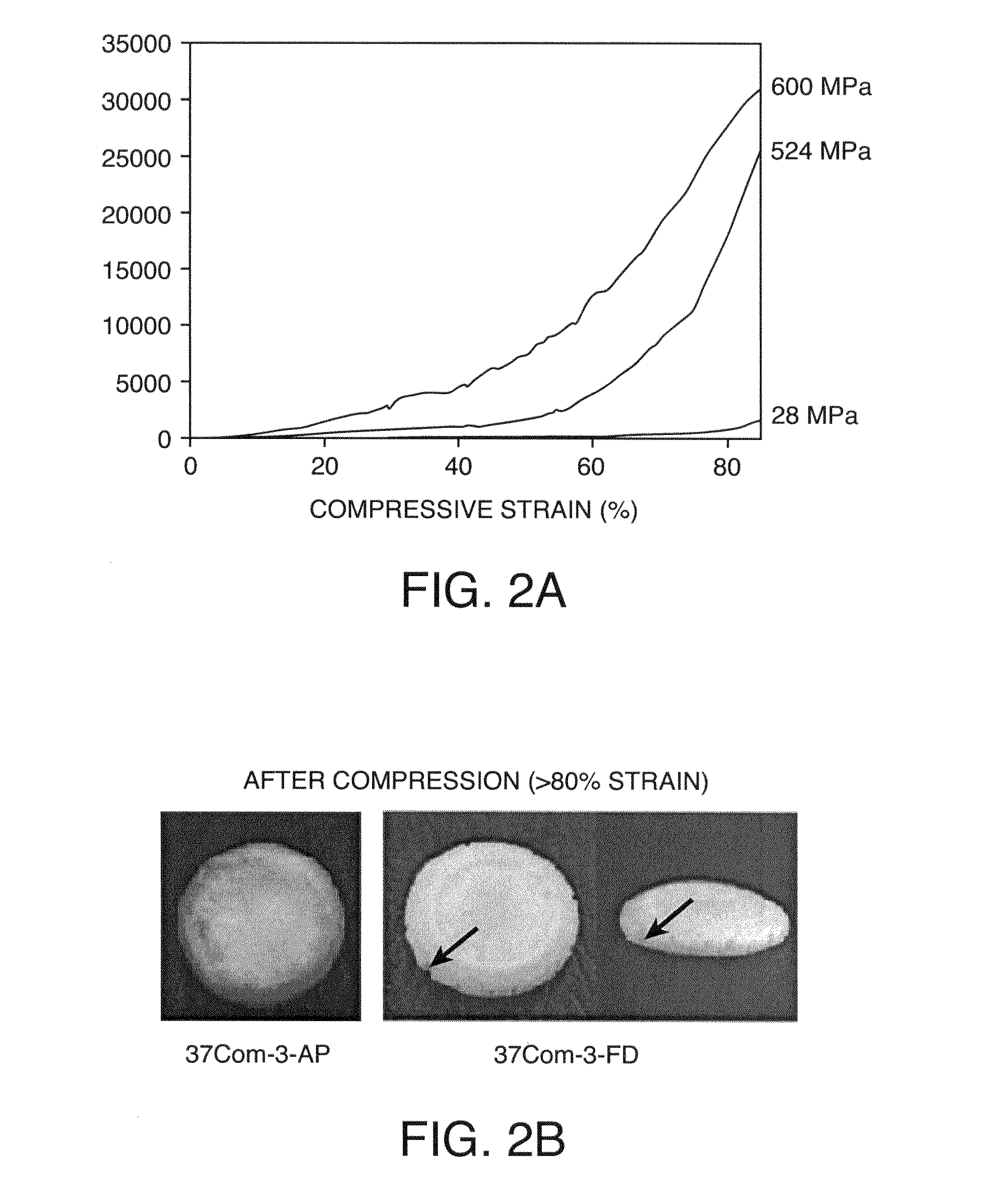

Thermal-Responsive Polymer Networks, Compositions, And Methods And Applications Related Thereto

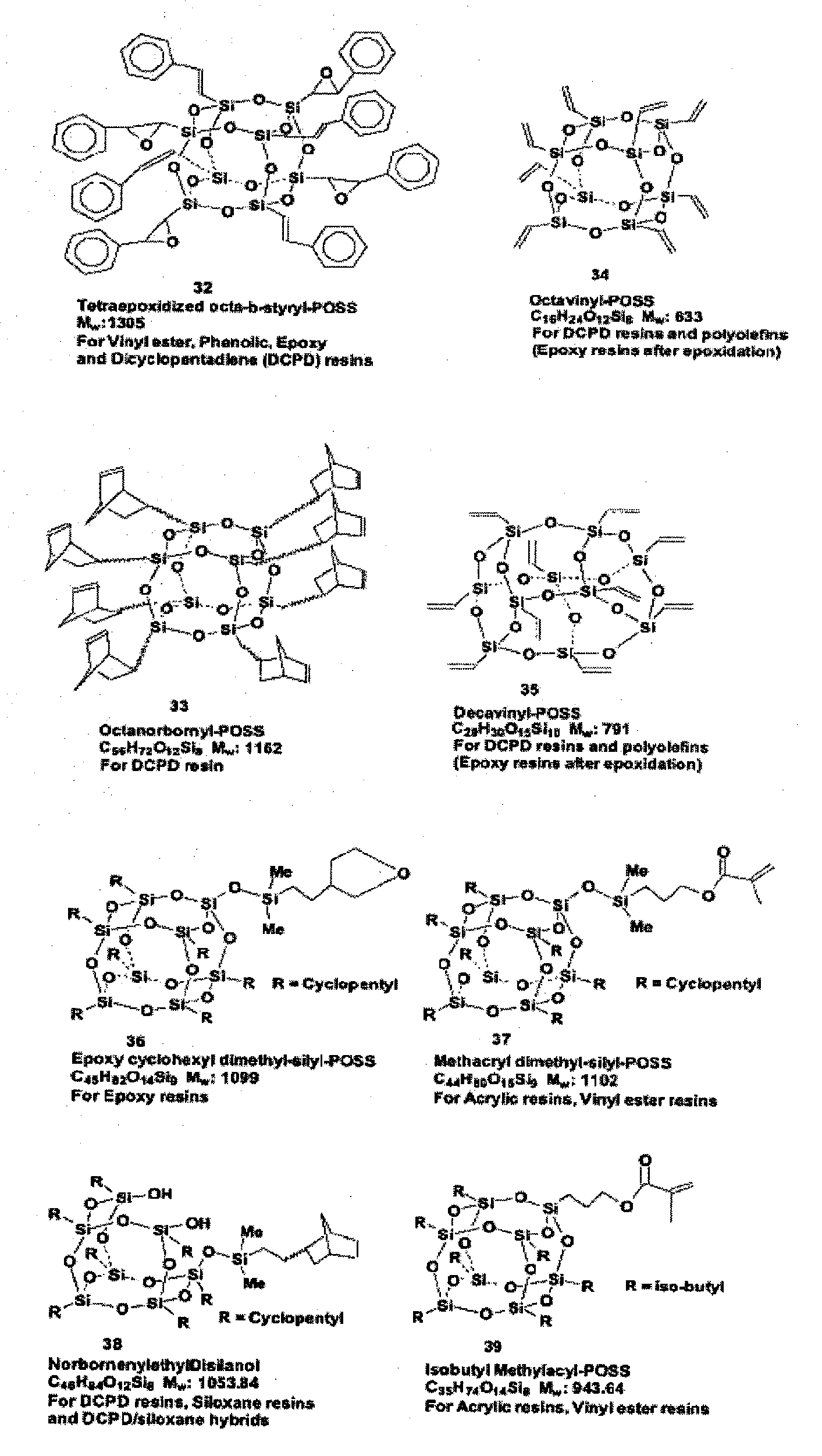

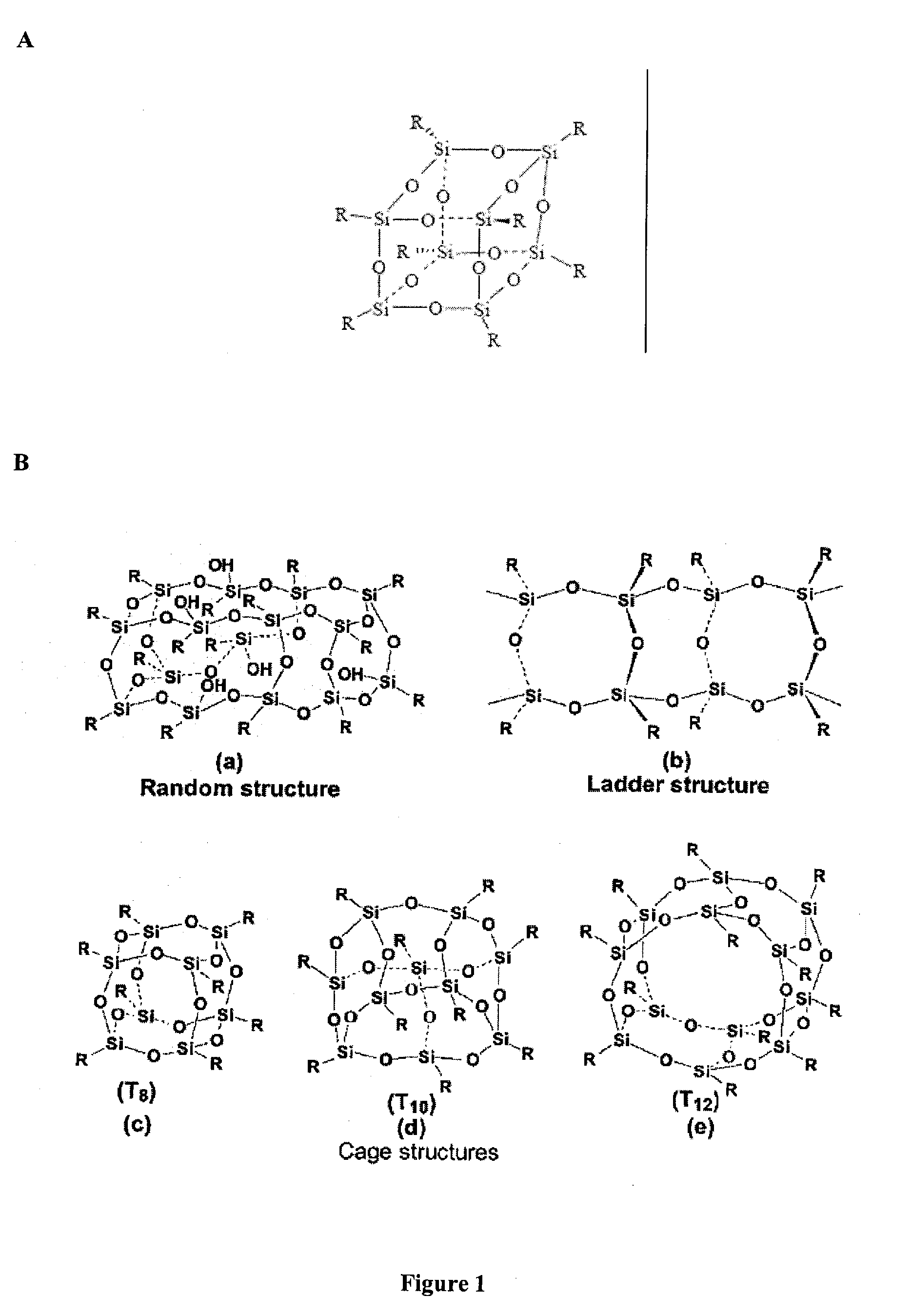

ActiveUS20100280561A1Reduce the amount requiredSurgeryJoint implantsOrganic baseBiocompatibility Testing

The invention relates to materials comprising polymer network containing siloxanes or organic-based core structures, preferably the materials have thermal-responsive properties. In some embodiments, the invention relates to an organic core functionalized with polymers. In another embodiment, organic core-polymer conjugates comprise polylactone segments. The organic core-polymer conjugates may be crosslinked together to form a material, and these materials may be functionalized with bioactive compounds so that the materials have desirable biocompatibility or bioactivity when used in medical devices. In some embodiments, the invention relates to silsesquioxane groups functionalized with polymers. In another embodiment, silsequioxane-polymer conjugates comprise polylactone segments. The silsequioxane-polymer conjugates may be crosslinked together to form a material, and these materials may be functionalized with bioactive compounds so that the materials have desirable biocompatibility or bioactivity when used in medical devices. In further embodiments, the invention relates to composite materials that contain a polymer matrix and aggregates, and in some embodiments, methods of making, and methods of using these materials. Preferably, the aggregates are calcium phosphate aggregates. Preferably, the material is resistant to fracture. In further embodiments, the materials are used in surgical procedures of bone replacement. In further embodiments, the materials contain polyhedral silsesquioxanes and / or biodegradable segments

Owner:UNIV OF MASSACHUSETTS MEDICAL SCHOOL

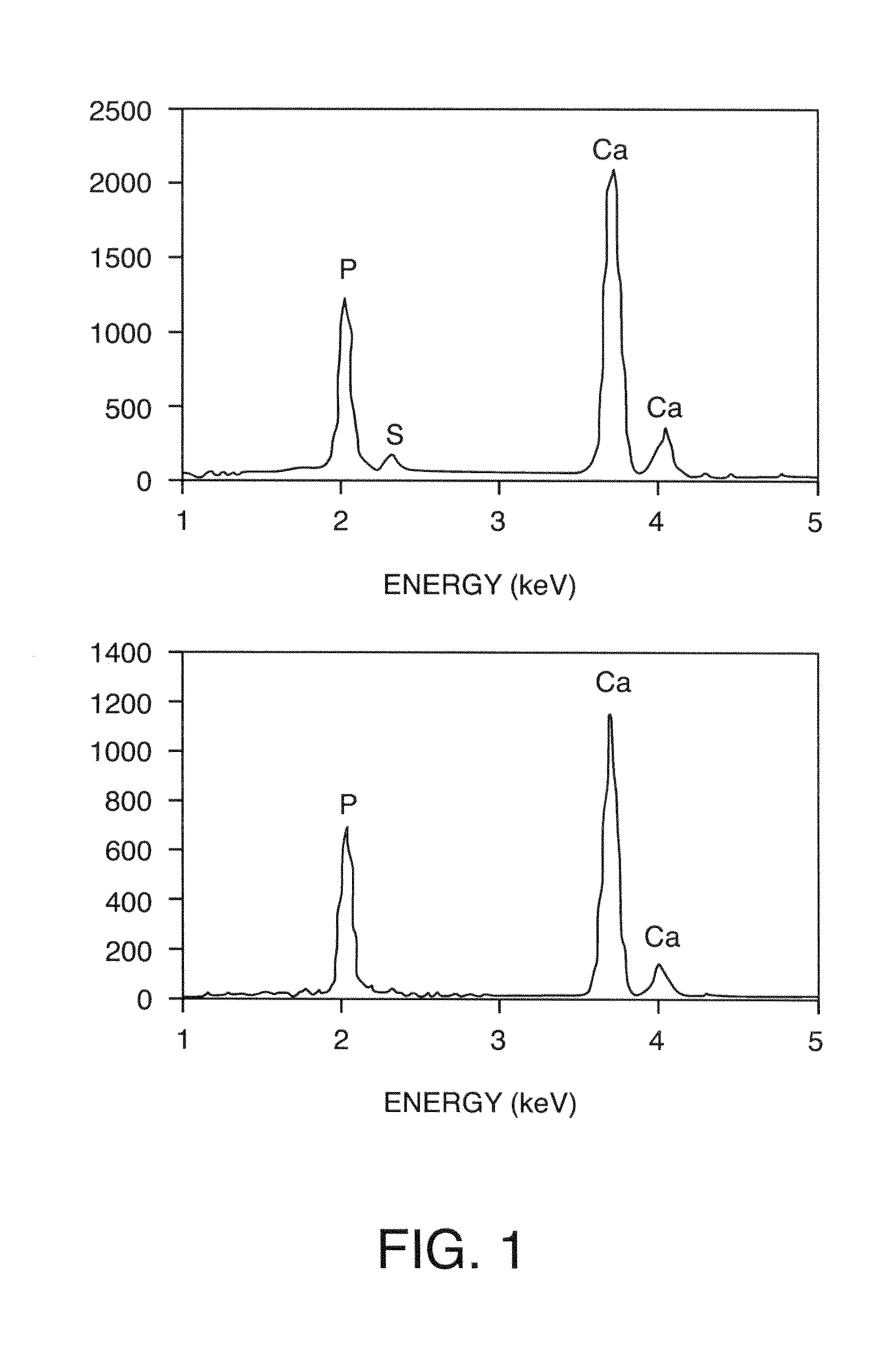

Polymer Compositions For Biomedical And Material Applications

The invention relates to composite materials that contain a polymer matrix and aggregates, and in some embodiments, methods of making, and methods of using these materials. Preferably, the aggregates are calcium phosphate aggregates. Preferably, the material is resistant to fracture. In further embodiments, the materials are used in surgical procedures of bone replacement. In further embodiments, the materials contain polyhedral silsesquioxanes and / or biodegradable segments. In further embodiments, the polymer matrix comprises biomolecules.

Owner:MASSACHUSETTS MEDICAL SCHOOL UNIV OF

Bone replacement materials utilizing bioabsorbable liquid polymers

The present invention is directed to bone replacement devices and compositions containing a synthetic, bioabsorbable, biocompatible liquid polymer that is the reaction product of a polybasic acid or derivative thereof, a polyol and a fatty acid, the liquid polymer having a melting point less than about 40° C., as determined by differential scanning calorimetry.

Owner:ETHICON INC

Replacement bone tissue

Bone replacement tissue suitable for bone grafting procedures, said bone replacement tissue being grown in a host until suitable for translocation into a desired position in a patient, and methods for manufacturing said bone replacement tissue.

Owner:SHERRY EUGENE +2

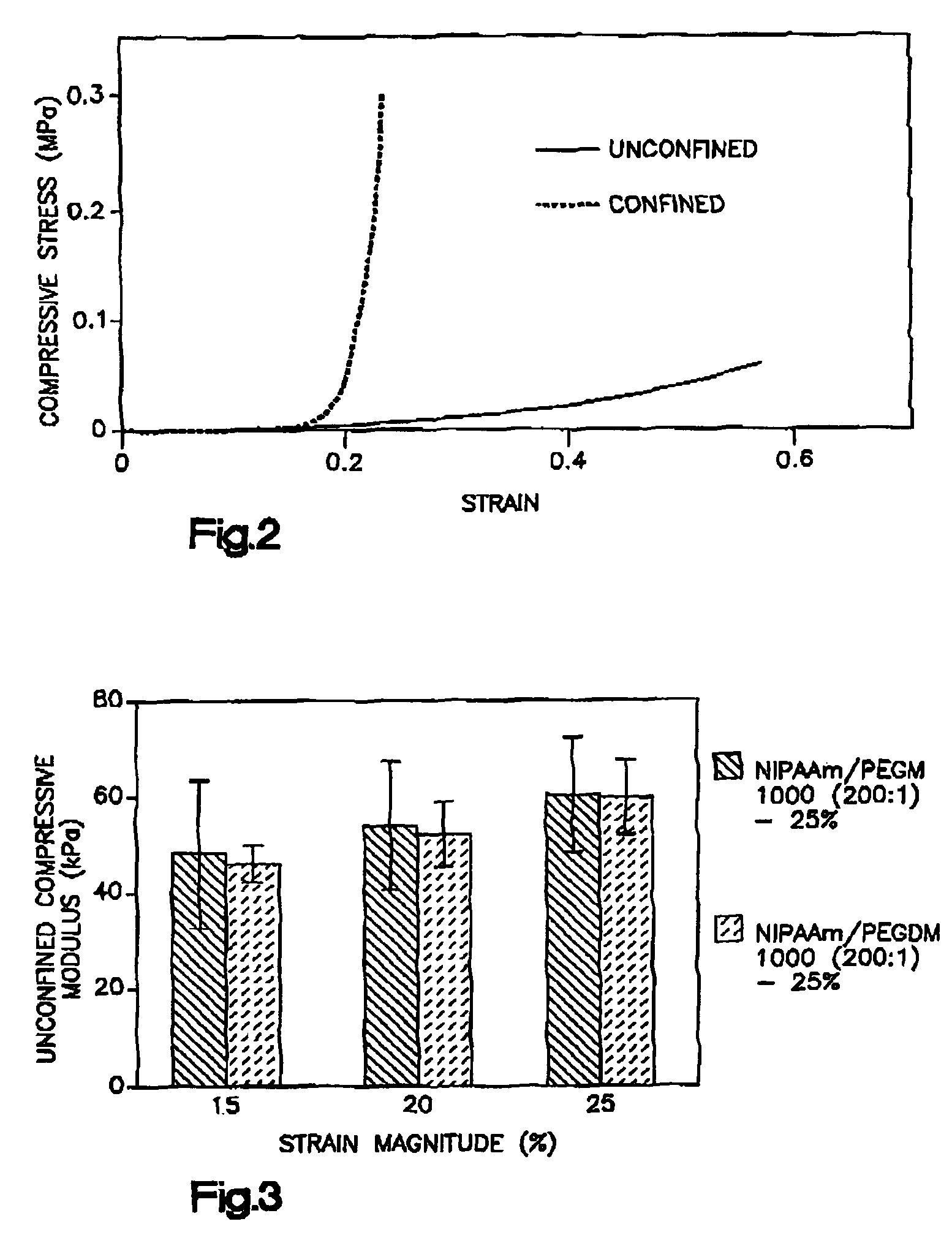

Thermogelling polymer blends for biomaterial applications

Thermogelling polymers are described containing poly (n-isopropyl acrylamide). Solutions of this polymer, copolymers or mixtures of the polymer with a second polymer such as poly(ethylene glycol), poly (vinyl pyrrolidone) or poly(vinyl alcohol) are liquids at room temperature and solids at body temperature. Thus, also provided are methods of implanting a hydrogel into a mammal by injecting the solution as a liquid at a temperature below body temperature into a selected site in the mammal at a temperature below body temperature, which then undergoes thermal phase transition to form a solid hydrogel in situ in the body as the implant warms to body temperature. Methods for using these thermal gelling materials in various applications including nucleus pulposus replacement / augmentation, wound care, disk replacement, cartilage replacement, joint replacement, surgical barriers, gastrointestinal devices, cosmetic and reconstructive surgery, and breast enlargement are also provided.

Owner:SYNTHES USA +1

Compositions For Biomedical Applications

The invention relates to composite materials that contain a polymer matrix and aggregates, and in some embodiments, methods of making, and methods of using these materials. Preferably, the aggregates are calcium phosphate aggregates. Preferably, the material is resistant to fracture. In further embodiments, the materials are used in surgical procedures of bone replacement. In further embodiments, the materials contain polyhedral silsesquioxanes and / or biodegradable segments. In further embodiments, the polymer matrix comprises biomolecules.

Owner:UNIV OF MASSACHUSETTS MEDICAL SCHOOL

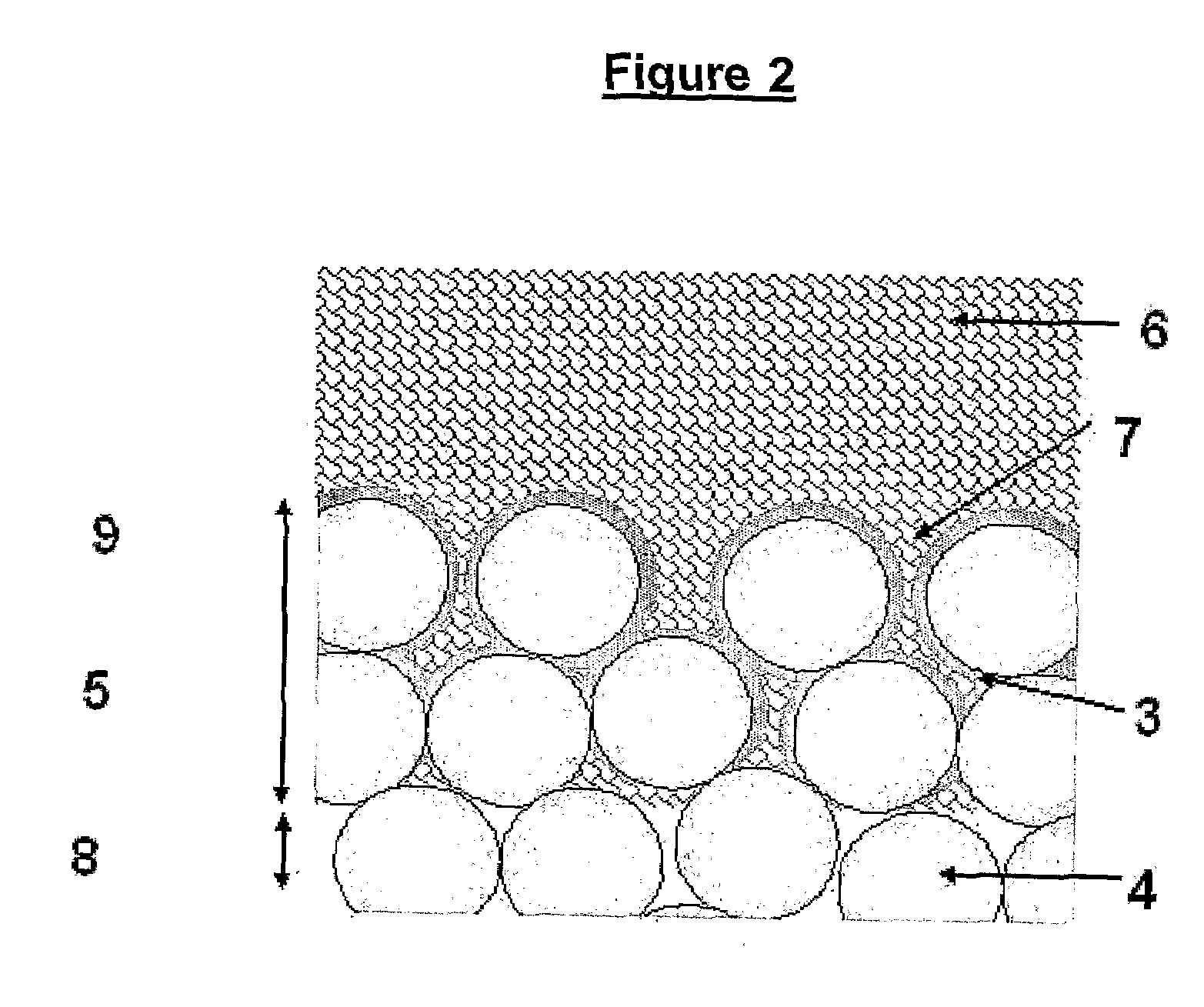

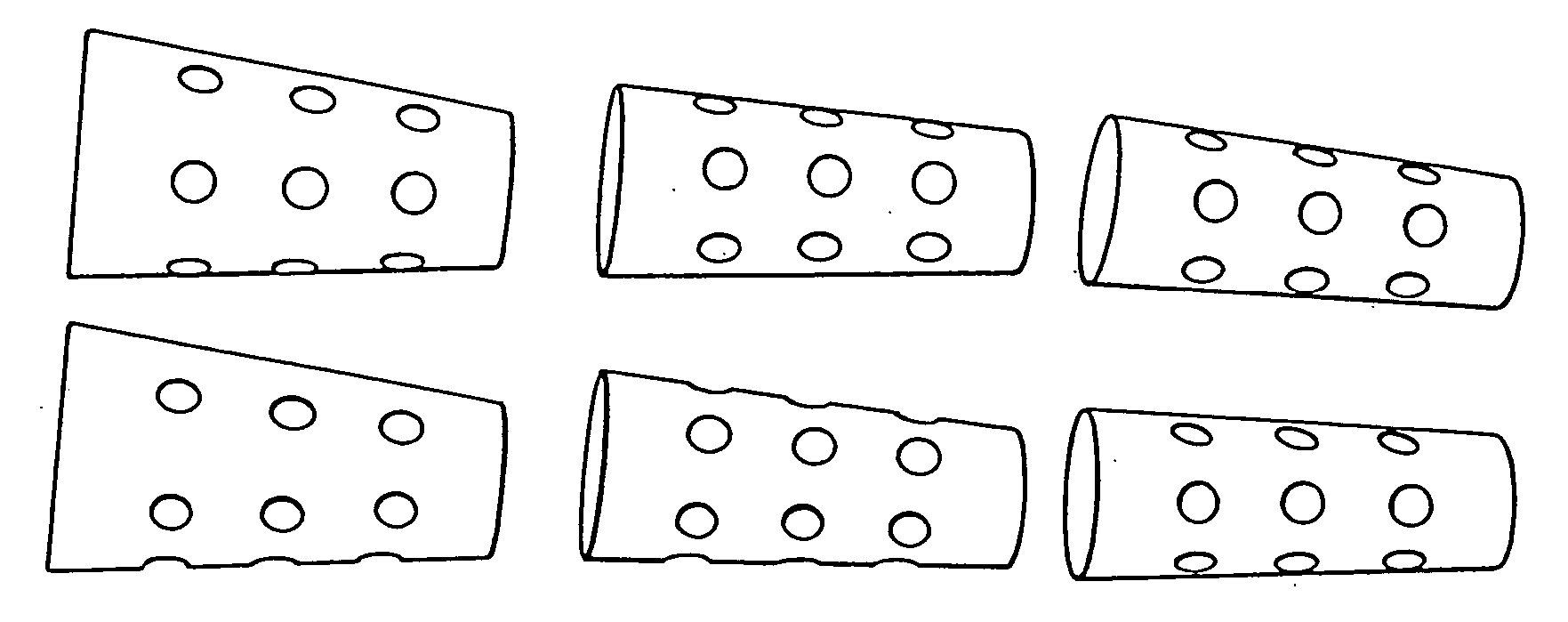

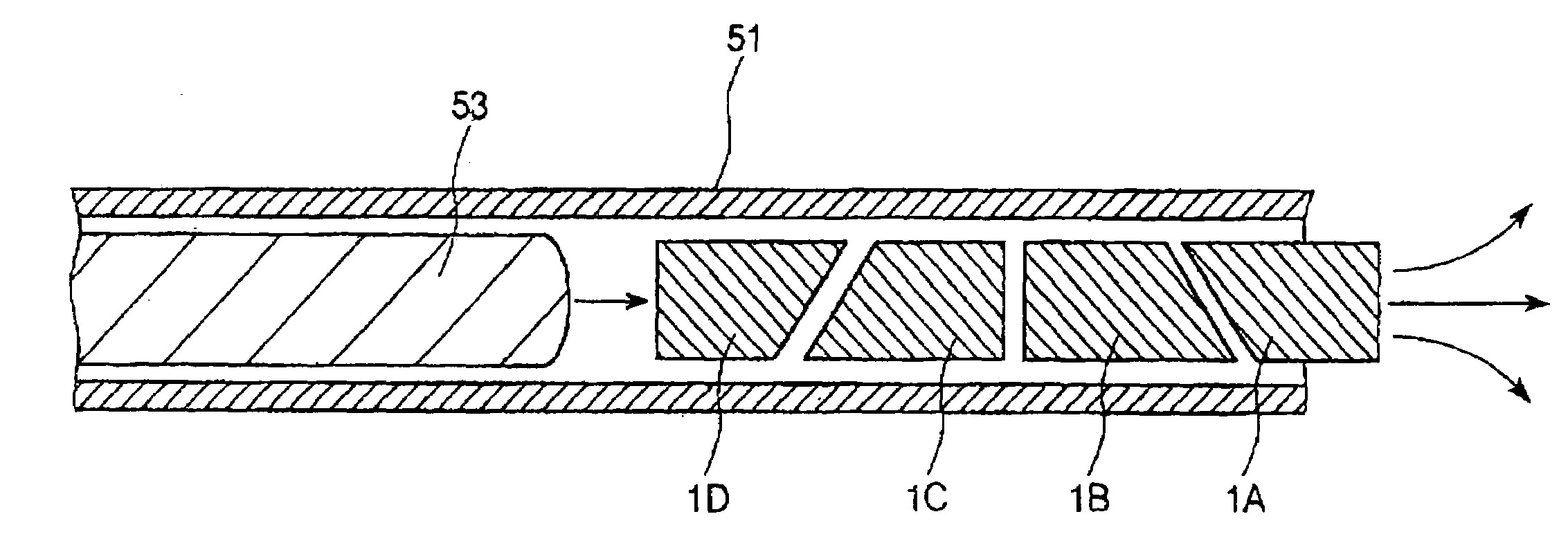

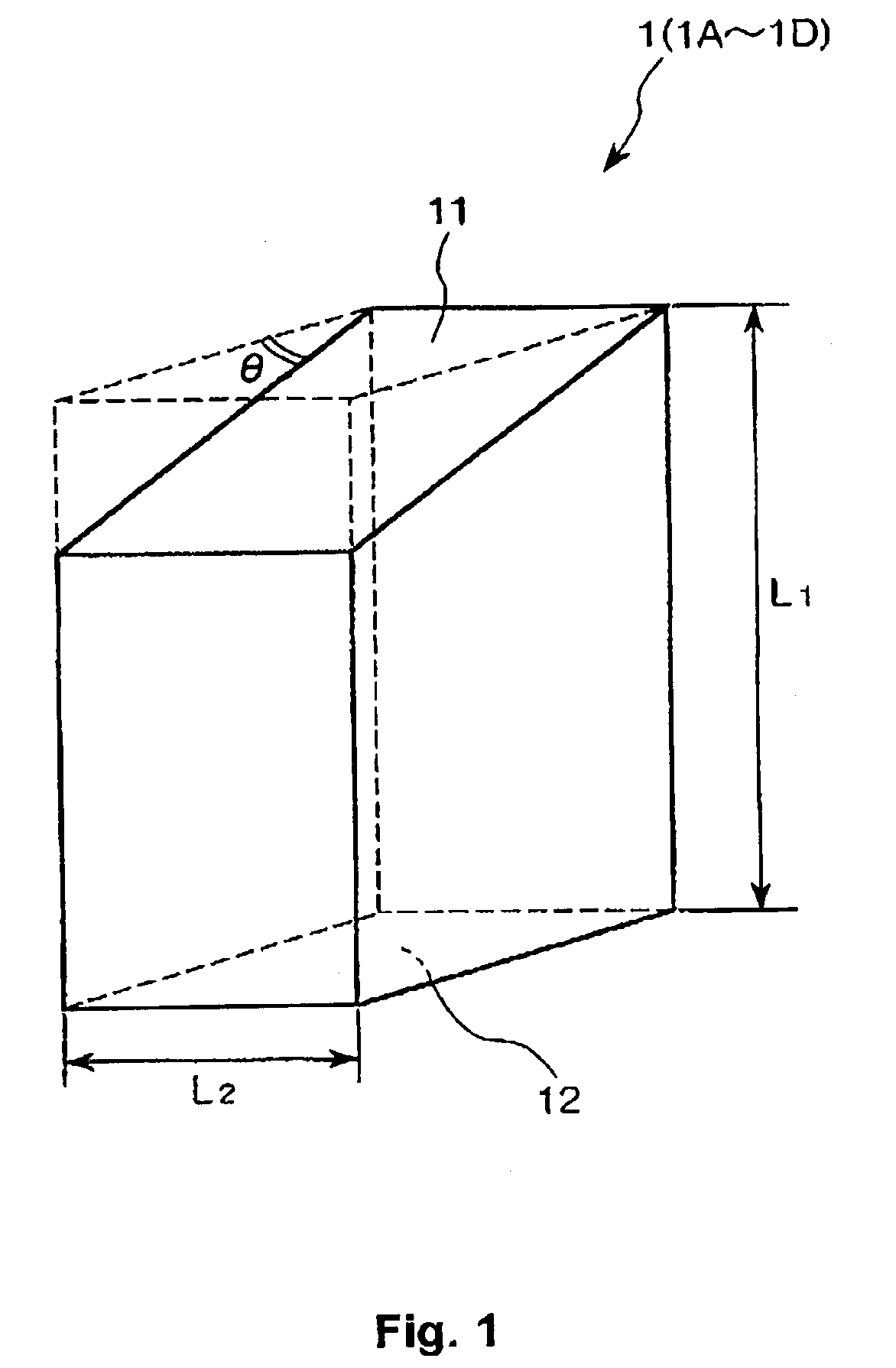

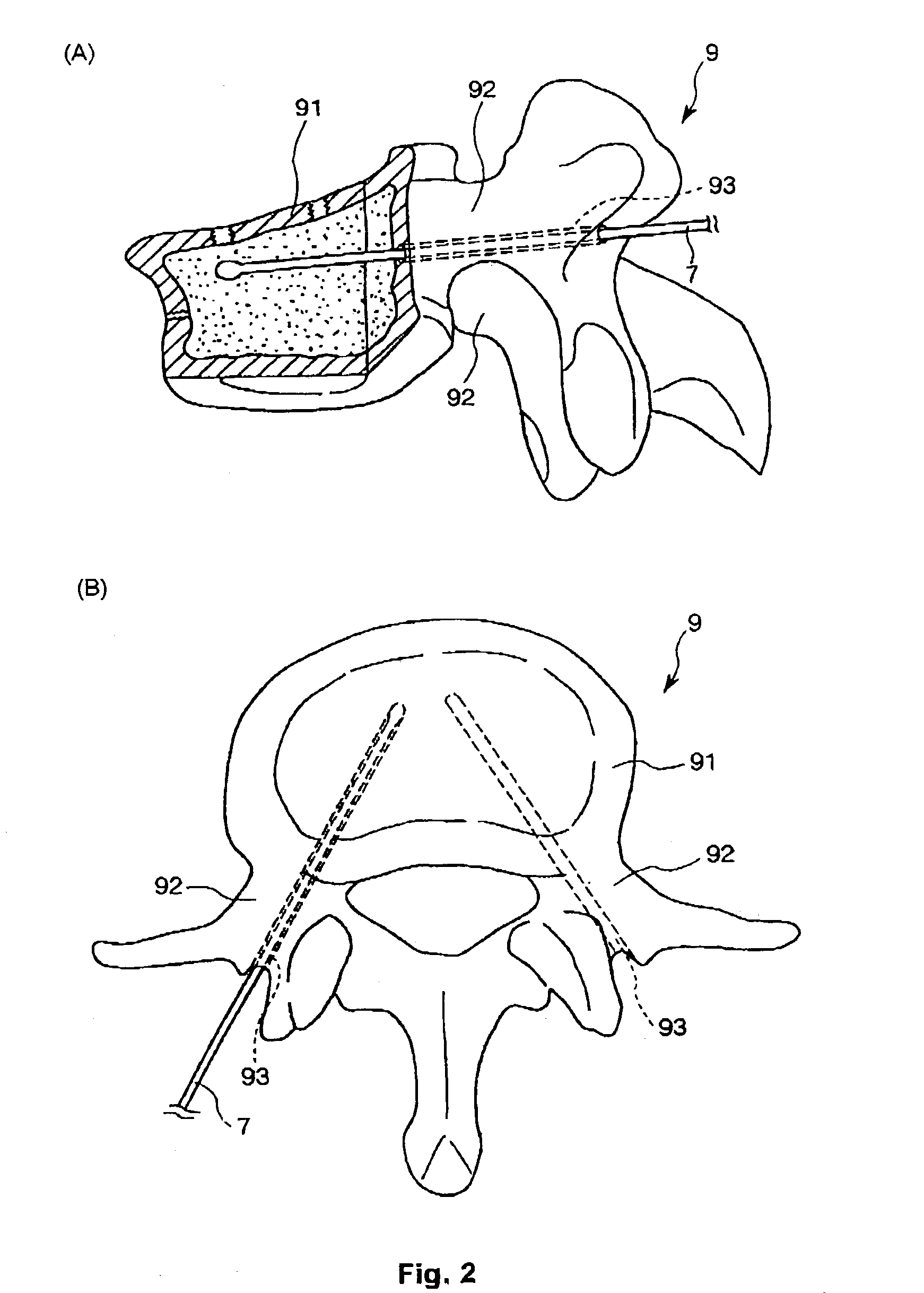

Bone replacement material

A bone replacement material for use in a treatment for repairing a vertebral body compression fracture is formed into a pellet having a roughly polyhedral shape. Each pellet having the roughly polyhedral shape has a pair of opposite surfaces, in which one of the opposite surfaces is inclined with respect to the other surface for a predetermined angle. The angle is preferably in the range of 10 to 60°. Further, the volume of each pellet of the bone replacement material 1 is in the range of 13 to 239 mm3. Furthermore, the bone replacement material is formed of calcium phosphate based compound having the Ca / P ratio of 1.0 to 2.0. By using such a bone replacement material, it is possible to carry out packing operation of the bone replacement material into a collapsed vertebral body smoothly, reliably and safely.

Owner:ASAHI KOGAKU KOGYO KK +1

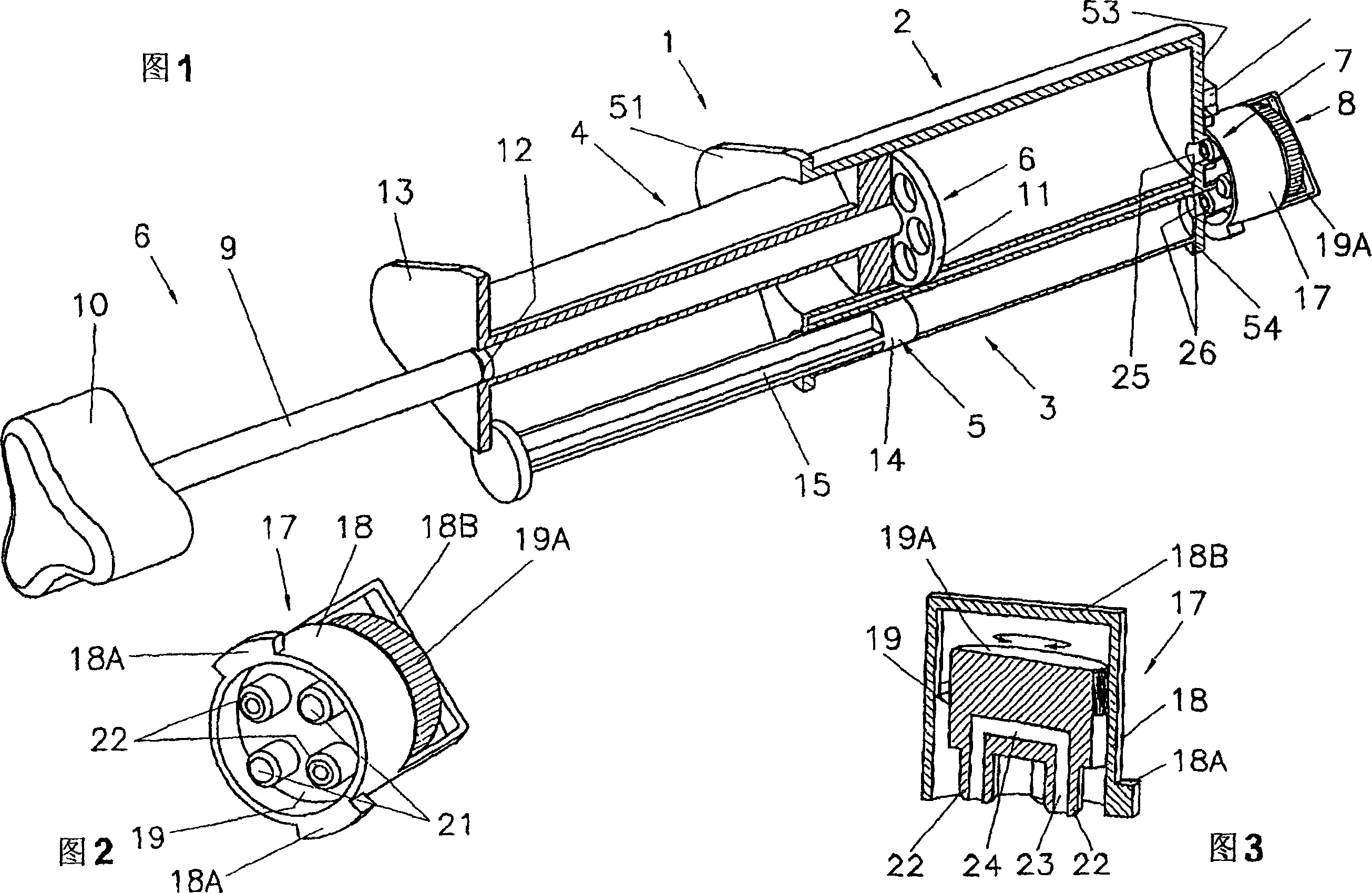

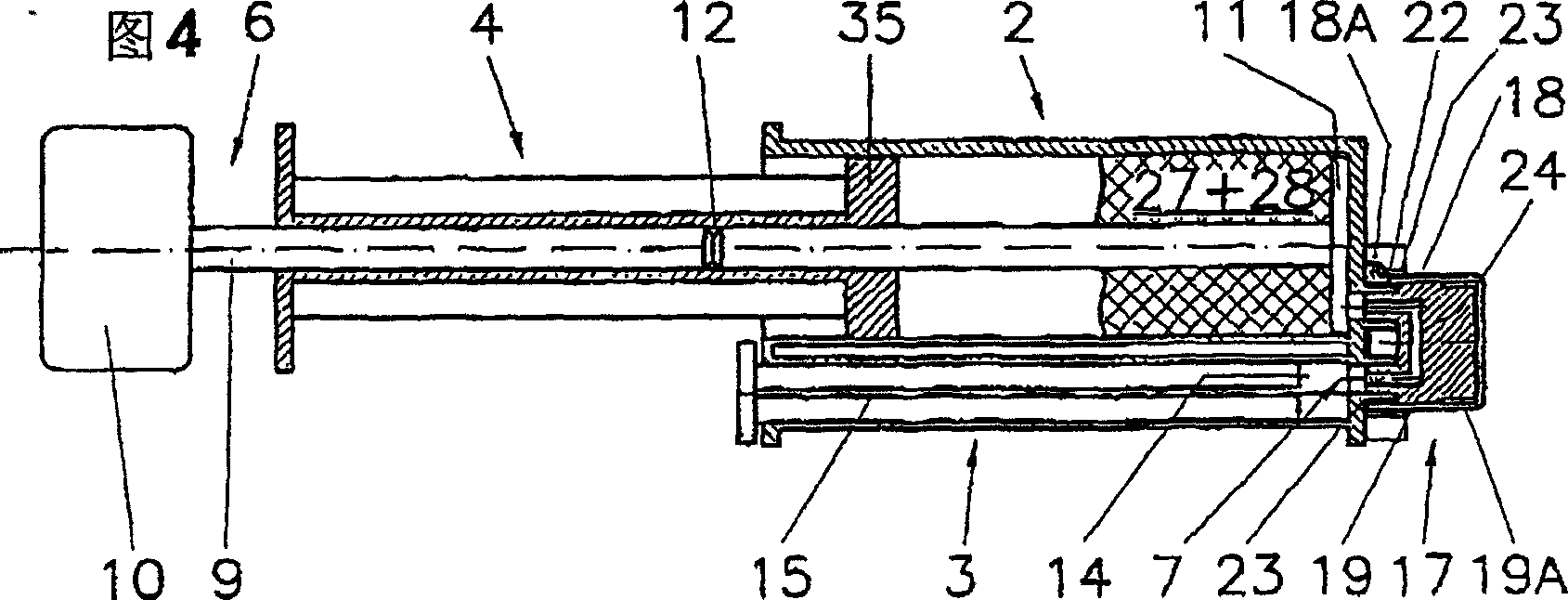

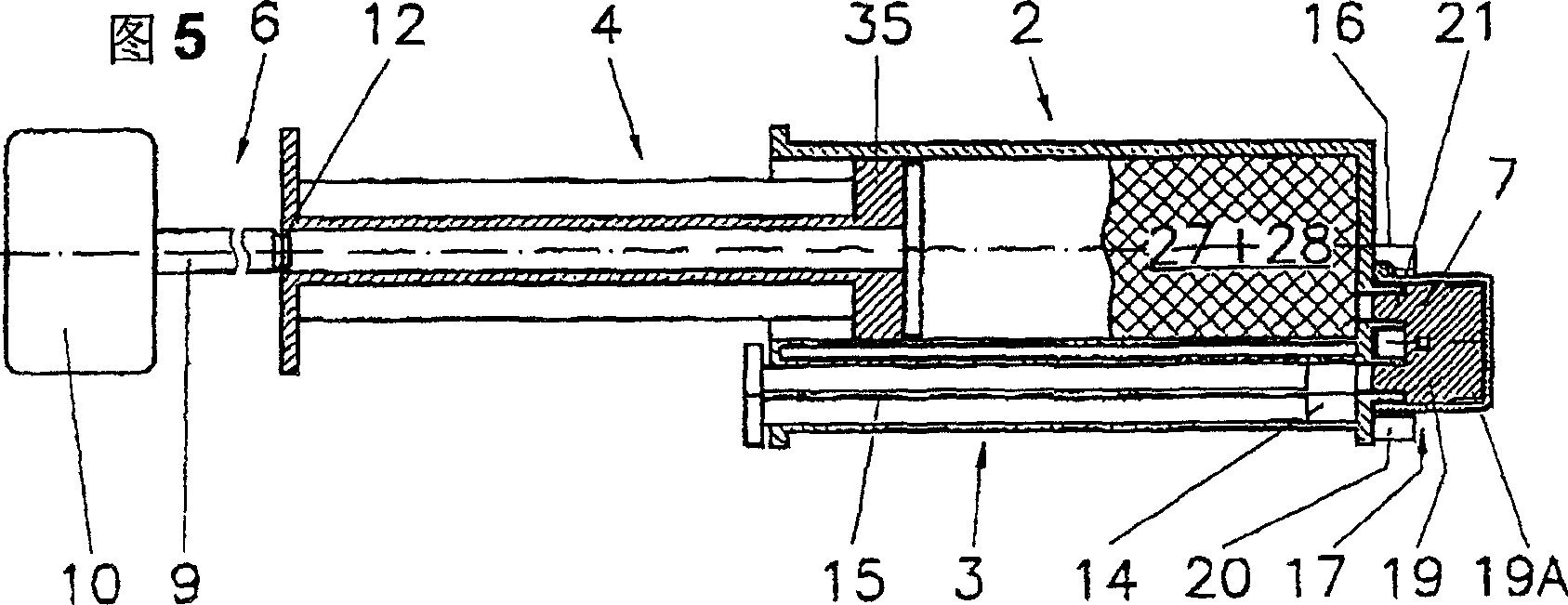

Device and method for the storage, mixing and dispensing of components

InactiveCN1852762ASimple structureEasy to operateLiquid surface applicatorsShaking/oscillating/vibrating mixersThermodynamicsProcess engineering

The device for storing, mixing and dispensing of components is provided with means for mixing a first component (27) with a second liquid component (28) and for dispensing the mixed material. The individual components (27, 28) are stored in adjacent containers (2, 3) and a valve arrangement (8) is arranged in the transfer region (7) between the outlet region (26) of the container (3) for the storage of the second liquid component (28) and the liquid inlet (25) of the container (2) for storage of the first component (27). Said device permits a problem-free storage of the differing components without physical separation of the containers and also the efficient mixing thereof. The above is particularly the case where the first component is a powder or granular in nature, or is porous in nature, for example, bone cement or bone replacement material.

Owner:MEDMIX SYST

Bone Implant, and Set for the Production of Bone Implants

InactiveUS20100185299A1Great mechanical adaptabilityMechanical performanceBone implantTissue regenerationBiological conditionBone implant

The invention relates to bone implants and sets for producing bone implants. Said bone implants are made from pasty or cementitious preparations which are introduced into open-cell metal structures comprising an interconnected pore system as solid or porous materials and are optionally allowed to set, the metal structure per se being biocompatible in biological conditions and being stable or corrodible. The bone implant according to the invention contains at least one open-cell metal structure that has an interconnected pore system which is at least partially filled with a preparation made of at least one bone replacement material. The open-cell metal structure is significantly less rigid than the solid material made of the same metal.

Owner:NIES BERTHOLD

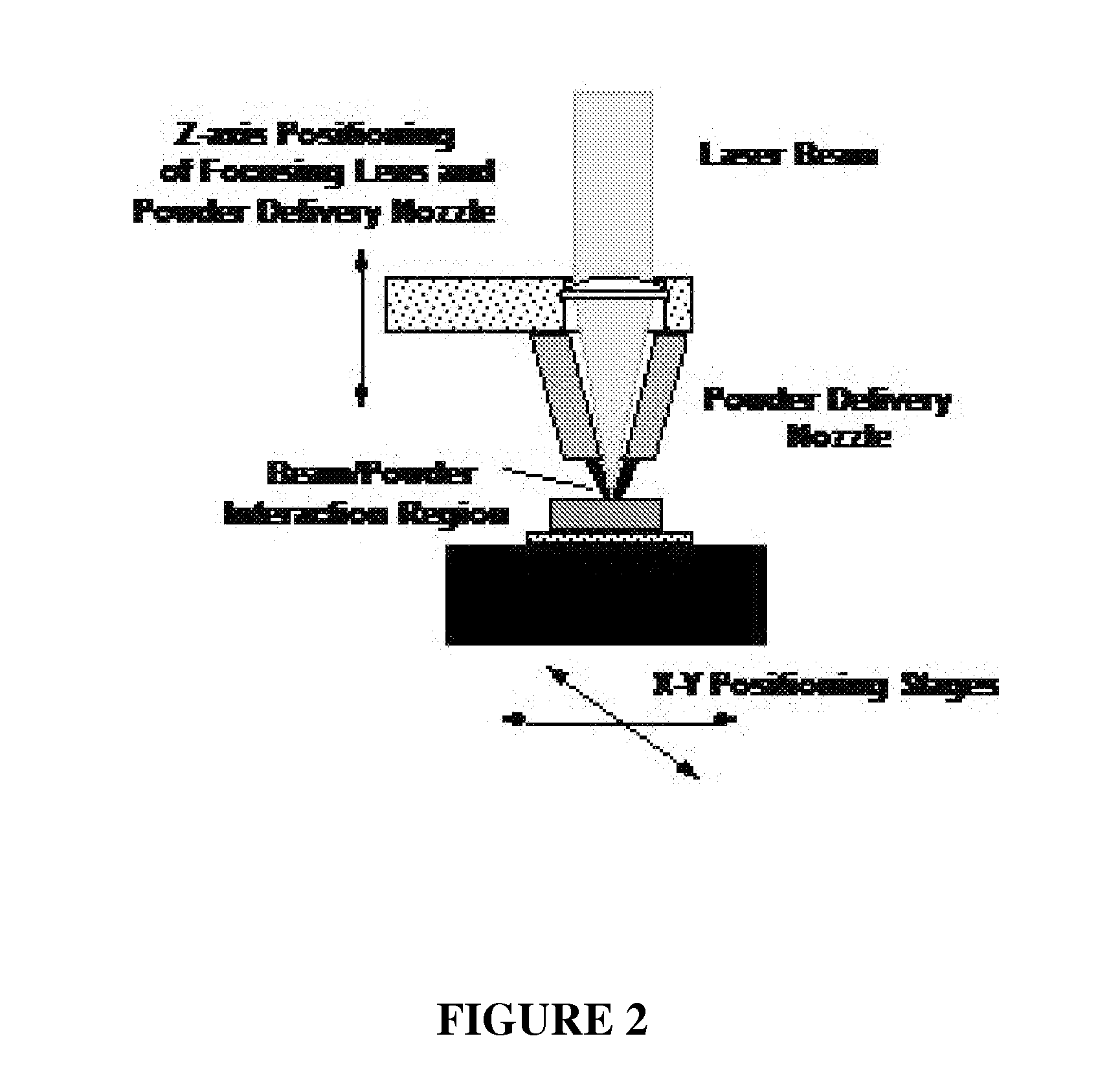

Customized Implants For Bone Replacement

ActiveUS20150351915A1Reduce the chance of solidificationLow process temperatureAdditive manufacturing apparatusBone implantCustom made implantNatural bone

The present invention relates to customized implants for bone replacement that are prepared from poly(ether ketone ketone) or PEKK, and to a computer-based imaging and rapid prototyping (RP)-based manufacturing method for the design and manufacture of these customized implants. The PEKK customized implants made using rapid prototyping demonstrate biomechanical properties similar (if not identical) to that of natural bone even when prepared without the use of processing aids such as carbon black and aluminum powder.

Owner:OXFORD PERFORMANCE MATERIALS

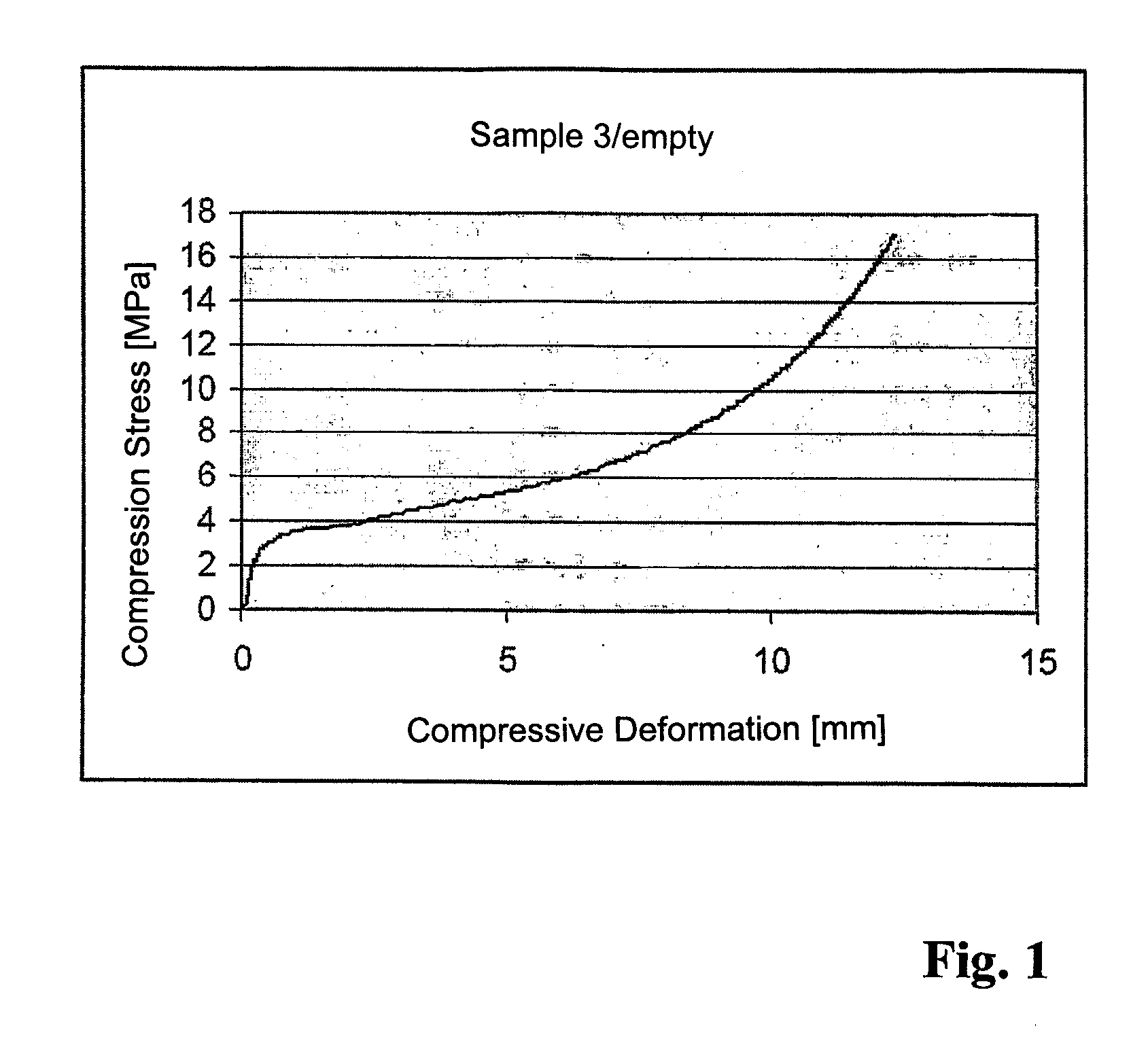

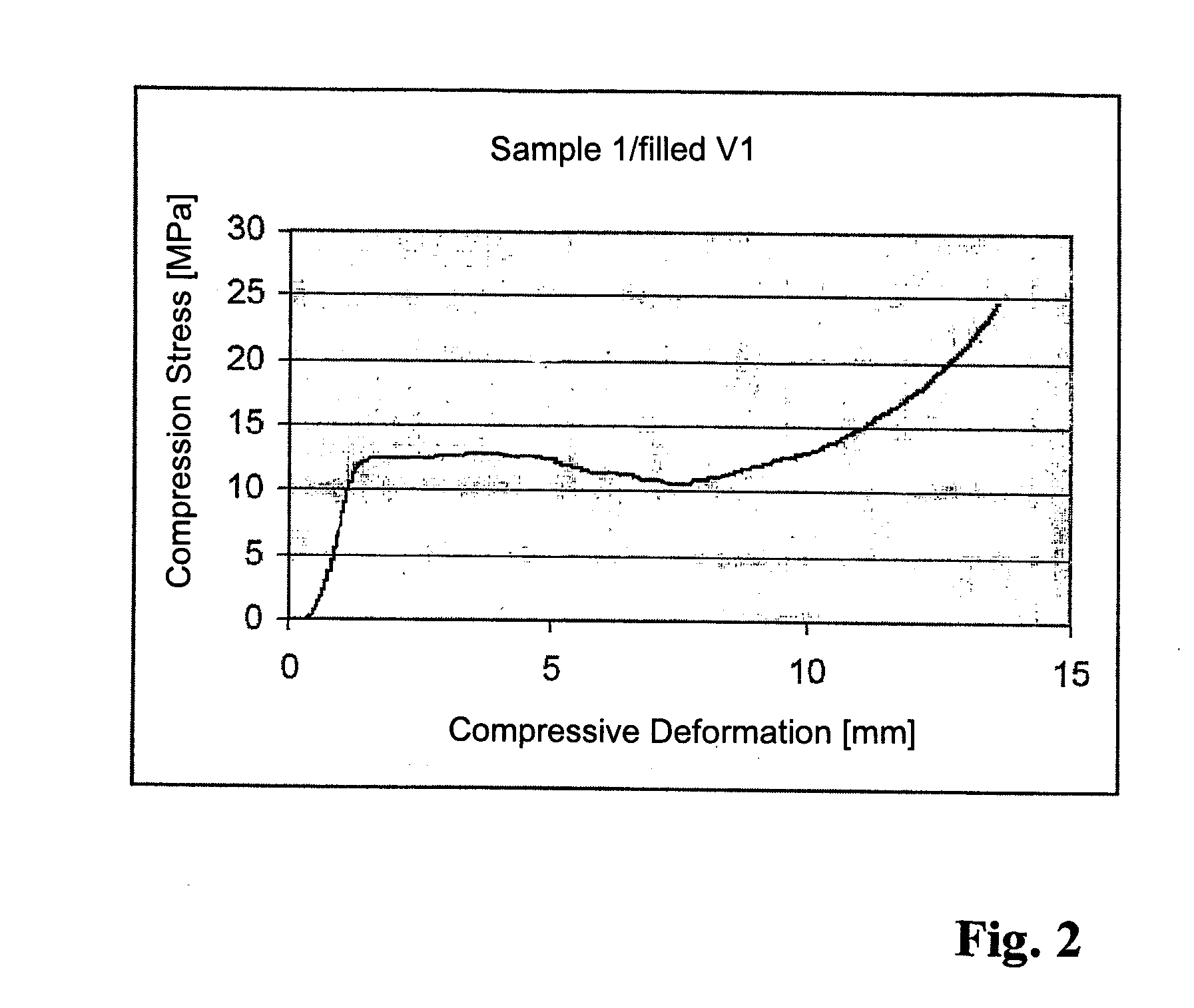

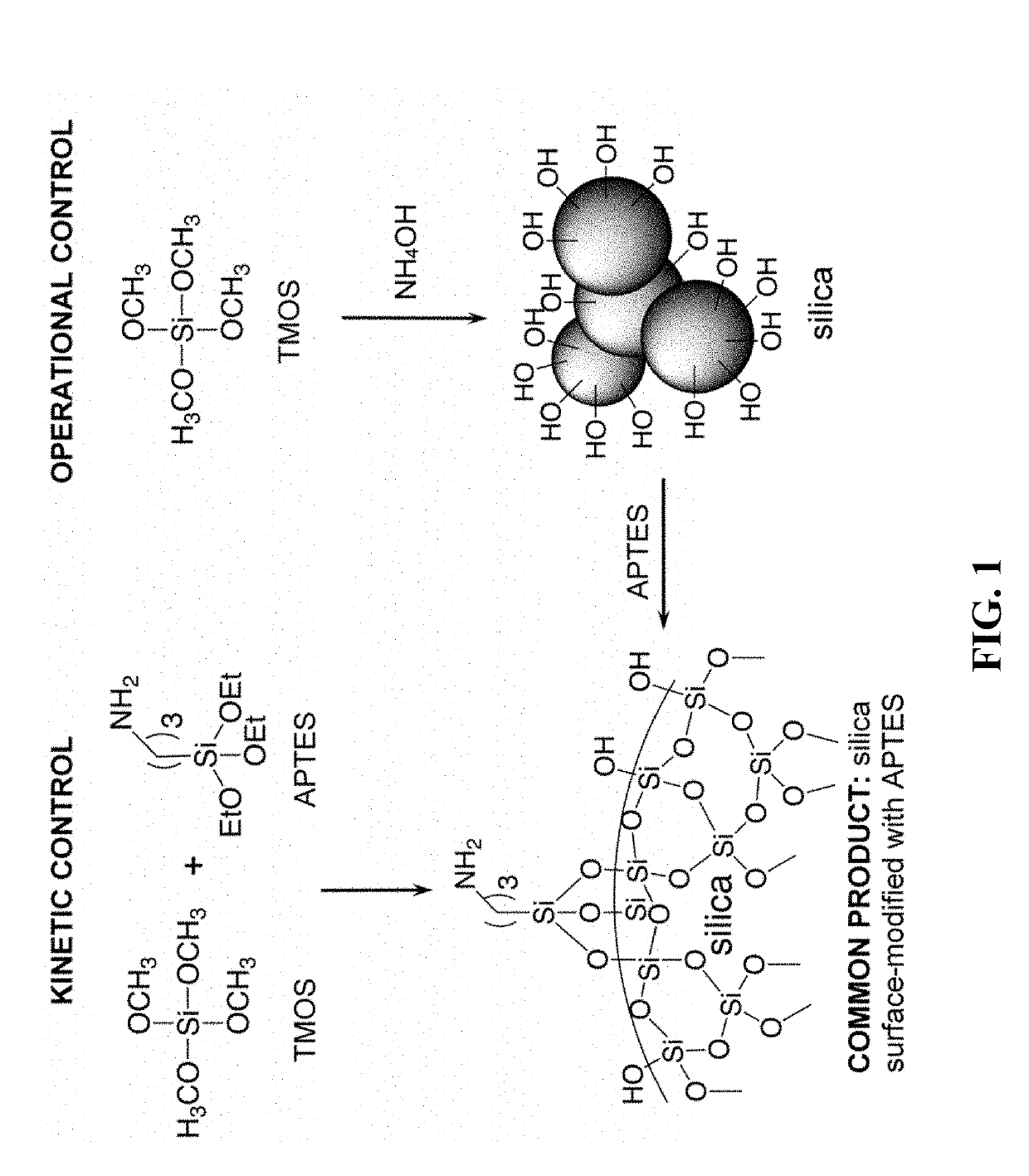

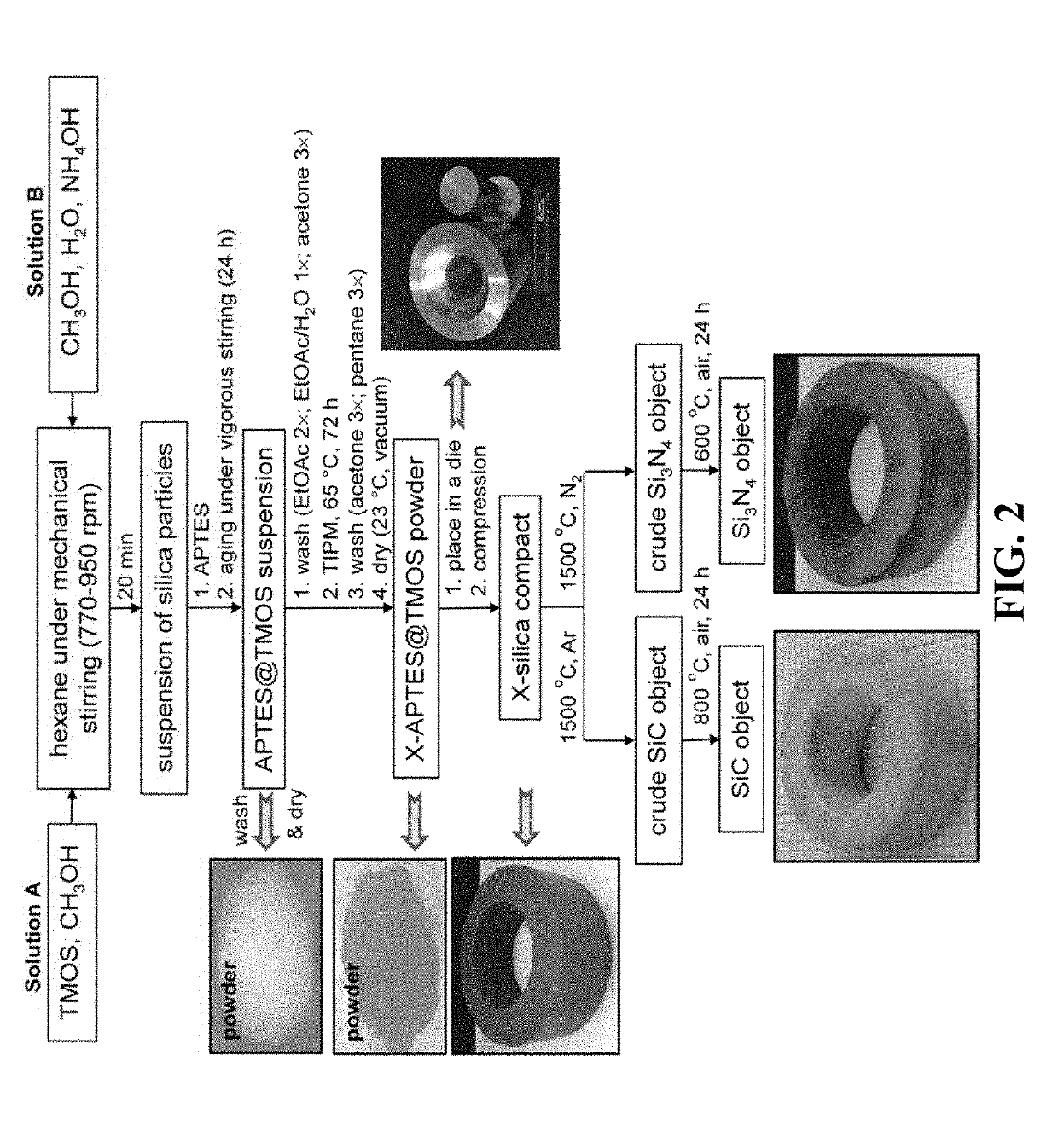

Novel highly porous ceramic and metal aerogels from xerogel powder precursors, and methods for their production and use

ActiveUS20190308912A1Speed up the processReduce lossesTransportation and packagingMetal-working apparatusConvertersBoride

The present invention discloses novel methods for producing highly porous ceramic and / or metal aerogel monolithic objects that are hard, sturdy, and resistant to high temperatures. These methods comprise preparing nanoparticulate oxides of metals and / or metalloids via a step of vigorous stirring to prevent gelation, preparing polymer-modified xerogel powder compositions by reacting said nanoparticulate oxides with one or more polyfunctional monomers, compressing said polymer-modified xerogel powder compositions into shaped compacts, and carbothermal conversion of the shaped xerogel compacts via pyrolysis to provide the highly porous ceramic and / or metal aerogel monolithic objects that have the same shapes as to their corresponding xerogel compact precursors. Representative of the highly porous ceramic and / or metal aerogel monolithic objects of the invention are ceramic and / or metal aerogels of Si, Zr, Hf, Ti, Cr, Fe, Co, Ni, Cu, Ru, Au, and the like. Examples include sturdy, shaped, highly porous silicon carbide (SiC), silicon nitride (Si3N4), zirconium carbide (ZrC), hafnium carbide (HfC), chromium carbide (Cr3C2), titanium carbide (TiC), zirconium boride (ZrB2), hafnium boride (HfB2), and metallic aerogels of iron (Fe), nickel (Ni), cobalt (Co), copper (Cu), ruthenium (Ru), gold (Au), and the like. Said aerogel monolithic objects have utility in various applications such as, illustratively, in abrasives, in cutting tools, as catalyst support materials such as in reformers and converters, as filters such as for molten metals and hot gasses, in bio-medical tissue engineering such as bone replacement materials, in applications requiring strong lightweight materials such as in automotive and aircraft structural components, in ultra-high temperature ceramics, and the like.

Owner:UNIVERSITY OF MISSOURI

Reduced exothermic bone replacement cement

ActiveUS20040044096A1Reduce amountReduce fluid volumeImpression capsSurgical adhesivesBone cementBone replacement

A bone cement having a dry component including a large constituent and a small constituent. The small constituent fills a substantial volume of the interstitial spaces between the particles of the large constituent. Therefore, only a second or minor interstitial space is left remaining between the individual particles of the small constituent and the particles of the small constituent and the particles of the large constituent. Therefore, a reduced amount of a polymerizable component need be added to the dry component to form a bone cement. Such a bone cement formulation decreases the exothermic temperature of the bone cement and decreases the possibility of tissue necrosis in the implantation area.

Owner:BIOMET MFG CORP

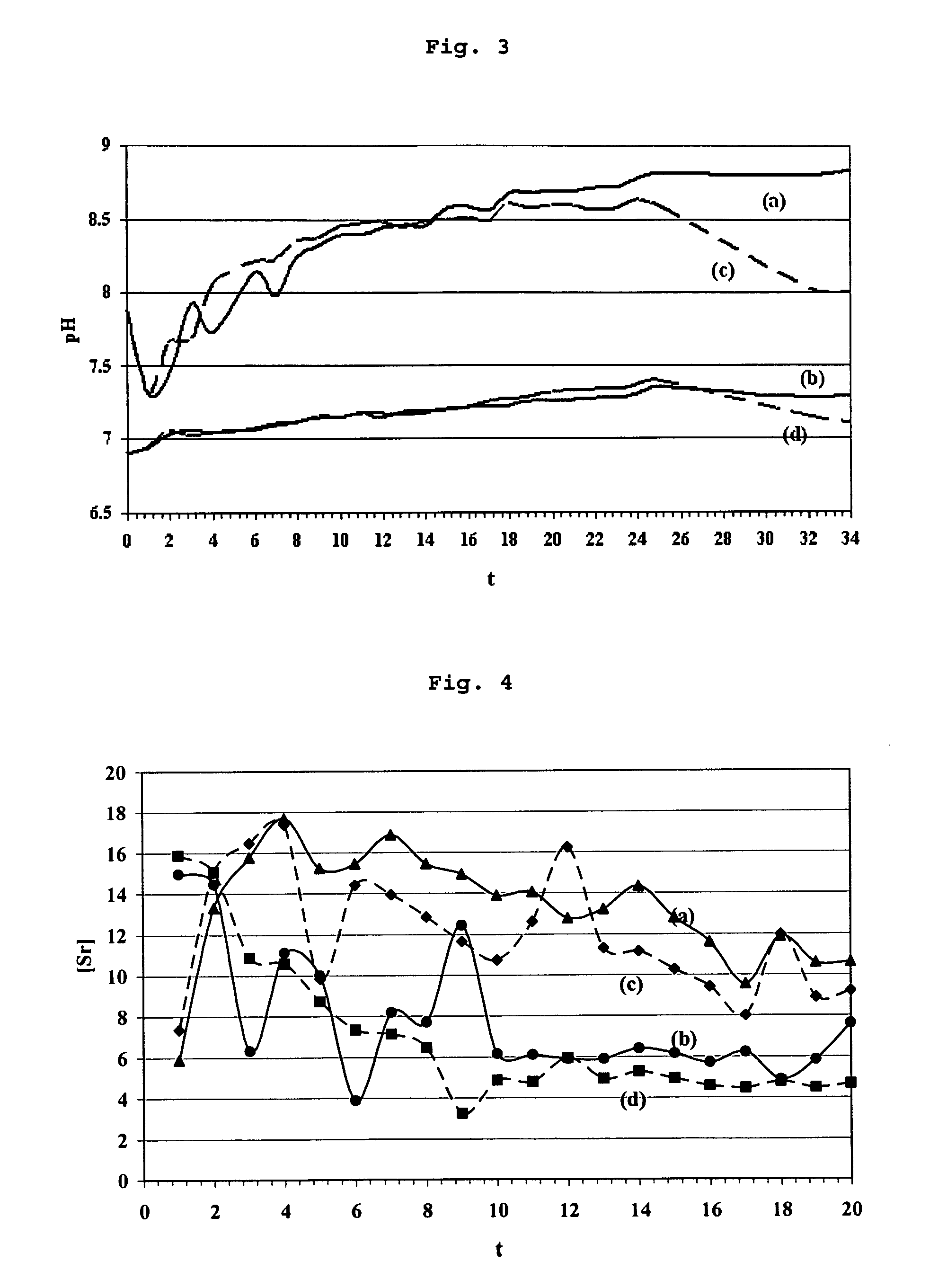

Composition for Injectable Cement Useful as Bone Replacement

InactiveUS20080027455A1High compressive strengthImprove absorption rateBiocideCosmetic preparationsPowder mixtureMicroparticle

The invention relates to a composition for injectable cement, comprising a mineral sold phase, a separate liquid phase and, optionally, microparticles of a biocompatible and biodegradable polymer. The mineral solid phase comprises a mixture of powders with the molar composition: (CP)6 (CaO)y (SrCO3)z, [CP being CaHPO42H2O, CaHPO4, Ca1-xSrxHPO4, an equimolar mixture of bis(Ca(H2PO4)2, H2O and CaO, or a mixture of two or three of said compounds] and y+z=4?1. The liquid phase comprises pure apyrogeneic water or a saline aqueous solution with pH 4 to 9. The ratio L / P [volume of liquid phase / mass of solid mineral phase] is at least 0.4 ml / g. The above is of application as bone replacement.

Owner:CENT NAT DE LA RECHERCHE SCI +1

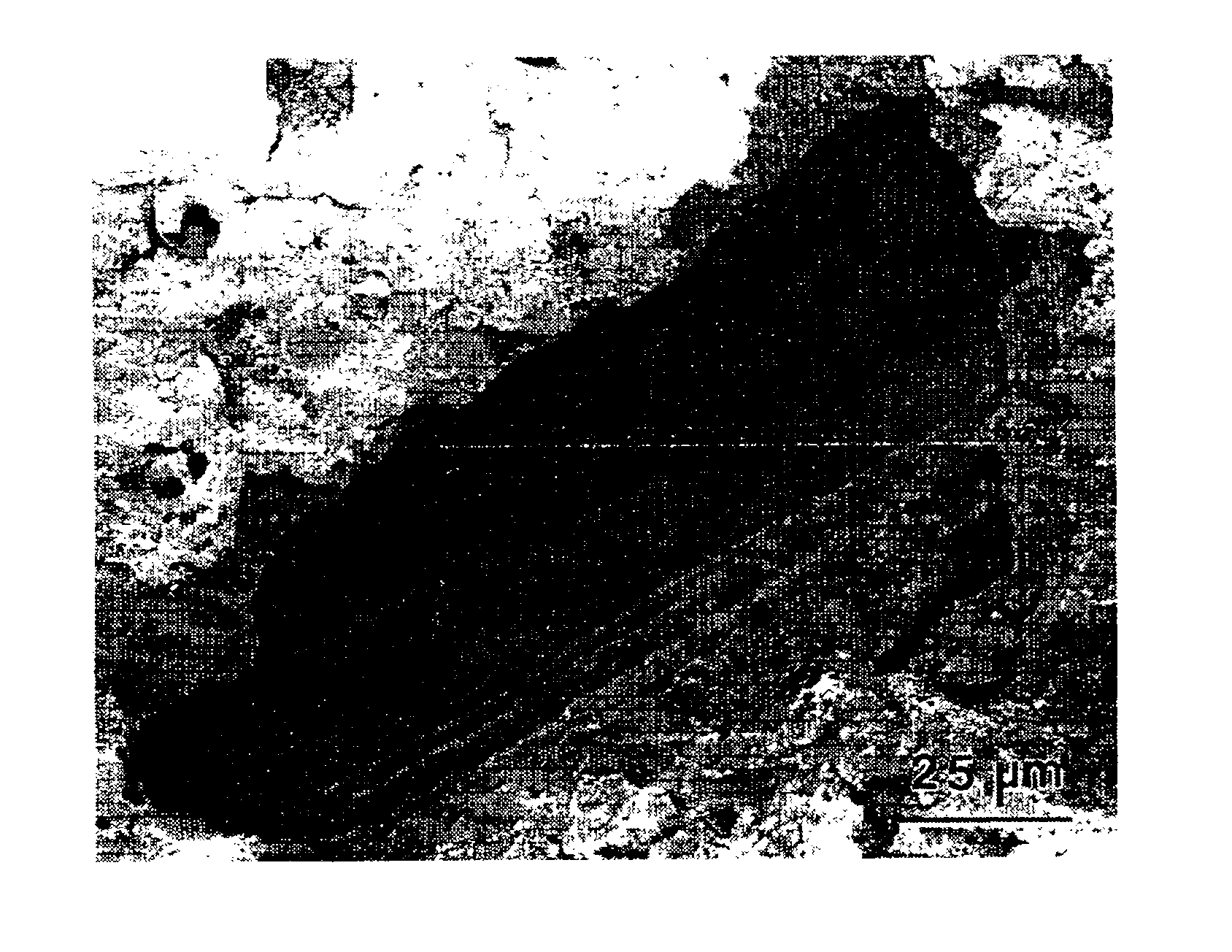

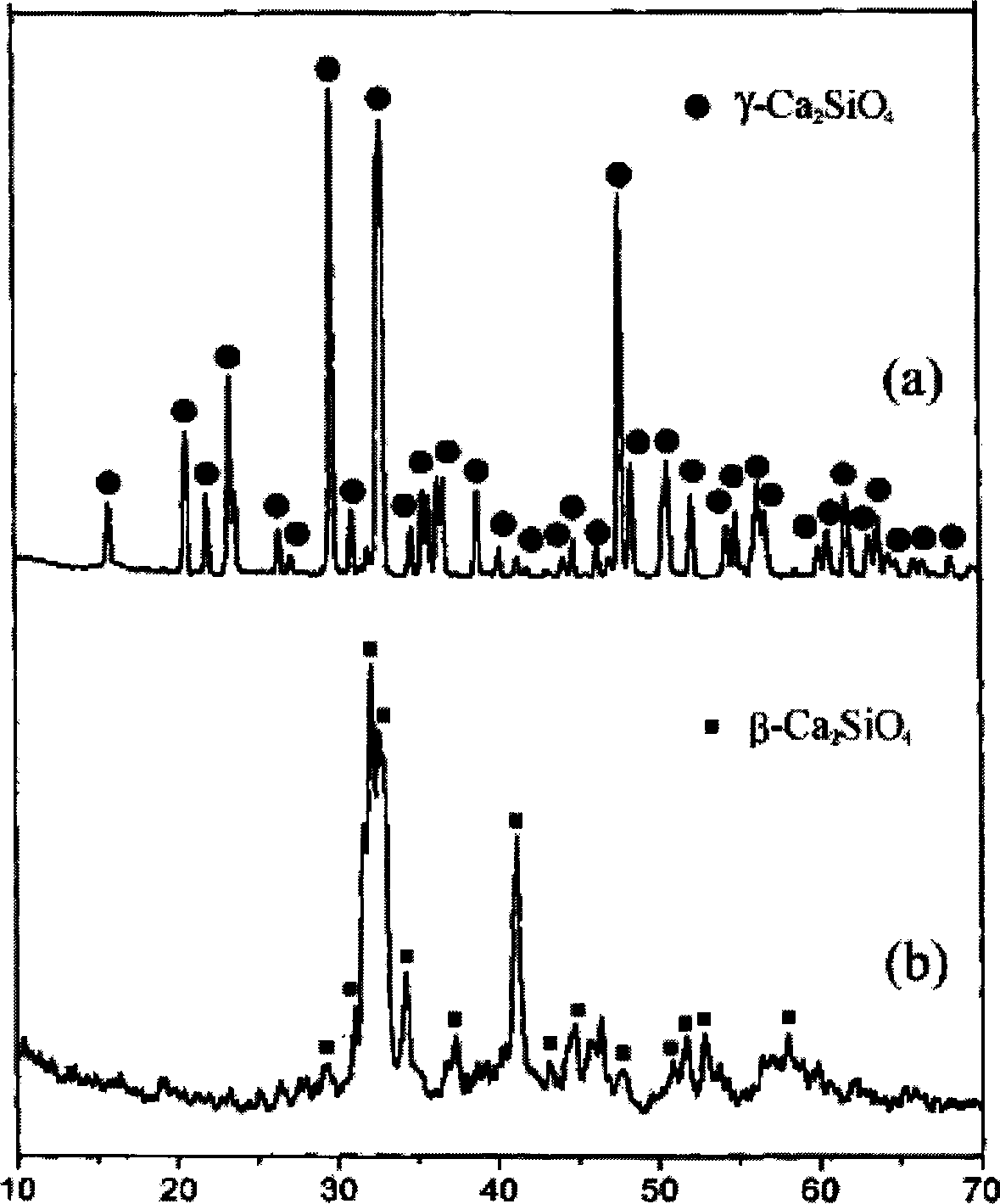

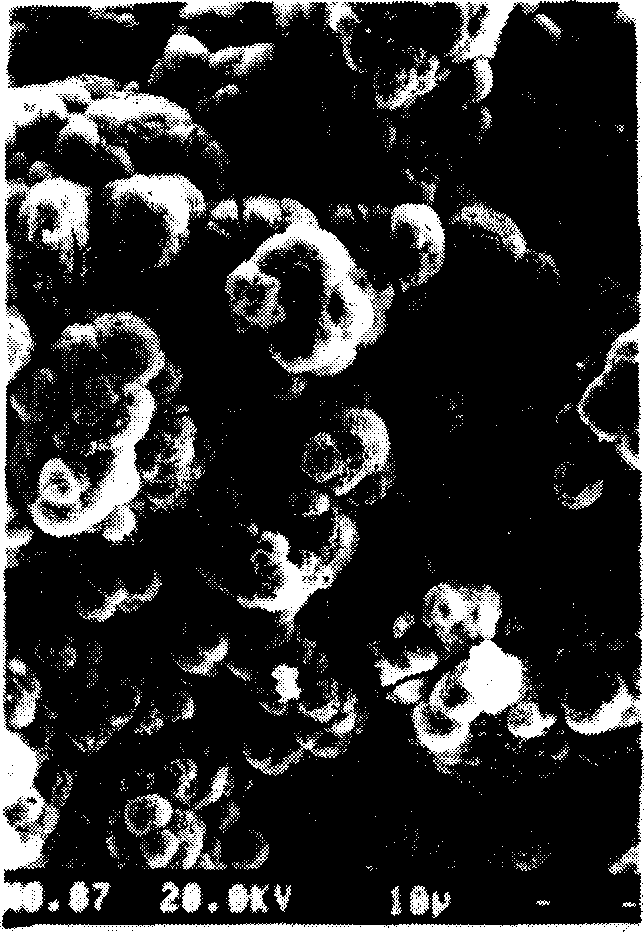

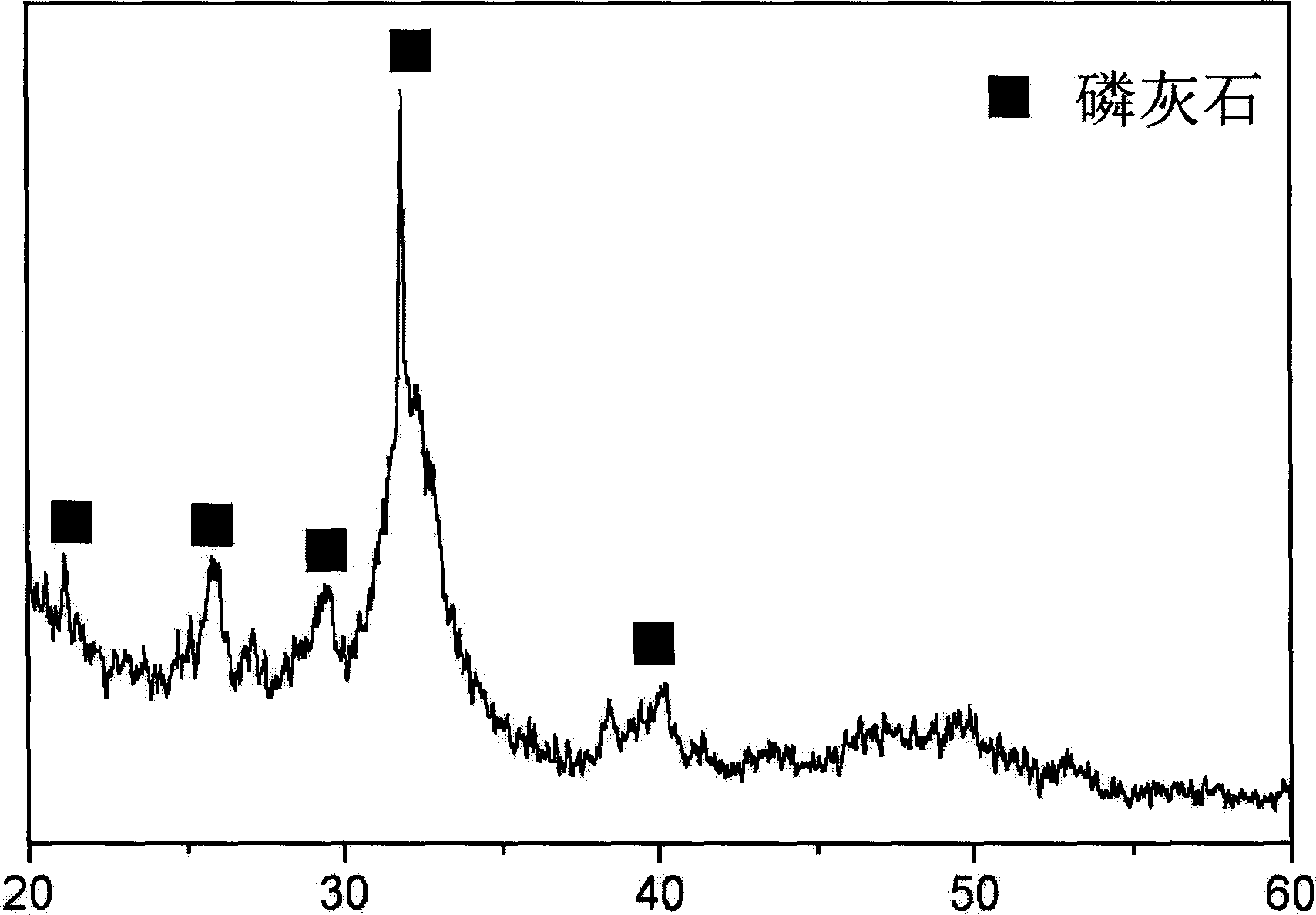

Dicalcium silicate coating layer-titanium alloy loading bone replacement material and its preparation method

The present invention relates to a bone substituted material. Said bone substitute material is dicalcium silicate coating layer deposited on the surface of titanium alloy of Ti-6Al-4V, said coating layer is formed from beta-Ca2SiO4 and glass phase, and its thickness if 50-400 micrometers. Its preparation method incldues the following steps: firstly, synthesizing gamma-Ca2SiO4, then using atmospheric plasma spraying process to deposit the dicalcium silicate coating layer on the titanium alloy base body, and the combination strength of said coating layer and base body is greater than 34-40 MPa.The tests show that the bone apatite can be formed on the surface of dicalcium silicate, and cell can quickly grow and proliferate on the beta-Ca2SiO4 coating layer surface, so that said substitute material possesses good biological activity and compatibility.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com