Dicalcium silicate coating layer-titanium alloy loading bone replacement material and its preparation method

A replacement material, dicalcium silicate technology, applied in medical science, prosthesis, etc., can solve the problems of unsatisfactory comprehensive mechanical properties, limited application, low fracture toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

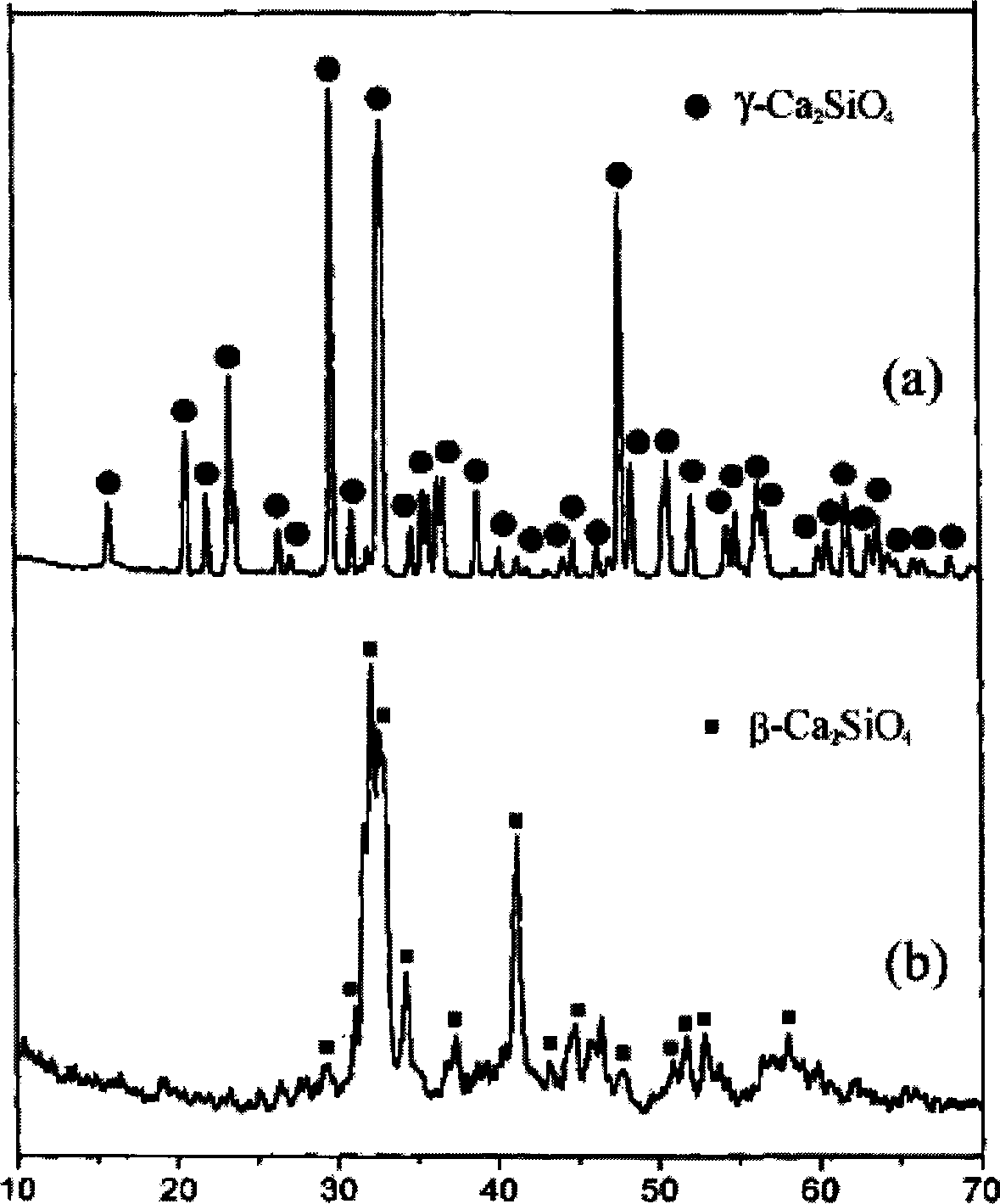

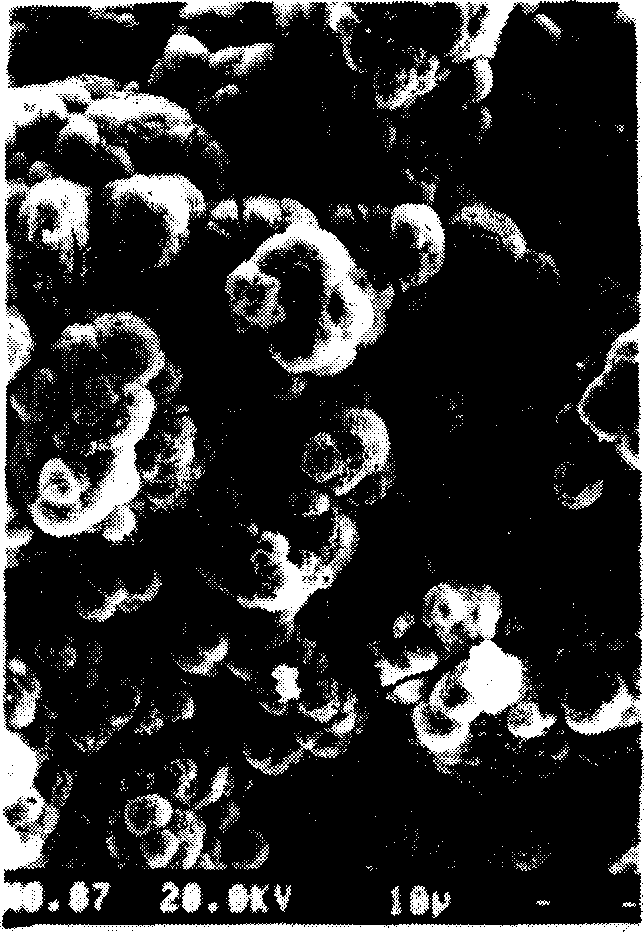

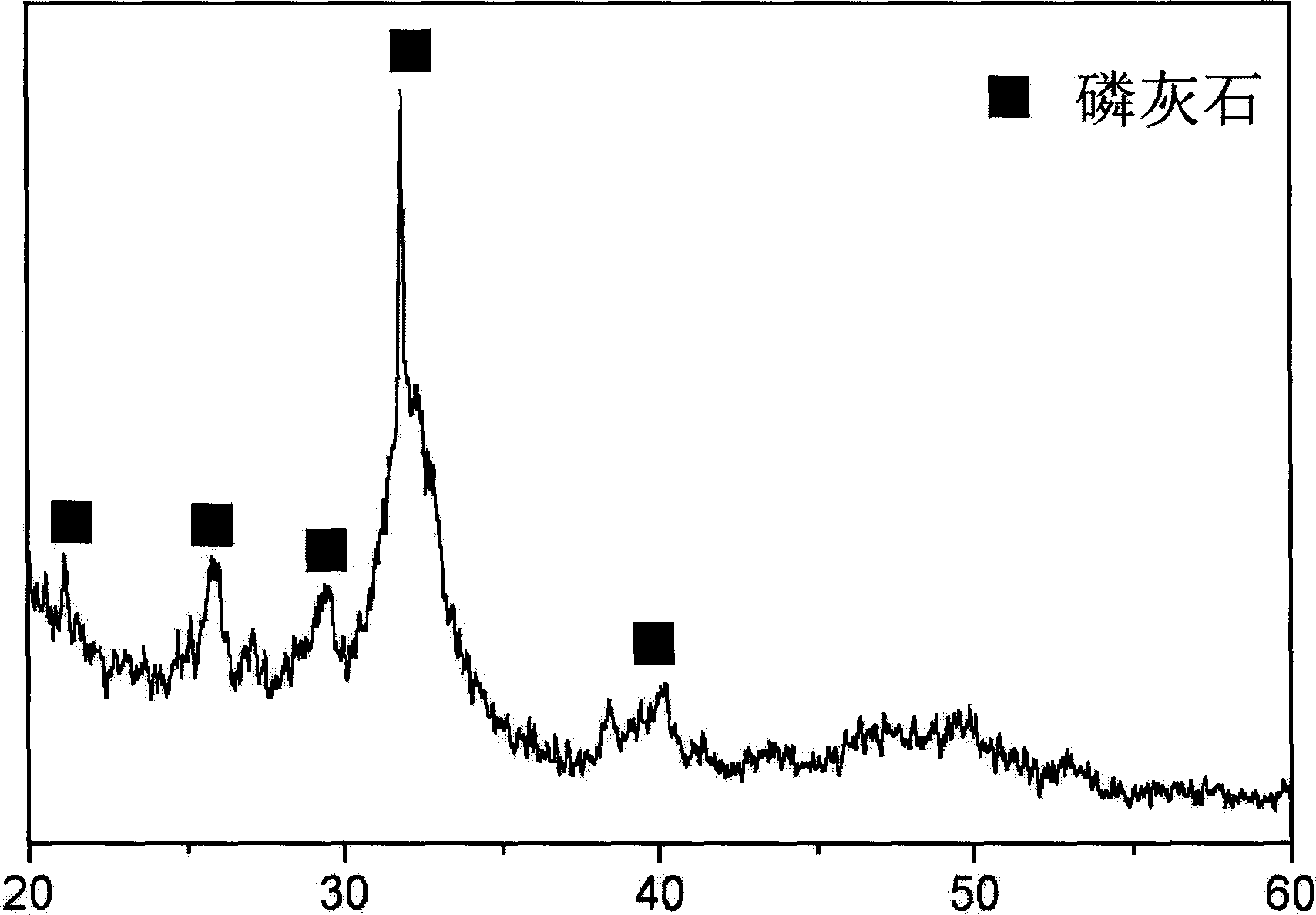

[0020] Chemically pure CaCO 3 and SiO 2 According to the molar ratio of 2:1 ingredients, ball milling and mixing in water medium for 12 hours, after drying, put it into a corundum crucible, keep it at 1440°C for 2 hours, and use solid phase synthesis reaction to prepare γ-Ca 2 SiO 4 Particles, whose particle size ranges from 5 to 30 μm. Using atmospheric plasma spraying technology, using the spraying parameters in Table 2, the γ-Ca 2 SiO 4 Powders were deposited on cleaned and blasted Ti-6Al-4V substrates. After spraying, the main crystal phase of dicalcium silicate coating is β-Ca 2 SiO 4 , while a glassy phase exists (see figure 1 ). The bonding strength of the coating measured by ASTM 633-79 method is about 39MPa. Simulated body fluid immersion experiments show that hydroxyapatite containing carbonate groups can be formed on the surface of dicalcium silicate coating within one day (see figure 2 and image 3 ). Mouse embryonic osteoblast culture experiments show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com