Patents

Literature

898 results about "Phase synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

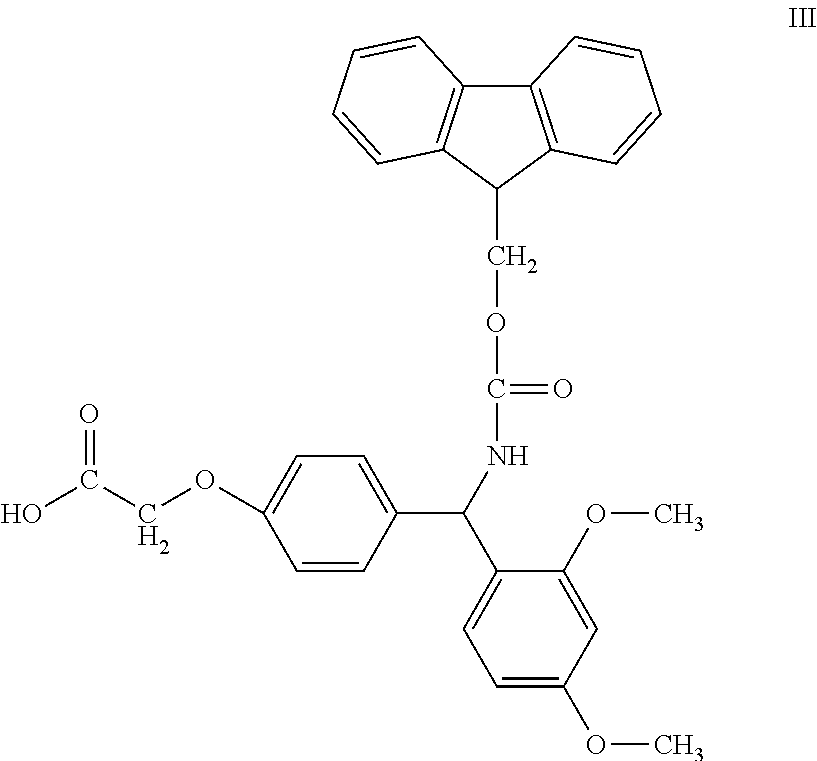

Topologically segregated, encoded solid phase libraries comprising linkers having an enzymatically susceptible bond

The invention relates to libraries of synthetic test compound attached to separate phase synthesis supports. In particular, the invention relates to libraries of synthetic test compound attached to separate phase synthesis supports that also contain coding molecules that encode the structure of the synthetic test compound. The molecules may be polymers or multiple nonpolymeric molecules. Each of the solid phase synthesis support beads contains a single type of synthetic test compound. The synthetic test compound can have backbone structures with linkages such as amide, urea, carbamate (i.e., urethane), ester, amino, sulfide, disulfide, or carbon-carbon, such as alkane and alkene, or any combination thereof. Examples of subunits suited for the different linkage chemistries are provided. The synthetic test compound can also be molecular scaffolds, such as derivatives of monocyclic of bicyclic carbohydrates, steroids, sugars, heterocyclic structures, polyaromatic structures, or other structures capable of acting as a scaffolding. Examples of suitable molecular scaffolds are provided. The invention also relates to methods of synthesizing such libraries and the use of such libraries to identify and characterize molecules of interest from among the library of synthetic test compound.

Owner:AVENTIS PHARMA INC

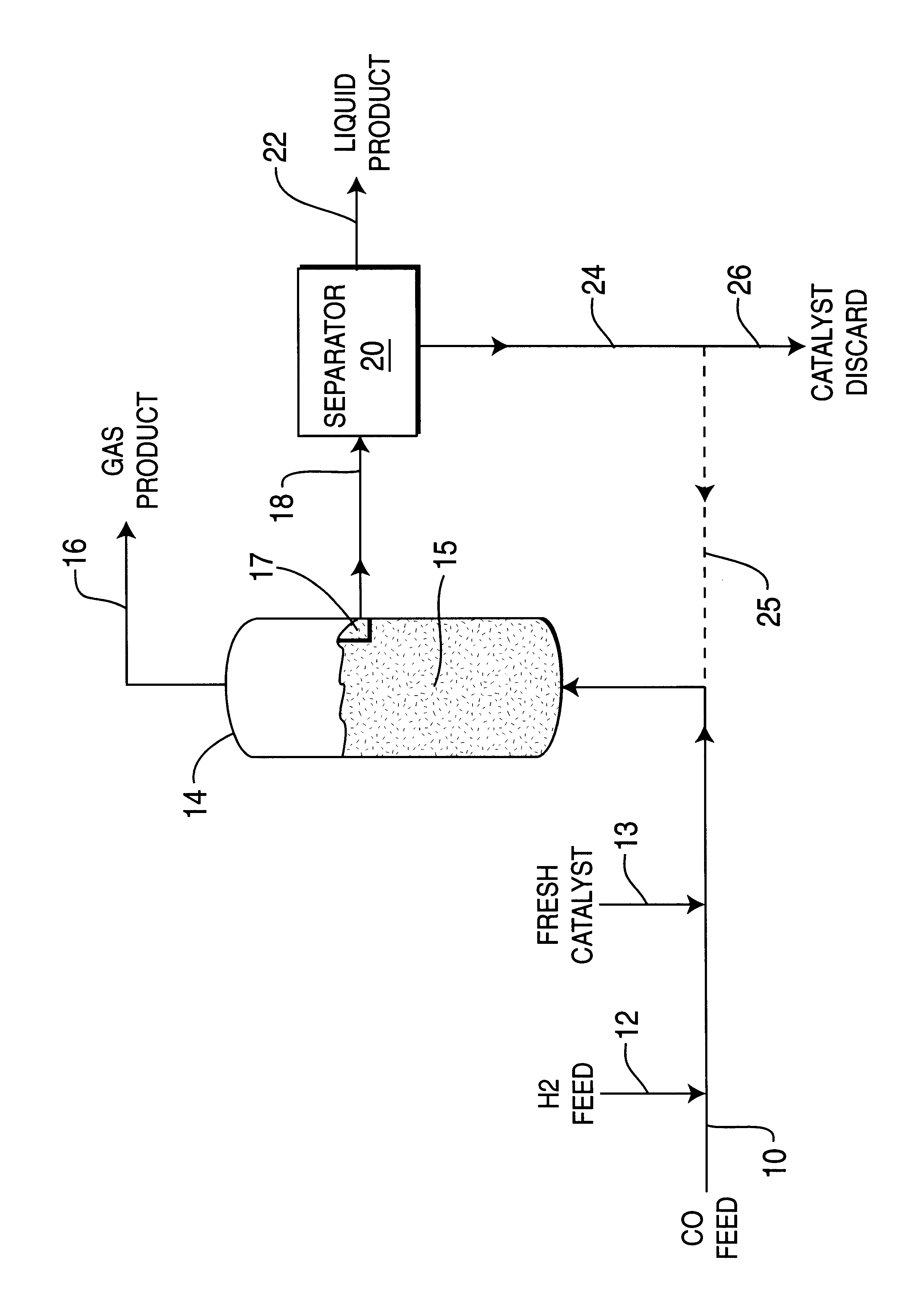

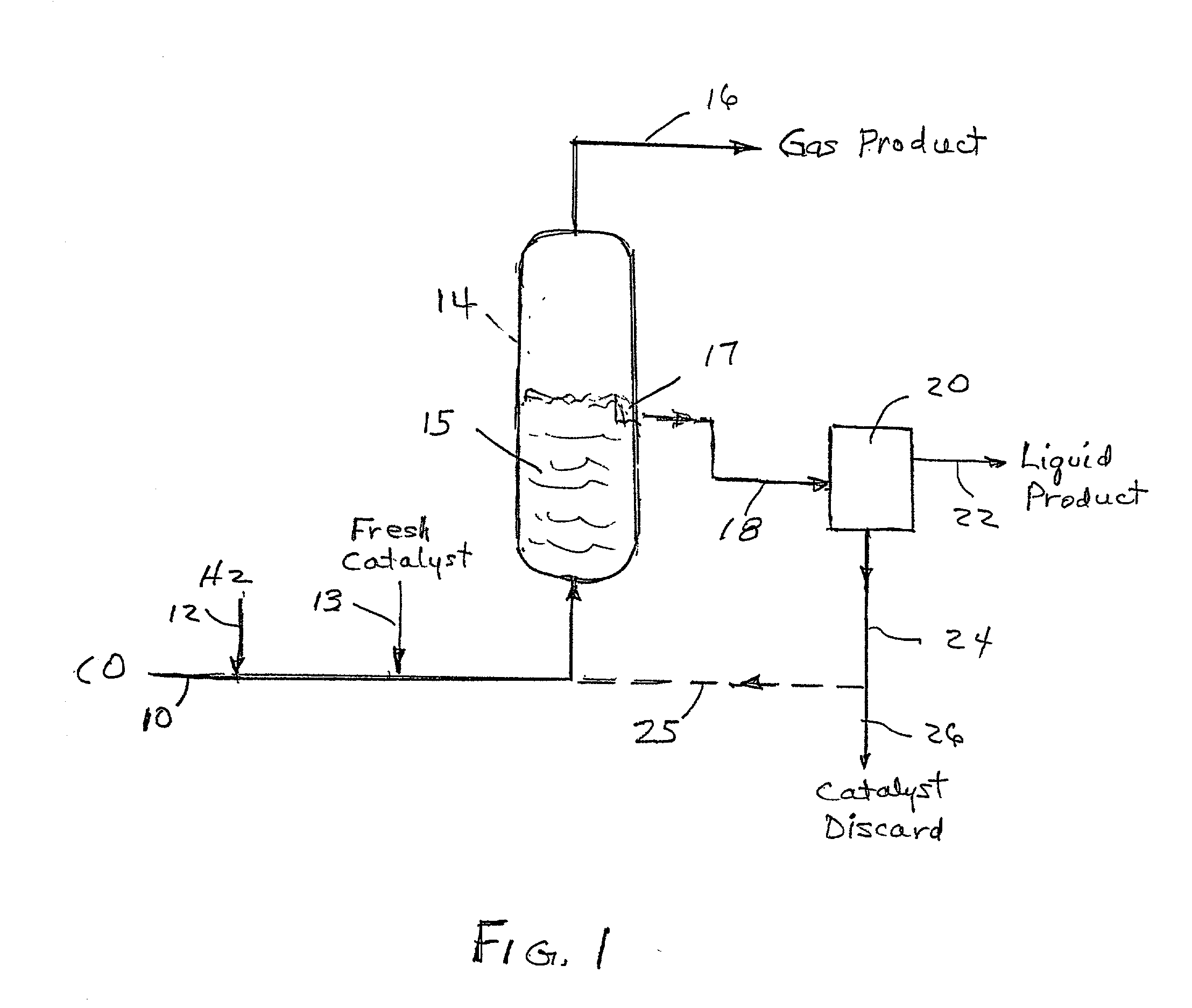

Skeletal iron catalyst having improved attrition resistance and product selectivity in slurry-phase synthesis processes

InactiveUS6277895B1High particle strengthGood attristion resistanceHydrocarbon from carbon oxidesOrganic compound preparationFixed bedSlurry

Particulate skeletal iron catalyst is provided which contain at least about 50 wt. % iron with the remainder being a minor portion of a suitable non-ferrous metal and having characteristics of 0.062-1.0 mm particle size, 20-100 m2 / g surface area, and 10-40 nm average pore diameter. Such skeletal iron catalysts are prepared and utilized for producing synthetic hydrocarbon products from CO and H2 feeds by Fischer-Tropsch synthesis process. Iron powder is mixed with non-ferrous powder selected from aluminum, antimony, silicon, tin or zinc powder to provide 20-80 wt. % iron content and melted together to form an iron alloy, then cooled to room temperature and pulverized to provide 0.1-10 mm iron alloy catalyst precursor particles. The iron alloy pulverized particles are treated with NaOH or KOH caustic solution at 30-95° C. temperature to extract and / or leach out most of the non-ferrous metal portion, and then screened and treated by drying and reducing with hydrogen and to provide the smaller size skeletal iron catalyst material. Such skeletal iron catalyst is utilized with CO+H2 feedstream for Fischer-Tropsch reactions in either a fixed bed or slurry bed type reactor at 180-350° C. temperature, 0.5-3.0 mPa pressure and gas hourly space velocity of 0.5-3.0 L / g Fe / hr to produce desired hydrocarbon products.

Owner:INST OF COAL CHEM ICCCHINESE ACADEMY OF SCI +1

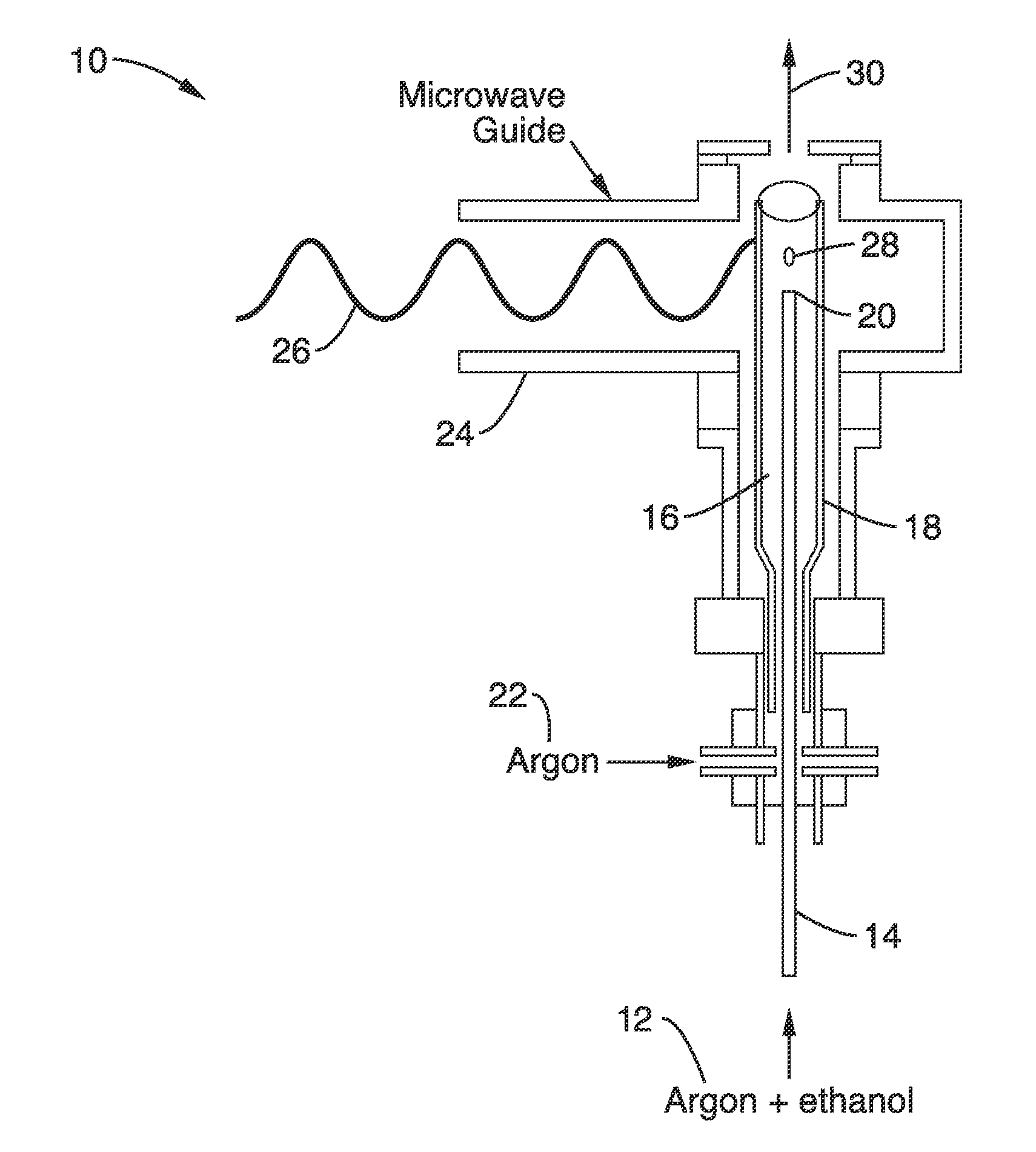

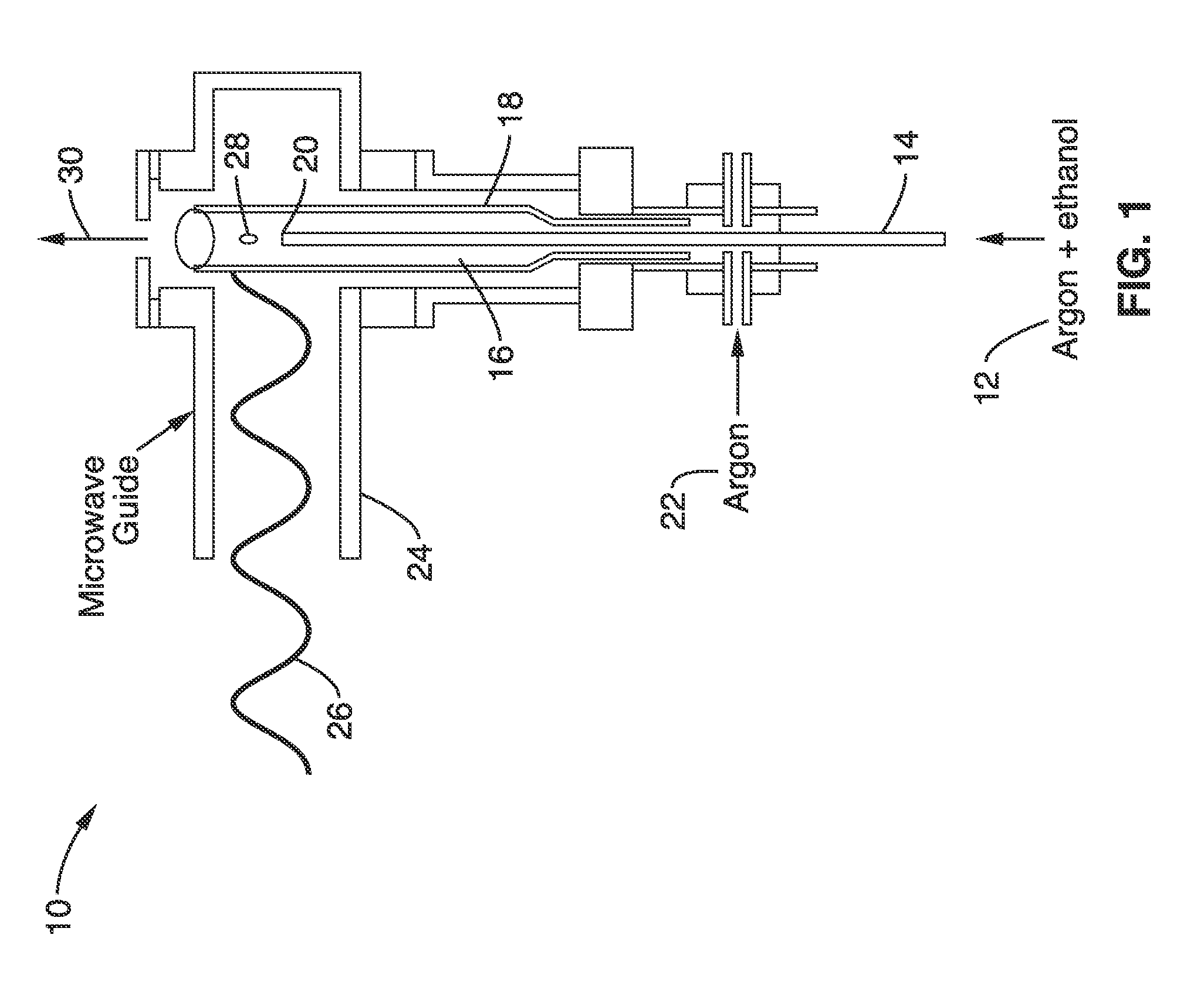

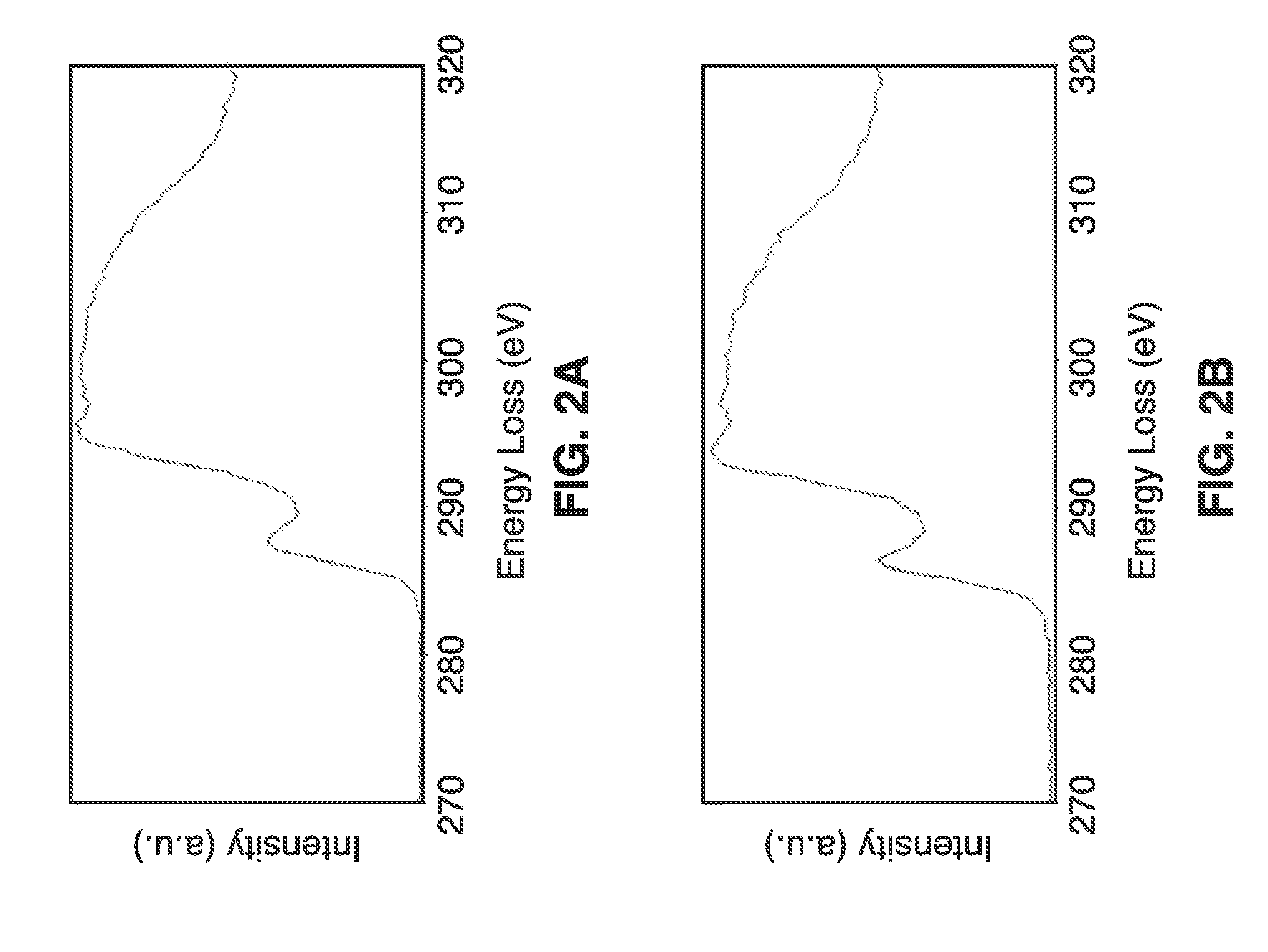

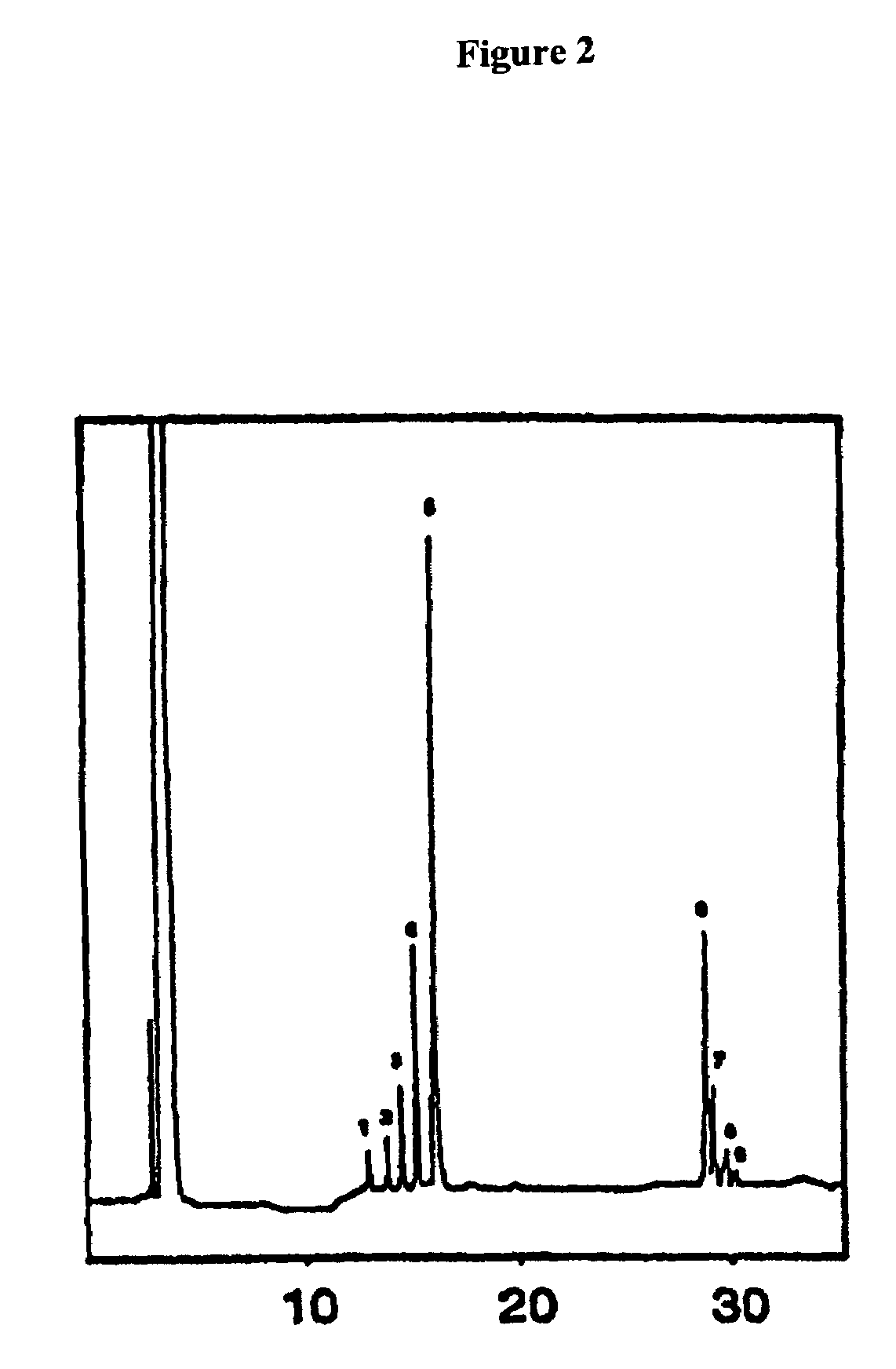

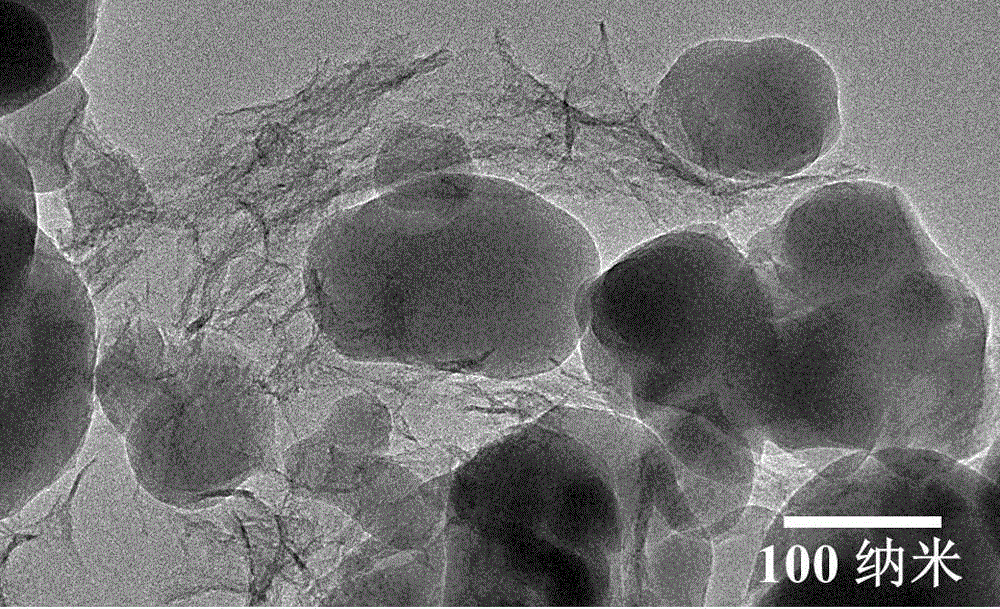

Substrate-free gas-phase synthesis of graphene sheets

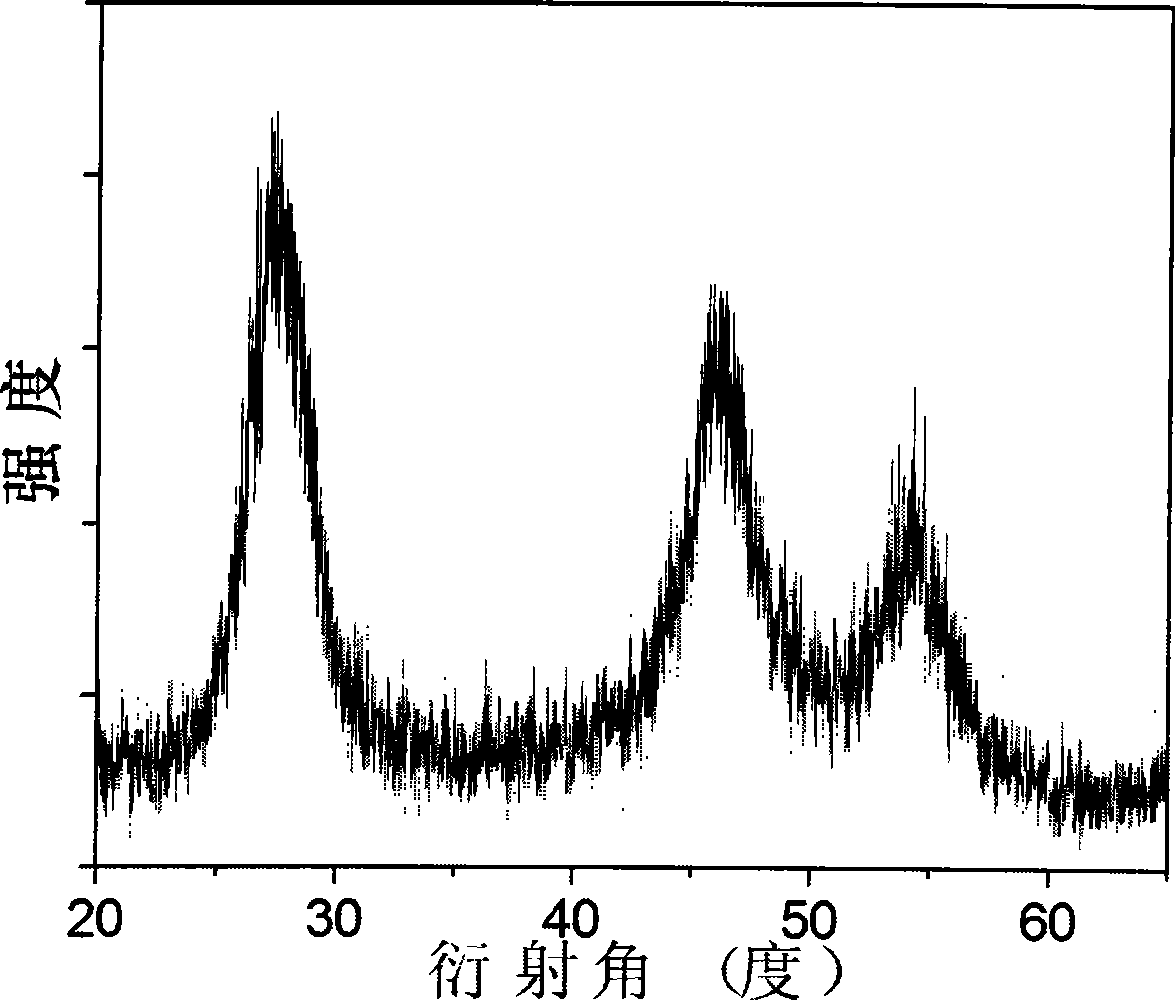

InactiveUS20100301212A1Uniform and easy to produceEasy to produceMaterial nanotechnologyMaterial analysis using wave/particle radiationGas phaseOxygen

A substrate-free gas-phase synthesis apparatus and method that is capable of rapidly and continuously producing graphene in ambient conditions without the use of graphite or substrates is provided. Graphene sheets are continuously synthesized in fractions of a second by sending an aerosol consisting of argon gas and liquid ethanol droplets into an atmospheric-pressure microwave-generated argon plasma field. The ethanol droplets are evaporated and dissociated in the plasma, forming graphene sheets that are collected. The apparatus can be scaled for the large-scale production of clean and highly ordered graphene and its many applications. The graphene that is produced is clean and highly ordered with few lattice imperfections and oxygen functionalities and therefore has improved characteristics over graphene produced by current methods in the art. The graphene that is produced by the apparatus and methods was shown to be particularly useful as a support substrate that enabled direct atomic resolution imaging of organic molecules and interfaces with nanoparticles at a level previously unachievable.

Owner:RGT UNIV OF CALIFORNIA

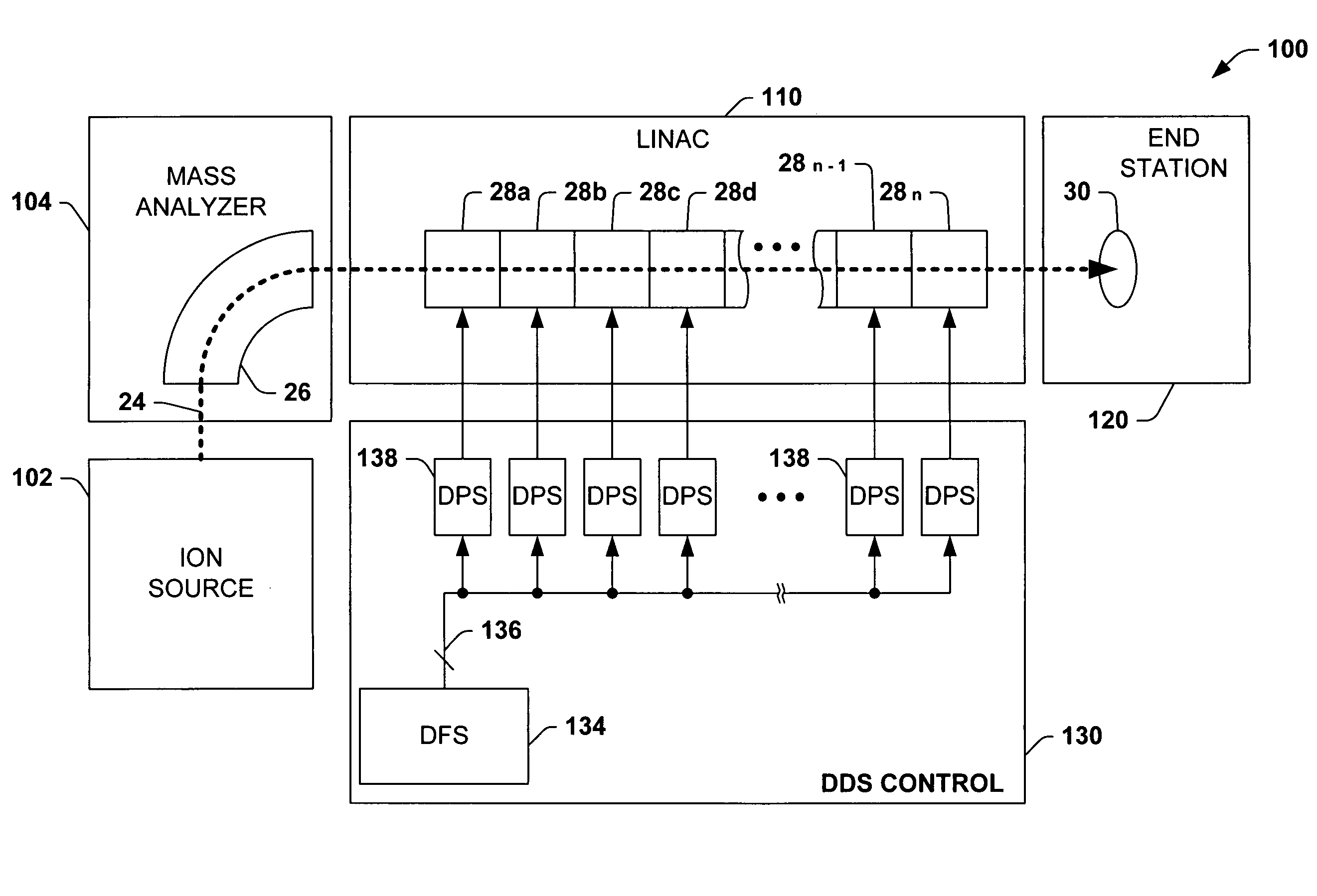

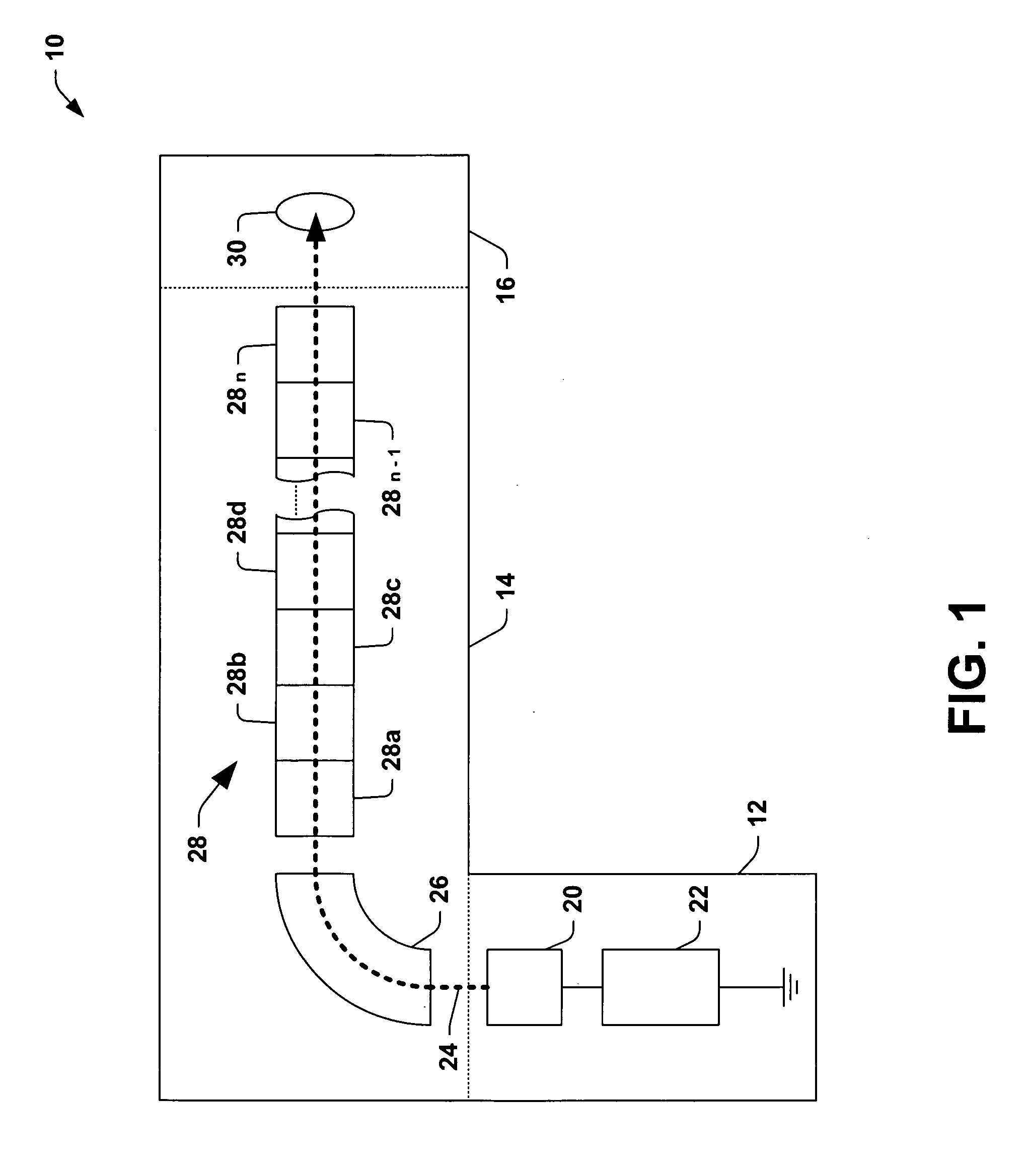

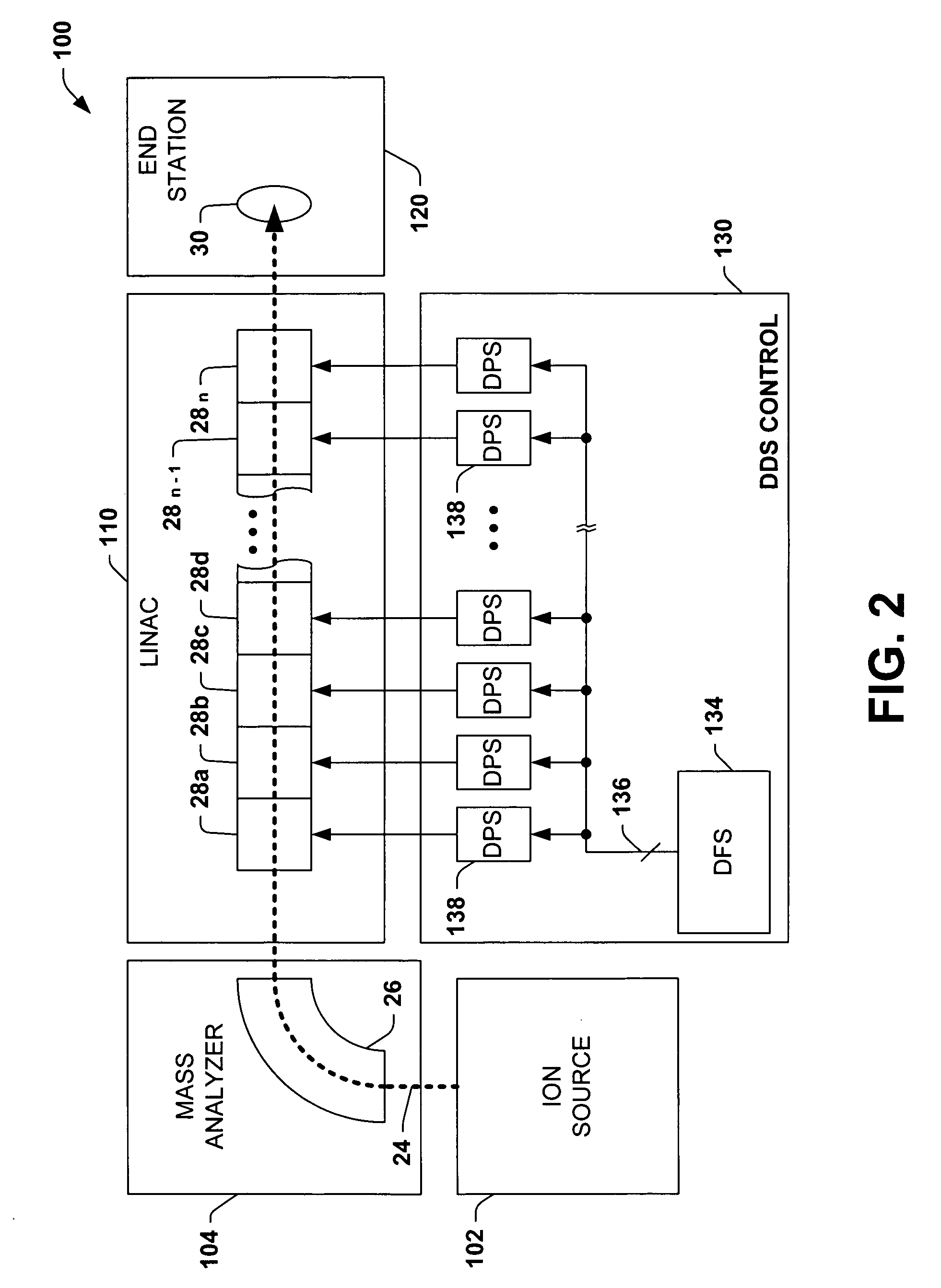

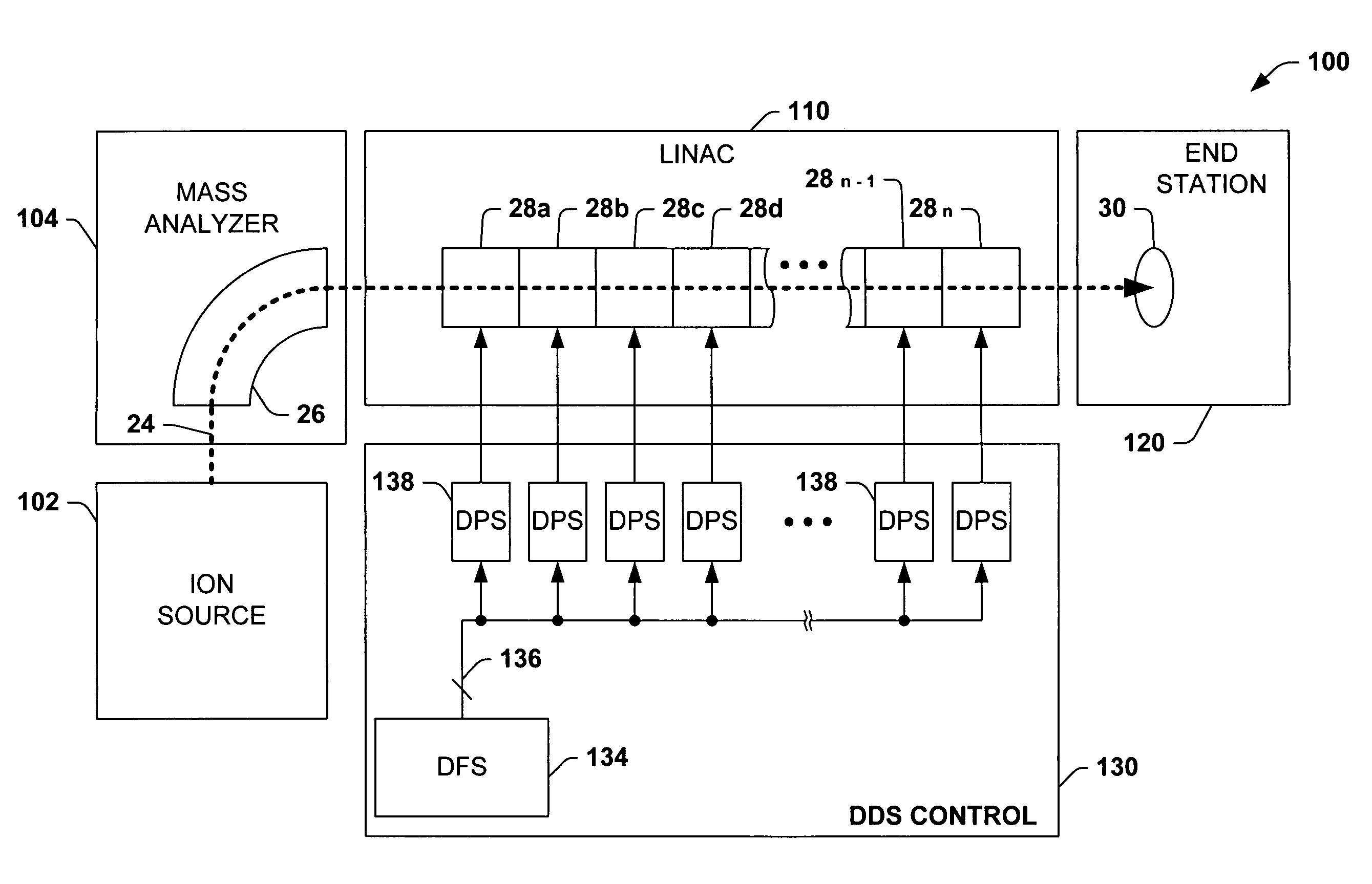

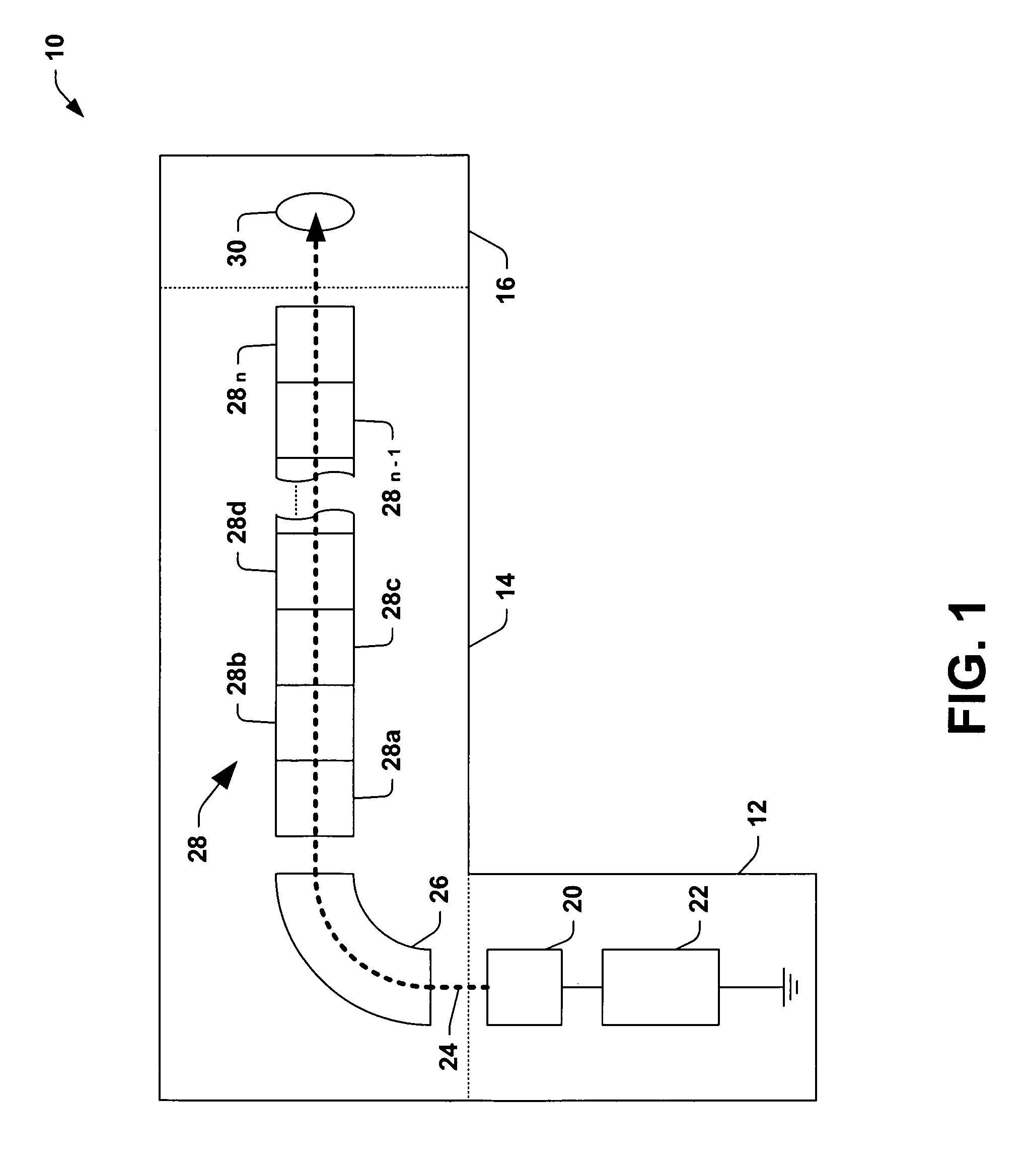

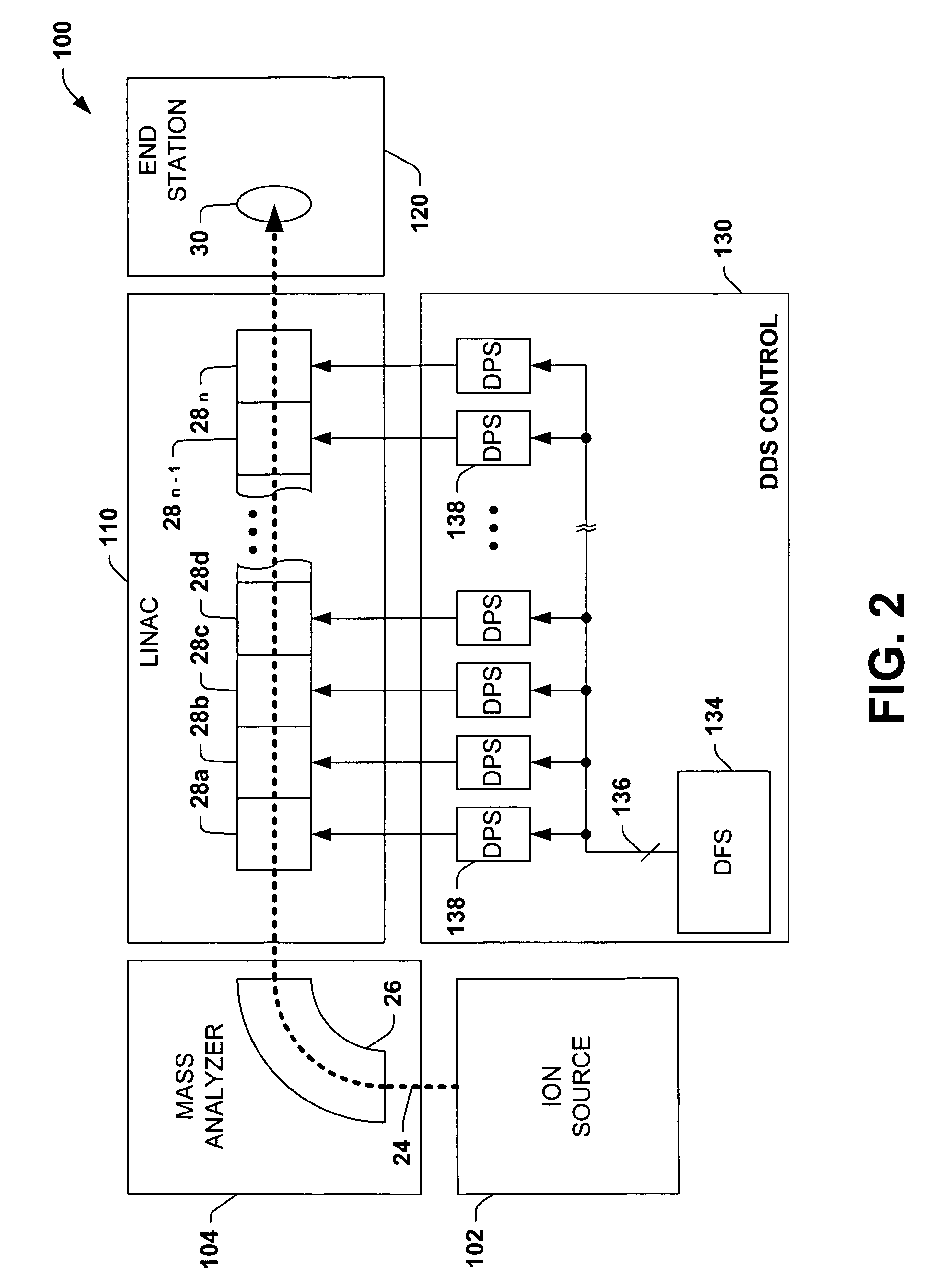

Application of digital frequency and phase synthesis for control of electrode voltage phase in a high-energy ion implantation machine, and a means for accurate calibration of electrode voltage phase

ActiveUS20070164237A1Effective controlEasy to controlPulse automatic controlElectric discharge tubesHigh energyPhase control

An improved HE LINAC-based ion implantation system is disclosed utilizing direct digital synthesis (DDS) techniques to obtain precise frequency and phase control and automated electrode voltage phase calibration. The DDS controller may be used on a multi-stage linear accelerator based implanter to digitally synchronize the frequency and phase of the electric fields to each electrode within each stage of the accelerator. The DDS controller includes digital phase synthesis (DPS) circuits for modulating the phase of the electric field to the electrodes, and a master oscillator that uses digital frequency synthesis or DFS to digitally synthesize a master frequency and phase applied to each of the DPS circuits. Also disclosed are methods for automatically phase and amplitude calibrating the RF electrode voltages of the stages.

Owner:AXCELIS TECHNOLOGIES

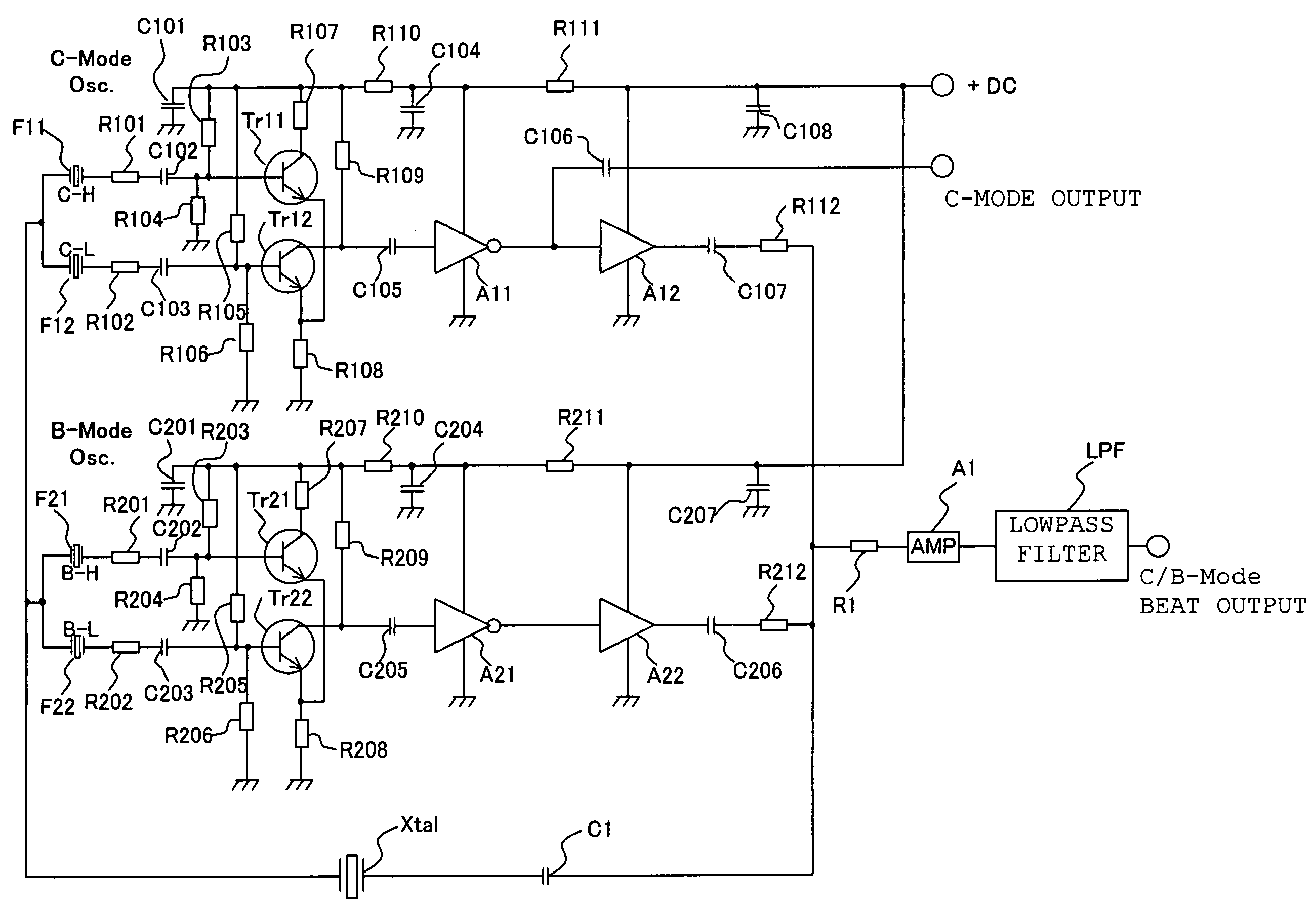

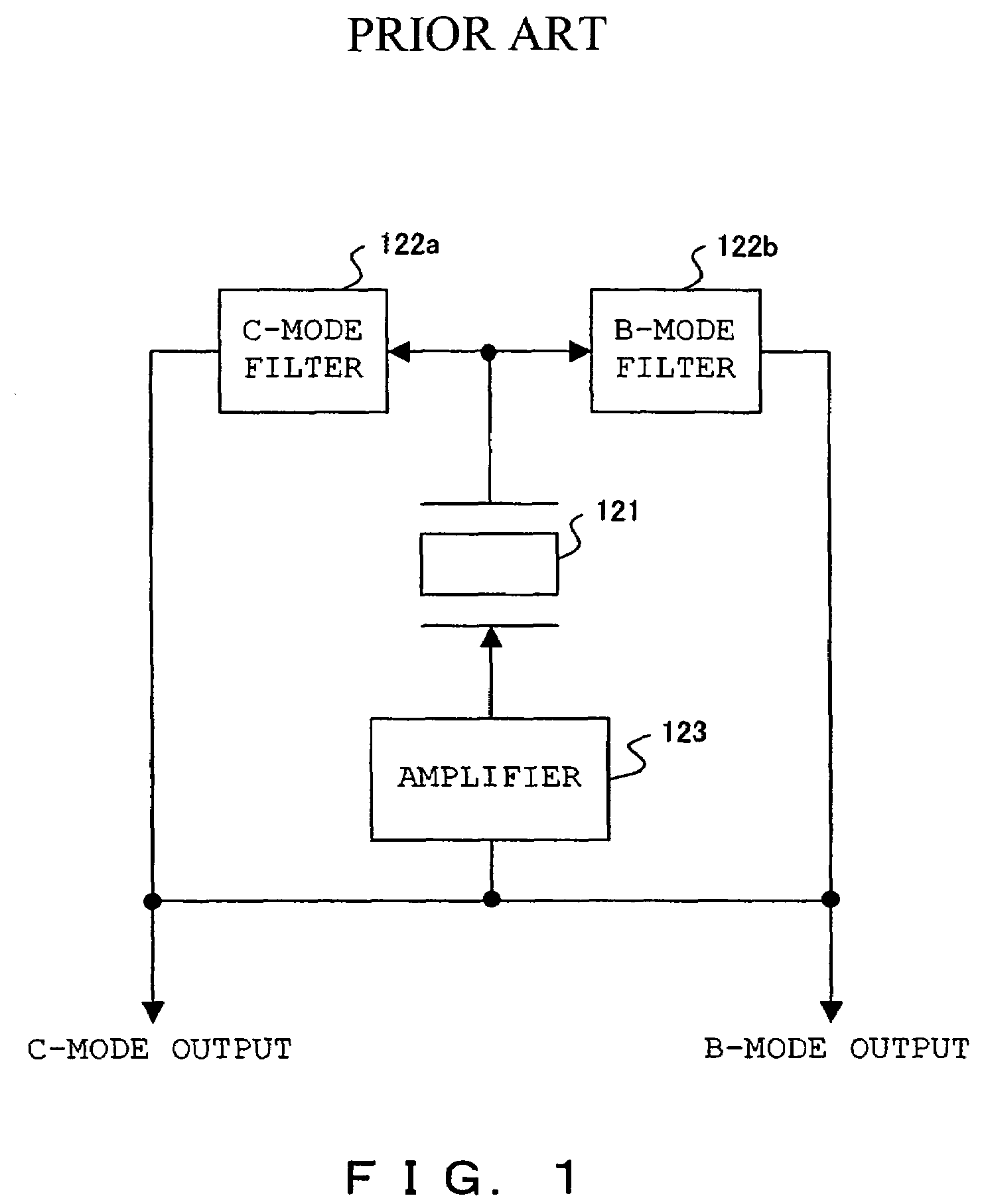

Crystal oscillator device, oscillation method and heater

InactiveUS7378916B2Improve thermal efficiencyImprove precision controlPiezoelectric/electrostriction/magnetostriction machinesOscillations generatorsResonanceQuantum electrodynamics

The crystal oscillator device for simultaneously generating oscillator signals with a plurality of oscillation modes of a crystal unit, comprising: a primary resonator unit filtering the oscillator signal with a primary oscillation mode, which is one of the oscillation modes, from the output of the crystal unit, a secondary resonator unit filtering the oscillation signal, bearing a different resonance frequency from that of the primary resonator unit, with the primary oscillation mode from the output of the crystal unit, a primary phase synthesis unit, synthesizing the phases of the output signal of the primary resonator unit and the output signal of the secondary resonator unit, a tertiary resonator unit, a quaternary resonator unit, and a secondary phase synthesis unit.

Owner:NIHON DEMPA KOGYO CO LTD

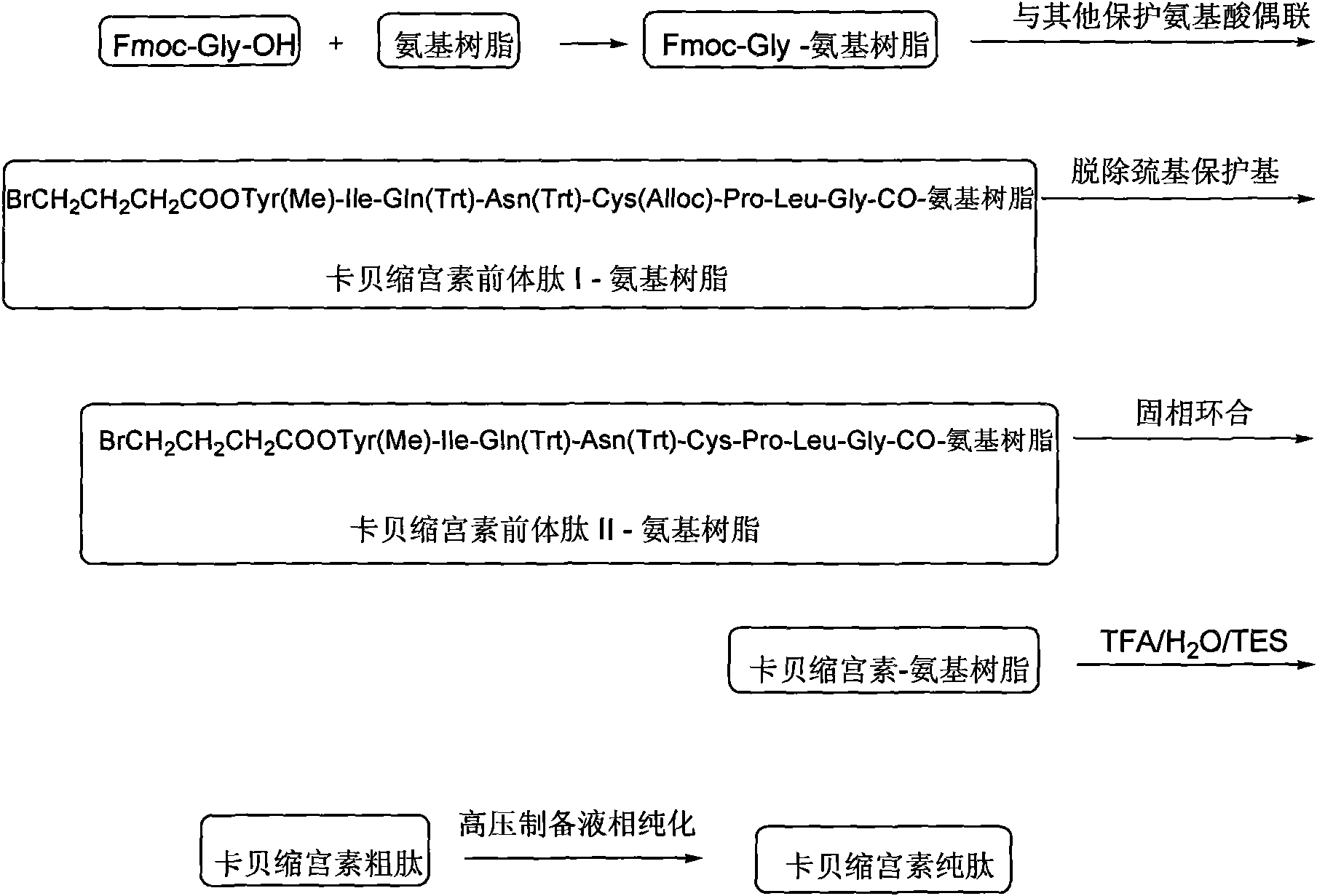

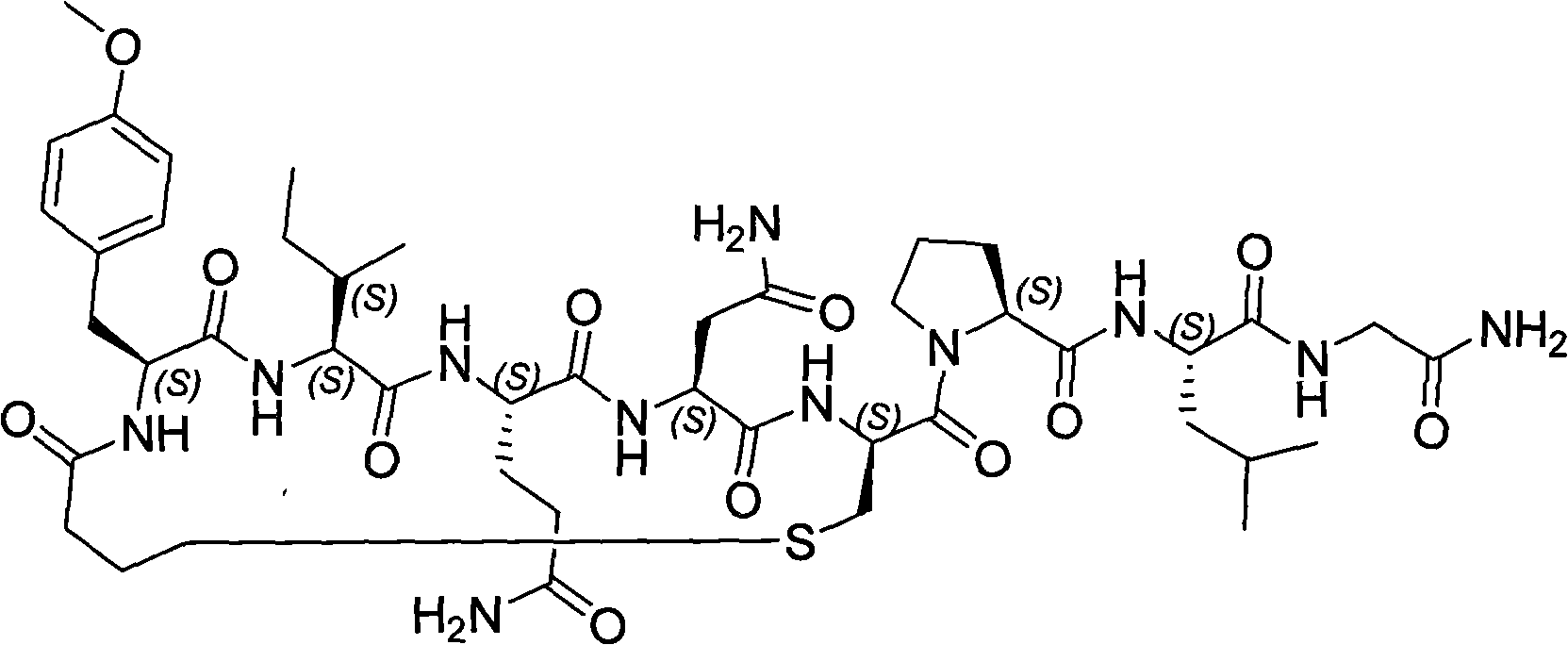

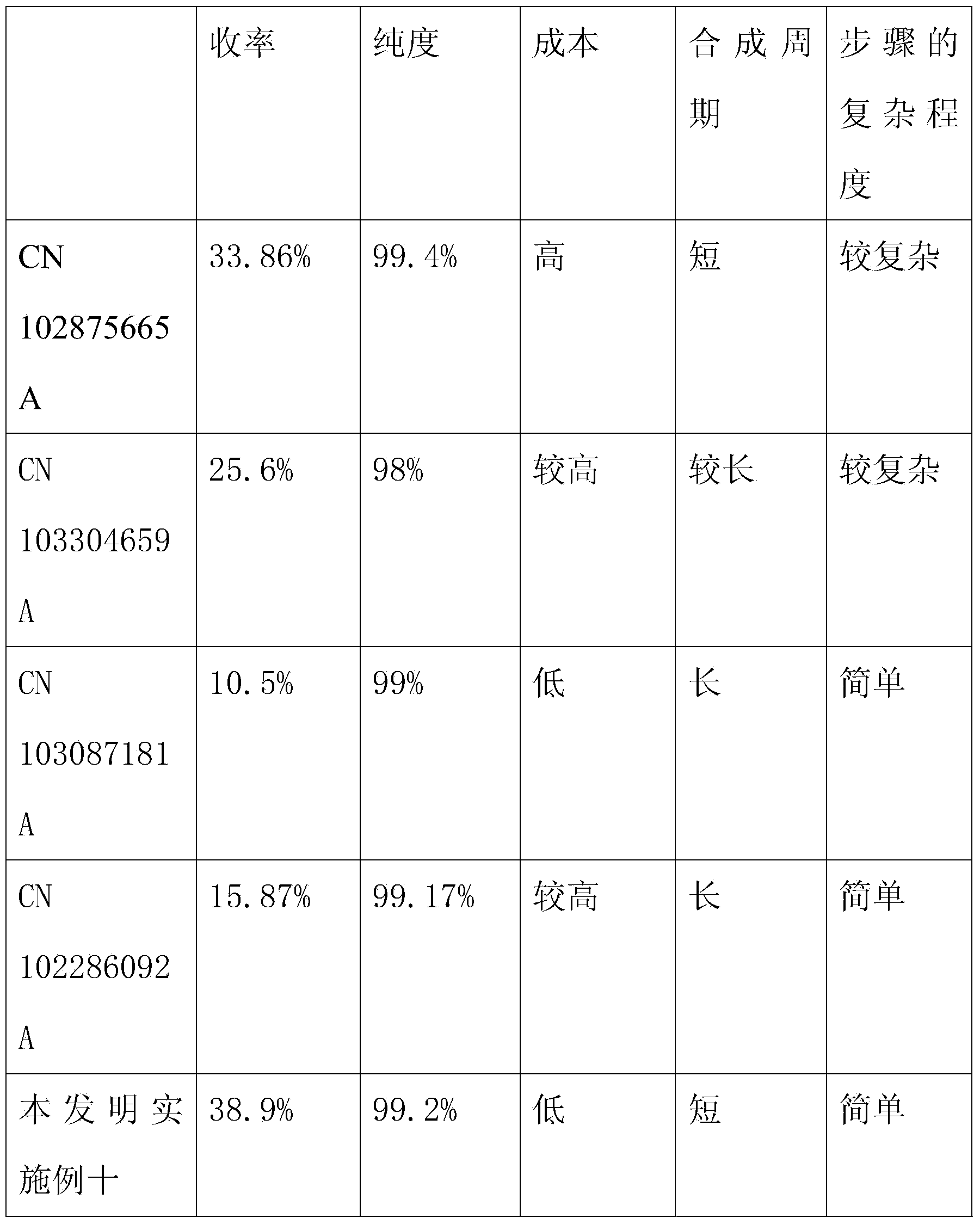

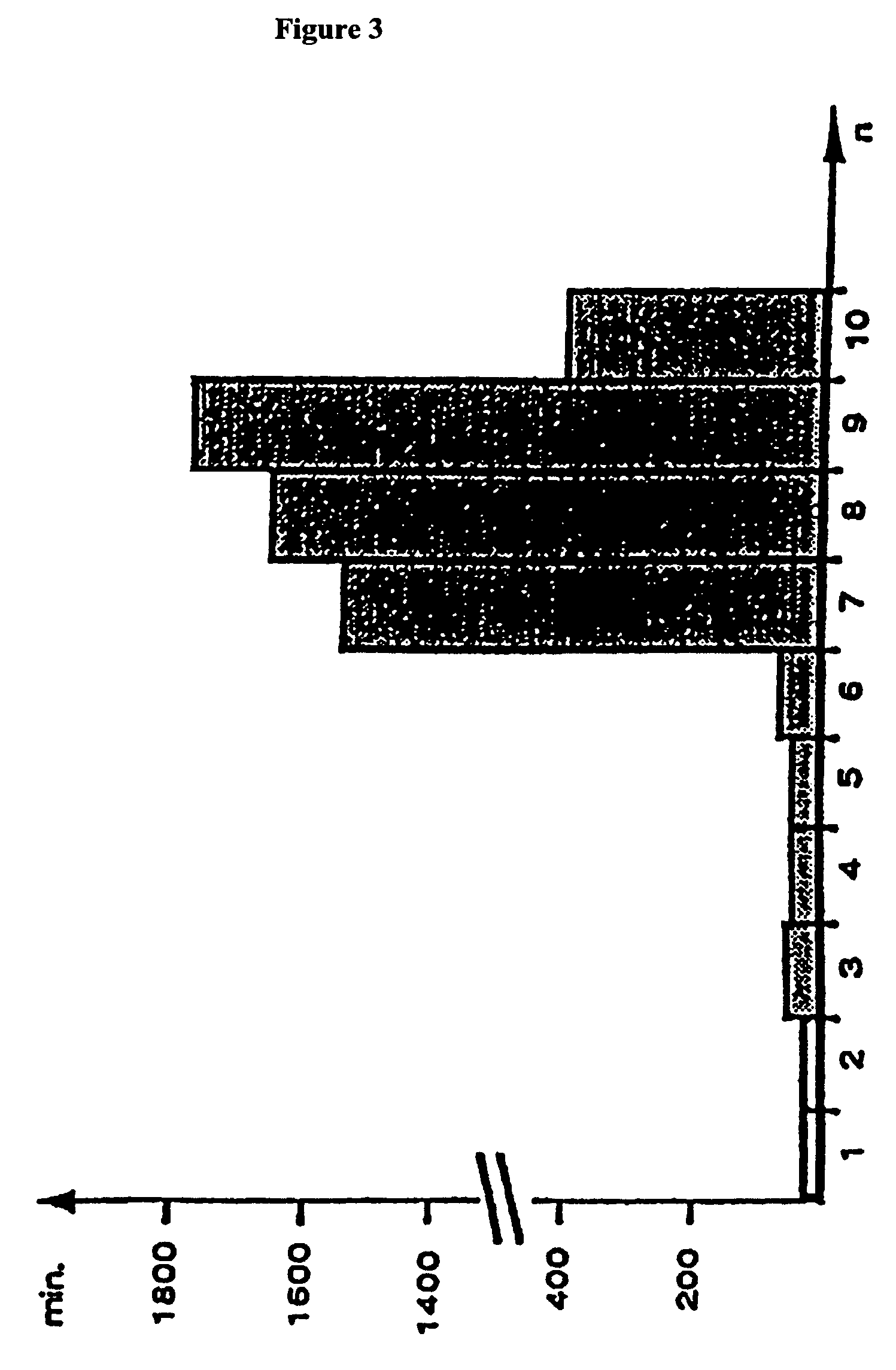

Solid phase preparation method of carbetocin

ActiveCN101555272AReduce investmentEasy to operatePeptide preparation methodsSexual disorderLithium chlorideFreeze-drying

The invention discloses a solid phase synthesis method of carbetocin. The technical proposal comprises the following steps of: obtaining Fmoc-Gly-amino resin by reaction of Fmoc-Gly-OH and amino resin with the substitutability being 0.2 mmol / g-0.9 mmol / g; sequentially connecting amino acids with Fmoc protecting groups by the solid phase synthesis method to obtain carbetocin precursor peptide I-amino resin; stripping off cysteine side chain protecting groups to obtain carbetocin precursor peptide II-amino resin; adding organic alkali and lithium chloride in solvent for cyclization to obtain carbetocin-amino resin; cracking to obtain carbetocin crude peptide; and purifying and freeze-drying to obtain the carbetocin. The method adopts the amino resin to synthesize carbetocin by the solid phase cyclization technology. The process is characterized by simple operation, easy post-treatment, high yield, low cost, and the like, and has considerable economical and practical value and broad application prospect.

Owner:HYBIO PHARMA

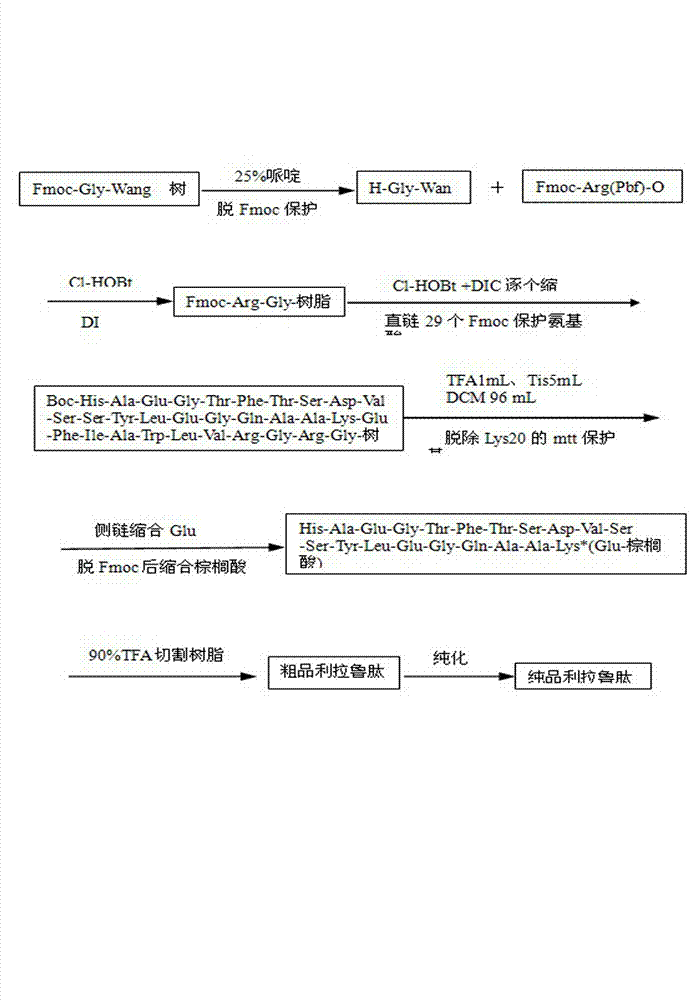

Solid-phase synthesis method for liraglutide

ActiveCN103864918AShort synthesis cycleImprove efficiencyPeptide preparation methodsBulk chemical productionSynthesis methodsSide chain

The invention discloses a solid-phase synthesis method for liraglutide. The solid-phase synthesis method for liraglutide comprises the following steps: 1) firstly synthesizing first to tenth amino acid segments 3, eleventh to nineteenth amino acid segments 2, and twentieth to thirty-first amino acid segments 1, wherein the twentieth lysine adopts Fmoc-Lys(Mtt)-OH, and the first histidine adopts Boc-His(Trt)-OH; 2) synthesizing pal-Glu(OH)-Otbu by adopting a liquid phase synthesis method; 3) selectively removing the Mtt protecting group on the twentieth lysine by use of 5% TFA (Trifluoroacetic Acid), connecting pal-Glu(OH)-Otbu with the side chain of the twentieth lysine to obtain a segment 4; 4) sequentially connecting the segments 2, the segments 3 and the segments 4 to obtain peptide resin completely protected by liraglutide; 5) cracking, purifying, and lyophilizing to obtain the liraglutide product.

Owner:哈尔滨吉象隆生物技术有限公司

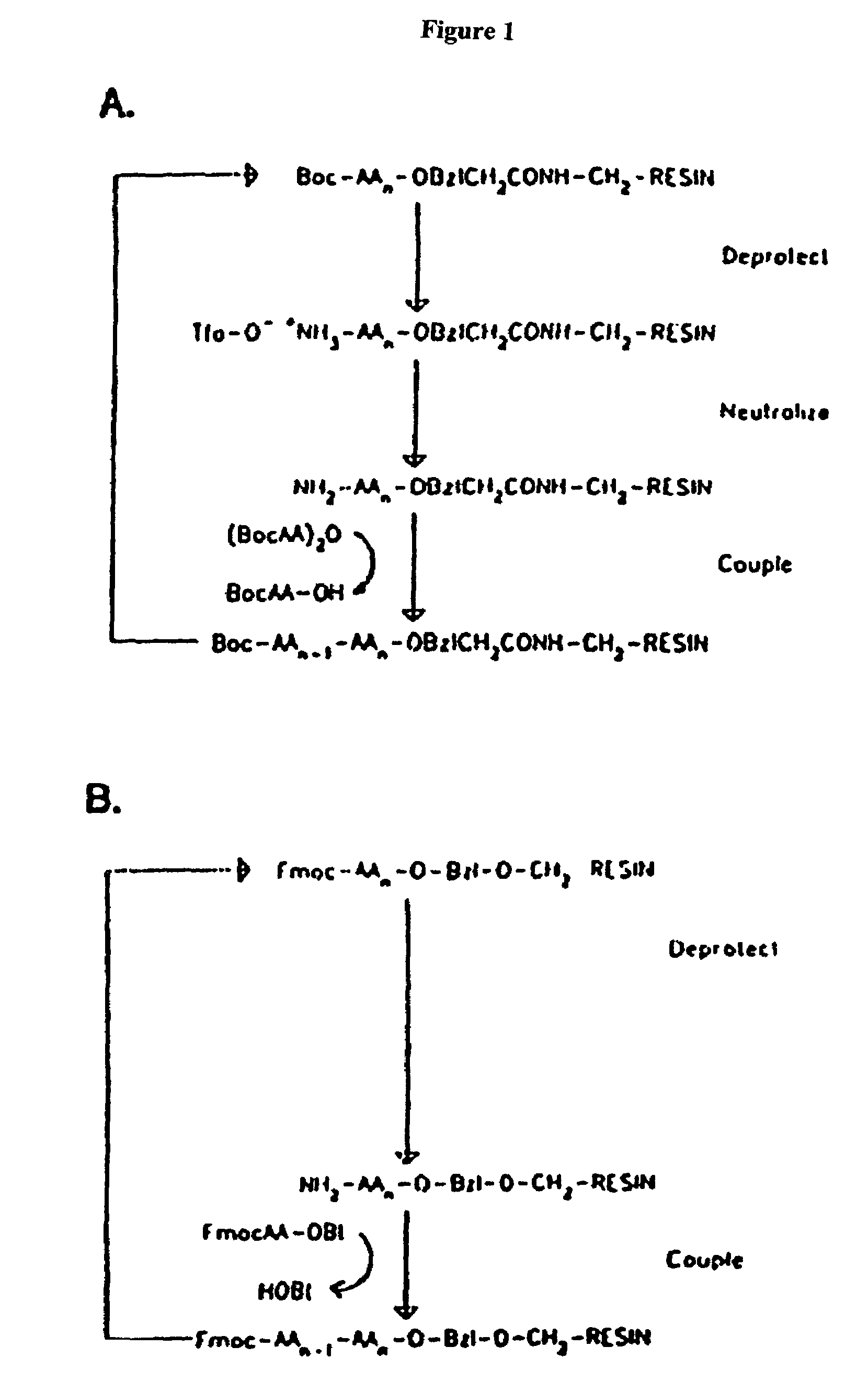

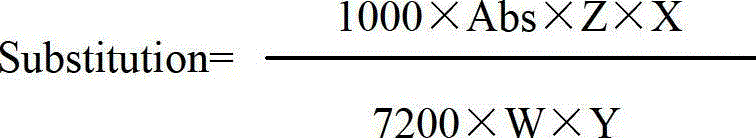

Solid-phase peptide synthesis and agent for use in such synthesis

InactiveUS7348404B2Peptide/protein ingredientsPeptide preparation methodsCombinatorial chemistrySolid-phase synthesis

The present invention relates to an improved process for the production of peptides by solid-phase synthesis. The invention also relates to agents which are useful in solid-phase peptide synthesis.

Owner:ZEALAND PHARM AS

Catalyst for gas-phase synthesis of oxalate and its preparing process

InactiveCN1381310AHigh reactivityHigh selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsNitriteGas phase

A catalyst for gas-phase synthesis of dimethyl (or diethyl) oxalate from CO and nitrite is prepared from alpha-Al2O3 as carrier and Ce and Pd as active components through the dipping method. Its advantages are high reaction activity and selectivity, long service life and easy control of reaction.

Owner:EAST CHINA UNIV OF SCI & TECH

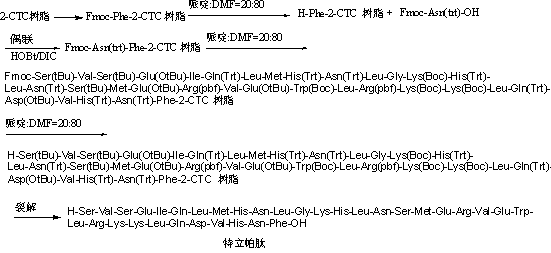

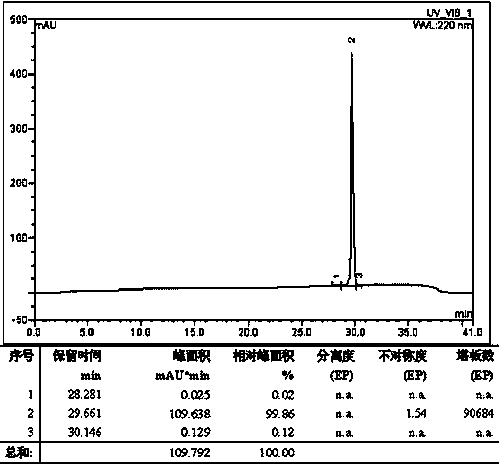

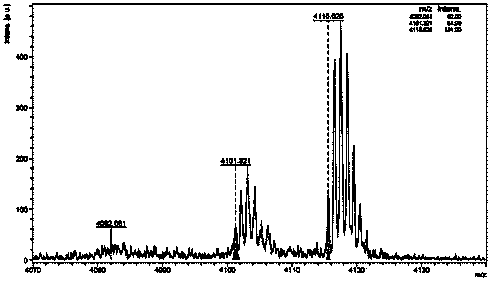

Complete solid-phase synthesis method for liraglutide

InactiveCN103145828AImprove reaction efficiencyHigh purityPeptide preparation methodsBulk chemical productionFreeze-dryingSide chain

The invention discloses a complete solid-phase synthesis method for liraglutide. 2-Cl-TrtResin is enabled to serve as a solid-phase carrier. DIC / HOBt is enabled to serve as a condensation agent. After processing of microwave reaction technology, reaction time is shortened, and condensation efficiency is improved. According to side chain modification, novel ivDde side chain protected lysine is adopted and side chain modification synthesis is carried out. During the process, 20% piperidine is adopted to get rid of Fmoc protection until linear chain polypeptide synthesis is finished. Then, after hydrazine hydrate is adopted to get rid of ivDde protection, a side chain modification reaction is carried out. Obtained liraglutide with complete protection on the solid phase carrier is processed by trifluoroacetic acid, and crude liraglutide is obtained. After purification and freeze-drying by a C18 column, pure liraglutide is obtained. After strong negative ion salt conversion and free-drying, acetic acid liraglutide acetate is obtained. The complete solid-phase synthesis method for the liraglutide is simple in operation, short in synthesis cycle, low in production cost, few in accessory substance, high in product yield and beneficial for mass production.

Owner:宁波瑞达医药科技有限公司

Method for preparing teriparatide

InactiveCN104017064APromote resultsLow purityPeptide preparation methodsParathyroid hormonesDipeptideSide chain

The invention relates to a method for preparing teriparatide, which comprises the following steps: A) in the presence of an activator system, coupling a resin solid-phase carrier and Fmoc-Phe-OH to obtain a Fmoc-Phe-resin; B) sequentially coupling amino acids with N terminal Fmoc protection and side chain protection according to the teriparatide main chain peptide sequence by solid-phase synthesis, wherein the 16th-17th amino acids in the peptide sequence are coupled by using pseudoproline dipeptide Fmoc-Asn(Trt)-Ser(PsiMe,MePro)-OH; and C) carrying out peptide resin cracking by using a TFA (trifluoroacetic acid) cracking solution containing NH4I / Me2S, purifying the crude product by HPLC (high performance liquid chromatography), and freeze-drying to obtain the teriparatide. The content of the technical impurity Met8(O)-teriparatide is lower than 0.1%. The technique for preparing teriparatide has the advantages of high purity and low cost, is suitable for large-scale production, and can effective control the Met8(O)-teriparatide content without influencing the total yield of the teriparatide.

Owner:ADLAI NORTYE BIOPHARMA CO LTD

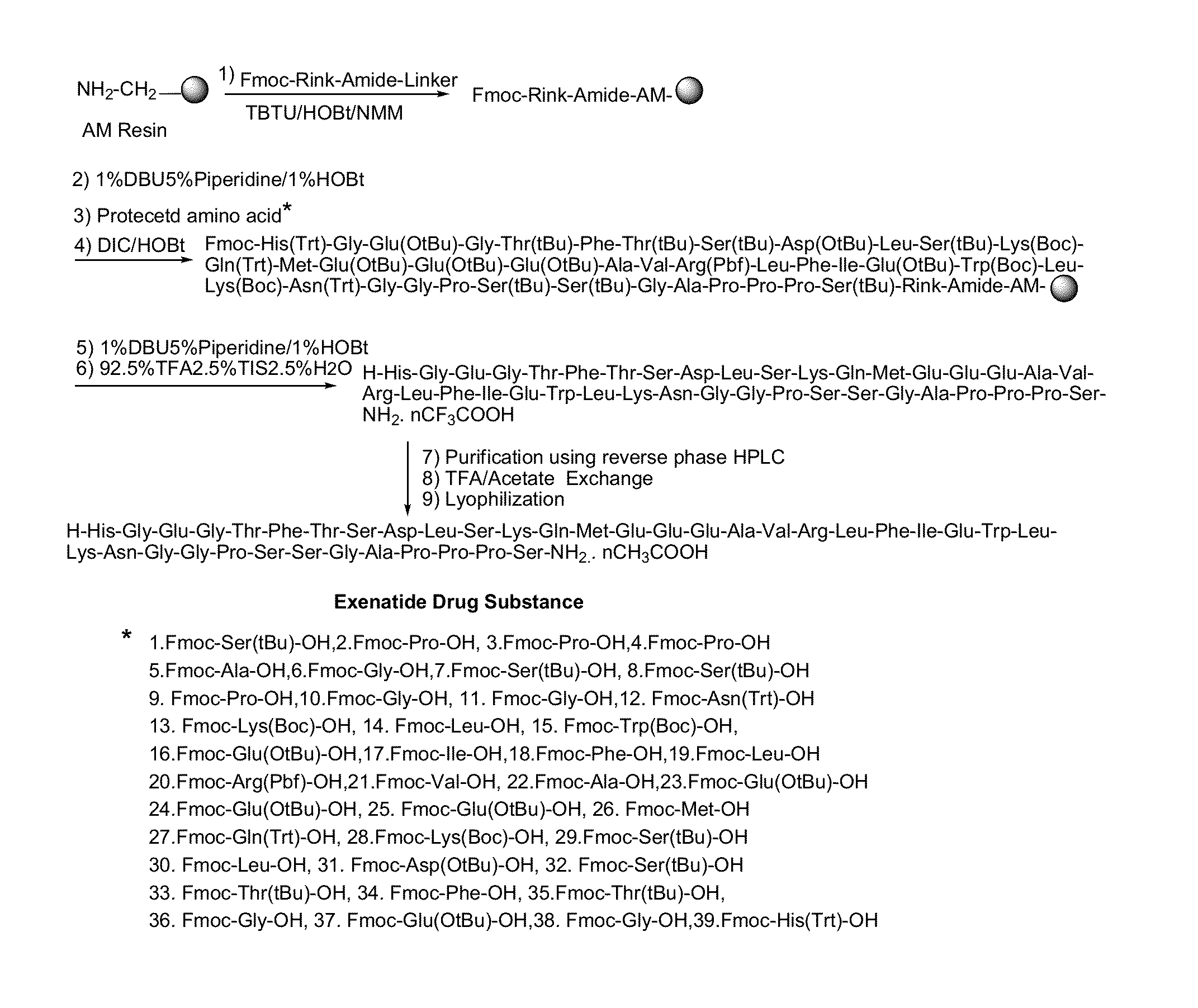

Method for preparing exenatide

InactiveUS20130289241A1Simple stepsEasy to operatePeptide/protein ingredientsPeptide preparation methodsCombinatorial chemistryExenatide

A method for preparing exenatide by solid-phase synthesis, including: 1) mixing an Fmoc-Rink amide AM resin with a deprotecting agent to obtain a Rink amide AM resin; 2) condensing an Fmoc-Ser(tBu)-OH with the Rink amide AM resin to obtain an Fmoc-Ser(tBu)-Rink amide AM resin; 3) repeating the Fmoc deprotection and the condensation between an amino acid and a polypeptide on the resin, and condensing an amino acid with a polypeptide on the resin from the C-terminal to the N-terminal, to form a polypeptide resin; and 4) separating the polypeptide and the resin on the polypeptide resin.

Owner:SHANGHAI AMBIOPHARM

Application of digital frequency and phase synthesis for control of electrode voltage phase in a high-energy ion implantation machine, and a means for accurate calibration of electrode voltage phase

ActiveUS7402821B2Effective controlEasy to controlStability-of-path spectrometersMaterial analysis by optical meansHigh energyPhase control

An improved HE LINAC-based ion implantation system is disclosed utilizing direct digital synthesis (DDS) techniques to obtain precise frequency and phase control and automated electrode voltage phase calibration. The DDS controller may be used on a multi-stage linear accelerator based implanter to digitally synchronize the frequency and phase of the electric fields to each electrode within each stage of the accelerator. The DDS controller includes digital phase synthesis (DPS) circuits for modulating the phase of the electric field to the electrodes, and a master oscillator that uses digital frequency synthesis or DFS to digitally synthesize a master frequency and phase applied to each of the DPS circuits. Also disclosed are methods for automatically phase and amplitude calibrating the RF electrode voltages of the stages.

Owner:AXCELIS TECHNOLOGIES

Solid-phase synthesis method of liraglutide

InactiveCN103087181ALess usableSmall quantityPeptide preparation methodsBulk chemical productionSide chainWang resin

The invention discloses a method for synthesizing liraglutide. The method comprises the following steps of: 1, selecting Fmoc-Gly-Wang resin and N terminal Fmoc protected and side chain protected amino acid as raw materials, wherein lysine on a 26th site adopts Fmoc-Lys(Mtt)-OH or Fmoc-Lys(Mmt)-OH, histidine on an N terminal adopts Boc-His(Trt)-OH or Boc-His(Boc)-OH; 2, selectively removing a Mtt or Mmt protecting group on the lysine by adopting 1 percent TFA (Trifluoroacetic Acid); 3, sequentially coupling one g-glutamic acid and palmitic acid on a side chain; and 4, cutting resin by the TFA to obtain a crude product of the liraglutide, and carrying out preparative liquid chromatography purification and lyophilization to obtain a pure product of the liraglutide. The method for synthesizing the liraglutide is simple in steps, saves time and labor, is less in difficult sequences in a coupling process, simple and easy to operate during side chain de-protection, less in byproducts and high in yield, and is suitable for industrialized production.

Owner:刘卫 +1

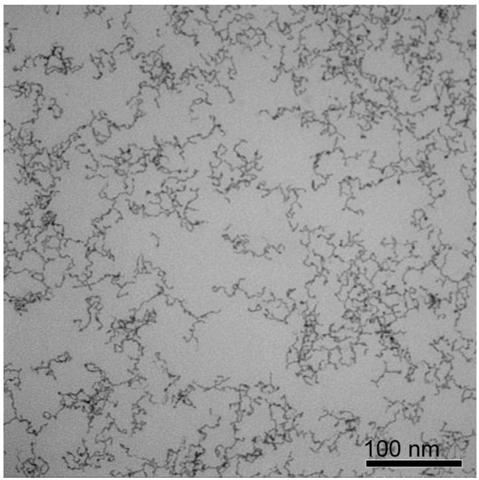

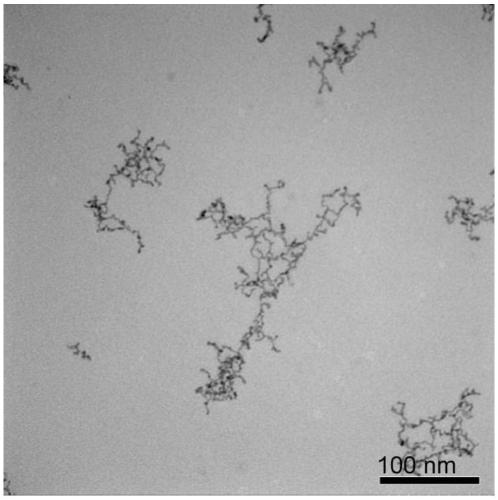

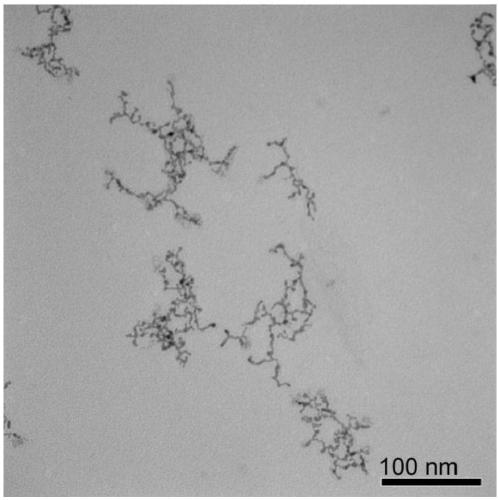

Platinum-non-precious metal alloy nanowire, and aqueous-phase synthesis method and application thereof

ActiveCN109014237AAchieve co-reductionHigh yieldMaterial nanotechnologyTransportation and packagingPlatinum saltsNanowire

The invention discloses a platinum-non-precious metal alloy nanowire, and an aqueous-phase synthesis method and application thereof, and belongs to the field of nanometer material science. According to the aqueous-phase synthesis method, coreduction of platinum salt and non-precious metal salt in an aqueous solution is achieved through a ligand, the controllable ultrafine platinum-non-precious metal alloy nanowire is successfully synthesized, and the technical problems are solved. A preparing method is simple, the yield is high, the steps are less, controllability is good, the nanowire in a product is small in diameter and uniform in structure, the surface of the ultrafine platinum-non-precious metal alloy nanowire prepared through the preparing method is easy to clean, and the ultrafine platinum-non-precious metal alloy nanowire has superior performance in hydrogen production through electrolytic water.

Owner:XI AN JIAOTONG UNIV

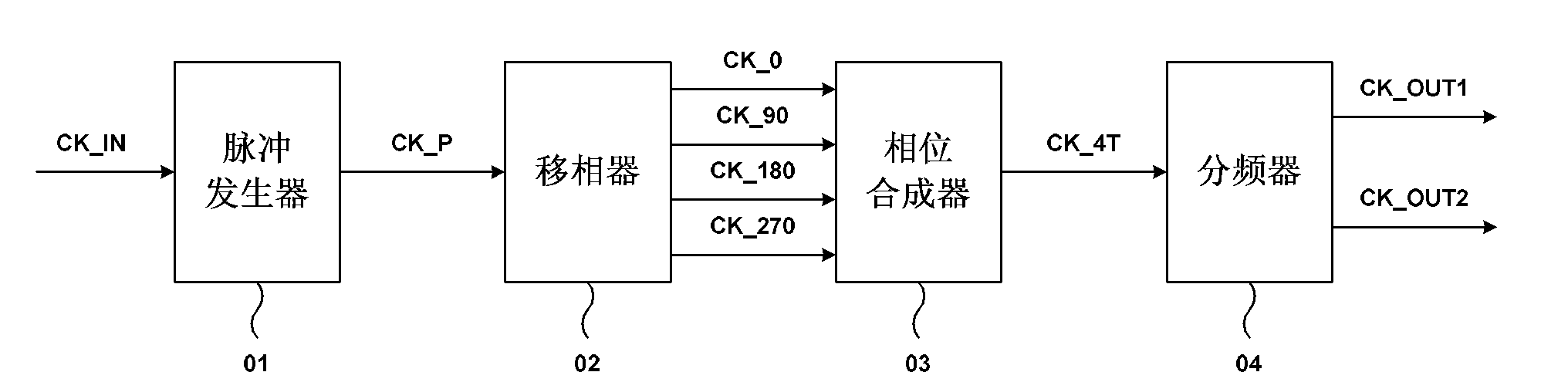

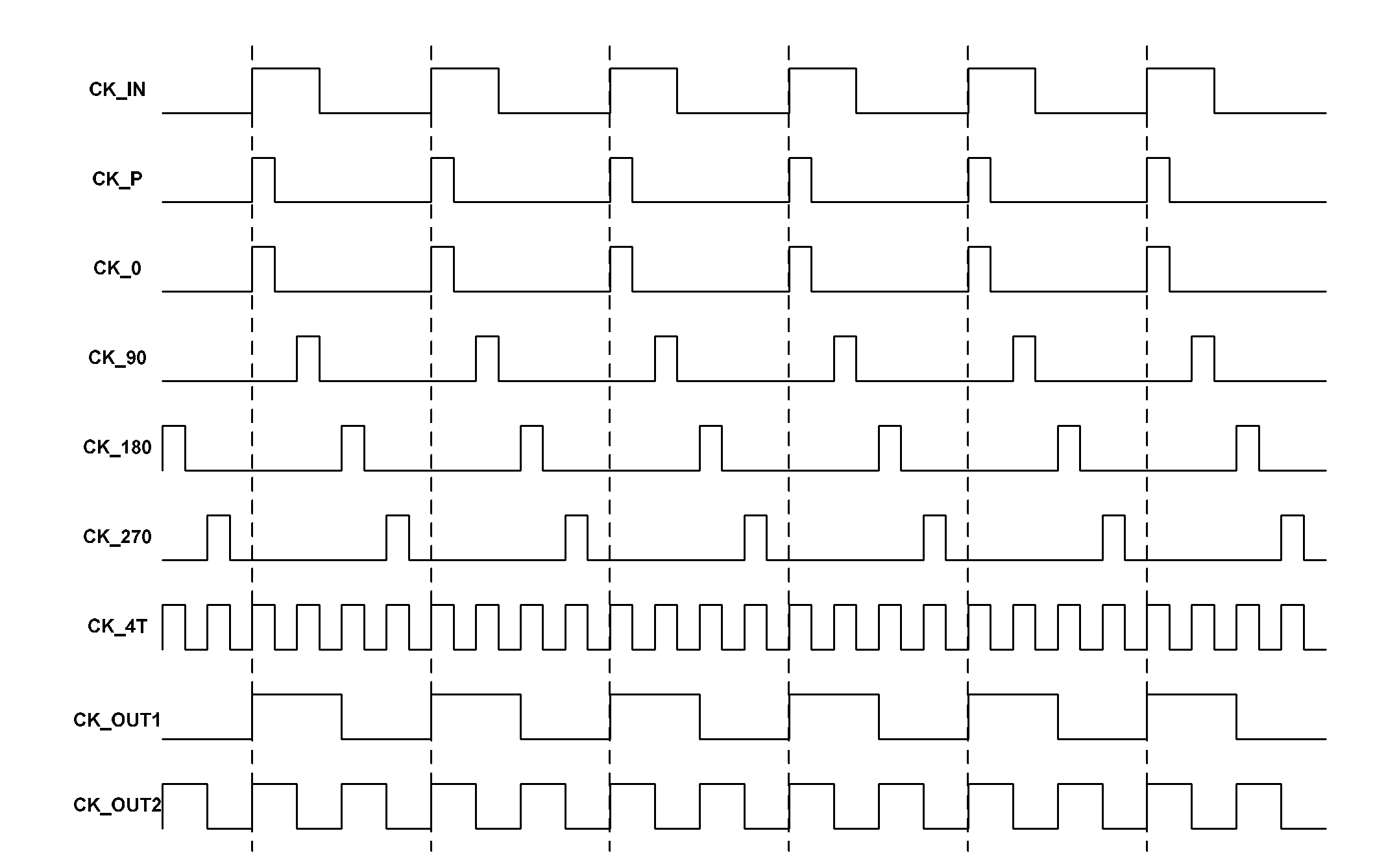

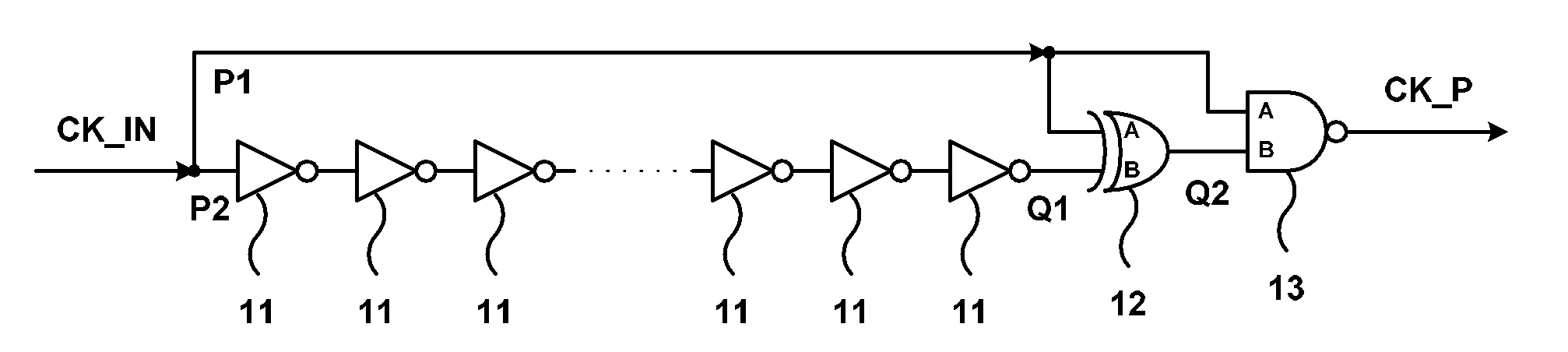

Clock frequency multiplier, device and clock frequency multiplication method

ActiveCN102158205AMultiplier implementationIncrease dynamic sampling redundancy designPulse manipulationPhase shiftedFrequency multiplier

The invention discloses a clock frequency multiplier, a clock frequency multiplication device and a clock frequency multiplication method. The clock frequency multiplier comprises a pulse generator, a phase shifter, a phase synthesizer and a frequency divider, wherein the pulse generator is used for regulating an external input clock signal into an equal periodic pulse clock signal; the phase shifter is used for performing phase shifting on the input equal periodic pulse clock signal for different time lengths according to a required frequency multiplication fold and a clock cycle to obtain phase shifted clock signals; the phase synthesizer is used for performing phase synthesis on the equal periodic pulse clock signal and each phase shifted clock signal to obtain a frequency multiplied clock signals; and the frequency divider is used for performing frequency division on the phase-synthesized frequency multiplied clock signal to obtain a frequency multiplied output clock signal, and outputting the frequency multiplied output clock signal. By the clock frequency multiplier, the clock frequency multiplication device and the clock frequency multiplication method, the frequency multiplication of the clock signal is realized under the condition of no phase-locked loops, and / or normal operations can be realized under the condition of radiation exposure.

Owner:LOONGSON TECH CORP

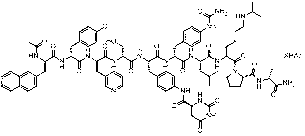

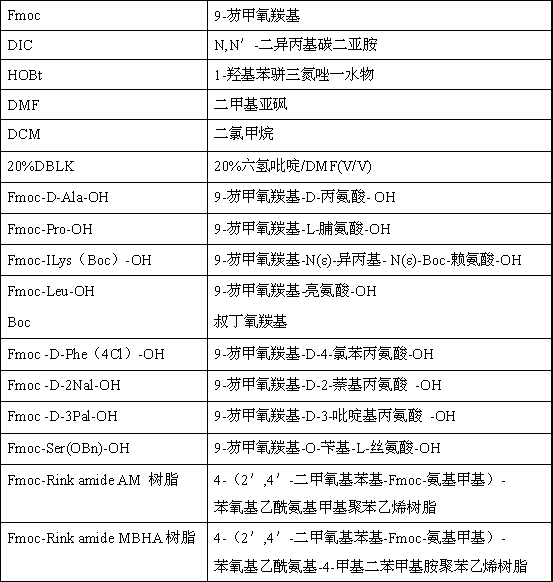

Method for synthesizing degarelix

InactiveCN102952174AReduce usageAvoid pollutionPeptide preparation methodsBulk chemical productionCombinatorial chemistryPhenylalanine

The invention discloses a method for synthesizing degarelix, wherein an amino resin protected with Fmoc is used as a raw material; according to a solid-phase synthesis method, DIC / HOBt (N,N'-diisopropylcarbodiimide / 1-hydroxybenzotrizole) is used as a coupling agent for transpeptidase reaction; 4-serine uses tert-butyl dimethyl to replace tertiary butyl for protection protecting hydroxyl; a hydroorotic acid fragment connected with 4-amino of 5-phenylalanine benzene ring is protected with triphenylmethyl at first, and then introduced, so that the rearrangement side reaction is prevented; and since D-4Aph (Cbm) is used for replacing D-4Aph (Cbm-tBu), a t-Bu removal difficulty is prevented and the occurrence of the side reaction is reduced. A synthesis technology of the method for synthesizing degarelix is simple in steps, easy to control, small in environment pollution and high in yield, thereby being applicable for industrial production.

Owner:济南环肽医药科技有限公司

Preparation method of liraglutide

ActiveCN106699871ALow costReduce generationPeptide preparation methodsBulk chemical productionSide chainFreeze-drying

The invention discloses a preparation method of liraglutide, and belongs to the technical field of medicines. The method comprises the following steps of (1) carrying out solid-phase synthesis to form four peptide segments of the liraglutide, wherein the peptide segment 1 is the (1-9)th amino acids in a liraglutide main chain sequence, the peptide segment 2 is the (10-14)th amino acids in the liraglutide main chain sequence, the peptide segment 3 is the (15-23)th amino acids in the liraglutide main chain sequence and the peptide segment 4 is the (24-31)th amino acids in the liraglutide main chain sequence; (2) stepwise coupling various peptide segments to obtain an all-protected liraglutide main chain peptide; (3) removing a protecting group of the 20th lysine and completing connection of side chains to obtain all-protected liraglutide peptide resin; and (4) carrying out cracking, purification and freeze-drying to obtain the liraglutide. The preparation method is high in production efficiency and stable in process, and a product is high in purity, high in yield and suitable for industrial production.

Owner:哈药集团股份有限公司 +1

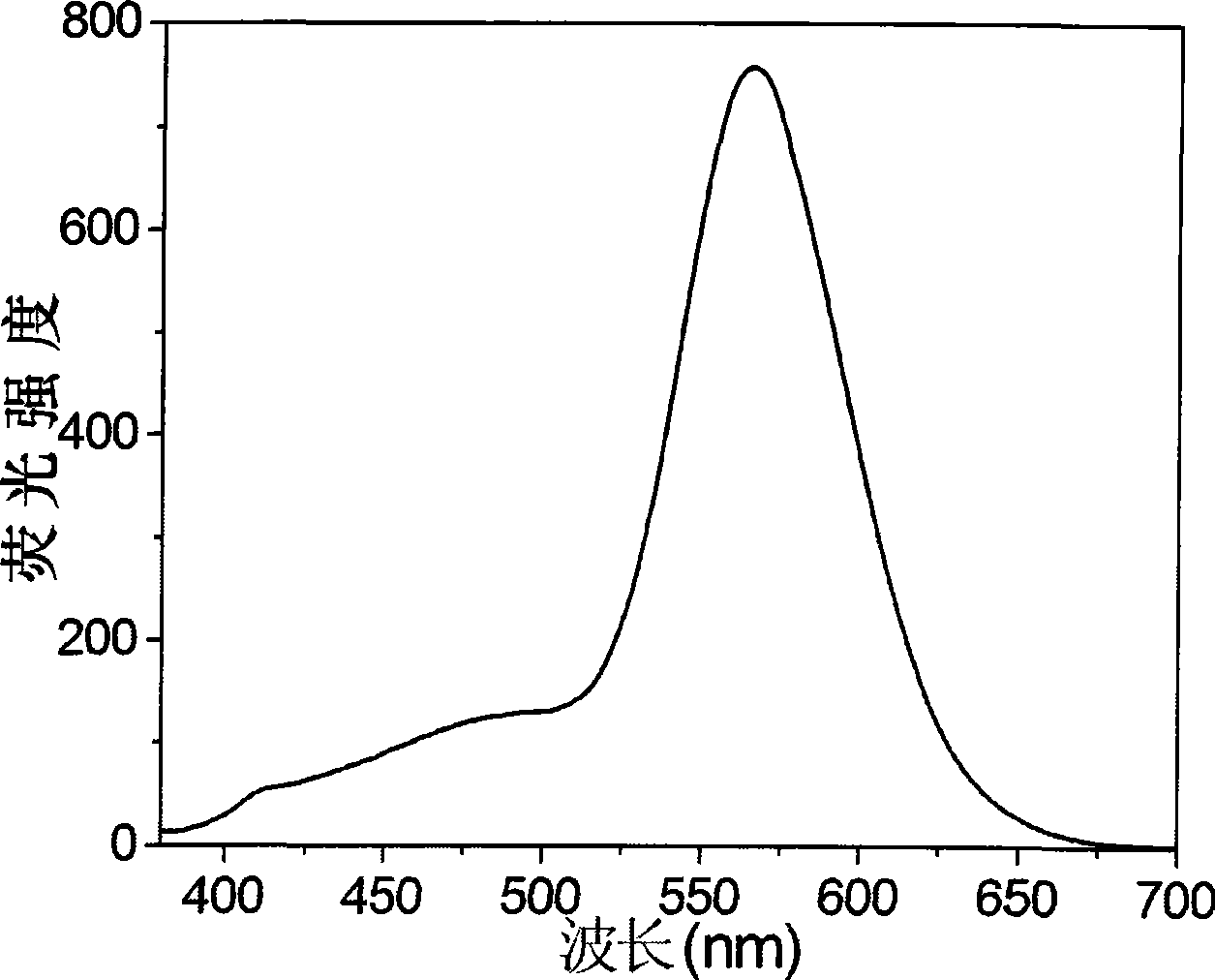

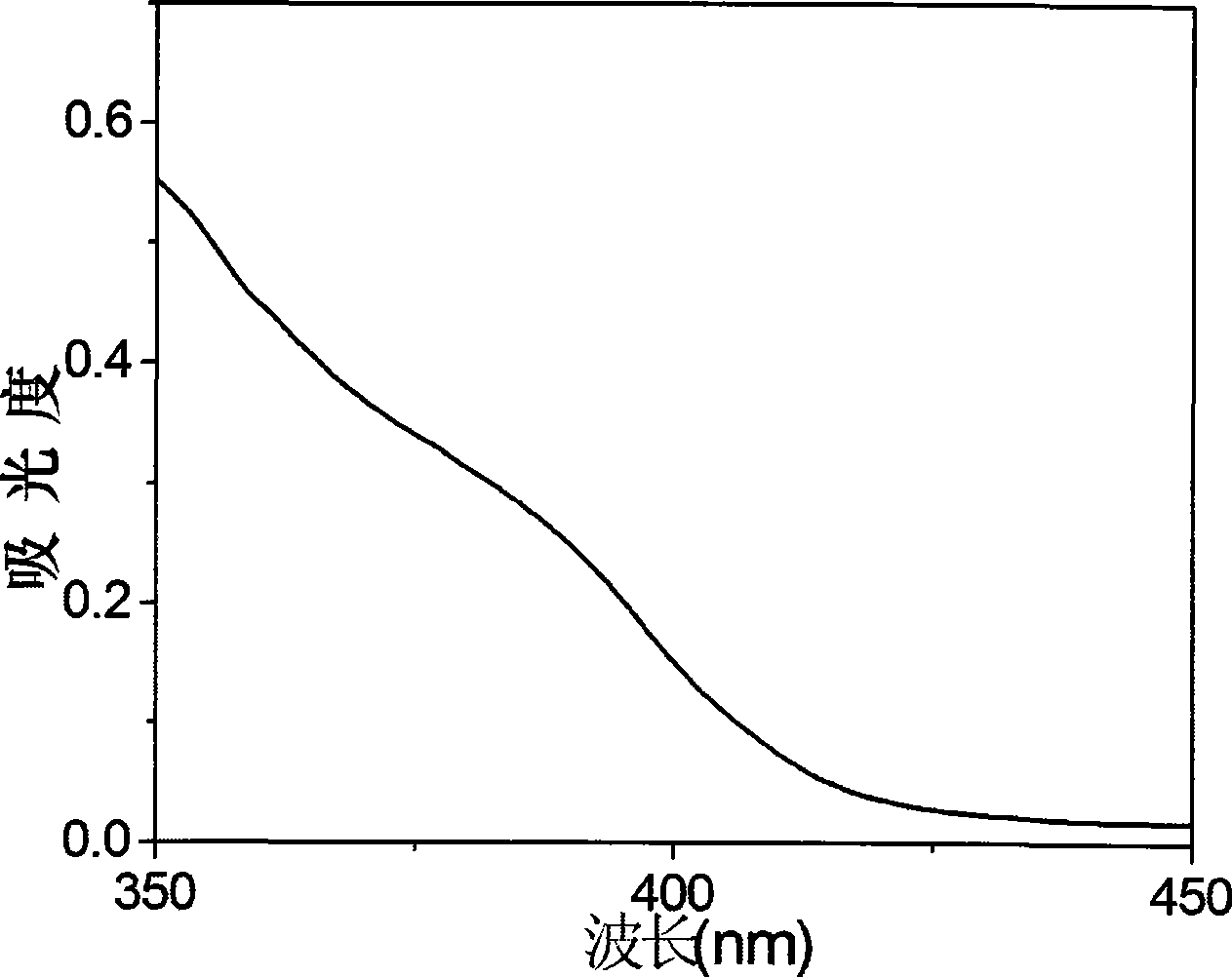

Aqueous phase synthesizing method for transient metal Mn doped ZnSe quantum dot

InactiveCN101503624ALow toxicitySuccessfully synthesizedMaterial analysis using wave/particle radiationColor/spectral properties measurementsFluorescenceZinc nitrate

The invention belongs to the technical field of preparation of quantum dot nanometer materials, and particularly relates to an aqueous phase synthesis method for transition metal Mn doped ZnSe quantum dots. The method comprises the steps of utilizing inorganic metal water-soluble compounds such as zinc nitrate, manganese chloride and the like and carboxylic acid reagents containing sulfhydryl groups as raw materials, and doping transition metal Mn into ZnSe semi-conductor nano-particles in aqueous solution by a nucleation doping method. The method has the advantages of mild reaction conditions, simple and safe operation, and good repetitiveness, eliminates the toxicity caused by the use of heavy metal elements in the prior quantum dots, and successfully synthesizes non-toxic quantum dots emitting yellow visible light. The quantum dots can be taken as a fluorescent marker to be widely applied to cell and tissue imaging due to low toxicity, and can be applied to in vivo imaging research.

Owner:JILIN UNIV

Supercritical fluid phase synthesis of methylene lactones using novel catalyst field of invention

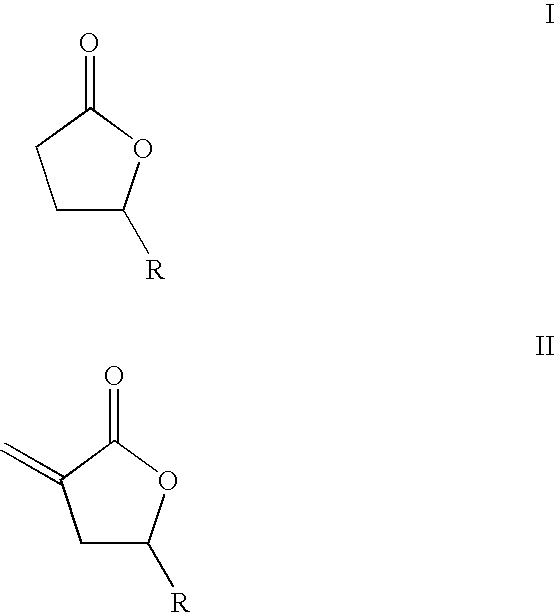

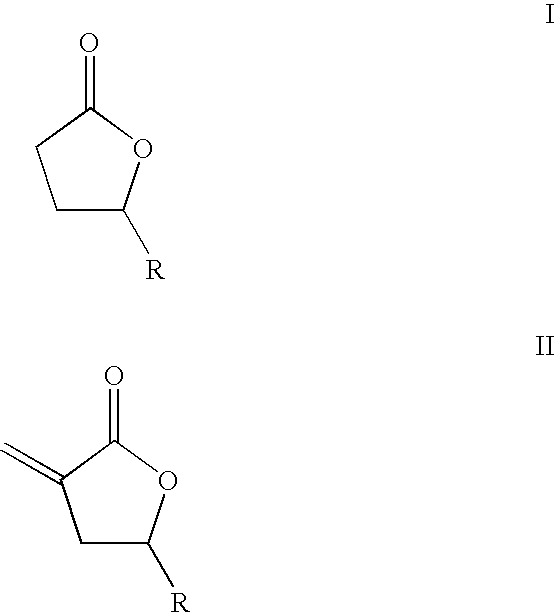

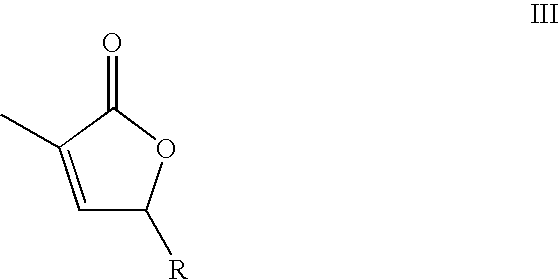

InactiveUS20060025608A1High activityImprove productivityOrganic chemistryCatalyst activation/preparationProduction rateMethylene-lactone

Process for converting certain lactones to their alpha-methylene substituted forms that not only exhibits high initial activity (conversion), but also provides high reactor productivity (mass of product per mass of catalyst per unit of time) and sustained maintenance of a high level of activity and productivity with time on stream.

Owner:EI DU PONT DE NEMOURS & CO

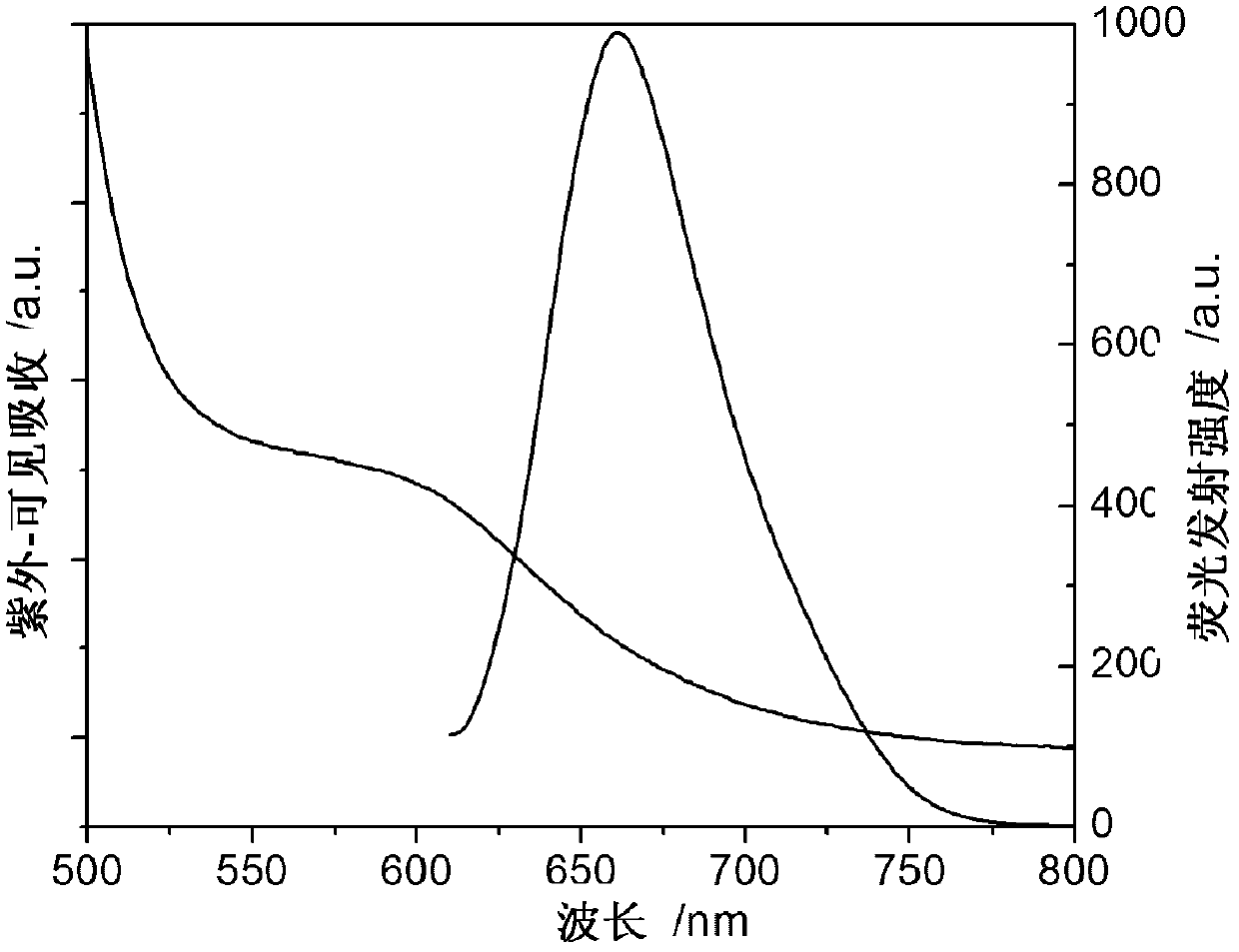

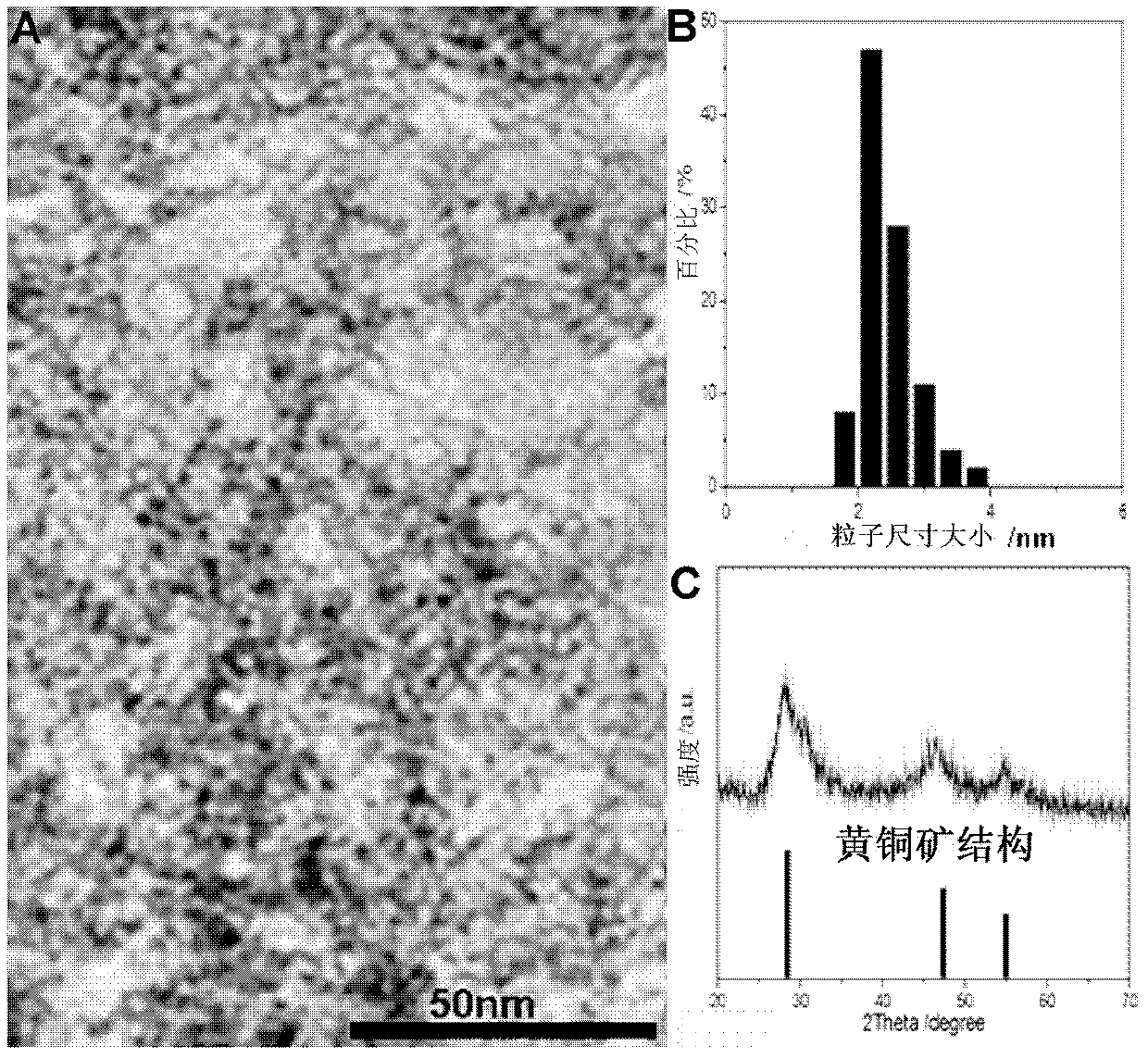

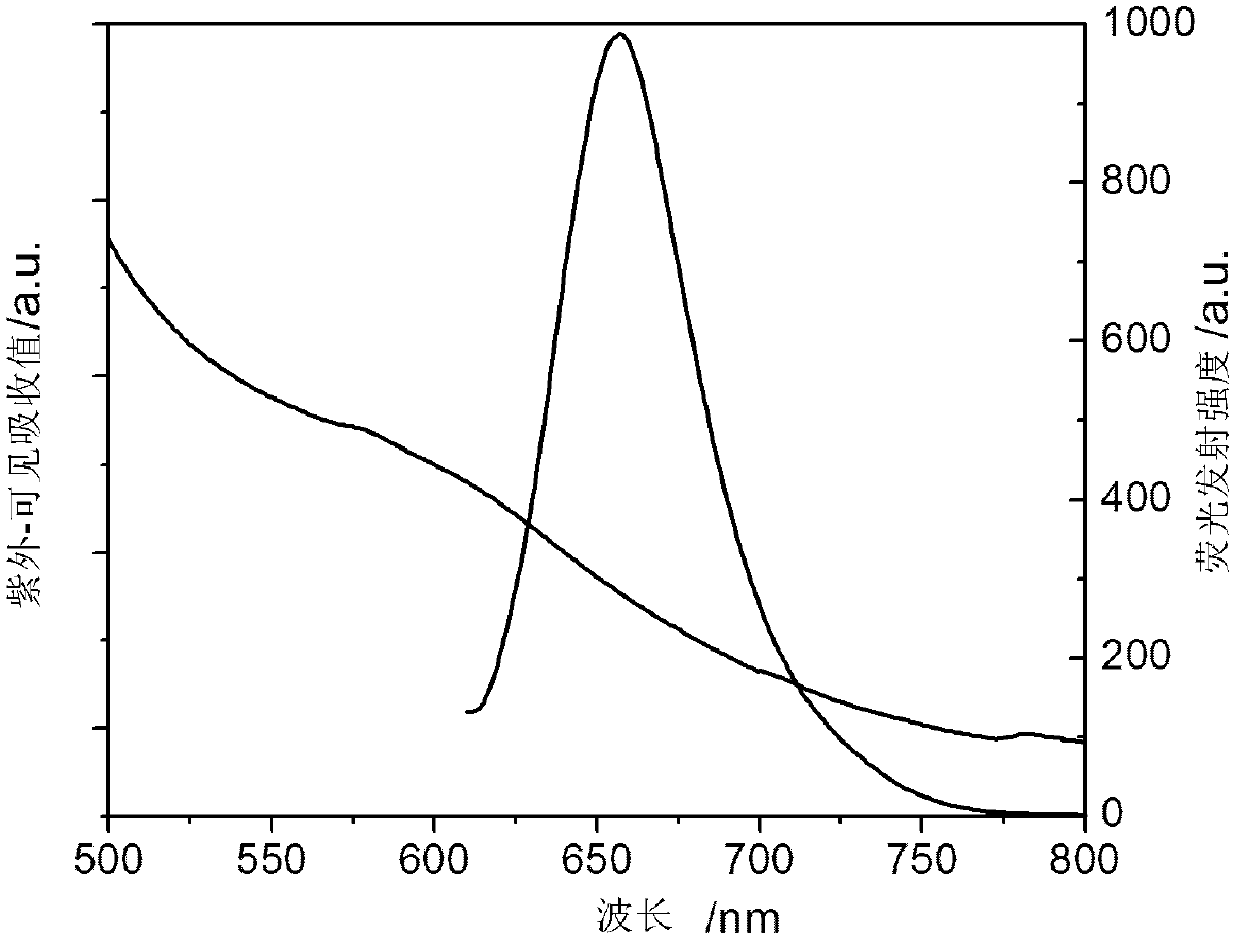

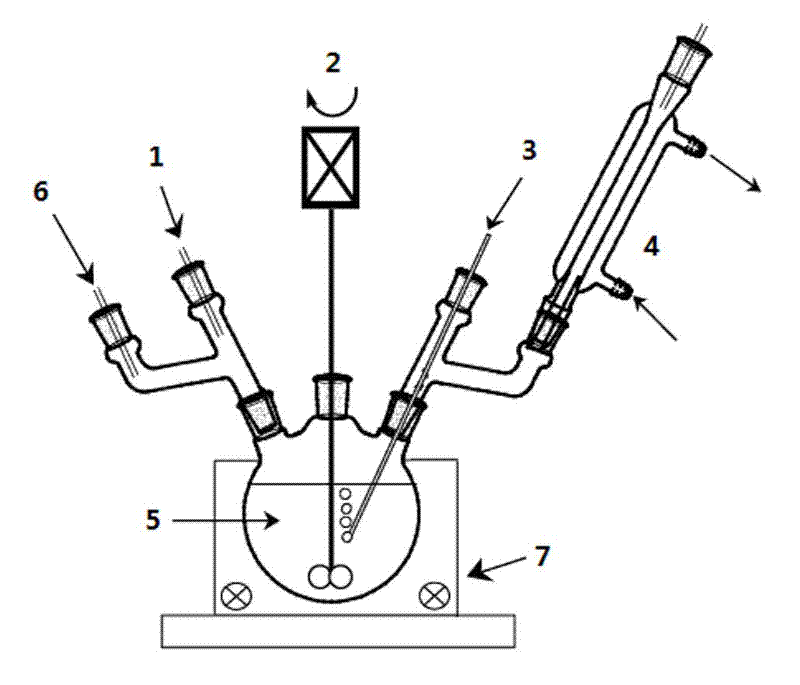

Hydro-thermal preparation method for novel near infrared water-soluble copper-indium-sulfur three-element quantum dots

InactiveCN102517003ALower requirementExcellent fluorescence propertiesLuminescent compositionsCarboxylic acidCadmium Cation

The invention belongs to the technical field of quantum dot preparation, and specifically to a method for preparing copper-indium-sulfur (CuInS2) three-element quantum dots under a hydro-thermal condition. According to the method, common metal salt compounds such as copper chloride and indium chloride, and a sulfhydryl-containing carboxylic acid such as mercaptopropionic acid and mercaptosuccinic acid are adopted to synthesize copper-indium-sulfur (CuInS2) nanoparticles with the particle size of 2-4 nm and emission wavelength in the near infrared region under the hydro-thermal condition. Compared to other organic phase synthesis of the near infrared quantum dots, the method of the present invention has characteristics of less variety of the raw materials, cheap price, simple method, easy operation, good repeatability, and low requirements on equipment. Compared to the traditional quantum dots, the synthesized water-soluble quantum dots of the present invention have the following advantages that: the synthesized water-soluble quantum dots do not contain mercury, cadmium and other toxic metal elements, the emission peak is located in the near infrared region, the synthesized water-soluble quantum dots provide strong penetrabilities for cells and other biological tissues, and the synthesized water-soluble quantum dots can be widely used in immunological assays, nucleic acid hybridizations, gene analysis, cell classification and imaging and other fields.

Owner:JILIN UNIV

Low-molecular carbon-free polysilazane and liquid-phase synthesis method thereof

InactiveCN102173398AExcellent dielectric propertiesWide variety of sourcesSilicon compoundsNitrogen and non-metal compoundsSynthesis methodsControllability

The invention discloses a low-molecular carbon-free polysilazane and a liquid-phase synthesis method thereof, and is characterized in that the low-molecular carbon-free polysilazane is liquid state, structurally contains Si-N, Si-H and N-H bonds and does not contains carbon or other foreign elements. The liquid-phase synthesis method comprises the following steps: (1) feeding organic solvents and halogenated silicane in a container which is provided with a raw material feed pipe, a gas pipe, a stirrer and a condenser; (2) introducing an excessive amount of hydronitrogen compounds into the container, standing for 0.5 to 7 hours, filtering in an inert atmosphere to obtain a clear solution; and (3) distilling under reduced pressure at room temperature or under heating to remove the organic solvents, to obtain a transparent solution. The silicon nitride ceramics produced by cracking the low-molecular carbon-free polysilazane are excellent in dielectric properties. The starting compounds for synthesis are easily available and low in price. The synthesis device has a simple structure, is convenient to operate and has good controllability. The synthetic product has a high purity and a high yield.

Owner:NAT UNIV OF DEFENSE TECH

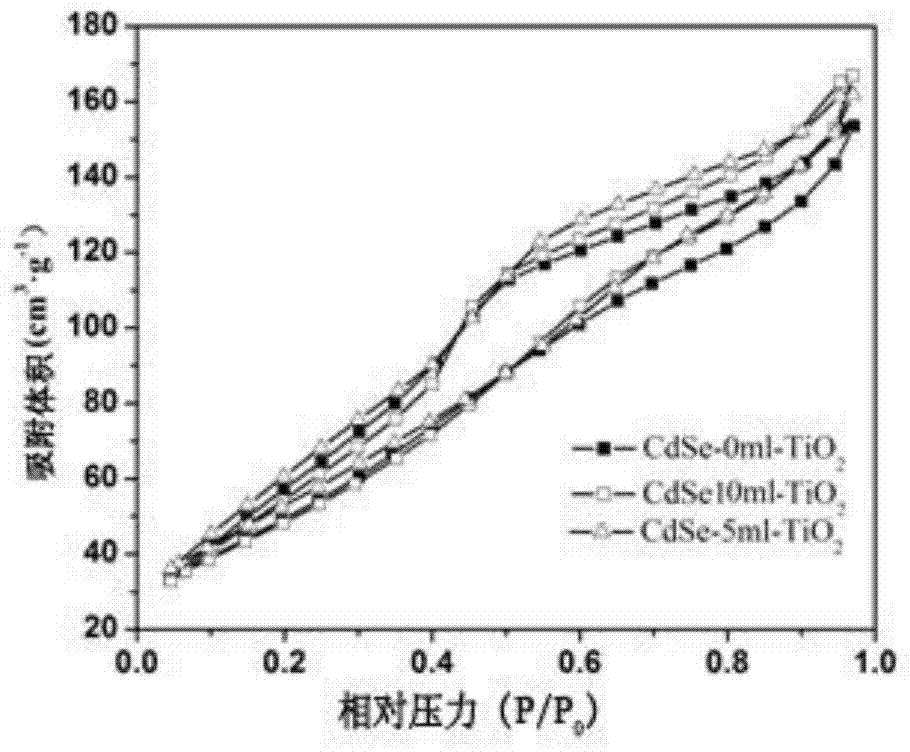

Method for preparing compound nanometer photocatalyst by adopting CdSe quantum dot

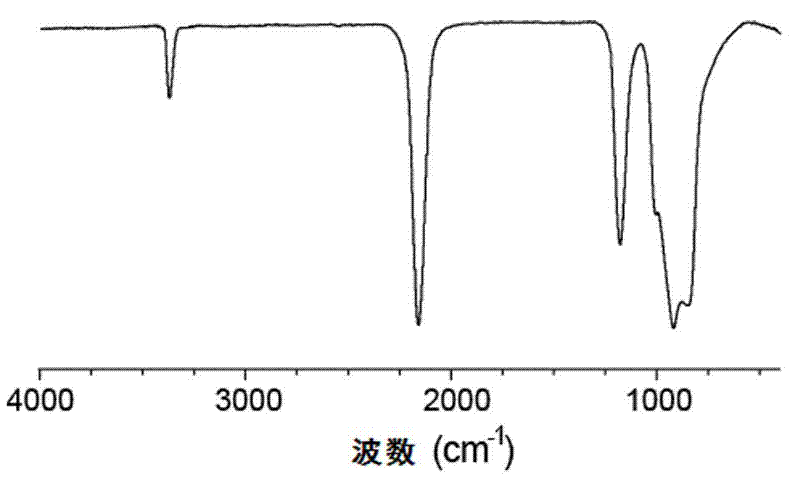

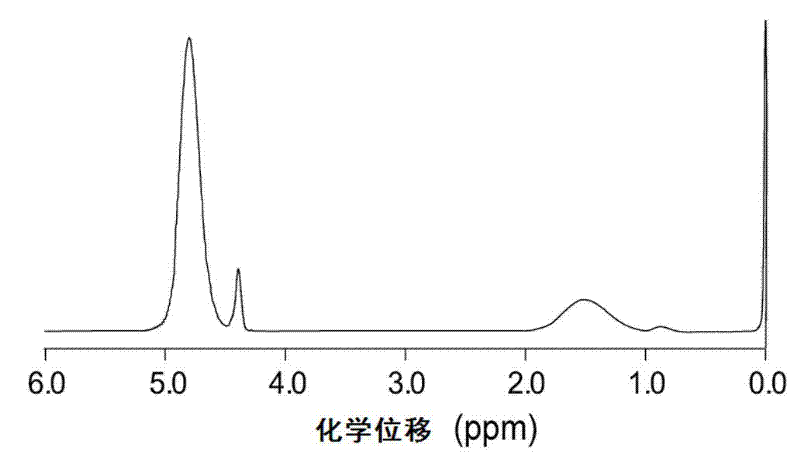

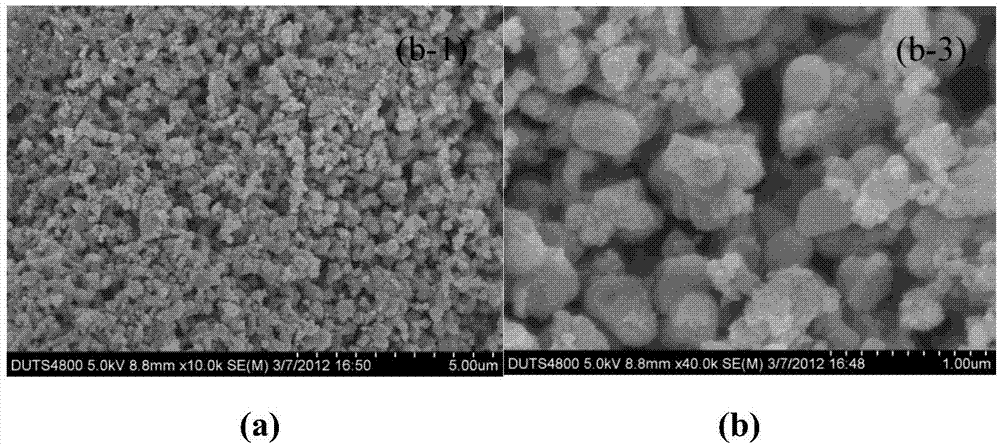

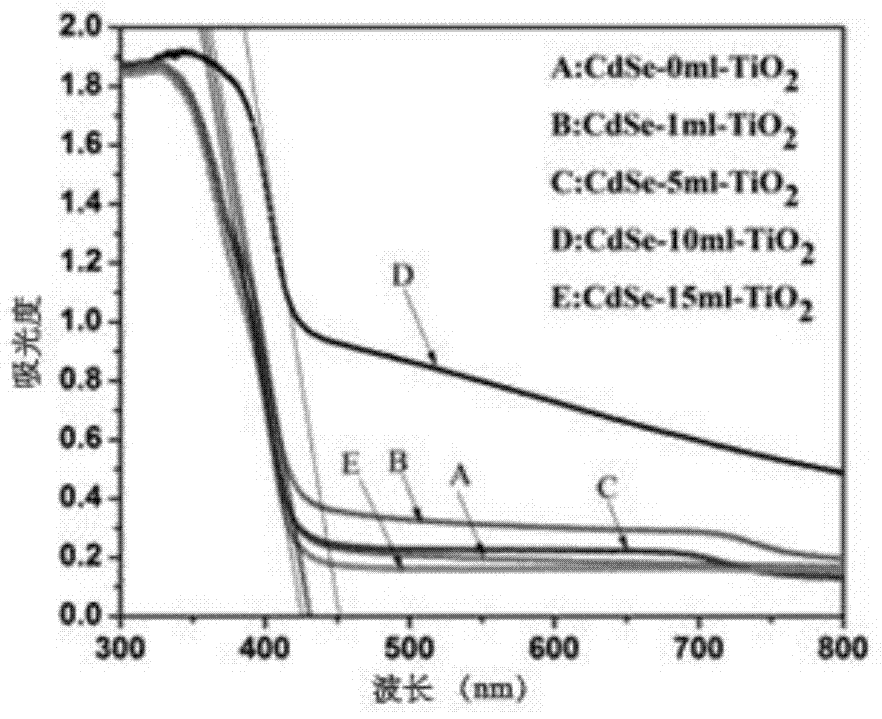

InactiveCN103537302AImproved particle size distributionReduce processing stepsPhysical/chemical process catalystsWater/sewage treatment by irradiationHYDROSOLSolvent

The invention discloses a method for synthesizing a cadmium selenide quantum dot modified titanium dioxide compound photocatalyst. The method for synthesizing the cadmium selenide quantum dot modified titanium dioxide compound photocatalyst comprises the following steps: 1) preparing cadmium selenide quantum dots in different grain diameters by adopting an aqueous phase synthesis method by virtue of selenide powder and CdCl2 under an alkali condition; 2) by adopting a sol-gel method, preparing spherical titanium dioxide powder with tetrabutyl titanate as a titanium source and ethanol as a solvent while the synthesized cadmium selenide quantum dots are added, so that the compound photocatalyst is prepared. The method for synthesizing the cadmium selenide quantum dot modified titanium dioxide compound photocatalyst has the advantages that narrow-bandwidth semiconductor cadmium selenide quantum dot modified titanium dioxide is used for preparing the compound photocatalyst which can absorb visible light, operation is easy, and performance is stable; meanwhile, a better pollutant degradation effect is realized, so that the method for synthesizing the cadmium selenide quantum dot modified titanium dioxide compound photocatalyst has a good application prospect.

Owner:DALIAN UNIV OF TECH

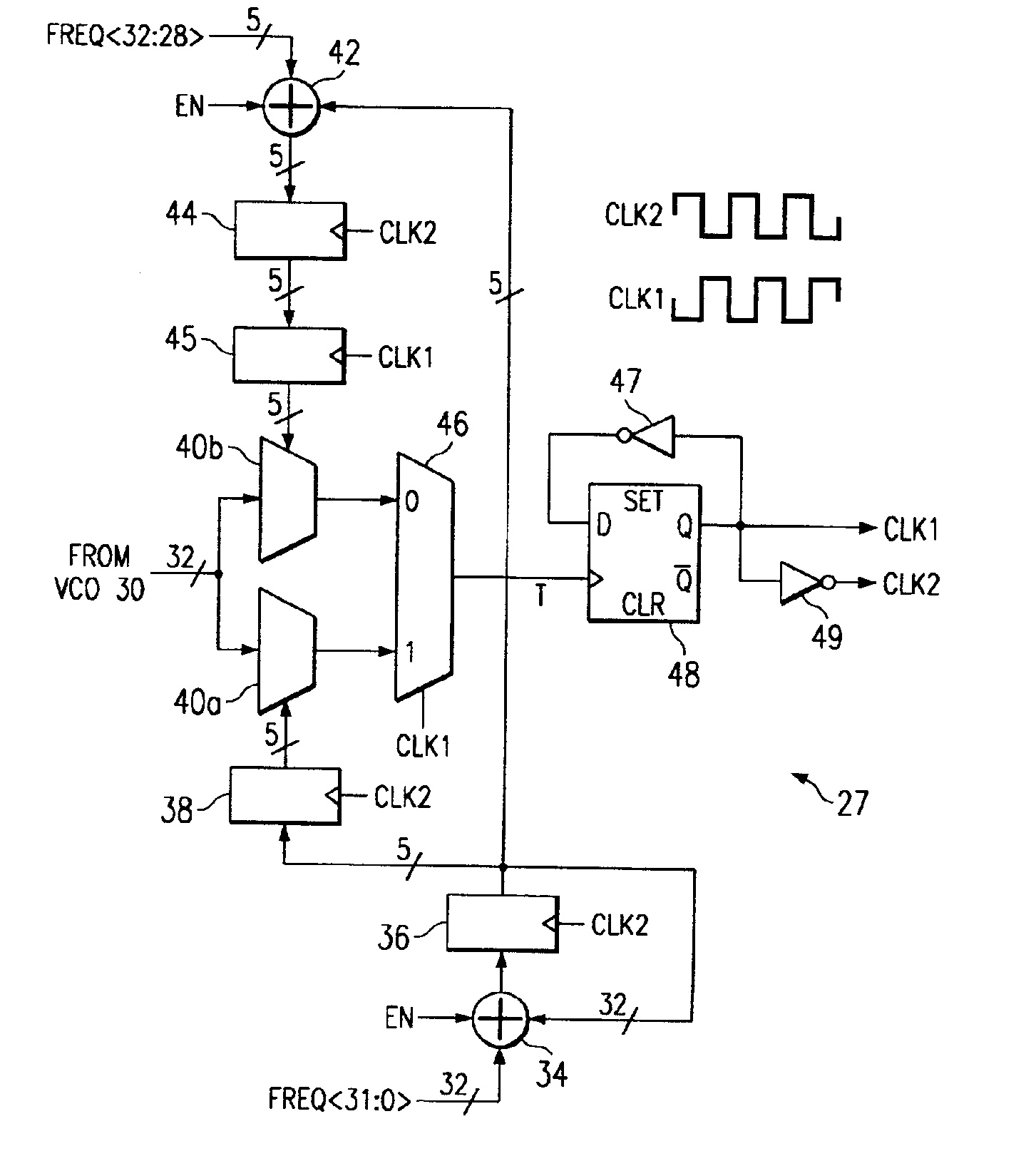

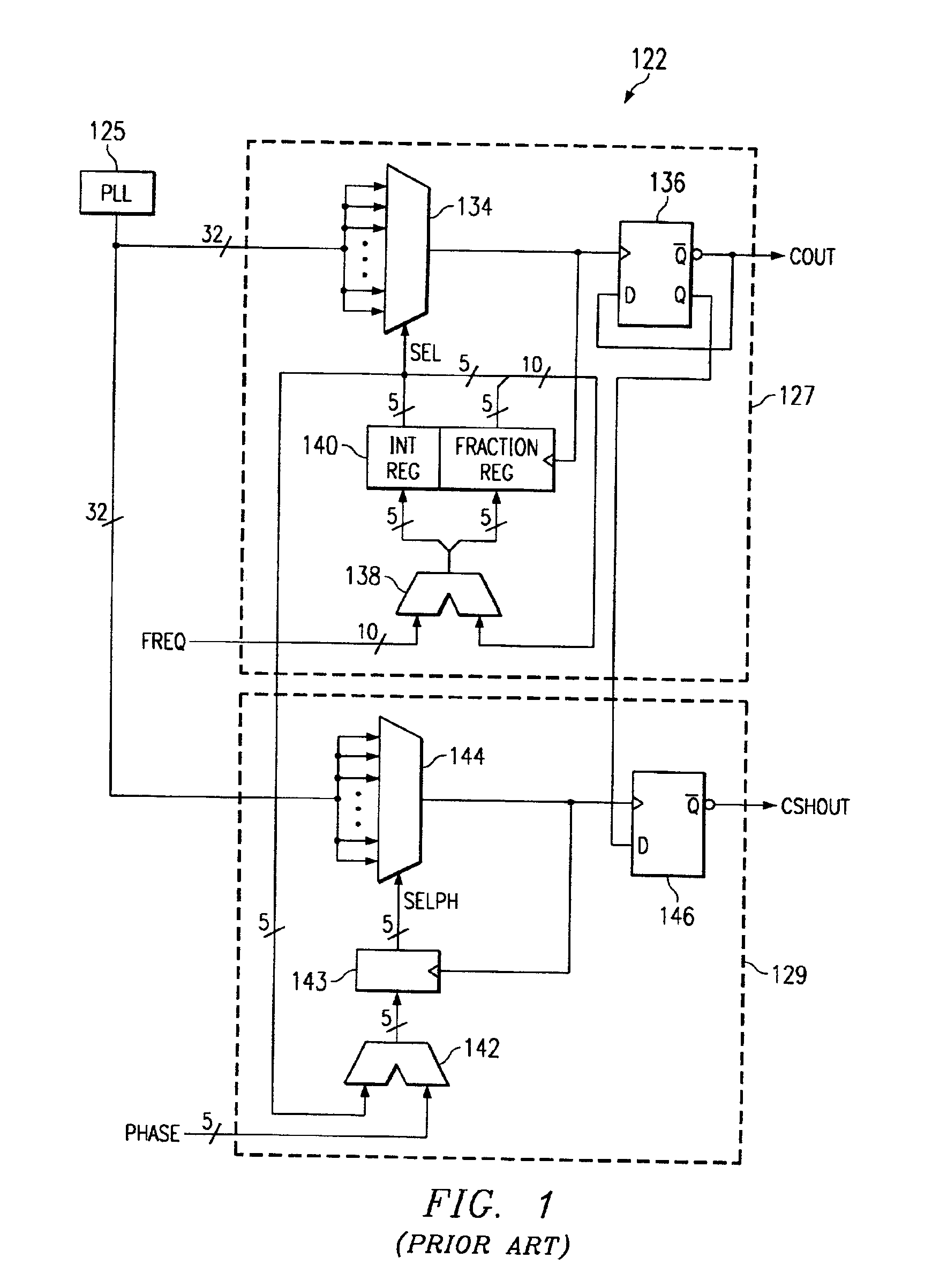

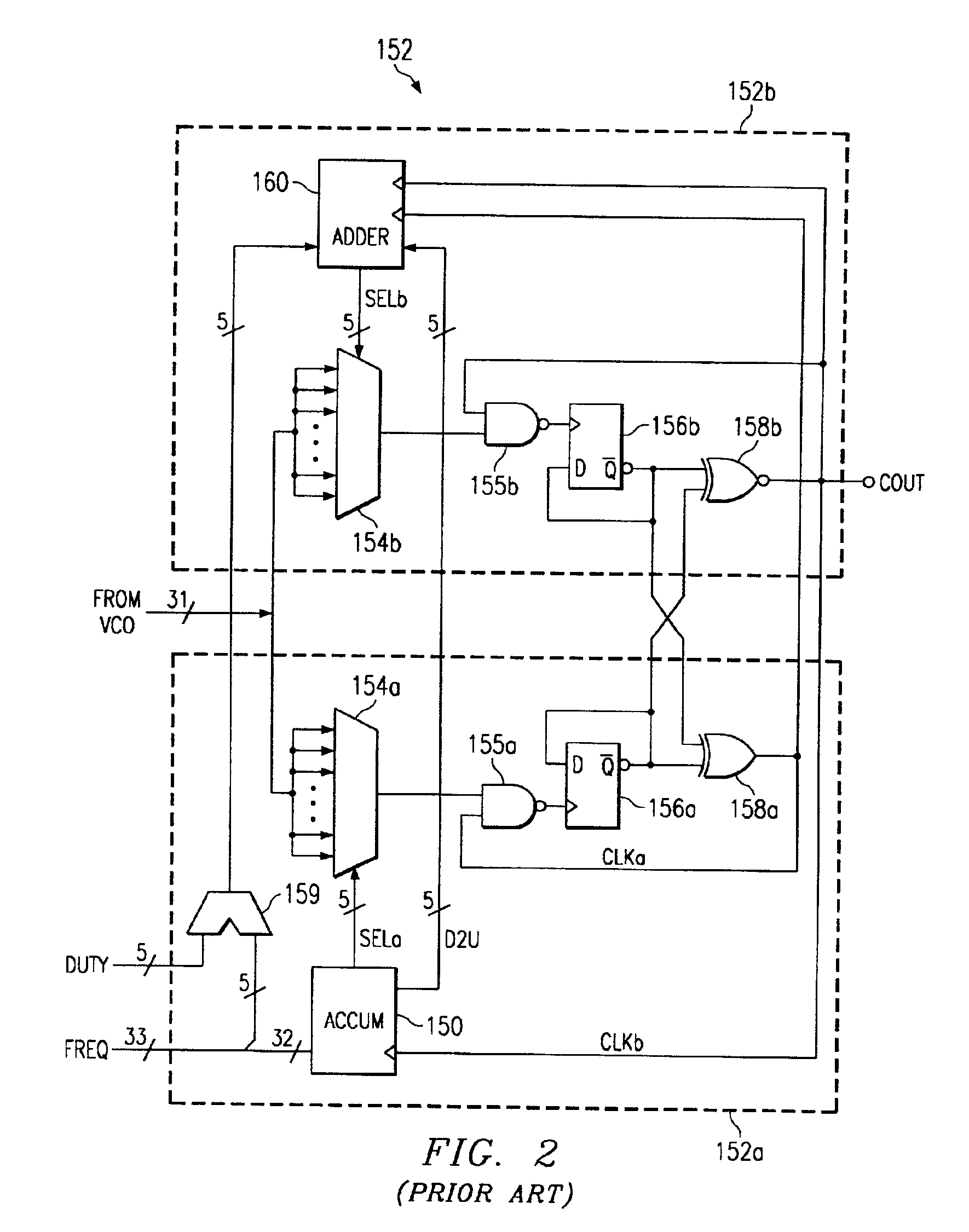

Scalable high-speed precision frequency and phase synthesis

ActiveUS6940937B2Increase the output frequencyIncrease the number ofPulse automatic controlAngle demodulation by phase difference detectionPhase shiftedPhase difference

A clock synthesis circuit (22) including a phase-locked loop (25) and one or more frequency synthesis circuits (27; 77; 227; 237) is disclosed. A disclosed implementation of the phase-locked loop (25) includes a voltage-controlled oscillator (30) having an even number of differential stages (31) to produce an even number of equally spaced clock phases. In one arrangement, the frequency synthesis circuit (27) includes two adder legs that generate select signals applied to first and second multiplexers (40a, 40b), for selecting among the clock phases from the voltage-controlled oscillator (30). The outputs of the first and second multiplexers (40a, 40b) are applied to a two-to-one multiplexer (46) which is controlled by the output clock signal (CLK1), to drive clock edges to a T flip-flop (48) to produce the output clock signals (CLK1, CLK2). In another embodiment, more than two adder and register units (55) control corresponding multiplexers (56) for selecting clock phases from the voltage-controlled oscillator (30) for application to an output multiplexer (58), which is controlled by a clock control circuit (60) to apply the selected clock phases to the T flip-flop (62). In another embodiment, primary and phase-shifted frequency synthesis circuits (227, 327) receive initialization values (INIT1, INIT2) that establish the phase differential and ensure proper initialization.

Owner:TEXAS INSTR INC

Nanofiber membrane with heavy metal absorption function and preparation method thereof

ActiveCN103055722ALarge specific surface areaIncrease contentSemi-permeable membranesWater contaminantsPolyolefinSorbent

The invention discloses a nanofiber membrane with a heavy metal absorption function and a preparation method of the nanofiber membrane with the heavy metal absorption function. Polyolefin copolymer is adopted as base material, and the chemical modification nanofiber membrane with the heavy metal absorption function is prepared through surface chemical modification and active molecule solide-phase synthesis process. The nanofiber membrane with the heavy metal absorption function overcomes the shortcomings that the process is complex, cost is high, secondary pollution is prone to being caused, and the like in performance aspect, and effective absorption for heavy metal ions is achieved by means of the principle that amino polyacid complexes the heavy metal ions. Due to the adoption of the solid-phase synthesis process, the amino polyacid is enabled to be well fixed on the surface of the nanofiber membrane and to absorb the heavy metal ions in a repeated recycle mode. The nanofiber membrane with the heavy metal absorption function can be widely applied to the fields of water treatment and the like.

Owner:WUHAN TEXTILE UNIV +1

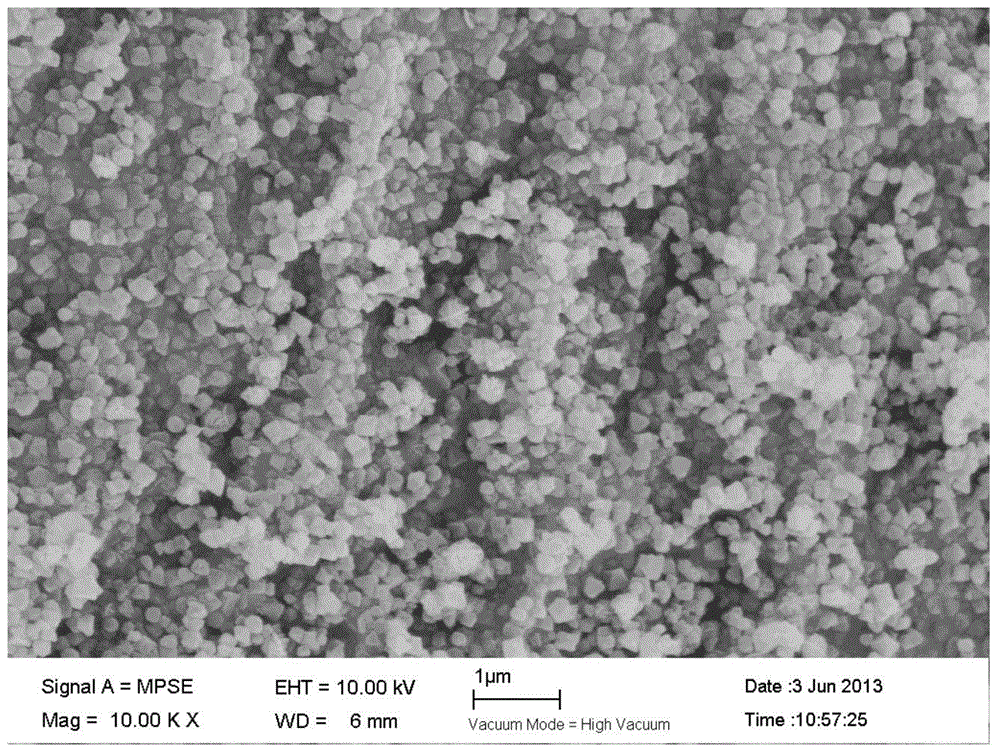

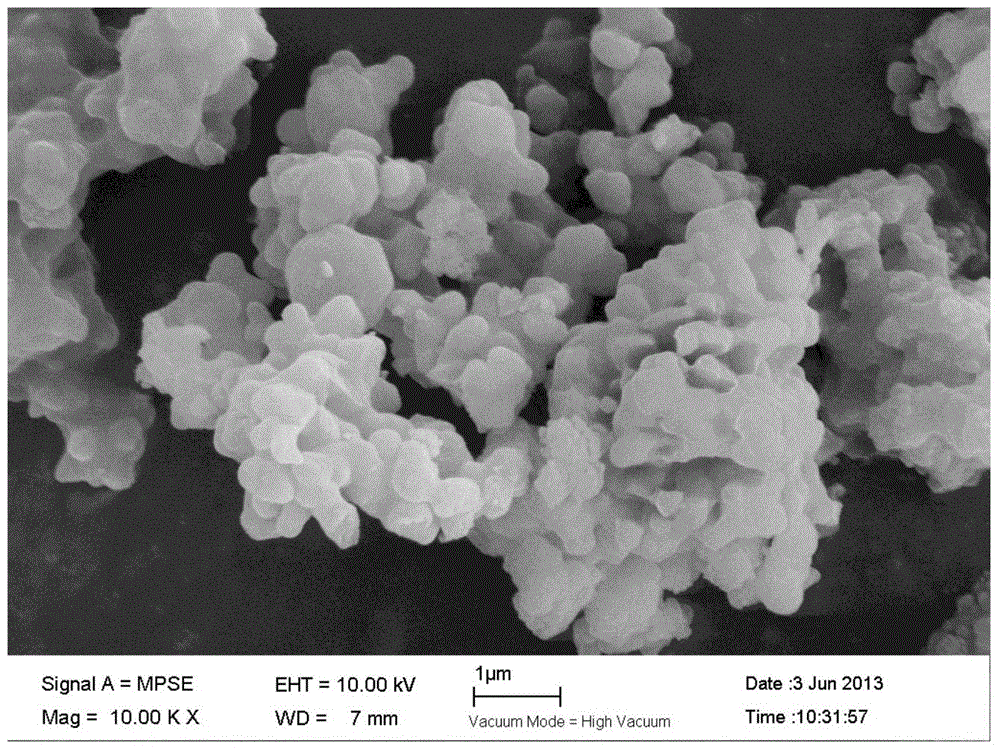

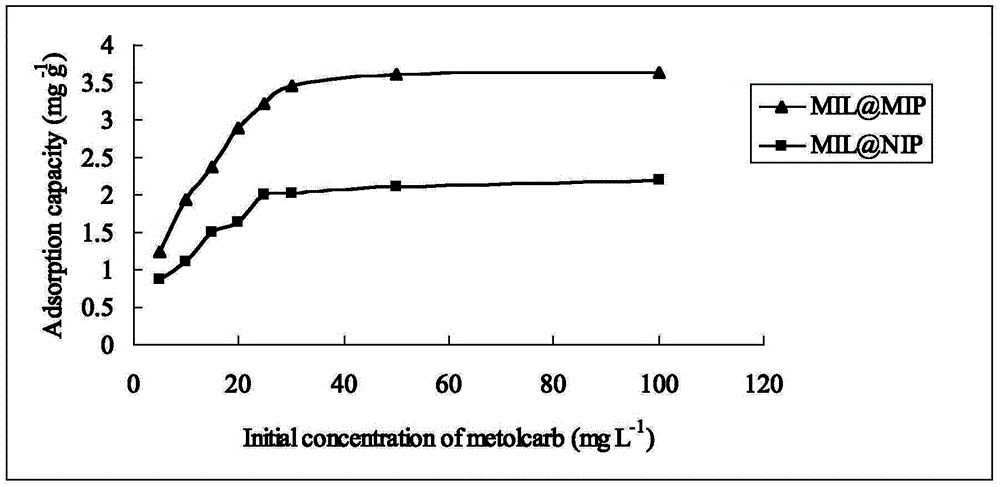

Aqueous phase metal organic framework molecular imprinting material of enriched trace meta-tolyl-N-methylcarbamate (MTMC)

ActiveCN104014320AIncrease mass transfer rateLarge specific surface areaOther chemical processesFunctional monomerTriethoxysilane

The invention relates to an aqueous phase metal organic framework molecular imprinting material of enriched trace meta-tolyl-N-methylcarbamate (MTMC). The product is prepared by the following steps: with a metal organic framework material MIL-101 subjected to aqueous-phase synthesis as a supporter, MTMC as a template molecule, 3-aminopropyltriethoxysilane as a functional monomer, and with tetraethoxysilane as a crosslinking agent, synthesizing a precursor of MIL@MIP through a sol-gel method; and removing the template molecule in the precursor by utilizing Soxhlet extraction, thus obtaining the aqueous phase metal organic framework molecular imprinting material of enriched trace MTMC, namely the MIL@MIP. An imprinting hole which is consistent with a space structure of the template molecule is obtained, and a selective identification effect on the template molecule MTMC is good.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

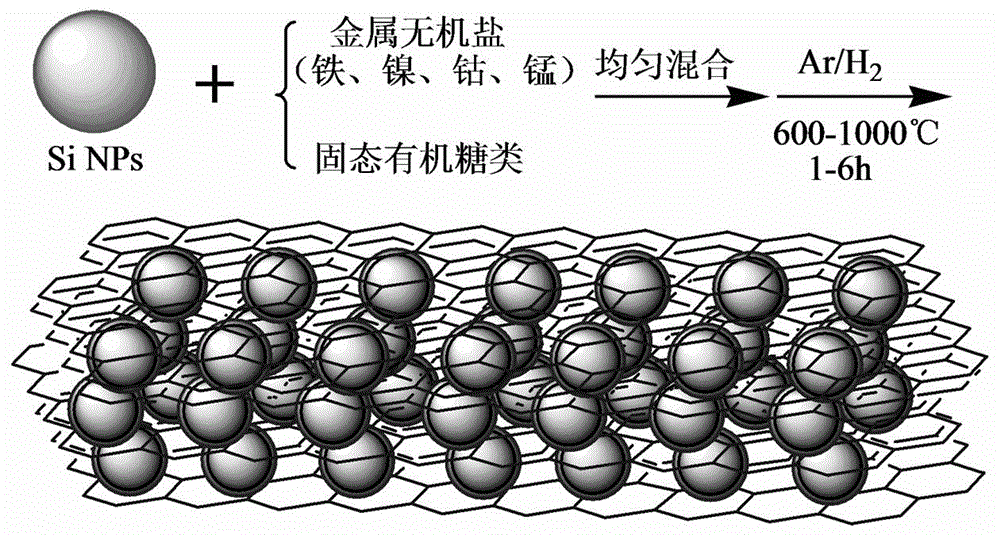

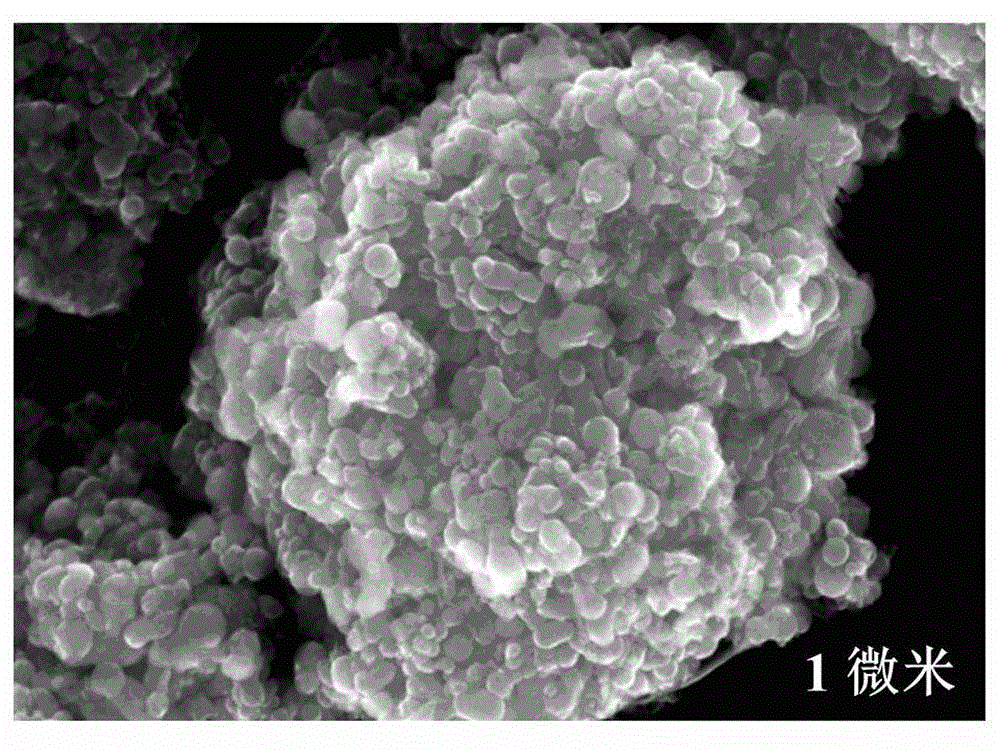

In-situ solid-phase synthesis method of silicon-graphene spheroidal composite material with multilevel structure and application thereof

InactiveCN104934573AAvoid volume effectImprove electronic conductivityCell electrodesFinal product manufacturePtru catalystElectronic conductivity

The invention brings forward a novel low-cost in-situ solid-phase preparation method. By the method, a silicon-graphene spheroidal composite material with a multilevel structure can be synthesized by one step. The composite material can be used as a high specific energy anode material to be applied in a lithium ion battery. Low-cost organic carbohydrate and inorganic transition metal salt which are respectively used as a carbon source and a metal catalyst precursor are selected to be uniformly mixed with a silicon nano-material; by a tube furnace heating method, in-situ catalytic growth of a graphene coated network happens on the surface of silicon nano-particles; and through the bridging effect of the graphene network, spheroidal micro-scale particles with a nanometer fine structure is self-assembled. The silicon-graphene spheroidal composite anode material with the multilevel structure has an advantage of high specific capacity. In addition, two main bottleneck problems such as poor electronic conductivity of a silicon anode material and severe volume effect during the cyclic process can be overcome simultaneously, and multiplying power and cycle performance of silicon anode can be raised greatly.

Owner:SUZHOU GREEN POWER TECH CO LTD

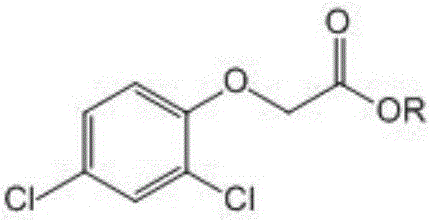

Chloracetate water phase synthesis technology and novel method for preparing 2,4-D ester

ActiveCN106242971AAvoid using effectsAvoid wastingOrganic compound preparationCarboxylic acid esters preparationAcetic acidAlcohol

The invention discloses a chloracetate water phase synthesis technology and a novel method for preparing 2,4-D ester, and belongs to the technical field of organic synthesis. According to the chloracetate water phase synthesis technology, alcohol and chloroacetic acid are used as raw materials for preparing chloracetate in the water phase. The method for preparing 2,4-D ester comprises the following steps that (1) chloracetate is prepared; (2) 2,4-dichloroindophenol sodium is prepared; (2) the chloracetate directly takes a reaction with 2,4-dichloroindophenol sodium under the alkaline condition to obtain the corresponding 2,4-D ester. The operation of the preparation method of the chloracetate provided by the invention is performed in the water phase, so that the purity of the obtained coarse ester is higher, and can reach 99.3 percent or higher only through simple distillation; the corresponding 2,4-D ester is prepared from the chloracetate; the preparation process of the 2,4-D ester is greatly simplified; the cost is effectively reduced; the reaction time is greatly shortened; in addition, the product yield is improved; the waste water quantity is effectively reduced; the green chemical industrial requirements are met.

Owner:QINGDAO UNIV OF SCI & TECH

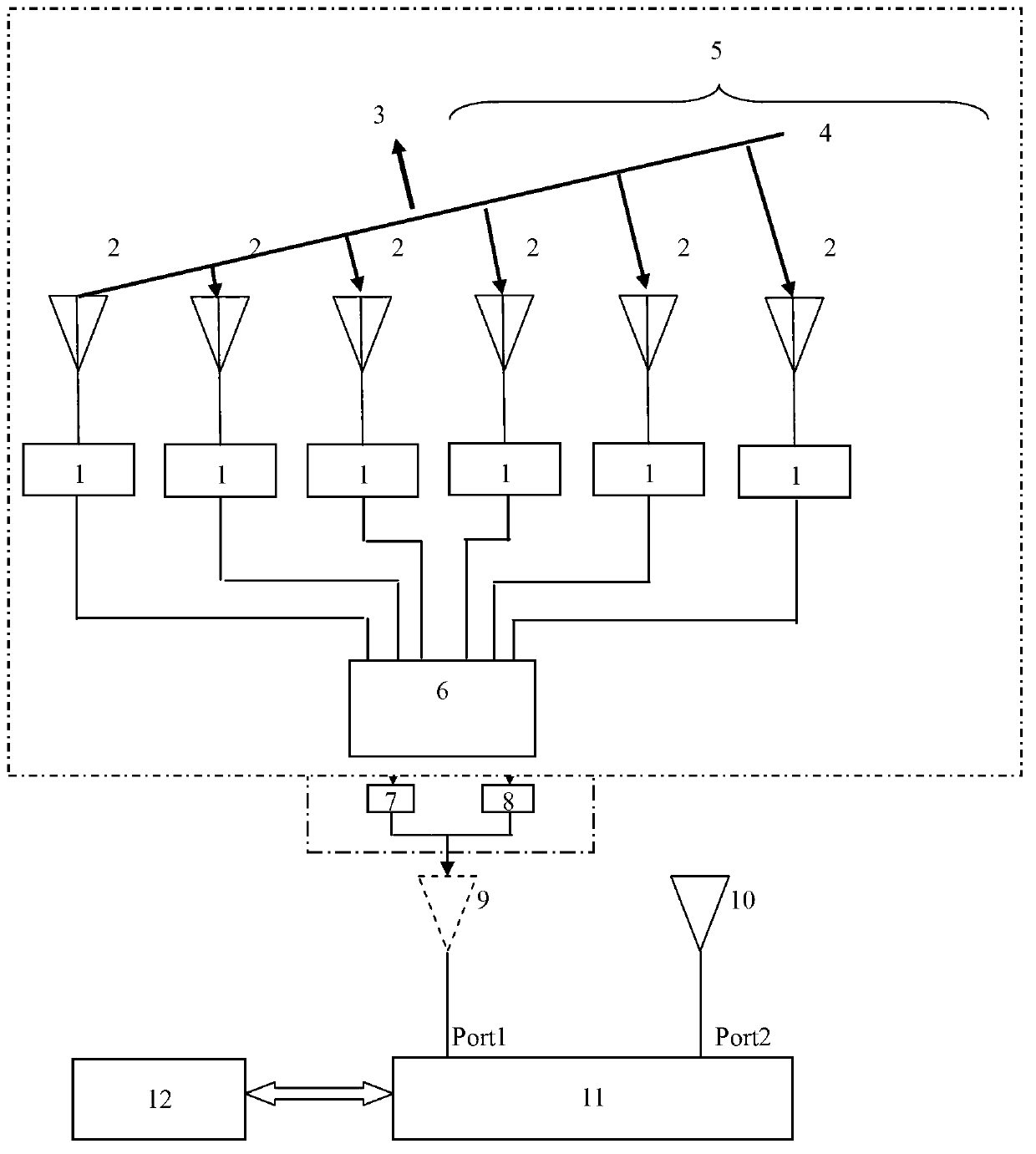

Phased array antenna equivalent isolation degree testing method

ActiveCN103217589AHigh precisionImprove test efficiencyAntenna radiation diagramsArbitrary unitAntenna gain

The invention discloses a plane antenna engineering equivalent testing method and particularly relates to a phased array antenna equivalent isolation degree testing method. The array antenna isolation degree is calculated in the first place, an arbitrary unit array element of a phased array antenna is subsequently chosen as a testing reference point, and then a gain correction coefficient of the array antenna is calculated. The plane antenna engineering equivalent testing method can successfully solve engineering test deviation due to uncertainty of gain of an antenna main lobe and the antenna, wherein the uncertainty of the gain of the antenna main lobe and the antenna is caused by variation of array antenna phase synthesis. By introducing correction factors such as the gain after phase synthesis, an antenna array angle and beam width deviation, the phased array antenna is changed to be an equivalent unit antenna. The phased array antenna equivalent isolation degree testing method is suitable for isolation degree engineering tests between the phased array antenna and a unit antenna and between the array antennas and can be popularized and applied to array antenna isolation degree engineering tests on all sorts of weapon equipment platforms.

Owner:SHAANXI AIRCRAFT CORPORATION

Skeletal iron catalyst having improved attrition resistance and product selectivity in slurry-phase synthesis processes

InactiveUS20020052423A1Good particle strength and attrition resistanceHigh yieldHydrocarbon from carbon oxidesOrganic compound preparationFixed bedSlurry

Particulate skeletal iron catalyst is provided which contain at least about 50 wt. % iron with the remainder being a minor portion of a suitable non-ferrous metal and having characteristics of 0.062-1.0 mm particle size (62-1000 micron), 20-100 m2 / g surface area, and 10-40 nm average pore diameter. Such skeletal iron catalysts are prepared and utilized for producing synthetic hydrocarbon products from CO and H2 feeds by Fischer-Tropsch synthesis process. Iron powder is mixed with non-ferrous metal powder selected from aluminum, antimony, silicon, tin or zinc powder to provide 20-80 wt. % initial iron content and melted together to form an iron alloy, then cooled to room temperature and pulverized to provide 0.1-10 mm iron alloy catalyst precursor particles. The iron alloy precursor particles are treated with NaOH or KOH caustic solution at 30-95° C. temperature to extract and / or leach out most of the non-ferrous metal portion, and then screened and treated by drying and reducing with hydrogen so as to provide smaller sized skeletal iron catalyst material. Such skeletal iron catalyst is utilized with CO+H2 feedstream for Fischer-Tropsch reactions in either a fixed bed or slurry bed type reactor at 180-500° C. temperature, 0.5-5.0 mPa pressure, and gas hourly space velocity of 0.5-3.0 L / g Fe / hr to produce desired hydrocarbon products.

Owner:HYDROCARBON TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com