Patents

Literature

992results about "Nitrogen and non-metal compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

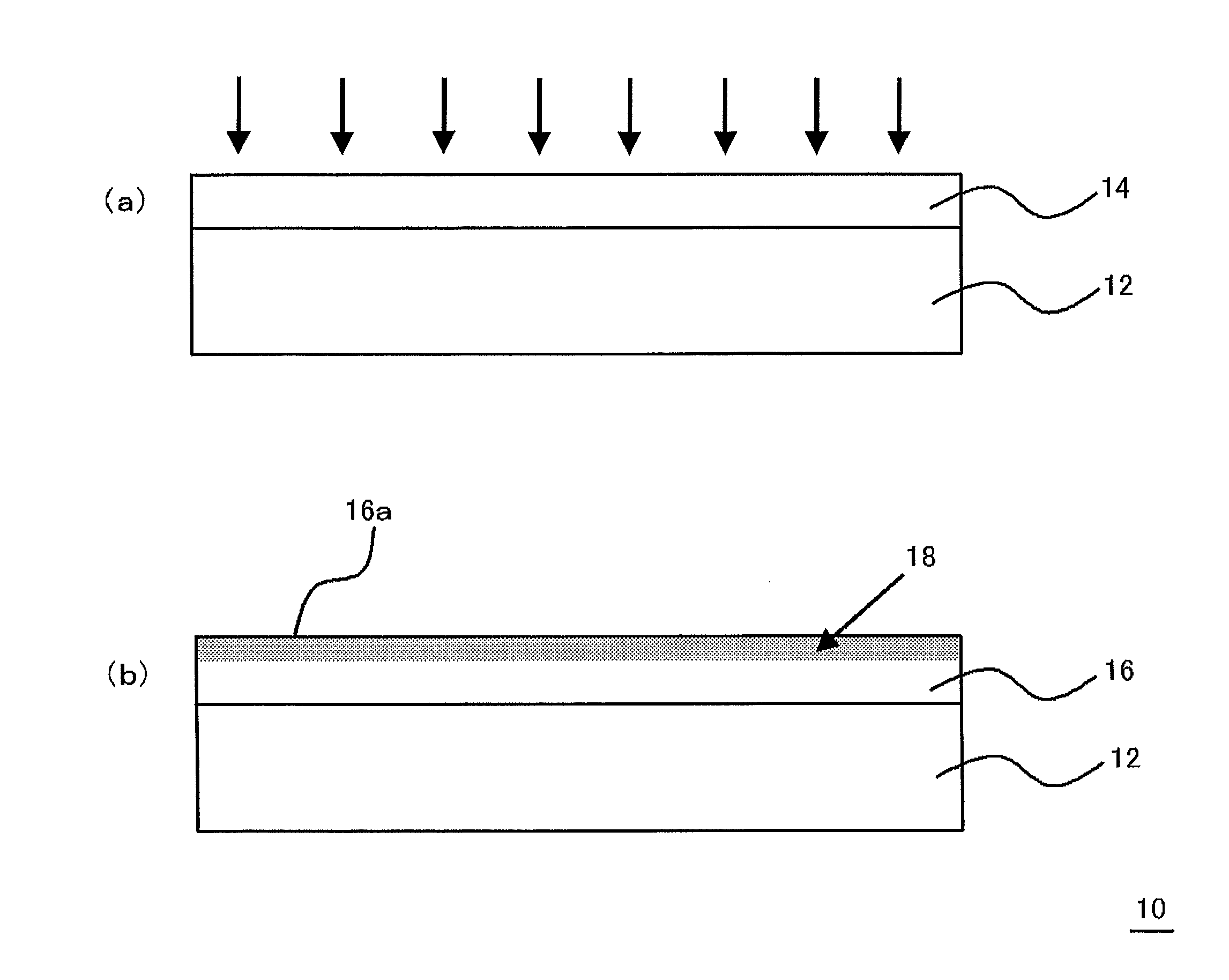

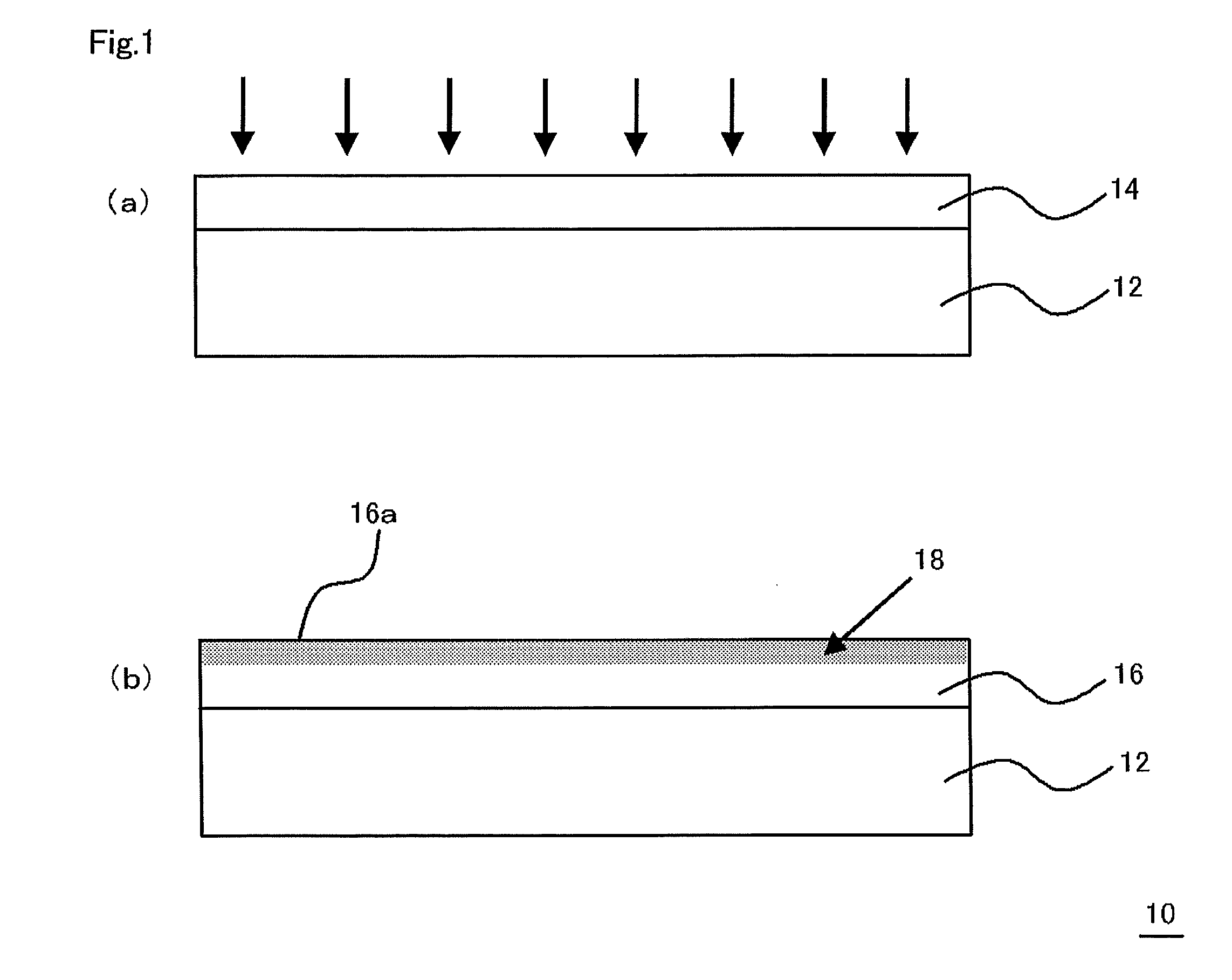

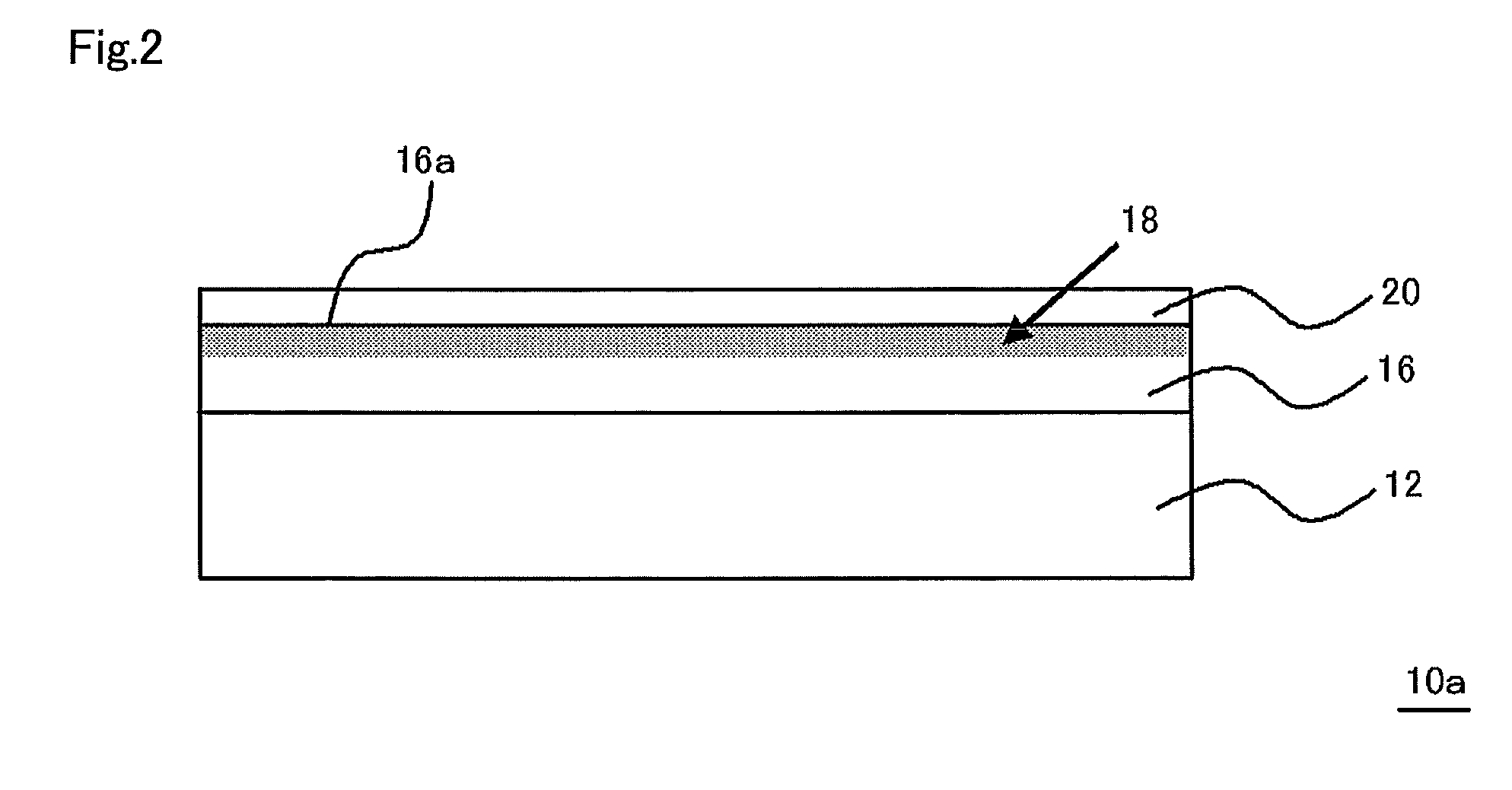

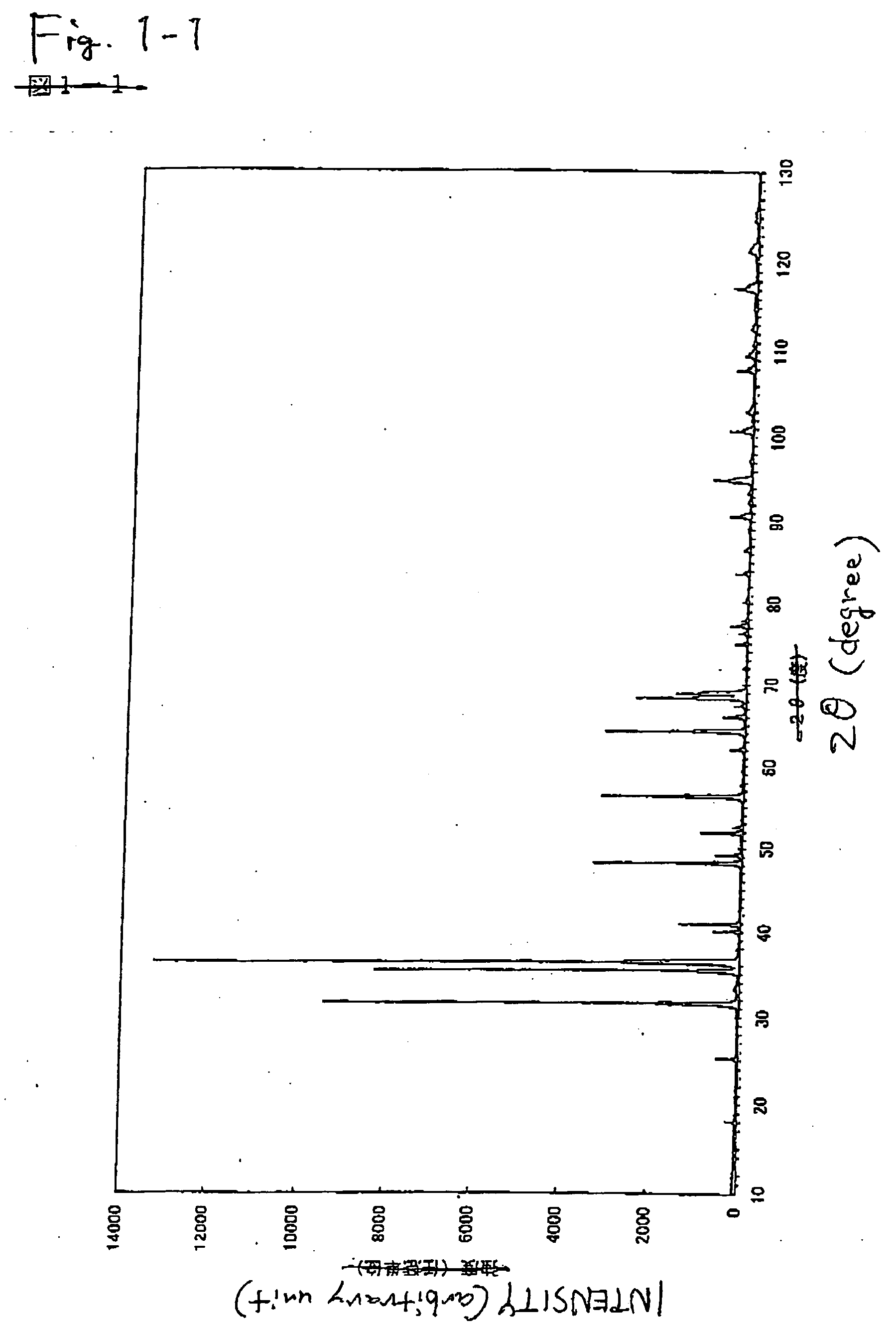

Multilayered material and method of producing the same

InactiveUS20120107607A1Reduce the impactIncrease production capacityRadiation applicationsPretreated surfacesWater vaporPolysilazane

A multilayered material is provided which includes a substrate and a silicon-containing film formed on the substrate, wherein the silicon-containing film has a nitrogen-rich area including silicon atoms and nitrogen atoms, or silicon atoms, nitrogen atoms, and an oxygen atoms and the nitrogen-rich area is formed by irradiating a polysilazane film formed on the substrate with an energy beam in an atmosphere not substantially including oxygen or water vapor and denaturing at least a part of the polysilazane film. A method of producing the multilayered material is also provided.

Owner:MITSUI CHEM INC

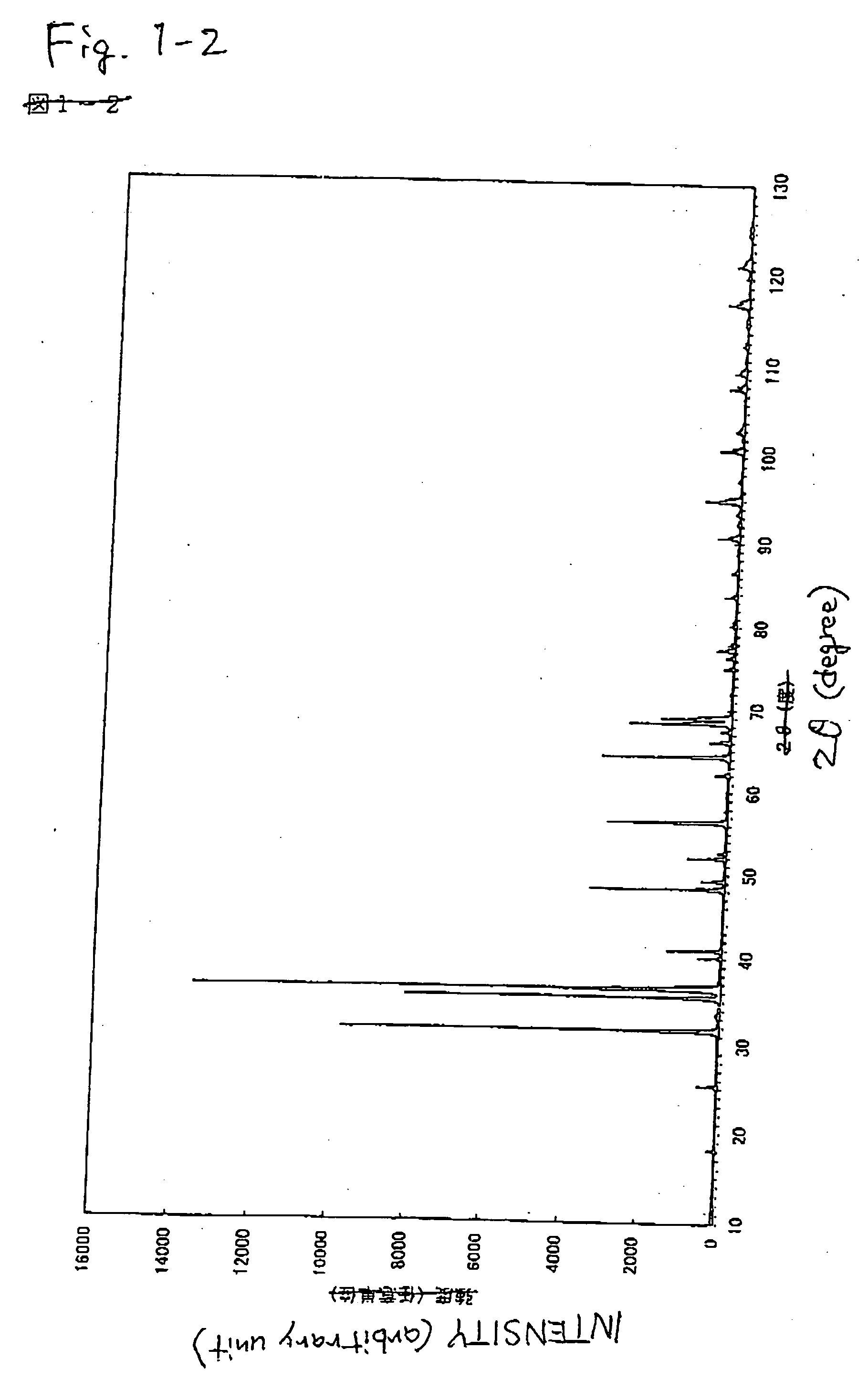

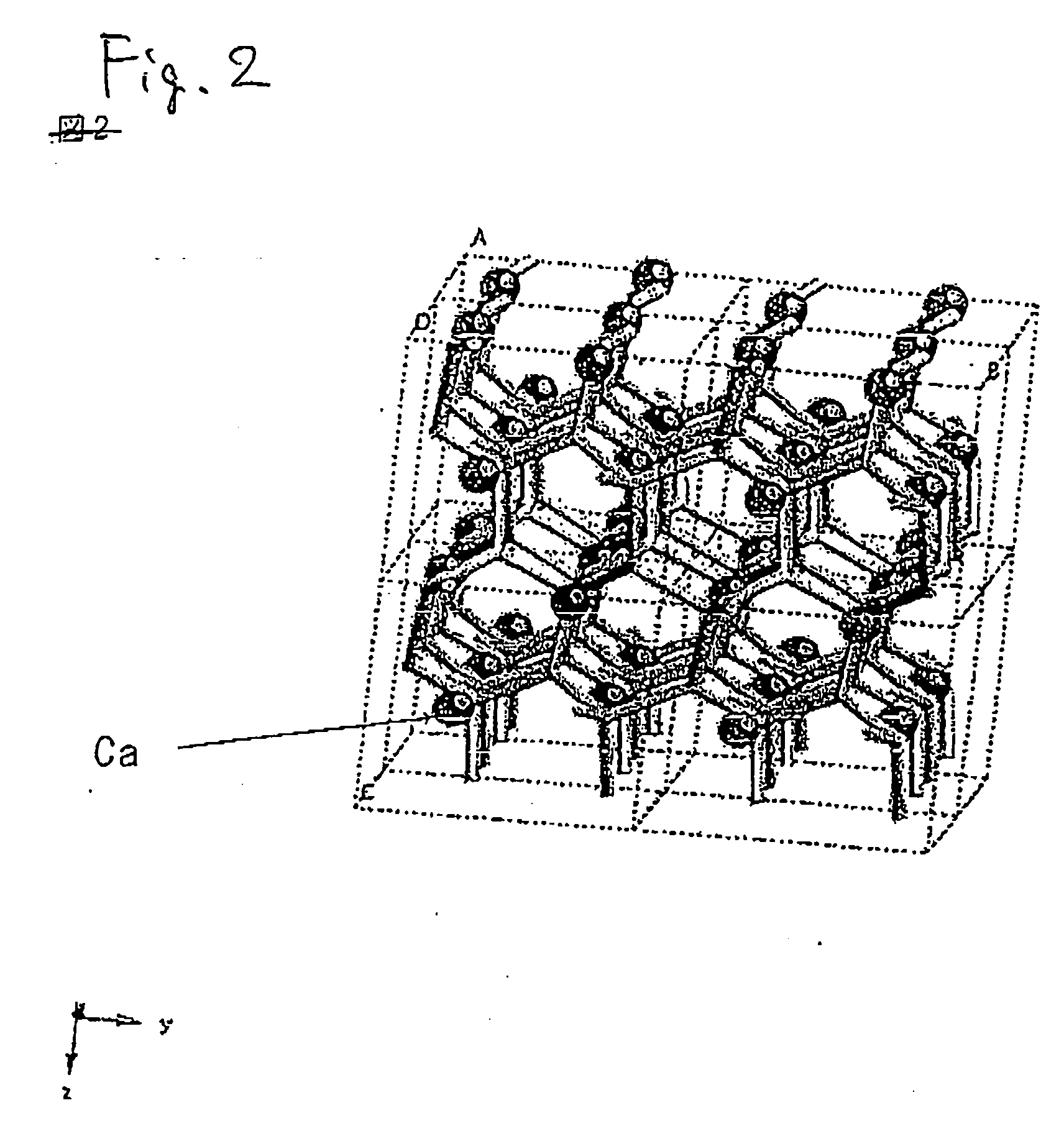

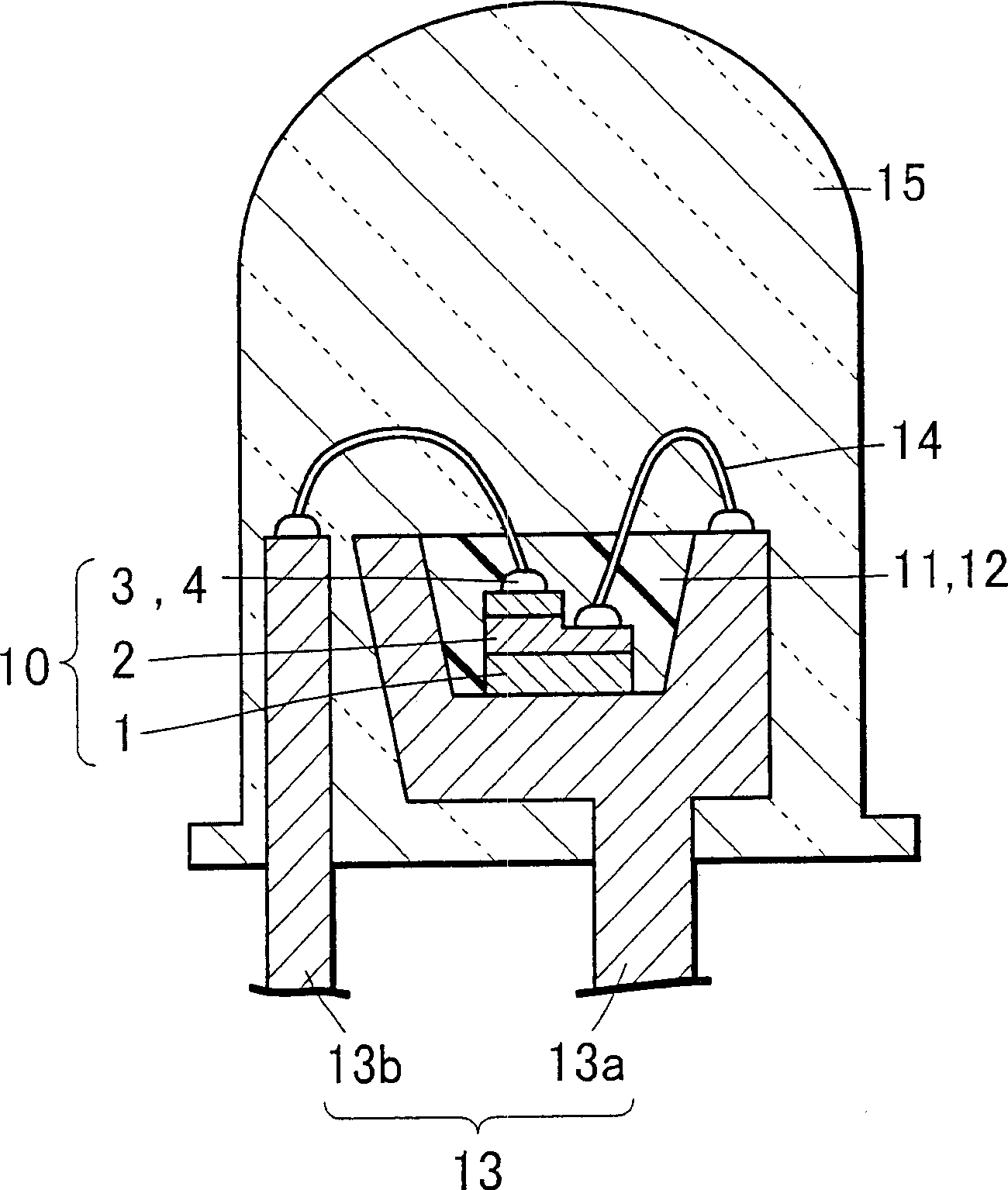

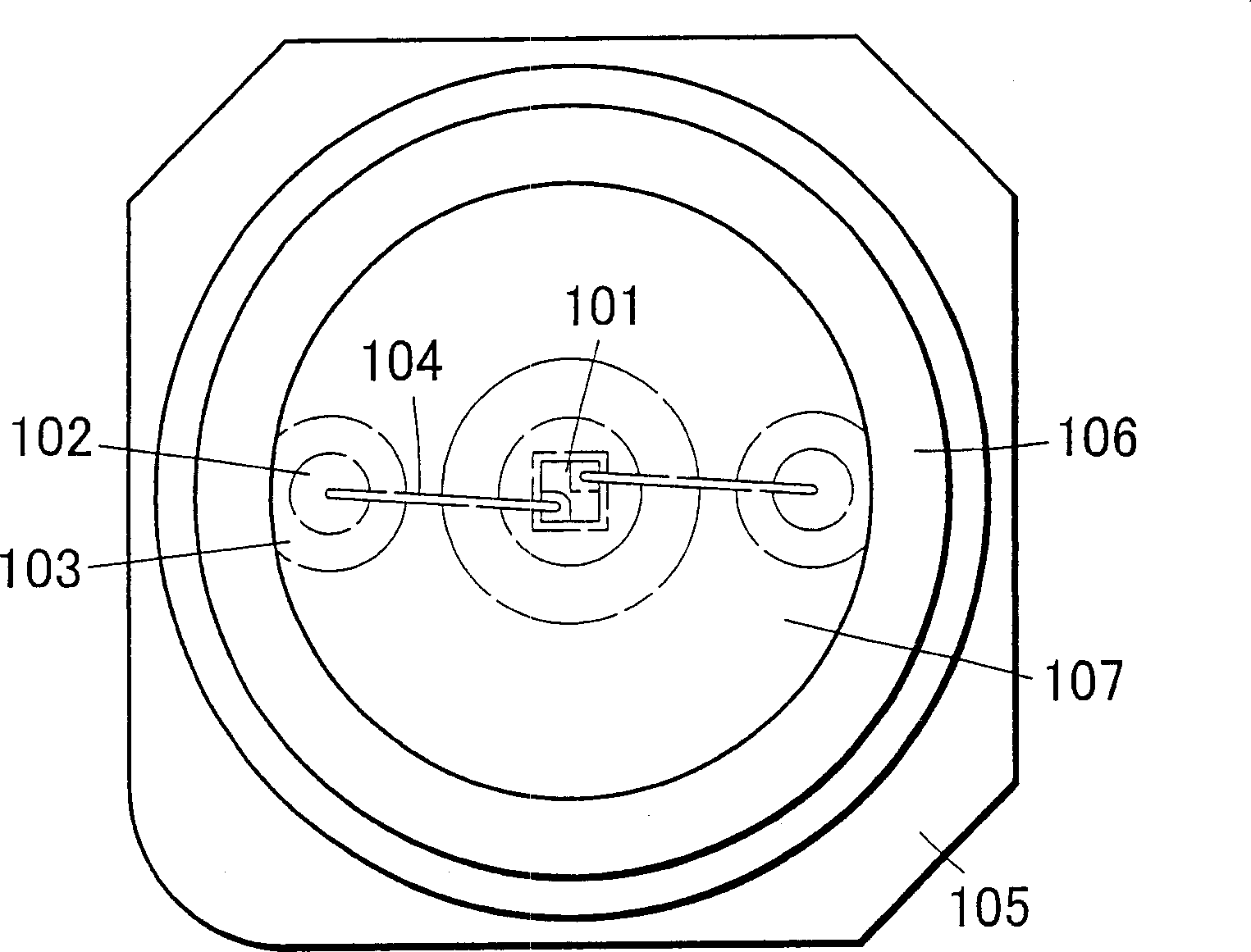

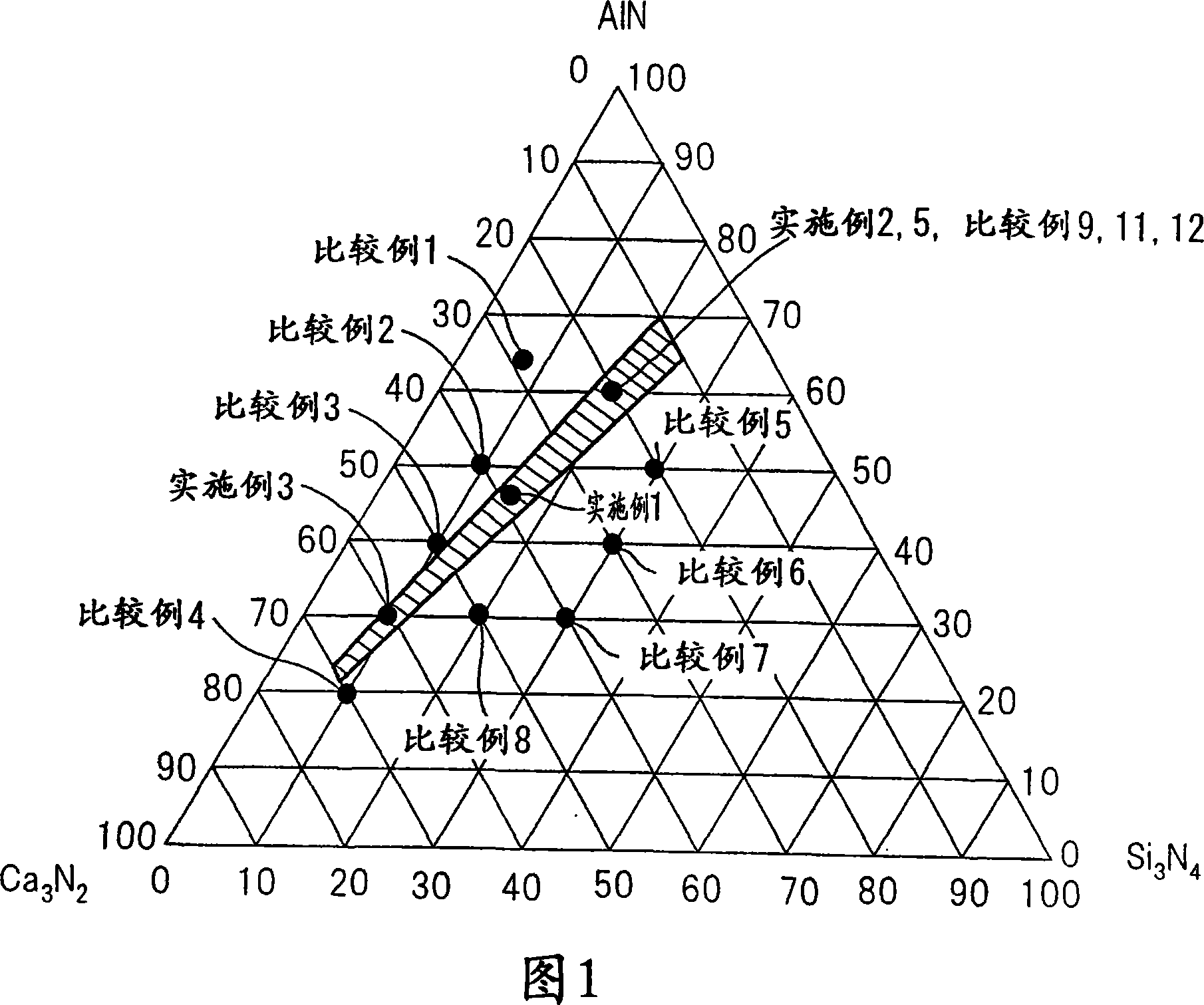

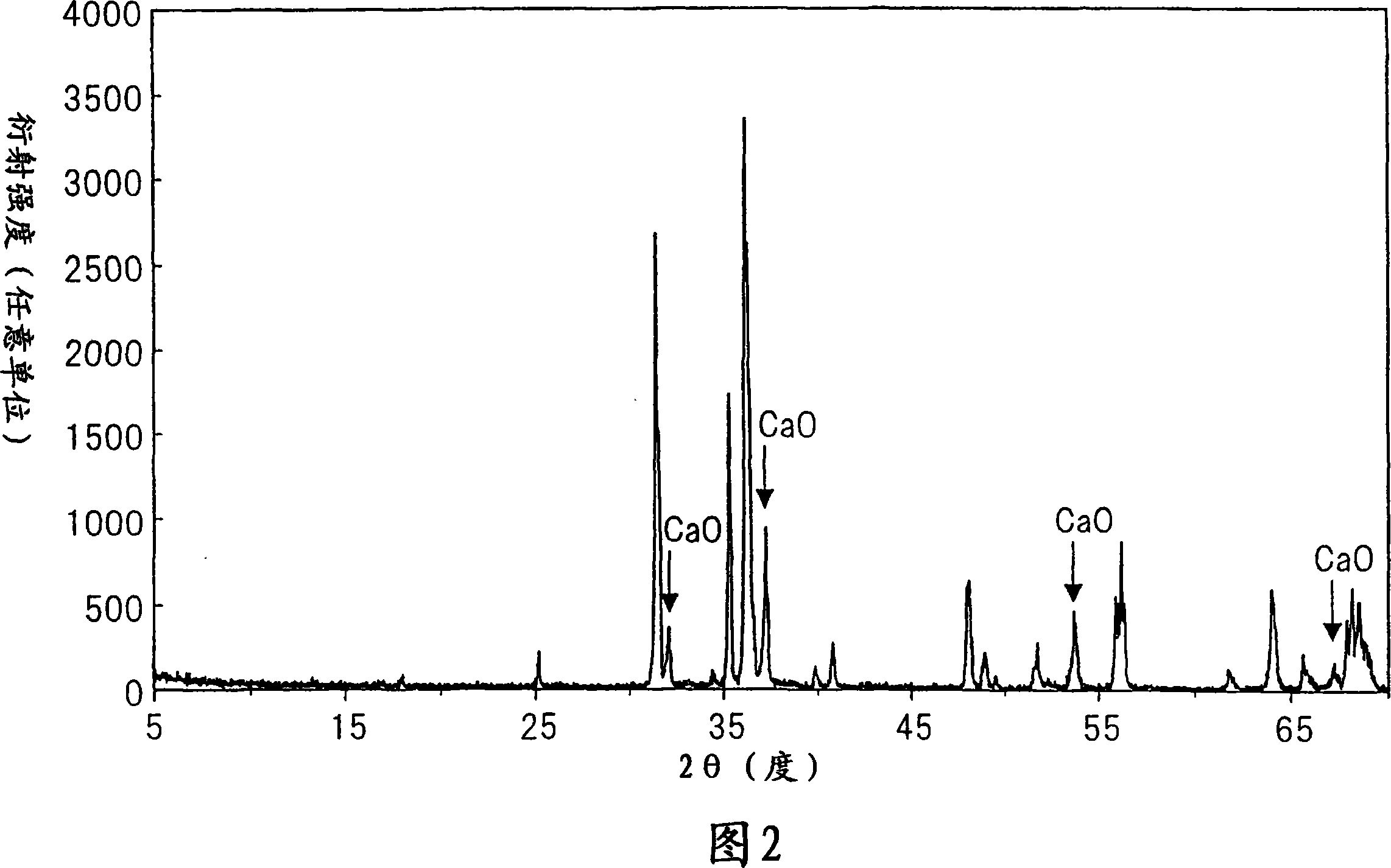

Phosphor and light-emitting equipment using phosphor

ActiveUS20070007494A1Increase brightnessGood colorOther chemical processesNitrogen-metal/silicon/boron binary compoundsFluorescenceRare earth

An object of the present invention is to provide an inorganic phosphor having fluorescence properties emitting an orange or red light which has a longer wavelength as compared with the cases of conventional sialon phosphors activated with a rare earth. The invention relates to a design of white light-emitting diode rich in a red component and having good color-rendering properties by employing a solid solution crystal phase phosphor which uses as a host crystal an inorganic compound having the same crystal structure as that of a CaSiAlN3 crystal phase and to which M Element (wherein M Element is one or two or more elements selected from the group consisting of Mn, Ce, Pr, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm, and Yb) is added as an emission center.

Owner:NICHIA CORP +1

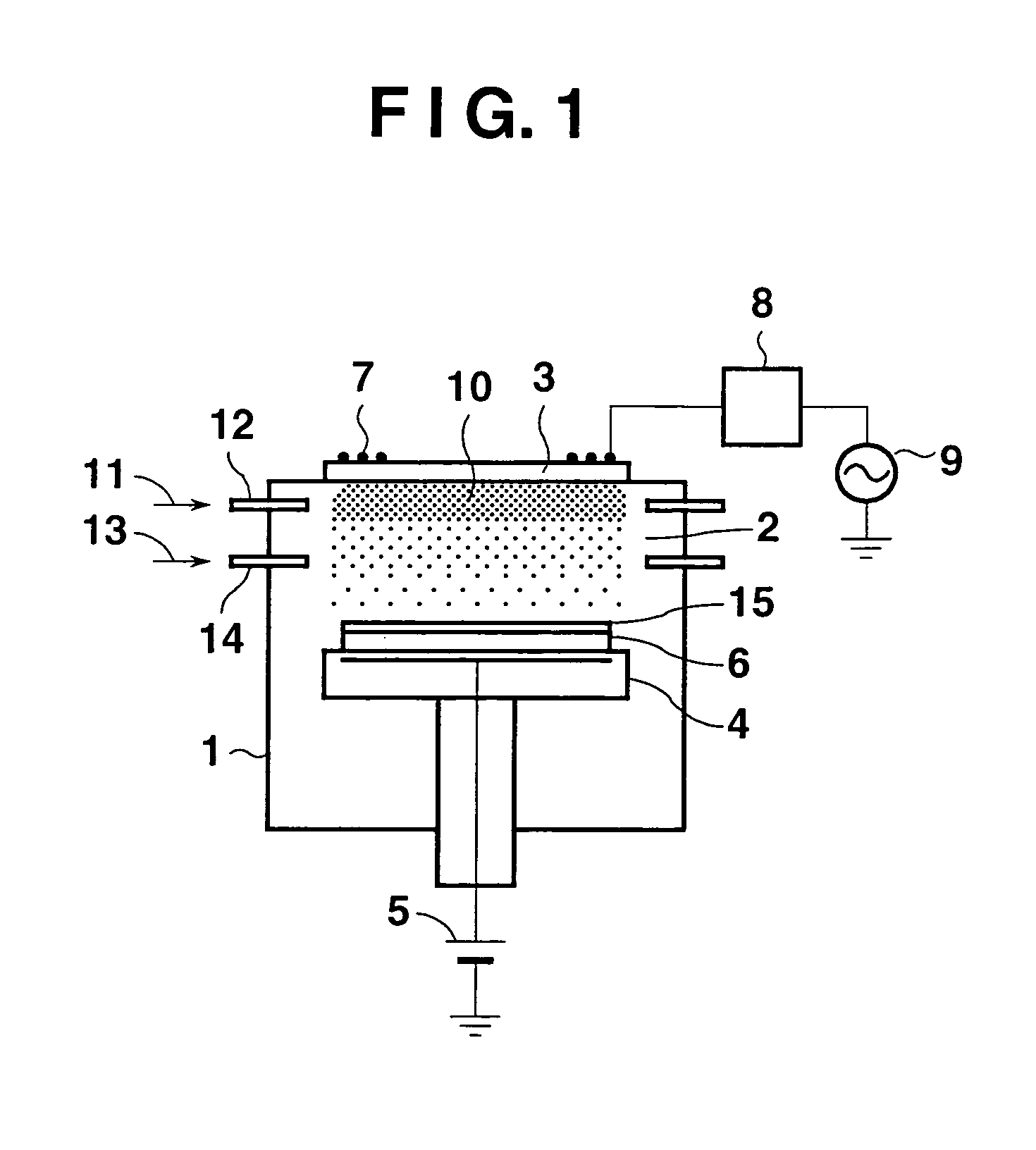

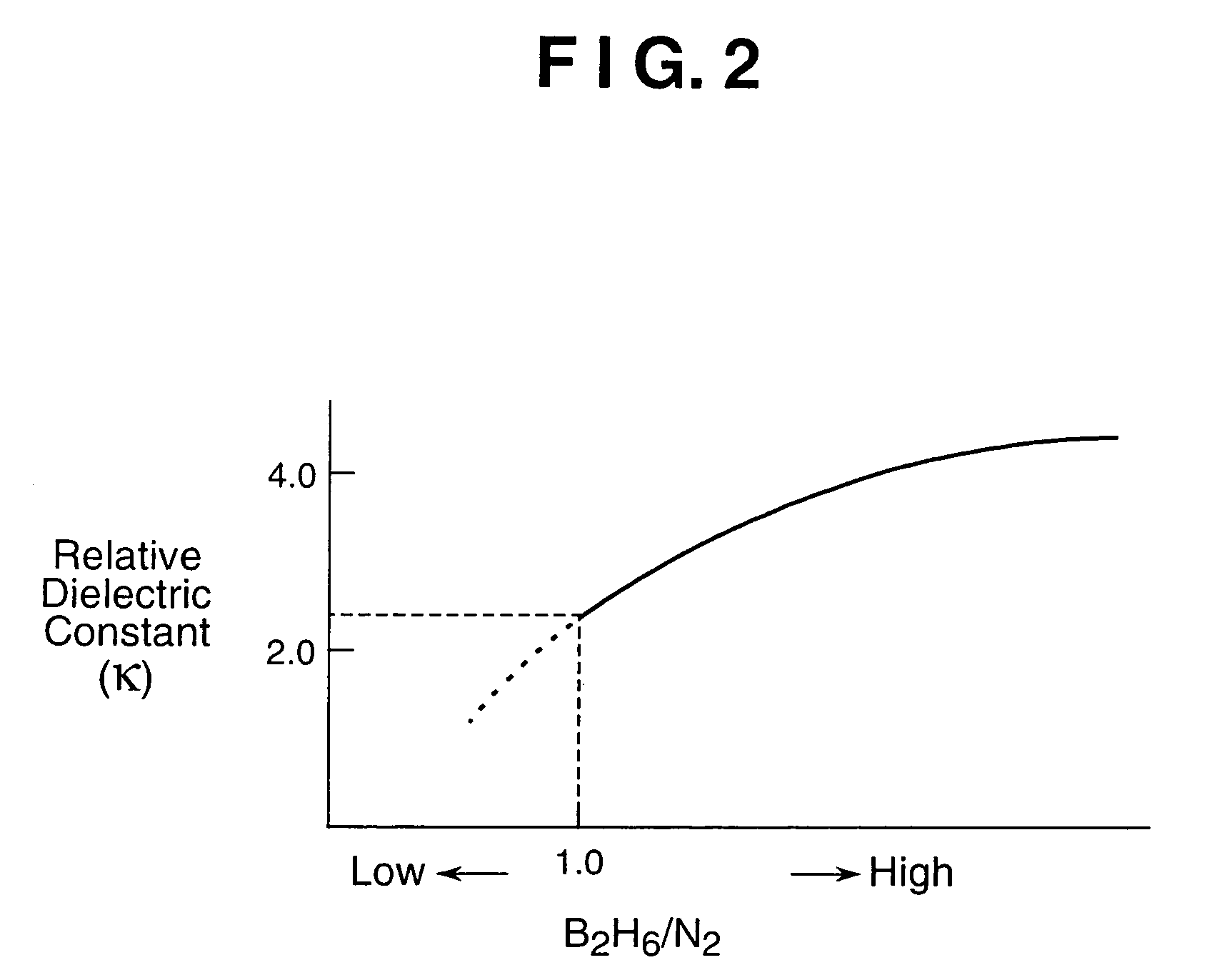

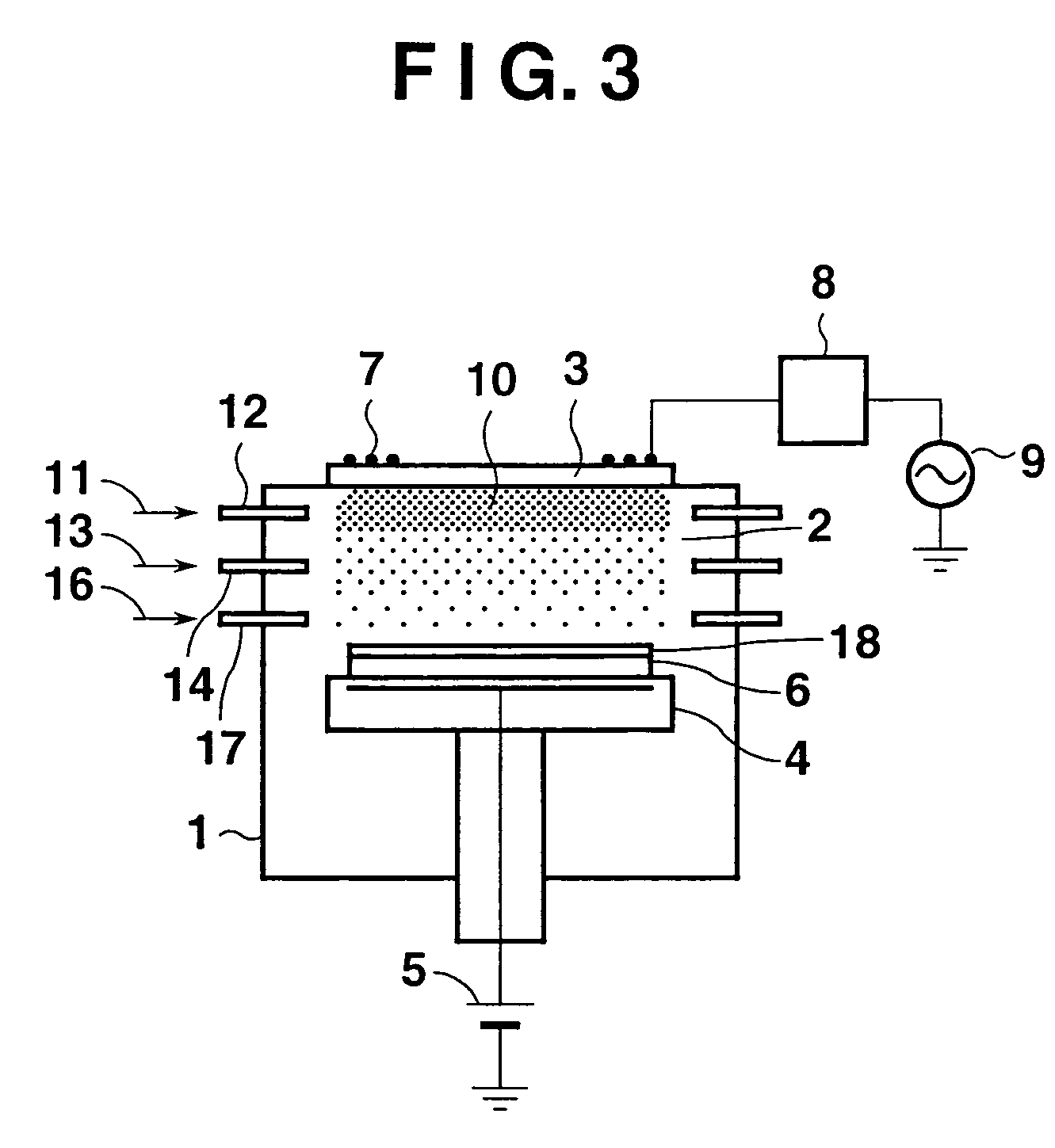

Film forming method and film forming device

InactiveUS6958175B2Increase resistanceImprove thermal conductivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenOptoelectronics

A plasma 10 is generated within a film formation chamber 2, and mainly a nitrogen gas 11 is excited within the film formation chamber 2. Then, the excited nitrogen gas 11 is reacted with a diborane gas 13 diluted with a hydrogen gas, thereby forming a boron nitride film 15 on a substrate 4. Thus, the boron nitride film 15 excellent in mechanical and chemical resistance, high in thermal conductivity, and having a low relative dielectric constant κ can be formed speedily.

Owner:M WATANABE CO LTD

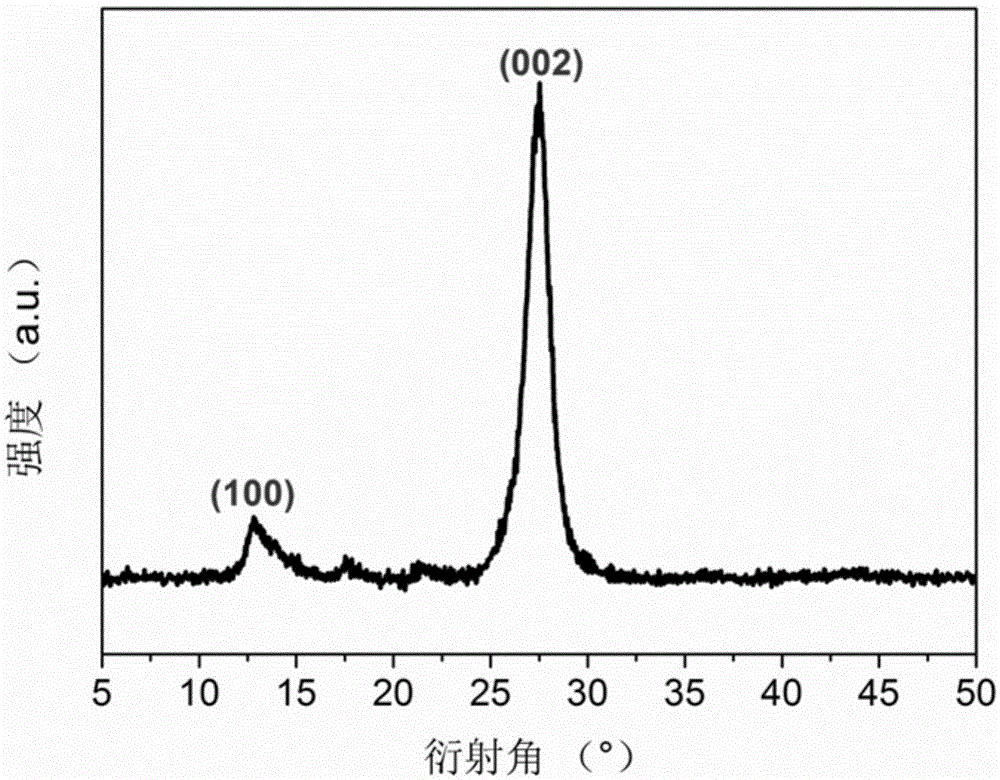

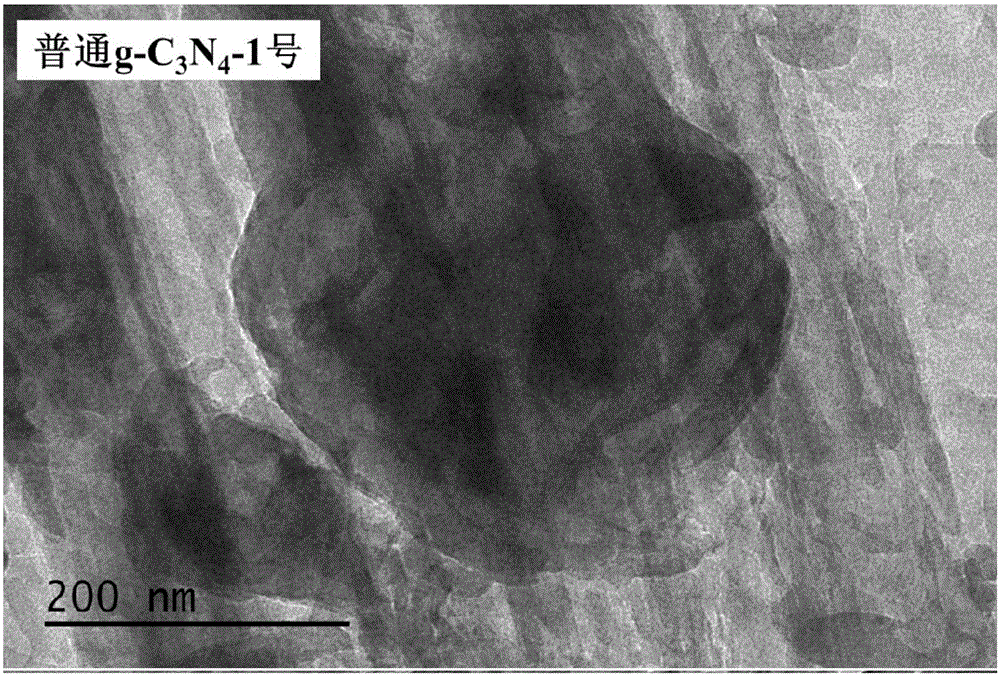

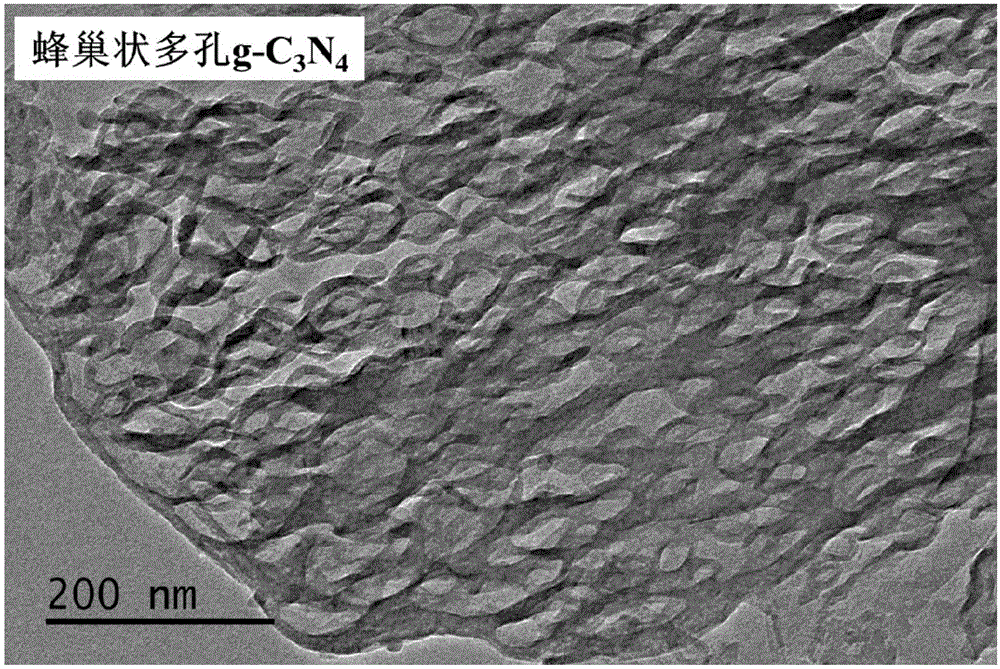

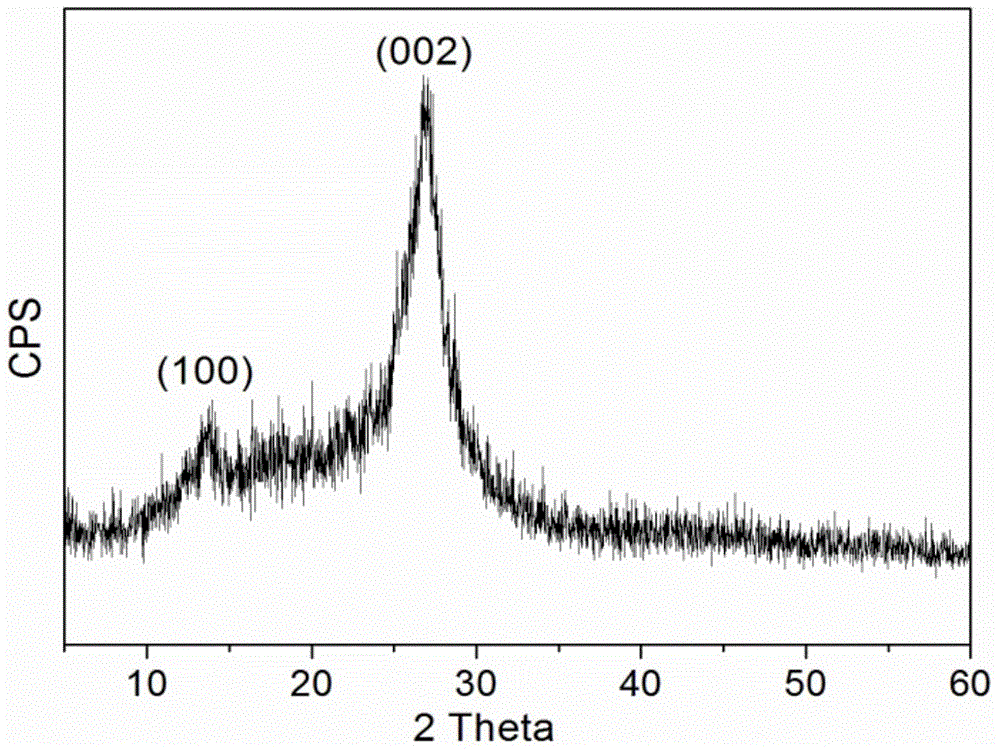

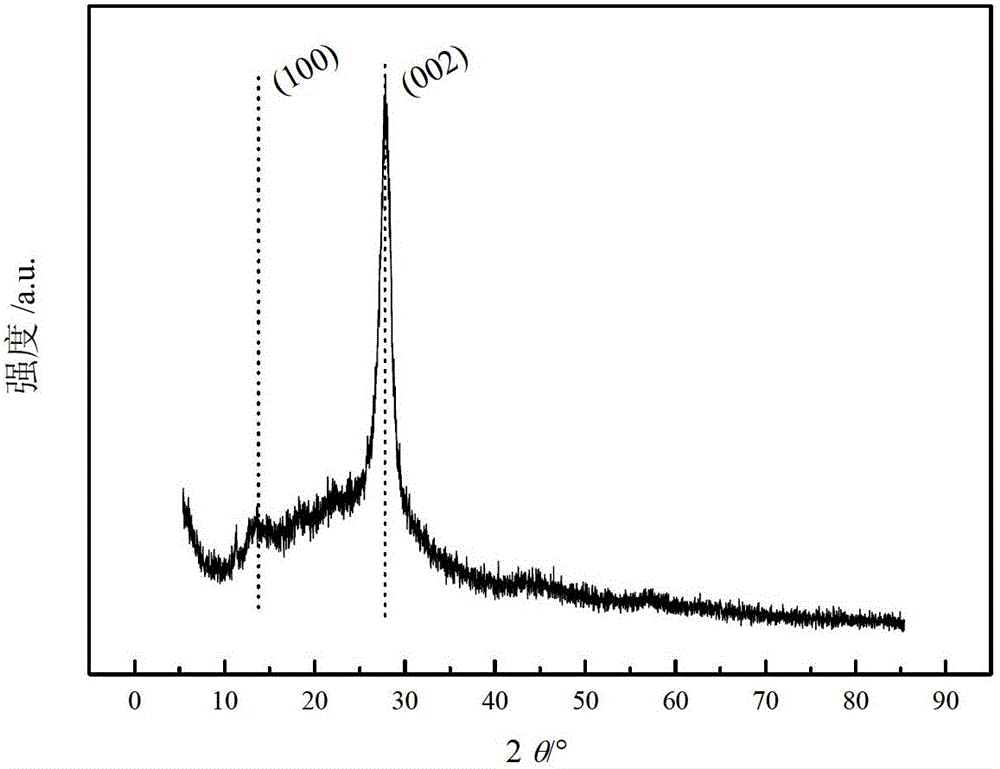

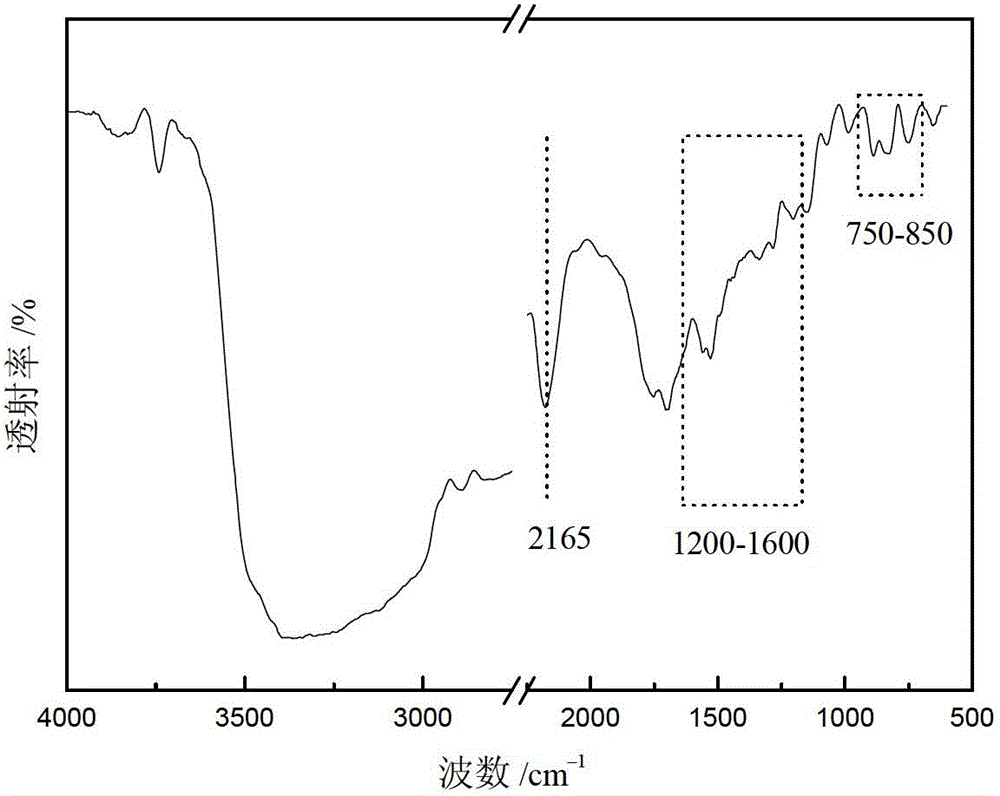

Graphite-phase carbon nitride (g-C3N4) material and preparation method and application thereof

ActiveCN105126893APlay a pore-forming roleAppropriate speedPhysical/chemical process catalystsWater/sewage treatment by irradiationCalcinationMaterials science

The invention relates to a method for preparing a graphite-phase carbon nitride (g-C3N4) material. The method includes the steps that a carbon nitride precursor and ammonium salt are evenly mixed, and then calcination is conducted so that the porous g-C3N4 material can be obtained. The ammonium salt is any one of ammonium base salts capable of generating ammonia gas through thermal decomposition or is the combination of at least two of the ammonium base salts. In the preparation process of the g-C3N4 material, the ammonium salt is added into the carbon nitride precursor to be mixed. In the high-temperature calcining process, the ammonium salt is subjected to pyrogenic decomposition to generate gas, a pore-forming effect on the g-C3N4 material is achieved, and the cellular porous g-C3N4 material is obtained. In the preparation process of the g-C3N4 material, template agents are not used, and thus the method is simple, efficient and environmentally friendly; the prepared g-C3N4 material is high in photocatalytic activity and can be used in the pollution control processes such as exhaust gas and wastewater treatment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

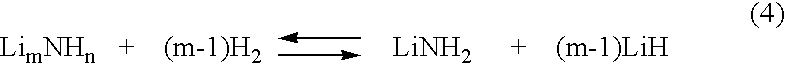

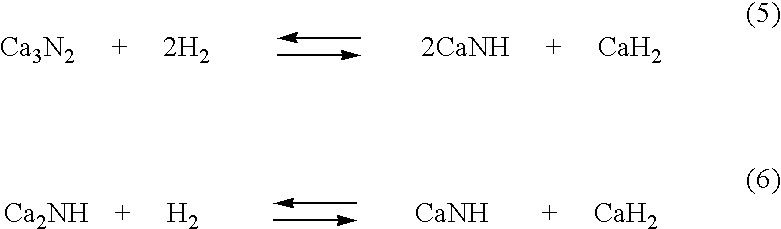

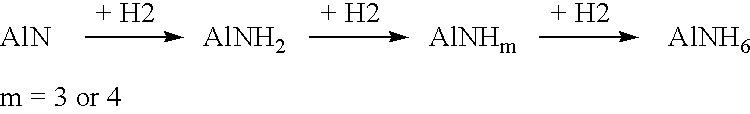

Method for reversible storage of hydrogen and materials for hydrogen storage

InactiveUS20030129126A1Physical/chemical process catalystsAlkali/alkaline-earth/beryllium/magnesium hydridesHydrogen fuel cellMetal

Owner:NAT UNIV OF SINGAPORE

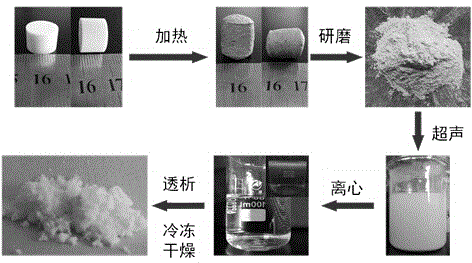

Method for preparing carbon nitride quantum dots

InactiveCN104140084AIncrease useHigh yieldNitrogen and non-metal compoundsFluorescent radiationCarbon nitride

A method for preparing carbon nitride quantum dots comprises the following steps of (1) material preparation, (2) drying and tabletting, (3) heating, (4) separation and (5) drying. Sodium chloride crystals are used as a template, the preparing process is simple and low in cost, and the sodium chloride crystals can be easily removed through water dissolution; melamine is used as the raw material, and annular carbon nitride basic structural units exist in melamine molecules, so that the yield of preparing the quantum dots is high, and product size uniformity is good; the prepared quantum dots are high in specific area, good in water solubility and good in dispersity, have strong fluorescent radiation visible under naked eyes, and have wide application prospects in the fields of fluorescence detection, light emitting devices, biomarker and the like.

Owner:NAT UNIV OF DEFENSE TECH

Oxonitride phosphor and method for production thereof, and luminescent device using the oxonitride phosphor

ActiveCN1705732AImprove luminous brightnessImprove featuresSolid-state devicesNitrogen and non-metal compoundsPhosphorRare earth

An oxonitride phosphor which comprises a crystal containing at least one Group II element selected from the group consisting of Be, Mg, Ca, Sr, Ba and Zn, at least one Group IV element selected from the group consisting of C, Si, Ge, Sn, Ti, Zr and Hf, and a rare earth metal as an activator R. The oxonitride phosphor is exited by an excitation light source of an ultraviolet to visible region and emits a light having a color of from a blue-green region to a yellow region.

Owner:NICHIA CORP

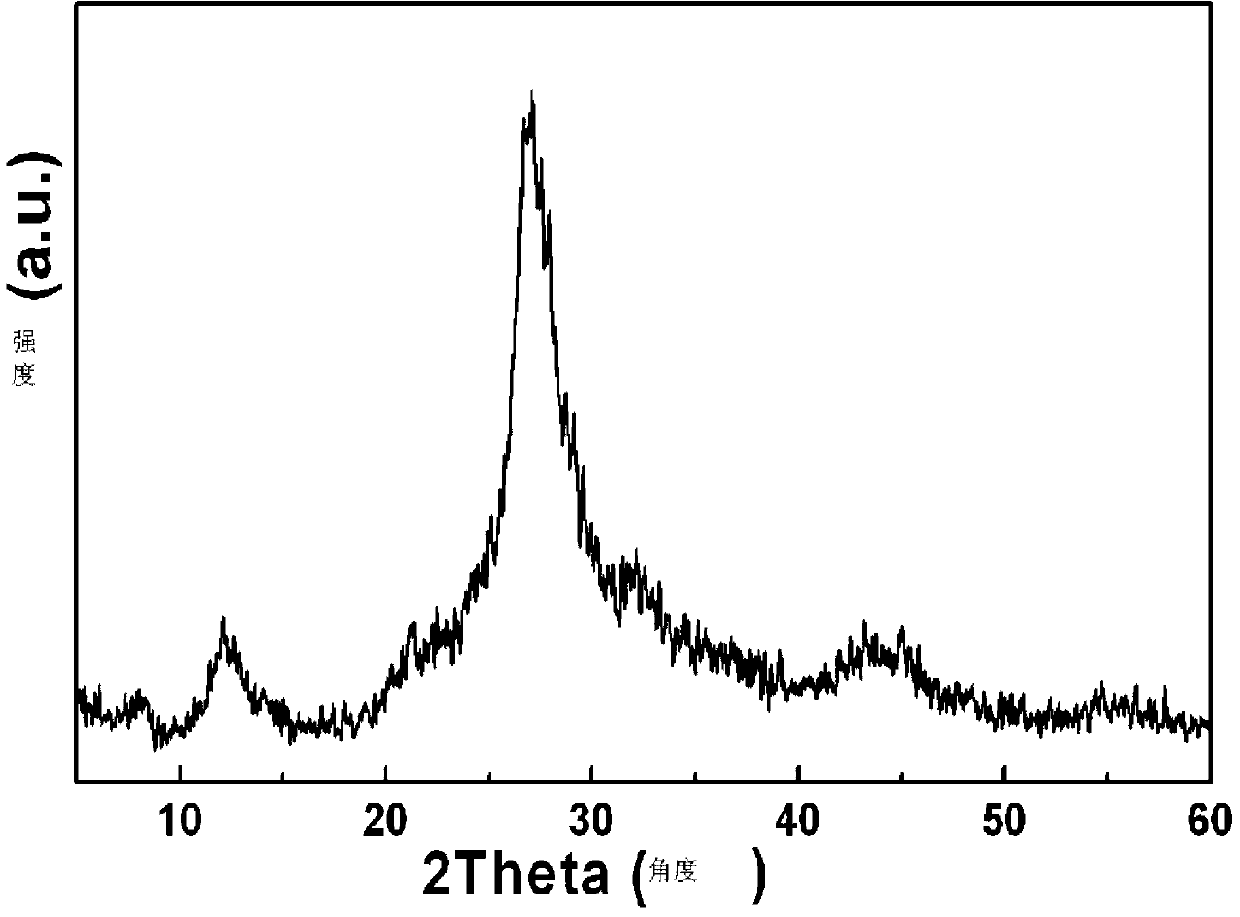

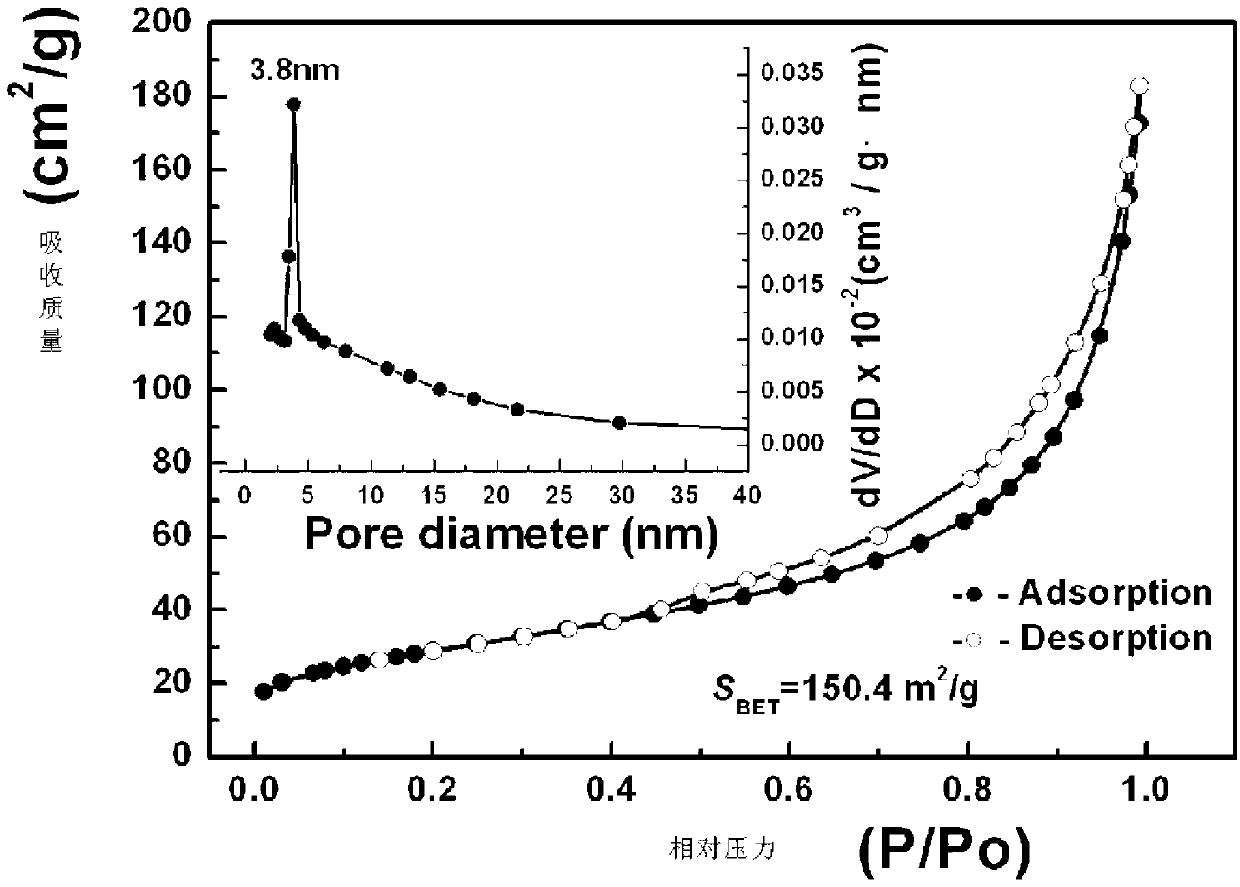

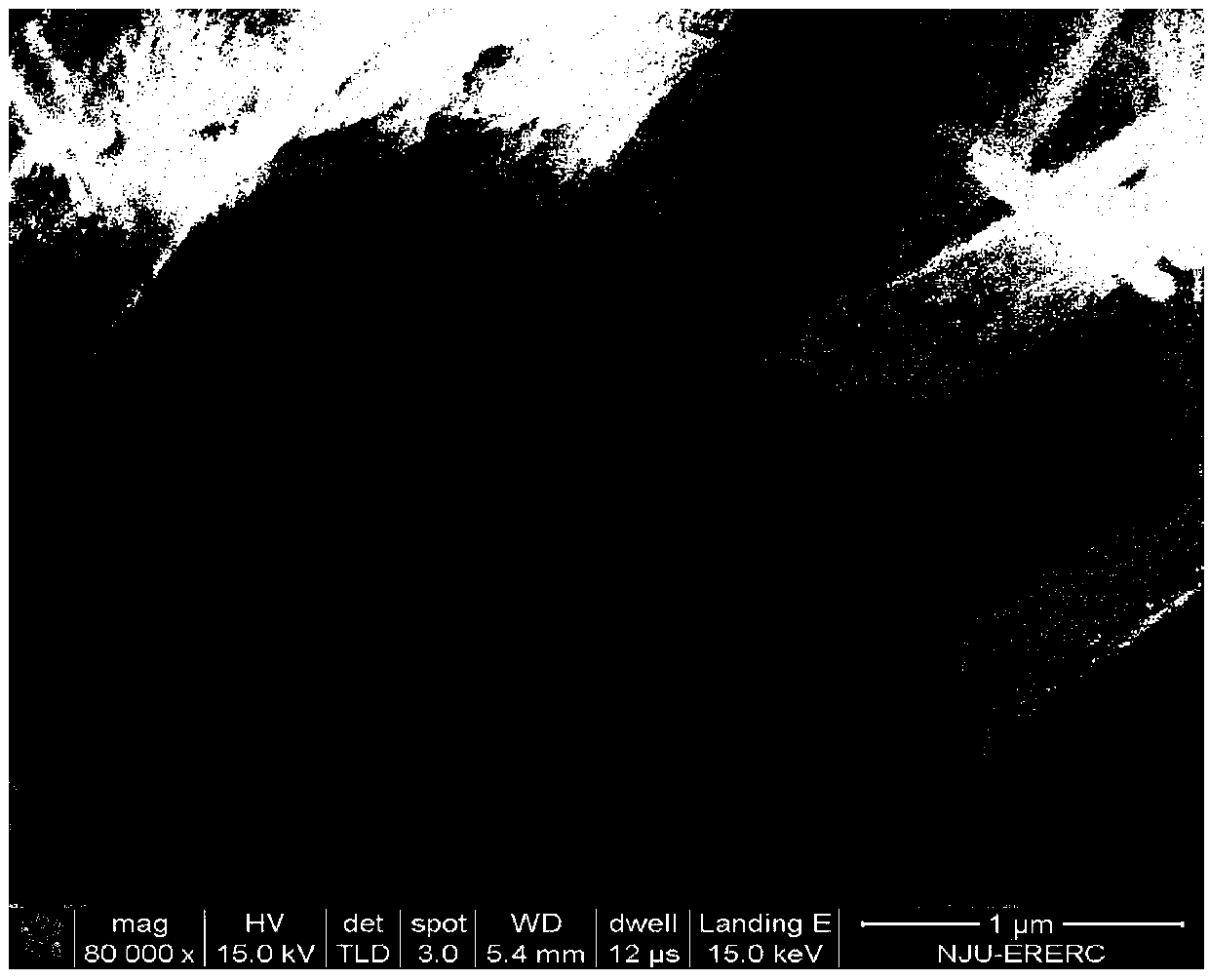

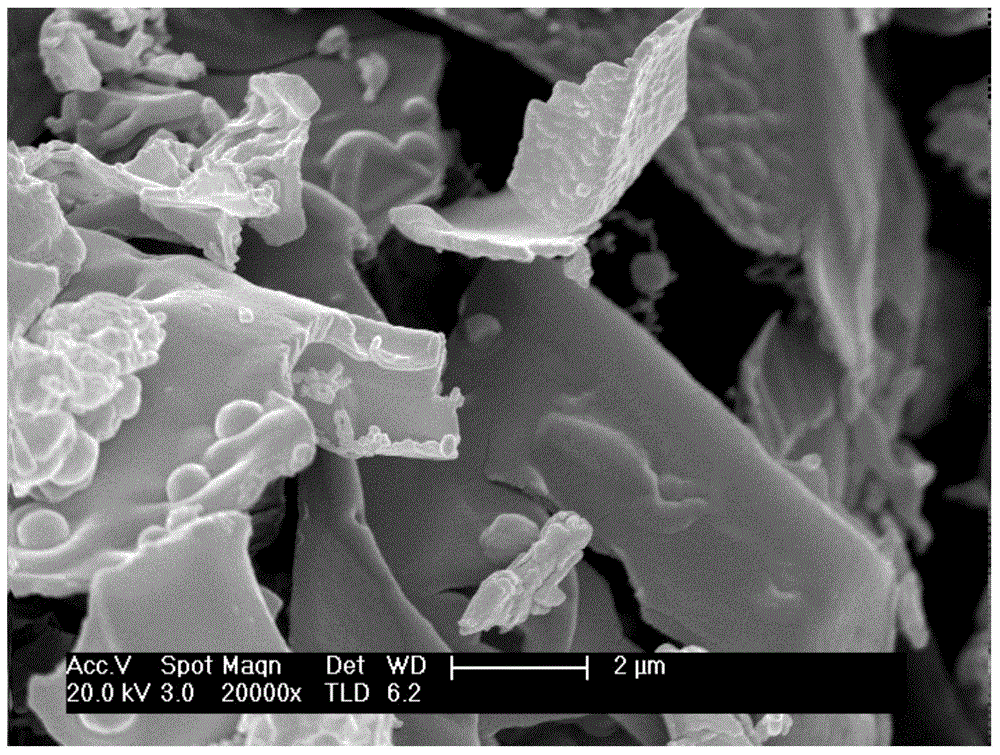

Mesoporous C3N4 photocatalytic material prepared by using molten salt method and application thereof in photocatalysis field

InactiveCN102992282AEase of mass productionEase of large-scale industrial productionPhysical/chemical process catalystsNitrogen and non-metal compoundsMuffle furnaceBlocking layer

The invention discloses a mesoporous C3N4 photocatalytic material prepared by using a molten salt method and a preparing method thereof. The method comprises the following steps that water-soluble low-melting-point molten salt is fully mixed with melamine, small molten salt drops are used as a blocked layer under the melting temperature of the molten salt, C3N4 grows in a way of being coated with the small drops, and the molten salt is recycled by water washing after reaction, so as to obtain the C3N4 photocatalytic material. The C3N4 photocatalytic material is in a wormlike mesoporous structure, the mesoporous size is within 3.8+ / -1nm, and the forming mechanism of the mesoporous C3N4 photocatalytic material is that the small molten salt drops are used as the growth blocked layer. When the material is prepared, water-soluble low-melting-point chloride salt is used as the molten salt and is fully mixed with melamine to obtain a mixture, the mixture is subjected to the heat treatment in a muffle furnace for 1-5h under the temperature being 400-680 DEG C to obtain samples, and the samples after the heat treatment are washed by water to recycle the molten salt, so as to obtain the mesoporous C3N4 photocatalytic material. In the whole process, a template is not introduced, and the operation is easy and feasible, so that the large-scale industrial production can be realized easily.

Owner:NANJING UNIV

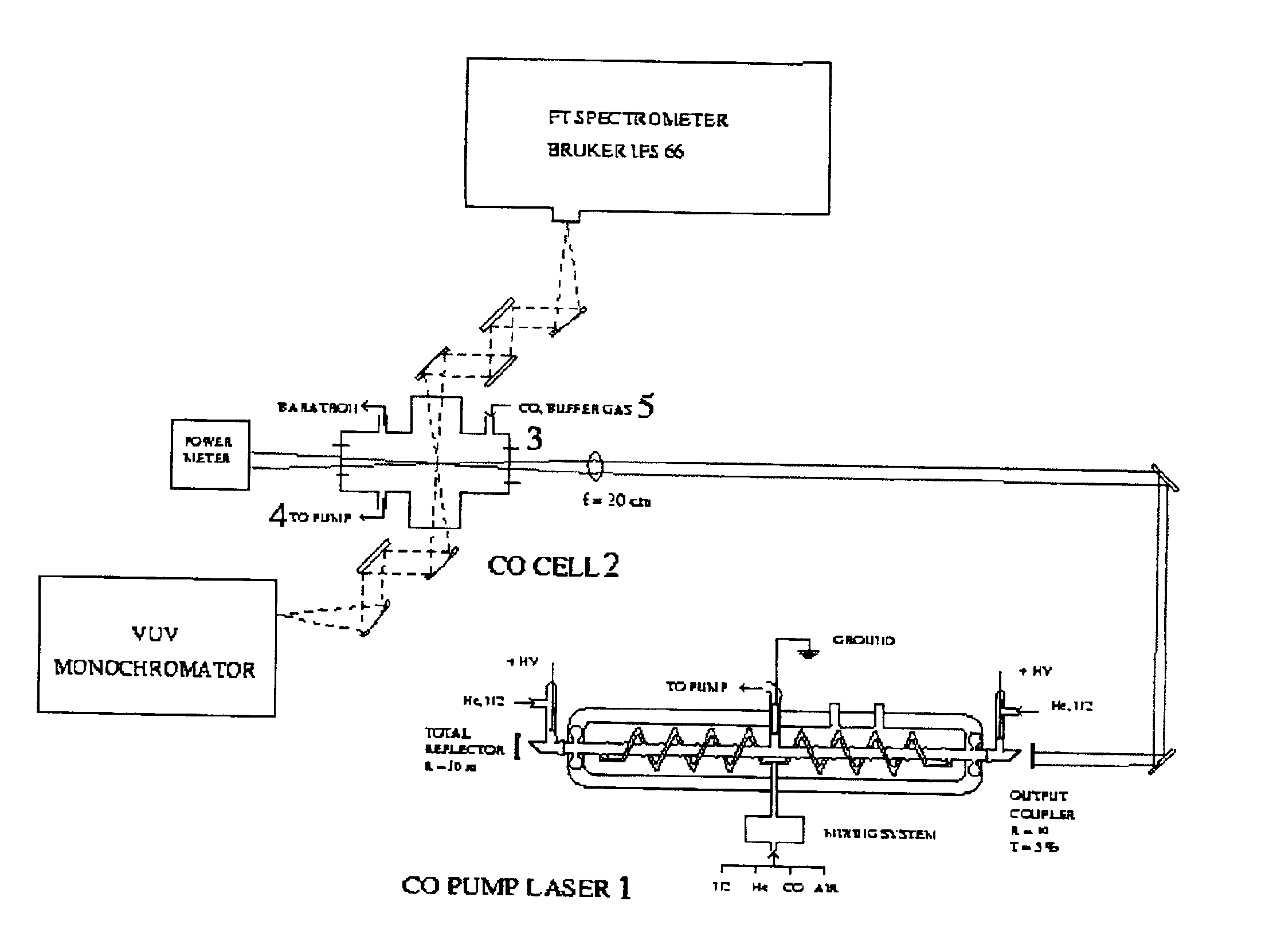

Synthesis method for producing carbon clusters and structured carbon clusters produced thereby

InactiveUS6855301B1Increase ratingsOptimizationMaterial nanotechnologyElectrolysis componentsSynthesis methodsMolecular cluster

The present invention includes carbon synthesis devices and systems. The invention also includes machines and instruments using those aspects of the invention. The present invention also includes methods of carbon synthesis. The present invention includes an array of carbon nanotubes, each nanotube having a longitudinal axis. The nanotubes are placed into an array such that the longitudinal axes of all nanotubes in the array are substantially parallel. The array may be a two-dimensional array or a three-dimensional array. The present invention also includes methods of preparing such carbon molecular clusters and arrays thereof.

Owner:THE OHIO STATES UNIV

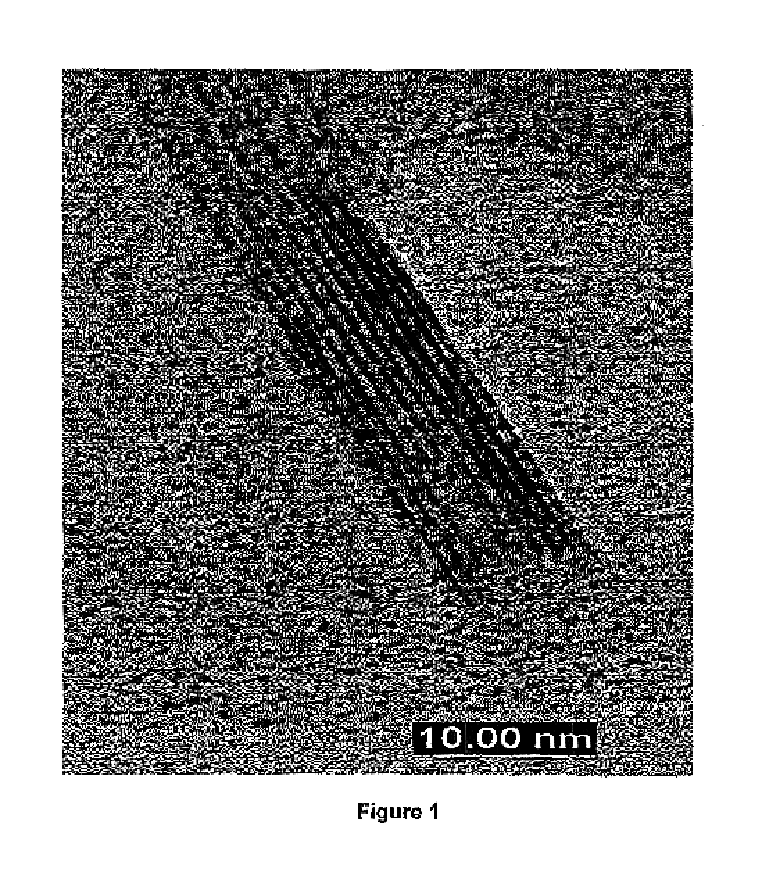

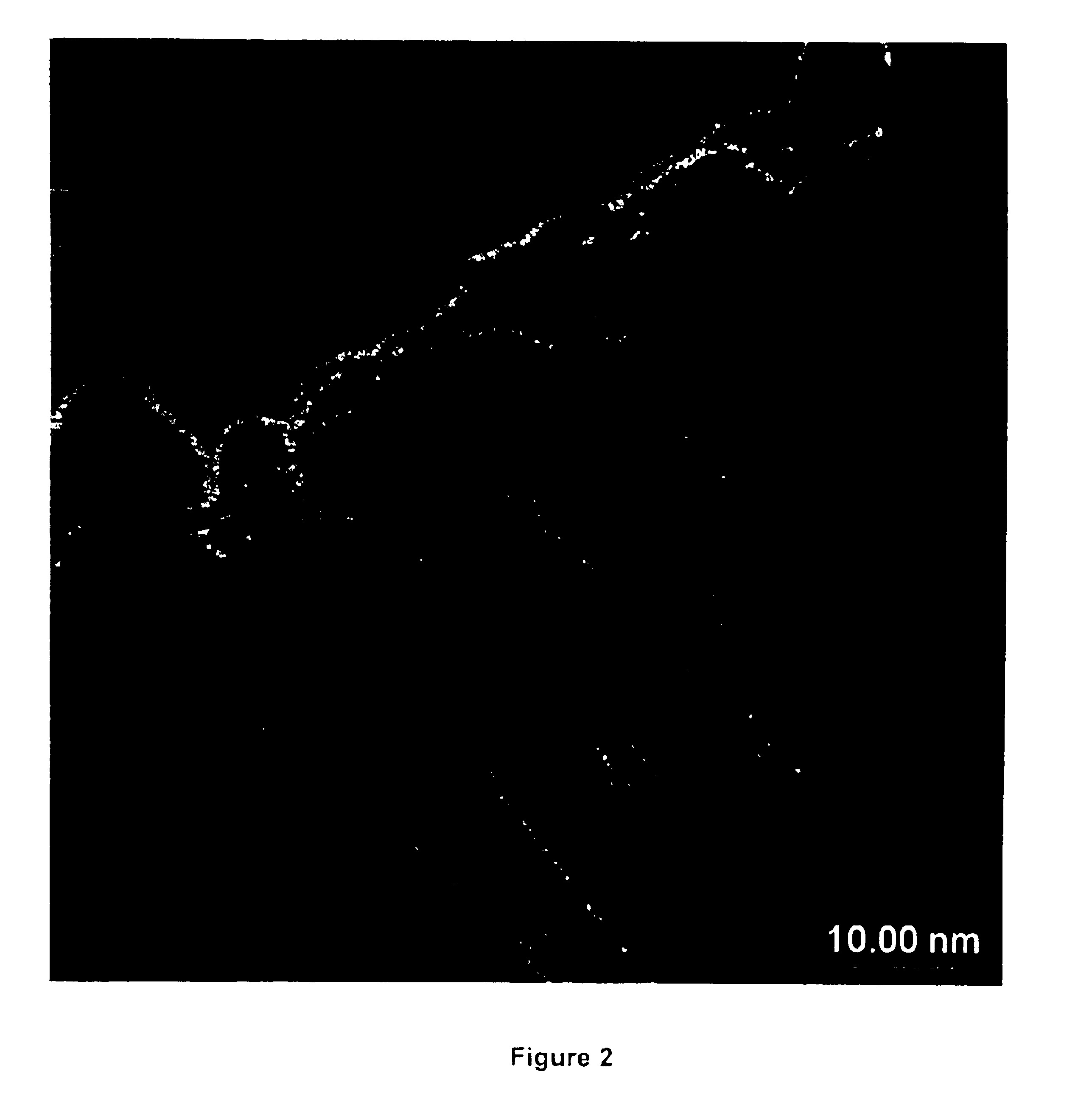

Carbon catalyst, slurry containing the carbon catalyst, process for producing carbon catalyst, and fuel cell, storage device, and environmental catalyst each employing carbon catalyst

InactiveUS20100323272A1Reduced responseImprove responseMaterial nanotechnologyCyanogen compoundsFiberFuel cells

The present invention is made to provide a carbon catalyst capable of preventing the coarsening of particles of nanoshell structure of carbon which causes reduction in activity for oxygen reduction reaction. The carbon catalyst is produced by the steps of: preparing a carbon precursor polymer; mixing a transition metal or a compound of the transition metal into the carbon precursor polymer; spinning the mixture of the carbon precursor polymer and the transition metal or the compound of the transition metal into fibers; and carbonizing the fibers.

Owner:GUNMA UNIVERSITY +1

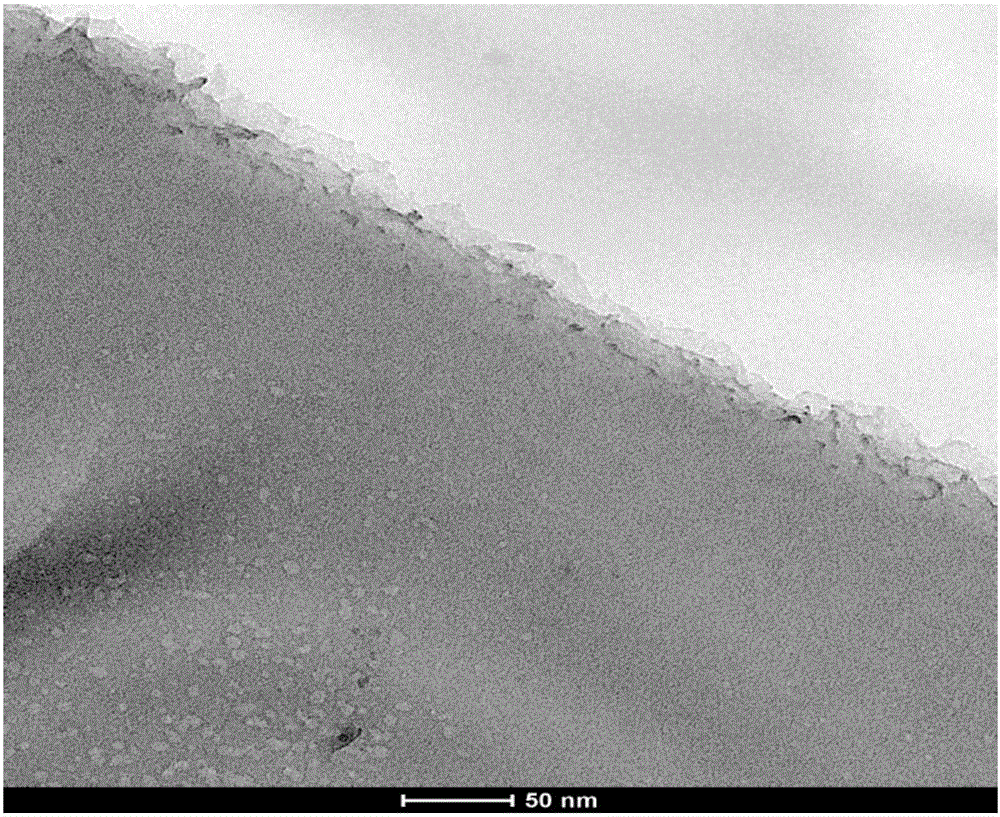

Spherical mesoporous carbon nitride material and preparation method thereof

ActiveCN103011099ANo pollutionEasy to makeNanotechnologyNitrogen and non-metal compoundsHydrofluoric acidShielding gas

The invention provides a spherical mesoporous C3N4 material with a hollow cavity nanostructure and a preparation method thereof. The preparation method comprises the following steps: modifying a nano solid SiO2 spherule to get a solid SiO2 material coated with mesoporous SiO2 on the outer layer, further adding alkali, selectively etching off the inner-layer solid SiO2 to get nano hollow mesoporous SiO2, fully impregnating the nano hollow mesoporous SiO2 in a water solution of a nitrogen-containing precursor, performing centrifugal drying, performing high-temperature roasting in protective gas, and then using hydrofluoric acid to dissolve the SiO2 to get the spherical hollow mesoporous nano C3N4. The prepared product has the specific surface area of 300-800m<2> / g and a cavity capable of loading other materials, is easy to perform mass transfer and can be further widely applied.

Owner:泰州市海通资产管理有限公司

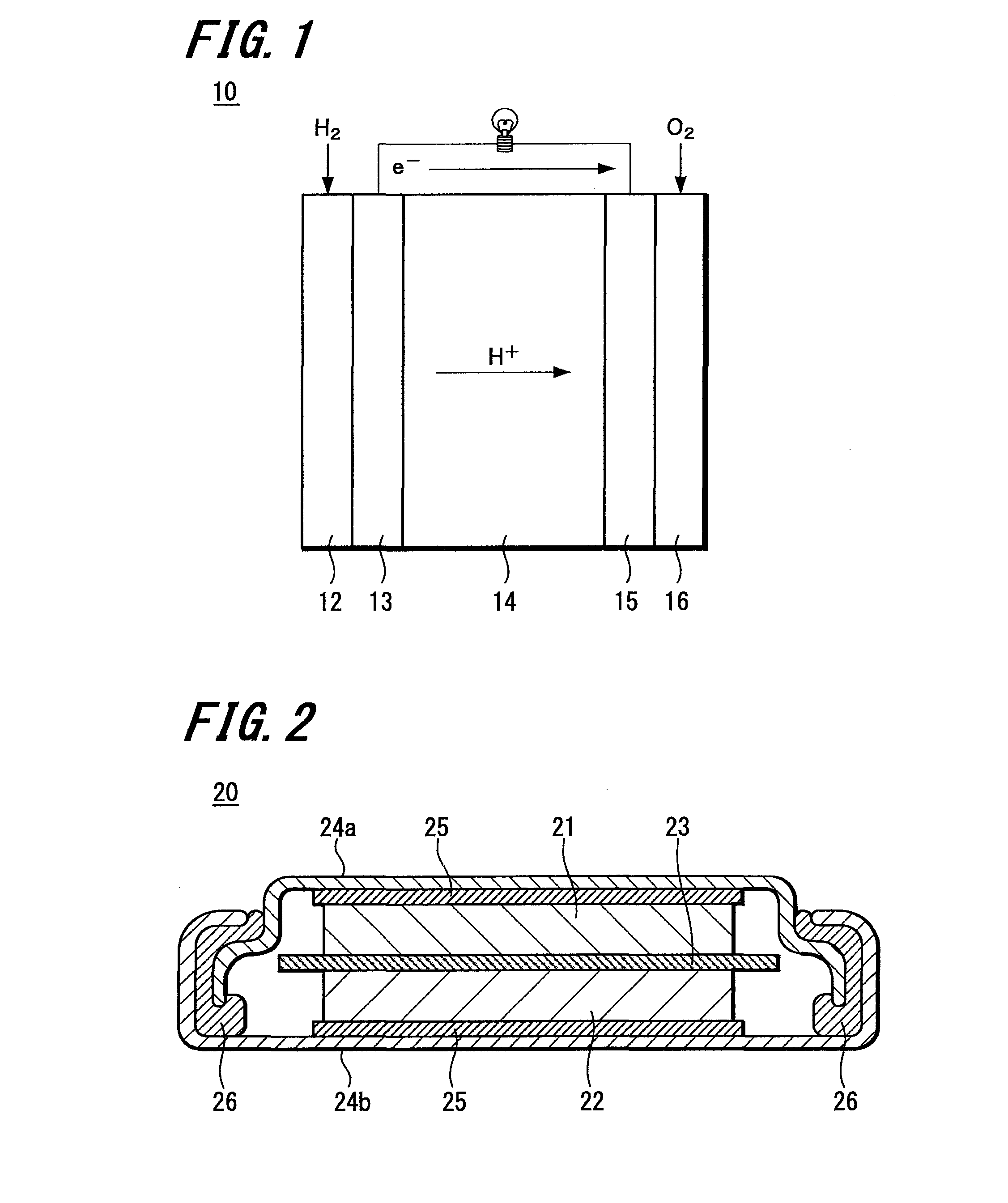

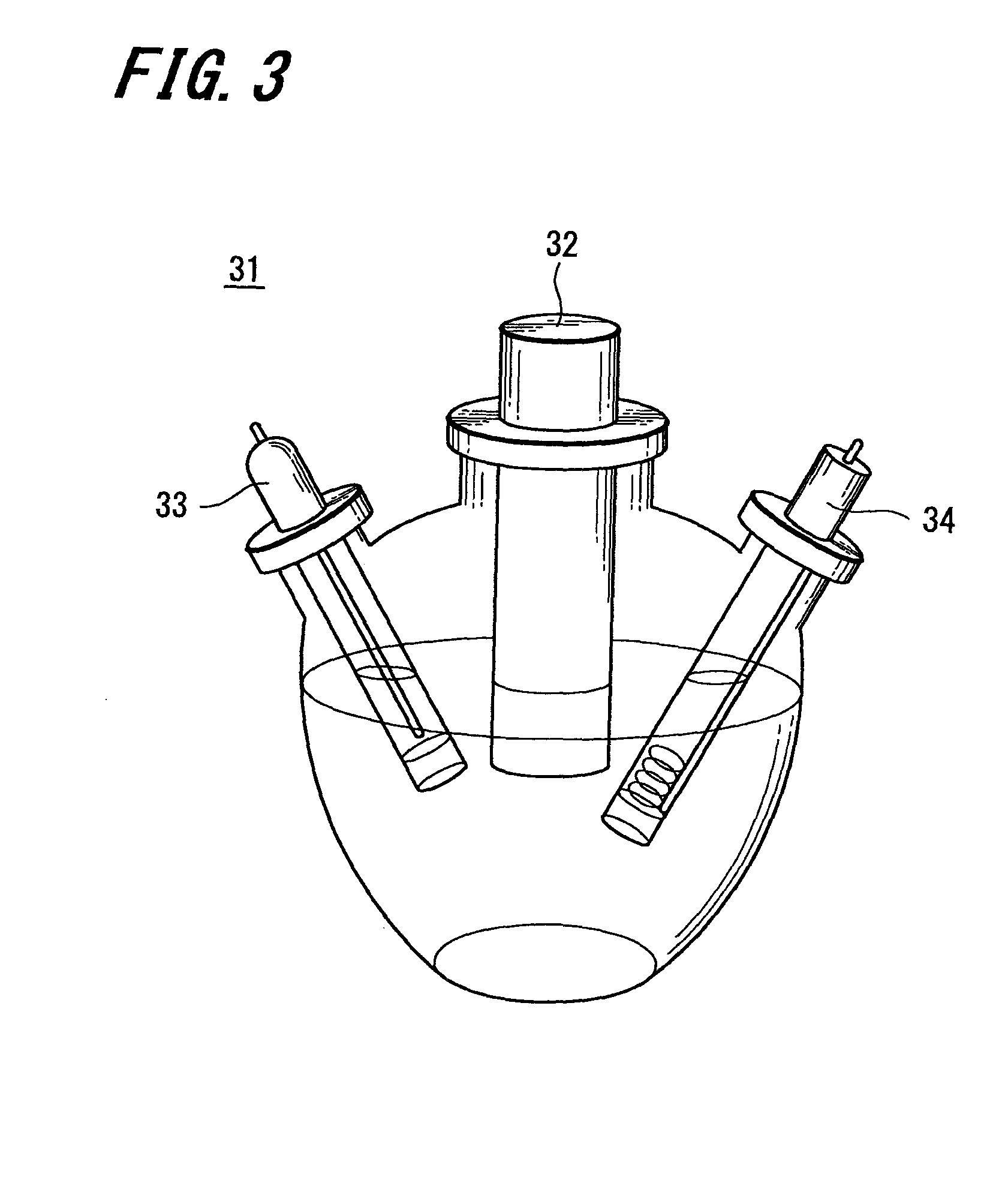

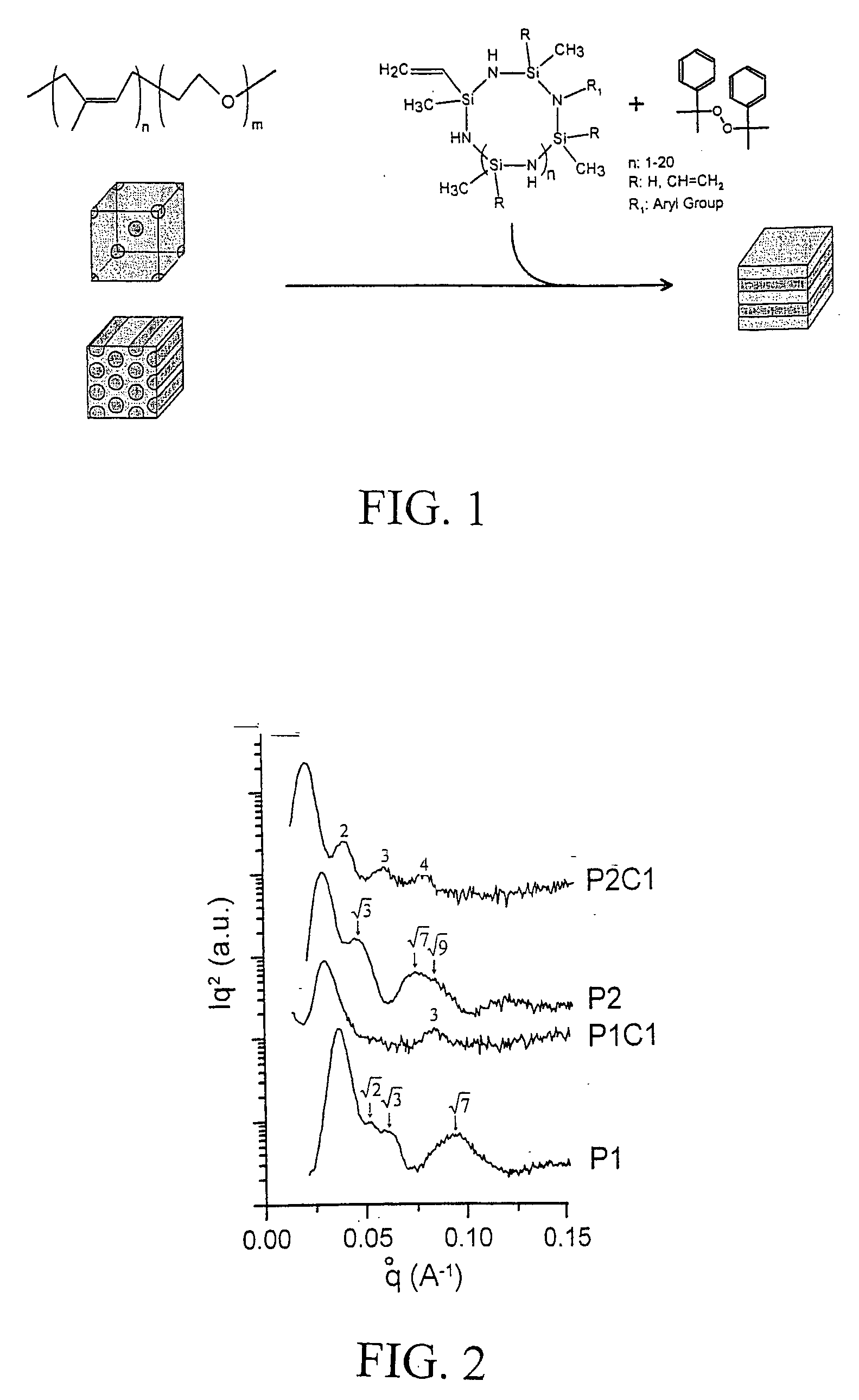

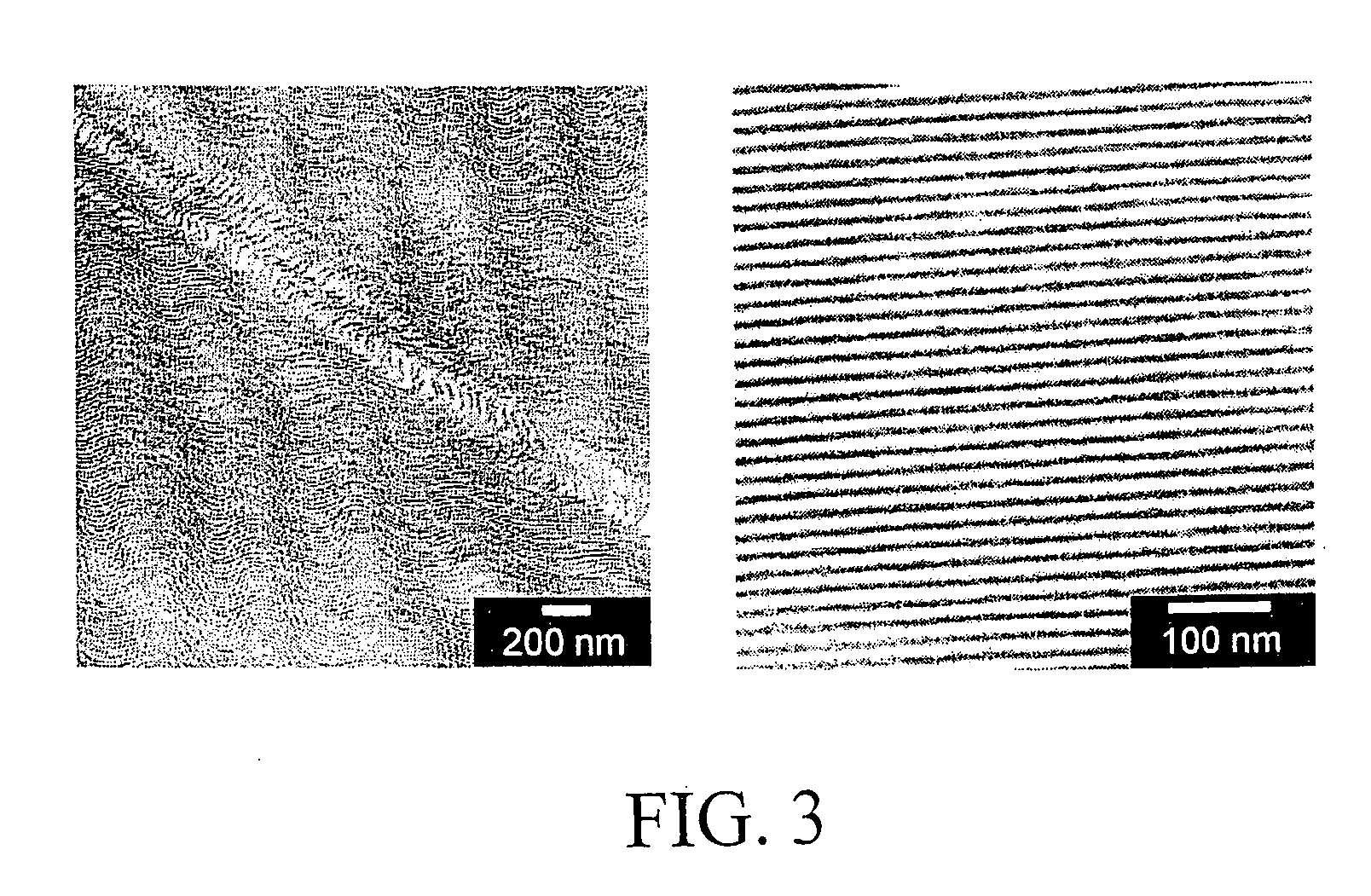

High temperature SiCN and SiC-type nanostructured ceramic material from block copolymer mesophases

InactiveUS20050036931A1Simple and easily controlled pathwayCarbon compoundsNitrogen and non-metal compoundsNon oxide ceramicsPolymer science

A block copolymer, preferably a block copolymer such as poly(isoprene-block-ethylene oxide), PI-b-PEO, is used as a structure directing agent for a polymer derived ceramic (PDC) precursor, preferably a silazane, most preferably a silazane commercially known as Ceraset. The PDC precursor is preferably polymerized after mixing with the block copolymer to form a nanostructured composite material. Through further heating steps, the nanostructured composite material can be transformed into a nanostructured non-oxide ceramic material, preferably a high temperature SiCN or SiC material.

Owner:CORNELL RES FOUNDATION INC

Method for efficiently preparing graphene-like carbon nitride

ActiveCN106542509ANo preprocessing requiredEasy to makeNitrogen and non-metal compoundsBiomedical sensorsHigh energy

The present invention provides a method for efficiently preparing graphene-like carbon nitride. The method is characterized by comprising: using a nitrogen-rich organic matter as a raw material, adding a microwave absorbing agent, mixing, placing into a ceramic crucible, placing the crucible into the center of an industrial high-energy resonant cavity, vacuumizing, and carrying out high-energy microwave irradiation heating so as to rapidly and efficiently prepare the graphene-like carbon nitride. According to the present invention, the obtained graphene-like carbon nitride has characteristics of high specific surface area, high yield and high purity, and can be used in the fields of degradation of organic matters, hydrogen production through photolysis of water, catalyst carriers, biomedical sensors, and the like.

Owner:ZHANGJIAGANG DONGDA IND TECH RES INST +1

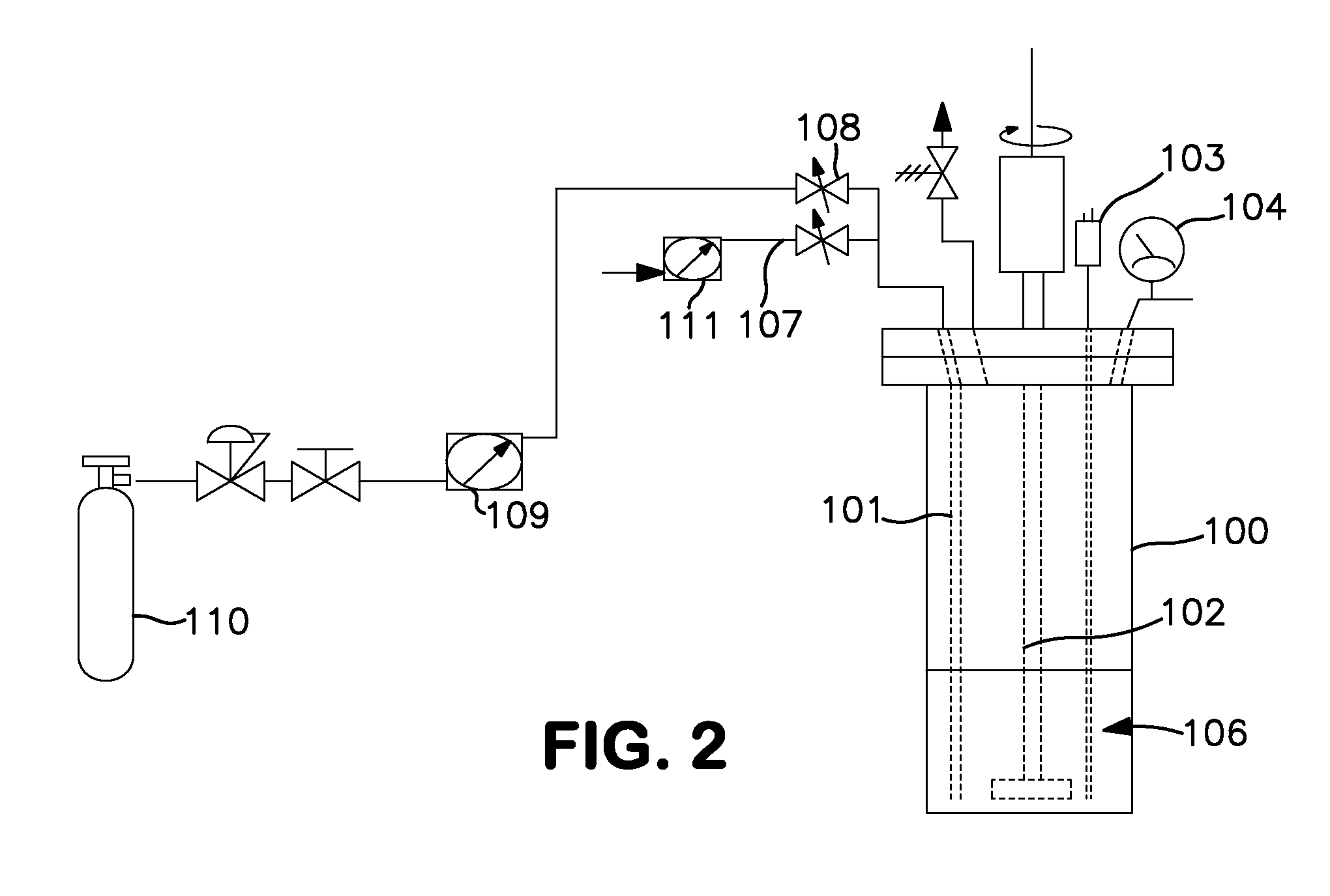

Apparatus and method for the condensed phase production of trisilylamine

ActiveUS20130089487A1Increased formationPromote formationSilicon compoundsNitrogen and non-metal compoundsDistillationSynthesis methods

The present invention is directed to a condensed phase batch process for synthesis of trisilylamine (TSA). An improved synthesis method that incorporates a solvent to help promote a condensed-phase reaction between ammonia gas (or liquid) and liquified monochlorosilane (MCS) in good yields is described. This method facilitates the removal of the byproduct waste with little to no reactor down time, substantial reduction of down-stream solids contamination and high-purity product from first-pass distillation.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

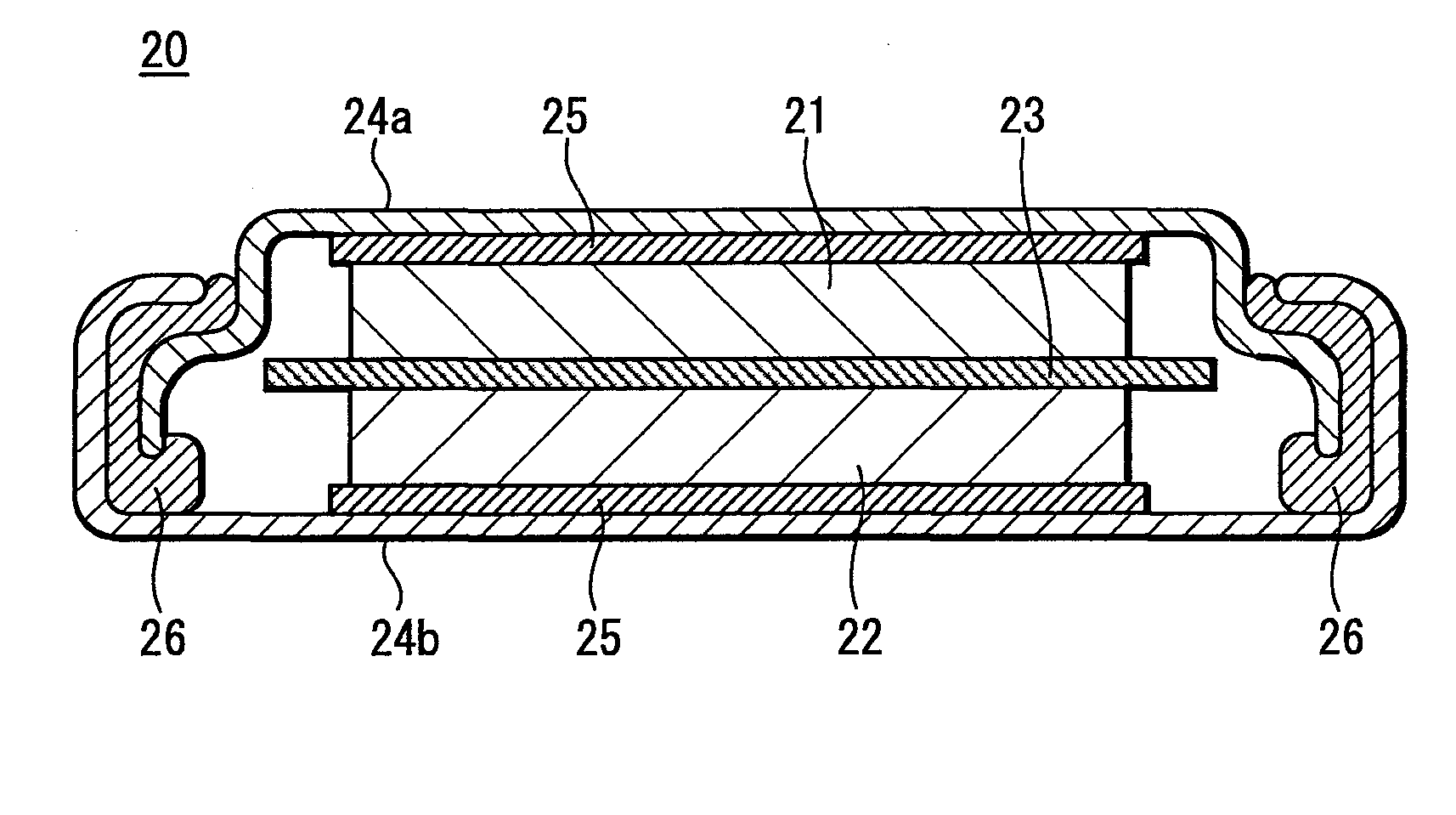

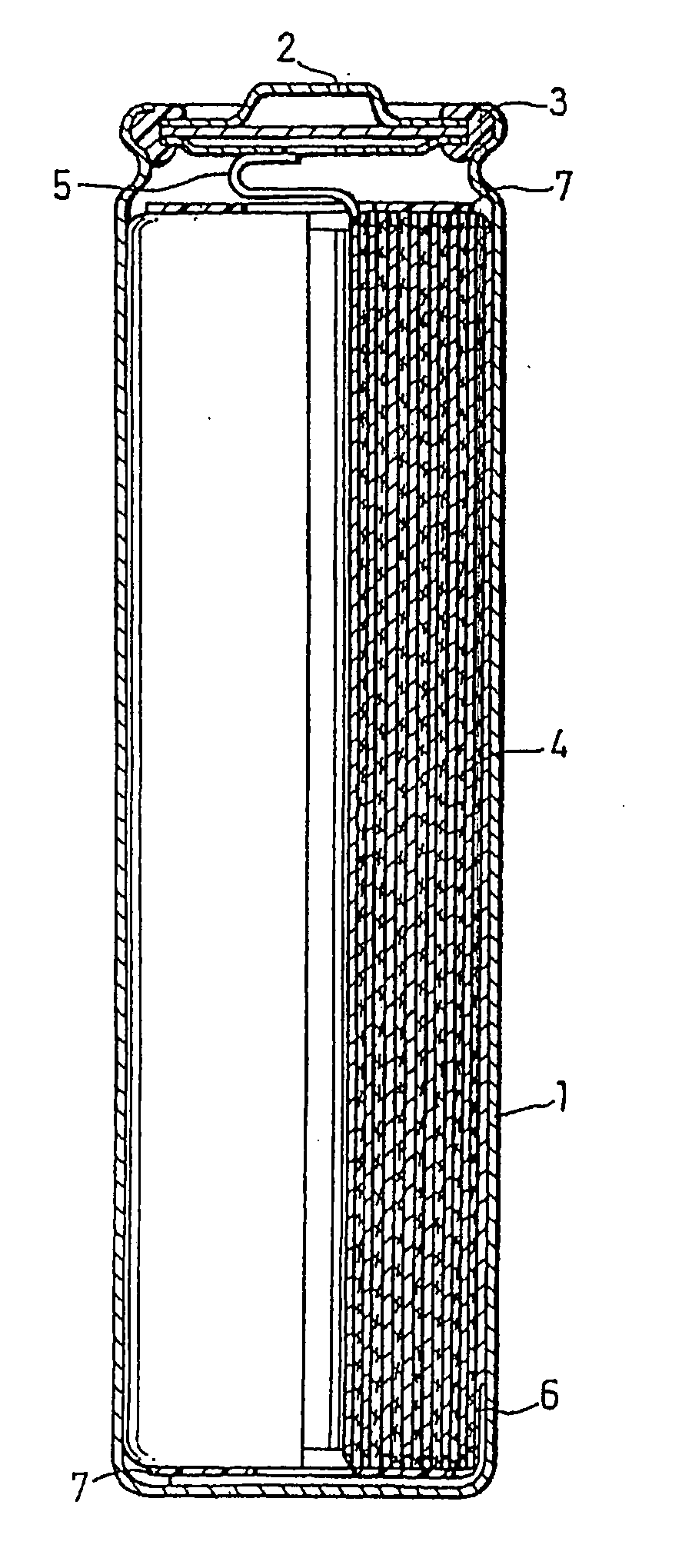

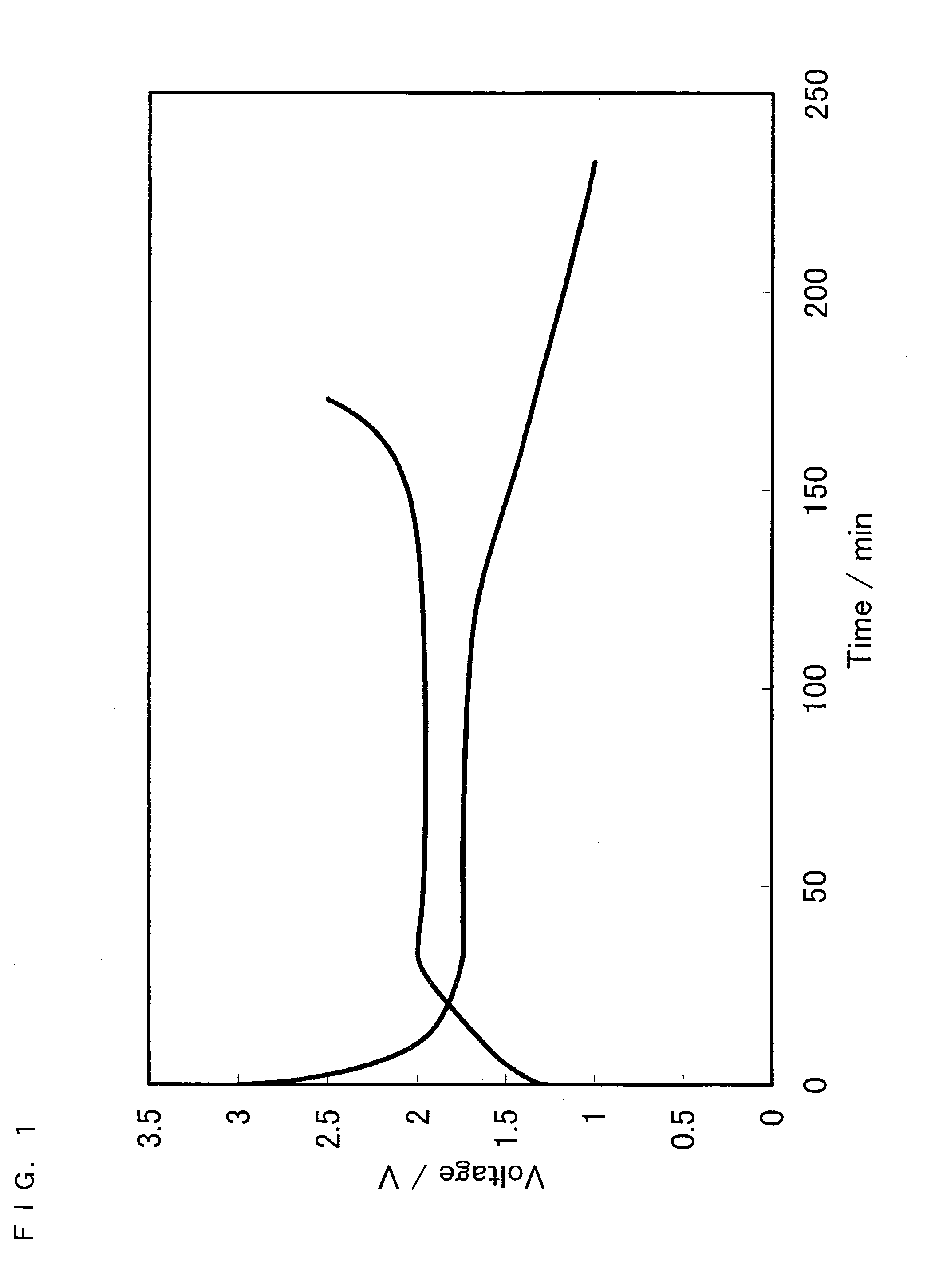

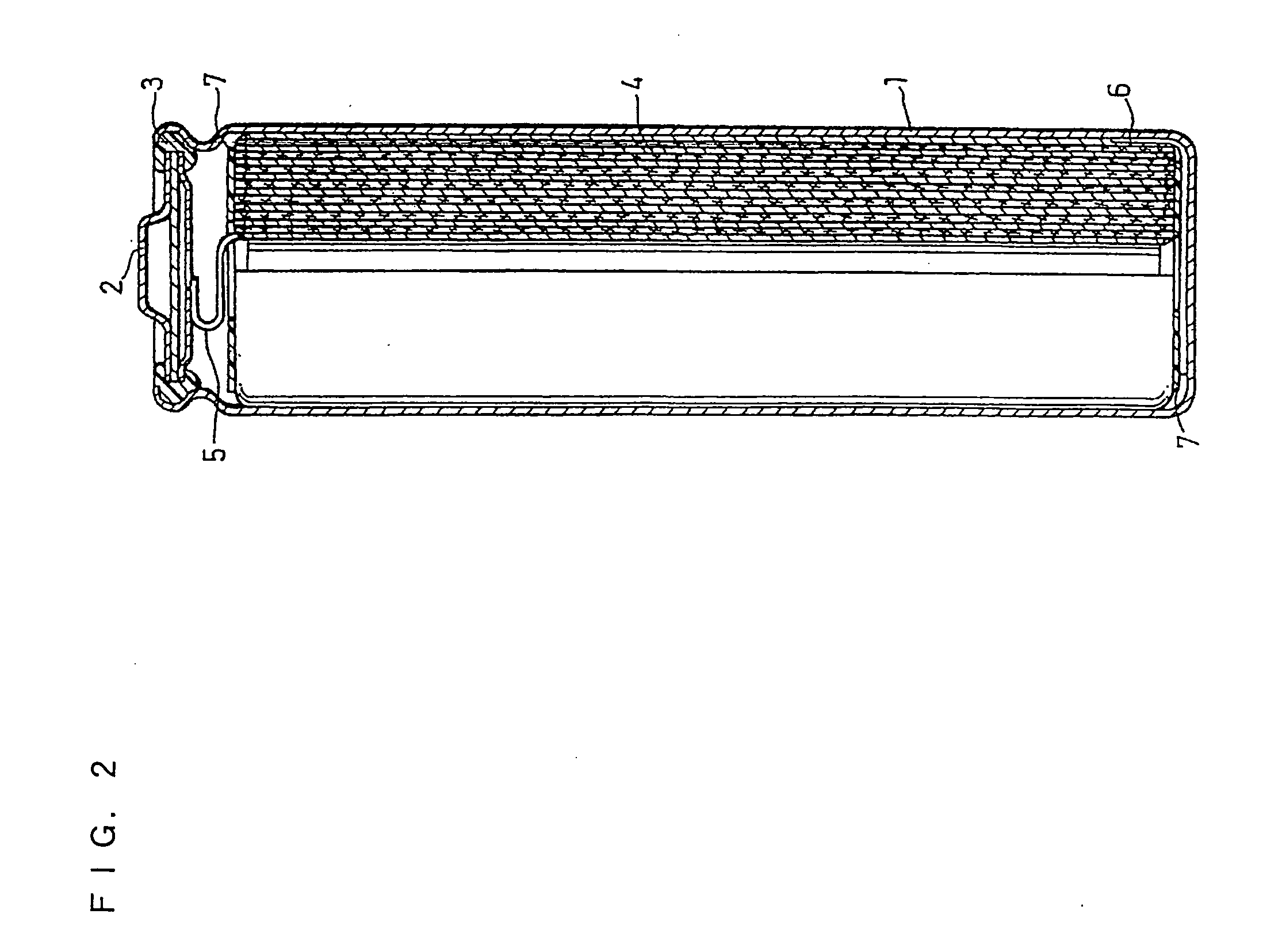

Active material, manufacturing method thereof, and non-aqueous electrolyte secondary battery including the active material

InactiveUS20050281727A1Improve conductivityLarge capacityElectrode manufacturing processesSecondary cellsMaterials scienceNon aqueous electrolytes

A resistivity of an active material is reduced to drastically decrease an amount of a conductive auxiliary agent to be added, in order to provide a non-aqueous electrolyte secondary battery with high capacity. A material represented by a composition formula: LixMeOyNz, wherein 0≦x≦2, 0.1<y<2.2, 0<z<1.4, and Me is at least one selected from the group consisting of Ti, Co, Ni, Mn, Si, Ge, and Sn is used as an active material.

Owner:PANASONIC CORP

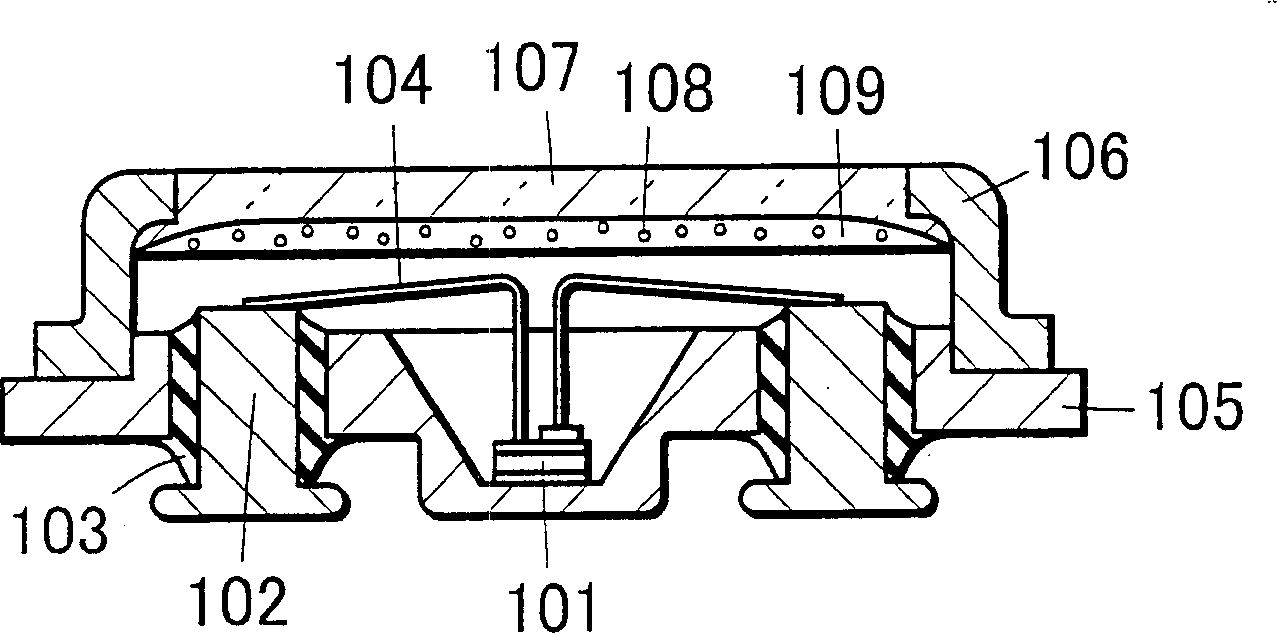

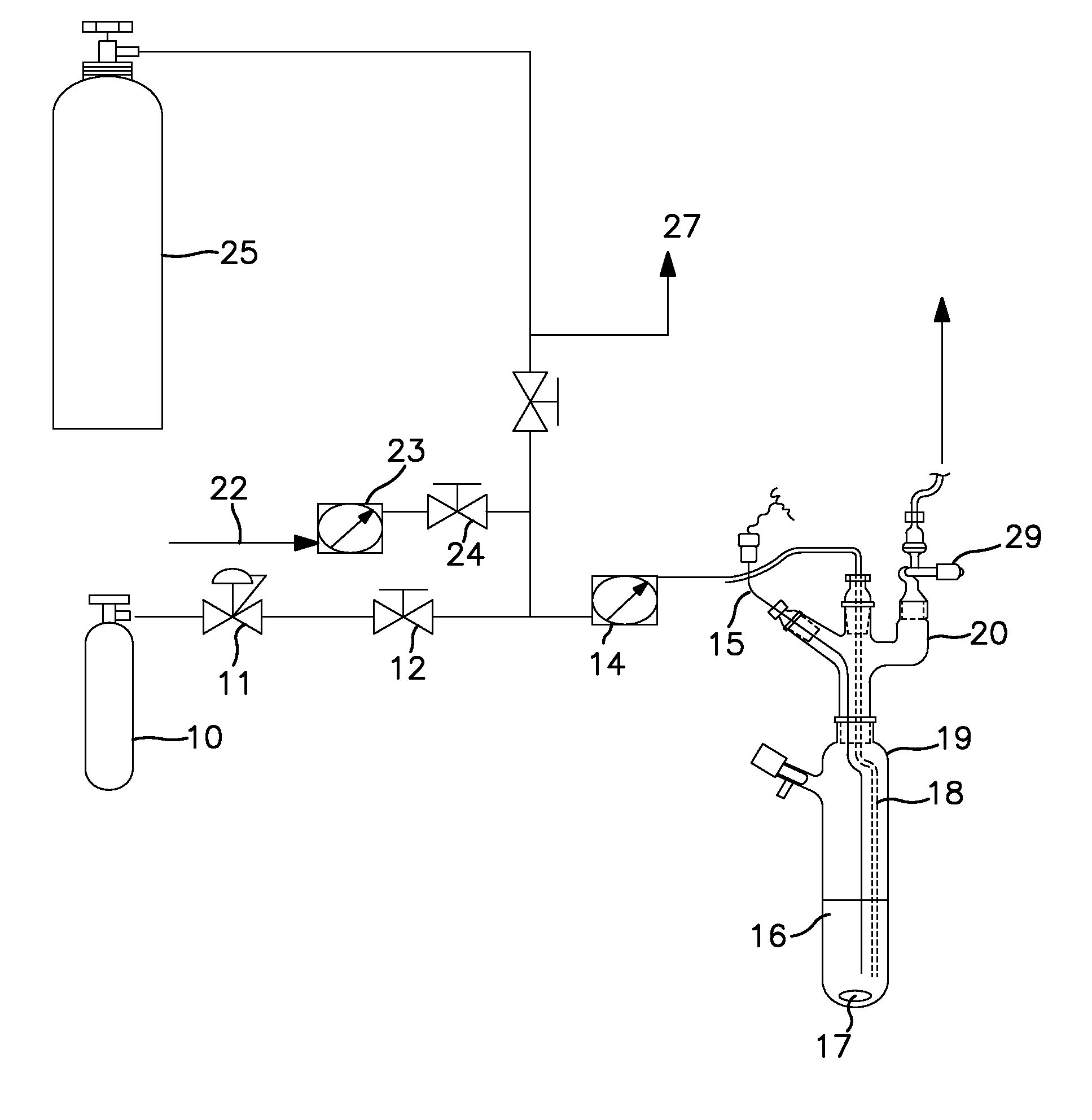

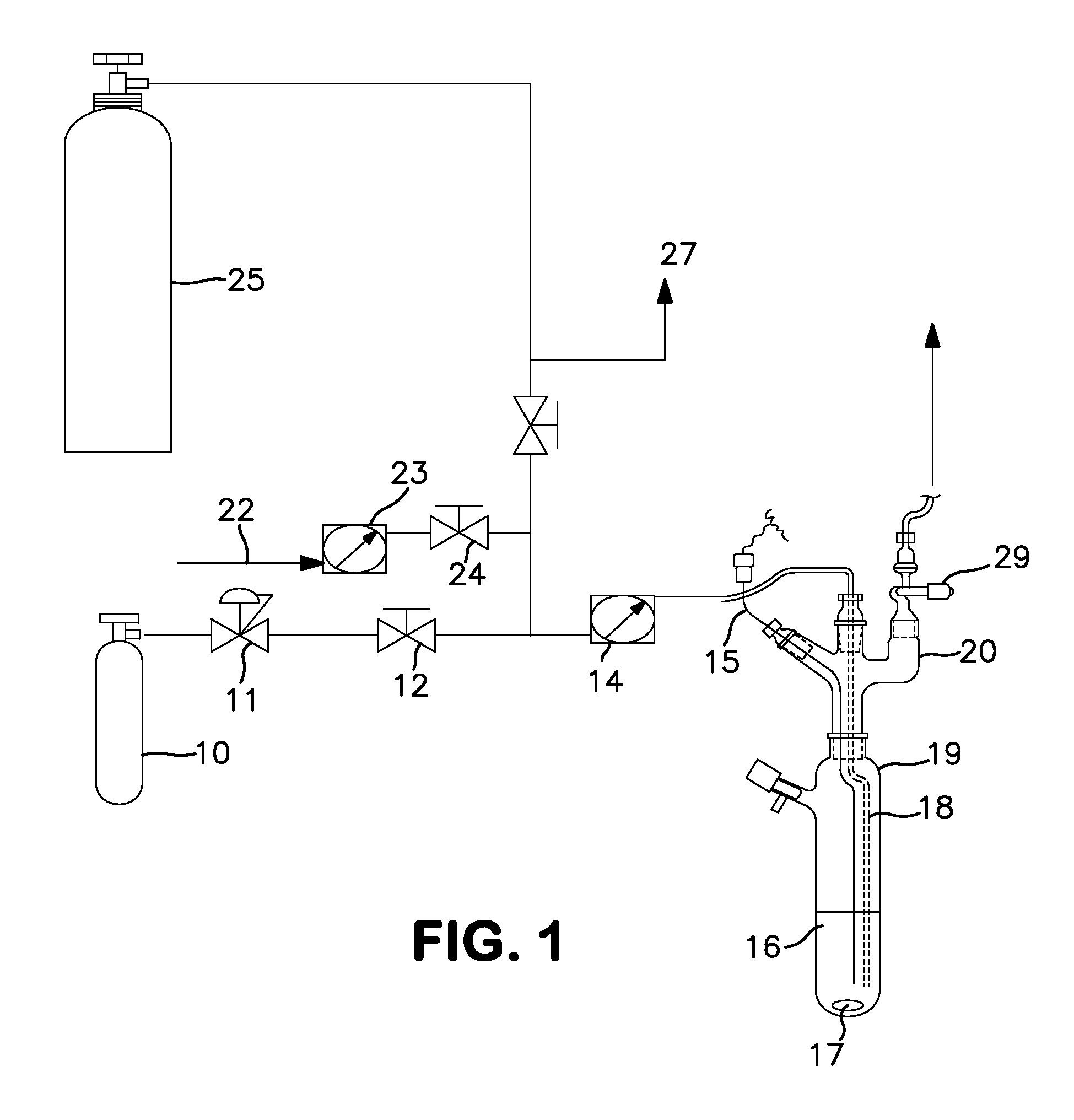

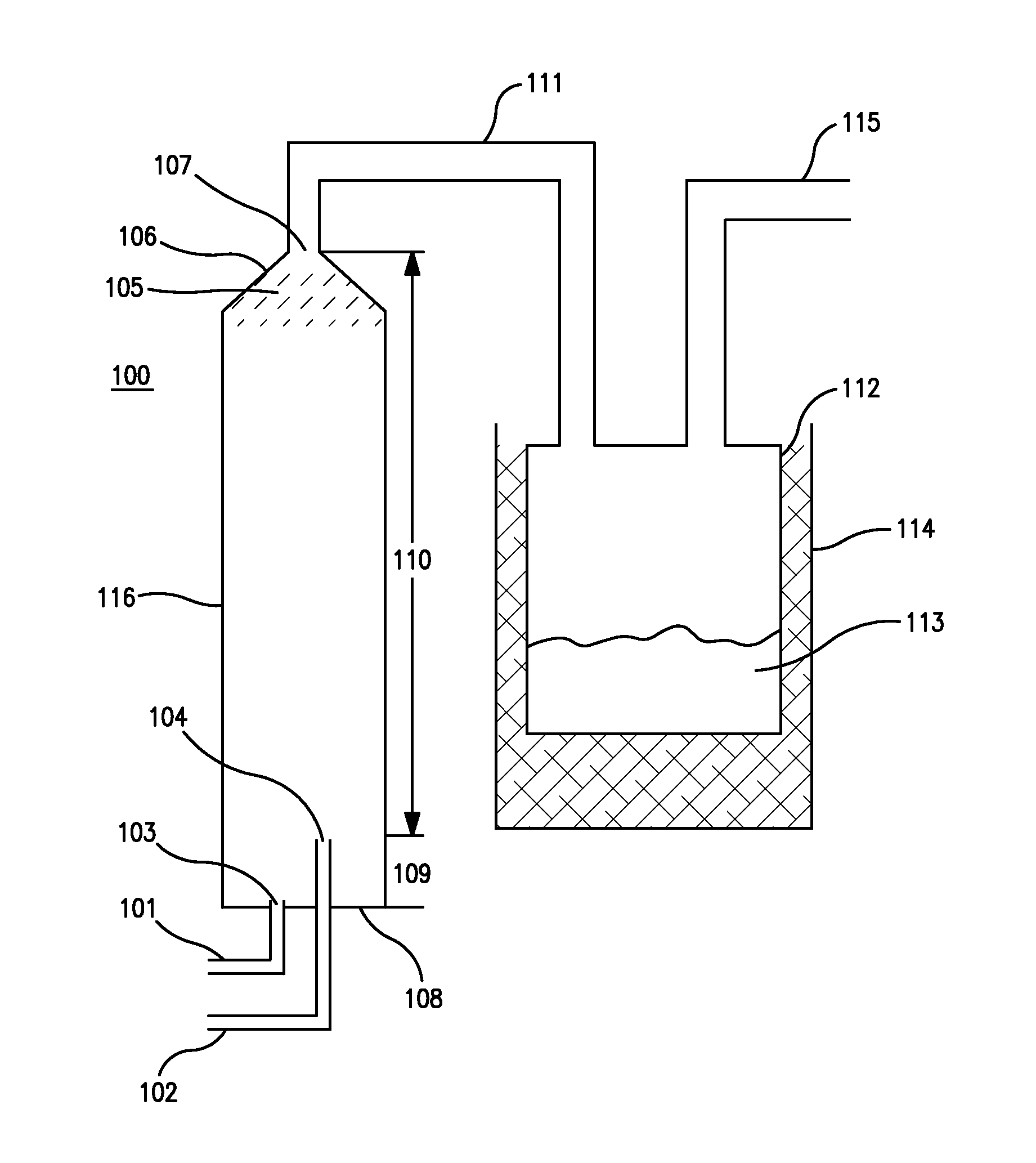

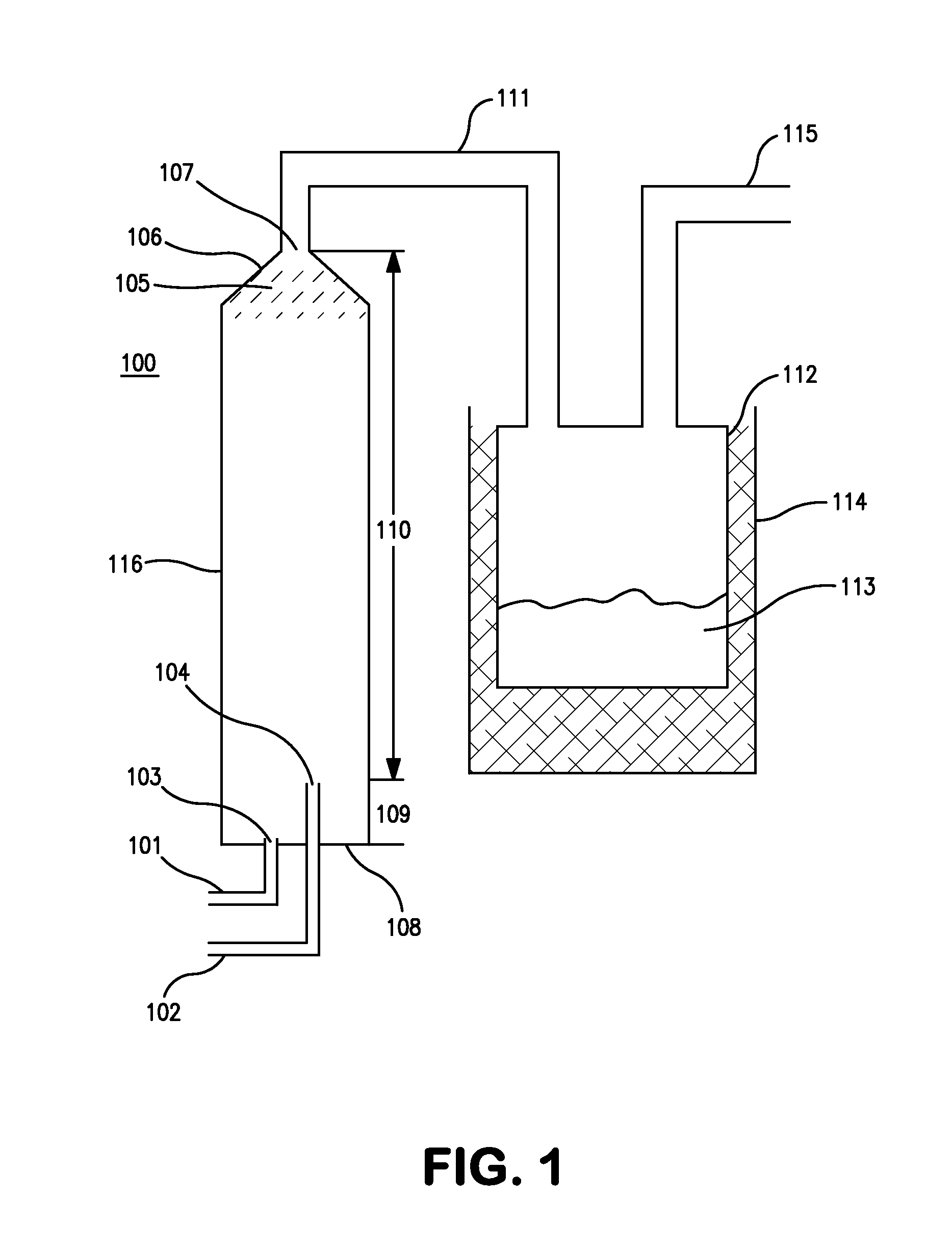

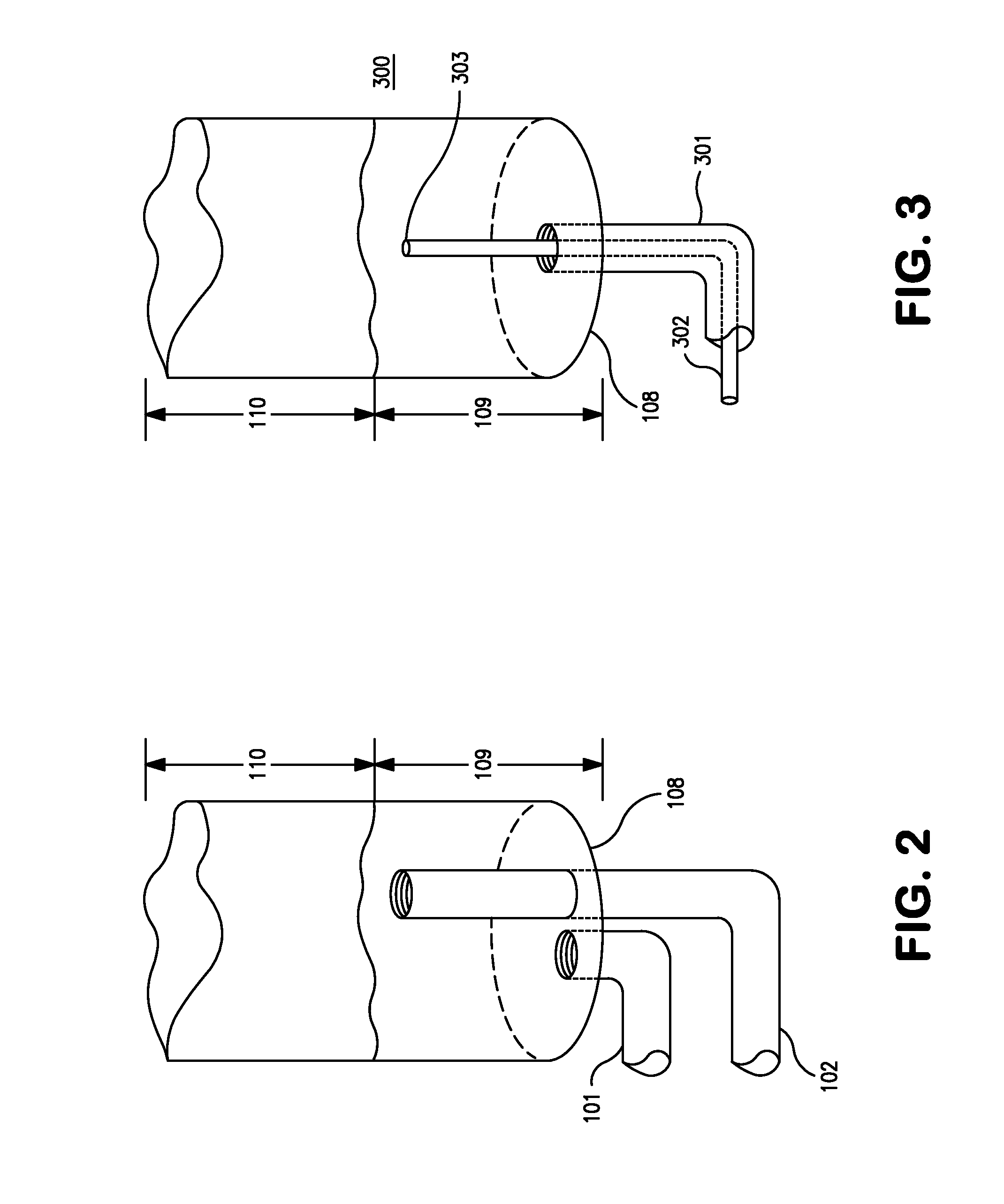

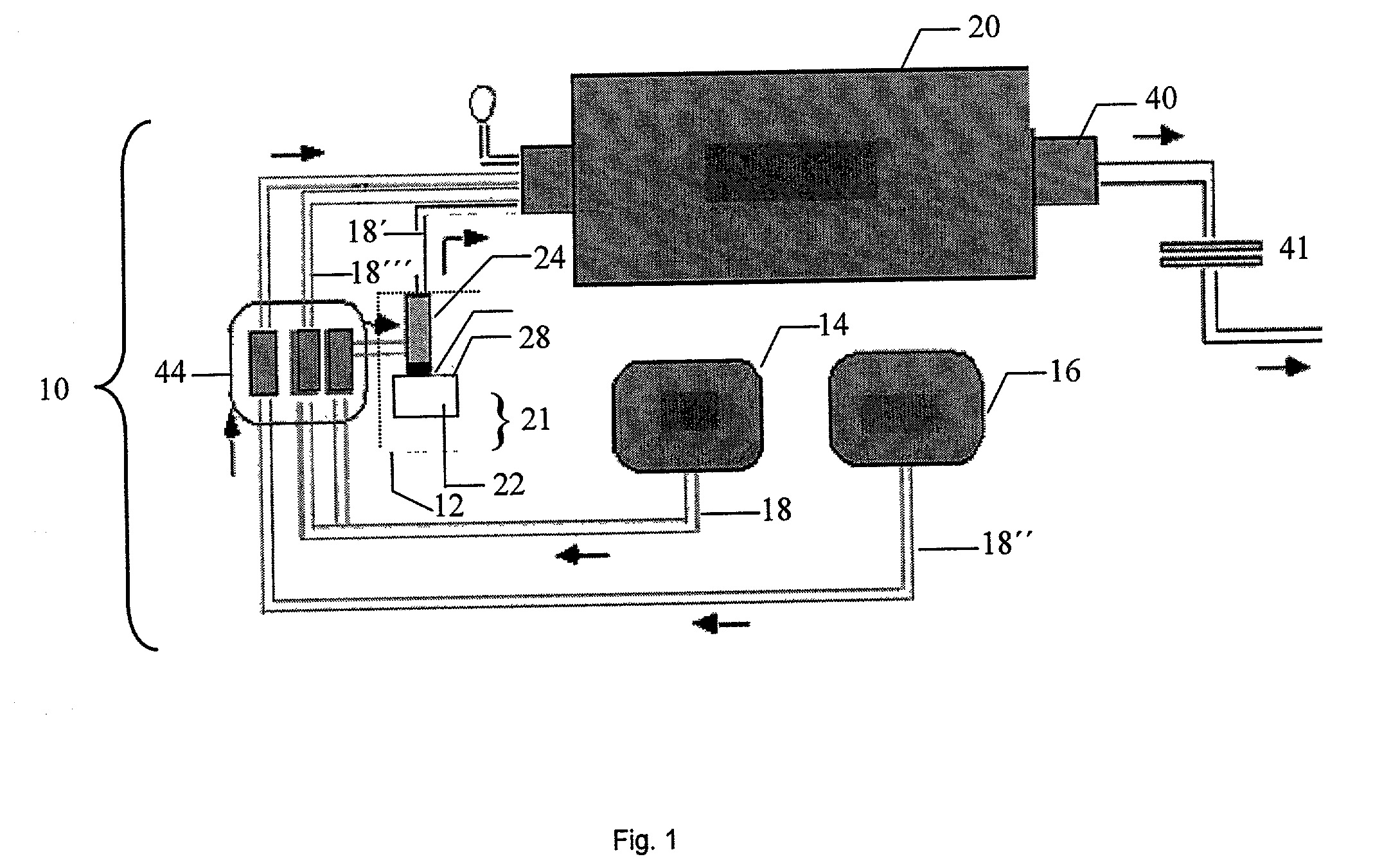

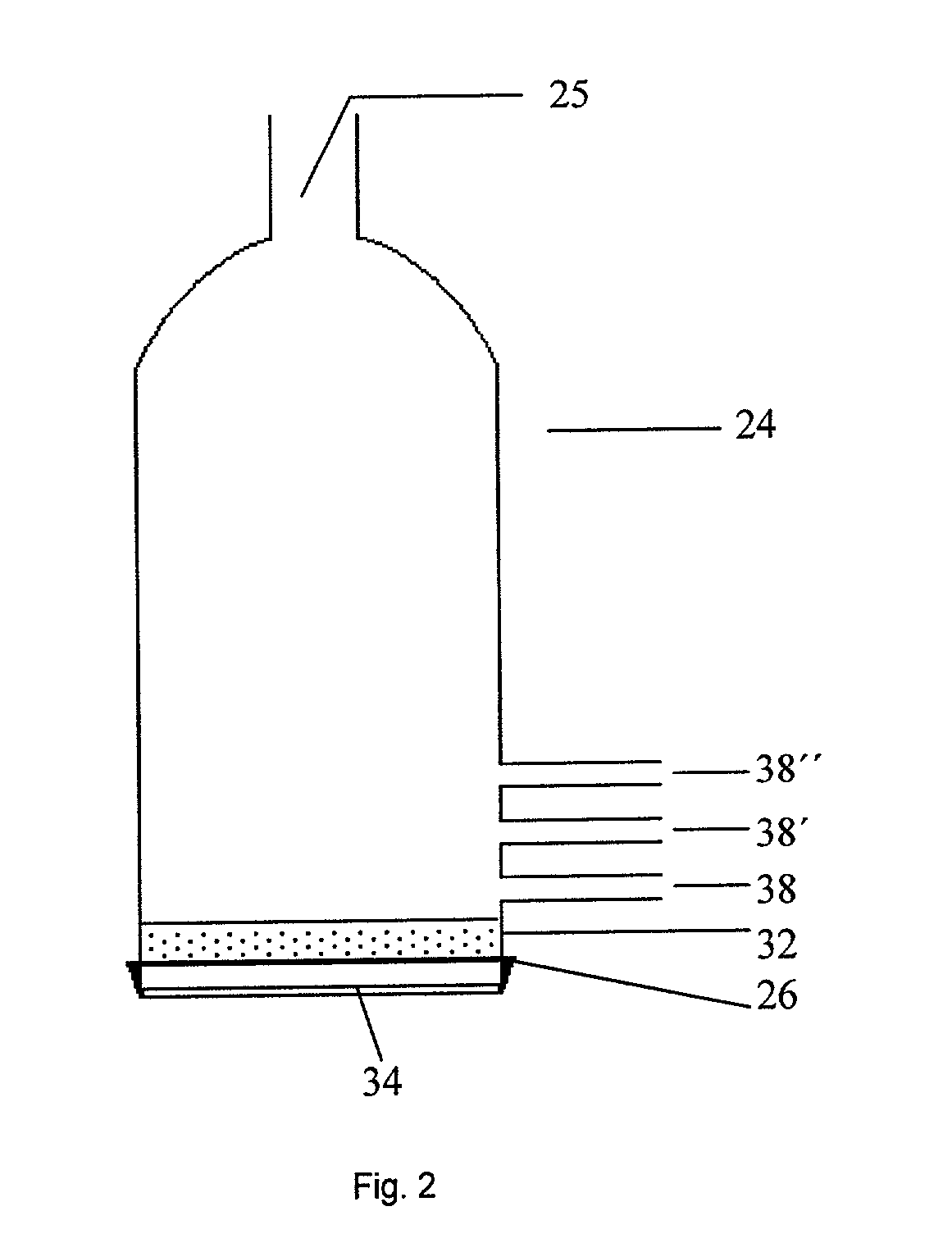

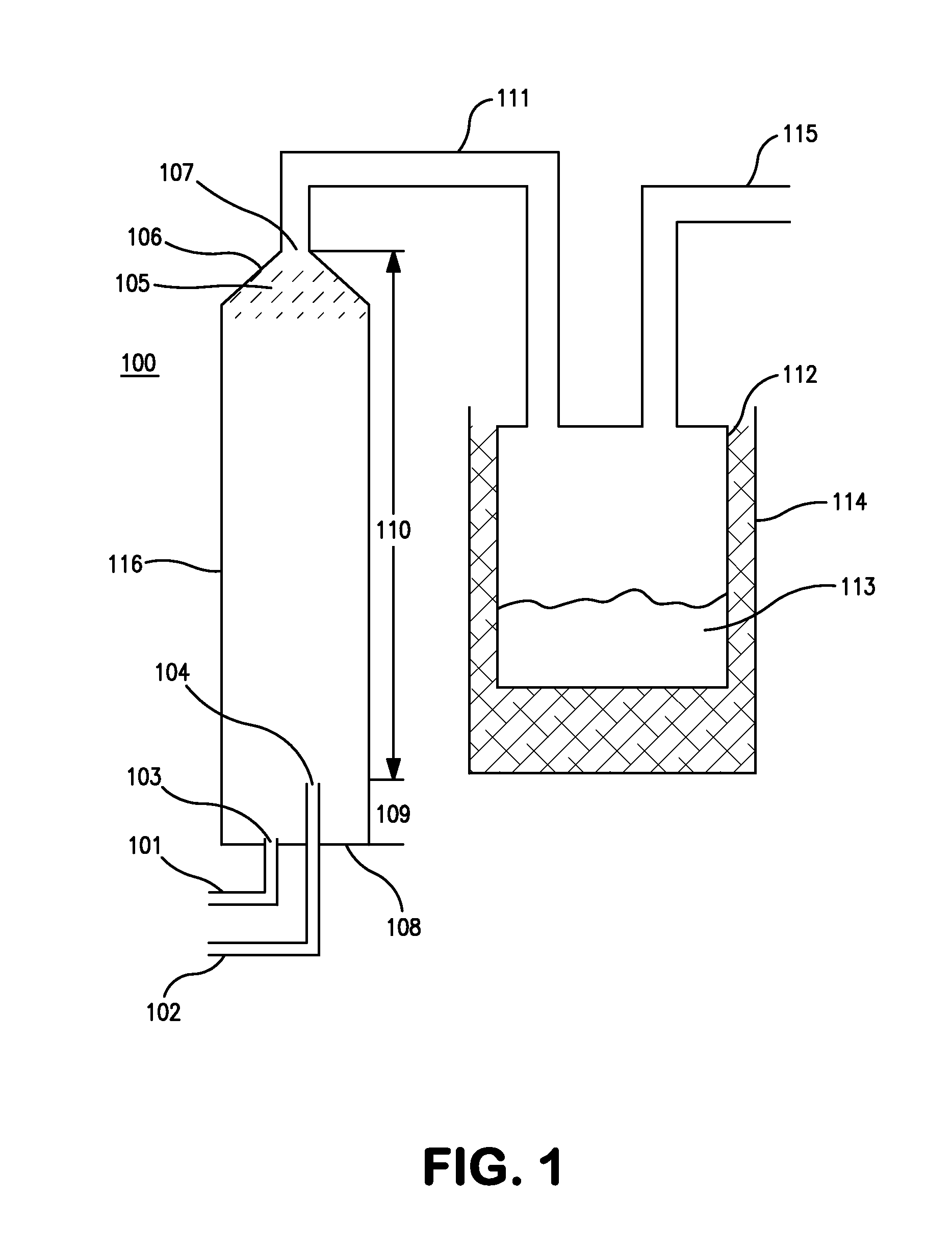

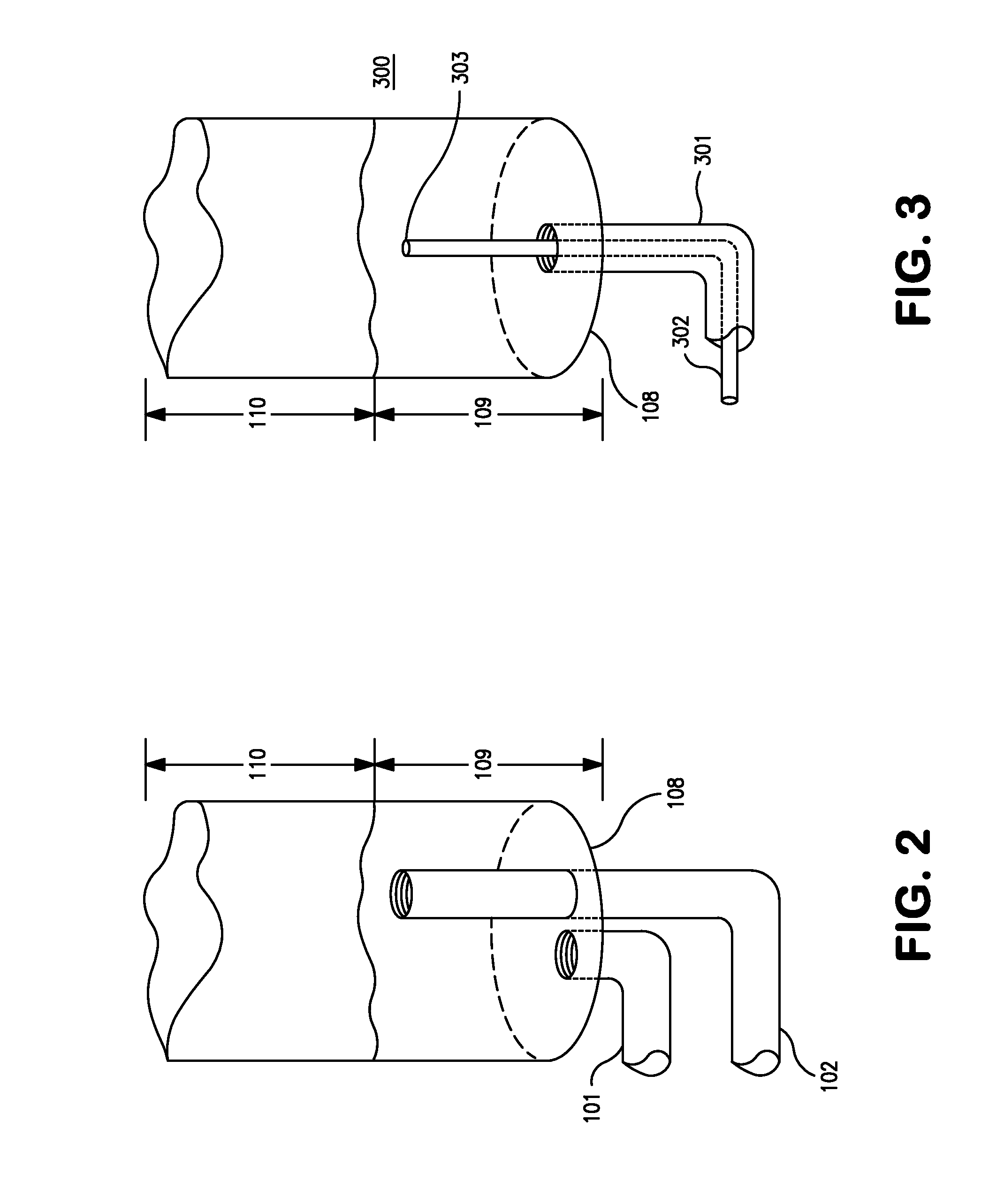

Apparatus and method for the production of trisilylamine

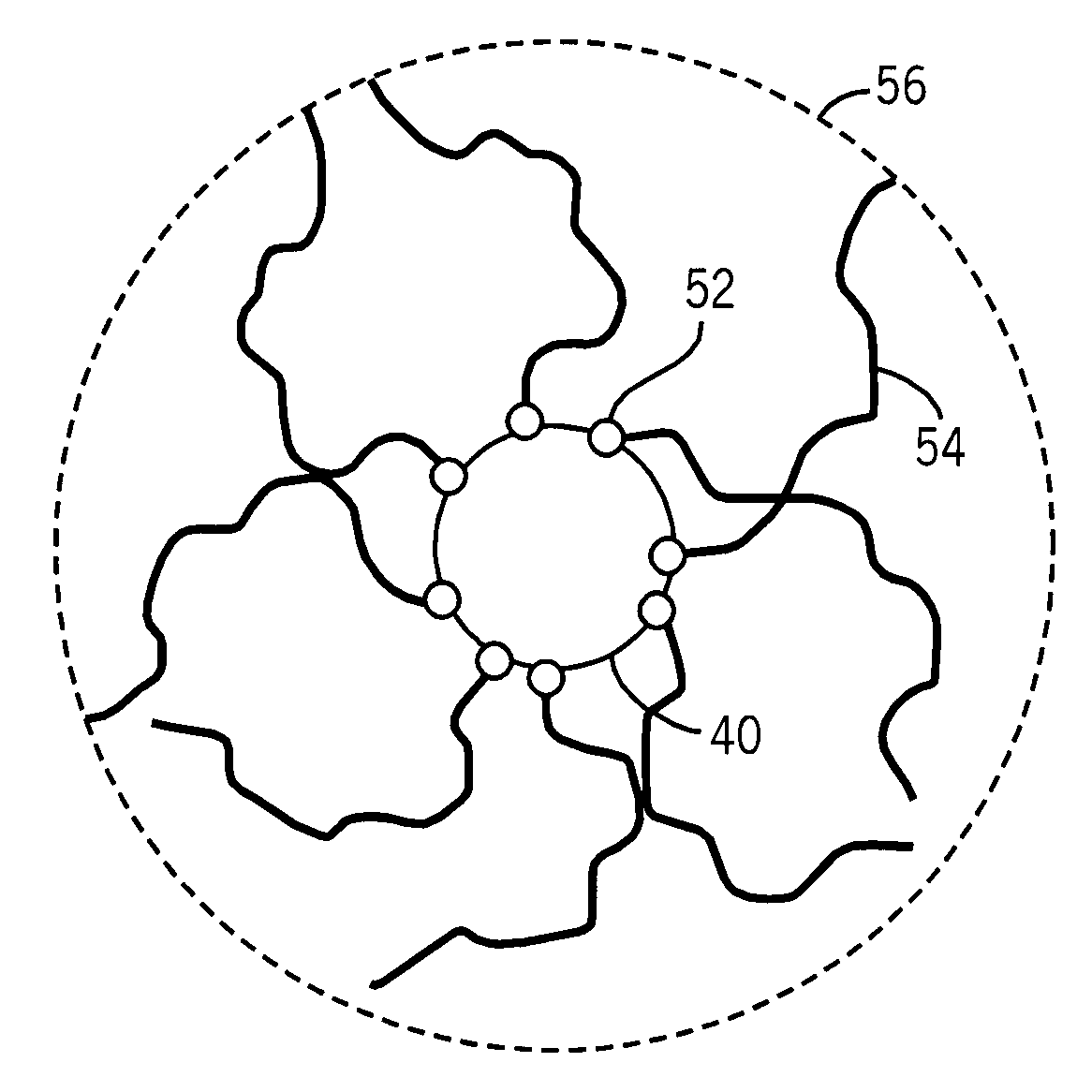

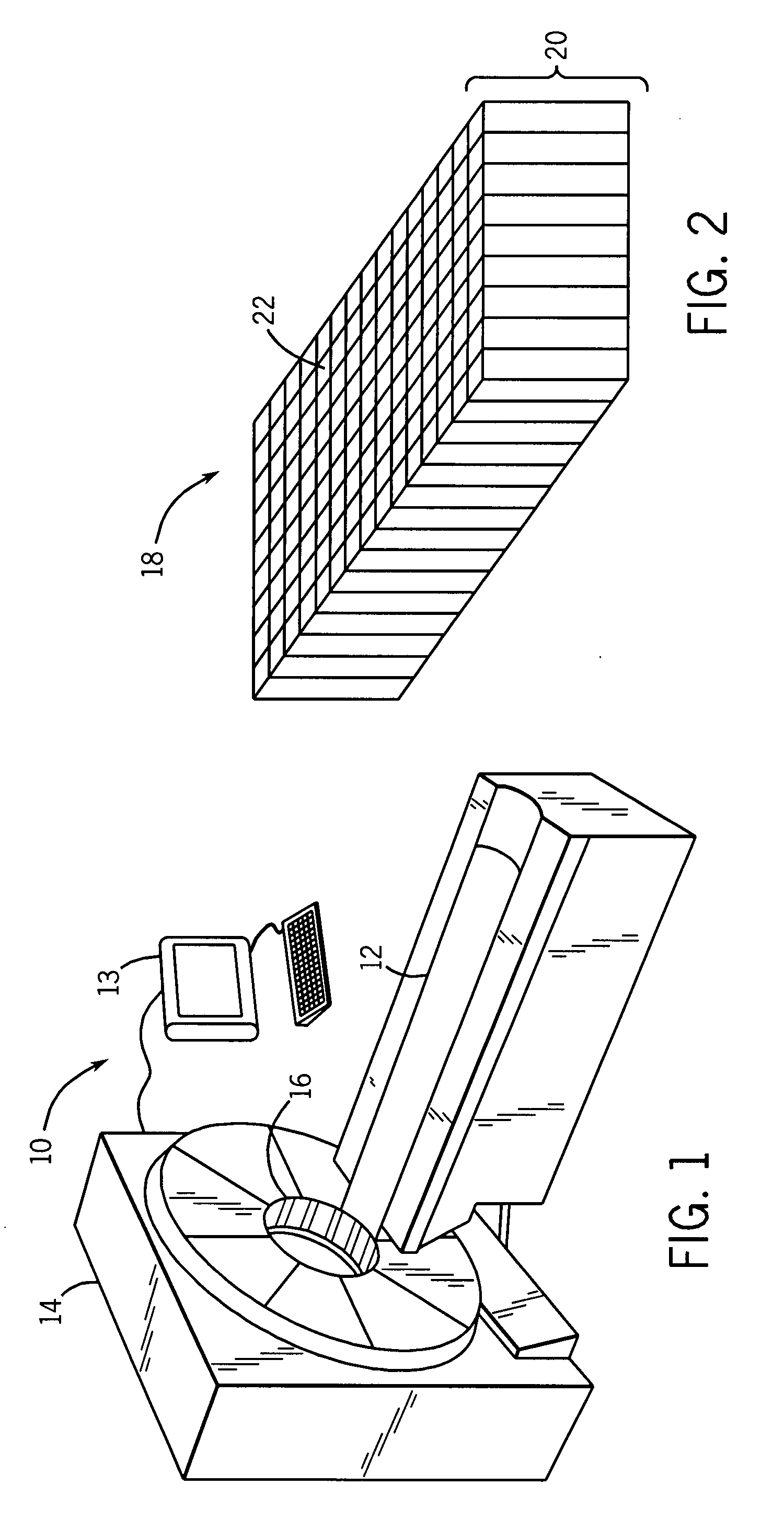

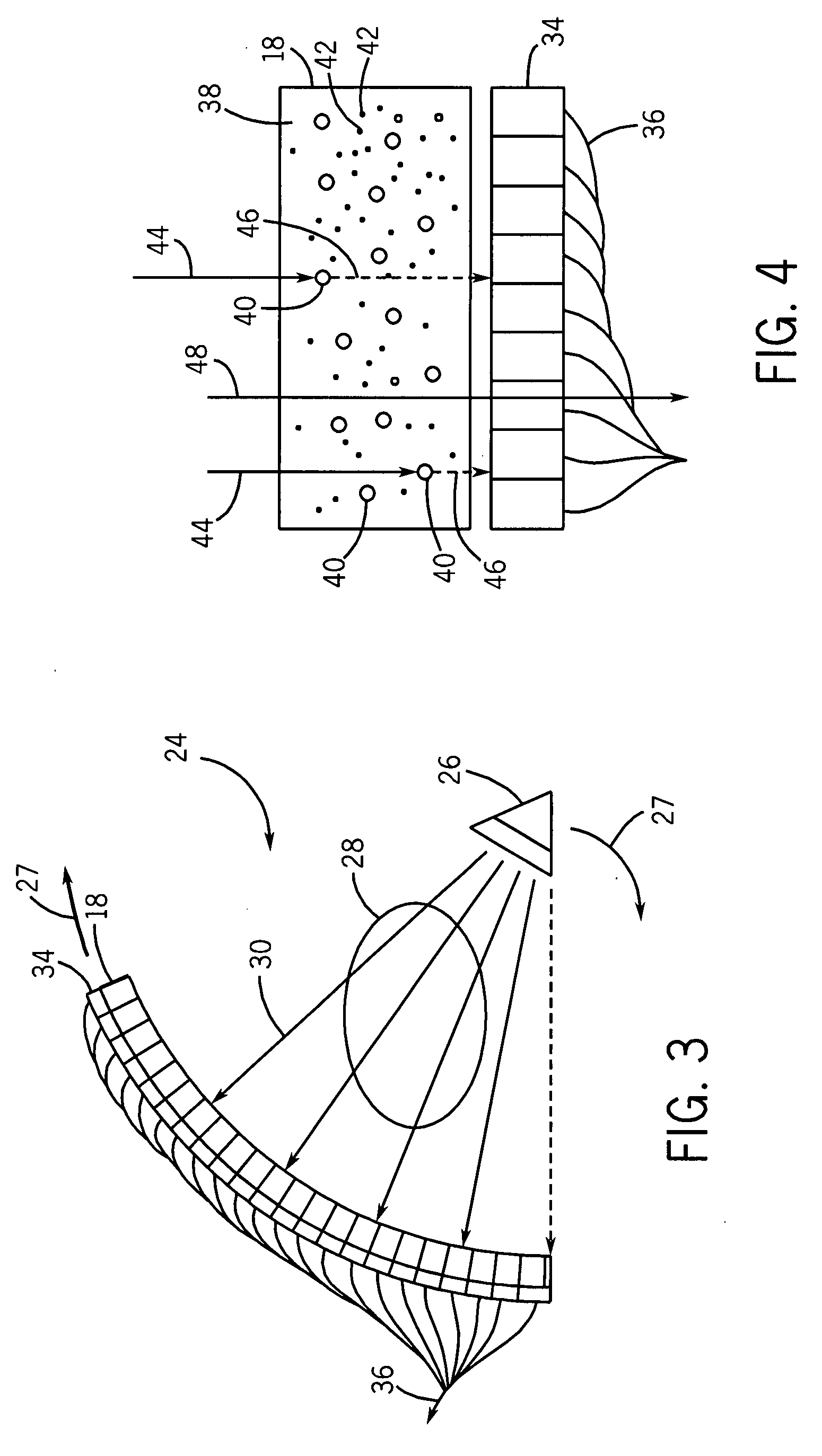

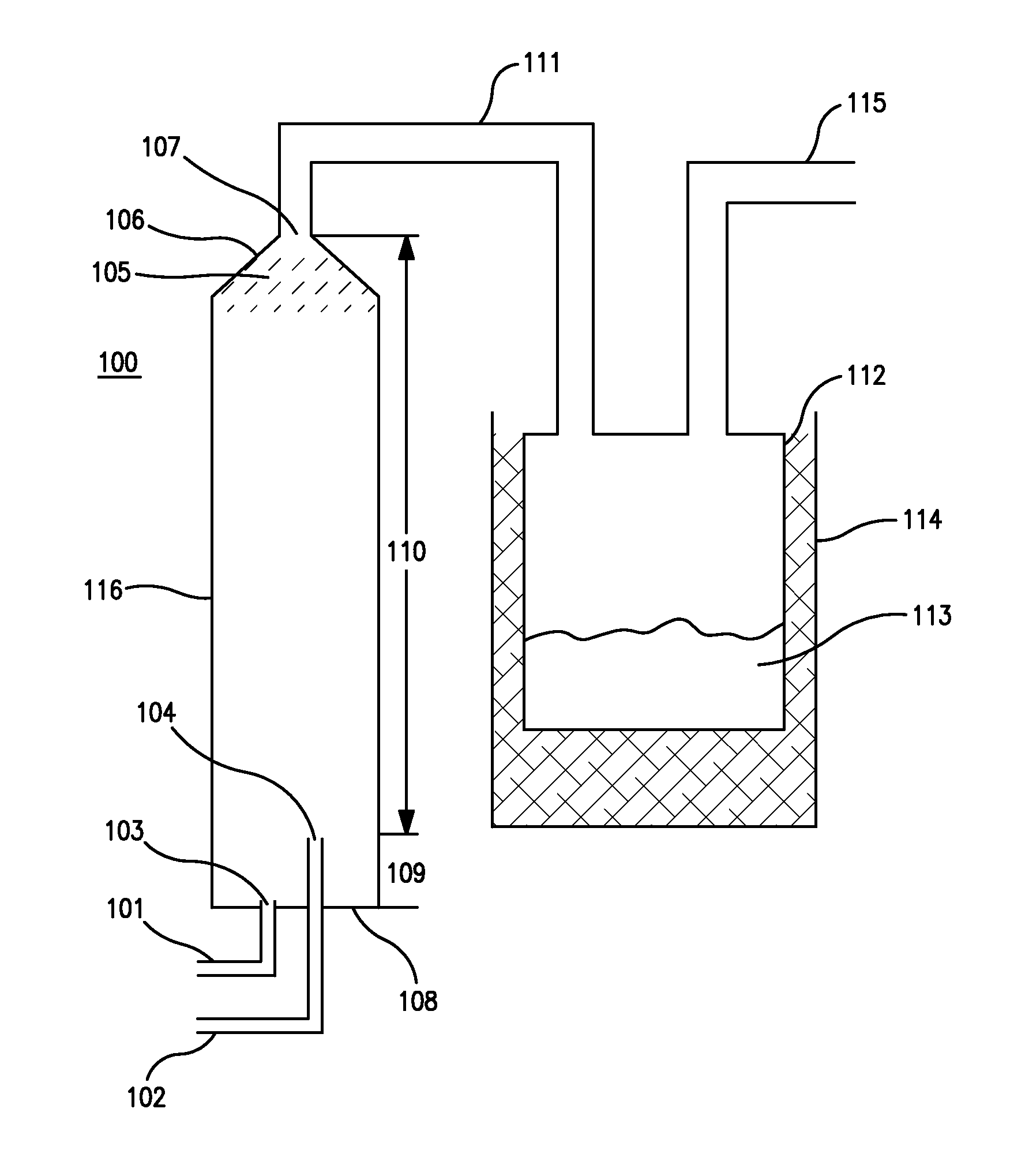

ActiveUS20100310443A1Increase volumeHigh volume high efficiency synthesisGroup 4/14 element organic compoundsPressurized chemical processReaction zoneProduct gas

There is described an apparatus, a tubular laminar flow, plug flow reactor, for making silylamines and particularly trisilylamine (TSA) in high yields from ammonia gas and a monohalosilane gas. The apparatus can be a tubular flow reactor comprising a first portion of the reactor defining a gas entry zone, a second portion of the reactor defining a reaction zone and a third portion of the reactor defining a separation zone, the reaction zone providing a reactant contacting region. Trisilylamine can be recovered in the separation zone in a cold trap collection vessel.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Preparation process of trisilylamine

ActiveUS20110178322A1Low costEasy to separateSilicon organic compoundsChemical/physical/physico-chemical processesLow oxygenAtmosphere

Provided is a preparation process of trisilylamine capable of preparing high-purity trisilylamine more easily at a lower cost. More specifically, provided is a preparation process of trisilylamine, comprising a step of thermally decomposing perhydropolysilazane under an oxygen-free or low oxygen atmosphere.

Owner:SHIN ETSU CHEM IND CO LTD

Magnetic material for high frequency wave, and method for production thereof

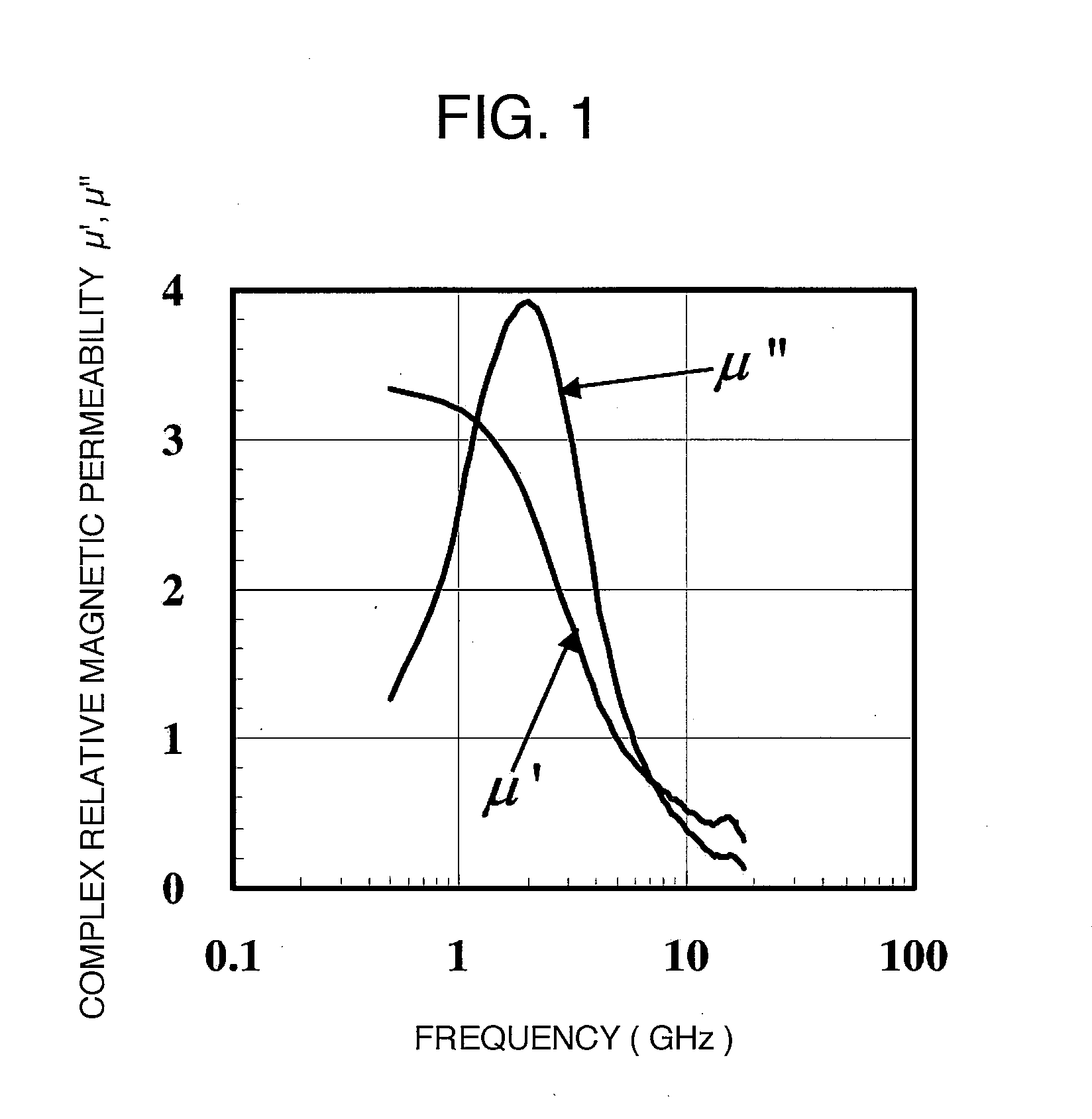

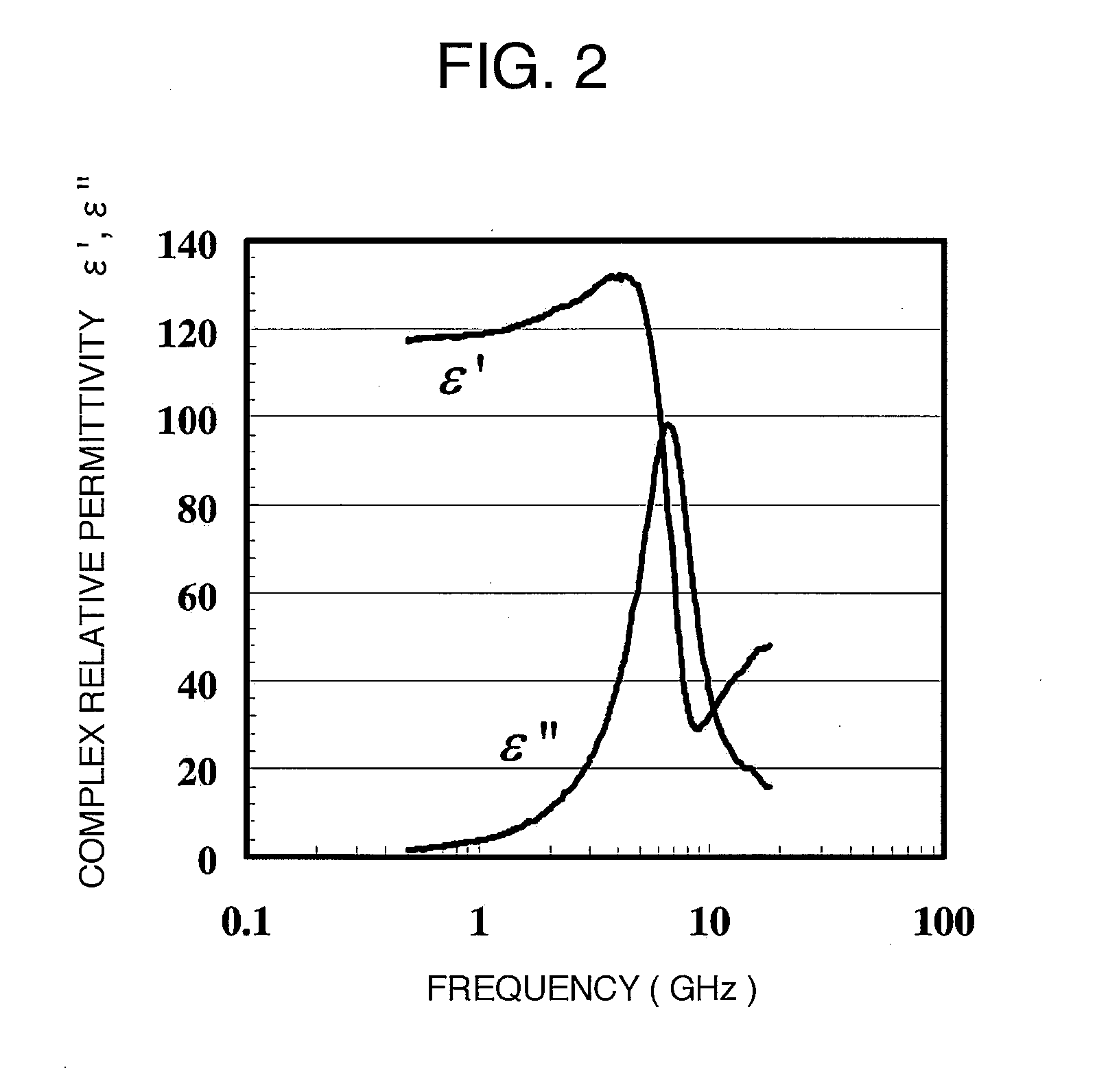

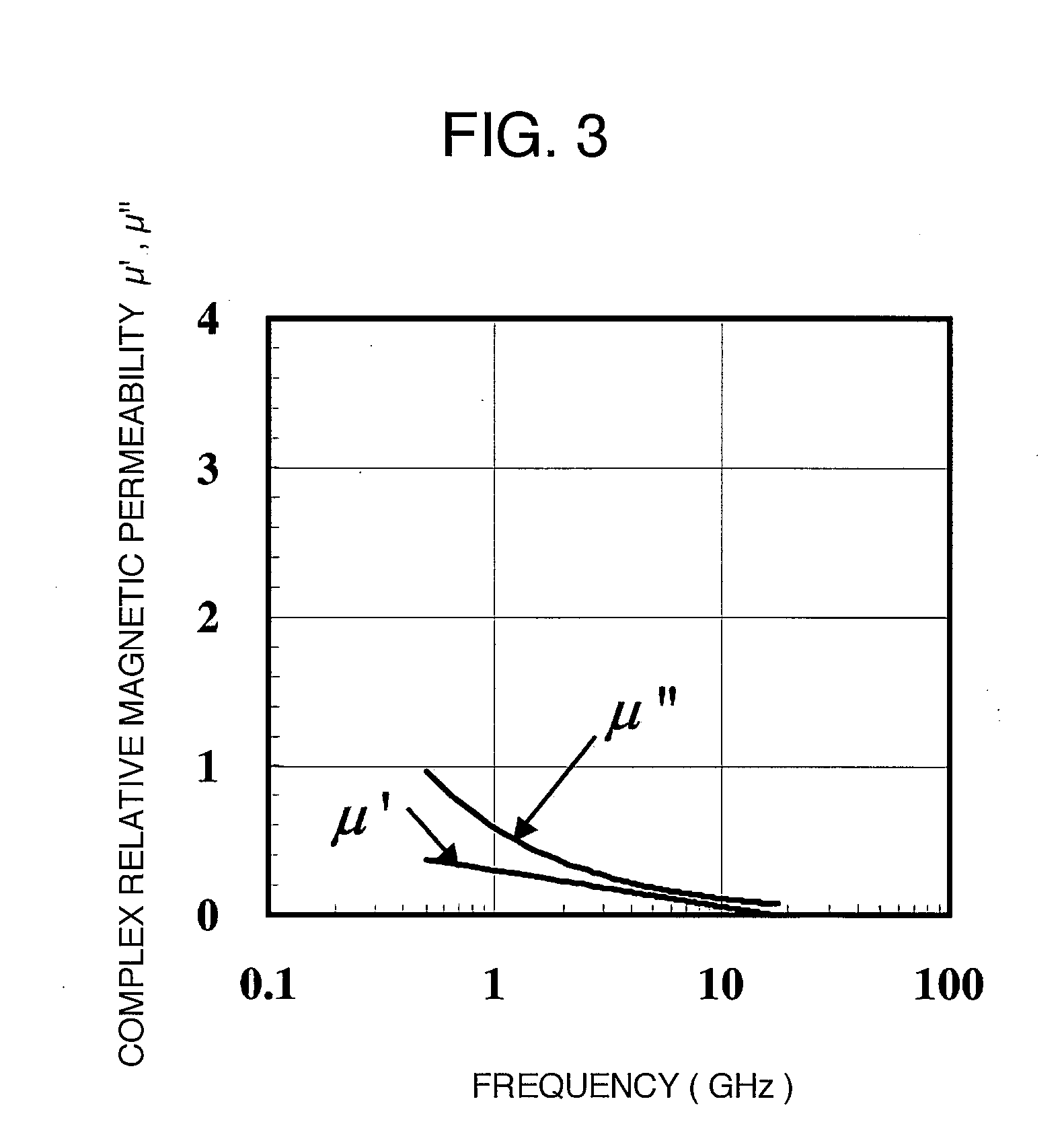

InactiveUS20100068512A1Small eddy-current lossImprove permeabilityMaterial nanotechnologyMagnetic paintsRare-earth elementEddy current

Disclosed is a magnetic material for a high frequency wave which has high magnetic permeability and small eddy-current loss, particularly a magnetic material for a high frequency wave which can be used suitably in an information device which works in a high frequency field of 1 GHz or higher. Specifically disclosed is a composite magnetic material for a high frequency wave, which comprises a (rare earth element)-(iron)-(nitrogen)-based magnetic material and a (rare earth element)-(iron)-(nitrogen)-based magnetic material whose surface is coated with a ferrite magnetic material.

Owner:ASAHI KASEI KK +1

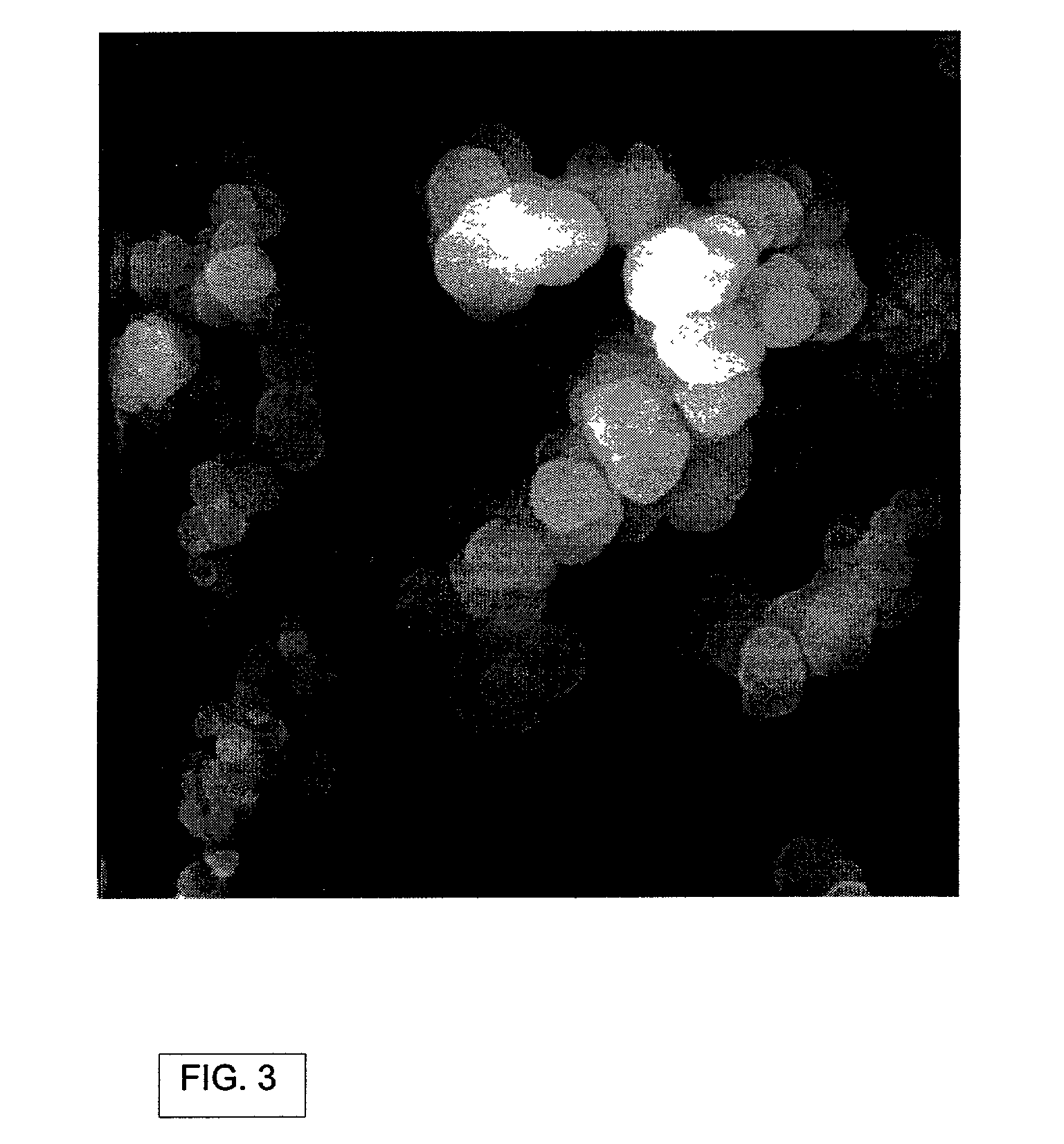

Organoboron route and process for preparation of boron nitride

InactiveUS20020155052A1Simple preparation processEasy to purifyMaterial nanotechnologyPolycrystalline material growthCrystal structureWhiskers

An organoboron route and process for preparation of boron nitride utilizing aerosol assisted vapor phase synthesis (AAVS) wherein organoboron precursors are nitrided in one or two heating steps, and wherein a boron oxide nitride intermediary composition is formed after the first heating step and may be further nitrided to form resultant spheroidal boron nitride powders including spheroidal particles that are smooth, bladed, have protruding whiskers, and are of turbostratic or hexagonal crystalline structure.

Owner:NEW MEXICO UNIV OF

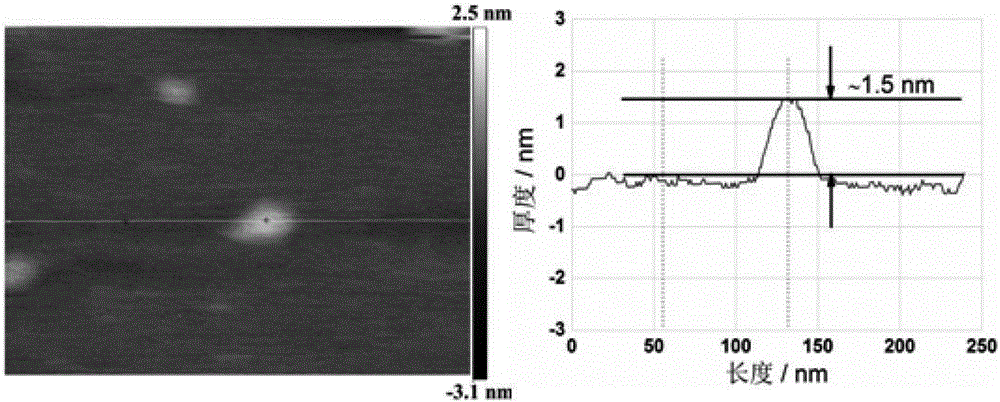

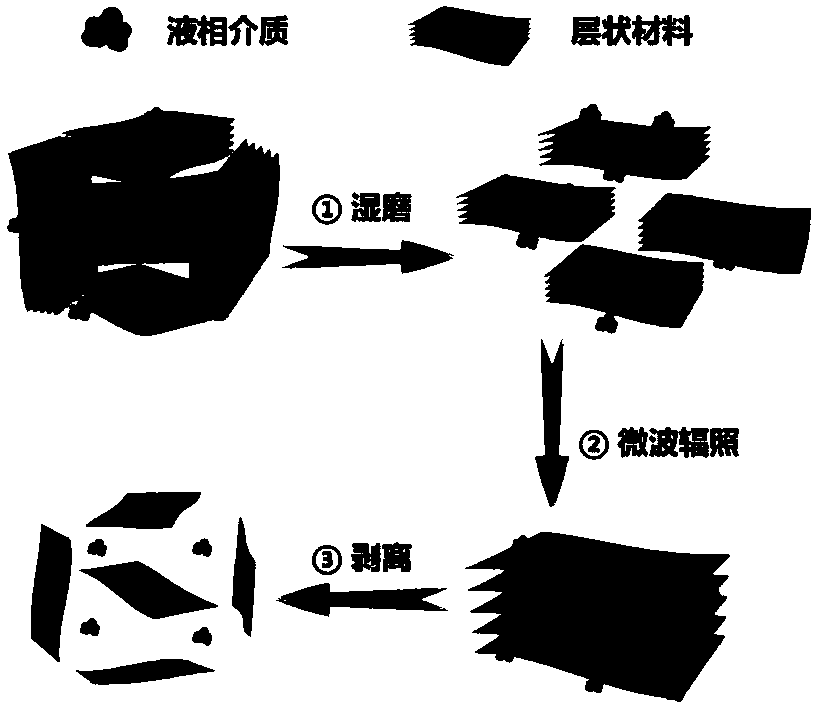

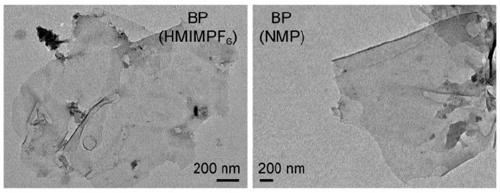

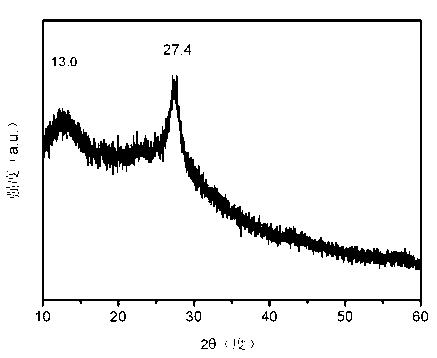

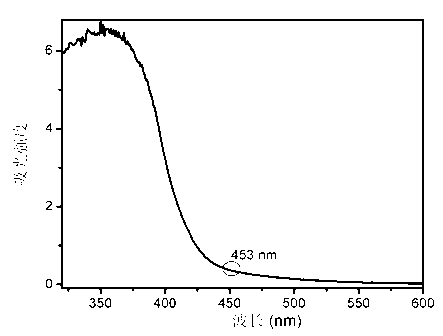

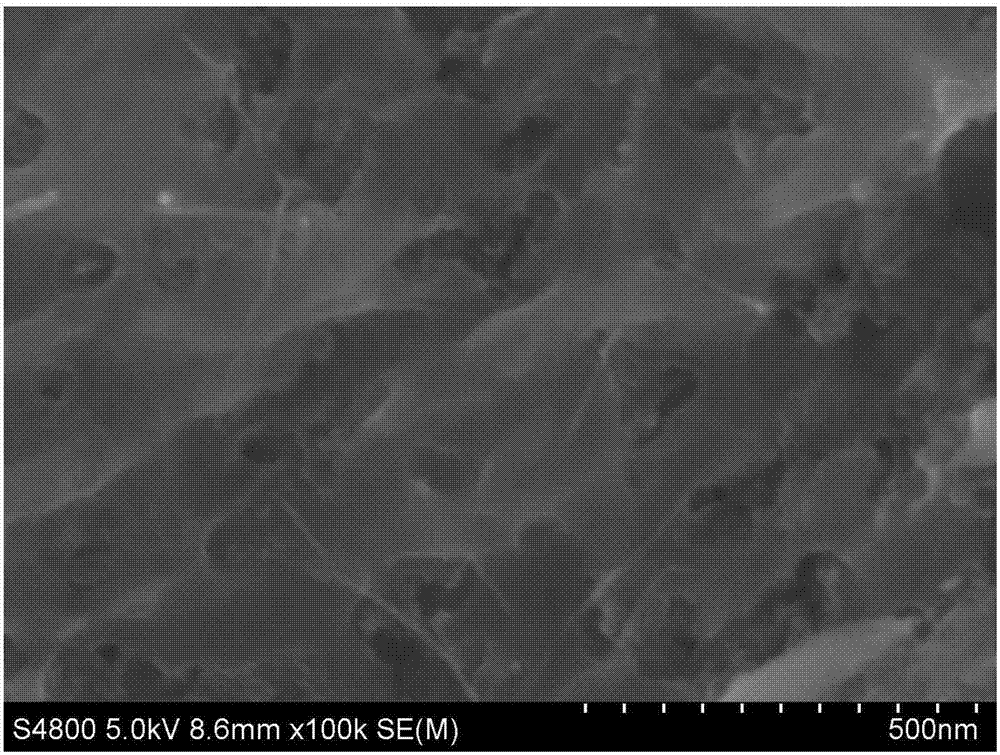

Method for preparing two-dimensional nanosheets by microwave-assisted liquid phase stripping of layered material

ActiveCN109205578AGood chemical stabilityHigh yieldMaterial nanotechnologyTantalum compoundsLiquid mediumUltrasonic dispersion

The invention discloses a method for preparing two-dimensional nanosheets by microwave-assisted liquid phase stripping of a layered material. The method comprises the following specific steps: 1) carrying out wet grinding of precursor powder of the layered material with a liquid medium in a mortar; 2) washing the wet-ground mixture with a same liquid medium and transferring into a microwave reaction tube; 3) placing the microwave reaction tube into a microwave reaction device, and carrying out microwave irradiation; 4) after microwave irradiation, washing and filtering the microwave mixture, and collecting a filter membrane; 5) carrying out ultrasonic dispersion of the obtained filter membrane in an organic solvent, and carrying out centrifugal separation, wherein a supernatant is a nanosheet dispersion liquid, and a precipitate is a separated unpeeled phase; and 6) filtering the obtained nanosheet dispersion liquid, collecting a filter membrane, and carrying out vacuum drying to obtain the nanosheet powder. The method is universal, fast and efficient in peeling various layered materials, and the prepared nanosheets are ultra-thin, large in size, small in peeling size reduction andhigh in chemical stability, and have broad application prospects in basic scientific researches, electronics, catalysis, energy, sensing and other hot fields.

Owner:SHANGHAI JIAO TONG UNIV

Polymer photocatalyst, and method of water-phase photo-catalytic selective alcohol oxidation

InactiveCN103127948AImprove conversion rateGood choicePhysical/chemical process catalystsOrganic compound preparationPtru catalystUltraviolet

The invention discloses a polymer photocatalyst and a method of water-phase photo-catalytic selective alcohol oxidation. According to the invention, an organic polymer carbon nitride catalyst is prepared, and is applied in a water-phase photo-catalytic selective alcohol oxidation system. Compared with common ultraviolet catalyst TiO2, visible light catalyst TiO2-xNx, metal sulfide, metal nitride, metal nitrogen oxides, and the like, when alcohol is oxidized in water phase with a green oxidant air / oxygen under mild conditions, the carbon nitride catalyst is more stable and shows higher efficiency. The preparation method of the carbon nitride catalyst is simple and feasible, and the catalyst comprises no metal element, such that the catalyst is cheap. With the catalyst, alcohol oxidation aldehyde synthesis or ketone synthesis processes are simple and feasible, such that industrialized large-batch productions of aldehyde and ketone compounds can be facilitated.

Owner:FUZHOU UNIV

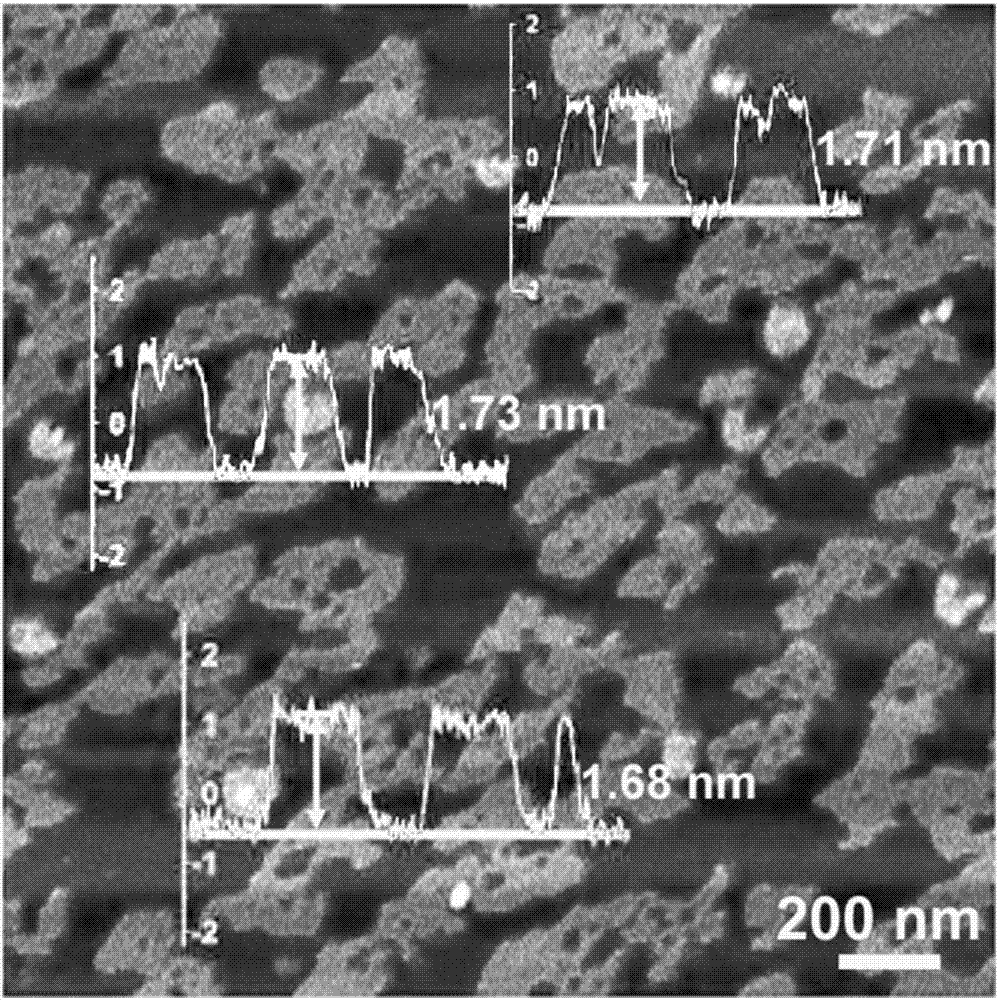

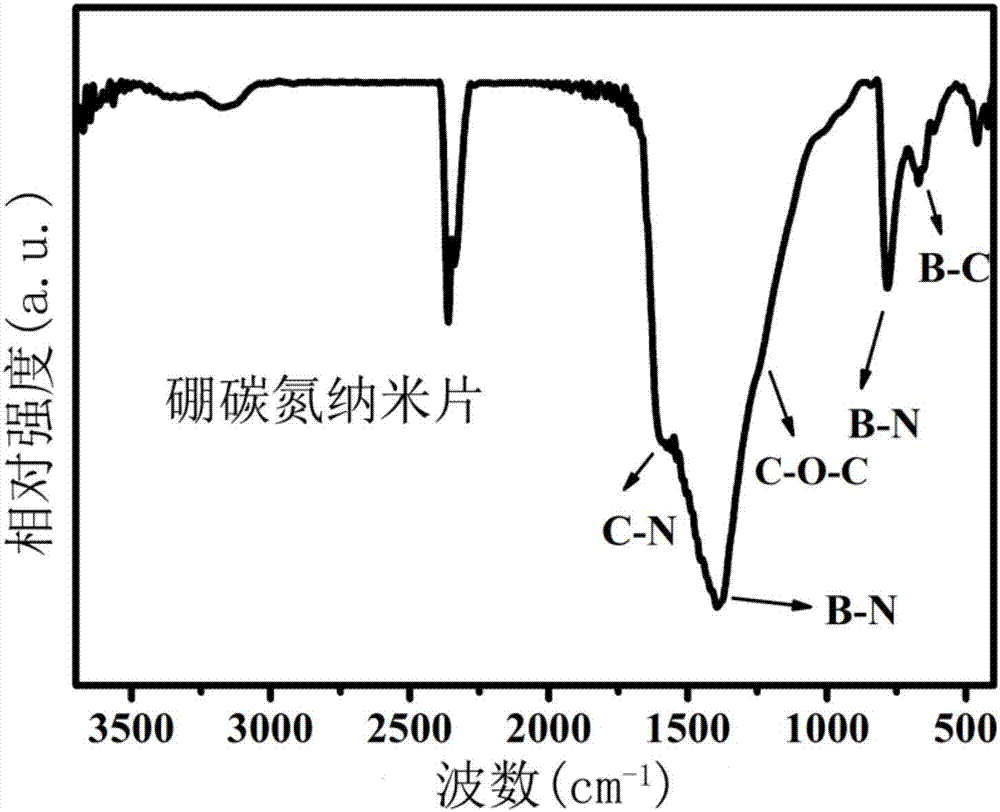

Method for preparing porous boron-carbon-nitrogen nanosheets through freeze drying

ActiveCN107082408AControllable component ratioRaw materials are cheap and easy to getMaterial nanotechnologyNitrogen and non-metal compoundsBall millRaw material

The invention provides a method for preparing porous boron-carbon-nitrogen nanosheets through freeze drying. The method includes the following steps that 1, a boron source, a carbon source and a nitrogen source are mixed in proportion, a raw material mixture is formed, water is added to dissolve the raw material mixture, and a raw material mixture solution is formed; 2, the raw material mixture solution is condensed and cured and then subjected to freeze drying; 3, powder obtained after freeze drying reacts for 0.5-12 h at the temperature of 800-1,200 DEG C in the atmosphere protection or vacuum environment; 4, the powder is ball-milled in a ball mill for 2-8 h; 5, after the ball-milled product is cooled to room temperature, the product is cleaned and dried, and the porous boron-carbon-nitrogen nanosheets are obtained. The method is simple in operation procedure, the yield can be increased, and the cost can be reduced. Various parameters in the reaction process are easy to monitor and control, the reaction mechanism can be easily studied, most critical influence factors are found out, and process conditions are stabilized as soon as possible; environmental protection is low, and environmental protection is promoted.

Owner:SHANDONG UNIV

Nitride red phosphor and process for producing the same

InactiveCN101090953ANitrogen and non-metal compoundsLuminescent compositionsFluorescenceLight emitting device

Owner:UBE IND LTD

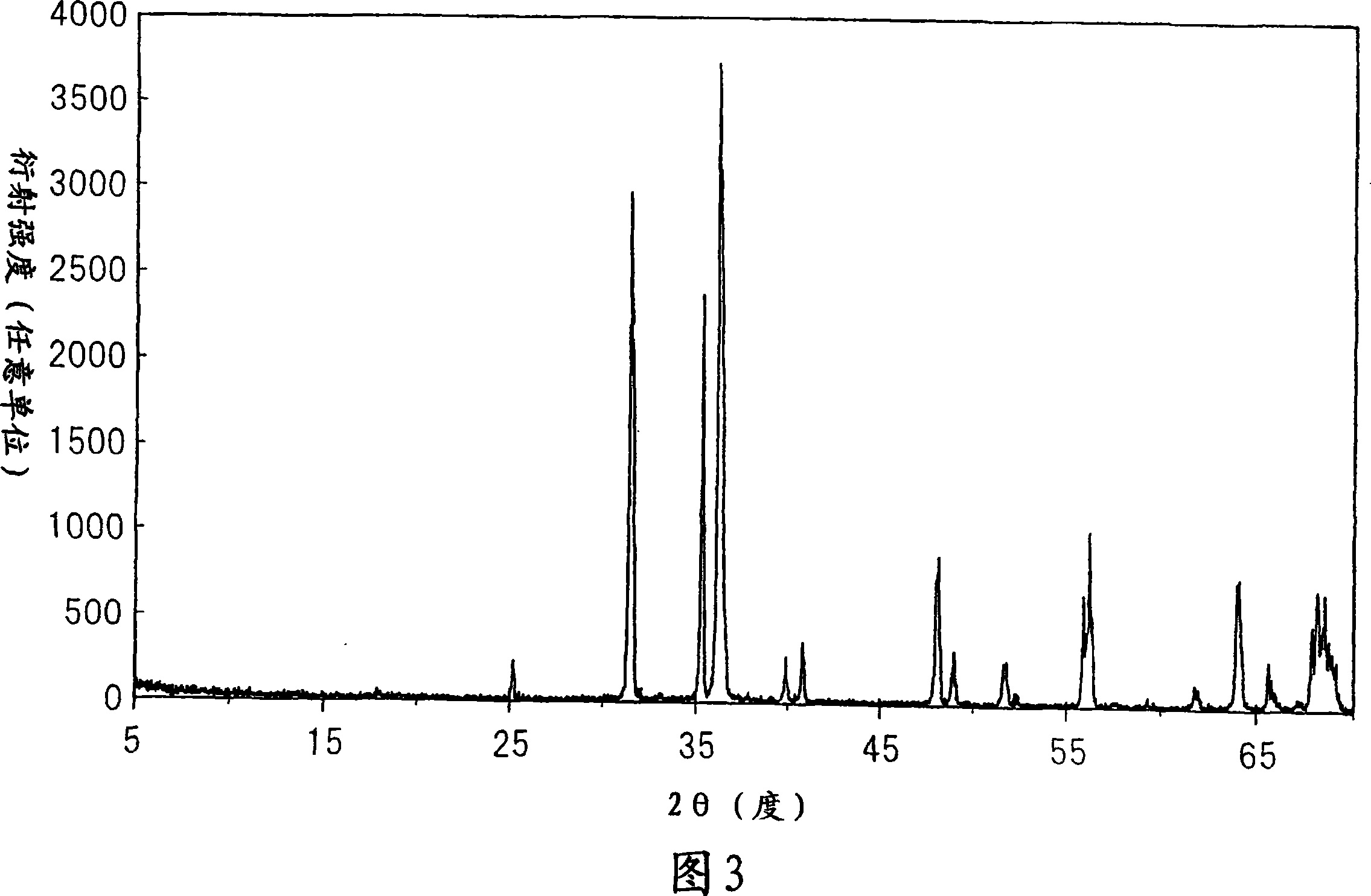

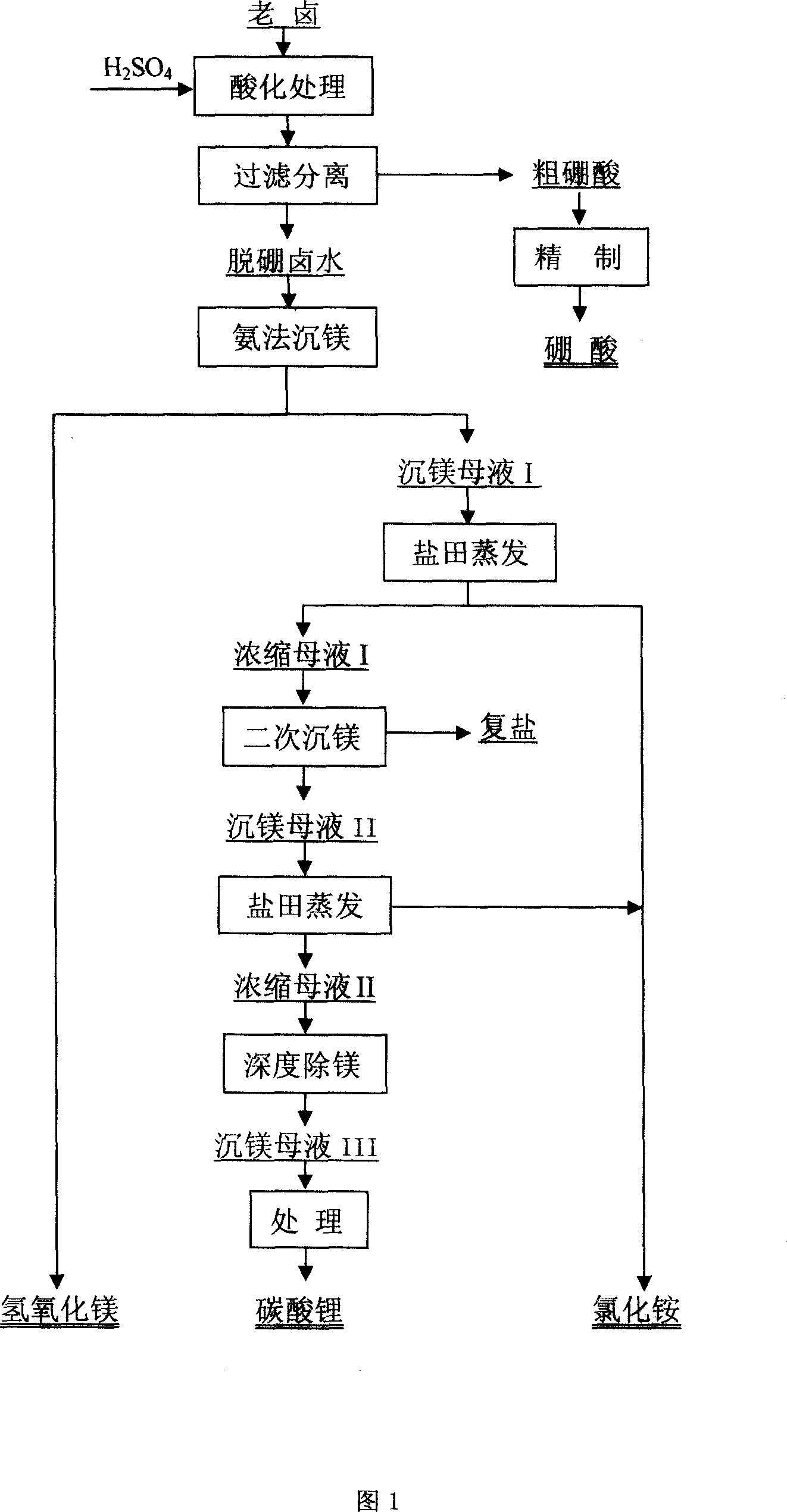

Method for combined extracting boron, magnesium and lithium from salt lake bittern

InactiveCN101024502AEfficient use ofIncrease profitBoron-oxygen compoundsNitrogen and non-metal compoundsResource utilizationPotassium

The invention relates to salt lake resource developing and comprehensive utilization. It uses boron, magnesium and lithium bittern as raw material, adopting combination distilling technology to make boric acid, magnesium hydroxide, lithium carbonate, and ammonium chloride. The recycling ratio of boron, magnesium and lithium reach 87%, 95%, and 92%. It has the advantages of simple technology, little device investment, high utilization coefficient of resource, high yield, good product quality, low producing cost and no pollution.

Owner:WESTERN MINING GROUP +1

Preparation method of graphite phase carbonitride

ActiveCN105752953AEasy to makeEasy to operateNitrogen and non-metal compoundsHigh energyShielding gas

The invention discloses a preparation method of graphite phase carbonitride. A preparation process comprises the following steps of using nitrogen-rich organic matters are raw materials; graphite or silicon carbide is used as a microwave absorption agent; the nitrogen-rich organic matters and the microwave absorption agent are uniformly mixed; in a microwave radiation electromagnetic field, the pressure is controlled to be 5 to 35 kPa, the microwave radiation power is 2 to 10 kW, the temperature rise speed is controlled to be 50 to 500 DEG C / min, and the heat insulation reaction is performed for 5 to 30 min at 450 to 700 DEG C; the graphite phase carbonitride is obtained. The method is based on a high-energy microwave radiation treatment method; the graphite phase carbonitride in a layered structure can be fast and efficiently obtained; the method is simple and efficient; the cost is low; varies kinds of expansive or environment-harmful reagents such as catalysts, organic solvents and protection gas are not used. The method has the advantages that the environment-friendly effect is achieved; the raw material pretreatment is not needed, and the like. The method belongs to a green preparation method favorable for large-scale business production.

Owner:ZHANGJIAGANG DONGDA IND TECH RES INST +1

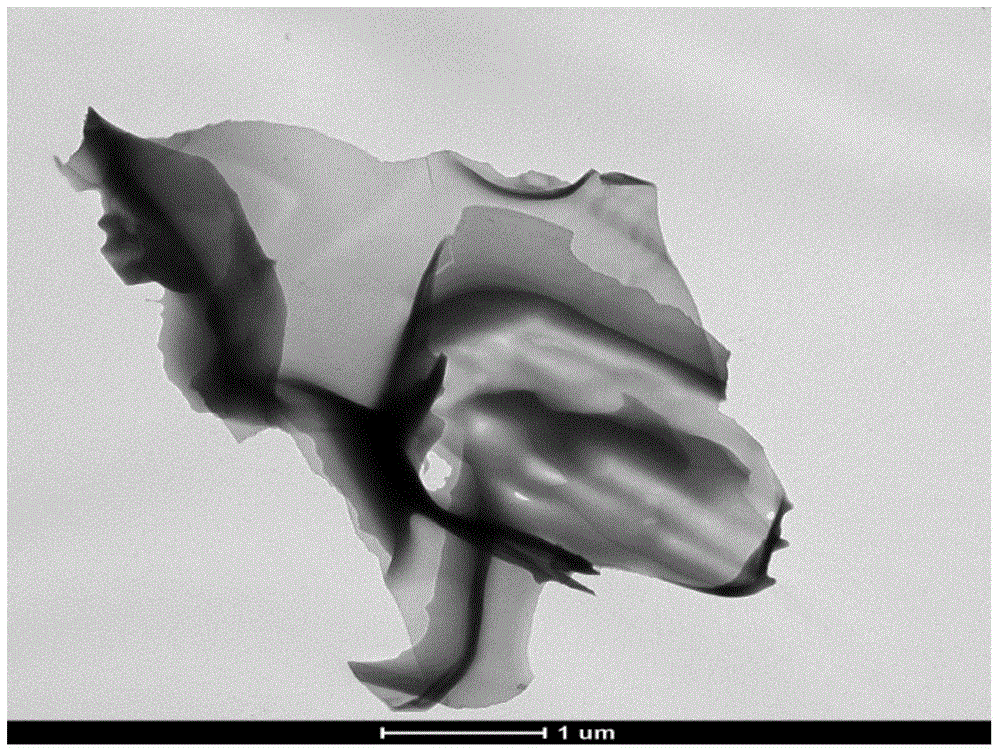

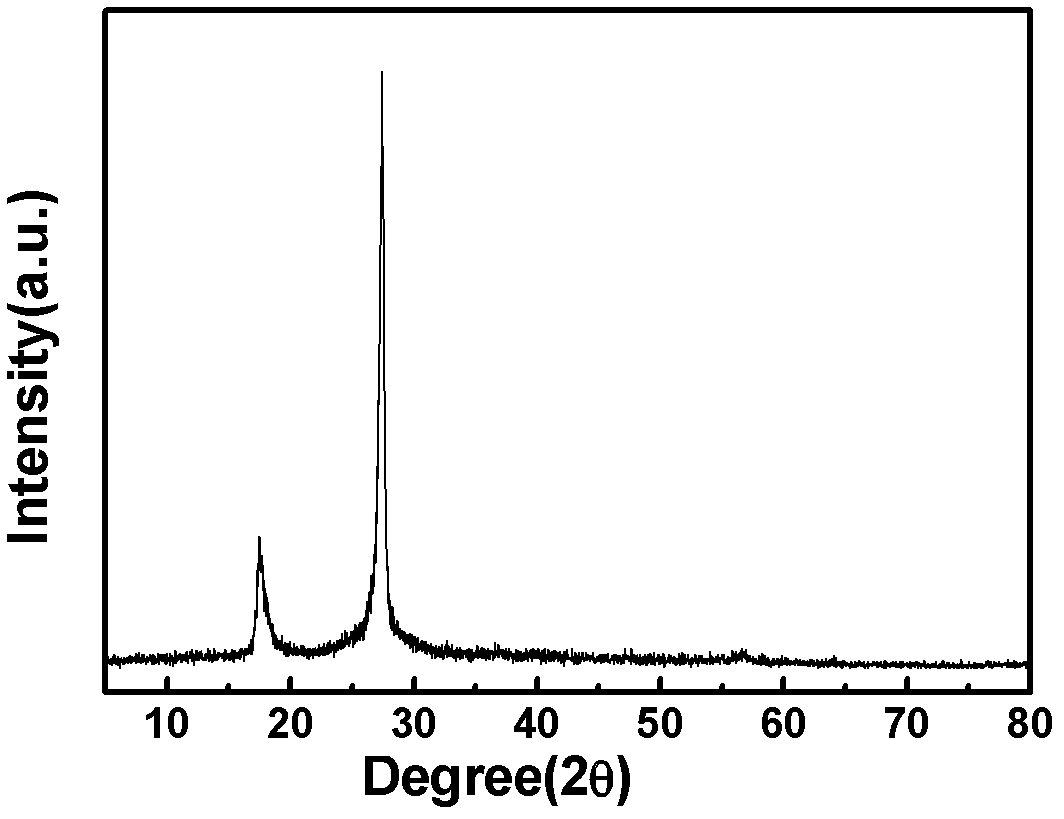

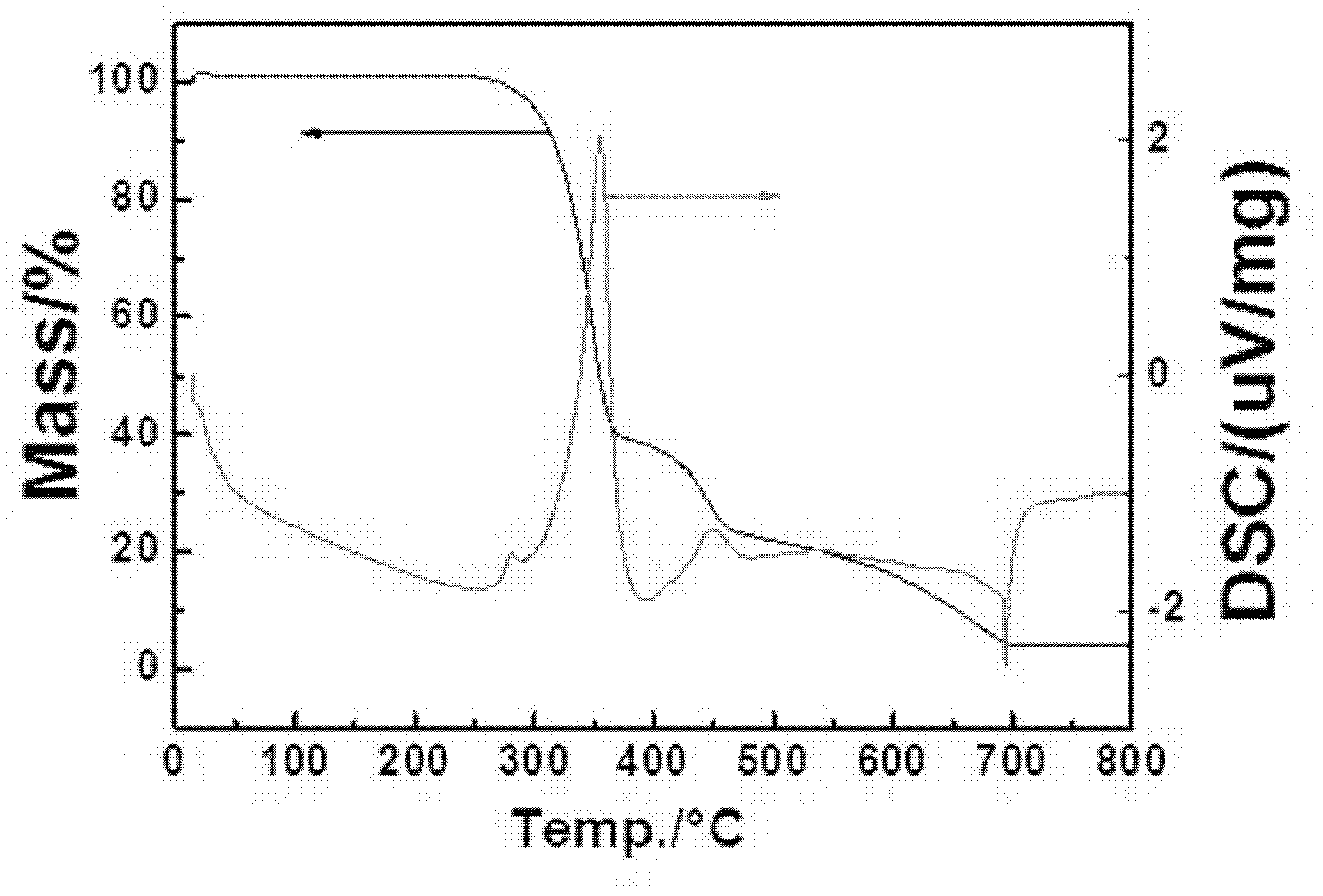

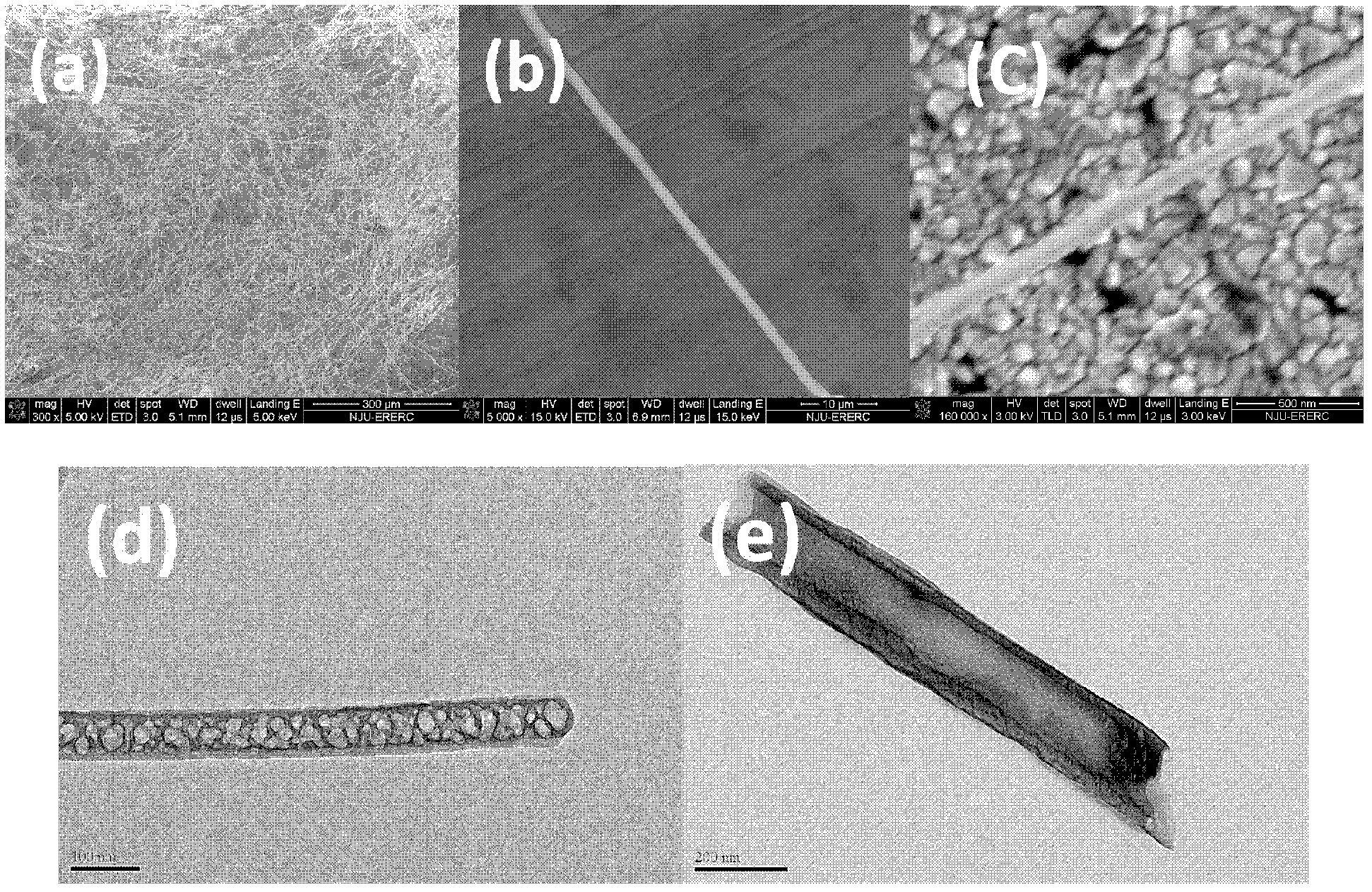

Preparation method for self-assembly carbonitride nanotube and nanotube prepared by using same

ActiveCN102616757AImprove conductivityMild preparation conditionsNanotechnologyNitrogen and non-metal compoundsFluorescenceRare earth

The invention relates to a preparation method for a self-assembly carbonitride nanotube. The preparation method comprises the following steps: adding melamine into glycol to form a saturated solution: slowly adding an aqueous solution of nitric acid with a concentration of 0.12 + / - 0.02 mol / L into the saturated solution until a great amount of white precipitate is generated, centrifugating the white precipitate, rinsing the white precipitate with ethanol and drying the white precipitate at a temperature of 60 + / - 10 DEG C so as to obtain white powder; and calcining the obtained white powder in a muffle furnace at a temperature of 350 + / - 10 DEG C for more than 0.6 h so as to obtain the self-assembly carbonitride nanotube. The preparation method provided in the invention has the advantages of mild preparation conditions, low sintering temperature, a simple process and energy conservation; the nanotube synthesized by using the preparation method has excellent photo-conductive performance, emission wavelength of fluorescence of the nanotube can generate wavelength red shift as sintering time prolongs, and the nanotube can generate fluorescence of a variety of colors after doped by rare earth metal ions.

Owner:KUSN INNOVATION INST OF NANJING UNIV

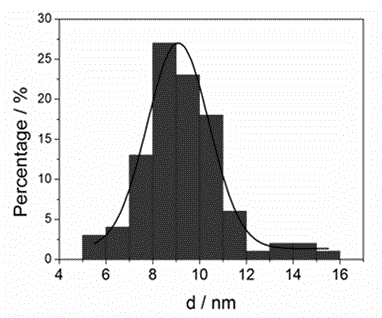

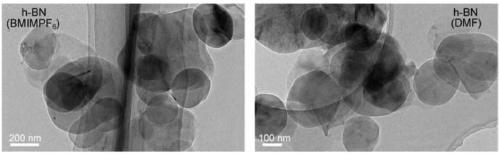

Nano-scale metal halide scintillation materials and methods for making same

Crystalline scintillator materials comprising nano-scale particles of metal halides are provided. The nano-scale particles are less than 100 nm in size. Methods are provided for preparing the particles. In these methods, ionic liquids are used in place of water to allow precipitation of the final product. In one method, the metal precursors and halide salts are dissolved in separate ionic liquids to form solutions, which are then combined to form the nano-crystalline end product. In the other methods, micro-emulsions are formed using ionic liquids to control particle size.

Owner:GENERAL ELECTRIC CO

Catalysts for production of biodiesel fuel and glycerol

InactiveUS20090119979A1Inexpensive and commercially availableSimplifies evacuationFatty acid esterificationNitrogen-metal/silicon/boron binary compoundsTrans esterificationBiodiesel

A method of producing biodiesel through the trans-esterification of a triglyceride, comprising mixing a triglyceride, an alcohol, and a catalyst to form a mixture, where said catalyst is non-metal quaternary ammonium hydroxide or non-metal quaternary phosphonium hydroxide, removing volatile components from said mixture, and allowing the remaining mixture to separate into a biodiesel-rich layer and a glycerol-rich layer.

Owner:IMPERIAL PETROLUEM

Apparatus and method for the production of trisilylamine

There is described an apparatus, a tubular laminar flow, plug flow reactor, for making silylamines and particularly trisilylamine (TSA) in high yields from ammonia gas and a monohalosilane gas. The apparatus can be a tubular flow reactor comprising a first portion of the reactor defining a gas entry zone, a second portion of the reactor defining a reaction zone and a third portion of the reactor defining a separation zone, the reaction zone providing a reactant contacting region. Trisilylamine can be recovered in the separation zone in a cold trap collection vessel.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

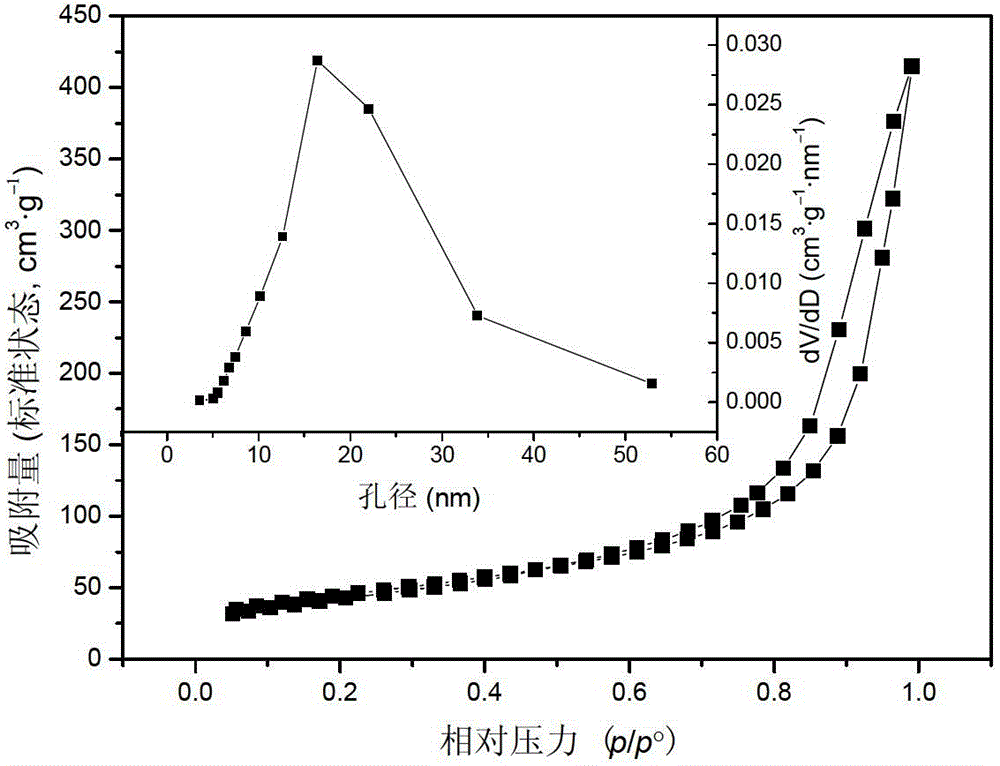

High-specific-surface-area mesoporous graphite-phase carbon nitride material and preparation method thereof

The invention relates to the field of inorganic materials, in particular to a high-specific-surface-area mesoporous graphite-phase carbon nitride material and a preparation method thereof. The graphite-phase carbon nitride material which is yellow powder is 5-28nm in pore diameter, 120-220m<2> / g in specific surface area and 0.4-0.7cm<3> / g in pore volume. The preparation method includes: dispersing guanidine hydrochloride solution on nano SiO2 microspheres or mesoporous silicon oxide materials, stirring, drying, calcining in an inert atmosphere, and removing a mould plate to obtain the mesoporous graphite-phase carbon nitride material. The raw material guanidine hydrochloride is low in cost and safe, the preparation method is simple, and the product is high in specific surface area. Further, adjustment of pore volume and specific surface area of the mesoporous graphite-phase carbon nitride material can be realized by adjusting usage of template agent.

Owner:PETROCHINA CO LTD +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com