Preparation method of graphite phase carbonitride

A graphite-phase carbon nitride and graphite technology, which is applied in the direction of nitrogen and non-metallic compounds, can solve the problems of rapid heating of bulk phases that are difficult to exert microwave irradiation, low power, and influence on preparation efficiency, etc., and achieves controllable structure and properties, The effect of simple preparation process and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 10g melamine (C 3 h 6 N 6 ) and 2g of graphite powder were ground and mixed evenly. The mixture is then placed in a ceramic crucible and placed in a resonant cavity of an industrial high-energy microwave oven. Vacuumize the resonant cavity of the microwave oven to 5kPa, then turn on the microwave, and start to keep warm after the temperature reaches 450°C. At this time, the microwave power is about 2kW. After 5 minutes, turn off the microwave oven, let the reaction system cool down to room temperature with the furnace, and then take out the sample. A large amount of bright yellow powder can be seen in the crucible.

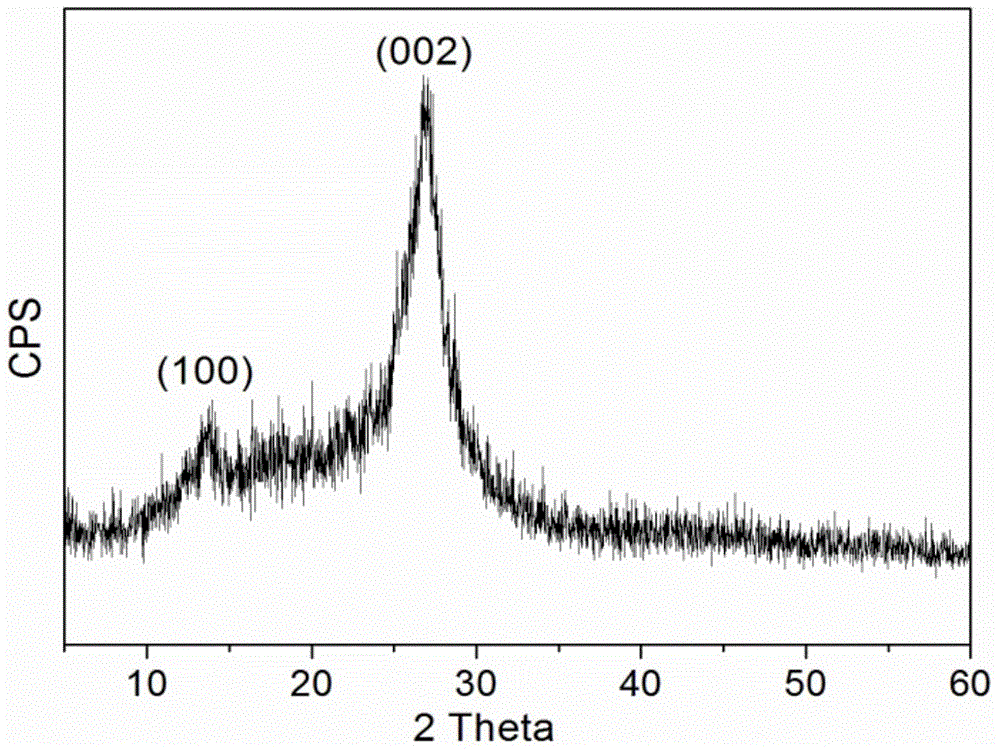

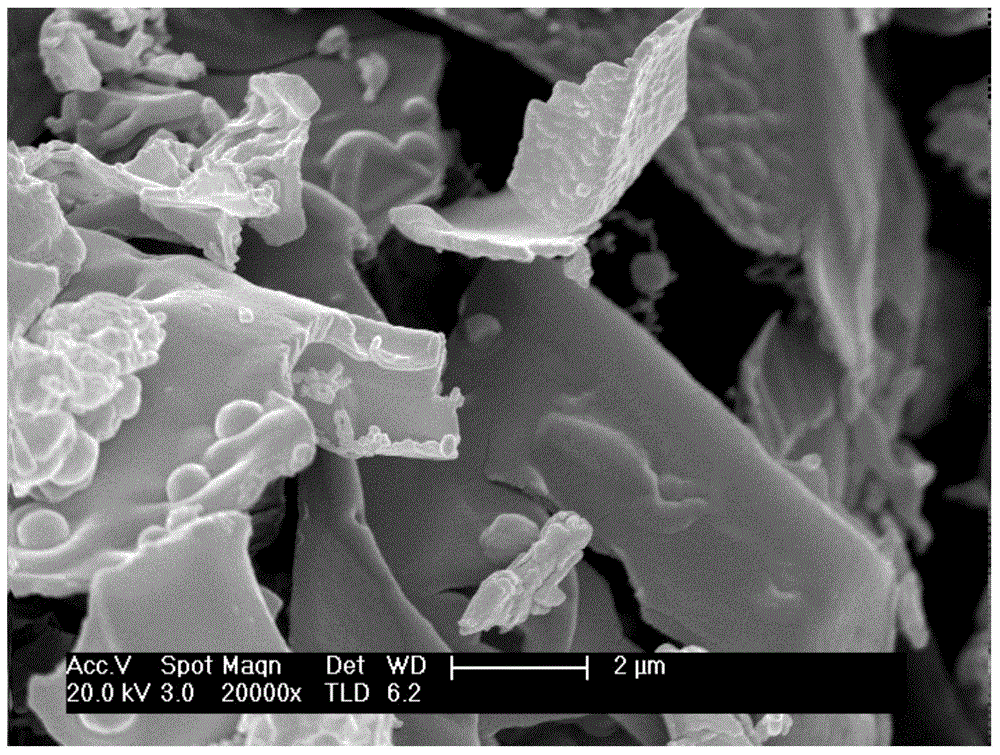

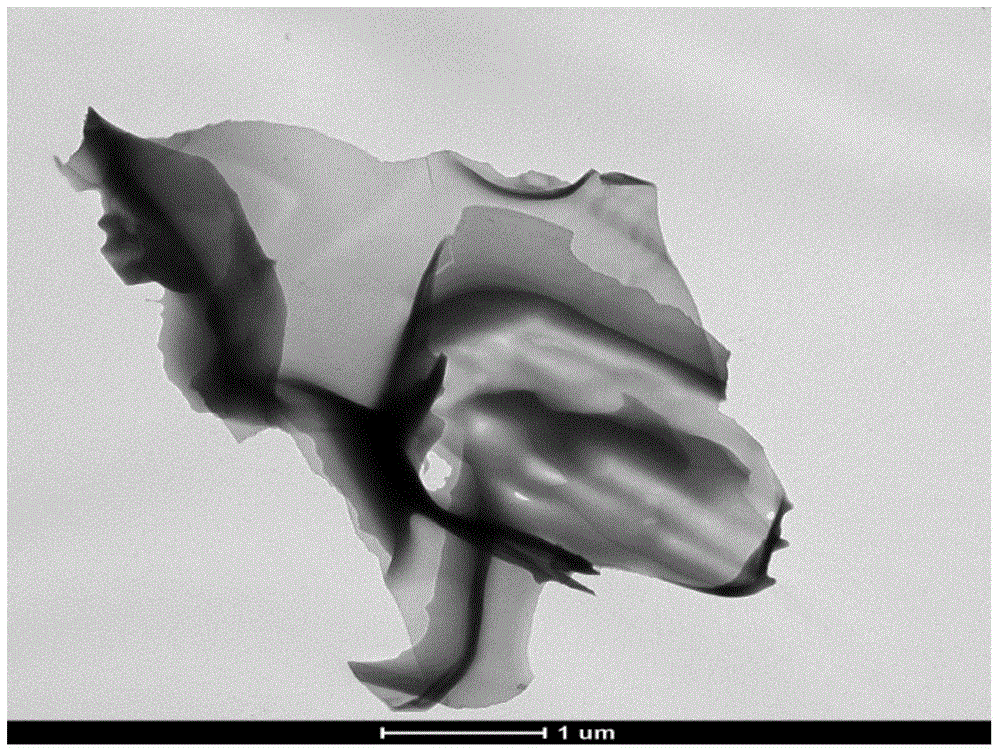

[0056] The structure of the bright yellow powder obtained after microwave irradiation was characterized by X-ray diffraction, scanning electron microscopy, and transmission electron microscopy, and it was confirmed that the product was pure graphite phase carbon nitride, and the product was pure, with a yield of about 46wt%.

[0057] figure 1 It is the...

Embodiment 2

[0060] Weigh the same two-component raw materials in Example 1 and move them into a ceramic crucible after thorough mixing. After placing the crucible in an industrial high-energy microwave resonator, start vacuuming to 5kPa. Turn on the microwave again, set the microwave irradiation power to 3kW, start to keep warm after the temperature reaches 550°C, turn off the microwave after 10min, let the reaction system cool down to room temperature with the furnace, and take out the yellow sample. Through the analysis of X-ray diffraction and scanning electron microscope characterization adopted in Example 1, it can be proved that the obtained yellow product is graphite phase carbon nitride. Because the microwave power is increased, the heating temperature is higher, the color of the obtained graphite phase carbon nitride is deepened, and the yield is about 41wt%.

[0061] The X-ray diffraction pattern of the product shows that a (100) diffraction peak appears at the position of 13.3...

Embodiment 3

[0064] The two-component raw materials in Example 1 were weighed and thoroughly mixed, then transferred into a ceramic crucible and placed in a resonant cavity of an industrial high-energy microwave oven. Evacuate the resonant cavity of the microwave oven to a vacuum of 10kPa. Turn on the microwave, set the microwave irradiation power to 3kW, start to keep warm after the temperature reaches 550°C, turn off the microwave after 20min, let the reaction system cool down to room temperature with the furnace, and take out the dark yellow sample. Through the characterization analysis such as X-ray diffraction and scanning electron microscopy adopted in Example 1, it can be proved that the dark yellow product obtained is graphite phase carbon nitride. Due to the further extension of the holding time, the color of the graphitic carbon nitride changed to dark yellow, and the yield was 39wt%.

[0065] The X-ray diffraction pattern of the product shows that a (100) diffraction peak appears...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com