Patents

Literature

338 results about "Graphitic carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of graphitic carbon. : the portion of the carbon in iron or steel that is present as graphite —distinguished from combined carbon.

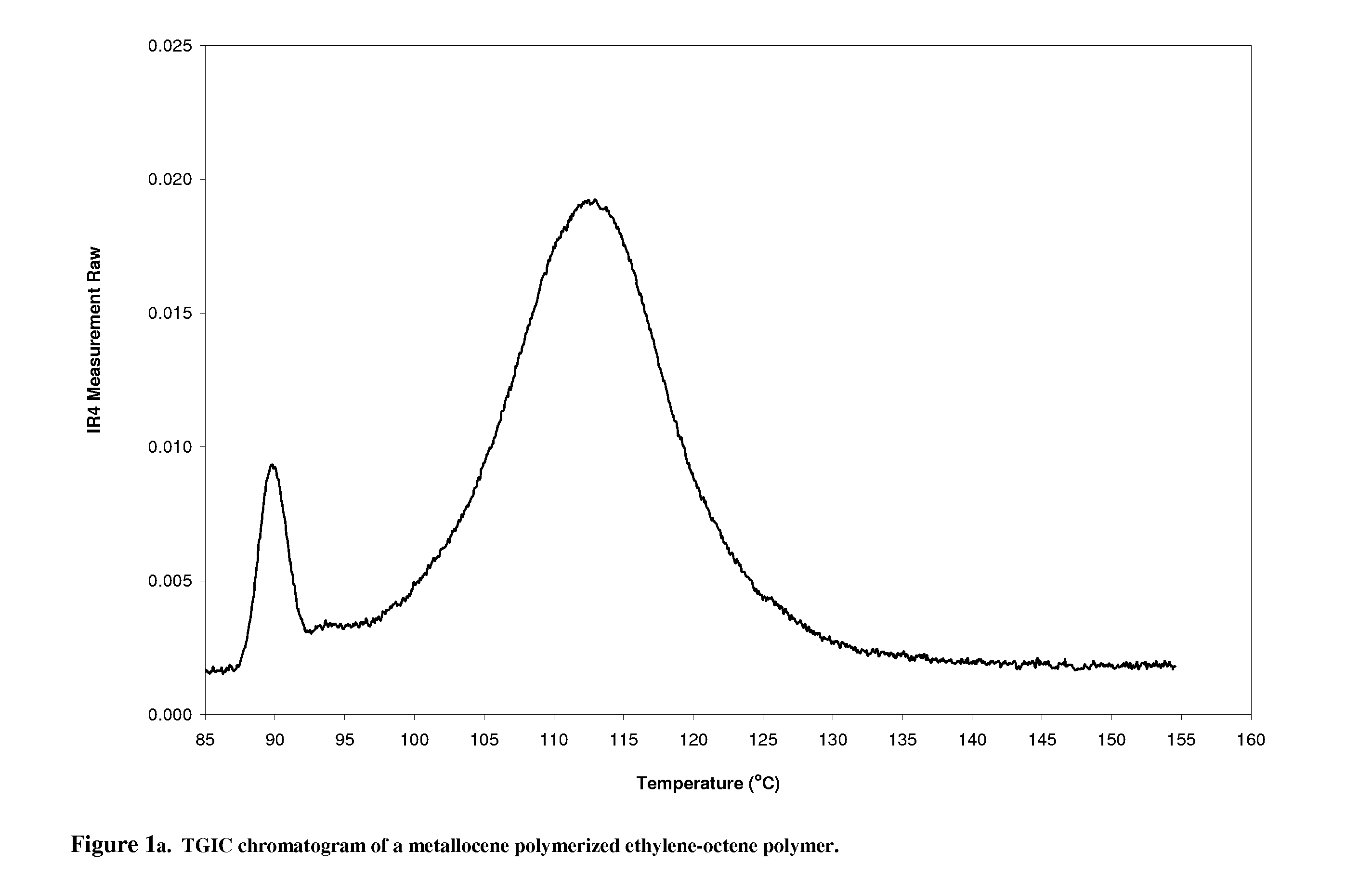

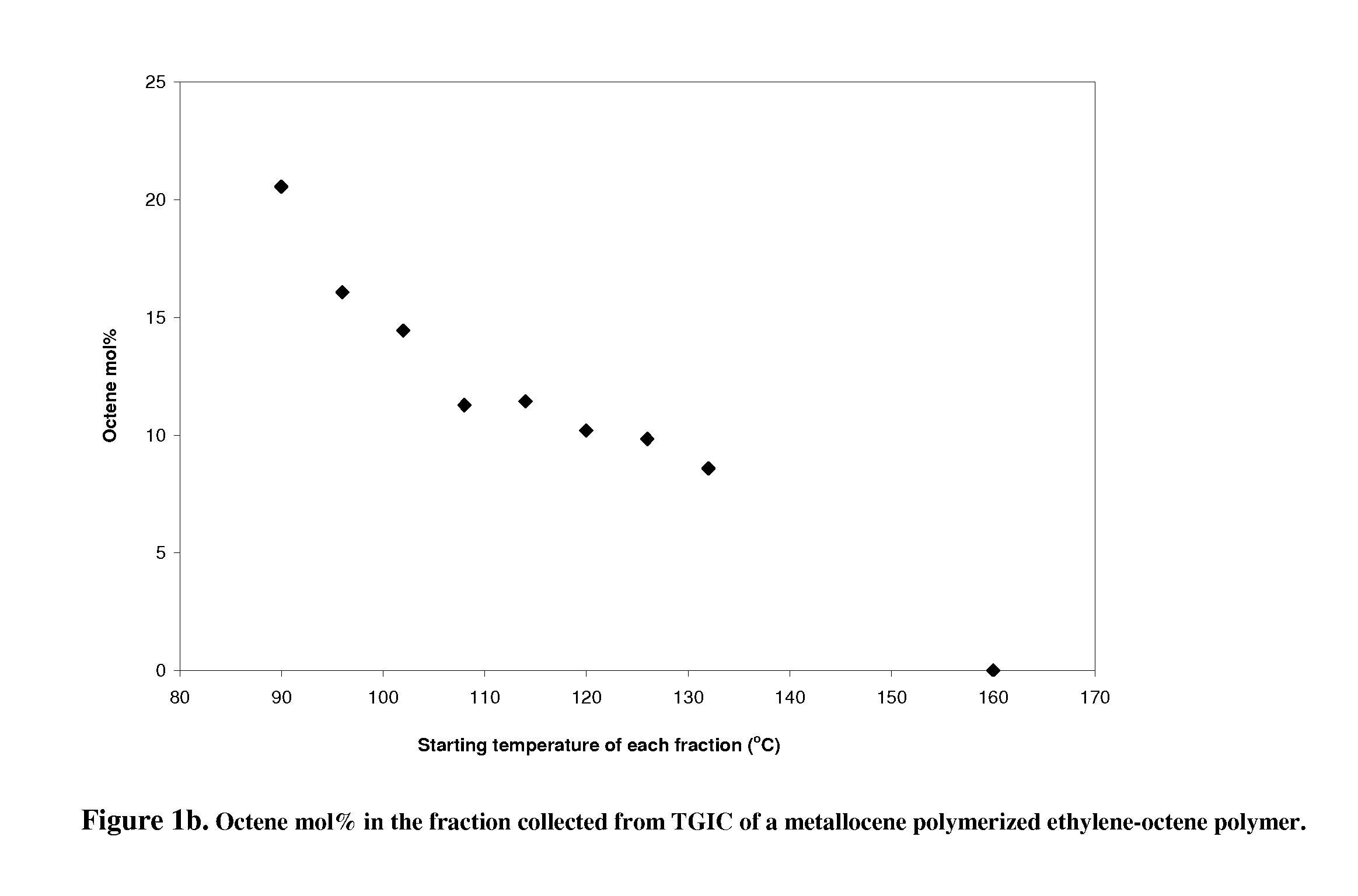

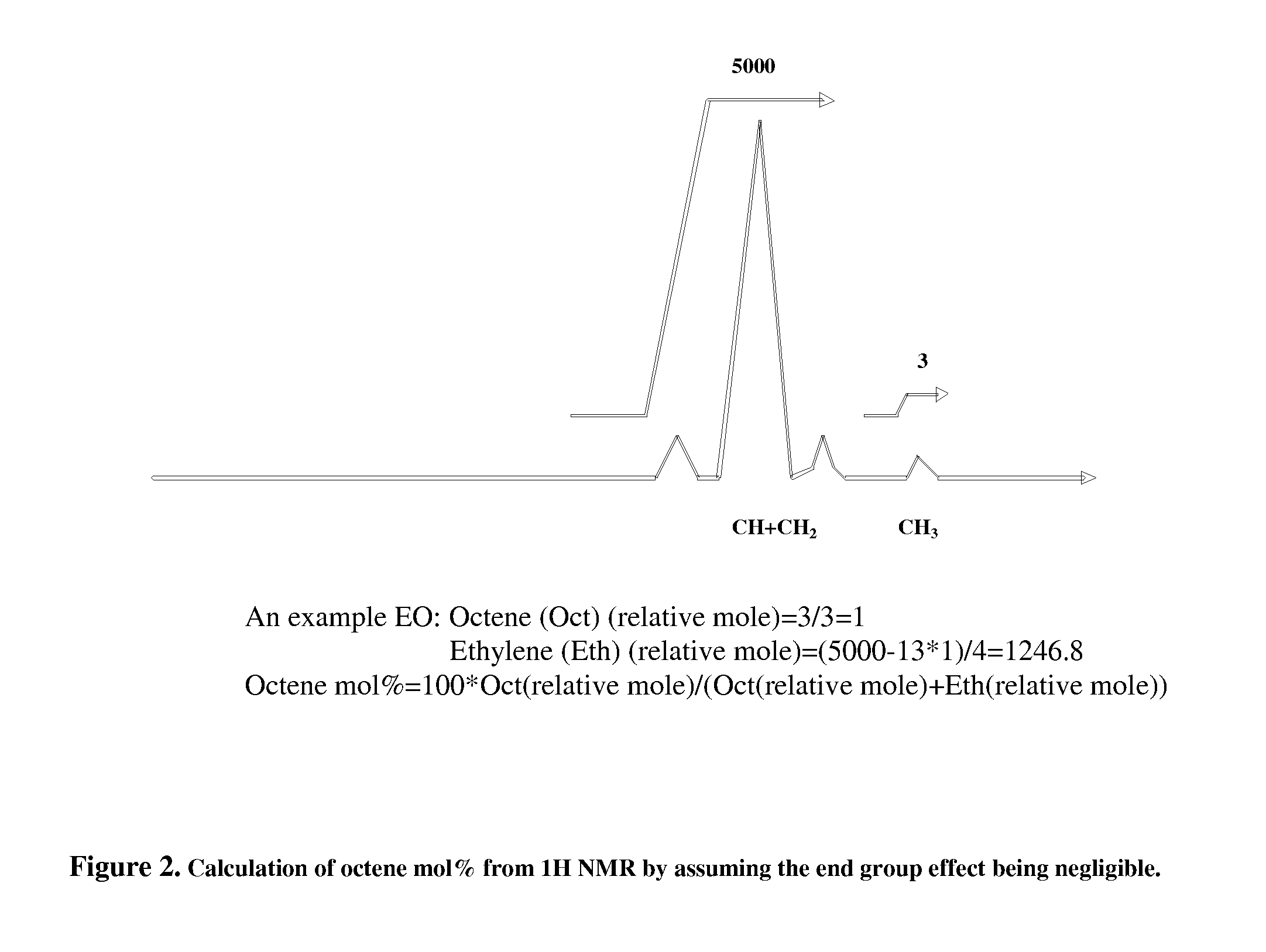

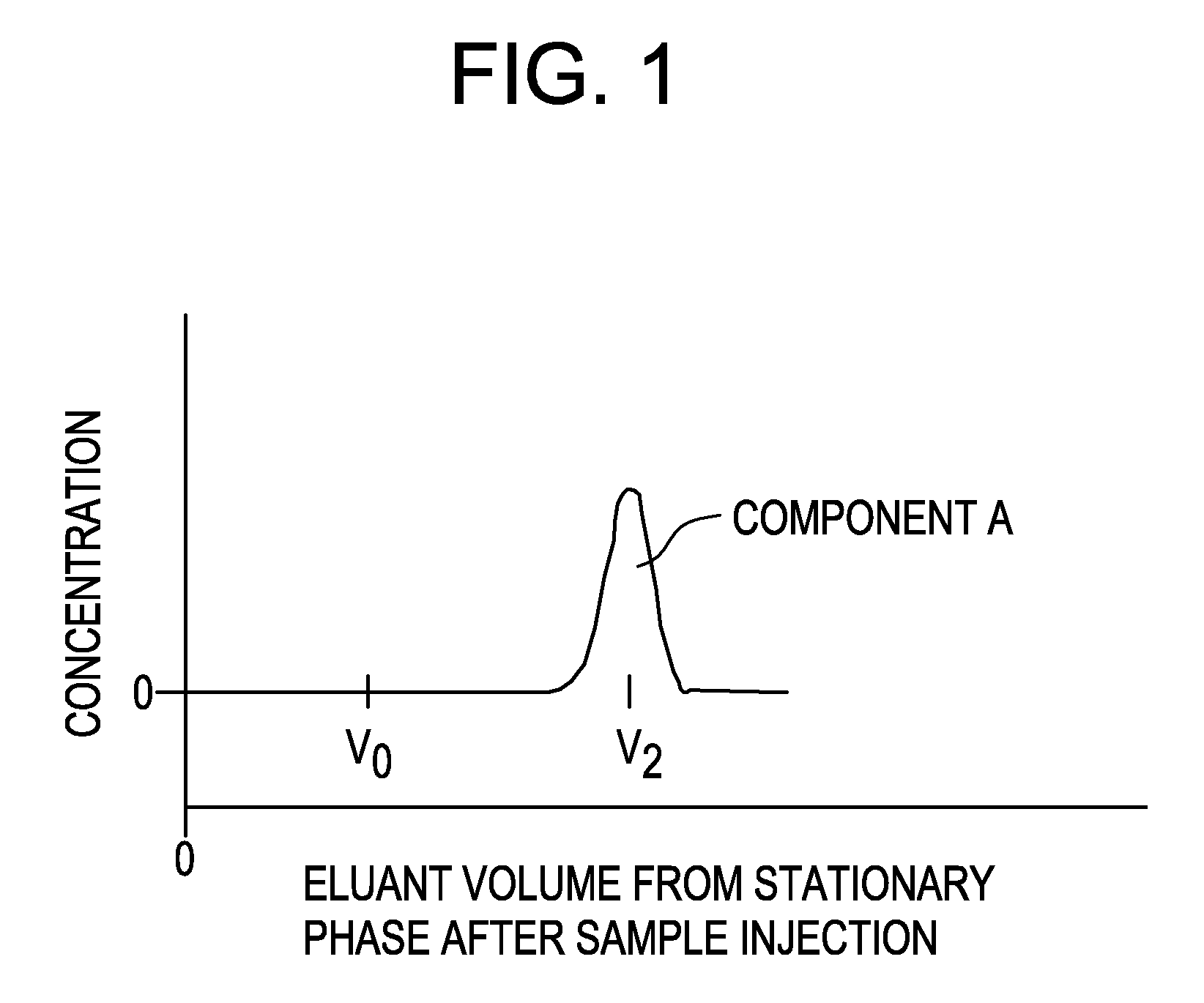

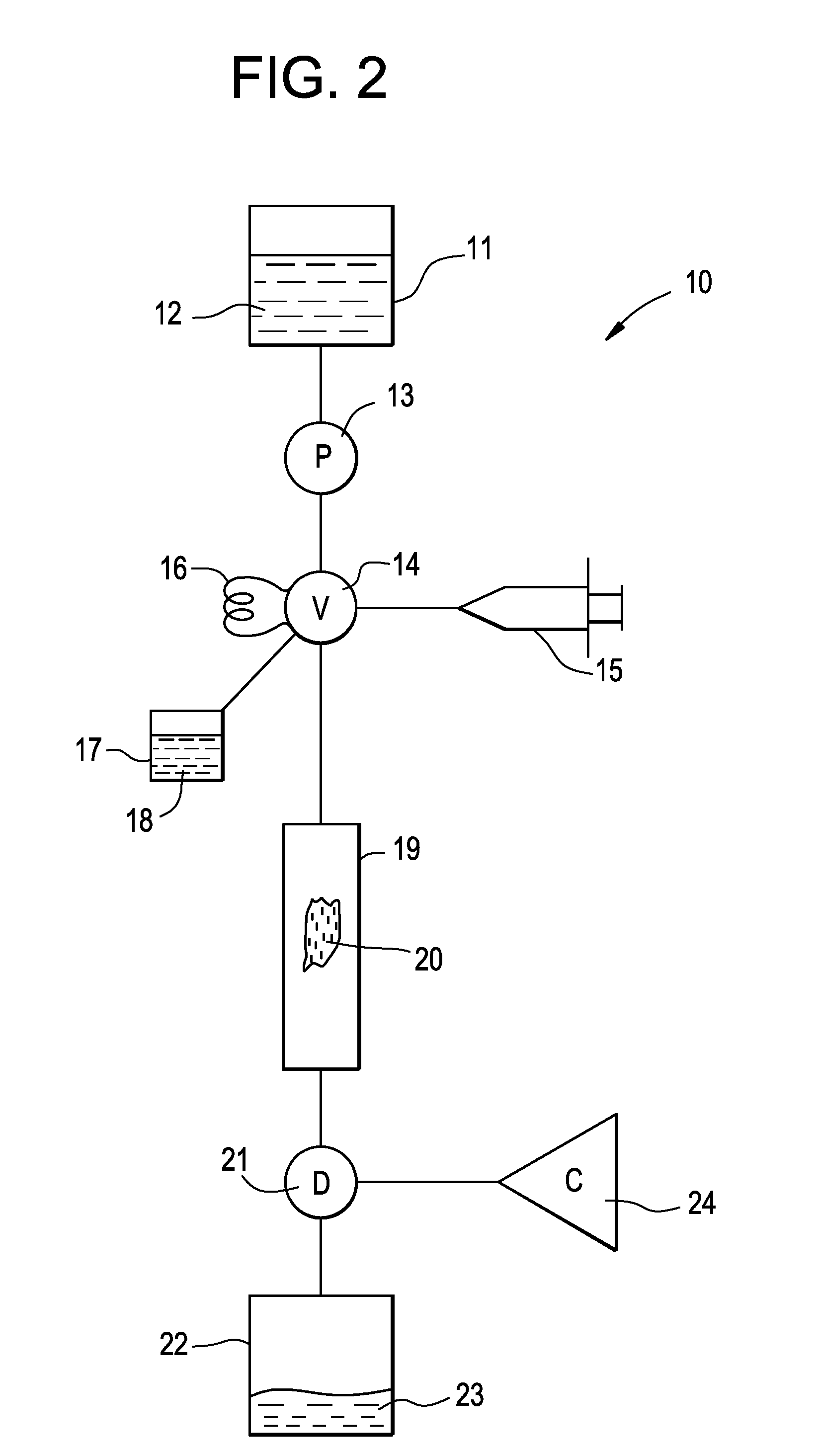

Chromatography of polyolefin polymers

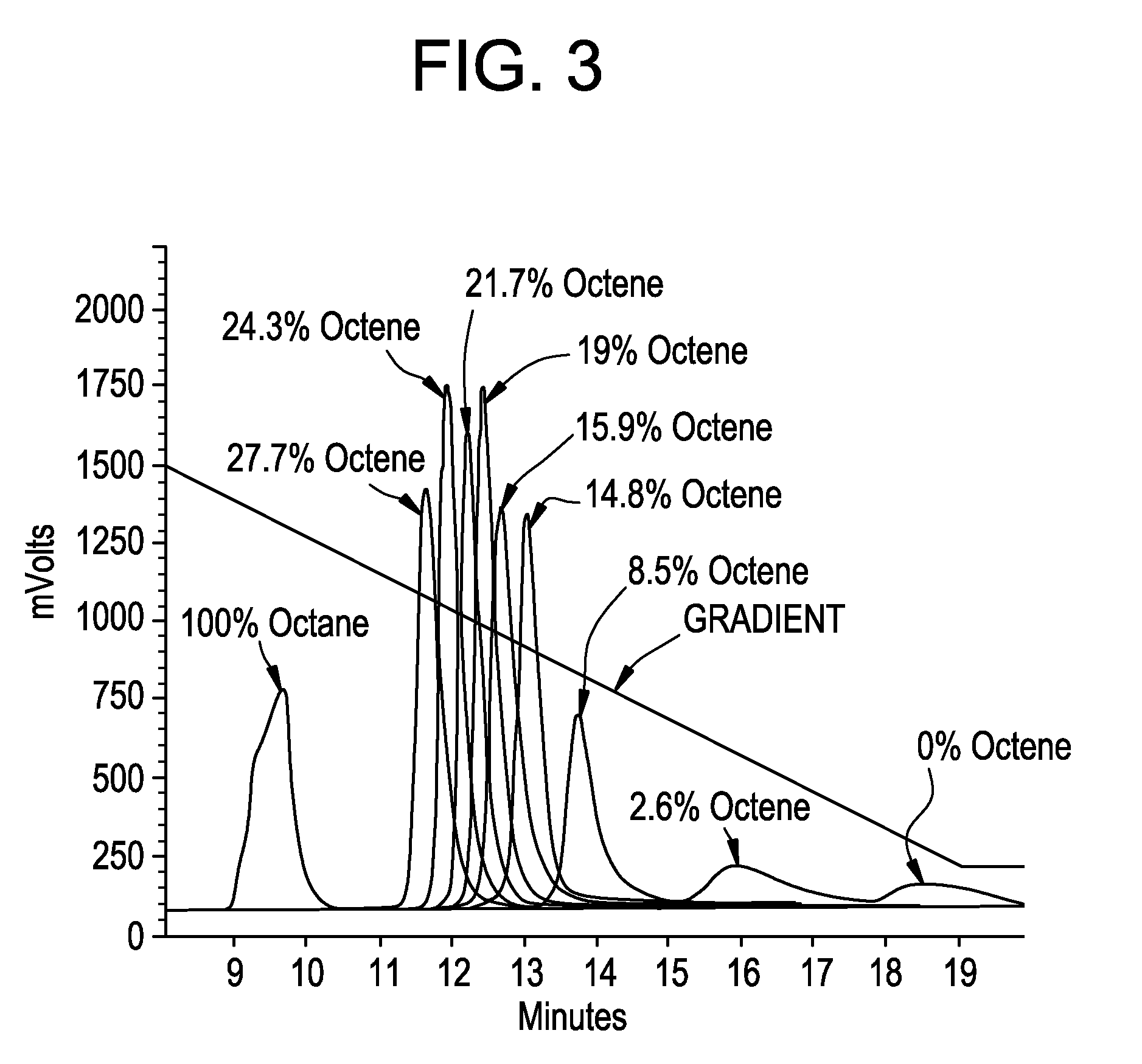

A method for multi-dimensional chromatography of a polyolefin polymer, comprising introducing a solution of the polyolefin polymer into a liquid flowing through a first liquid chromatography stationary phase or a field flow fractionation device and subsequently flowing the solution through a second liquid chromatography stationary phase, the second liquid chromatography stationary phase comprising graphitic carbon, the polyolefin polymer emerging from the liquid chromatography stationary phase with a retention factor greater than zero.

Owner:THE DOW CHEM CO

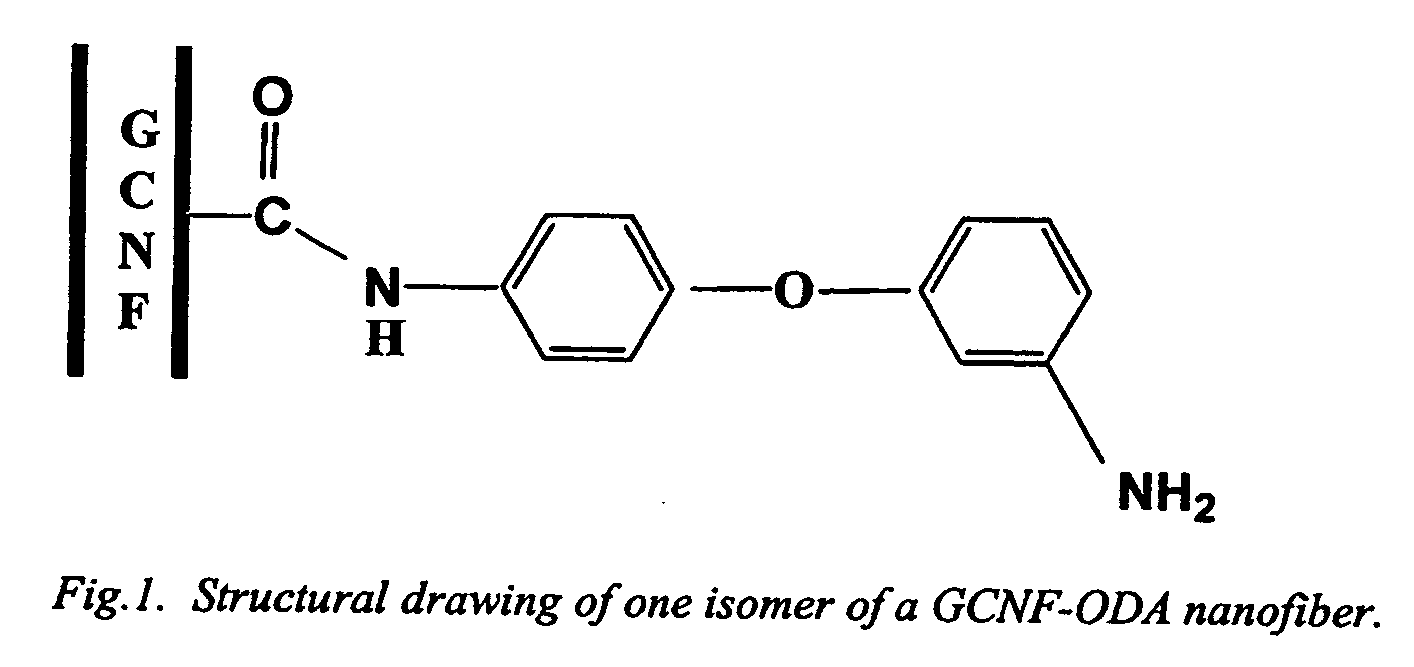

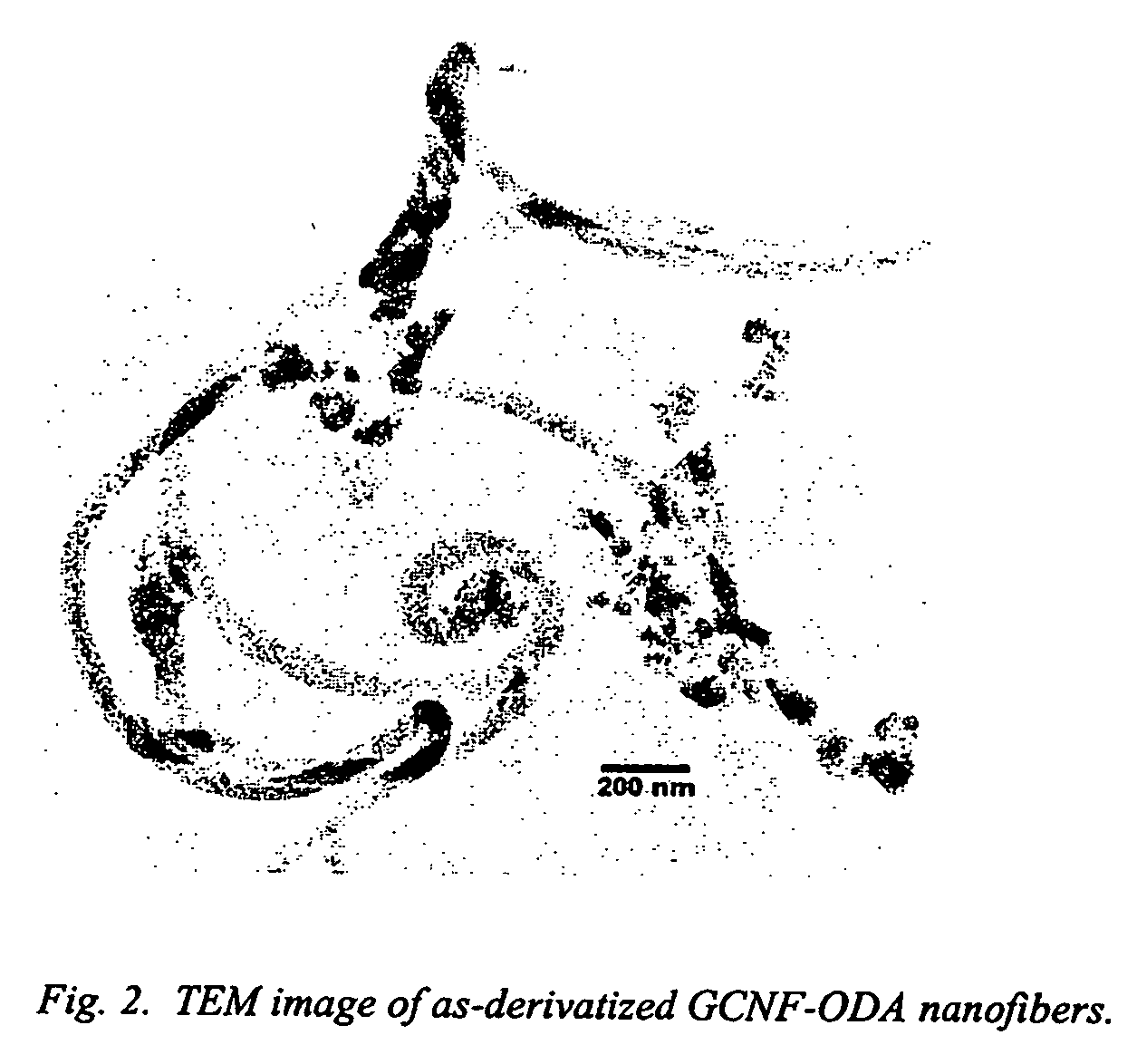

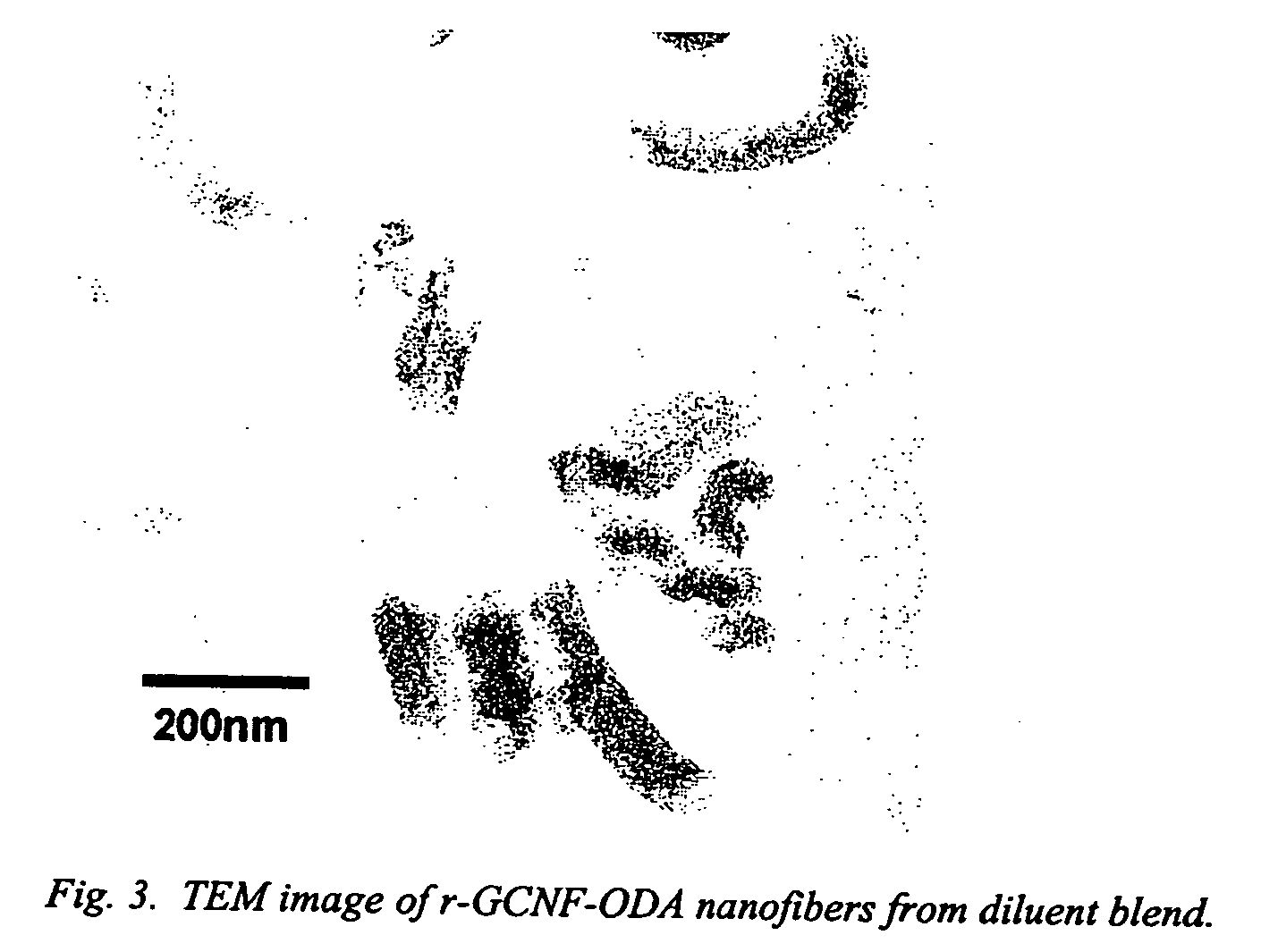

Reactive graphitic carbon nanofiber reinforced polymeric composites showing enhanced flexural strength

Composites comprising at least one graphite-carbon nanofiber (GCNF) and a polymer phase covalently linked to a surface thereof.

Owner:VANDERBILT UNIV

Chromotography of polyolefin polymers

ActiveUS8076147B2Separation efficiency can be improvedIon-exchange process apparatusComponent separationStationary phasePolymer science

A method and apparatus for chromatography of a polyolefin polymer by flowing a solution of the polyolefin polymer through liquid flowing through a graphitic carbon liquid chromatography stationary phase. The method can be used to determine the monomer to comonomer ratio of a polyolefin copolymer such as a copolymer of ethylene and 1-octene or a copolymer of propylene and ethylene.

Owner:THE DOW CHEM CO

Porous carbon electrode with conductive polymer coating

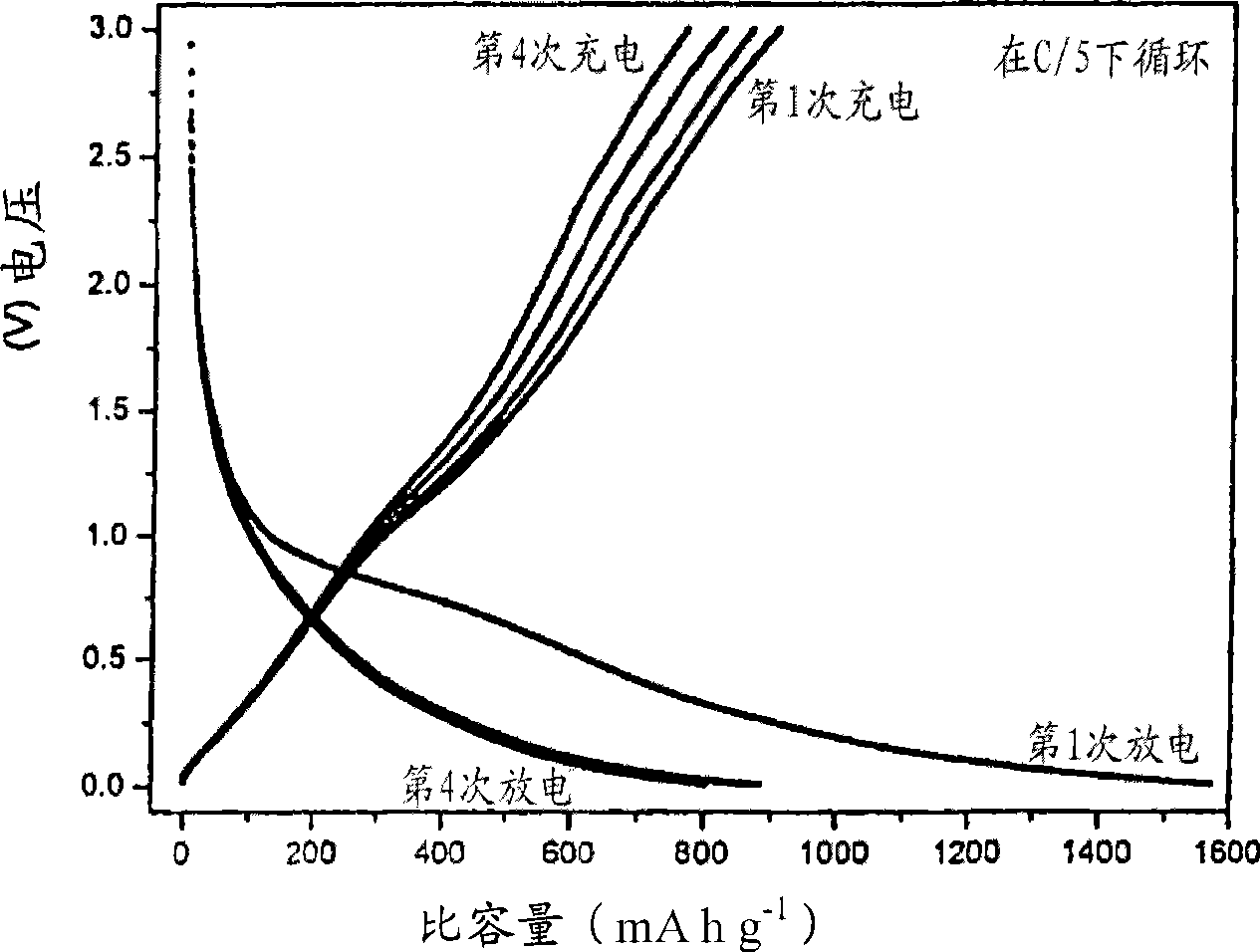

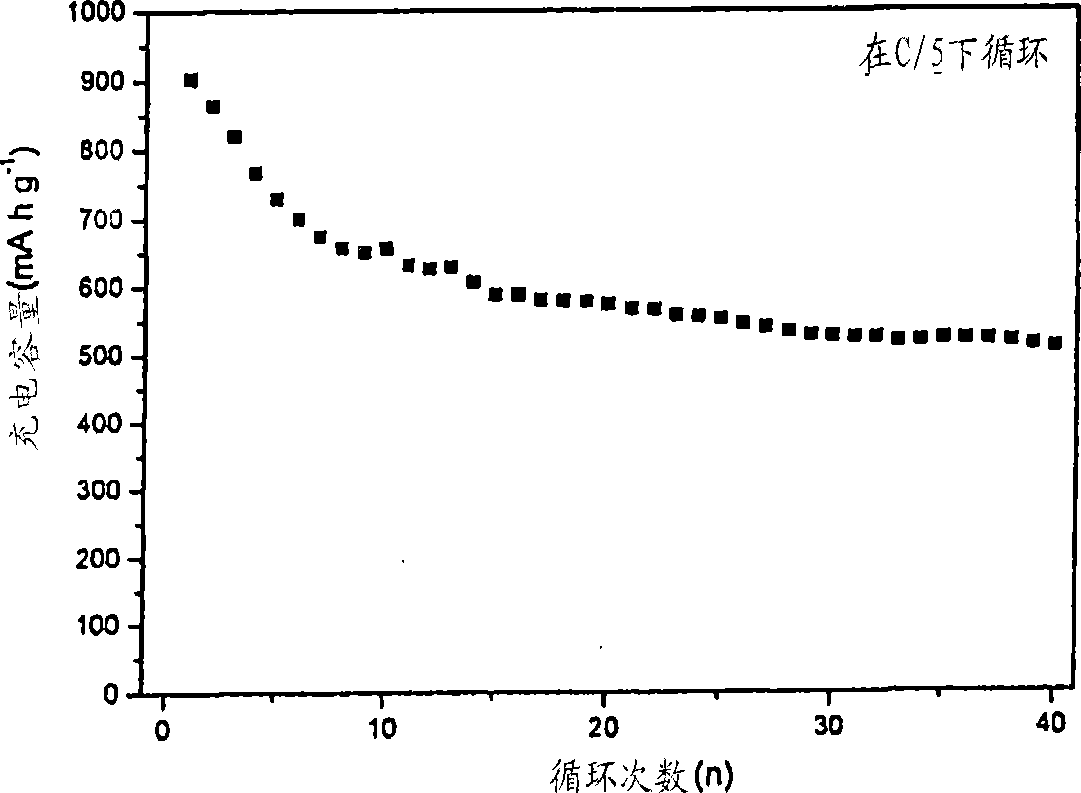

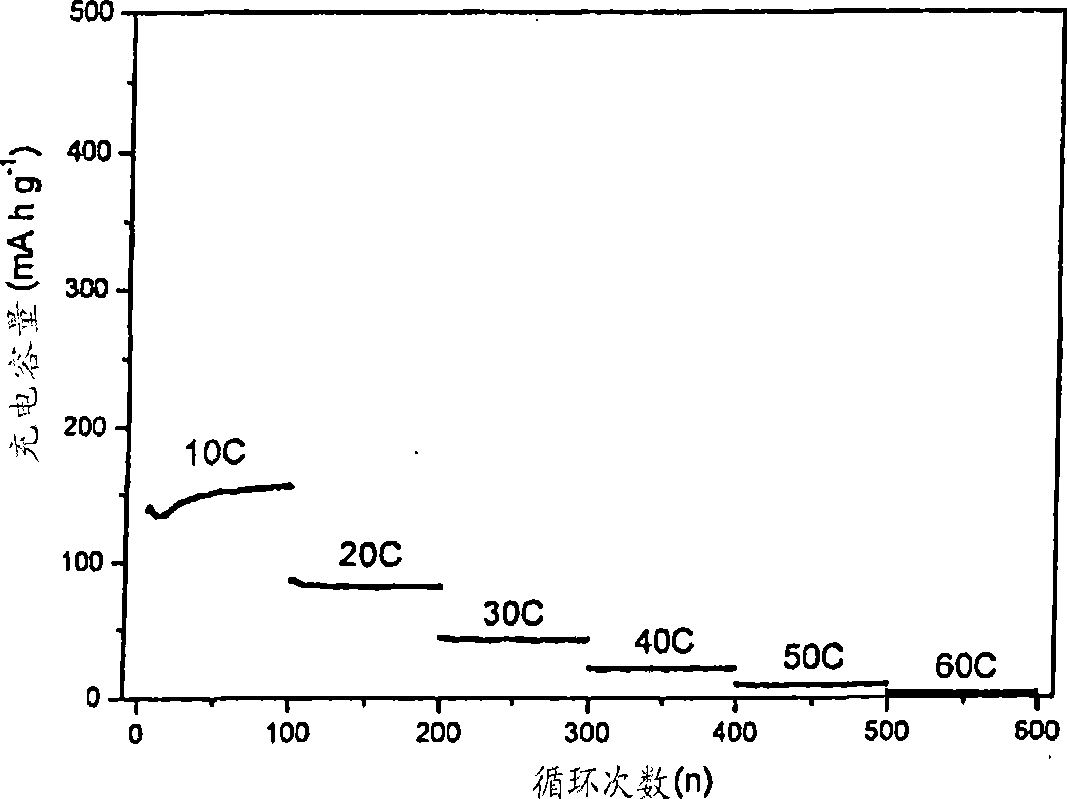

This disclosure relates to a porous electrically conductive carbon material having interconnected pores in first and second size ranges from 10[mu]m to 100nm and from less than 100nm to 3nm and a graphene structure and to diverse uses of the material such as an electrode in a lithium-ion battery and a catalyst support, e.g. for the oxidation of methanol in a fuel cell. The carbon material has been heat treated to effect conversion to non-graphitic carbon with the required degree of order at a temperature in the range from 600 DEG C to 1000 DEG C. A lithium-ion battery and an electrode for a lithium-ion battery are also claimed.

Owner:促进科学E.V.麦克斯-普朗克公司

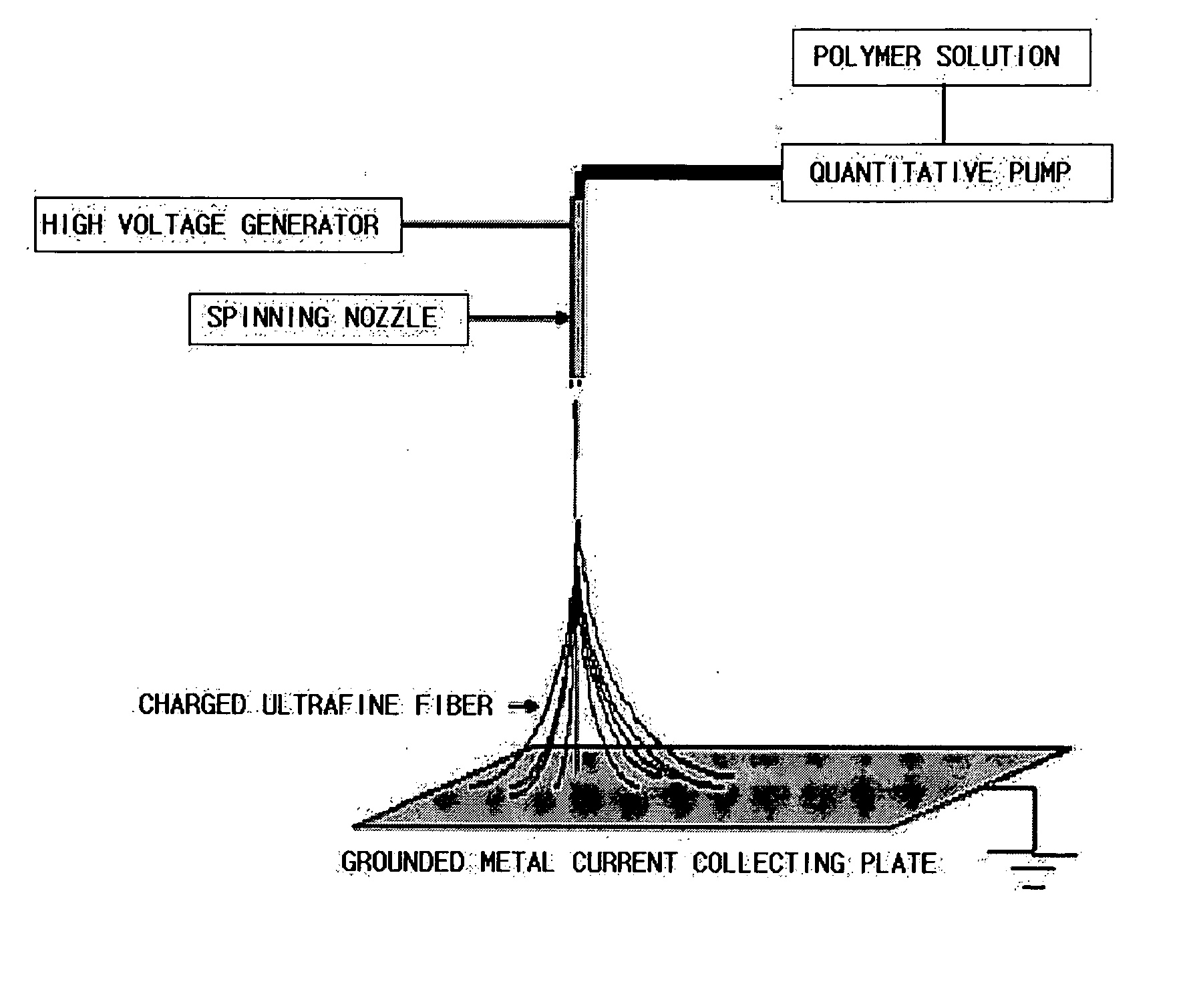

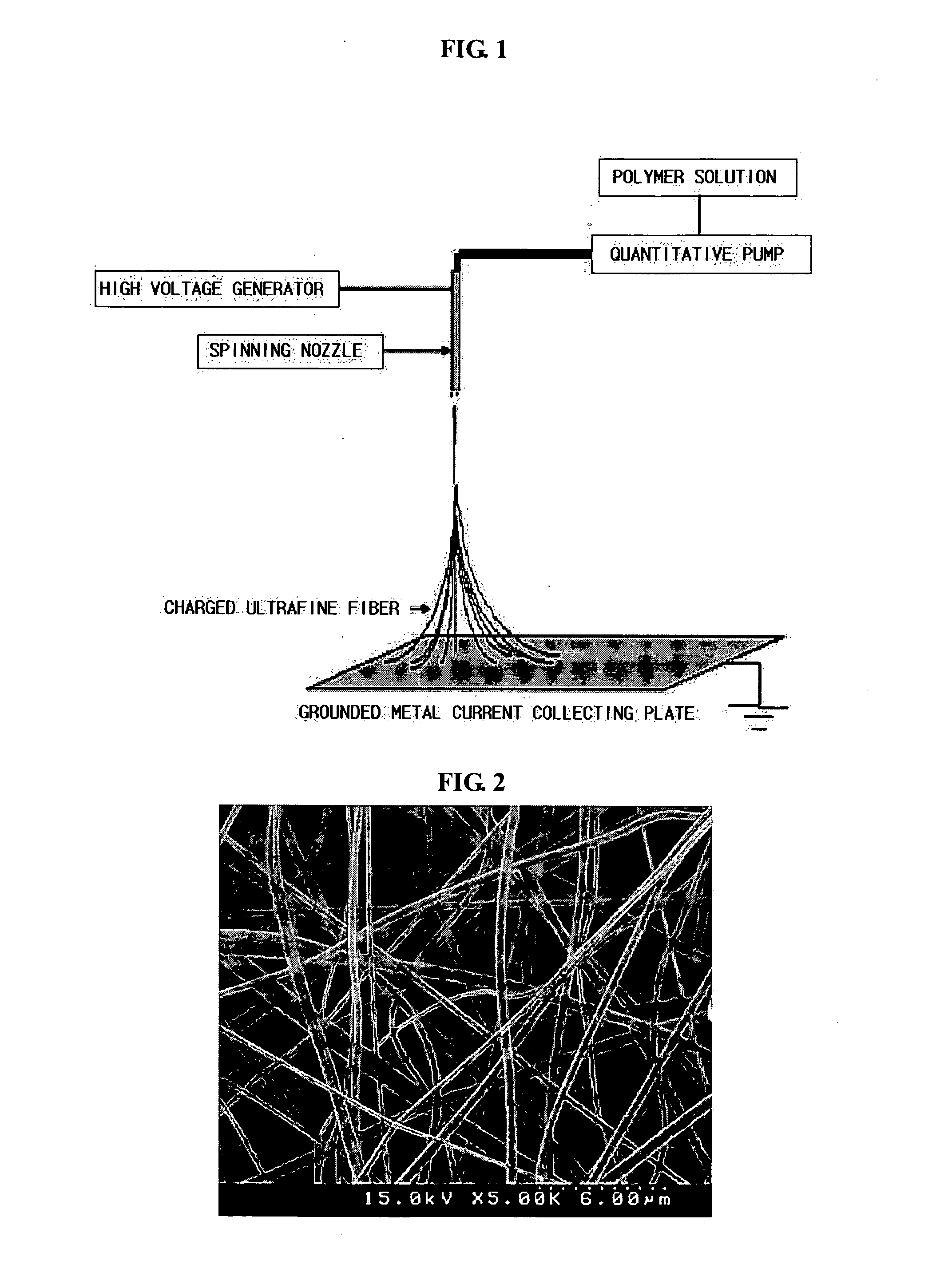

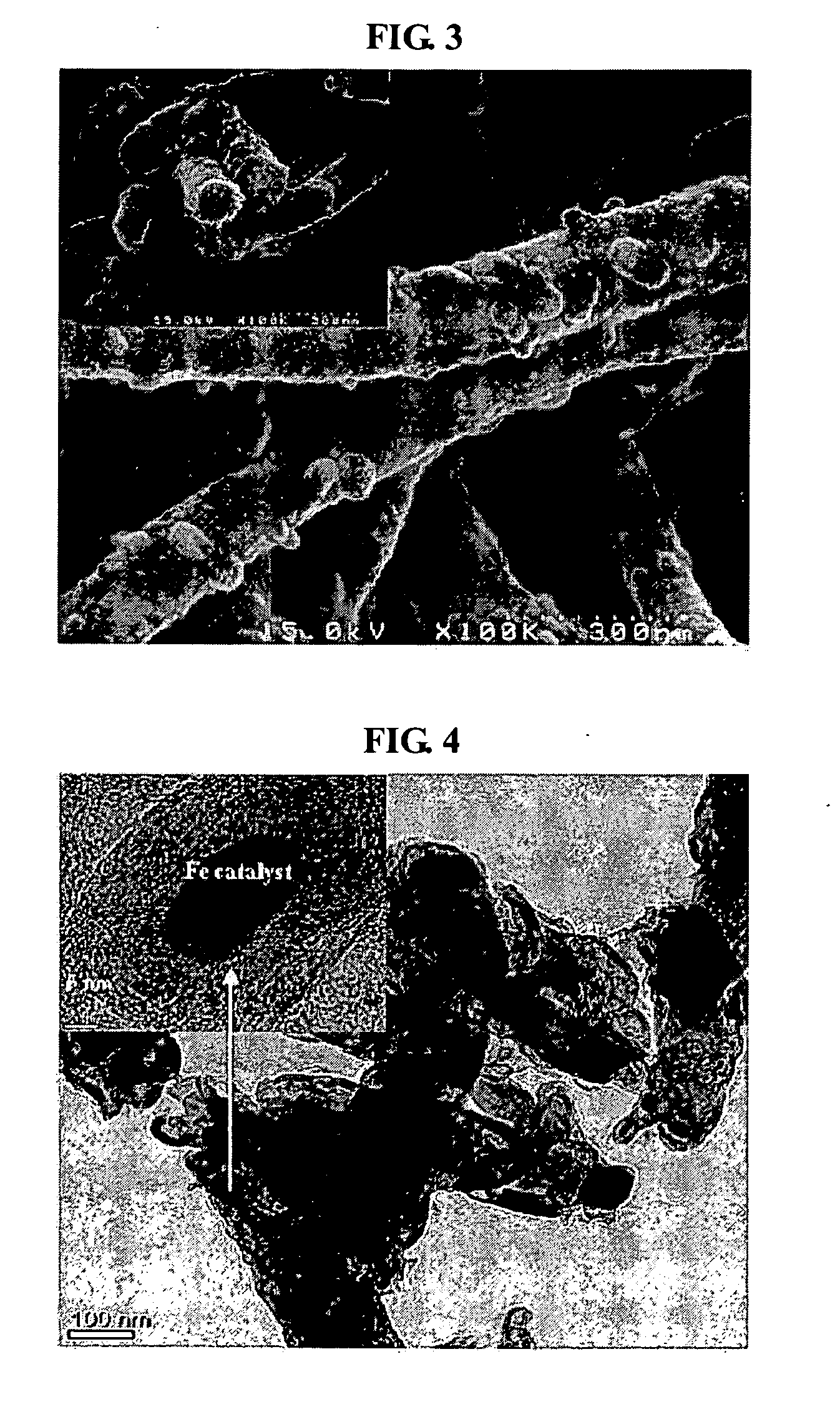

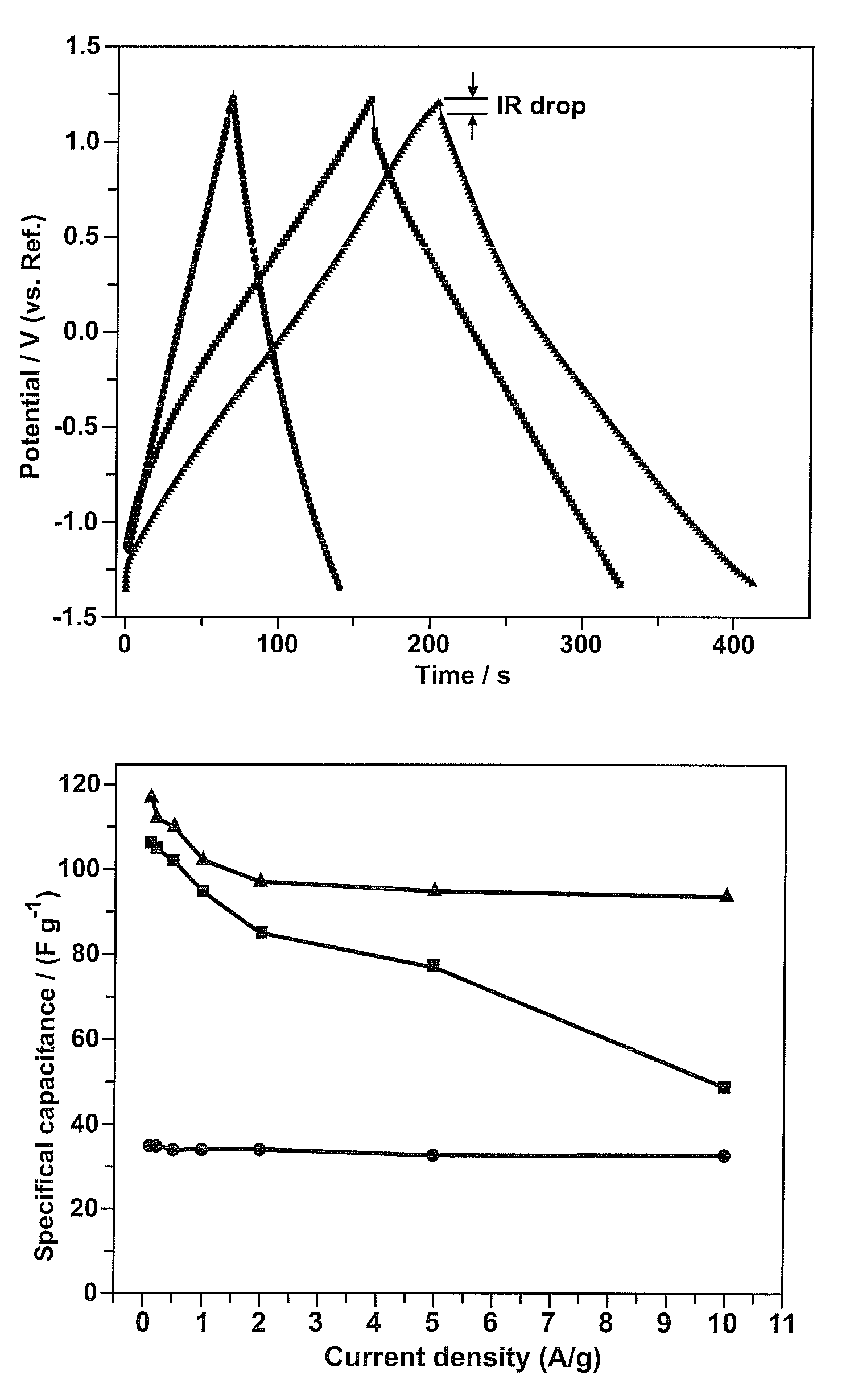

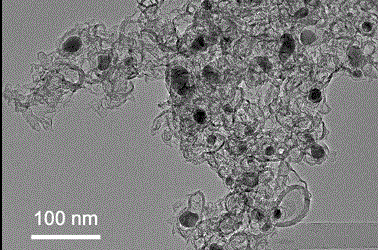

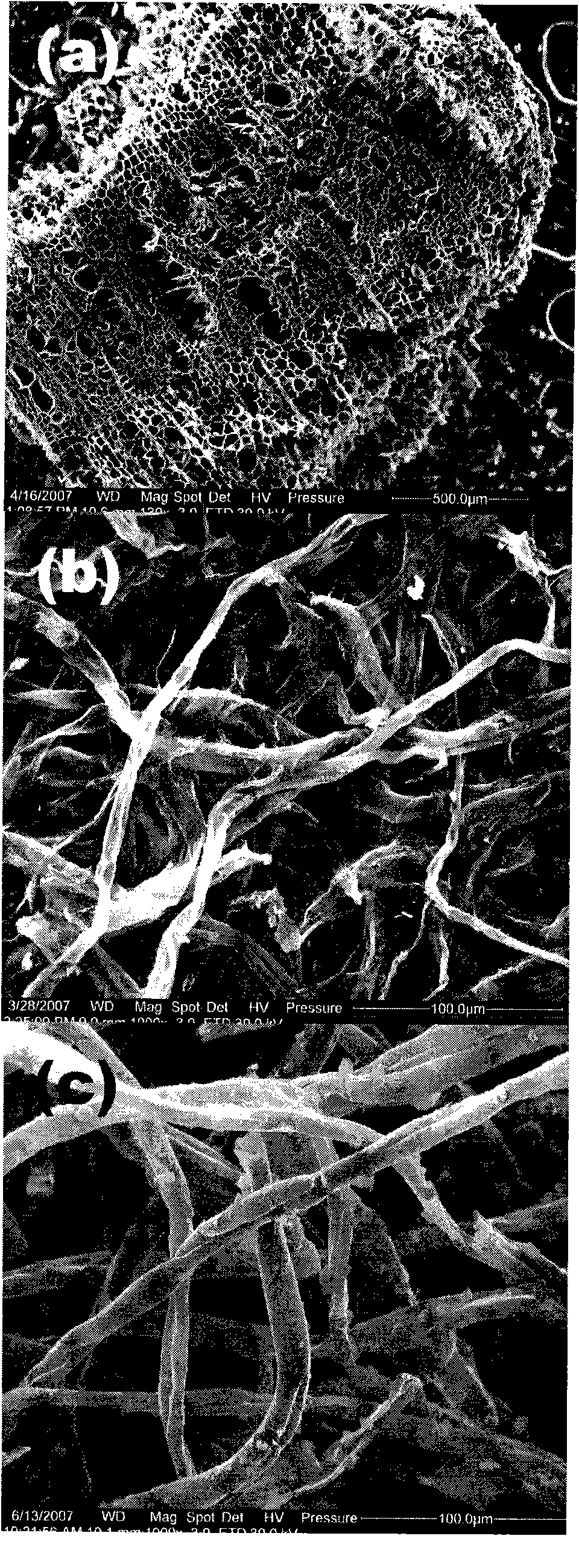

Ultrafine porous graphitic carbon fiber and preparation method thereof

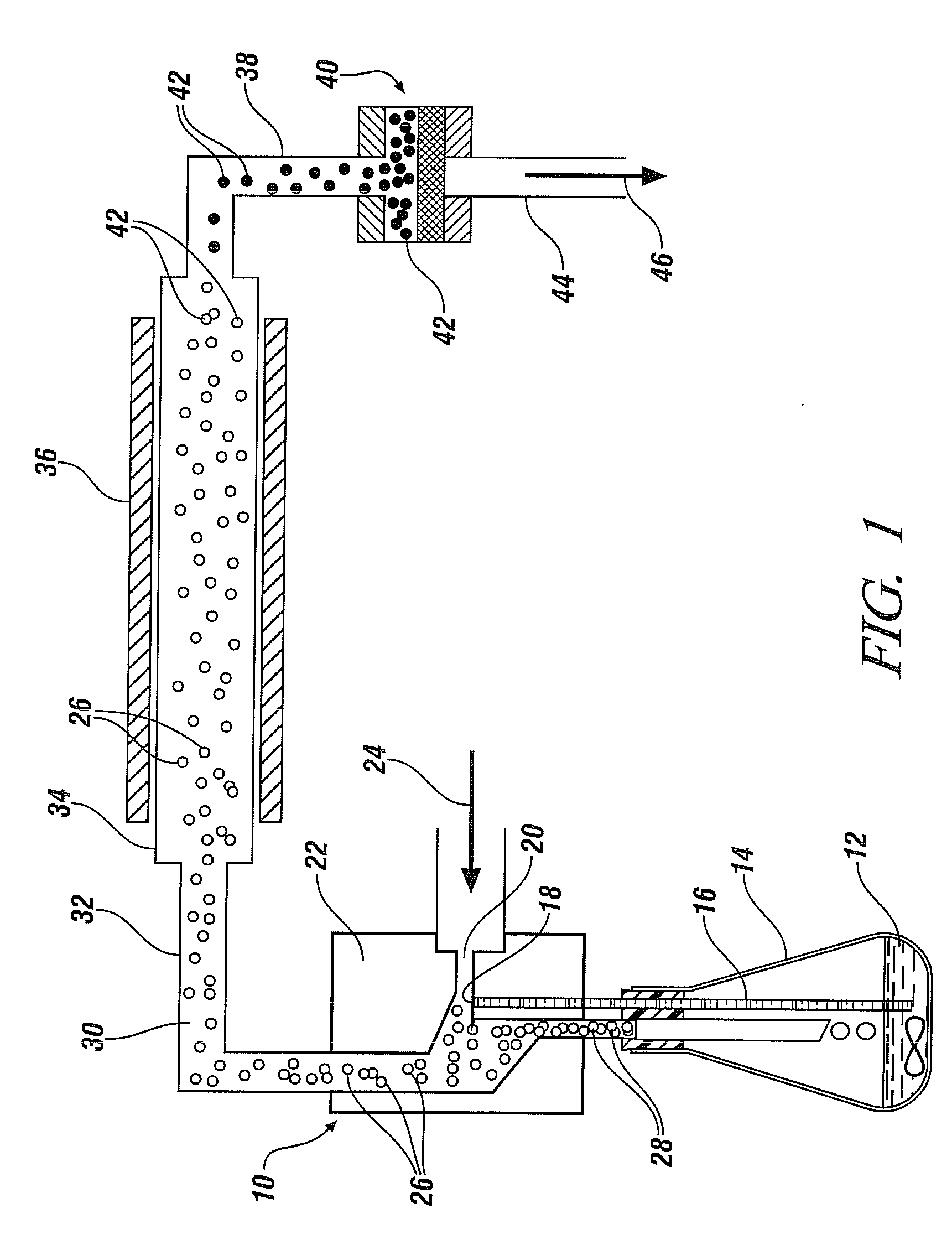

ActiveUS20070134151A1Physical/chemical process catalystsElectric discharge heatingFiberCarbon fibers

The present invention discloses an ultrafine graphitic carbon fiber and a preparation method thereof. An ultrafine fiber having a diameter of 1 to 3000 nm is prepared by electrospinning a halogenated polymer solution containing a metal compound inducing graphitization. In carbonization, an ultrafine porous graphitic carbon fiber having a large specific surface area, micropores and macropores is prepared by the graphitization by a metal catalyst generated from the metal compound. The ultrafine carbon fiber can be used as a carbon material for storing hydrogen, an adsorbing material of biochemically noxious substances, an electrode material of a supercapacitor, a secondary cell and a fuel cell, and a catalyst carrier material.

Owner:KOREA INST OF SCI & TECH

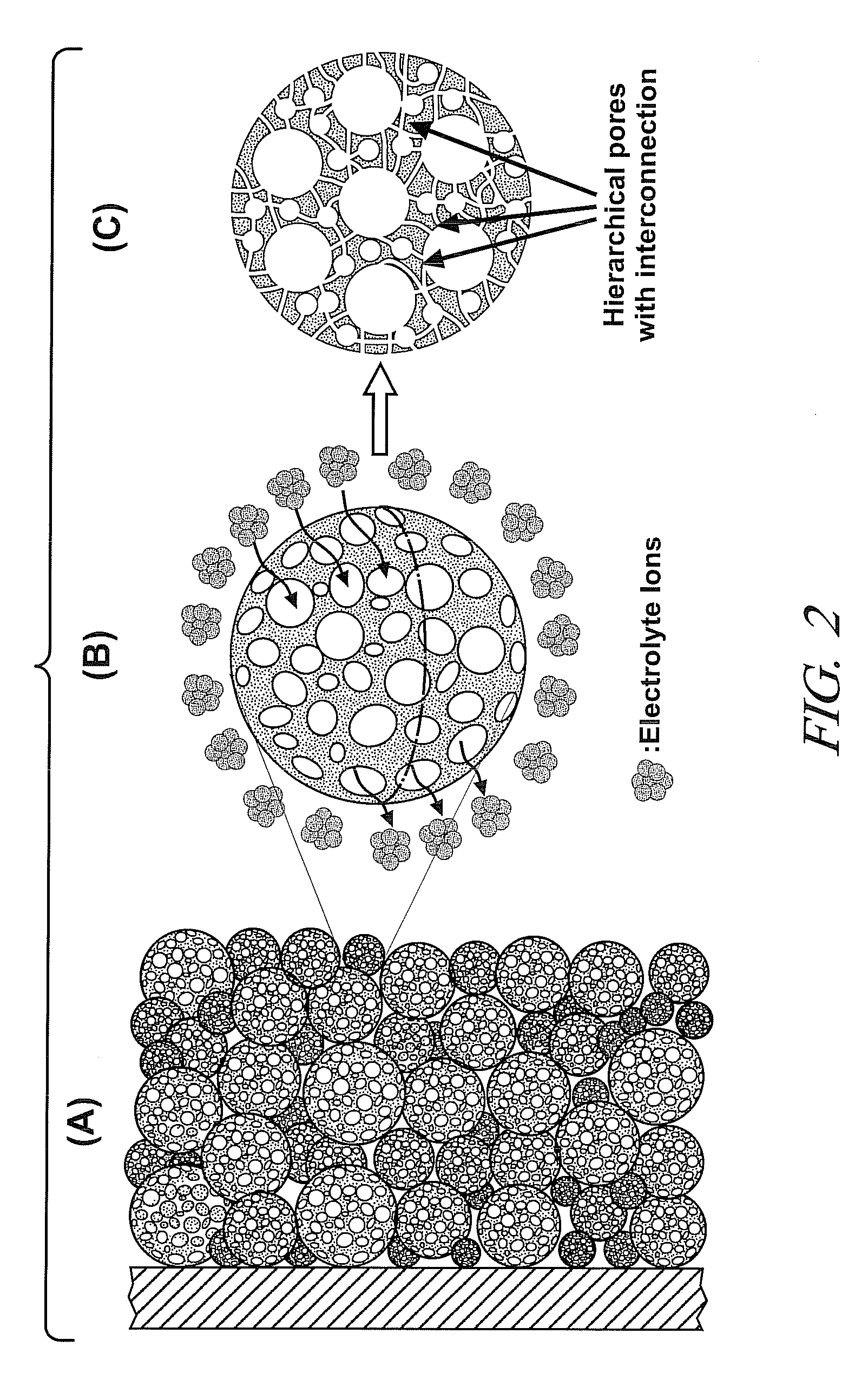

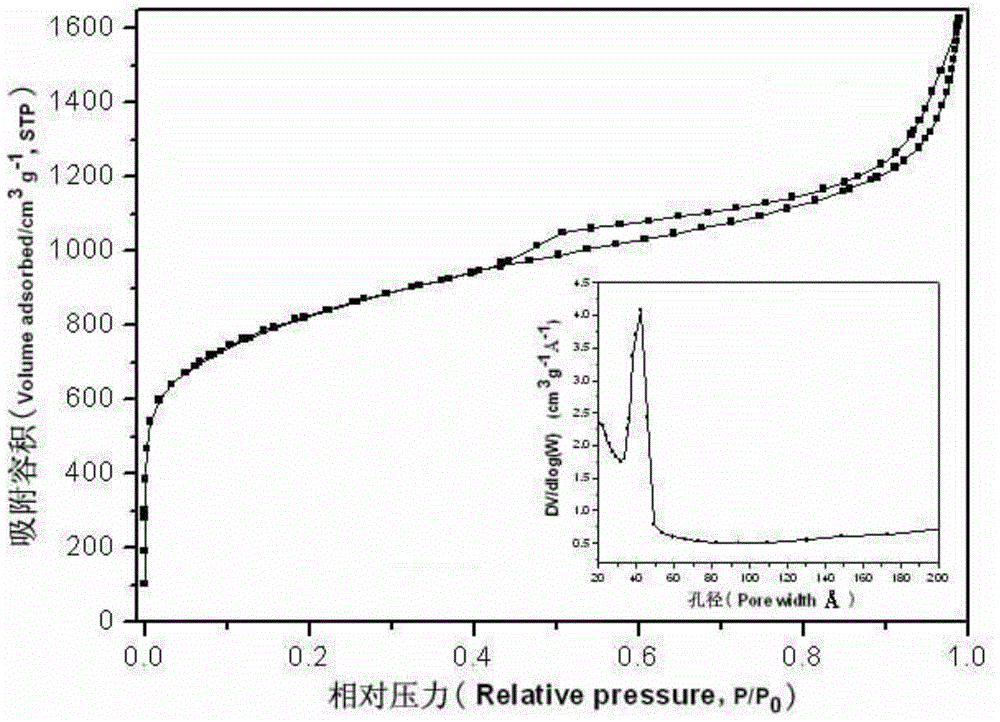

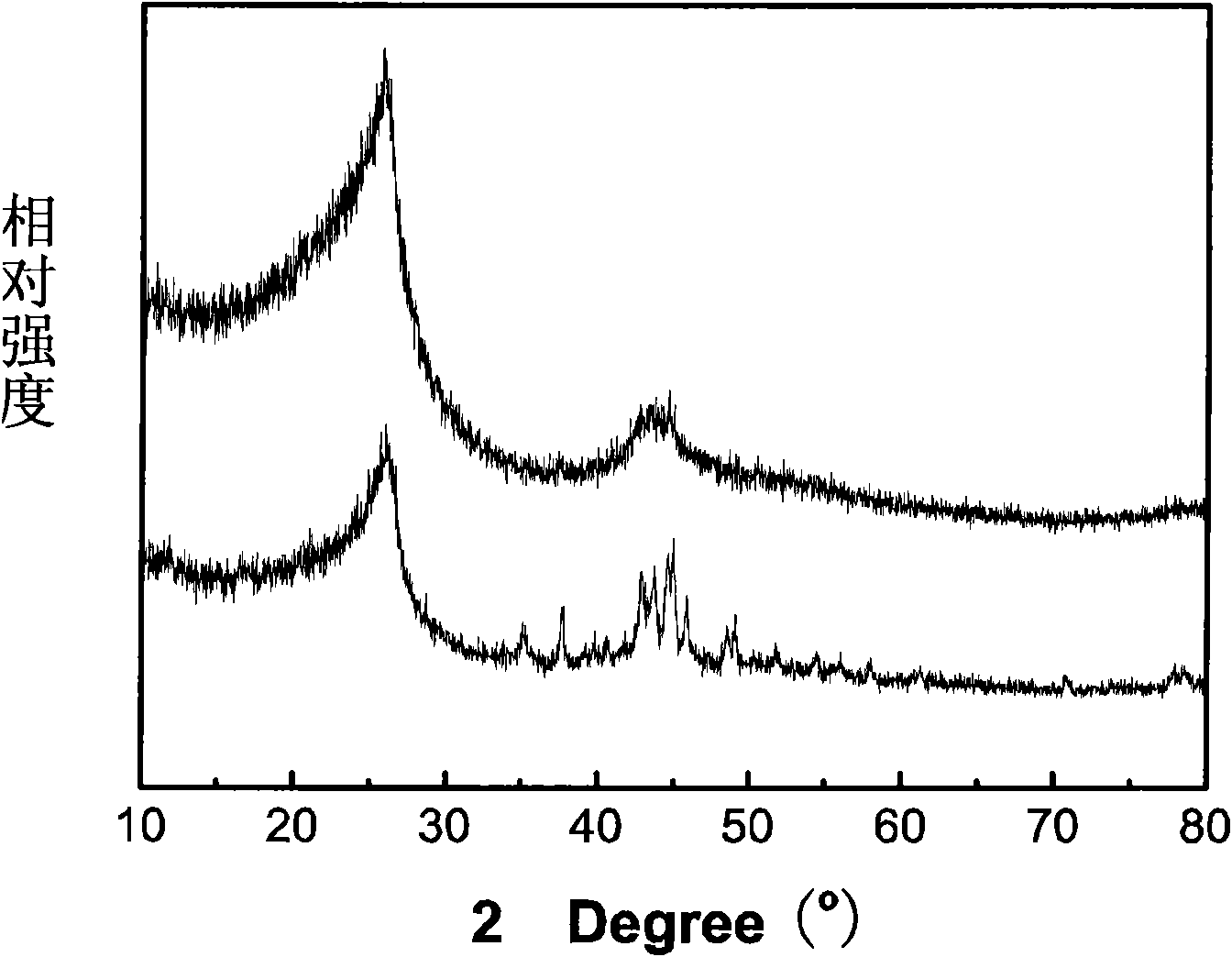

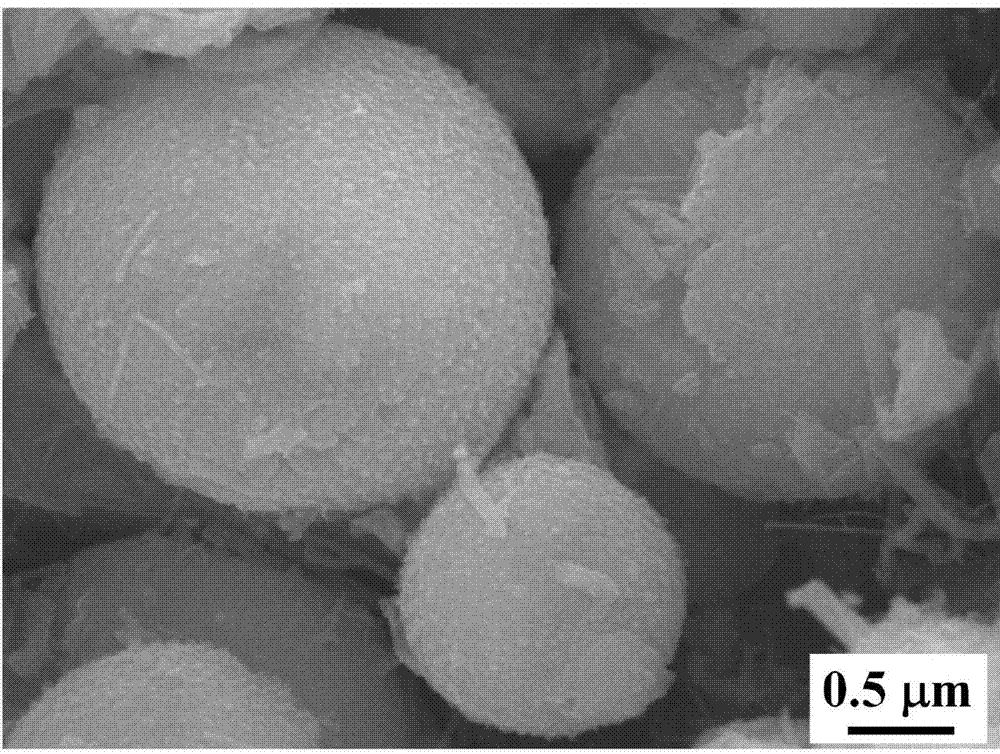

Hierarchially porous carbon particles for electrochemical applications

ActiveUS20120300364A1Improve electronic conductivityLower capability requirementsCarbon compoundsElectrolytic capacitorsPorous carbonSilicon oxide

Hierarchically porous graphitic carbon particles are prepared by an aerosol process using a aqueous solution of a carbon precursor compound in which different sized particles or clusters of silicon oxide species are dispersed. The aerosol is heated to evaporate the solvent. The solid residue is carbonized and non-carbon species removed to obtain small porous particles of graphitic carbon. The interconnected, different size pores in the small carbon particles make them very useful as electrode materials in electrochemical devices, such as supercapcitors, in which efficient ion transport through the pores or the particles is required.

Owner:RGT UNIV OF CALIFORNIA +1

Preparation of aluminium titanium carbide intermediate alloy grain refiner in the ultrasonic field

The invention relates to the composition, structure characteristics and preparation method of a new type of aluminum-titanium-carbon master alloy grain refiner and its application to aluminum and aluminum alloy grain refinement methods and effects. The present invention proposes a composition of an aluminum-titanium-carbon master alloy refiner prepared under the action of an ultrasonic field, which is characterized in that the main component of this type of refiner only needs to include aluminum (Al) , Titanium (Ti), carbon (C) without the need for other additional components. The method for preparing an aluminum-titanium-carbon master alloy under the action of an ultrasonic field proposed by the present invention is characterized in that raw materials such as pure aluminum ingot, potassium fluorotitanate, and graphite carbon are prepared according to the pre-designed master alloy composition; The aluminum ingot is melted by internal heating, and then various raw materials are added; ultrasonic waves are added to the melt that starts to react; after the reaction is completed, the temperature is raised, kept warm, left still, and slag is removed, and then cast into ingots or continuously cast and rolled into wire rods, thereby Get the required master alloy refiner with various components and shapes.

Owner:TSINGHUA UNIV

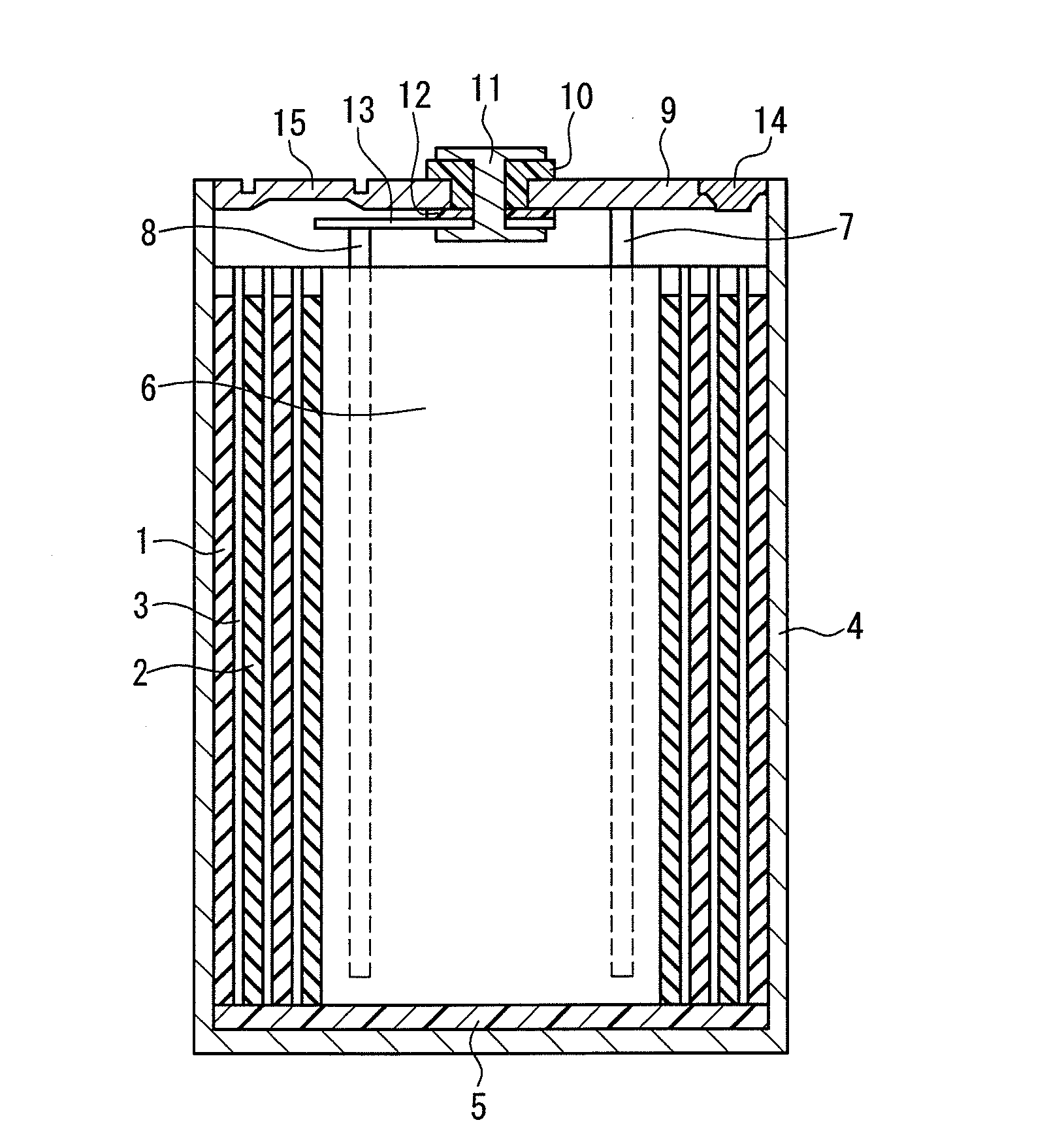

Non-aqueous secondary battery

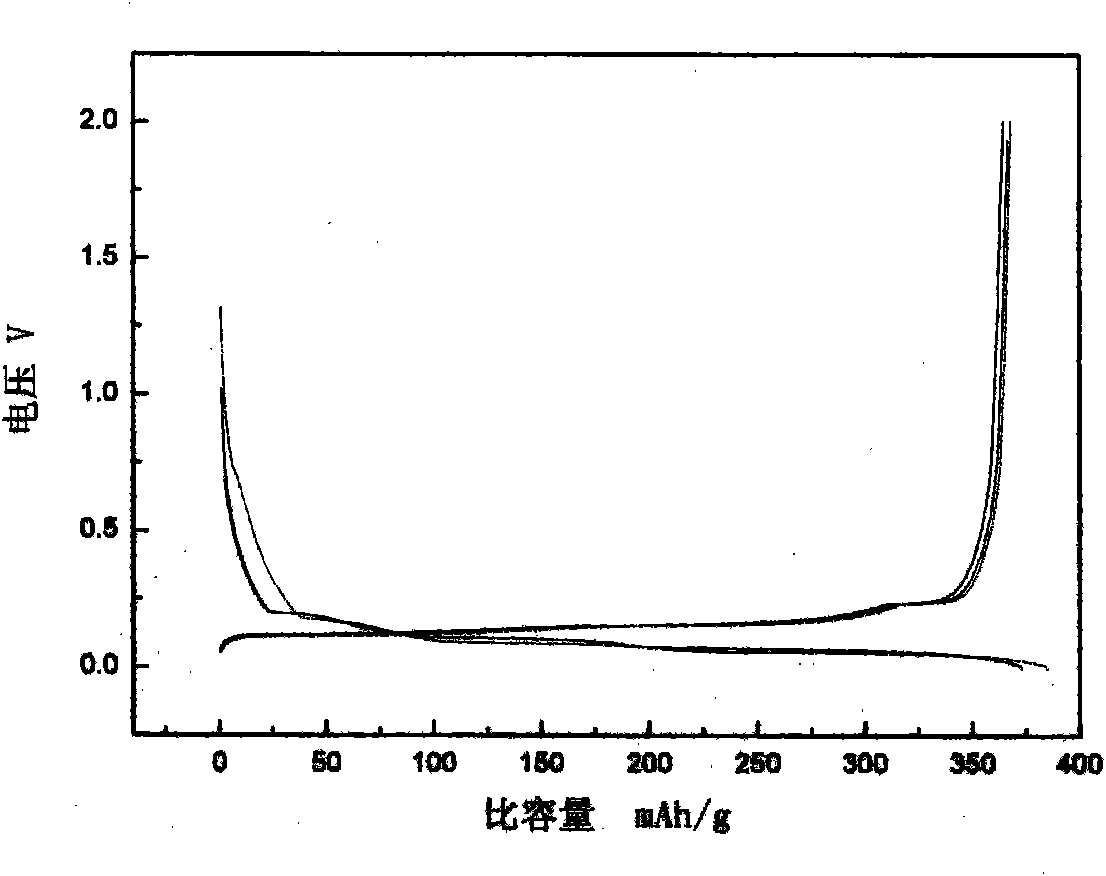

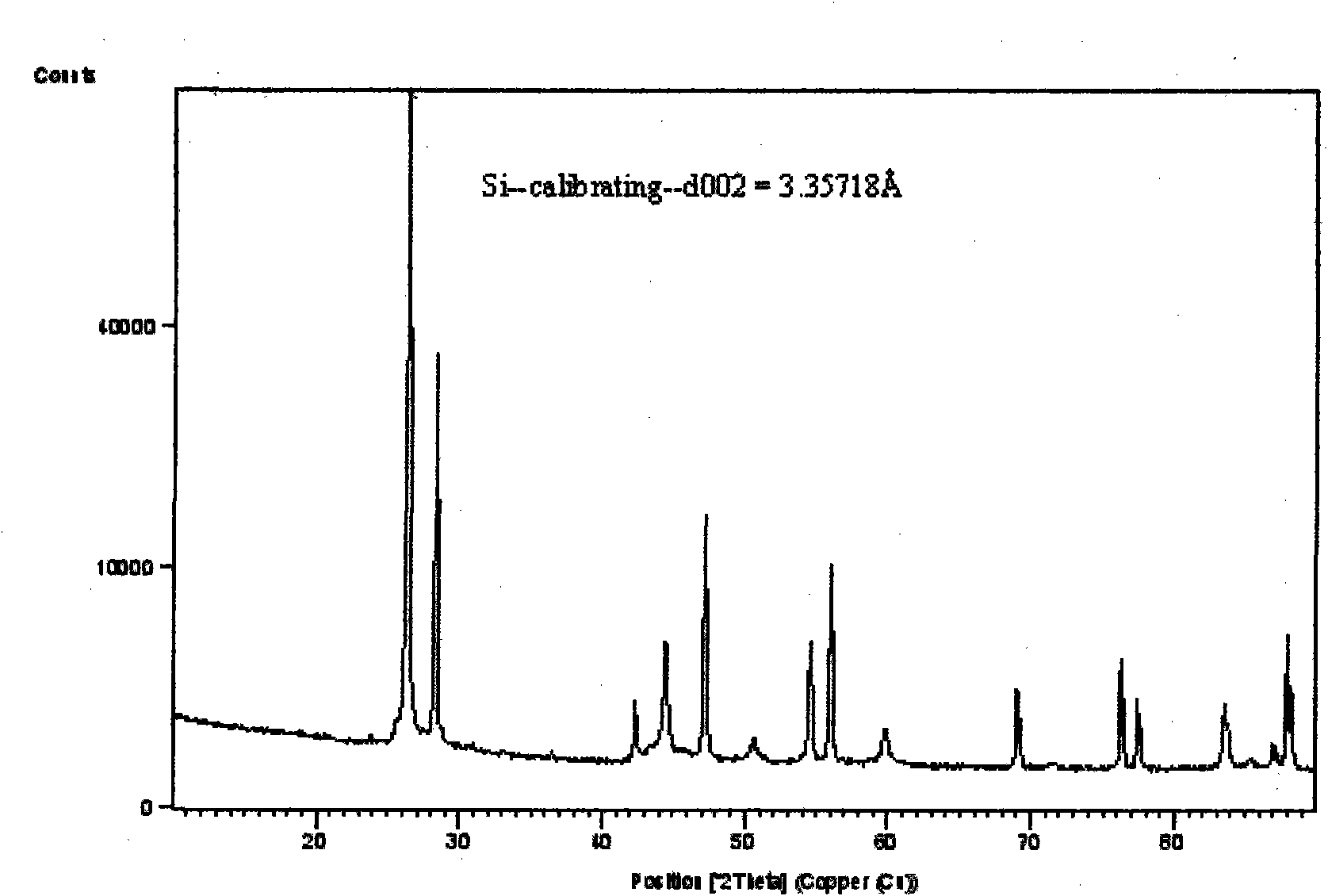

ActiveUS20120288742A1Large capacityImprove storage characteristicsFinal product manufactureOrganic electrolyte cellsCarbon coatingX-ray

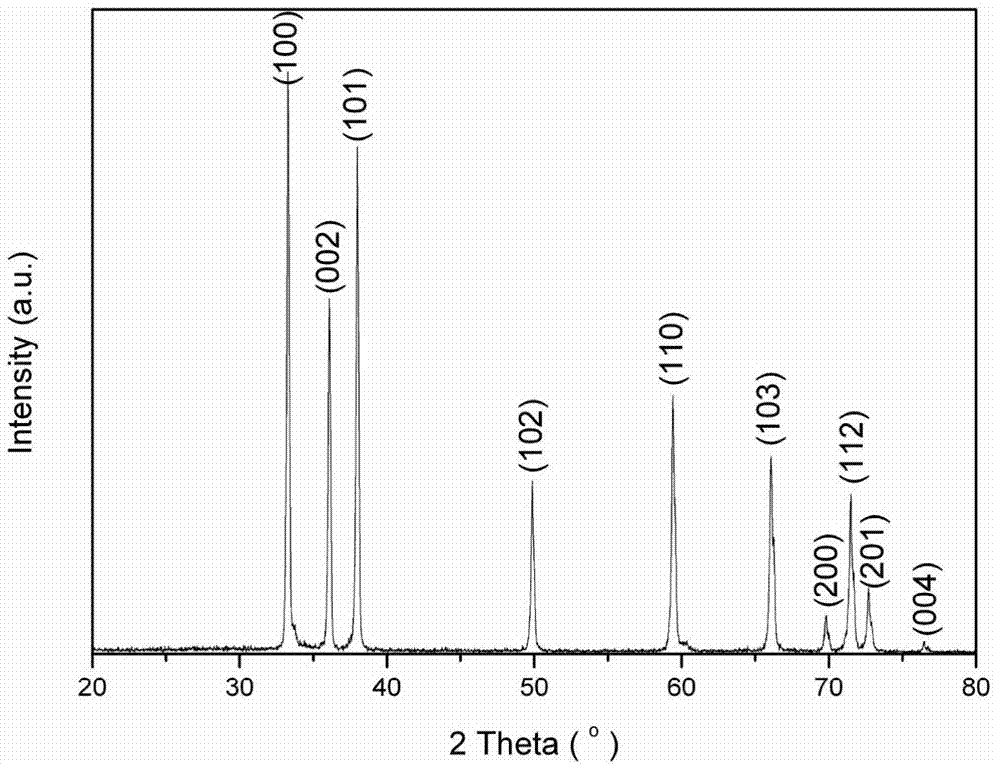

The non-aqueous secondary battery of the present invention includes a positive electrode, a negative electrode, a non-aqueous electrolyte, and a separator, the negative electrode contains a negative electrode active material containing a graphitic carbon material and a composite in which a carbon coating layer is formed on a surface of a core material containing Si and O as constituent elements, the composite has a carbon content of 10 to 30 mass %, the composite has an intensity ratio I510 / I1343 of a peak intensity I510 at 510 cm−1 derived from Si to a peak intensity I1343 at 1343 cm−1 derived from carbon of 0.25 or less when a Raman spectrum of the composite is measured at a laser wavelength of 532 nm, and the half-width of the (111) diffraction peak of Si is less than 3.0° when the crystallite size of an Si phase contained in the core material is measured by X-ray diffractometry using CuKα radiation.

Owner:MAXELL HLDG LTD

Lithium ion battery cathode material and preparation method thereof

The invention discloses a lithium ion battery cathode material and a preparation method thereof, which lower the cost of the lithium ion battery cathode material and improve the high-energy density thereof. The lithium ion battery cathode material takes more than one of natural crystalline graphite, natural cryptocrystalline graphite and natural crystalline vein graphite as matrixes, a non-graphitic carbon material is coated outside the matrixes, and the coated particles are compounded with a conductive material. The preparation method of the lithium ion battery cathode material comprises the following steps of mixing and drying a liquid phase, carbonizing, carrying out high-temperature treatment and compounding. Compared with the prior art, the graphite with lower carbon content is taken as a raw material to greatly reduce the raw material cost; by adopting a hot air drying mode, the preparation process is simplified and a coating layer is more solid and compact; and by adopting lower carburizing temperature and the temperature for high-temperature heat treatment, energy consumption is reduced, and product cost is further lowered.

Owner:BTR NEW MATERIAL GRP CO LTD

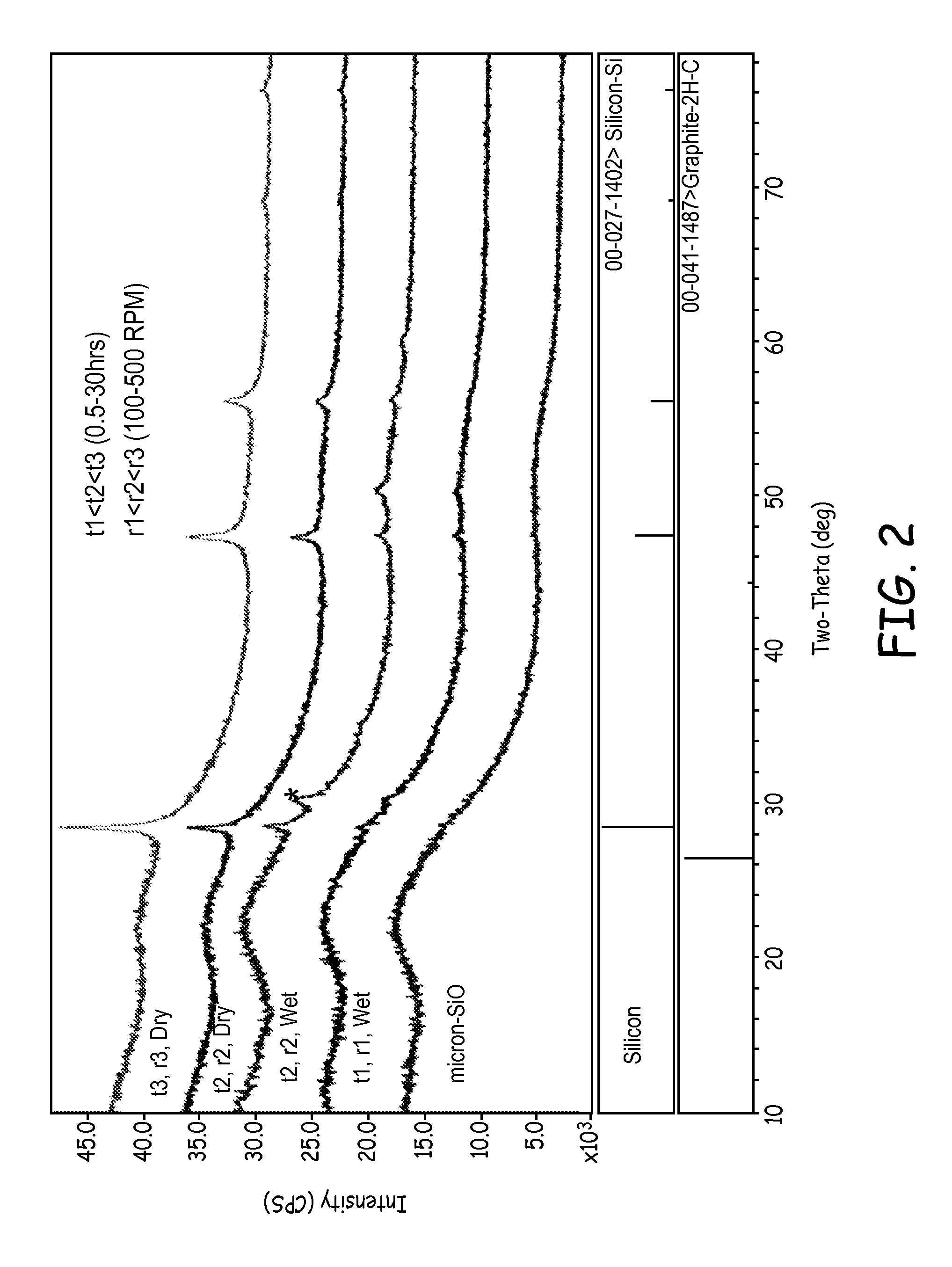

Silicon-silicon oxide-carbon composites for lithium battery electrodes and methods for forming the composites

ActiveUS20140370387A1High energyElectrode manufacturing processesLi-accumulatorsCarbon compositesHigh energy

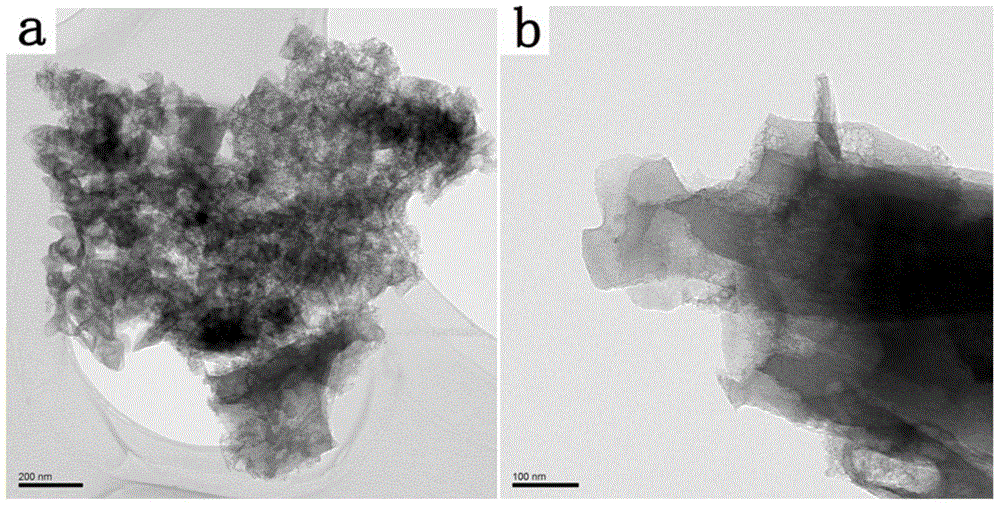

Composite silicon based materials are described that are effective active materials for lithium ion batteries. The composite materials comprise processed, e.g., high energy mechanically milled, silicon suboxide and graphitic carbon in which at least a portion of the graphitic carbon is exfoliated into graphene sheets. The composite materials have a relatively large surface area, a high specific capacity against lithium, and good cycling with lithium metal oxide cathode materials. The composite materials can be effectively formed with a two step high energy mechanical milling process. In the first milling process, silicon suboxide can be milled to form processed silicon suboxide, which may or may not exhibit crystalline silicon x-ray diffraction. In the second milling step, the processed silicon suboxide is milled with graphitic carbon. Composite materials with a high specific capacity and good cycling can be obtained in particular with balancing of the processing conditions.

Owner:IONBLOX INC

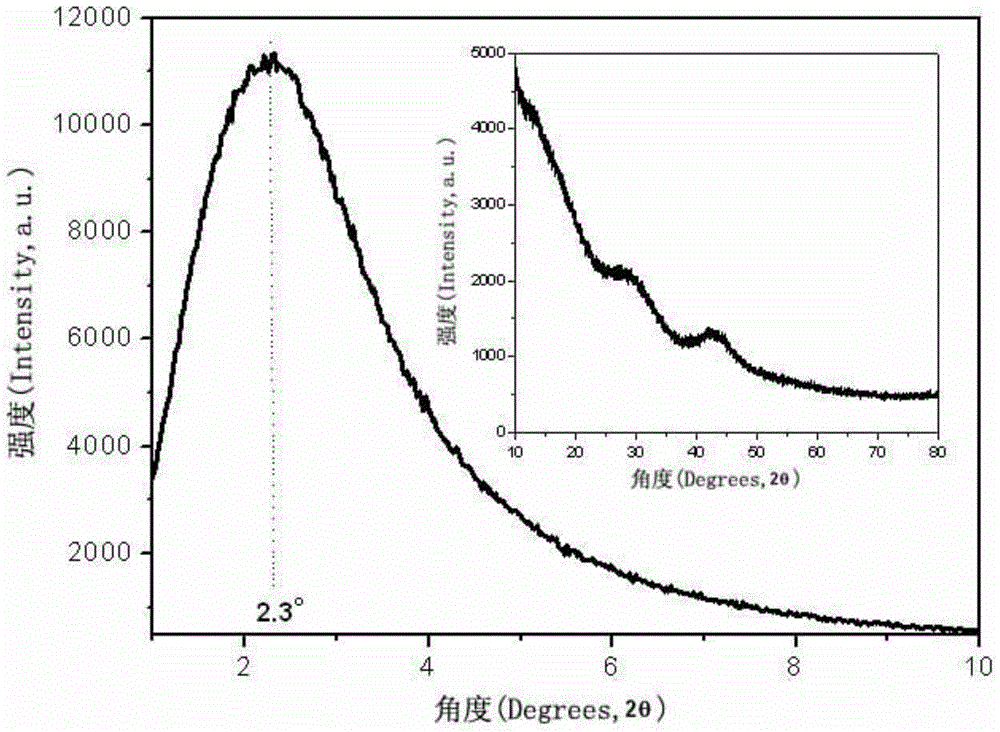

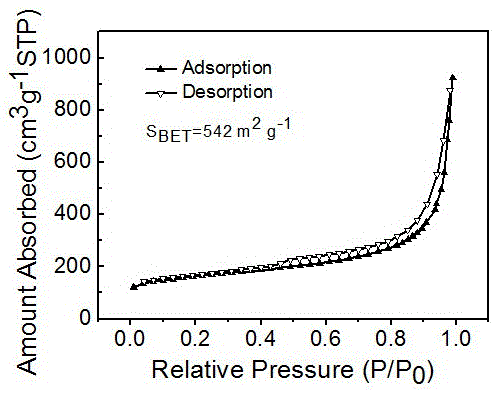

Preparation method of ordered mesoporous carbon material with high specific surface area by using metal organic skeleton

InactiveCN104418315ALarge specific surface areaNarrow pore size distributionMetal-organic frameworkSolvent

The invention discloses a preparation method of an ordered mesoporous carbon material with high specific surface area by using metal organic skeleton. Zinc salt and terephthalic acid as raw materials react under room temperature through simple stirring, solvent exchange and vacuum drying to obtain a metal organic skeleton material MOF-5 with cubic shape; and then metal organic skeleton material MOF-5 as a carbon source is directly carbonized at high temperature to obtain ordered mesoporous carbon material with high surface area and developed hole structure. The preparation method has the advantages of economic steps, low cost, simple operation process and mild conditions; the target product has narrow pore size distribution, large specific surface area and amorphous and graphitic carbon structure, can be used suitable as an adsorbent, a catalyst carrier, an electrode material and hard template for synthesis of other mesoporous materials, and has certain market application prospect.

Owner:SUZHOU OST ADVANCED MATERIALS +1

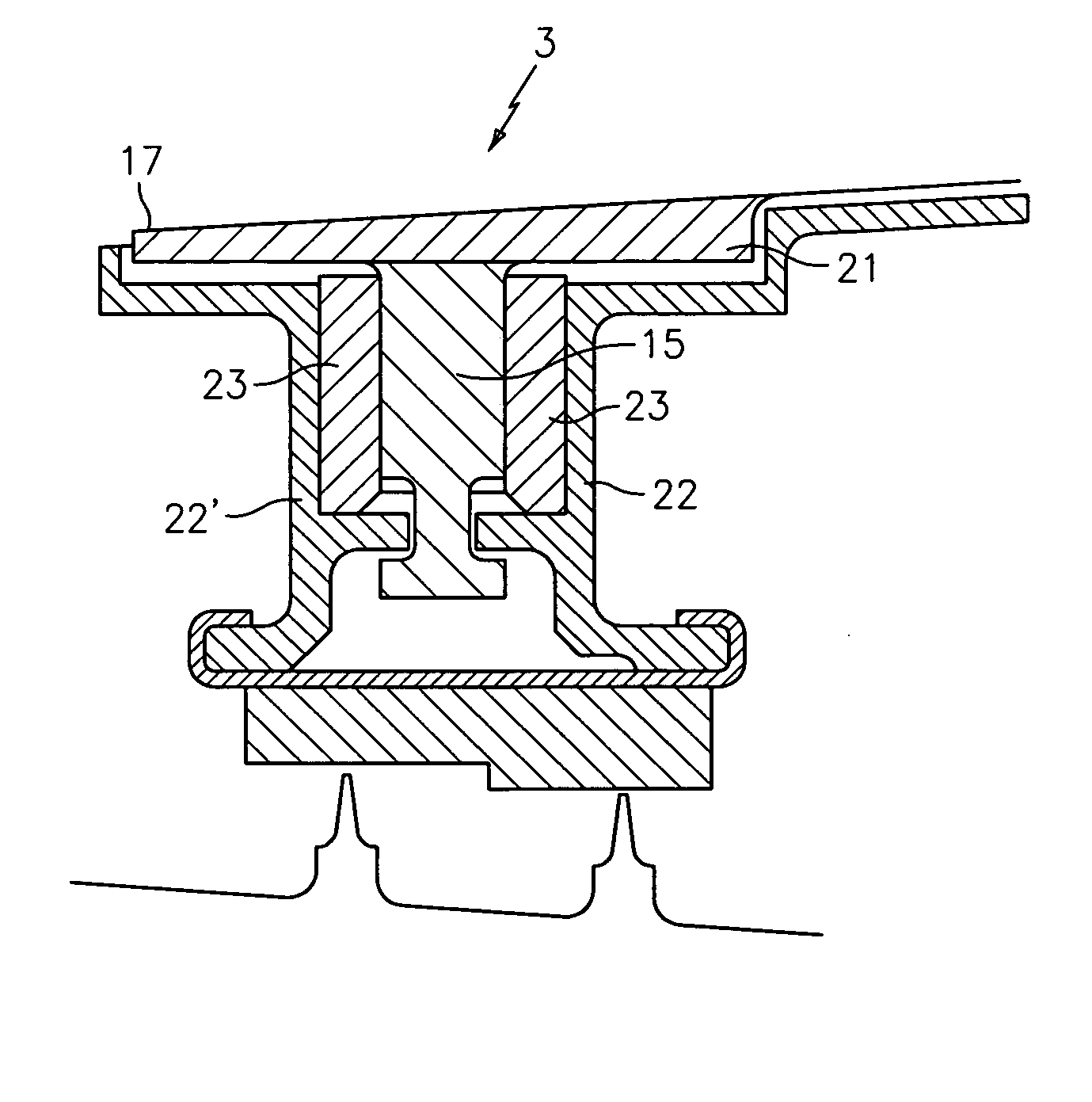

Variable vane electro-graphitic bushing

InactiveUS20050084190A1Reduce wearImprove thermal stabilityPump componentsGas turbine plantsElectricityEngineering

A method for improving the wear characteristics of ID bushings comprising the steps of providing an ID bushing comprising electro-graphitic carbon.

Owner:UNITED TECH CORP

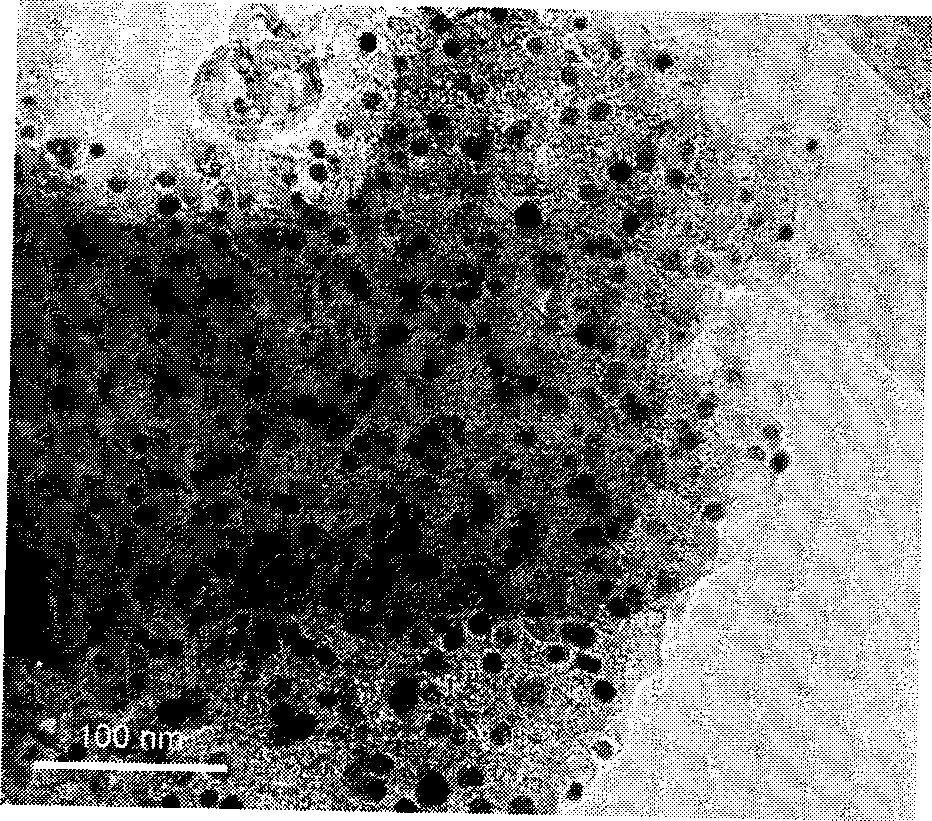

Iron-nitrogen-doped graphene porous material with dual-site catalytic oxygen reduction activity, and preparation method and application therefor

InactiveCN105609793ALarge specific surface areaMany active sitesCell electrodesPyrroleNitrogen doped

The invention belongs to the technical field of a nanomaterial, and specifically relates to an iron-nitrogen-doped graphene porous material with dual-site catalytic oxygen reduction activity, and a preparation method and an application therefor. The porous material is formed by embedding graphite-carbon-coated iron carbide into a nitrogen-doped porous graphene band network structure; the preparation method for the iron-nitrogen-doped graphene porous material comprises the steps of preparing a graphene oxide solution; adding a proper amount of conductive macromolecular pyrrole to the graphene oxide solution; obtaining uniform hydrogel through a hydrothermal process; performing oxidative polymerization on the hydrogel by ferric iron; then dispersing the hydrogel into a fresh ferric iron solution to complete adsorption; then performing drying and high-temperature carbonization thermal processing; and finally removing non-active and free iron phase from the reaction system by dilute acid so as to obtain the iron-nitrogen-doped graphene porous material. The porous material can be used as the negative electrode catalyst for a fuel cell, and shows quite high catalytic oxygen reduction activity, so that the porous material has quite important research meaning and bright application prospects.

Owner:FUDAN UNIV

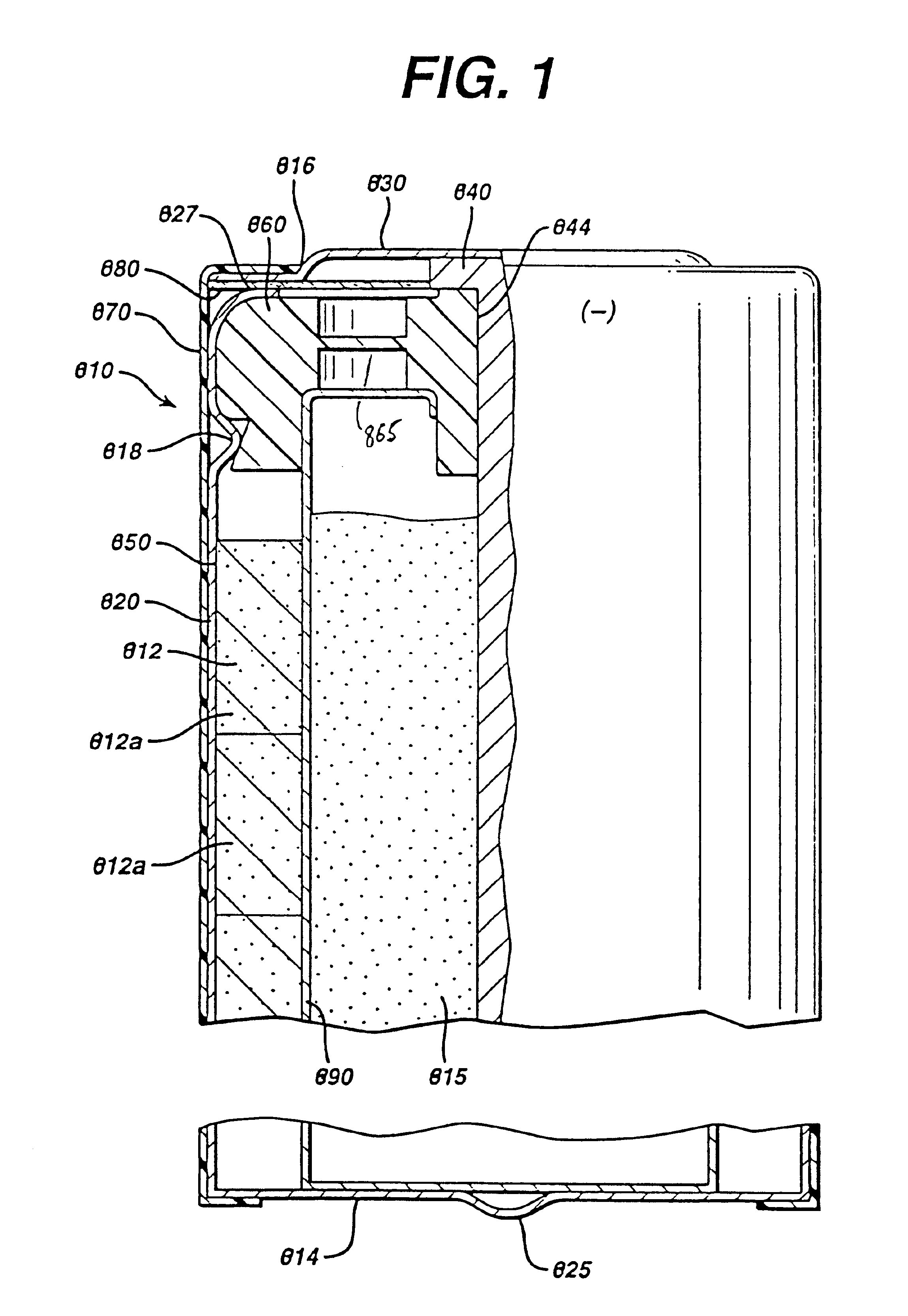

Alkaline cell with improved cathode

InactiveUS6841302B2Reduce cathode resistanceElevates cell 's running voltageAlkaline accumulatorsPositive electrodesFiberCarbon nanofiber

An alkaline cell having an anode comprising zinc, an aqueous alkaline electrolyte, a cathode mixture comprising cathode active material comprising copper oxide or copper hydroxide. Graphitic carbon, preferably expanded graphite or graphitic carbon nanofibers are added to the cathode mixture thereby resulting in a sharp drop in cathode resistivity. The cathode active material preferably comprises between about 80 and 92 percent by weight of the cathode. The sharp drop in cathode resistivity resulting from the addition of expanded graphite or graphitic carbon nanofibers makes the cell suitable for use as a primary alkaline cell having good capacity. The graphitic carbon, preferably graphitic nanofibers comprise preferably between about 4 and 10 percent by weight of the cathode. The carbon nanofibers have an average diameter desirably less than 500 nanometers, preferably between about 50 and 300 nanometers.

Owner:DURACELL U S OPERATIONS

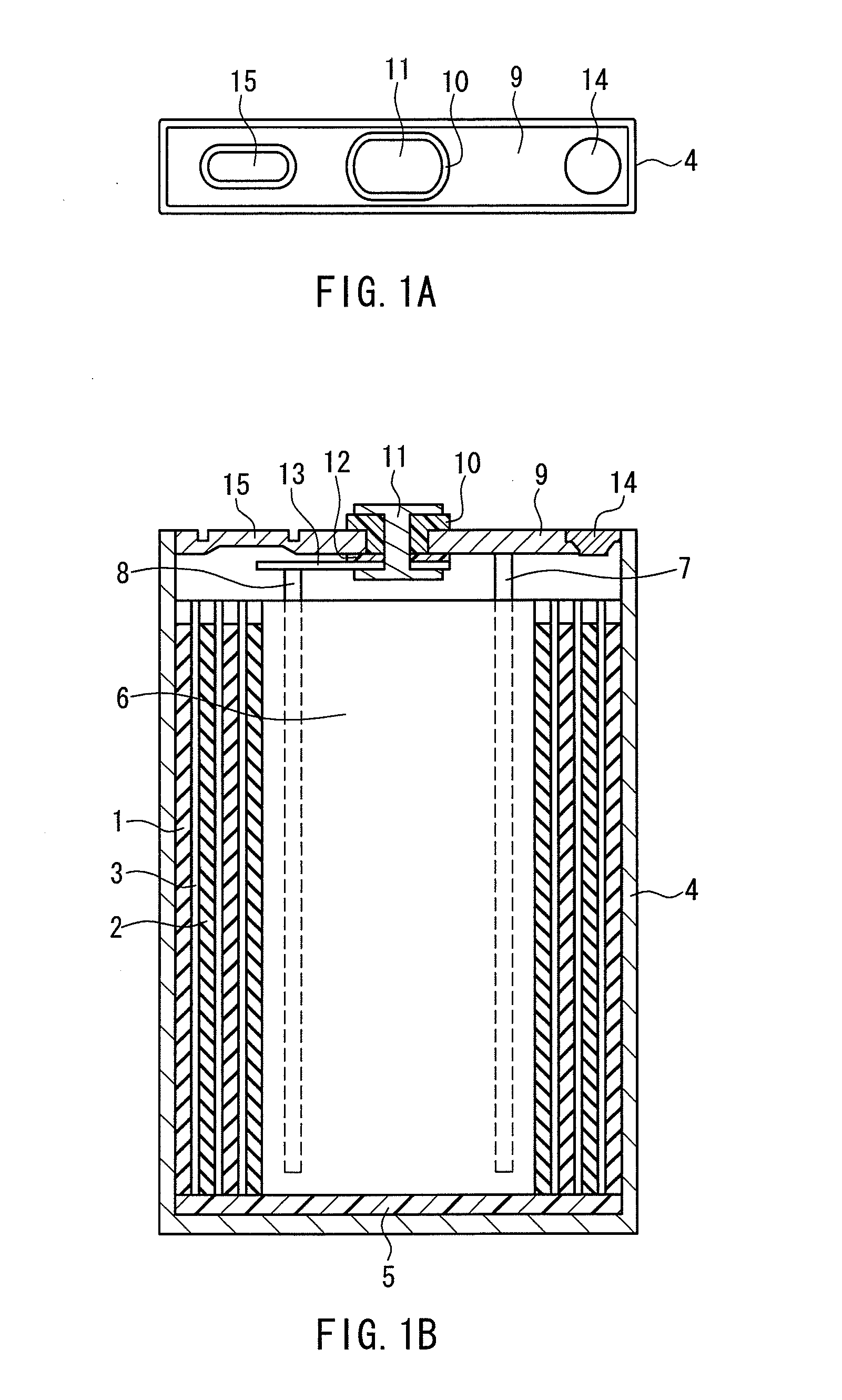

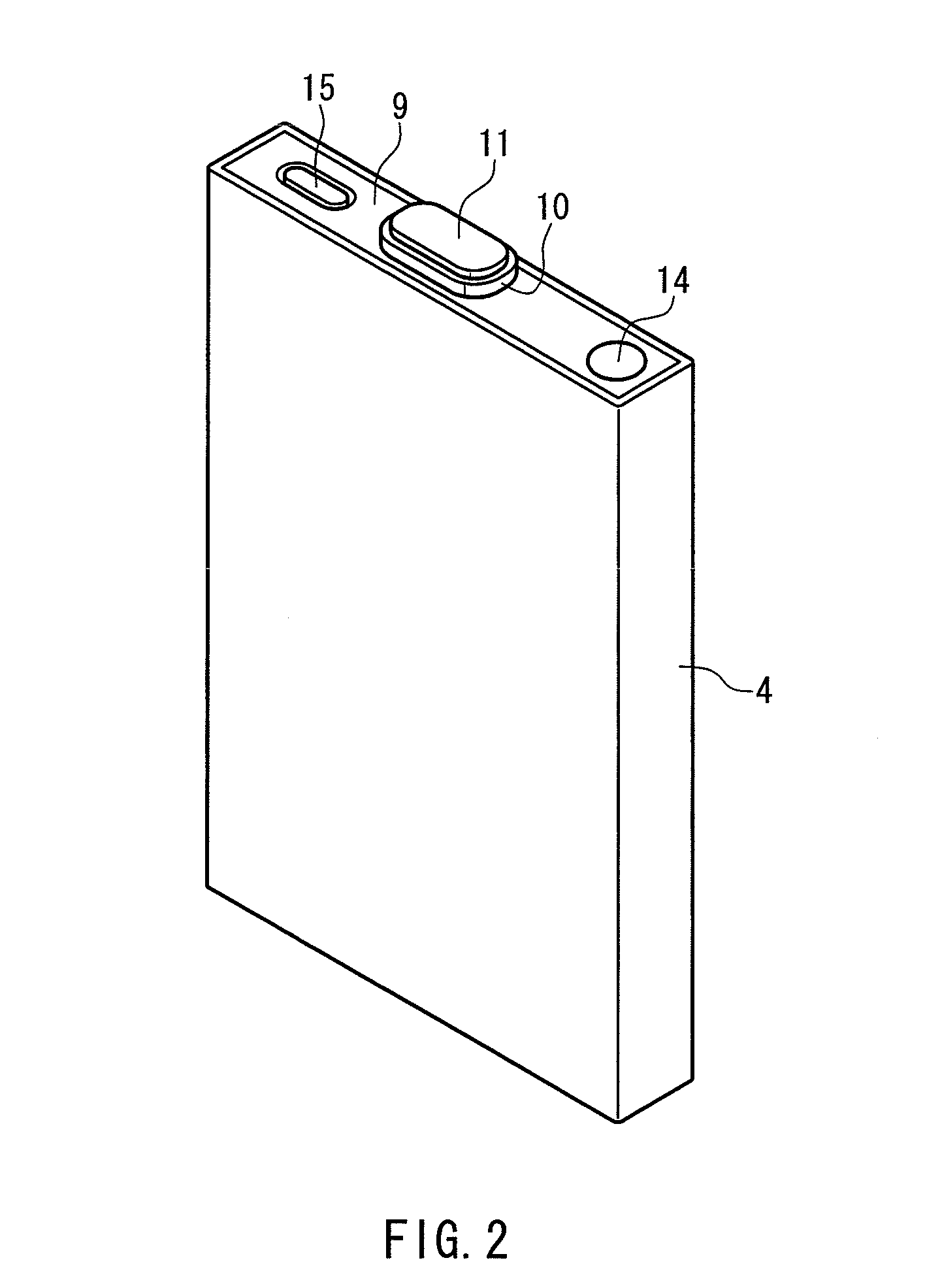

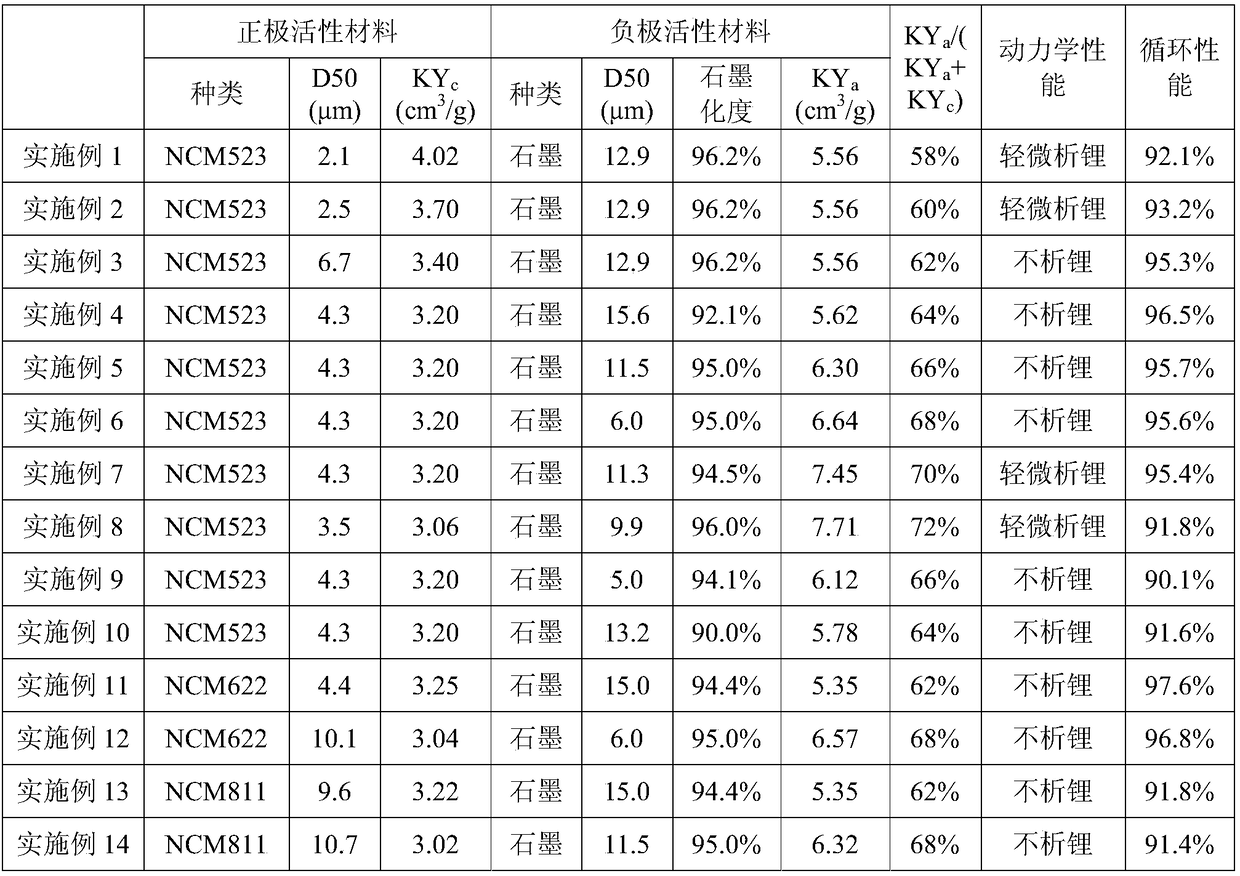

Lithium ion battery

ActiveCN108807974AImprove mechanical propertiesImprove cycle performanceElectrode carriers/collectorsNegative electrodesEngineeringGraphitic carbon

The invention provides a lithium ion battery which comprises a positive electrode piece, a negative electrode piece, an isolating membrane and electrolyte solution. The positive electrode piece comprises a positive electrode current collector and positive electrode diaphragm layers, the positive electrode diaphragm layers are arranged on at least one surface of the positive electrode current collector and comprise positive electrode active materials, the negative electrode piece comprises a negative electrode current collector and negative electrode diaphragm layers, and the negative electrodediaphragm layers are arranged on at least one surface of the negative electrode current collector and comprise negative electrode active materials. The positive electrode active materials include materials, the chemical formulas of the materials are LiaNixCoyMzO2, the negative electrode active materials include graphitic carbon materials, and the battery meets the equation of 58%<=KYa / (KYa+KYc)*100%<=72%. According to the battery, the voltage-resistant abilities of the positive electrode active materials and the negative electrode active materials are reasonably matched, and the interface integrity of the positive electrode piece and the negative electrode piece can be effectively ensured, so that the lithium ion battery has excellent dynamics performance and circulation performance.

Owner:CONTEMPORARY AMPEREX TECH CO

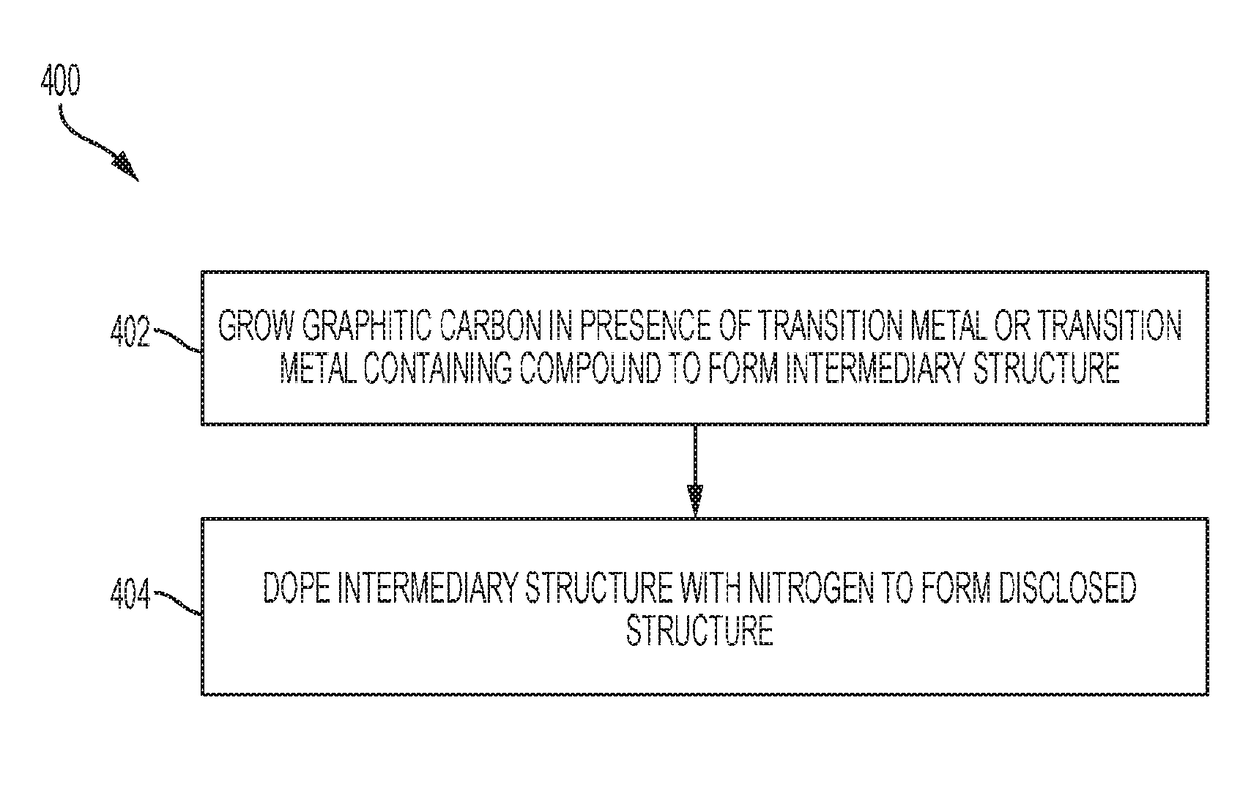

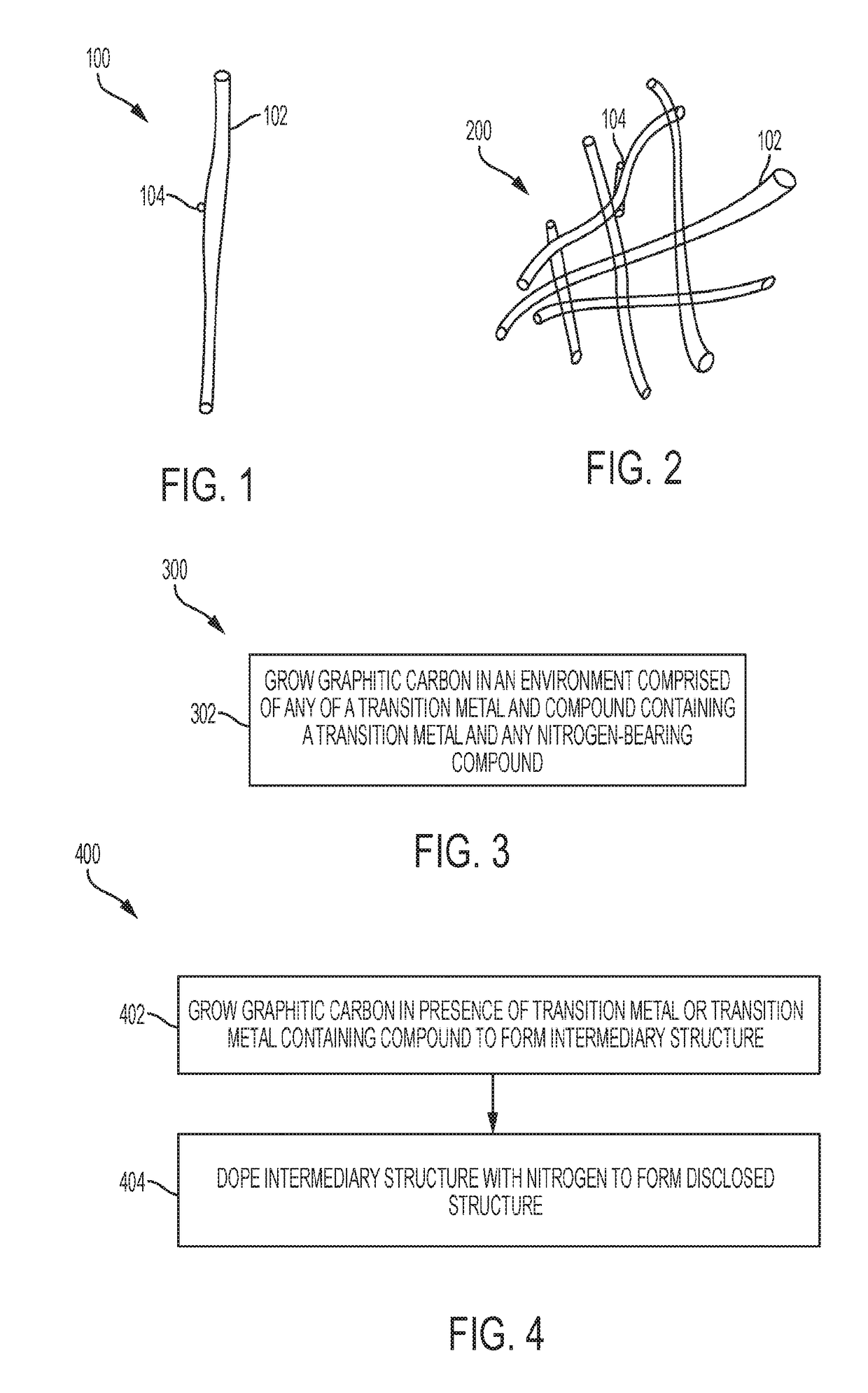

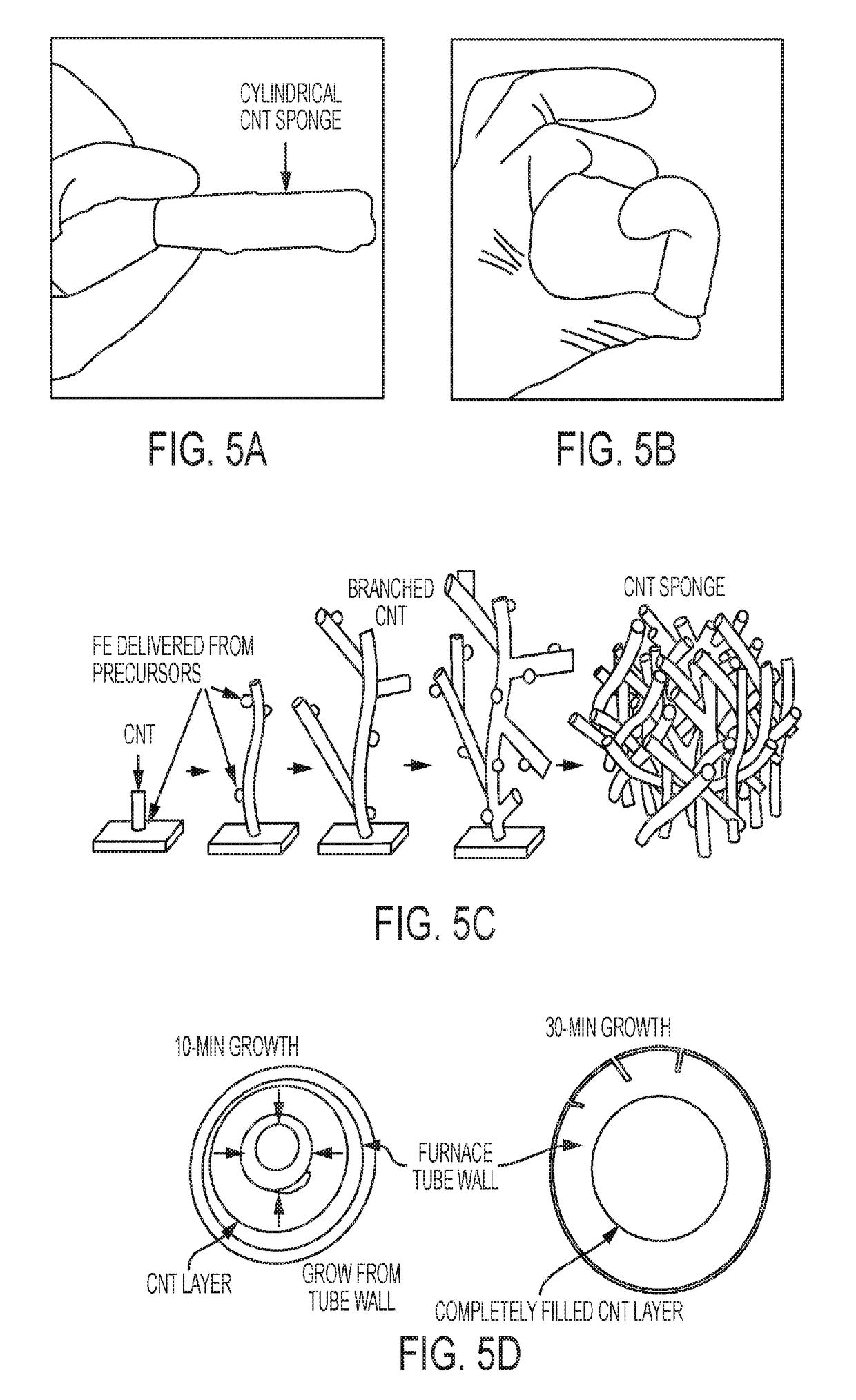

Non-noble element catalysts and methods for making

ActiveUS20170354953A1Produced economicallyFuel and secondary cellsCell electrodesNitrogenElement composition

Disclosed are non-noble element compositions of matter, structures, and methods for producing the catalysts that can catalyze oxygen reduction reactions (ORR). The disclosed composition of matter can be comprised of graphitic carbon doped with nitrogen and associated with one or two kinds of transition metals. The disclosed structure is a three dimensional, porous structure comprised of a plurality of the disclosed compositions of matter. The disclosed structure can be fashioned into an electrode of an electrochemical cell to serve as a diffusion layer and also to catalyze an ORR. Two methods are disclosed for producing the disclosed composition of matter and structure. The first method is comprised of two steps, and the second method is comprised of a single step.

Owner:TEXAS A&M UNIVERSITY

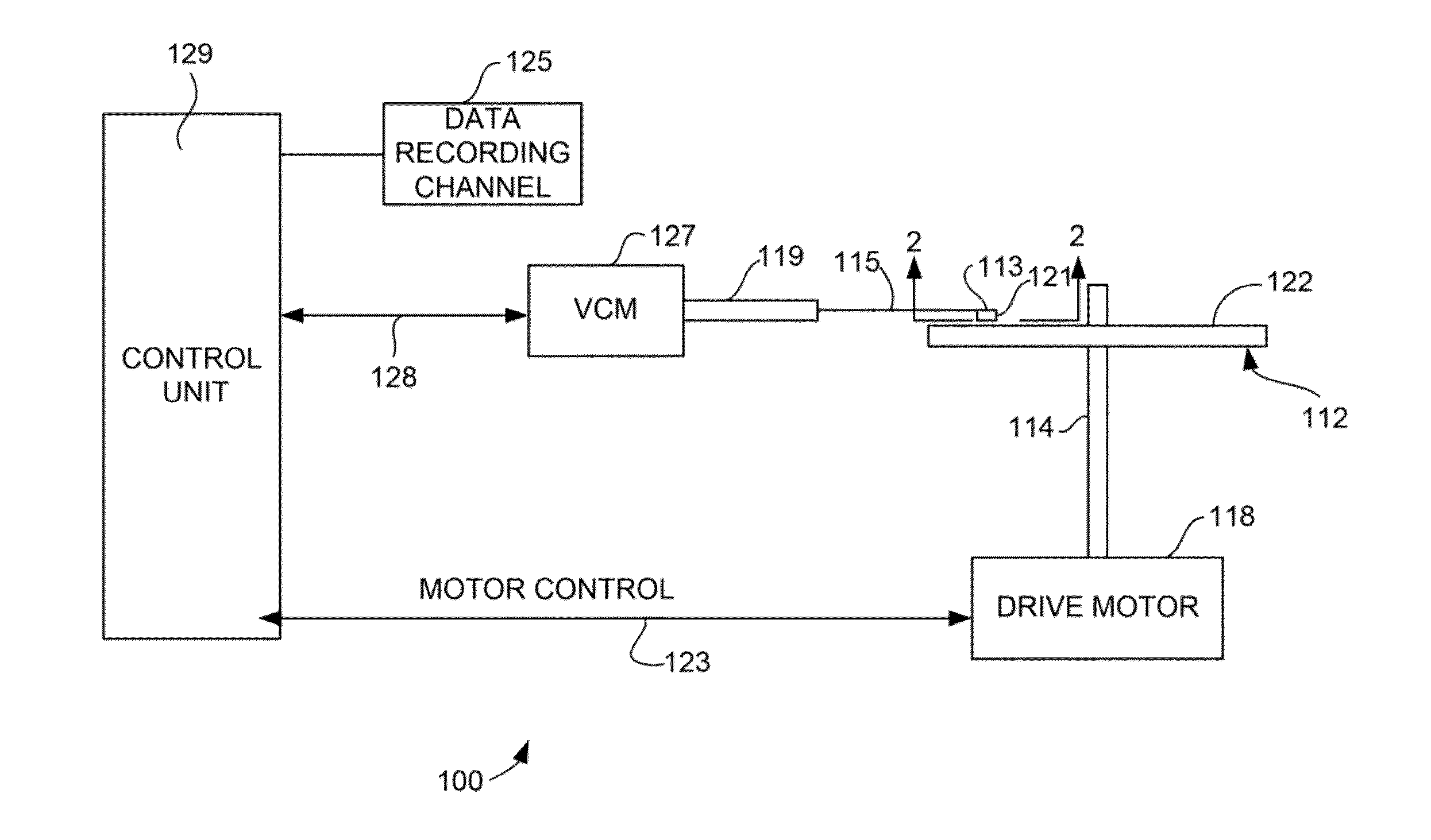

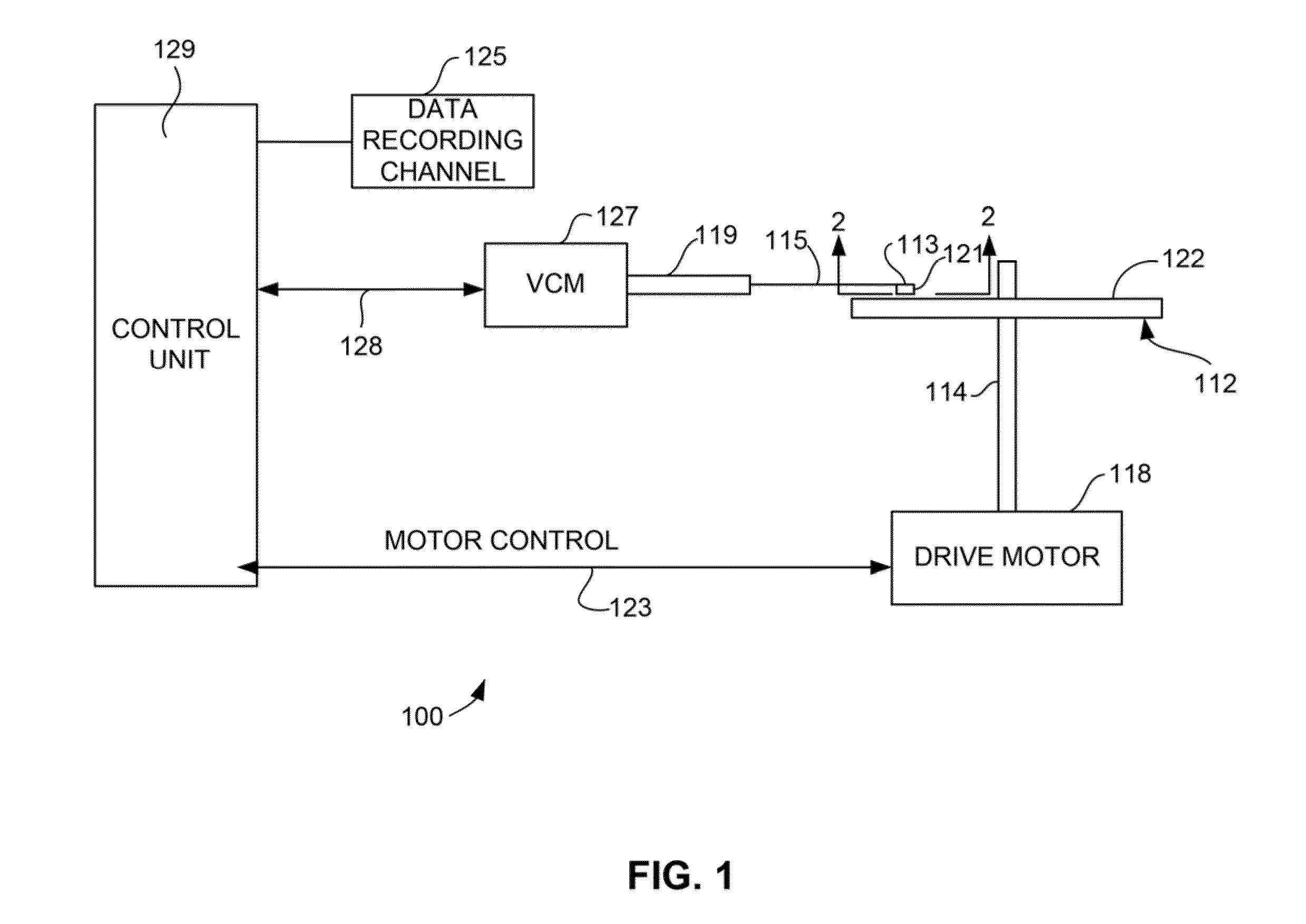

FePt-C BASED MAGNETIC RECORDING MEDIA WITH ONION-LIKE CARBON PROTECTION LAYER

InactiveUS20130114165A1Reduce thicknessImproves protection against corrosion againstDisposition/mounting of recording headsProtective coatings for layersMagnetic mediaThin layer

A magnetic media for magnetic data recording having a plurality of magnetic grains protected by thin layers of graphitic carbon. The layers of graphitic carbon are formed in a manner similar to onion skins on an onion and can be constructed as single monatomic layers of carbon. The thin layers of graphitic carbon can be formed as layers of graphene or as fullerenes that either cover or partially encapsulate the magnetic gains. The layers of graphitic carbon provide excellent protection against corrosion and wear and greatly reduce magnetic spacing for improved magnetic performance.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Composite silicon carbide body and method for its preparation

A method for manufacturing a silicon carbide composite body and includes the steps of forming a slurry including silicon carbide and a carbonaceous precursor, adding to the slurry composite granules containing a carbonaceous binder and carbon black, drying the slurry, shaping the dried slurry and sintering the dried and shaped slurry at a temperature of at least 2000° C. to form a body containing silicon carbide and non-graphitic carbon. The invention further relates to the composite body formed and the mixture prior to sintering.

Owner:SCHUNK INGKERAMIK

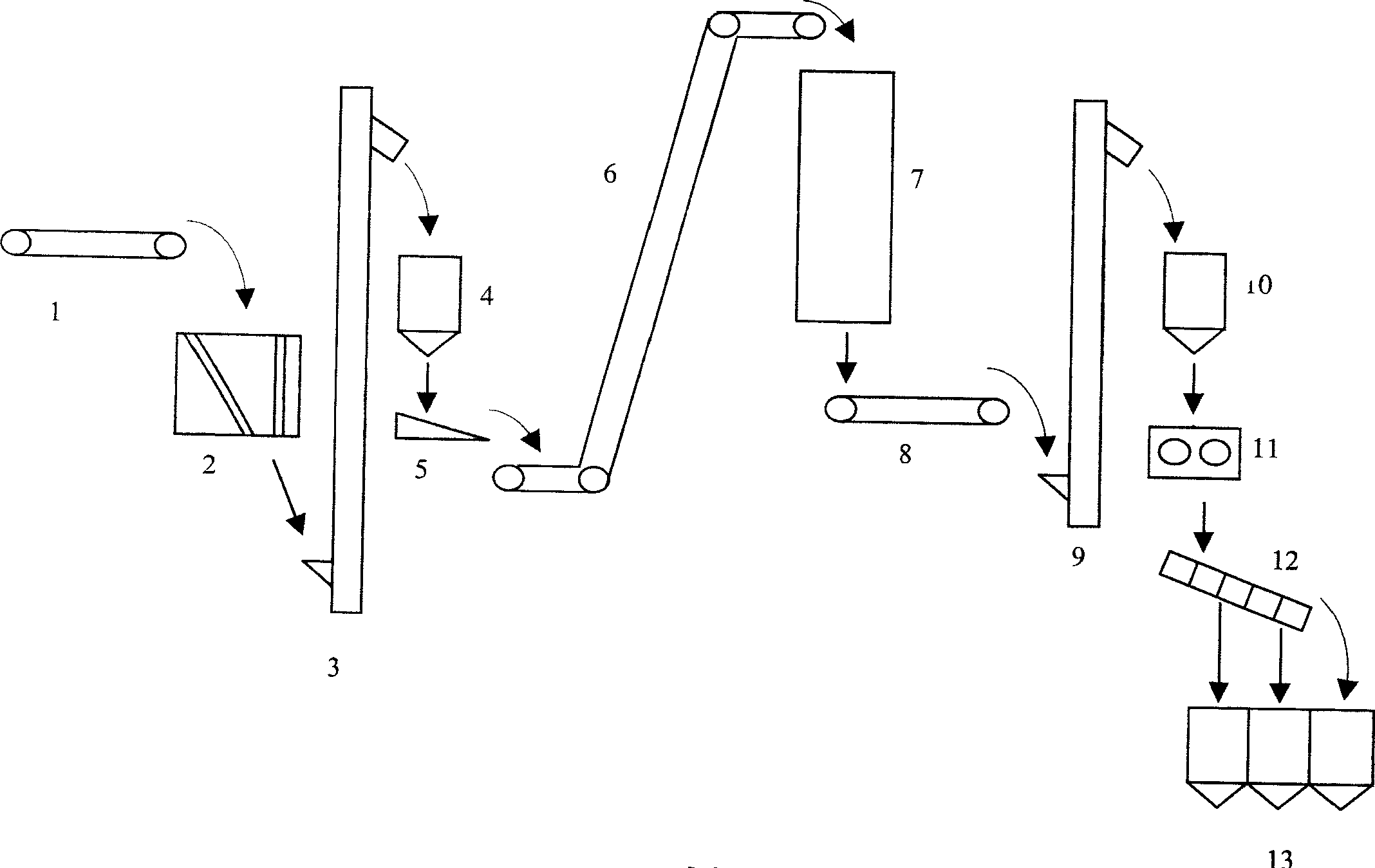

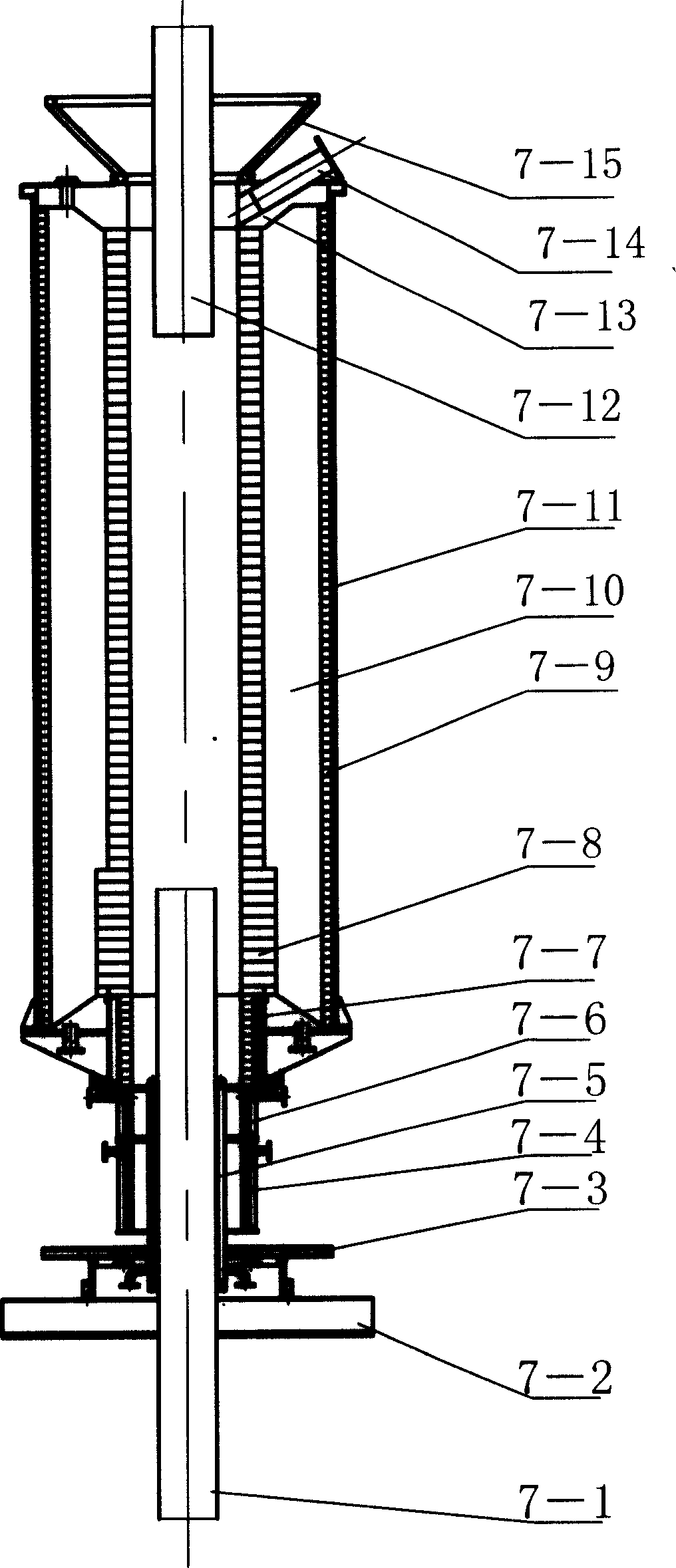

Continuous production and apparatus for high-purity graphite carbon material

ActiveCN1613756ASolve ultra-high temperature resistanceSolve insulation problemsFurnace cooling arrangementsFurnace coolingRefractoryGraphite

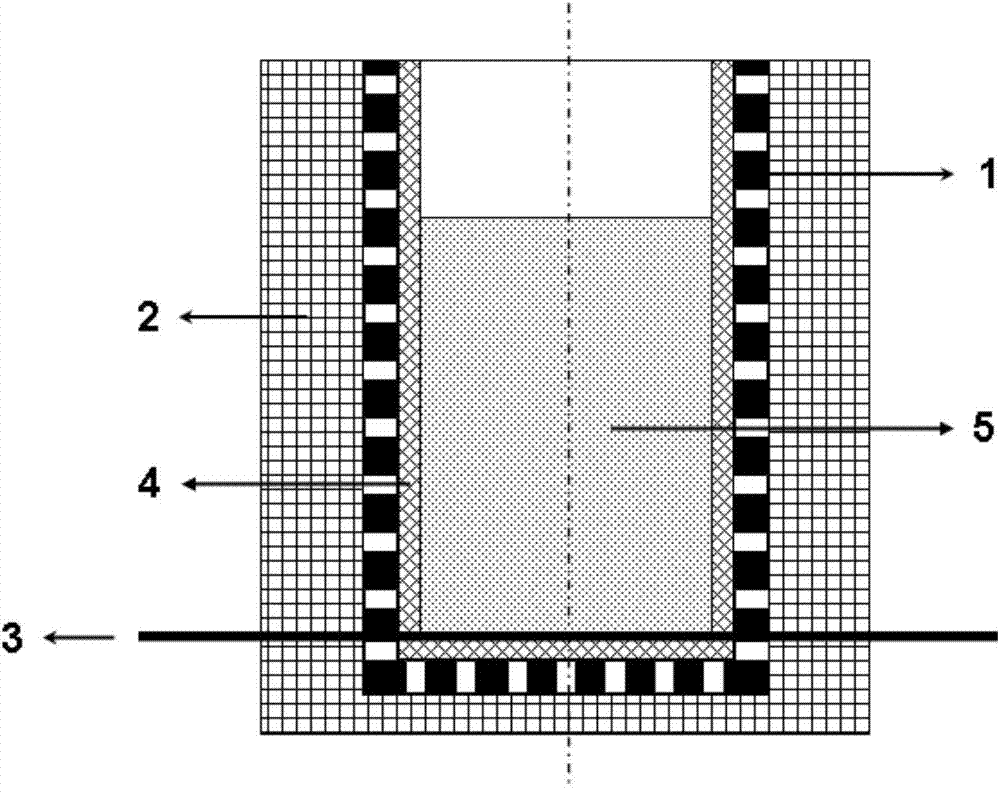

A production of high-purity graphitic carbon material and its apparatus are disclosed. The process involves raw material system, roasting system and post-treating system: 1) breaking forged petroleum coke by raw material system with grain size up to 0-60 mm and controlling water content <=5%; 2) delivering the treated material into vertical roasting electric furnace and high-temperature treating, preheating, purifying and graphitizing under high-temperature, controlling temperature at 1800-3000deg.C, cooling and discharging at 50-250deg.C with 6-21 hrs; and 3) breaking and screening discharged material by post-treating system with grain size up to 0-50 mm, classifying and packing. The vertical roasting electric furnace consists of upper and lower electrode, supporting frame, material disc, the third cooling section, electrode cooling cover, furnace core carbon fireproof material, furnace casing, furnace lid , smoke conduit, and bucket.

Owner:JIANGSU SURUN HIGH CARBON

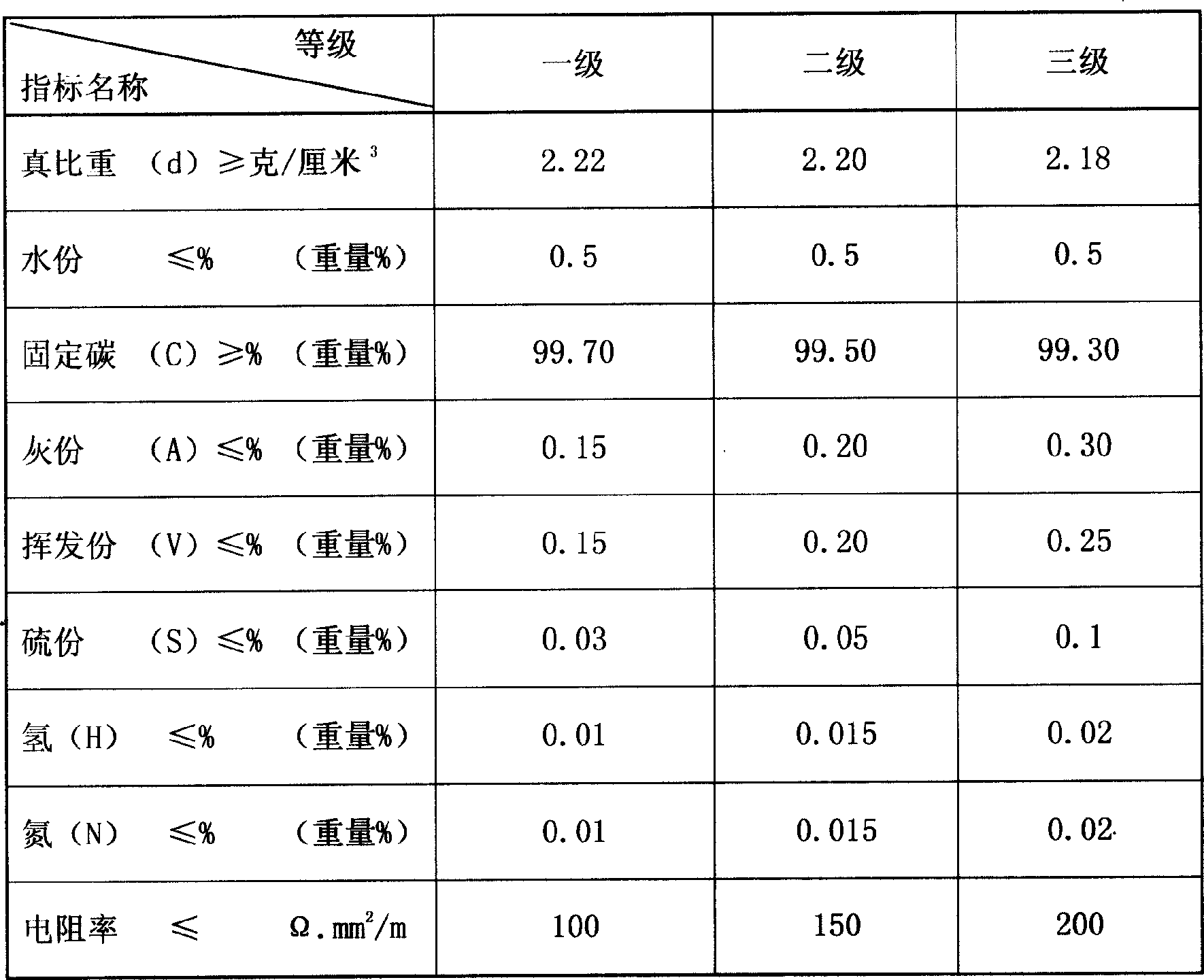

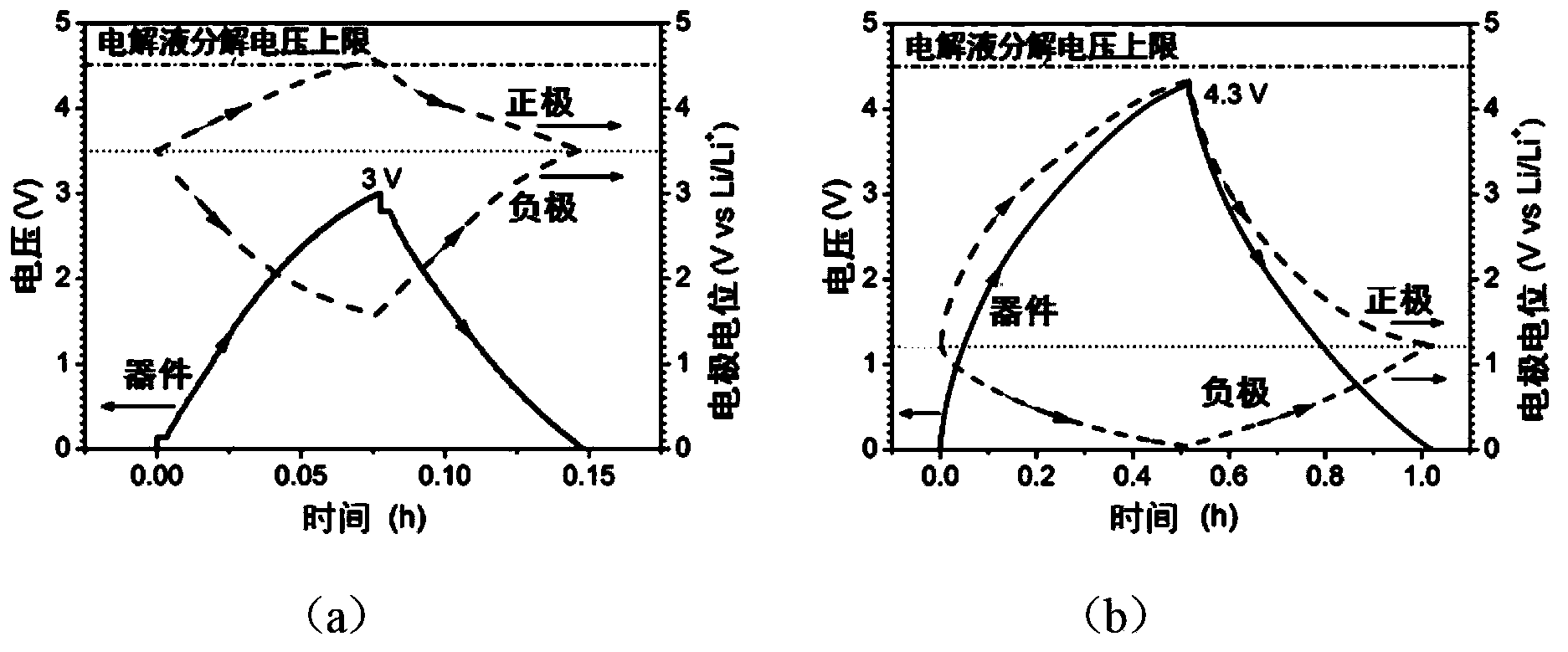

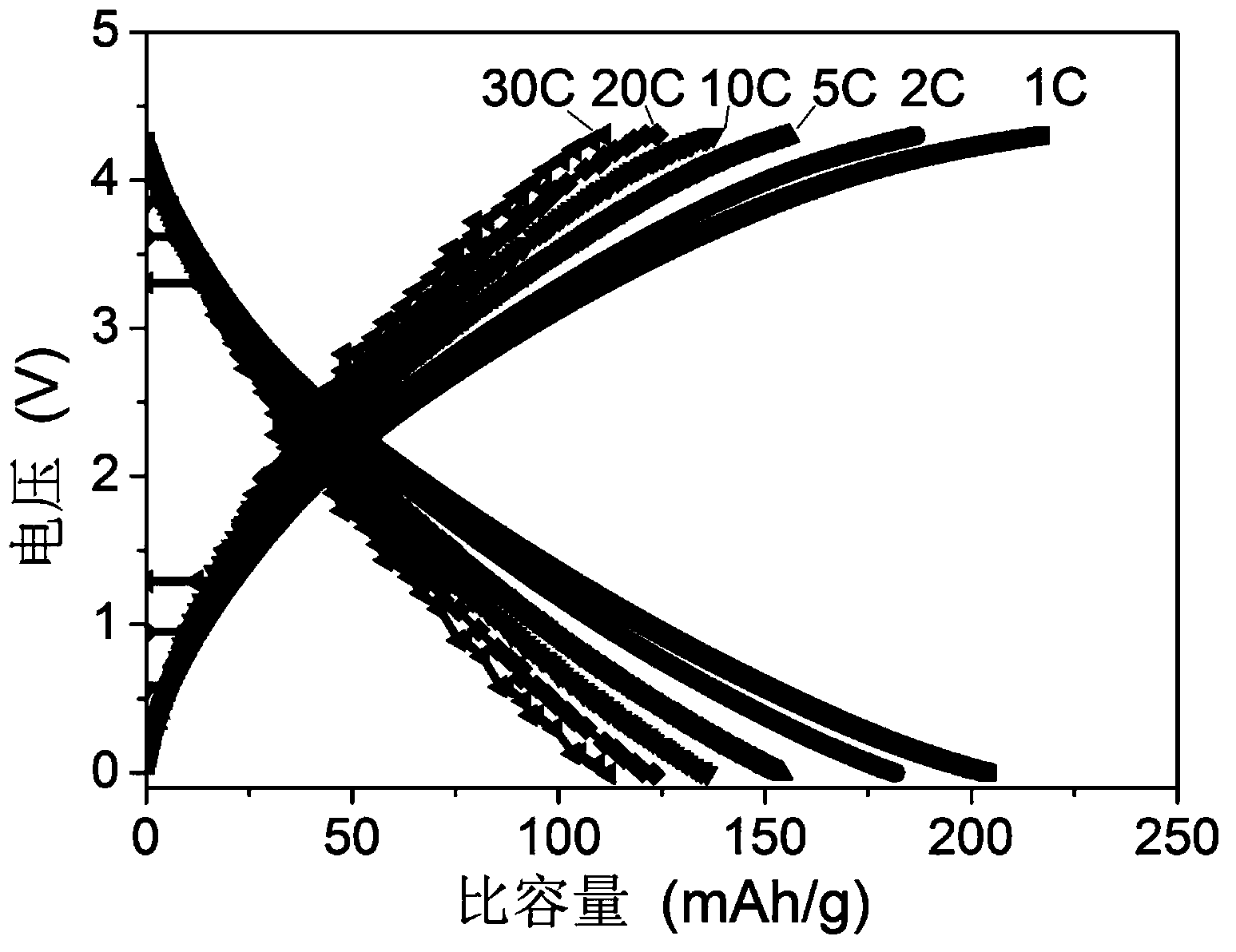

High-energy high-power density lithium ion supercapacitor and assembling method thereof

ActiveCN103680972AHigh specific capacityHigh output energy densityLiquid electrolytic capacitorsLithiumDecomposition

The invention discloses a high-energy high-power density lithium ion supercapacitor and an assembling method thereof and belongs to the technical field of electrochemical energy storage devices. In order to greatly improve the energy density of the lithium ion supercapacitor, non-graphitic carbon materials with a certain oxygen-containing functional groups are used as positive and negative electrodes, after the electrodes are embedded in advance, a lithium salt organic electrolyte solution is used as an electrolyte solution, and the lithium ion supercapacitor is assembled. According to the design and assembling mode, the positive and negative electrodes can be always positioned in the most suitable potential interval in the operating process of a device, and the characteristics of high specific capacity and high power of the non-graphitic carbon materials are exerted to the greatest degree. Moreover, an available voltage window of the electrolyte can be fully utilized, so that the operating voltage of the device reaches an upper limit of decomposition voltage of the electrolyte, and the energy density and power density of the lithium ion supercapacitor are greatly improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

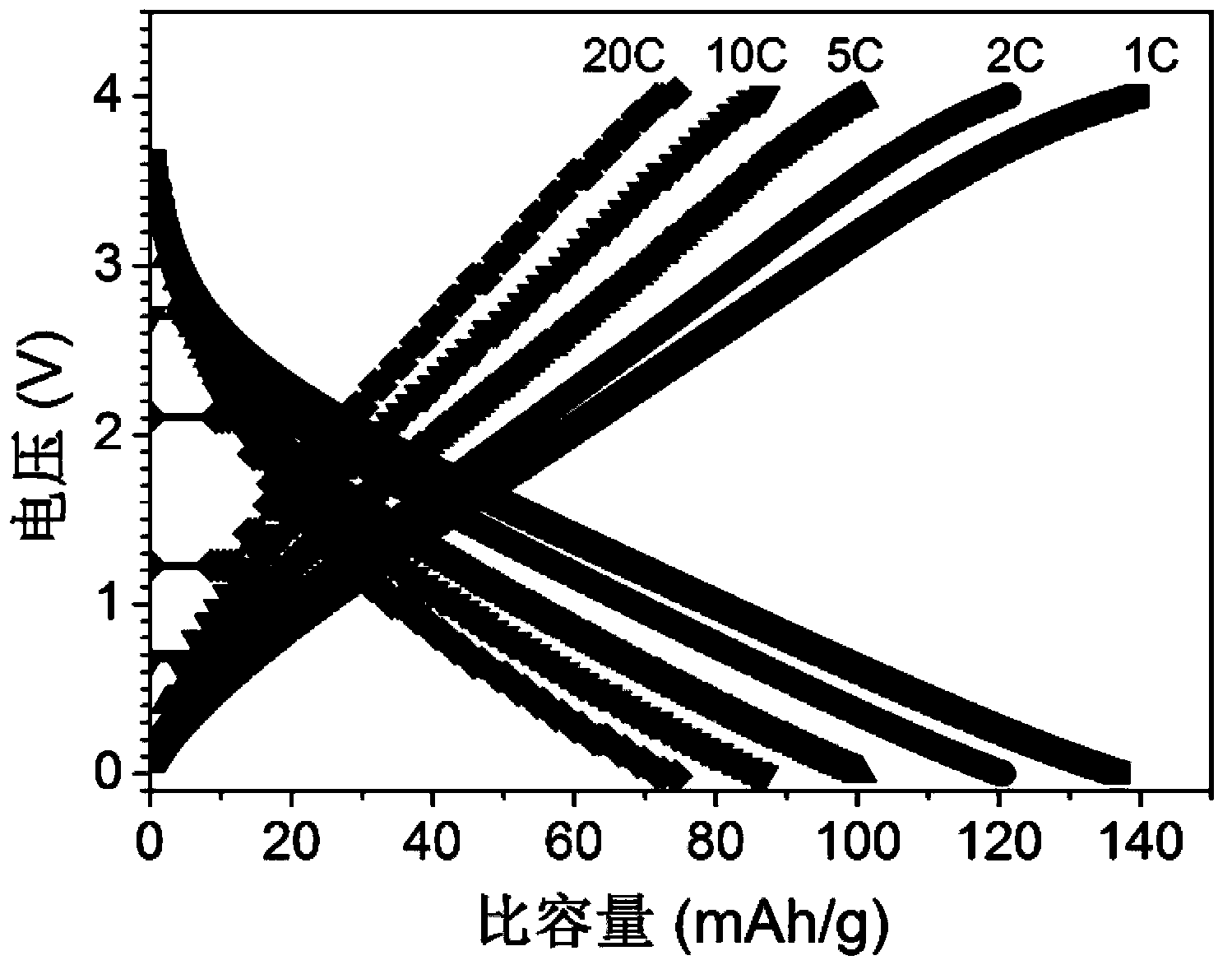

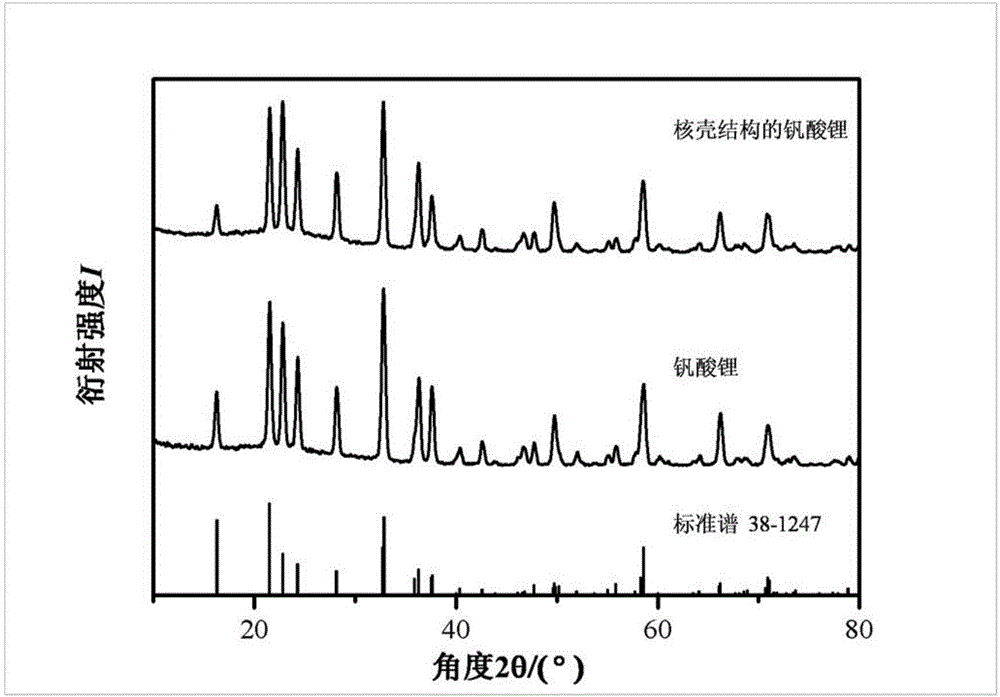

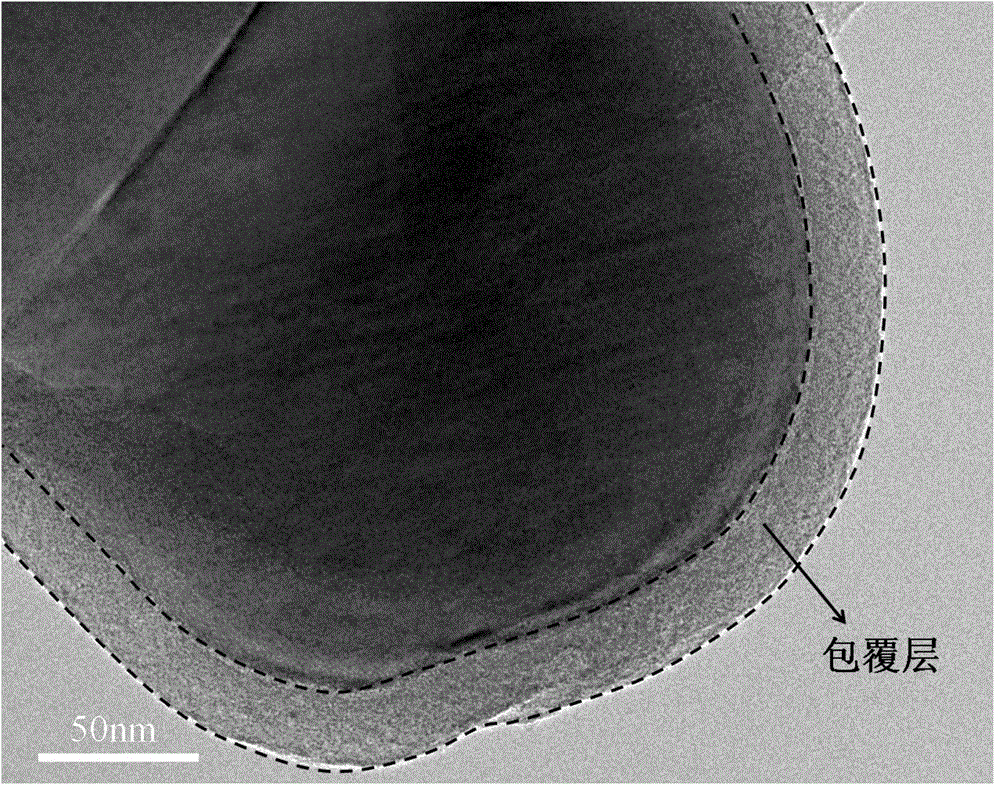

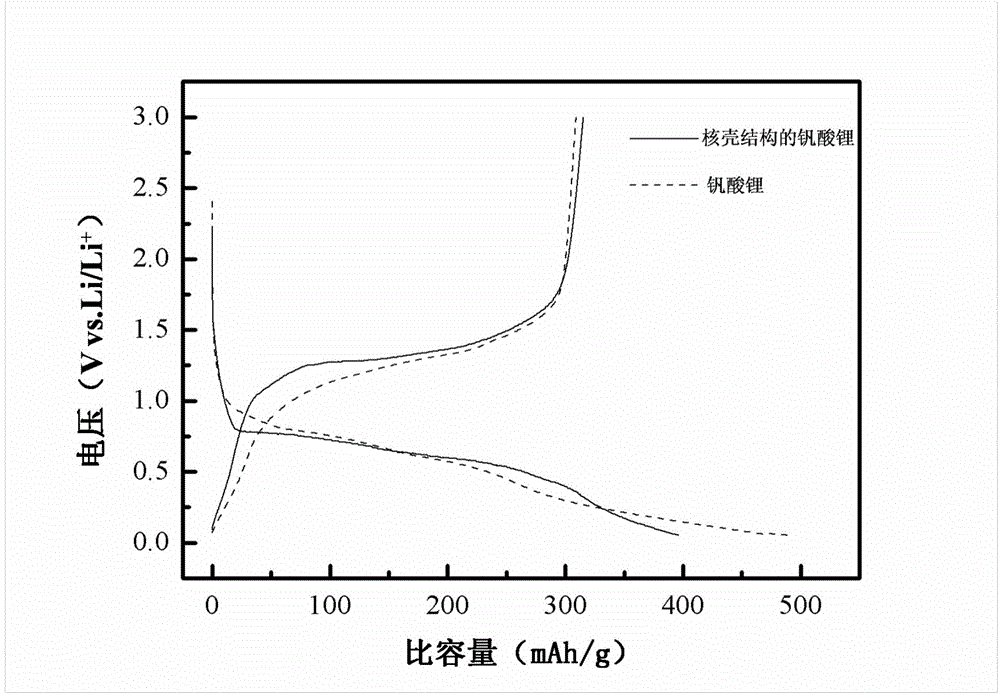

Lithium vanadate anode material, anode, battery and anode material preparation method

The invention discloses a lithium vanadate anode material, an anode, a battery and an anode material preparation method, and belongs to the field of batteries. The lithium vanadate anode material is of a core-shell structure, the core is lithium vanadate, the shell is a coating layer, lithium vanadate is nanometer granules or micrometer level secondary granules formed by nanometer granules, the thickness of the coating layer is 2-30nm, and the coating layer comprises a conductive coating layer or / and a stable coating layer. An organic carbon source is introduced into a high temperature reactor with an inert gas as a carrier by using a chemical vapor deposition method, in order to from the conductive coating layer of amorphous carbon or graphitic carbon on the surface of the core. The conductive coating layer and the stable coating layer are prepared by using a vacuum coating method, a magnetron sputtering method, a pulsed laser deposition method or an atomic layer deposition method. Lithium vanadate is used as an active anode material to obtain high coulombic efficiency, large specific capacity and good rate capability, and the proper embedded escape potential and the considerable volume of lithium vanadate are fully utilized.

Owner:HUAZHONG UNIV OF SCI & TECH

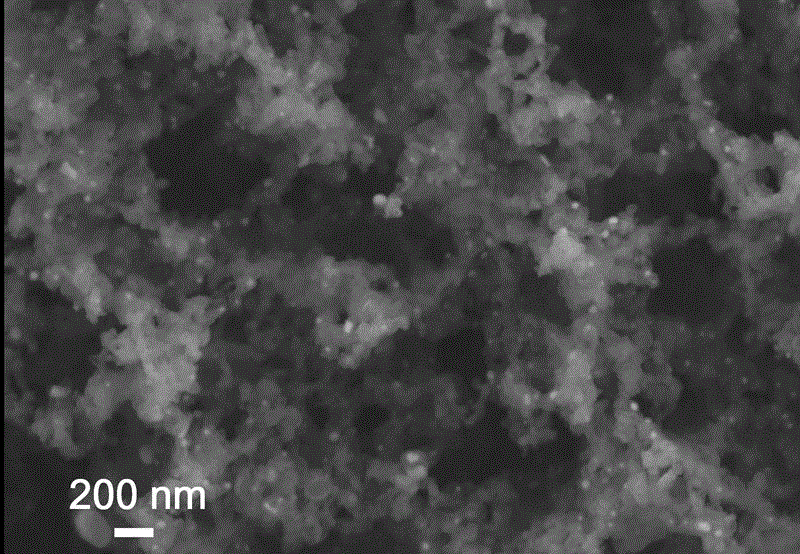

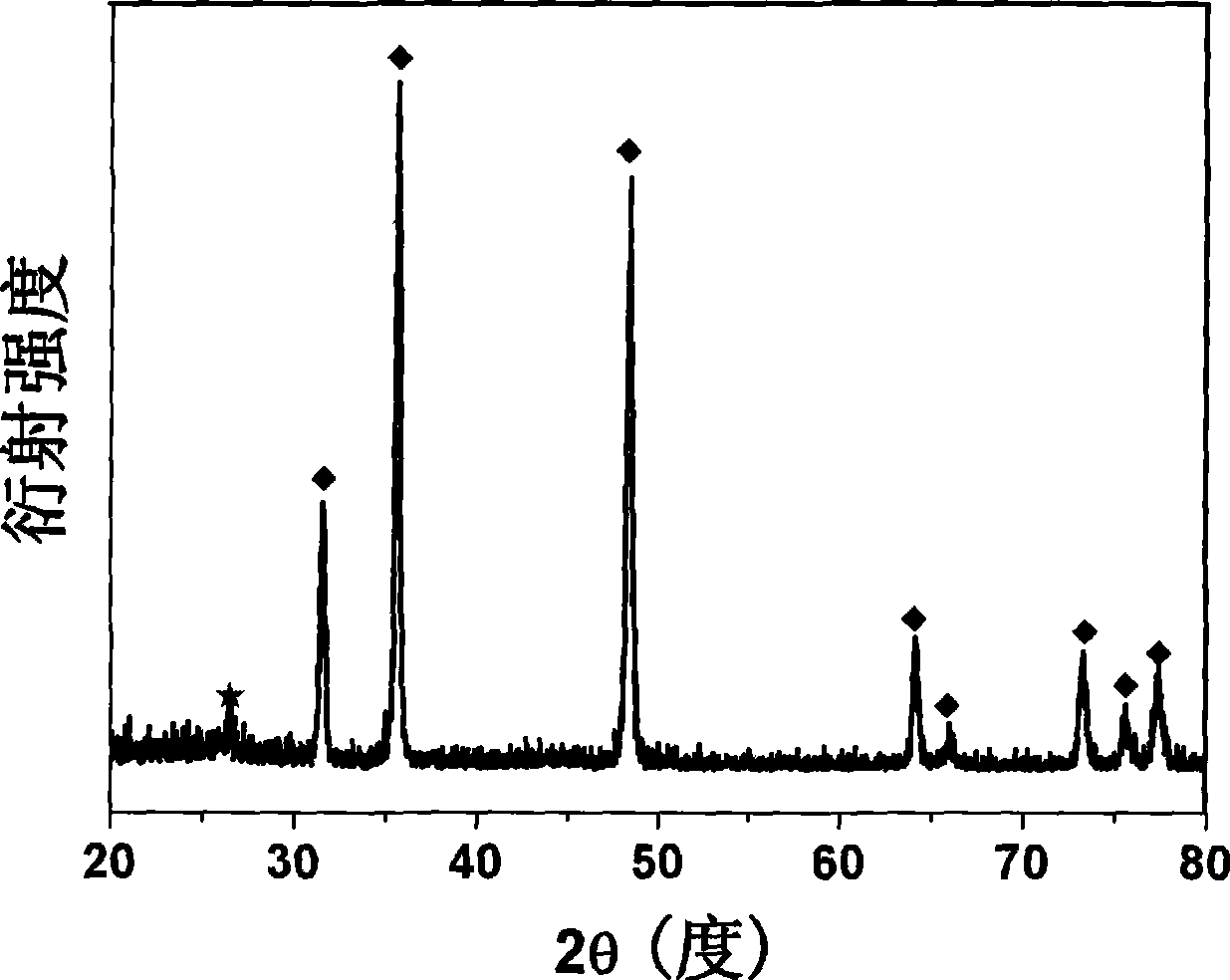

In-situ synchronous synthesizing method of tungsten carbide/graphitic carbon nano complexes

ActiveCN101456552AEvenly distributedWidely distributed and cheapTungsten/molybdenum carbideState of artCarbonization

The invention relates to a method for synthesizing a tungsten carbide / graphite carbon nano composition through in-situ synchronization, which relates to a method for preparing the tungsten carbide / graphite carbon nano composite. The method solves the problem of nonuniform tungsten carbide distribution in the prior art for preparing the tungsten carbide / graphite carbon nano composite. The method comprises: firstly, pretreatment of carbon sources; secondly, dissolution of a graphitized catalyst and tungsten sources into a solvent, addition of the pretreated carbon sources, and dispersion; thirdly, pre-carbonization; fourthly, heat treatment; fifthly, acid treatment; and sixthly, physical activation or chemical activation. The method has the advantages of simple technology, uniform tungsten carbide distribution, small environmental pollution, low cost and simple required equipment, and is easy to realize commercialization.

Owner:佛山市菲玛斯新材料科技有限公司

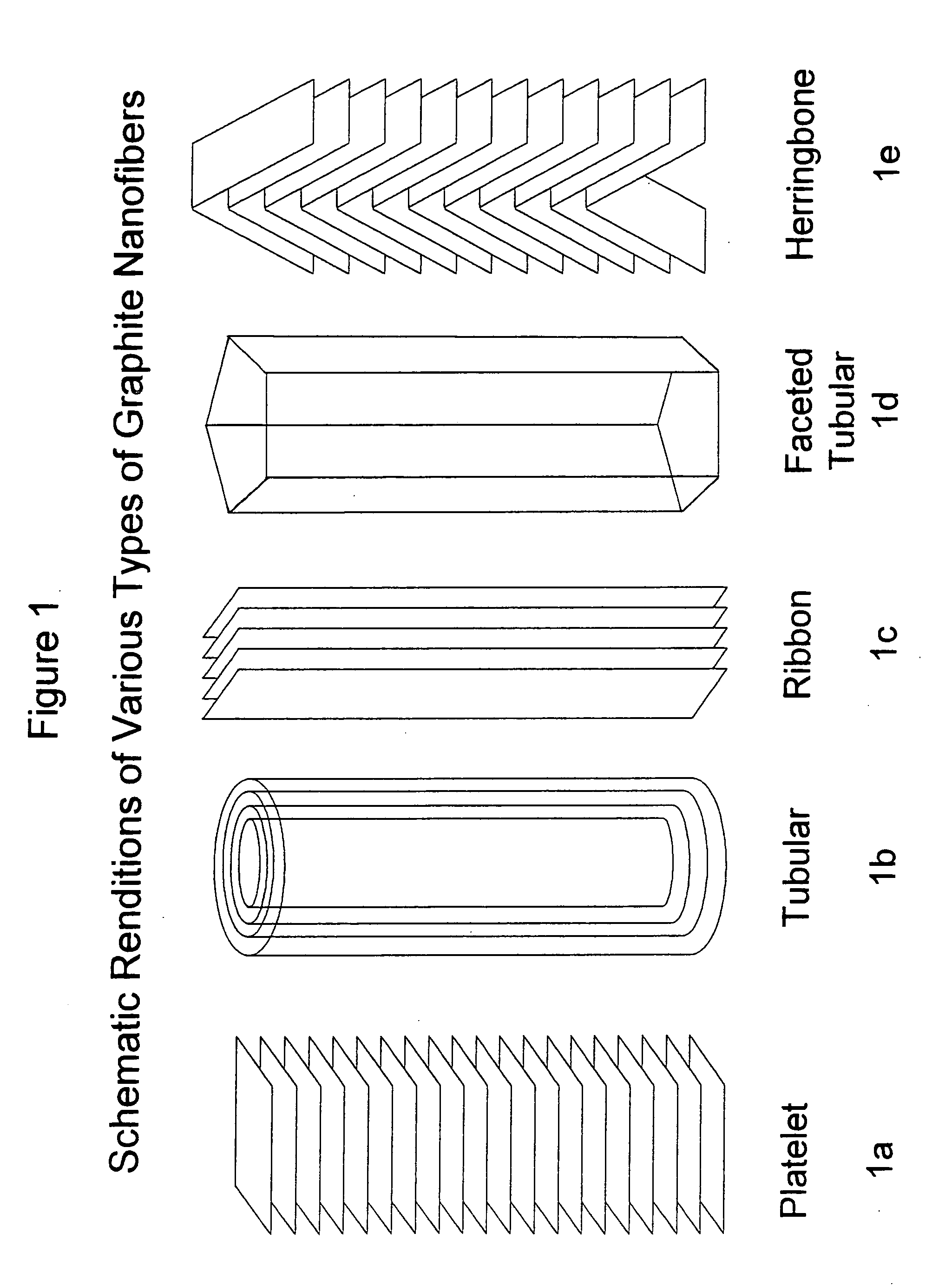

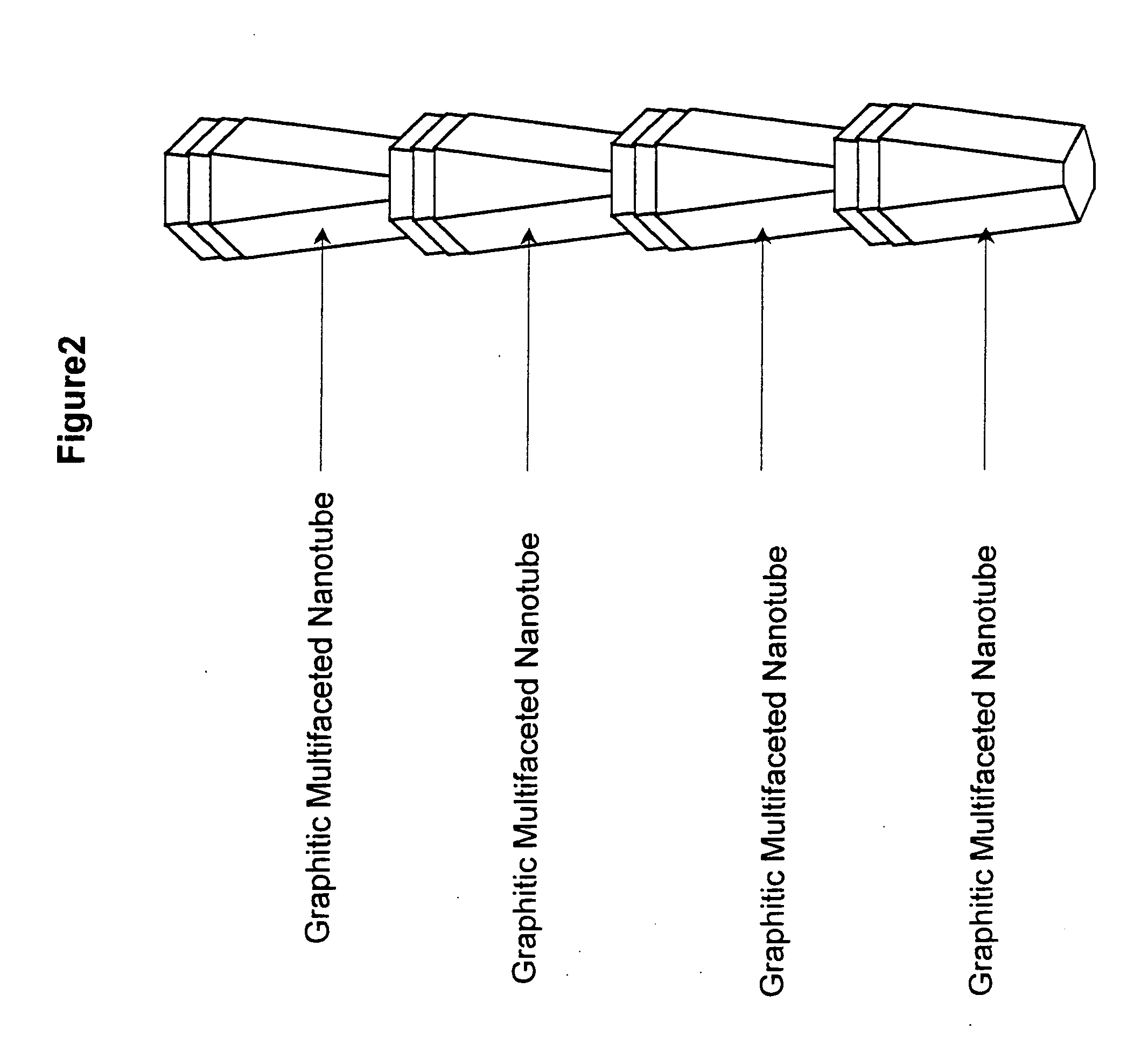

Conductive polymeric structures containing graphite nanofibers having graphite sheets parallel to the growth axis

Electrically conductive polymer composite materials comprised of: a) an effective amount of substantially crystalline graphitic carbon nanofibers comprised of graphite sheets that are substantially parallel to the longitudinal axis of the nanofiber, preferably wherein said grip sheets form a multifaceted tubular structure; and b) a polymeric component.

Owner:CATALYTIC MATERIALS

Method for the preparation of porous graphite carbon with high crystallinity using sucrose as a carbon precursor

InactiveUS20090041653A1High crystallinityHigh catalytic activityMaterial nanotechnologyCarbon compoundsSilica particleGraphite carbon

The present invention relates to a process for preparing a porous graphite carbon with high crystallinity, which comprises the steps of: (a) hydrothermally treating sucrose (i.e. carbon precursor), transitional metal precursor and uniform-sized silica particles at the same time to prepare a polymer; and (b) carbonizing the polymer, which can provide a porous graphite carbon with remarkably improved crystallinity suitable for a catalyst support for a fuel cell.

Owner:HYUNDAI MOTOR CO LTD

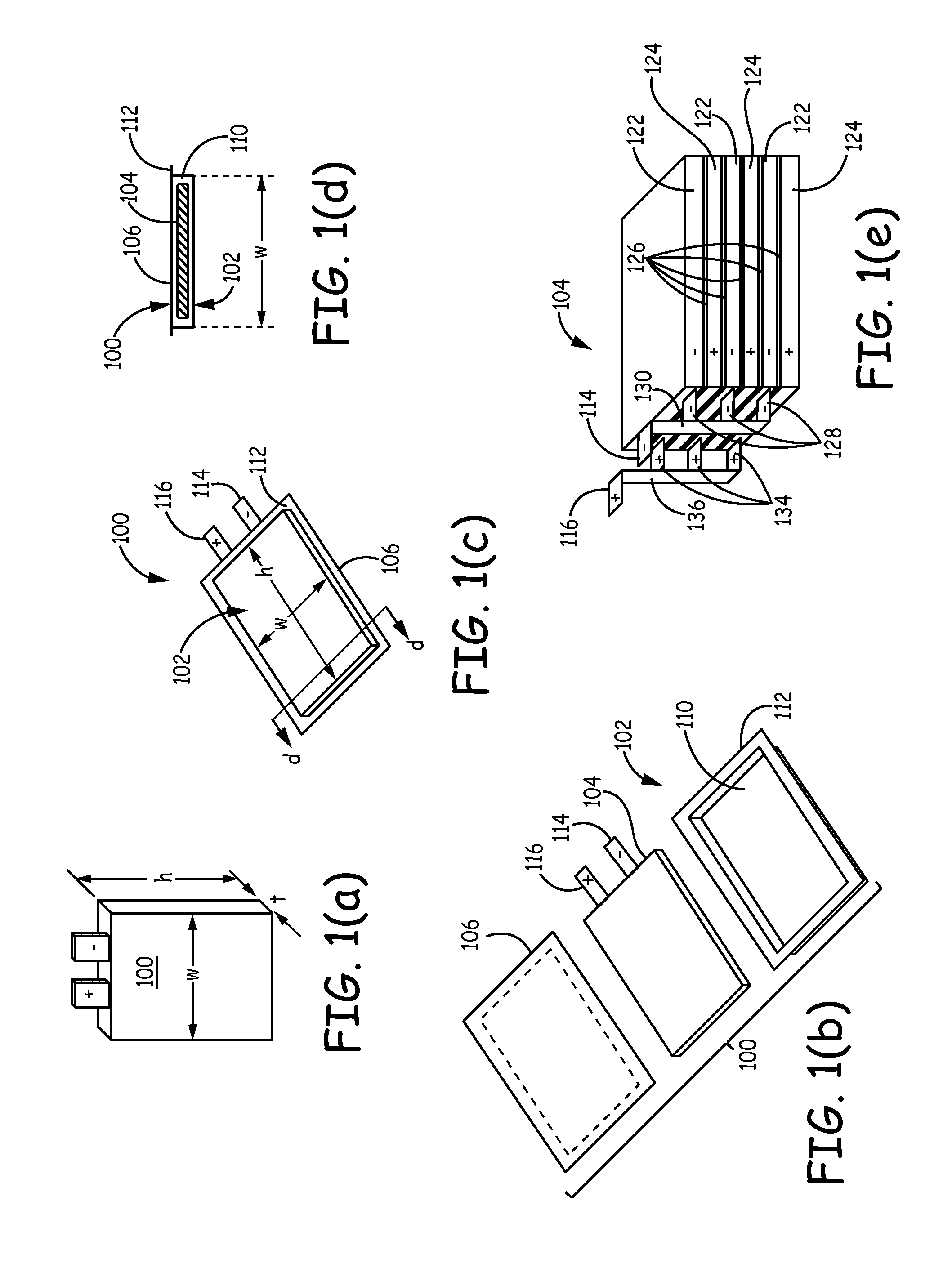

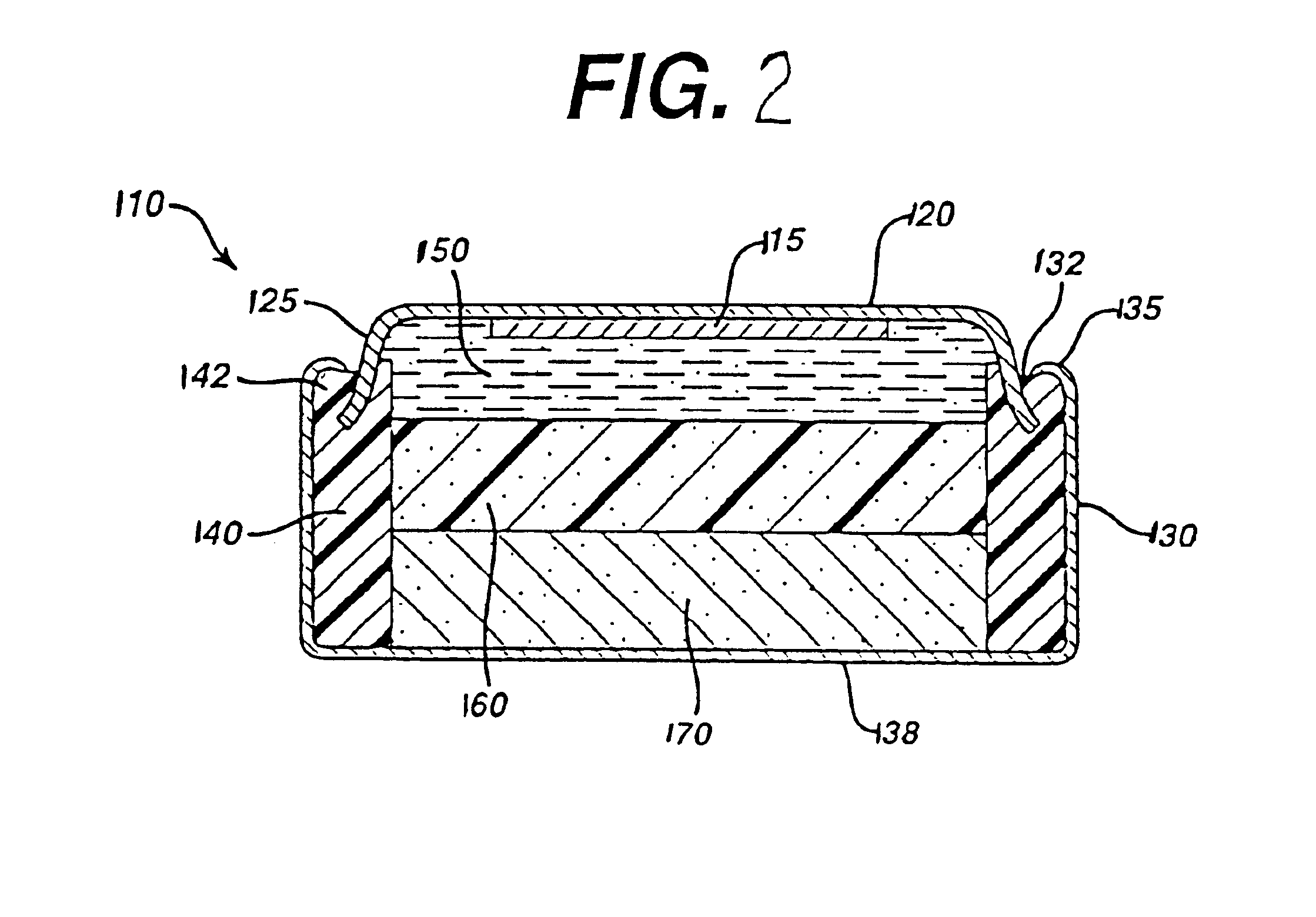

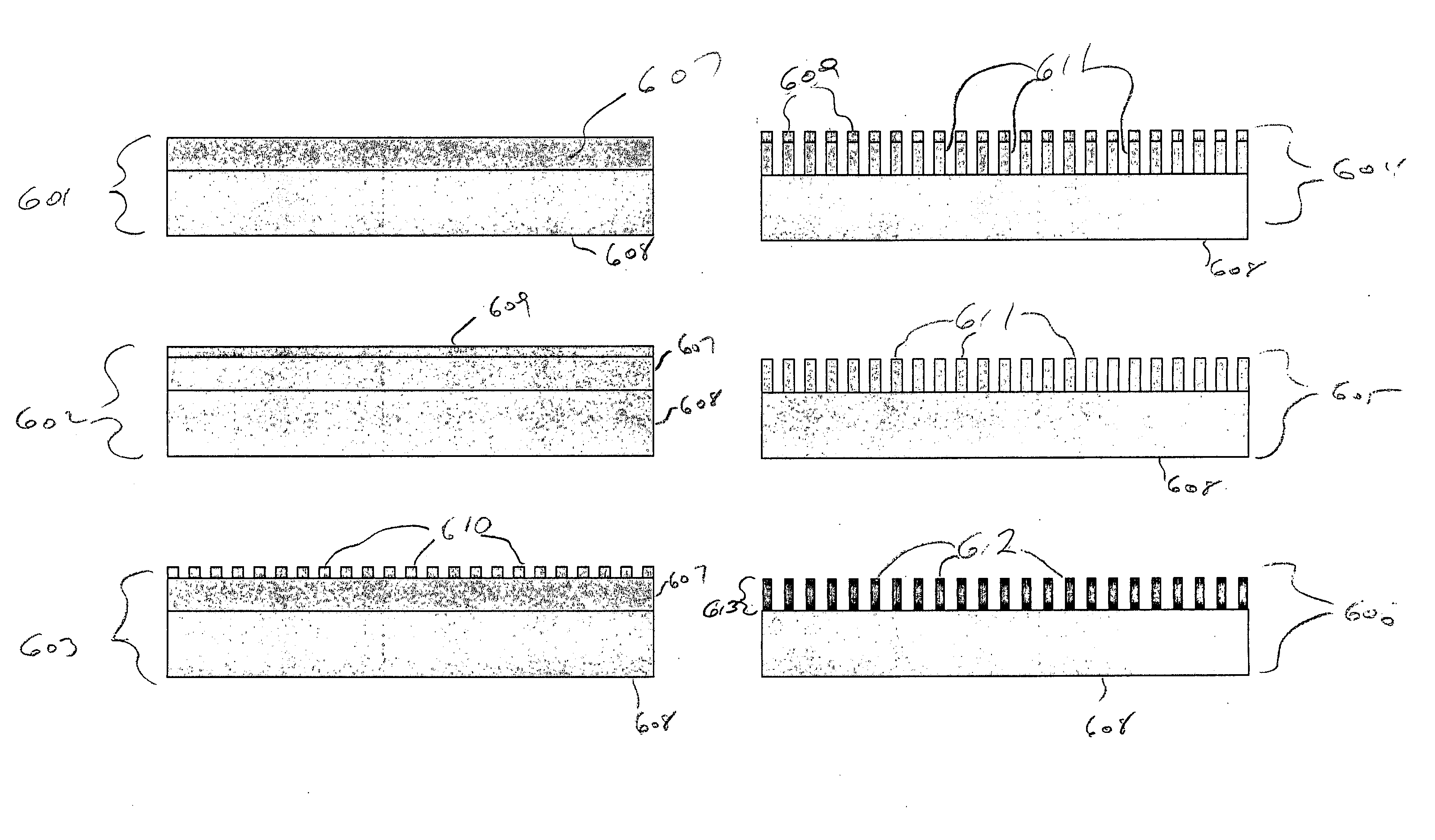

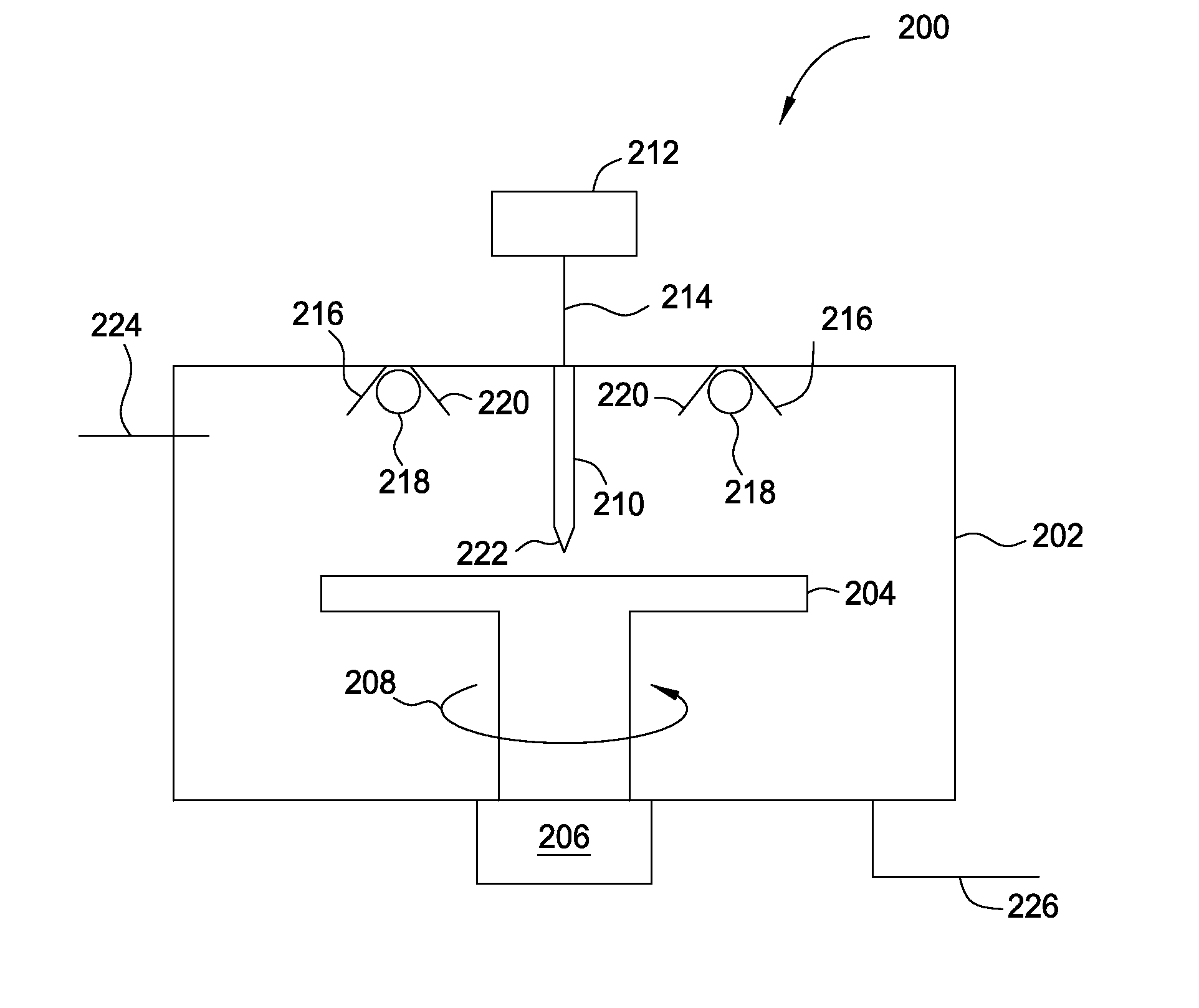

Graphitic nanostructured battery

InactiveUS20060172189A1Improve battery performanceImprove battery lifeMaterial nanotechnologyElectrode thermal treatmentDielectricNanopillar

A method and apparatus are disclosed wherein a battery comprises at least one electrode formed from a graphitic carbon nanostructured surface wherein the nanostructured surface consists of a plurality of nanoposts formed from graphitic carbon such that the graphitic nanoposts serve both as an operational feature (i.e., dielectric / electrode) and control feature of the battery itself. In one embodiment, the nanostructured surface consists of a plurality of nanoposts wherein a select portion of each nanopost is formed to serve as the dielectric of the nanostructured battery, and the balance of each nanopost is utilized to impart the control features to the nanostructured battery.

Owner:LGS INNOVATIONS +1

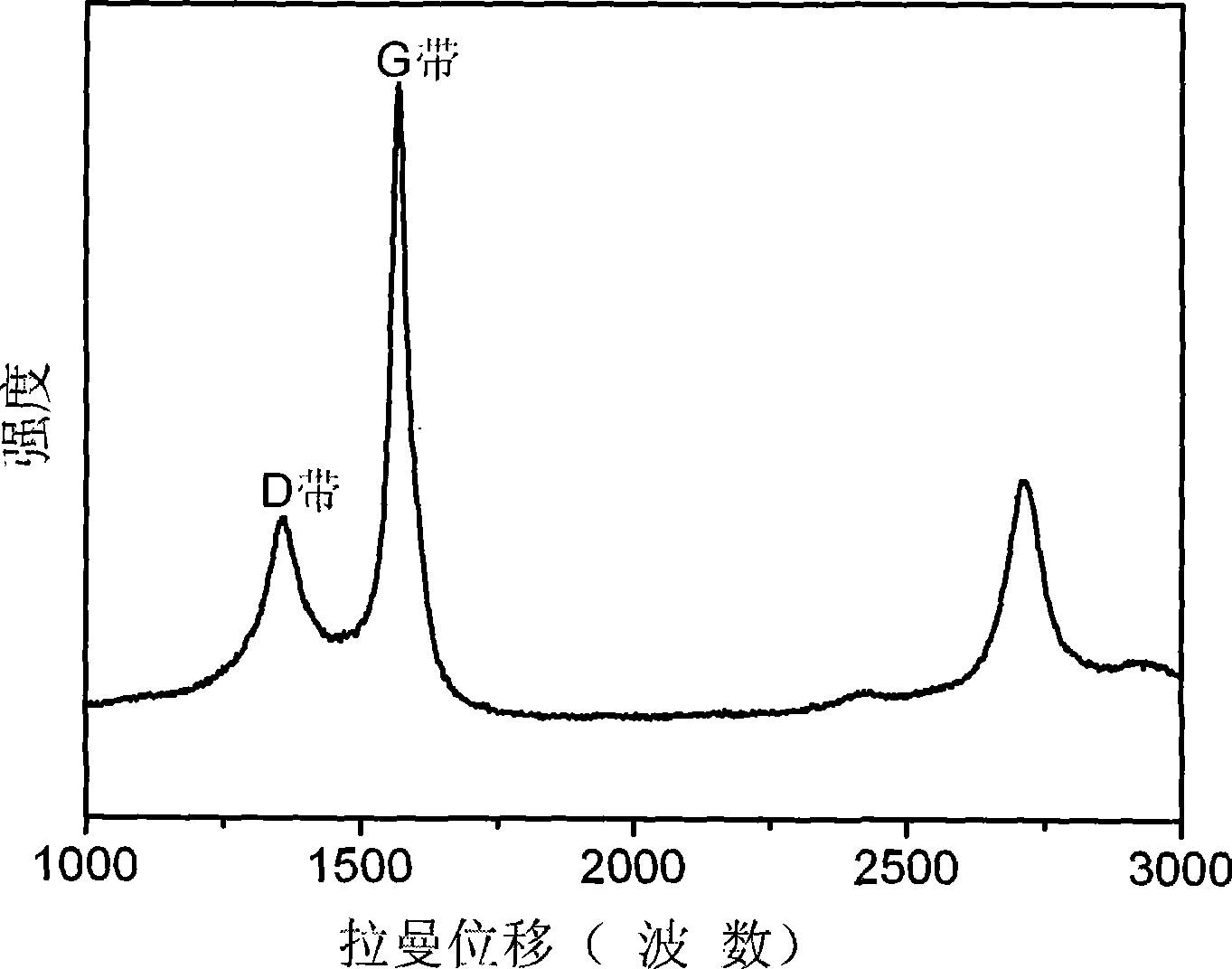

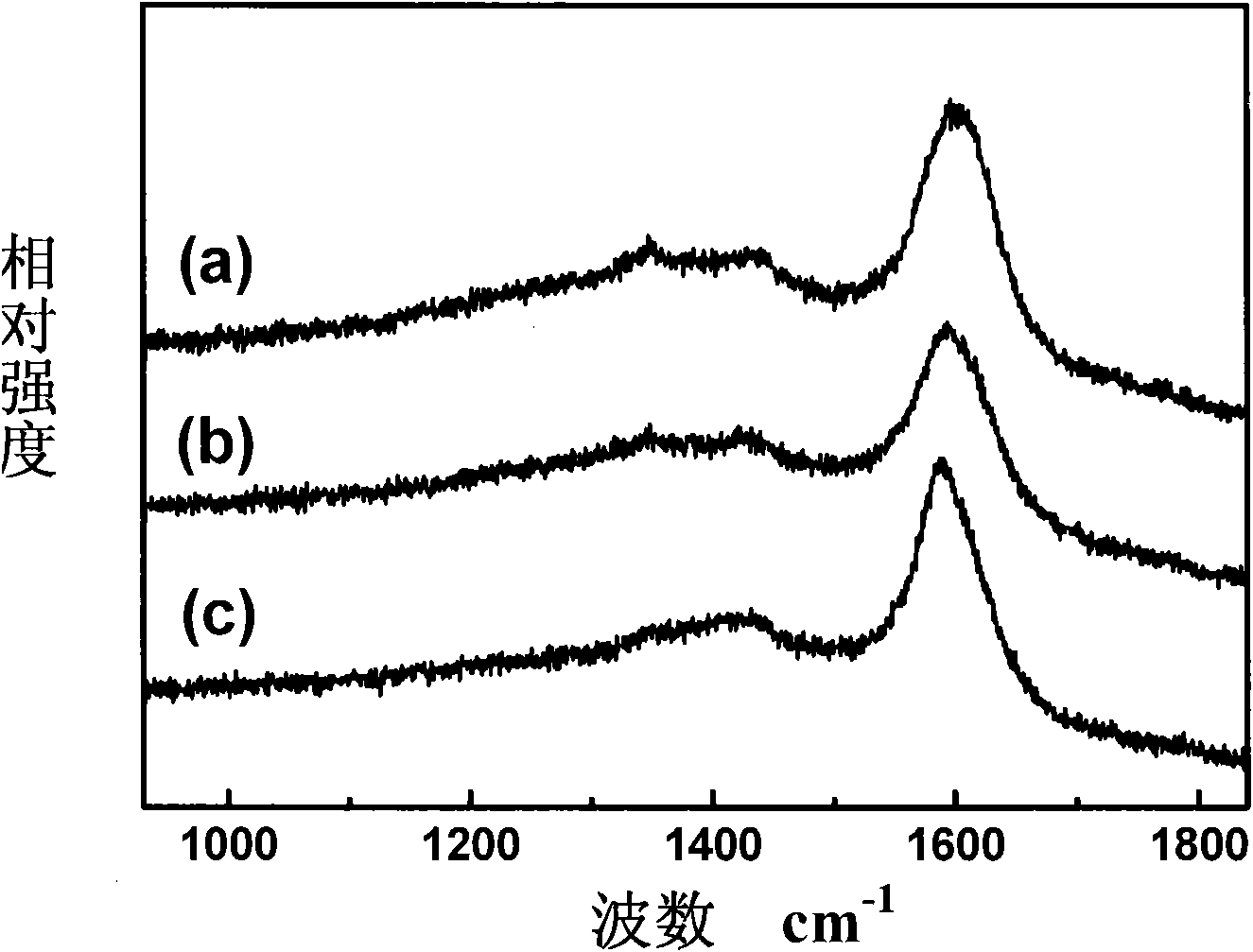

Micro-wave preparation method for biomass-based graphitized carbon and carbon-carbon composite material

InactiveCN101613100ALarge specific surface areaHigh degree of graphitizationCarbon compositesMicrowave

The invention relates to graphitic carbon, in particular to a non-hard template method for preparing a graphite composite material with large specific surface area by taking a PPy / biomass complex as a carbonization precursor and quickly carbonizing and graphitizing the carbonization precursor under the action of microwave. The concrete preparation method comprises the steps: firstly, adopting ferric trichloride as a catalyst, and adopting steam phase polymerization technology to prepare a Fe / PPy / biomass complex; then performing micro-wave carbonization treatment on the prepared Fe / PPy / biomass complex; and finally removing generated ferric carbide from a sample through acid treatment to obtain a graphitized carbon material with high specific surface area. With similar methods, the applicant also successfully prepares a metallic carbide / graphitized carbon composite material.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Carbon material electrical heating membrane and preparing method

InactiveCN1770930AHigh electrothermal conversion rateSignificant power saving effectHeating element materialsElectricityGraphite

This invention discloses one carbon materials generating film and its process method, which makes use of one micro carbon powder, conductive carbon powder excellent electricity and thermal property and adds proper stabilizer, adhesive agent and disperser to make flexible electricity film materials. Comparing with current technique, the invention product is of high conversion efficiency and good saving effect and can product low temperature, middle temperature type with highest temperature of 350 degrees and its voltage is between 3.6V to 650V with wide utility range and with simple process.

Owner:贵州航天江南工业贸易有限公司 +1

Growing graphene on substrates

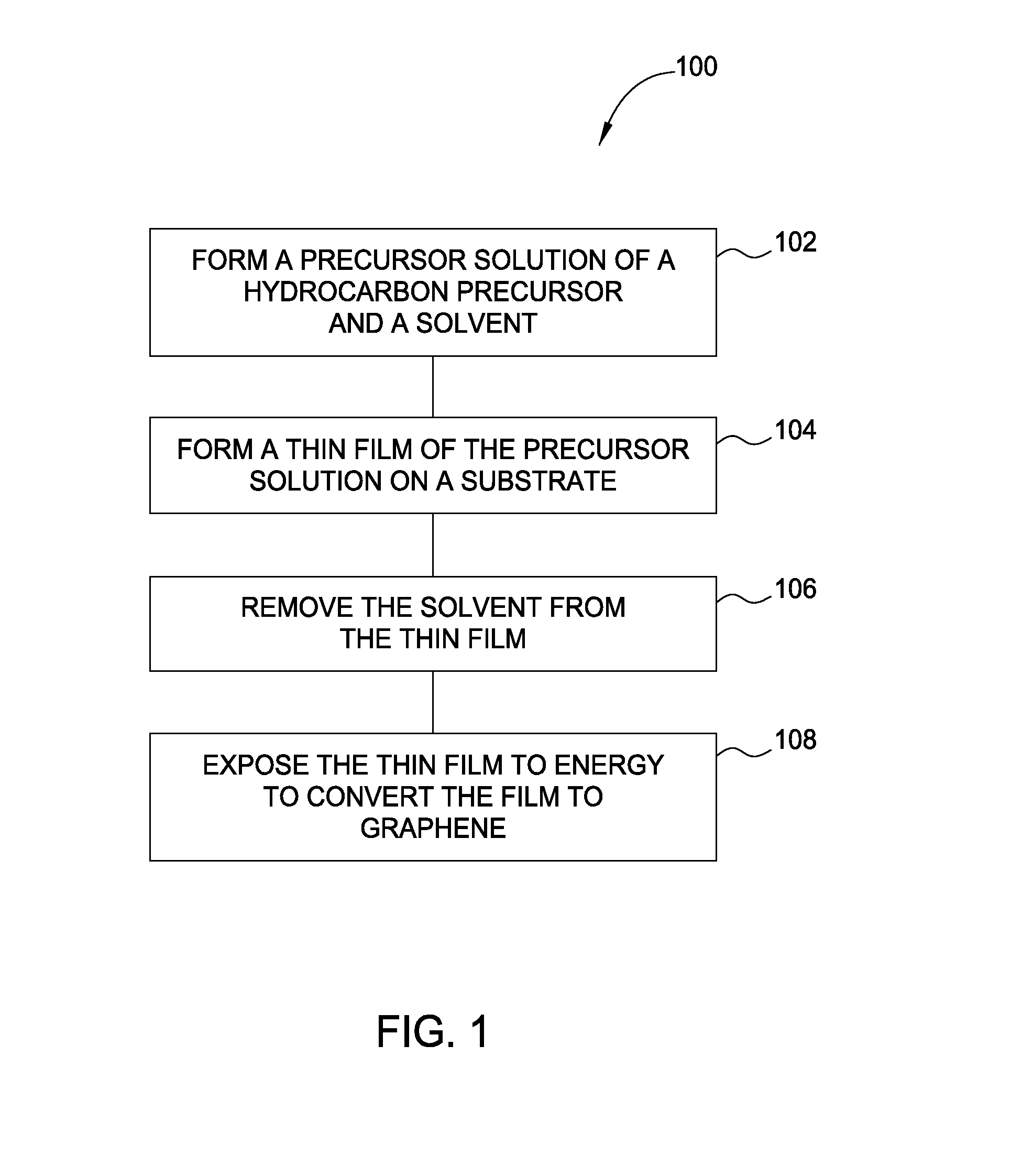

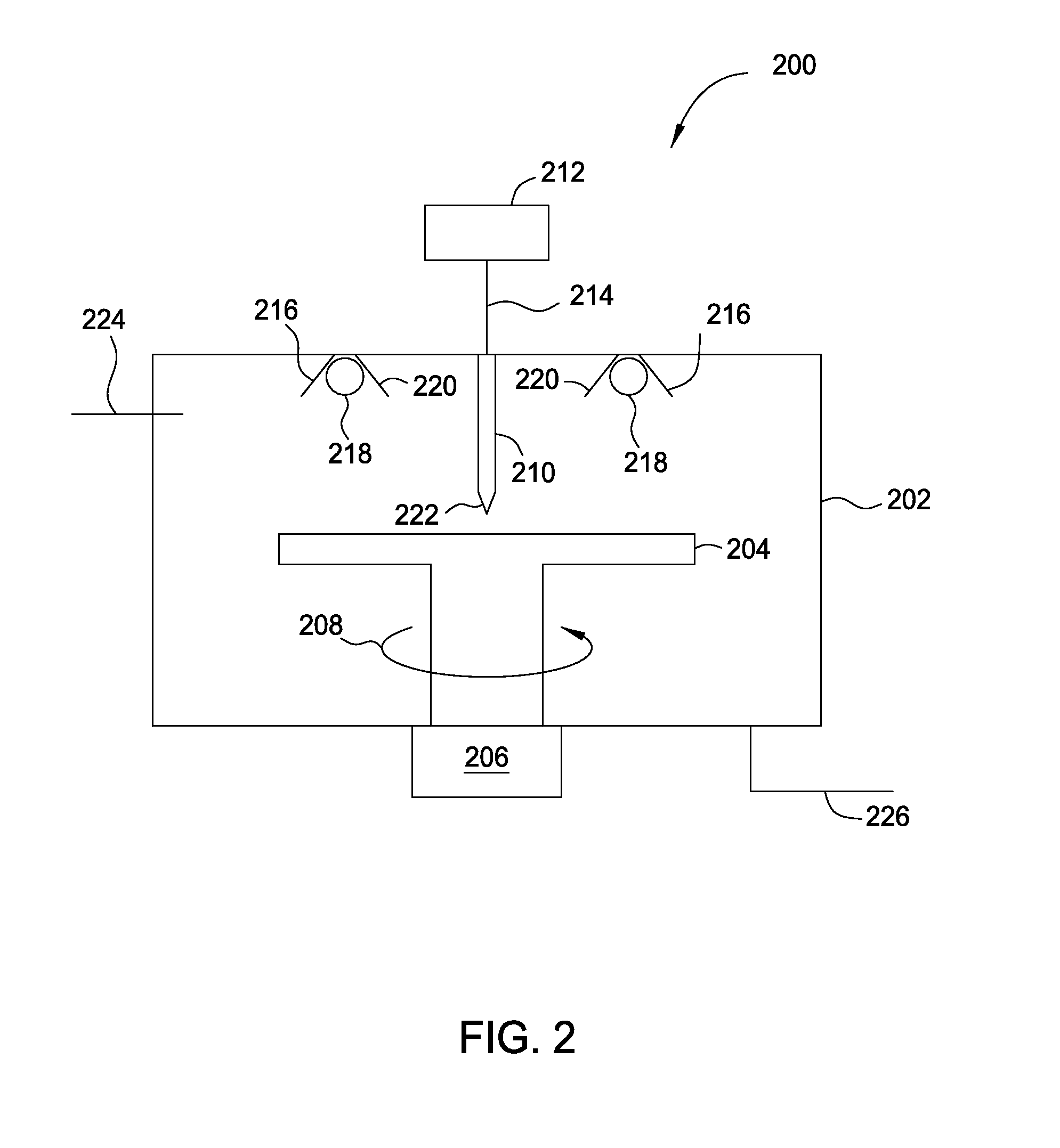

Embodiments described herein provide methods and apparatus for forming graphitic carbon such as graphene on a substrate. The method includes providing a precursor comprising a linear conjugated hydrocarbon, depositing a hydrocarbon layer from the precursor on the substrate, and forming graphene from the hydrocarbon layer by applying energy to the substrate. The precursor may include template molecules such as polynuclear aromatics, and may be deposited on the substrate by spinning on, by spraying, by flowing, by dipping, or by condensing. The energy may be applied as radiant energy, thermal energy, or plasma energy.

Owner:APPLIED MATERIALS INC

Method for preparing spherical aluminum nitride powder

The invention provides a method for preparing a spherical aluminum nitride powder. The method comprises the following steps of: 1, mixing aluminum powder with aluminum nitride powder and ammonium chloride powder, putting the mixture into a mortar for grinding, wherein the aluminum powder is spherical aluminum powder having the particle size range from 0.5 micron to 3 microns; and the aluminum nitride powder is prepared from an aluminum source which is spherical aluminum powder having the same particle size with the raw material aluminum powder through in-situ nitrogenation; 2, putting the evenly ground powder in a porous graphite crucible with a graphitic carbon felt exterior heat preservation layer and an interior protective layer and reacting in a reaction device; 3, electrifying graphite paper, and igniting the powder from bottom to cause a combustion reaction; 4, after natural cooling, releasing nitrogen in the reaction chamber, and opening the reaction device, and obtaining an off-white powder in the porous graphite crucible, namely the spherical aluminum nitride powder; and 5, controlling the particle size of the spherical aluminum nitride powder through the particle size of the spherical aluminum powder. The method provided by the invention has the characteristics of low energy consumption, simple process and low cost; and the prepared spherical aluminum nitride powder is good in homogeneity and controllable in particle size.

Owner:咸阳瞪羚谷新材料科技有限公司

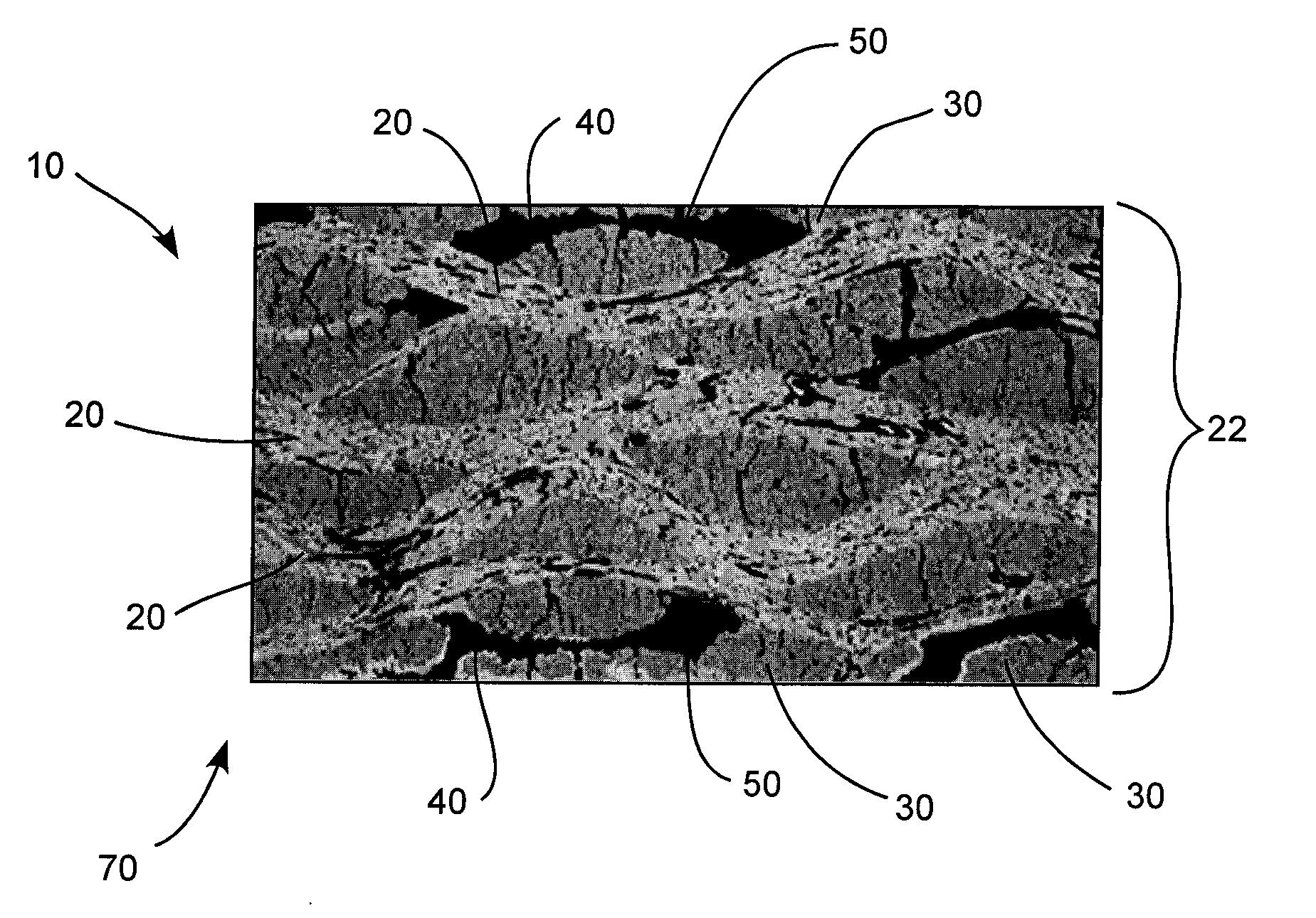

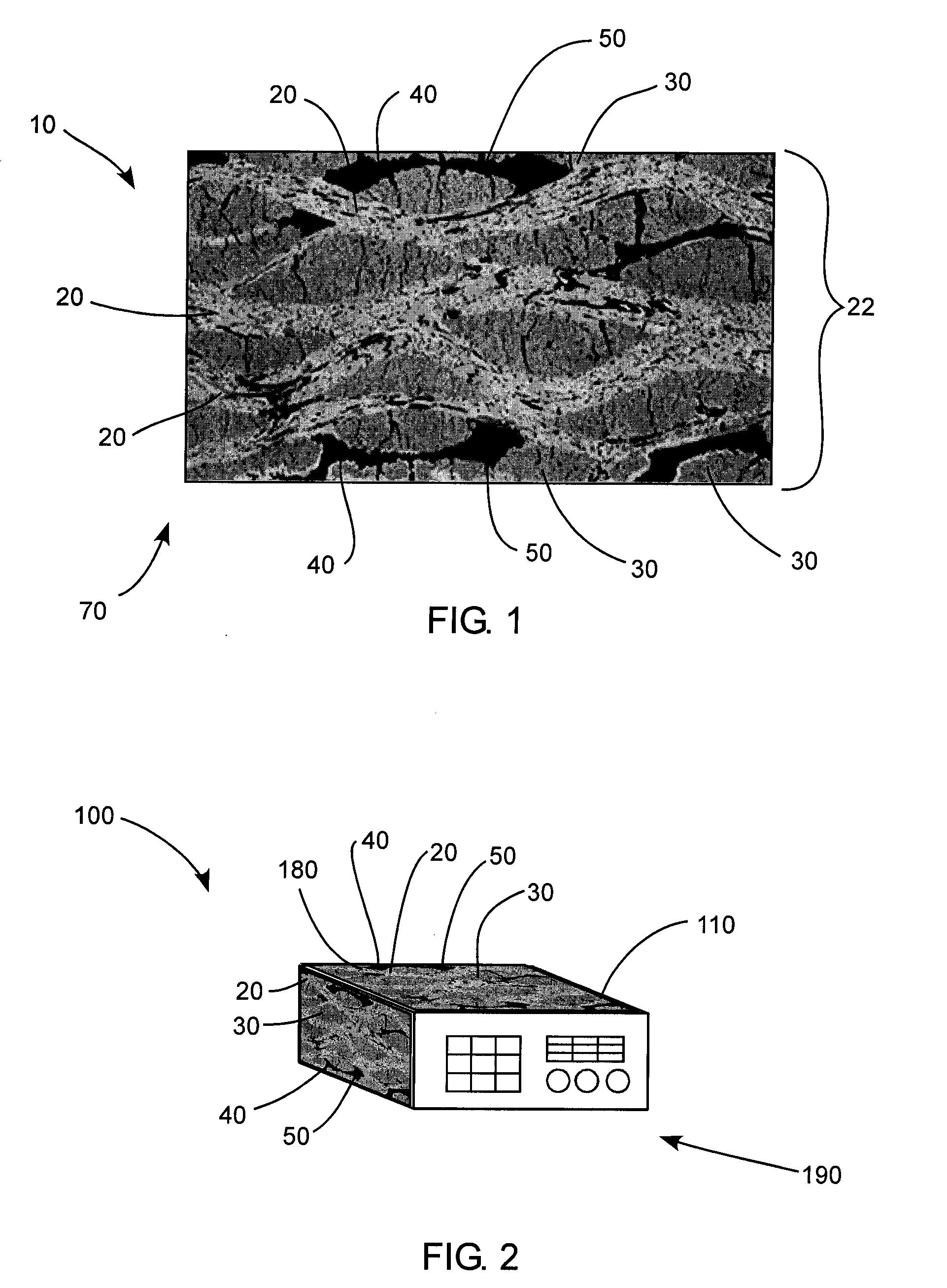

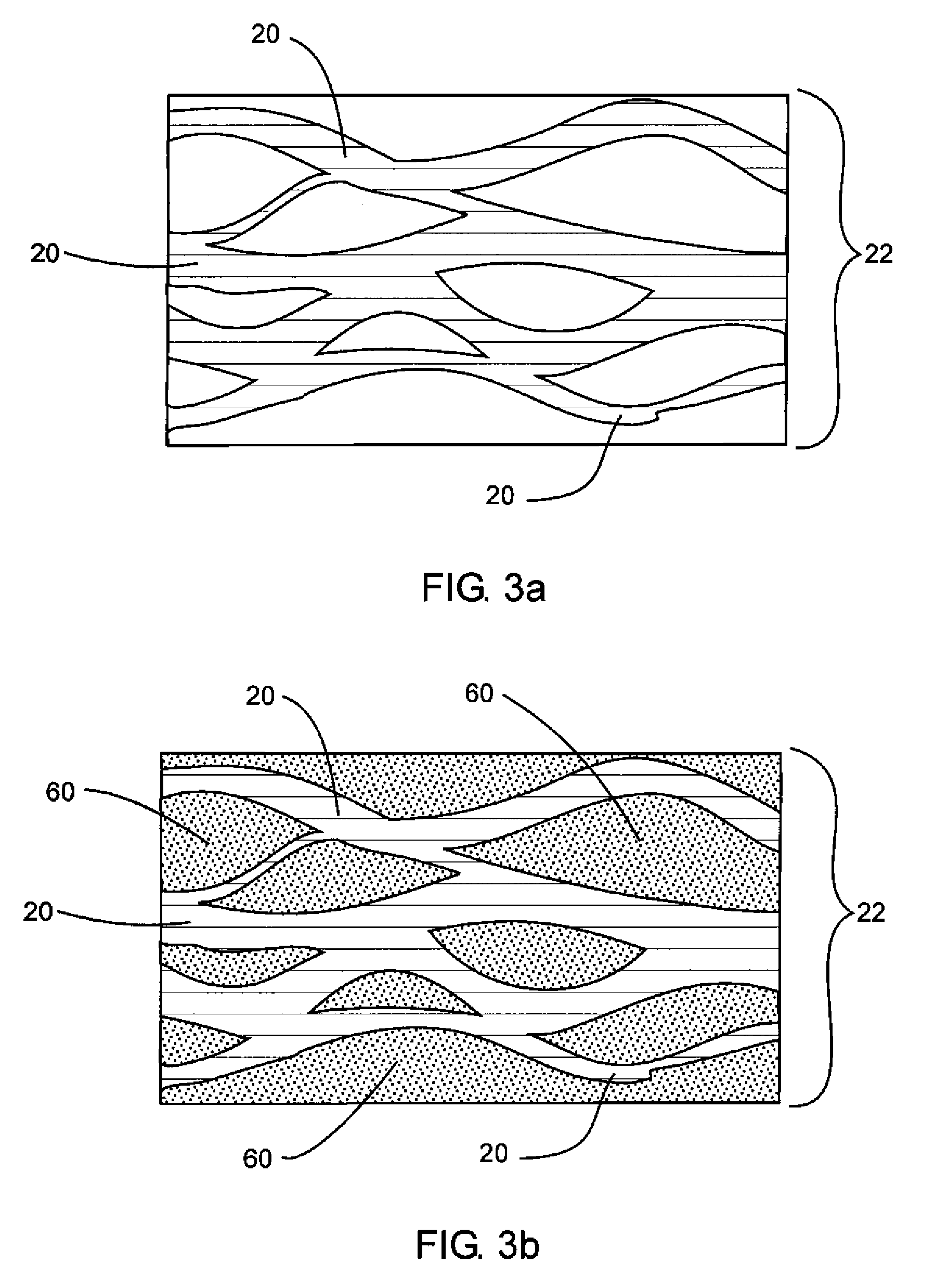

Thermally Conductive Structural Composite Material and Method

ActiveUS20090004393A1Reduce weightHigh strengthLayered productsPretreated surfacesFiberCarbon fibers

A heat dissipative composite material including a carbon fiber lay-up having a resin pyrolized to form a graphitic carbon laminate structure. A structural resin fills voids in the graphitic carbon laminate structure and provides strength to the graphitic carbon laminate structure.

Owner:ALBANY ENGINEERED COMPOSITES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com