High-energy high-power density lithium ion supercapacitor and assembling method thereof

A supercapacitor, high power density technology, applied in the direction of capacitors, electrolytic capacitors, liquid electrolytic capacitors, etc., can solve the problems of power density limitation, difficulty in reaching the energy storage level of secondary batteries, etc., achieve high power density, increase energy density, The effect of high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Graphene (oxygen content 6.5at%, specific surface area 412m 2 / g) Make positive and negative electrode sheets, and electrochemically pre-insert lithium on two graphene electrode sheets. The positive electrode is discharged at a constant current to 1.16V relative to metal lithium and the voltage is maintained for more than 12 hours; the negative electrode is charged and discharged in a constant current cycle at 0.01~1.16V relative to metal lithium, until the charge and discharge capacity remains stable, and finally discharge at a constant current To the vicinity of 1.16V relative to lithium metal and hold the pressure for more than 12 hours. The positive and negative electrode sheets with pre-inserted lithium are assembled into a sandwich structure lithium ion supercapacitor.

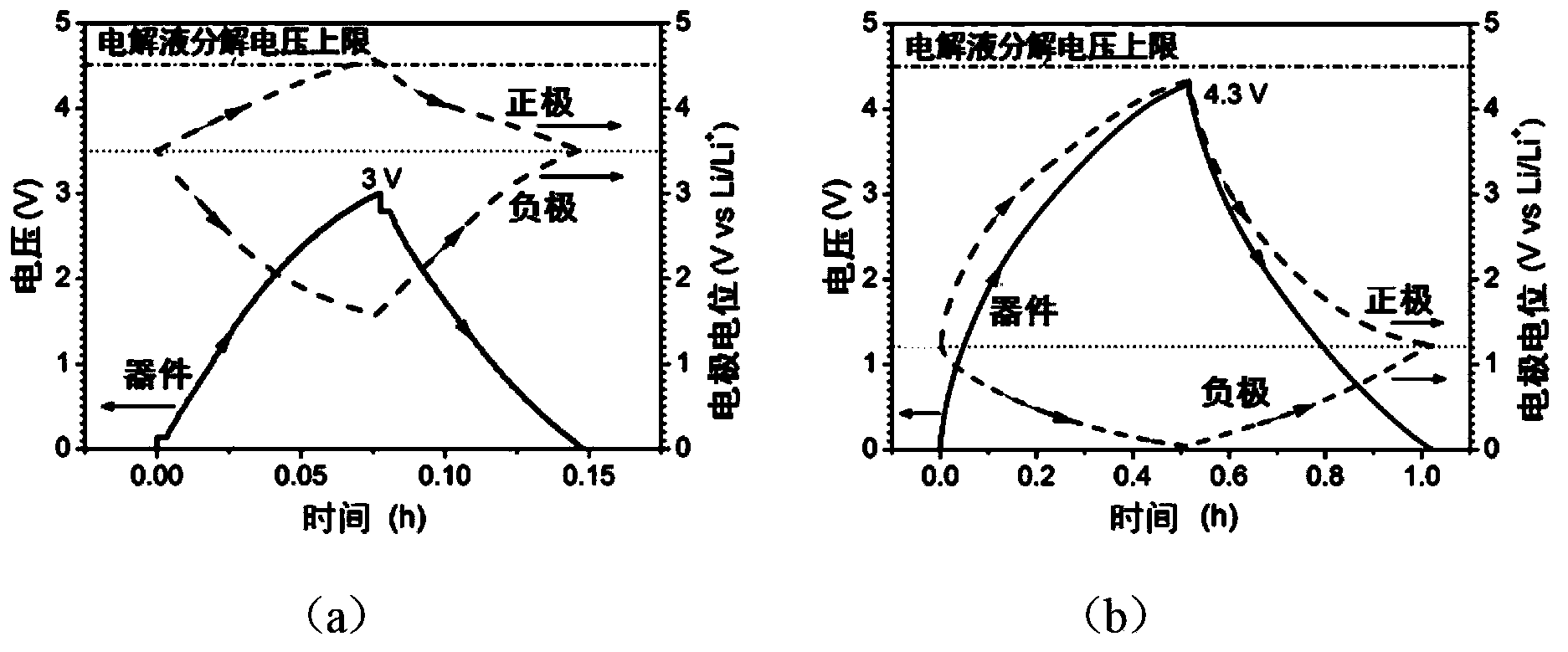

[0028] The energy storage performance of lithium ion supercapacitors and their positive and negative electrodes after pre-insertion of lithium on the electrodes is as follows figure 1 As shown in (b)...

Embodiment 2

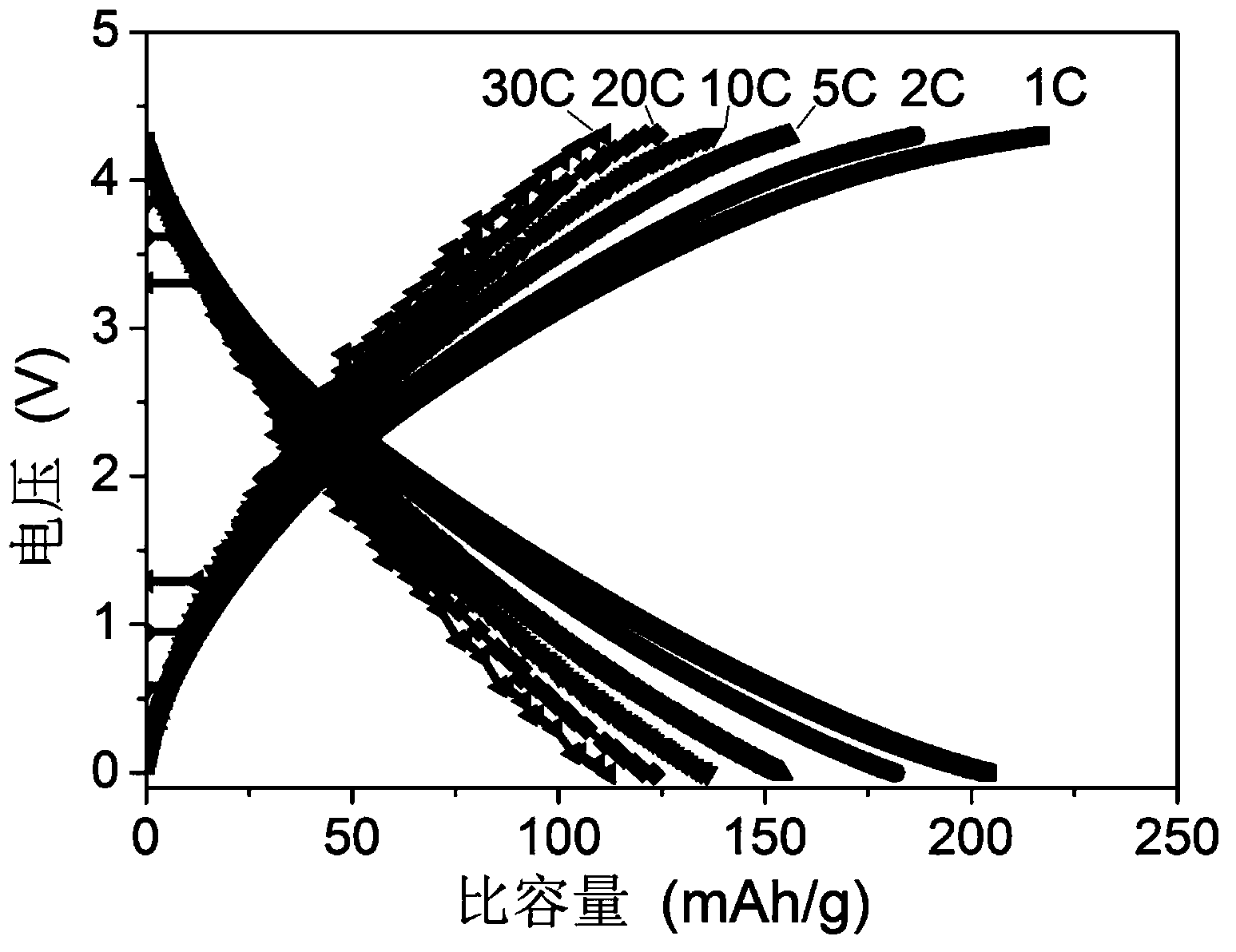

[0031] Hierarchical porous carbon (10.5at% oxygen content, specific surface area 1169m 2 / g, medium / large pores accounted for 68%) were made into positive and negative electrode sheets, and the two graphene electrode sheets were electrochemically pre-inserted with lithium. The positive electrode is discharged at a constant current to 1.22V relative to lithium metal and the voltage is maintained for more than 12h; the negative electrode is charged and discharged in a constant current cycle at 0.01~1.22V relative to metal lithium, until the charge and discharge capacity remains stable, and finally discharge at a constant current To the vicinity of 1.22V relative to metal lithium and keep the pressure for more than 12h. The positive and negative electrode sheets with pre-inserted lithium are assembled into a sandwich structure lithium ion supercapacitor.

[0032] Such as image 3 The constant current charge and discharge curves of the hierarchical pore carbon-based lithium ion super...

Embodiment 3

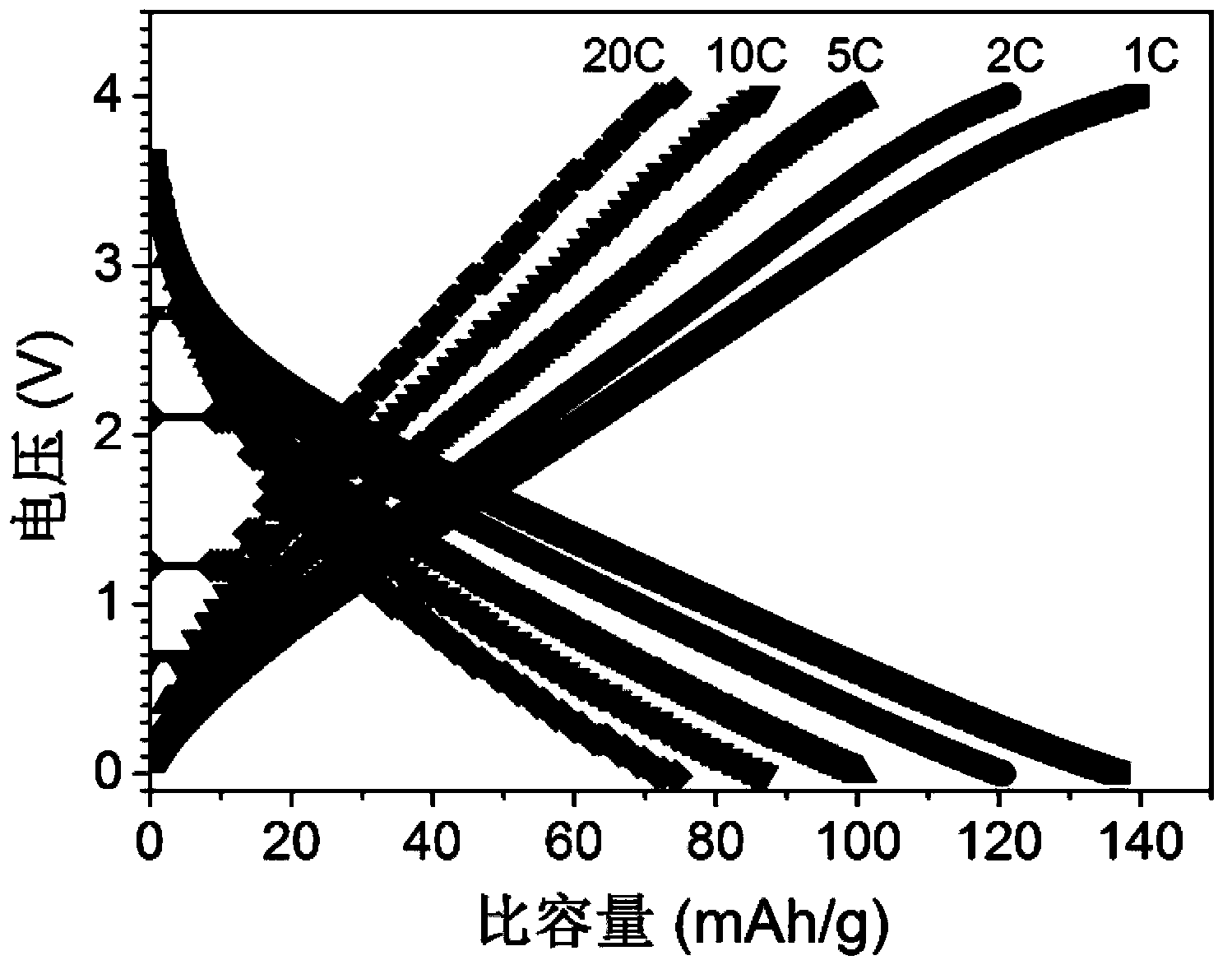

[0034] Multi-walled carbon nanotubes (diameter 2 / g, oxygen content 4.5at%) were made into positive and negative electrode sheets, and the two graphene electrode sheets were electrochemically pre-inserted with lithium. The positive electrode sheet is discharged at a constant current to 1.12V relative to the metal lithium and the pressure is maintained for more than 12 hours; the negative electrode sheet is charged and discharged at a constant current cycle at 0.01~1.12V relative to the metal lithium until the charge and discharge capacity remains stable, and finally discharge at a constant current To the vicinity of 1.12V relative to lithium metal and hold the pressure for more than 12 hours. The positive and negative electrode sheets with pre-inserted lithium are assembled into a sandwich structure lithium ion supercapacitor.

[0035] Such as Figure 4 The constant current charging and discharging curves of the multi-wall carbon nanotube-based lithium ion supercapacitor shown at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com