Lithium ion battery cathode material embedded nano metal loaded carbon nanosheet as well as preparation method and application thereof

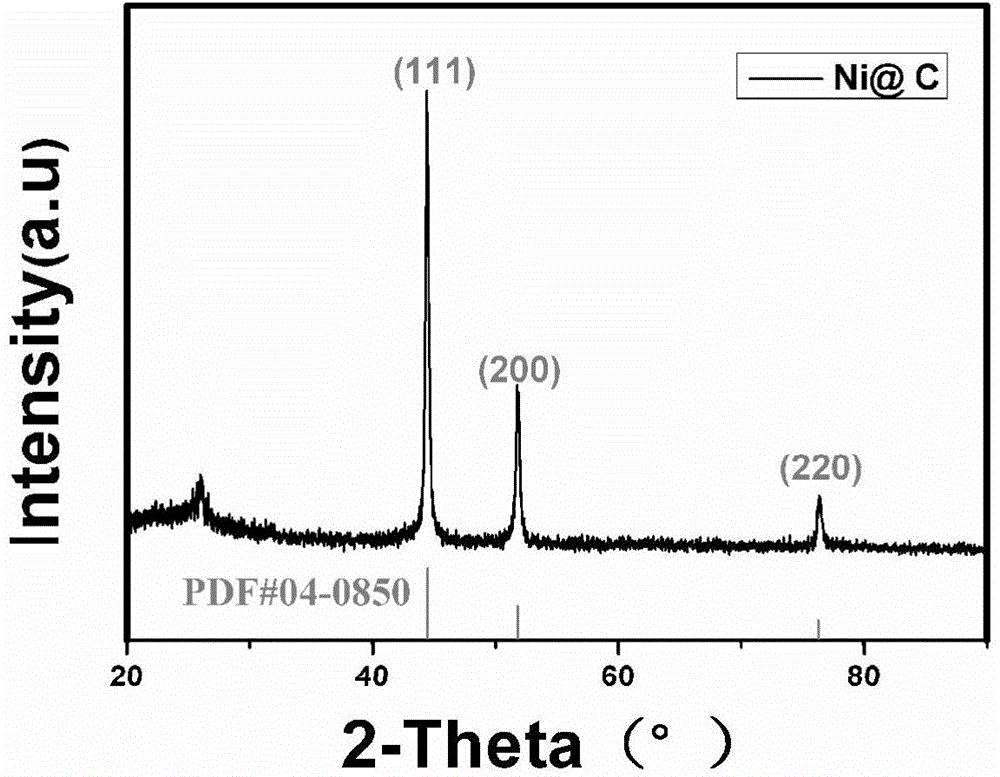

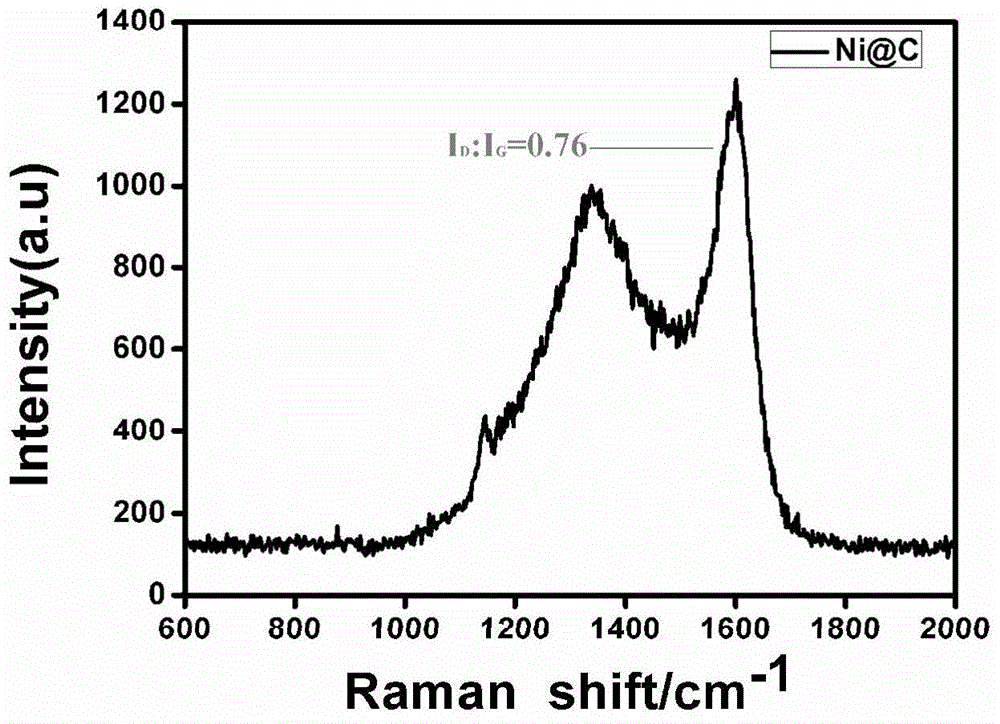

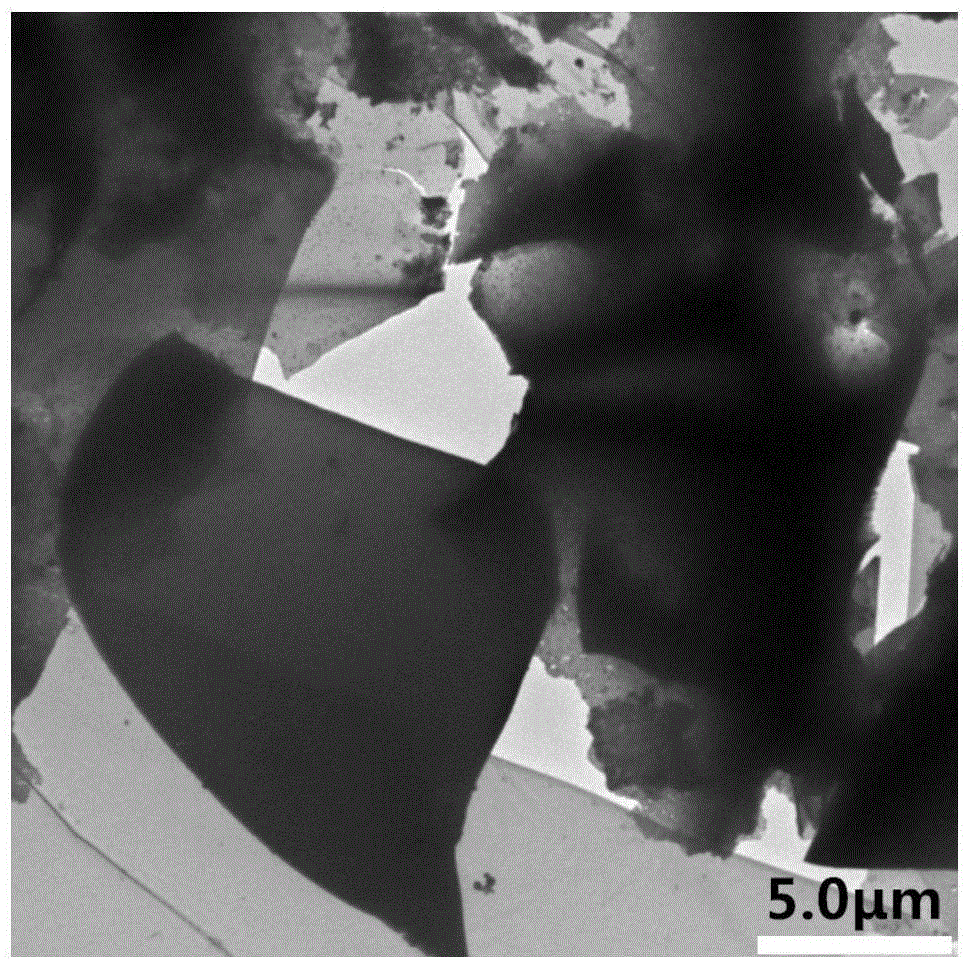

A lithium-ion battery and nano-metal technology is applied in the fields of highly graphitized carbon nanosheets, the application of lithium-ion battery anode materials, and the preparation of embedded nano-metal-supported carbon nanosheet lithium-ion battery anode materials, which can solve the problem of nickel nanosheets. The problems of large particle size, poor performance of lithium battery, and a lot of capacity drop, to achieve the effect of large specific surface area, uniform size, and abundant active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of an embedded nano-nickel loaded carbon nanosheet lithium-ion battery negative electrode material, comprising the following steps:

[0042] (1) Precursor preparation: with glucose as carbon source, nickel nitrate as metal source, and inert salt sodium chloride as template and dispersant, weigh 0.6g Ni(NO 3 ) 2 ·6H 2 O, 2.0g glucose and 5g NaCl were put into a mortar and ground for 30min, then added 7mL distilled water, stirred for 10min to make Ni(NO 3 ) 2 Dissolved with glucose, put the mixture in an oven at 40°C, and then put it into a tube furnace.

[0043] (2) Precursor pyrolysis treatment: The prepared precursor samples are evenly spread on the bottom of the corundum ark, the ark is placed in the constant temperature zone of the tube furnace, and the nitrogen gas is passed for 30 minutes to discharge the air in the tube furnace, and the nitrogen gas is continued , under nitrogen atmosphere, at 5°C.min -1 Carry out temperature programming ...

Embodiment 2

[0046] Similar to Example 1, the difference is that the preparation method of the precursor in step (1) of this example is as follows: glucose is used as the carbon source, nickel nitrate is used as the metal source, and the inert salt sodium chloride is used as the template and dispersant, and the 0.6g Ni(NO 3 ) 2 ·6H 2 O, 2.0g glucose and 7g NaCl were put into a mortar and ground for 30min, then added 7mL distilled water, stirred for 10min to make Ni(NO 3 ) 2 Dissolved with glucose, put the mixture in an oven at 40°C, and then put it into a tube furnace.

Embodiment 3

[0048] Similar to Example 1, the difference lies in the step (1) precursor preparation method of this example, specifically: glucose is used as the carbon source, nickel nitrate is used as the metal source, and the inert salt sodium chloride is used as the template and dispersant, called Take 0.6g Ni(NO 3 ) 2 ·6H 2 O, 2.0g glucose and 10g NaCl were put into a mortar and ground for 30min, then added 7mL distilled water, stirred for 10min to make Ni(NO 3 ) 2 Dissolved with glucose, put the mixture in an oven at 40°C, and then put it into a tube furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com