Patents

Literature

502results about How to "High degree of graphitization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing non-metallic element doped carbon coated metal nanoparticle magnetic composite

ActiveCN105478755AGood dispersionHigh purityTransportation and packagingMetal-working apparatusDispersityCyanamide compound

The invention discloses a method for preparing a non-metallic element doped carbon coated metal nanoparticle magnetic composite. The method comprises the steps that water-soluble metal divalent salt, a cyanamide compound and a nitrogen or boron or sulfur containing non-metallic compound are added into a methanol solution to be mixed, dissolved, dried and ground, and obtained homogeneous-phase powder is subjected to roasting pyrolysis under the protection of inert gas; and a pyrolysis product is subjected to acid pickling, washing, drying and grinding, and a target product is obtained. According to the whole preparing process of the method, metal ion reduction, metal nanoparticle coating and doping of nitrogen / boron / sulfur and other non-metallic elements are achieved in one step. The composite prepared through the method is high in degree of graphitization, good in dispersity between particles and high in purity, and the preparing method has the advantages that the cost is low, the process is simple, and large-quantity synthesis can be easily achieved.

Owner:合肥庐阳科技创新集团有限公司

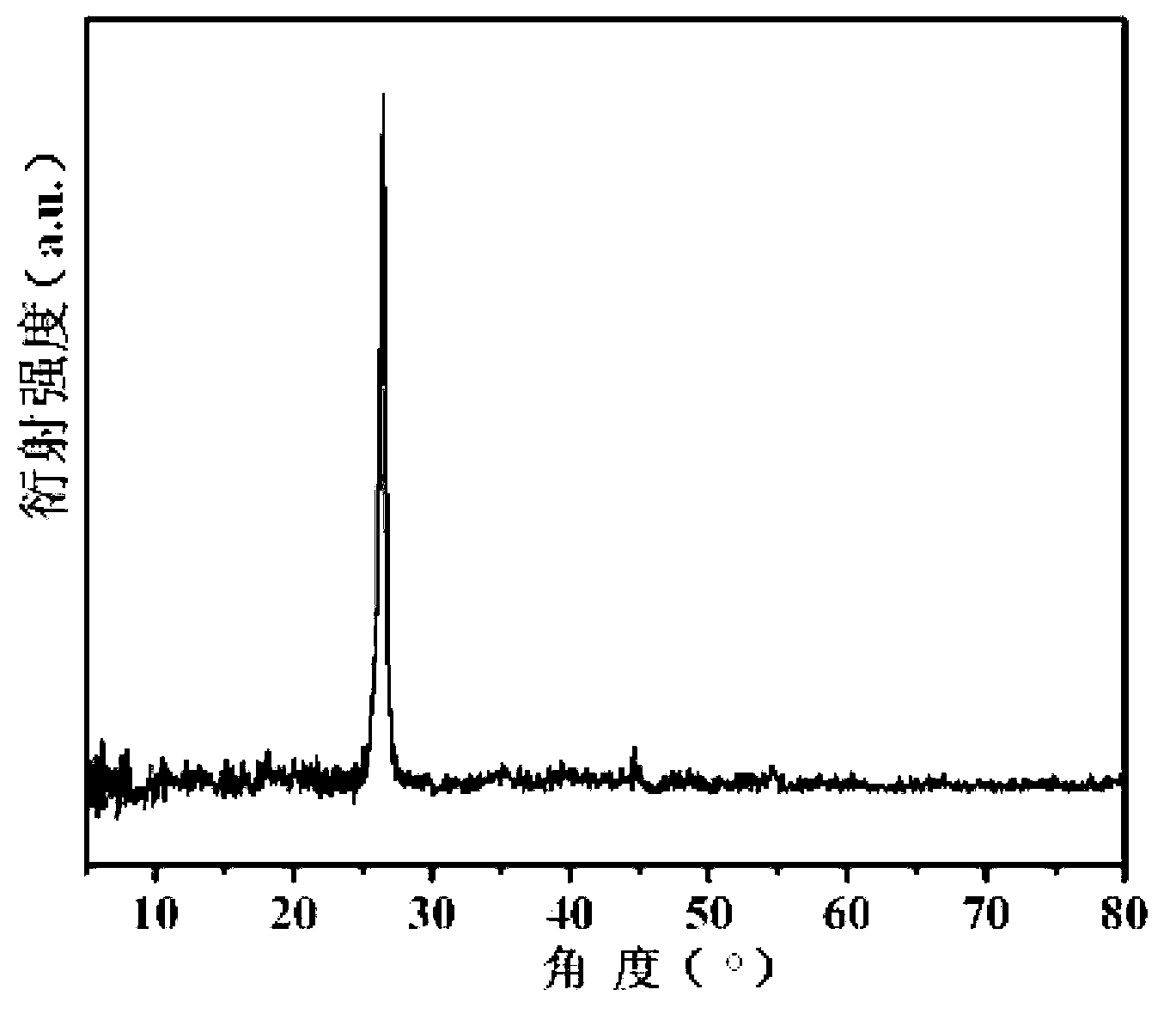

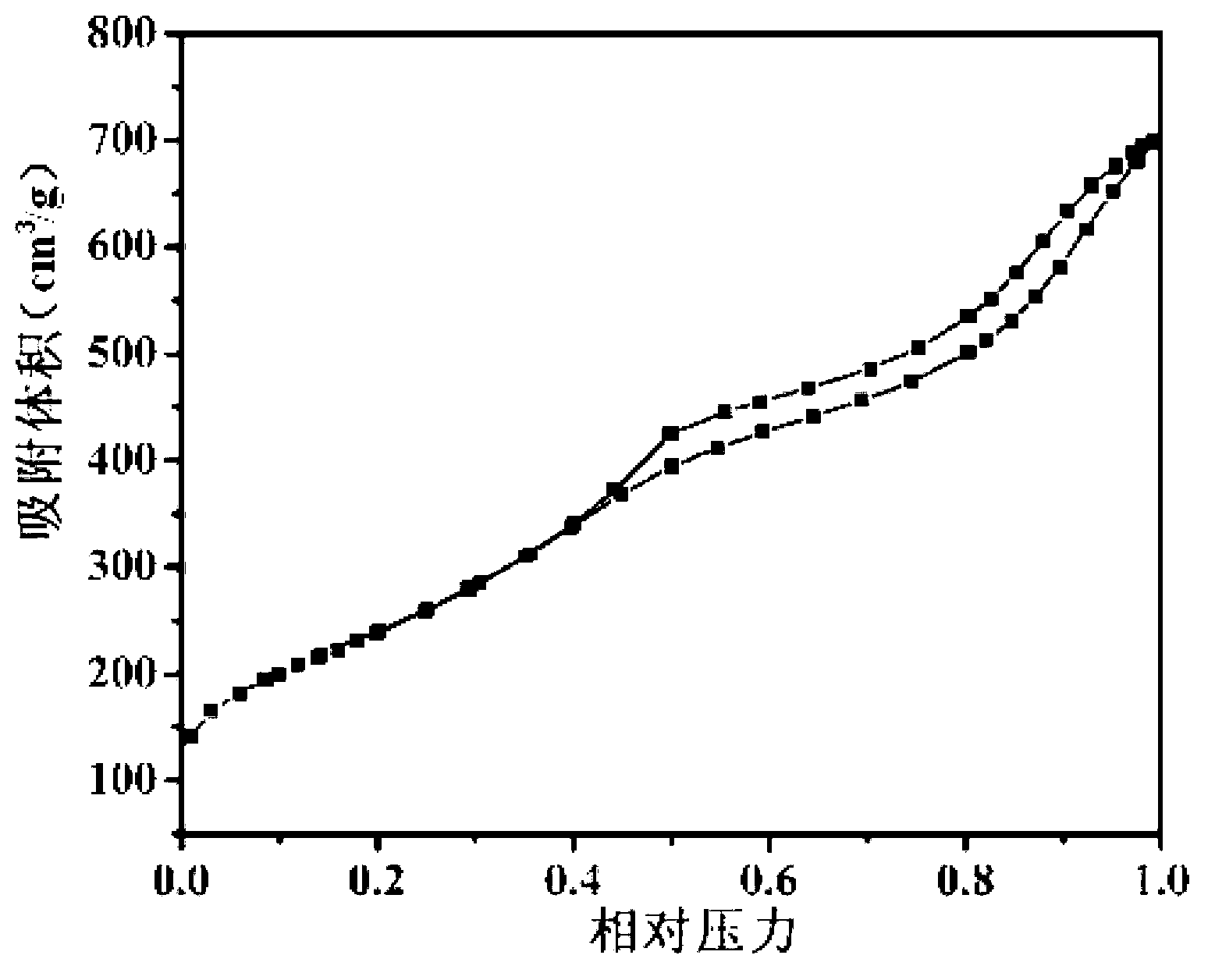

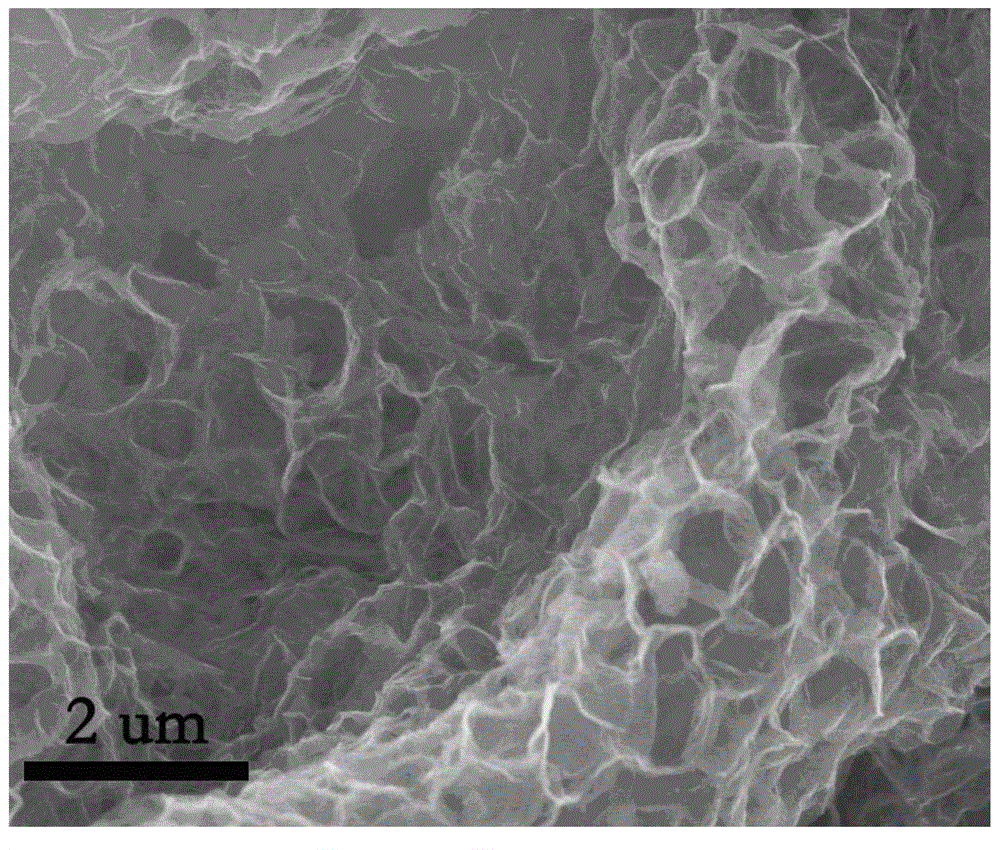

Preparation method of high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial

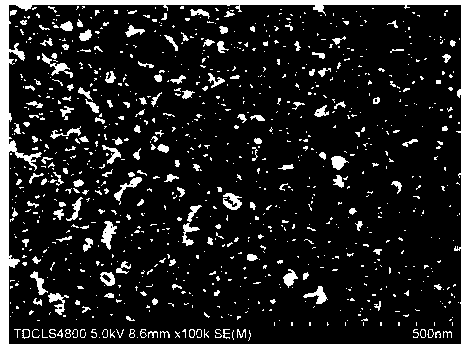

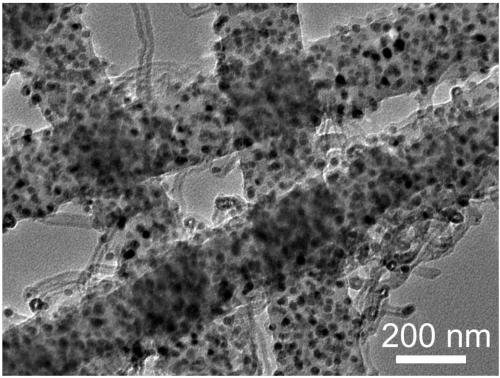

ActiveCN103303912AAchieve preparationHigh degree of graphitizationMaterial nanotechnologyNano-carbonLow nitrogenPore diameter

The invention discloses a preparation method of a high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial, relating to a preparation method of a carbon material and aiming at solving the problems of small specific surface area, low nitrogen content, low productivity, poor graphitizing degree and high cost of the nitrogen-doped graphitizing carbon nanomaterial prepared by the prior art. The preparation method comprises the steps of: I. preparing a complex; II. curing and carbonizing the complex; and III. carrying out acid leaching method treatment, and drying. Compared with an existing nitrogen-doped graphitizing carbon nanomaterial, the prepared high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial has the advantages that the graphitizing degree is improved, the nitrogen content is increased, and the specific surface area is obviously increased, and the high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial has obvious pore diameter distribution. The preparation method is used for preparing the high-specific-surface-area porous nitrogen-doped graphitizing carbon nanomaterial.

Owner:HEILONGJIANG UNIV

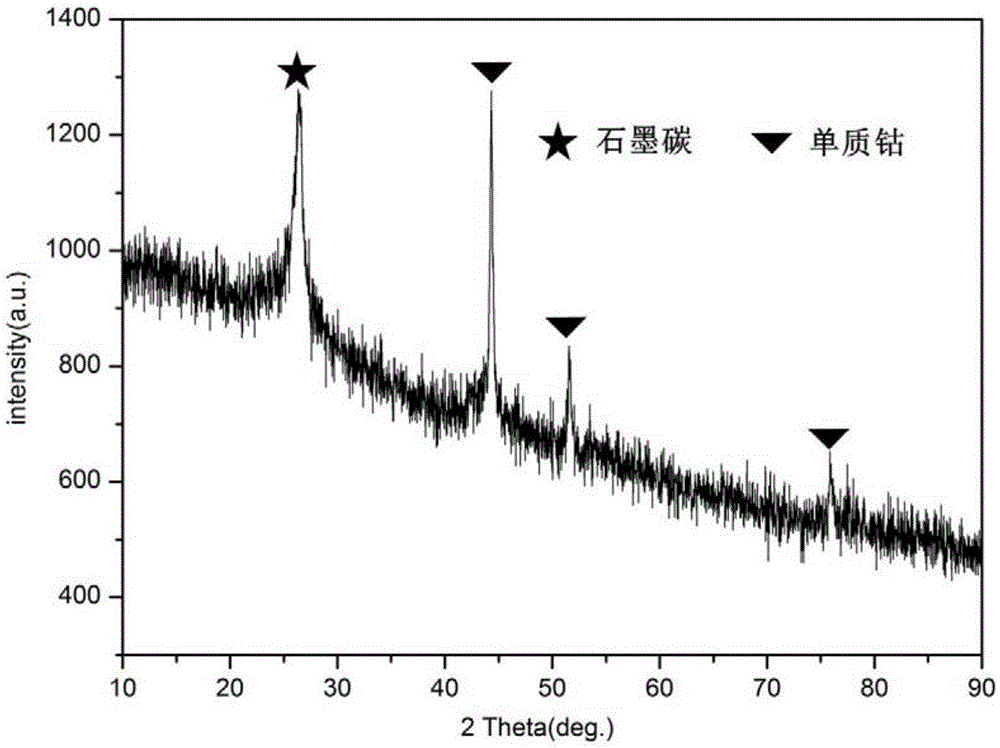

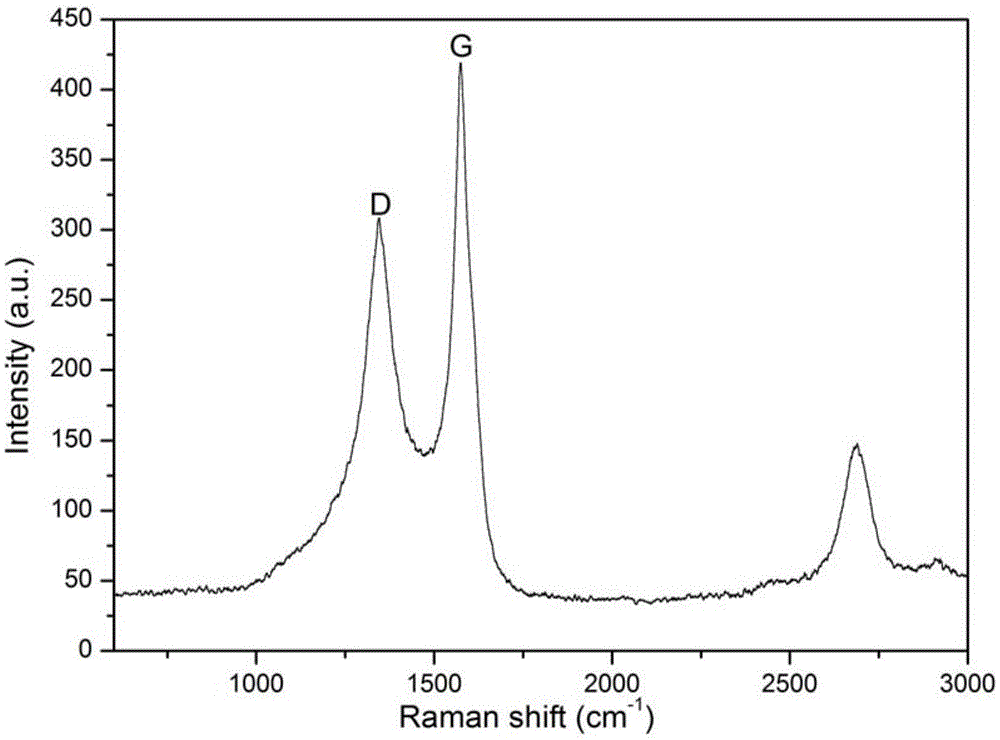

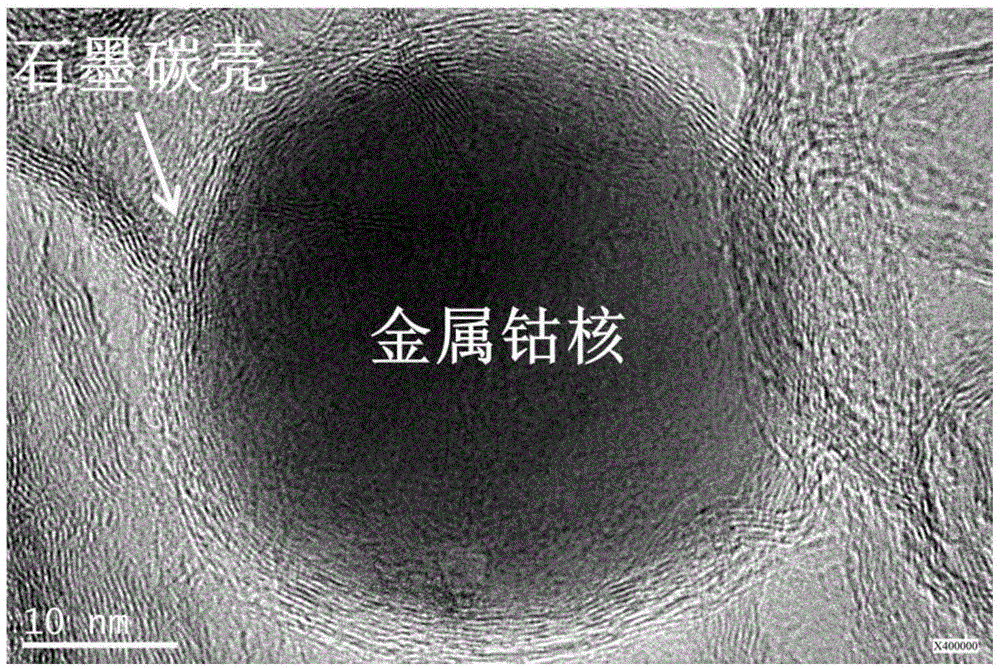

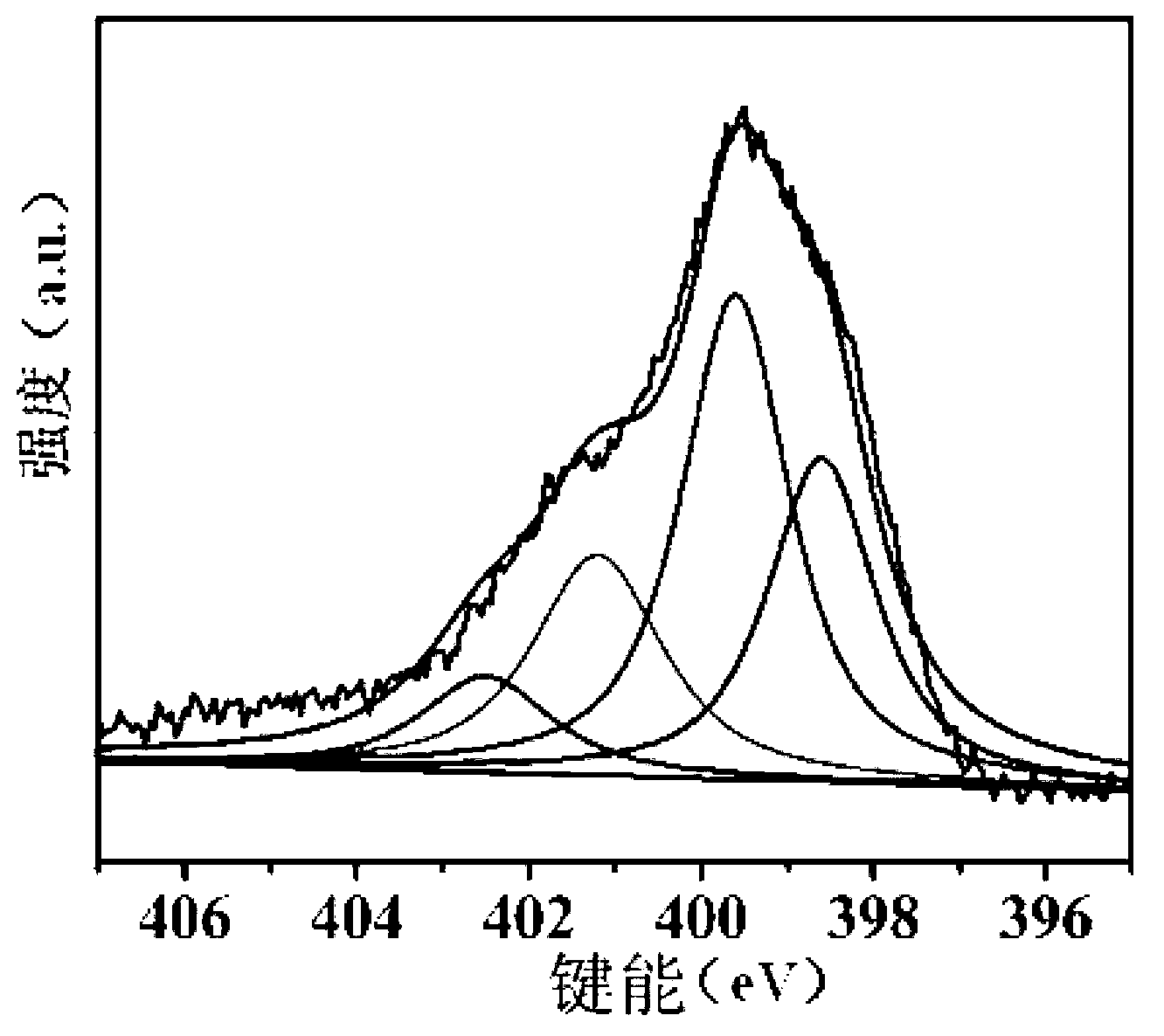

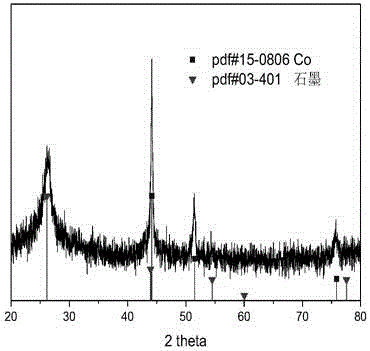

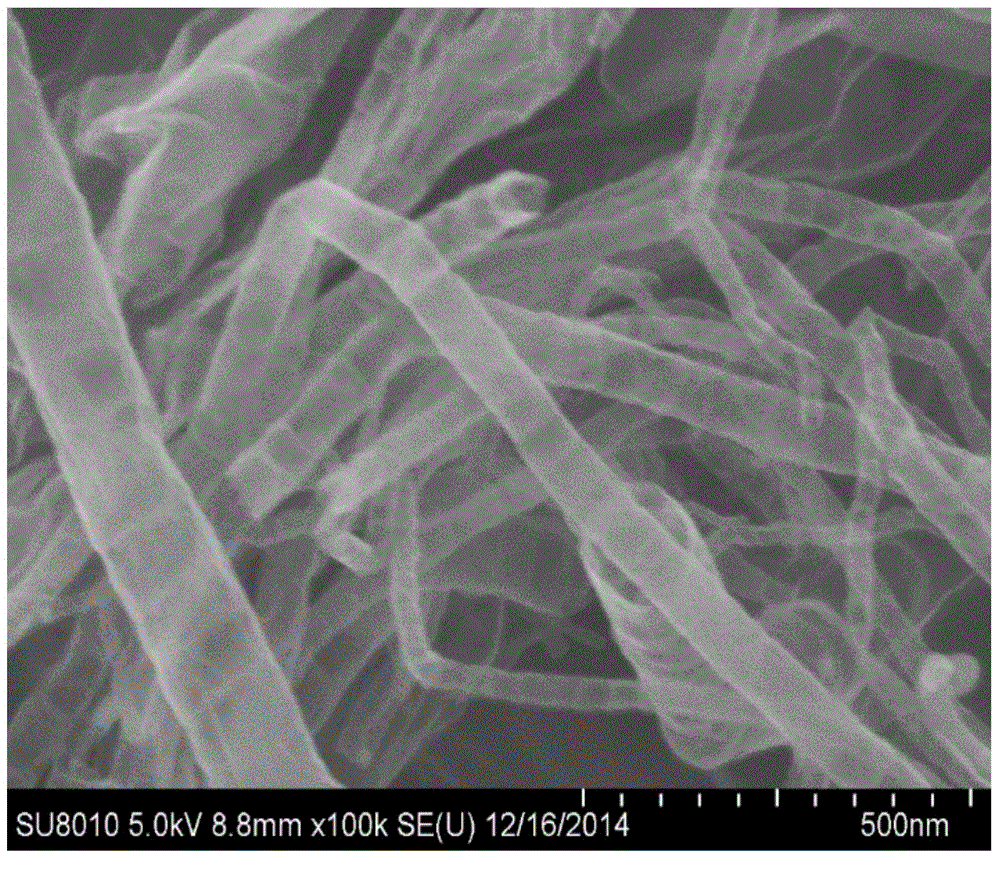

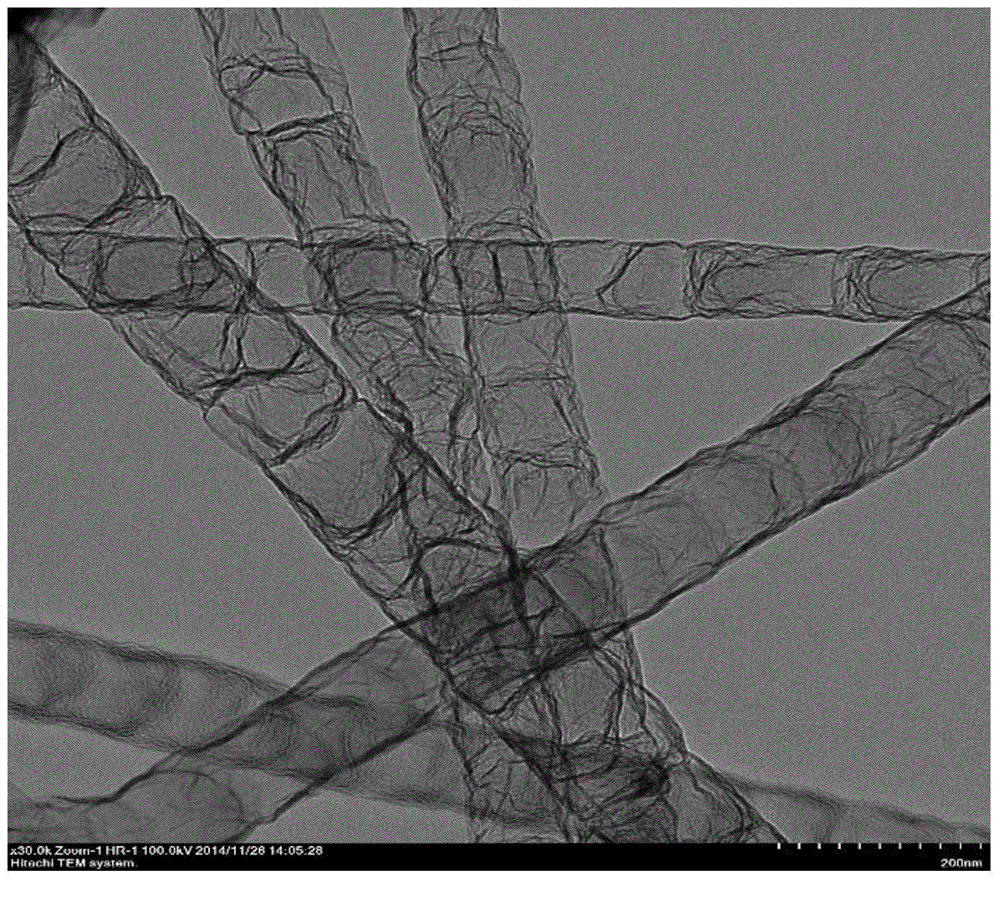

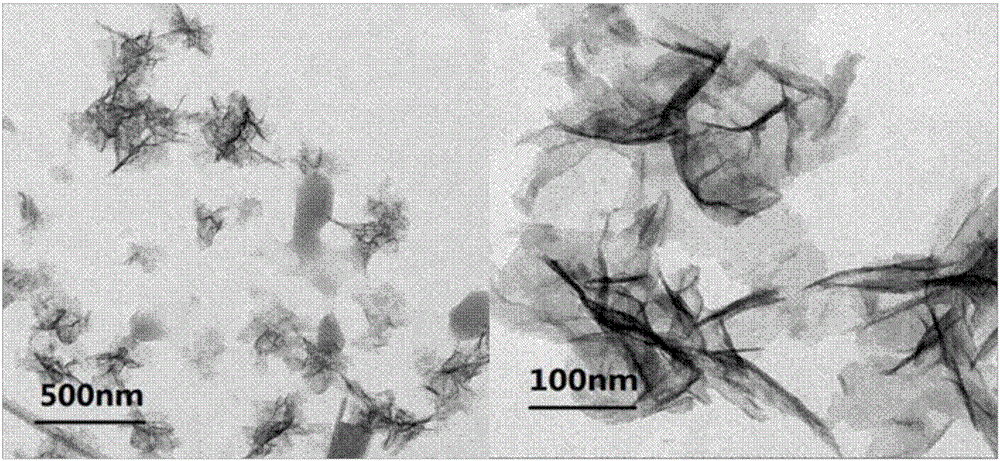

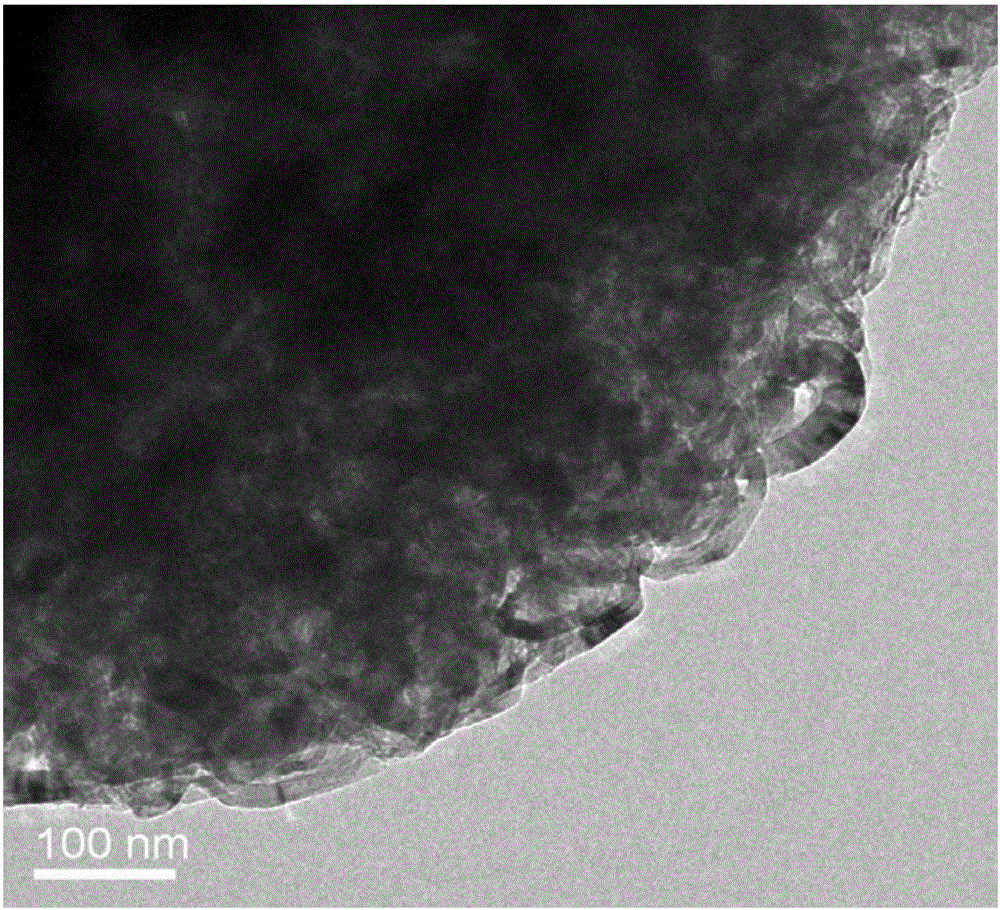

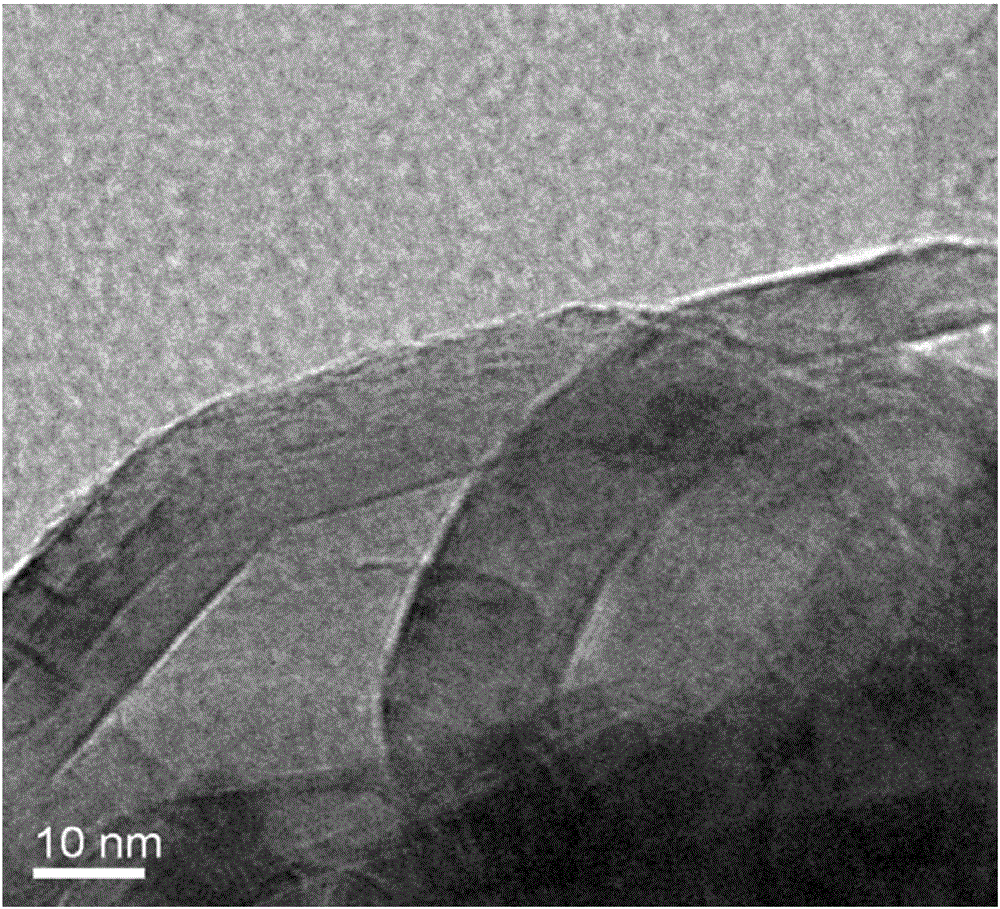

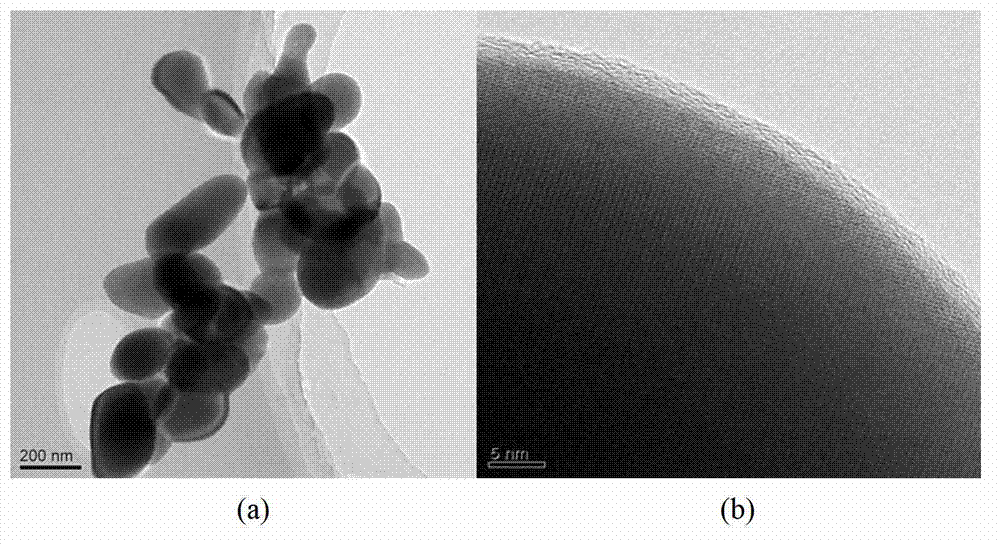

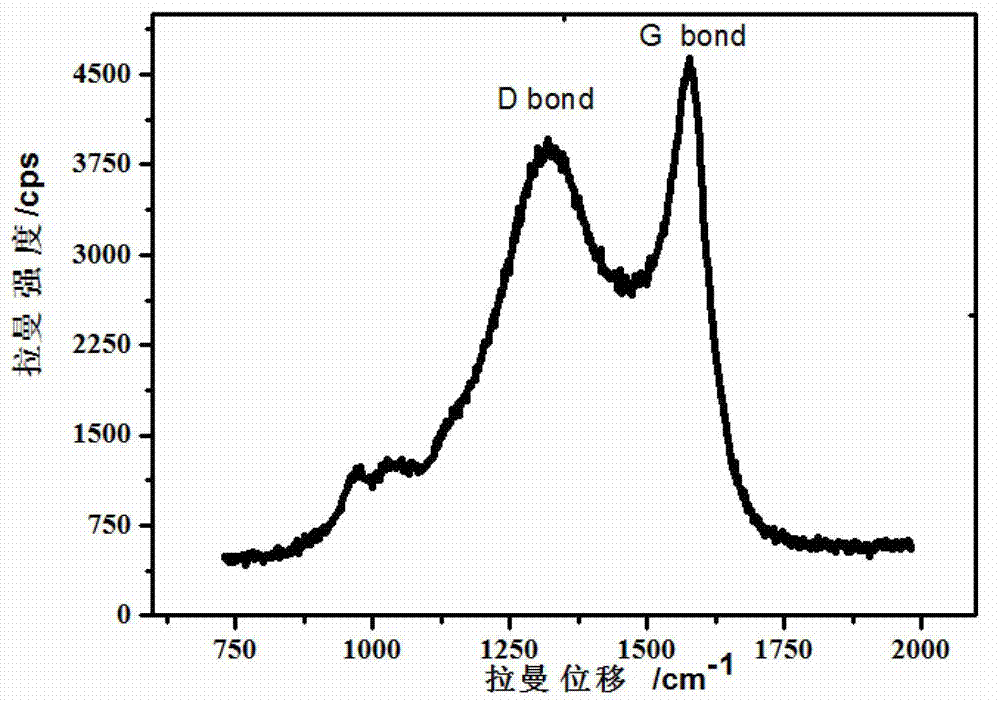

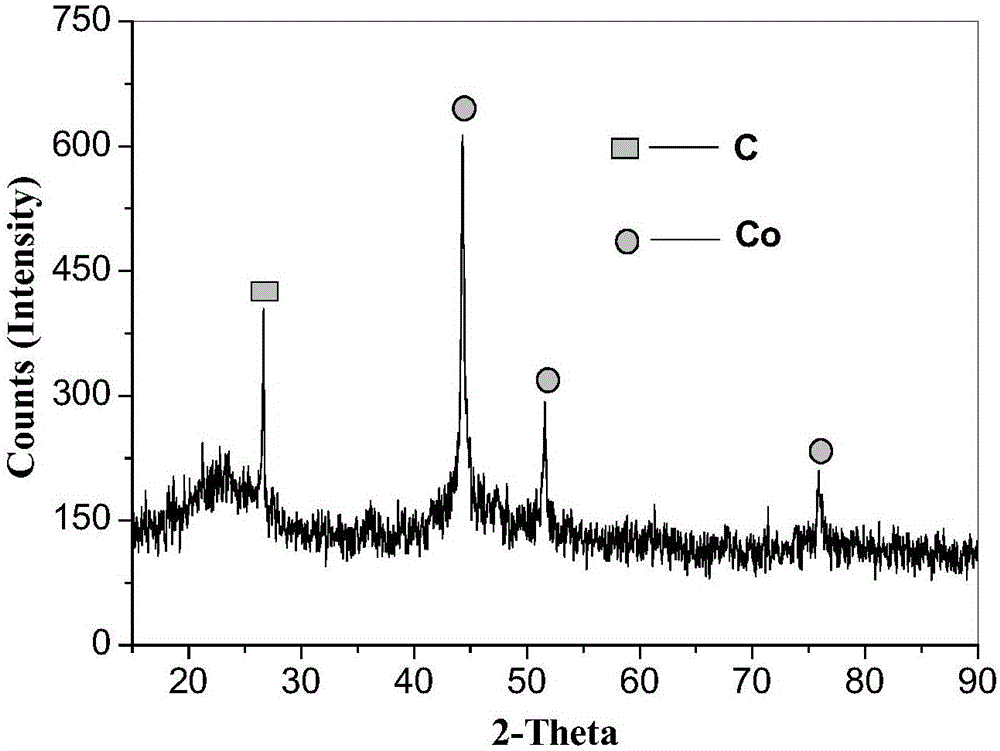

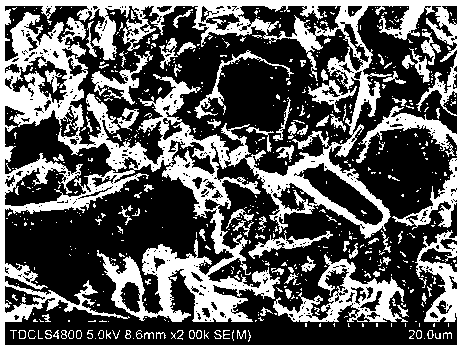

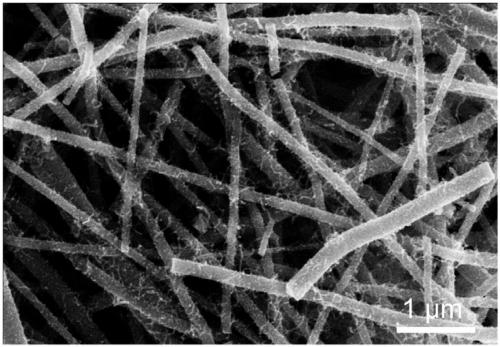

Method for synthesis of cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material

The invention discloses a method for synthesis of a cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The method includes: dissolving a soluble cobalt salt and an amine polymer in a hydrophilic reagent according to a mole ratio of 1:(2-200), performing evaporation at 60DEG C, conducting grinding after cooling, performing calcination at 400-1400DEG C under nitrogen atmosphere, then treating the sample with acid, and carrying out washing, centrifugation and drying so as to obtain the cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The obtained cobalt nanoparticles have small particle size and are employed to coat the head of a carbon nanotube evenly so as to combine tightly with the carbon nanotube. The composite material has application prospects in fuel cell anode materials, lithium ion battery cathode materials and the like. The method designed by the invention has the advantages of easily available raw materials, simple process and no pollution, short preparation period, mild reaction conditions, low cost, and mass synthesis capability, etc.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

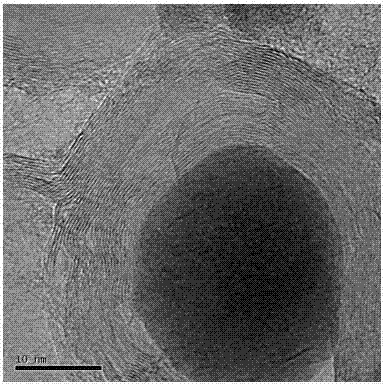

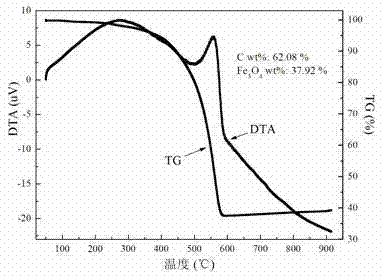

Carbon cladded ferriferrous oxide negative electrode material of lithium ion battery and preparation method thereof

InactiveCN102790217AHigh degree of graphitizationLarge specific surface areaCell electrodesSolid carbonButton battery

The invention discloses a carbon cladded ferriferrous oxide negative electrode material of a lithium ion battery and a preparation method thereof. The negative electrode material is a carbon cladded Fe3O4 composite material and has a particle size in a range of 1 to 100 nm. The preparation method comprises the following steps: with NaCl used as a dispersing agent and a supporter, fully mixing NaCl with a metal oxide source and a solid carbon source; drying an obtained mixed solution under vacuum to obtain a mixture; placing the mixture into a tubular furnace for calcination in an inert atmosphere so as to obtain a calcined product; and rinsing and grinding the calcined product to obtain carbon cladded metal oxide nanometer particles. The method is safe and non-toxic and is simple to operate; during charging and discharging tests of a lithium ion button cell made of the carbon cladded ferriferrous oxide negative electrode material, discharge specific capacity can be maintained at 620 to 900 mAh / g after 30 cycles of charging and discharging at a current of 0.1C (with current density being 92 mA / g), and discharge specific capacity can be maintained at 600 to 760 mAh / g after 50 cycles of charging and discharging at a current of 1C (with current density being 920 mA / g); and the negative electrode material of the lithium ion battery has high reversible capacity and good cycling stability.

Owner:TIANJIN UNIV

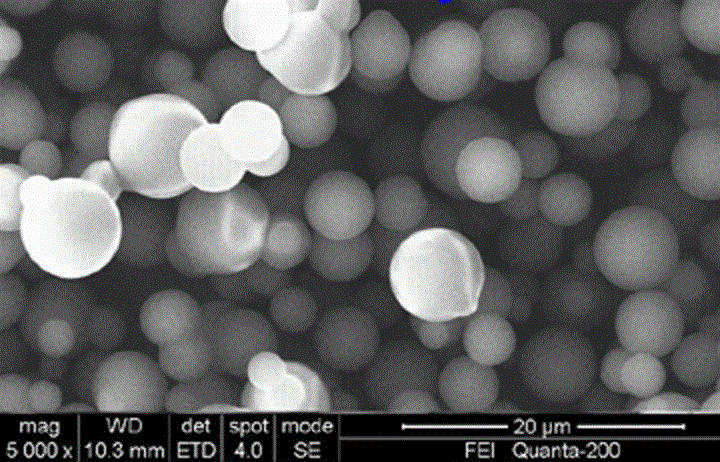

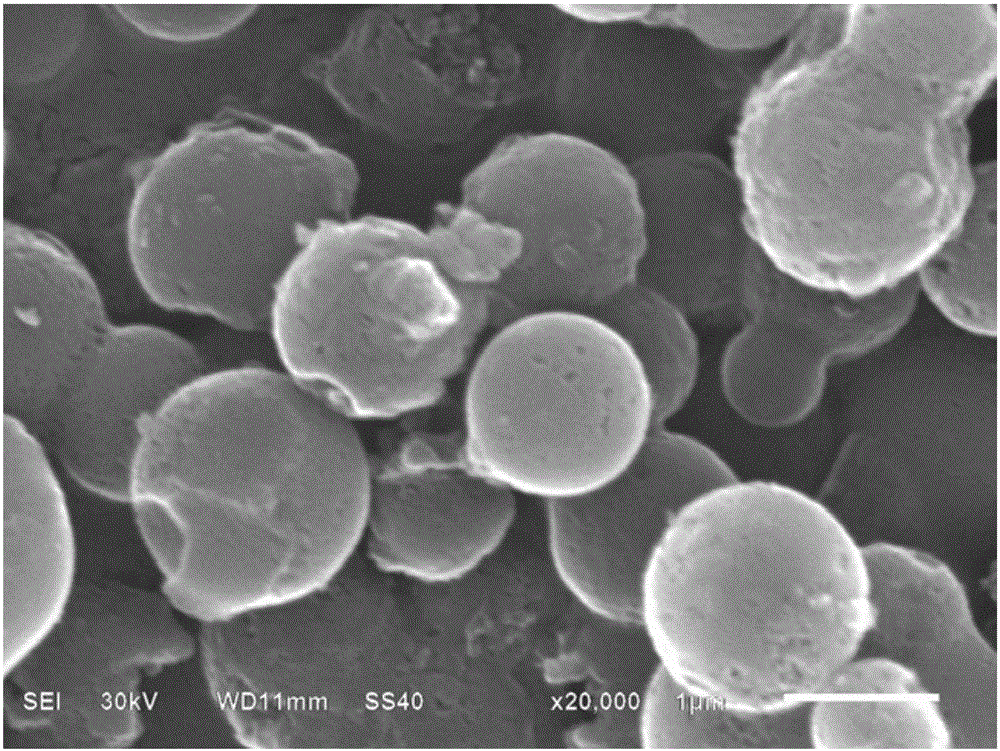

Low temperature hydrothermal preparation method of biomass carbon microsphere / nanosphere

InactiveCN104649246ALow hydrothermal carbonization temperatureImprove securityMaterial nanotechnologyBiomass carbonPtru catalyst

The invention discloses a low temperature hydrothermal preparation method of alkali catalysis or Lewis acid / proton acid catalysis biomass. The method is as below: adding a certain amount of biomass, deionized water and a proper amount of alkali or Lewis acid / protonic acid into carbide carbon of biomass to a teflon inner liner, stirring to dissolve soluble biomass, filling into a stainless steel reaction kettle, and placing in an oven and reacting for a while at preset temperature, and reacting insoluble biomass in a device equipped with a heating sleeve and a thermostat magnetic stirrer under the preset temperature, wherein the reaction conditions are as below: temperature of 110-160 DEG C (preferably 120-140 DEG C) and reaction time of 6-72 h (preferably 12-36 h); naturally cooling to room temperature, conducting high speed centrifugal separation, and re-dispersing and repeatedly washing the obtained solid with deionized water and 95% ethanol to obtain a colorless supernatant, and drying to obtain carbon microsphere / nanosphere. The method provided by the invention has the advantages of low hydrothermal carbonation temperature and high carbon production rate of the biomass, and is applicable to large-scale industrial production; and the product can be used as a catalyst carrier or adsorbent.

Owner:HUNAN NORMAL UNIVERSITY

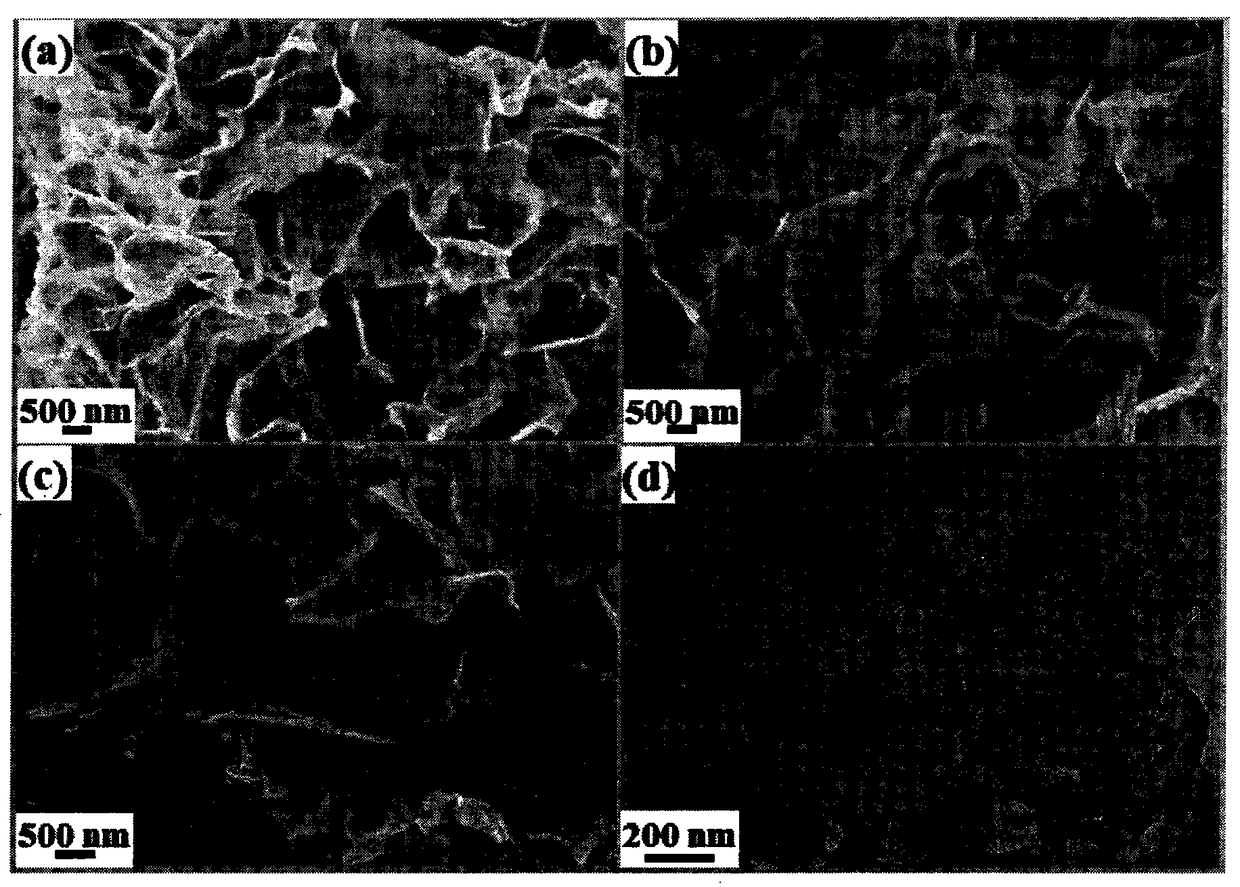

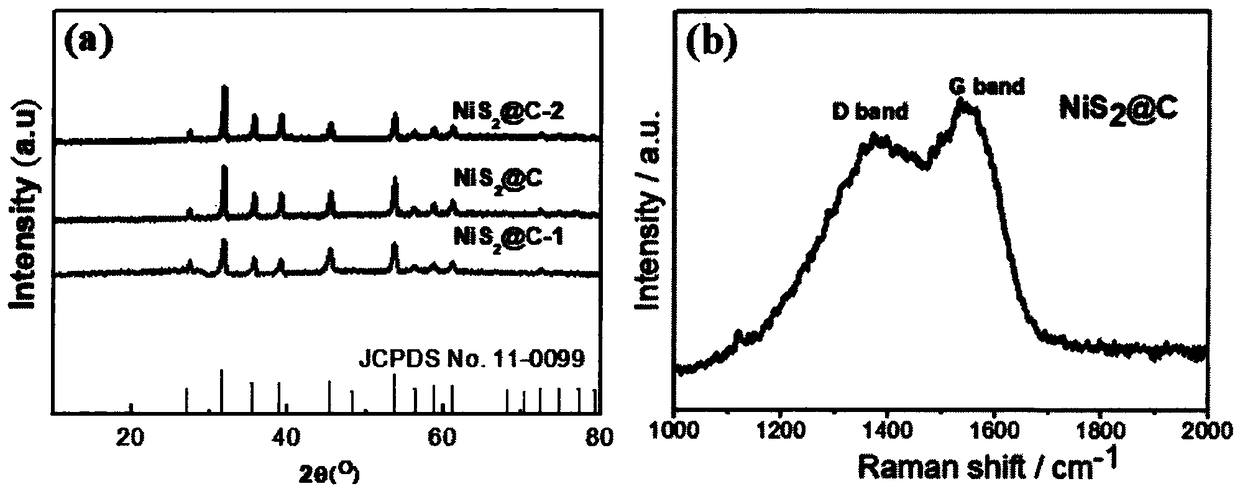

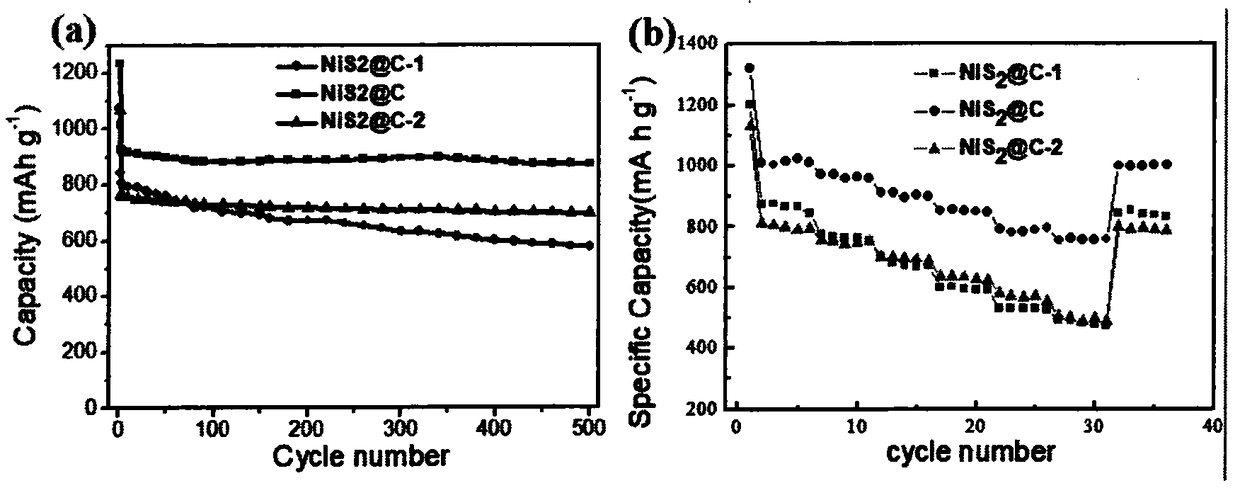

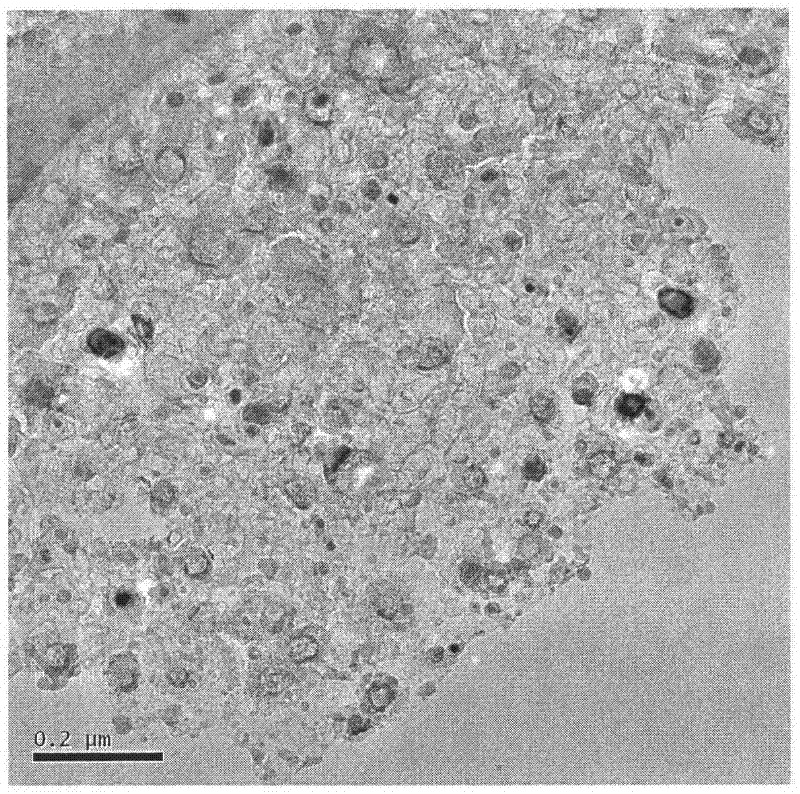

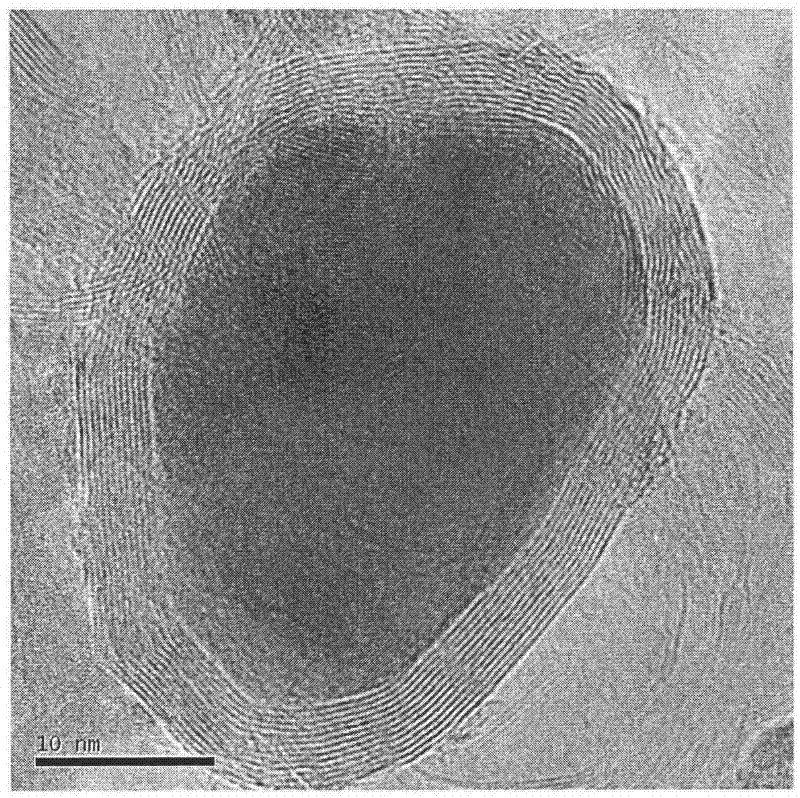

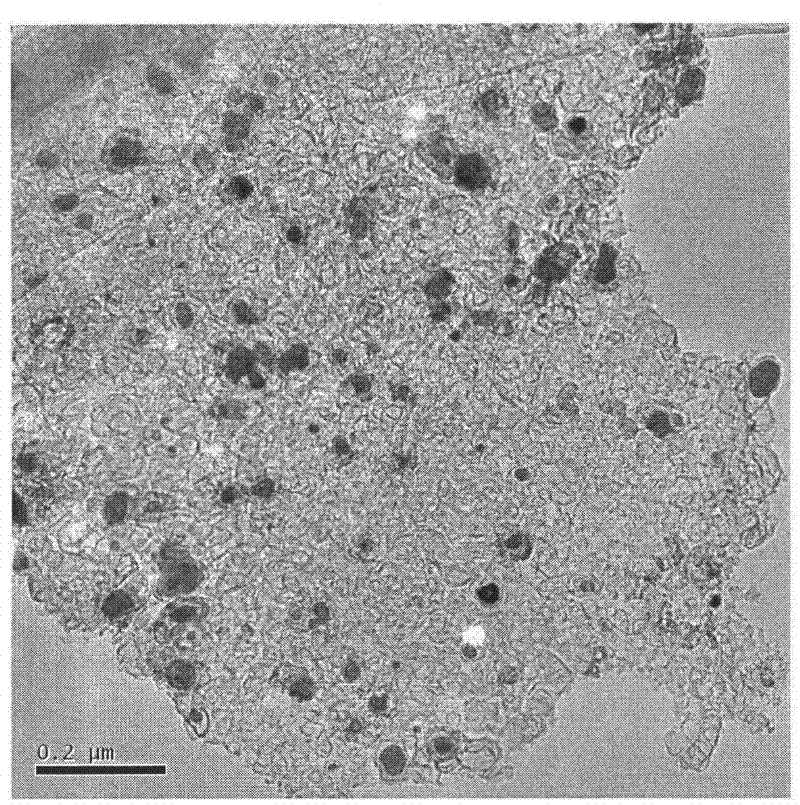

Nickel disulfide carbon nano composite material and preparation method and application thereof

InactiveCN108832097AGood biocompatibilityStrong adhesionMaterial nanotechnologyHybrid capacitor electrodesCarbon compositesCarbon layer

The invention relates to a nickel disulfide carbon nano composite material and a preparation method and an application thereof, wherein the composite material is formed by coating a nickel disulfide nanosheet with a carbon layer. The preparation method comprises the following steps of preparing a nickel hydroxide nanosheet precursor by a hydrothermal method, performing magnetic stirring and dispersing in deionized water to obtain a uniform dispersion liquid of the nickel hydroxide nanosheet precursor, adding a buffering agent tris(hydroxymethyl) aminomethane hydrochloride, and adjusting the pHvalue to be 8.5 by adopting an alkali solution with the pH value of 13, adding dopamine hydrochloride, and magnetically stirring at room temperature for in-situ polymerization, and carrying out washing and centrifugally drying to obtain a nickel hydroxide nanosheet precursor / polydopamine composite material, and carrying out heat treatment and vulcanization with sublimed sulfur powder in a tubularfurnace in nitrogen atmosphere at a certain temperature to obtain the composite material. The preparation process is simple, easy to operate, green and non-toxic and friendly in material preparationprocess; and the prepared nickel disulfide carbon nano composite material is stable in structure, uniform in morphology and high in dispersion. The obtained nickel disulfide carbon nano composite material can be an ideal electrode material of a high-performance lithium ion battery, a supercapacitor and other new energy devices.

Owner:DONGHUA UNIV

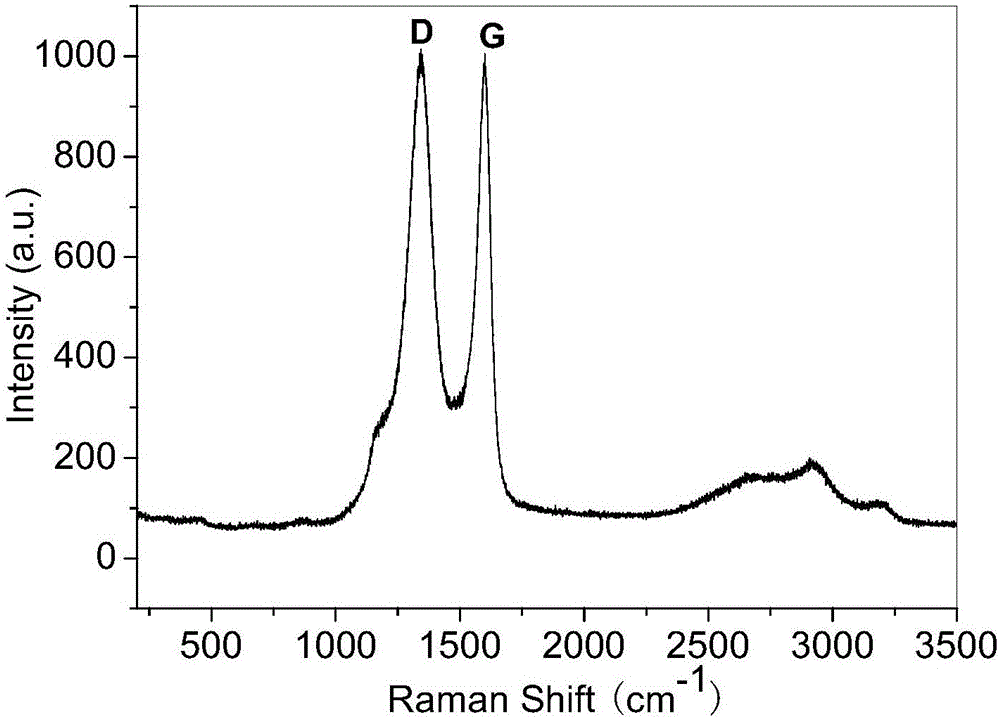

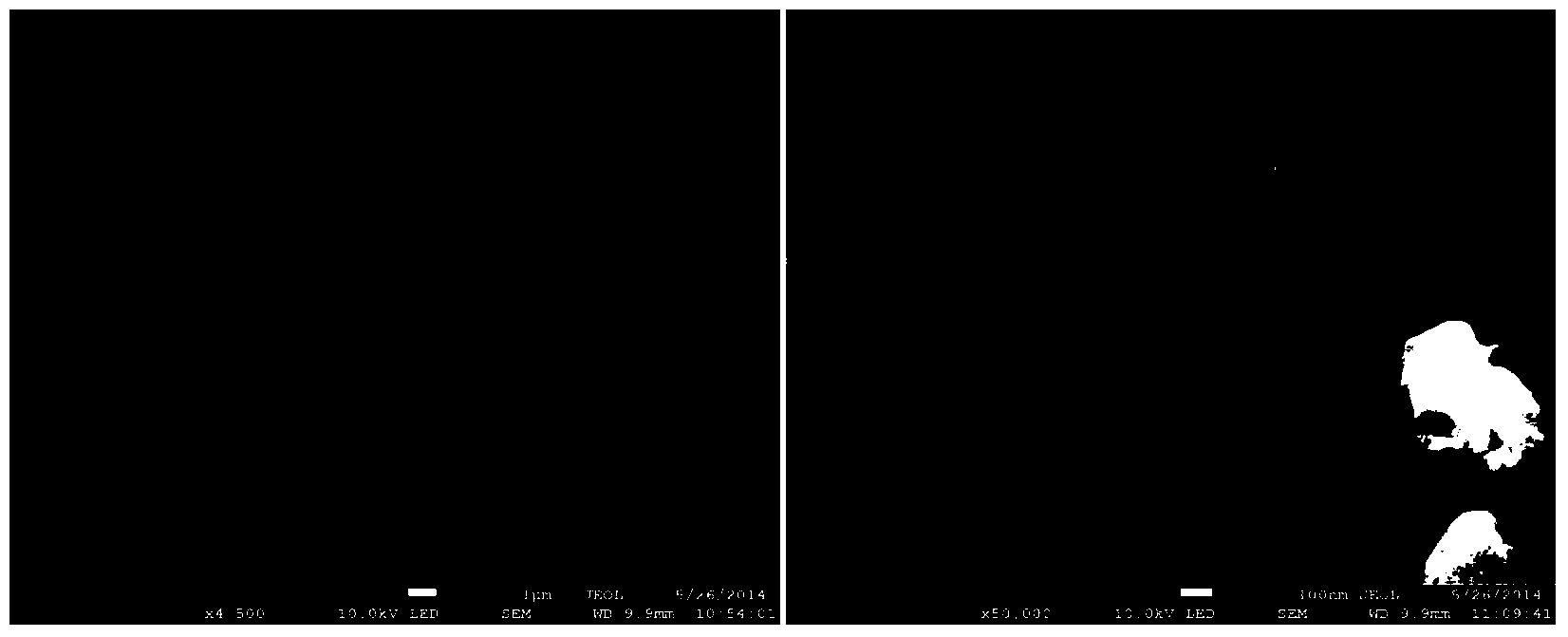

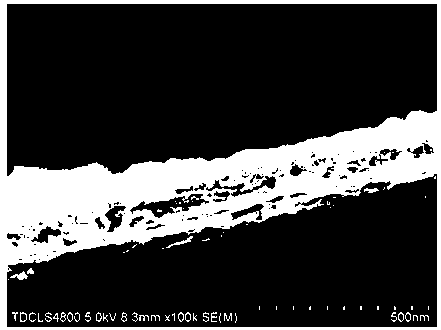

Preparation method of carbon-coated metallic nano-particles

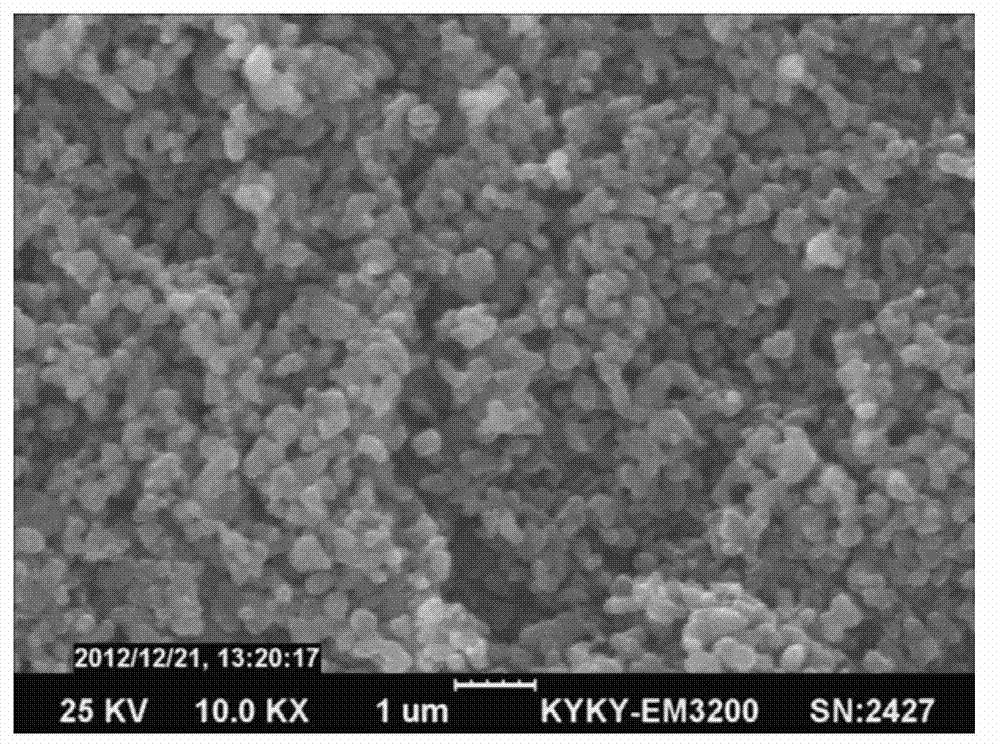

InactiveCN102500295AEasy to operateHigh degree of graphitizationMicroballoon preparationMicrocapsule preparationTube furnaceCarbon coated

The invention discloses a preparation method of carbon-coated metallic nano-particles, which comprises the steps that: NaCl serves as dispersant and a carrier, and is fully mixed with a metal source and a solid carbon source; the mixed solution is dried under a vacuum condition, and mixture is obtained; the mixture is put into a tubular furnace and calcinated in the inertial / reduction atmosphere, and a calcinated product is obtained; and the calcinated product is washed and ground, and the carbon-coated metallic nano-particles are obtained. The method is safe, non-toxic, environmental-friendly and simple to operate, so that the grain sizes of the prepared carbon-coated nano-particles are controlled to be 0nm to 100nm, the graphitization degree of a carbon layer is high, the dispersion of the particles is good, and the yield is high. The carbon-coated metallic nano-particles which are prepared through the preparation method have better magnetism and larger specific surface areas, can be used for electronic and magnetic materials, and can be used for magnetic resonance imaging, targeted drug transportation and other fields through functionalization treatment and other steps.

Owner:TIANJIN UNIV

Carbon fiber supported metal catalyst as well as preparation method and application thereof

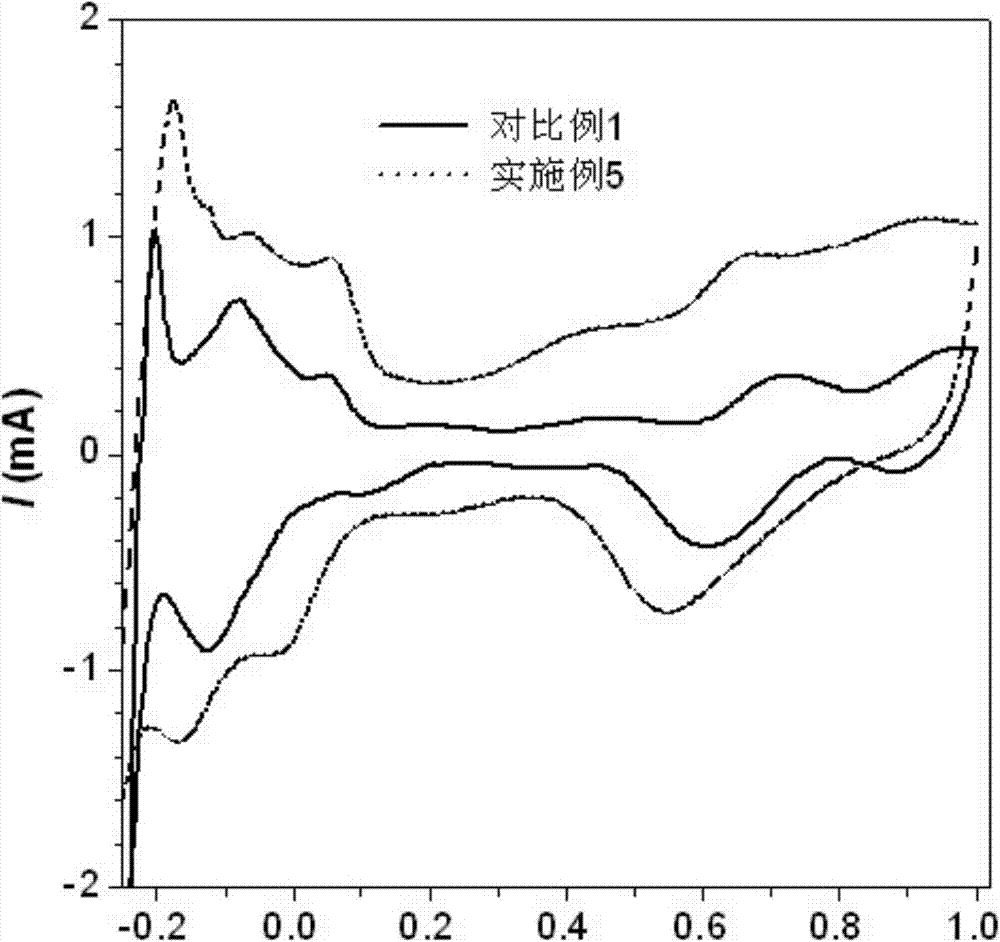

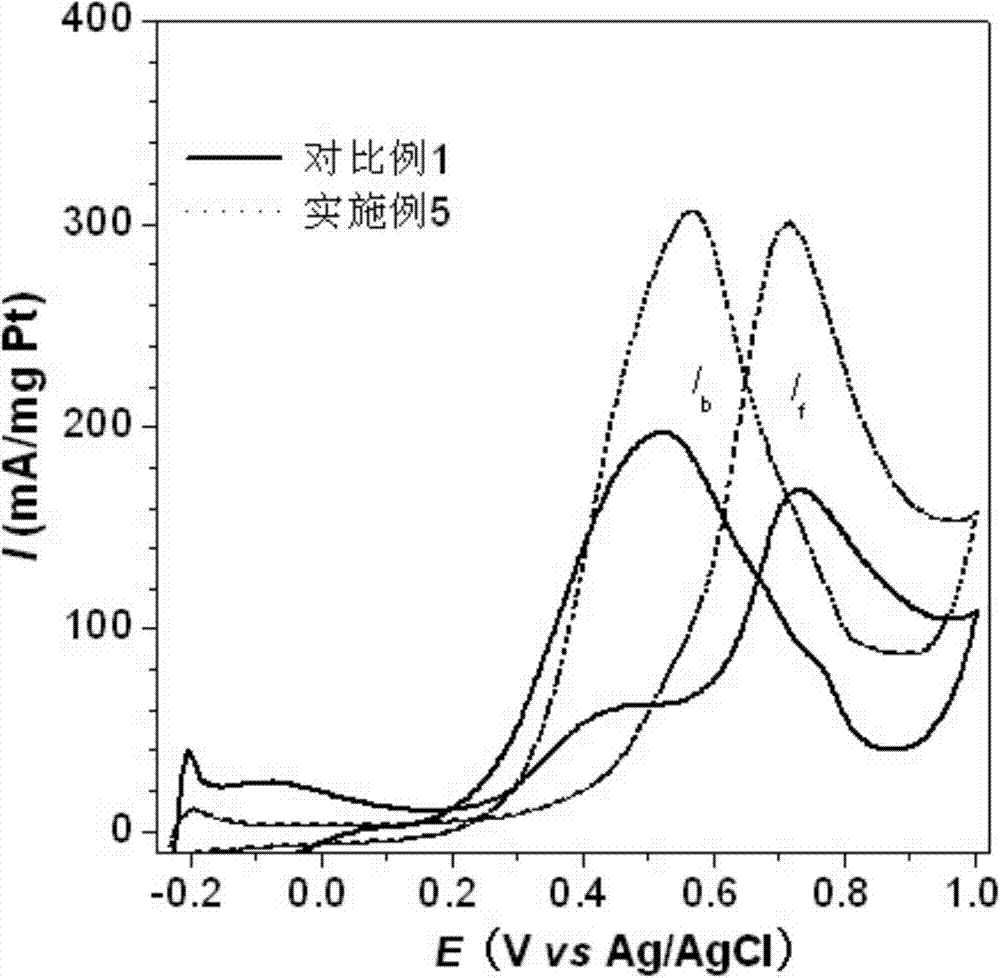

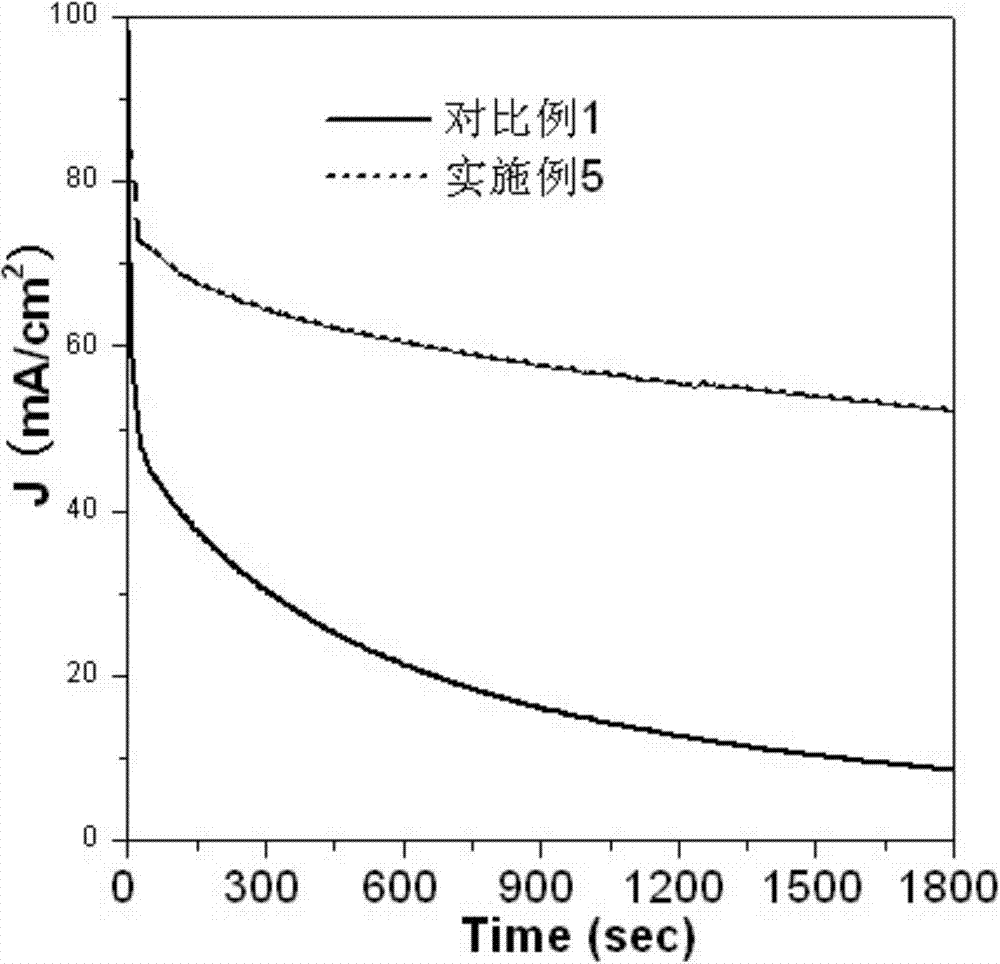

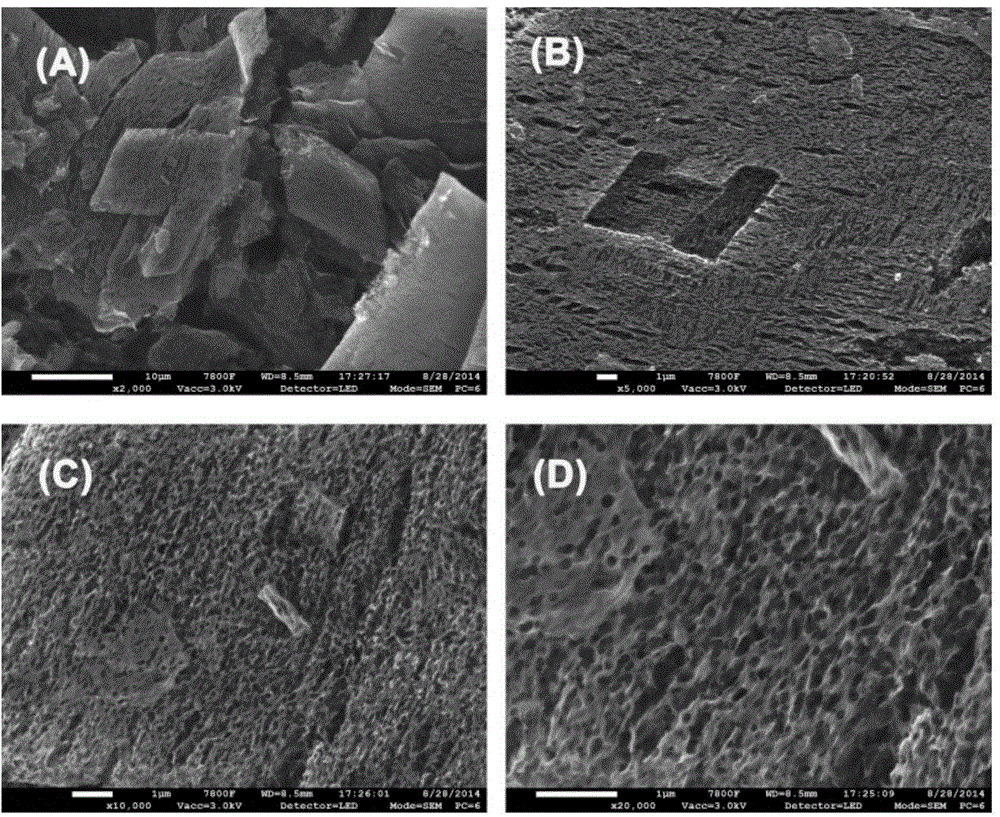

InactiveCN103545536AConducive to loadHigh catalytic activityHybrid capacitor electrodesCell electrodesFiberHigh current density

The invention relates to a carbon fiber supported metal catalyst as well as a preparation method and an application thereof. The materials such as graphene nano belt, a multi-arm carbon nano tube and graphene are adopted as graphitization template-based additives, and composite carbon fiber with high graphitization degree and high conductivity is obtained by electrostatic spinning and wet spinning processes and a high-temperature carbonization process, wherein the preferential amount of the template-based additives is 0.5-5% by weight; the high-graphitization composite carbon fiber is used as a carrier of the catalyst, and a metal / carbon nano fiber catalyst for a fuel cell is obtained by reduction; the catalyst has a large initial electrochemical-activity surface area and strong CO toxicity resistance; the current density attenuation is reduced in a 30 minutes of chronoamperometry test, and the catalyst shows higher electrochemical activity, higher current density and better electrochemical stability; and moreover, the catalyst taking the high-graphitization carbon fiber as a carrier shows remarkably high durability.

Owner:上海氢尚新能源科技有限公司

Graphitized wetable cathode carbon block for aluminium electrolysis bath and production method thereof

InactiveCN101158048AGood electrical and thermal conductivityHigh degree of graphitizationShaping pressAluminium electrolysisGraphite

The invention relates to a graphitized wettable cathode carbon block used in an aluminum electrolytic tank and a production method thereof, and is characterized in that the graphitized wettable cathode carbon block consists of a graphitized carbon block matrix and a TiB2 compound layer integrated on the matrix. The production method of the graphitized wettable cathode carbon block is characterized in that when the cathode carbon block is produced through vibration molding, the working surface of the cathode carbon block is integrated with and molded by a TiB2 compound layer; a pressing molded greed block is roasted, leached, graphitized and processed by machine and a graphitized wettable cathode carbon block is prepared. The carbon block matrix of the graphitized wettable cathode carbon block used in the aluminum electrolytic tank of the invention has good electric and heat conductivity, and the TiB2 compound layer integrated and molded on the matrix is roasted and treated by high temperature heat process, thus the compound intensity can be effectively improved, so the graphitized wettable cathode carbon block used in aluminum electrolytic tank has excellent electrolyte corrosion resistance and aluminum liquid scouring resistance as well as good electric and heat conductivity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

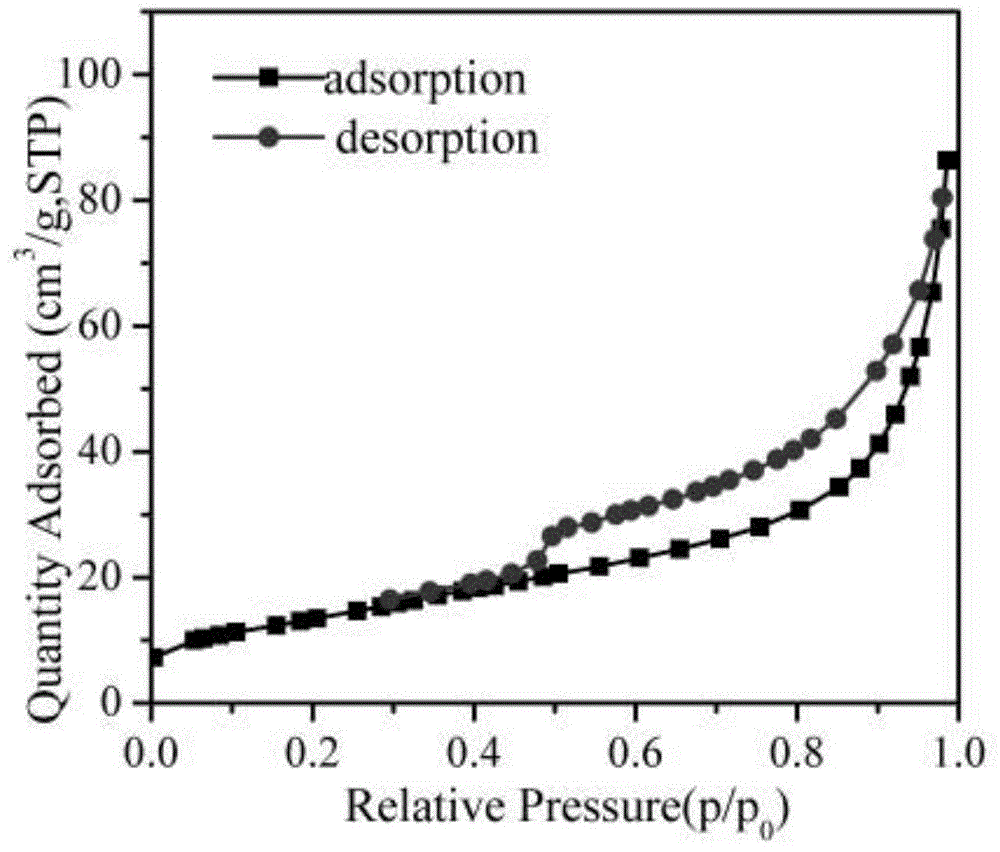

Porous carbon material and preparation and application thereof

ActiveCN105692580AImprove intrinsic performanceStable structureCarbon preparation/purificationPorous carbonIn situ polymerization

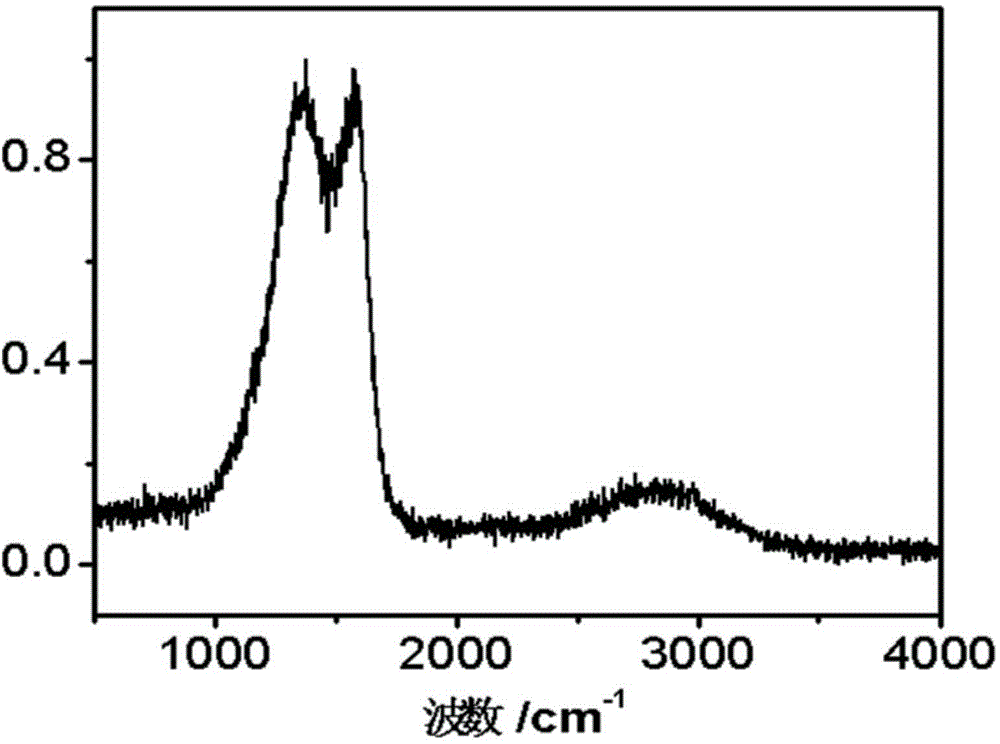

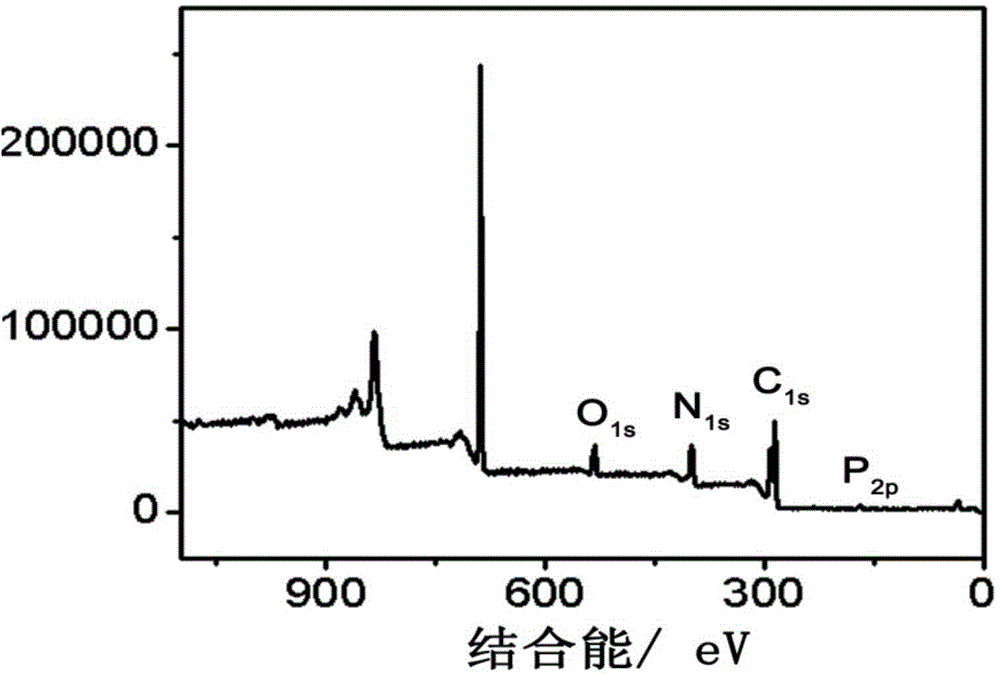

The invention relates to porous carbon and its preparation method. Specifically, the carbon material has a prismatic block shape from macroscopic view, and the size of a single block body is 5-20 m (side length of the prism). The single-block material has a hierarchical porous structure, including macropores of 50-300 nm, a mesoporous structure of 2-10 nm and micropores of less than 2 nm. The macropore structure is composed of three-dimensional graphene wall, and the mesopores and the micropores are composed of holes in the graphene wall. Nitrogen and phosphor are doped in crystal lattice of the carbon material, wherein doping concentration of nitrogen is 0.5-15.5%, and doping concentration of phosphor is 0.5-8.5%. The material is formed by in situ polymerization of a soft template and metal under catalytic dual effects. The material has potential application value in fields of catalysis, energy storage, adsorption and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Three-dimensional network graphene for lithium battery and preparing method thereof

ActiveCN104986758AAvoid wrappingLarge specific surface areaCell electrodesElectrolytic agentElectrical battery

The invention relates to three-dimensional network graphene for a lithium battery and a preparing method thereof. The preparing method of the three-dimensional network graphene for the lithium battery comprises the steps that firstly, high-purity expanded graphite, an anion type organic surface active agent, a dispersing agent, an antifoaming agent and a solvent are fully mixed, so that thick few-layer graphene slurry is obtained; liquid swelling high polymer materials are added, composite slurry is obtained after even mixing, and the composite slurry is coated in holes of porous foam materials; finally, the porous foam materials are fully carbonized and then are further processed, so that three-dimensional network graphene powder is obtained. The graphene prepared through the method is of a porous network structure on the microscopic scale, and thus the graphene is high in specific surface area, high in conductivity, high in heat conductivity and good in electrolyte wettability; when the graphene is mixed into positive electrode and negative electrode materials of the lithium battery for manufacturing pole pieces, the electron conduction can be effectively improved, the internal resistance of the battery can be greatly lowered, the amount of heat generated when the battery is charged and discharged is educed, the power density, the energy density and the safety of the battery are further improved, and the service life of the battery is prolonged.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

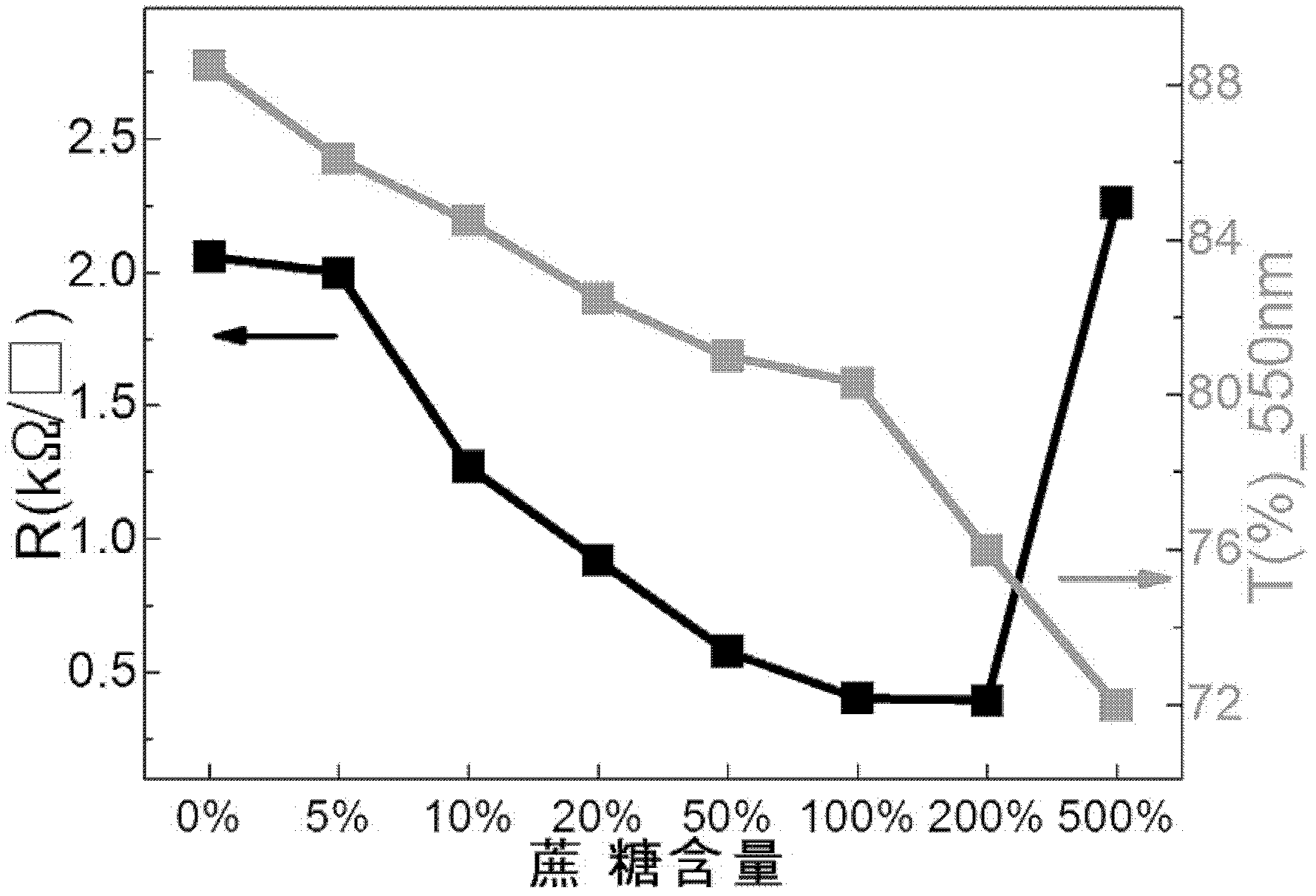

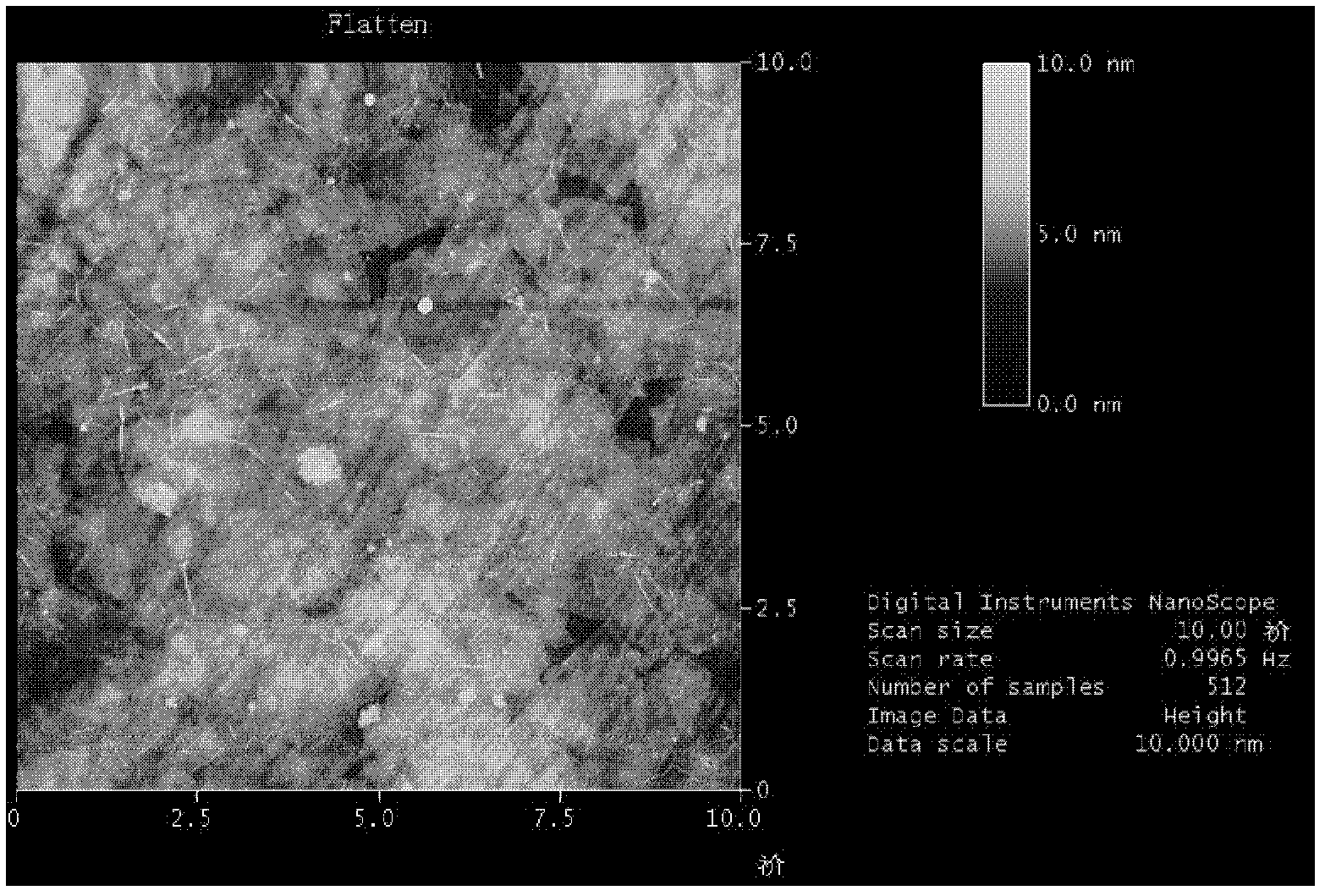

Graphene-carbon nano composite transparent conducting thin film and preparation method thereof

InactiveCN103021503AMild in natureSimple processMaterial nanotechnologyGrapheneComposite filmOptical transmittance

The invention provides a graphene-carbon nano composite transparent conducting thin film and a preparation method thereof. The graphitization degree of the graphene-carbon nano-composite thin film prepared by the steps of adding various char formation precursors to graphene oxide dispersion liquid and then carrying out thermal reduction is obviously increased, and thus the electric conduction performance of the thin film is substantially improved, and the light transmittance of the film is not affected. In addition, compared with the pure graphene thin film, the film has the advantages that the roughness is less than 0.2nm, and the evenness is high. The preparation method provided by the invention is simple in technology; reagents used in the preparation method have a mild property; and the preparation method can be applied to the large-scale production and has a very good application prospect in the field of photoelectricity such as touch screens, solar cells and light emitting diodes.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

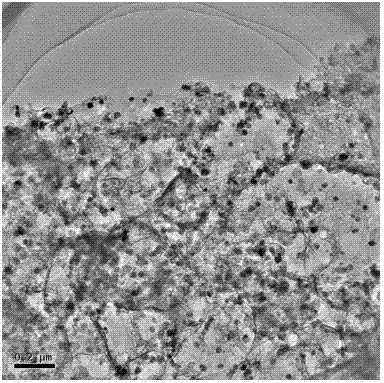

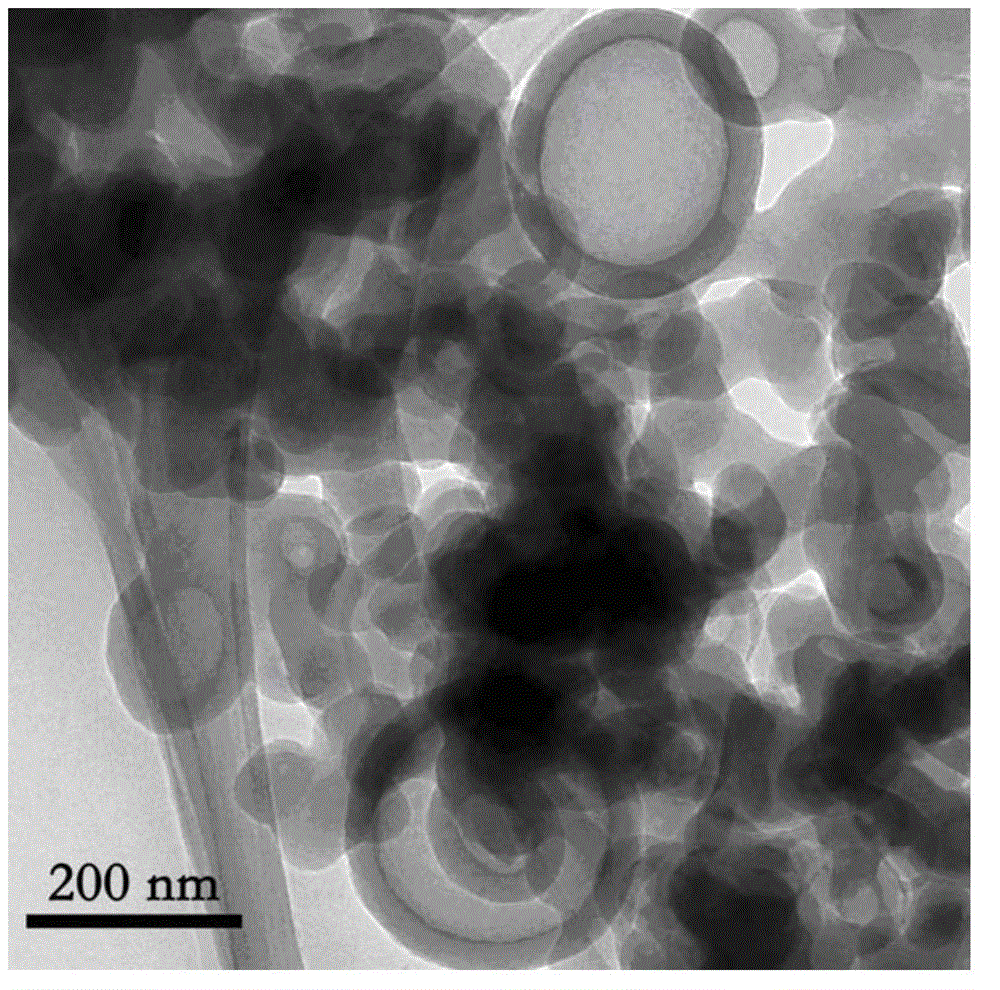

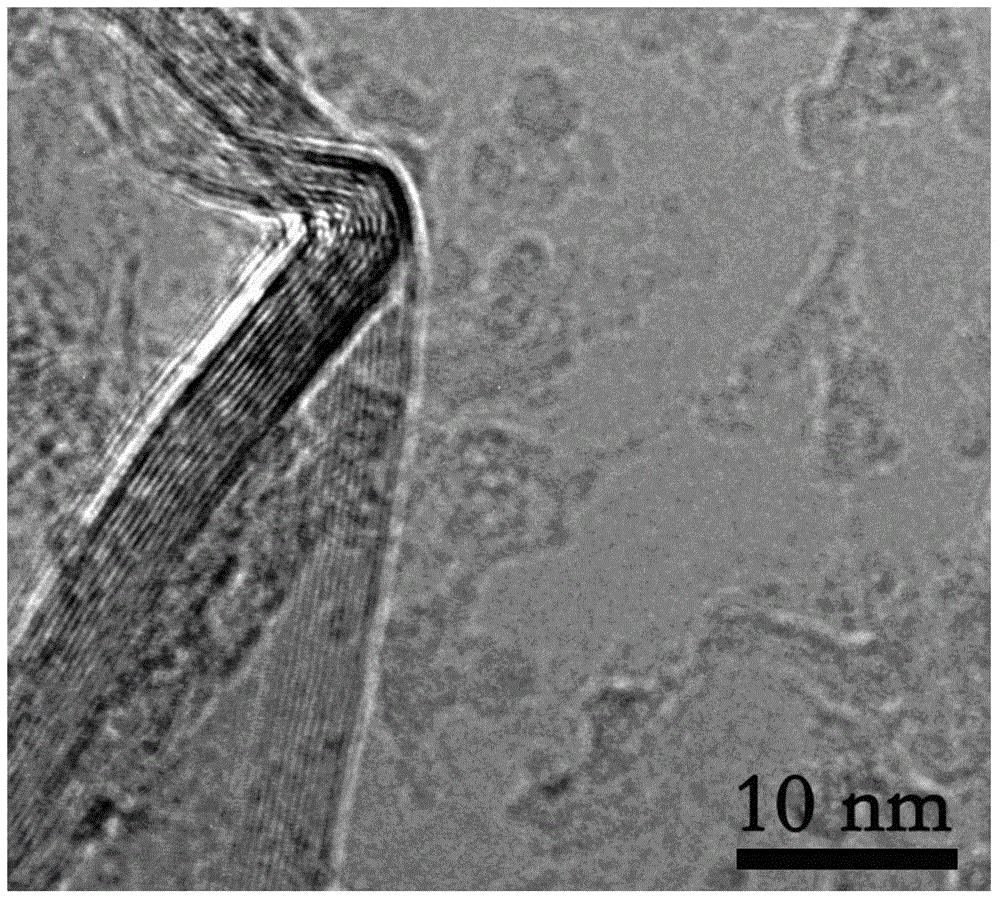

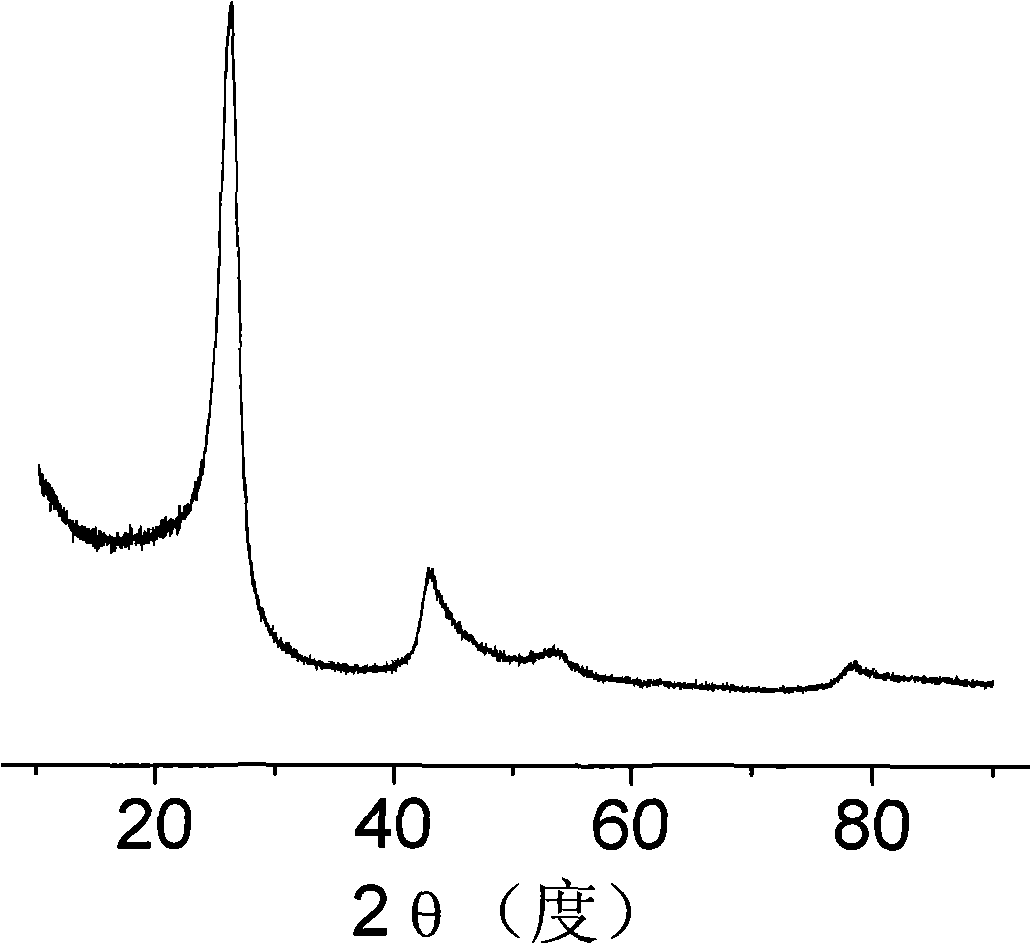

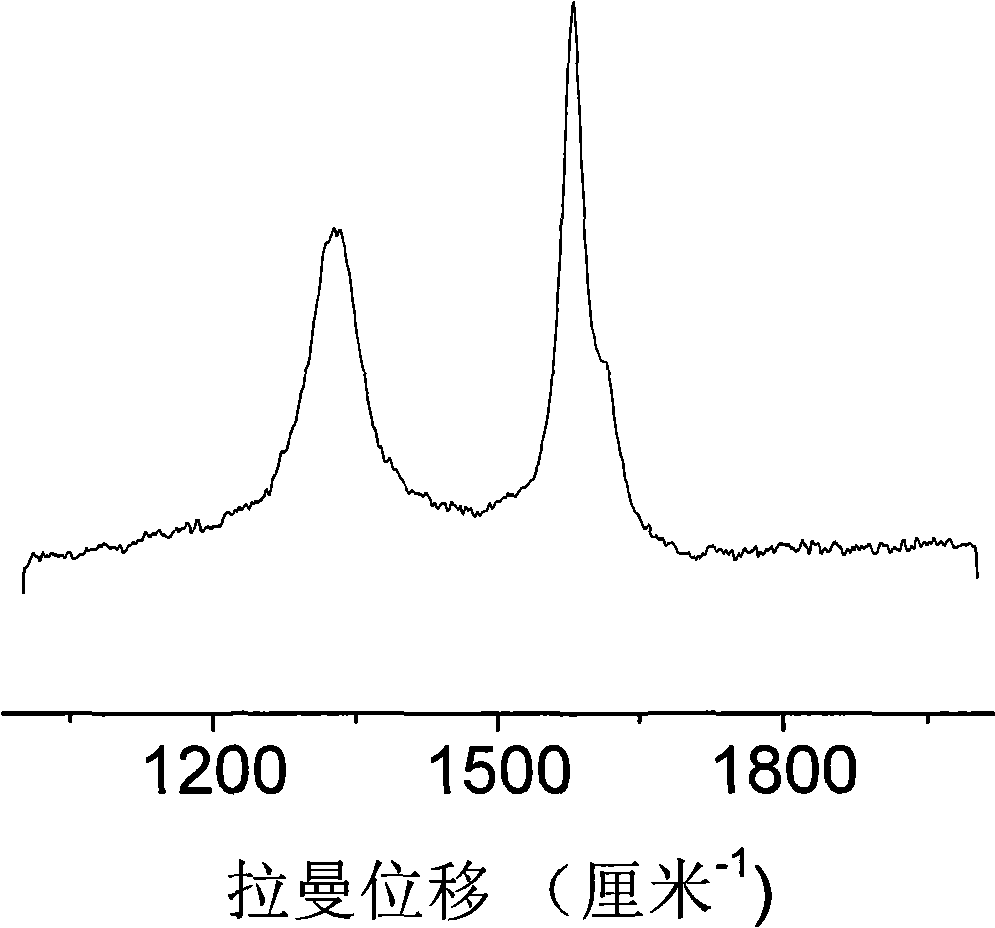

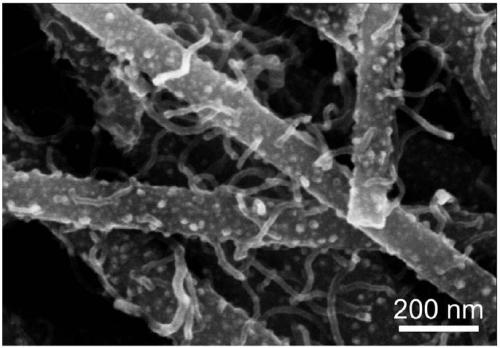

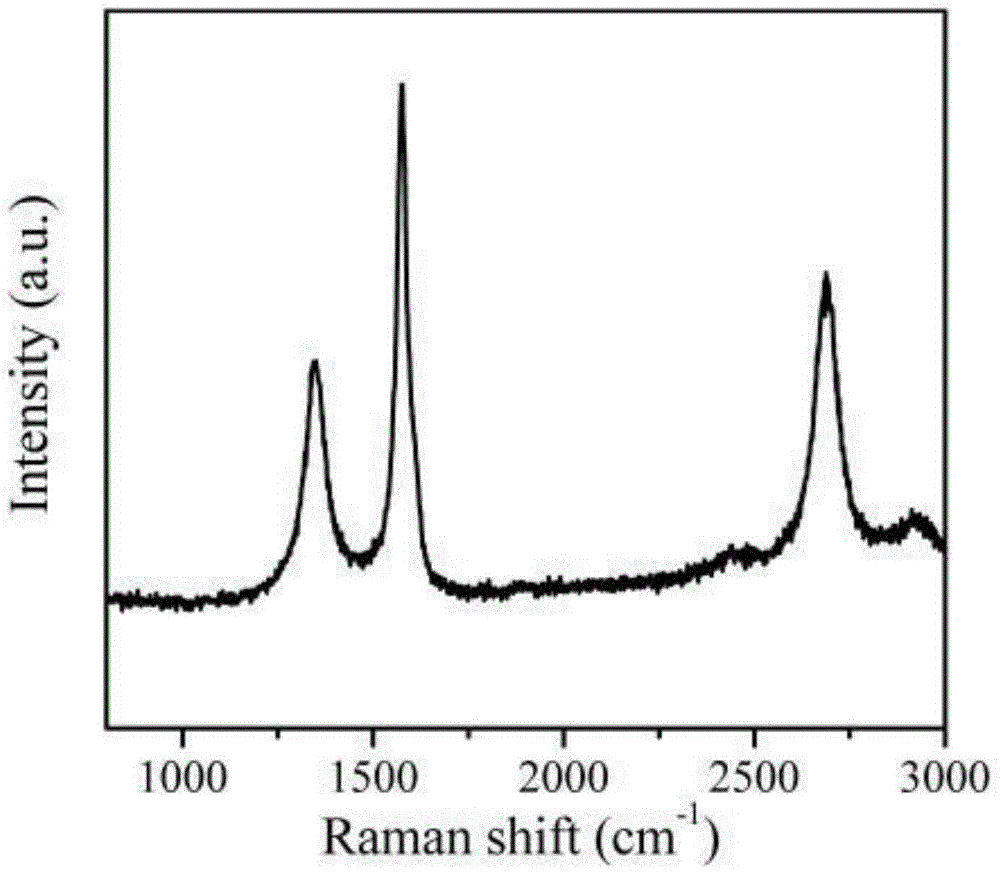

Highly-graphitized carbon nanowire ball material and preparation method thereof

The invention discloses a highly-graphitized carbon nanowire ball material and a preparation method thereof. An activated carbon material is prepared from carbohydrate used as a carbon source through hydrothermal and carbonization activation, the prepared activated carbon material is dipped in a metal salt catalyst solution and dried, a prepared dipped sample is treated at the high temperature under the protection of inert gas, and a graphitized carbon and metal composite is obtained; the obtained composite is treated with an acidic solution, washed, subjected to solid-liquid separation and dried, and the highly-graphitized carbon nanowire ball material is prepared. The wire ball is formed by winding carbon nanowires with the diameters of 10-100 nm, the diameter of the wire ball is 0.2-5 mu m, and the graphitization degree is 0.7-1. The highly-graphitized carbon nanowire ball material has the advantages of uniform dispersion, high graphitization degree, large specific surface area, low cost of raw materials, simple process, no pollution, easiness in industrial production and the like and has wide application prospect in the fields of electrochemical energy storage, adsorption separation, catalyst carriers, medicines and the like.

Owner:XIANGTAN UNIV

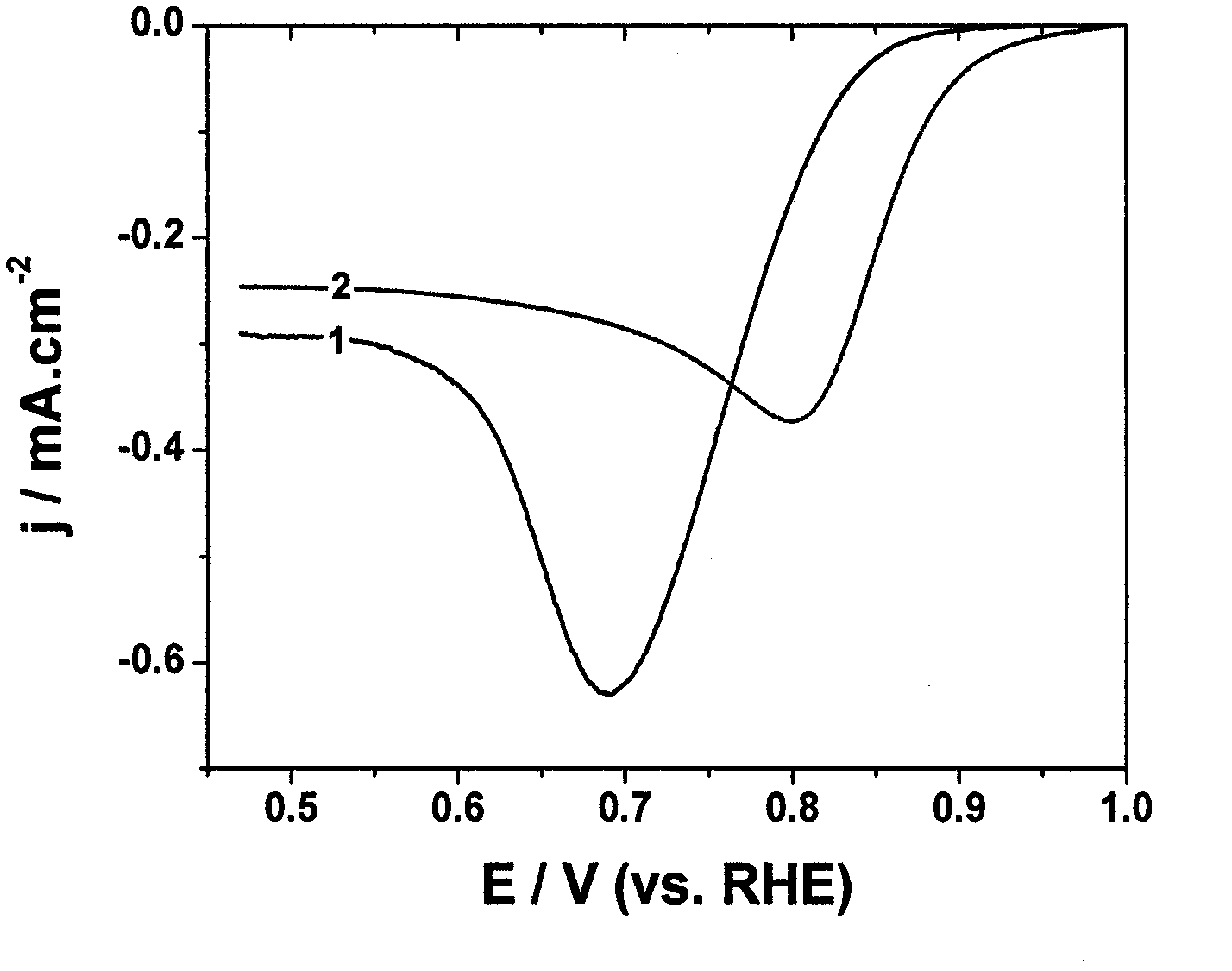

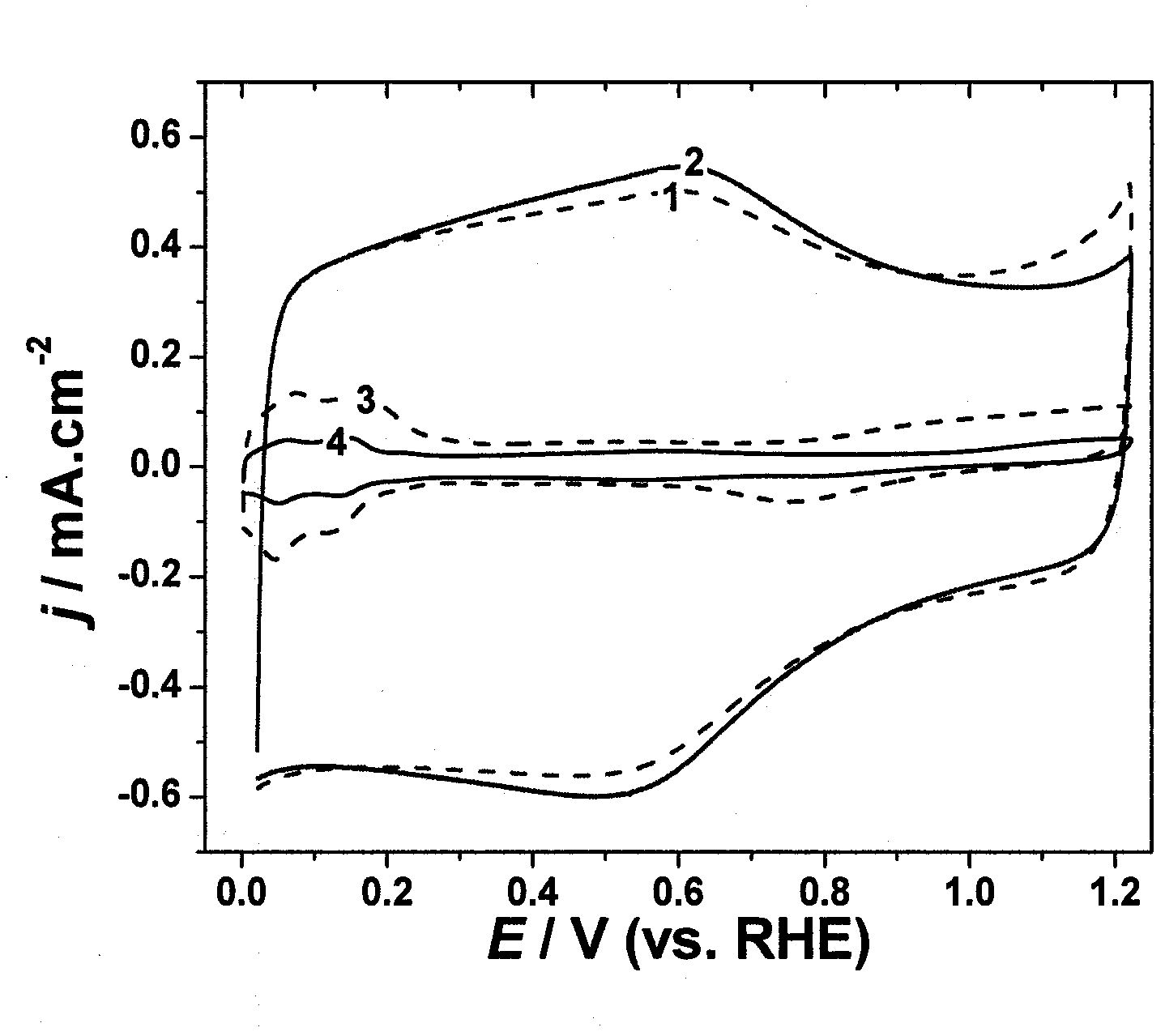

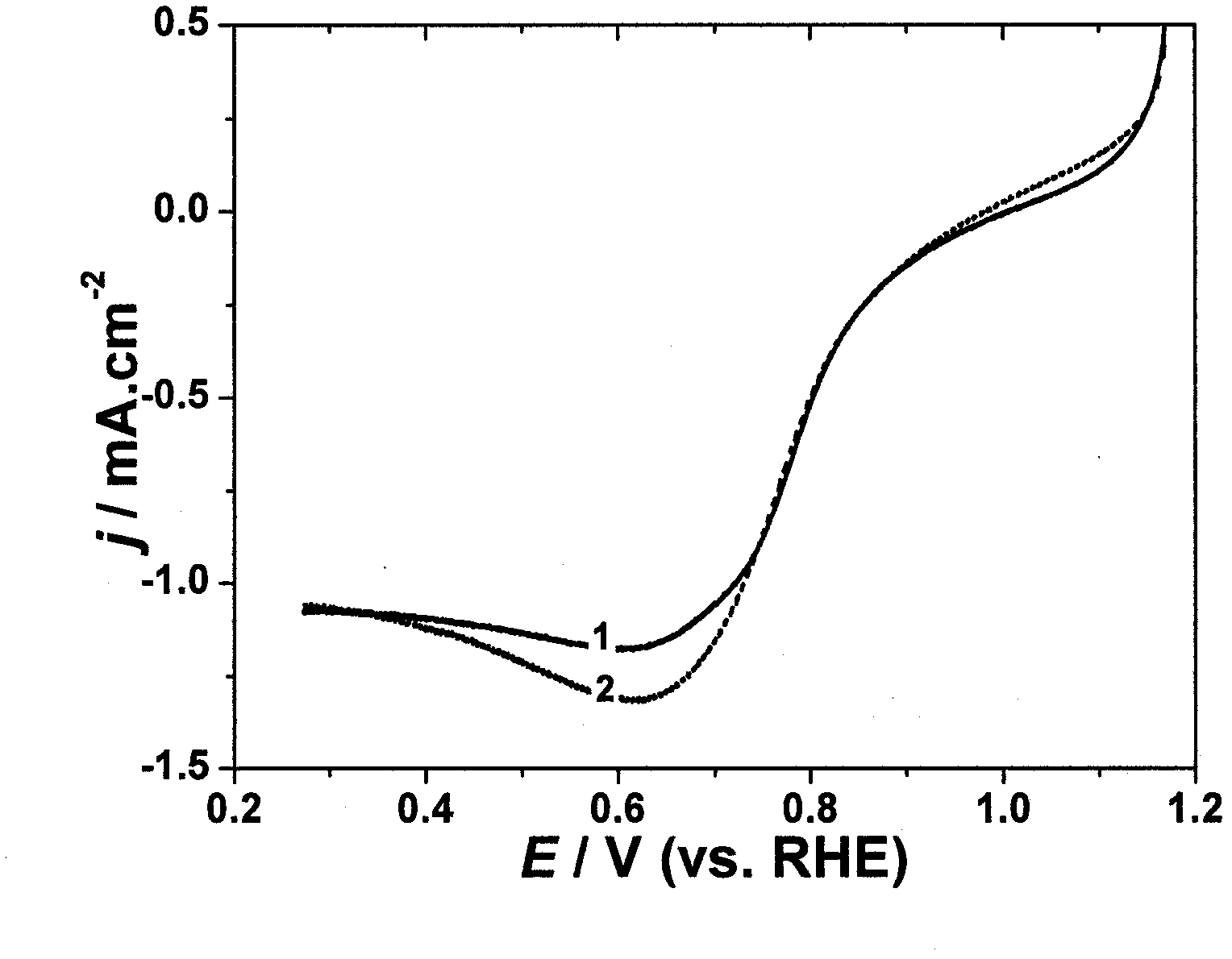

Oxygen reduction non-noble metal catalyst and preparation method thereof

InactiveCN102626649AImprove conductivityHigh degree of graphitizationPhysical/chemical process catalystsCell electrodesInorganic compoundOxygen

The invention which provides an oxygen reduction non-noble metal catalyst and a preparation method thereof belongs to the technical field of fuel cells. The nitrogen doped non-noble metal fuel cell catalyst having a graphite-like structure is formed by introducing nitrogen-containing monomers into layered inorganic compound interlayers and carrying out interlayer polymerization-pyrolysis. The active nitrogen loss is effectively reduced and the graphitization degree of the catalyst is effectively improved by utilizing an almost closed effect of the layered compound to improve the catalytic activity and the stability of the non-noble metal catalyst. The method of the invention has the advantages of simplicity and easy implement, and low production cost; and the catalyst prepared through the method has the advantages of good oxygen reduction catalytic activity and good stability, and can be applied to a fuel cell with a proton exchange membrane as an electrolyte. The fuel cell manufactured with the catalyst can be widely applied to electric automobiles, various spacecrafts, and portable electronic devices, such as cameras, notebook computers, electric toys and the like.

Owner:CHONGQING UNIV

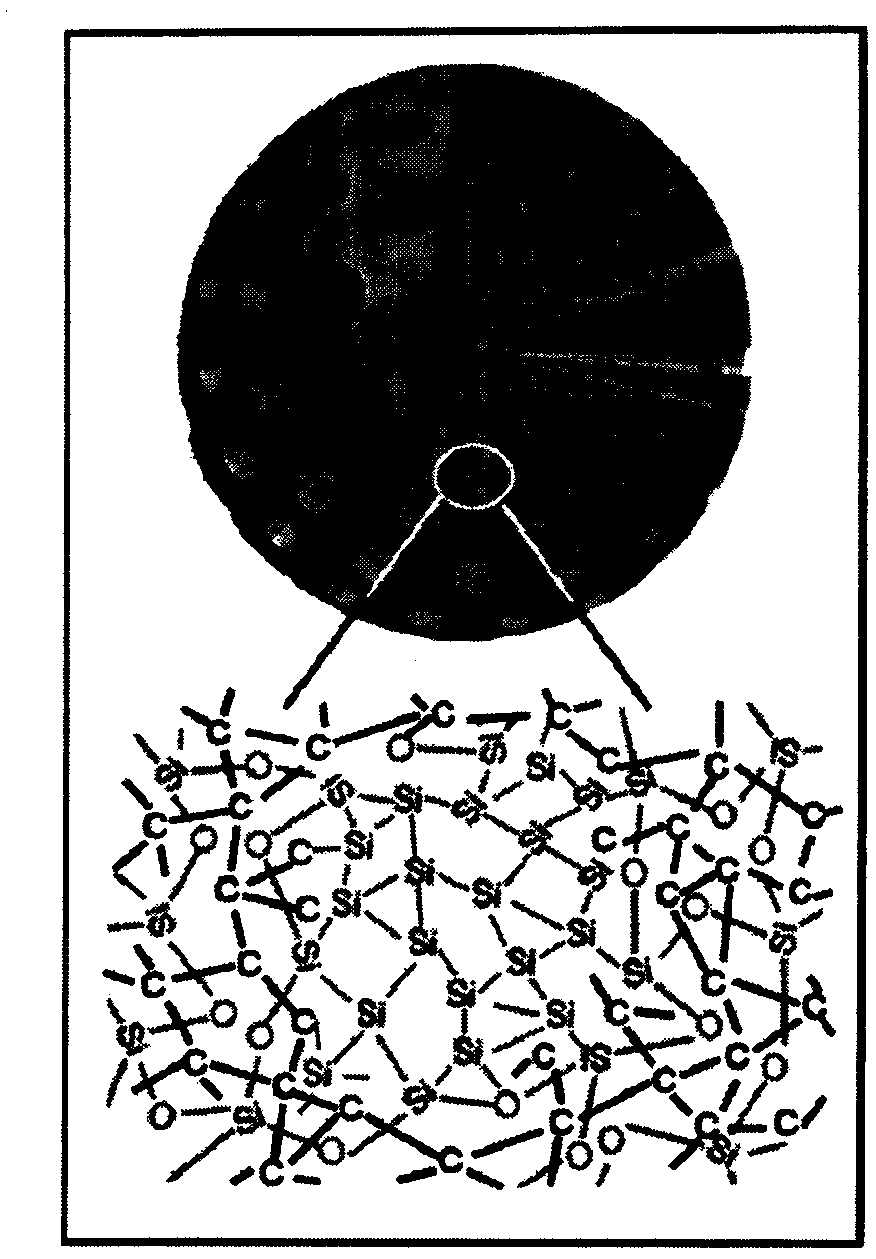

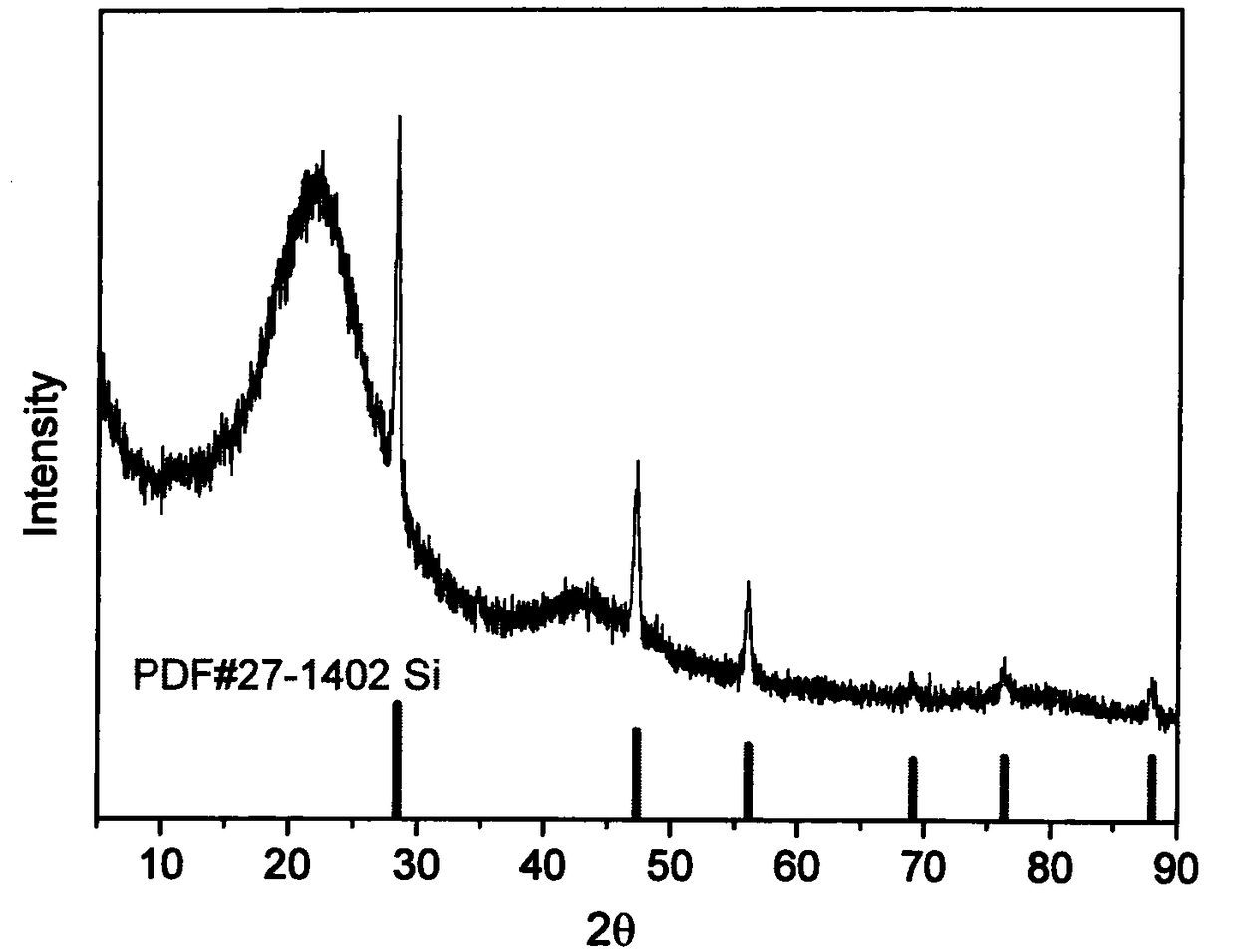

High-performance silicon/carbon anode nanocomposite and preparation method thereof

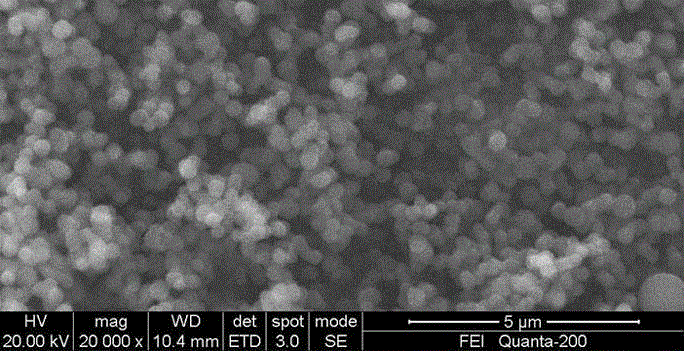

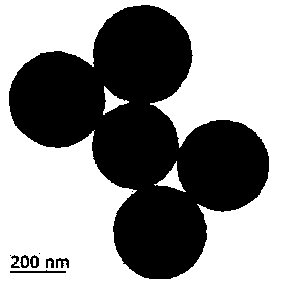

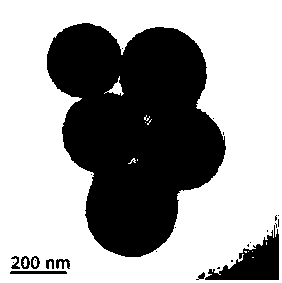

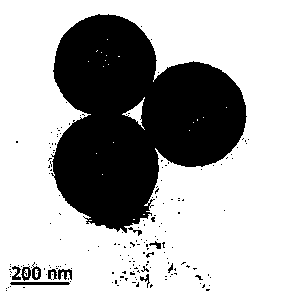

ActiveCN108428876ARich varietyGuaranteed stabilityMaterial nanotechnologyCell electrodesLithiumCarbon nanosphere

The invention provides a high-performance silicon / carbon anode nanocomposite and a preparation method thereof. The high-performance silicon / carbon anode nanocomposite is characterized by containing carbon nano-spherical particles with mesoporous channels, and the spherical particles and / or the mesoporous channels are filled with elementary silicon particles. The prepared silicon / carbon anode nanocomposite is of a porous structure, the elementary silicon particles are dispersed in a carbon skeleton and the mesoporous channels, the volume expansion effect during lithium-ion charge and dischargeis low, and electrochemical cycle performance is stable.

Owner:DONGHUA UNIV

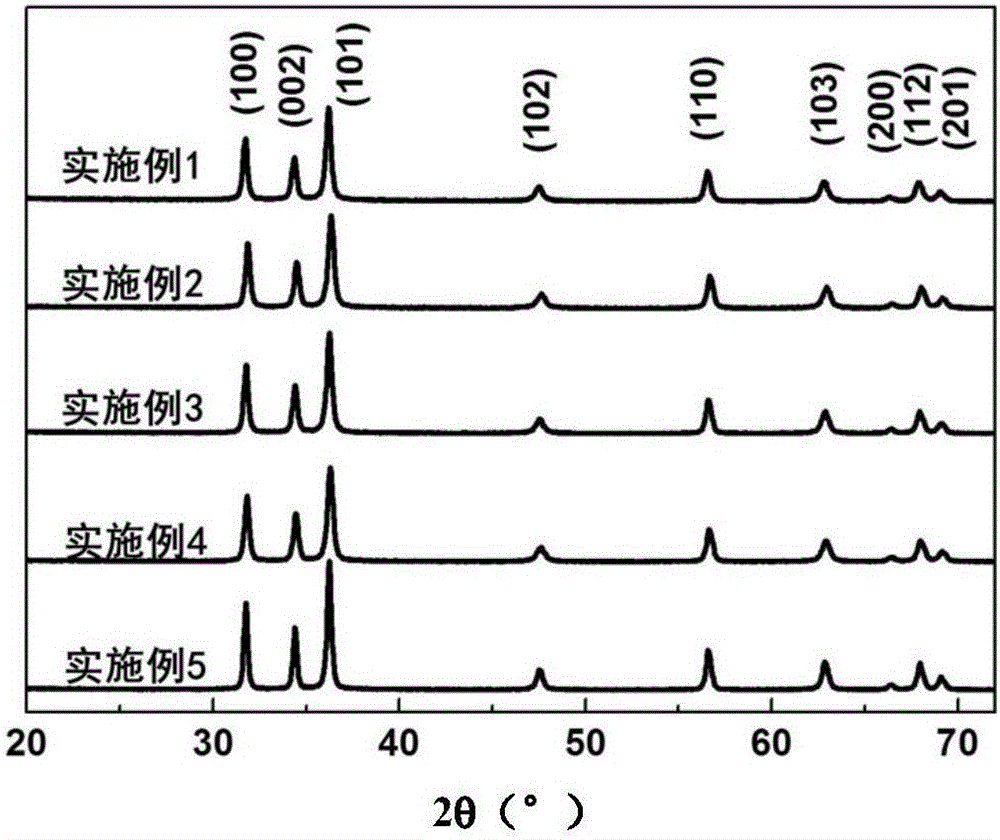

High-power lithium iron phosphate positive pole material and manufacturing method thereof

ActiveCN103247778AHigh degree of graphitizationIncrease output powerCell electrodesCarbon coatingLithium iron phosphate

The invention discloses a high-power lithium iron phosphate positive pole material and a manufacturing method thereof. The method comprises the following steps of: fully mixing a lithium source, an iron source and a phosphorus source according to a mole ratio of Li to Fe to P being (1-1.2):1: (1-1.05), sintering under an inert atmosphere to prepare a lithium iron phosphate precursor, introducing a catalyst and a carbon source, and optimizing a sintering process and the reaction atmosphere to prepare the LiFePO4 / C composite positive material with high degree of graphitization and a carbon coating layer. The lithium iron phosphate positive pole material prepared by the invention has uniform grains, and is good in monodispersity, high in conductivity, excellent in electrical performance, simple in preparation method, economic and is easy to realize industrial production.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

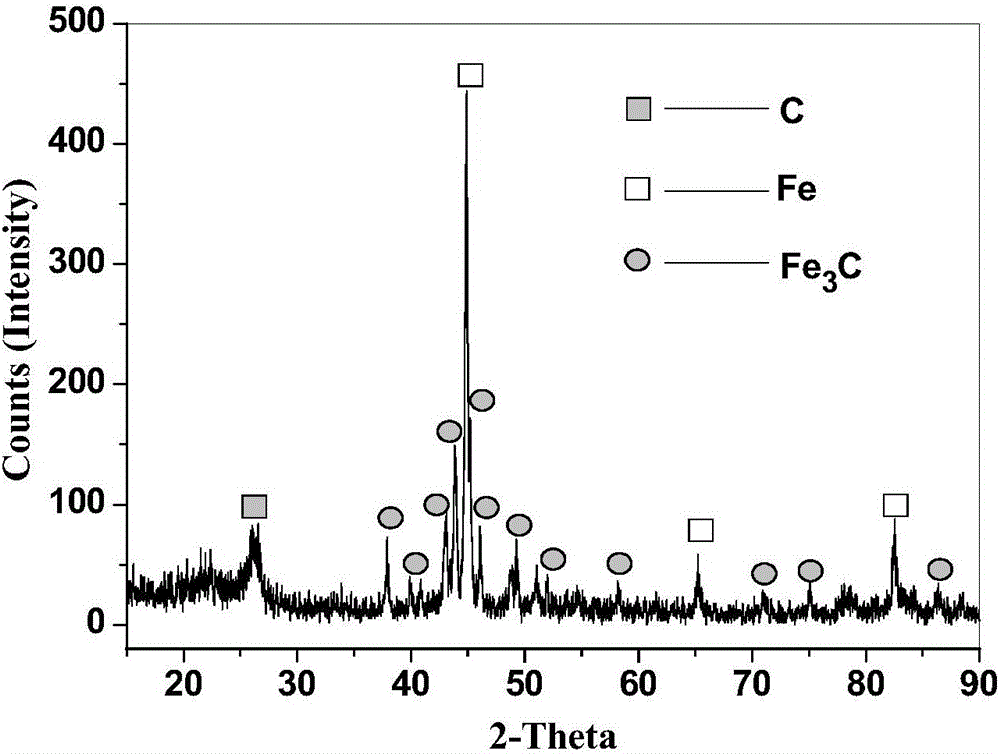

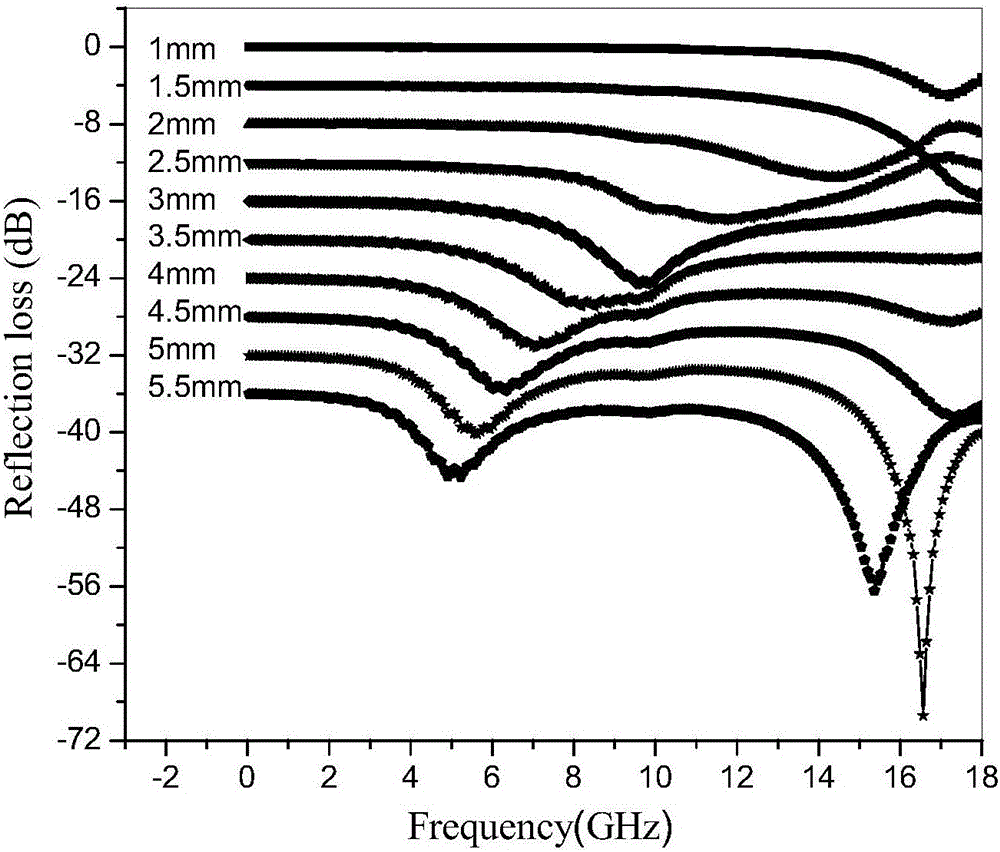

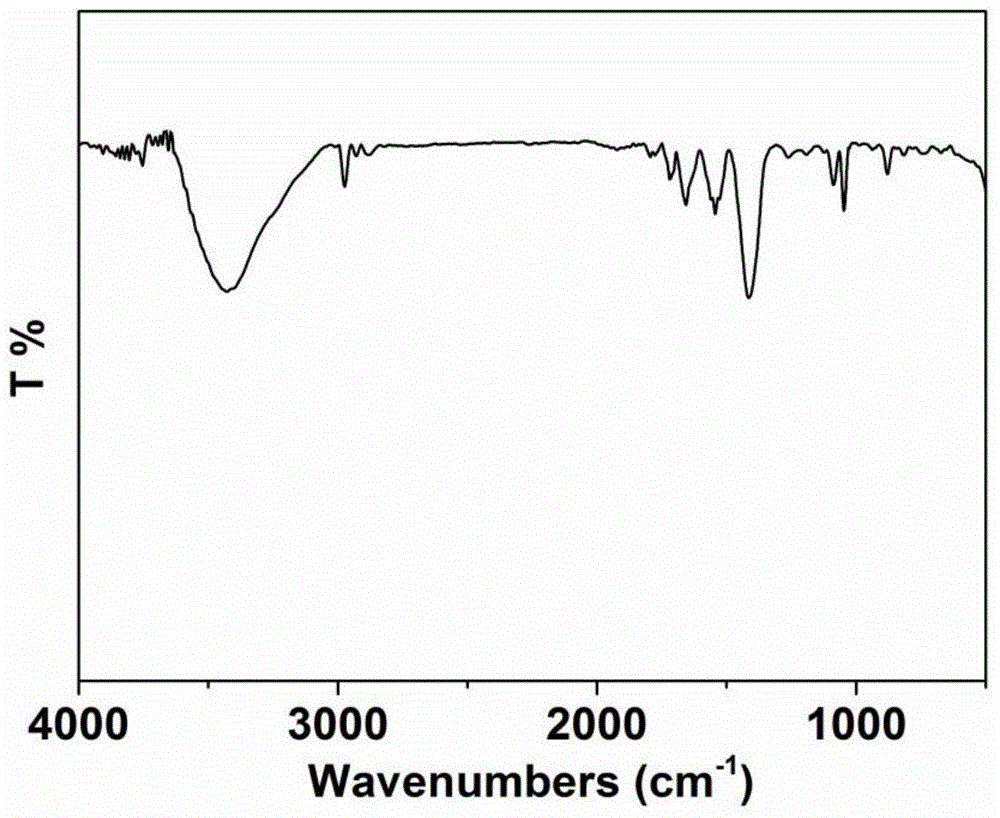

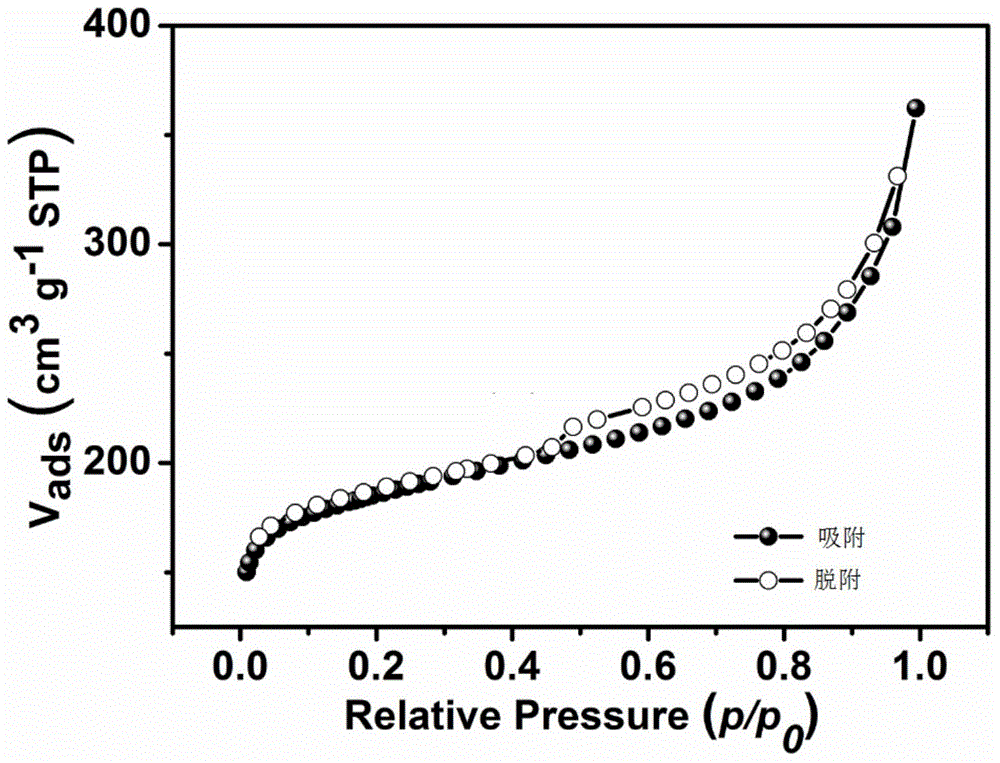

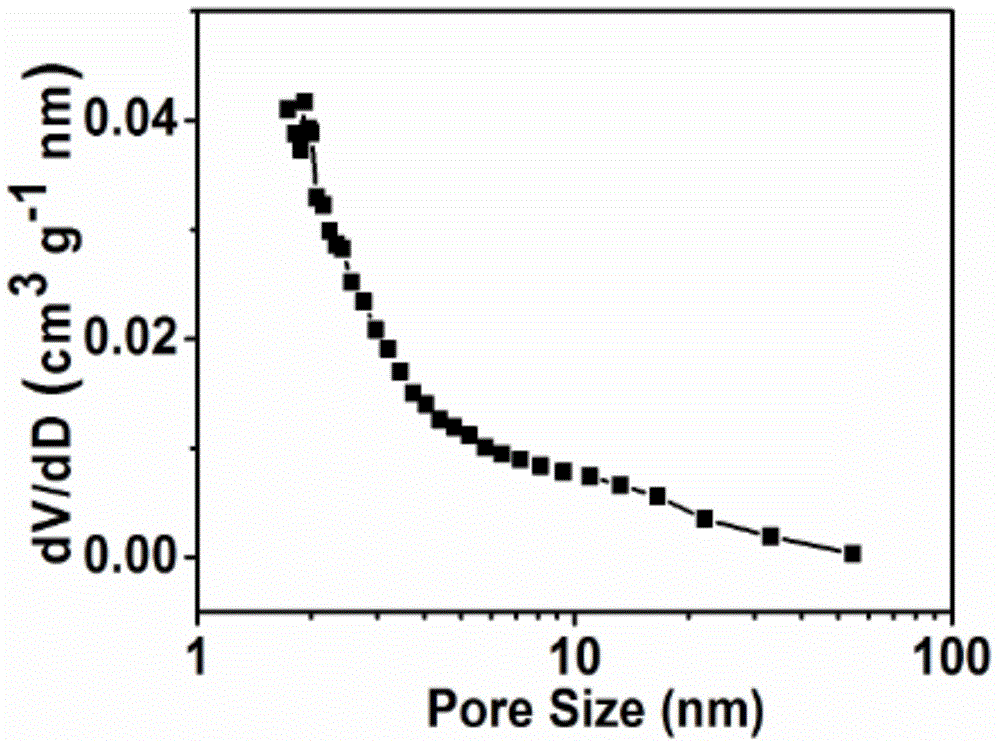

Method for preparing porous carbon ball composite absorbing material loaded with magnetic metal element

The invention relates to a method for preparing a porous carbon ball composite absorbing material loaded with a magnetic metal element. The method includes the steps of 1] preparing a precursor solution containing magnetic metal ion salt; 2] placing porous carbon balls into the precursor solution for stirring and dipping; 3] filtering, then washing and drying the porous carbon balls; 4] calcining the dried porous carbon balls in an inert atmosphere; and 5] cooling to room temperature in the inert atmosphere and then obtaining a porous carbon ball composite absorbing material loaded with a magnetic metal element. The invention makes use of the high specific surface area and the strong adsorption of the porous carbon balls, introduces the precursor solution containing magnetic metal ion salt including cobalt salt, nickel salt and the like into channels of the carbon balls by capillary action, combines with hydrophilic oxygen-containing functional groups, and obtains the porous carbon ball composite absorbing material loaded with the magnetic metal element like cobalt or nickel through drying and sintering in the inert atmosphere. The whole preparation process is simple in technique, convenient to operate, and less demanding on production equipment.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

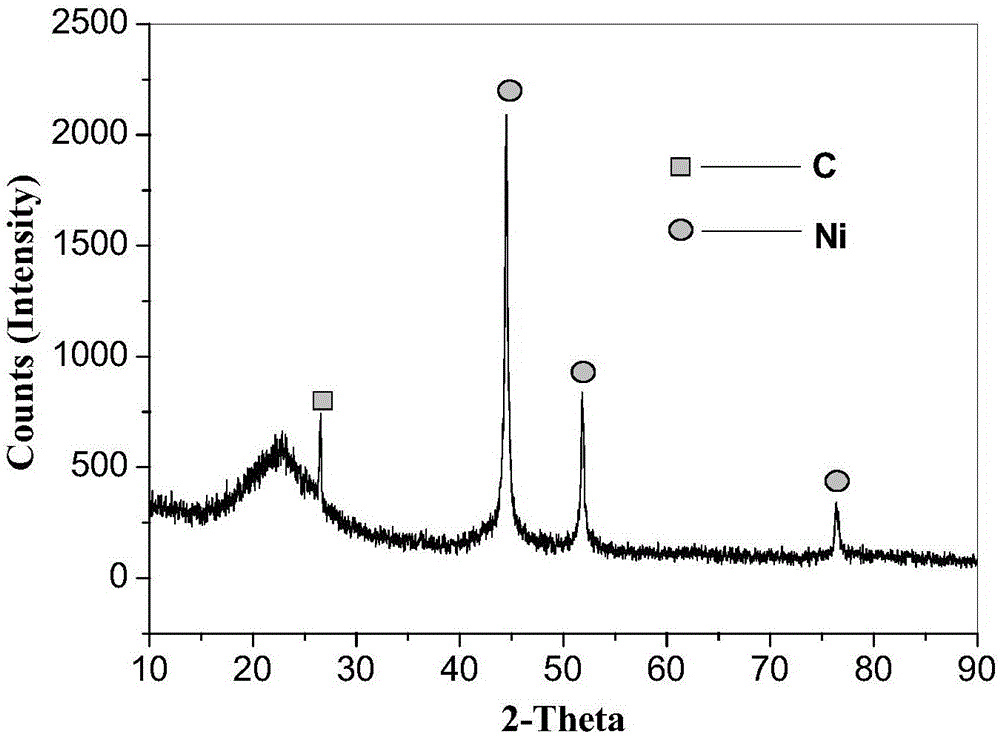

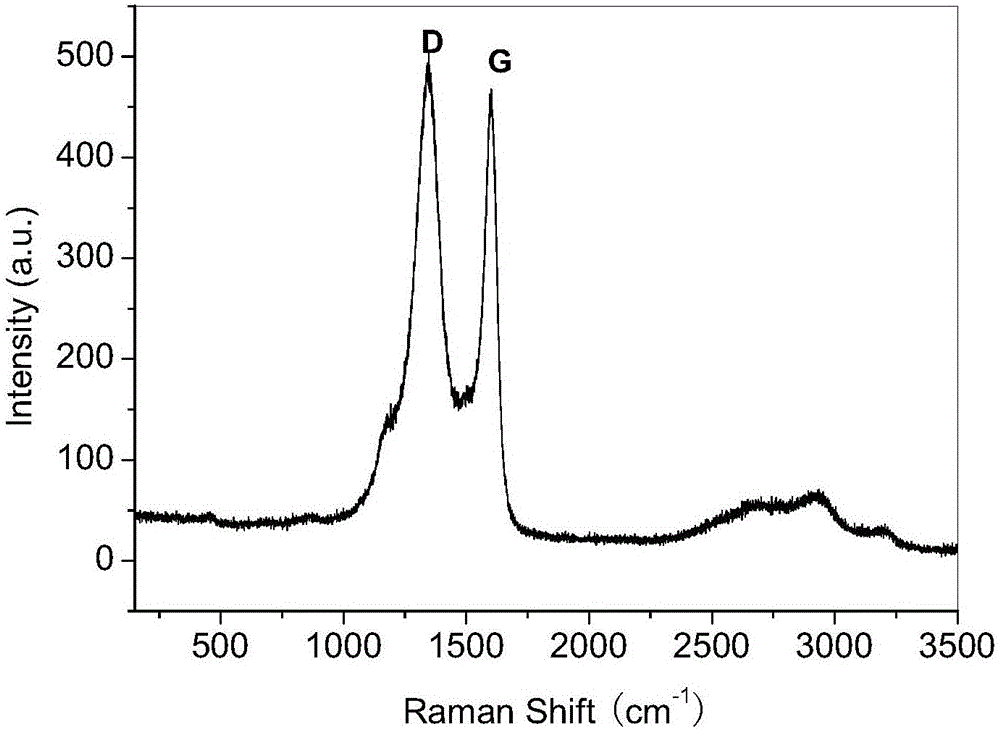

Preparation method of iron/iron carbide-loaded porous carbon sphere composite wave-absorbing material

InactiveCN105838324ASimple processEasy to operatePhysical/chemical process catalystsOther chemical processesIron saltsPorous carbon

The invention relates to a preparation method of an iron / iron carbide-loaded porous carbon sphere composite wave-absorbing material. The method comprises the following steps: 1) preparing an iron-salt-containing precursor solution; 2) stirring porous carbon spheres in the precursor solution for impregnation; 3) filtering out the porous carbon spheres, washing and drying; 4) calcining the dried porous carbon spheres in an inert atmosphere; and 5) cooling to room temperature in an inert atmosphere to obtain the iron / iron carbide-loaded porous carbon sphere composite wave-absorbing material. The iron salt precursor solution is introduced to the inside of the ducts of the carbon spheres by using the high specific area and strong adsorptivity of the porous carbon spheres through the capillary actions and is combined with the hydrophilic oxygen-containing functional group; and finally, the drying and sintering treatment in the inert atmosphere are performed to obtain the simple substance iron / iron carbide-loaded porous carbon sphere composite material. The whole preparation process is simple in technique and convenient to operate, and has low requirements for the production equipment.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Nitrogen and sulfur co-doped carbon-loaded non-noble metal type oxygen reduction catalyst and preparation method thereof

InactiveCN104998673AImprove stabilityExcellent resistance to methanolPhysical/chemical process catalystsCell electrodesDistillationVacuum drying

The invention discloses a nitrogen and sulfur co-doped carbon-loaded non-noble metal type oxygen reduction catalyst and a preparation method thereof and discloses a M-N-S-C oxygen reduction catalyst and a preparation method thereof. The raw materials of the catalyst comprise copolymer P (TPT+Tp) of tripyrrole-[1,3,5]-triazine (TPT) and thiophene (Tp) and non-noble metal salt. The preparation method of the catalyst includes the following steps that firstly, a Friedel-Crafts reaction is adopted for synthesizing the copolymer P (TPT+Tp) of the tripyrrole-[1,3,5]-triazine (TPT) and the thiophene (Tp); secondly, the P (TPT+Tp) and the non-noble metal salt are added into ethanol, mixtures are placed in an ultrasonic dispersing instrument, a whole system is evenly dispersed due to ultrasound, and then the ethanol is dried by distillation and placed in a vacuum drying box to be dried for 4 h at the temperature of 80 DEG C; thirdly, thermal treatment is performed for the first time and nitrogen doped materials are obtained; fourthly, the nitrogen doped materials are completely washed through dilute acid; fifthly, thermal treatment is performed for the second time, and then the M-N-C oxygen reduction catalyst can be obtained.

Owner:XIANGTAN UNIV

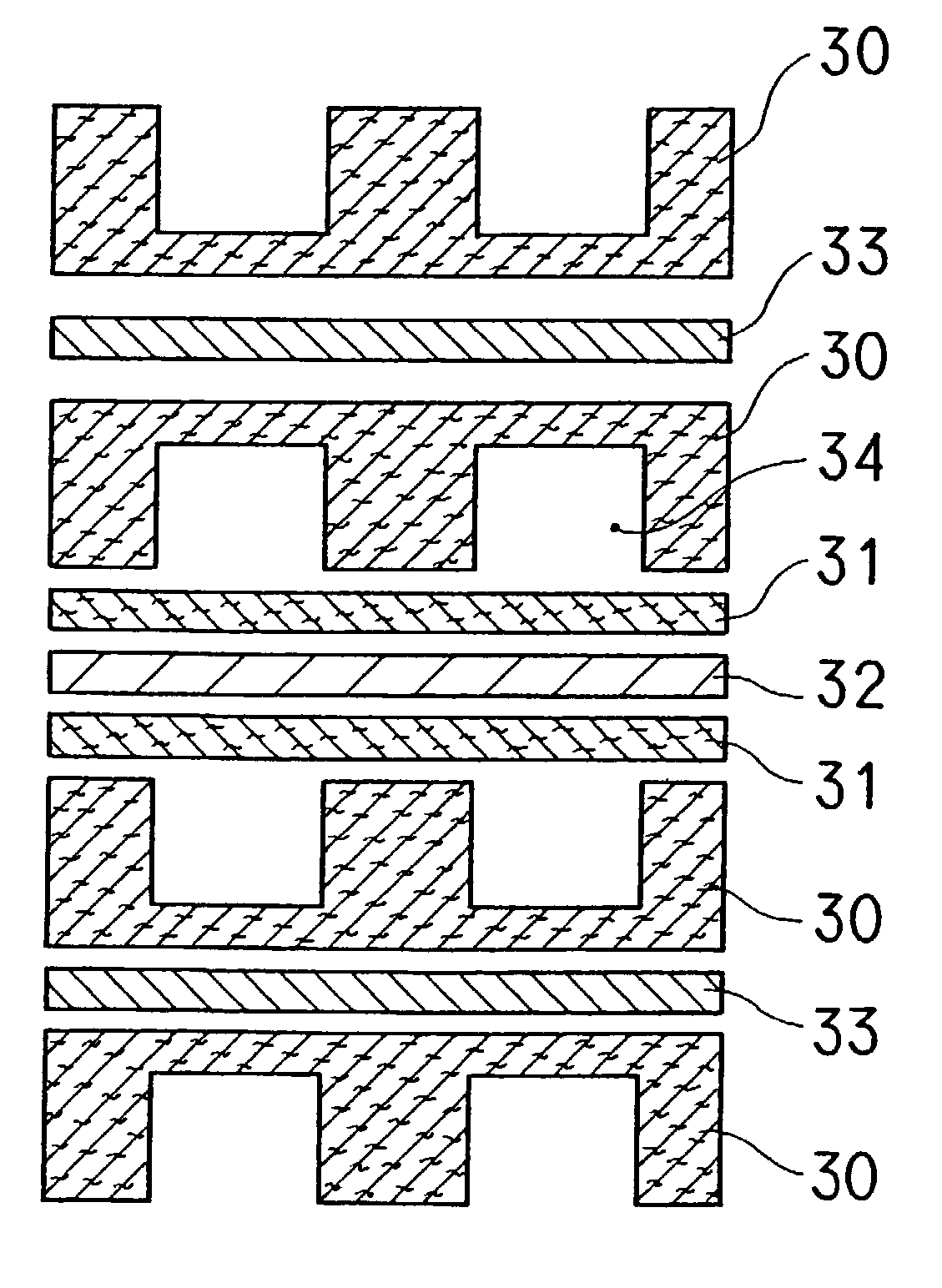

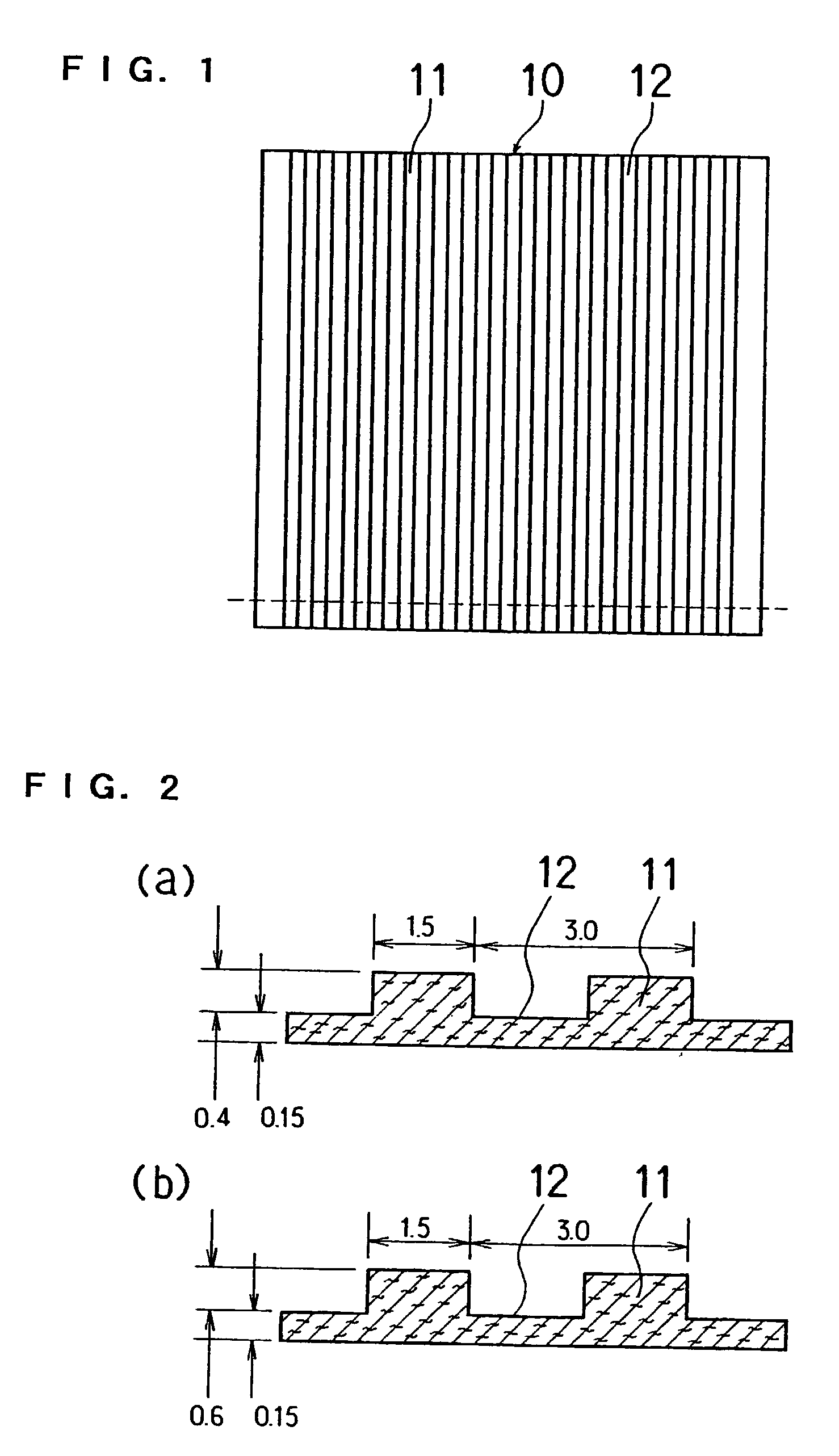

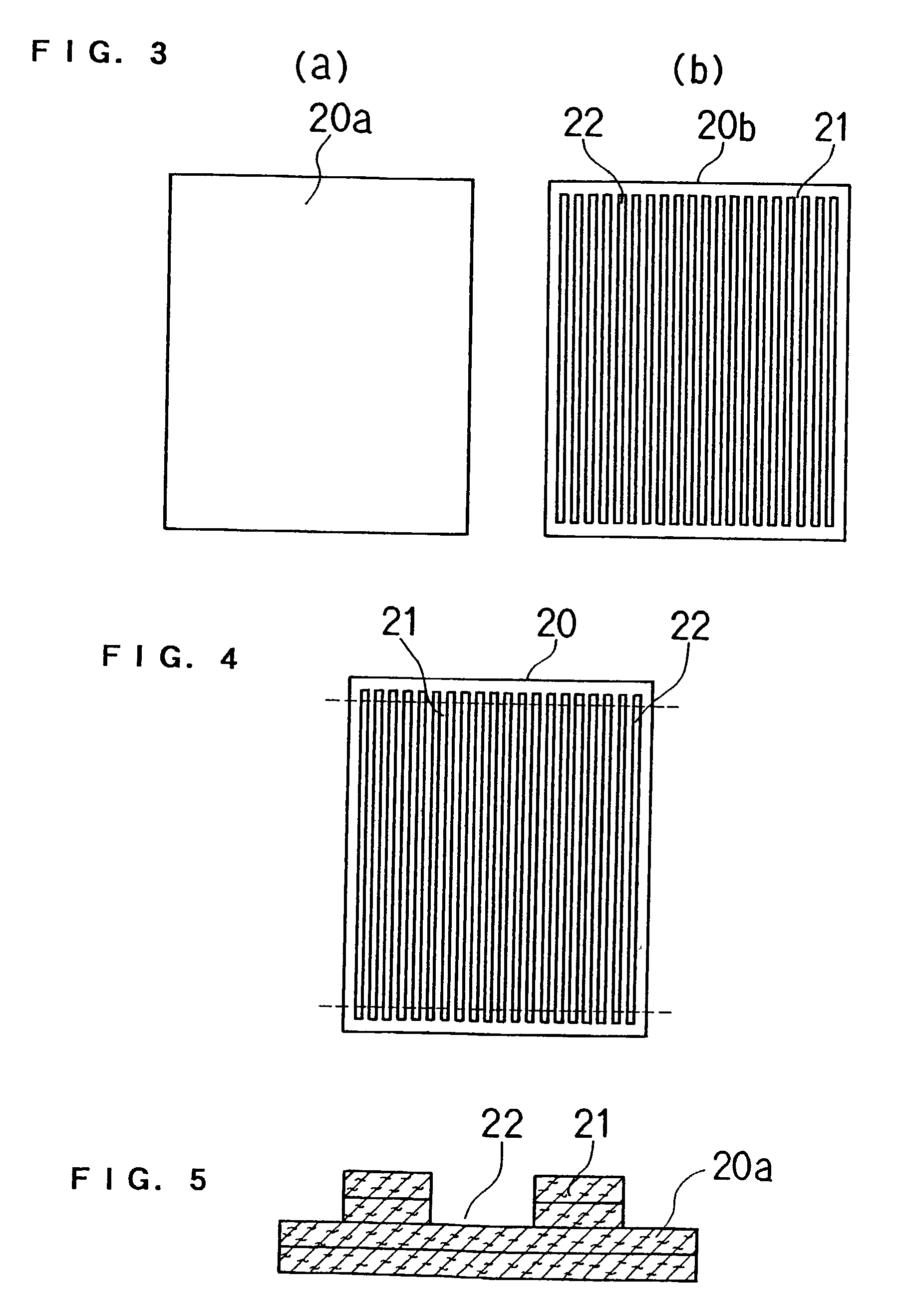

High polymer electrolyte fuel cell

InactiveUS20020192539A1Easy to getGood orientationFuel cell auxillariesActive material electrodesFiberCarbon fibers

The present invention discloses an improved gas diffusion layer for use in porous electrodes of polymer electrolyte fuel cells. The gas diffusion layer comprises a gas flow path having a bottom face facing an electrolyte membrane, and the properties of a carbon fiber that forms the bottom face of the gas flow path are different from the properties of a carbon fiber that forms the side wall of the gas flow path and / or the top face of the gas flow path. It is preferable that there is a difference in the graphitization degree, graphite orientation degree or fiber microstructure, and the hydrophilic group density of the carbon fiber forming the bottom face of the gas flow path is particularly small. Accordingly, it is possible to obtain a gas diffusion layer imparted with water retention property, without sacrificing the gas permeability.

Owner:PANASONIC CORP

Method for preparing graphene

The invention provides a method for preparing graphene. The method comprises the following steps: (A) mixing a biomass material, an anionic surfactant and water to carry out a hydrothermal reaction at a temperature of 150-250 DEG C for 1-24 hours to obtain a precursor; (B) mixing a metal catalyst with the precursor obtained in the step (A) to obtain a precursor containing the metal catalyst; and (C) heating the precursor containing the metal catalyst obtained in the step (B) to obtain graphene. According to the preparation method, the biomass material is used as a carbon source, the biomass material reacts under a hydrothermal condition to generate a gaseous-phase product, the anionic surfactant can be used for enriching bubbles and the biomass material in a bulk phase solution, and the bubbles are used as a template to form hollow carbon spheres so as to obtain the precursor which has a relatively thin spherical shell layer and relatively high surface activity and can be easily catalyzed by a metal catalyst, and graphene having relatively high graphitizing degree can be obtained.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

Lignin-based graphene/zinc oxide hybrid composite material and preparation method and application

ActiveCN106024423AGood dispersionReduce aggregationHybrid capacitor electrodesCell electrodesActive agentNano hybrid

The invention belongs to the technical field of organic / inorganic hybrid composite materials and discloses a lignin-based graphene / zinc oxide hybrid composite material and a preparation method and application thereof. The method comprises the following steps of: dissolving lignin into water, carrying out heating in an alkaline condition, adding an active agent for reaction and then adding a carboxylated reagent solution for constant-temperature reaction to obtain carboxylated lignin; adding a zinc salt to a carboxylated lignin water solution, carrying out heating reaction, adding a weak acid reagent, stirring the weak acid reagent evenly and drying the mixture to obtain a carboxylated lignin and zinc salt compound; and carrying out high-temperature calcination to obtain the lignin-based graphene / zinc oxide hybrid composite material. In the process of the preparation method, an active functional group of the carboxylated lignin and zinc ions form a chemical bond effect to form a precursor; and a lignin-based graphene / zinc oxide nano hybrid composite structure is prepared through high-temperature calcination; and the lignin-based graphene / zinc oxide nano hybrid composite structure has a potential application prospect in the fields of a super capacitor, a lithium-ion battery and photocatalysis.

Owner:SOUTH CHINA UNIV OF TECH

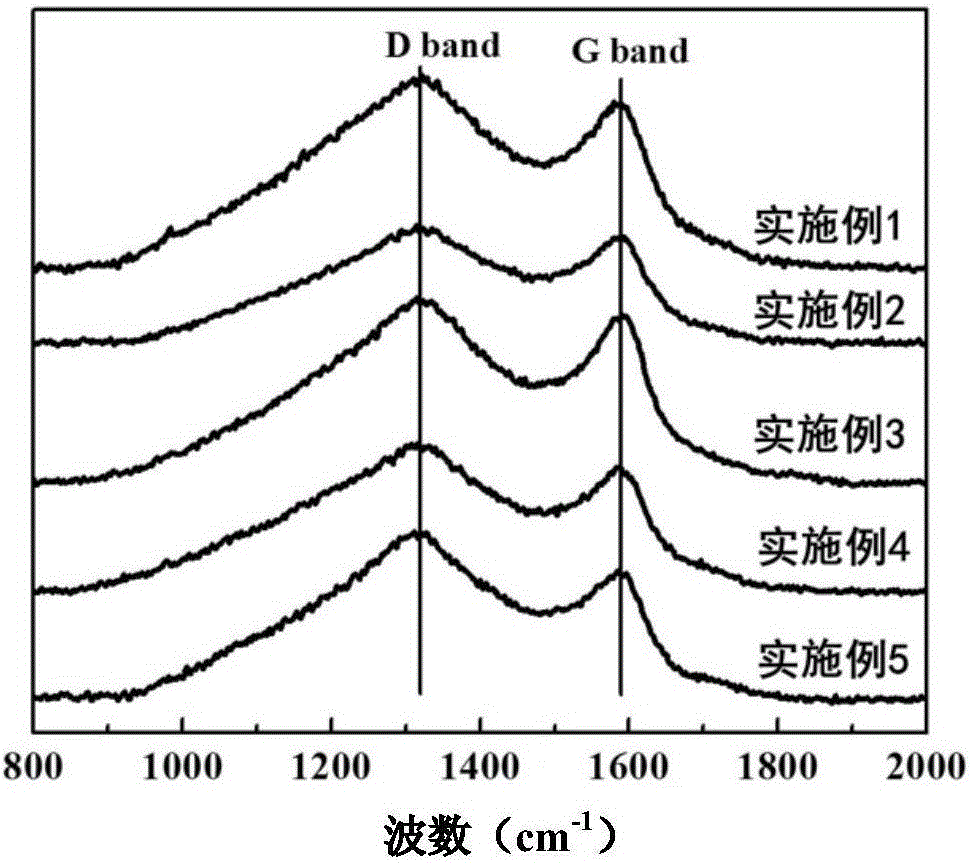

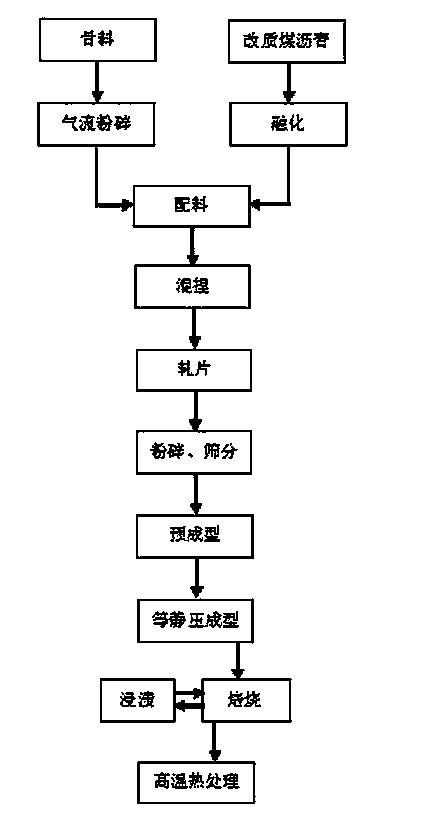

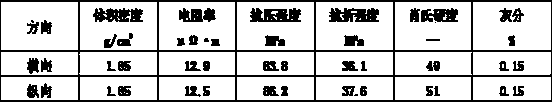

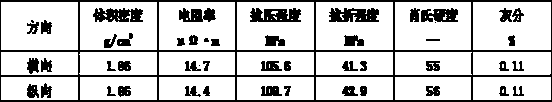

Preparation method of isostatic pressing microcrystalline graphite product

The invention relates to a preparation method of an isostatic pressing microcrystalline graphite product. The isostatic pressing microcrystalline graphite product comprises the following components by weight: 35-50% of microcrystalline graphite, 10-25% of artificial graphite, 10-25% of electrically calcined pitch coke and 30-40% of modified coal tar pitch. The isostatic pressing microcrystalline graphite product is obtained by the steps of pretreating raw material, burdening, kneading, rolling, fragmenting and pulverizing, preforming, performing isostatic compaction, roasting, dipping, performing heat treatment under high temperature and the like. The unique part in the method is the usage of the natural microcrystalline graphite as a main aggregate, the resource can be used in a reasonable mode, high temperature graphitization heat treatment at more than 2500 DEG C on the product is not required, so that preparation period can be shortened, and the energy consumption is greatly reduced. The prepared isostatic pressing microcrystalline graphite has the advantages of high volume density, mechanical strength, low resistivity, fine and compact structure, and isotropy.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

Preparation method for petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth

InactiveCN107591527AUniform particle sizeStable structureMaterial nanotechnologyCell electrodesTetraethyl orthosilicateEnvironmental resistance

The invention relates to a preparation method for a petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth, and belongs to the technical field of nanometer material production. The preparation method comprises the steps of mixing ethanol, deionized water, ammonia water, tetraethyl orthosilicate, resorcinol and formaldehyde for reaction; drying a solid phase and performing calcination in argon; etching the solid phase with a sodium hydroxide solution to obtain the solid phase, and drying the solid phase to obtain the hollow mesoporous carbon nanometer sphere; mixingsodium molybdate dihydrate, thiourea and the hollow mesoporous carbon nanometer sphere for hydrothermal reaction, performing centrifugal washing after hydrothermal reaction, drying the solid phase, and performing high-temperature calcination under protection of argon atmosphere to obtain the petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth. The preparation method has the advantages that the raw material is low in cost, the process is environmental-friendly, high yield is achieved, and the prepared petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth can be used as a lithium ion battery electrode material, a photocatalytic material or an electrocatalytic material.

Owner:YANGZHOU UNIV

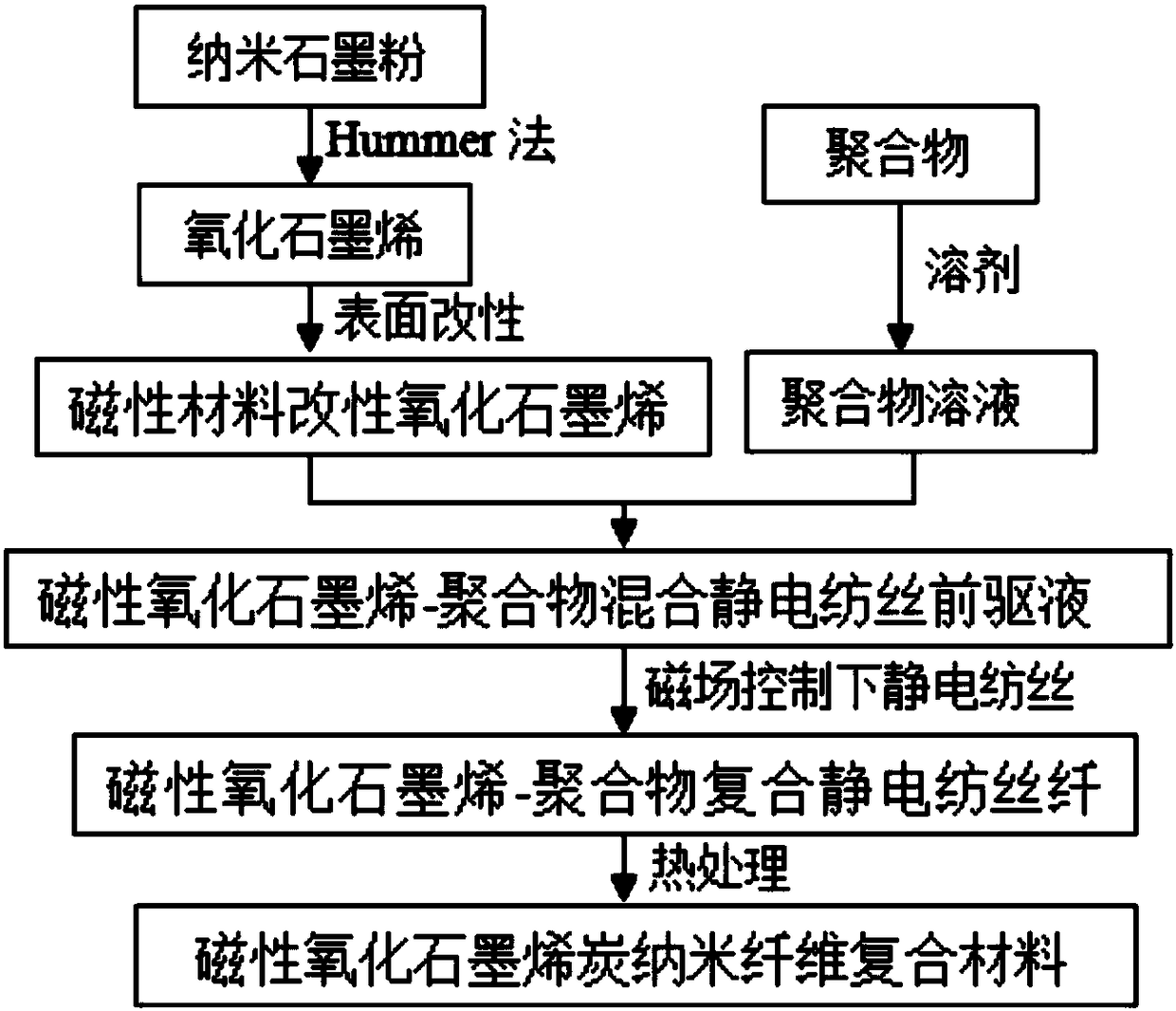

Preparation method of array magnetic reduced graphene oxide-carbon nanofiber

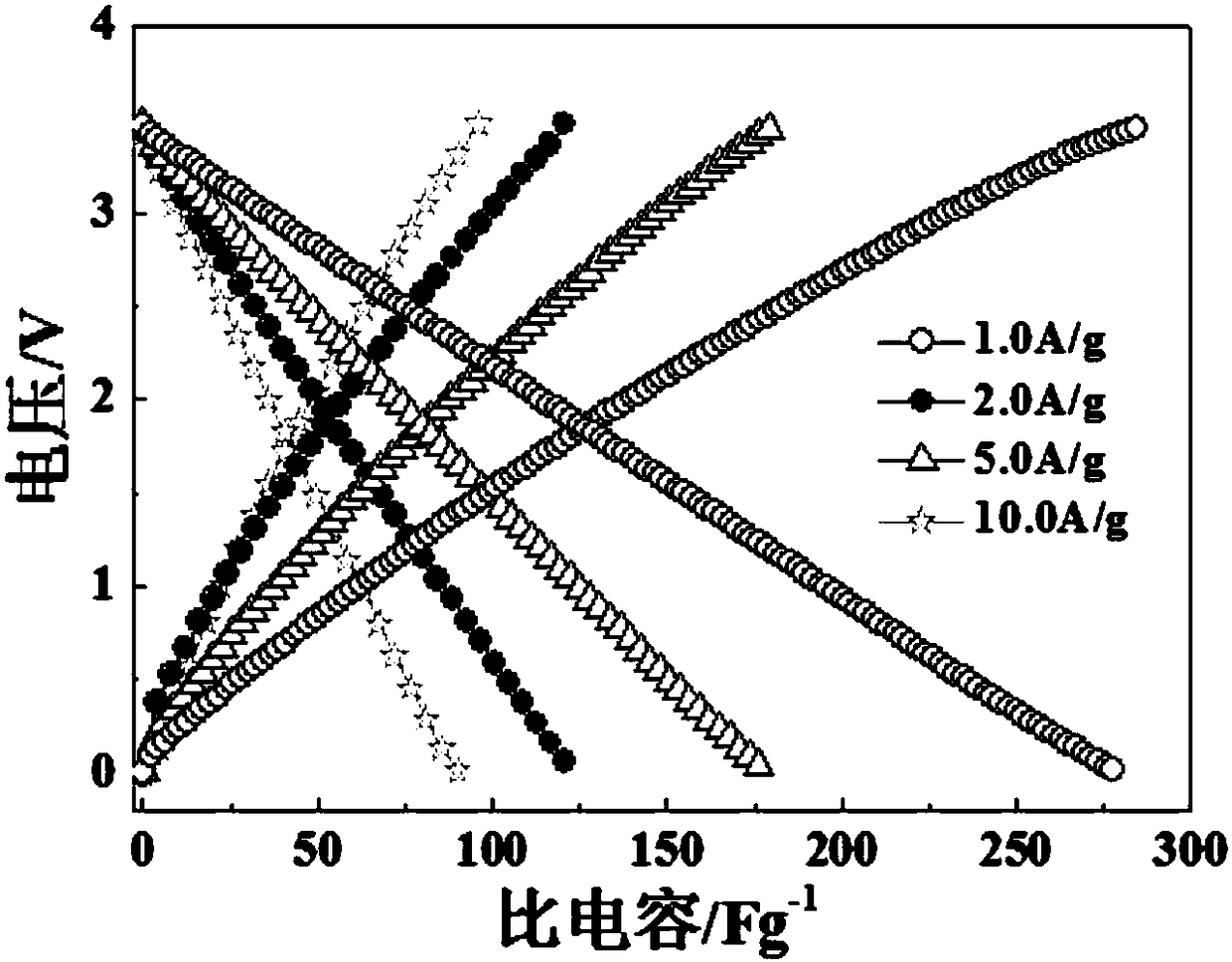

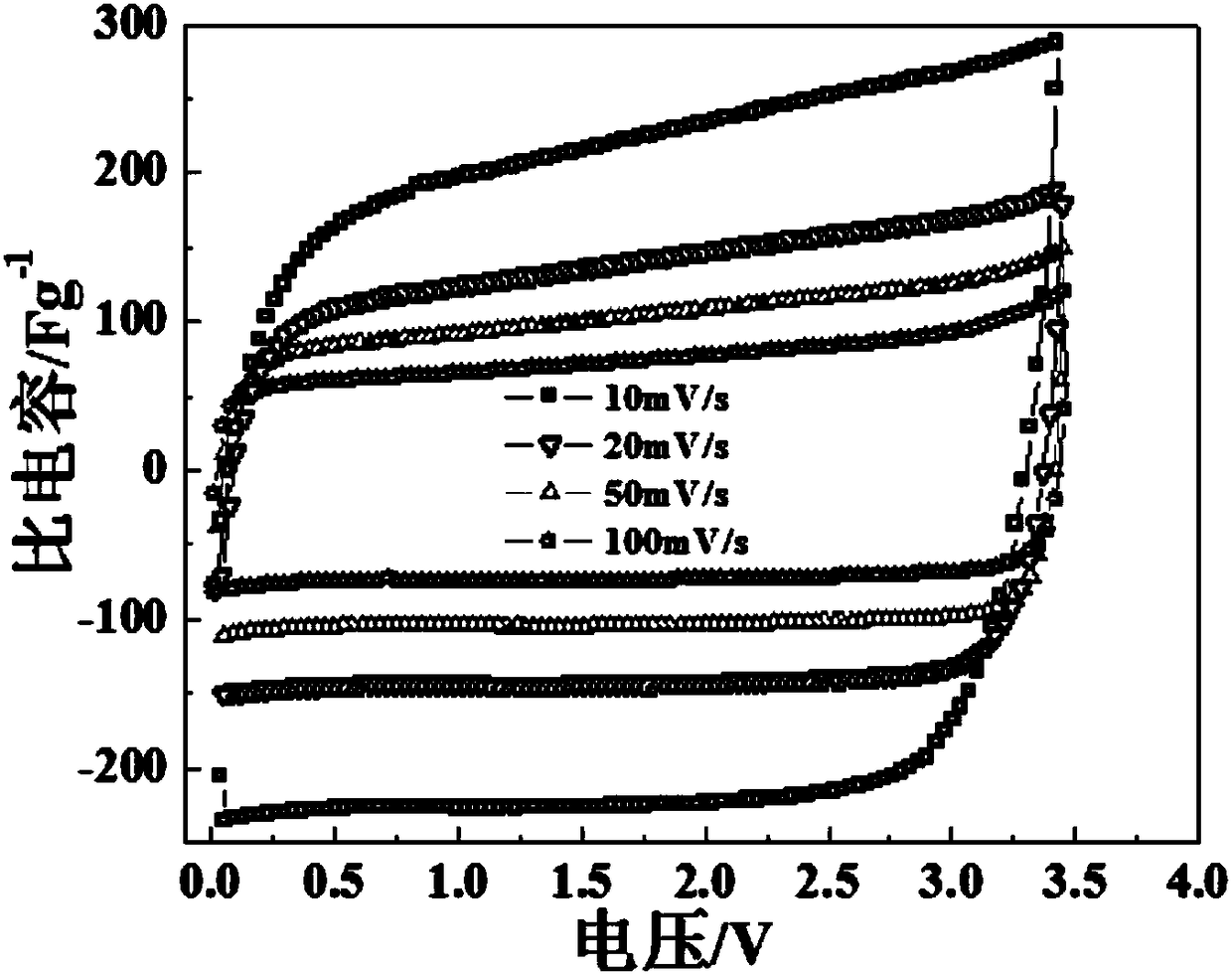

ActiveCN108315834AEasy to manufactureIncrease load capacityHybrid capacitor electrodesCell electrodesCapacitanceCharge discharge

The invention discloses a preparation method of array magnetic reduced graphene oxide-carbon nanofiber. The method comprises the following steps: taking flake graphite as a raw material, and preparinggraphene oxide with a Hummer method, so as to obtain the graphene oxide; preparing the graphene oxide and magnetic material precursor into magnetic material modified graphene oxide with a hydrothermal / solvothermal method, preparing the magnetic material modified graphene oxide, polymer and a solvent into a magnetic graphene oxide-polymer mixed electrostatic spinning precursor solution, preparingmagnetic graphene oxide-polymer compounded electrostatic spinning fiber, and performing heat treatment, so as to obtain a magnetic graphene oxide carbon nanofiber composite material. The method has the advantages that an RGO surface loaded nano metal oxide particle has a pseudocapacitor characteristic, can improve the charge energy storage density of the composite material, and is suitable for high-capacity power supercapacitors, with the specific capacitance being 240.3CP / F*g<-1>-254.1CP / F*g<-1> and the charge discharge efficiency being 99.1% to 99.6%.

Owner:锦州凯美能源有限公司

Preparation method and application of network structure nano NaVPO4F/C composite material and application thereof

ActiveCN104112858AHigh porosityImprove conductivityMaterial nanotechnologyCell electrodesPorosityCarbon layer

The invention discloses a network structure nano NaVPO4F / C composite material, and a preparation method thereof. The preparation method comprises the steps of adding a proper amount of alcohol to a mixed aqueous solution of a sodium source, a vanadium source, a fluorine source, a phosphorus source, a reducing agent and a carbon source; carrying out a solvothermal reaction at a temperature of 120-210 DEG C to obtain a carbon coated NaVPO4F precursor; and then calcining at a temperature of 750-900 DEG C under an inert atmosphere. In a high temperature environment, amorphous carbon is partially burned; a degree of graphitization is increased; NaVPO4F particles are fused and crystallized; grains grow; the carbon layer coating the NaVPO4F precursor can inhibit NaVPO4F particles from fusing together to some degree; and finally the network structure nano NaVPO4F / C composite material is formed. The material has a unique network structure and good porosity, and is beneficial to rapid migration of an electrolyte. Electrical conductivity of the whole material is improved due to effective compounding with carbon, and further electrochemical performance of NaVPO4F is increased. The network structure nano NaVPO4F / C composite is an excellent positive electrode material of the sodium ion battery.

Owner:SOUTHWEST UNIV

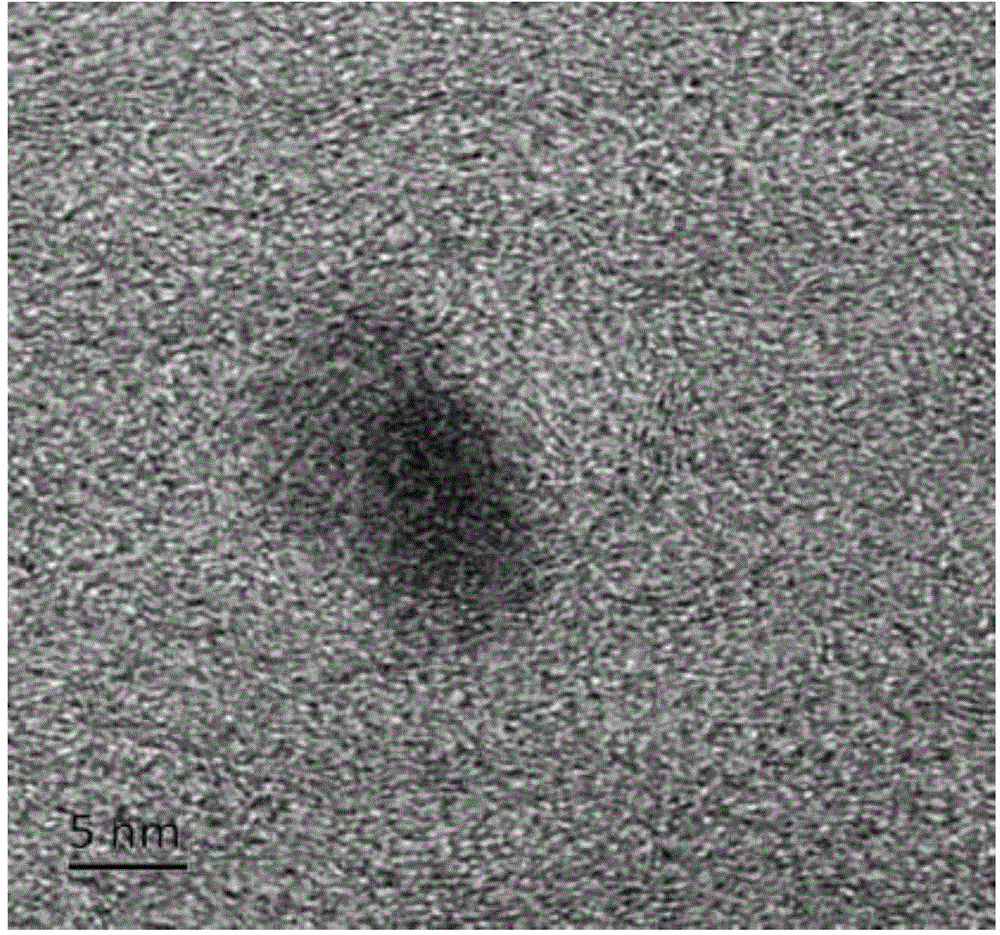

Graphitized stephanoporate material with carbon element and method of producing the same

The invention relates to a method for preparing graphitized porous carbon materials, which comprises that: hydrous metal oxide nano-particles dispersed in an aqueous solution are taken as templates to form metal oxide-organic polymer composite structures through condensation polymerization of a phenolic aldehyde precursor around a template phase; and in the subsequent high-temperature carbonization process, the composition structures form graphitized structures under the catalysis action of metal, and the graphitized porous carbon materials are obtained after the metal is dissolved by acid, wherein partial materials have magnetism. The materials can be applied in the fields of battery, adsorption, catalysis, water pollution removal, and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

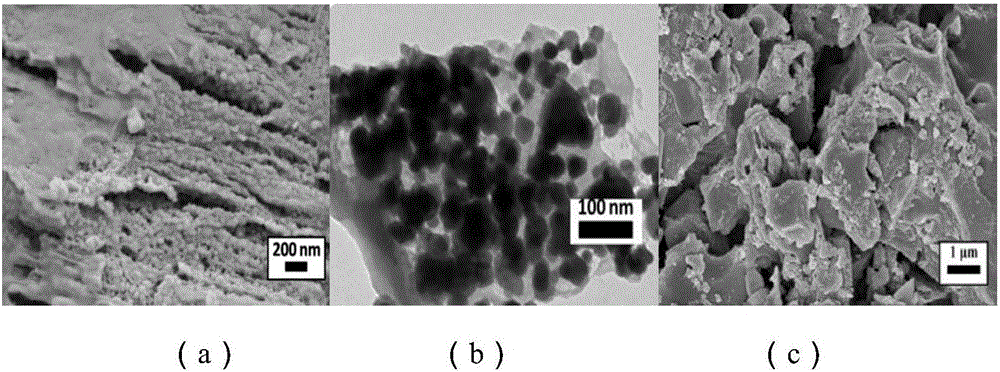

Pyrolysis preparation method of two-dimensional nano-sheet-layer lithium ion battery negative electrode material

InactiveCN103227327AReduce manufacturing costHigh degree of graphitizationCell electrodesPhysical chemistryGraphite

The invention discloses a pyrolysis preparation method of a two-dimensional nano-sheet-layer lithium ion battery negative electrode material. The method comprises the steps that: a mixed solution comprising glucose, ferric nitrate and sodium chloride is prepared by using deionized water; the solution is dried and grinded into powder; the powder is added into a tubular furnace and is heated, and is cooled with the furnace; the powder is fetched and finely grinded, such that gray-black powder is obtained; the gray-black powder is dispersed into deionized water, such that a suspension liquid is obtained; pump-filtration and washing are carried out, such that black powder is obtained; the black powder is dispersed in hydrochloric acid; and water-bath heating, refluxing, pump-filtration, and washing are carried out, such that the two-dimensional nano-sheet-layer lithium ion battery negative electrode material is obtained. According to the method, the raw materials are cheap and are easy to obtain; a preparation cost is low; a process is simple and feasible; and continuous large-scale production can be carried out. The obtained material has high graphitization degree, large specific surface area, and substantial mesoporous characteristics. As the lithium ion battery negative electrode material, the material has good circulation performance, good rate performance, good stability, and wide application prospect.

Owner:TIANJIN UNIV

Preparation method of Ni3Fe-loaded nitrogen-doped carbon nanometer composite material, and product and applications thereof

ActiveCN109248703ARegular shapeImprove hydrogen evolution activityCatalyst activation/preparationElectrodesElectrospinningAir atmosphere

The invention discloses a preparation method of a Ni3Fe-loaded nitrogen-doped carbon nanometer composite material, and a product and applications thereof. The preparation method comprises following steps: 1, a Ni<2+> / Fe<3+> / PVP mixed sol is prepared; 2, the Ni<2+> / Fe<3+> / PVP mixed sol is subjected to electrostatic spinning so as to obtain solid carbon fiber film; 3, the solid carbon fiber film issubjected to pre-oxidation at air atmosphere at 200 to 300 DEG C, programmed heating is adopted for heat processing at 400 to 1000 DEG C at an inert atmosphere so as to obtain the Ni3Fe-loaded nitrogen-doped carbon nanometer composite material. The preparation method is low in cost, is easy, and is universal; the obtained Ni3Fe-loaded nitrogen-doped carbon nanometer composite material is of a one-dimensional composite structure (carbon nanometer fiber and carbon nanotube); Ni3Fe alloy particles can be embedded into the carbon nanometer fiber and carbon nanotube uniformly; the Ni3Fe-loaded nitrogen-doped carbon nanometer composite material can be taken as a water electrolysis hydrogen evolution electrocatalytic material, and possesses relatively high activity and excellent stability.

Owner:NANJING NORMAL UNIVERSITY

Method for preparing lignin-based carbon fiber hydrogen storage material by electrostatic spinning process

ActiveCN104947246AWide variety of sourcesLow priceFilament/thread formingFibre chemical featuresAir atmosphereMicro nano

The invention relates to a method for preparing a hydrogen storage material, and particularly relates to a method for preparing a lignin-based carbon fiber hydrogen storage material by electrostatic spinning. The method comprises the following steps: preparing a sodium lignin sulfonate / polyacrylonitrile / nickel acetate / boric acid spinning solution; preparing sodium lignin sulfonate / polyacrylonitrile composite micro-nano fiber through electrostatic spinning; drying in a vacuum drying oven and pre-oxidizing in an air atmosphere in a muffle furnace; and gradually heating and calcining in a condition of continuously introducing an inert gas into the tubular furnace to obtain sodium lignin sulfonate / polyacrylonitrile composite carbon fiber containing a Ni-B catalyst, wherein Ni-B realizes an effect of catalytic graphitization. The prepared sodium lignin sulfonate / polyacrylonitrile composite carbon fiber has relatively high graphitization degree, and the hydrogen absorption capacity under the conditions of 298K and 95bar reaches 0.92wt% within 60s.

Owner:QUANGANG PETROCHEM RES INST OF FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com