Preparation method and application of network structure nano NaVPO4F/C composite material and application thereof

A technology of network structure and composite materials, applied in the field of sodium vanadium phosphate materials, can solve the problems of poor rate performance, uneven carbon coating, low battery capacity, etc., and achieve improved electrochemical performance, low cost, and unique network structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, carbon-coated NaVPO 4 Synthesis of F precursors

[0035] Weigh 2mmol NH 4 VO 3 and 2mmol NaF were dissolved in 10ml deionized water to obtain liquid I; weigh 2mmol NH 4 h 2 PO 4 Dissolve 3mmol vitamin C in 10ml deionized water to obtain liquid II; slowly drop liquid I into liquid II and stir for 10 minutes to obtain liquid III; add 50 ml of absolute ethanol dropwise to liquid III, stir for 10 minutes, and then transfer to In a solvothermal reaction kettle, react at 180°C for 24 hours, filter and wash after cooling, and freeze-dry the solid to obtain carbon-coated NaVPO 4 F precursor.

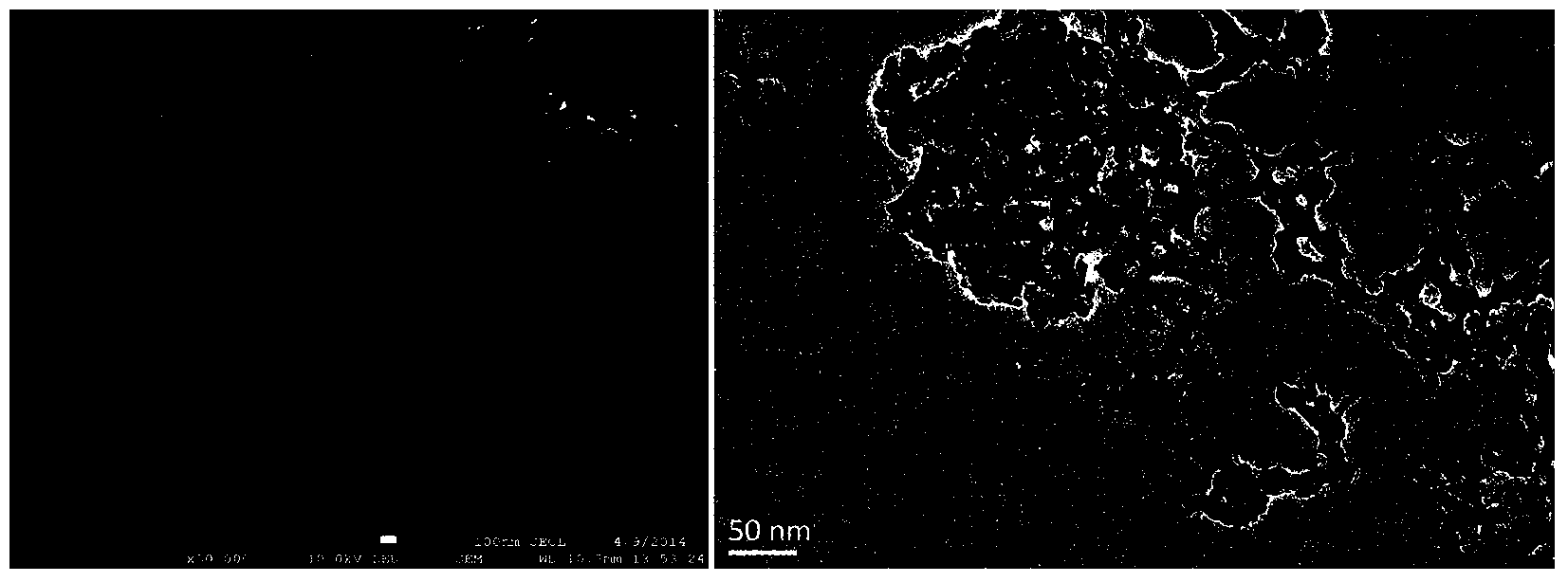

[0036] The appearance of the obtained product is as figure 1 As shown, the particle shape is regular, the particle size is very small (nanoscale), and the surface is uniformly covered by carbon. The component analysis results of the obtained product are as follows: Figure 4 As shown, the synthesized material is carbon-coated NaVPO 4 F precursor.

Embodiment 2

[0037] Embodiment two, network structure nano-NaVPO 4 Synthesis of F / C Composites

[0038] The carbon-coated NaVPO that embodiment one makes 4 The F precursor was calcined at 750 °C for 6 hours under the protection of argon, and cooled to room temperature to obtain nano-NaVPO with network structure. 4 F / C composites.

[0039] The appearance of the obtained product is as figure 2 As shown, there are uniform nanoparticles. The component analysis results of the obtained product are as follows: Figure 4 Shown, the synthetic substance is NaVPO 4 F, its crystal form is monoclinic.

Embodiment 3

[0040] Embodiment three, network structure nano-NaVPO 4 Synthesis of F / C Composites

[0041] The carbon-coated NaVPO that embodiment one makes 4 The F precursor was calcined at 800°C under argon protection for 6 hours, cooled to room temperature, and the network structure nano-NaVPO was obtained. 4 F / C composites.

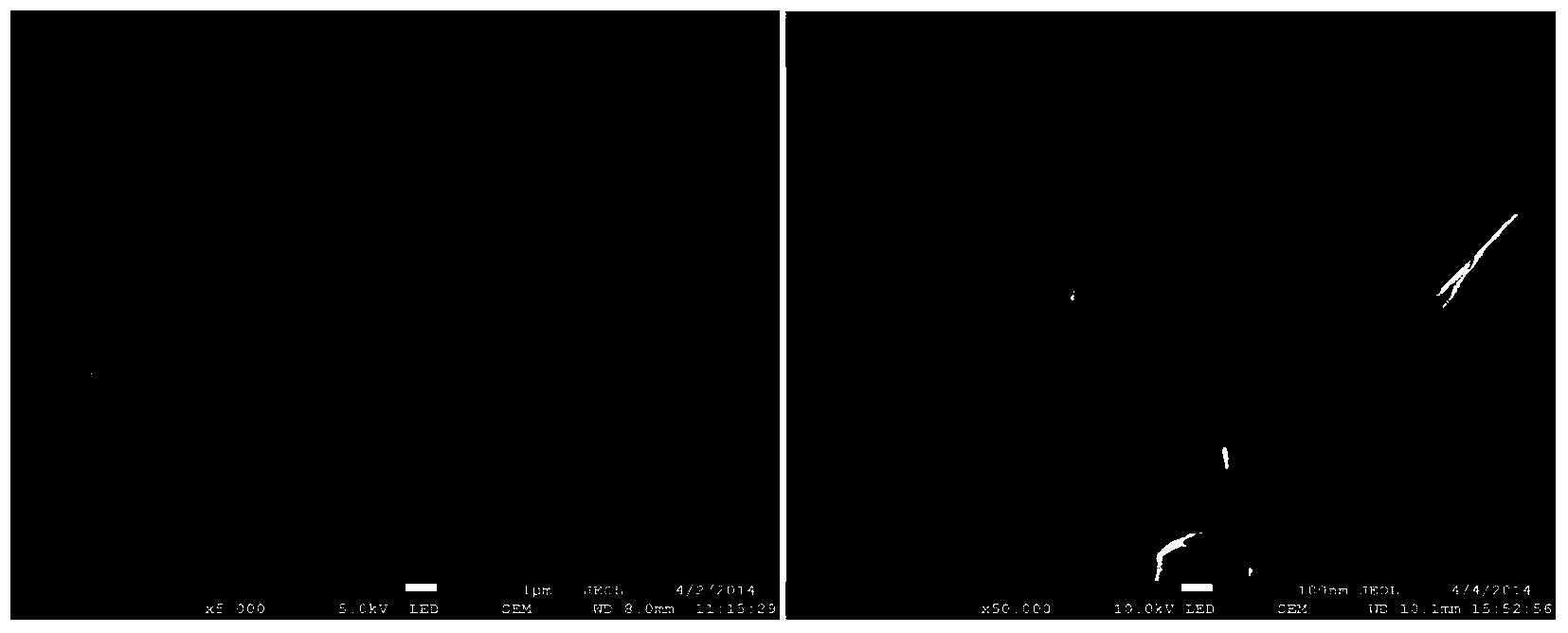

[0042] The appearance of the obtained product is as image 3 As shown, there are uniform nanoparticles. The component analysis results of the obtained product are as follows: Figure 4 Shown, the synthetic substance is NaVPO 4 F, its crystal form is monoclinic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com