Porous carbon material and preparation and application thereof

A porous carbon material, multi-level porous technology, applied in the preparation/purification of carbon, etc., can solve the problems of increased production cost, low graphitization layer, and high price of template agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a porous carbon material, comprising the following steps,

[0031] (a) Add melamine, glucose and nickel sulfate in a molar ratio of 30:1:0.005 to water at 95°C to obtain a mixed solution, add sodium phosphate whose amount is 0.3 times the amount of melamine to the mixed solution, and stir until the dissolution is complete, Dry by rotary evaporation to obtain precipitate;

[0032] (b) Place the precipitate obtained in step (a) in a tube furnace, under the protection of nitrogen, raise the temperature to 500°C at 10°C / min, keep it warm for 1 hour, then raise the temperature to 950°C at 10°C / min, and keep it warm for 3 hours, a composite of carbon material and metal nickel is obtained;

[0033] (c) Pickling the composite obtained in step (b) at 80° C. in 1M sulfuric acid solution for 2 hours, washing with a large amount of deionized water, and air-drying to obtain a porous carbon material.

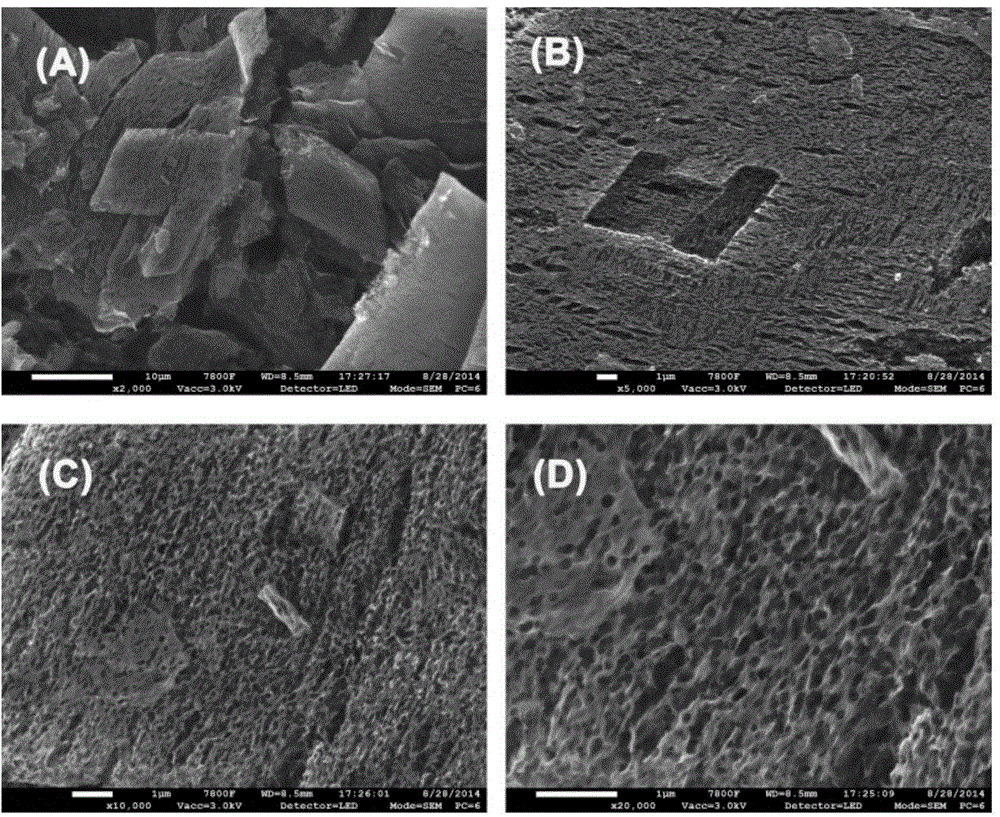

[0034] The size of a single prismatic block of the porous...

Embodiment 2

[0042] A method for preparing a porous carbon material, comprising the following steps,

[0043] (a) Add melamine, glucose and nickel citrate with a molar ratio of 40:1:0.0025 to water at 95°C to obtain a mixed solution, add the same amount of ammonium phosphate to the mixed solution, stir until it is completely dissolved, and dry by rotary evaporation to obtain Precipitate;

[0044] (b) Place the precipitate obtained in step (a) in a tube furnace, under the protection of nitrogen, raise the temperature to 500°C at 5°C / min, keep it warm for 1 hour, then raise the temperature to 1000°C at 5°C / min, and keep it warm for 3 hours, a composite of carbon material and metal nickel is obtained;

[0045] (c) Pickling the compound obtained in step (b) at 80° C. in 1M hydrochloric acid solution for 0.5 hours, washing with a large amount of deionized water, and air-drying to obtain a porous carbon material.

[0046] The size of a single prismatic block of the porous carbon material obtai...

Embodiment 3

[0048] A method for preparing a porous carbon material, comprising the following steps,

[0049] (a) Add melamine, glucose and nickel chloride with a molar ratio of 80:1:0.01 to water at 95°C to obtain a mixed solution, add the same amount of phosphoric acid to the mixed solution, stir until the solution is complete, and then dry it by rotary evaporation to obtain a precipitate thing;

[0050] (b) Place the precipitate obtained in step (a) in a tube furnace, under the protection of nitrogen, raise the temperature to 450°C at 3°C / min, keep the temperature for 3 hours, then raise the temperature to 850°C at 10°C / min, and keep the temperature for 2 hours, a composite of carbon material and metal nickel is obtained;

[0051] (c) Pickling the compound obtained in step (b) at 80° C. in 1M hydrochloric acid solution for 2 hours, washing with a large amount of deionized water, and air-drying to obtain a porous carbon material.

[0052] The size of a single prismatic block of the por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Large hole size | aaaaa | aaaaa |

| Mesopore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com