Novel water-based adhesive for polyester filament canvas shoes and preparation method thereof

A technology of adhesive and filament sail is applied in the field of new water-based adhesive for polyester filament canvas shoes and its preparation, which can solve the problems of low product qualification rate, delamination of rubber sole cloth, low initial adhesion strength, etc. , to achieve the effect of excellent process performance, high final adhesive strength and improved internal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

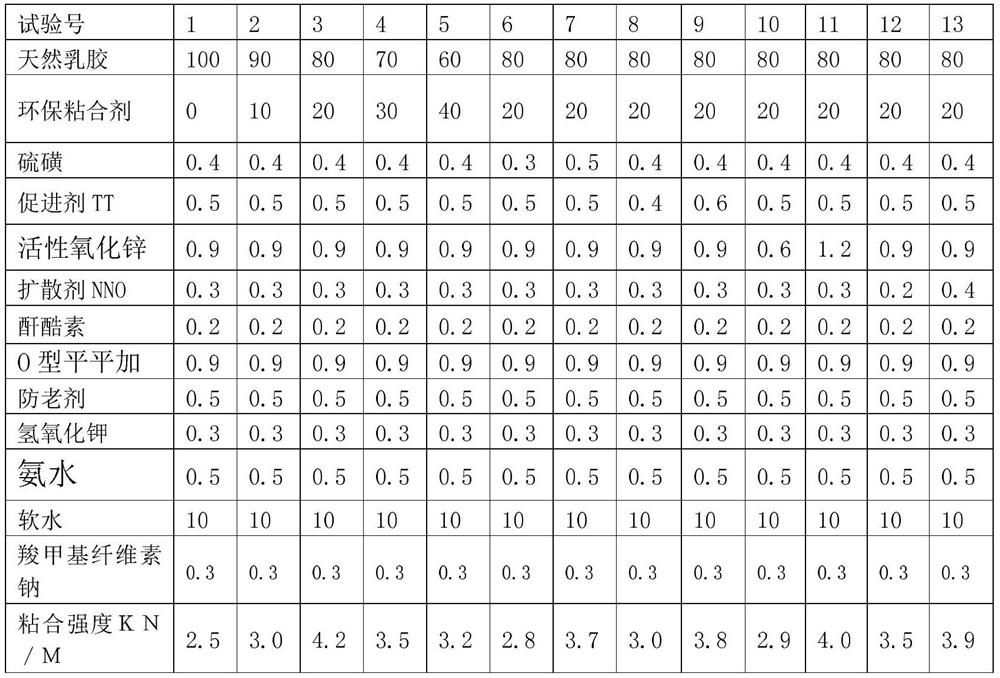

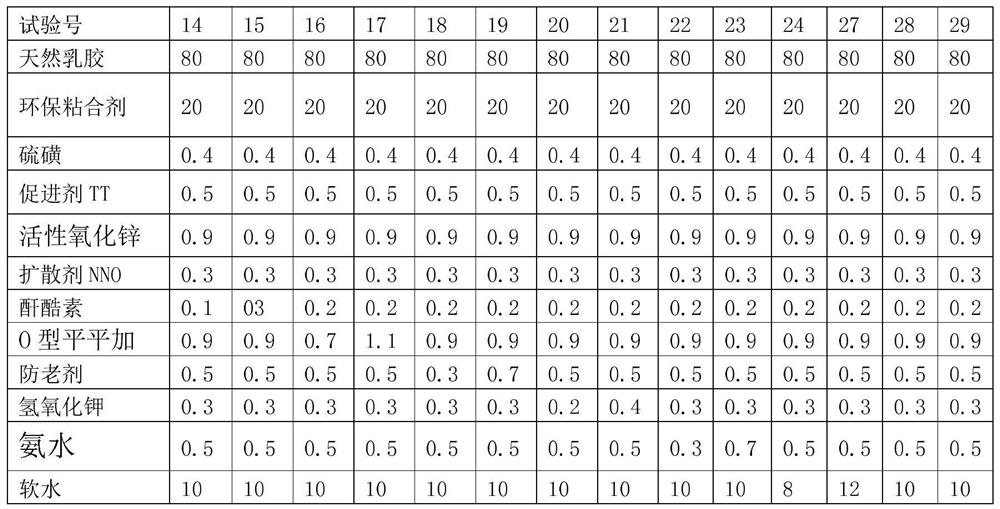

[0071] Embodiment 1 of the present invention: new water-based adhesive for polyester filament canvas shoes, including 80kg of natural latex, 20kg of environmentally friendly adhesive, 10kg of soft water, 0.3kg of sodium carboxymethyl cellulose, 0.40kg of sulfur, and accelerator TMTD 0.50kg, active zinc oxide 0.9kg, diffusing agent 0.3kg, anti-aging agent 0.5kg, anhydride casein 0.2kg, O-type flat plus 1kg, ammonia water 0.5kg, potassium hydroxide 0.4kg and fungicide DC-F 0.07kg Prepare ingredients.

[0072] The preparation method of novel water-based adhesive for polyester filament canvas shoes, each component is taken according to the above-mentioned parts by weight;

[0073] 1) Prepare powder water emulsion: dissolve 0.35kg potassium hydroxide with 3kg soft water (reserve another 0.05kg potassium hydroxide for later use), then add sulfur, accelerator TMTD, active zinc oxide, diffusing agent, anti-aging agent, anhydride casein in sequence Add 1.5kg of soft water, stir evenly...

Embodiment 2

[0077] Embodiment 2 of the present invention: new water-based adhesive for polyester filament canvas shoes, including 85 kg of natural latex, 15 kg of environmental adhesive, 10 kg of soft water, 0.35 kg of sodium carboxymethyl cellulose, 0.46 kg of sulfur, and accelerator TMTD 0.60kg, active zinc oxide 0.95kg, diffusing agent 0.25kg, anhydride casein 0.2kg, O-type Pingpingjia 1.1kg, ammonia water 0.5kg, potassium hydroxide 0.3kg, anti-aging agent 0.50kg and anti-fungal agent DC-F 0.07kg For the preparation of raw materials.

[0078] The preparation method is the same as in Example 1.

Embodiment 3

[0079] Embodiment 3 of the present invention: new water-based adhesive for polyester filament canvas shoes, including 80kg of natural latex, 20kg of environmentally friendly adhesive, 10kg of soft water, 0.35kg of sodium carboxymethyl cellulose, 0.46kg of sulfur, and accelerator TMTD 0.60kg, active zinc oxide 0.85kg, diffusion agent anhydride casein 0.25kg, anhydride casein 0.2kg, O-type Pingpingjia 1.0kg, ammonia water 0.5kg, potassium hydroxide 0.45kg, anti-aging agent 0.50kg and anti-fungal agent DC- F 0.07kg is raw material for preparation.

[0080] The preparation method is the same as in Example 1.

[0081] The obtained new water-based adhesive for polyester filament canvas shoes has high stability, can bond multi-specification upper fabrics, has high initial tack and final tack, and realizes the bonding between the adhesive and the shoe. All rubber parts are vulcanized synchronously.

[0082] Use a glue brush to paint the prepared polyester filament canvas shoes with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com