Patents

Literature

570 results about "Rubber shoes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

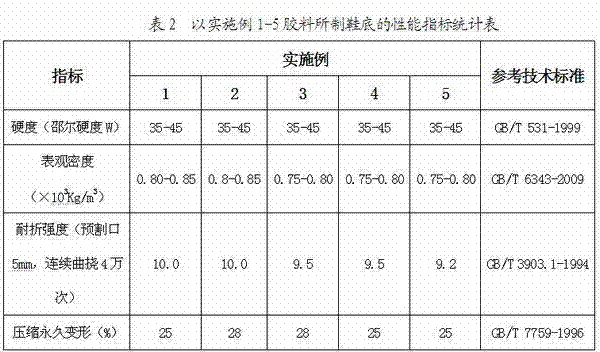

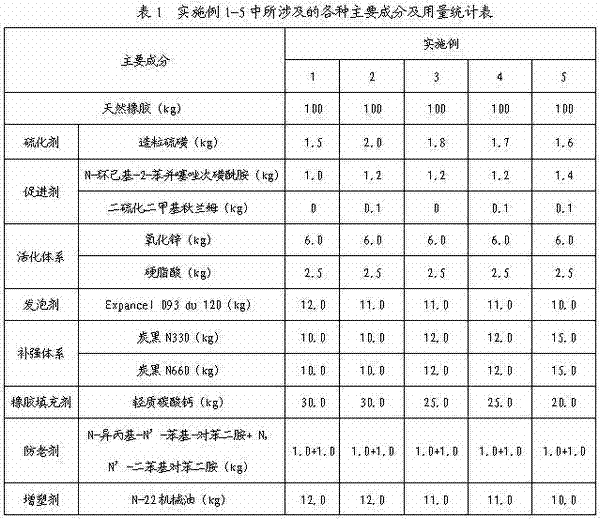

Ultralight high-elastic rubber sole material and preparation method thereof

InactiveCN103205026AIncrease elasticityImprove bending resistanceSolesSpecific gravityButadiene-styrene rubber

The invention discloses an ultralight high-elastic rubber sole material and a preparation method thereof. The ultralight high-elastic rubber sole material comprises the following raw materials in parts by weight: 40-60 parts of natural rubber, 30-40 parts of synthetic rubber, 10-20 parts of SEBS (Styrene-Butadiene-Styrene Block Copolymer) rubber, 10-20 parts of synthetic EVA (Ethylene Vinyl-Acetate Copolymer), 30-40 parts of ultralight white carbon black, 6-10 parts of naphthenic oil, 3-5 parts of high-activity zinc oxide, 3-5 parts of activating agents, 2-3 parts of vulcanization accelerators, 1-2 parts of stearic acid, 2-3 parts of diethylene glycol and 1-3 parts of anti-aging agents. The preparation method of the ultralight high-elastic rubber sole material comprises four steps. The ultralight high-elastic sole rubber prepared through the method disclosed by the invention has the advantages of scientificity in formula, low cost, simple preparation process and lighter specific gravity of the sole material and effectively enhances the elasticity and bending resistant degree of a sole.

Owner:南平市天时雨投资合伙企业(有限合伙)

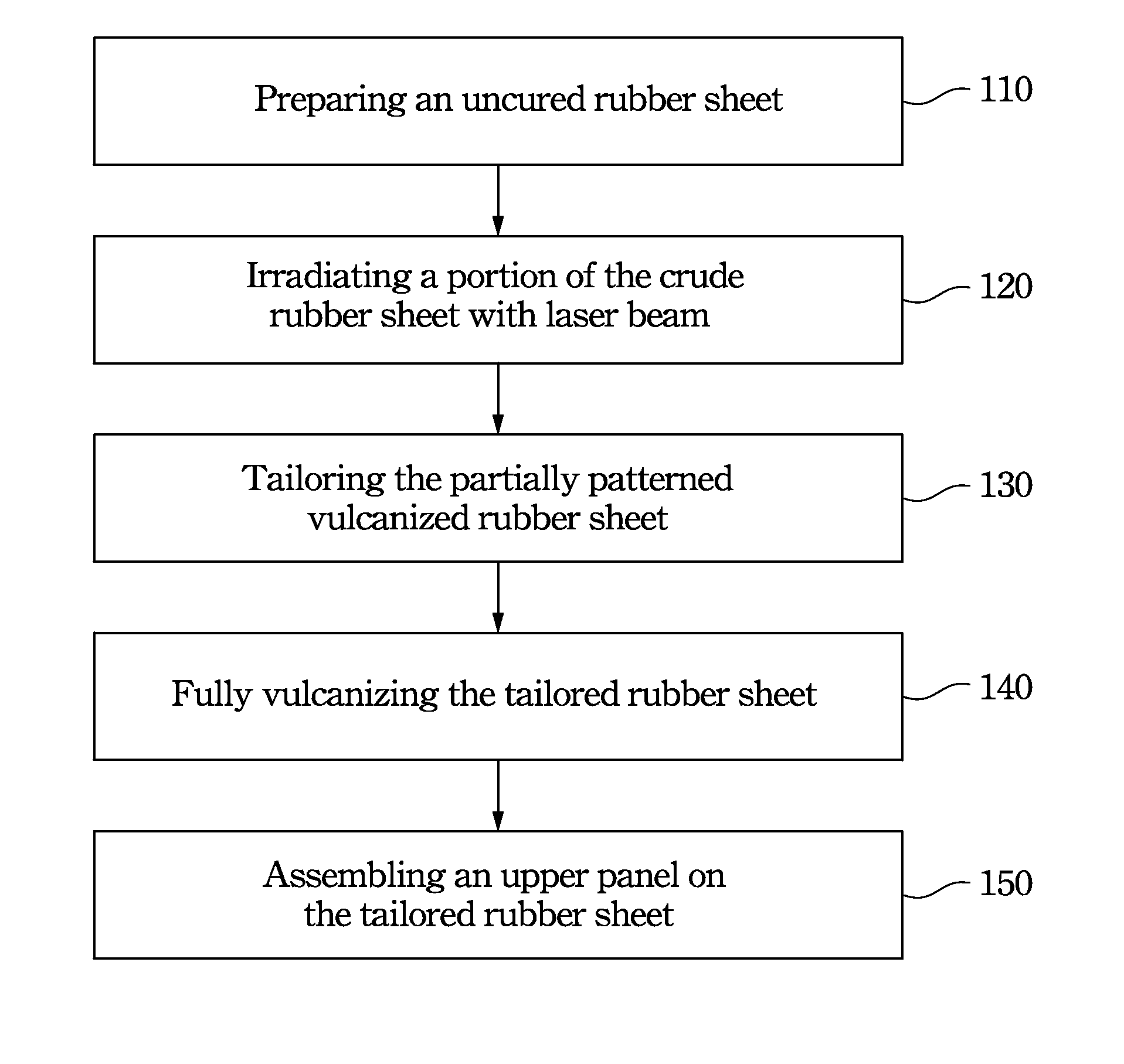

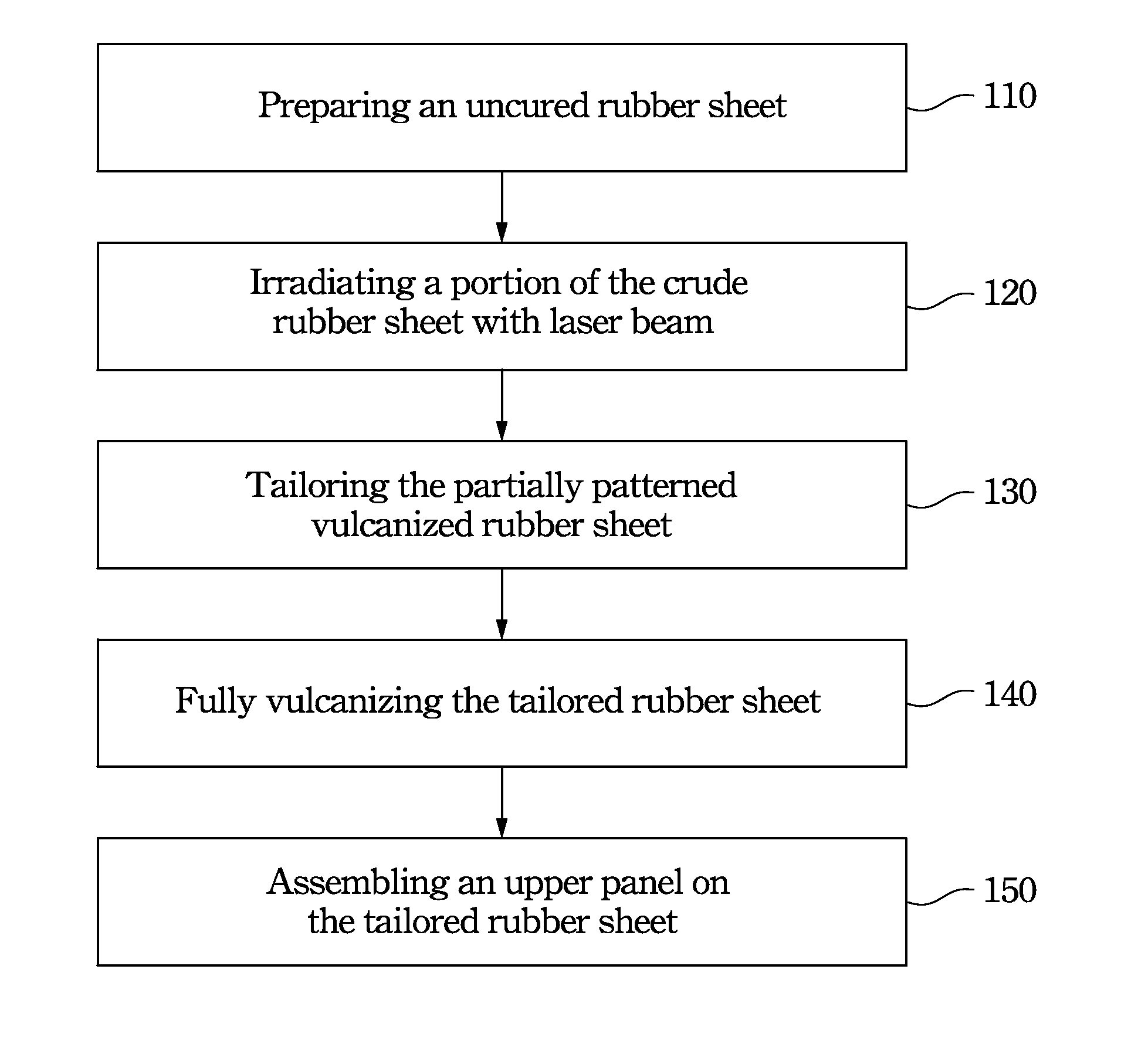

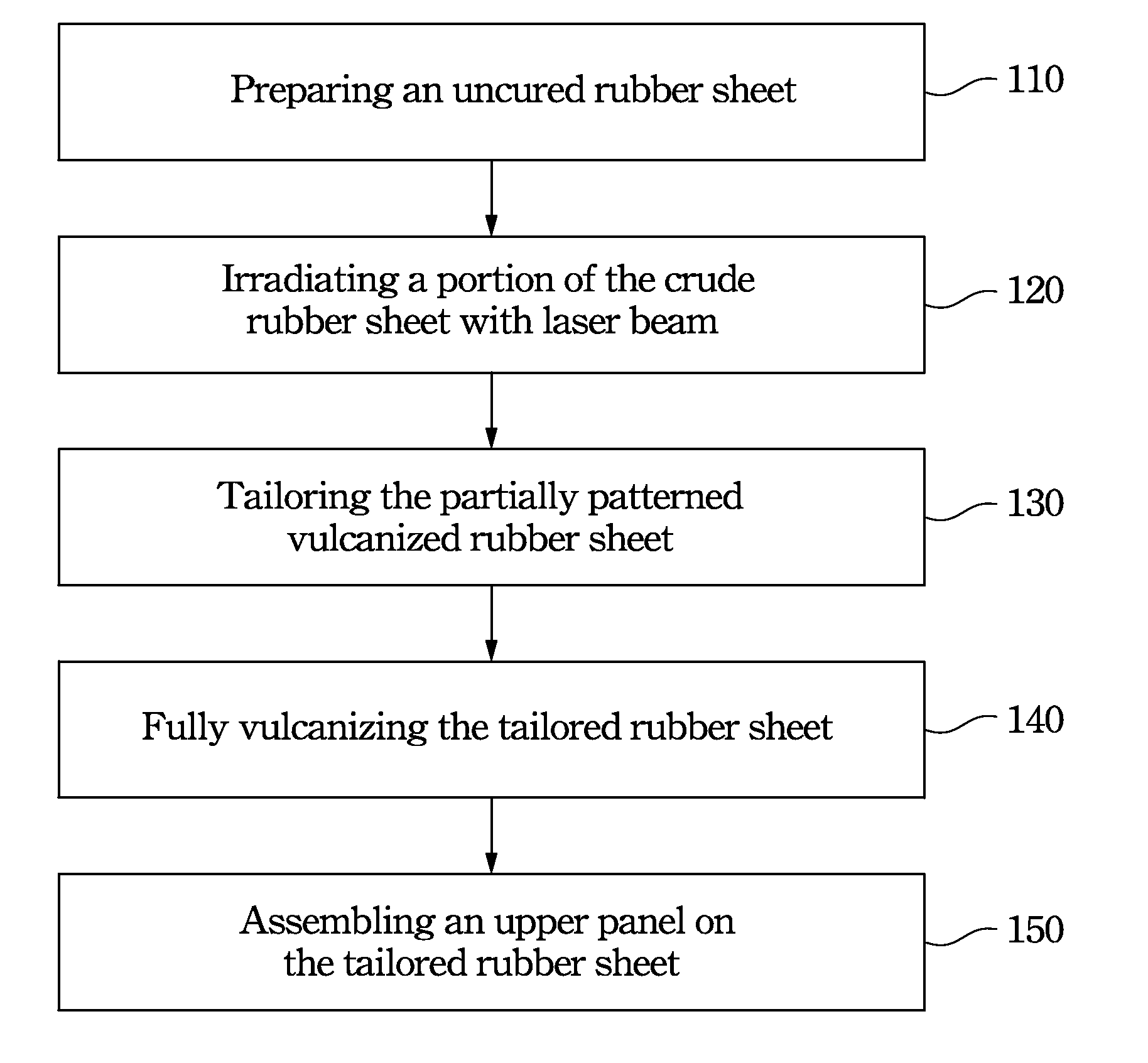

Method of preparing a rubber shoe sole

ActiveUS8689381B2Increase variabilityTime and cost-effectiveShoemaking devicesSolesEngineeringRubber sheet

Disclosed herein is a novel method of preparing shoe sole. The method of preparing shoe sole includes irradiating an uncured rubber sheet by laser beam to pattern and vulcanize a portion of the uncured rubber, tailoring the partially patterned vulcanized rubber into a shoe shape, and afterward fully vulcanizing the partially patterned vulcanized rubber sheet to form a shoe sole. An additional step of assembling the upper panel of shoe sole on the partially vulcanized rubber sheet is also performed.

Owner:SHEI CHUNG HSIN IND

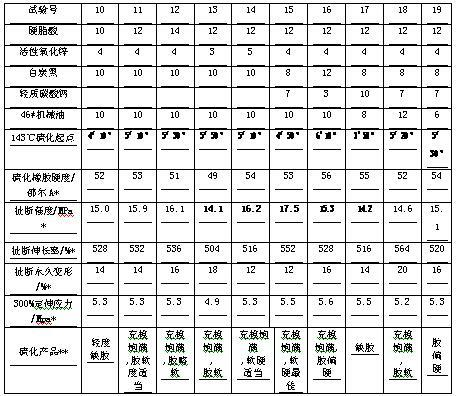

Rubber for sneaker sole and preparation method thereof

The invention discloses rubber for a sneaker sole, and the rubber provided by the invention comprises the following components in parts by weight: 30-70 parts of butadiene rubber, 10-30 parts of natural rubber, 10-30 parts of bromobutyl rubber, 15-40 parts of carboxylated nitrile rubber, 2-5 parts of polyethylene glycol, 0.5-2 parts of stearic acid, 2-5 parts of zinc oxide, 1.5-2 parts of vulcanizer, 1.6-2.1 parts of accelerator, 0.5-2.0 parts of tackifier, 30-70 parts of white carbon black, 3-3.2 parts of coupling agent, 2-5 parts of softening oils, 1-3 parts of anti-aging agent and 0.5-1 part of paraffin. The invention further discloses a preparation method of the rubber. The rubber for the sneaker sole, provided by the invention, has incomparable slip prevention performance compared with the ordinary rubber shoe sole, and has multiple functions such as excellent wear resistance, bend resistance, and the like.

Owner:ANTA CHINA

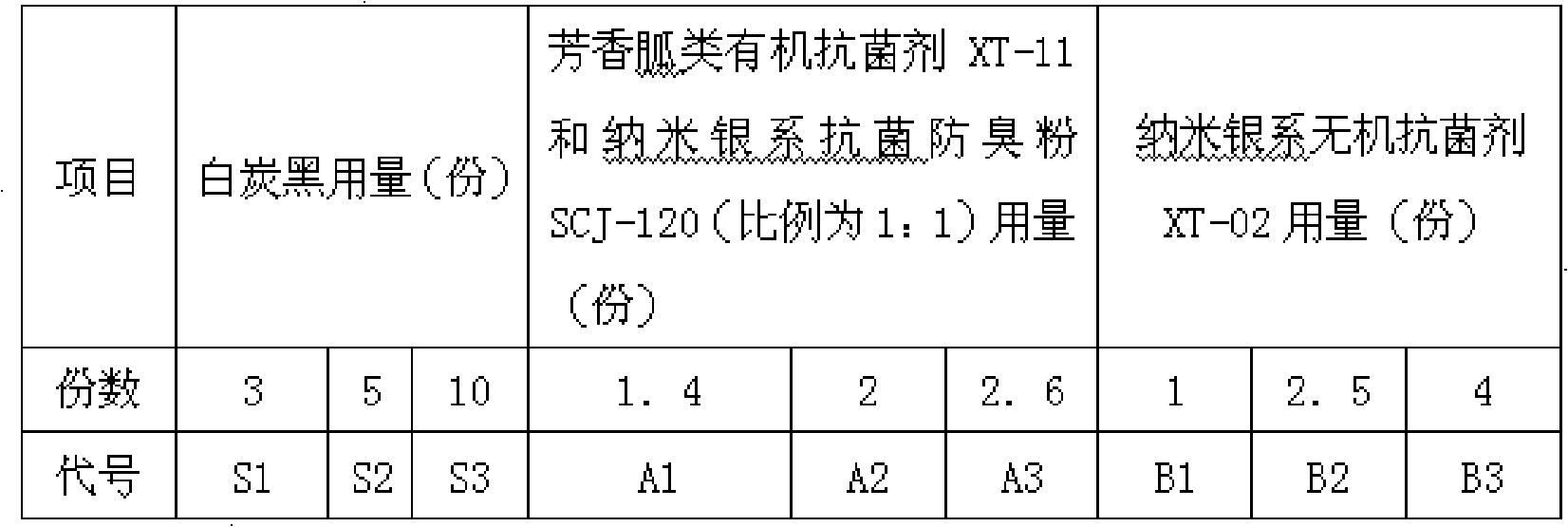

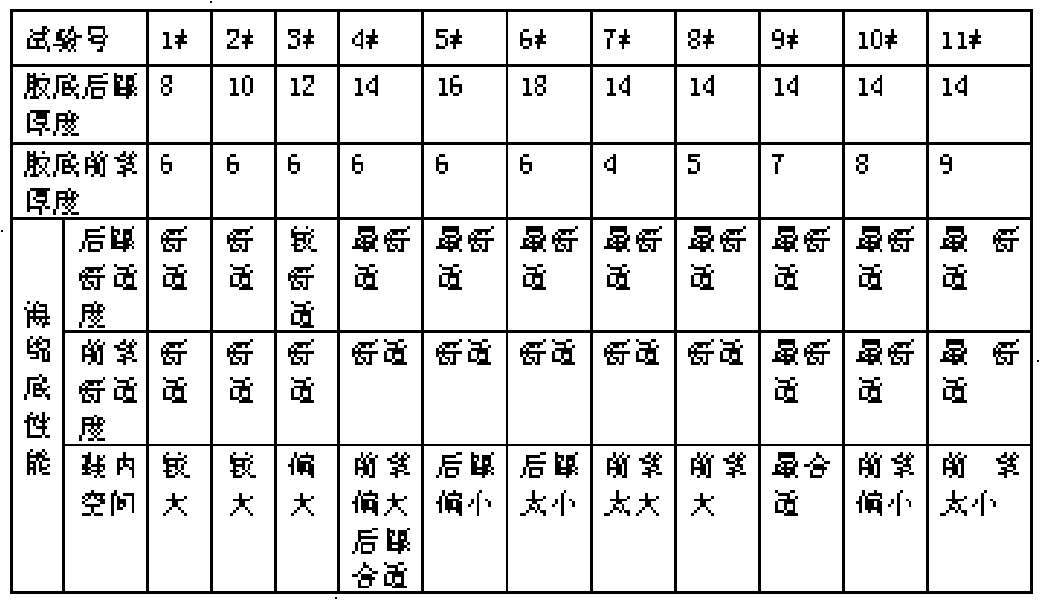

Light high elasticity deodorant rubber spongy cushion for shoes and preparation method thereof

The invention provides a light high elasticity deodorant rubber spongy cushion for shoes and a preparation method thereof. The light high elasticity deodorant rubber spongy cushion comprises components based on parts by weight: 50-150 parts of natural rubber, 2-50 parts of cis-butadiene rubber, 2-3 parts of sulphur, 0.8-4.5 parts of vulcanization accelerator, 1.5-5 parts of sulfurization activator, 1.5-2.5 parts of foaming agent, 15-25 parts of stearic acid, 35-45 parts of filler and 1.5-3 parts of deodorant. The rubber spongy cushion has reasonable elasticity and light specific gravity, reduces the fatigue degree when being worn, is good in the effect of preventing funguses such as candida albicans, staphylococcus aureus, bacillus coli and the like as well as bacteria, and greatly improves the hygiene and the functionality of the rubber shoes; furthermore, the rubber spongy cushion prepared by the method has proper thickness, so as to improve the comfort feeling. In addition, the materials selected by the invention can be easily obtained, and the invention has the advantages of low cost, simple preparation method, easy implementation and good performance of the produced product.

Owner:JIHUA 3537 SHOE MAKING

Super high wear resistance rubber sole and preparation thereof

ActiveCN101328288AImprove the ability to resist external forceHigh strengthSolesDomestic articlesWear resistantCarbon black

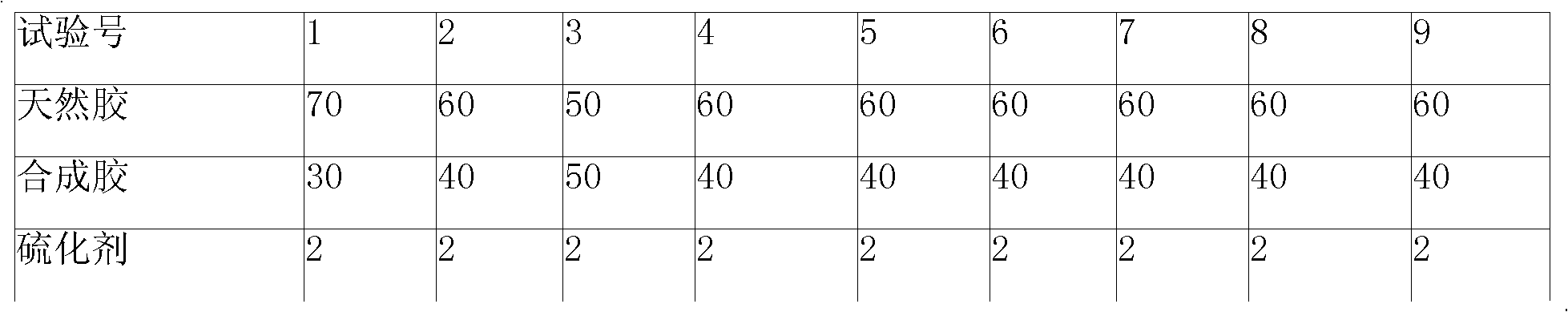

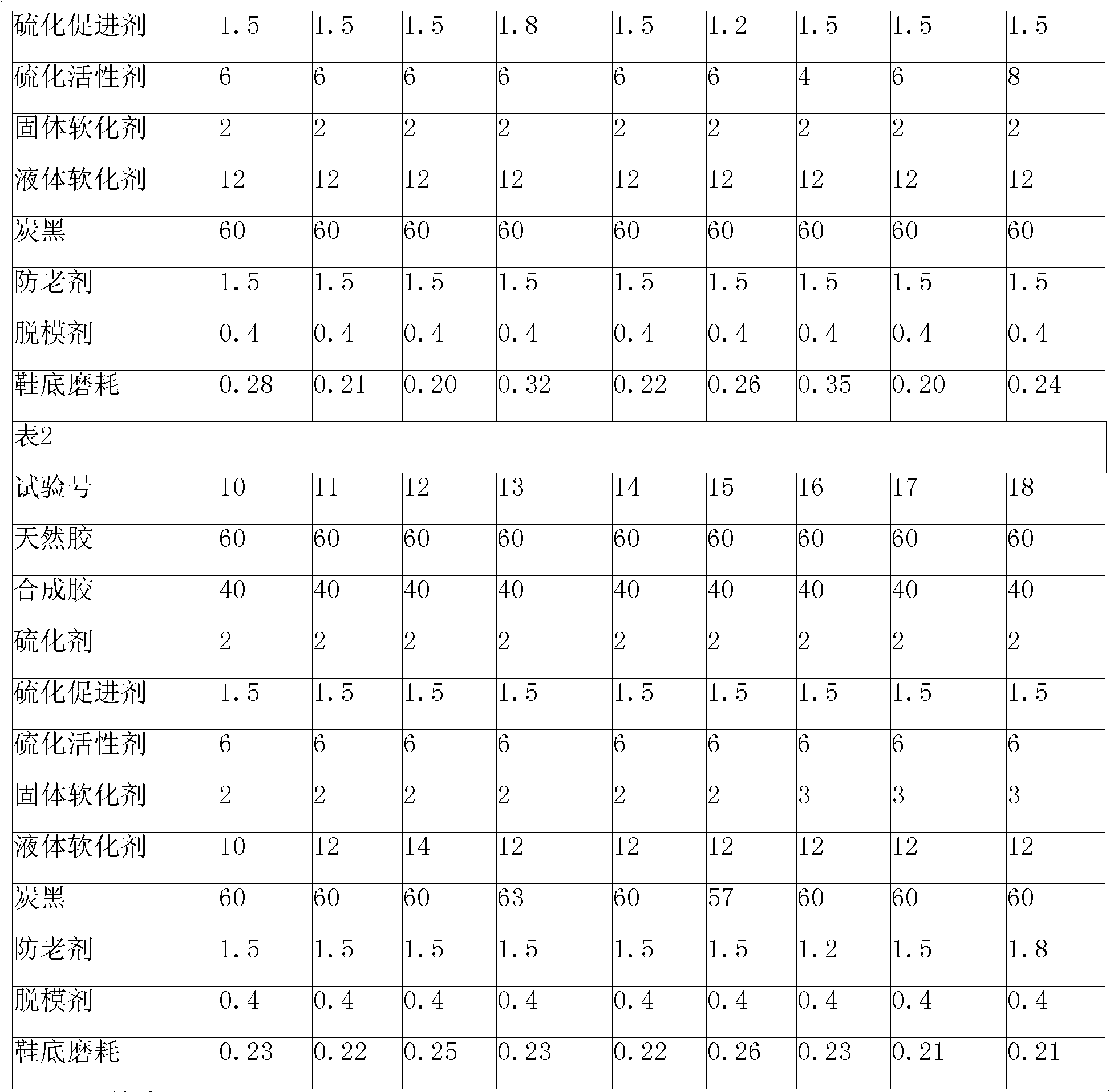

The invention discloses a highly wear resistant rubber sole and a preparation method thereof. The rubber sole is mainly made by plastication, masterbatching, mixing and remixing of natural rubber, synthetic rubber, sulfidizer, vulcanization accelerator, vulcanization activator, solid softener, liquid softener and carbon black. The rubber sole has the advantages of enhancing the outside force resistance of the rubber, improving the extension modulus and the tensile strength of the rubber, improving the resilience force of the outer bottom, lowering the Hardness HA of rubber materials and radically realizing the highly wear resistant performance; moreover, in the invention, the rubber materials for the highly wear resistant rubber sole are not mixed with plastic materials, and the weight of the synthetic rubber against the total weight of framework materials is not more than 40 percent, while the wear resistance of the sole reaches the Akron wear volume 0.15 to 0.30cm<3> / 1.61km, which is far higher than the wear resistance (0.5cm<3> / 1.61km) of the rubber for tires, so that the service life of the rubber sole is prolonged more than three times.

Owner:际华制鞋工业有限公司

Protection rubber shoes used for industrial and mining enterprises

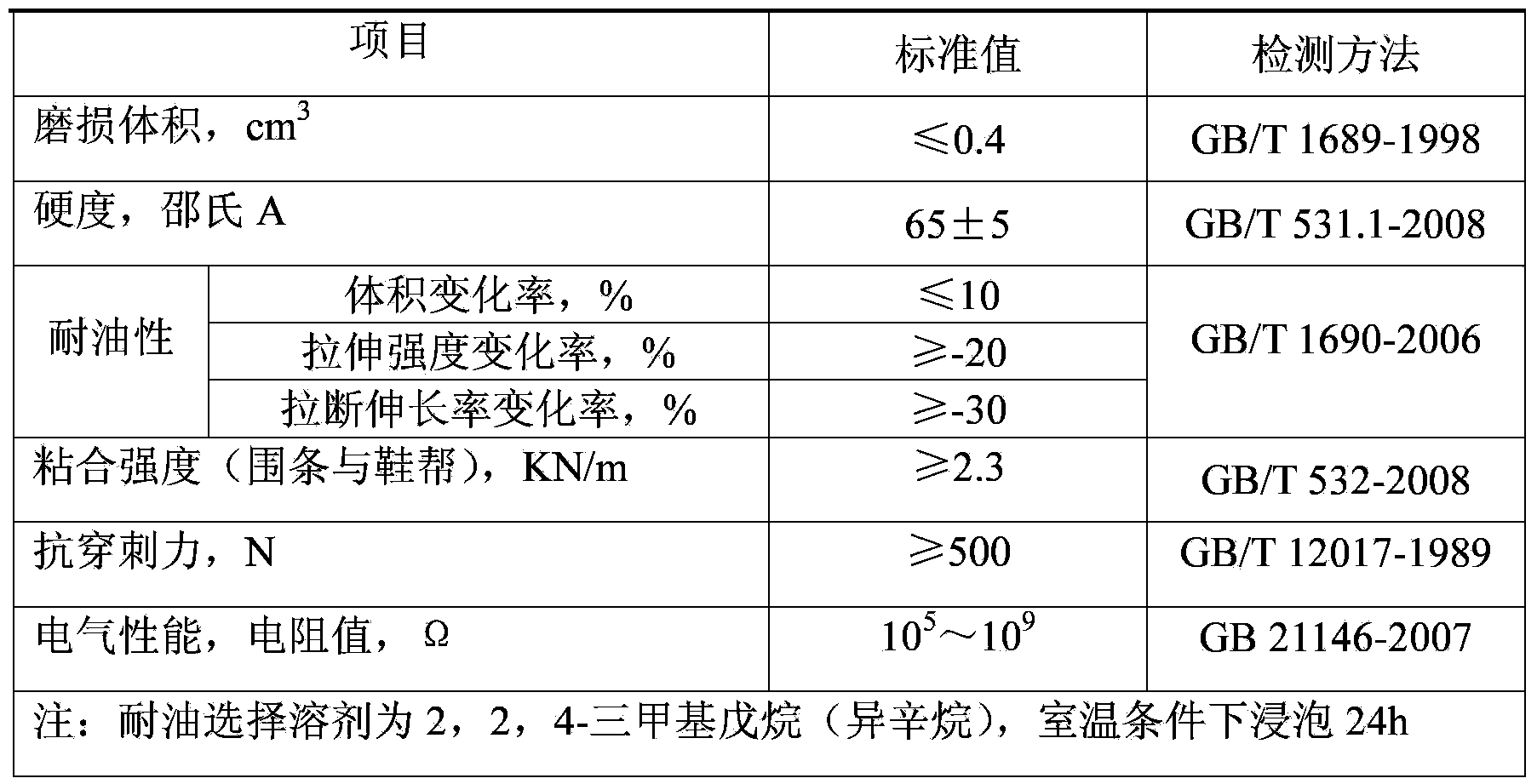

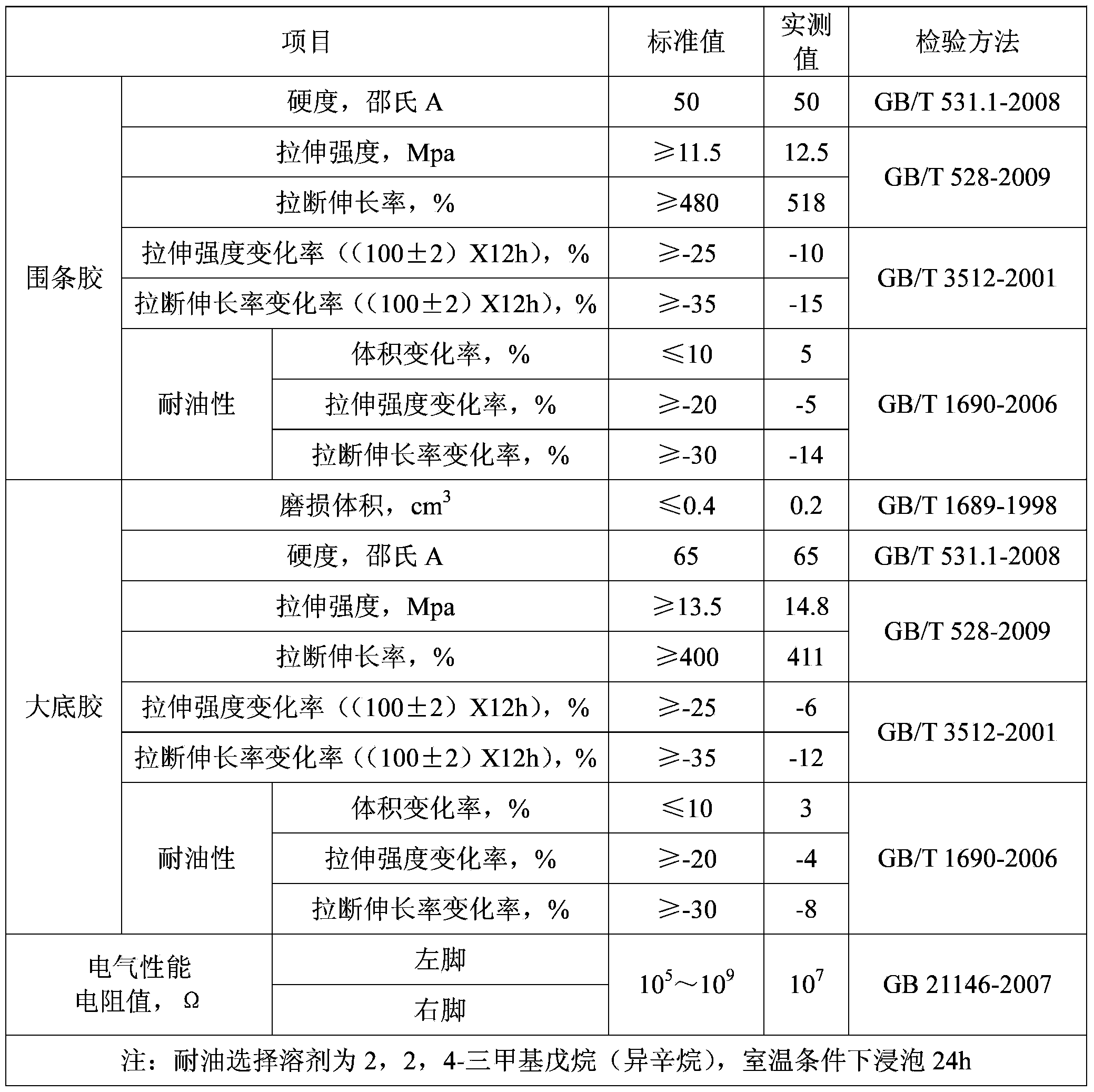

The invention discloses a pair of protection rubber shoes used for industrial and mining enterprises. The rubber shoes are in a low-top, soft-opening and lace-up type, each vamp is composed of terylene filament mesh fabric and terylene filament canvas, each sole is composed of an antistatic insole and a black rubber outsole formed through vulcanization, and ant-slipping abrasion-resistant sheets are respectively arranged on each toe cap and each heelpiece. The sole and surround bar rubber good in comprehensive performance is obtained by improving and optimizing compounding ingredients of original sole and surround bar rubber. The protection rubber shoes made of the rubber material have anti-puncture performance, the soles have the oil-resistant and antistatic functions, and therefore the protection rubber shoes are suitable for being used in the industrial and mining enterprises.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

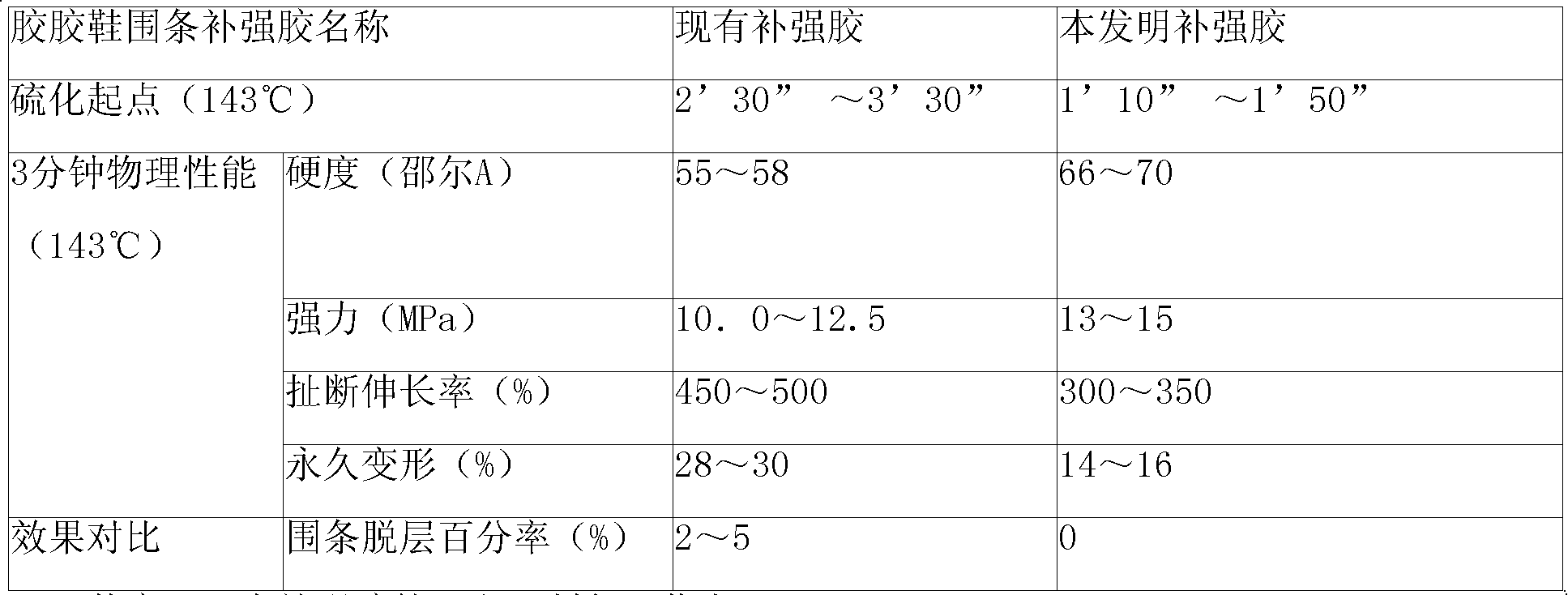

Ultra-low-temperature fast-curing reinforcing glue for rubber shoes and preparation method thereof

ActiveCN101225194AIncrease the speed of cross-linking and settingSolve delaminationWeltsUpperPolymer scienceVulcanization

The invention discloses an ultra low temperature fast vulcanization strengthening adhesive used by rubber shoes and a preparation method of the strengthening adhesive, which is characterized in that: firstly, natural rubber is masticated to form masticated rubber, product A is obtained by mixing the masticated rubber and the synthetic rubber, the product B is obtained by mixing the polyethylene glycol and the silica, the product C is obtained by mixing the vulcanizing agent, the vulcanization accelerator and the vulcanization active agent; the product A is put into the rubber refiner to be refined for 0.5 to 1 minute, the product C is added into the rubber refined and keep on refining for 2 to 5 minutes, and then softener is added into the refiner to be refined homogenously, when the discharged material reaches the flattening machine, the supplementary re-processing is carried out to obtain the rubber compound, at last sulfur is added into the rubber compound to obtain the ultra low temperature fast vulcanization strengthening adhesive. The preparation method of the strengthening adhesive has the advantages that: the prescription of the strengthening adhesive materials are improved, the crosslinking stress of the strengthening adhesive is enhanced, thus, the crosslinking stress is ensured to be larger than the rebound force of the outsole plus the expansive force produced by the foaming sponge, and the crosslinking calibration speed is increased; meanwhile, the rubber foxing delamination problem is totally avoided.

Owner:JIHUA 3537 SHOE MAKING

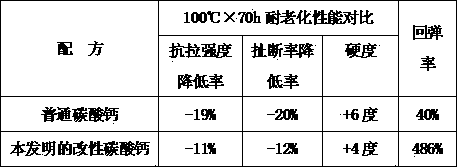

Modified calcium carbonate for wear-resistant rubber shoe soles and preparation method thereof

ActiveCN103408801AUniform particle sizeLarge specific surface areaSolesPigment treatment with macromolecular organic compoundsDispersityRubber material

The invention provides a modified calcium carbonate for wear-resistant rubber shoe soles, which is prepared from the following raw materials in parts by weight: 95-100 parts of ground calcium carbonate, 0.2-0.3 part of stearyl alcohol based polyethenoxy ether, 0.3-0.4 part of polyoxyethylene sorbitan fatty acid ester, 0.1-0.4 part of PE (polyethylene) wax, 0.5-0.8 part of triphenyl phosphite, 0.5-1 part of teflon micropowder, 0.1-0.3 part of ananti-aging agent 4020, 1-2 parts of ABS (acrylonitrile-butadiene-styrene) high rubber powder, 0.2-0.5 part of high-wear-resistance carbon black, 0.1-0.2 part of zirconium fluoride, 1-2 parts of dioctyl terephthalate (DOTP), 0.5-0.6 part of polyvinyl alcohol and 1-2 parts of a titanate coupling agent TMC-TTS. The preparation method comprises the following steps: drying calcium carbonate, proportionally and sequentially adding the other raw materials in batches, thoroughly mixing in a high-speed stirrer, drying and grinding. The modified calcium carbonate provided by the invention has the advantages of favorable dispersity and favorable wear resistance, and can lower the cost and enhance the working properties and wear resistance of shoe rubber when being used in shoe sole rubber materials.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

Water soluble adhesive and preparation method thereof

ActiveCN101486882APrevent agingMaintain performanceNatural rubber adhesivesFootwearNon toxicityPolymer science

The invention provides a water-soluble adhesive and a preparation method thereof. The water-soluble adhesive is prepared mainly by natural latex, soft water, a vulcanizing agent, a vulcanization accelerator, a vulcanizing activator, a dispersant, anhydride casein, borax, a stabilizer, a wetting agent, ammonia and potassium hydroxide. In order to improve the performance of the water-soluble adhesive, carboxymethyl cellulose sodium, the wetting agent, an age inhibitor, an antifoaming agent and a mildew inhibitor also can be added; the obtained water-soluble adhesive is an environment-friendly material which is used for shoes, has the processing advantages of low energy consumption, non-toxicity, good processing property, simple operation and the like in the preparation process, strengthens self deterioration resistance, greatly prolongs the storage stabilization period of slurry, improves the intrinsic performance of the adhesive, and fundamentally realizes the demand of high adhesive strength on rubber shoes.

Owner:际华制鞋工业有限公司

Special sizing material for foaming rubber sole

The invention discloses a special sizing material for a foaming rubber sole, which utilizes natural rubber, a physical foaming agent and various compounding agents to be effectively matched to produce the sizing material for producing a foaming sole by an upper-joint glue injection process, so that the error of expansion ratios of different parts of a de-molded sole is obviously reduced, the appearance quality of the foaming sole is improved, and the sole qualified rate and the appearance grade are improved; and the sizing material produced by the invention is used when the foaming rubber sole is machined, so that the problems that the size stability of the foaming rubber sole is not good when a shoe is produced by using the upper-joint glue injection process and the appearance is rough are solved. The special sizing material is applicable to preparing the foaming soles of shoes including fashion shoes, winter heat-preservation shoes and the like.

Owner:JIHUA 3514 LEATHER & FOOTWARE

Material for high-wear-resistant rare earth rubber shoes and preparation method thereof

ActiveCN107216504AIncrease the amount addedGuaranteed basic physical propertiesSolesDomestic footwearVulcanizationPolymer science

The invention discloses a material for high-wear-resistant rare earth rubber shoes and a preparation method thereof. The material is prepared from rare earth polybutadiene rubber (NdBR), isoprene rubber (IR), solution polymerized butadiene styrene rubber (SSBR), a softening agent, an activating agent, a coupling agent, a vulcanizing agent, a vulcanization accelerator, an anti-aging agent and surface modified ground rubber. The invention adopts a die pressing method to prepare a series of rubber shoe sole materials with wear resistance (DIN wear is 30 to 120mm<3>), slip limit (dry slip is 0.6 to 1.1, and wet slip is 0.3 to 0.6), and moderate hardness (Shore A) 60 to 70; the material has the following advantages that (1) the wear resistance is better; (2) the slip limit is improved; (3) the comfort is increased; (4) the production cost can be remarkably reduced, the profit space is improved, and the energy is saved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST JINJIANG CO LTD +1

Ultrahigh adhesion strength rubber shoe surrounded strip adhesive as well as preparation method and application

InactiveCN102382599AImprove stabilityImprove adhesion strengthSolesNatural rubber adhesivesVulcanizationPolymer science

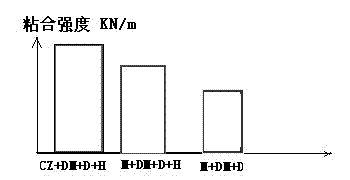

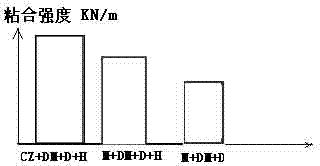

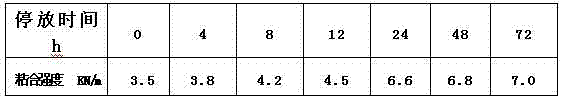

The invention discloses an ultrahigh adhesion strength rubber shoe surrounded strip adhesive, comprising natural rubber, vulcanization accelerator, resorcinol, peptizer, sulphur, vulcanization activator, white carbon black, anti-aging agent, adhesive and gasoline. In the ultrahigh adhesion strength rubber shoe surrounded strip adhesive comprising natural rubber, a function system is formed by the natural rubber, the accelerator H, the resorcinol, the white carbon black and the adhesive A, and the adhesion strength of a rubber shoe surrounded strip reaches 4.5 to 5.0KN / m through a prepared product. The stability of the adhesive is improved and the permeability and the brushing performance of the adhesive to a cloth cover is increased by improving an accelerator system and selecting the most appropriate plasticity so that the adhesive strength of the product is more stable and the adhesive strength of the rubber shoe surrounded strip is further improved. With the adoption of the ultrahigh adhesion strength rubber shoe surrounded strip adhesive, reasonable use conditions are also improved, and the production time can be saved and the use effect can be improved by using the product in this manner.

Owner:JIHUA 3537 SHOE MAKING

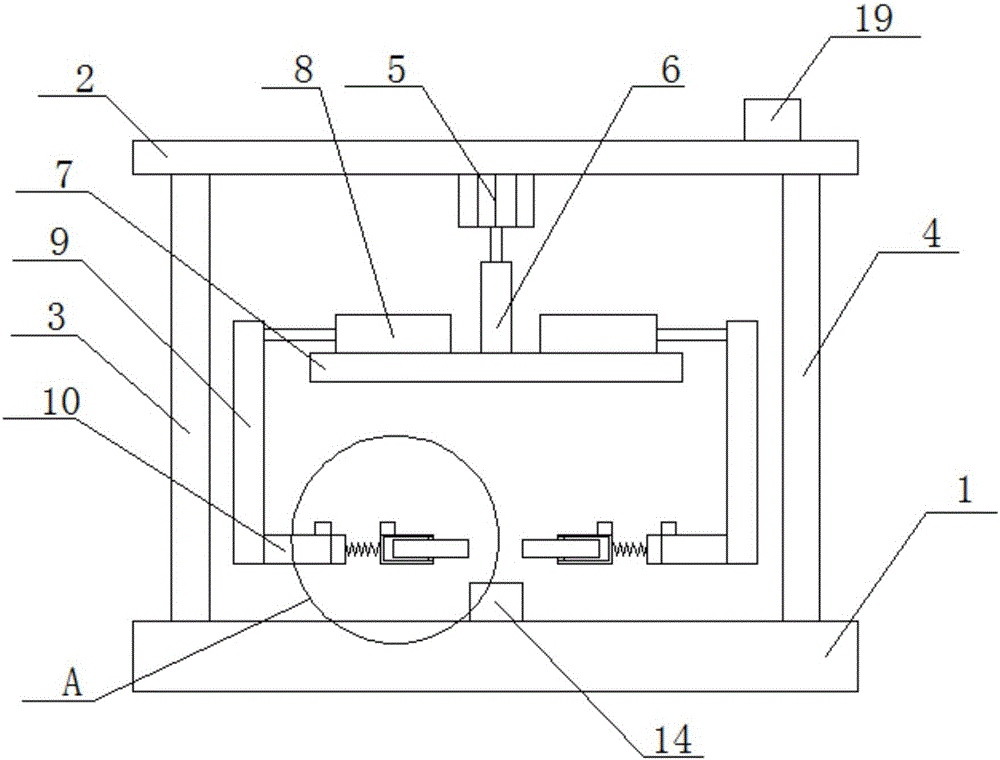

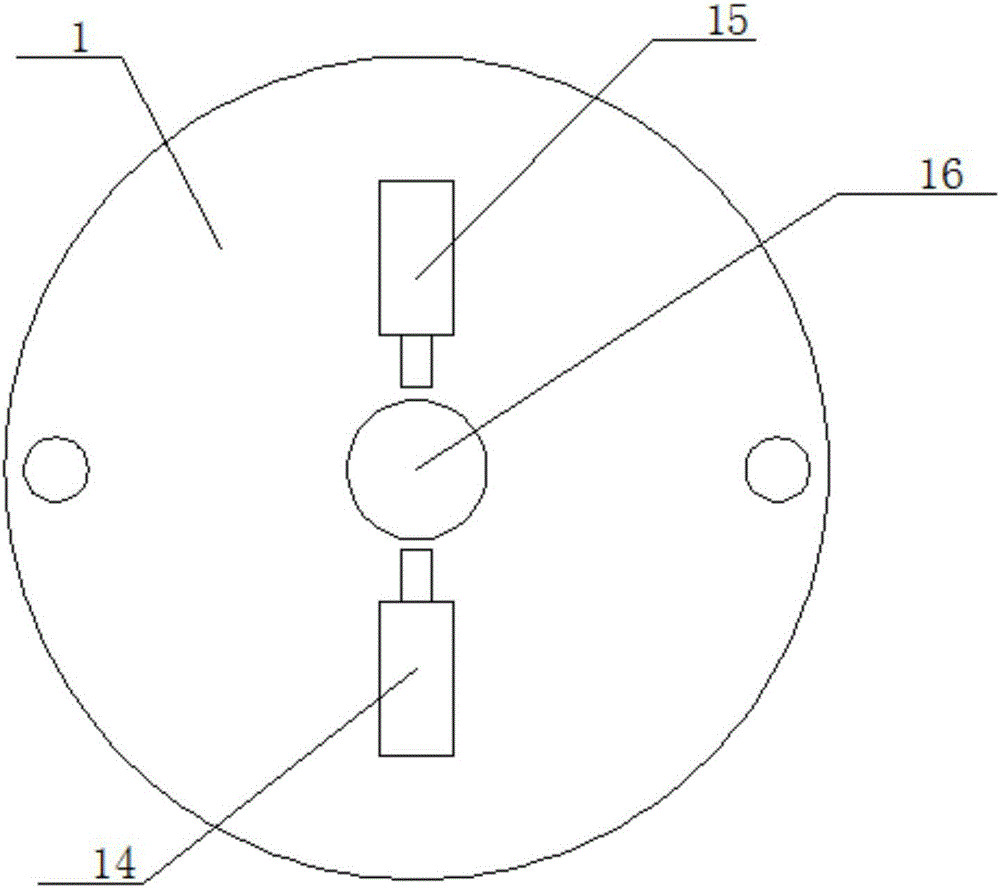

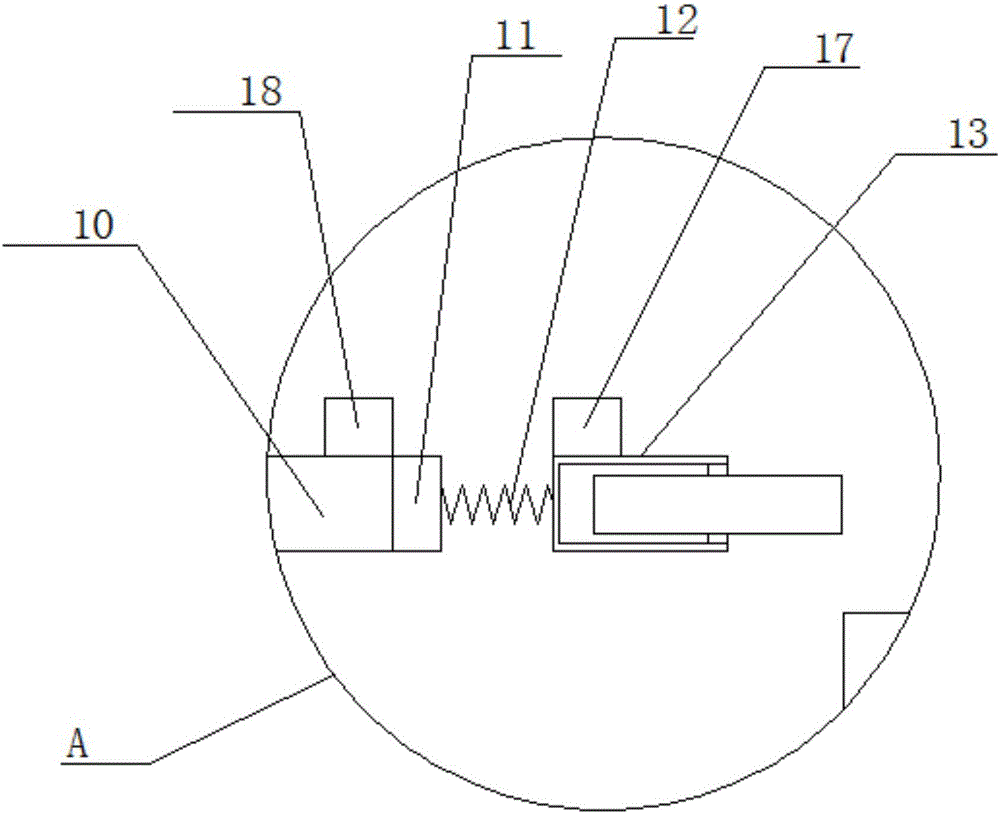

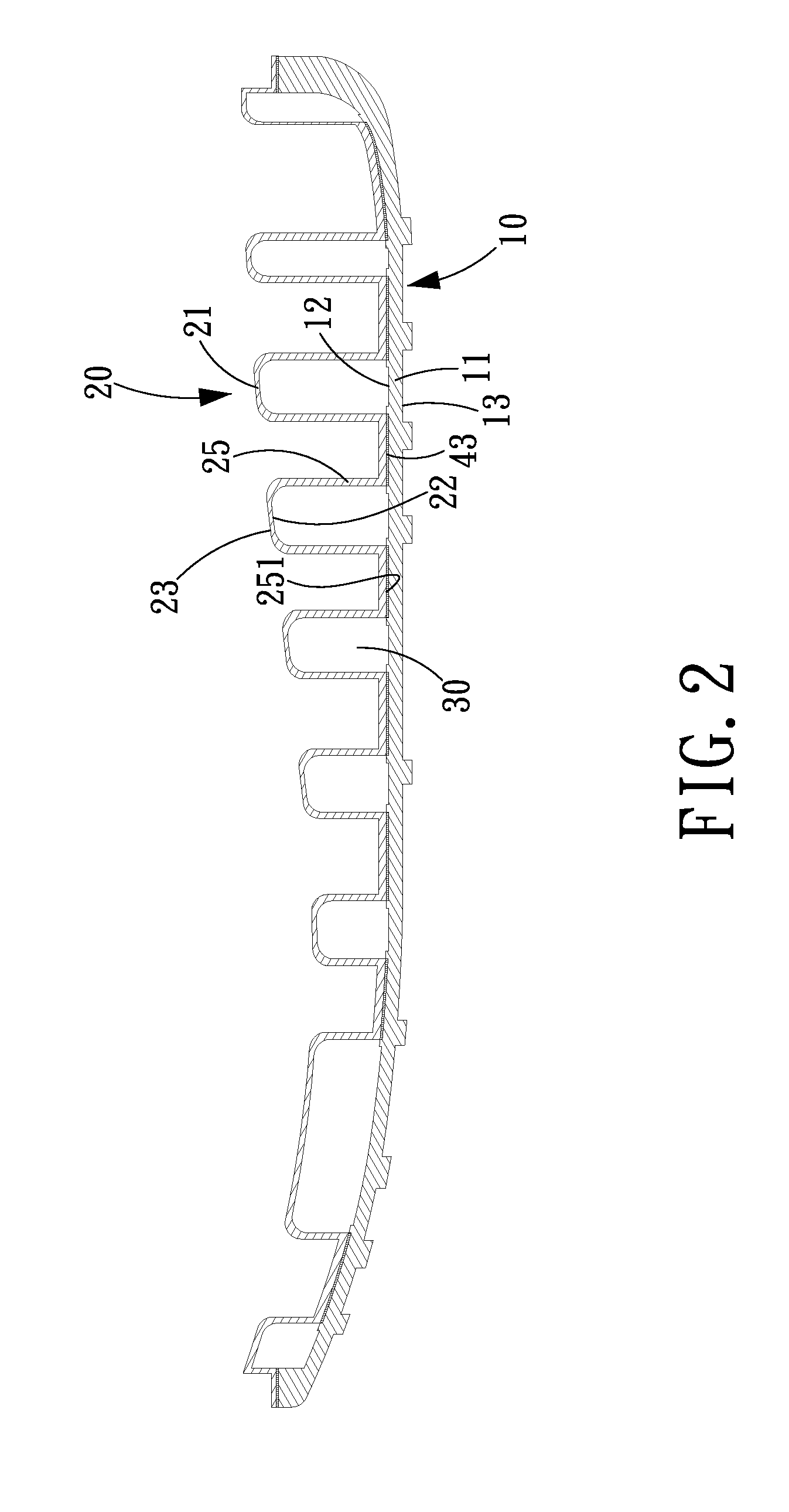

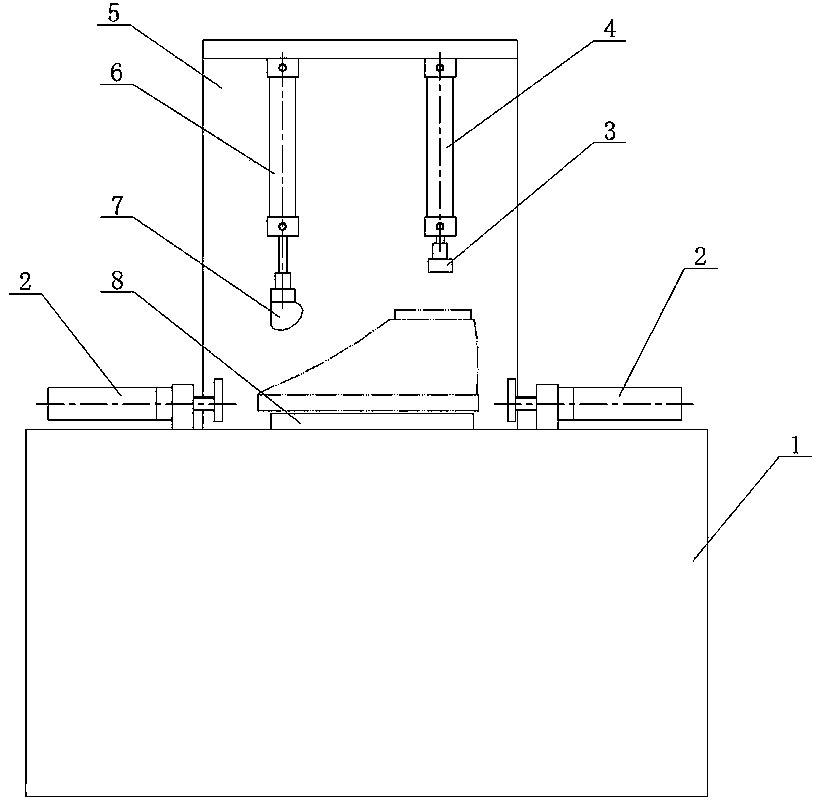

Rubber shoes surrounding strip press fit machine capable of improving press fit quality

The invention relates to a rubber shoes surrounding strip press fit machine capable of improving press fit quality. The rubber shoes surrounding strip press fit machine comprises a base, a top plate, a first strut, a second strut, a first cylinder, a second cylinder, a shoe die supporting plate, a rotating mechanism, a reinforced press fit mechanism and a PLC. The rubber shoes surrounding strip press fit machine capable of improving press fit quality is ingenious in design and high in feasibility and has dual press fit functions, and the cylinders arranged on the base can fix the shoes and perform press fit on a surrounding strip. The reinforced press fit mechanism which the rubber shoes surrounding strip press fit machine is uniquely provided with can perform omnidirectional press fit on the surrounding strip through a rotating mode, and the rubber shoes surrounding strip press fit machine has a series of protection measures, so that the damage to the shoes caused by the cylinders can be avoided.

Owner:JIANGSU KUNTAI MACHINERY

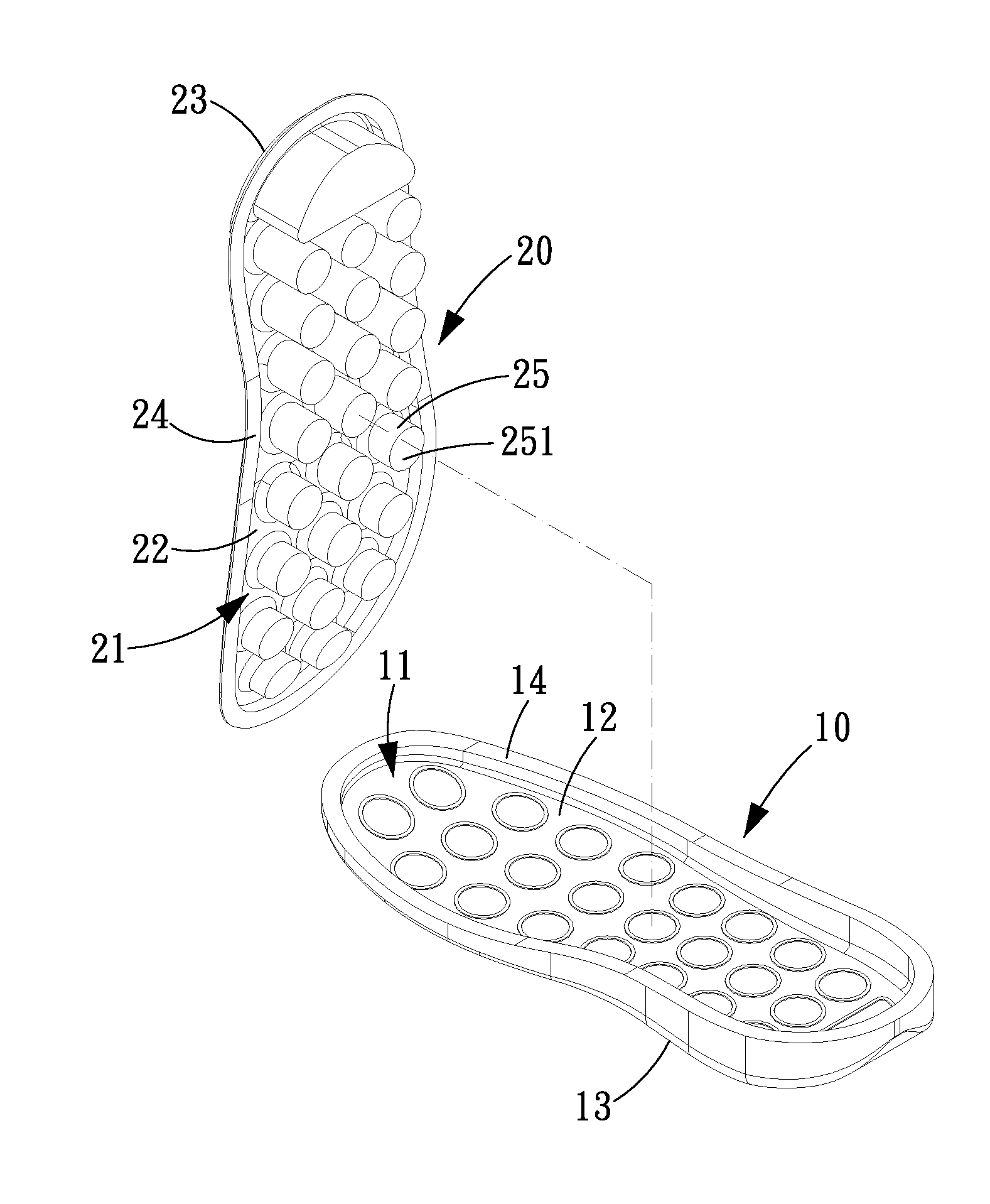

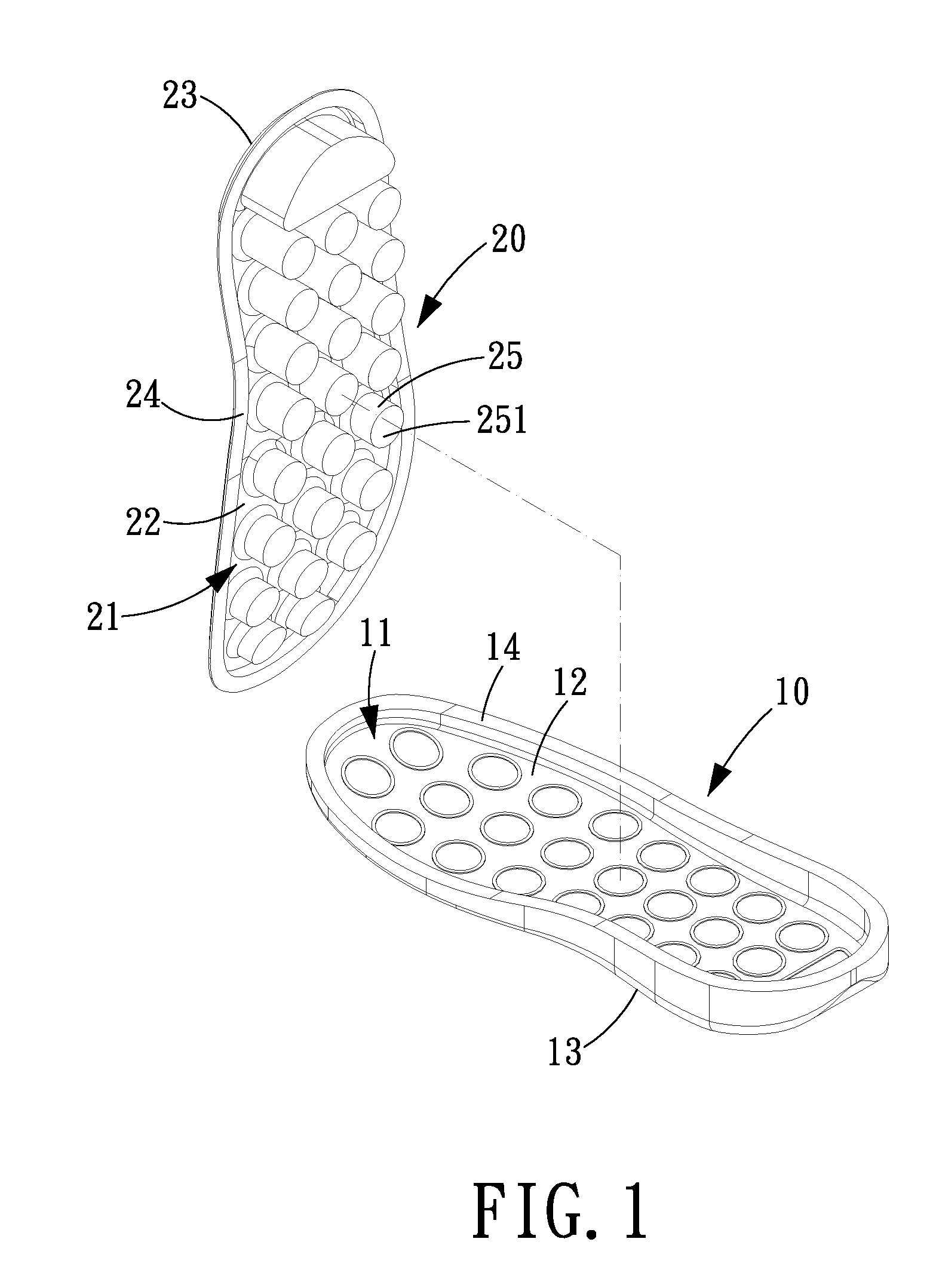

Rubber Shoe Sole with an Air Cell and Method for Making the Same

A method for making a rubber shoe sole with an air cell includes: a first curing step including putting rubber raw material into a mould assembly to form a lower member and an upper member of the shoe sole; a second curing step including putting raw material at a conjunction of the lower member and the upper member, pressing the lower and upper members against each other, and hot melting the rubber raw material to bond the lower and upper members together, whereby to form the air cell between the lower and upper members after the lower and upper members are bonded together; and a finishing step including demoulding and trimming the lower and upper members which have been bonded together by hot melting, so that a final product of the rubber shoe sole with an air cell is obtained.

Owner:WU TSAN SUNG +1

Wear resistant undersole rubber material for shoes

The invention discloses a wear resistant undersole rubber material for shoes. The rubber material comprises the following components by weight: 60 parts of smoke sheet rubber, 90 parts of cis-butadiene rubber, 3 parts of a vulcanizing agent, 3.3 parts of a promoter, 7.5 parts of zinc carbonate, 3 parts of stearic acid, 3 parts of an antioxidant, 70 parts of white carbon black, 5.6 parts of diethylene glycol, 30 parts of machine oil, 20 parts of potter's clay powder and 7.5 parts of the resin RX-80. The wear resistant undersole rubber material provided in the invention has incomparable super wear resistance compared to common rubber soles and has a plurality of good performance like wet-skid resistance, resistance to impact, etc.

Owner:WUHU FENGXUE RUBBER

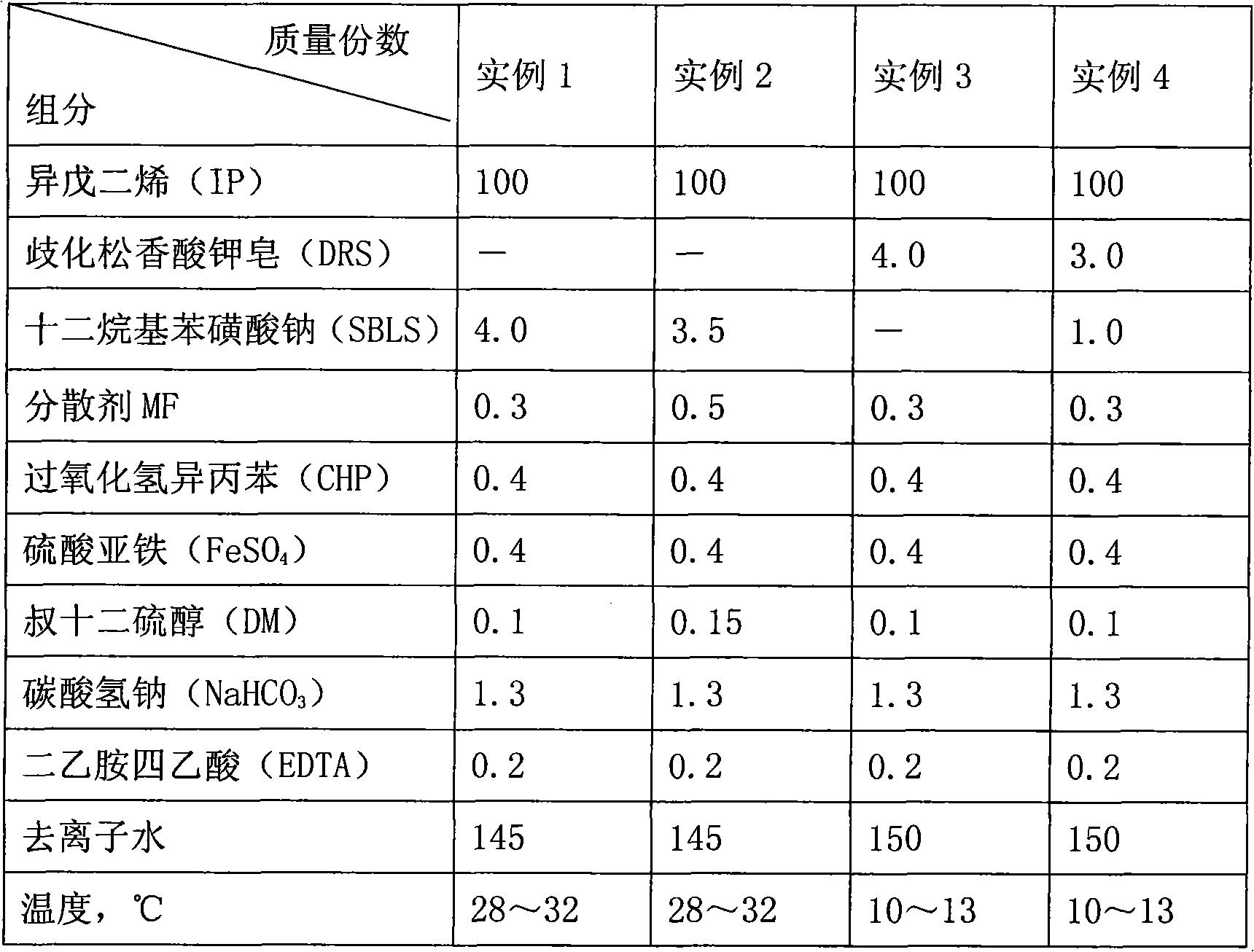

Preparing methods of polyisoprene emulsion and rubber thereof

The invention discloses a preparation method of a polyisoprene rubber latex and a polyisoprene rubber, wherein, the polyisoprene rubber latex is obtained by the emulsion polymerization of isoprene and is then aggregated by breaking emulsion to obtain the polyisoprene rubber. The technological process for preparing latex in the invention is easy to control and the obtained polyisoprene rubber latex has stable quality; the crude rubber has good physical and mechanical properties and can meet the requirements of a plurality of purposes and the diversified demands of the market. The polyisoprene rubber prepared by the invention is mixed and vulcanized with a processing method commonly-adopted by the production of rubber and can be used for manufacturing rubber products, such as various tires, triangular belts, conveyer belts, sealing rings, rubber tubes, rubber shoes and buffering blocks.

Owner:SHANGHAI SHENGDA MEDICAL HEALTH CO LTD

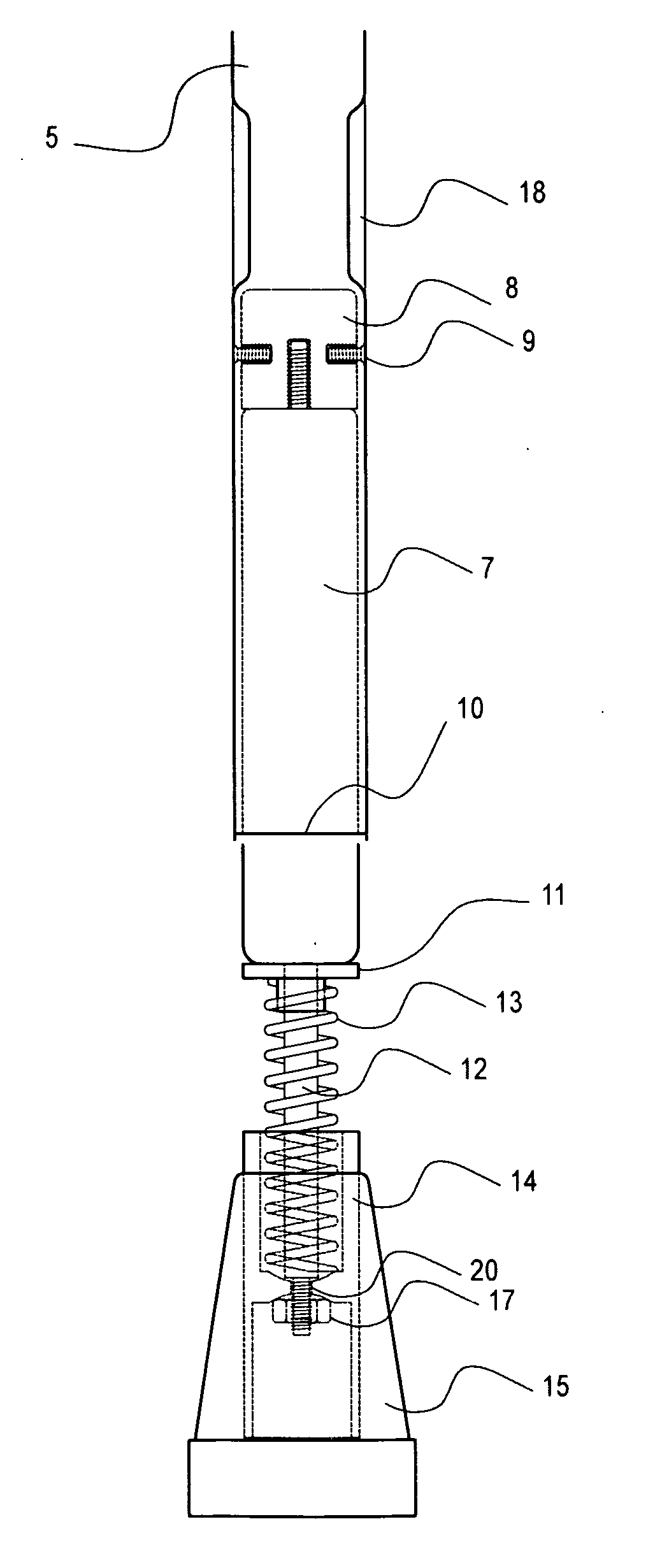

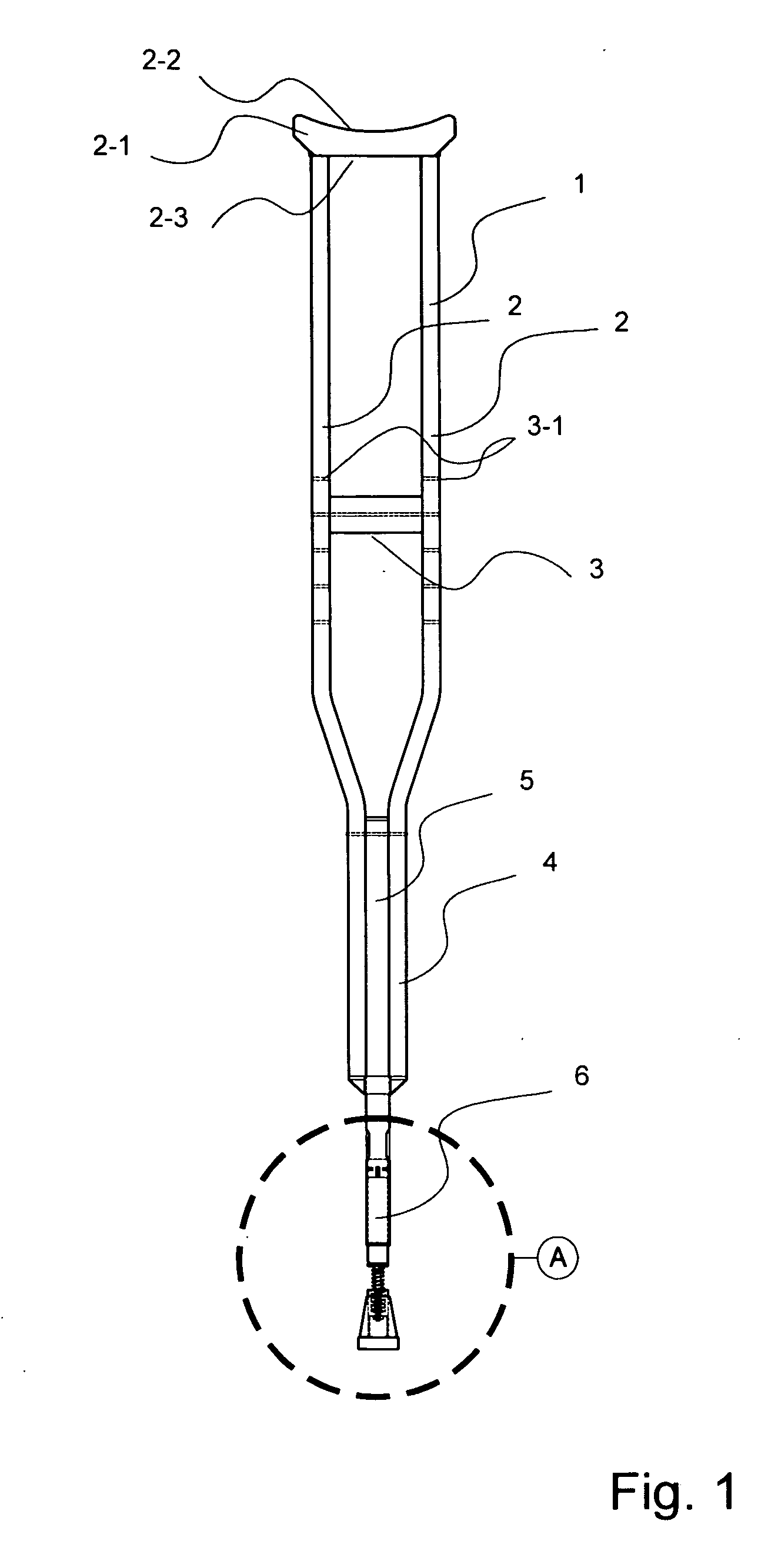

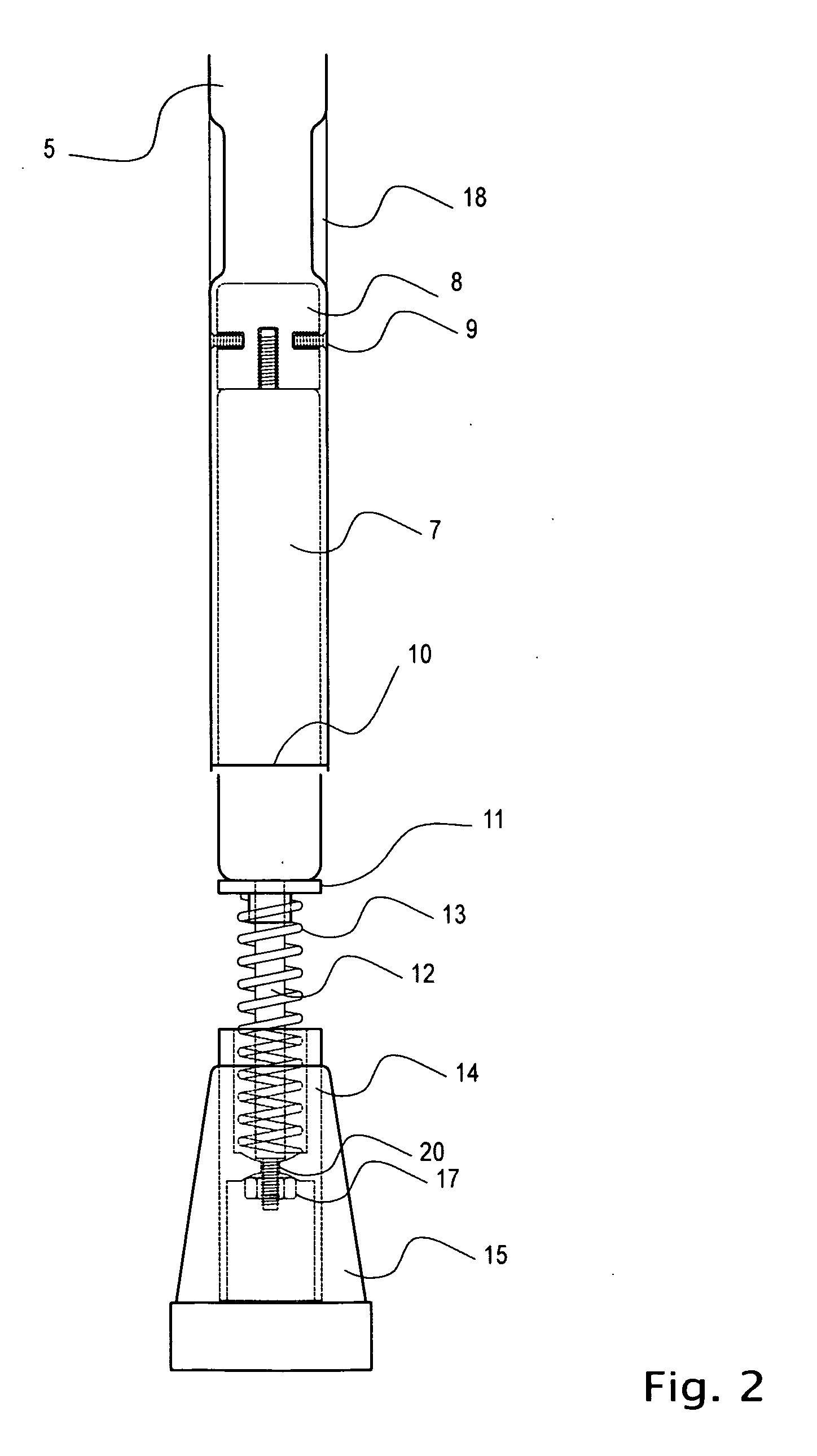

Custom fitted crutch with two shock-absorbers

InactiveUS20070089770A1Reduce the impactFeel smoothWalking sticksCrutchesEngineeringUltimate tensile strength

A crutch equipped with double shock absorbers is provided. The crutch of the current invention has an air shock absorber vertically combined with a spring shock absorber in one base shaft. A rubber shoe receives bottom of the spring shock absorber. The crutch of the current invention absorbs the shock of stepping ground firstly with the spring shock absorber and then reduces the impact with the air shock absorber. The double shock absorbing mechanism provides a smooth feeling of stepping the ground to a user. The strength of the resilient force of the crutch can be adjusted for each user, based on weight of a user, by medical doctor's characterization.

Owner:PARK DAE SHIK

Anti-skid rubber sole and preparation method thereof

ActiveCN106832470AImprove skid resistanceIncrease polaritySolesDomestic articlesPolymer scienceVulcanization

The invention relates to a rubber sole, and provides an anti-skid rubber sole. The anti-skid rubber sole is prepared from the following raw materials: NBR / PVC emulsion co-precipitation alloy, low-melting point polyamide, natural rubber, soluble polymerized styrene-butadiene rubber, brominated butyl rubber, white carbon black, an anti-aging agent, polyethylene glycol, a silane coupling agent, polyethylene wax, diethylene glycol, zinc oxide, stearic acid, insoluble sulfur, a vulcanization accelerator D and a vulcanization accelerator DM. The anti-skid rubber sole is vulcanized and molded in a mold of a space aluminum material, the vulcanizing temperature is 170 DEG C, the pressure is 16.5MPa-17.5MPa, and the vulcanizing time is 210-250s.

Owner:MAOTAI FUJIAN SOLES CO LTD

Novel high-resilience foamable rubber shoe sole material and preparation method thereof

The invention discloses a novel high-resilience foamable rubber shoe sole material and a preparation method thereof. The material is characterized of being prepared from, by mass, 10-15% of chloroprene rubber, 8-12% of natural rubber, 10-15% of ethylene-vinyl acetate copolymer, 20-25% of butadiene rubber, 6-12% of butadiene styrene rubber, 5-10% of ethylene propylene diene monome, 5-12% of white carbon black, 3-6% of naphthenic oil, 0.5-1.5% of resin, 1-3% of an active agent, 1-3% of a foaming agent, 1-3% of a modified flowable agent and 0.5-1.5% of a bridging agent. The preparation method comprises the steps of material compounding, banburying, mixing, open milling, stamping and vulcanization, so that a finished product is obtained. According to the novel high-resilience foamable rubber shoe sole material and the preparation method thereof, the characteristics that compatible and complementary elements exist among all types of rubber raw materials are utilized, the novel foamable rubber shoe sole material having the mechanical properties such as high resilience, high abrasion resistance and low weight is obtained, and the material is widely applied to the field of rubber shoe sole manufacturing.

Owner:JINJIANG XINQIDA SHOES MATERIALS CO LTD

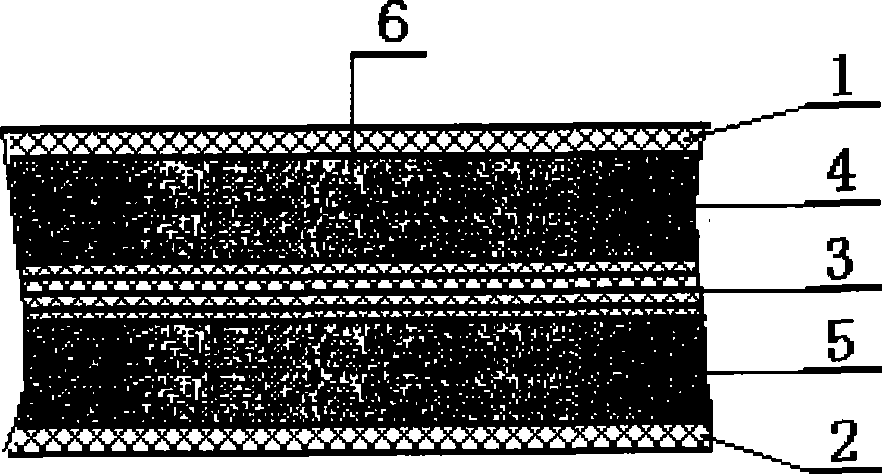

Modifed asphalt waterproof curling material of environmental-protective plastic

ActiveCN101074357AImprove high temperature performanceReduce dosageOther chemical processesRoof covering using flexible materialsBituminous waterproofingWaste rubber

An environmental-protection plastic modified asphalt water-proofing coiling material consists of upper and lower clad, intermediate embryo-layer and modified asphalt sizing material layer; modified asphalt sizing materials are arranged on the modified asphalt sizing material layer, which comprise asphalt, thermoplastic styrene-butadiene rubber, polypropylene resin, waste rubber powder, waste braided bag, waste mobile oil and filler triple superphosphate; it substitutes partial polypropylene resin with waste polypropylene braided bag; it substitutes SBS raw material with thermoplastic styrene-butadiene rubber shoes off-cut; it substitutes new mobile oil with waste mobile oil. It's cheap, convenient, economical, reliable, practical and operational. It utilizes refuse, saves resources and has better ageing resistance.

Owner:上海北新月皇新材料集团有限公司

Rubber shoes with oilproof and antiskid functions

The invention relates to rubber shoes with oilproof and antiskid functions. An oilproof undersole is prepared from the raw materials in parts by weight: 100 parts of nitrile rubber, 1-3 parts of sulfur, 0.5-1.0 part of accelerant DM, 1.0-1.5 parts of accelerant CZ, 3-5 parts of zinc oxide, 1-3 parts of stearic acid, 8-15 parts of liquid coumarone, 10-18 parts of dibutyl phthalate, 30-40 parts of argil, 2-4 parts of pine tar, 45-55 parts of high-wear-resistant carbon black and 0.5-1.5 parts of anti-aging agent. An oilproof edge strip and a toe cap are prepared from the raw materials in parts by weight: 80-95 parts of neoprene, 5-20 parts of standard rubber, 0.3-0.5 part of accelerant DM, 0.3-0.5 part of accelerant NA-220, 3-5 parts of zinc oxide, 3-5 parts of magnesium oxide, 2-4 parts of stearic acid, 0.3-0.5 part of paraffin, 3-5 parts of pine tar, 4-6 parts of dibutyl phthalate, 3-5 parts of spindle oil, 55-65 parts of argil, 20-30 parts of high-wear-resistant carbon black and 0.5-1.5 parts of anti-aging agent. Oilproof rubber paste is prepared from the raw materials in parts by weight: 100 parts of neoprene, 0.4-0.8 part of accelerant DM, 0.4-0.8 part of accelerant NA-220, 3-5 parts of zinc oxide, 3-5 parts of magnesium oxide, 4-8 parts of phenolic resin, 15-25 parts of calcium carbonate and 0.5-1.5 parts of anti-aging agent. The shoes are good in oilproof and antiskid effects, low in cost and high in percent of pass.

Owner:JIHUA 3517 RUBBER PROD

Rubber shoe foxing strip pressing machine

The invention discloses a rubber shoe foxing strip pressing machine. The rubber shoe foxing strip pressing machine comprises a workbench and a backboard, and is characterized in that a shoe tree liner plate is arranged in the center of the workbench, four flat pressing air cylinder assemblies are arranged at the front, at the back, on the left and on the right of the shoe tree liner plate, a left top and a right top are arranged above the shoe tree liner plate, the left top is connected to a piston rod of a left air cylinder, the right top is connected to a piston rod of a right cylinder, and the left cylinder and the right cylinder are fixedly installed on the front face of the backboard. The rubber shoe foxing strip pressing machine is specially used for pressing rubber shoe foxing strips after the rubber shoe foxing strips are bonded to the side faces of the rubber shoes, work efficiency is improved, and the quality of the rubber shoes is improved.

Owner:RUIAN HONGDA LEATHER & PLASTIC MACHINERY FACTORY

Method of Preparing a Rubber Shoe Sole

ActiveUS20120260437A1Easy to manufactureReduces laminationSolesShoemaking devicesEngineeringRubber sheet

Disclosed herein is a novel method of preparing shoe sole. The method of preparing shoe sole includes irradiating an uncured rubber sheet by laser beam to pattern and vulcanize a portion of the uncured rubber, tailoring the partially patterned vulcanized rubber into a shoe shape, and afterward fully vulcanizing the partially patterned vulcanized rubber sheet to form a shoe sole. An additional step of assembling the upper panel of shoe sole on the partially vulcanized rubber sheet is also performed.

Owner:SHEI CHUNG HSIN IND

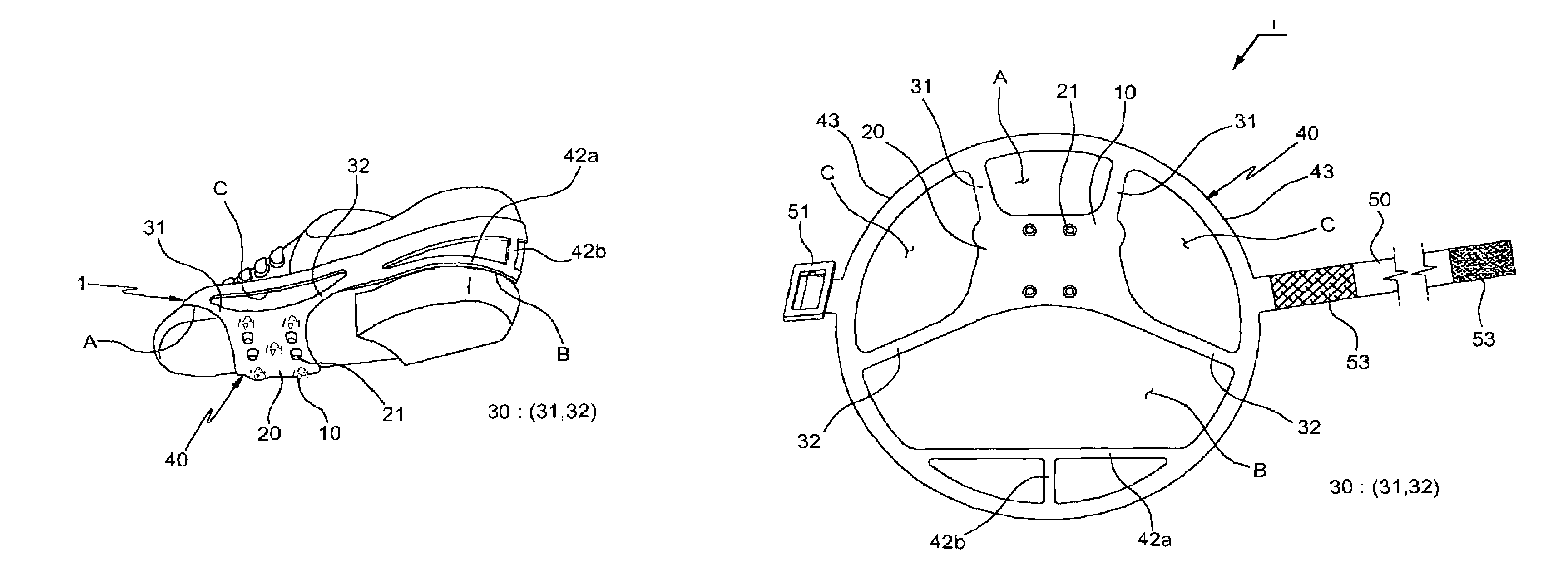

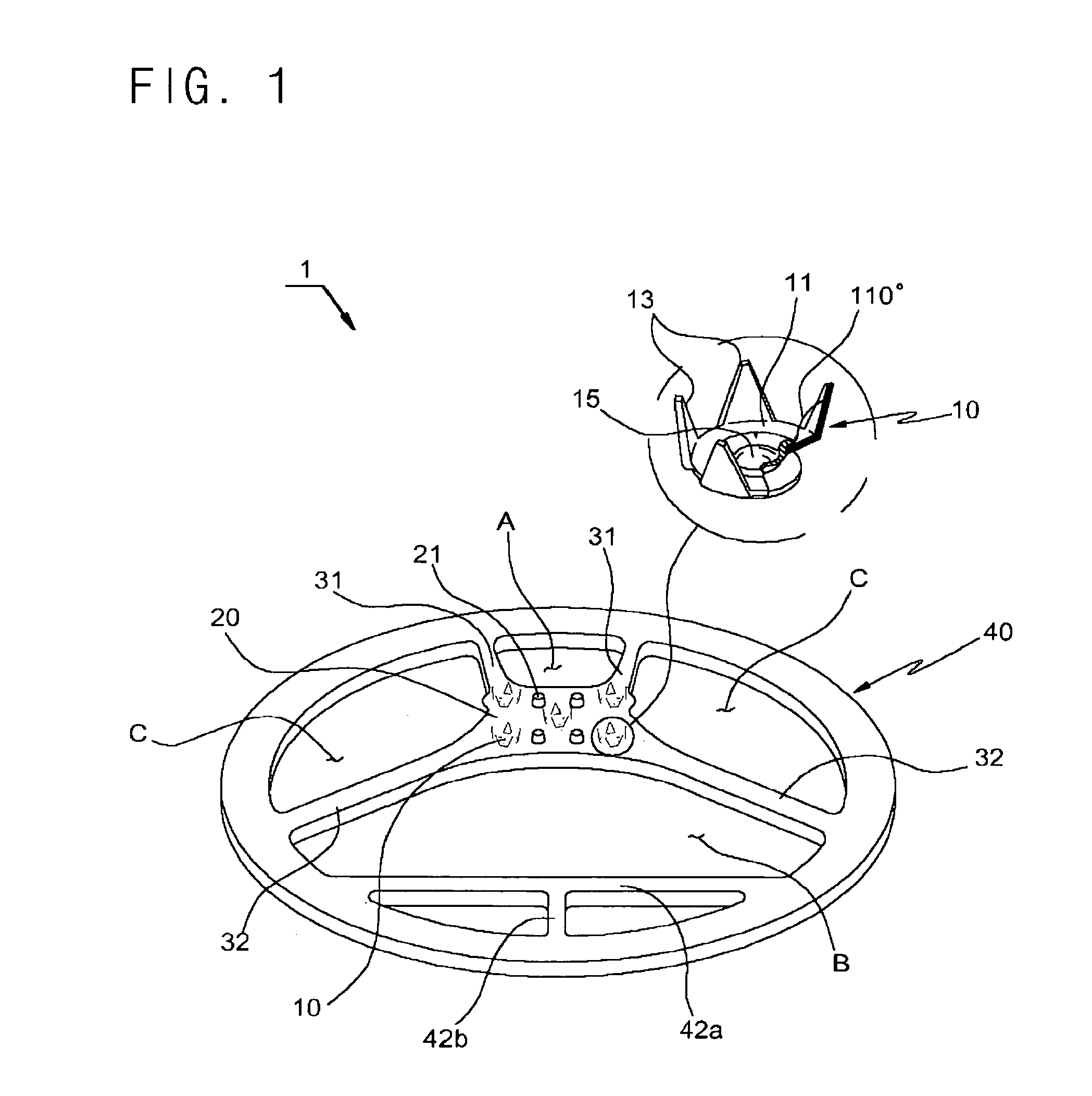

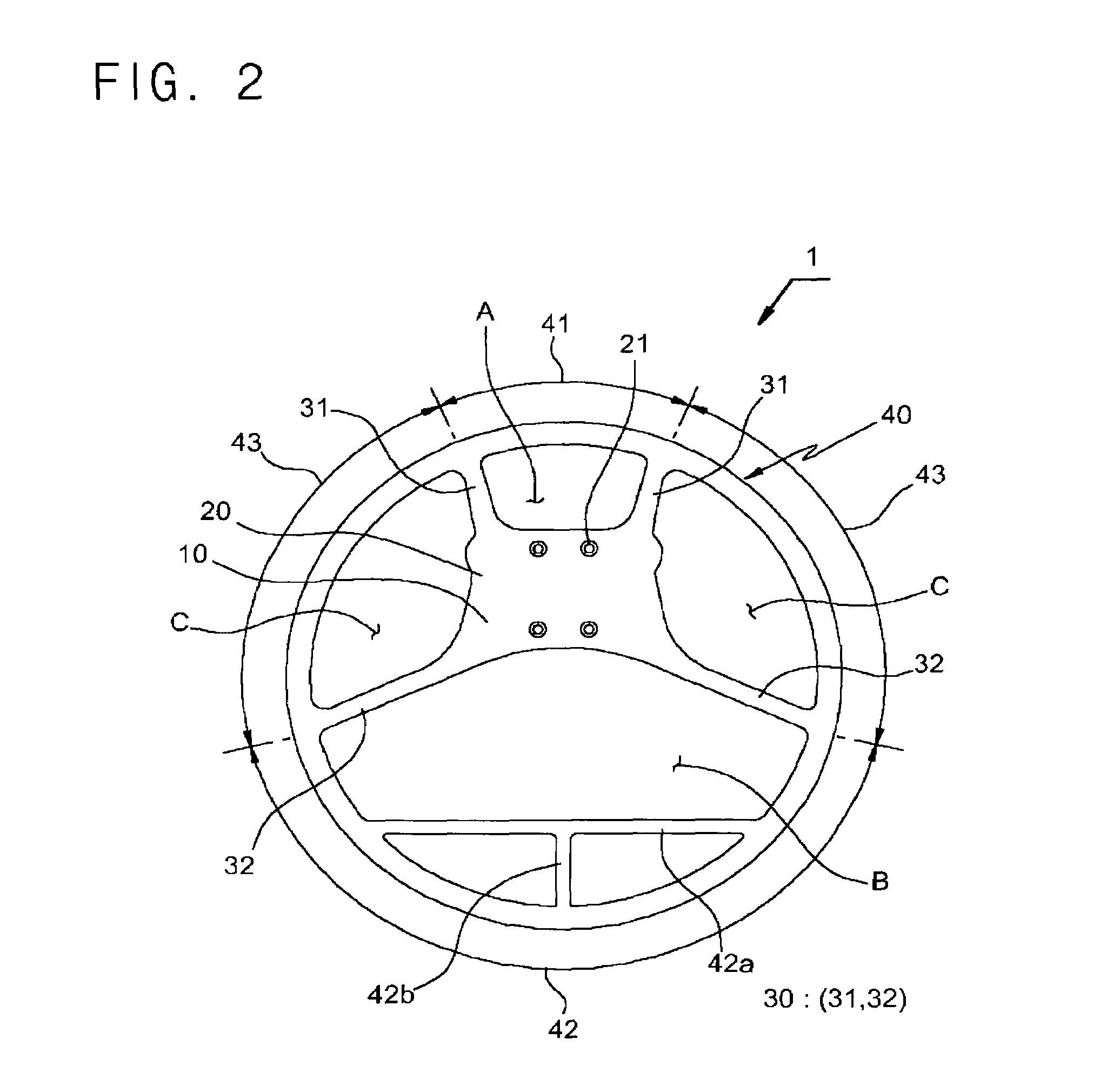

Safety crampon with generality put on

Disclosed is a safety crampon with generality put on, which encircles front / rear / left / right sides of shoes around a spike pad to elastically press and grip them so that the crampon is not come off from the shoes, thereby ensuring safety. Also, the safety crampon has excellent wearing feeling and walking owing to characteristics of an elastic material, can be put on all kinds of shoes including mountain-climbing boots, high-heeled shoes, and rubber shoes, allows a user to safely climb a mountain and safely walk on a skiddy icy road of the ground, and has a conveniently portable advantage. The antiskid safety crampon includes a spike pad made of an elastic material such as a foaming resin or rubber and provided with a plurality of spikes, a hook formed in the spike pad in a single body with the spike pad to be fixably hooked over shoes, a limb band oriented from four edges of the spike pad toward the contour, and a ring band inscribed in a front end of the limb band, wherein the spike pad, the hook, the limb band and the ring band are formed of an elastic material in a single body with one another.

Owner:WOO KYUNG TECH

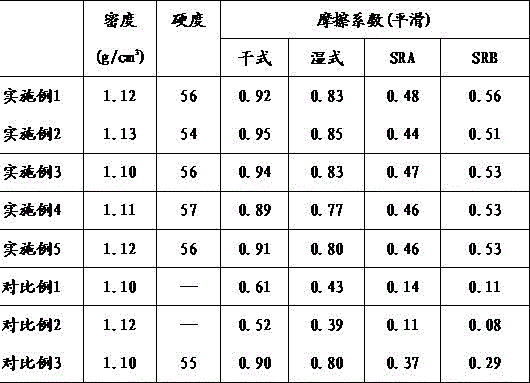

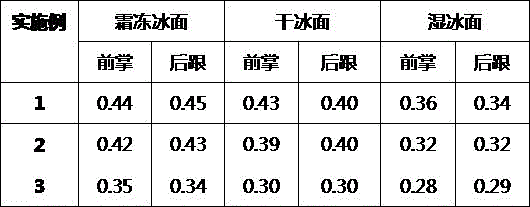

Antiskid rubber composition for ice surface and production method thereof

ActiveCN105801948AImprove hydrophilicityImprove skid resistanceSolesVulcanizationPolyethylene glycol

The invention relates to the technical field of rubber, and provides an antiskid rubber composition for an ice surface and a production method thereof. Rubber shoe soles produced by virtue of the antiskid rubber composition for the ice surface have a good antiskid effect on a pavement interface of a snowfield, a frost ice surface, a dry ice surface and a wet ice surface, can still maintain relatively good mechanical performance in an environment of -40 DEG C, and have good market prospect and high practicability; the production method is simple and easy to operate and suitable for mass production and application. The antiskid rubber composition for the ice surface is prepared from the following raw materials: neoprene, solution polymerized styrene-butadiene rubber, carboxylation nitrile rubber, white carbon black, waste rubber powder, an anti-aging agent, polyethylene glycol, a silane coupling agent, polyethylene wax, zinc oxide, sulfur and a vulcanization accelerant.

Owner:茂泰(福建)新材料科技有限公司

Method for preparing natural rubber exhaust gasket for forming rubber shoes

InactiveCN101940386AImprove conduction abilityEffective isolationUpperBootlegsSurface layerRoom temperature

The invention discloses a method for preparing a natural rubber exhaust gasket for forming rubber shoes. The method comprises the following steps of: vulcanizing natural rubber to obtain a rubber body of the exhaust gasket; painting a layer of gasoline mucilage on the reverse side of interlock and drying; cutting the interlock and the rubber body of the exhaust gasket according to the shape requirements of the rubber gasket, placing the rubber body of the exhaust gasket on the side of the interlock painted with the gasoline mucilage, putting in a module and boiling in water for heating, and taking the rubber exhaust gasket out and cooling to obtain an exhaust gasket blank; and painting room-temperature silicon disulfide rubber on the interlock side of the exhaust gasket blank and standing at room temperature for more than 5 days to obtain the finished product. In the method, the high-elasticity vulcanized sponge rubber of the natural rubber is used as the substrate of the exhaust gasket, the elasticity and flexibility of the rubber body are adjusted by using a boiling and foaming process, the surface of the rubber substrate is enhanced due to the adoption of the high-elasticity interlock, the service life of the exhaust gasket is prolonged and the force transfer effect is improved; moreover, due to the room-temperature silicon disulfide rubber coating on the surface layer, the rubber components of the rubber shoes are effectively isolated and the original shape of the patterns of the rubber components of the rubber shoes is maintained.

Owner:JIHUA 3537 SHOE MAKING

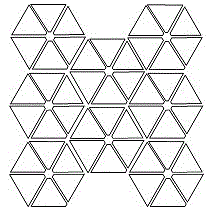

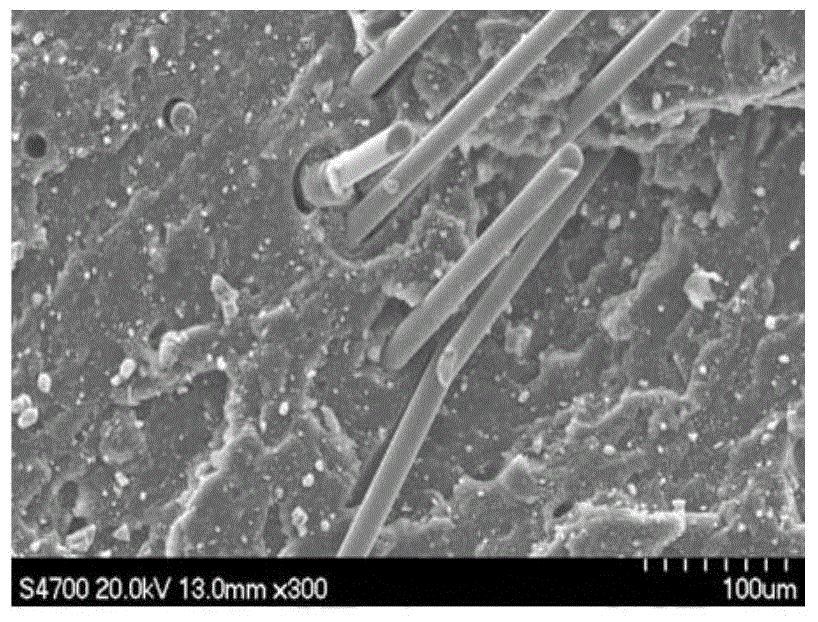

Directionally-arranged short-fiber composite rubber non-slip shoe sole material and preparation method thereof

The invention discloses a directionally-arranged short-fiber composite rubber non-slip shoe sole material and a preparation method thereof. The material is made of a rubber compound and a short fiber, and the rubber compound is made of crude rubber, a reinforcing agent and an auxiliary as raw materials. The short fiber in the material has a certain orientation degree and can be combined with various shoe sole materials for molding, and therefore the non-slip performance, particularly the non-slippery performance of a shoe sole on various interfaces (ice surfaces, steel plates, ceramic tiles, glass and the like) is increased.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

Oil-resistant anti-static rubber shoe sole and preparation method thereof

The invention relates to an oil-resistant anti-static rubber shoe sole which is prepared from the following raw materials in parts by weight: 840-960 parts of NBR / PVC, 40-50 parts of magnesium oxide, 12-24 parts of stearic acid, 12-16 parts of an antiager, 280-320 parts of white carbon black, 18-22 parts of a coupling agent, 170-190 parts of light calcium carbonate, 110-130 parts of dioctyl-phthalate, 8-10 parts of polyethylene glycol, 12-17 parts of sulphur and 14-30 parts of an accelerant. Rubber-plastic alloy (NBR / PVC=70 / 30) is used as a main rubber material, the rubber-plastic alloy has excellent oil resistance and ageing resistance, heat conduction / conductivity is excellent due to that the NBR / PVC is a polarity high polymer material simultaneously, static electricity generated by a human body during wearing is released through a show outsole, and then an excellent anti-static effect is realized. For meeting environmental protection needs, conventional carbon black is replaced by the white carbon black in the formula to reinforce a sizing material, the coupling agent is added in the formula to improve the bonding strength of the white carbon black and the NBR / PVC simultaneously, and the polyethylene glycol is used to adjust the acid-base property of rubber compound to meet the normal vulcanizing process.

Owner:天津市富华皮革制品有限公司

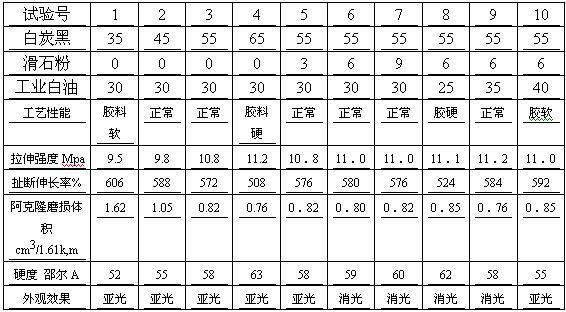

Formula and preparation method of extinction type shoe rubber

The invention discloses a formula and a preparation method of extinction type shoe rubber, wherein the extinction type shoe rubber comprises 45-65 parts of natural rubber, 35-55 parts of solution-polymerized styrene butadiene rubber, 1.5-2.5 parts of sulfur, 1.5-4 parts of vulcanization accelerator, 6-11 parts of vulcanization activator, 30-40 parts of industrial white oil, 5-7 parts of diglycol and 50-60 parts of precipitated silica. The extinction effect is realized by directly utilizing the body material of the extinction type shoe rubber prepared by the invention, a material with the similar refractive index to the natural rubber is adopted as the body material to realize the light transmission action of the rubber, and an anisotropic material is adopted as the scattering body of the light inside a rubber body to realize the extinction of the vulcanized rubber. The method has simple process, does not need to spray extinction surface oil on the surface of a rubber shoe and does not need to carry out sanding processing on a mould surface, lowers the production cost, and reduces the labor intensity of workers; because the body material of the extinction type shoe rubber performs an extinction action, the surface effect can not be changed due to use.

Owner:JIHUA 3537 SHOE MAKING

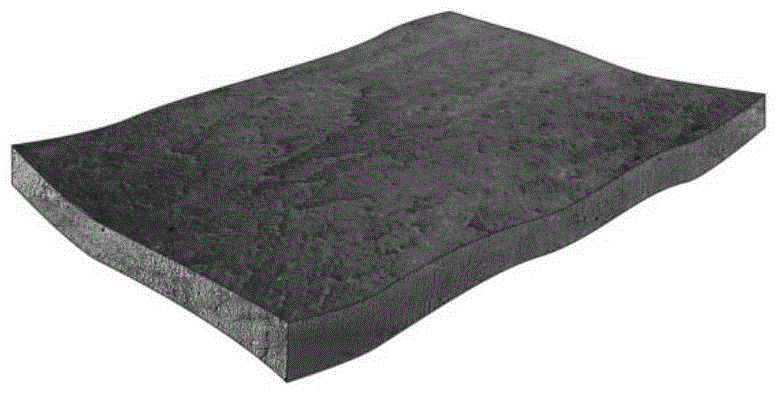

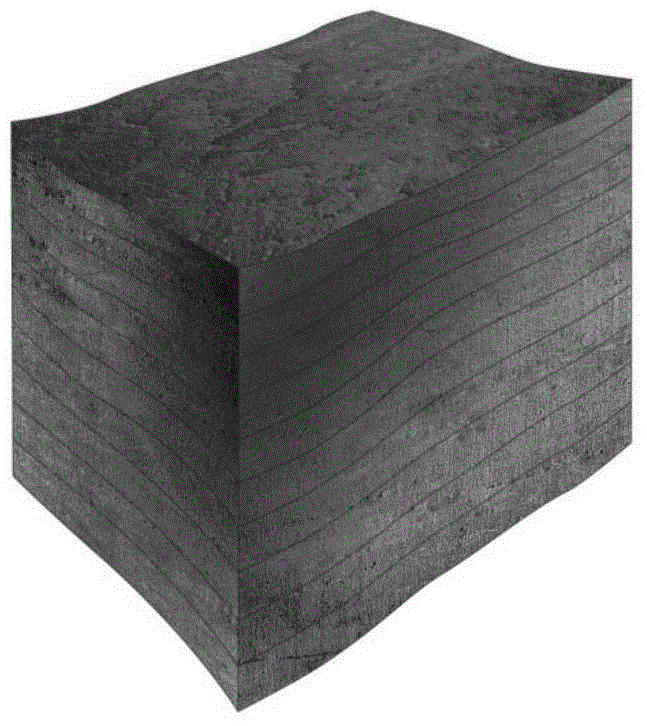

Foamed rubber shoe sole

The invention discloses a foamed rubber shoe sole production formula and a preparation method thereof. A foamed rubber shoe sole consists of the following components in percentage by weight: 40-60 percent of natural rubber, 0.5-1.5 percent of sulfur, 1-3 percent of zinc oxide, 20-40 percent of silicon dioxide, 1-3 percent of recycled rubber powder, 1-3 percent of stearic acid, 0.5-3 percent of vulcanization accelerator, 10-20 percent of engine oil, 0.1-0.5 percent of toner powder and 4-10 percent of foaming agent, wherein the total content of the components is 100 percent. The foamed rubber shoe sole produced with the method has the characteristics of wearing resistance, water resistance, aging resistance, low production cost, light weight, high damping performance and high comfort.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD TAIZHOU POWER SUPPLY BRANCH +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com