Light high elasticity deodorant rubber spongy cushion for shoes and preparation method thereof

A rubber sponge, high elasticity technology, applied in the field of rubber shoes, can solve the problems of insufficient elasticity, uncomfortable wearing, unfavorable human health, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

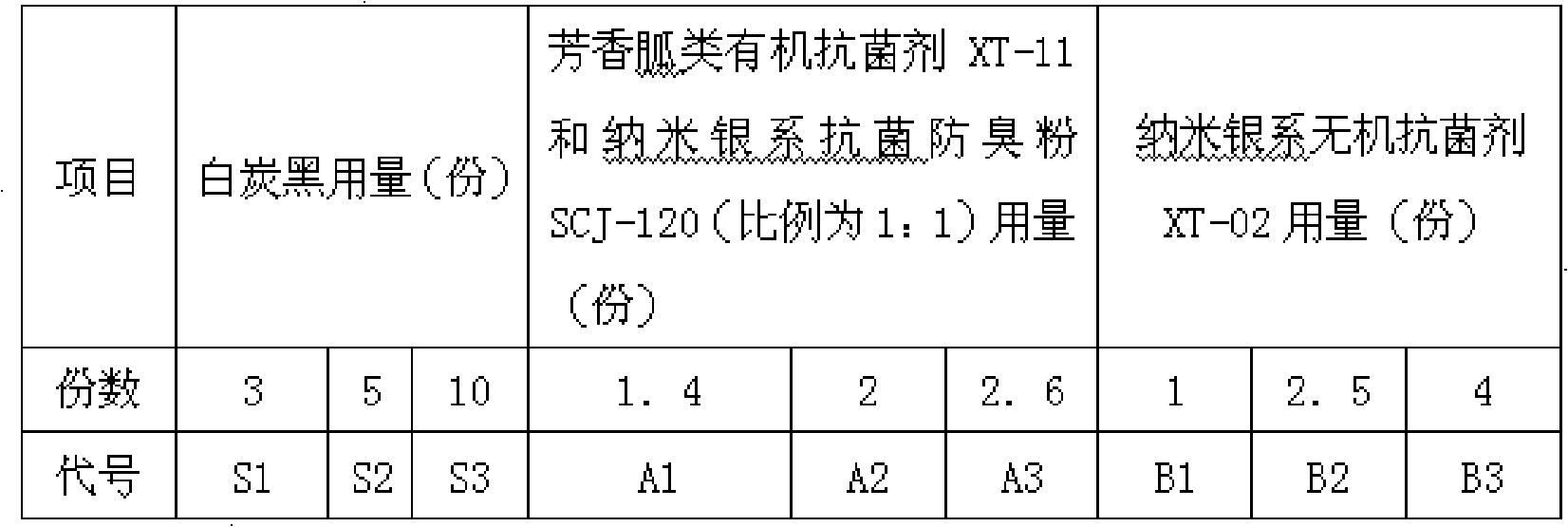

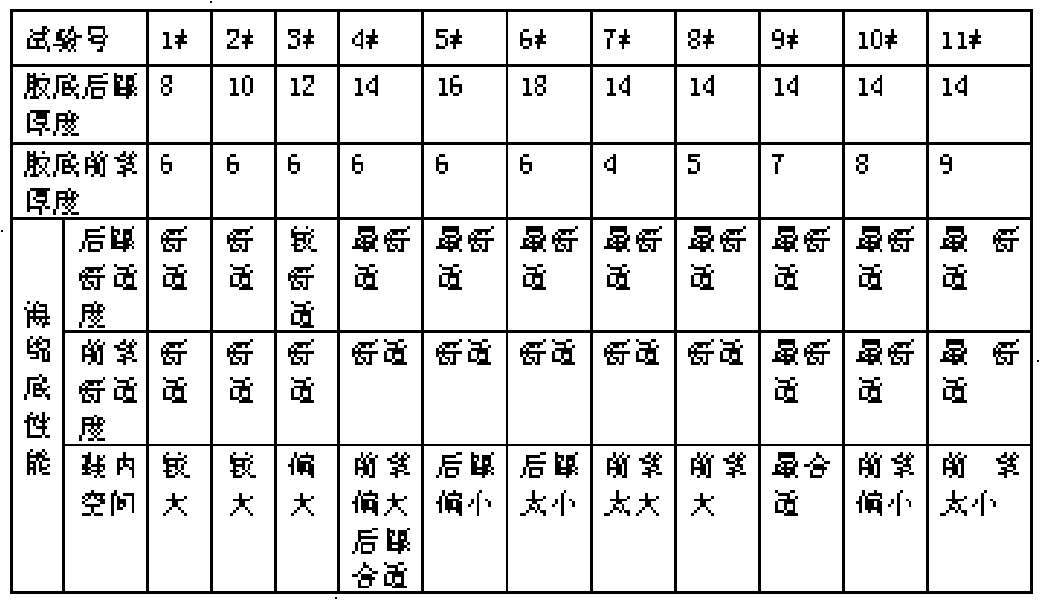

[0039] Embodiment 1: calculate according to parts by weight, light weight highly elastic deodorant rubber sponge pad for shoes is made of 80 parts of natural rubber, 20 parts of butadiene rubber, 2 parts of sulfur, 4 parts of vulcanization accelerator (vulcanization accelerator is made of 1.2 parts of accelerator M, 1.8 parts of accelerator DM and 1.0 parts of accelerator DS), 5 parts of vulcanization activator, 2 parts of foaming agent (foaming agent H: foaming agent AC=0.8:1.2), 18 parts of stearic acid, 3 parts of odorant (deodorant is composed of 2 parts of odor-sustaining agent and 1 part of rubber foam deodorant), 40 parts of filler (filler is composed of 15 parts of pottery clay, 10 parts of calcium carbonate, 5 parts of white carbon black, Composed of 8 parts of hemp powder and 2 parts of short fiber), 1.3 parts of aromatic guanidine organic antibacterial agent XT-11, 1.3 parts of nano-silver antibacterial and deodorant powder SCJ-120 and 2.5 parts of nano-silver inorga...

Embodiment 2

[0043] Embodiment 2: Calculated according to parts by weight, the lightweight and highly elastic deodorant rubber sponge pad for shoes is made of 60 parts of natural rubber, 40 parts of butadiene rubber, 2 parts of sulfur, 2.5 parts of vulcanization accelerator, 4 parts of vulcanization activator, foaming 1.8 parts of stearic acid, 18 parts of stearic acid, 3 parts of deodorant (deodorant consists of 2 parts of odor release agent and 1 part of rubber foam deodorant), 40 parts of filler (filler consists of 15 parts of pottery clay, 10 parts of calcium carbonate, 8 parts of white carbon black, 7 parts of hemp powder and 2 parts of short fiber), 1.3 parts of aromatic guanidine organic antibacterial agent XT-11, 1.3 parts of nano-silver antibacterial and deodorant powder SCJ-120, 2.5 parts Nano-silver inorganic antibacterial agent XT-02.

[0044] The preparation method of light weight highly elastic deodorant rubber sponge pad for shoes:

[0045] The natural rubber is masticated ...

Embodiment 3

[0047] Embodiment 3: Calculated according to parts by weight, the lightweight and highly elastic deodorant rubber sponge pad for shoes is made of 98 parts of natural rubber, 2 parts of butadiene rubber, 2 parts of sulfur, 4 parts of vulcanization accelerator, 5 parts of vulcanization activator, foaming 1.8 parts of stearic acid, 18 parts of stearic acid, 3 parts of deodorant (deodorant consists of 2 parts of odor release agent and 1 part of rubber foam deodorant), 50 parts of filler (filler consists of 15 parts of pottery clay, 13 parts of calcium carbonate, 10 parts of white carbon black, 7 parts of hemp powder and 3 parts of short fiber), 1.3 parts of aromatic guanidine organic antibacterial agent XT-11, 1.3 parts of nano-silver antibacterial and deodorant powder SCJ-120, 2.5 parts Nano-silver inorganic antibacterial agent XT-02.

[0048] The preparation method of light weight highly elastic deodorant rubber sponge pad for shoes:

[0049] First, the natural rubber is mastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com