Nano-silver antibacterial shirt fabric and preparation method for same

A nano-silver antibacterial and nano-silver fiber technology, which is applied in the field of shirt fabrics, can solve the problems of incapability of antibacterial, bacteriostasis and sterilization, and poor functionality, achieve bacteriostatic and bactericidal functions, easy to use, and improve functionality and use. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

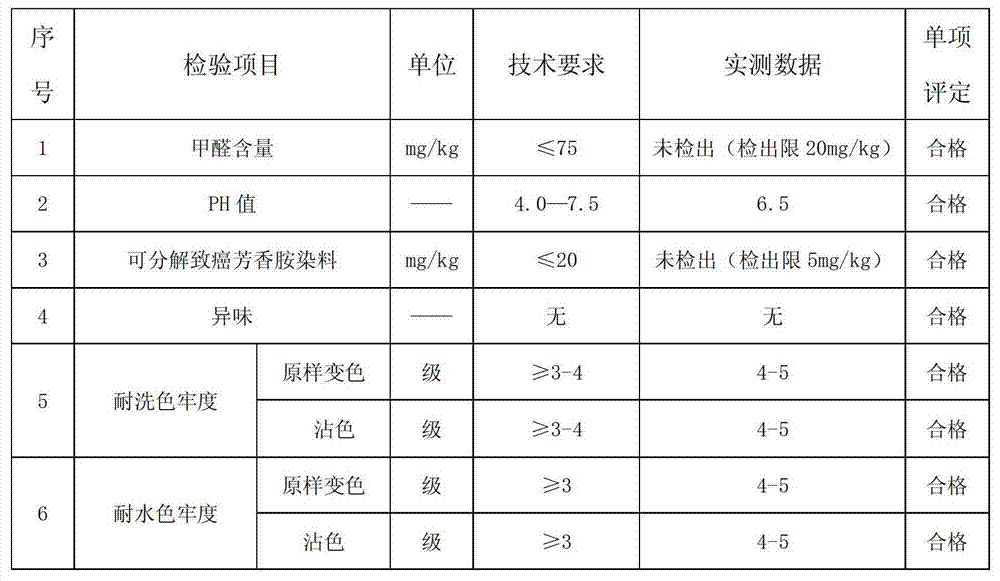

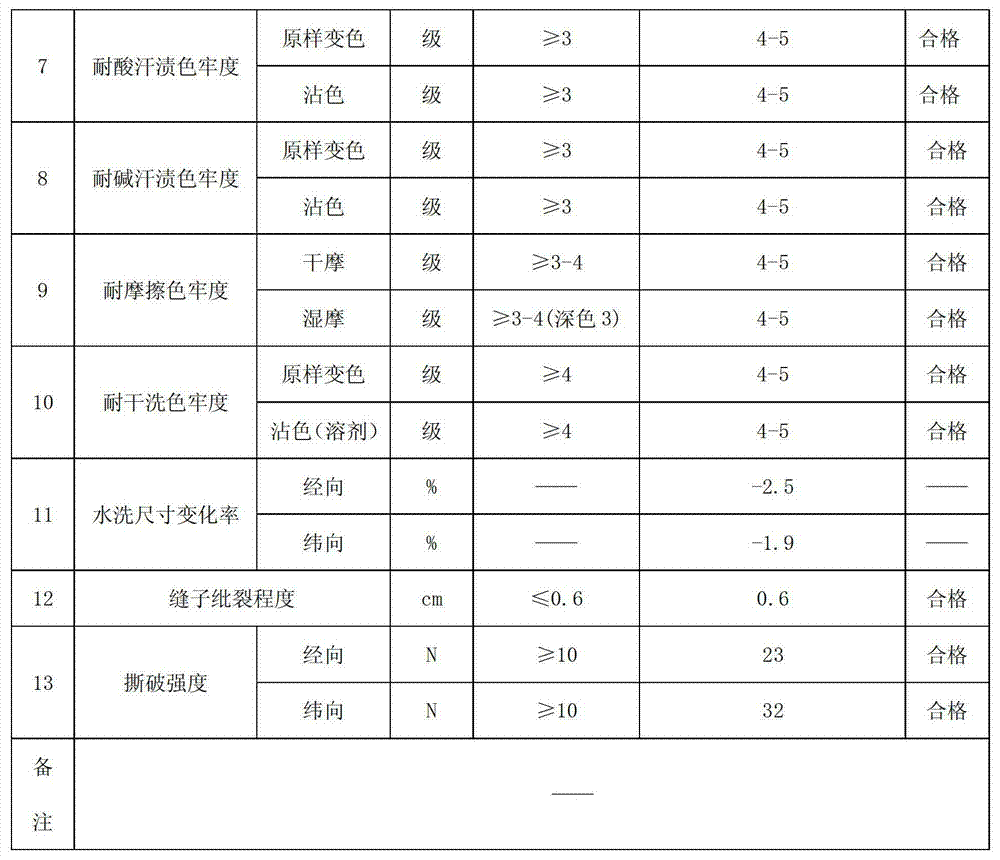

[0036] 1. Product specifications

[0037] 147cm CF14.8tex×Modal 48 / bamboo pulp fiber 48 / nano silver 4 14.8tex, 512 threads / 10cm×512 threads / 10cm, 6 / 6↗, yarn-dyed twill.

[0038] The warp yarn is compact spun cotton yarn, main indicators: average grade 3.0; main body length 29mm; micronaire value 3.9; 16mm short staple rate 7.5%; impurity content 1.4%; moisture regain 7.5%.

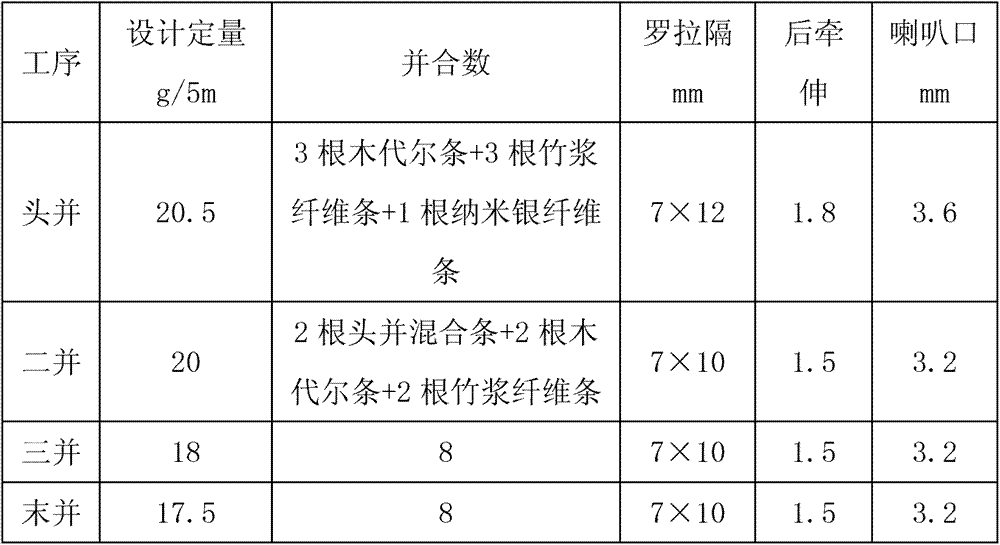

[0039] The weft yarn is modal / bamboo pulp fiber / nano-silver blended yarn. Modal uses 1.3D×39mm cotton-type staple fiber, bamboo pulp fiber uses 1.5D×38mm cotton-type staple fiber, and nano-silver fiber is 1.4D×38mm. Cotton-type short fiber, the blending ratio of the three is: Modal accounts for 48%, bamboo fiber accounts for 48%, nano-silver fiber accounts for 4%, and Modal and bamboo fiber account for a large proportion, so as to maximize Respective functionalities, nano-silver fibers only need to account for 4% to have good antibacterial properties. These kinds of fibers have their own advantages and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com