Patents

Literature

169 results about "Vinyl sulfone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

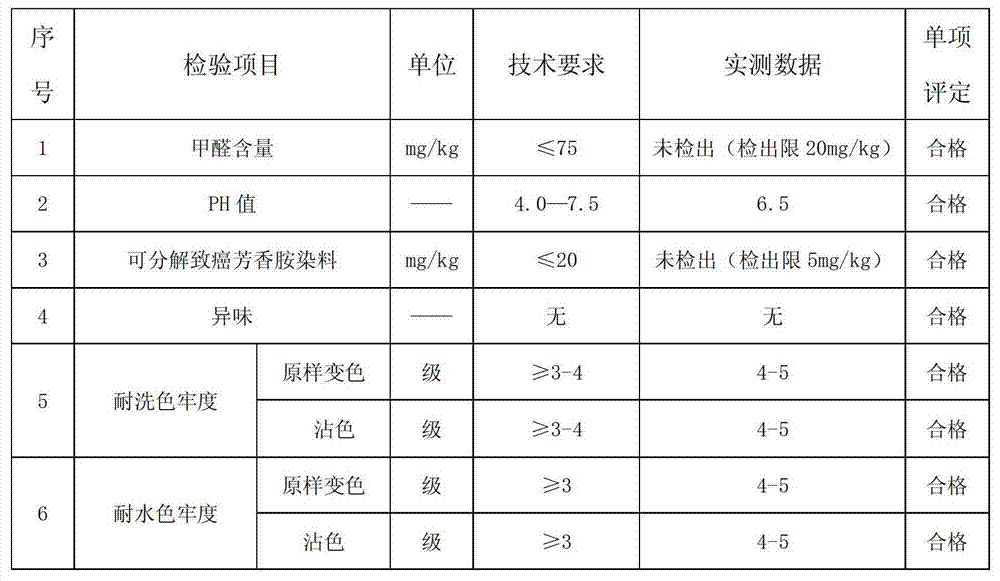

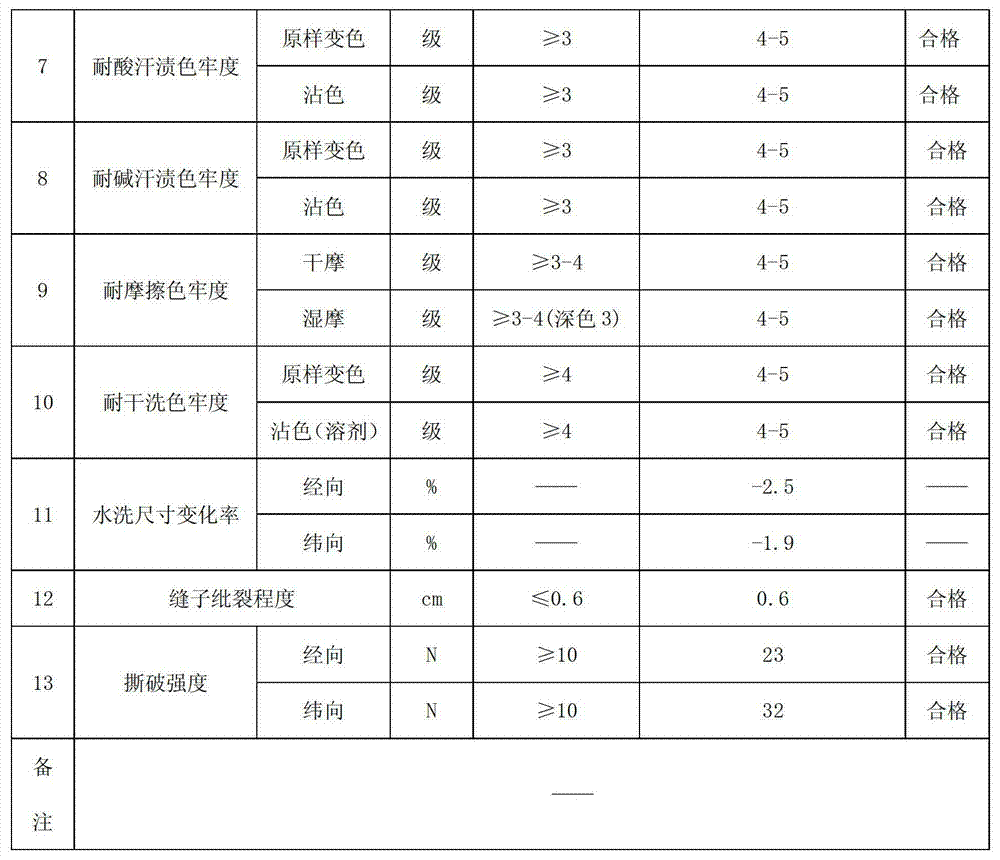

Nano-silver antibacterial shirt fabric and preparation method for same

InactiveCN103205835ABreaking strength without damageElongation at break without damageSucessive textile treatmentsBleaching apparatusFiberAfter treatment

The invention provides a nano-silver antibacterial shirt fabric. Warp of the fabric is compact spinning cotton yarns CF 14.8 tex; weft yarns are blended yarns 14.8 tex of 48%modal fibers / 48%bamboo pulp fibers / 4%nano-silver fibers; and the warp density is 512yarns / 10cm, and the weft density is 512yarns / 10cm. The invention further provides a preparation method for the nano-silver antibacterial shirt fabric. The method comprises the following steps: a, spinning; b, warp and cheese dyeing: cone loosening, caging filling, feeding into a cylinder, pretreatment, dyeing, aftertreatment, dehydration, drying and cone fastening, wherein the pretreatment is performed at a temperature of 120 DEG C for 30min to 60min, the NaOH utilization amount is 1.4g / L to 1.6g / L, the utilization amount of H2O2 in a concentration of 27.5% is in a range of 4.3g / L to 4.7g / L, the bath ratio during dyeing is 1:10, reactive dyes containing two active groups of vinyl sulfone and monochlorotriazine, the utilization amount of the dyes is in a range of 3g / L to 5g / L, the utilization amount of Na2SO4 is in a range of 10g / L to 60g / L, and the utilization amount of Na2CO3 is in a range of 5g / L to 20g / L; c, weaving: warping, sizing, drafting and weaving the fabric, wherein K-5000 size is used during sizing; and d, after treatment.

Owner:JIANGSU YDTEX GRP LTD

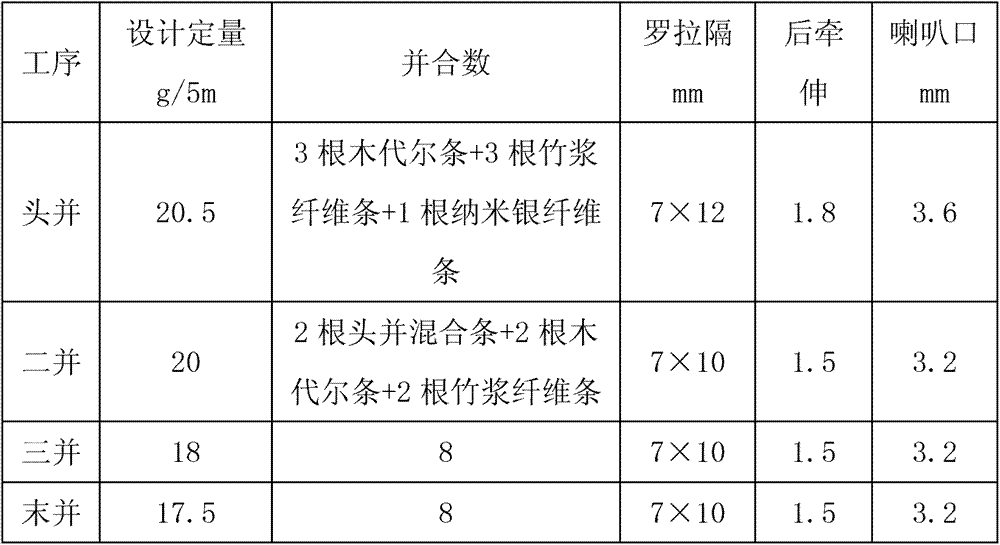

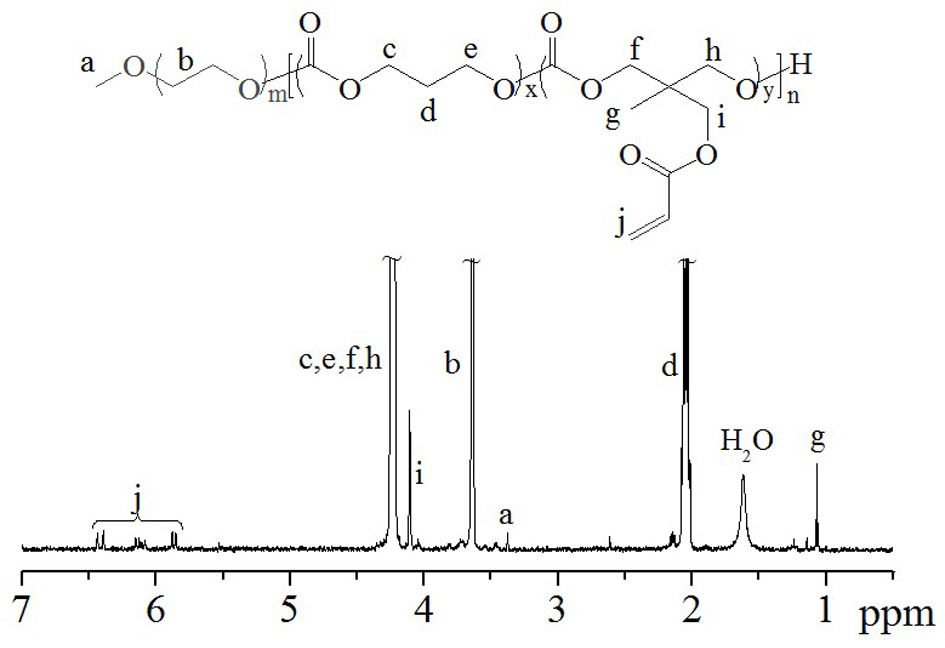

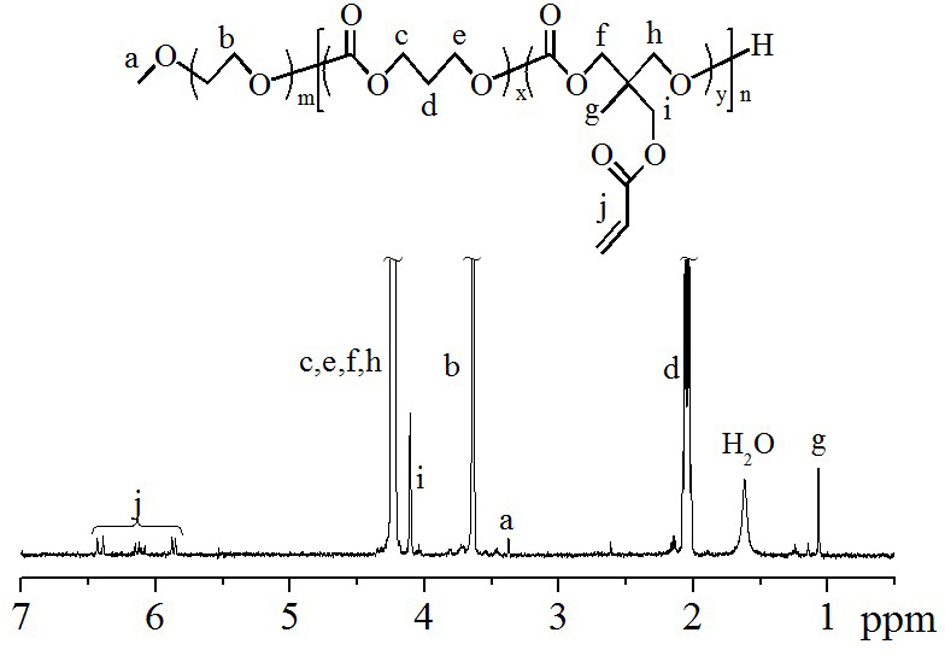

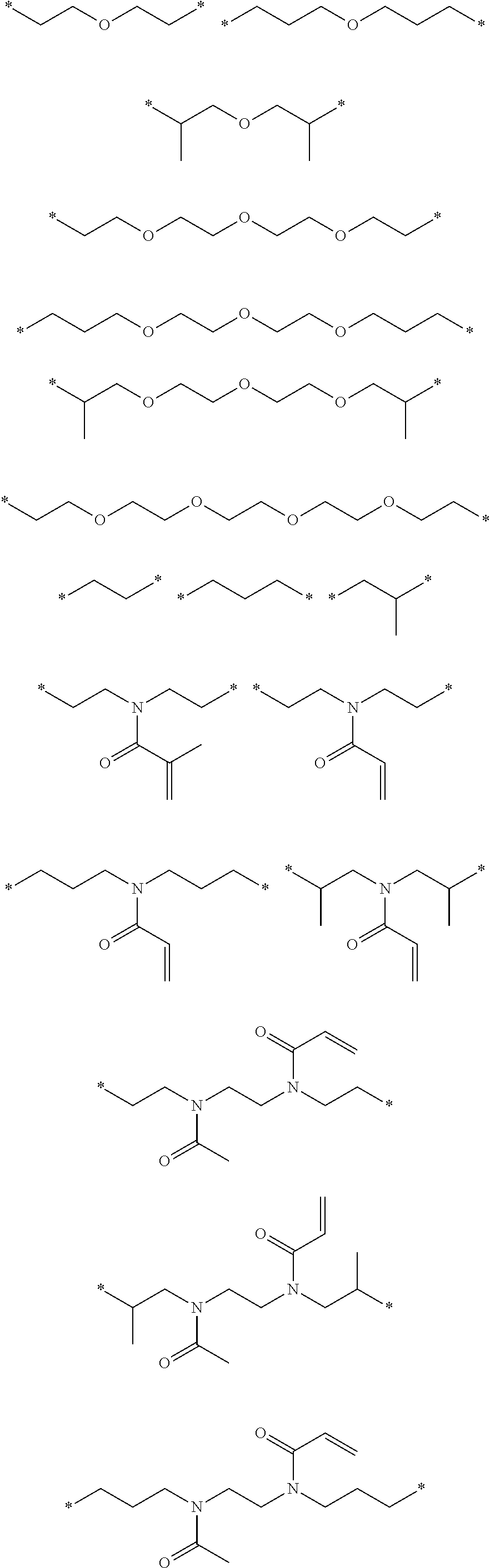

Vesicles consisting of amphiphilic polymer and application of vesicles

InactiveCN102657873AEasy to packEfficient packagingGenetic material ingredientsPharmaceutical non-active ingredientsBackbone chainDouble bond

The invention discloses vesicles consisting of amphiphilic polymer and application of the vesicles. A main chain of the amphiphilic polymer consists of a hydrophilic chain segment and a biodegradable hydrophobic chain segment, wherein the molecular weight of the hydrophilic chain segment is 4 to 6kDa; the molecular weight of the hydrophobic chain segment is 3 to 5 times that of the hydrophilic chain segment; the hydrophobic chain segment is formed by performing random copolymerization on a monomer A and a monomer B in a molar ratio of (5-20):1; the monomer A is trimethylene carbonate or cyclic carbonate; the monomer B is acrylate-based carbonate or vinyl sulfone-based carbonate; the hydrophobic chain segment is grafted with a short branched chain; the grafting position is a double bond of the monomer B; a monomer forming the short branched chain is 3-mercaptopropionic acid, cysteamine hydrochloride or cysteine; and the grafting rate is 0.3 to 1. The vesicles are directly prepared from the amphiphilic polymer in an aqueous solution and used as a carrier and a release system of a protein medicine, the encapsulating efficiency and bioavailability of the protein medicine can be improved, and the stability of the encapsulated protein is enhanced.

Owner:SUZHOU UNIV

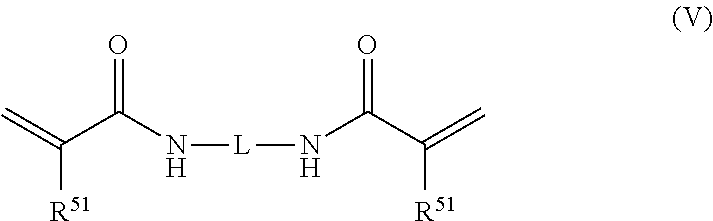

Ink composition, ink set and image forming method

An aqueous ink composition including: a water-soluble polymerizable compound containing two or more polymerizable functional groups each selected from the group consisting of a (meth)acrylamide group, a maleimide group, a vinyl sulfone group, and an N-vinyl amide group, wherein a ratio of a molecular weight of the compound relative to a number of the polymerizable functional groups contained in a single molecule of the compound is 175 or less; a polymerization initiator; and water.

Owner:FUJIFILM CORP

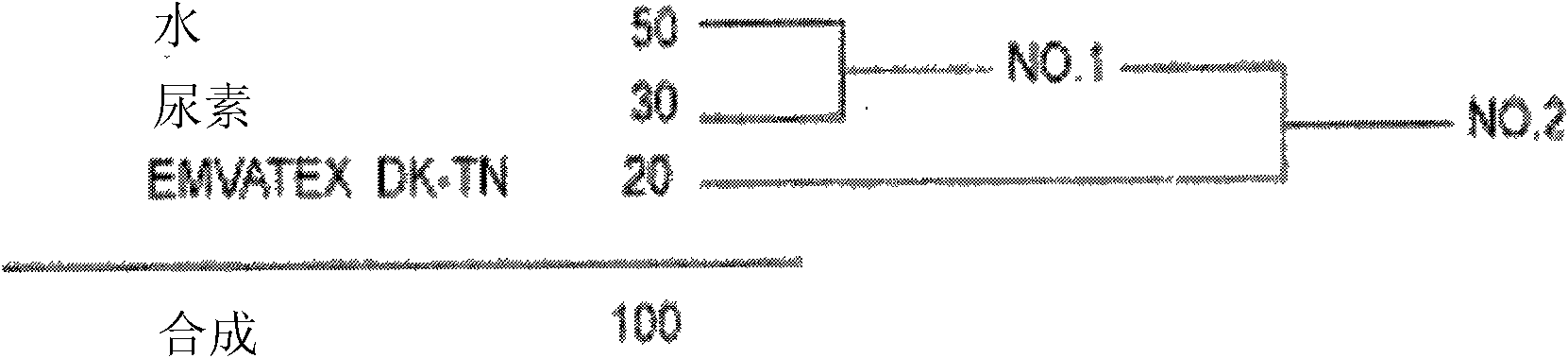

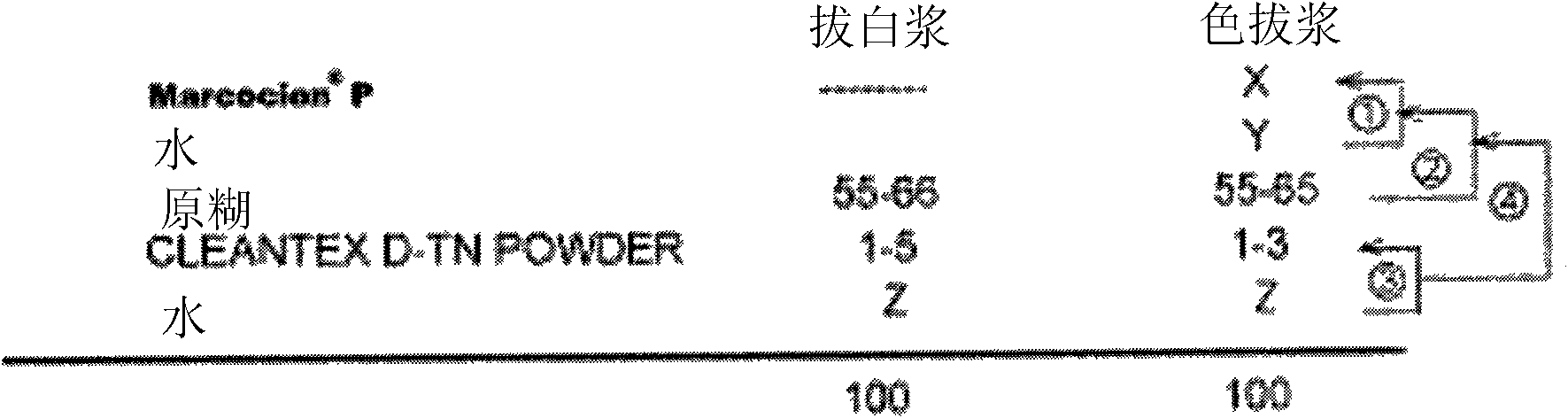

Cotton cloth reactive dye discharge printing process

InactiveCN101654876AImprove discharge/coloring effectImprove discharge effectDyeing processVinyl sulfoneEconomic benefits

The invention relates to a cotton cloth reactive dye discharge printing process for use in textile dyeing and printing production, in particular to a reactive dye discharge printing process. The invention aims to substitute for the conventional reduction discharge process which is not environment-friendly and high in cost and has white discharge and poor red coloring in application by introducingthe cotton cloth reactive dye discharge printing process. The process comprises the following steps of: 1, ground dyeing of the cotton cloth with a vinyl sulfone reactive dye; 2, discharge printing ofthe cotton cloth with a color paste made from a discharge printing agent and an alkali-resisting P-type reactive dye; 3, baking for decolorization; 4, steaming of the cotton for color development; 5,water washing; and 6, drying. The formula thereof comprises: a primary paste containing 20 percent of discharge printing agent DK-TN, 20 to 30 percent of carbamide and the balance of water; a white discharging paste containing 50 to 60 percent of primary paste, 1 to 10 percent of leucotrope and water; and a color discharging paste containing Marcocion P dye stuff, 50 to 60 percent of primary paste, 1 to 8 percent of leucotrope D-TN and 2 to 4 percent of water / saleratus. The cotton cloth reactive dye discharge printing process has the advantages of updating the conventional process and the currently introduced discharge printing process, improving the discharge printing effect, reducing the printing cost, decreasing the added materials and reducing the amount of sewage generated in a process of water washing unfixed dyes. The reactive dye process is simple in technique, bright in color, soft in hand feeling and good in environment protection, belongs to innovation development, saves energy, improve efficiency and has enormous social and economic benefits.

Owner:董建圆

Purified cotton cloth reactive dye wet steaming deep color dyeing method

InactiveCN101328688AStrong penetrating powerImprove uniformityDyeing processLiquid/gas/vapor textile treatmentCotton clothSteaming

The invention provides a pure cotton cloth reactive dye wet short steaming dyeing dark color method, belonging to a cloth dyeing method. The dyeing method comprises the following steps that: a vinyl sulfone reactive dye is selected, and a penetrating agent CWA, urea and a chelated dispersing agent DF101 are dissolved in a dye solution so as to obtain a mixed solution; sodium hydroxide and sodium silicate with a concentration equal to 38 baume degrees are dissolved in water to obtain an alkaline agent solution; the mixed solution and the alkaline agent solution are mixed according to the volume ratio of between 8 and 2, and are fed into a dye solution trough so as to obtain a dye solution; and when dipped in the dye solution for one time and rolled by a padder for one time, cloth is subjected to steam fixation and water washing, soap boiling and water washing so as to complete dyeing. The pure cotton cloth reactive dye wet short steaming dyeing dark color method completes dipping, rolling, padding, steaming and water washing at one step after the dye and the alkaline agent solution are mixed, thereby ensuring simple working procedure and short flow; moreover, the method adopts less equipment and has lower energy consumption, no migration, high dyeing quality and better dyeing penetration, evenness, and smoothness of dyed cloth than the prior dyeing method.

Owner:郭利

One-bath dyeing method for soybean fiber/tencel blended fabric

The invention relates to a dyeing method for soybean fiber / natural silk blended intertexture, which comprises: taking modification treatment to the blended intertexture with modifying liquid contained soda and cation modifier of quaternary ammonium compound with epoxy radical; adding non-ion polyoxyethylene ether compound as dye leveller into dyeing liquid; taking dyeing process with vinyl sulfone dyestuff or reactive dyes contained opposite radicals; then, clearing and completing the concolore bath dyeing. This invention cuts process and time, saves energy and cost, and improves performance of the product.

Owner:SUZHOU UNIV +1

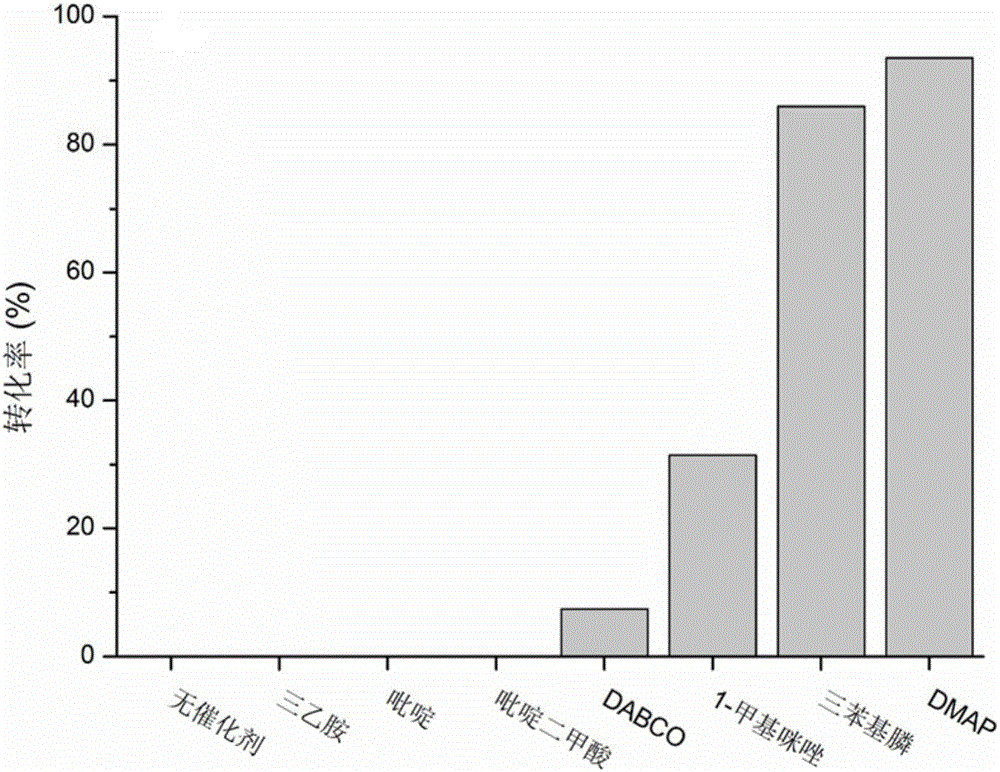

Preparation method of vinyl sulfone derivatives

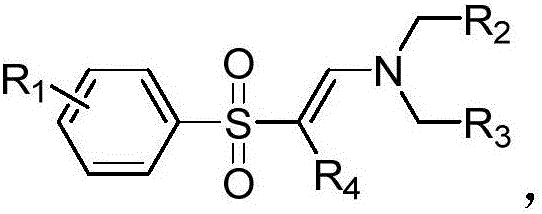

ActiveCN105820095AHigh yieldImprove conversion rateOrganic chemistryOrganic compound preparationVinyl sulfoneNitrogenous heterocyclic compound

The invention relates to a preparation method of vinyl sulfone derivatives. The vinyl sulfone derivatives have the structure disclosed as General Formula I. According to the preparation method, compounds i react with divinyl sulfone in the presence of a catalyst, wherein R is selected from H or C1-C8 alkyl; n is a whole number which is greater than or equal to 1; and the catalyst is selected from triaryl phosphine compounds or nitrogen heterocycle compounds. Under the action of the selected catalyst, the reaction can quickly occur under room temperature conditions to obtain the products. The method has the advantages of mild conditions, high reaction speed, high conversion rate and the like. The prepared products have the advantages of hydrolysis resistance, alkali resistance, broad reaction spectrum and the like, and have very high application value.

Owner:DALIAN UNIV OF TECH

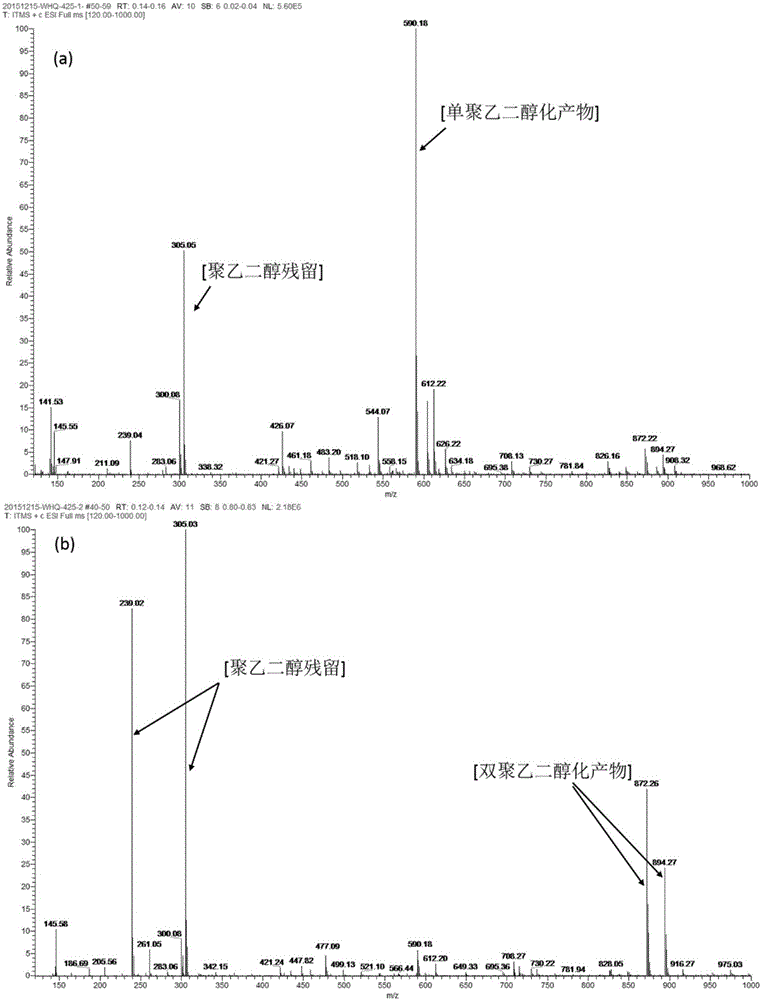

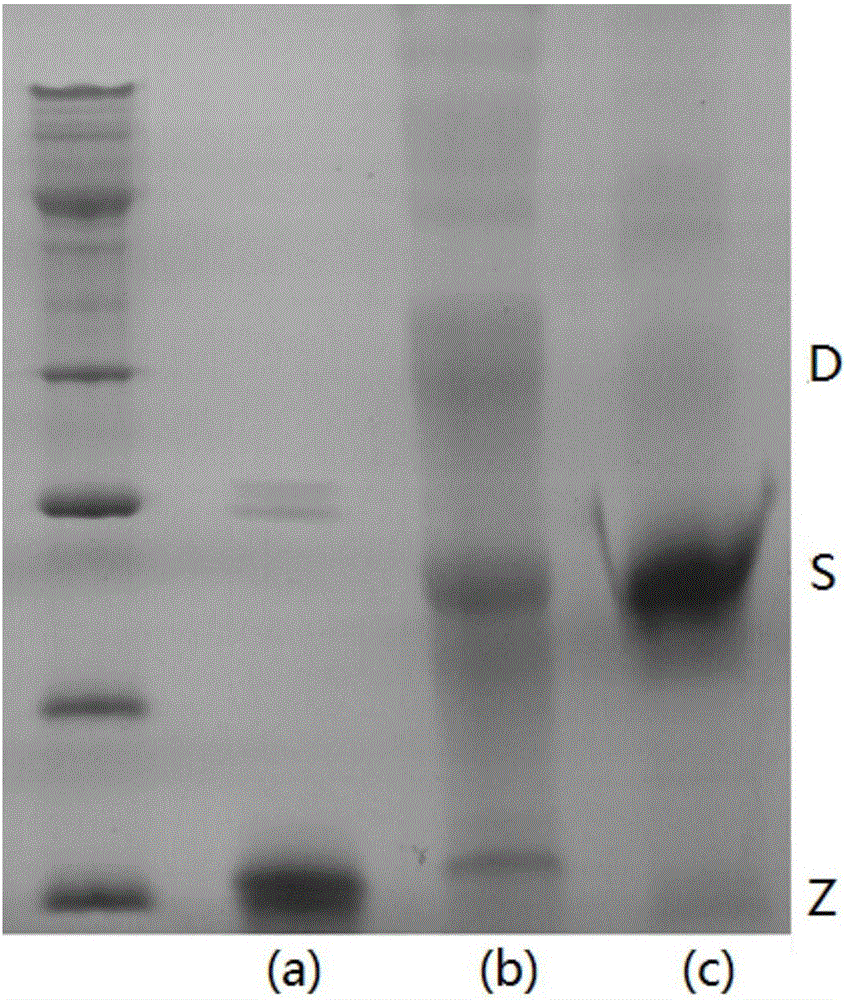

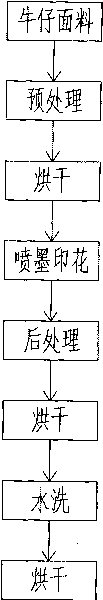

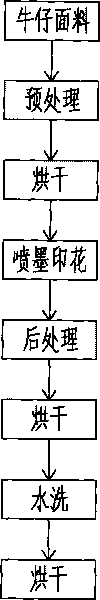

Reactive ink for printing and dyeing and method for carrying out jet printing on denim fabric by adopting same

The invention relates to reactive ink for printing and dyeing, containing the following components of 5%-20% of vinyl-sulfone epoxy resin-based high-polymer reactive dyes, 0.5%-1% of surface active agents OP-10, 5%-10% of propylene glycol PEG and 69%-89.5% of deionized water, and the PH value of the high-polymer reactive ink for printing and dyeing is 7-9 through adding a PH-value buffer solution after mixing the components. The invention also relates to a method for carrying out jet printing on a denim fabric by adopting the ink, comprising the following steps of: pretreating and drying the denim fabric, then carrying out jet printing by adopting the high-polymer reactive ink for printing and dyeing, after treating and drying the denim fabric, and finally washing and drying the denim fabric. After being used, the reactive ink for printing and dyeing and the method for carrying out jet printing on the denim fabric have the advantages of environmental protection and energy saving; the printed denim fabric has the advantages of high washing-resistant color fastness and wear-resistant color fastness and favorable hand feeling; and meanwhile, the quality level and the additional value of denim garment are enhanced.

Owner:GUANGDONG JUNAN JEANS RES INST

Method for producing coagulant for active dye wastewater

InactiveCN102092830AImprove performanceIncreased sensitivityWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationProcess equipmentVinyl sulfone

The invention relates to a printing and dyeing industrial wastewater treatment technology, and discloses a novel formula of a coagulation decolorant for active dye wastewater. The coagulation decolorant is a compound coagulation decolorant which is prepared by blending sodium polyacrylate serving as an additive, alkaline aqueous solution of polyvinyl alcohol, and dicyandiamine-formaldehyde polycondensate. The process equipment is general equipment, and raw materials are readily available. The formula of the coagulation decolorant is suitable for treating active dye wastewater and wastewater generated after printing and dyeing process production of cotton knitted fabrics, linen knitted fabrics and the like; and the wastewater mainly contains s-triazines, halogenated pyridines, vinyl sulfones and double active radical type compounds. The decolorization rate of the coagulation decolorant is more than 90 percent.

Owner:上海康鸣高科技有限公司

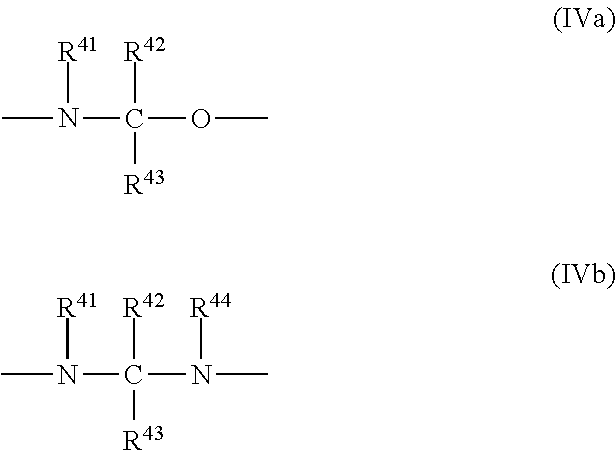

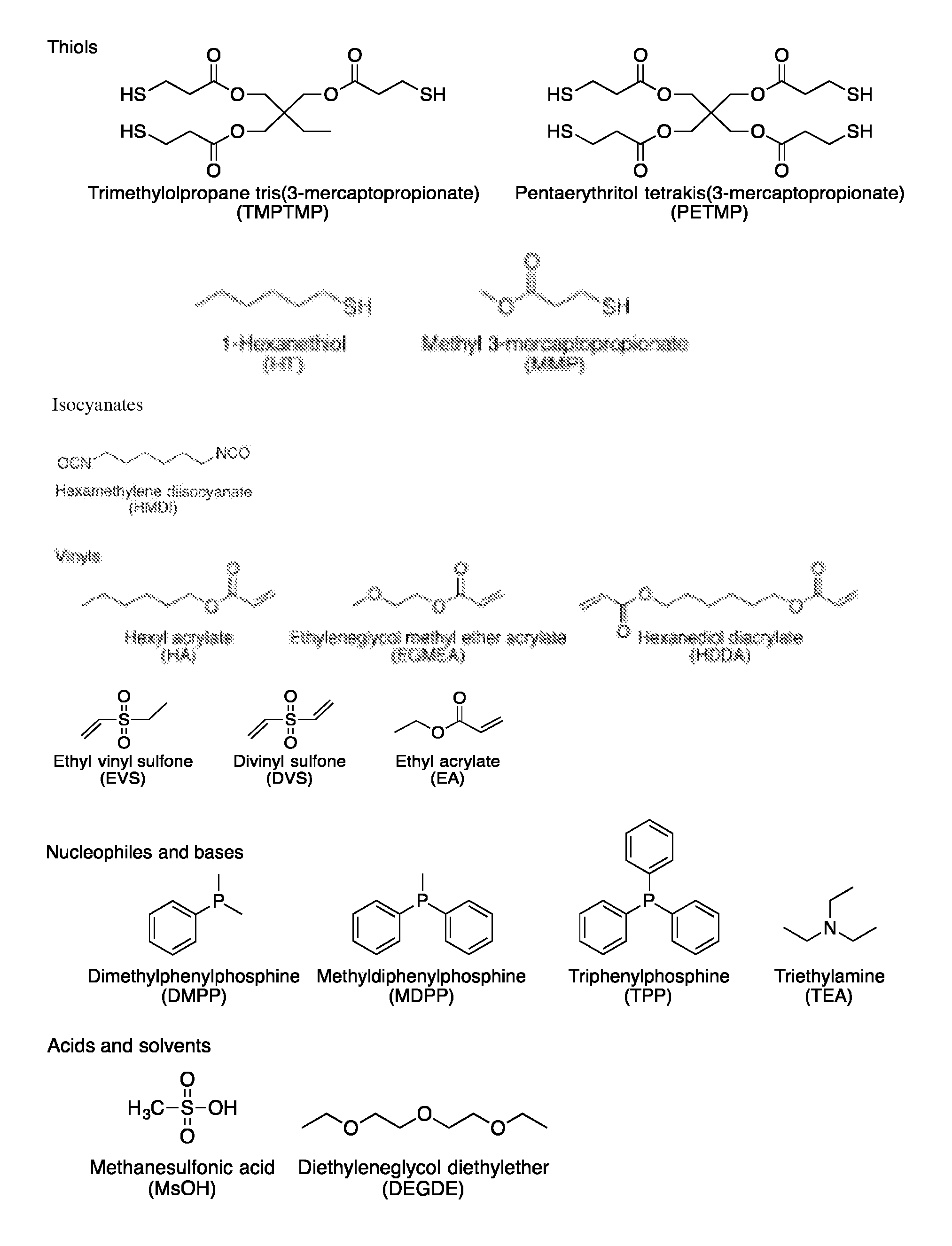

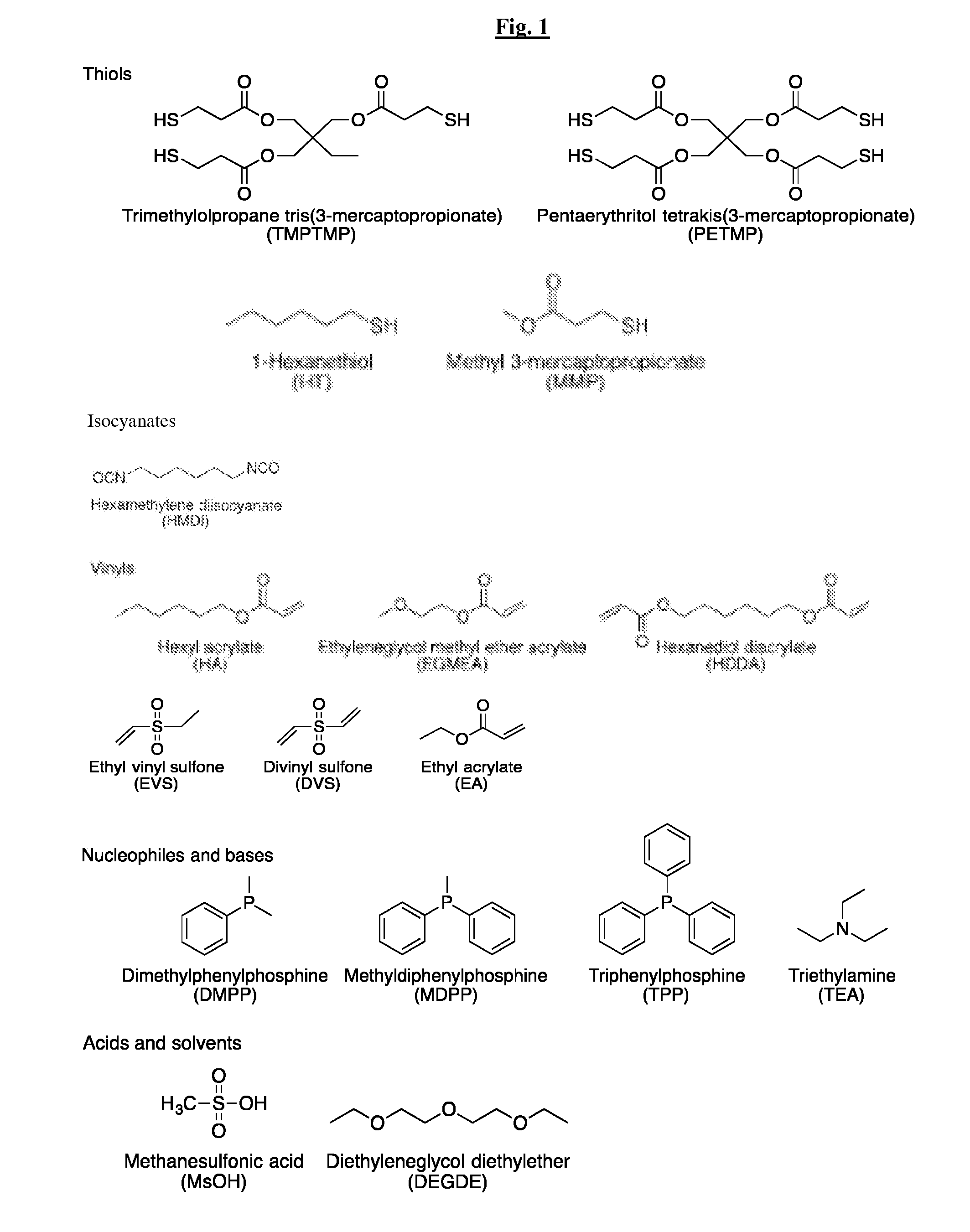

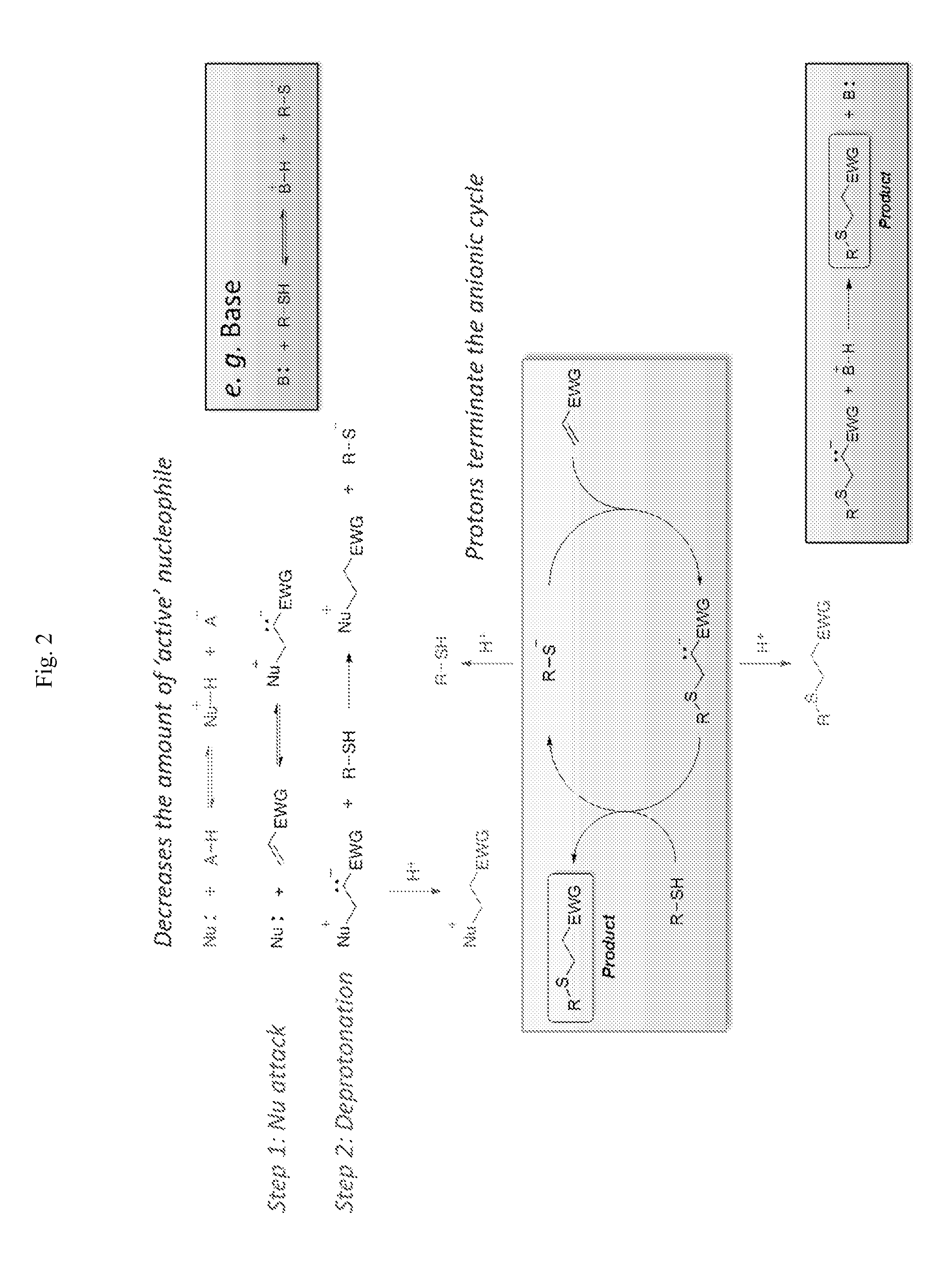

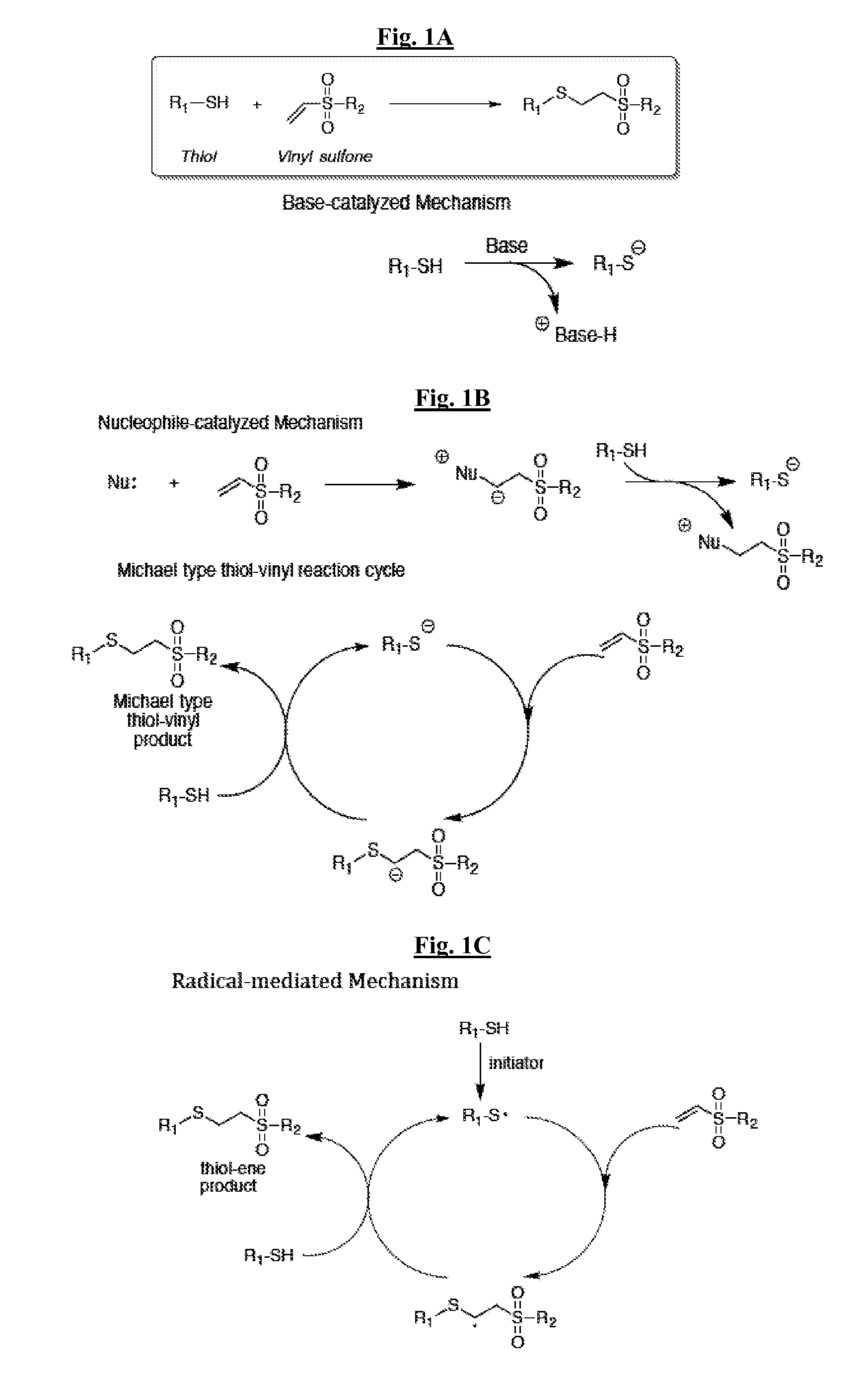

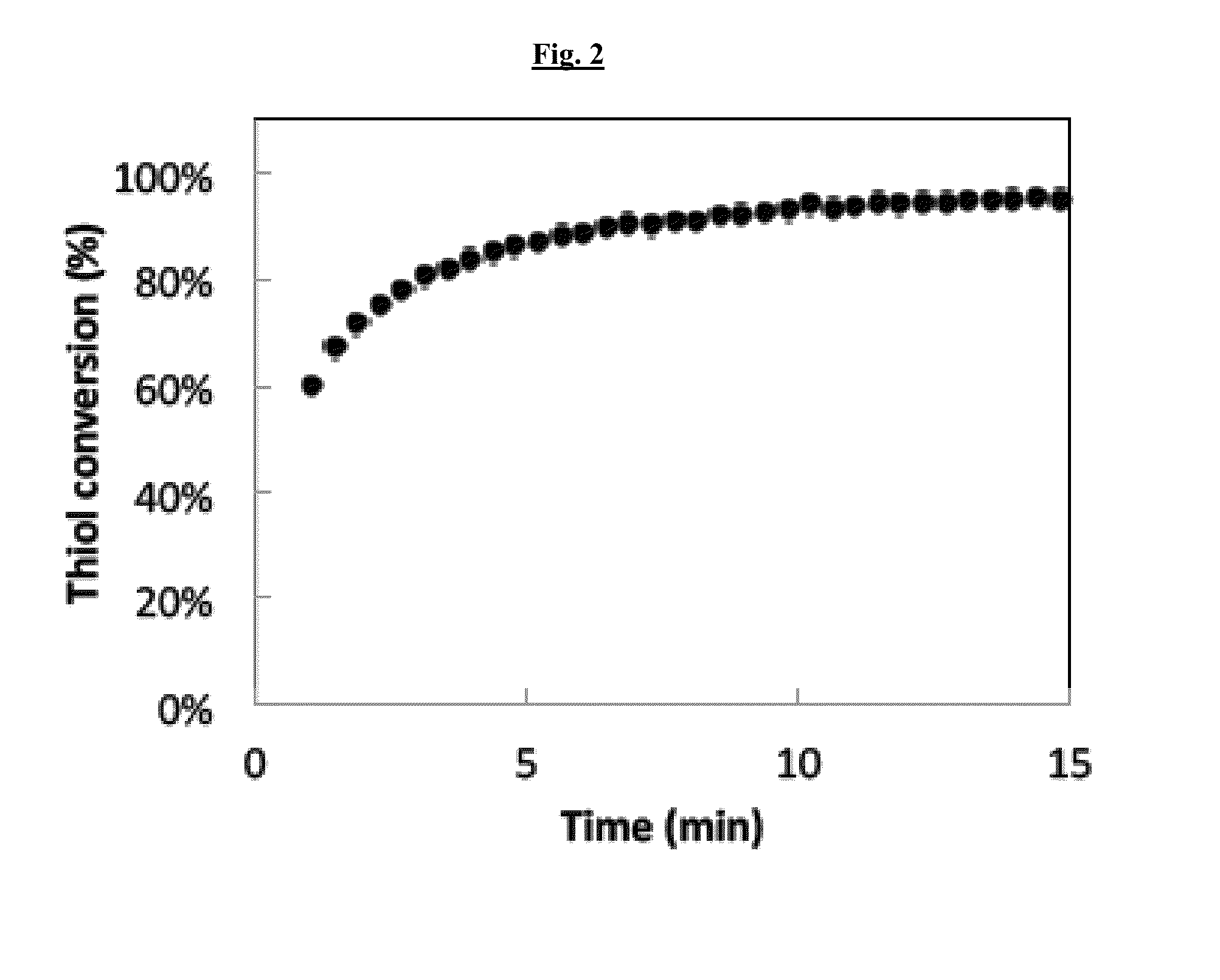

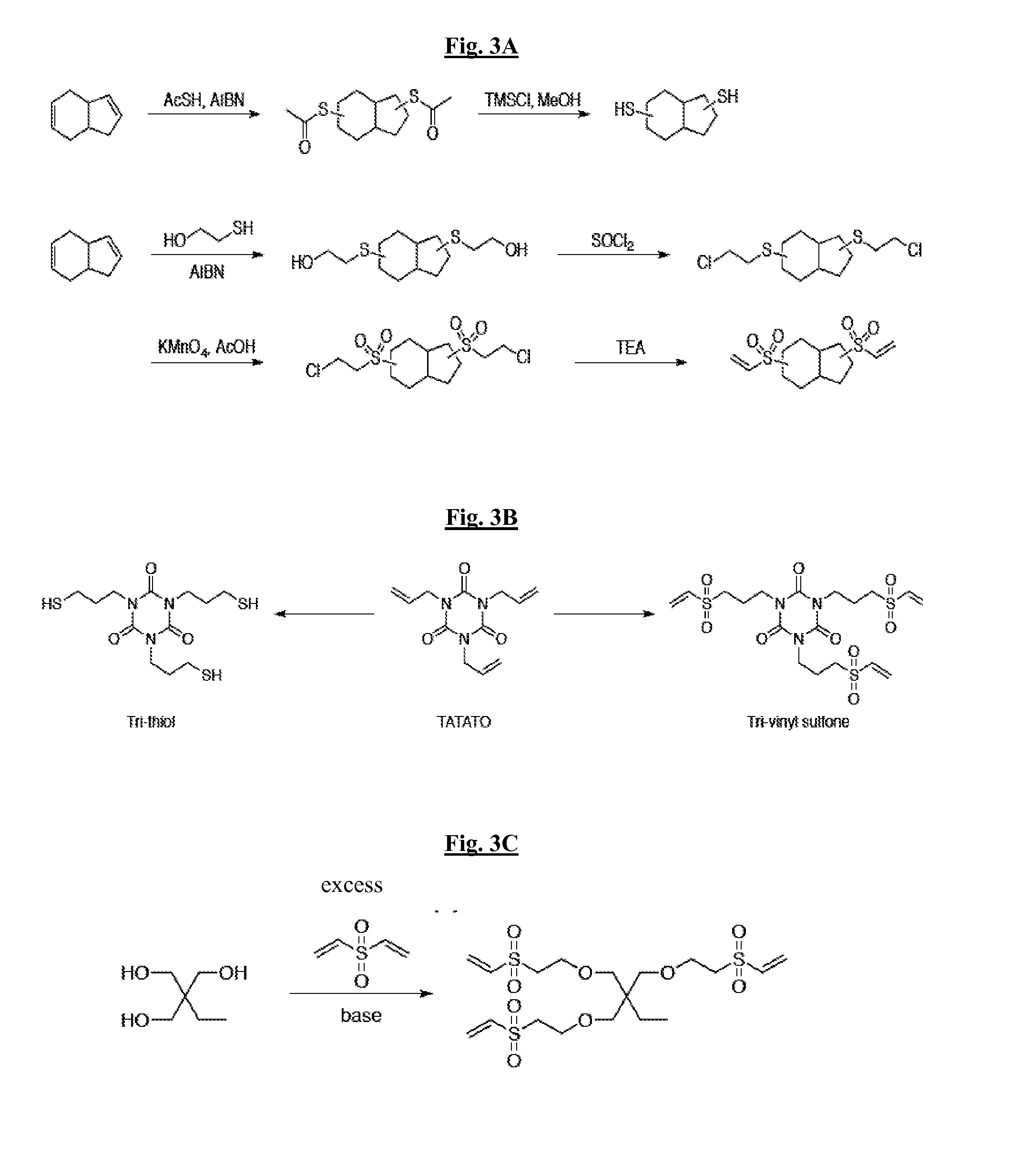

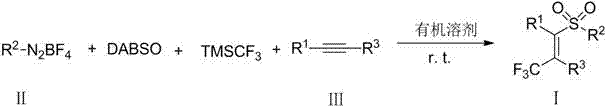

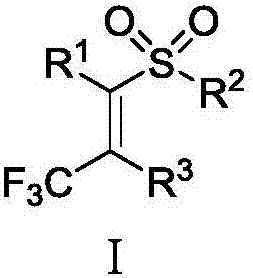

Novel thiol-containing dual cure polymers and methods using same

The invention includes a composition comprising a vinyl sulfone monomer, a thiol monomer and an acrylate monomer. In one embodiment, the thiol monomer reacts with the vinyl sulfone monomer preferentially over the acrylate monomer, and this differential selectivity allows for the control of the architecture of crosslinking polymer network. The invention further includes a composition comprising an electrophilic monomer, a nucleophilic monomer, a nucleophilic catalyst and an acid, wherein the concentrations of the nucleophilic catalyst and acid are selected as to provide a specific induction time for the polymerization reaction of the composition.

Owner:UNIV OF COLORADO THE REGENTS OF

Formula of reactive dye

The invention relates to a formula of reactive dye, and belongs to the technical field of printing dye. The formula comprises the following constituents in parts by weight: 20 to 40 parts of 2,4-difluoro-5-chloropyrimidine dye, 30 to 50 parts of vinyl sulfone dye, 20 to 40 parts of alpha-bromo-acrylic amide dye, 1 to 8 parts of dye leveller peregal O, 1 to 10 parts of sodium sulfate, 1 to 10 parts of sodium chloride, 2 to 8 parts of disodium hydrogen phosphate, 10 to 20 parts of sodium dihydrogen phosphate, 5 to 15 parts of sodium hydroxide, 1 to 20 parts of sodium carbonate, and 5 to 15 parts of urea. The dye has relatively high fastness and wet fastness, bright color, excellent performance and high applicability, and both the color and the performance of the dye can meet the requirements on fiber and apparel fabric by the market.

Owner:GUANGDONG JINCHAO GRP

High-purity active black printing dye

InactiveCN105273439AHigh blacknessBroad absorption spectrumOrganic dyesDyeing processInorganic saltsTextile printer

The invention provides a high-purity active black printing dye. The dye comprises the following components in percentage by weight: 65-75% of active black 5, 12-22% of active orange 7, 11-16% of active orange 72 and 1-6% of a cosolvent, wherein the cosolvent is inorganic salt electrolyte; the active black 5, the active orange 7 and the active orange 72 are raw powder dyes prepared by nanofiltering, desalting, atomizing and drying reaction liquid after synthesizing the dyes. The dyes used by the high-purity active black printing dye are vinyl sulfone dyes and are the same in aging time and temperature after printing; the color fixation is sufficient; the color fixation rate is increased; the desalination rate of the nanofiltered and desalted dyes is greater than 98%; the dye is high in purity, low in content of salt and excellent in printing levelling property; the salt emission amount in wastewater can be reduced.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

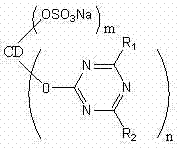

Cyclodextrin fixing fiber with envelope property and preparation method thereof

The invention relates to a Cyclodextrin fixing fiber with envelope property and a preparation method thereof. As for the Cyclodextrin fixing fiber, the Cyclodextrin is fixed on the fiber through the combination mode of a covalent bond; the fiber with envelope property is prepared from reactive Cyclodextrin containing triazinyl and vinyl sulphone and the fiber or fabric through bath finishing under the alkali condition. The processing technology of the fiber is simple and can realize industrialization easily, thus laying a foundation for further developing the functional textiles such as fragrance-keeping, health care, deodorization, mosquito-preventing textiles and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Processing method of alkali-resistant dischargeable mercerized colored spun yarn

InactiveCN102517908AAlkali-resistant mercerizingChange the contradictory situation of discharge dyeing performanceBiochemical fibre treatmentDyeing processYarnPolymer science

The invention relates to a processing method of alkali-resistant dischargeable mercerized colored spun yarn, belonging to the field of spinning. The method comprises the following steps of: a, dyeing sliver, wherein the sliver is dyed with the required color by use of a dischargeable reactive dye containing two active groups of monochloro-sym-triazine and vinyl sulfone; b, spinning, wherein the dyed sliver obtained by the step a is spun with the true-color or dyed sliver according to a proportion; c, singeing and reeling the colored spun yarn obtained by the step b; and d, mercerizing the colored spun yarn obtained by the step c. The processing method provided by the invention originates the alkali-resistant dischargeable mercerized colored spun yarn, not only maintains the original features of the colored spun yarn, but also enables the colored spun yarn to be resistant to strong alkali mercerizing; the colored fabric has the alkali-resistant dischargeable performance; and the shortcoming that the common colored spun yarn is alkali-resistant but not dischargeable or is dischargeable but not alkali-resistant is overcome.

Owner:WUXI NATURAL GREEN FIBER TECH

Formula of reactive dye

The invention provides a formula of a reactive dye. The formula of the reactive dye comprises, by weight, 20-40 parts of a cyclically fluorinated reactive dye, 30-50 parts of a vinyl sulfone dye, 20-40 parts of an alpha-bromoacrylamide reactive dye, 1-8 parts of a dye leveller peregal O, 1-10 parts of sodium sulfate, 1-10 parts of sodium chloride, 2-8 parts of disodium hydrogen phosphate, 10-20 parts of sodium dihydrogen phosphate, 5-15 parts of sodium hydroxide, 1-20 parts of sodium carbonate and 5-15 parts of urea. The reactive dye has the advantages of high fastness and wet fastness, bright color, excellent performances and strong applicability, the hue and the performances of the reactive dye can adapt to market requirements of the formula and uses of the reactive dye in fibers and clothes, and the dye has excellent fastness, especially color fastness to light, color fastness to chlorine and color fastness to perspiration, and also has very good lifting capacity level. The dye has good contact color fastness uniform tone after being washed, and the hue and the performances of the dye can adapt to market requirements on the fibers and the clothes.

Owner:WUXI CHANGAN SHUGUANG GLOVE FACTORY

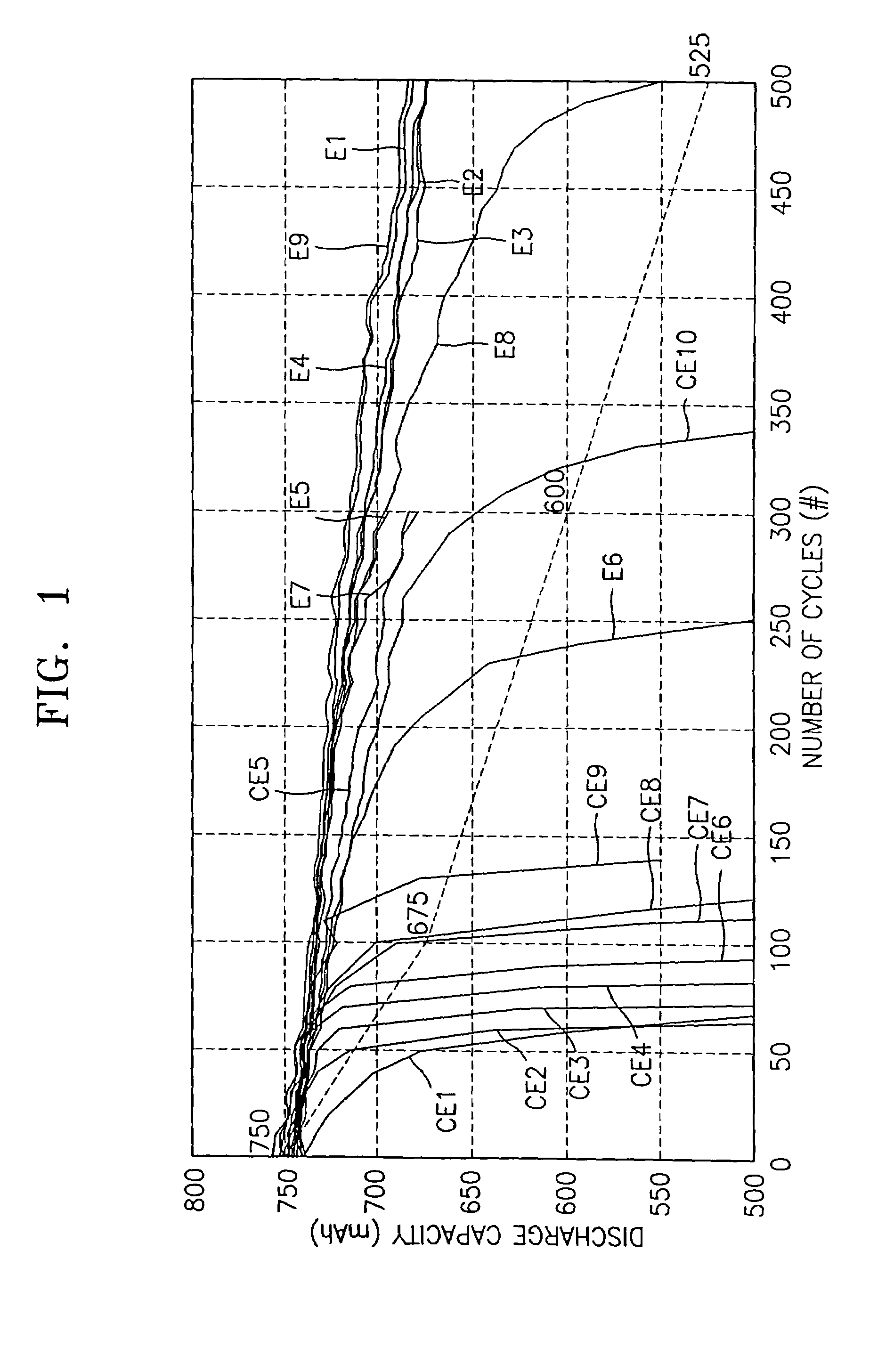

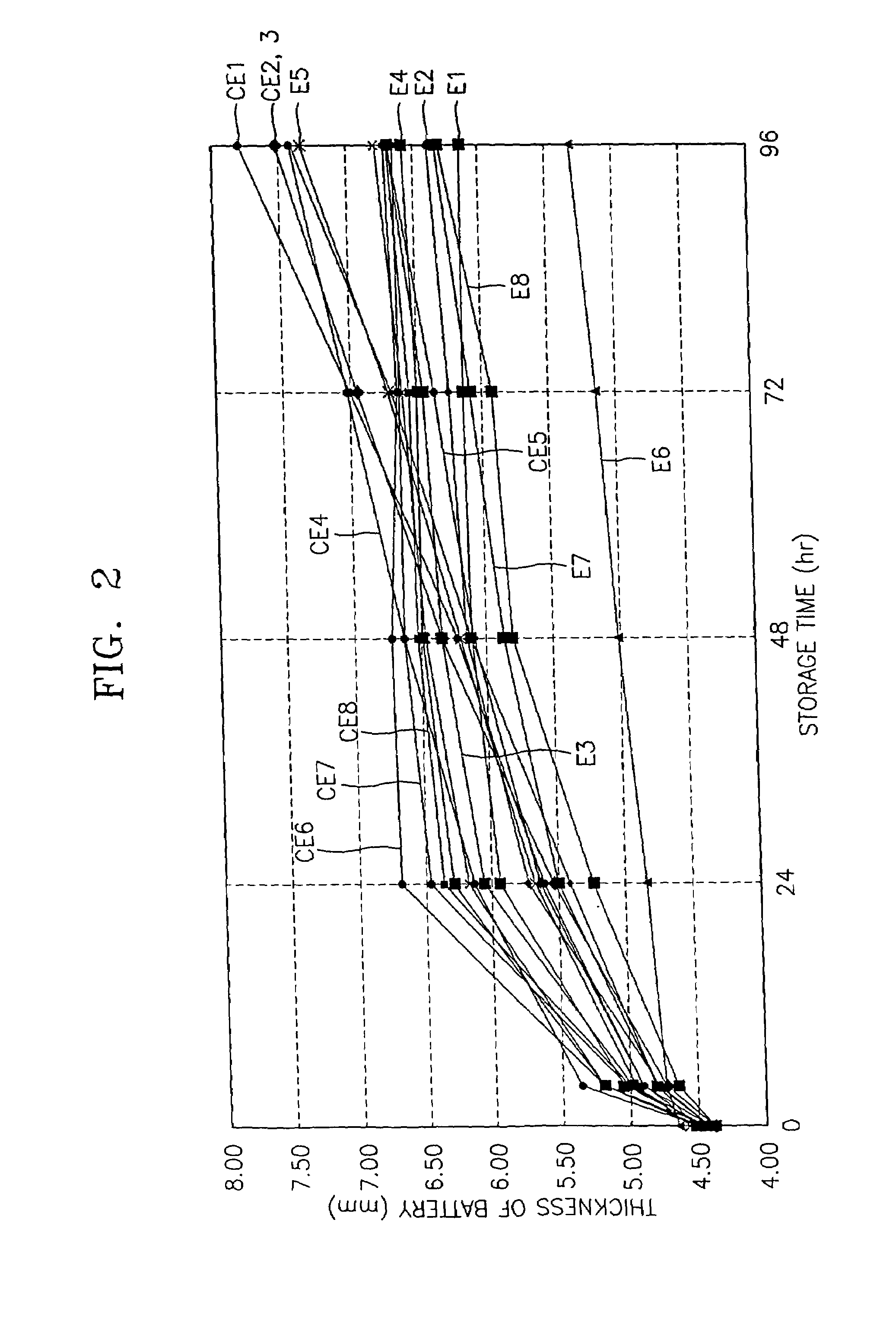

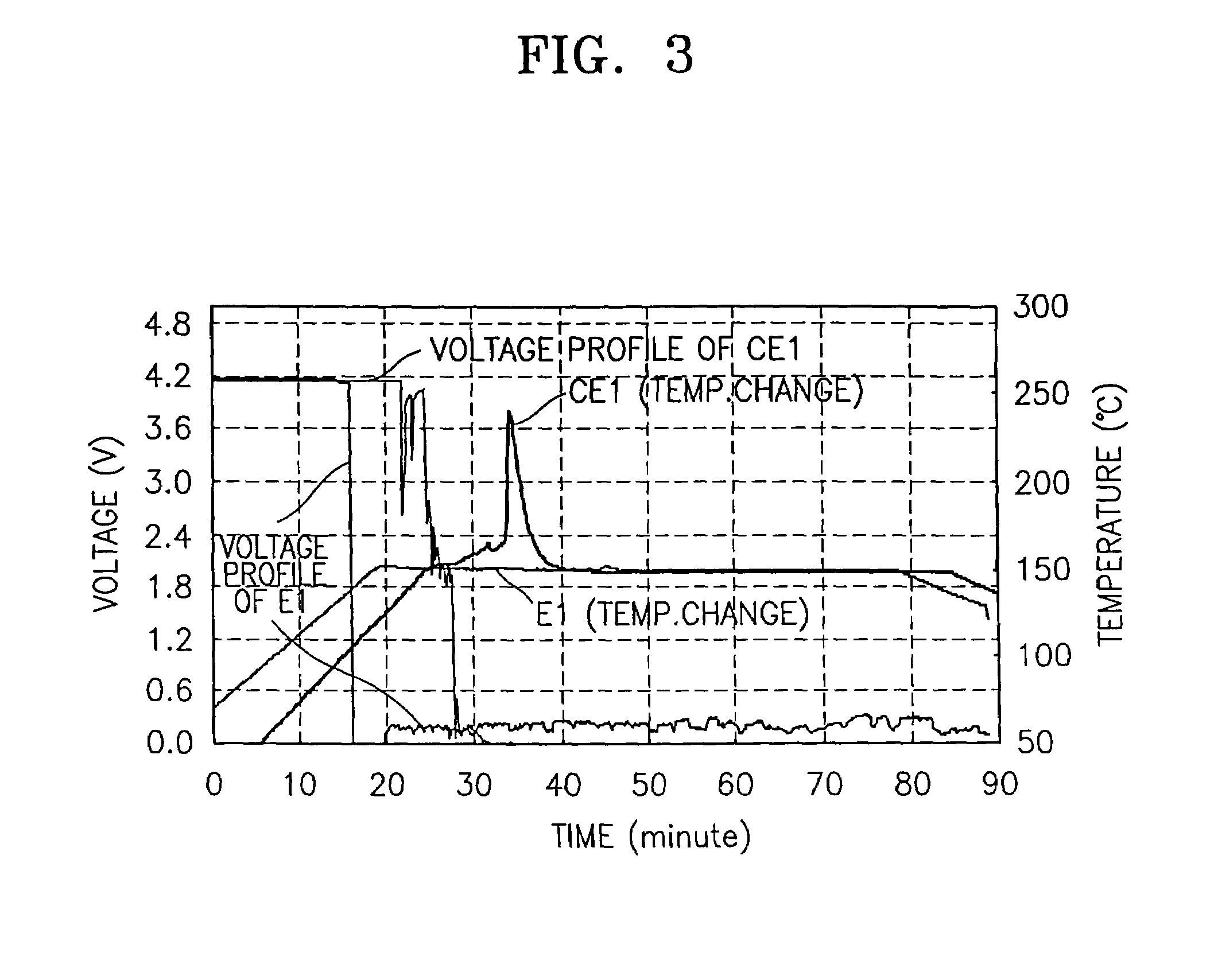

Lithium battery having effective performance

ActiveUS7078132B2Improve charge and discharge cycle characteristicsEffective effective characteristicsOrganic electrolyte cellsLi-accumulatorsVinyl sulfoneSolvent

A lithium battery which has an anode, a cathode having a compound capable of intercalating and deintercalating lithium, a separator interposed between the cathode and the anode, and an electrolyte solution having an electrolyte solute dissolved in a nonaqueous solvent. The nonaqueous solvent includes a mixed solvent containing 8 to 15% by volume of ethylene carbonate, 10 to 35% by volume of γ-butyrolactone, 35 to 65% by volume of at least one linear carbonate selected from the group consisting of dimethyl carbonate, diethyl carbonate, ethylmethyl carbonate, methylpropyl carbonate, ethylpropyl carbonate and methylbutyl carbonate and 8 to 15% by volume of fluorobenzene, and 0.5 to 9 parts by volume of vinylene carbonate based on 100 parts by volume of the mixed solvent. The nonaqueous solvent may further include 0.05 to 5 parts by volume of vinyl sulfone, isooxazole or a mixture thereof based on 100 parts by volume of the mixed solvent.

Owner:SAMSUNG SDI CO LTD

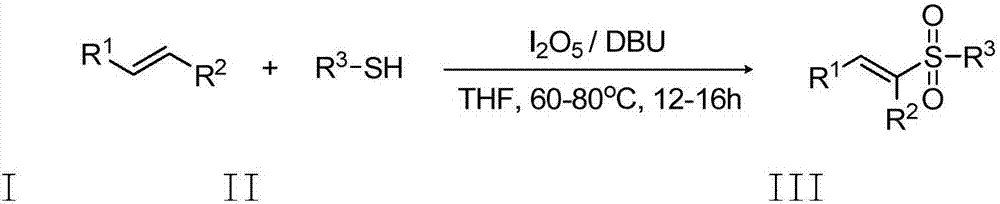

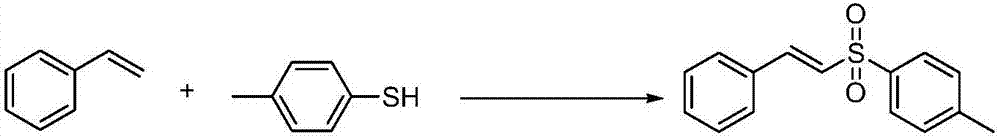

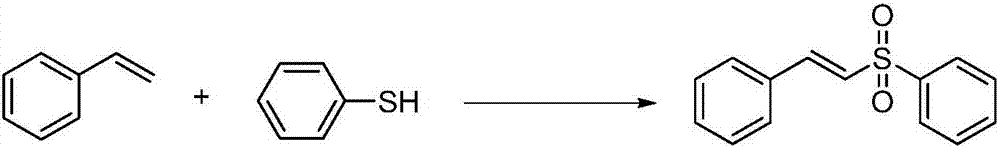

Preparation method of E-vinyl sulfones compound

InactiveCN107417582ARaw materials are cheap and easy to getAtom economy is highOrganic chemistryOrganic compound preparationOrganic baseOxygen

The invention discloses a preparation method of an E-vinyl sulfones compound. The preparation method comprises the following steps: dissolving raw materials of olefin and thiophenol (thioalcohol) into a tetrahydrofuran solvent; then adding lodine pentaoxide and organic base DBU (1,8-diazabicyclo undec-7-ene); directly reacting for 12 to 16 hours under 60 to 80 DEG C; separating and purifying a coarse product after stopping reacting, thus obtaining the E-vinyl sulfones compound. The preparation method has the advantages that raw materials are simple and can be easily obtained, the price is cheap, the reaction requires no metal catalyst, metal pollution is avoided, the operation is simple and is free of harsh conditions of water free, oxygen free and the like, the adaptive range of a substrate is wide, the reaction stereoselectivity is high, the process conditions are stable, and a prepared product is easy to purify.

Owner:QUFU NORMAL UNIV

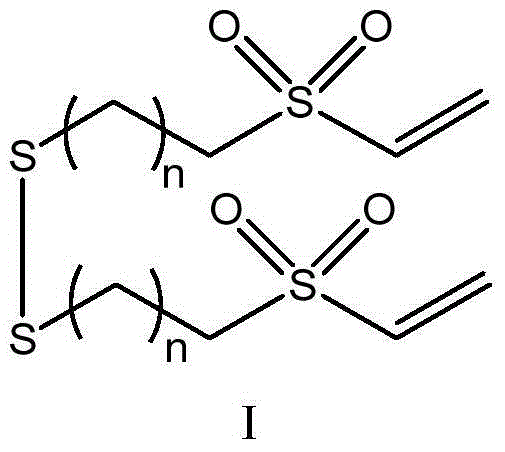

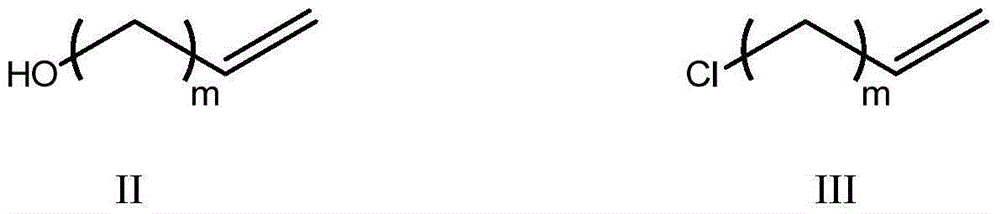

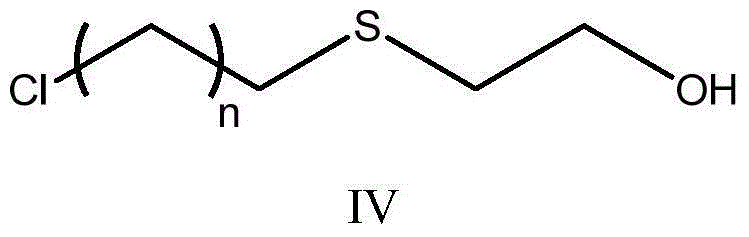

Omega-vinylsulphonyl disulfide compound as well as preparation method and application thereof

ActiveCN104311465AImprove stabilityImprove hydrolysis resistanceCarrier-bound/immobilised peptidesHydropoly/poly sulfide preparationMaterials preparationCoupling

The invention discloses an omega-vinylsulphonyl disulfide compound as well as a preparation method and an application thereof. The compound has a structure with a structural formula I described in the specification, wherein n is an integer of 4-18. The compound can form a highly-ordered self-assembled film on the surfaces of noble metals such as gold and silver, wherein a vinylsulphonyl group on the surface of the self-assembled film can respectively react with biological / chemical molecules that contain sulfydryl, amino and hydroxyl under a certain condition for molecular coupling, biological active material preparation, biochemical sensor chip modification, and the like. The self-assembled film prepared by the compound has the advantages of hydrolysis resistance, alkali resistance, and response spectrum resistance, and the like.

Owner:DALIAN UNIV OF TECH

Novel dental composites systems and methods of making the same and using same

The invention includes a composition comprising a vinyl sulfone monomer, a thiol monomer, and optionally an isocyanate monomer. The invention further includes a composition comprising a composition comprising the tetra(2-mercapto)silane (SiTSH) monomer and at least one selected from the group consisting of (a) a Michael acceptor, optionally an isocyanate monomer, and optionally at least one catalyst selected from the group consisting of a base, nucleophile, photolabile base, photolabile nucleophile, and mixtures thereof; (b) an ene monomer, and optionally a polymerization photoinitiator. In certain embodiments, once the composition is polymerized, the polymerized system is suitable for use as a dental composite system. In other embodiments, the polymerized system is stable to acidic and basic conditions. In yet other embodiments, the polymerized system forms microparticles. The invention further includes a method of generating a dental polymeric material.

Owner:UNIV OF COLORADO THE REGENTS OF

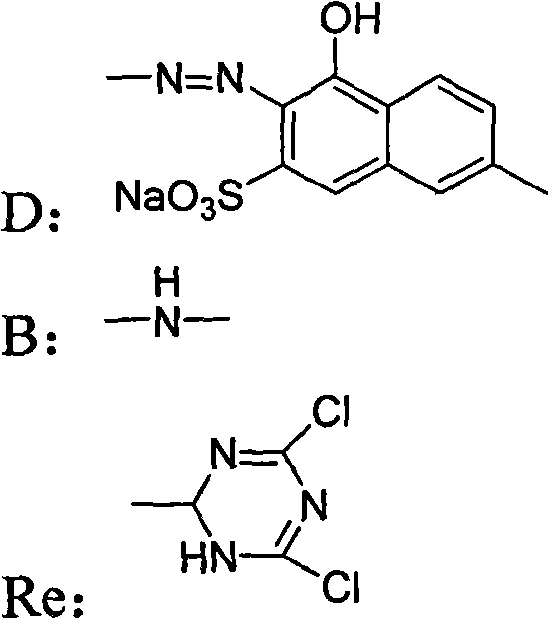

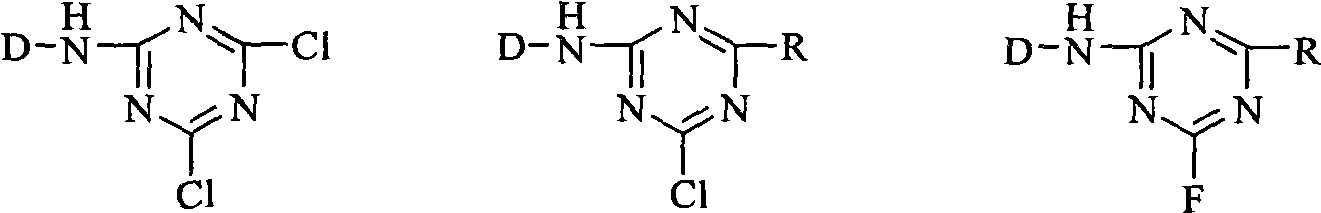

Double-temperature dyeing method of chloro-s-triazine and vinyl sulfone double-active group active dye

The invention discloses a double temperature dyeing method for a reactive dye with double active groups of monochlorotriazine and vinyl sulfone. The formulas of the double temperature dyeing method are as follows respectively: 0.01 to 10 percent of M or B type reactive dye (the weight relative to that of fabrics or yarns), 10 to 100g / L of glauber salt or common salt, and 2 to 30g / L of calcined soda, wherein the bath ratio is between 1 to 6 and 1 to 15; or 0.01 to 10 percent of M or B type reactive dye, 10 to 100g / L of glauber salt or common salt, and 2 to 4g / L of base substituent 310-F, wherein the bath ratio is between 1 to 6 and 1 to 15; or 0.01 to 10 percent of M or B type reactive dye, 10 to 100g / L of glauber salt or common salt, 1 to 2g / L of base stabilizer 310, and 0.8 to 2g / L of sodium hudroxide, wherein the bath ratio is between 1 to 6 and 1 to 15. The dying process is as follows: cotton, hemp or an adhesive fabric, double temperature dyeing, soaping, and finishing. The utilization rate of the dye is improved by between 2 and 5 percent; the using amount of an alkaline agent can save 20 to 30 percent; and after the dyeing, the stage temperature is increased, the desorption rate of the hydrolised dye is increased, the loose color on fiber is reduced, and the water scrubbing is reduced after the soaping. The method reduces the drainage of sewage, and is favorable to the environmental protection.

Owner:ZHEJIANG SCI-TECH UNIV

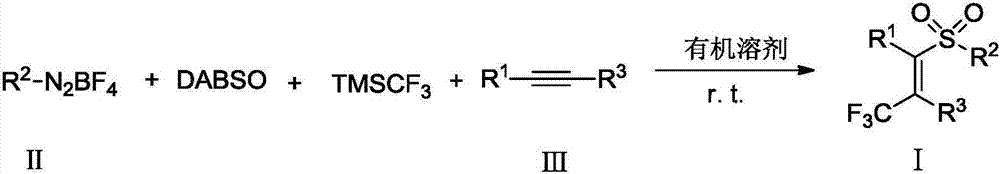

Beta-trifluoromethyl vinyl sulfone compounds as well as preparation method and application thereof

ActiveCN107473995AReduce usageRich organic small molecule structureOrganic chemistryOrganic compound preparationSynthesis methodsOperability

The invention belongs to the technical field of organic compounds and particularly provides beta-trifluoromethyl vinyl sulfone compounds, a preparation method thereof and an application of the compounds to tumor cell proliferation resistance. The beta-trifluoromethyl vinyl sulfone compounds are prepared from a multicomponent reagent (trifluoromethyl) trimethylsilane (TMSCF3), alkyne, diazonium salt and DABCO.(SO2)2 in an organic solvent DMSO through a one-step reaction. Reaction conditions are quite mild, alkyne bi-functionalization is realized directly through the one-step cascade reaction of the four raw materials, the operation is simple, defects of tedious steps, low operability and yield and poor selectivity of the traditional synthesis method of vinyl sulfone derivatives are overcome, and the method is applicable to large-scale preparation and has quite good application prospect. In-vitro pharmacological activity screening tests show that the compounds have an anti-proliferation effect on tumor cells, part of the compounds have an obvious tumor inhibition activity, the half maximal inhibitory concentration IC50 value can reach mu m level, and the compounds can be used for preparing a kind of novel anti-tumor reagents.

Owner:FUDAN UNIV

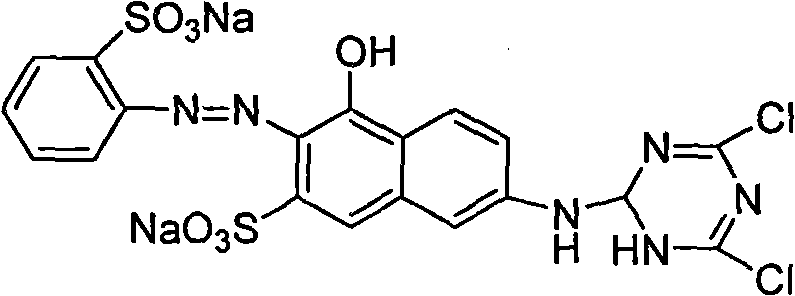

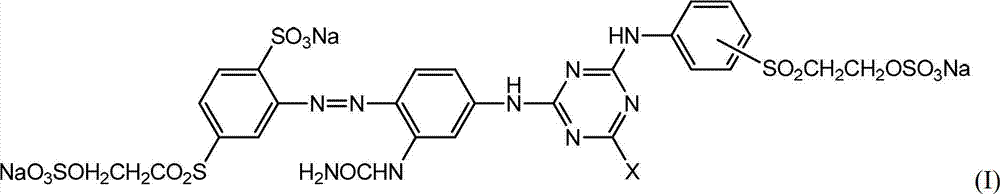

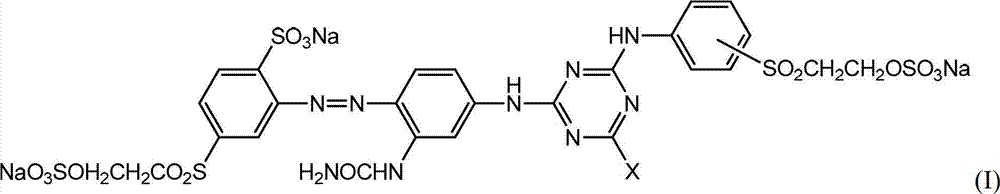

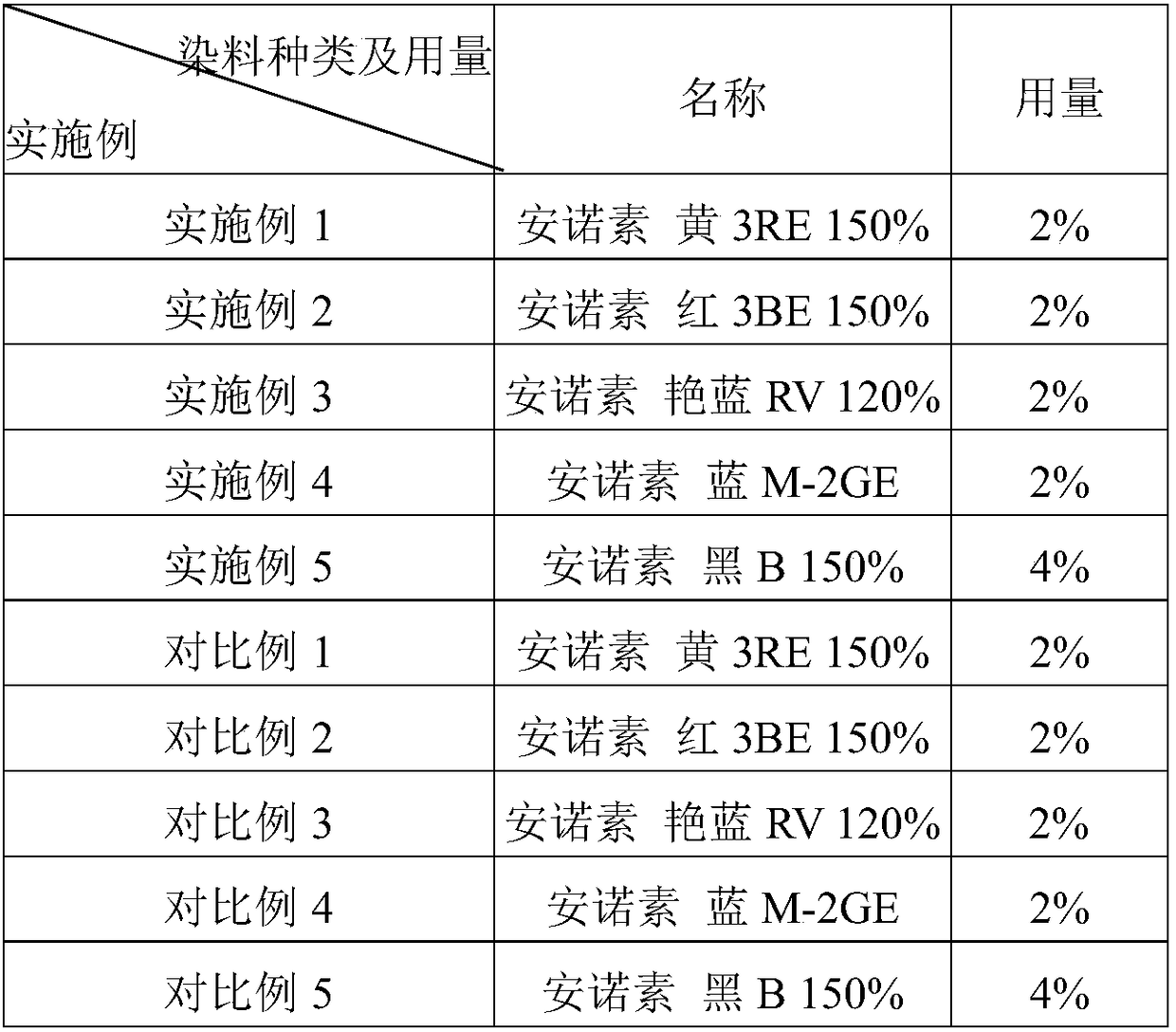

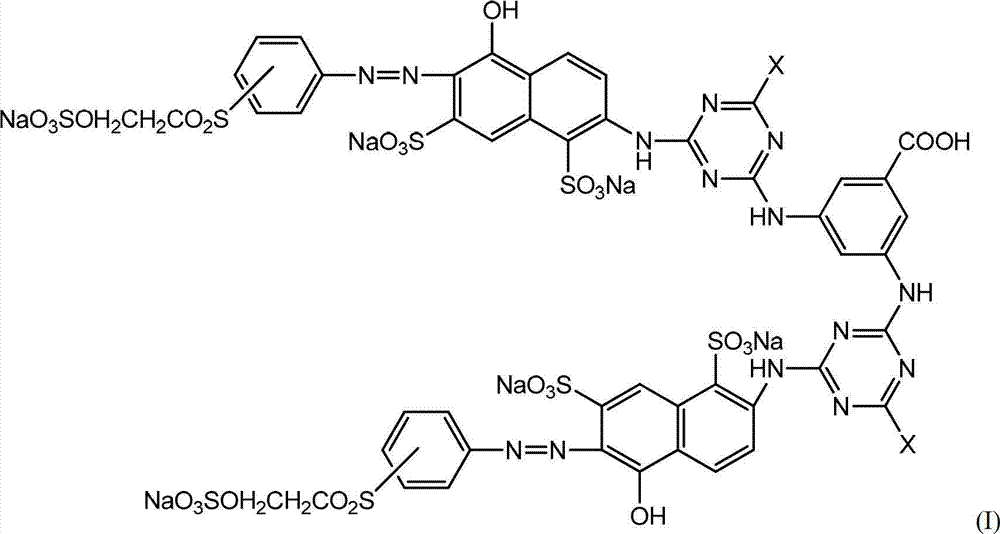

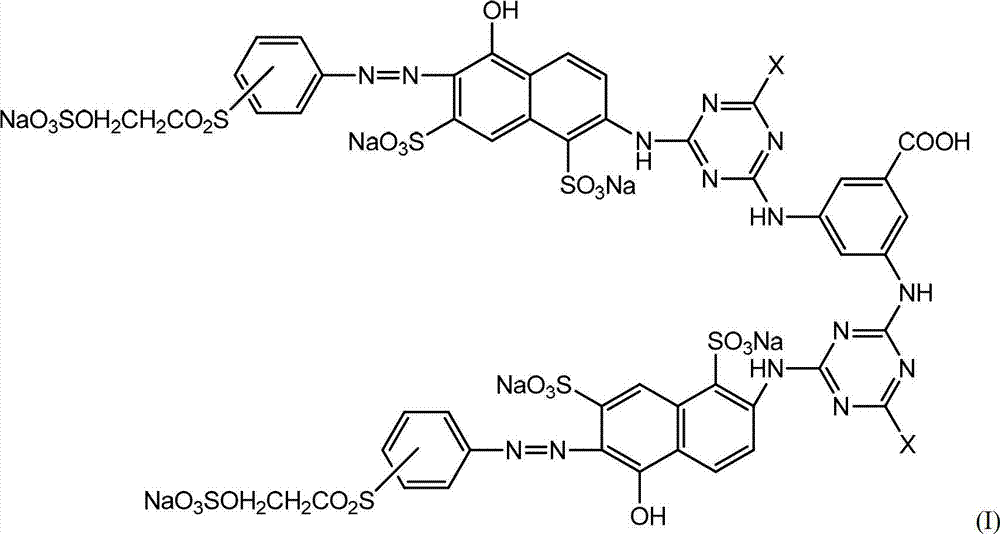

Composite reactive yellow dye and preparation method thereof

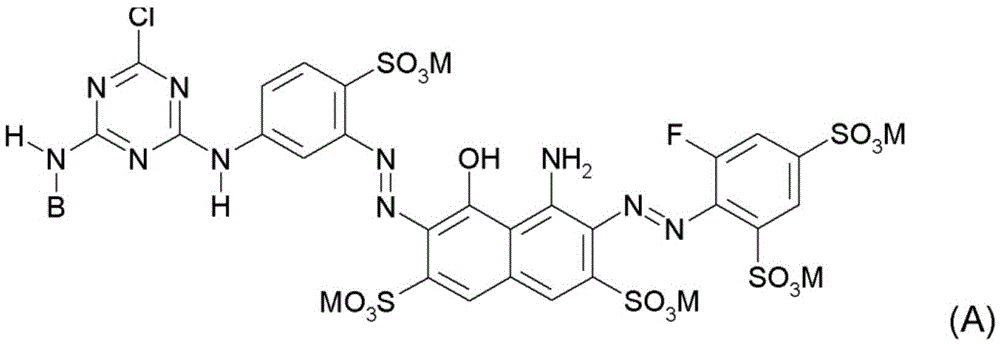

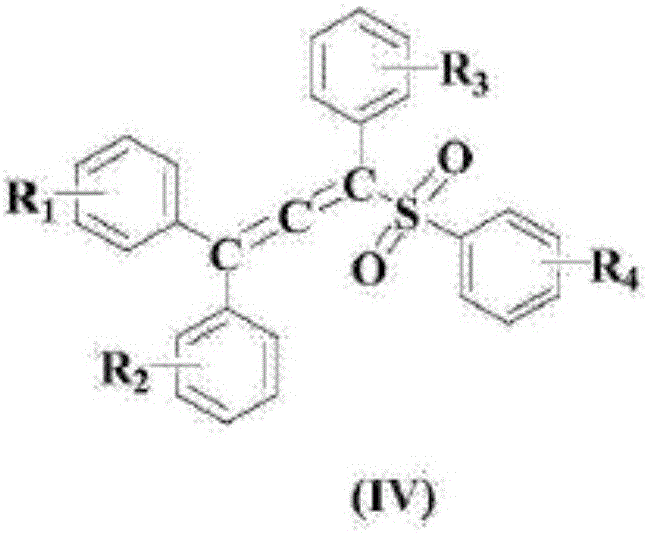

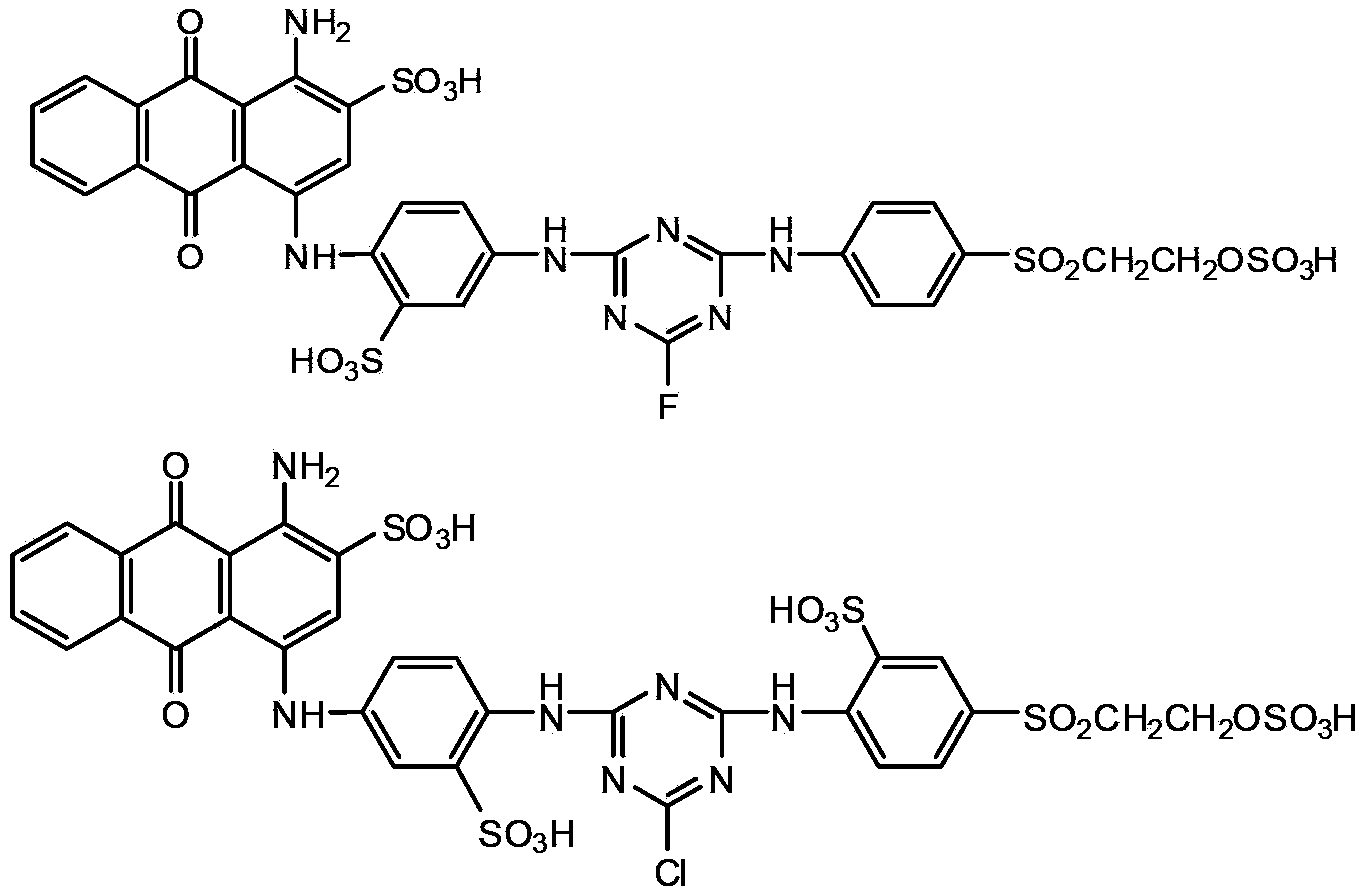

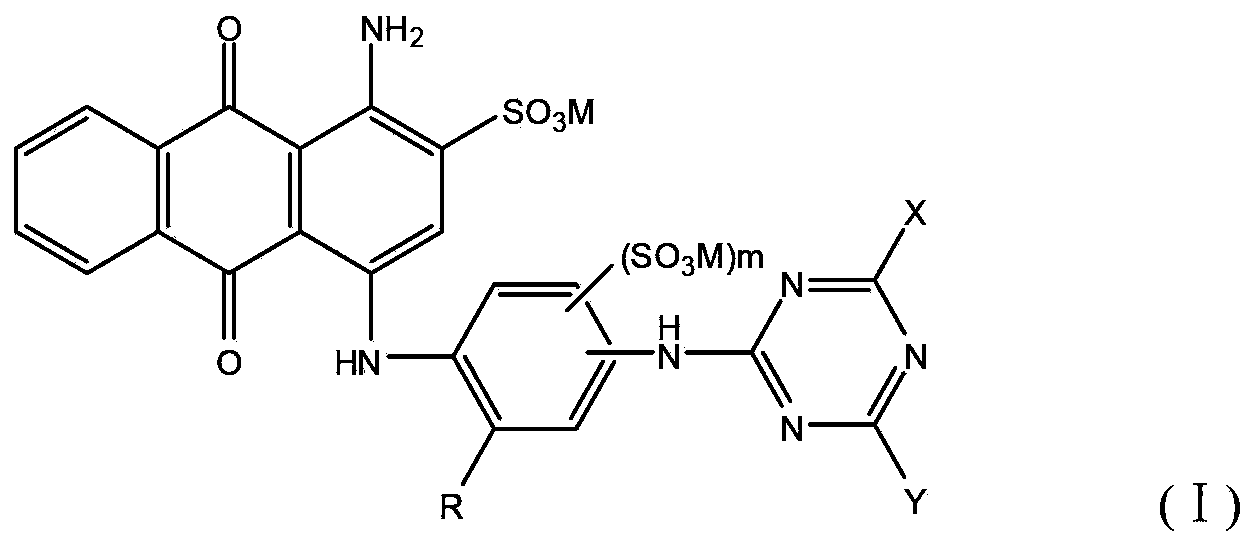

The invention discloses a composite reactive yellow dye and a preparation method thereof. The composite reactive yellow dye is shown as a formula (I), wherein X is Cl or F; and vinyl sulfone sulfuric acid ester group is at a meta-position or a para-position of phenyl. The novel composite reactive yellow dye has a red-light yellow dye structure with three reactive groups and is obtained by compounding solutions in proportion and performing standardization and spray-drying. The solubility is high and more than 200g / l, the product is bright-colored, the color fastness is as high as 90 percent, the dyeing buildup is improved, the composite reactive yellow dye can be used for dark color dyeing, reactivity is high, saline-alkaline resistance is good, stability is ensured, and the composite reactive yellow dye is suitable for common dip dyeing, pad dyeing, and pollution-free dyeing and finishing processes such as cold batch dyeing and wet short-steaming dyeing.

Owner:无锡润新染料有限公司

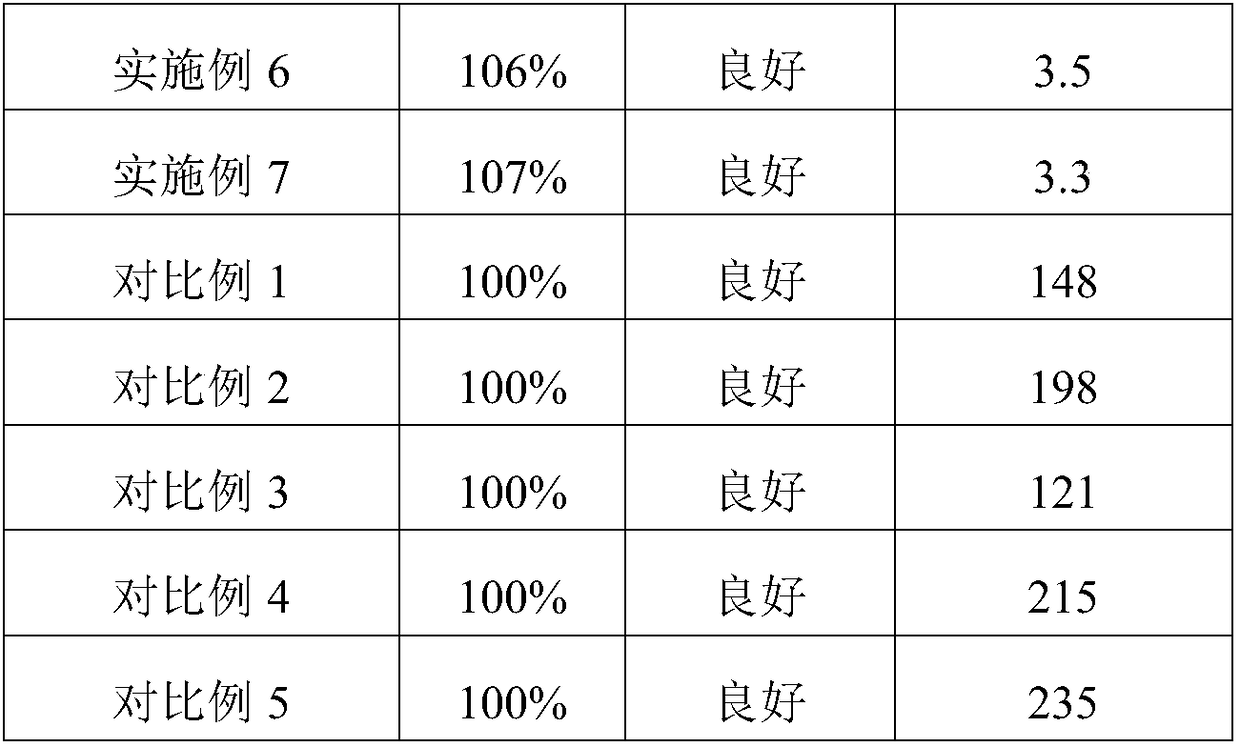

Active dye printing process

The invention discloses an active dye printing process which includes the steps of printing, drying, roll alkali treatment, steaming fixation, washing, soaping and washing. In the printing process, dyes in printing paste are divinyl sulfone active dyes or 'double-active-group active dyes comprising a vinyl sulfone active group and a chorotriazine active group'. In roll alkali treatment, mangle expression is 30-50%. Adopted fixation alkali liquor comprises 5-15% of sodium carbonate, 5-10% of sodium silicate, 0.5-2% of sodium hydroxide and the balance water. In the printing process, alkali agents and urea added into the printing paste can be omitted, roll alkali treatment and steaming fixation are performed after printing and drying, urea is omitted in the process, ammonia nitrogen emissioncan be greatly reduced, and sewage discharge can reach standards. Besides, dye hydrolysis can be reduced, the stability of the color paste is prolonged, steaming time is shortened, steaming efficiencyis improved, and product production cost is reduced.

Owner:SHANGHAI ANOKY GRP +5

Method for synthesizing vinyl sulfone compound

InactiveCN107176915AReduce usageNo pollution in the processOrganic chemistryOrganic compound preparationSulfonyl chlorideChromatographic separation

The invention relates to a method for synthesizing a vinyl sulfone compound. The vinyl sulfone compound has a chemical molecular formula shown in the description, wherein R1 is one selected from H, a straight-chain alkyl electron-donating group, a nitro electron withdrawing group, F, Cl and Br, and R2, R3 and R4 each is selected from H and straight-chain alkyl. The synthetic method comprises the steps of adding an inorganic base in an organic reaction solvent by taking an aryl sulfonyl chloride compound and a tertiary amine compound as reaction substrates and taking eosin Y as a catalyst under the action of visible light, carrying out a reaction for 1 to 3 hours at the temperature of -5 DEG C to 5 DEG C under the irradiation of an LED (light-emitting diode) lamp, carrying out water washing treatment, extraction and drying after the reaction ends, then, carrying out reduced-pressure distillation to remove the organic solvent, and then, carrying out thin-layer chromatography and column chromatography separation, thereby preparing the vinyl sulfone compound. Compared with the prior art, the method provided by the invention has the advantages that the steps are simple, the reaction conditions are mild, the controllability is good, the consumption of metal complexes is avoided, the reaction cost is reduced, and the method is pollution-free to environments.

Owner:TONGJI UNIV

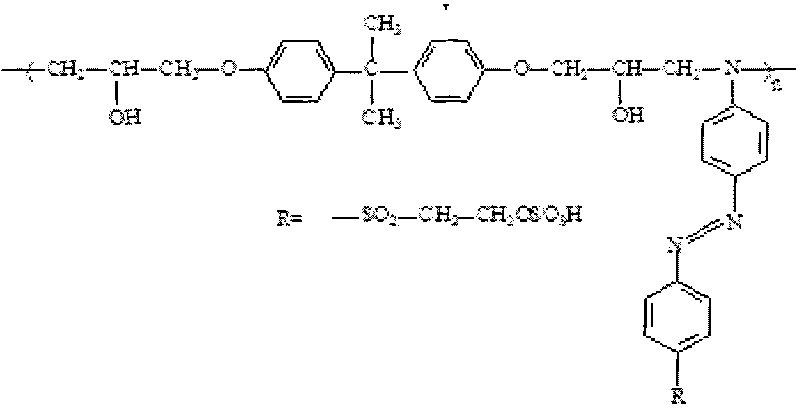

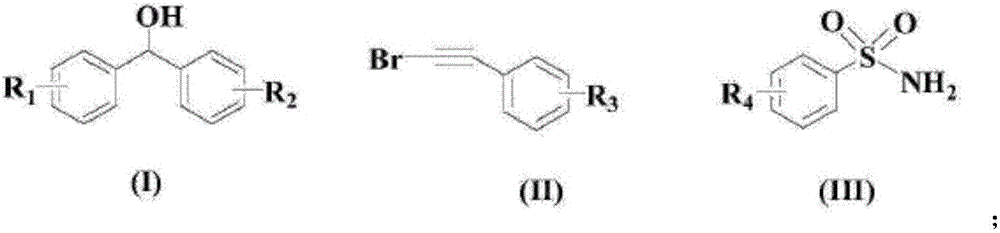

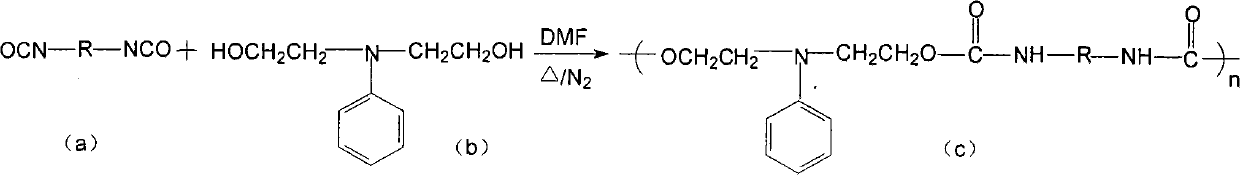

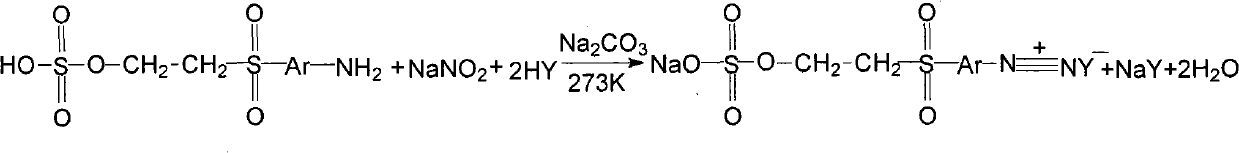

Method for preparing water soluble vinyl-sulfone polyurethane class high molecular reactive dye with diazo coupling method

The present invention relates to a method for preparing water soluble vinyl-sulfone polyurethane class high molecular reactive dye with a diazo coupling method. A polyurethane precursor is used as a high molecular skeleton, diazo salt is then prepared from hydroxyethyl sulfone sulfate class arylamine, the diazo salt finally has diazo coupling reaction with the polyurethane precursor, and the water soluble vinyl-sulfone polyurethane class high molecular reactive dye is prepared. The dye having good water solubility can react with materials containing hydroxy or amino groups under alkaline conditions to complete color fixation. The problems about dyeing fastness, etc are solved. The method has the advantages of simple synthesis thought, easy functionality control, high diazo coupling rate, etc. The dye can be used for dyeing materials containing cotton, hemp, silk, fur, leather, paper, etc, can be used in the spinning processing of spandex stock solution for preparing colored spandex, can be used as the coloring agent and the filler of plastics, rubber, paint and adhesives, and can be used as the coloring agent ingredient of digital jet printing ink.

Owner:WUHAN TEXTILE UNIV

Reactive orange dye and preparation method thereof

The invention discloses a reactive orange dye and a preparation method thereof. The structure of the reactive orange dye is shown as a formula I, wherein X is Cl or F; and vinyl sulfone sulfate group is at a para-position or a meta-position of phenyl. The invention discloses a novel composite reactive orange dye. A dye structure with four active groups is adopted, and the reactive orange dye is prepared by compounding solutions according to proportion, performing standardization and spray-drying. The product is high in solubility and bright in color, and can be used for dyeing a dark color, the solubility is more than 200g / l, the color fastness reaches 90%, and the dyeing buildup is good; and the reactive orange dye is high in reactivity and good in saline-alkaline tolerance stability, and is suitable for common dip dyeing, pad dyeing, and pollution-free dyeing and finishing processes such as cold batch dyeing and wet short-steaming dyeing.

Owner:无锡润新染料有限公司

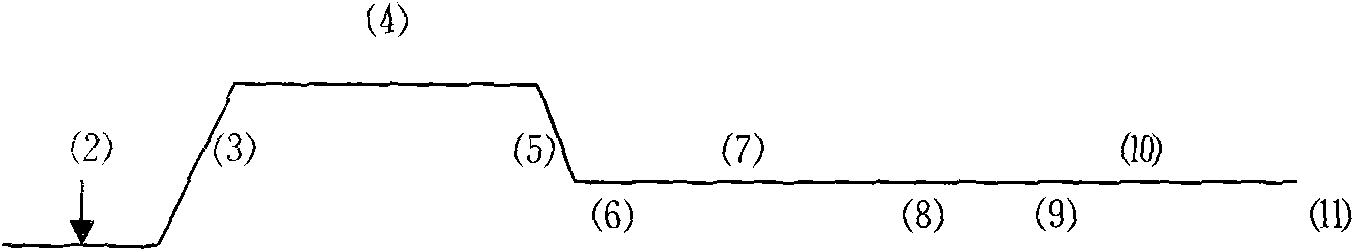

Active dye applied to wool and wool dyeing method

InactiveCN104278558AOptimize the dyeing processAchieve energy saving and emission reductionDyeing processVinyl sulfoneSewage

The invention relates to a wool dyeing method and in particular relates to an active dye for wool and a wool dyeing method. In order to reduce the emission of pollutants, reduce energy consumption and improve the dyeing efficiency, the invention provides a novel wool dyeing method. According to the novel wool dyeing method, dyes and additives are reasonably selected and the dyeing process is optimized, so that the purpose of saving energy, reducing emission and improving the dyeing efficiency can be achieved, and the development requirements of relevant fields can be met. Compared with the existing wool dyeing process of the active dye, the wool dyeing process has the characteristics that a common vinyl sulfone active dye is adopted instead of alpha-acrylamide active dye generated in Australia and applied to the wool, and the dye cost is reduced; the processes of washing with alkali at high temperature, soaping and overflowing and washing for a plurality of times are omitted, the energy consumption is reduced, the sewage discharging amount is greatly reduced, and the dyeing efficiency is improved; the dyeing step is carried out at 85 DEG C, the fixation step is carried out at 30 DEG C, and the damage to the wool is reduced; the low-temperature fixation process is adopted, the fixation rate can reach over 98%, all color fastness indexes are improved, particularly the dyed products does not need to be soaped, both dry rubbing fastness and wet rubbing fastness reach over grade IV, and the wool fabric product is free of color staining during post-treatment; and the dyed wool can meet the crabbing requirements of fine wool fabric products.

Owner:朱梁

Dyeing and finishing technique of cellulose fiber textile

The invention discloses a dyeing and finishing technique of cellulose fiber textile, which sequentially comprises the following steps of: pretreating, dyeing, water washing, neutralizing, soaping and water washing the fiber textile; and the dyeing technique comprises the steps of: under the conditions of 30 DEG C and bath ratio of 1:7-1:15, adding vinyl sulfone type low-temperature dye with the weigh of 2-10% of the textile, and carrying out heat preservation for 10-15min; then, adding anhydrous sodium sulphate and sodium hydroxide which is 1 / 4-1 / 3 of the total weight, and carrying out heat preservation for 10-15min; adding another sodium hydroxide which is 3 / 4-2 / 3 of the total weight, and carrying out heat preservation for 10-15min; and heating to 40 DEG C at the speed of 1 DEG C / min, carrying out heat preservation for 40-60min, and completing the dyeing technique. The dyeing and finishing technique of the cellulose fiber textile has the characteristics of low using quantity of dye, high soaping fastness, low using quantity of alkali color fixing agent, less pollution discharge and reduced cost.

Owner:冯惠英

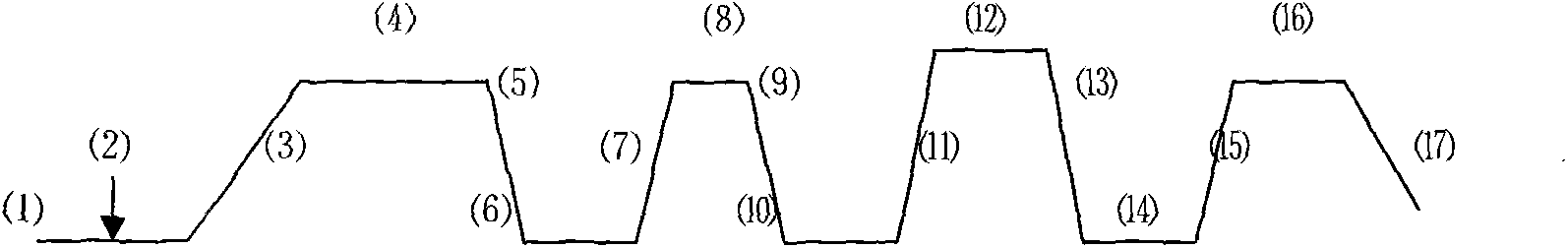

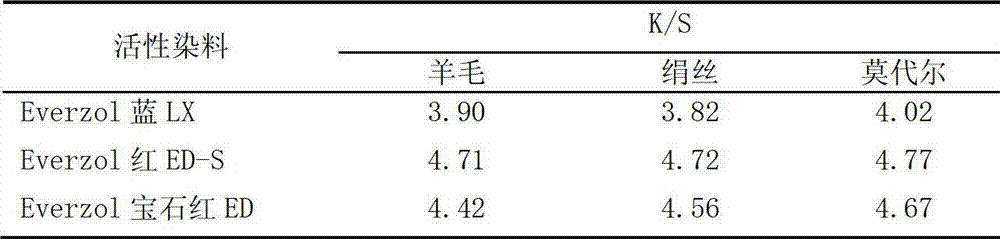

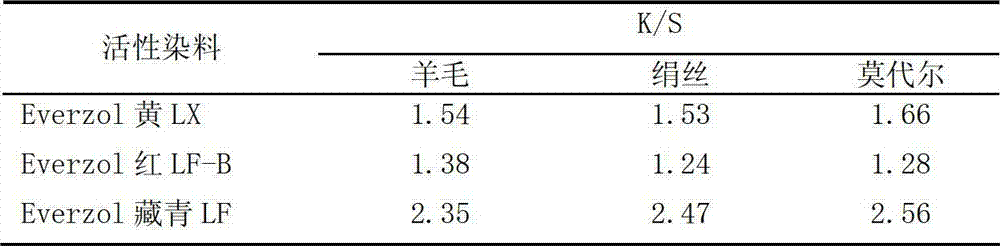

Dyeing method for hybrid loose fibers

InactiveCN102965978AShorten the processing flowGood same colorBleaching apparatusDyeing processYarnVinyl sulfone

The invention relates to a dyeing method for hybrid loose fibers and particularly relates to a method for co-bath dyeing of the hybrid loose fibers including wool fibers, spun silk fibers and regenerated cellulose fibers in a same cylinder, which belongs to the field of fabric dyeing. According to the technical scheme, the dyeing method comprises the step of performing pretreatment on the hybrid loose fibers subjected to co-bath in the same cylinder, wherein the pretreatment comprises the procedures of performing reduction bleaching on the fibers by sodium hydrosulfite and oxidation bleaching on the fibers by hydrogen peroxide, and then performing once same-color dyeing on the hybrid loose fibers through co-bath in the same cylinder by vinyl sulfone reactive dyes or reactive dyes containing vinyl sulfone groups. The dyeing method is used for dyeing the three loose fibers in the same dyeing cylinder by the reactive dyes, fulfills the aim of dyeing the three fibers, and changes the conventional processing mode of dyeing the three loose fibers for three times independently in the current spinning processing of colored blended yarns, thus greatly reducing the processing flow of the colored blended yarns, lowering the production costs of the colored blended yarns, achieving remarkable effects of energy conservation and emission reduction, and ensuring good homochromatism of the three fibers.

Owner:SUZHOU UNIV +1

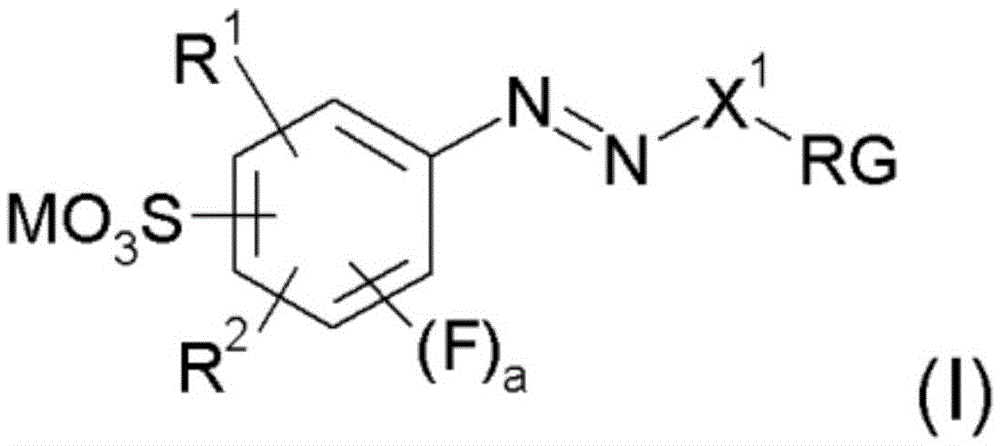

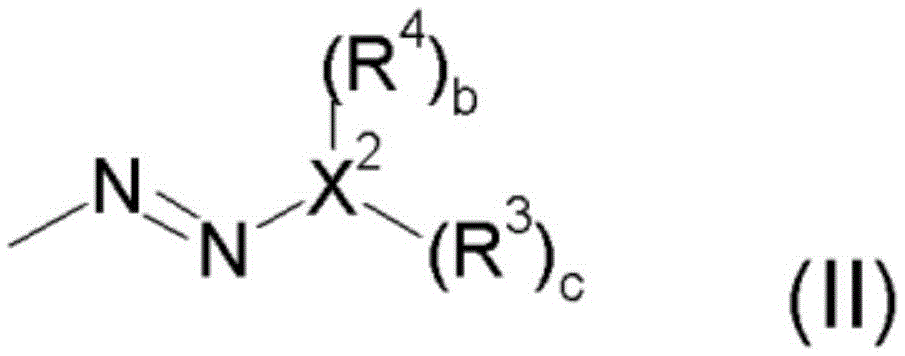

Reactive brilliant blue dye and preparation method thereof

InactiveCN104341794AHigh color fixing rateHigh fastnessReactive dyesDyeing processCellulose fiberProtein fiber

The invention belongs to the field of fine chemical engineering, and particularly relates to a reactive brilliant blue dye and a preparation method thereof. The structure of the reactive brilliant blue dye is a compound as shown in a general formula (I) in the specification, wherein each group in the formula is defined in the specification. The preparation method comprises the following steps: firstly, enabling cyanuric chloride (or cyanuric fluoride) to react with a compound with a vinyl sulfone sulfate or chloroethyl sulfone group to obtain a first condensation compound; enabling the first condensation compound to react with a compound shown in a general formula (II) in the specification to obtain a second condensation compound, namely a part of reactive brilliant blue dye containing a vinyl sulfone sulfate or chloroethyl sulfone group as shown in the general formula (I); and hydrolyzing the second condensation compound under an alkaline condition to obtain another part of reactive brilliant blue dye containing a vinyl sulfone group in the general formula (I). The preparation method disclosed by the invention is low in cost, low in energy consumption, low in pollution and suitable for industrial large-scale production; the reactive brilliant blue dye is used for dyeing and printing of protein fibers, synthetic fibers, cellulosic fibers and blended fabrics thereof; and the fabric is bright and gorgeous in color after being dyed.

Owner:中国中化股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com