Patents

Literature

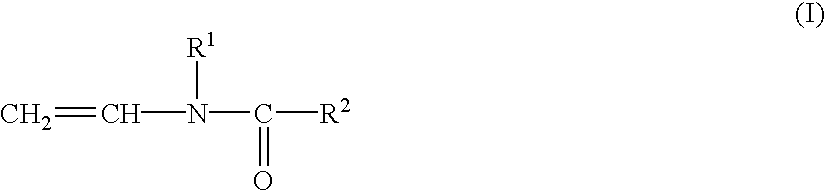

147 results about "Vinyl Amide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

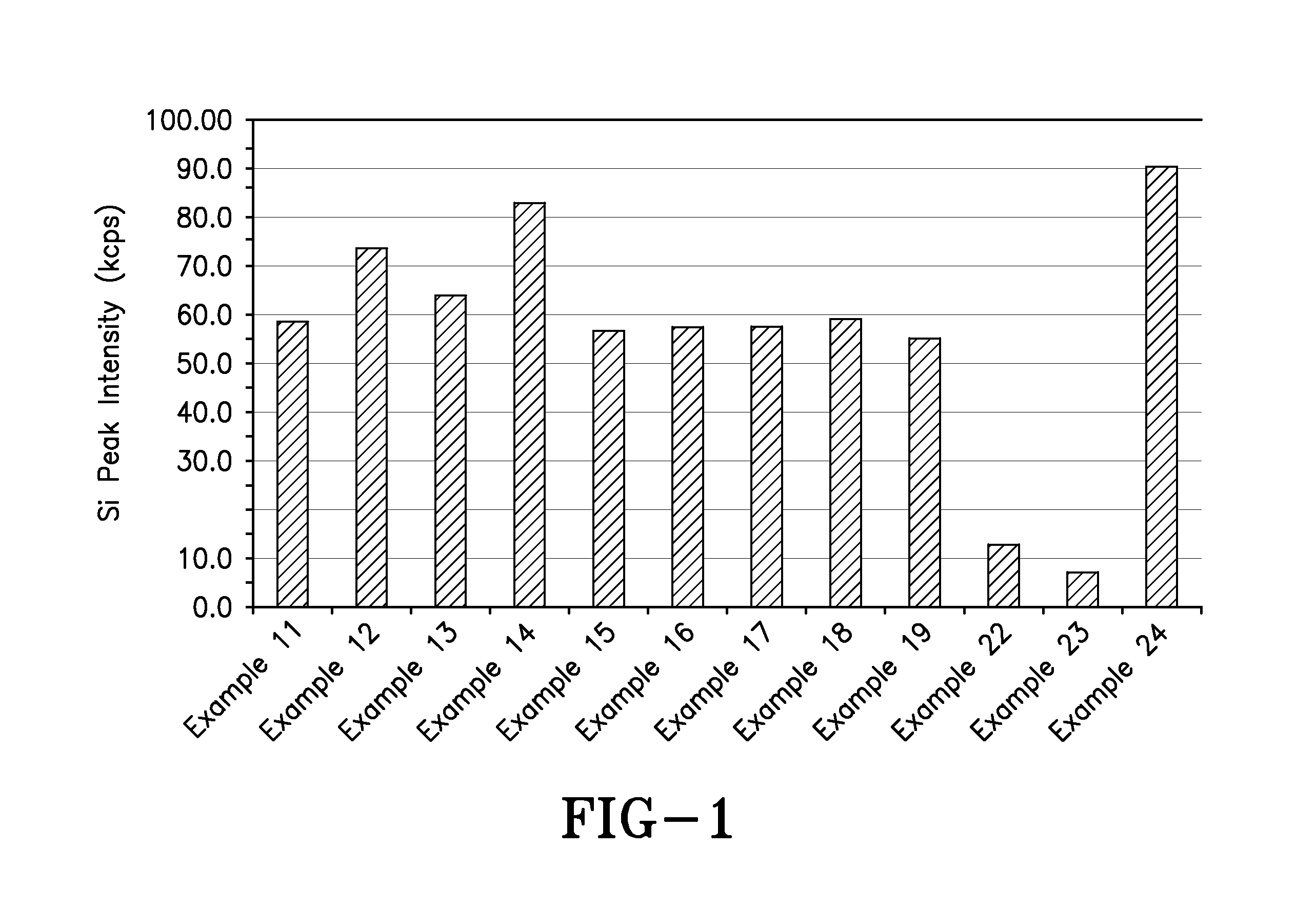

Silicone hydrogels comprising n-vinyl amides and hydroxyalkyl (meth)acrylates or (meth)acrylamides

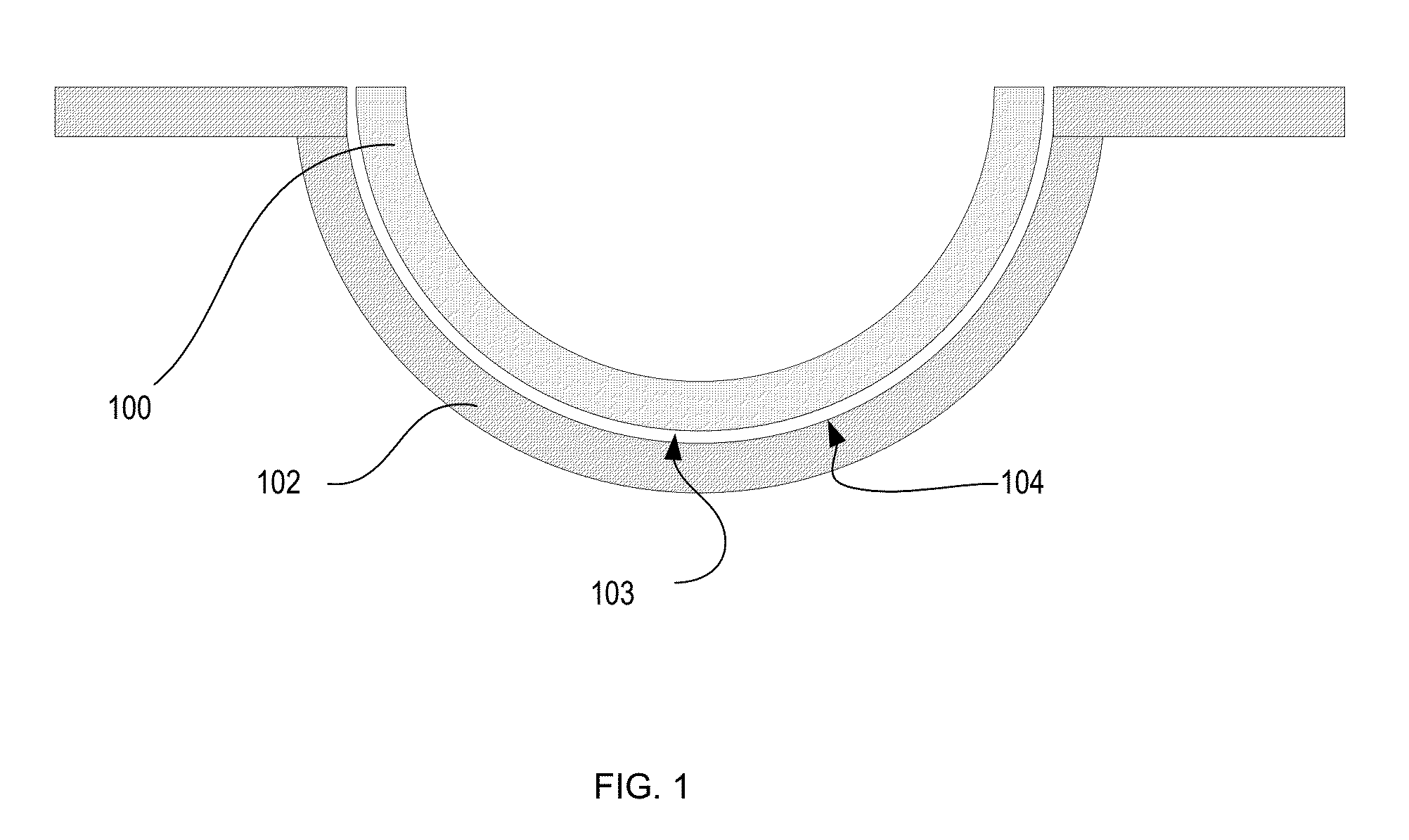

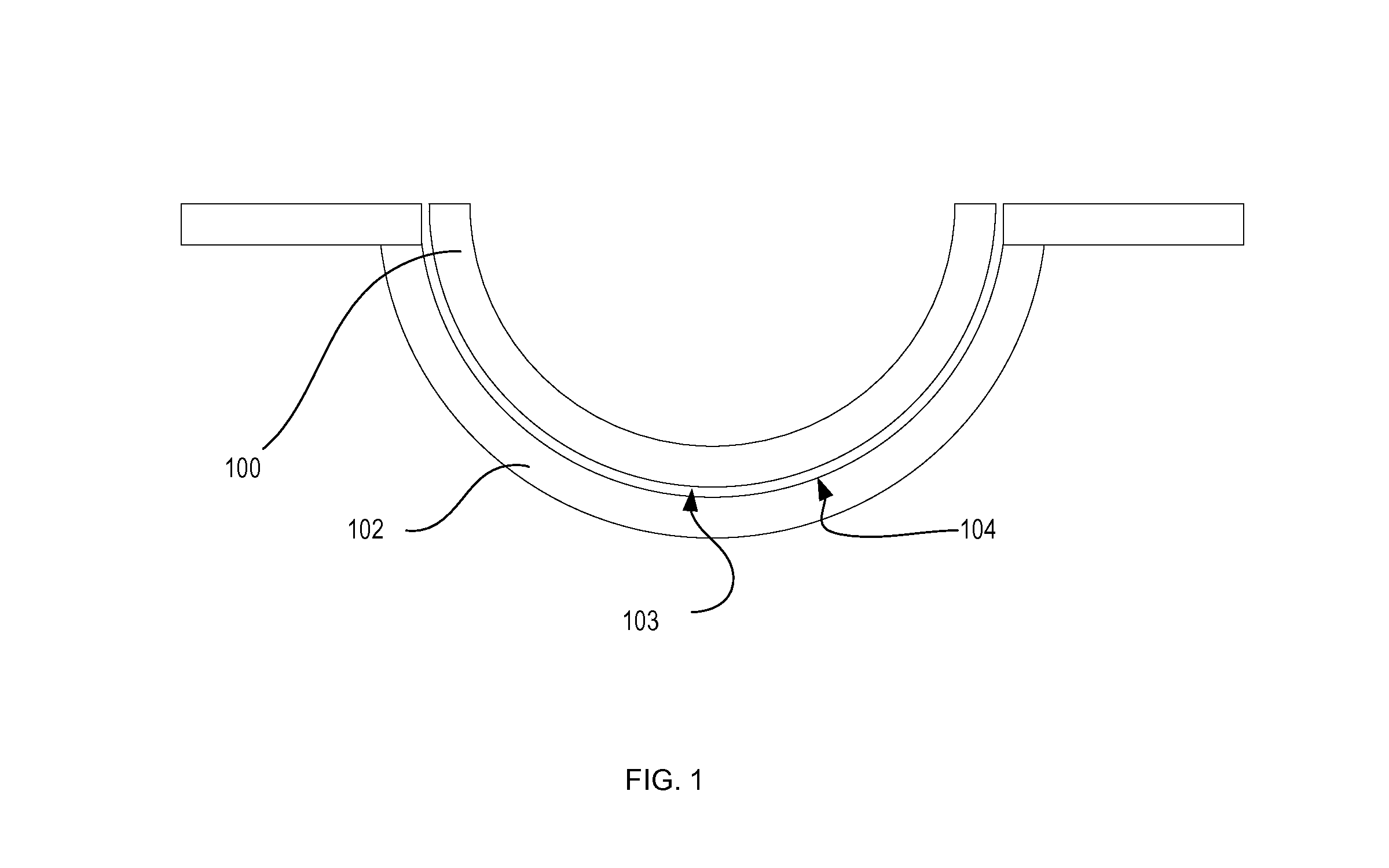

The present invention relates to a process comprising the steps of reacting a reactive mixture comprising at least one silicone-containing component, at least one hydrophilic component, and at least one diluent to form an ophthalmic device having an advancing contact angle of less than about 80°; and contacting the ophthalmic device with an aqueous extraction solution at an elevated extraction temperature, wherein said at least one diluent has a boiling point at least about 10° higher than said extraction temperature.

Owner:JOHNSON & JOHNSON VISION CARE INC

Water-soluble film and package using the same

InactiveUS6956070B2Improve solubilityGood chemical resistanceOrganic detergent compounding agentsSynthetic resin layered productsVinyl AmidePolyvinyl alcohol

The present invention provides a water-soluble film which comprises a modified polyvinyl alcohol containing an N-vinylamide monomer unit in an amount of 1 to 10 mole percent, and a carboxyl group and a lactone group in a total amount of 0.020 to 4.0 mole percent in the molecule, and having a degree of polymerization of 300 to 3000, and a degree of hydrolysis of 75 to 99.5 mole percent. Further, the present invention provides a package obtained by packaging an acidic substance, a chlorine-containing compound, or the like using the water-soluble film.

Owner:KURARAY CO LTD

Ink compositions and methods of use thereof

Disclosed herein are rapid radiation curable ink compositions that can cure at speeds that are greater than the speeds at which other commercially available ink compositions cure. The rapidly curing ink compositions advantageously display an increased cure speed, improved adhesion and solvent resistance when compared with other commercially available compositions. The ink compositions of the invention are substantially free of solvent, and include an ethylenically unsaturated hyperbranched oligomer having an average functionality of at least 6 per oligomer, a difunctional ethylenically unsaturated compound, and a photoinitiator. The ink compositions optionally include a surfactant and / or a vinyl amide monomer.

Owner:COLLINS INK CORP

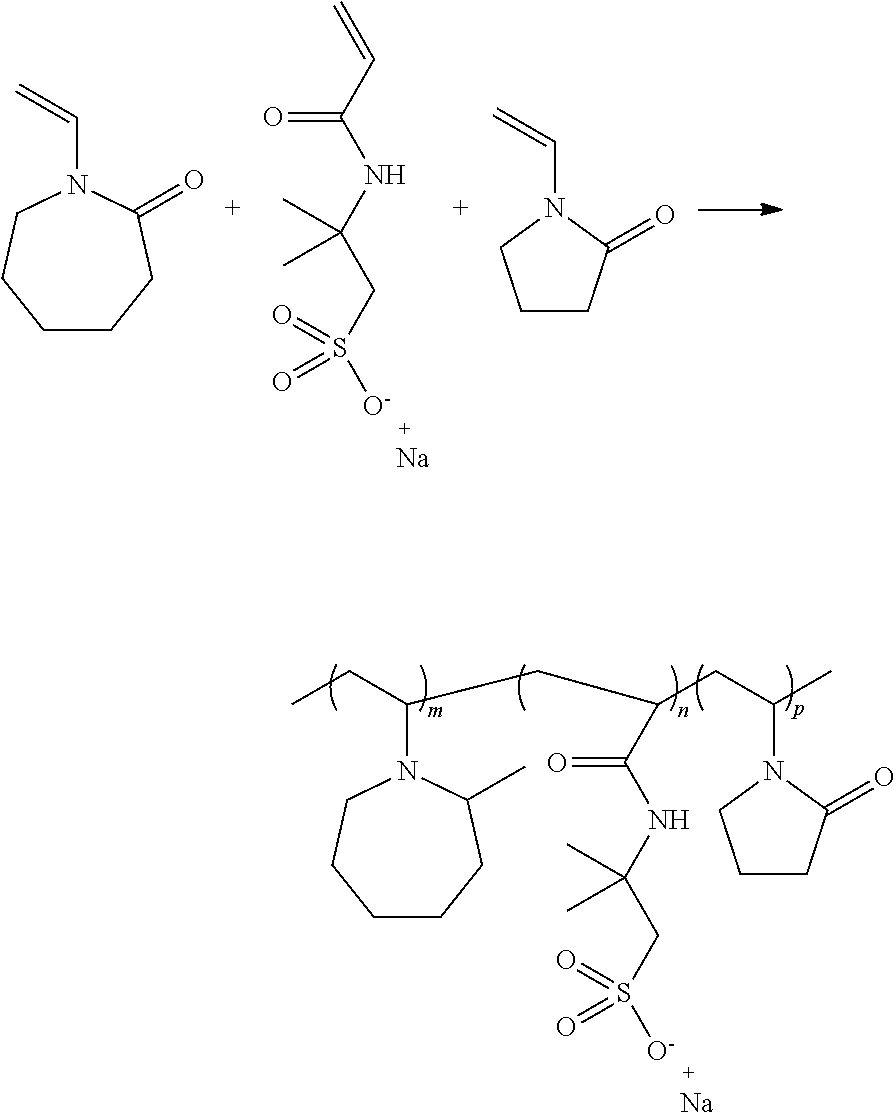

High-Temperature Crosslinked Polymer for Use in a Well

A method comprising the steps of: (A) forming a fluid comprising a crosslinked polymer, wherein the crosslinked polymer comprises: (i) a first monomeric unit of one or more N-vinyl lactams; and (ii) a crosslinker selected from the group consisting of: divinyl ether, diallyl ether, vinyl or allyl ethers of polyglycols or polyols, divinylbenzene, 1,3-divinylimidazolidin-2-one, divinyltetrahydropyrimidin-2(1H)-one, dienes, allyl amines, N-vinyl-3(E)-ethylidene pyrrolidone, ethylidene bis(N-vinylpyrrolidone), and any combination of any of the foregoing; and (B) introducing the fluid into a portion of a well. The crosslinked polymer may additionally comprise: a second monomeric unit selected from the group consisting of: acrylamide, N-substituted acrylamides, methacrylamide, N-substituted methacrylamides, acrylates, methacrylates, acrylic acid, methacrylic acid, N-vinylamides, N-allyl amides, vinyl alcohol, vinyl ethers, vinyl esters, allyl alcohol, allyl ethers, allyl esters, vinylpyridine, vinyl sulfonates, allyl sulfonates, vinylimidazole, allylimidazole, diallyldimethylammonium chloride, and any combination of any of the foregoing.

Owner:HALLIBURTON ENERGY SERVICES INC

Paper or board treating composition of carboxylated surface size, polyacrylamide and crosslinker

InactiveUS6281291B1Less viscousEasy to handleNatural cellulose pulp/paperSpecial paperCardboardMeth-

A composition useful in paper and board making comprises a carboxylated surface size containing at least 40 mole percent of hydrophobic groups and at least about 25 mole percent of carboxylated groups such as styrene-(meth)acrylic aicd copolymers or styrene-maleic acid (anhydride or salt) copolymers, a hydrophilic polyacrylamide and a crosslinking agent such as glyoxylated vinylamide polymers, formaldehyde, melamine-formaldehyde condensates and glyoxyl-extended materials.

Owner:KEMIRA OY

Silicone hydrogels comprising n-vinyl amides and hydroxyalkyl (METH)acrylates or (METH)acrylamides

The present invention relates to a process comprising the steps of reacting a reactive mixture comprising at least one silicone-containing component, at least one hydrophilic component, and at least one diluent to form an ophthalmic device having an advancing contact angle of less than about 80°; and contacting the ophthalmic device with an aqueous extraction solution at an elevated extraction temperature, wherein said at least one diluent has a boiling point at least about 10° higher than said extraction temperature.

Owner:JOHNSON & JOHNSON VISION CARE INC

Color cosmetic compositions

ActiveUS20070231286A1Improved color cosmetic compositionSimple compositionCosmetic preparationsOrganic active ingredientsVinyl AmideCarboxylic acid

Color cosmetic compositions include a rheology modifier (thickener) and film-former copolymer which is a crosslinked, linear copolymer of poly(vinyl amide polymerizable carboxylic acid) e.g. poly(vinyl pyrrolidone-acrylic acid), which is compatible with iron oxides generally present in such compositions, e.g. gel and emulsion color cosmetic formulations such as gel eyelid enhancers, oil-in-water emulsion eyeliner and oil-in-water emulsion foundation products.

Owner:ISP INVESTMENTS LLC

Dispersible alcohol/cleaning wipes via topical or wet-end application of acrylamide or vinylamide/amine polymers

ActiveUS7670967B2Desired level of strength of the fibrous substrateEnhance a fibrous substrateCosmetic preparationsToilet preparationsFiberVinyl Amide

The present invention is directed to a wet wipe product. The wet wipe product comprises a fibrous substrate and a triggerable binder formulation. The triggerable binder formulation is capable of binding the fibers in the fibrous substrate. The triggerable binder formulation may include acrylamide polymers, vinylamide / amine polymers, and mixtures. The triggerable binder formulation is insoluble in a wetting composition comprising an insolubilizing agent but is dispersible in disposal water.

Owner:MGL TECHNICAL ASSOC LLC

Epoxy modified lacquer putty

An epoxy modified puddy for metallic materials is composed of components A and B. Said component A is prepared from epoxy modified unsaturated polyester resin, functional filler, quinone substance, cobalt naphthenate (or isooctoate), polyvinyl chloride or SiO2 gas, and active diluent. Said component B is vinylamide polymer. Its advantages are long application time (60 min) and high low-temp high-moisture performance.

Owner:ZHUZHOU HUALIAN HI TECH

Ink composition, ink set and image forming method

An aqueous ink composition including: a water-soluble polymerizable compound containing two or more polymerizable functional groups each selected from the group consisting of a (meth)acrylamide group, a maleimide group, a vinyl sulfone group, and an N-vinyl amide group, wherein a ratio of a molecular weight of the compound relative to a number of the polymerizable functional groups contained in a single molecule of the compound is 175 or less; a polymerization initiator; and water.

Owner:FUJIFILM CORP

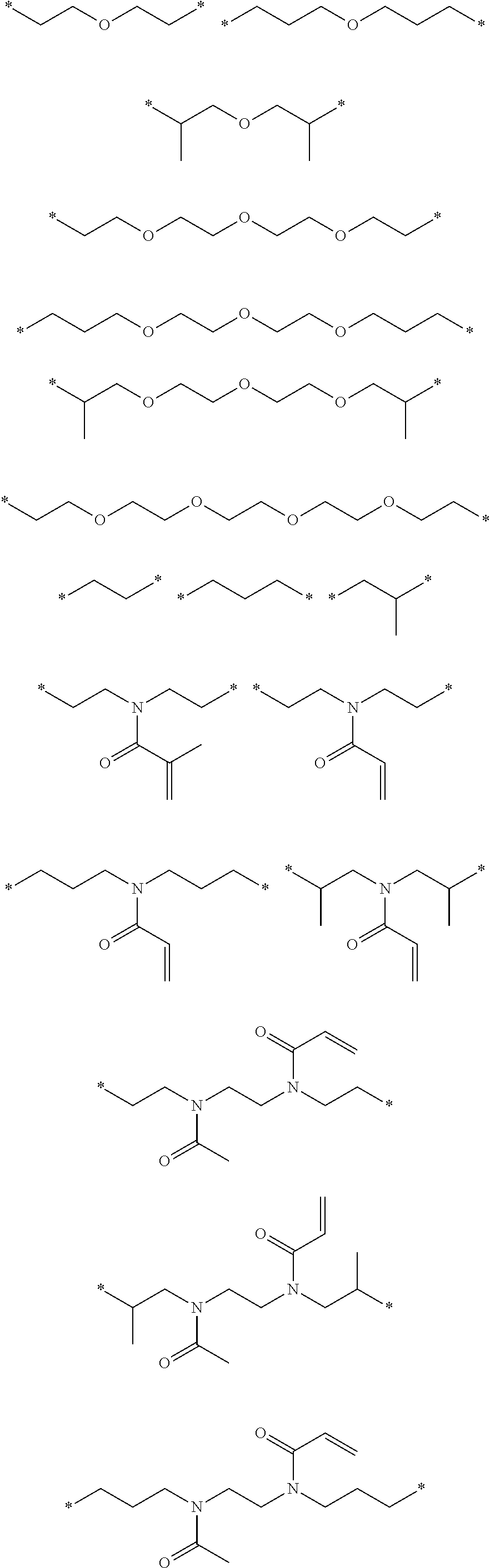

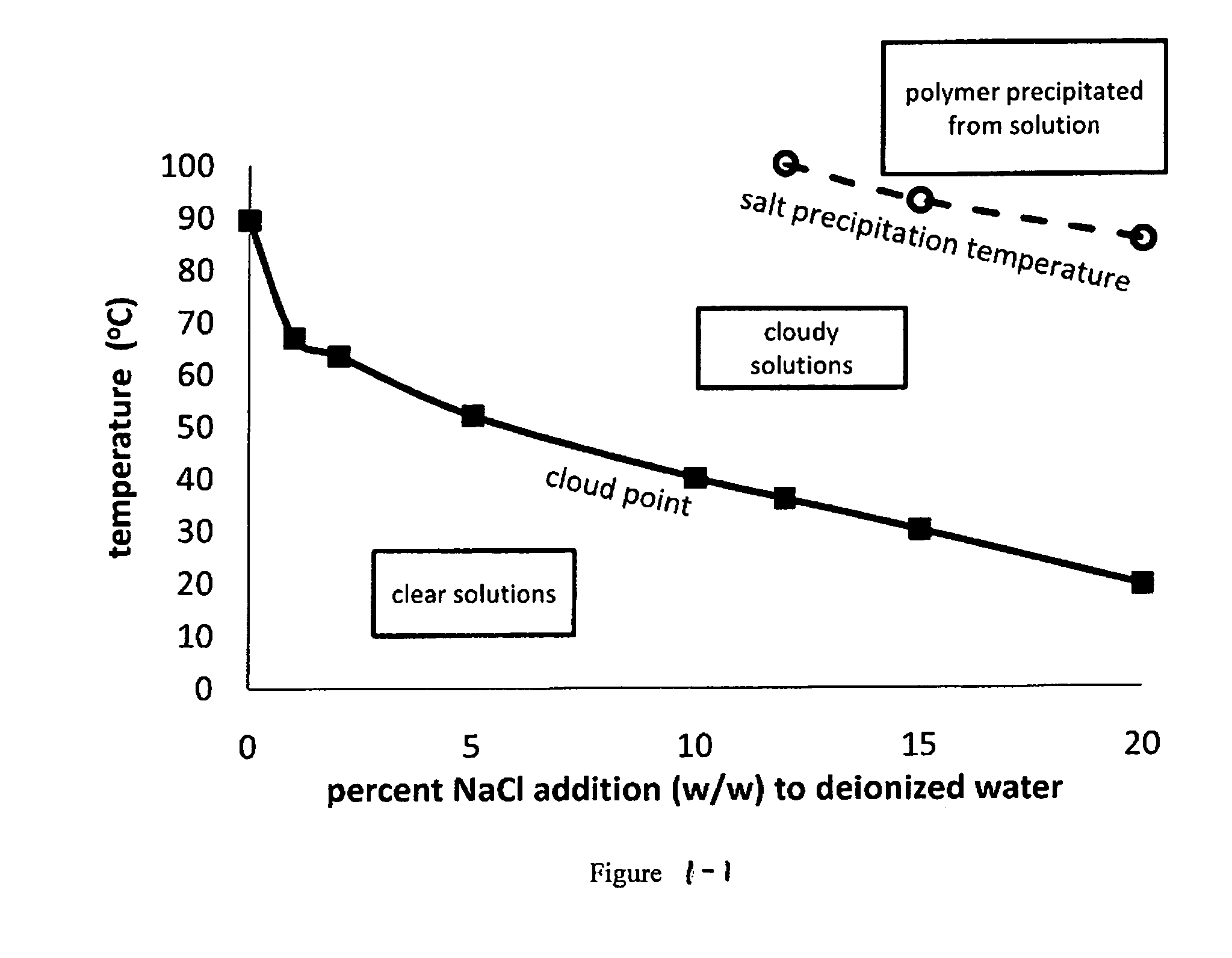

Non-homopolymers exhibiting gas hydrate inhibition, salt tolerance and high cloud point

Polymers are provided that offer gas hydrate inhibition, salt tolerance, and high cloud point. The polymers are polymerized from at least (A) 50 mole percent or more of a monomer selected from the group consisting of: N-vinyl-2-caprolactam, one of its analogues, and combinations thereof, (B) an alkenyl sulfonic acid monomer, salt thereof, or combinations thereof, and (C) an TV-vinyl amide, a (meth)acrylamide or one of its analogues, or combinations thereof. In one embodiment, the (A) monomer is N-vinyl-2-caprolactam, the (B) monomer is 2-acrylamido-2-methylpropane sulfonic acid or salt thereof, and the (C) monomer is N-vinyl-2-pyrrolidone, acrylamide, methacrylamide, or combinations thereof.

Owner:ISP INVESTMENTS INC

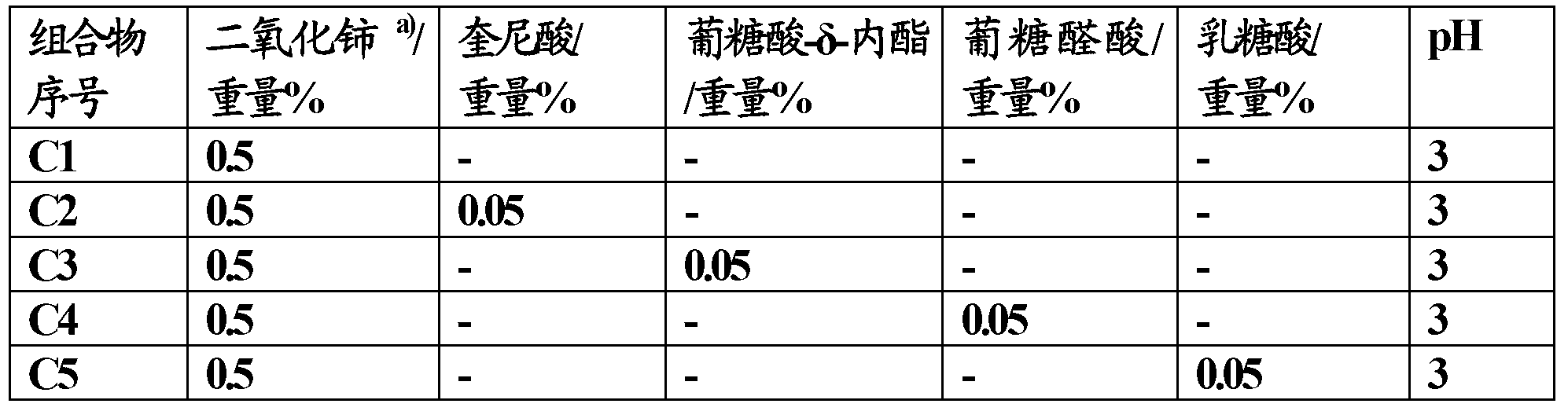

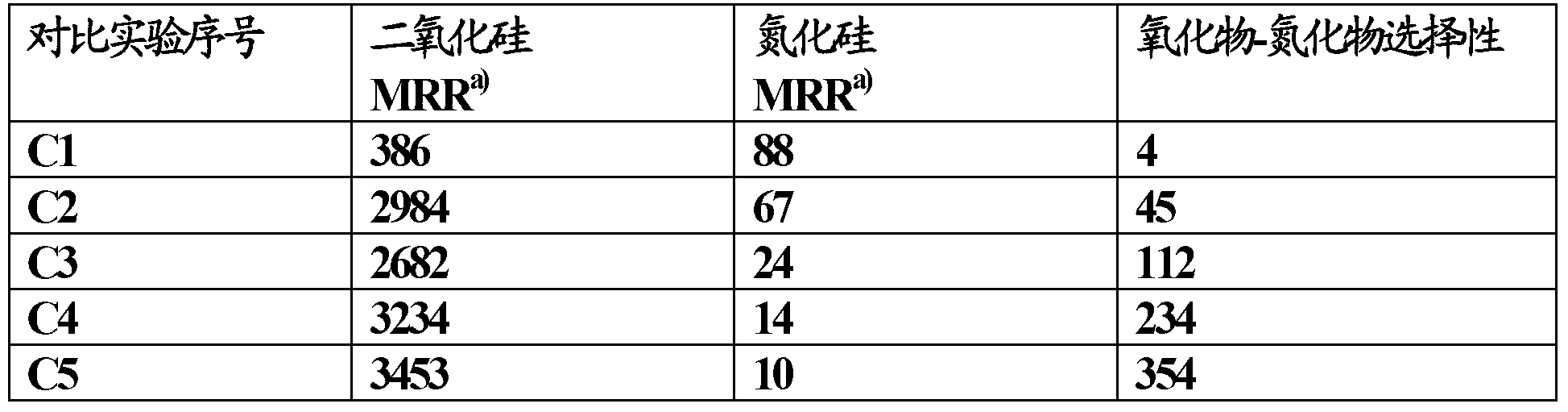

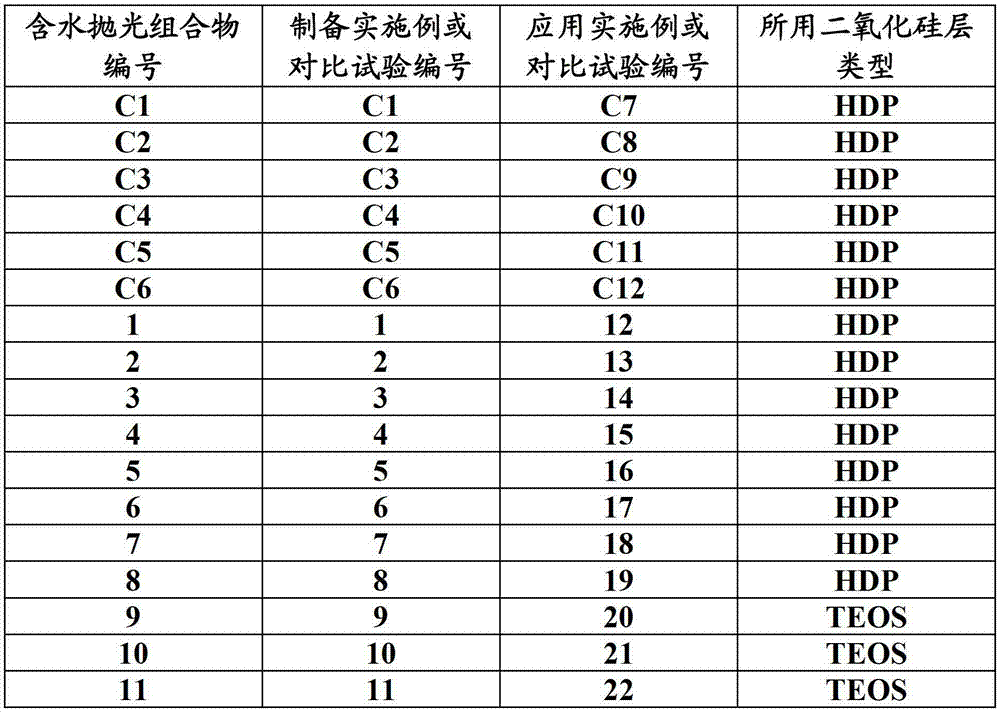

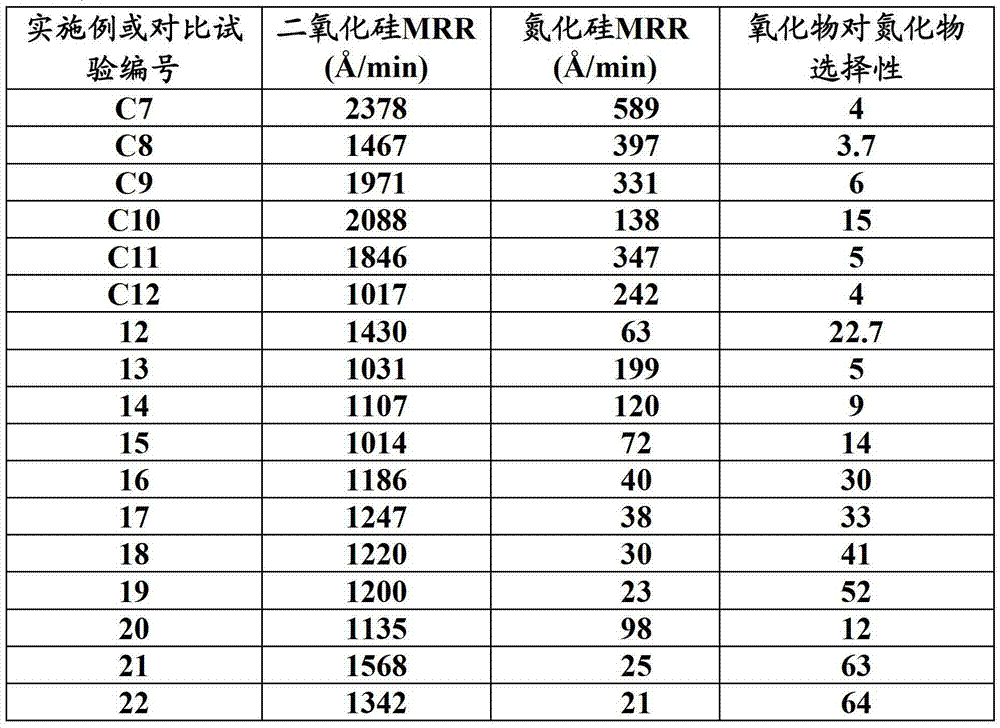

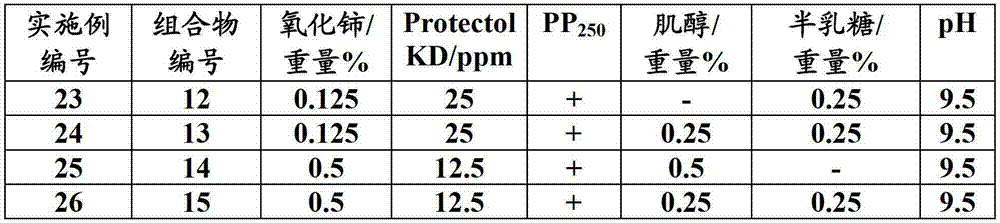

Aqueous polishing composition and process for chemically mechanically polishing substrate materials for electrical, mechanical and optical devices

InactiveCN103189457AGood choiceOptimizationOther chemical processesSemiconductor/solid-state device manufacturingWater dispersibleVinyl Amide

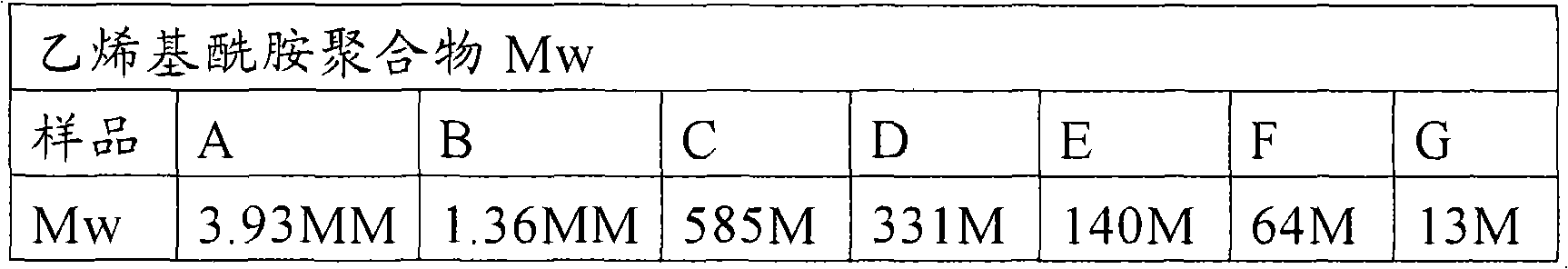

An aqueous polishing composition comprising (A) abrasive particles which are positively charged when dispersed in an aqueous medium having a pH in the range of from 3 to 9 as evidenced by the electrophoretic mobility; (B) water-soluble and water-dispersible hydroxy group containing components selected from (b1 ) aliphatic and cycloaliphatic hydroxycarboxylic acids, wherein the molar ratio of hydroxy groups to carboxylic acid groups is at least 1; (b2) esters and lactones of the hydroxycarboxylic acids (b1 ) having at least one hydroxy group; and (b3) mixtures thereof; and (C) water-soluble and water-dispersible polymer components selected from (c1 ) linear and branched alkylene oxide polymers; (c2) linear and branched, aliphatic and cycloaliphatic poly(N-vinylamide) polymers; and (c3) cationic polymeric flocculants having a weight average molecular weight of less than 100,000 Dalton.; and a process for polishing substrate materials for electrical, mechanical and optical devices.

Owner:BASF SE

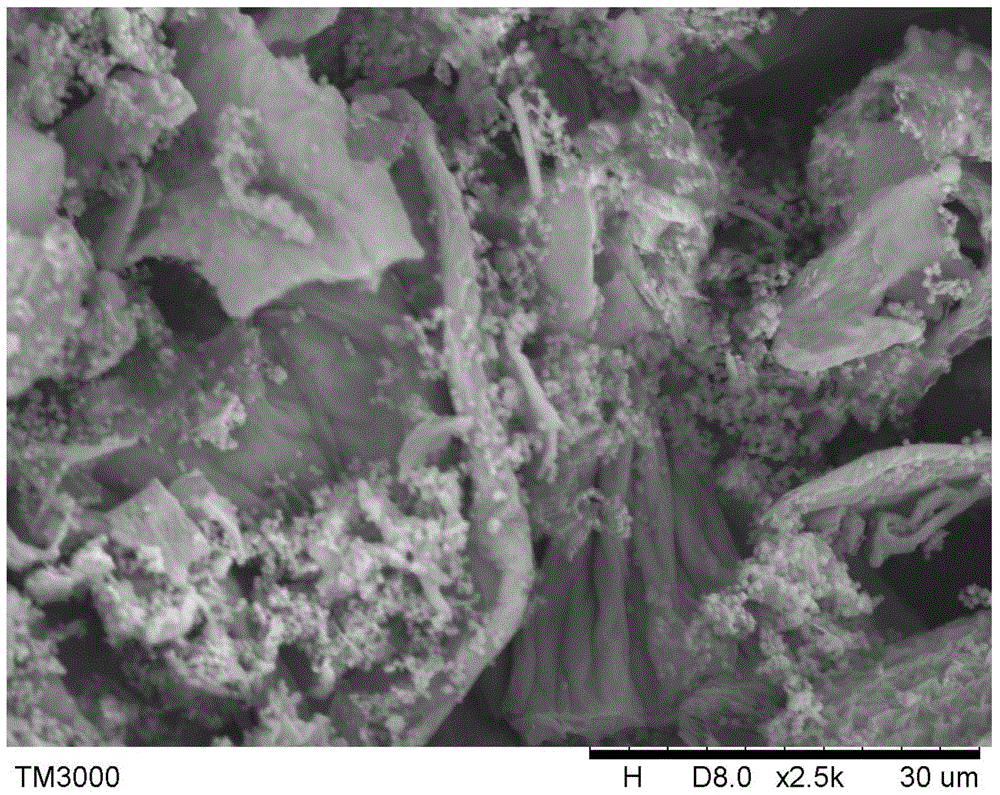

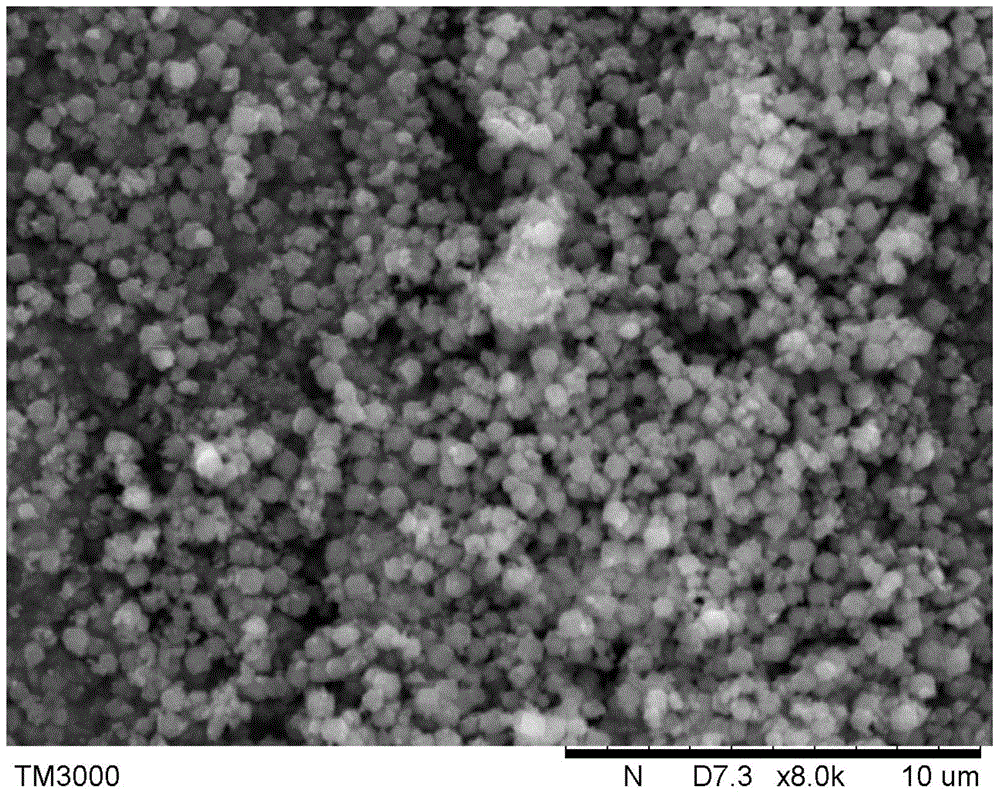

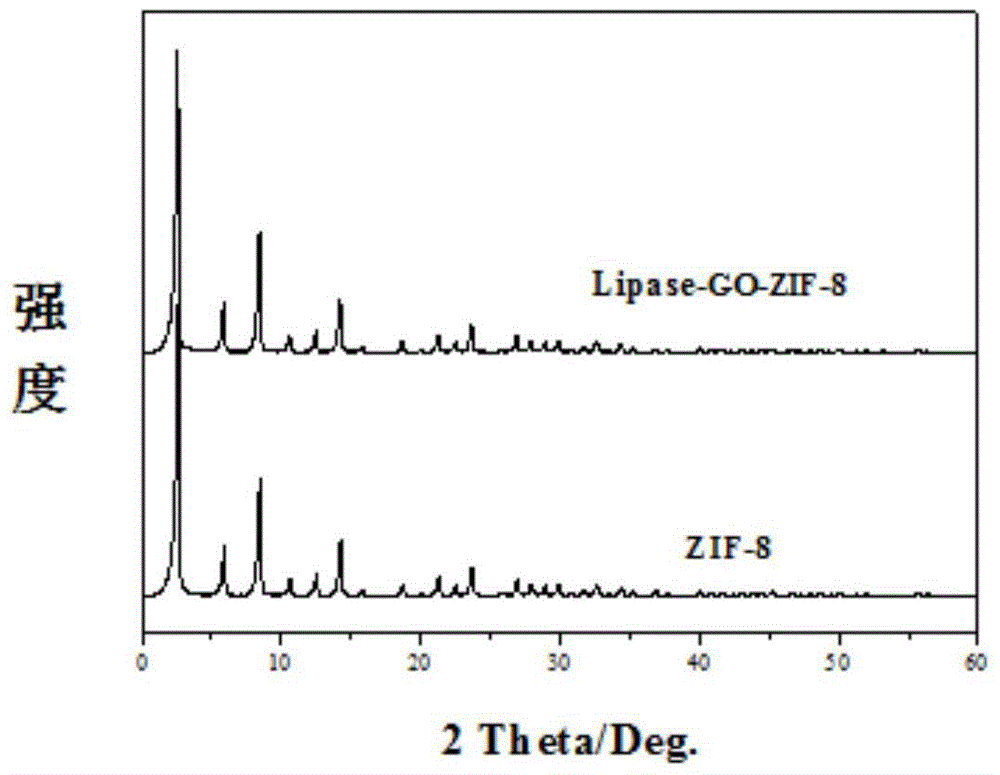

Enzyme-GO-MOFs nano composite catalyst and preparation method thereof

InactiveCN105734038ASynthetic conditions are mildHigh protein immobilization rateHydrolasesOxidoreductasesVacuum dryingStock solution

The invention discloses an enzyme-GO-MOFs nano composite catalyst and a preparation method thereof. The preparation method comprises the following steps: (1) adding a modifier into an enzyme liquid so as to obtain a modified enzyme solution, wherein the modifier is an N-vinyl amide polymer or pluronic F-127; the N-vinyl amide polymer is one or a mixture of more of polyvinylpyrrolidone, poly N-vinyl caprolactam and poly N-ethylene formamide; (2) mixing GO and a metallic salt solution, performing ultrasonic treatment, further adding an organic ligand solution into the mixed solution so as to obtain a GO-MOFs composite material synthesized stock solution, and performing ultrasonic treatment for another time; (3) adding a modified enzyme solution into the GO-MOFs composite material synthesized stock solution, and performing ultrasonic treatment so as to obtain a reaction liquid; (4) centrifuging the reaction liquid, collecting precipitate, washing the precipitate, and performing vacuum drying, thereby obtaining the enzyme-GO-MOFs nano composite catalyst. The preparation method disclosed by the invention is simple and feasible, and the nano composite material catalyst is gentle in synthesis condition and high in protein immobilization rate.

Owner:NANJING UNIV OF TECH

Aqueous polishing composition and process for chemically mechanically polishing substrate materials for electrical, mechanical and optical devices

InactiveUS20130161285A1Improved oxide-to-nitride selectivityExcellent globalOther chemical processesDecorative surface effectsWater dispersibleVinyl Amide

An aqueous polishing composition comprising (A) abrasive particles which are positively charged when dispersed in an aqueous medium having a pH in the range of from 3 to 9 as evidenced by the electrophoretic mobility; (B) water-soluble and water-dispersible hydroxy group containing components selected from (b1) aliphatic and cycloaliphatic hydroxycarboxylic acids, wherein the molar ratio of hydroxy groups to carboxylic acid groups is at least 1; (b2) esters and lactones of the hydroxycarboxylic acids (b1) having at least one hydroxy group; and (b3) mixtures thereof; and (C) water-soluble and water-dispersible polymer components selected from (c1) linear and branched alkylene oxide polymers; (c2) linear and branched, aliphatic and cycloaliphatic poly(N-vinylamide) polymers; and (c3) cationic polymeric flocculents having a weight average molecular weight of less than 100,000 Dalton.; and a process for polishing substrate materials for electrical, mechanical and optical devices.

Owner:BASF AG

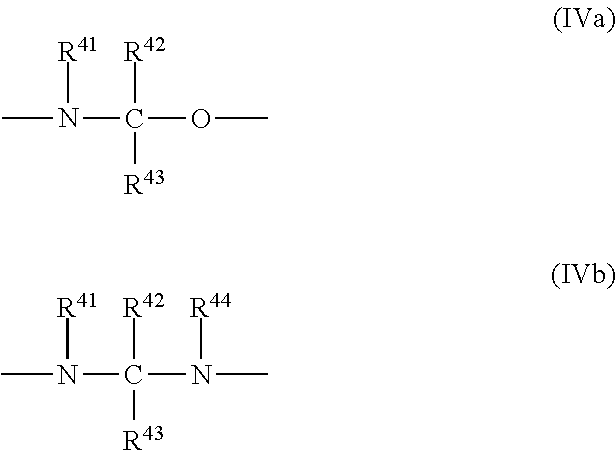

A high-temperature high-pressure (HTHP) stable synthetic polymer for water based oil-well servicing fluids

Stable water based High-Temperature-High-Pressure (HTHP) and / or Non-HTHP crosslinked copolymers for oil and gas applications consist of (i) a crosslinked, linear polyvinyl amide / polymerizable carboxylic acid) copolymer, having a composition, by weight, of 25-75 wt. % of a vinyl amide monomer selected from vinyl pyrrolidone, vinyl caprolactam, N-vinyl-N-methylacetamide and mixtures thereof, and 25-75 wt. % of a polymerizable carboxylic acid monomer selected from acrylic acid, (meth)acrylic acid, crotonic acid, itaconic acid, maleic acid and mixture thereof; and (ii) a crosslinker in an amount of 0.01-5% based on weight of total monomers. Also discloses relevant compositions comprising said copolymer and method of use thereof.

Owner:ISP INVESTMENTS LLC

Aqueous polishing composition and process for chemically mechanically polishing substrates for electrical, mechanical and optical devices

InactiveCN103097476AGood choiceOther chemical processesSemiconductor/solid-state device manufacturingWater dispersibleAlcohol

An aqueous polishing composition having a pH of 3 to 11 and comprising (A) abrasive particles which are positively charged when dispersed in an aqueous medium free from component (B) and of a pH of 3 to 9 as evidenced by the electrophoretic mobility; (B) anionic phosphate dispersing agents; and (C) a polyhydric alcohol component selected from the group consisting of (c1) water-soluble and water-dispersible, aliphatic and cycloaliphatic, monomeric, dimeric and oligomeric polyols having at least 4 hydroxy groups; (c2) a mixture consisting of (c21) water-soluble and water-dispersible, aliphatic and cycloaliphatic polyols having at least 2 hydroxy groups; and (c22) water-soluble or water-dispersible polymers selected from linear and branched alkylene oxide homopolymers and copolymers (c221 ); and linear and branched, aliphatic and cycloaliphatic poly(N-vinylamide) homopolymers and copolymers (c222); and (c3) mixtures of (c1) and (c2); and a process for polishing substrates for electrical, mechanical and optical devices.

Owner:BASF AG

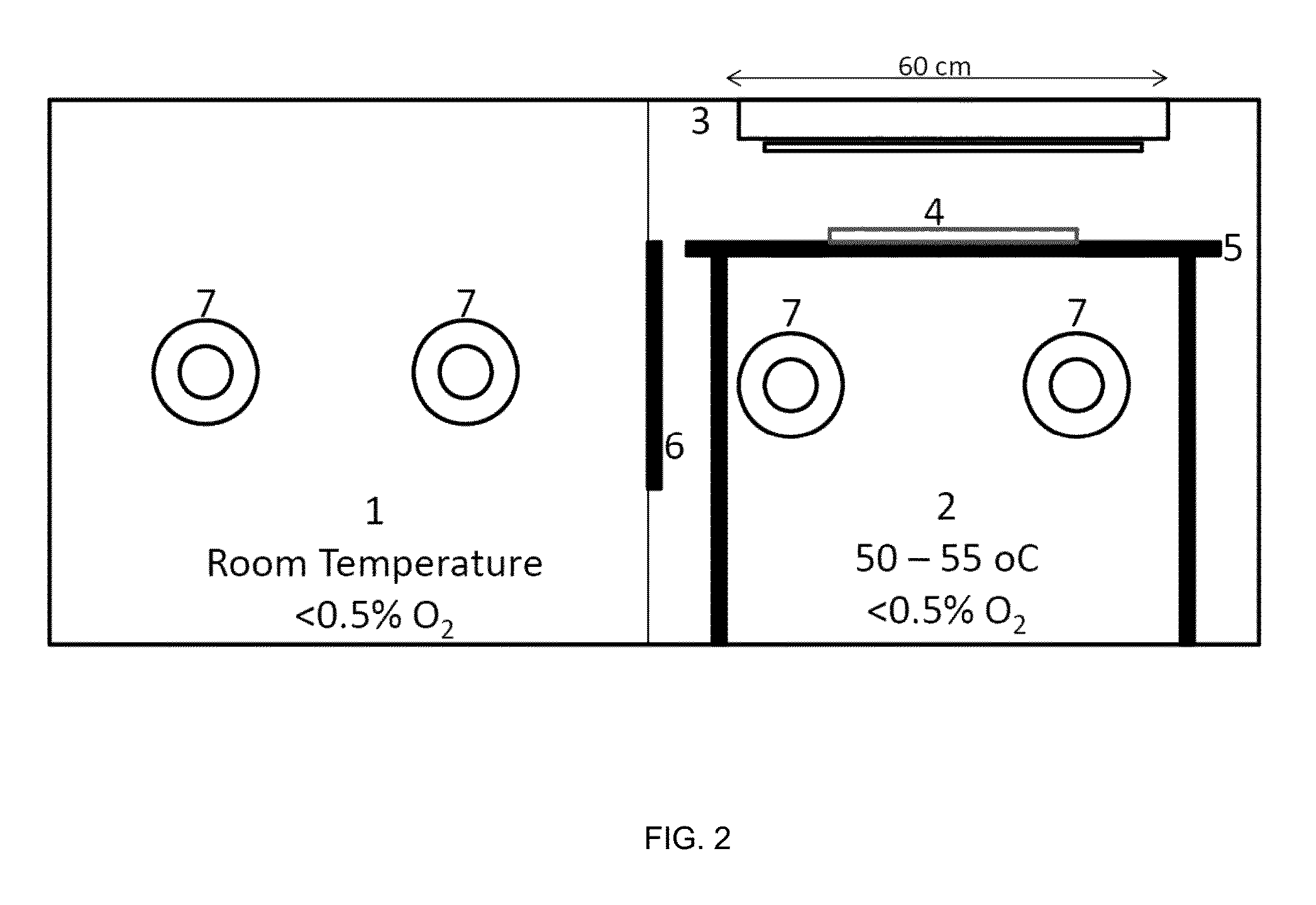

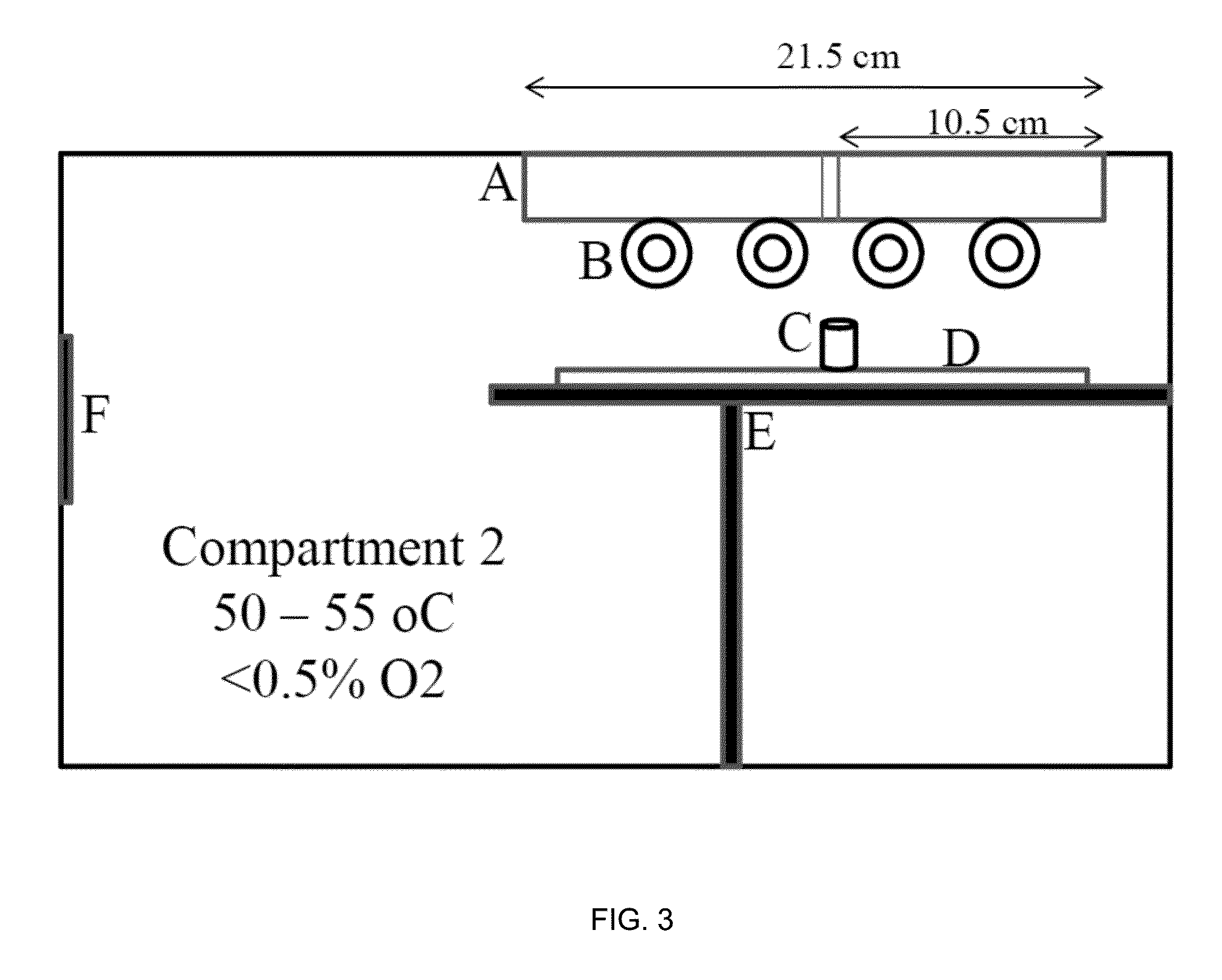

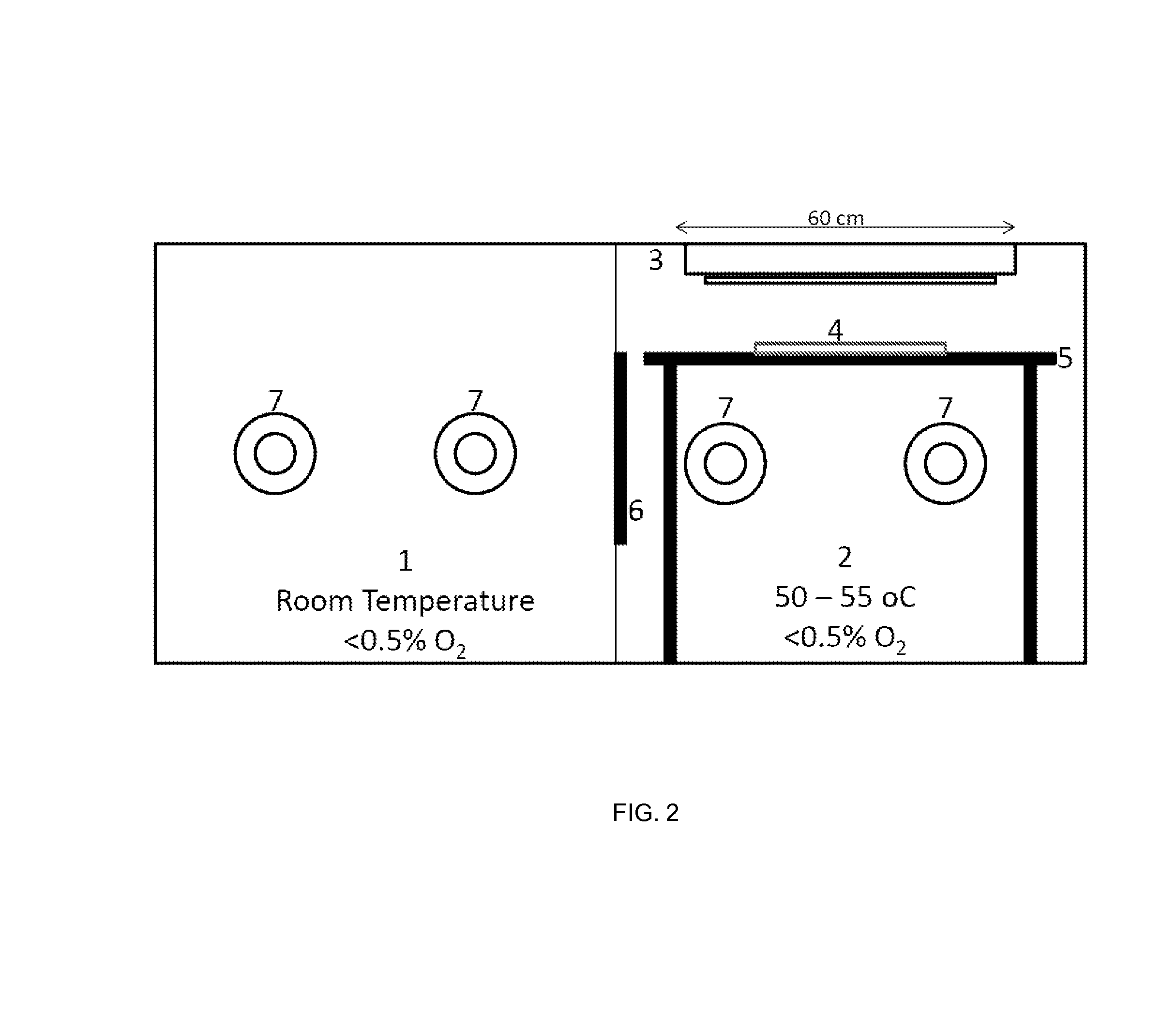

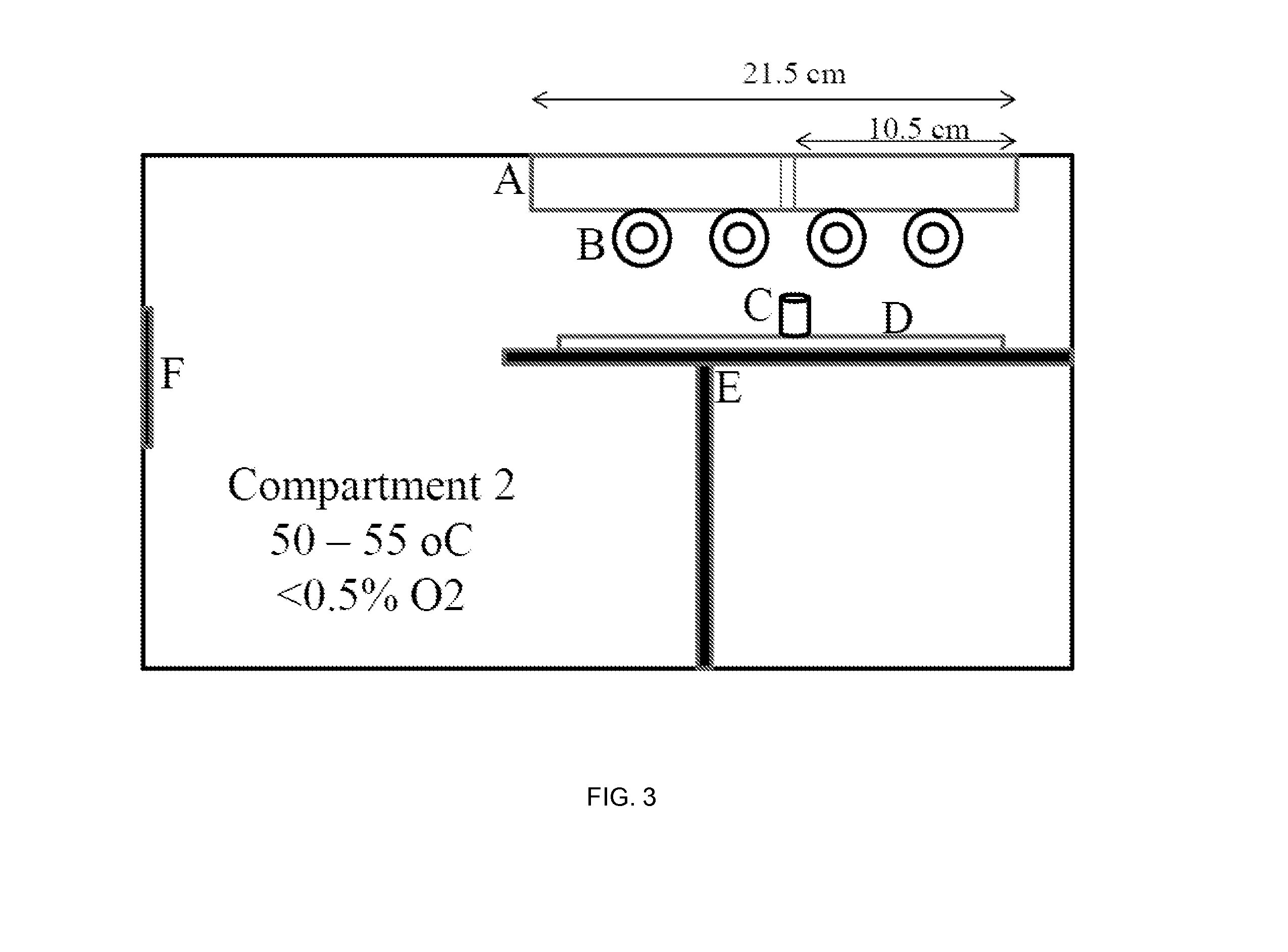

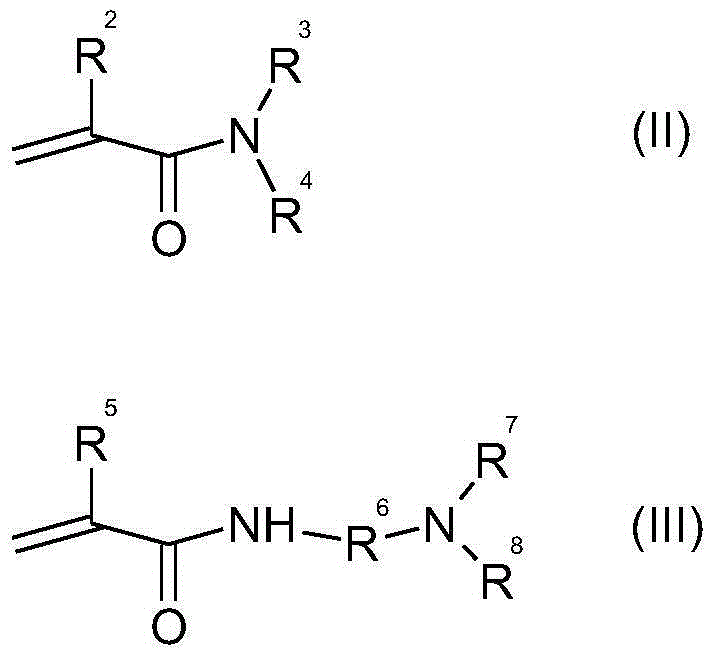

N-vinyl amides polymer and laponite composite hydrogel and preparation method

The invention provides a preparation method of high-strength and high-tenacity N-vinyl amides polymer and laponite composite hydrogel, which comprises the following steps of: dispersing laponite in water, stirring to obtain a uniform and transparent dispersing solution, then sequentially adding a N-vinyl amides monomer, an initiator and a water-soluble dye, uniformly stirring, deoxidizing and sealing; heating a reaction system for reacting to obtain laponite cross-linked nano-composite hydrogel; or placing the reaction system in a thermostatic environment, illuminating the obtained laponite cross-linked nanocomposite hydrogel by using an UV (ultraviolet) light. By dispersing the laponite in the water fully, adding the N-vinyl amides monomer and the initiator, selecting a water-bath heating mode or an UV light induced reaction mode, and adopting an in-situ free radical polymerization method, the invention obtains the hydrogel with a high-strength and high-tenacity N-vinyl amides polymer and laponite nano-composite structure.

Owner:SOUTH CHINA UNIV OF TECH

Support for solid-phase synthesis and process for producing the same

The present invention relates to a support for solid-phase synthesis, which contains a porous copolymer particle, the copolymer particle containing 25 to 60% by weight of an aromatic-vinyl structural unit, 20 to 55% by weight of a vinyl cyamide structural unit, 5 to 18% by weight of an ethylenically-unsaturated-carboxylic-acid structural unit, and 2 to 15% by weight of an aromatic-divinyl structural unit. The support according to the invention fluctuates little in the degree of swelling depending on the kind of the organic solvent in contact therewith.

Owner:NITTO DENKO CORP

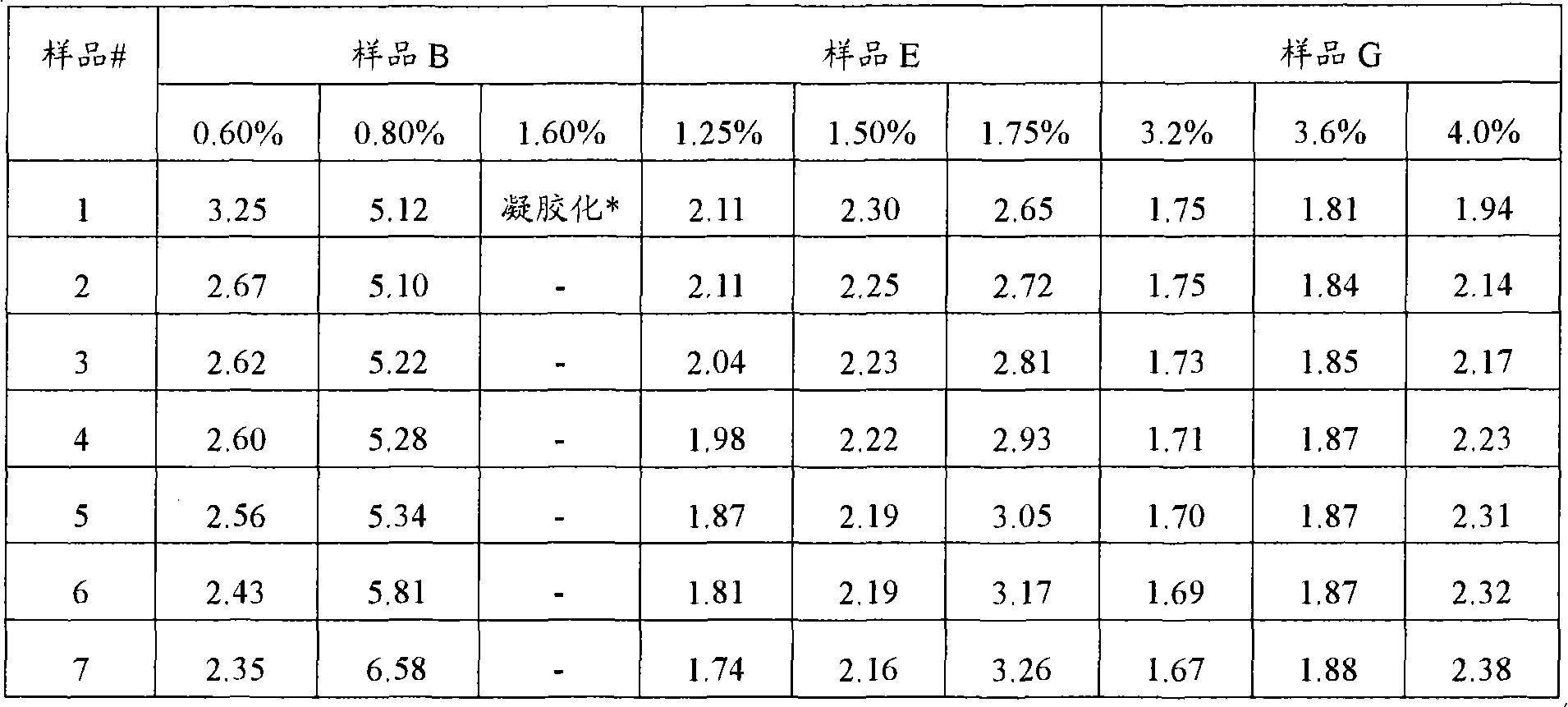

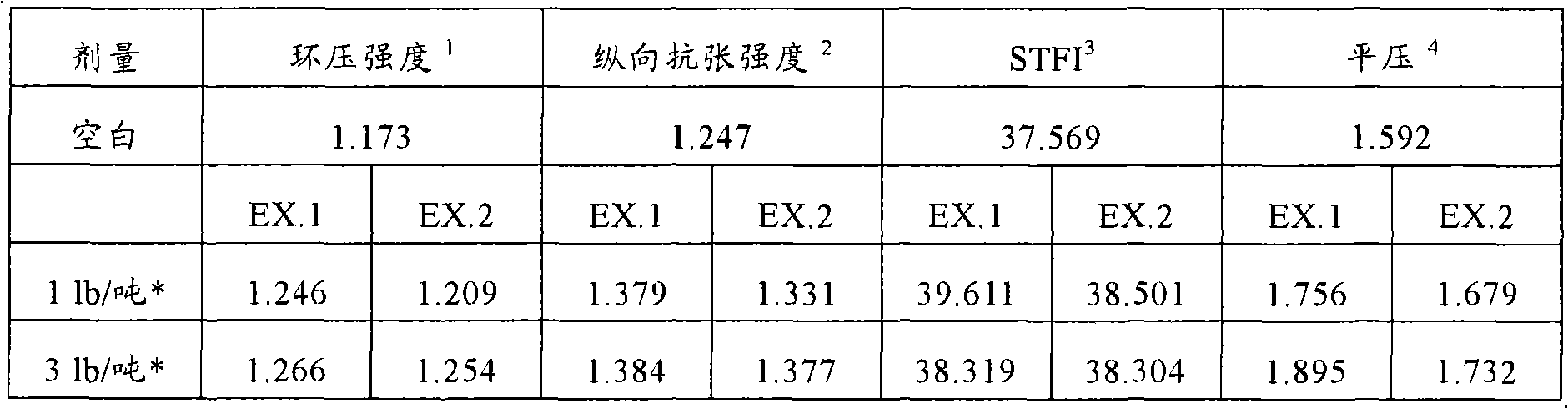

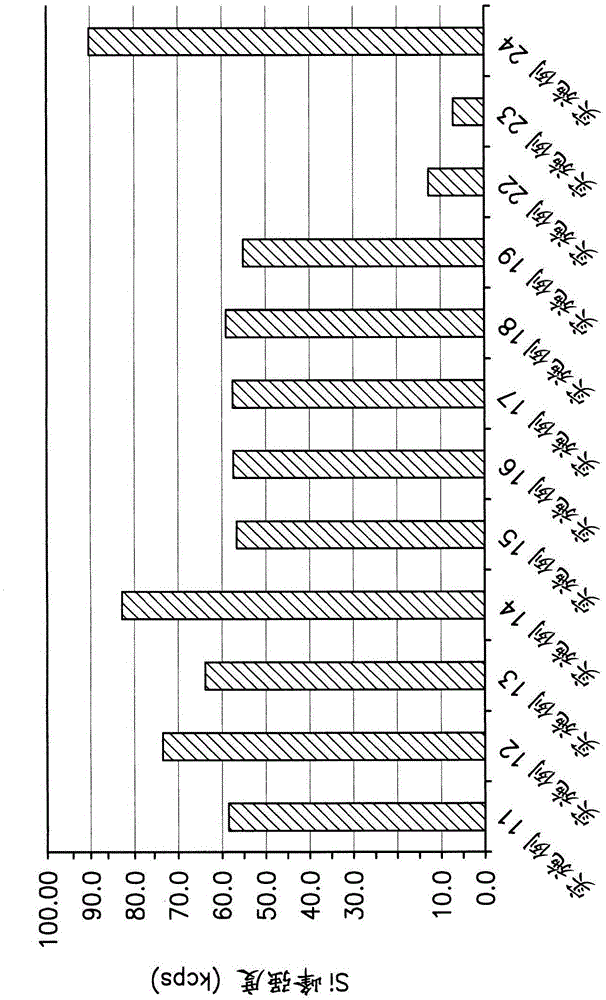

Glyoxalation of vinylamide polymer

ActiveCN101553508AImprove performanceNon-fibrous pulp additionPaper/cardboardCellulosePolymer science

The present invention is directed to a method for preparing a cellulose reactive adduct of polyvinylamide and a composition resulting from the method. The preparation of the cellulose reactive adduct is carried out close to a Critical Concentration defined herein. When the reaction is run close to this Critical Concentration, the risk of gelation is minimized, consumed glyoxal is maximized, and shelf live is enhanced. Additionally, the glyoxalated vinylamides of the present invention impart improved wet and dry strengthening efficiency to paper and paperboard when compared to adducts disclosedin previously described art.

Owner:BASF AG

Aqueous polishing composition and process for chemically mechanically polishing substrates for electrical, mechanical and optical devices

InactiveUS20130200038A1Improved oxide-to-nitride selectivityExcellent globalOther chemical processesDecorative surface effectsWater dispersiblePolyol

An aqueous polishing composition having a pH of 3 to 11 and comprising (A) abrasive particles which are positively charged when dispersed in an aqueous medium free from component (B) and of a pH of 3 to 9 as evidenced by the electrophoretic mobility; (B) anionic phosphate dispersing agents; and (C) a polyhydric alcohol component selected from the group consisting of (c1) water-soluble and water-dispersible, aliphatic and cycloaliphatic, monomeric, dimeric and oligomeric polyols having at least 4 hydroxy groups; (c2) a mixture consisting of (c21) water-soluble and water-dispersible, aliphatic and cycloaliphatic polyols having at least 2 hydroxy groups; and (c22) water-soluble or water-dispersible polymers selected from linear and branched alkylene oxide homopolymers and copolymers (c221); and linear and branched, aliphatic and cycloaliphatic poly(N-vinylamide) homopolymers and copolymers (c222); and (c3) mixtures of (c1) and (c2); and a process for polishing substrates for electrical, mechanical and optical devices.

Owner:BASF AG

Polymers and methods to mitigate the loss of silicone deposition from keratinous substrates

Owner:LUBRIZOL ADVANCED MATERIALS INC

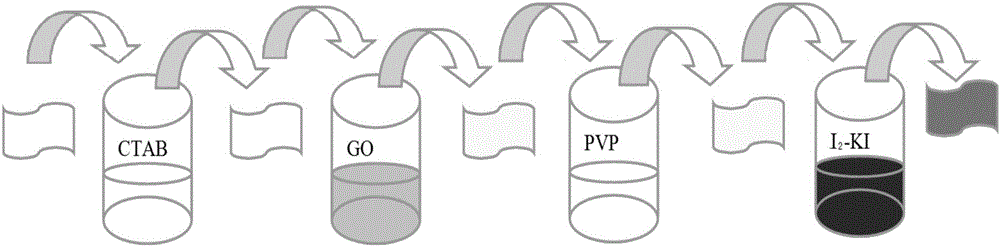

Antibacterial textile and preparation method thereof

ActiveCN106637924AImprove bindingImprove antibacterial propertiesBiochemical fibre treatmentVegetal fibresPolymer scienceVinyl Amide

The invention provides an antibacterial textile and a preparation method thereof. The preparation method comprises the steps of modifying a textile, dipping the textile into an N-vinyl amide polymer water solution such as graphene oxide and polyvinylpyrrolidone so as to generate a graphene oxide-N-vinyl amide polymer film, carrying out self-assembling on the oxide-N-vinyl amide polymer film and iodine, so as to obtain the antibacterial textile. The antibacterial textile has the beneficial effects that on one hand, the disadvantages of low binding capacity and infirmness of graphene oxide on the surface of the textile are overcome; on the other hand, the excellent biocompatibility among iodine and N-vinyl amide polymers such as graphene oxide and polyvinylpyrrolidone is adequately exerted; and by virtue of the excellent antibacterial property, the antibacterial textile can be applied to the development and use of medical products.

Owner:SUZHOU UNIV

Dispersible alcohol/cleaning wipes via topical or wet-end application of acrylamide or vinylamide/amine polymers

InactiveUS20060003654A1Increase heightProvide strengthCosmetic preparationsToilet preparationsFiberAlcohol

The present invention is directed to a wet wipe product. The wet wipe product comprises a fibrous substrate and a triggerable binder formulation. The triggerable binder formulation is capable of binding the fibers in the fibrous substrate. The triggerable binder formulation may include acrylamide polymers, vinylamide / amine polymers, and mixtures. The triggerable binder formulation is insoluble in a wetting composition comprising an insolubilizing agent but is dispersible in disposal water.

Owner:KIMBERLY-CLARK WORLDWIDE INC

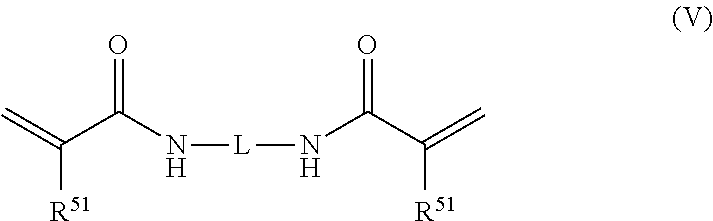

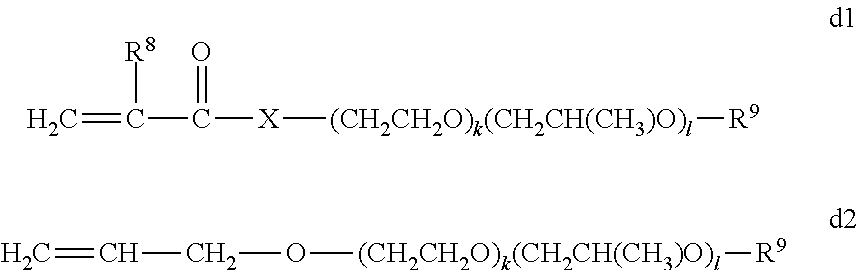

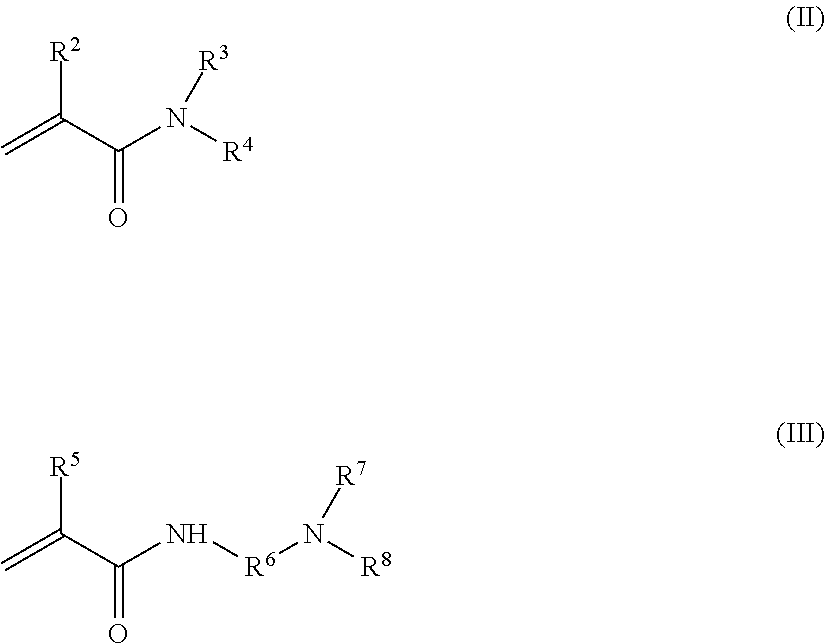

Surfactant Activated Microgel Polymers And Methods To Mitigate The Loss Of Silicone Deposition From Keratinous Substrates

InactiveUS20160015622A1Excellent yield stressExcellent detersive propertyCosmetic preparationsHair cosmeticsMonomer compositionMeth-

A conditioning and cleansing composition comprising at least one detersive surfactant, a silicone conditioning agent and a nonionic, amphiphilic polymer that mitigates the loss silicone deposition on keratinous substrates is disclosed. The nonionic, amphiphilic polymer is prepared by polymerizing a monomer composition comprising: a) from about 55 to about 95 wt. % of at least one vinyl amide monomer (based on the weight of the total monomers present); b) from about 5 to about 45 wt. % of at least one vinyl ester of an aliphatic carboxylic acid containing an acyl moiety having 2 to 22 carbon atoms (based on the weight of the total monomers present); c) from about 0 to about 1 wt. % of at least one polyunsaturated crosslinking monomer containing at least two polymerizable ethylenically unsaturated moieties (based on the total dry weight of the polymer); d) from about 0 to about 10 wt. % of at least one C1-C22 alkyl (meth)acrylate (based on the weight of the total monomers present); e) from about 0 to about 10 wt. % of an alkoxylated associative monomer (based on the weight of the total monomers present); f) from about 0 to about 10 wt. % of an alkoxylated semi-hydrophobic monomer (based on the weight of the total monomers present); and g) from about 0 to about 5 wt. % of at least one vinyl ester of an aliphatic carboxylic acid containing an acyl moiety having 2 to 22 carbon atoms (based on the weight of the total monomers present) other than vinyl acetate.

Owner:LUBRIZOL ADVANCED MATERIALS INC

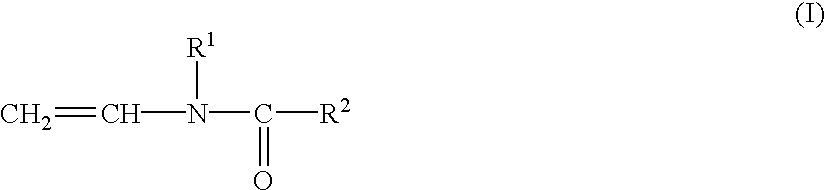

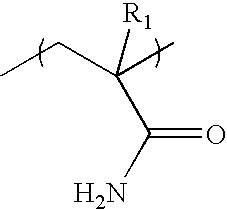

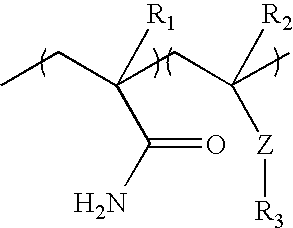

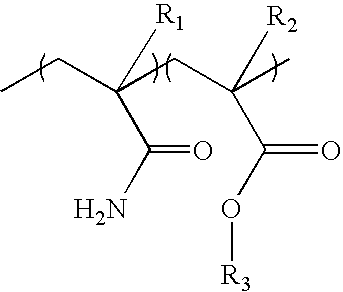

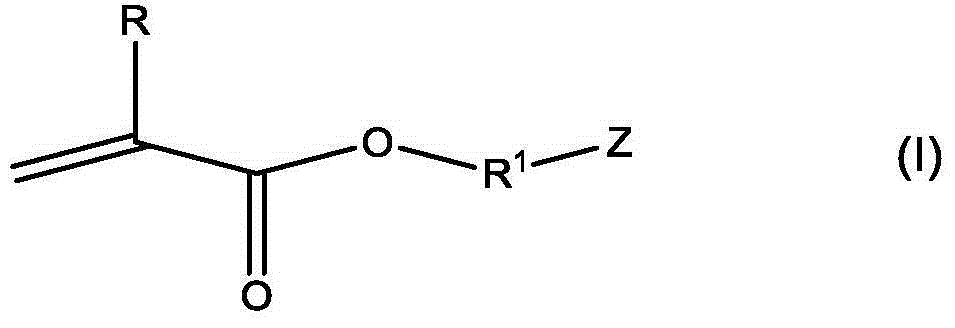

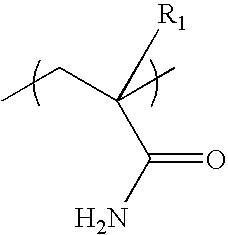

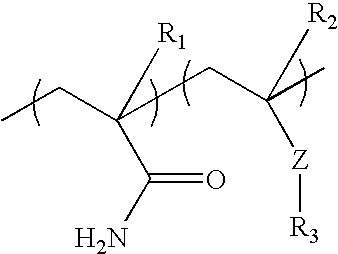

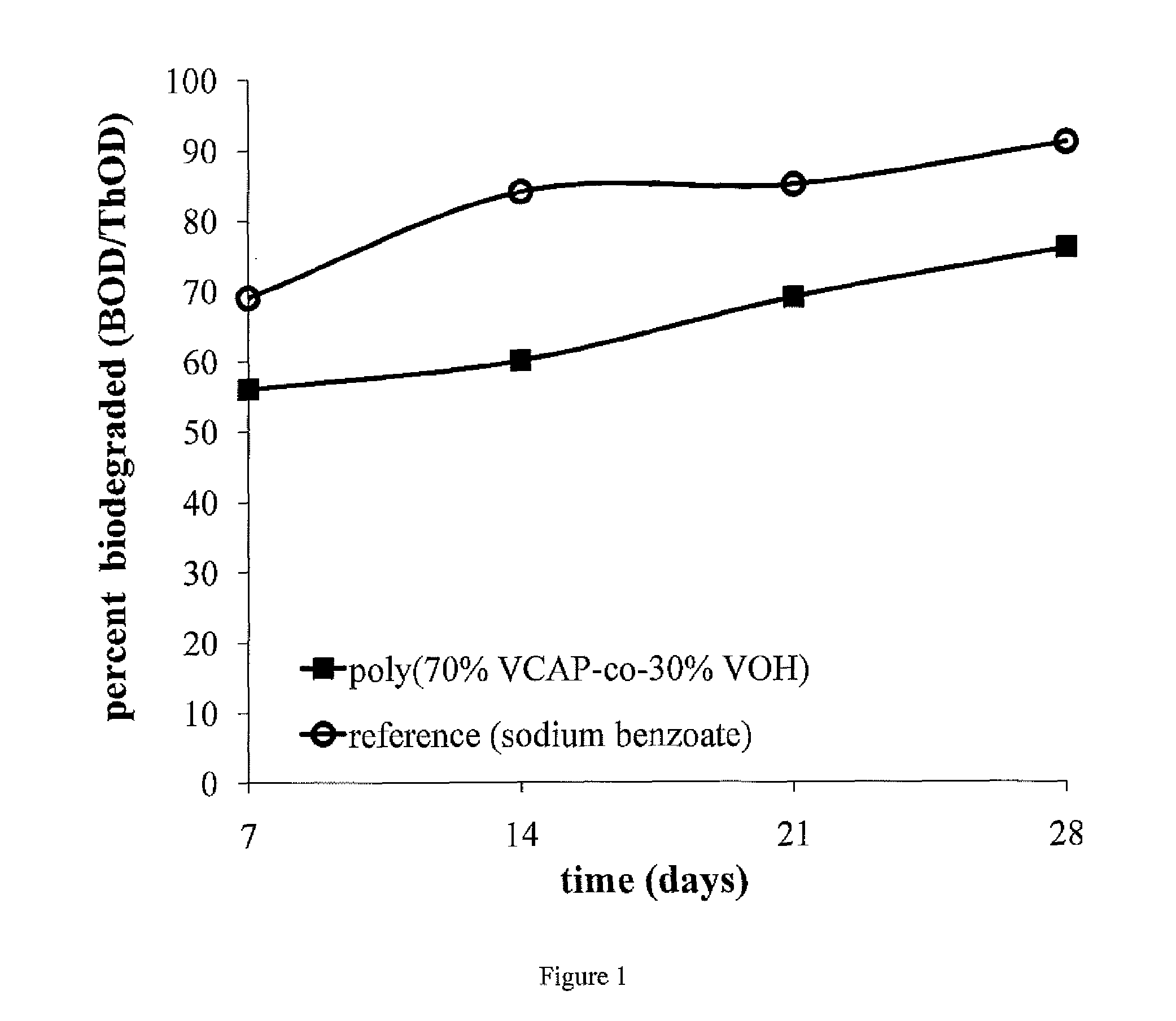

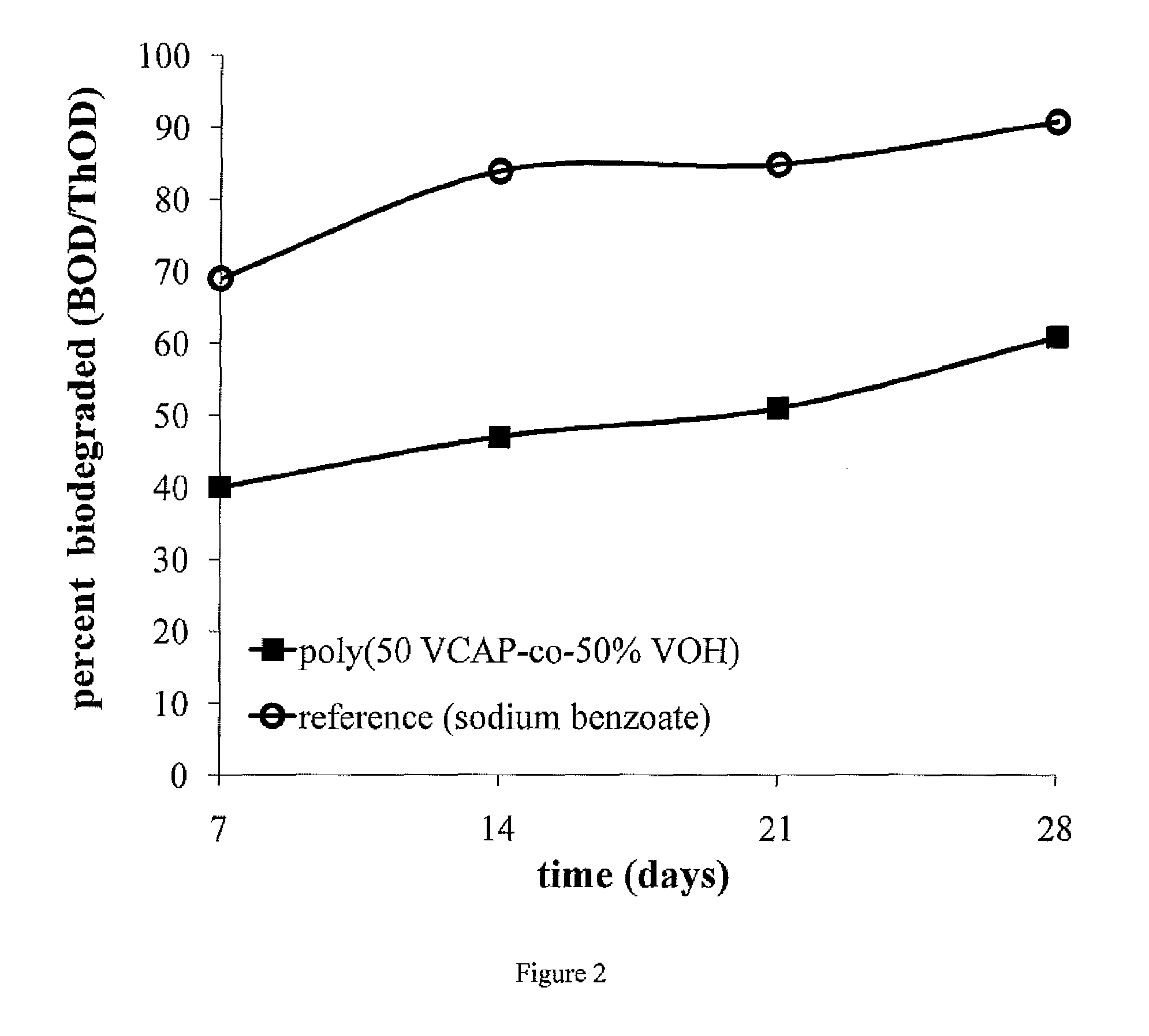

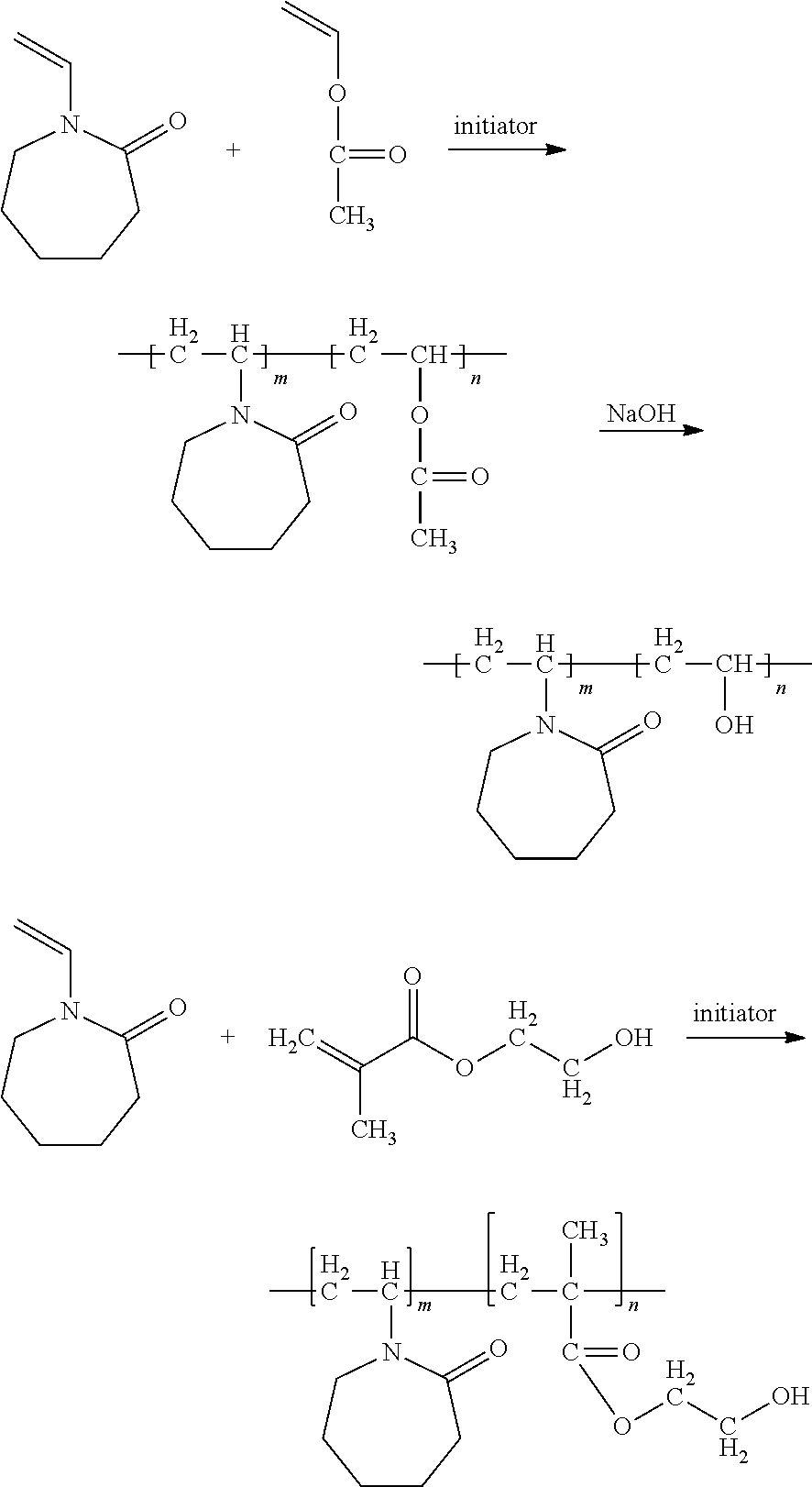

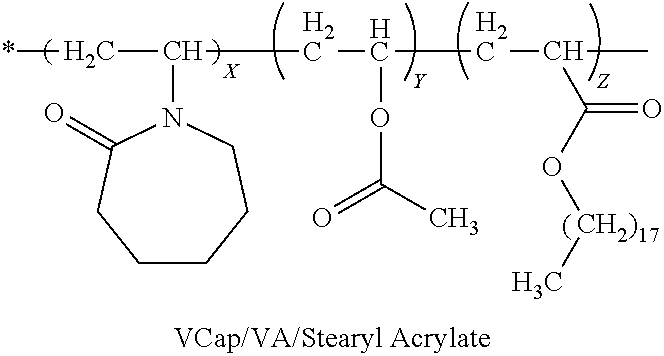

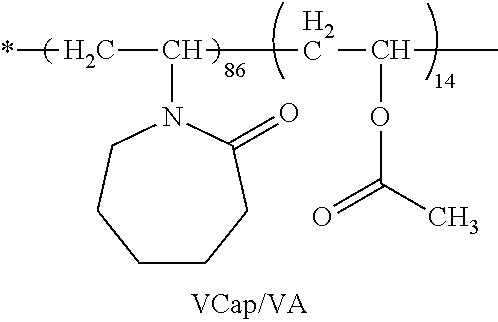

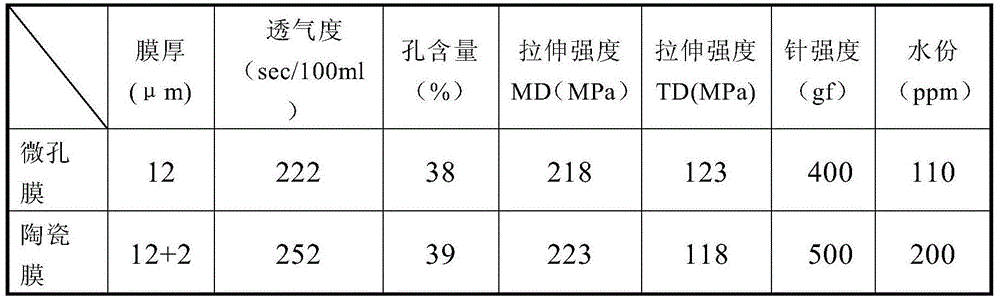

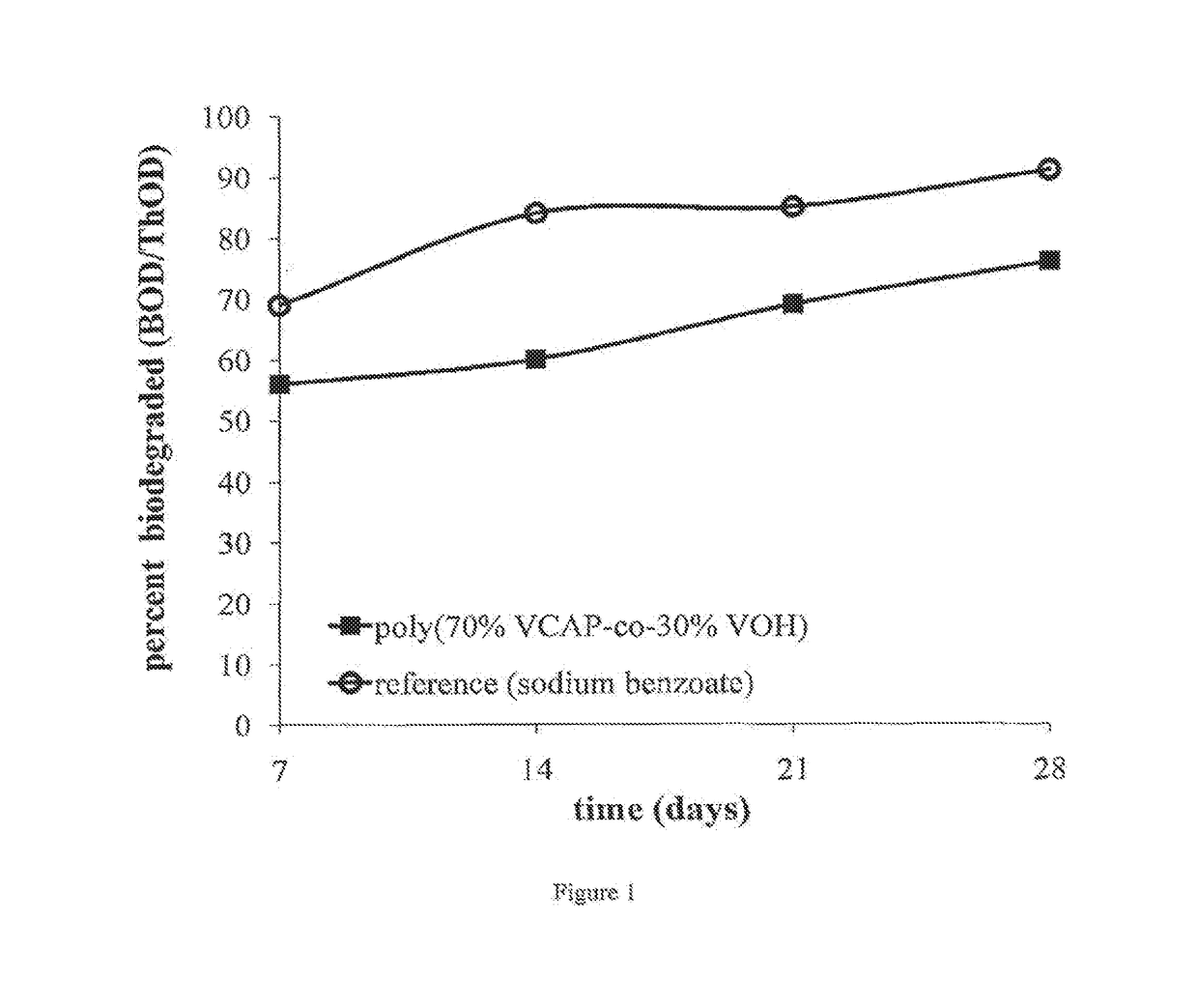

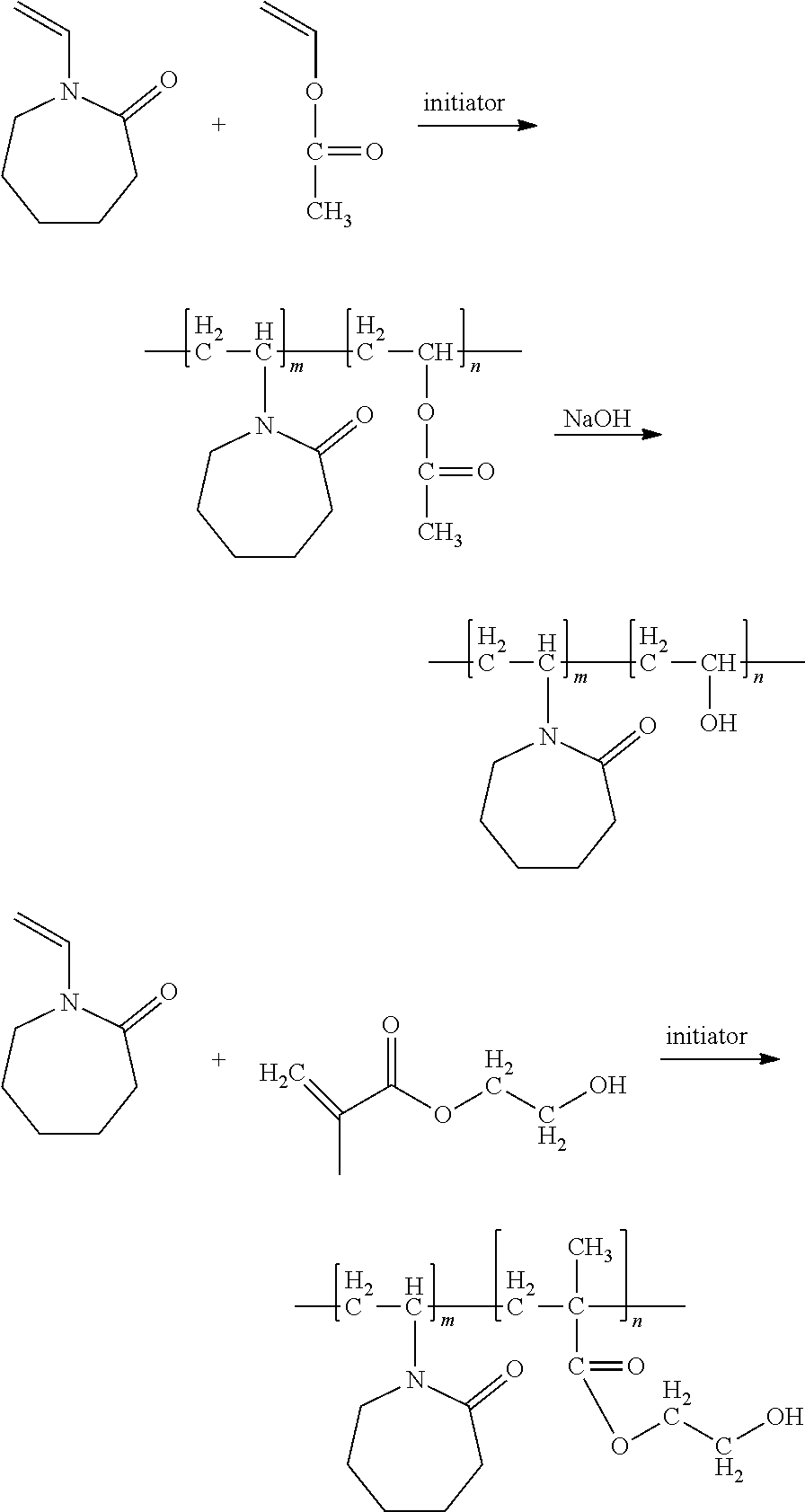

Polymers Having N-Vinyl Amide And Hydroxyl Moieties, Their Compositions And The Uses Thereof

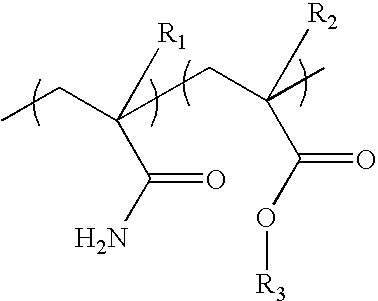

The invention relates to polymers derived at least from one: (A) one N-vinyl amide unit, and (B) one hydroxyl-containing acrylate unit, and to polymers derived at least from: (A) N-vinyl-2-caprolactam, and (B) one non-acrylate unit having: (i) at least one hydroxyl group, and / or (ii) at least one functional group convertible to a hydroxyl group wherein at least one group is converted to hydroxyl functionality in the final polymer product. Such polymers may exhibit degradability, e.g., in seawater or soil environments. In preferred embodiments, these polymers and compositions thereof are used in oilfield applications, such as an inhibitor of gas hydrates and / or a kinetic inhibitor of gas hydrates. The polymer can assume alternating, block, and / or random configurations of the repeating units, with at least one ester group. The chemical structure subscripts m, and n may be any integer equal to or greater than 1.

Owner:ISP INVESTMENTS LLC

Coating compositions for forming toner coatings

The present invention provides coating compositions for forming a toner coating on a substrate containing a polymer comprising: (a) a N-vinyl amide monomer, (b) a vinyl acetate monomer, and (c) a solvent. The coating compositions may further comprise an additional hydrophobic monomer moiety. The present invention further provides coating compositions for forming a toner coating on a substrate containing a polymer comprising: (a) a N-vinyl amide monomer, (b) a styrene monomer, and (c) a solvent. The present invention further provides toner substrates coated with the coating compositions.

Owner:ISP INVESTMENTS LLC

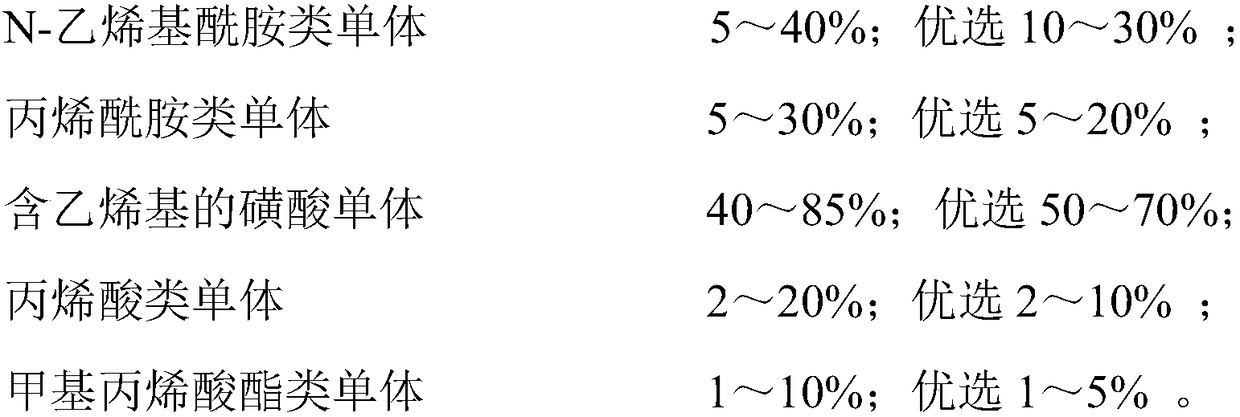

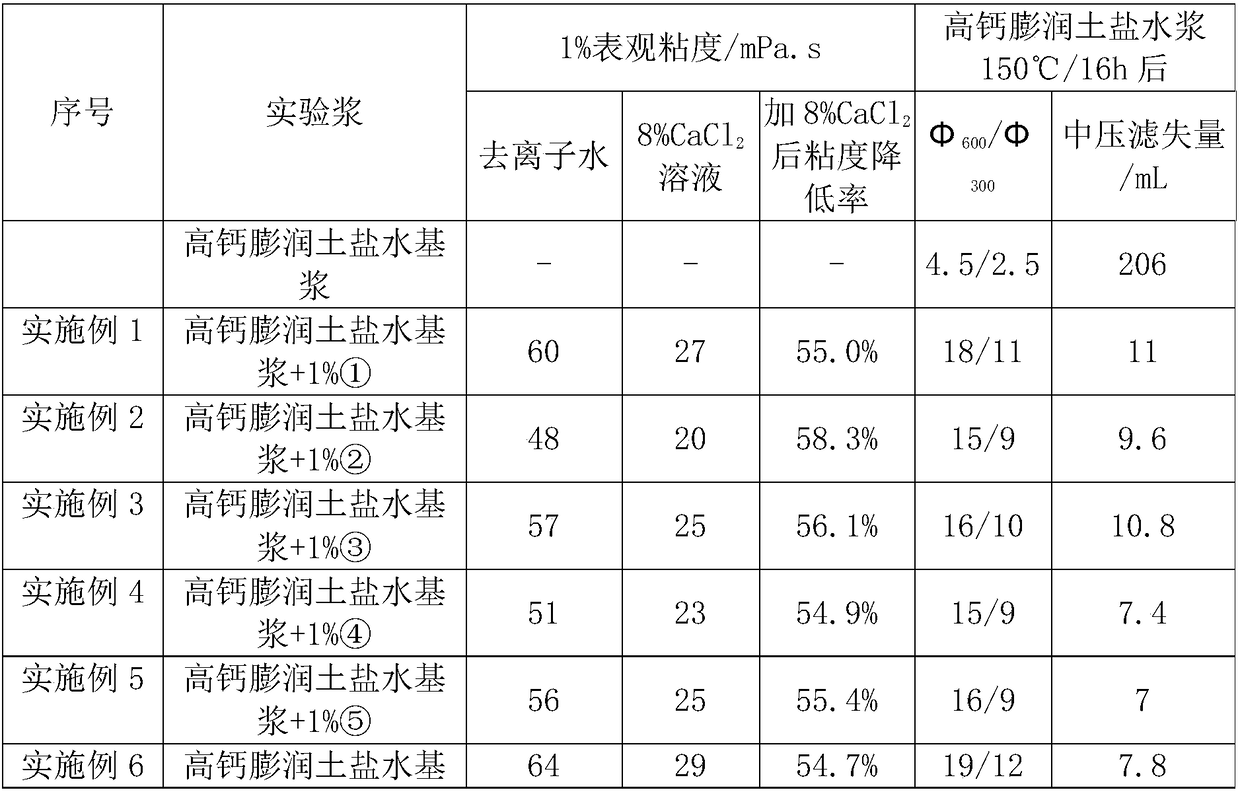

Tackifying anti-calcium salt polymer filtrate reducer and preparation method

ActiveCN108117621AHigh molecular weightProtective effect is goodDrilling compositionMethacrylatePolymer science

The invention discloses a tackifying anti-calcium salt polymer filtrate reducer and a preparation method. The filtrate reducer is prepared by polymerizing raw materials of the following monomers in percentage by mass: 5-40% of an N-vinyl amide monomer, 5-30% of an acrylamide monomer, 40-85% of a sulfoacid monomer containing vinyl, 2-20% of an acrylic acid monomer and 1-10% of a methacrylate monomer. The filtration reducer is reasonably interacted with clay particles under high calcium salt by controlling the proportion of adsorption groups and hydrated groups on polymer molecular chains, so that the filtrate reducer is in a proper dispersed state to form a filter cake which is low in permeability, flexible and thin and compact, and the filtration loss of a drilling fluid is reduced; meanwhile, the anti-calcium filtrate reducer has a relatively great molecular weight. Compared with existing anti-salt polymer filtration reducers, the reducer has the advantages that the viscosity reduction rate of the filtrate reducer in a high calcium salt aqueous solution is small, and plays certain roles of coating, inhibiting and viscosity-shearing improving in the high calcium salt drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

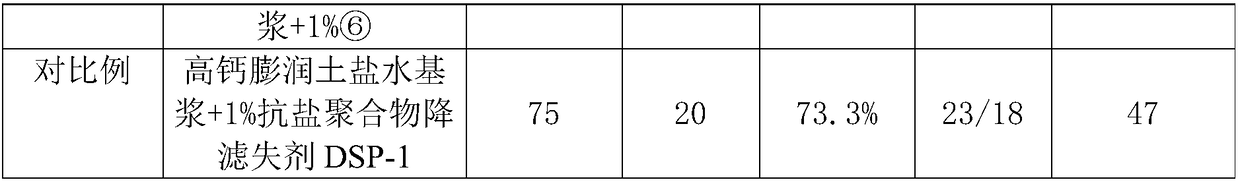

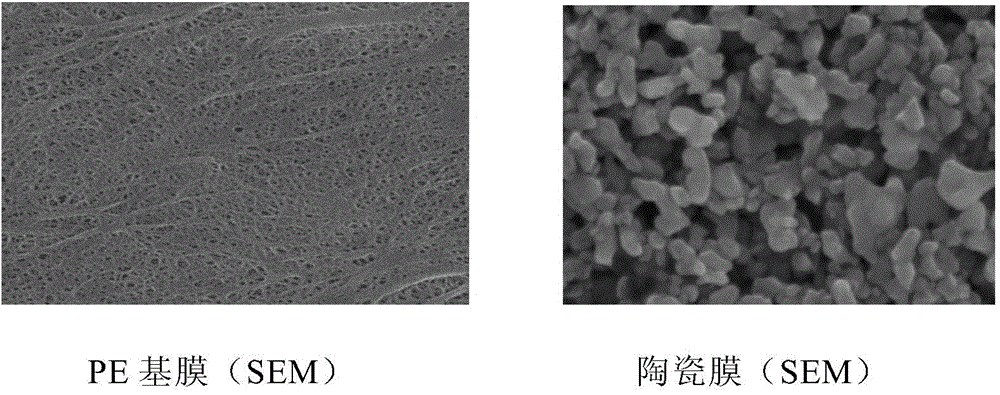

Manufacture method and applications of high temperature resistant and deformation resistant composite microporous membrane

InactiveCN105713228AImprove high temperature stabilityImprove mechanical propertiesCell component detailsCarbamatePolymer science

The invention discloses a manufacture method and applications of a high temperature resistant and deformation resistant composite microporous membrane. The manufacture method comprises the following steps: (a) providing a polymer microporous membrane; (b) dispersing ceramic nano particles into an aqueous adhesive to form aqueous slurry; (c) painting the aqueous slurry on the surface of the polymer microporous membrane to form a composite microporous membrane; wherein the aqueous adhesive comprises a main adhesive and an interlayer adhesive, the main adhesive is prepared from cellulose ether, natural polymer and derivatives thereof, or a mixture of cellulose ether and natural polymer and derivatives thereof; the interlayer adhesive is prepared from polyacrylamide, poly(vinyl amide), polyvinylpyrrolidone, polymethyl methacrylate, polycarboxylic acid, modified paraffin resin, carbomer, polyacrylic acid, urethane acrylate, polyacrylate copolymer emulsion, cis-polybutadiene, butadiene styrene rubber, polyurethane, carbamate, and liquid glue made of part of acrylic epoxy resin, isobornyl acrylate, starch, modified polyurea, and low molecular polyvinyl wax, and the weight ratio of the main adhesive to the interlayer adhesive is 20:55-65:5.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

Polymers having n-vinyl amide and hydroxyl moieties, their compositions and the uses thereof

The invention relates to polymers derived at least from one: (A) one N-vinyl amide unit, and (B) one hydroxyl-containing acrylate unit, and to polymers derived at least from: (A) N-vinyl-2-caprolactam, and (B) one non-acrylate unit having: (i) at least one hydroxyl group, and / or (ii) at least one functional group convertible to a hydroxyl group wherein at least one group is converted to hydroxyl functionality in the final polymer product. Such polymers may exhibit degradability, e.g., in seawater or soil environments. In preferred embodiments, these polymers and compositions thereof are used in oilfield applications, such as an inhibitor of gas hydrates and / or a kinetic inhibitor of gas hydrates. The polymer can assume alternating, block, and / or random configurations of the repeating units, with at least one ester group. The chemical structure subscripts m, and n may be any integer equal to or greater than 1.

Owner:ISP INVESTMENTS LLC

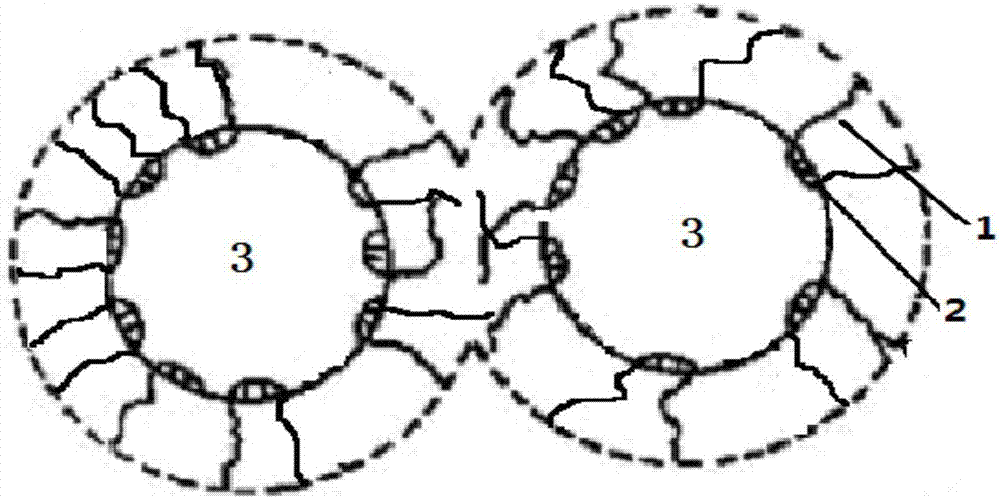

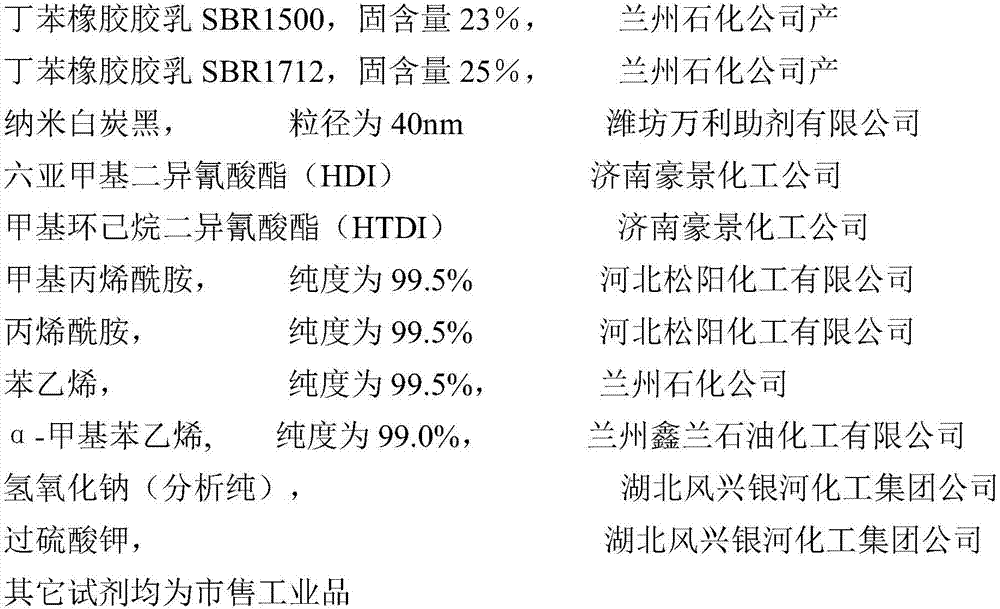

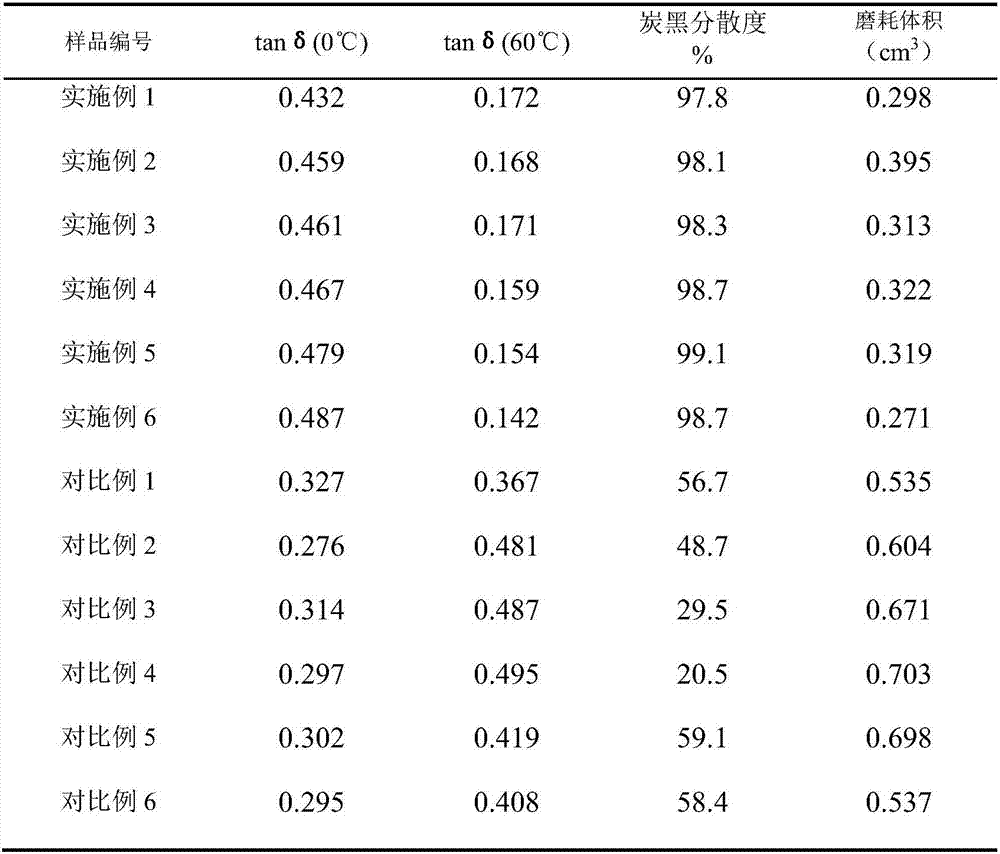

Rubber composition containing modified nano white carbon black and preparation method of rubber composition

ActiveCN107266748APrevent slippingAvoid scorchingSpecial tyresIn situ polymerizationButadiene-styrene rubber

The invention provides rubber composition with butadiene styrene rubber filled with modified nano white carbon black. Nano white carbon black is modified with aliphatic diisocyanate, then vinyl amide is added for a blocking reaction, then aryl ethylene monomers are pre-emulsified and subjected to in-situ polymerization with unsaturated bonds in vinyl amide, so that a barrier layer adopting a high dispersion structure and having good connection strength is formed on surfaces of nano white carbon black granules, the nano white carbon black granules can be separated under the high temperature or high shearing action and then directly mixed with a butadiene styrene rubber emulsion, and rubber composition with high wear resistance, low friction and wet slip resistance is prepared for tire tread rubber through condensation. The problem that nano white carbon black easily agglomerates again during processing can be effectively solved. The invention further provides a preparation method of the composition.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com