Patents

Literature

874results about How to "Synthetic conditions are mild" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycyclic benzothiadiazole non-fullerene acceptor material, preparation method thereof and application of material

ActiveCN109134513AImprove solubilityPromote absorptionOrganic chemistrySolid-state devicesSolubilityOrganic solar cell

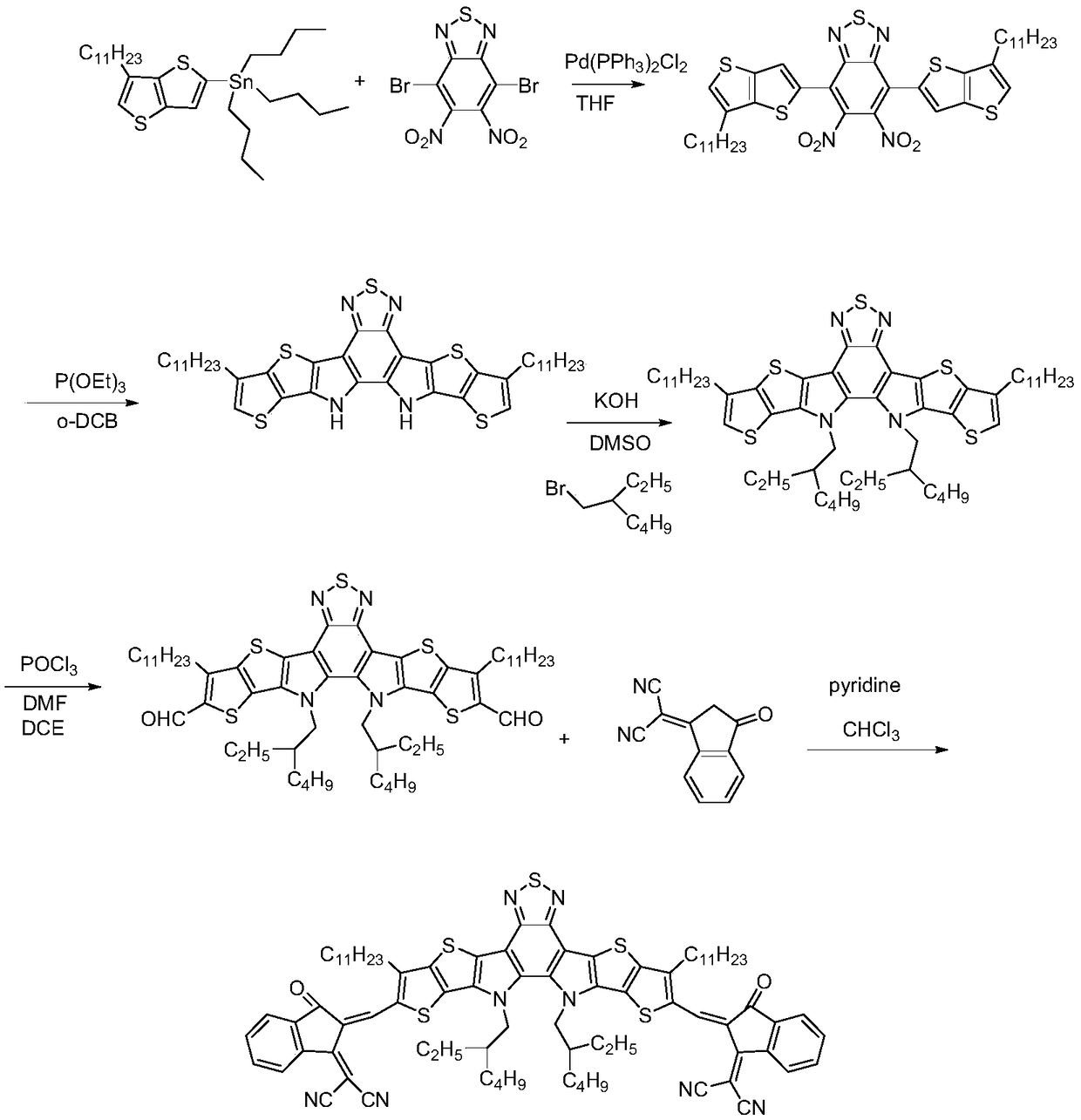

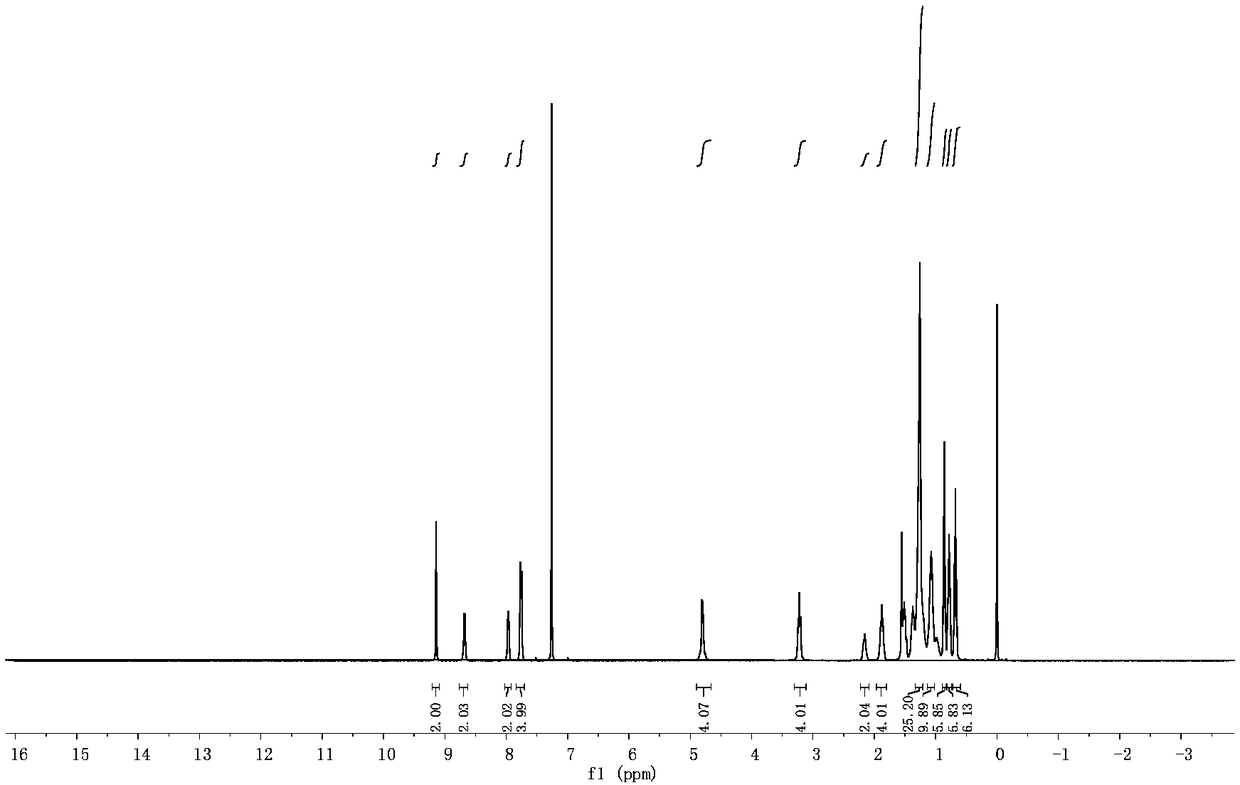

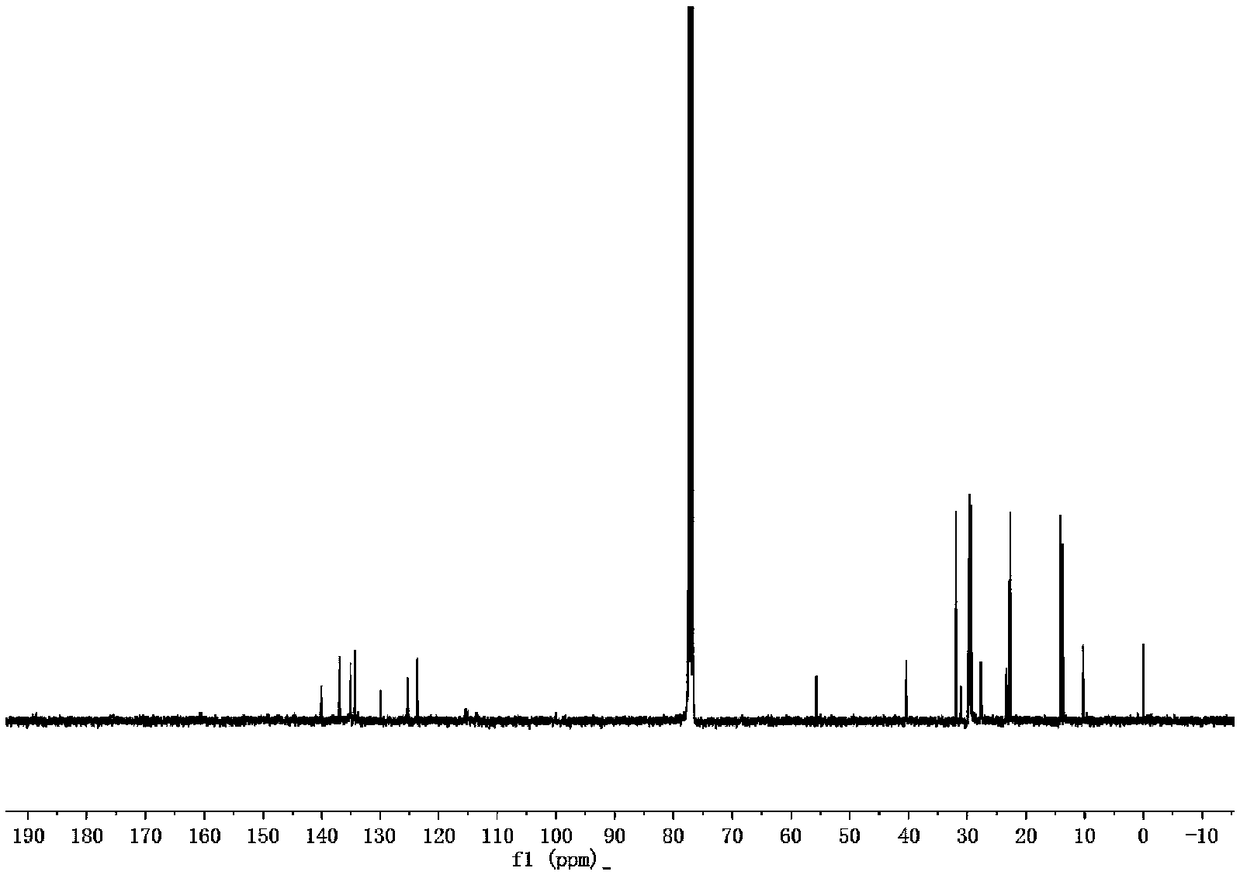

The invention discloses a polycyclic benzothiadiazole non-fullerene acceptor material, a preparation method thereof and an application of the material. The polycyclic benzothiadiazole non-fullerene acceptor material comprises a polycyclic benzothiadiazole center core and electrophilic end groups, the polycyclic benzothiadiazole center core is of a nitrogen bridge trapezoidal polycyclic structure,the electrophilic end groups are connected to two ends of the center core, 4, 7-dibromo-5, 6-binitro benzothiadiazole serves as a raw material in the preparation process, Stille coupling and Vilsmeier-Haack reaction are sequentially performed to obtain the polycyclic benzothiadiazole center core, and end-group structures are introduced by Knoevenagel reaction to obtain the polycyclic benzothiadiazole non-fullerene acceptor material. The acceptor material is good in solubility and easily processed into a film, has a good photoelectric conversion function and is used for preparing an organic solar battery device, and photoelectric conversion efficiency reaches nearly 16% of single battery conversion efficiency.

Owner:CENT SOUTH UNIV

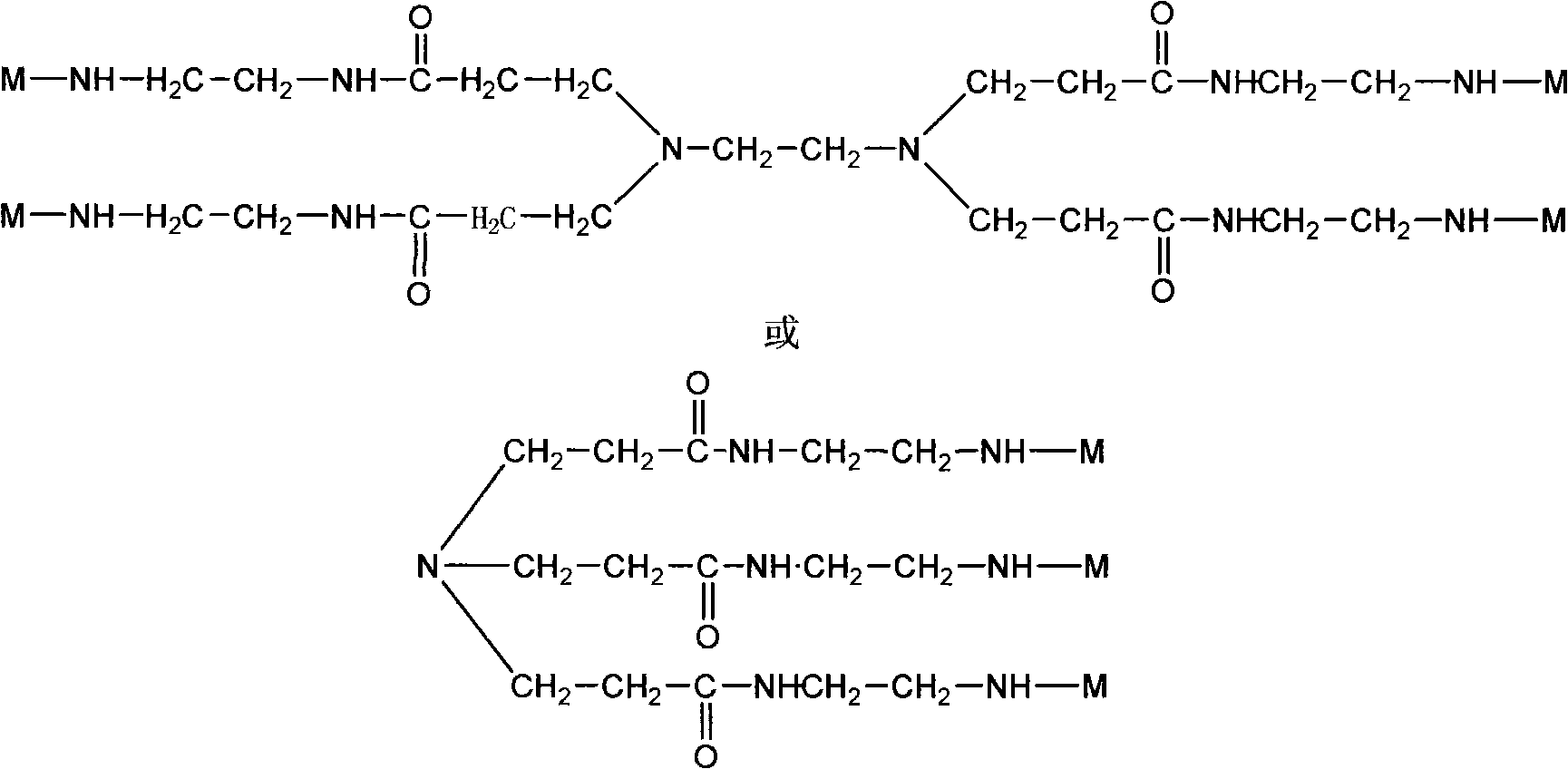

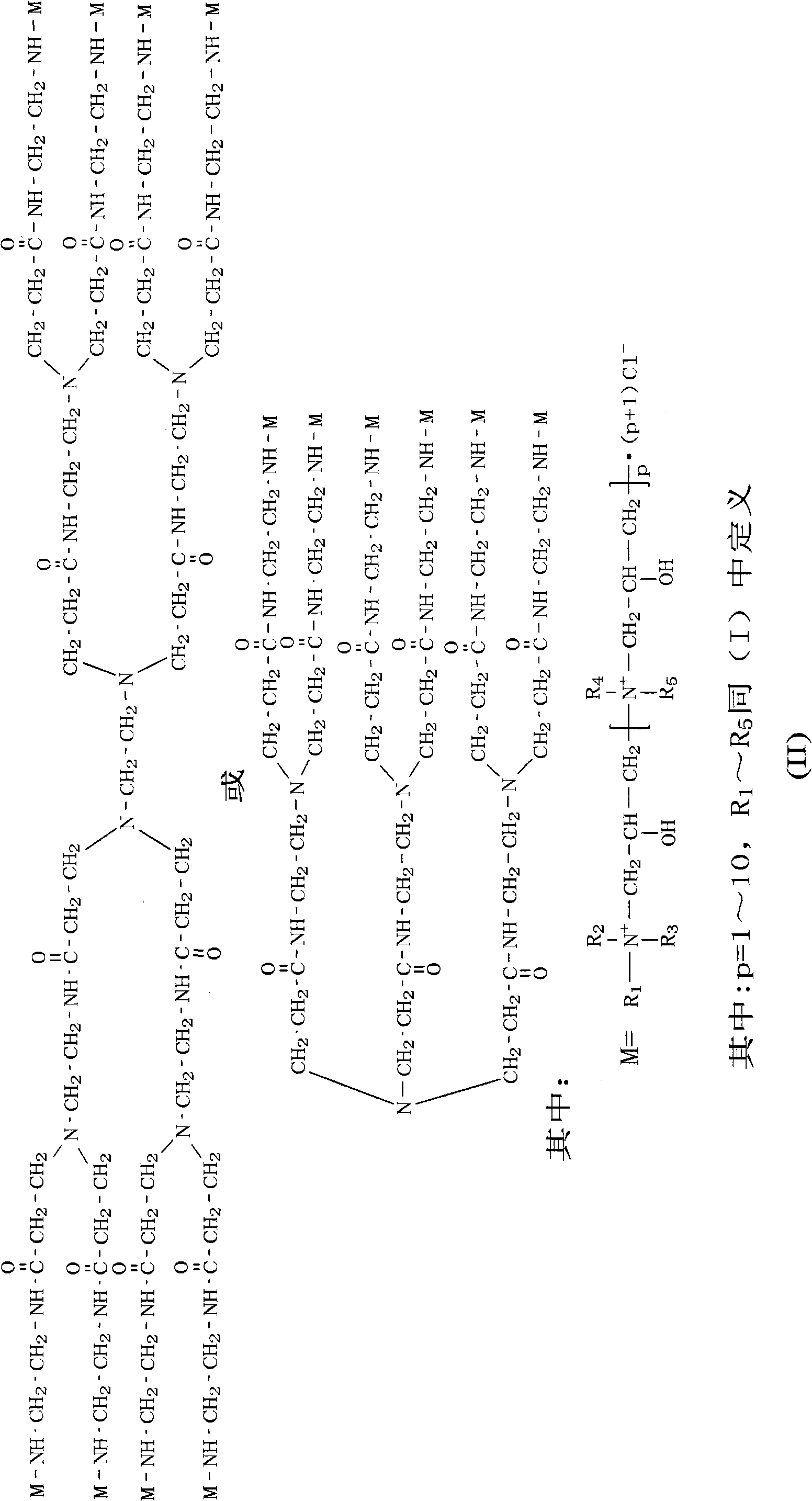

Method for preparing stellate poly quaternary ammonium salt high efficient reverse-phase emulsifier

ActiveCN101357992AAdequate supplySynthetic conditions are mildWater/sewage treatment by flocculation/precipitationNon-miscible liquid separationChemistrySewage

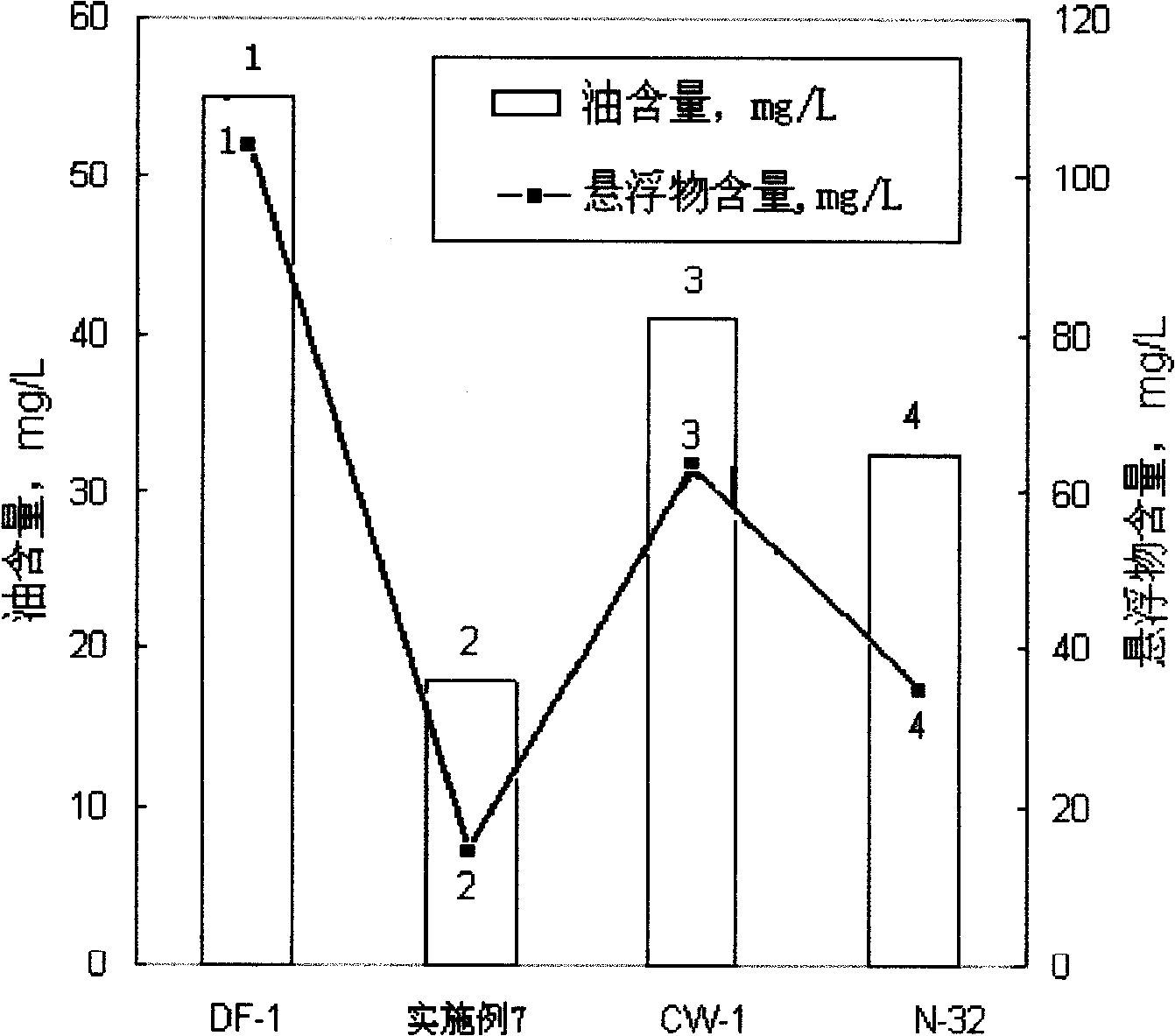

The invention provides a method for preparing a high efficiency antiphase demulsifying agent of astroid poly (quaternary ammonium salt), which belongs to the technical field of water curing. Firstly, linear poly (quaternary ammonium salt) is prepared with organic amines such as secondary amine and tertiary amine together with epichlorohydrin through ring-expansion polymerization; subsequently, PAMAM is used as a cross-linking agent, thus getting the antiphase demulsifying agent. The antiphase demulsifying agent is characterized in that the reaction conditions are gentle; raw materials are available; the product structure is unique; the antiphase demulsifying agent contains cationic organic polymer macromolecules, which has the properties of electric neutralization, substitution, absorption and bridging; such pollutants as oil and suspended matter in oil-contaminated water can be effectively removed by adding 5 to 30ppm of the antiphase demulsifying agent; such indices as oil content, colour shade, COD and so on in polluted water to be polluted are effectively reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

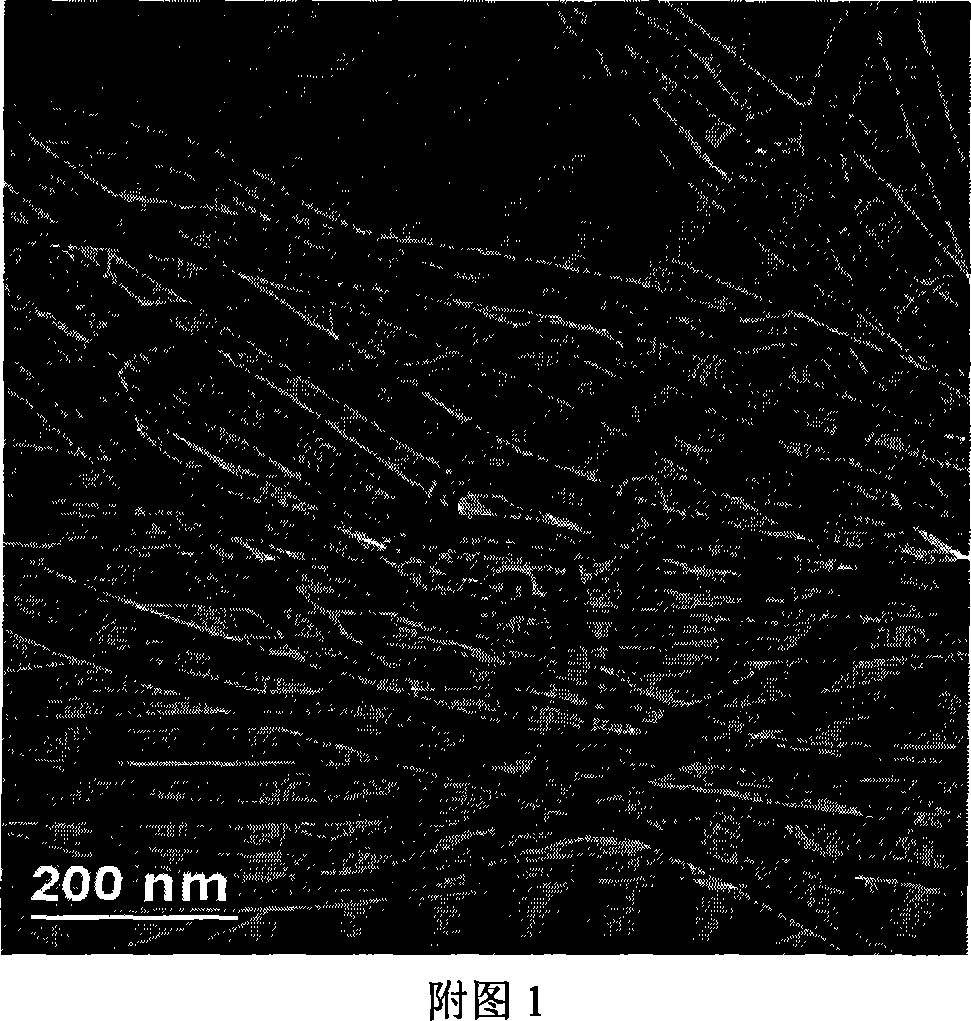

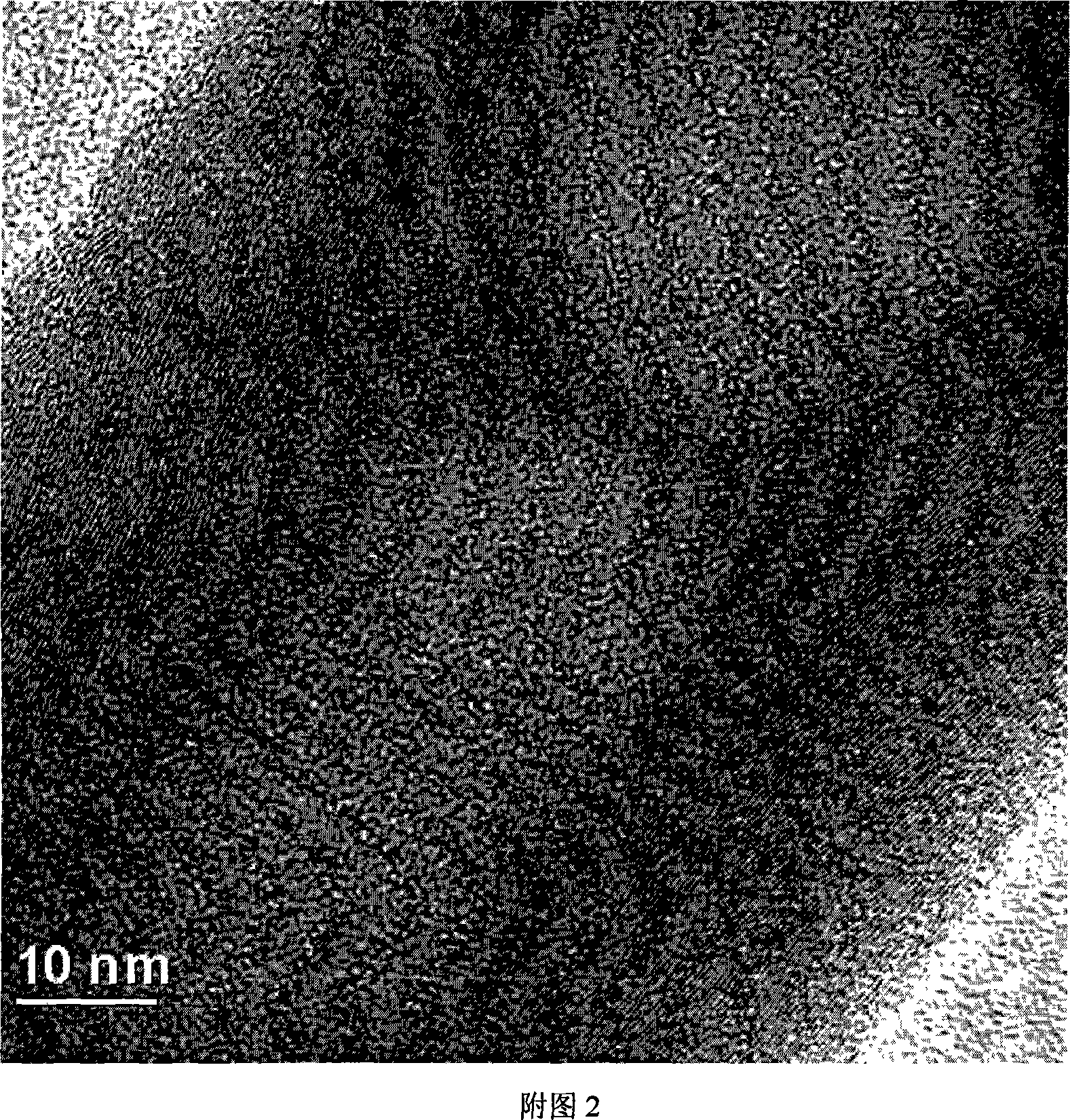

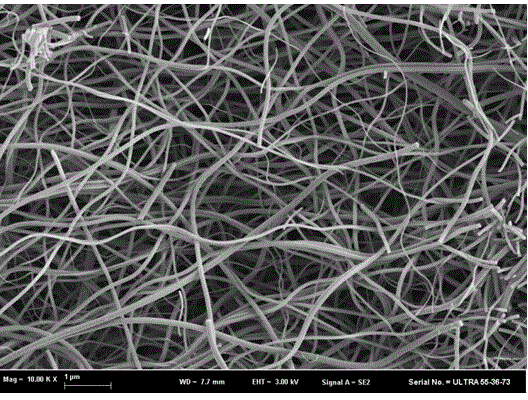

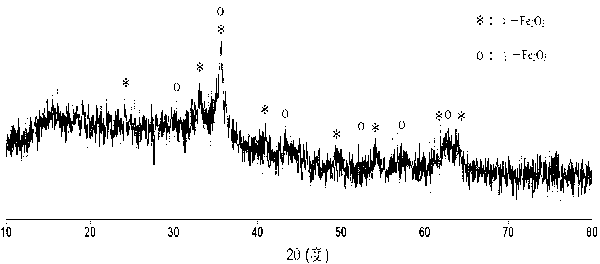

High nitrogen doped corrugated carbon nanotube material and its synthesis process

InactiveCN101066758AWide variety of sourcesSimple production processNanostructure manufactureMetal/metal-oxides/metal-hydroxide catalystsIron(II) oxideCarbon nanotube

The present invention relates to high nitrogen doped corrugated carbon nanotube material and its synthesis process. The synthesis process includes the following steps: mixing Fe source and proper amount of distilled water, soaking porous molecular sieve to carry ferric oxide or ferrous oxide, stoving and roasting at 300-1000 deg.c for 0.5-24 hr to obtain catalyst; setting the catalyst inside a pipe furnace, leading organic amine into the furnace under the protection of Ar or N2 and reacting at 650-1000 deg.c for 0.2-4.0 hr to obtain high nitrogen doped corrugated carbon nanotube mixture containing the catalyst; soaking the mixture in proper amount of or excessive hydrofluoric acid, sulfuric acid, nitric acid or acid for 0.5-24 hr; and washing in distilled water, suction filtering and drying to obtain high nitrogen doped corrugated carbon nanotube material. The material has nitrogen content of 10-40 %, reinforced surface polarity, etc, and is suitable for industrial production.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

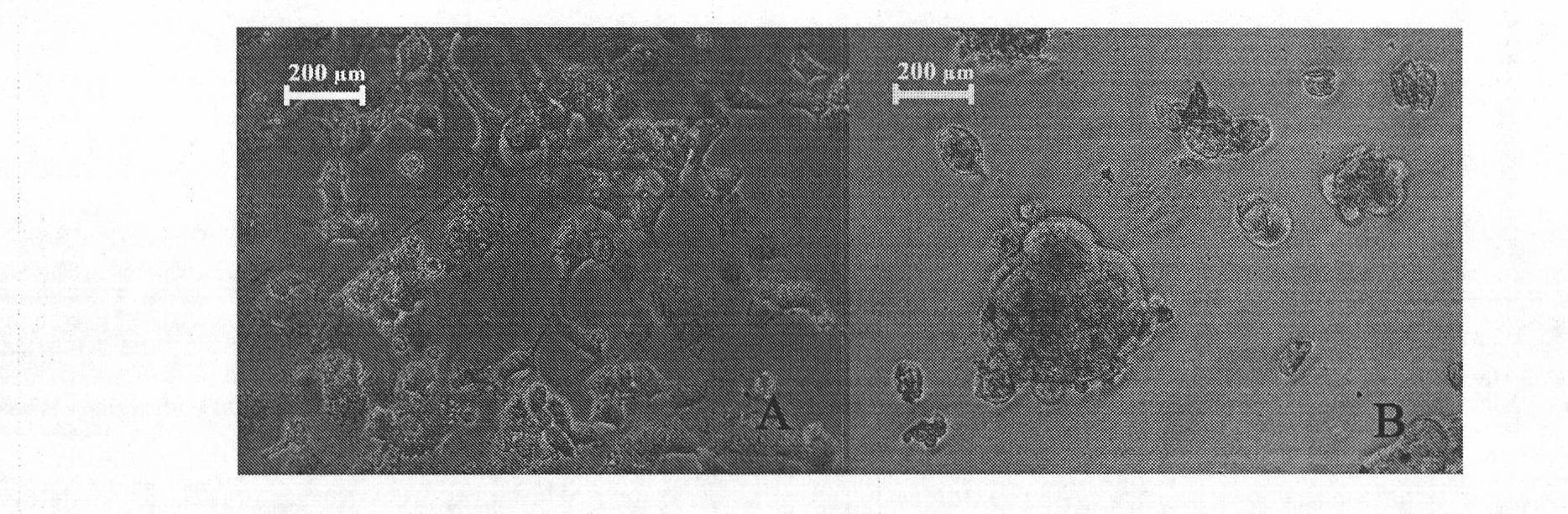

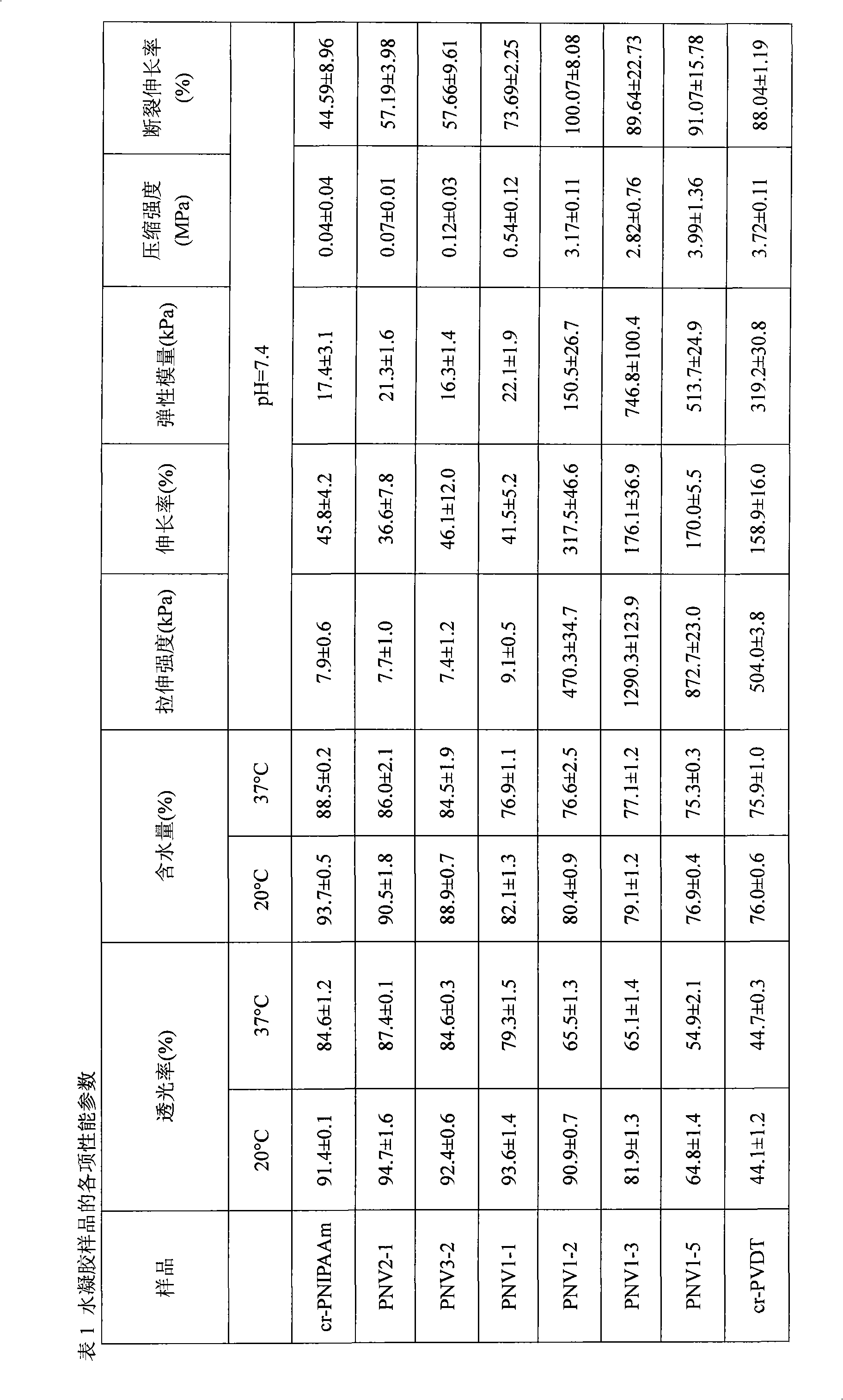

High-strength temperature-sensitive hydrogel as well as preparation method and application thereof

InactiveCN101824123AImprove mechanical propertiesAvoid damageVector-based foreign material introductionForeign genetic material cellsCross-linkBiocompatibility Testing

The invention relates to high-strength temperature-sensitive hydrogel as well as a preparation method and application thereof. The high-strength temperature-sensitive hydrogel is prepared by copolymerizing 2-vinyl-4,6-diamino-1,3,5-triazine and N-isopropyl acrylamide as raw materials in the presence of a cross-linking agent and an initiator, wherein the mass ratio of the 2-vinyl-4,6-diamino-1,3,5-triazine as a monomer to the N-isopropyl acrylamide is 0.2-2:1. The high-strength temperature-sensitive hydrogel has high stretching and compression resistance and favorable biocompatibility and optical property, and the surface of the hydrogel has the capacities of adsorbing DNA (Deoxyribonucleic Acid) transfection cells and regulating the attaching and disattaching behaviors of the cells through temperature. The preparation method of the hydrogel is simple, and the hydrogel is easy to store for a long term and transport for a long distance.

Owner:TIANJIN UNIV

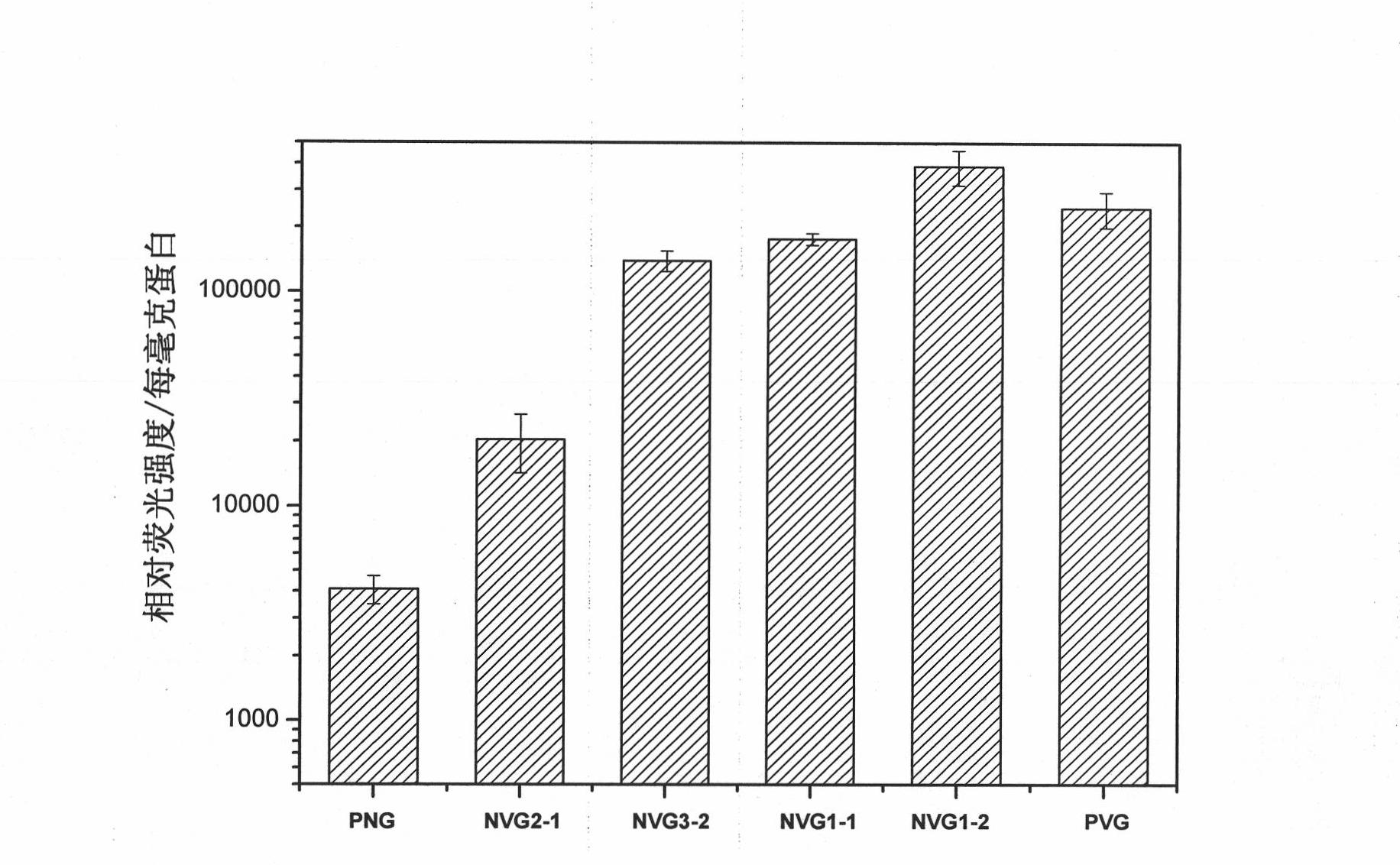

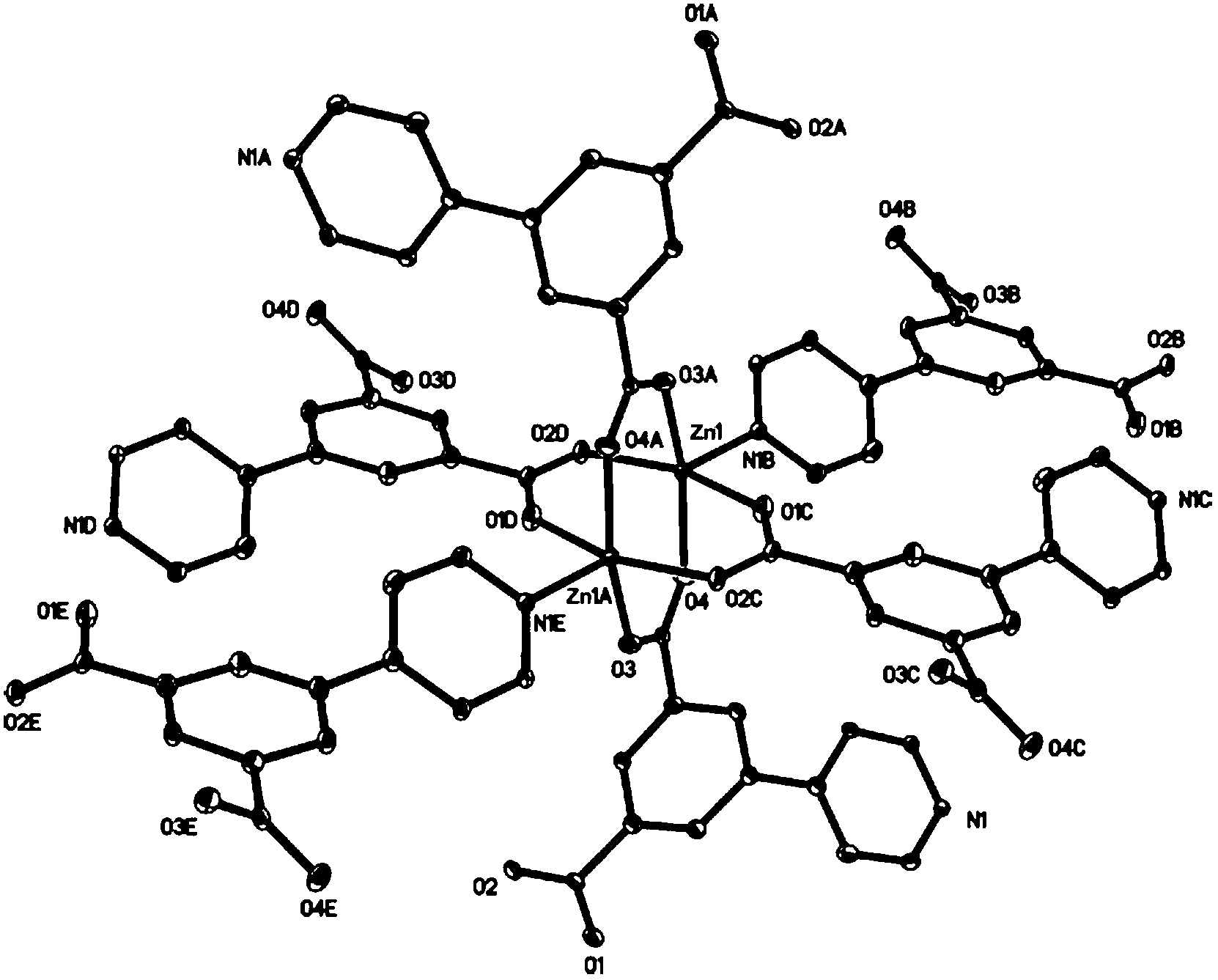

Luminous metal-organic framework material with chemical sensing function as well as preparation method and application thereof

InactiveCN103242352AHigh purityImprove stabilityChemiluminescene/bioluminescenceFluorescence/phosphorescenceOrganic solventMetal-organic framework

The invention relates to a luminous metal-organic framework material with a chemical sensing function, a preparation method of the luminous metal-organic framework material, and an application of the material in detection of nitrobenzene organic matters. The preparation method comprises the following steps of: dissolving 5-(4-pyridyl)-1, 3-phthalic acid and zinc salt into an organic solvent in a certain proportion; and then synthesizing in a solvothermal way so as to obtain the luminous metal-organic framework material. The preparation method is simple in preparation process, high in material purity and excellent in stability. The synthesized metal organic framework material has the maximum emission wavelength of 381nm in water, and the fluorescence intensity of the synthesized metal organic framework material is gradually reduced as the unceasing increase of the concentration of the nitrobenzene organic matters, therefore, the material can be well applied to the detection of the nitrobenzene organic matters, and has the advantages of being fast in speed, simple, convenient, great in selectivity, high in sensitivity, etc.

Owner:LIAOCHENG UNIV

Preparation method of nonionic waterborne epoxy curing agent

The invention provides a preparation method of a nonionic waterborne epoxy curing agent, which comprises the following steps: (1) heating and dissolving epoxy resin and polyether polyol, evenly mixing, dropwisely adding catalyst at 50-130 DEG C to carry out polymerization reaction, and after the reaction finishes, dissolving the product in the epoxy resin and solvent to prepare a mixed solution; (2) while stirring, dropwisely adding a monoepoxy compound into basic amine, and reacting at 10-100 DEG C; (3) dropwisely adding the mixed solution in the step (1) into the reaction product in the step (2) at 30-120 DEG C, and enabling the reaction at 10-90 DEG C; and after the reaction finishes, diluting by adding water until the solid content reaches 30-80%, thereby obtaining the nonionic waterborne epoxy curing agent. The method has the advantages of simple technique and mild reaction conditions; the adopted cosolvent has the advantages of low toxicity or no toxicity, and low VOC (volatile organic compound) content; and the substance cured by the product has the advantages of favorable compatibility with epoxy resin and high toughness of the paint film.

Owner:CHINA PETROCHEMICAL CORP

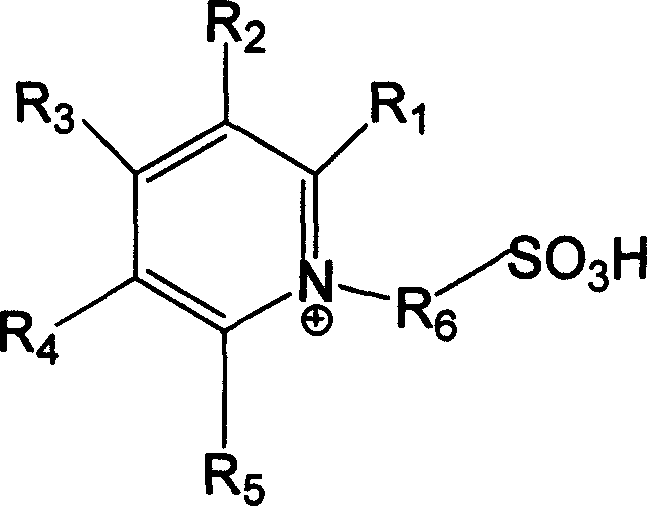

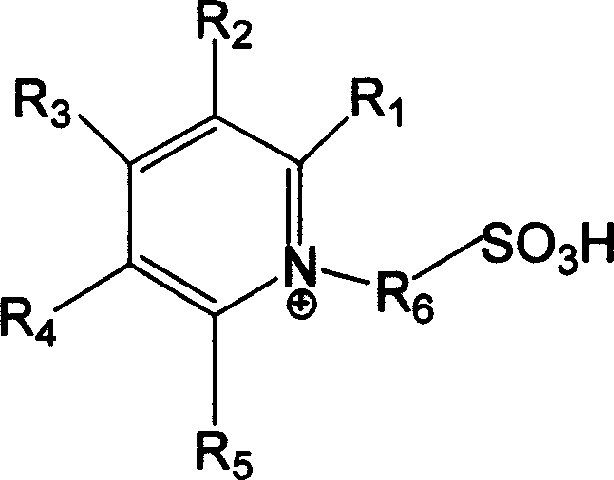

Pyridine sulfonic acid salt ion liquid and its preparing process and application

InactiveCN1594280ALow viscositySynthetic conditions are mildOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolventIon

The invention provides a pyridine sulfonic acid salt ion liquid and its preparing process use thereof, wherein the preparation comprises the steps of, mixing pyridinesulfonic acid inner salt with equal mol ratio of acids or their solution, heating with stirring simultaneously, reacting 1-24 hrs, and distilling distillation.

Owner:TSINGHUA UNIV

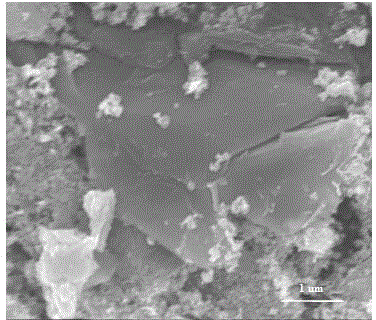

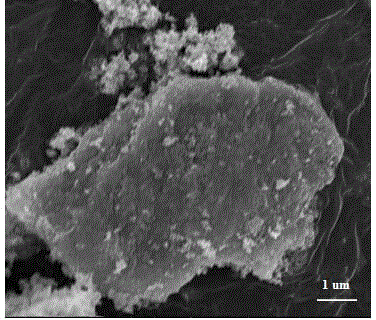

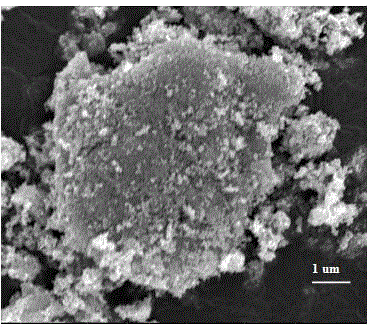

Preparation method for nano-zinc oxide modified graphene hybrid material

ActiveCN104098088ASimple processSynthetic conditions are mildMaterial nanotechnologyZinc oxides/hydroxidesZinc hydroxideVulcanization

The invention discloses a preparation method for a nano-zinc oxide modified graphene hybrid material. The method includes: preparing a graphene oxide suspension solution; dissolving a zinc salt in water, adding the solution into the graphene oxide suspension solution, conducting ultrasonic treatment, adding an alkali reagent dropwise to obtain a zinc hydroxide graphene oxide suspension solution; under ultraviolet light irradiation, performing static aging to obtain a zinc hydroxide-graphene oxide gel, adding an excessive reducing agent, carrying out reaction, using water and ethanol to conduct repeated washing, and performing drying to obtain a zinc hydroxide-graphene dry gel; placing the gel in a muffle furnace, and conducting treatment at high temperature to obtain the gray nano-zinc oxide modified graphene hybrid material. The nano-zinc oxide obtained by the invention has a large specific surface area, can effectively promote vulcanization crosslinking, greatly reduces the using amount of zinc oxide, and is of great importance to full utilization of zinc resources and ecological economy. At the same time, without affecting the performance of graphene, the method is in favor of further expanding the potential application scope of graphene.

Owner:SOUTH CHINA UNIV OF TECH

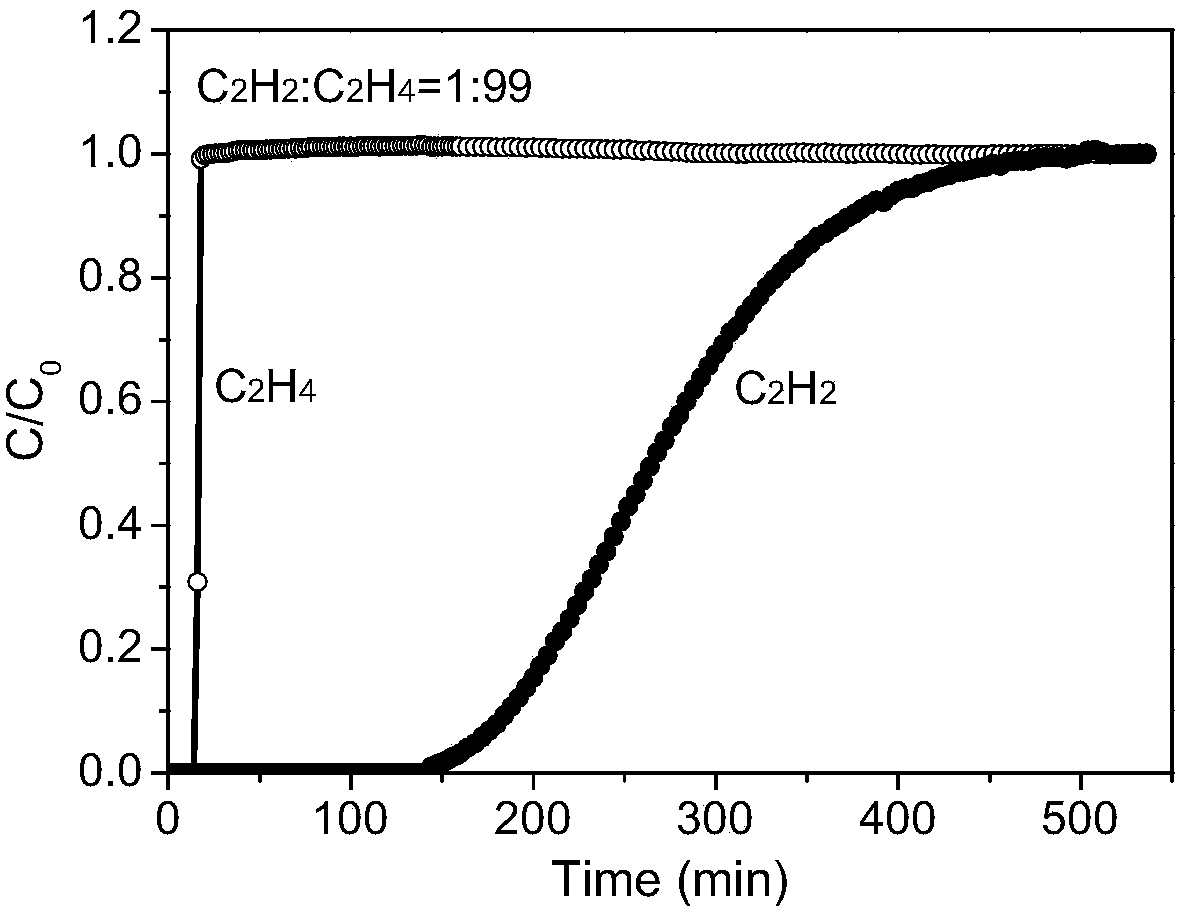

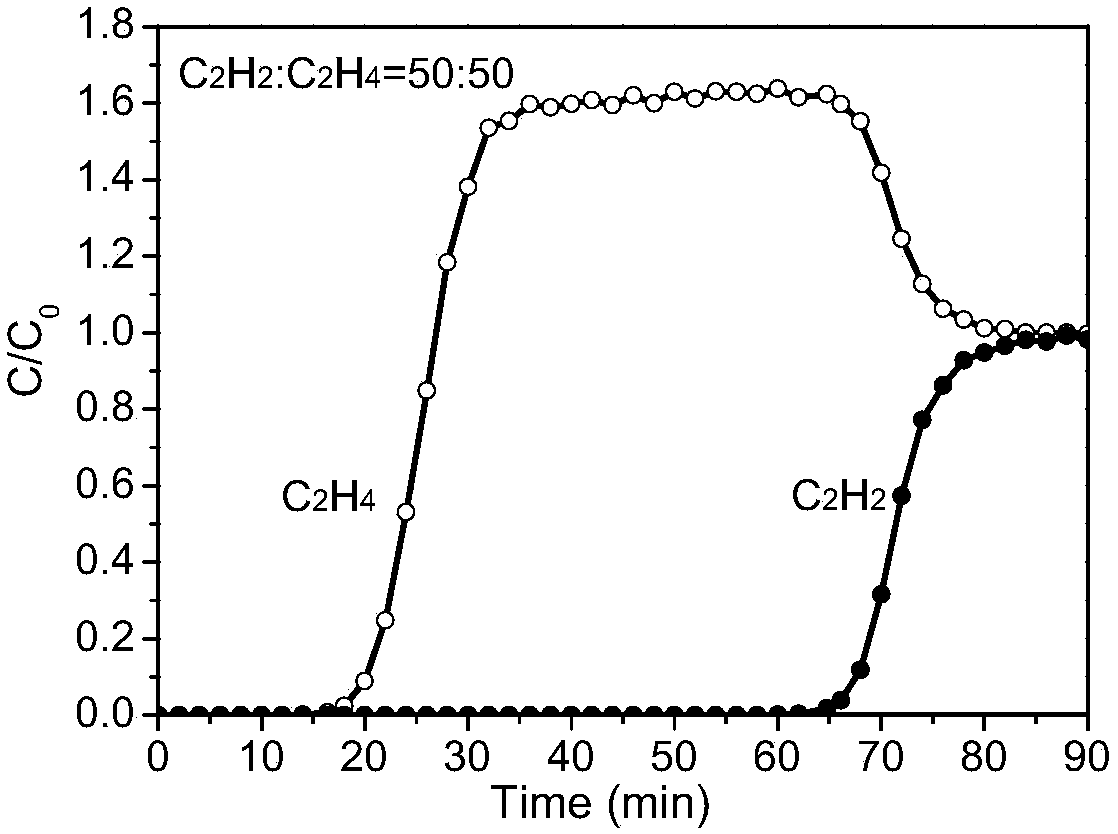

Method for separating ethylene and acetylene from mixed gas

ActiveCN108014751AEasy synthesis costLower synthesis costOther chemical processesAdsorption purification/separationAlkaline earth metalGallic acid ester

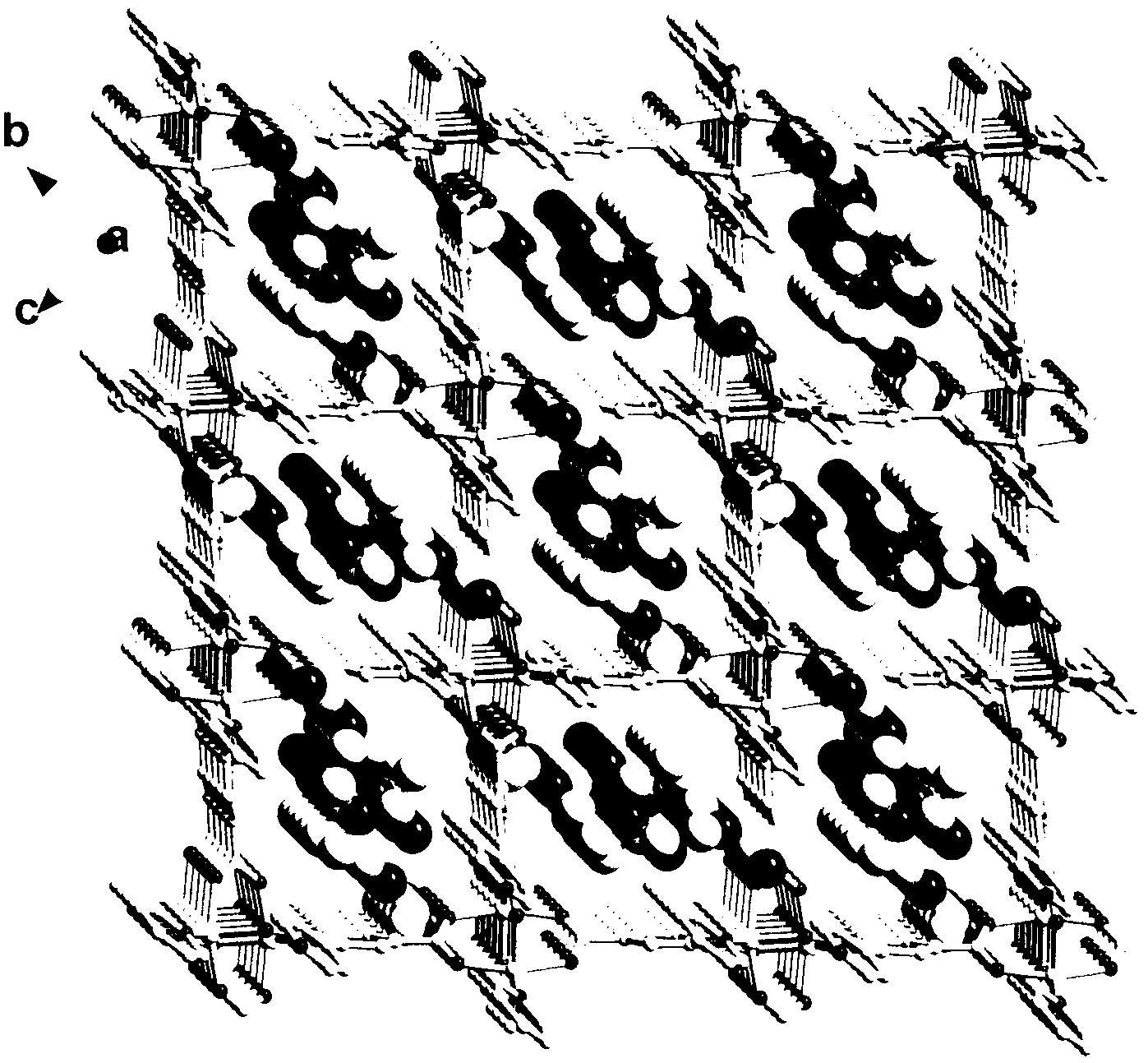

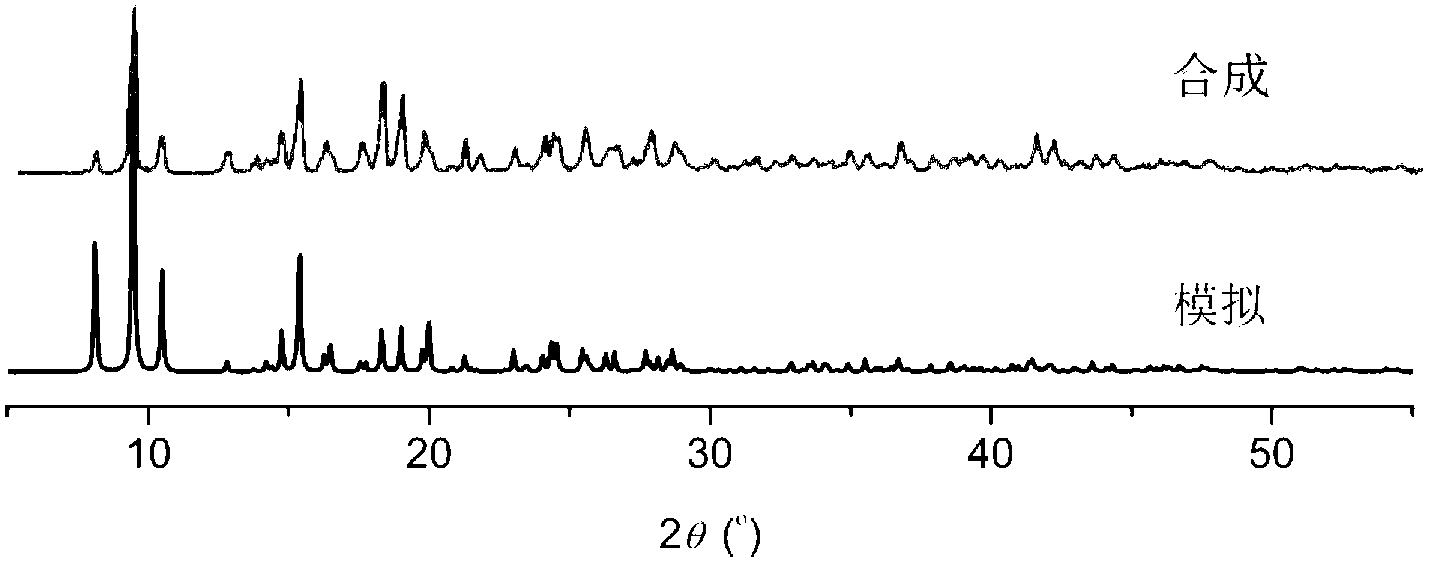

The invention discloses a method for separating ethylene and acetylene from a mixed gas. The method comprises the step of using a metal organic frame material as an adsorbent for separating the ethylene and the acetylene from the mixed gas containing the ethylene and the acetylene; the metal organic frame material has a structural formula of M(C7O5H4).2H2O, wherein M is a metal ion, and the metalorganic frame material is a three-dimensional network structure formed by coordination bonds or intermolecular forces from a transition metal ion or alkaline earth metal ion and gallic acid. The metalorganic frame material has a large adsorption capacity for the acetylene and an excellent selectivity for adsorption and separation of ethylene / acetylene. The materials for the synthesis of the material is cheap and easy to obtain, the material preparation process is simple, and the cost is low; and the material has good regeneration and repetition performance, can still maintain the original adsorption effect after vacuum or heating regeneration, and has broad industrial application prospects.

Owner:ZHEJIANG UNIV

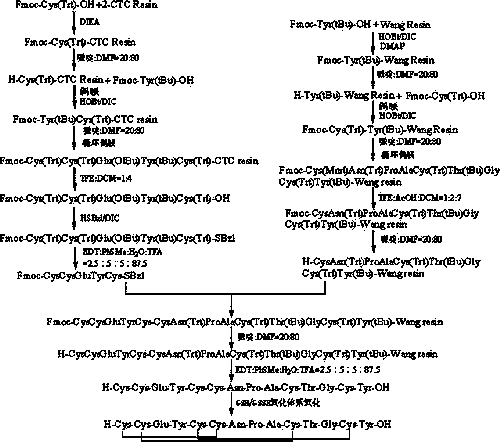

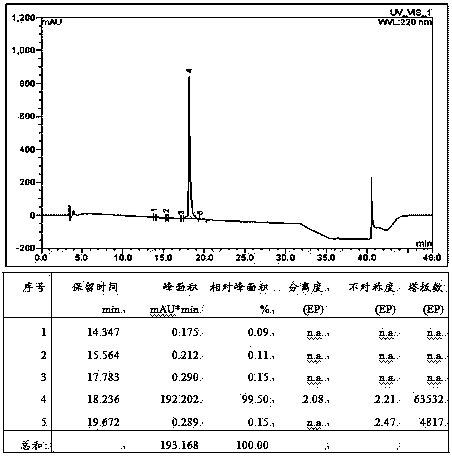

Method for preparing linaclotide

InactiveCN104163853AHigh purityHigh yieldPeptide preparation methodsBulk chemical productionCrystallographyWang resin

The invention relates to a method for preparing linaclotide. The method comprises the following steps of A, synthesizing a pentapeptide fragment I of Fmoc-CysCysGluTyrCys-SBzl by a solid-liquid phase method, B, a nonapeptide fragment resin II of H-CysAsn(Trt)ProAlaCys(Trt)Thr(tBu)GlyCys(Trt)Tyr(tBu)-Wang resin by the solid-liquid phase method, C, adding the pentapeptide fragment I into the nonapeptide fragment resin II, carrying out thioester exchange and S-to-N acyl transfer to obtain a novel tetrakaideca-peptide fragment resin, removing a Fmoc protective group, and carrying out pyrolysis to obtain high-purity linaclotide linear peptide, and D, carrying out oxidation by a GSH / GSSH oxidation system to obtain linaclotide. Through thioester exchange and S-to-N acyl transfer, the method for preparing linaclotide is realized and has the advantages of mild synthesis conditions, high product purity, high yield and large-scale production feasibility.

Owner:ADLAI NORTYE BIOPHARMA CO LTD

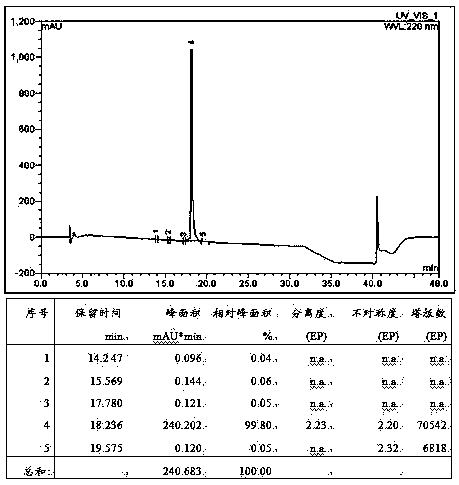

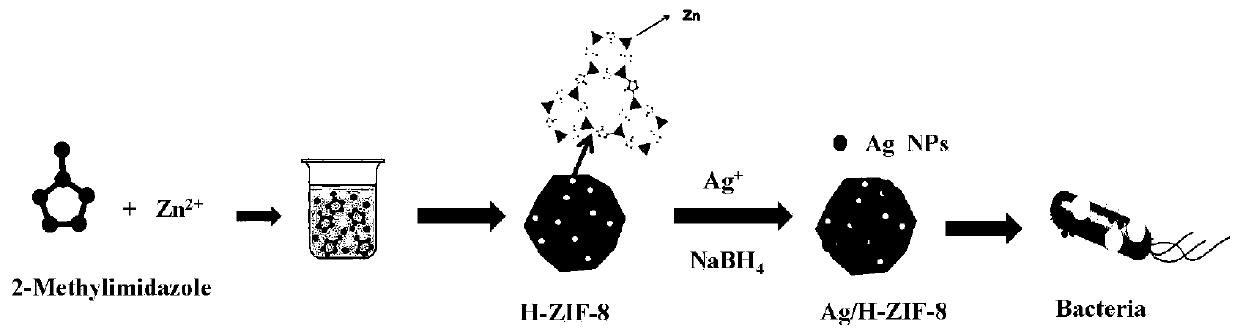

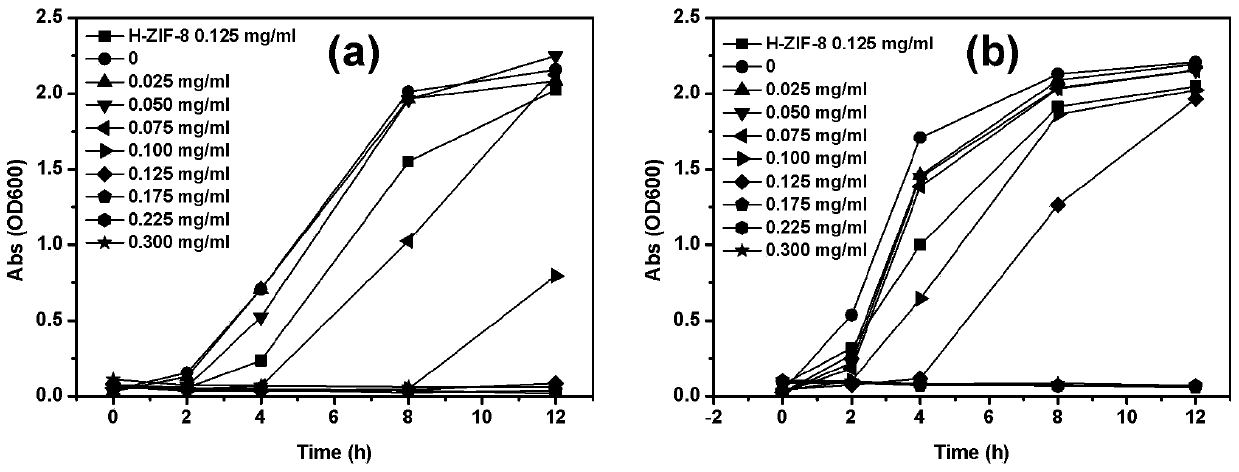

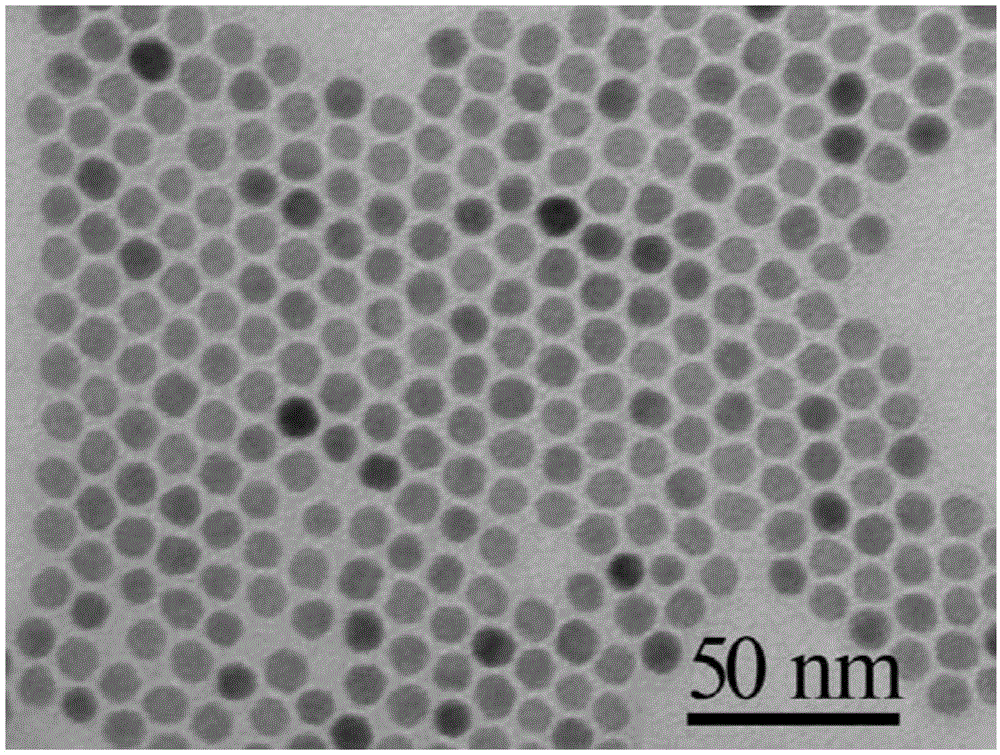

Ag/ZIF-8 anti-bacterial agent and preparation method thereof

InactiveCN109758474AImprove stabilityFacilitated DiffusionAntibacterial agentsPowder deliveryNanoparticleAnti bacterial

The invention relates to an Ag / ZIF-8 antibacterial agent and a preparation method thereof, and belongs to the technical field of nano materials. The invention provides the Ag / ZIF-8 composite anti-bacterial agent and the preparation method. The Ag / ZIF-8 composite anti-bacterial agent is prepared by dispersing Ag nanoparticles onto ZIF-8 by impregnation and reduction. The used ZIF-8 material has a multi-stage pore structure and a large specific surface area, and has good stabilization and dispersion effects on Ag nanoparticles. According to the Ag / ZIF-8 anti-bacterial agent, the provided Ag / ZIF-8 nano anti-bacterial agent has small particles and a spherical or polyhedral structure with the particle diameter of 10-200nm, thereby being beneficial to increasing the adhesion of the Ag / ZIF-8 anti-bacterial agent to bacteria; the Ag nanoparticles and the ZIF-8 have a synergetic anti-bacterial effect, multiple indicating bacteria present efficient and board spectrum anti-bacterial effects; thepreparation method is simple in process, economical and feasible.

Owner:DALIAN NATIONALITIES UNIVERSITY

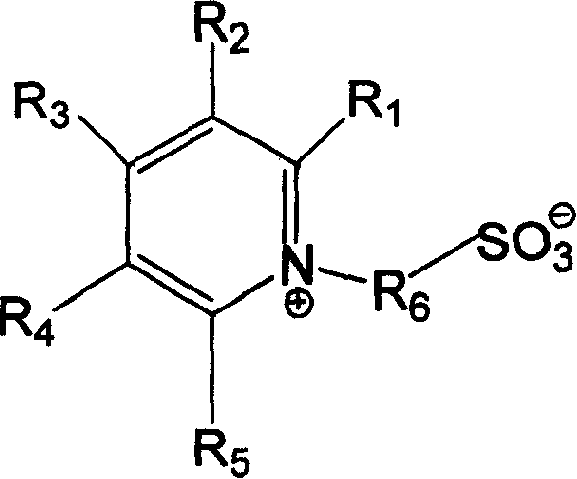

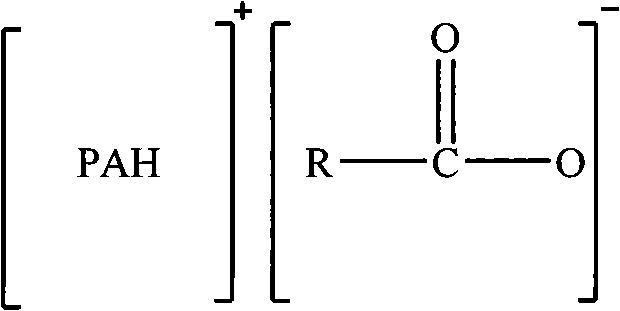

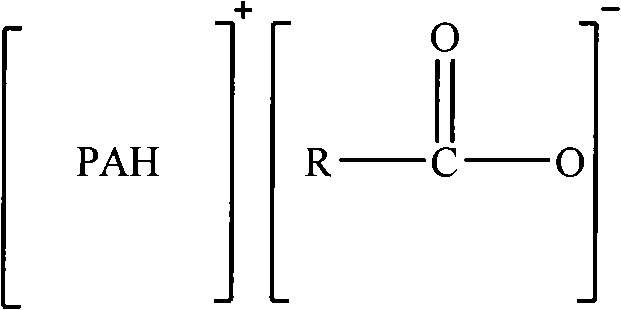

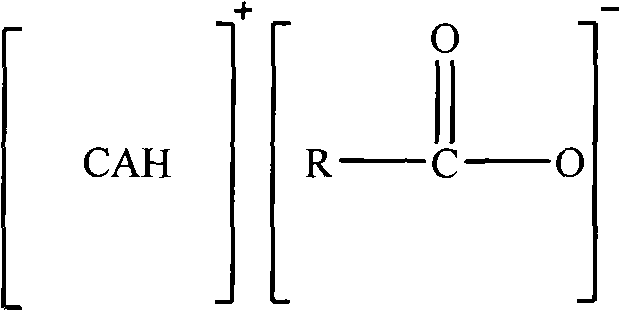

Recyclable sulfur dioxide gas absorbent and preparation method thereof

InactiveCN101537300ASynthetic conditions are mildShorten the timeDispersed particle separationDesorptionCarboxylic acid

The invention provides a recyclable sulfur dioxide gas absorbent and a preparation method thereof, wherein the absorbent is an ion liquid with a cation belonging to a multi-nitrogen straight chain amine, which is shown by a chemical formula at the right side, wherein PA is a multi-nitrogen straight chain amine matter and R is H or C1-C2 alkyl. The preparation method of the absorbent is characterized in that t the multi-nitrogen straight chain amine matter and the short chain carboxylate as raw materials and the reaction is carried out in a solvent or carried out directly without a solvent. The absorption amount of the SO2 is increased with the increment of the amount of the functional nitrogen; furthermore, the absorbent can be circularly used repeatedly by desorption, can achieve balanced absorption and desorption quickly, and desorption rate within 1 hour is more than 95% and the absorbent can be used for acidic gasses such as SO2, and the like.

Owner:HEFEI UNIV OF TECH

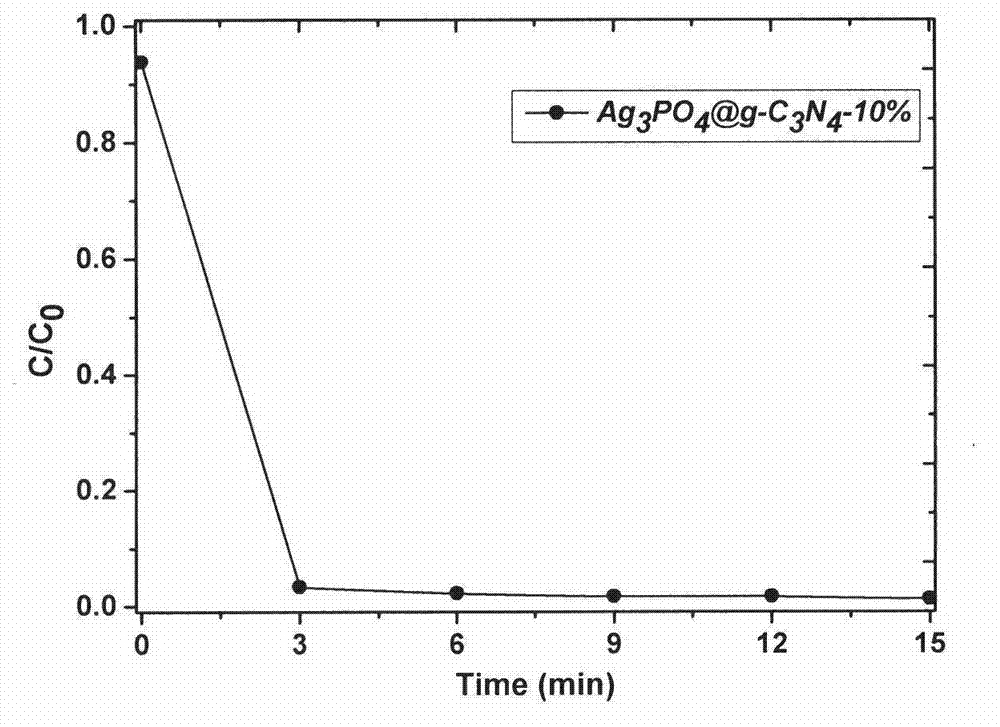

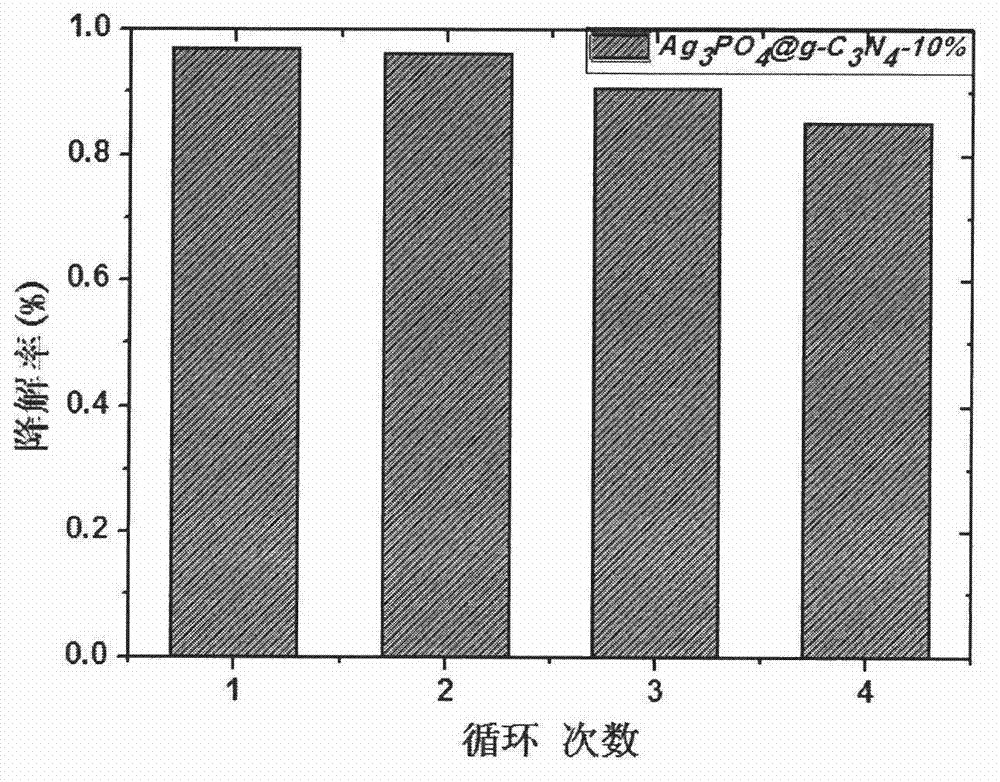

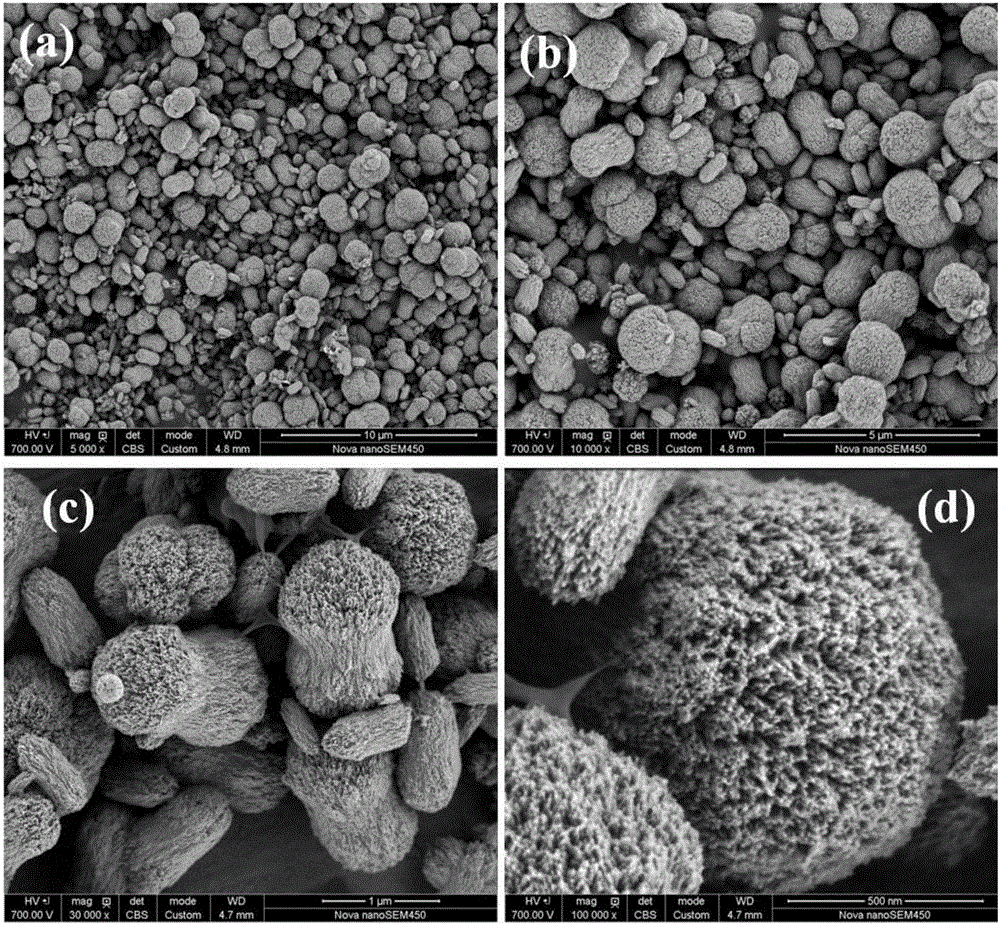

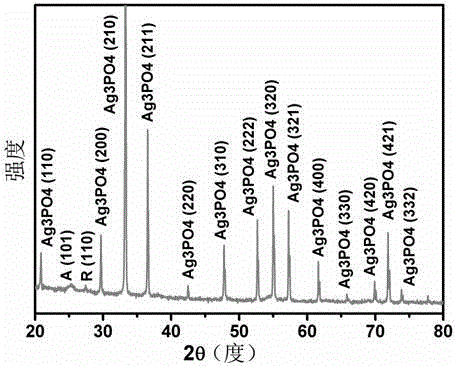

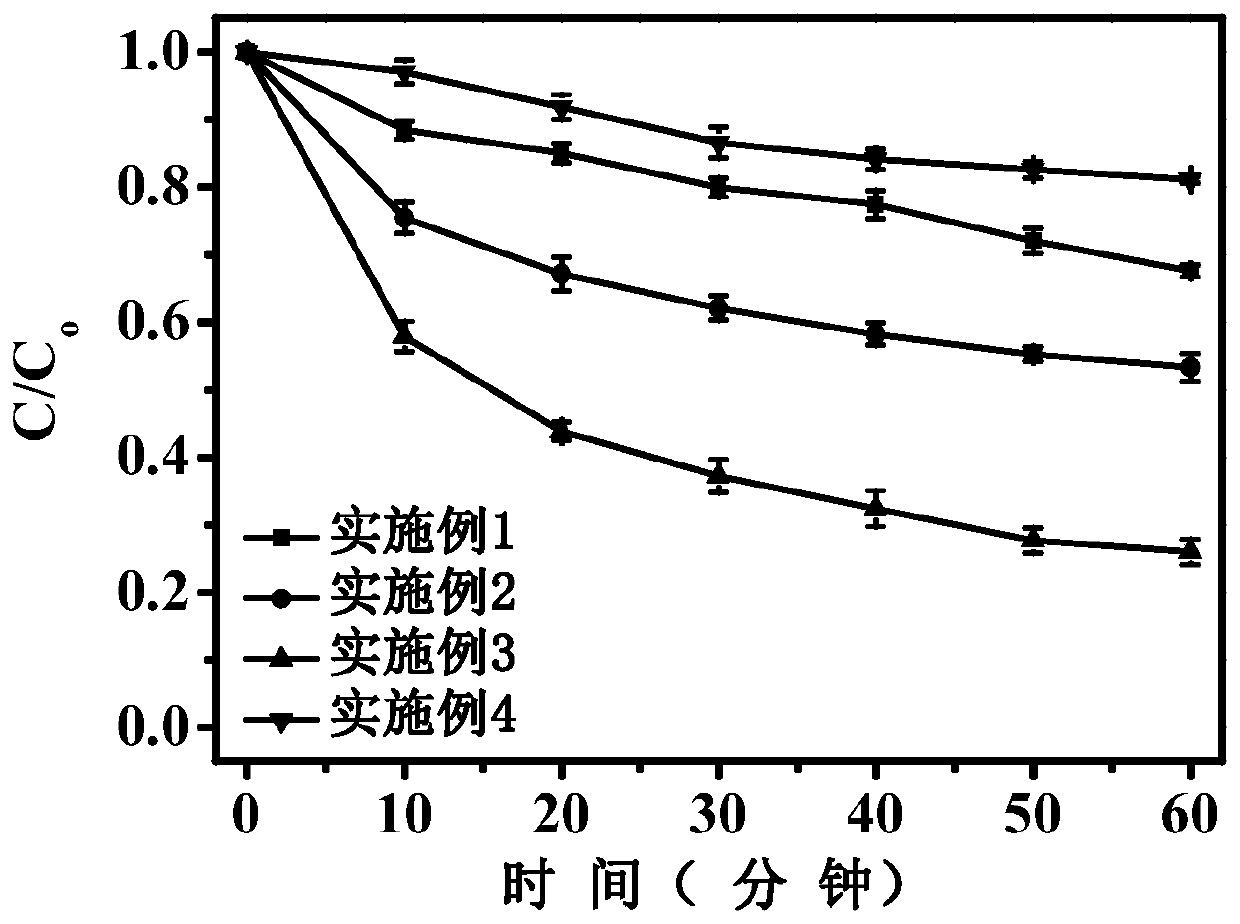

Method for preparing composite visual light catalytic material Ag3PO4 and g-C3N4

InactiveCN103028428ASimple manufacturing methodSynthetic conditions are mildPhysical/chemical process catalystsWater/sewage treatment by irradiationPhosphate ionSodium phosphates

The invention discloses a method for preparing a novel efficient composite visual light catalytic material Ag3PO4@g-C3N4. First, g-C3N4 in a flaky structure is processed in a silver salt solution under ultrasonic action so as to load silver ions on the surface of g-C3N4. Then, a sodium phosphate solution is dropped in and continuously agitated, and the composite material Ag3PO4@g-C3N4 is formed through the in-situ precipitation reaction of the silver ions loaded on the surface of the g-C3N4 and phosphate radical ions. The method has the advantages of simple and easily-controlled preparing process, convenience in operation, low cost and high product visual light catalytic activity.

Owner:EAST CHINA UNIV OF SCI & TECH

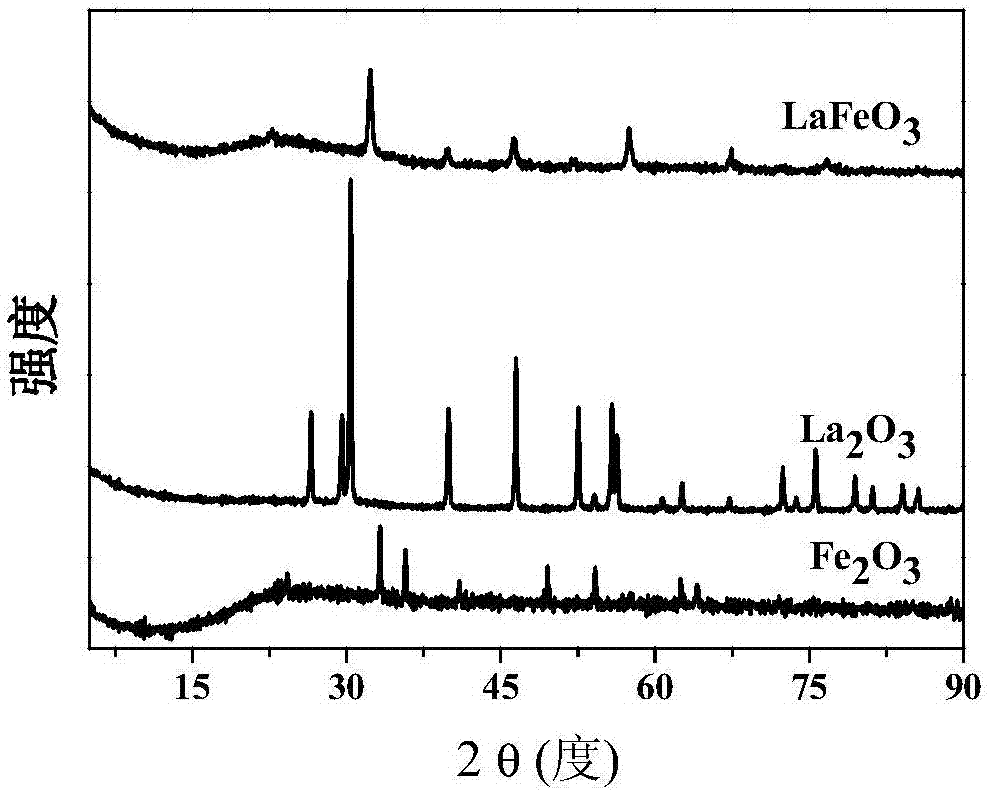

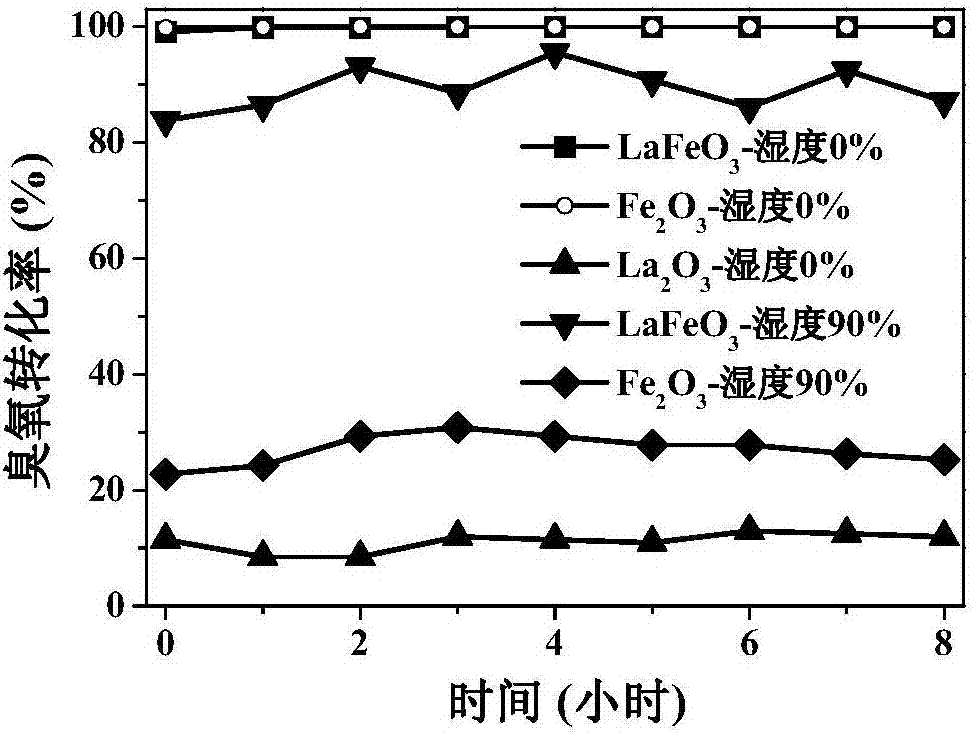

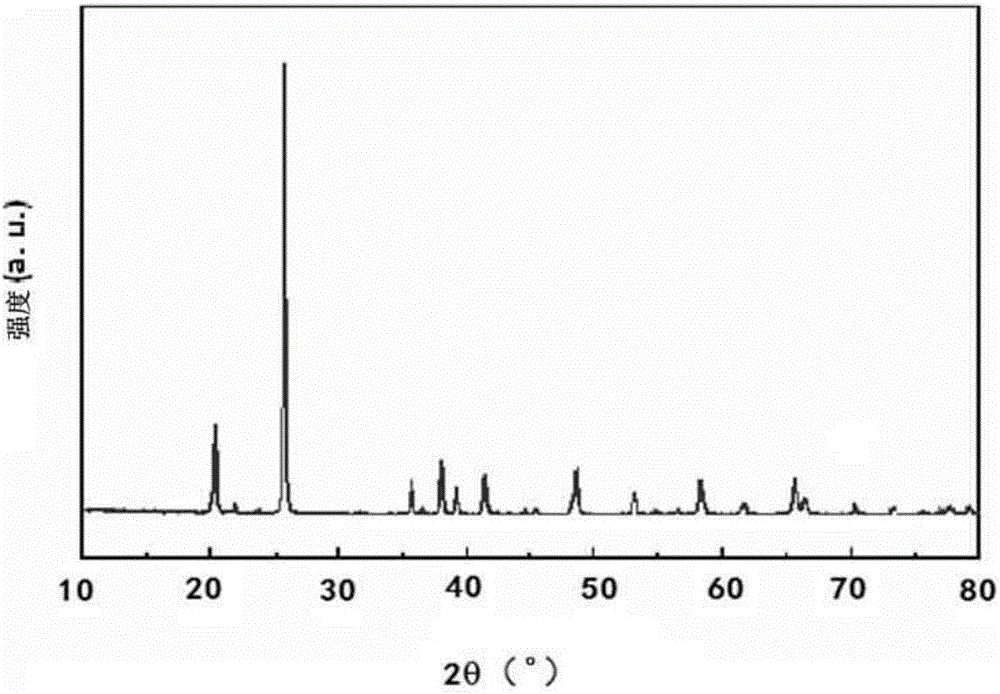

Perovskite ozone decomposition catalyst and preparation method and application thereof

ActiveCN107376926AImprove decomposition efficiencyExcellent catalytic decomposition activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic decompositionStructural formula

The invention relates to a perovskite ozone decomposition catalyst. The active component of the catalyst is pure-phase or transition metal-doped perovskite lanthanum ferrite, wherein the structural formula of the active component of the catalyst is LaMxFe(1-x)O3, wherein M is a transition metal and x is smaller than or equal to 0.2 and greater than or equal to 0. Ferric nitrate, lanthanum nitrate, nitrate of optional transition metal and citric acid ae taken as raw materials, the perovskite ozone decomposition catalyst is synthesized by adopting sol-gel auto-combustion method, and a catalyst with a perovskite crystal phase is obtained through grinding, burning and loading; and the grain size of the obtained catalyst is 10-100nm and the specific surface area is 5-50m<2> / g. The catalyst has excellent catalytic performance on ozone at a room temperature, especially has good humidity resistance, can be applied to catalytic decomposition of the ozone in a high-humidity environment, is simple in preparation technology and mild in condition, and has a good application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

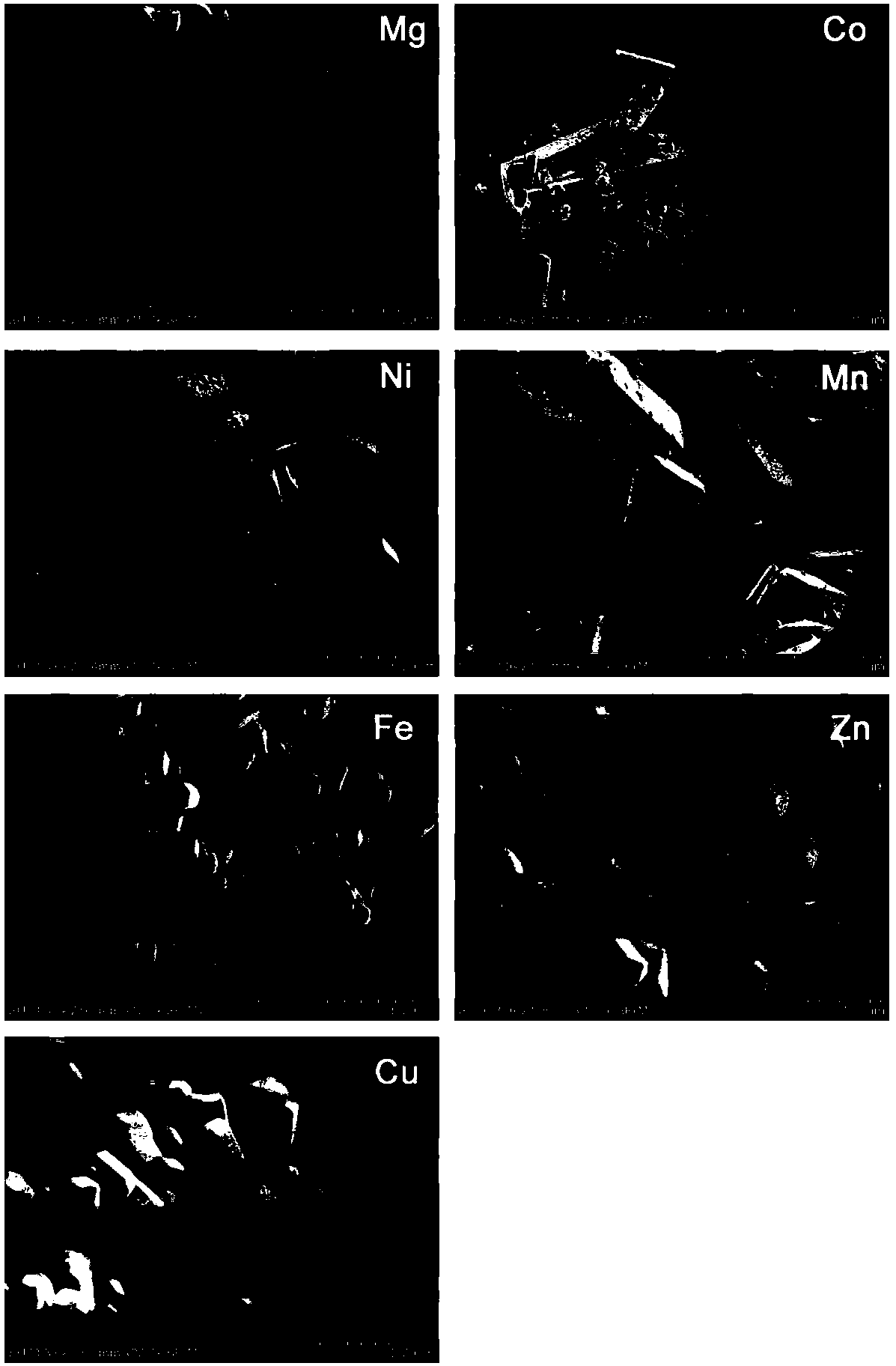

Lithium-rich manganese-based cathode material precursor, cathode material and preparation method thereof

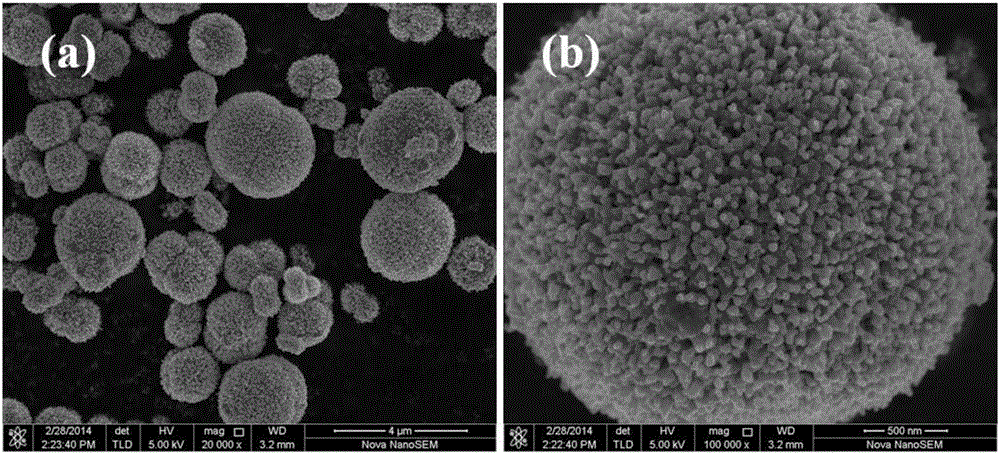

ActiveCN106564967AAccelerates and intensifies the mass transfer processWell mixedMaterial nanotechnologyCell electrodesNickel saltManganese

The invention belongs to the field of electrode material preparation and relates to a lithium-rich manganese-based cathode material precursor, a cathode material and a preparation method thereof. The preparation method comprises the following steps: mixing metal salts (manganese salt, cobalt salt and nickel salt) and a surfactant and water, and dissolving to obtain a metal salt solution; putting a precipitant in water, stirring and dissolving to obtain a precipitant solution; carrying out liquid-liquid coprecipitation reaction on the metal salt solution and the precipitant solution in a hypergravity field reactor, filtering, cleaning, and carrying out vacuum drying so as to obtain a precursor; mixing the precursor and lithium salt and then calcining so as to obtain the lithium-rich manganese-based cathode material. By the coprecipitation method based on the hypergravity technology, the lithium-rich manganese-based cathode material precursor with primary particle being below 100 nm and secondary particle being 1-10 microns is rapidly prepared, and furthermore the prepared cathode material has advantages of uniform component distribution and particle size distribution, small granularity and high activity. Initial irreversible capacity can be reduced, and cycle performance of a lithium ion secondary battery can be enhanced.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Polystyrene/calcium alginate composite gel microsphere in nuclear shell structure and preparation method thereof

InactiveCN101857698AAchieve adsorptionSynthetic conditions are mildPharmaceutical non-active ingredientsOn/in organic carrierUltrasonic emulsificationFiltration

The invention provides a polystyrene / calcium alginate composite gel microsphere in a nuclear shell structure and a preparation method thereof, relating to biopolymer materials. The polystyrene / calcium alginate composite gel microsphere in the nuclear shell structure takes a polystyrene microsphere as a core and calcium alginate gel as a shell, wherein the grain size of the core is 1-100 microns, and the thickness of the shell layer is 50-800 nm. The preparation method comprises the following steps of: mixing polystyrene microsphere with aqueous solution containing a surface active agent I, and carrying out ultrasonic emulsification to obtain mixed solution A; adding sodium alga acid solution in the mixed solution A, and stirring to obtain mixed solution B; adding organic solution containing a surface active agent II into the mixed solution B, and stirring to obtain mixed solution C; adding calcium chloride solution which has the same volume with the sodium alga acid solution into the mixed solution C under stirring to react, and carrying out vacuum filtration, washing the solution until no calcium ion residue exists on the surface and drying to obtain a product D; and dispersing the product D into water, centrifuging the mixture, pouring out supernate and taking out precipitate to obtain the product.

Owner:XIAMEN UNIV

Preparation method of high-purity lithium tetrafluoroborate

The invention provides a preparation method of high-purity lithium tetrafluoroborate; and the method comprises the following steps that high-purity lithium fluoride and a boron trifluoride coordination compound react in chain carbonate organic solvent, and lithium tetrafluoroborate is obtained after filtration, concentration, extractive crystallization, washing and drying. In the preparation method of high-purity lithium tetrafluoroborate, the boron trifluoride coordination compound has wide sources of raw materials and is low in price, the linear carbonate organic solvent has low toxin and is environment-friendly, the synthetic reaction conditions are mild, the operation is simple, the equipment investment is low, the lithium tetrafluoroborate productivity is high, the yield is high, the energy consumption is low, the post-treatment is simple, and the method is applicable to large-scale production.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

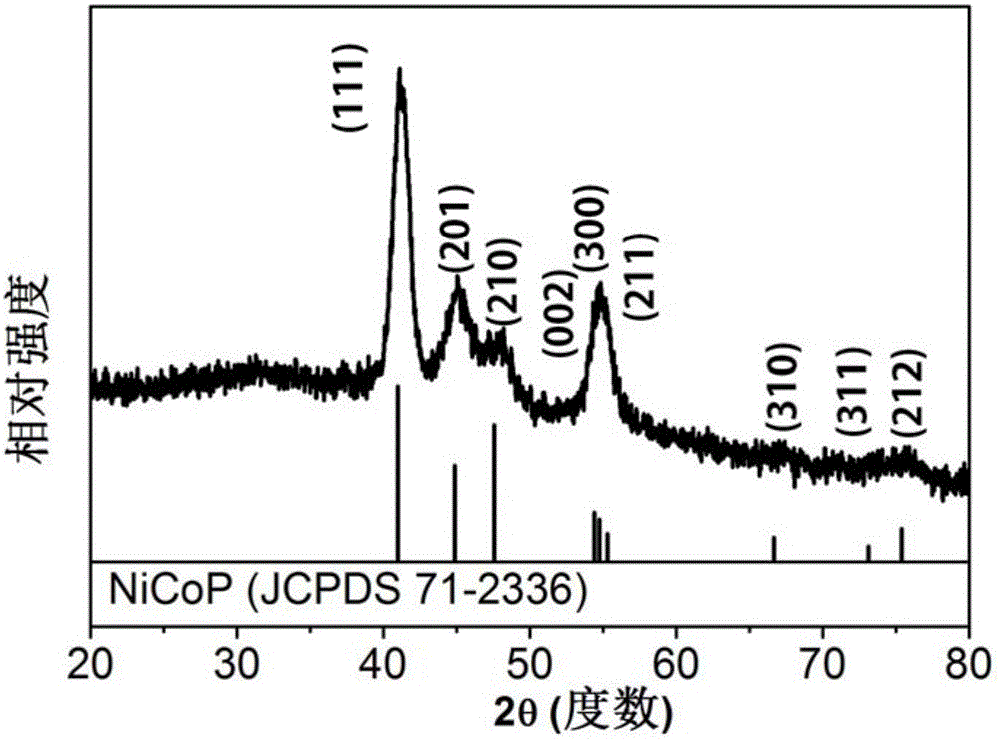

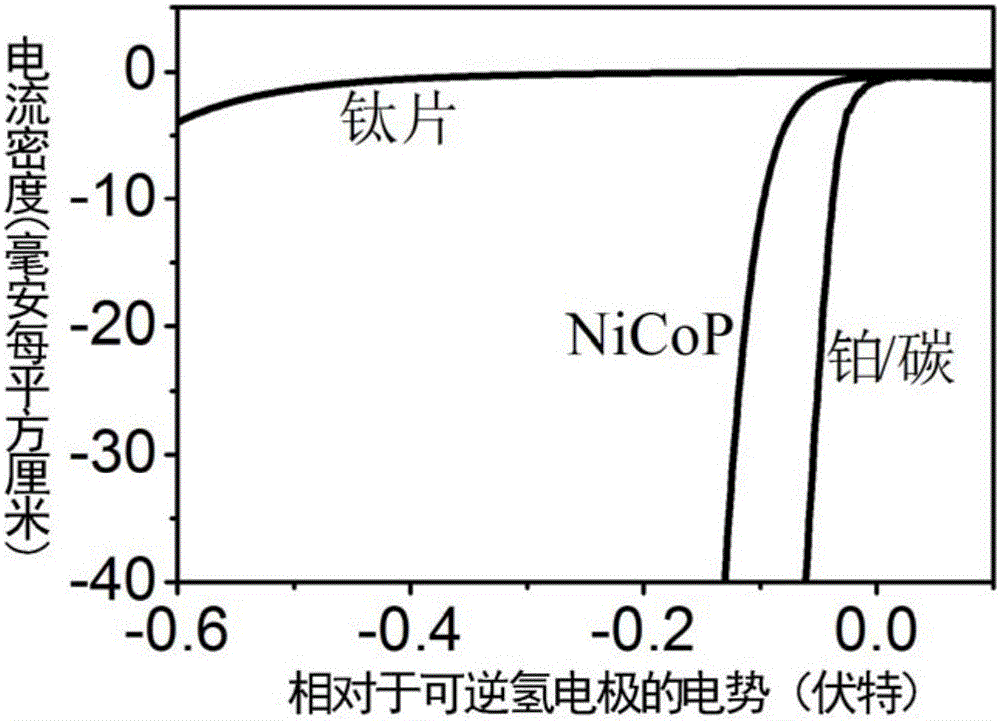

Nickel-cobalt-phosphorus crystal, and preparation method and application thereof

InactiveCN105152149AGood catalytic activityStable catalytic performancePhysical/chemical process catalystsPhosphidesChemistryCrystal

The invention provides a nickel-cobalt-phosphorus crystal, and a preparation method and an application thereof. The nickel-cobalt-phosphorus crystal prepared through controlling the proportions of elements in nickel-cobalt-phosphorus, the morphology and the dimension has very good catalysis activity in water electrolysis as a water electrolysis catalyst. According to the embodiment in the invention, the nickel-cobalt-phosphorus crystal has similar catalysis activity to commercial platinized carbon electrodes as a water electrolysis catalyst, can be used in electrocatalytic hydrogen evolution and oxygen production, has a stable catalysis performance and has very good industrial application prospect. Compared with traditional high temperature solid phase reaction, the nickel-cobalt-phosphorus crystal preparation method provided by the invention has the advantages of simple operating process, mild synthesis conditions, easy control of the product morphology, great shortening of the growth time of the synthesized nickel-cobalt-phosphorus crystal, reduction of the reaction temperature, energy consumption saving, high product yield, low cost and large-scale industrial production.

Owner:UNIV OF SCI & TECH OF CHINA

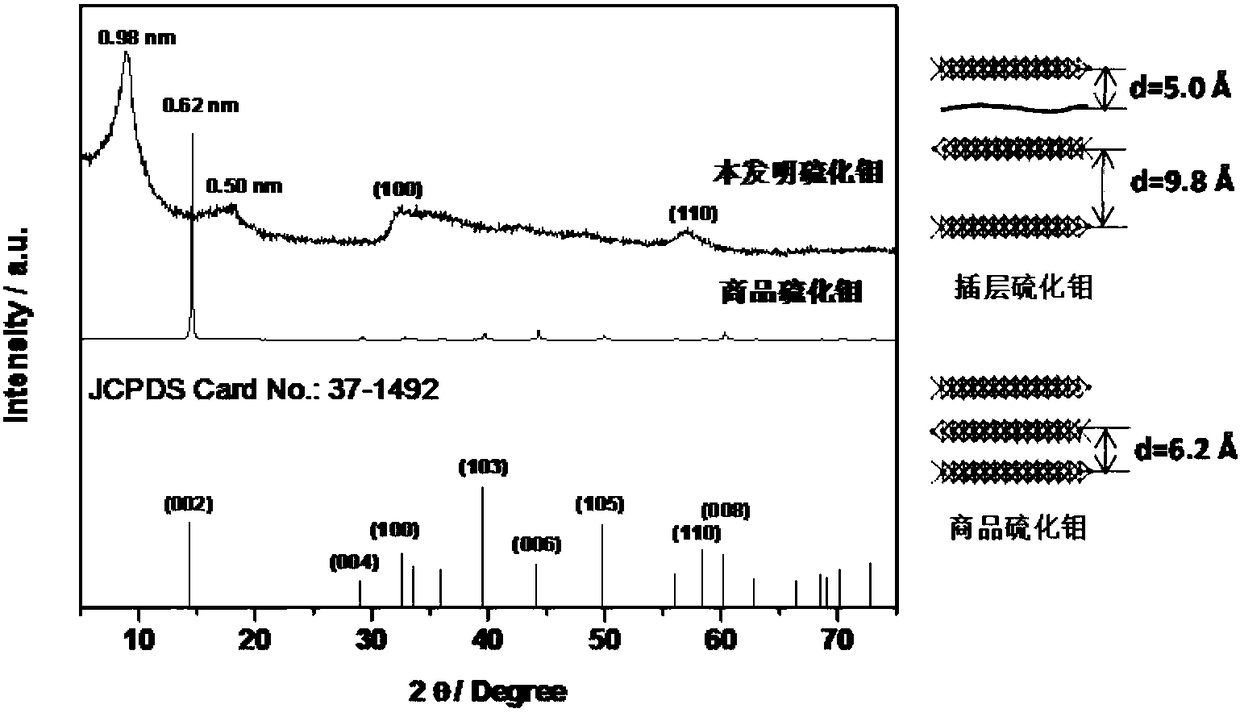

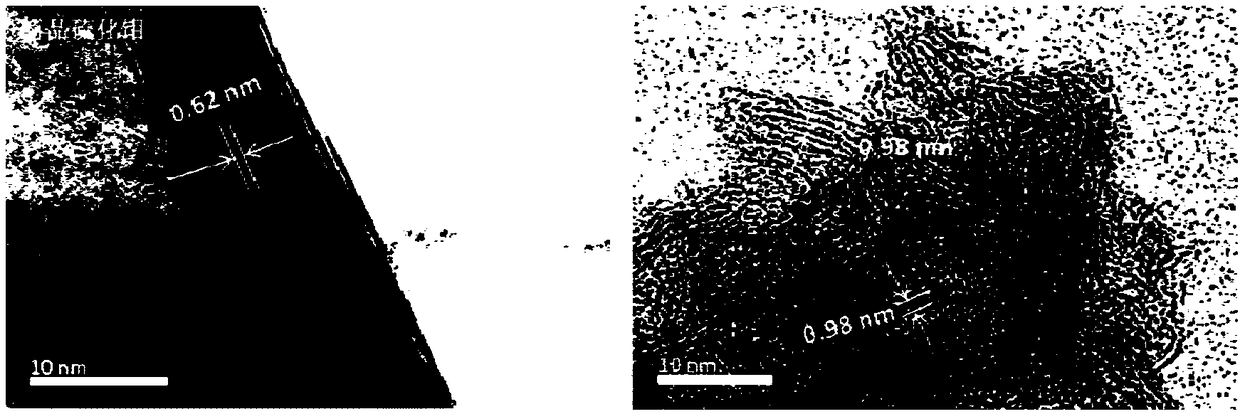

Preparation method of nano molybdenum disulfide (MoS2) hydrogenation catalyst exposed at high active site

ActiveCN108067257ARelieve pressureSynthetic conditions are safeMaterial nanotechnologyPhysical/chemical process catalystsFiltrationReactive site

The invention discloses a preparation method of a nano molybdenum disulfide (MoS2) hydrogenation catalyst exposed at a high active site. The preparation method comprises the following steps: dissolving or dispersing a certain amount of molybdenum source and sulfur source in a high-viscosity solution, and adding a reducing agent to obtain a solution or suspension liquid; adjusting and controlling the types of the molybdenum source, the sulfur source, the solvent and the reducing agent; putting the prepared solution or suspension liquid into a closed stainless steel reactor, controlling the reaction temperature to be 120-240 DEG C, and controlling the reaction time to be 3-72 hours; and after the reaction is finished, performing cooling, suction filtration, washing and drying to obtain the nano MoS2 hydrogenation catalyst exposed at the high active site. The synthetic method disclosed by the invention has the advantages of mild conditions, simple operation, high yield and the like, and the prepared nano MoS2 catalyst with expanded interlayer spacing and few layers has a high hydrogenation active site exposure rate. The nano MoS2 hydrogenation catalyst exposed at the high active site,synthesized by the method disclosed by the invention, has very high catalytic hydrogenation activity when being applied to the field of catalytic hydrogenation of oil products.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

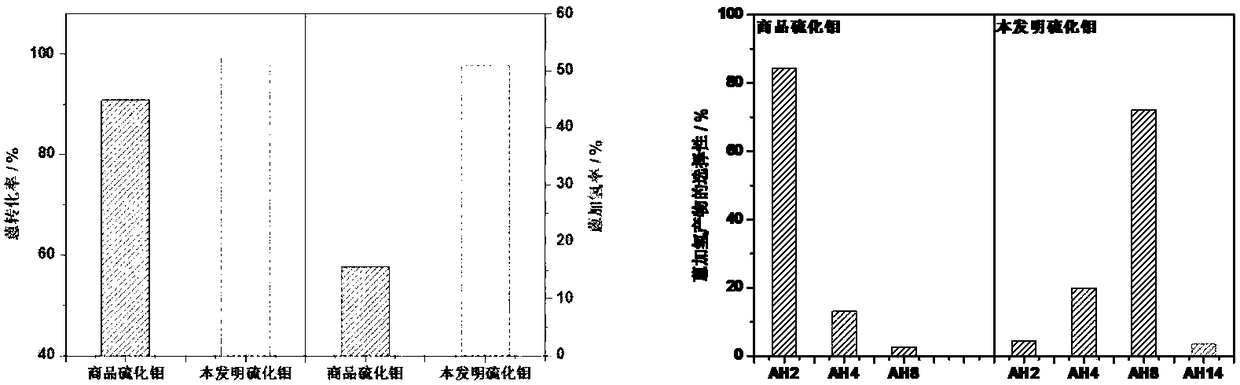

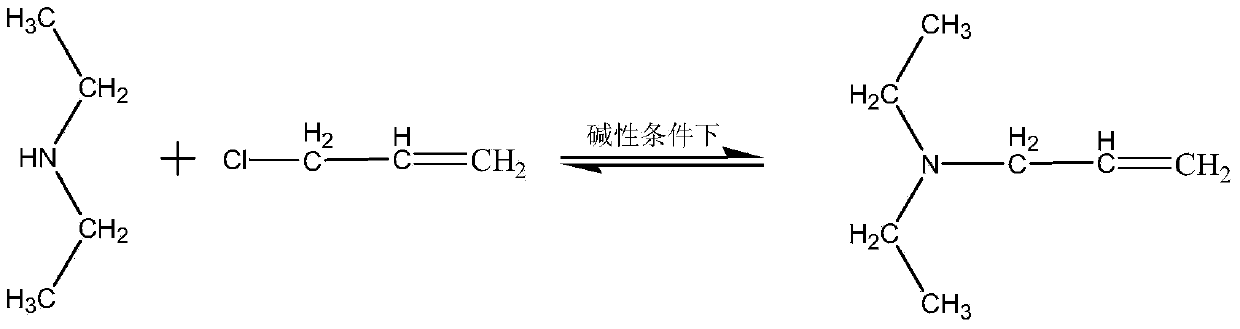

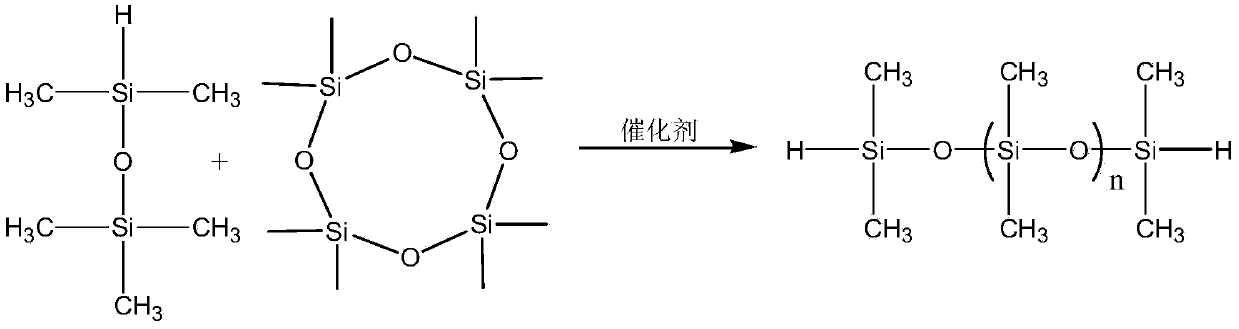

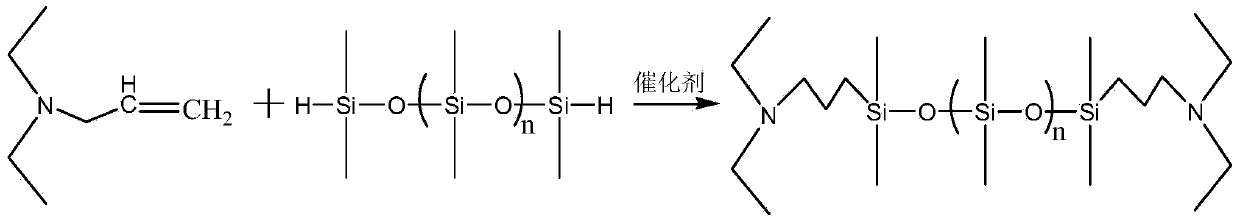

Preparation method for organosilicone positive ion waterborne polyurethane

ActiveCN104327238AEasy to separateSimple and fast operationPolyurea/polyurethane coatingsCarbonizationHydrosilylation

The invention relates to a preparation method for organosilicone positive ion waterborne polyurethane. The preparation method comprises the following steps: (1) reacting diethylamine with allyl chloride in the presence of an alkaline to generate diethyl allylamine; (2) carrying ring opening on D4 under the effect of a catalyst and blocking by using HMM (hexamethylmelamine) to generate dihydro-blocked polysiloxane; (3) carrying out hydrosilylation reaction on dihydro-blocked polysiloxane and diethyl allylamine; (4) carrying out quaternization reaction on the production of the addition reaction and chloropropanol; and (5) generating a prepolymer through reaction between HMDI and PTMEG1000 and extending chains in water by using the quaternization product to generate the organosilicone positive ion waterborne polyurethane. The preparation method provided by the invention is simple and convenient to operate, mild in reaction condition, free of carbonization and products are easily separated and recycled. Firstly, polysiloxane with amido at two terminals is salified and then chains are extended, and the conventional step of salifying positive ions with an acid and then neutralizing is cancelled, so that use of a nitrogen-containing chain extender is reduced, the cost is saved and the problem that positive ion polyurethane gets yellow is prevented.

Owner:QILU UNIV OF TECH

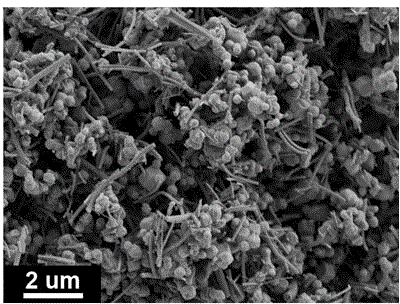

Silver phosphate/titanium dioxide nanocomposite and preparation method thereof

InactiveCN104383947AFast shippingEasy to separatePhysical/chemical process catalystsWater/sewage treatment by irradiationPhosphateUltraviolet lights

The invention discloses a silver phosphate / titanium dioxide nanocomposite. The silver phosphate / titanium dioxide nanocomposite is formed by silver phosphate nanoparticles and titanium dioxide nanofibers according to a mole ratio of (0.2-2) to 1, wherein the silver phosphate nanoparticles are loaded on the surfaces of the titanium dioxide nanofibers to form heterojunctions. A preparation method of the silver phosphate / titanium dioxide nanocomposite comprises the following steps: (1) preparing a spinning solution from butyl titanate, polyvinylpyrrolidone, dimethylformamide and an acid solution, and preparing titanium dioxide nanofibers by an electrostatic spinning manner; (2) dispersing the titanium dioxide nanofibers in deionized water, adding silver salt, and stirring without light; (3) preparing a dihydric phosphate solution, dropwise adding the dihydric phosphate solution into the solution prepared by the step (2) by magnetically stirring without light, and reacting to obtain the silver phosphate / titanium dioxide nanocomposite. The composite has double functions and are relatively high in catalytic activity in an ultraviolet light area and a visible light area. The method is simple and liable to operate, high in repeatability, mild in synthesis condition and low in cost, and is suitable for industrial production.

Owner:ZHEJIANG SCI-TECH UNIV

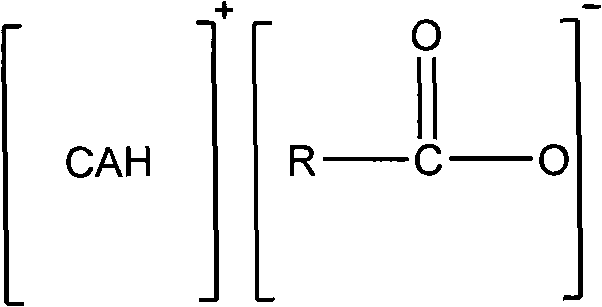

Cyclic amine sulfur dioxide gas absorbent and preparation method thereof

InactiveCN101537304AEffective absorptionHigh selectivityDispersed particle separationDesorptionCarboxylic acid

The invention provides a cyclic amine SO2 gas absorbent and a preparation method thereof, wherein the absorbent is an ion liquid with a cation belonging to cyclic amines; a chemical formula at the right side shows a cyclic amine short chain carboxylate, wherein CA is the cyclic amine; and R is H or C1-C2 alkyl. The preparation method of the absorbent is characterized in that the cyclic amine and the short chain carboxylate are taken as raw materials, and the reaction is carried out in a solvent or carried out directly without a solvent. The absorption amount of the SO2 is increased with the increment of the amount of the functional nitrogen; furthermore, the absorbent can be circularly used repeatedly by desorption, can achieve balanced absorption and desorption quickly, and desorption rate within 1 hour is more than 90% and the absorbent can be used for acidic gasses such as SO2, and the like.

Owner:HEFEI UNIV OF TECH

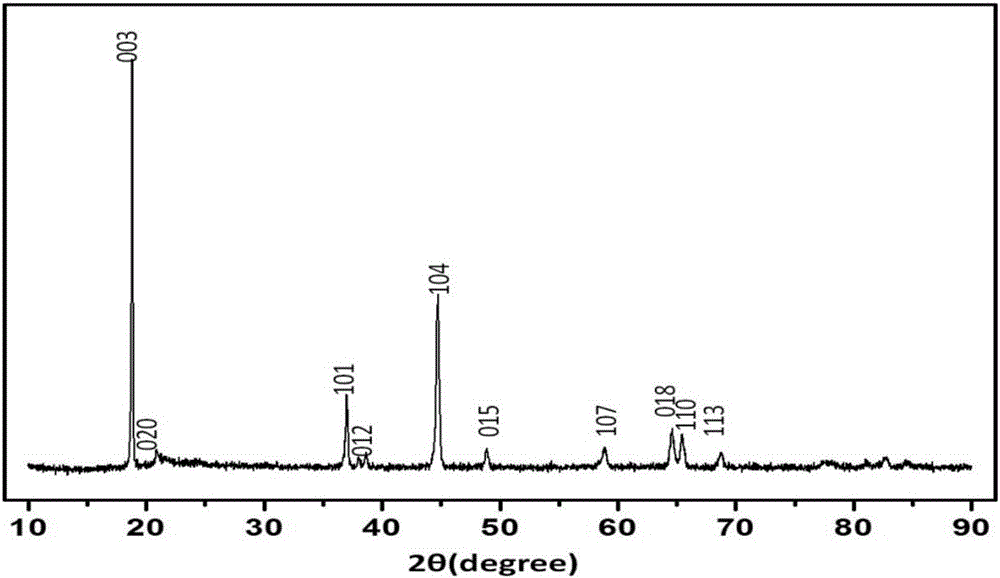

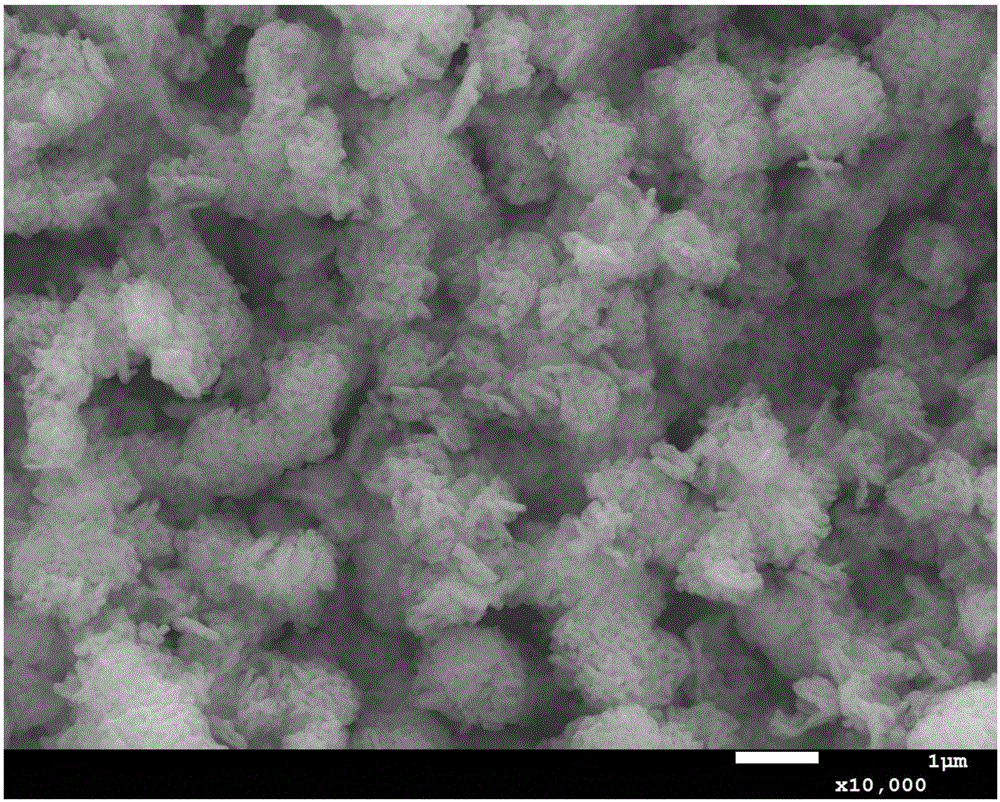

Preparation method of nano spherical ferric phosphate as well as nano ferric phosphate prepared by the method, lithium ferric phosphate and lithium battery

ActiveCN107522188AControllable particle sizeUniform particle size distributionCell electrodesNanotechnologyPhosphate productLithium-ion battery

The invention discloses a preparation method of nano spherical ferric phosphate as well as nano ferric phosphate prepared by the method, lithium ferric phosphate and a lithium battery. The method comprises the following steps: mixing: dropwise adding a mixed solution consisting of a phosphorus source compound solution and an oxidant solution into a soluble ferrous compound solution, adding a nano spherical control agent, and stirring and mixing; reacting: stirring at 50 to 100 DEG C under a refluxing condition, and reacting for 5 to 10 h; filtering: magnetically filtering the mixed solution after the reaction by adopting a high magnetic filter, press filtering the filtered solution, and obtaining a ferric phosphate crude product; and calcining: calcining for 24h at 650 to 850 DEG C under the protection of inert gas, and cooling to obtain a final ferric phosphate product. By adopting the method, the morphology of the ferric phosphate product can be controlled, and the performance of the lithium ferric phosphate can be improved.

Owner:YOSHIHIRO COMM EQUIP GRP CO LTD

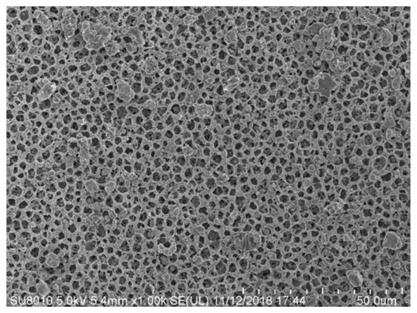

Method of preparing hierarchical porous channel molecular sieve membrane and application thereof

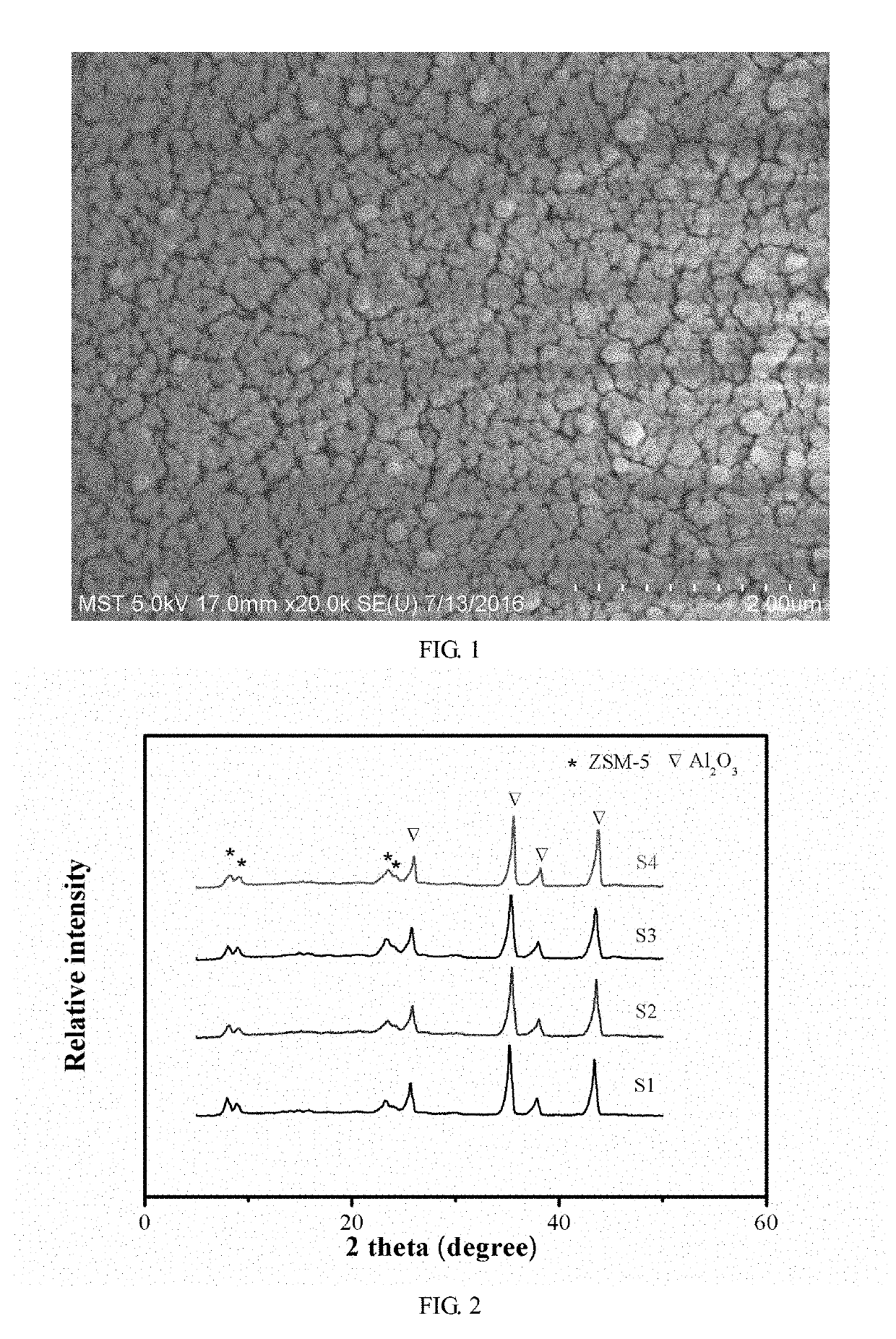

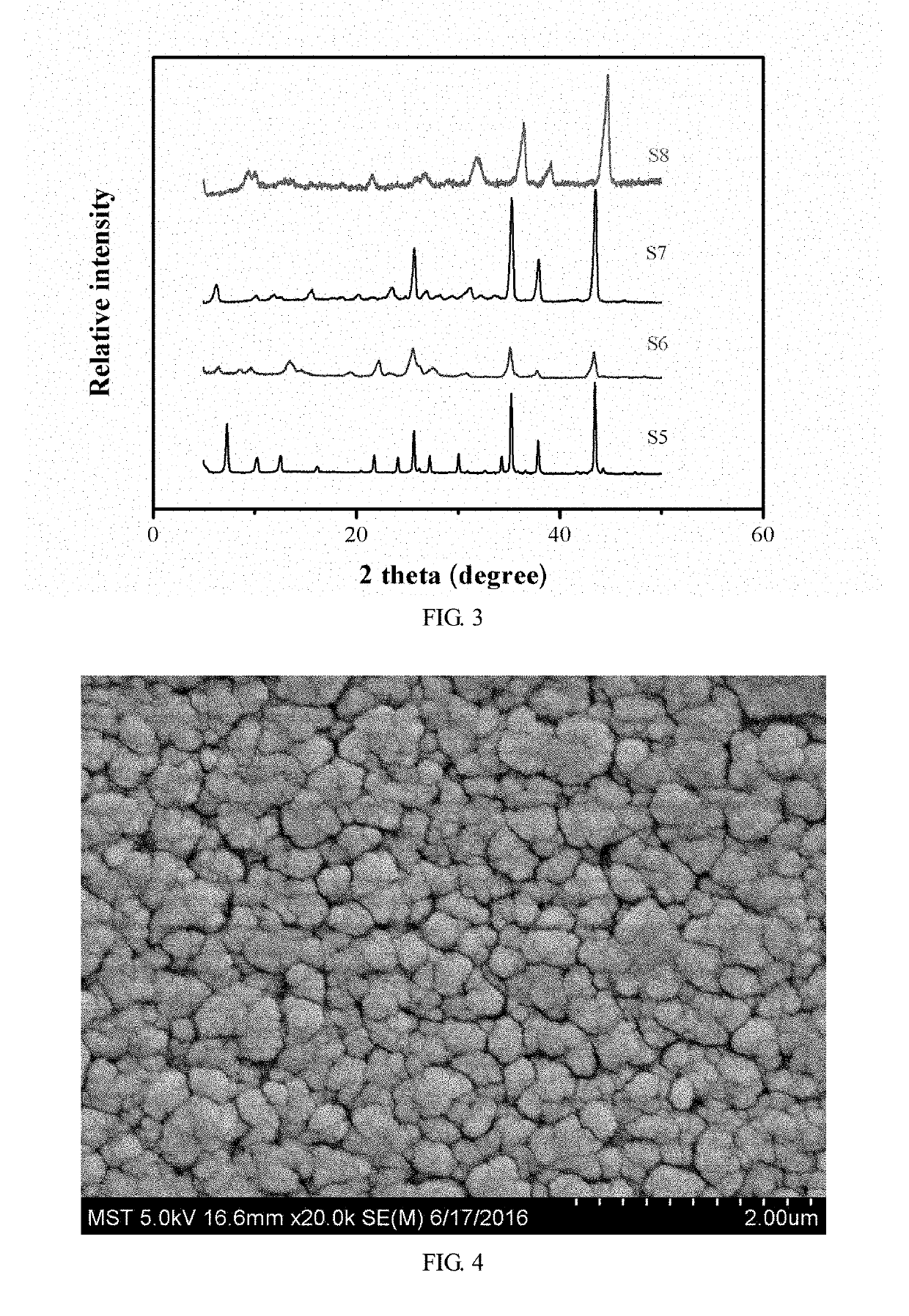

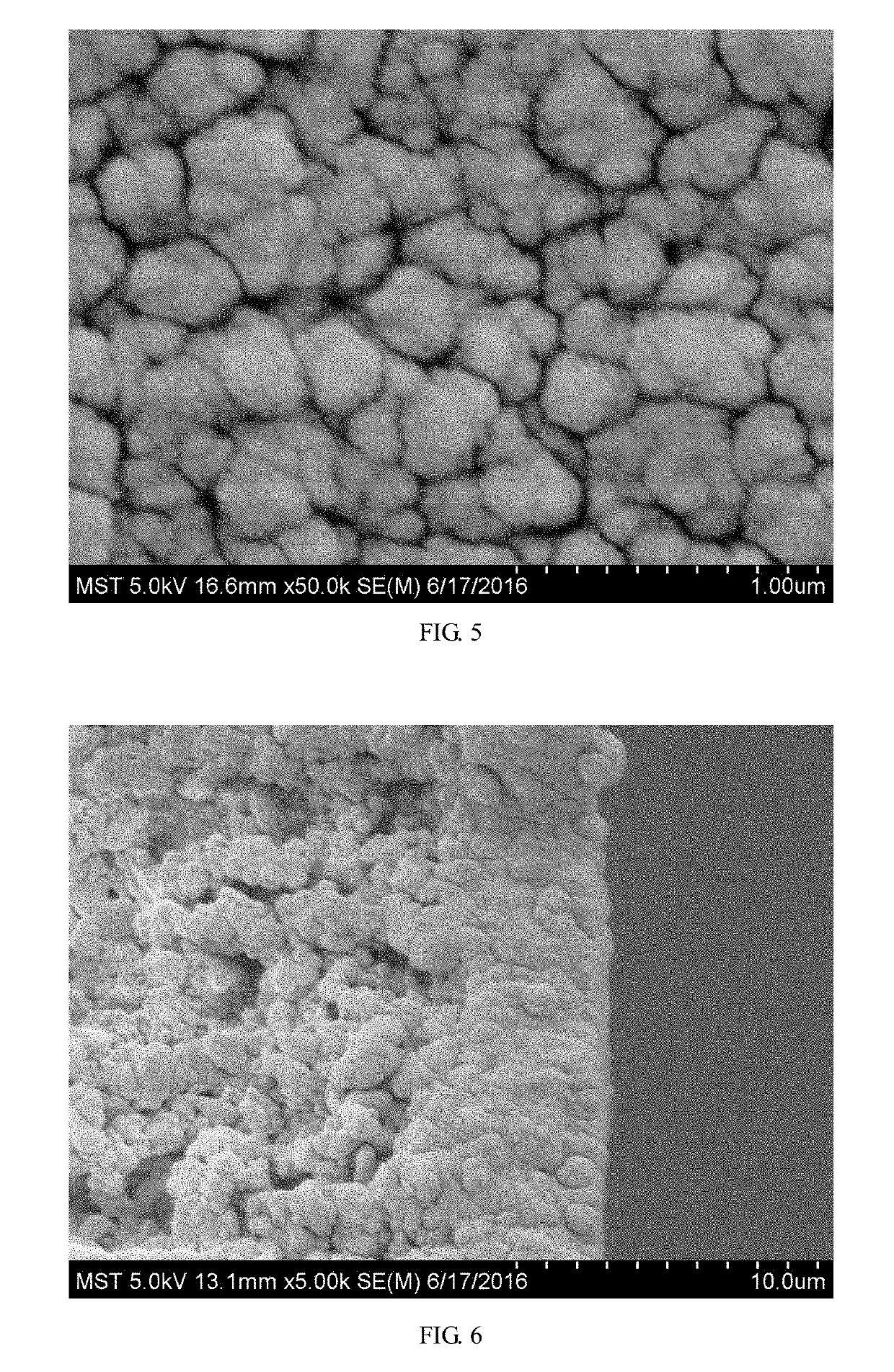

ActiveUS20190262779A1Improves pure water fluxMild and controllable synthesis conditionSemi-permeable membranesMembranesPorous channelHierarchical porous

The invention relates to a method for preparing a hierarchical porous zeolite membrane and an application thereof, comprising the following steps: a mesoporous structure-directing agent is added to limit the growth of zeolite crystals, and self-assembled in the crystallization process to generate a mesoporous structure. Based on a seed crystal induced secondary nucleation mechanism, this method can realize one-step hydrothermal synthesis of hierarchical porous zeolite membrane with the advantages of mild and controllable synthesis conditions, simple process, good repeatability, reduced energy consumption and cost savings. The hierarchical porous zeolite membrane prepared by the method has good cut-off performance, and the cut-off molecular weight is adjustable between 200 to 500,000 Da.

Owner:NANJING UNIV OF TECH

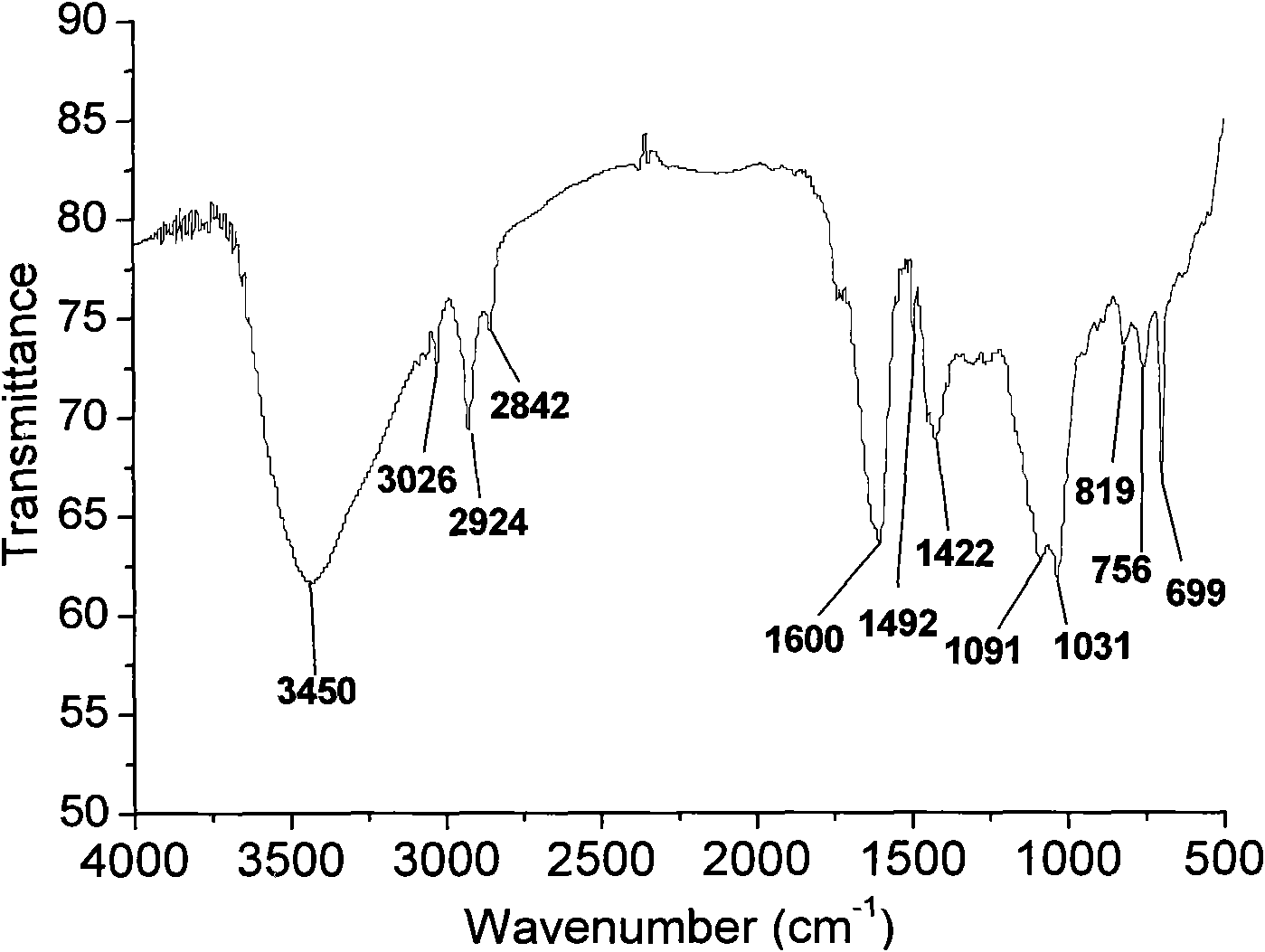

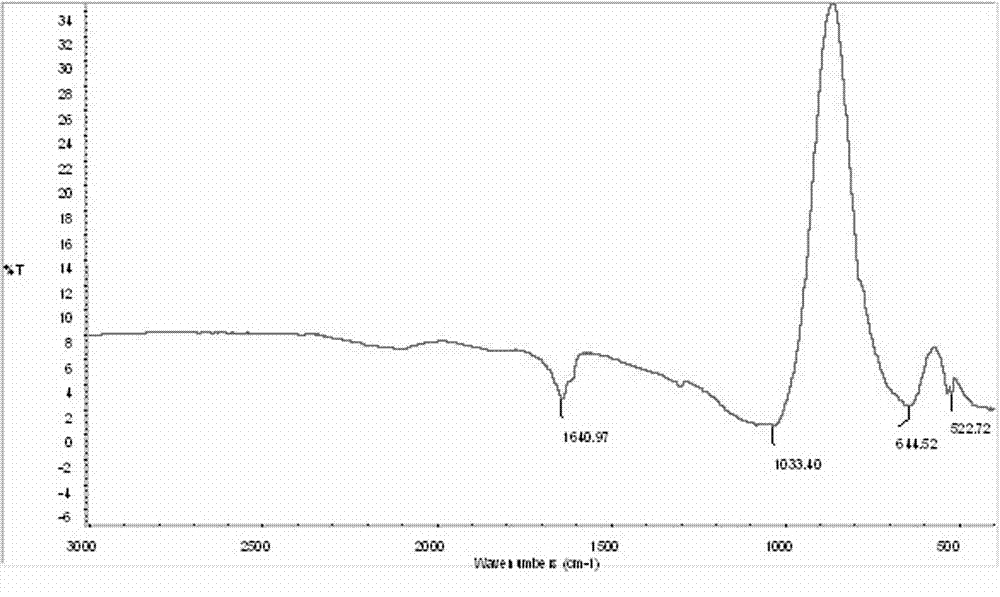

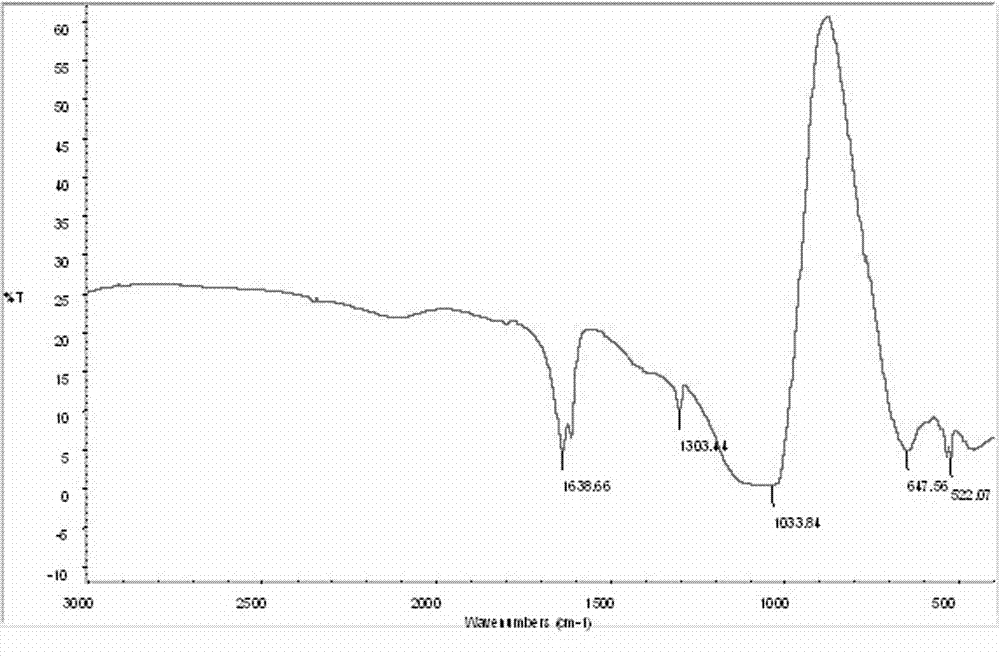

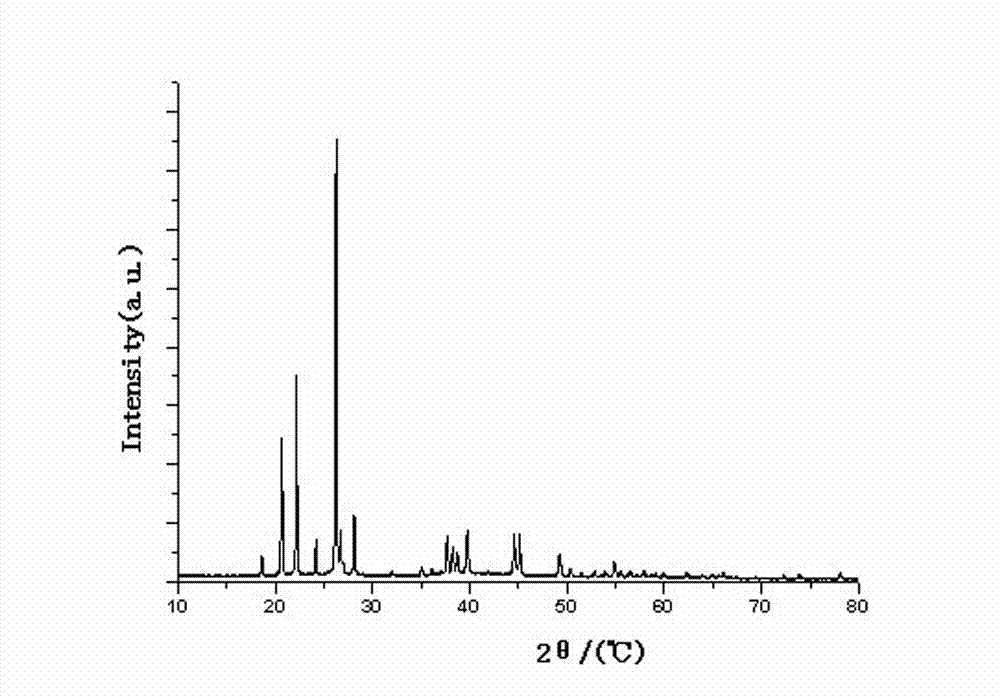

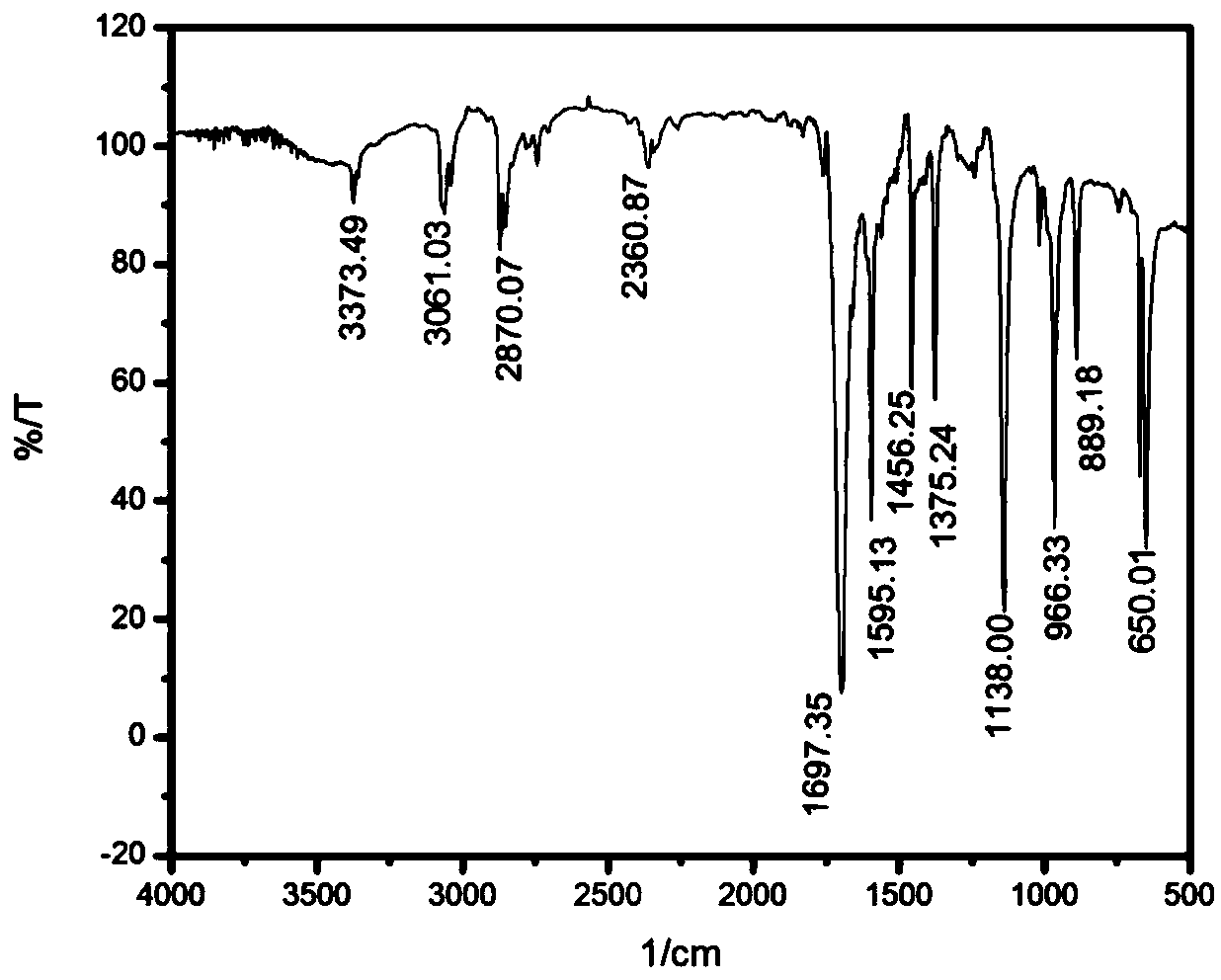

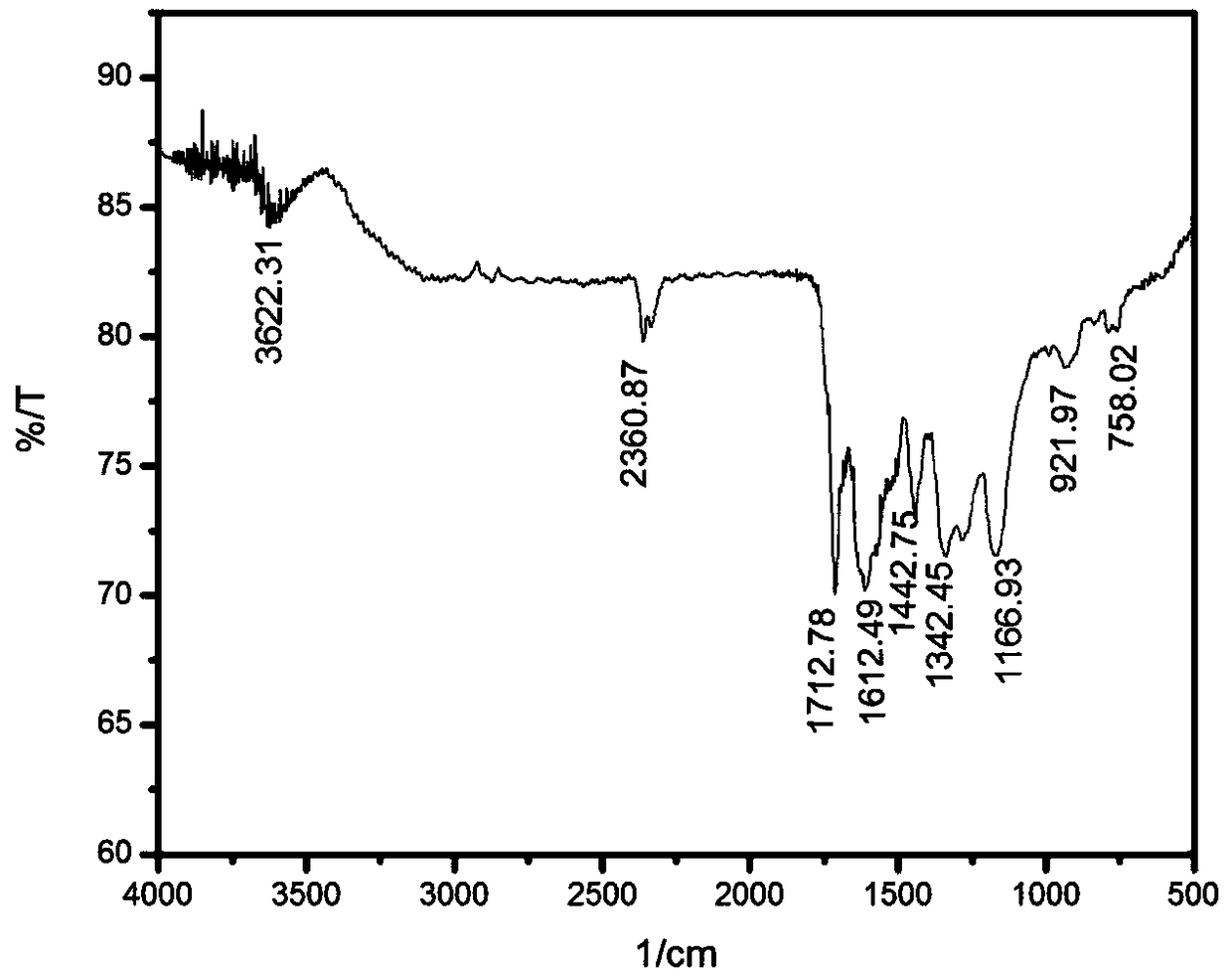

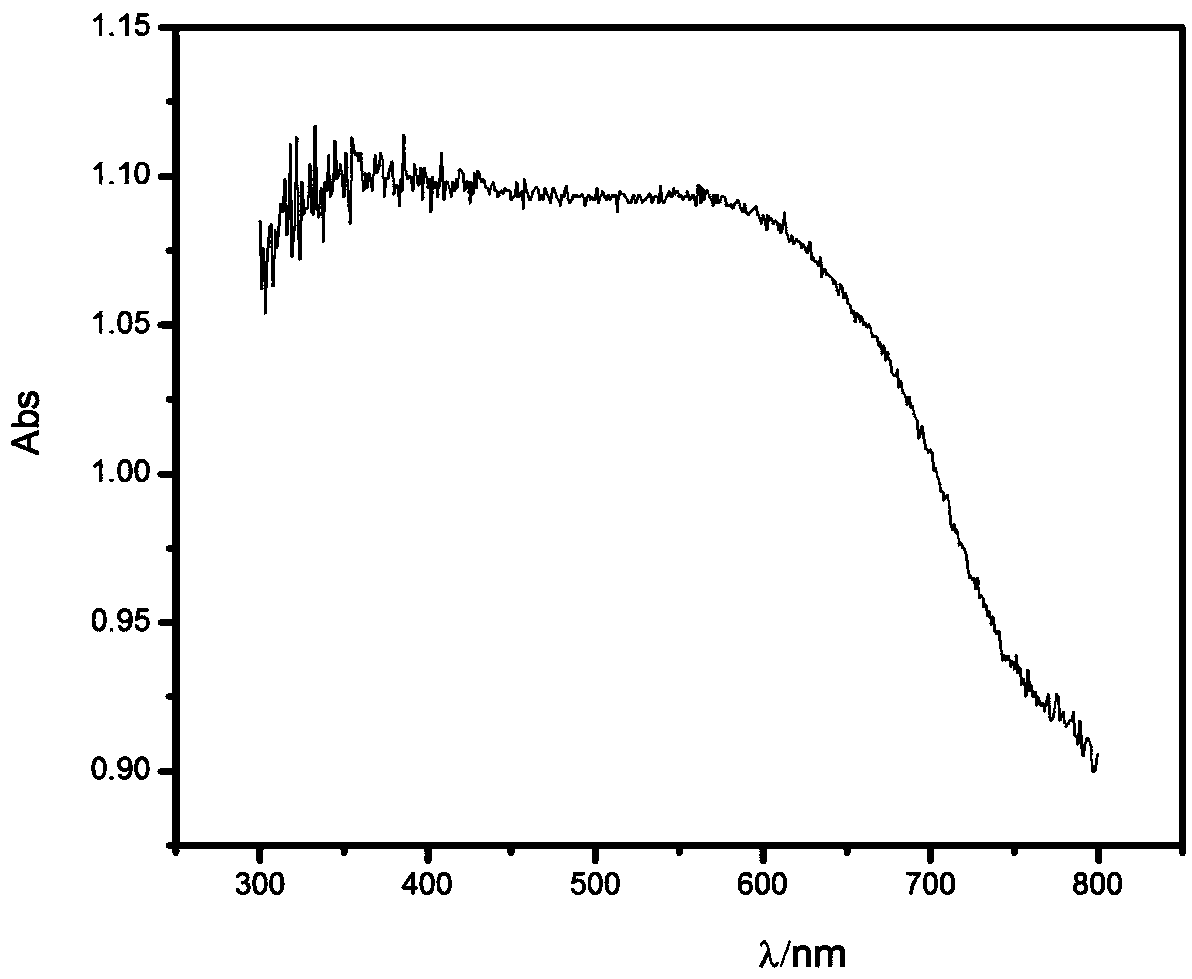

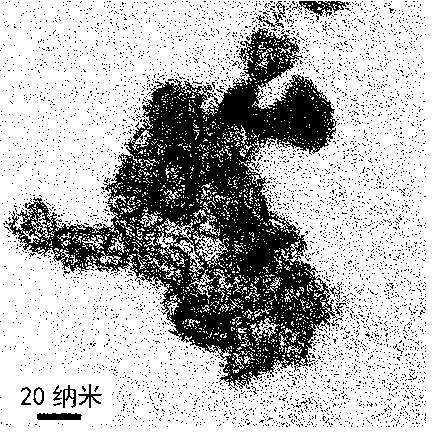

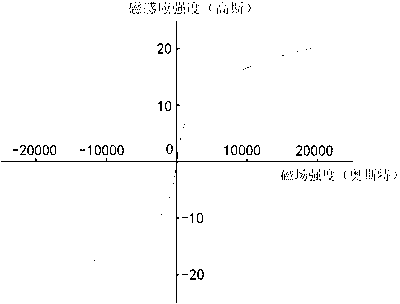

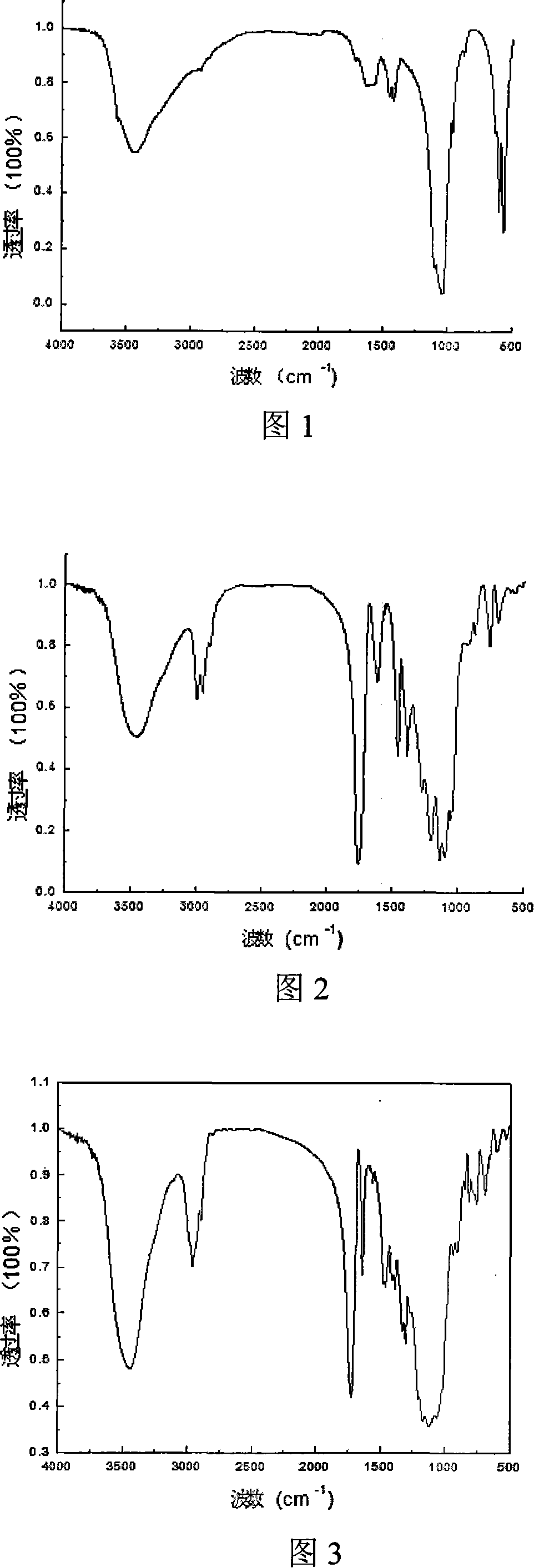

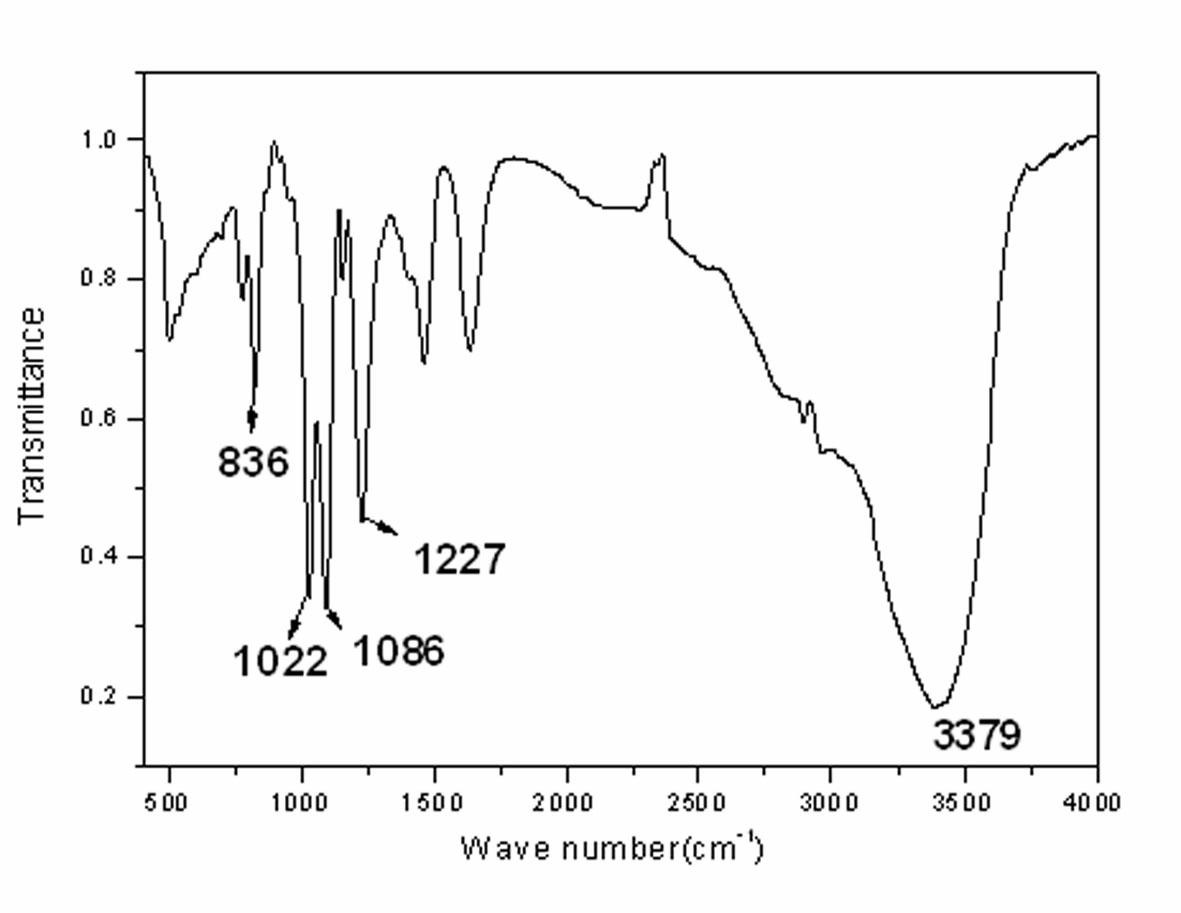

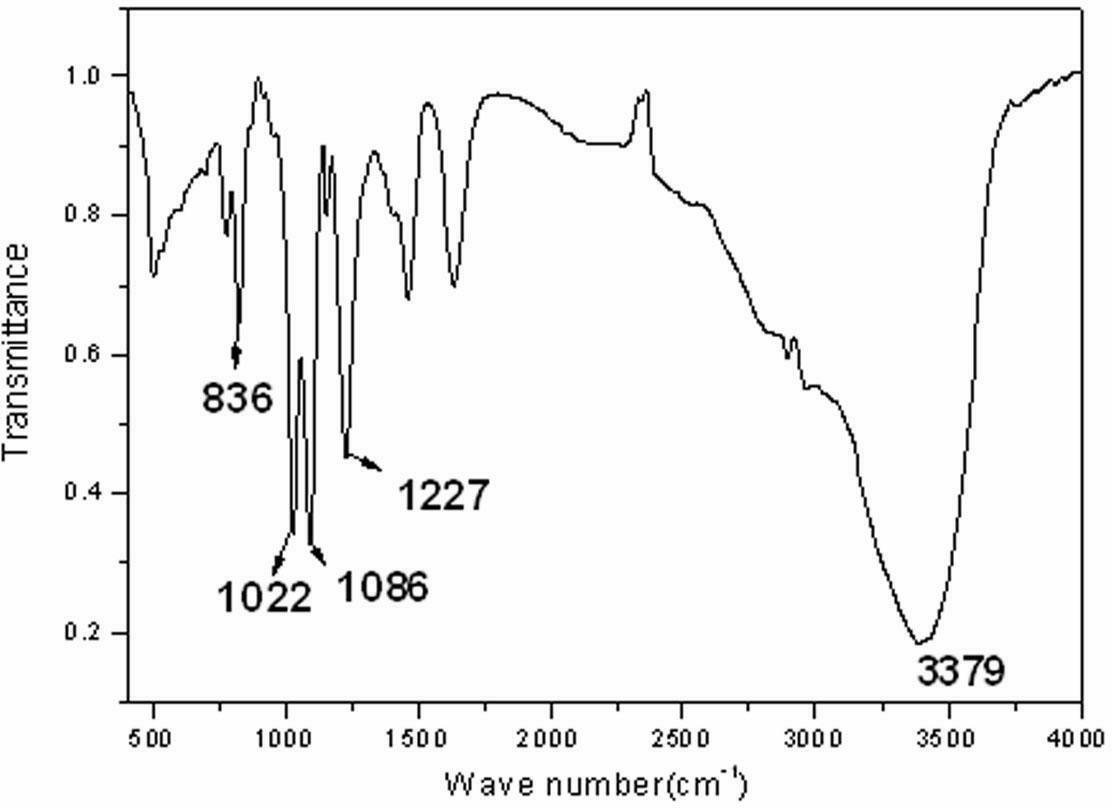

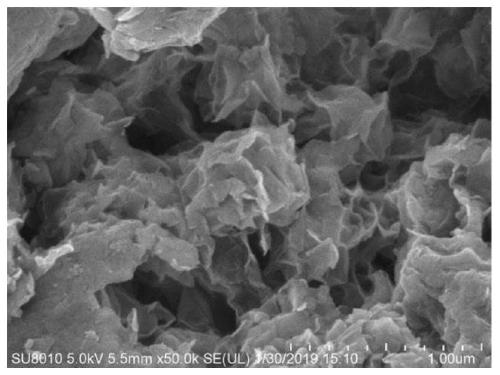

Conjugated micro-porous polymer and preparation method thereof

ActiveCN108892759ALarge specific surface areaImprove thermal stabilityThermal stabilityConjugated microporous polymer

The invention provides a preparation method of a conjugated micro-porous polymer. By performing infrared spectral characterization on prepared compounds of two structures, the compounds prepared in the invention are conjugated micro-porous polymers, are conjugated micro-porous polymers of novel structures, have the advantages of being large in specific surface area, porous, excellent in thermal stability and the like, and lay a good foundation for wide application of the conjugated micro-porous polymers in the fields of gas absorption, conduction, biodegradation and the like.

Owner:TAIZHOU UNIV

Preparation method of magnetic nanometer iron oxide adsorbent for removing arsenic from water

InactiveCN103272553AHas adsorption propertiesThe production process is simpleOther chemical processesAlkali metal oxides/hydroxidesFerric hydroxideHydration reaction

The invention provides a preparation method of a magnetic nanometer iron oxide adsorbent for removing arsenic from water and belongs to the technical field of synthesis of a magnetic nanometer adsorbing material for water pollution control. The preparation method comprises the following steps of: step one, mixing a ferric salt aqueous solution and an alkaline aqueous solution to prepare ferric hydroxide, centrifugally separating ferric hydroxide, adding glacial acetic acid, and stirring till forming a hydration ferric oxide colloidal solution; and step two, adding an organic solvent to the colloidal solution, so that hydration ferric oxide reacts with the organic solvent to form a compound precipitate, separating, drying and baking to obtain the magnetic nanometer iron oxide adsorbent. The prepared magnetic nanometer iron oxide adsorbent is not required to be compounded with other materials; the preparation method is simple; the cost of raw materials is low; and the magnetic nanometer iron oxide adsorbent has a good absorption effect on arsenic in water and can be used for purifying water.

Owner:WUHAN UNIV

Method of preparing compound osseous tissue renovating material interconsistency agent of polylactic acid/hydroxyapatite

The invention relates to a method for preparing an inclusive agent of a polylactic acid or hydroxyapatite composite bone tissue restoring material, which comprises the following steps: getting processed hydroxyapatite by refluxing hydroxyapatite in the alcohol solution with surface modifier as the coupler for 12-48 hours; dissolving polylactic acid macromole monomer with terminal ethenyl and the processed hydroxyapatite in the organic solvent with initiating agent; protecting with nitrogen; extracting after extracting and drying the reactor; separating and purifying no-grafted polylactic acid macromole monomer; extracting the remainder; drying; getting the inclusive agent. The inclusive agent has the wide application, the low cost, the simple method, the mild synthesis condition, the strong utility and the easy industry production, which provides the boundary interaction of the organic or inorganic phase in polylactic acid or hydroxyapatite composite bone tissue restoring material, and improves the ergology property of bone tissue restoring material.

Owner:JINAN UNIVERSITY

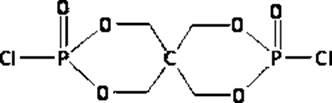

Reactive intumescent flame retardant for polyurethane and synthesis method of reactive intumescent flame retardant

InactiveCN102585135ADoes not affect mechanical propertiesHigh phosphorus and nitrogen flame retardant ingredientsGroup 5/15 element organic compoundsHalogenHigh carbon

The invention discloses a reactive intumescent flame retardant for polyurethane and a synthesis method of the reactive intumescent flame retardant, relates to a flame retardant technology, in particular to a novel intumescent flame retardant which contains an acid source, a carbon source and a gas source simultaneously and contains a hydroxyl group serving as an active group. The chemical name ofthe reactive intumescent flame retardant for polyurethane is 3,9-di{N,N-di(2-ethoxyl)-amino}-2,4,8,10-4-oxo-3,9-diphosphate spiro-3,9-dioxo-[5,5]-undecane. The structure of the reactive intumescent flame retardant is shown as a formula (I). The synthesis method comprises the following steps of: adding 3,9-di{N,N-di(2-ethoxyl)-amino}-2,4,8,10-4-oxo-3,9-diphosphate spiro-3,9-dioxo-[5,5]-undecane into water; dropwise adding diethanolameine and triethylamine at the temperature of 0-5 DEG C; reacting at the temperature of 50-60 DEG C for 4-6 hours; concentrating under reduced pressure; purifying; and performing vacuum drying to obtain the flame retardant. The flame retardant and the synthesis method of the reactive intumescent flame retardant have the advantages of integration of phosphorus, nitrogen and carbon, high phosphorus and nitrogen flame-retardant ingredients, no containing of halogen, nontoxicity, environmental friendliness, high carbon forming property, high compatibility with apolyurethane system, simple process, mild synthesis condition and suitability for industrial implementation.

Owner:ZHONGBEI UNIV

Photocatalytic membrane, preparation method thereof and degradation application of photocatalytic membrane on disinfection by-product precursor

ActiveCN109772454AAvoid churnNot easy to loseWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsUltrafiltrationFiltration

The invention discloses a photocatalytic membrane, a preparation method thereof and degradation application of the photocatalytic membrane on a disinfection by-product precursor. The preparation method of the photocatalytic membrane comprises the following steps that molybdenum disulfide (MoS2) and graphene oxide (GO) are compounded to prepare a MoS2 / RGO (reduced graphene oxide) compound; a polyvinylidene fluoride ultrafiltration membrane is provided and immersed in a Tris-dopamine hydrochloride solution to obtain a polydopamine loaded polyvinylidene fluoride ultrafiltration membrane; then theMoS2 / RGO compound is dissolved in water and subjected to ultrasonic treatment, an aqueous solution of the MoS2 / RGO compound is subjected to vacuum suction filtration on the polydopamine loaded polyvinylidene fluoride ultrafiltration membrane, and then vacuum drying is carried out to prepare the photocatalytic membrane. The preparation method of the photocatalytic membrane and the prepared photocatalytic membrane can be used for efficiently degrading the disinfection by-product precursor in a visible light area.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

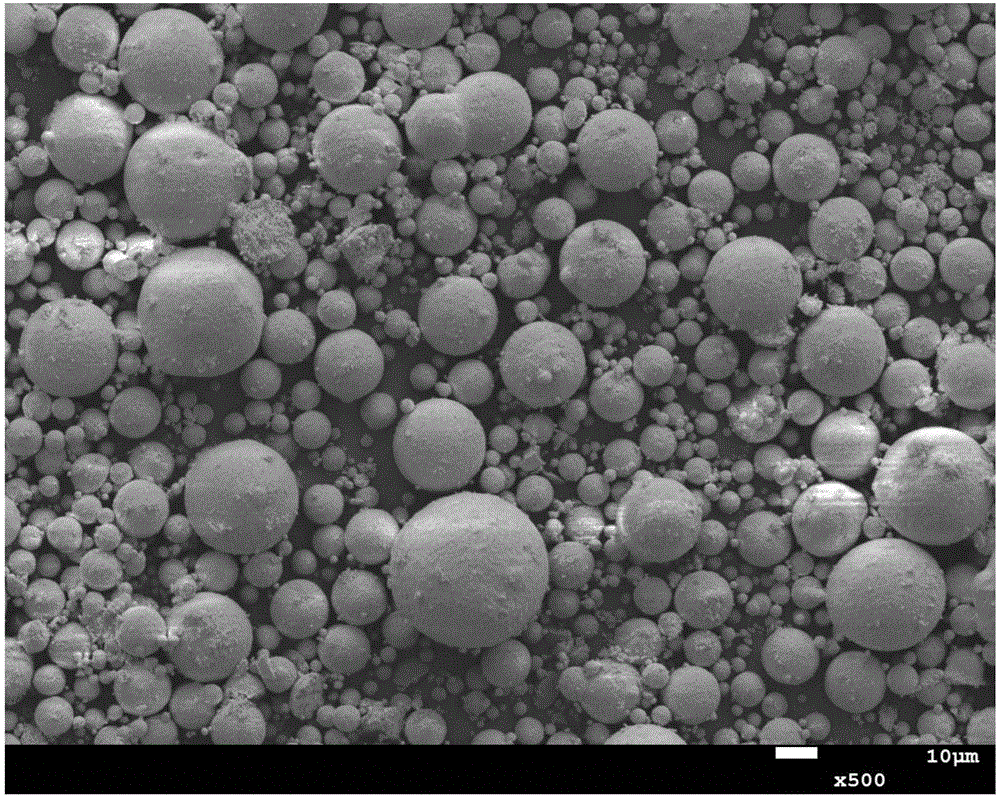

Supported polyolefin catalyst, preparation and application

The invention relates to a supported polyolefin catalyst, preparation method and application; a carrier is spherical organic benzene zirconium phosphate; the main catalyst for olefin polymerization is a metallocene compound, the central atom Ti, Zr or Hf of the metallocene compound accounts for 0.01-50% of the carrier content; organic ligands are cyclopentadienyl and the derivative thereof, or indenyl and the derivative thereof, or flourenyl and the derivative thereof, or the bridging cyclopentadienyl and the derivative thereof, or the bridging indenyl and the derivative thereof, or the bridging flourenyl and the derivative thereof; the catalyst is used for homopolymerization or copolymerization of any one of or the mixture of any two or more of ethene, and alpha-olefin, cycloolefin and dialkene of C3-C20; the cocatalyst is alkyl aluminium, alkylaluminium halide or alkylaluminoxane; the ratio of Al and the central atom zirconium of the metallocene compound is 10-3000; the polymerization temperature is minus 78 DEG C to 200 DEG C, the pressure is 0.1 to 10MPa, and the catalytic activity is high.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com