Patents

Literature

202 results about "Iron(II) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron(II) oxide or ferrous oxide is the inorganic compound with the formula FeO. Its mineral form is known as wüstite. One of several iron oxides, it is a black-colored powder that is sometimes confused with rust, the latter of which consists of hydrated iron(III) oxide (ferric oxide). Iron(II) oxide also refers to a family of related non-stoichiometric compounds, which are typically iron deficient with compositions ranging from Fe0.84O to Fe0.95O.

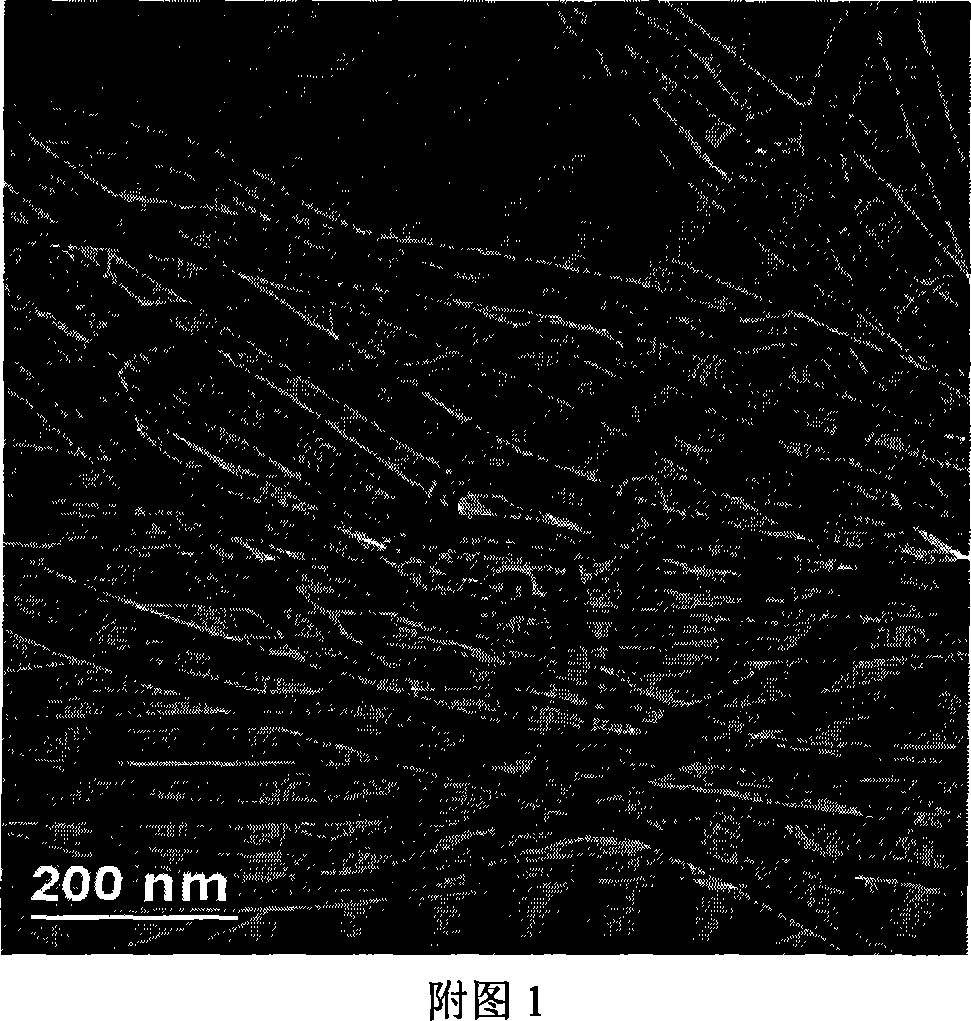

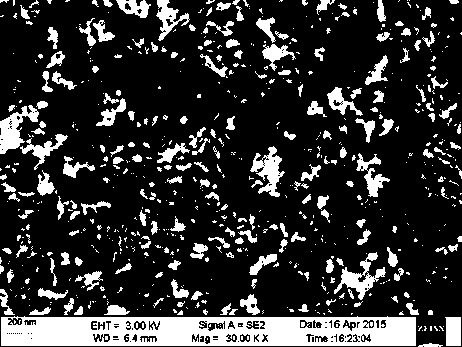

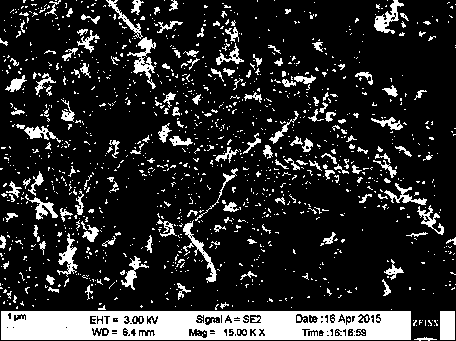

High nitrogen doped corrugated carbon nanotube material and its synthesis process

InactiveCN101066758AWide variety of sourcesSimple production processNanostructure manufactureMetal/metal-oxides/metal-hydroxide catalystsIron(II) oxideCarbon nanotube

The present invention relates to high nitrogen doped corrugated carbon nanotube material and its synthesis process. The synthesis process includes the following steps: mixing Fe source and proper amount of distilled water, soaking porous molecular sieve to carry ferric oxide or ferrous oxide, stoving and roasting at 300-1000 deg.c for 0.5-24 hr to obtain catalyst; setting the catalyst inside a pipe furnace, leading organic amine into the furnace under the protection of Ar or N2 and reacting at 650-1000 deg.c for 0.2-4.0 hr to obtain high nitrogen doped corrugated carbon nanotube mixture containing the catalyst; soaking the mixture in proper amount of or excessive hydrofluoric acid, sulfuric acid, nitric acid or acid for 0.5-24 hr; and washing in distilled water, suction filtering and drying to obtain high nitrogen doped corrugated carbon nanotube material. The material has nitrogen content of 10-40 %, reinforced surface polarity, etc, and is suitable for industrial production.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

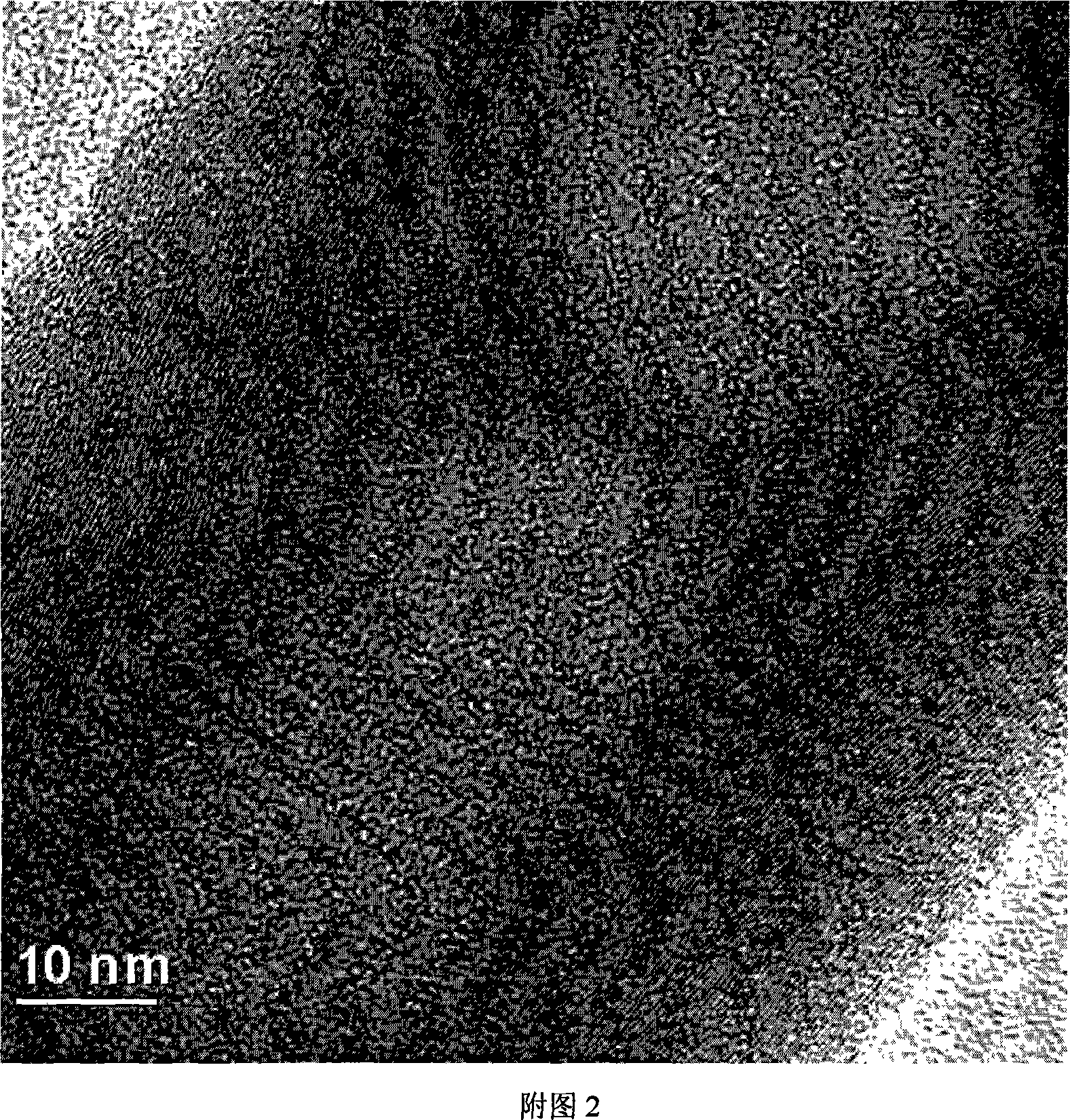

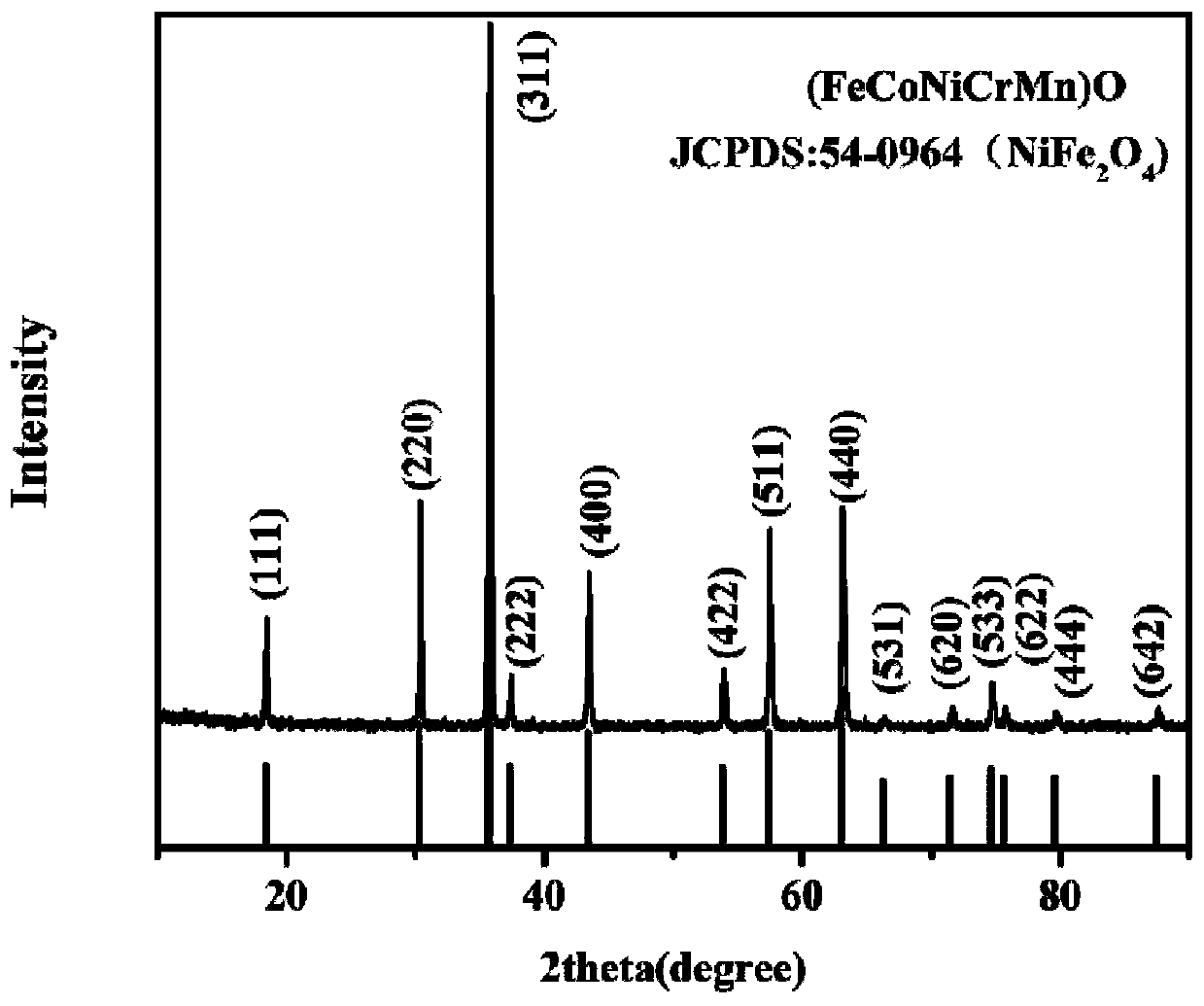

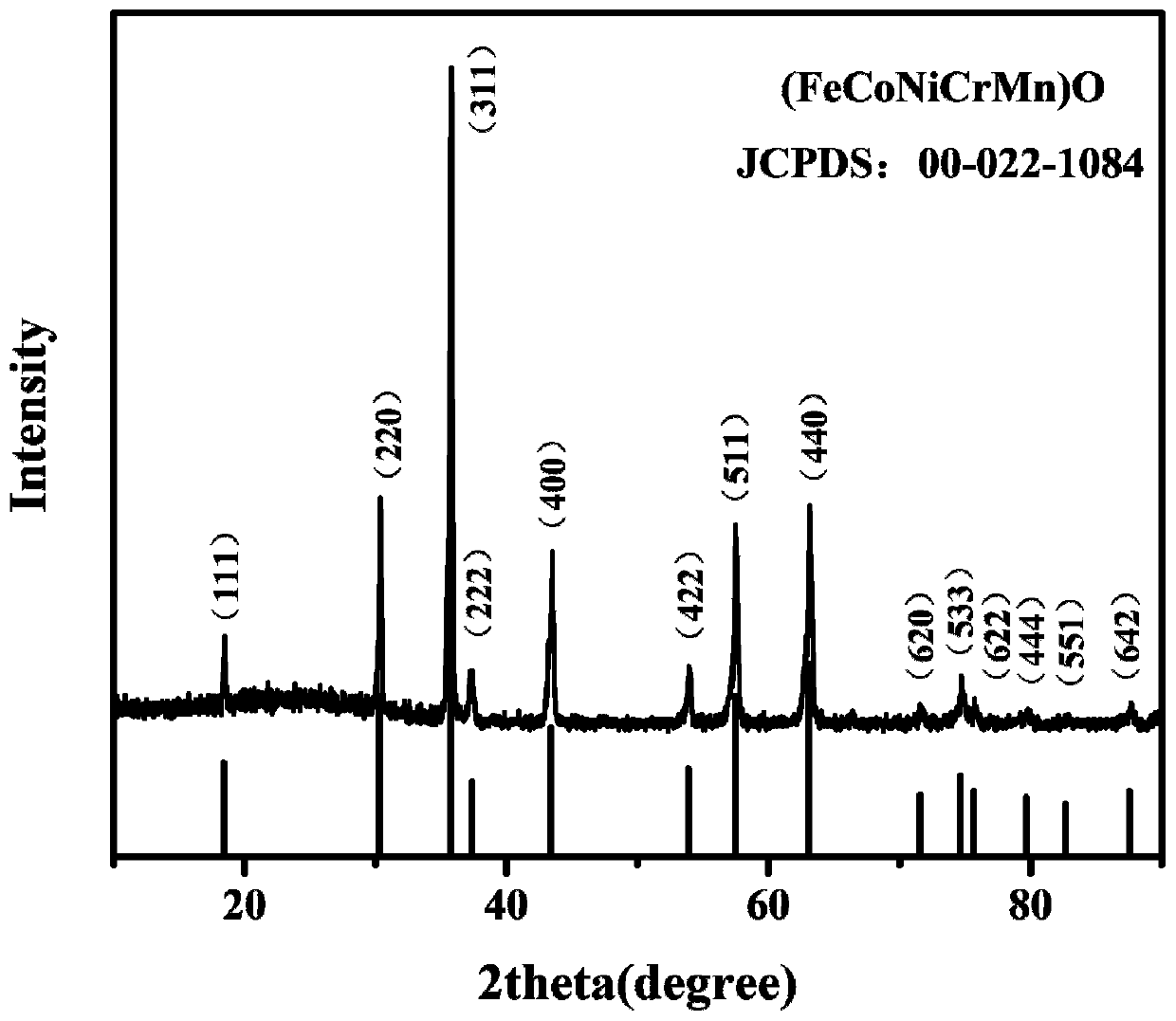

Spinel type high-entropy oxide electrode material and preparation method thereof

ActiveCN110364717AHigh specific capacityImprove cycle stabilityNegative electrodesSecondary cellsIron(II) oxideSpace group

The invention relates to a spinel type high-entropy oxide electrode material and a preparation method thereof, and belongs to the field of nanomaterial preparation and new energy. The chemical formulaof the high-entropy oxide electrode material is one of (FeCoNiCrMn)O, (FeZnNiCrMn)O, (FeCoZnCrMn)O and (FeCoNiCrMnCu)O. The preparation method includes the steps of 1) mixing and ball-milling iron oxide, chromium oxide, manganese oxide and M metal oxide, wherein the M metal oxide is two or more of nickel oxide, zinc oxide, copper oxide and cobalt oxide; and 2) carrying out high-temperature calcination, and obtaining the spinel type high-entropy oxide electrode material by adopting a cooling mode of furnace cooling, air quenching and liquid nitrogen quenching. The particle diameter of the high-entropy oxide is 100-500nm, and the high-entropy oxide is determined to be in a spinel structure according to XRD; and the space group of the material is Fd-3m, and the specific surface area is 5-100m<2>g<-1>.

Owner:东北大学秦皇岛分校

Reactive adsorbent for heavy elements

InactiveUS20060049091A1Improve the level ofReduce manufacturing costWater treatment parameter controlWater/sewage treatment by irradiationSorbentFerrous

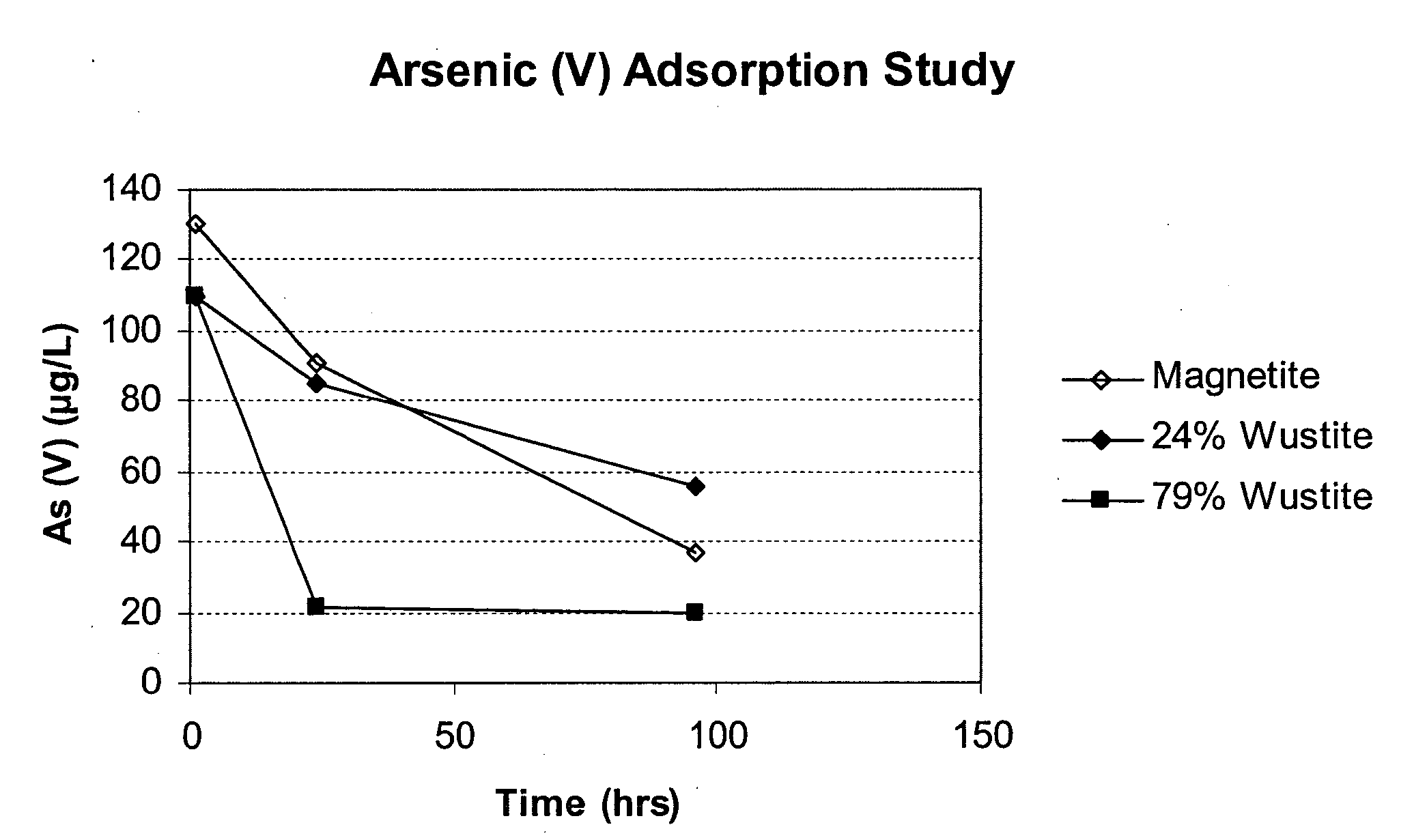

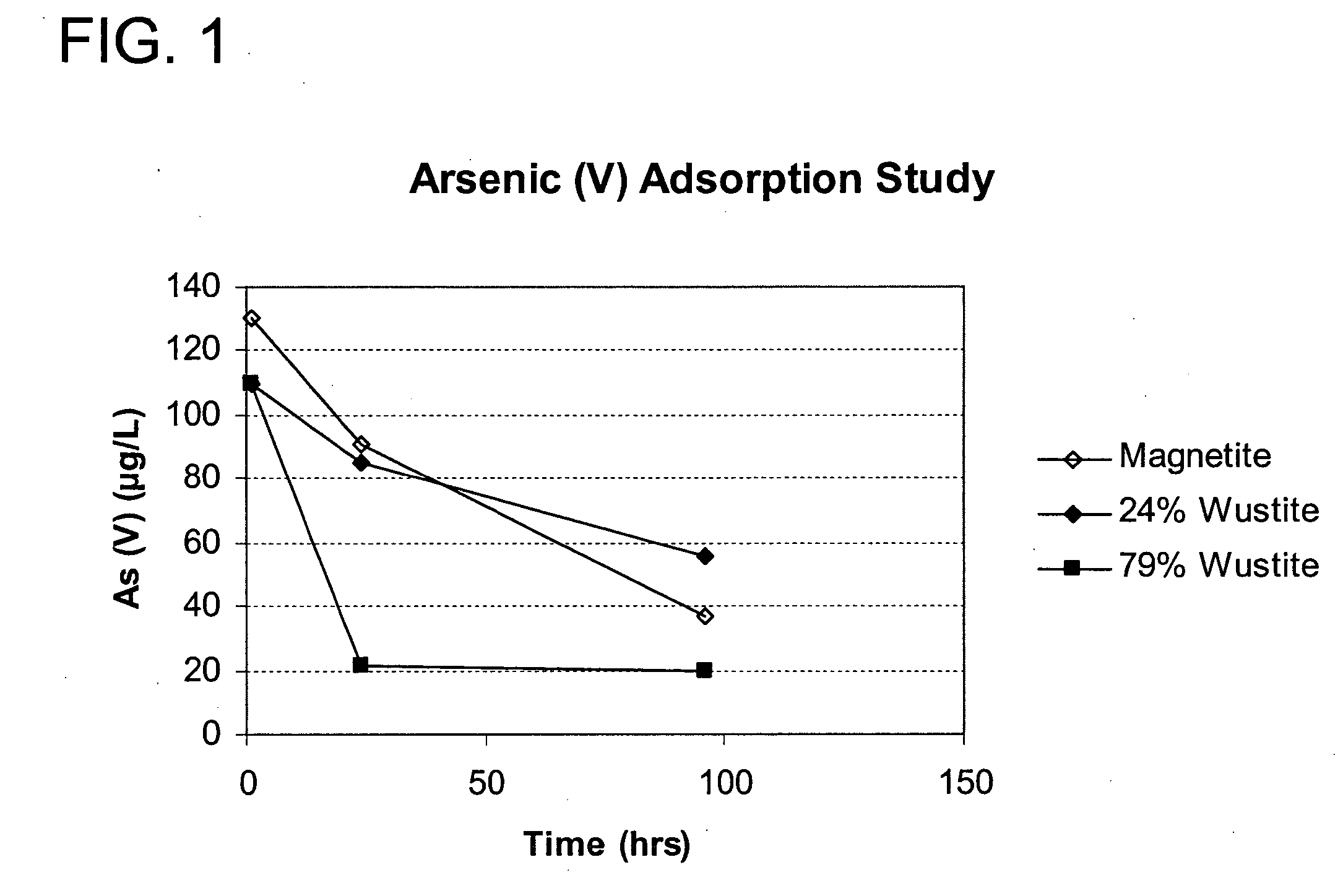

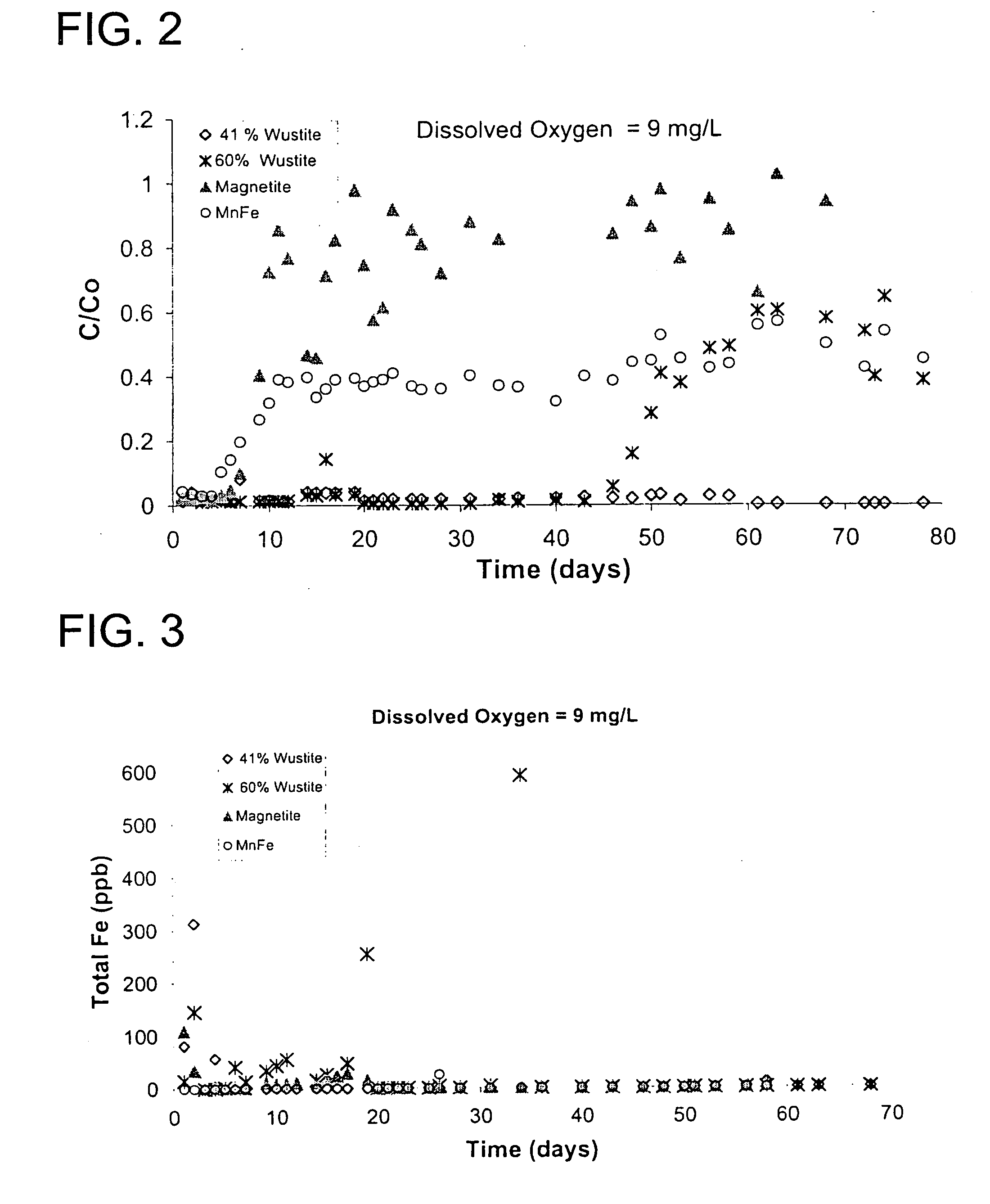

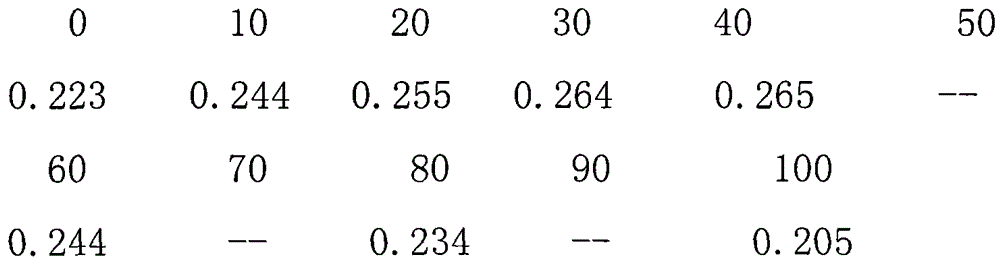

An adsorbent is disclosed which uses an iron-containing metal oxide as an adsorbent for removing heavy elements from contaminated waters and method for the use of the same. The bed includes a non-stoichiometric ferrous oxide Fe1-xO, which is structurally in a Wustite crystal phase form having the rock salt, face-centered cubic lattice.

Owner:PELTECH +1

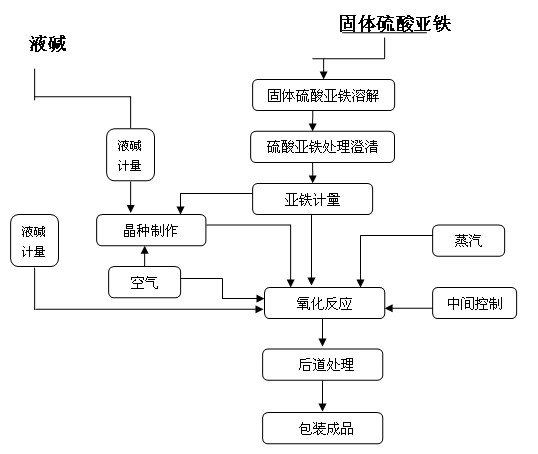

High-purity iron oxide black pigment and production method thereof

ActiveCN102139927AHeavy metal content controlHigh purityFerroso-ferric oxidesIron(II) oxideIron oxide black

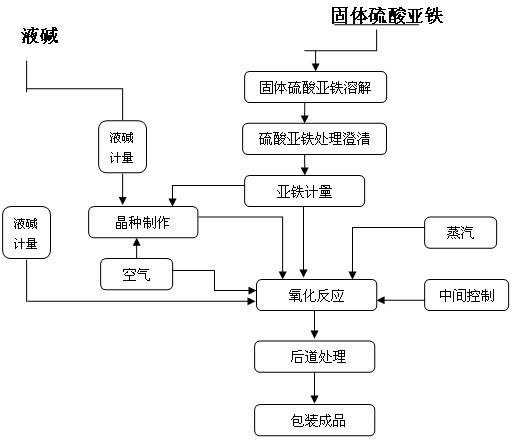

The invention relates to a high-purity iron oxide black pigment and a production method thereof. The production method comprises the following steps of: with a crystal seed as a carrier in a liquid phase method production process, carrying out reaction on ferrous sulphate and sodium hydroxide in an oxidation barrel, immediately generating ferrous hydroxide sol under the alkali condition, introducing steam and warming for reaction, introducing air for oxidation after a specified temperature is reached, and reacting for a period of time to obtain the high-purity iron oxide black pigment. The granules of the product obtained by the method are small and uniform compared with a synthetic method, and the yield is high and the coloured light is good; meanwhile, the purity of the product is controlled, thus the operating requirement in the industry is met. The invention also aims at providing the high-purity iron oxide black pigment prepared by adopting the method.

Owner:SHENGHUA GROUP DEQING HUAYUAN PIGMENT

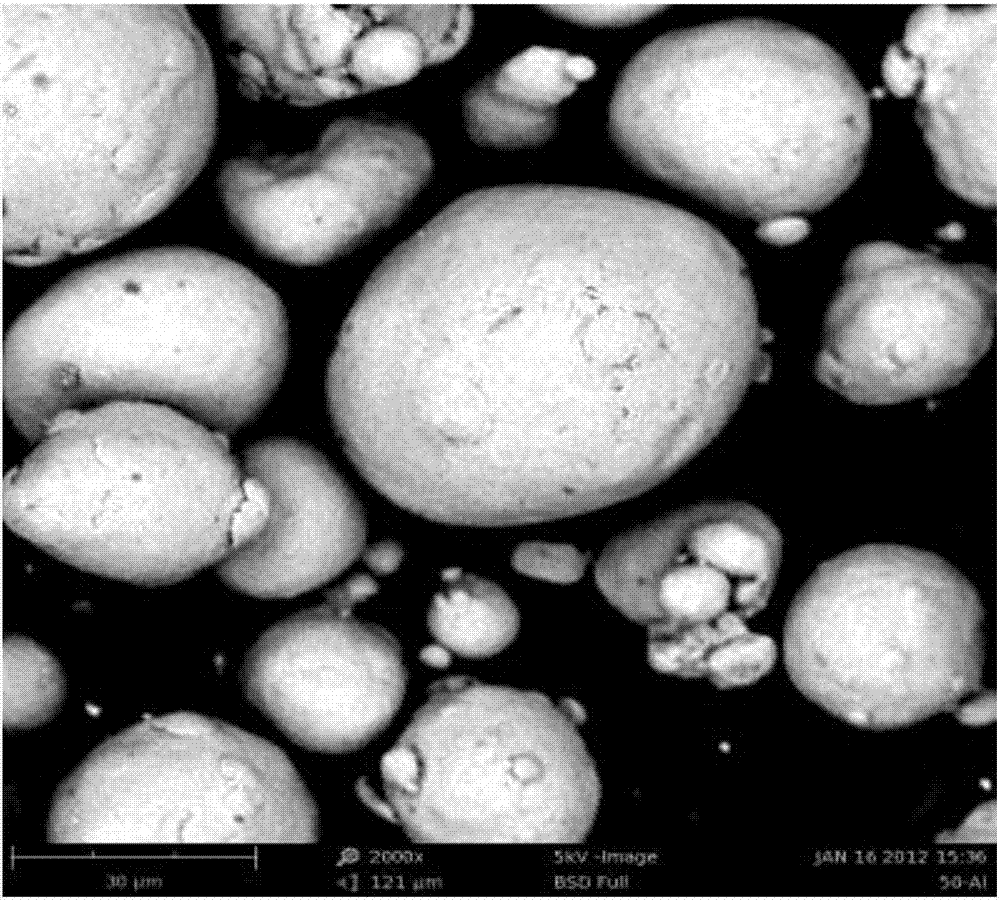

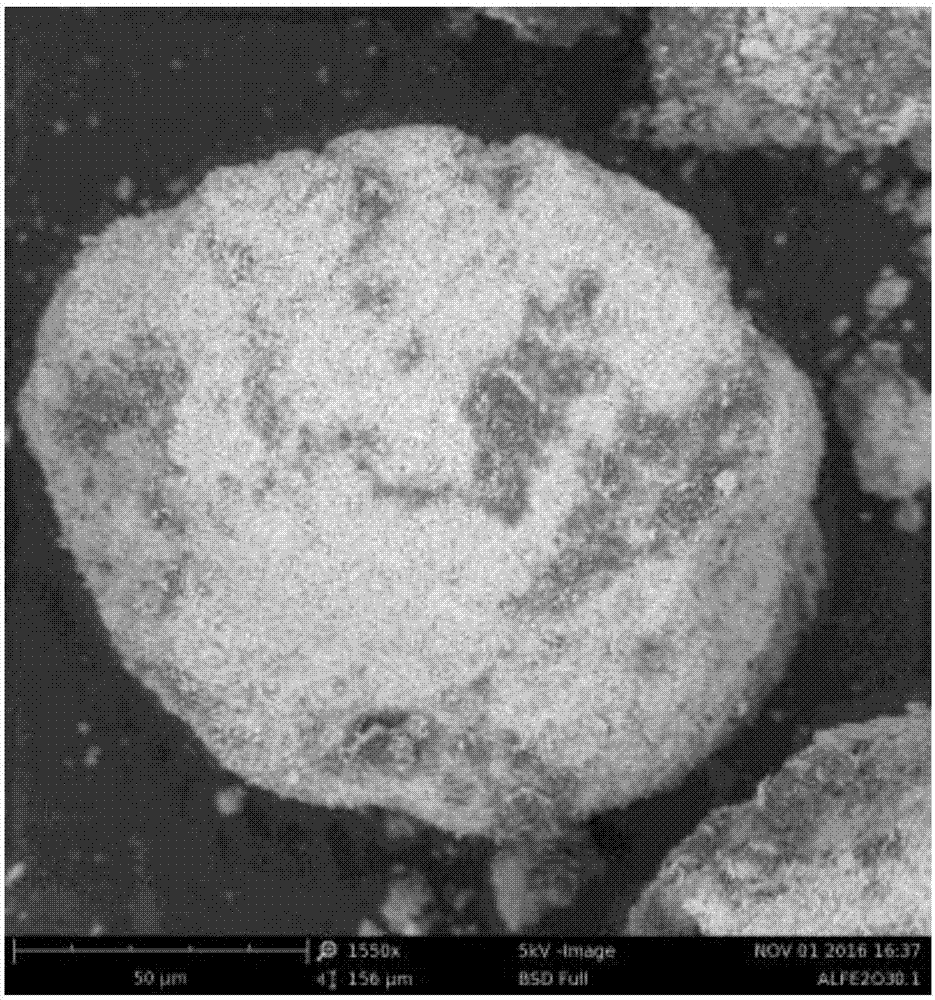

Preparation method for composite material with micro/nano core-shell structure

ActiveCN106925772AUniform coating effectDense coating effectTransportation and packagingMetal-working apparatusMicron scaleIron(II) oxide

The invention discloses a preparation method for a composite material with a micro / nano core-shell structure. The method comprises the step of compounding micron-scale metal particles with nano-scale metal oxide particles to form the composite material with the micro / nano core-shell structure through the coordination effect of polyphenol hydroxyl compounds and a ferric ion solution, wherein the micron-scale metal particles are aluminium powder, iron powder, copper powder, nickel powder, tungsten powder or zinc powder with a particle size ranging from 1 [mu]m to 1000 [mu]m, and the nano-scale metal oxide particles are aluminium oxide, ferric oxide, ferroferric oxide, ferrous oxide, copper oxide, tungsten trioxide, nickel oxide or zinc oxide with a particle size ranging from 1nm to 1000nm. According to the preparation method disclosed by the invention, a shell material achieves a uniform and compact coating effect; and moreover, the preparation method is short in treatment time, a reagent is environmentally friendly and free of toxicity, and a post-treatment process is simple and convenient.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

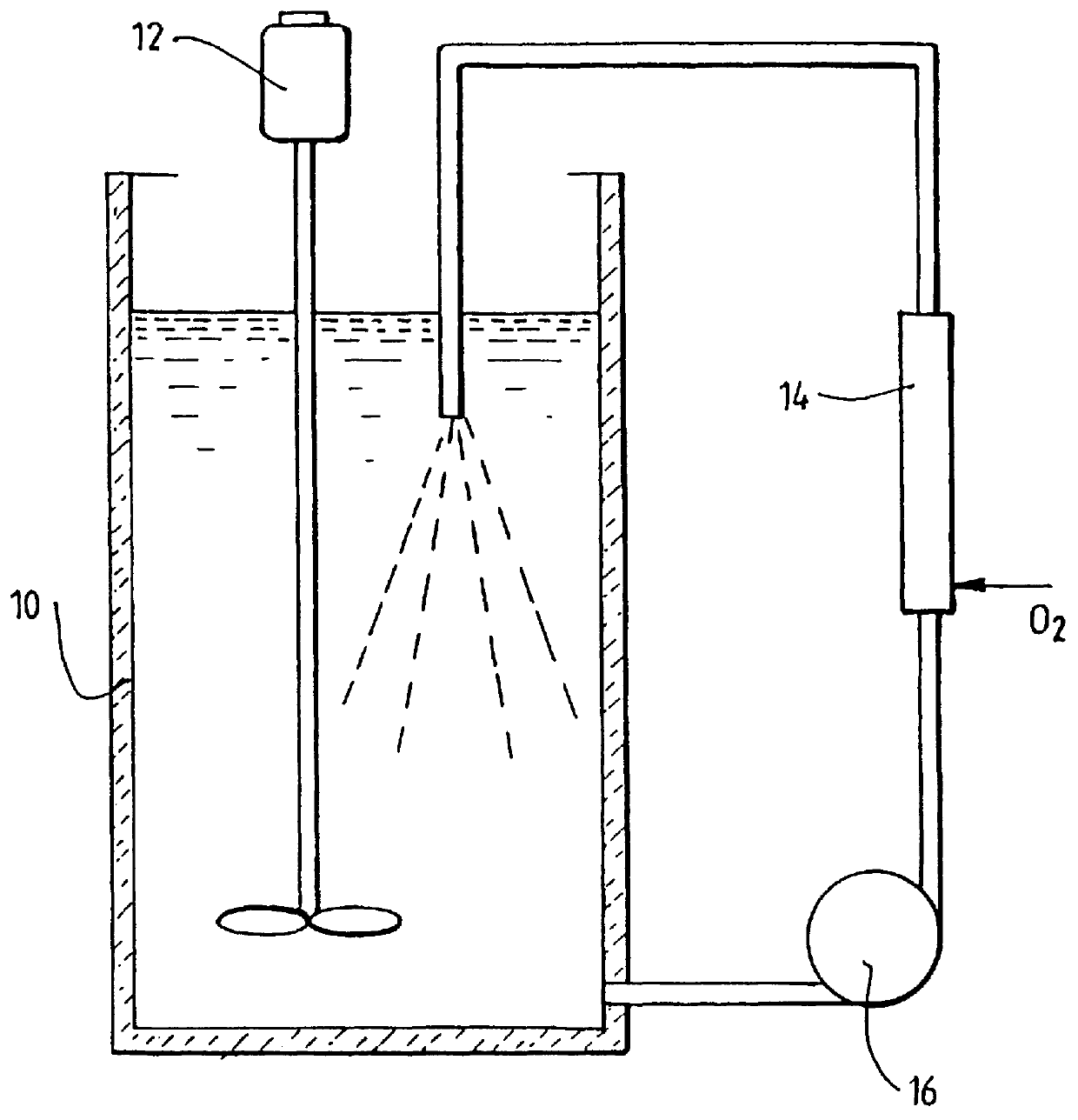

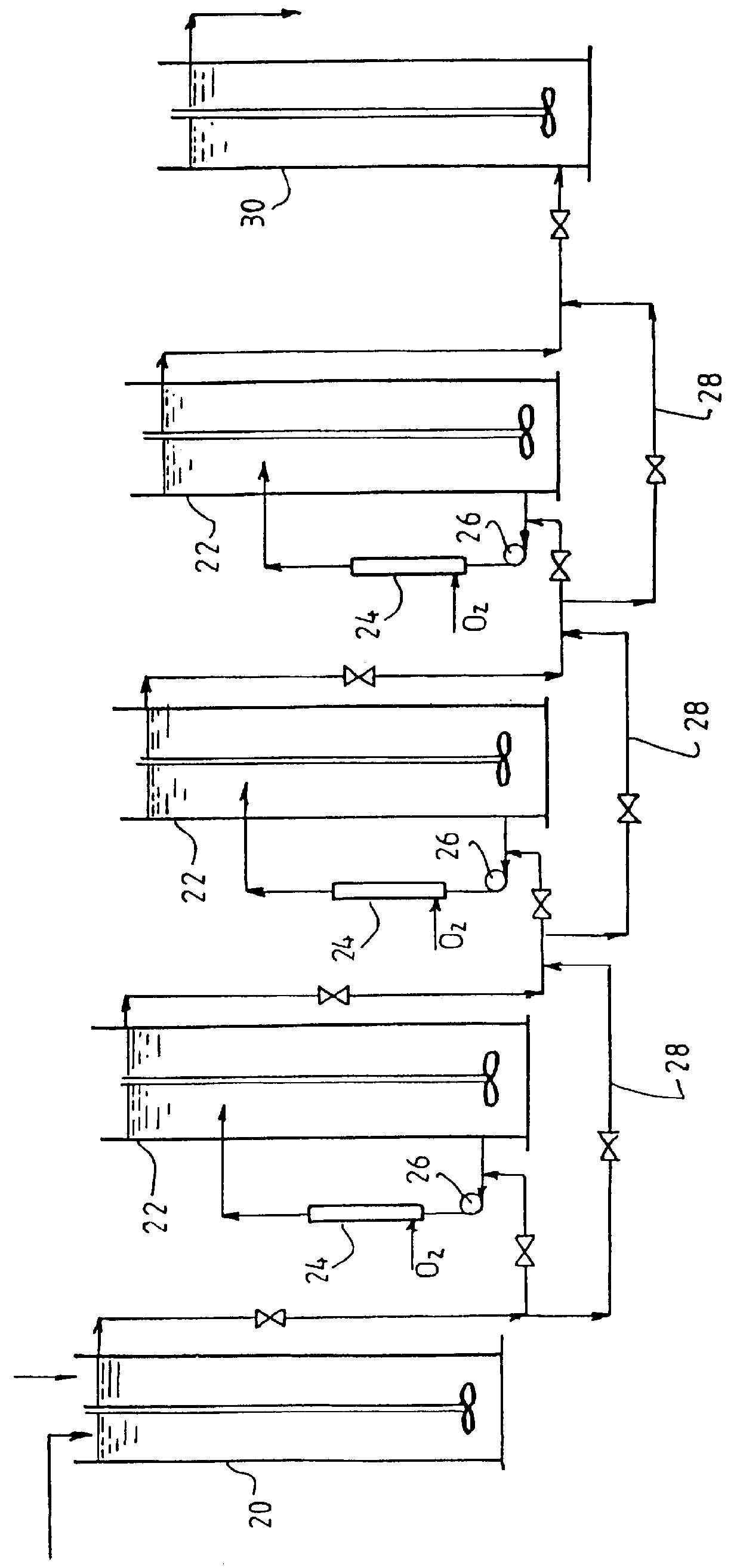

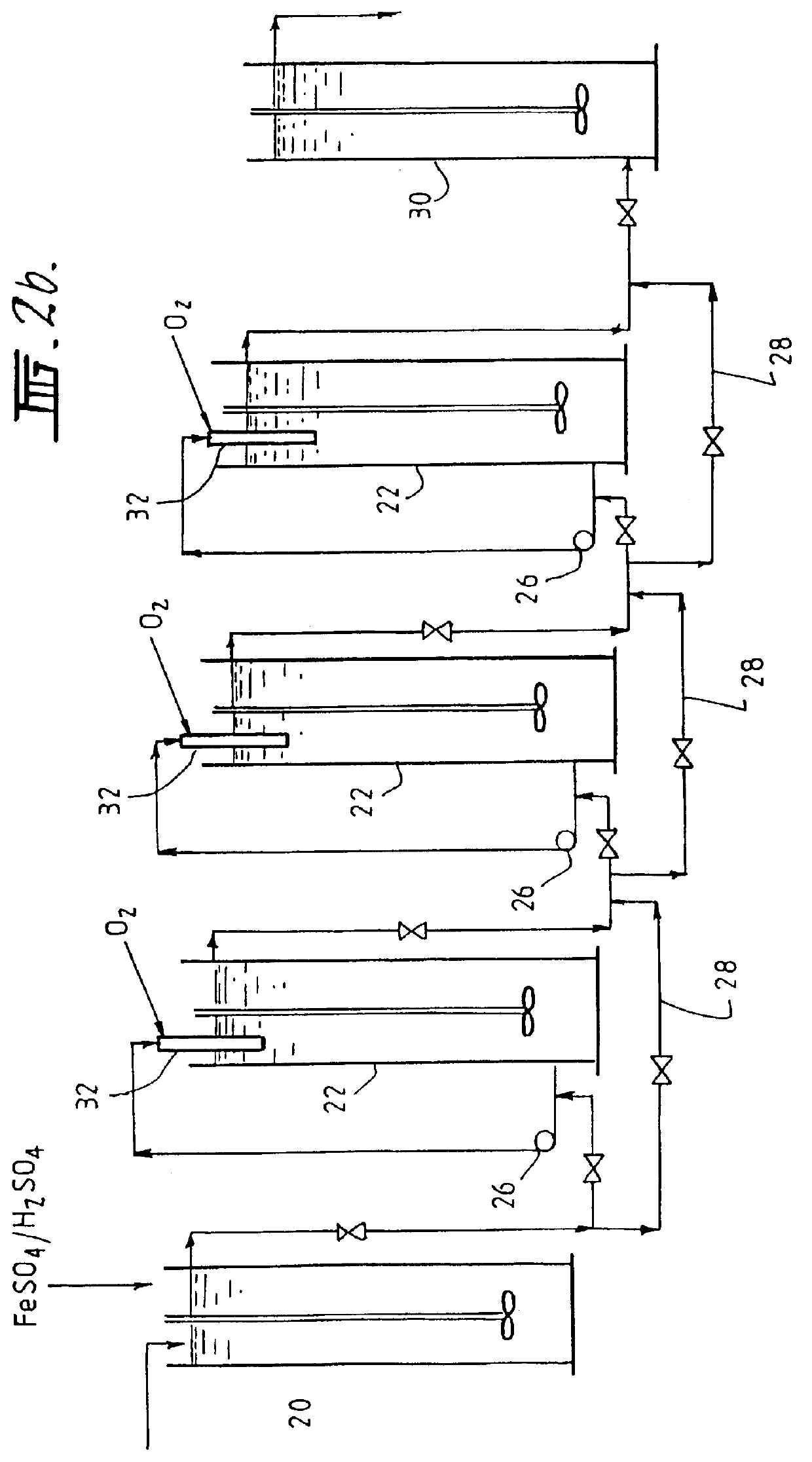

Leaching of mineral ores

A process for oxidation of ferrous ions in solution, and more particularly a process for improved base metal and / or uranium leaching from ores, concentrates or tailings using ferric ion as an oxidizing agent. A reaction vessel (10) holds a ferrous ion-containing solution, for example, a copper sulphide leach slurry or concentrate. An agitator (12) may be provided to promote leaching of the base metal into solution. Some of the ferrous ion-containing solution is drawn off from the reaction vessel (10) and pumped through an in-line mixer (14) via a feed pump (16). Oxygen is injected into the reactor (14) to facilitate oxidation of the ferrous sulphate to form ferric sulphate. The ferric ion-containing solution is then recirculated back to the reaction vessel (10) where the ferric ions are reused in the dissolution of copper sulphide into soluble copper sulphate. The two processes of ferrous oxidation and metal leaching can be conducted either simultaneously or sequentially to effect recovery of copper, other base metals or uranium from ores, concentrates or tailings.

Owner:ATOMAER

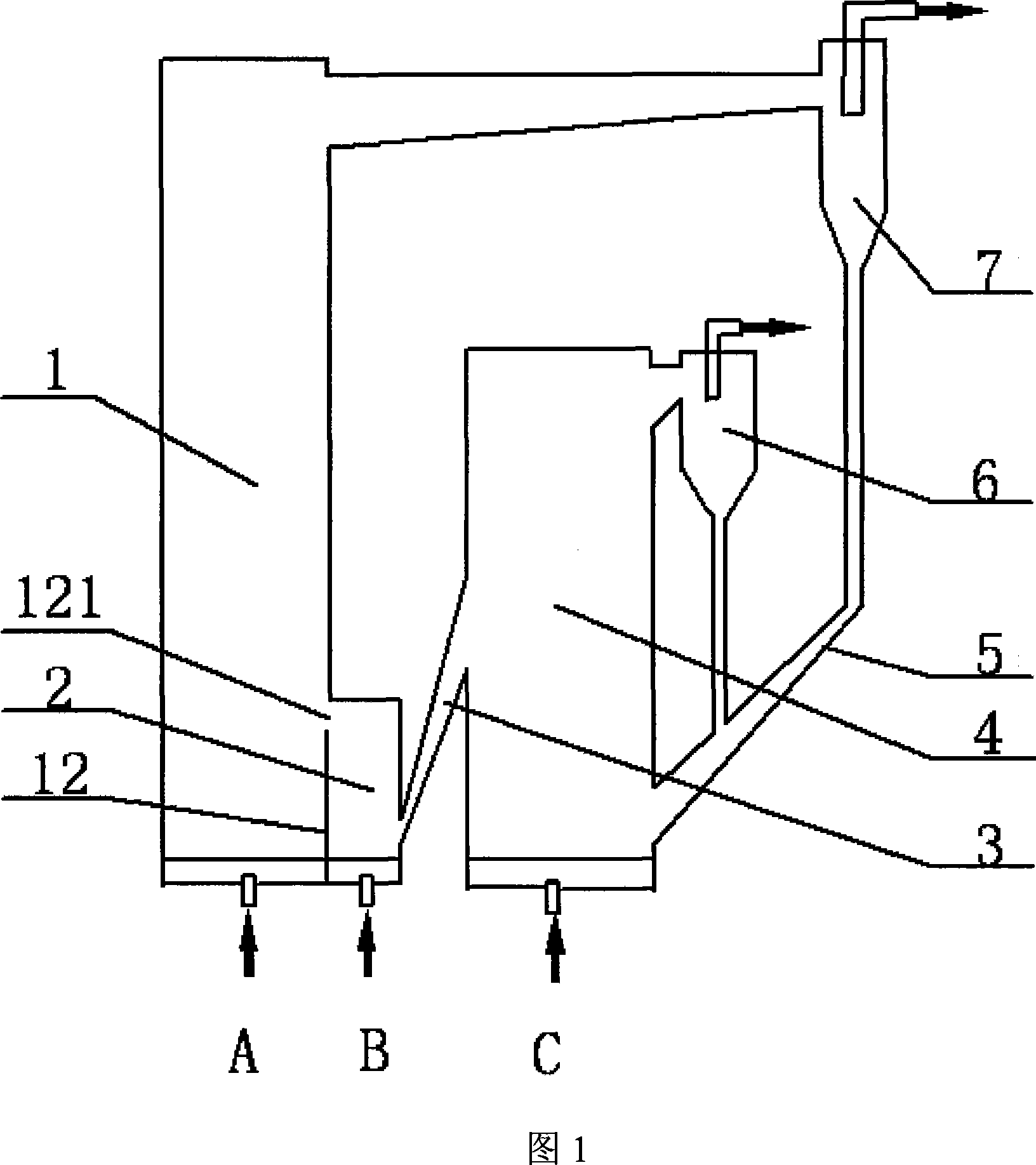

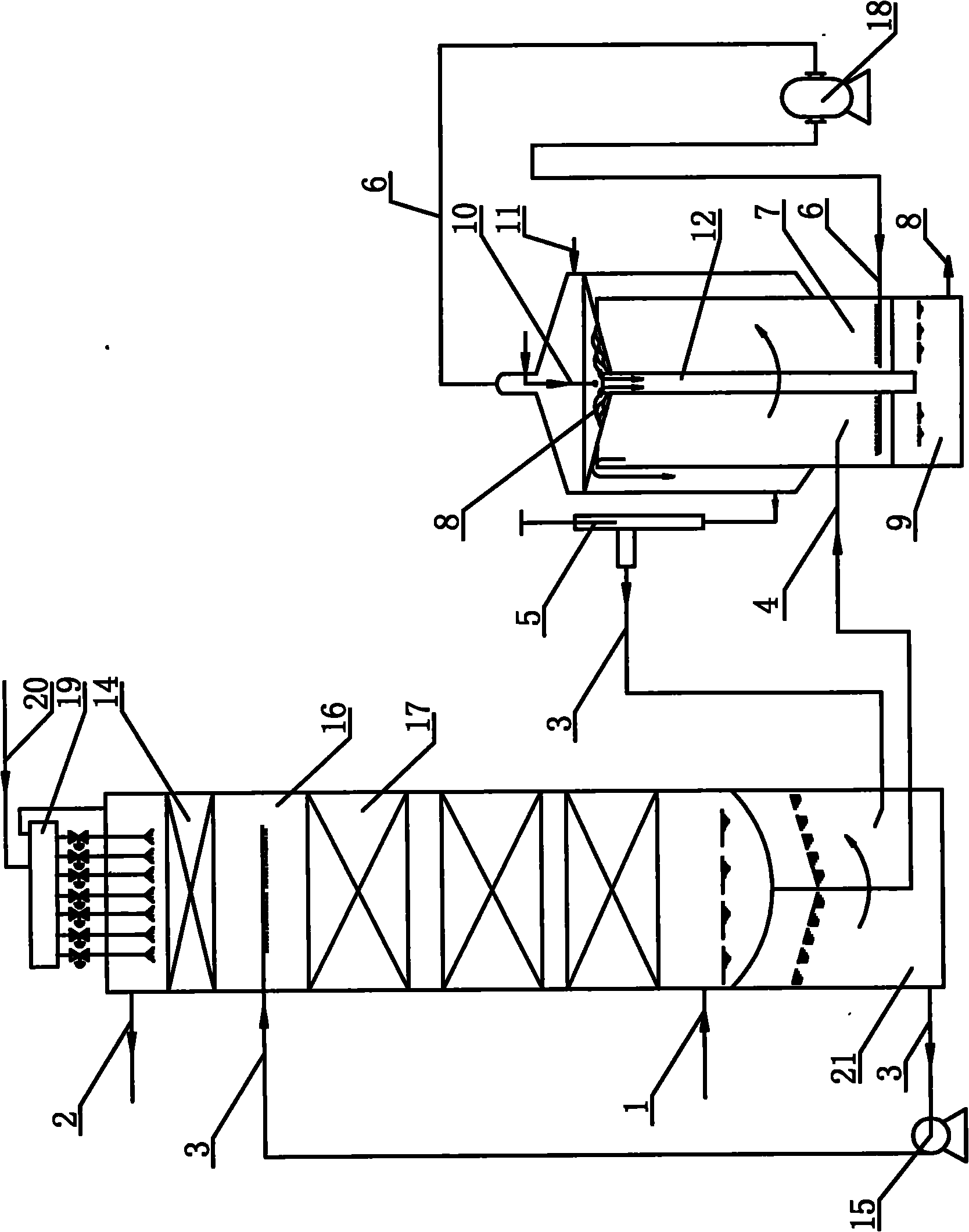

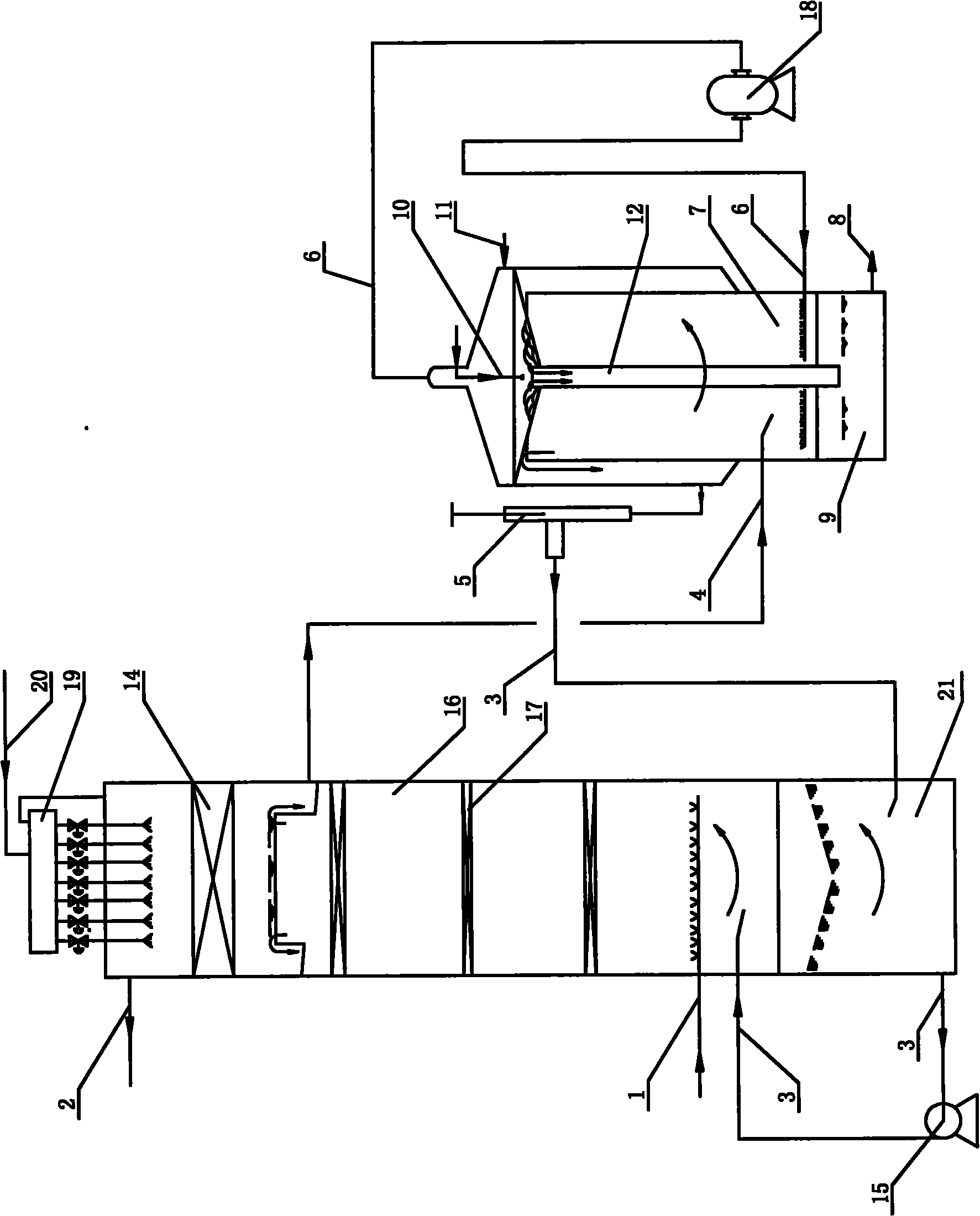

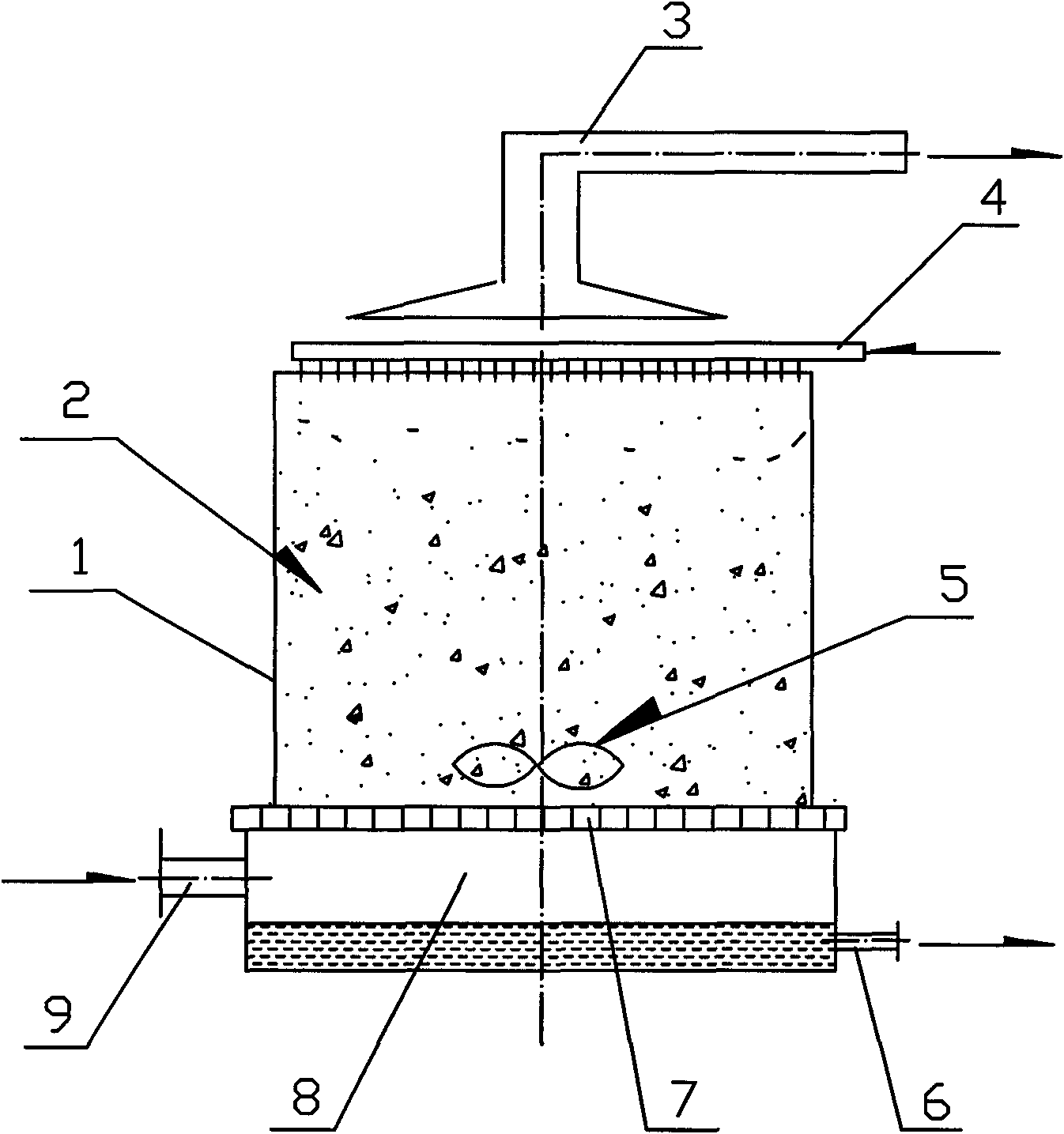

Gas fuel oxygen-carried hydrogen-produced and carbon dioxide separation method and device

ActiveCN101100284AEffective isolationReduce consumptionHydrogenCarbon compoundsHigh concentrationHydrogen

This invention relates to a method for producing hydrogen by using combustible reducing gas as raw material, and using iron / ferrous oxide as oxygen-carrier, during the reaction in a fluidized bed reactor, with coproduct of high concentration carbon dioxide. This invented equipment comprises: a circulation fluidized bed, a moveable bed, a bubbling fluidized bed, a hydrogen separator unit and a carbon dioxide separator. A horn type bucket is used under the bottom of hydrogen separator and connecting the lower part of the bubbling fluidized bed; the bottom of the carbon dioxide separator is connected with horn type bucket; a contraction type bucket is used for connection middle lower part of the bubbling fluidized bed and the moveable bed; the upper part of moveable bed is connected with the middle part of the circulation fluidized bed; the lower ends of the circulation fluidized bed and moveable bed and bubbling fluidized bed are equipped with fluidized steam inlets A and B gas fuel inlet C. This invention has advantages of: simple struction, low cost and high efficiency.

Owner:TSINGHUA UNIV

Composite metal oxide phosphorous removal adsorbent and preparation method thereof

ActiveCN105013435ALow priceImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionIron(II) oxideSorbent

The invention discloses a composite metal oxide phosphorous removal adsorbent and a preparation method thereof. The composite metal oxide phosphorous removal adsorbent comprises main materials and an auxiliary material. The main materials comprise, by weight, 35-50% of alumina, 25-35% of iron oxide and 25-35% of calcium oxide. The auxiliary material comprises bentonite as a binder and the weight of the auxiliary material is 3-5% that of the main materials. The preparation method comprises raw material pre-treatment, blank molding, blank drying, presintering treatment, roasting treatment and cooling. The composite metal oxide phosphorous removal adsorbent has excellent physical and chemical properties and a high phosphorous removal adsorption capability and solves the problem of use of a single metal oxide. The composite metal oxide phosphorous removal adsorbent reduces sewage factory product water phosphorous content, satisfies upgrading and reconstruction purposes, realizes first-level A discharge standard and has a good development prospect and a practical meaning.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

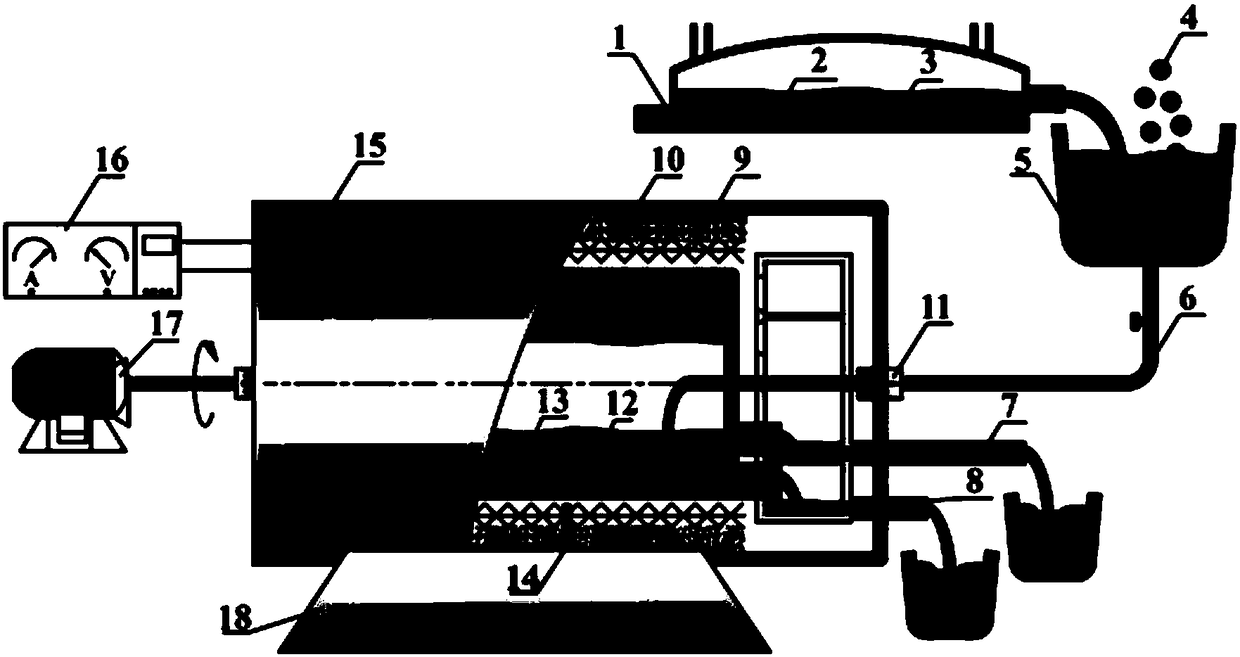

Method and device for achieving low-temperature quick separating of metallic copper in copper slag through supergravity

ActiveCN108165756AHigh purityHigh recovery rateProcess efficiency improvementMagnetiteSilicon dioxide

The invention discloses a method and device for achieving low-temperature quick separating of metallic copper in copper slag through the supergravity and belongs to the field of comprehensive utilization of resources. Firstly, 3-5% of carbon powder is added in the copper smelting slag discharging process to serve as a reducing agent to reduce magnetite particles in the slag into ferrous oxide, andthe ferrous oxide and silicon dioxide in the slag form a fayalite phase; then, copper slag melts are continuously added into a supergravity reactor through a flow guiding system, and the temperatureof the copper slag is controlled; and then, a centrifugal rotation system is started, the supergravity reactor is driven by a motor to conduct centrifugal rotation, the gravity coefficient and the separating time are controlled, and continuous separating between the metallic copper and the molten slag is achieved through the supergravity generated by centrifugal rotation. According to the method and device, under the condition of the supergravity, low-temperature quick separating between the metallic copper in the copper slag and the molten slag is achieved, the copper-slag separating efficiency is improved, the purity degree and recovery rate of the metallic copper are increased, the metallic copper with the Cu content being larger than 85% and an iron-slag-rich phase with the Cu contentbeing lower than 0.15% are obtained, and the recovery rate of Cu reaches 97% or above; and according to the method, operation is easy, the cost is low, and continuous production can be achieved.

Owner:UNIV OF SCI & TECH BEIJING

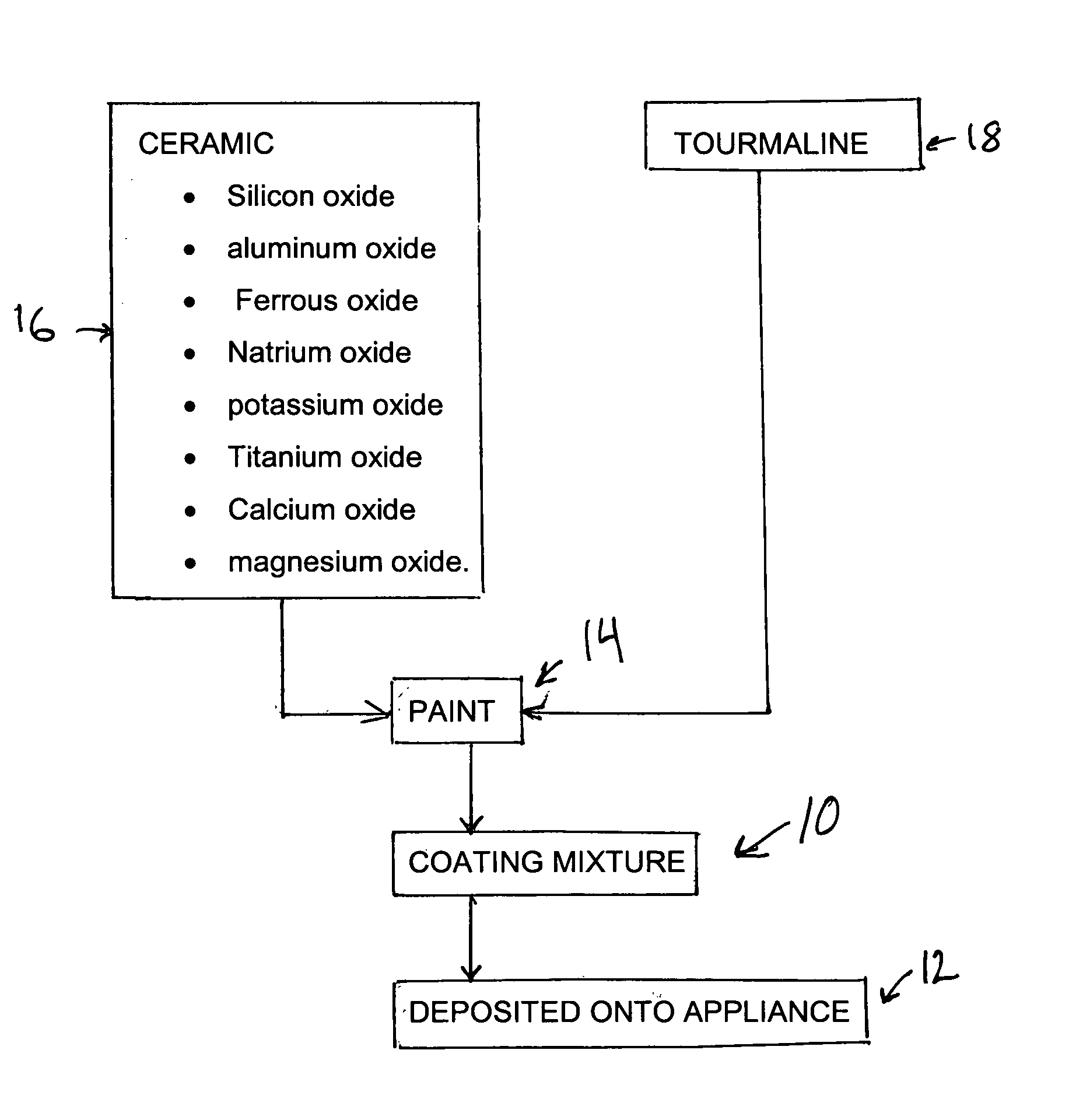

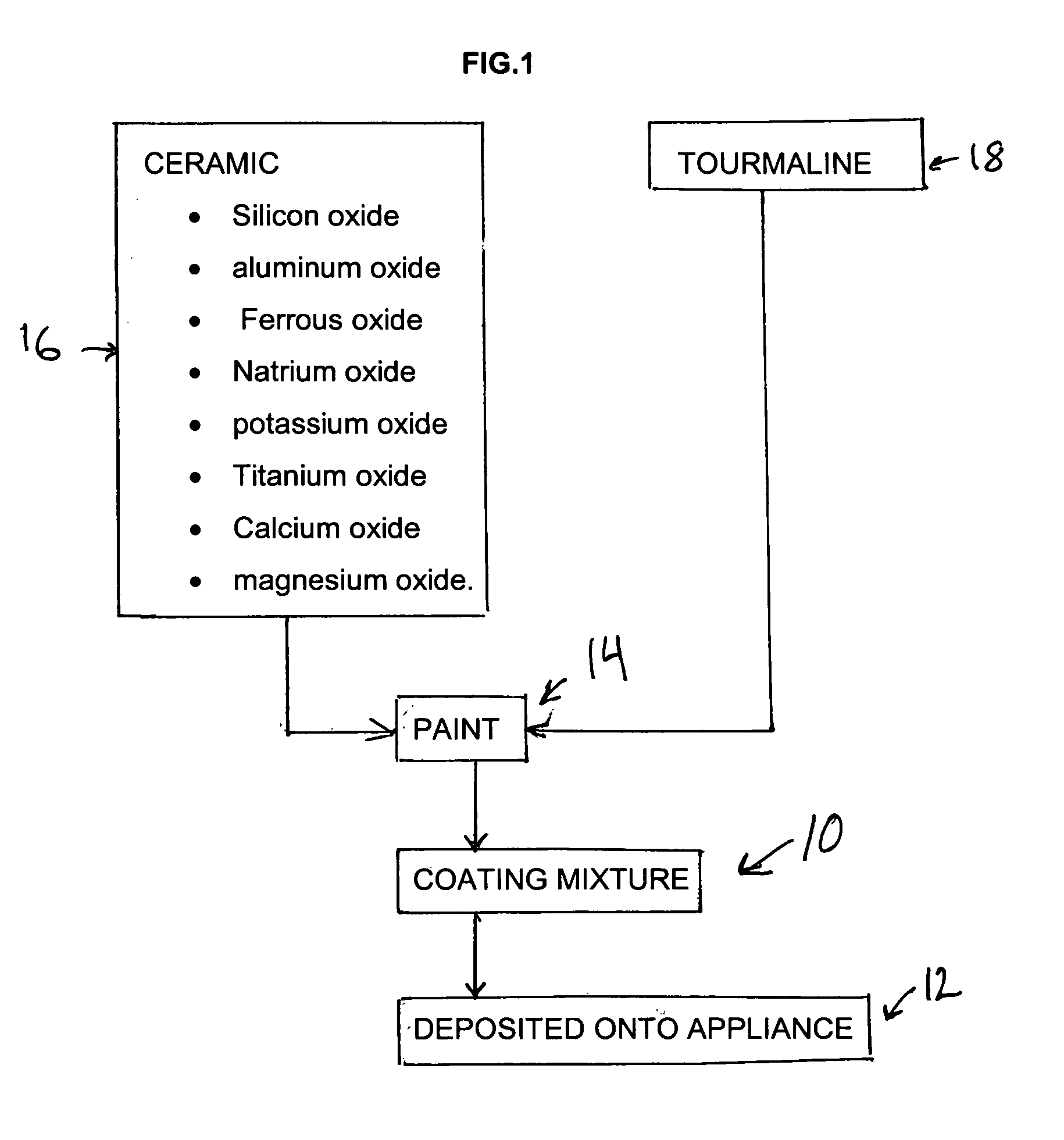

Ceramic and tourmaline hair appliances

InactiveUS20070029302A1Distribute heat efficiently and evenlyEasy dischargeCurling-ironsCurling-tongsIron(II) oxideSilicon oxide

A coating mixture is applied to a hair appliance such as a styling iron, a dryer, or a roller by being mixed with a paint or by other known deposition means, and includes a ceramic component and a tourmaline component. Preferably, the ceramic component contains one or more of Silicon oxide, aluminum oxide, Ferrous oxide, Natrium oxide, potassium oxide, Titanium oxide, Calcium oxide, and magnesium oxide. The tourmaline component comprises crushed tourmaline particles of a size and concentration generally known in the art. By applying both components, preferably in the form of a mixed paint, a surface on an appliance or accessory that is adapted to receive heat will emit ions and, due to the known characteristics of both ceramic and tourmaline, will retain and distribute heat efficiently and evenly.

Owner:CONAIR CORP

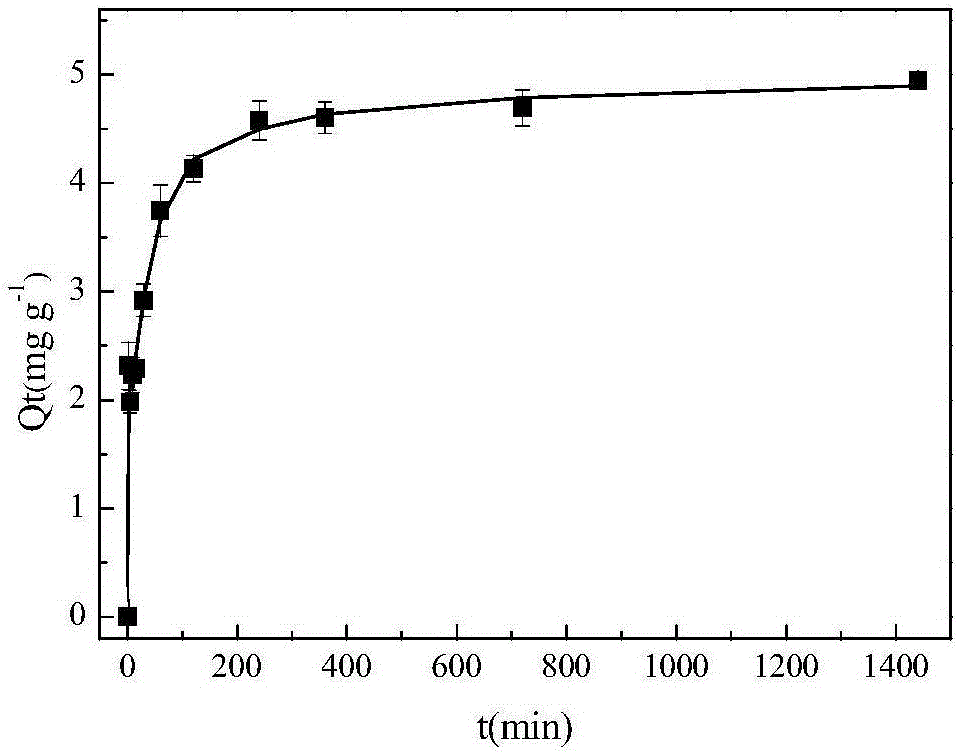

Preparation method of magnetic nano Fe3O4 particles by biological catalysis and application of particles to treatment of uranium-containing wastewater

InactiveCN103877927AImprove adsorption capacityThe synthesis process is simpleOther chemical processesAlkali metal oxides/hydroxidesThiobacillus ferrooxidansIron(II) oxide

The invention provides an ecological and environment-friendly new method for preparing magnetic nano Fe3O4 particles by biological catalysis, and application of the particles to treatment of uranium-containing wastewater. The method comprises the following concrete steps: (1) culturing and domesticating thiobacillus ferrooxidans; (2) preparing bio-polymeric ferric sulfate; (3) synthesizing the magnetic nano Fe3O4 particles; (4) performing a test of adsorbing uranium in the uranium-containing wastewater by the magnetic nano Fe3O4 particles. The obtained magnetic nano Fe3O4 particles are simple in preparation synthesis route, mild in reaction condition and easy to operate; a biological catalysis oxidant is used for replacing a conventional chemical oxidant (nitrite), so that cancerogenic substances are prevented from being discharged to the environment and the environment-friendly effect is really achieved. Meanwhile, the obtained magnetic nano Fe3O4 particles can reduce the content of uranium in the low-concentration uranium-containing wastewater with the concentration of 0.45-0.50mg / L by more than 90% and have very important practical meaning in aspects of uranium-containing wastewater treatment, uranium recovery and the like in uranium mining and metallurgy.

Owner:NANHUA UNIV

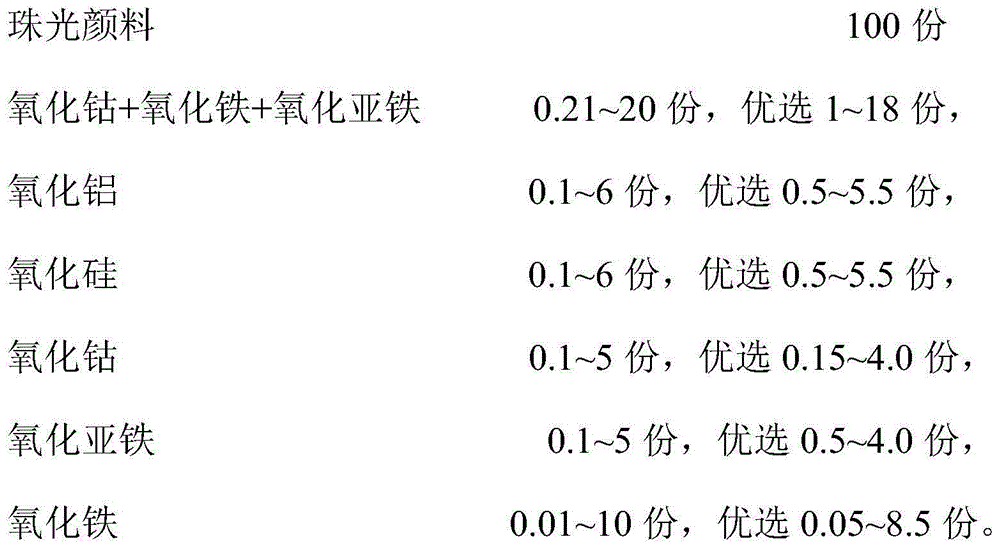

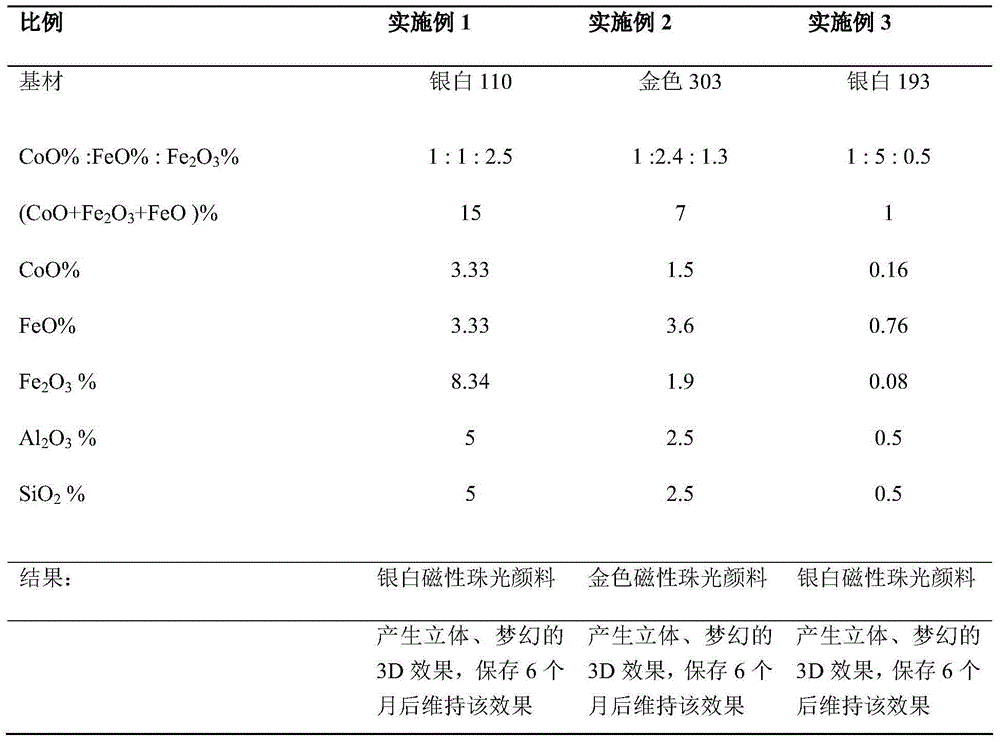

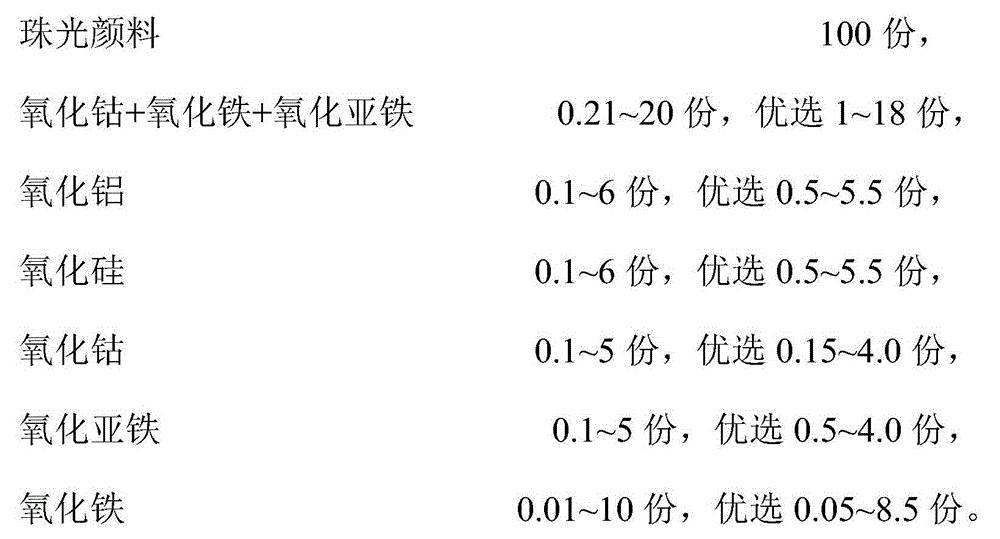

Magnetic pearlescent pigment with 3D (three-dimensional) effect and preparation method of magnetic pearlescent pigment

ActiveCN104893366AReduce the loss of ferroferric oxideReduce magnetic lossInorganic pigment treatmentCobalt oxideChemistry

The invention discloses magnetic pearlescent pigment with a 3D (three-dimensional) effect and a preparation method of the magnetic pearlescent pigment. The magnetic pearlescent pigment comprises pearlescent pigment, a magnetic coating and a protecting layer, wherein the magnetic coating is located on one or more pearlescent pigment layers and comprises cobalt oxide, iron oxide and iron protoxide; the protecting layer is located on the magnetic coating; the pearlescent pigment comprises a base material and one or more pearlescent pigment layers. The prepared magnetic pearlescent pigment with the 3D effect can have a stereoscopic and dreamlike 3D effect by utilizing the magnetic tracking phenomenon of a surface magnetism material. By means of the preparation method of the magnetic pearlescent pigment with the 3D effect, the problem that ferrous iron is easily oxidized in the prior art can be solved, loss of ferroferric oxide is reduced, magnetic loss is reduced, part of produced iron cobaltate is stable and not prone to oxidation, and long-time storage of the pigment is guaranteed.

Owner:GUANGXI CHESIR PEARL MATERIAL CO LTD

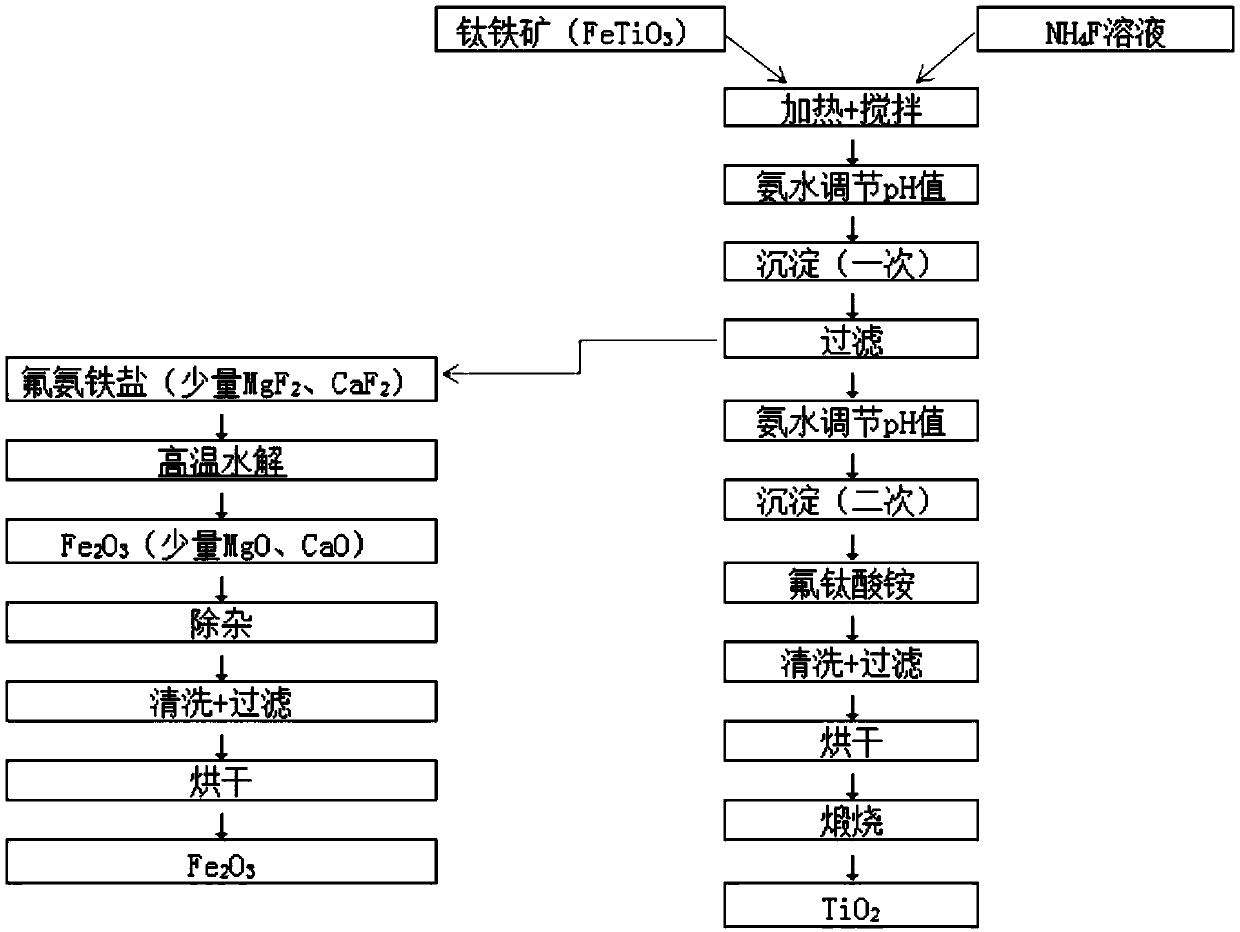

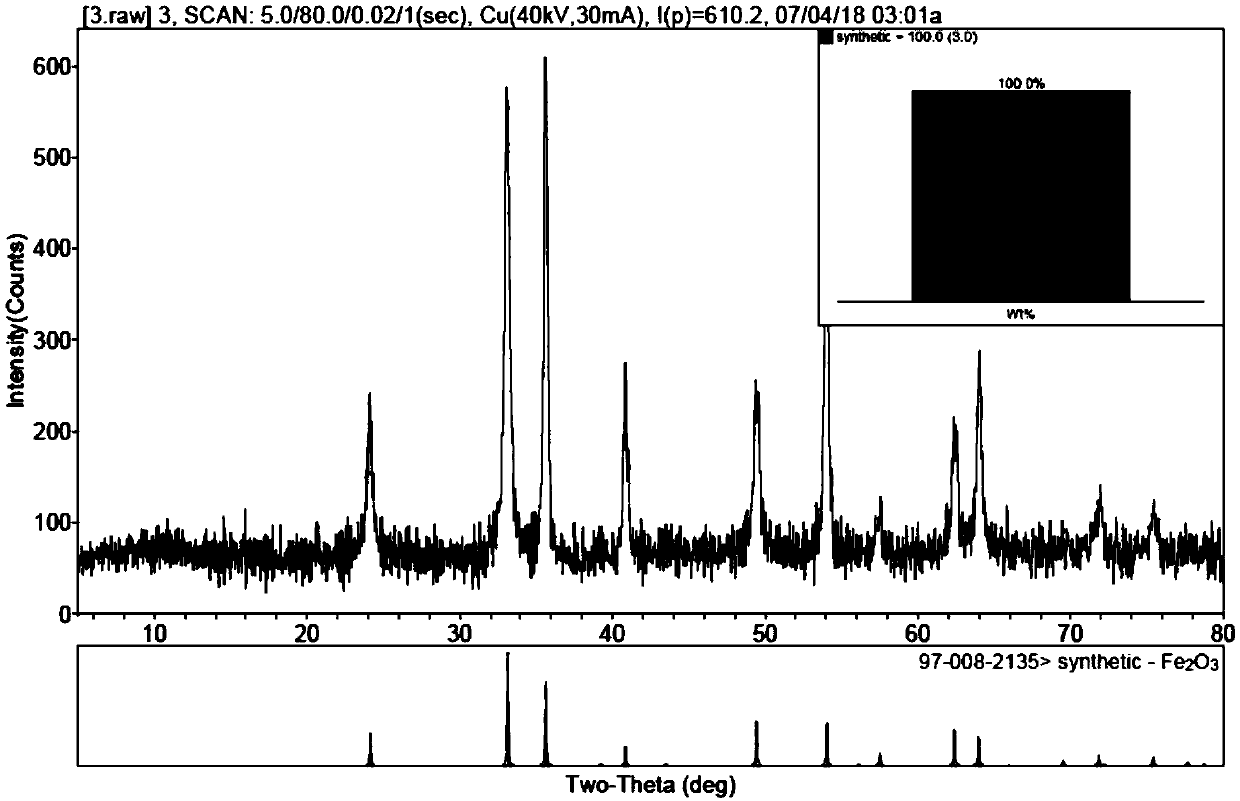

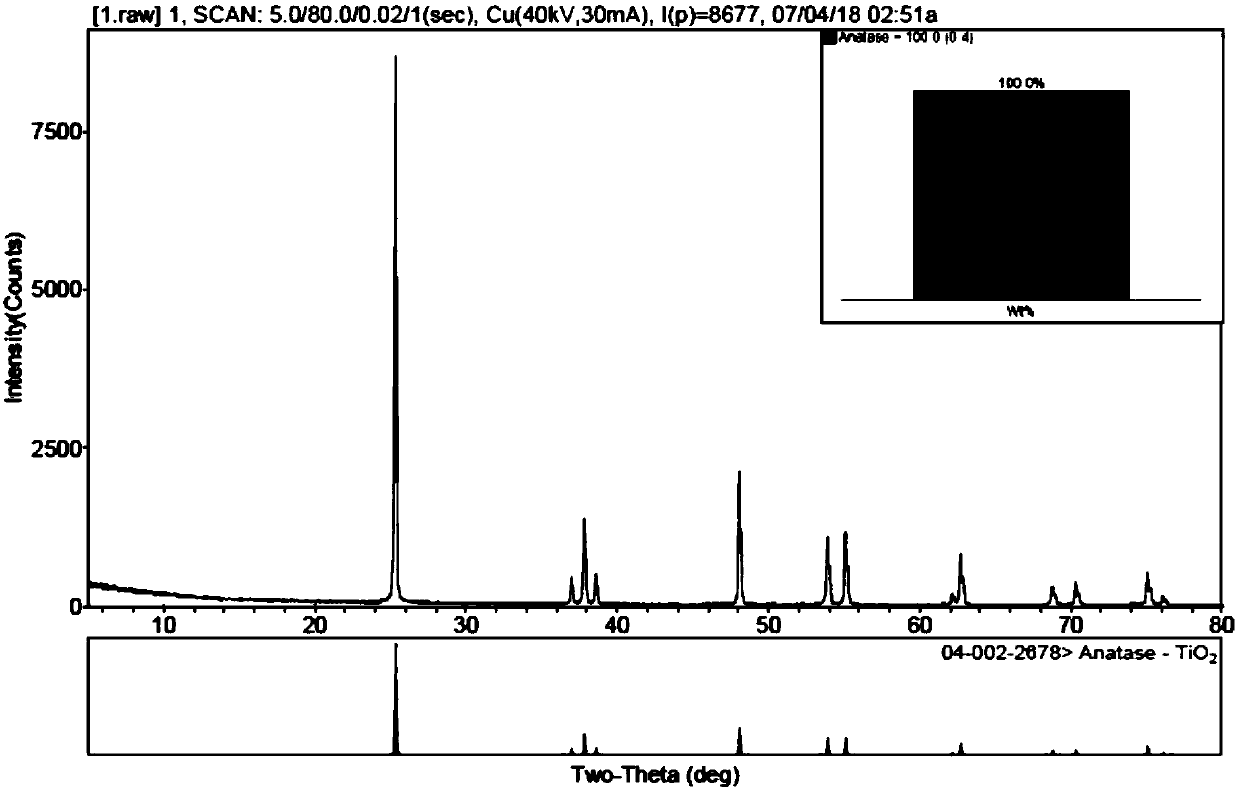

Method for preparing titanium dioxide and iron oxide by using fluoride purifying titanium-iron material

InactiveCN109626420ALow calcium and magnesium impuritiesEasy to separateMaterial nanotechnologyFerric oxidesIron(II) oxideAmmonium compounds

The invention provides a method for preparing titanium dioxide and iron oxide by using a fluoride purifying titanium-iron material. The method comprises the steps of mixing and heating a titanium-ironmaterial and a fluorine ammonium compound solution to obtain a mixture, wherein the fluorine ammonium compound is an ammonium fluoride or ammonium hydrogen fluoride; regulating the primary pH of themixture to obtain a first precipitate; separating the first precipitate and then regulating the secondary pH of the residual material to obtain a second precipitate; hydrolyzing the first precipitateat high temperature to obtain Fe2O3; roasting the second precipitate to obtain TiO2. By adopting the method, titanium and iron elements in the titanium-iron material can be thoroughly separated, and high-quality TiO2 and Fe2O3 pigment products are respectively obtained. The method is especially suitable for purifying and purifying treatment of high-calcium-magnesium titanium iron resources in a Panxi area (components and their analogs), materials with low calcium and magnesium impurity contents are obtained, namely titanium-rich materials, and titanium dioxide or titanium metal is produced fora subsequent sulfuric acid method and a chlorination method.

Owner:HUNAN KUNTAI METALLURGICAL ENG TECHCO LTD

Gas desulfurization and regeneration process and device by liquid phase iron oxide powder suspension method

InactiveCN101890287AImprove oxidation regeneration efficiencyImprove flotation efficiencyDispersed particle separationIron(II) oxideOxygen

The invention relates to a gas desulfurization and regeneration process by a liquid phase iron oxide powder suspension method, which is characterized in that: iron oxide powder or ferrous oxide powder suspension is adopted to remove hydrogen sulfide from gas; and the method comprises the following steps of: 1) mixing iron oxide powder or ferrous oxide powder with the granularity between 0.01 and 300 micrometers and water to form the suspension for desulfurization, and pumping the suspension into a desulfurization tower for circular spray by using a pump; 2) fully mixing sulfur-containing gas and the suspension for desulfurization in the desulfurization tower, discharging the desulfurized gas from the top of the desulfurization tower, and adding the suspension which has absorbed the sulfur into a regeneration tank; 3) in the regeneration tank, reacting oxygen-containing cyclic gas with the sulfur-containing suspension to generate iron oxide and sulfur element, and floating sulfur foam; and 4) flowing the regenerated iron oxide or ferrous oxide powder suspension out of the regeneration tank, and discharging into an intermediate tank on the bottom of the desulfurization tower for recycling. The process has the advantages that: the process has good desulfurization effect; the desulfurized suspension can be regenerated and recycled; and the equipment occupies a small area and runs safely.

Owner:姜辉

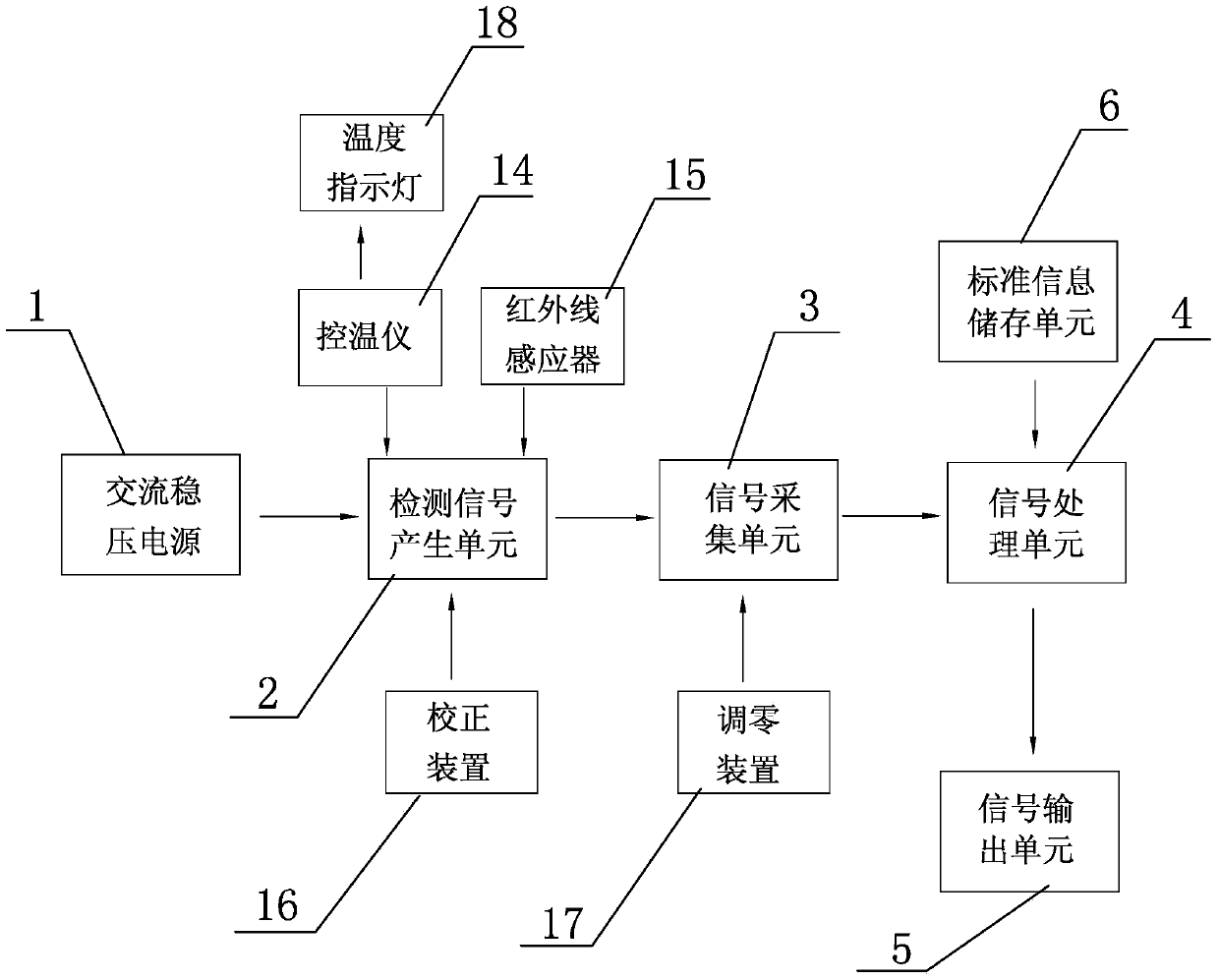

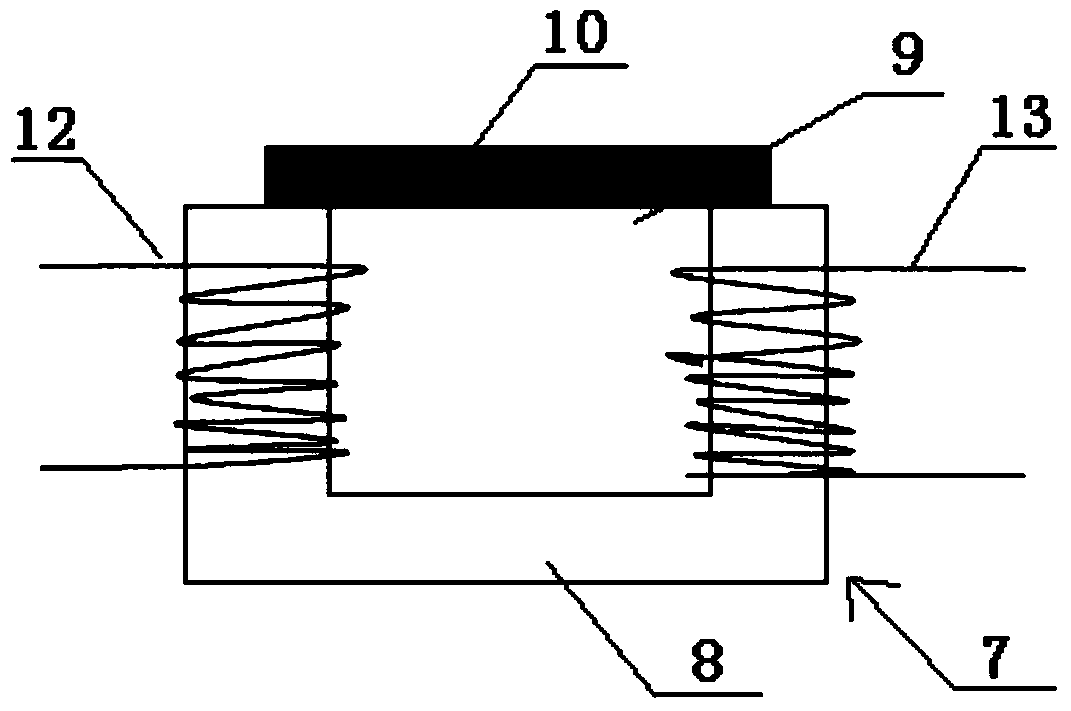

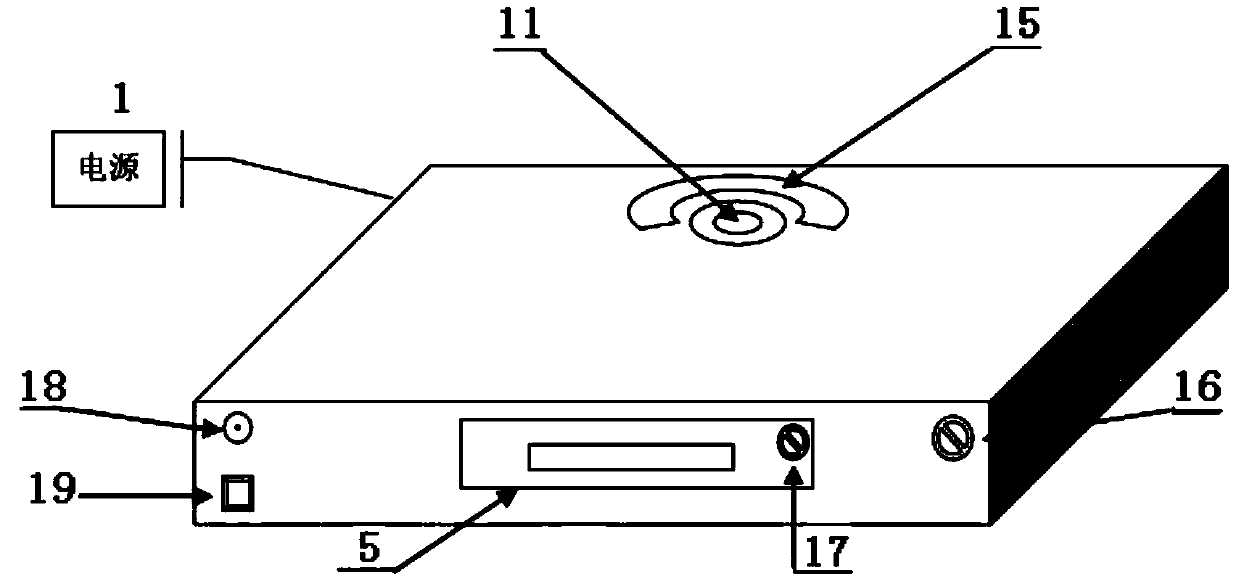

Rapid detection method and device for ferrous oxide in sintered ores

ActiveCN103499634ARapid determinationEasy to operateMaterial magnetic variablesSample MeasureTransformer

The invention discloses a rapid detection method and a device for ferrous oxide in sintered ores. The detection method comprises the following steps: subjecting a sample to a pre-treatment, establishing a standard curve between the sintered ore magnetic conductivity and the corresponding ferrous oxide content in the sintered ore, and finally substituting the measured sample magnetic conductivity into the standard curve between the sintered ore magnetic conductivity and the ferrous oxide content to calculate the concentration of ferrous oxide in the sinter ore sample. The device comprises a detection signal generating unit, the upper end of the iron core of the transformer of the detection signal generating unit is provided with a magnetic circuit disconnecting gap, the magnetic circuit disconnecting gap is provided with a sample measuring cavity, which is used to place an sintered ore sample and make the sample contact and connect to the iron core; a signal collecting unit is used to convert the collected voltage signals into magnetic conductivity signals and then transmits the magnetic conductivity signals to a signal processing unit, the signal processing unit is used to substitute the magnetic conductivity into the standard curve to calculate the ferrous oxide concentration of the sample, and the device has the advantages of low detection cost, rapid analysis speed, and accurate detection result.

Owner:王博

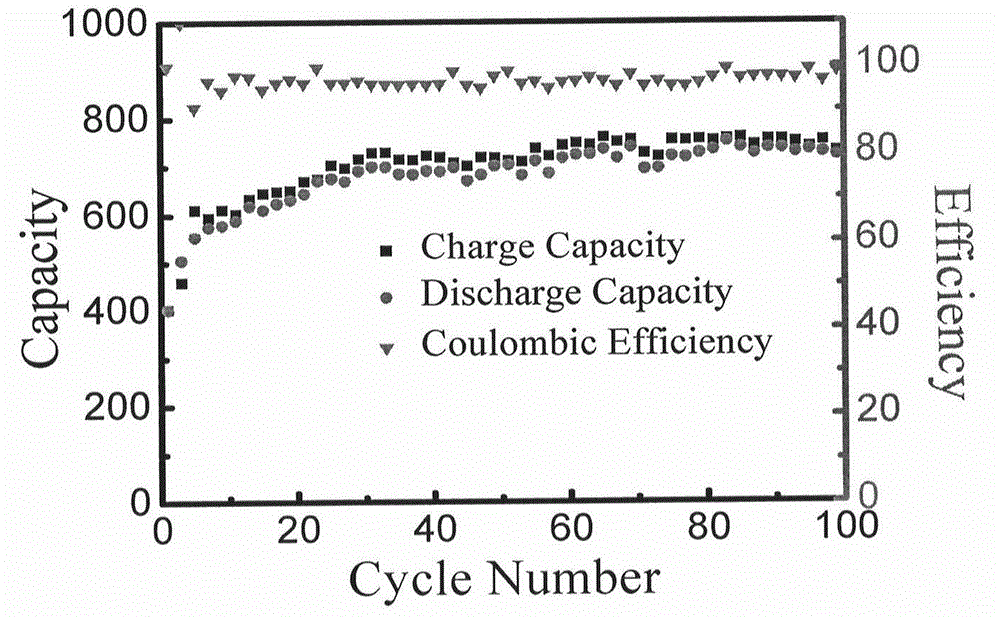

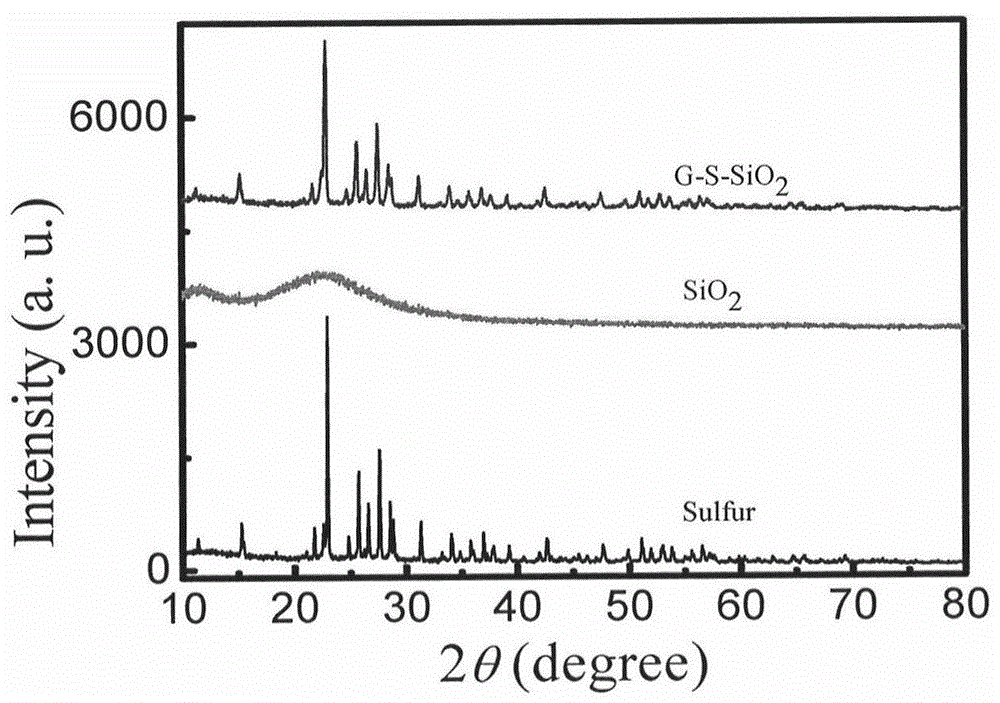

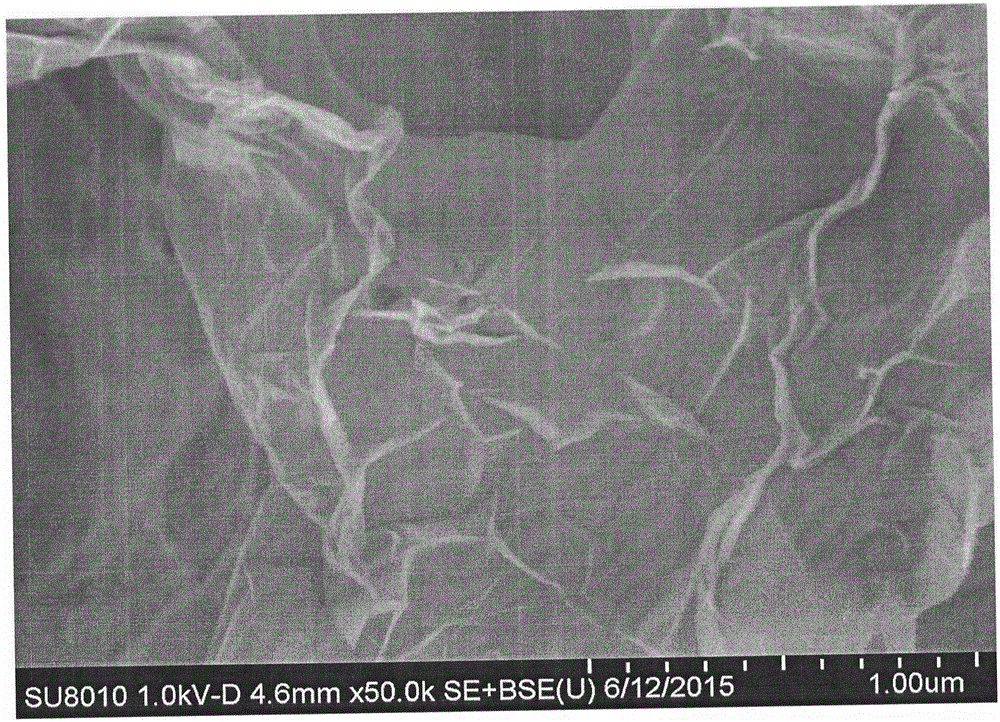

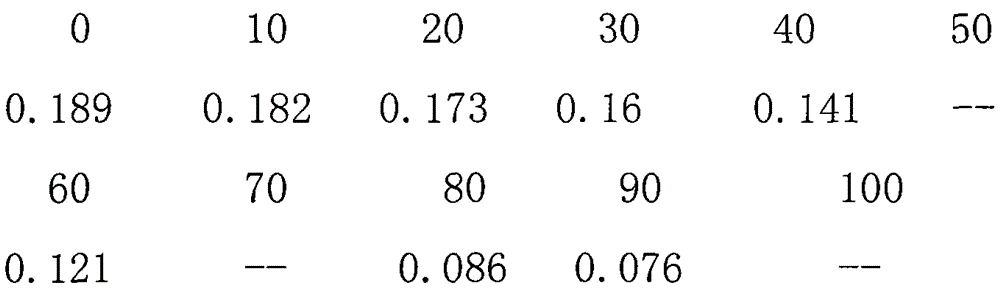

Preparation method of sulfur/carbon/oxide combined electrode material

InactiveCN105006553ASimple processEasy to operateCell electrodesLi-accumulatorsIron(II) oxideCarbon nanotube

The invention relates to a preparation method of a sulfur / carbon / oxide combined electrode material. The preparation method comprises depositing sulfur and oxide on a carbon material as a carrier with excellent performances to obtain the sulfur / carbon / oxide combined electrode material. The carbon material is one of graphene, CMK-3, carbon nanotubes and carbon black. The oxide is one of silica, copper oxide, silver oxide, nickel oxide, ferrous oxide, tin oxide and titanium oxide. The sulfur / carbon / oxide combined electrode material comprises 50-90wt% of sulfur, 5-20wt% of carbon and 5-30wt% of the oxide. Through control of acid types and pH, and organic solvent types and properties, the sulfur / carbon / oxide combined electrode material with fine particles and high coating uniformity is obtained. The sulfur / carbon / oxide combined electrode material as a lithium-sulfur battery positive pole material has high specific capacity and excellent cycling properties and has a good application prospect in the field of batteries.

Owner:CHINA JILIANG UNIV

Pyrite cinder separation, recovery and recycling method

InactiveCN105984893ASave landSaving and efficient useCalcium/strontium/barium carbonatesSolid waste disposalIron(II) oxideAluminium hydroxide

The invention discloses a pyrite cinder separation, recovery and recycling method and belongs to the technical field of an inorganic chemistry industry. The method comprises carrying out suspended separation on calcium hydroxide and alumina through water, dissolving and separating alumina through an ammonium salt, dissolving iron sesquioxide / ferrous oxide in the pyrite cinder through strong phosphoric acid, filtering to separate the mixture of sulfur, phosphorus and silica insoluble with strong phosphoric acid from iron sesquioxide / ferrous oxide, and separating and recovering resource materials such as iron sesquioxide / ferrous oxide and alumina or aluminum hydroxide. The separated product can be used for an industrial raw material and agricultural fertilizer.

Owner:耿兆翔

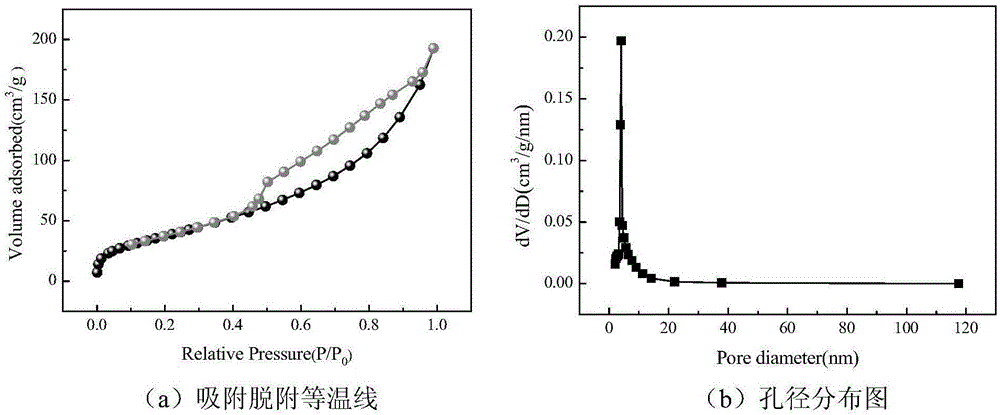

Preparation method and application of alumina-loaded nano ferrous sulfide composite material

InactiveCN106732330AGood removal effectEffectively distributes the load evenlyOther chemical processesWater contaminantsIron(II) oxideNanoparticle

The invention belongs to the technical field of water treatment, and in particular relates to a preparation method and application of an alumina-loaded nano ferrous sulfide composite material; the alumina-loaded nano ferrous sulfide composite material is mainly used for treating mercury-containing wastewater. The preparation method of the alumina-loaded nano ferrous sulfide composite material comprises the steps of preparing ferrous sulfide particle suspension liquid by taking a sulfide salt and a divalent ferric salt as raw materials and using a coprecipitation method in the N2 environment; after that, continuously adding alumina suspension liquid, which is taken as a carrier, into the ferrous sulfide particle suspension liquid, and enabling nano ferrous sulfide particles to completely cover the surface of alumina under the conditions of ultrasonic stirring and heating so as to obtain the alumina-loaded nano ferrous sulfide composite material. The alumina-loaded nano ferrous sulfide composite material has the beneficial effects that (1) the preparation method is simple, convenient and efficient, and the material can be synthesized in one step by using the coprecipitation method and is short in preparation period, low in cost and good in effect; (2) by enabling the alumina to be loaded in the composite material, ferrous oxide nanoparticles are effectively dispersed, and the defects that the ferrous oxide nanoparticles are easy to agglomerate and easy to oxidize are overcome.

Owner:ZHEJIANG UNIV

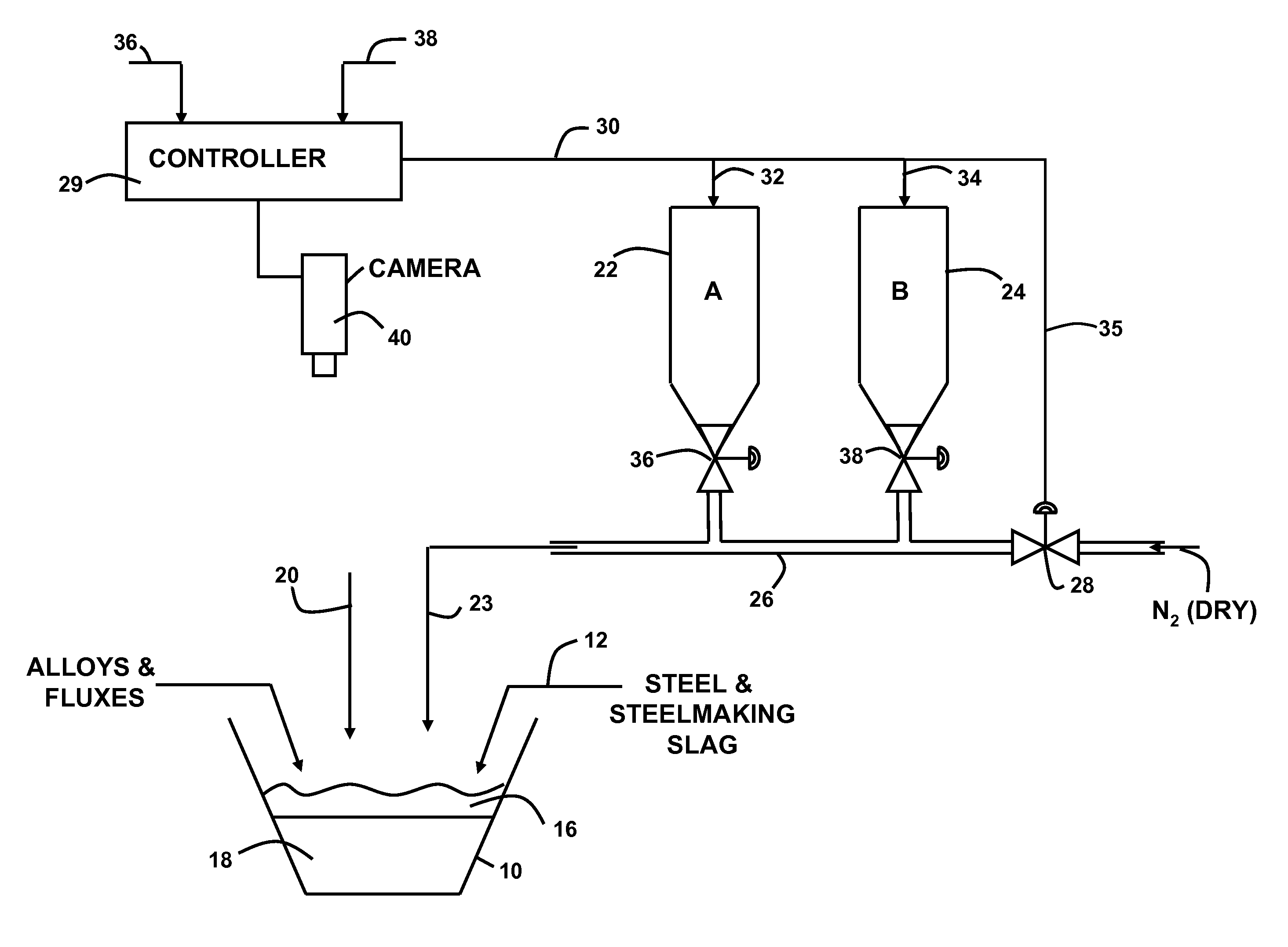

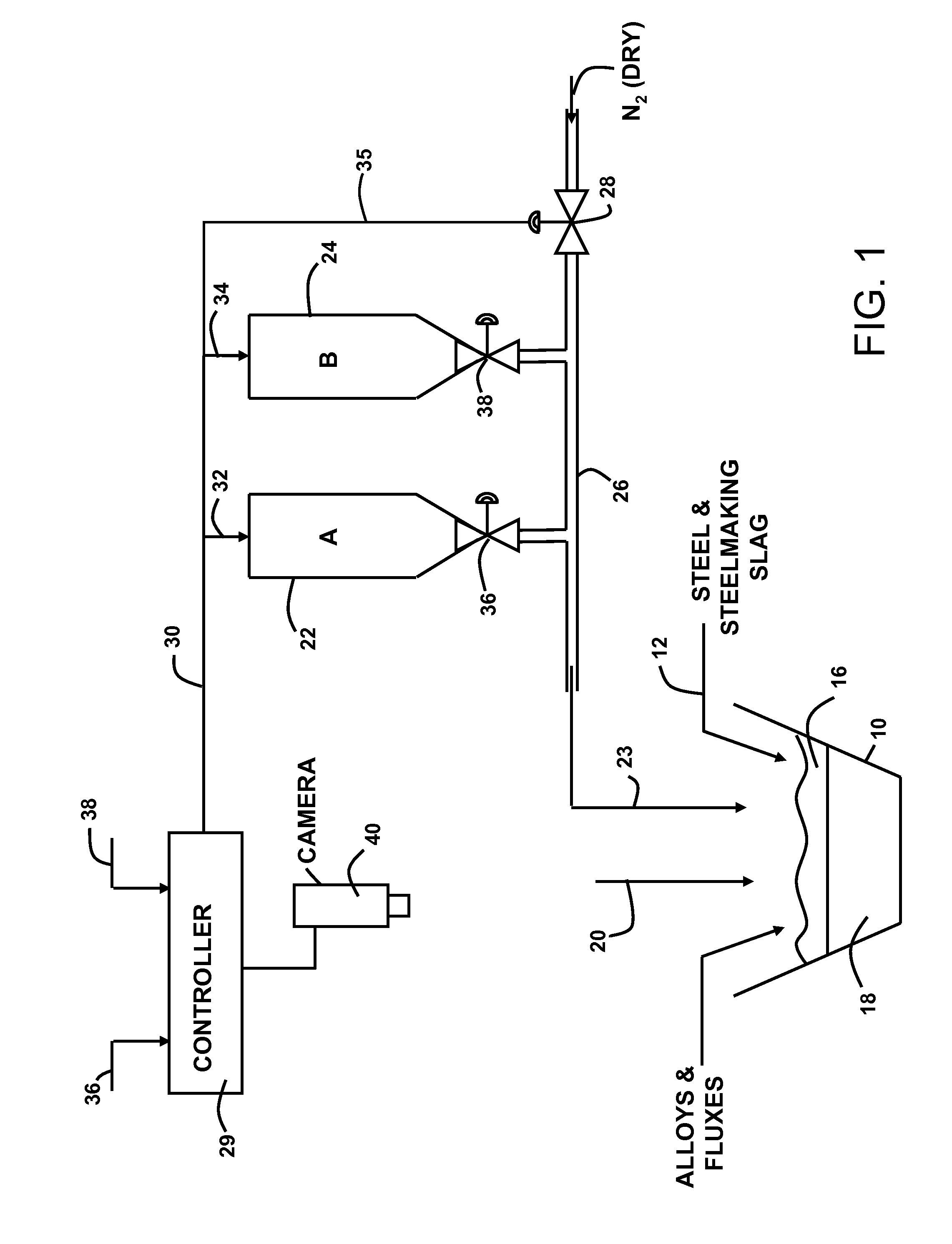

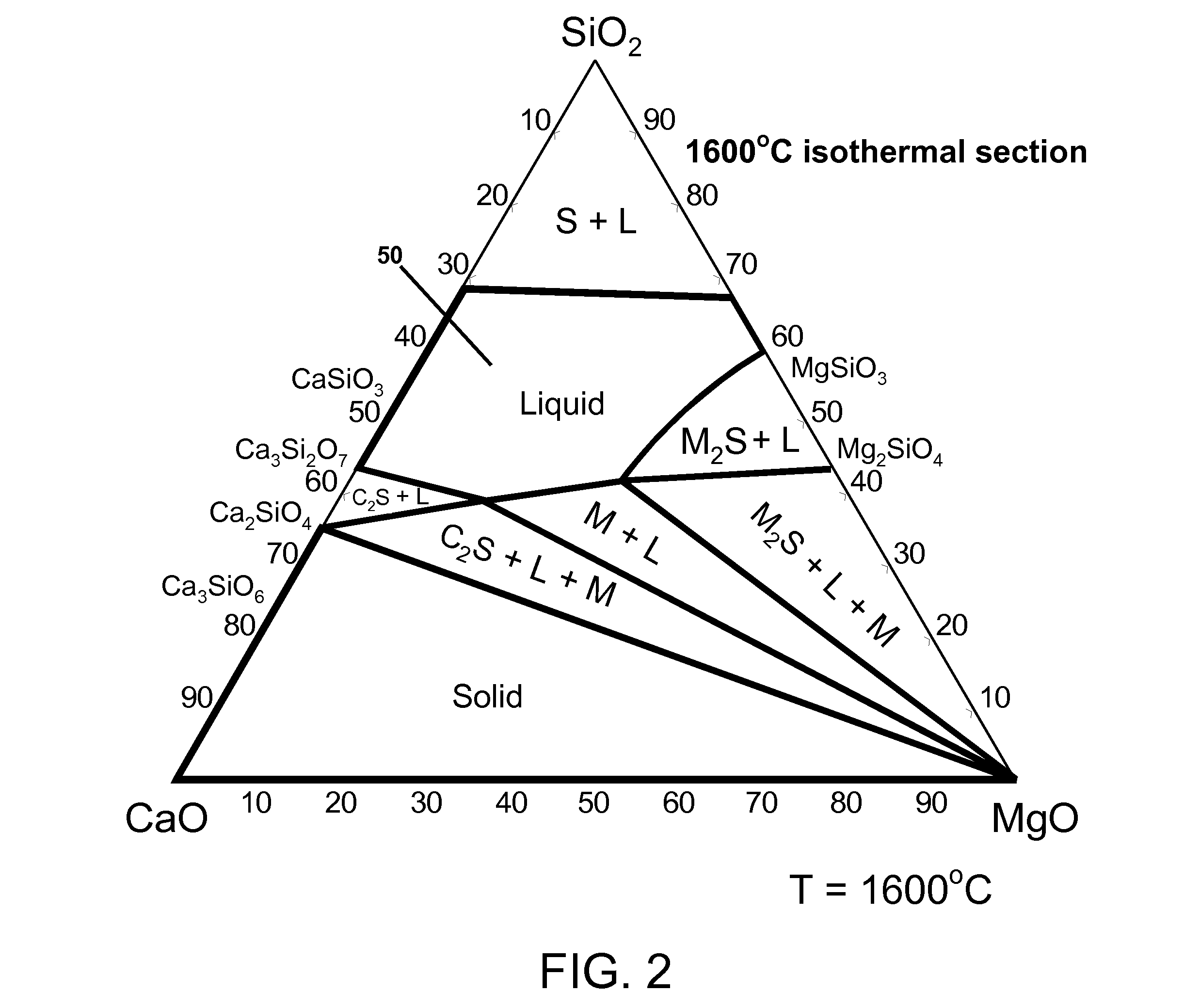

Composition for reducing the oxygen potential of slag

InactiveUS20130019715A1Easy to producePromote productionBlast furnace componentsBlast furnace detailsSteelmakingSilicon oxide

A slag composition containing steelmaking slag and from about 0.3 to about 10 weight percent of reducing agent. The steelmaking slag contains from about 20 to about 55 weight percent of calcium oxide, from about 8 to about 50 weight percent of ferrous oxide, from about 4 to about 20 weight percent of magnesium oxide, from about 8 to about 30 weight percent of silicon oxide, from 0.5 to about 10 weight per cent aluminum oxide, and from about 0.5 to about 10 weight percent of manganese oxide. The reducing agent contains from about 15 to about 70 weight percent of calcium carbide and from about 10 to about 50 weight percent silicon carbide, wherein the ratio of calcium carbide to silicon carbide is between 0.7 and 7.

Owner:NUFLUX

Artware of basalt and preparation method

In the invention, shale clay of Changbai mountain and low-temp, clay are uniform mixed, then are processed by ball-milling, seasoning, mud treating, base stretching, polishing, carving and firing. The carving technology includes ornamental engraving, relief sculpturing, line engraving and shadow engraving. In firing process, wood is used as fuel, reduction flame firing principle is used to make iron oxide in pottery clay is reducted to generate black ferrous oxide by charcoal in high temp, 1000-1100 deg,C, for 24 hours, that is the reason that black pottery handicraft article is black on whole body.

Owner:孙吉春

Method for removing heavy metal in solid organic waste compost

ActiveCN101624300AImprove qualityReduce heavy metal concentrationClimate change adaptationOrganic fertilisersThiobacillus ferrooxidansYeast

The invention relates to a method for removing heavy metal in solid organic waste compost, which comprises the following steps: (1) adding sulfur powder into solid organic waste compost according to a use amount of 10-150 g of sulfur powder for one 1kg of compost; (2) adding ferrous sulfate heptahydrate solution into the compost; (3) inoculating microorganism compound bacteria including thiobacillus ferrous oxide, thiobacillus thiooxidans, white rot fungi, yeast and penicillium according to a use amount of 1g of compound bacteria for 1 kg of compost; (4) spraying and leaching the inoculated compost which is arranged on a stacking bed and keeping water content in the stacking bed to be not lower than 65 percent; (5) during leaching time of 4-14 days, monitoring the concentration of heavy metal of leaching liquid in real time till the concentration of heavy metal meets the national standard; and (6) adding slaked lime into the compost to adjust pH value to 7 after the leaching is finished. The invention has the advantages that the removal rate of heavy metal in leaching reaches over 90 percent, the lose rate of nutrient elements such as N, P and the like is lower than 5 percent, and the method has simple operation and low running cost.

Owner:安徽徽粮生物科技有限公司

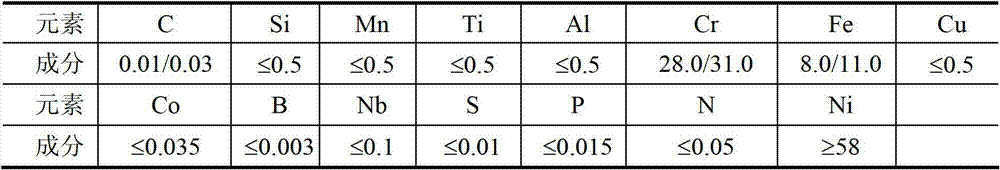

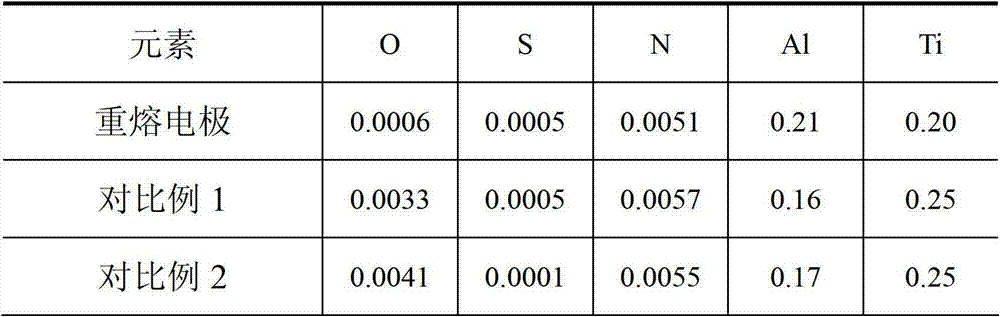

Process method for producing 1 ton of I-690 alloy electroslag remelted ingot in industrialized mode

The invention belongs to the technical field of electroslag remelting, relates to improvement on a process for producing Inconel 690 alloy electroslag remelted ingot in an industrialized mode, in particular to a process method for producing 1 ton of I-690 alloy electroslag remelting ingot in an industrialized mode. A vacuum induction furnace smelts an electrode bar of phi 240 mm; the size of a crystallizer is phi 340 / 380*1,500 mm; the remelting process parameters comprise: remelting voltage of 47 to 55 V, current of 7,500 to 8,500 A and slag quantity of 38 to 45 kg; according to the I-690 alloy component requirement, the remelting adopts a new proportioned pentabasic slag system; the components comprise calcium fluoride, calcium oxide, aluminum oxide, magnesium oxide and titanium dioxide; the purity of each component is required to be more than 98.5 percent; the total content of unstable oxide impurities such as manganese oxide, ferrous oxide and silica is less than 0.5 percent; the granularity is less than 50 meshes; before the remelting process, the electrode is roasted at the temperature of 700 DEG C for 8 to 12 hours and the slag is roasted at the temperature of 680 DEG C for 8 to 12 hours for use; and in the remelting process, argon and burning gas are adopted for protection. By the process, the content of the remelted I-690 alloy is reduced to be below 20 ppm, the sulfur content is reduced to be below 5 ppm, oxide inclusion is effectively removed, and high-quality remelted alloy is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

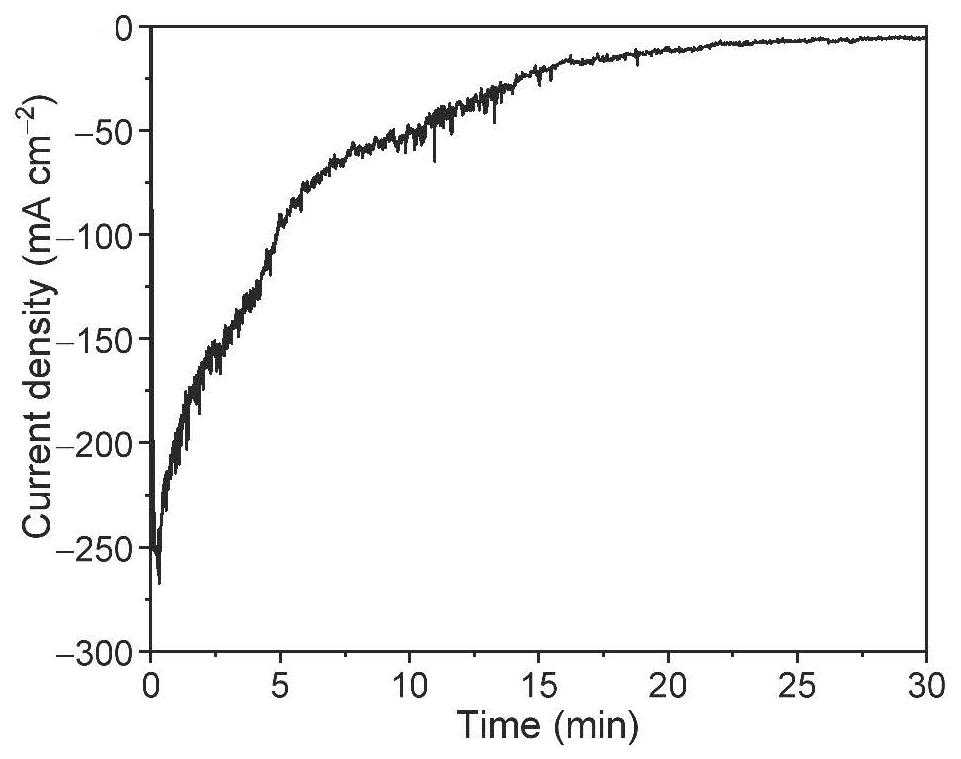

Method for synthesizing ammonia through electro-catalysis of nitrate or nitrite

The invention discloses a method for synthesizing ammonia through electro-catalysis of nitrate or nitrite, an electro-catalyst adopted in the method is a metal-metal oxide, and the metal-metal oxide is used as a cathode or is loaded on the surface of a conductive material to serve as the cathode. The metal-metal oxide is selected from one or a combination of more of ruthenium-ruthenium oxide, copper-copper oxide, copper-cuprous oxide, nickel-nickel oxide, iron-ferric oxide, iron-ferrous oxide, iron-ferroferric oxide, cobalt-cobalt oxide, cobalt-cobaltosic oxide and zinc-zinc oxide. The catalytic electrode material provided by the invention is stable in structure and simple in preparation process, and can be effectively prepared in an amplified manner, so that the application of the catalytic electrode material in changing nitrate or nitrite-containing wastewater into valuable ammonia is realized. The catalytic electrode material provided by the invention can realize efficient electro-catalysis of reduction of nitrate or nitrite into ammonia, and has high selectivity.

Owner:HUNAN UNIV

Method for extracting copper, nickel and cobalt intermediate products from copper and cobalt ore at low cost

InactiveCN102560109AImprove leaching rateNo pollutionProcess efficiency improvementIron(II) oxideCrusher

The invention relates to a method for extracting copper, nickel and cobalt intermediate products from copper and cobalt ore at low cost. The method comprises the following steps of: crushing copper and cobalt ore by using a crusher, grinding by using an ore gridding machine into powder with the particle size of less than or equal to 100 meshes; placing the ore powder with the particle size of less than or equal to 100 meshes in a reaction kettle, performing agitation leach by using hydrochloric acid at normal temperature and normal pressure, and allowing copper, nickel, cobalt, iron, magnesium, and calcium in a form of chloride in the ore to enter lixivium; adjusting the pH value to be 0.5 to 1.5, and adding iron powder in an amount which is not less than 1.5 times that of the copper in the solution and replacing to remove copper; dropwise adding ammonia water and hydrogen peroxide simultaneously at the temperature of 90DEG C with continuous stirring to adjust the pH and ferrous oxide ions to generate goethite and remove iron; and extracting nickel and cobalt by using an organic extracting agent P204. The method is low in investment, energy consumption and production cost, and simple and reasonable; and leaching rate is high.

Owner:JIANGXI UNIV OF SCI & TECH

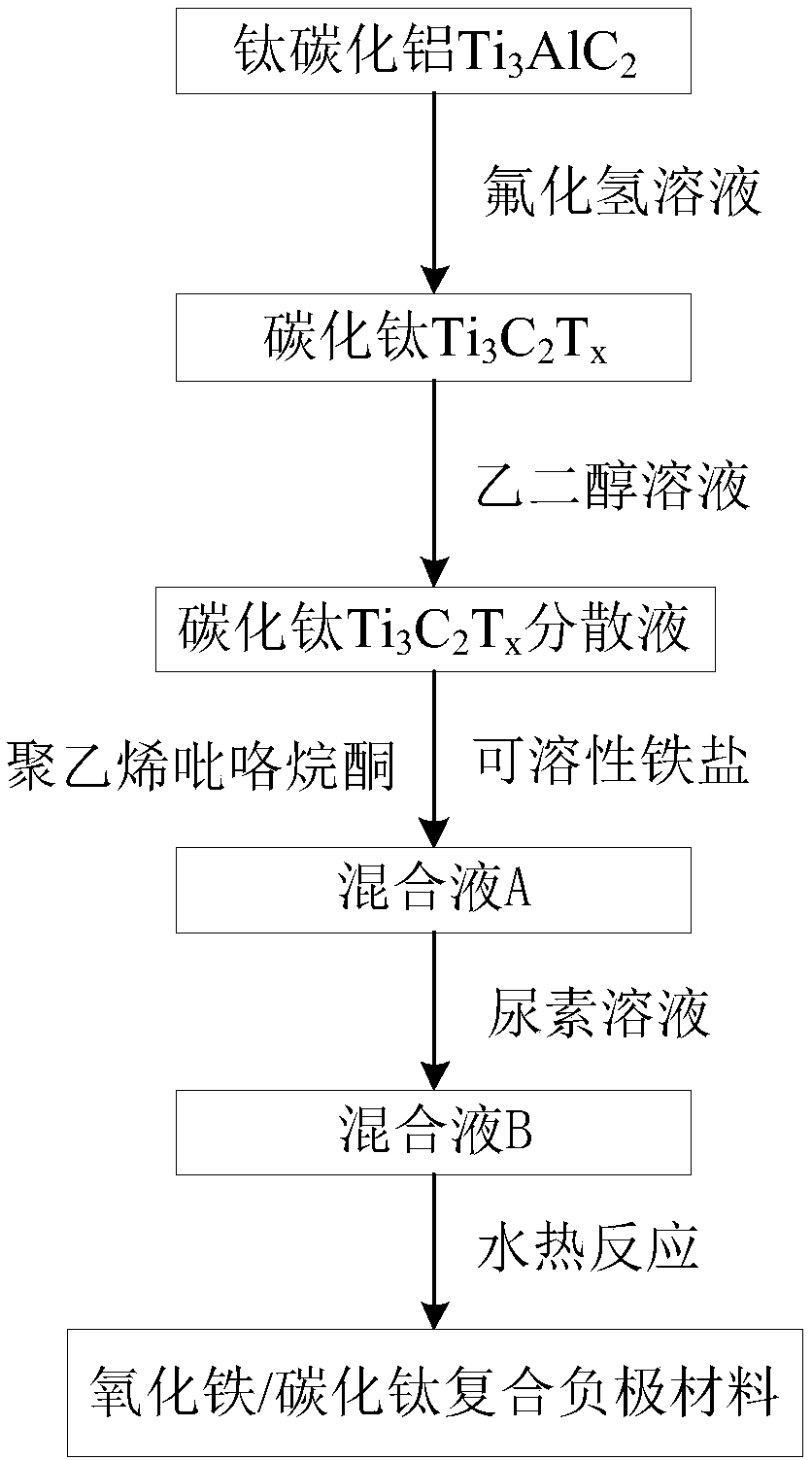

Iron oxide/titanium carbide composite cathode material and preparation method thereof

InactiveCN108365190AReduce energy consumptionSimple processCell electrodesIron(II) oxideUranium carbide

The invention relates to an iron oxide / titanium carbide composite cathode material and a preparation method thereof. The method comprises the following steps: dispersing titanium carbide in an organicsolution to form uniform titanium carbide dispersion liquid; then adding soluble ferric salt and polyvinylpyrrolidone in the titanium carbide dispersion liquid and stirring the materials to obtain mixed liquor A; dropping an urea solution in the mixed liquor A while stirring to obtain mixed liquor B; placing the mixed liquor B at the temperature of 80-200 DEG C and performing a hydrothermal reaction for 1-24 h, and performing steps of centrifugation, washing and drying on a reaction product to obtain the iron oxide / titanium carbide composite cathode material. The preparation technology is simple, a high temperature process is not required, energy consumption is low, the cycle performance of the iron oxide / titanium carbide composite cathode material is greatly increased, and the conductivity and capacity conservation rate are good.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD +1

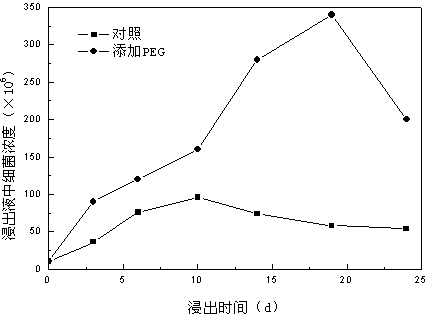

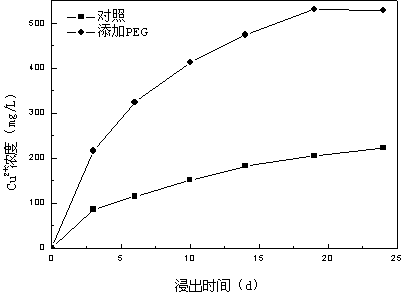

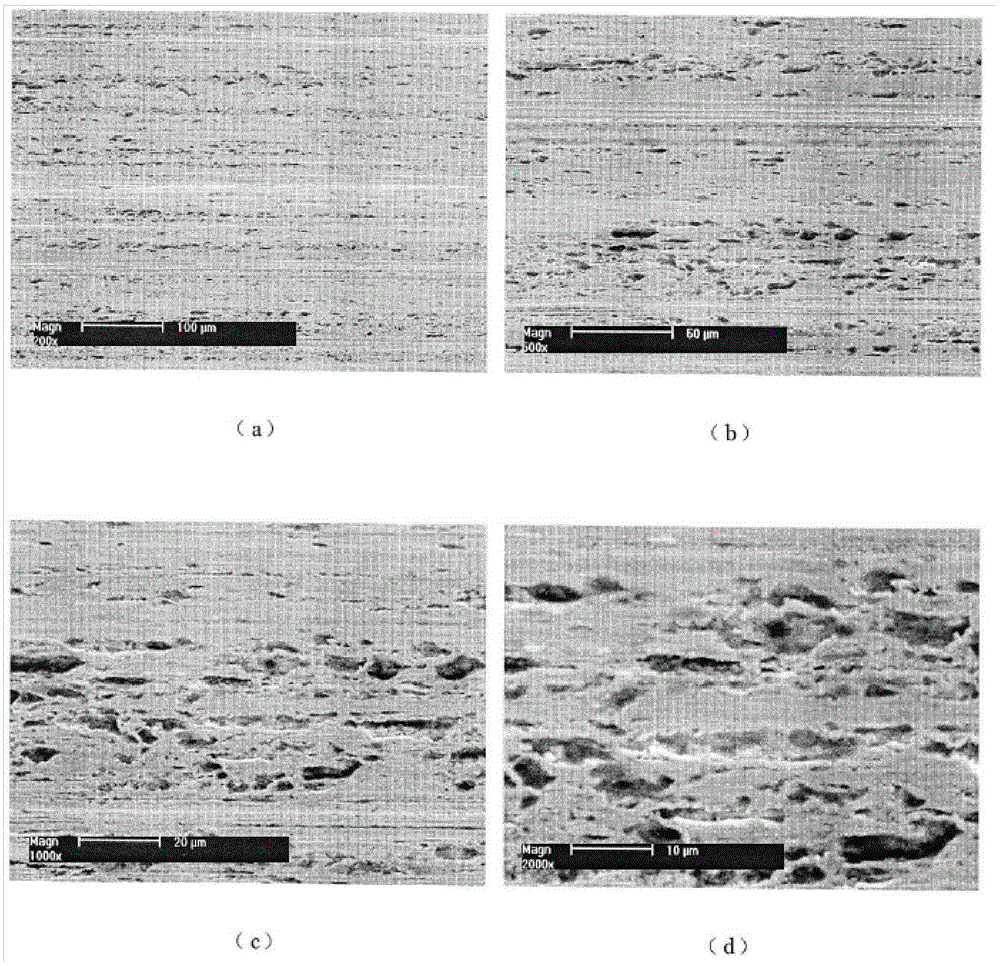

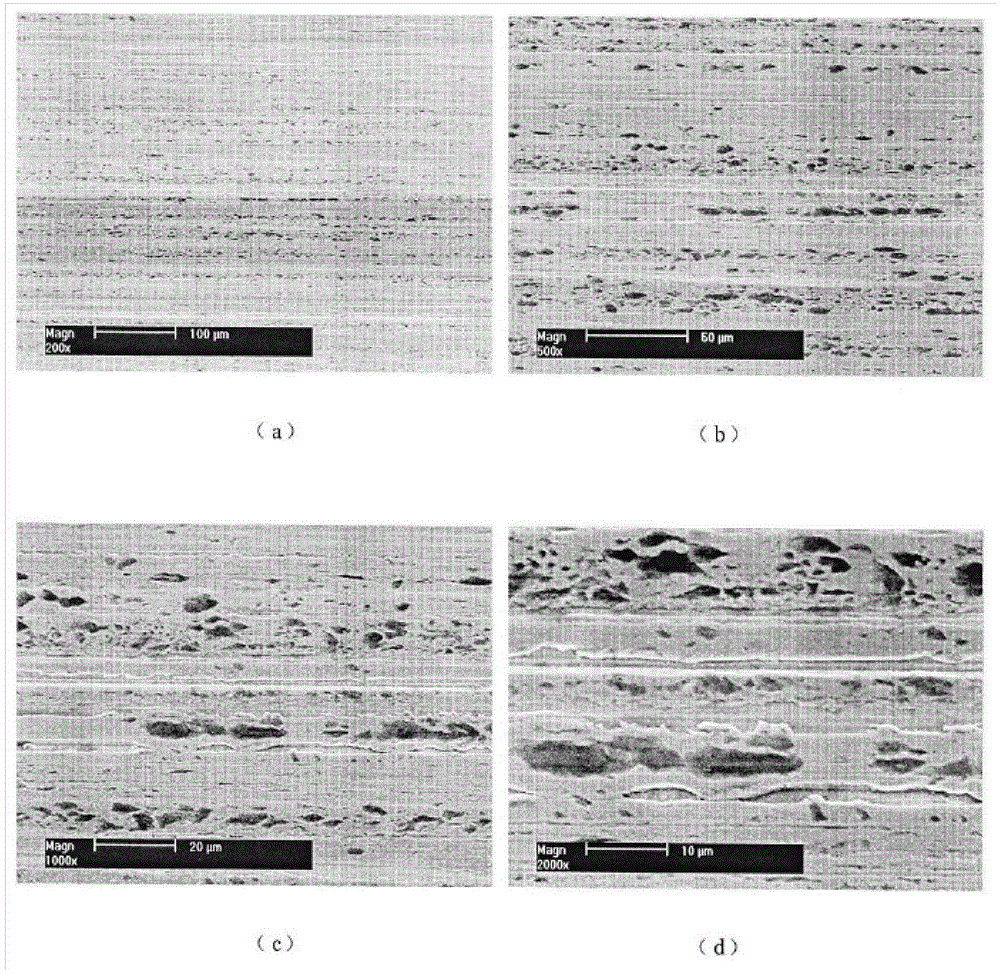

Method of promoting bioleaching of copper pyrites by adding nonionic surfactant

ActiveCN103993171AImproved bioleachingIncrease speedProcess efficiency improvementIron(II) oxideUltraviolet lights

The invention belongs to the field of hydrometallurgy and particularly relates to a method of promoting bioleaching of copper pyrites by adding a nonionic surfactant. The technical scheme is as follows: the method comprises the following steps: crushing and grinding a copper pyrites sample and sterilizing the sample by ultraviolet light to obtain a product as a leaching sample; putting the leaching sample in a 9L basic salt solution sterilized; inoculating ferrous oxide thiobacillus; then, adding polyethylene glycol, wherein the addition of polyethylene glycol is 30-90mg / L; adjusting the initial leaching pH to 1.8-3.5 by using dilute sulphuric acid; under the condition of 25-35 DEG C and 150-180r / min, oscillating and leaching for 18-25 days; and adding polyethylene glycol to at least increase the leaching ratio of copper pyrites by 1.36 times. The invention provides a novel path for increasing the bioleaching rate of low-grade copper pyrites and is of important meaning to promote large-scale industrial application of a low-grade copper pyrite bioleaching process.

Owner:NORTHEASTERN UNIV

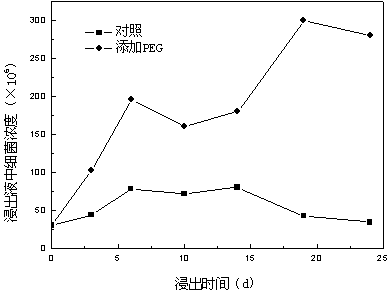

Pre-fused compound dephosphorizer, preparation method of pre-fused compound dephosphorizer and method for smelting ultralow phosphorous steel

The invention relates to the field of smelt low-phosphorous steel, in particular to pre-fused compound dephosphorizer. The pre-fused compound dephosphorizer is composed of, by weight percent, 30%-60% of a mixture of iron sesquioxide (Fe2O3) and ferrous oxide (FeO), 20%-50% of calcium oxide (CaO), 0%-10% of aluminum oxide (Al2O3), 0%-10% of silicon dioxide (SiO2), 0%-10% of magnesium oxide (MgO), 5%-30% of calcium fluoride (CaF2) and unavoidable impurities. The invention also relates to a preparation method of the pre-fused compound dephosphorizer. The invention further relates to a method for smelting ultralow phosphorous steel. The dephosphorizing rate of the pre-fused compound dephosphorizer can reach 80% or above, and the phosphorous content in liquid steel can be controlled within 0.003%.

Owner:上海盛宝冶金科技有限公司

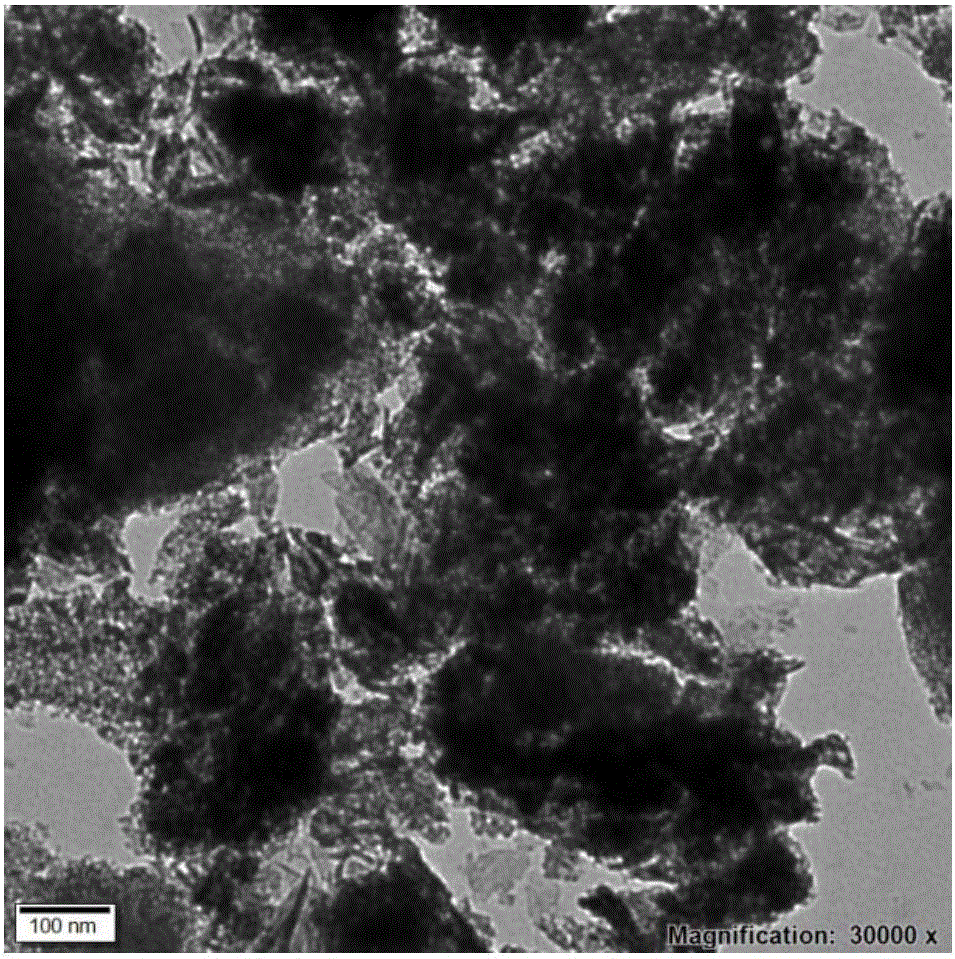

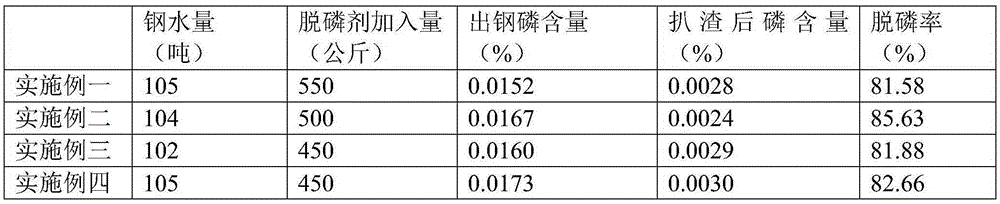

Stable nitrogen-doped carbon nanotube and iron oxide composite anode material and preparation method thereof

InactiveCN105375009AImproved magnification performanceImprove efficiencyCell electrodesSecondary cellsIron(II) oxideNew energy

The invention relates to the field of new energy materials and electrochemistry, in particular to a stable nitrogen-doped carbon nanotube and iron oxide composite anode material and a preparation method thereof. With a nitrogen-doped carbon nanotube as a main body, the stable nitrogen-doped carbon nanotube and iron oxide composite anode material is characterized in that iron oxide particles are loaded on the outer surface of the nitrogen-doped carbon nanotube, wherein the iron oxide is a main component; and the load amount of the iron oxide accounts for 10%-90% of total weight of the iron oxide particles and the nitrogen-doped carbon nanotube. The stable nitrogen-doped carbon nanotube and iron oxide composite anode material is simple in preparation technology, low in production cost, friendly to environment, high in safety and good in experimental repeatability.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

Metal wear repairing agent and preparation method thereof as well as lubricating oil

ActiveCN104789297AFast productionReduce coefficient of frictionAdditivesAluminium chlorideIron(II) oxide

The invention provides a metal wear repairing agent and a preparation method thereof as well as lubricating oil. The metal wear repairing agent comprises the following components in part by weight: 2-6 parts of hydroxyl silicate ore, 0.3-0.7 part of apatite, 4.5-5.5 parts of vermiculite, 0.2-0.7 part of aluminum chloride, 0.2-1 part of chrysotile, 0.02-0.07 g of lanthanum oxide and 0.05-0.15 part of ferrous oxide; the preparation method of the metal wear repairing agent comprises the following steps: 1) pulverizing a mixture I of hydroxyl silicate ore, apatite, vermiculite, aluminum chloride, chrysotile into particles having a diameter smaller than or equal to 0.05 mm; 2) drying the pulverized particles, removing moisture and crystal water; 3) S03: adding lanthanum oxide and ferrous oxide powder to obtain a mixture II, grinding the mixture II again until a powdered mixture is obtained. According to the invention, the metal wear repairing agent can repair damaged surfaces, reduce the friction, and improve the abrasion resistance.

Owner:张涵

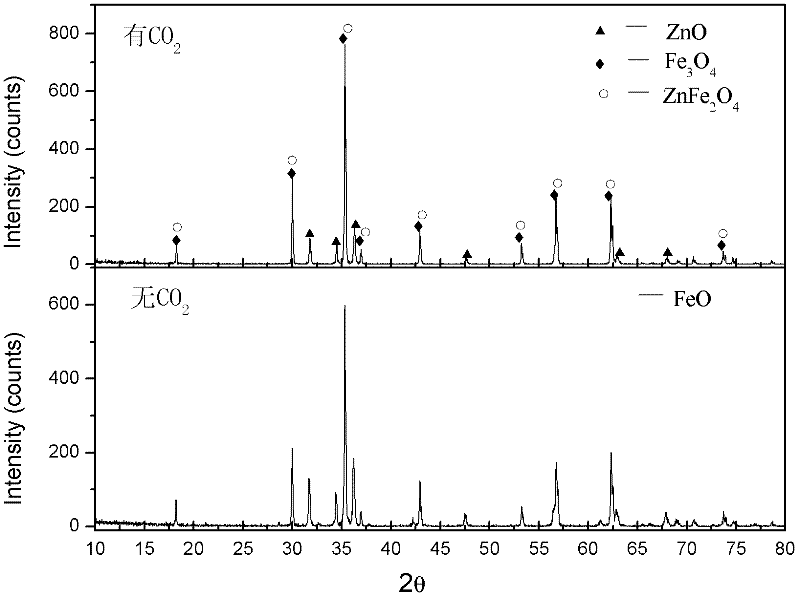

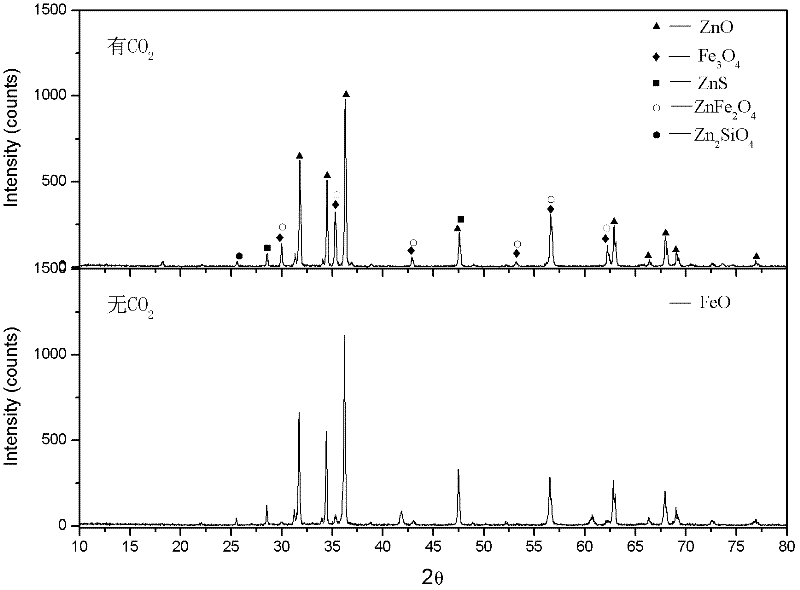

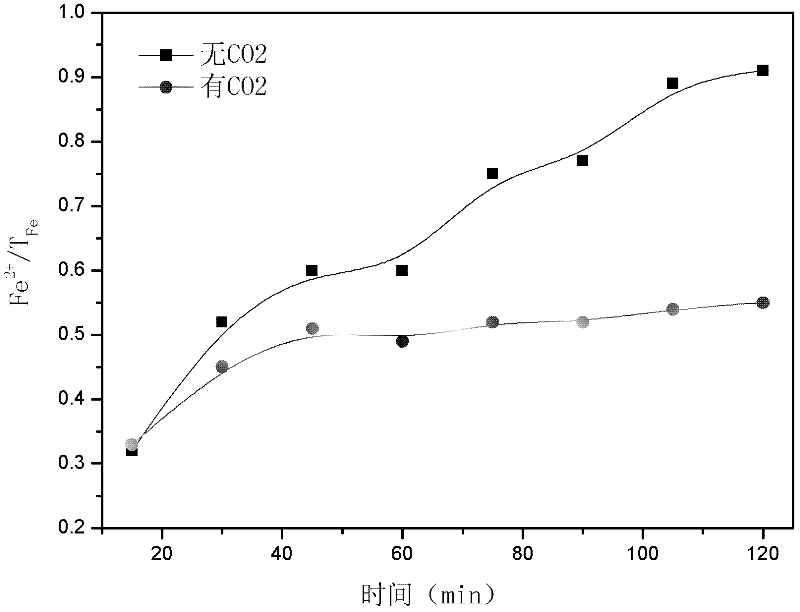

Method for inhibiting generation of ferrous oxide in high iron zinc calcine reduction roasting process by utilizing partial pressure of CO2

The invention provides a method for inhibiting generation of ferrous oxide in a high ferrum zinc calcine reduction roasting process by utilizing partial pressure of CO2. With adoption of the method, transformation of magnetic ferroferric oxide to ferrous oxide is inhibited in the reduction roasting process through controlling concentration of CO, partial pressure of CO / (CO+CO2), gas flow, roasting temperature and roasting time by adopting a high-temperature reduction roasting process and at the condition of a weak reducing atmosphere, thereby the ferrous dissolving amount in a follow-up wet method zinc galvanizing process is lowered, the iron precipitation burden of a zinc leaching liquid and the environmental problem brought by iron precipitation slag stockpiling are greatly lightened; and the method is beneficial for realizing that the zinc is cleaned and smelted.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com