Pre-fused compound dephosphorizer, preparation method of pre-fused compound dephosphorizer and method for smelting ultralow phosphorous steel

A composite dephosphorization agent and ultra-low phosphorus steel technology, which is applied in the smelting field of low phosphorus steel, can solve the problems of high unit consumption in the treatment process, reduced scrap steel amount, and many equipments required, and achieves simple preparation process and reduced smelting cost. , the effect that is beneficial to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

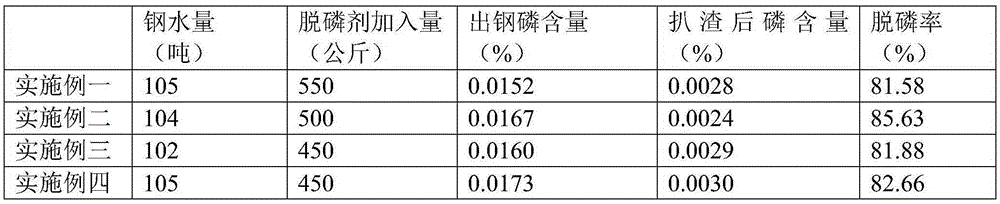

Examples

Embodiment 1

[0037] (1) Preparation of pre-melted composite dephosphorization agent:

[0038] Ferric oxide (Fe 2 o 3 ) and ferrous oxide (FeO) mixture 400kg; calcium oxide (CaO) 450kg; aluminum oxide (Al 2 o 3 ) 40kg; silicon dioxide (SiO 2 ) 30kg; magnesium oxide (MgO) 20kg; calcium fluoride (CaF 2 ) 60kg after pulverization, mixing and / or pelletizing, melting at a high temperature of 1100°C~1600°C, cooling and crushing, and processing to obtain 950kg of premelted composite dephosphorization agent for converter tapping with a particle size of 10~20mm.

[0039] (2) Smelting ultra-low phosphorus steel:

[0040] The tapping temperature of the converter is controlled between 1560°C and 1660°C, the phosphorus content is controlled below 0.02% when tapping, and the slag blocking treatment is carried out by using non-deoxidation and sliding plate slag blocking technology; the steel is uniform from the beginning of tapping to the end of tapping. Add pre-melted composite dephosphorizing agen...

Embodiment 2

[0042] (1) Preparation of pre-melted composite dephosphorization agent:

[0043] Ferric oxide (Fe 2 o 3 ) and ferrous oxide (FeO) mixture 450kg; calcium oxide (CaO) 400kg; aluminum oxide (Al 2 o 3 ) 20kg; silicon dioxide (SiO 2 ) 30kg; magnesium oxide (MgO) 20kg; calcium fluoride (CaF 2 ) 80kg after pulverization, mixing and / or pelletizing, melting at a high temperature of 1100°C~1600°C, cooling and crushing, and processing to obtain 960kg of premelted composite dephosphorization agent for converter tapping with a particle size of 15~20mm.

[0044] (2) Smelting ultra-low phosphorus steel:

[0045] The tapping temperature of the converter is controlled between 1560°C and 1660°C, the phosphorus content is controlled below 0.02% when tapping, and the slag blocking treatment is carried out by using non-deoxidation and sliding plate slag blocking technology; the steel is uniform from the beginning of tapping to the end of tapping. Add pre-melted composite dephosphorization ag...

Embodiment 3

[0047] (1) Preparation of pre-melted composite dephosphorization agent:

[0048] Ferric oxide (Fe 2 o 3 ) and ferrous oxide (FeO) mixture 500kg; calcium oxide (CaO) 350kg; aluminum oxide (Al 2 o 3 ) 40kg; silicon dioxide (SiO 2 ) 30kg; magnesium oxide (MgO) 20kg; calcium fluoride (CaF 2 ) 60kg after crushing, mixing and / or pelletizing, melting at a high temperature of 1100°C~1600°C, cooling and crushing, and processing to obtain 950kg of premelted composite dephosphorization agent for converter tapping with a particle size of 12~18mm.

[0049] (2) Smelting ultra-low phosphorus steel:

[0050] The tapping temperature of the converter is controlled between 1560°C and 1660°C, the phosphorus content is controlled below 0.02% when tapping, and the slag blocking treatment is carried out by using non-deoxidation and sliding plate slag blocking technology; the steel is uniform from the beginning of tapping to the end of tapping. Add pre-melted composite dephosphorizing agent to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com