Patents

Literature

50results about How to "Play a role in mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

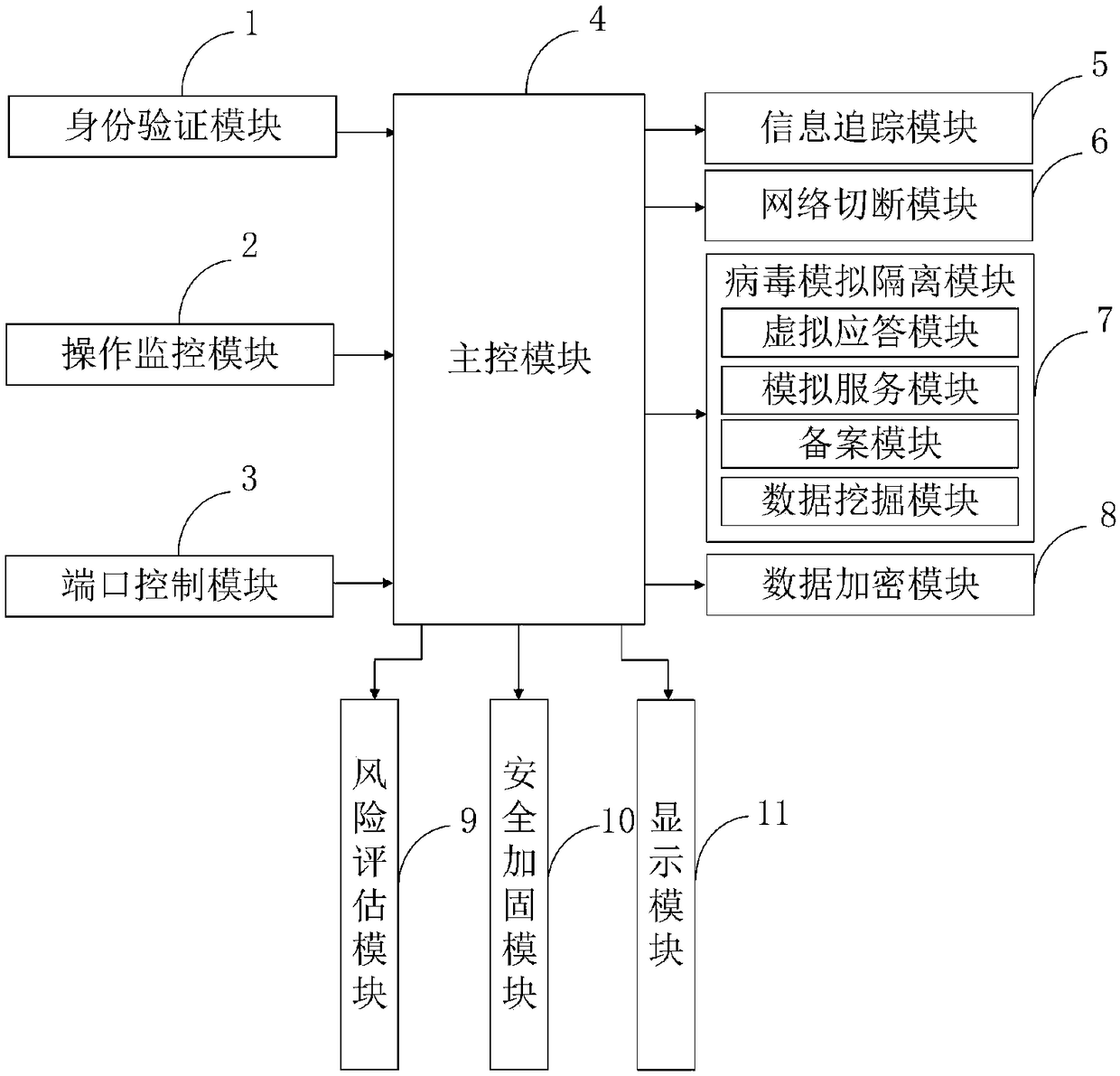

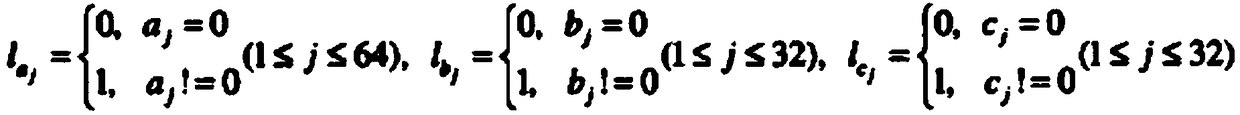

Computer information security system

PendingCN109492397APlay a role in mixingThe effect of mixing hasDigital data protectionPlatform integrity maintainanceData integrityOriginal data

The invention belongs to the technical field of information security. The invention discloses a computer information security system. The computer information security system comprises an identity verification module, an operation monitoring module, a port control module, a main control module, an information tracking module, a network cutoff module, a virus simulation isolation module, a data encryption module, a risk assessment module, a security reinforcement module and a display module. The data encryption module adopts a mode of converting serial data into a parallel data matrix to perform encryption operation, original data sequence and relation are effectively disrupted through matrix operation, the data mixing effect is well achieved, and the data integrity is guaranteed; Meanwhile, the original security configuration value is modified into the preset security configuration standard value through the security reinforcement module, reinforcement of computer security configuration is achieved, the whole method is automatically completed through a computer program, manual operation is not needed, time and labor are saved, and the computer security reinforcement efficiency is improved.

Owner:平顶山工业职业技术学院

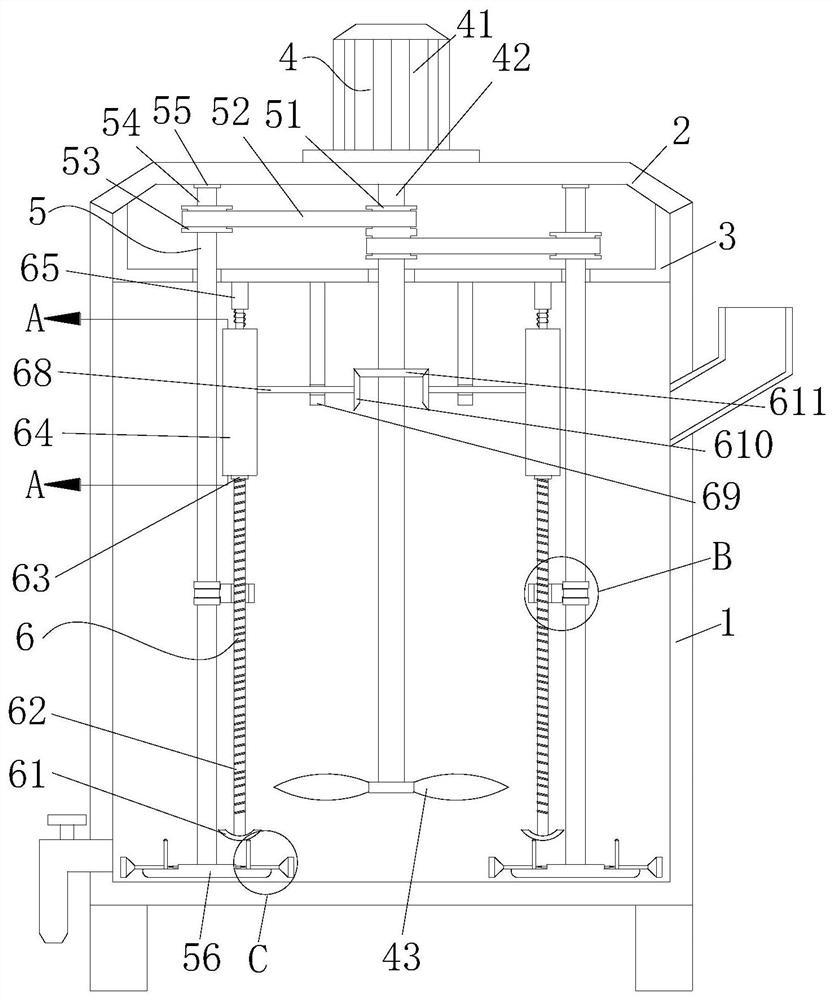

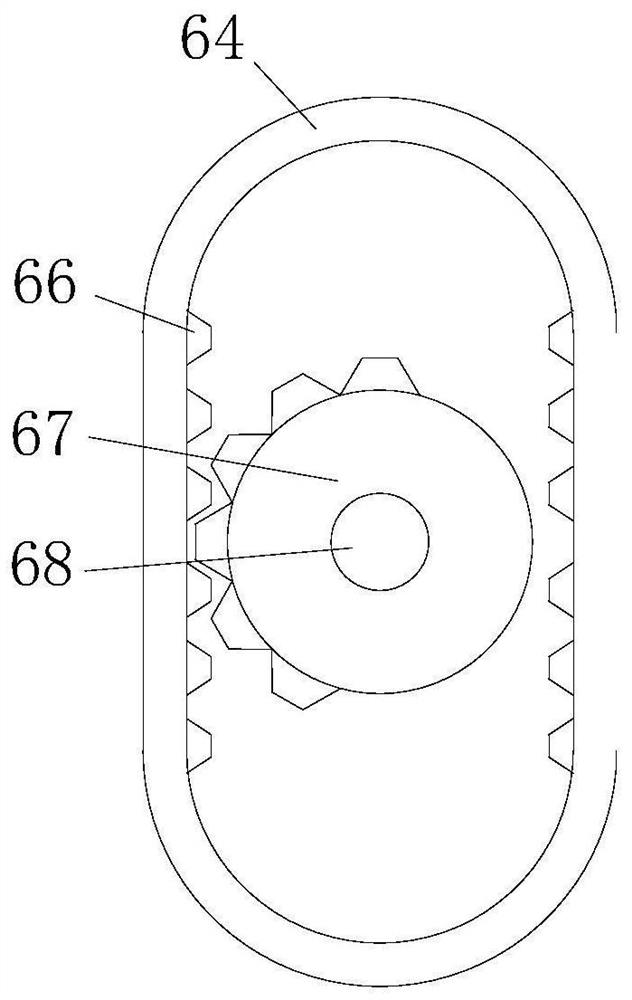

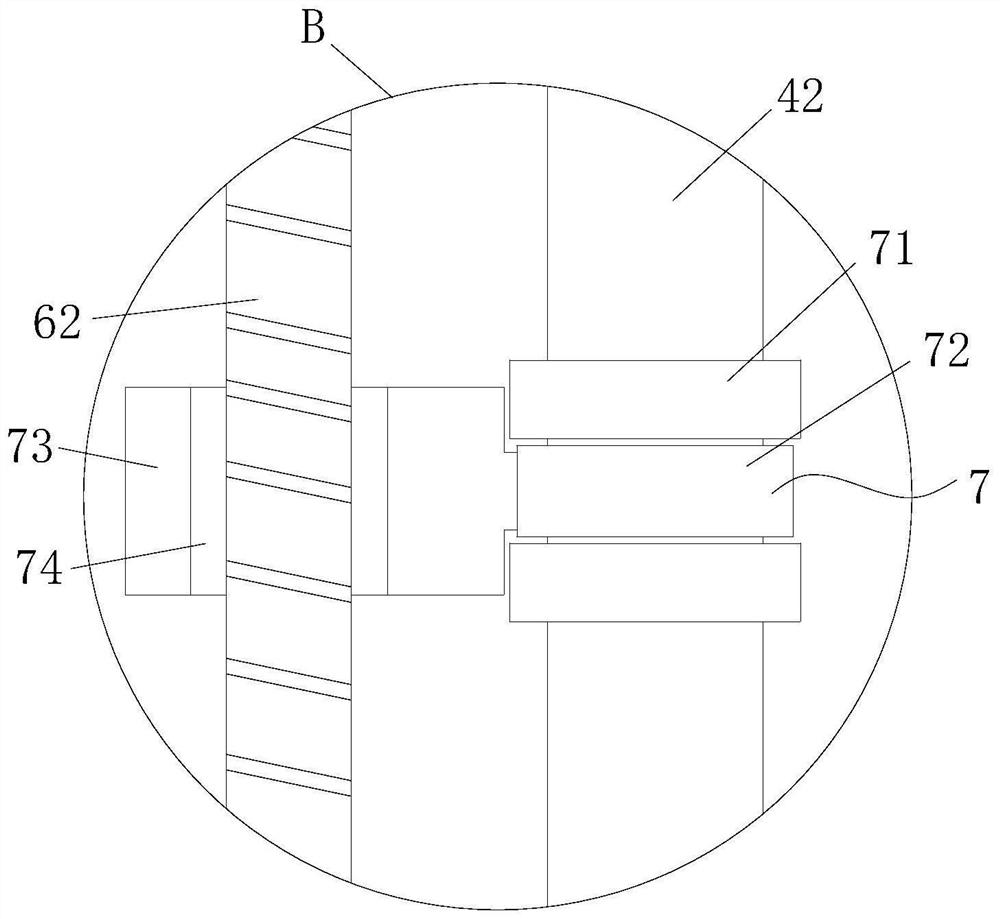

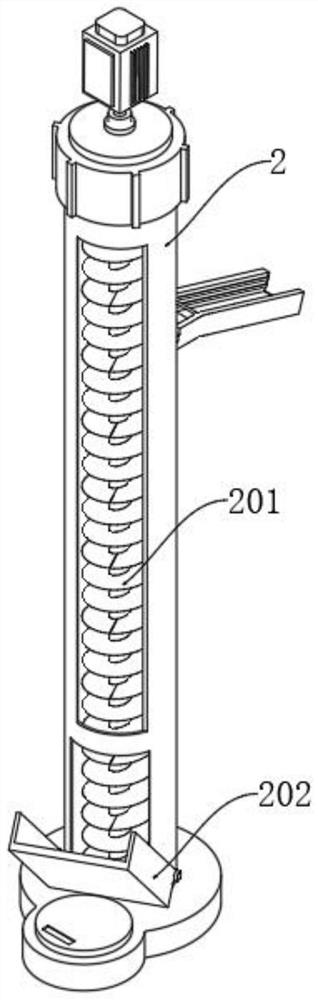

Novel double-shaft stirrer

Owner:泰州润达环保科技有限公司

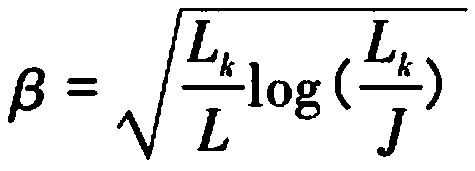

Concrete mixing equipment capable of improving concrete quality

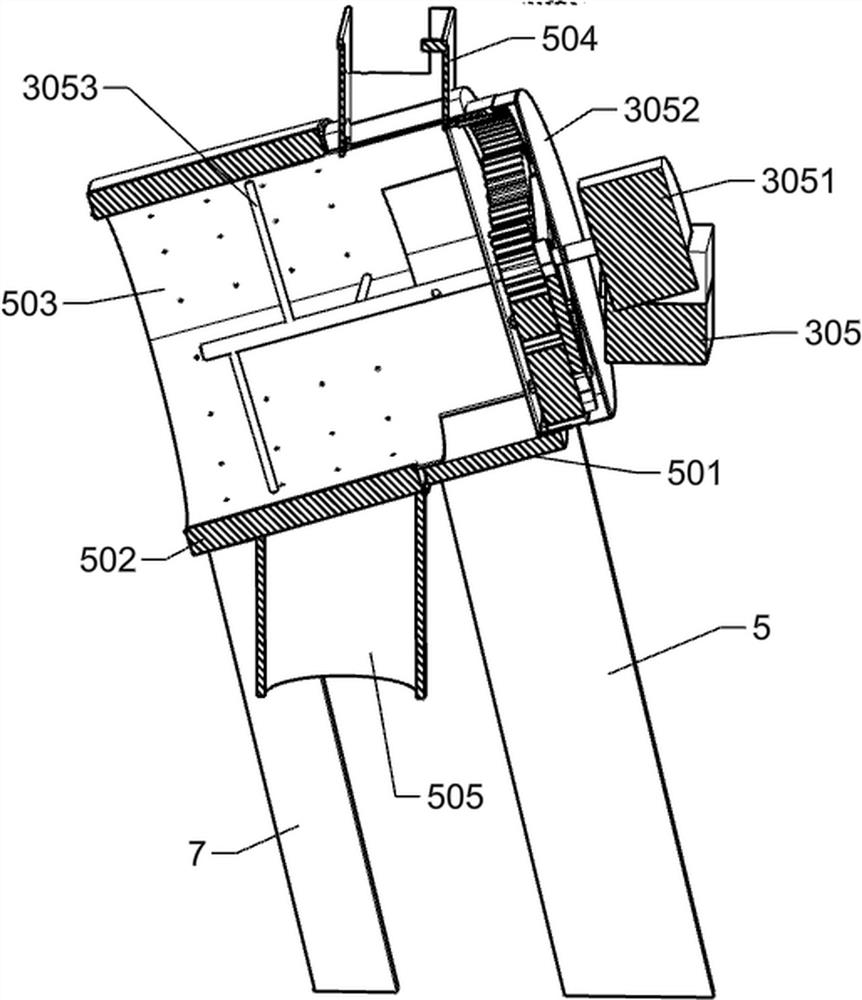

InactiveCN111844443AQuality improvementQuick clean upDischarging apparatusMixing operation control apparatusDrive wheelDrive shaft

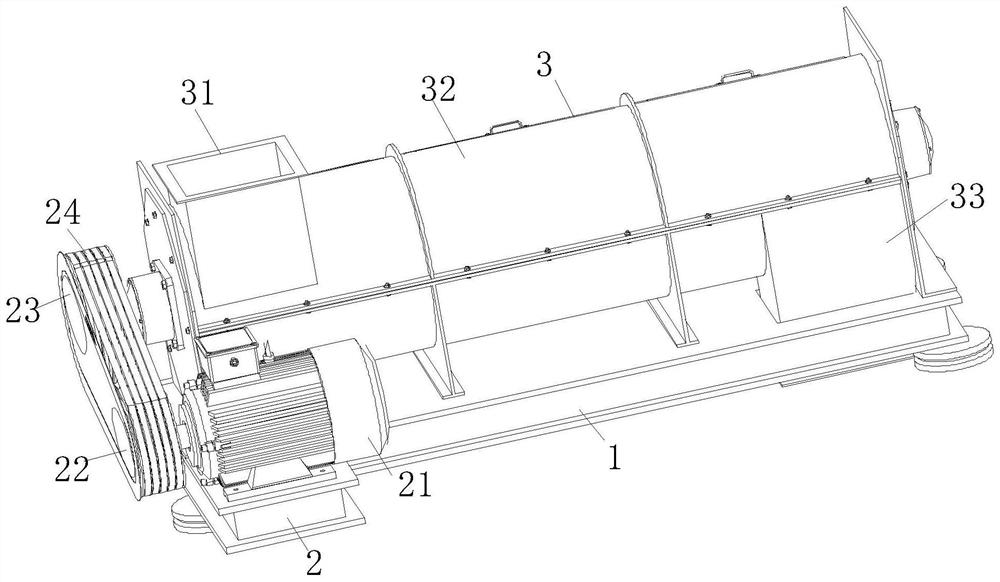

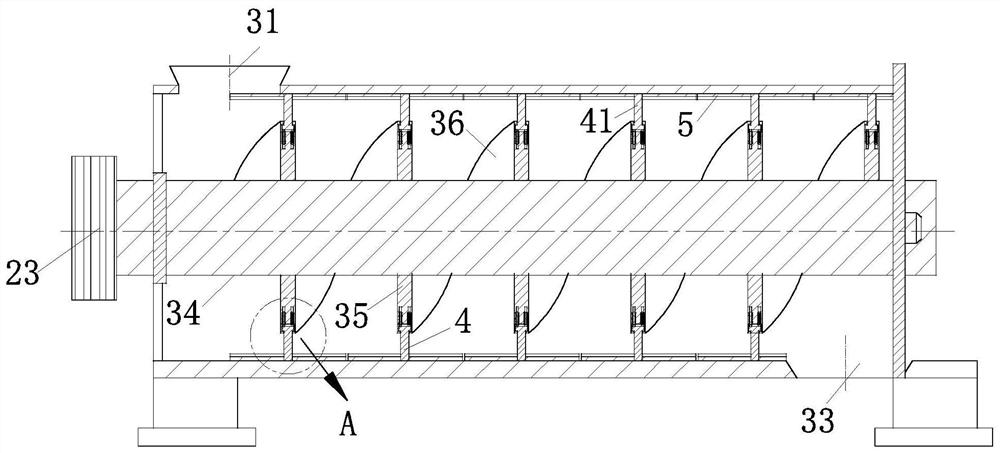

The invention relates to the technical field of concrete, in particular to concrete mixing equipment capable of improving concrete quality. The concrete mixing equipment comprises a rack, wherein a transmission mechanism is mounted on the rack; a mixing mechanism is arranged on the rack; the mixing mechanism is connected to the transmission mechanism; a blocking mechanism is connected on the mixing mechanism; the blocking mechanism is arranged inside a mixing barrel on the transmission mechanism; the bottom of the blocking mechanism is fixedly provided with a scraping knife; the transmission mechanism comprises a motor fixedly arranged on the rack; the end part of the motor is connected to a drive wheel through a transmission shaft; the drive wheel is connected to a driven wheel through abelt; and the driven wheel is connected on the mixing mechanism. The blocking mechanism can be arranged to dismount and replace the scraping knife, and the arranged scraping knife can quickly clear concrete adhered on the inner side wall of the mixing barrel, so that the concrete is not adhered to the inner side wall of the mixing barrel to condense into blocks, and therefore, concrete productionquality is improved.

Owner:银培源

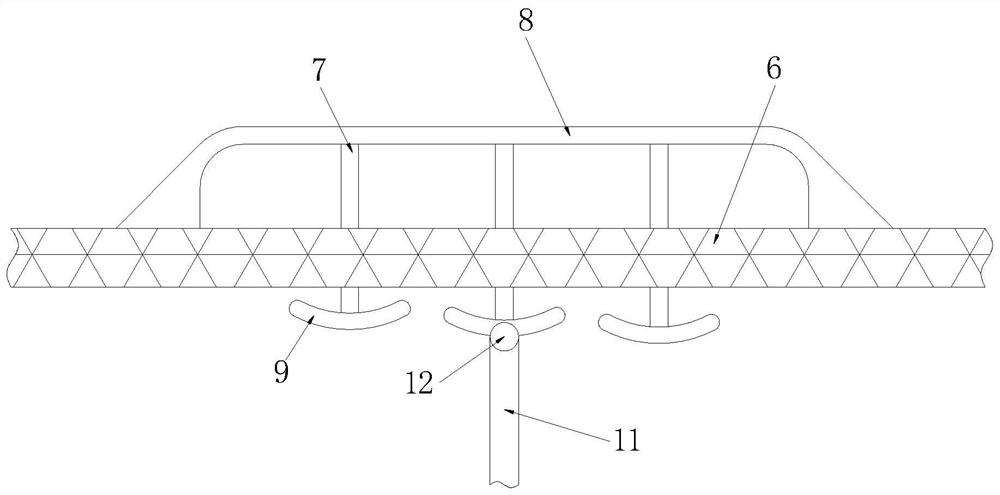

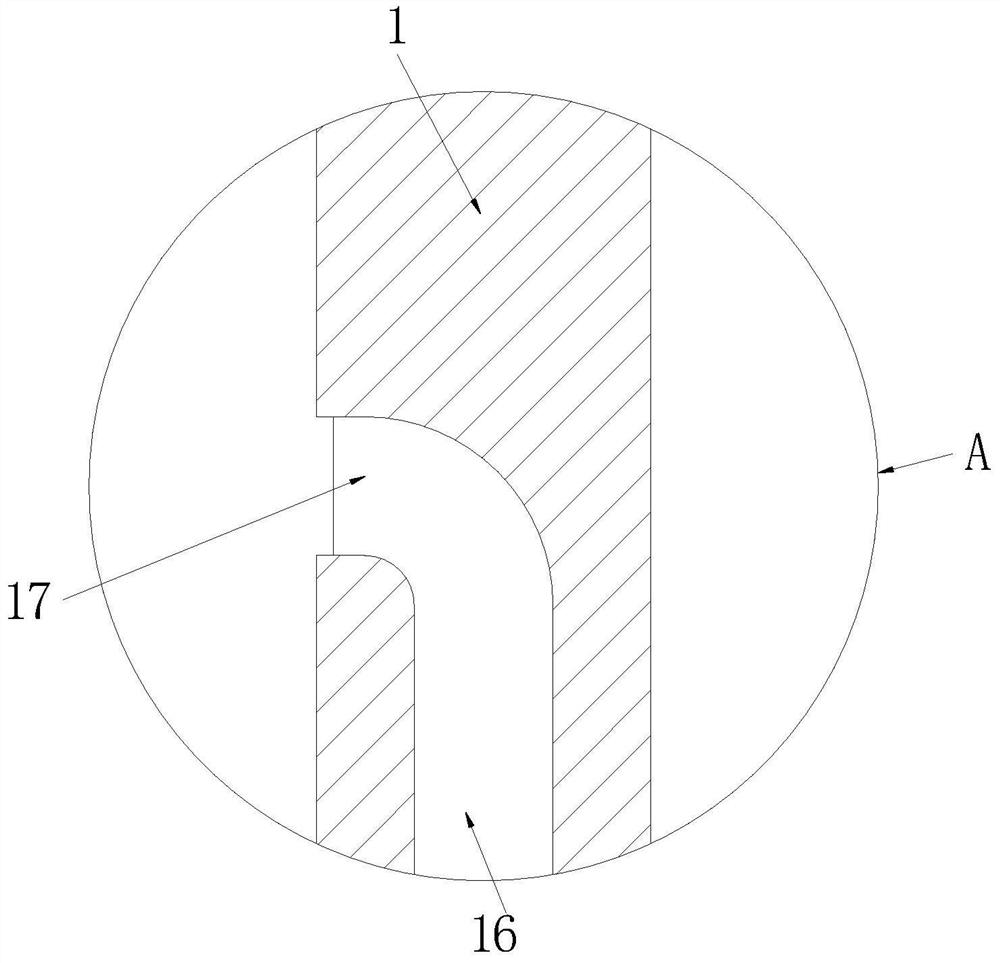

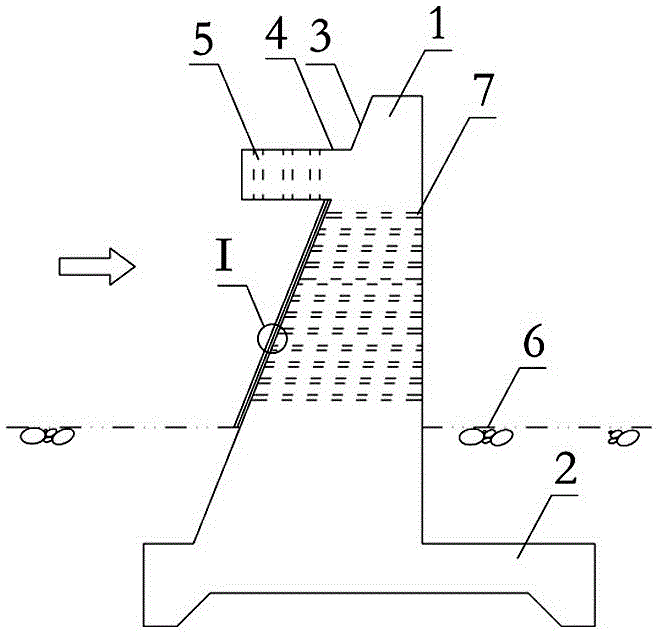

Multifunctional scouring resistance sand blocking dike

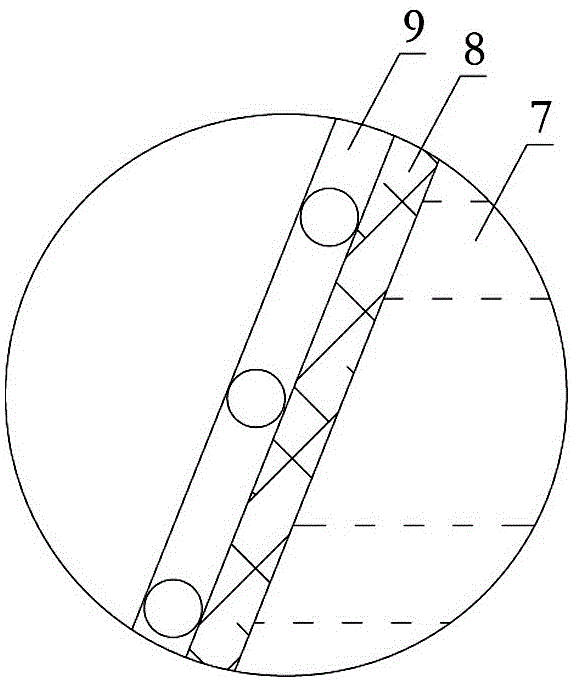

ActiveCN105464042AReduce flow rateConducive to siltClimate change adaptationStream regulationAggradationReinforced concrete

The invention discloses a multifunctional scouring resistance sand blocking dike which comprises a wall body made of cast-in-place reinforced concrete. The longitudinal section of the wall body is of a right-angled trapezoidal structure. The bottom foundation of the wall body is of a tooth plate structure. The inclined wall face, located on the upper stream side, of the upper portion of the wall body is fixedly connected with a water permeable baffle extending towards the upper stream side. The water permeable baffle is provided with multiple vertical water permeable holes in the vertical direction. Multiple horizontal water permeable units are arranged on the portion, between the water permeable baffle and a river bed, of the wall body. Each horizontal water permeable unit is formed by multiple rectangular horizontal water permeable holes at up-down intervals. The portion, located at each horizontal water permeable unit, on the inclined wall face of the upper stream side is covered with water permeable geotechnical cloth, and the water permeable geotechnical cloth is fixed to the inclined wall face on the upper stream side through a steel wire net frame. By the adoption of the multifunctional scouring resistance sand blocking dike, the flow speed of the upper stream side of the sand blocking dike is lowered, and fine sediment aggradation is facilitated; and the sand blocking wall body share the dike top excess flow, so that the back-water height of the front of the dike is lowered, the water flow energy below the dike is weakened, and the scouring effect on the sand blocking underwater bed is weakened.

Owner:YELLOW RIVER ENG CONSULTING

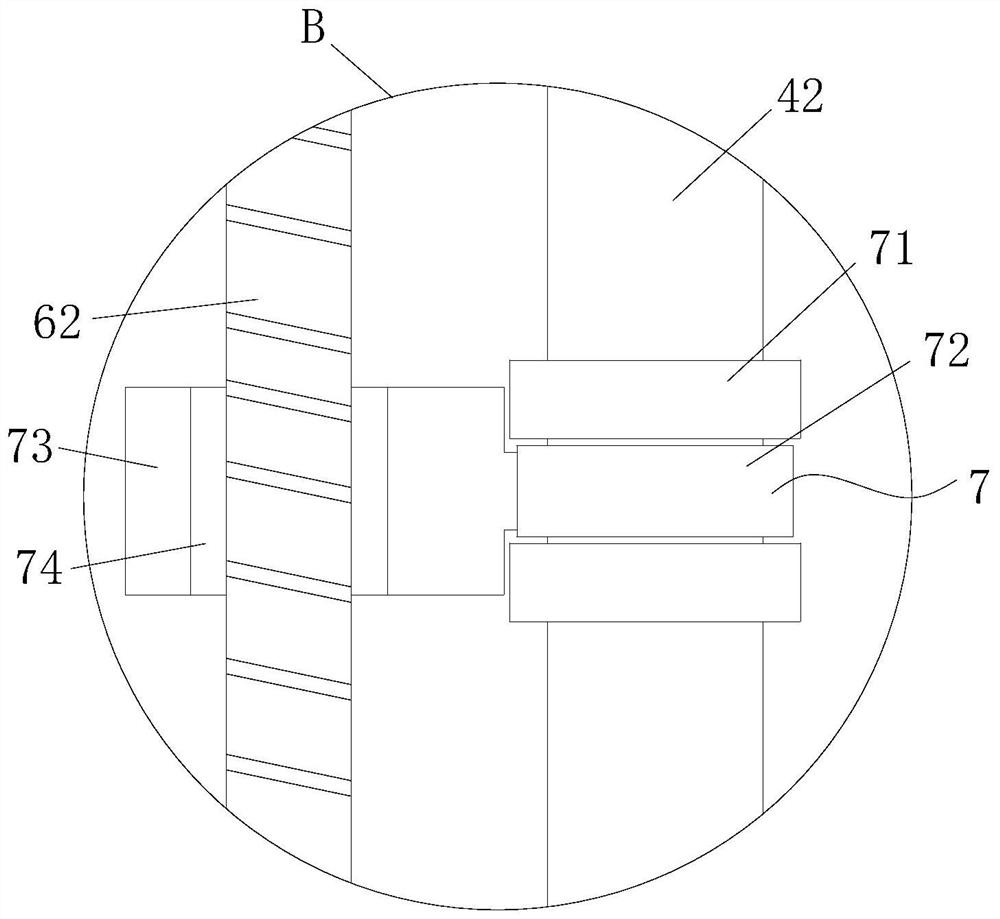

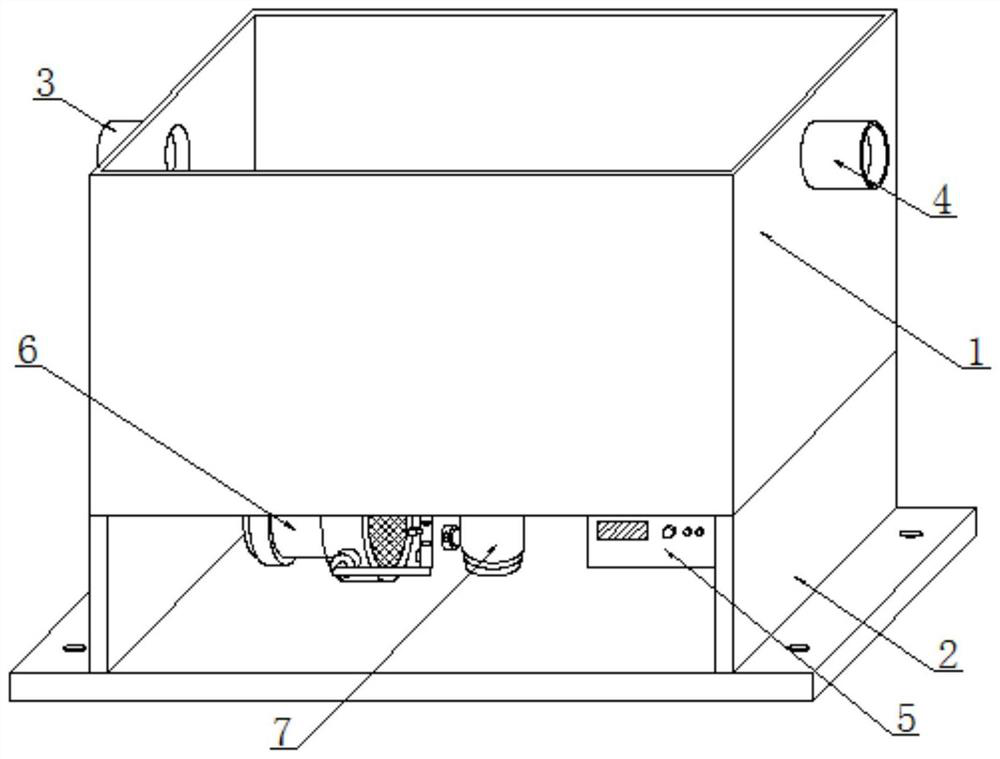

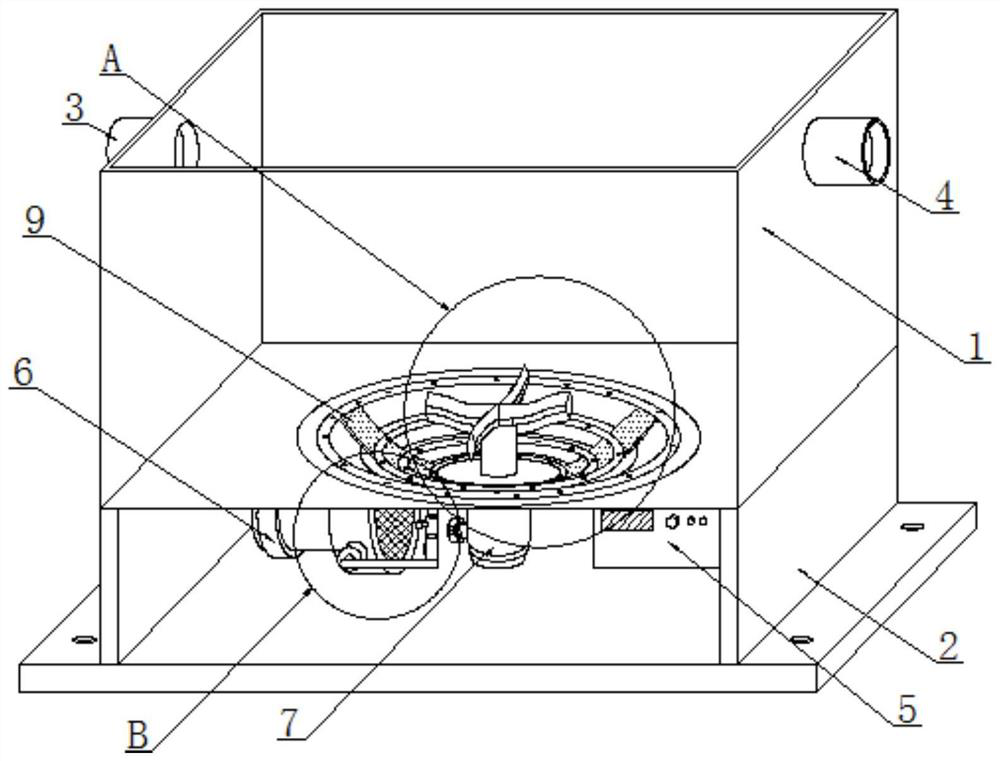

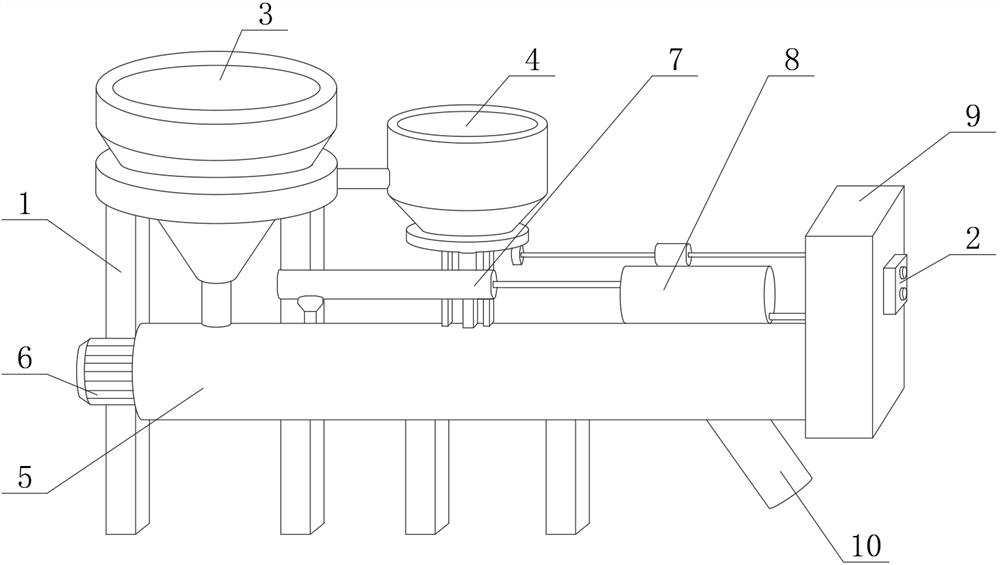

Integrated water-fertilizer quantitative top application device

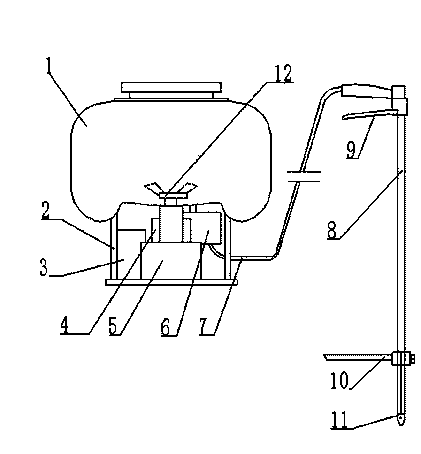

InactiveCN104303680ASave human effortGuaranteed errorPressurised distribution of liquid fertiliserAgriculture gas emission reductionFertilizerMechanical engineering

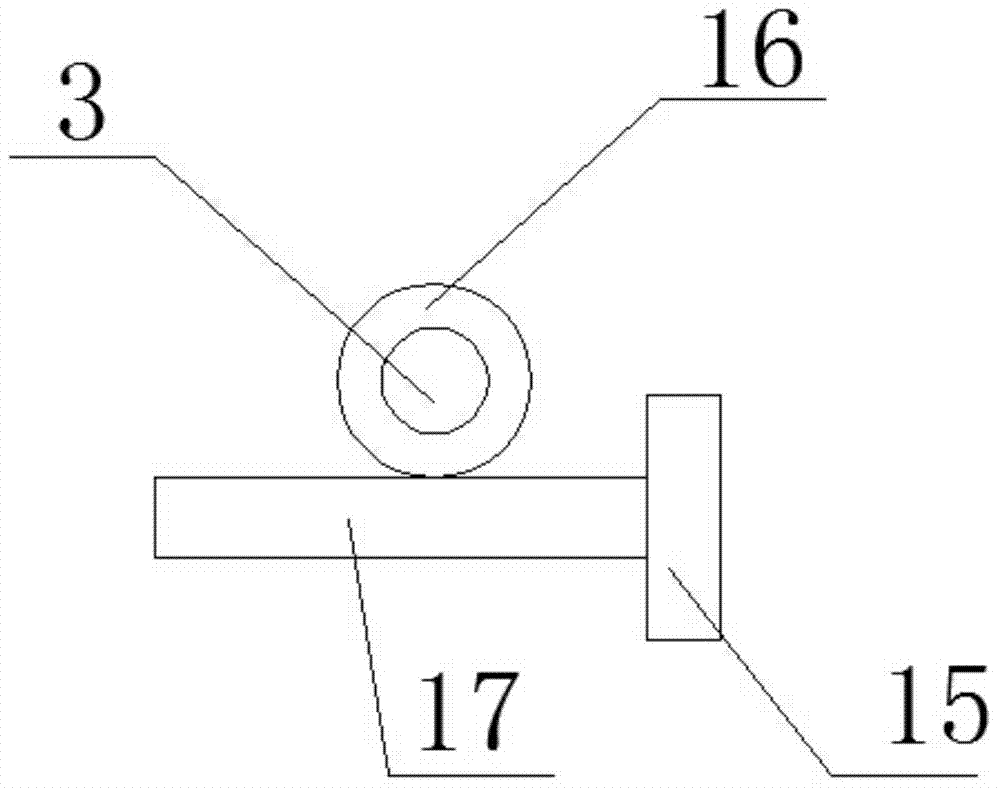

The invention discloses an integrated water-fertilizer quantitative top application device. The device comprises a fertilizer container (1) and a gun body (8), wherein a water pump (6), a singlechip controller (3) and a power supply (5) are arranged on a mounting support (2) arranged under the fertilizer container (1) and are connected with each other; the fertilizer container (1) is connected with the gun body (8) by virtue of the water pump (6) and a plastic pipe (7). According to the integrated water-fertilizer quantitative top application device, the device is operated by driving the water-fertilizer by virtue of the water pump, so that labor force is reduced; quantitative fertilizer application is realized by only pressing a valve on the gun body to control the operation time of the water pump by virtue of the singlechip controller, so that the error of the fertilizer application amount per time can be controlled to be within 1ml.

Owner:贵州省烟草公司遵义市公司务川分公司 +1

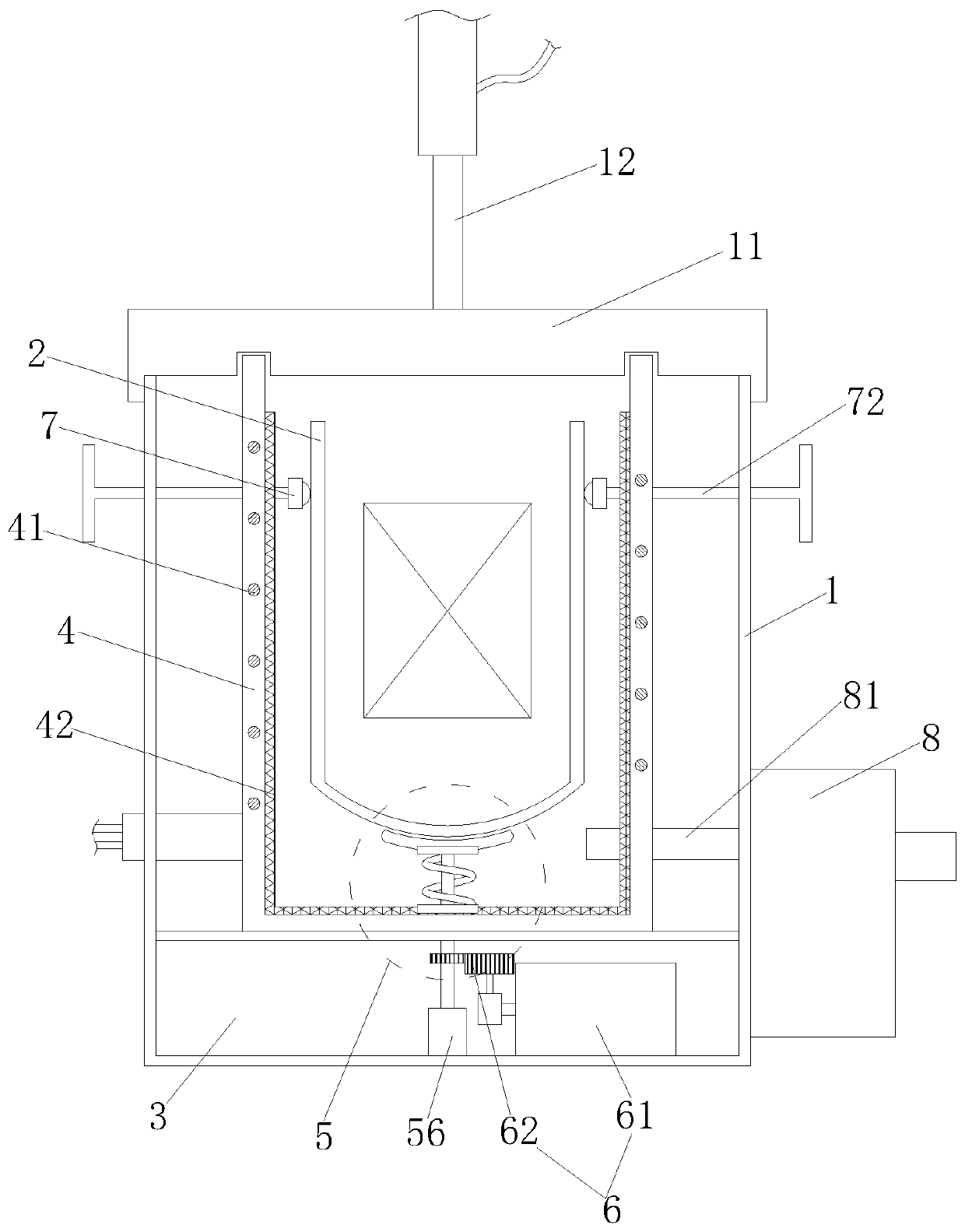

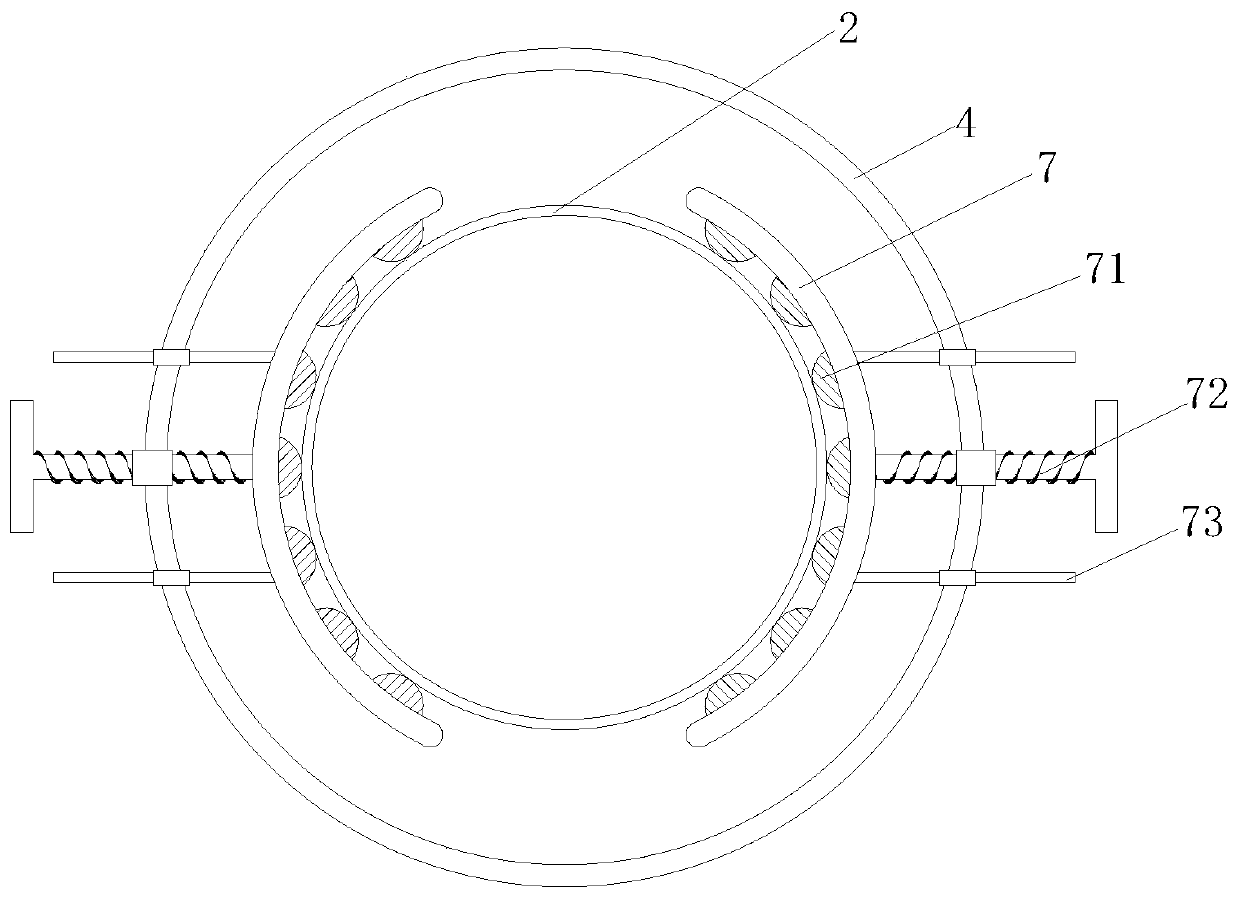

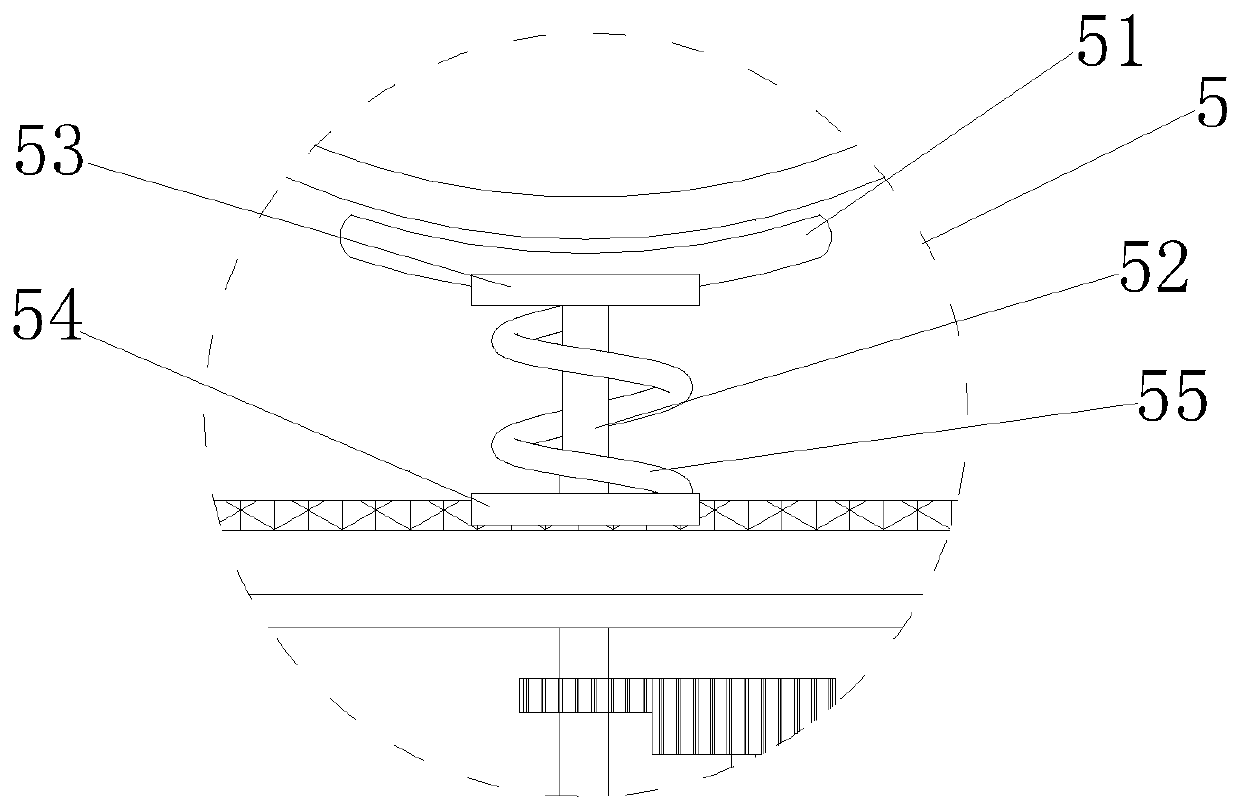

Rotary stirring rare earth alloy smelting device

PendingCN110567271ATo drive rotationStable and stableStirring devicesCharge treatment typeRare earthAlloy

The invention discloses a rotary stirring rare earth alloy smelting device. A heating sleeve sleeves the outer side of a graphite crucible; a support frame is arranged on the lower side of the graphite crucible; a driving device for driving the support frame to rotate is arranged on the lower side of the support frame; multiple arc clamping arms are arranged on the side wall of the graphite crucible; and multiple balls are embedded in the inner arc sides of the clamping arms. The graphite crucible is supported and stabilized by the support frame; meanwhile, the support frame drives the graphite crucible to rotate; the balls are arranged on the inner arc sides of the clamping arms; the clamping arms and the side wall of the graphite crucible are in rotary fit through a rolling effect of theballs to achieve an effect of uniformly mixing molten metal in the graphite crucible; and an auxiliary stirring device is not added in the graphite crucible, so that the pollution of the molten metalby a stirring shaft is prevented, and meanwhile, the problem of difficult cleaning of the stirring shaft after use of the graphite crucible is solved.

Owner:ANHUI BAO TOU STEEL RARE EARTH PERMANENT MAGNETICALLOY IND

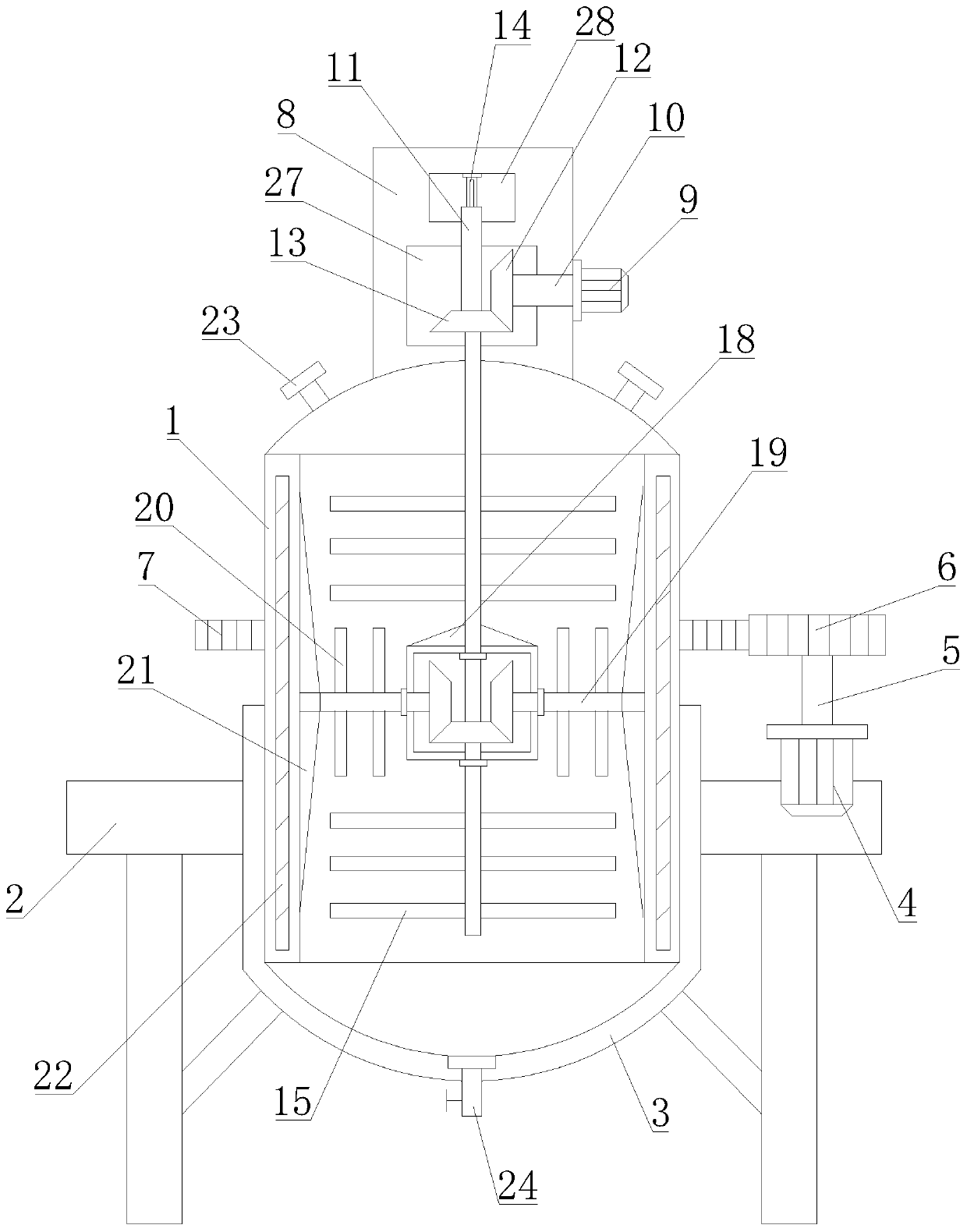

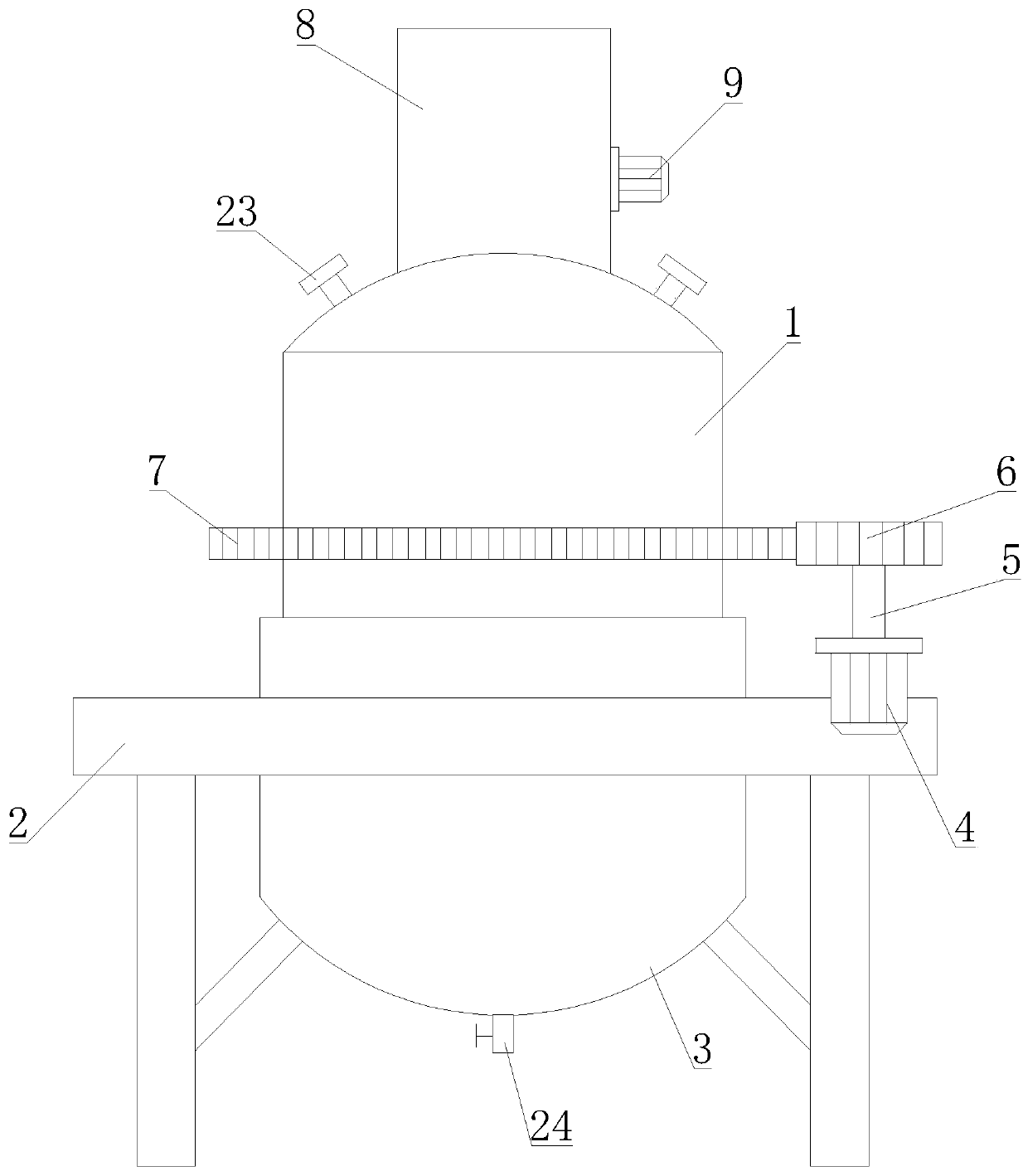

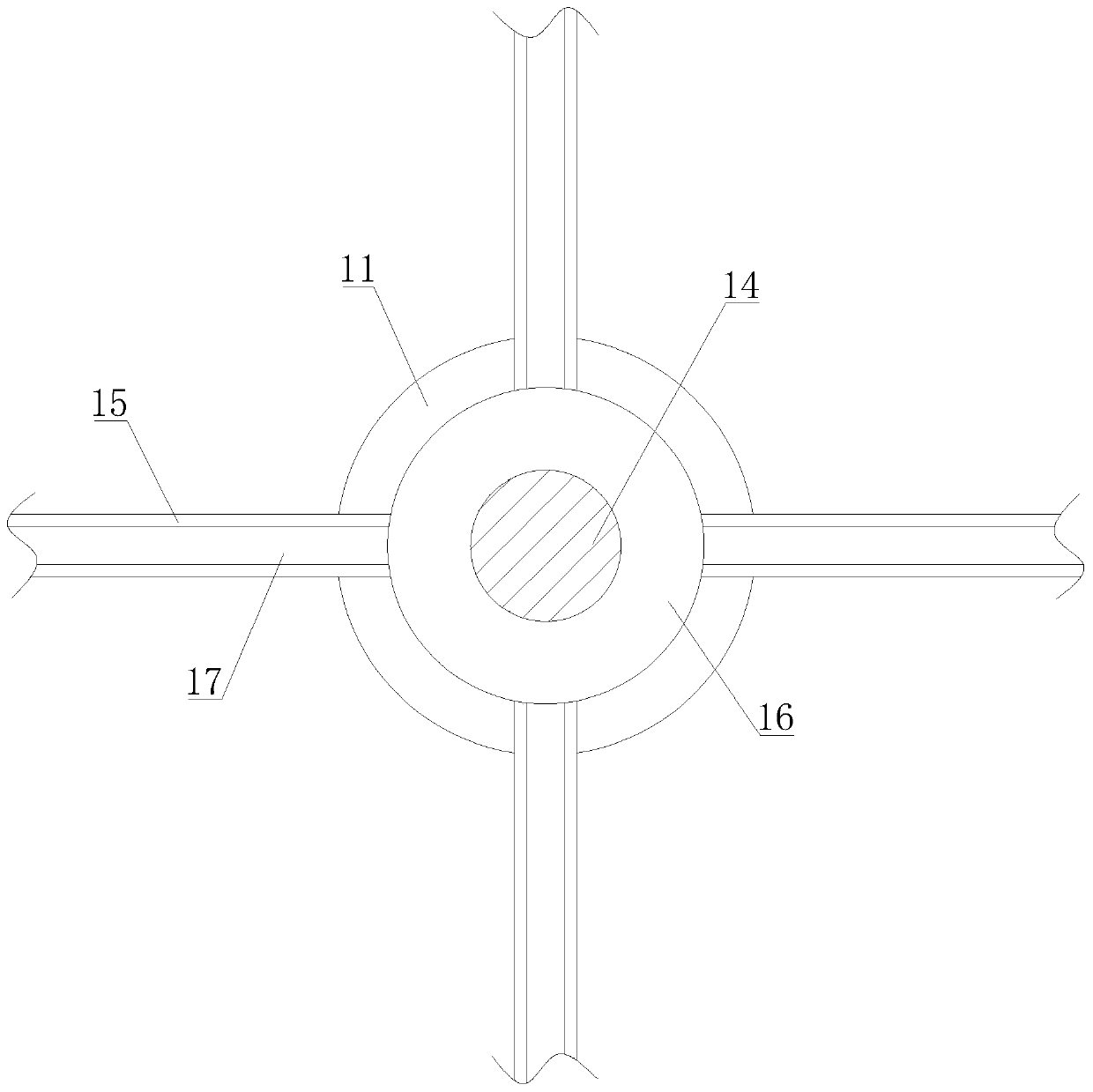

Vertical efficient reaction kettle for producing organic silicon sealant

InactiveCN110918033APlay a role in mixingImprove stirring and mixing effectChemical/physical/physico-chemical stationary reactorsLiquid storage tankEngineering

The invention discloses a vertical efficient reaction kettle for producing an organic silicon sealant. The vertical efficient reaction kettle comprises a reaction kettle body, the reaction kettle bodyis rotationally connected with a heat preservation cover, and an electric heating ring is arranged on the reaction kettle body; a first gear is arranged on a first transmission shaft, a second gear is arranged on the reaction kettle body, and the first gear is in engaged transmission connection with the second gear; a first rotating part is rotationally connected with the reaction kettle body; afirst liquid storage tank is arranged on the first rotating piece; an electric heating pipe is inserted into the first liquid storage tank; a second transmission shaft is in transmission connection with a first rotating part; a first stirring piece is arranged on the first rotating piece, and a second liquid storage tank is arranged on the first stirring piece; the second liquid storage tank communicates with the first liquid storage tank; a second rotating piece is rotationally connected with a second fixed piece, and the first rotating piece is in transmission connection with the second rotating piece; and a second stirring piece and a spoiler are arranged on the second rotating piece. Raw materials can be uniformly heated and fully mixed, the stirring efficiency is high, the stirring effect is good, and the product quality is remarkably improved.

Owner:江西纳森科技有限公司

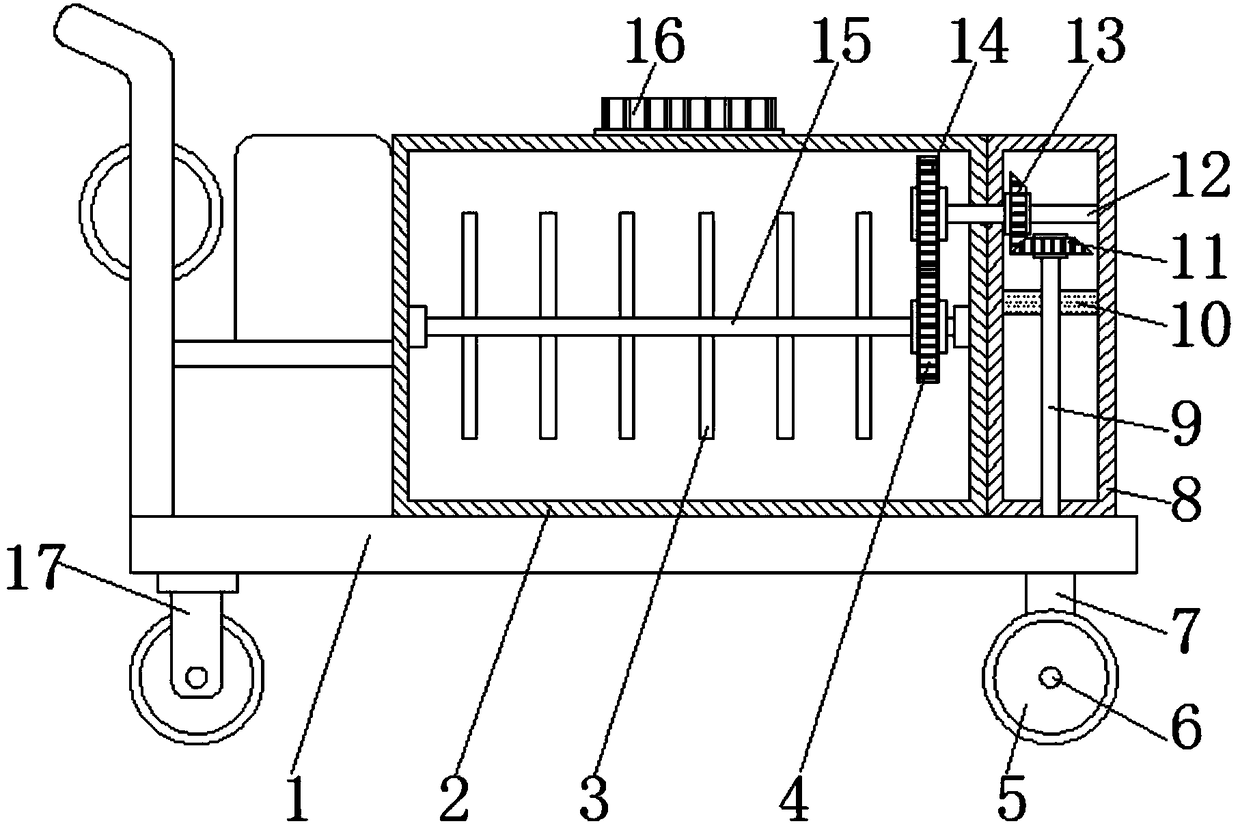

Agricultural pesticide spraying device good in mixing effect

InactiveCN108719246ASolve the problem of waterSolve the problem of adequate mixing of pesticidesShaking/oscillating/vibrating mixersTransportation and packagingAgricultural engineeringMixing effect

The invention discloses an agricultural pesticide spraying device good in mixing effect. The agricultural pesticide spraying device comprises a vehicle body, wherein a mixing box and a shell are fixedly connected to the top of the vehicle body, an inner cavity of the shell is movably connected with a stirring shaft, and stirring rods are fixedly connected to the top and the bottom of the stirringshaft; a first gear sleeves the right end of the stirring shaft, and a second gear sleeves the top of the first gear. By means of the cooperation of the vehicle body, the mixing box, the stirring rods, the first gear, rollers, a third rotating rod, a support, the shell, a second rotating rod, a positioning plate, a second bevel gear, a first rotating rod, a first bevel gear, the second gear, the stirring shaft, a box cover, universal wheels, a fourth bevel gear and a third bevel gear, the problem that existing agricultural pesticide spraying equipment cannot fully mix water and pesticide is solved, and the agricultural pesticide spraying device has the advantage of making the water and the pesticide mixed more uniformly and is worthy of popularization.

Owner:肖赟

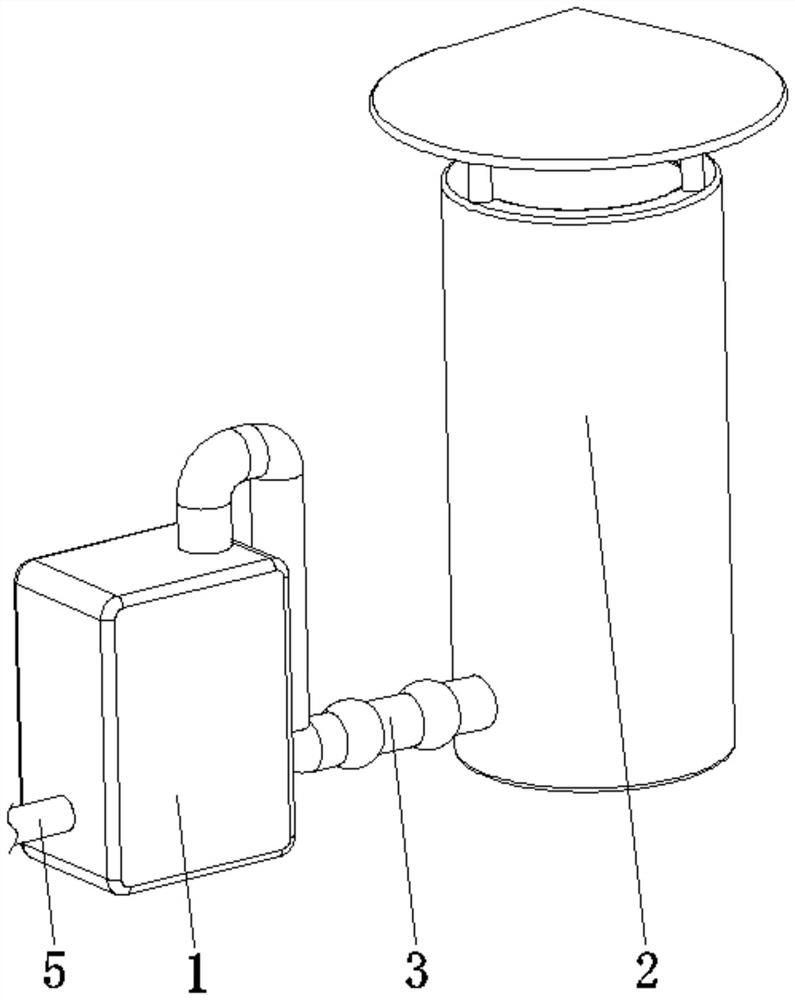

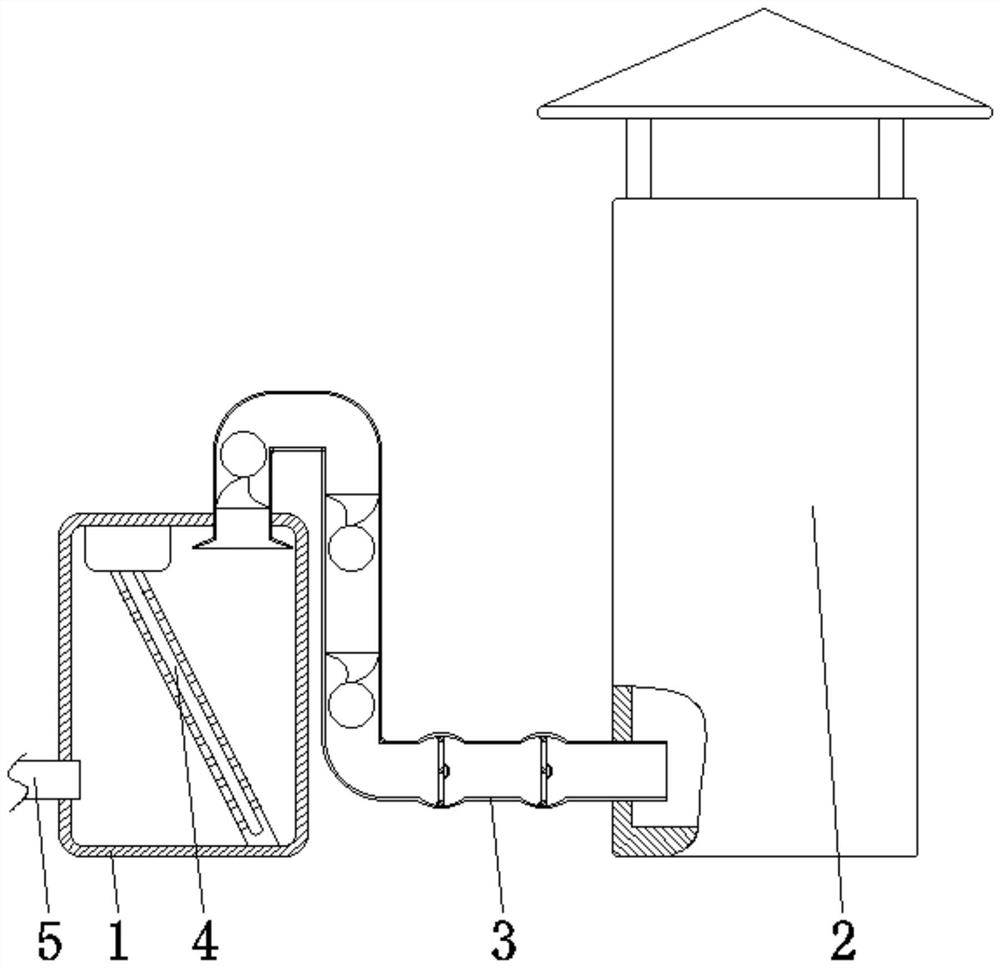

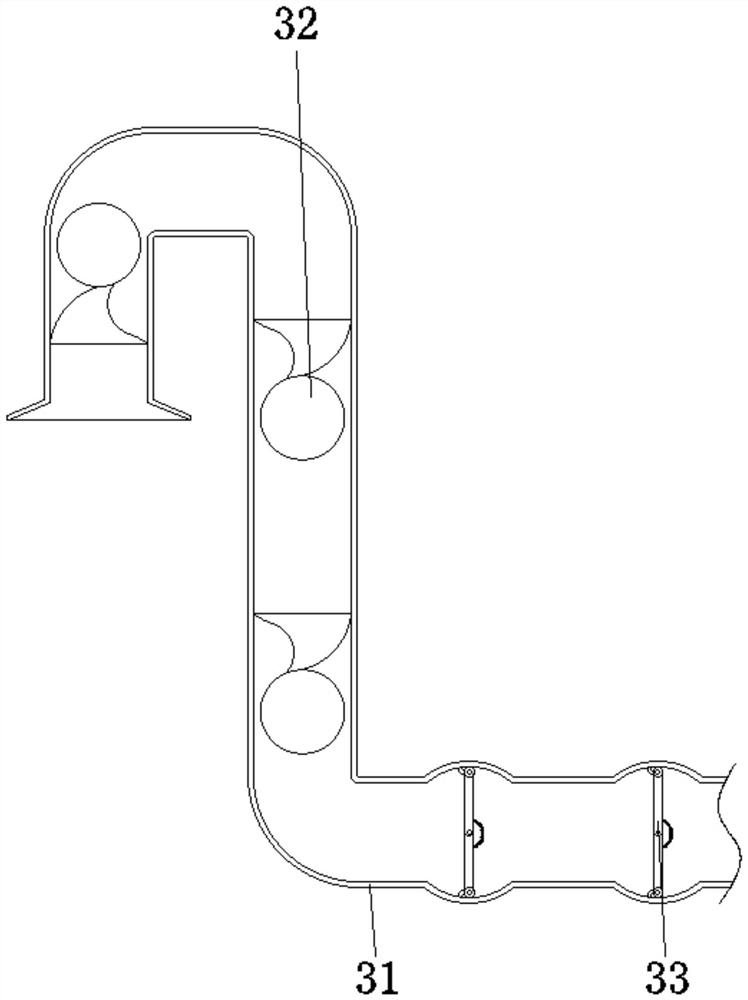

Flue gas denitration equipment

InactiveCN112915897AExtend the mixing timeWell mixedGas treatmentTransportation and packagingThermodynamicsFlue gas

The invention discloses flue gas denitration equipment, which comprises a mixing chamber, a denitration chamber, a conveying pipe device, an ammonia spraying device and a gas inlet pipe. The conveying pipe device is fixedly connected between the mixing chamber and the denitration chamber, the gas inlet pipe is fixed to one side of the bottom of the surface of the mixing chamber and communicates with the mixing chamber, one end of a zigzag pipeline is communicated with one side of the top of the mixing chamber, the end, away from the mixing chamber, of the zigzag pipeline is communicated with one side of the bottom of the surface of the denitration chamber, a first-stage mixing device is arranged in the zigzag pipeline and close to the mixing chamber, and a secondary mixing device is arranged in the zigzag pipeline and is close to the denitration chamber. The invention relates to the technical field of denitration equipment. According to the flue gas denitration equipment, the purpose of uniform mixing is achieved, flue gas and ammonia gas can make full contact, mixing is rapid and uniform, follow-up denitration work is facilitated, emission of harmful substances is reduced, pollution to the environment is reduced, human health is facilitated, and the use performance is improved.

Owner:陈世君

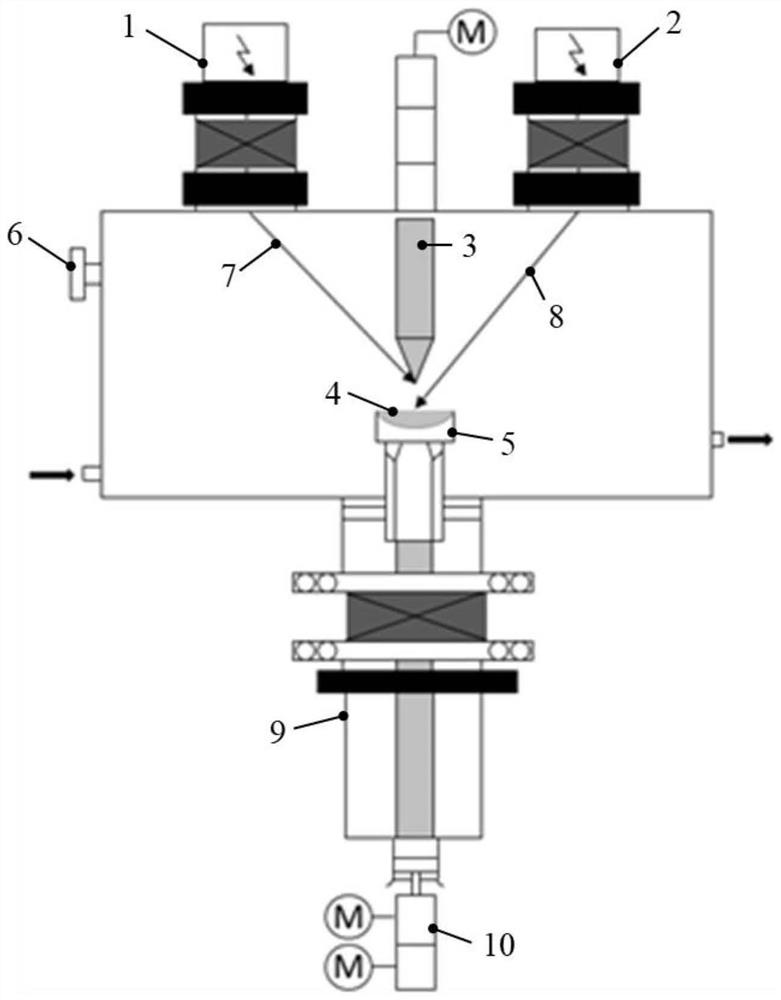

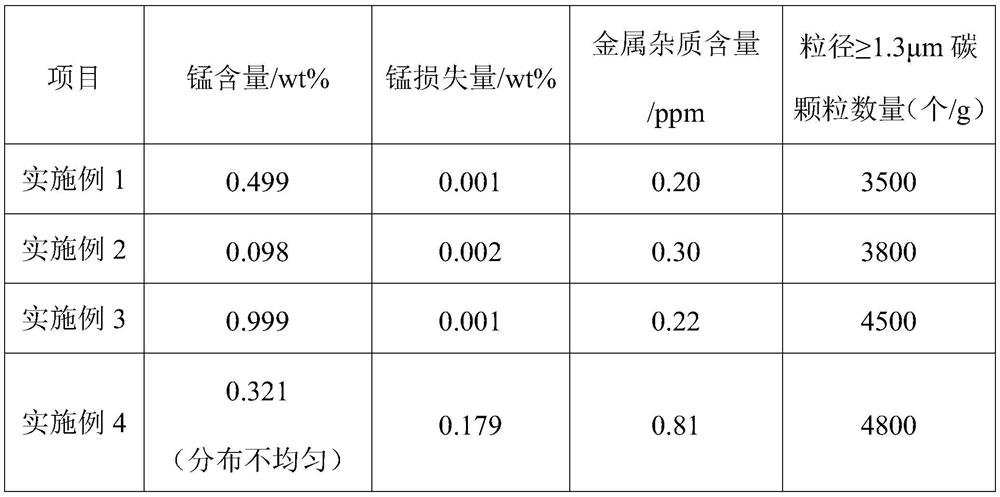

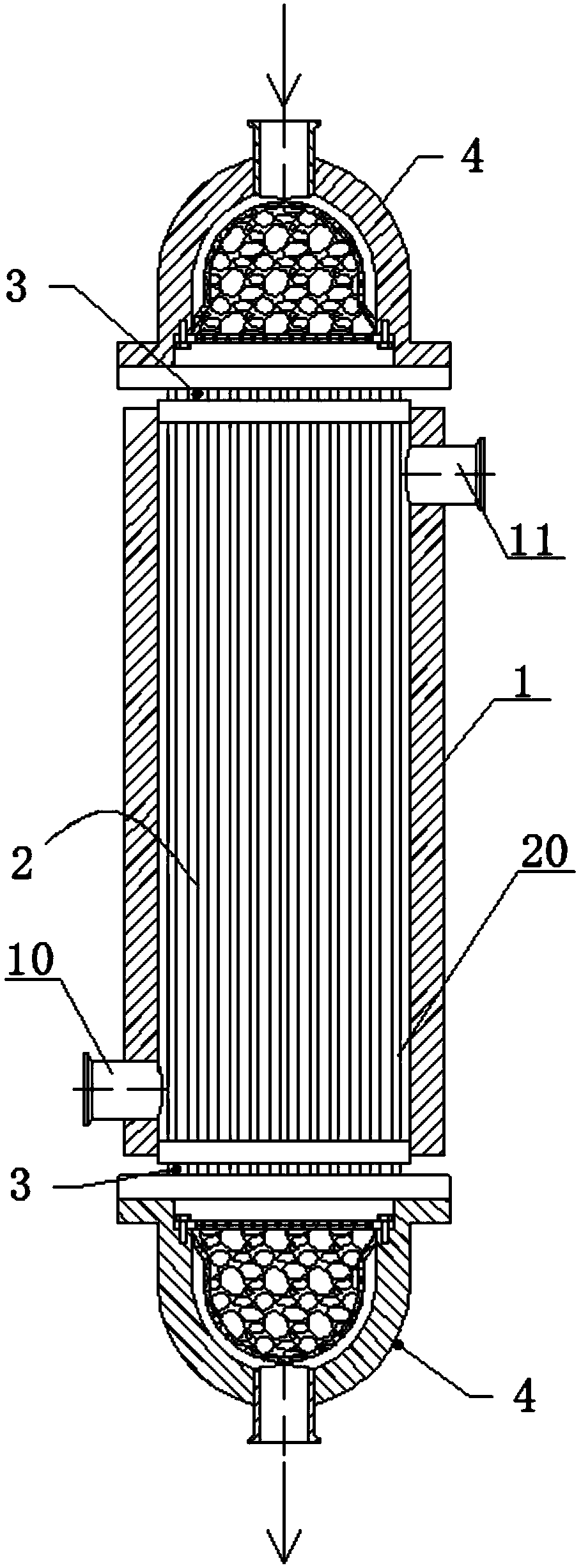

Preparation method of ultrahigh-purity copper-manganese alloy

PendingCN113737011APromotes homogeneous mixingReduce metal lossIncreasing energy efficiencyVacuum induction meltingHot isostatic pressing

The invention provides a preparation method of an ultra-high-purity copper-manganese alloy, which adopts electron beam melting to prepare the ultra-high-purity copper-manganese alloy. The preparation method of the ultra-high-purity copper-manganese alloy comprises the following steps: carrying out acid pickling and mixing on an ultra-high-purity copper raw material and a manganese raw material, carrying out hot isostatic pressing to obtain an ultra-high-purity copper-manganese alloy blank, and carrying out electron beam melting and dummy ingot on the blank to obtain the ultra-high-purity copper-manganese alloy. According to the preparation method of the ultra-high-purity copper-manganese alloy, hot isostatic pressing is adopted to promote uniform mixing of the raw materials, and metal loss in the electron beam melting process is reduced; the double electron guns are used for smelting, refining of an ultrahigh-purity copper-manganese alloy solution can be achieved while the ultrahigh-purity copper-manganese alloy blank is smelted, the mixing effect is achieved in the process that the blank is dropped into the water-cooling copper crucible after being smelted, and the ultrahigh-purity copper-manganese alloy is more uniform; compared with traditional vacuum induction melting, carbon particle inclusions of the ultrahigh-purity copper-manganese alloy obtained through electron beam melting are reduced, and it can be ensured that the sputtering performance of the prepared target material is stable in the sputtering process; and the preparation method of the ultra-high-purity copper-manganese alloy has the advantages of simple process operation and wide applicability.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

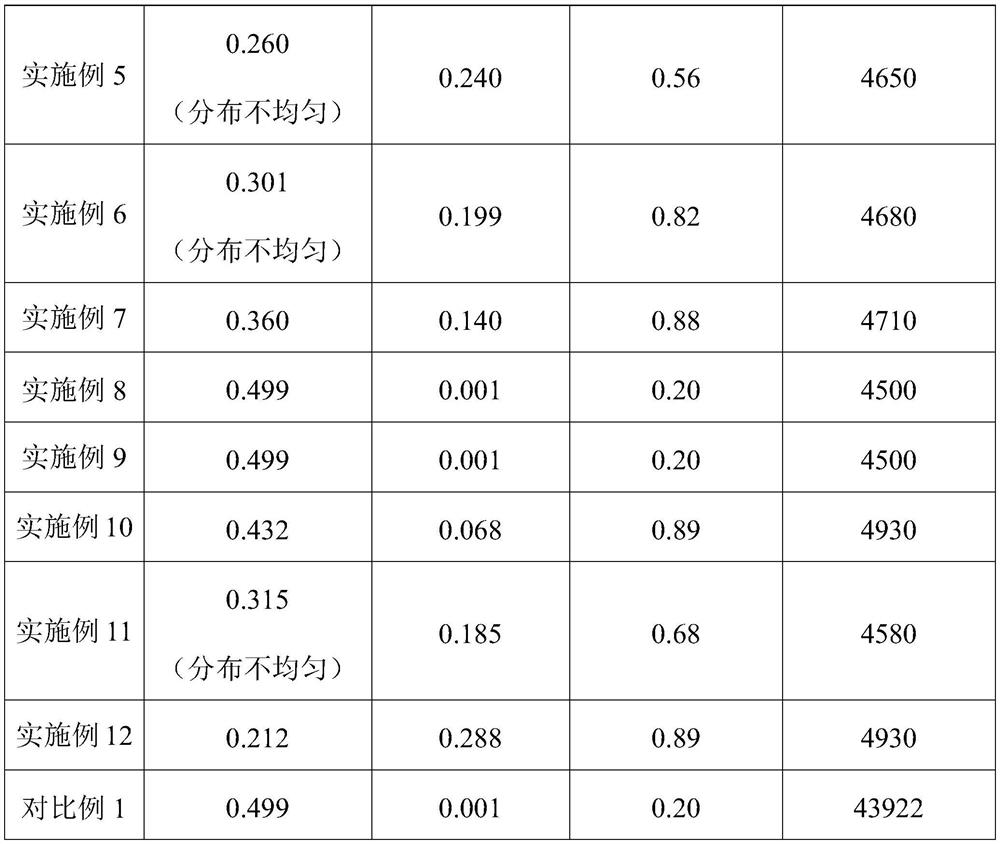

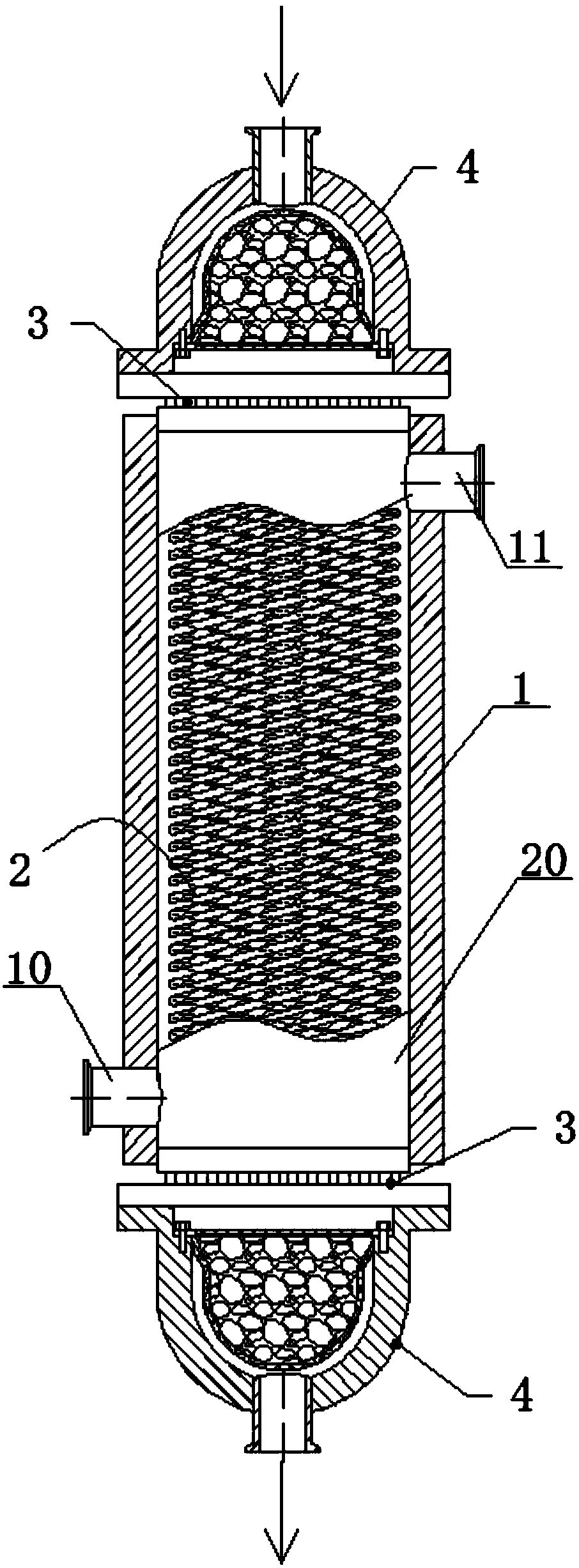

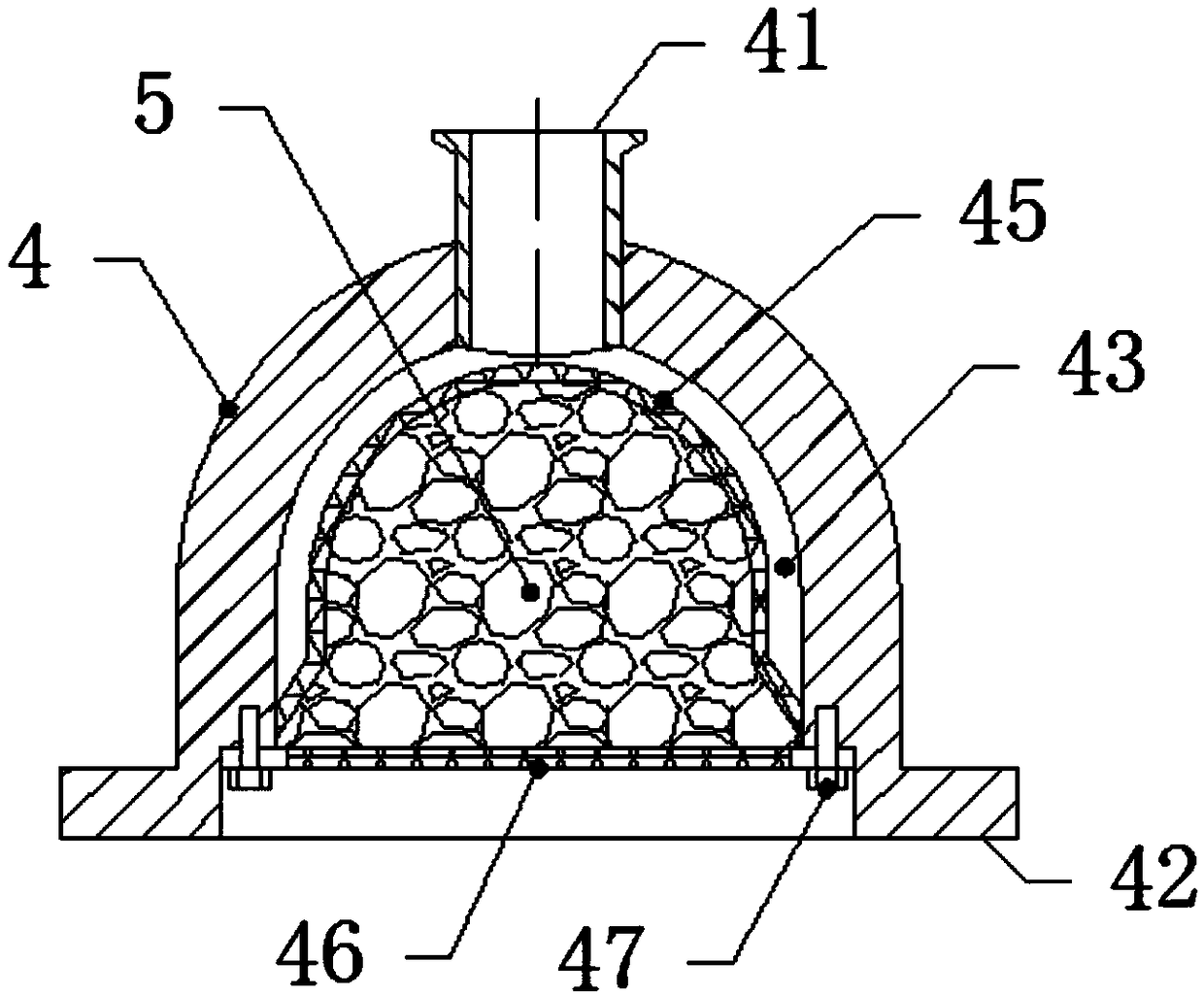

Multi-line reactor

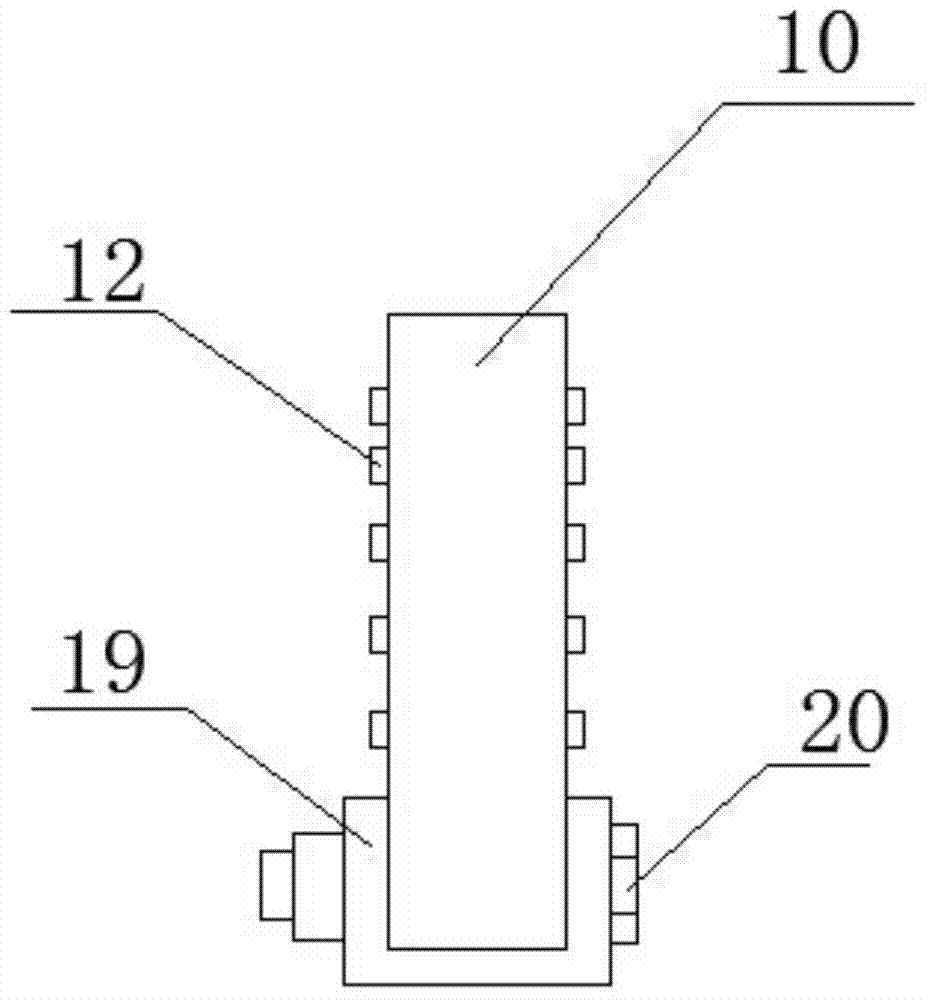

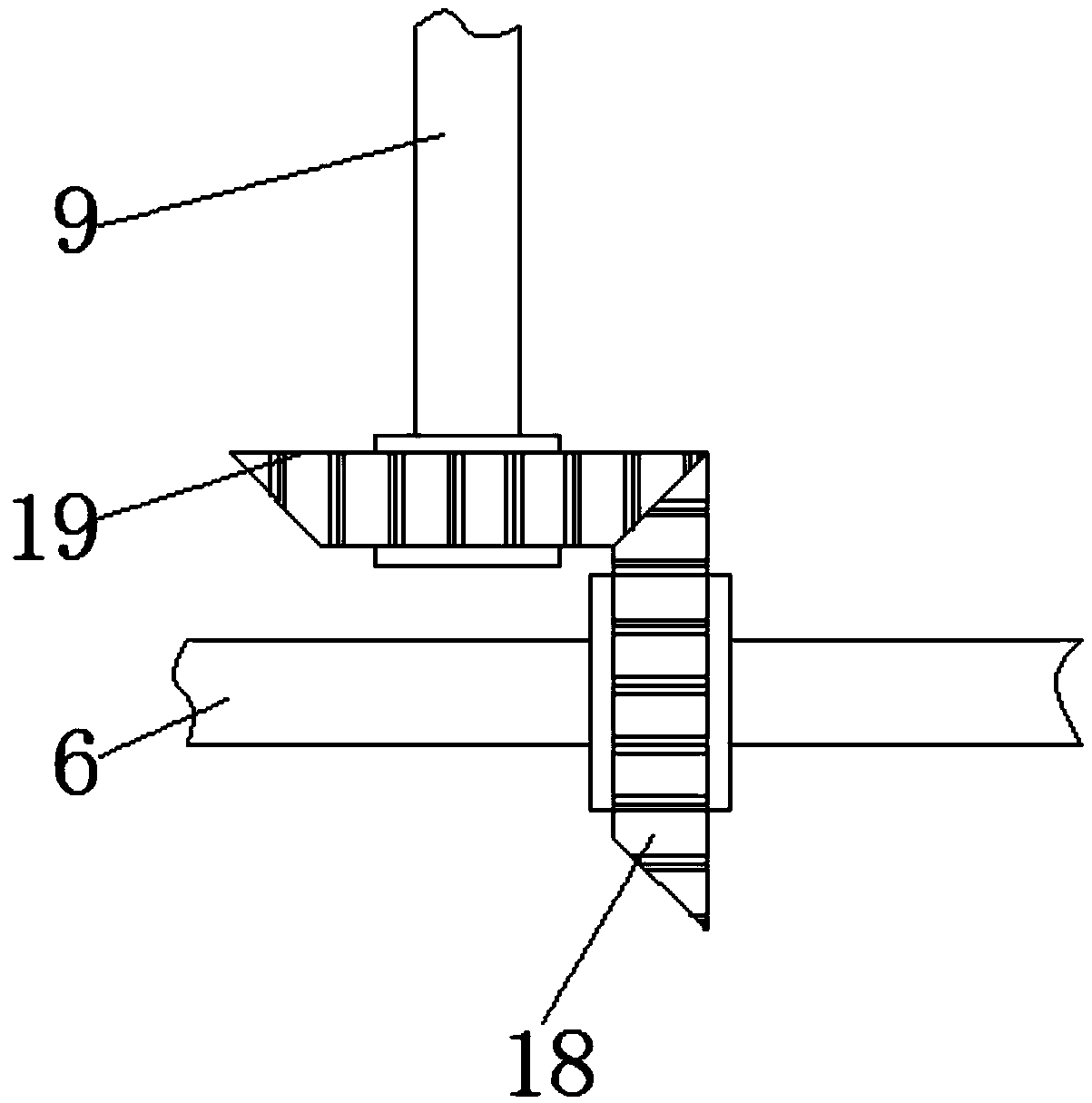

PendingCN109482128AEasy to installEasy to fixChemical/physical/physico-chemical stationary reactorsEngineeringReaction tube

The invention discloses a multi-line plug flow reactor, comprising a shell, a reaction tube bundle, tube plates and end enclosures, wherein the upper end and the lower end of the shell are respectively connected with the tube plates; the reaction tube bundle is arranged in the shell, and comprises multiple reaction tubes, the reaction tubes are arranged in parallel, and the upper end and the lowerend of each reaction tube both penetrate through and are fixedly connected to the tube plates; the upper end and the lower end of the shell are respectively provided with an end enclosure, the end enclosures are connected with the tube plates, each end enclosure is of a cavity structure with openings at the upper and the lower parts, the end enclosures are connected with the tube plates to form amixed cavity, and the mixed cavity is used for filling a filler playing a mixing role and / or a catalysis role. The multi-line reactor has the following beneficial effects that on the one hand, the filler can play a mixing role, so as to uniformly mix incoming materials; on the other hand, the filler can also be prepared from a catalyst, so as to perform a catalysis reaction during mixing, and beconvenient for the mounting, fixing and replacement of the catalyst.

Owner:SHANDONG NERVE PHARMA FLUID SYST CO LTD

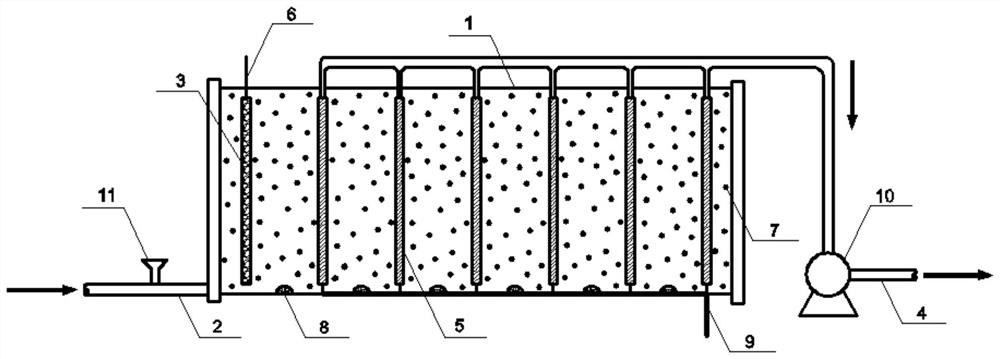

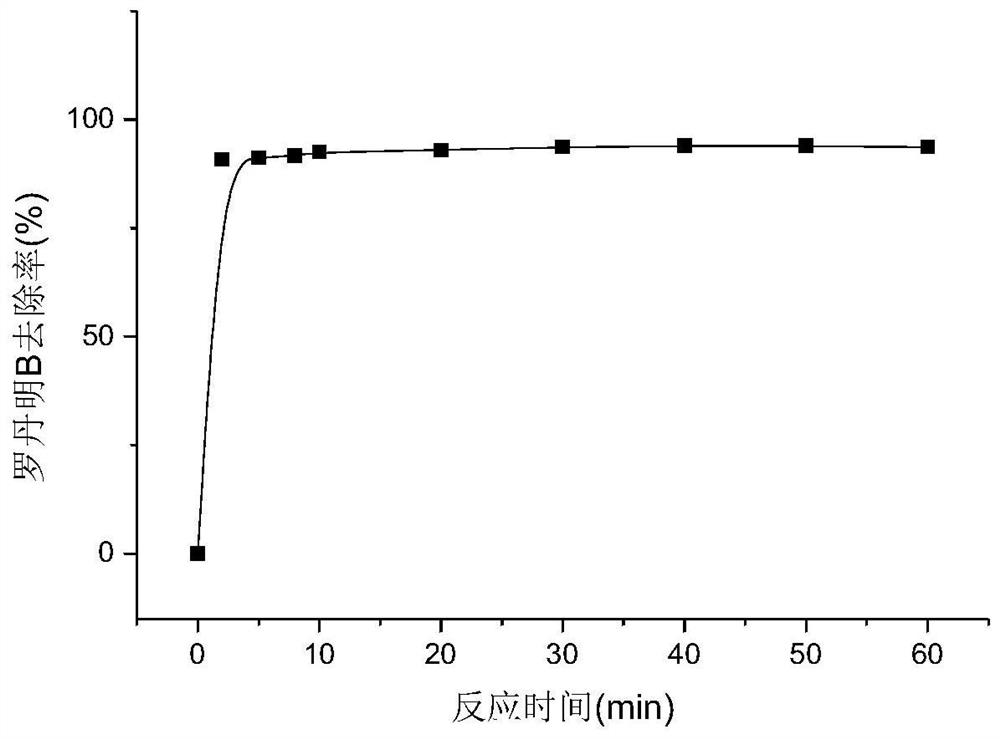

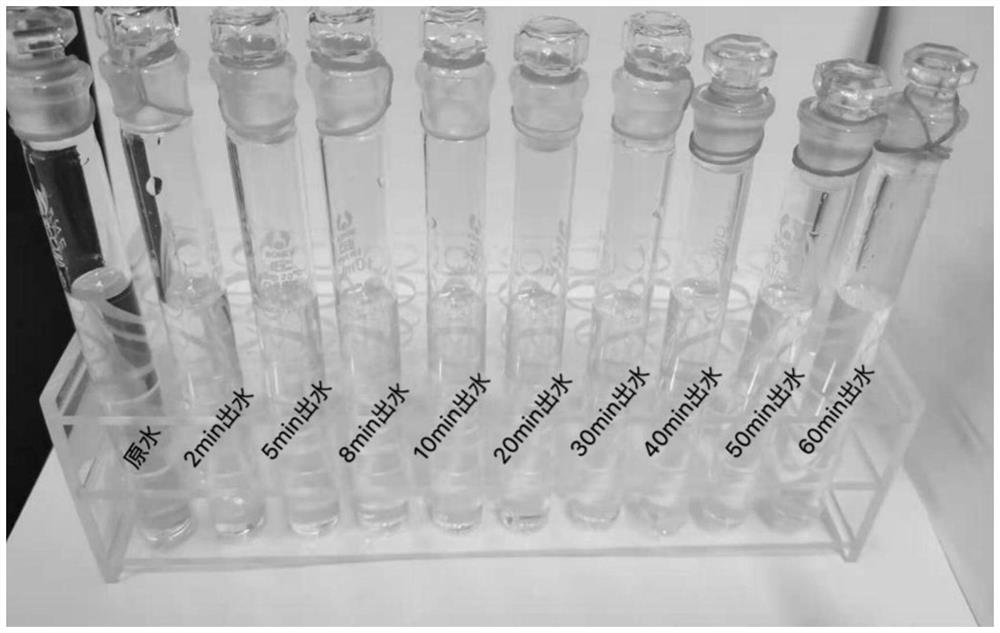

Method for deeply treating refractory pollutants by using conductive filter membrane-heterogeneous Fenton-like water treatment device

PendingCN113735337AShort processEasy to handleWater treatment compoundsWater contaminantsAdvanced oxidation processFiltration

The invention relates to a method for deeply treating refractory pollutants by using a conductive filter membrane-heterogeneous Fenton-like water treatment device. The deep treatment method combines a conductive filter membrane and a heterogeneous Fenton-like oxidation method, takes an electrode plate as an anode, takes the conductive filter membrane as a cathode, and the space between the conductive filter membranes is filled with a carbon material with catalytic performance, so that a reactor can synchronously complete the Fenton-like reaction and the membrane filtration effect, the water treatment process is greatly shortened, and the water treatment effect is improved. The treatment method disclosed by the invention has the advantages of inhibiting the deposition and enrichment of pollutants on the membrane, reducing the use of a catalytic agent in an advanced oxidation process and the discharge of metal ions such as iron and manganese, improving the Fenton-like treatment efficiency, shortening the water treatment flow and improving the water treatment effect of the refractory pollutants.

Owner:SHANDONG UNIV

Mixing equipment for animal husbandry feed

InactiveCN112439343AWell mixedPlay a role in mixingShaking/oscillating/vibrating mixersFeeding-stuffControl theoryAnimal husbandry

The invention relates to mixing equipment for animal husbandry feed. The mixing equipment comprises a mixing tank and a tank cover, the tank cover is buckled on an opening in the upper end of the mixing tank, and a first mixing mechanism is arranged on the tank cover; a rotating mechanism is arranged in the mixing tank and comprises two fixed limiting rings, a rotating ring, a connecting plate anda threaded hole, the two fixed limiting rings are fixedly arranged outside a first rotating rod in a sleeving mode, the rotating ring is arranged between the two fixed limiting rings, and the rotating ring is movably arranged outside the first rotating rod in a sleeving mode; and the connecting plate is fixedly connected to the outer side wall of the rotating ring, and the threaded hole is formedin the connecting plate and is in threaded connection with a threaded rod. By additionally arranging multiple stirring mechanisms and turning mechanisms, when the feed is mixed, the feed at differentparts in the mixing tank can be stirred and mixed through the multiple stirring mechanisms, so that the effect of rapid stirring and mixing can be achieved, and the effect of uniform mixing can alsobe achieved.

Owner:成善华

Food fermentation tank with solid-liquid separation function

InactiveCN108384705AWith solid-liquid separation functionPlay a role in cleaningBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringFermentation

The invention discloses a food fermentation tank with a solid-liquid separation function. The tank comprises a fermentation tank body, a base, a top spraying pipe, a water through hole, a rotating wheel, a drainage pipe, a handle, a water spraying opening, a connecting pipe and a second sealing door; a stirrer is arranged on the left side of the fermentation tank body, the base is welded to the lower end of the fermentation tank body, the top spraying pipe is arranged at the upper portion inside the fermentation tank body, the water through hole runs through the outer wall of a mixing tank, the rotating wheel is arranged at the right side of a fermentation tank door through a stirring shaft, the drainage pipe is arranged below the fermentation tank body, the handle is arranged on the outerside of the first sealing door, and the water spraying opening is formed below the top spraying pipe. According to the food fermentation tank with the solid-liquid separation function, the water through hole is formed in the outer wall of the mixing tank, water can be added into the mixing tank and water inside the mixing tank can be drained conveniently, and fermented solid and fermented water inside the mixing tank can be separated conveniently.

Owner:江西省食品发酵研究所

High-efficiency livestock feed mixing device

ActiveCN112452194AWell mixedPlay a role in mixingShaking/oscillating/vibrating mixersFeeding-stuffCrop livestockEngineering

The invention relates to a high-efficiency livestock feed mixing device, which comprises a mixing tank and a tank cover, the tank cover is buckled on an opening in the upper end of the mixing tank, and a first mixing mechanism is arranged on the tank cover; by additionally arranging the multiple stirring mechanisms and a turning mechanism, when a feed is mixed, the feed at different parts in the mixing tank can be stirred and mixed through the multiple stirring mechanisms, so that the effect of rapid stirring and mixing can be achieved, the effect of uniform mixing can be achieved, and meanwhile, due to the arrangement of the turning mechanism, the mixing device can be used for stirring the feed, the feed at the bottom of the mixing tank and the feed at the upper part of the mixing tank can be mixed, so that the feed is mixed more uniformly, and in the use process, the mixing device can achieve the effect of efficiently mixing the feed and the effect of uniformly mixing the feed; and therefore, the use value is higher.

Owner:辽宁明瑞农牧科技有限公司

Aeration device for sewage treatment

PendingCN111977775AExpand the range of aerationAeration holes are evenly distributedWater treatment parameter controlTransportation and packagingAeration rateElectric machinery

The invention discloses an aeration device for sewage treatment and particularly relates to the technical field of sewage treatment aeration devices. The aeration device comprises an aeration tank, wherein a water inlet is soldered in the outer surface at the upper end of one side of the aeration tank in a running through manner, and a water outlet is soldered in the outer surface at the upper endof the other side of the aeration tank in a running through manner; a supporting seat is soldered on the lower surface of the aeration tank; a control tank is soldered on one side of the lower surface of the aeration tank; an aeration component is arranged on the lower surface inside the aeration tank; an aeration fan is arranged on one side of the upper surface of the supporting seat; a motor isarranged on the lower surface of the aeration tank; a gas delivery pipe is arranged on the front surface of the aeration fan in a running through manner; an airflow sensor is arranged at the upper end of the gas delivery pipe; and a battery valve is arranged at the upper end, close to the position of the airflow sensor, of the gas delivery pipe. The aeration device for sewage treatment has a large aeration range, can control the volume of the aeration rate of aeration and is provided with an assistant agitation device.

Owner:铜陵六国威立雅水务有限责任公司

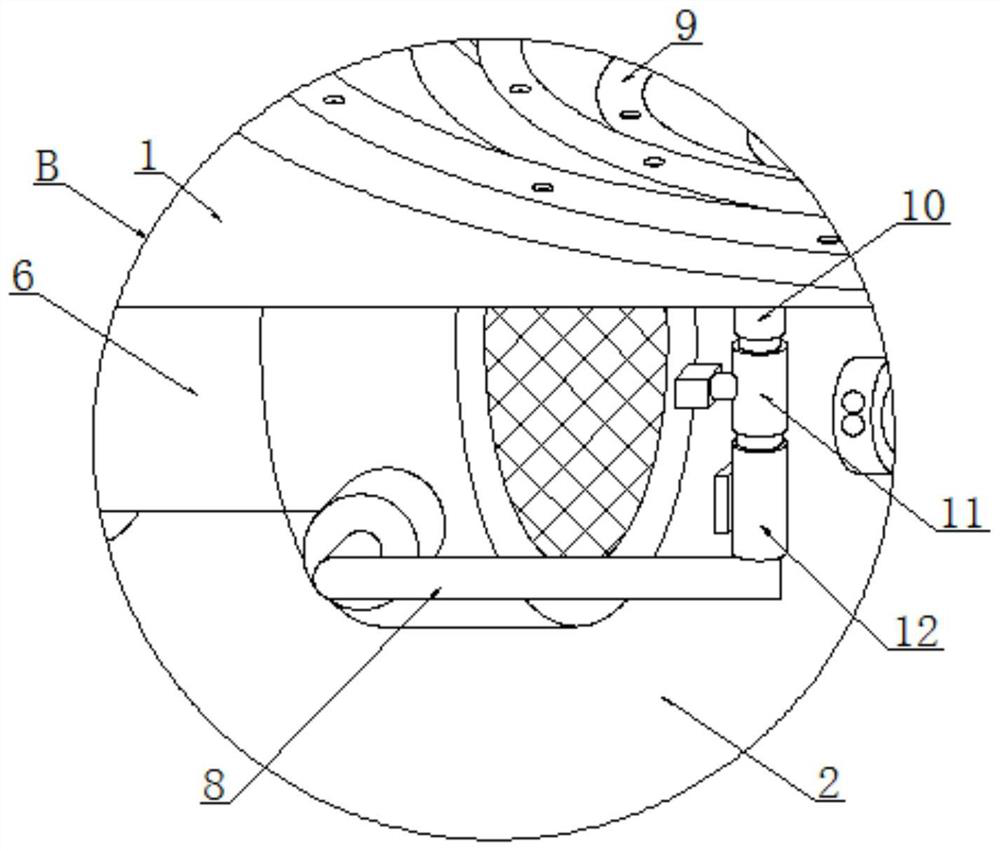

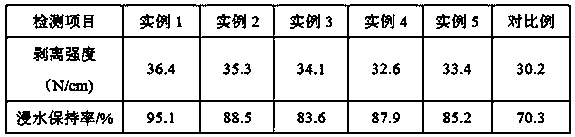

Waterproof solar energy back plate glue

InactiveCN109321181AReduce self-aggregationEvenly dispersedNon-macromolecular adhesive additivesMacromolecular adhesive additivesTurpentineWater resistant

The invention discloses waterproof solar energy back plate glue, and belongs to the technical field of a high polymer material. In parts by weight, 40 to 50 parts of epoxy resin, 15 to 20 parts of ethylene-vinyl acetate copolymers, 2 to 5 parts of turpentine, 8 to 16 parts of phosphorus oxychloride, 15 to 22 parts of modified graphene, 8 to 15 parts of polyaspartic ester, 5 to 8 parts of epoxidized soybean oil, 5 to 12 parts of isocyanates, 8 to 15 parts of carbonate and 60 to 80 parts of solvents are sequentially weighed; the epoxy resin and solvents are mixed in a stirring machine; the ethylene-vinyl acetate copolymers, turpentine, phosphorus oxychloride, modified graphene, polyaspartic ester, epoxidized soybean oil, isocyanates and carbonate are added into the stirring machine; stirringand mixing are performed for 30 to 60 min under the conditions of the temperature being 20 to 30 DEG C and the rotating speed being 300 to 400 r / min to obtain the waterproof solar energy back plate glue. The solar energy back plate glue prepared by the technical scheme has the characteristic of excellent water-resistant performance and bonding intensity.

Owner:FOSHAN WANHE NEW ENERGY TECH CO LTD

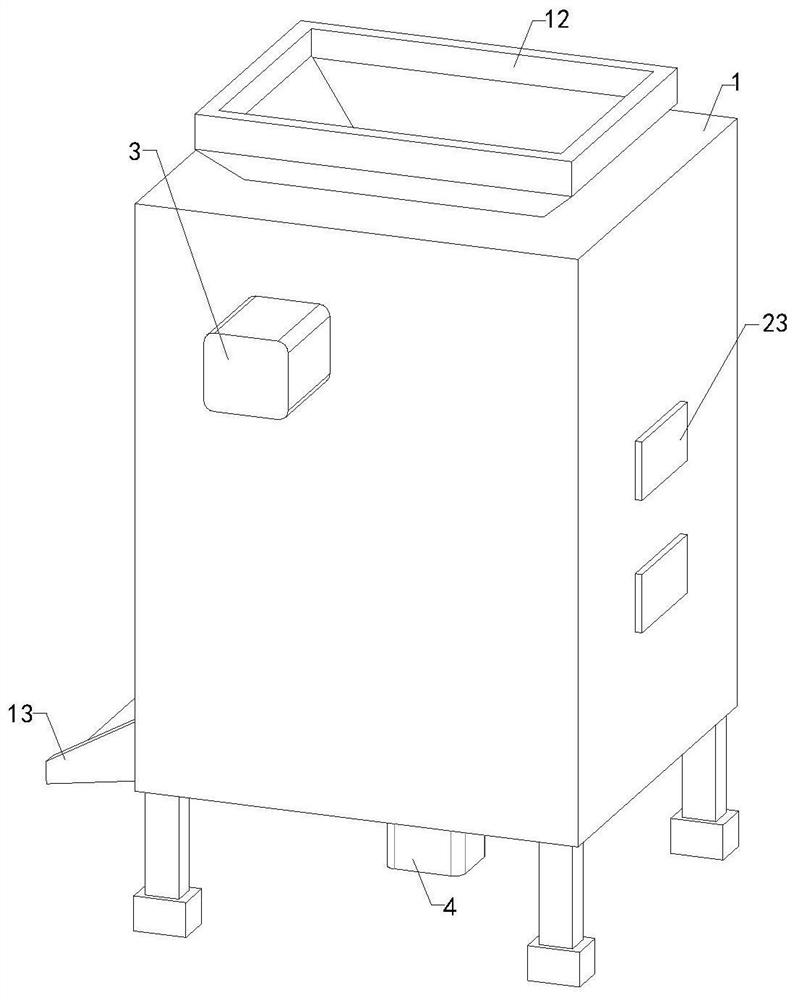

Forage smashing device for animal husbandry

ActiveCN112243710AEasy to controlAdjust the lengthFeeding-stuffTransportation and packagingAnimal scienceDust control

The invention relates to a smashing device, in particular to a forage smashing device for animal husbandry. The forage smashing device for the animal husbandry can adjust the smashing length of forage, can remove dust from the forage and can bring convenience to mixing with other feed. According to the scheme, the forage smashing device for the animal husbandry comprises a bottom plate, supportinglegs, a transverse plate, a gear device, a feeding device, inclined plates, long legs, transverse rods and the like; and the supporting legs, the inclined plates, the long legs, second supporting rods and short rods are fixedly installed on the bottom plate, wherein the two supporting legs are symmetrically arranged, the two inclined plates are symmetrically arranged, the two long legs are symmetrically arranged, the two second supporting rods are symmetrically arranged, the two short rods are symmetrically arranged, and the transverse plate is fixedly connected to the supporting legs. According to the forage smashing device, the gear device and the feeding device are additionally arranged, the gear device plays a good role in controlling the feeding device, and the feeding device achieves the purpose of supplying materials to a cutting device.

Owner:湖南德人牧业科技有限公司 +1

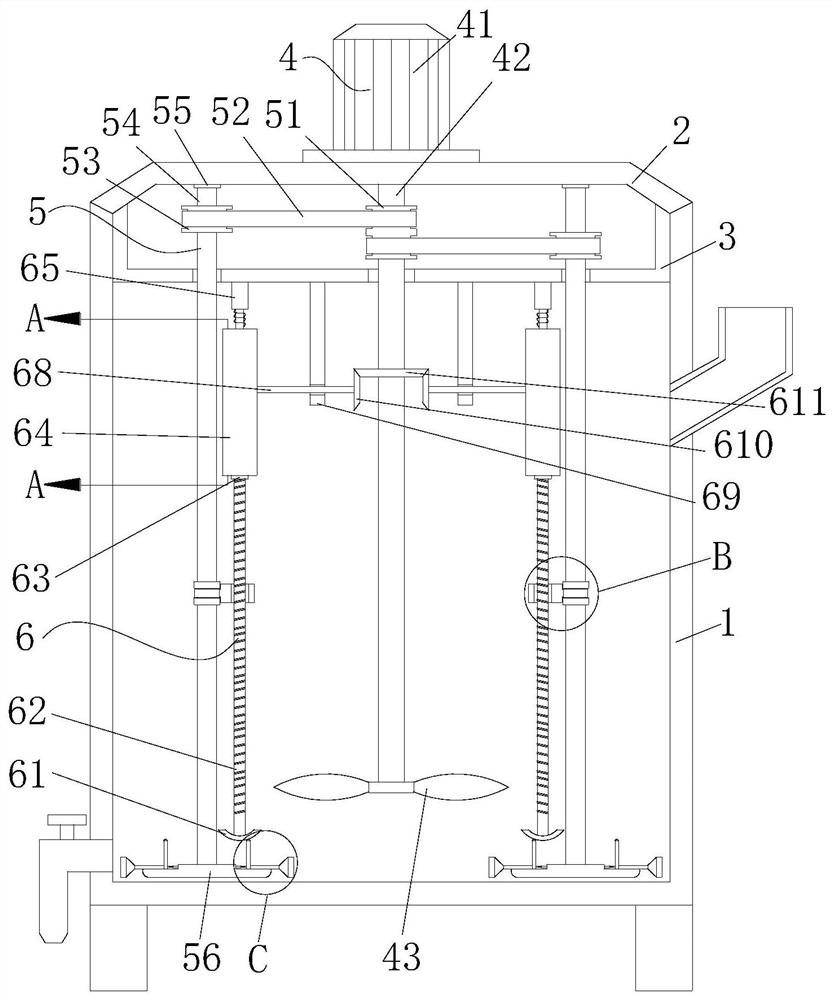

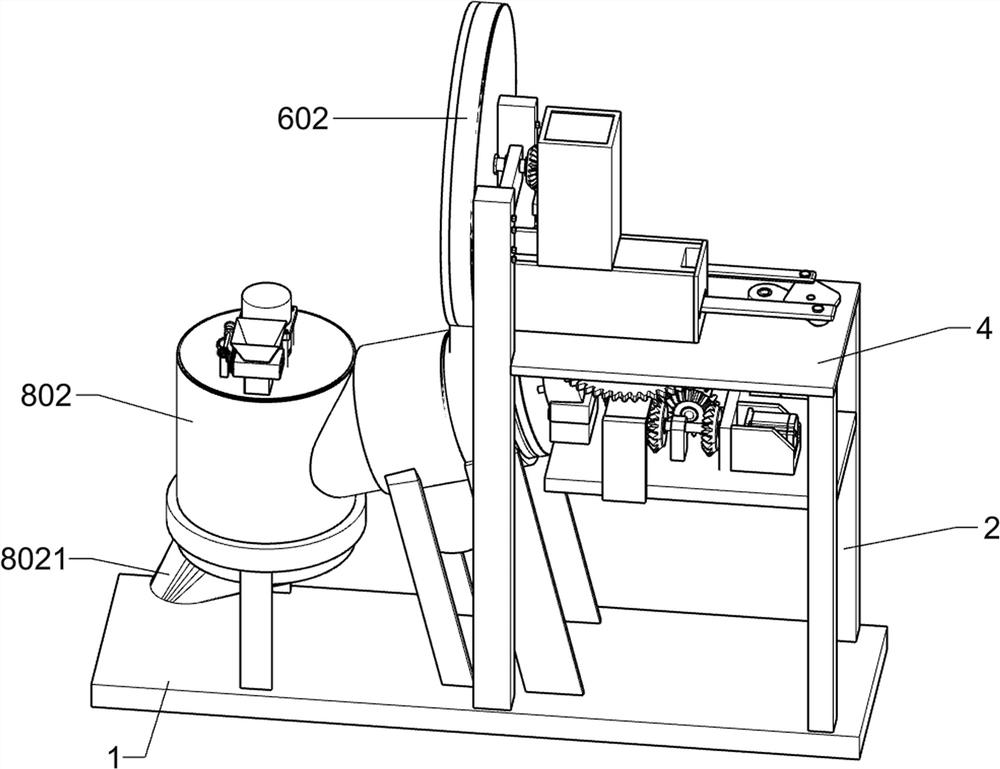

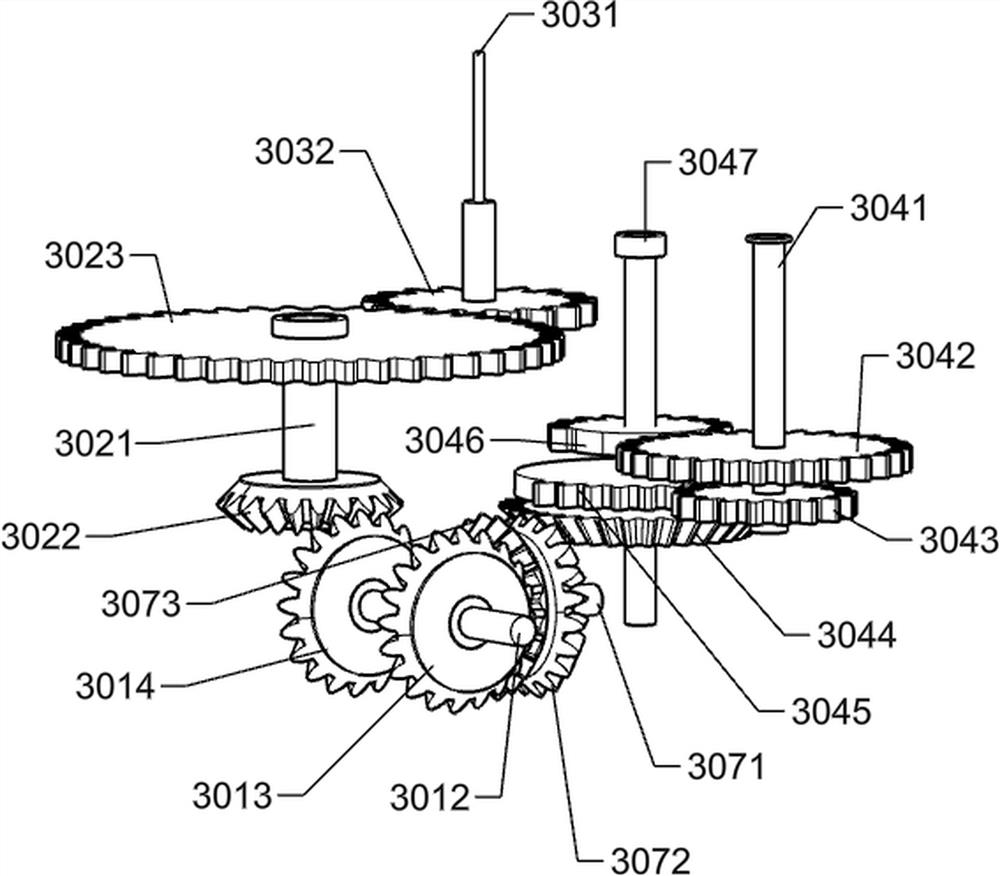

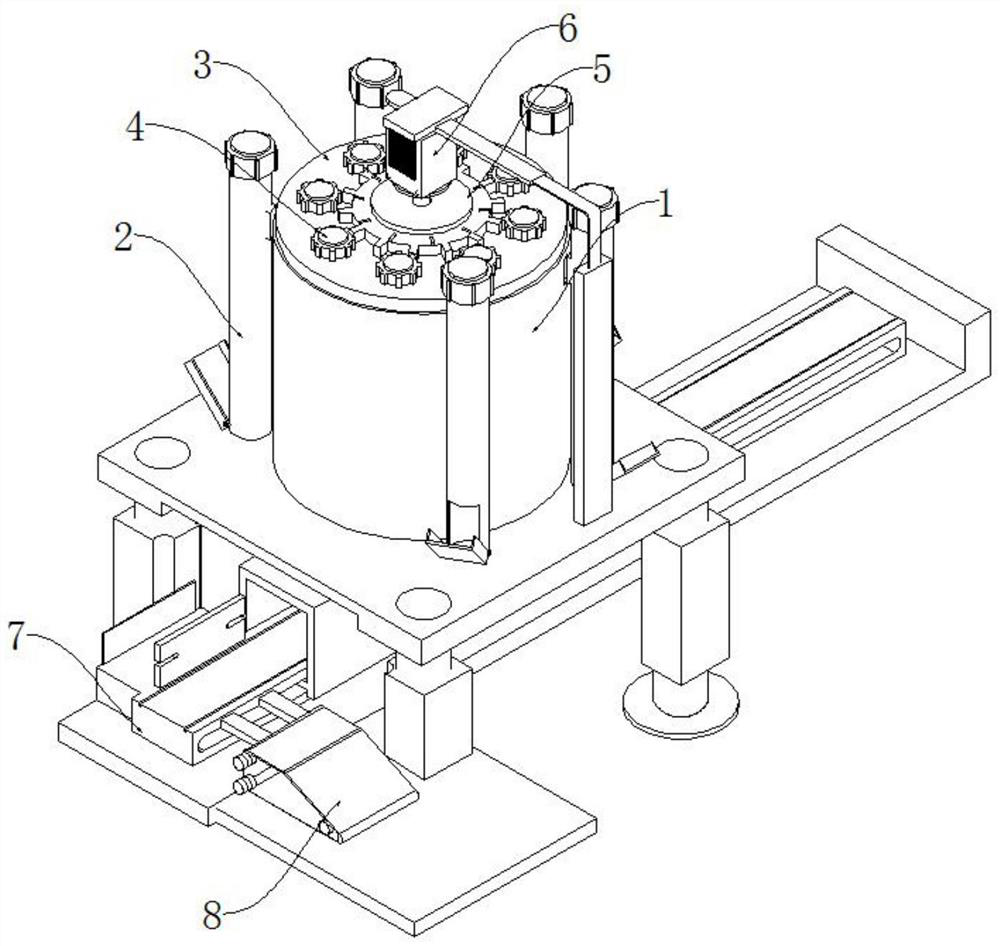

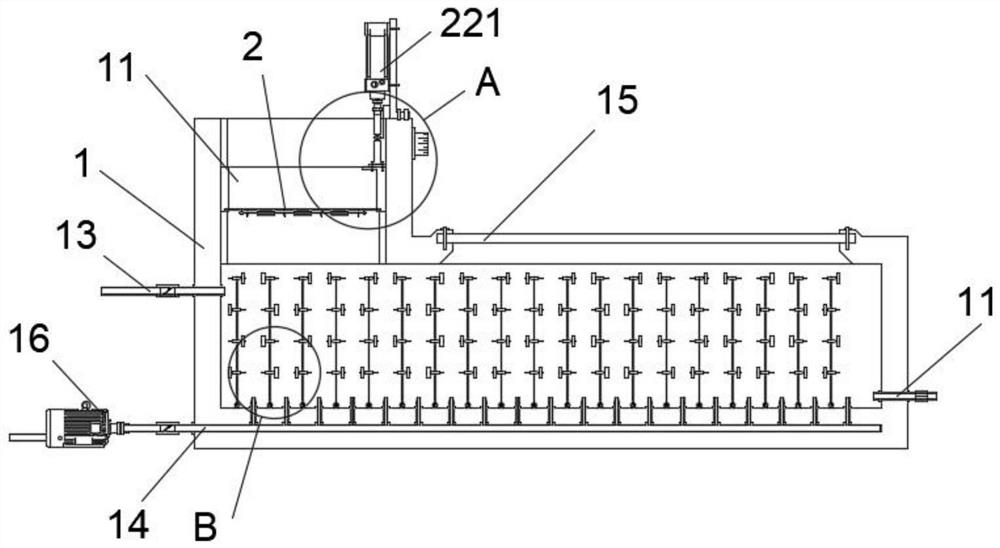

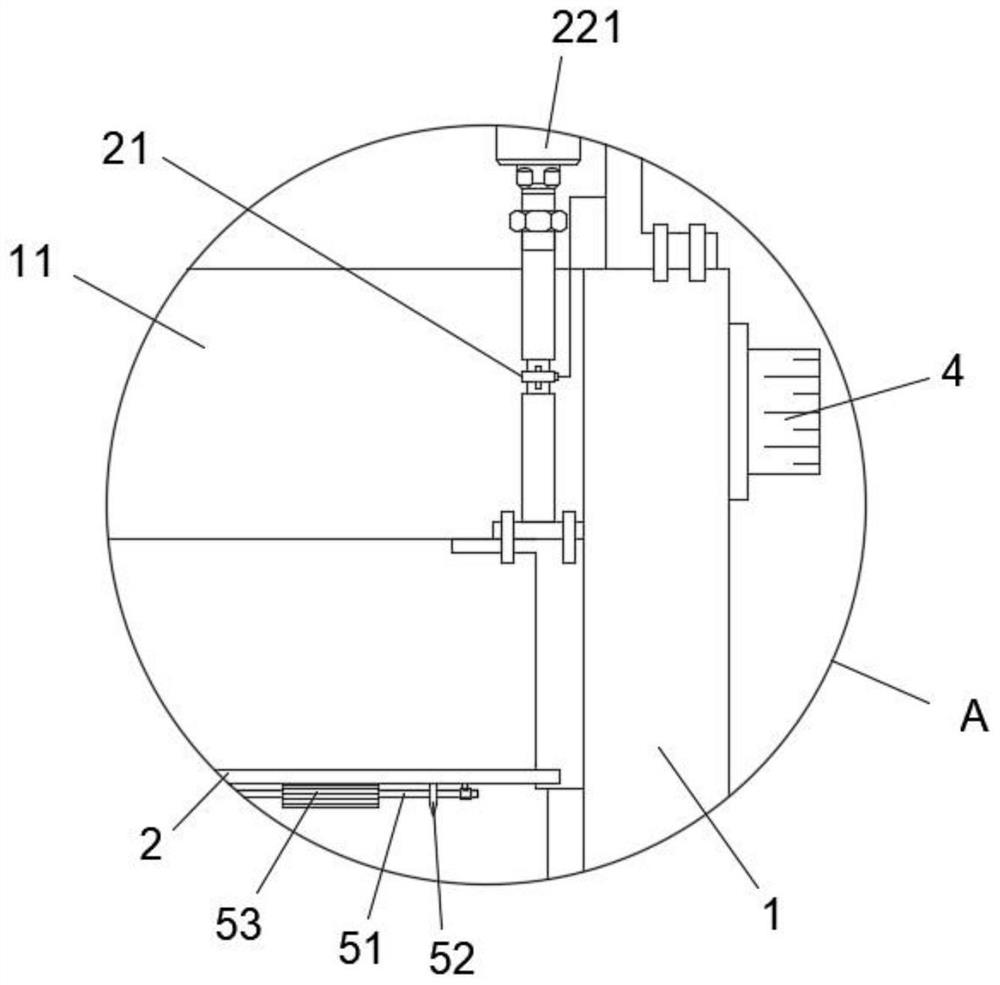

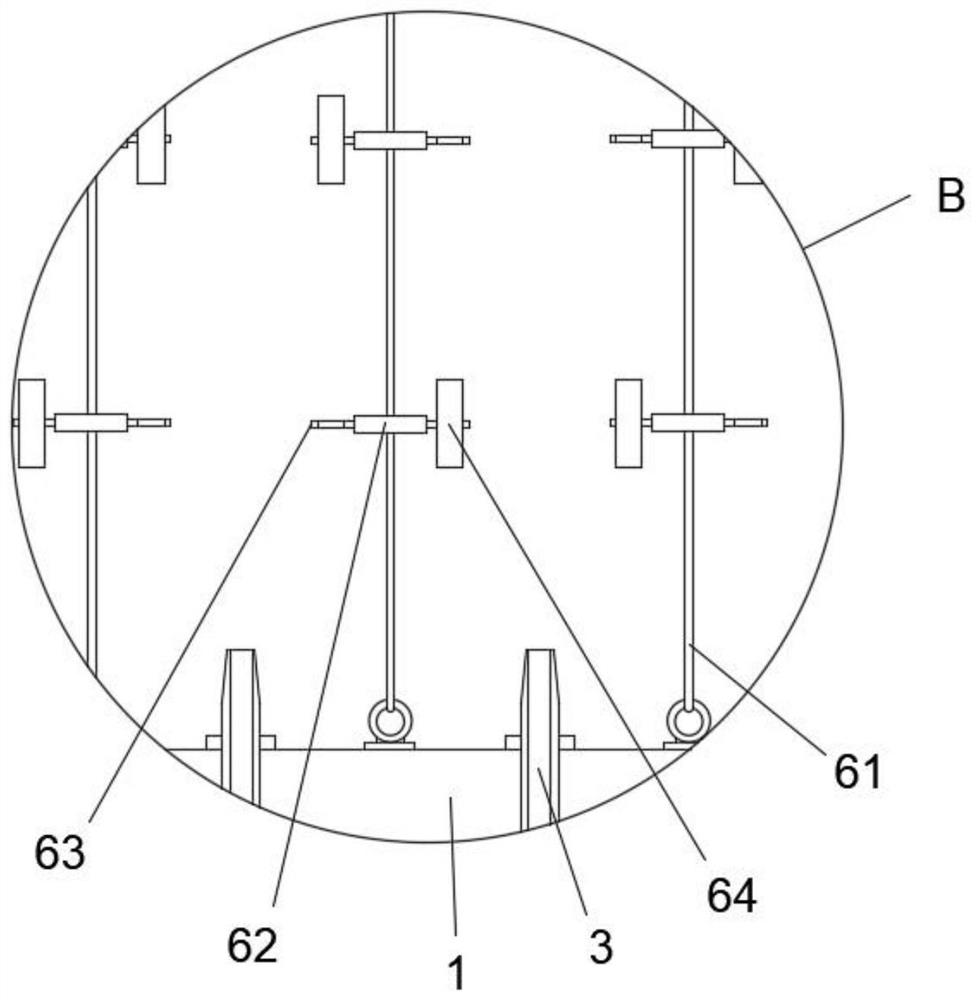

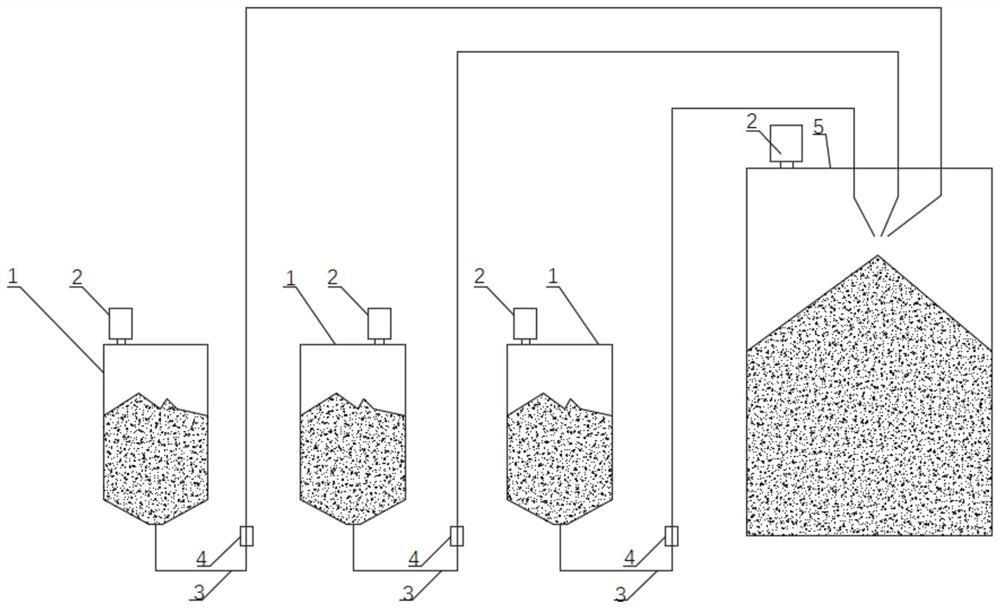

Automatic mixing and moving feeding system for novel building material production process

InactiveCN114407195AEasy accessReduce the overall heightDischarging apparatusPretreatment controlDrive wheelConstruction engineering

The invention discloses an automatic mixing and moving feeding system for a novel building material production process, and particularly relates to the technical field of building material production, the automatic mixing and moving feeding system comprises a mixing barrel, the outer side of the mixing barrel is provided with a batching bin, the top of the mixing barrel is provided with a barrel cover, and the surface of the barrel cover is movably provided with a driving wheel; a large disc wheel is installed on the central axis of the surface of the barrel cover, a driving motor is connected to the top of the large disc wheel through a shaft, a feeding table is installed below the mixing barrel, a transmission roller is arranged on the surface of the feeding table, a conveying crawler belt is installed on the right side of the front end of the feeding table, and a background is fixed to the left side of the front end of the feeding table; and a feeding barrel is arranged above the transmission roller. According to the invention, the inner and outer layer structure is adopted in the mixing barrel, the hollow discharging pipe is arranged in the middle, and the sealing ring is additionally arranged on the inner wall, in contact with the discharging pipe, of the bottom of the mixing barrel, so that leakage is prevented, and materials can be mixed in the space between the mixing barrel and the discharging pipe.

Owner:灌云县斯威特再生资源有限公司

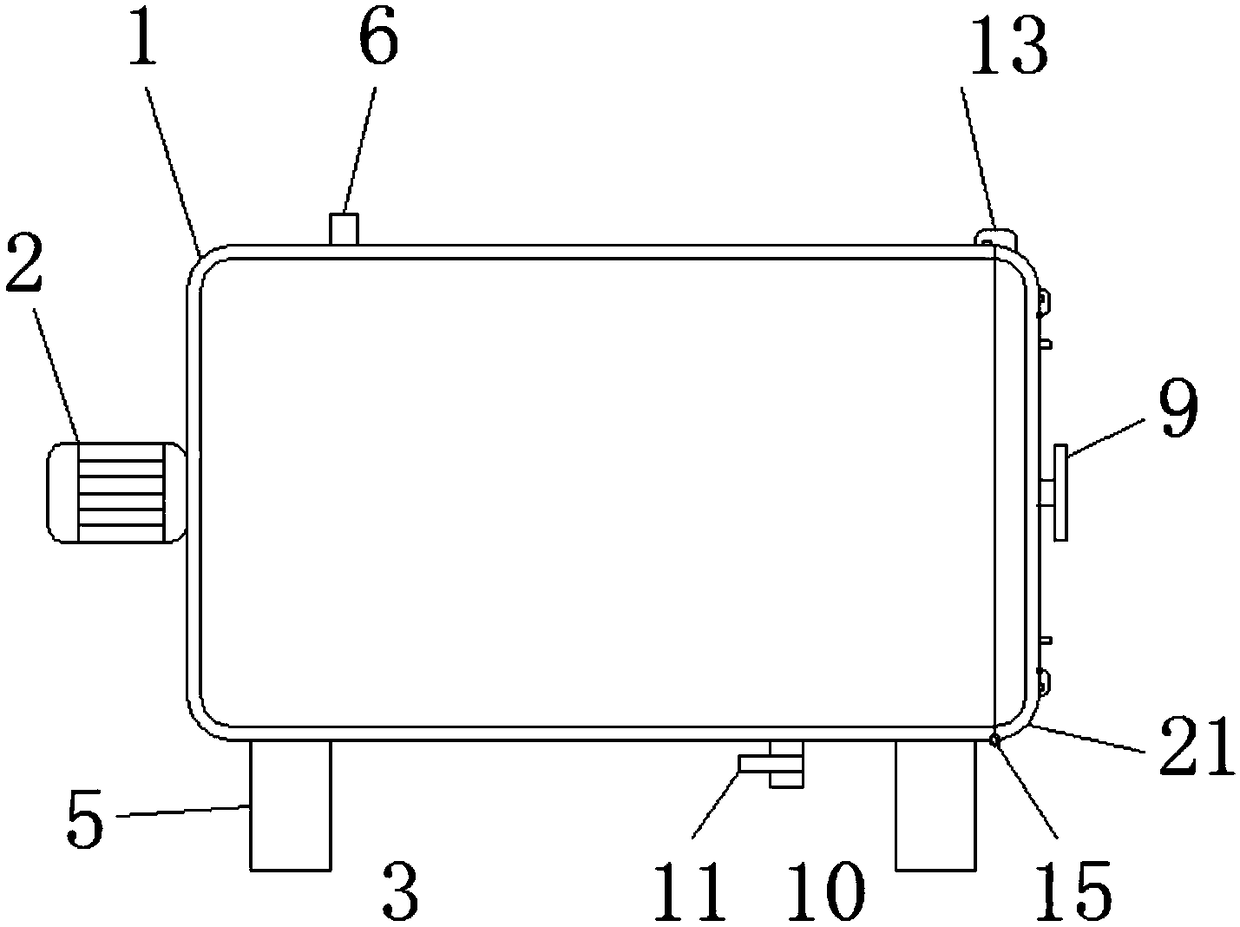

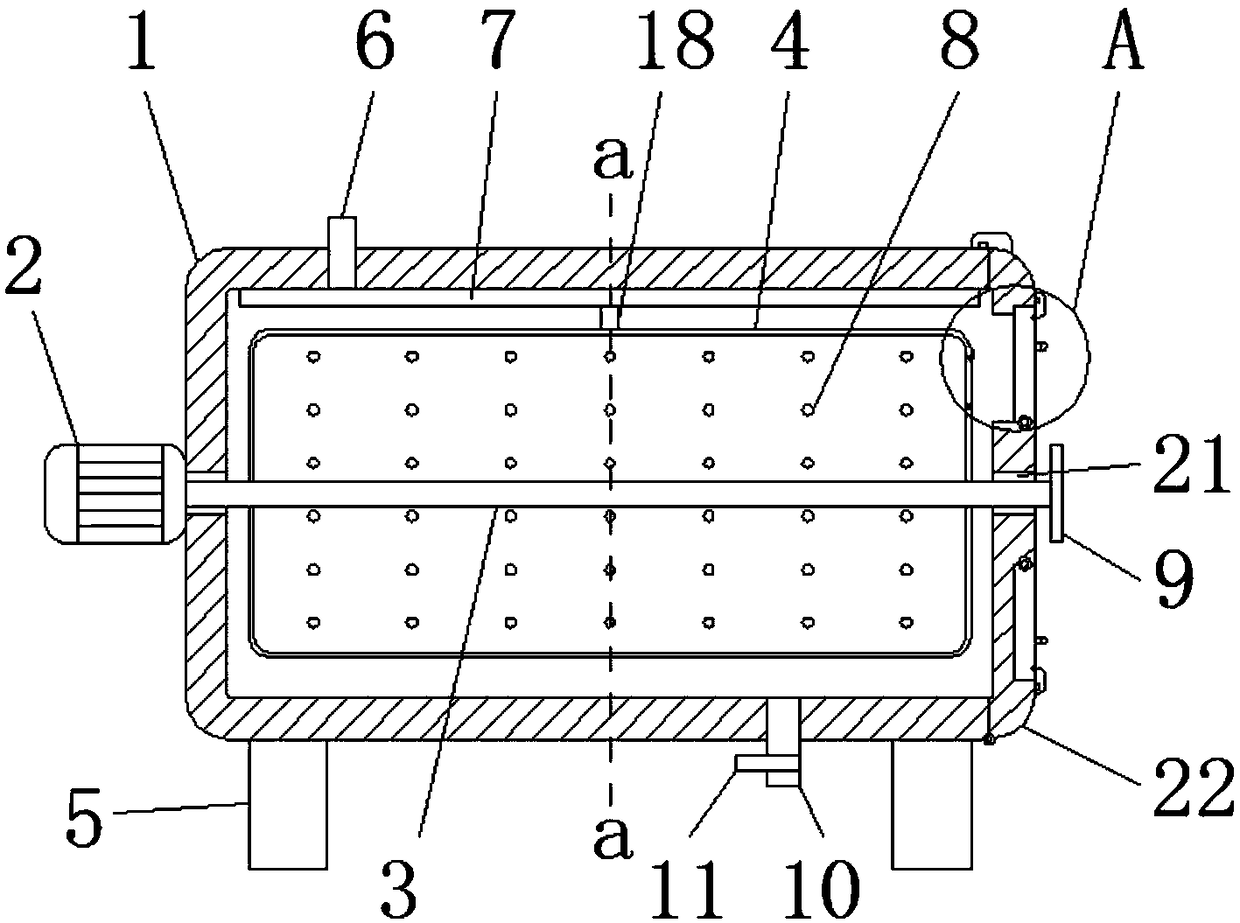

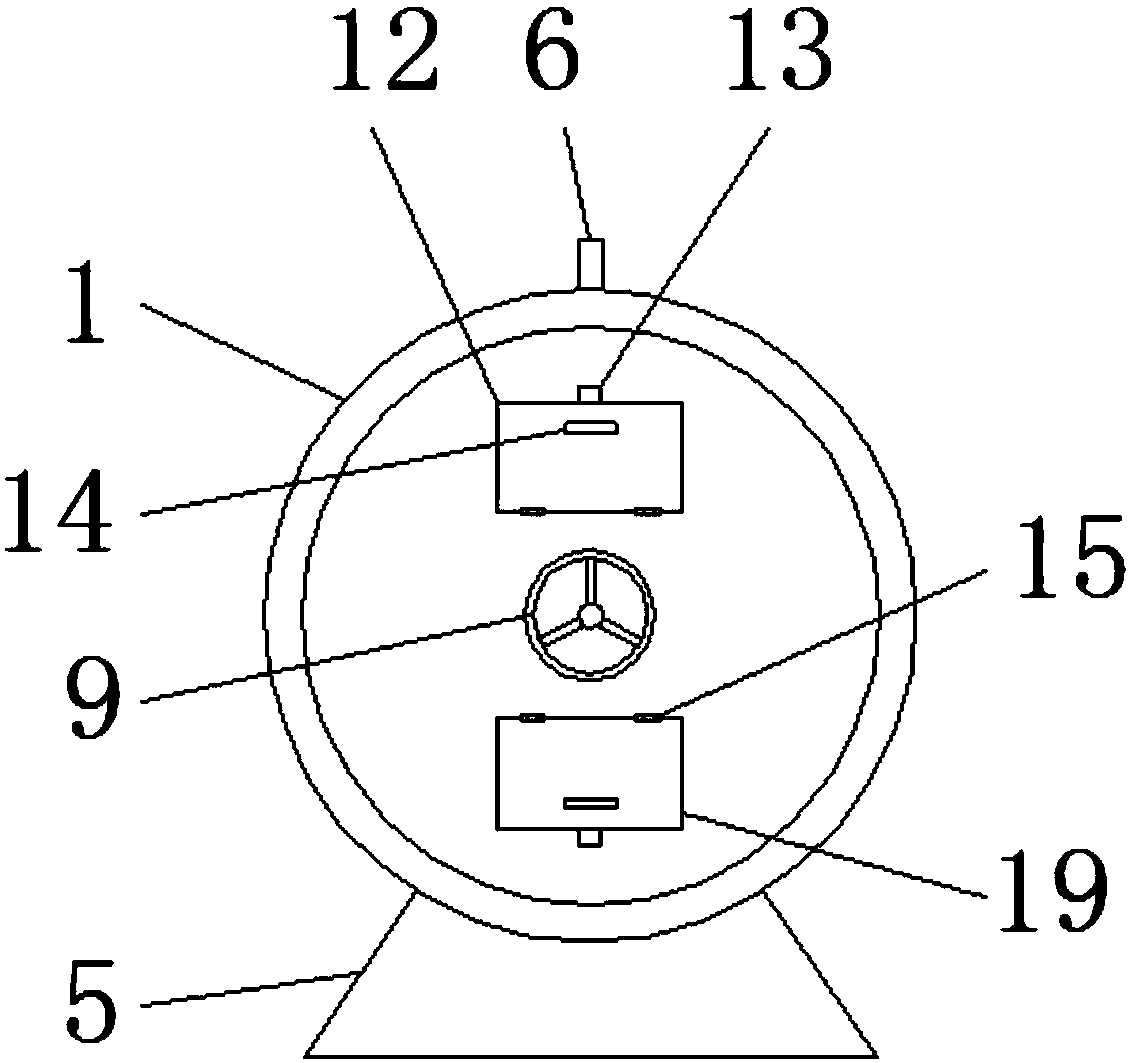

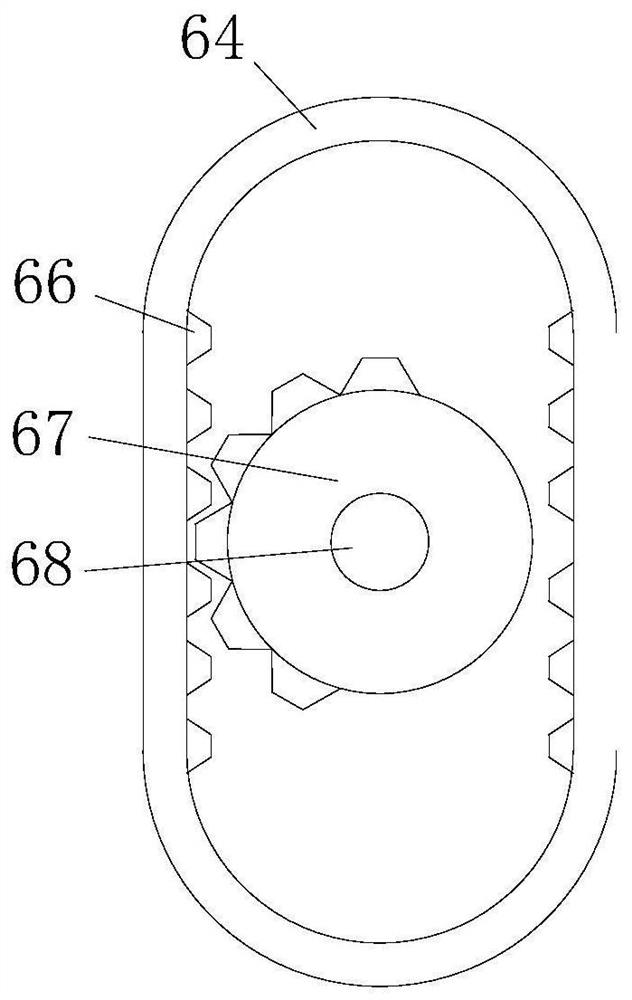

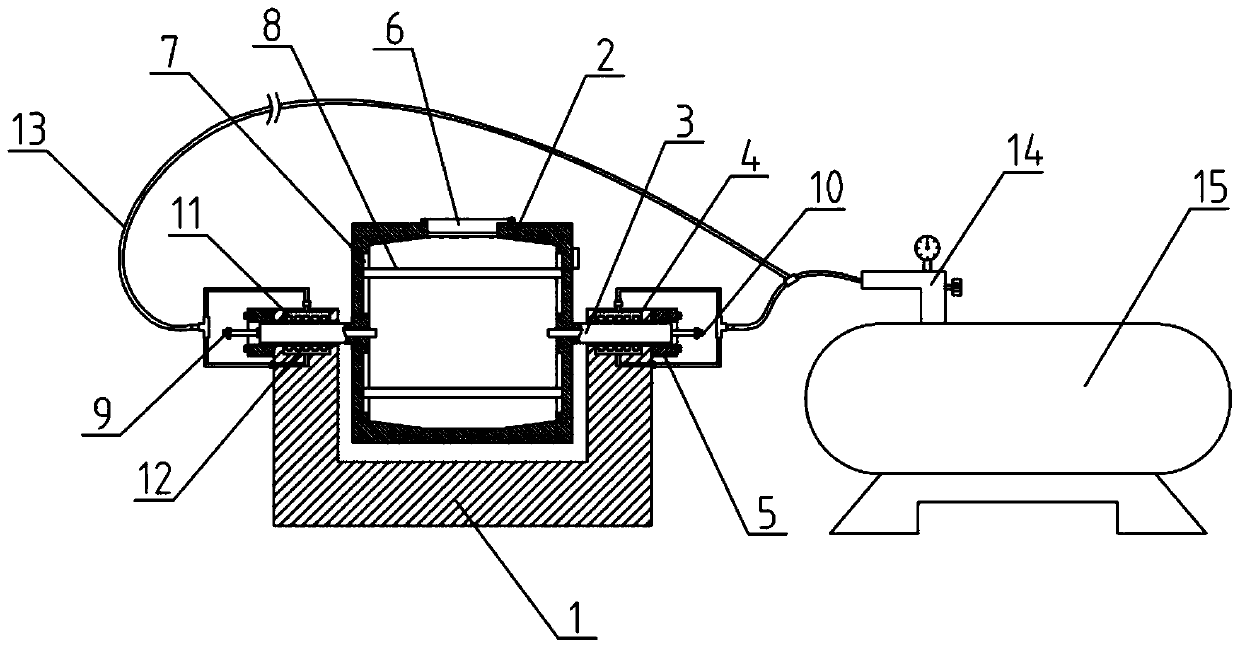

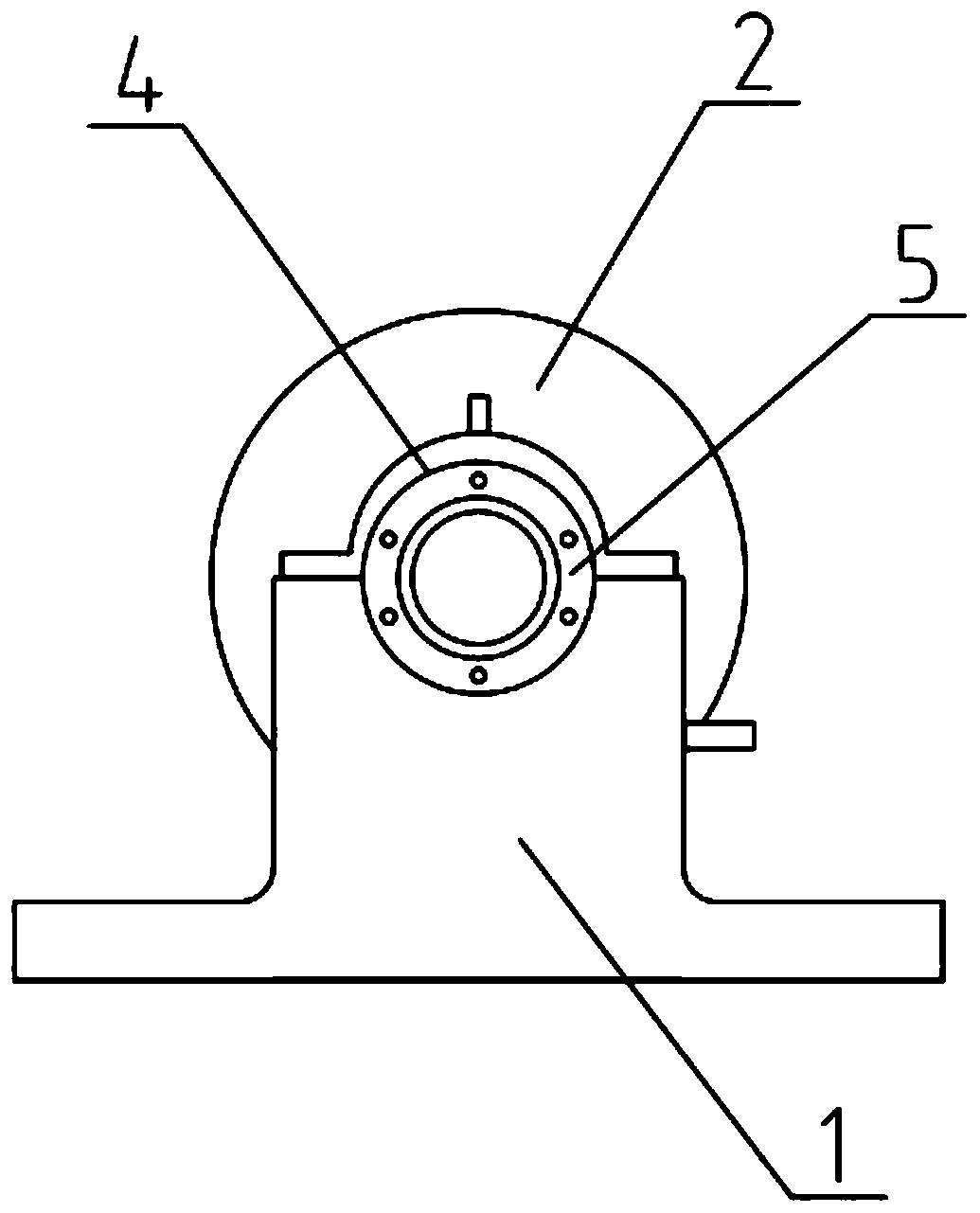

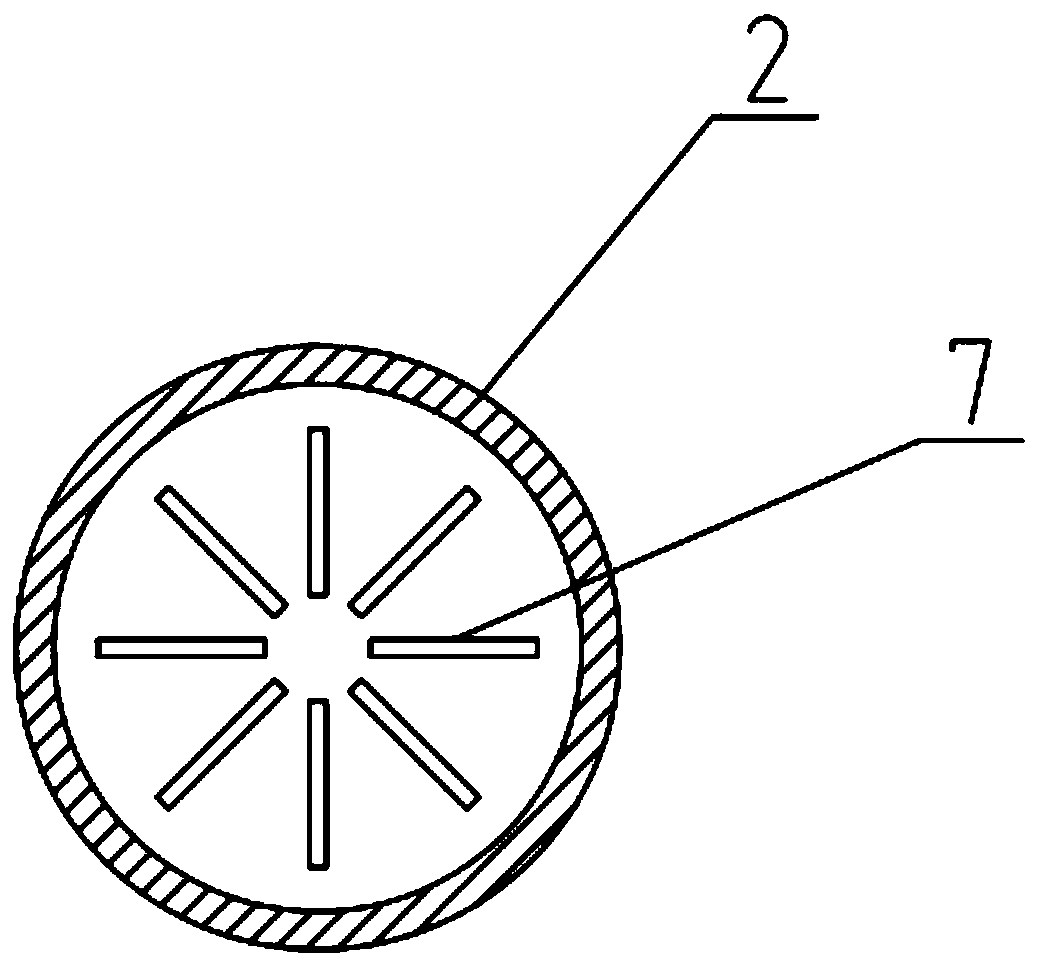

High-efficiency mixer for producing neodymium-iron-boron magnet

InactiveCN110433702AShorten the timeImprove work efficiencyRotating receptacle mixersTransportation and packagingMagnetic powderRadial position

The invention provides a high-efficiency mixer for producing a neodymium-iron-boron magnet. The high-efficiency mixer for producing the neodymium-iron-boron magnet comprises a base, a rotating box, supporting shafts, bearing pads, protecting covers, an opening, sliding grooves, mixing rods, a nitrogen inlet, a nitrogen outlet, upper floating holes, lower floating holes, an air inlet pipe, an air purifier and an air pump device. The supporting shafts are symmetrically arranged at the middle of two sides of the rotating box, the rotating box is arranged on the upper part of the base through thesupporting shafts in an erecting mode, the bearing pads for limiting the radial position of the supporting shafts are connected to the upper parts of the supporting shafts, and the protecting covers for limiting the axial position of the supporting shafts are connected to the end parts of the supporting shafts. According to the high-efficiency mixer for producing the neodymium-iron-boron magnet, the sliding grooves and the mixing rods are arranged, when the rotating box begins to start rotating, the mixing rods in each sliding groove fall and slide alternately due to gravity action, a mixing role is played on iron-boron magnetic powder of an inner cavity, the mixing uniformity is improved, the mixing quality and efficiency are improved, the structure is novel, the installation is easy, andthe operation is easy.

Owner:GANZHOU JIATON ADVANCED MATERIALS

Physiotherapy device for chronic vascular nerve complications of diabetes

ActiveCN113813165AEasy to dryAchieve separationRotary stirring mixersVibration massagePhysical medicine and rehabilitationPharmaceutical drug

The invention discloses a physiotherapy device for chronic vascular nerve complications of diabetes. The device is provided with a physiotherapy box, wherein an electric push rod is rotationally mounted on the side wall of the physiotherapy box. The physiotherapy device comprises a movable plate, a turbine, blades and a movable shaft, wherein the movable plate is movably mounted on the inner wall of the physiotherapy box, and massage rollers are arranged on the side surface of the movable plate; the turbine is mounted at the upper end of a motor shaft, and a slow flow cavity is formed in the physiotherapy box on the outer side of the turbine; the blades are fixedly mounted at the lower end of the motor shaft, and a protection box is fixed to the portion, on the outer sides of the blades, of the physiotherapy box; the movable shaft and the bearing are arranged in a sealing box, and a partition plate is fixed in the sealing box. According to the physiotherapy device for chronic vascular nerve complications of diabetes, in the process of soaking the feet of a diabetic patient, separation between the feet and solid medicines can be achieved, injury to wounds of the patient is prevented, in the soaking process, the legs and the feet of the patient can be massaged, and subsequent drying treatment on the legs and the feet is also facilitated.

Owner:AFFILIATED HOSPITAL OF JIANGSU UNIV

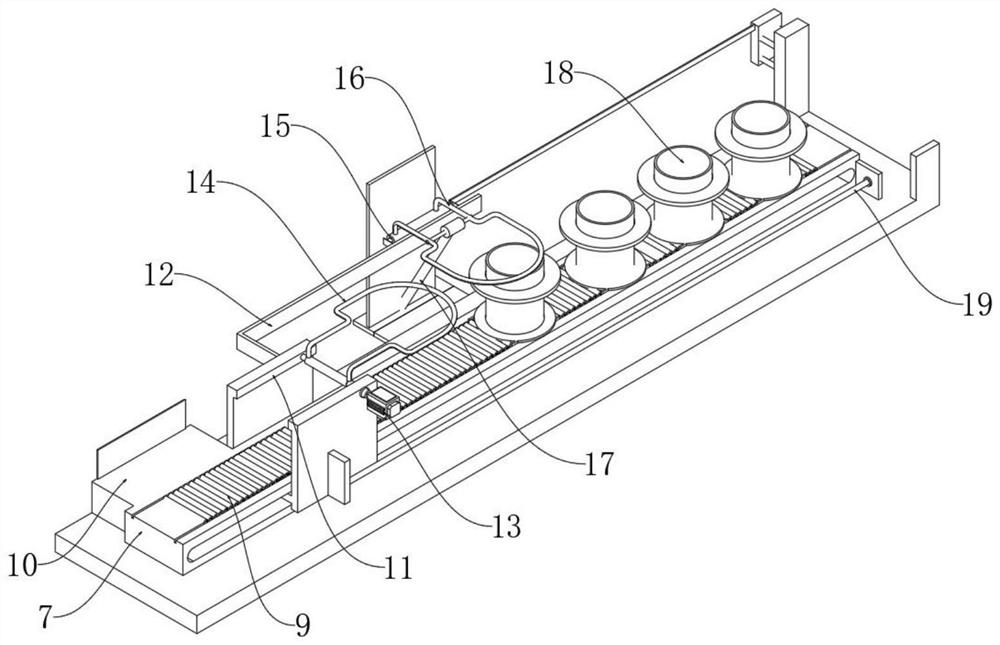

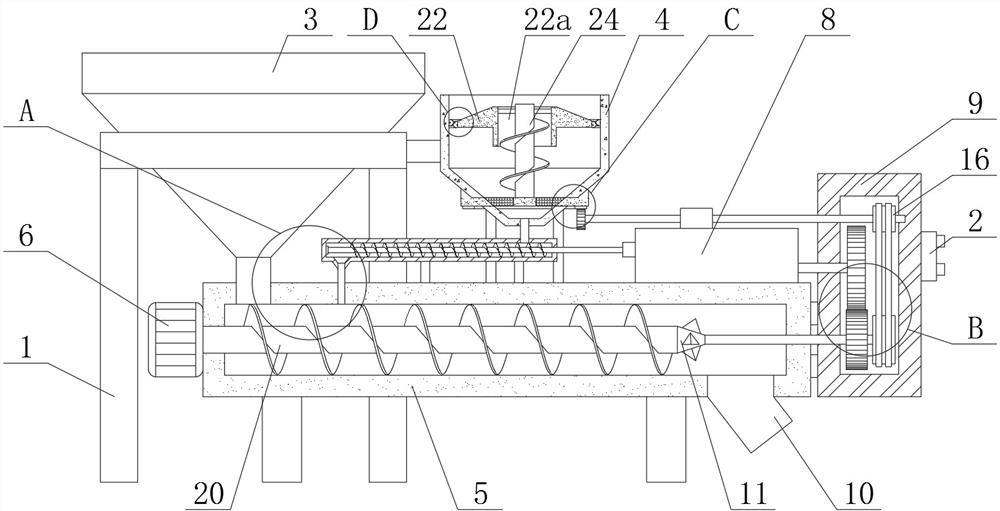

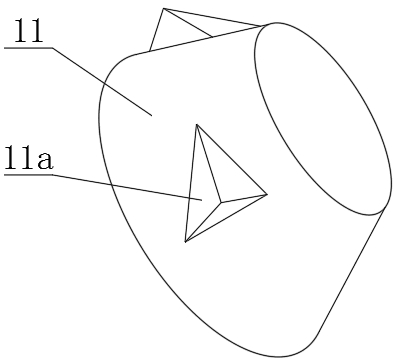

Pretreatment equipment for flour processing and working method thereof

ActiveCN113953003AImprove efficiencyQuality improvementSievingScreeningPretreatment methodFood science

The invention discloses a pretreatment method for flour processing. The pretreatment method for flour processing mainly comprises the following manufacturing steps that 1, grinding operation is conducted, and specifically, dietary alkali is ground to obtain alkali powder with a reduced diameter; 2, sieving operation is conducted, and specifically, the alkali powder obtained in the step 1 is subjected to sieving to obtain alkali powder with the same diameter as flour, so as to prevent the flour and the alkali powder from being concentrated and layered due to shaking in subsequent transportation operation; and 3, matching operation is conducted, specifically, the flour and the alkali powder obtained in the step 2 are matched according to the proportion of 1000: 1, the flour and the alkali powder which are prepared according to the proportion are obtained, the alkali powder and the flour can be blended in a flow state at the same time, the uniform mixing effect is achieved on the whole, when the mixed alkali powder and flour flow through a conical disc, the space is enlarged, the fluidity is improved, the effect of improving the mixing effect is further achieved, when the mixed flour and alkali powder pass through the conical disc, a dispersing block moves relative to the flour and the alkali powder, so that the flour and the alkali powder can be further dispersed, and the mixing effect can be improved.

Owner:安徽昊晨食品股份有限公司

Ozone gas uniform anti-blocking sewage treatment tank

InactiveCN112897744ALow adhesionImprove easeWater treatment parameter controlSpecific water treatment objectivesSewage treatmentSewage

The invention relates to the technical field of water treatment equipment, in particular to an ozone gas uniform anti-blocking sewage treatment tank which comprises a tank body, a filter screen, an exhaust pipe, an alarm device, a cutting device and a stirring device, ozone bubbles are used for mixing an additive and sewage, and the ozone gas uniform anti-blocking sewage treatment tank can sterilize and disinfect the sewage, the ozone bubbles permeate into gaps between the impurities and the filter screen when floating upwards, so that adhesion between the impurities and the filter screen is avoided, the difficulty in cleaning the filter screen is reduced, the working efficiency of sewage treatment is improved, and the device has practical significance and popularization value and is expected to generate good economic benefits.

Owner:罗开平

Water treatment device convenient for cleaning sewage filter screen plate

PendingCN113697994ALong cycleImprove efficiencyWater/sewage treatment by centrifugal separationTreatment involving filtrationElectric machineryHollow cylinder

The invention discloses a water treatment device convenient for cleaning a sewage filter screen plate. The water treatment device comprises a box body, the upper end of the box body is provided with a box cover abutting against the box body, the bottom of the box body is provided with four support members, the bottom of the box body is fixedly connected with a fixed plate, the fixed plate is fixedly connected with a driving motor, the output end of the driving motor is fixedly connected with a telescopic rod, the telescopic rod penetrates through the bottom of the box body and is rotationally connected with the box body, the upper end of the telescopic rod is fixedly connected with a hollow cylinder, the outer wall of the hollow cylinder is fixedly connected with a stirring pipe communicated with the hollow cylinder, and a pipe opening is formed in the end, away from the hollow cylinder, of the stirring pipe. According to the sewage treatment device disclosed by the invention, impurities and sundries on the screen plate can be cleaned through one driving motor, so that the use period of the screen plate can be prolonged, sewage and a sewage treatment agent can be effectively mixed, the sewage treatment efficiency is improved, the screen plate is also convenient to mount and dismount, and the operation is simple, convenient and rapid.

Owner:谢林才

Perfume capable of continuously keeping fragrance and preparation method thereof

InactiveCN110192991AEvenly dispersedEasy to prepareCosmetic preparationsToilet preparationsRetention timeSodium starch

The invention provides a perfume capable of continuously keeping fragrance and a preparation method thereof. The essential oil is firstly added to a modified solution to prepare the modified essentialoil, and then the modified essential oil is added to anhydrous ethanol, the steps of uniform ultrasonic dispersion, ageing, and filtering are carried out, the preparation method is simple, and the product has a long fragrance retention time. The method utilizes polyethylene glycol 6000, gamma-polyglutamic acid, sodium starch octenyl succinate, and collagen liquid to modify the essential oil, andsubstantially forms a similar coating effect on the essential oil, under the action of ethanol, the collagen is decomposed, so that the essential oil encapsulated in collagen slowly evaporates, gamma-polyglutamic acid slowly degrades naturally with time, and more essential oil is released to achieve the effect of continuous fragrance retention. The polyethylene glycol 6000 has good non-volatilityand further enhances the continuous fragrance retention effect. The sodium starch octenyl succinate has an emulsification thickening effect, which is beneficial to the good encapsulation of the essential oil.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

Multifunctional anti-scouring sand bar

ActiveCN105464042BReduce flow rateConducive to siltClimate change adaptationStream regulationAggradationReinforced concrete

The invention discloses a multifunctional scouring resistance sand blocking dike which comprises a wall body made of cast-in-place reinforced concrete. The longitudinal section of the wall body is of a right-angled trapezoidal structure. The bottom foundation of the wall body is of a tooth plate structure. The inclined wall face, located on the upper stream side, of the upper portion of the wall body is fixedly connected with a water permeable baffle extending towards the upper stream side. The water permeable baffle is provided with multiple vertical water permeable holes in the vertical direction. Multiple horizontal water permeable units are arranged on the portion, between the water permeable baffle and a river bed, of the wall body. Each horizontal water permeable unit is formed by multiple rectangular horizontal water permeable holes at up-down intervals. The portion, located at each horizontal water permeable unit, on the inclined wall face of the upper stream side is covered with water permeable geotechnical cloth, and the water permeable geotechnical cloth is fixed to the inclined wall face on the upper stream side through a steel wire net frame. By the adoption of the multifunctional scouring resistance sand blocking dike, the flow speed of the upper stream side of the sand blocking dike is lowered, and fine sediment aggradation is facilitated; and the sand blocking wall body share the dike top excess flow, so that the back-water height of the front of the dike is lowered, the water flow energy below the dike is weakened, and the scouring effect on the sand blocking underwater bed is weakened.

Owner:YELLOW RIVER ENG CONSULTING

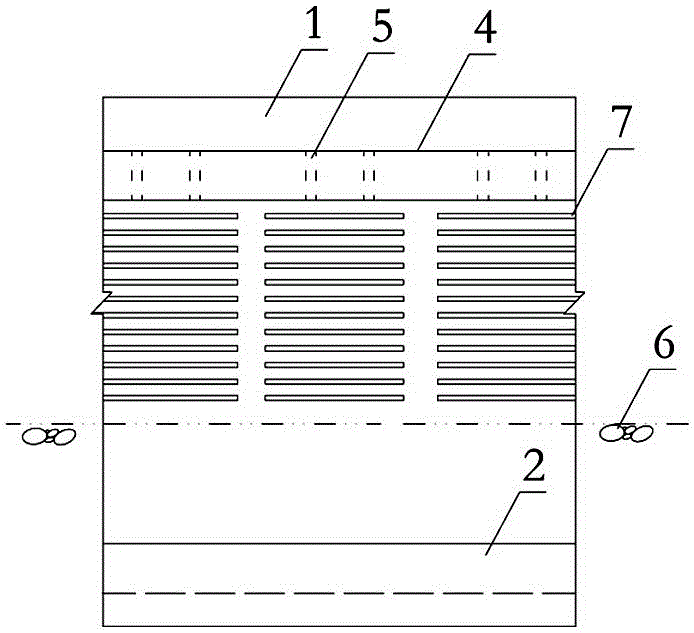

Powder material mixing device

InactiveCN111974238AEasy to adjust and installSmall footprintFlow mixersTransportation and packagingPhysicsPowder

The invention discloses a powder material mixing device. The powder mixing device comprises a mixing bin and a plurality of powder bins used for storing different powder materials. Independent pneumatic conveying mechanisms are arranged at the bottoms of the powder bins respectively, independent flow adjusting assemblies are arranged on the pneumatic conveying mechanisms respectively, the tail ends of the pneumatic conveying mechanisms are led into the mixing bin from the top and point to the lower portion, and the tail ends of all the pneumatic conveying mechanisms can be gathered at one point or located in a same small-size horizontal circle after extending along the conveying paths of the pneumatic conveying mechanisms. The device does not need independent proportioning and mixing equipment, and is small in occupied space, simple in process, reliable in operation, low in energy consumption, easy to maintain and environment-friendly.

Owner:WISDRI ENG & RES INC LTD

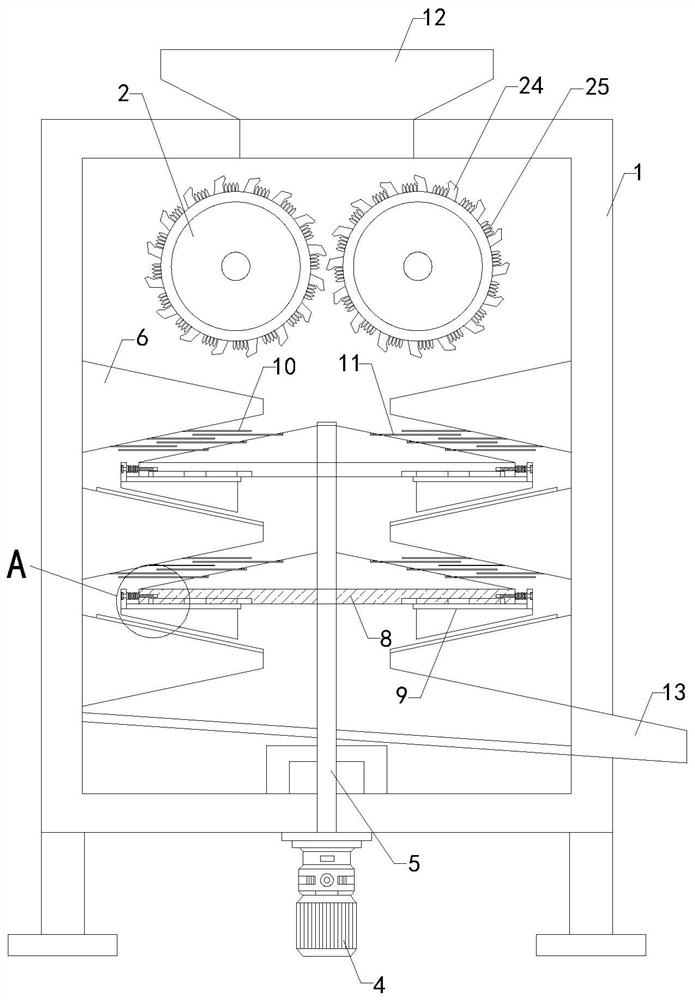

Crusher for medicinal material processing

ActiveCN112871395BSimple and fast operationSimple structureGrain treatmentsMedicinal herbsBlade plate

The invention relates to the technical field of medicinal material processing accessory devices, in particular to a kind of pulverizer for medicinal material processing; it does not need to pretreat the medicinal material, is easy to operate, and is integrally formed, simple in structure, convenient for later maintenance, and can ensure the crushing effect of the medicinal material ; Including the box body, the interior of the box body is provided with a working chamber, the upper half area and the lower half area of the box body are respectively provided with a crushing mechanism and a crushing mechanism, the crushing mechanism includes two sets of crushing rollers and crushing motors, and the rollers of the two sets of crushing rollers There are crushing teeth that engage with each other on the surface. The crushing mechanism includes a crushing motor. The top output end of the crushing motor is provided with a rotating shaft. Two groups of crushing devices and two groups of cutting devices are arranged on the rotating shaft. The crushing device includes an annular guard plate, a fixed tooth plate, a fixed circular plate and an inclined plate device, the cutting device includes a fixed knife plate and a movable knife plate, the top of the box is provided with a feeding hopper, and the bottom of the box is provided with a discharge hopper .

Owner:河北万岁药业有限公司

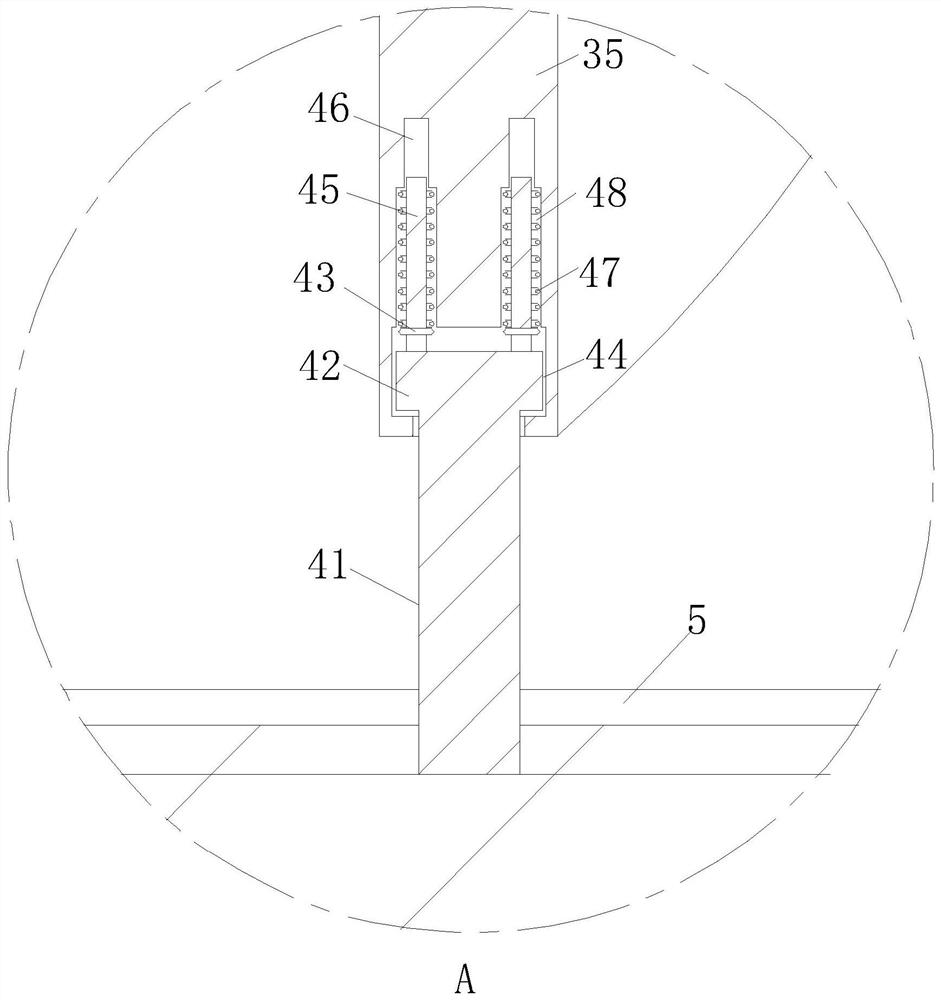

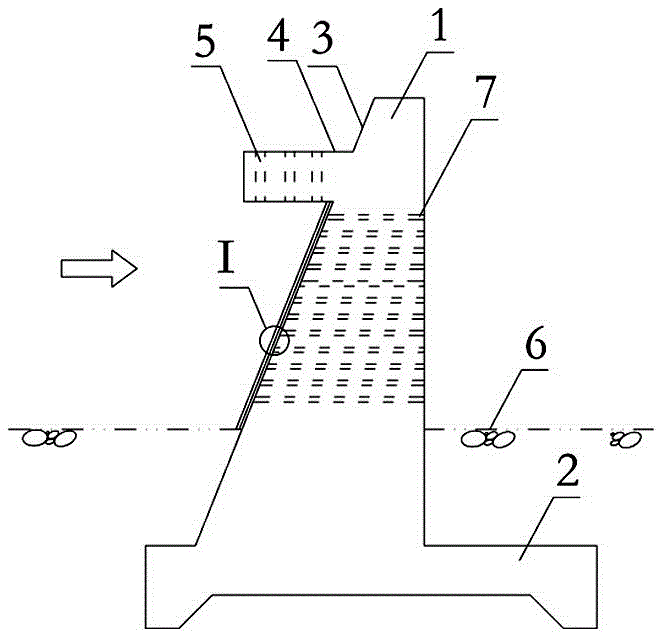

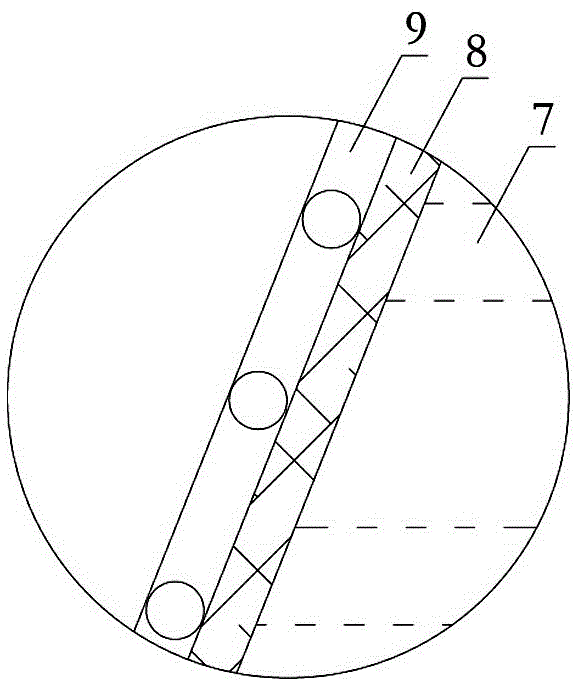

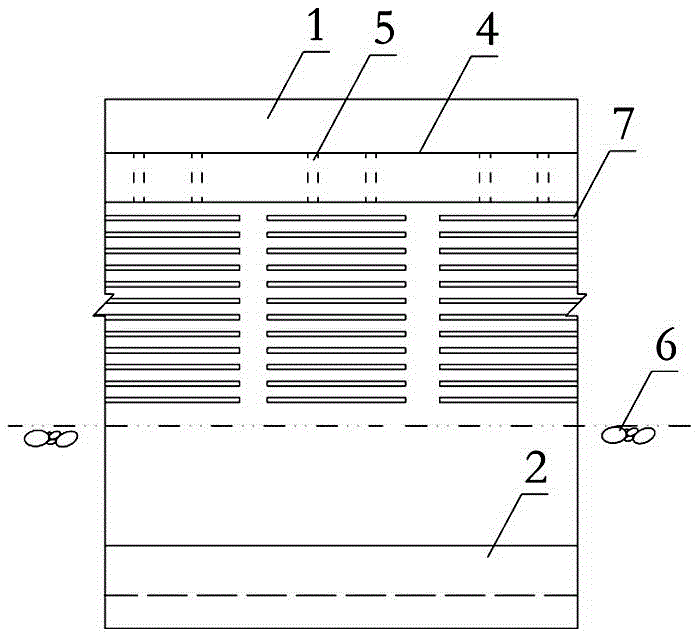

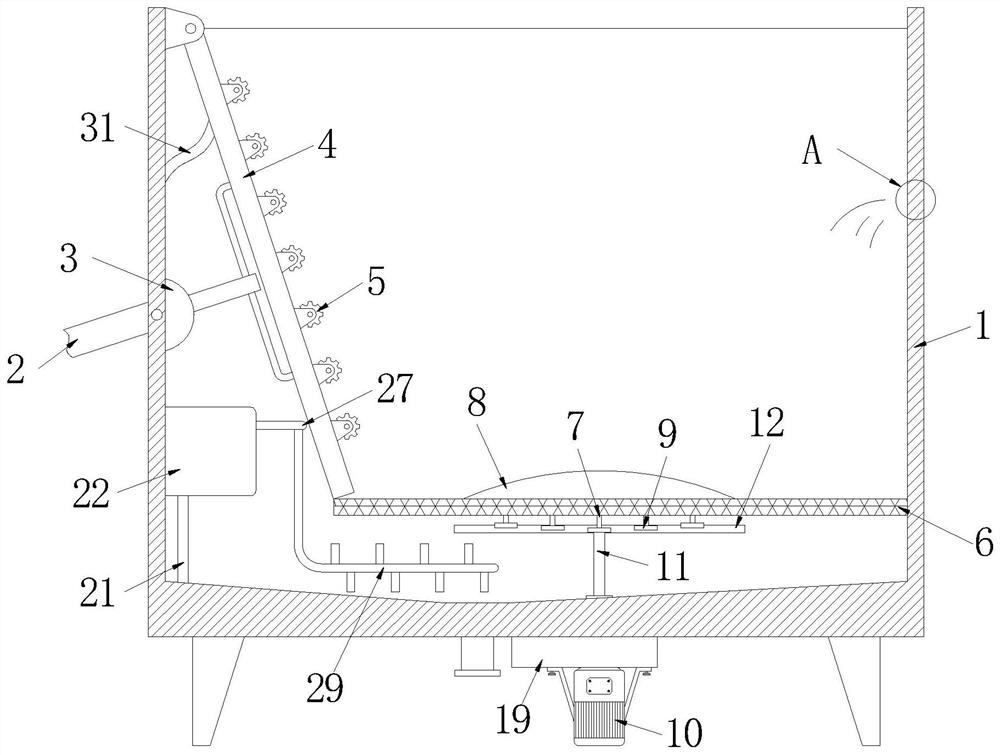

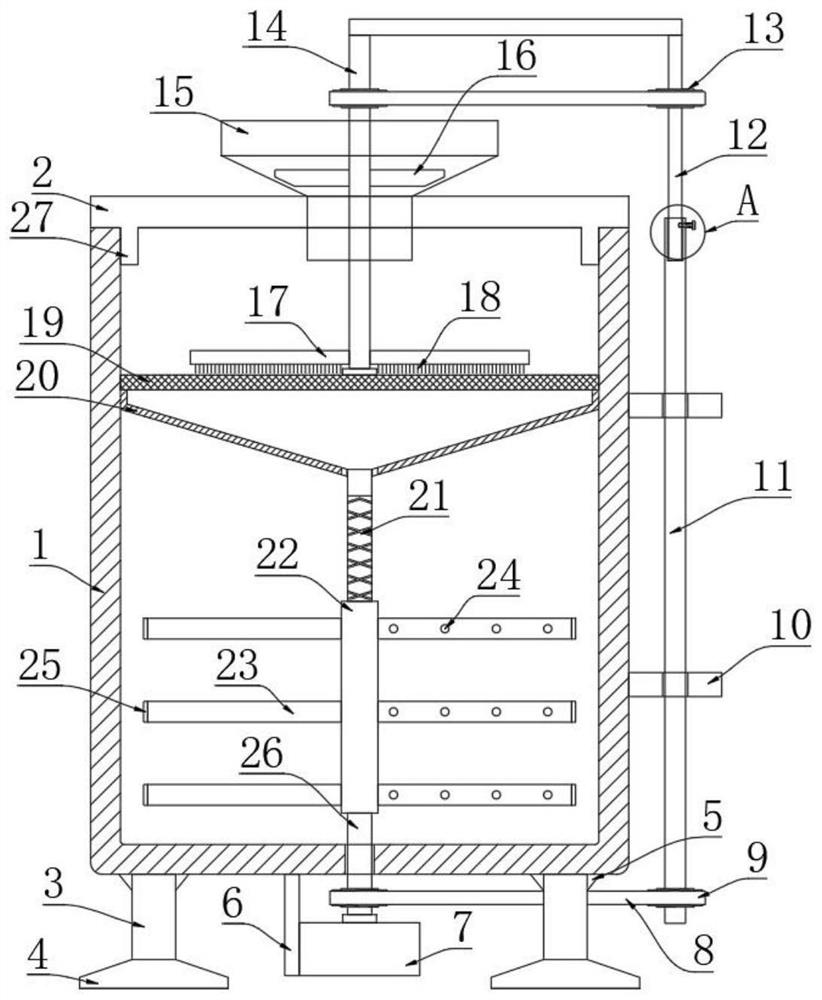

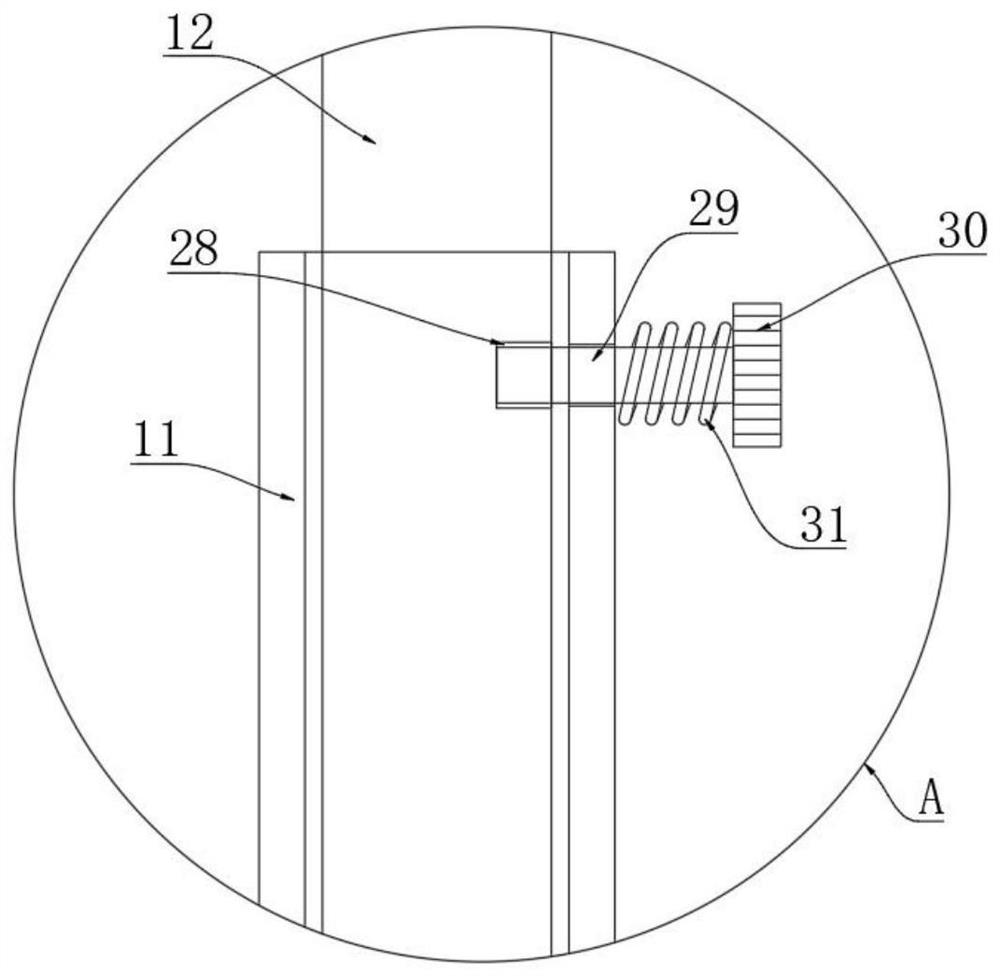

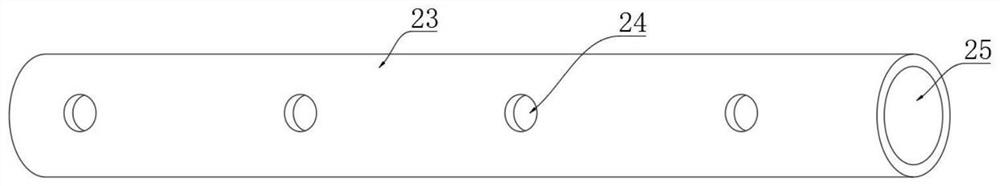

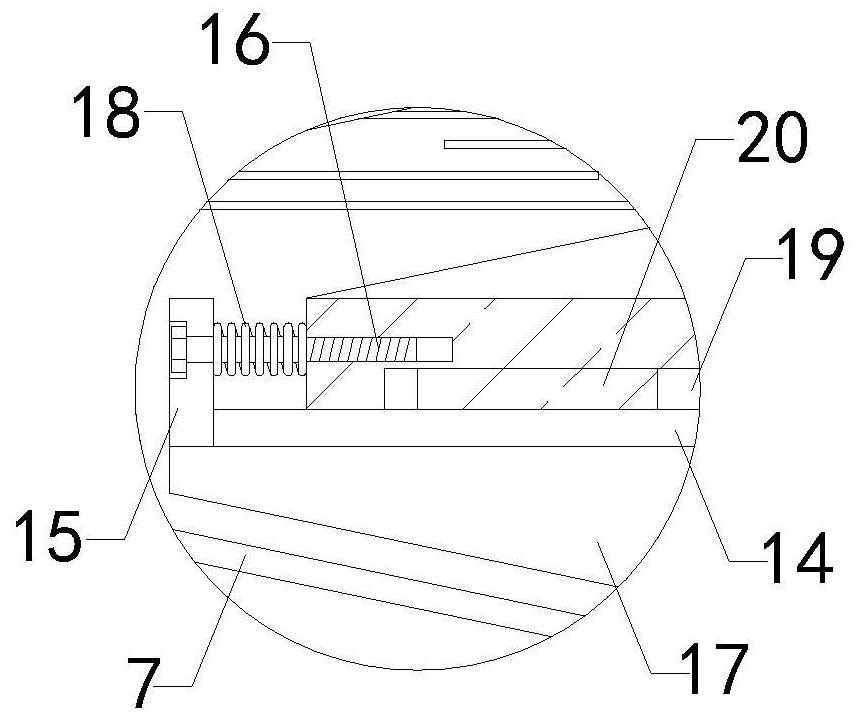

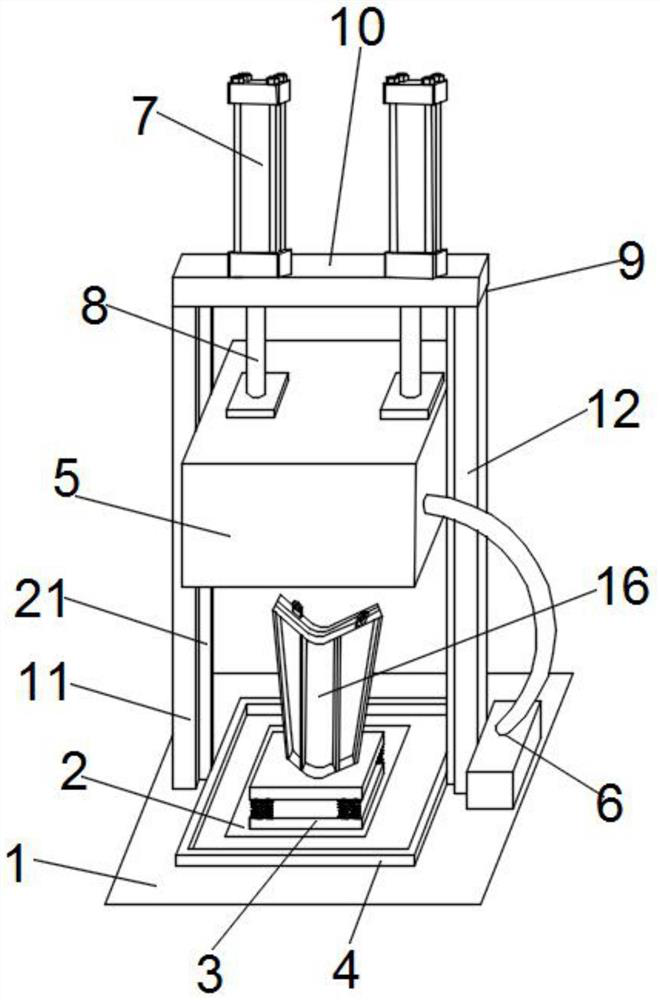

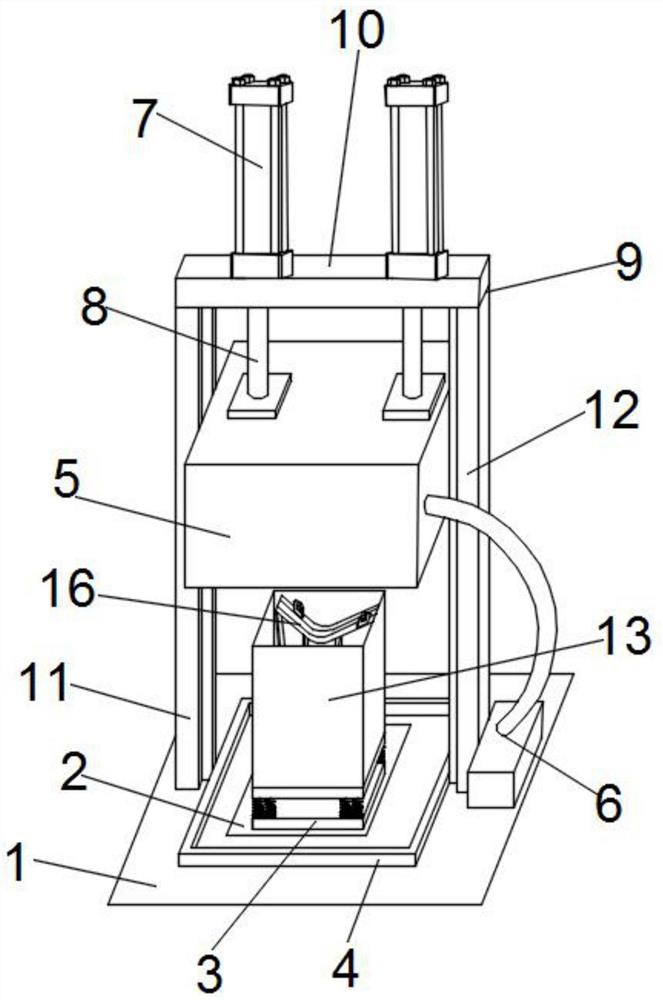

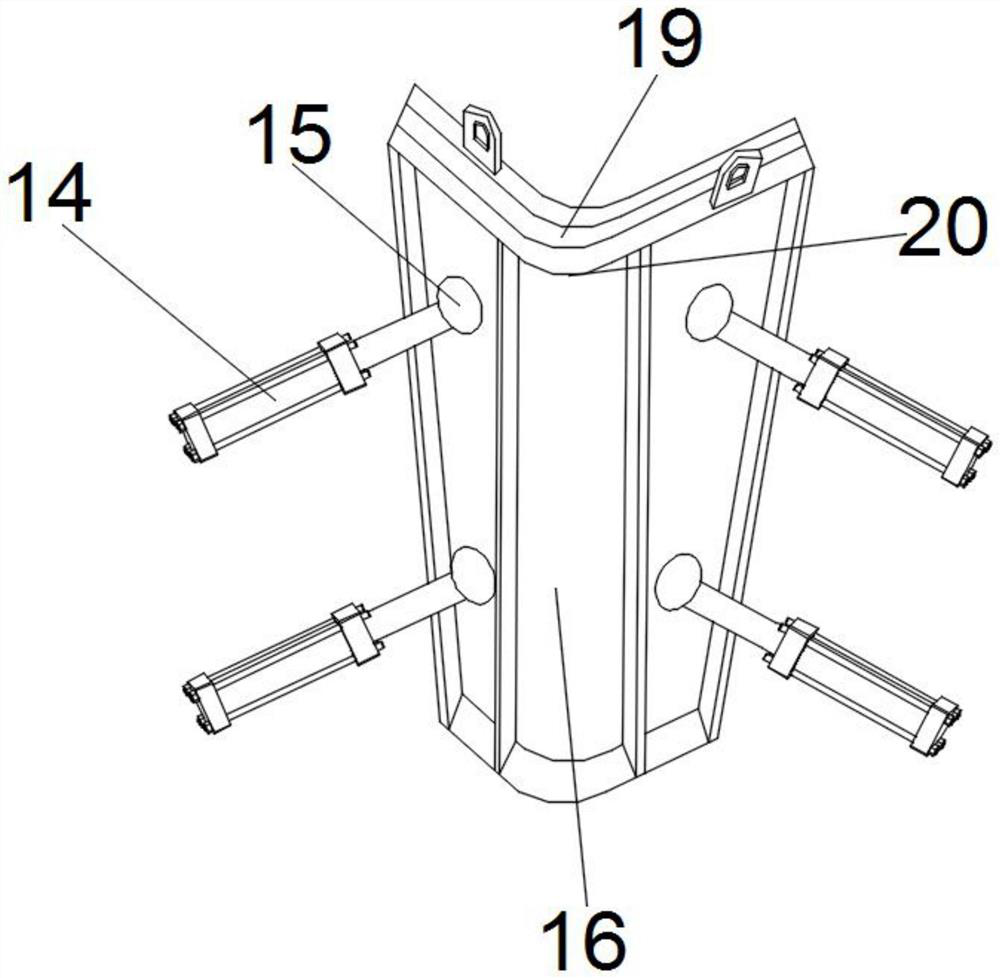

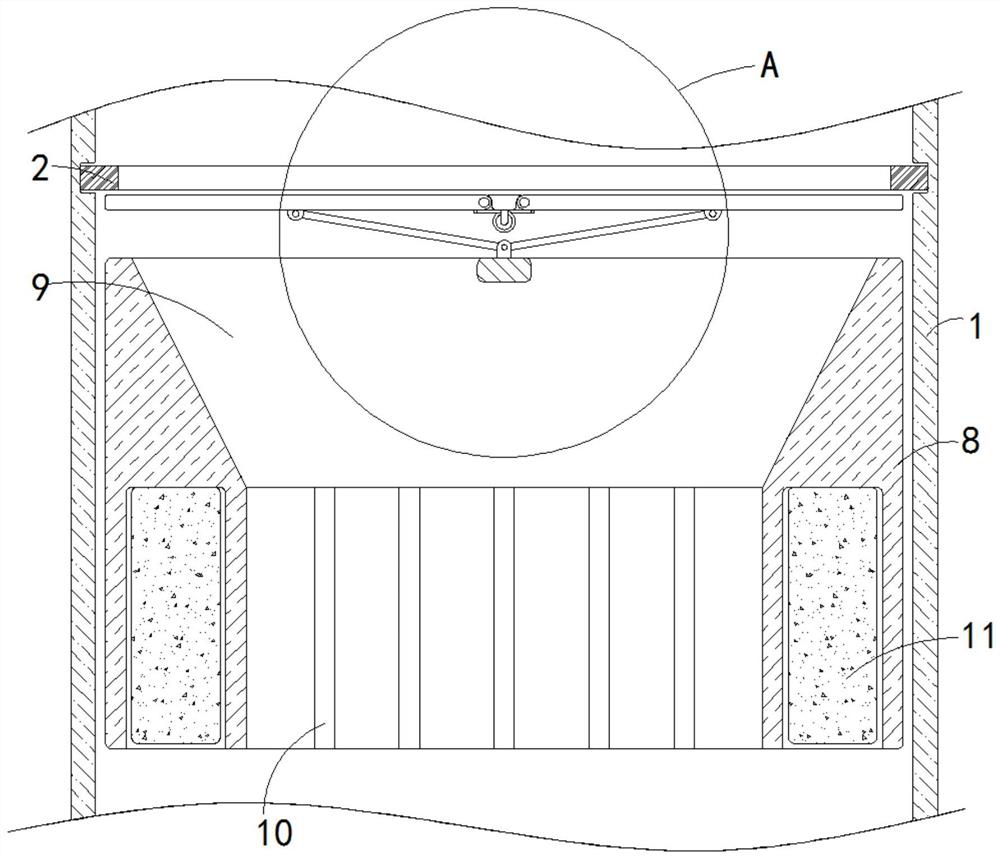

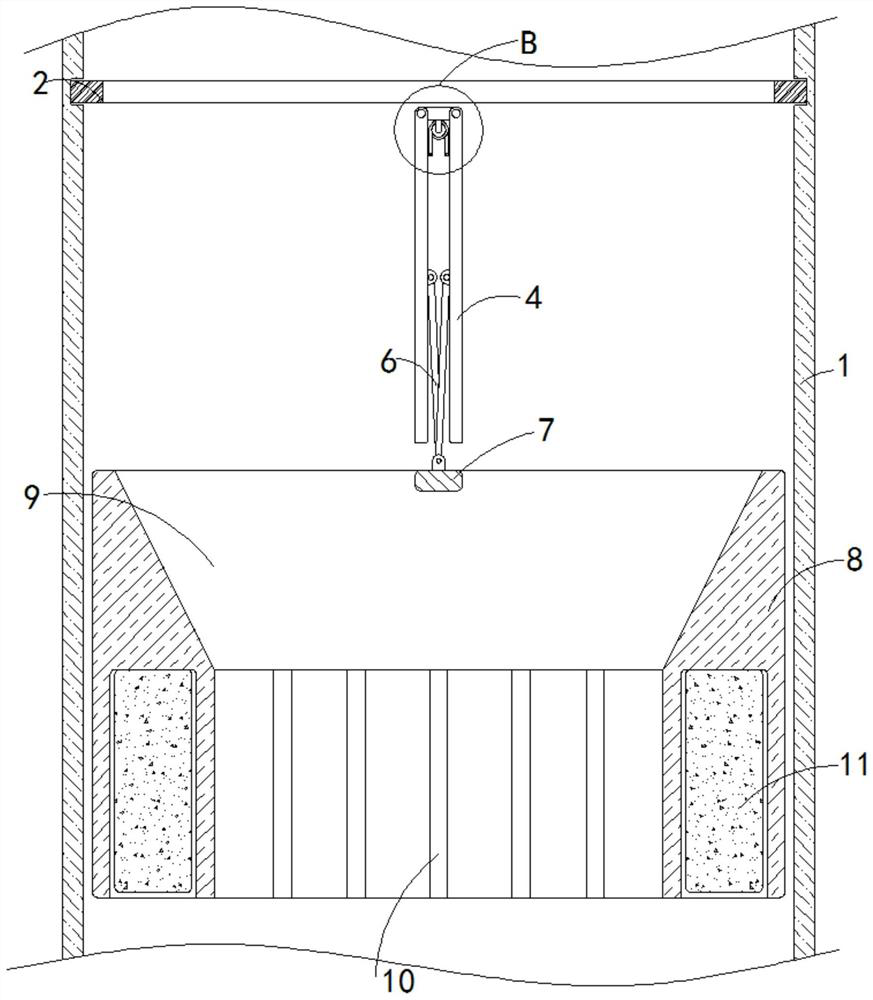

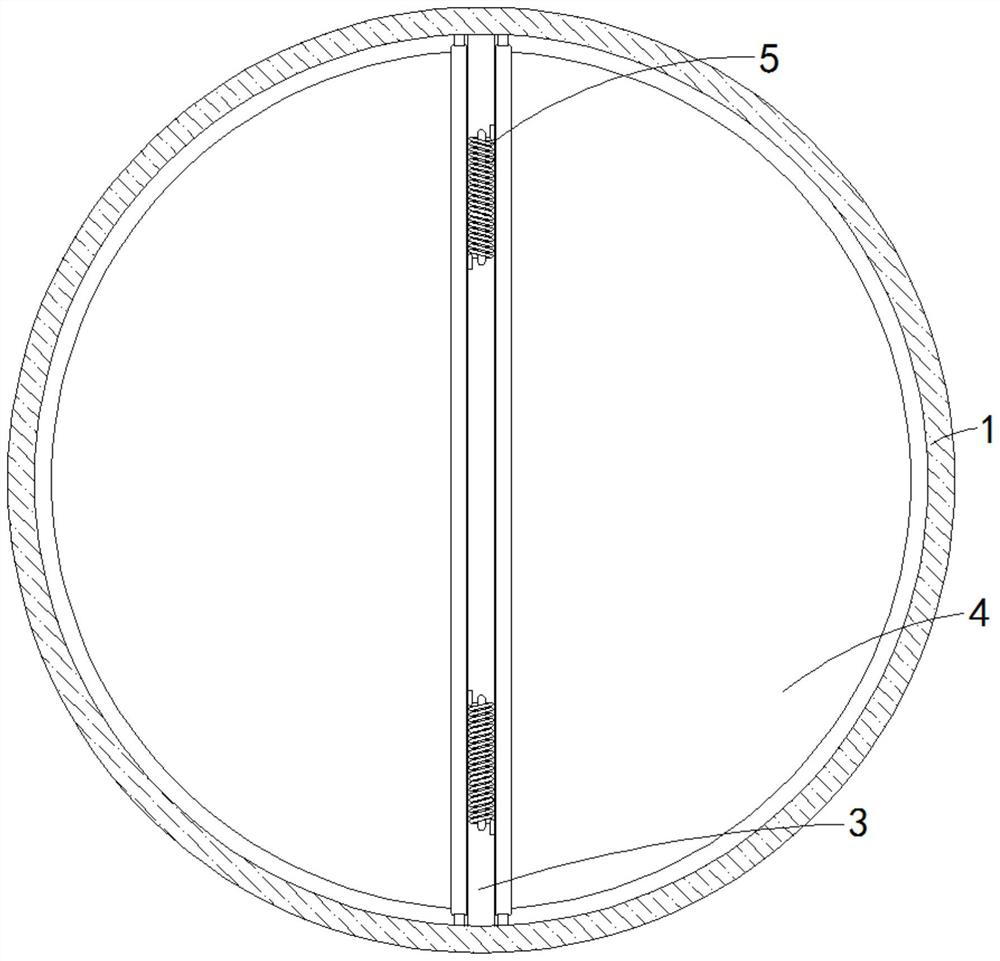

A molding equipment and molding process for realizing high-density refractory preform

The invention relates to the field of steelmaking, in particular to a molding device and a molding process for realizing high-density refractory prefabricated parts, comprising a groove recessed on the ground, a vibration table is fixed in the groove, and the groove is surrounded and fixed on the ground In the sealing gasket, the upper part of the sealing gasket is provided with a sealing chamber and the bottom edge of the sealing chamber is aligned with the sealing gasket. The side of the sealing chamber is connected with a negative pressure suction device, and the top surface of the sealing chamber is fixed at the end of the screw shaft of the cylinder. Fixed on the top plate of the fixed frame, the left support plate and the right support plate of the fixed frame are fixed on the ground, the left support plate and the right support plate are respectively fixed on the left and right outer sides of the gasket, vibrated by negative pressure , avoids the air from being drawn into the slurry from the outside of the mold during the vibration process, quickly discharges and exhausts the gas wrapped in the slurry, greatly improves the density of the preform, and can effectively resist the erosion of the slag. slag blocking effect.

Owner:浙江红鹰铭德高温材料科技有限公司

Bubble tube for desulfurization tower with anti-backflow and split flow

Owner:宁夏峰业环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com