High-efficiency livestock feed mixing device

A mixing device, high-efficiency technology, applied in feed, mixer, shake/oscillation/vibration mixer, etc., can solve the problems of time-consuming and labor-intensive, low efficiency, and the bottom of the mixing tank cannot be fully mixed, saving time and effort The effect of labor cost, labor cost reduction and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

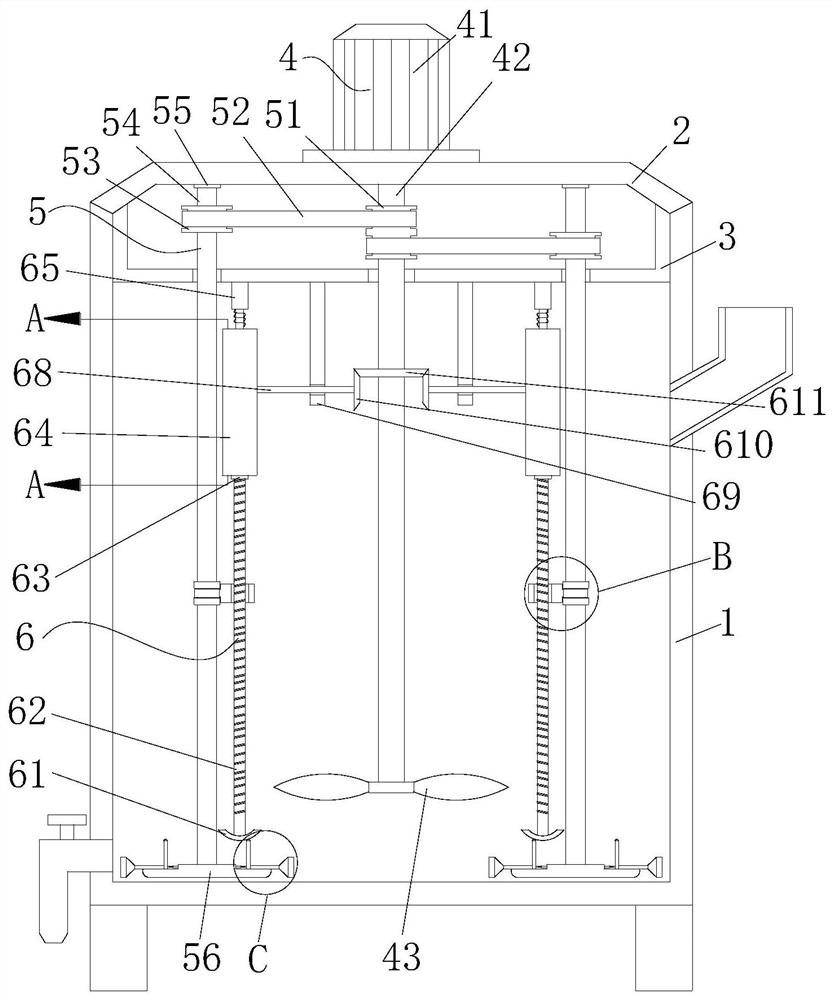

[0032] Attached below Figure 1-4 The present invention is further described with embodiment:

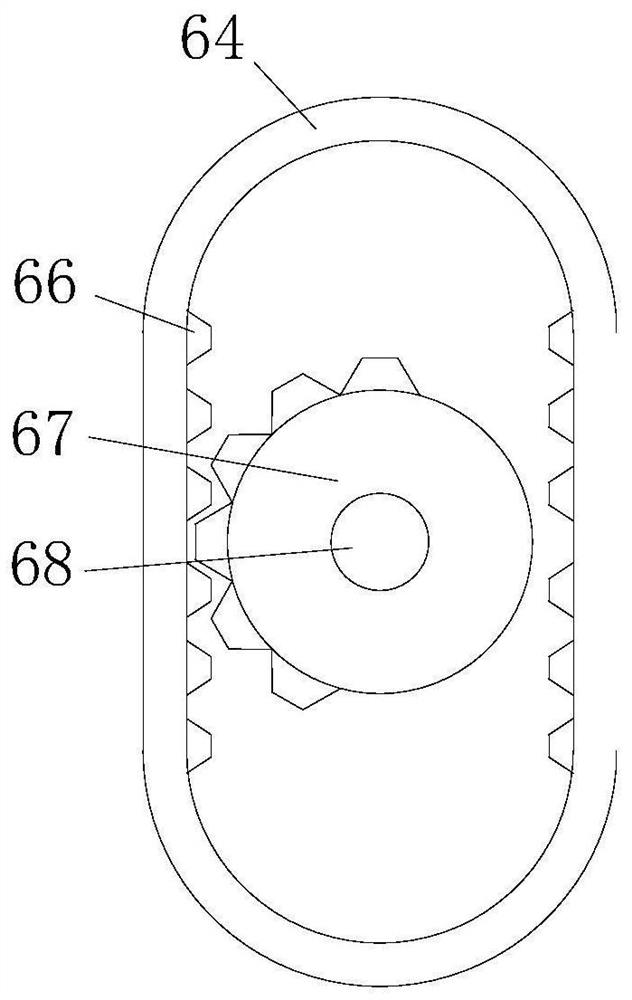

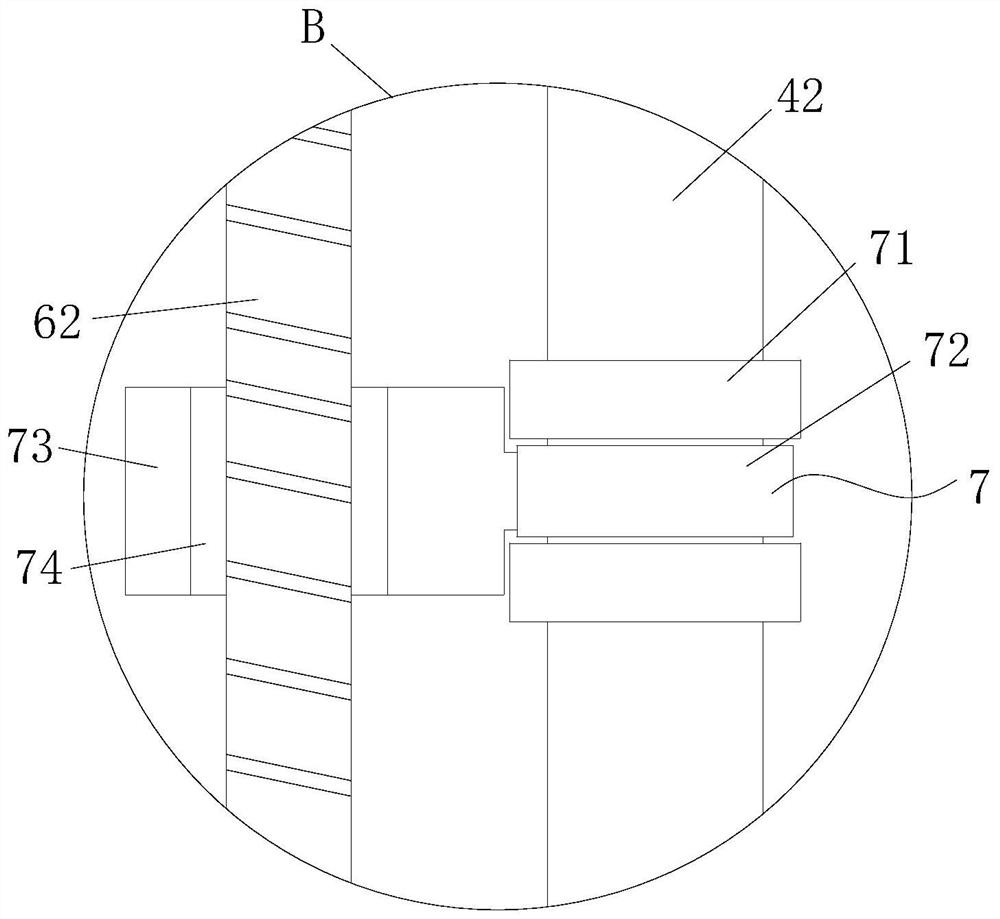

[0033]A mixing device for high-efficiency livestock feed, comprising a mixing tank 1 and a tank cover 2, the tank cover 2 is fastened on the upper opening of the mixing tank 1, a No. 1 mixing mechanism 4 is arranged on the tank cover 2, and the No. 1 mixing mechanism 4 includes Driving motor 41, No. 1 rotating rod 42 and No. 1 stirring paddle 43, No. 1 rotating rod 42 is movably inserted on the tank cover 2, and the upper end of tank cover 2 is connected with driving motor 41, and driving motor 41 is fixedly arranged on the tank On the outer top wall of the cover 2, the lower end of the No. 1 rotating rod 42 is connected with a No. 1 stirring paddle 43, and the inner wall of the tank cover 2 is fixedly connected with a blocking plate 3, and the blocking plate 3 is movably sleeved on the No. 1 rotating rod. 42, the side wall of the sealing plate 3 and the mixing tank 1 is slidably a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com