Patents

Literature

7046results about "Feeding-stuff" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

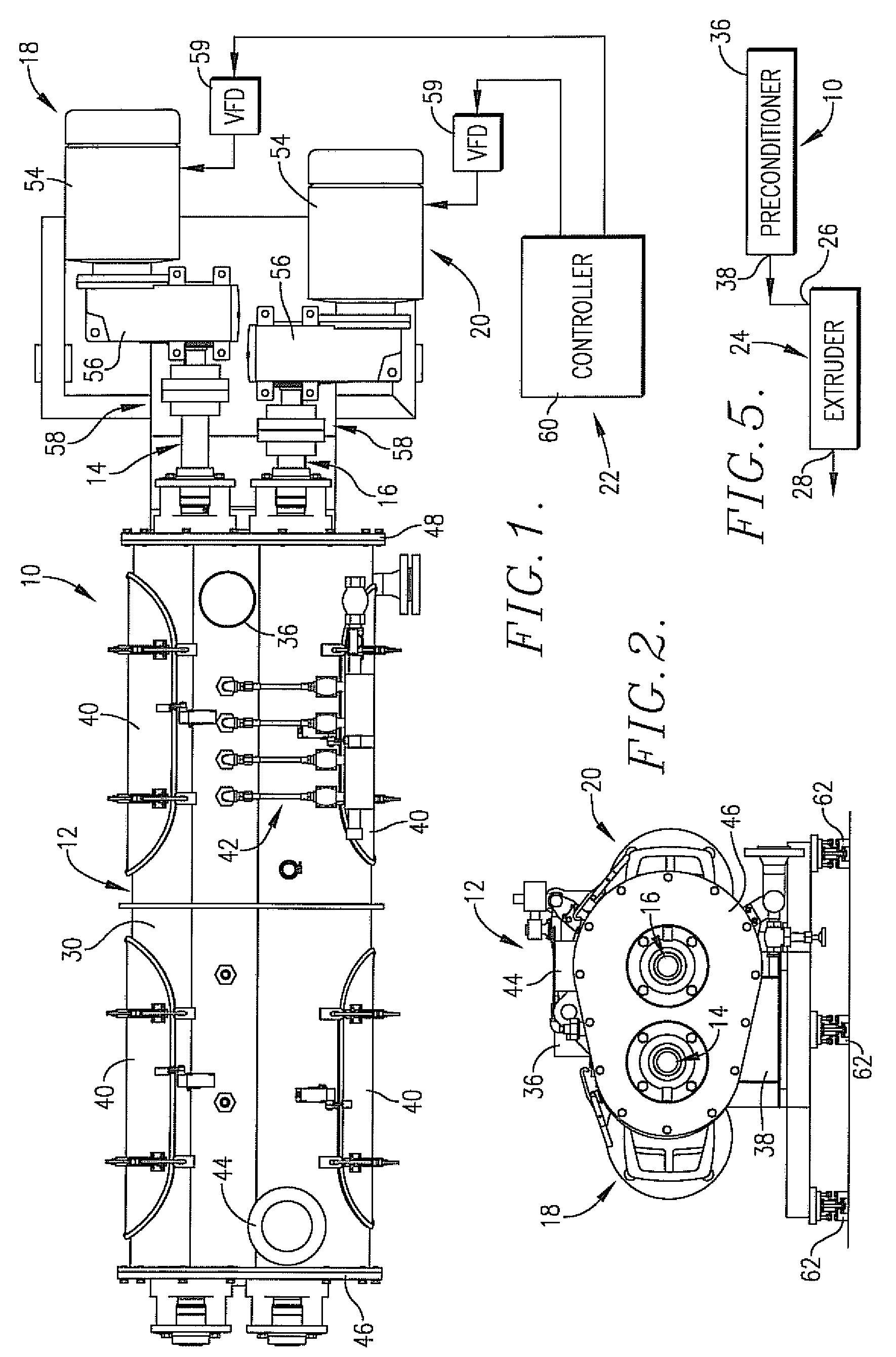

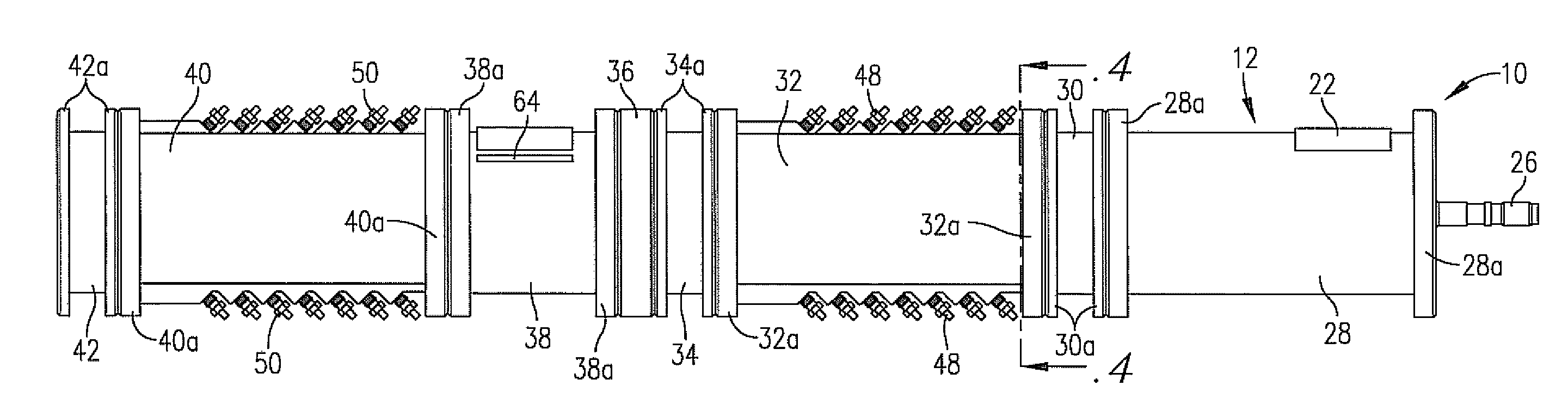

Method and apparatus for producing fully cooked extrudates with significantly reduced specific mechanical energy inputs

ActiveUS7521076B1The implementation process is simpleLow costMilk preservationFeeding-stuffEngineeringPreconditioner

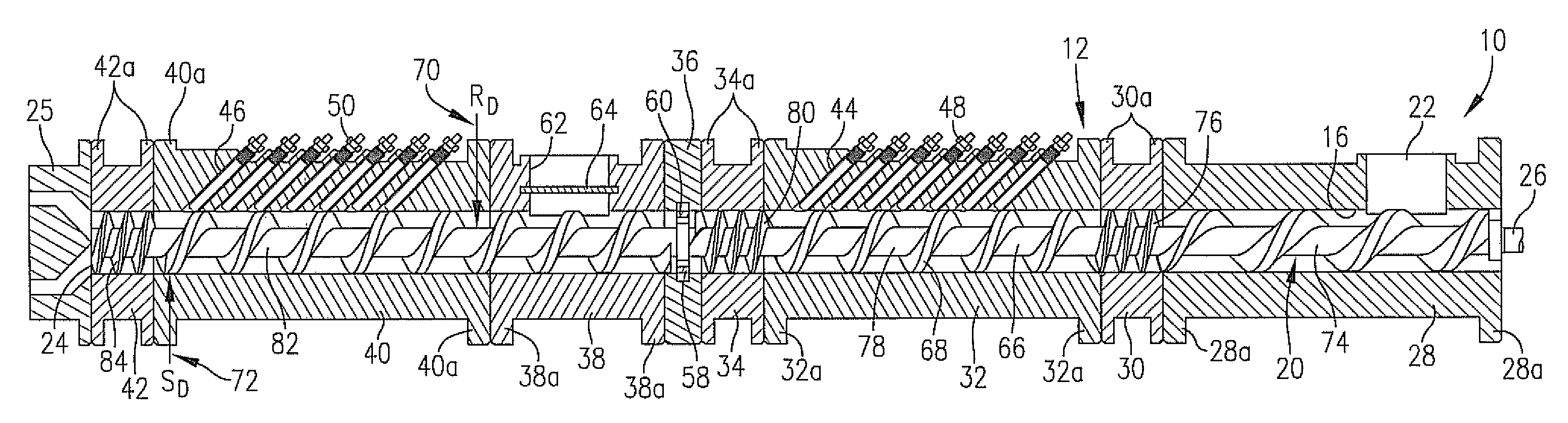

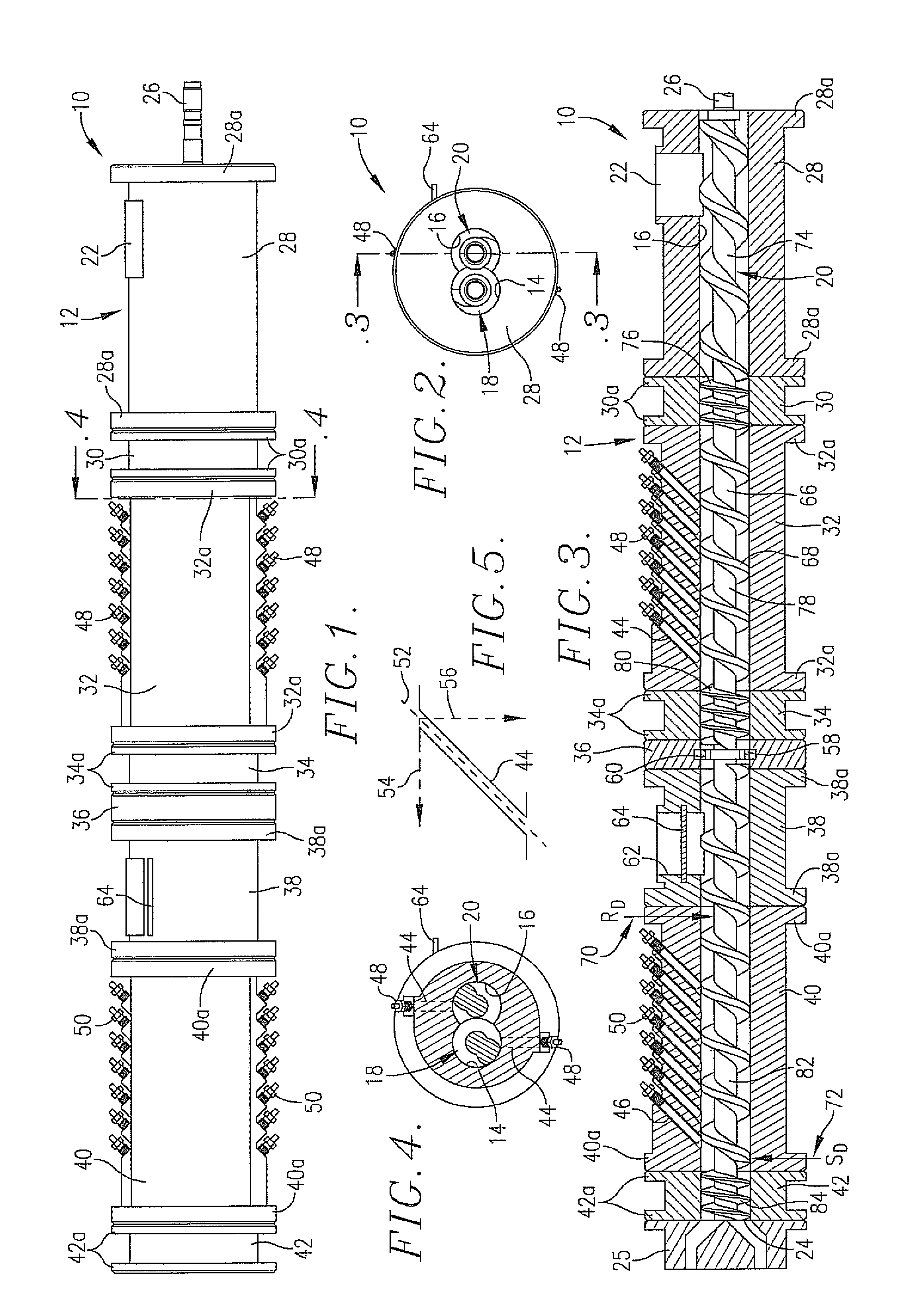

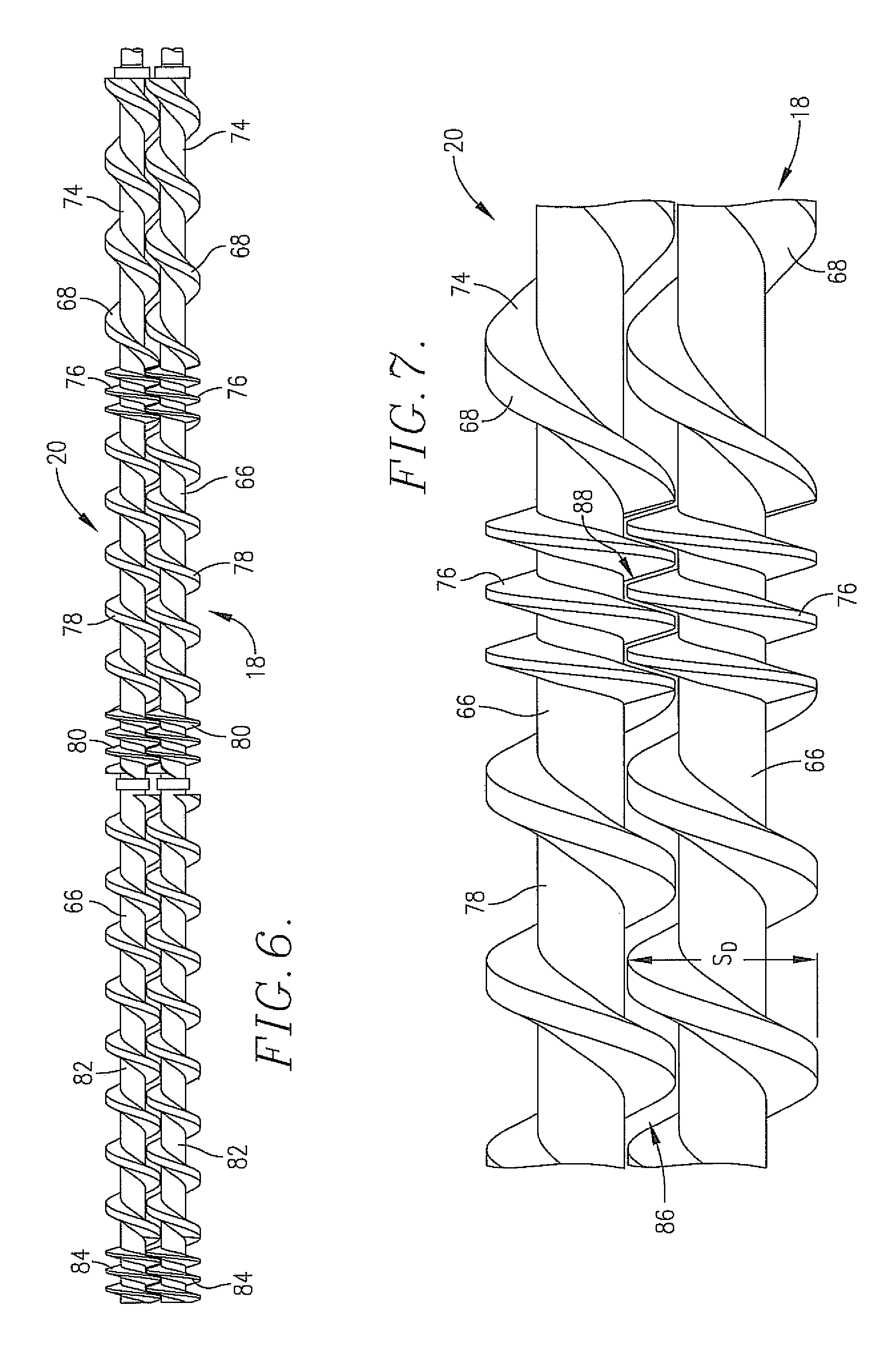

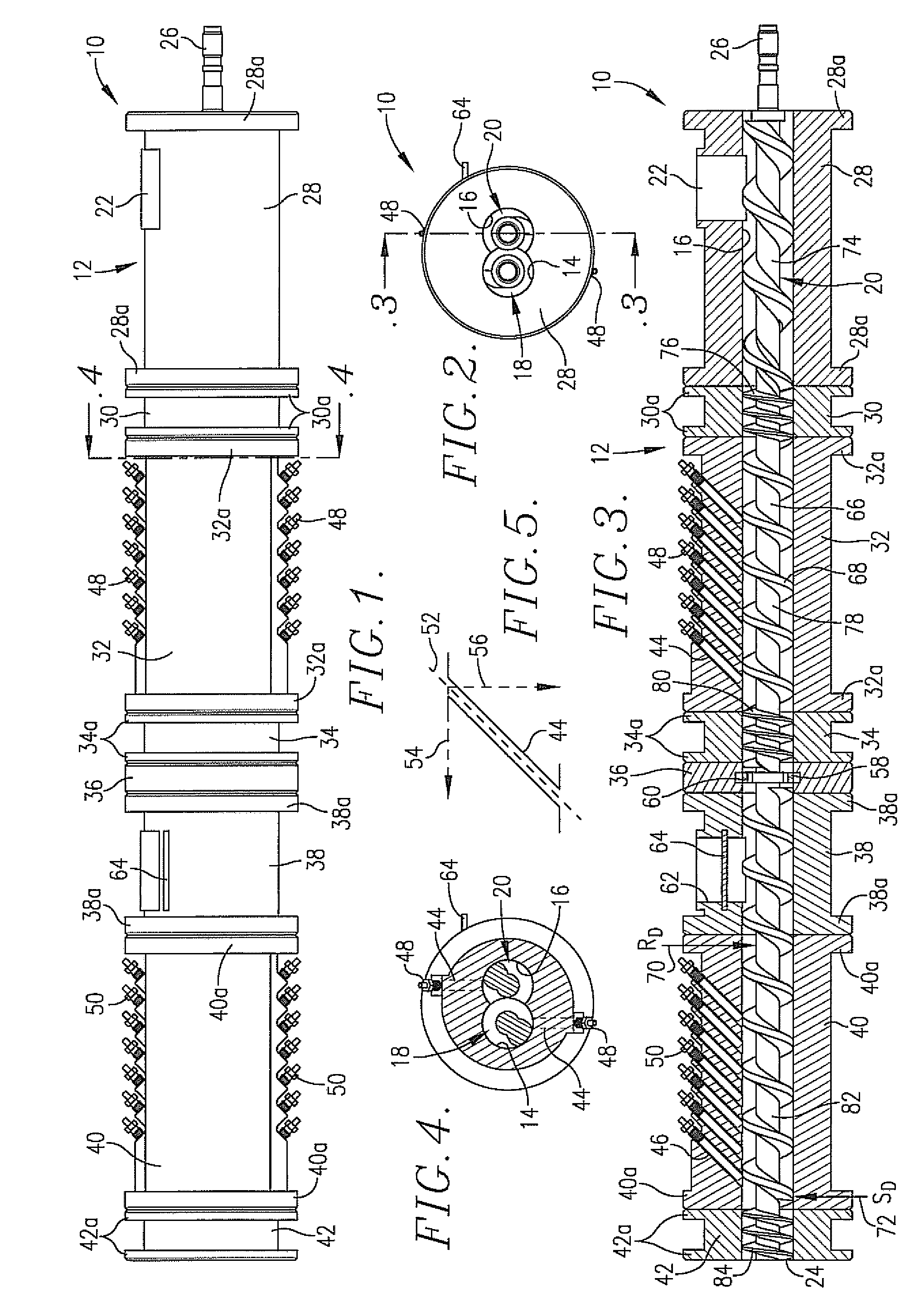

Improved extruders and methods for the extrusion cooking of comestible products such as human foods or animal feeds are provided wherein the products may be produced with very low specific mechanical energy (SME) inputs as compared with conventional processing. The methods preferably involve introduction of very high levels of steam into the extruder barrel (12) during processing, which concomitantly reduces necessary SME inputs required to achieve desired cook and expansion levels in the products. In accordance with the invention, fully-cooked pet foods can be fabricated with SME inputs of up to about 18 kWhr / T, whereas aquatic feeds can be fabricated with SME inputs of up to about 16 kWhr / T. In preferred forms, the extruder (10) includes specially configured, intermeshed extrusion screws (18, 20) and a plurality of obliquely oriented steam inlets (48, 50), and an upstream, dual-shaft preconditioner (90) is used having individual variable frequency drives (98, 100) which allow infinite variablility in the speed and rotational direction of the preconditioner shafts (94, 96).

Owner:WENGER MFG LLC

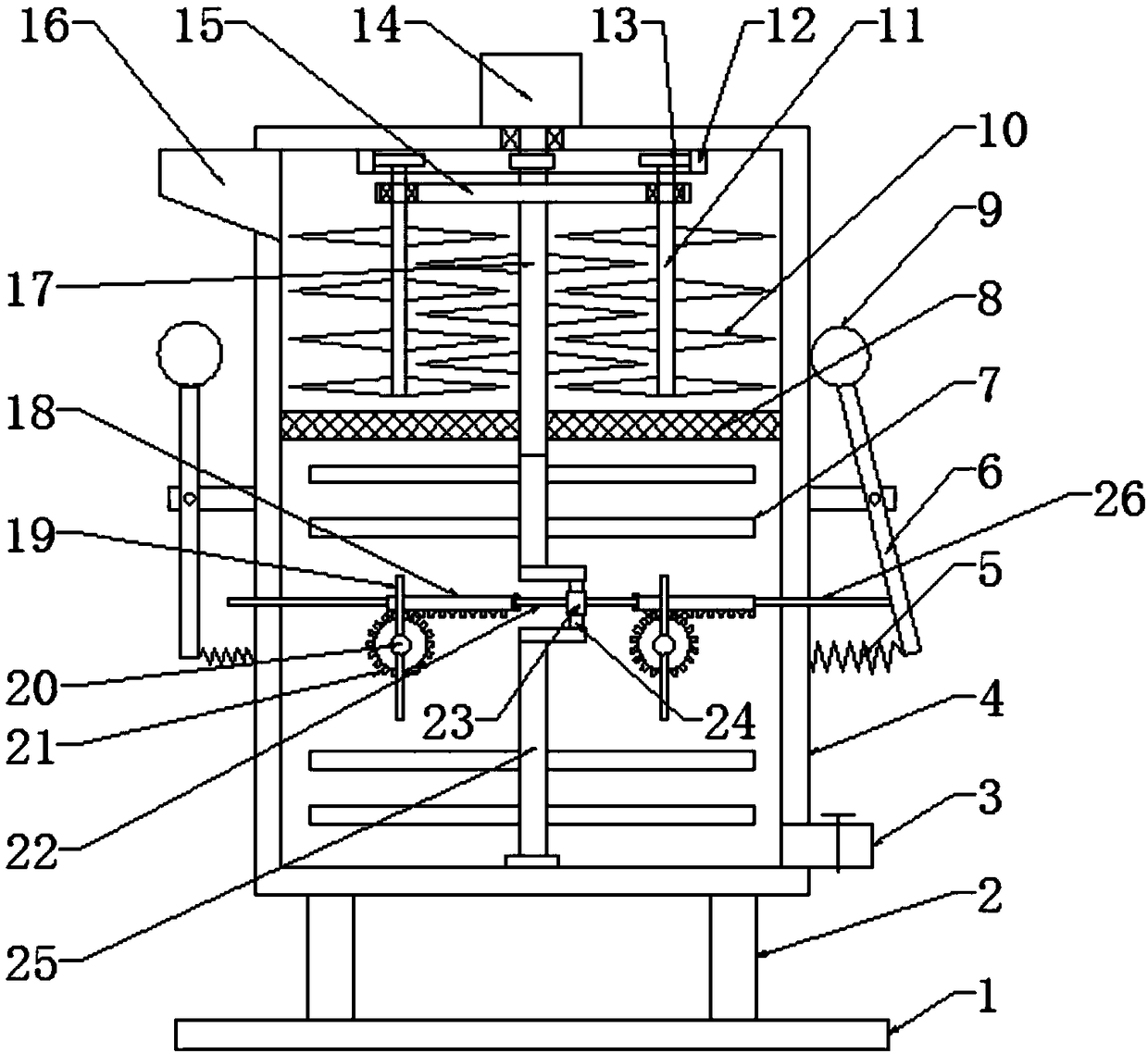

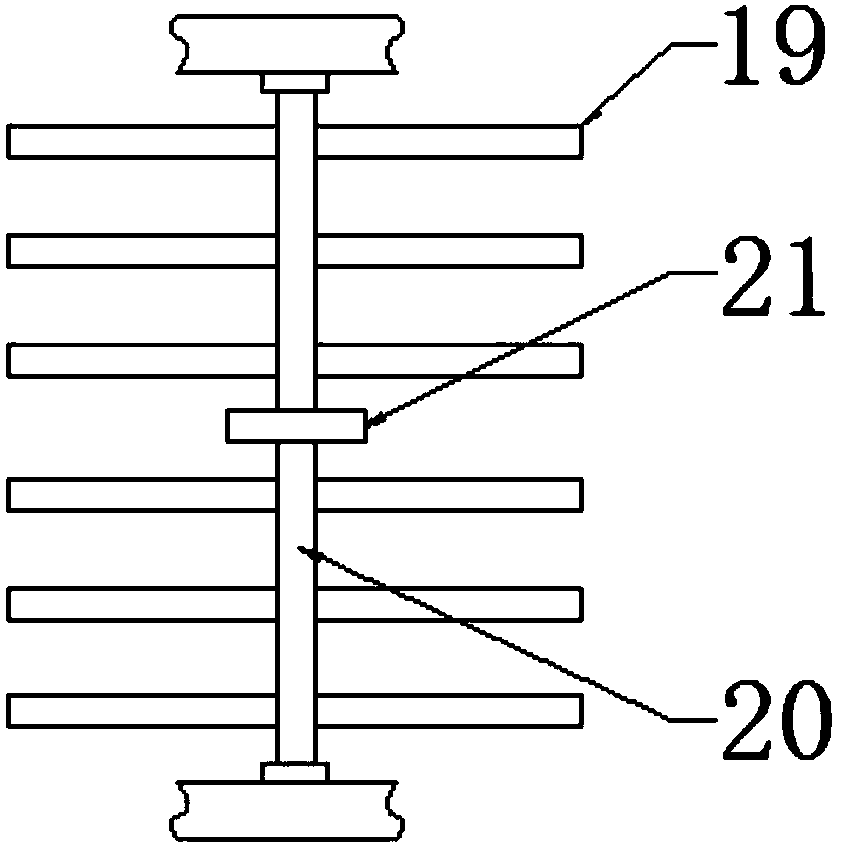

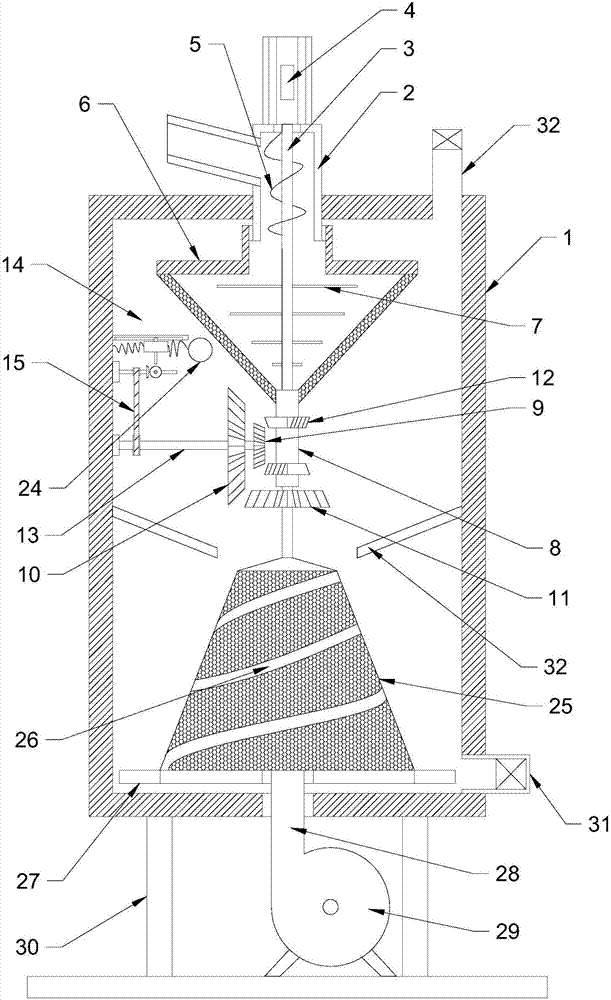

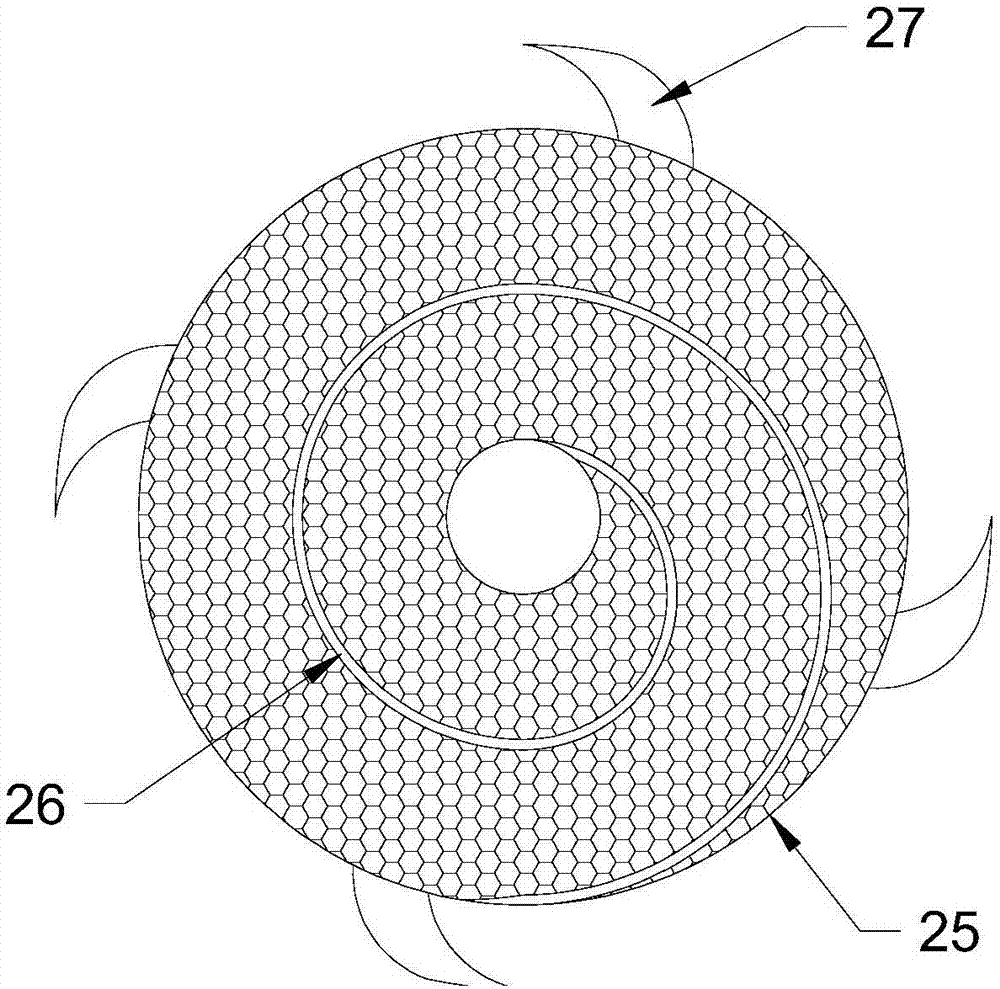

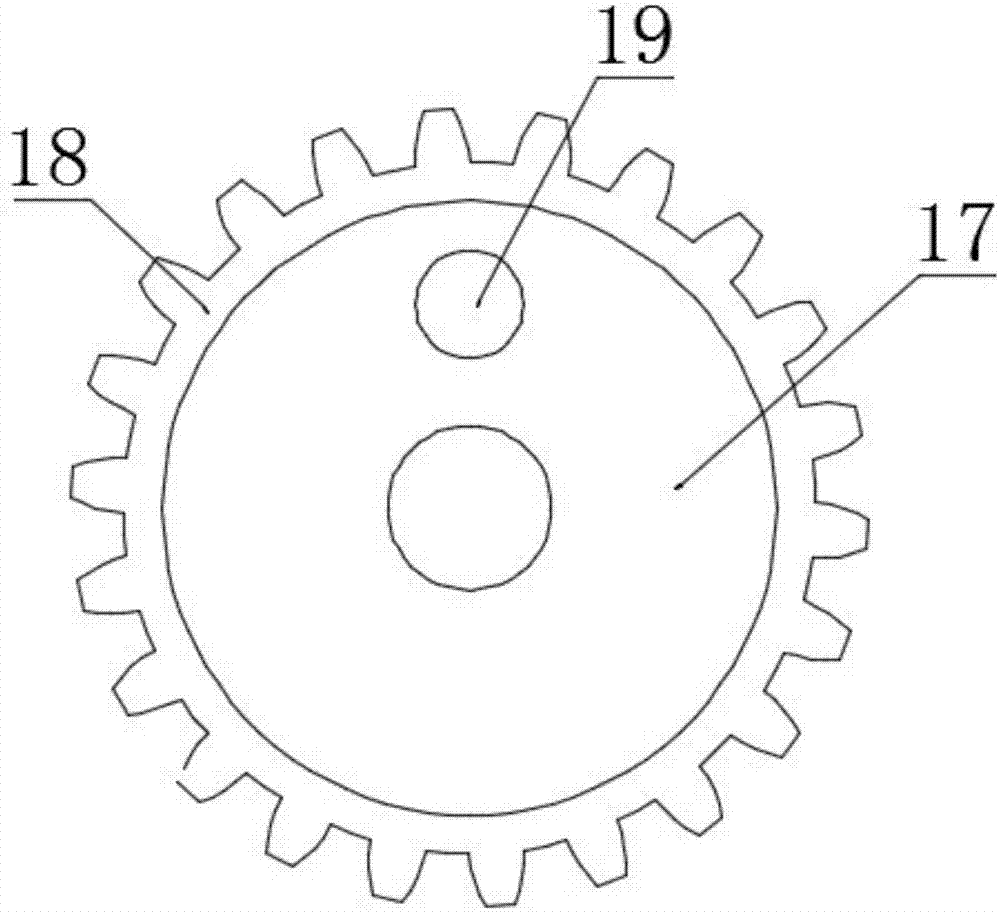

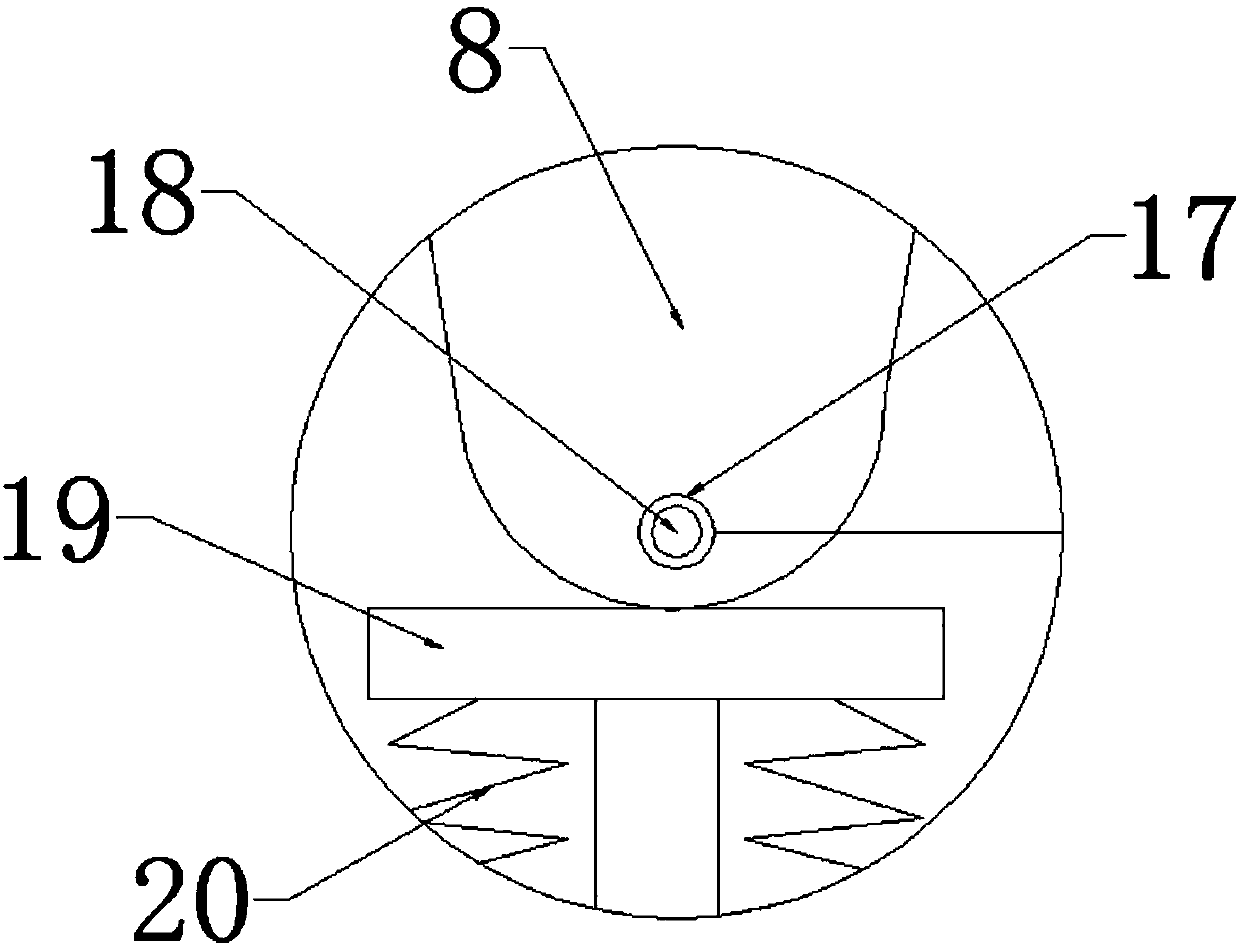

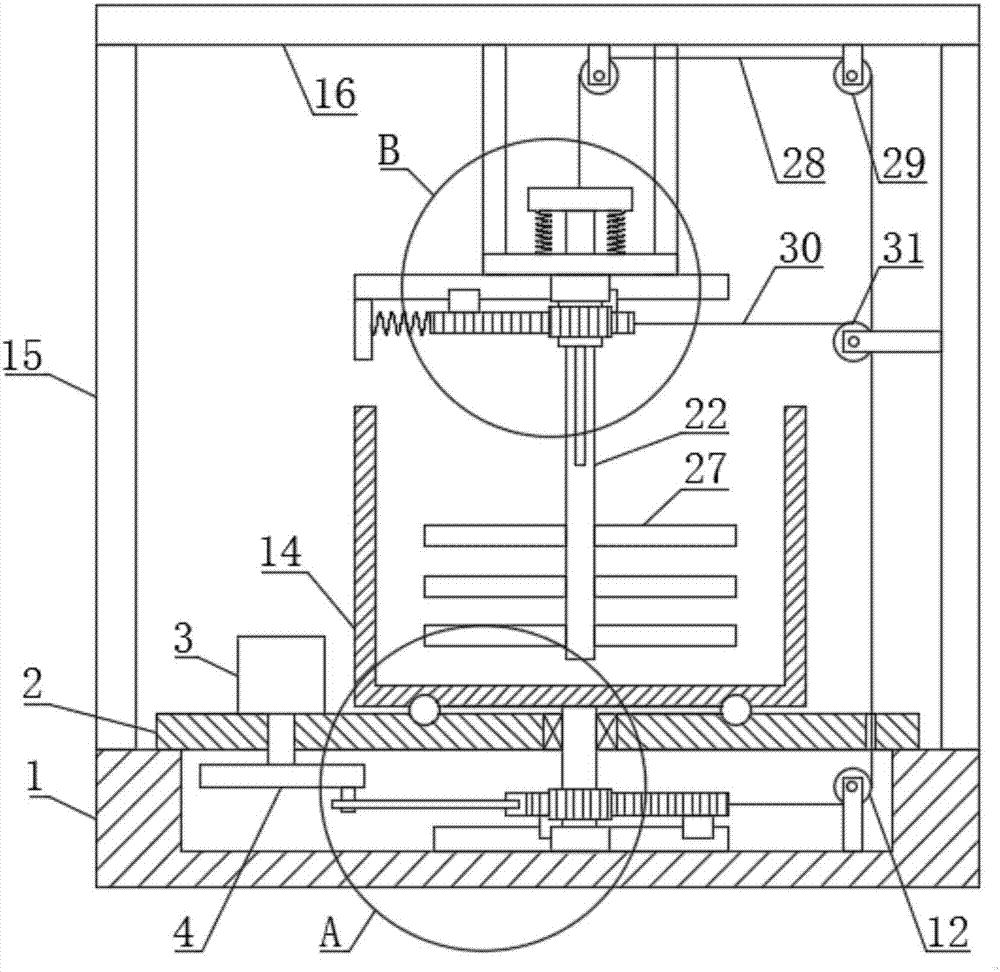

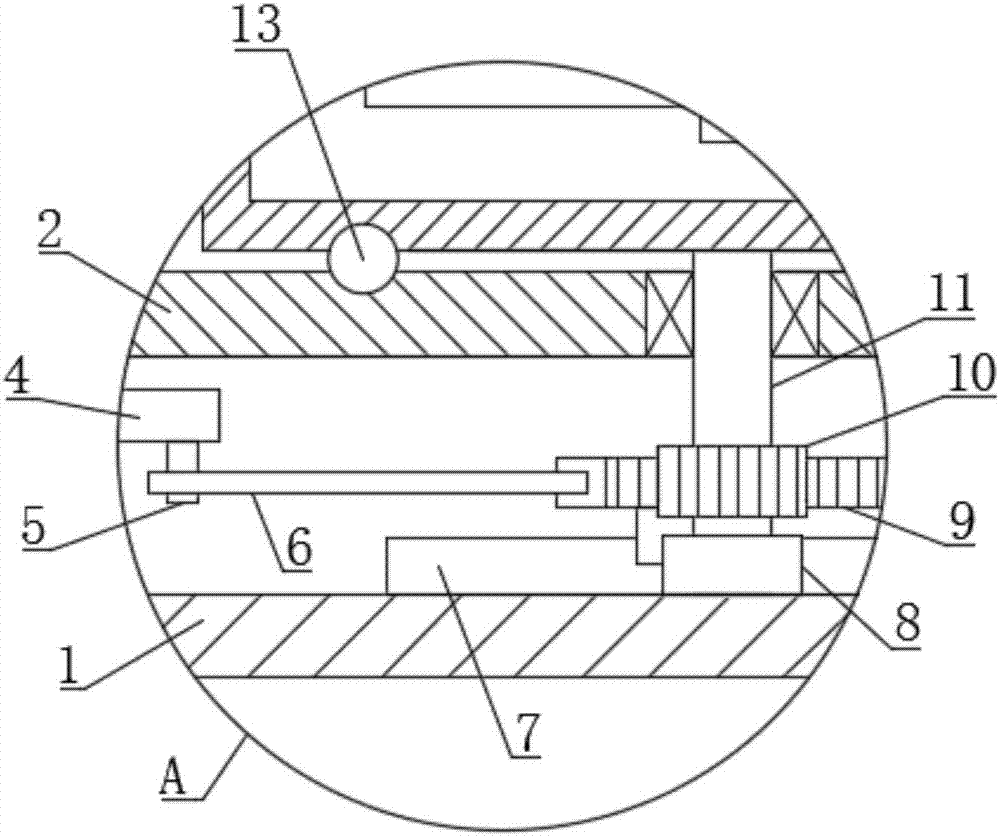

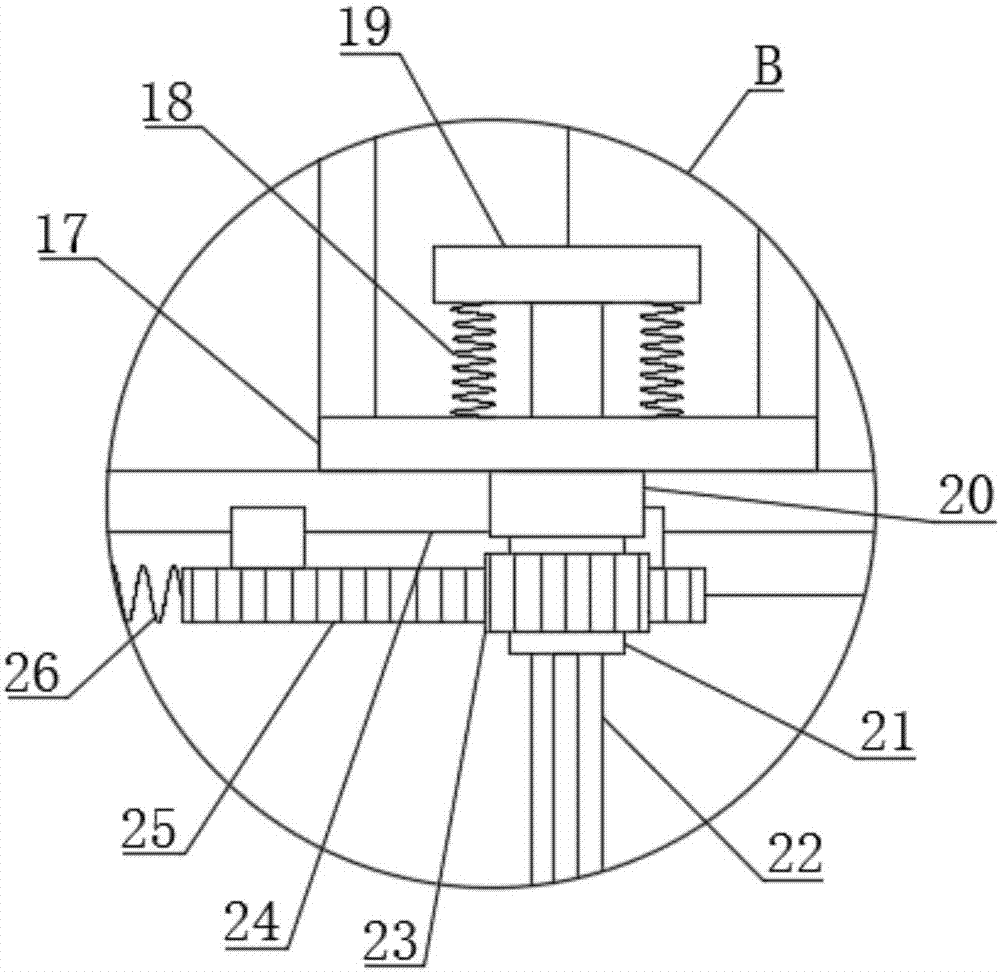

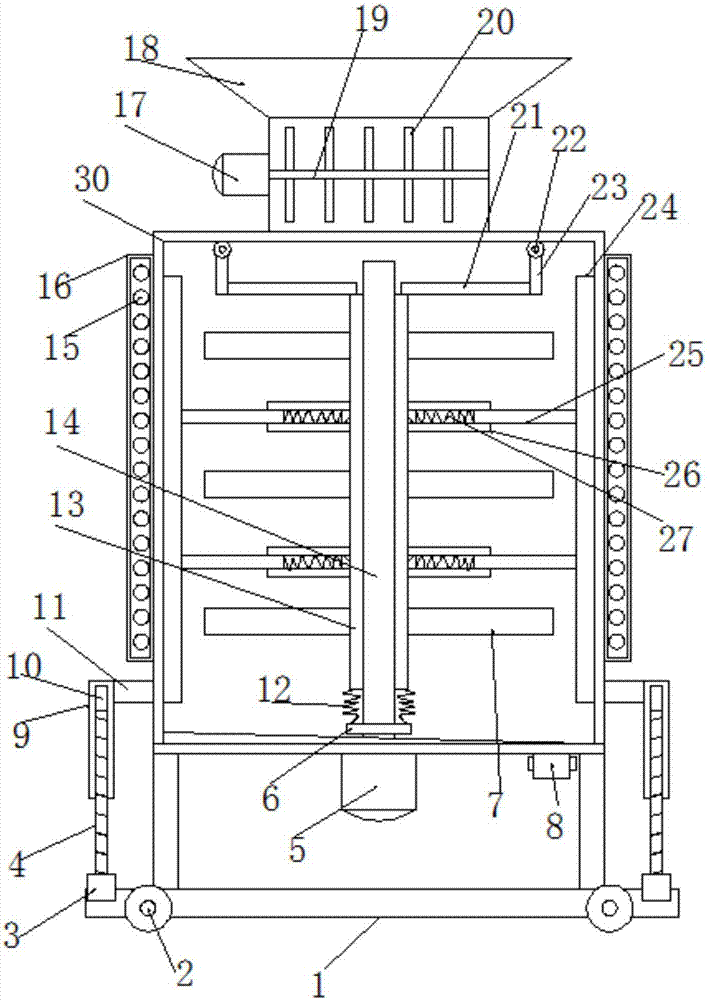

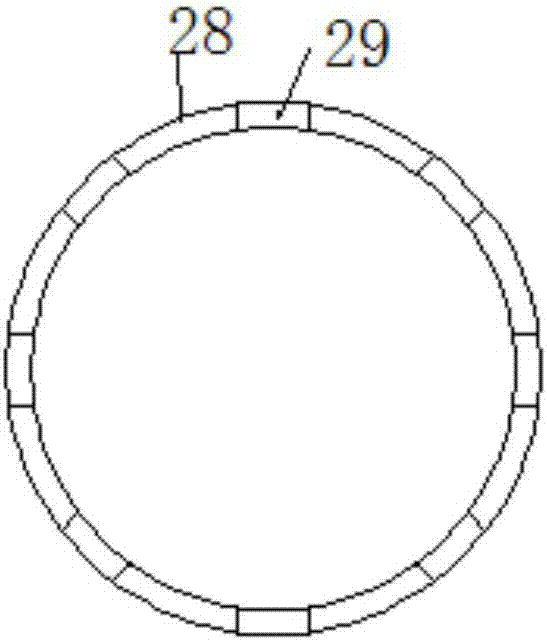

Stirring and mixing device for feed production

InactiveCN107684869AAvoid cloggingImprove crushing efficiencyFeeding-stuffRotary stirring mixersEngineeringOmni directional

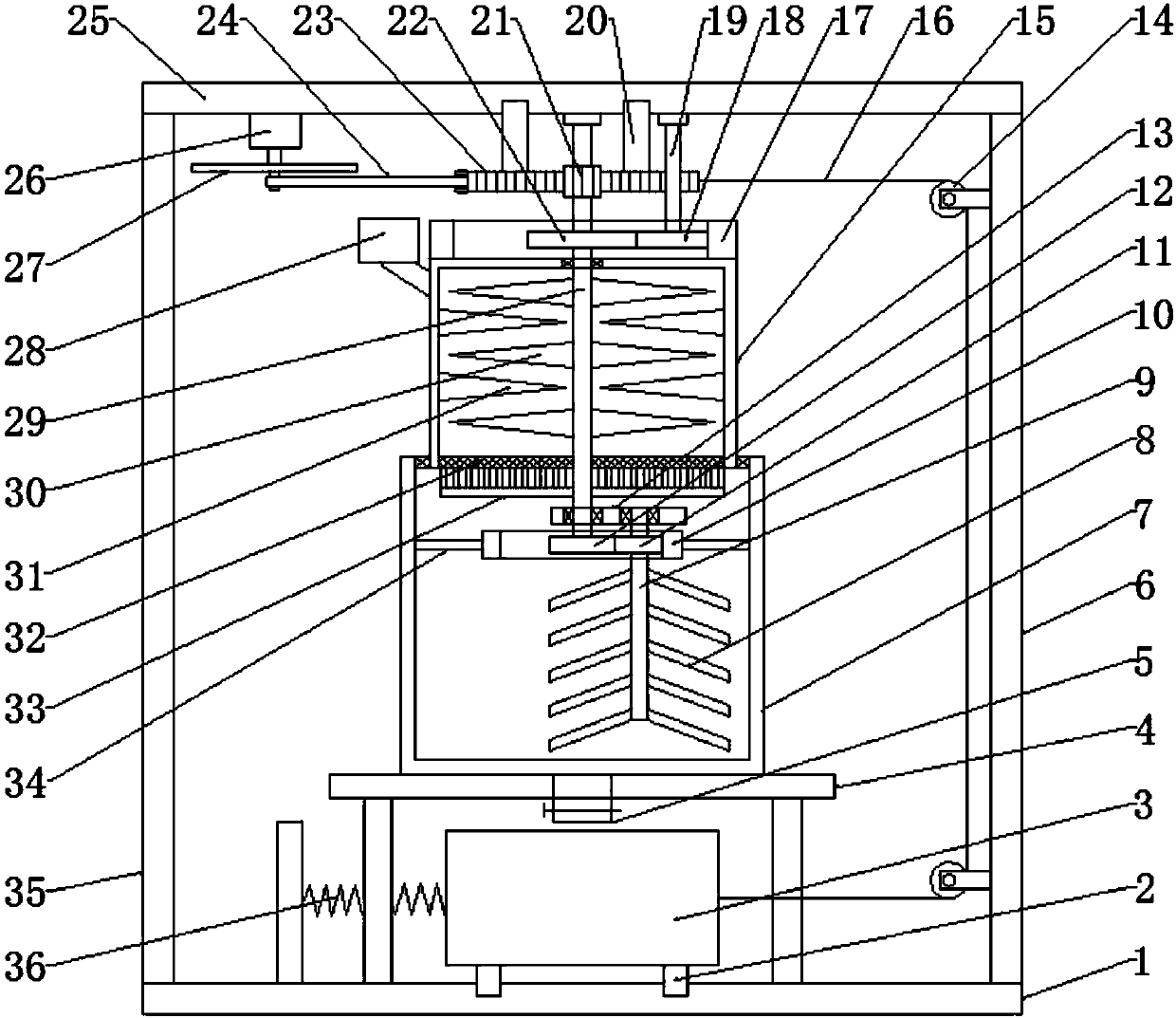

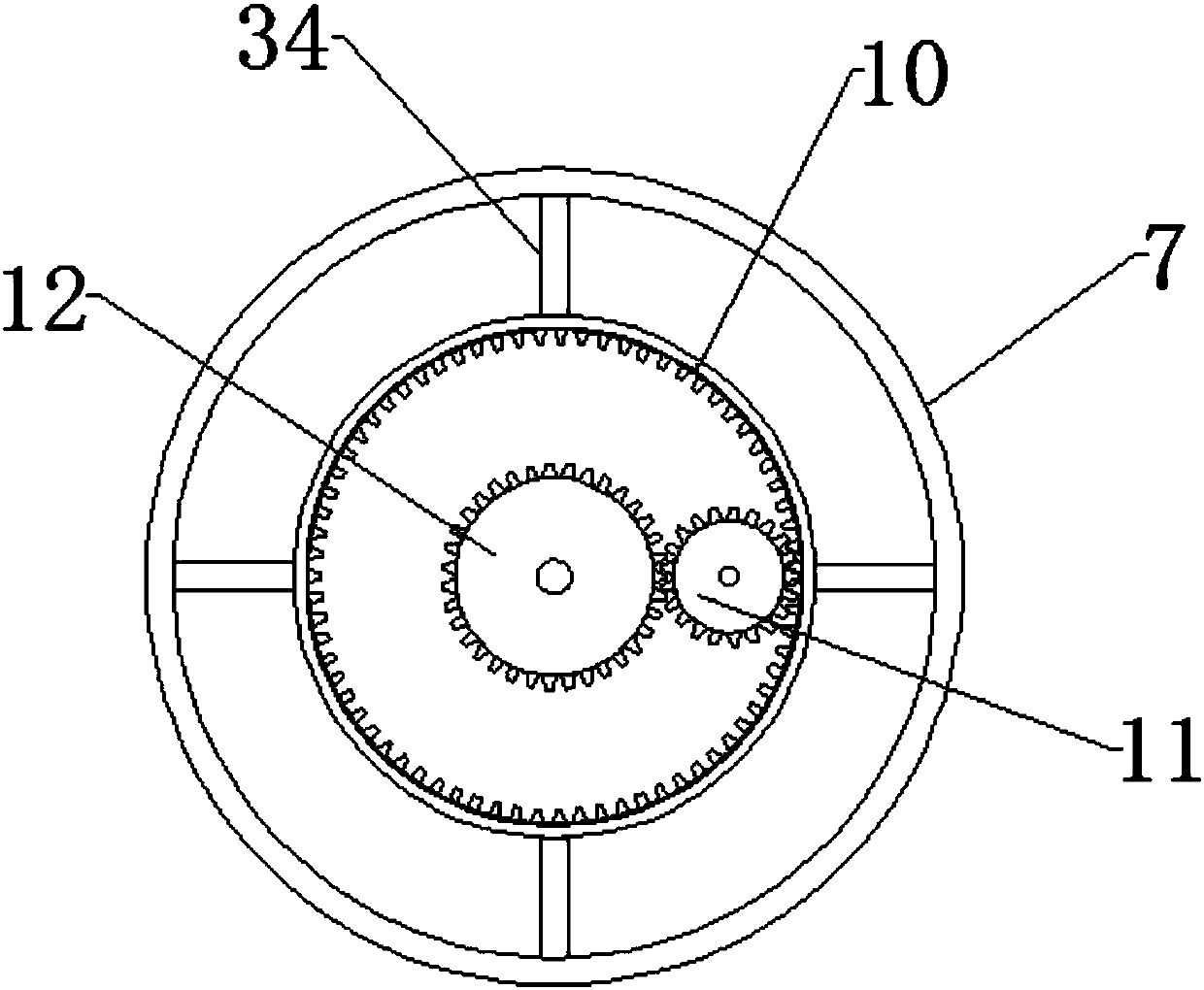

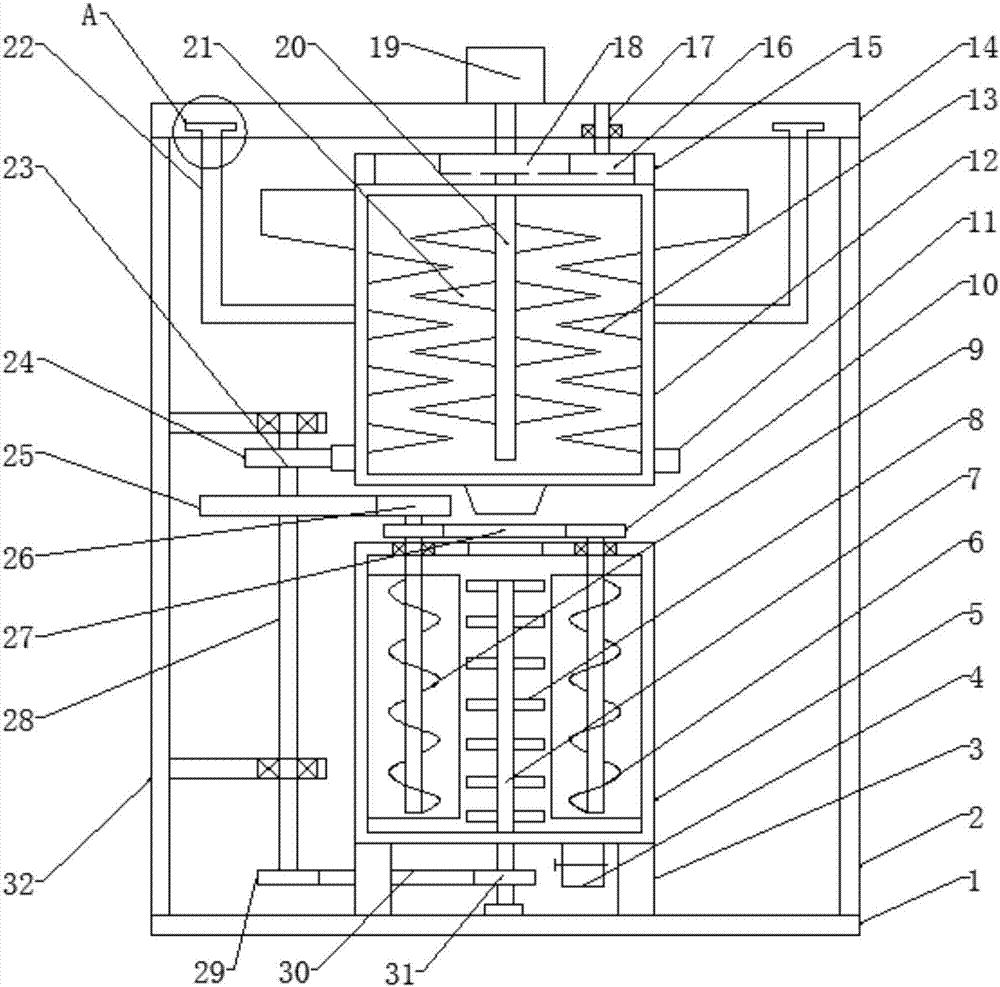

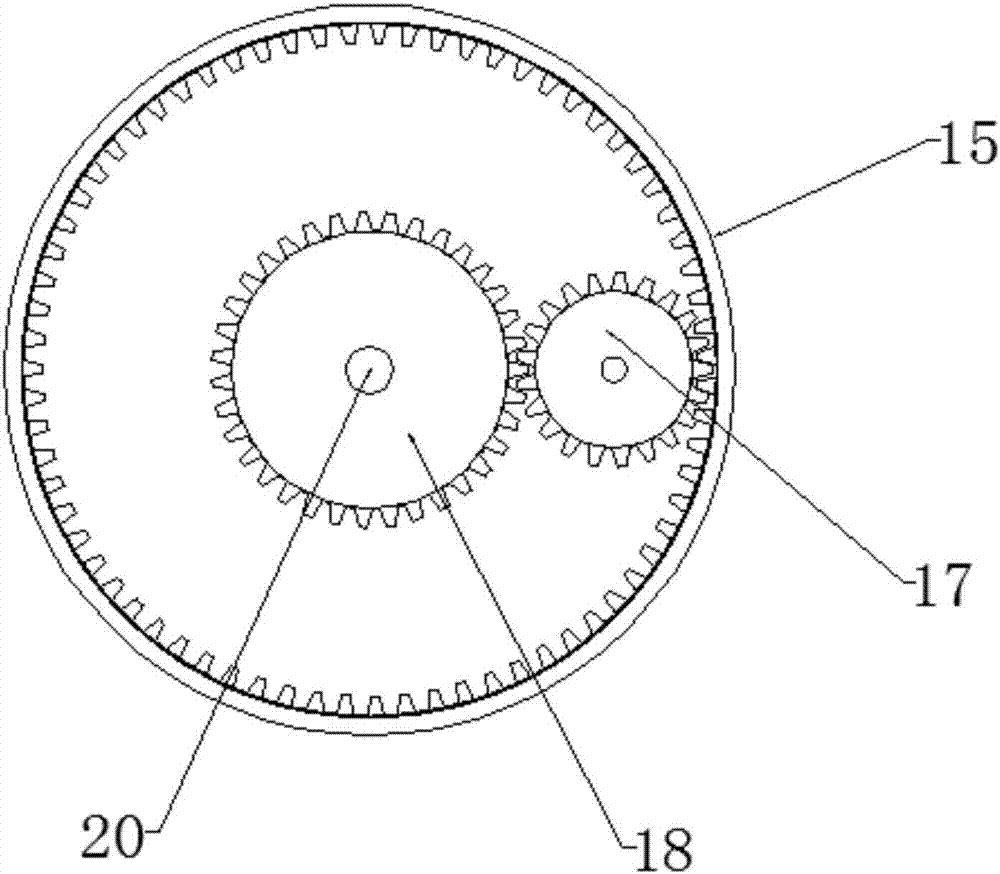

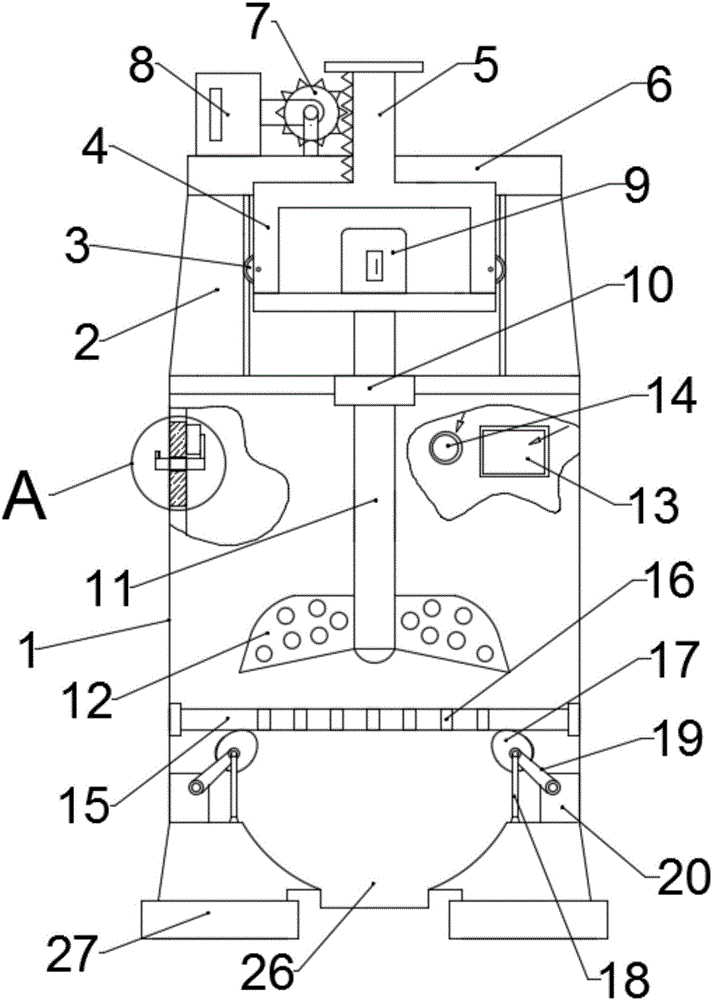

The invention discloses a stirring and mixing device for feed production. The stirring and mixing device comprises a bottom plate, a mixing barrel, a grinding barrel, a first rotary shaft, a first gear, a rack, a connecting rod, a disk, a motor, a second gear, a third gear, a first inner gear ring, a first grinding blade, a second grinding blade, a screen, a support rod, a hairbrush, a fourth gear, a fifth gear, a third rotary shaft, a second inner gear ring and a stirring rod. According to the stirring and mixing device disclosed by the invention, through cooperation of the motor, the disk, the connecting rod, the rack, the first gear, the first rotary shaft and the first grinding blade, the first grinding blade rotates forwards and backwards to improve the grinding efficiency; through cooperation of the second gear, the third gear, the first inner gear ring and the second grinding blade, the second grinding blade is driven to rotate in a direction opposite to the rotation direction of the first grinding blade, thus, the grinding efficiency is further improved; through cooperation of the fourth gear, the fifth gear, the second inner gear ring, the third rotary shaft and the stirring rod, omni-directional stirring is performed in the mixing barrel to improve the mixing efficiency.

Owner:郑州味觉信息技术有限公司

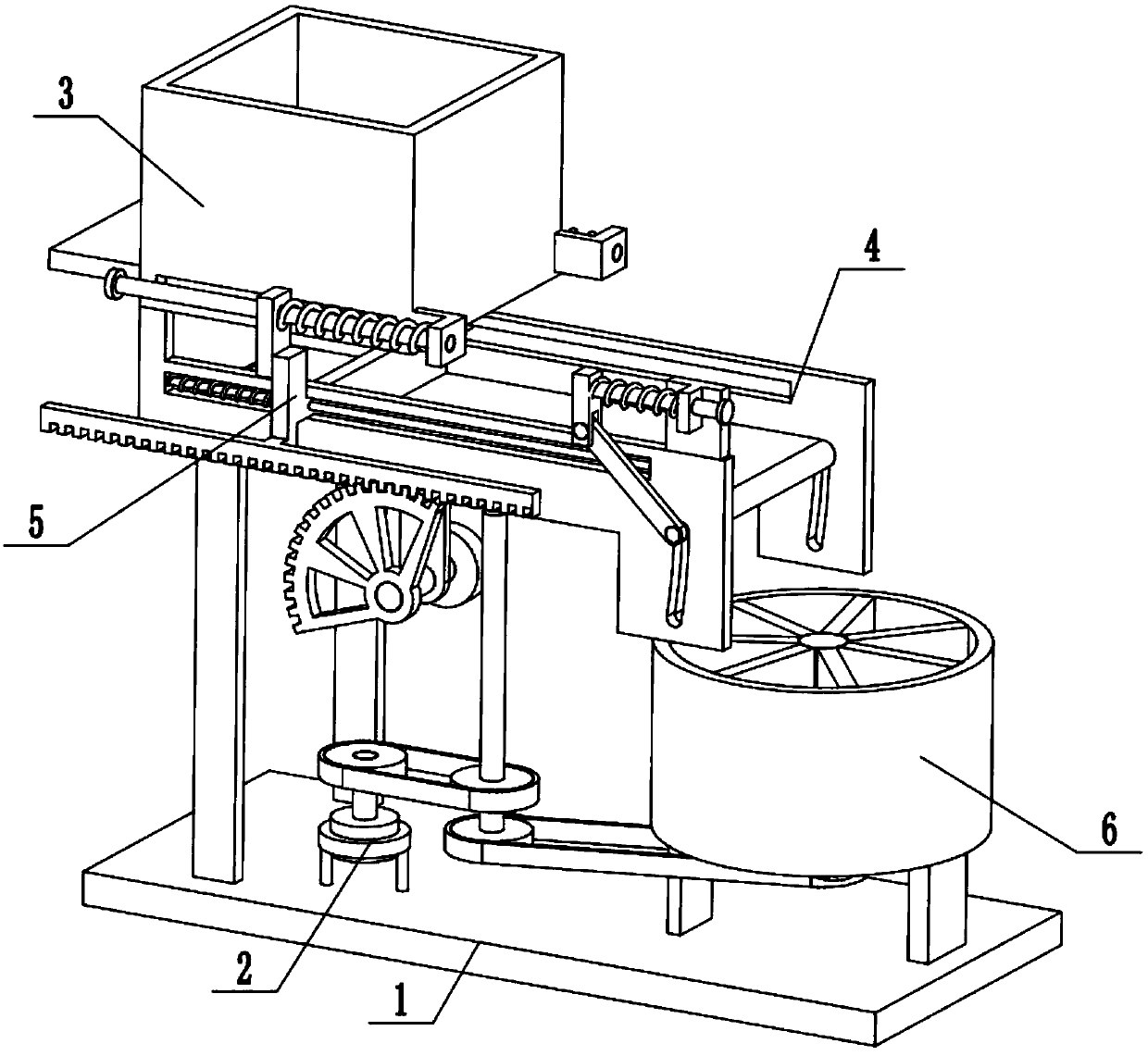

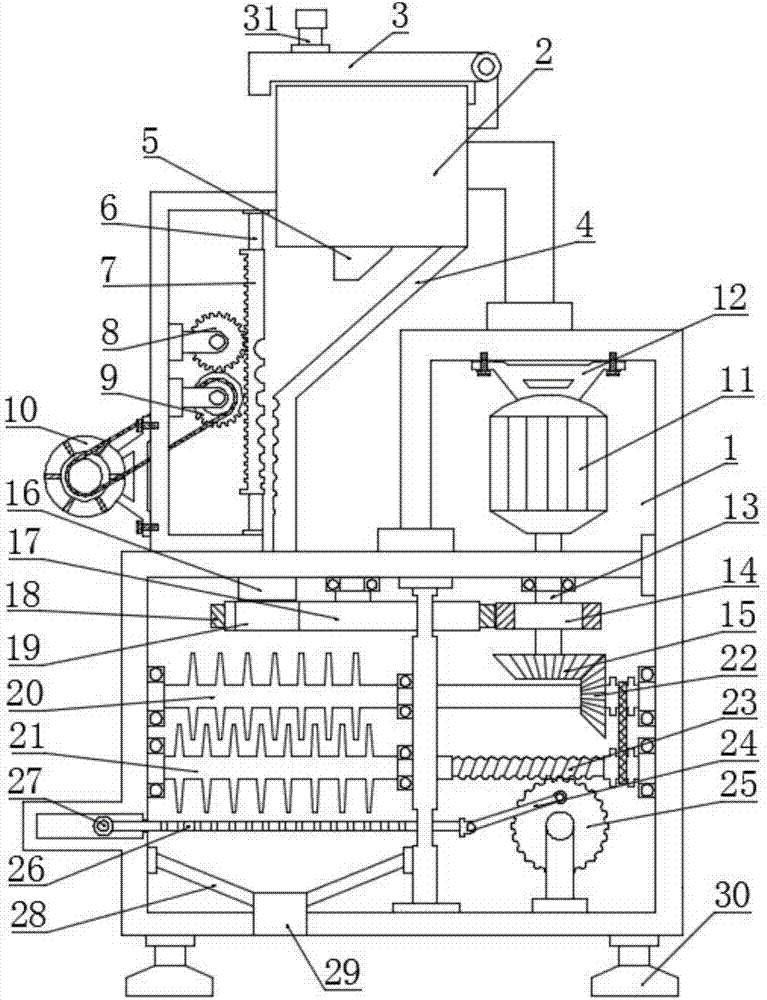

Crushing and mixing integration equipment for feed production

InactiveCN107282234AImprove work efficiencyFast crushingFeeding-stuffTransportation and packagingMotor driveArchitectural engineering

Owner:邹铁梅

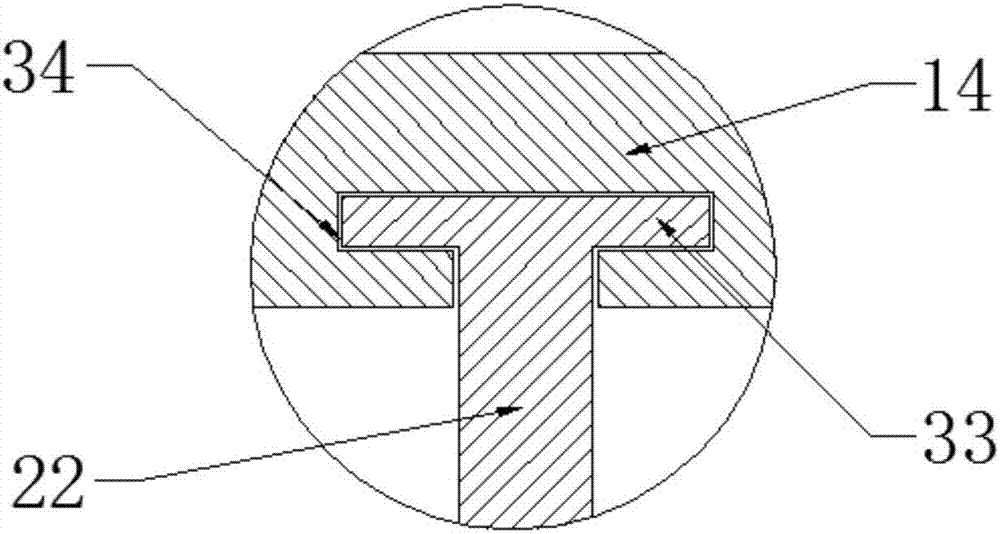

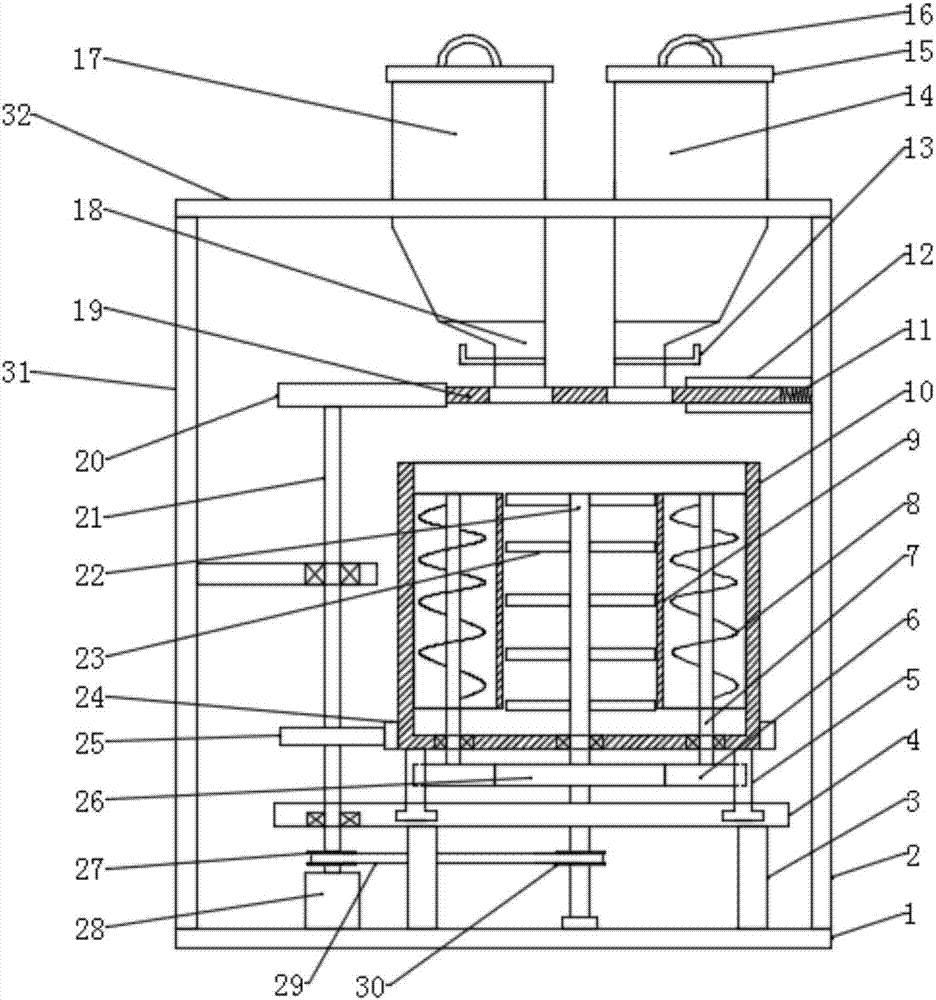

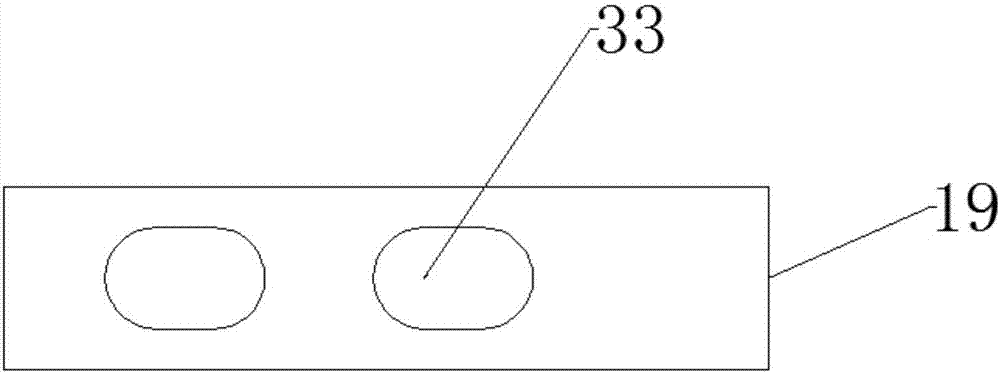

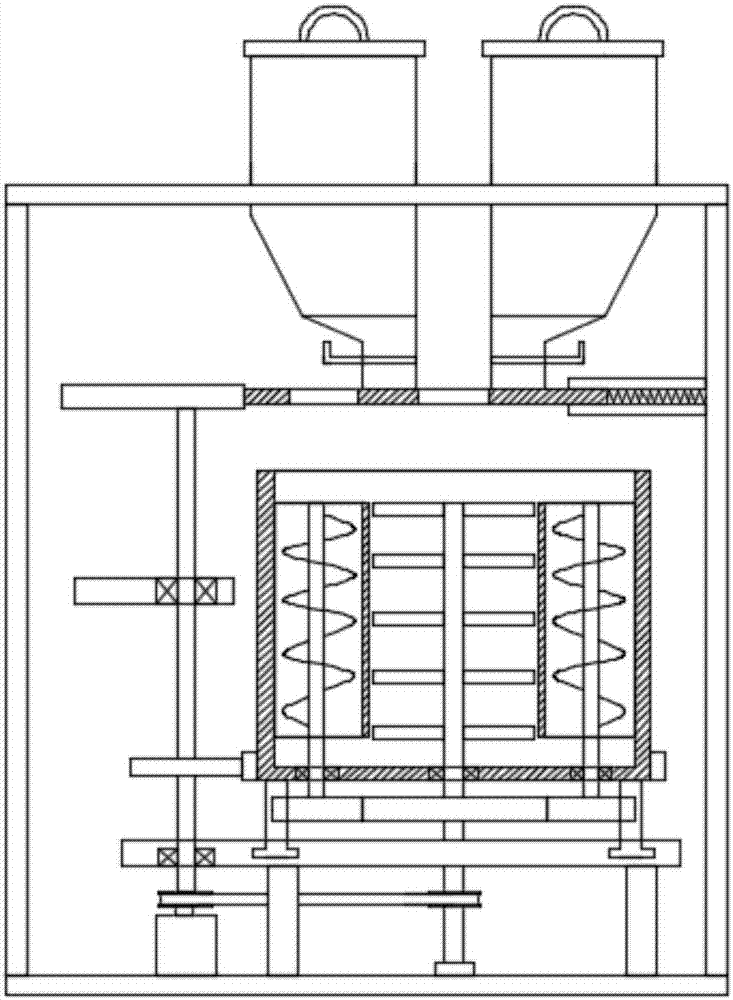

Highly effective feed mixing preparation device special for aquaculture

InactiveCN107343665AImprove mixing efficiencyWell mixedRotating receptacle mixersFeeding-stuffHelical bladeEngineering

The invention discloses a highly effective feed mixing preparation device special for aquaculture. The device includes a base plate, a stirring drum, T-shaped supporting rods, an electric motor, a first rotating shaft, a first belt pulley, a belt, a second belt pulley, a second rotating shaft, stirring rods, a third gear, an outer gear ring, a cam, a discharging board, a solid feed drum and a liquid feed drum. According to the invention, the electric motor, the first rotating shaft, the third gear, the outer gear ring, the first belt pulley, the belt, the second belt pulley and the second rotating shaft are arranged to work together to drive the stirring rods and the stirring drum rotating reversely so as to improve stirring and mixing efficiency. With the arrangement of a first gear, a second gear, a third rotating shaft and helical blades, feed at the bottom of the stirring drum is brought upward and moves to the bottom of the stirring drum under the effect of gravity; and after continuous cycles, the stirring and mixing efficiency is further improved. The arrangement of the cam and the discharging board realizes intermittent discharging and avoids the problems of incomplete and uneven stirring and mixing caused by discharging feed too fast and too much under the condition of continuous discharging.

Owner:武汉中智德远科技开发有限公司

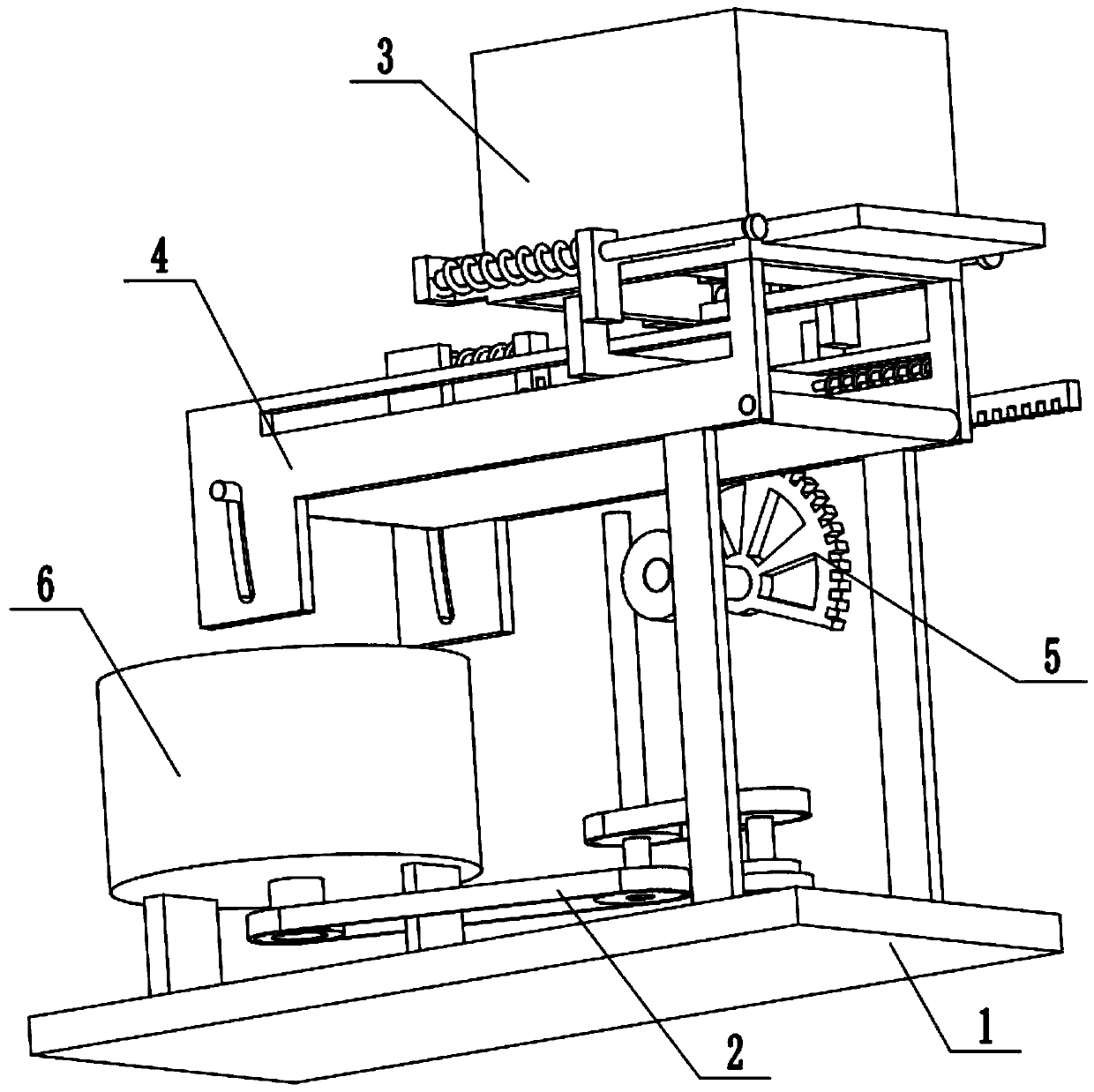

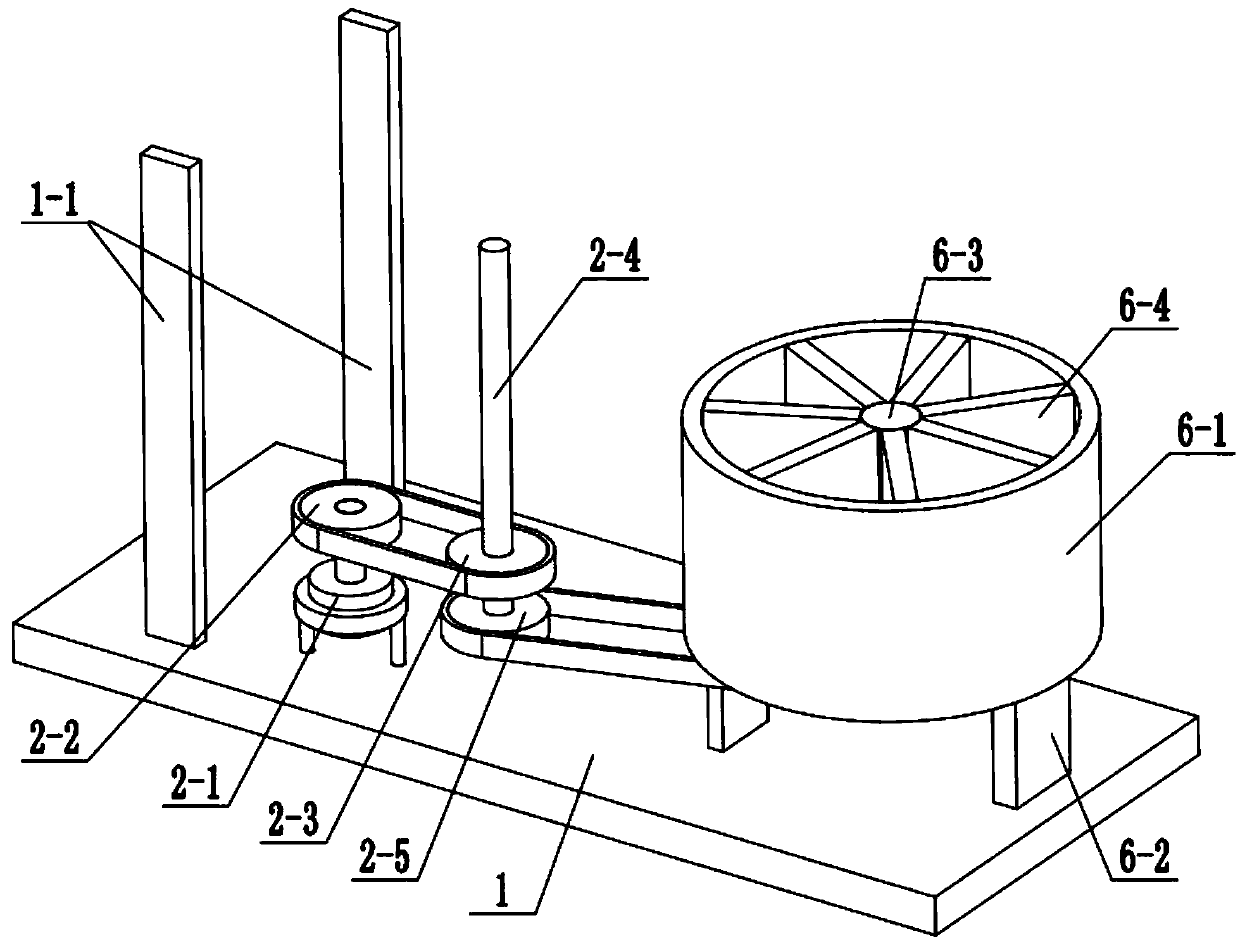

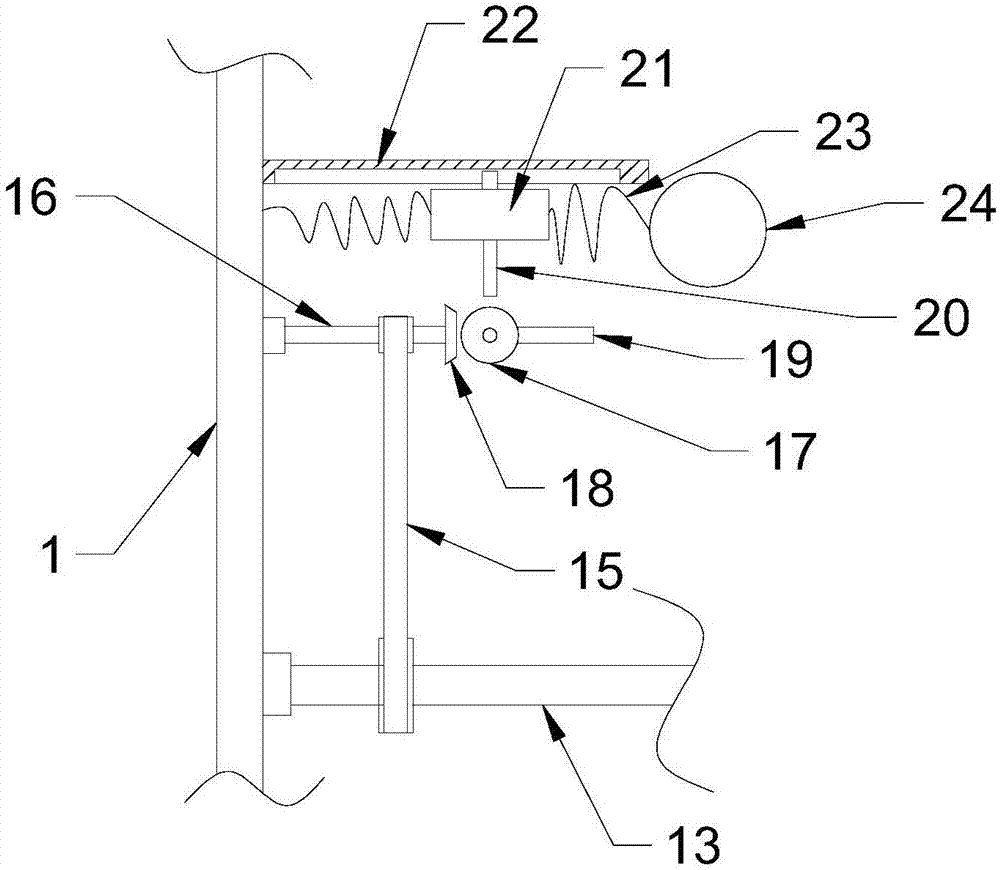

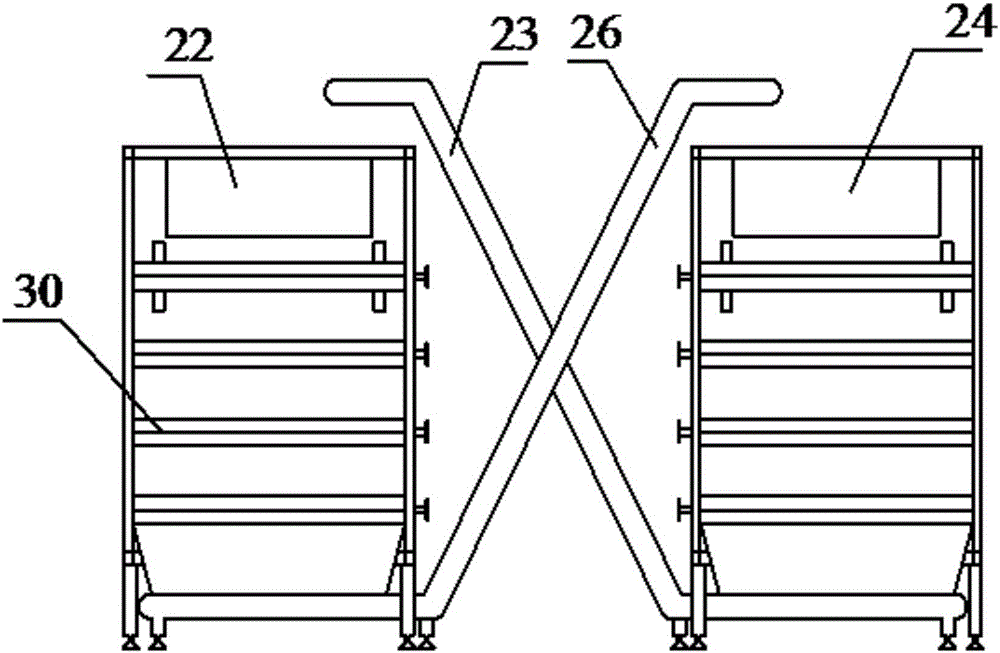

Intermittent feeding and distributing device for animal husbandry

InactiveCN109619636AStir wellEnsure mixing uniformityFeeding-stuffConveyor partsEngineeringAnimal husbandry

The invention relates to the field of distributing and mixing devices, in particular to an intermittent feeding and distributing device for the animal husbandry. A feeding base assembly is fixedly connected to the left end of a discharging plate assembly. The left end of a base is fixedly connected with two supporting plates. The left end of the discharging plate assembly is fixedly connected to the two supporting plates. An intermittent pushing plate is slidingly connected to the discharging plate assembly. The upper end of the intermittent pushing plate is attached to the feeding base assembly. The discharging plate assembly is in meshing and transmission connection with a power device. The power device is fixedly connected to the base. The defects that at present, feed is artificially mixed and mixing is not uniform, so livestock feeding nutrients are not balanced, lots of labor is consumed and the work efficiency is low are overcome; the various-feed intermittent feeding and distributing device which is free of artificial mixing, even in mixing and high in work efficiency is provided, and by means of the low-quantity and high-frequency feeding mode, it is ensured that materialscan be evenly stirred after being fed.

Owner:郭鹏 +9

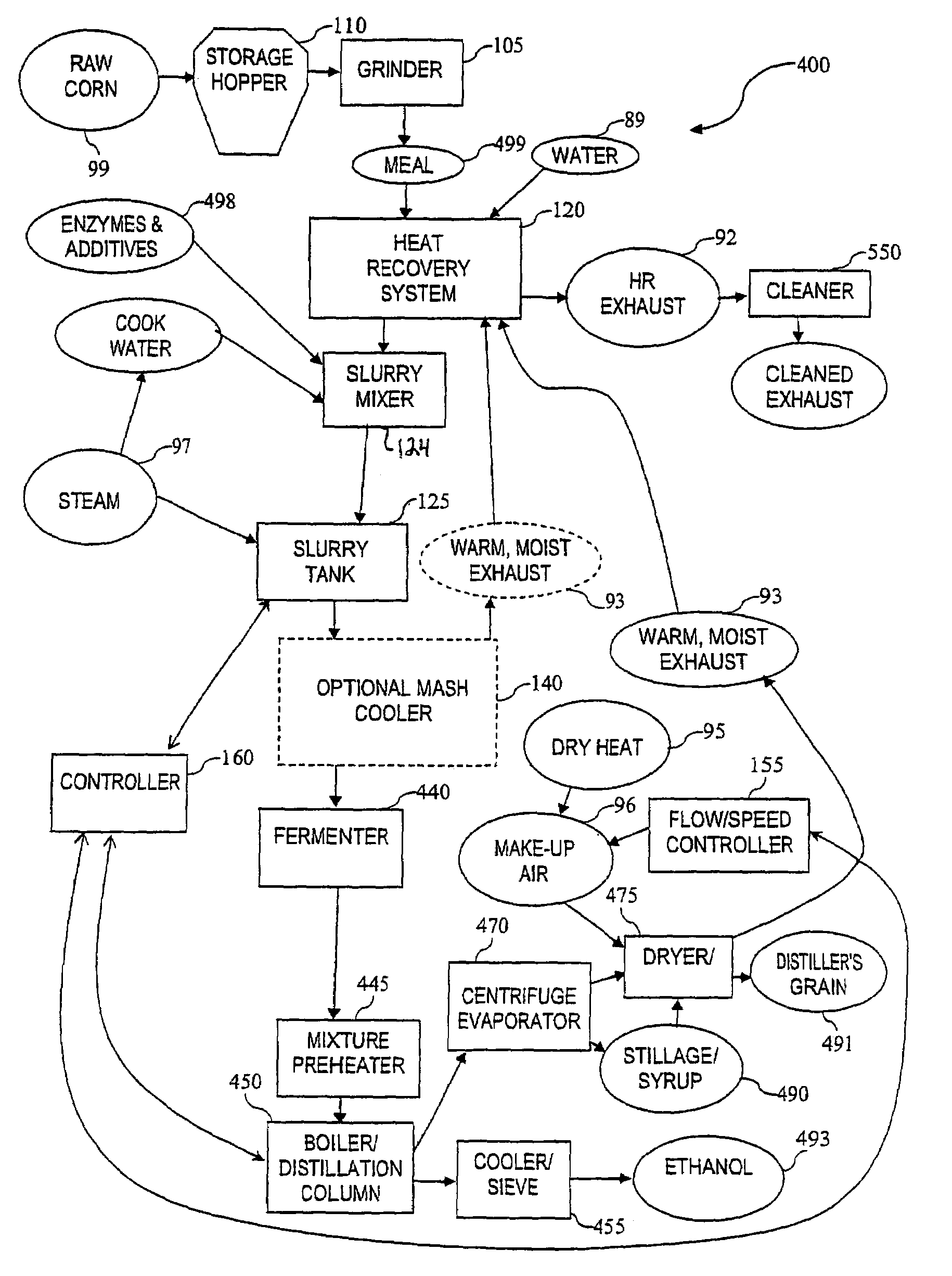

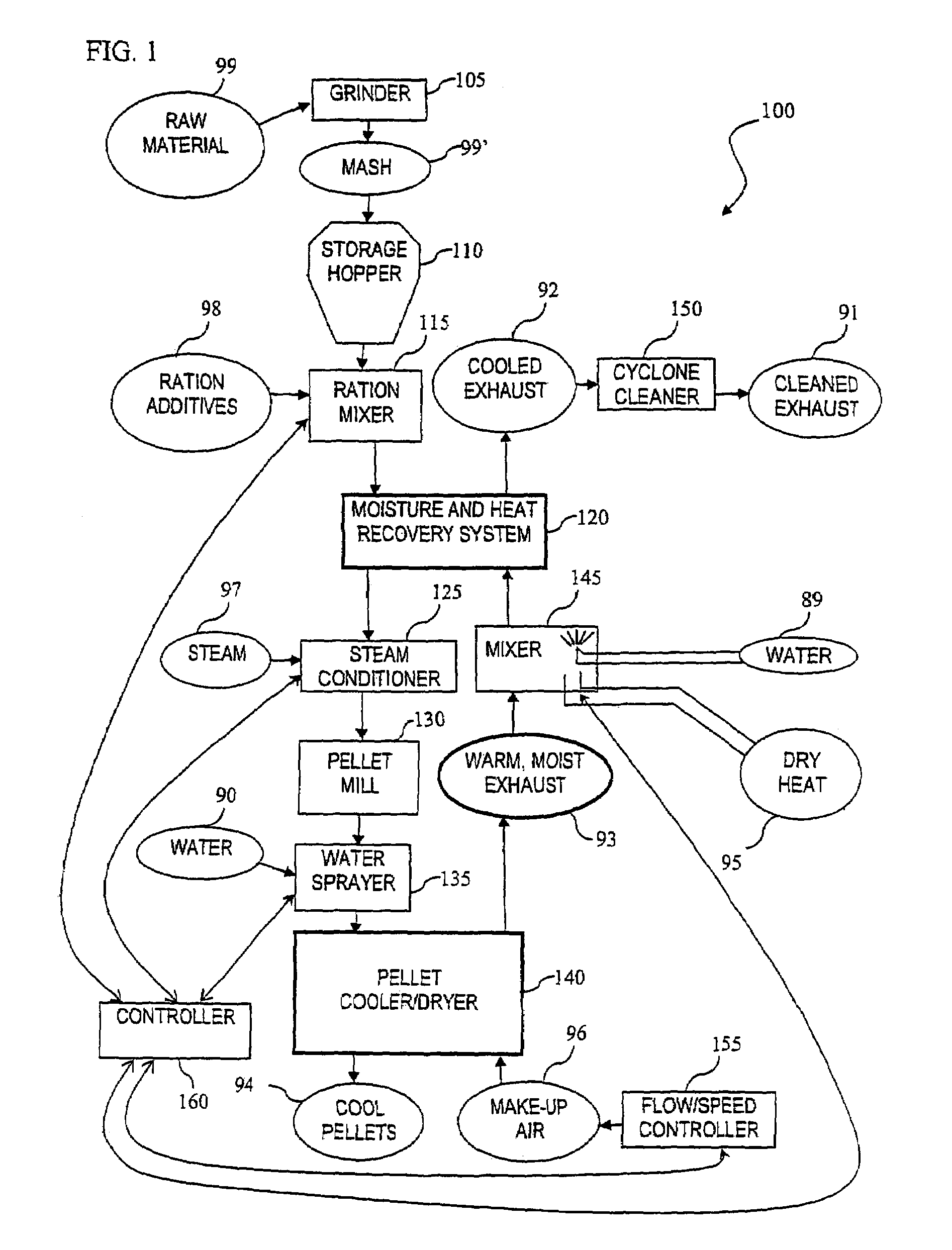

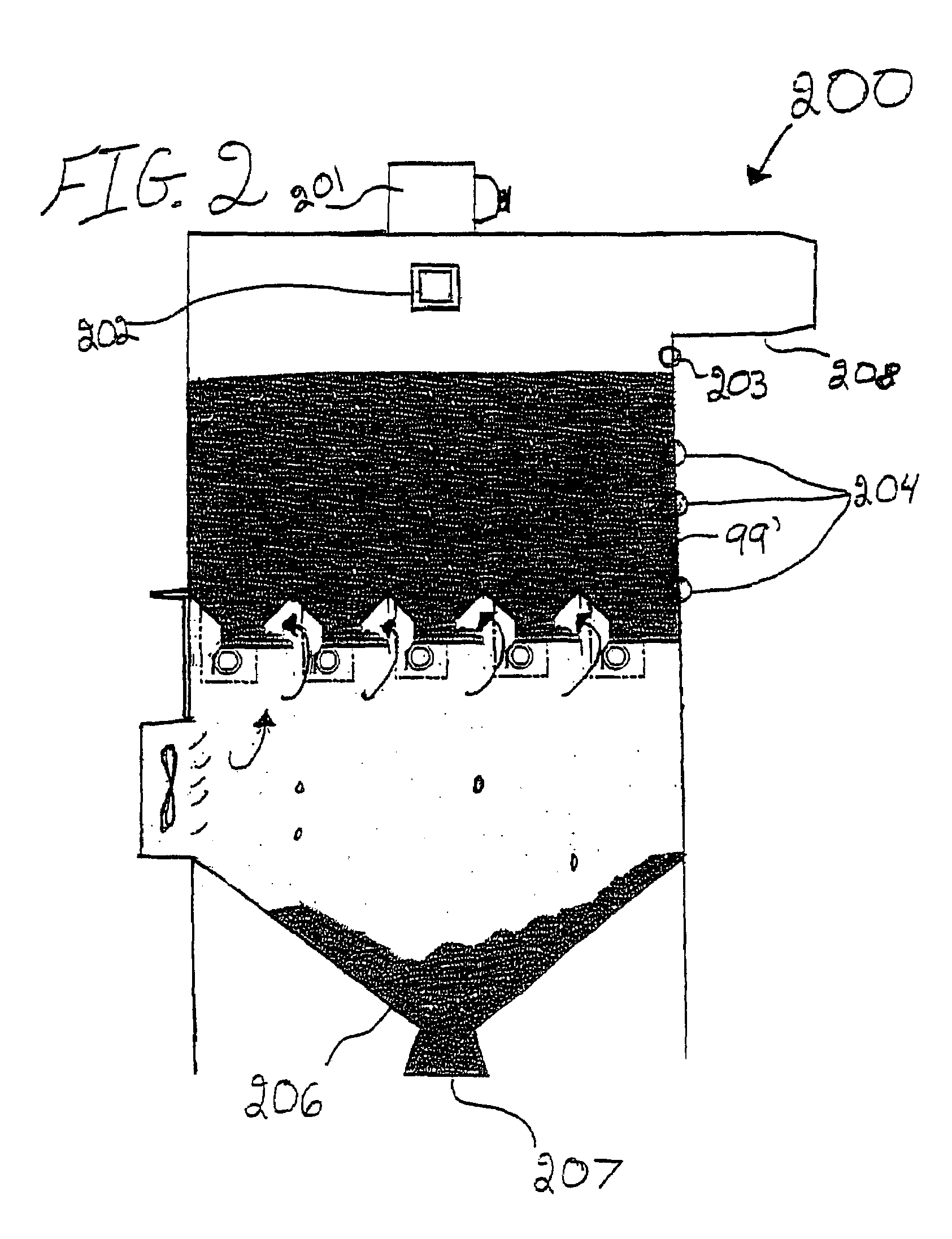

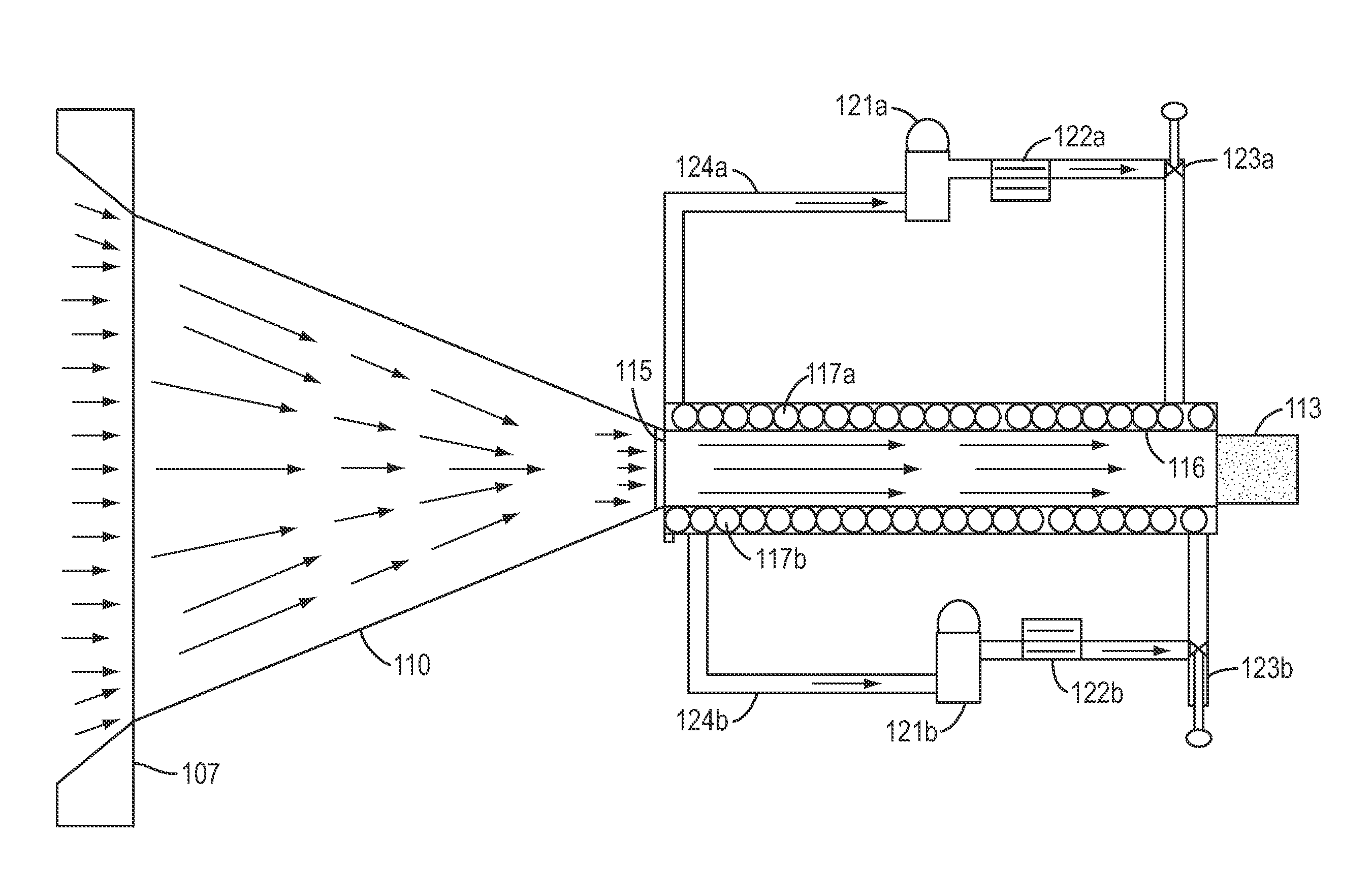

Heat-moisture control in agricultural-product production using moisture from water vapor extraction

InactiveUS7404262B2Reduce the amount requiredHigh production costDrying using combination processesMeat/fish preservation by heatingWater vaporSprayer

A method and apparatus for agricultural product production with heat and moisture control with optional heat and moisture recovery. Some embodiments transfer heat and moisture from a warm, moist exhaust air stream to incoming agricultural material, steam condition the material, pelletize the material into warm pellets, cool the warm pellets with make-up air to produce the warm, moist exhaust air used to transfer heat to the incoming material and to produce cooled pellets, wherein the cooled pellets are at a temperature lower than the warm moist air. In some embodiments, the system includes counter-flow devices to transfer heat and moisture. In some embodiments, a controller is used to adjust system devices and overall system flow. In some embodiments a water sprayer, to moisten agricultural product when the product is over dry, and an air flow controller, to slow air flow through the pellet dryer / cooler when ambient temperatures are dryer / cooler, are provided.

Owner:PESCO +1

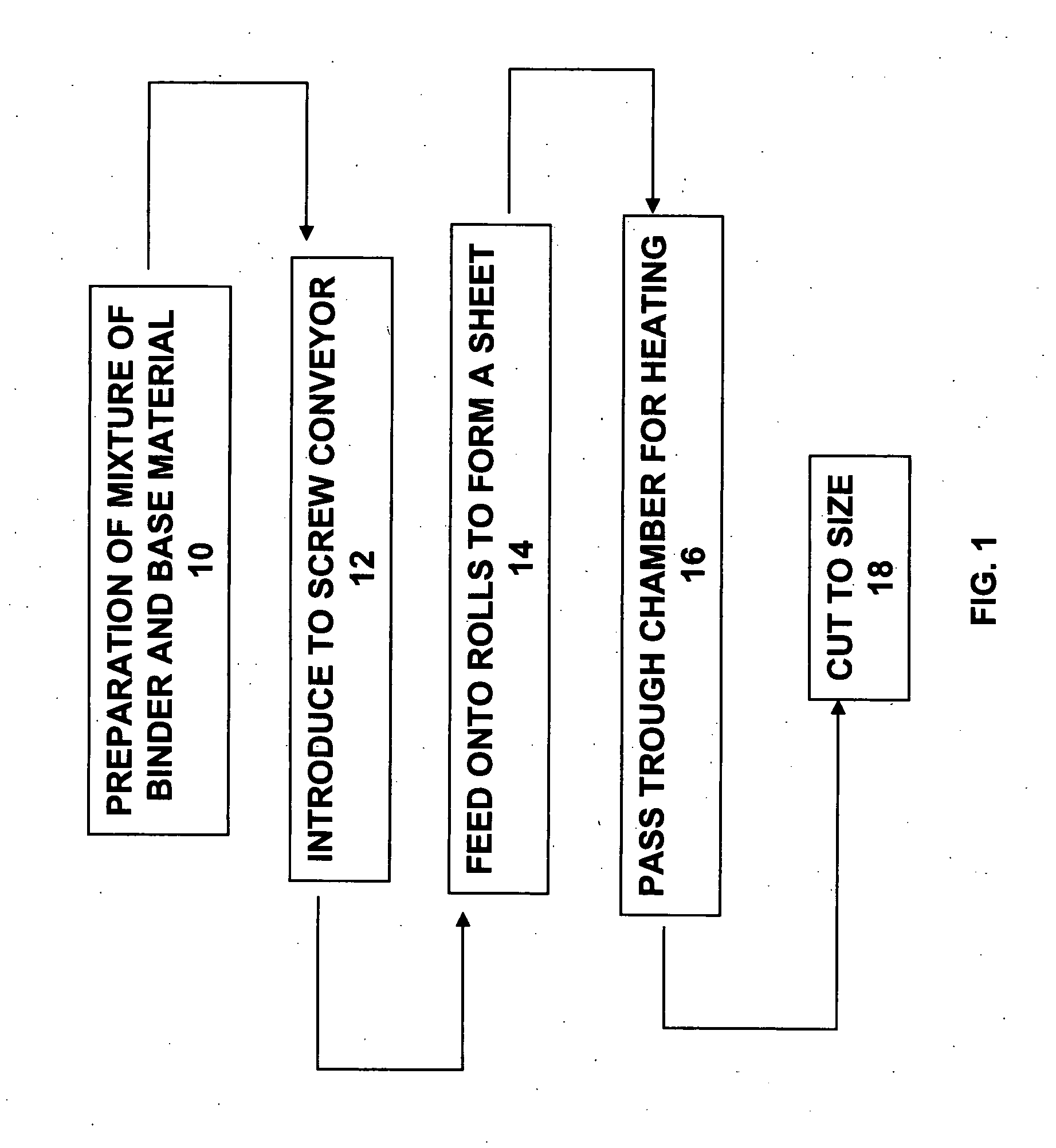

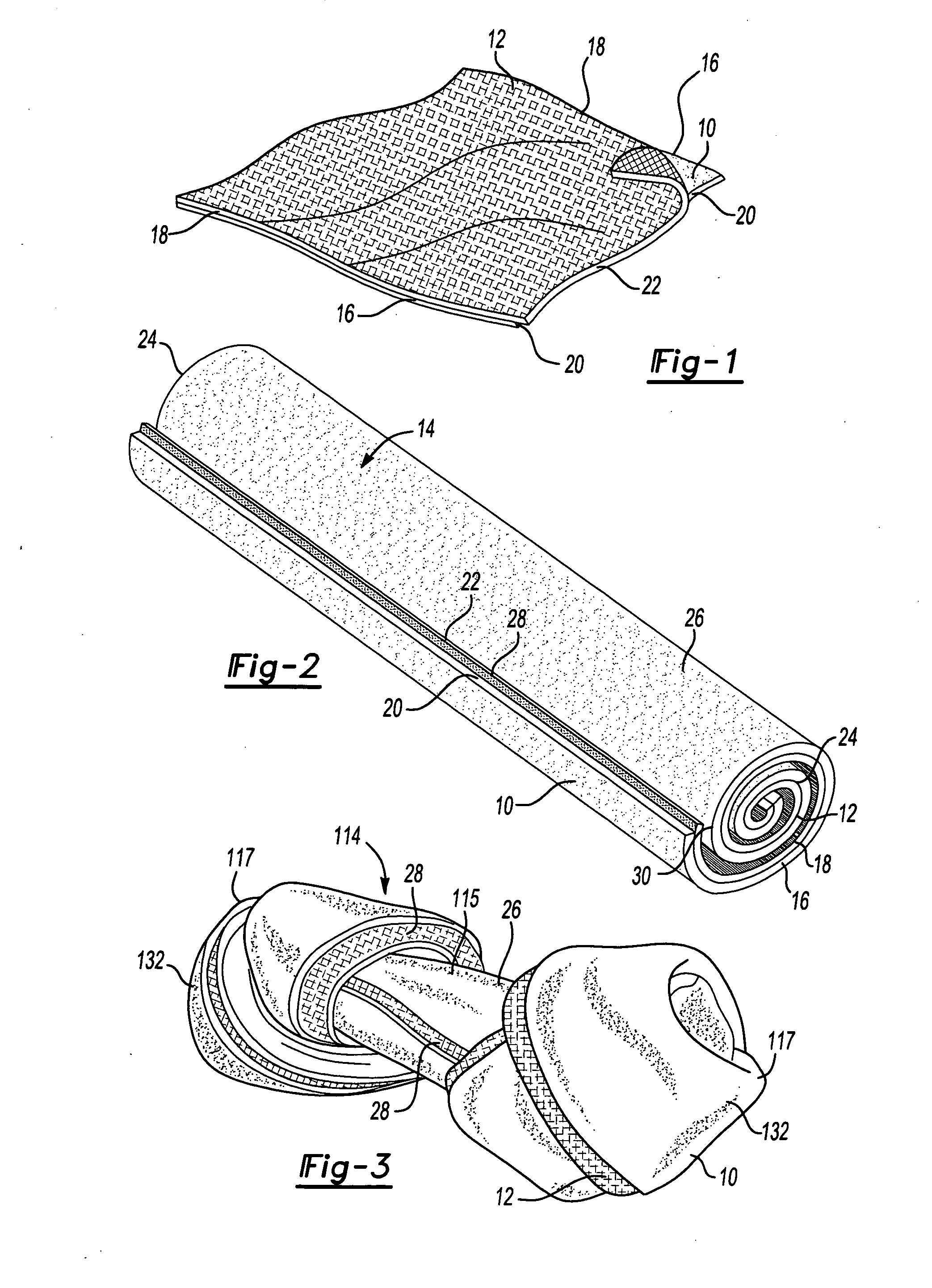

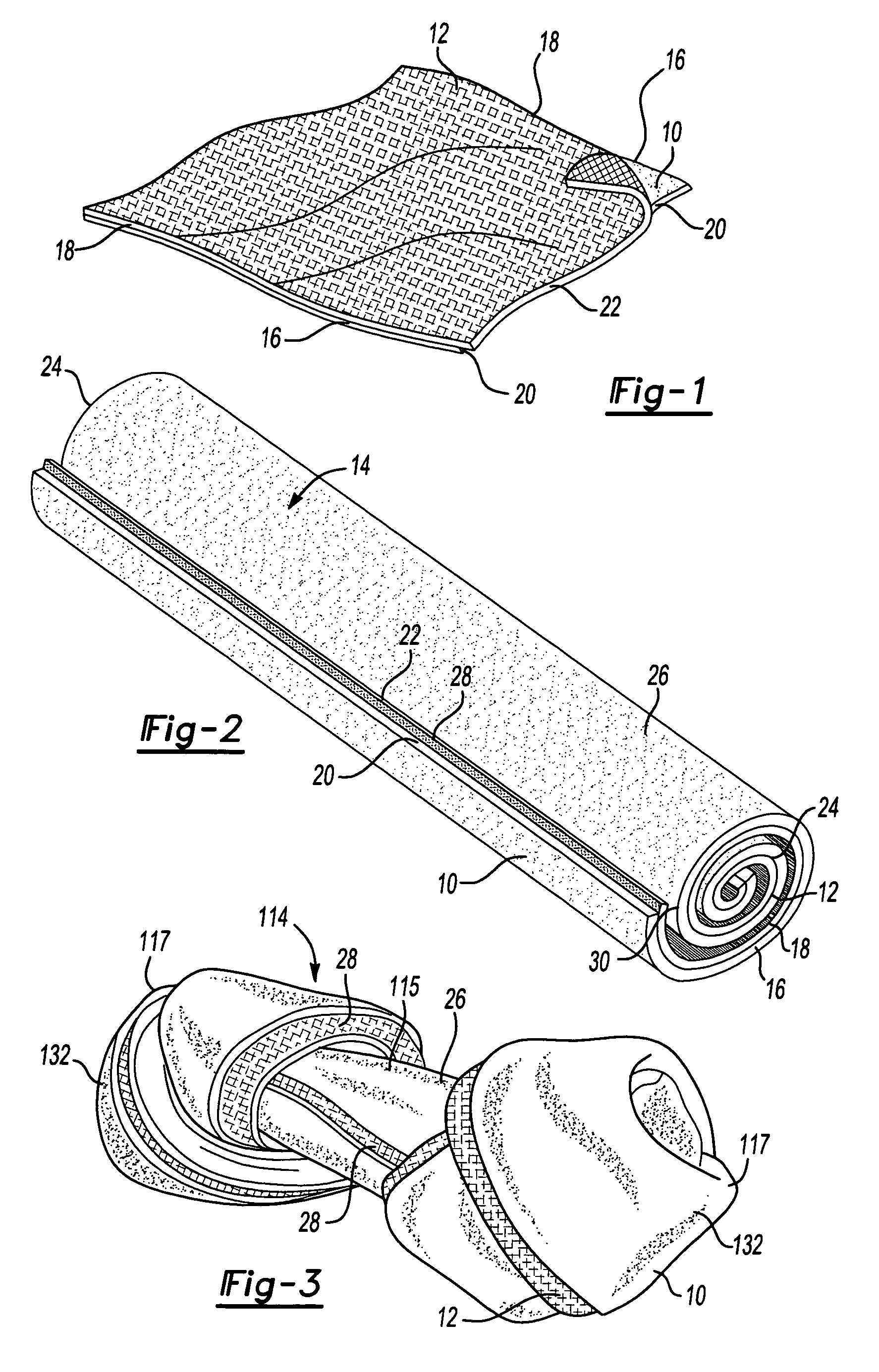

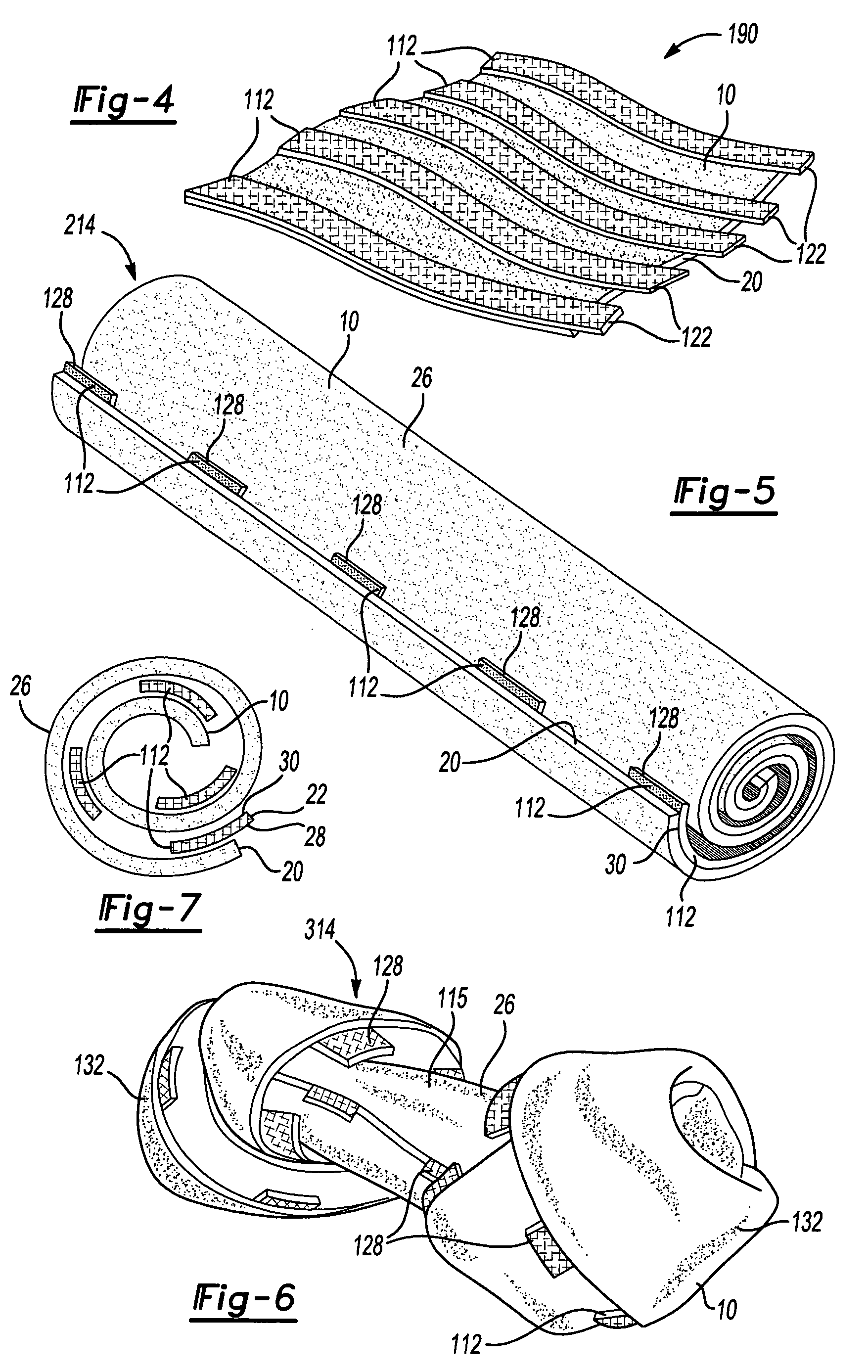

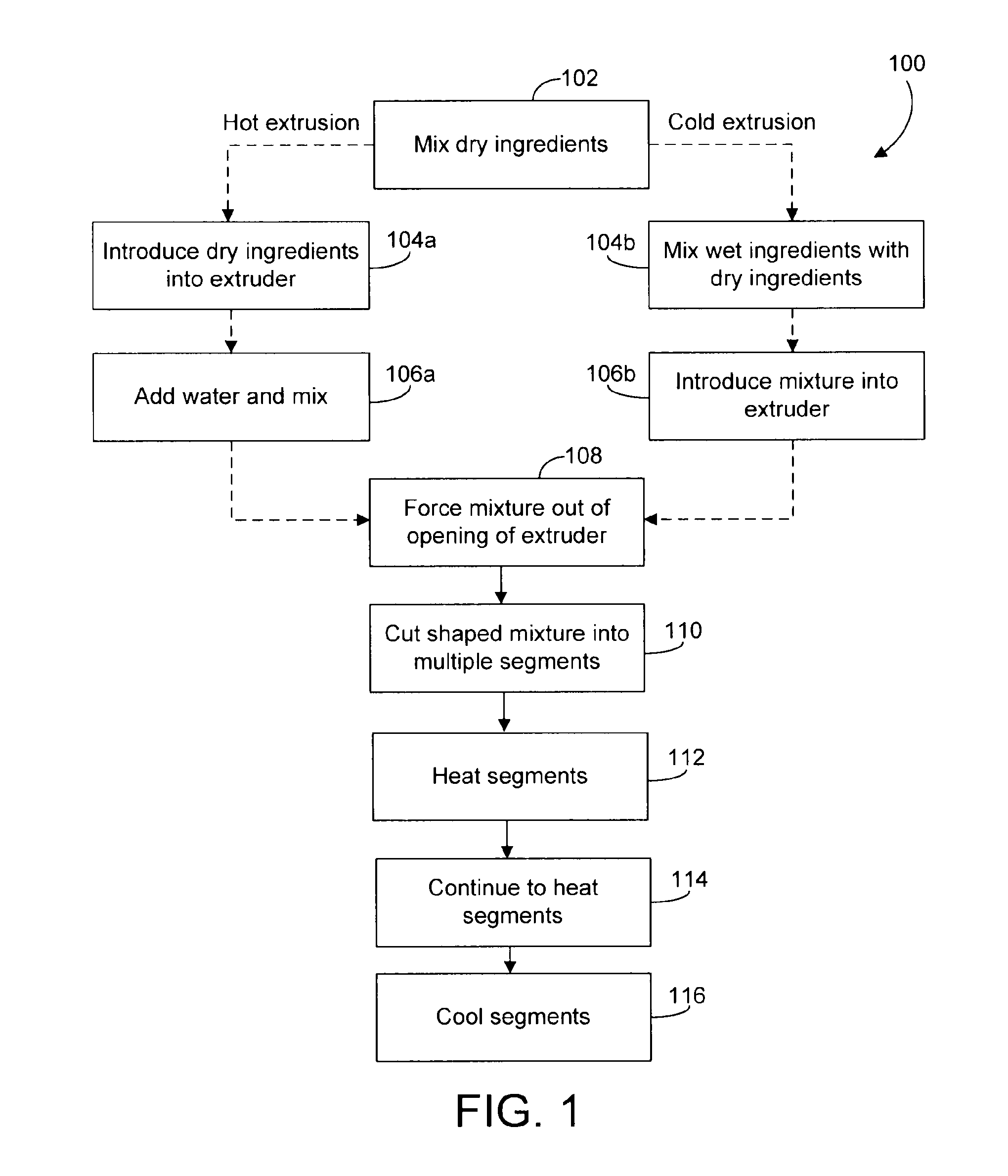

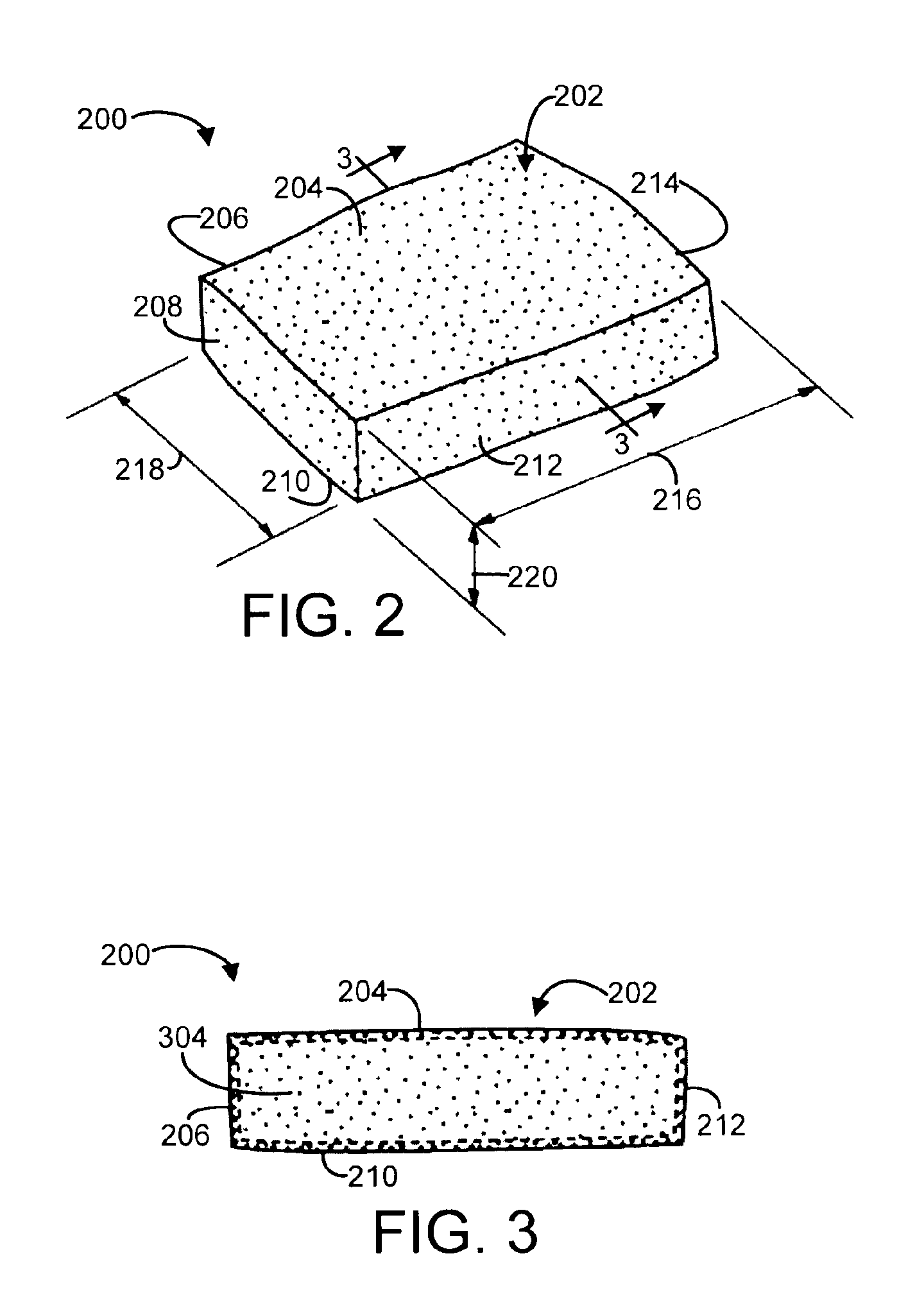

Apparatus and process for forming pet treats

An animal chew is provided formed by rolling a mixture of binder and base material into a sheet. Base material, such as an edible material, including but not limited to starch, protein matter, vegetable or plant matter, is mixed with a binder. The mixture is then supplied to a screw conveyor followed by introduction onto rollers to form a sheet. The sheet may then be cut into a desired shape. The overall process may be made continuous, and the manufacturing conditions may be selectively controlled at each step, with respect to variable such as temperature and moisture levels, to substantially maintain the overall nutritional value of the formed edible compositions.

Owner:T F H PUBLICATIONS

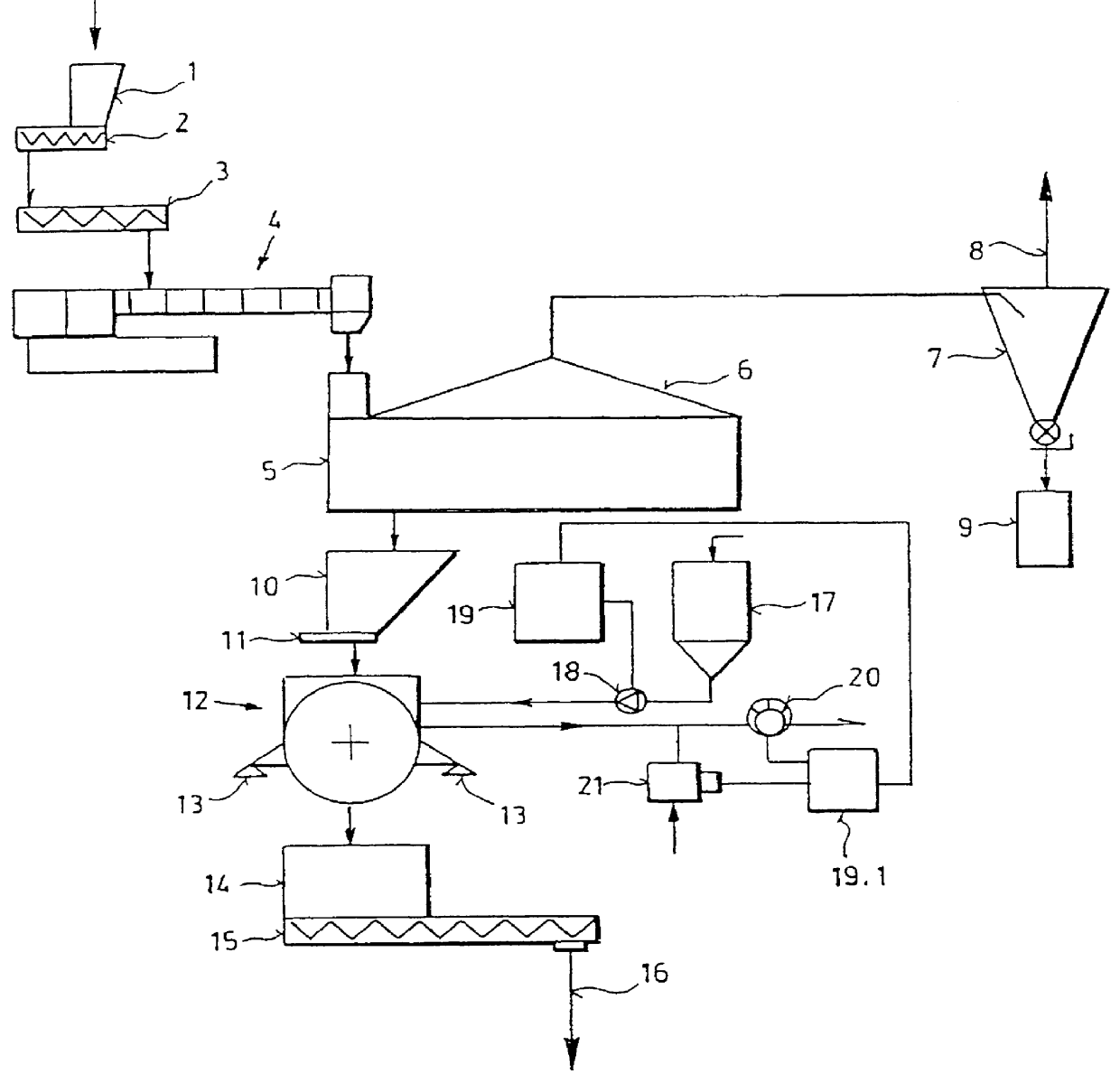

Method of incorporating fatty matter into granulated products

InactiveUS6136353APromote absorptionImprove permeabilityFeeding-stuffAnimal feeding stuffMetering pumpVacuum pump

PCT No. PCT / CH96 / 00265 Sec. 371 Date Dec. 16, 1998 Sec. 102(e) Date Dec. 16, 1998 PCT Filed Jul. 22, 1996 PCT Pub. No. WO98 / 03080 PCT Pub. Date Jan. 29, 1998A method and apparatus for incorporating fatty matter into granulated feed products such as extrudates, pellets and expander pellets with a fat-supplying liquid. Pellets produced in the extruder or expander of press (4) are dried in a dryer (5) and pass through an intermediate container (10) into a mixer (12). Using a metering pump (18) a predetermined amount of fat-supplying liquid is added to the mixer (12) and spread on the surface of product pieces through the mixing process. After a predetermined period of time a vacuum pump (20) generates a negative pressure in the mixer so as to evacuate the air from capillaries or pores of the product pieces. The negative pressure in the mixer is then relieve through an expansion valve (21) so that the air entering into the mixer and into the pores or capillaries of the product pieces transports the fat-supplying liquid on the surface of the product pieces as well as additional fat-supplying liquid into the pores and capillaries, thereby filling them to the extend that a high proportion of approximately 30% fat-supplying liquid is incorporated in the pores of capillaries of the product pieces.

Owner:BUEHLER AG

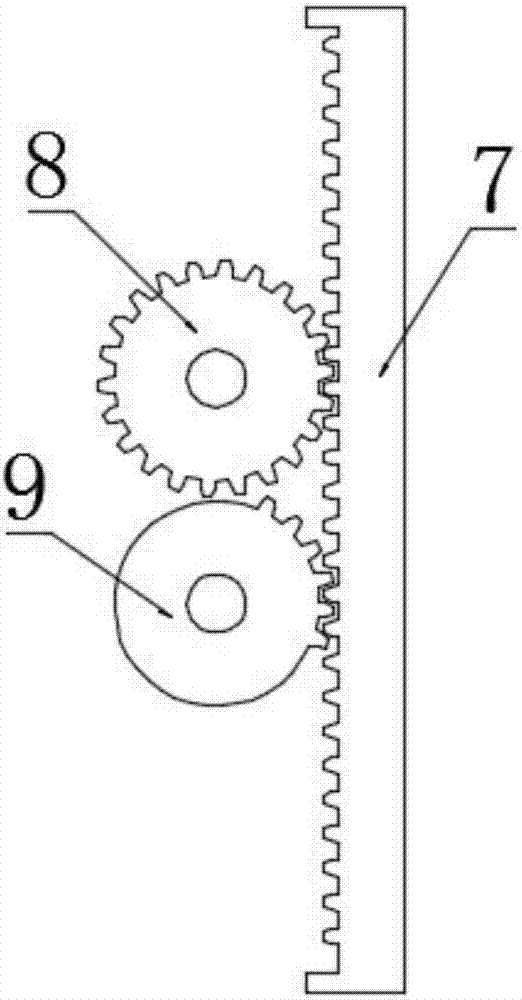

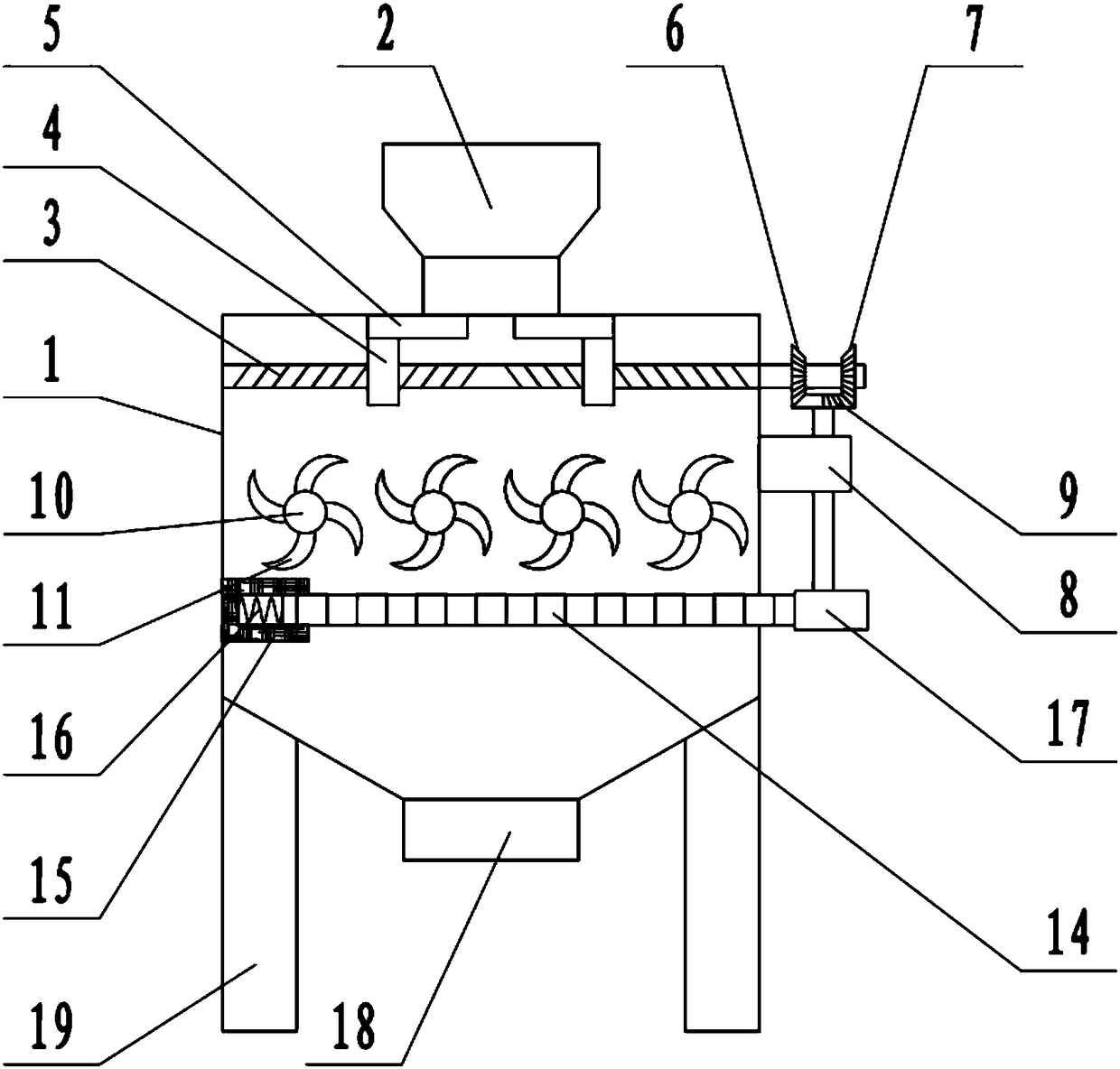

Crushing and stirring integrated equipment for feed production

InactiveCN108142969AMix well and evenlyAvoid vibrationFeeding-stuffTransportation and packagingKnife bladesCrankshaft

The invention discloses crushing and stirring integrated equipment for feed production. The crushing and stirring integrated equipment comprises a bottom plate, a stirring tank, a motor, a first rotating shaft, a mesh screen, a supporting plate, second rotating shafts, first gears, inner gear rings, a first crushing blade, second crushing blades, a crankshaft, a connecting rod journal, racks, second gears, third rotating shafts and knocking devices, wherein each knocking device comprises a swinging rod, a spring and a knocking ball. According to the crushing and stirring integrated equipment disclosed by the invention, the motor, the first rotating shaft, the second rotating shafts, the first gears and the inner gear rings are arranged and cooperate with each other to sufficiently and uniformly crush feed raw materials, so that the crushing efficiency is improved; the crankshaft, the connecting rod journal, the racks, the second gears and the third rotating shafts are arranged, so thatthe stirring manners are diversified, the stirring and mixing efficiency is improved, and the mixing of feeds is more sufficient and uniform; and the knocking devices are arranged, so that the situation that too many feeds are stuck to the side walls of the stirring tank, and waste is generated can be avoided.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

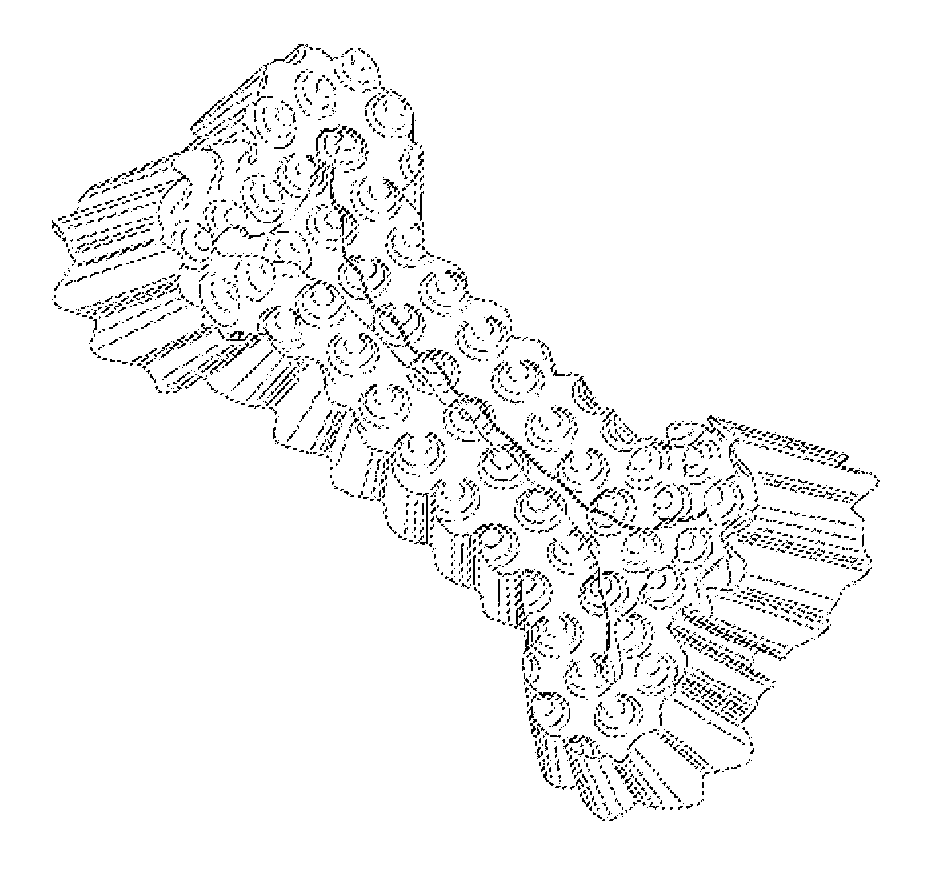

Edible pet chew

ActiveUS20080118606A1Sufficient malleabilityMeat/fish preservationFeeding-stuffAnimal scienceBiology

Owner:PETMATRIX

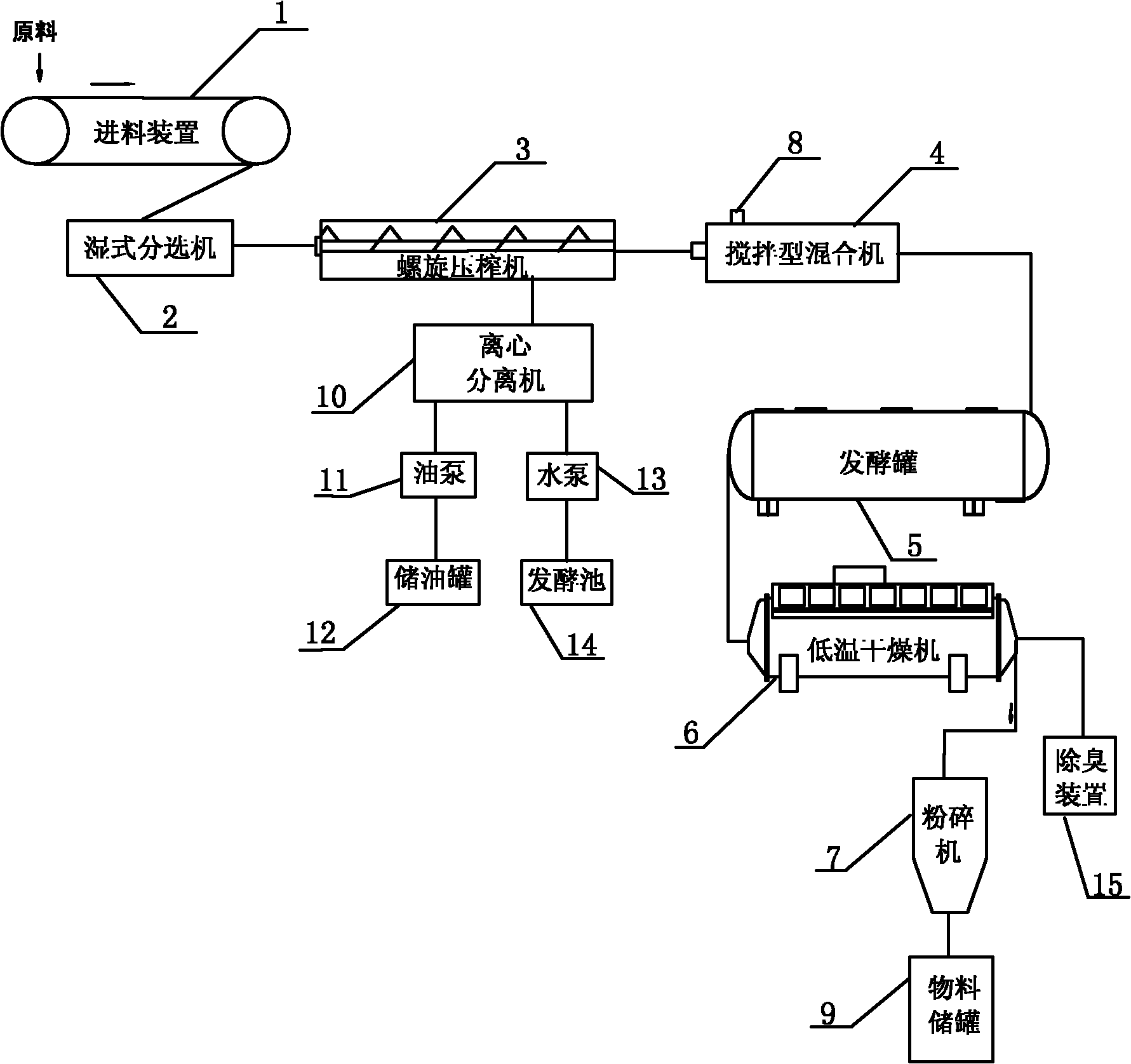

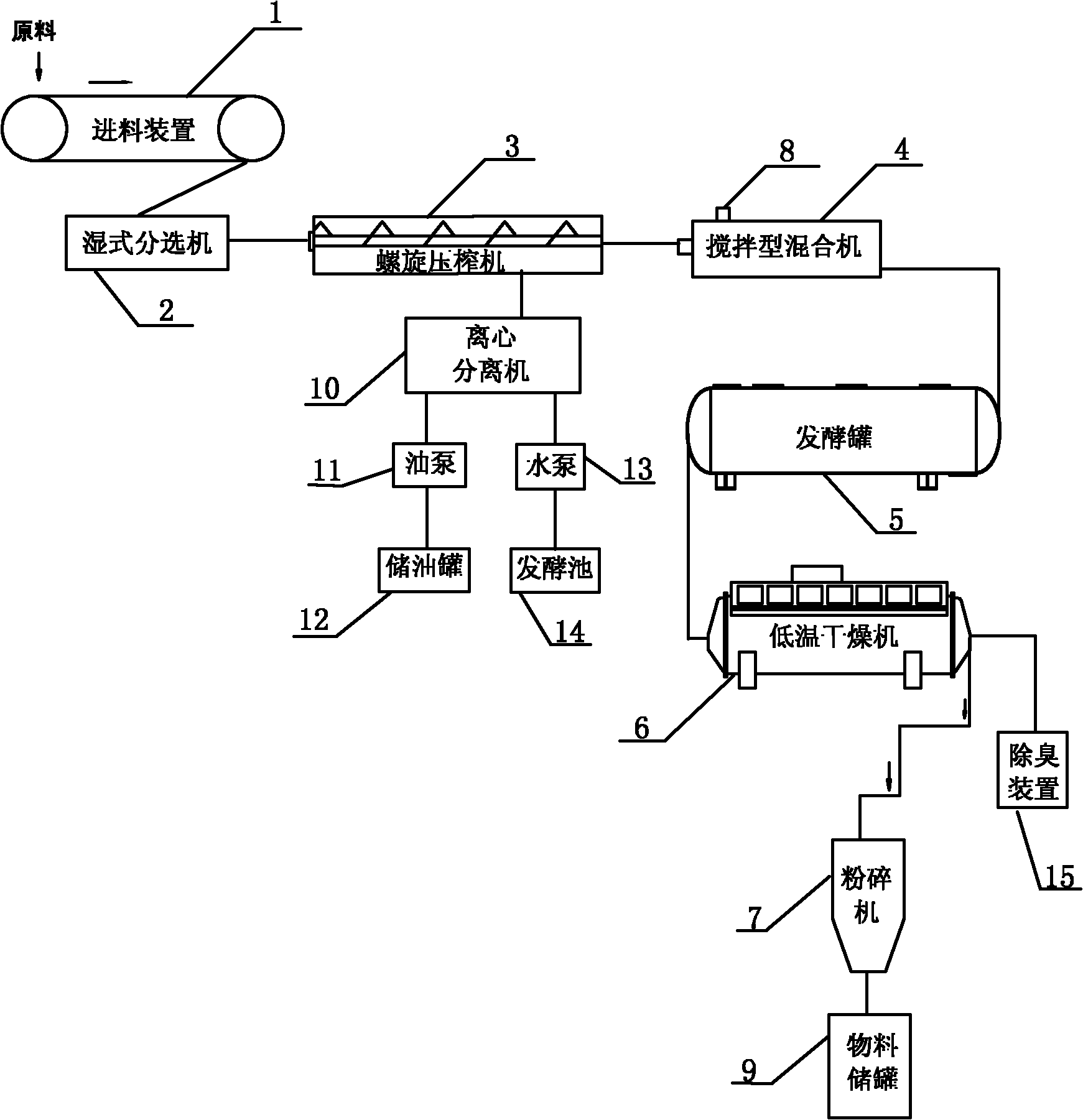

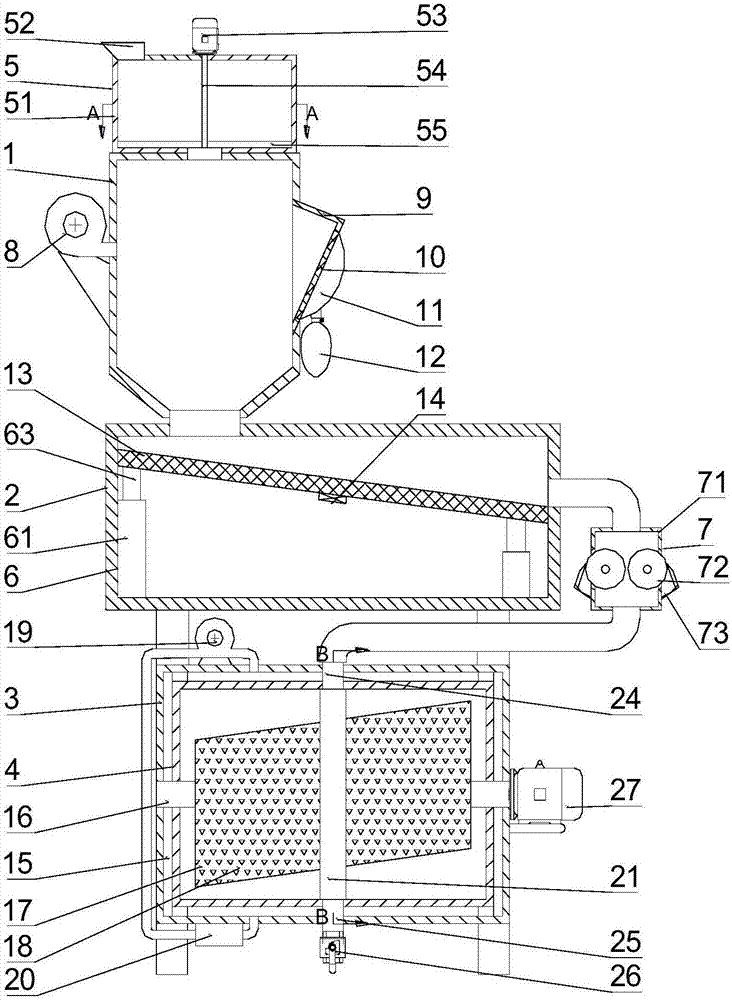

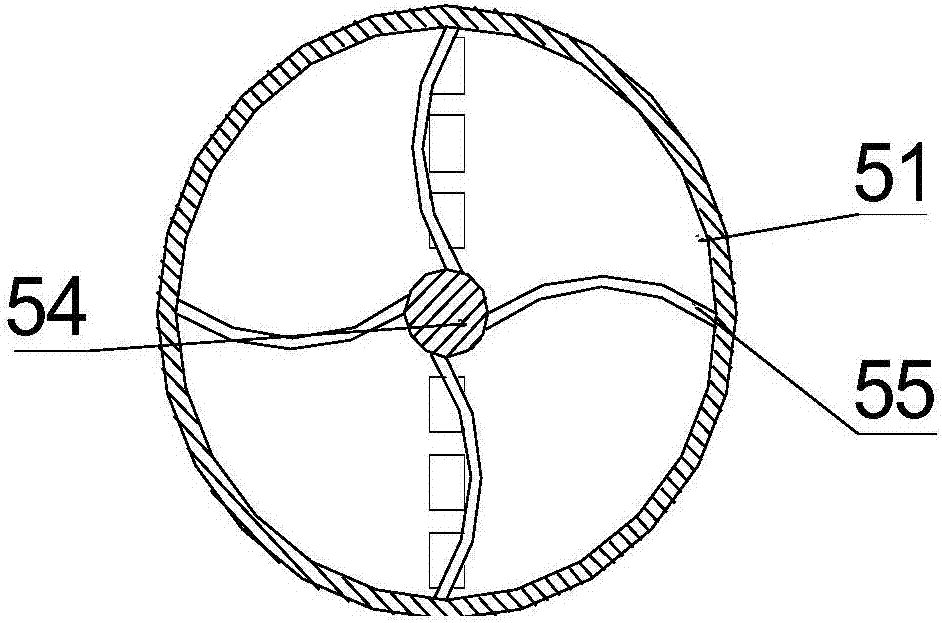

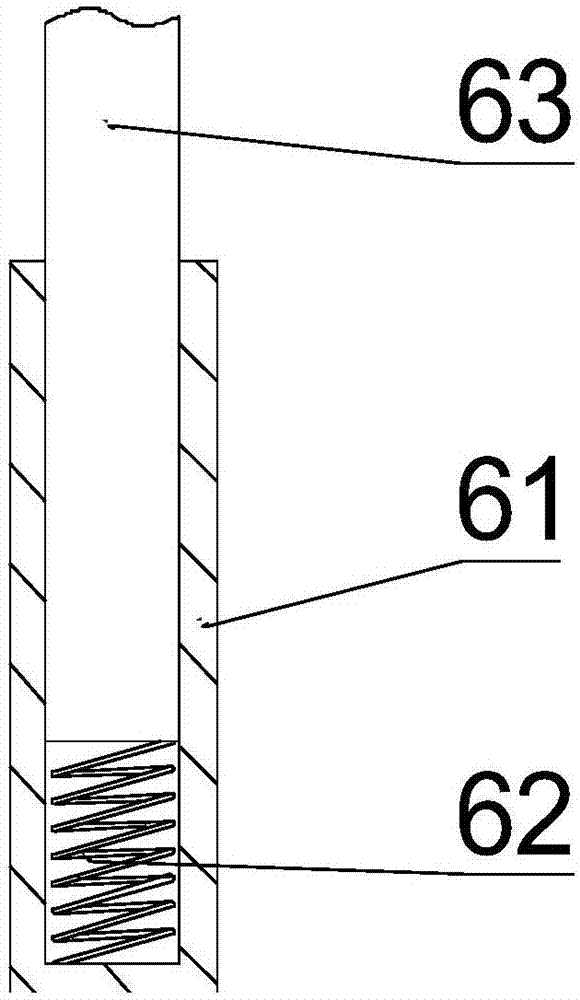

Method and system for preparing restaurant-kitchen wastes into livestock and poultry feed

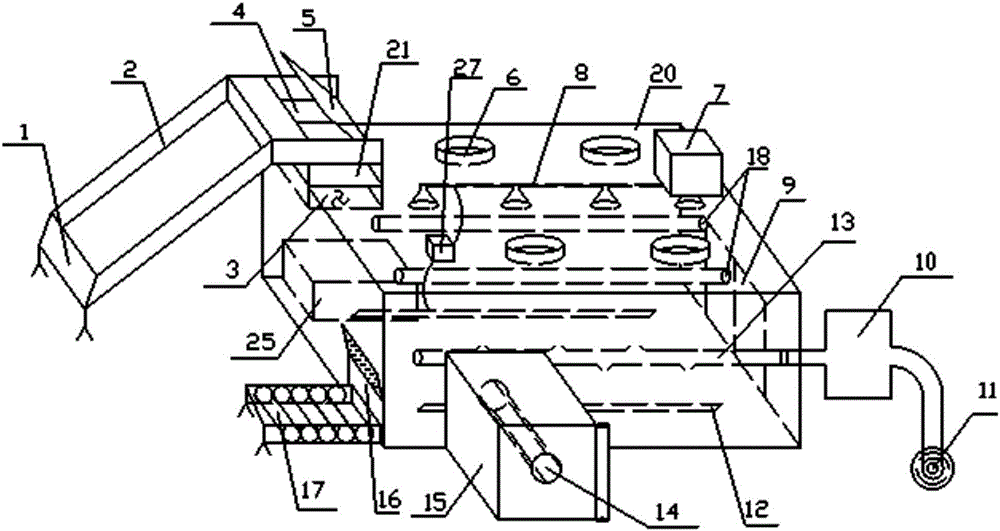

InactiveCN102125166AGood flavor and colorImprove fermentation effectFeeding-stuffFood processingMixed materialsCrusher

The invention discloses a method and a system for preparing restaurant-kitchen wastes into a livestock and poultry feed, wherein the method comprises the following steps: carrying out sorting preprocessing on restaurant-kitchen wastes so as to obtain biodegradable restaurant-kitchen wastes; carrying out solid-liquid separation on the obtained biodegradable restaurant-kitchen wastes; adding bran, corn flour and coarse meal into the obtained product so as to obtain a mixed material; adding composite fungicides into the mixed material according to the inoculum concentration (8-20 wt%) so as to ferment the mixed material; and finally, drying and cooling the fermented mixture, then packing the obtained object so as to obtain a livestock and poultry feed product. The system comprises a feed device, a wet sorting machine, a pressafiner, an agitated mixer, a fermentation tank, a low-temperature drying machine, a crusher and a finished product material storage tank which are sequentially connected; and the system has the advantages that the growth of putrefying bacterias and the reproduction of pathogenic microorganisms in restaurant-kitchen wastes can be inhibited, and the freshness retaining effect and organoleptic quality of the livestock and poultry feed are good; meanwhile, the protein content of the livestock and poultry feed can be improved; in addition, the system is low in used equipment cost, small in energy consumption, high in production efficiency and beneficial to environmental protection.

Owner:张荣尚

Edible pet chew

ActiveUS7677203B2Sufficient malleabilityMeat/fish preservationFeeding-stuffAnimal scienceCompanion animal

Owner:PETMATRIX

Rotary feed crushing and drying device

ActiveCN107952540ACrushed fullyFull and efficient screeningSievingFeeding-stuffDischarge efficiencyEngineering

The invention discloses a rotary feed crushing and drying device including a machine body; a crushing screen cylinder is arranged in the machine body, a knocking device is arranged on the left side ofthe crushing screen cylinder, and a drying conical cylinder is arranged below the crushing screen cylinder. According to the rotary feed crushing and drying device, a crushing knife and a crushing screen cylinder with a periodic square rotation are used to fully smash and screen feed, thereby improving the efficiency of smashing and screening. The knocking device linkaged with a rotary shaft canknock the outer wall of the crushing screen cylinder, and the clogging of screen holes and the feed residues can be avoided. The drying conical cylinder with a cone structure and an annular stock guide are used to enable the feed to roll down uniformly on the surface of a drying screen cylinder, the feed is evenly dried, a spiral raised line is provided to increase the falling time of the feed, and the drying effect is ensured. According to an arc-shaped feed discharging scraper and a feed discharging pipe which is in tangential communication with the machine body, the feed discharging efficiency is increased, so that the feed discharging is more thorough.

Owner:南宁扬翔农牧有限公司

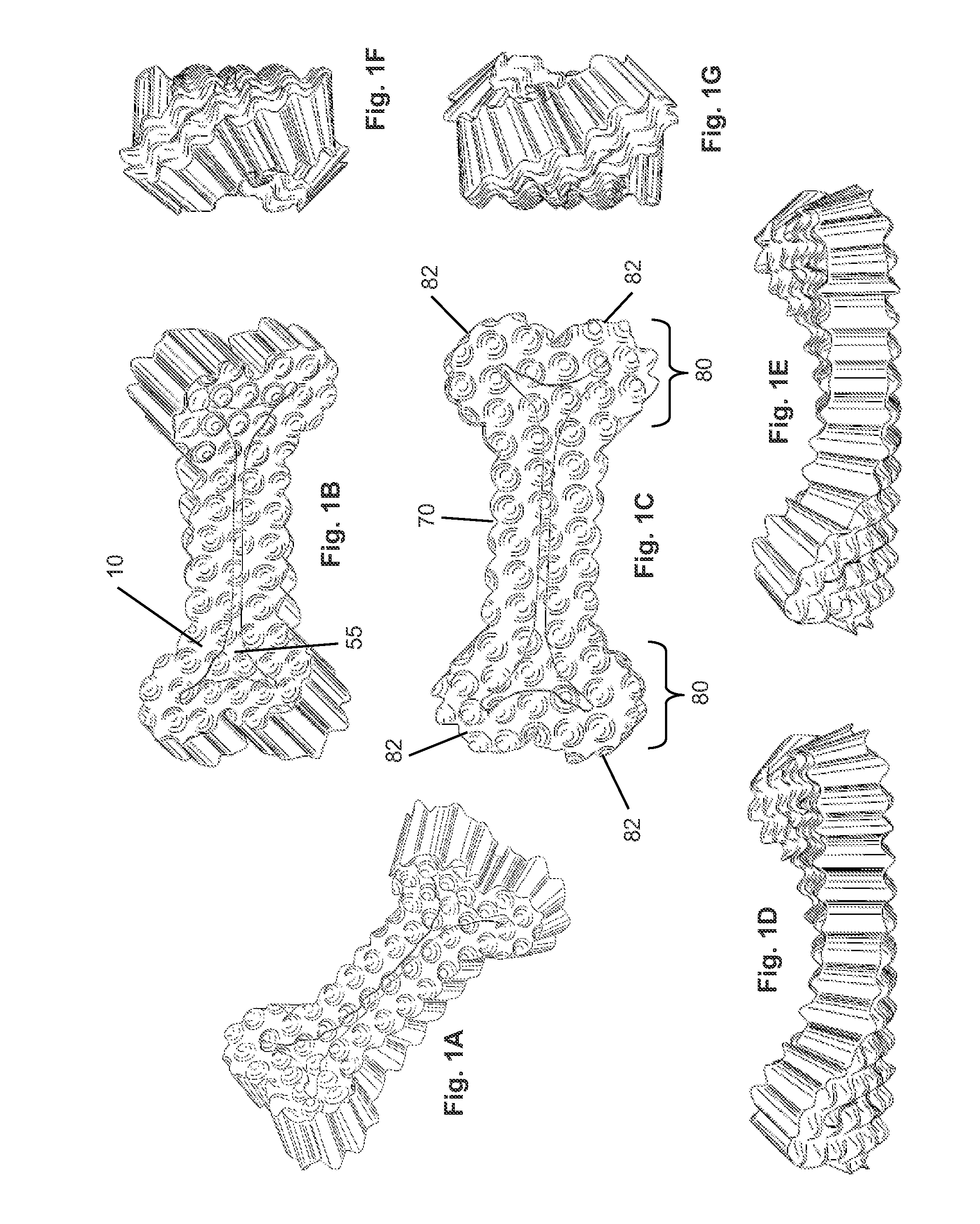

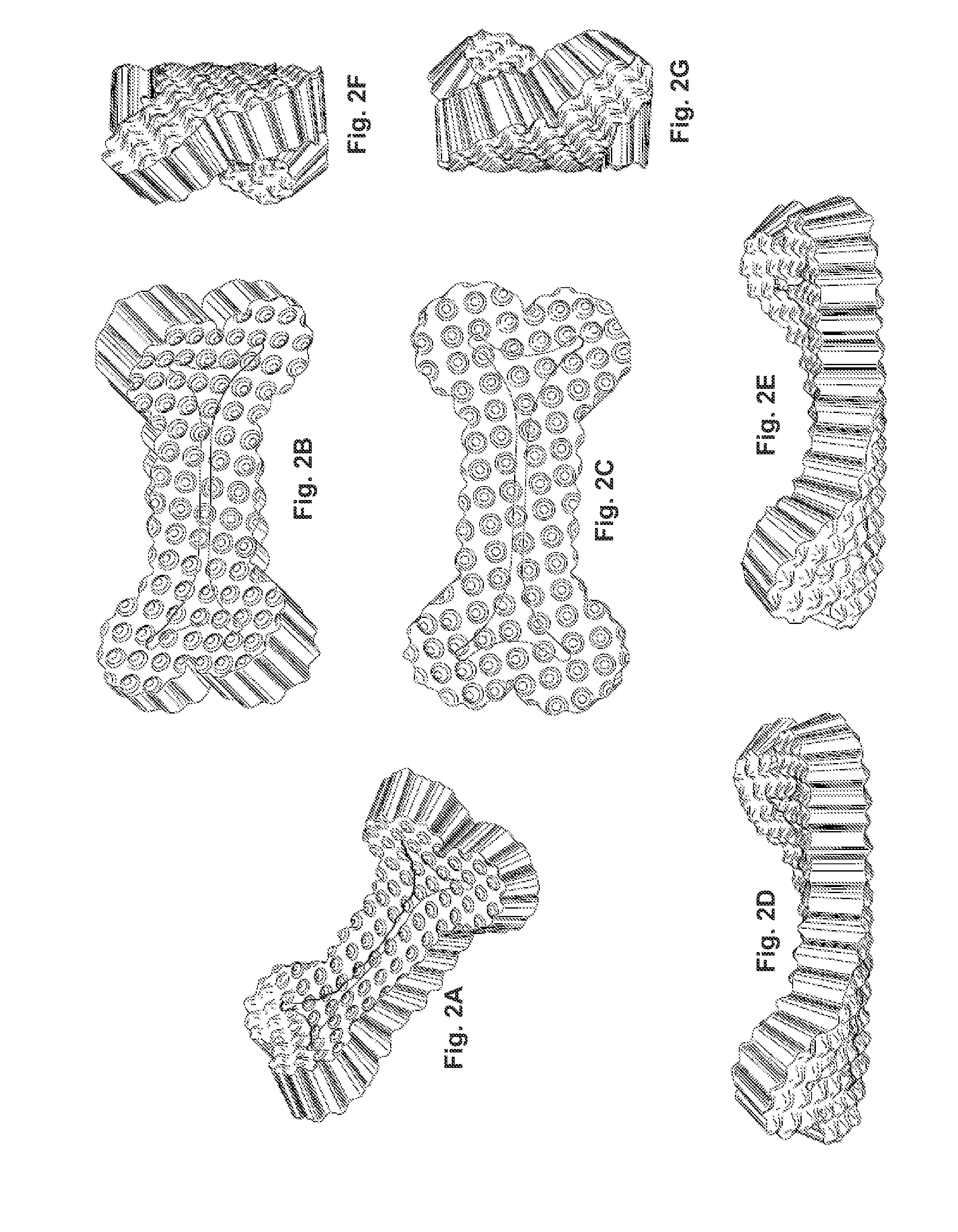

Appetizing and Dentally Efficacious Animal Chews

ActiveUS20130273125A1Effective maintenanceImprove effectivelyCosmetic preparationsFeeding-stuffActive agentDental health

Described herein are chewable articles intended to be provided to animals for purposes including dental cleaning, breath freshening, nutrition, administration to the animal of beneficial agents, satisfaction of the animal's urge to chew, and general enjoyment by the animal. The chews are made to be appetizing to the animal, to satisfy an urge to chew, to effect abrasive cleaning of the animal's teeth, to deliver one or more active agents to the oral cavity of the animal, or a combination of these. The chews have a resilient, chewable texture and are shaped to facilitate dental cleaning, to facilitate oral grasping by the animal, to appeal to human owners of the animal, to enhance the human-animal bond, or a combination of these. Also disclosed are apparatus and methods for making such chewable articles and for formulating and using them to effect dental health in animals.

Owner:BIG HEART PET INC

Efficient feed smashing device

The invention discloses an efficient feed smashing device. A fixed plate is fixedly connected to the left side of the upper end of a device body, a movable tooth plate externally sleeves the fixed plate, the left end of the movable tooth plate is in engaged connection to a free gear, and the movable tooth plate is in intermittent engaged to an incomplete gear; the incomplete gear is in intermittent engaged to the free gear; a first bevel gear is arranged at the lower end of a transmission gear, and is fixedly connected to the lower end of a driving shaft, a second bevel gear is fixedly connected to a first smashing roller, and the right end of the first smashing roller is in belt transmission to a driving worm; the lower end of the driving worm is in engaged connection to a worm wheel, the edge of the worm wheel is hinged to a connecting rod, and the end portion of the connecting rod is hinged to a sieve plate. By means of a matching action of the free gear, the incomplete gear and the movable tooth plate, the movable tooth plate reciprocates up and down to grind the feed movably, and the ground feed is then secondarily smashed by the first smashing roller and the second smashing roller and the smashed feed is finally vibrated in a reciprocating manner to fall off on the sieve plate. The device is simple and applicable in structure, the feed smashing quality and efficiency are improved greatly, and the labor force is saved.

Owner:常园争

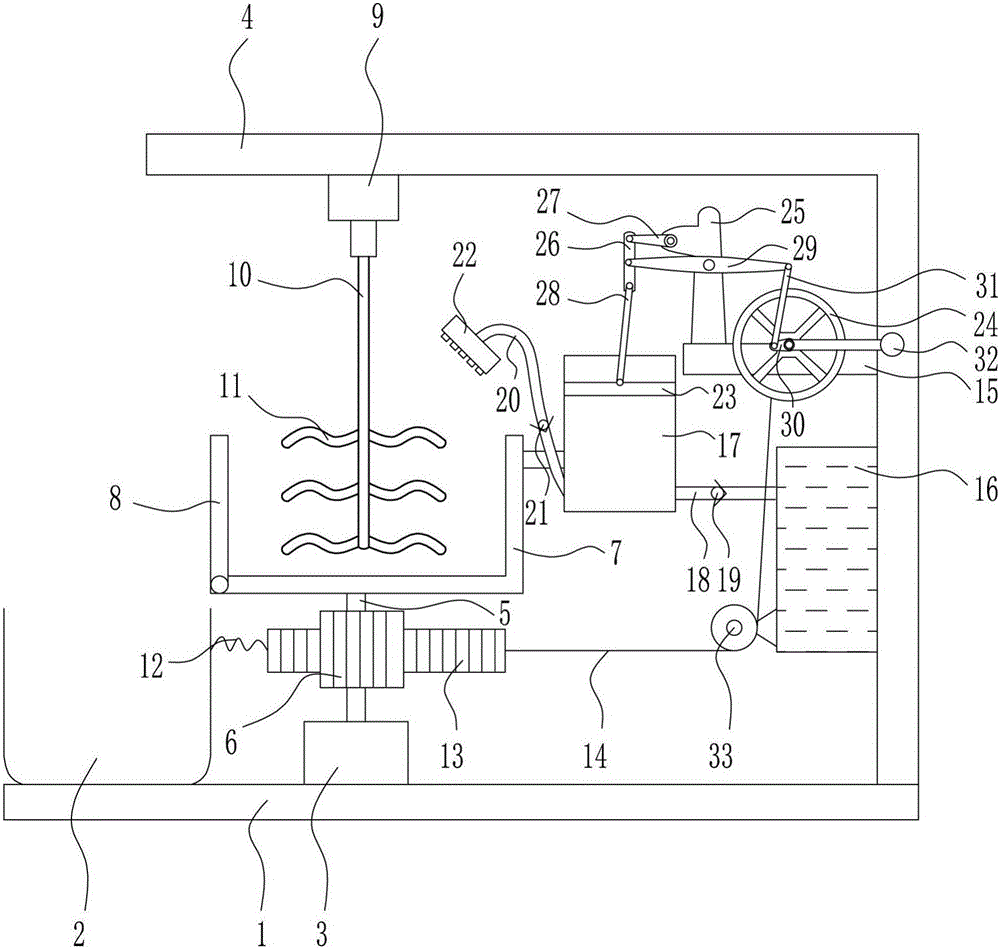

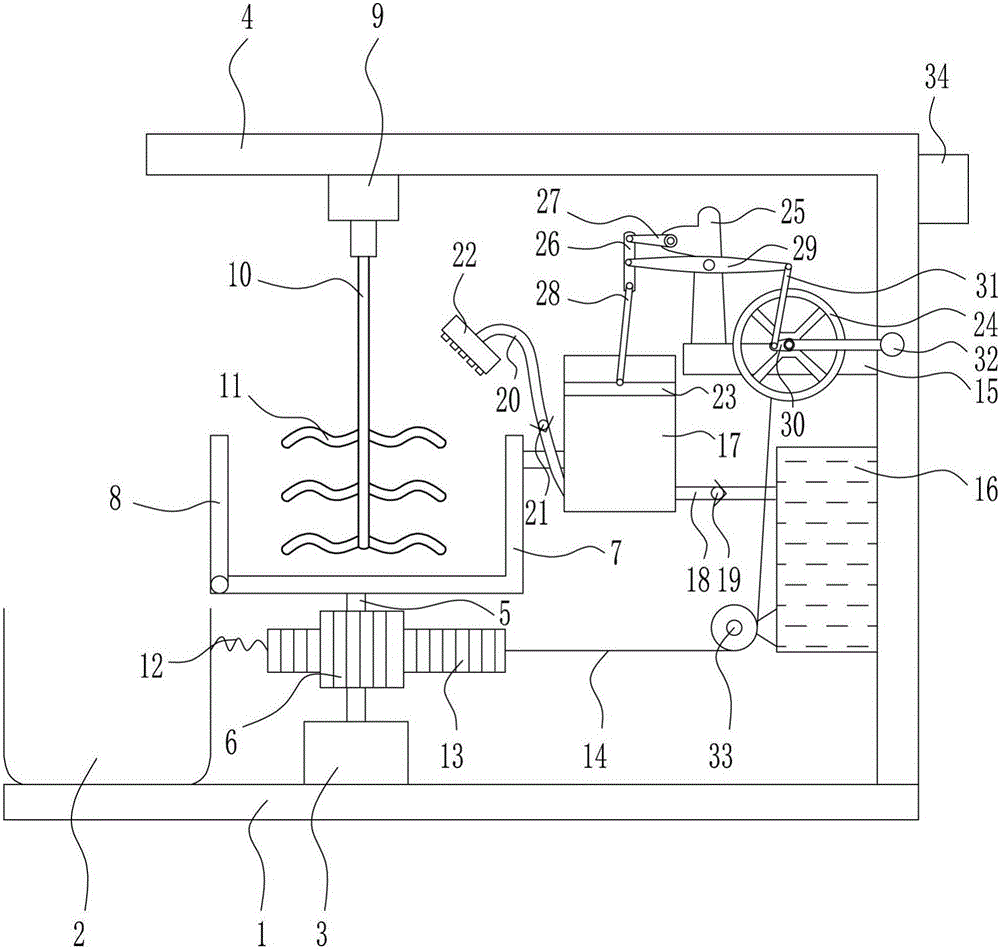

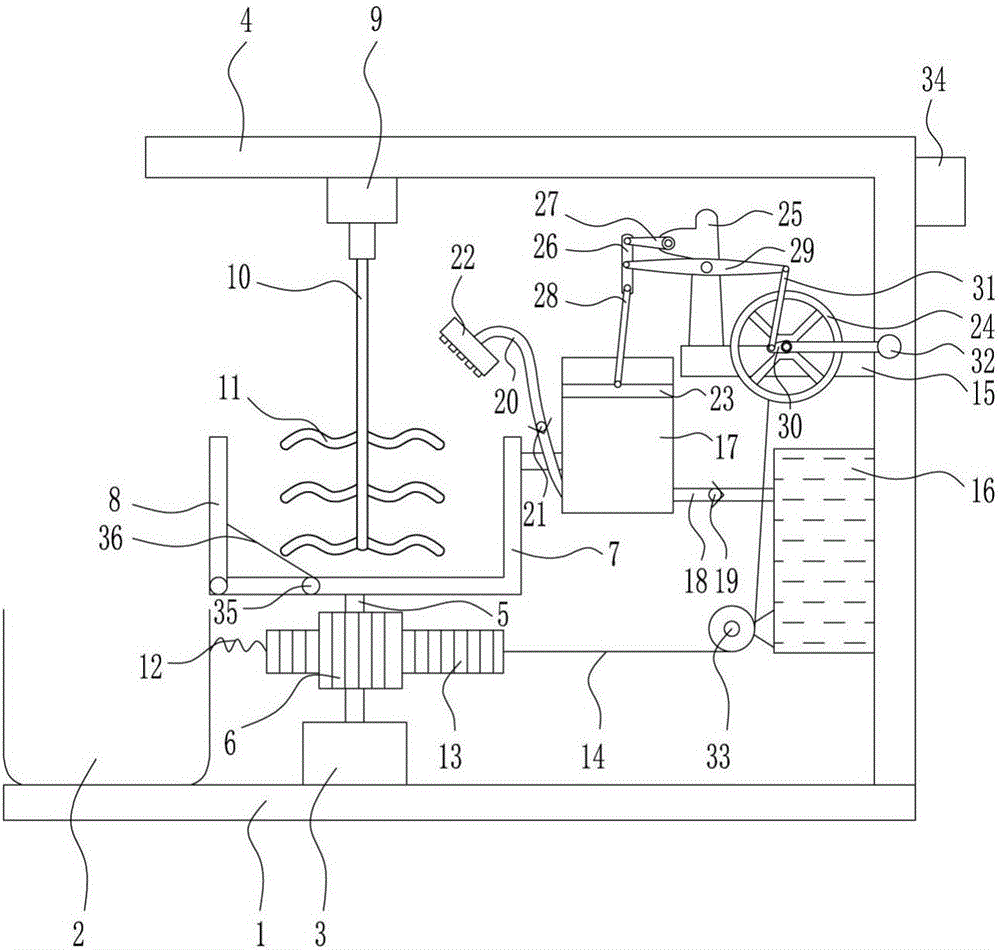

Arm exercise type feed stirring device for animal husbandry

InactiveCN106108081AReasonable mixing timeImprove stirring efficiencyRotating receptacle mixersFeeding-stuffArm exerciseEngineering

The invention relates to an animal husbandry feed stirring device, in particular to an arm exercise type feed stirring device for animal husbandry. The arm exercise type feed stirring device for animal husbandry is diverse in function, reasonable in feed stirring time and high in stirring efficiency. In order to achieve the technical aim, the arm exercise type feed stirring device for animal husbandry comprises a bottom plate, a collecting frame, a bearing seat, a support shaped like an Arabic number '7', a rotary shaft, a gear, a stirring tank, a rotary plate, a motor, a rotary rod, stirring rods, a spring, a compression cylinder, a water inflow pipe, a first one-way valve, a water outflow pipe, a sprayer, a piston, a roller, a supporting frame, a movable rod, a first connecting rod, a swing rod, a cam, a handle, a pulley and the like. The mode that the handle is shaken by hand in a forward and backward alternate mode is adopted, the roller rotates in a forward and backward alternate mode while the handle is shaken in the forward and backward alternate mode, then the piston is driven to pump water, and the pumped water is sprayed into the stirring tank through the sprayer.

Owner:杨国锋

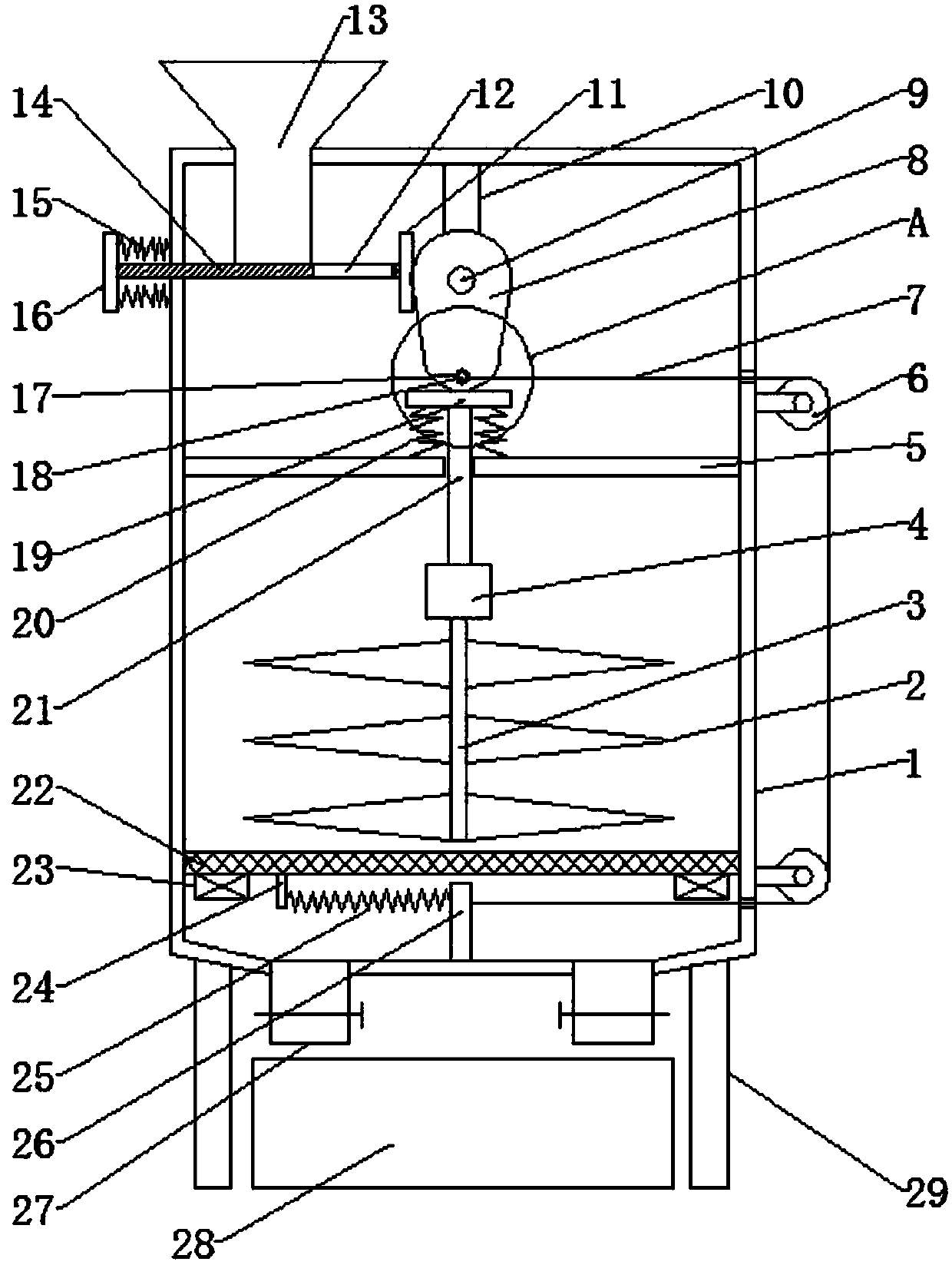

Animal husbandry feed efficient crushing apparatus

The present invention discloses an animal husbandry feed efficient crushing apparatus, which comprises a box, a collecting frame, a material inlet hopper, a material blocking plate, a first fixing plate, a first spring, a second fixing plate, a cam, a first motor, a third fixing plate, a support rod, a second motor, a rotation shaft, a crushing cutter blade, a second spring, a sieve mesh, a pushing plate, a third spring, a pulling rope, a bush and a pin shaft. According to the present invention, by arranging the cam, the material blocking plate and the first spring, the intermittent and uniform material feeding is achieved by matching the components, and the incomplete and insufficient crushing caused by the excessive material feeding at one time is avoided; by arranging the second spring,the second motor and the rotation shaft, the crushing cutter blade is driven to rotate and continuously move up and down by matching the components, such that the crushing is complete, uniform and rapid, and the working efficiency is improved; and by arranging the pushing plate, the third spring and the pulling rope, the blocking plate continuously pushes the feed to the material outlets at bothsides by matching the components, such that the material discharging is convenient, and the clogging is avoided.

Owner:罗娟

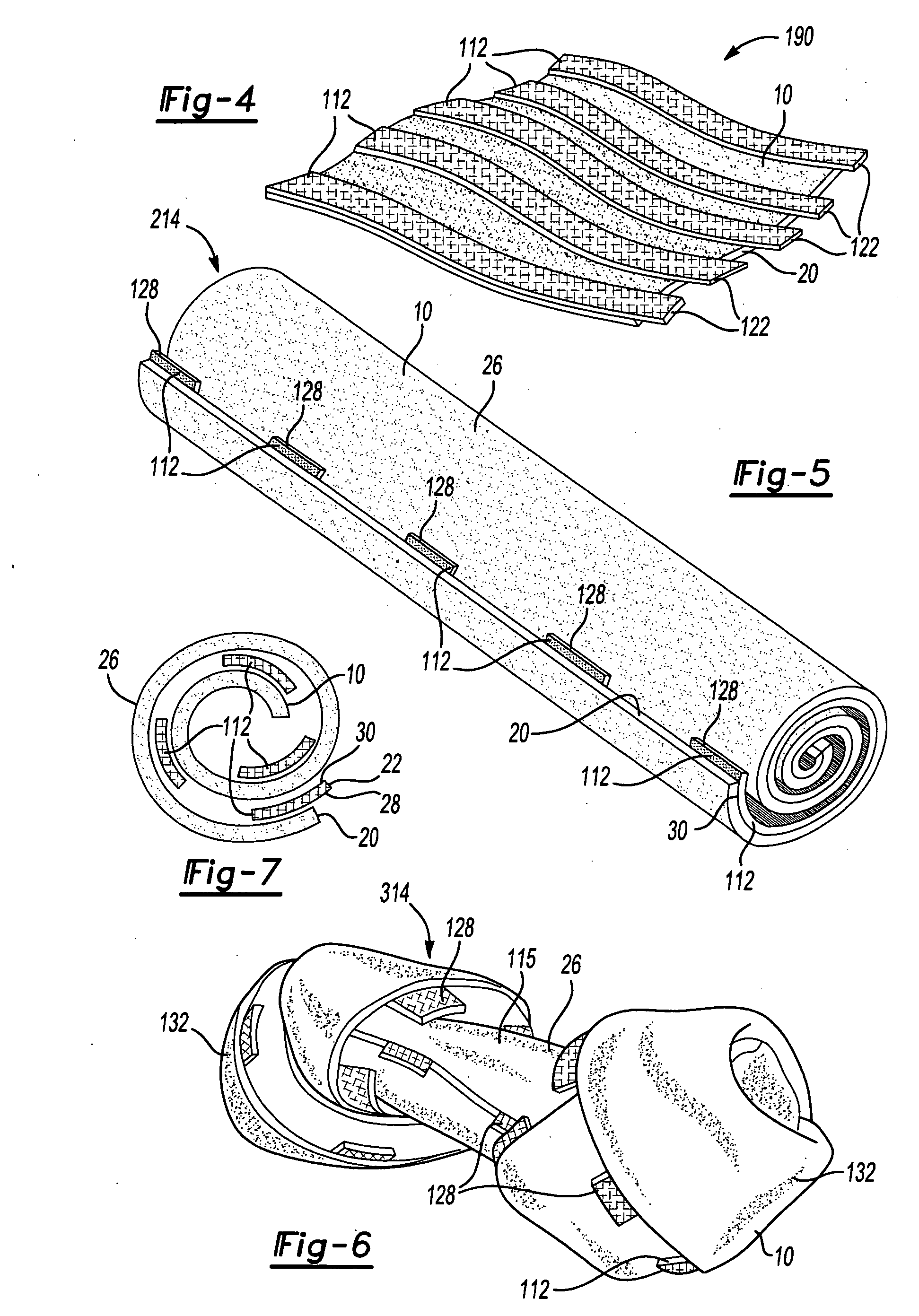

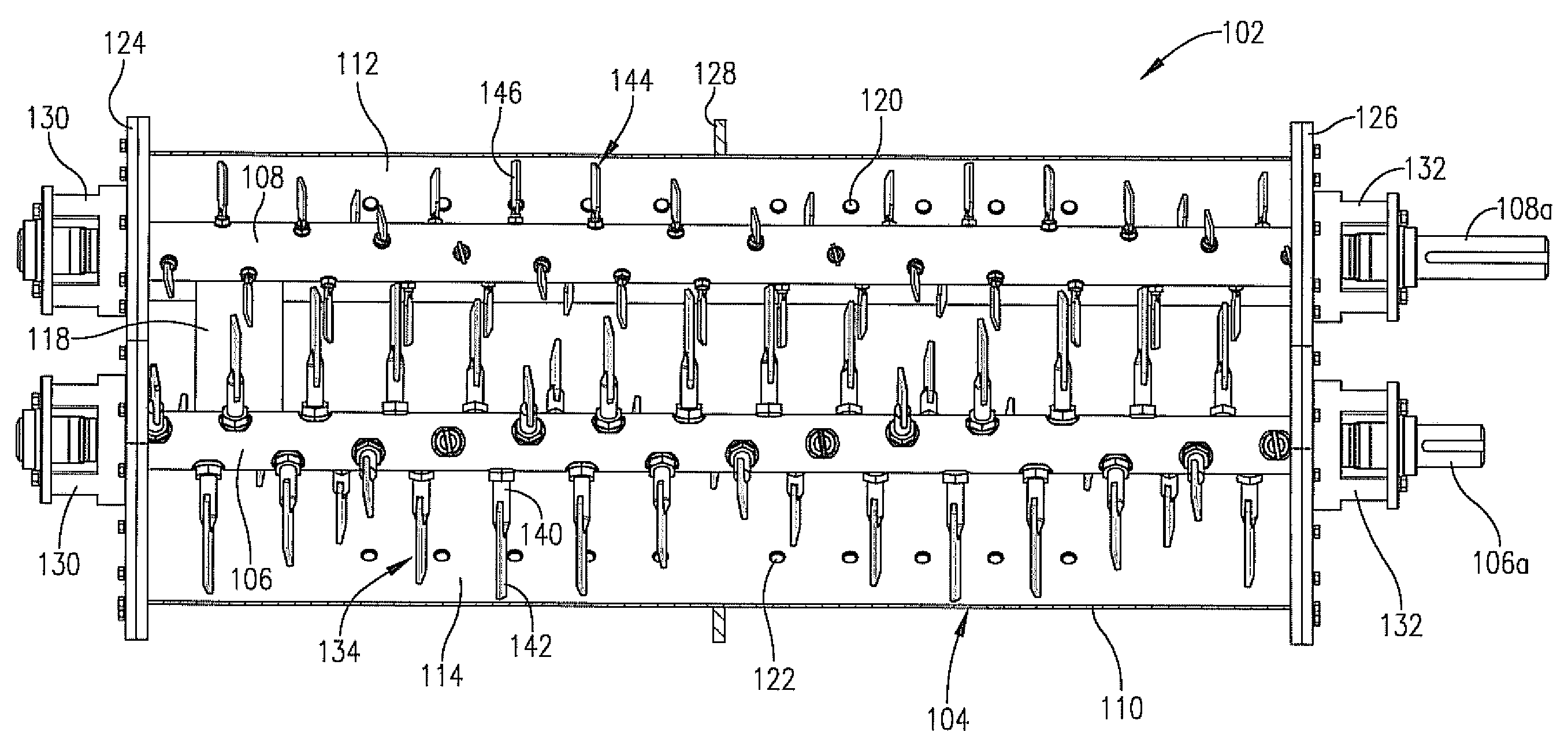

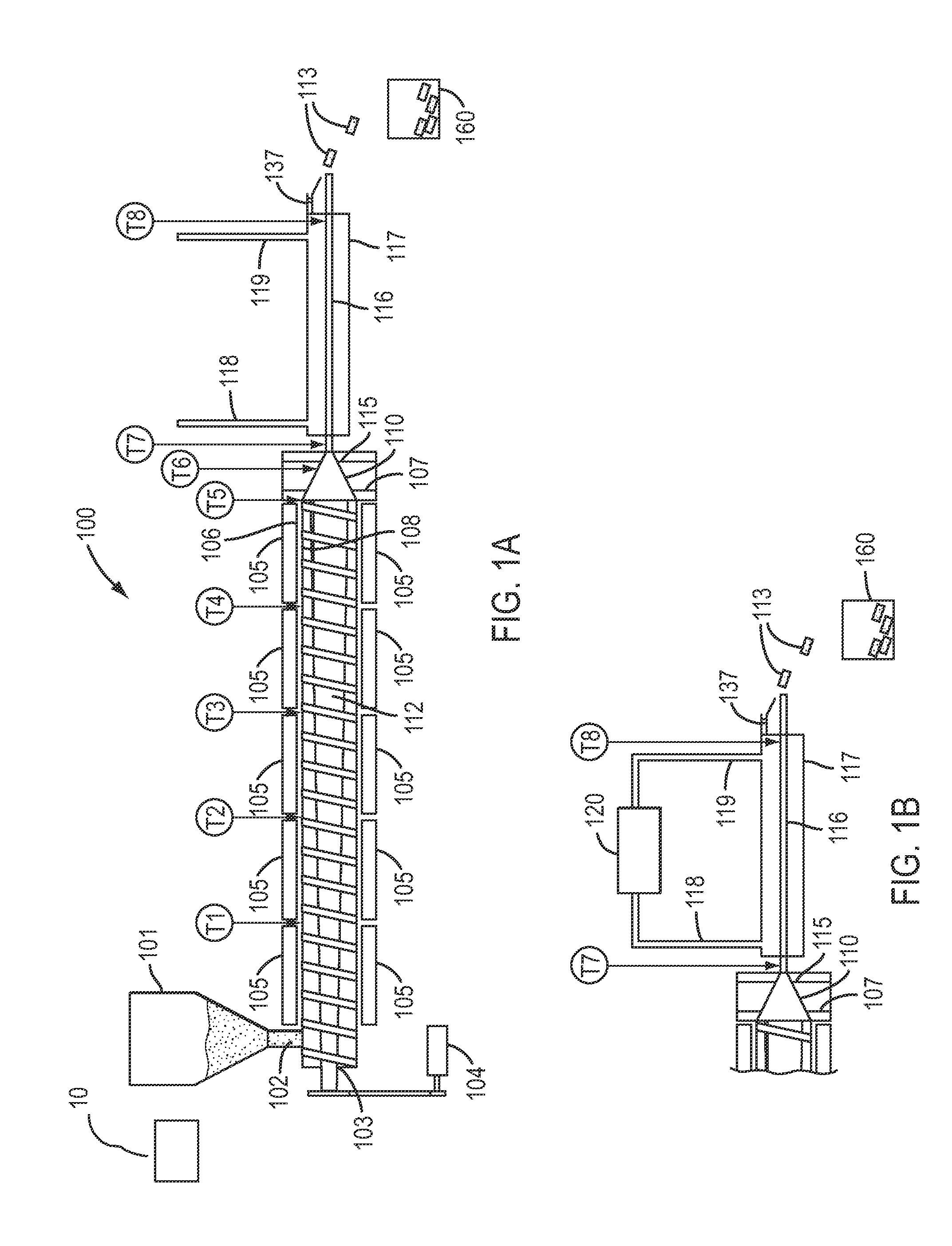

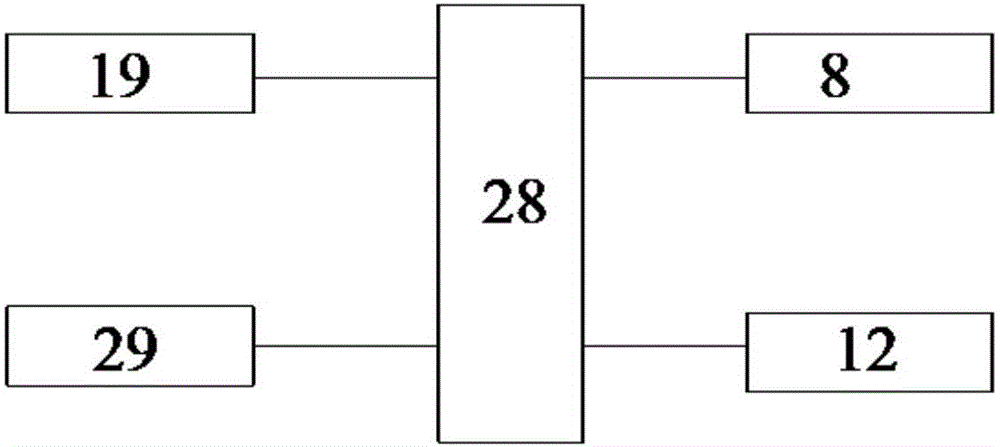

Preconditioner having independently driven high-speed mixer shafts

InactiveUS20080095910A1Facilitate easy changeFeeding-stuffRotary stirring mixersRetention timeEngineering

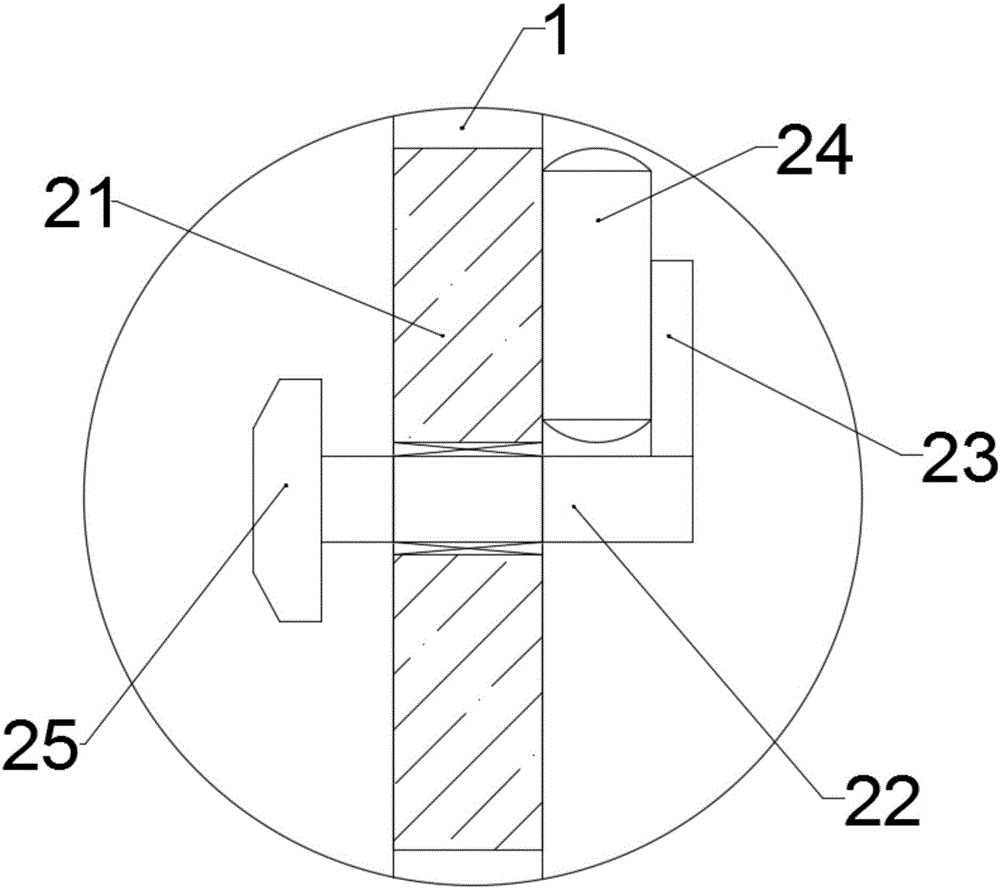

An improved, dual-shaft preconditioner (10, 70, 102) is provided having independent drive mechanism (18, 20, 78, 80) operatively coupled with a corresponding preconditioner shaft (14, 16, 74, 76, 106, 108) and permitting selective rotation of the shafts (14, 16, 74, 76, 106, 108) at rotational speeds and directions independent of each other. Preferably, the speed differential between the shafts (14, 16, 74, 76, 106, 108) is at least about 5:1. The mechanisms (18, 20, 78, 80) are operatively coupled with a digital control device (60) to allow rotational speed and direction control. Preferably, the preconditioner (10, 70, 102) is supported on load cells (62, 100) also coupled with control device (60) to permit on-the-go changes in material retention time within the preconditioner (10, 70, 102). The preconditioner (10, 70, 102) is particularly useful for the preconditioning and partial gelatinization of starch-bearing feed or food materials, to an extent to achieve at least about 50% cook in the preconditioned feed or food materials.

Owner:WENGER MANUFACTURING INC

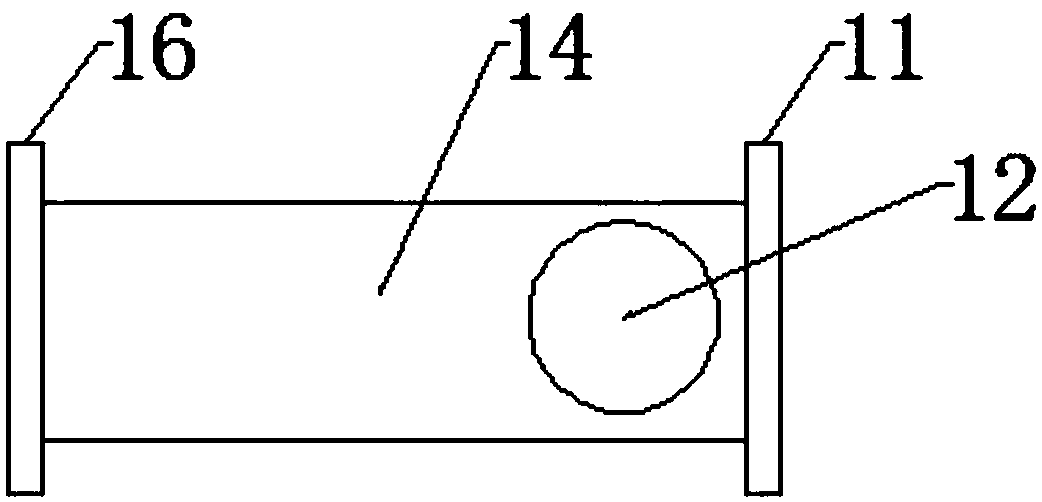

Feed crushing device capable of intermittently unloading

ActiveCN108246440AGuaranteed crushing effectImprove crushing efficiencyFeeding-stuffGrain treatmentsMotor driveEngineering

The invention discloses a feed crushing device capable of intermittently unloading. The feed crushing device comprises a housing, a charge hole, crushing shafts, a crushing motor, a discharge hole andsupporting legs, wherein a two-way lead screw is arranged inside the housing; the two ends of the two-way lead screw are separately equipped with slide blocks in a sleeving mode; the upper ends of the slide blocks are fixedly connected with baffle plates; the right end of the two-way lead screw is equipped with a left bevel gear and a right bevel gear in a sleeving mode; a half bevel gear sleevesthe upper shaft stretching end of a double-axis motor; the crushing shafts are arranged inside the housing; a plurality of crushing blades are distributed on the crushing shafts; the two ends of eachcrushing shaft are rotatably connected with the inner wall of the housing; and the outer side wall of the housing is fixedly connected with the crushing motor. The double-axis motor drives the baffleplates to intermittently open and close, so that feed is controlled to intermittently drop, and much feed is prevented from entering 01 within short time to bring relatively great burden, and therefore, the crushing effect is guaranteed. The crushing shafts are arranged, so that crushing efficiency is improved; and feed is screened while crushing is performed.

Owner:赣州金明畜牧饲料设备有限公司

Non-antibiotic sucking pig milk replacer and preparation method

ActiveCN103598447ALess nutrient lossMaximize utilizationFeeding-stuffAnimal feeding stuffDiseaseSucrose

The invention discloses a non-antibiotic sucking pig milk replacer, which comprises various raw materials as follows: puffed corn, puffed soybean, plasma protein powder, steamed fish meal, soybean protein concentrate, low protein whey powder, lactose, fermented soybean meal, glucose, cane sugar, salt, anti-oxidant, lysine, threonine, methionine, tryptophan, zinc oxide, butyrin, microecology preparation, compound acidifying agent, compound enzyme preparation, compound vitamin premix and compound mineral matter premix. The invention employs synergism between butyrin, zinc oxide, acidifying agent and microecology preparation, and in the prerequisite that the antibiotics are not used, the product can help pigling to realize early stage weaning and get rid of weaning stress, and adjust sucking pig gastrointestinal tract health, control diarrhea, increase survival rate, and comprehensively improve immunity and disease resistance of sucking pig.

Owner:哈尔滨大北农牧业科技有限公司 +1

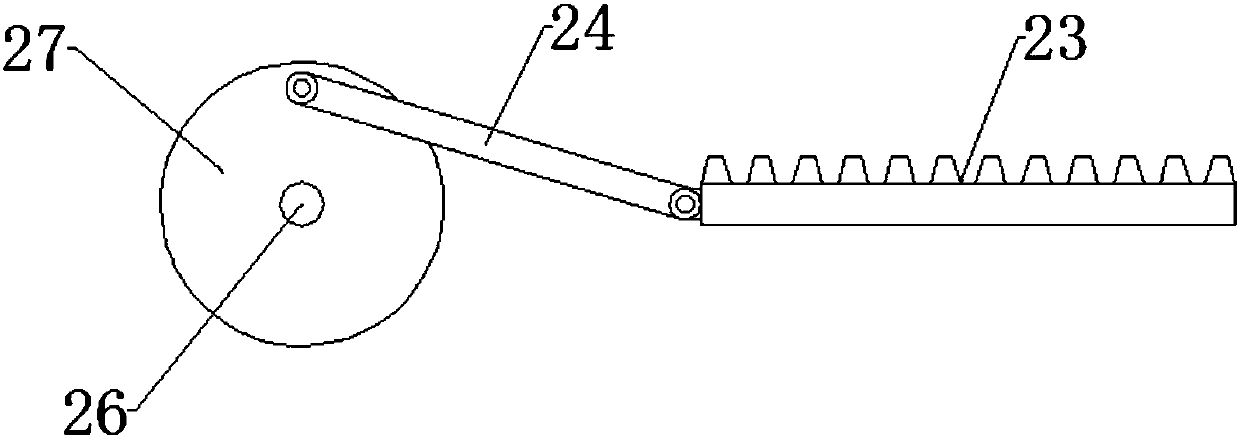

Multi-direction high-efficiency feed mixing device

InactiveCN107456906AWell mixedImprove mixing efficiencyRotating receptacle mixersShaking/oscillating/vibrating mixersMotor shaftSpeed reduction

The invention discloses a multi-direction high-efficiency feed mixing device. The multi-direction high-efficiency feed mixing device comprises a base, wherein a groove is arranged in the base; a support plate is arranged at the top part of the base; a speed reduction motor is arranged at the top part of the support plate; a motor shaft at the bottom end of the speed reduction motor penetrates through the support plate and is connected with a rotary disc; the right side of the bottom part of the rotary disc is rotationally connected with a connecting rod through a pin shaft; a first slide rail is arranged at the bottom part of the groove in the base; the upper part of the first slide rail is glidingly connected with a first gear rack through a slide block, and the left end of the first gear rack is hinged to the right end of the connecting rod; the bottom part of the groove in the base is rotationally connected with a first rotary shaft through a first bearing with a base, a first gear is arranged on the first rotary shaft and is engaged with the first gear rack, and the top end of the first rotary shaft penetrates through the support plate and is fixedly connected with a mixing box. The multi-direction high-efficiency feed mixing device has the advantages that the speed reduction motor is used as a power source to drive in working, so that the operation is simple, and the convenience in control and use is realized; the rotary disc is rotated, and then the mixing box is positively and reversely rotated, so that the feed is more sufficiently mixed, and the uniformity of the feed in mixing is effectively improved.

Owner:宁波新材料科技城犀鸟工业设计有限公司

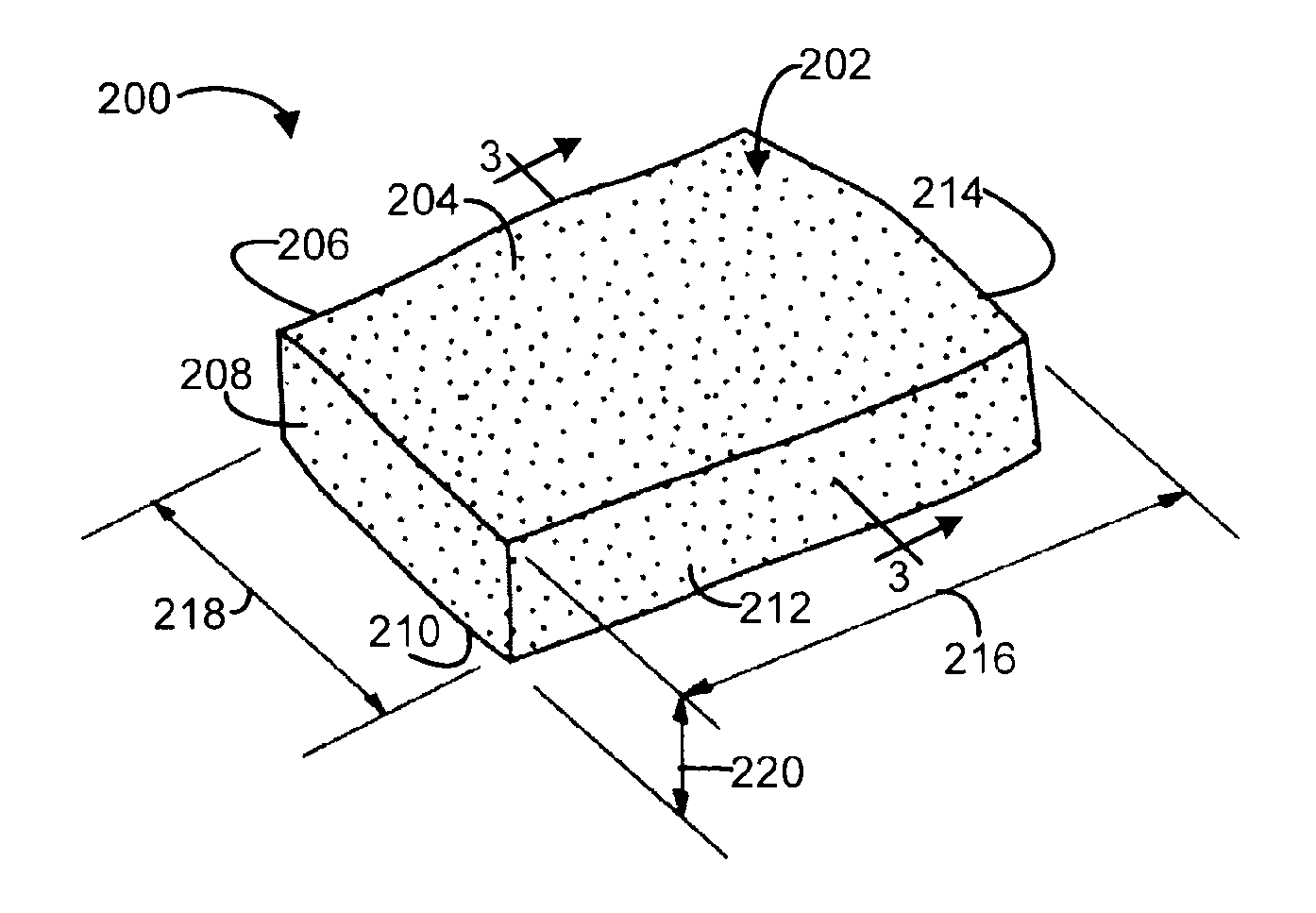

Puffed pet treat

An animal protein-based dog treat has a soft crunch and a stable shelf life without use of an appreciable amount of sodium or chemical preservatives. A method of producing the dog treat entails use of extrusion and heating processes to trap moisture in the interior of the dog treat, and then to expand and evaporate the moisture. This process creates in an internal portion of the dog treat voids or air pockets that provide desired texture and strength characteristics.

Owner:TRIDENT SEAFOODS

Distiller grain pellet production devices

ActiveUS8287268B1Increased durabilityCompact and efficient formFeeding-stuffMouldsHigh densityMetallurgy

A device for producing a high density compact livestock feed from a loose granular material according to various embodiment can include a source for supplying a loose granular material to be treated. A series of successive treatment zones comprises a heating zone, a compression zone, and a cooling zone. The heating zone comprises at least one heater and at least one screw compression dryer configured to receive the loose granular material to be treated for drying. Rotation of the screw transfers the treated material to the compression zone. The compression zone comprises a compression chamber for compacting the treated material to form a high density compact body. The treated material is pressed through the compression chamber while a two-dimensional cross-section compression is applied to the treated material. The cooling zone comprises a cooling unit for cooling the high density compact body received from the compression zone.

Owner:JOHNSON RAYMOND T +1

Separating drying device for fodder machining production

PendingCN107309085AEvenly and evenly heatedImprove bake qualitySievingGas current separationAgricultural scienceGas heater

The invention discloses a separating drying device for fodder machining production. The device comprises a blanking cylinder, a first screen net, a communication box, a small particle receiving bin, a high-pressure draught fan, a large particle screening box, a second screen net, an elastic telescopic device, a vibration motor, a slag removal device, an outer shell, an inner shell, a rotating column, an air blower, an air flue type gas heater, an inclined columnar rotating cylinder, a rotating ring and a fixed ring; fodder enters the slag removal device through a discharging pipe, slag is attracted by a magnet roller and scraped by a scraping knife, the air blower feeds hot air generated by the air flue type gas heater into a hot air cavity, hot air in the hot air cavity enters the air flue type gas heater again, heat recycling is formed, in the rotating process of the inclined columnar rotating cylinder, fodder in the inclined columnar rotating cylinder slides to the right side from the left side and then slides to the left side from the right side in a reciprocated manner, fodder is in the dynamic state, fodder can be evenly heated, and the baking quality of the fodder can be improved.

Owner:银川金帮手信息科技有限公司

Poultry feed stirring device

PendingCN107297181AQuick mixSimple structureFeeding-stuffTransportation and packagingMotor driveEngineering

The invention discloses a poultry feed stirring device which comprises a base, wherein rollers are arranged on the left and right sides of the base; a stirring box is arranged above the base; the box bottom of the stirring box is connected and fixed with the base through supporting legs; a preliminary mixing box is arranged at the upper end of the stirring box; the preliminary mixing box is communicated with the stirring box; a material feeding hopper is arranged at the upper end opening of the preliminary mixing box; a horizontal stirring shaft is horizontally arranged in the preliminary mixing box; horizontal stirring rods are symmetrically arranged on the outer side of the horizontal stirring shaft; the left end of the horizontal stirring shaft penetrates through the preliminary mixing box and is connected with the output end of a horizontal motor; the horizontal motor drives the horizontal stirring shaft and the horizontal stirring rods to rotate so as to preliminarily stir materials. The poultry feed stirring device is simple and reasonable in structure, has a dual stirring function, can quickly mix the materials, and also has drying and deironing functions; furthermore, the whole stirring box is separable, thus facilitating later maintenance; the poultry feed stirring device is high in practicality.

Owner:ZHENGZHOU UNIV

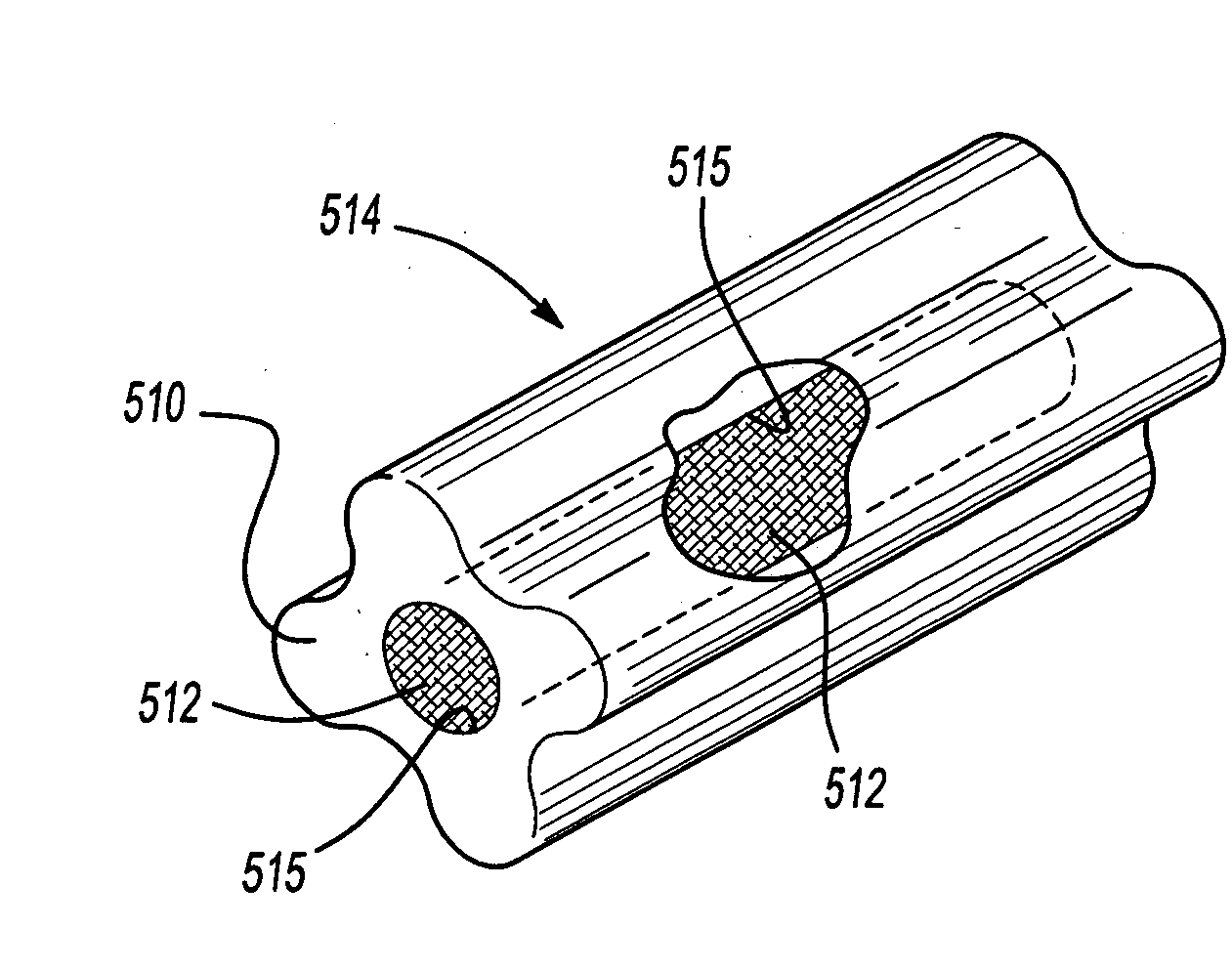

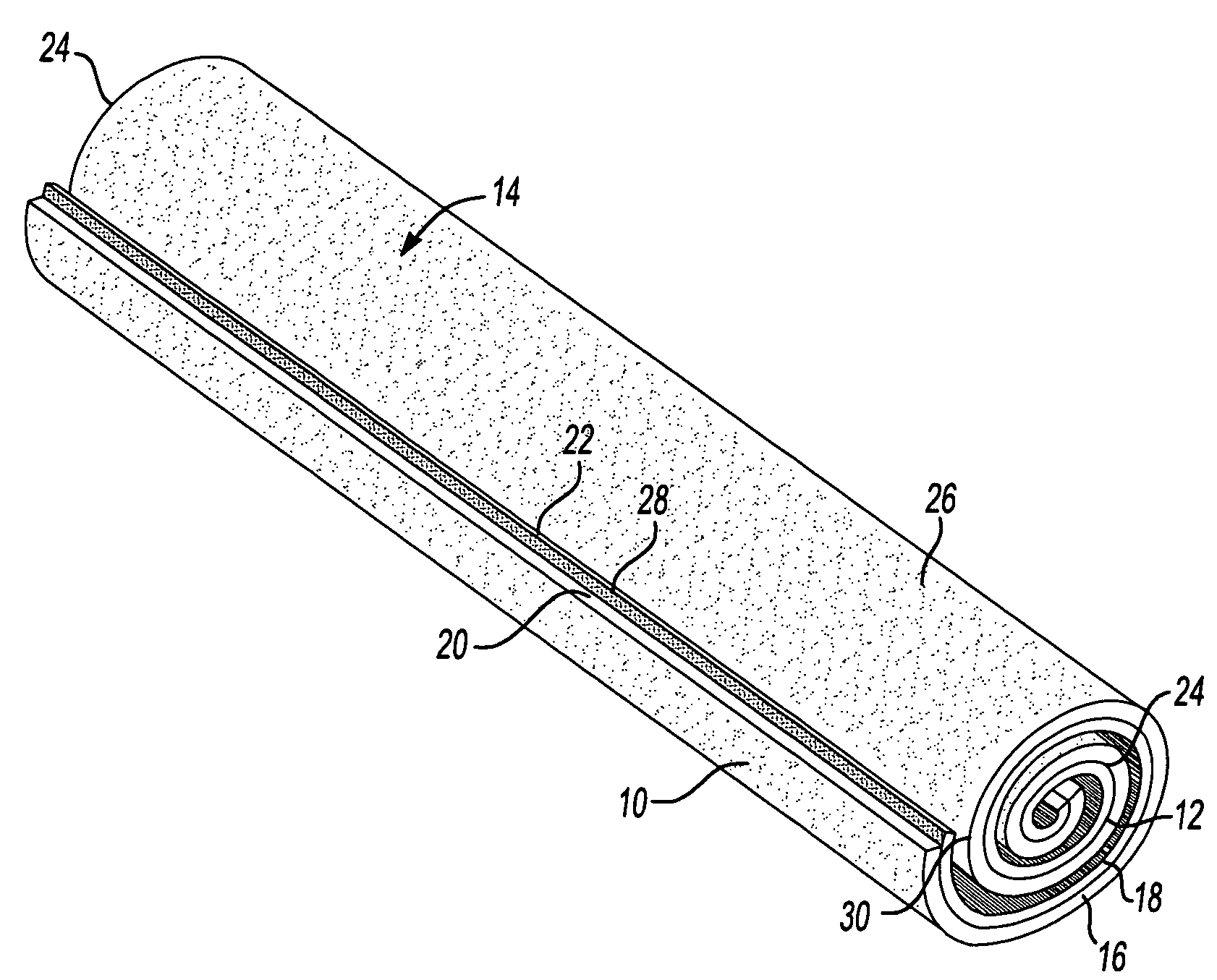

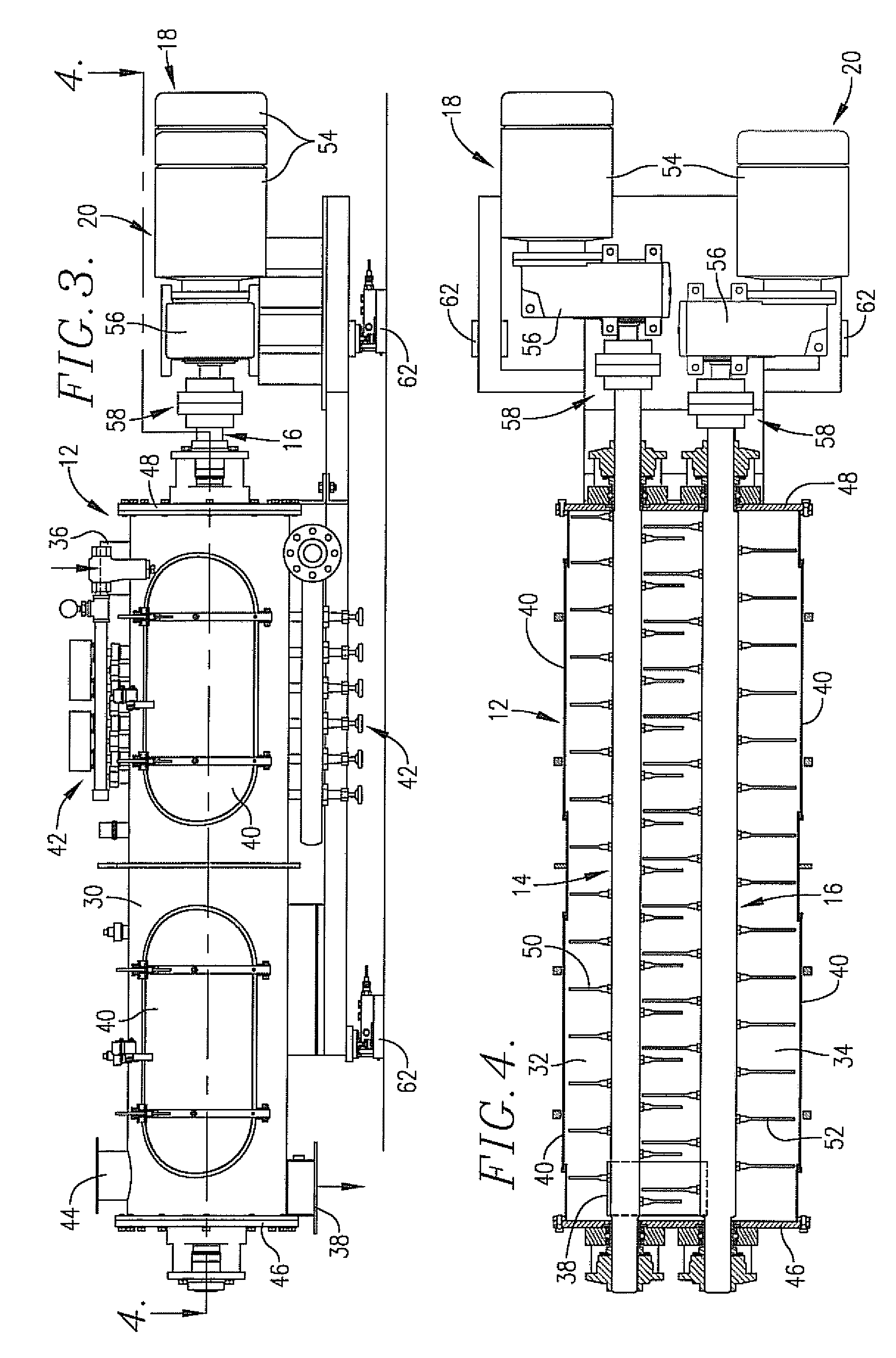

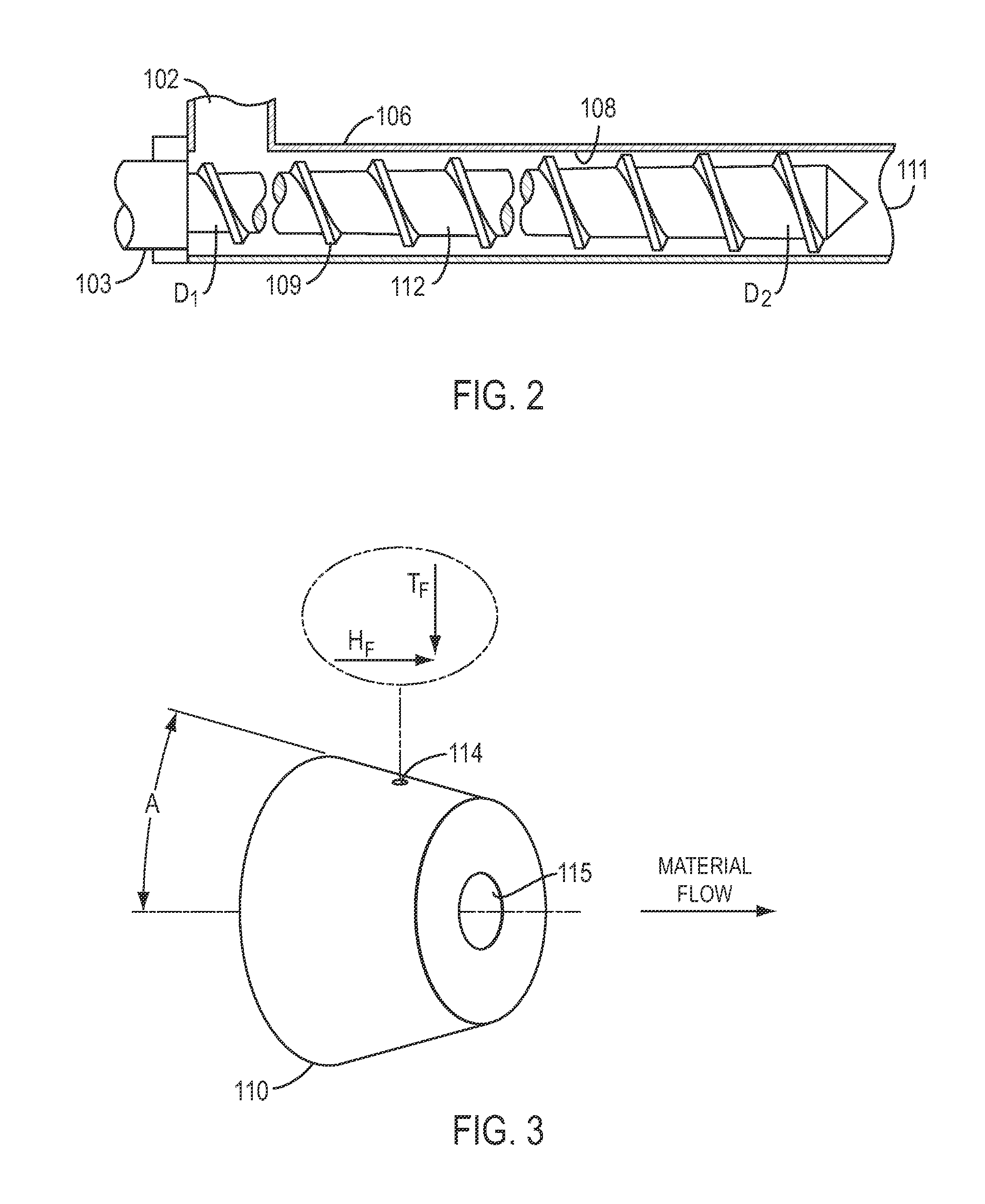

Cooking extruder with enhanced steam injection properties

ActiveUS20080223223A1Overcome problemsAvoid flowFeeding-stuffWorking-up animal fodderEngineeringPitch length

An improved extruder (10) is provided which permits successful introduction of very high quantities of injected steam into material being processed, on the order of 6-8% or more by weight steam. The extruder (10) includes an elongated extruder barrel (12) having at least one elongated, axially rotatable, helically flighted extrusion screw (16,18) therein. The barrel (12) is equipped with obliquely oriented steam injection ports (44, 46) along the length thereof, housing steam injectors (48, 50). The barrel (12) includes relatively high free volume steam injection heads (32 and 38, 40) having therein screw sections (78, 82) of relatively long pitch length, together with steam restriction heads (30, 34, and 42) on opposite sides of the injection heads (32, and 38, 40) having therein relatively short pitch length screw sections (76, 80, 84).

Owner:WENGER MFG LLC

Banana planting by-product fermented feed and processing method thereof

The invention relates to a banana planting by-product fermented feed and a processing method thereof. A tannin degradant, a fermenting agent, a moisture adsorbent, a nutritive additive and the like are added by taking banana stem leaves as main raw materials and one or more than one crop straw and pasture as auxiliary raw materials to prepare the fermented feed for feeding ruminants such as beefs, milch cows, sheep and the like through process links of equipment kneading, shaping, sealed anaerobic packaging and the like. The invention has simple process, high production rate and good technical economical efficiency, is simple and easy to apply and opens up the novel utilization way of the banana by-product; the fermented feed obviously reduces the adverse effect of tannin on the ruminants after being treated, has good feeding value, improved palatability and fragrant smell and meets the green concept; the product form is varied; and feed products have small volume and high density and can be stored and transported for long. The fermented feed has obvious social and economic benefits in the aspects of relieving the condition that the forage grass in the sheep / cattle farming in farming areas is insufficient, improving the growth effect of animals, reducing the feed cost, saving energy, improving efficiency and the like.

Owner:GUANGDONG OCEAN UNIVERSITY

Extruded hard pellet feed for lactating sows and preparation method thereof

ActiveCN102524582AFully gelatinizedImprove digestibilityFeeding-stuffAnimal feeding stuffAnimal scienceRapeseed

The invention discloses an extruded hard pellet feed for lactating sows, which is prepared by the following raw materials in parts by weight: 50-55 parts of corn, 3-4.5 parts of imported super steam fish meal, 3-5 parts of fermented soya bean meal, 8-10 parts of flour, 10-15 parts of wheat, 13.5-15.1 parts of non-transgenic soya bean, 2-4 parts of rapeseed meal, 5-10 parts of extruded-soybean, 1-2 parts of mineral substance premix, 0.2-0.3 parts of vitamins premix, 1.0-2.0 parts of calcium hydrogen phosphate, 2.5-4 parts of soybean oil, 1-2 parts of calcium propionate and 0.1-0.2 parts of oligosaccharide. The extruded hard pellet feed is prepared by tempering the raw materials in the formula by using a double-shaft squeezing well-done extruder under a certain condition and then curing under a certain curing condition. The crude protein of the extruded hard pellet feed is greater than 16.2%, the curing degree is above 80%, the extruded hard pellet feed has comprehensive nutrition and extrusion, the anti-nutrition factors are destroyed, and after the extruded hard pellet feed is used for feeding pregnant sows, the birth weights of piglets are above 1.6 kg in average.

Owner:安徽天邦饲料科技有限公司

Vertical particle material handling device for agricultural feed processing

InactiveCN106733012AGuaranteed normal processingImprove filtering effectSievingFeeding-stuffEngineeringCam

The invention discloses a vertical particle material handling device for agricultural feed processing. The vertical particle material handling device comprises a processing shell. Supporting guiding side pillars are fixedly arranged on the left side and the right side of the outer wall of the processing shell. A lifting rack is upwards integrally fixed at the middle position of the top side wall of a rack body of a motor mounting rack. A main stirring motor is arranged on a bottom plate in the inner cavity of the rack body of the motor mounting rack. Crushing cutting blades are arranged on the outer side wall at the bottom end of a shaft body of a rotary crushing rotating shaft. An elastic filter screen is horizontally arranged on the left side wall and the right side wall at the lower part of an inner cavity of the processing shell. The edges of cams cling to the lower surfaces of a left screen body and a right screen body of the elastic filter screen. A transparent observation window is arranged in an observation opening. By means of the vertical particle material handling device, the omnidirectional cutting effect is achieved, the cams on two sides can finely adjusted up and down when the elastic filter screen is used for screening, the screening effects of the mesh bodies is enhanced, and a master worker can more clearly grasp operation of the device.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

Equipment and method using fermentation dross to produce high activity high nutrition forage

ActiveCN105054261AIncrease contentReduce energy consumptionFeeding-stuffFood processingFiberAir filter

The invention discloses equipment using fermentation dross to produce high activity high nutrition forage; the equipment comprises a box body; an inner side of the top of the box body is provided with an air window, an atomizer mechanism, and ultraviolet lamp tubes; an outer side of the top of the box body is provided with a water container and a mixing chamber; the upper portion of the mixing chamber is provided with a cooling zone; the lower portion of the mixing chamber is provided with a blender and a connected fermentation bed mechanism arranged in sequence from top to bottom, wherein the fermentation bed mechanism is arranged in the box body; the bottom of the box body is provided with a ventilation input pipe and electric heaters; the ventilation input pipe is connected in sequence with an air filter and a blower / air cooler; a side face of the box body is provided with a discharge window, another side face of the box body is provided with an access door and an ozone generator, and a temperature humidity control module is arranged in the box body. The invention also discloses a method using fermentation dross to produce high activity high nutrition forage; the method can realize full fermentation, is high in fiber degraded rate, large in protein raising rate, high in active substance content, and less in energy loss; inner environment conditions of the equipment are easy to control.

Owner:肖兵南

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com