Patents

Literature

101 results about "Preconditioner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, preconditioning is the application of a transformation, called the preconditioner, that conditions a given problem into a form that is more suitable for numerical solving methods. Preconditioning is typically related to reducing a condition number of the problem. The preconditioned problem is then usually solved by an iterative method.

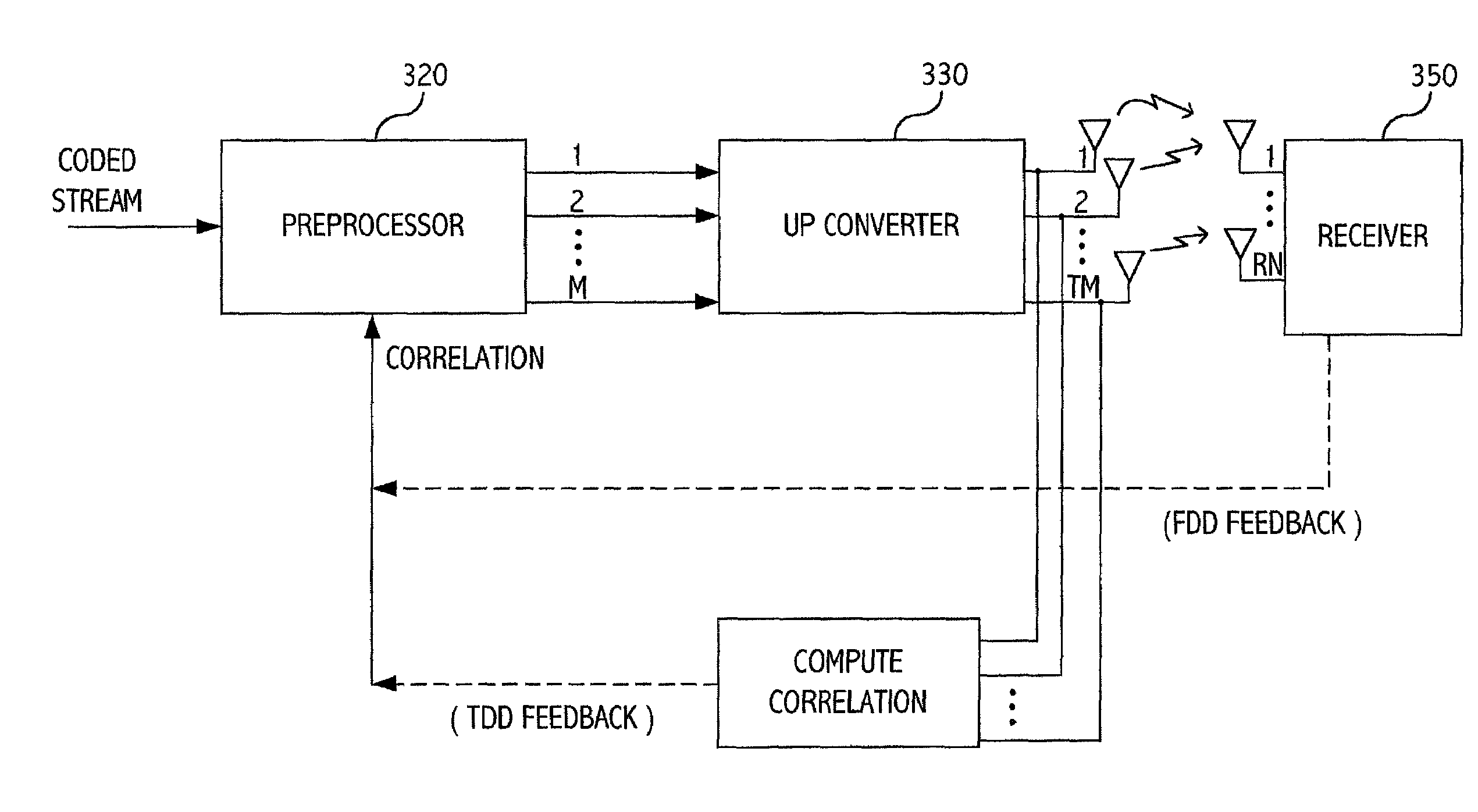

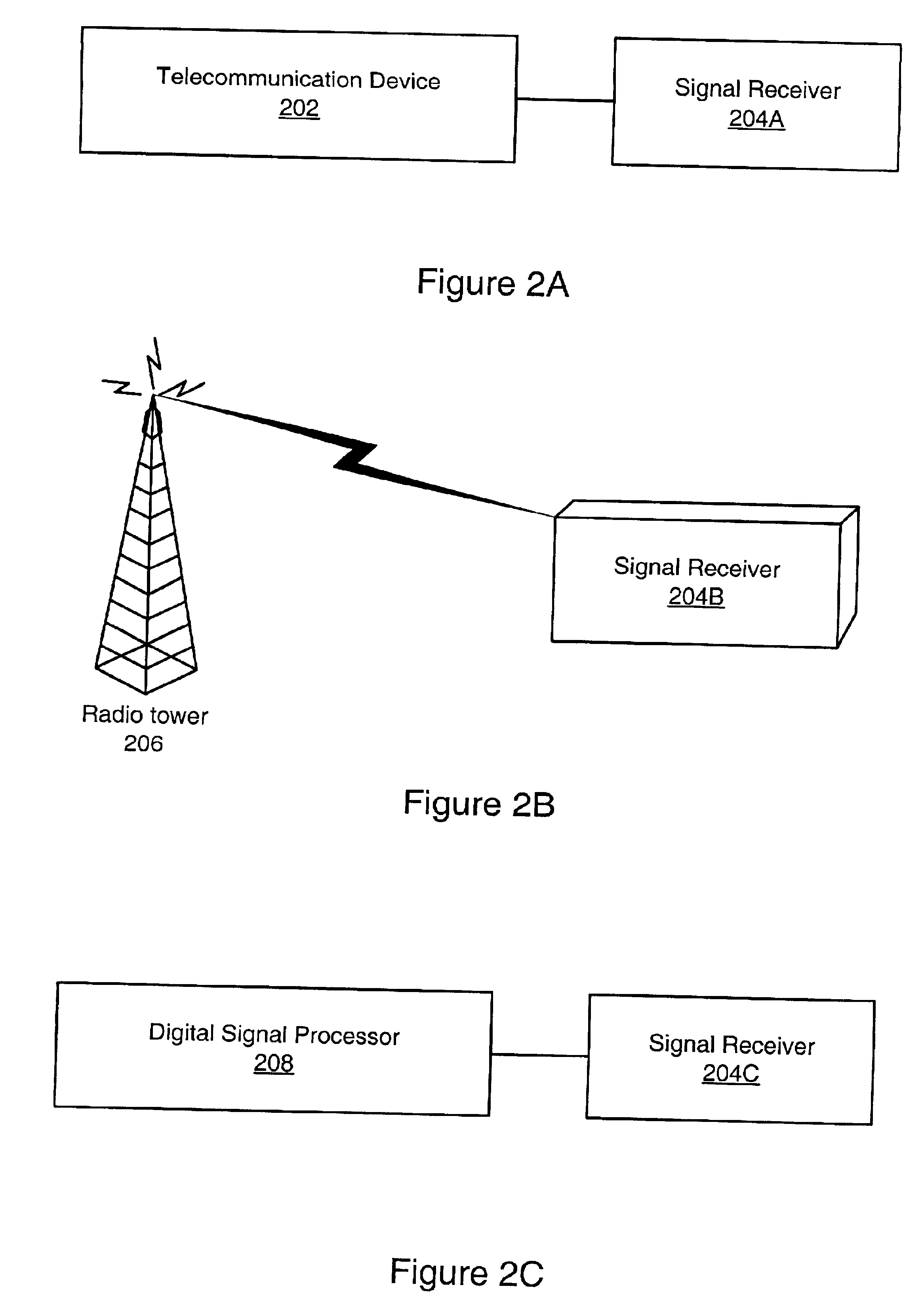

Transmit signal preprocessing based on transmit antennae correlations for multiple antennae systems

InactiveUS7149254B2Improve system performanceSpatial transmit diversityPolarisation/directional diversityAlgorithmDecomposition

The present invention provides a method and system for preprocessing transmit signals in spatial multiplexing and diversity systems that include multiple transmit antennae. The method includes generating a representative correlation matrix based upon estimates of a correlation between each pair of the plurality of antennae. An equivalent eigenvalue decomposition of the representative correlation matrix is determined. A preprocessing matrix based upon the equivalent eigenvalue decomposition is generated. Finally, a preprocessor preprocesses the transmit signals by multiplying blocks of data of the transmit signals with the preprocessing matrix. The representative correlation matrix can be an exact estimate of the correlation between each pair of the multiple antennae, or the representative correlation matrix can be an approximate estimate of the correlation between each pair of the multiple antennae.

Owner:INTEL CORP

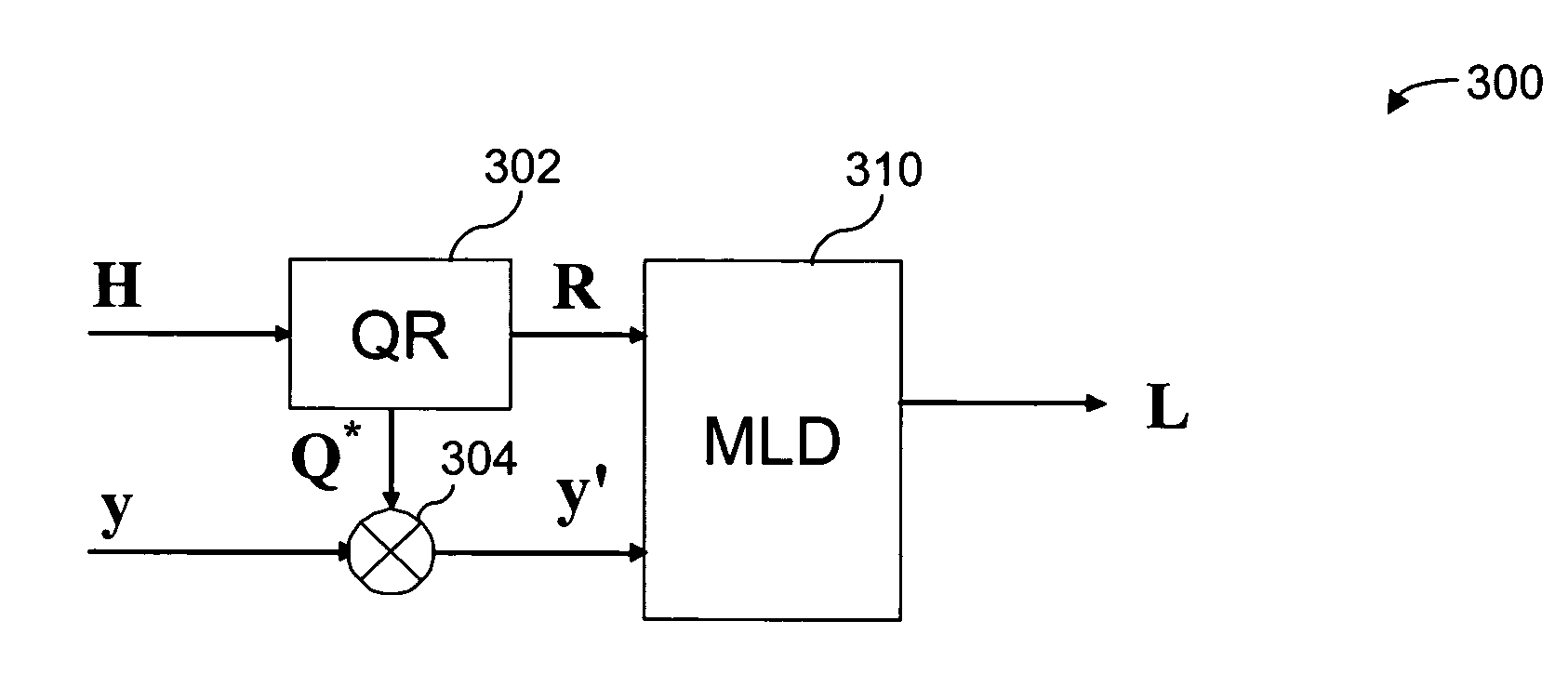

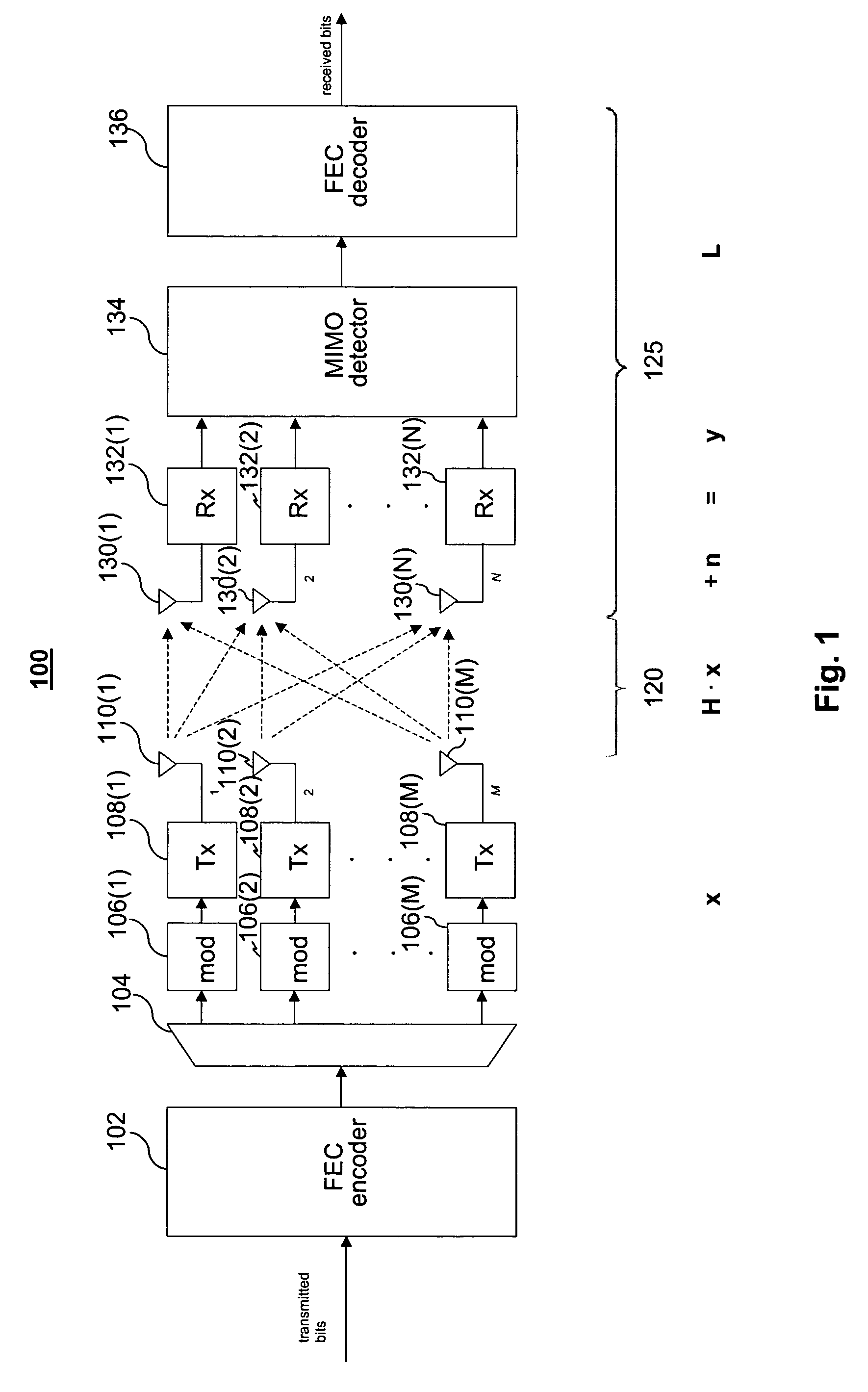

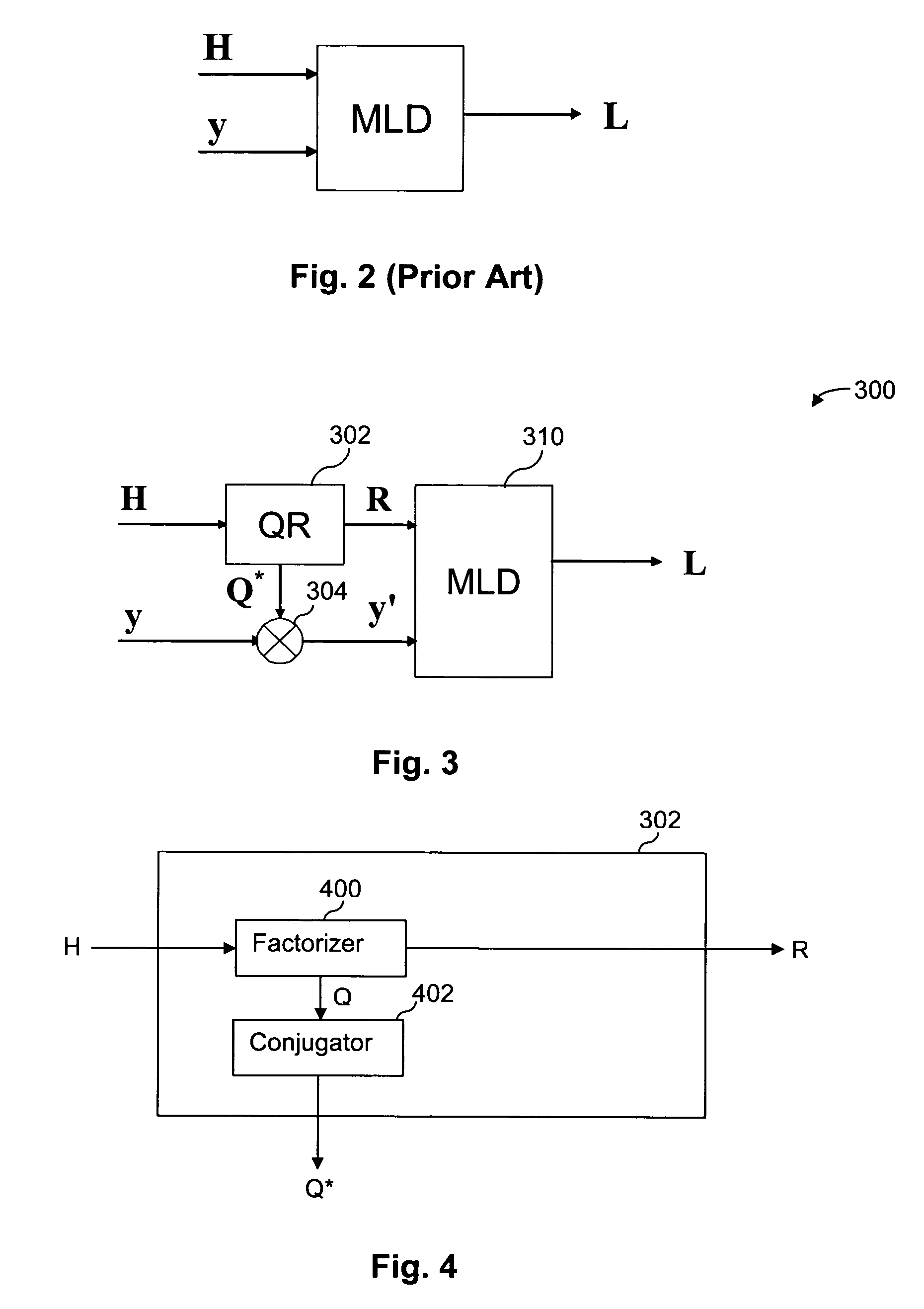

MIMO receiver using maximum likelihood detector in combination with QR decomposition

ActiveUS7489746B1Reduce computational complexityPolarisation/directional diversityAmplitude-modulated carrier systemsQR decompositionRound complexity

A MIMO receiver is provided with a preprocessor for performing QR decomposition of a channel matrix H wherein the factored reduced matrix R is used in place of H and Q*y is used in place of the received vector y in a maximum likelihood detector (“MLD”). The maximum likelihood detector might be a hard-decision MLD or a soft-decision MLD. A savings of computational complexity can be used to provide comparable results more quickly, using less circuitry, and / or requiring less consumed energy, or performance can be improved for a fixed amount of time, circuitry and / or energy. Where the MLD uses approximations, such as finite resolution calculations (fixed point or the like) or L1 Norm approximations, the reduced number of operations resulting from using the reduced matrix results in improved approximations as a result of the finite resolution operations. Other methods of reducing the channel matrix might be used for suitable and / or cumulative advantages.

Owner:QUALCOMM INC

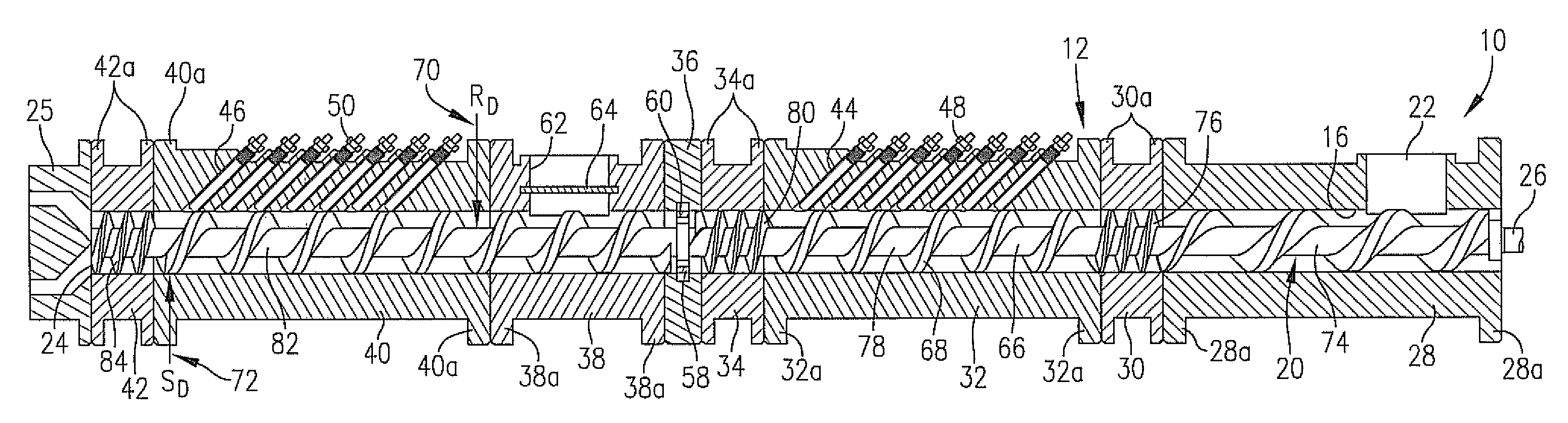

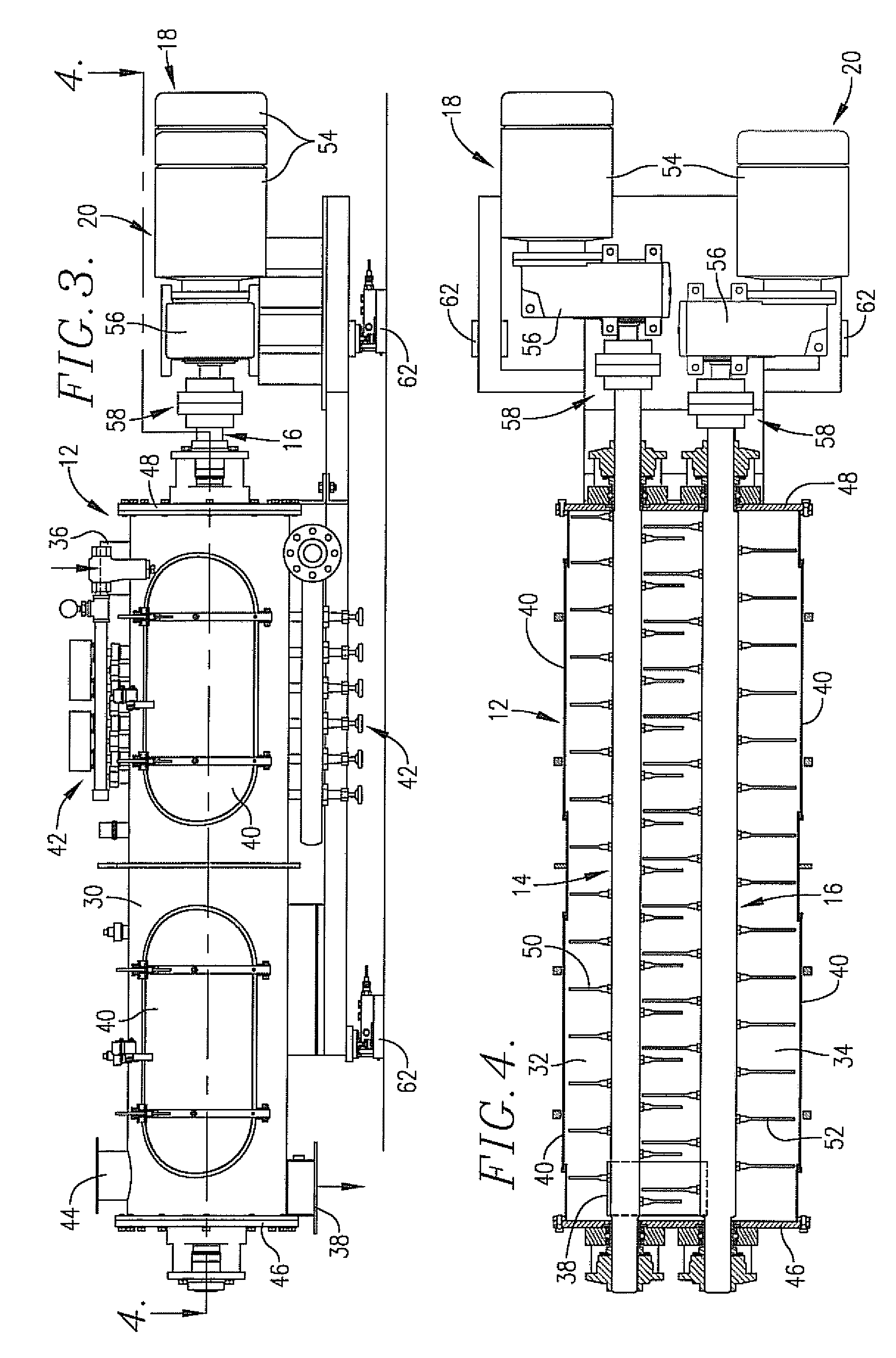

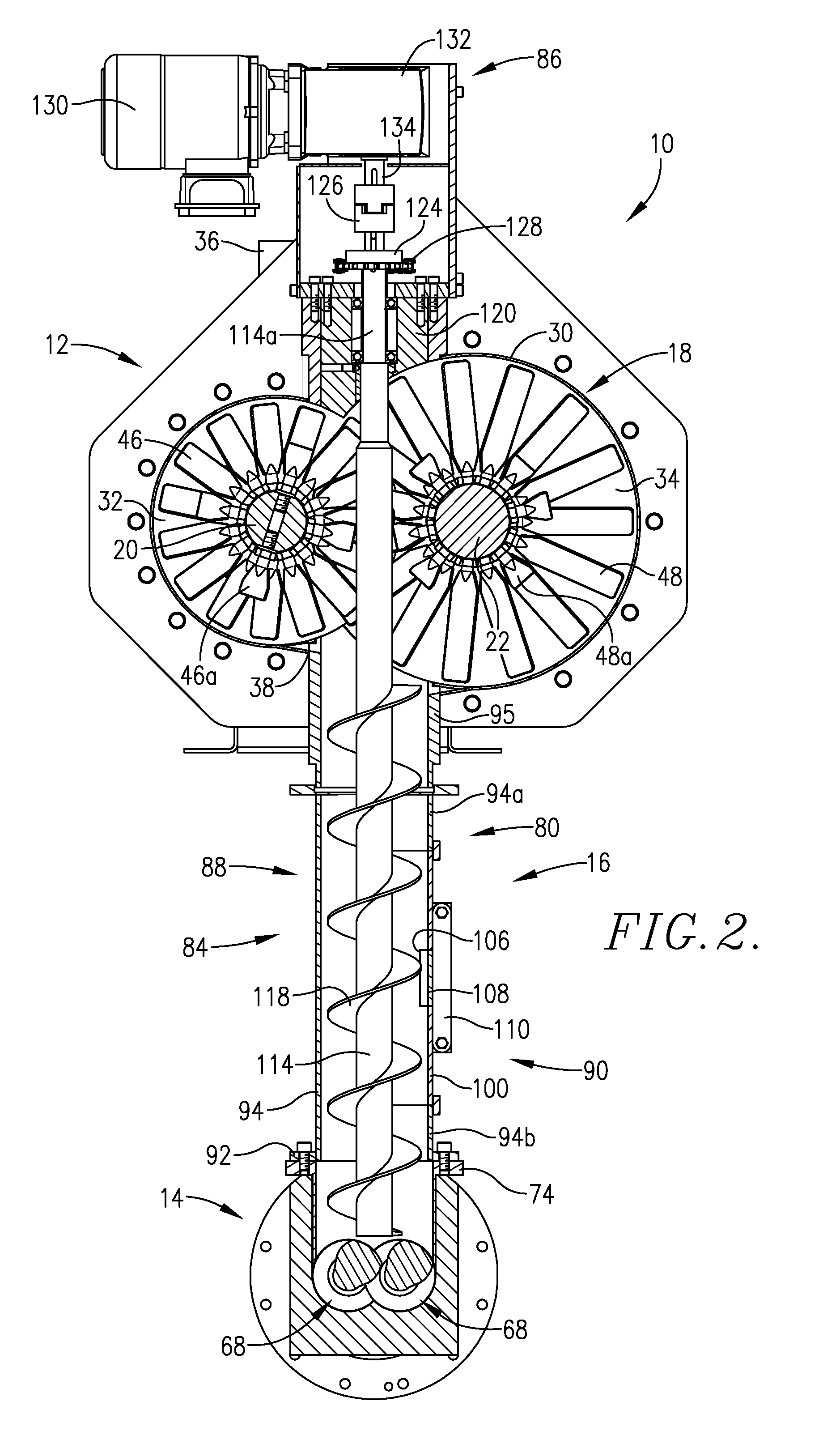

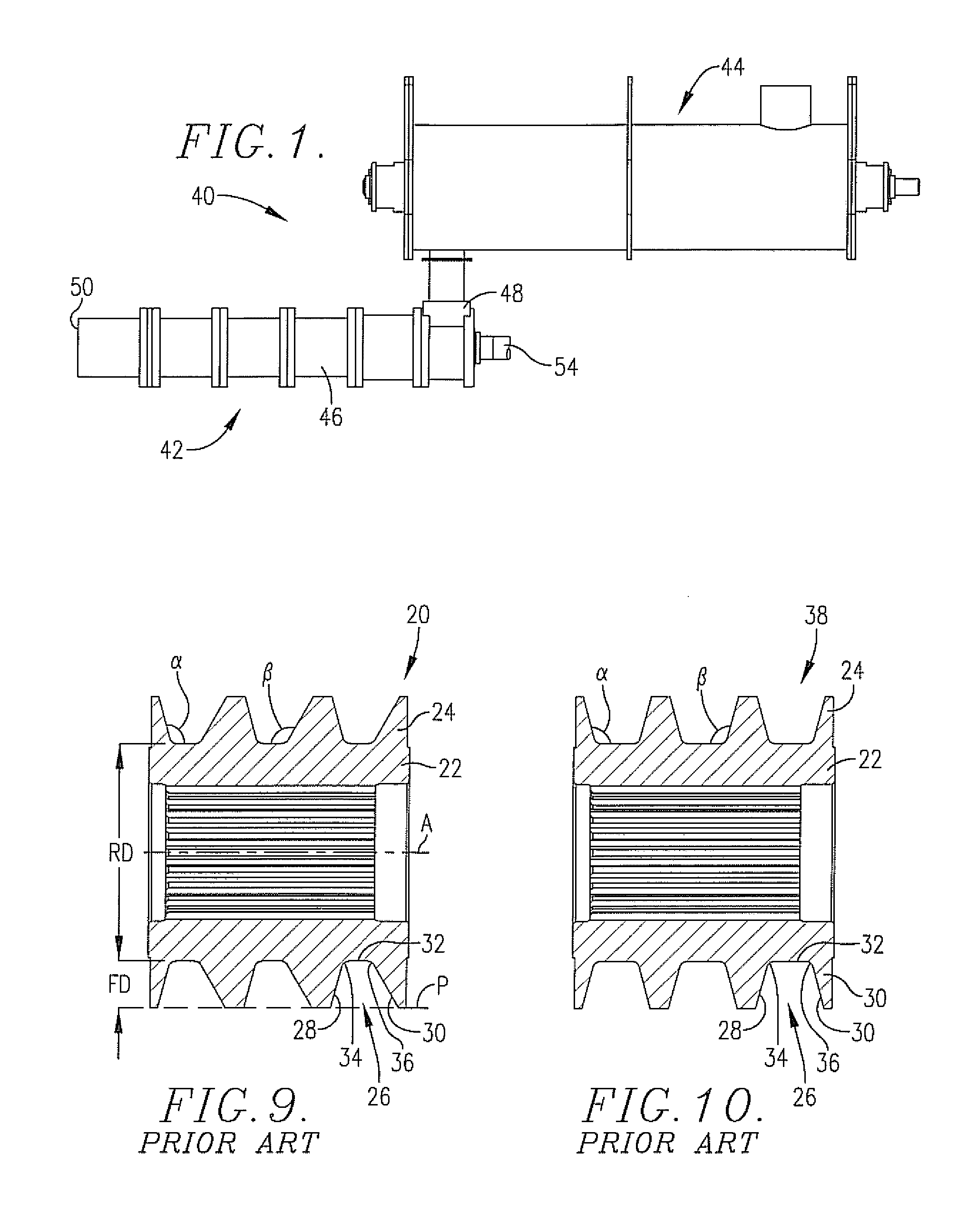

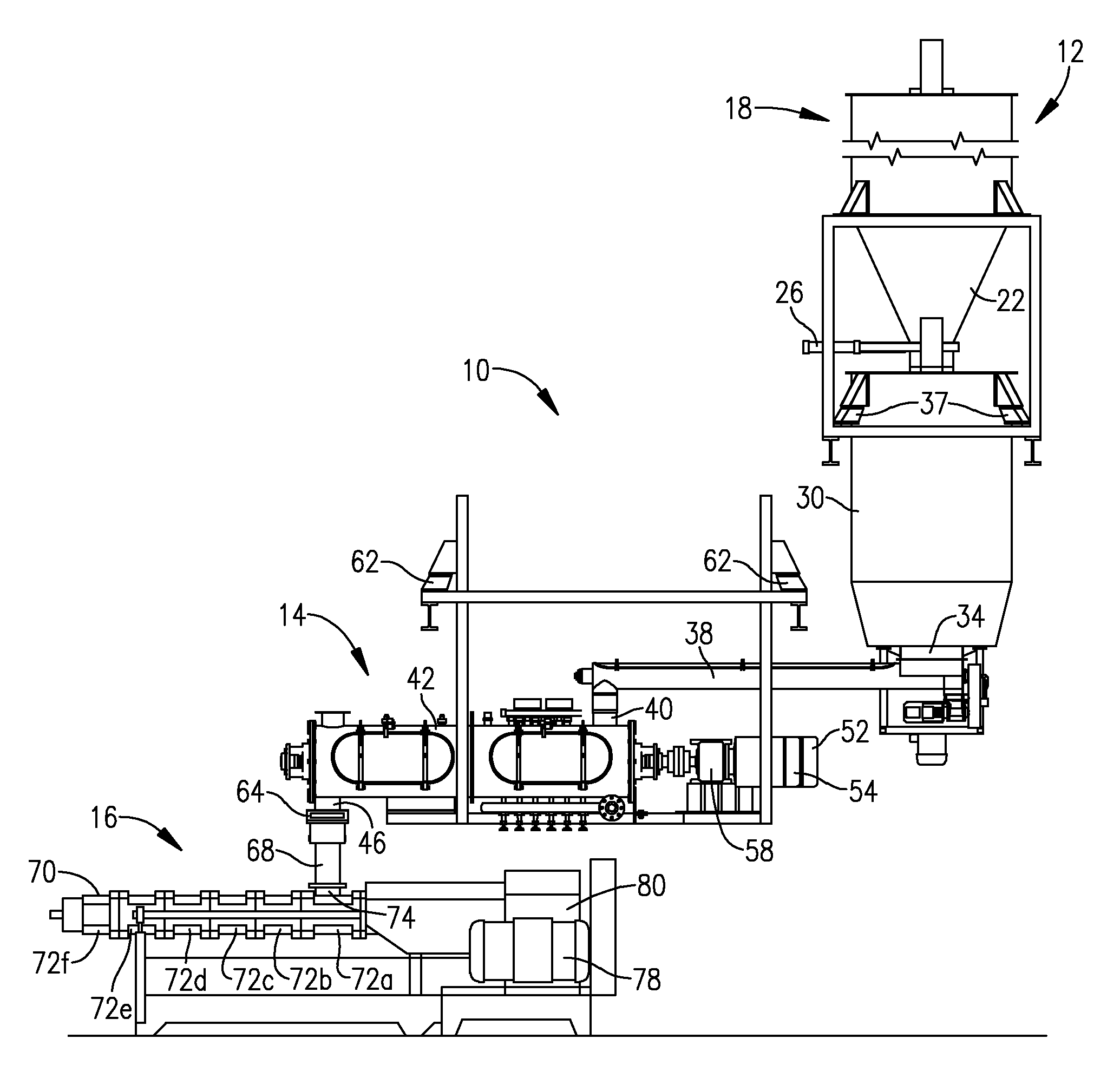

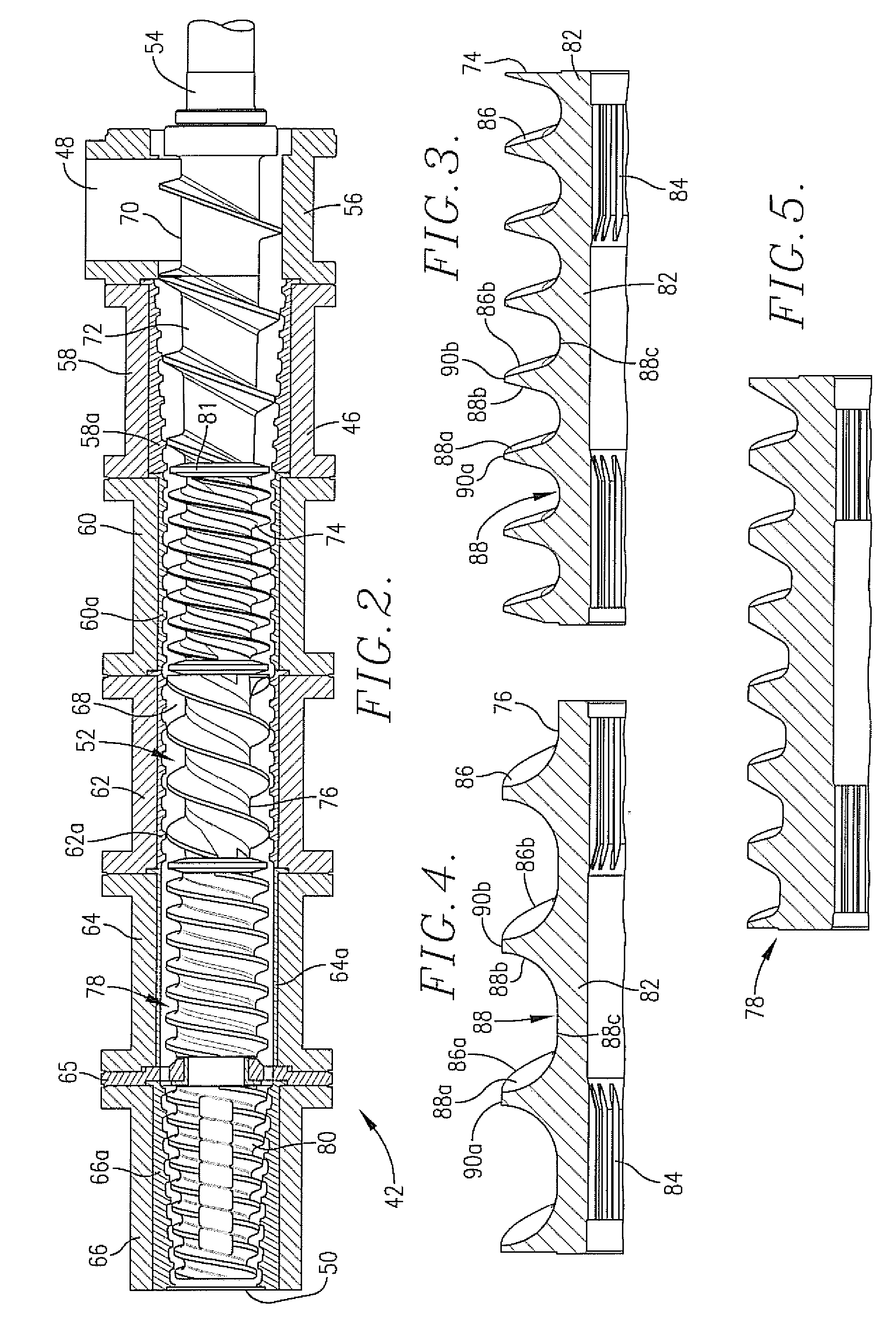

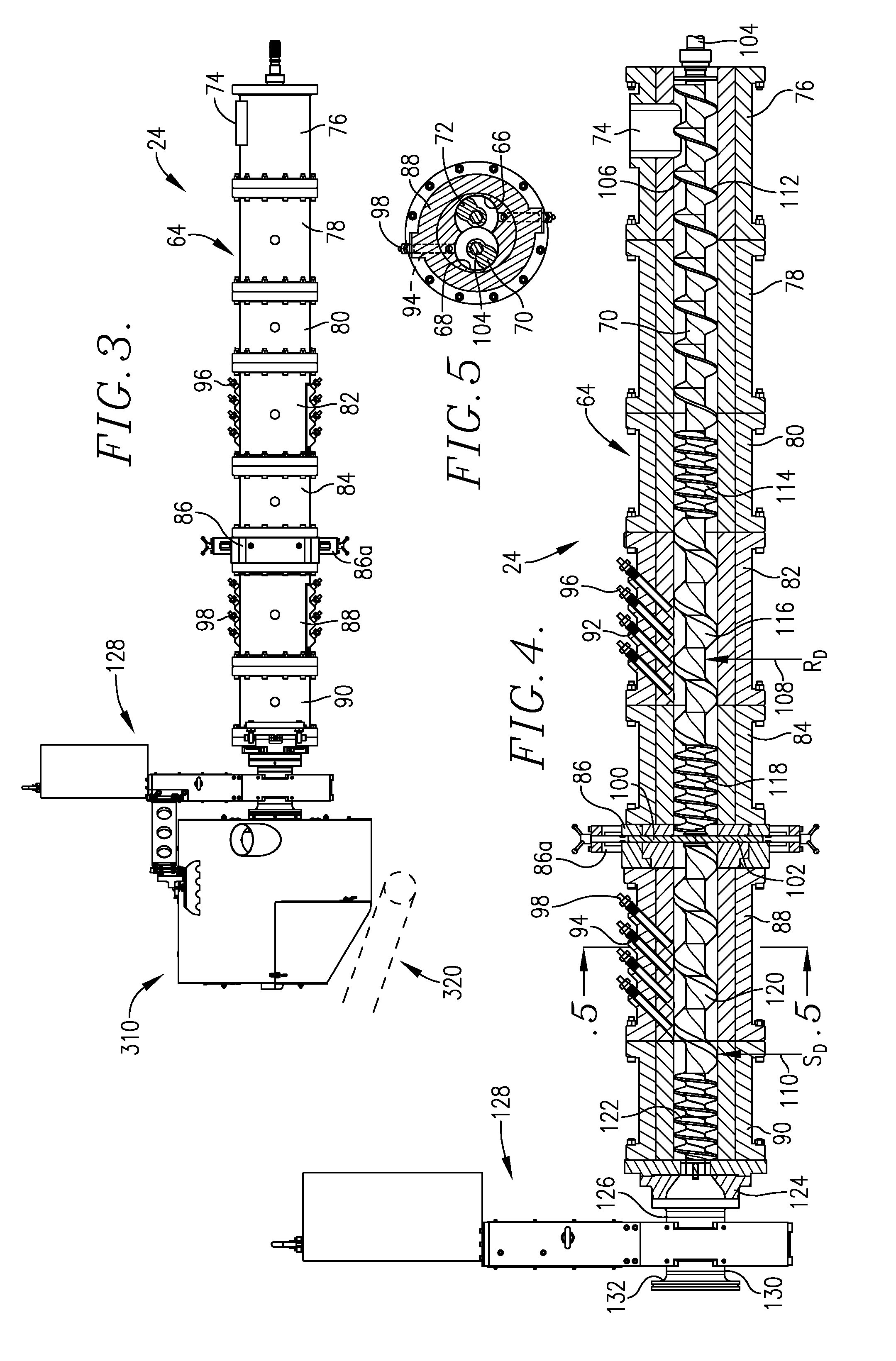

Method and apparatus for producing fully cooked extrudates with significantly reduced specific mechanical energy inputs

ActiveUS7521076B1The implementation process is simpleLow costMilk preservationFeeding-stuffEngineeringPreconditioner

Improved extruders and methods for the extrusion cooking of comestible products such as human foods or animal feeds are provided wherein the products may be produced with very low specific mechanical energy (SME) inputs as compared with conventional processing. The methods preferably involve introduction of very high levels of steam into the extruder barrel (12) during processing, which concomitantly reduces necessary SME inputs required to achieve desired cook and expansion levels in the products. In accordance with the invention, fully-cooked pet foods can be fabricated with SME inputs of up to about 18 kWhr / T, whereas aquatic feeds can be fabricated with SME inputs of up to about 16 kWhr / T. In preferred forms, the extruder (10) includes specially configured, intermeshed extrusion screws (18, 20) and a plurality of obliquely oriented steam inlets (48, 50), and an upstream, dual-shaft preconditioner (90) is used having individual variable frequency drives (98, 100) which allow infinite variablility in the speed and rotational direction of the preconditioner shafts (94, 96).

Owner:WENGER MFG LLC

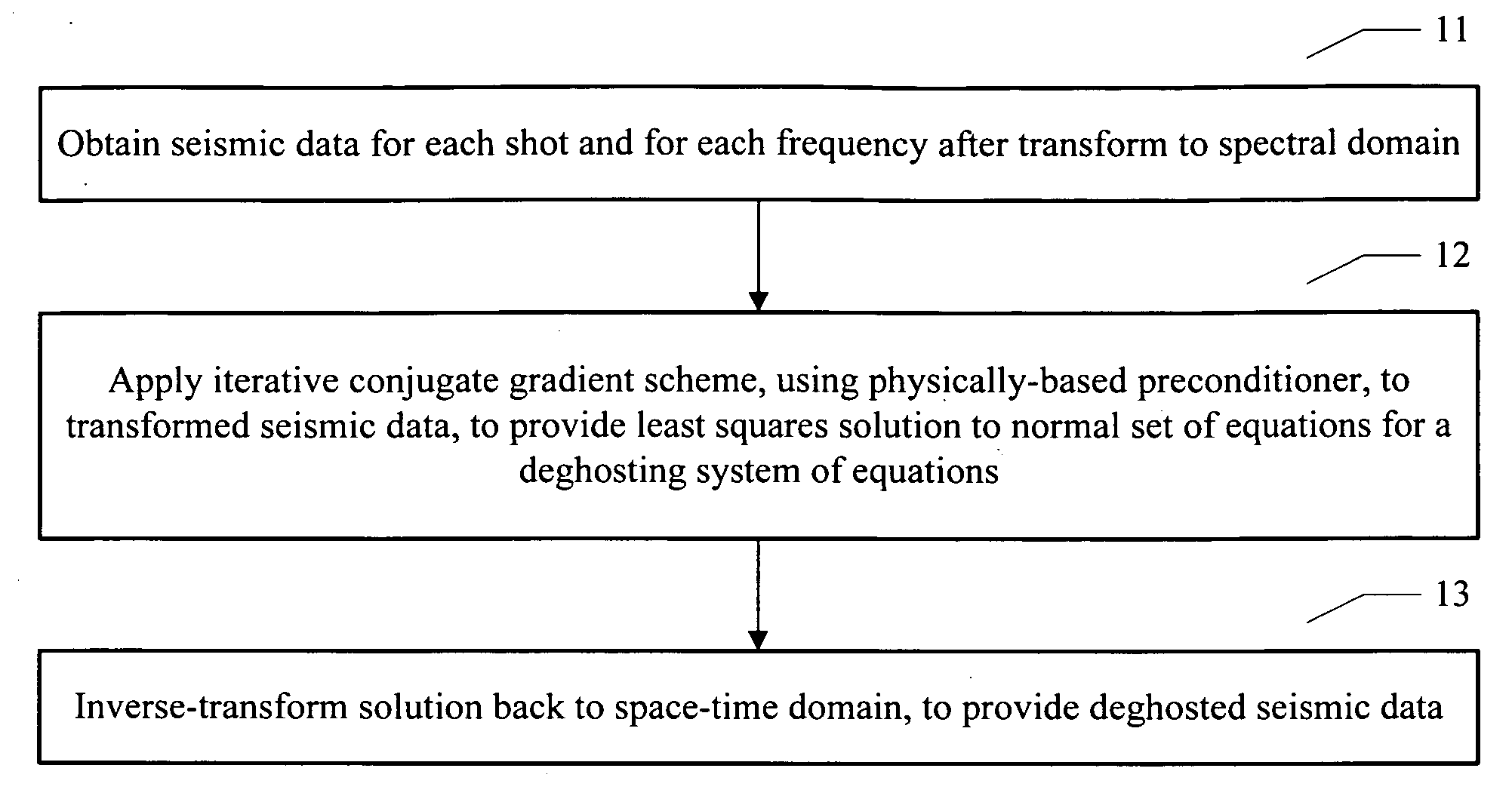

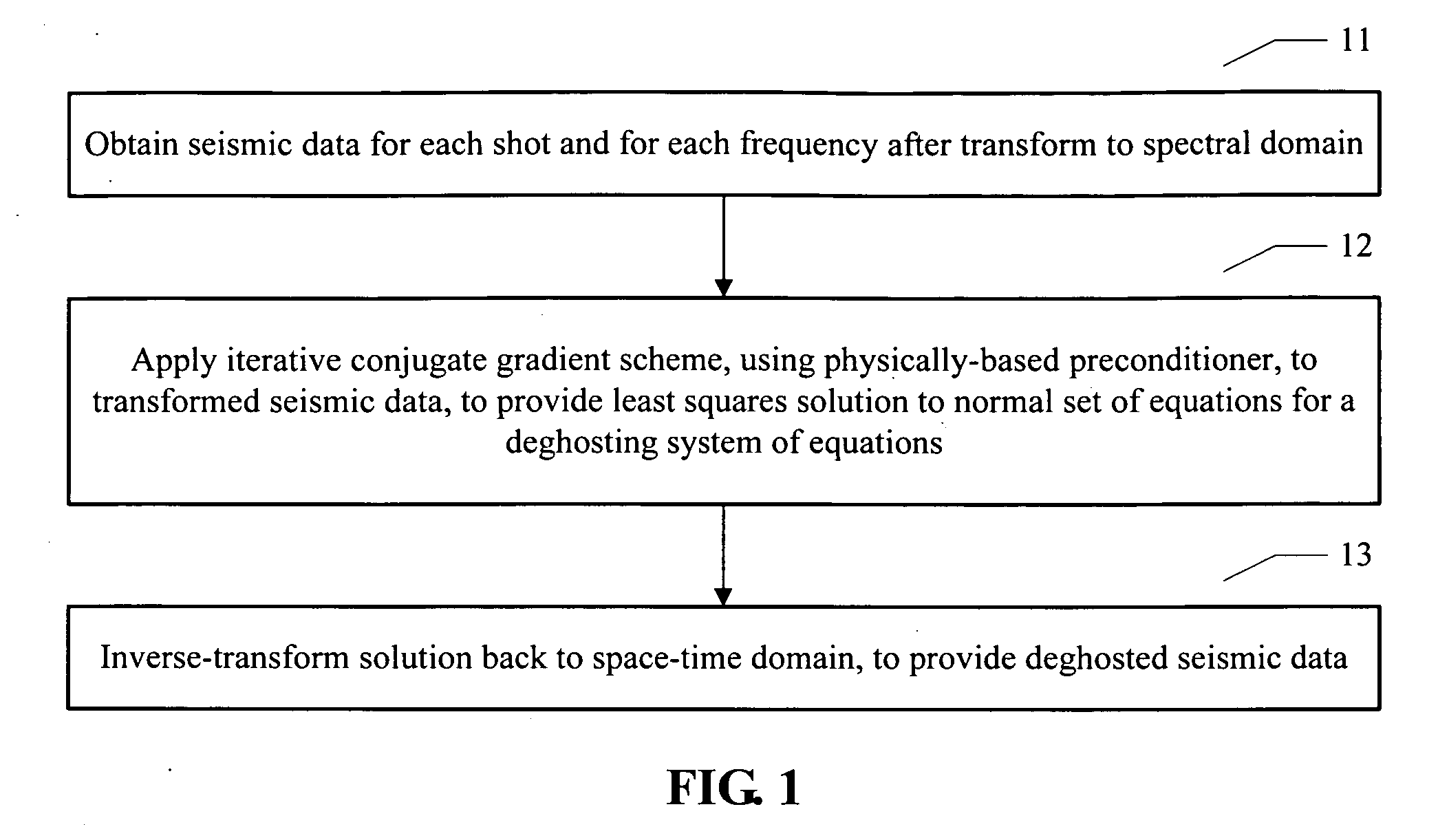

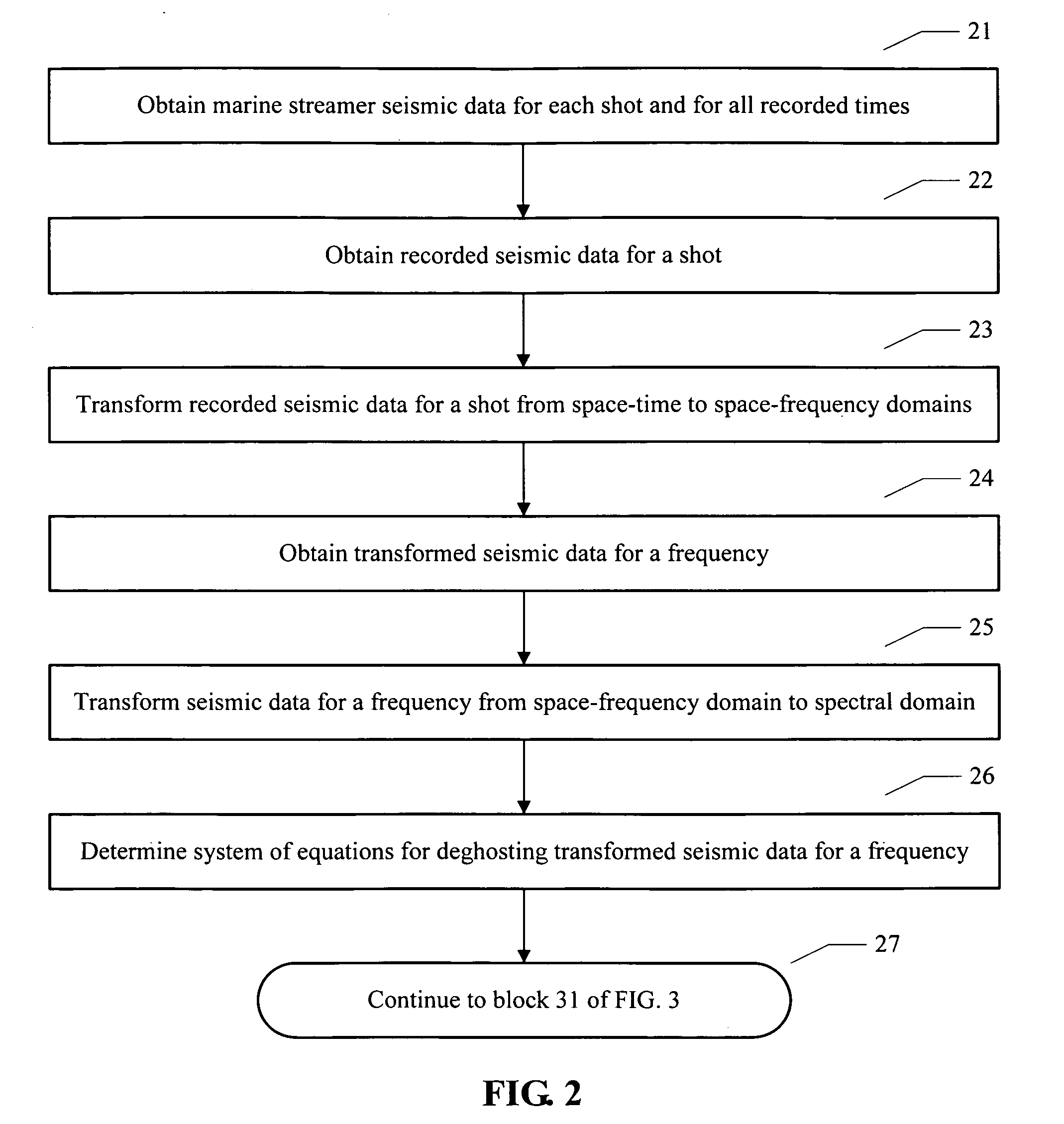

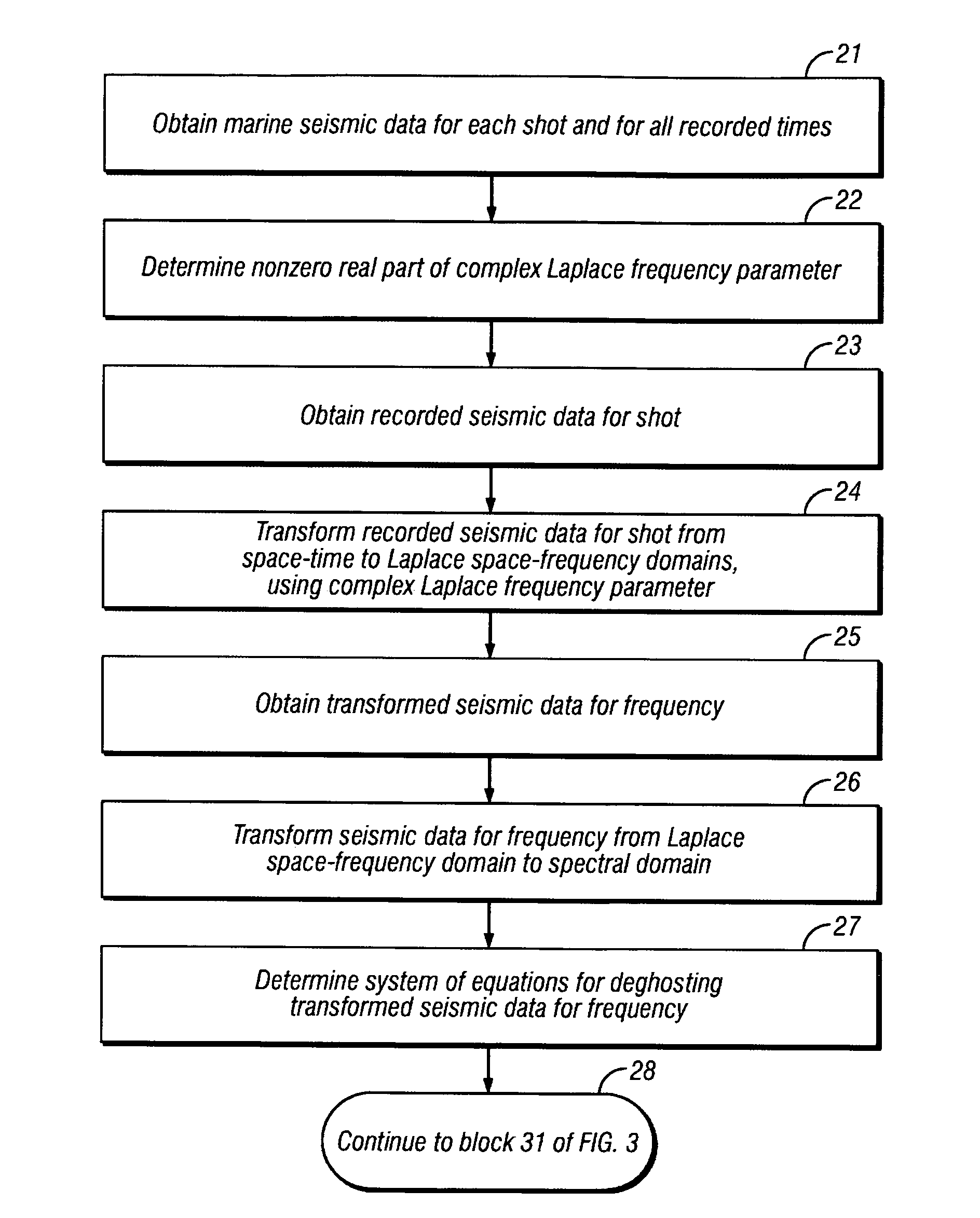

Method for deghosting marine seismic streamer data with irregular receiver positions

InactiveUS20090251992A1Seismic signal receiversSeismic signal processingSpace time domainSpectral domain

Seismic data are obtained for each seismic source activation in a marine streamer and for each frequency, after being transformed to a spectral domain. An iterative conjugate gradient scheme, using a physically-based preconditioner, is applied to the transformed seismic data, to provide a least squares solution to a normal set of equations for a deghosting system of equations. The solution is inverse-transformed back to a space-time domain to provide deghosted seismic data.

Owner:PGS GEOPHYSICAL AS +1

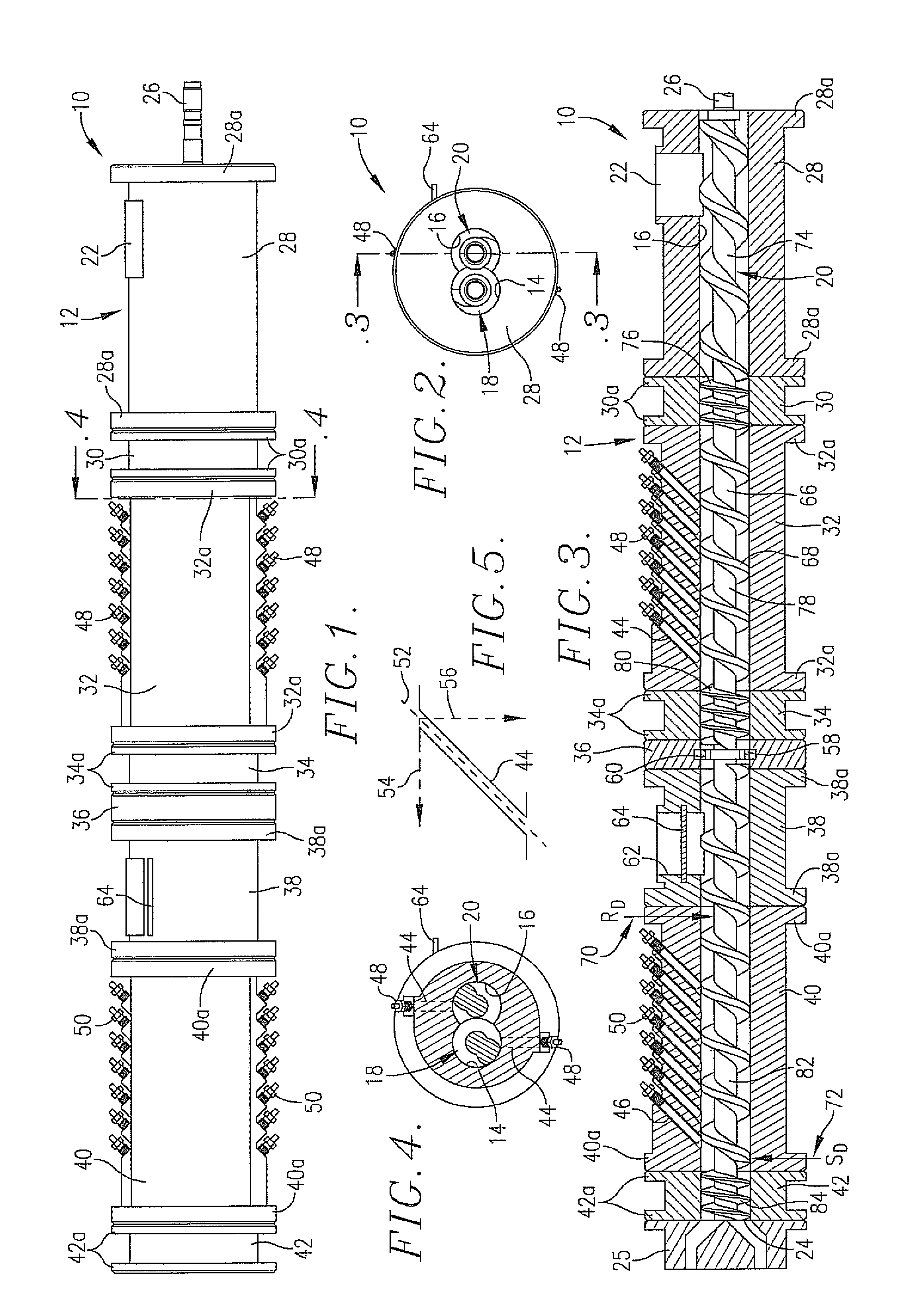

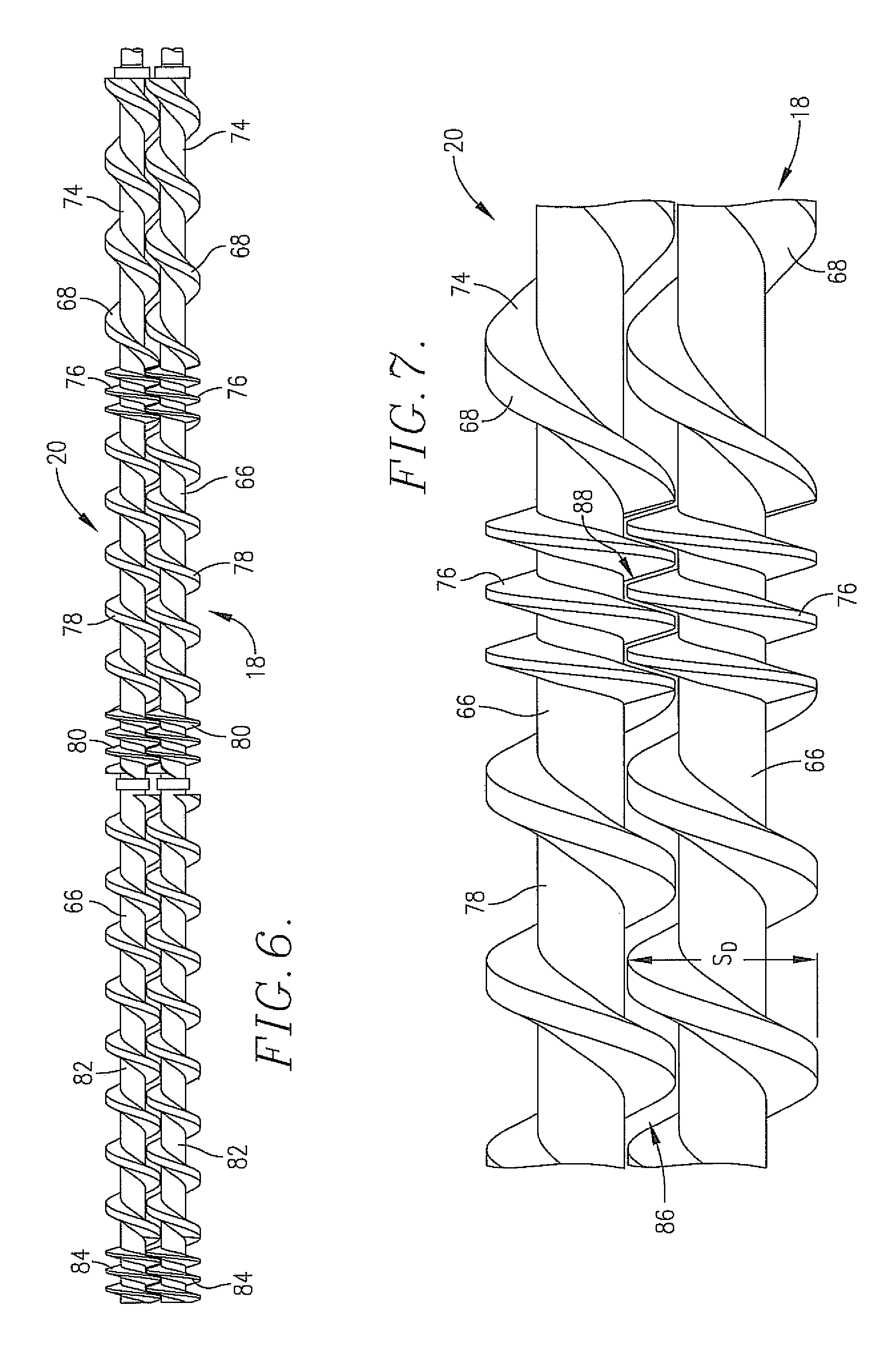

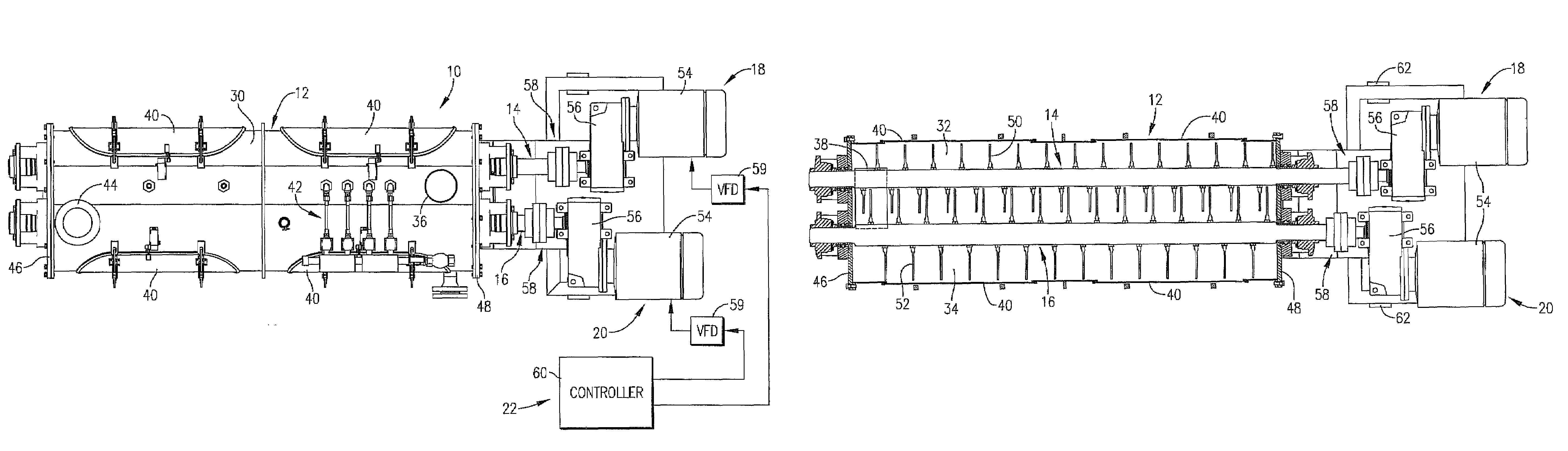

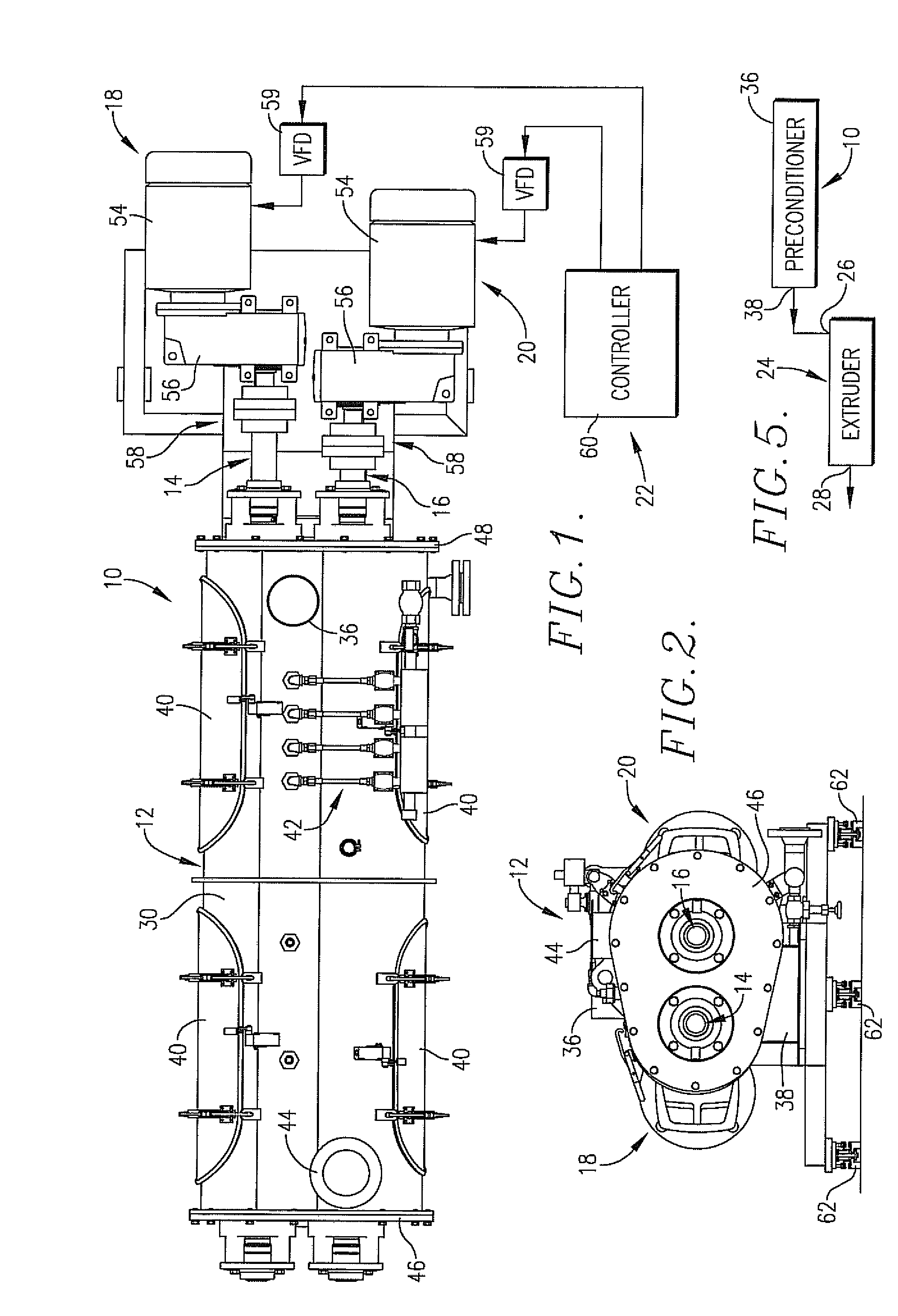

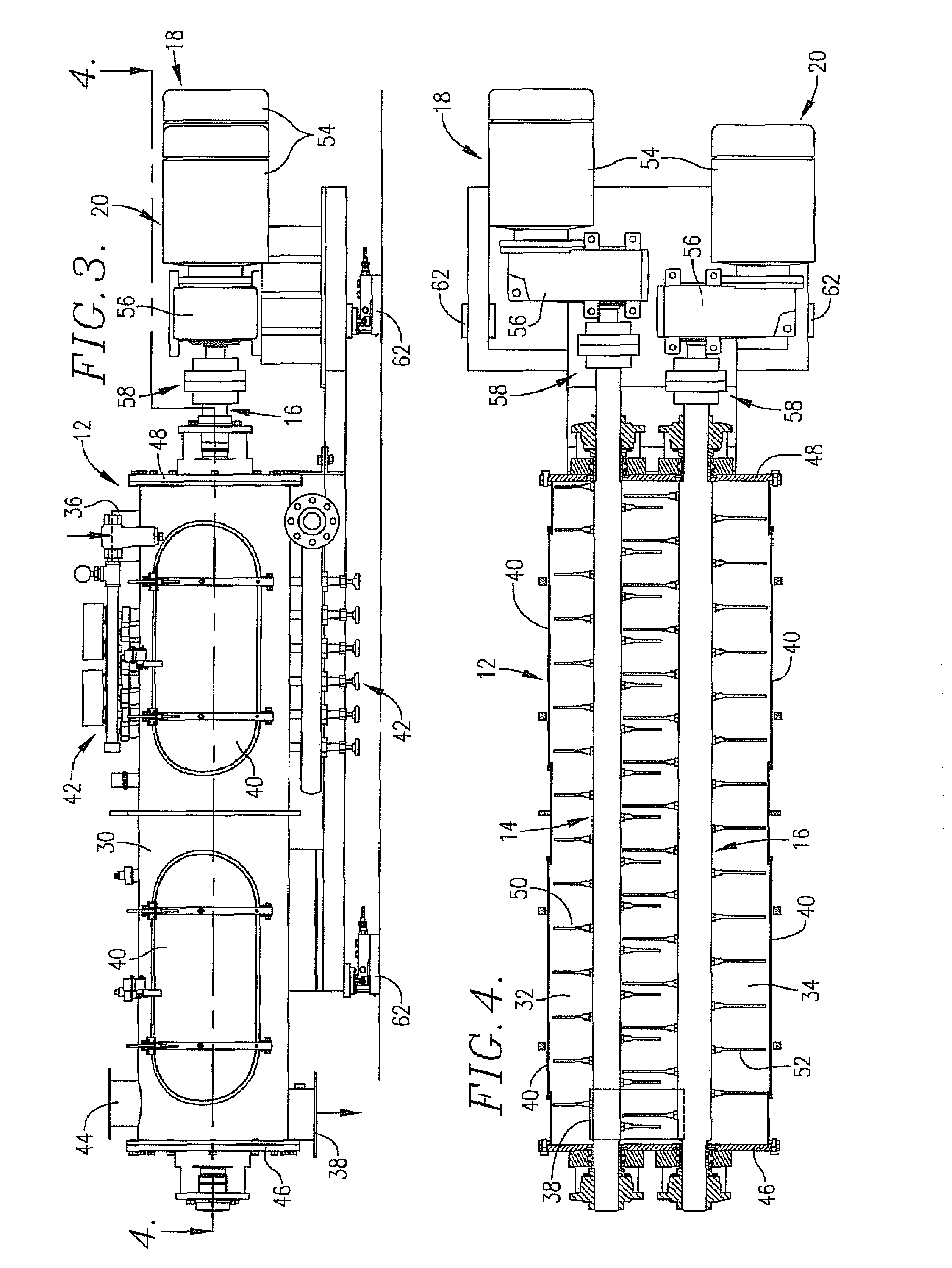

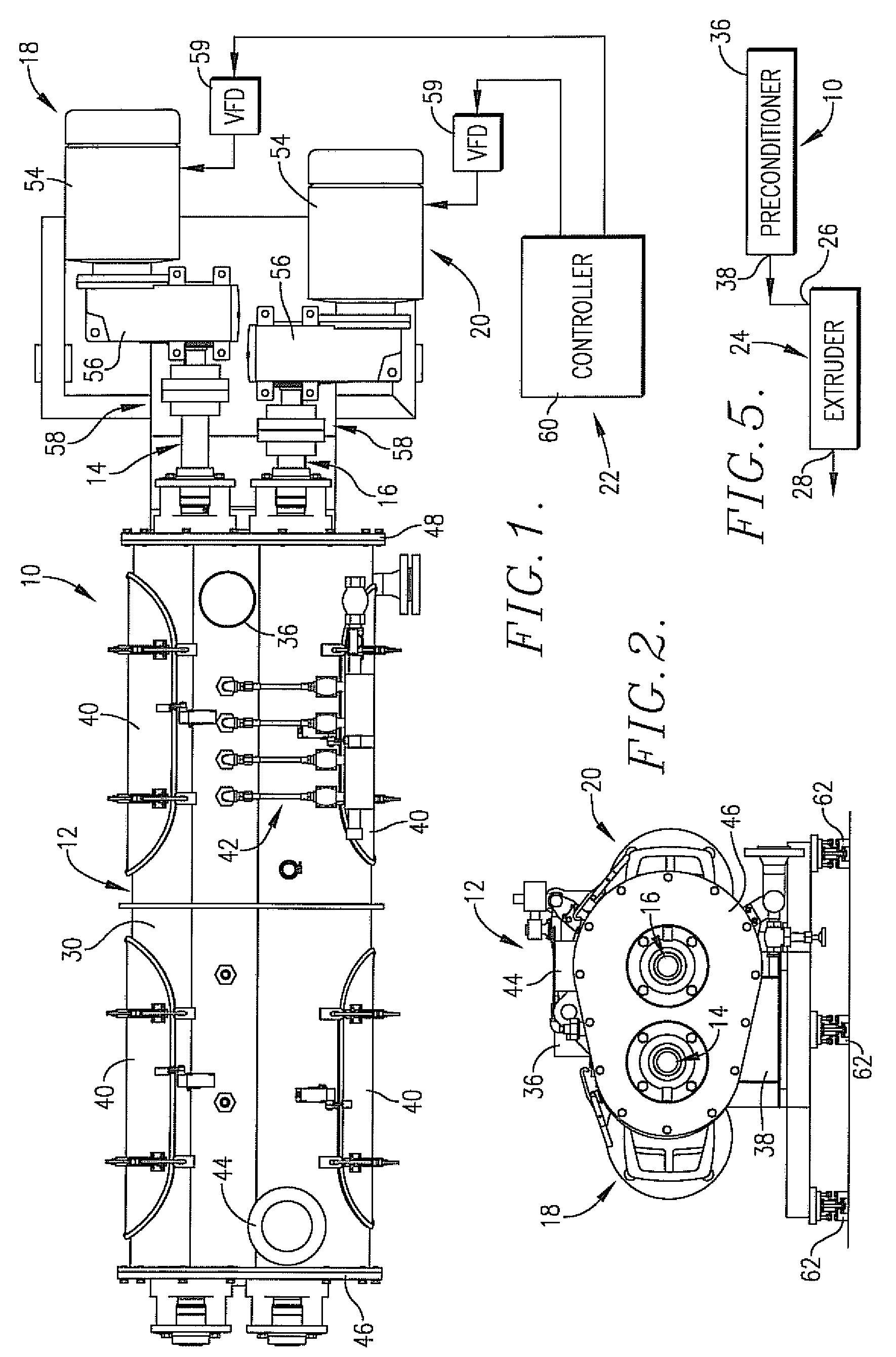

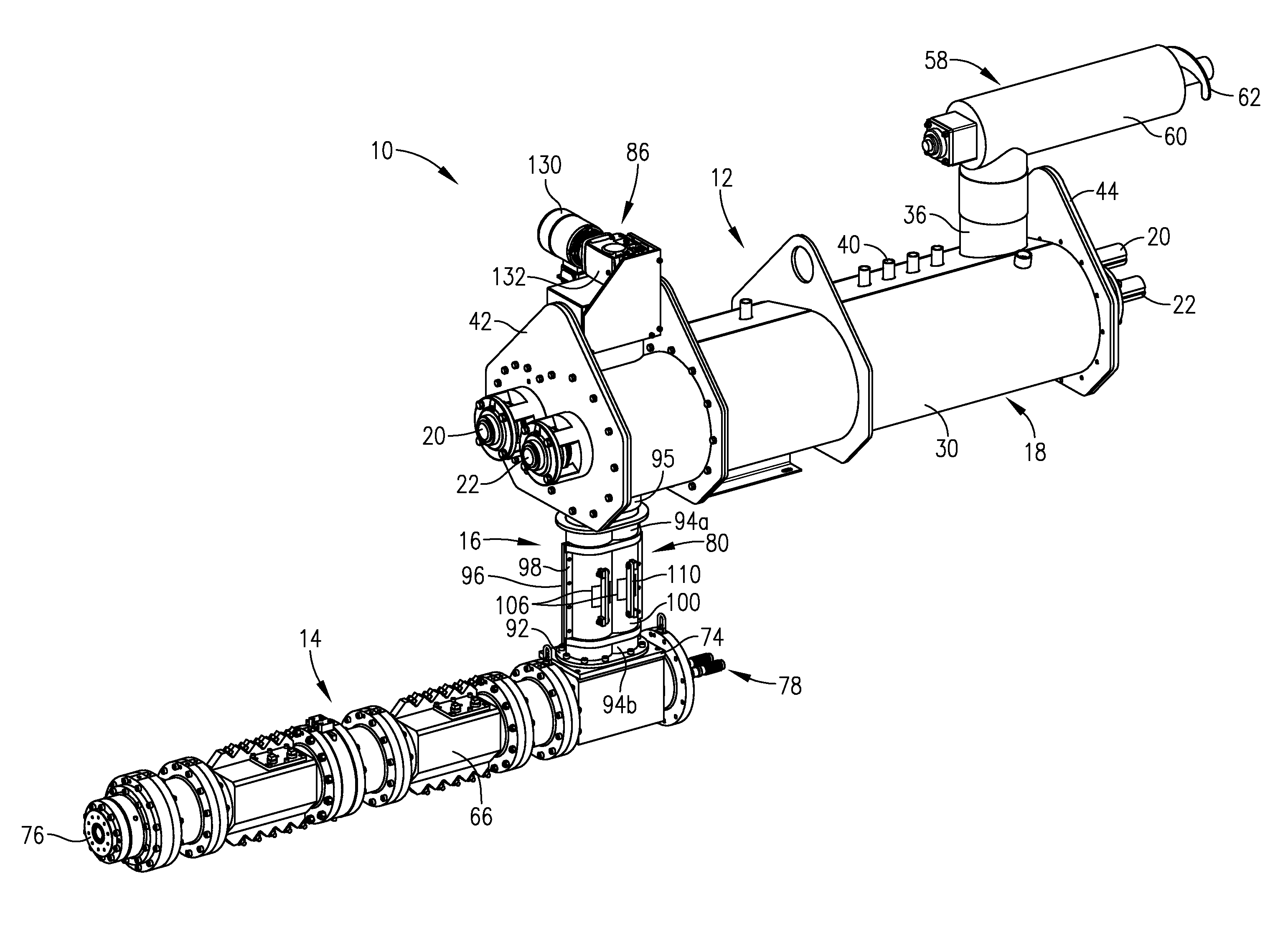

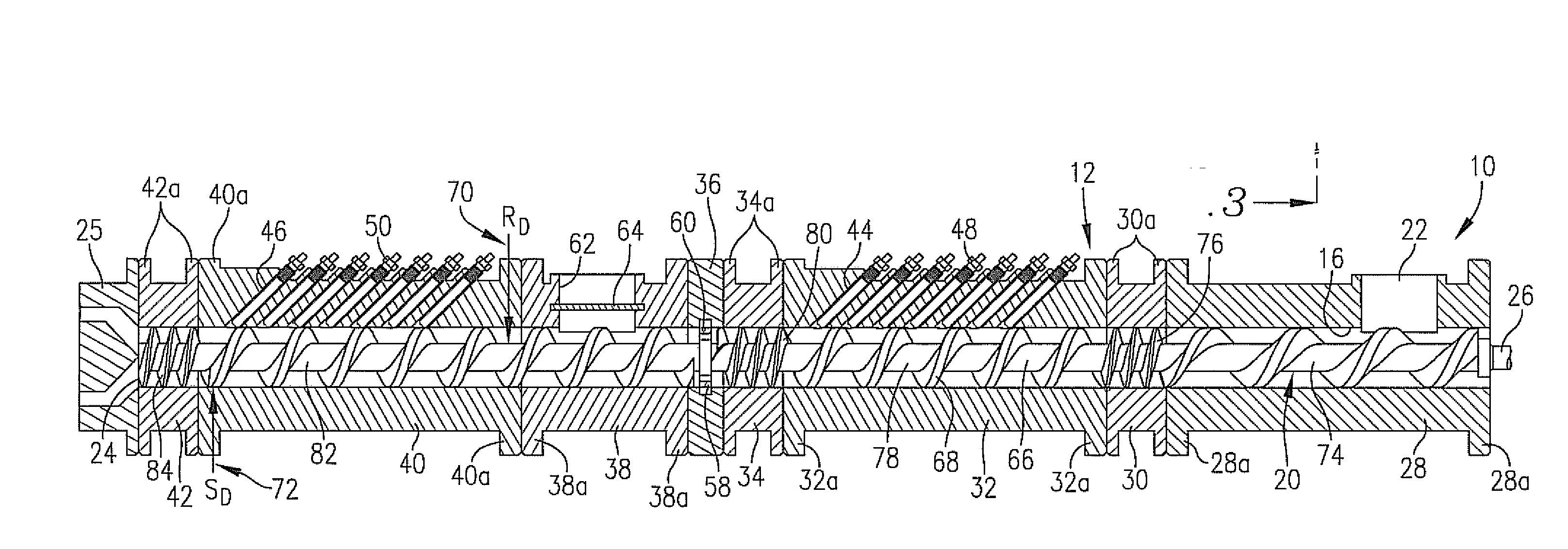

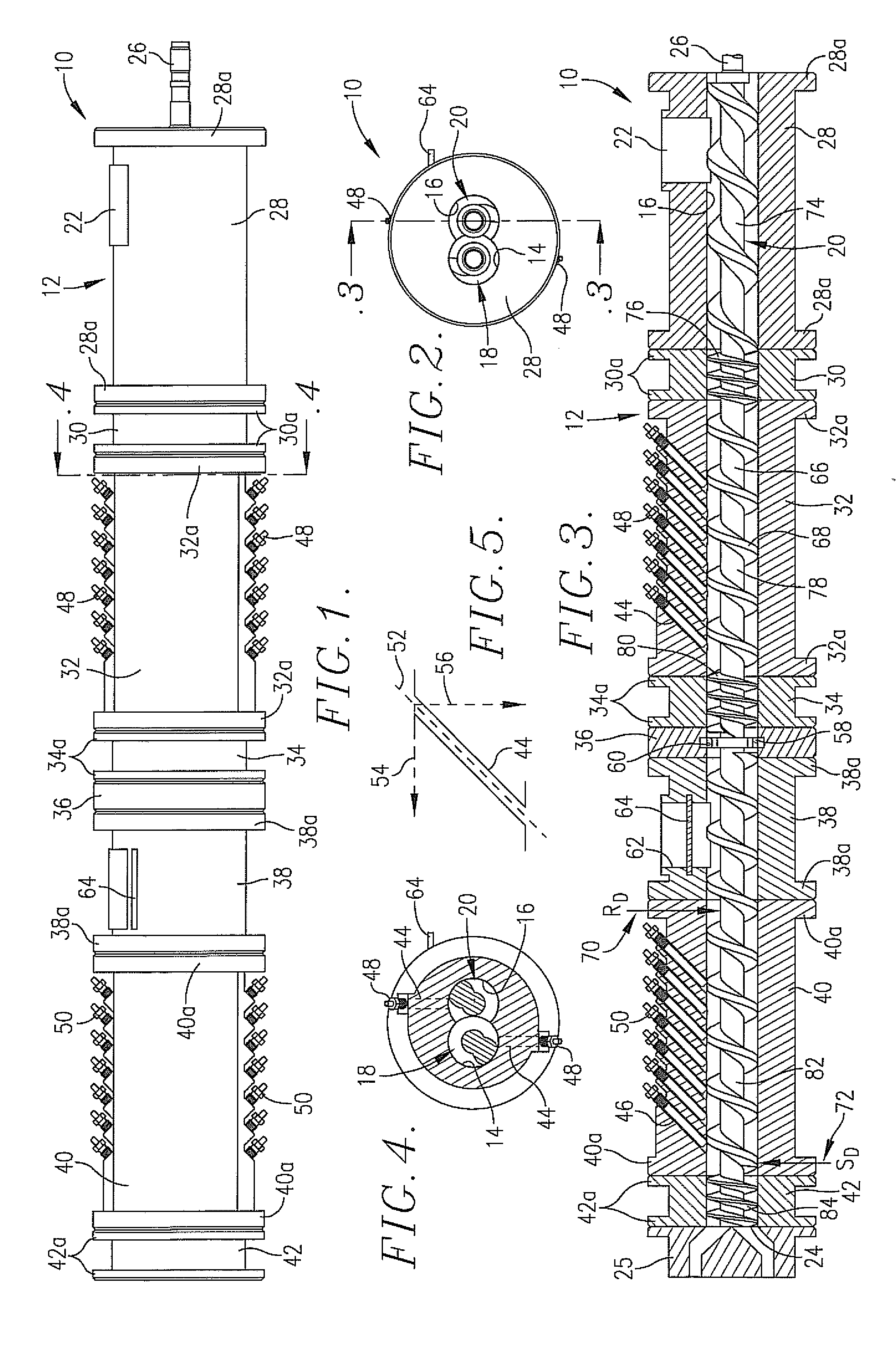

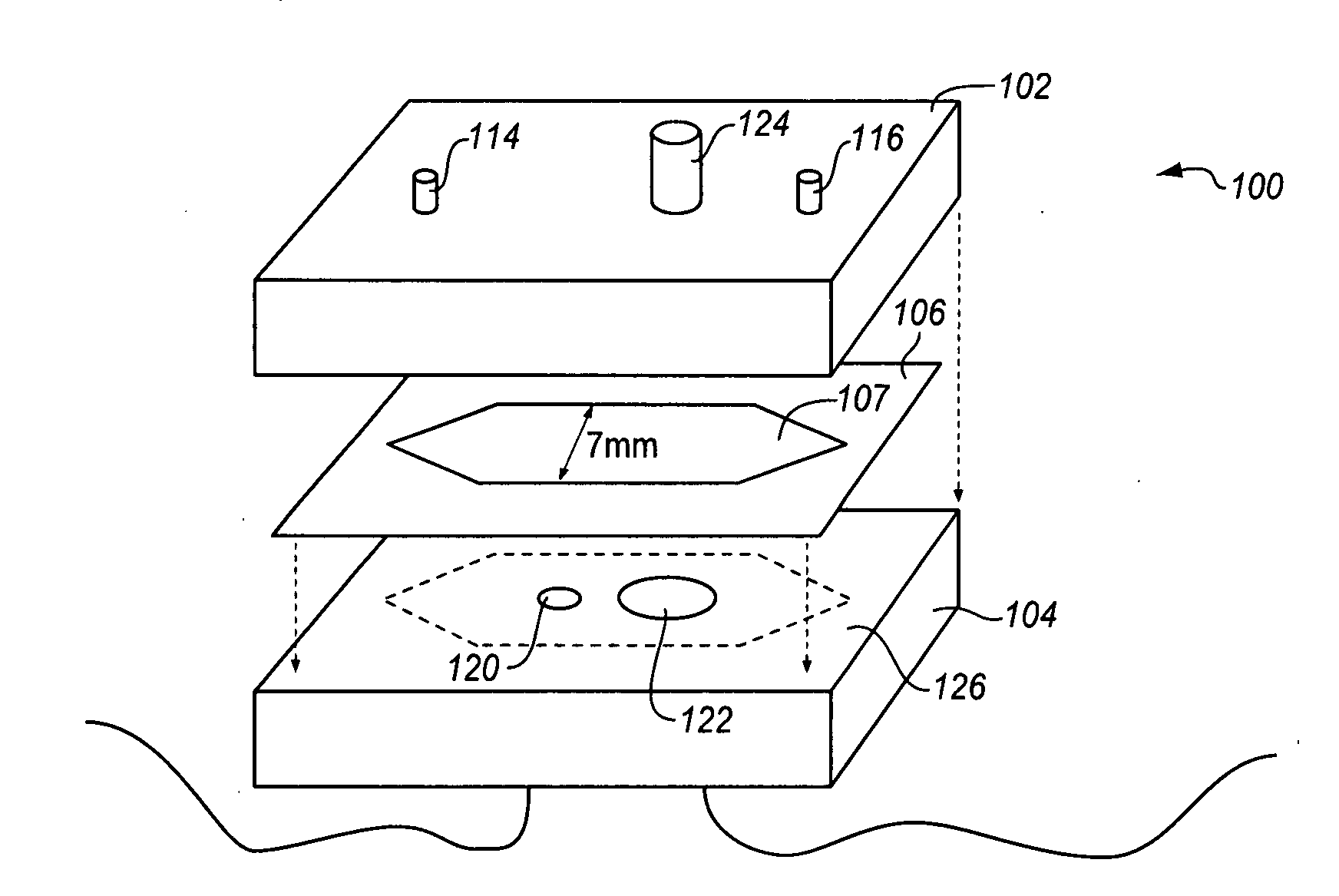

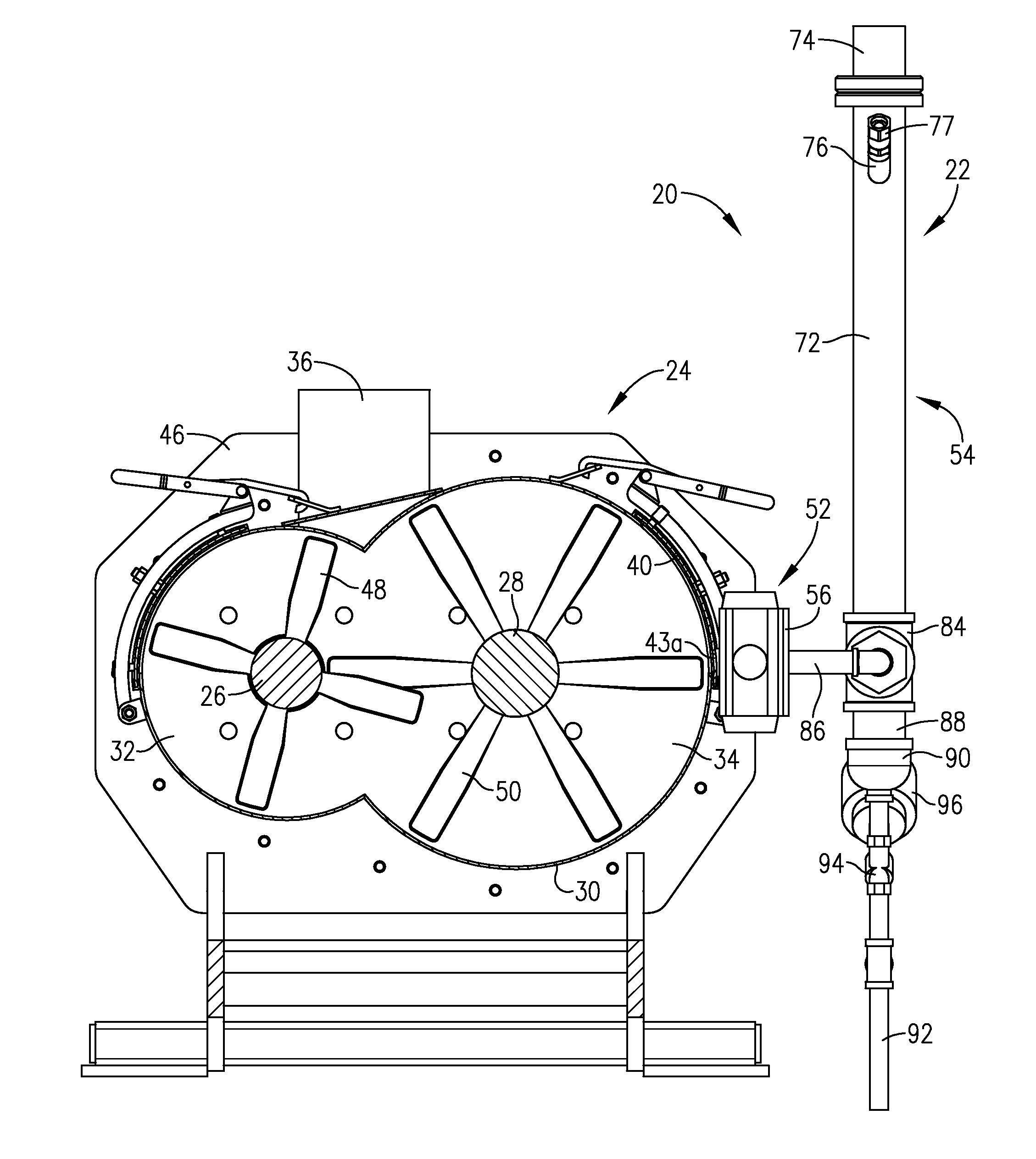

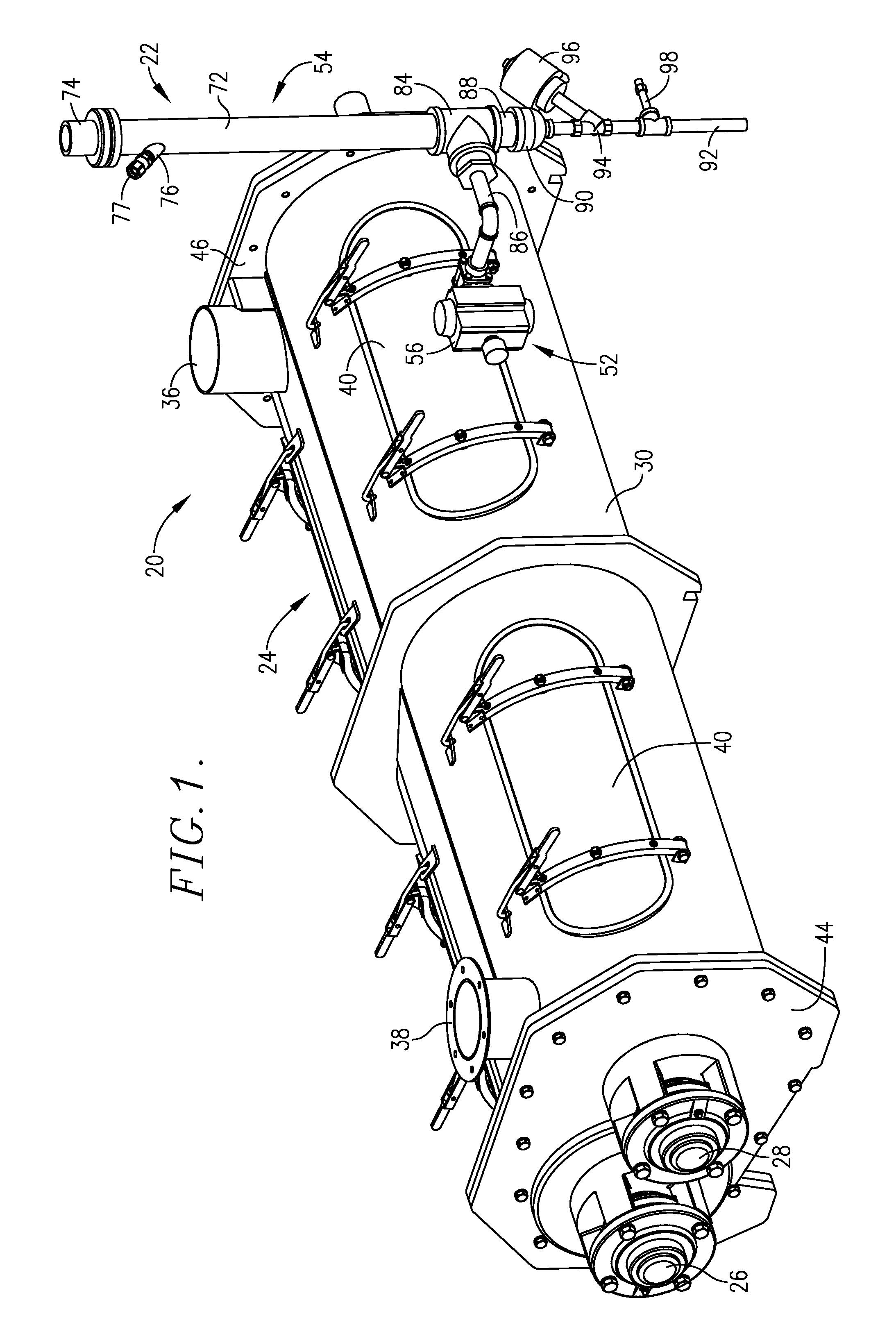

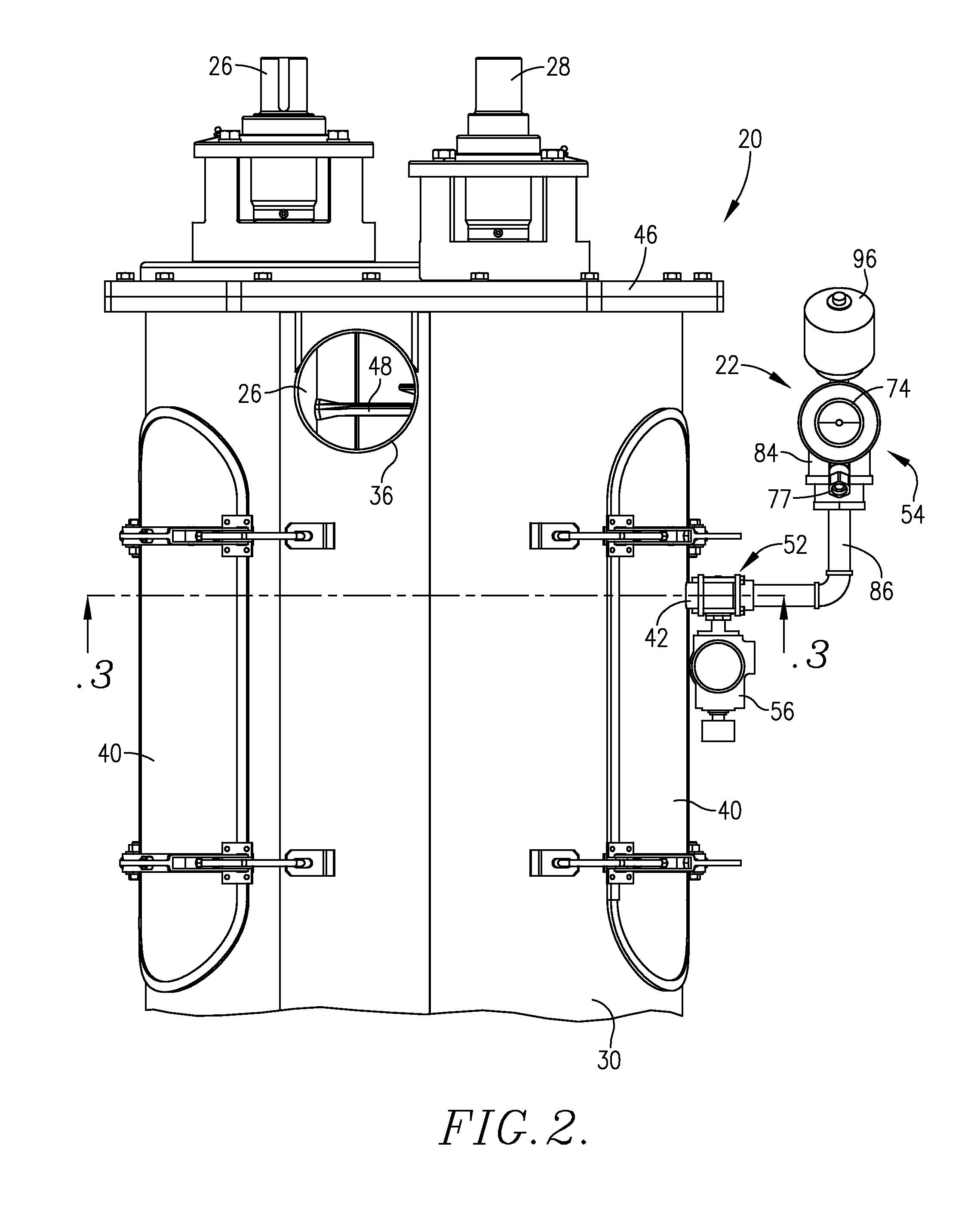

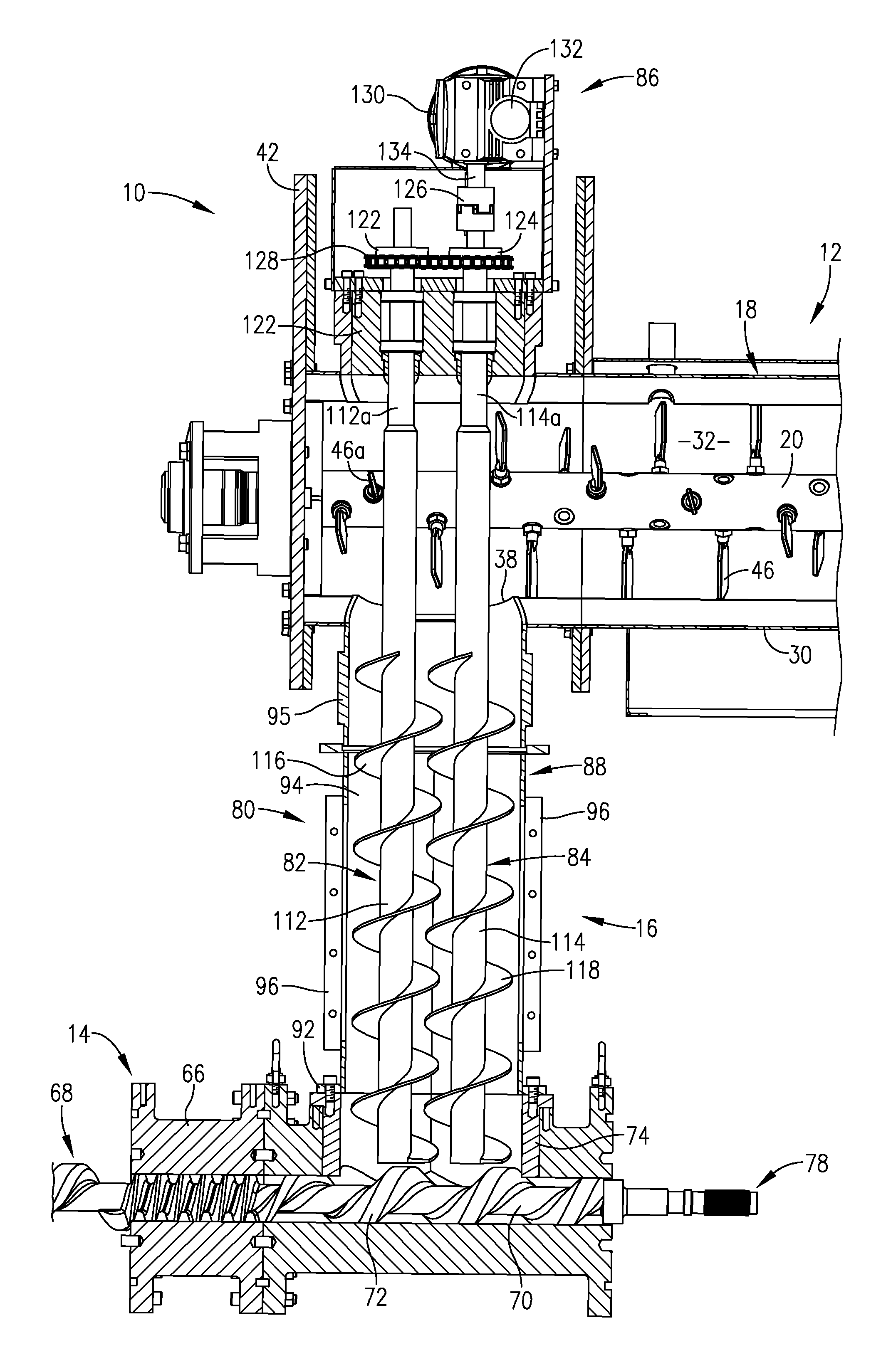

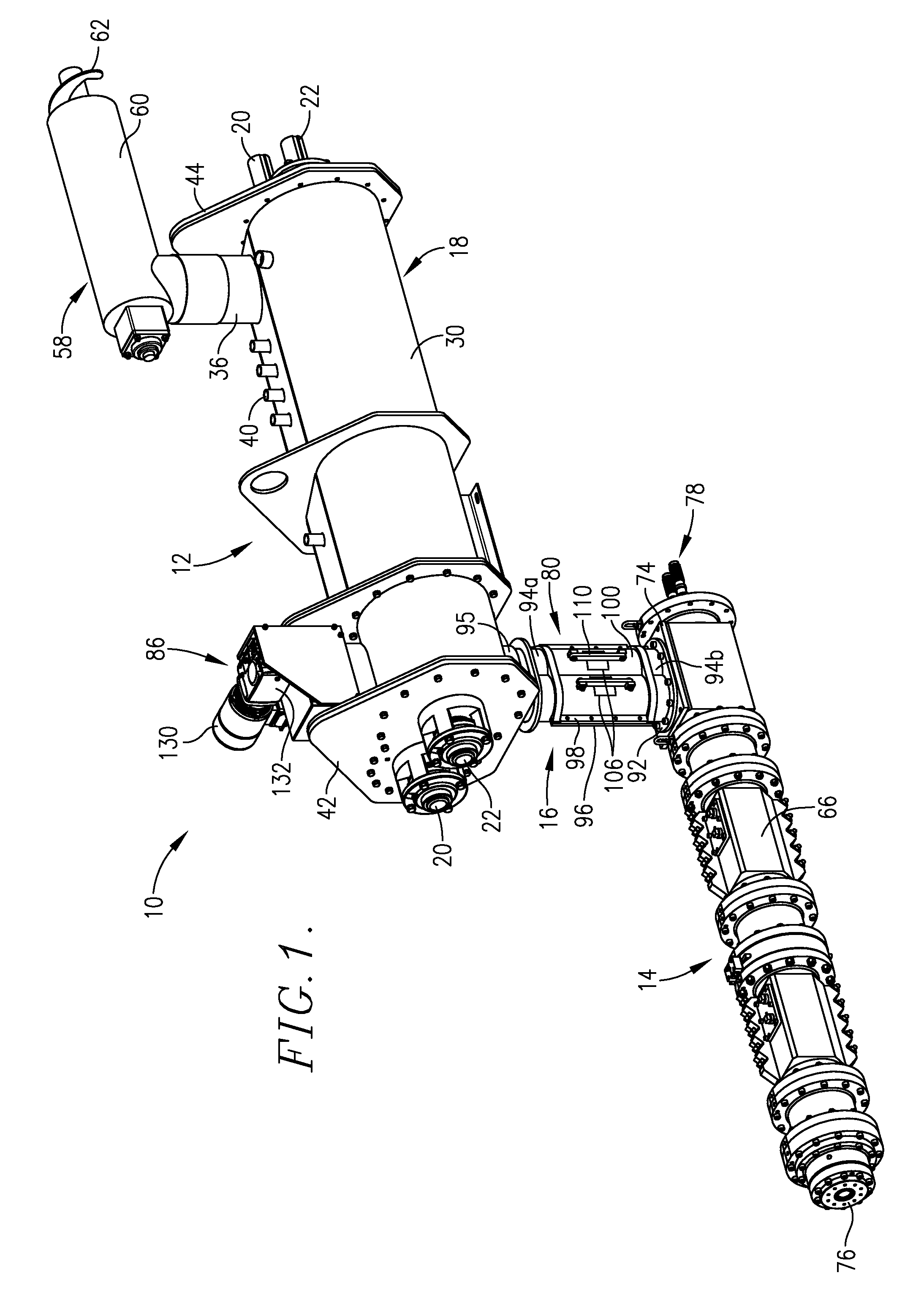

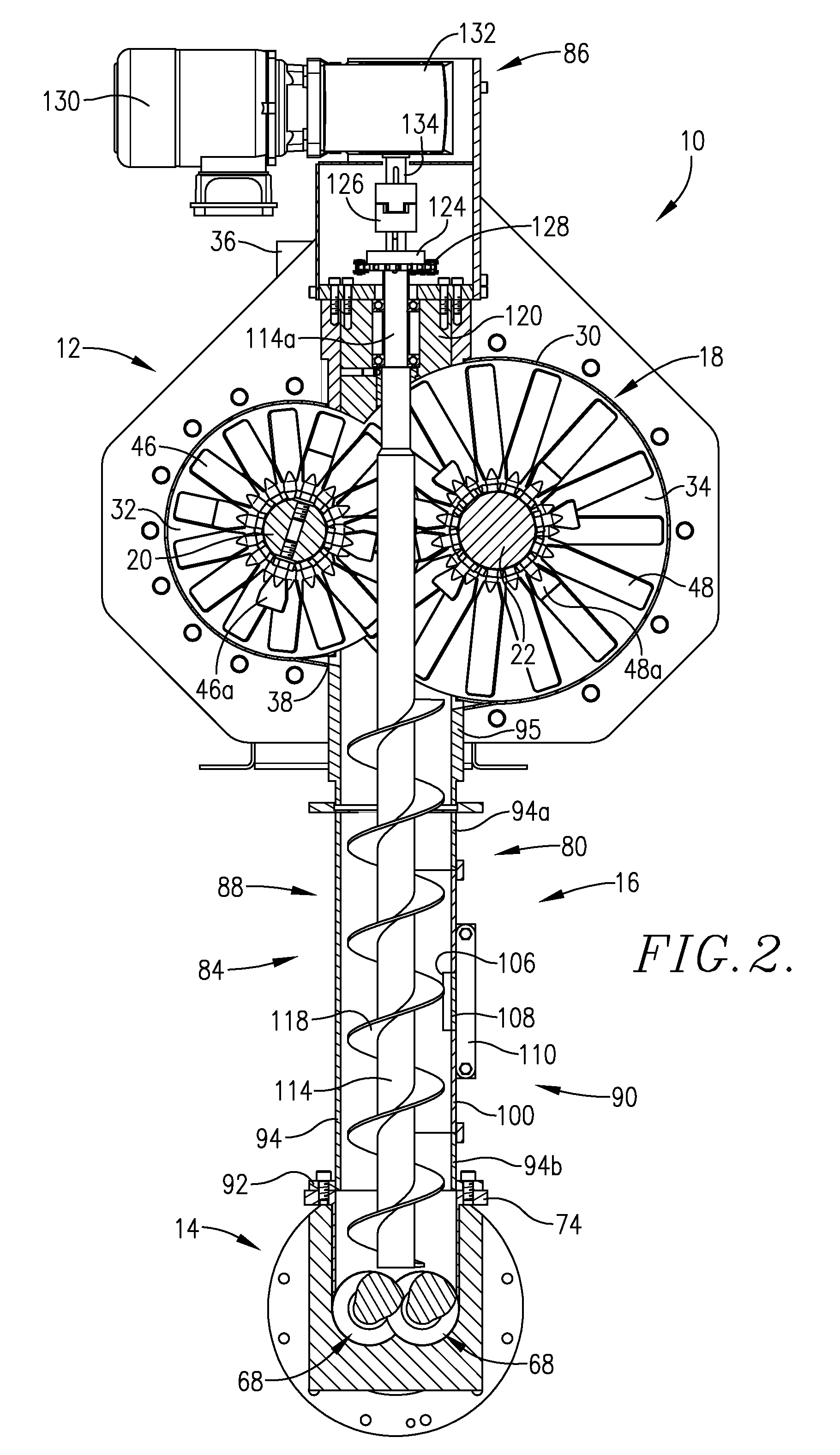

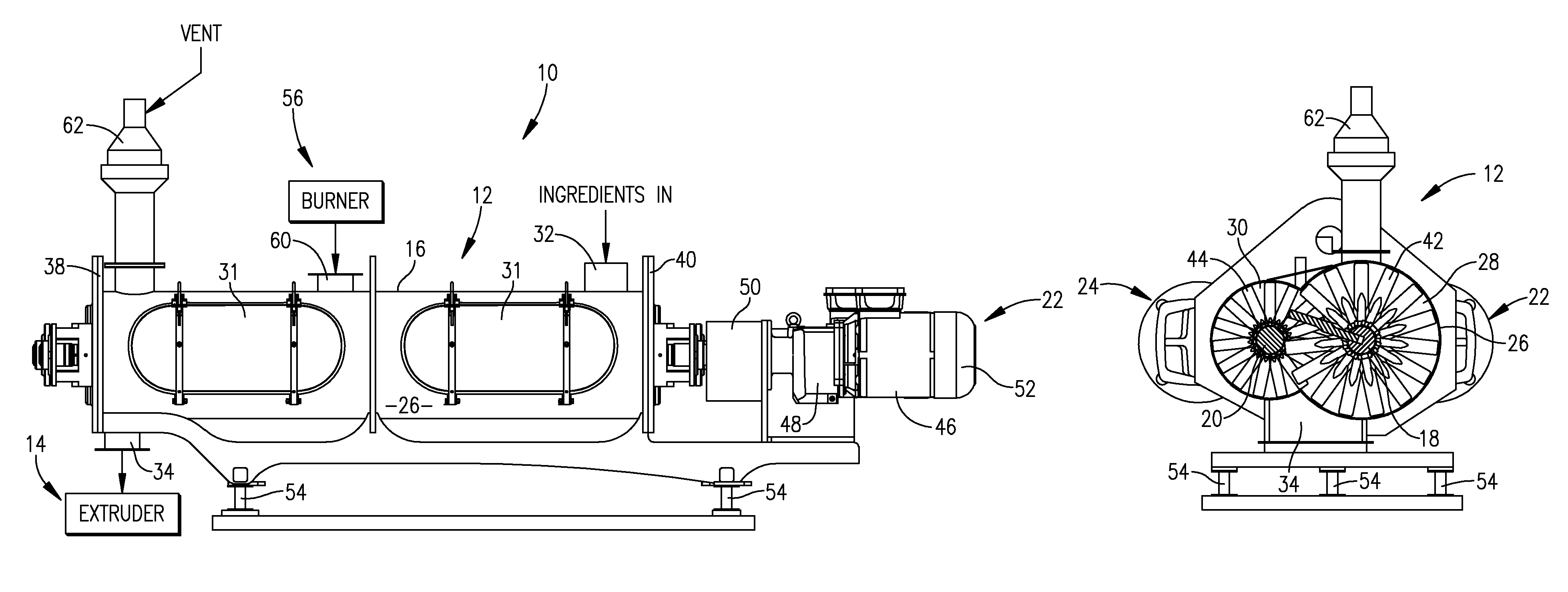

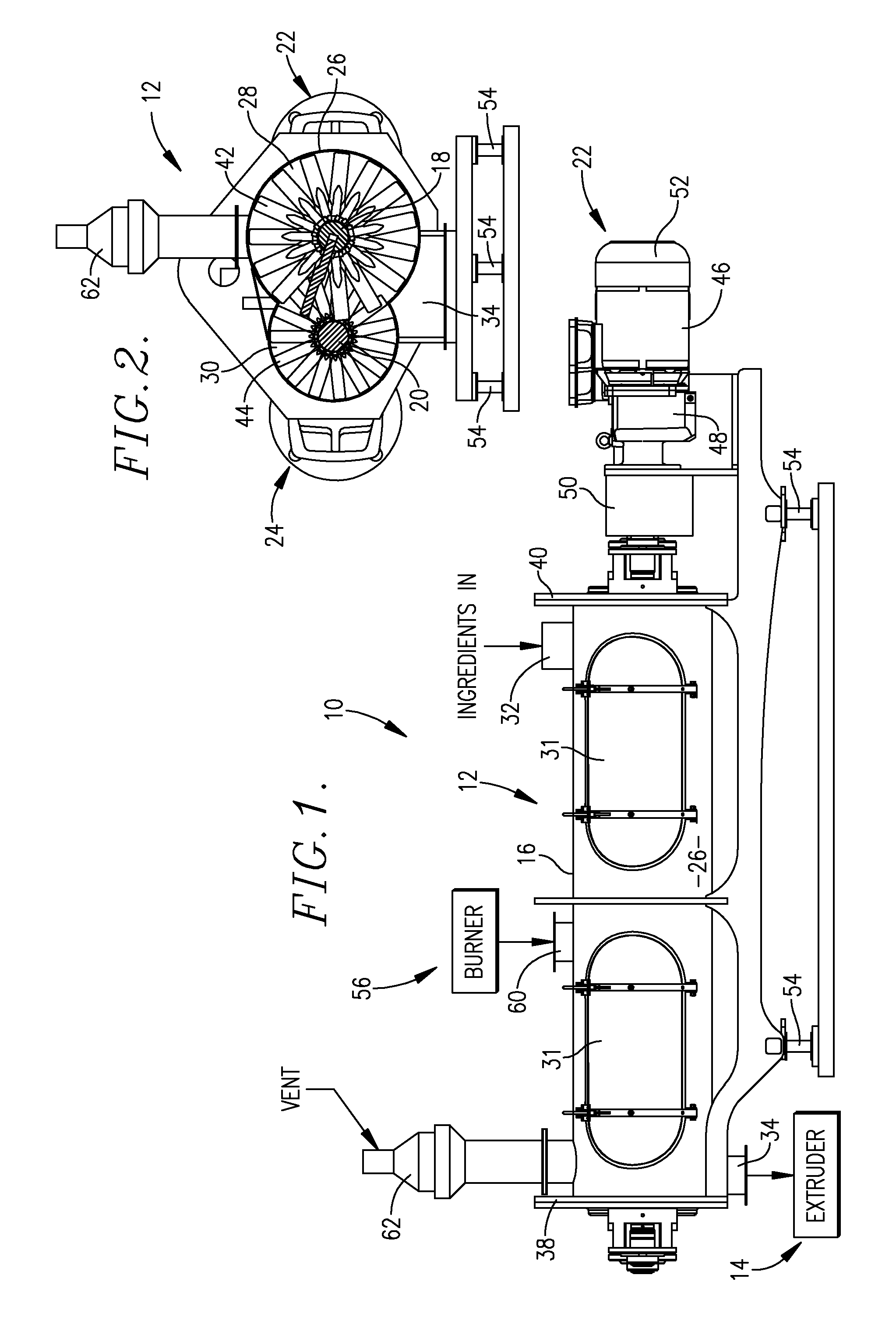

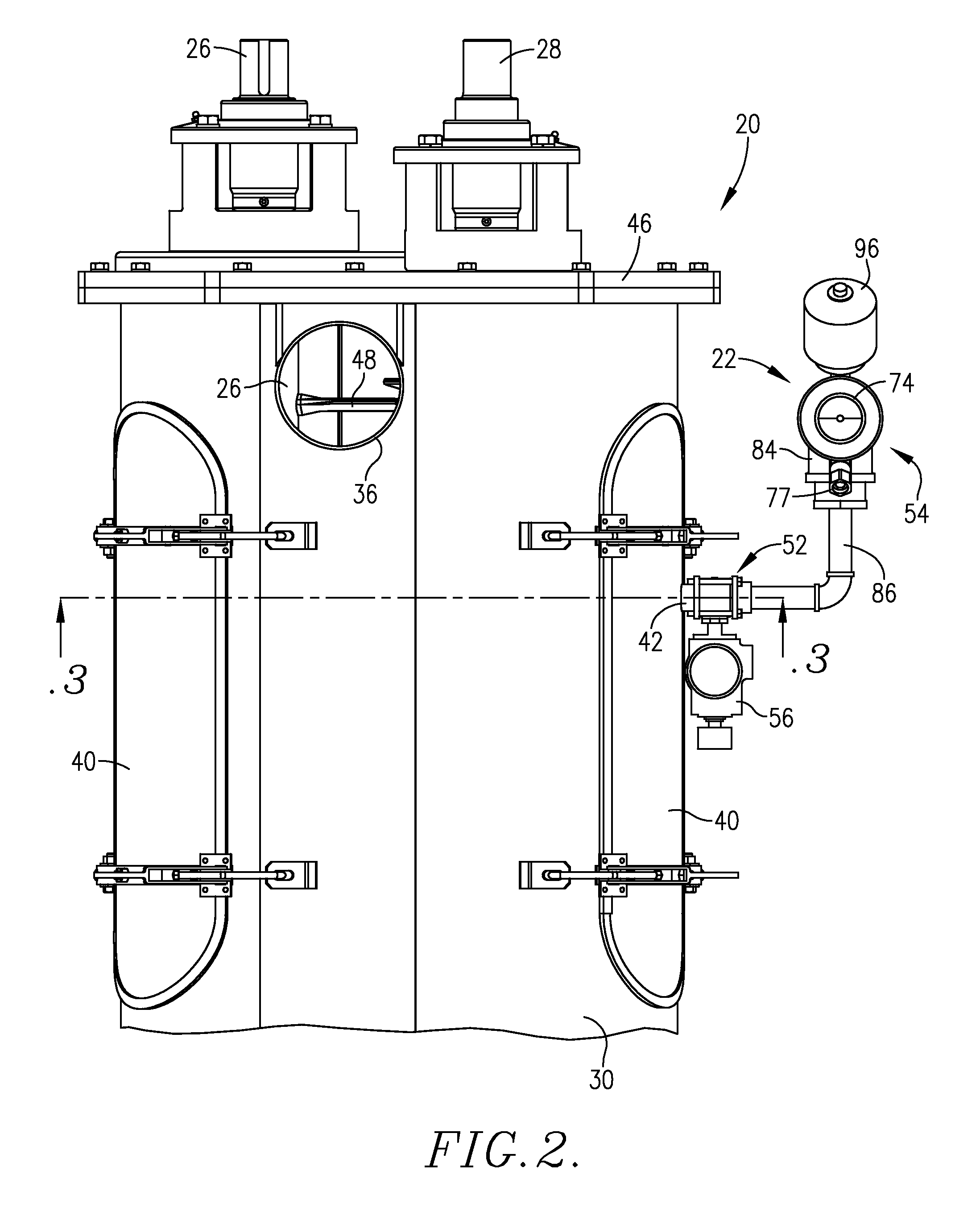

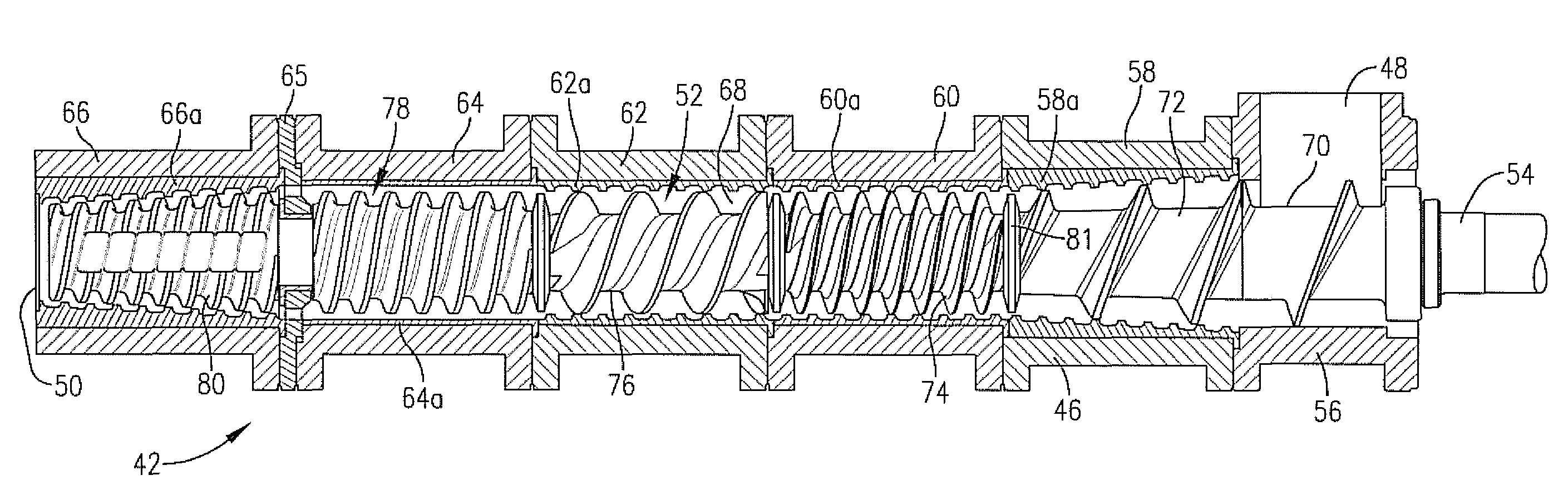

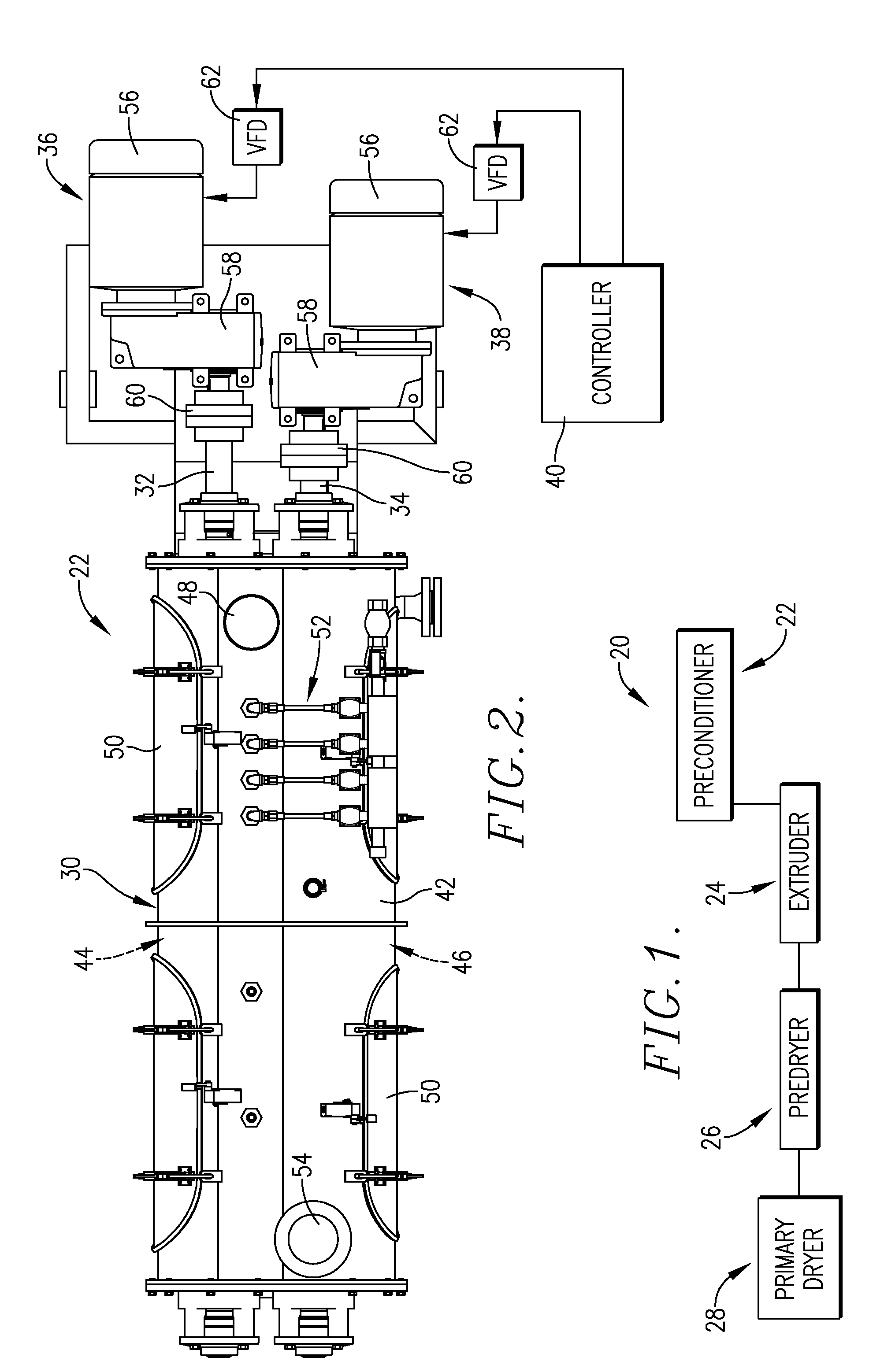

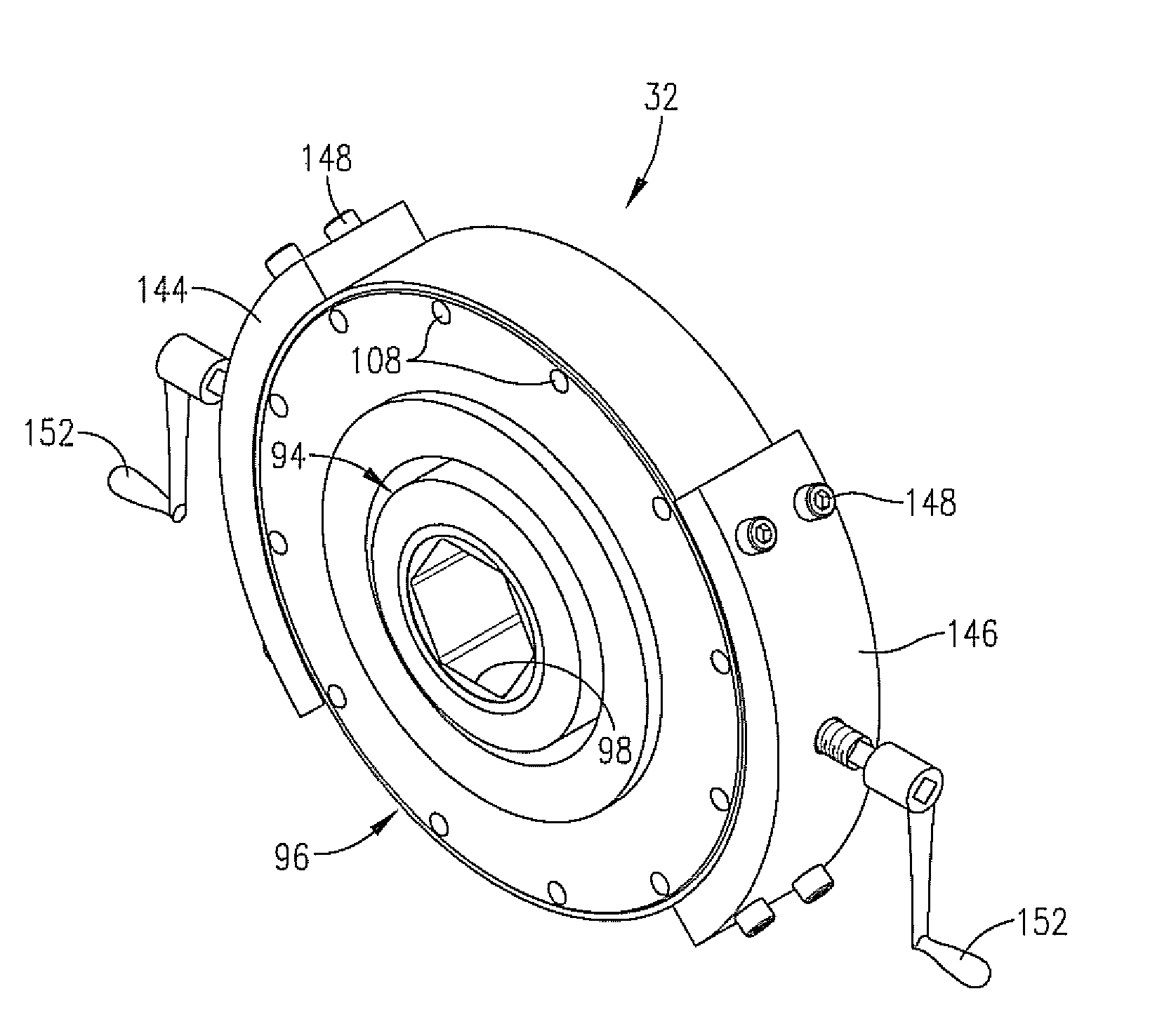

Preconditioner having mixer shafts independently driven with variable frequency drives

ActiveUS7448795B2Facilitate easy changeMultiple dynamo-motor startersRotary stirring mixersRetention timeEngineering

An improved, dual-shaft preconditioner (10, 70) is provided having independent drive mechanism (18, 20, 78, 80) operatively coupled with a corresponding preconditioner shaft (14, 16, 74, 76) and permitting selective rotation of the shafts (14, 16, 74, 76) at rotational speeds and directions independent of each other. The mechanisms (18, 20, 78, 80) are operatively coupled with a digital controller (60) to allow rotational speed and direction control. Preferably, the preconditioner (10, 70) is supported on load cells (62, 100) also coupled with controller (60) to permit on-the-go changes in material retention time within the preconditioner (10, 70). The preconditioner (10, 70) is particularly useful for the preconditioning and partial gelatinization of starch-bearing feed or food materials.

Owner:WENGER MFG LLC

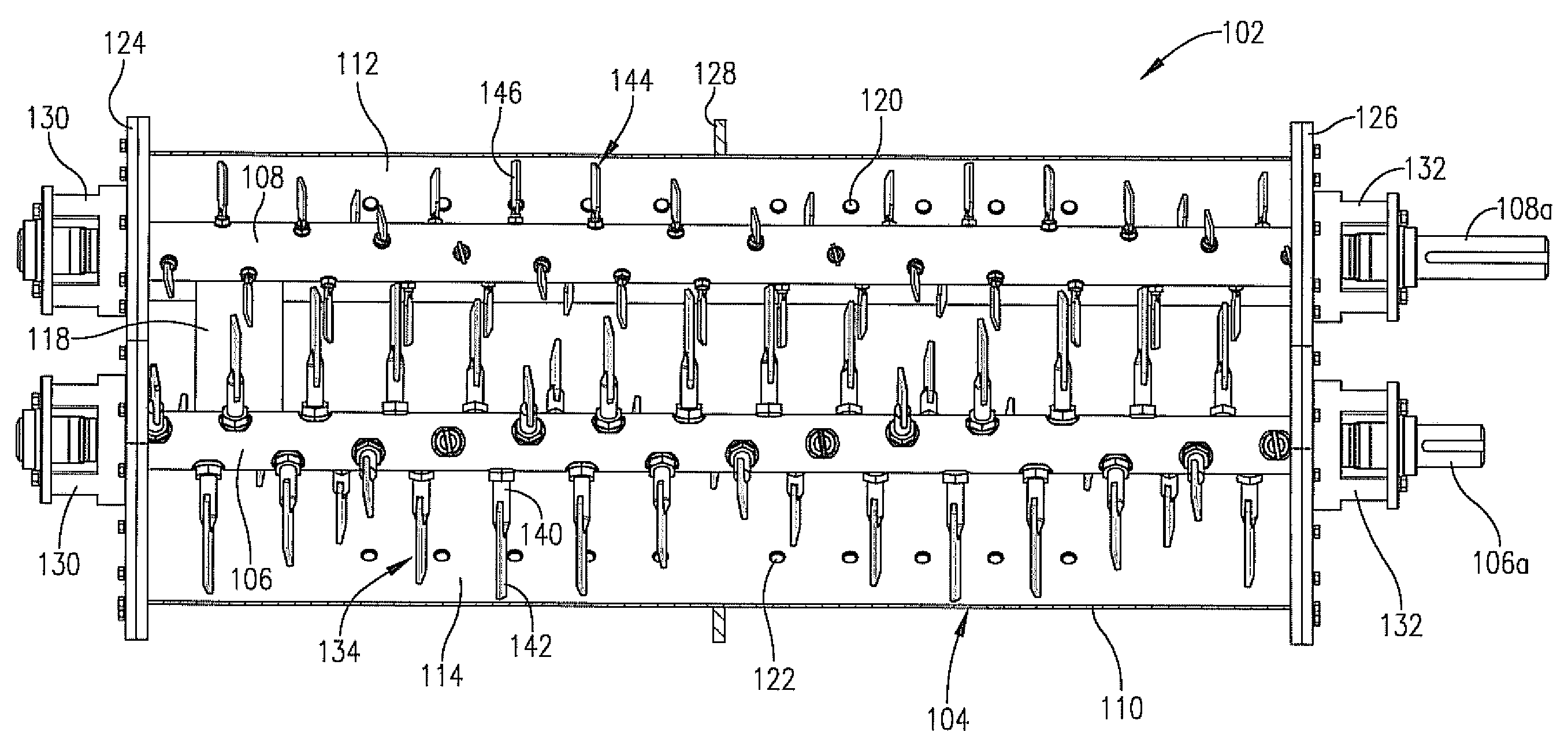

Preconditioner having independently driven high-speed mixer shafts

InactiveUS20080095910A1Facilitate easy changeFeeding-stuffRotary stirring mixersRetention timeEngineering

An improved, dual-shaft preconditioner (10, 70, 102) is provided having independent drive mechanism (18, 20, 78, 80) operatively coupled with a corresponding preconditioner shaft (14, 16, 74, 76, 106, 108) and permitting selective rotation of the shafts (14, 16, 74, 76, 106, 108) at rotational speeds and directions independent of each other. Preferably, the speed differential between the shafts (14, 16, 74, 76, 106, 108) is at least about 5:1. The mechanisms (18, 20, 78, 80) are operatively coupled with a digital control device (60) to allow rotational speed and direction control. Preferably, the preconditioner (10, 70, 102) is supported on load cells (62, 100) also coupled with control device (60) to permit on-the-go changes in material retention time within the preconditioner (10, 70, 102). The preconditioner (10, 70, 102) is particularly useful for the preconditioning and partial gelatinization of starch-bearing feed or food materials, to an extent to achieve at least about 50% cook in the preconditioned feed or food materials.

Owner:WENGER MANUFACTURING INC

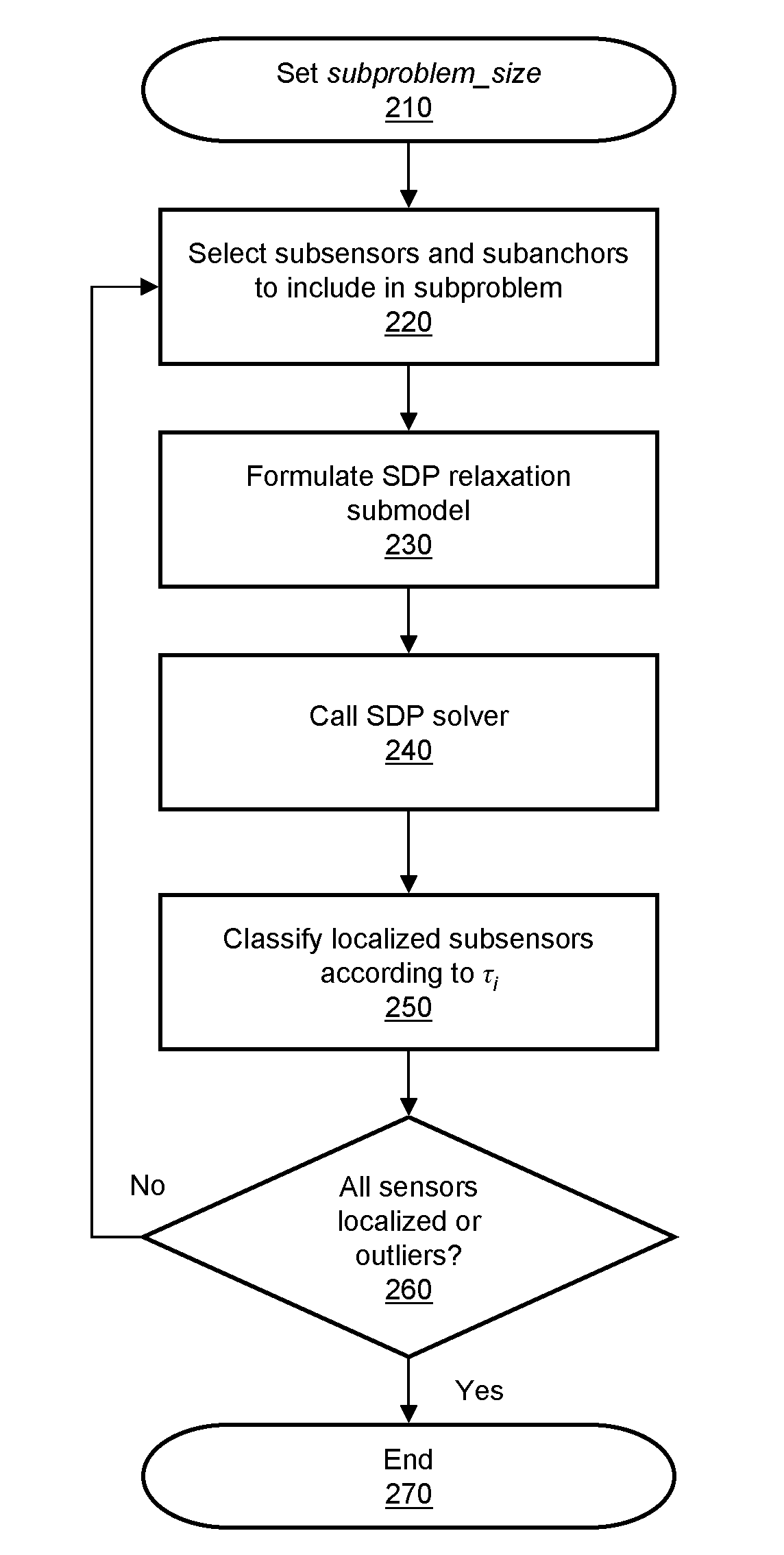

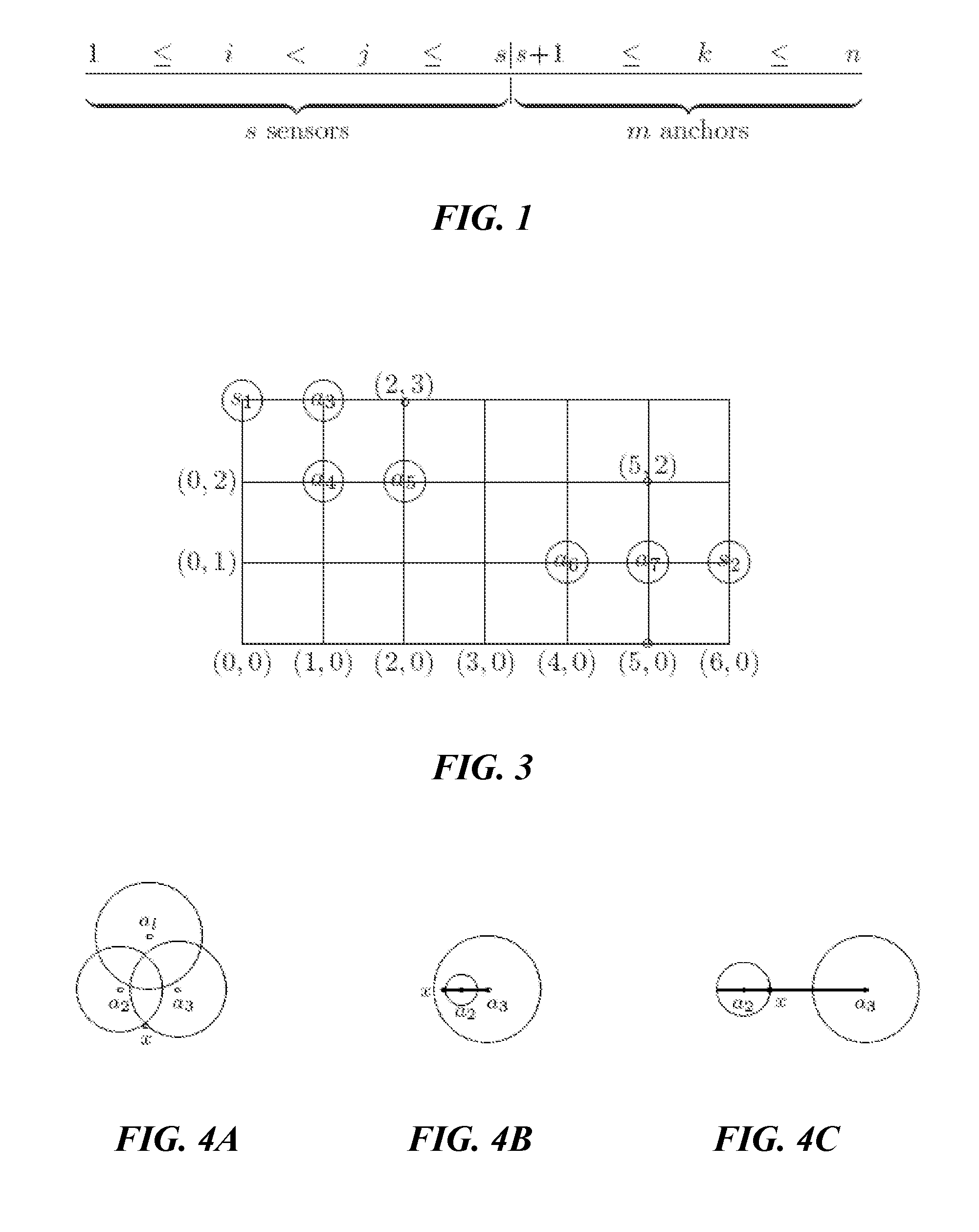

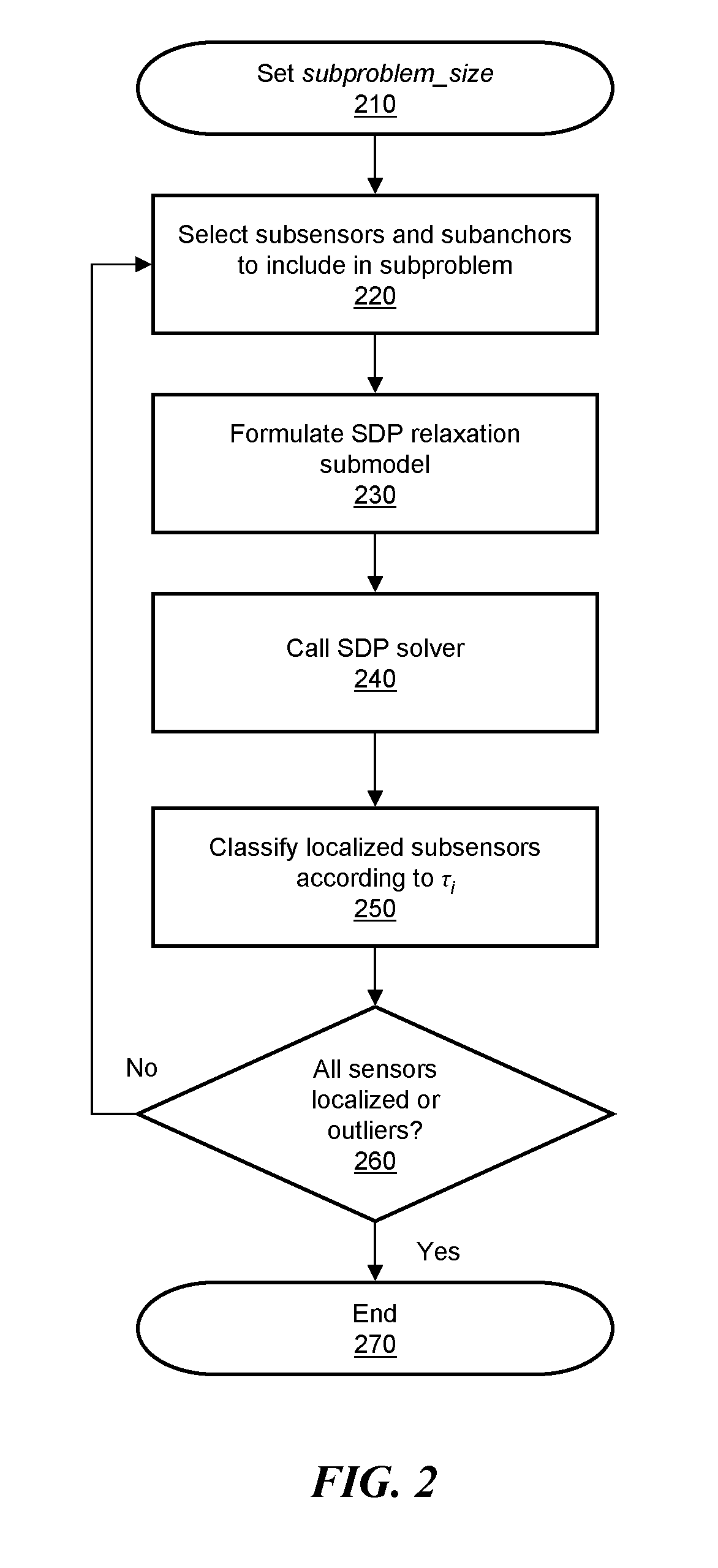

Scalable sensor localization for wireless sensor networks

InactiveUS7970574B2Error minimizationSolve small or large problems more accuratelyNetwork traffic/resource managementNetwork topologiesWireless sensor networkingSelf adaptive

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

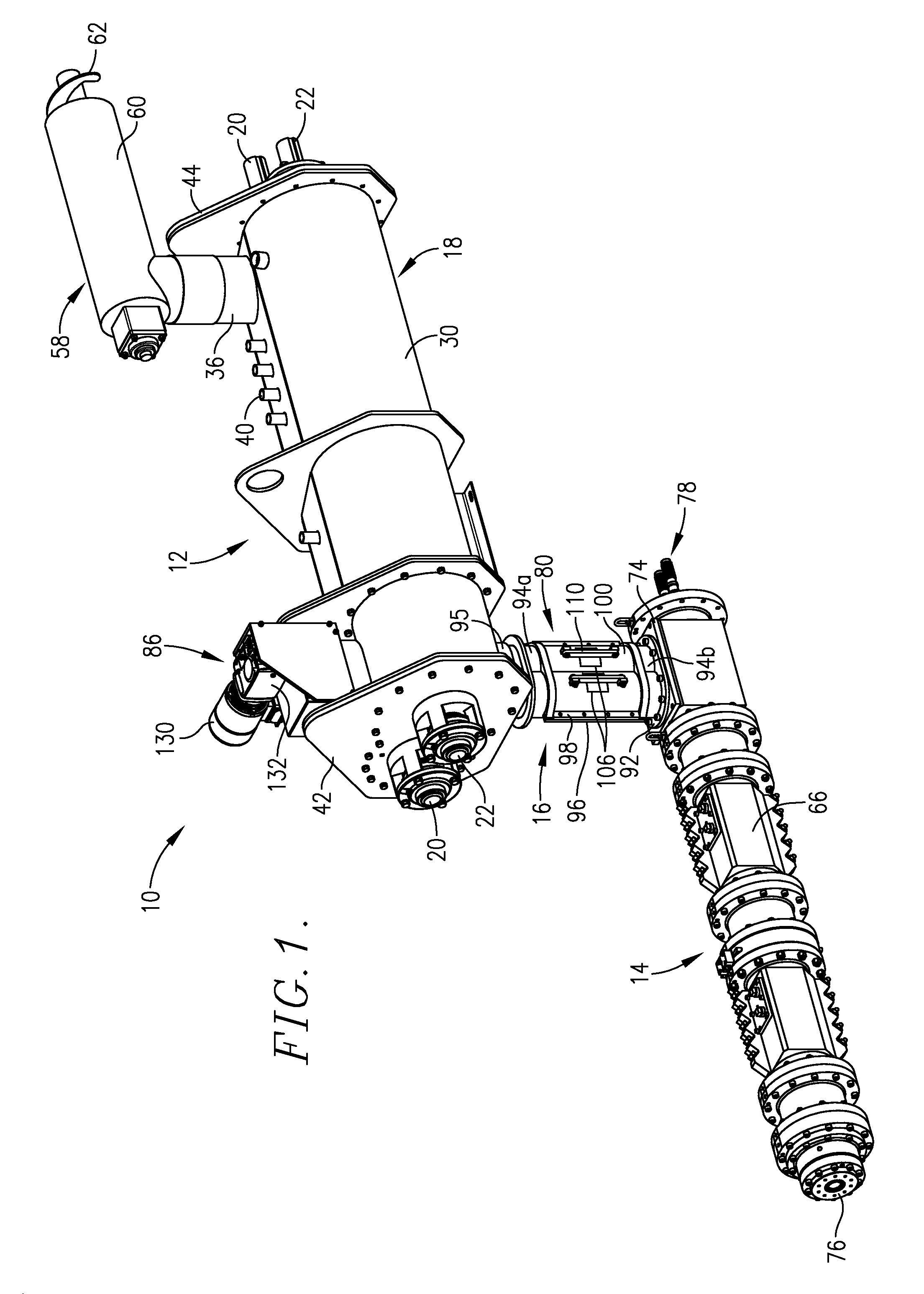

Apparatus for positive feeding from a preconditioner

ActiveUS8177414B1Rotary stirring mixersTransportation and packagingInterconnectionAtmospheric pressure

An improved screw feeder assembly is provided for interconnection between the outlet of a preconditioner and the inlet of an extruder barrel. The assembly includes an upright housing with a pair of elongated shafts equipped with auger flighting within the housing and driven by means of motor. Preferably, the housing is mechanically coupled to the outlet and inlet with the shafts extending through the preconditioner vessel and downwardly to a point within the inlet and closely adjacent the screw(s) within the extruder barrel; the flighting is provided along the length of the housing, from a point closely adjacent the outlet and into the extruder inlet. This provides a positive conveyance of preconditioned material from the outlet to the inlet. Use of the assembly allows maintenance of superatmospheric pressures and temperatures above 212° F. within the preconditioner, which permits more efficient processing.

Owner:WENGER MFG LLC

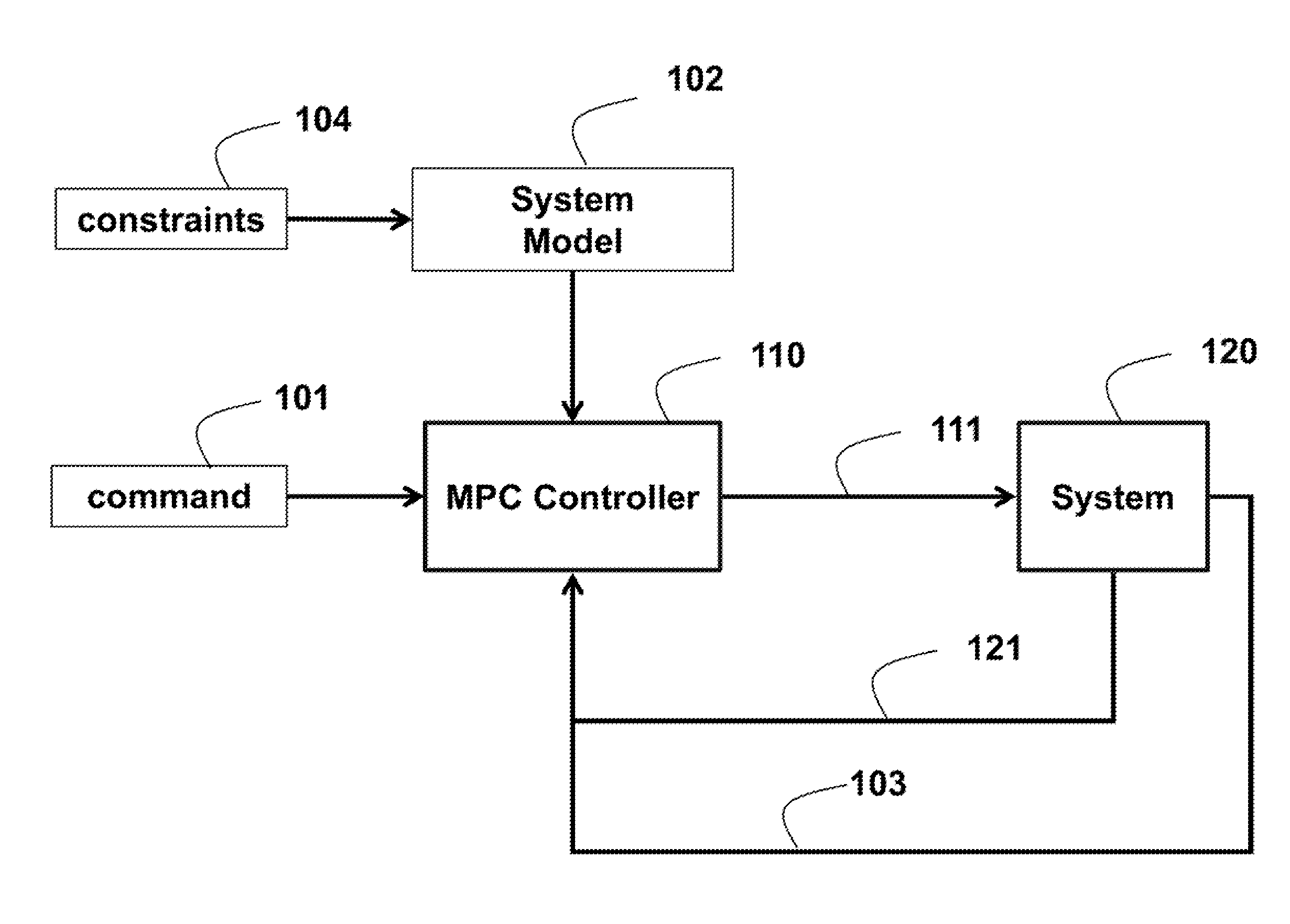

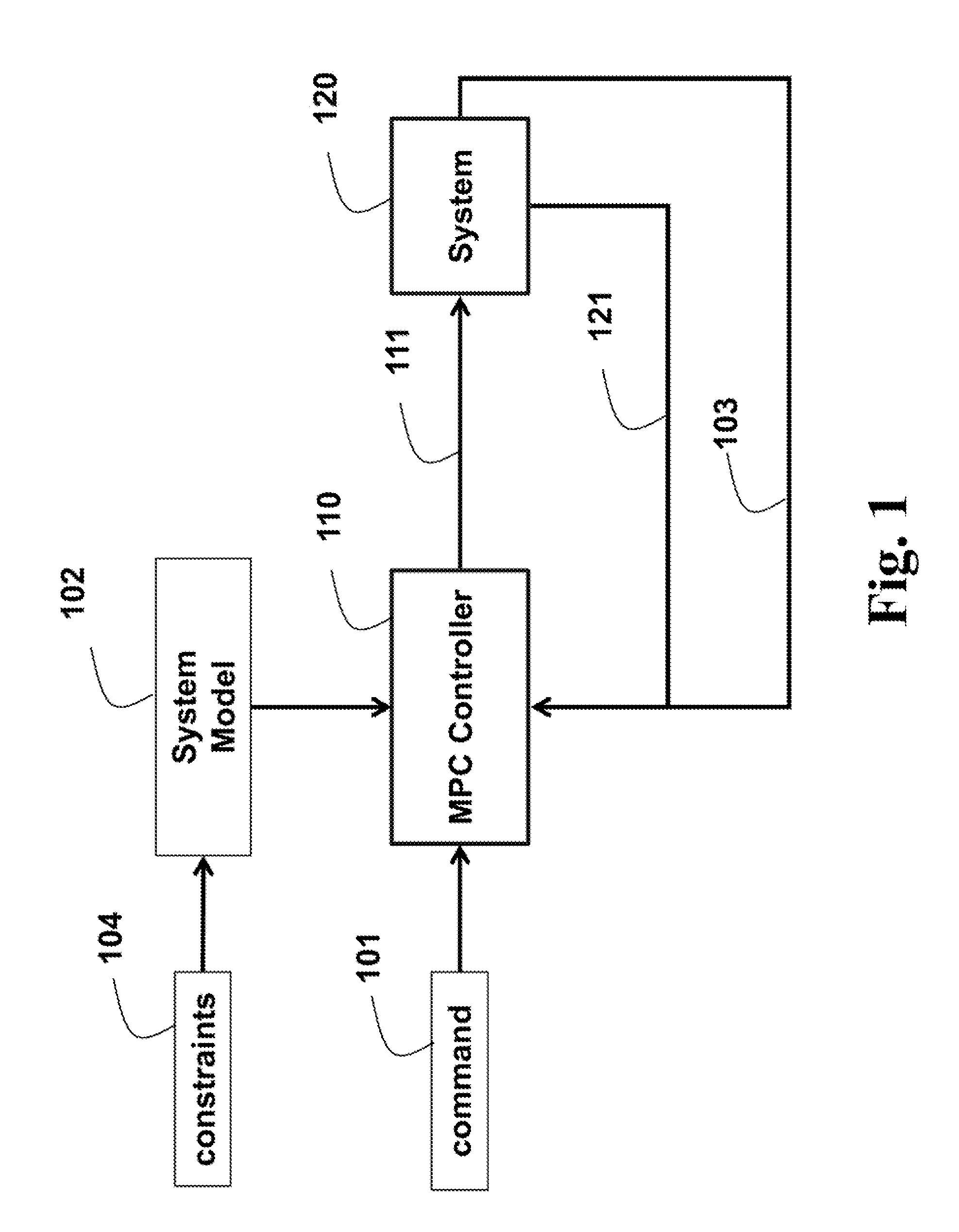

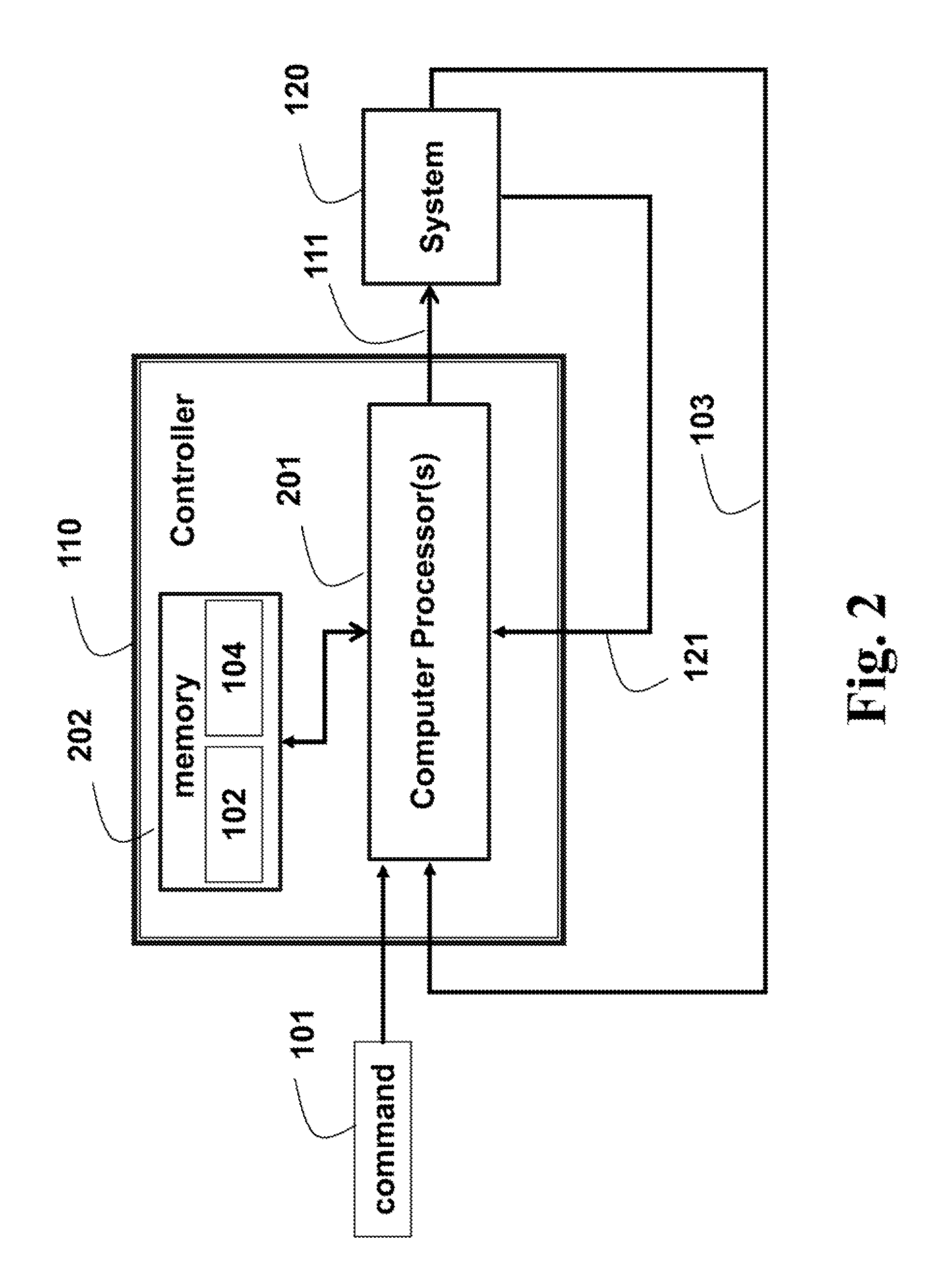

Method and Apparatus for Preconditioned Continuation Model Predictive Control

ActiveUS20150253749A1Reduce in quantityReduce complexityComplex mathematical operationsAdaptive controlContinuationControl system

A method for a continuation model predictive control (CMPC) of a system determines at least a part of a preconditioner using an approximate coefficient function and determines a solution vector by solving a matrix equation of the CMPC with a coefficient matrix defined by an exact coefficient function at a current time step of a control using an iterative method with the preconditioner. The approximate coefficient function applied to a vector approximates a result of an application of the exact coefficient function to the vector. A control signal for controlling the system is generated using the solution vector.

Owner:MITSUBISHI ELECTRIC CORP +1

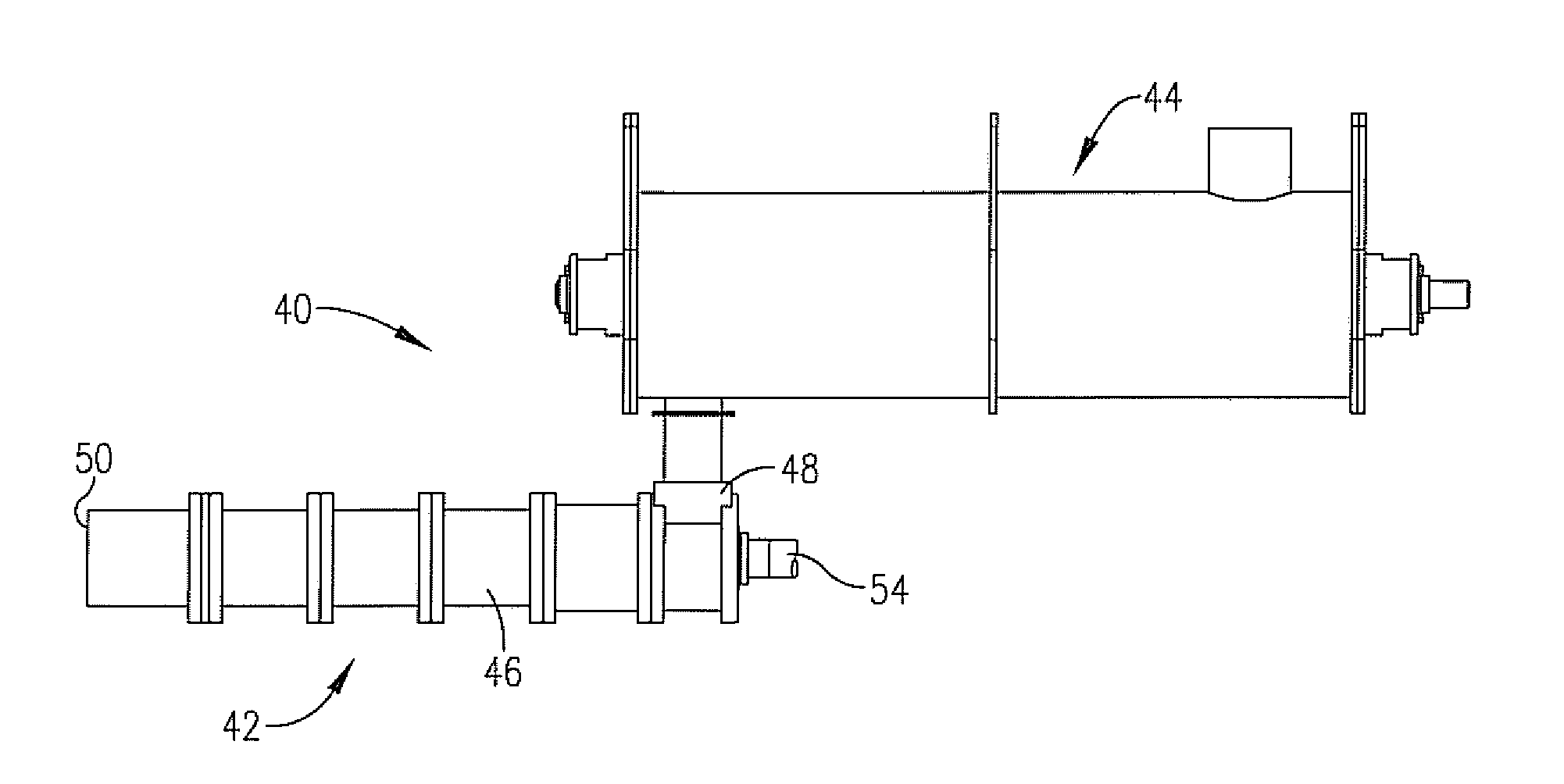

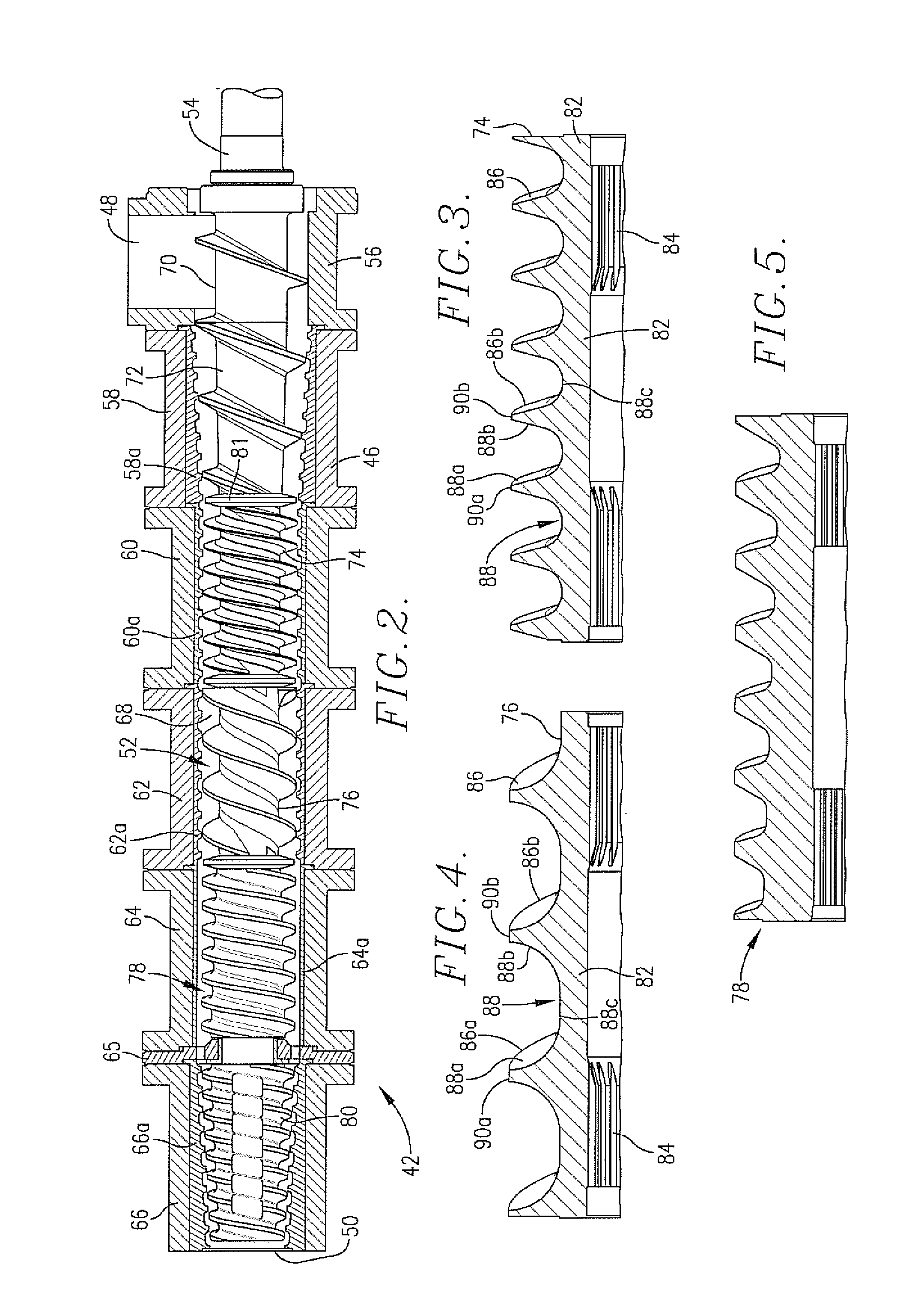

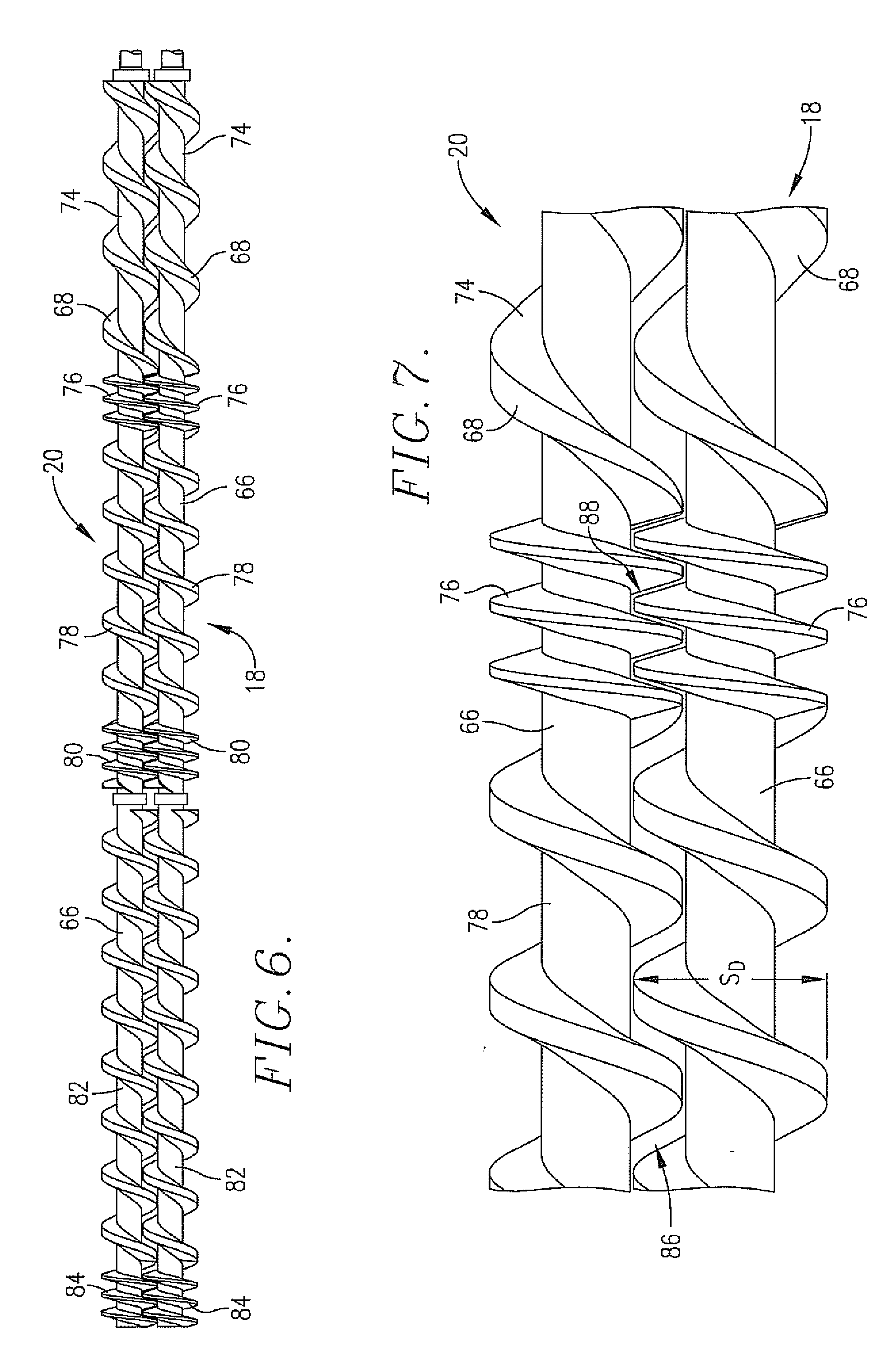

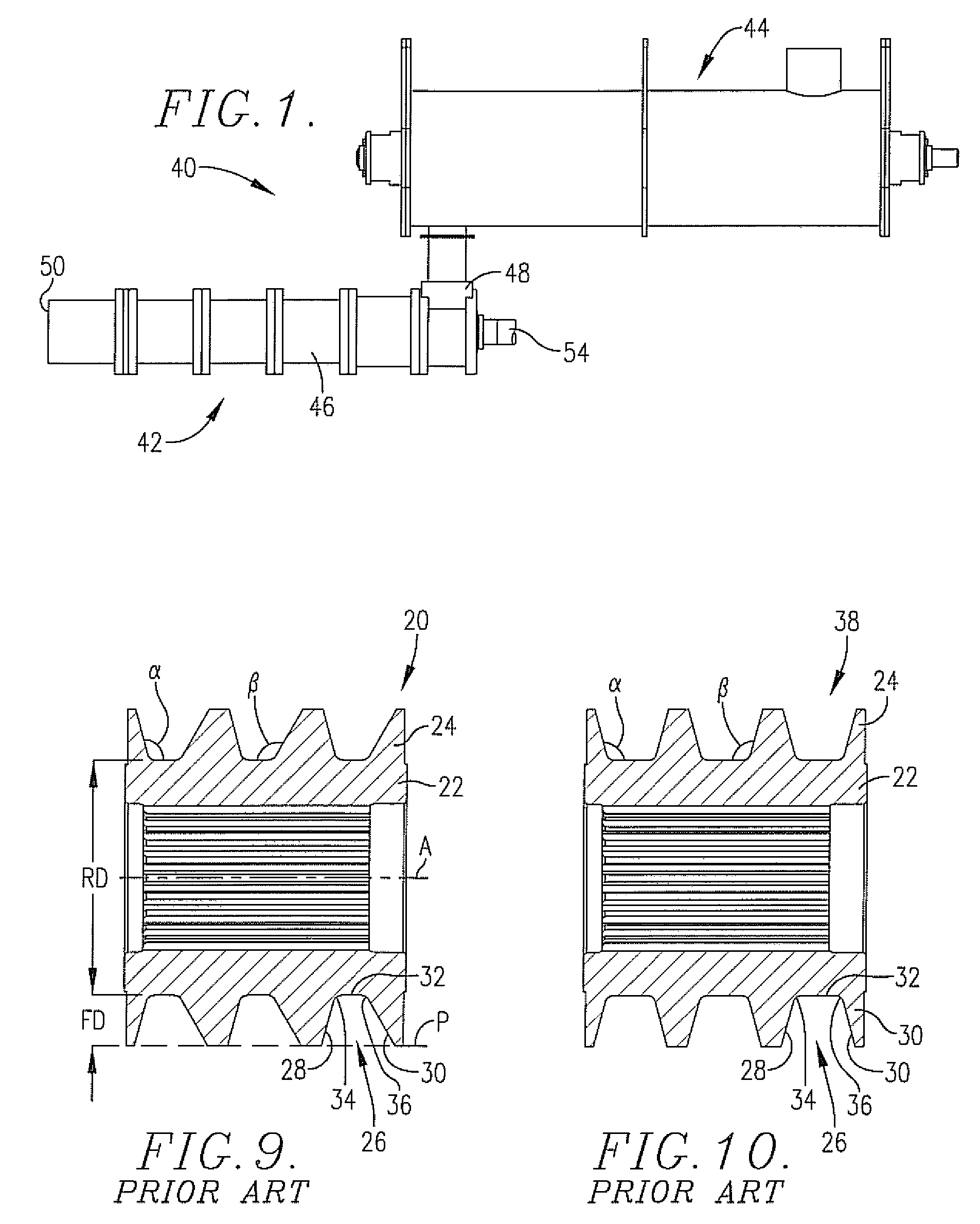

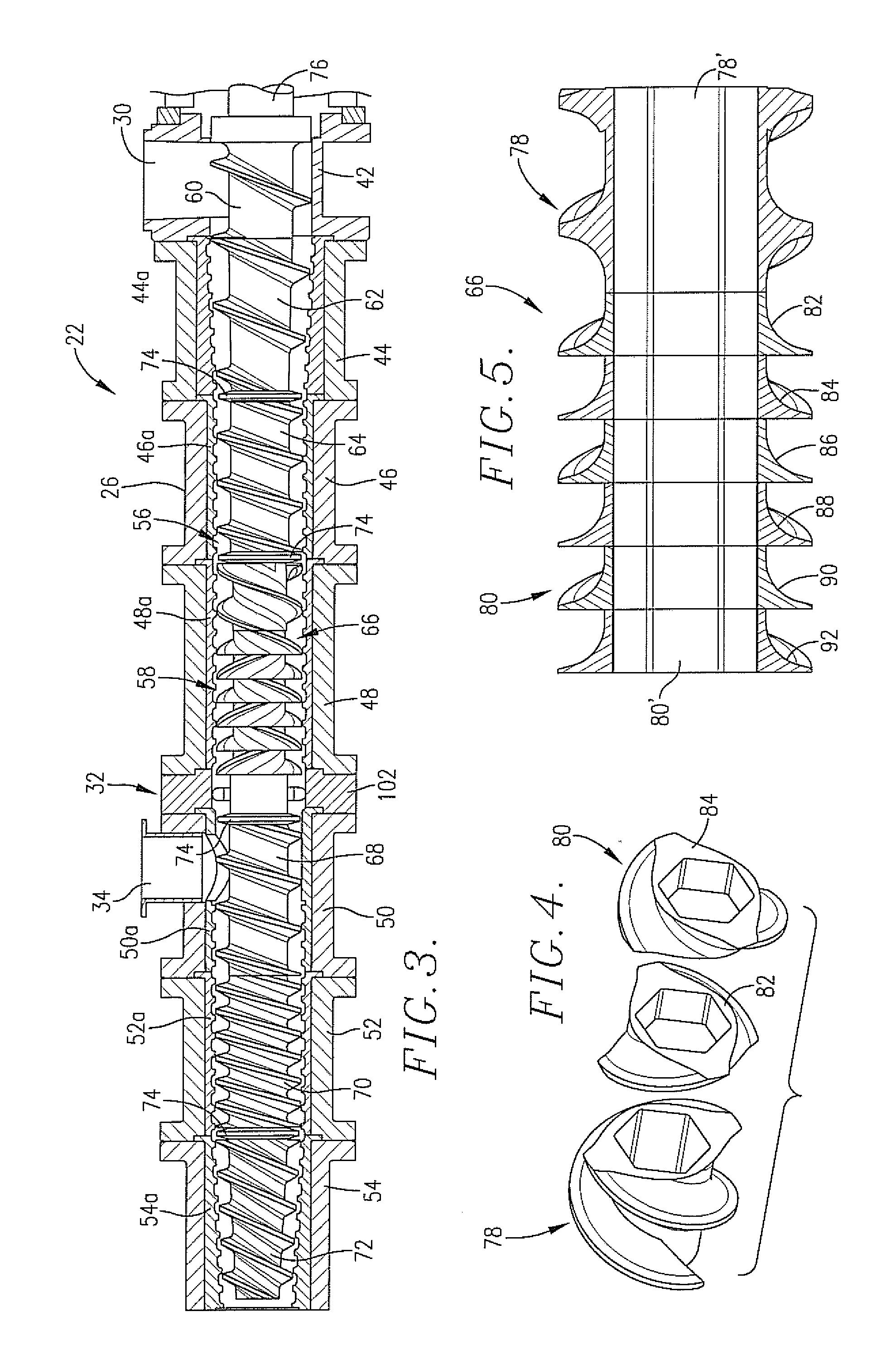

Single screw extruder for processing of low viscosity preconditioned materials

InactiveUS20090175119A1Overcome problemsEnhance the beneficial effectRotary stirring mixersTransportation and packagingEngineeringPre treatment

Improved single screw extruders systems (40) are provided including a single screw extruder (42, 92) as well as an upstream preconditioner (44). The extruders (42, 92) include a single, internal, elongated, helically flighted, axially rotatable screw assembly (52) having one or more improved screw sections (74, 74a, 76). The screw sections (74, 74a, 76) include specially configured flighting (86) wherein adjacent flighting portions (86a, 86b) have smoothly arcuate surfaces (88) extending between the respective flighting portion peripheries (90a, 90b). This flighting design provides smooth, substantially surge-free operation while increasing SME and cook values. The preferred preconditioner (44) has independently controlled mixing shafts (106, 108) allowing the shafts (106, 108) to be rotated at different rotational speeds and / or directions.

Owner:WENGER MANUFACTURING INC

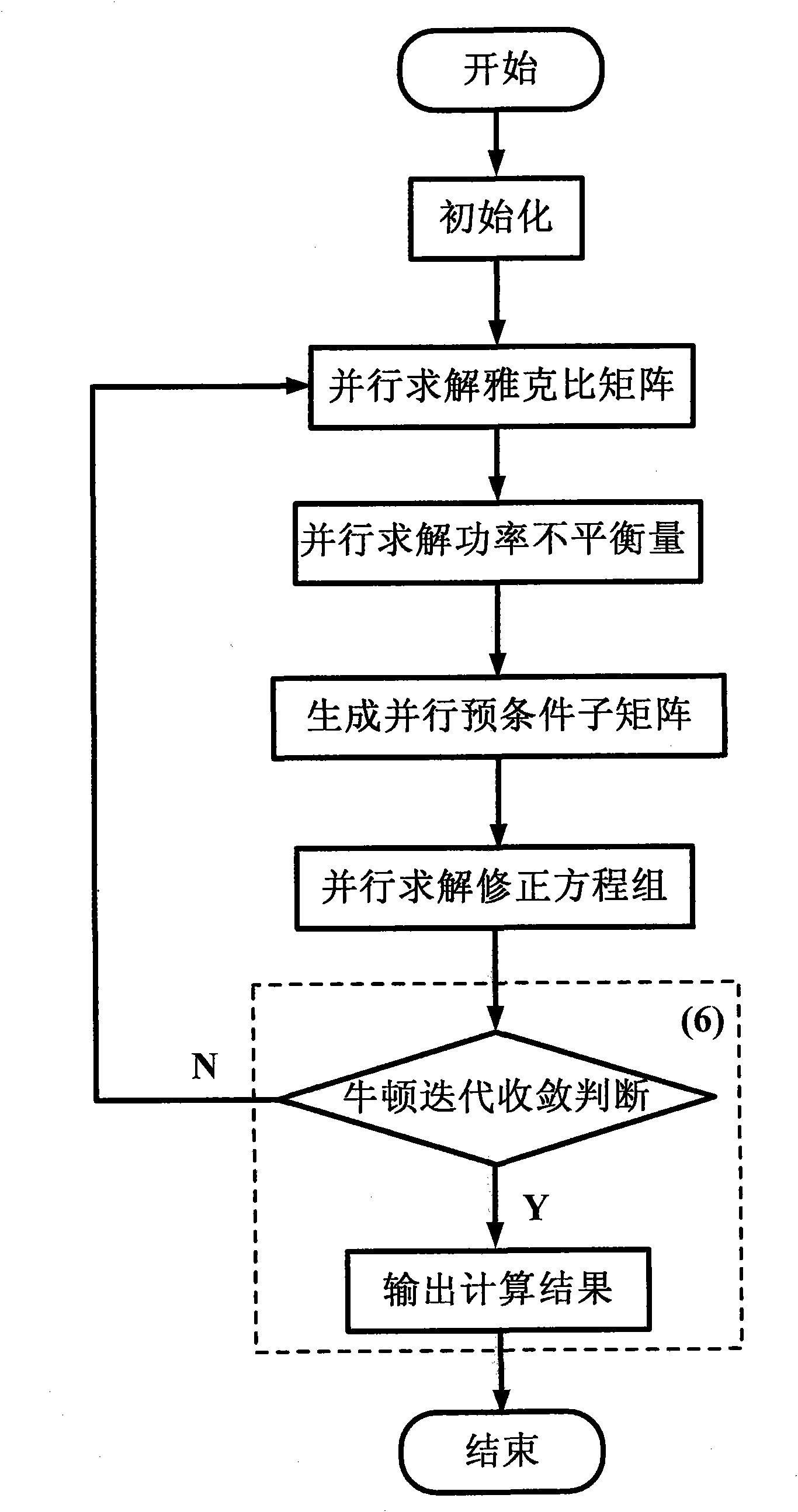

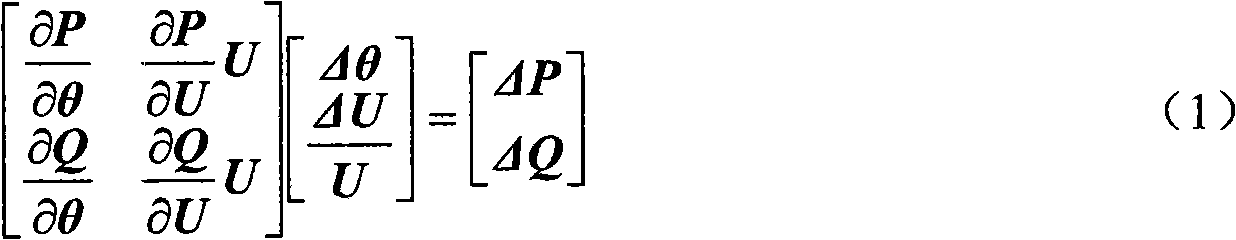

Parallel computation method for Newton power flow of large-scale electric power system

ActiveCN101976835ASimple calculationImprove versatilityAc network circuit arrangementsPower flowParallel computing

The invention discloses a parallel computation method for Newton power flow of a large-scale electric power system, which belongs to the technical field of safe analysis and computation of electric power systems. A modified equation set of the Newton power flow is resolved by using a computer according to a parallel cluster through a program in combination with parallelization technology for updating a Jacobian matrix by a generalized minimal residual method combined with a quasi-diagonal parallel preconditioner so as to realize parallelization of a power flow resolving process of the large-scale electric power system. The method does not need network partitioning in any form and has simple computation and high generality; a forward / backward sweeping dependency relationship does not exist inside an algorithm, and parallel efficiency and computation speed are high; and computation can be performed by the common parallel computer and the parallel cluster and the method is convenient to popularize and apply, and the like. The method can be applied to the parallel power flow computation of the electric power system and is particularly suitable for the parallel computation of the Newton power flow of a large-scale complex electric power system.

Owner:CHONGQING UNIV

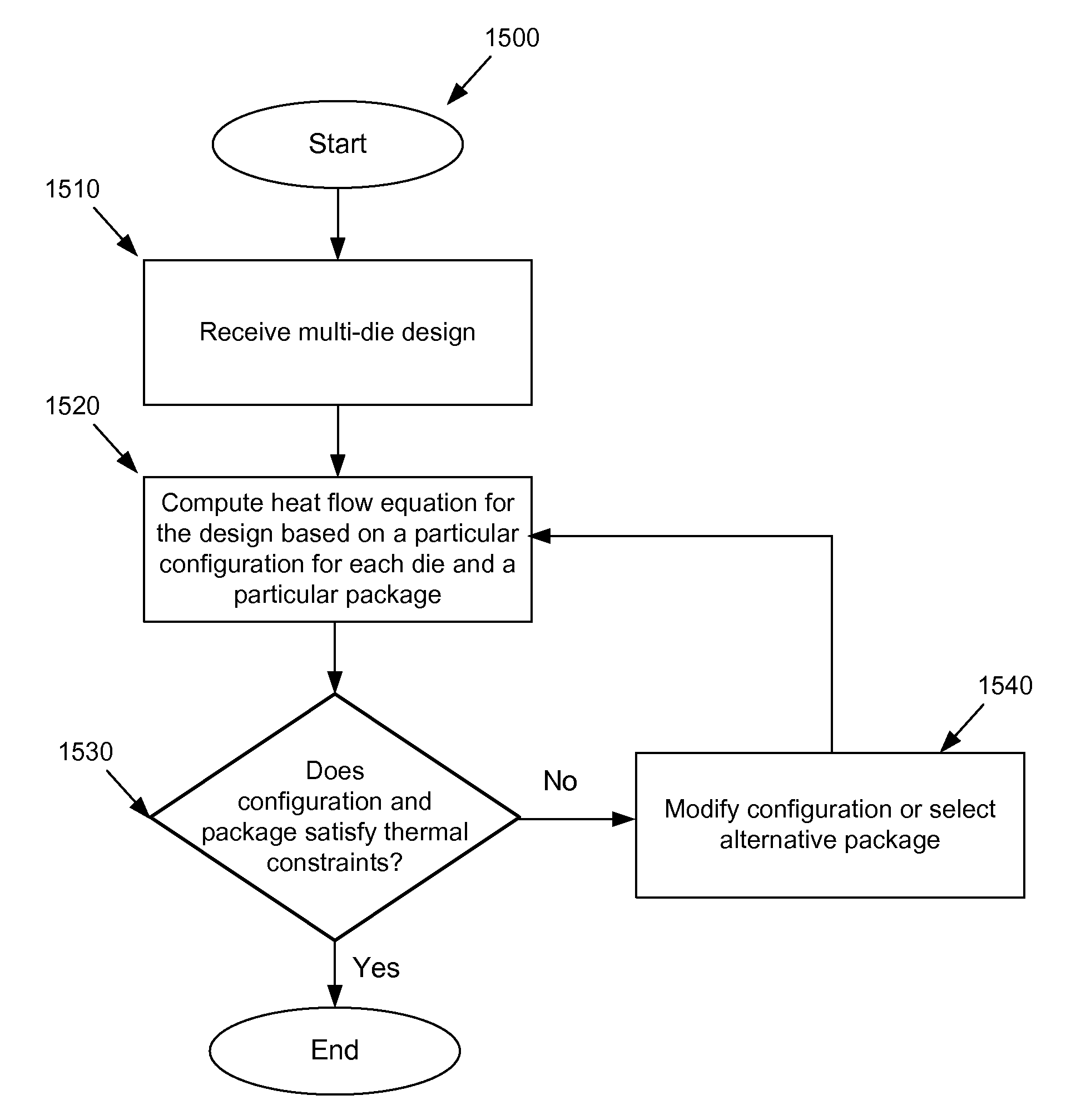

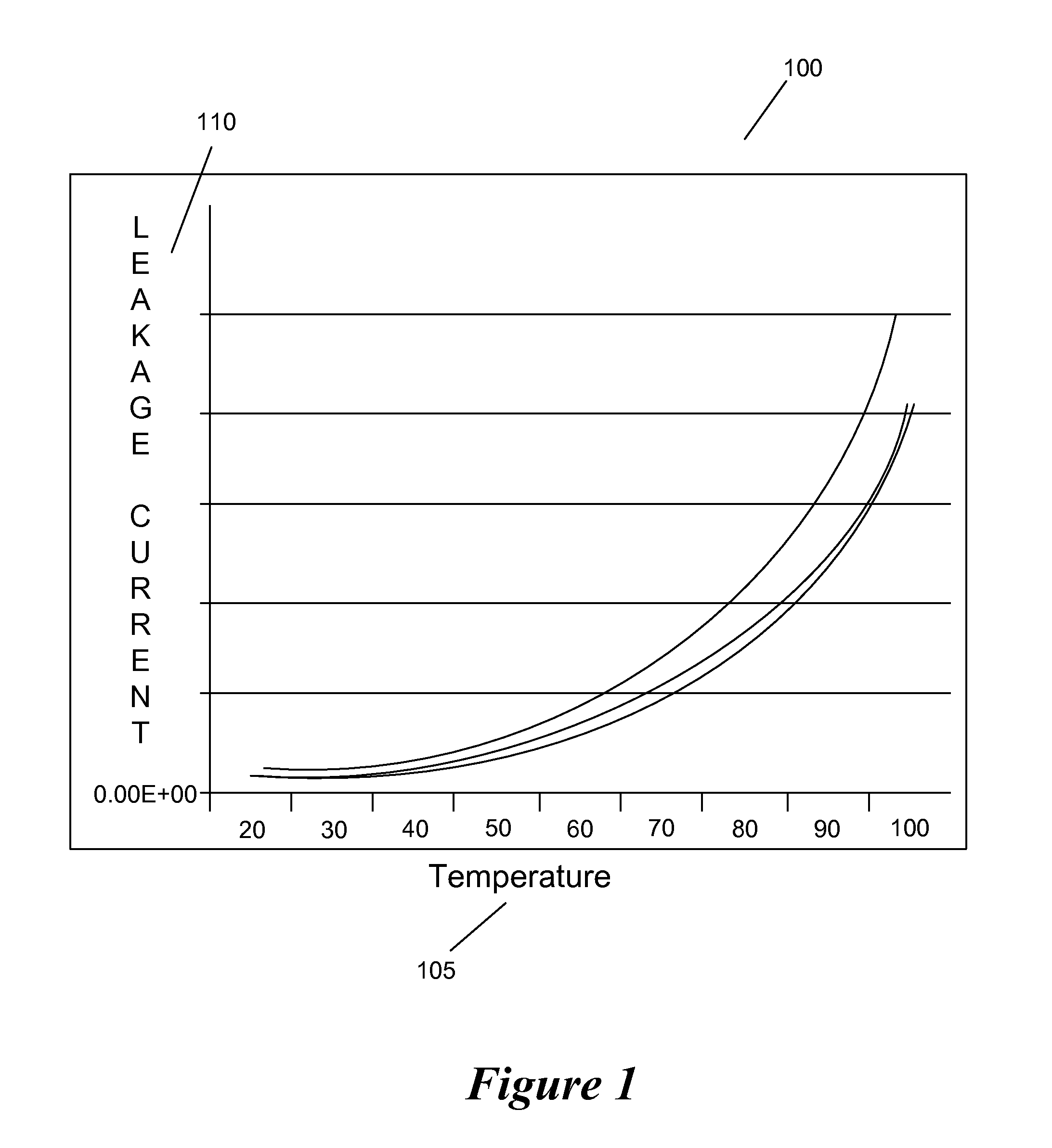

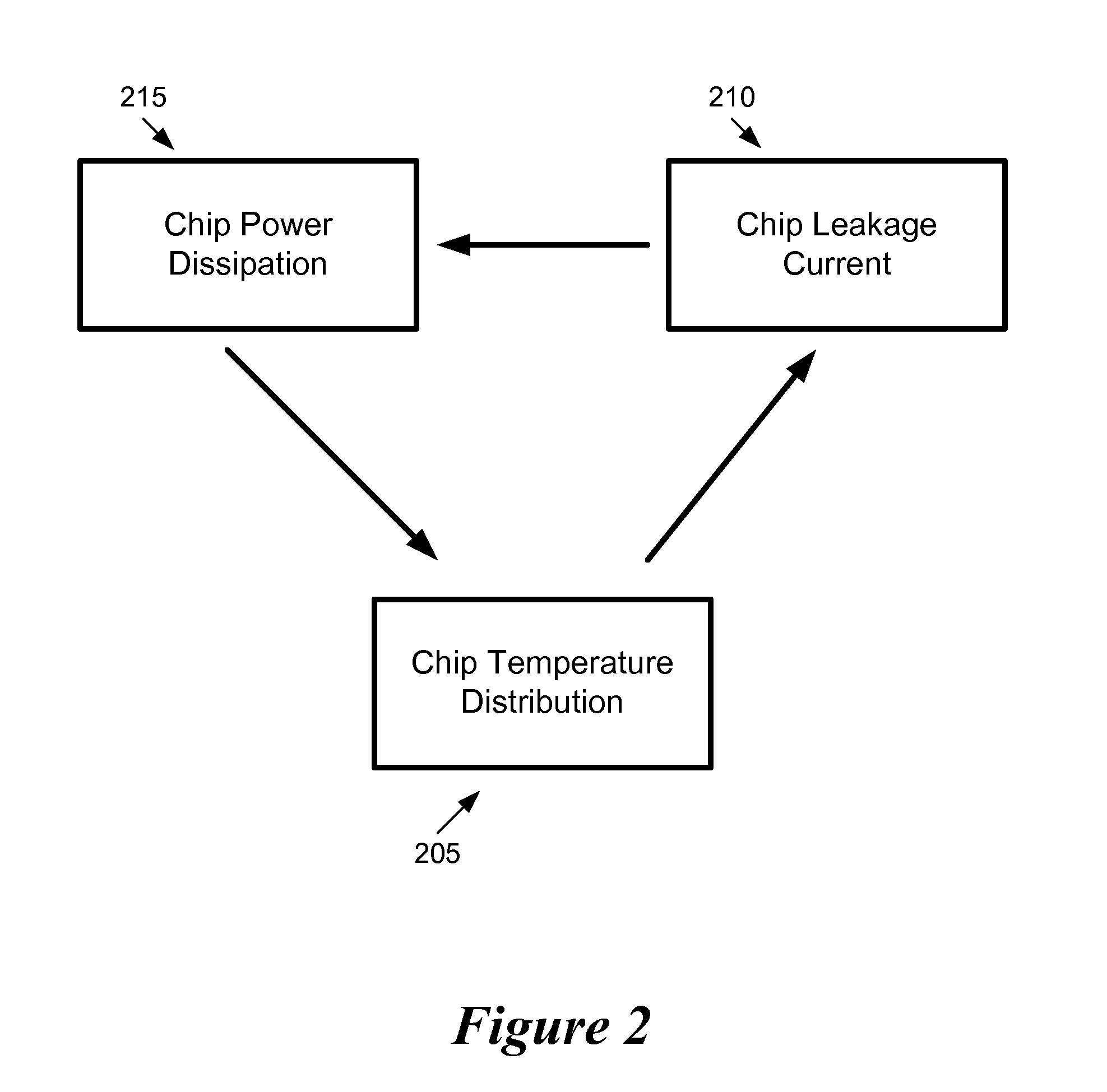

Method and apparatus for multi-die thermal analysis

InactiveUS20100023903A1Computer aided designSoftware simulation/interpretation/emulationDie (integrated circuit)Engineering

Some embodiments of the invention provide a method for performing thermal analysis of a multi-die integrated circuit (IC) design layout. The thermal analysis produces a temperature distribution for analyzing internal properties of each die within the multi-die design and for analyzing thermal interactions between two or more dies of the design based on an internal configuration of the two or more dies. Therefore, in some embodiments, the temperature distribution shows a temperature distribution for each die and the individual temperature distribution show varying temperature across each of the dies. Some embodiments reduce the number of iteration required to perform the thermal analysis by constructing a high quality preconditioner based on thermal conducting segments introduced to model thermal effects at the boundaries between two dies.

Owner:CADENCE DESIGN SYST INC

Method and apparatus for producing fully cooked extrudates with significantly reduced specific mechanical energy inputs

InactiveUS20100062093A1Avoid excessive wearLow costTailstocks/centresFeeding-stuffEngineeringPreconditioner

Improved extruders and methods for the extrusion cooking of comestible products such as human foods or animal feeds are provided wherein the products may be produced with very low specific mechanical energy (SME) inputs as compared with conventional processing. The methods preferably involve introduction of very high levels of steam into the extruder barrel (12) during processing, which concomitantly reduces necessary SME inputs required to achieve desired cook and expansion levels in the products. In accordance with the invention, fully-cooked pet foods can be fabricated with SME inputs of up to about 18 kWhr / T, whereas aquatic feeds can be fabricated with SME inputs of up to about 16 kWhr / T. In preferred forms, the extruder (10) includes specially configured, intermeshed extrusion screws (18, 20) and a plurality of obliquely oriented steam inlets (48, 50), and an upstream, dual-shaft preconditioner (90) is used having individual variable frequency drives (98, 100) which allow infinite variablility in the speed and rotational direction of the preconditioner shafts (94, 96).

Owner:WENGER MANUFACTURING INC

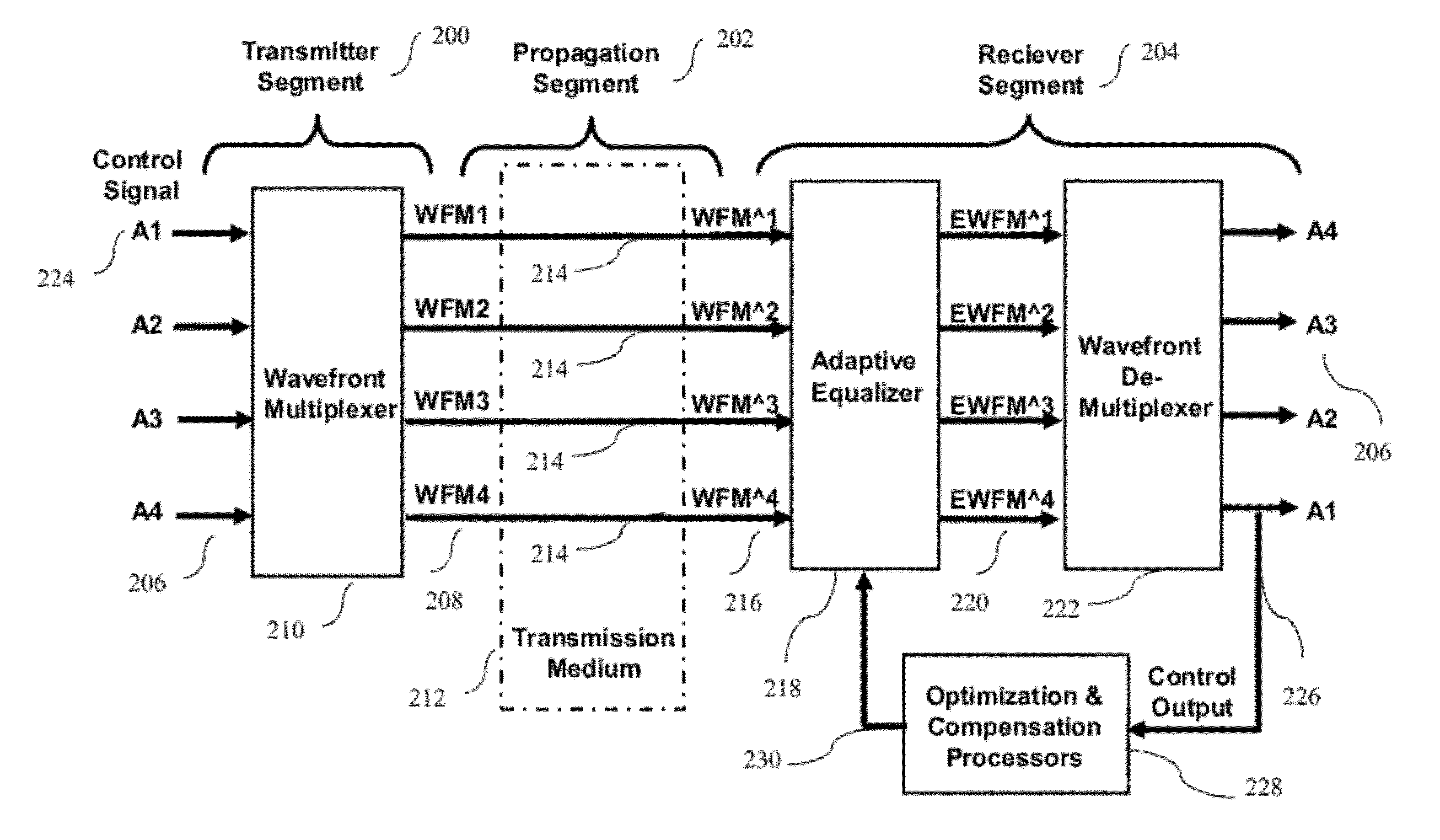

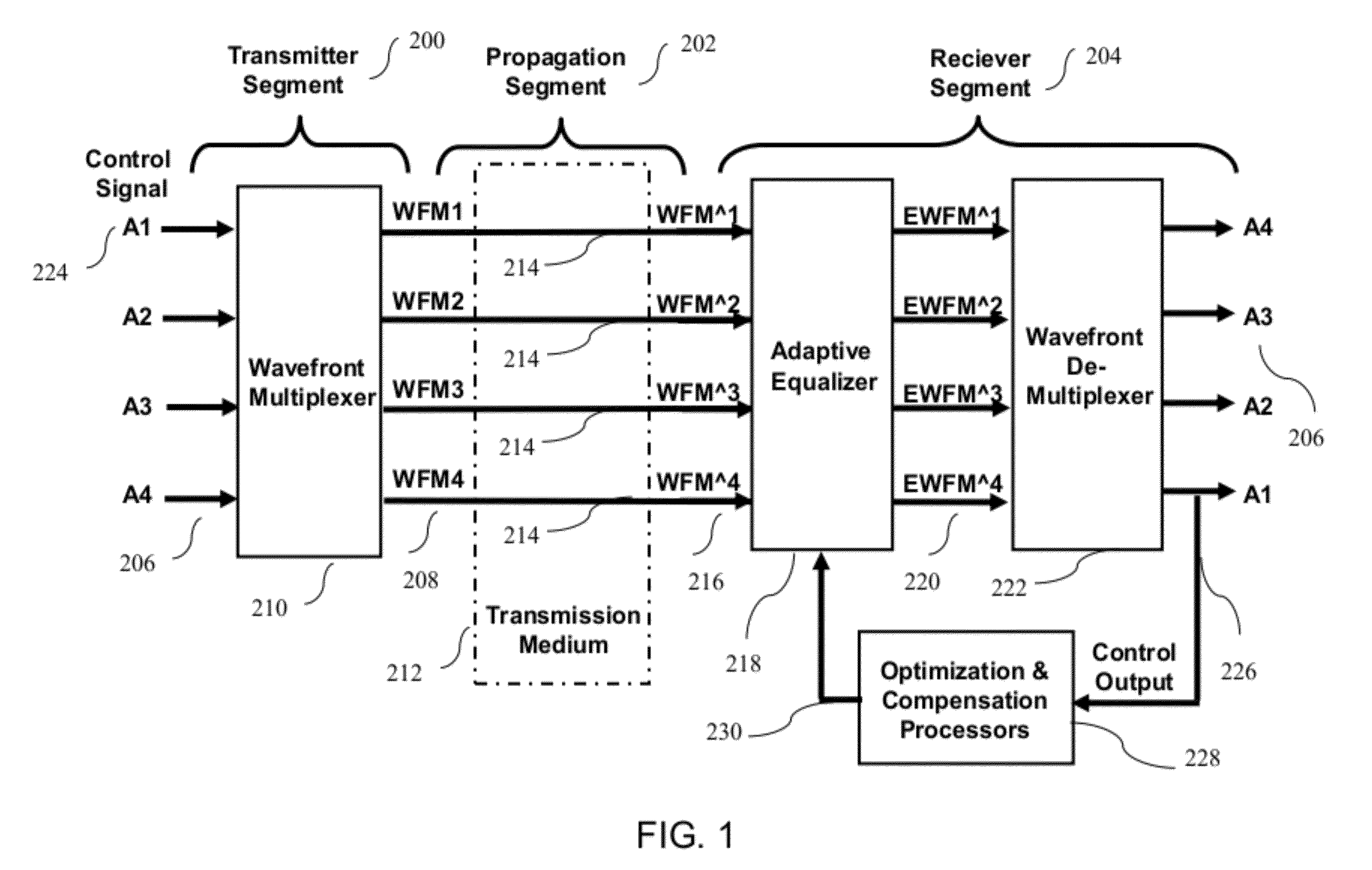

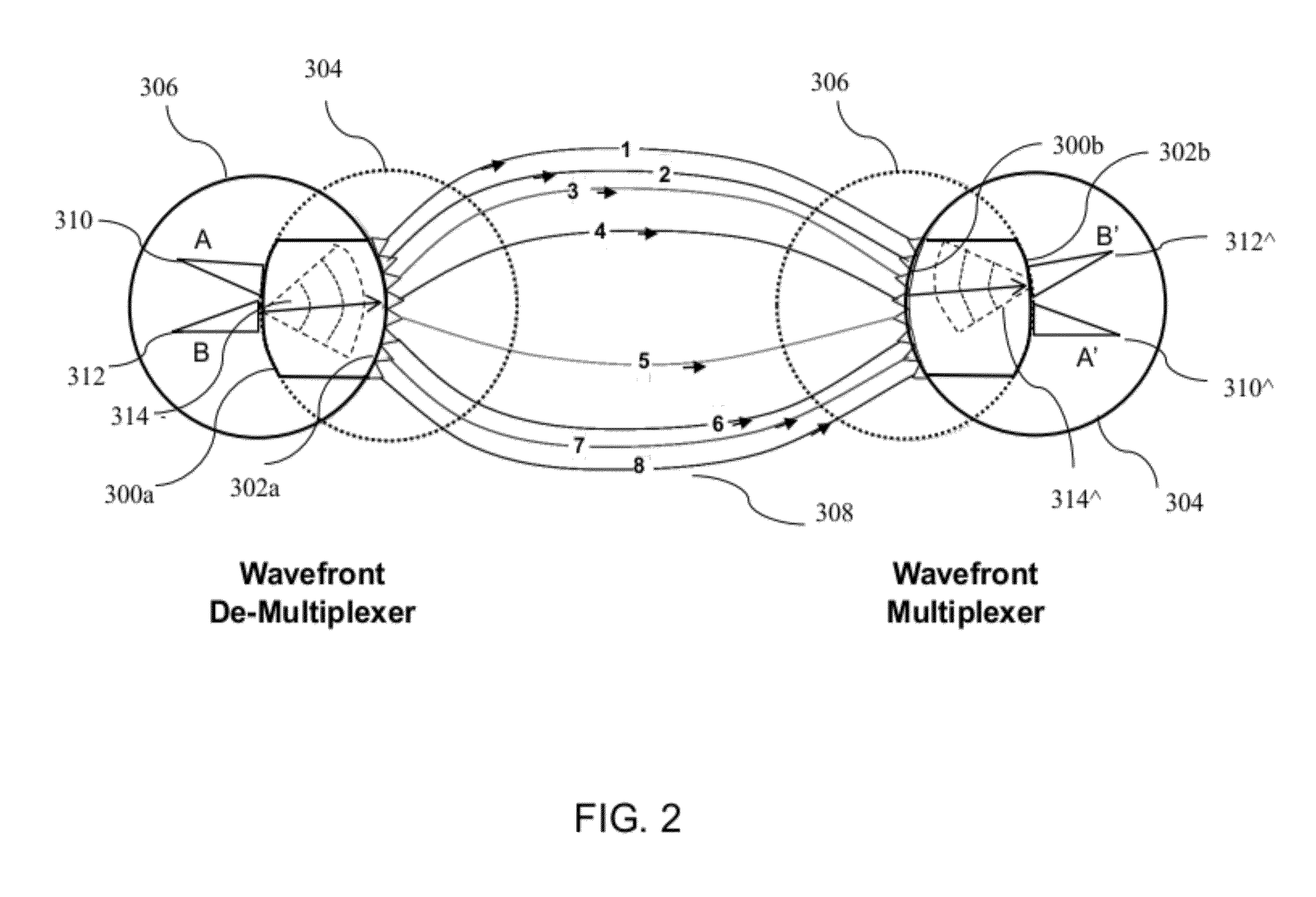

Coherent Power Combining via Wavefront Multiplexing on Deep Space Spacecraft

InactiveUS20120140780A1Increase power levelFrequency-division multiplex detailsTime-division optical multiplex systemsData streamTransmitted power

A communication system and method for a deep space spacecraft receiver to perform post-processing to dynamically combine received signal power coherently for pre-processed signal streams radiated non-coherently from a distributed, multiple element, Ka-band transmitting array via multiple concurrent propagation paths. Mutually orthogonal data and pilot signals travel though the multiple propagation paths. A pre-processor utilizing wavefront multiplexing restructures signal streams on the ground into multi-channel wavefrom structures along with injections of pilot signals for diagnostic and probing purposes. These restructured, or “wavefront multiplexed” (WFM) signals are transmitted through propagation channels to a receiver on the spacecraft, wherein adaptive equalization and wavefront de-multiplexing coherently separates the mixtures of received WFM signals. Transmitting power can be dynamically allocated for the multiple concurrent data streams, radiated to different spacecraft within the same field of view according to continuously changing demand by changing the relative input power ratios of the WFM signal mixtures.

Owner:CHANG DONALD C D

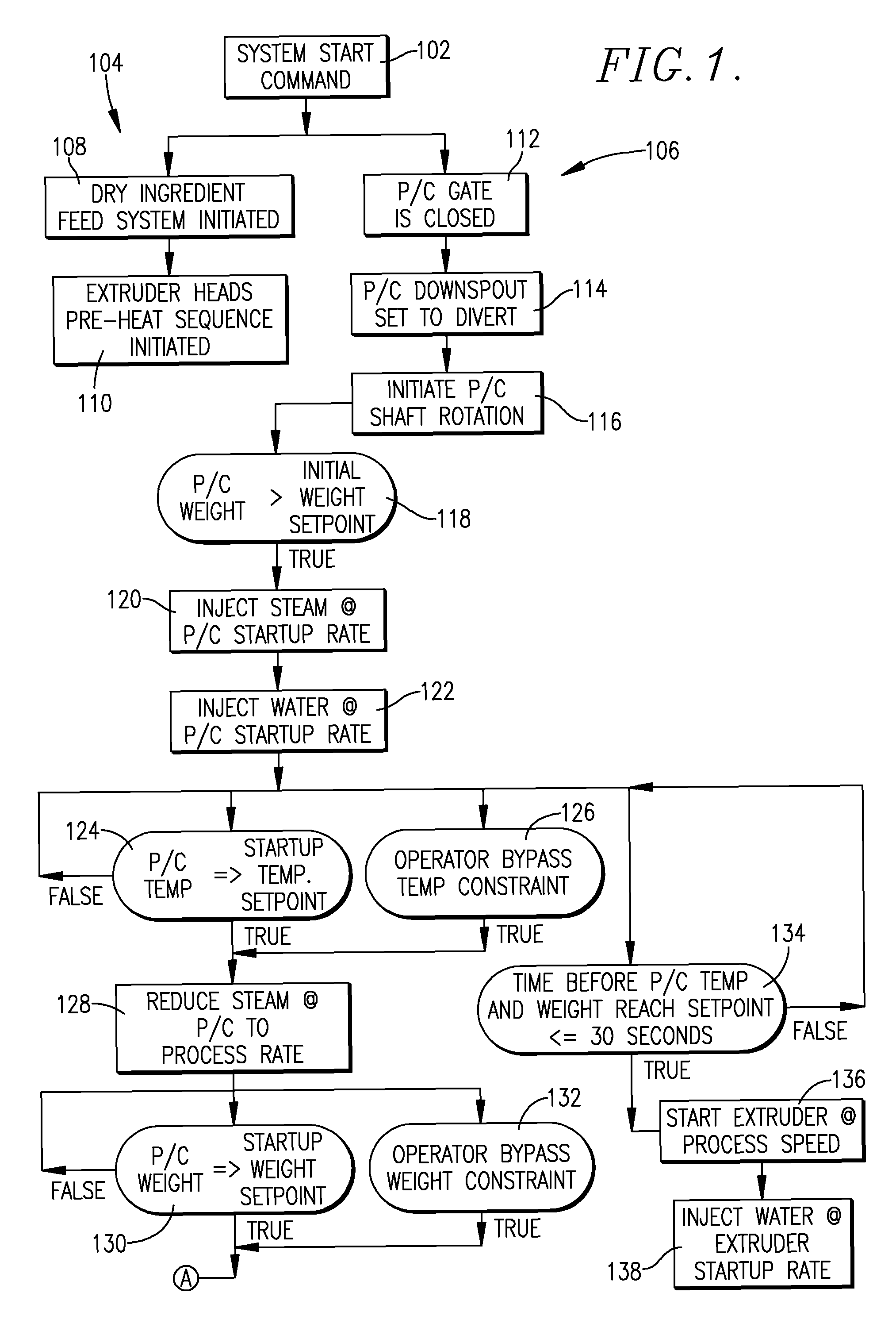

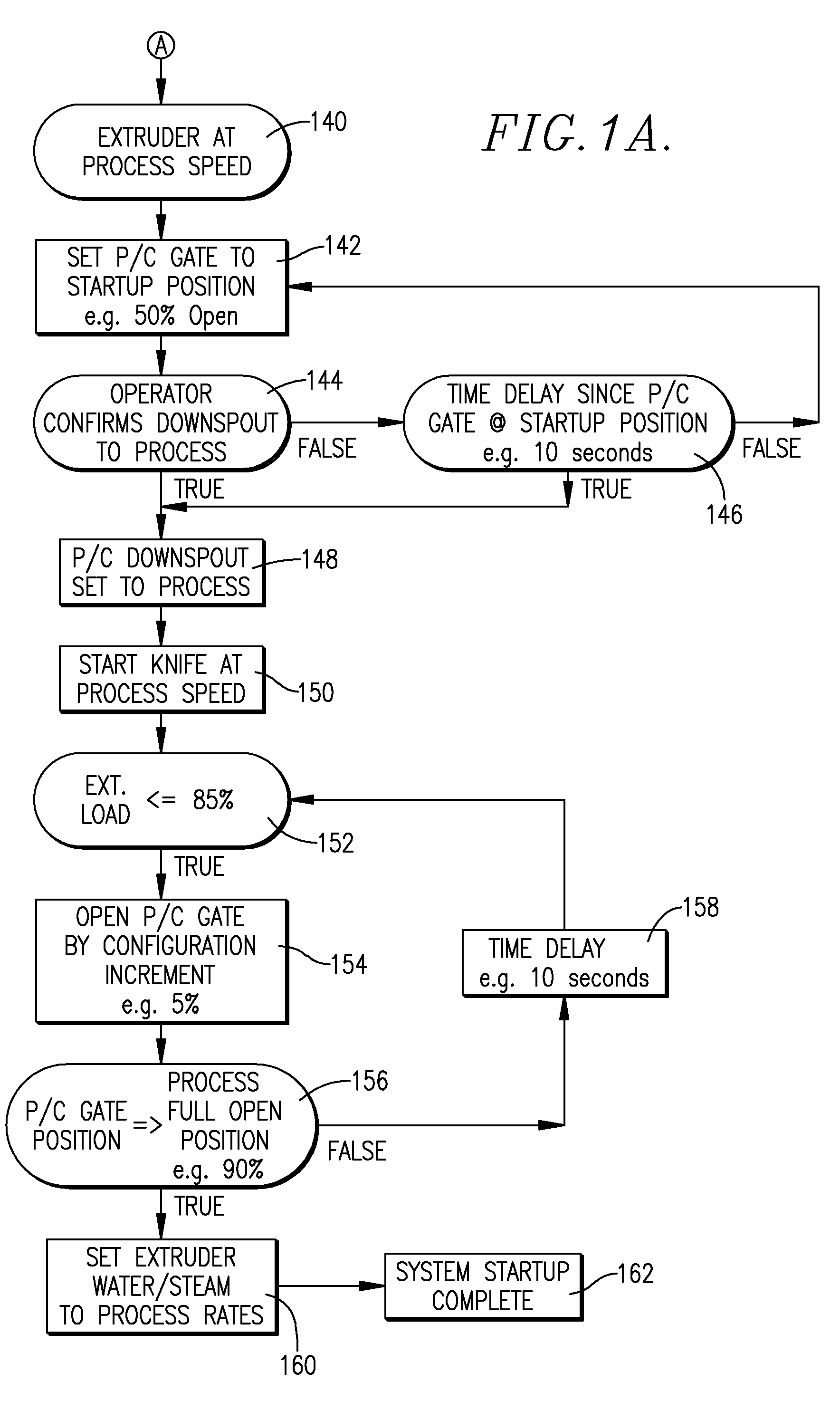

Method of preconditioner control with reduced or zero waste

ActiveUS7794134B1Easy to disassembleSignificant to useOther chemical processesFeeding-stuffDownstream processingProcess engineering

Improved, low- or no-waste control methods for food processing systems including a preconditioner (14) and a downstream processing device such as an extruder (16) are provided. The control methods include both startup and shutdown sequences, and an optional flush sequence. During startup, a gate (64) of preconditioner (14) is initially closed and is thereafter sequentially opened to a full open, normal operating position after predetermined preconditioner temperature and / or weight set points are achieved. Shutdown involves terminating the flow of ingredients to the preconditioner (14) while the gate (64) remains open, with the preconditioner operated to deliver the preconditioned material within the preconditioner (14) to the extruder (16) for as long as possible in order to minimize any residual waste within the preconditioner.

Owner:WENGER MFG LLC

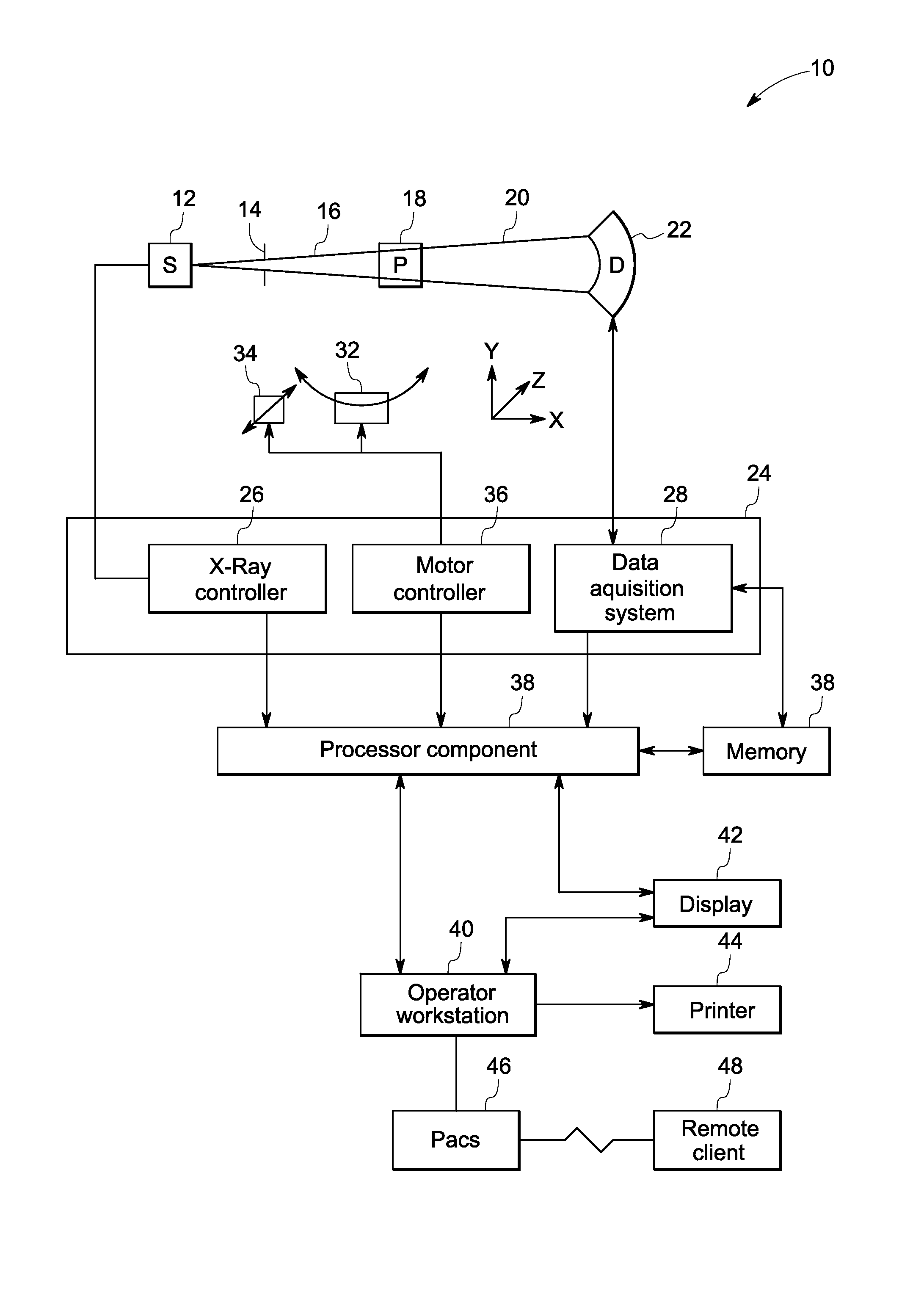

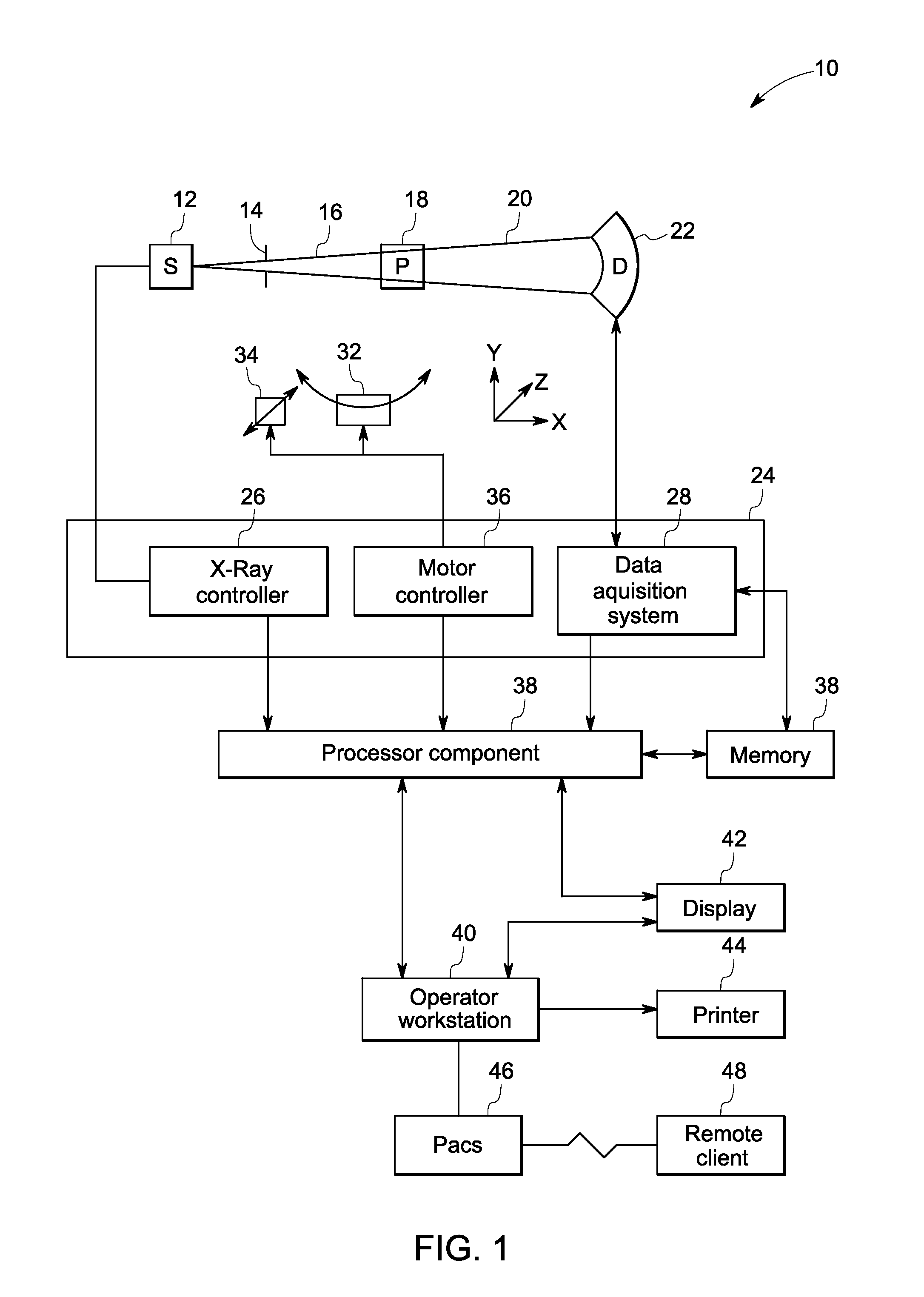

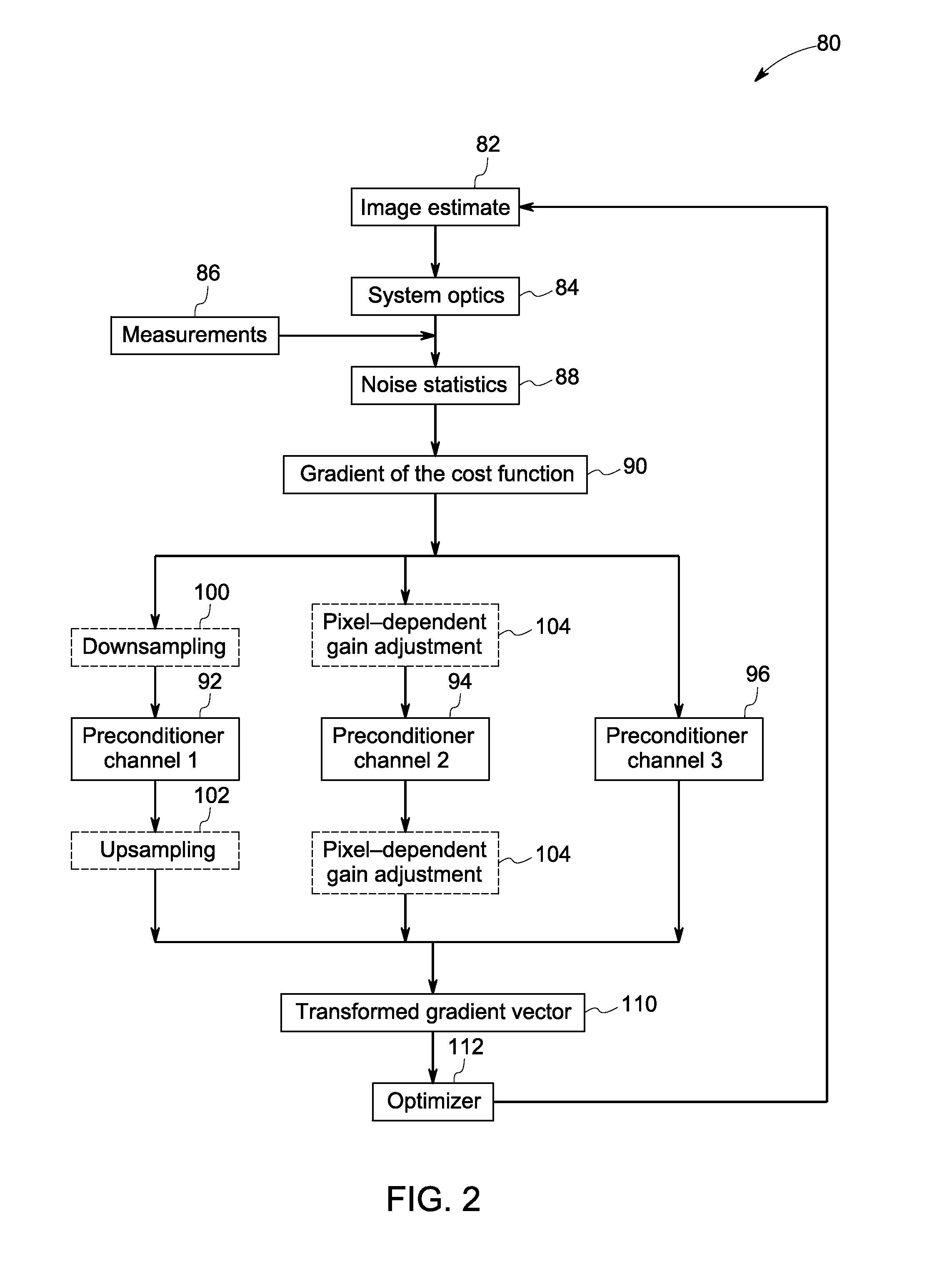

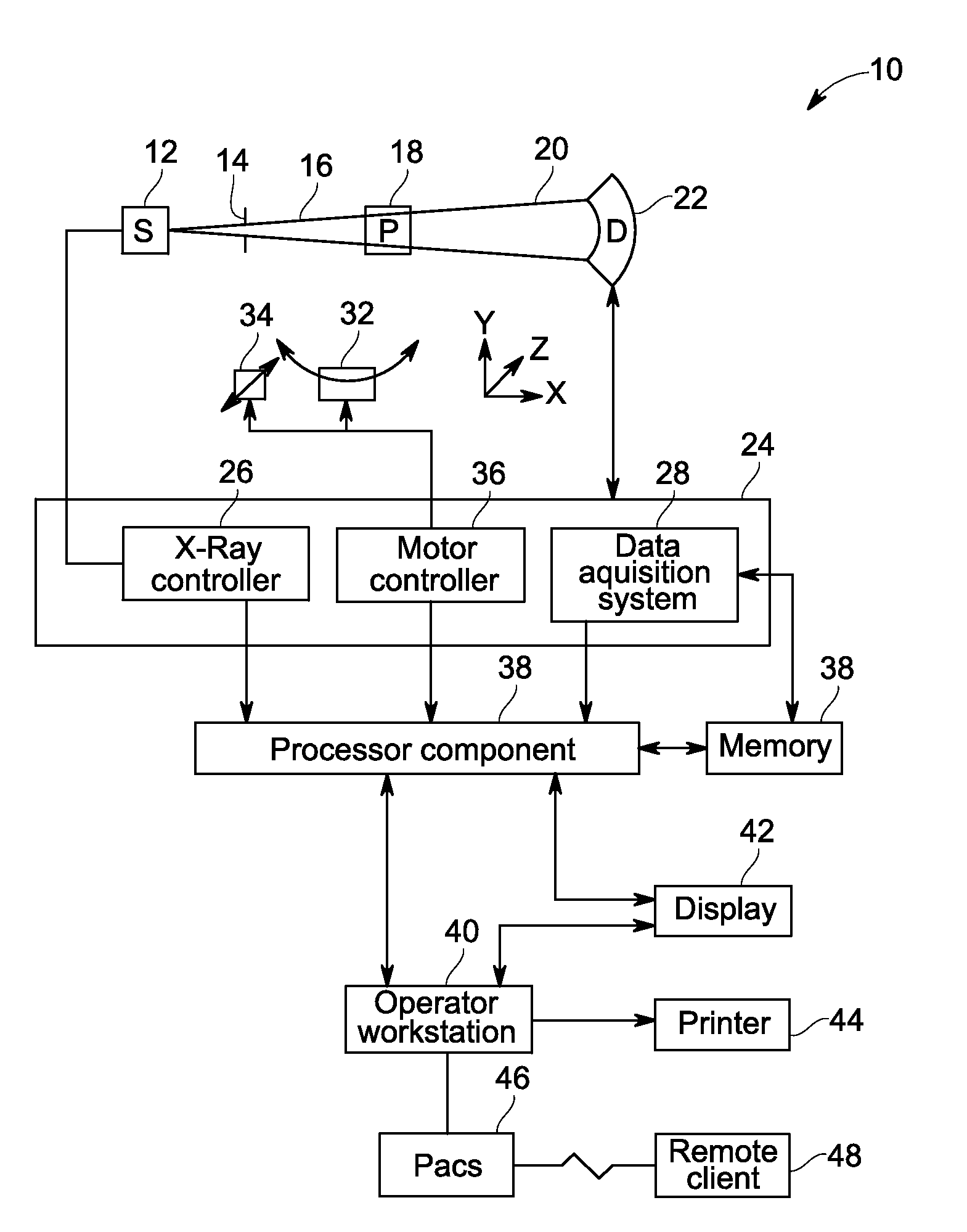

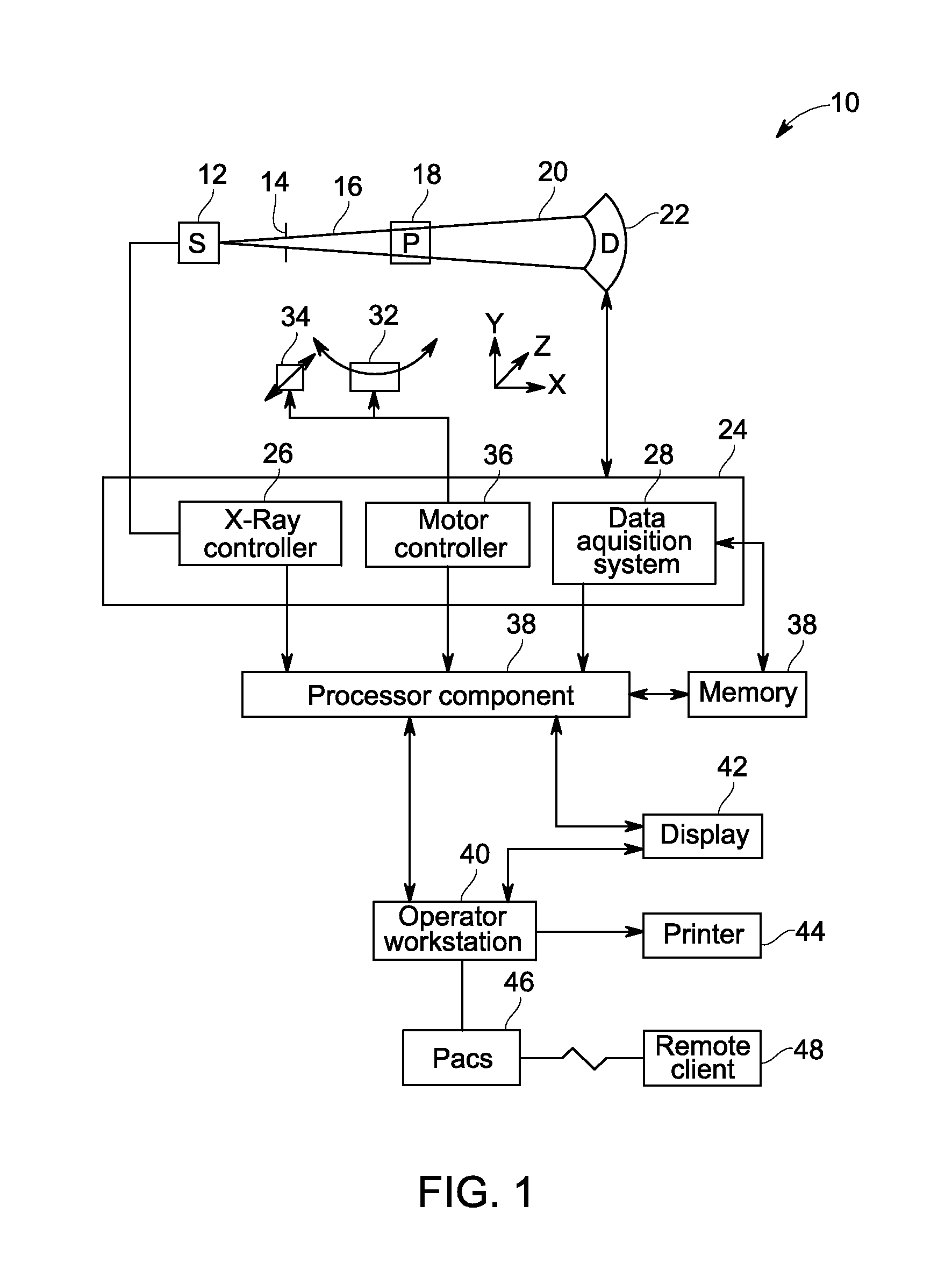

Iterative reconstruction in image formation

ActiveUS20140369581A1Reconstruction from projectionCharacter and pattern recognitionImage estimationImage formation

The use of the channelized preconditioners in iterative reconstruction is disclosed. In certain embodiments, different channels correspond to different frequency sub-bands and the output of the different channels can be combined to update an image estimate used in the iterative reconstruction process. While individual channels may be relatively simple, the combined channels can represent complex spatial variant operations. The use of channelized preconditioners allows empirical adjustment of individual channels.

Owner:RGT UNIV OF MICHIGAN +1

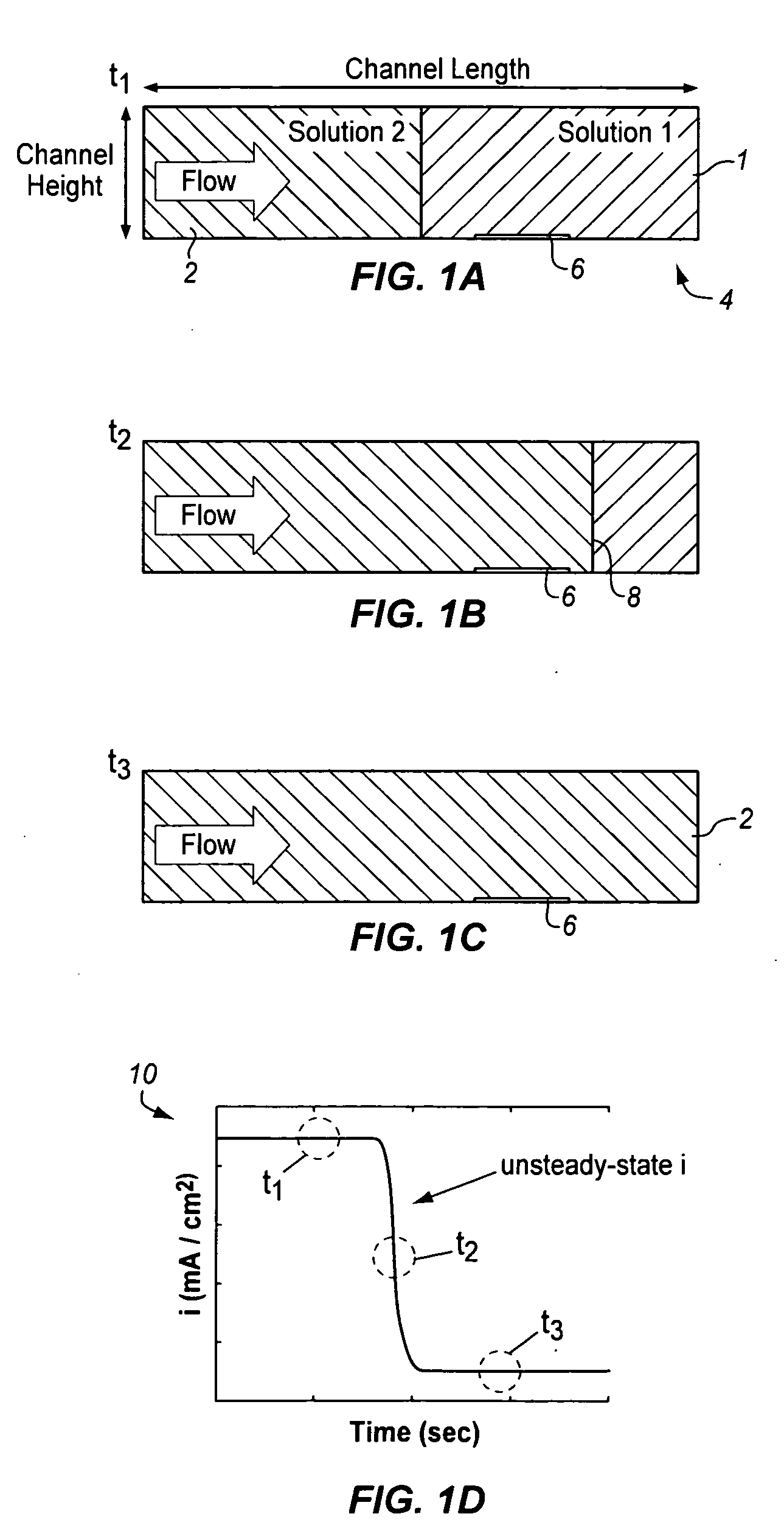

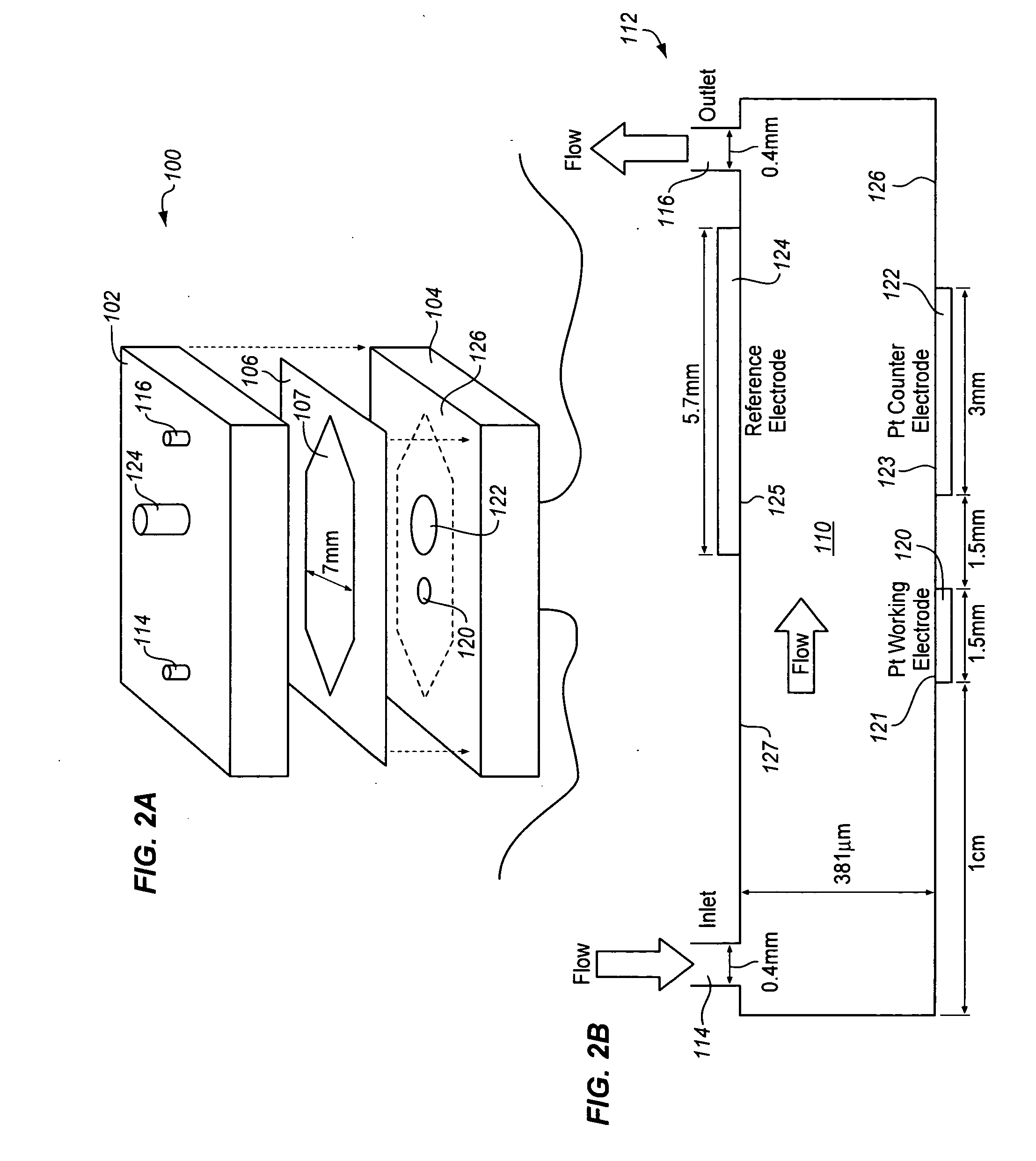

Monitoring of electroplating additives

ActiveUS20110025338A1Small footprintAccurate measurement of concentrationCellsWeather/light/corrosion resistanceEngineeringPreconditioner

The working electrode in the flow channel of a flow-through electrolytic detection cell is preconditioned by flowing a preconditioning electroplating solution with preconditioner species through the flow channel while applying a negative potential. Flow of liquid through the flow channel is rapidly switched from preconditioning solution to a target solution containing an organic target solute to be measured. The transient response of the system resulting from exposure of the working electrode to organic target solute is detected by measuring current density during an initial transient time period. An unknown concentration of target solute is determined by comparing the transient response with one or more transient responses characteristic of known concentrations. A preferred measuring system is operable to switch flow from preconditioning solution to target solution in about 200 milliseconds or less.

Owner:NOVELLUS SYSTEMS

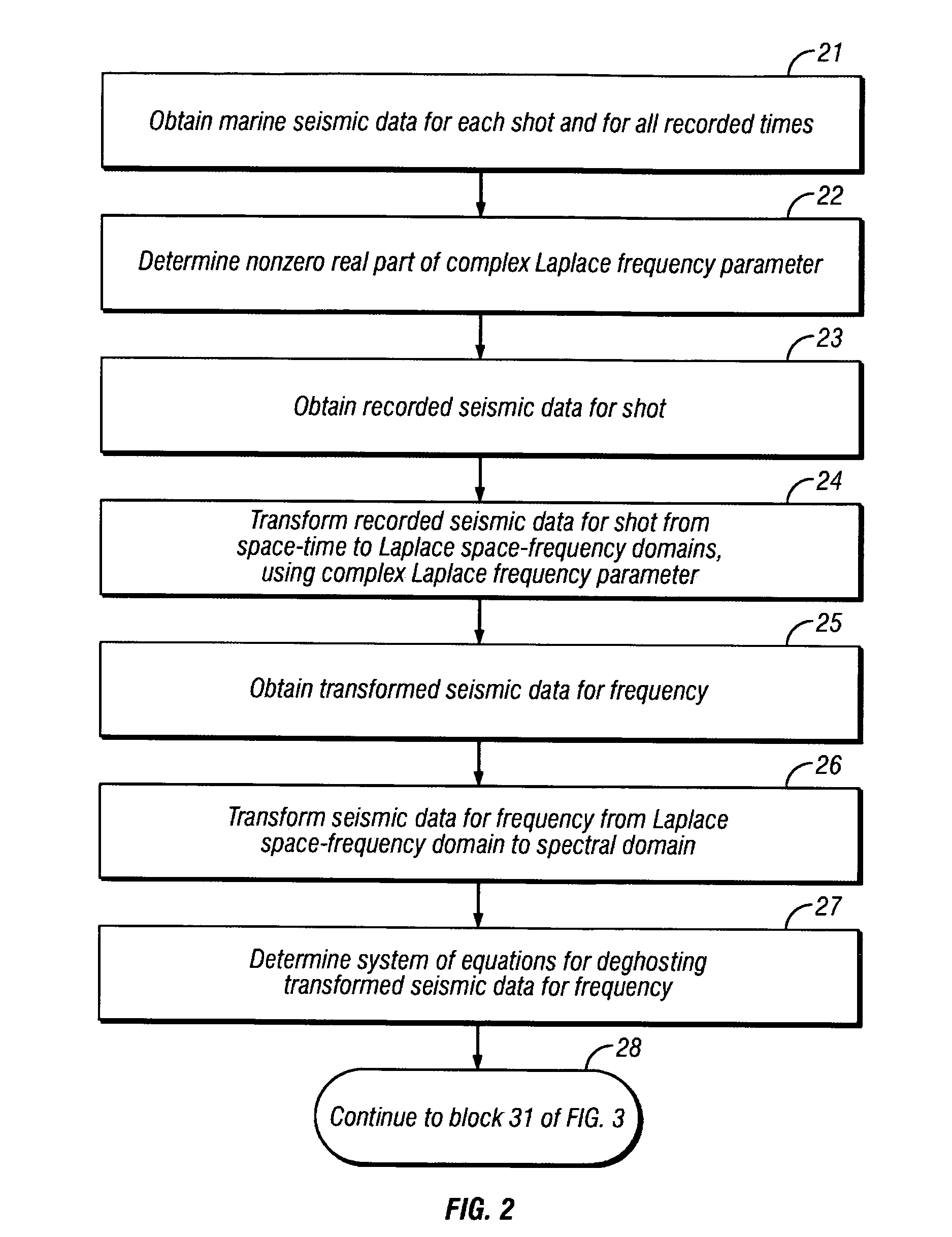

Method for full-bandwidth deghosting of marine seismic streamer data

Seismic data recorded in a marine streamer are obtained, with the seismic data being representative of characteristics of subsurface earth formations and acquired by deployment of a plurality of seismic receivers overlying an area of the subsurface earth formations to be evaluated, the seismic receivers generating at least one of an electrical and optical signal in response to seismic energy. A complex Laplace frequency parameter is used to transform the seismic data from a space-time domain to a spectral domain. An iterative conjugate gradient scheme, using a physically-based preconditioner, is applied to the transformed seismic data, to provide a least squares solution to a normal set of equations for a deghosting system of equations. The solution is inverse-transformed back to a space-time domain to provide deghosted seismic data, which is useful for imaging the earth's subsurface.

Owner:PGS GEOPHYSICAL AS

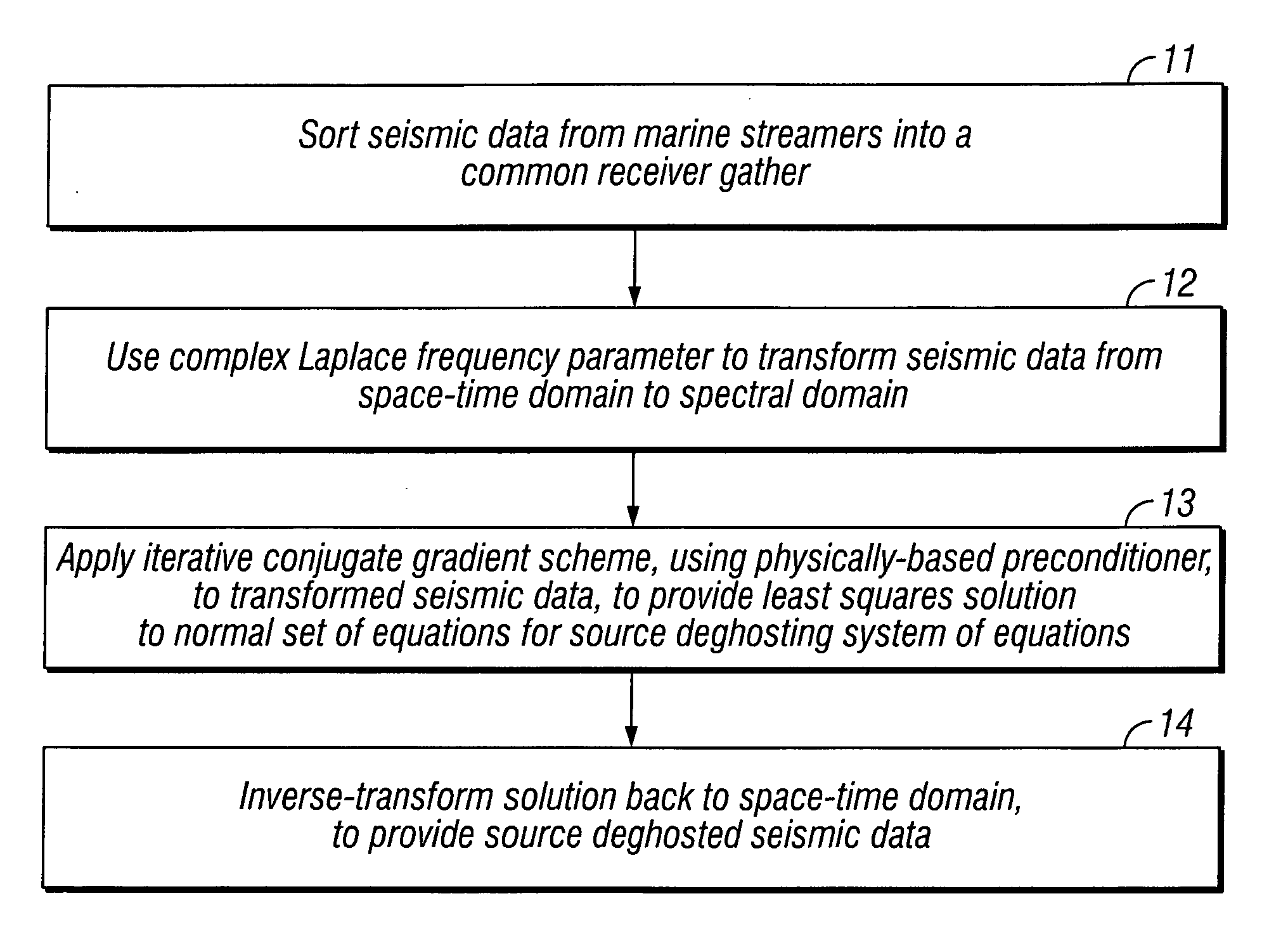

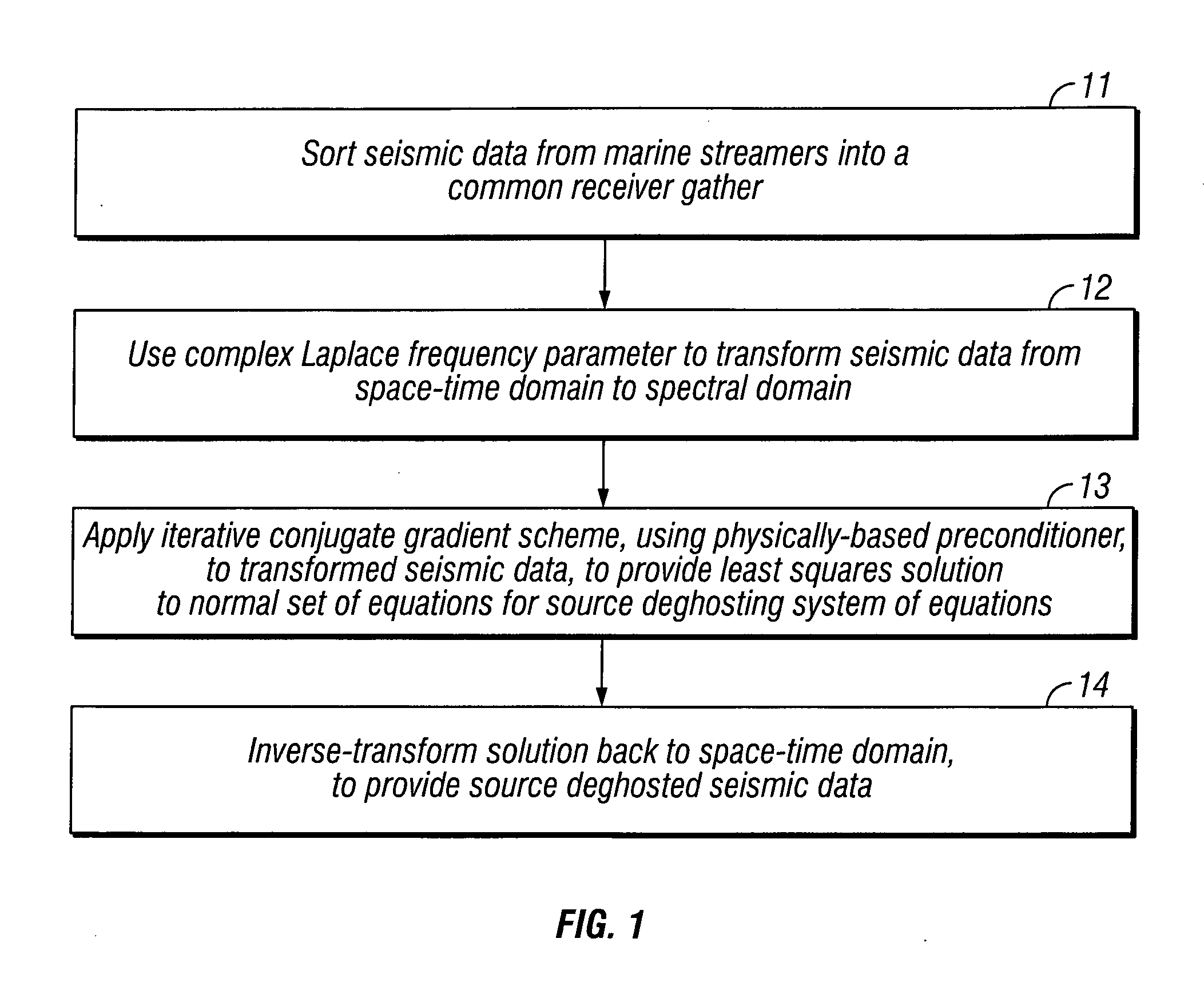

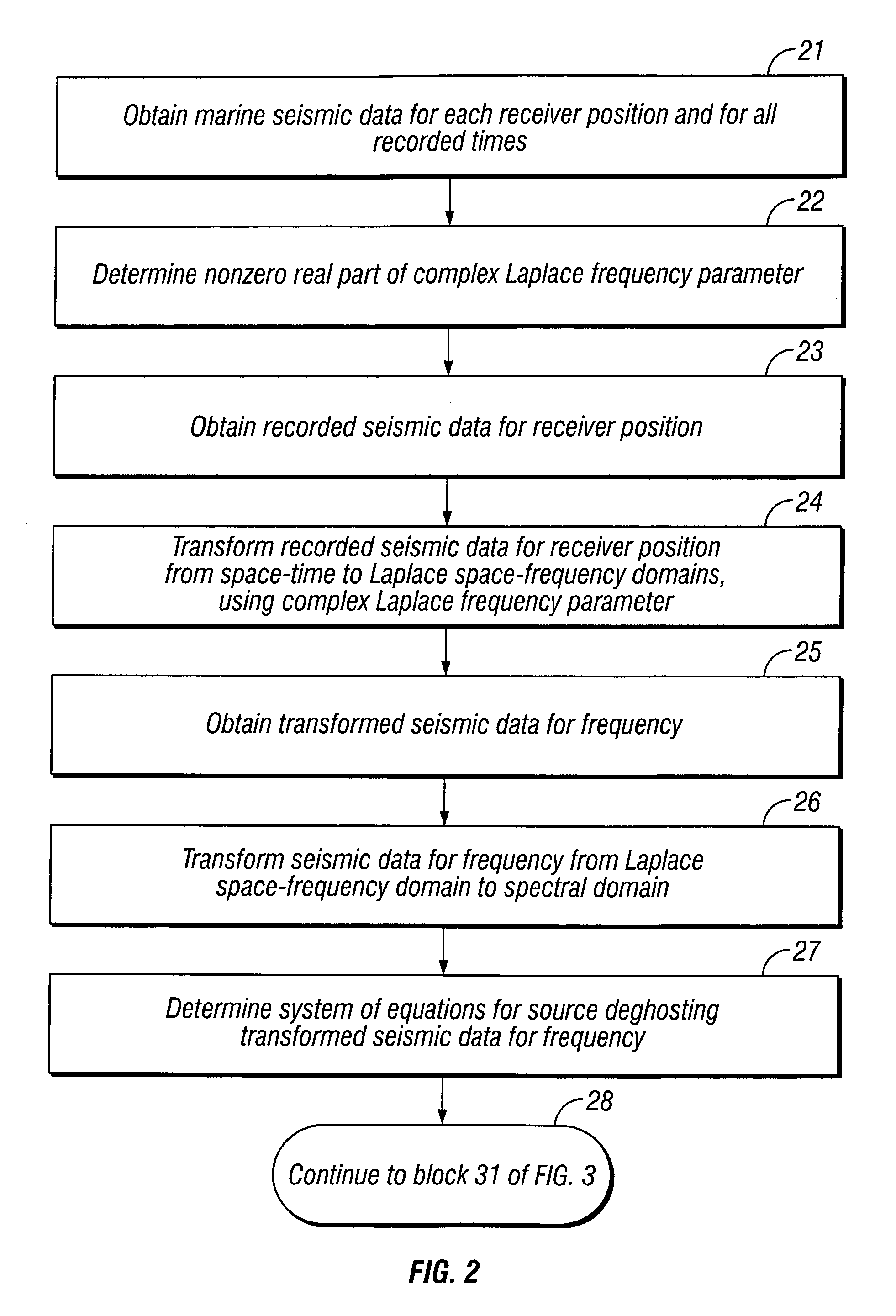

Method for full-bandwidth source deghosting of marine seismic streamer data

Seismic data recorded in a marine streamer are obtained, sorted as a common receiver gather. A complex Laplace frequency parameter is used to transform the seismic data from a space-time domain to a spectral domain. An iterative conjugate gradient scheme, using a physically-based preconditioner, is applied to the transformed seismic data, to provide a least squares solution to a normal set of equations for a source deghosting system of equations. The solution is inverse-transformed back to a space-time domain to provide source deghosted seismic data, which is useful for imaging the earth's subsurface.

Owner:PGS GEOPHYSICAL AS

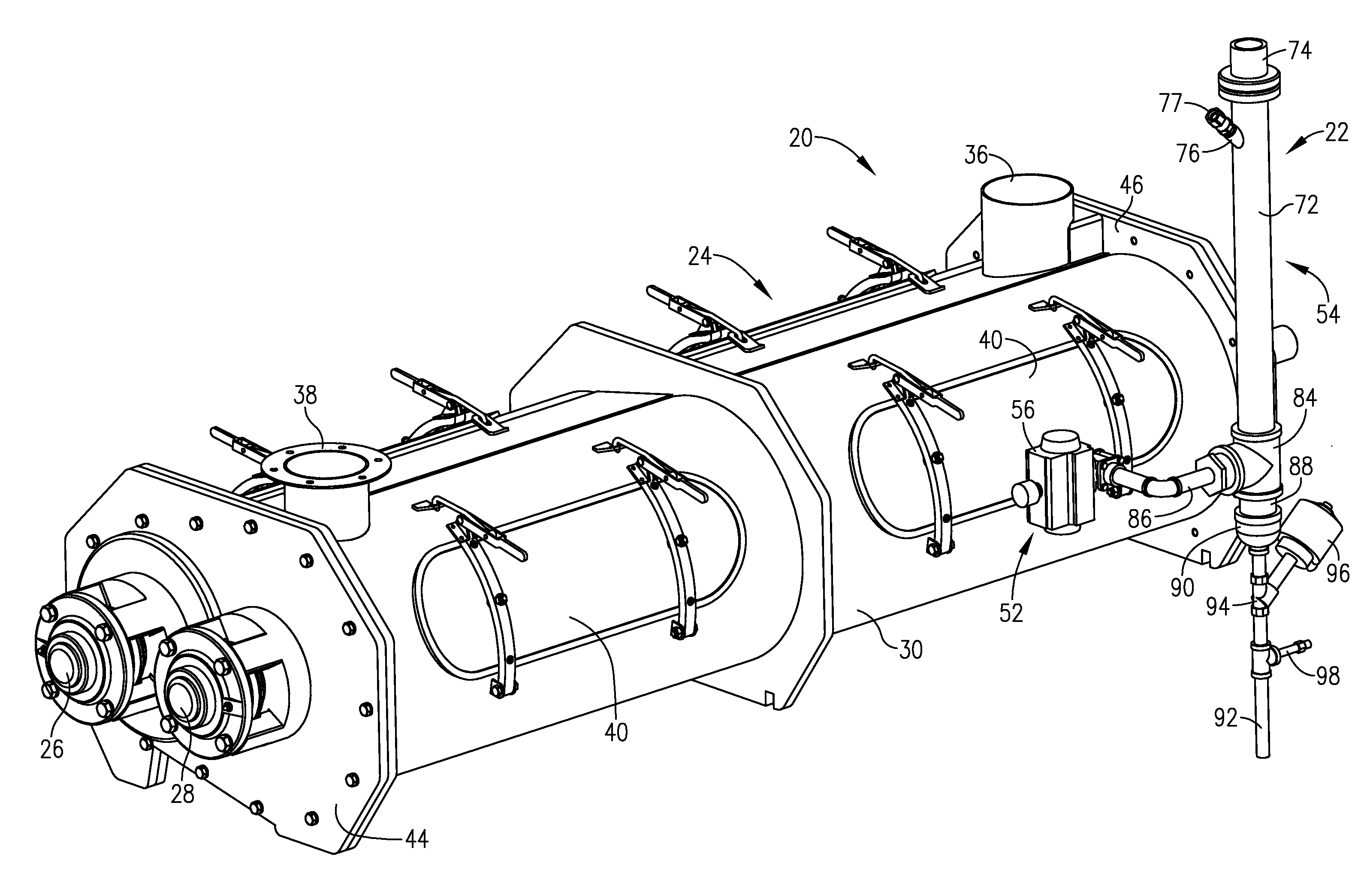

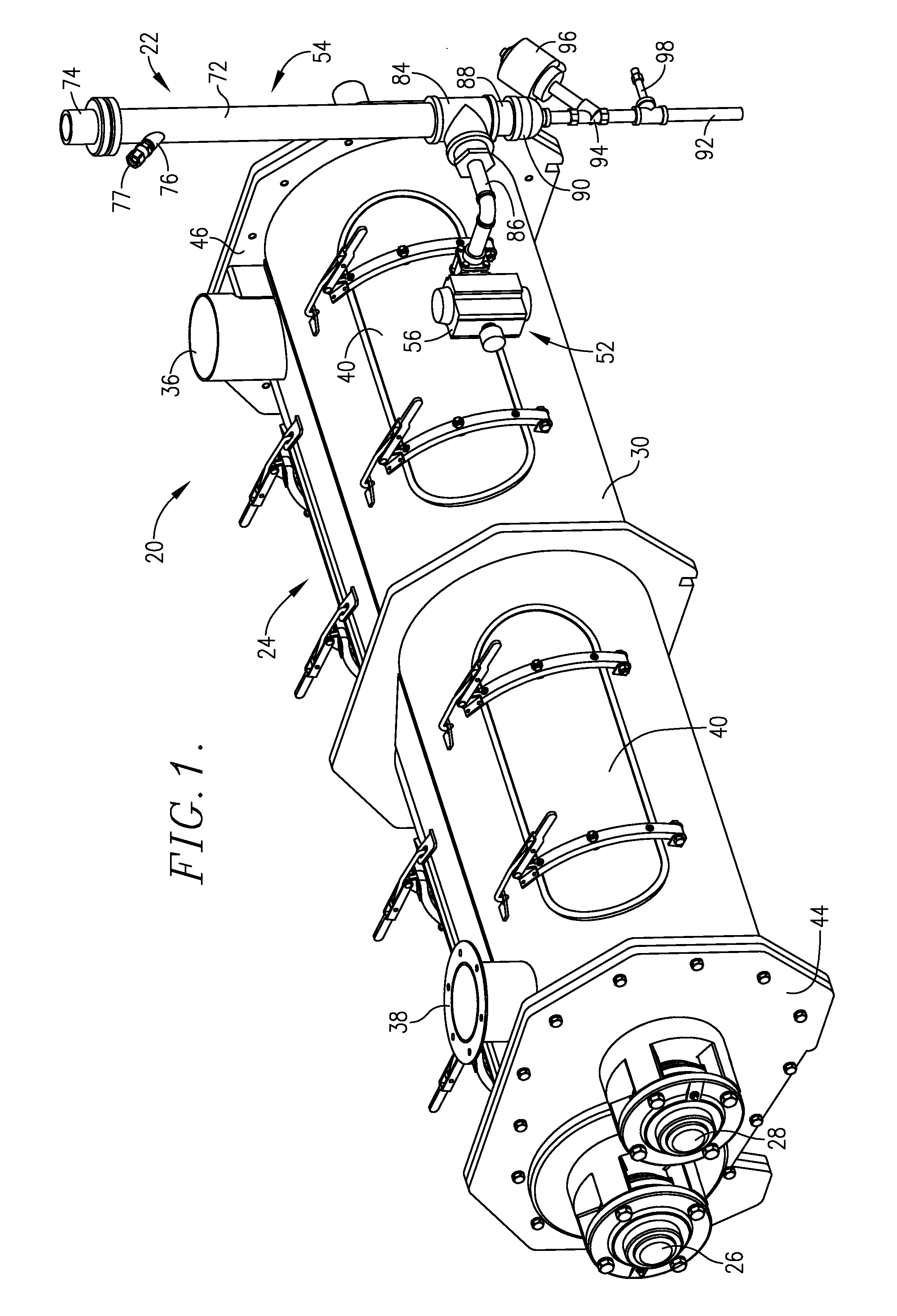

Steam/water static mixer injector for extrusion equipment

Apparatus (20) for injection of fluid into extrusion system components such as a preconditioner (24) or extruder (100) is provided, preferably as a composite assembly including a fluid injection valve (52) and an interconnected static mixer section (54). Alternately, use may be made of the fluid injection valve (52) or static mixer section (54) alone. The invention greatly simplifies the fluid injection apparatus used in extrusion systems, while giving more efficient absorption of thermal energy with a minimum of environmental contamination, and the ability to inject multiple streams into the extrusion systems.

Owner:WENGER MFG LLC

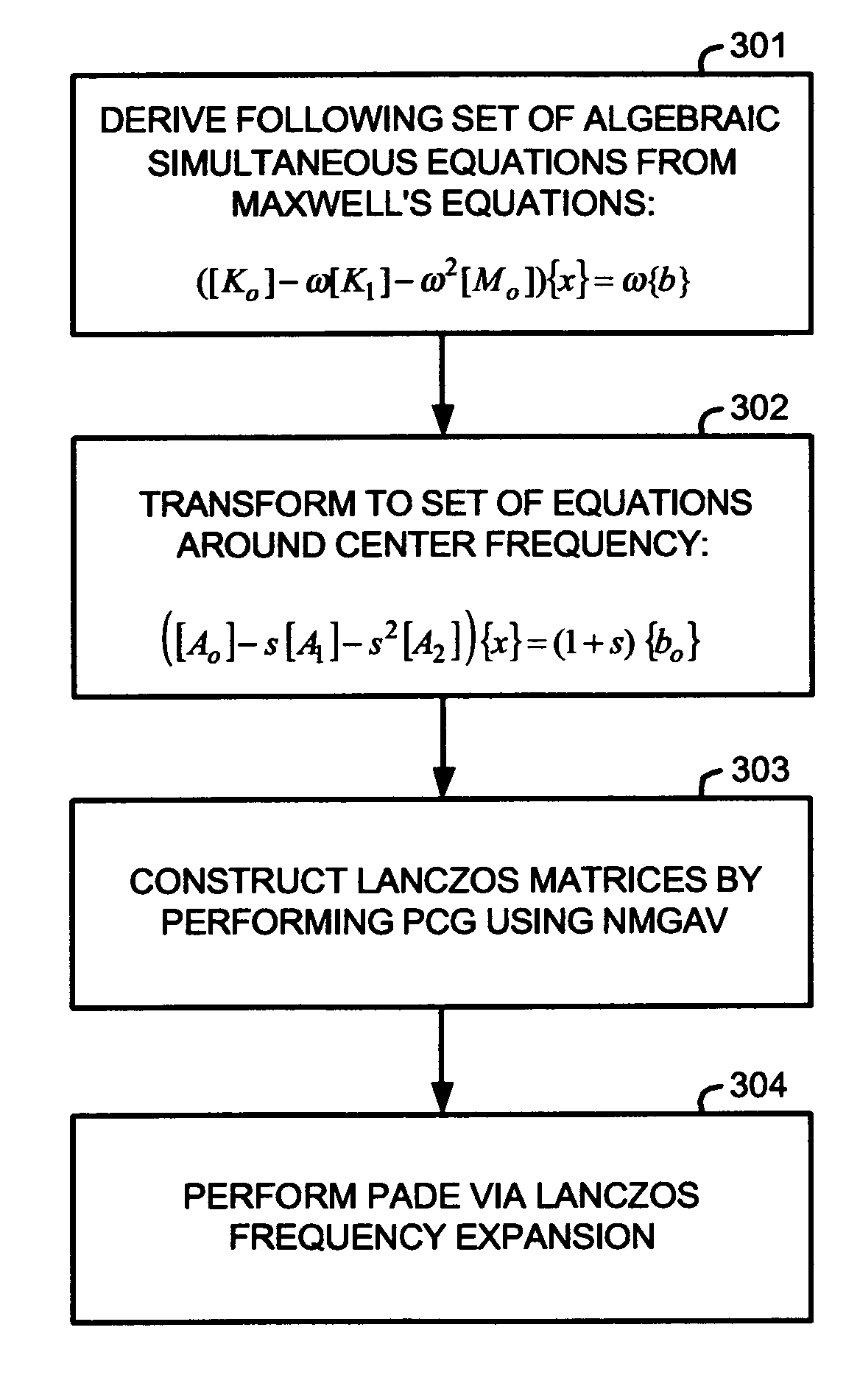

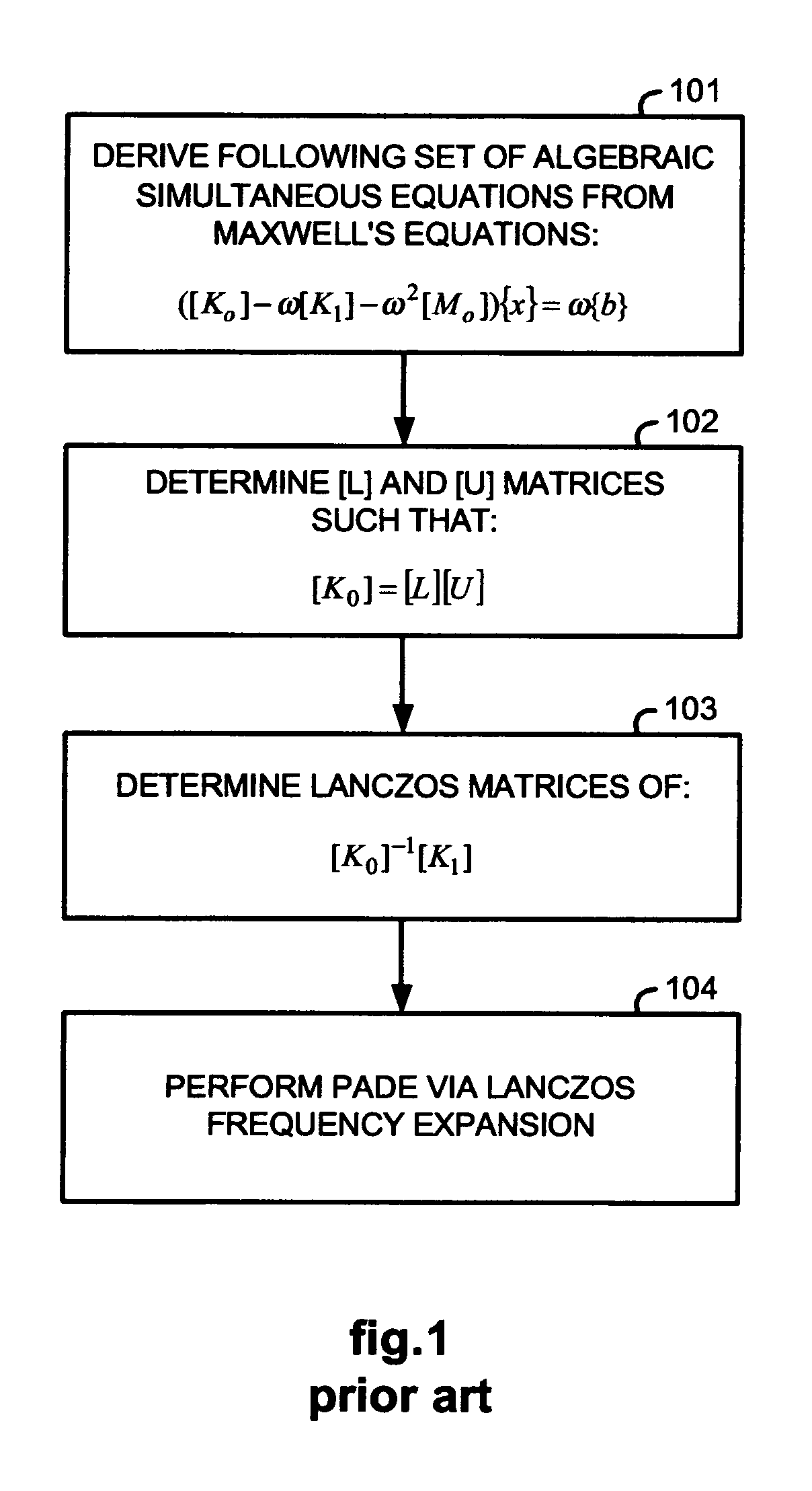

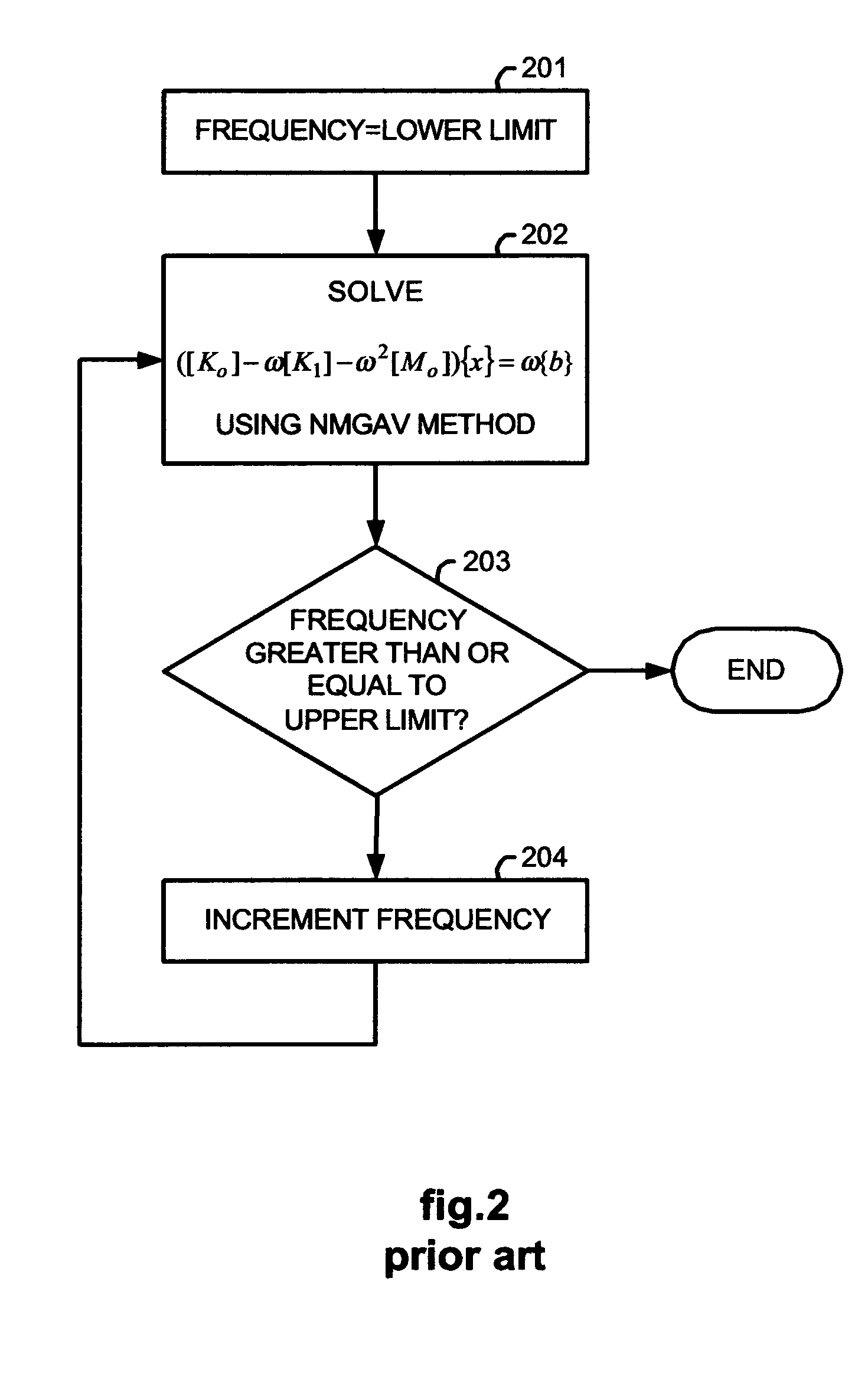

Method for determining electrical and magnetic field effects

InactiveUS20050197808A1Computation using non-denominational number representationComplex mathematical operationsMatrix decompositionScalar potential

A method for determining electrical and magnetic field effects determines Lanczos matrices by performing a preconditioned conjugate gradient method using a nested multi-grid, vector and scalar potential preconditioner so that Pade via Lanczos frequency expansion may be used to determine the electrical and magnetic field effects over a frequency range without having to perform computationally slow and memory intensive matrix decomposition.

Owner:OPTIMAL CORP

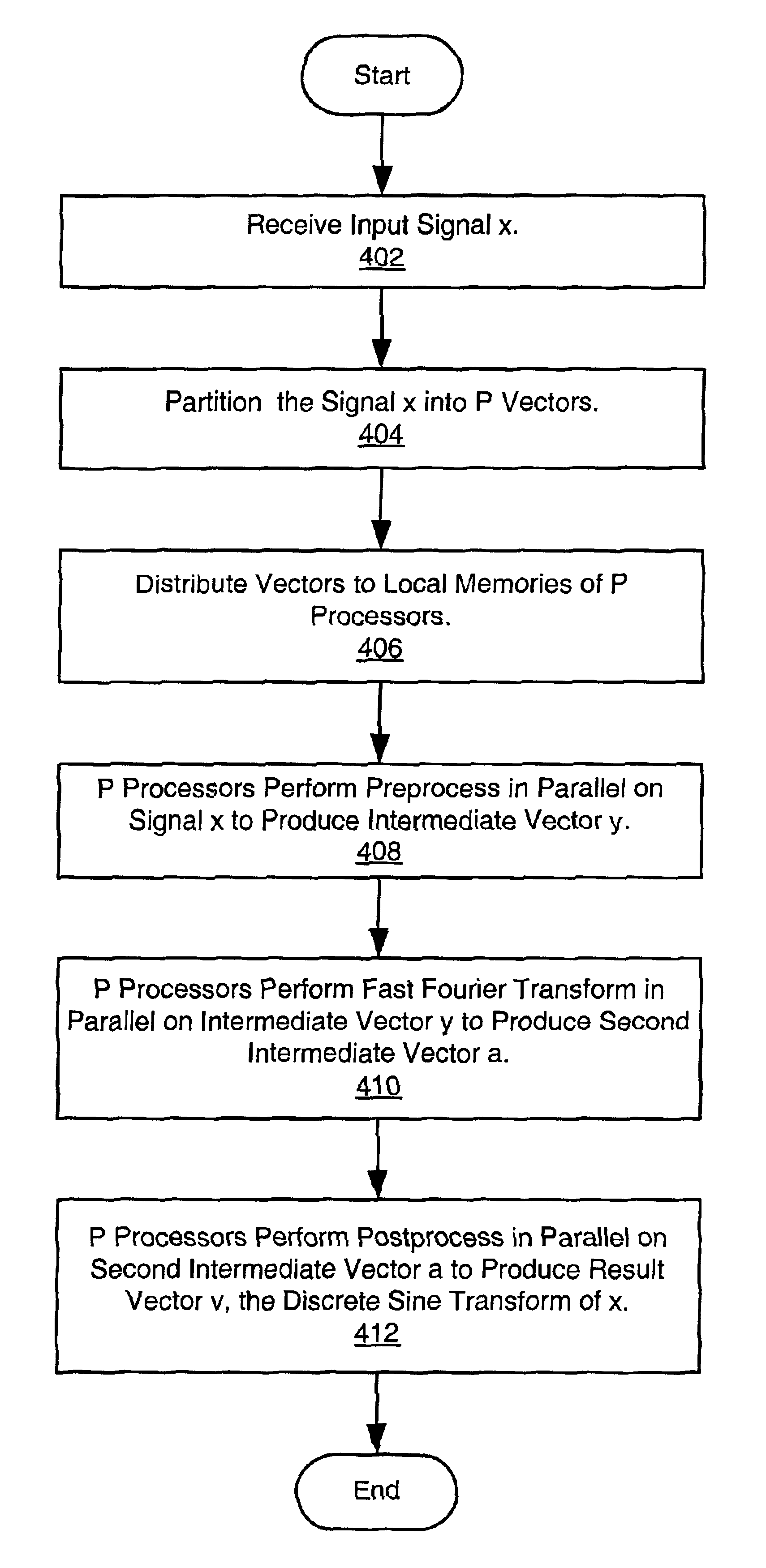

System and method for computing a discrete transform

InactiveUS6839727B2Digital computer detailsComplex mathematical operationsFast Fourier transformPost processor

A system and method for parallel computation of Discrete Sine and Cosine Transforms. The computing system includes a plurality of interconnected processors and corresponding local memories. An input signal x is received, partitioned into P local vectors xi, and distributed to the local memories. The preprocessors may calculate a set of coefficients for use in computing the transform. The processors perform a preprocess in parallel on the input signal x to generate an intermediate vector y. The processors then perform a Fast Fourier Transform in parallel on the intermediate vector y, generating a second intermediate vector a. Finally, the processors perform a post-process on the second intermediate vector a, generating a result vector v, the Discrete Transform of signal x. In one embodiment, the method generates the Discrete Sine Transform of the input signal x. In another embodiment, the method generates the Discrete Cosine Transform of the input signal x.

Owner:ORACLE INT CORP

Method for positive feeding of preconditioned material into a twin screw extruder

Owner:WENGER MANUFACTURING INC

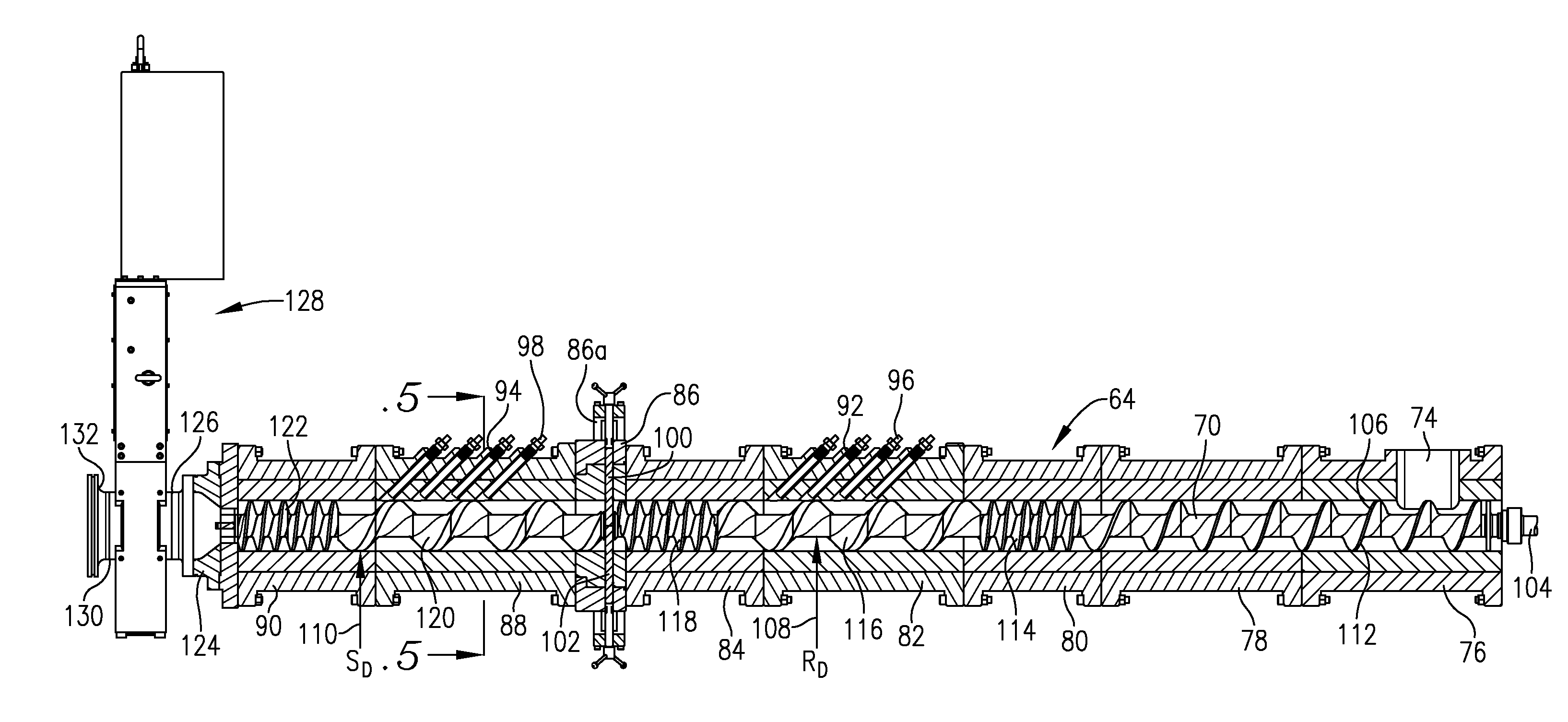

Extrusion processing of high meat quantity feeds using preconditioner with hot air input

InactiveUS7963214B1Rotary stirring mixersMixing/kneading with horizontally-mounted toolsPre treatmentPreconditioner

The present invention is directed to improved preconditioners (12) especially useful for the production of high meat-content pet foods. The preconditioners (12) include an elongated housing (16) with one or more elongated, axially rotatable mixing shafts (18, 20) therein, each having a plurality of outwardly extending mixing elements (42, 44). The preconditioner (12) is provided with apparatus (56) for directing relatively large quantities of heated non-steam gas into the preconditioner (12) in lieu of most or all of the steam normally used with preconditioners. This serves to heat material passing through the preconditioner (12) without the addition of substantial moisture.

Owner:WENGER MANUFACTURING INC

Steam/water static mixer injector for extrusion equipment

InactiveUS20150016211A1Minimize and eliminate pluggingFlow mixersFeeding-stuffThermal energyEngineering

Owner:WENGER MANUFACTURING INC

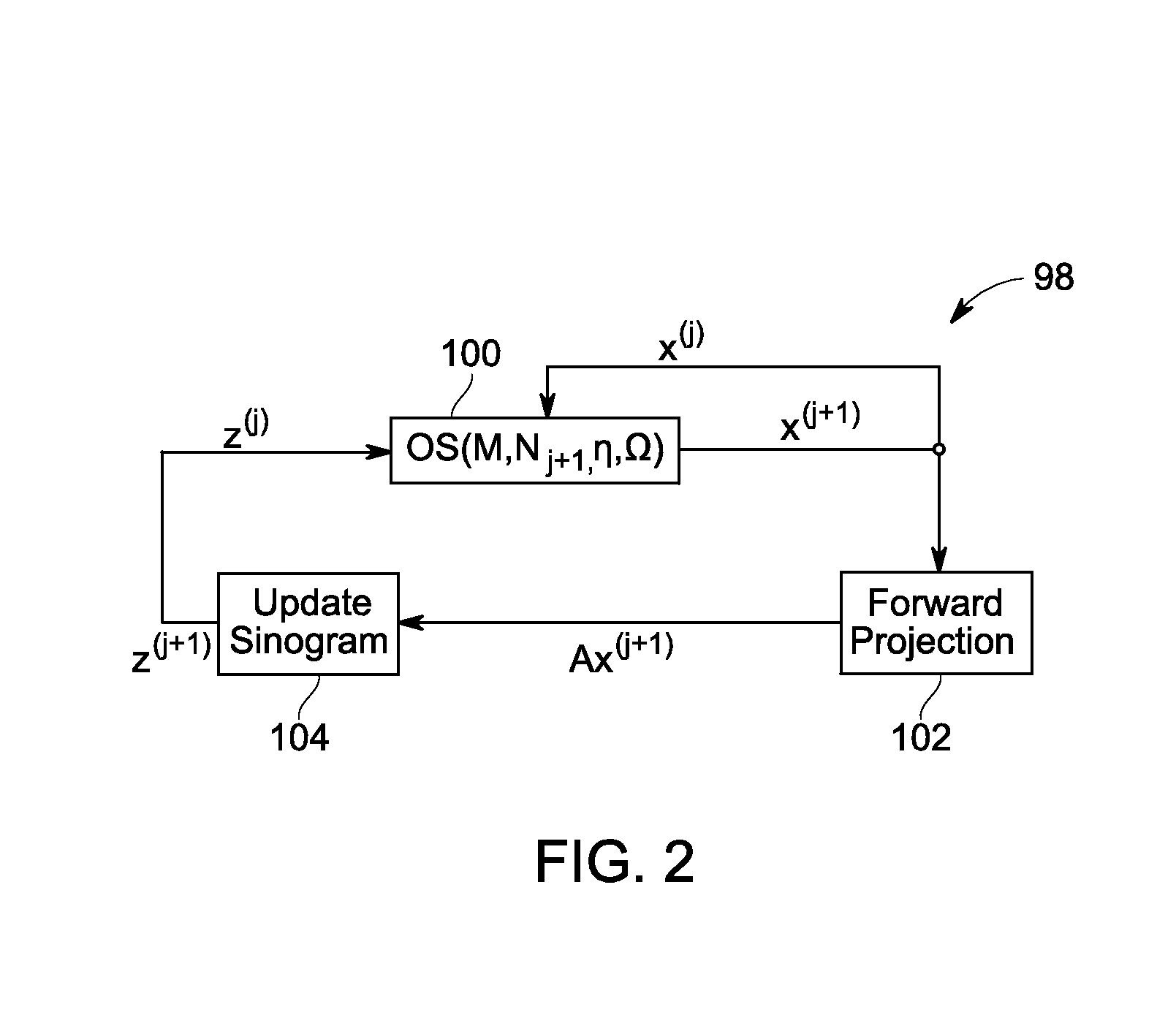

Accelerated iterative reconstruction

ActiveUS20140369580A1Reconstruction from projectionCharacter and pattern recognitionInner loopTheoretical computer science

A framework for an iterative reconstruction algorithm is described which combines two or more of an ordered subset method, a preconditioner method, and a nested loop method. In one type of implementation a nested loop (NL) structure is employed where the inner loop sub-problems are solved using ordered subset (OS) methods. The inner loop may be solved using OS and a preconditioner method. In other implementations, the inner loop problems are created by augmented Lagrangian methods and then solved using OS method.

Owner:RGT UNIV OF MICHIGAN +2

Single screw extruder for processing of low viscosity preconditioned materials

InactiveUS8246240B2Enhance the beneficial effectEnhanced advantageDischarging apparatusRotary stirring mixersPre treatmentPreconditioner

Improved single screw extruders systems (40) are provided including a single screw extruder (42, 92) as well as an upstream preconditioner (44). The extruders (42, 92) include a single, internal, elongated, helically flighted, axially rotatable screw assembly (52) having one or more improved screw sections (74, 74a, 76). The screw sections (74, 74a, 76) include specially configured flighting (86) wherein adjacent flighting portions (86a, 86b) have smoothly arcuate surfaces (88) extending between the respective flighting portion peripheries (90a, 90b). This flighting design provides smooth, substantially surge-free operation while increasing SME and cook values. The preferred preconditioner (44) has independently controlled mixing shafts (106, 108) allowing the shafts (106, 108) to be rotated at different rotational speeds and / or directions.

Owner:WENGER MANUFACTURING INC

Production of engineered feed or food ingredients by extrusion

ActiveUS20140087044A1Reducing and eliminating needMilk preparationAnimal feeding stuffAdditive ingredientSlurry

Improved processes for the production of engineered feed or food ingredients by extrusion comprise the steps of directing a dry fraction and a byproduct slurry fraction in serial order through a preconditioner and twin-screw extruder in order to create a wet extrudate, which is thereafter dried. The dry fraction is selected from sources of plant-derived starch and / or protein, sources of animal-derived functional proteins, and mixtures thereof. The slurry fraction comprises aqueous byproduct slurries from meat, dairy, vegetable, and fruit processing. The extrusion processes yield high-quality ingredients without the need for conventional rendering.

Owner:WENGER MFG LLC

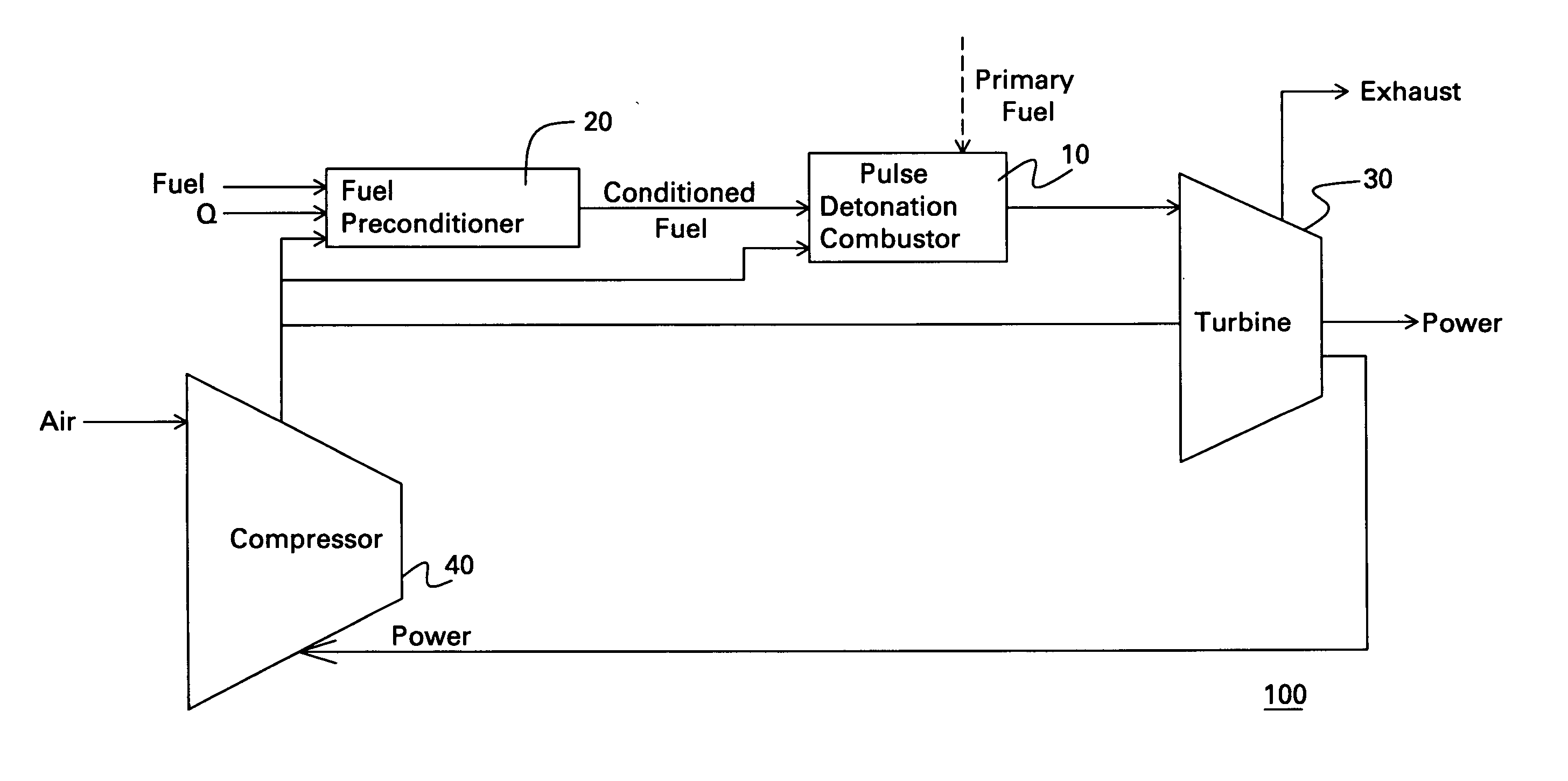

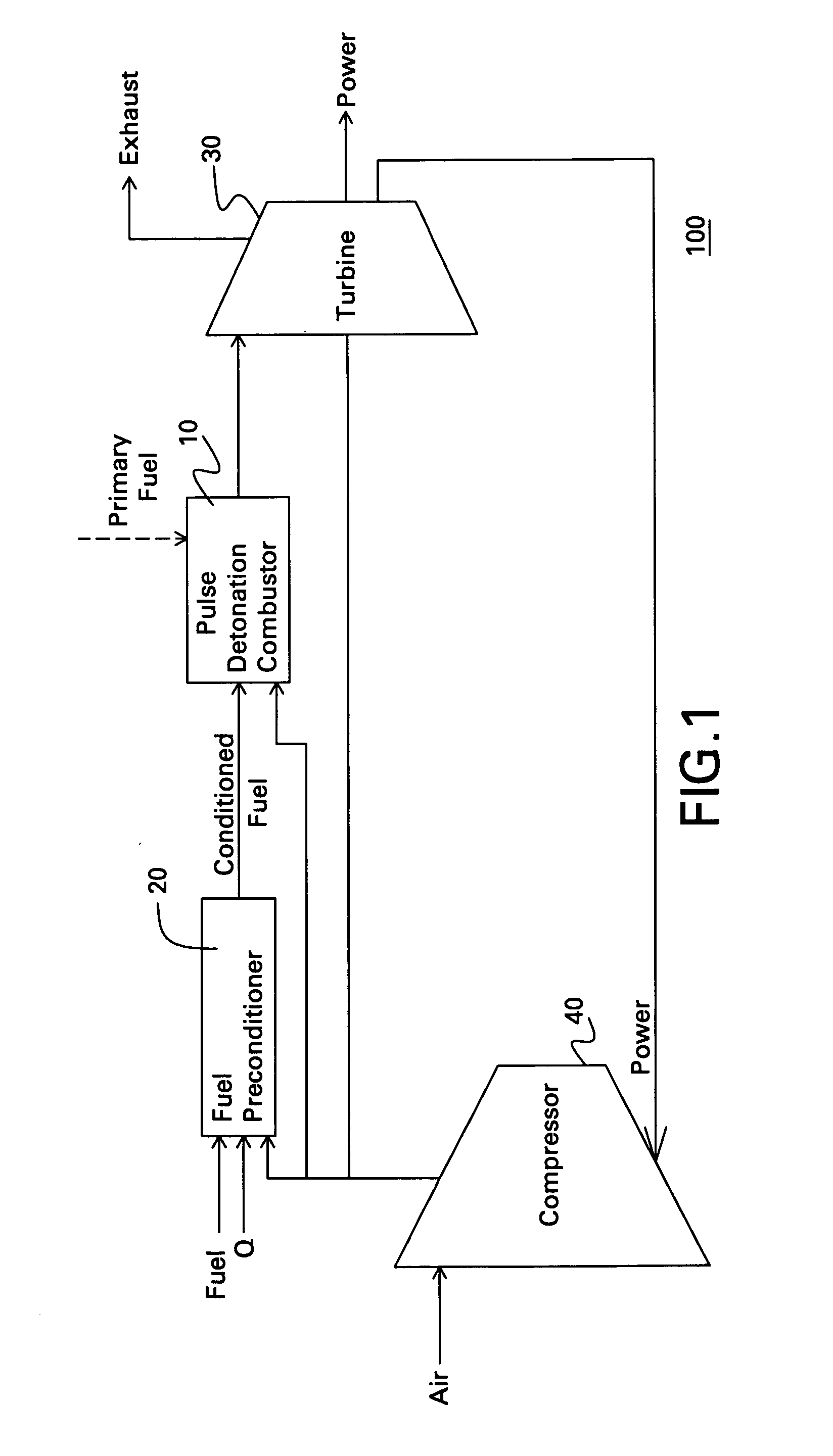

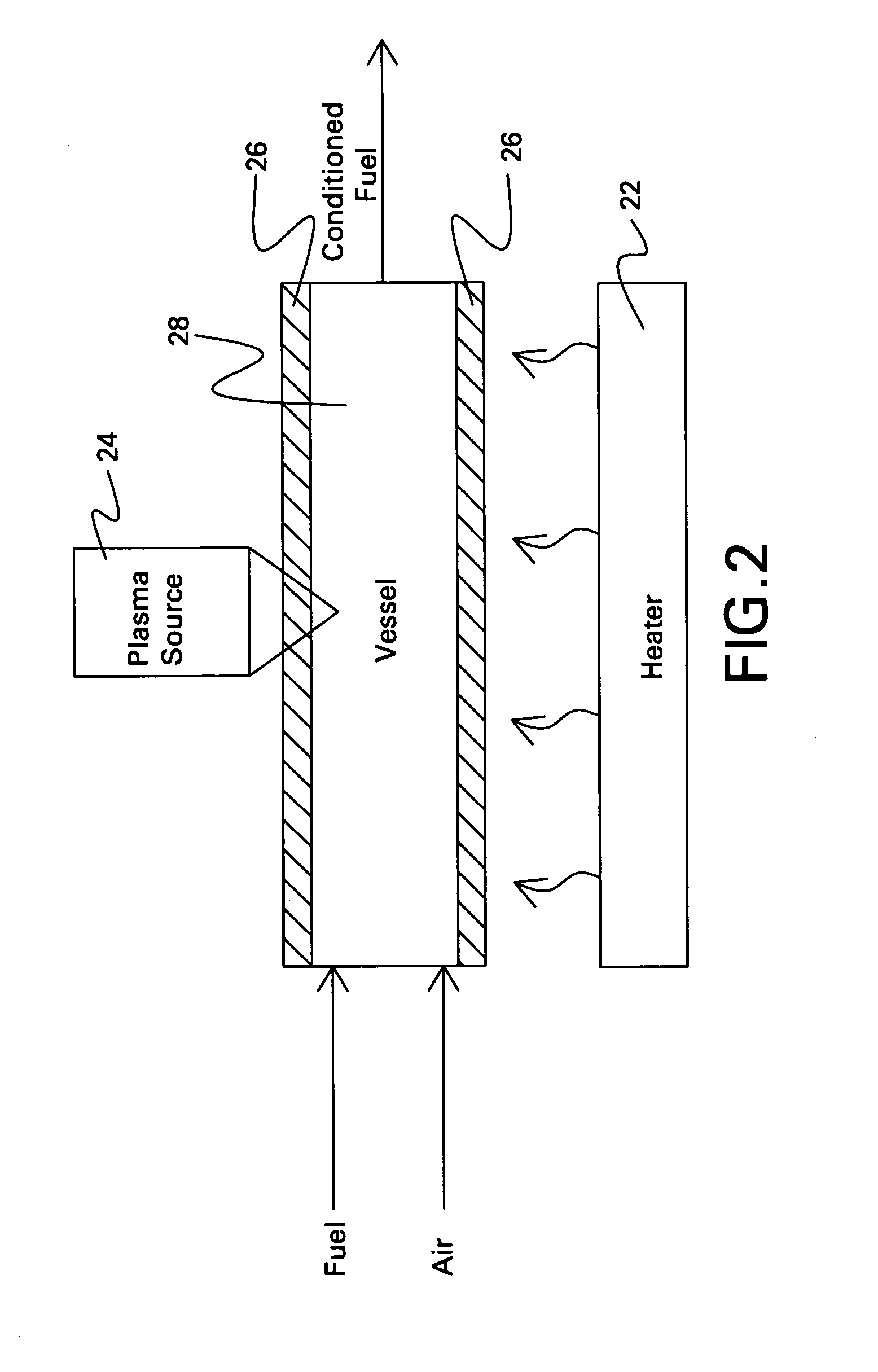

Pulse detonation power system and plant with fuel preconditioning

A power system includes a fuel preconditioner adapted to convert a fuel to at least one conditioned fuel, a pulse detonation combustor, and a turbine. The pulse detonation combustor is adapted to receive the conditioned fuel and a primary oxidizer and to detonate a mixture including the conditioned fuel and the primary oxidizer and exhaust a number of detonation products. The turbine is positioned downstream from and in flow communication with the pulse detonation combustor. A power plant includes at least one fuel preconditioner and a number of power systems. Each power system includes a pulse detonation combustor and a turbine positioned downstream from and in flow communication with the pulse detonation combustor.

Owner:GENERAL ELECTRIC CO

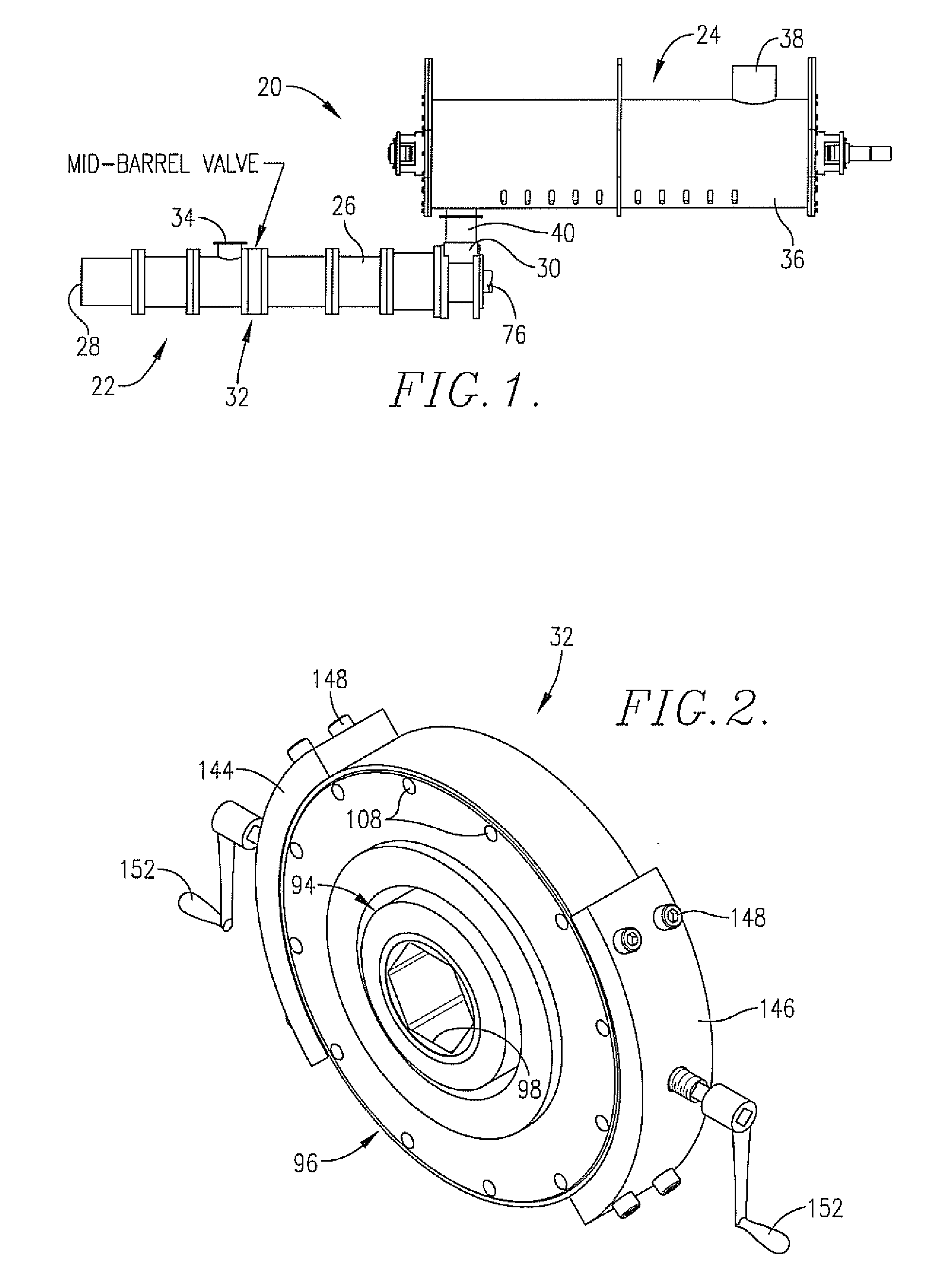

Extruder having variable mid-barrel restriction and adjacent high intensity mixing assembly

InactiveUS20090175120A1Desirable resultMinimize excessive expansionRotary stirring mixersTransportation and packagingEngineeringHigh intensity

Improved, high Specific Mechanical Energy extrusion systems (20) are provided including a single or twin extruder (22) and an upstream preconditioner (24). The extruder (22) includes an elongated barrel (26) with at least one elongated, axially flighted, rotatable screw assembly (58) therein. The barrel (26) includes a mid-barrel variable restriction valve assembly (32), and the screw assembly (58) has a disrupting / homogenizing screw section (66) therein upstream of the valve assembly (32). The screw section (66) includes a plurality of alternating pitch screw parts (82-92). Preferably, the barrel (26) also has an atmospheric vent (36) downstream of the valve assembly (32).

Owner:WENGER MANUFACTURING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com