Patents

Literature

2346results about "Tailstocks/centres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

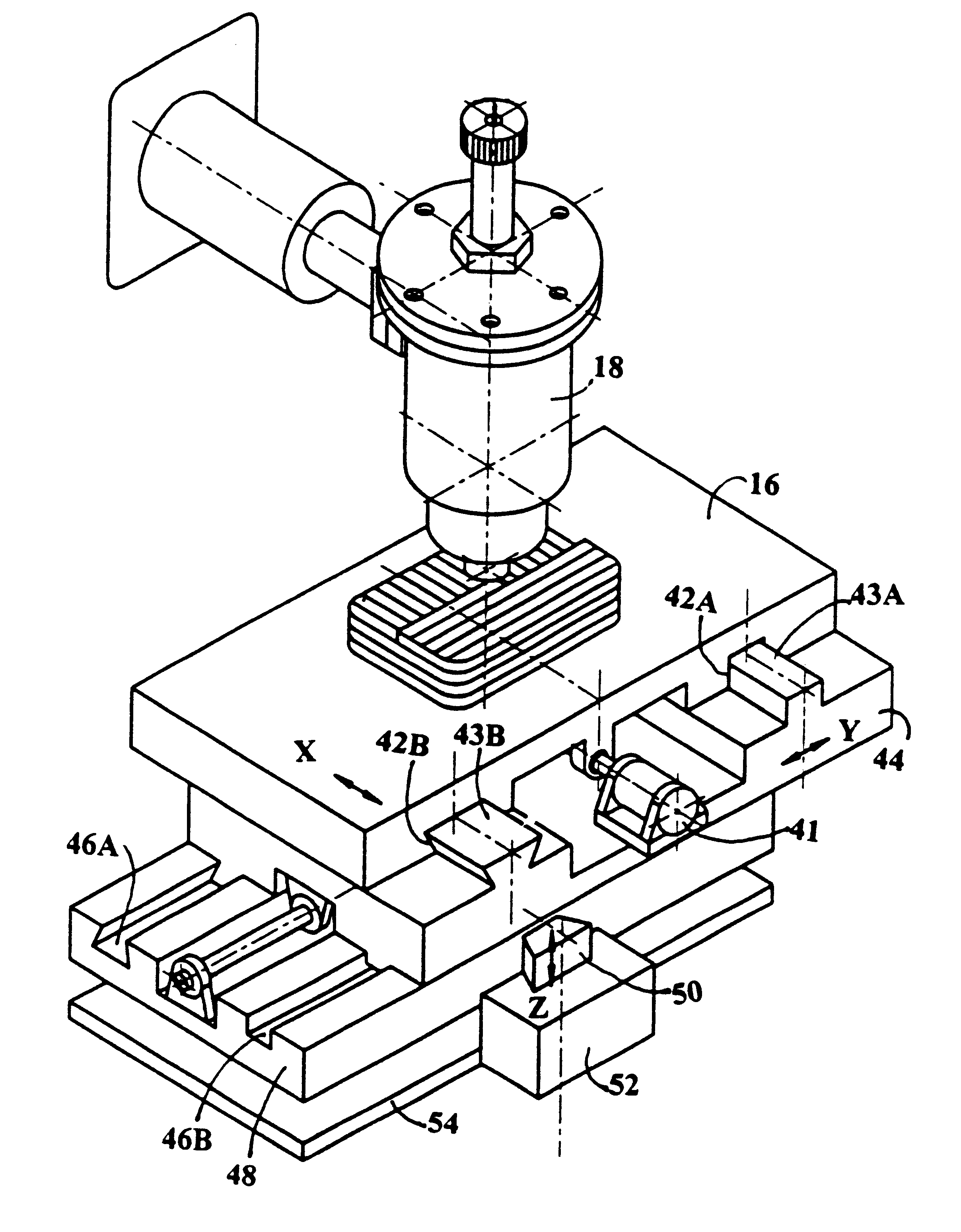

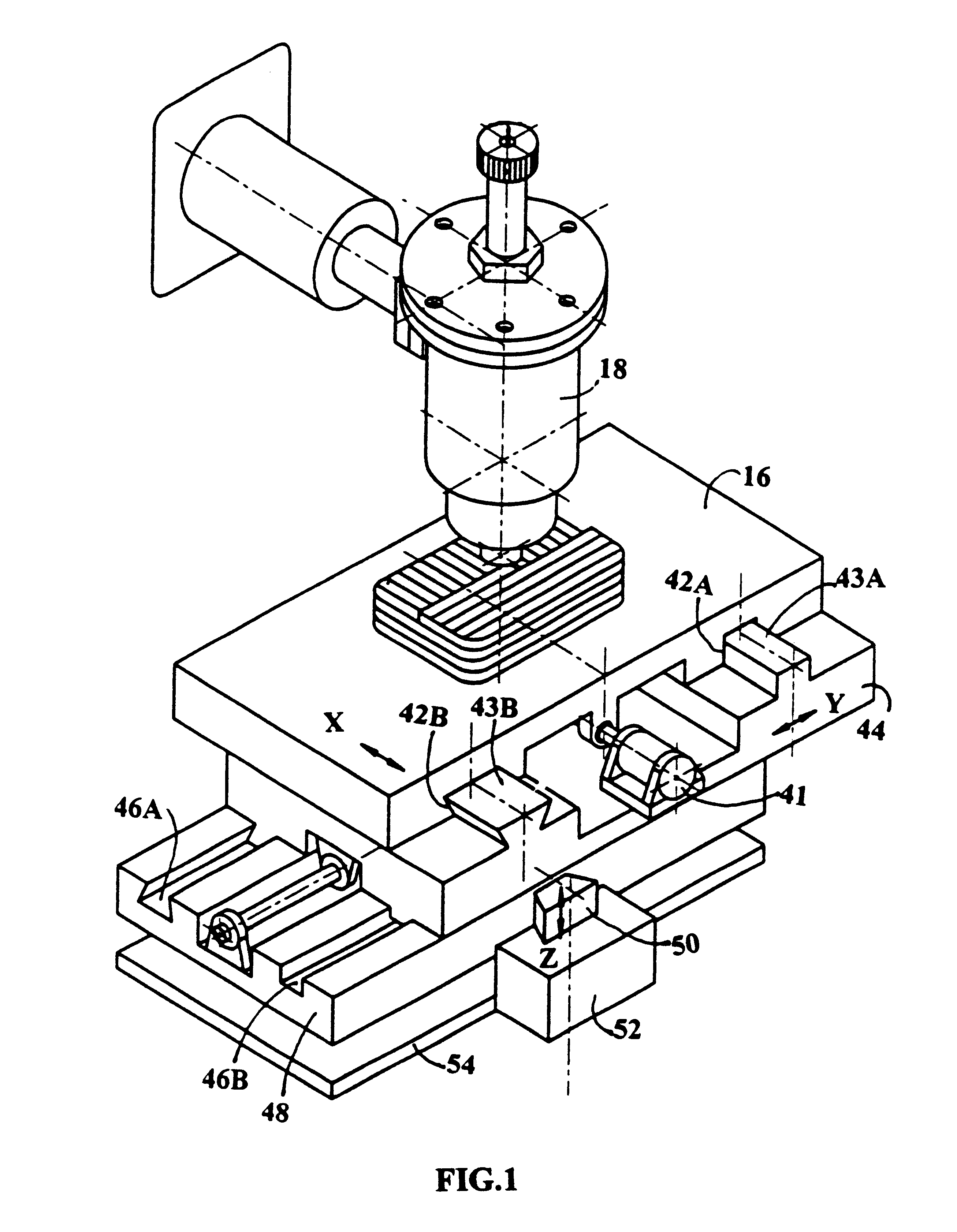

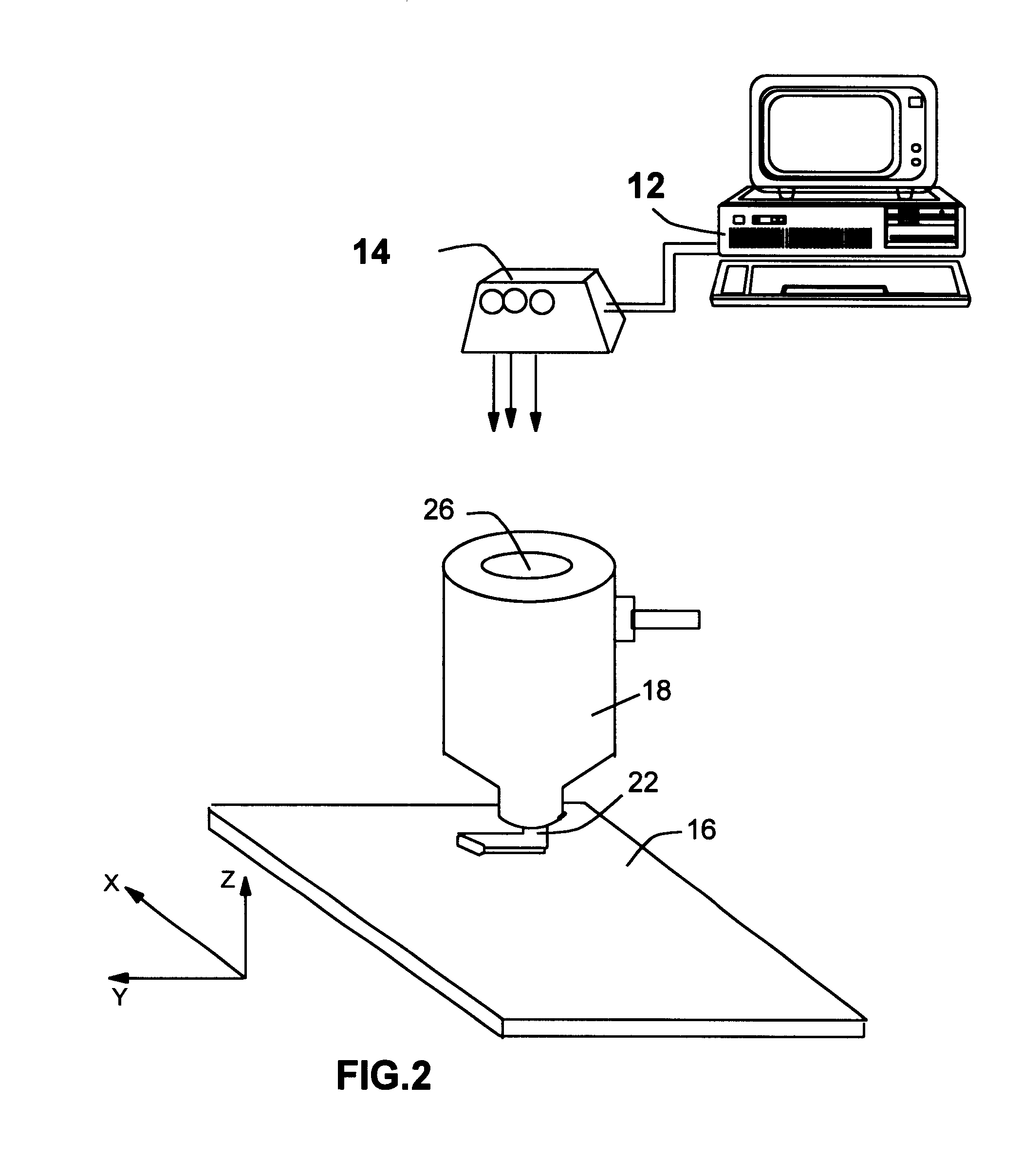

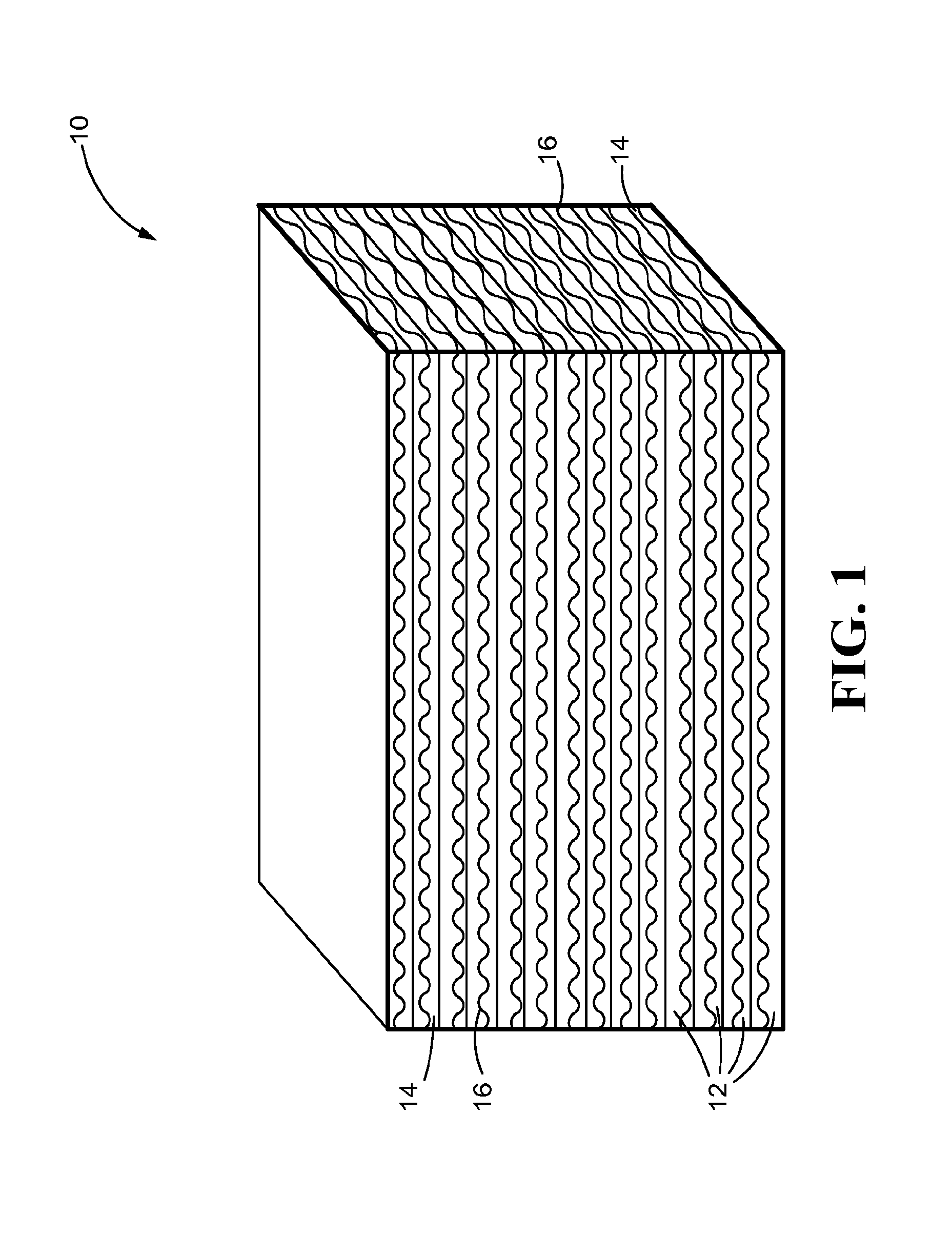

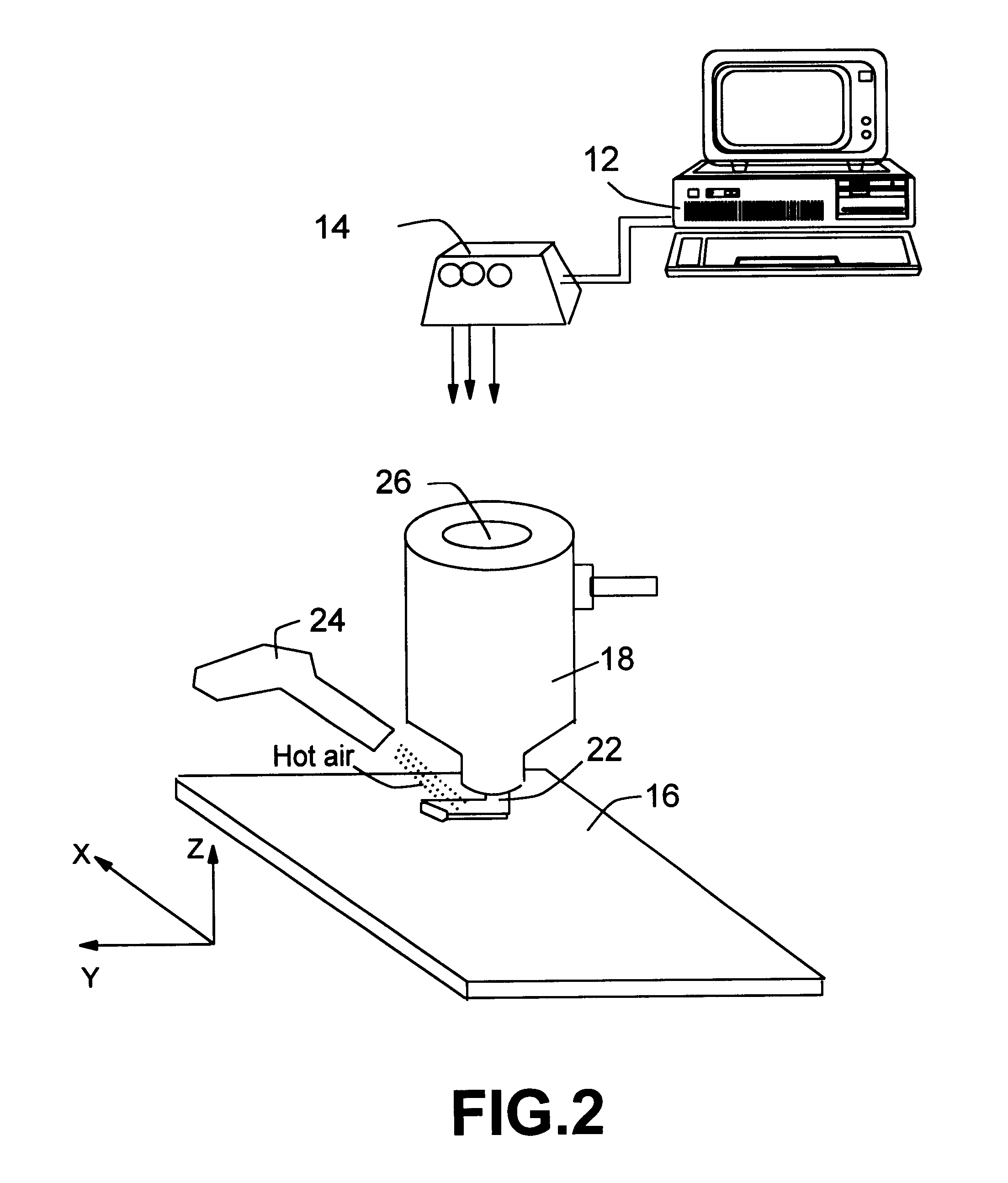

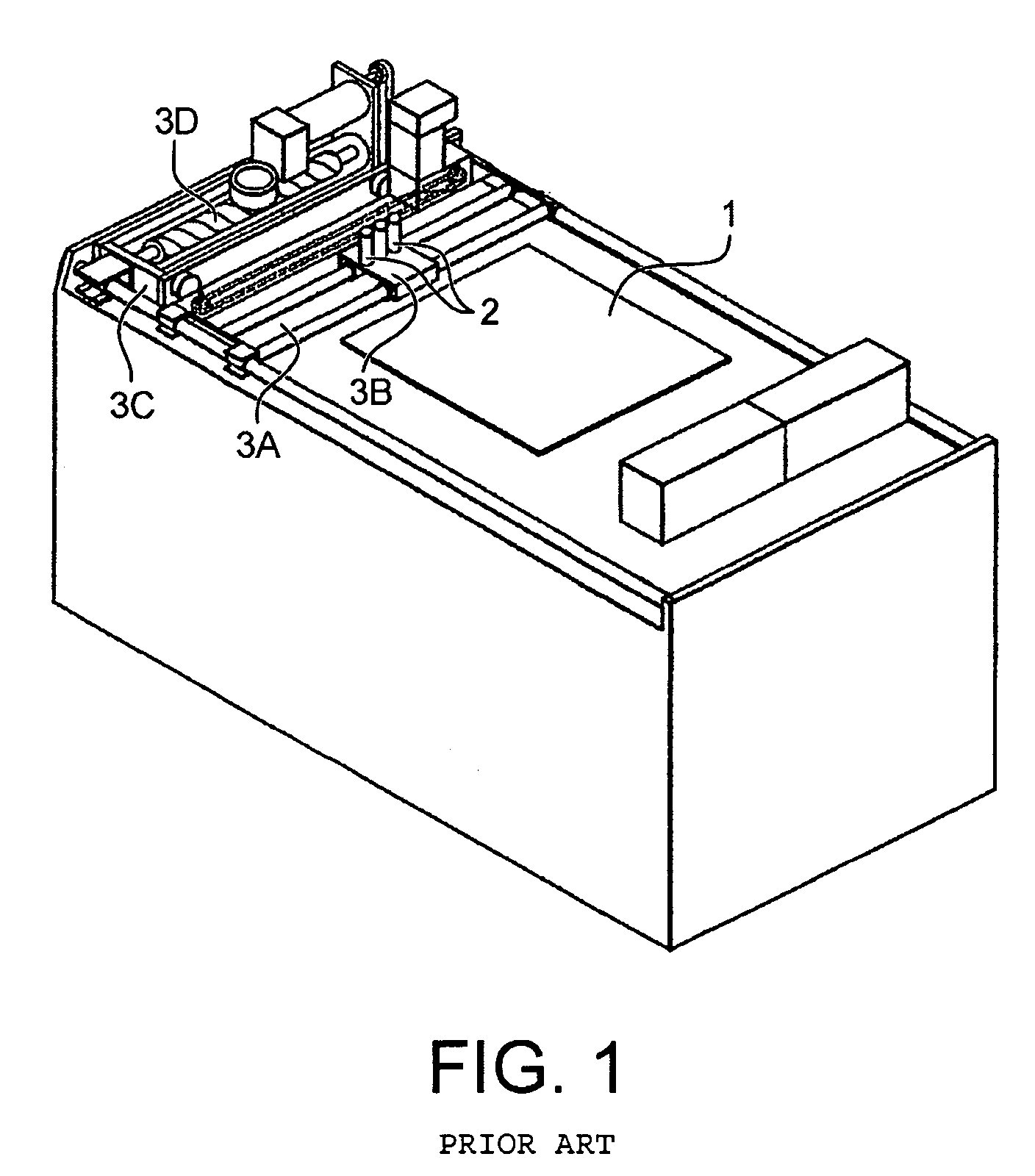

Rapid prototyping and fabrication method for 3-D food objects

InactiveUS6280785B1Versatile and Realistic Rapid PrototypingRapid productionLayered productsConfectioneryFree formControl signal

A freeform fabrication method for making a three-dimensional food object from a design created on a computer, including: (a) providing a support member by which the object is supported while being constructed; (b) operating a material dispensing head for dispensing a continuous or intermittent strand of food composition in a fluent state; this food composition including a liquid ingredient and a primary body-building food material and the dispensed food composition having a rigidity and strength sufficient for permitting the food composition to be built up layer by layer into a three-dimensional shape in a non-solid state; and (c) operating control devices for generating control signals in response to coordinates of the object design and controlling the position of the dispensing head relative to the support member in response to the control signals to control dispensing of the food composition to construct a 3-D shape of this object. The method optionally includes an additional step of applying a heat treatment to the 3-D shape after this 3-D shape is constructed. This method can be used to form an intricate shape of a cake mix, which is then baked in an oven. It can also be used to form a custom-designed decorative shape on the top surface of a pre-made cake.

Owner:NANOTEK INSTR GRP LLC

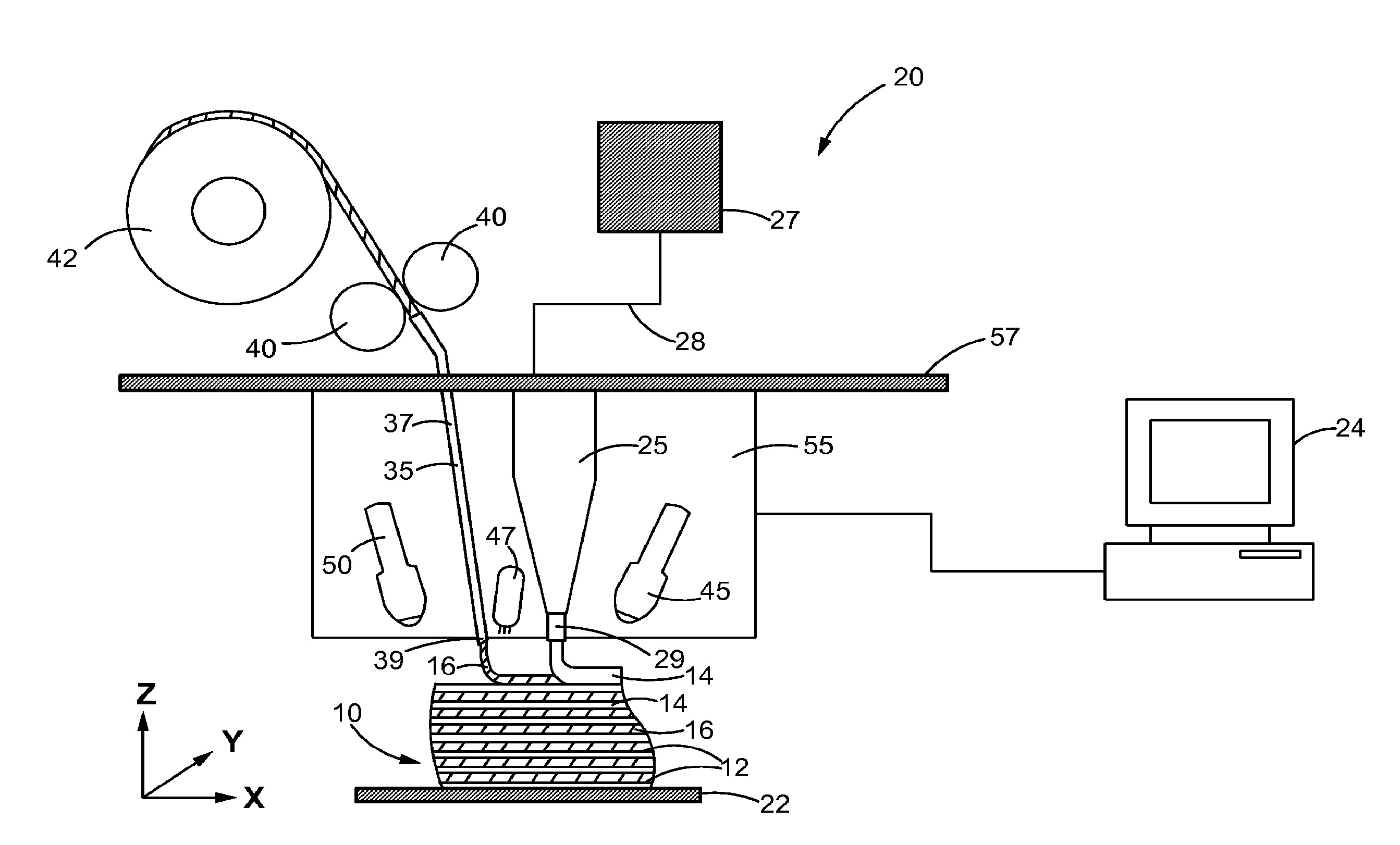

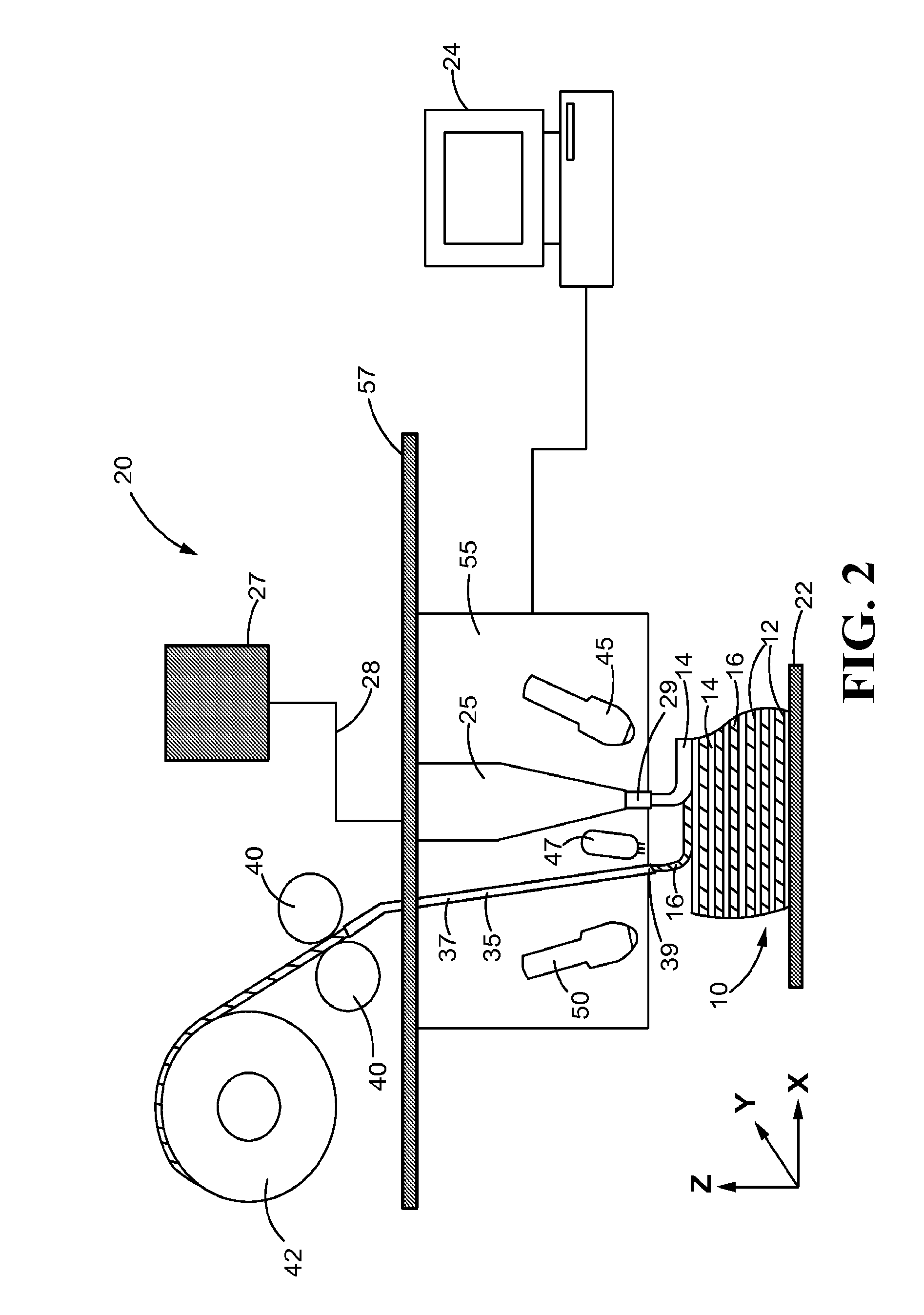

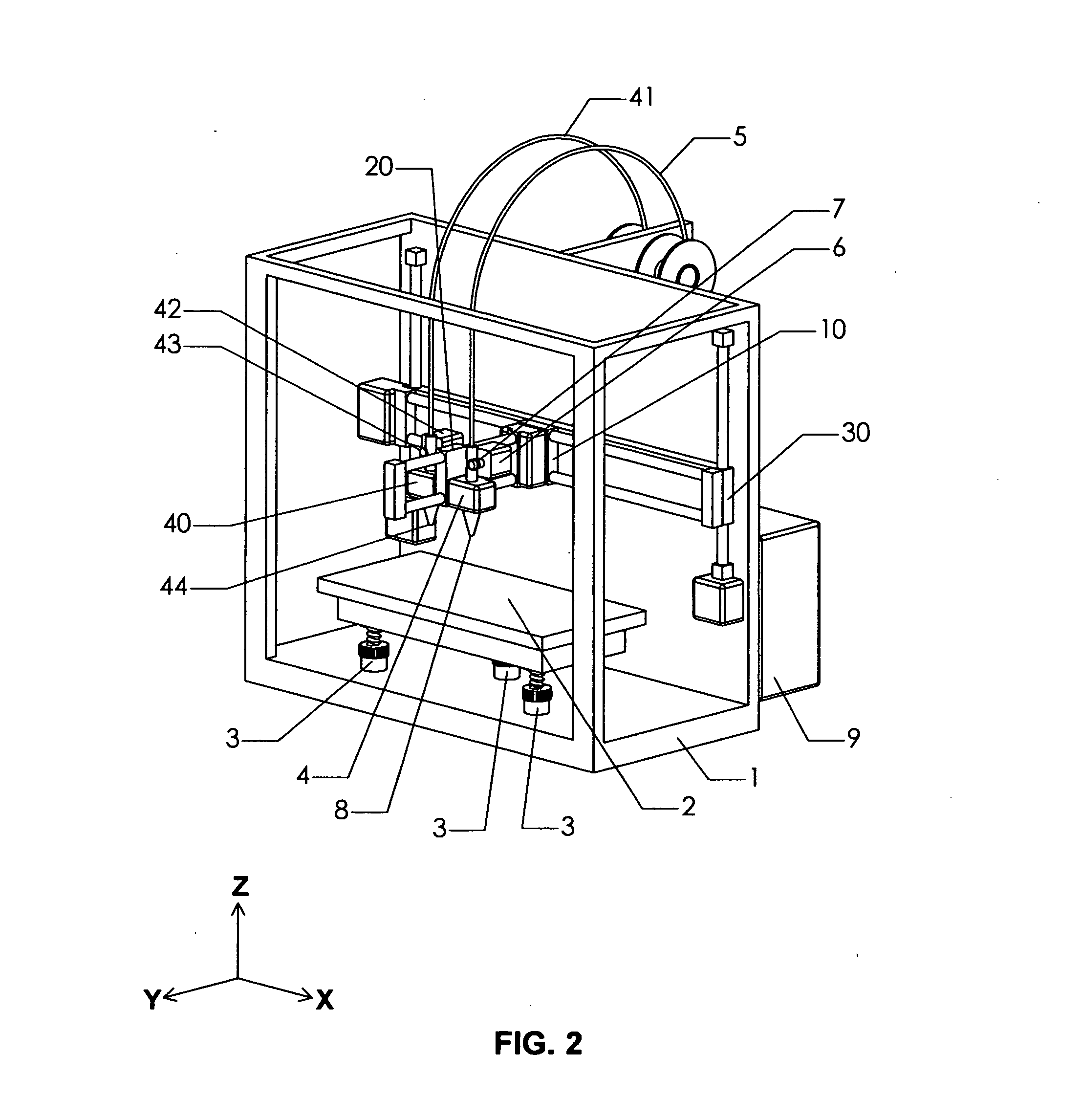

Continuous fiber-reinforced component fabrication

ActiveUS20160114532A1Additive manufacturing apparatusTailstocks/centresAdditive layer manufacturingElectrical and Electronics engineering

A machine for fabricating a fiber-reinforced component by additive manufacturing is disclosed. The machine may have a surface, a matrix feed configured to deposit a plurality of matrix layers on the surface, and a fiber feed configured to deposit a fiber layer on at least one of the plurality of matrix layers. The deposition of the plurality of matrix layers and the fiber layer may be controlled by a computer.

Owner:RTX CORP

Method for rapidly making a 3-D food object

InactiveUS6280784B1Rapid productionBroad spectrumConfectionerySweetmeatsControl signalAdditive ingredient

Owner:NANOTEK INSTR GRP LLC

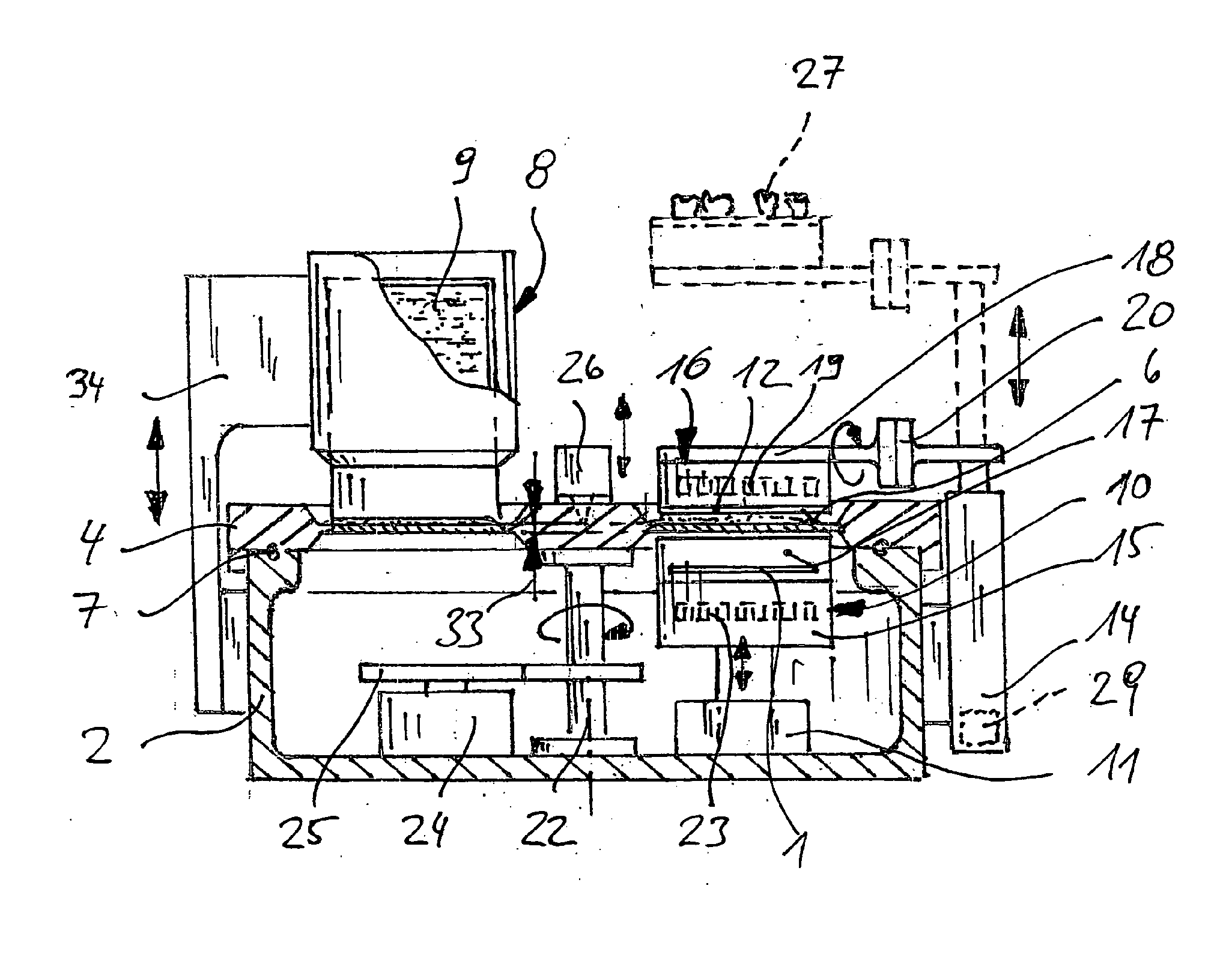

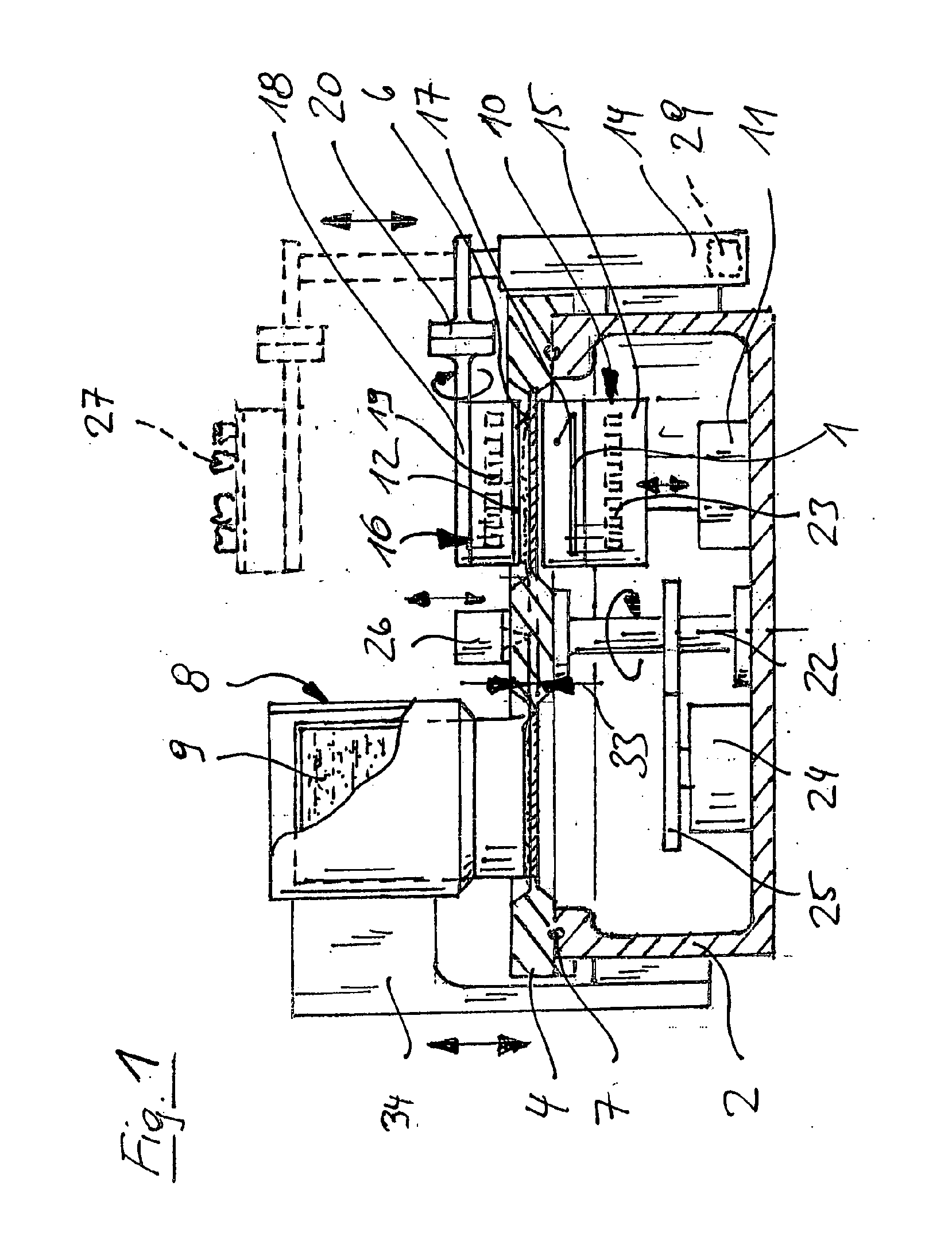

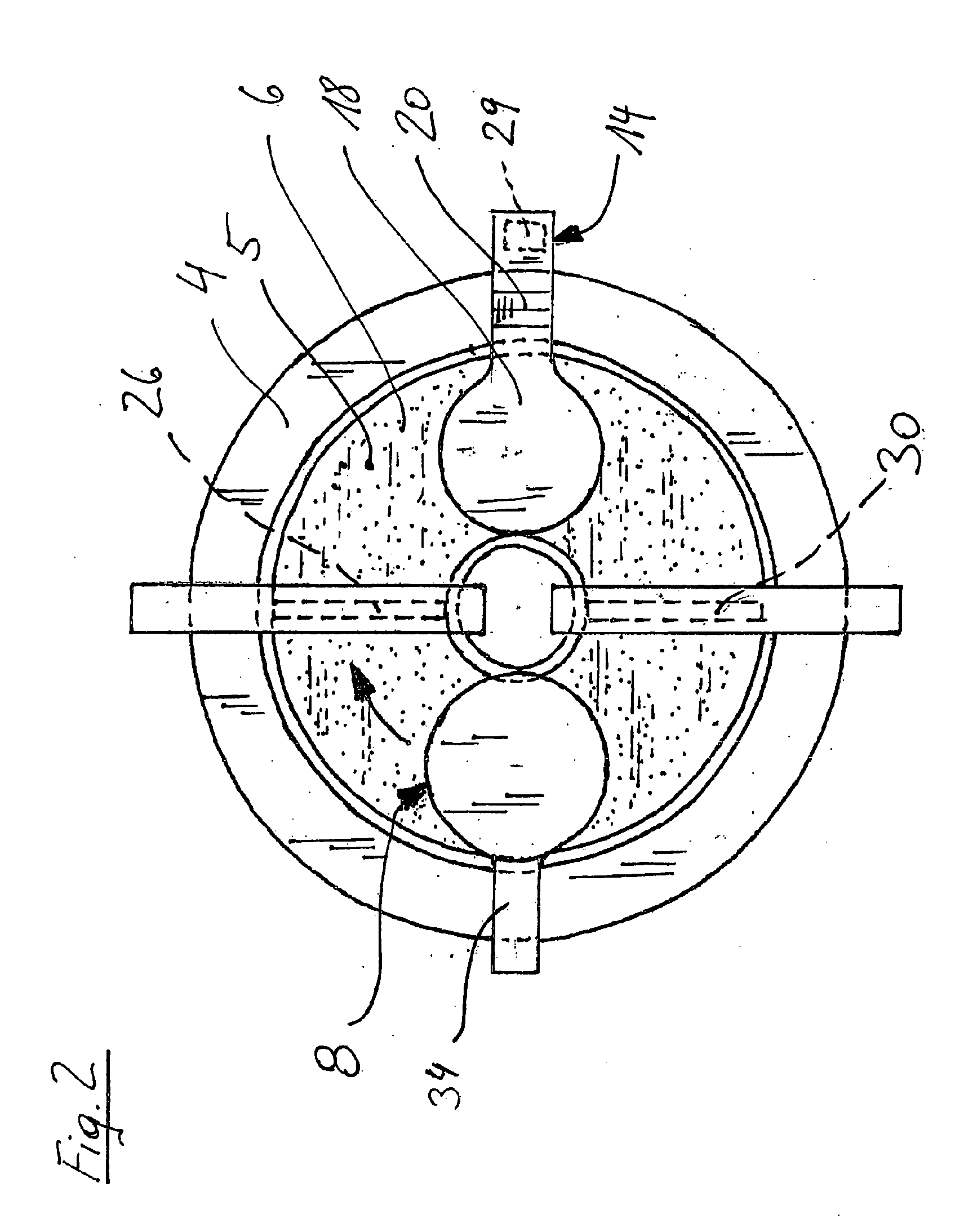

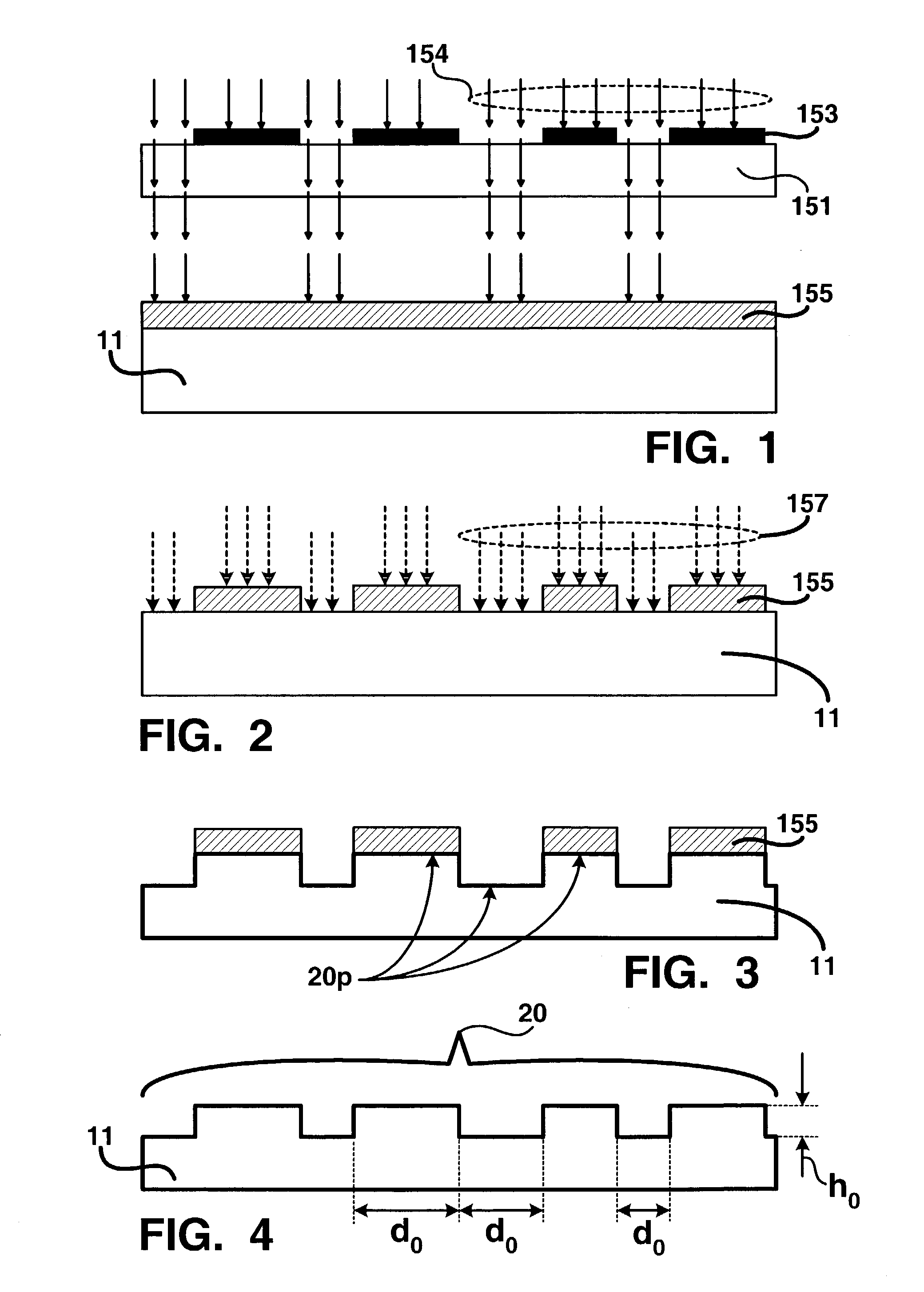

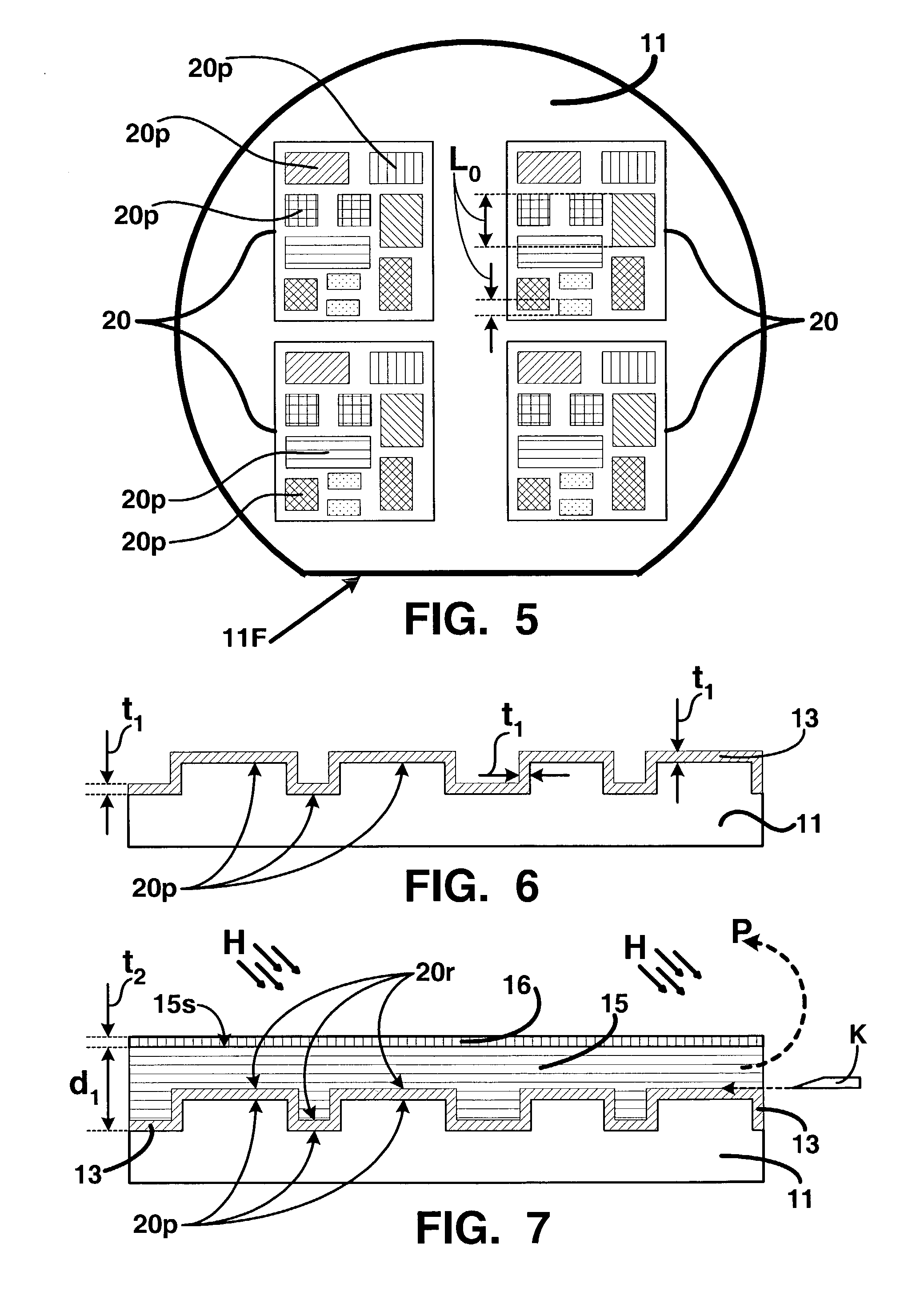

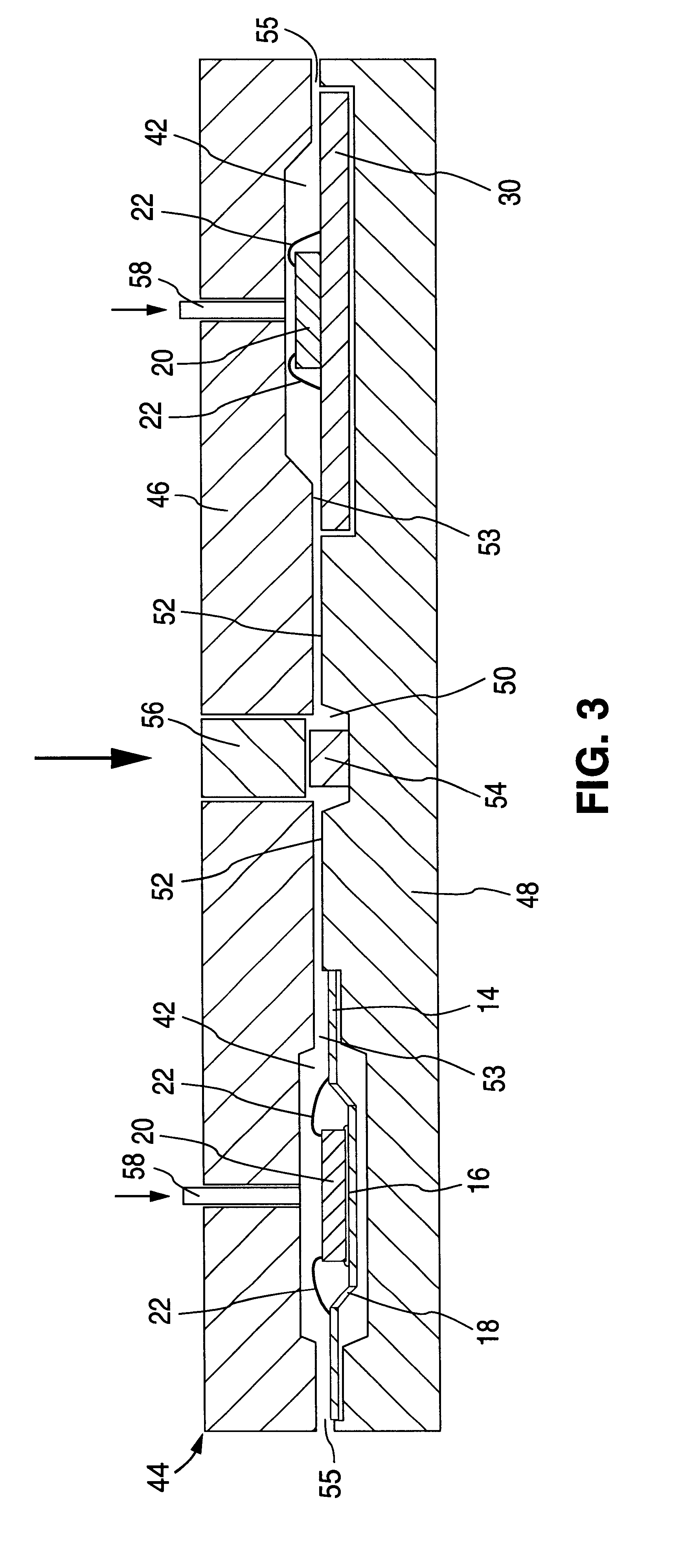

Device And Method For Processing Light-Polymerizable Material For Building Up An Object In Layers

ActiveUS20110309554A1High viscositySimple methodAdditive manufacturing apparatusTailstocks/centresControl cellStructural engineering

A method and a device for processing a light-polymerizable material (5, 55) for building up an object (27) in layers, using a lithography based generative manufacture having a construction platform (12) for building up the object (27), a projecting exposure unit (10, 60) that can be controlled for locally selected exposing of a surface on the construction platform (12, 62) to an intensity pattern having a prescribed shape, and a control unit (11, 61) prepared for polymerizing overlapping layers (28) on the construction platform (12, 62) in successive exposure steps, each having a prescribed geometry, by controlling the projecting exposure unit (10, 60), in order to thus successively build up the object (27) in the desired shape, said shape resulting from the sequence of layer geometries. The invention is characterized in that a further exposure unit (16, 66) for exposing the surface of the construction platform (12, 62) is provided on the side opposite the projecting exposure unit (10, 60), and that the construction platform (12, 62) is designed to be at least partially transparent to light, and that the control unit (11, 61) is designed for controlling the further exposure unit (16, 66) at least while building up the first layer (28), said layer adhering to the construction platform (12, 62), for exposing in the prescribed geometry.

Owner:VIENNA UNIVERSITY OF TECHNOLOGY +1

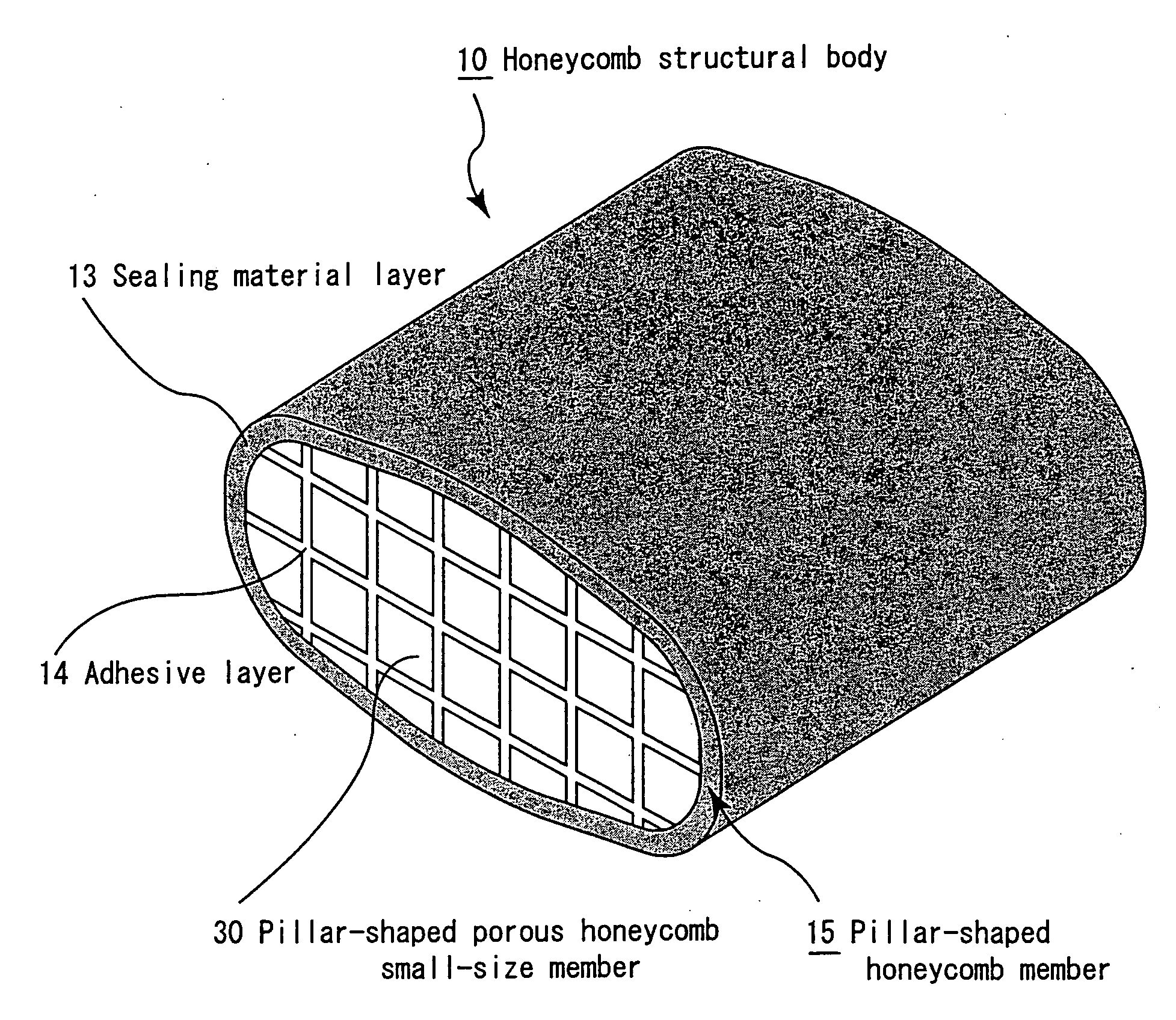

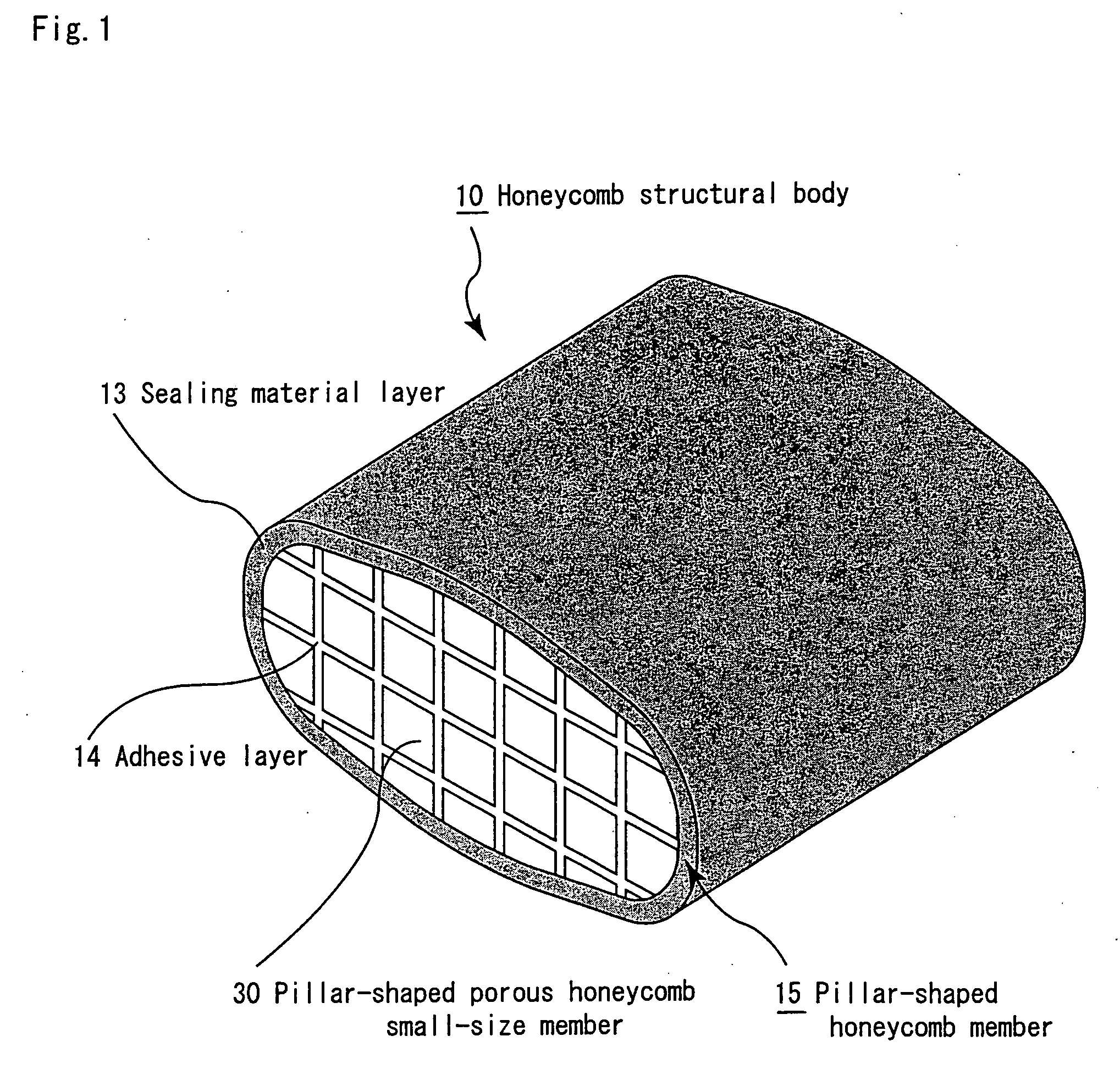

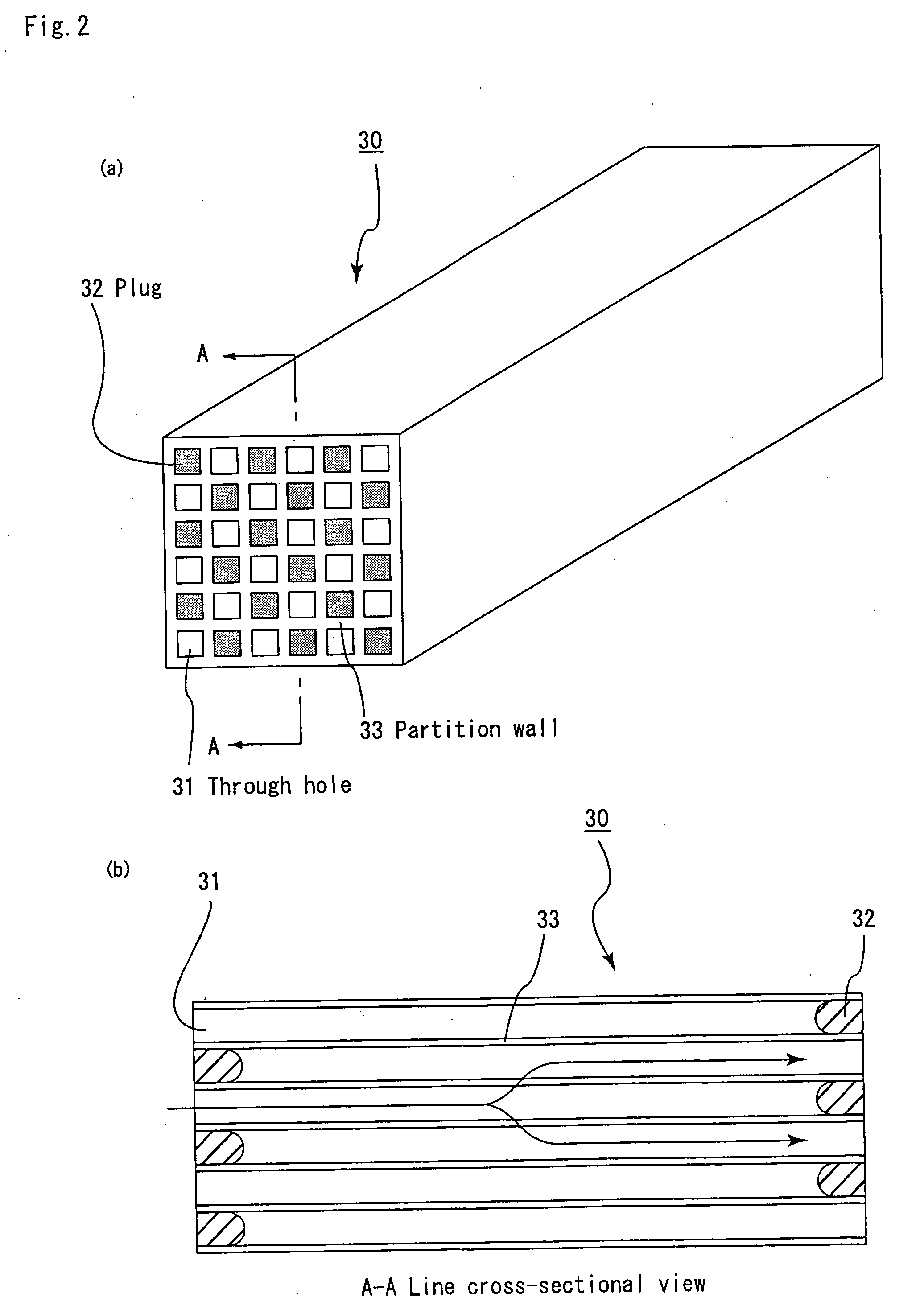

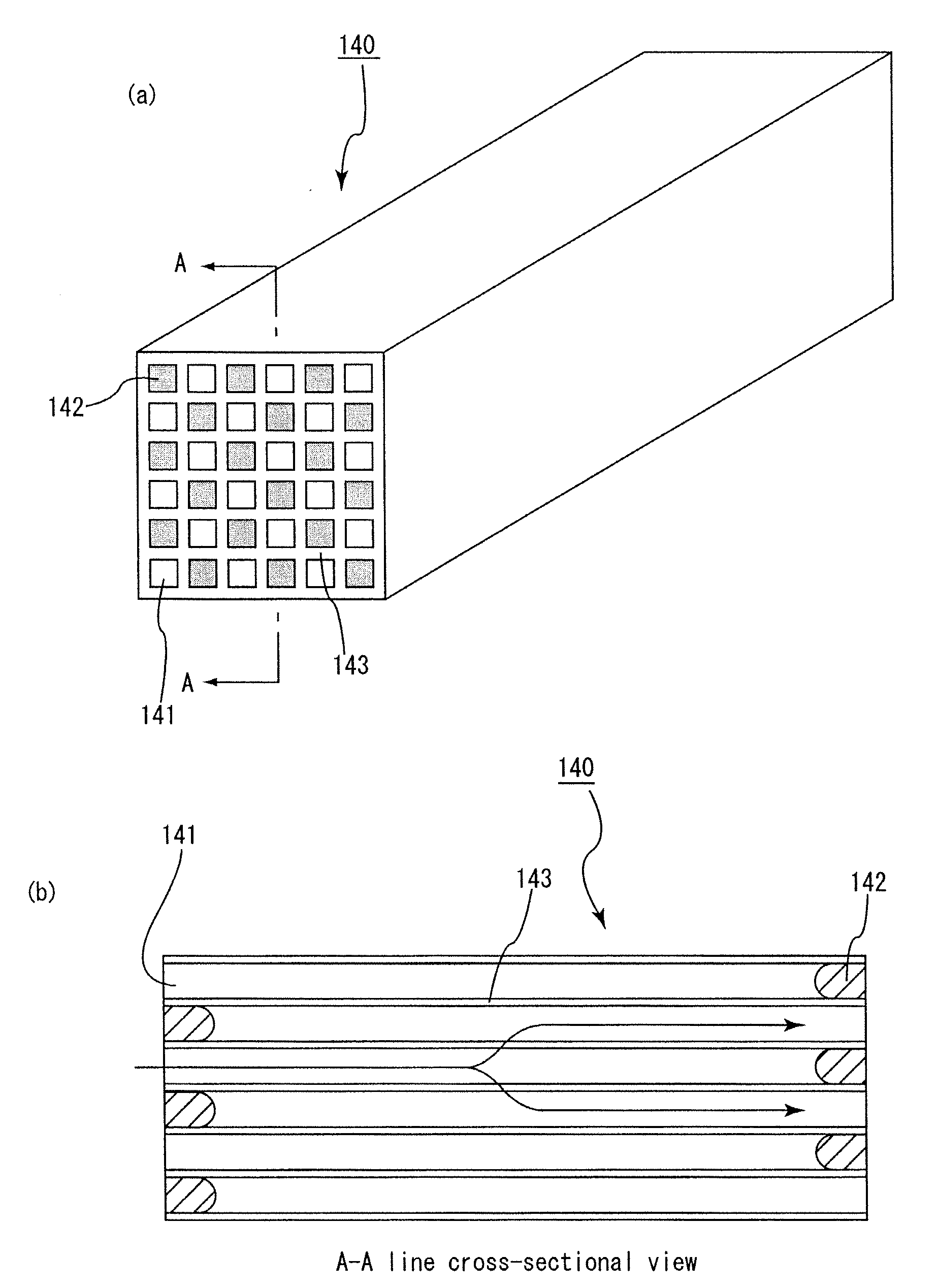

Manufacturing method of honeycomb structural body, and sealing material

ActiveUS20070126160A1Improve assembly effectAvoid separationExhaust apparatusConfectioneryHoneycomb structureRaw material

An object of the present invention is to provide a manufacturing method of a honeycomb structural body which makes the profile of a cross section perpendicular to the length direction thereof less likely to generate dispersion, and also makes the thickness of its sealing material layer thinner, and a sealing material that is suitably used in the manufacturing method of the honeycomb structural body. According to the present invention, the manufacturing method of a honeycomb structural body with a sealing material layer formed on the peripheral portion of a pillar-shaped porous honeycomb member includes a sealing material applying step of applying a paste-like sealing material, which is a raw material of the sealing material layer, onto a circumferential face of the pillar-shaped porous honeycomb member, and a scraping step of fitting a ring-shaped scraper, which can be brought into contact with the circumferential face of the pillar-shaped porous honeycomb member so as to slide thereon, to the pillar-shaped porous honeycomb member and moving said ring-shaped scraper in the length direction, thereby expanding the paste-like sealing material applied onto the circumferential face of the pillar-shaped porous honeycomb member so as to spread over the entire circumferential face of the pillar-shaped porous honeycomb member.

Owner:IBIDEN CO LTD

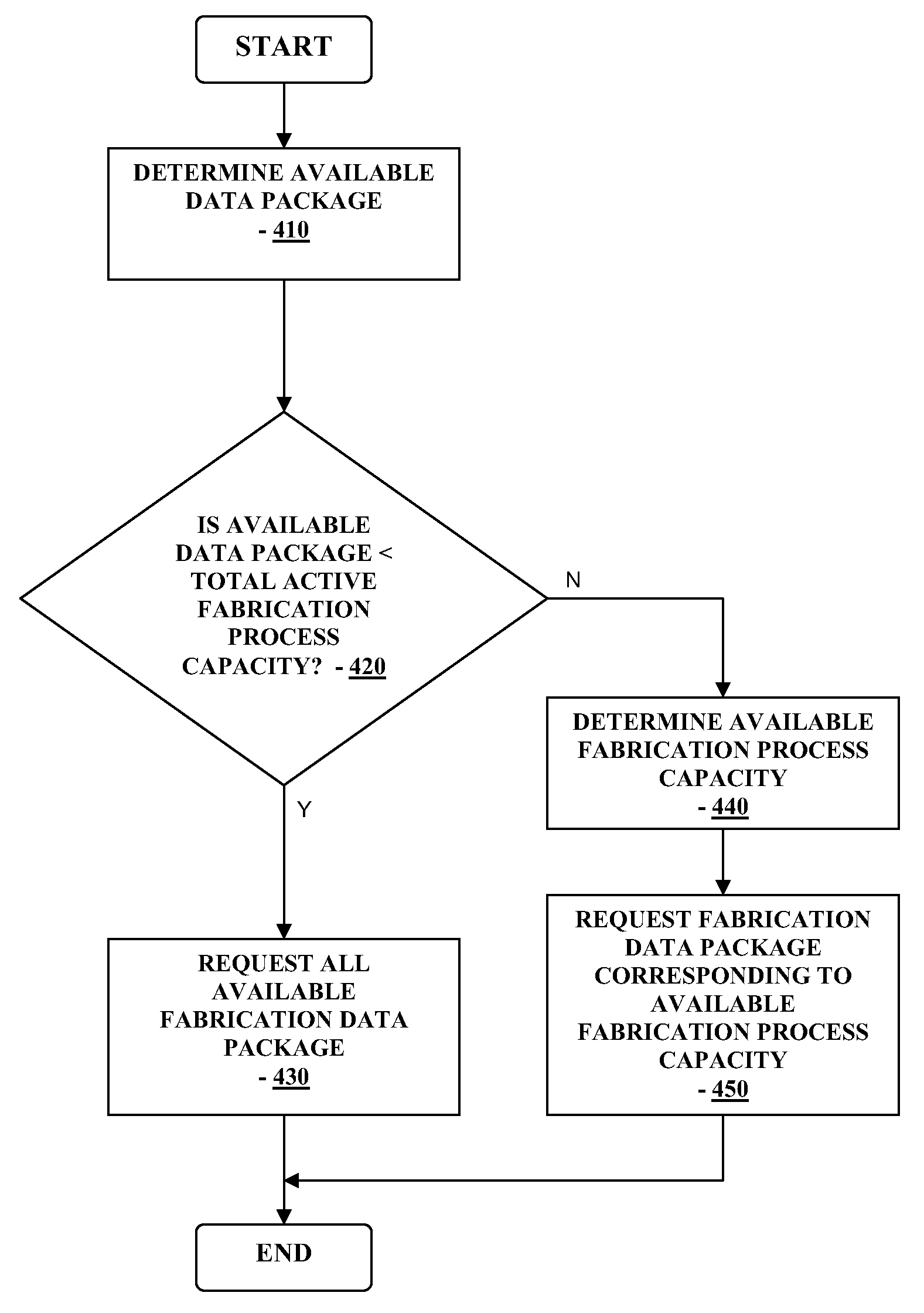

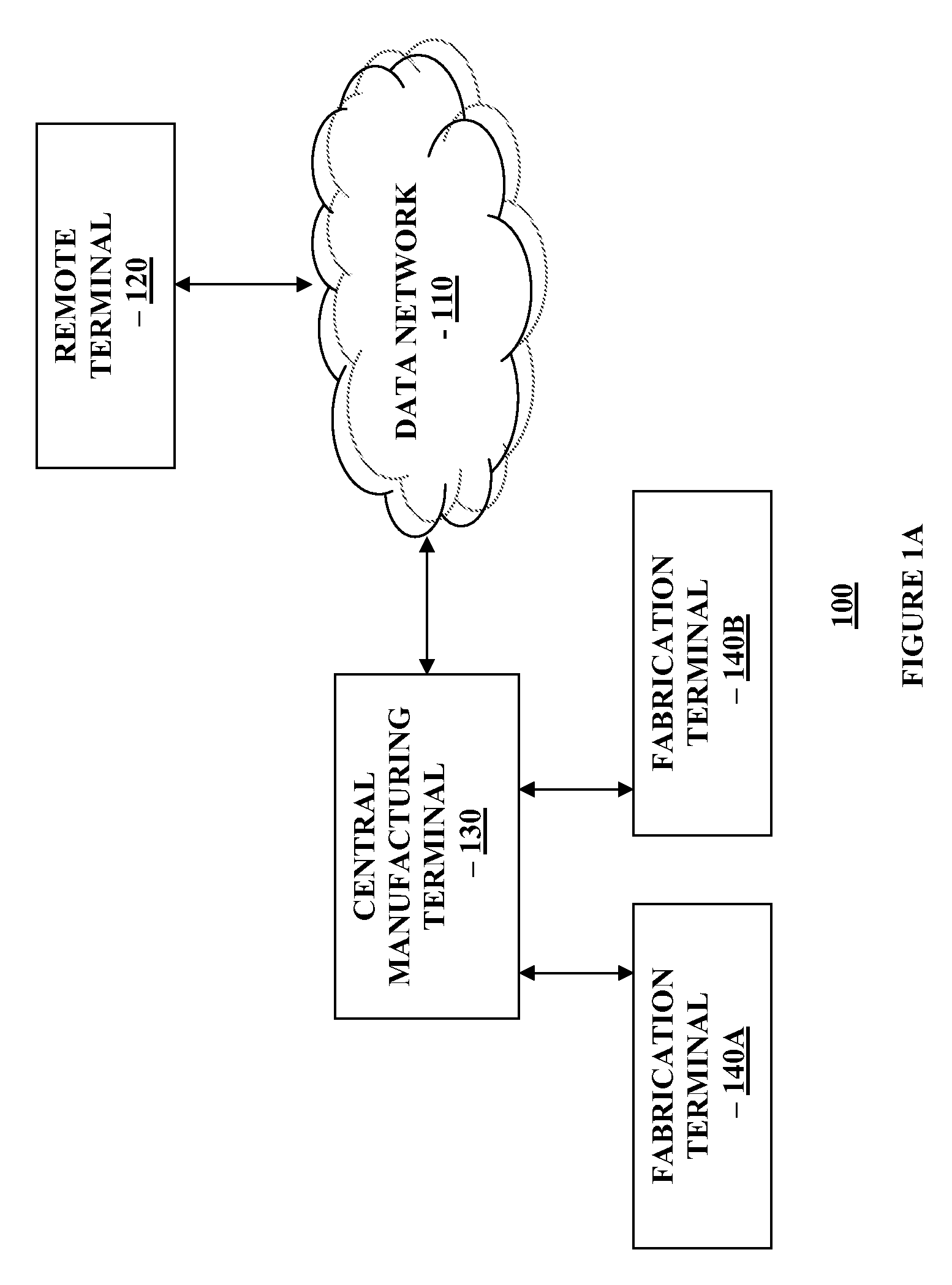

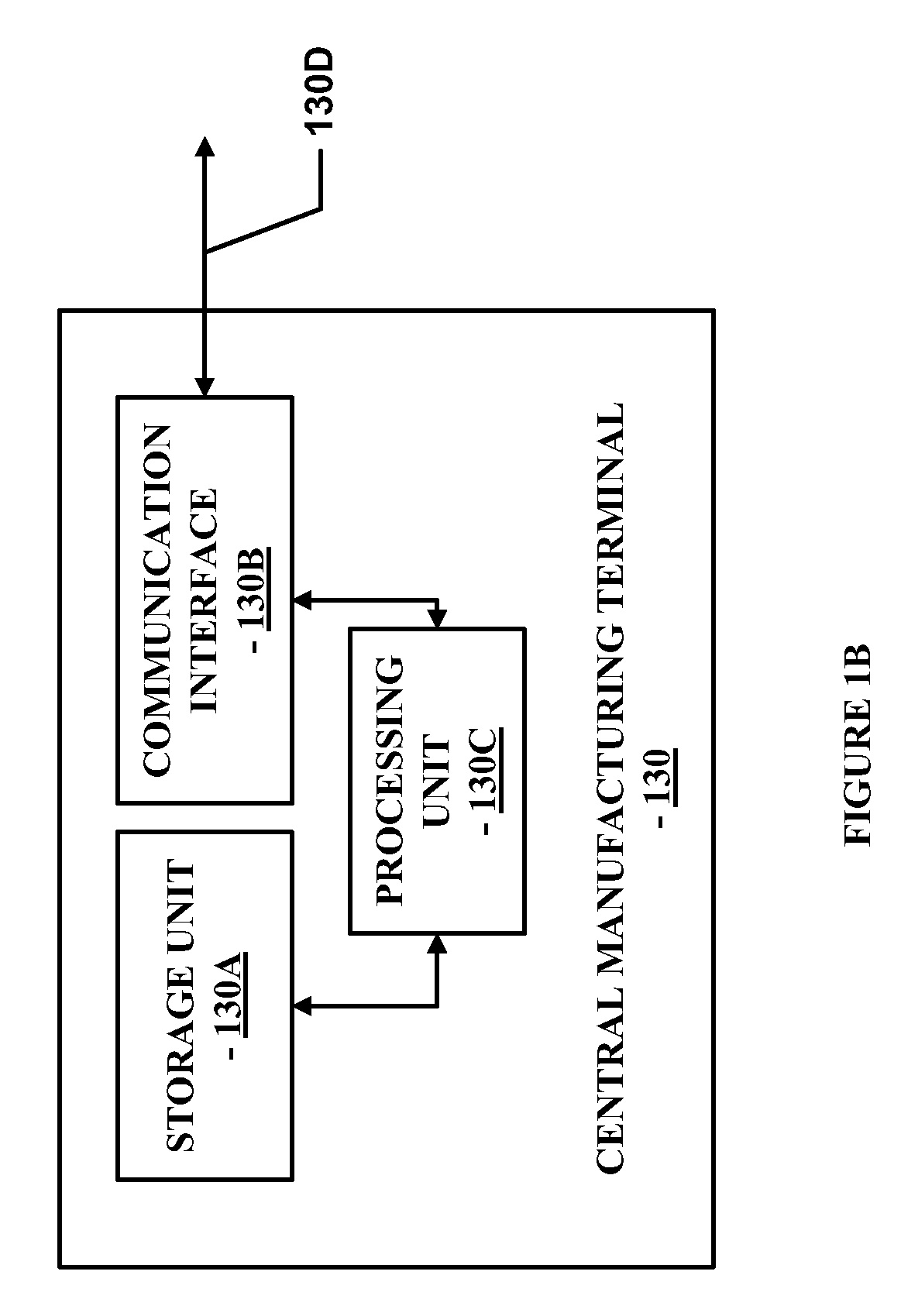

Method and system for providing automated high scale fabrication of custom items

Method and system for providing volume manufacturing of customizable items including receiving a data package including a plurality of manufacturing parameters, each of the plurality of manufacturing parameters associated with a unique item, verifying the received data package, and implementing a manufacturing process associated with the received data package is provided.

Owner:ALIGN TECH

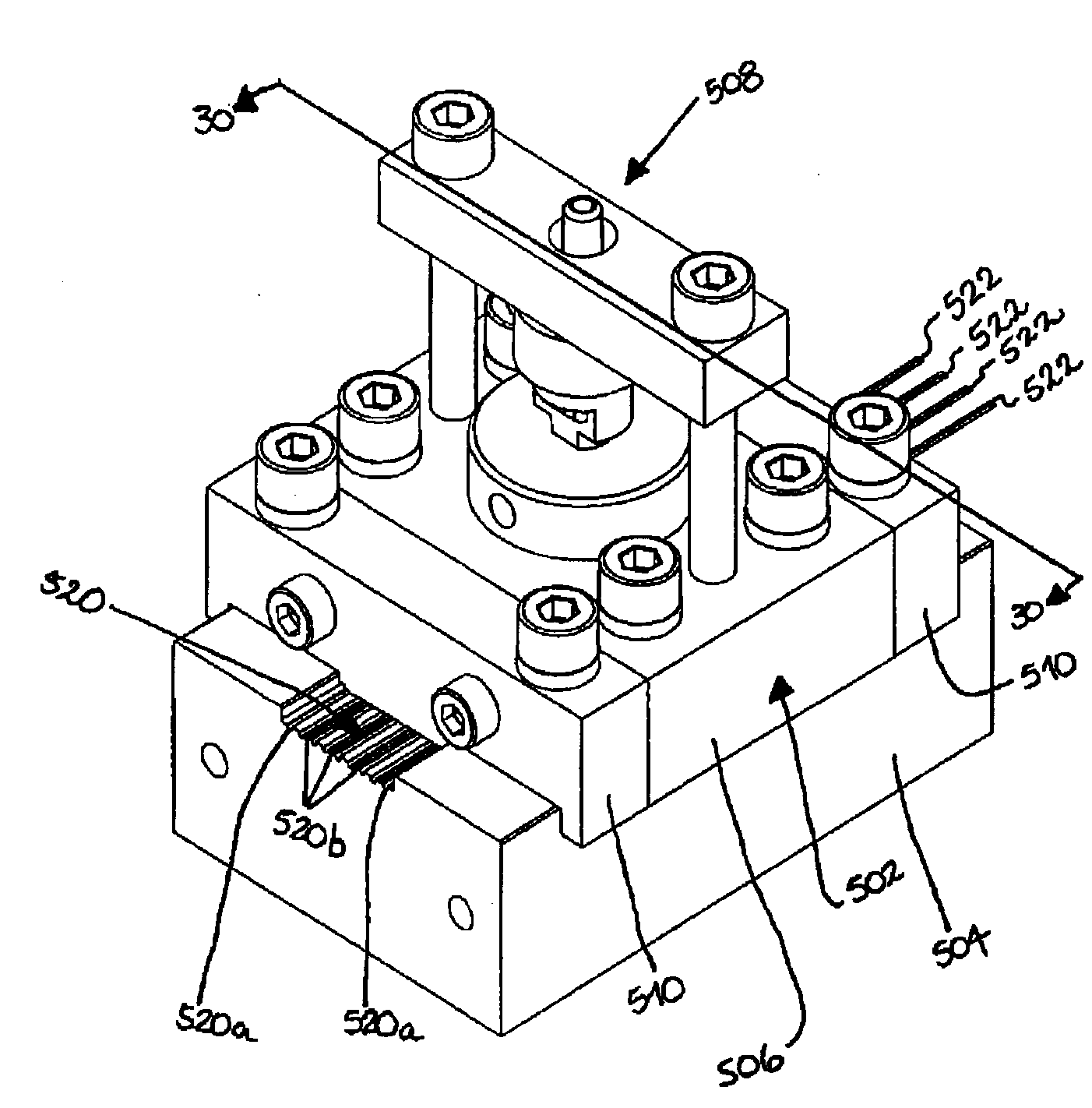

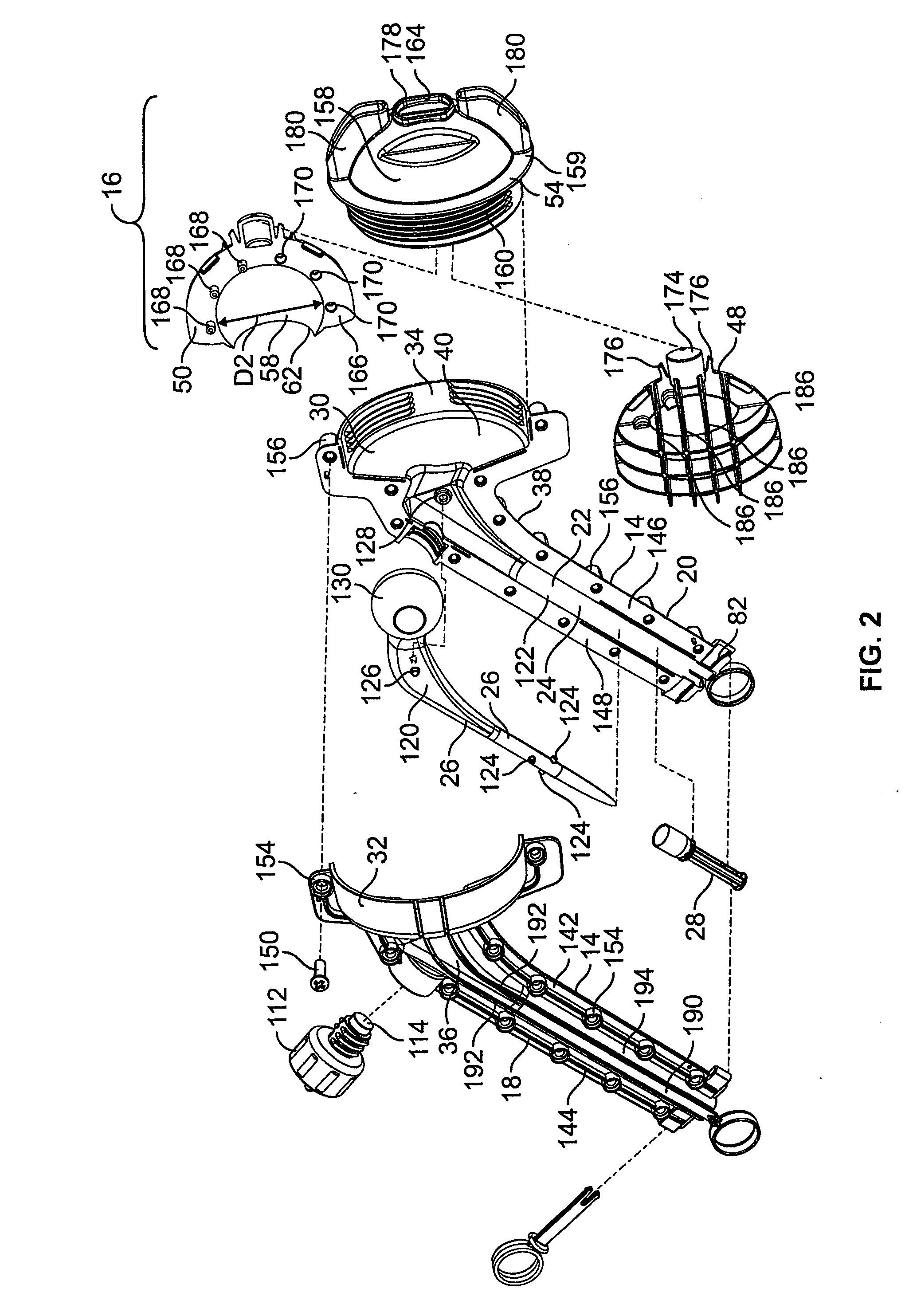

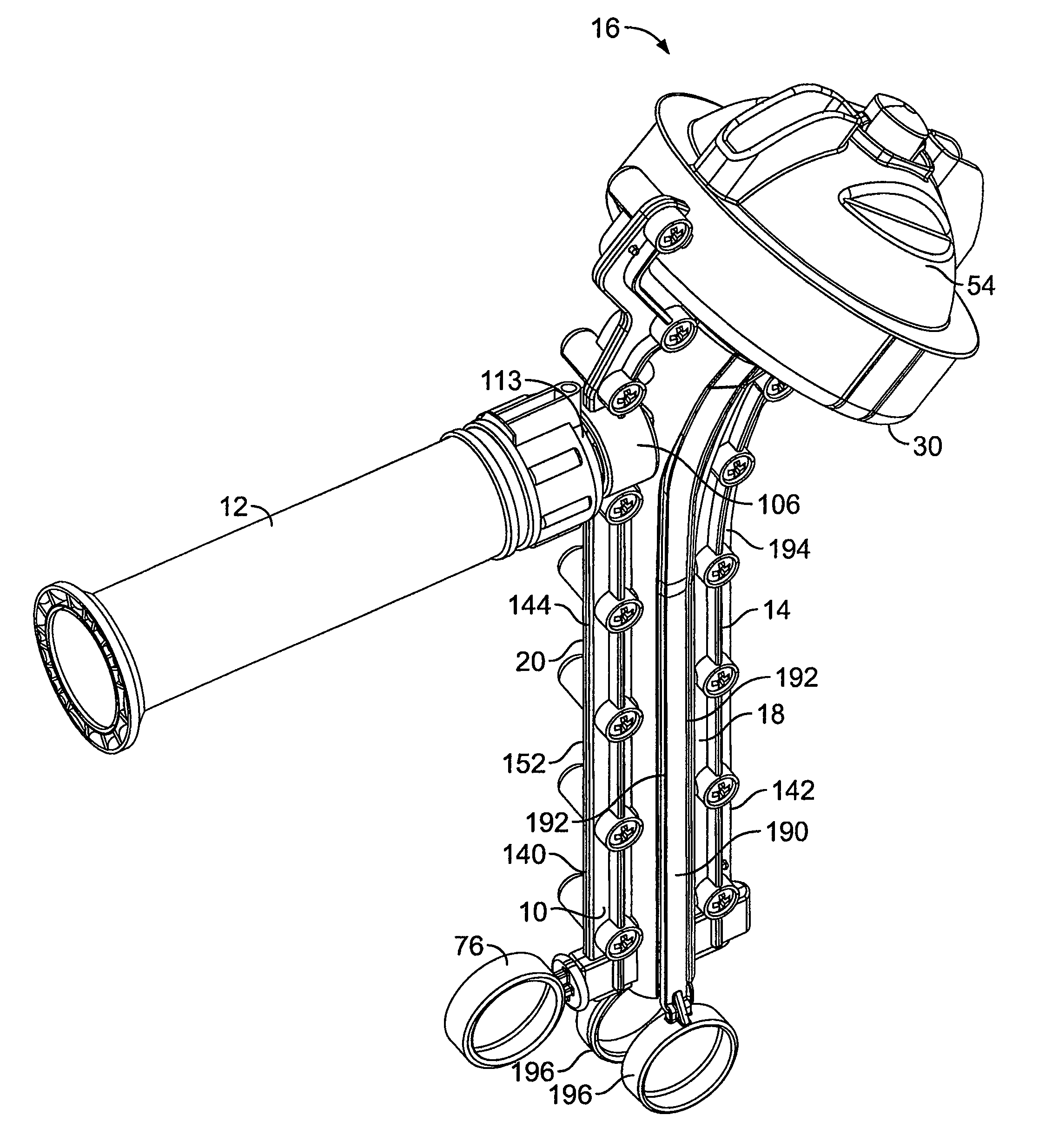

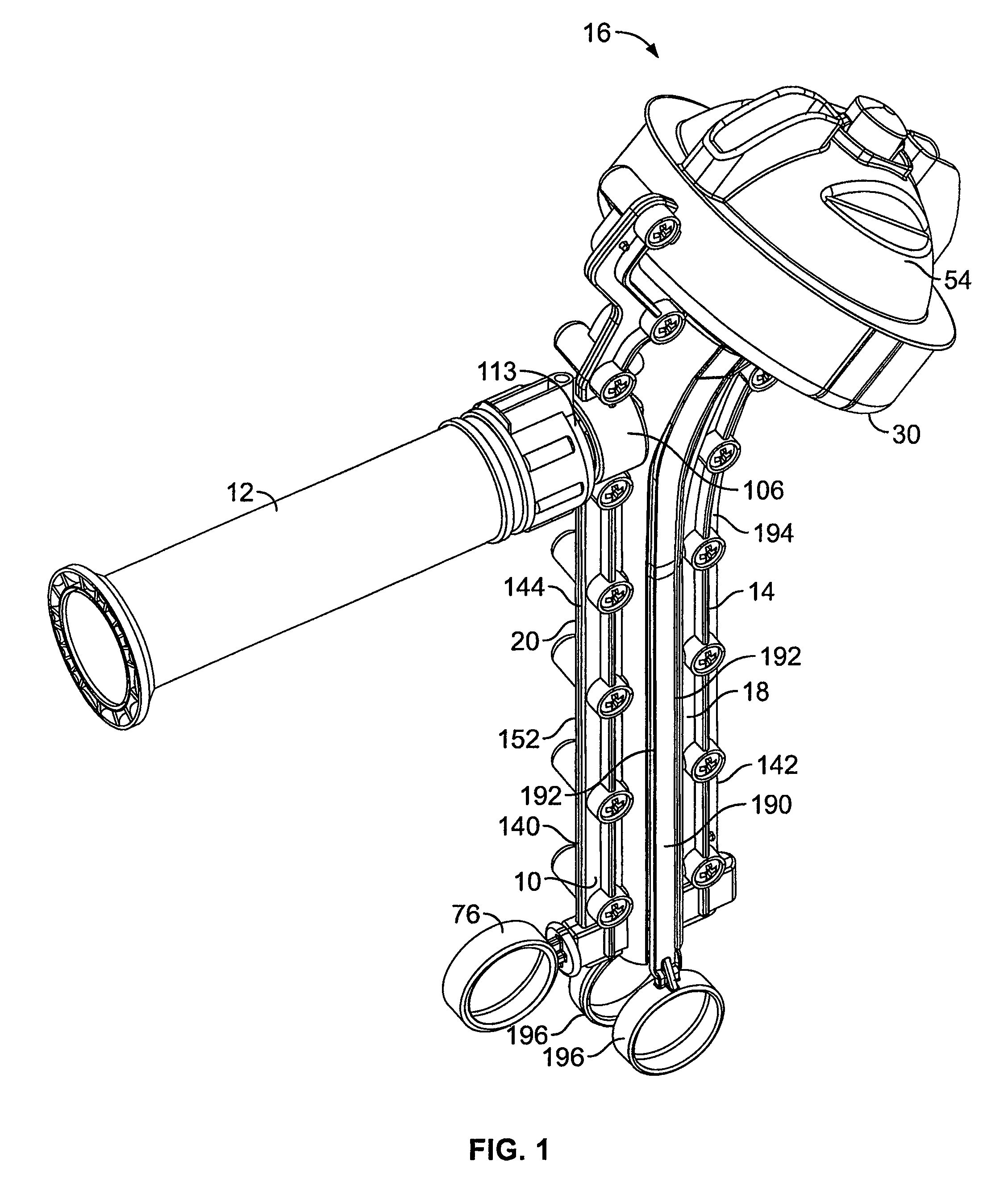

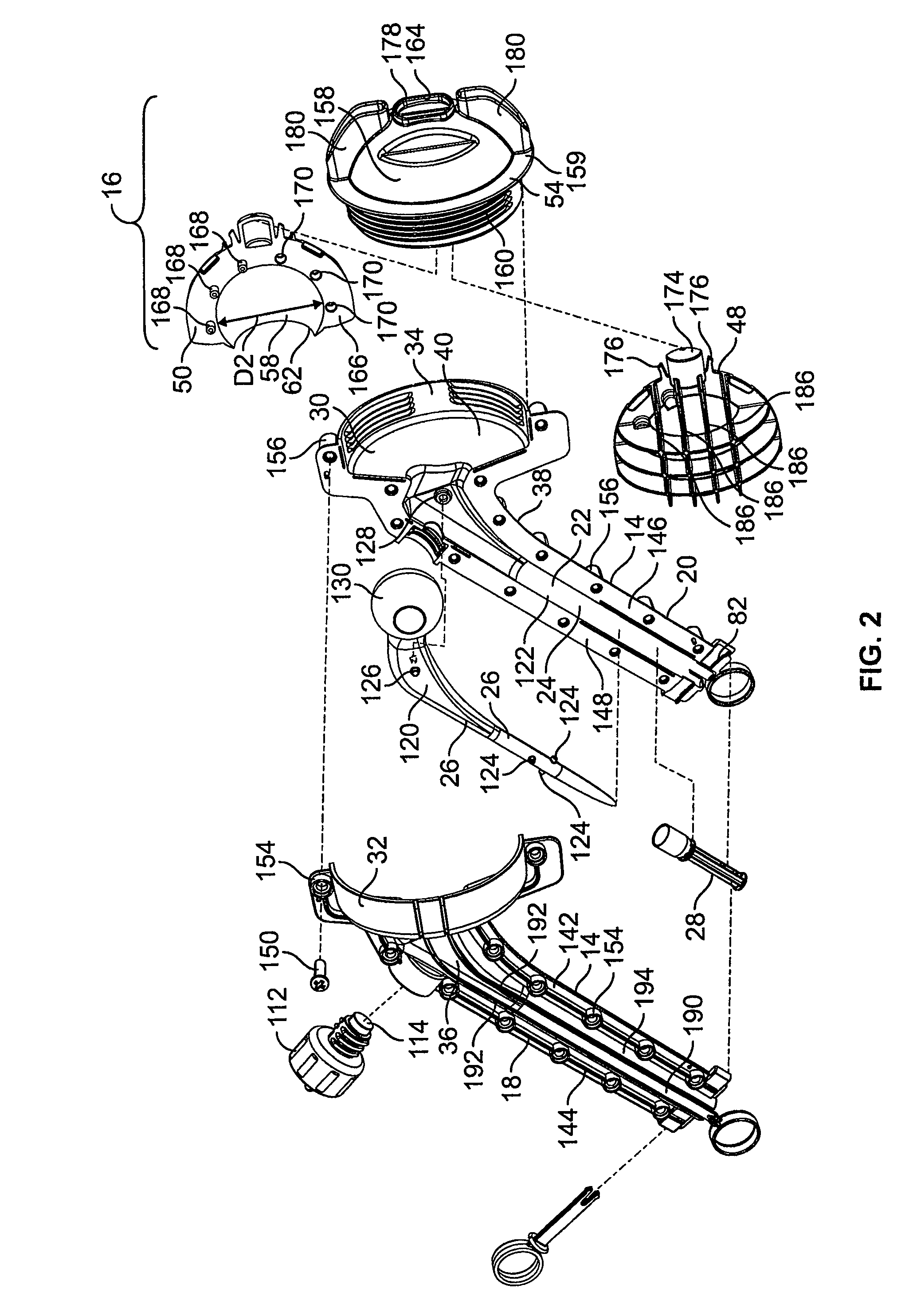

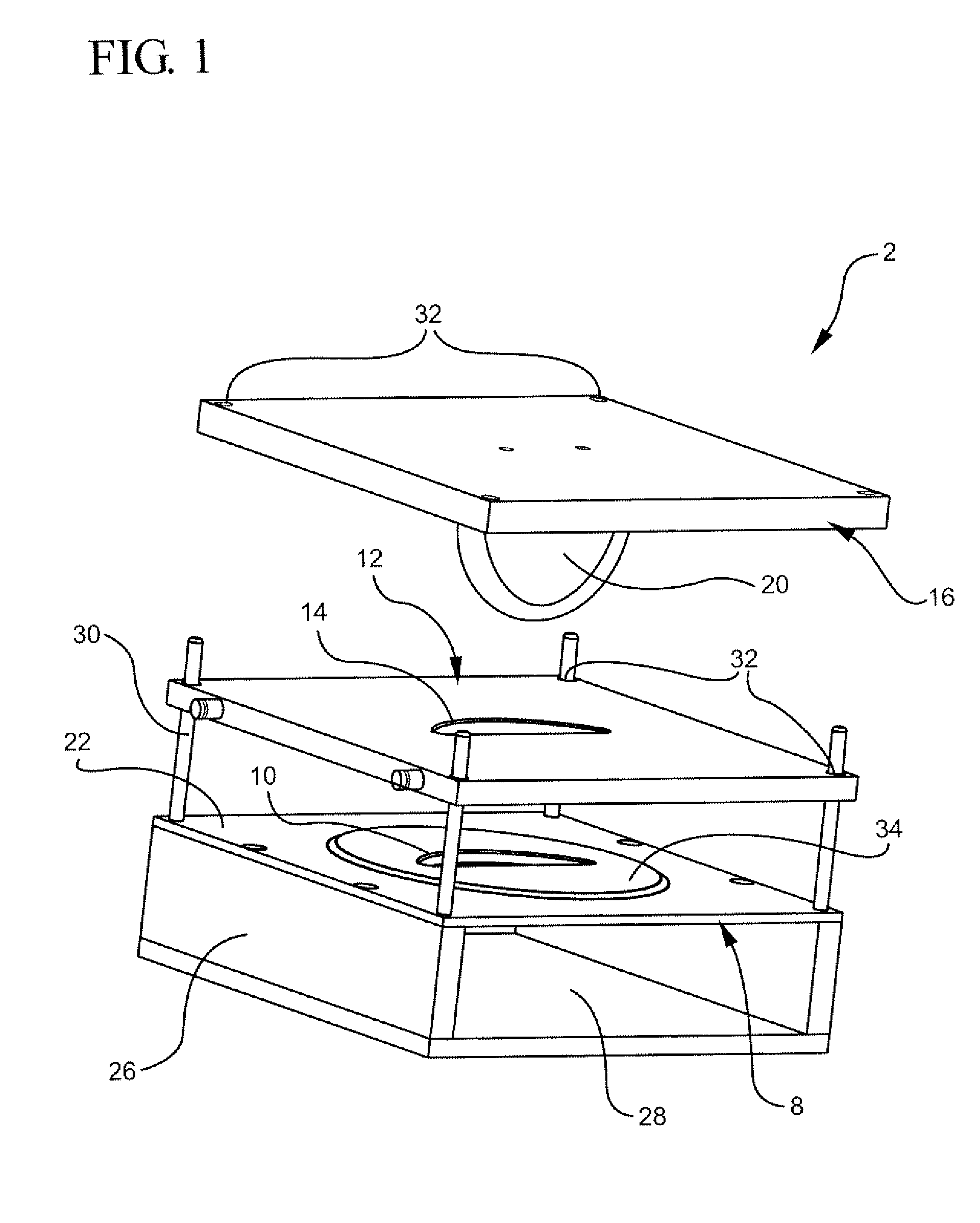

Nerve cuff injection mold and method of making a nerve cuff

A mold for a nerve cuff having a first molding body defining a first molding cavity and a second molding body defining second molding cavity. The first and second molding bodies being mountable to one another thereby providing for the first and second molding cavities to interface. When interfacing the first and second molding cavities and injecting moldable material therebetween provides the nerve cuff following curing of the moldable material. An industrial mold including interfacing first and second cavities is also disclosed. A removable cassette for interposing between a first and a second molding cavity is also disclosed. Methods of making a nerve cuff are disclosed herein. Nerve cuffs produced by the foregoing molds, cassettes, industrial molds and methods are also disclosed.

Owner:4491343 CANADA

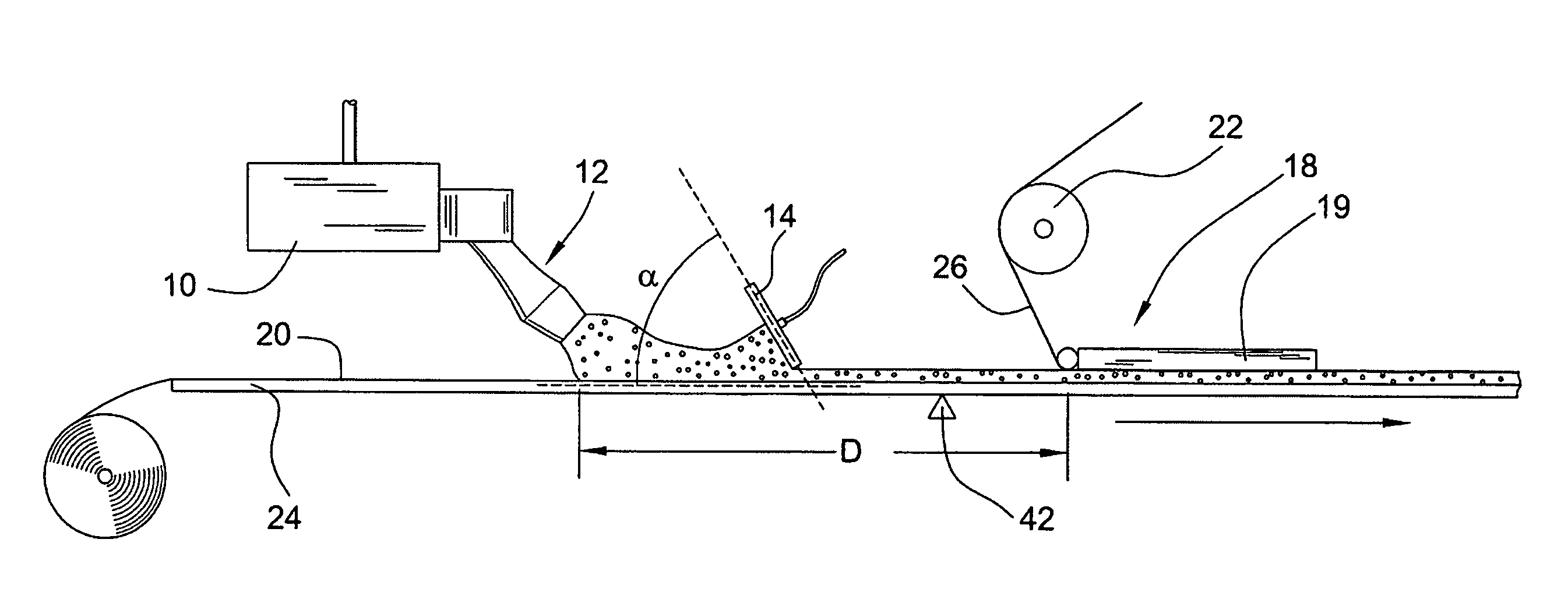

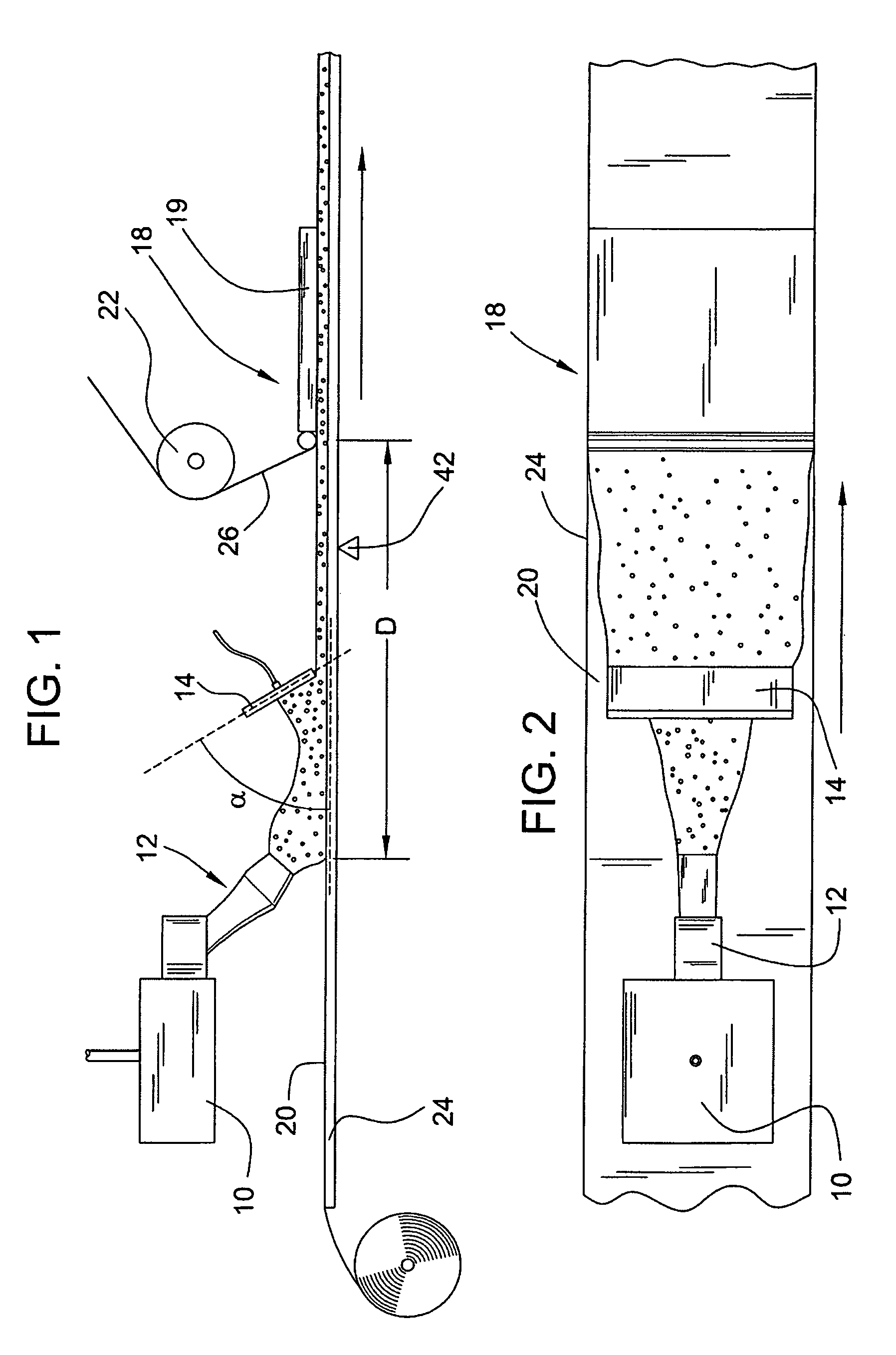

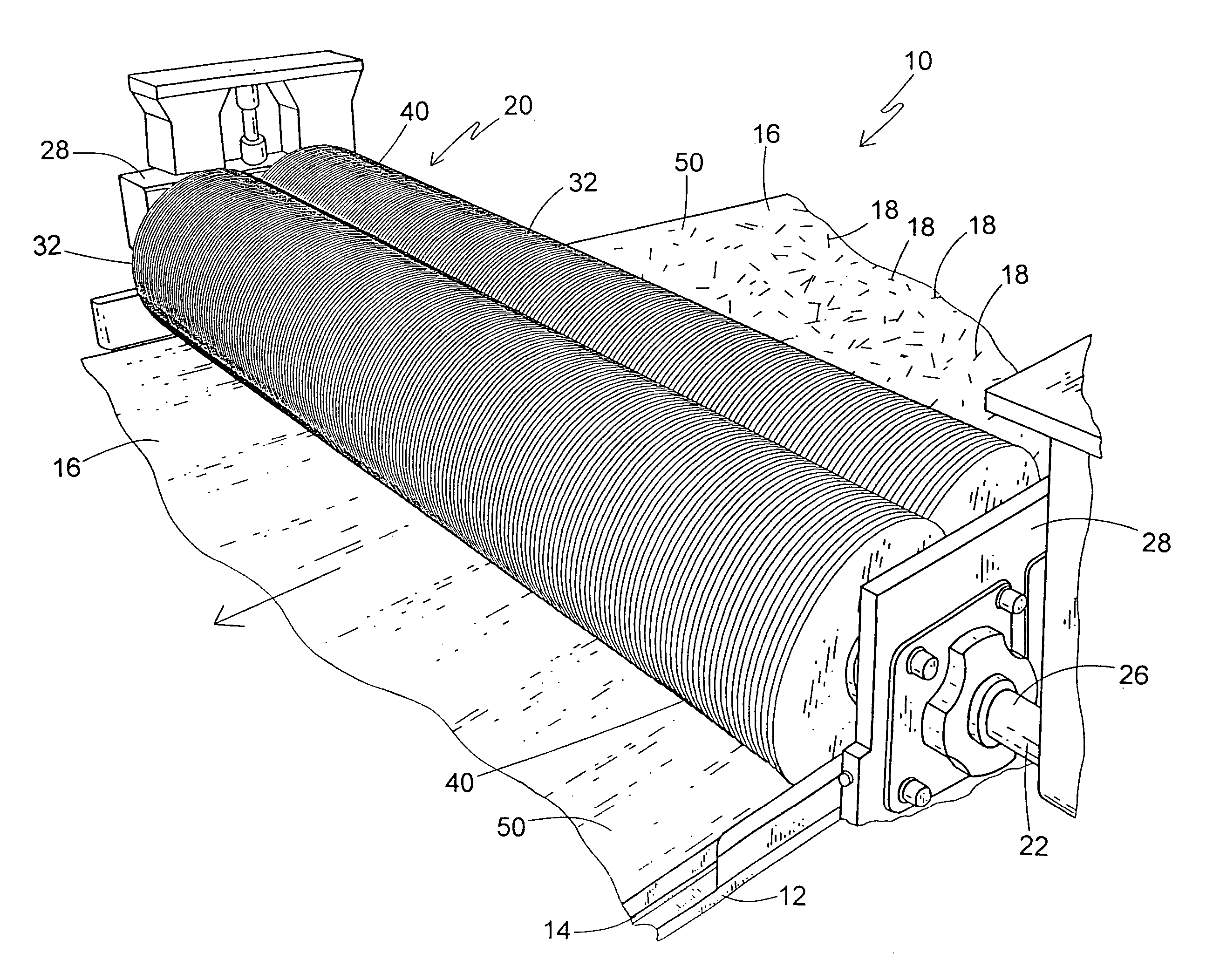

Slurry spreader for cementitious board production

InactiveUS7364676B2Increase productionSubstantial eliminationConfectioneryPress rollersCement boardEngineering

The invention provides a board forming system comprising a forming table comprising a belt with a surface for conveying a backing layer; a mixer fitted with a mechanism capable of depositing cementitious slurry material over a top surface of the backing layer; and a slurry spreader positioned downstream of the mixer, wherein a portion of the slurry spreader comprises a plurality of apertures which are connected to a source of pressurized fluid. The slurry spreader is configured such that the pressurized fluid flows out of the slurry spreader through the apertures so as to provide a continuous film of fluid across an outer surface of the slurry spreader. The slurry spreader is positioned such that it can contact at least a portion of the cementitious slurry after the slurry exits the discharge and before the slurry is spread across the width of the backing layer such that the thickness of the slurry is approximately equal to the desired slurry thickness for board formation. The invention further provides methods for forming cementitious board comprising the use of the slurry spreader.

Owner:UNITED STATES GYPSUM CO

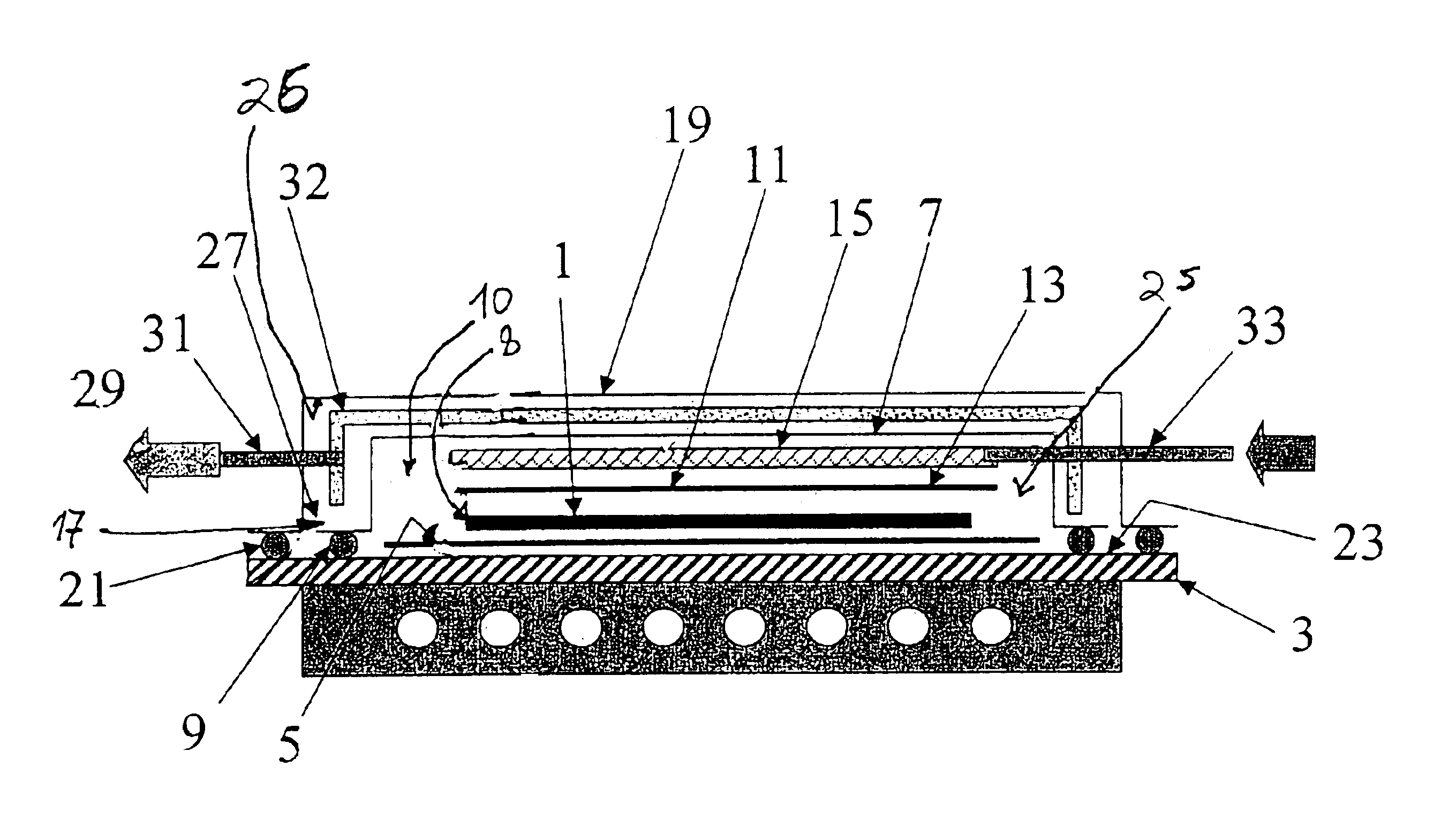

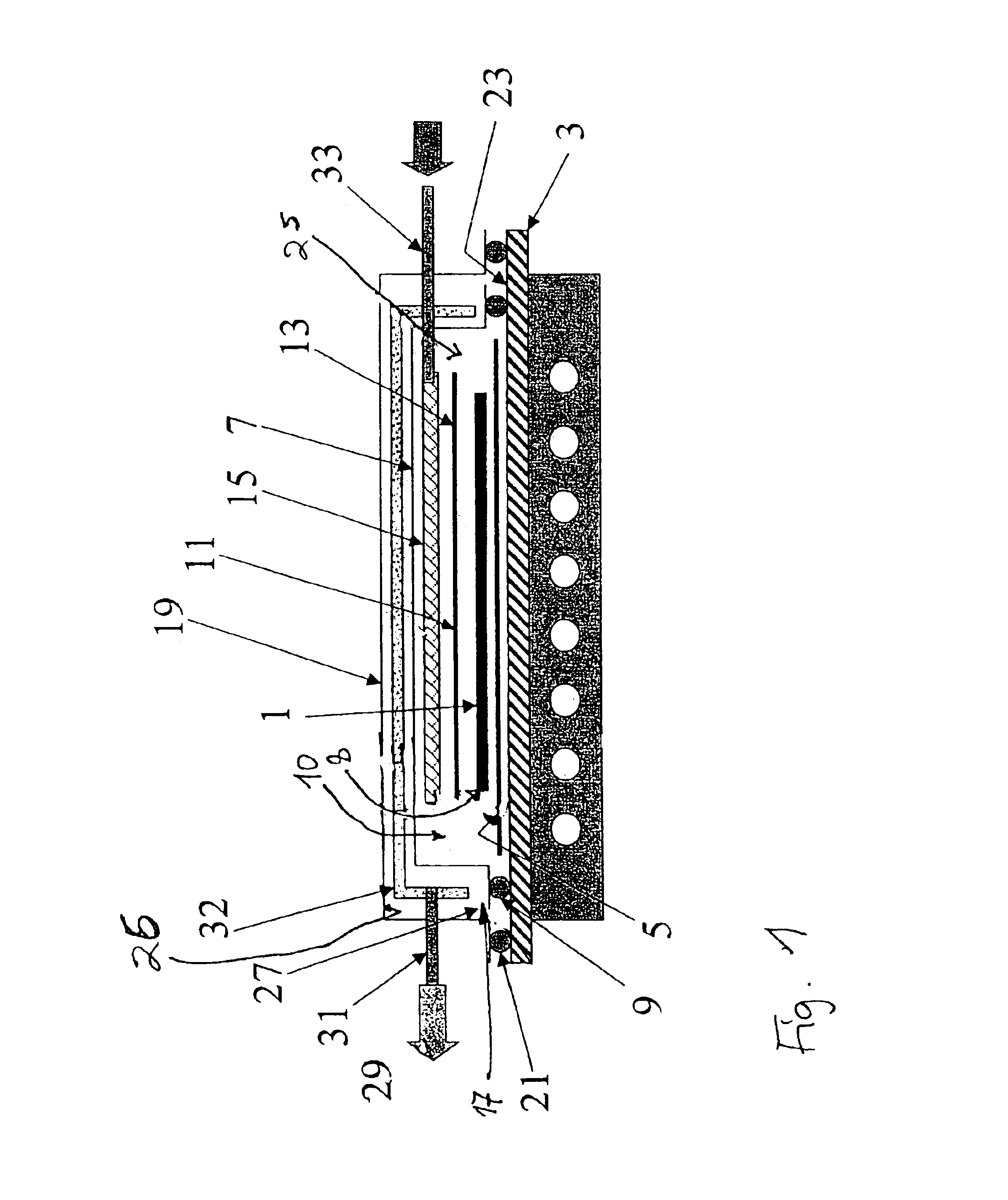

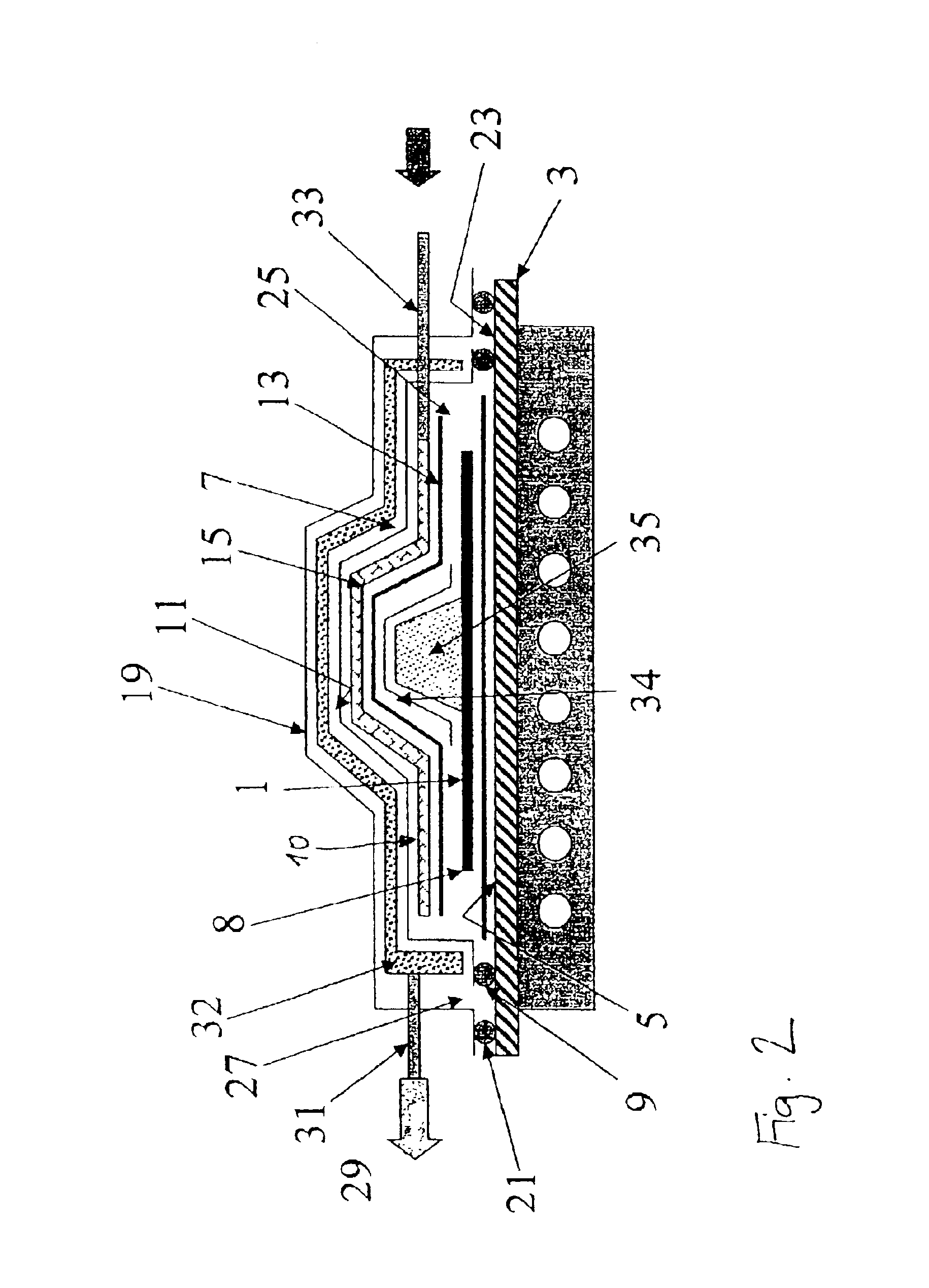

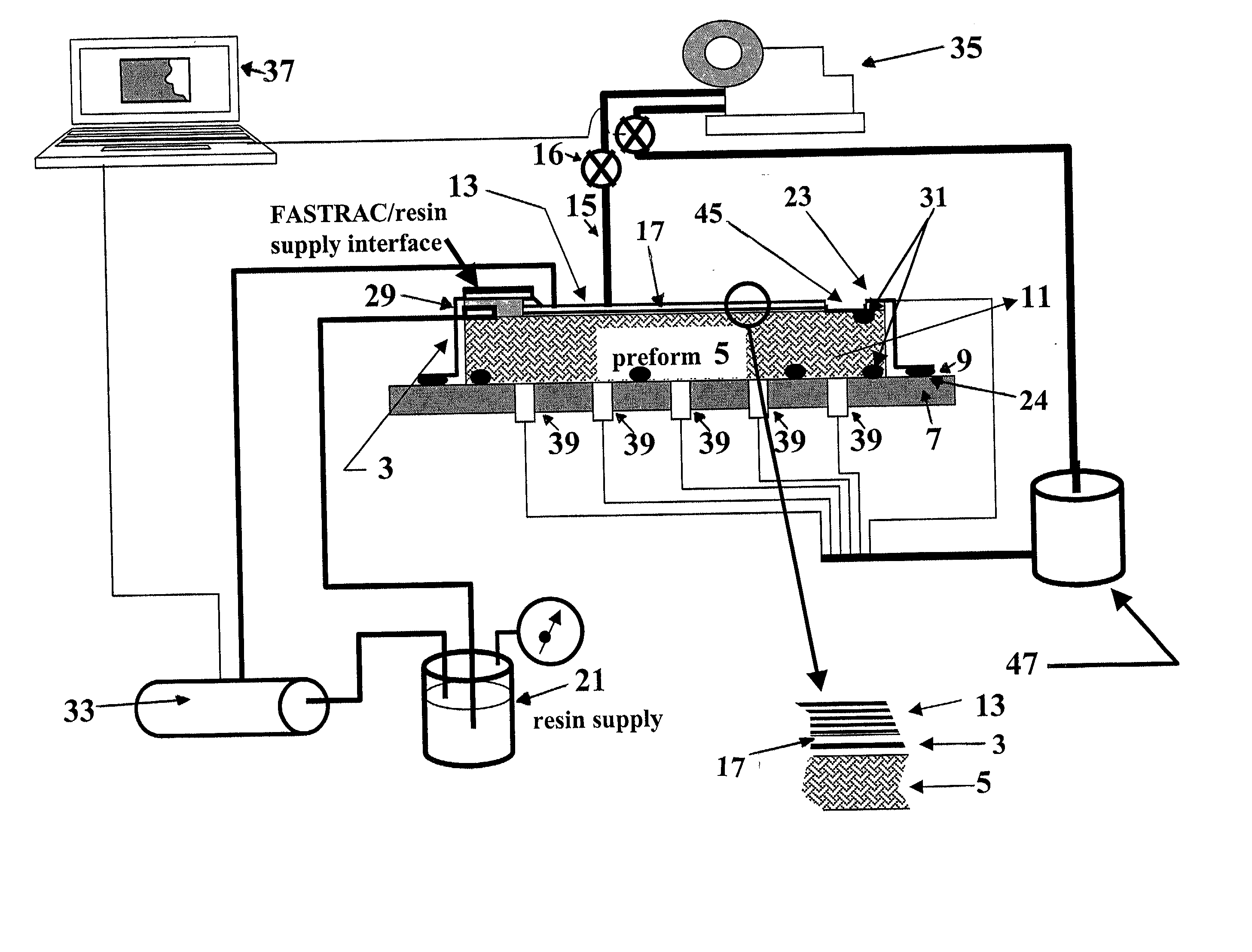

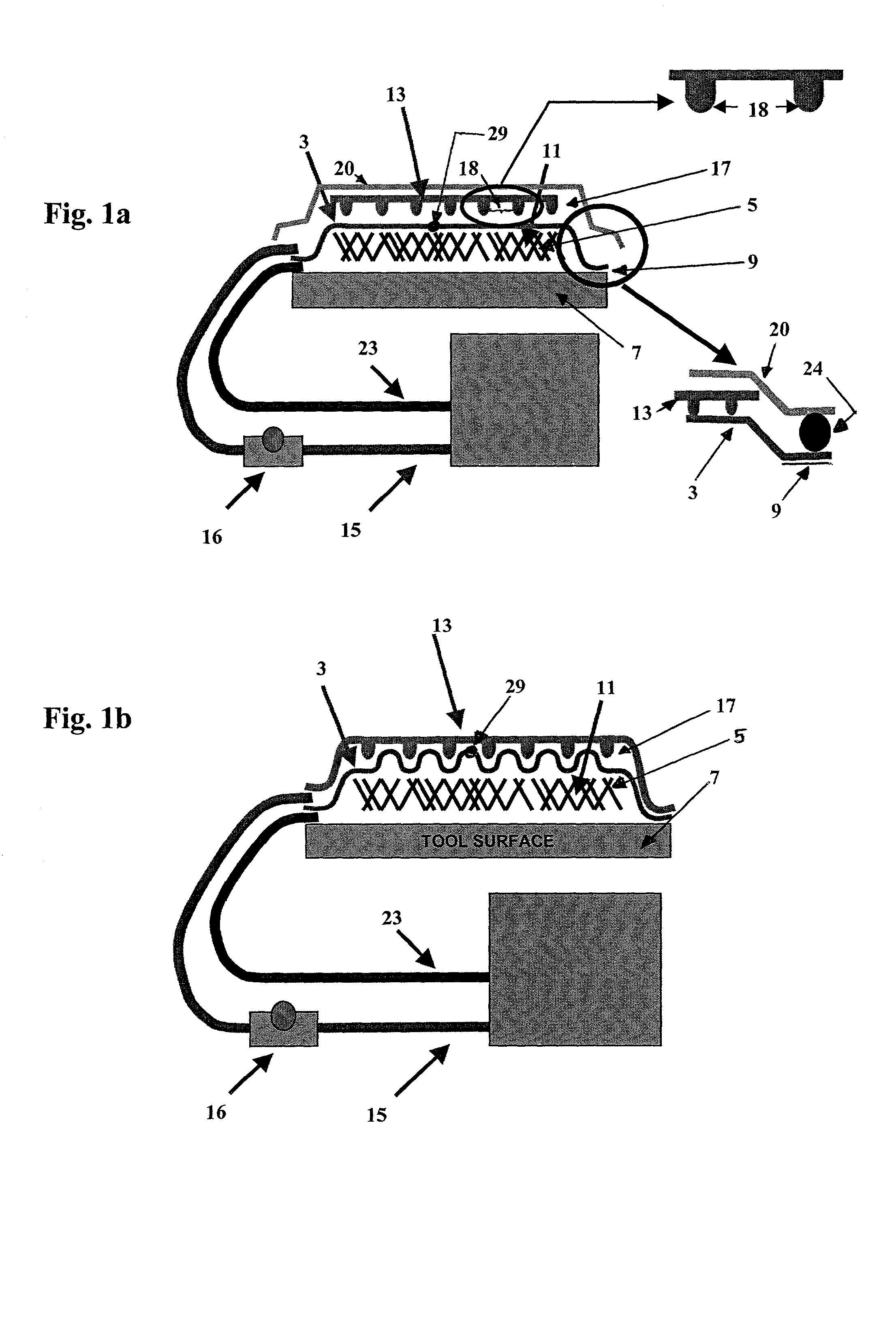

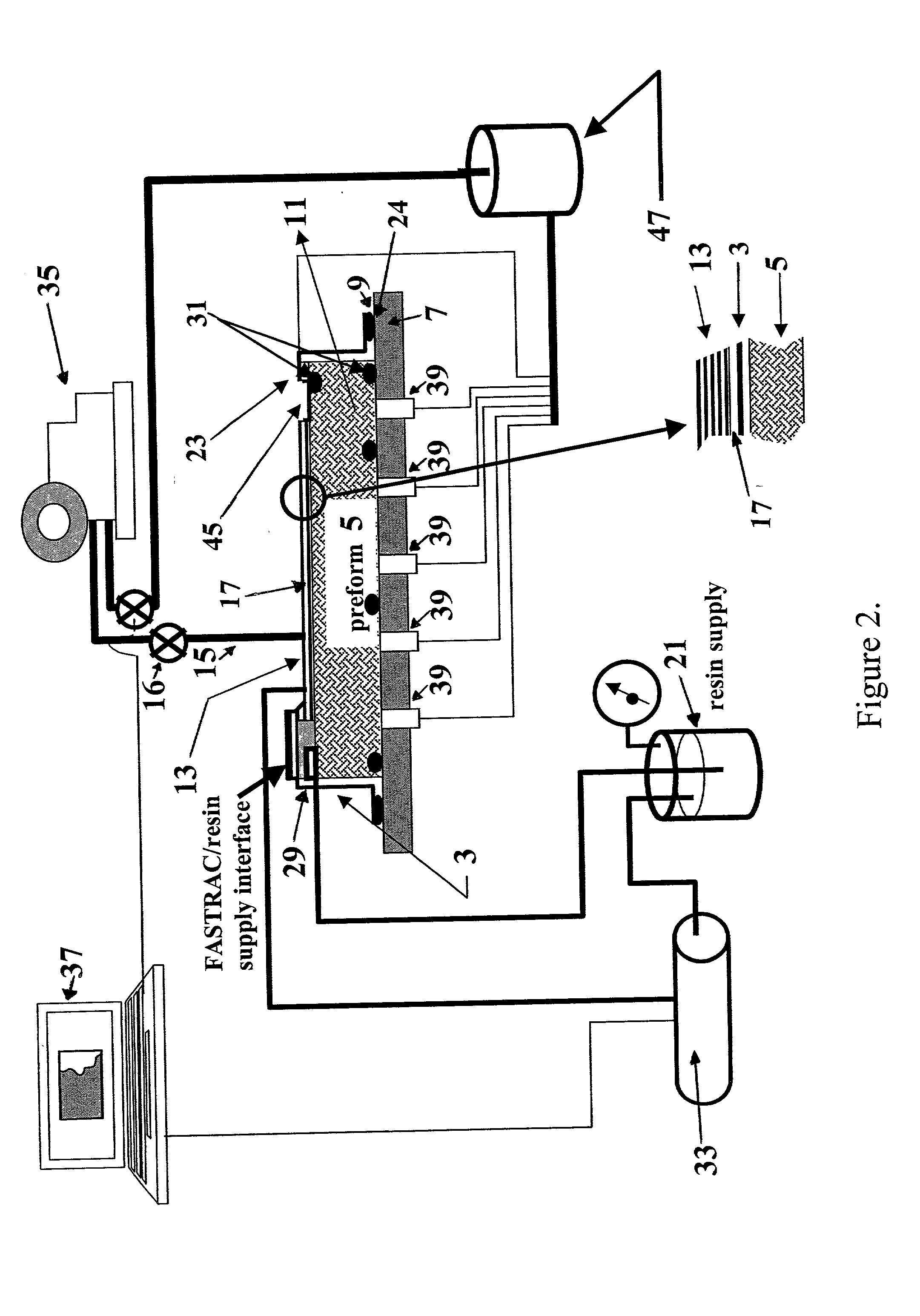

Method and device for producing fiber-reinforced components using an injection method

InactiveUS6843953B2Produced cost-effectivelyTop quality componentsConfectioneryWood working apparatusFibrous compositesMaterials science

In a method for producing fiber-reinforced plastic components made of dry fiber composite preforms by an injection method for injecting matrix material, the arrangement of the fiber composite preform on one surface of the preform resulting in a flow promoting device, on a tool, creates a first space by a gas-permeable and matrix-material-impermeable membrane surrounding the preforms. Formation of a second space arranged between the first space and the surroundings by a foil, which is impermeable to gaseous material and matrix material, is provided, with removal by suction, of air from the second space resulting in matrix material being sucked from a reservoir into the evacuated first space and with the flow promoting device causing distribution of the matrix material above the surface of the preform facing the flow promoting device, thus causing the matrix material to penetrate the preform vertically.

Owner:AIRBUS DEFENCE & SPACE

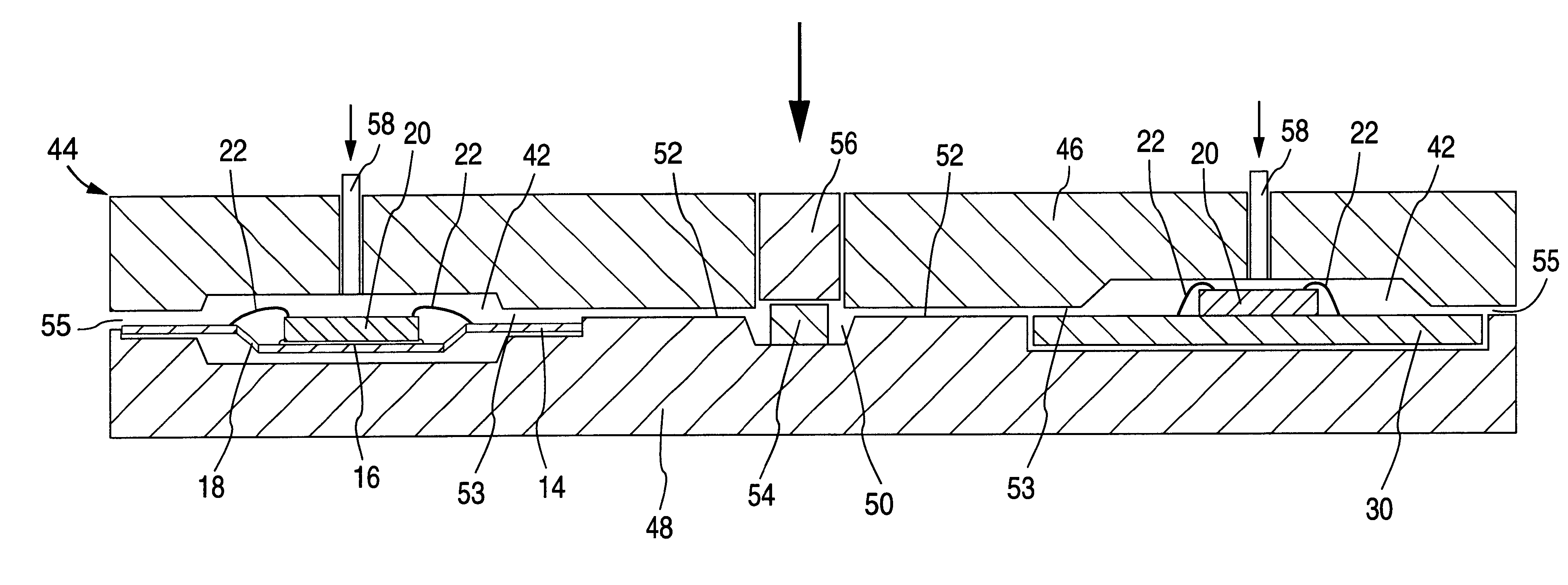

Apparatus for embossing a flexible substrate with a pattern carried by an optically transparent compliant media

An apparatus for embossing a flexible substrate with an optically transparent compliant media is disclosed. The complaint media includes an optically transparent imprint stamp with an imprint pattern therein. The flexible substrate is coated with a photopolymer material. The compliant media can be connected with an optically transparent belt material to form an embossing belt or connected with an optically transparent cylinder to from an embossing drum. A coated side of the flexible substrate is urged into contact with the imprint stamp and the imprint pattern is embossed in the photopolymer material and an ultraviolet light passing through the compliant media contemporaneously cures the photopolymer material during the embossing.

Owner:APPLIED MATERIALS INC

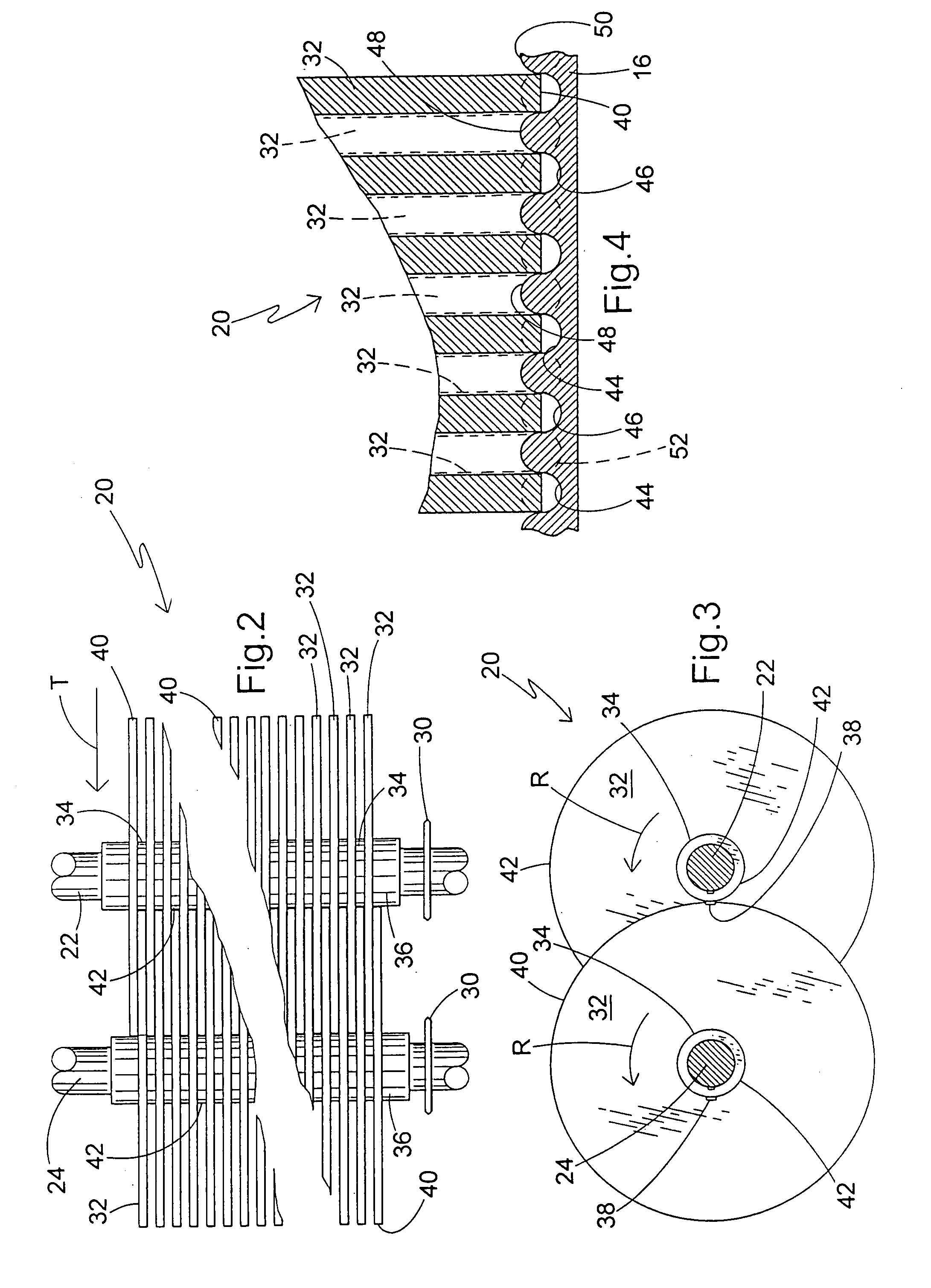

Thermoplastic molding process and apparatus

InactiveUS6900547B2Promote formationLow rateSemiconductor/solid-state device detailsConfectioneryFiberLower upper

A system and method for forming an article from thermoplastic material and fiber. The method includes heating thermoplastic material to form a molten thermoplastic material for blending with the fiber. The molten thermoplastic material is blended with the fibers to form a molten composite material having a concentration of fiber by weight. The molten composite material may then be extruded through dynamic dies to deliver discrete controlled material that is gravitated onto a lower portion of a mold. The lower portion of the mold may be moved in space and time while receiving the flow of composite material to deposit a predetermined quantity of molten composite material thereon conforming to mold cavities of the lower and an upper portion of the mold. The upper portion of the mold may be pressed against the predetermined quantity of molten composite material and closing on the lower portion of the mold to form the article.

Owner:D&D MFG LLC

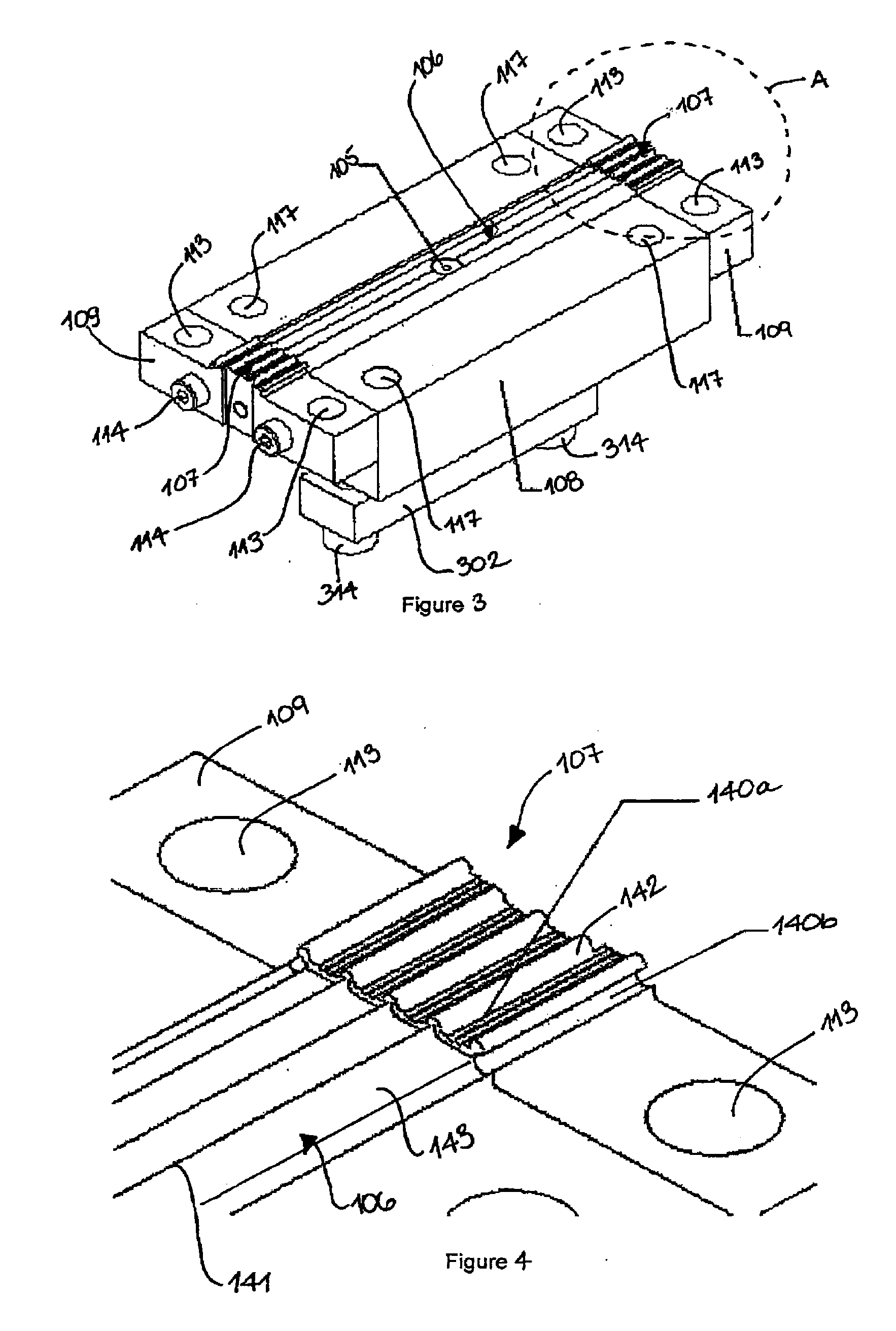

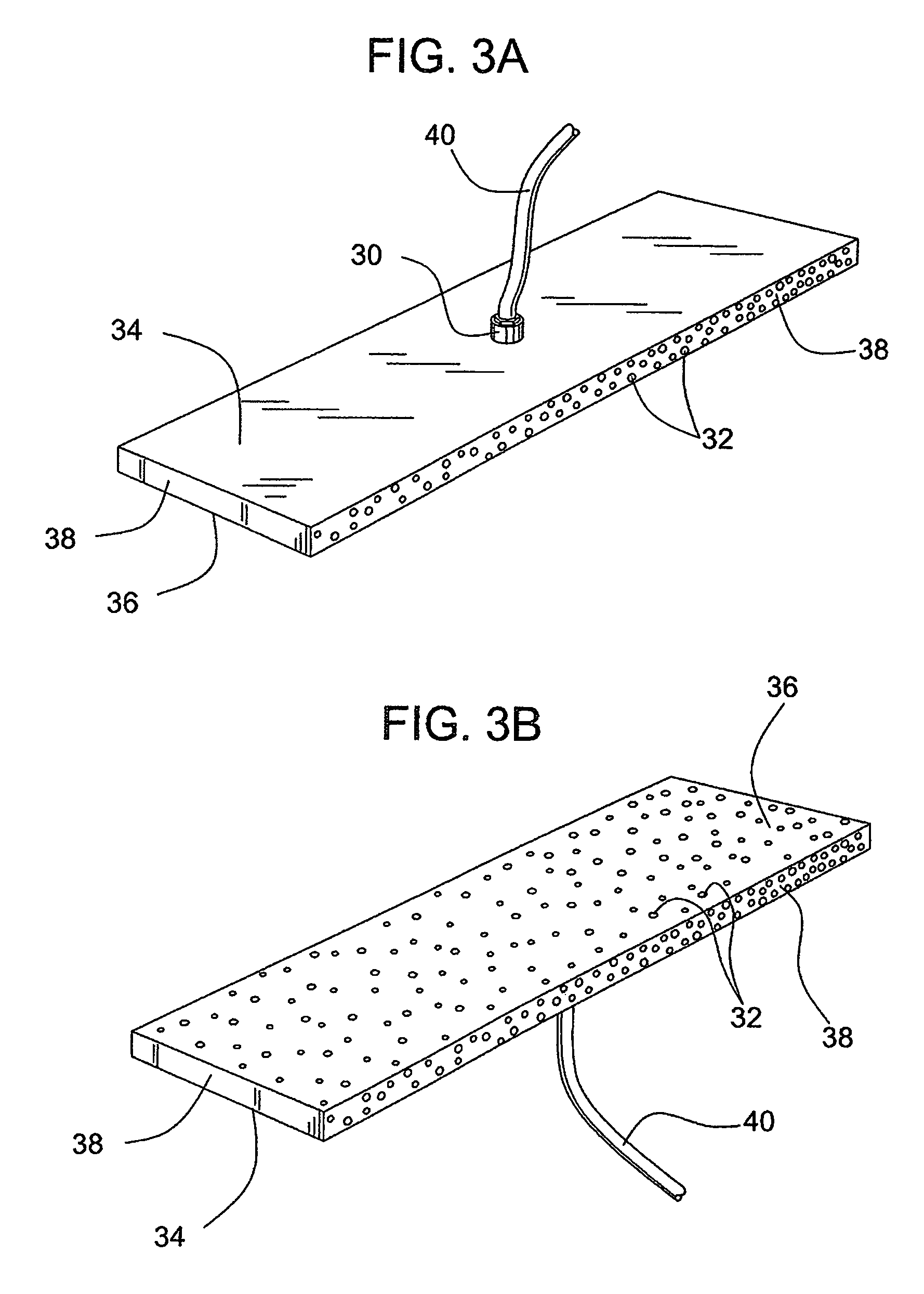

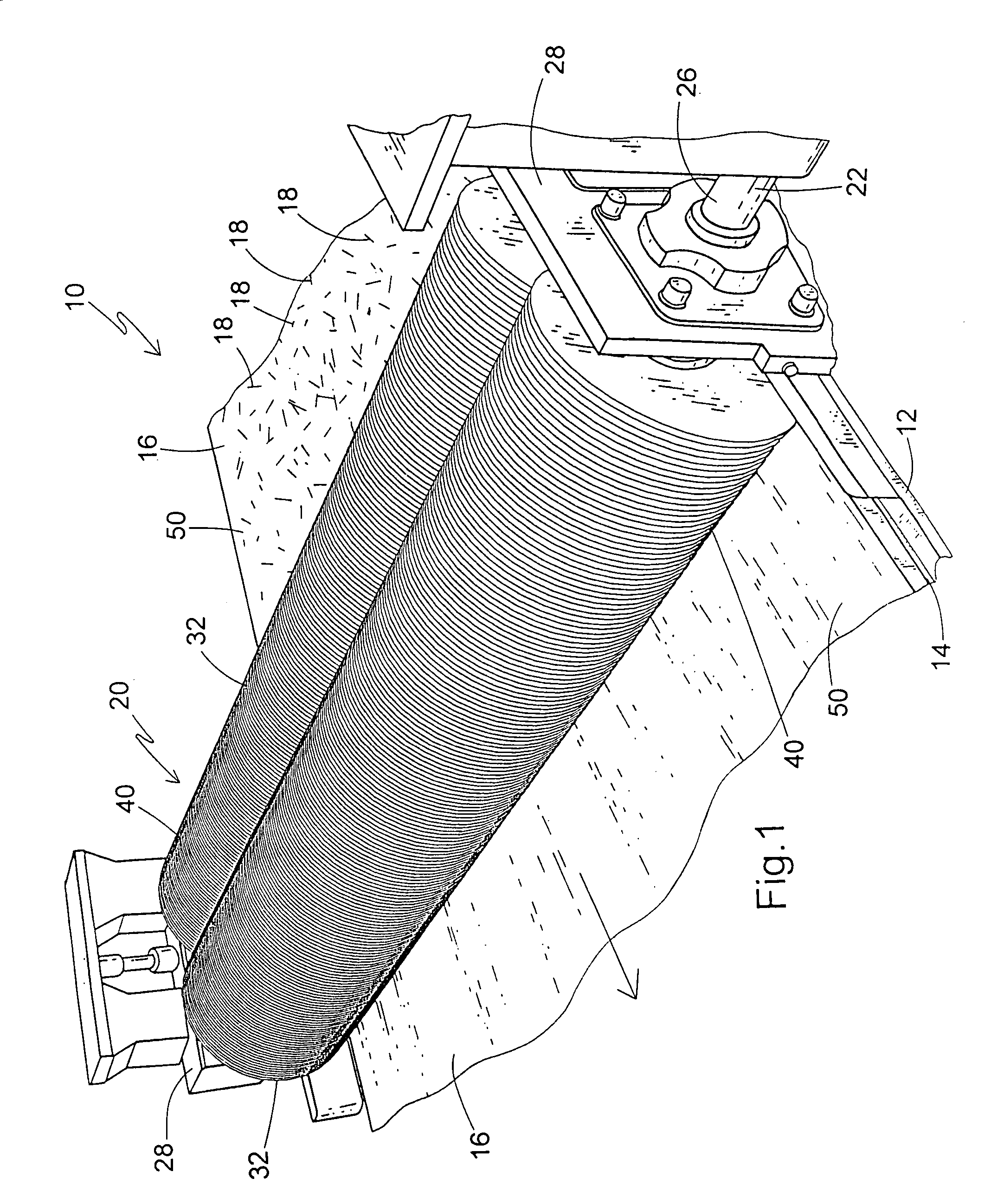

Embedment device for fiber-enhanced slurry

ActiveUS20050064055A1Reduces board line downtimePrevent buildupTransportation and packagingRotary stirring mixersFiberProduction line

An embedment device for use in a structural panel production line wherein a slurry is transported on a moving carrier relative to a support frame, and chopped fibers are deposited upon the slurry, includes a first elongate shaft secured to the support frame and having a first plurality of axially spaced disks, a second elongate shaft secured to the support frame and having a second plurality of axially spaced disks, the first shaft being disposed relative to the second shaft so that the disks intermesh with each other. The intermeshing relationship enhances embedment of the fibers into the slurry and also prevents clogging of the device by prematurely set slurry particles.

Owner:UNITED STATES GYPSUM CO

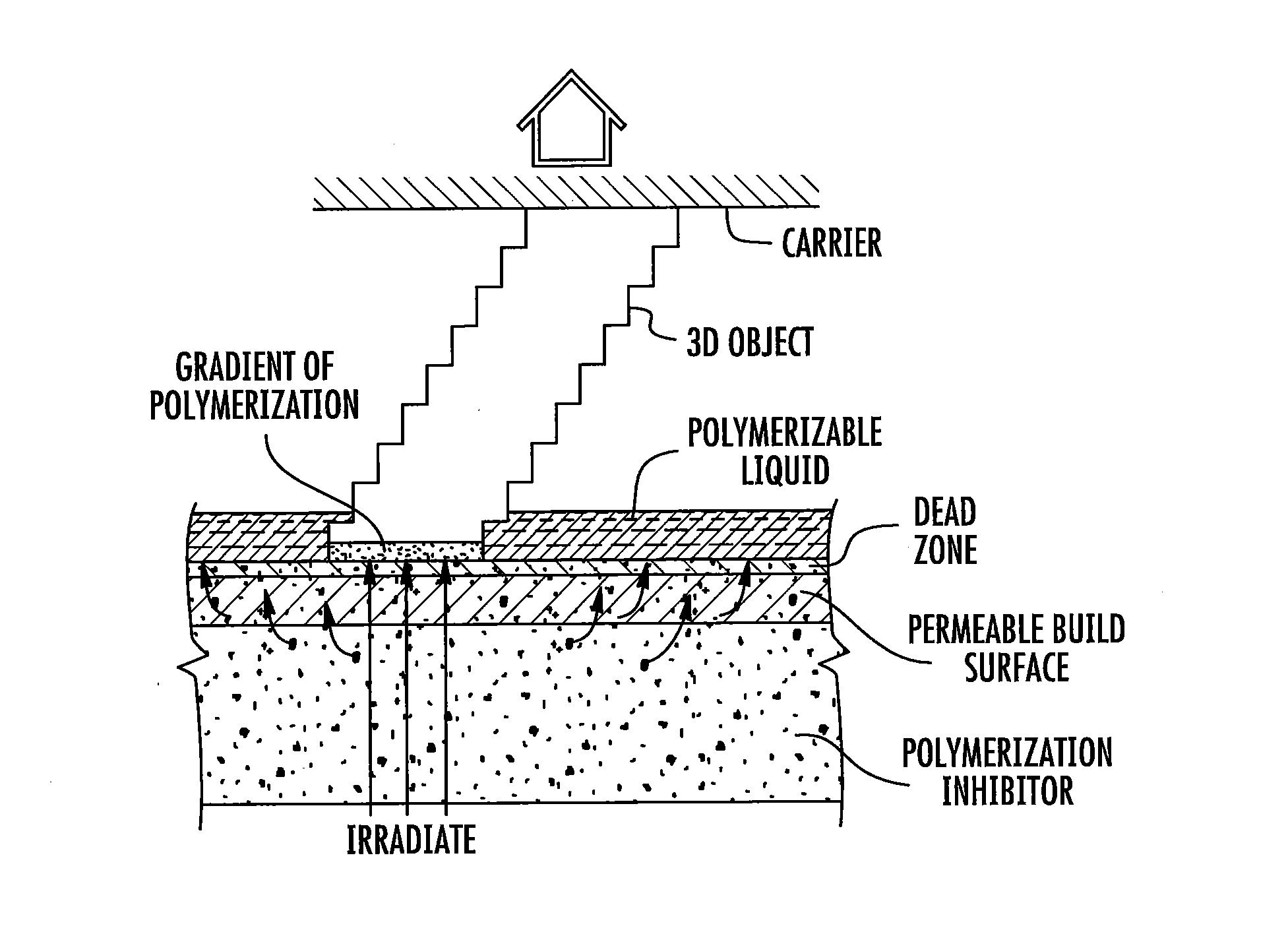

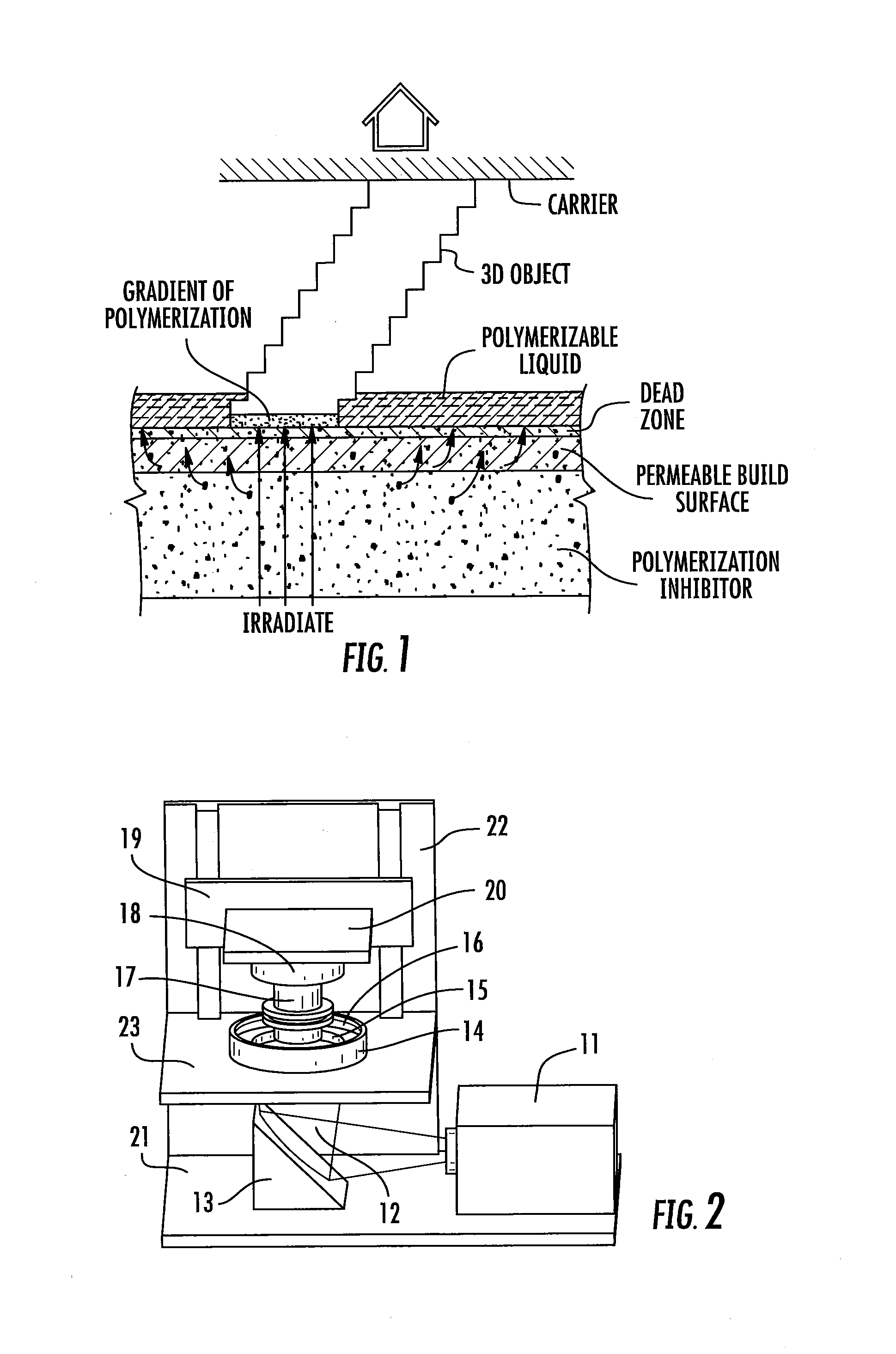

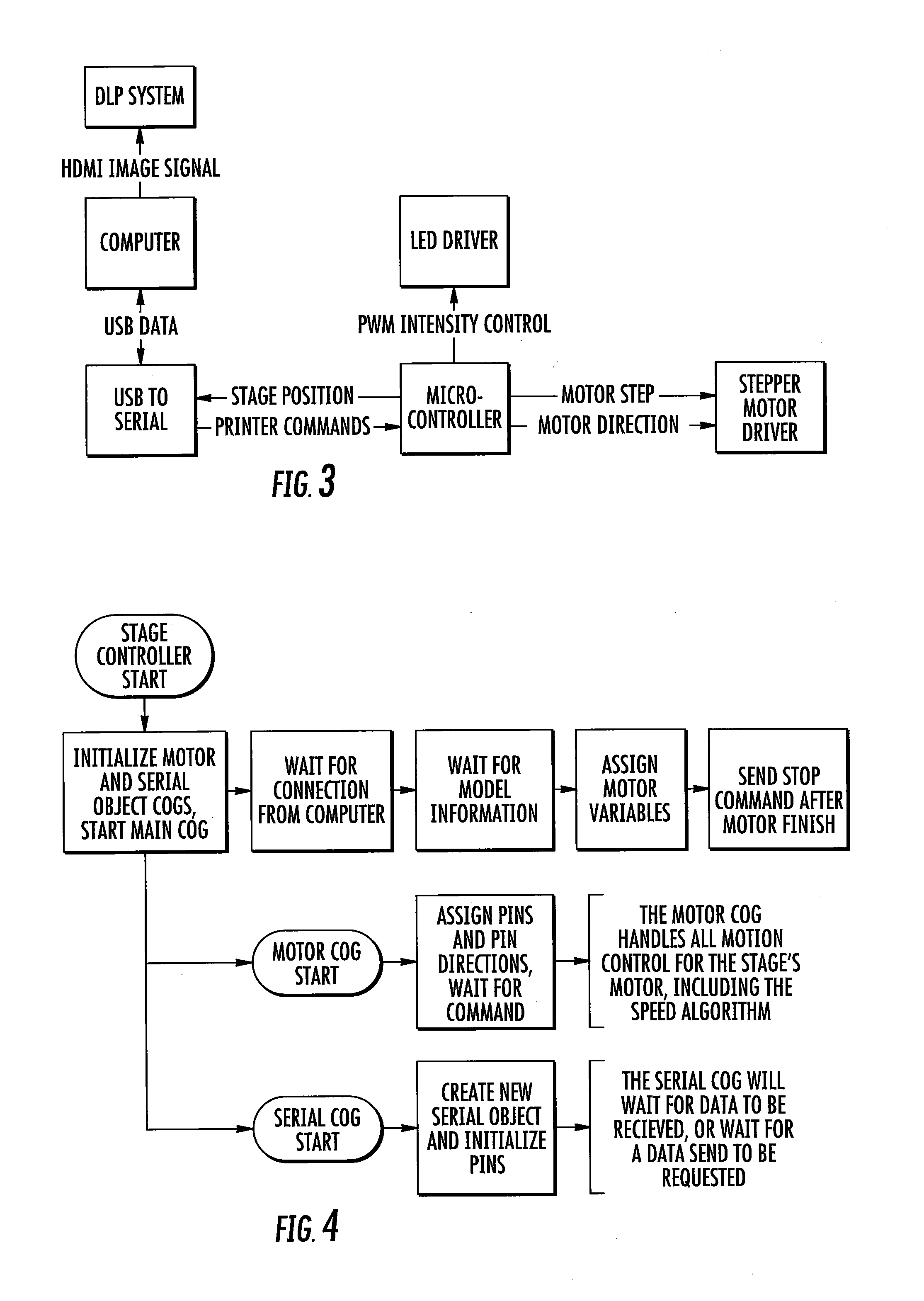

Three-dimensional printing with supported build plates

ActiveUS20160046075A1Low viscosityManufacturing platforms/substratesTailstocks/centresEngineering3 dimensional printing

A method of forming a three-dimensional object includes: providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; filling the build region with a polymerizable liquid, irradiating the build region with light through the optically transparent member to form a solid polymer from the polymerizable liquid, and advancing said carrier away from said build surface to form said three-dimensional object from said solid polymer. The irradiating step includes projecting focused light at the build region, and the advancing step is carried out at a rate that is dependent on an average light intensity of the focused light.

Owner:CARBON INC

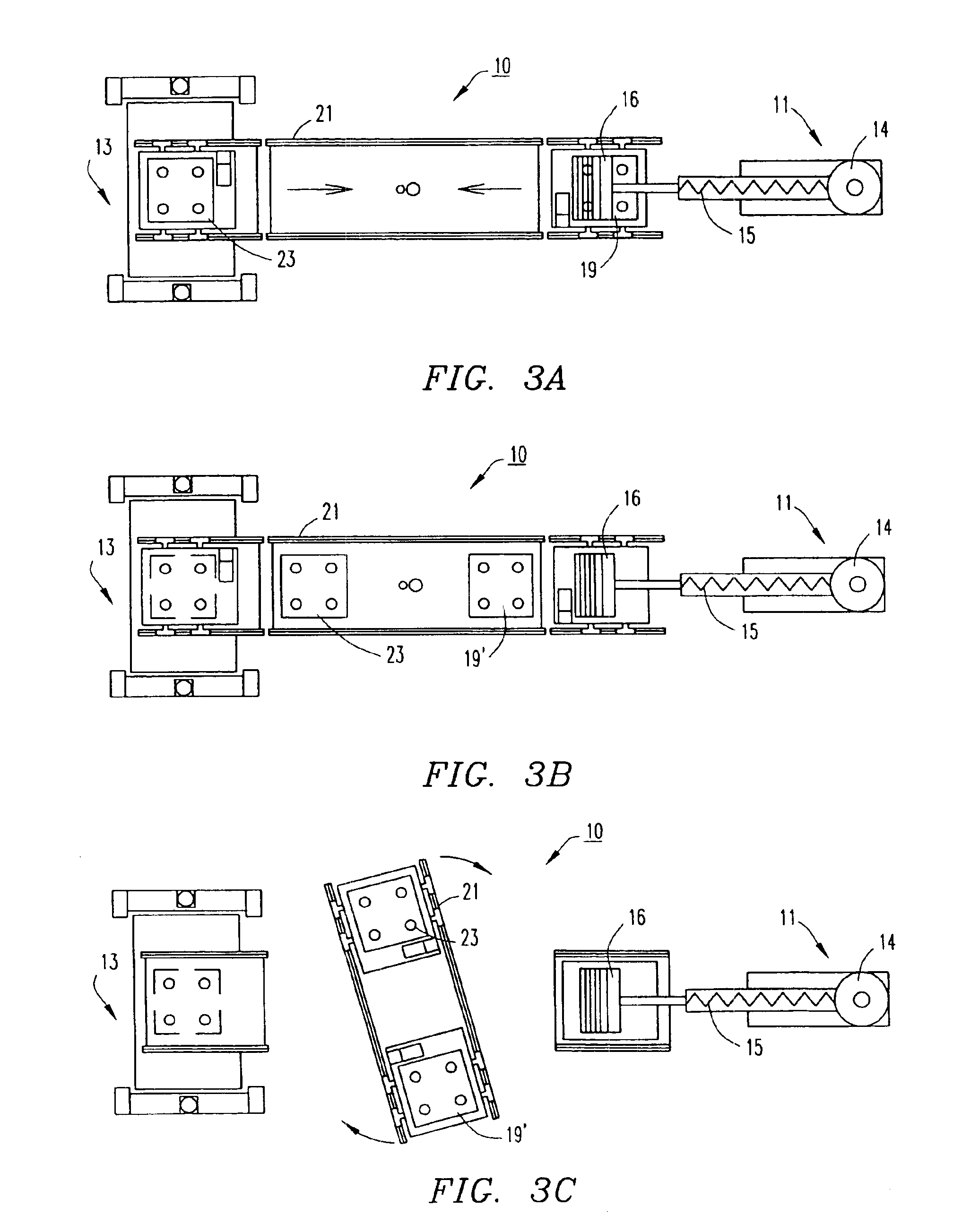

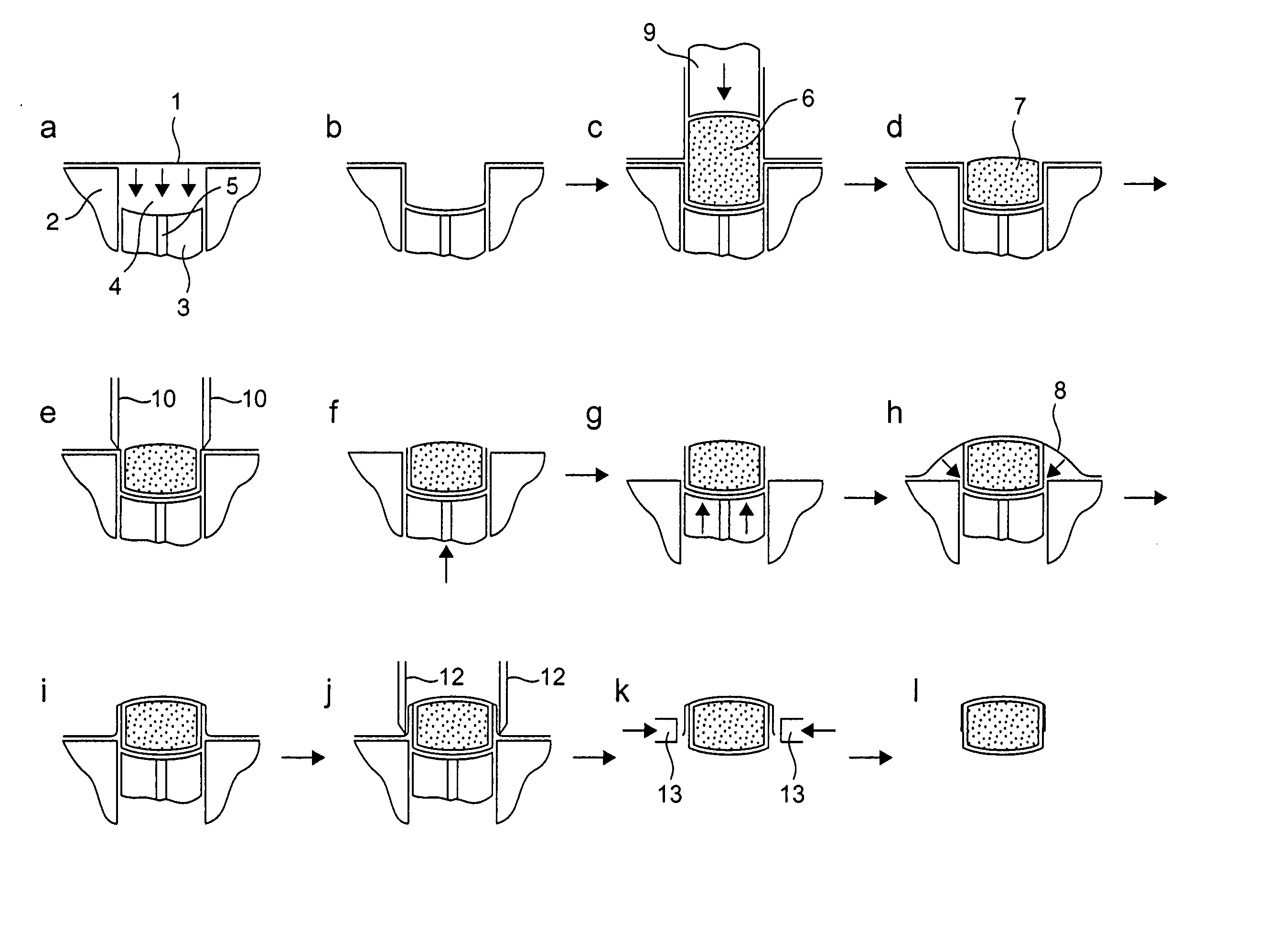

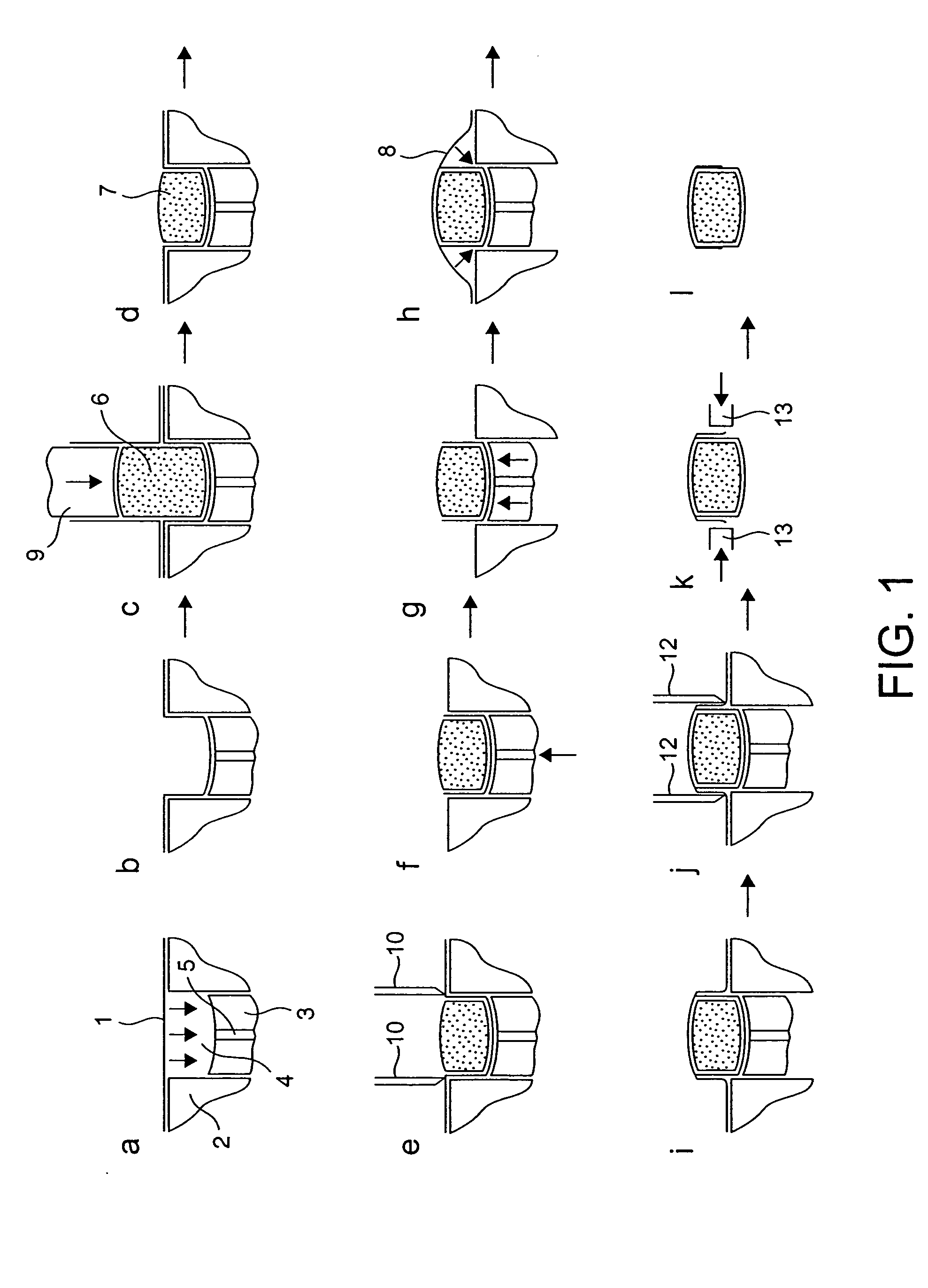

Molded body treating apparatus, sealing method of honeycomb molded body, and method for manufacturing cell-sealed honeycomb fired body

ActiveUS20080116601A1Internal combustion piston enginesDispersed particle filtrationHoneycombEngineering

A molded body treating apparatus includes a support, at least one flat plate and a first movement mechanism. The support is configured to support a honeycomb molded body which has a first end portion and a second end portion in a longitudinal direction of the honeycomb molded body and which includes a plurality of cells each extending along the longitudinal direction from a first end at the first end portion to a second end at the second end portion. Either the first end or the second end of each of the plurality of cells is sealed with a plug material paste. The first movement mechanism is configured to move the at least one flat plate along the longitudinal direction to press the either one of the first and second end portions.

Owner:IBIDEN CO LTD

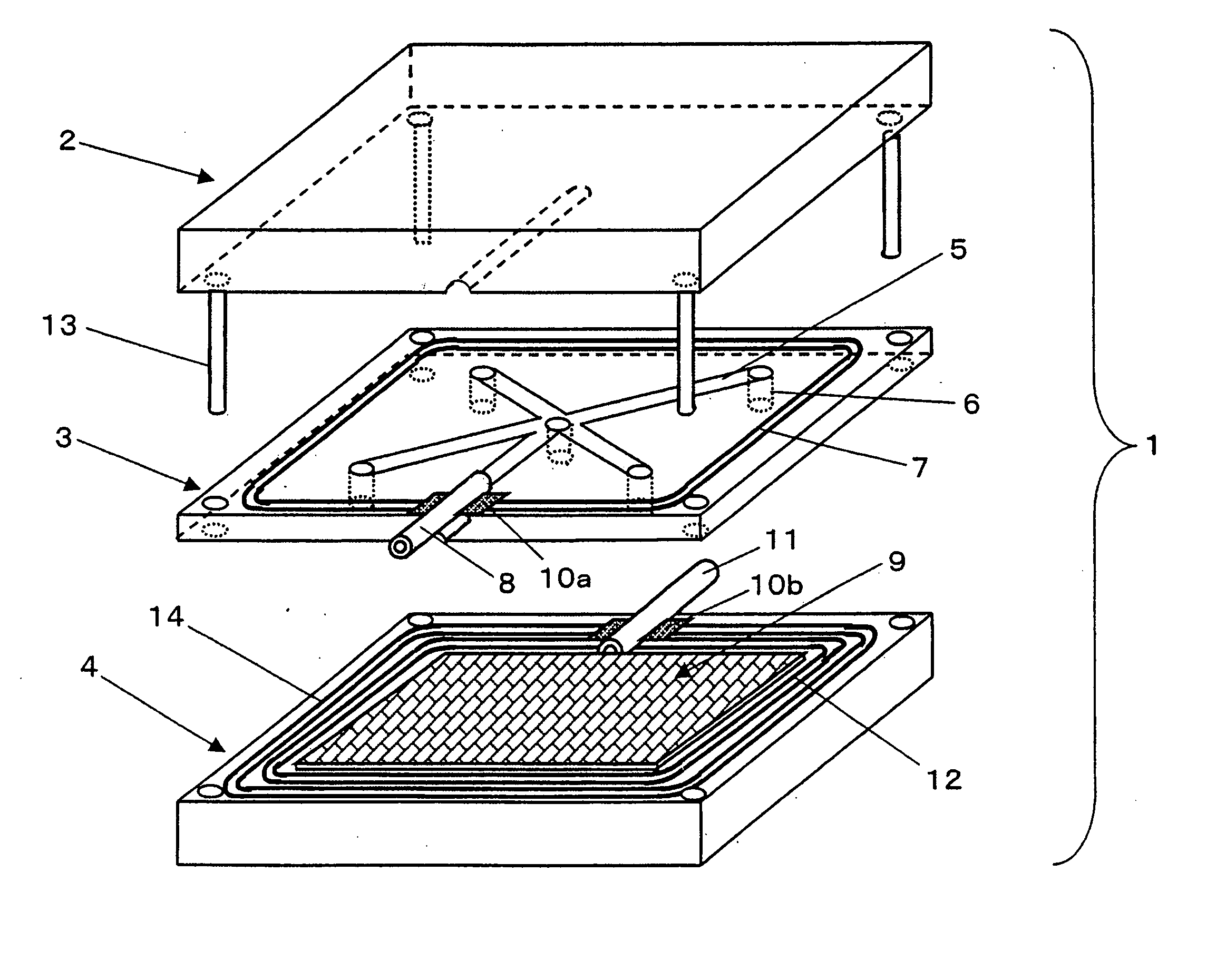

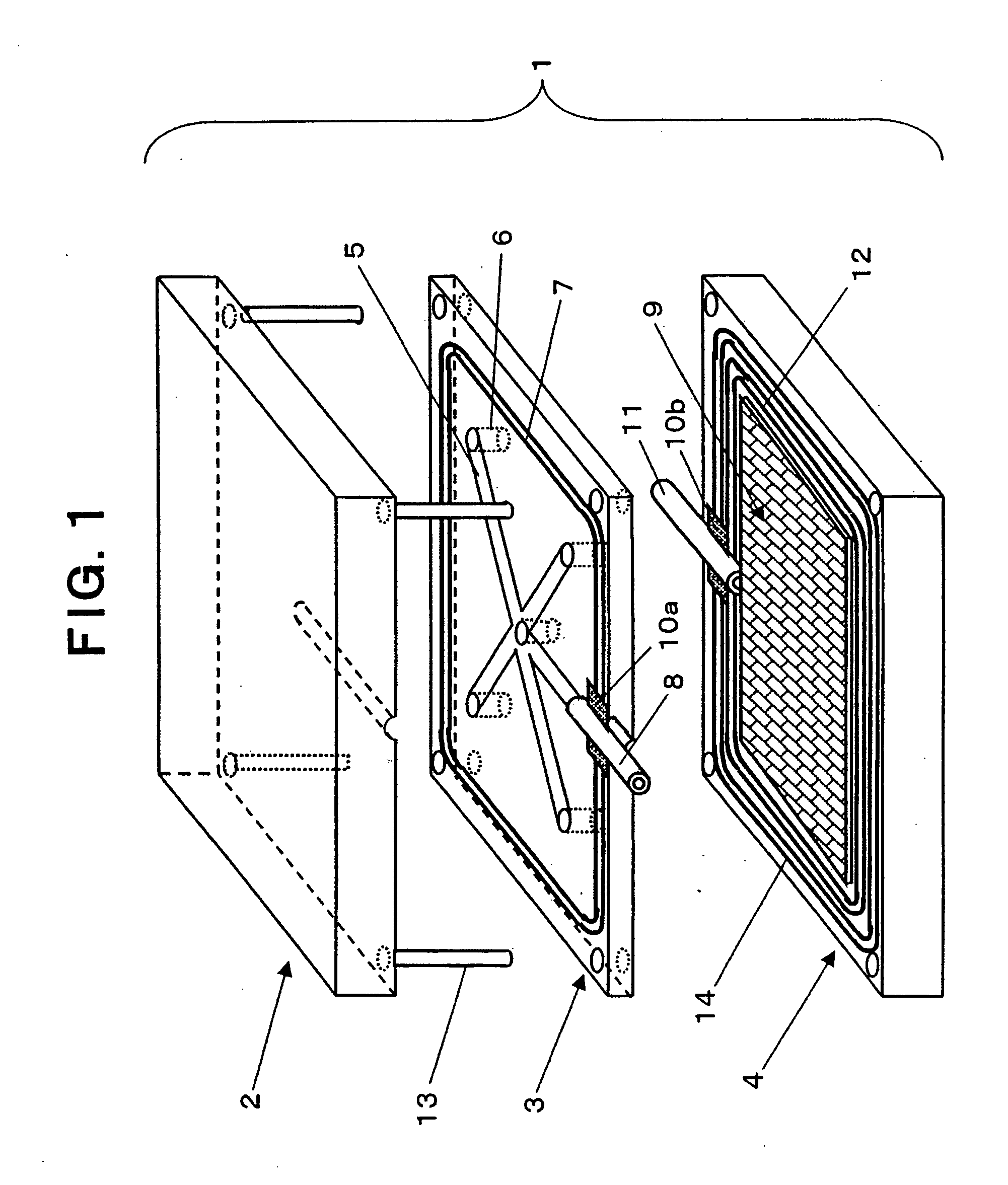

Rtm molding method and device

InactiveUS20070182071A1Shorten molding timeReduce the amount of solutionConfectioneryWood working apparatusFiber

An RTM molding method comprising disposing a reinforcing fiber substrate in a cavity of a mold consisting of a plurality of dies, clamping the mold, and thereafter injecting resin to complete molding, characterized in that divided areas with respect to the surface direction of the reinforcing fiber substrate are assumed, each divided area is one in which injected resin expands over the entire surface in the area and can be substantially uniformly impregnated in the thickness direction of the substrate, and resin introducing paths are formed for respective assumed divided areas for introducing the injected resin into the respective divided areas; and an RTM molding device. When a relatively large molded product is to be molded, a molding step from resin injection to impregnating / curing can be implemented at high speed without generating a non-resin-flowing area, thereby enabling a high-quality molded product to be produced free from voids, etc., with a molding time shortened and production speed and volume increased.

Owner:TORAY IND INC

Jointed linkage system

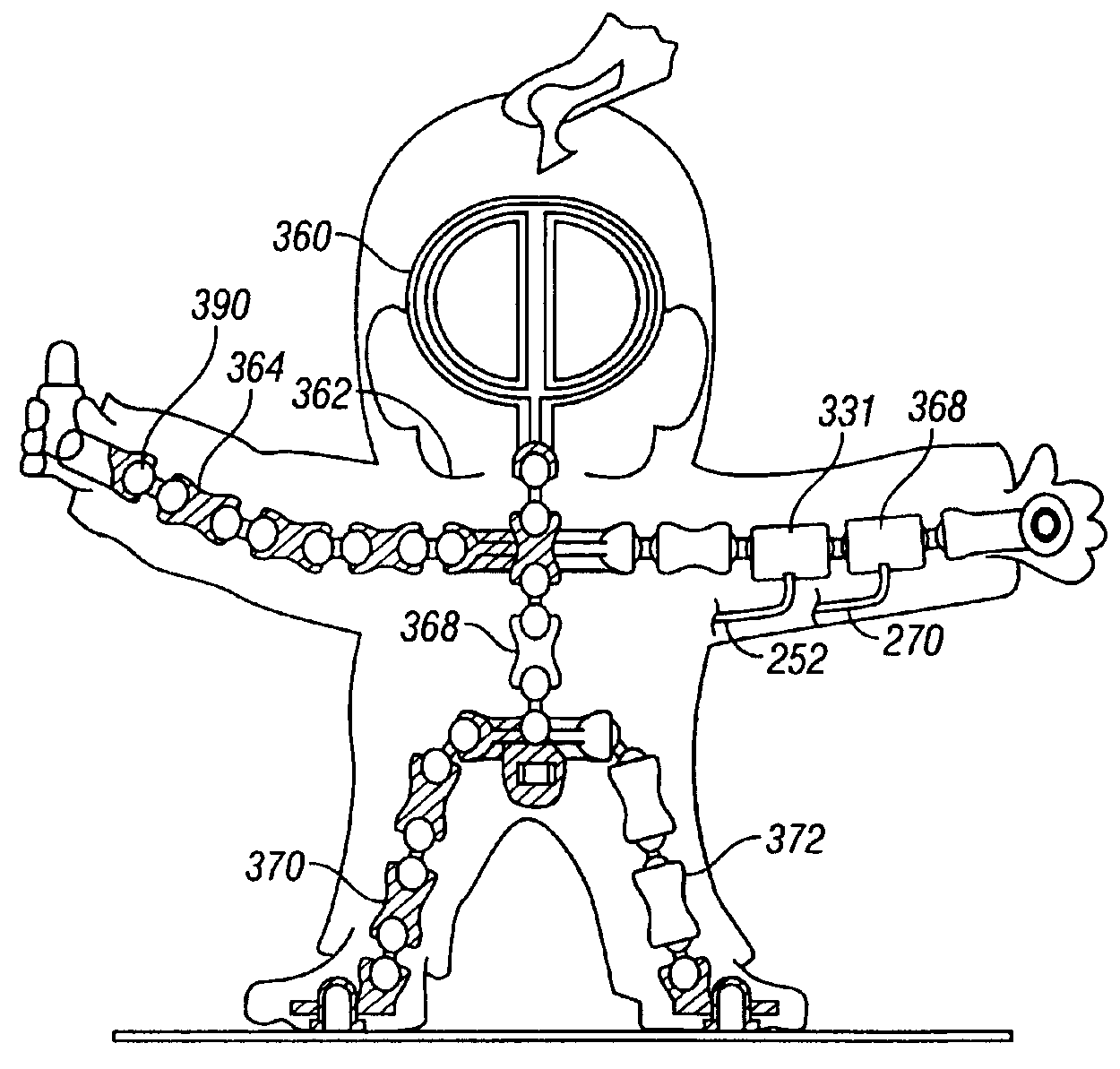

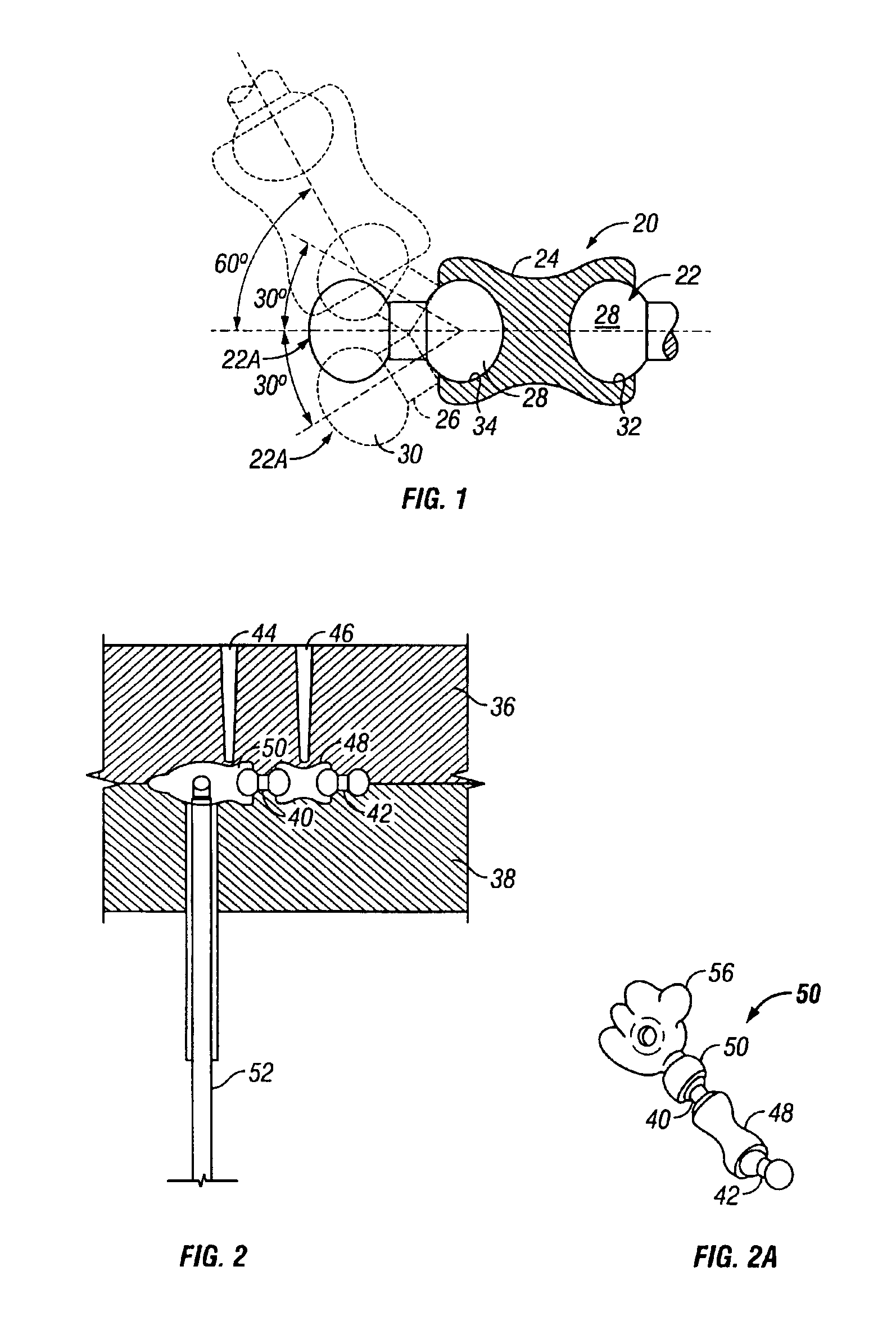

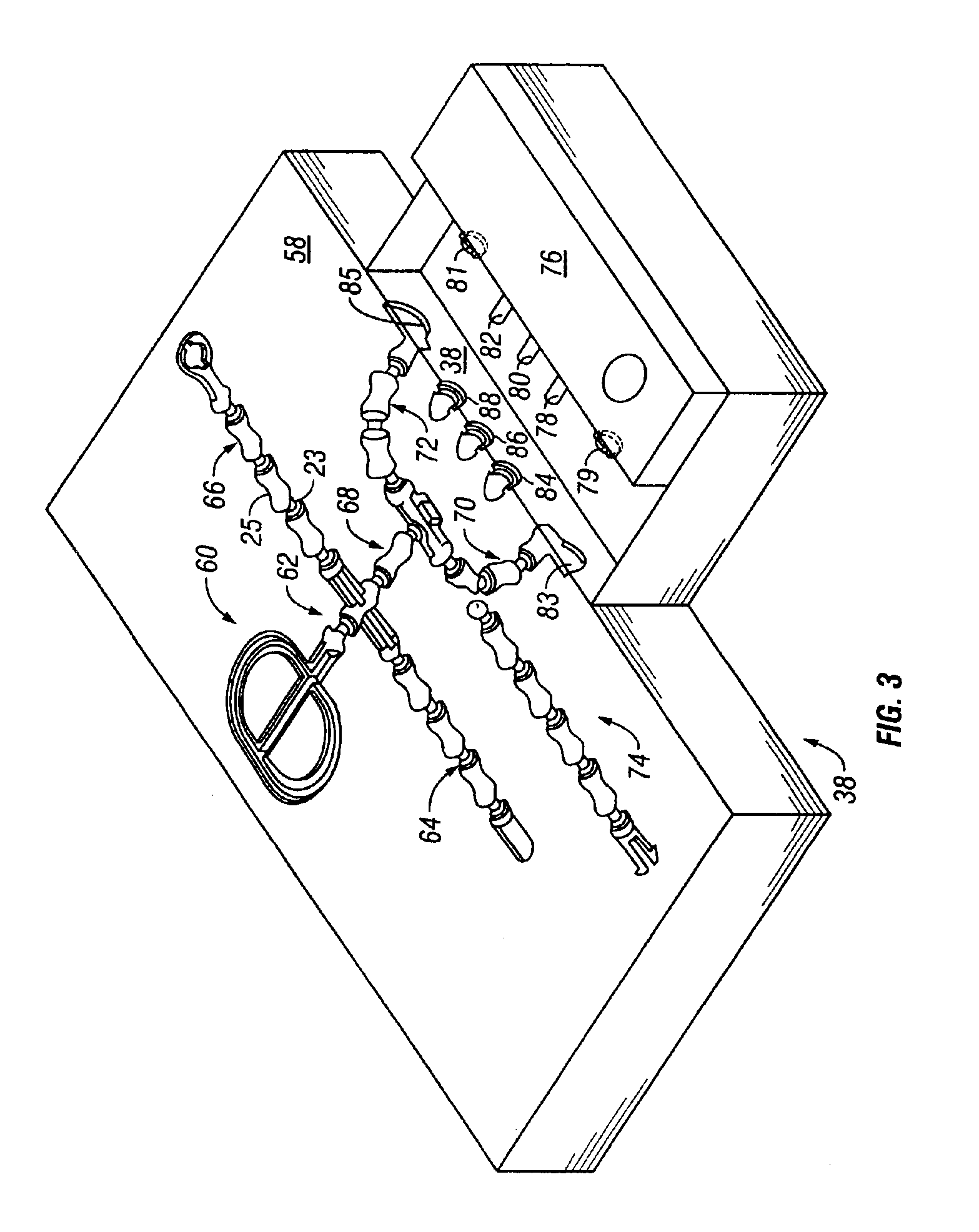

A system for molding a jointed linkage support system with joints that allow movement and bending in many directions and degrees of freedom. A chain-like linkage system made up of a series of joints is molded in a single step from materials having different melting temperatures in a series of alternating communicating mold cavities. The jointed linkage support system emerges from the mold fully assembled. An electrical switch may be provided within one of the joints between sleeves and rods whereby movement of the rod relative to the sleeve actuates the switch.

Owner:C J ASSOCS

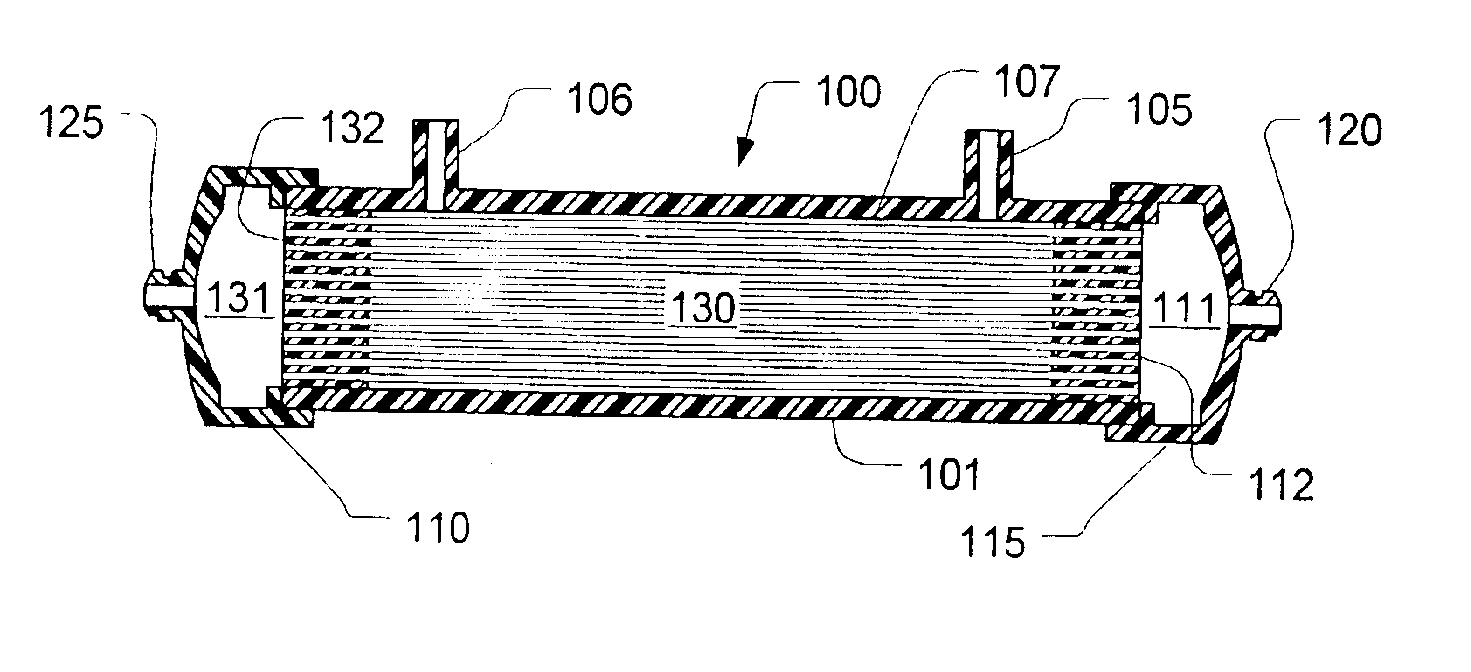

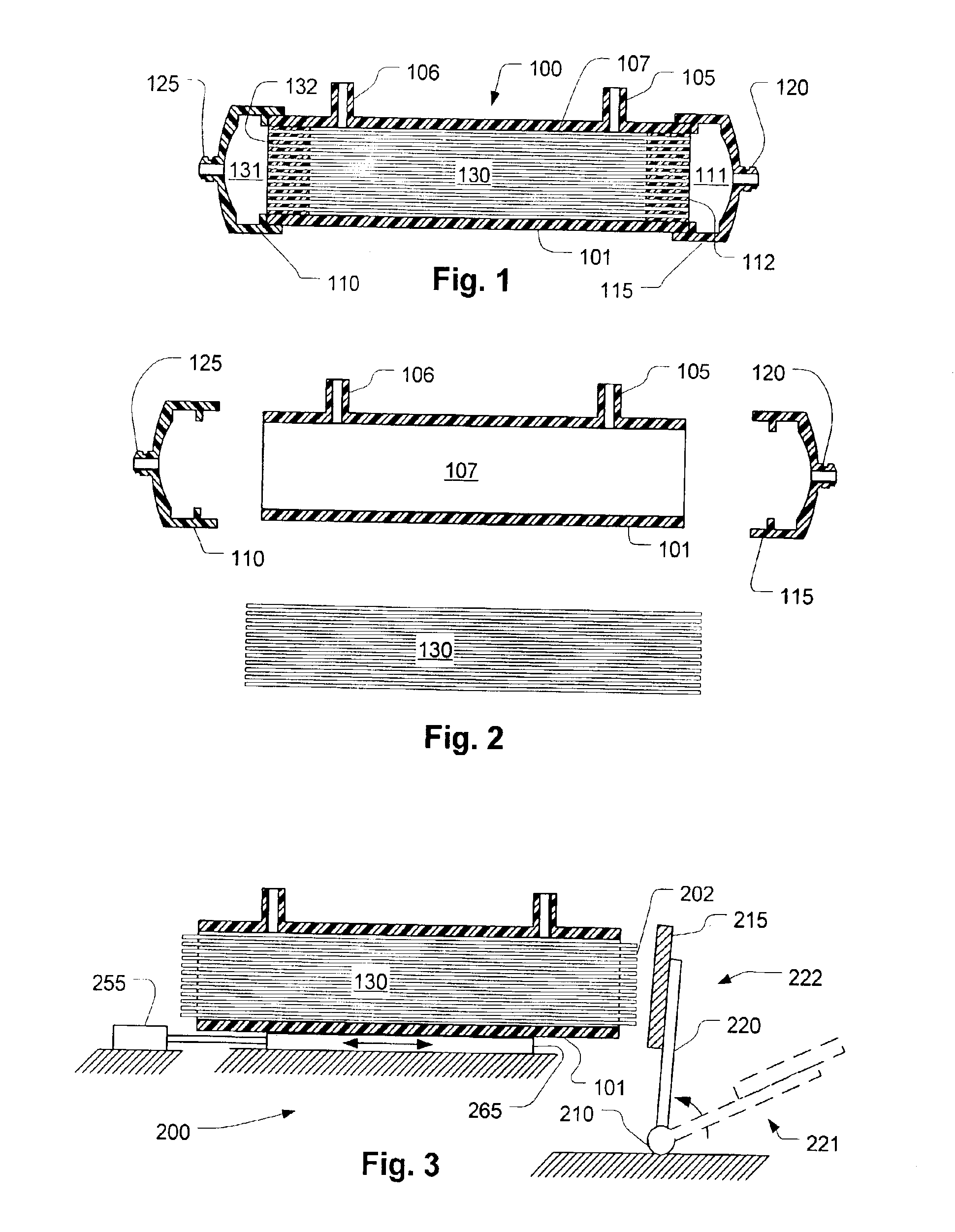

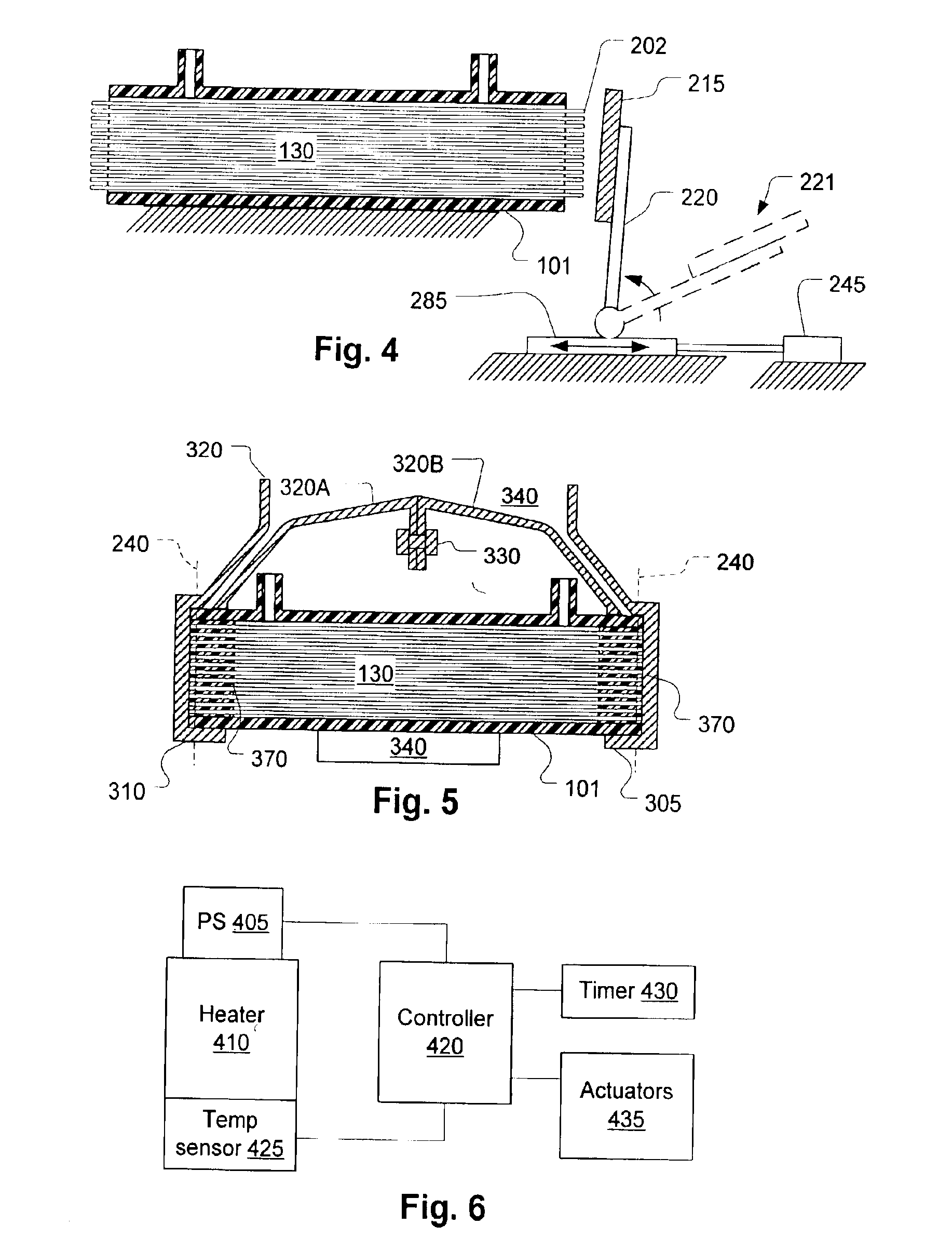

Method and apparatus for manufacturing filters

InactiveUS6872346B2Speed productionShort amount of timeSemi-permeable membranesTailstocks/centresEngineeringMechanical engineering

A problem in the manufacture of filters using tubular membrane bundles is keeping potting material from flowing into the openings at the ends of the tubes. A preferred embodiment of a method for manufacturing a tubular membrane filter employs a non-contact heat source such as radiant heating to melt the tips of the tubular membranes. This prevents the migration of potting material into the tubes when the potting material is flowed into the ends of tube bundles during the manufacturing process for a filter.

Owner:NXSTAGE MEDICAL

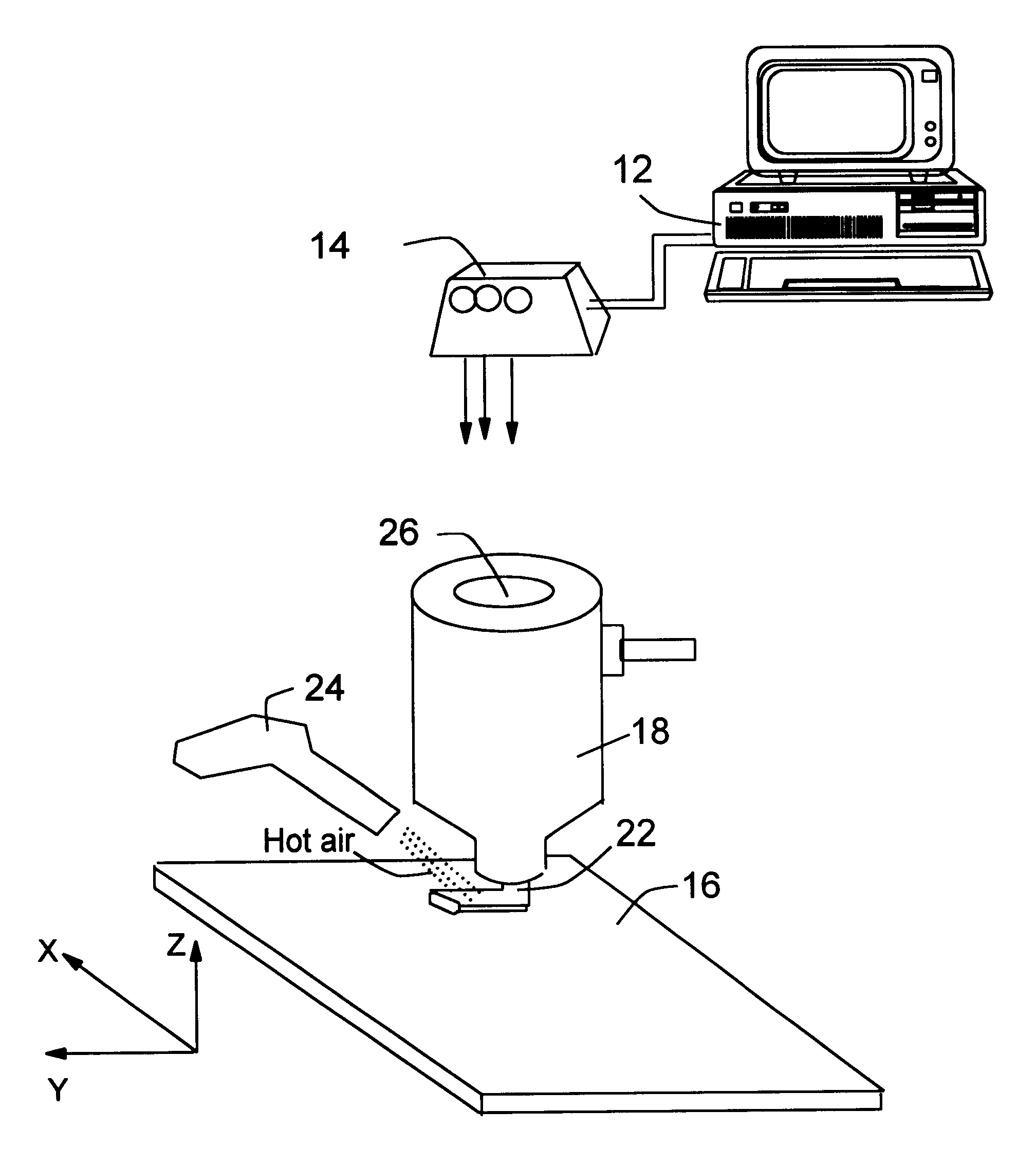

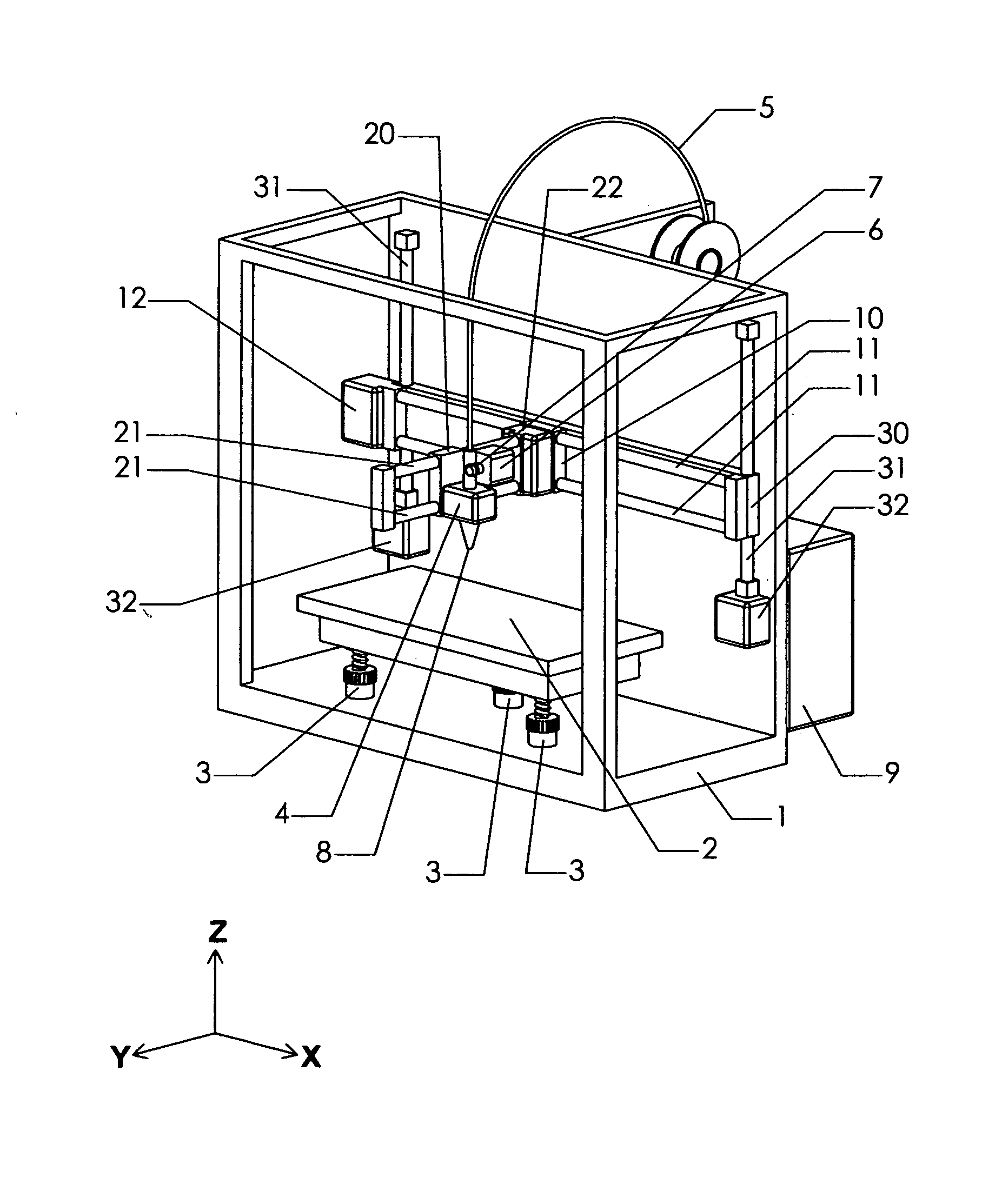

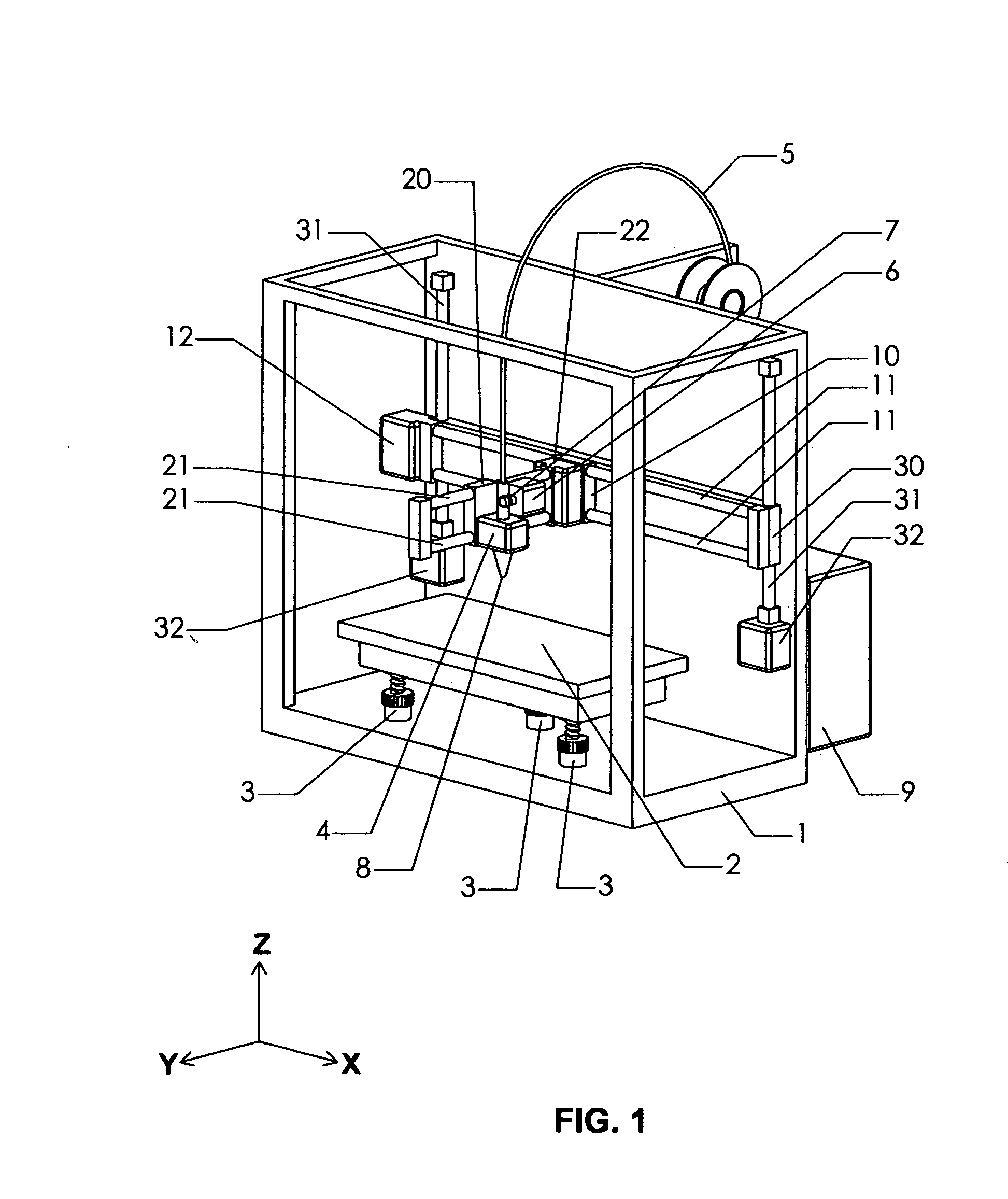

Multiple color extrusion type three dimensional printer

InactiveUS20140363532A1Additive manufacturing apparatusTailstocks/centresComputer printingEngineering

The present invention provides an apparatus for manufacturing multiple color three-dimensional (3D) objects using an additive extrusion type manufacturing build process where the multiple color three-dimensional (3D) object is built layer by layer using a single extrusion nozzle in contact or close proximity to each build layer of the 3D object being manufactured.

Owner:WOLFGRAM KIRK W

Spacer mold and methods therefor

Owner:ZIMMER ORTHOPAEDIC SURGICAL PRODS

Method of molding plastic semiconductor packages

InactiveUS6309916B1Good package releaseImprove adhesionSemiconductor/solid-state device detailsConfectioneryShell moldingSemiconductor package

In the manufacture of semiconductor packages having molded plastic bodies, the plating of all of the surfaces of the molding tool that comes into contact with the molten resin during molding with a nodular thin dense chromium ("NTDC") coating prevents the surfaces from adhering to the package body and ensures good package release, without formation of cracks or craters in the package body. This, in turn, permits the amount of both release agents and adhesion promoters used in the molding compound to be substantially reduced, or eliminated altogether, thereby resulting in a package body having improved strength and adhesion with the components of the package, and hence, an improved resistance of the package body to the propagation of cracks and its subsequent penetration by moisture.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

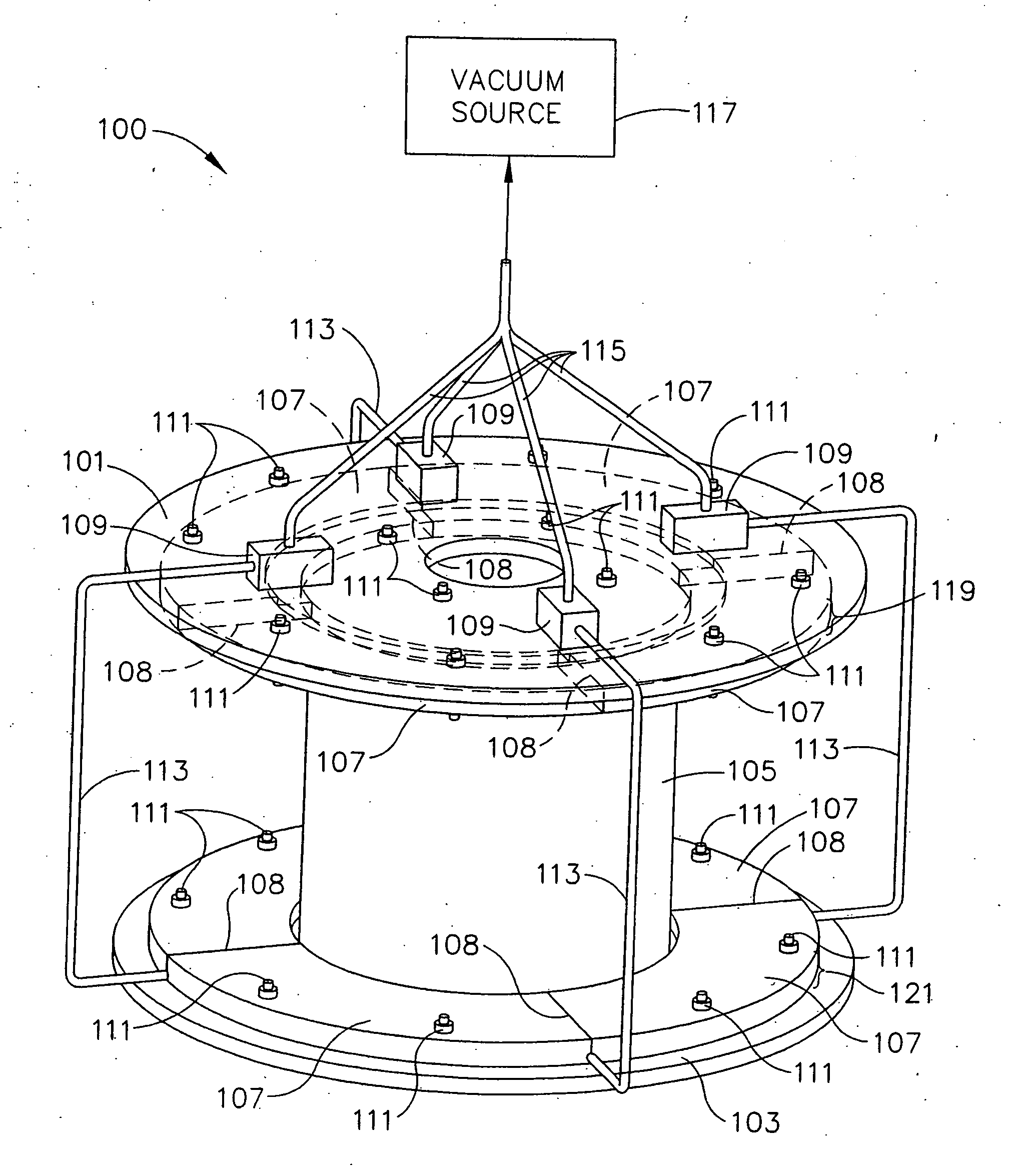

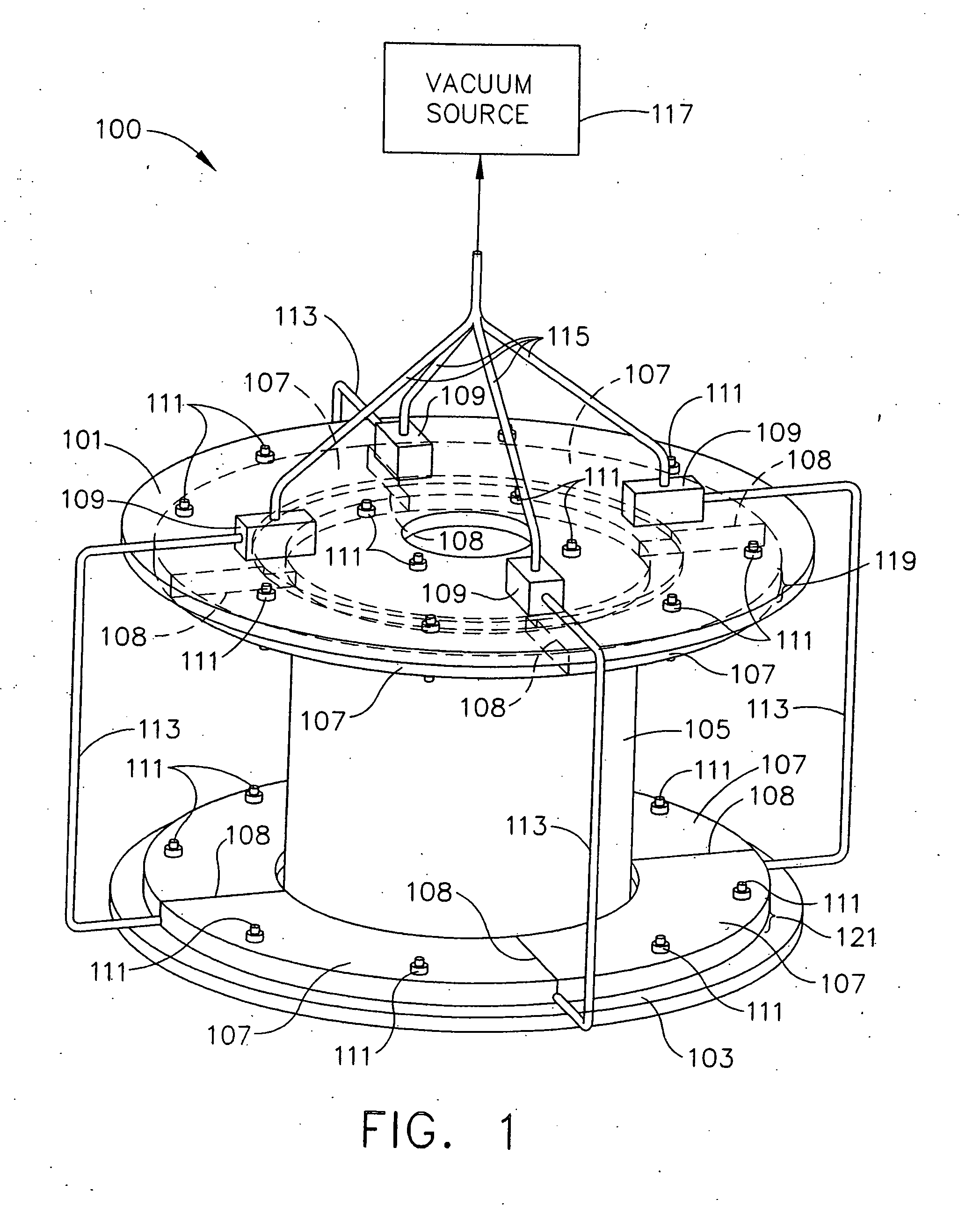

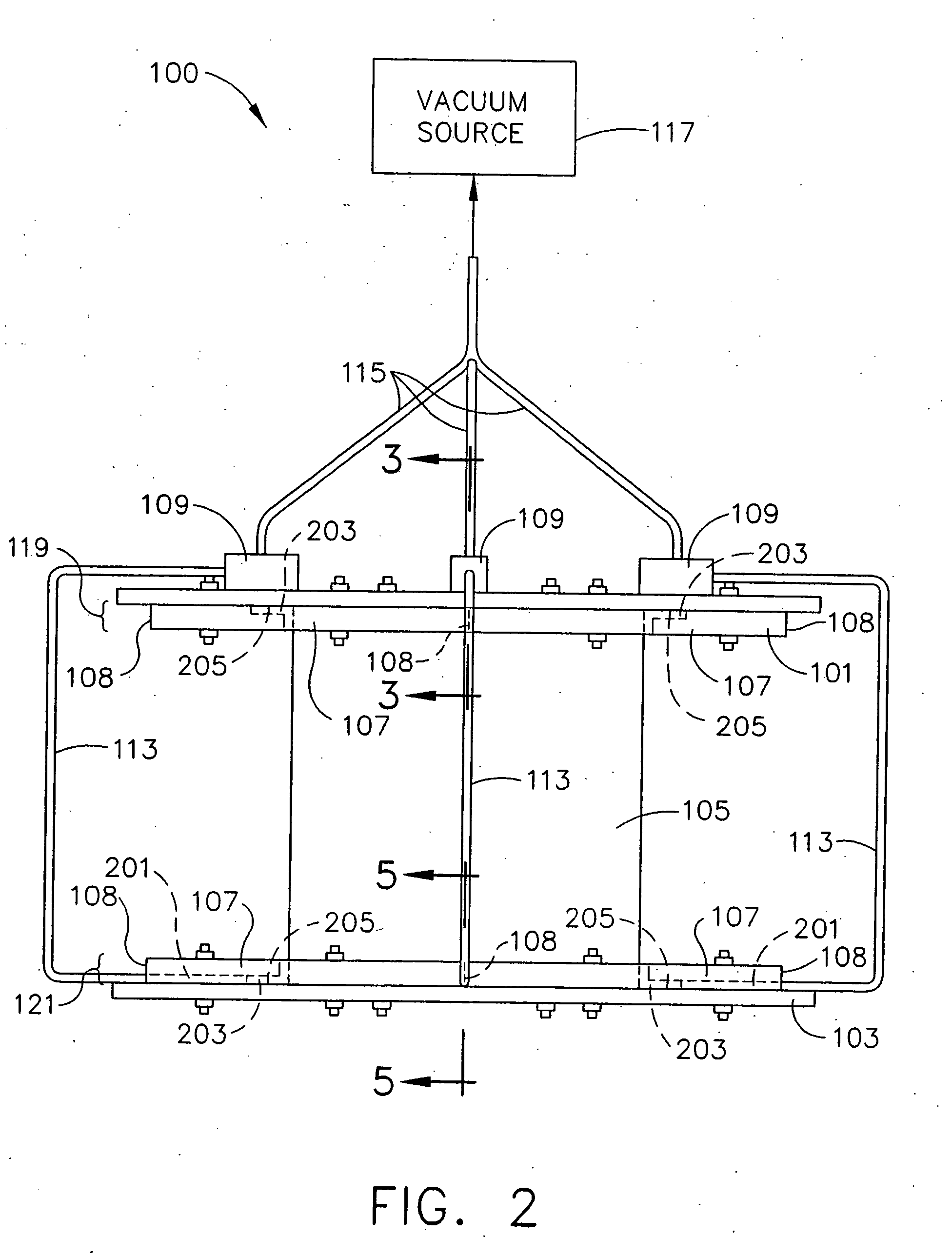

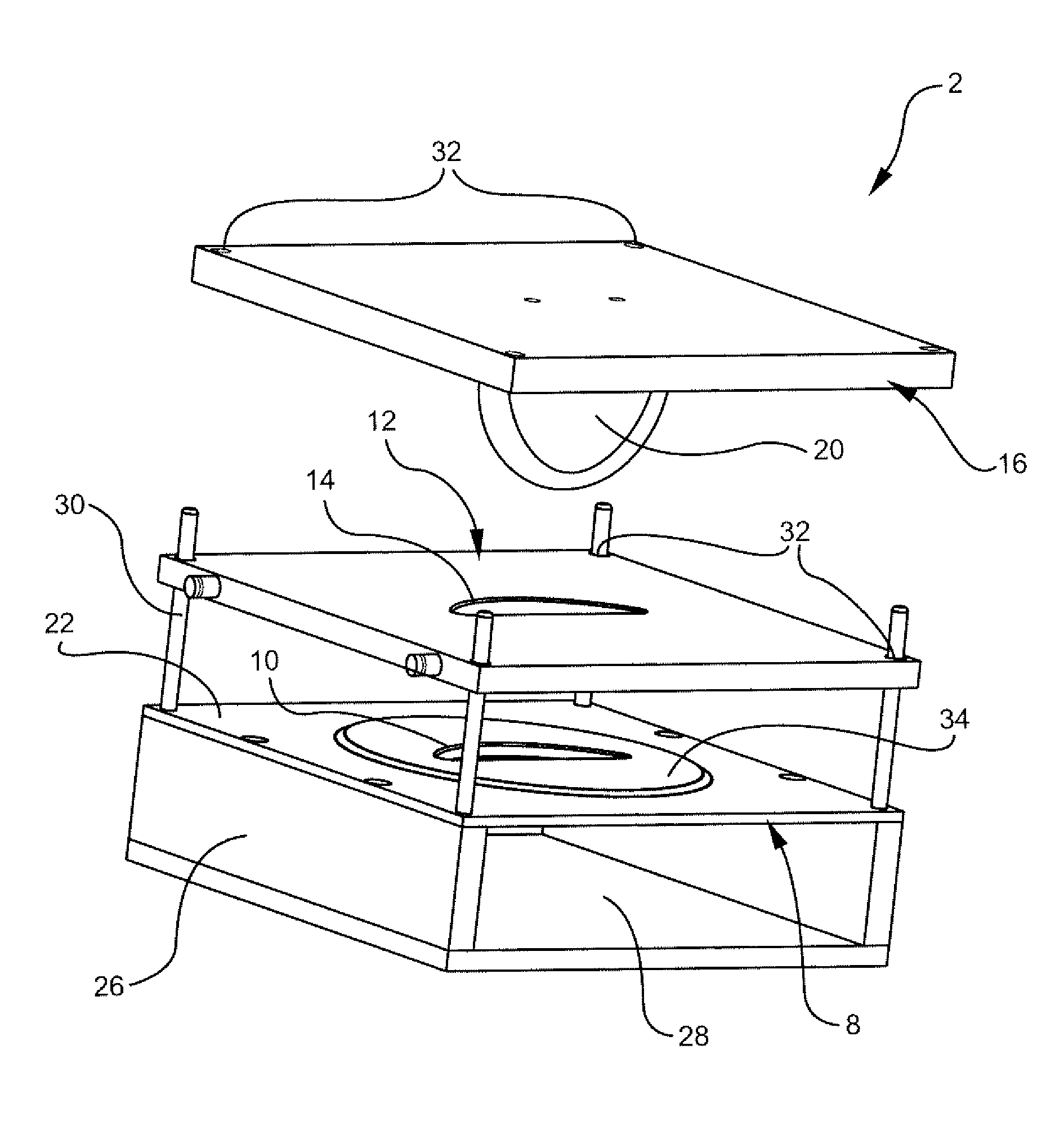

Apparatus for fabricating reinforced composite materials

A mold tool for forming a reinforced matrix composite part for a gas turbine engine, comprising a body. The body comprises a body surface capable of receiving a first portion of a composite preform. A first endplate and second endplate are attached to the body and include a substantially planar surface disposed perpendicular to the body surface. A first and second set of plates are attached to the first and second endplate adjacent to the body surface and have a geometries that includes a first and second cavity bounded by the first and second plate and first and second endplate. The first and second cavities have a volume sufficient to receive a second portion of a composite preform. The second cavity is in fluid communication with the first cavity, which is in fluid communication with a vacuum source.

Owner:GENERAL ELECTRIC CO

Thermoplastic molding process and apparatus

A system and method for forming an article from thermoplastic material and fiber. The method includes heating thermoplastic material to form a molten thermoplastic material for blending with the fiber. The molten thermoplastic material is blended with the fibers to form a molten composite material having a concentration of fiber by weight. The molten composite material may then be extruded through dynamic dies to deliver discrete controlled material that is gravitated onto a lower portion of a mold. The lower portion of the mold may be moved in space and time while receiving the flow of composite material to deposit a predetermined quantity of molten composite material thereon conforming to mold cavities of the lower and an upper portion of the mold. The upper portion of the mold may be pressed against the predetermined quantity of molten composite material and closing on the lower portion of the mold to form the article.

Owner:D&D MFG LLC

Spacer mold and methods therefor

Owner:ZIMMER ORTHOPAEDIC SURGICAL PRODS

Powder compaction and enrobing

InactiveUS20050147710A1RobustQuicker release characteristicLayered productsConfectioneryMetallurgyMethyl cellulose

An apparatus and method is disclosed for forming a compacted powder slug coated with a film. The powder, e.g. of a medicament, is compacted and enrobed to produce compacted powder slugs by preferably mechanically compacting a powder and forming a film of a material, preferably hydroxy propyl methyl cellulose, by vacuum or pressure differential, about the surface of the powder thus compacted.

Owner:BIOPROGRESS TECH

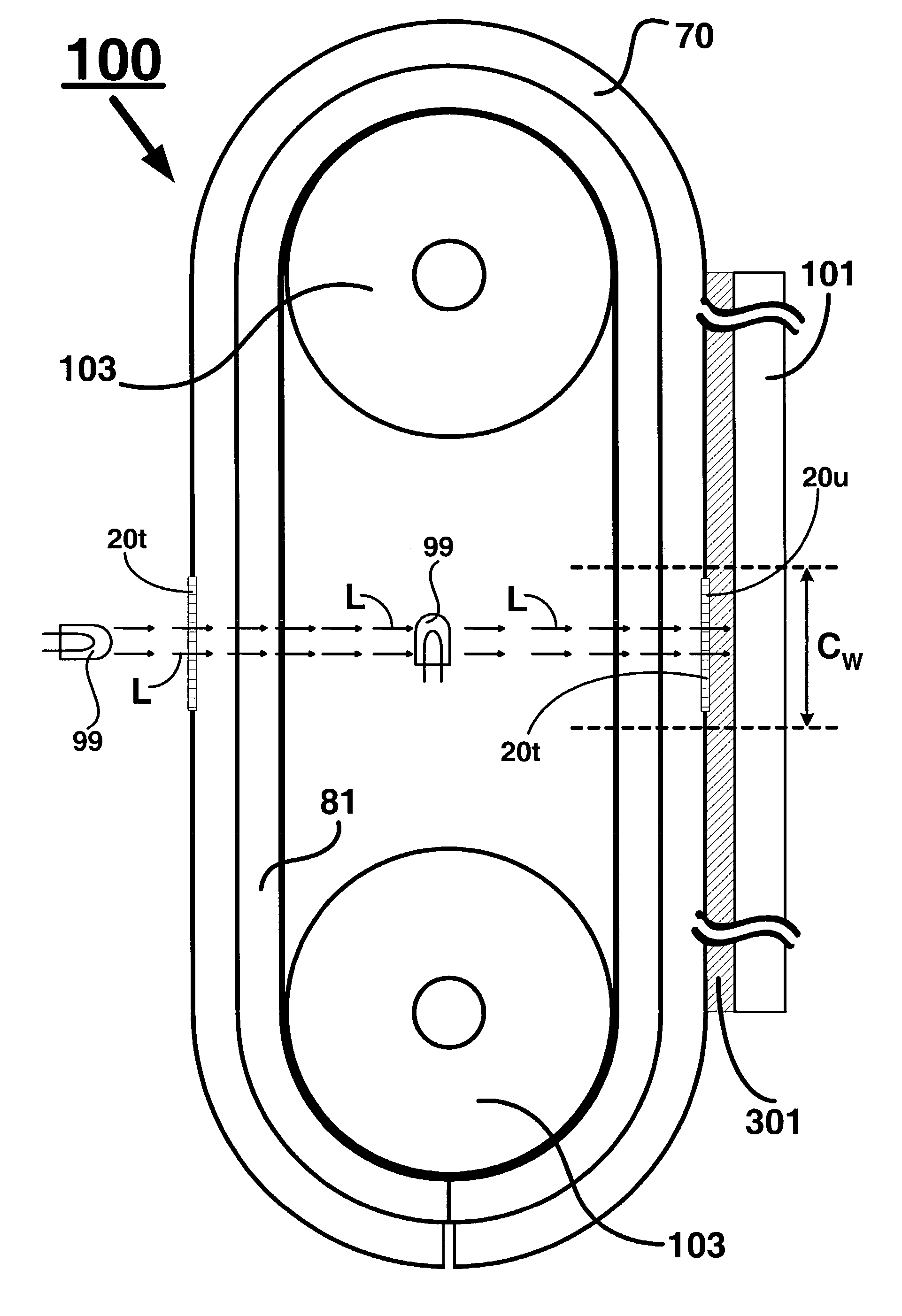

Apparatus and method for selectively distributing and controlling a means for impregnation of fibrous articles

InactiveUS20020155186A1Quick configurationMinimize and eliminate wasteTailstocks/centresConfectioneryFiberLine tubing

A process and apparatus for producing fiber reinforced resin structures using vacuum assisted resin transfer molding technology, wherein the apparatus and process employ a first fluid impervious flexible sheet containing therein a resin port; a fiber containing preform; a primary vacuum line; a resin channeling means; and a secondary vacuum line. The fluid impervious flexible sheet is placed over or around the fiber containing preform to form a chamber to which the primary vacuum line is connected. The resin channeling means is positioned on top of the fluid impervious flexible sheet, exterior to the chamber containing the preform in a fashion so as to form a pocket between or around the resin channeling means and said fluid impervious flexible sheet to which the secondary vacuum is applied. Activation of the secondary vacuum causes formation of channels in the fluid impervious flexible sheet. These channels increase the speed and efficiency of resin impregnation of the fiber containing preform.

Owner:UNITED STATES OF THE ARMY AS REPRESENTED BY THE SEC OF THE

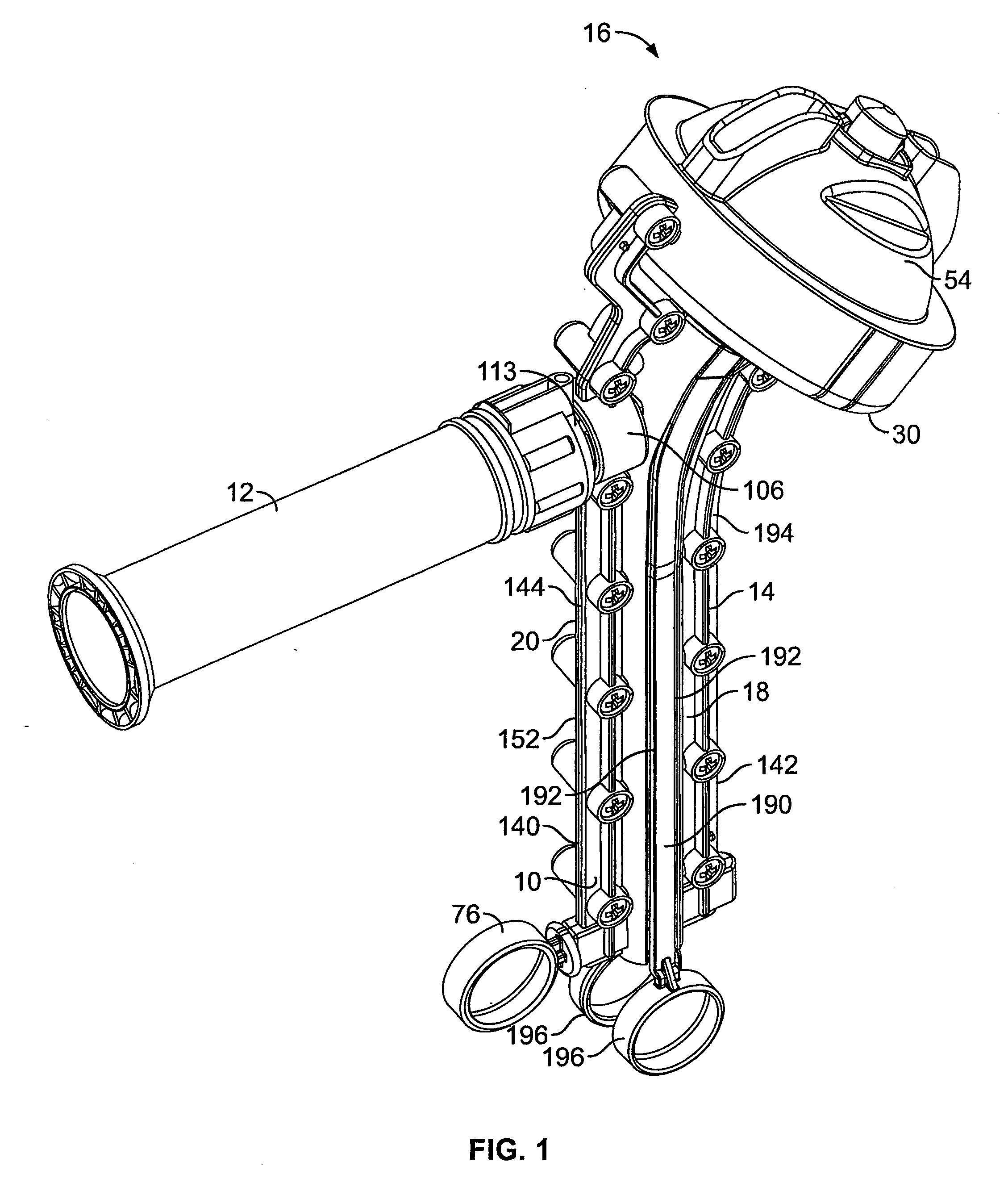

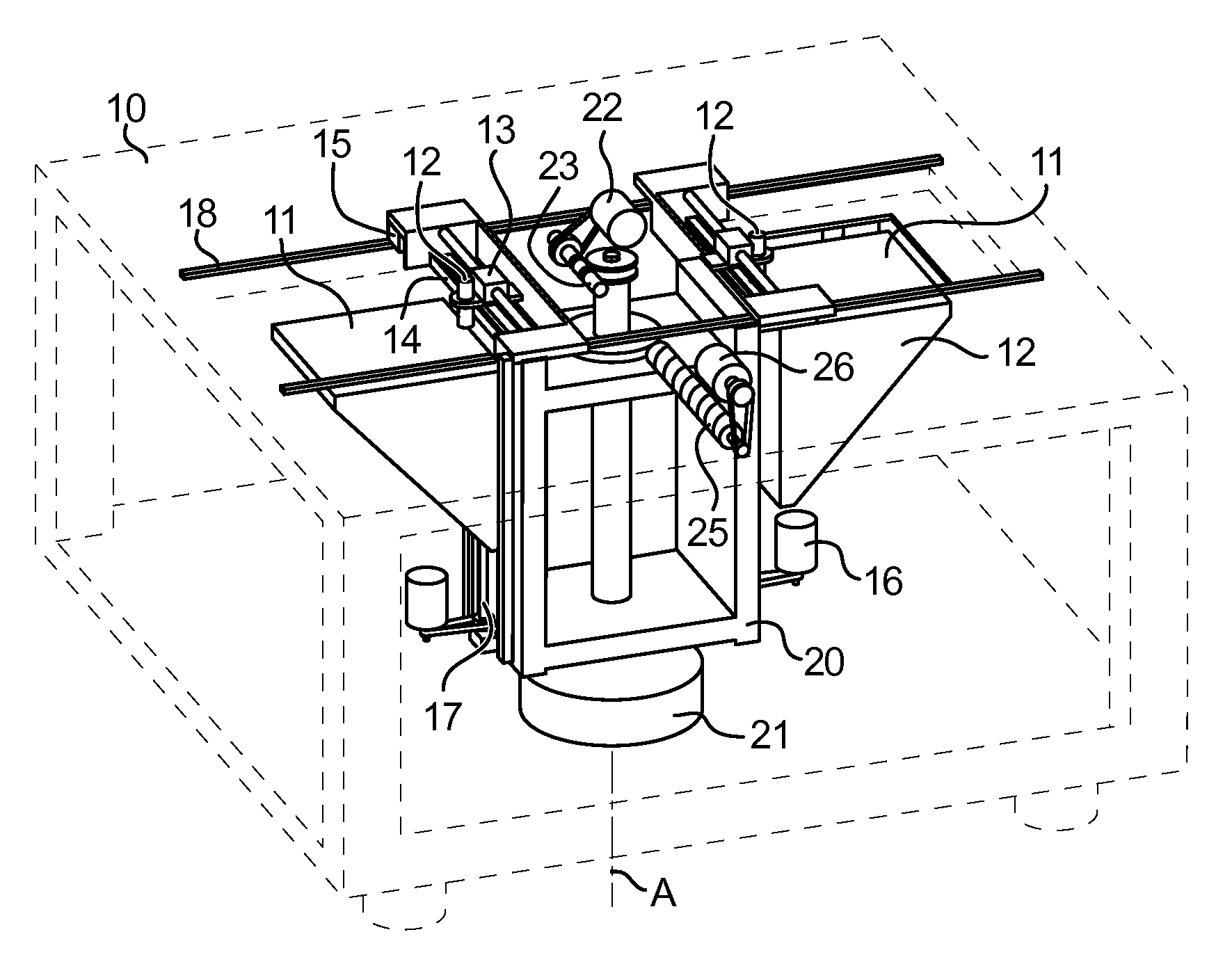

Preformed support device and method and apparatus for manufacturing the same

ActiveUS20090240342A1Increase the cross-sectional areaEliminate needConfectioneryWood working apparatusMammalian tissueEngineering

A device for making a seamless, anatomically contoured, prosthetic device for supporting or maintaining the position of mammalian tissue, organ or structure or a replacement thereof, such as a breast implant, includes a support plate, an ironing plate or a clamping plate and a core plate, each of which is made from a thermally conductive material. The support plate and the ironing or clamping plates have openings formed through the thickness thereof. The core plate has a core extending outwardly from a lower surface thereof which is received through the openings in the ironing or clamping plate and the support plate.

Owner:ETHICON INC

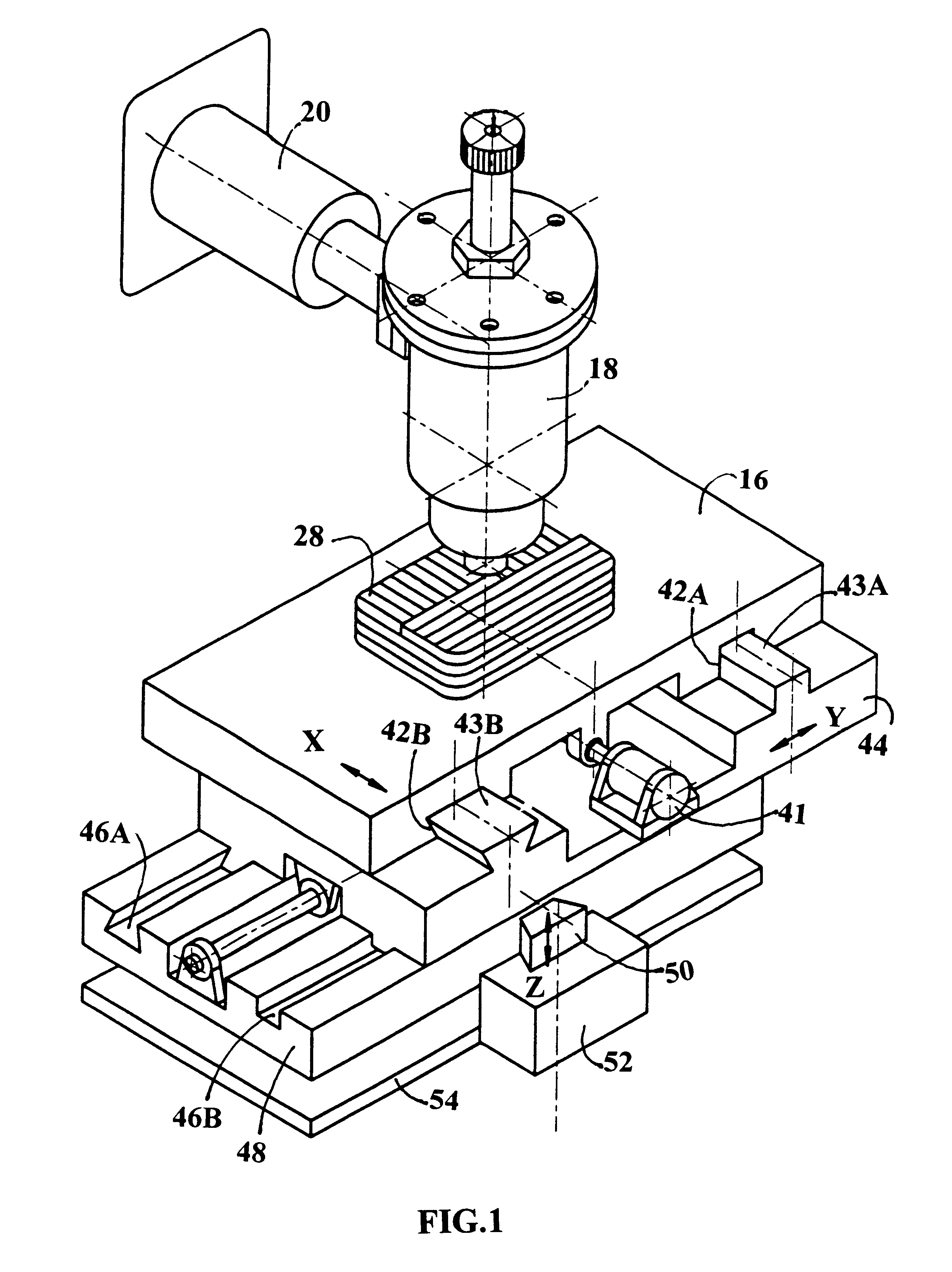

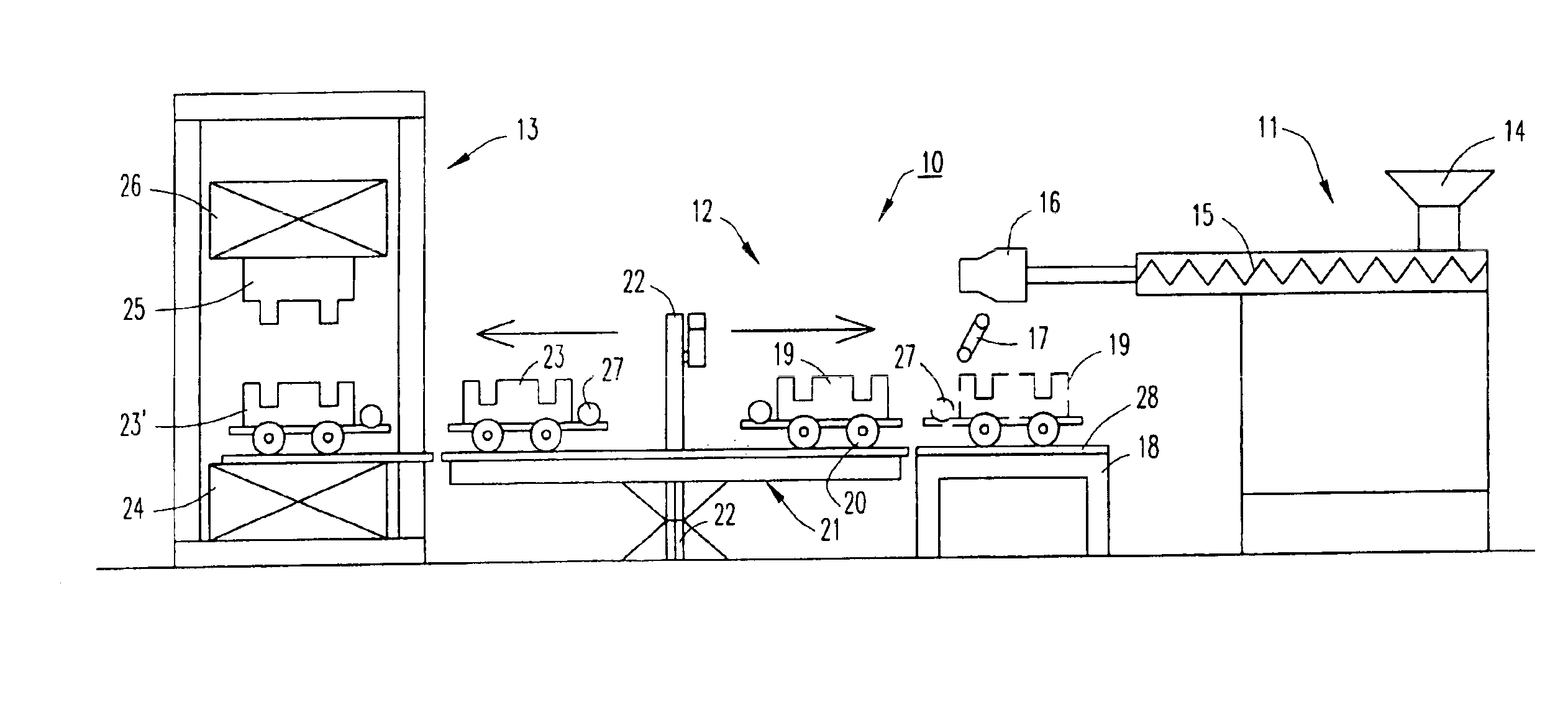

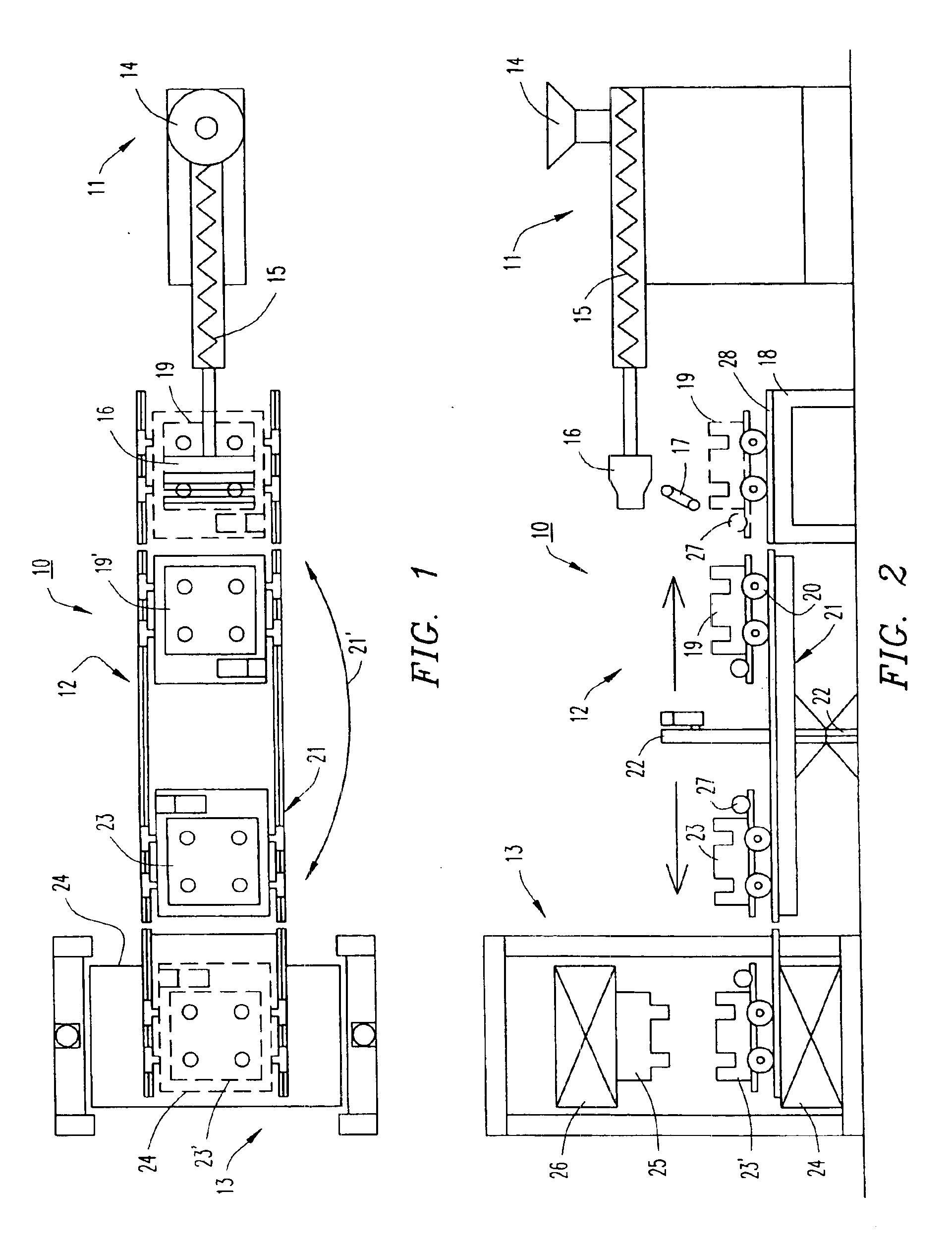

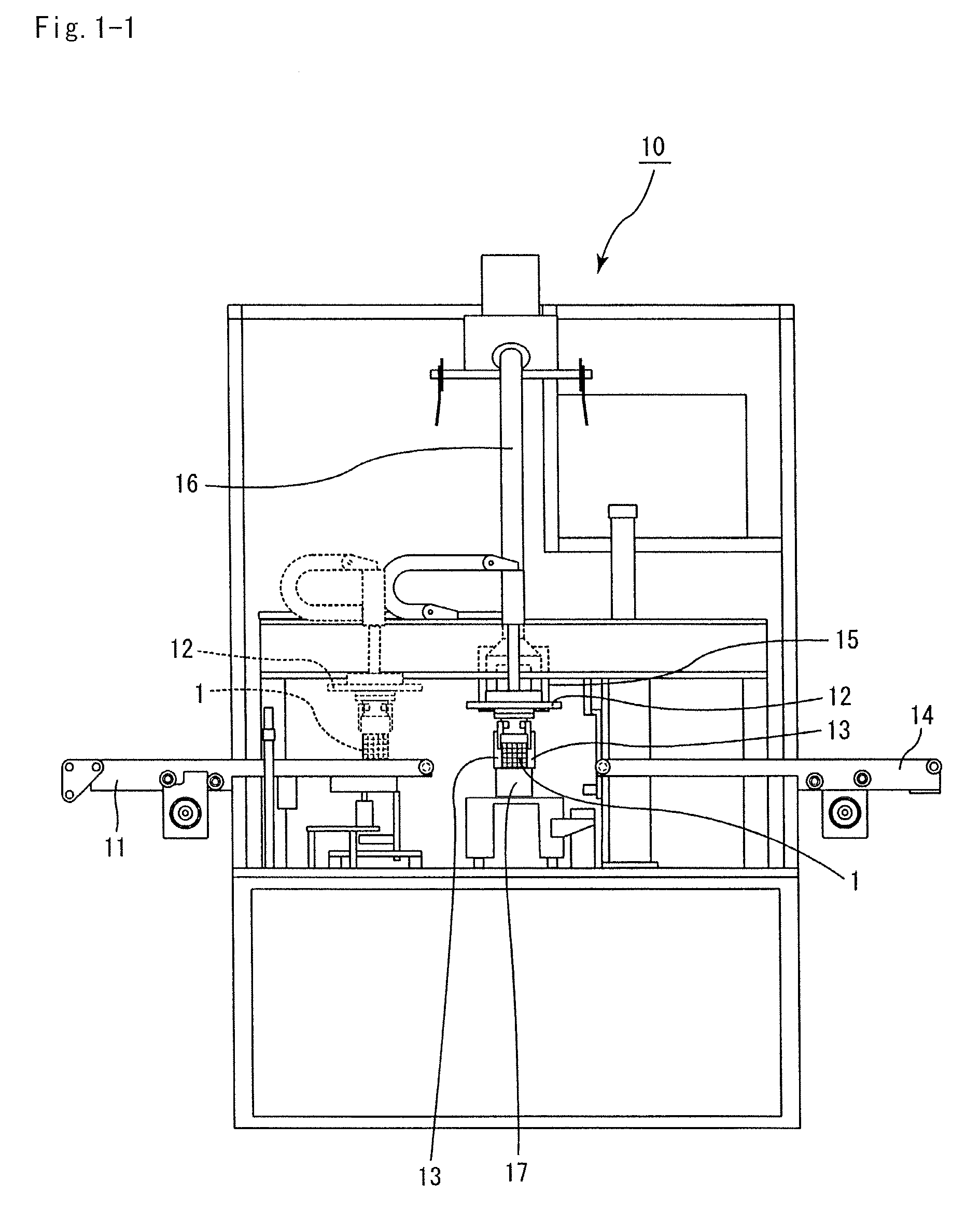

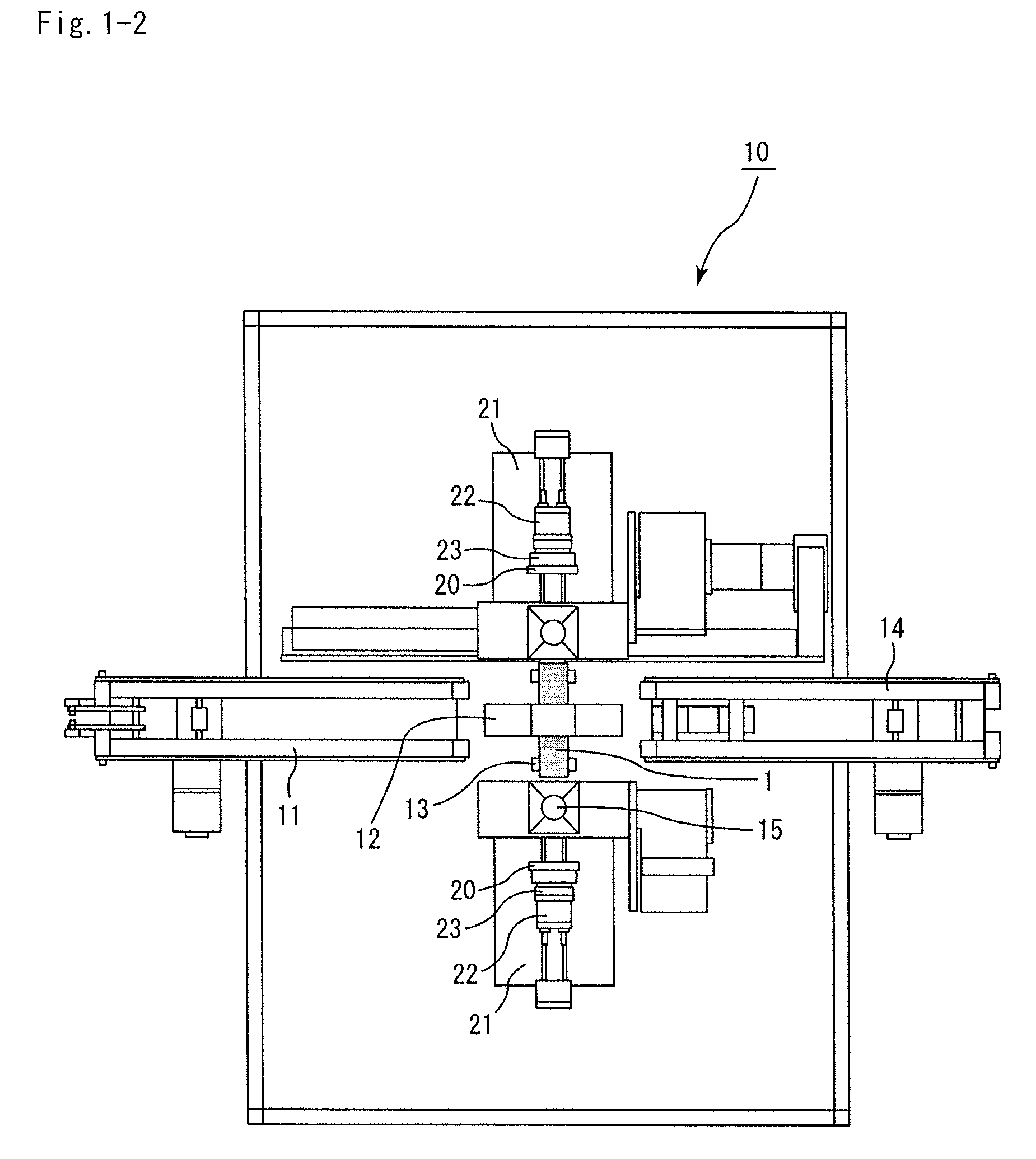

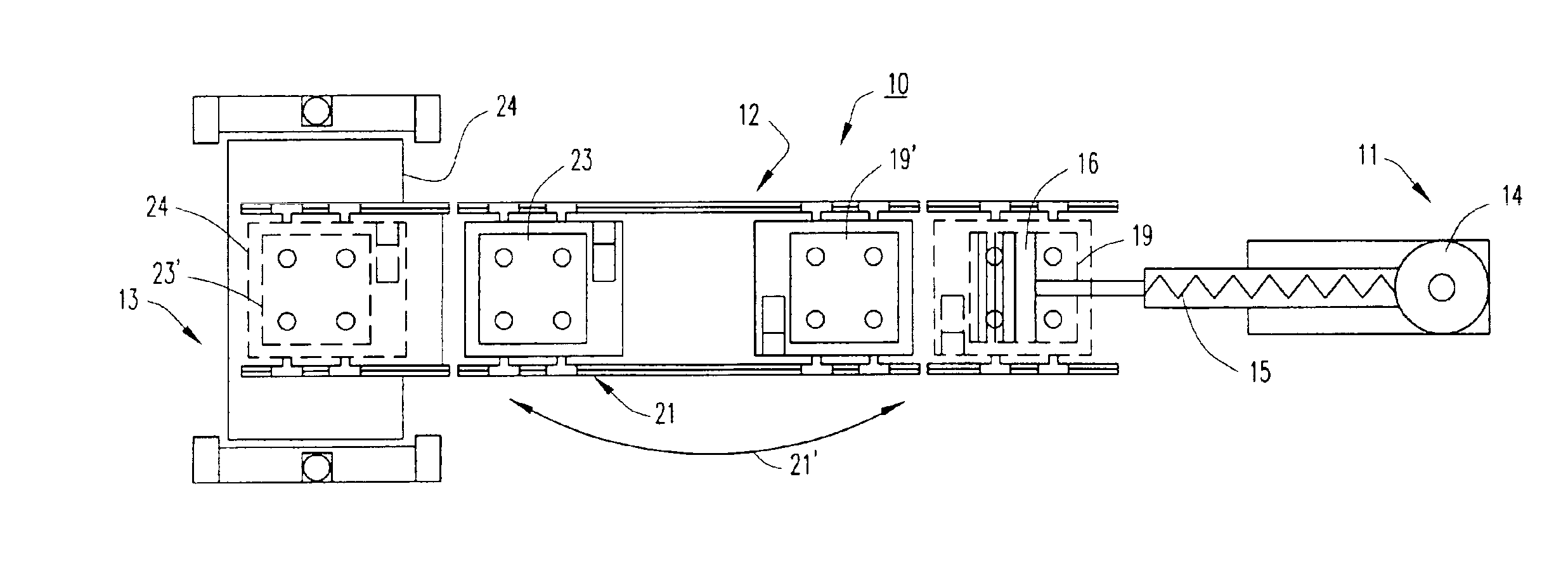

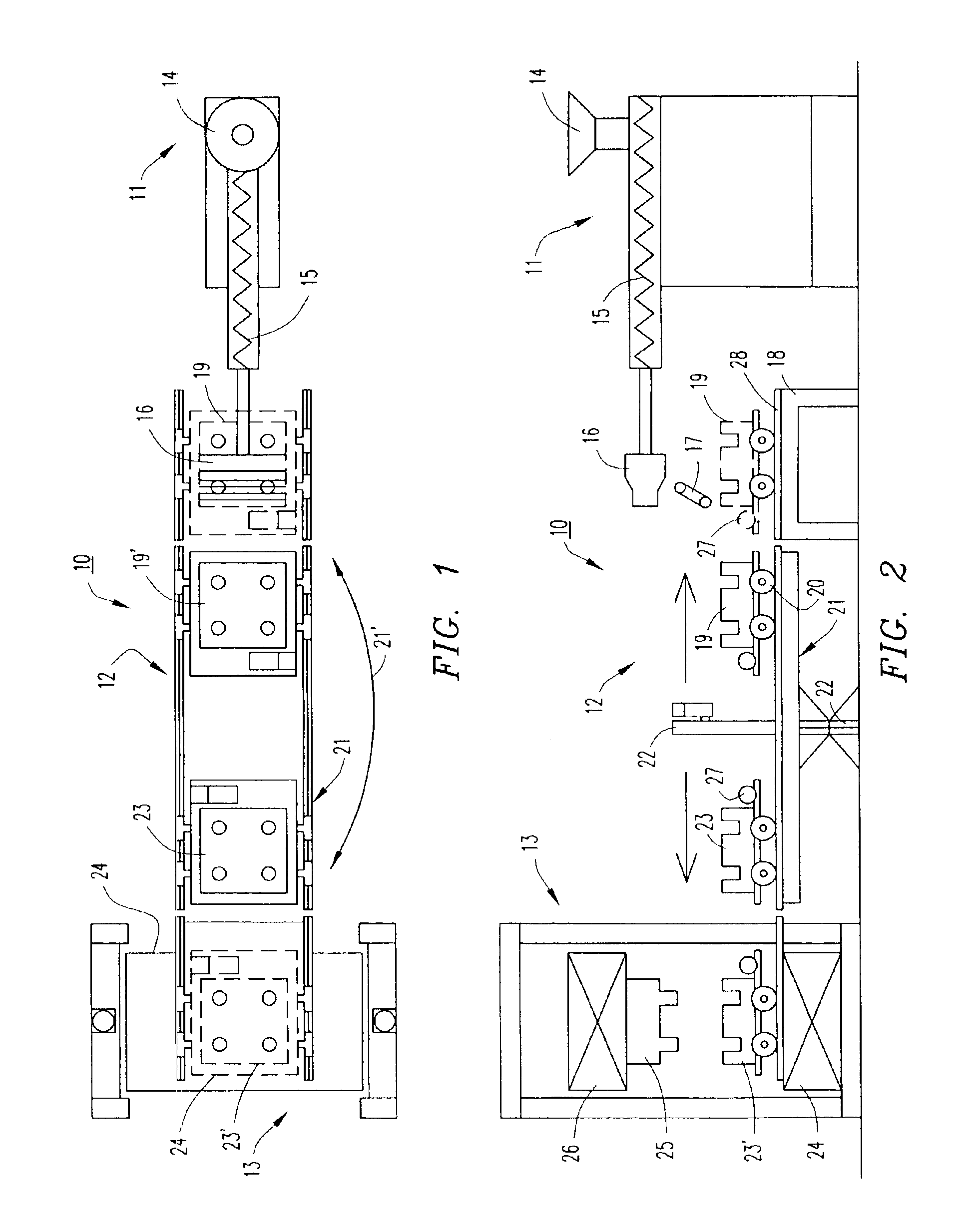

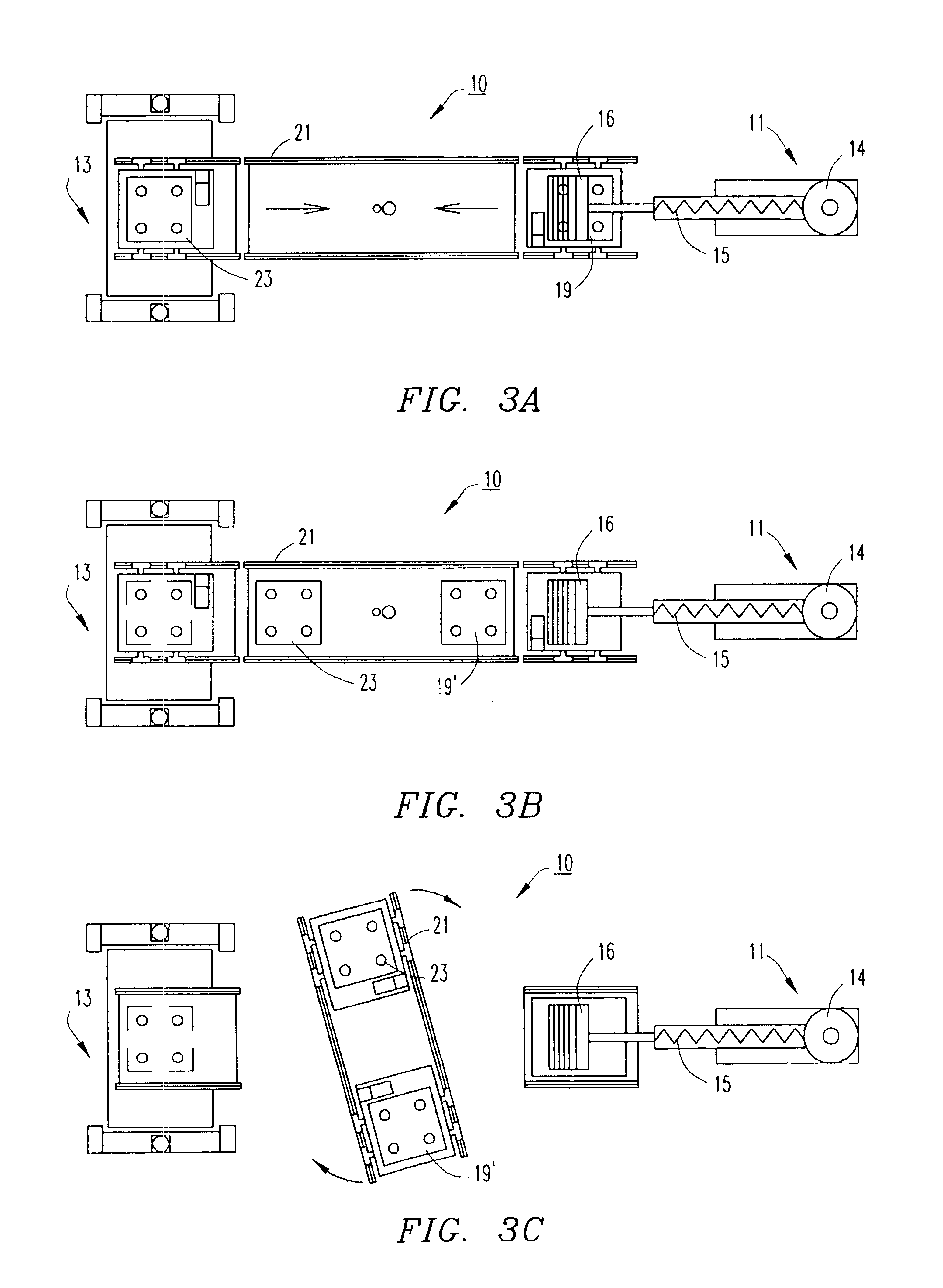

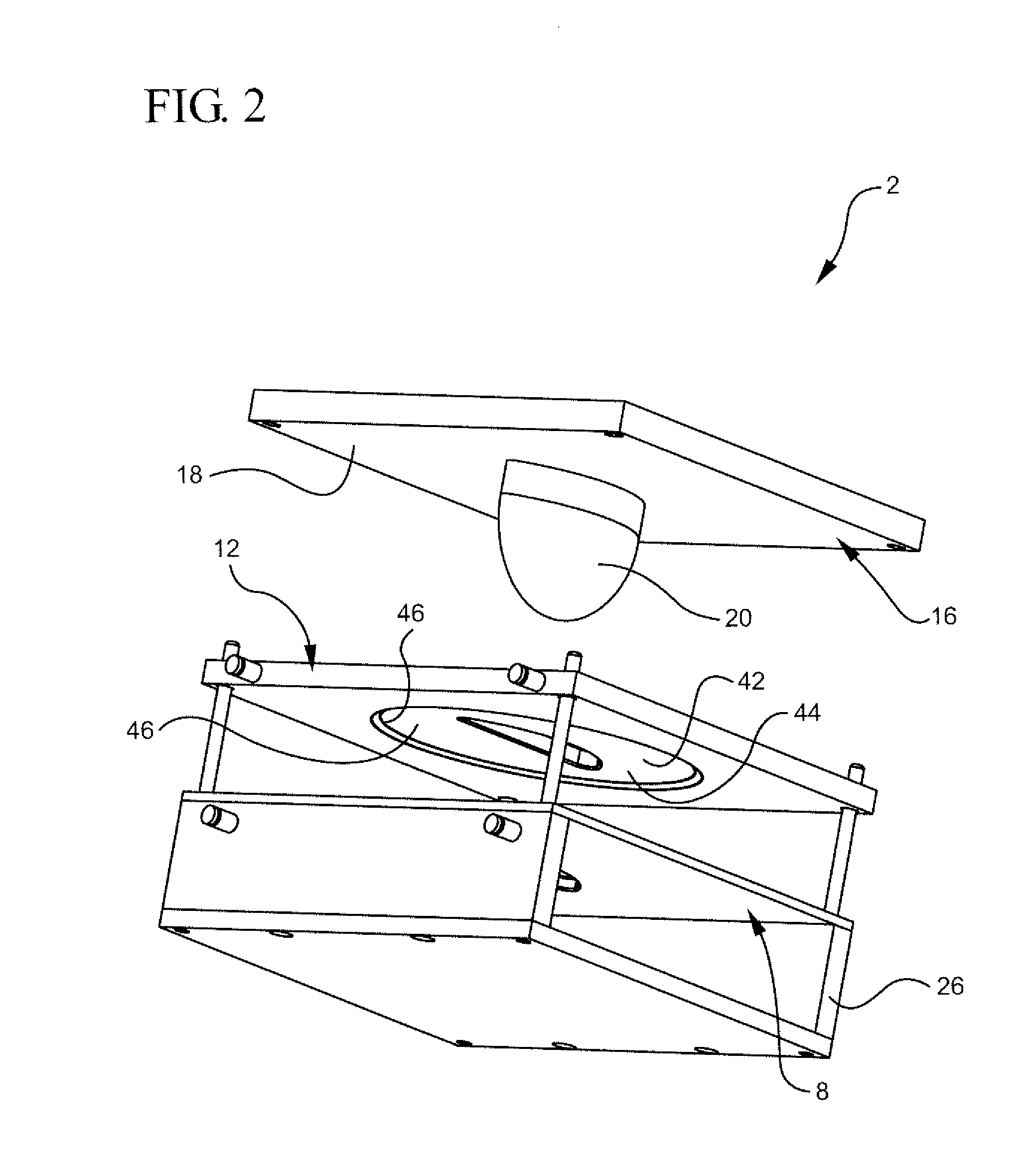

Method and machine for producing three-dimensional objects by means of successive layer deposition

Inventive machine allowing the simultaneous fabrication of several objects by a method of “rapid prototyping” type, by depositing a succession of layers of heat-fusible fluid.It chiefly comprises a crossbar (20) carrying two platforms (11) on each of which an object is fabricated by deposition. Two fixed work stations are arranged diametrically opposite each other so that the jet (12) of each of these fixed stations can perform a depositing operation at the same time as the other jet (12). After each deposit, the crossbar is rotated 180° to alternate the depositing operations of the two different materials.Particular application to prototyping jewellery models.

Owner:MARSAC NICOLAS

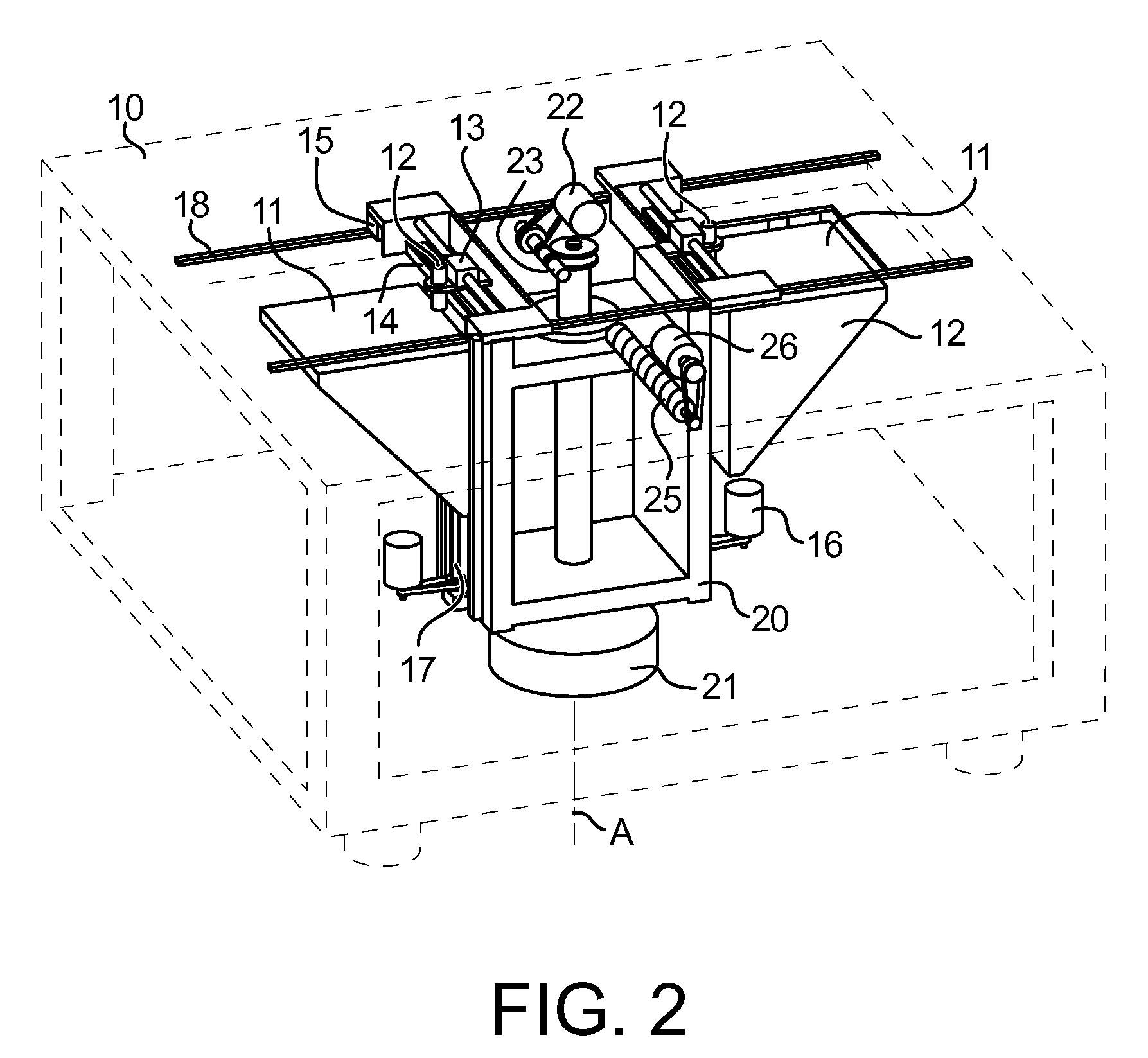

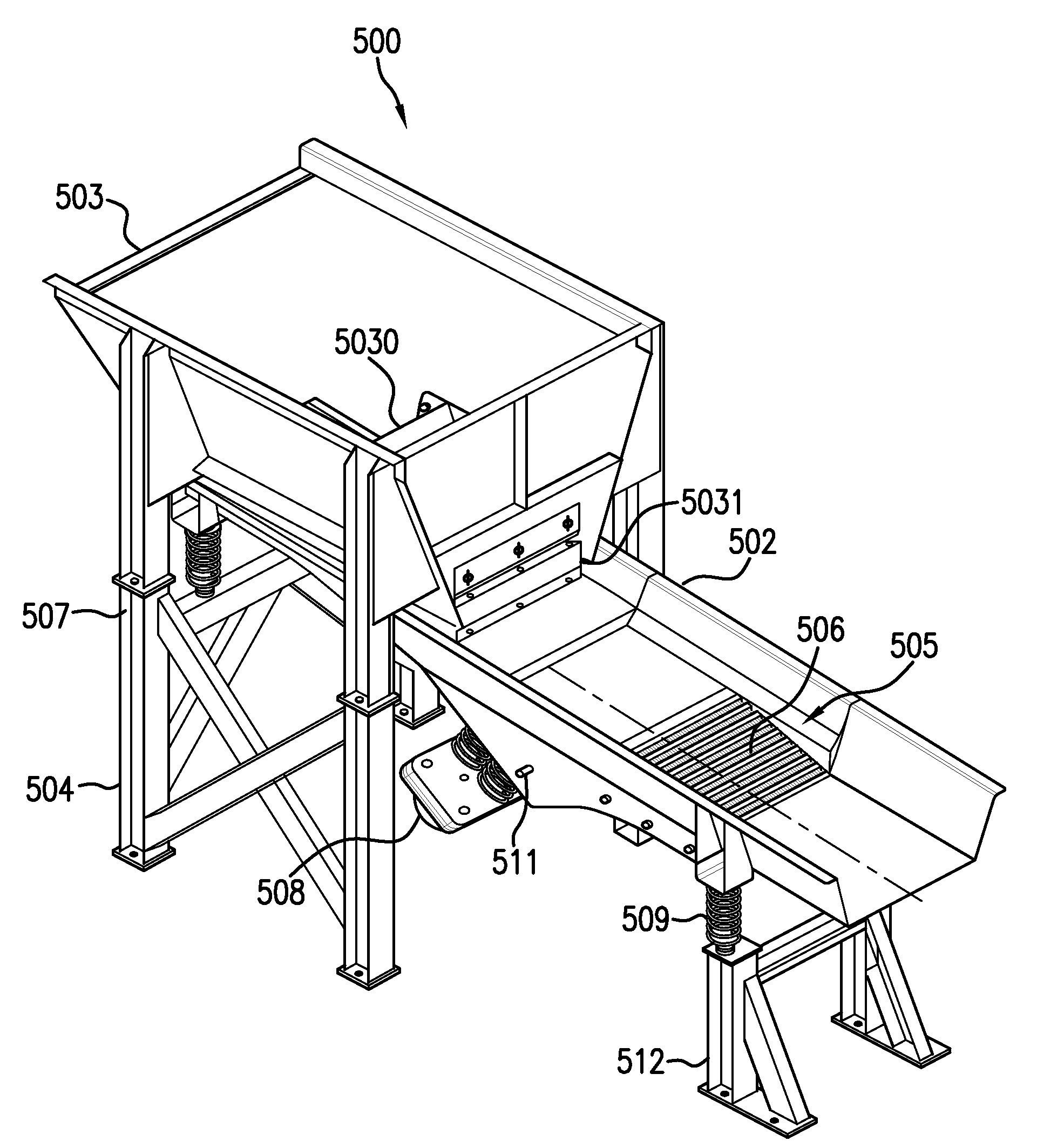

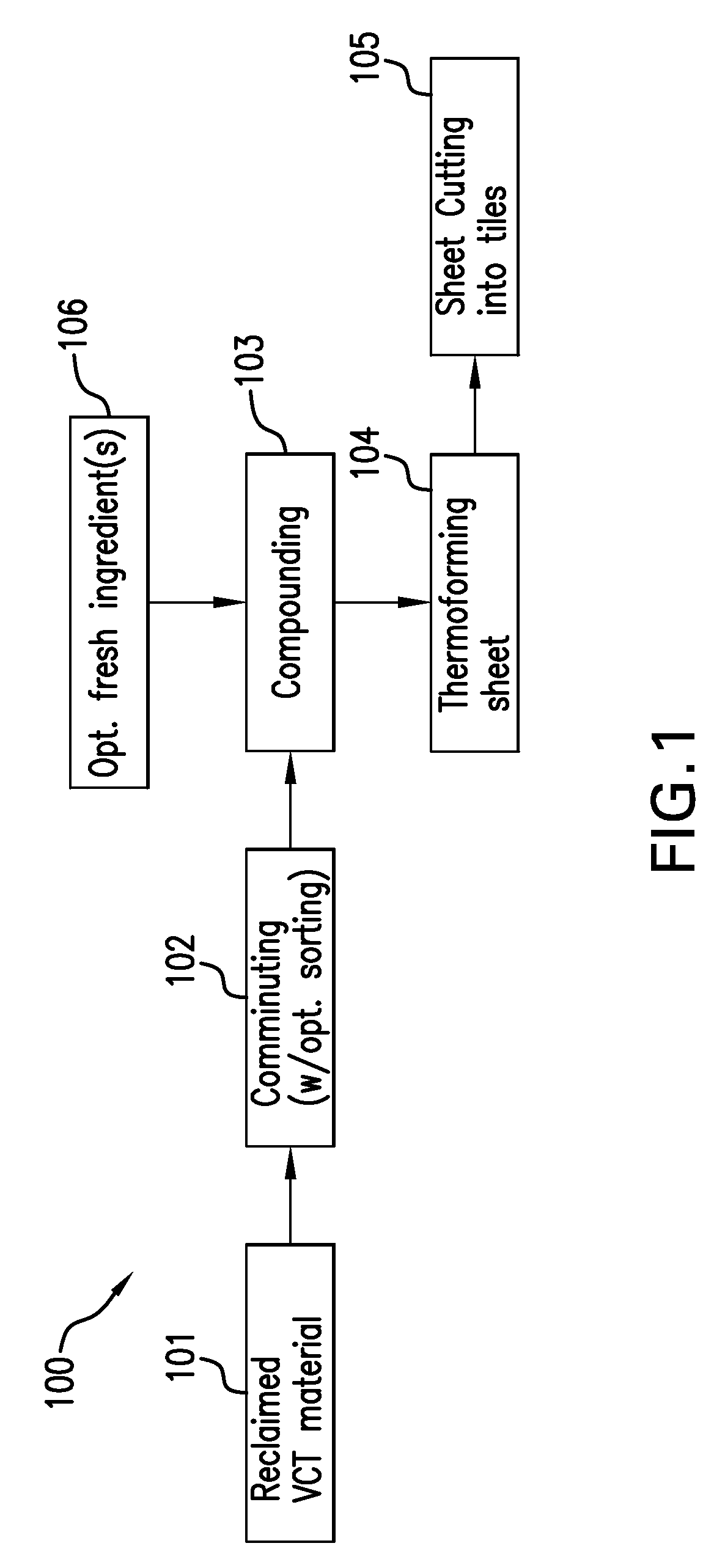

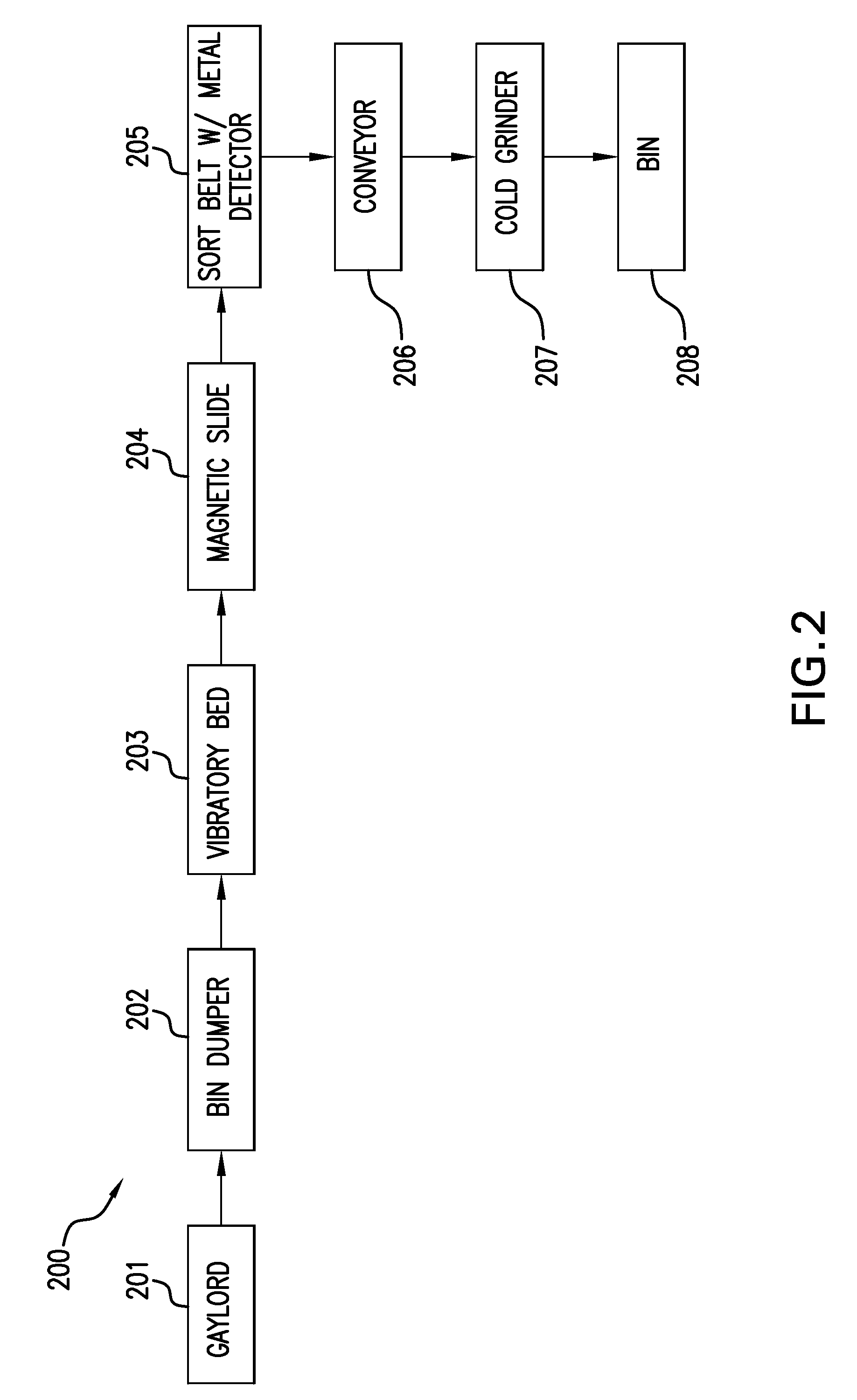

Surface Coverings Containing Reclaimed VCT Material, and Methods and Systems For Making and Using Them

InactiveUS20090226662A1Offset rising material costReduces virgin material requirementCovering/liningsWallsAdhesivePre treatment

Surface coverings, such as vinyl flooring, carpeting and the like, comprising reclaimed VCT material, are disclosed. Vinyl composition tile (VCT) having at least 5% by weight reclaimed vinyl composition tile material which can include a surface adhesive, and filler, where the mixture is a thermoformed solidified material in individual tile form is disclosed. Methods for making these surface covering materials and using them to provide floor coverings are also disclosed. A system for presorting and grinding reclaimed VCT to provide feed material for these and other uses is also disclosed.

Owner:MANNINGTON MILLS

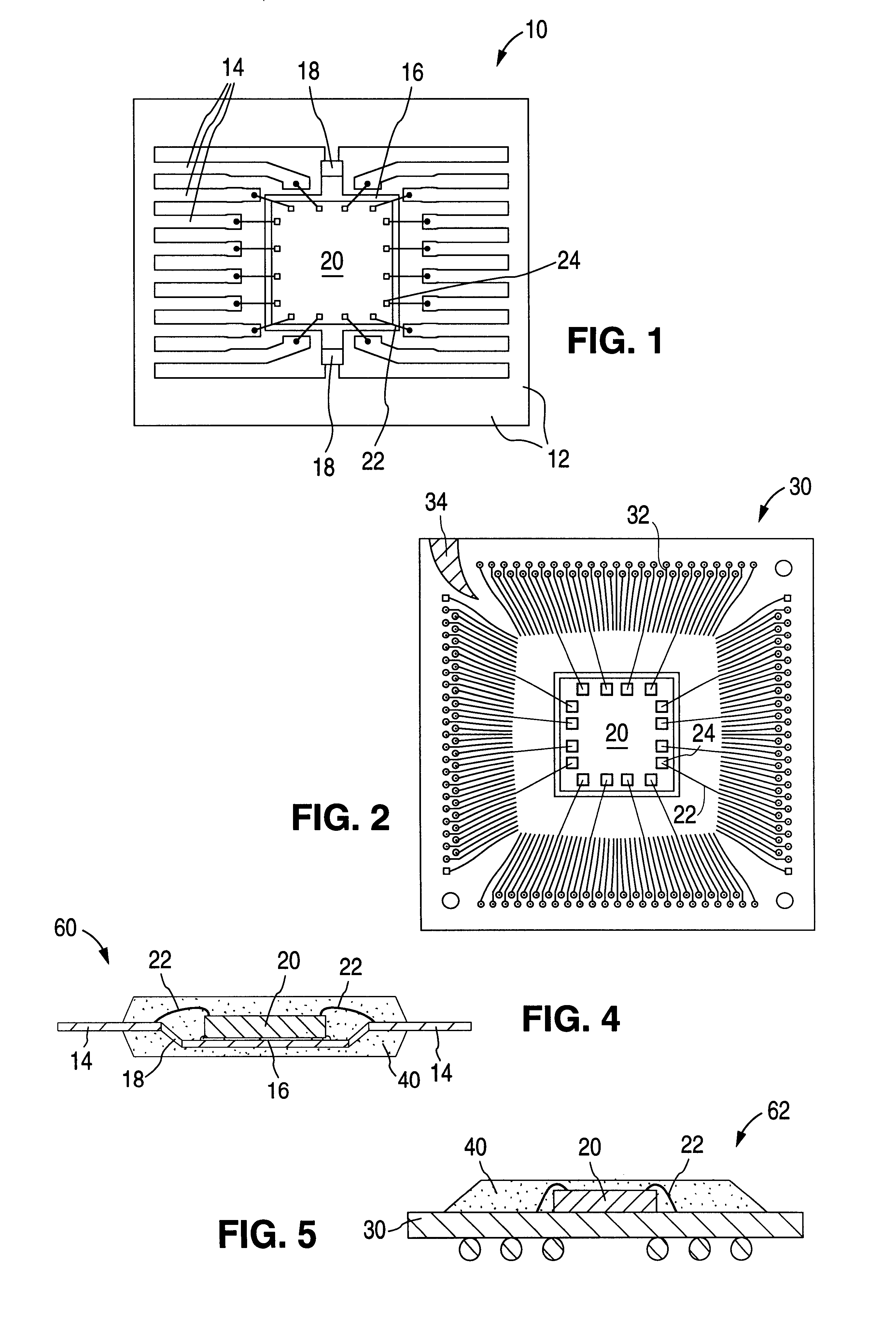

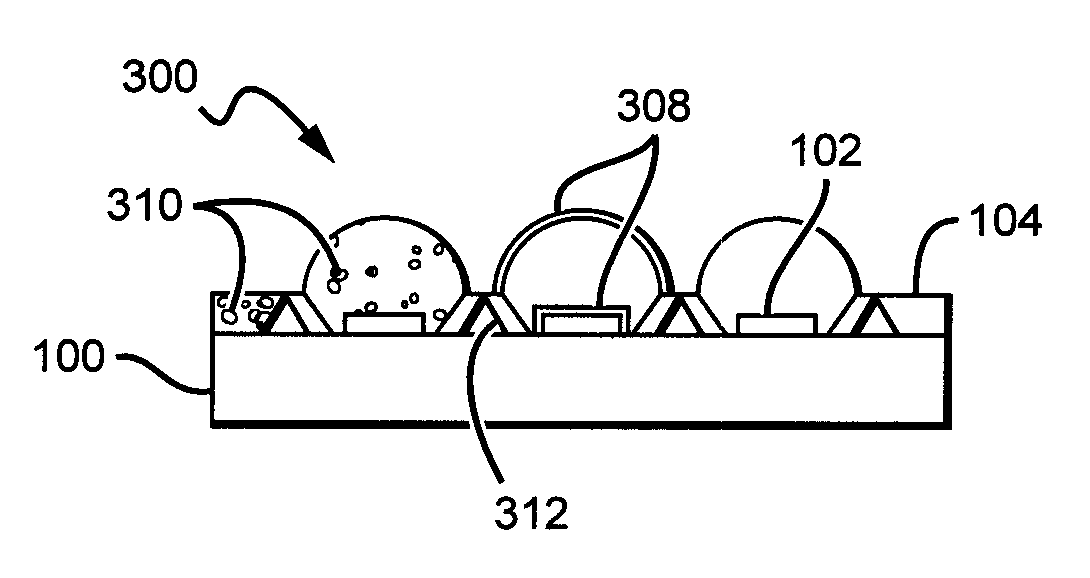

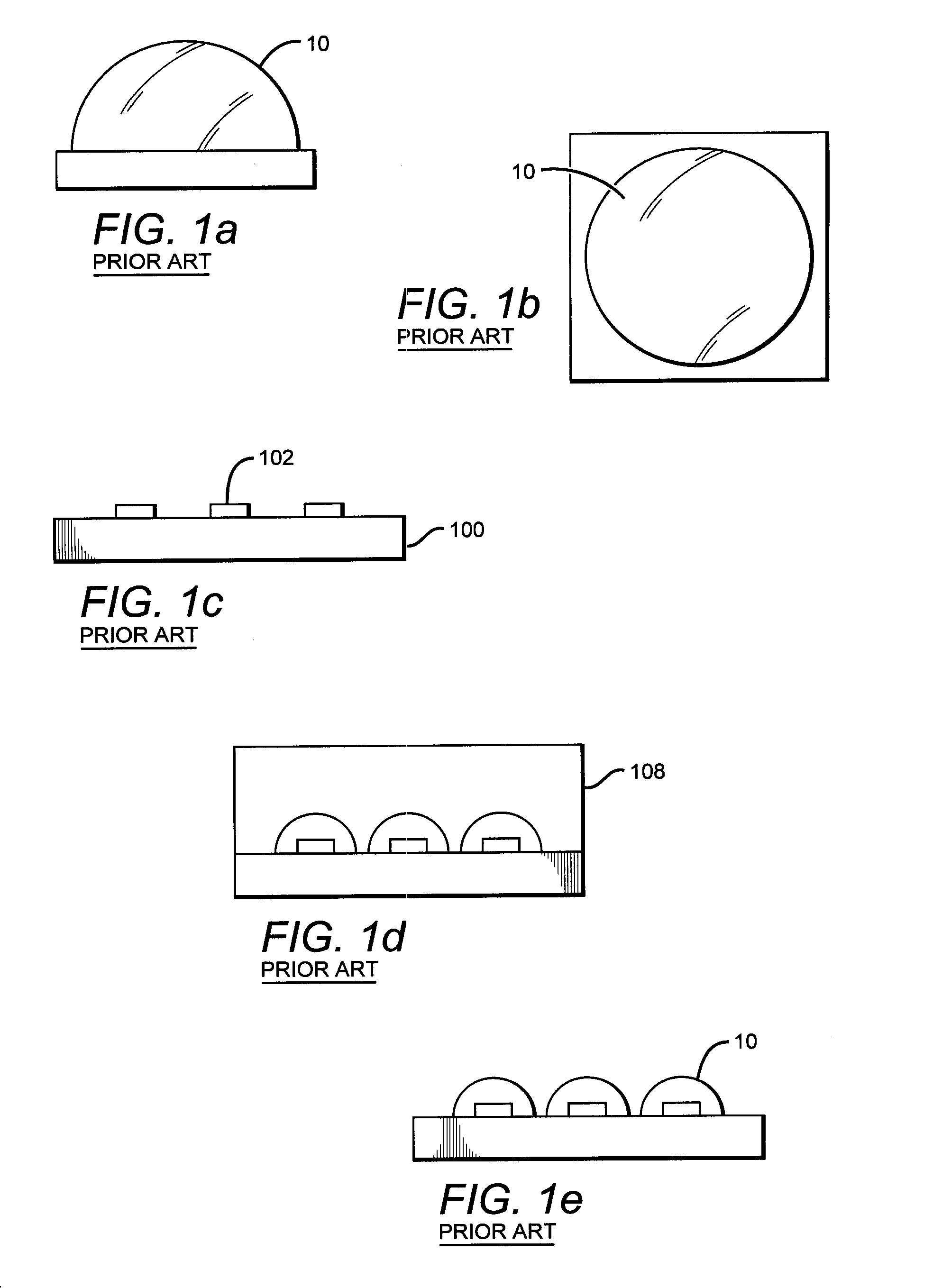

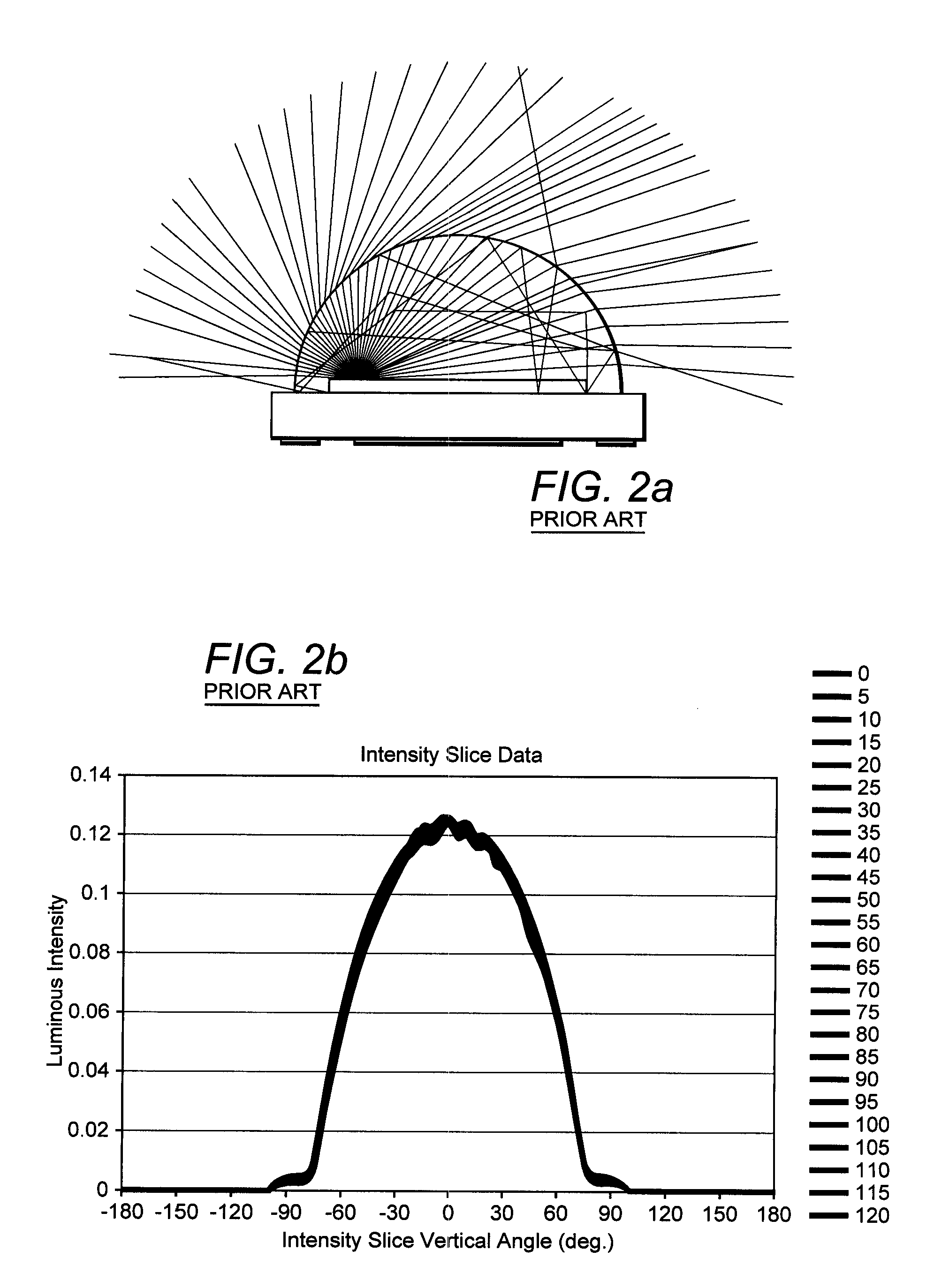

Complex primary optics and methods of fabrication

A light emitter package with primary optic and method of fabricating the same is disclosed that comprises a light emitter disposed on a surface. The package further comprises at least one intermediate element on the surface and at least partially surrounding the light emitter. Furthermore, an encapsulant is over the light emitter forming a primary optic. The intermediate element at least partially defines the shape of the primary optic.

Owner:CREELED INC

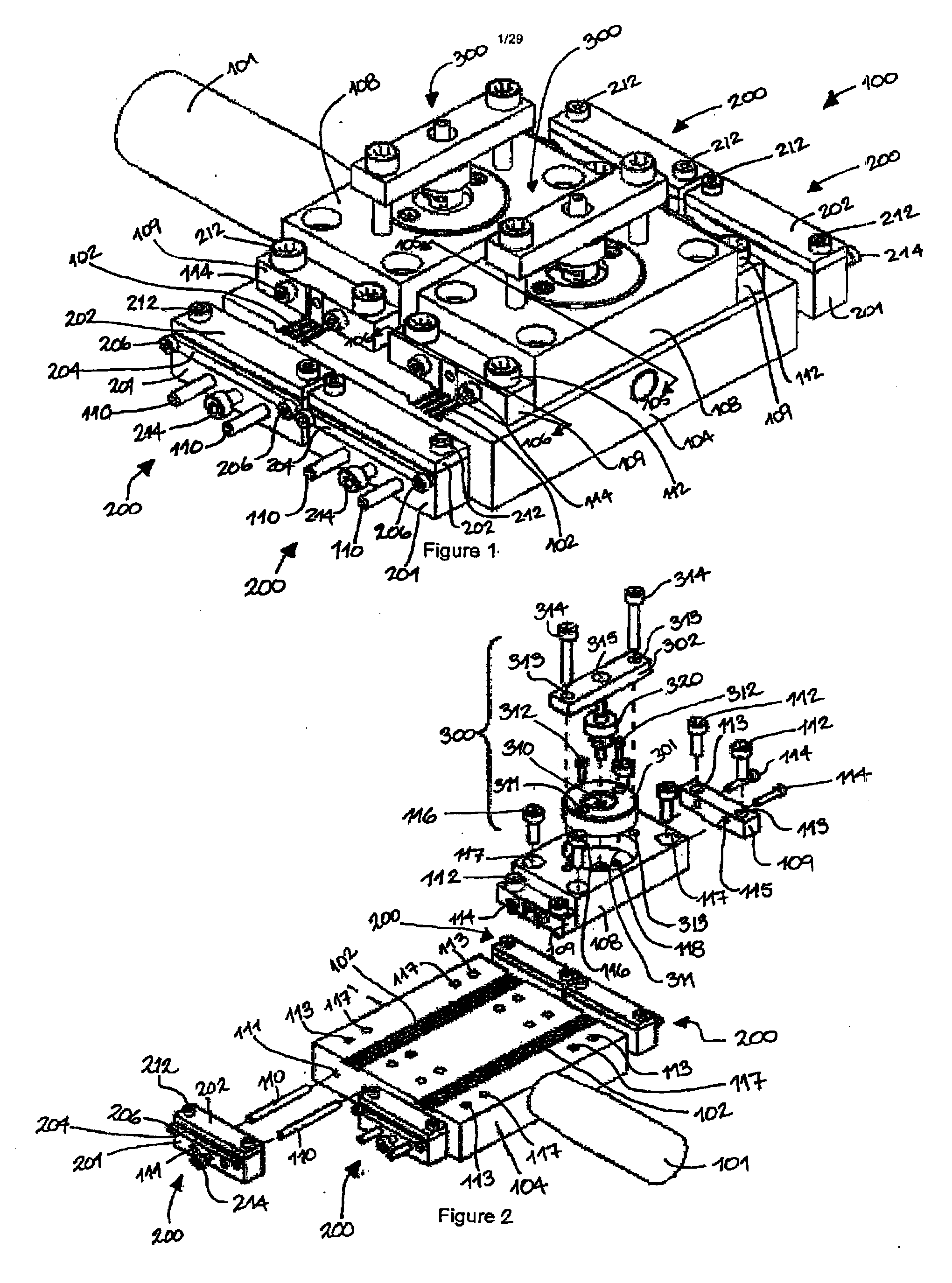

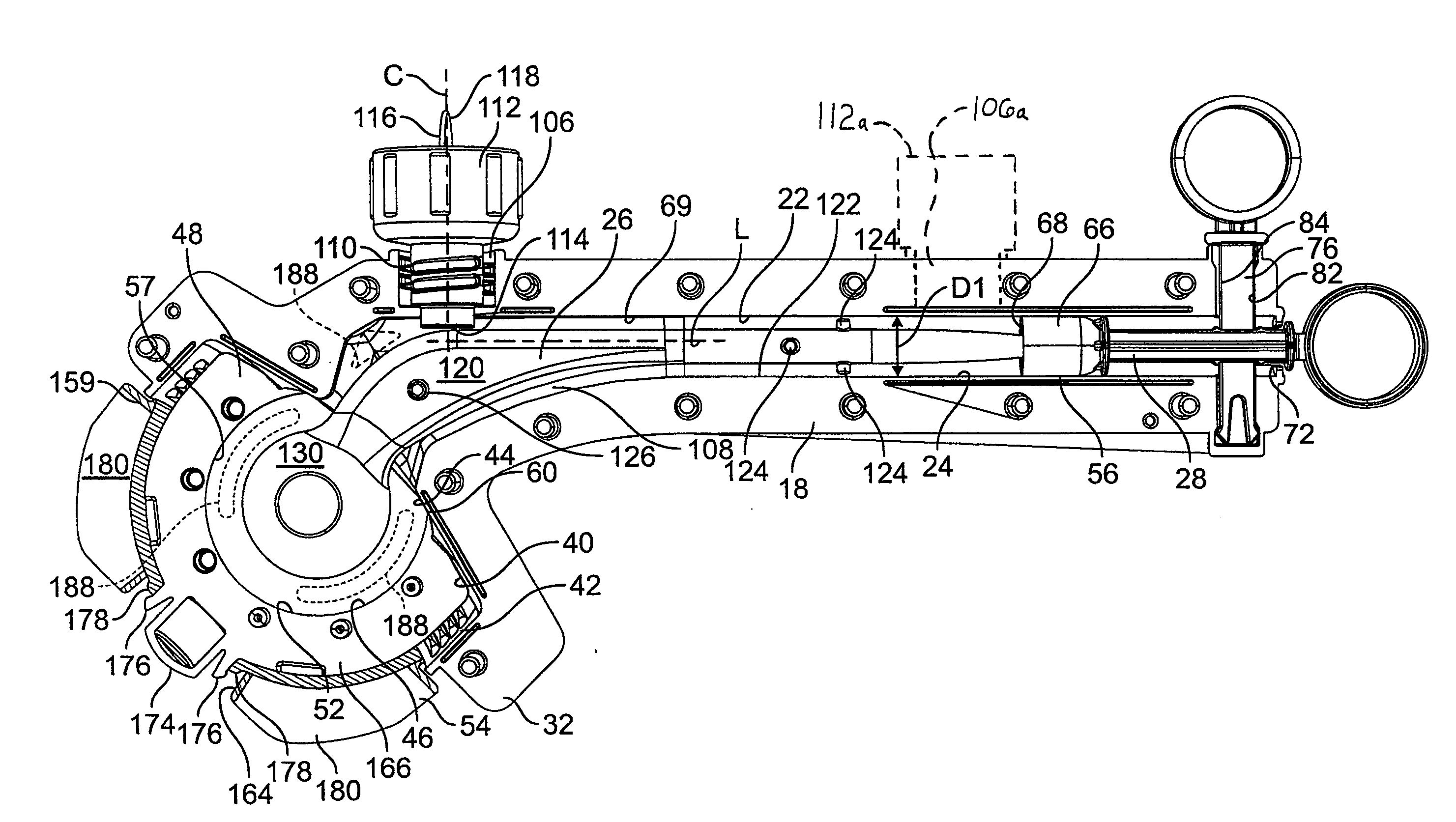

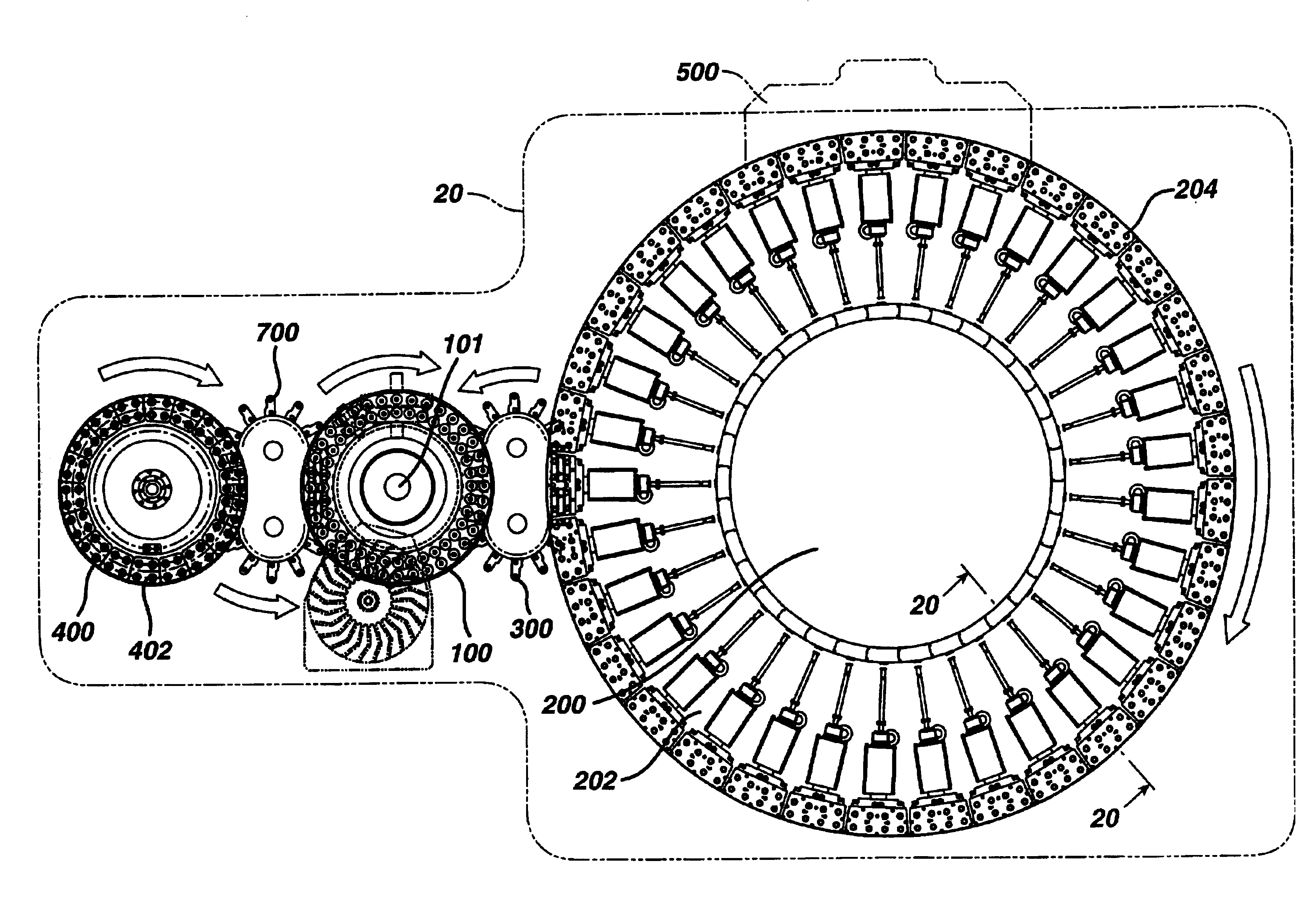

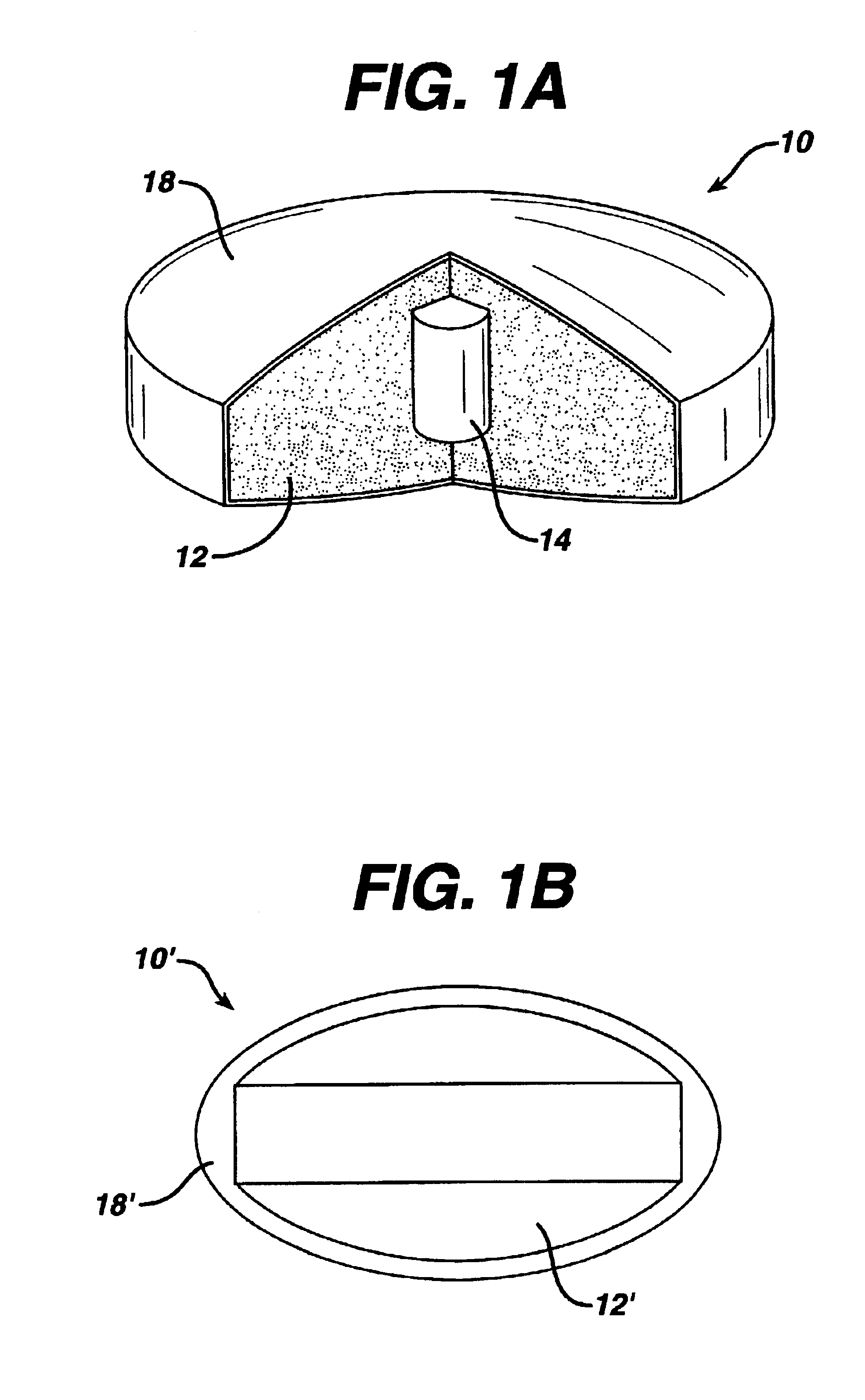

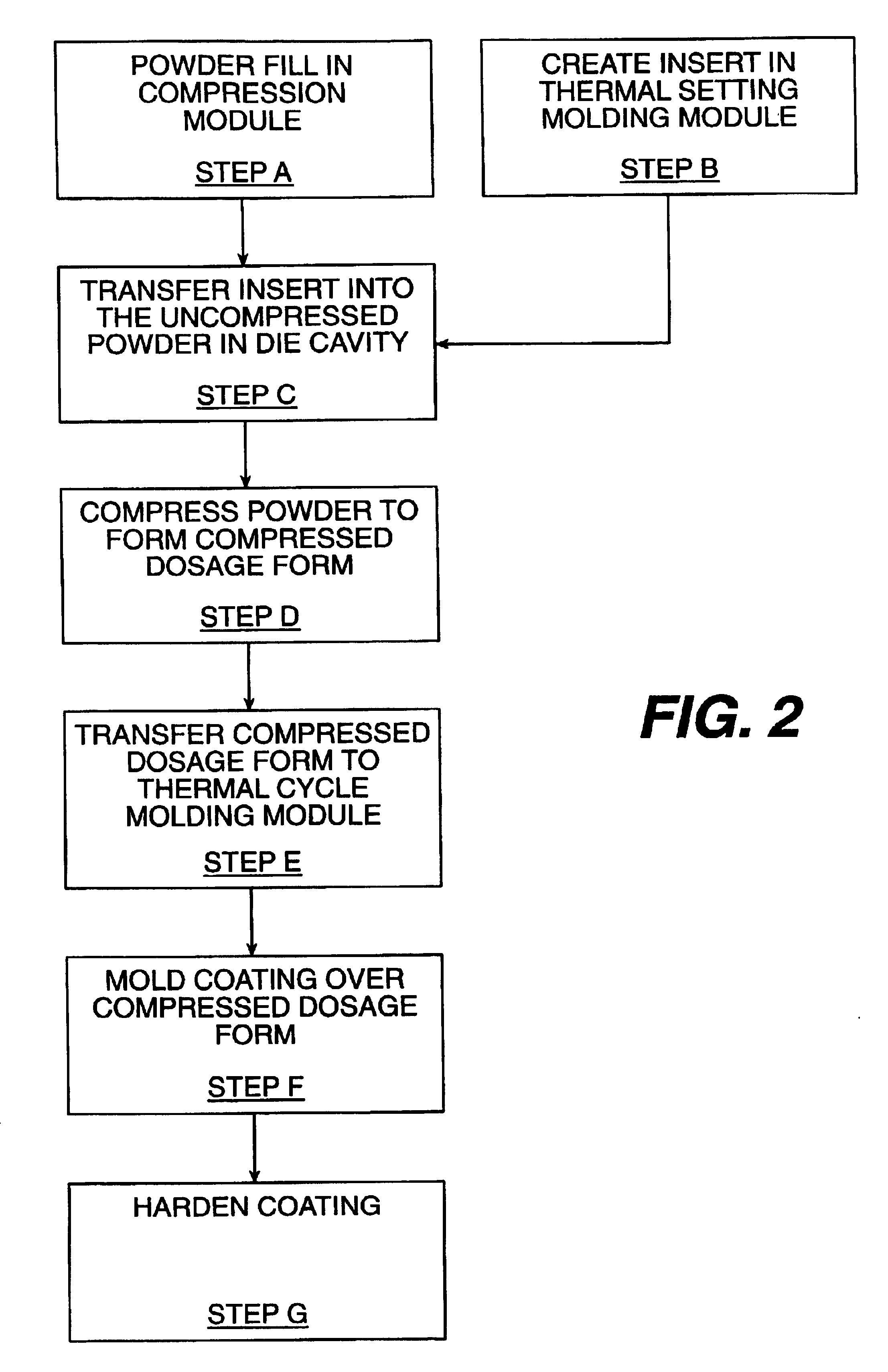

Apparatus for manufacturing dosage forms

InactiveUS6837696B2Organic active ingredientsTurning machine accessoriesComputer moduleBiomedical engineering

Systems, methods and apparatuses for manufacturing dosage forms, and to dosage forms made using such systems, methods and apparatuses are provided. Novel compression, thermal cycle molding, and thermal setting molding modules are disclosed. One or more of such modules may be linked, preferably via novel transfer device, into an overall system for making dosage forms.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com